Patents

Literature

229results about "Printed circuit coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

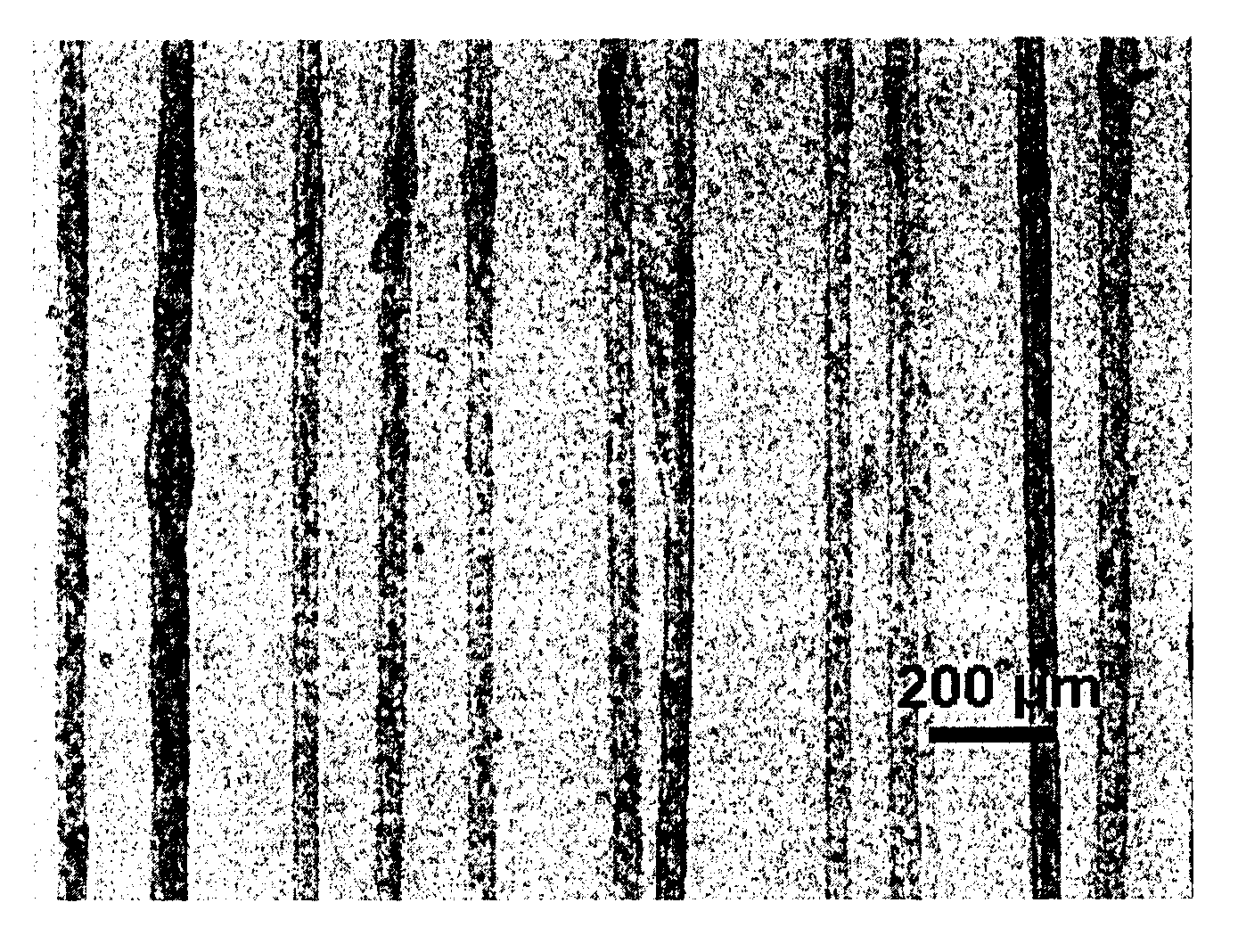

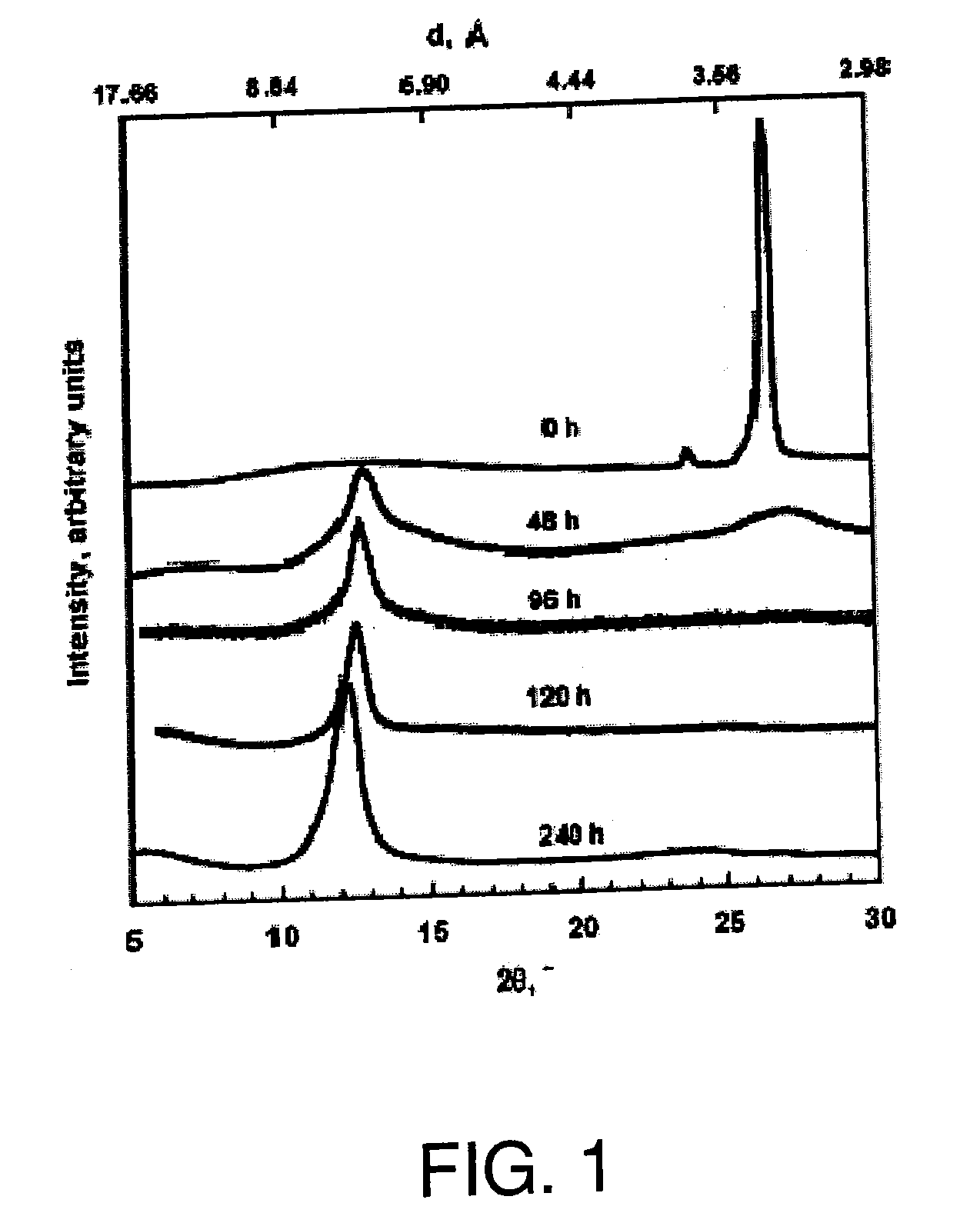

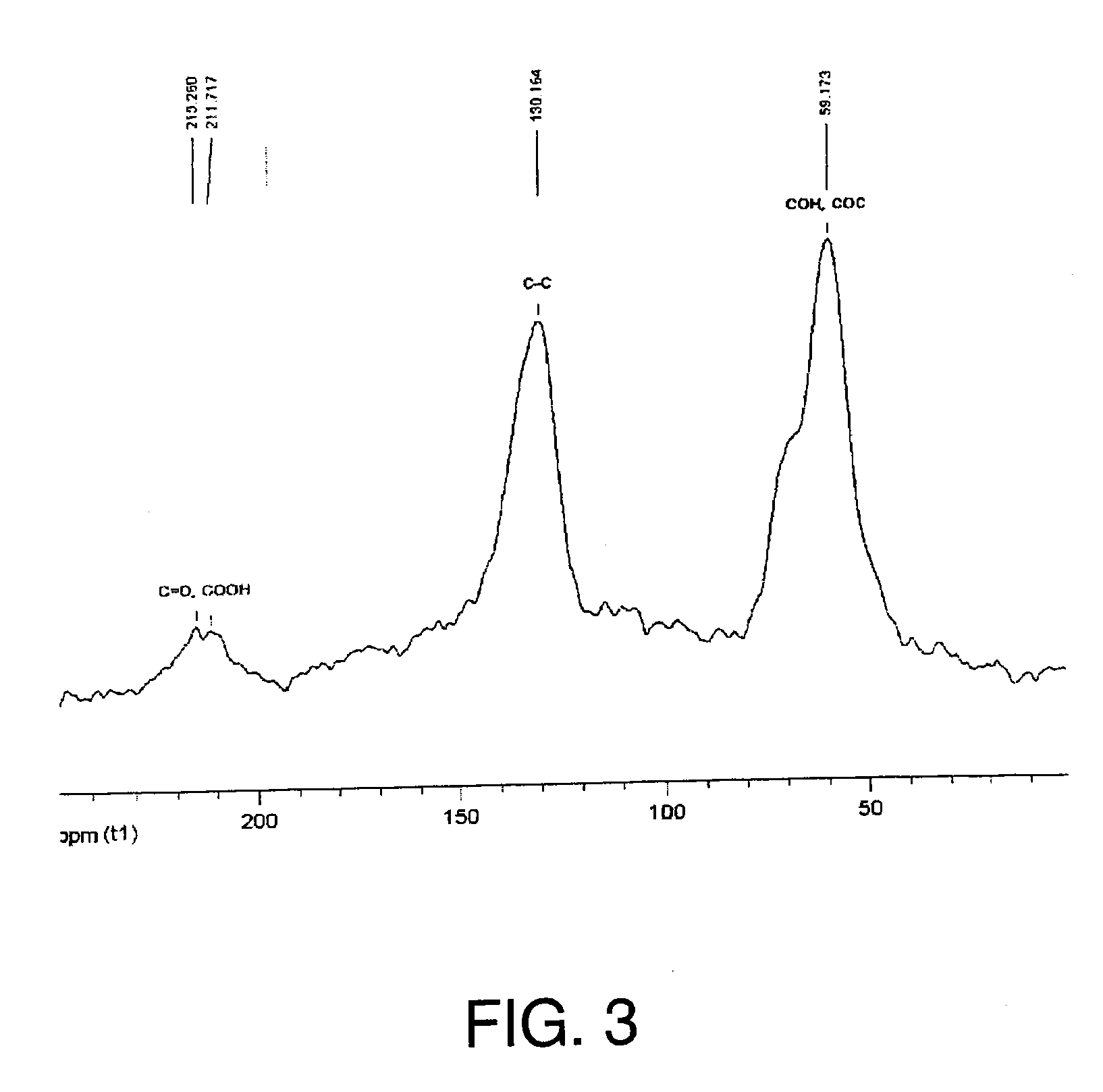

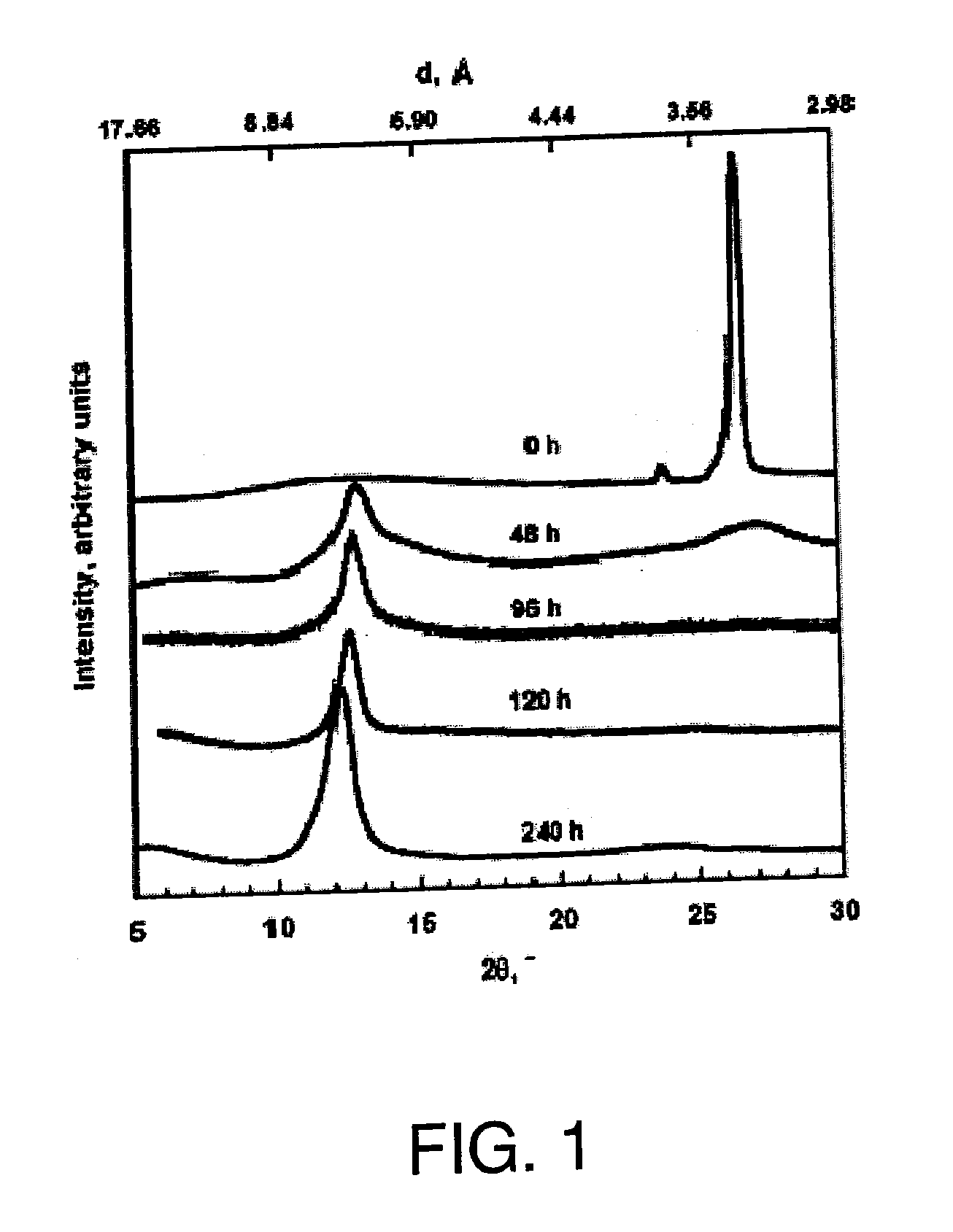

Thermally exfoliated graphite oxide

ActiveUS20070092432A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphiteX-rayMaterials science

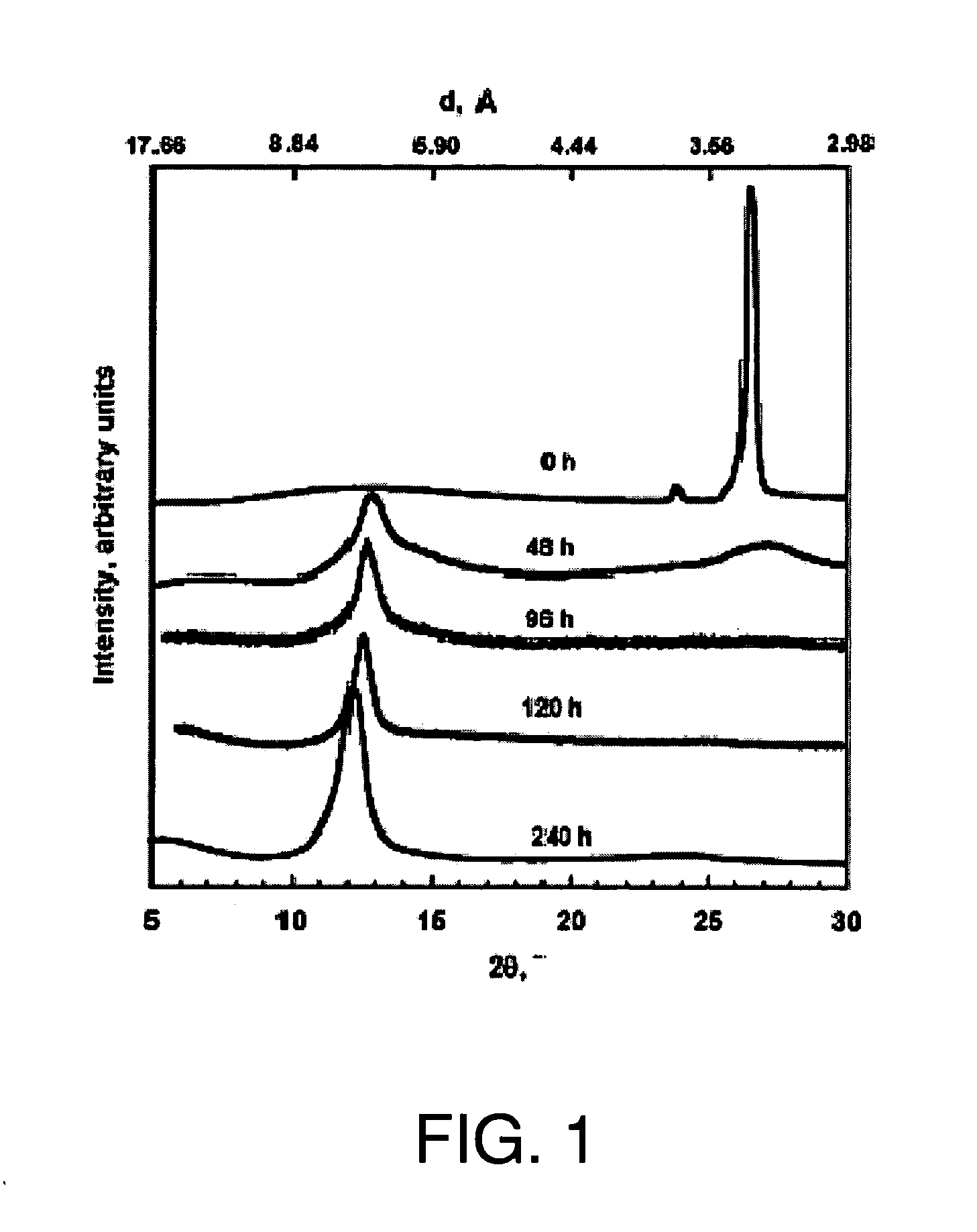

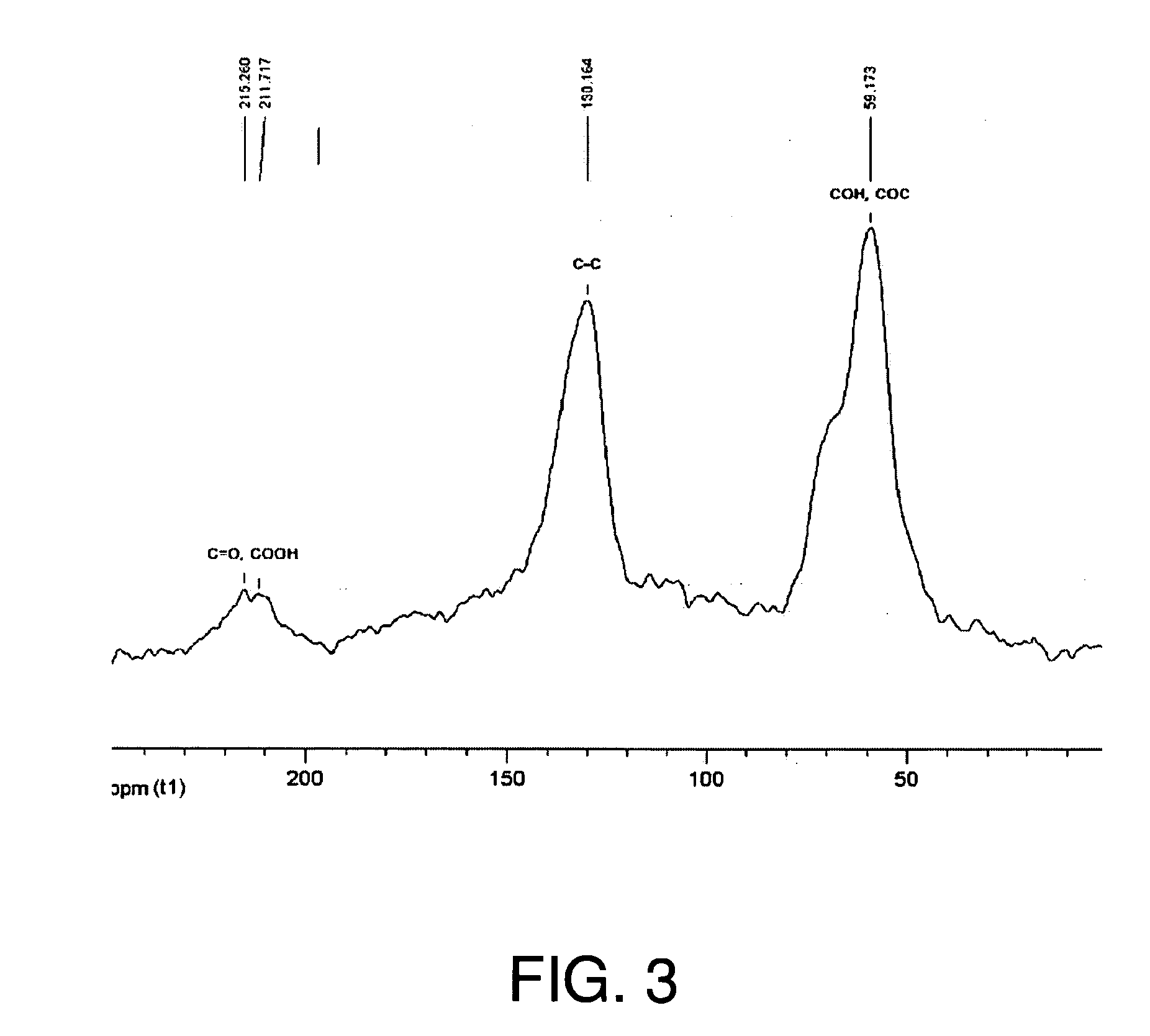

A modified graphite oxide material contains a thermally exfoliated graphite oxide with a surface area of from about 300 m2 / g to 2600 m2 / g, wherein the thermally exfoliated graphite oxide displays no signature of the original graphite and / or graphite oxide, as determined by X-ray diffraction.

Owner:THE TRUSTEES FOR PRINCETON UNIV

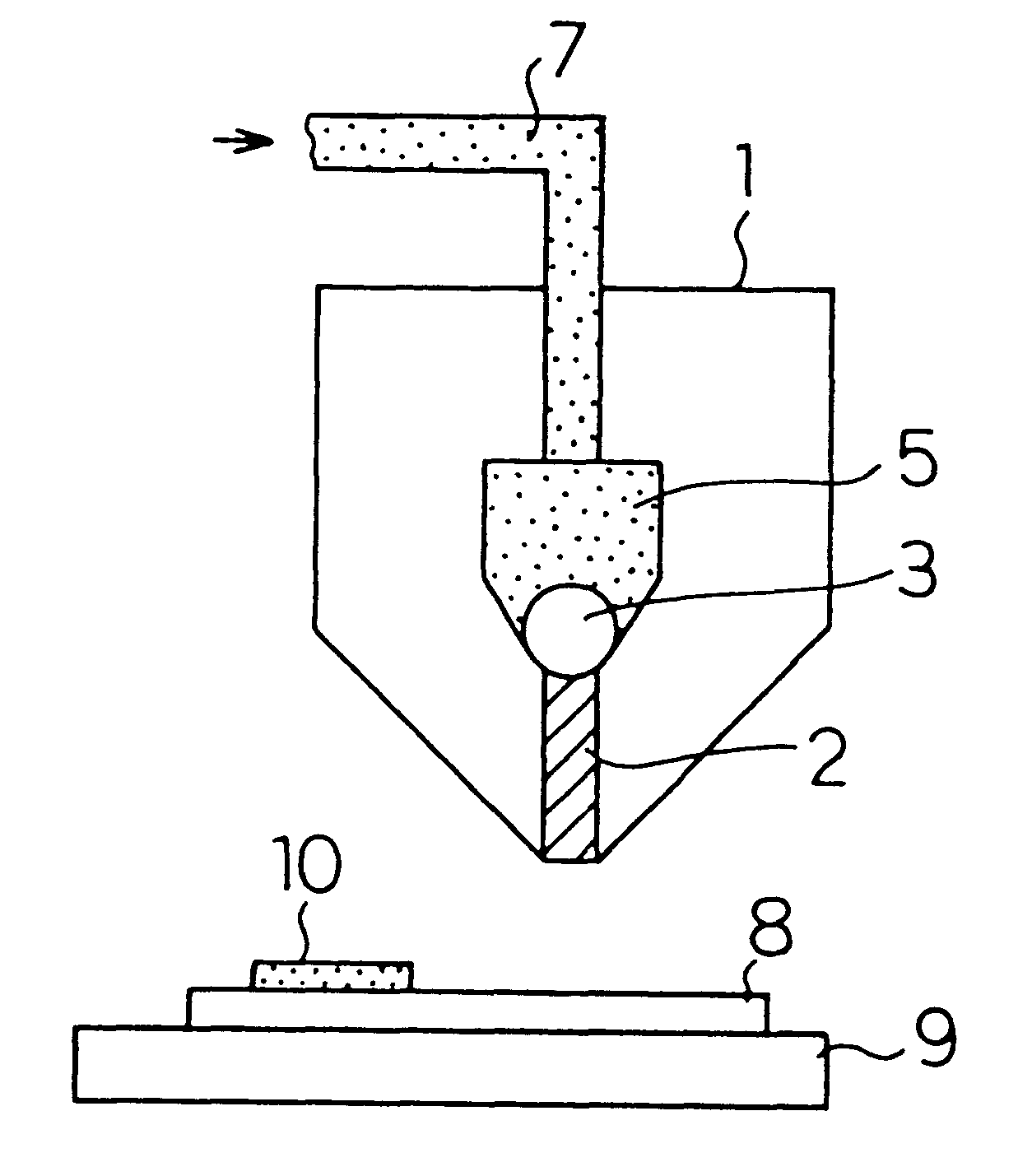

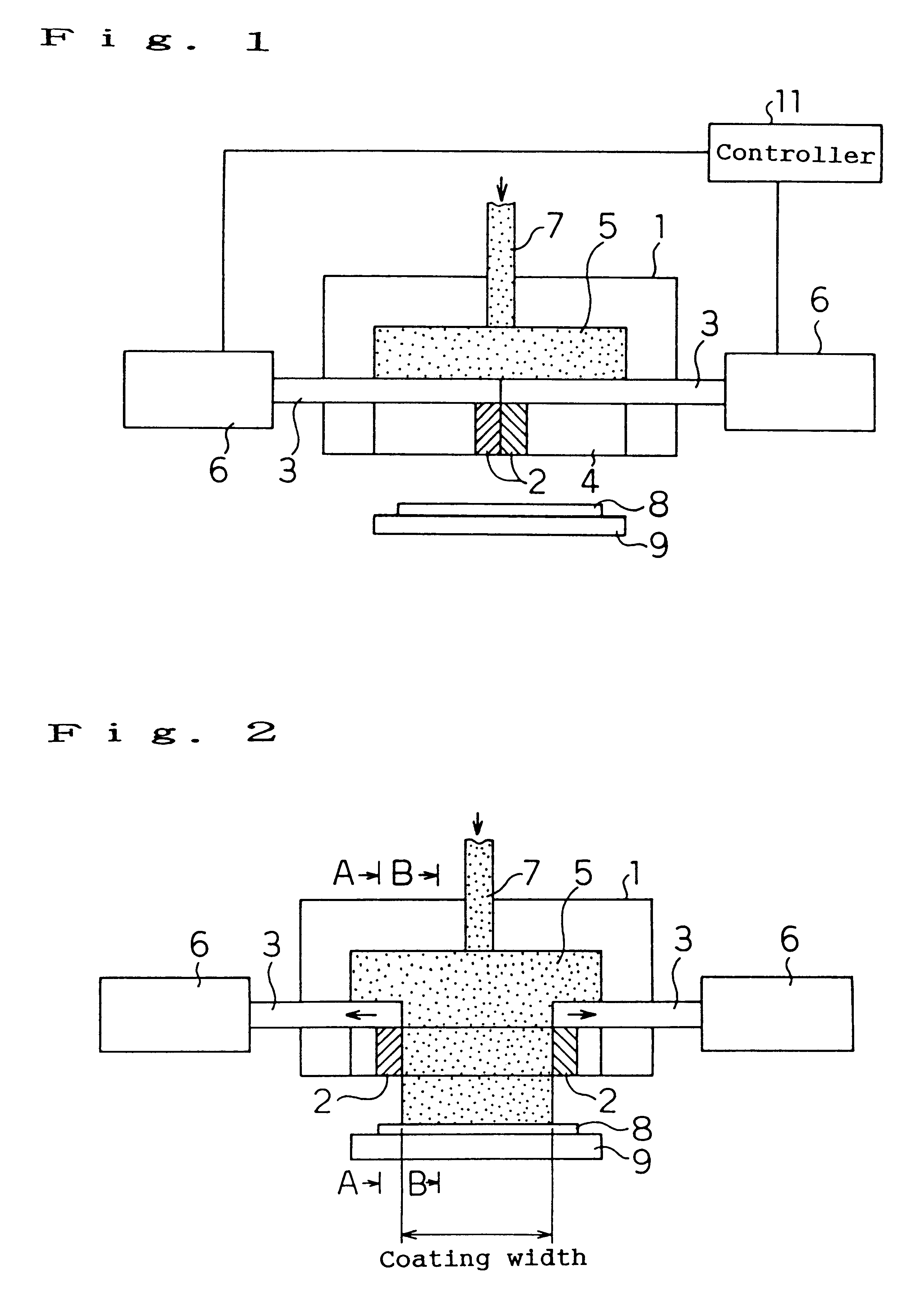

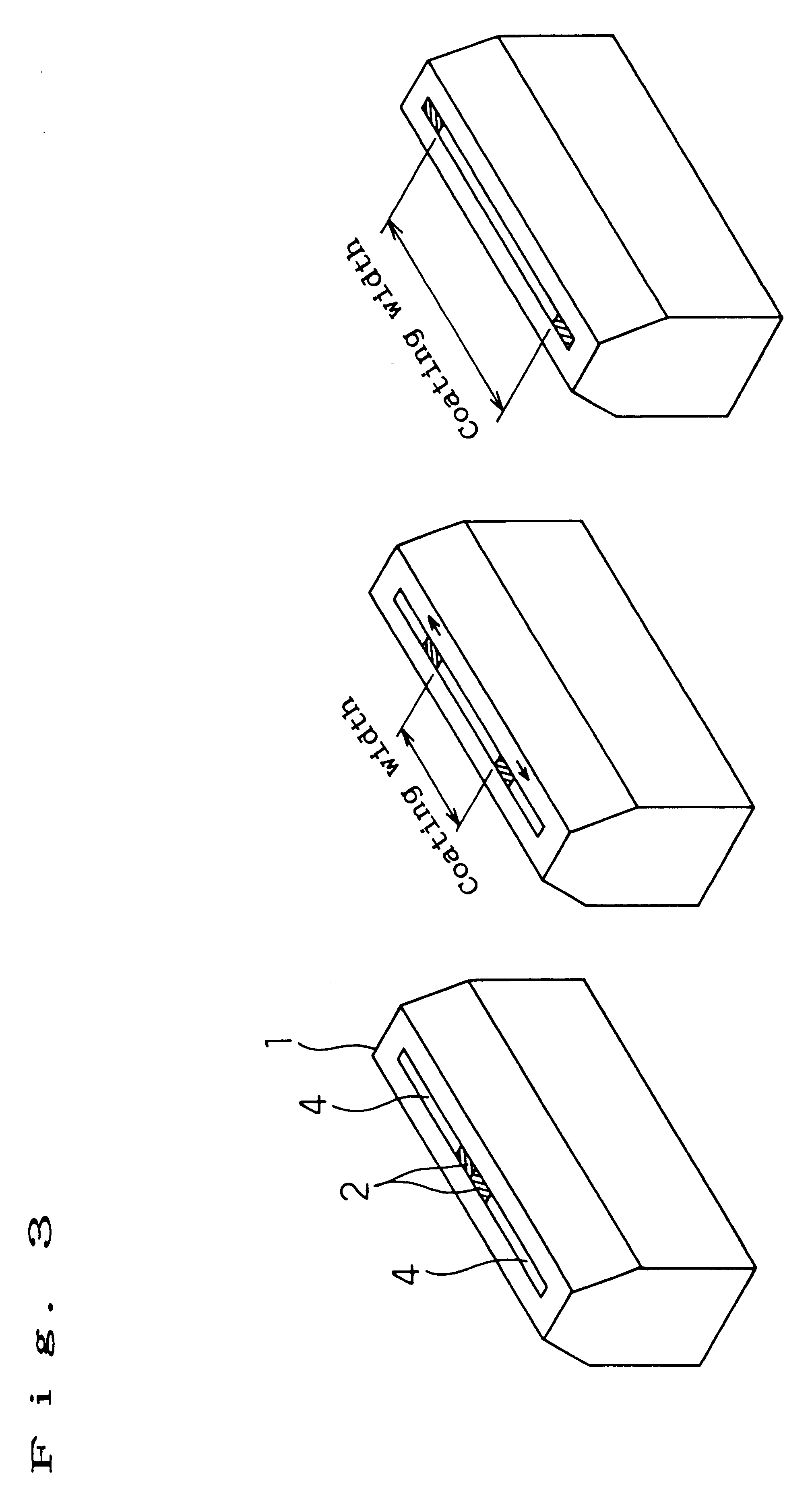

Coating apparatus and coating method

InactiveUS6423144B1Reduce lossesReduce lossLiquid surface applicatorsCoatingsMaterials scienceCoating

A coating method has running step of running a nozzle and / or a base material, change step of changing discharge-port slit widths of said nozzle, and coating step of discharging a coating solution from said slit and coating said base material with said coating solution; wherein said running step, change step, and coating step are executed by combining them.

