Thin line conformal coating apparatus and method

a conformal coating and thin line technology, applied in the direction of superimposed coating process, liquid transfer device, liquid/solution decomposition chemical coating, etc., can solve the problems of undesirable coating, significant overspray, and bead deposited on the board may spread to locations, so as to improve the ability of needle valve applicator, improve the ability of precision and/or speed, and reduce the viscosity of conformal coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

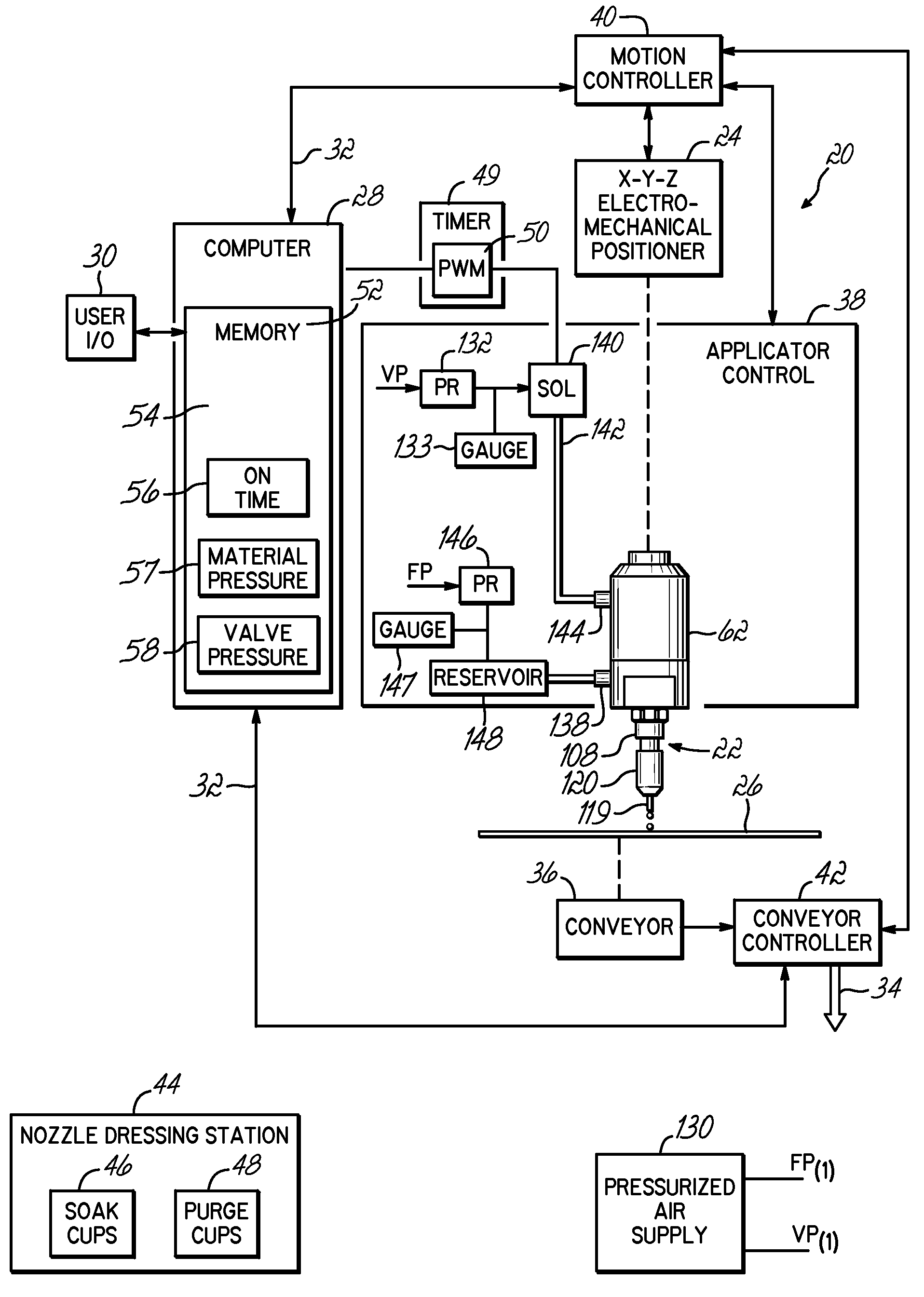

