Patents

Literature

1101 results about "Aliphatic amine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aliphatic amine is an amine in the molecule of which there are no aromatic rings directly on the nitrogen atom.

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

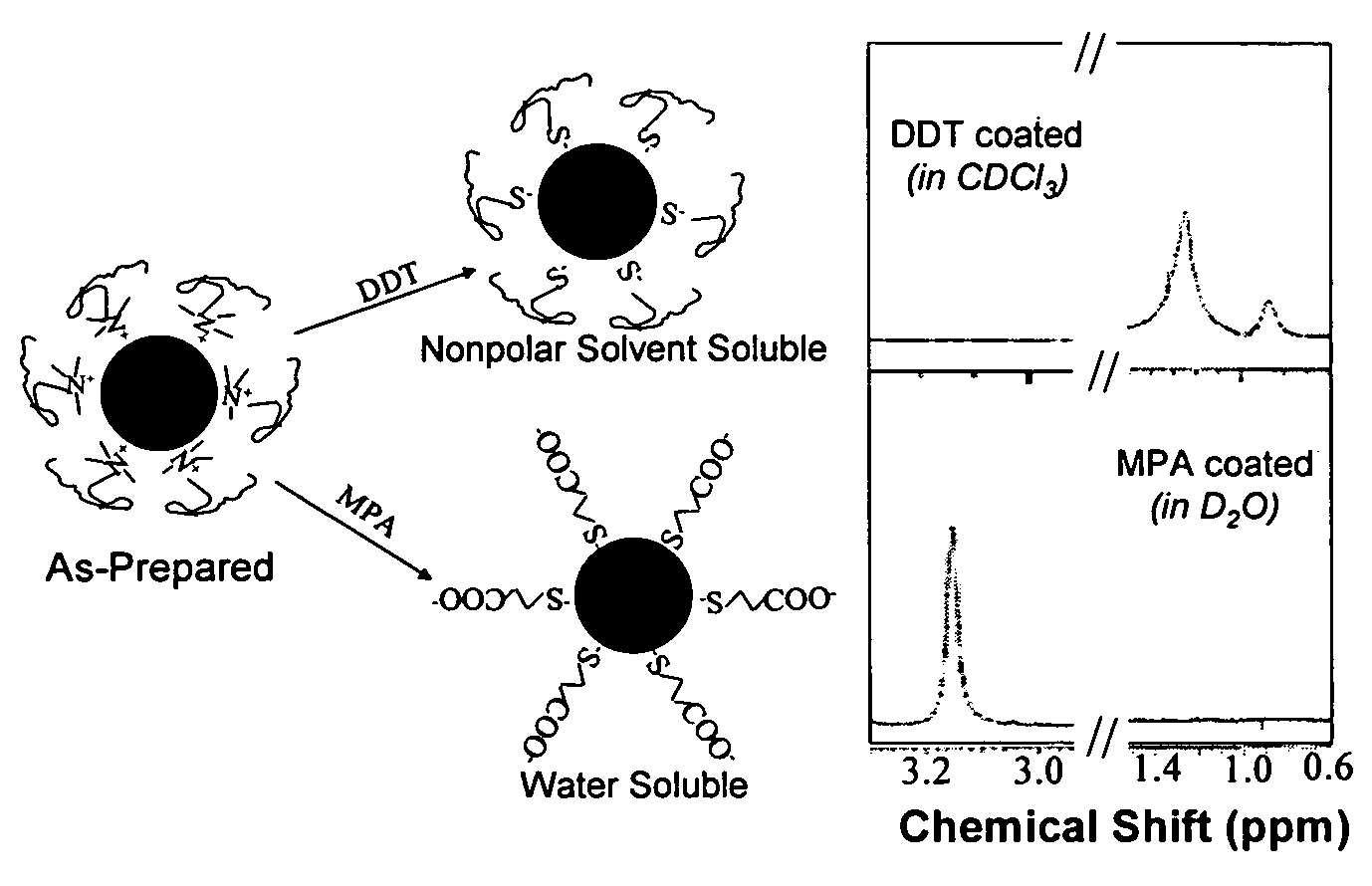

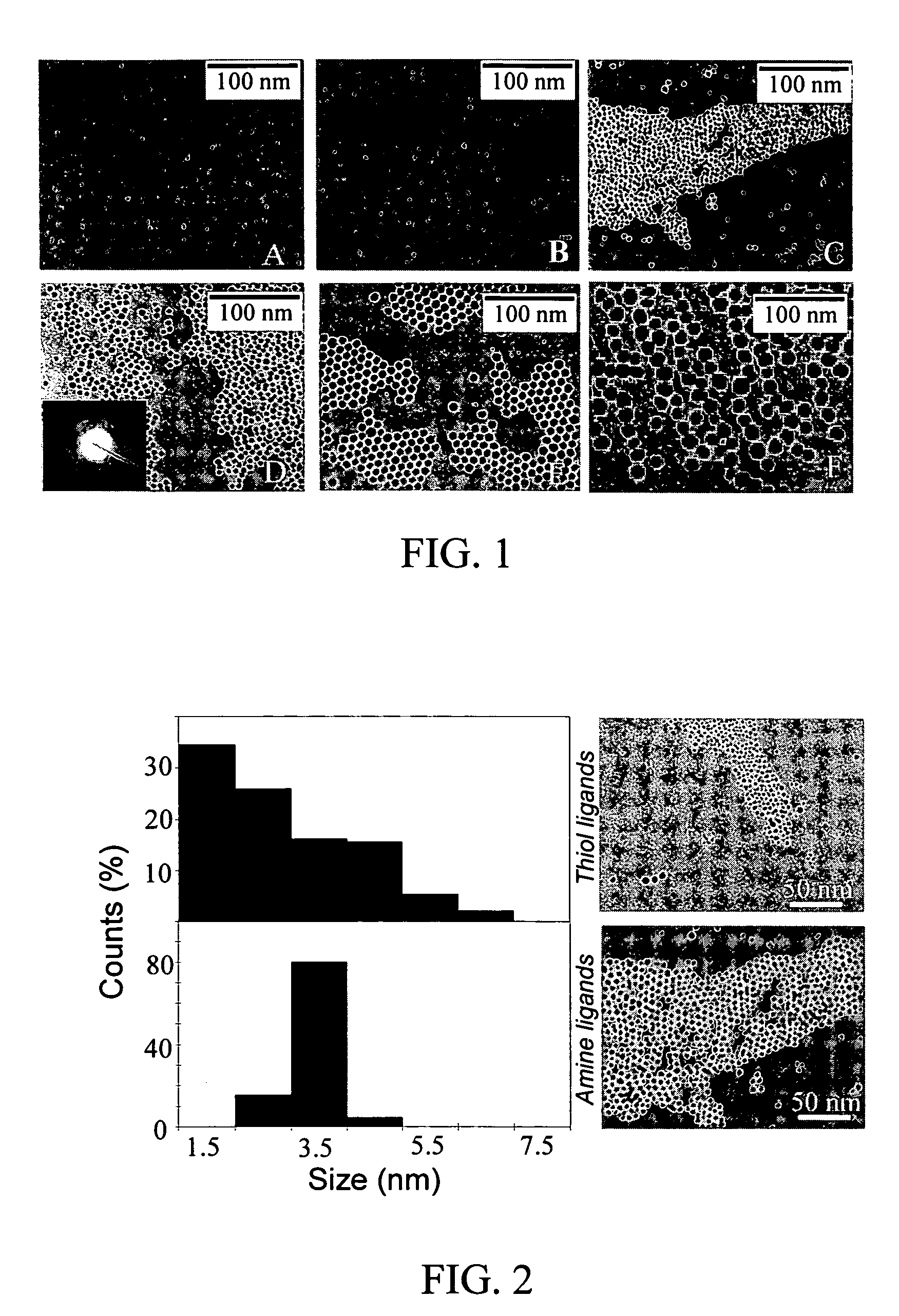

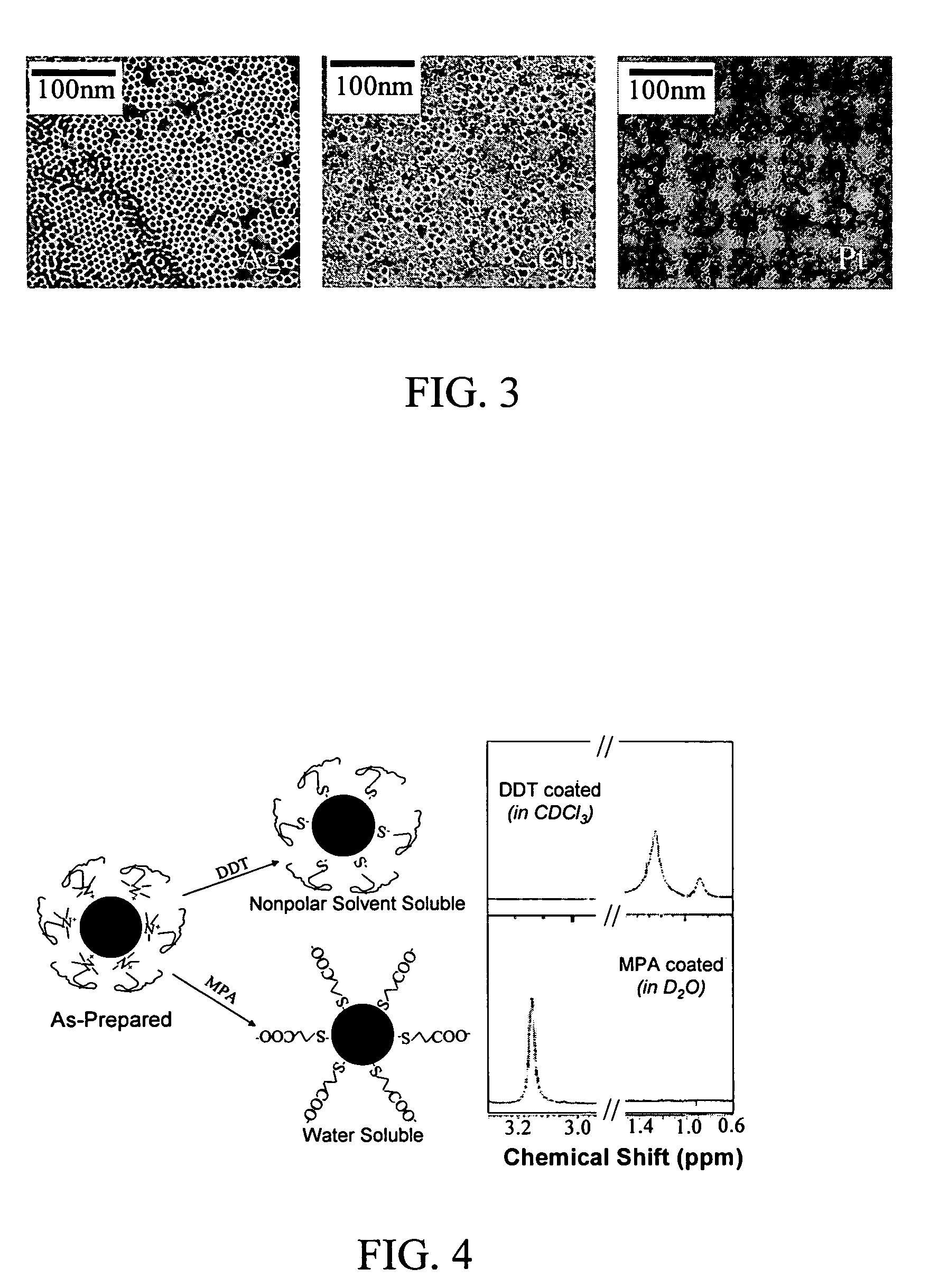

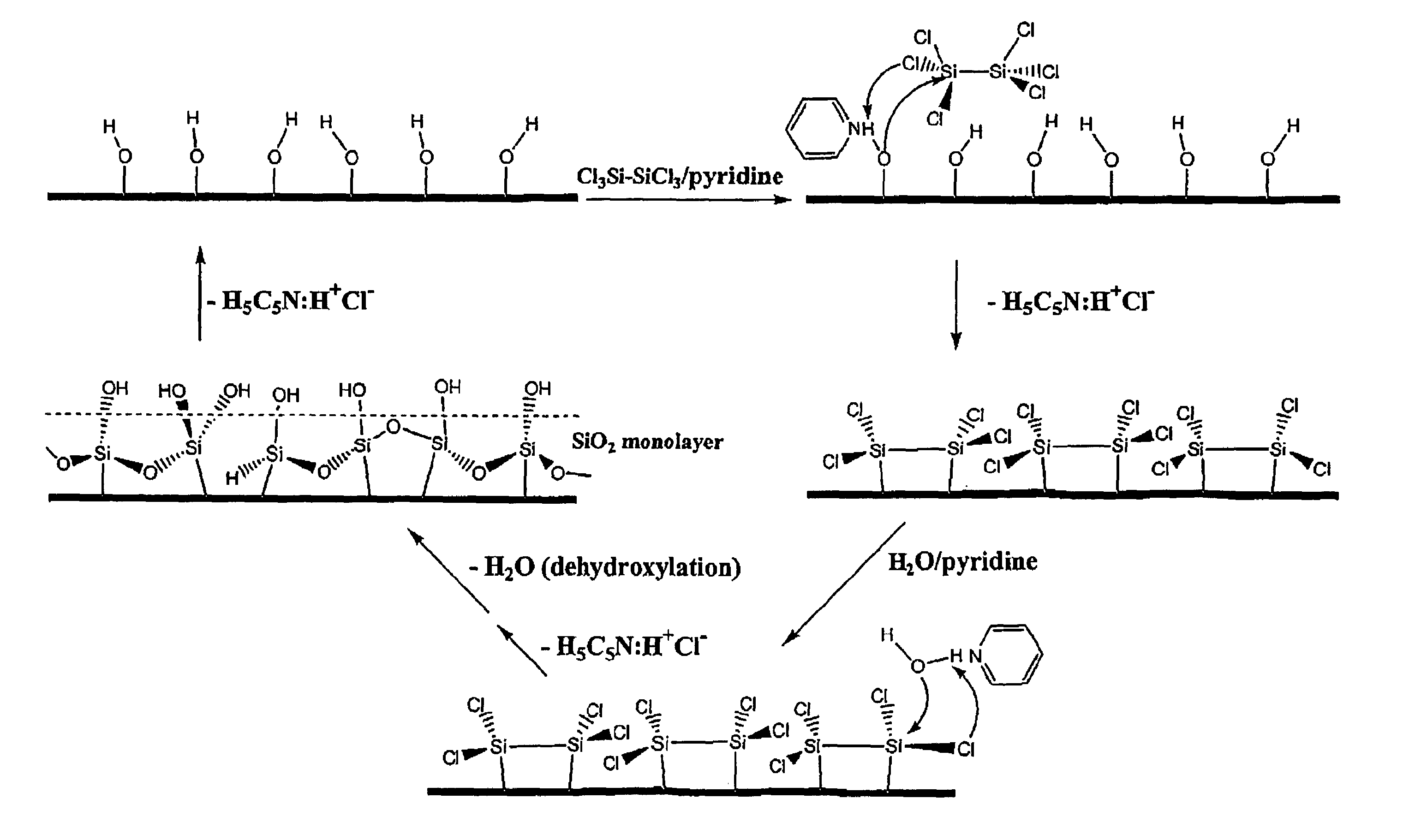

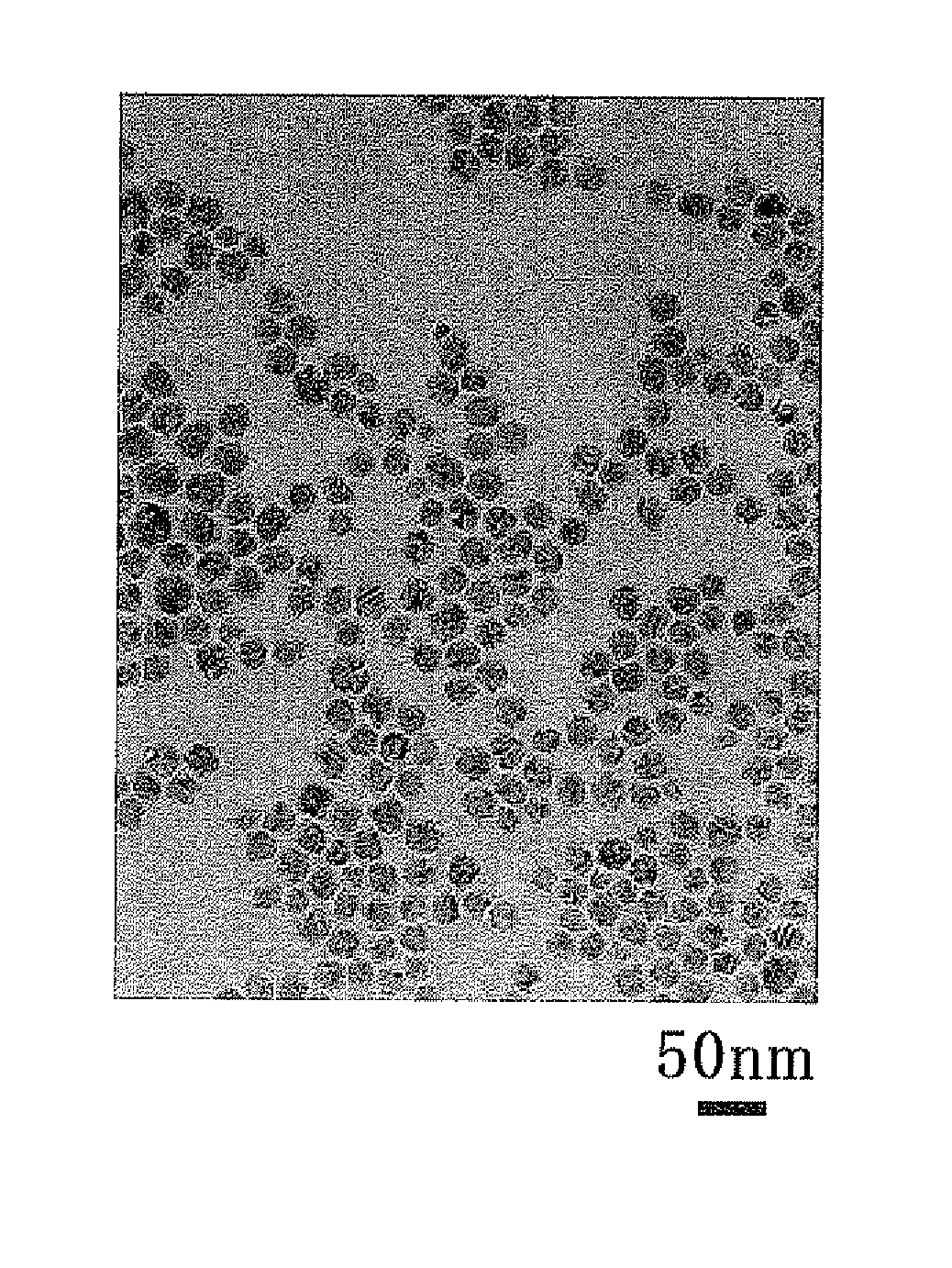

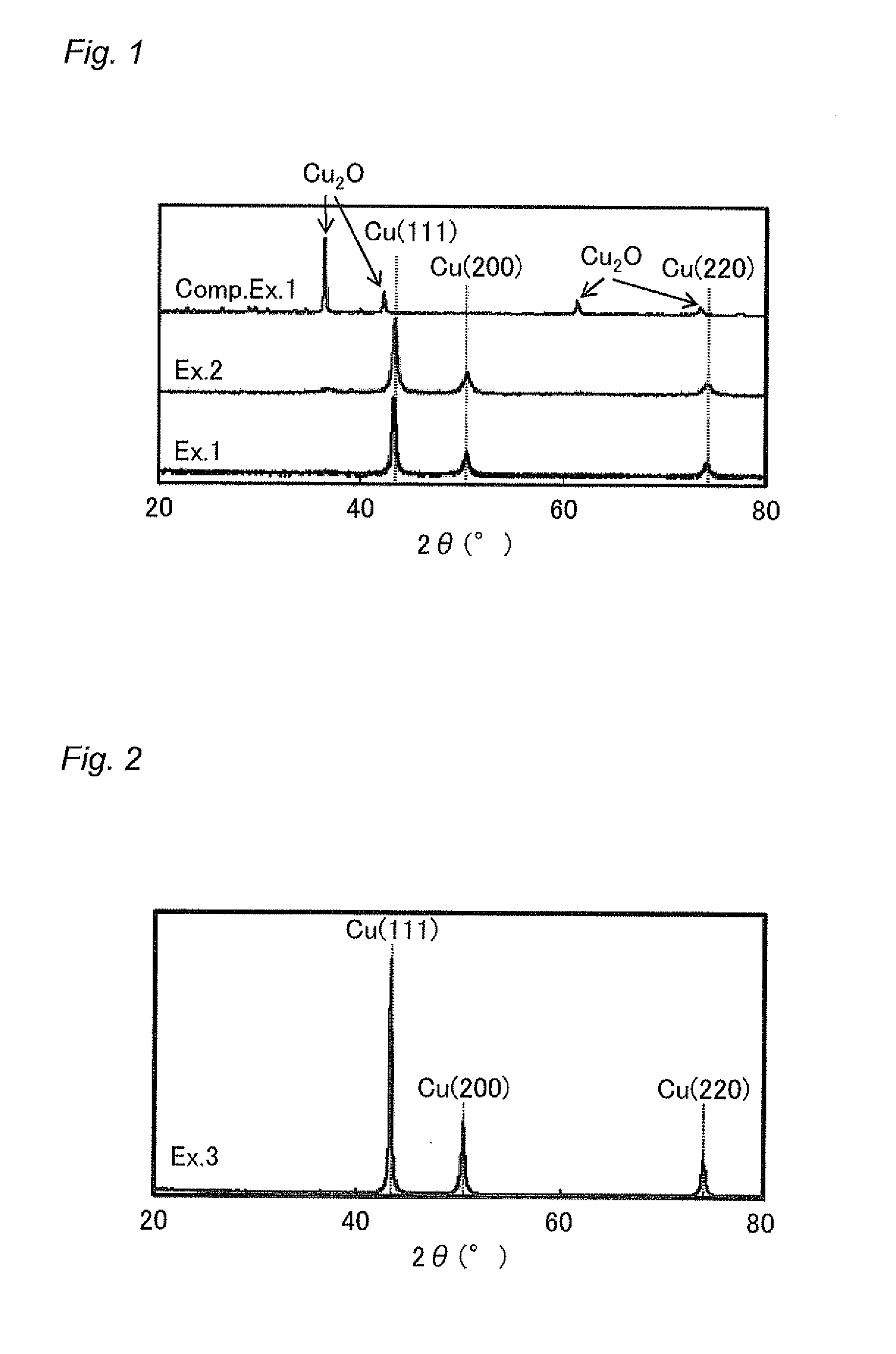

Monodisperse noble metal nanocrystals

Nanoparticle compositions of noble metals, and methods of making them, are described. The nanoparticle compositions are made by reacting a salt or complex of a noble metal, such as Au, Ag, Cu or Pt, with a weak ligand, and a reducing agent, in a single liquid phase. The noble metal is typically provided as a halide or carboxylate. The ligand is preferably a fatty acid or aliphatic amine. The reducing agent is preferably a borohydride reagent, hydrazine, or a mixture thereof. Nanocrystals in the size range of 1 nm to 20 nm are produced, and can be made in substantially monodisperse form.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Method of polishing a silicon-containing dielectric