Owner:PANASONIC CORP

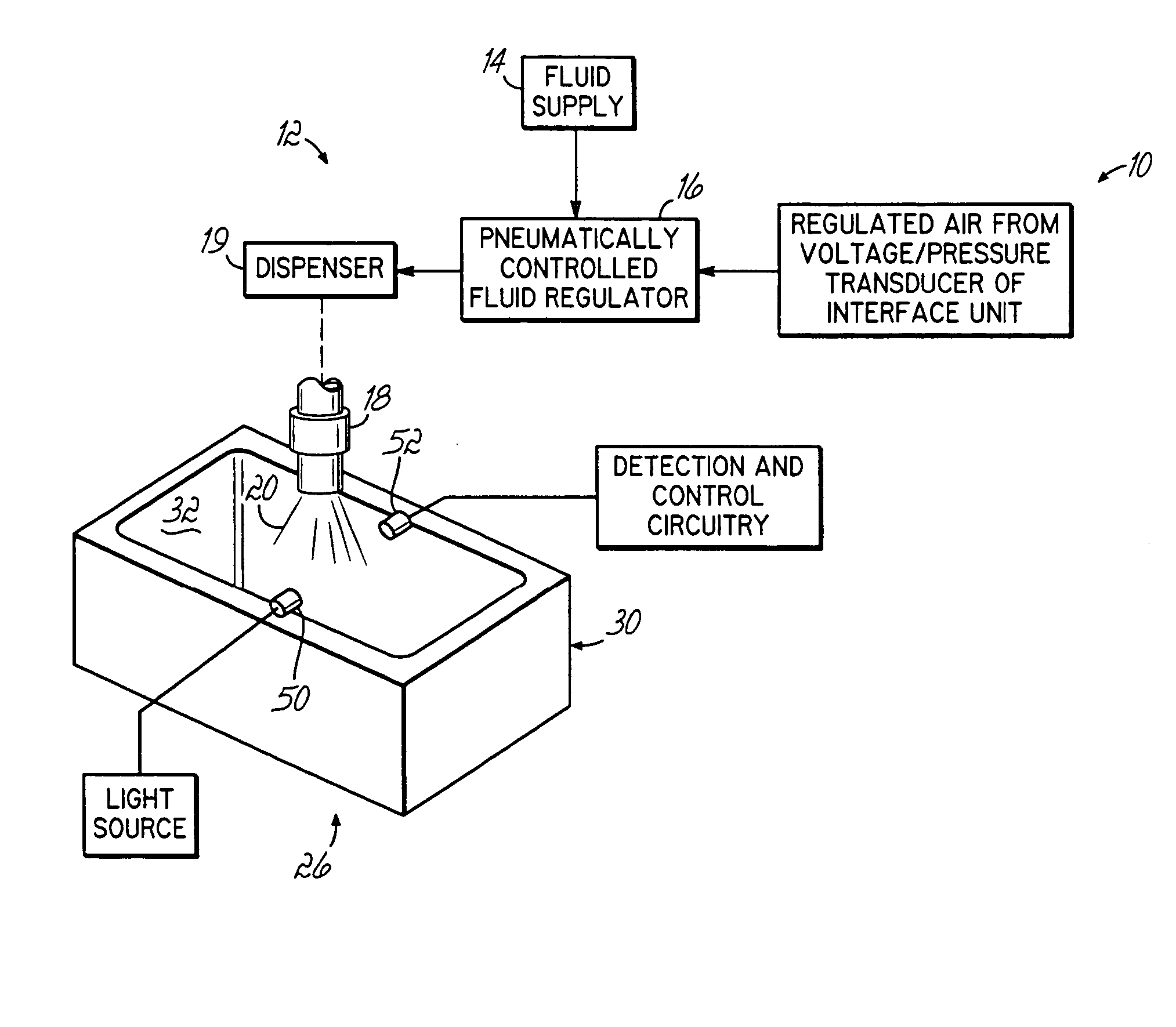

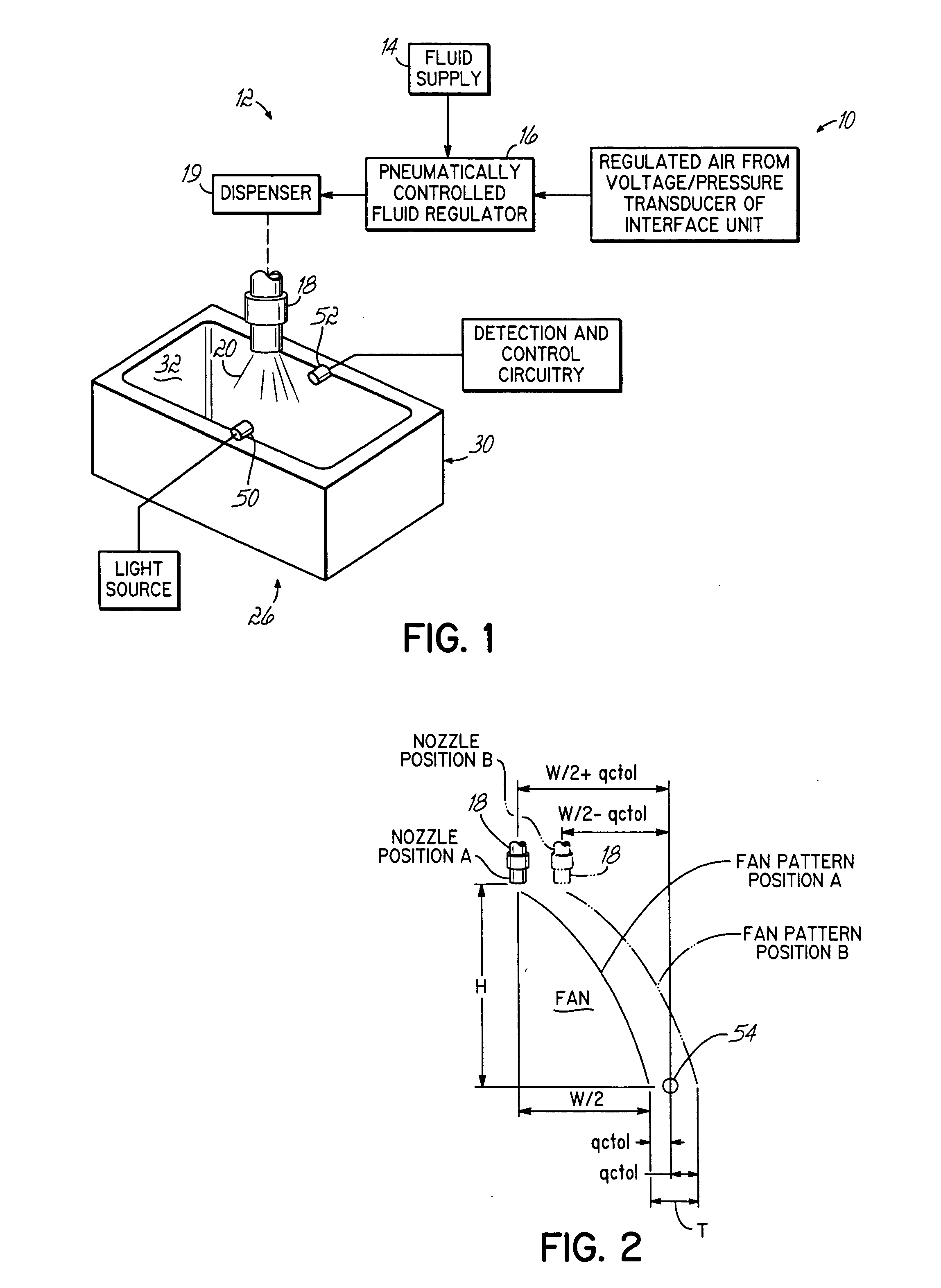

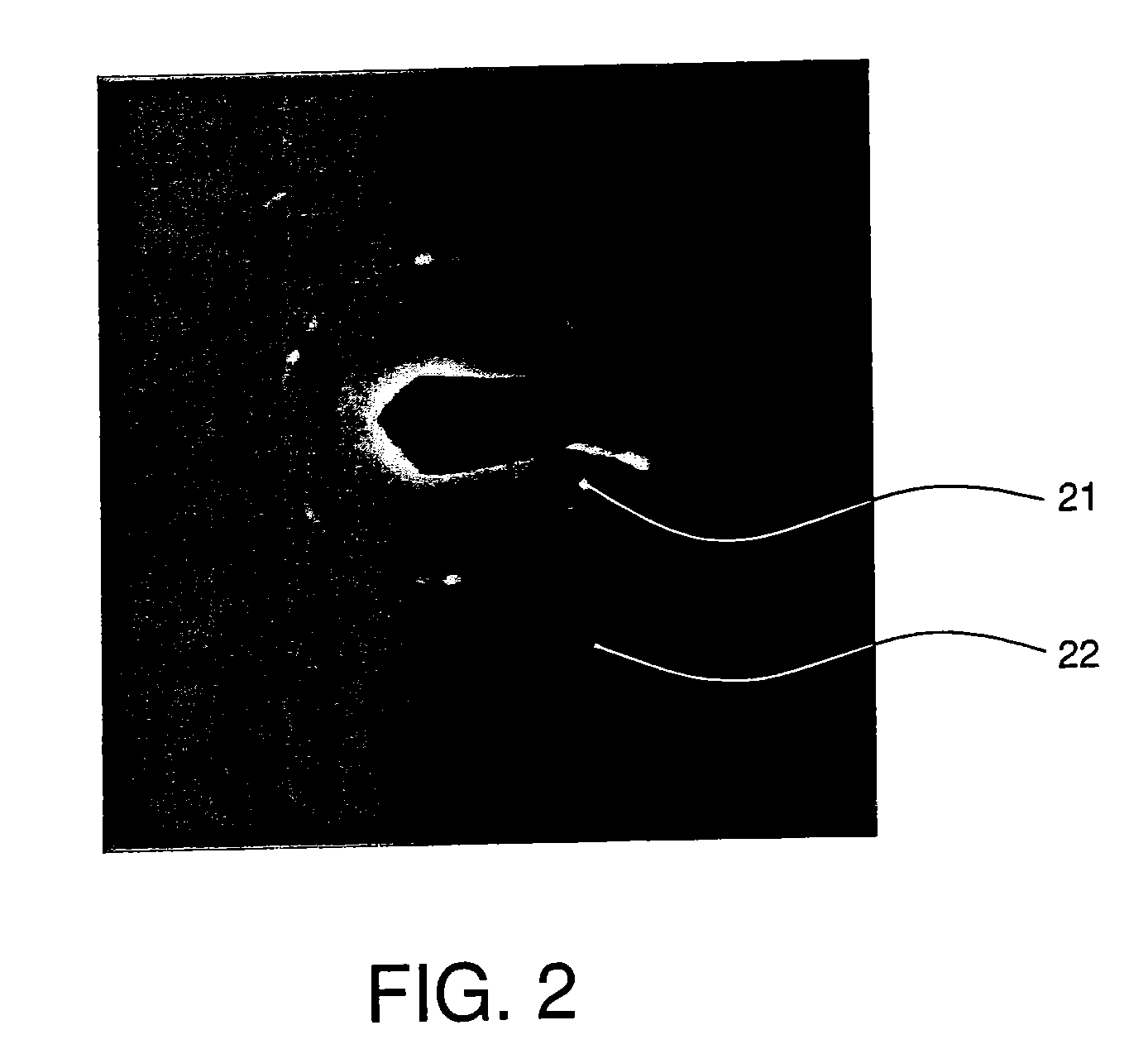

Method and apparatus for detecting a liquid spray pattern

InactiveUS20050023367A1Liquid surface applicatorsSelf-acting watering devicesPattern detectionEngineering

During a liquid spray pattern detection procedure, the sensor (50, 52) is operable to detect the presence or absence of an edge of the dispensed liquid spray pattern. The nozzle (18) of the liquid dispensing system is moved to a predetermined position (A) relative to the sensor (50, 52) to determine the presence or absence of the spray pattern and is then moved to a second predetermined position (B) relative to the sensor (50, 52) to again determine the presence or absence of the spray pattern. Based on these determinations, the width of the spray pattern can be verified. This provides a quick means to verify that the width of the dispensed pattern is within certain tolerances.

Owner:NORDSON CORP

Device and Method to Additively Fabricate Structures Containing Embedded Electronics or Sensors

Owner:NORTHEASTERN UNIV

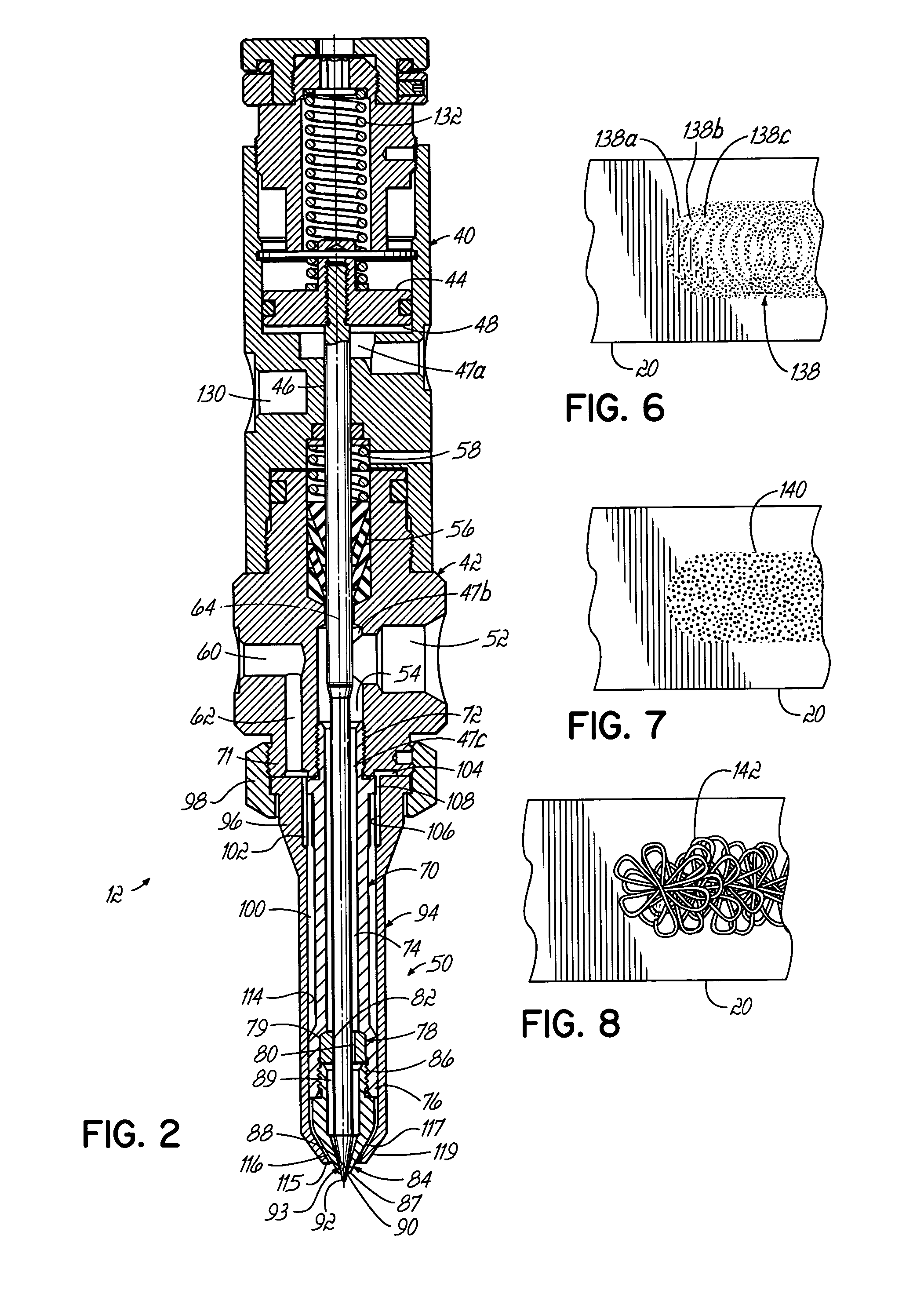

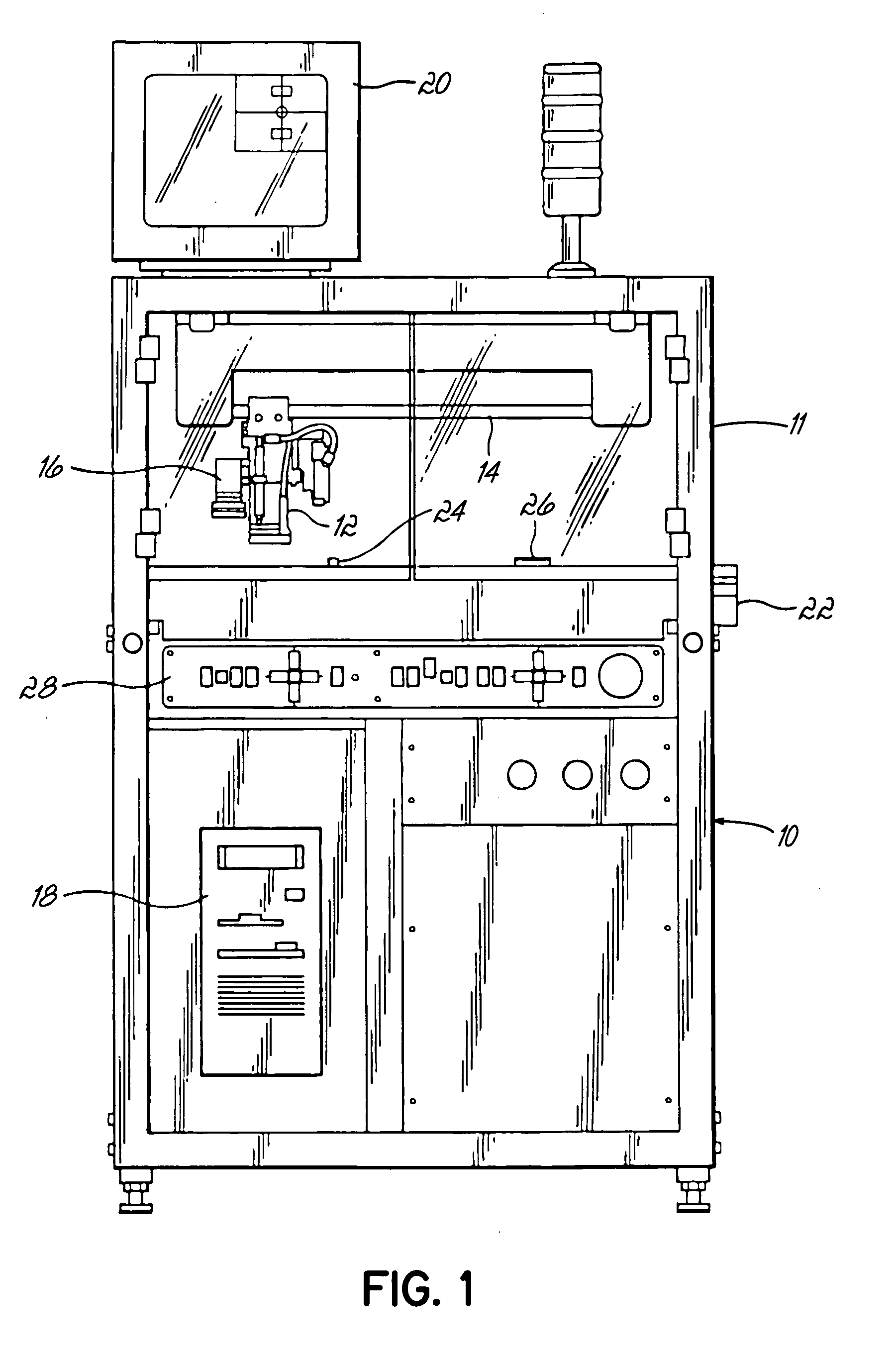

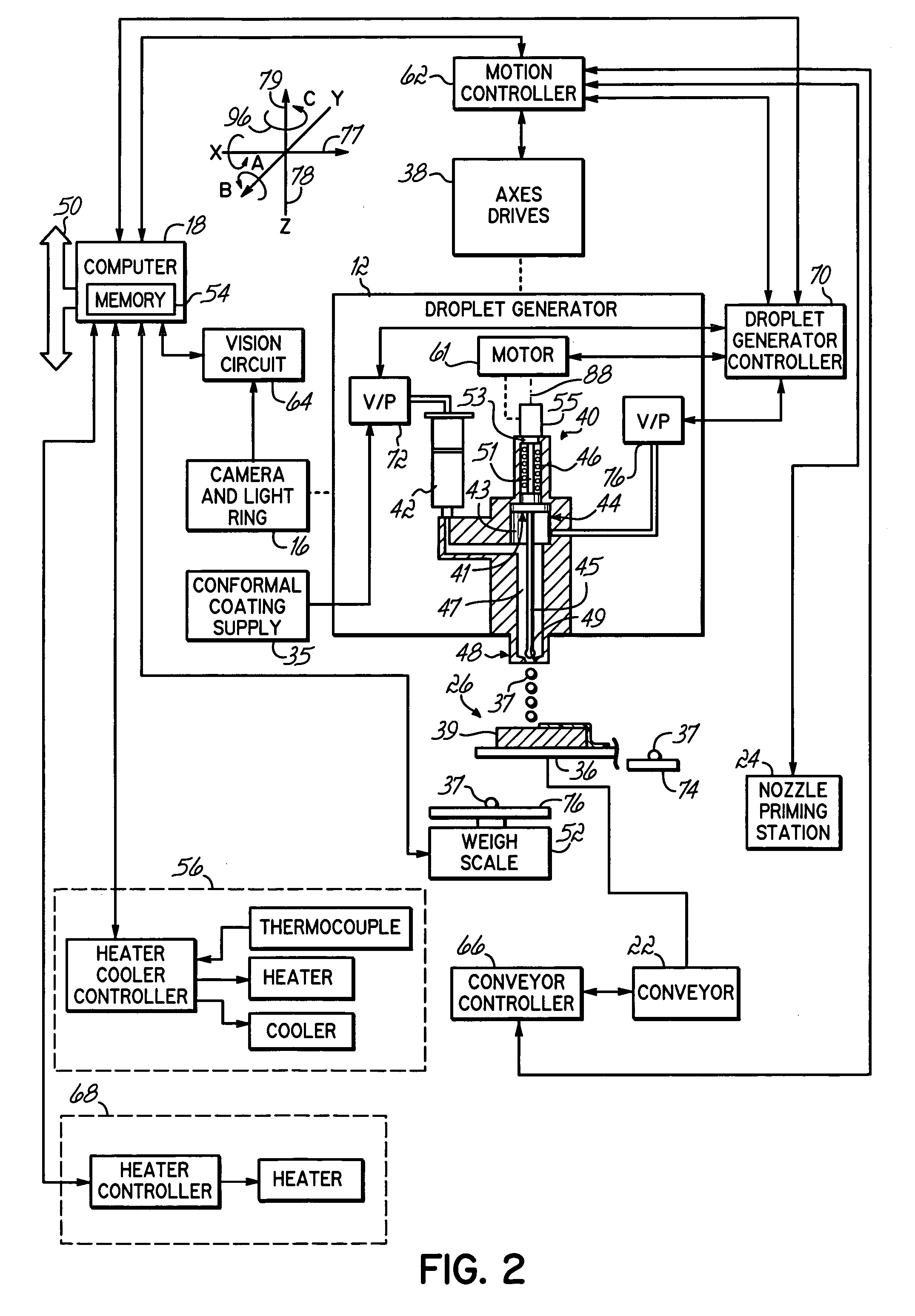

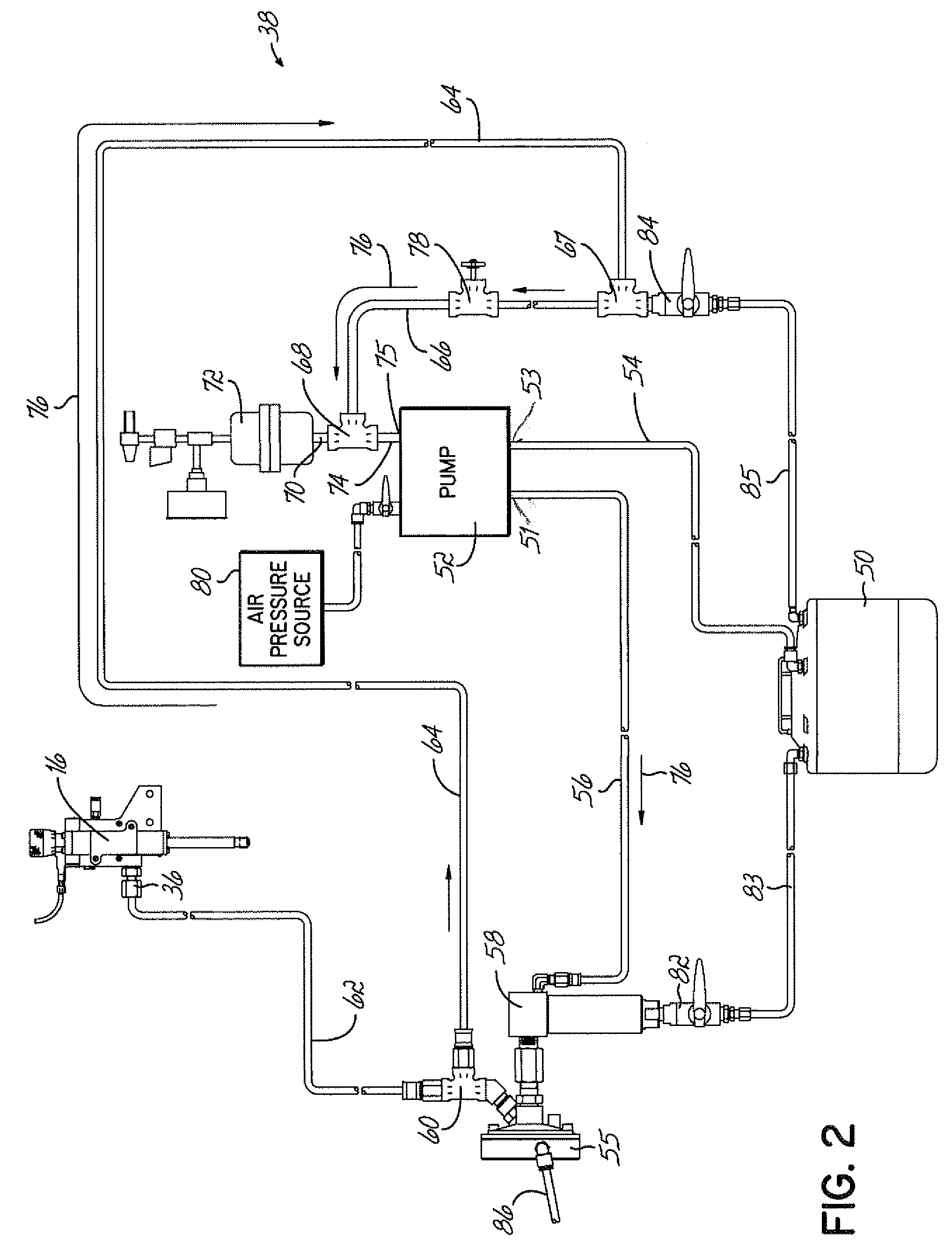

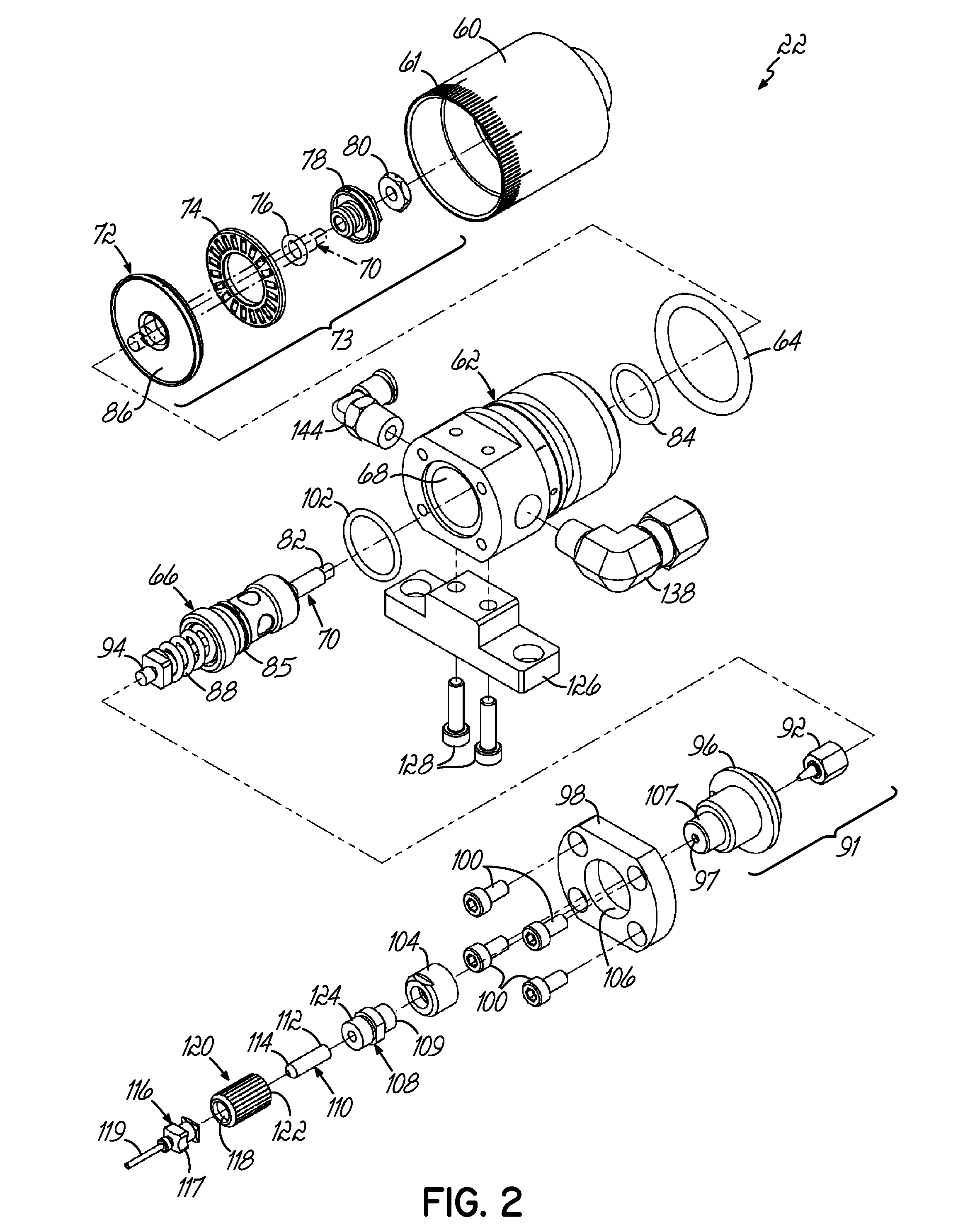

Conformal coating applicator and method

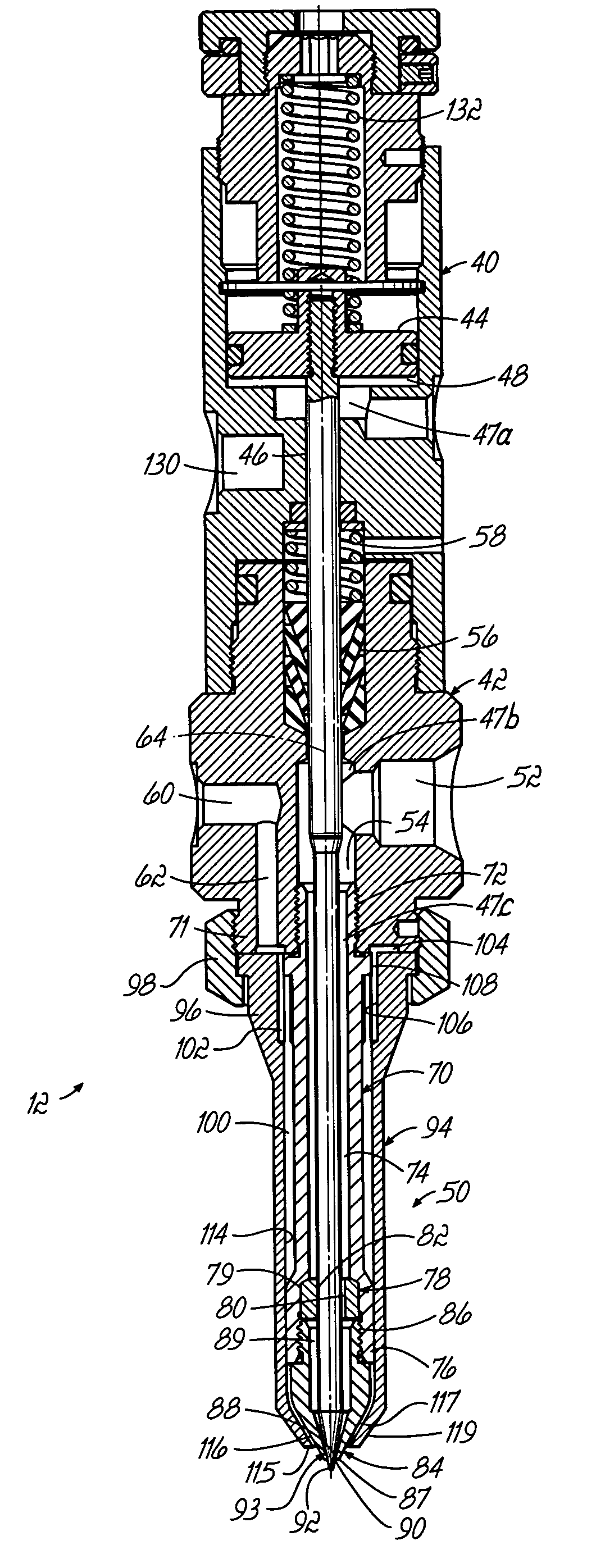

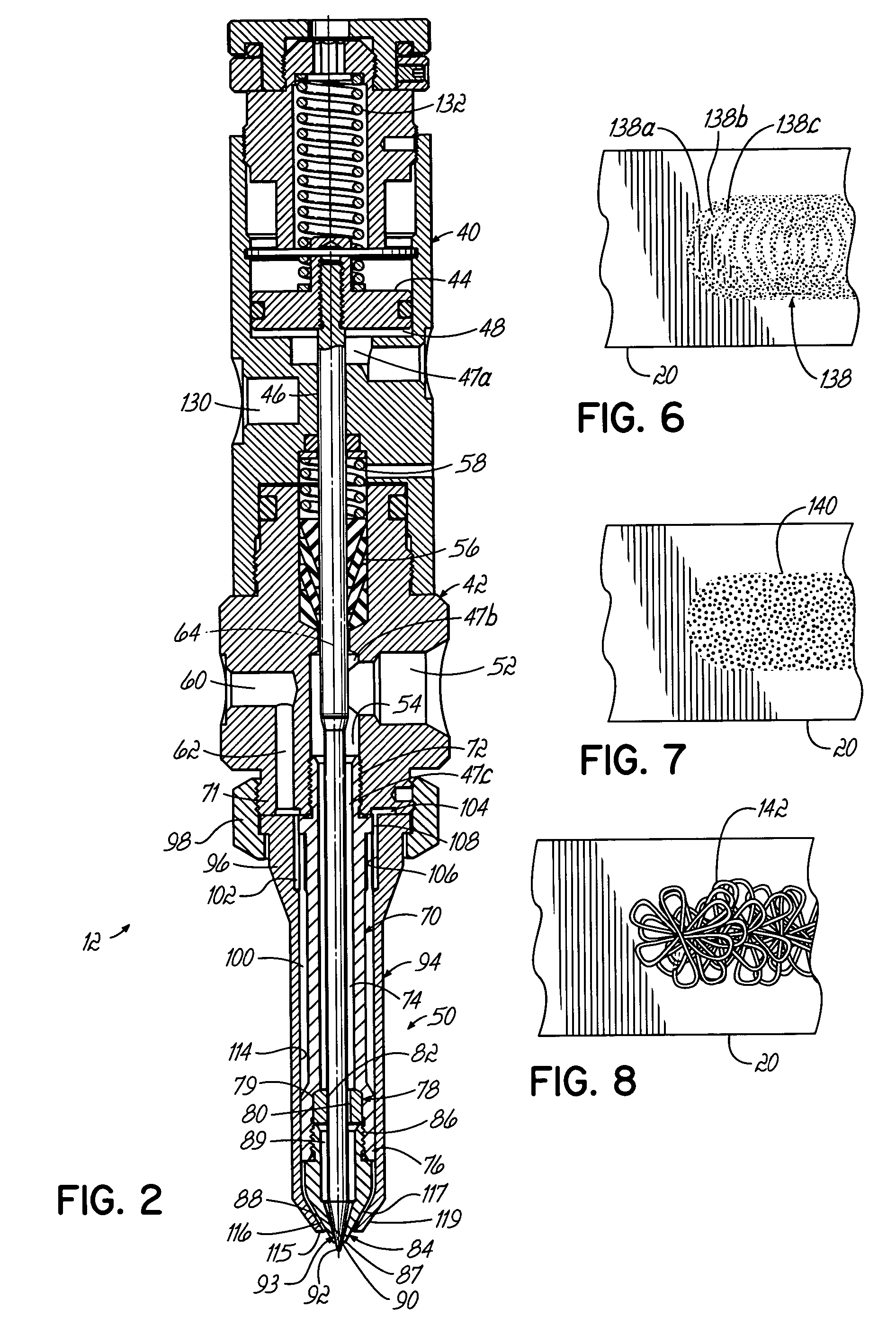

ActiveUS7028867B2Easy to handleSimplify disassemblyMovable spraying apparatusLiquid flow controllersConformal coatingNeedle guide

An applicator for dispensing a conformal coating material onto a substrate. The applicator has a body with a nozzle having a dispensing orifice at a distal end of the body, and assist air is supplied to a location adjacent the dispensing orifice. A seat is disposed in the nozzle around the dispensing orifice, and an end of a needle is movable into contact with and through the seat to terminate a flow of the coating material through the dispensing orifice and eliminate any coating material flow path downstream of the seat. A needle guide is used to laterally support the needle above the nozzle. The distal end of a nozzle is the distal end of the applicator and is exposed for cleaning.

Owner:NORDSON CORP +1

Printed electronics

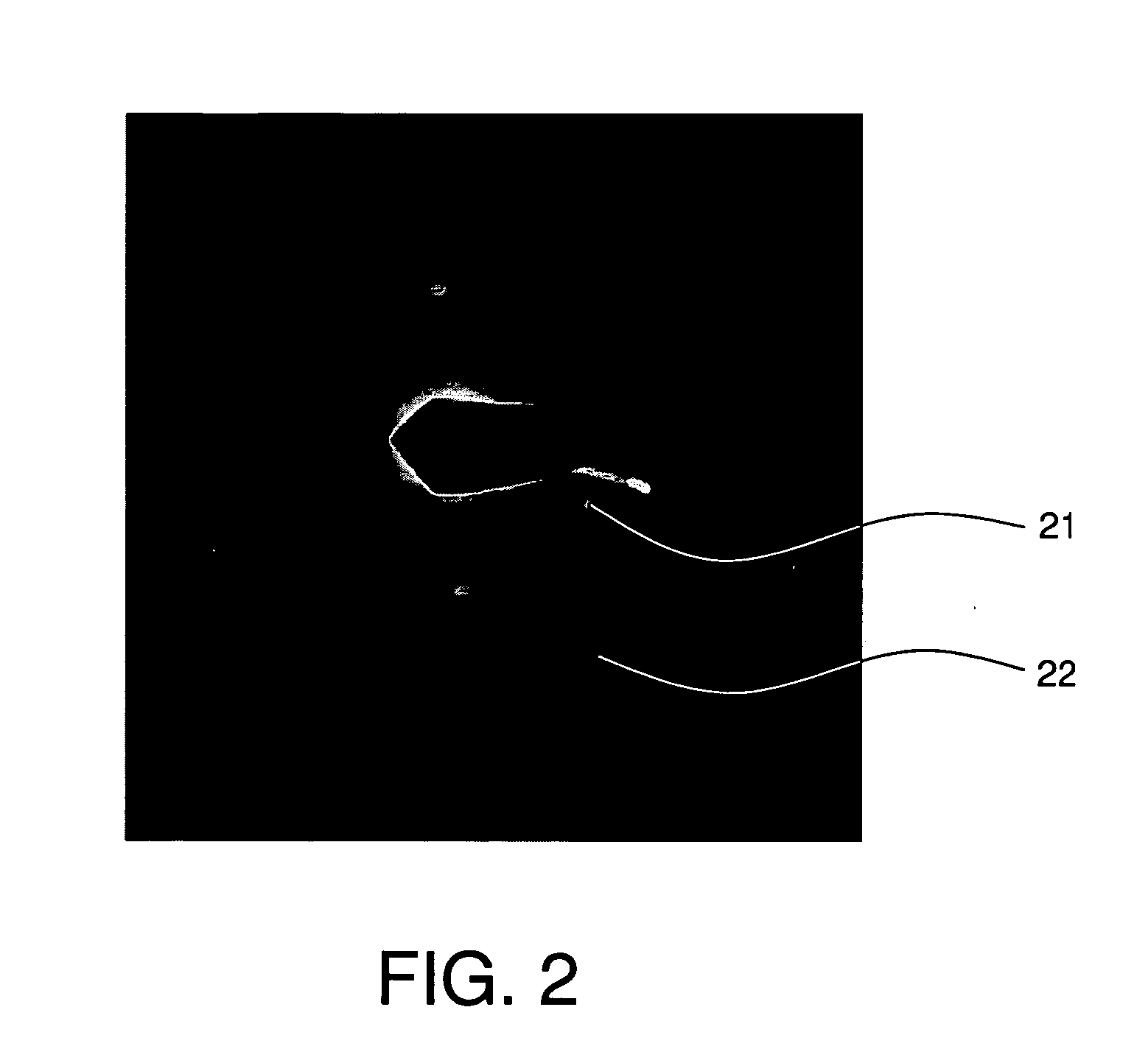

Printed electronic device comprising a substrate onto at least one surface of which has been applied a layer of an electrically conductive ink comprising functionalized graphene sheets and at least one binder. A method of preparing printed electronic devices is further disclosed.

