Conductive adhesive compositions with electrical stability and good impact resistance for use in electronics devices

A composition and conductive technology, applied in the field of interconnected compositions, can solve the problems of poor impact resistance of conductive adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Preparation of samples of prepolymers and samples of epoxy-amine system physical mixtures. A physical mixture of epoxy resin and amine (component A) was prepared by adding 55.56% by weight of a diglycidyl ether of bisphenol-A and a diglycidyl ether of bisphenol-F (from Tohto Kasei Co. .A mixture of commercially available ZS1059) and 44.44% by weight of poly(oxy(methyl-1,2-ethanediyl), α-(2-aminomethylethyl)ω-2(2-amino Methylethoxy) (commercially available as Jeffamine® D-2000 from Huntsman Petrochemical Co.). The prepolymer (component B) was obtained by heating the physical mixture in a conventional oven at 120° C. for 6 hours .Components A and B were detected with IR spectroscopy and component B was at a wavelength of 3439em -1 Absorption peaks are shown at , which indicates the presence of hydroxyl functional groups in the sample. Component A does not have a wavelength of 3439cm -1 shows an absorption peak at , which indicates the absence of hydroxyl fun...

Embodiment 2

[0041] Example 2. Examination of the initial contact resistance of conductive adhesives by five different adhesive formulations catalyzed by imidazole and containing epoxy-aliphatic amine prepolymer. Formulation The formulation was prepared by first dissolving Novolac 1166 in gamma-butyrolactone at 120°C. The solution was cooled to room temperature and the remaining ingredients were added and mixed thoroughly with a mechanical stirrer. The composition of the formulation is shown in Table 2.

[0042] components

Formula A

Formula B

Formula C

Formula D

Formula E

Novolac 1166

0.72

0.72

0.61

0.61

0.72

γ-butyrolactone

5.62

5.62

4.75

4.75

5.62

Component B

14.06

14.06

11.78

11.88

14.06

4-Methyl-2-phenylimidazole

0.72

0.72

0.60

0.60

0.72

8-Hydroxyquinoline

1.30

1.30

1.10

1.10

...

Embodiment 3

[0048] Embodiment 3. Prepare two other samples according to the same method as the sample of Example 2, and their formulations are shown in Table 5.

[0049] components

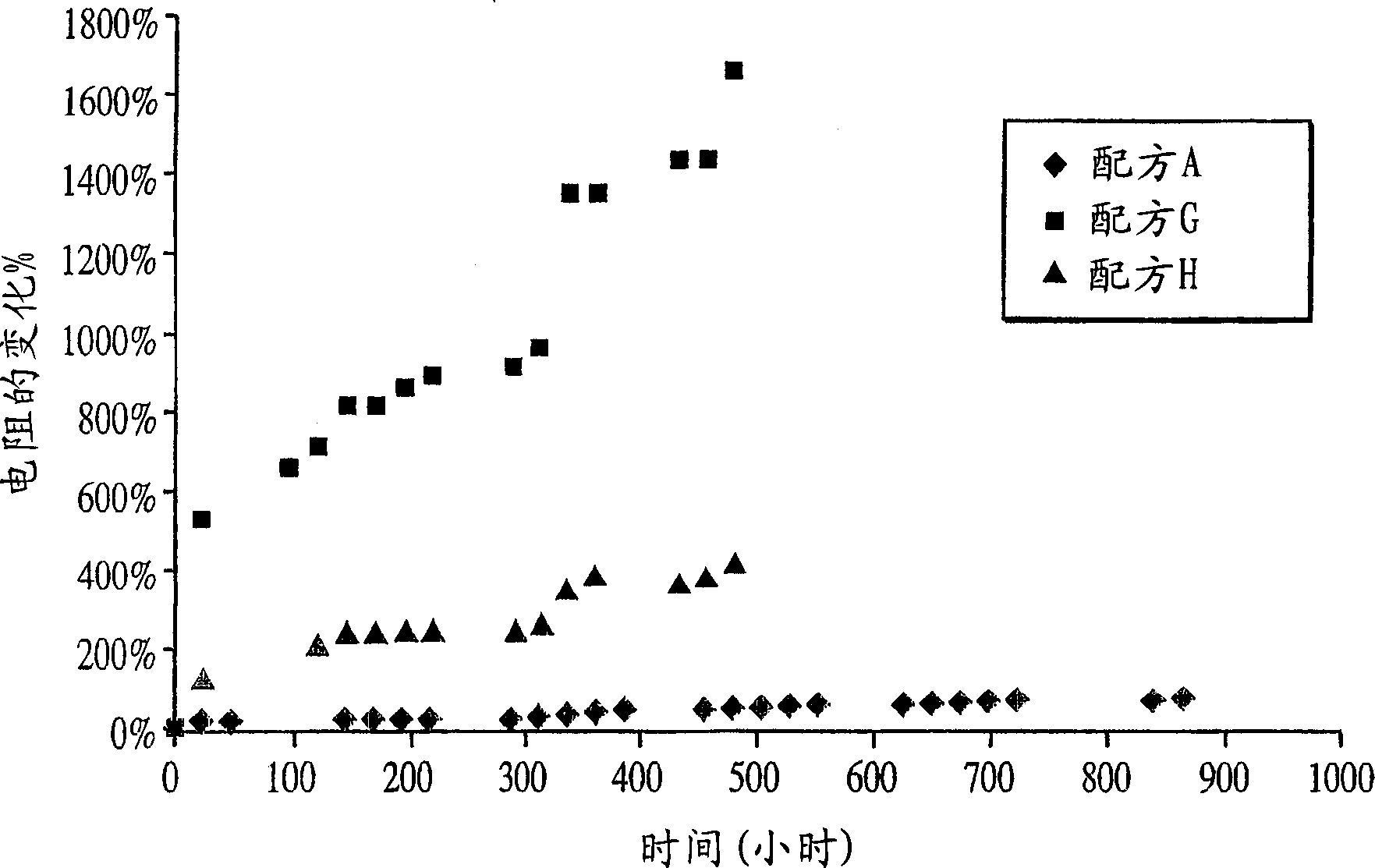

[0050] After the coupons were formulated and placed on the plate, the initial contact resistance was measured. The panels were then placed in a humid chamber maintained at 85°C and 85% relative humidity, and the contact resistance was measured periodically with a Keithley 2010 multimeter. As shown in Figure 1, the change in resistance value of the sample without any corrosion inhibitor is more obvious. Also, when imidazole was used as a catalyst and a corrosion inhibitor was added to the formulation, the resistance was much more stable in conditions of high temperature and high humidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com