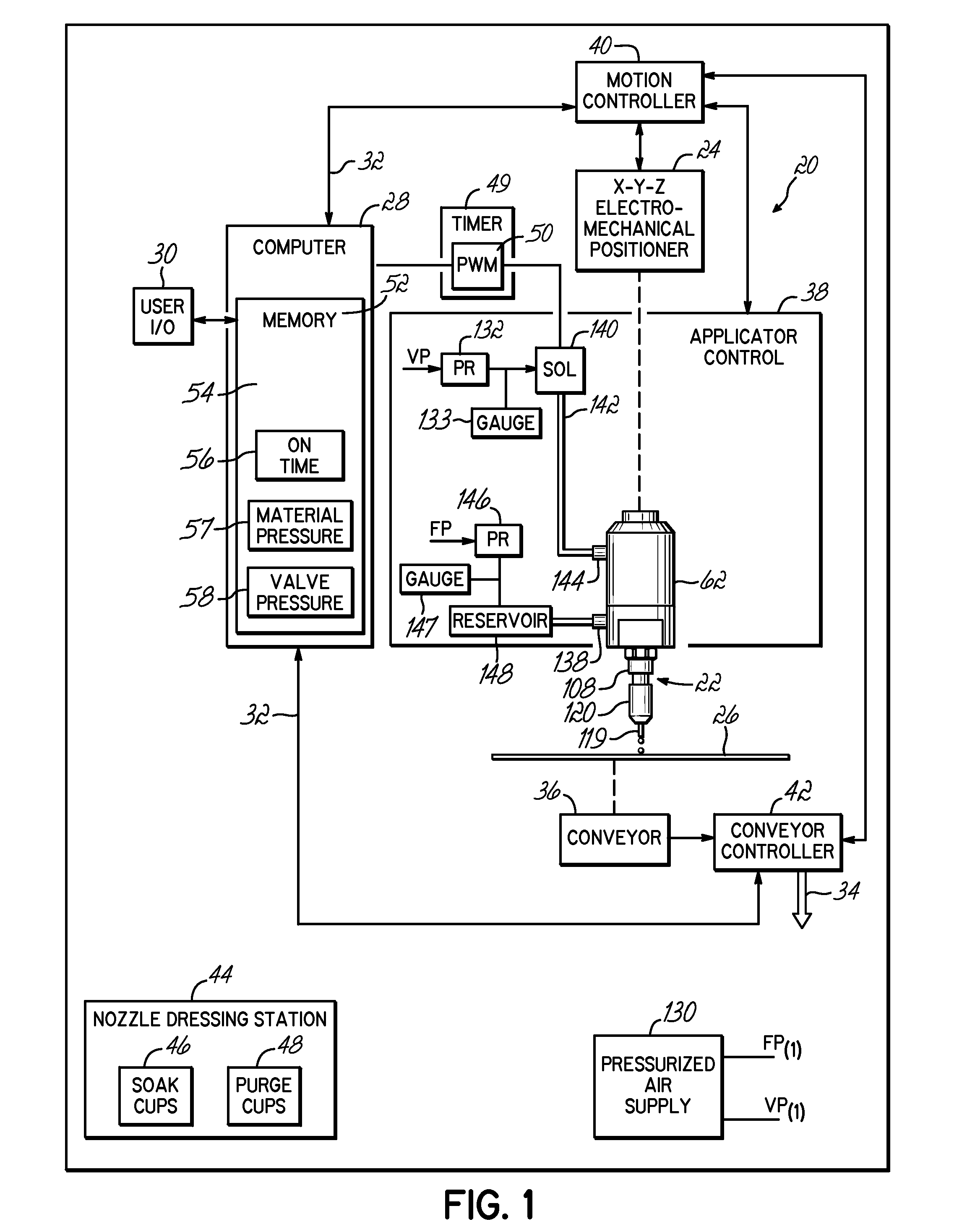

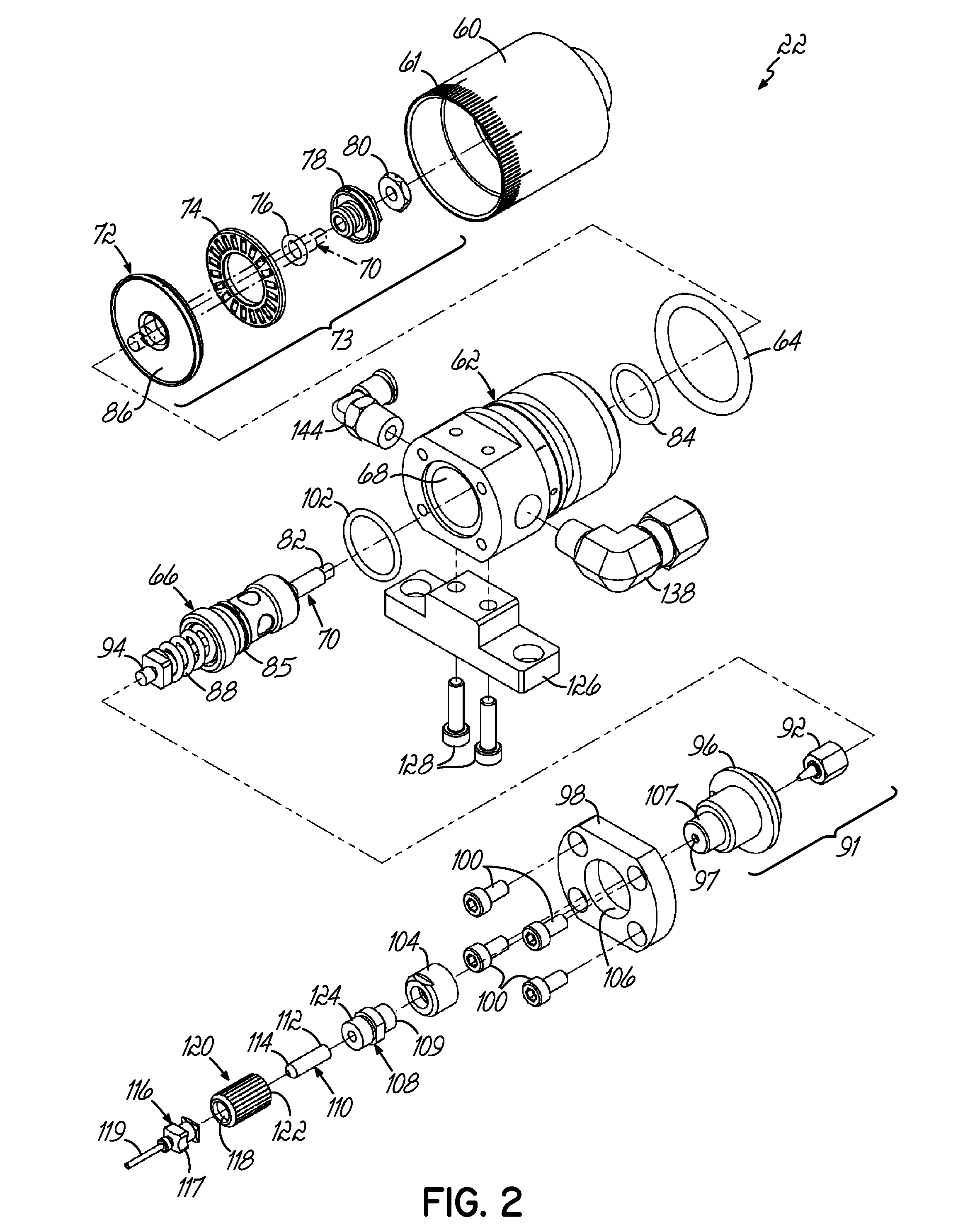

[0017]Referring to FIG. 1, one exemplary example of a conformal coating system 20 includes a conformal coating applicator or dispenser 22 mechanically suspended from an X-Y-Z positioner 24. The X-Y-Z electro-mechanical positioner 24 includes a drive coupled to independently controllable motors (not shown) in a known manner. The X-Y-Z positioner 24 is capable of rapidly moving the conformal coating applicator 22 with respect to a substrate 26.

[0018]A computer 28 may be a programmable logic controller (“PLC”), a microprocessor based controller, a hardened personal computer or other conventional programmable control device capable of carrying out the functions described herein as will be understood by those of ordinary skill. A user I / O 30, for example, a visual display device such as an LCD screen (not shown) and a user input device such as a keyboard (not shown) are connected to the computer 28 in a known manner. The computer provides outputs to a timer 49, for example, a pulse width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosities | aaaaa | aaaaa |

| pulse width | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com