InactiveUS7071105B2Other chemical processesSemiconductor/solid-state device manufacturingThiolHydroxamic acid

The invention is directed to a method of polishing a silicon-containing dielectric layer involving the use of a chemical-mechanical polishing system comprising (a) an inorganic abrasive, (b) a polishing additive, and (c) a liquid carrier, wherein the polishing composition has a pH of about 4 to about 6. The polishing additive comprises a functional group having a pKa of about 4 to about 9 and is selected from the group consisting of arylamines, aminoalcohols, aliphatic amines, heterocyclic amines, hydroxamic acids, aminocarboxylic acids, cyclic monocarboxylic acids, unsaturated monocarboxylic acids, substituted phenols, sulfonamides, thiols, salts thereof, and combinations thereof. The invention is further directed to the chemical-mechanical polishing system, wherein the inorganic abrasive is ceria.

Owner:CABOT MICROELECTRONICS CORP

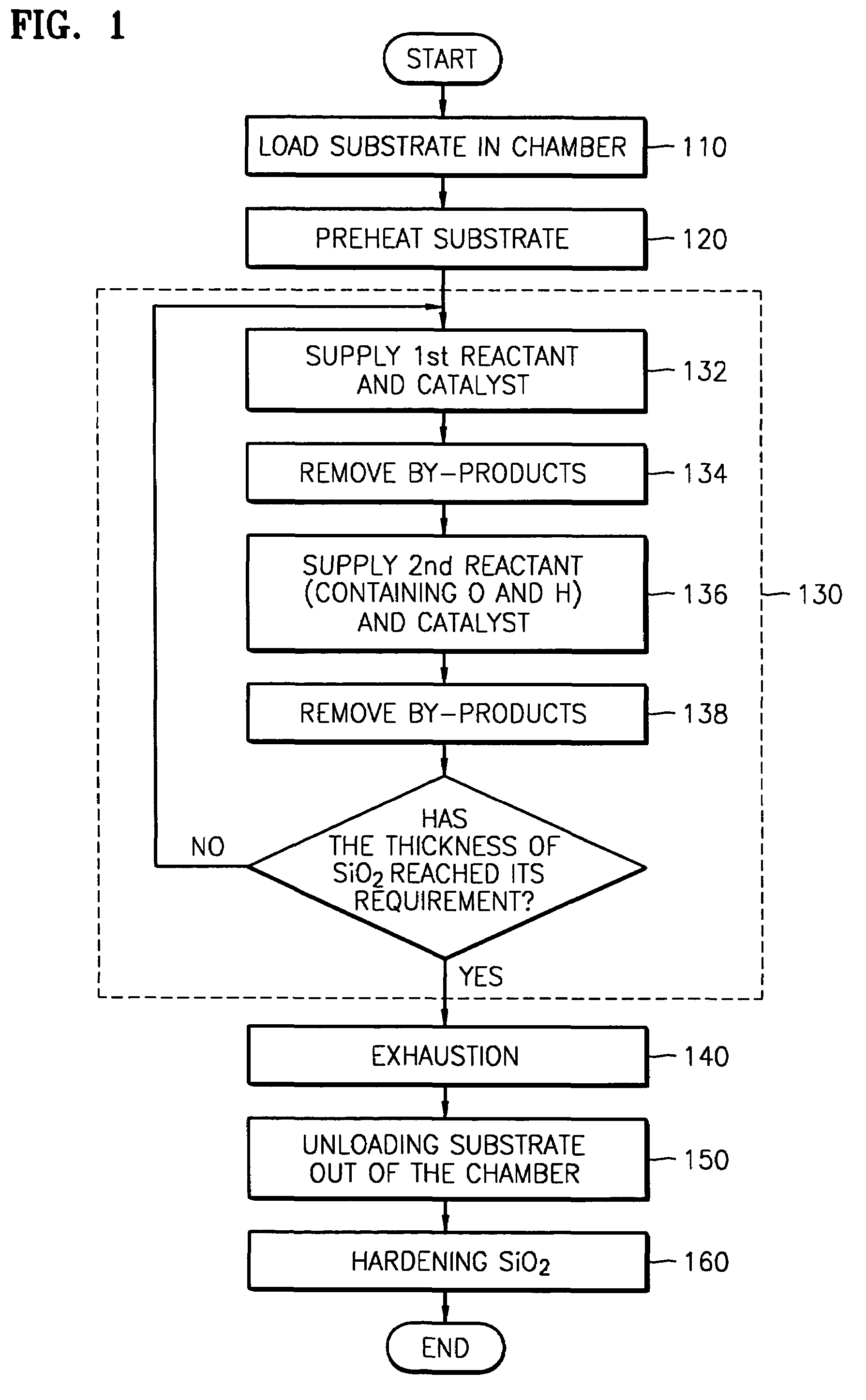

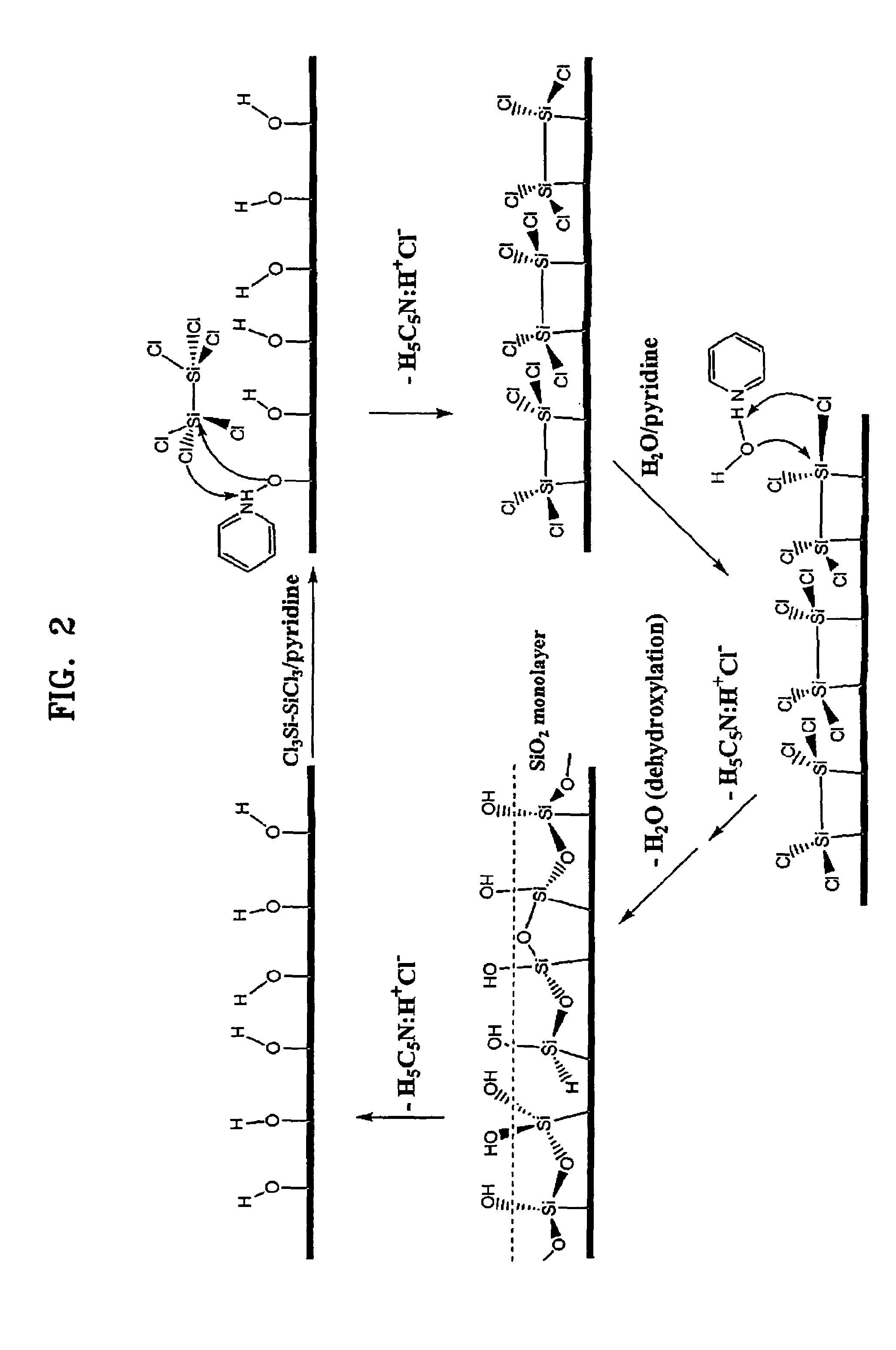

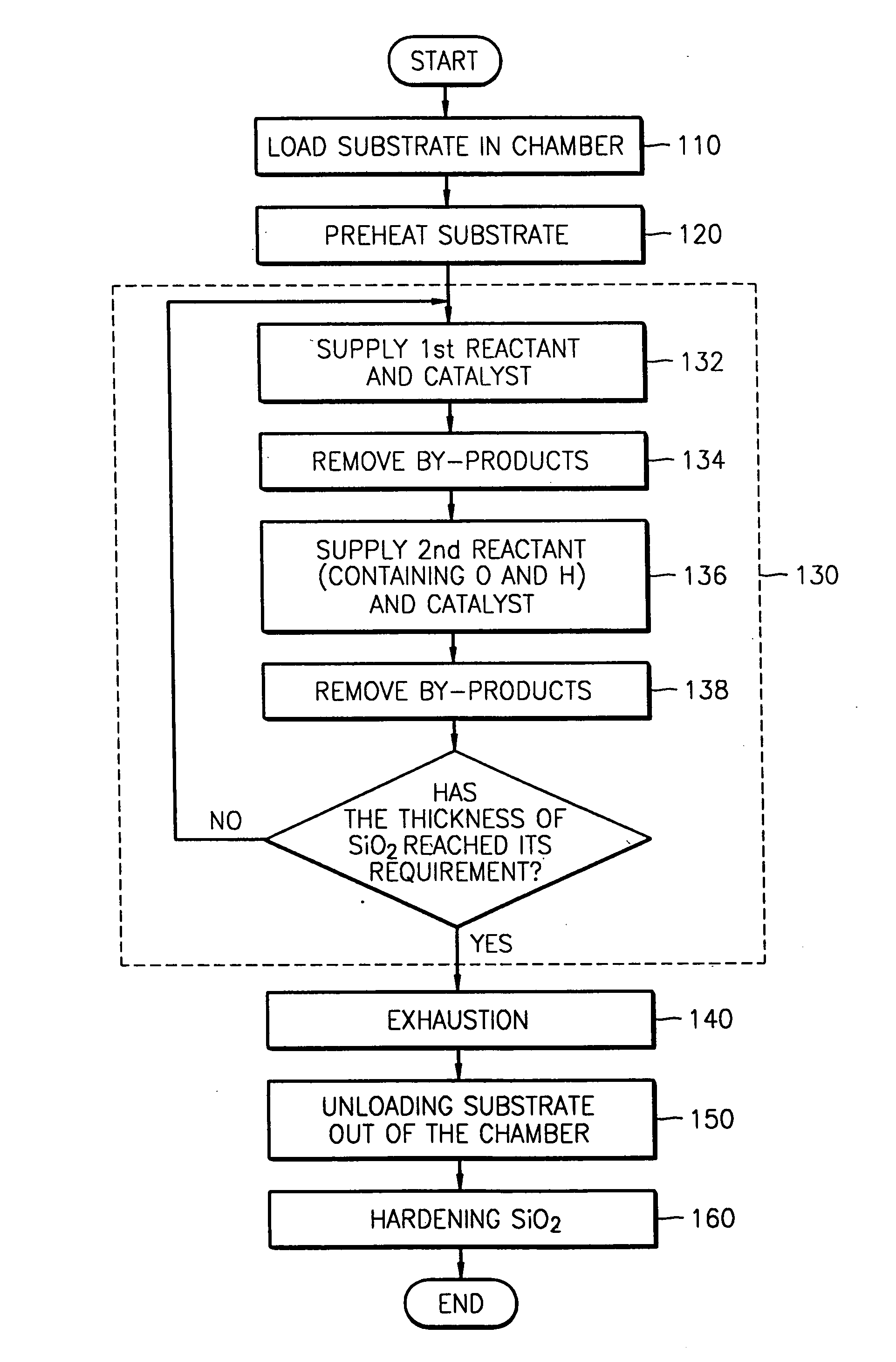

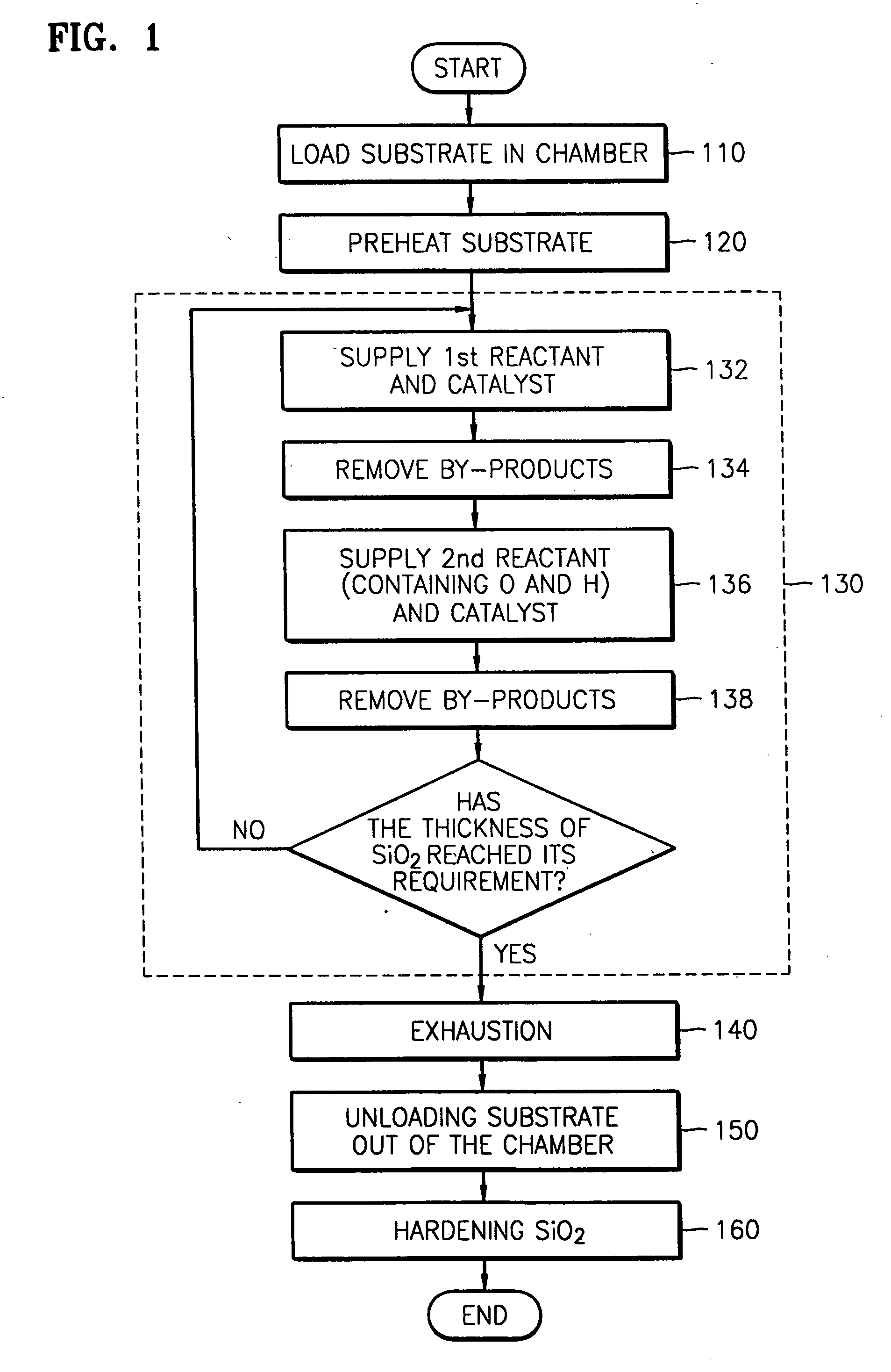

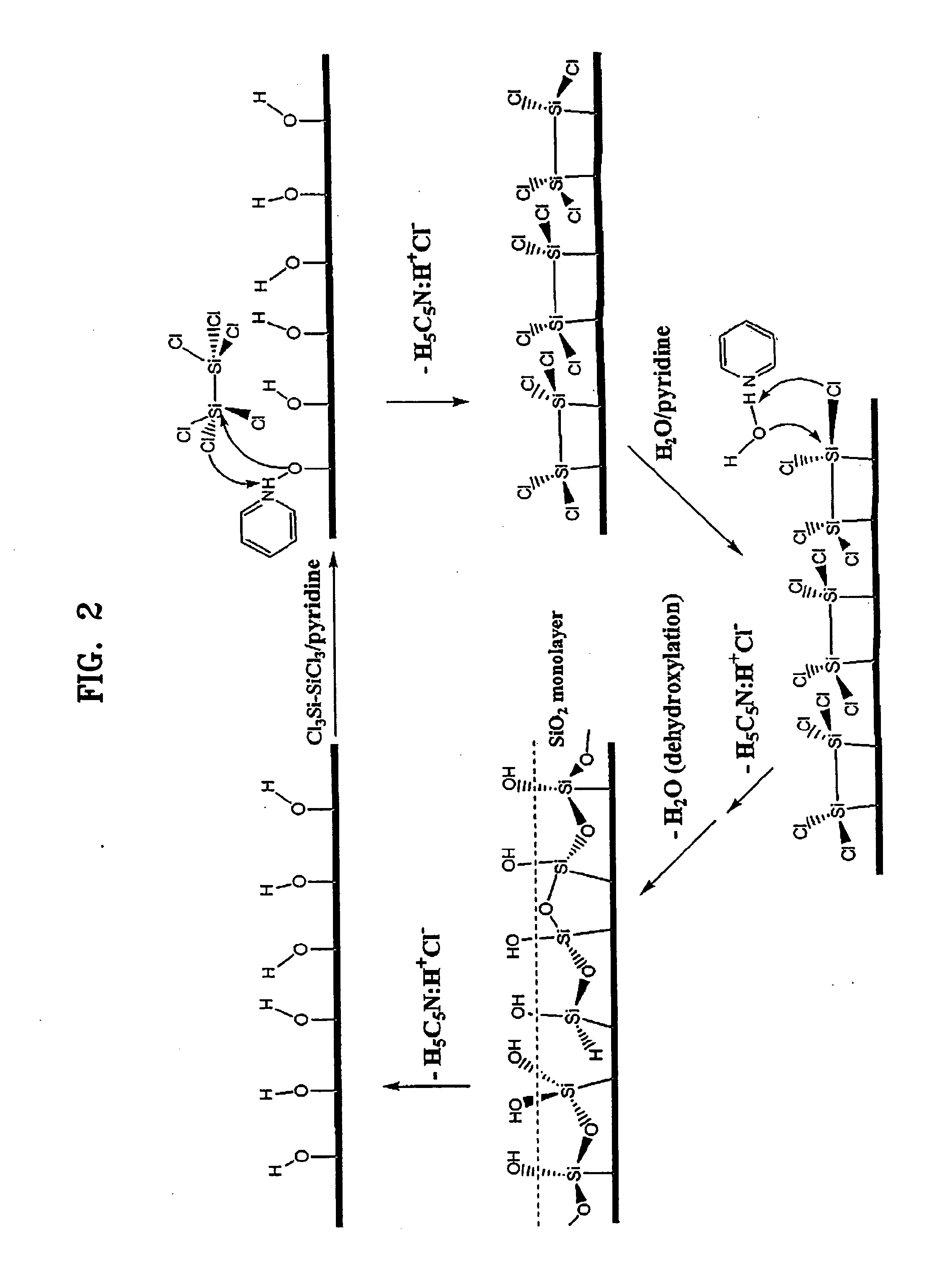

Methods for forming silicon dioxide layers on substrates using atomic layer deposition

ActiveUS6992019B2Increase surface densityEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAliphatic amineImproved method

Improved methods are disclosed for catalyst-assisted atomic layer deposition (ALD) to form a silicon dioxide layer having superior properties on a semiconductor substrate by using a first reactant component consisting of a silicon compound having at least two silicon atoms, or using a tertiary aliphatic amine as the catalyst component, or both in combination, together with related purging methods and sequencing.