Owner:VORBECK MATERIALS CORP +1

Conductive ink containing thermally exfoliated graphite oxide and method of making a conductive circuit using the same

ActiveUS20080302561A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphiteConductive polymerPhysical chemistry

Owner:THE TRUSTEES FOR PRINCETON UNIV

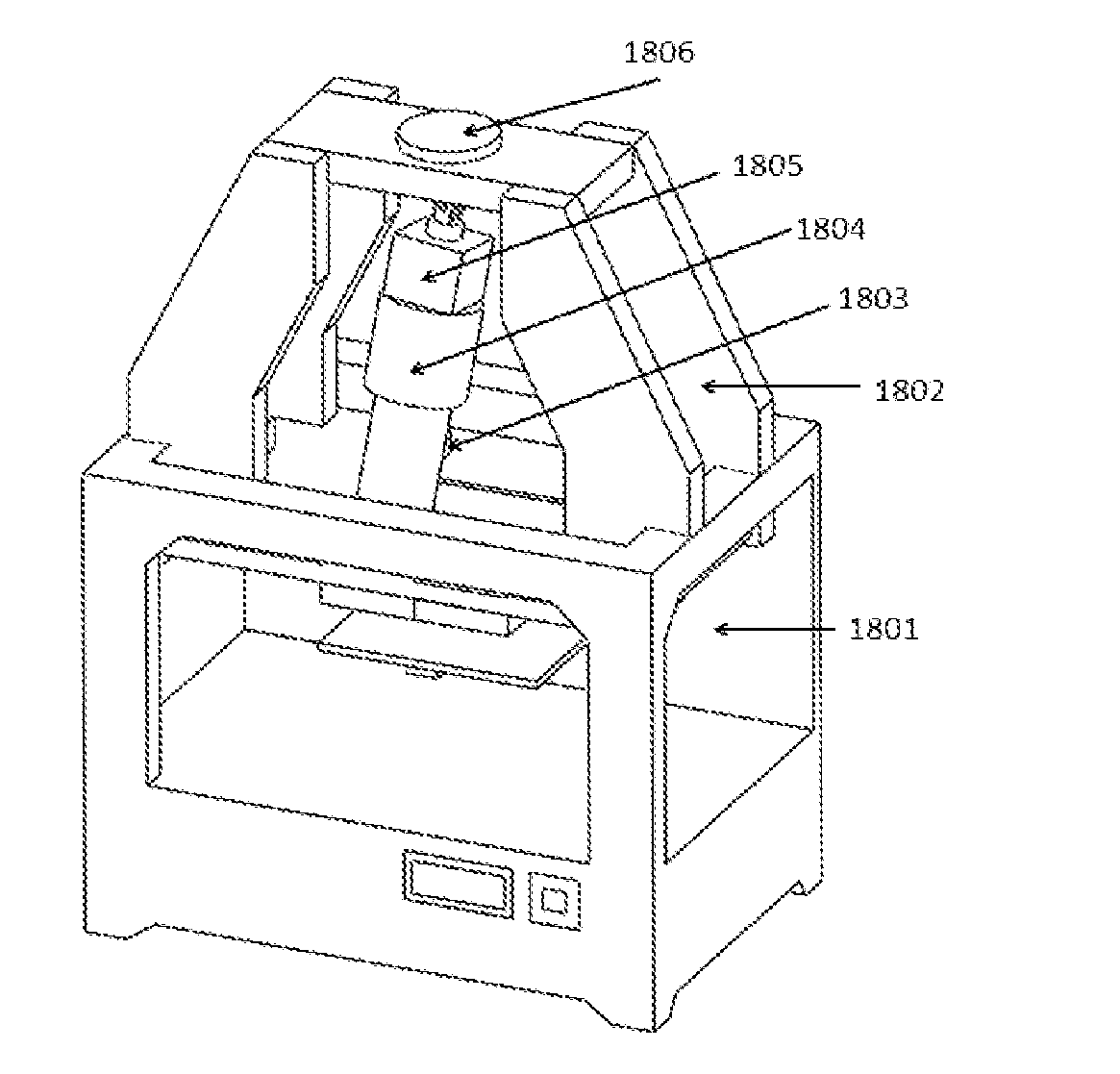

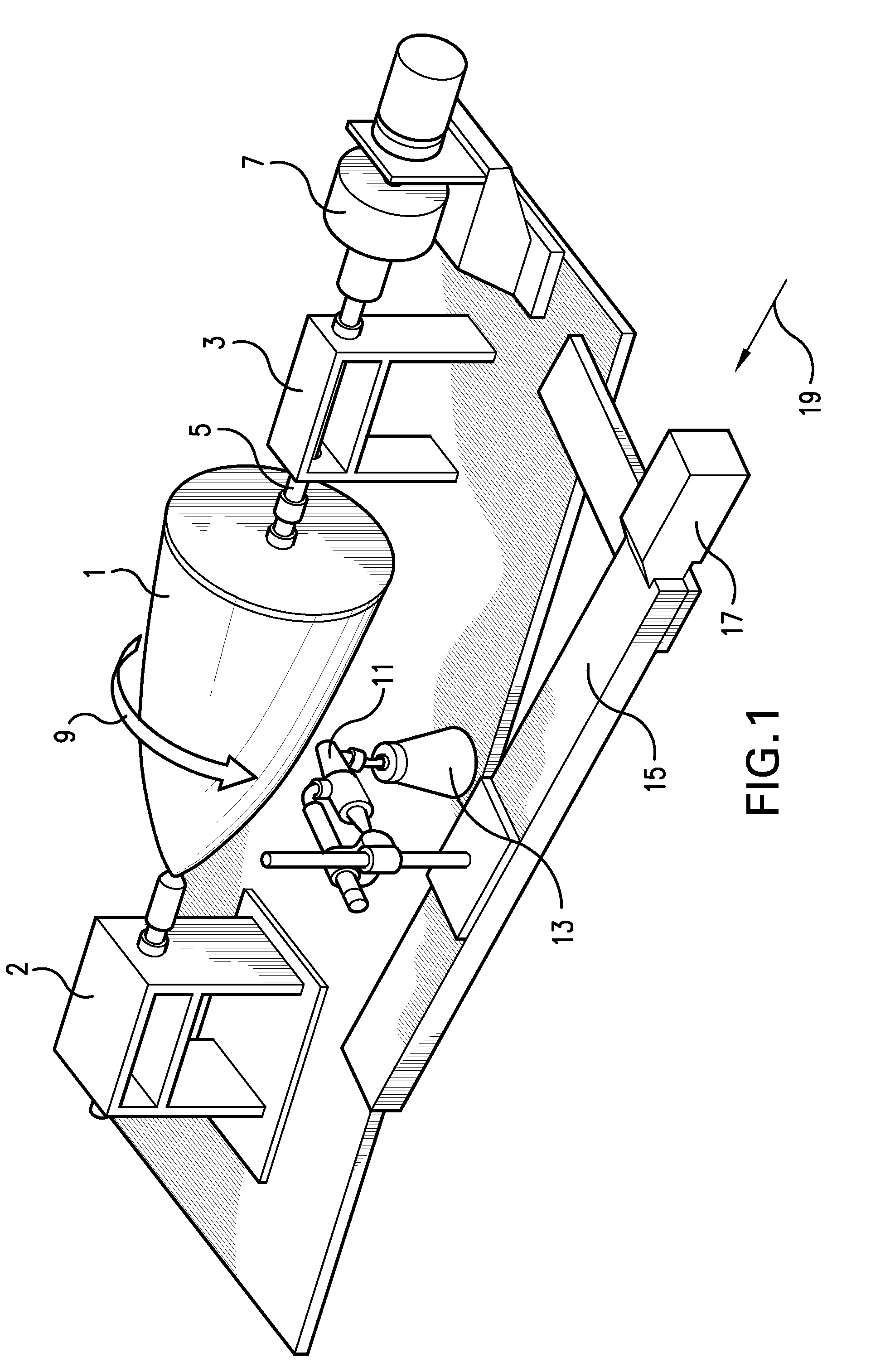

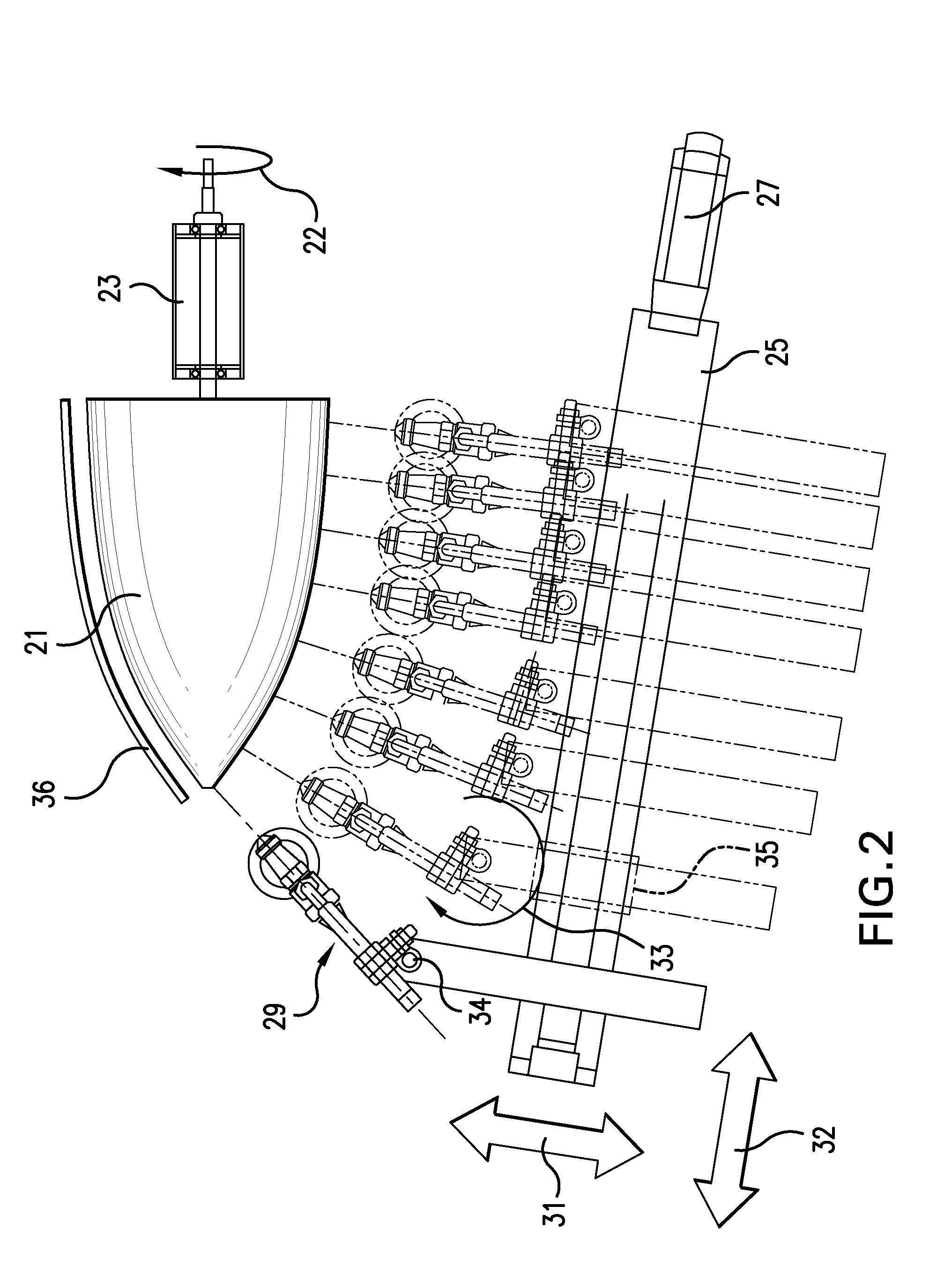

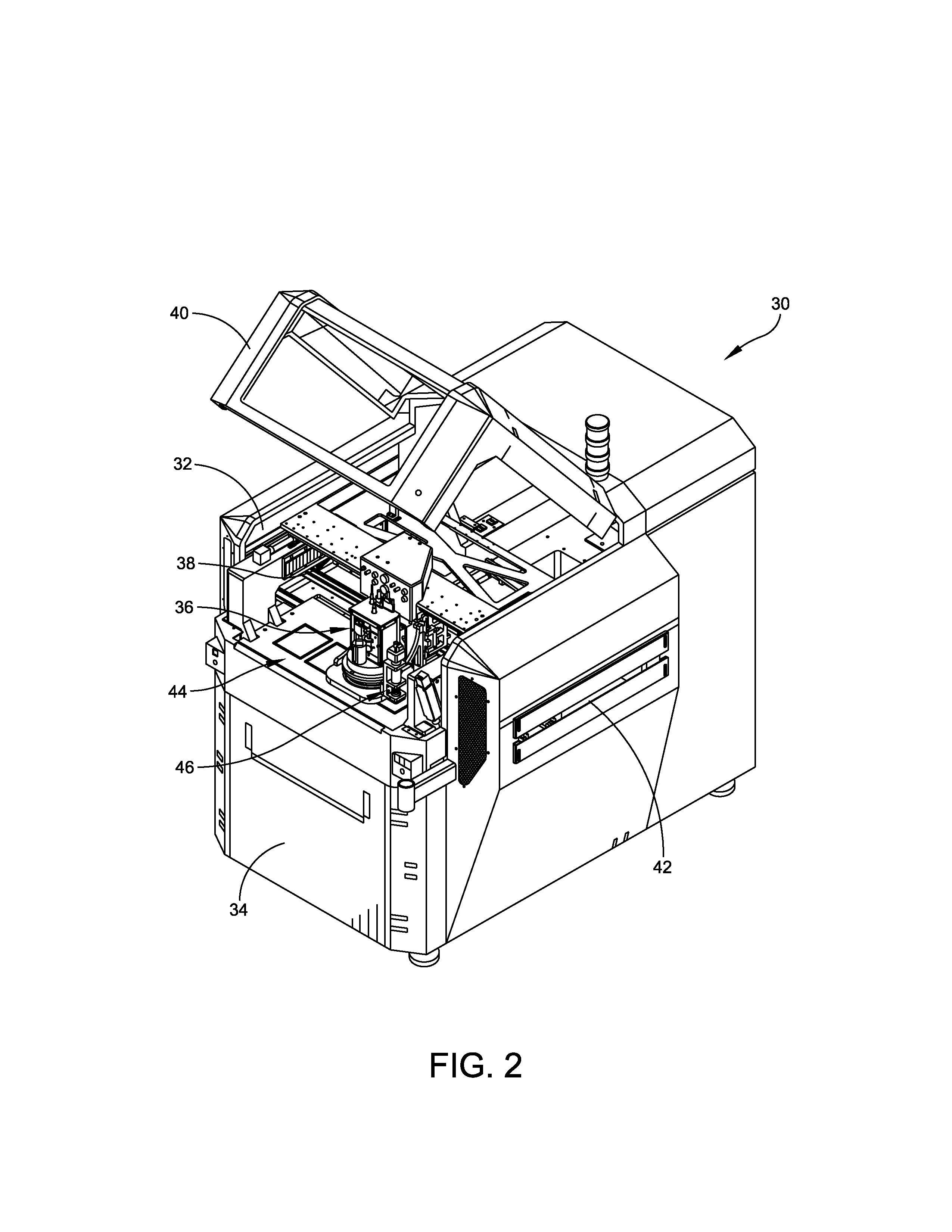

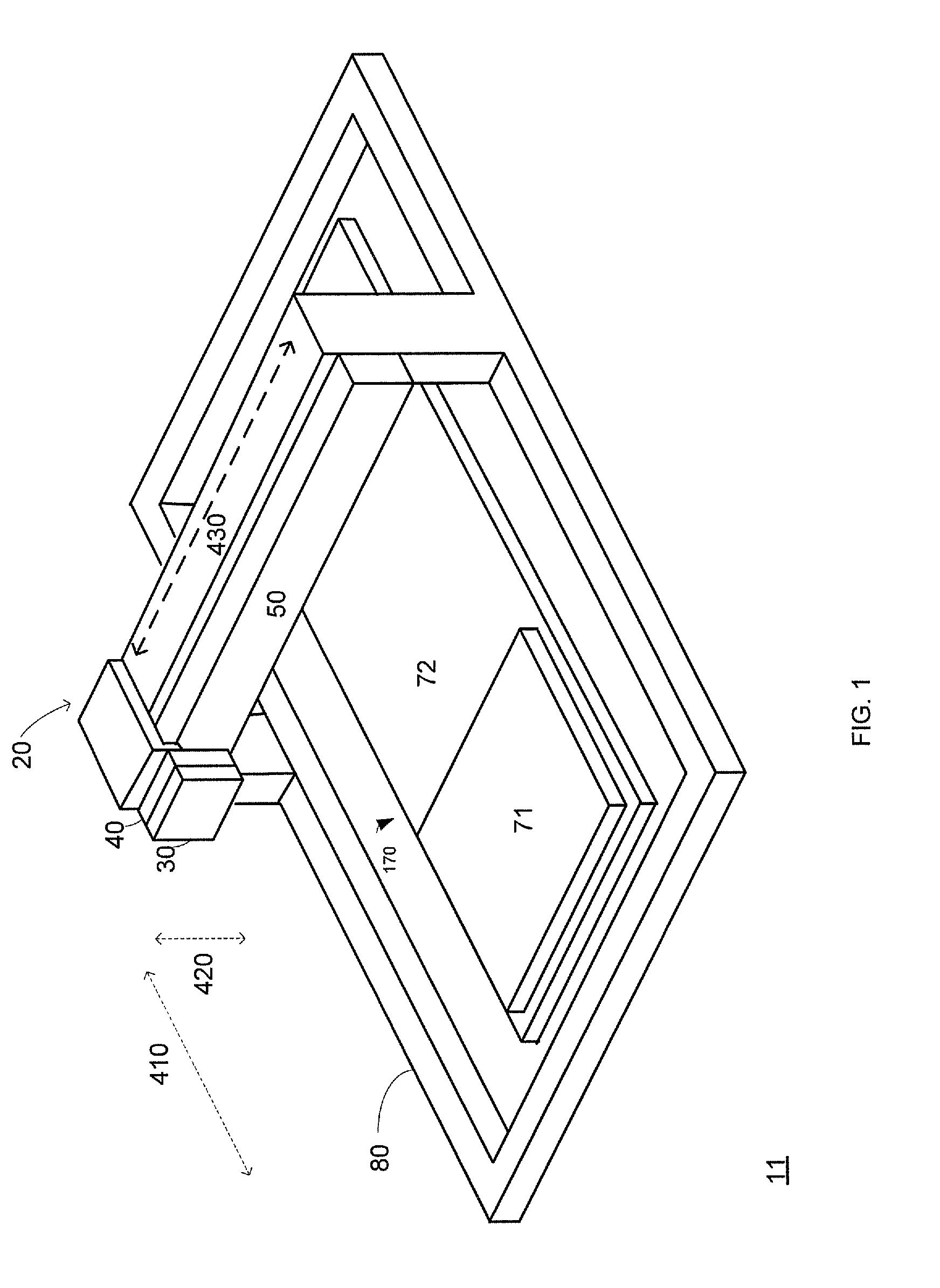

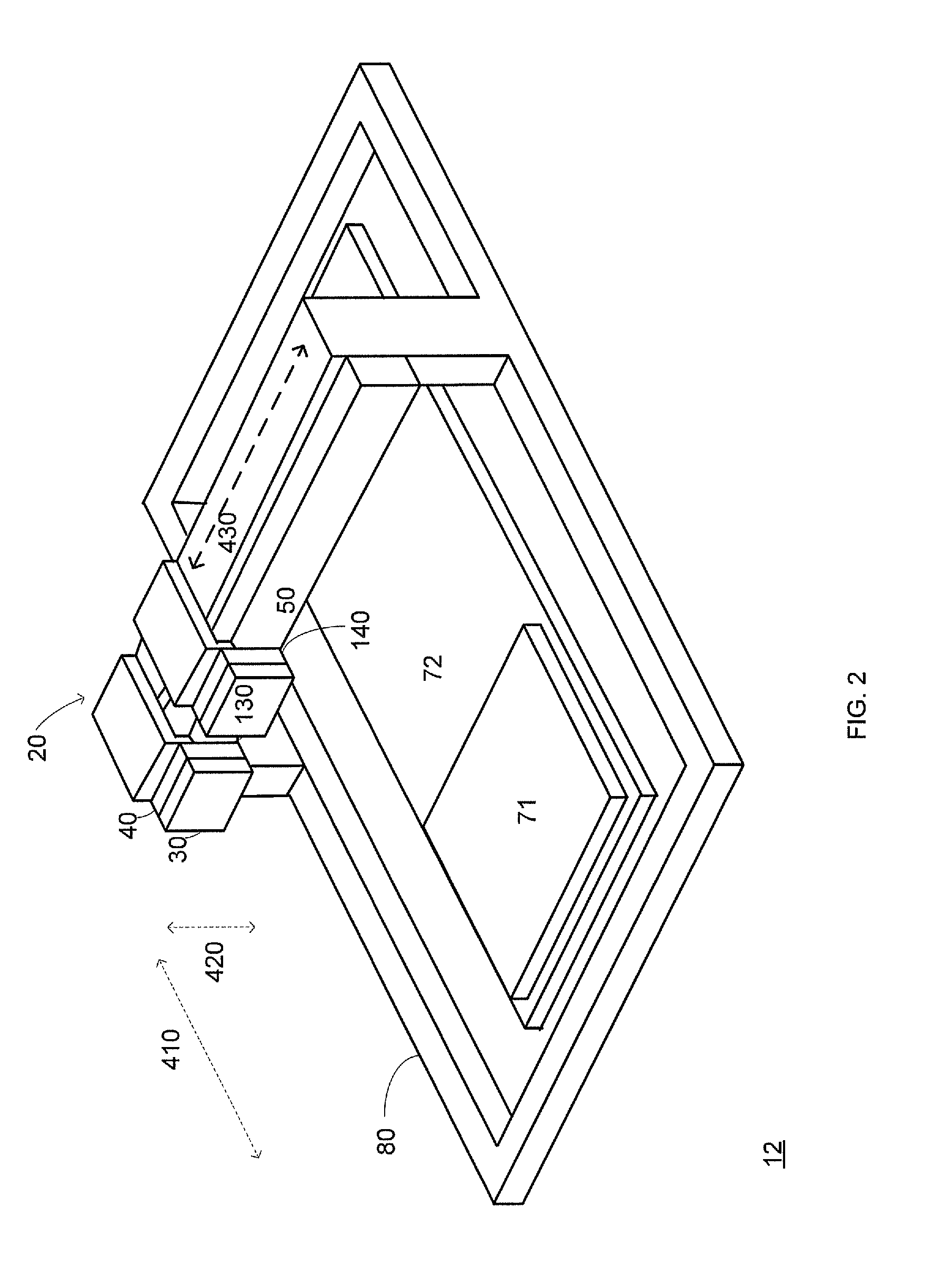

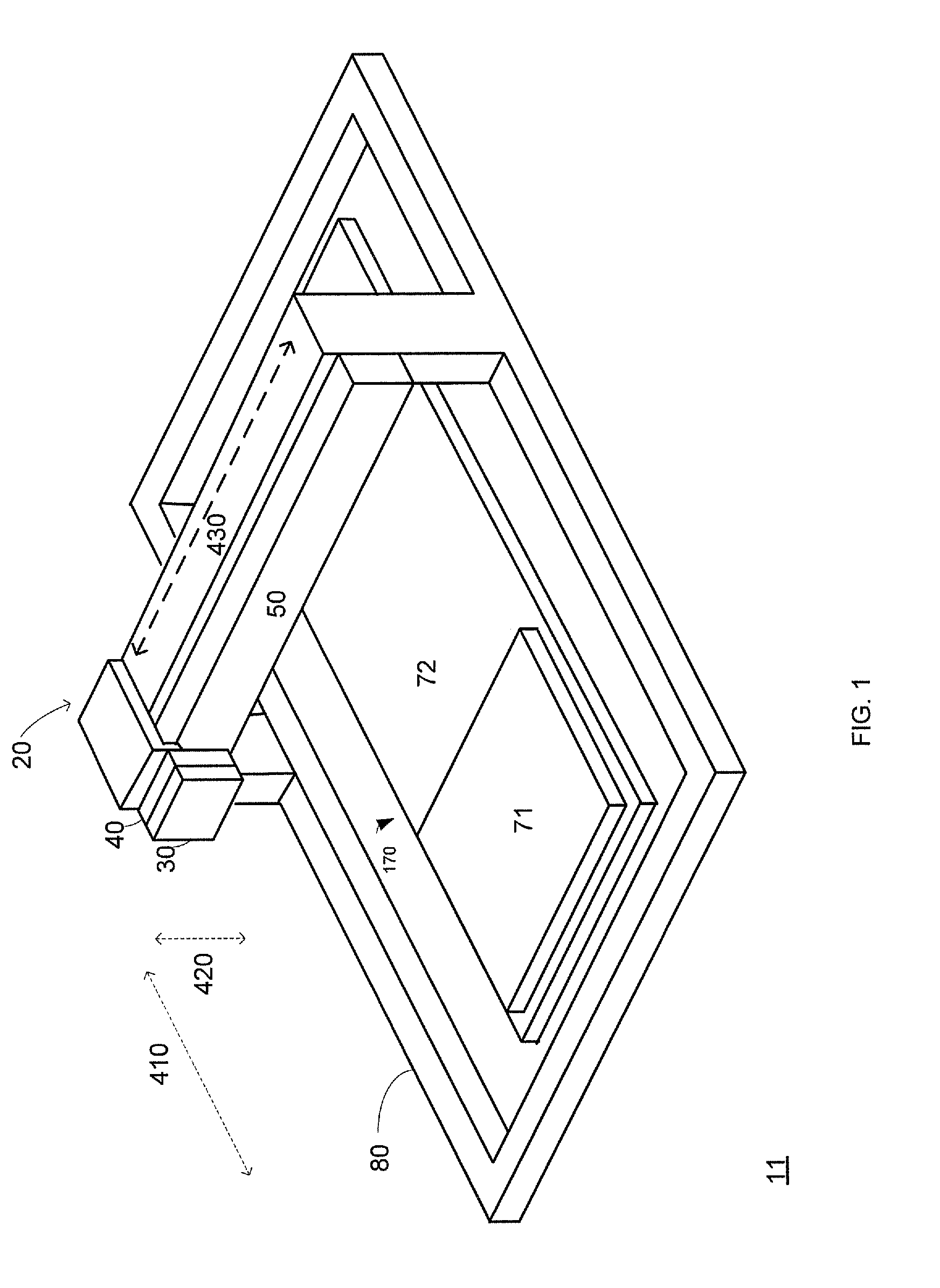

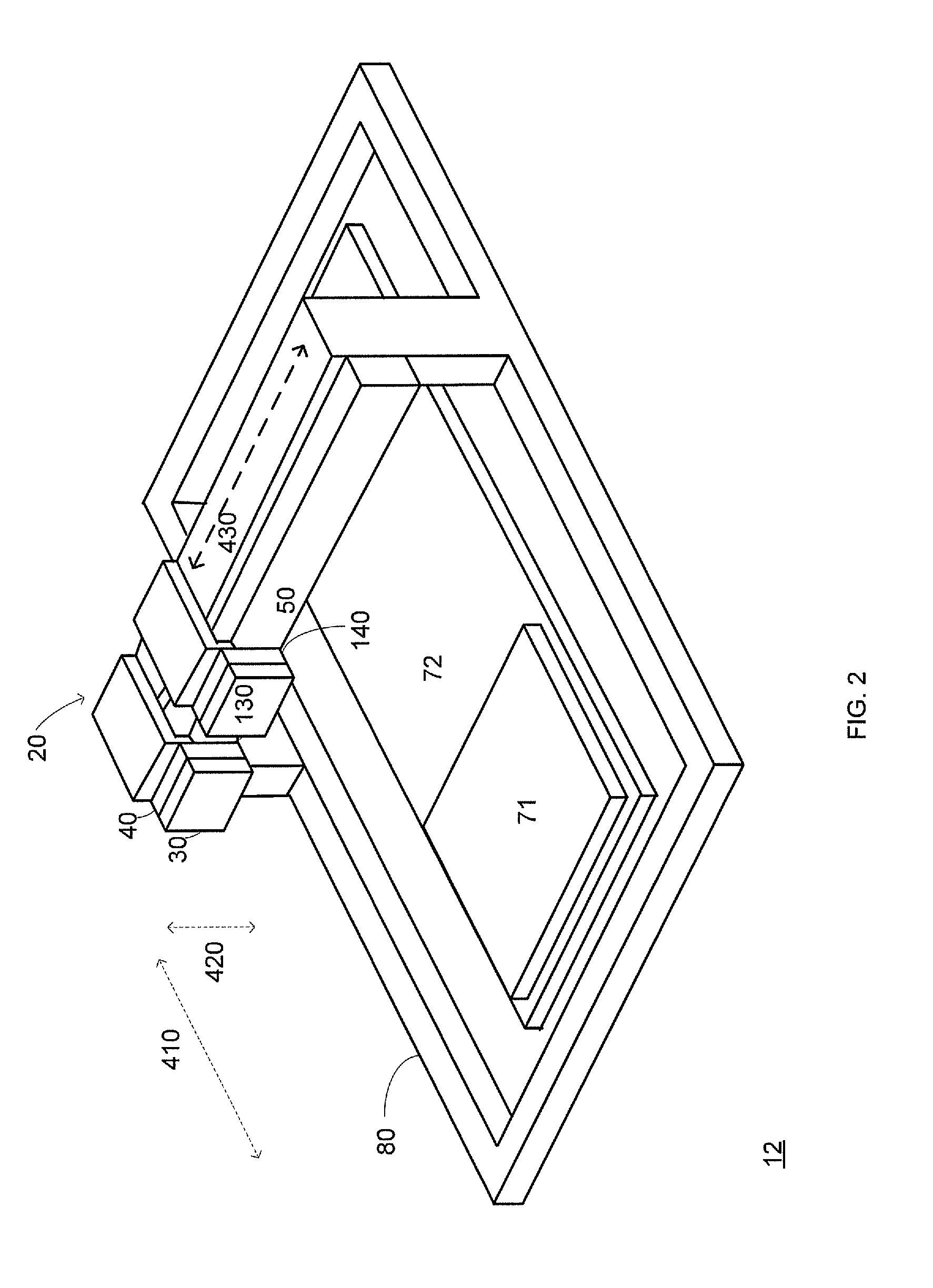

Apparatus and method for spray coating

InactiveUS20090317554A1Programme-controlled manipulatorLiquid/solution decomposition chemical coatingSpray coatingEngineering

A spray coating apparatus for spraying material on a substrate includes a frame and a gantry coupled to the frame. The gantry may be configured to provide x-axis, y-axis and z-axis movement. A device is coupled to the gantry. The device may be configured to rotate about the z-axis and pivot about a point on the z-axis. A spray head is coupled to the device. A controller is coupled to the gantry and the spray head. The controller may be configured to control the automated movement of the gantry to provide x-axis, y-axis and z-axis movement and rotational and pivoting movement of the spray head. Other embodiments of the spray coating device and related methods are further disclosed.

Owner:SPECIALTY COATING SYST

Conformal coating applicator and method

ActiveUS20050095365A1Easy to handleSimplify disassemblyMovable spraying apparatusLiquid flow controllersEngineeringConformal coating

An applicator for dispensing a conformal coating material onto a substrate. The applicator has a body with a nozzle having a dispensing orifice at a distal end of the body, and assist air is supplied to a location adjacent the dispensing orifice. A seat is disposed in the nozzle around the dispensing orifice, and an end of a needle is movable into contact with and through the seat to terminate a flow of the coating material through the dispensing orifice and eliminate any coating material flow path downstream of the seat. A needle guide is used to laterally support the needle above the nozzle. The distal end of a nozzle is the distal end of the applicator and is exposed for cleaning.

Owner:NORDSON CORP +1

Printed electronics

Printed electronic device comprising a substrate onto at least one surface of which has been applied a layer of an electrically conductive ink comprising functionalized graphene sheets and at least one binder. A method of preparing printed electronic devices is further disclosed.

Owner:VORBECK MATERIALS CORP +1

Polymerization method for formation of thermally exfoliated graphite oxide containing polymer

ActiveUS20080306225A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphitePolymer scienceMonomer

Owner:THE TRUSTEES FOR PRINCETON UNIV

Method of conformal coating using noncontact dispensing

InactiveUS20050095366A1Easy to controlImprove abilitiesSemiconductor/solid-state device detailsSolid-state devicesEngineeringConformal coating

A method of noncontact dispensing is provided for conformal coating applications by jetting a viscous material onto a substrate. Dispensing by a jetting process results in small wetted areas thus providing highly discrete and selective conformal coating capabilities. Enhanced selectivity permits the coating of small areas and geometries and provides excellent edge definition between coated and uncoated areas.

Owner:NORDSON CORP

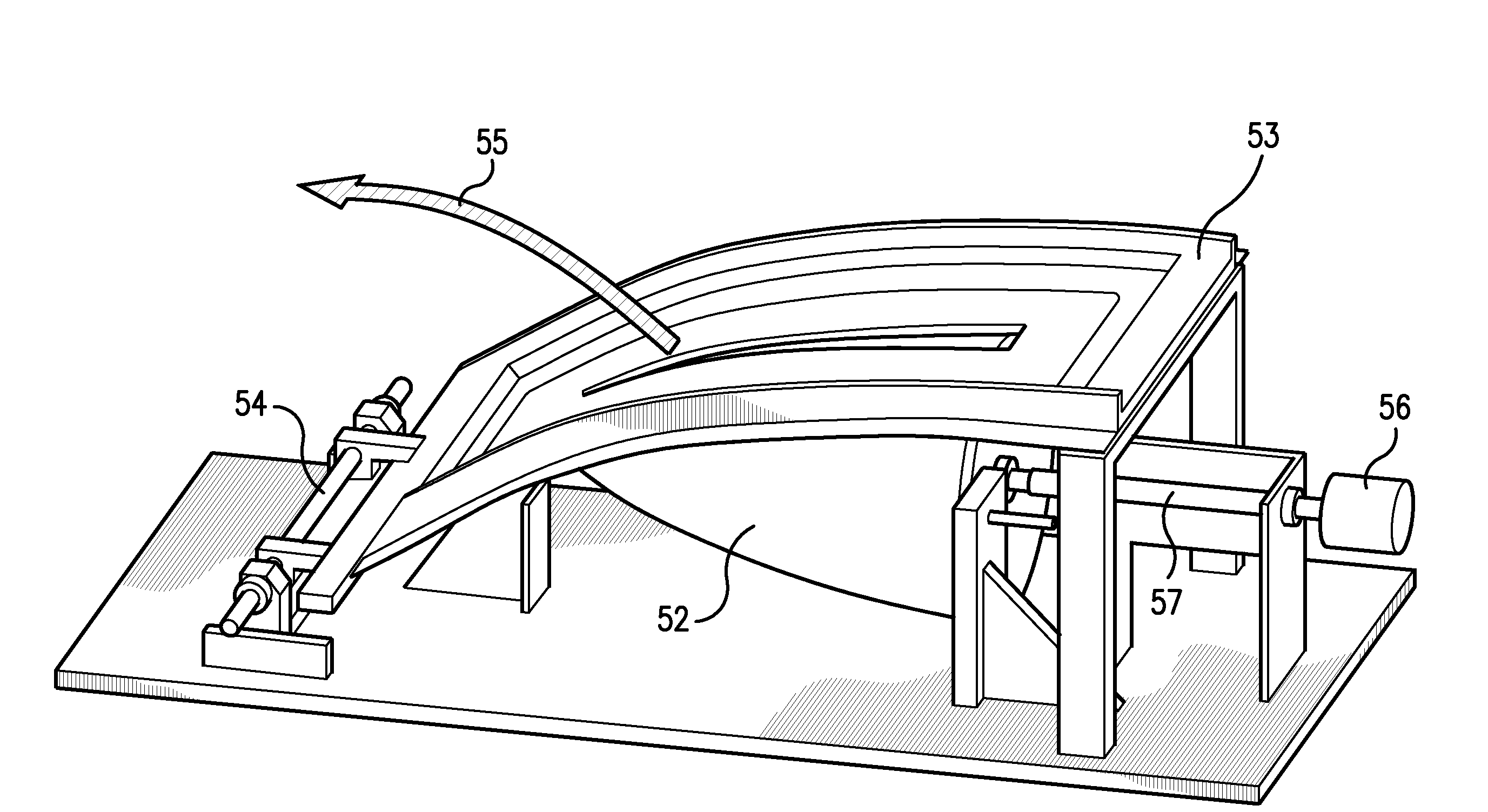

Method and apparatus for applying electronic circuits to curved surfaces

ActiveUS20080028956A1Reduce expensesEasy screening3D rigid printed circuitsScreen printersDielectricElectricity

An electric circuit is applied to an object having a curved surface. The curved surface of the object is divided into sections, and the circuit is applied one section at a time. The circuit is formed between layers of dielectric material. The dielectric is applied by a computer-controlled device, which controls the position of a spray head and the rotation of the object, such that the spray head is held substantially perpendicular to the surface of the object at all times, and such that a controlled thickness of dielectric material can be deposited. The fine-featured circuits formed by the invention are rugged, and can be used on objects intended to be exposed to harsh environments.