Owner:SAMSUNG ELECTRONICS CO LTD

Structural modified epoxy adhesive compositions

InactiveUS20020164485A1Reduce opening timeGood substrate adhesionSynthetic resin layered productsThin material handlingSilanesFirming agent

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

Method of polishing a silicon-containing dielectric

The invention is directed to a method of polishing a silicon-containing dielectric layer involving the use of a chemical-mechanical polishing system comprising (a) an inorganic abrasive, (b) a polishing additive, and (c) a liquid carrier, wherein the polishing composition has a pH of about 4 to about 6. The polishing additive comprises a functional group having a pKa of about 4 to about 9 and is selected from the group consisting of arylamines, aminoalcohols, aliphatic amines, heterocyclic amines, hydroxamic acids, aminocarboxylic acids, cyclic monocarboxylic acids, unsaturated monocarboxylic acids, substituted phenols, sulfonamides, thiols, salts thereof, and combinations thereof. The invention is further directed to the chemical-mechanical polishing system, wherein the inorganic abrasive is ceria.

Owner:CABOT MICROELECTRONICS CORP

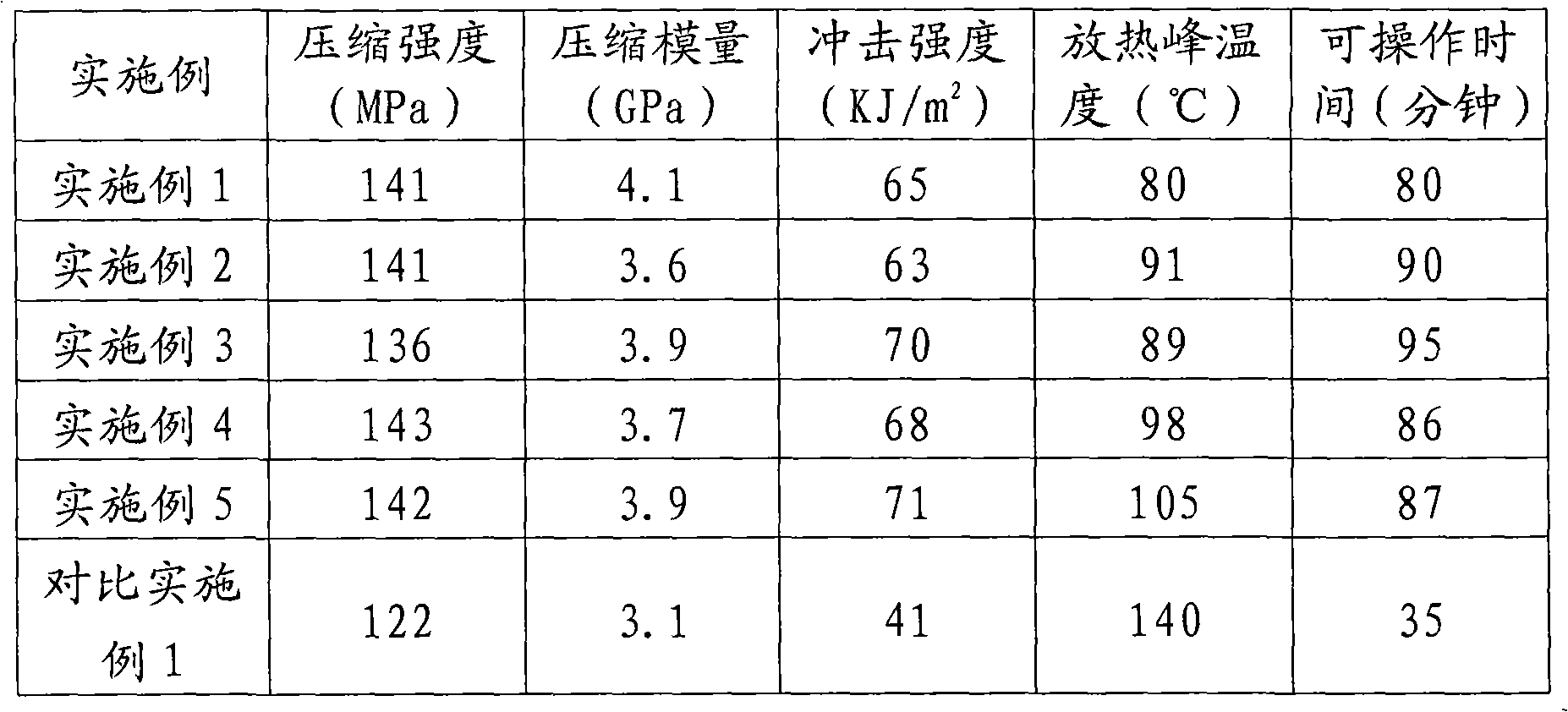

High impact-resistant epoxy resin filling adhesive and preparation method thereof

InactiveCN102093832AImprove toughnessImprove the modulus of compressionEpoxynovolac adhesivesEpoxyAdhesive

The invention relates to a high impact-resistant epoxy resin filling adhesive and a preparation method thereof. The high impact-resistant epoxy resin filling adhesive consists of a component A and a curing agent in a weight ratio of 100:6.5-100:7.5, wherein the component A consists of the following raw materials in percentage by weight: 20 to 60 percent of epoxy resin, 5 to 15 percent of toughening agent, 0.1 to 0.5 percent of thixotropic agent, 2 to 10 percent of diluent, 30 to 70 percent of filler and 0.1 to 0.5 percent of aid; and the curing agent is one or a mixture of more of straight chain aliphatic amine, aliphatic cyclic amine, polyether amine and low molecular weight polyamide. The preparation method for the high impact-resistant epoxy resin filling adhesive comprises the following steps of: mixing the component A and the curing agent in a proper weight ratio, and curing at the temperature of between 10 and 35DEG C for 16 hours.