Owner:II VI DELAWARE INC

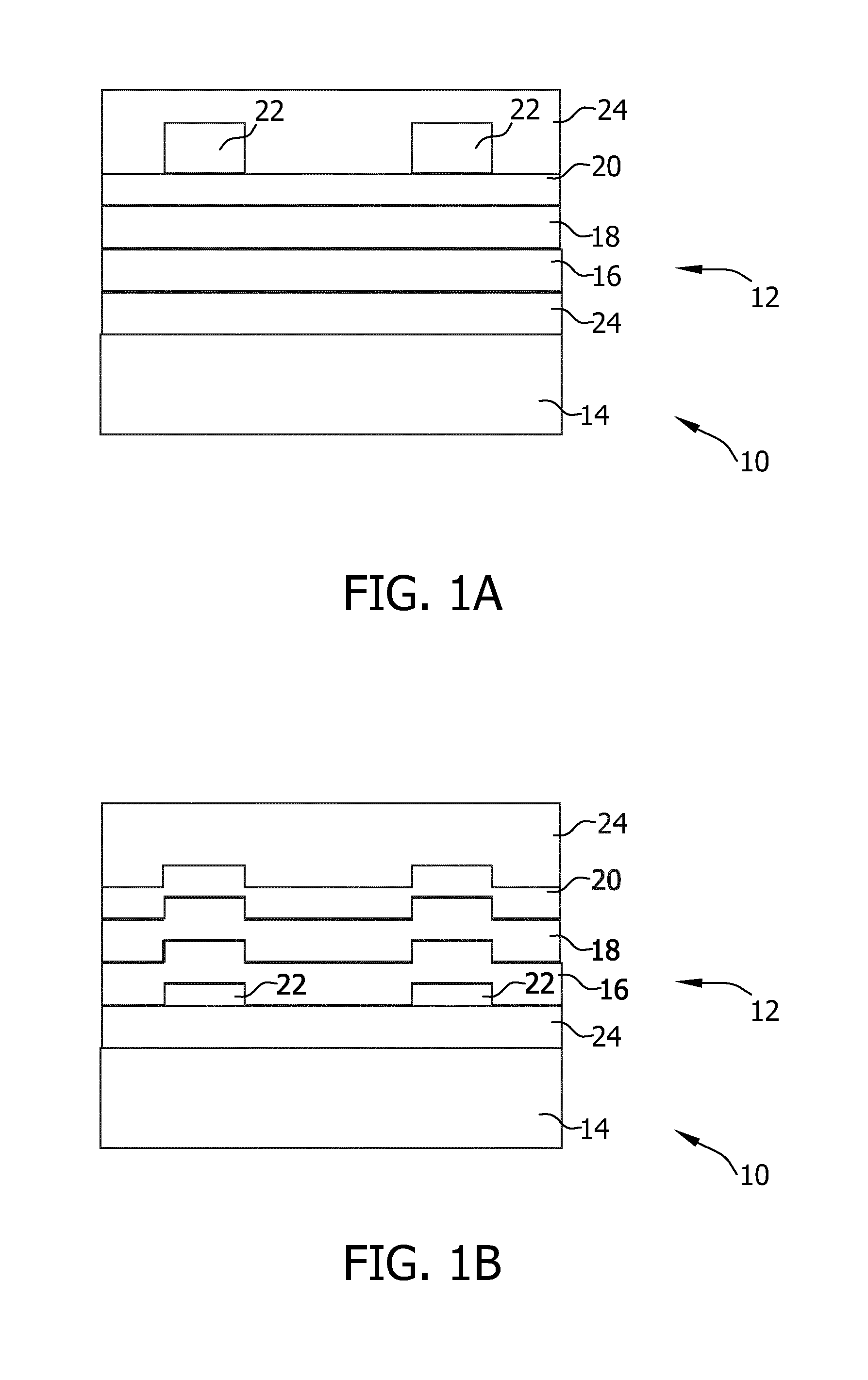

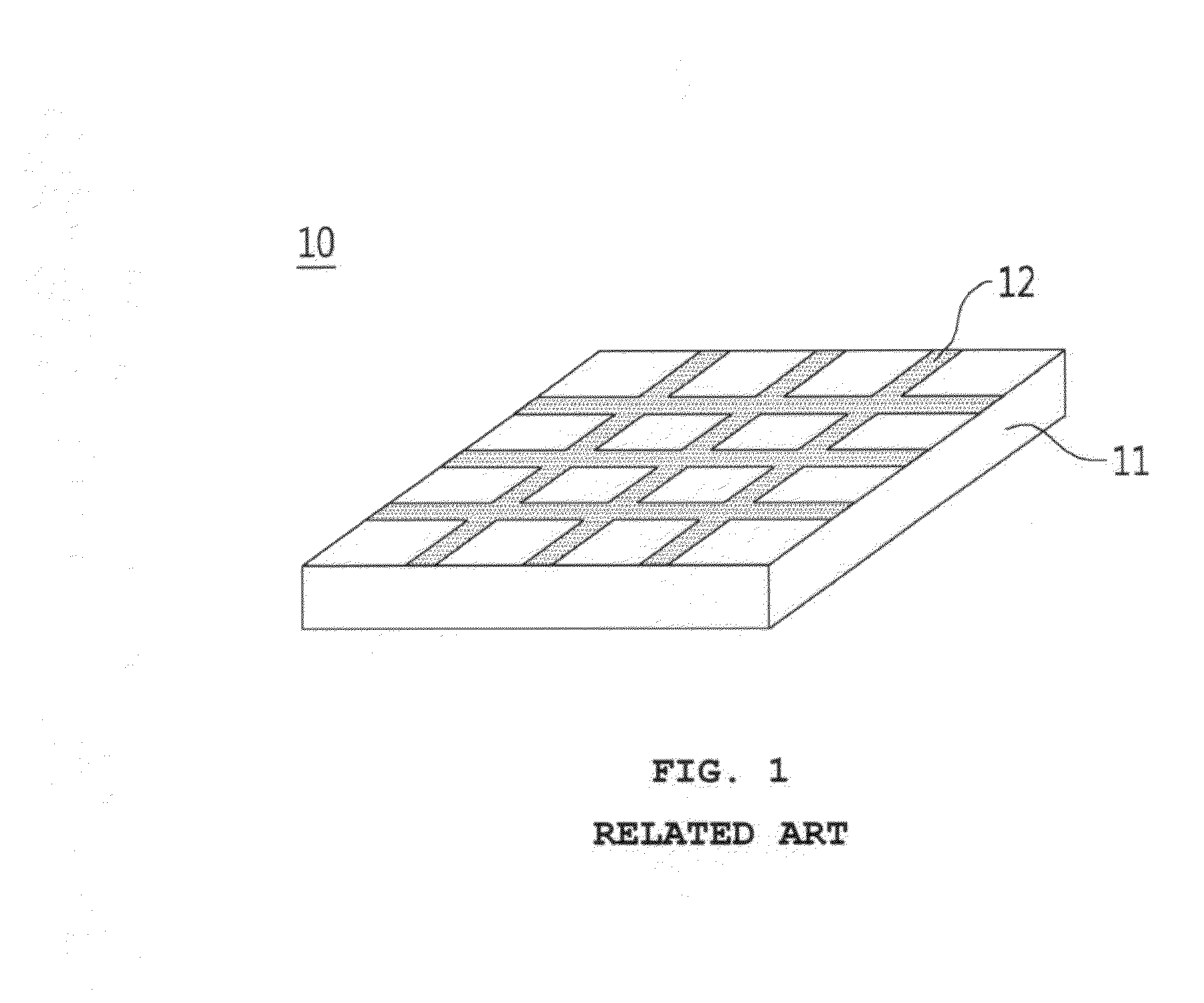

Transparent body for use in a touch screen panel manufacturing method and system

InactiveUS20150083464A1Easy to manufactureImprove performanceVacuum evaporation coatingSputtering coatingAdhesiveRefractive index

A process for manufacturing a transparent body for use in a touch screen panel is provided. The process includes: depositing a first transparent layer stack over a transparent substrate, wherein said first transparent layer stack includes at least a first dielectric film with a first refractive index, and a second dielectric film with a second refractive index different from the second the first refractive index; providing a structured transparent conductive film in a manner such that the first transparent layer stack and the transparent conductive film are disposed over the substrate in this order, and wherein the structured transparent conductive film has a sheet resistance of 100 Ohm / square or below; and providing a transparent adhesive onto the structured transparent conductive film configured for attaching the layer stack to the touch screen panel.

Owner:APPLIED MATERIALS INC

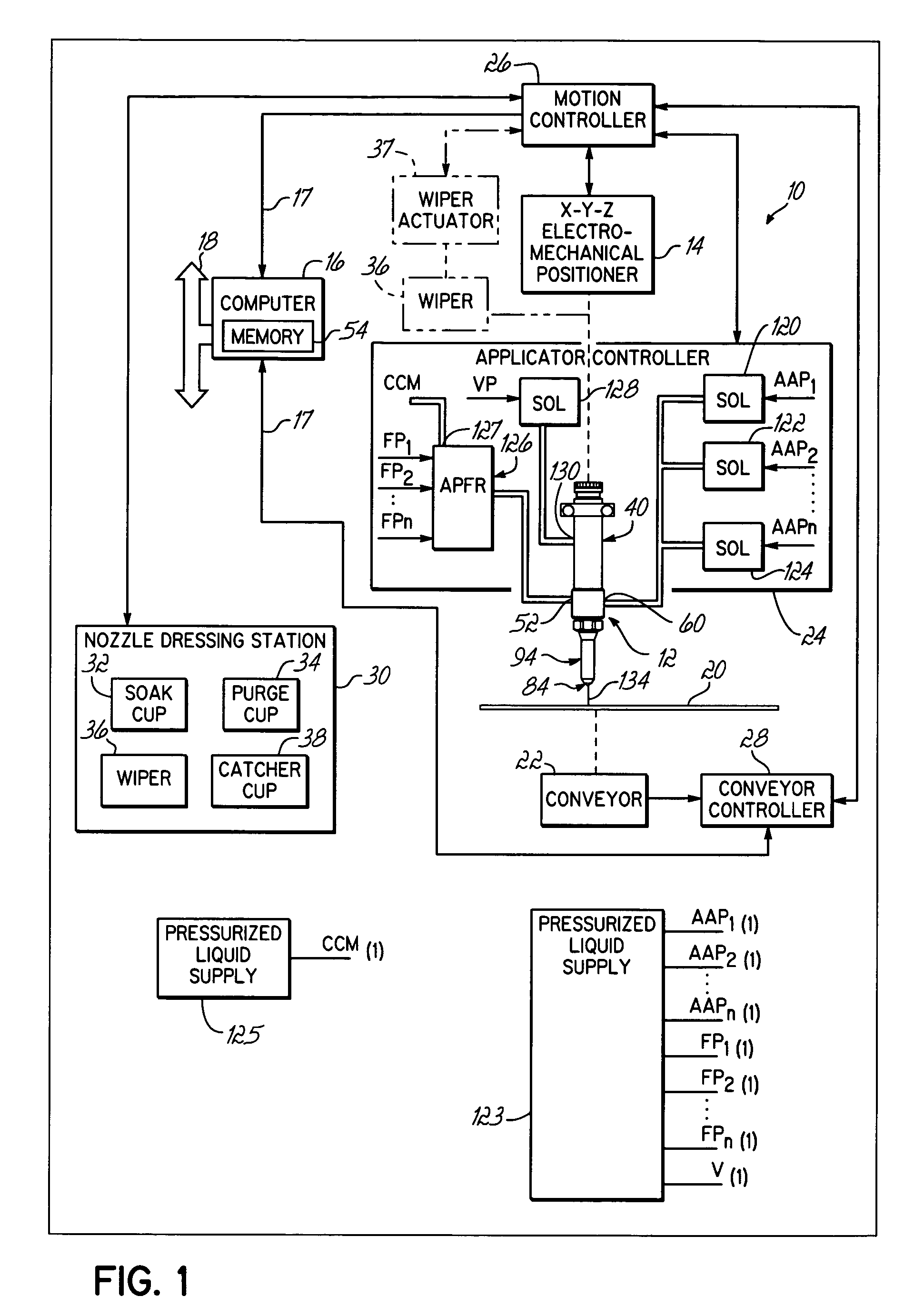

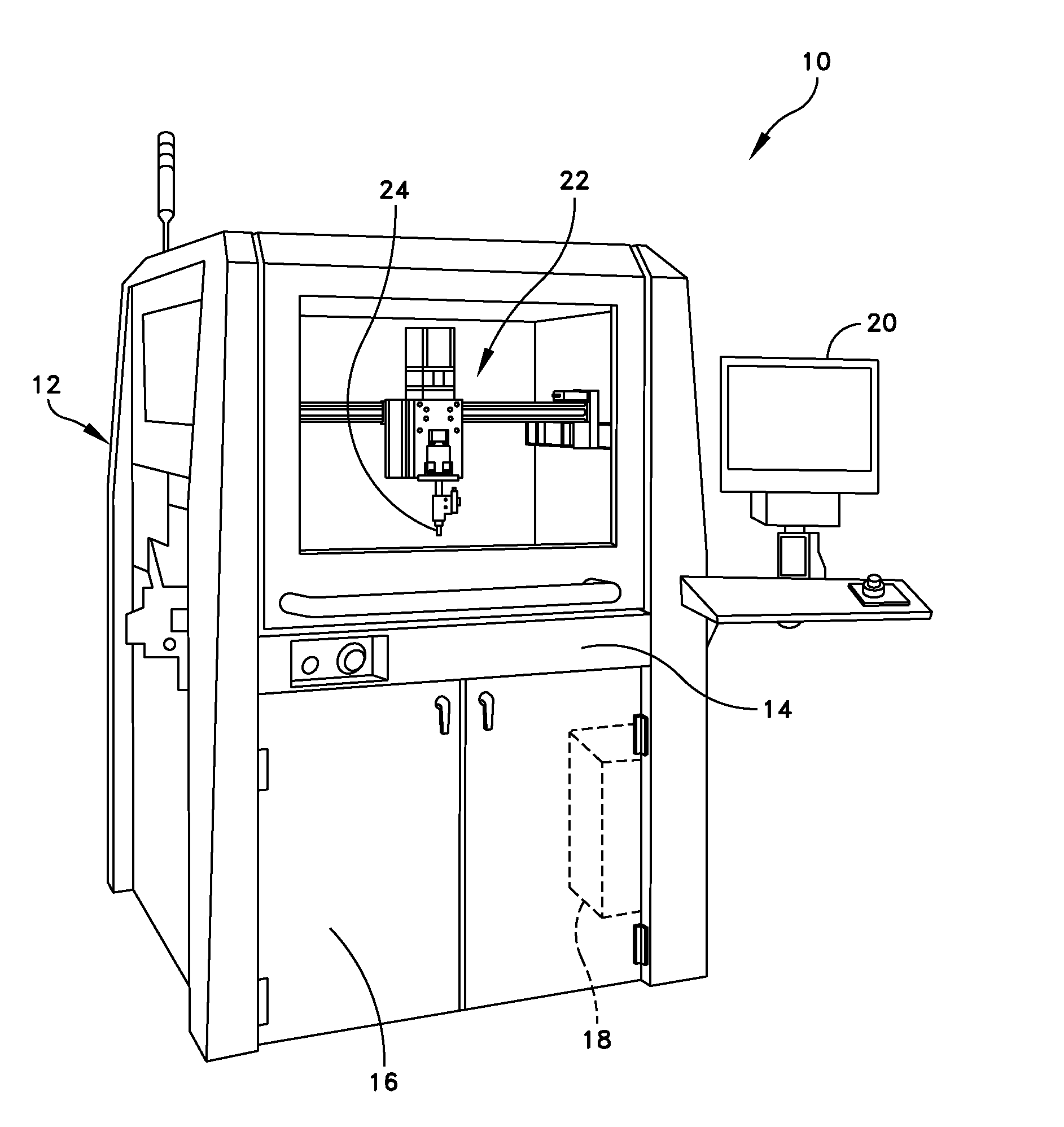

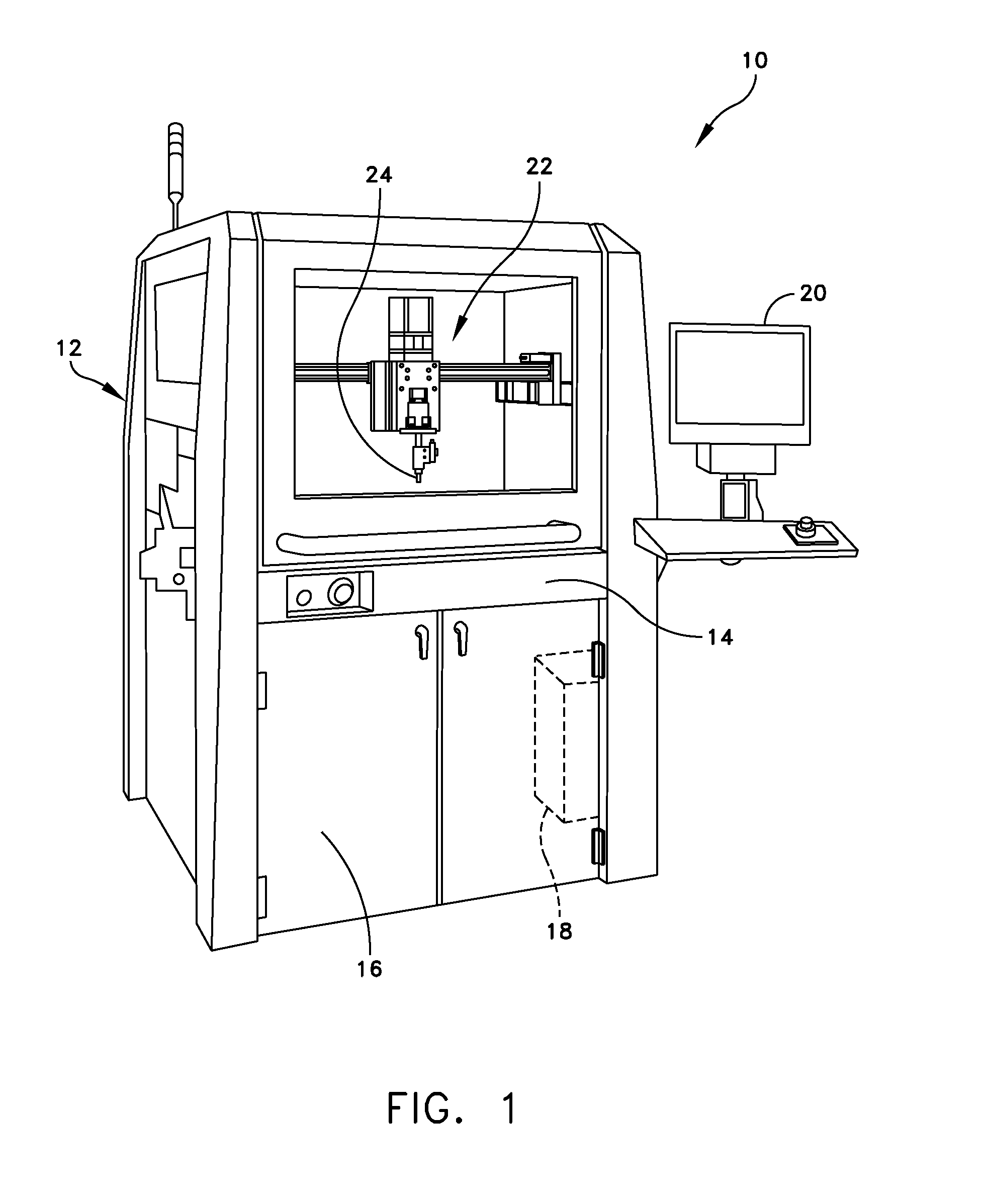

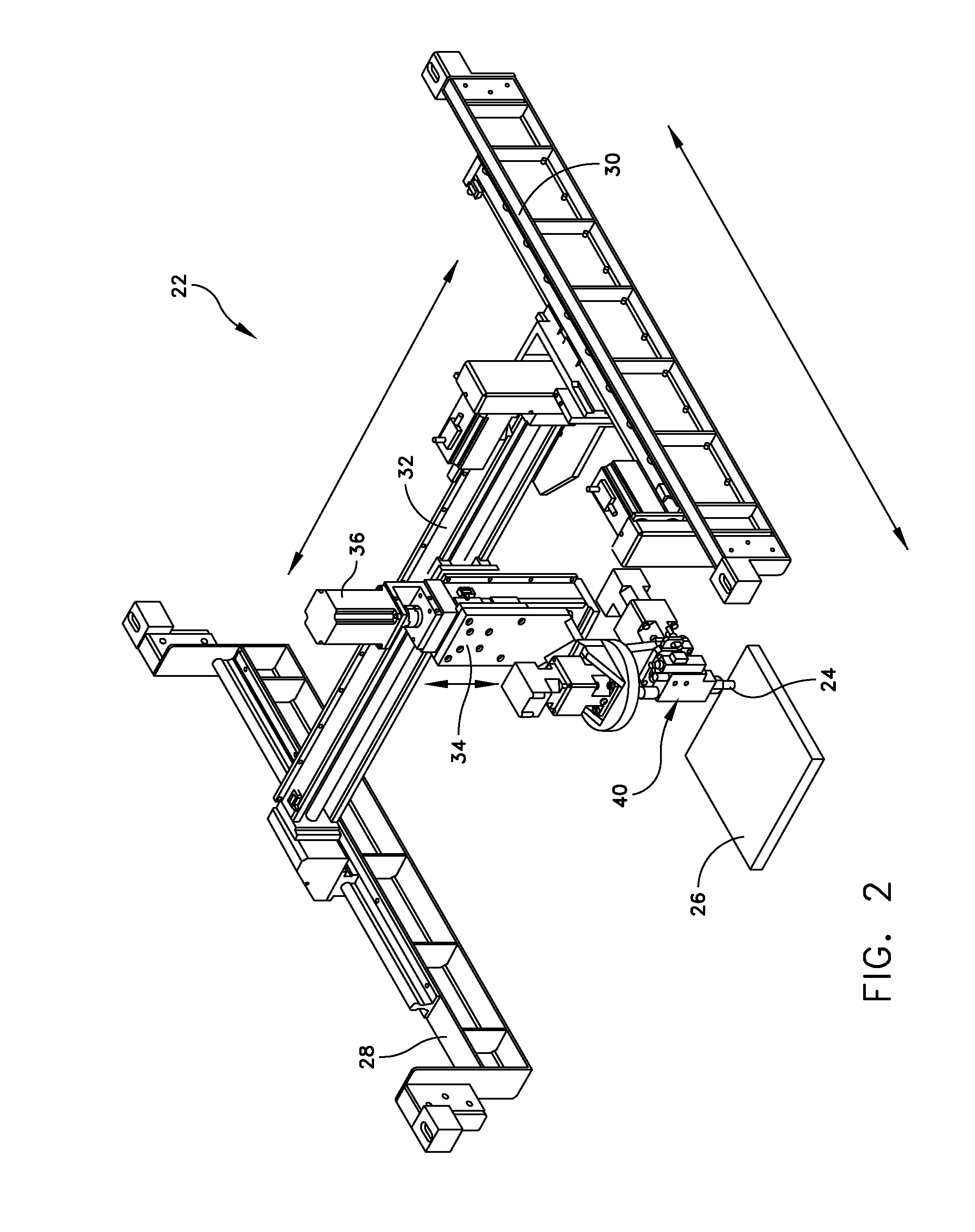

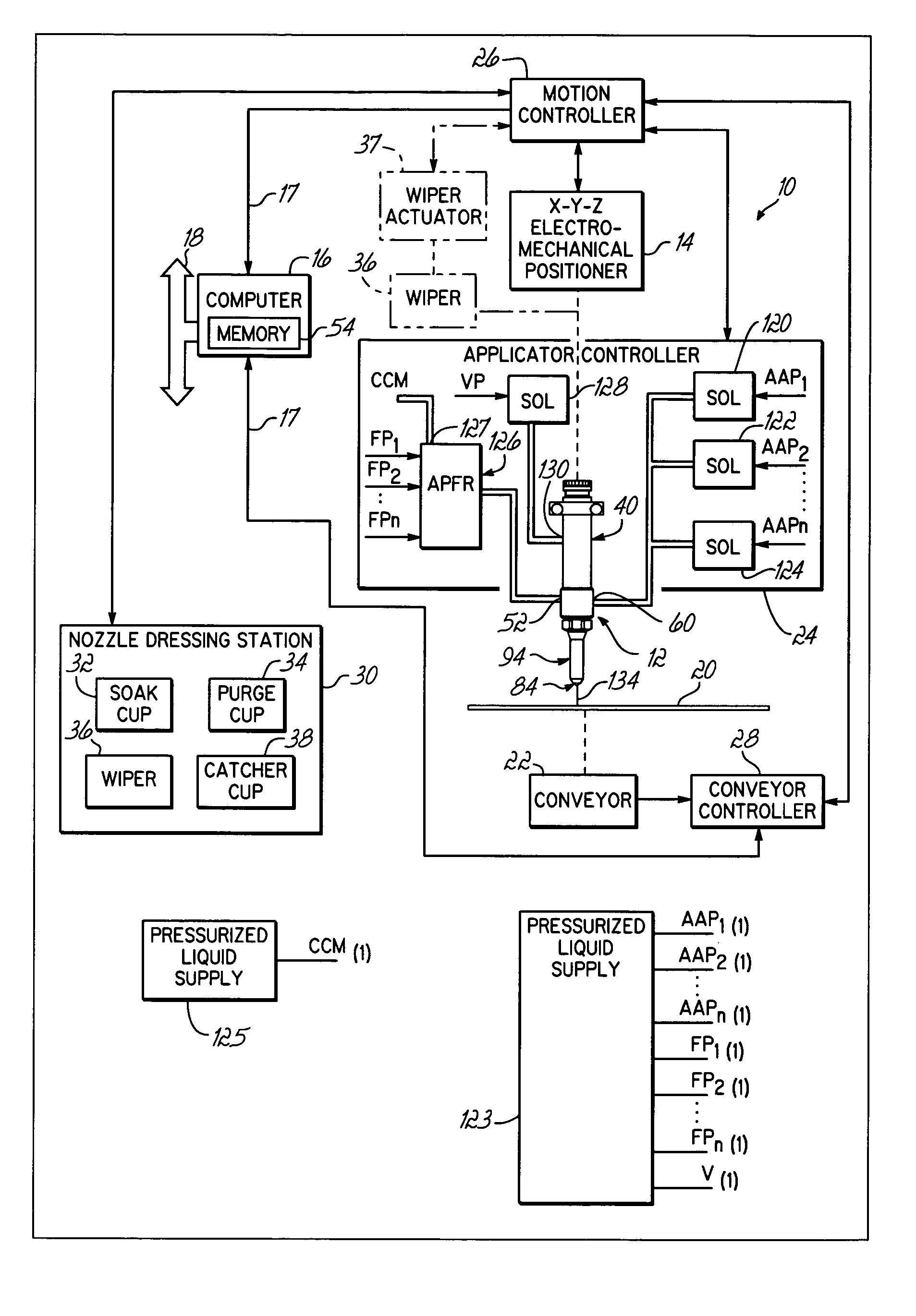

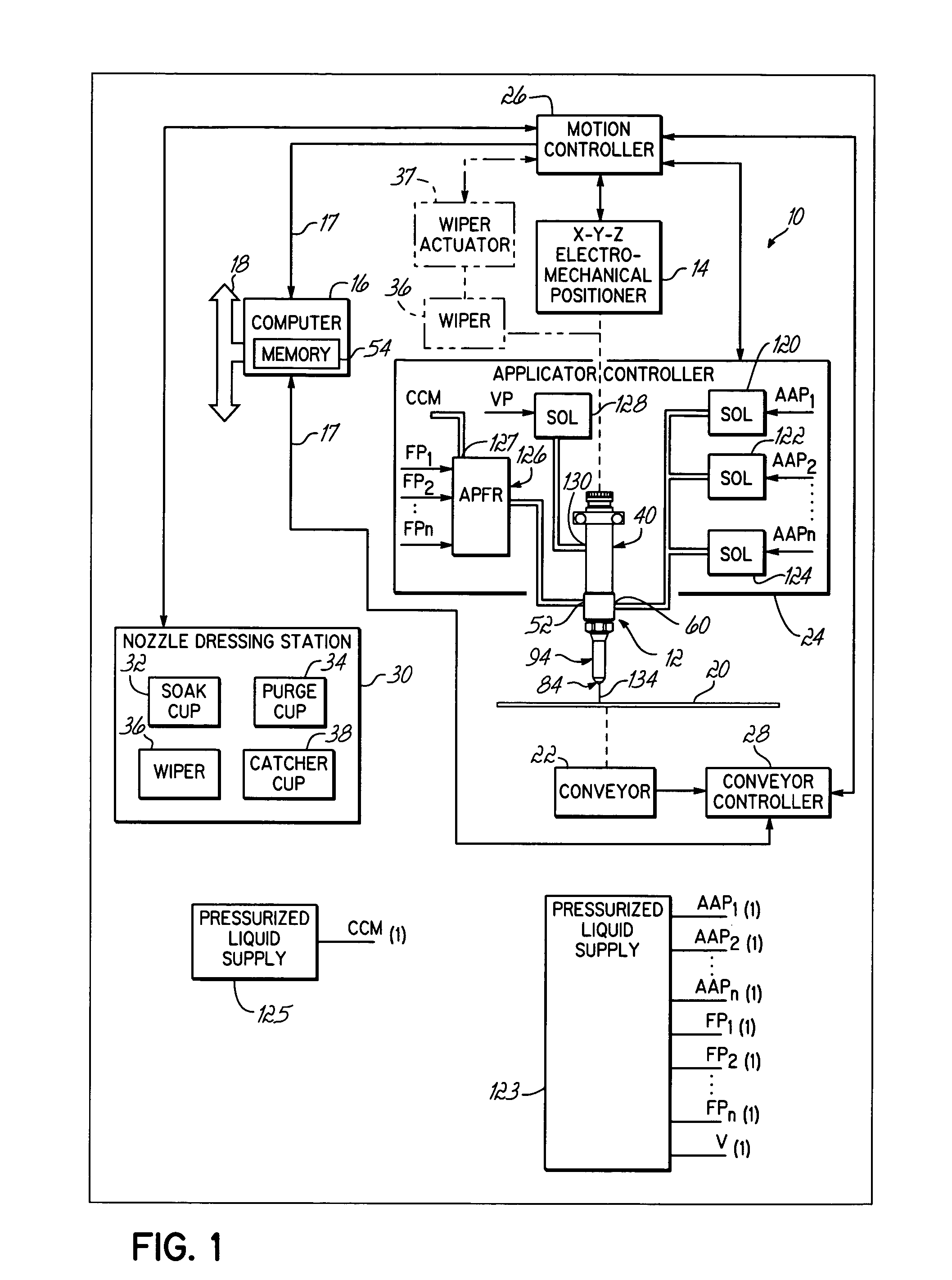

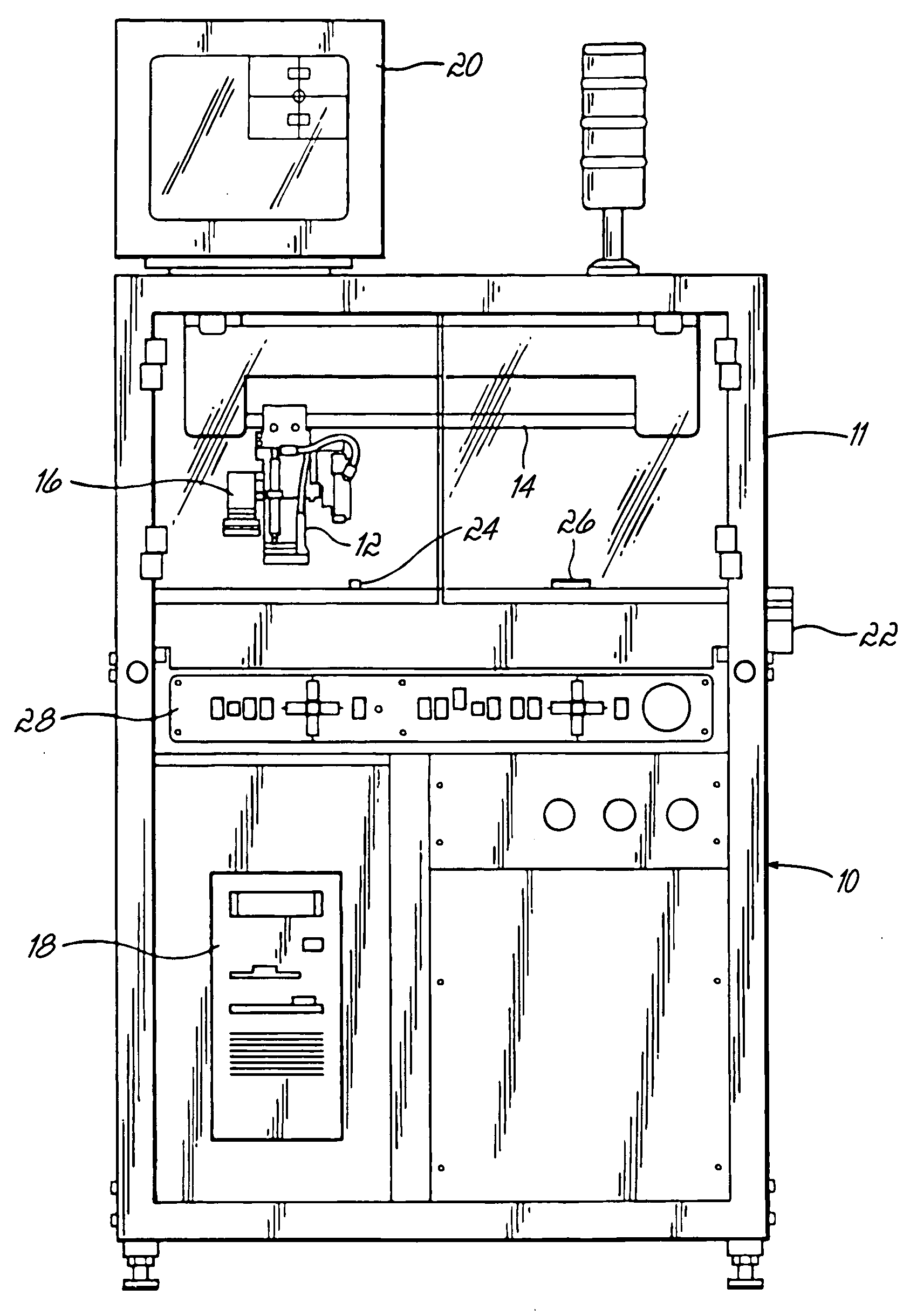

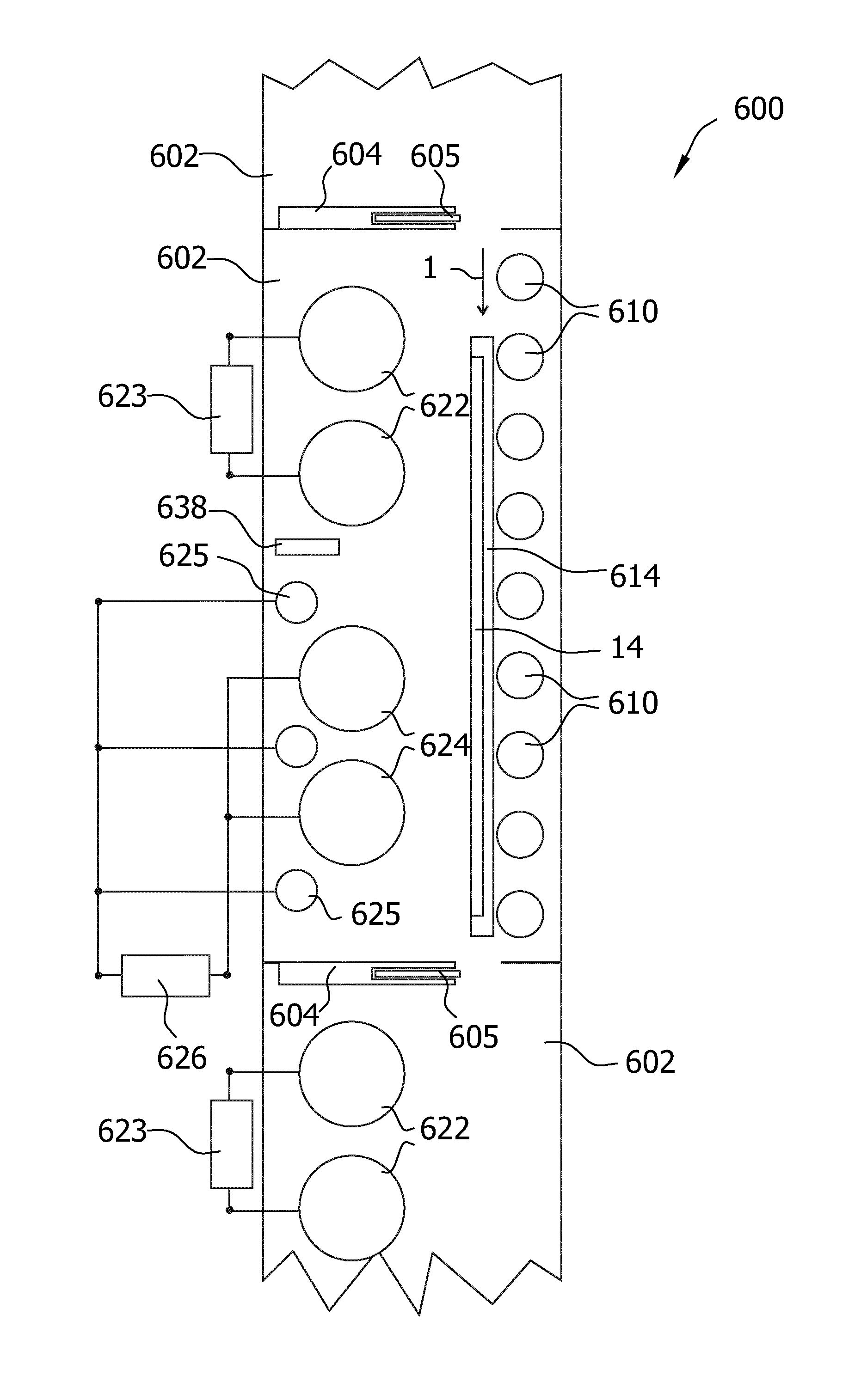

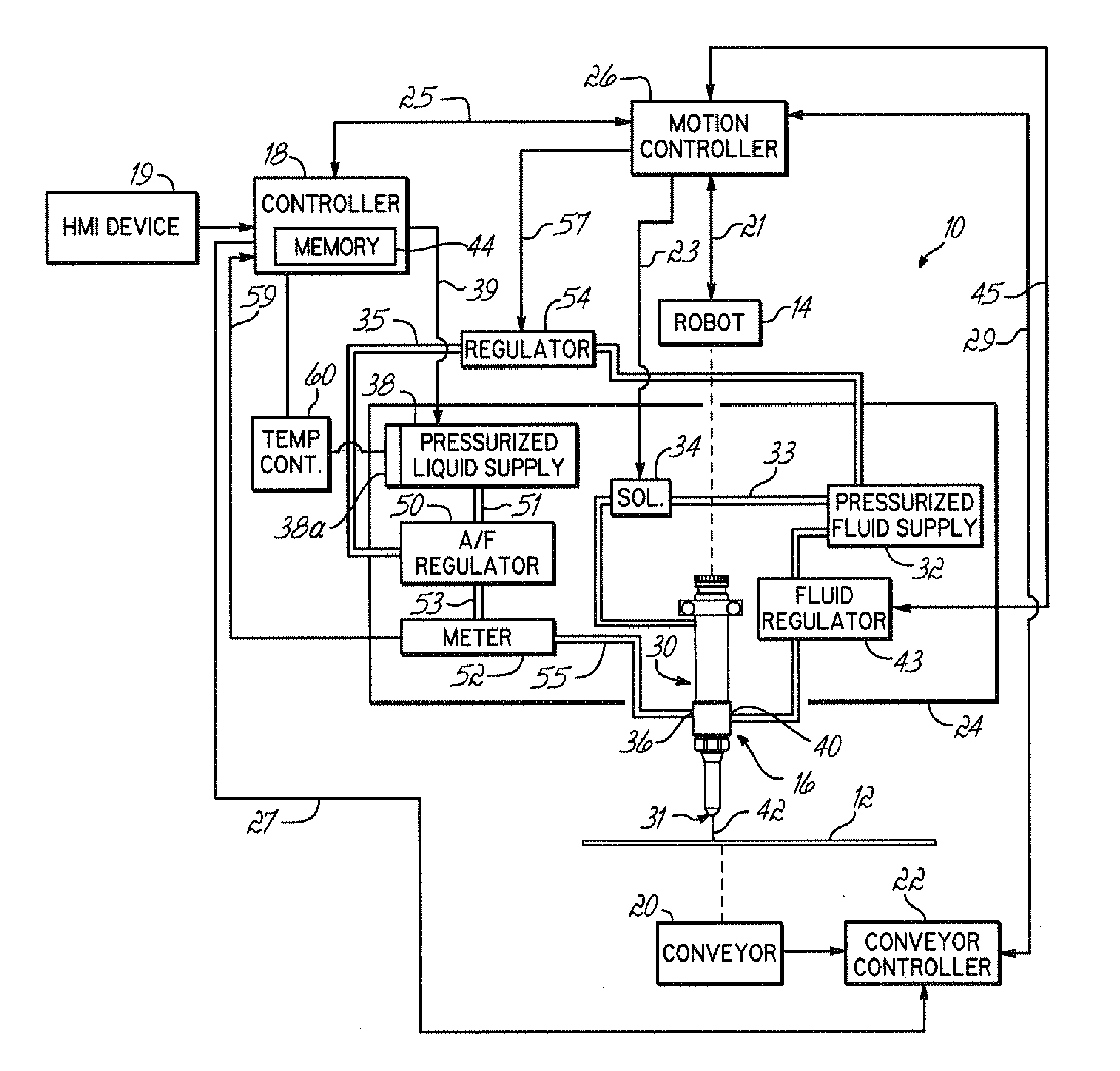

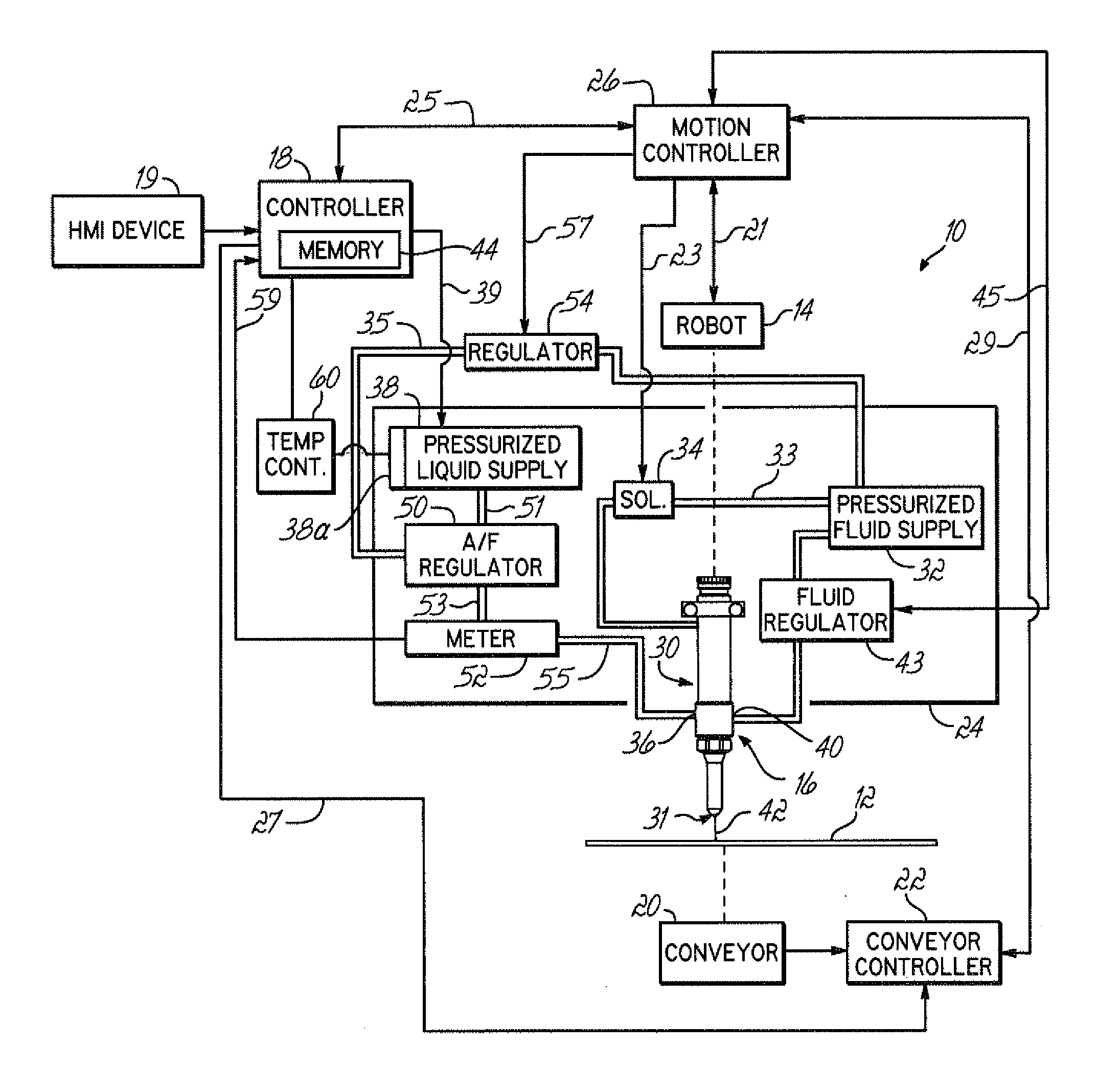

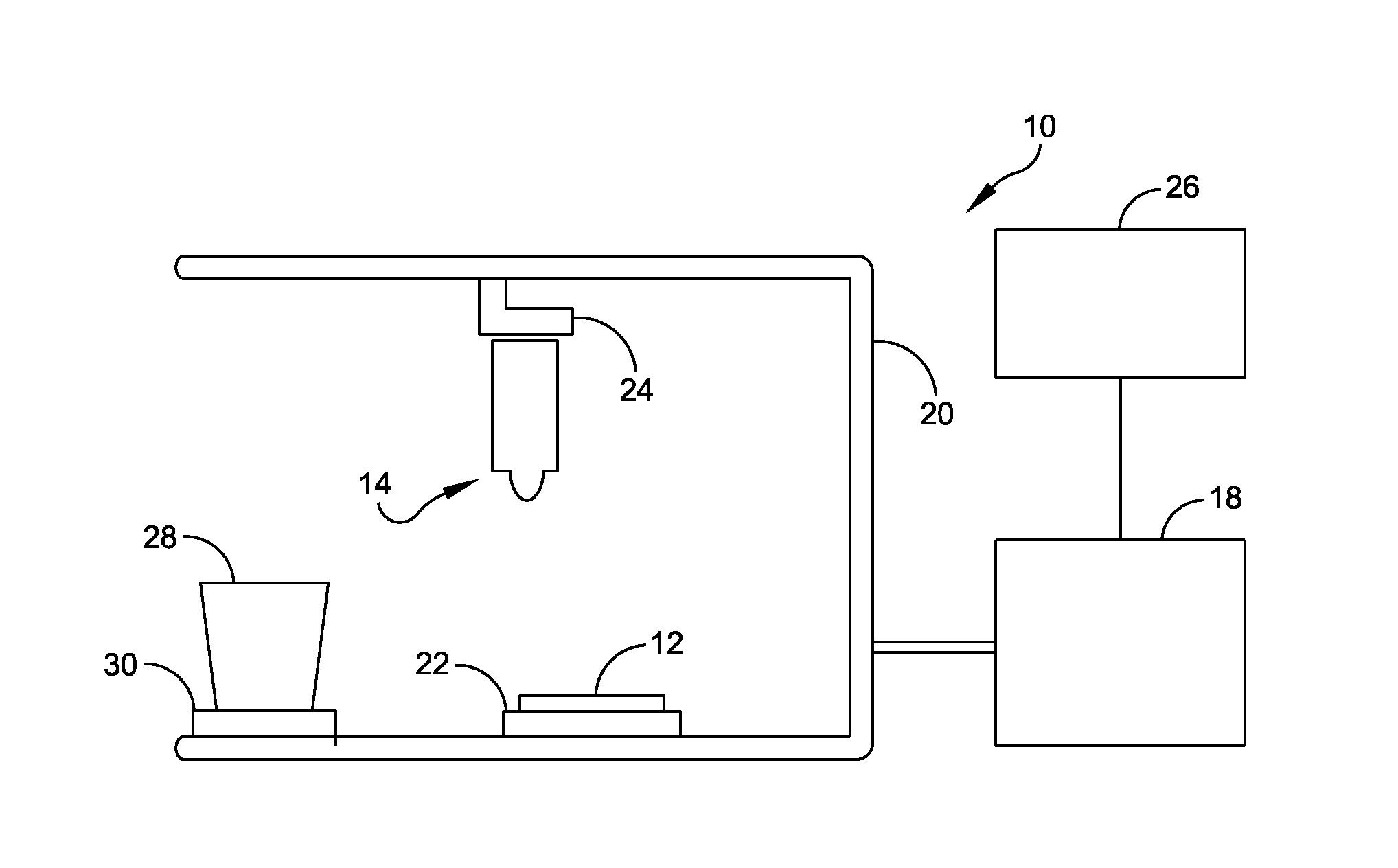

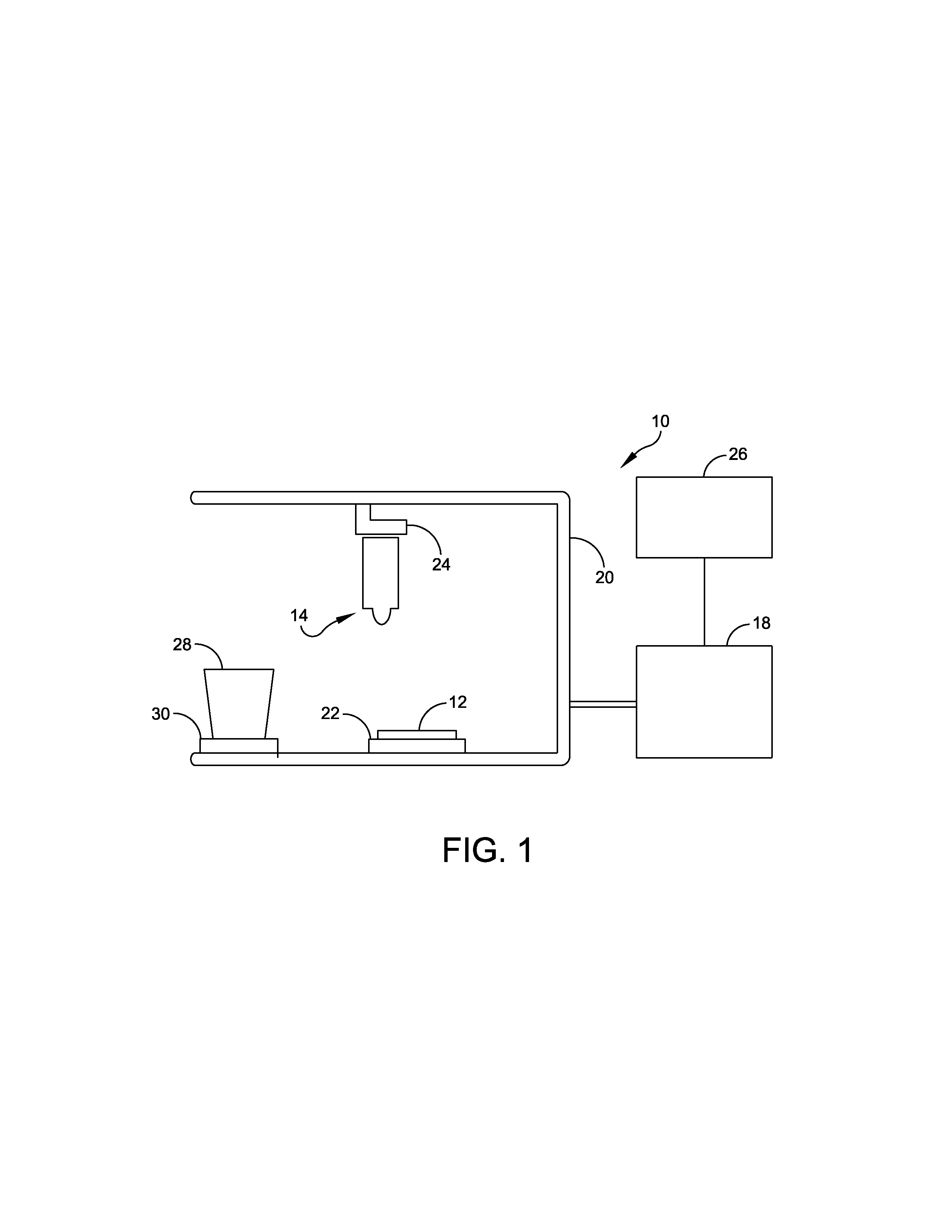

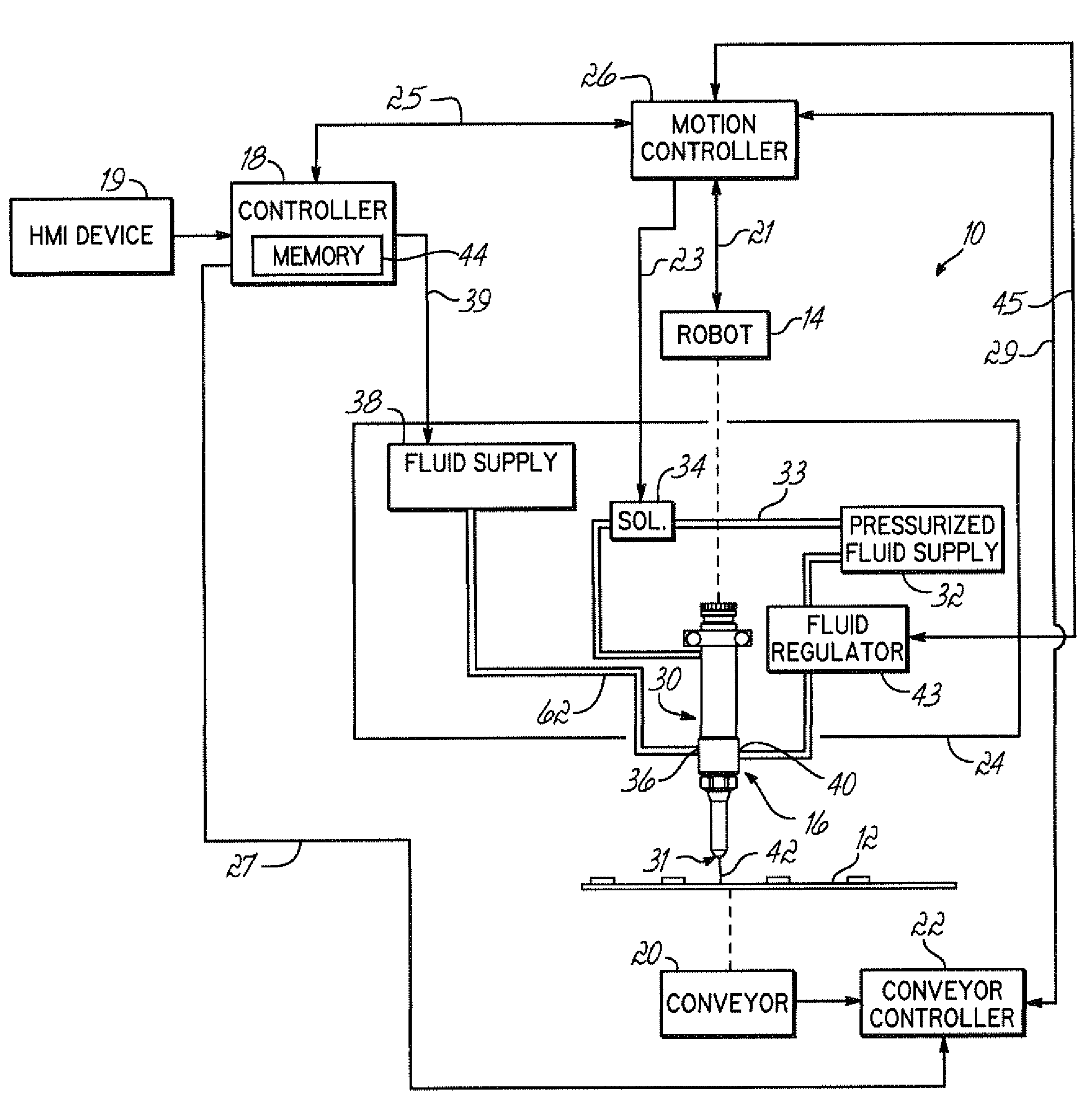

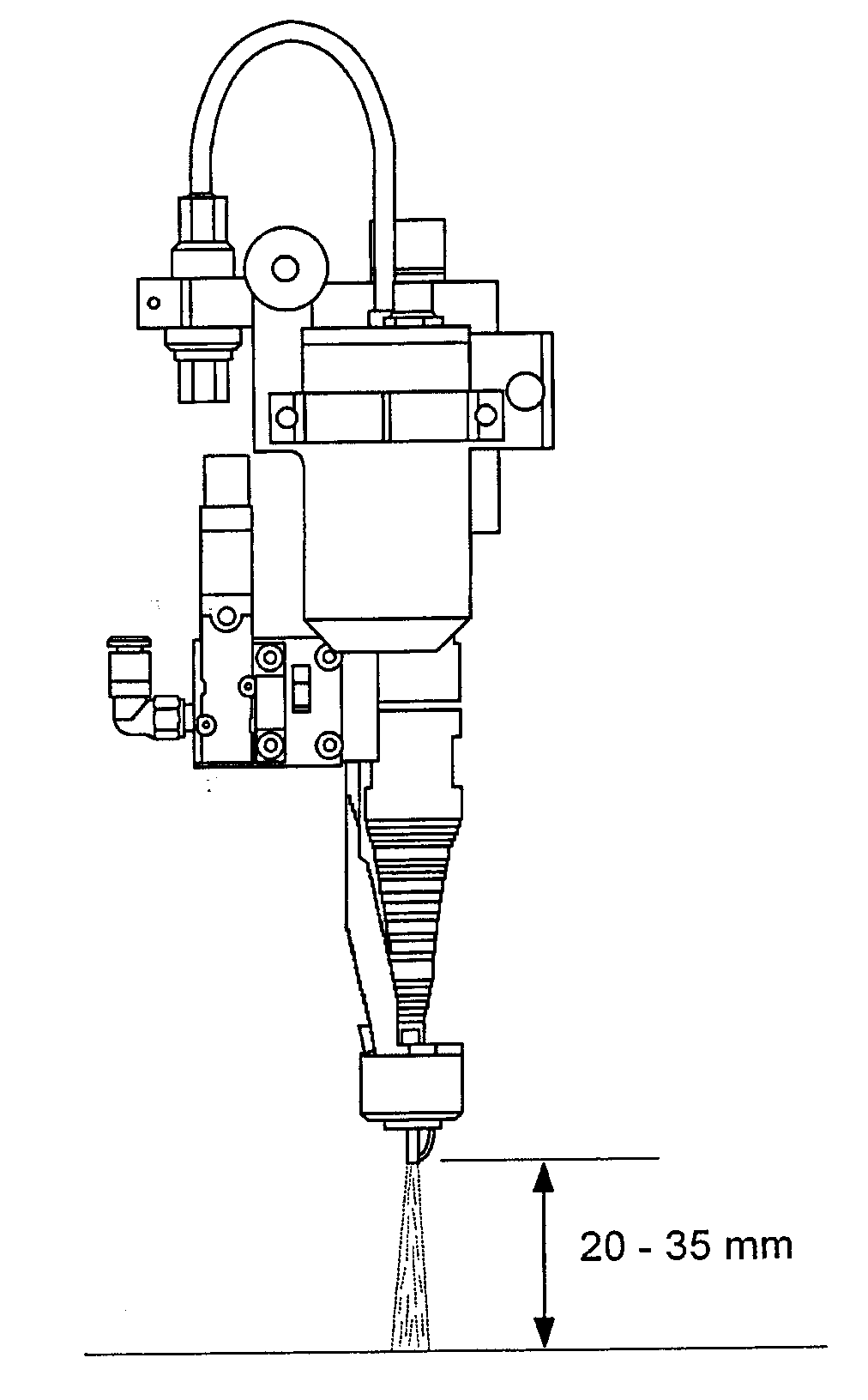

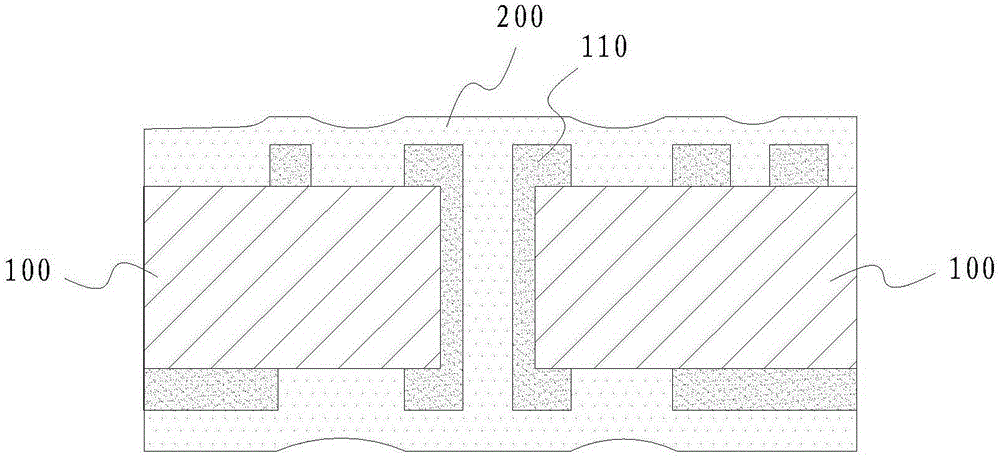

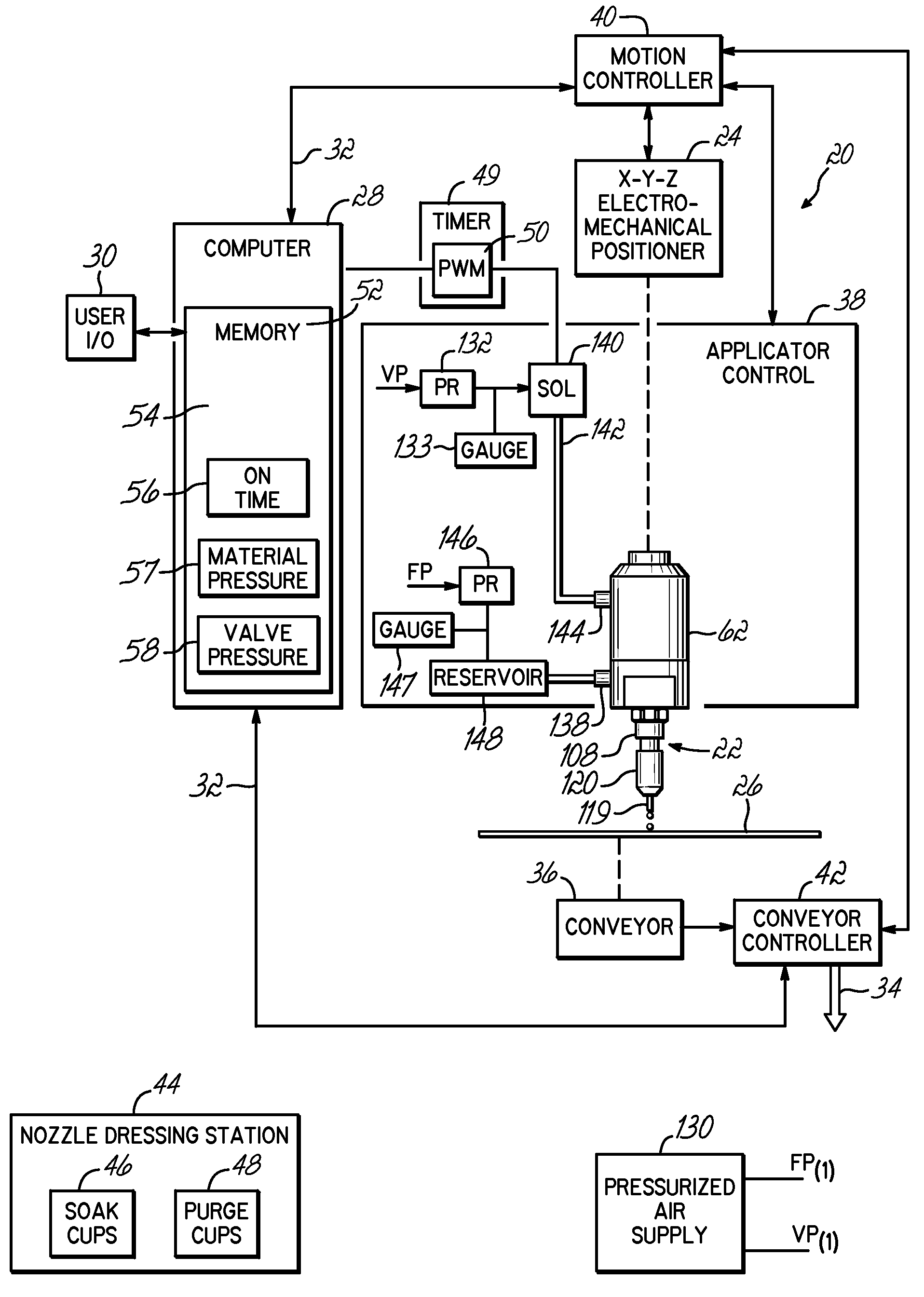

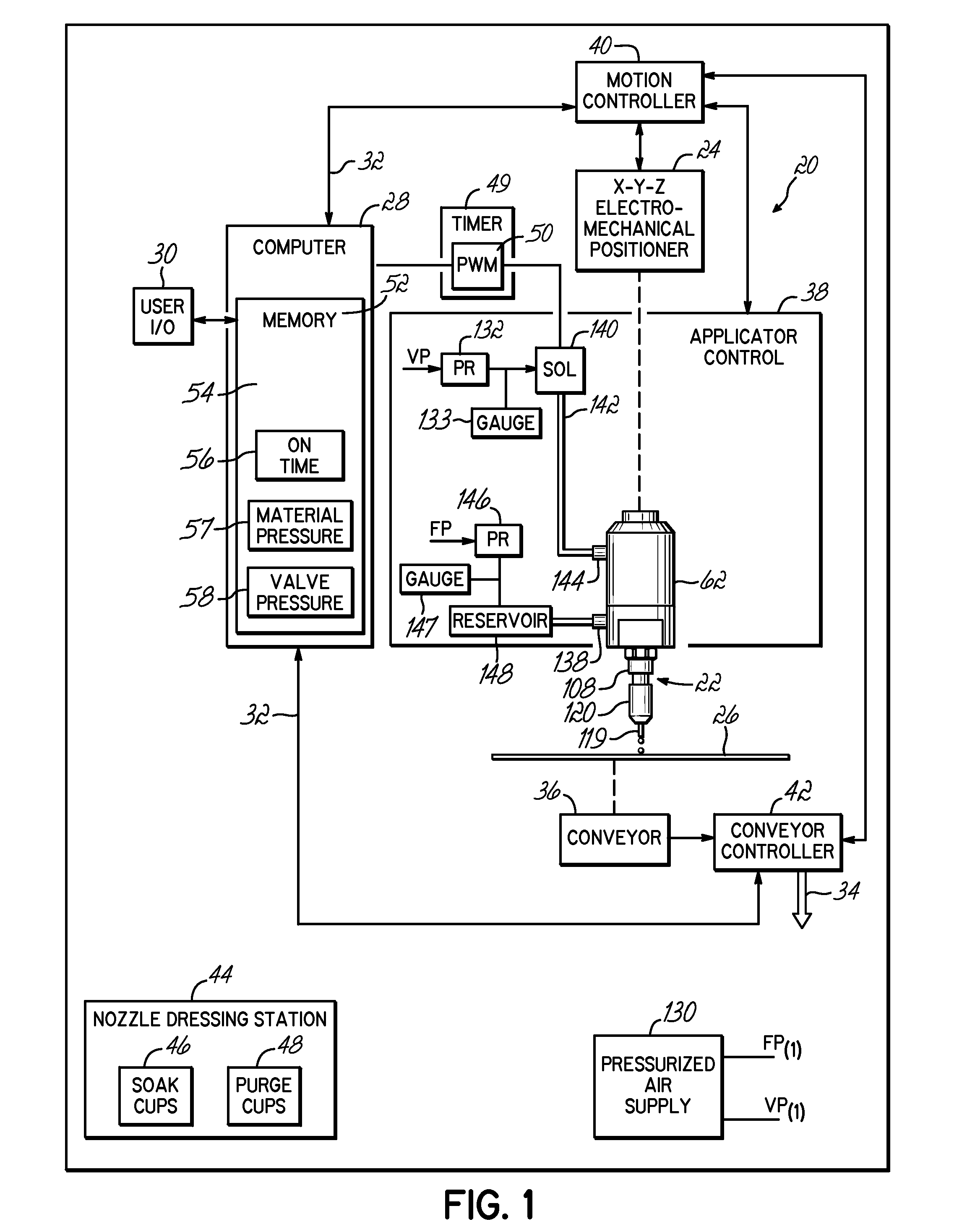

Systems and methods for applying a liquid coating material to a substrate

InactiveUS20090104343A1Liquid surface applicatorsVacuum evaporation coatingCoating systemControl system

Systems and methods for applying liquid coating materials to a substrate, such as an electronic component or circuit board. A control system (18, 24, 26) of a coating system (10) controls an applicator (16) and a robot (14) moving the applicator (16) to apply the liquid coating material to the substrate (12) in accordance with the information contained in a coating program. The control system (18, 24, 26) determines a volume of liquid coating material actually dispensed onto the substrate (12) during the coating program, and compares the dispensed volume to a desired dispensed volume of liquid coating material to produce an error signal representing the difference between the calculated and desired volume values. The control system (18, 24, 26) uses the error signal to change the dispensed volume of liquid coating material on a subsequent substrate by a future coating program.