Owner:YANTAI DARBOND TECH

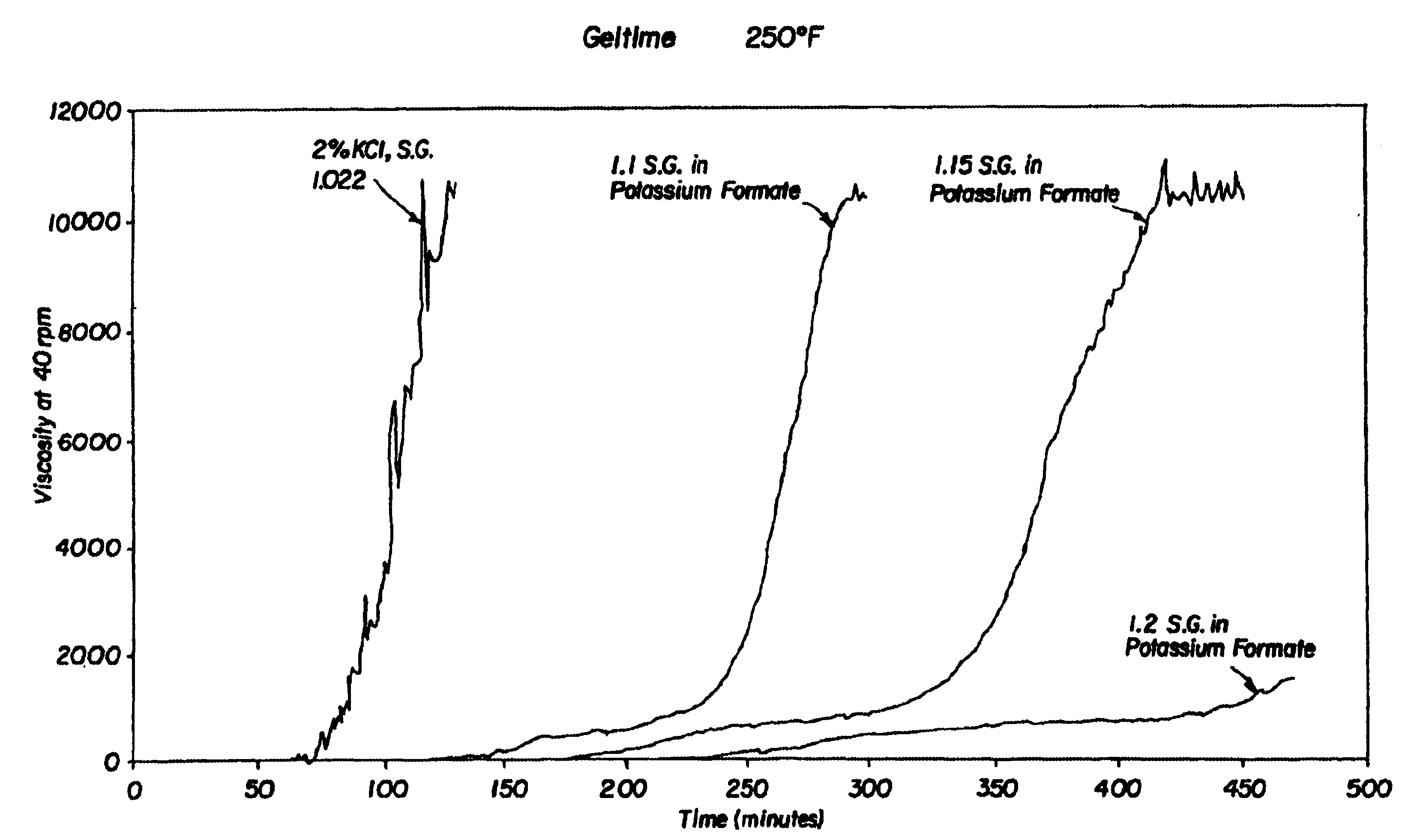

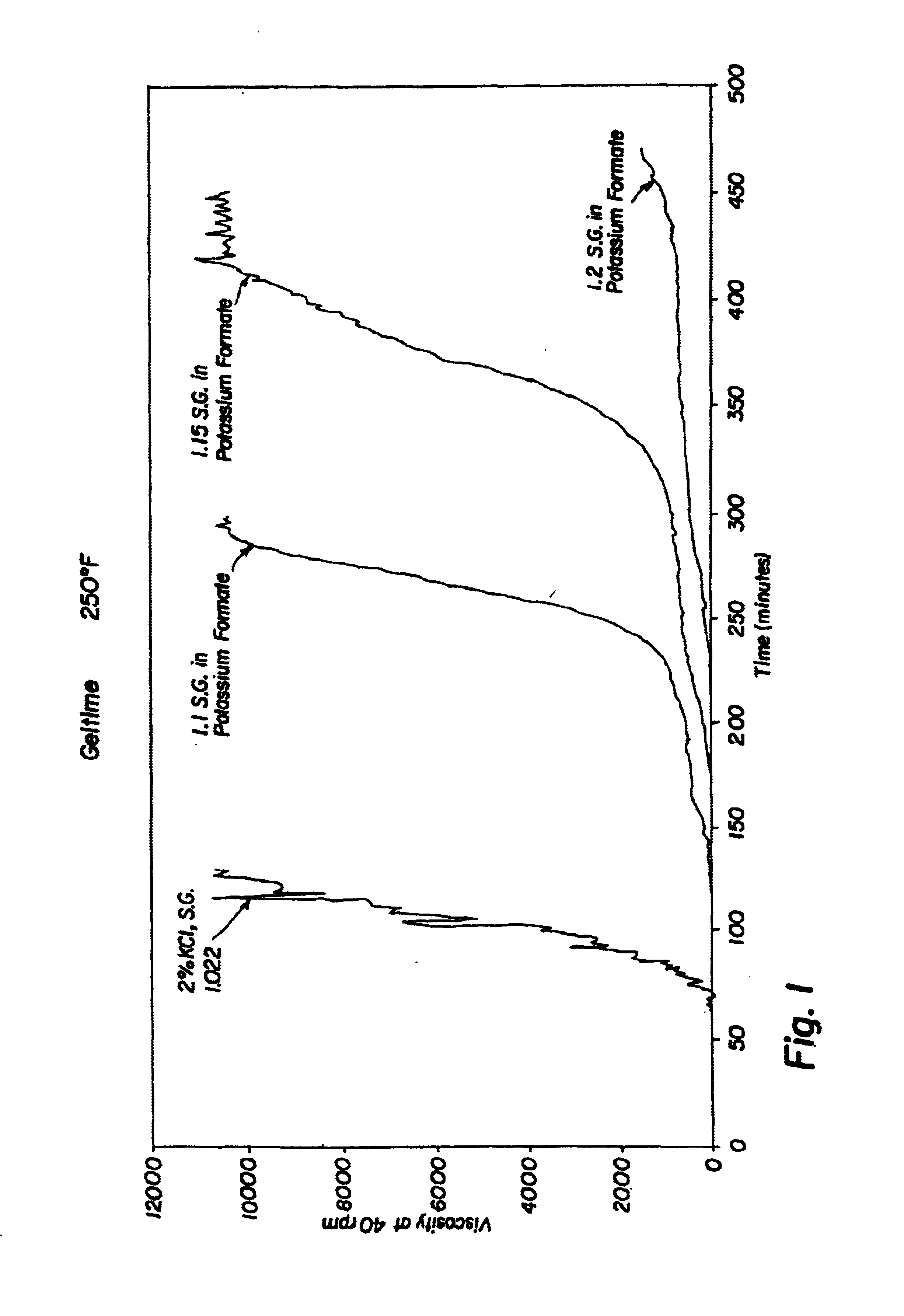

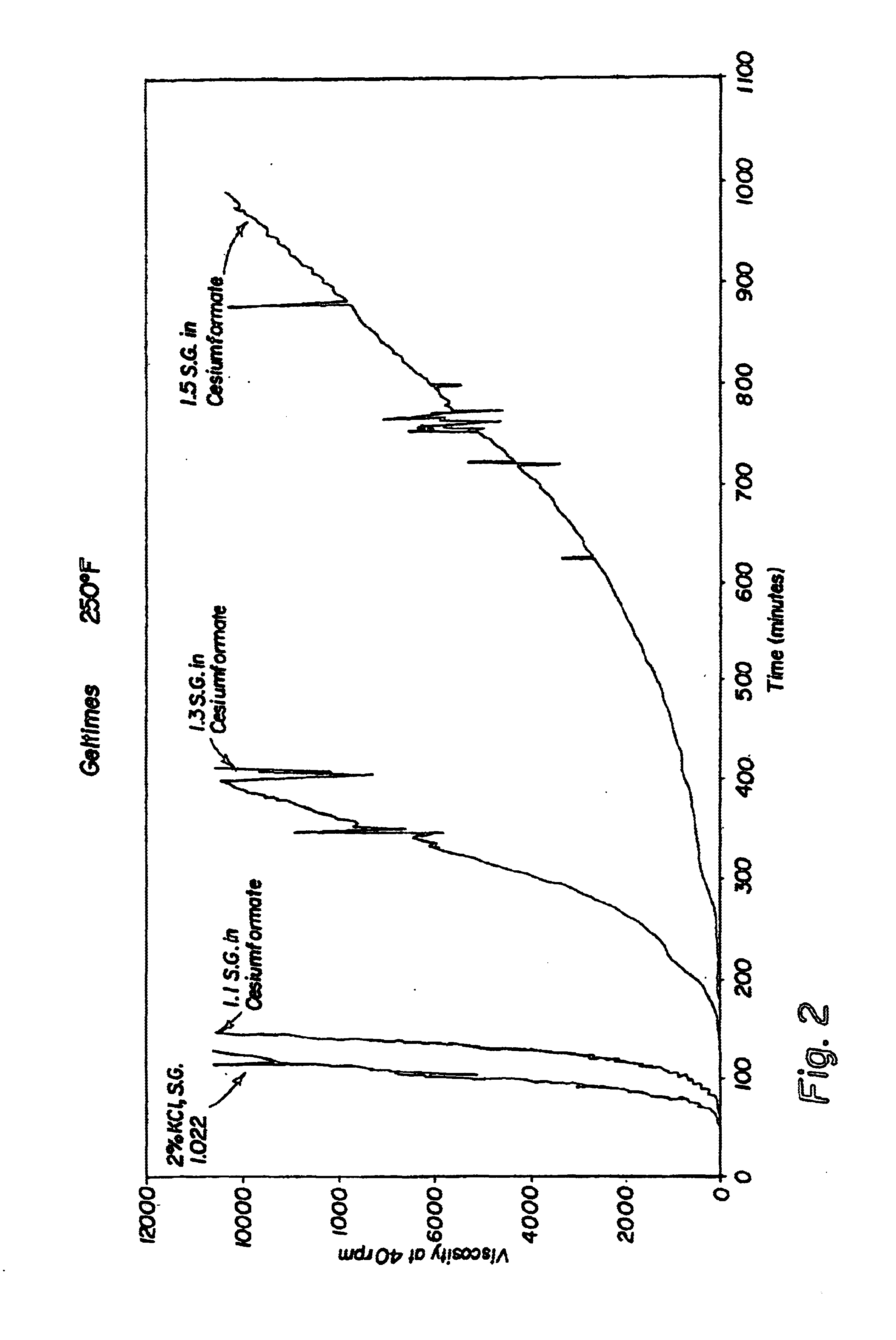

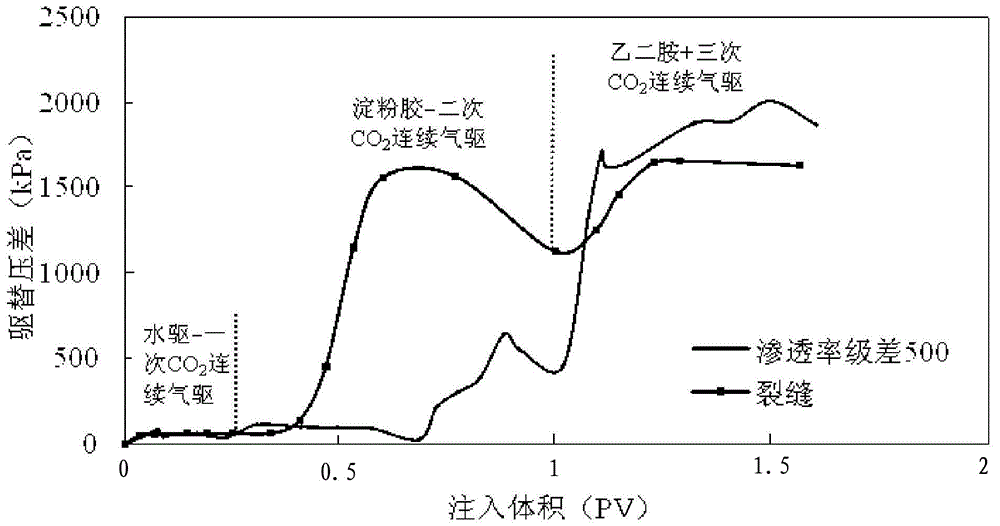

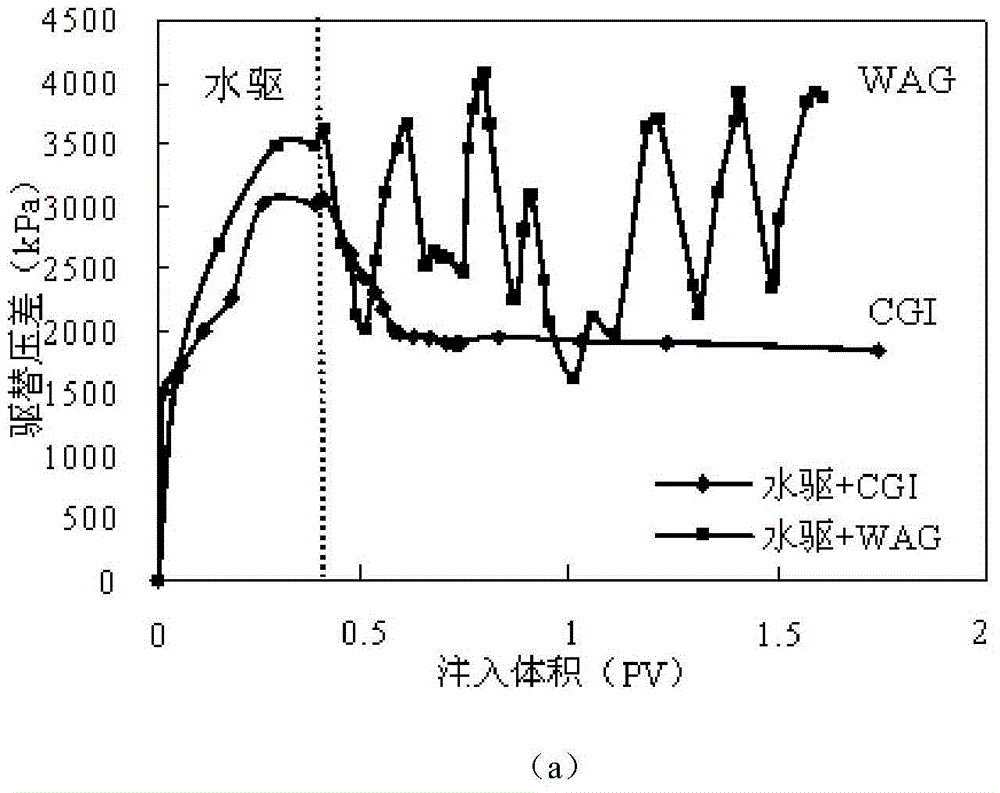

Compositions and methods including formate brines for conformance control

Compositions and methods are provided for reducing the permeability of subterranean zones. More particularly, water-soluble polymeric compositions which form cross-linked gels in the zones. In general, the composition comprises (a) at least one water-soluble polymer; (b) at least one organic gelling agent capable of cross-linking the water-soluble polymer; and (c) at least one water-soluble formate. More preferably, the water-soluble polymer is a copolymer of (i) at least one non-acidic ethylenically unsaturated polar monomer, and (ii) at least one copolymerisable ethylenically unsaturated ester. The gelling agent is preferably selected from the group consisting of a polyalkyleneimine, polyfunctional aliphatic amine, an aralkylamine, and a heteroaralkylamine. The preferred water-soluble formate is selected from the group consisting of ammonium formate, lithium formate, sodium formate, potassium formate, rubidium formate, cesium formate, and francium formate. Water is used to make an aqueous composition prior to use in a subterranean formation. The methods of this invention for reducing the permeability of a subterranean zone are comprised of the steps of introducing an aqueous composition according to the invention into a subterranean zone, and then allowing the aqueous composition to form a cross-linked gel in the zone. Preferably, the method includes the step of subsequently producing hydrocarbons from the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

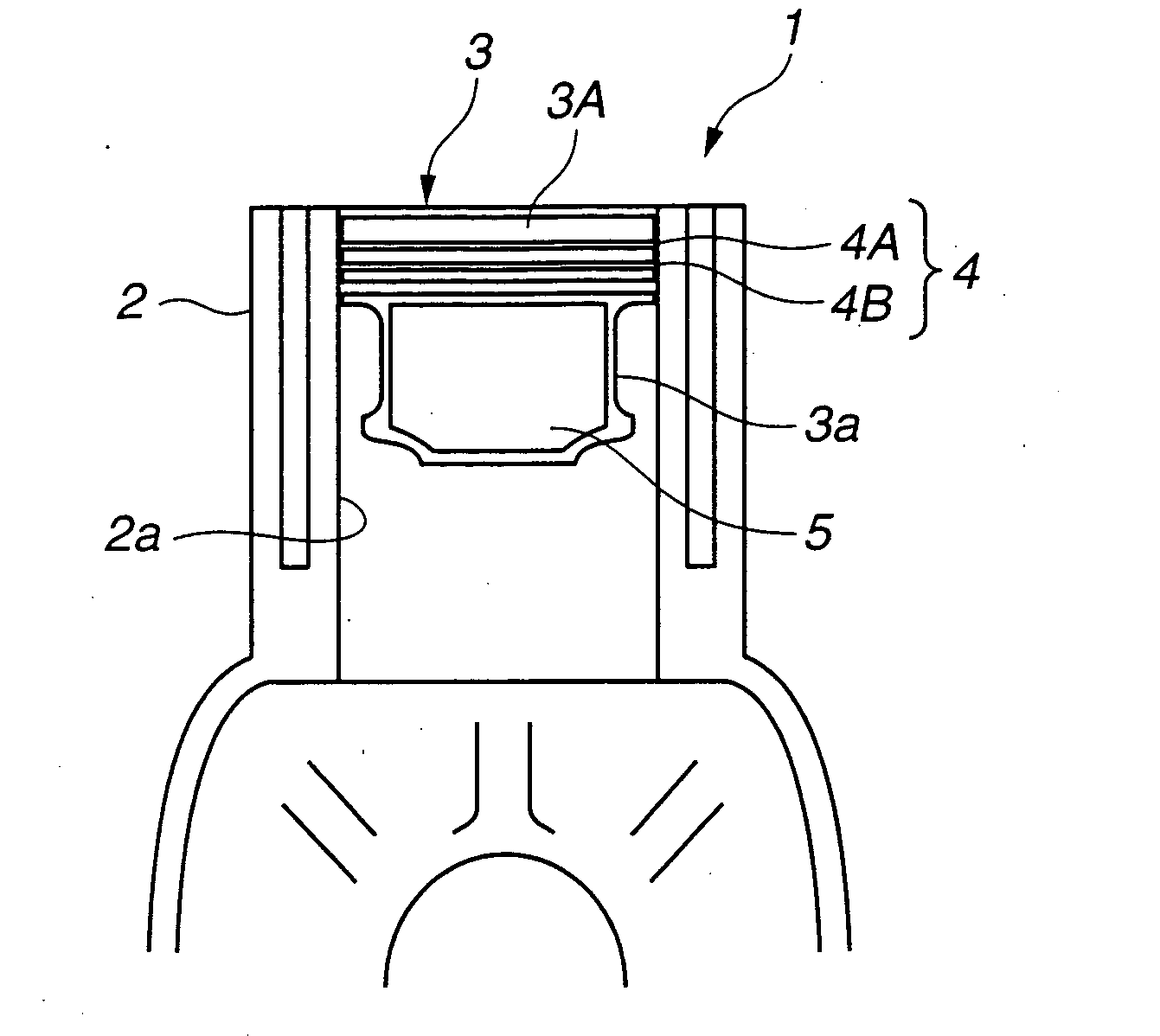

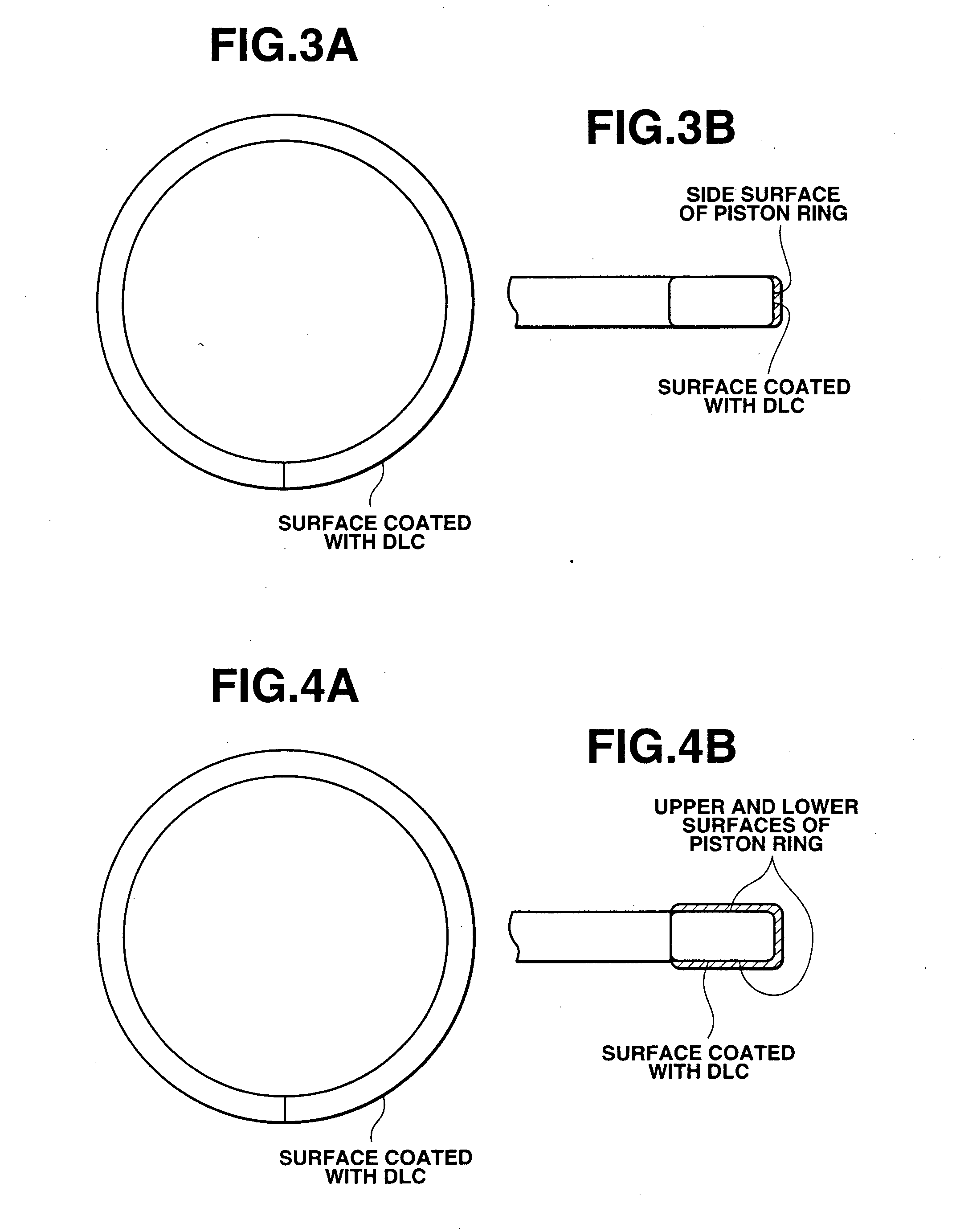

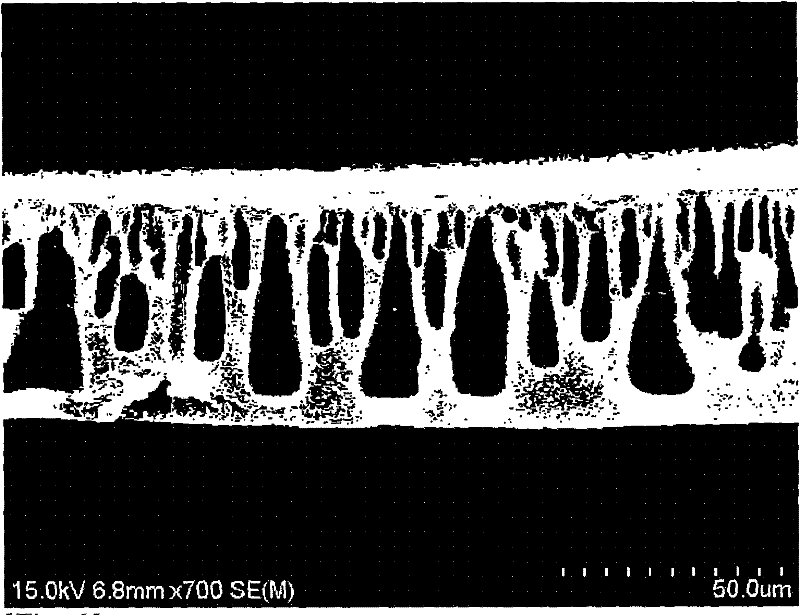

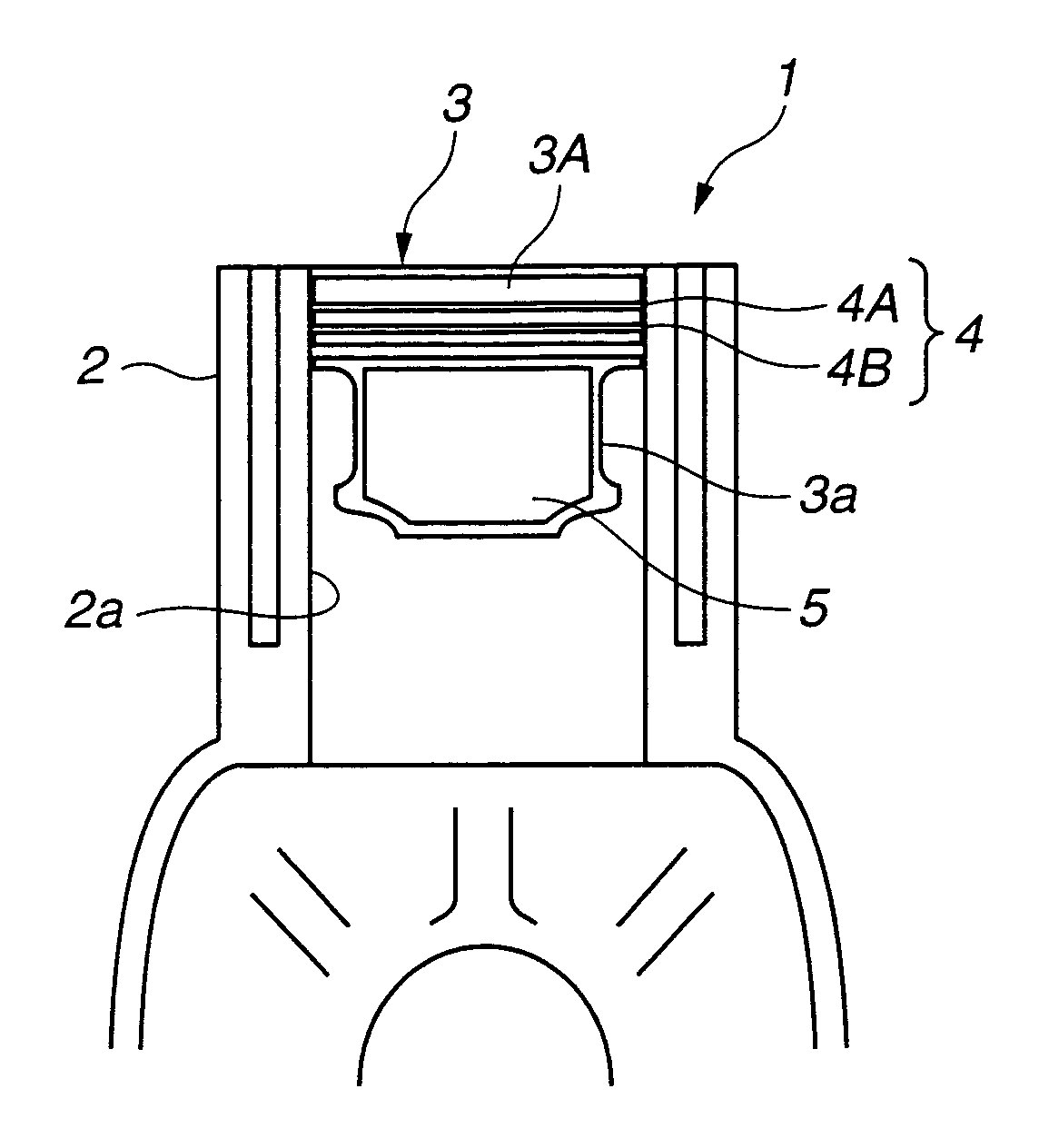

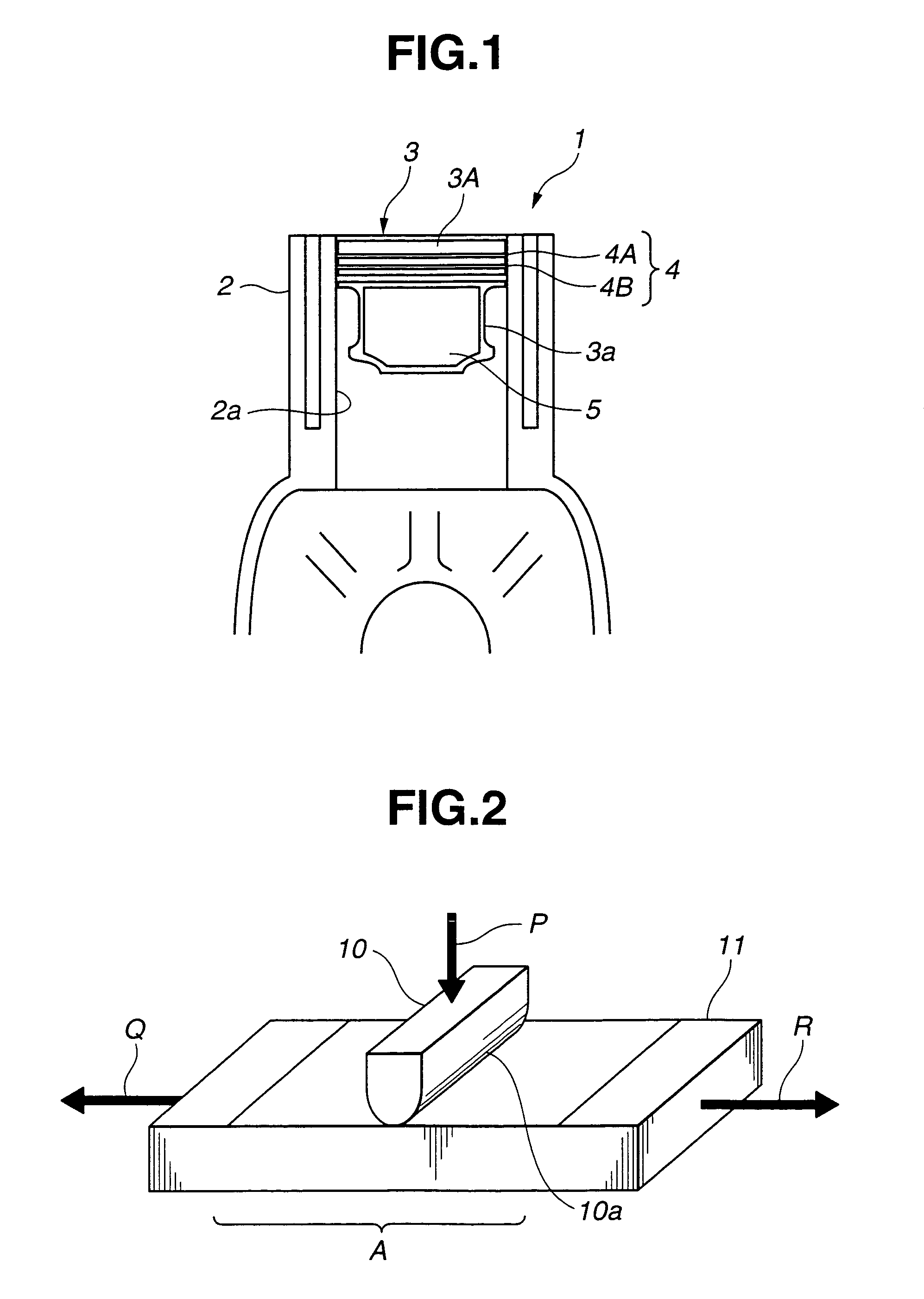

Piston for internal combustion engine

ActiveUS20050005892A1Excellent abrasion resistanceReduce coefficient of frictionCasingsPlungersPiston ringAliphatic amine