Owner:NORDSON CORP

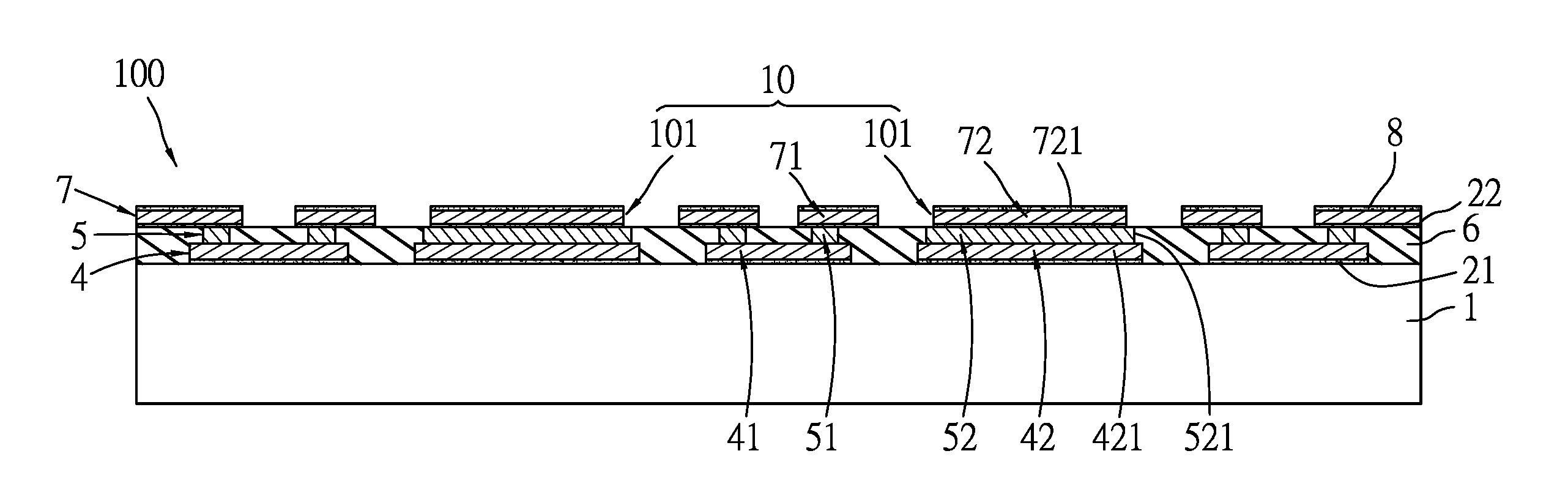

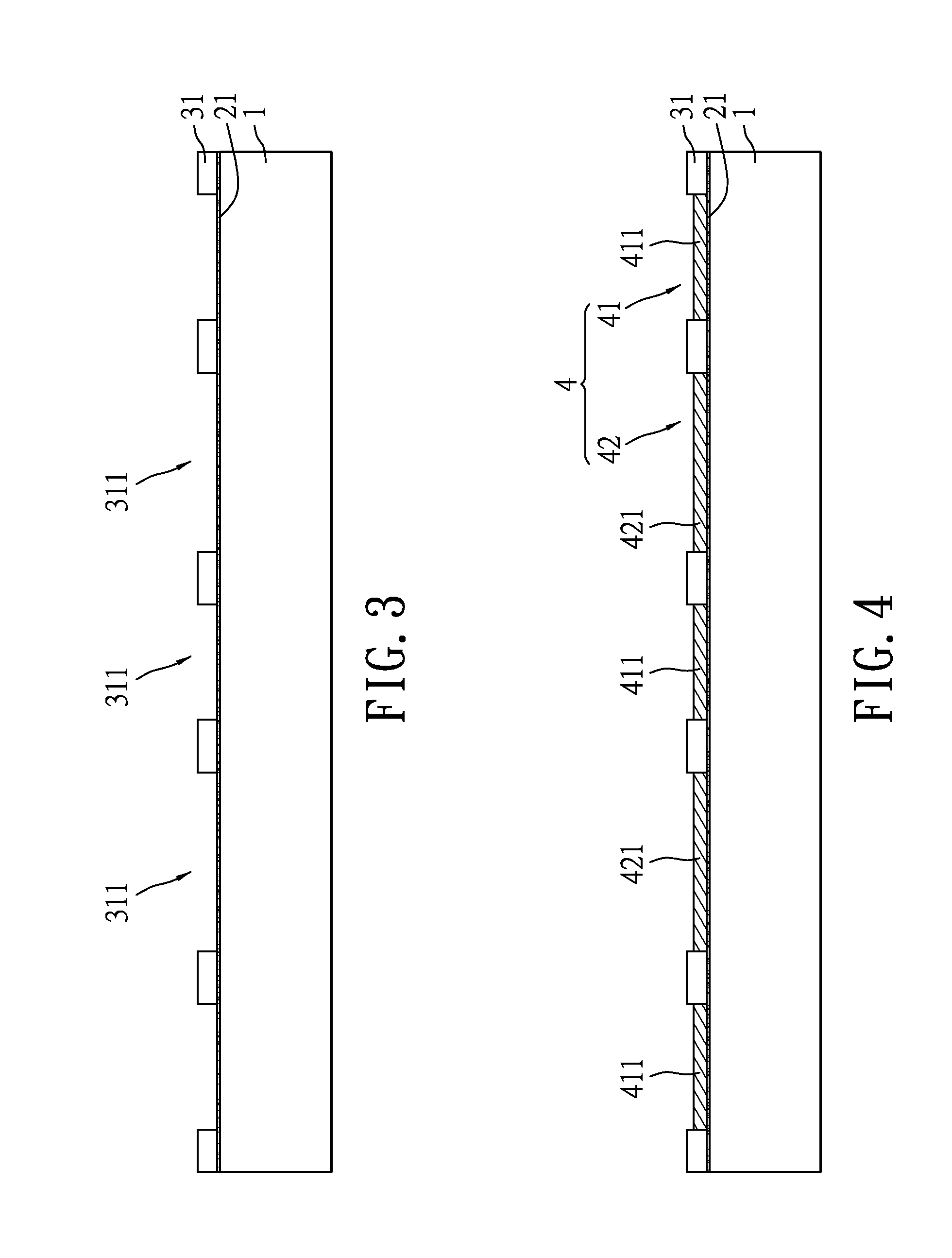

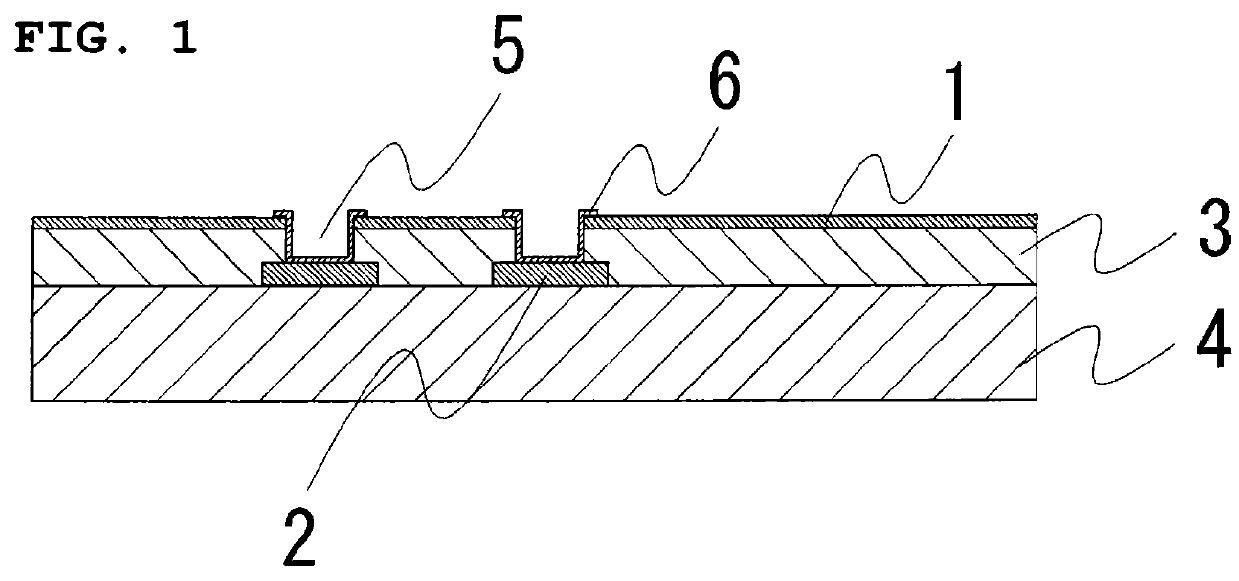

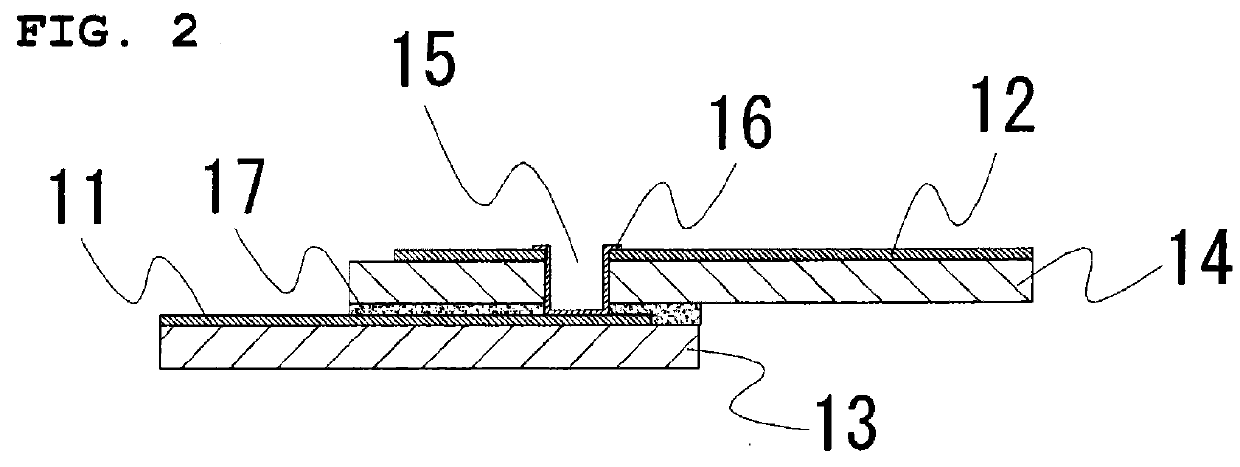

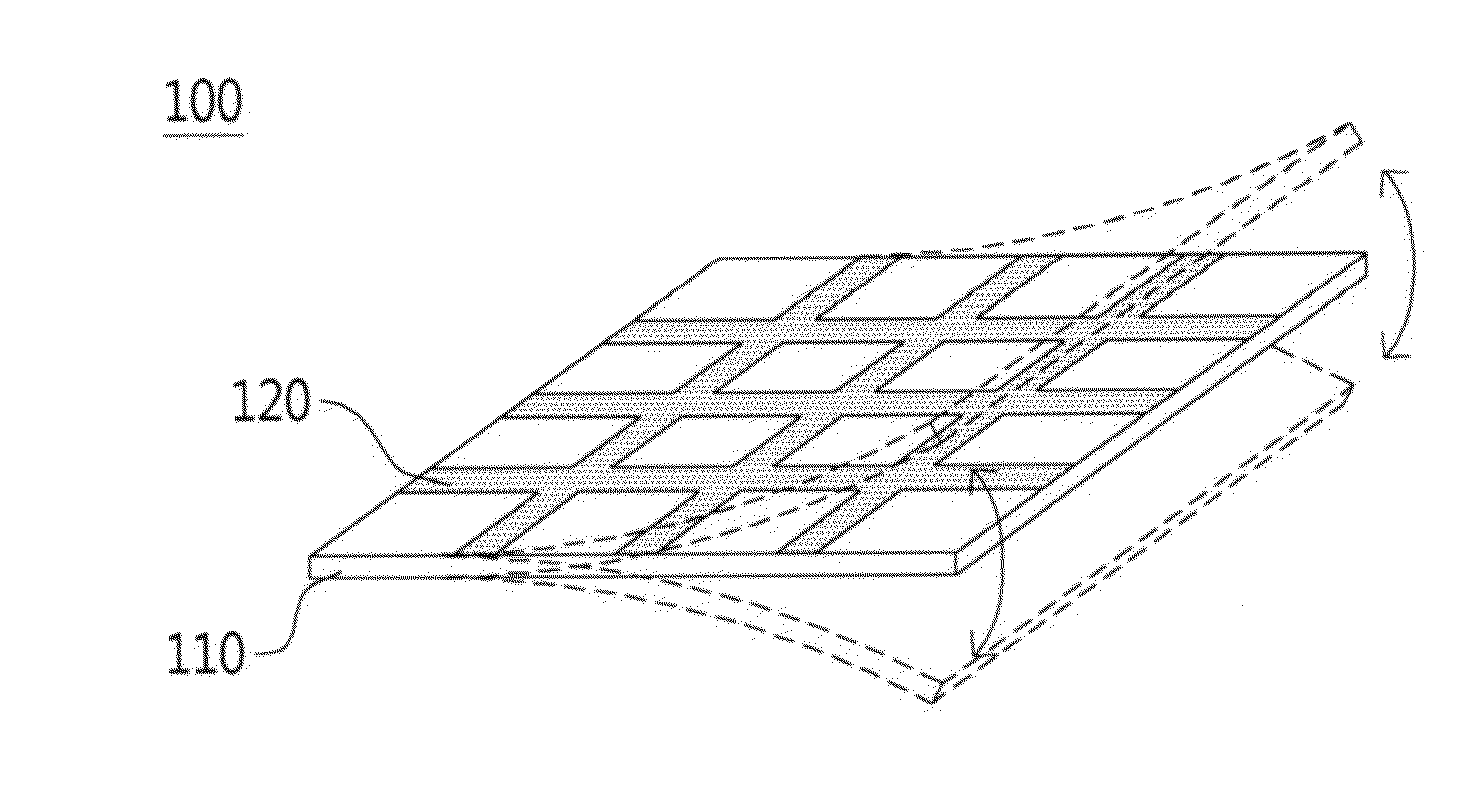

Multilayer circuit board and method for manufacturing the same

ActiveUS20150319868A1Overcomes drawbackPrinted circuit aspectsLiquid/solution decomposition chemical coatingOptoelectronicsCeramic substrate

A method for manufacturing a multilayer circuit board includes: forming a first patterned conductive layer on a ceramic substrate, the first patterned conductive layer having a first circuit pattern and a first submount pattern; forming a second patterned conductive layer on the first patterned conductive layer, the second patterned conductive layer having a second circuit pattern and a second submount pattern; forming an insulating layer on the ceramic substrate; and forming a third patterned conductive layer on the insulating layer. The third patterned conductive layer having a third circuit pattern and a third submount pattern. The first, second and third submount patterns are stacked one above another.

Owner:TONG HSING ELECTRONICS IND LTD

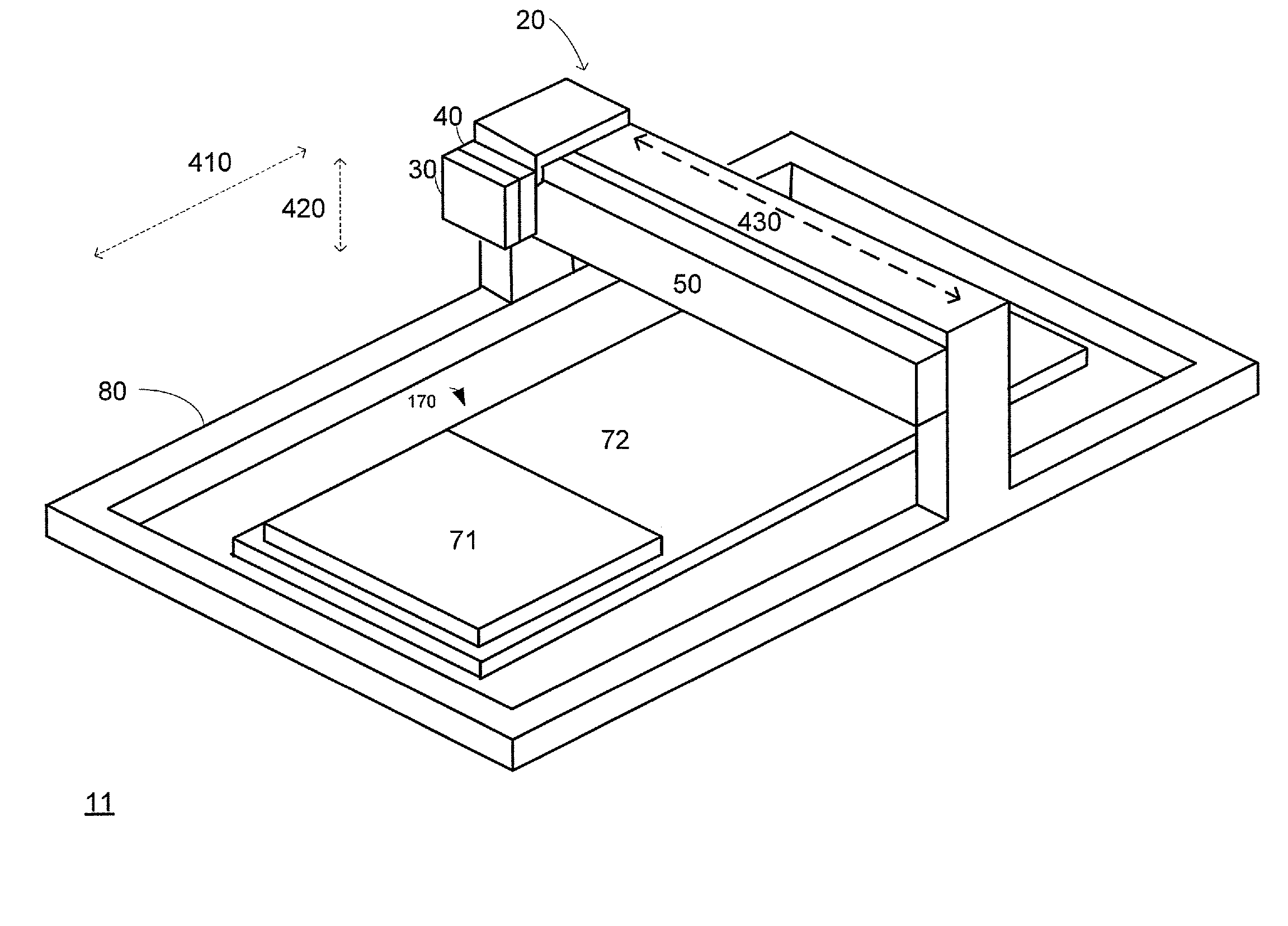

Material deposition system and method for depositing materials on a substrate

A material deposition system includes a frame, a support coupled to the frame to support an electronic substrate during a deposit operation, a gantry coupled to the frame, and a deposition head coupled to the gantry. The deposition head is movable over the support by movement of the gantry. The deposition head includes a chamber to hold material, an actuator to push a volume of material out of the chamber, a needle extending from the chamber and terminating in a needle orifice, and at least two air jets located on opposite sides of the needle orifice. A desired volume of material is formed at the needle orifice in response to the actuator, and each of the at least two air jets produce a timed pulse of air to create a micro-droplet from the desired volume and to accelerate the micro-droplet to high velocity.

Owner:ILLINOIS TOOL WORKS INC

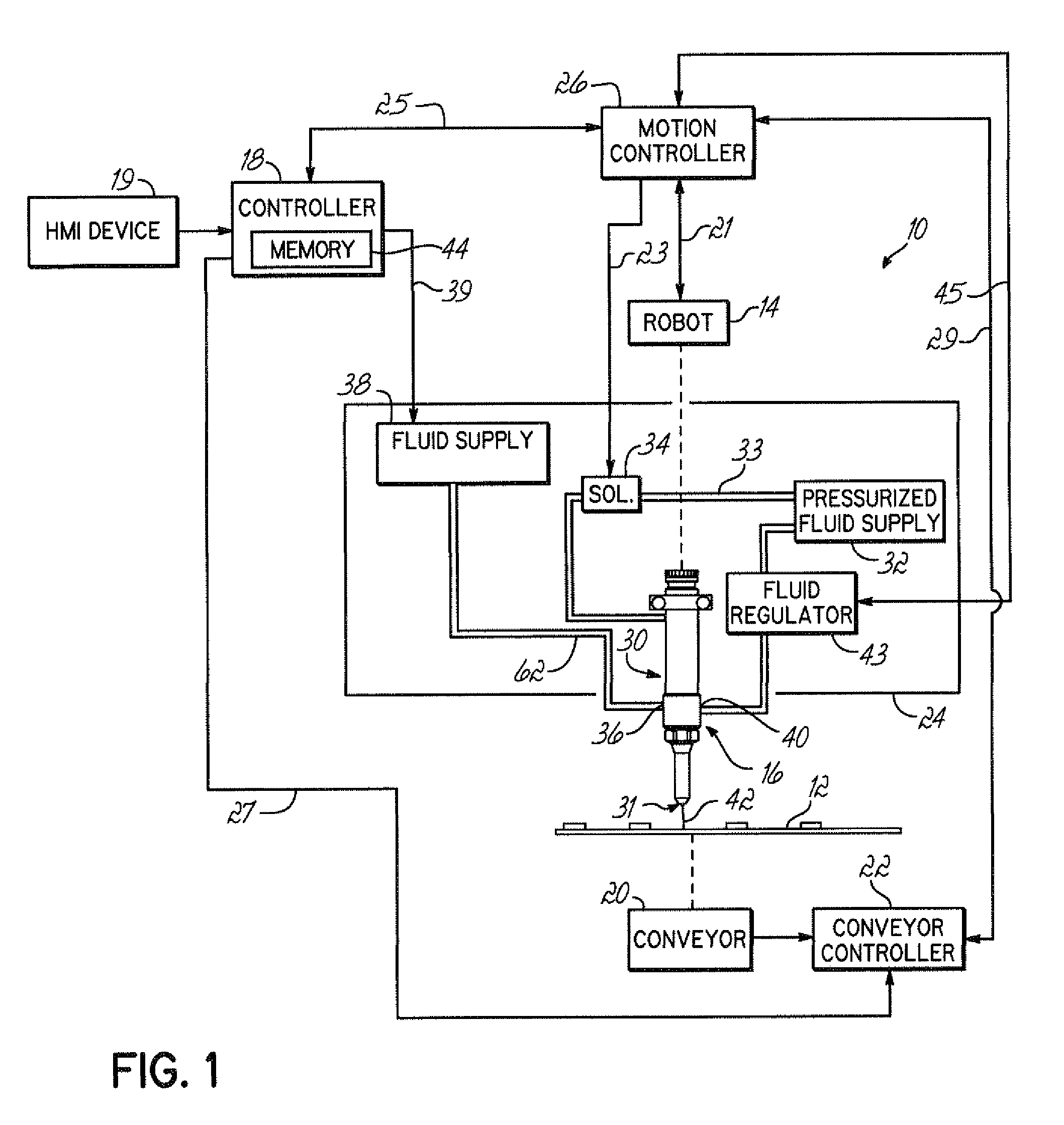

Closed-loop bubble elimination system and methods for applying a conformal coating material to a substrate

InactiveUS20080166490A1Printed circuit aspectsLiquid/solution decomposition chemical coatingClosed loopConformal coating

Systems and methods for applying a conformal coating material to a substrate, such as an electronic component or circuit board. The systems and methods rely on a pressure-regulated fluid circulation loop connecting an outlet of a pump with an inlet of a pump and an applicator that is connected in fluid communication with the fluid circulation loop. Amounts of the conformal coating material dispensed by the applicator, which are diverted from the fluid circulation loop, may be replenished by fresh amounts supplied from a non-pressurized reservoir, which are siphoned by the pump into the fluid circulation loop.

Owner:NORDSON CORP

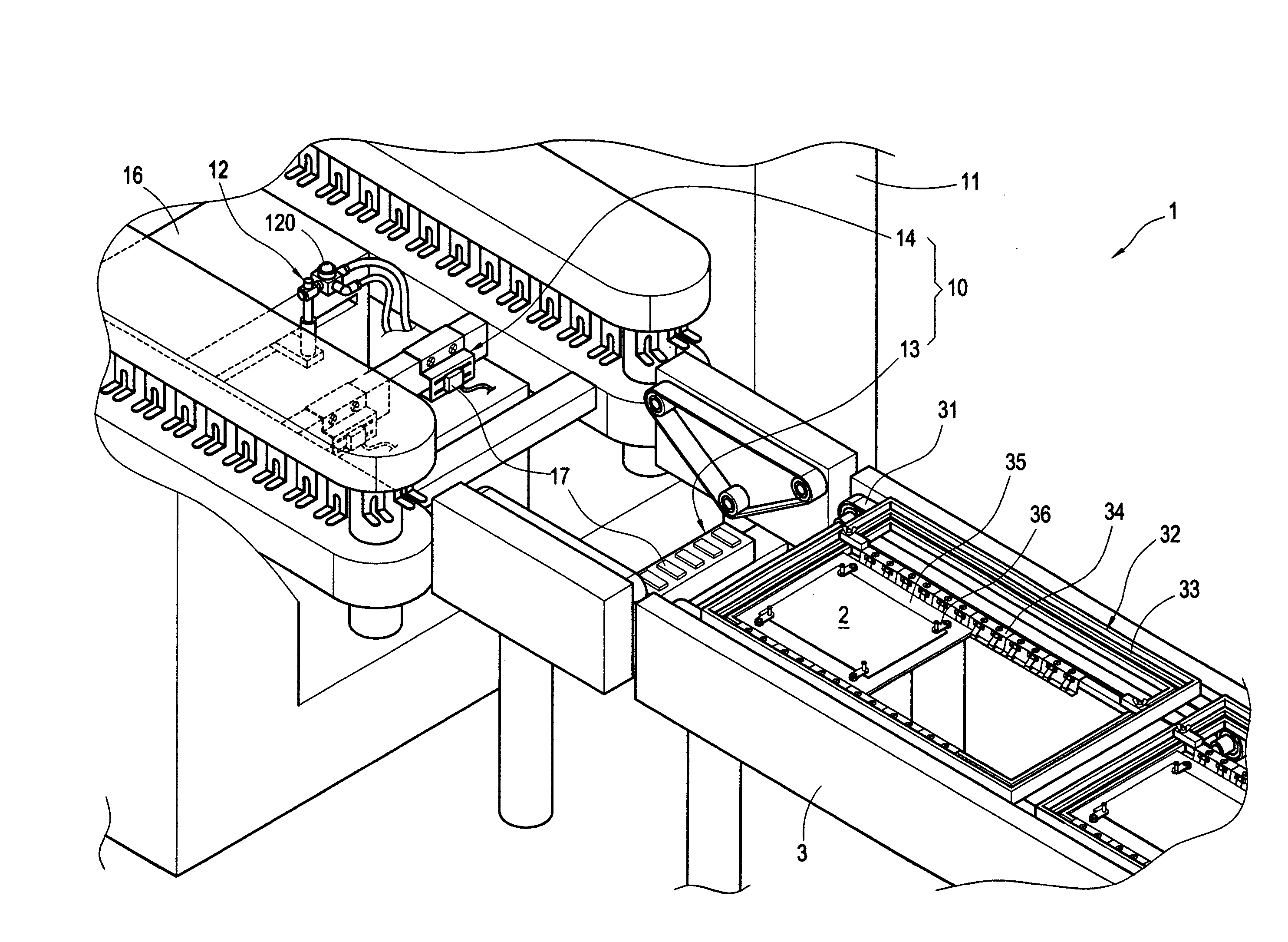

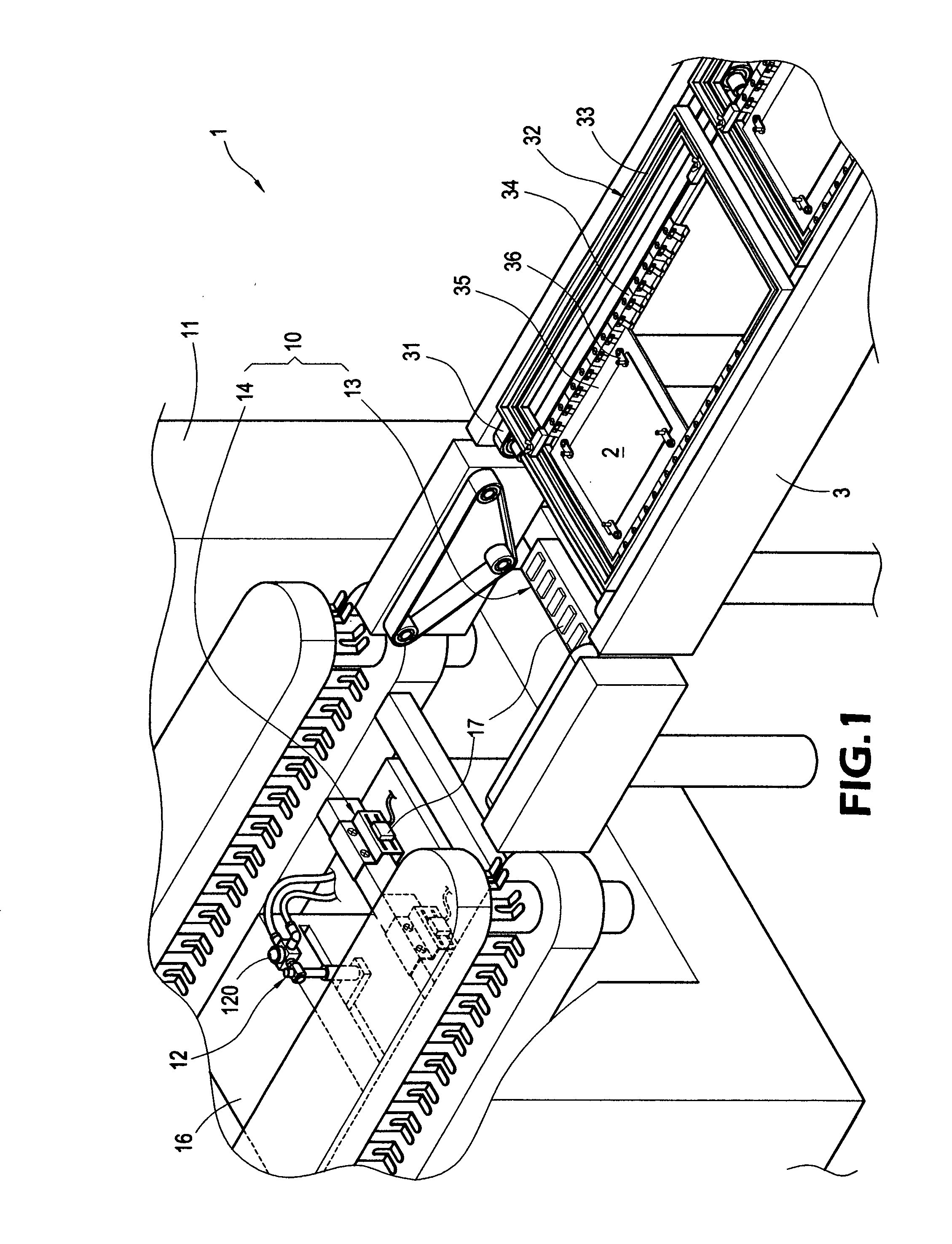

Coating system

Disclosed is a coating system for the selective application of coatings to substrates to apply a uniform coating to selected areas of the substrate without the need for masking. The system comprises a first coating applicator for coating large areas of the substrate, a second coating applicator for coating small areas of the substrate, a motion and positioning system for both coating applicators and a system controller. Also disclosed is an ultrasonic spray coating system comprising an ultrasonic transducer with spray forming head, integrated fluid delivery device with air and liquid supply passage ways, support brackets and an ultrasonic power generator.

Owner:ULTRASONIC SYST GMBH

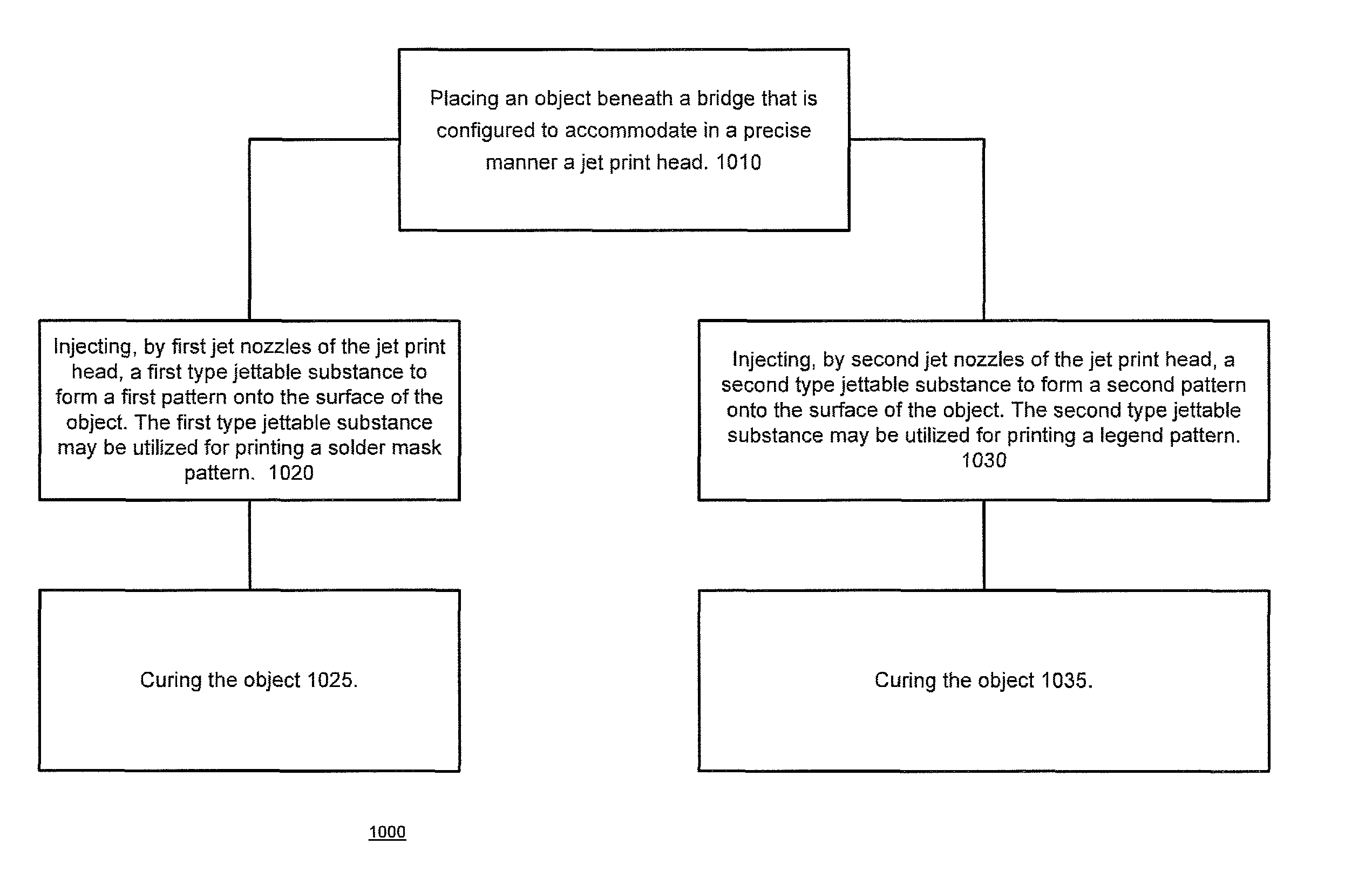

Method and system for printing on a printed circuit board

InactiveUS8534787B2Improve accuracyImprove reliabilityTypewritersInspection/indentification of circuitsSolder maskNozzle

A method, a printing system and a printing bridge. The printing bridge is configured to accommodate in a precise manner a jet print head. The jet print head includes first jet nozzles for injecting a first type jettable substance to form a first pattern onto the surface of a object, and a second jet nozzles for injecting a second type of jettable substance to form a first pattern onto the surface of a object. The first type jettable substance is utilized for printing a solder mask pattern and the second type jettable substance is utilized for printing a legend pattern.

Owner:CAMTEK LTD

Metal film forming method and conductive ink used in said method

InactiveUS20160057866A1Improve conduction reliabilitySimple moldingSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceReducing agent

An object of the invention is to provide a simple method capable of easily forming a metal film on a surface of a perforated substrate that is adjacent to the hole in the substrate. The metal film forming method includes a step of heating a perforated substrate having a hole while a surface of the substrate adjacent to the hole is in contact with a conductive ink containing a metal salt and a reducing agent.

Owner:JSR CORPORATIOON

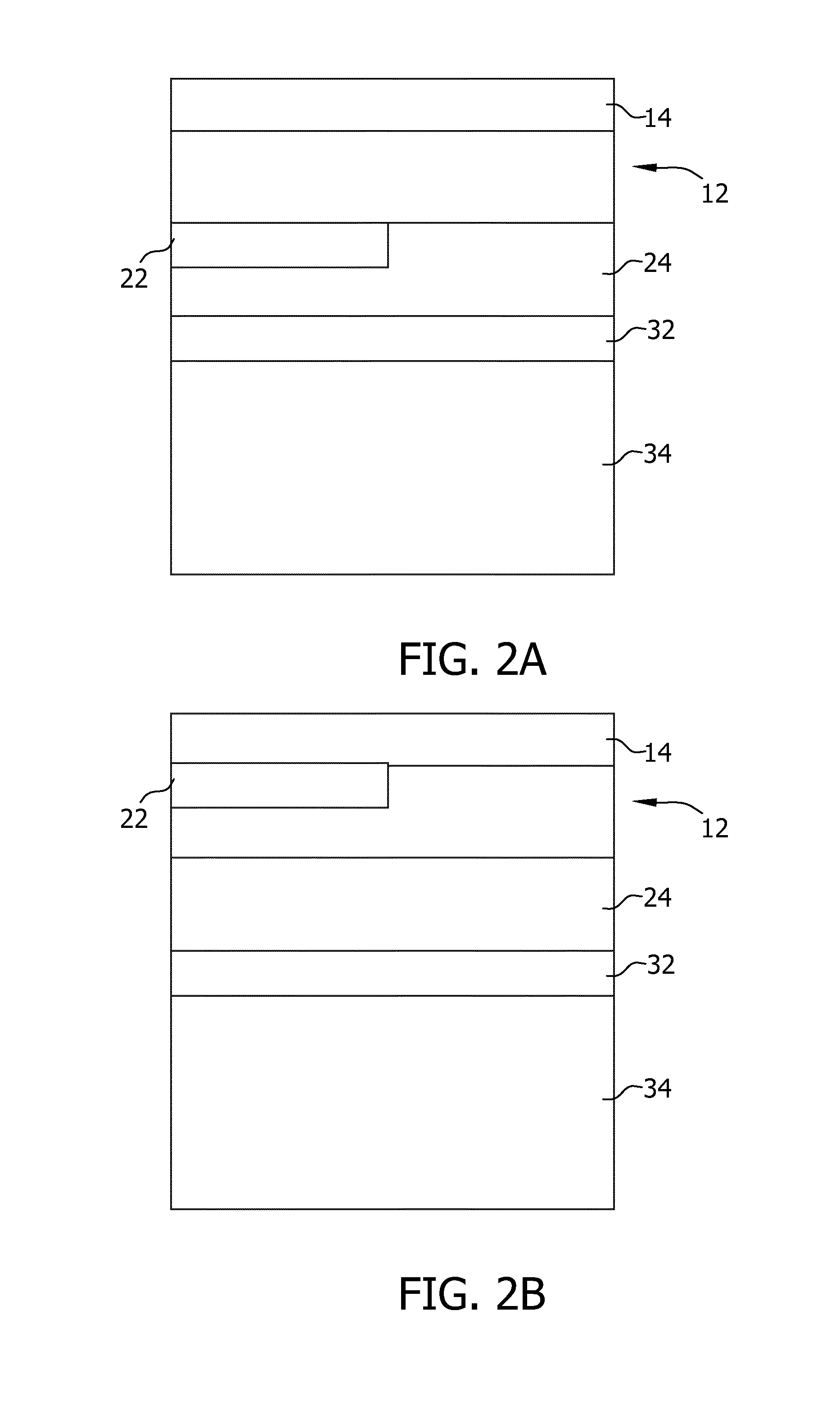

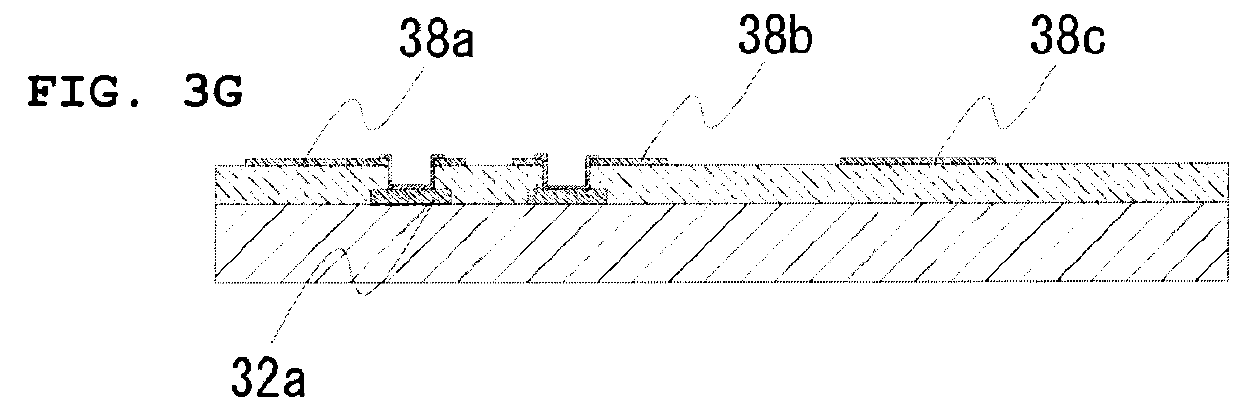

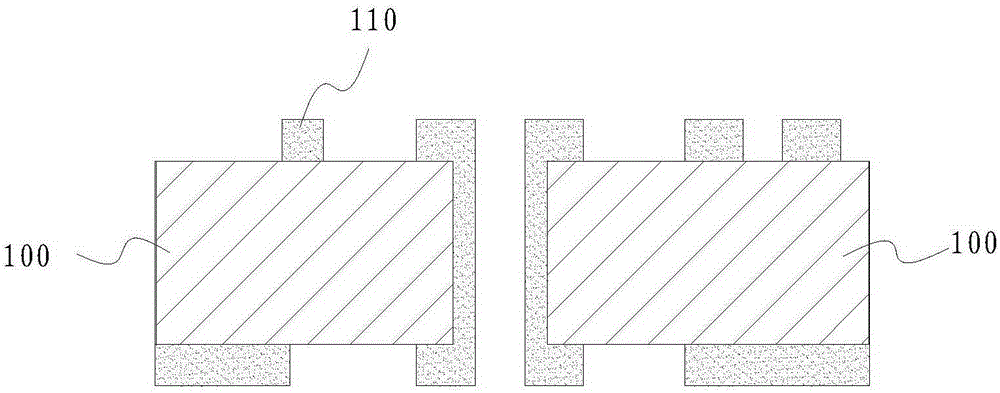

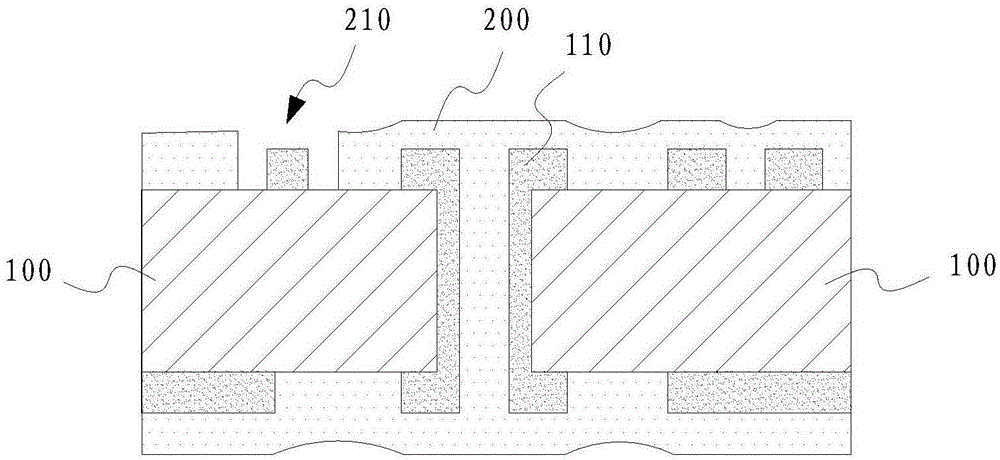

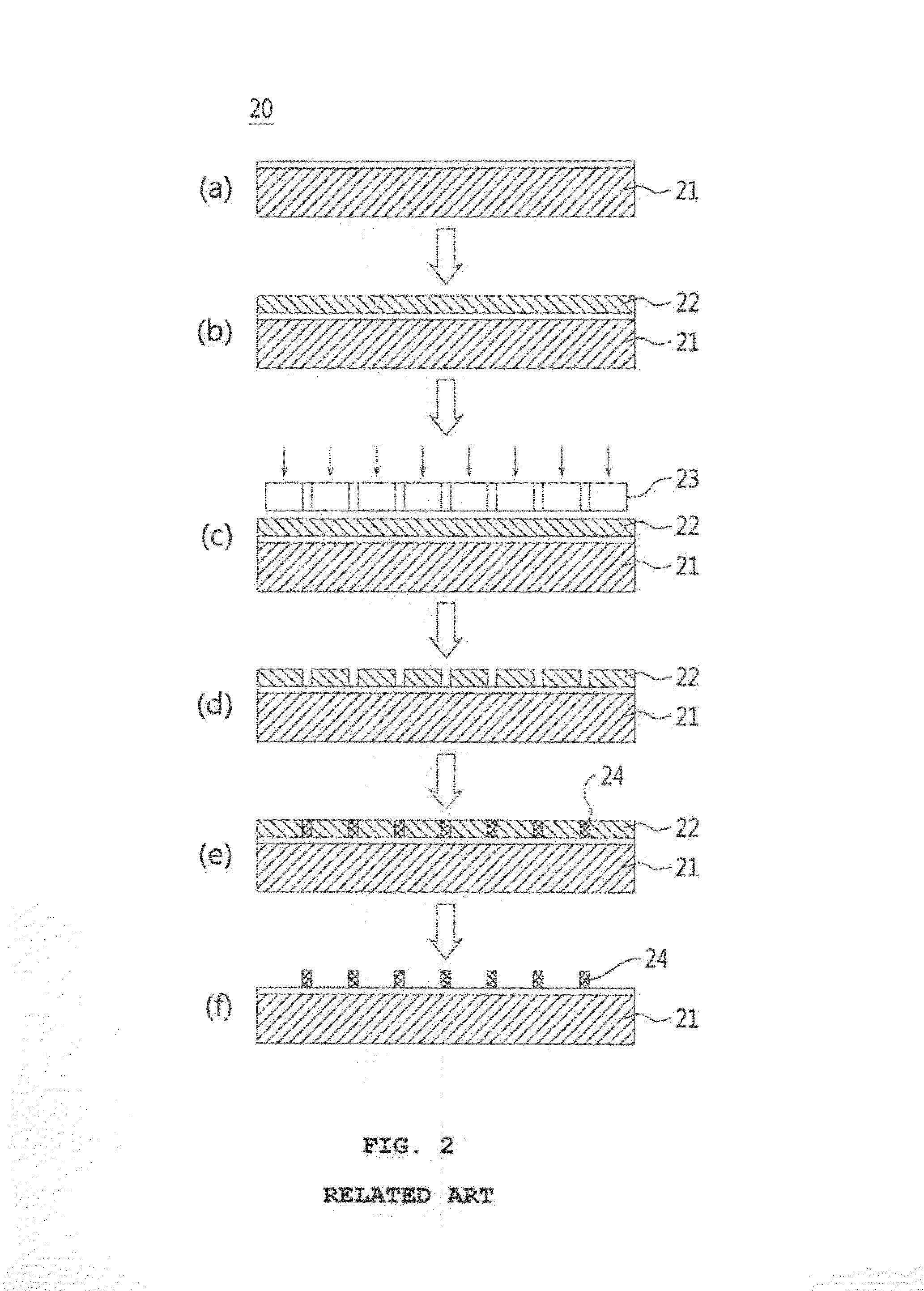

Packaging substrate resistance welding processing method

ActiveCN105228364ANon-metallic protective coating applicationPrinted circuit coatingMicrometerEngineering