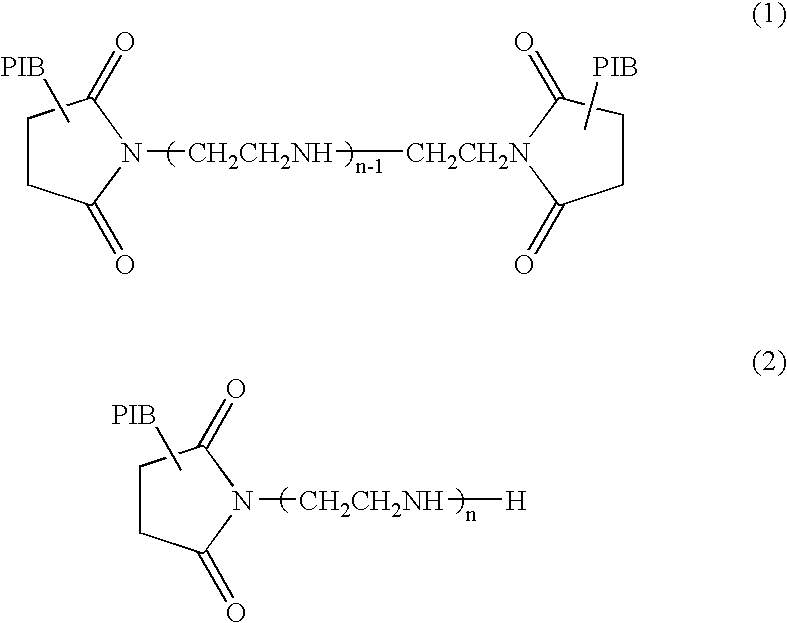

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

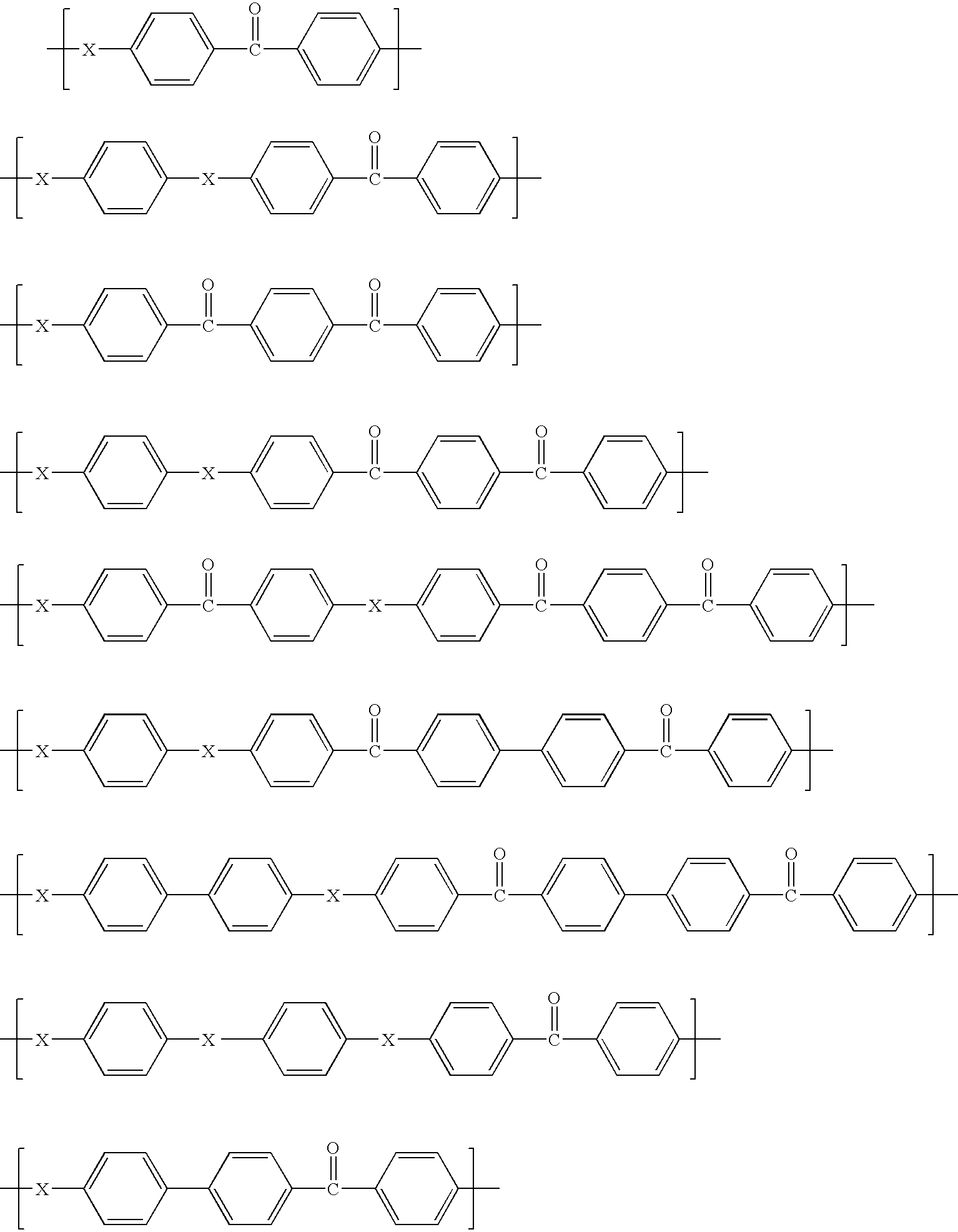

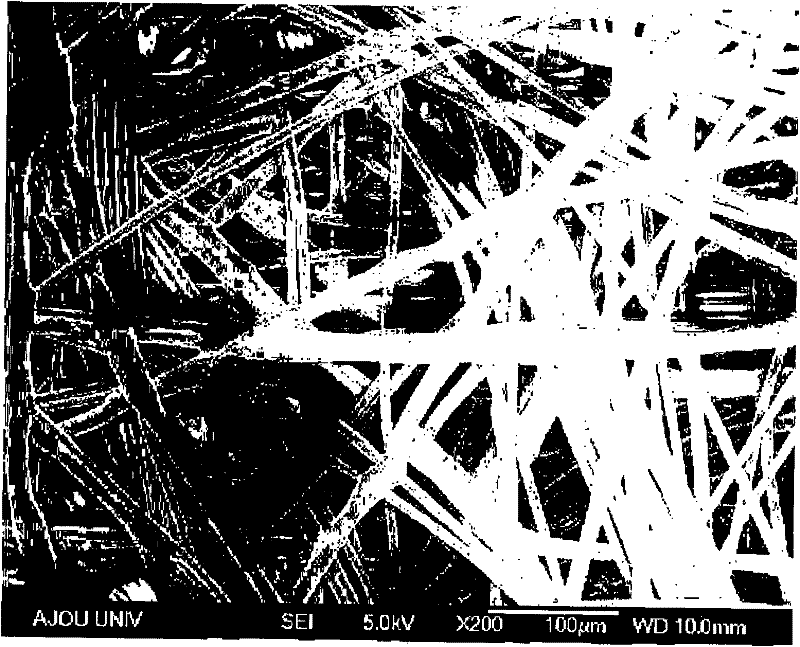

Functionalized porous poly(aryl ether ketone) materials and their use

ActiveUS20060094852A1Good chemical resistanceSimple and cost-effective and industrially feasibleMembranesSemi-permeable membranesPolymer scienceHydrazine compound

Functionalized porous poly(aryl ether ketone) articles are prepared by reacting ketone groups in the backbone of poly(aryl ether ketone) polymer with a primary amine reagent. Preferred functional primary amines are primary aliphatic amines or substituted hydrazines containing one or more target functional groups including polar groups, such as hydroxyl groups, ˜OH, amino groups, ˜NH2, ˜NHR, ˜NRR′, and ethylene oxide groups, ˜OCH2CH2—, negatively or positively charged ionic groups, such as ˜SO3−, ˜COO−, and ˜NH4+ groups, hydrophobic groups such as siloxane or perfluorcarbone groups, and non-polar groups, such as linear or branched hydrocarbon groups. The functionalized porous poly(aryl ether ketone) article can be prepared by reacting primary amine with a pre-formed, shaped porous poly(aryl ether ketone) article or by functionalizing the surface of a non-porous precursor article that is subsequently converted into a porous article.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

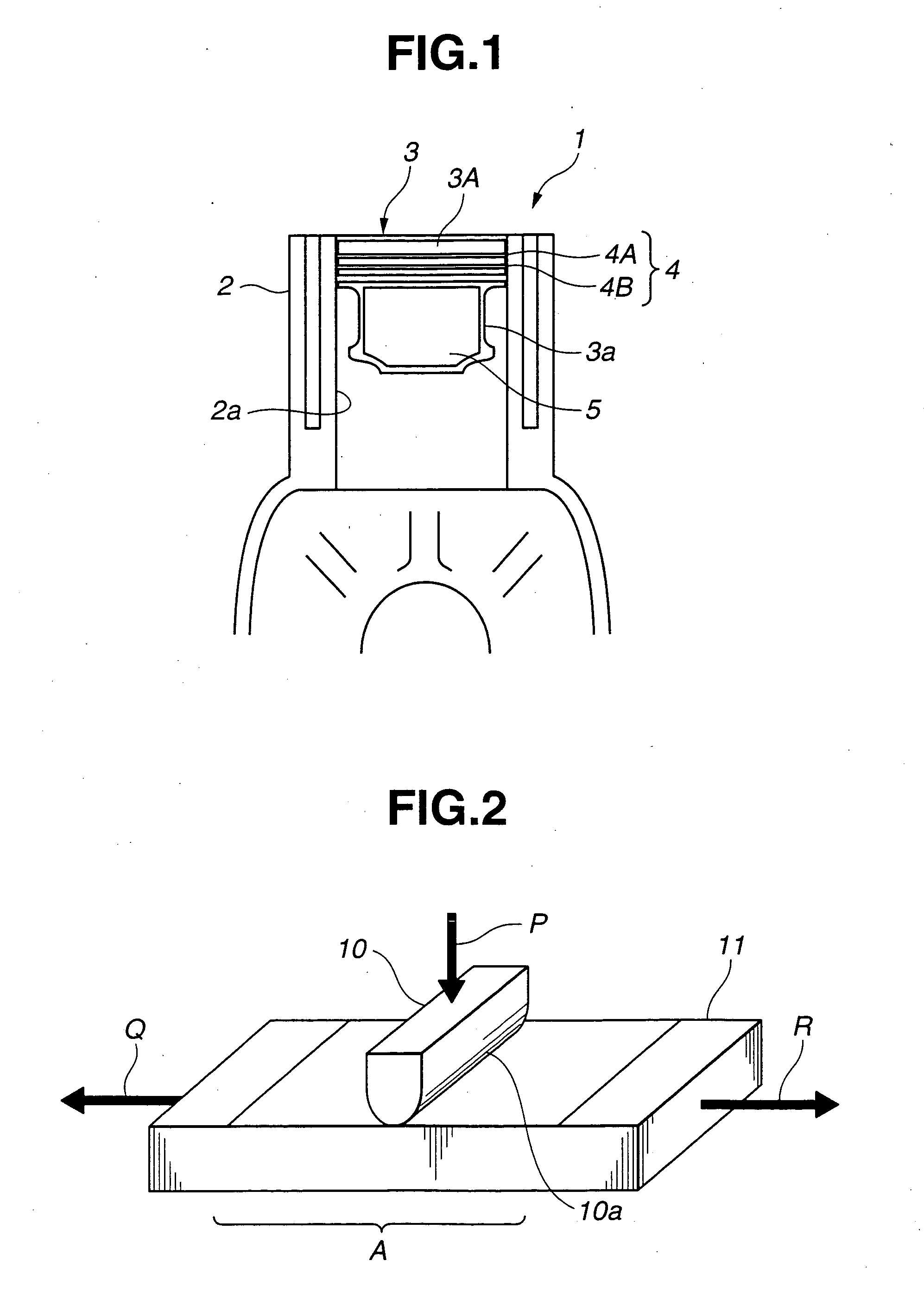

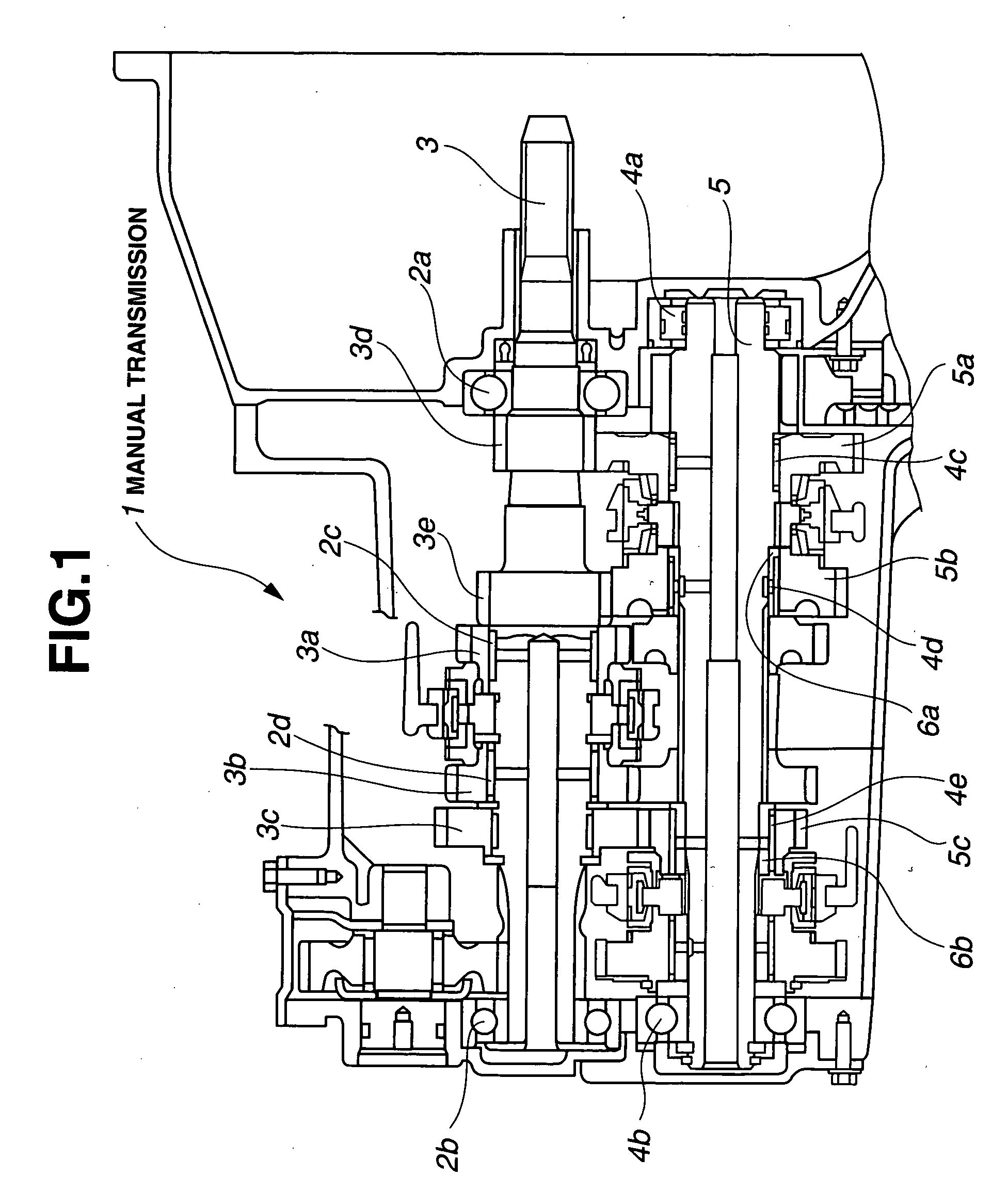

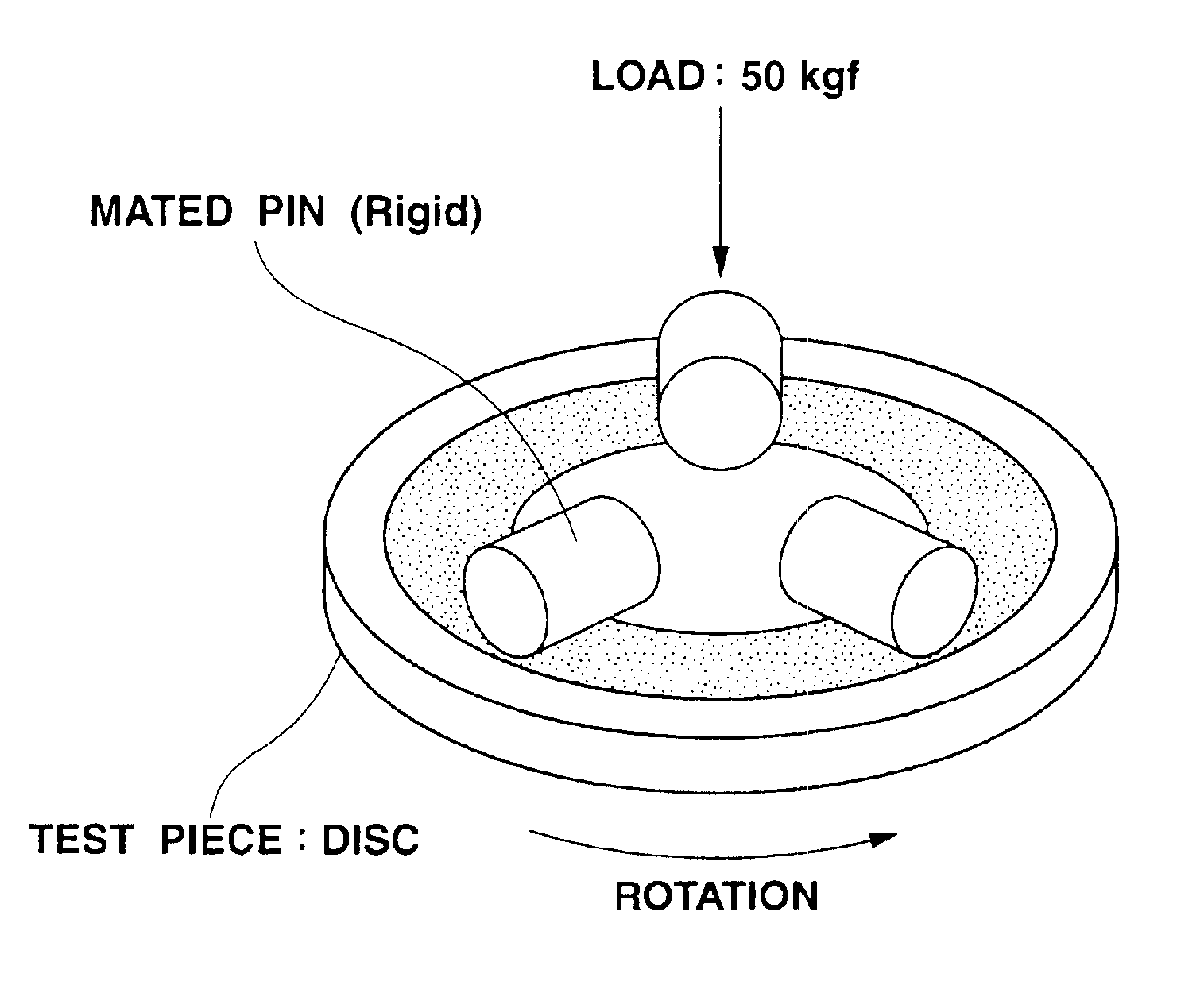

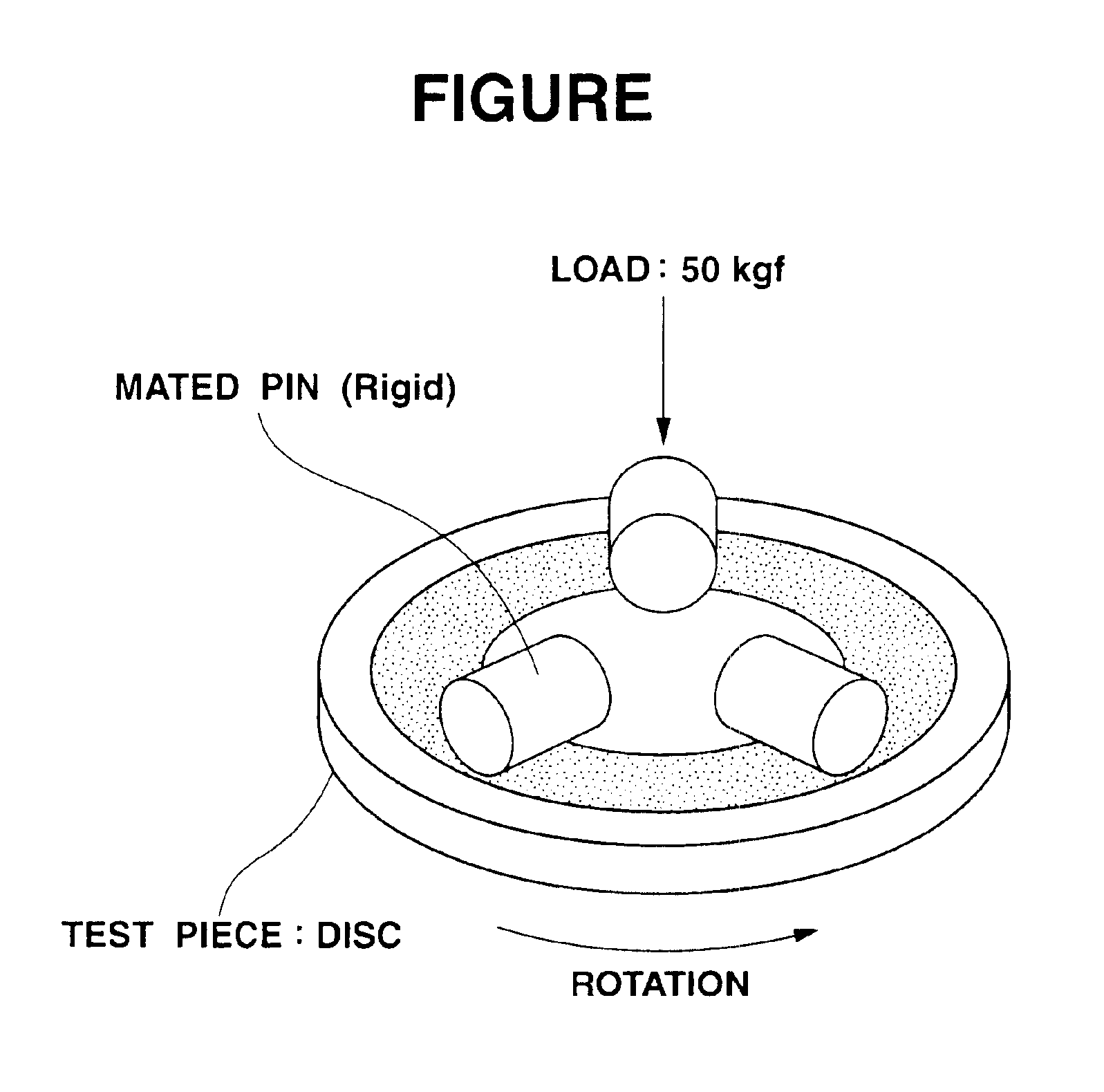

Low-friction sliding member in transmission, and transmission oil therefor

ActiveUS20050082139A1High in friction reduction effectLow friction propertiesToothed gearingsGear lubrication/coolingHydrogenAliphatic amine

A low-friction sliding member in a transmission is at least one of sliding members which are in slidable contact with each other in presence of a transmission oil composition. The low-friction sliding member includes a base material having a sliding section. A hard carbon thin film is coated at a sliding surface of the sliding section of the base material. The hard carbon thin film contains hydrogen in an amount not more than 20 atomic %. The transmission oil composition contains at least one of organic oxygen-containing compound and aliphatic amine compound.

Owner:NISSAN MOTOR CO LTD

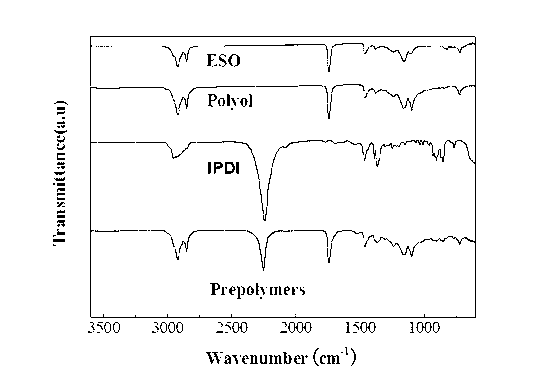

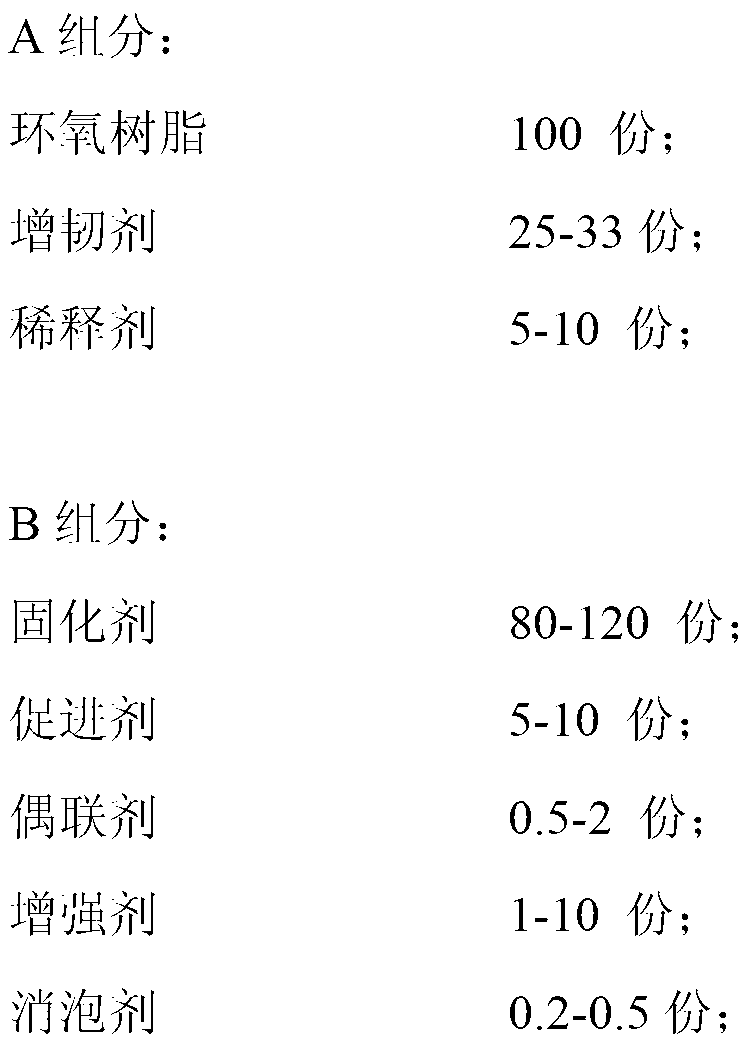

High-performance thermosetting epoxy resin adhesive for roads and bridges and preparation method thereof

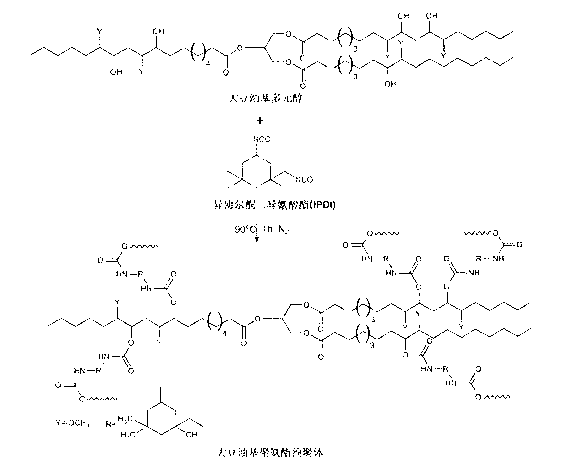

InactiveCN103160234AIncreased durabilityFast curing reactionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyBridge deck

The invention provides a high-performance thermosetting epoxy resin adhesive for roads and bridges. The adhesive comprises a component A and a component B, wherein, the component A comprises the following components in parts by mass: 100 parts of epoxy resin, 25 to 33 parts of flexibilizer, and 5 to 10 parts of diluent; the component B comprises the following components in parts by mass: 80 to 120 parts of curing agent, 5 to 10 parts of accelerant, 0.5 to 2 parts of coupling agent, 1 to 10 parts of reinforcing agent, and 0.2 to 0.5 part of antifoaming agent; and the ratio of the component A to the component B is 100:100-100:120. According to the adhesive, a flexible long-chain aliphatic amine serving as the curing agent has a curing reaction with the epoxy resin to form a solid crosslinking structure, so that the epoxy resin adhesive is high in adhesion capability and water resistance; The toughness of the epoxy asphalt adhesive is improved by adopting the soybean oil-based polyurethane to be adapted to the flexibility of a steel plate, and the soybean oil-based polyurethane containing massive hydroxyl has good compatibility with the epoxy resin. The adhesive is applicable to adhesion and waterproofing of steel bridge decks, viaducts, cement concrete bridge decks, tunnels, expressways and other decks. The invention discloses a preparation method of the high-performance thermosetting epoxy resin adhesive.

Owner:NANJING UNIV

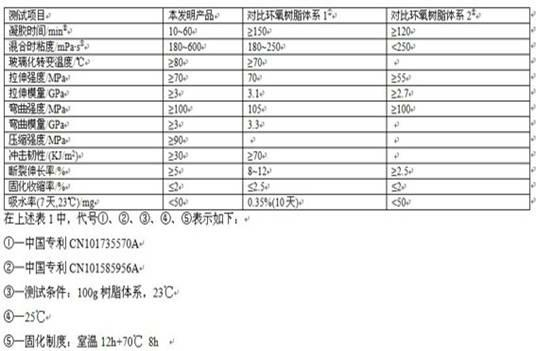

Fast curing epoxy resin system for blades of wind driven generator and preparation method thereof

The invention discloses a fast curing epoxy resin system for blades of a wind driven generator and a preparation method thereof. The fast curing epoxy resin system comprises a resin part and a curing agent part. The fast curing epoxy resin system is characterized in that the curing agent part includes a high-activity aliphatic amine curing agent, a high-activity aliphatic cyclic amine curing agent and a curing accelerating agent, and the proportion of the high-activity aliphatic amine curing agent to the high-activity aliphatic cyclic amine curing agent to the curing accelerating agent is (40-80): (10-50): (5-25) (in parts by weight). The fast curing epoxy resin system is formed by mixing the resin part with the curing agent part according to the proportion of 100: (20-40) in parts by weight. The invention greatly shortens the gel time under the condition of meeting the requirements for performance needed by the blades of the wind driven generator by adopting a method using the high-performance and high-activity amine curing agents and the curing accelerating agent in a mixing way; and the gel time of 100g of the fast curing epoxy resin system at a temperature of 23 DEG C is 10-60 minutes, thereby meeting the requirements for the application of the fast curing epoxy resin system for the blades of the wind driven generator of above a megawatt grade.

Owner:DONGFANG TURBINE CO LTD

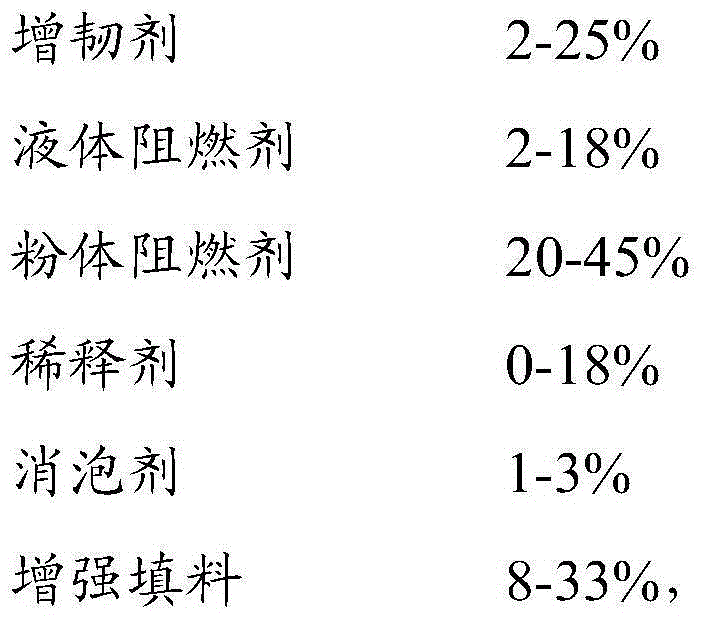

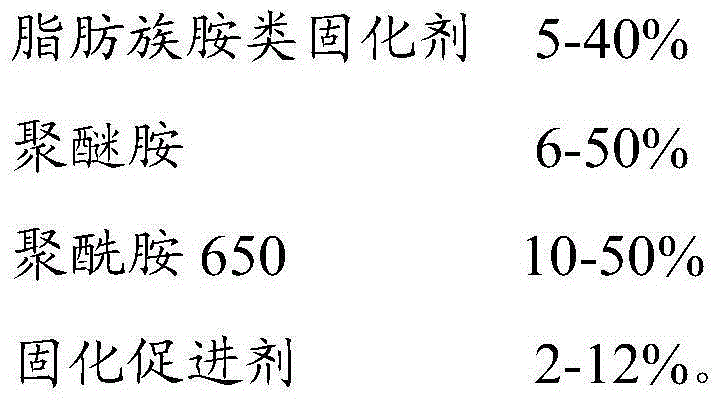

Two-component epoxy glue and preparation method thereof

ActiveCN105062395AReduced cured crosslink densityRelatively consistent viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAliphatic amine

The invention relates to two-component epoxy glue and a preparation method thereof. The two-component epoxy glue comprises a component A and a component B, and the component A comprises epoxy resin, a toughening agent, a liquid flame retardant, a powder flame retardant, a diluent, an antifoaming agent and reinforcing fillers; the component B comprises an aliphatic amine curing agent, polyether amine, polyamide 650 and a curing accelerator. According to the two-component epoxy glue and the preparation method thereof, screening is conducted on the components of the epoxy glue, performance complementation of the components is achieved, a two-component epoxy glue with excellent comprehensive performance is formed through synergetic cooperation, the toughness, the anti-stripping strength and the anti-impact performance of the epoxy glue are significantly improved, the flame-retardant performance can reach the grade UL94-V0, the operable time is more appropriate, the curing time is short, and the continuous production can be achieved.

Owner:GUANGZHOU BAIYUN CHEM IND

Semiconductor device with silicon dioxide layers formed using atomic layer deposition

InactiveUS20060040510A1High densityEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAliphatic amineImproved method

Improved methods are disclosed for catalyst-assisted atomic layer deposition (ALD) to form a silicon dioxide layer having superior properties on a semiconductor substrate by using a first reactant component consisting of a silicon compound having at least two silicon atoms, or using a tertiary aliphatic amine as the catalyst component, or both in combination, together with related purging methods and sequencing.