The invention relates to a packaging substrate resistance welding processing method, comprising the steps of: printing for the first time: printing a first layer of resistance welding ink on the surface of a core plate; performing windowing for the first time: windowing the first layer of resistance welding ink to obtain a first window; grinding: grinding the surface of the first layer of resistance welding ink to be flat; printing for the second time: printing a second layer of resistance welding ink on the first layer of resistance welding ink and the first window; and performing windowing for the second time: windowing the second layer of resistance welding ink to obtain a second window, wherein the second window is located in the scope of the first window. According to the invention, through twice resistance welding ink printing and twice windowing, the planeness error of the second layer of resistance welding ink on the external surface of the first layer of resistance welding ink is smaller than a micrometer grade; in addition, the second layer of resistance welding ink in the scope of the first layer of resistance welding ink is windowed for the second time to obtain a second window; twice printing does not influence windowing on a packaging substrate.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

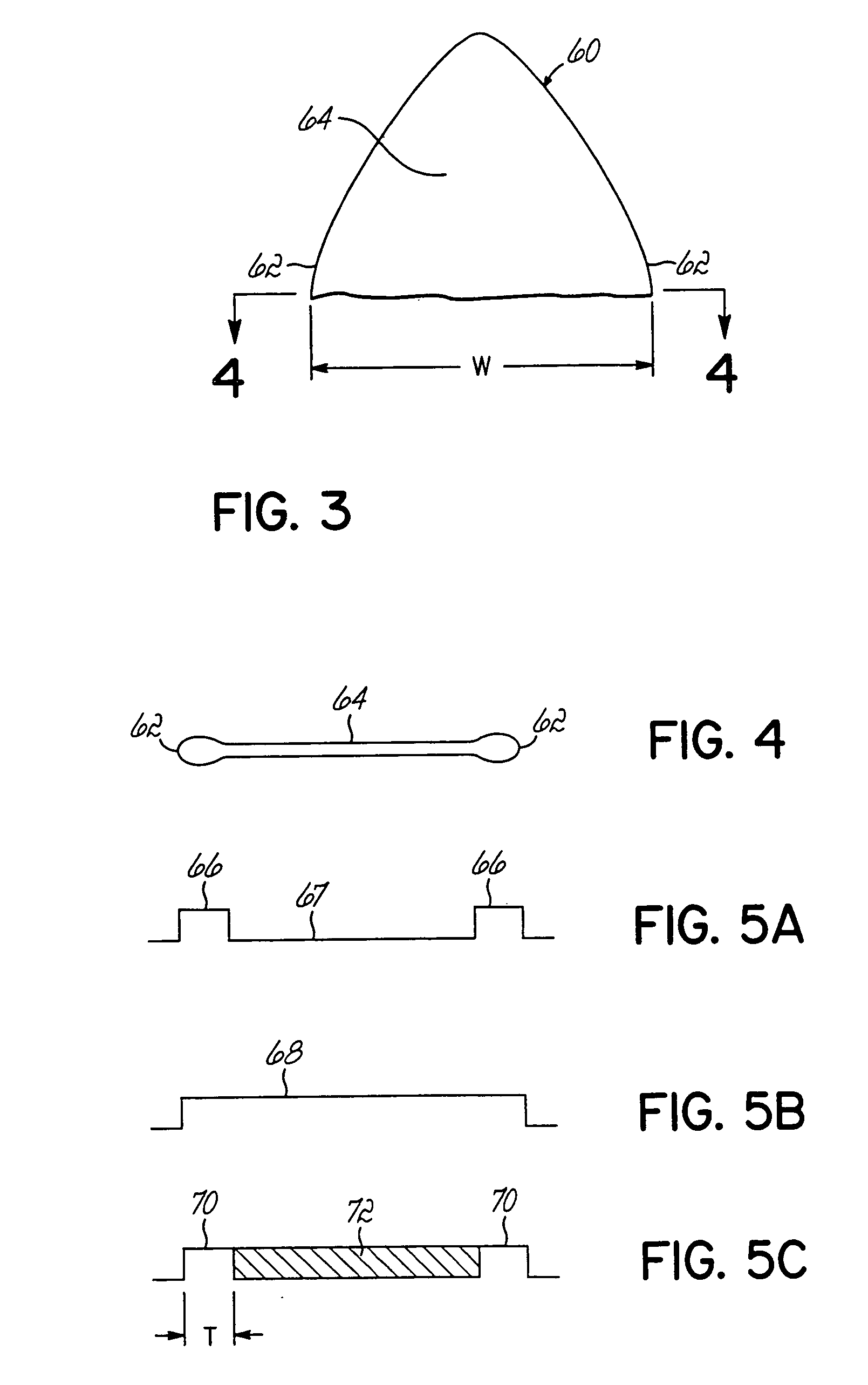

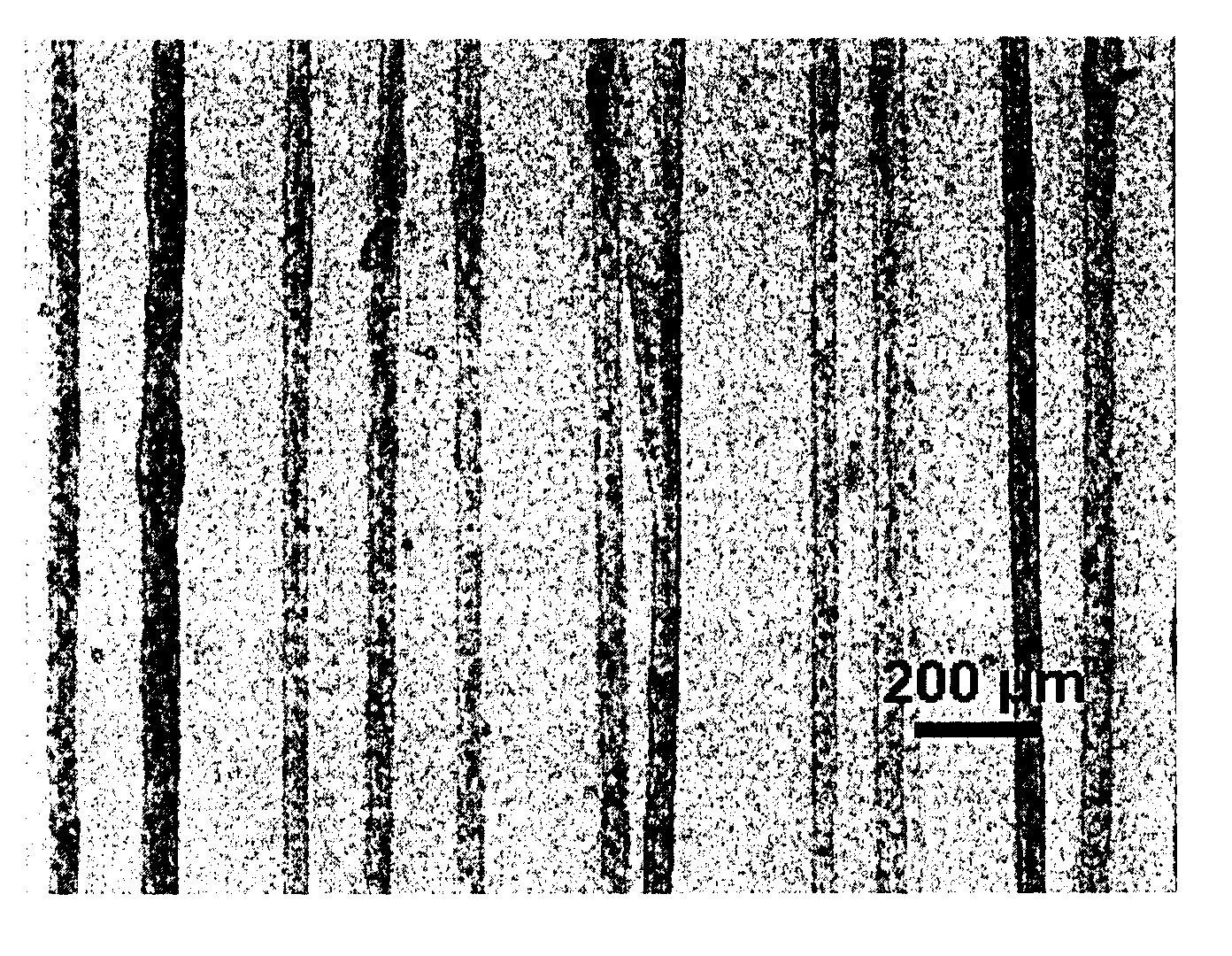

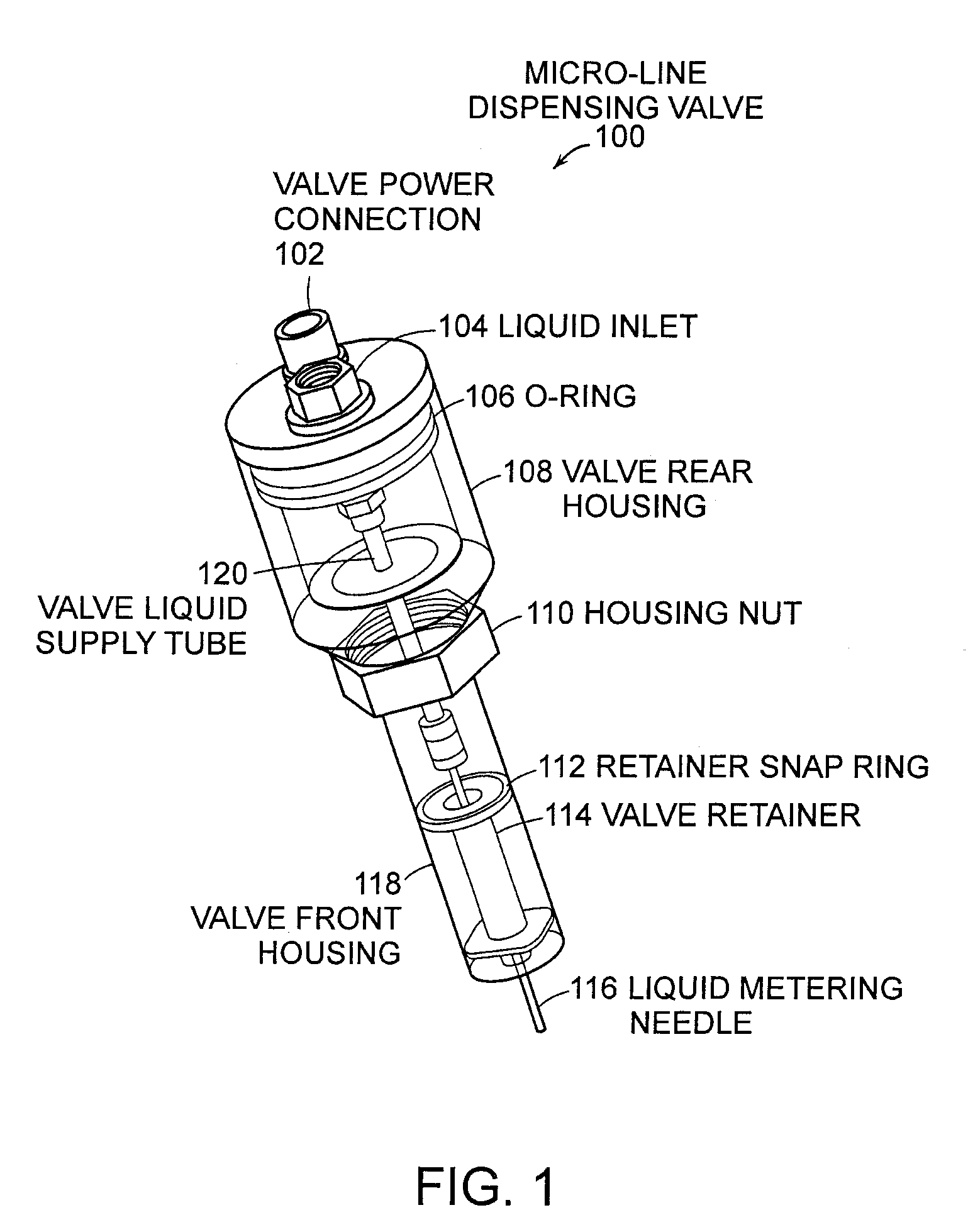

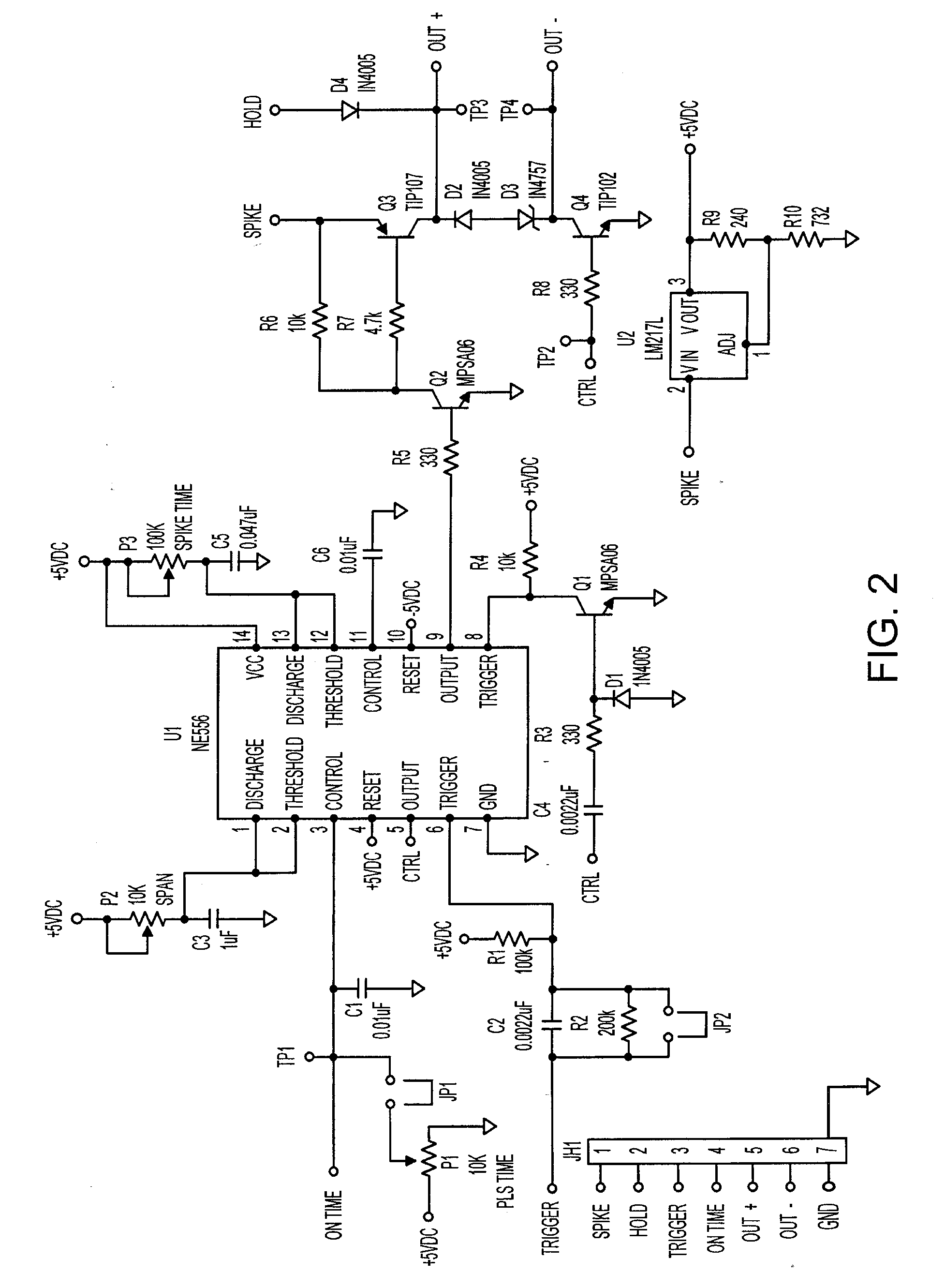

Thin line conformal coating apparatus and method

InactiveUS20080099515A1Low viscosityImprove abilitiesPrinted circuit aspectsMovable spraying apparatusCoating systemEngineering

A coating system with an applicator that has an air cylinder with a needle valve. A control has a timer that provides a string of electrical pulses to a solenoid. With each pulse, the solenoid applies pressurized air to a cylinder piston, thereby opening the needle valve and permitting coating material to flow past the needle valve. The needle valve is closed for durations of time between pulses, and the coating material is ejected from a dispensing needle in response to closings of the needle valve.

Owner:NORDSON CORP

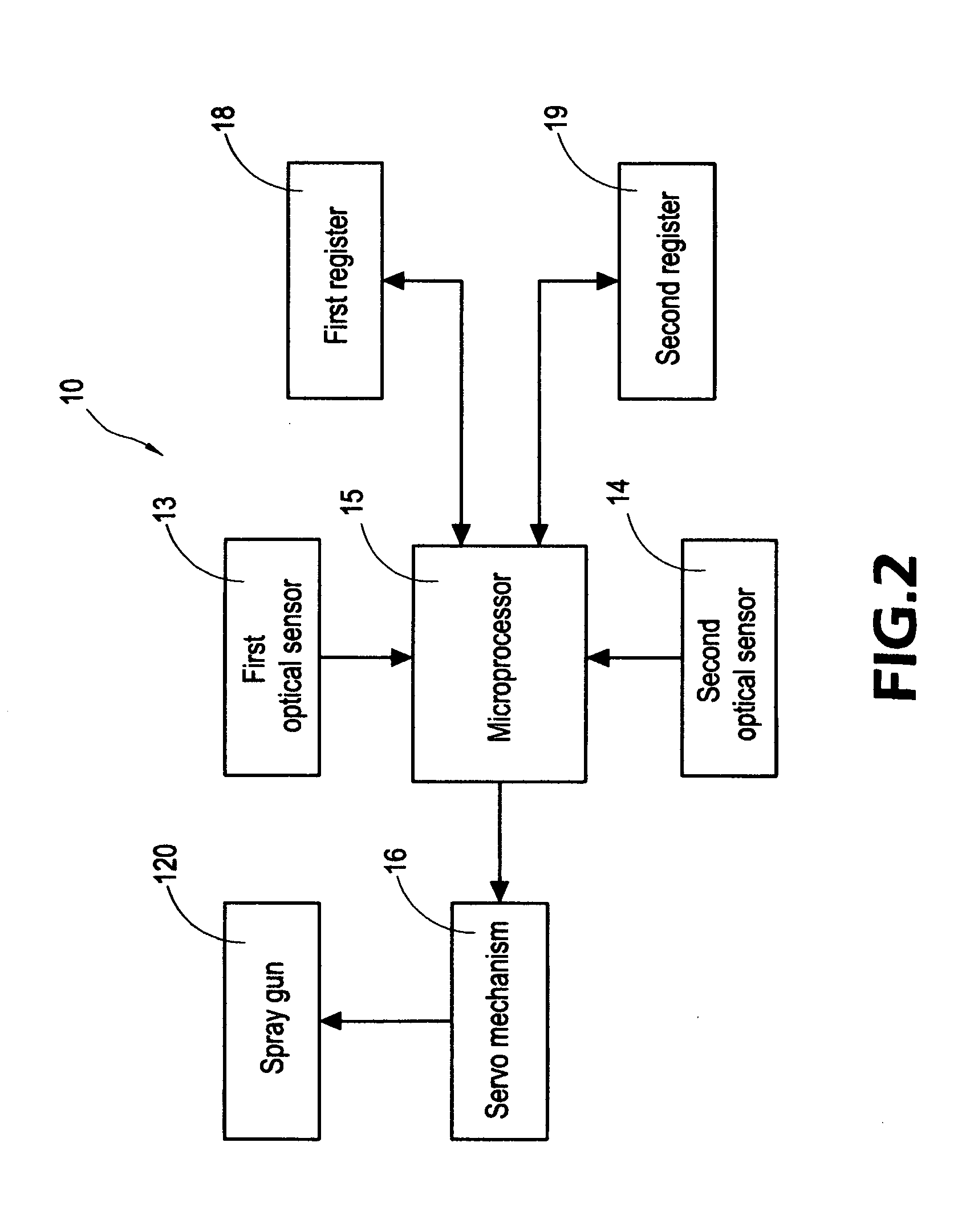

Automatic spraying method for flux of wave solder oven

InactiveUS20070172597A1Inspection/indentification of circuitsLiquid/solution decomposition chemical coatingPrinted circuit boardControl parameters

An automatic spraying method is used for spraying flux of wave solder oven. A first optical sensor senses the width of a printed circuit board (PCB) to obtain a first set parameter, and the first set parameter is stored in an address designated by a first register. A second optical sensor senses the length, the width and the spraying direction of the PCB to obtain a second set parameter, and the second set parameter is stored in an address designated by a second register. The control parameters such as initial spraying position, spraying area and spraying speed are calculated with reference to the first and the second sets parameters. The flux is sprayed on the PCB by a spray gun according to the control parameters.

Owner:DELTA ELECTRONICS INC

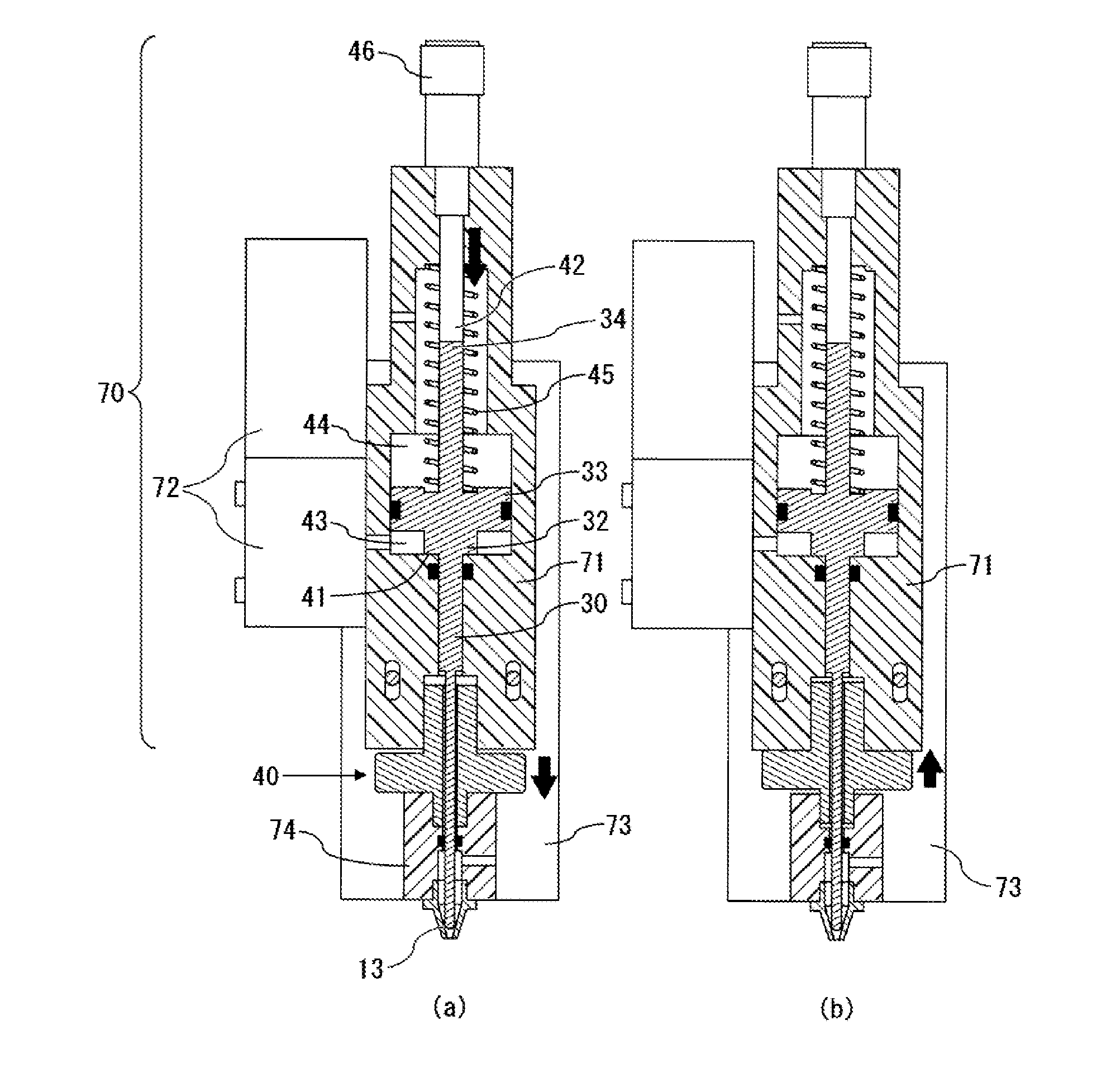

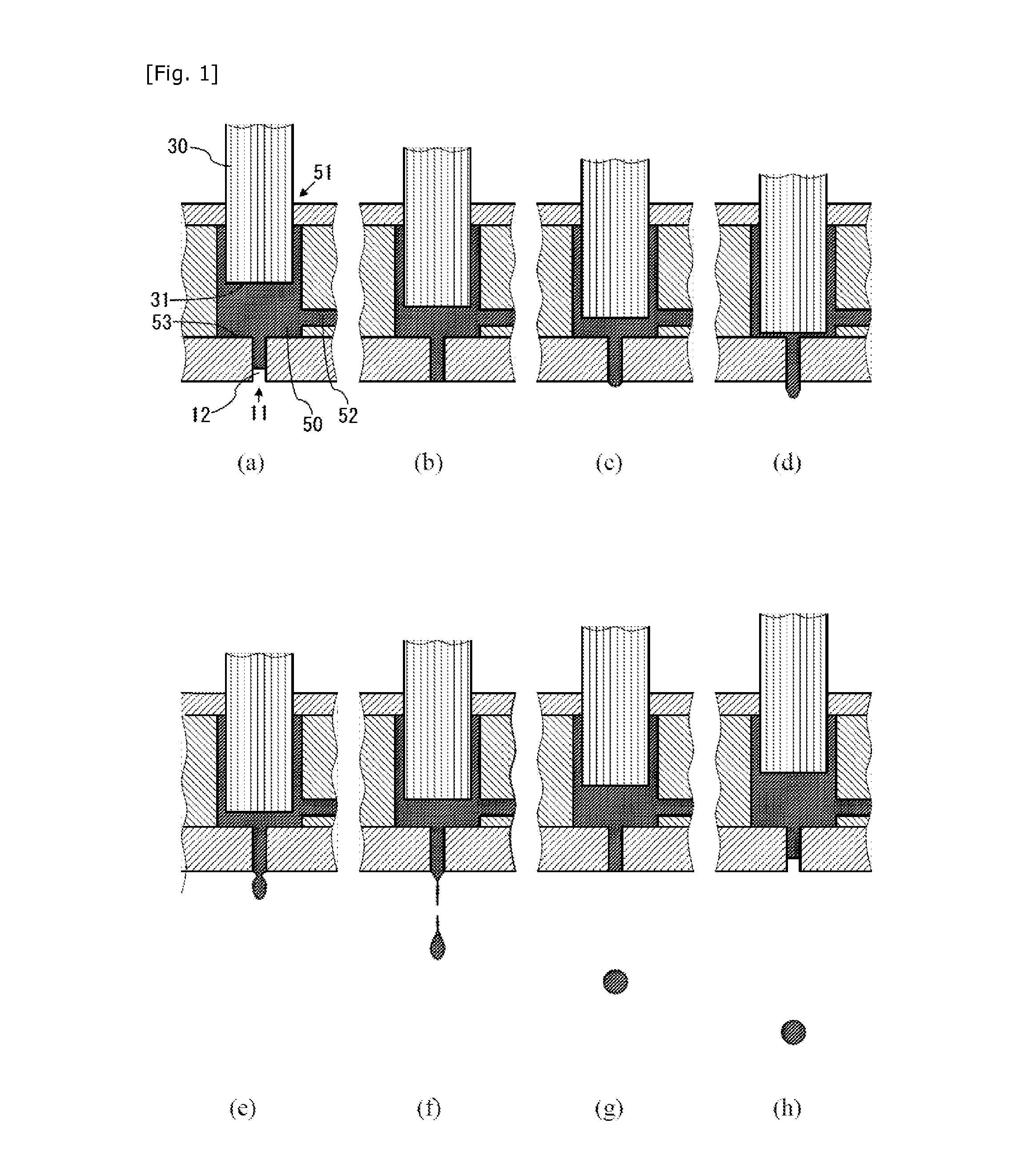

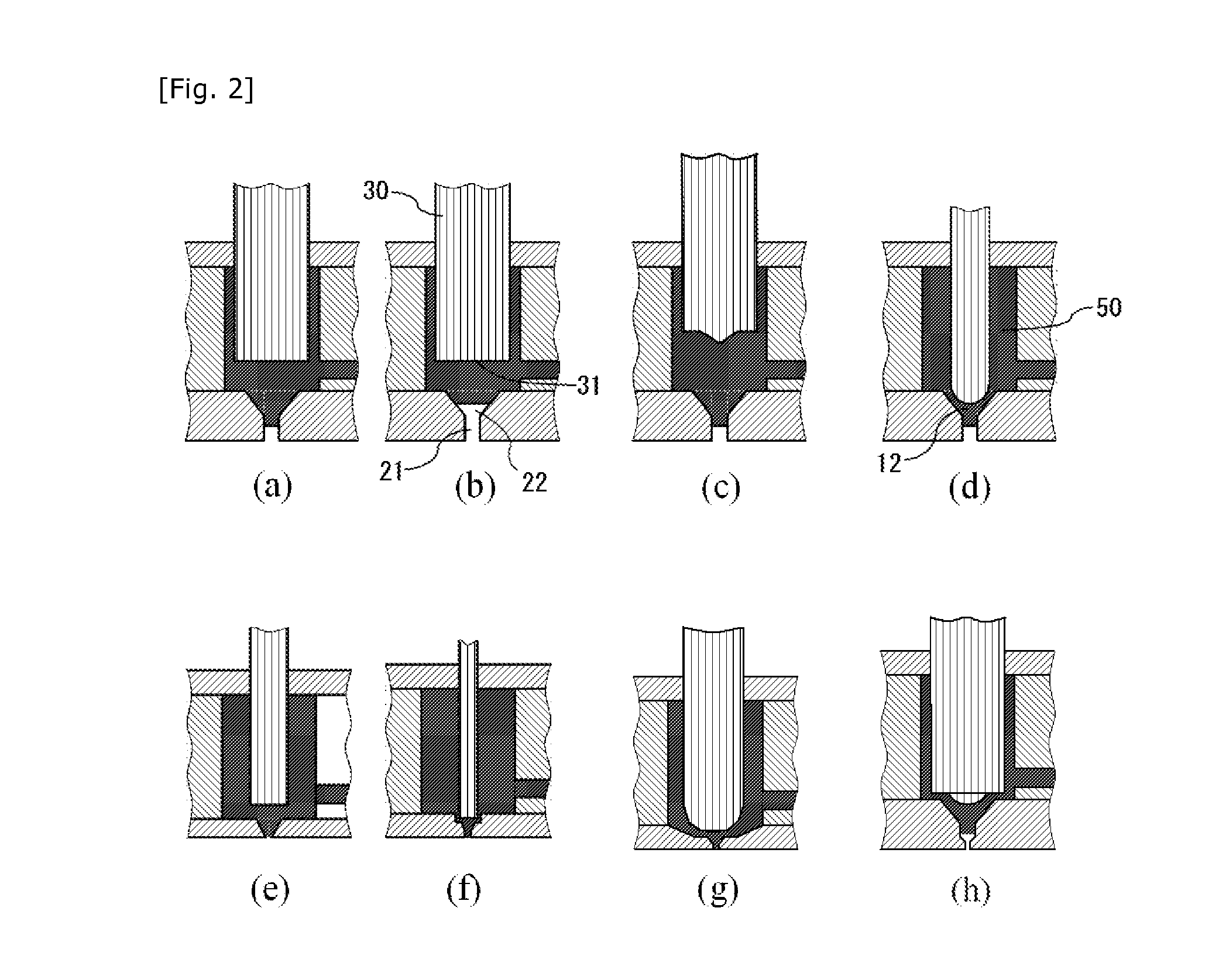

Droplet discharge device and method

ActiveUS20140217127A1Reduction of discharge accuracyLiquid surface applicatorsInking apparatusEngineeringMechanical engineering

An example of droplet discharge device includes a discharge path (12) having an end that constitutes a discharge opening (11), a plunger (30), a liquid chamber (50) into which the plunger (30) is inserted, a plunger driving mechanism that moves the plunger (30) forward and backward, and a plunger position determining mechanism that specifies a position of a tip portion of the plunger (30). The liquid material is discharged in a droplet state by applying inertial force to the liquid material with forward movement of the plunger (30) in a state where the tip portion of the plunger (30) and an inner wall of the liquid chamber (50) are not contacted with each other. A minute droplet is formed by moving the plunger (30) forward to push the liquid material out of the discharge opening (11) in an amount necessary to form a droplet of a desired size.

Owner:MUSASHI ENG INC

Method and system for printing on a printed circuit board

InactiveUS20100066786A1Reduces board handlingImprove deposition accuracyTypewritersInspection/indentification of circuitsSolder maskEngineering

A method, a printing system and a printing bridge. The printing bridge is configured to accommodate in a precise manner a jet print head. The jet print head includes first jet nozzles for injecting a first type jettable substance to form a first pattern onto the surface of a object, and a second jet nozzles for injecting a second type of jettable substance to form a first pattern onto the surface of a object. The first type jettable substance is utilized for printing a solder mask pattern and the second type jettable substance is utilized for printing a legend pattern.