Owner:LEE JOO WON +3

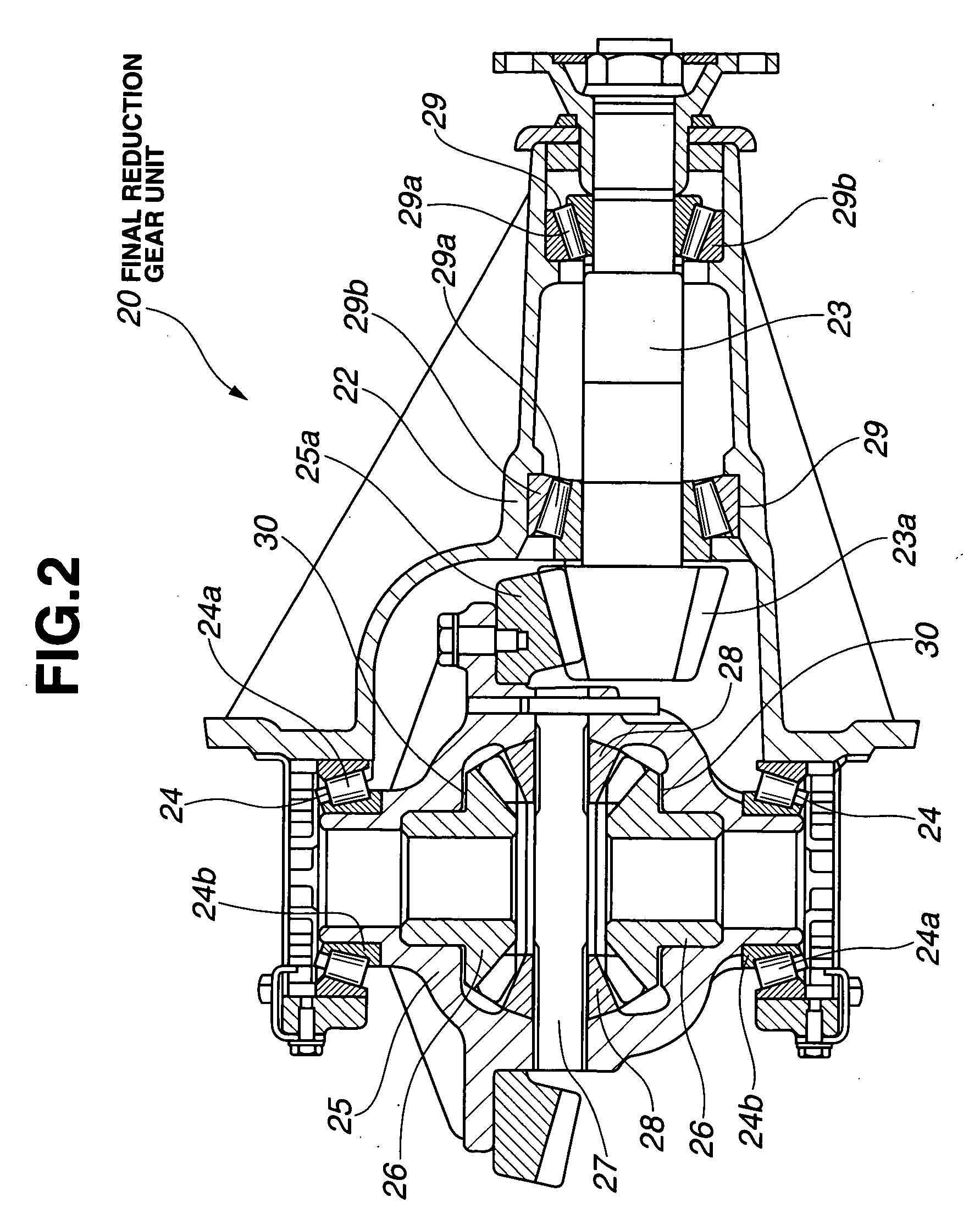

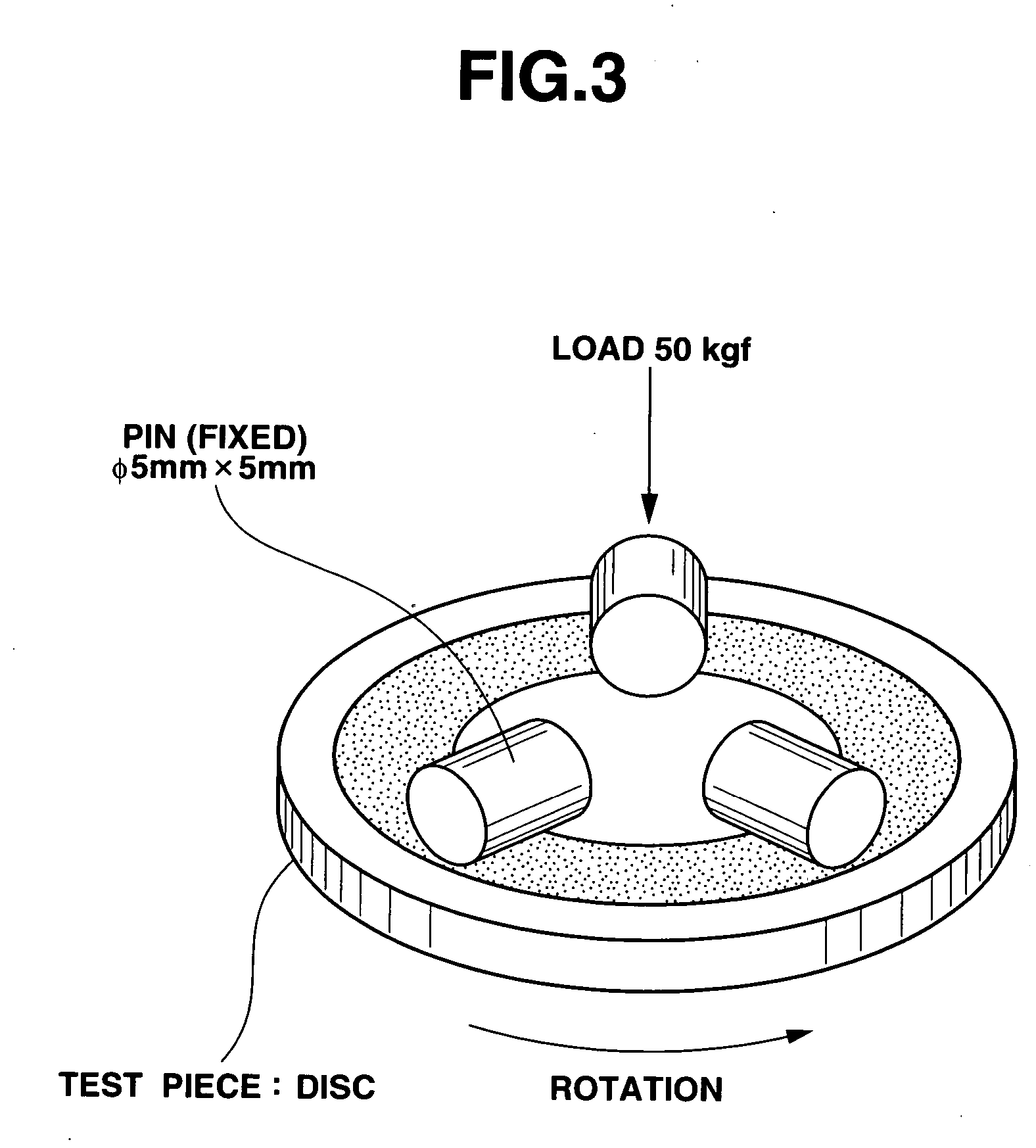

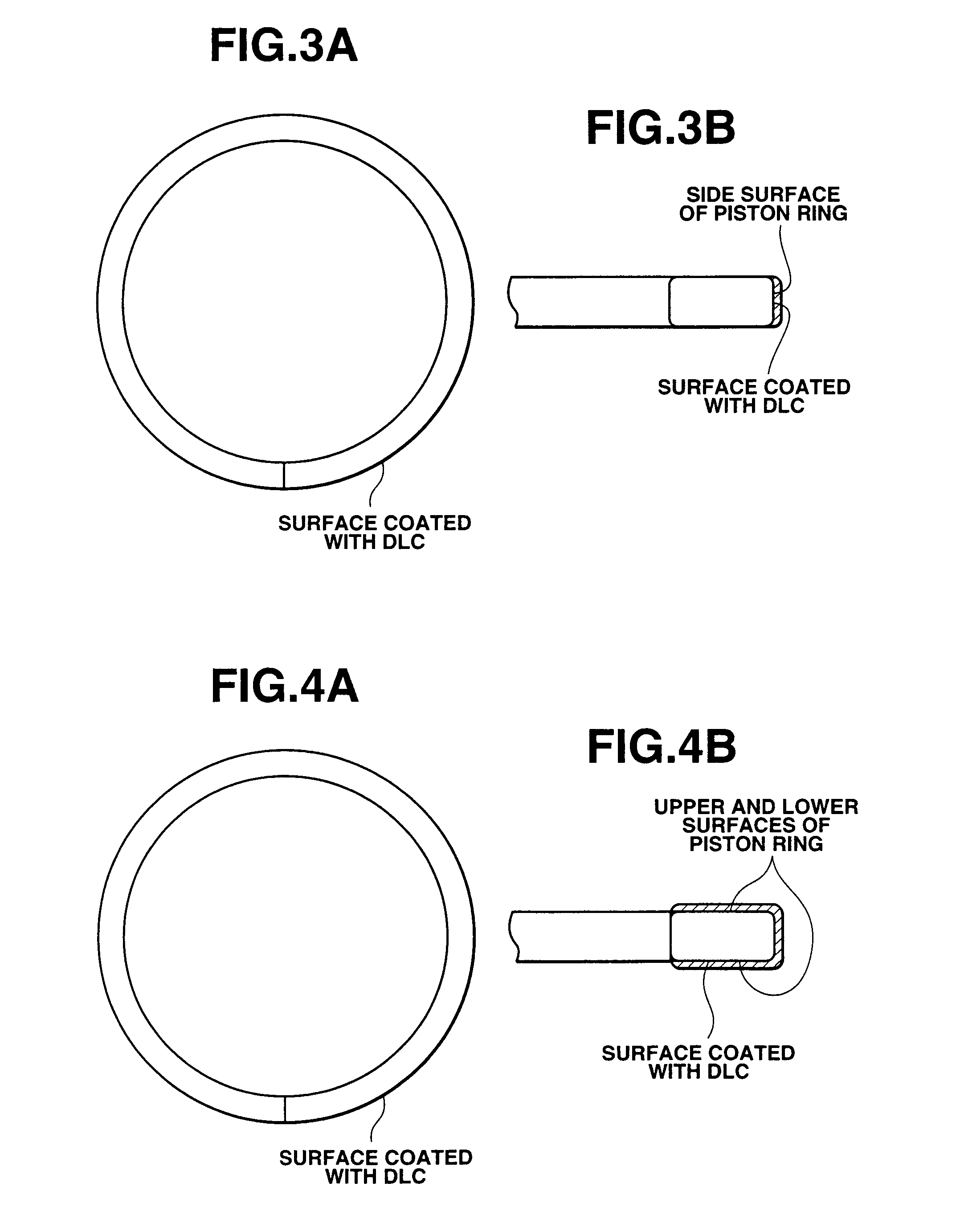

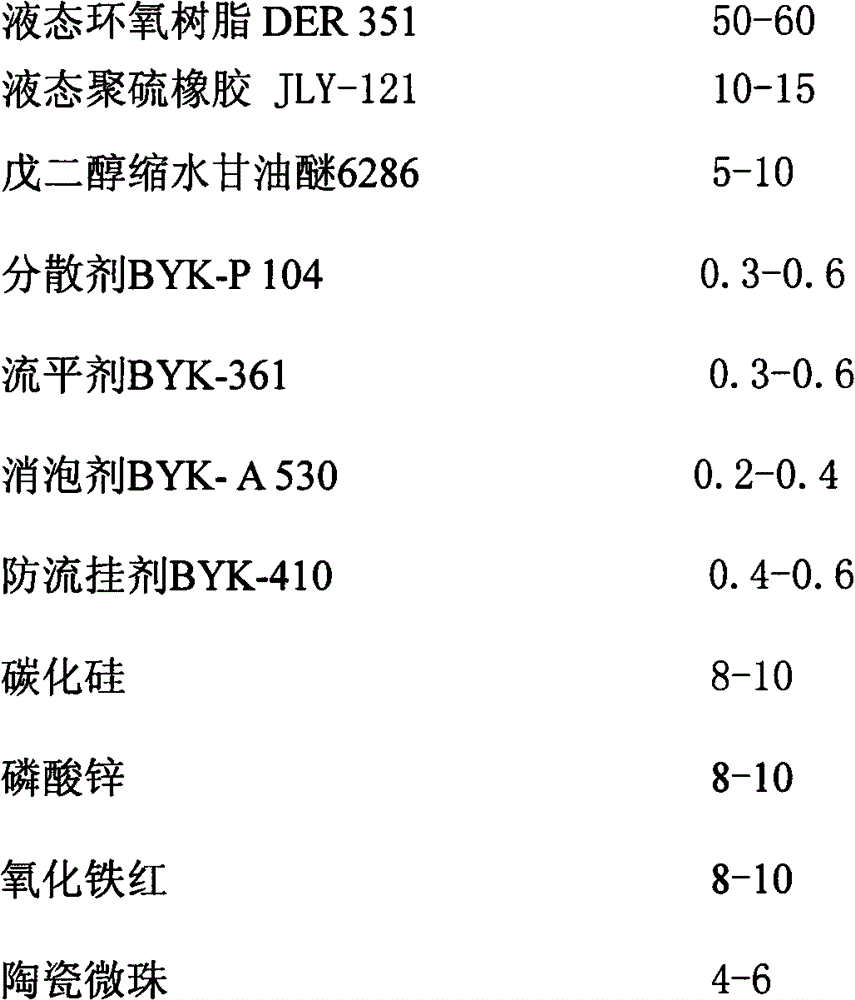

Low-friction sliding mechanism, low-friction agent composition and method of friction reduction

ActiveUS20060263604A1Reduce coefficient of frictionImprove fuel efficiencyCrankshaftsGear lubrication/coolingSimple Organic CompoundsFriction reduction

The invention provides a low-friction sliding mechanism, a low-friction agent composition, a friction reduction method, a manual transmission and a final reduction gear unit that can exert very excellent low friction characteristics to sliding surfaces present under various applications, and, in particular, that have more excellent low friction characteristics than that of a combination of an existing steel material and an organic Mo compound. The low-friction sliding mechanism has an oxygen-containing organic compound or an aliphatic amine compound interposed between sliding surfaces that a DLC coated sliding member and a sliding member form. The low-friction agent composition contains an oxygen-containing organic compound or an aliphatic amine compound. The friction reduction method includes supplying the low-friction agent composition between sliding surfaces that a DLC coated sliding member and a sliding member form. The manual transmission includes, as at least one of sliding members, a DLC coated sliding section. The final reduction gear unit includes, as at least one of sliding members, a DLC coated sliding section.

Owner:NISSAN MOTOR CO LTD +2

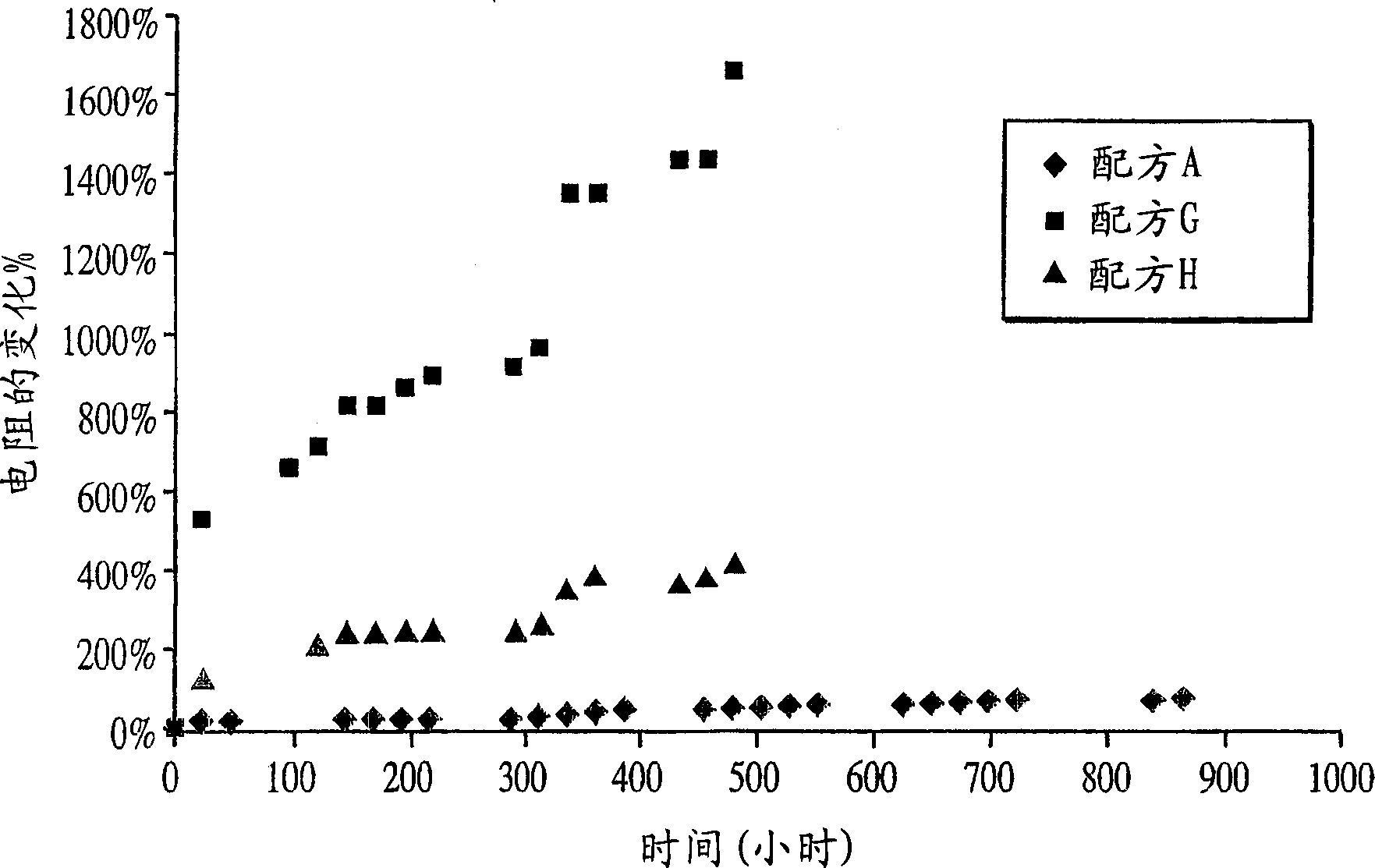

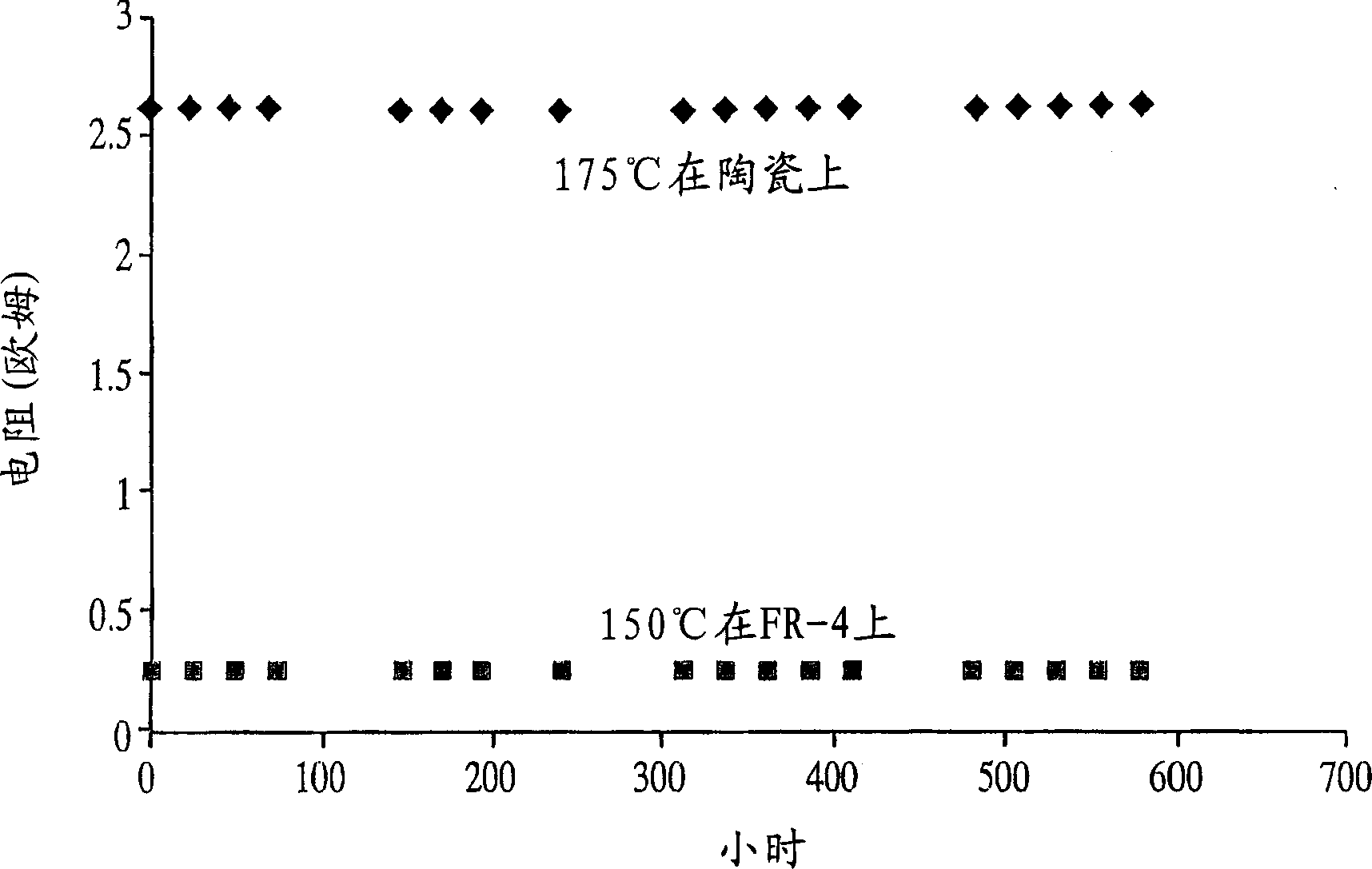

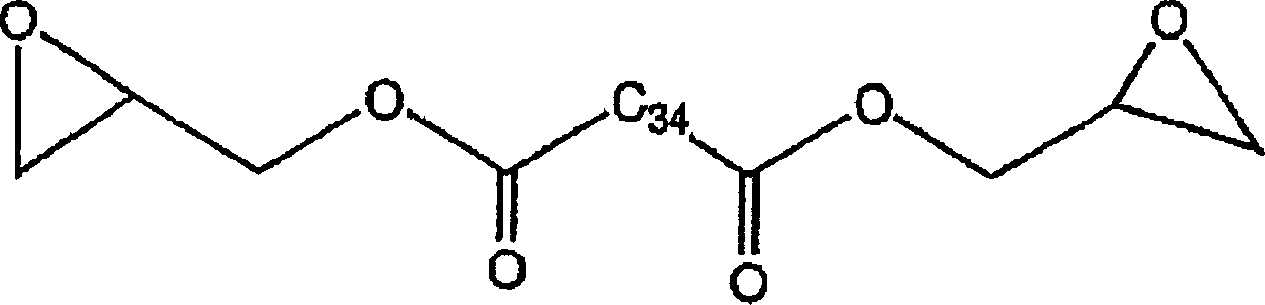

Conductive adhesive compositions with electrical stability and good impact resistance for use in electronics devices

InactiveCN1788062AStable shelf lifePrinted circuit assemblingSolid-state devicesPolymer sciencePtru catalyst

A composition that comprises a) an admixing of at least one epoxy resin and aliphatic amine wherein the ratio of epoxy function group / amine is greater than 1; b) a conductive filler; c) one or more corrosion inhibitors, oxygen scavengers or both; d) imidazole as a curing agent / catalyst; and e) optionally other additives such as organic solvents, flow additives, adhesion promoters and rheology modifiers. The reaction of epoxy and aliphatic amine with excess epoxy functionality results in a flexible resin with remaining active epoxy groups. The compositions exhibit improved electrical stability and impact resistance over other conductive adhesive compositions that do not comprise the admixture.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Low-friction sliding mechanism

ActiveUS6969198B2Increase resistanceReduce coefficient of frictionCrankshaftsCrossheadsDiamond-like carbonAliphatic amine

A low-friction sliding mechanism includes first and second sliding members having respective sliding surfaces slidable relative to each other and a lubricant applied to the sliding surfaces of the first and second sliding members. At least the sliding surface of the first sliding member is made of a diamond-like carbon material, and at least the sliding surface of the second sliding member is made of either an aluminum-based alloy material, a magnesium-based alloy material or a diamond-like carbon material. The lubricant contains a base oil and at least one of an ashless fatty-ester friction modifier and an ashless aliphatic-amine friction modifier.

Owner:NISSAN MOTOR CO LTD +1

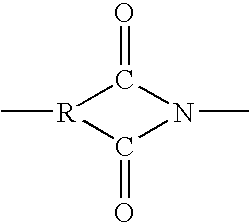

Process for production of isocyanate, isocyanate produced by the process, and use of the isocyanate

ActiveCN101203488AGood pipettingImprove productivityIsocyanic acid derivatives preparationOrganic compound preparationProduction ratePolyisocyanurate

The present invention provides a method for producing isocyanate, which is preferably used in the field of optical materials and is widely used as a raw material for polyurethane-based materials and polyisocyanurate-based materials, including a process capable of improving the productivity of hydrochloride . The manufacturing method of chain aliphatic isocyanate or cycloaliphatic isocyanate of the present invention comprises making chain aliphatic amine or cycloaliphatic amine and hydrogen chloride reaction, obtains chain aliphatic amine hydrochloride or cycloaliphatic amine A method for producing a chain aliphatic or cyclic aliphatic isocyanate according to a hydrochloride step, wherein the step is carried out at a pressure higher than atmospheric pressure by 0.01 MPa or more.

Owner:MITSUI CHEM INC

Wind-power class bi-component epoxy adhesive and preparation method thereof

InactiveCN101550325AQuick releaseAvoid high temperature damageModified epoxy resin adhesivesAliphatic amineResin adhesive

The invention discloses a wind-power class bi-component epoxy adhesive and a preparation method thereof. The epoxy adhesive is made from a main component A mainly consisting of epoxide resin and a filler and a curing agent component B and characterized in that the component A, according to percentage by weight, contains 50 percent to 68 percent of acrylic acid modified epoxide resin, 1 percent to 10 percent of high-property heat filler, 2 percent to 10 percent of epoxide diluter, 10 percent to 25 percent of thixotropic agent and 0.5 percent to 12.5 percent of additive, and the component B is divided into aliphatic amine, polyetheramine, alicyclic amine mixed-type general curing agent; and the mixing proportion of the component A and the component B is 100:30-100:50 according to portions by weight. The invention can improve exothermic peak temperature property during the curing reaction of epoxide resin adhesive and the toughness of the epoxy adhesive, thus being applicable to the cementation of large-scale composite material structural pieces, particularly meeting the requirements for low exothermic peak temperature in wind-power leaf pectization technology.

Owner:YANTAI DARBOND TECH

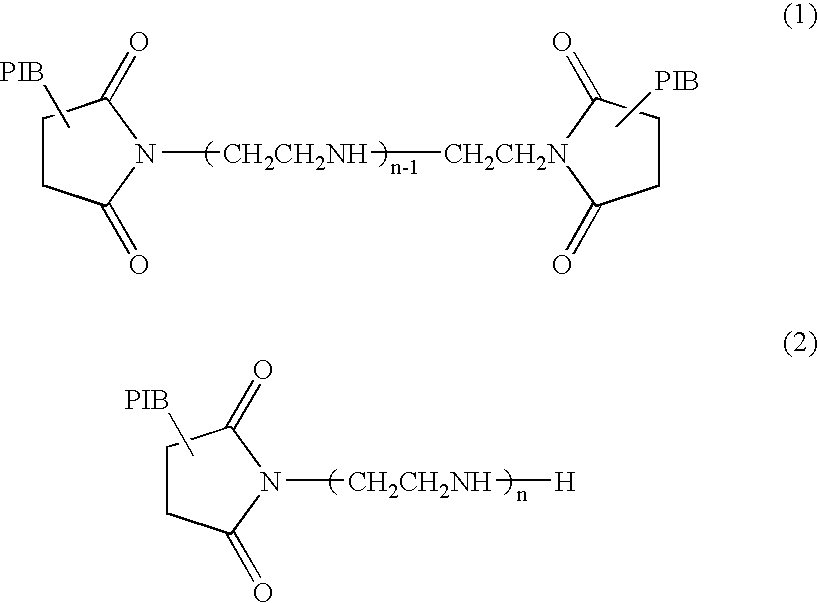

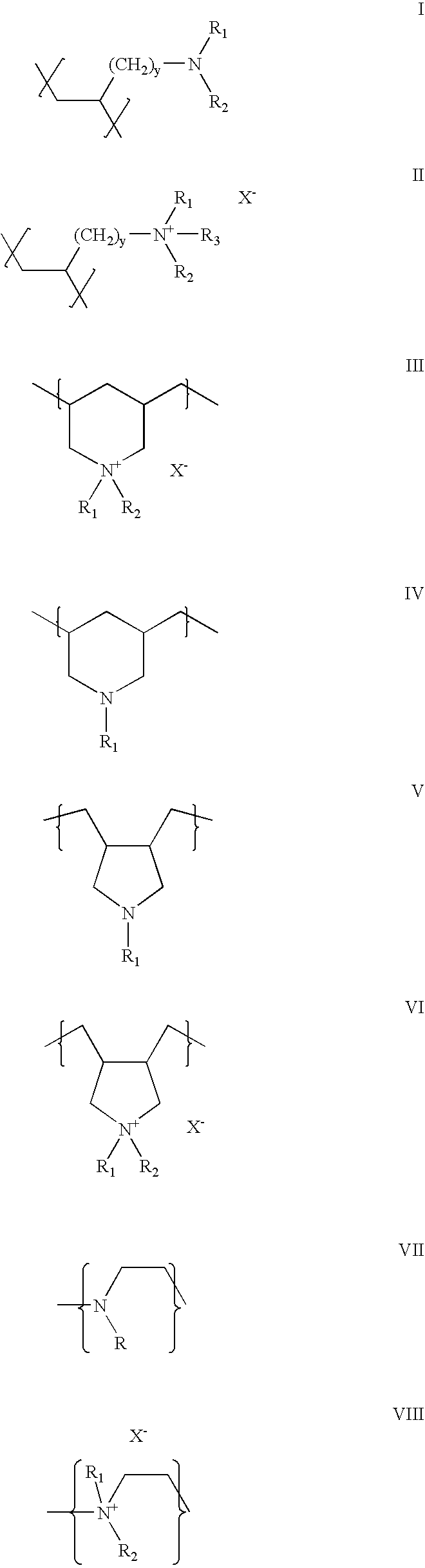

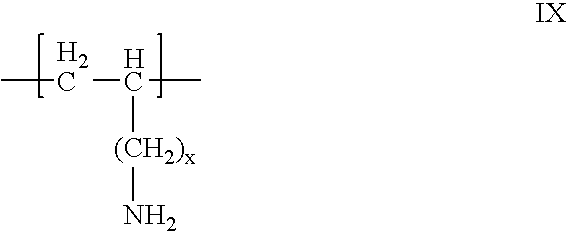

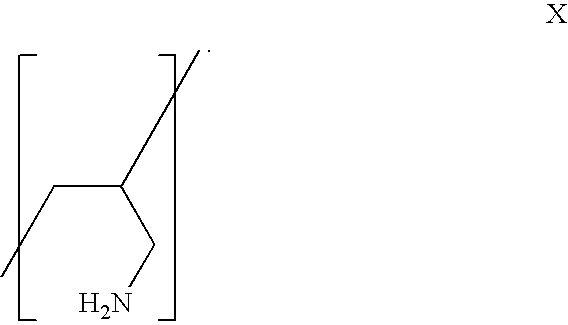

Aliphatic amine polymer salts for tableting

ActiveUS20060251614A1Large particle sizeExtended shelf lifeMetabolism disorderInorganic non-active ingredientsNephrosisAliphatic amine

The tablets, compositions and methods of the present invention, comprising a carbonate salt of an aliphatic amine polymer and s monovalent anion can prevent or ameliorate acidosis, in particular acidosis in patients with renal disease. The tablets and compositions of the present invention maintain a disintegration time of no greater than 30 minutes at 37° C. and at pH of at least 1 for a period of at least ten weeks at 60° C. Furthermore, the tablets are stable for extended periods of time without the need for specialized storage conditions.

Owner:GENZYME CORP

Lubricating grease special for constant-speed universal joint and preparing method thereof

ActiveCN101575548AImprove performanceImprove water resistanceThickenersAdditivesAntioxidantFriction modifier

The invention relates to lubricating grease special for a constant-speed universal joint and a preparing method thereof. The lubricating grease comprises base oil and thickener which is compounded by lithium-calcium composite and uramido composite, and the lubricating grease also contains: (a) borate extreme pressure anti-wear agent, (b) aliphatic amine derivative multi-effect friction modifying agent, (c) phosphoric extreme pressure anti-wear agent, (d) diphenylamine antioxidant and (e) viscosity index improver; wherein the base oil is mineral oil that accounts for 70 to 95 percent of the total weight of the lubricating grease, synthetic oil or the mixture of the mineral oil and the synthetic oil in optional proportion. The thickener which is compounded by the lithium-calcium composite and the uramido composite accounts for 1 to 25 percent of the total weight of the lubricating grease; and the lubricating grease has excellent extreme pressure anti-wear property, thermal stability, oxidation stability, water resisting property, mechanical stability, shear stability, anticorrosion property, and the like, and the lubricating grease can meet the lubricating demands of the constant-speed universal joint of automobiles and has low cost and high efficiency.

Owner:杭州得润宝油脂股份有限公司

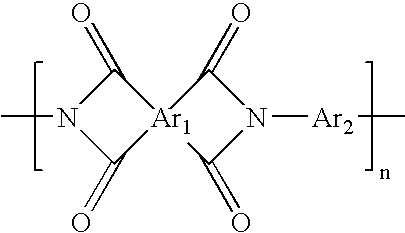

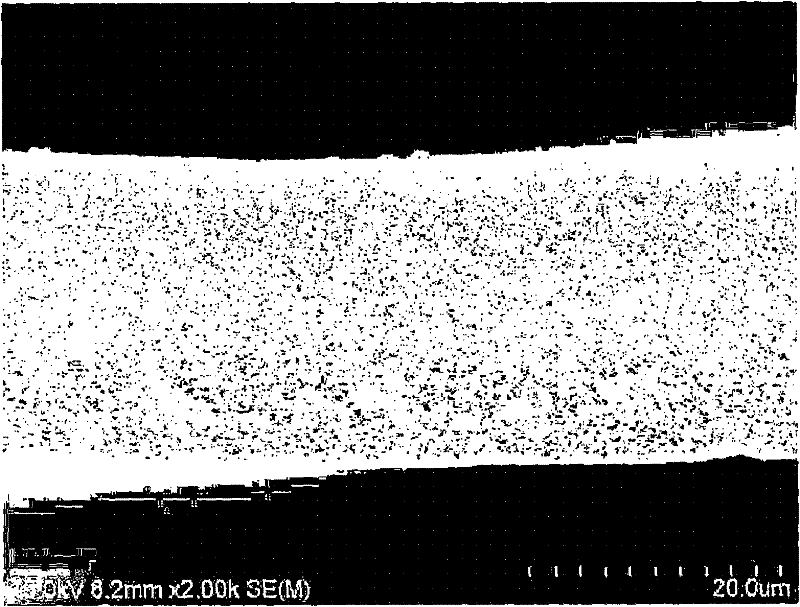

Forward osmosis membrane having high flux for removing salt from sea water and manufacturing method threrof

ActiveCN102665882APollution minimizationEasy inflowSemi-permeable membranesMembranesPolymer sciencePolyamide

The forward osmosis membrane of high flux for desalinating seawater and a method for manufacturing the same are provided to minimize the reverse diffusivity of salt by applying hydrophilicity to a polysulfone-based hydrophobic membrane. CONSTITUTION: The forward osmosis membrane of high flux for desalinating seawater is the structure of a composite membrane. The composite membrane is composed of a non-woven fabric layer, a hydrophilic polymer support layer, and a polyamide layer. The hydrophilic polymer support layer includes 0.1 to 10 weight% of sulfonated polysulfone-based polymer represented by chemical formula 1. In chemical formula 1, A is selected from chemical formula 2; B is selected from chemical formula 3; m divides the sum of n and m is between 0.2 and 0.7; and x is between 50 and 2,300. A method for manufacturing the forward osmosis membrane includes the following: a hydrophilic polymer containing solution is doped on the non-woven fabric layer to form the hydrophilic polymer support layer; the polyamide layer is formed on the surface of the hydrophilic polymer support layer by contacting a polyfunctional acid halide compound containing organic solution with an aqueous solution containing polyfunctional amine or alkylated aliphatic amine.

Owner:TORAY ADVANCED MATERIALS KOREA

Piston for internal combustion engine

ActiveUS7406940B2Increase resistanceReduce coefficient of frictionCasingsPlungersHydrogen atomPiston ring

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

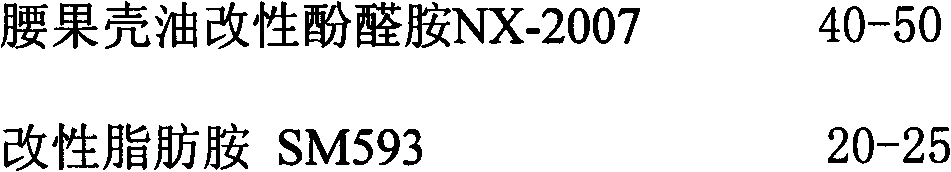

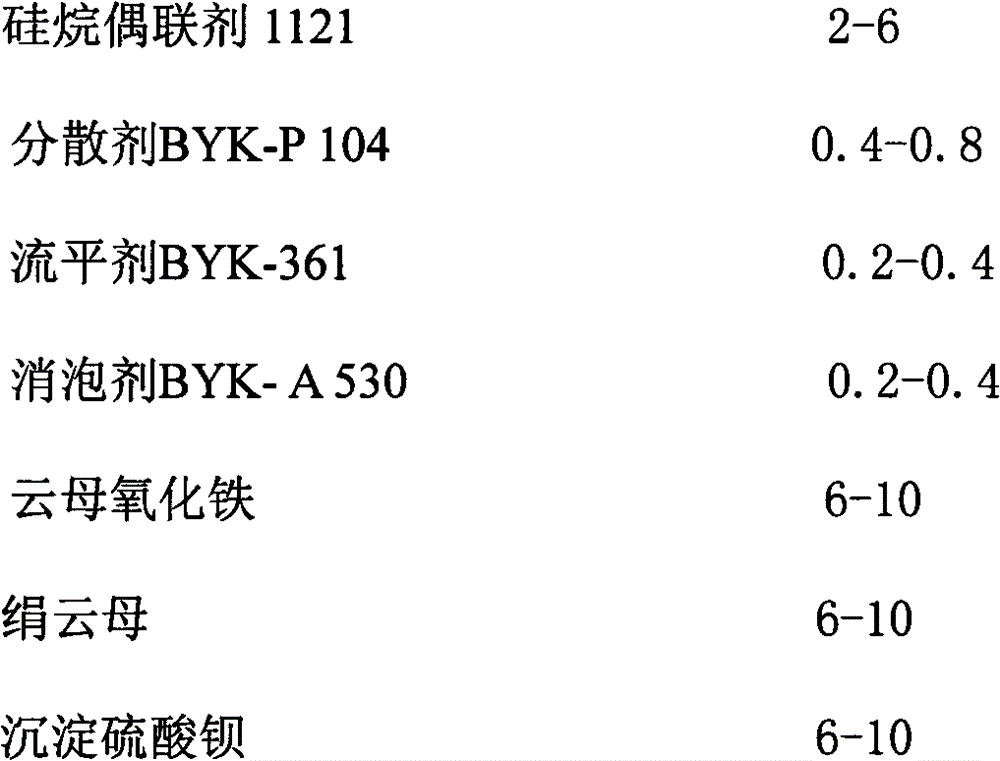

Epoxy anti-corrosive paint used for underwater concrete

InactiveCN102719173AStrong adhesionExcellent abrasion resistanceAnti-corrosive paintsEpoxy resin coatingsMicrosphereSolvent free

The invention discloses epoxy anti-corrosive paint used for underwater concrete. Liquid epoxy resin DER351 is used as a base material; polysulfide rubber is used as a flexibilizer; pentanediol diglycidyl ether 6286 is used as a diluent; zinc phosphate and iron oxide red are used as active anti-corrosive pigment; spherical silicon carbide, ceramic microspheres, mica iron oxide, sericite and precipitate vitriolic barium are used as fillings; cashew shell oil, modified phenolic aldehyde amine and modified aliphatic amine are used as curing agents; and a silane coupling agent 1121 is used as an adhesion promoter. With the cooperation of functional promoters, the raw materials are made into solvent-free double-component epoxy anti-corrosive paint used for underwater concrete through conventional preparation technique equipment. The epoxy anti-corrosive paint used for underwater concrete is highly environmental-friendly and can be directly painted or smeared on damp interfaces of underwater concrete and rapidly solidified into films; the coating has great adhesion and strong abrasion resistance and corrosion prevention. The epoxy anti-corrosive paint used for underwater concrete is widely applied to the corrosion prevention of various underwater concrete facilities.

Owner:北京国泰瑞华精藻硅特种材料有限公司

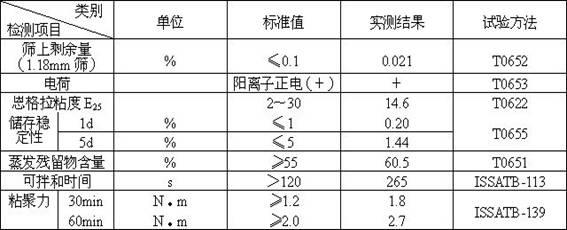

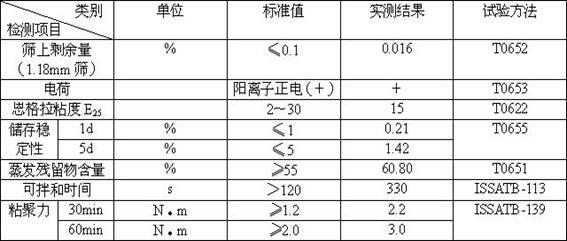

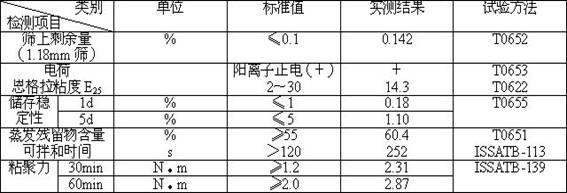

Technology for synthesizing bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier

InactiveCN102580607AWide applicabilityGood emulsifying effectTransportation and packagingMixingQuaternary ammonium cationDistillation

The invention relates to a technology for synthesizing a bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier. The technology comprises the steps of: (1) adding mixed fatty acid, long-chain aliphatic amine, an aromatic hydrocarbon solvent and a catalyst in a reaction vessel for backflow reaction, then removing the solvent through reduced pressure distillation, cooling and adding an alcohol solvent to obtain an amide or multi-acyl amide intermediate; (2) mixing aliphatic tertiary amine with hydrochloric acid, then dripping epoxy chloropropane, mixing for a reaction and cooling to a room temperature to obtain a quaternary ammonium salt intermediate; and (3) dripping the quaternary ammonium salt intermediate into the amide or multi-acyl amide intermediate for reaction so as to obtain the bisquaternary ammonium salt type cationic asphalt emulsifier. The technology for synthesizing the bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier, disclosed by the invention, has the advantages of wide raw material source, high cost performance, wide application range and convenience in popularization and application. The asphalt emulsion has uniform and fine particles and good storage stability; and wide slow-breaking quick-setting use performances can be obtained.

Owner:WUHAN UNIV OF TECH

Method for massively preparing overlength copper nanowires

The invention relates to a method for massively preparing overlength copper nanowires. The method comprises the following steps of: using metal copper salt as a copper source; using alkyl aliphatic amine as a directing agent and a reducing agent; using polyethylene glycol and polyvinylpyrrolidone as an auxiliary agent; using mixed liquid of polyalcohol, water and dimethylformamide as a solvent; uniformly mixing several reactants and the solvent; transferring the mixture to a flask; and heating the mixture until the mixture is boiling and flowing back, and obtaining copper nanowires after a certain time. The copper nanowires have the advantages of uniform feature, high purity and good monodispersity; the cost is relatively lower, and the reversal device is simpler; the feature is controllable, and the size regulation range is wide, so that the large-scale production of the copper nanowires is realized, and the method has the industrialization prospect.

Owner:珠海纳金科技有限公司

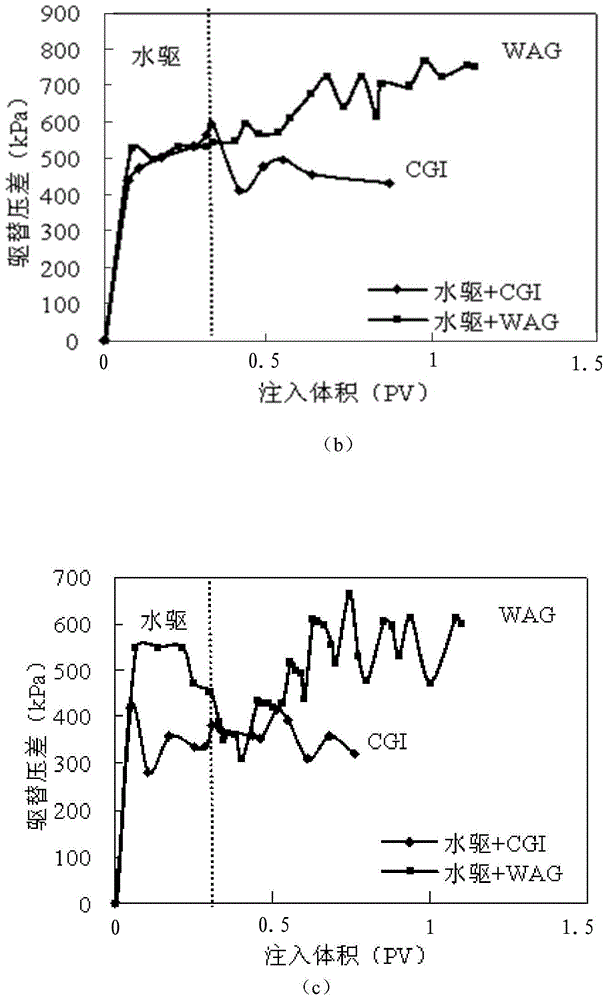

Carbon dioxide drive oil reservoir production method capable of realizing stage control on fluidity

ActiveCN104975829AExpand the affected volumeImprove mobility ratioFluid removalSealing/packingAliphatic amineProcess engineering

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Refrigerating-machine oil composition and compressor and refrigerating apparatus both employing the same

ActiveUS20090082232A1Improve the lubrication effectPositive displacement pump componentsCompression machines with non-reversible cycleHeat deflection temperatureAliphatic amine

Owner:IDEMITSU KOSAN CO LTD

Surface-coated metal nanoparticles, method for producing the same, and metal nanoparticle paste comprising the same

InactiveUS20120048426A1Good dispersionEasily pyrolyzedMaterial nanotechnologyLiquid surface applicatorsAliphatic amineFatty acid

Surface-coated metal nanoparticles comprising:metal nanoparticles having an average particle diameter of 1 to 100 nm, and an organic coating film provided on a surface of each of the metal nanoparticles, whereinthe organic coating film comprises a fatty acid having 8 or more carbon atoms and an aliphatic amine having 8 or more carbon atoms, anda molar ratio of the aliphatic amine to the fatty acid is aliphatic amine / fatty acid from 0.001 / 1 to 0.2 / 1.

Owner:TOYOTA CENT RES & DEV LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com