Owner:CAMTEK LTD

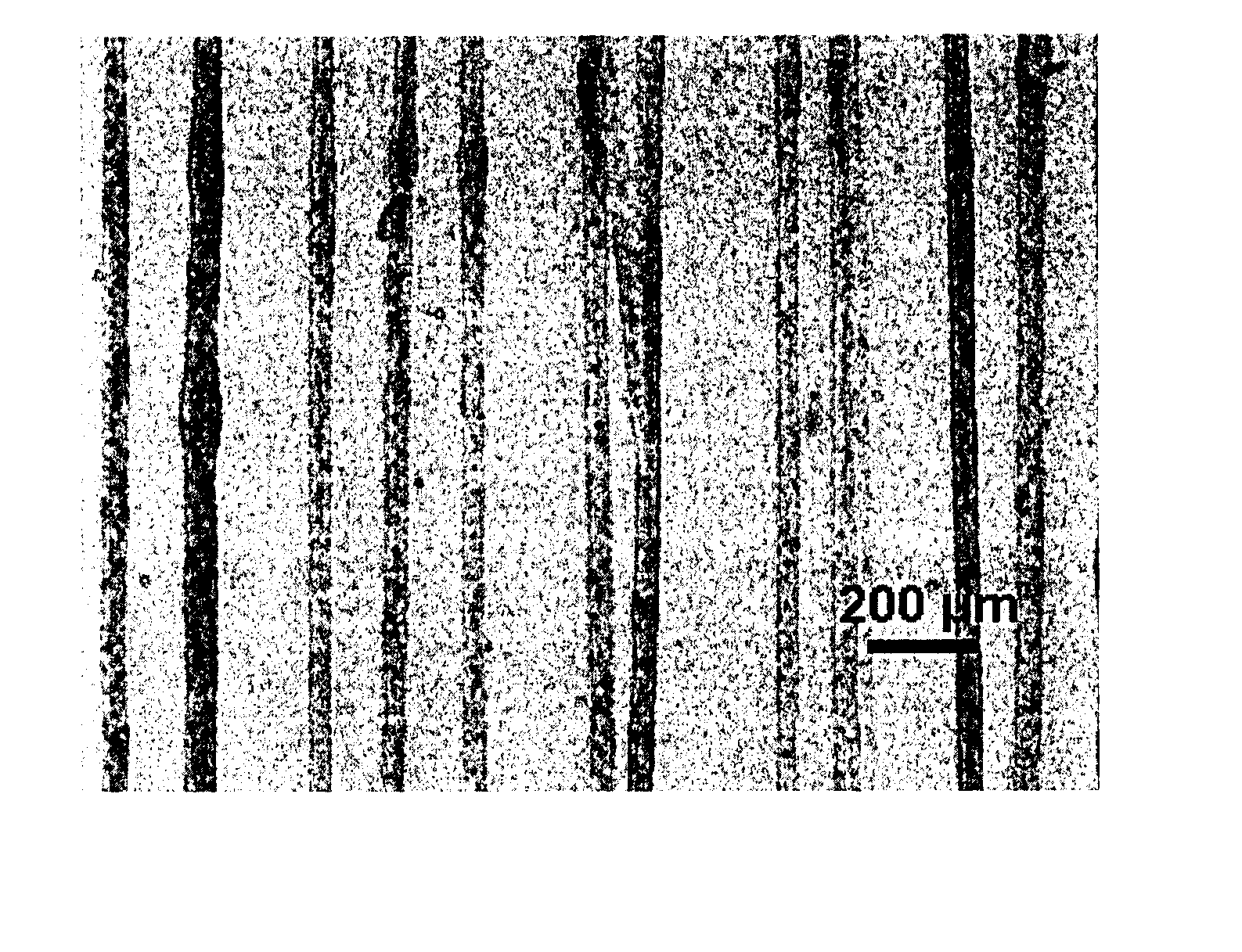

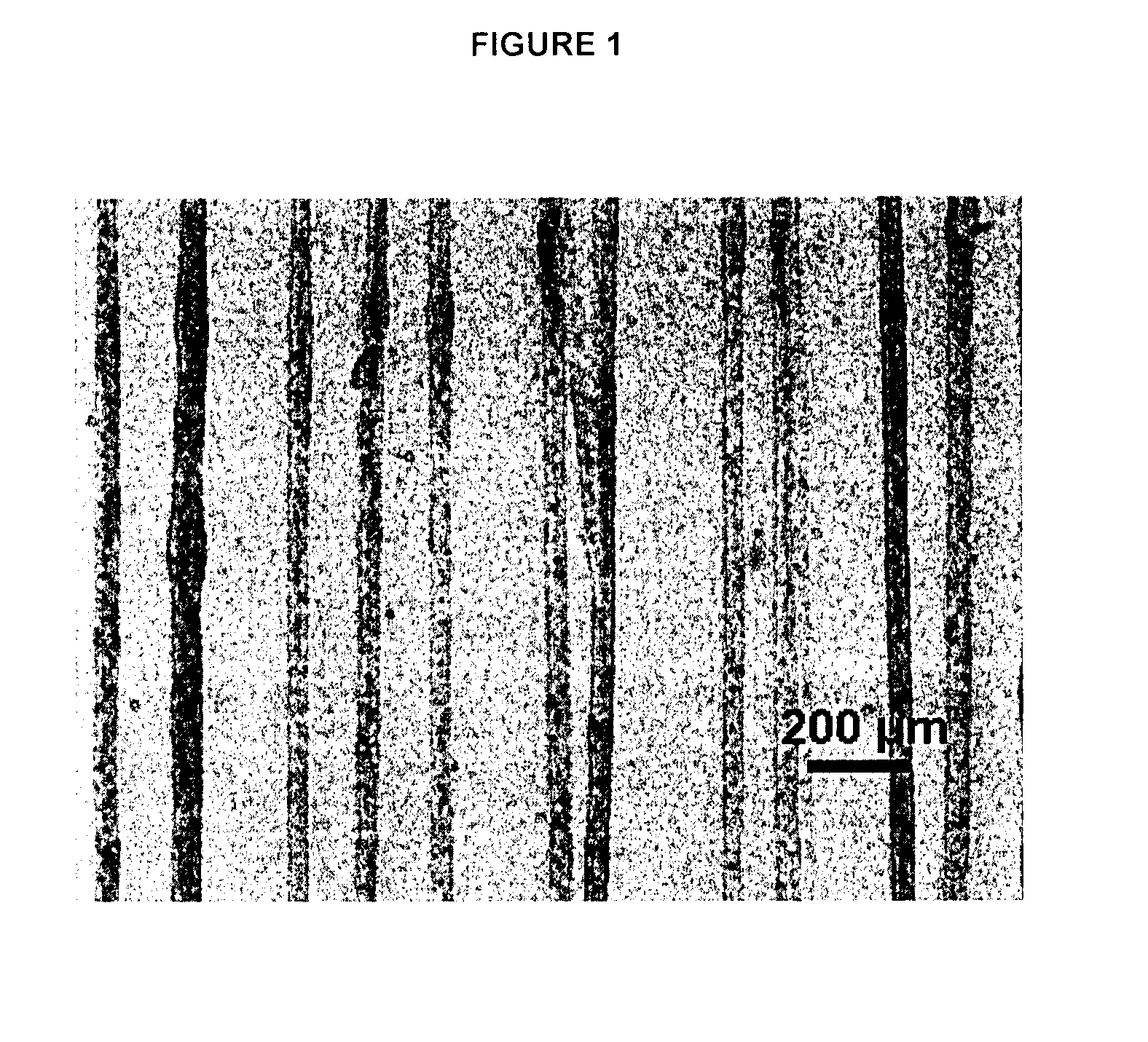

Flexible transparent electrode and method for manufacturing same

InactiveUS20160029475A1Reduce manufacturing costHigh transparencyConductive layers on insulating-supportsPretreated surfacesManufacturing cost reductionOptoelectronics

A flexible transparent electrode and a method for manufacturing the same are provided. The flexible transparent electrode includes: a substrate made of a flexible and transparent material, and a metal pattern which is formed on the substrate in a mesh form and has an electroconductive metal material, wherein the metal pattern is formed by being patterned on an upper side of the substrate using an electrohydrodynamic jet printing method and being sintered, and the electrohydrodynamic jet printing method is a method of forming a metal pattern on the upper side of the substrate after applying AC voltage of a predetermined power to the substrate and an injection nozzle of an electrohydrodynamic jet printing device. The flexible transparent electrode and the method for manufacturing the same can manufacture transparent electrode of a flexible structure through more simplified processes and reduce manufacturing costs.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

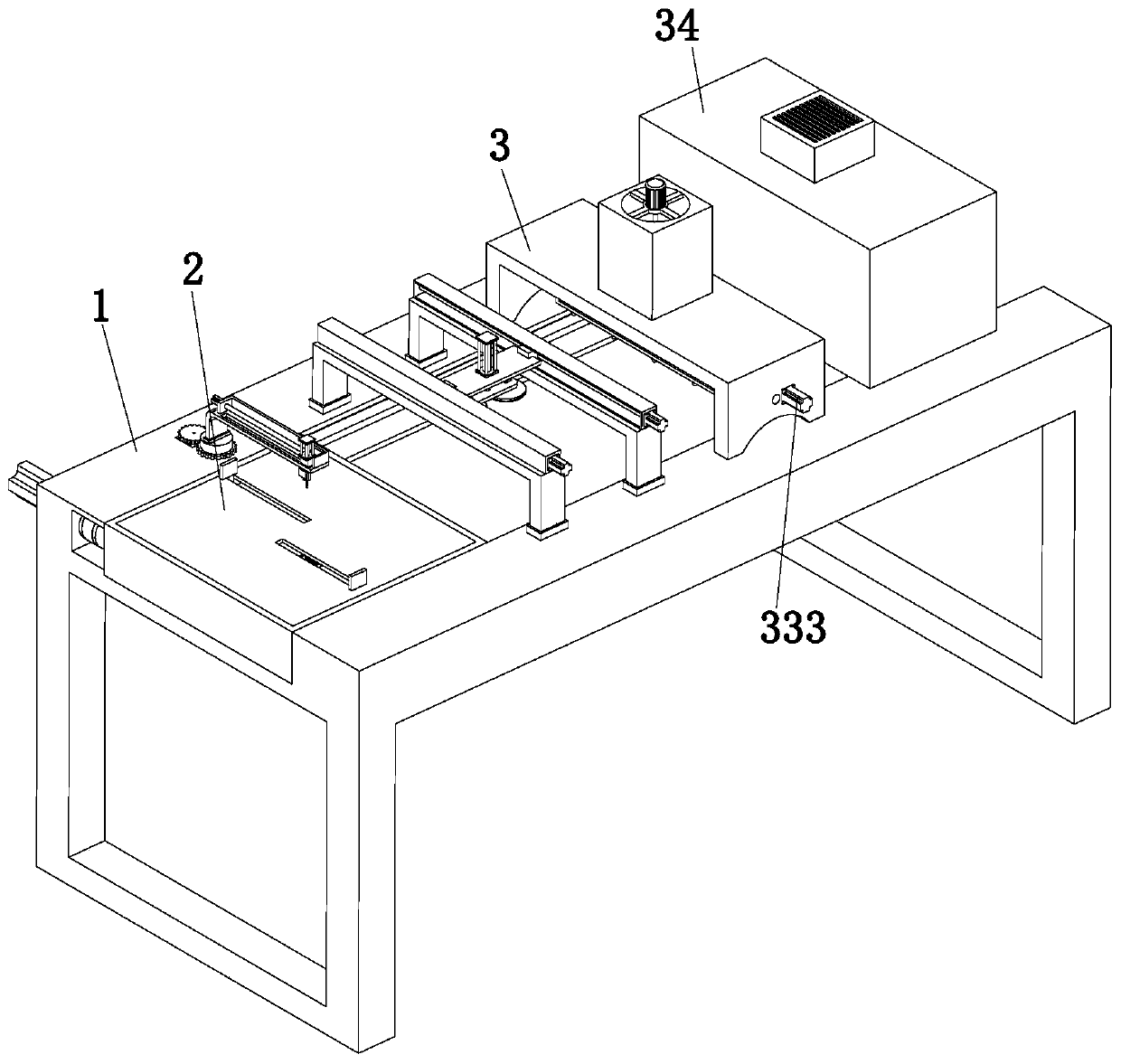

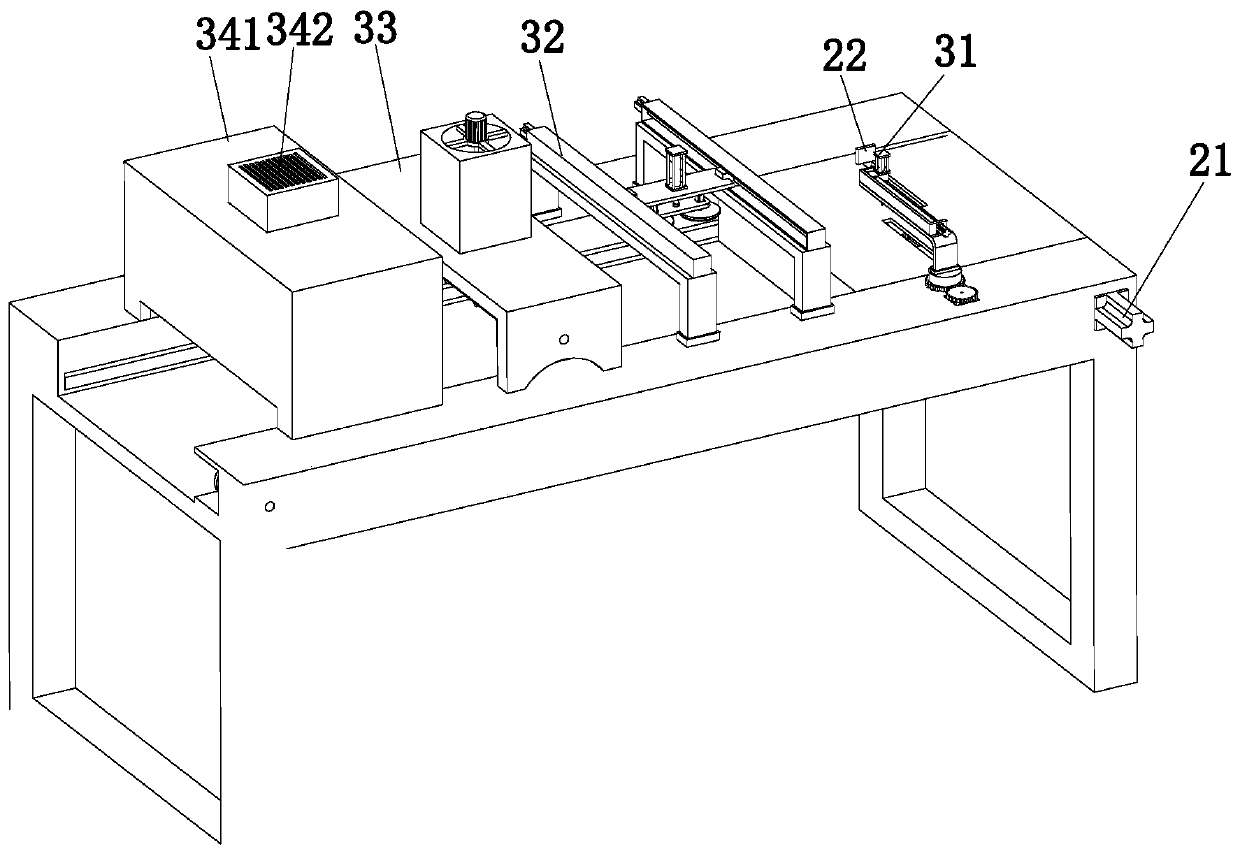

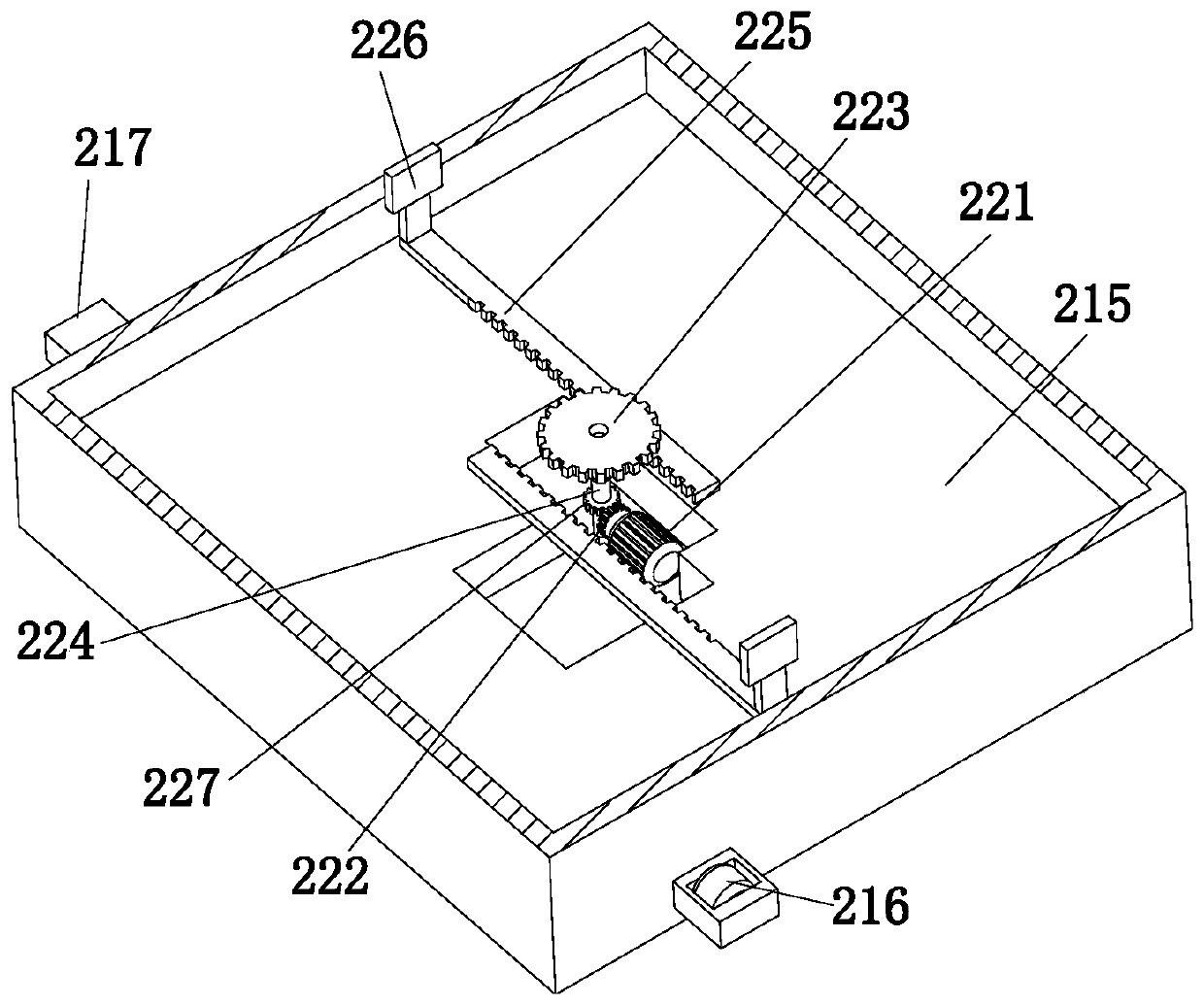

Multifunctional processing device for a circuit board

PendingCN111315140AAffect accuracyComprehensive grinding workInsulating layers/substrates workingPrinted circuit coatingMechanical engineeringElectrical and Electronics engineering

The invention discloses a multifunctional processing device for a circuit board, and belongs to the technical field of circuit board processing. The multifunctional processing device comprises a mounting frame, a moving assembly and a processing assembly. The moving assembly comprises a movable part and a fixed part. The fixed part is arranged on the movable part; the processing assembly is erected at the top of the mounting frame. The processing assembly comprises a circuit board drilling part, a circuit board polishing part, a circuit board coating part and a circuit board drying part whichare sequentially arranged at the top of the mounting frame; the conveying circuit board grinding part is arranged beside the circuit board drilling part, the circuit board coating part is arranged beside the circuit board grinding part, and the circuit board drying part is arranged beside the circuit board coating part. The rotating gear rotates to drive the two fixed toothed plates to rotate oppositely or rotate in an opposing way, the two fixed toothed plates move to drive the two fixed plates to move to fix the circuit board at the top of the movable plate, and the situation that the position of the circuit board deviates in processing and consequently the processing ccuracy of the circuit board is affected is prevented.

Owner:崔亮

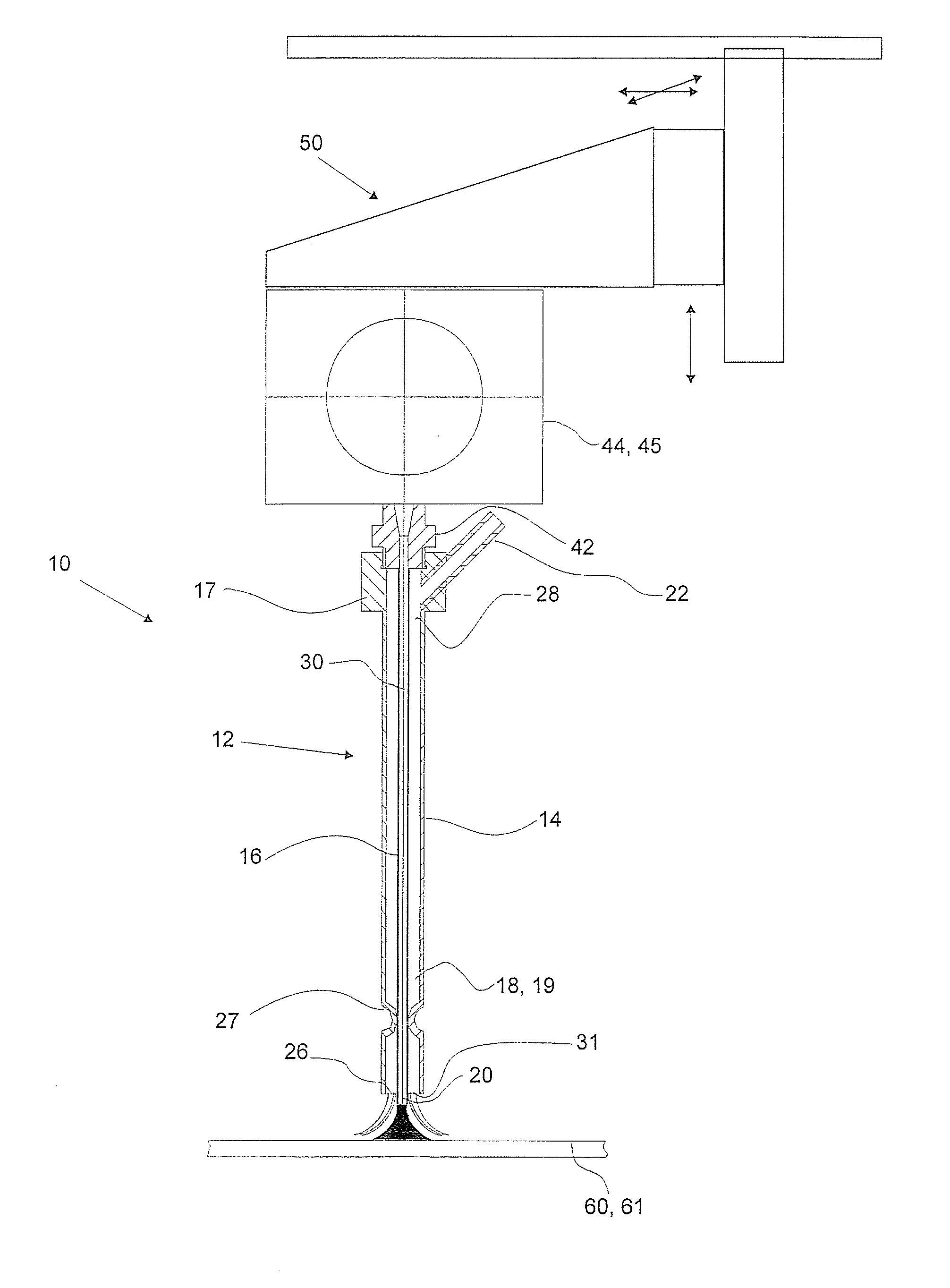

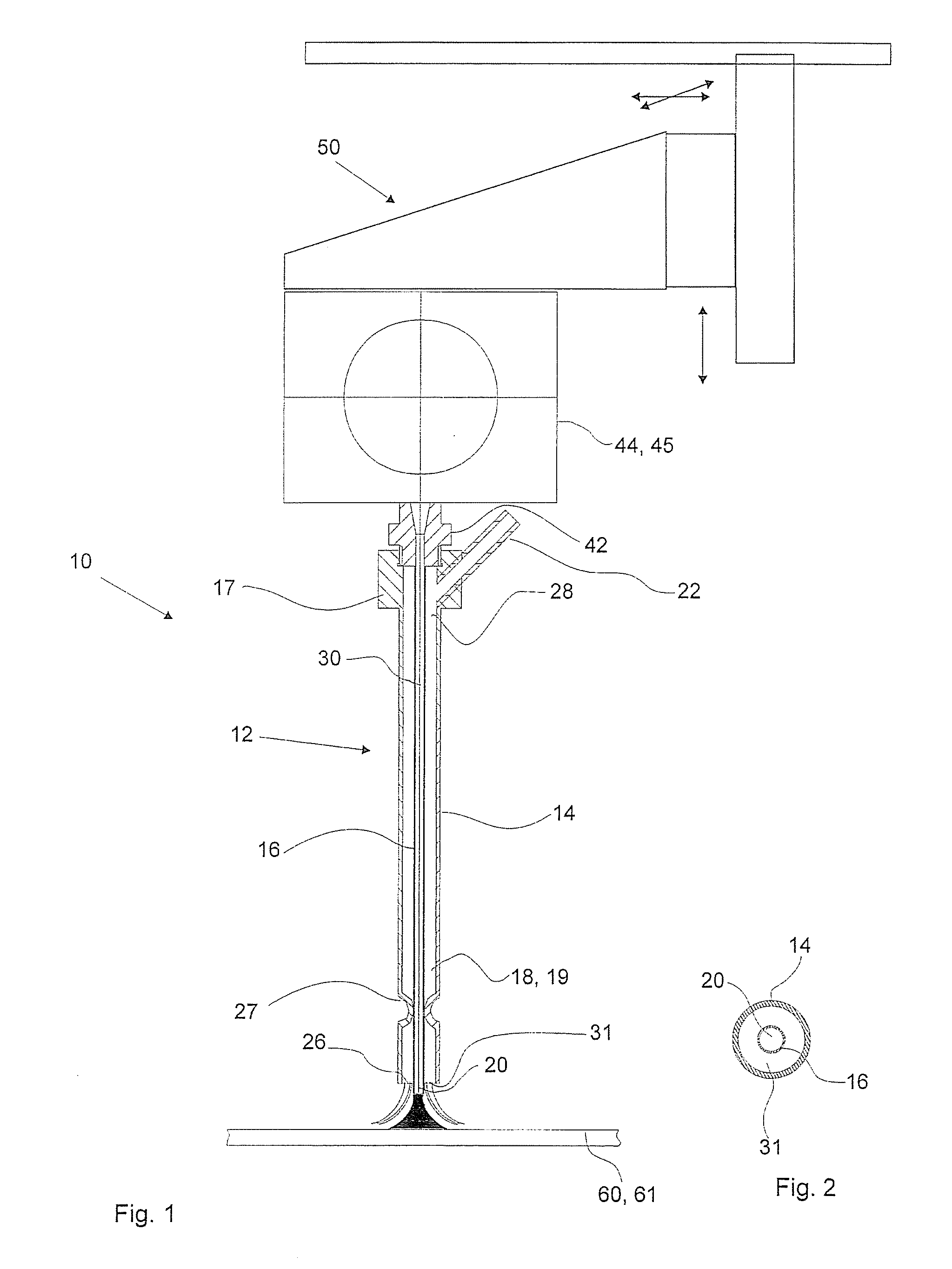

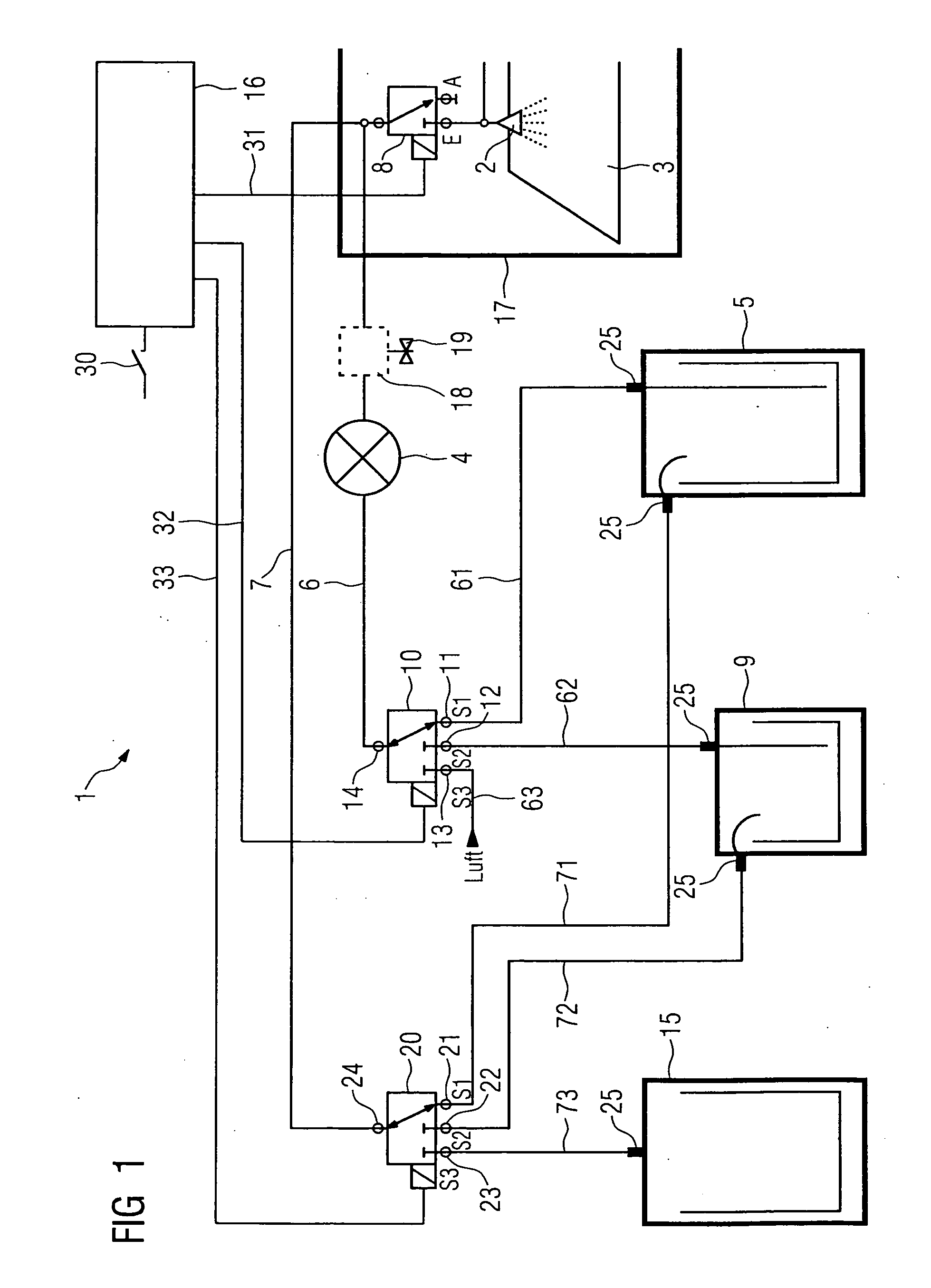

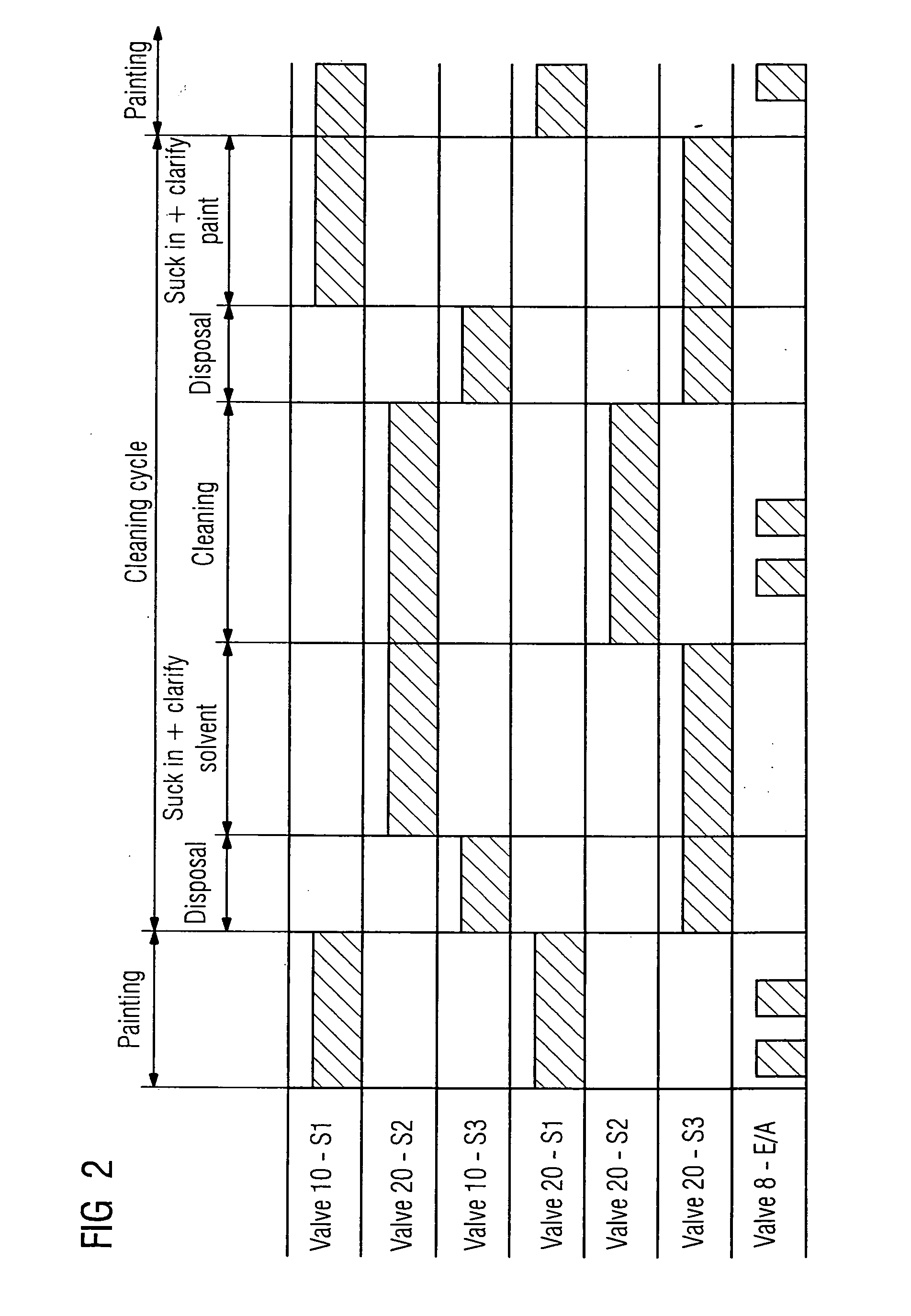

Apparatus for the coating of a substrate

ActiveUS20100224121A1High-precision meteringHigh-precision point-accurateLiquid surface applicatorsLiquid spraying apparatusProduct gasOperation mode

The invention relates to an apparatus for the coating of a substrate, in particular of a circuit board, with a material application device for applying a coating material and with a gas supplying device for the supply of a gaseous medium, the material application device having an inner tubular element, the gas supply device having an outer tubular element which is arranged coaxially to the inner tubular element and surrounds the latter, so as to form between the outer and the inner tubular element a gas supply duct which has an annular orifice at one end, the supply duct being configured so that the gaseous medium flows out, parallel to the coating material, through the annular orifice, in order, when it impinges on the substrate, to displace the applied coating material and thereby distribute it over the area. The apparatus is distinguished in that the material application device has a jet valve which, in a first operating mode, carries out a jetted supply of material into the inner tubular element.

Owner:REHM THERMAL SYST

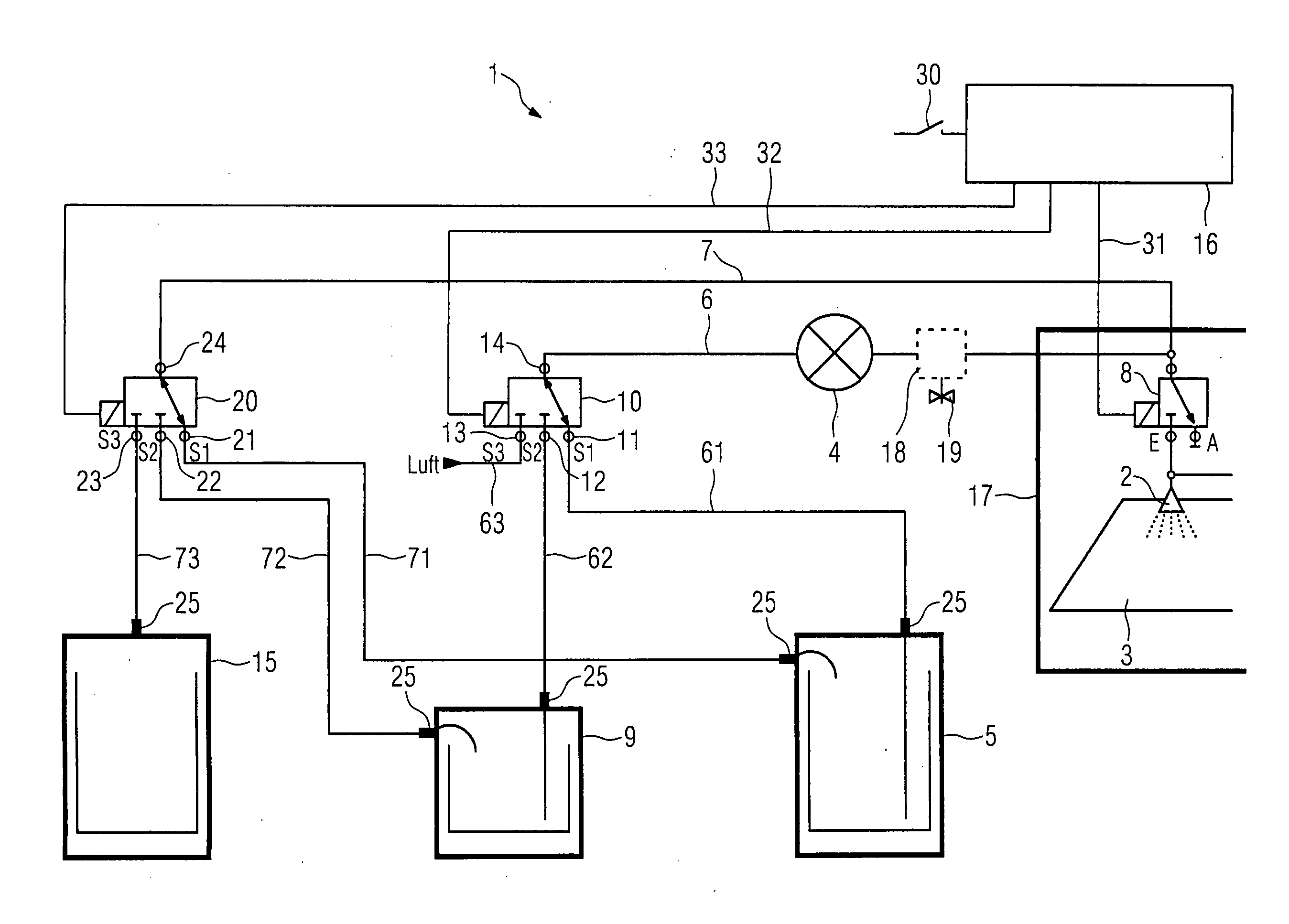

Painting machine

InactiveUS20090134241A1Reduce the amount requiredExplosion is possibleLiquid spraying apparatusGaseous fuel burnerLine tubingEngineering

A painting machine having a spray head for painting an object, a pump for conveying paint from a paint container via a feed line to the spray head and back via a return line to the paint container, the feed and return lines connected to a solvent container with a solvent for flush cleaning the painting machine. The feed and return lines are connected to a disposal container for disposing of paint and solvent residues, and at their respective container-side end to a first and second controllable multiway valve for switching the feed and return lines to the paint container, solvent container or disposal container. The painting machine has a control device for controlling the multiway valve such that execution of the consecutive operations of disposal of the paint, filling with solvent, flushing out the painting machine, disposing of the solvent, refilling with paint and also further conveyance of the paint are automated.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com