Patents

Literature

5168 results about "Sodium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

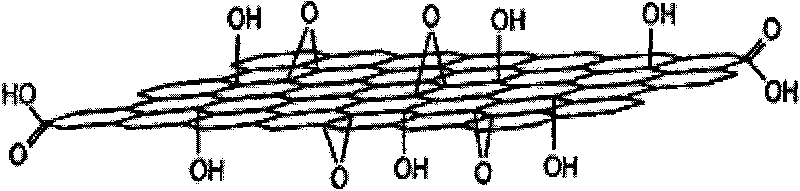

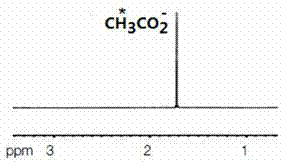

Sodium acetate, CH₃COONa, also abbreviated NaOAc, is the sodium salt of acetic acid. This colorless deliquescent salt has a wide range of uses.

Tape formulation for percutaneous administration containing fentanyi

PCT No. PCT / JP97 / 01595 Sec. 371 Date Jan. 13, 1998 Sec. 102(e) Date Jan. 13, 1998 PCT Filed May 13, 1997 PCT Pub. No. WO97 / 42952 PCT Pub. Date Nov. 20, 1997A tape formulation for percutaneous administration containing fentanyl which comprises fentanyl or a salt thereof, a pressure sensitive adhesive and sodium acetate, is disclosed. The salt of fentanyl is preferably fentanyl citrate. The tape formulation of the present invention is little irritation to the skin and excellent in the percutaneous permeation of fentanyl and has a high stability even after the passage of time.

Owner:HISAMITSU PHARM CO INC

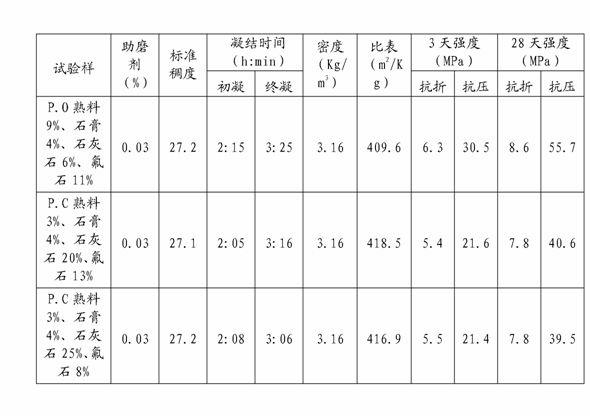

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

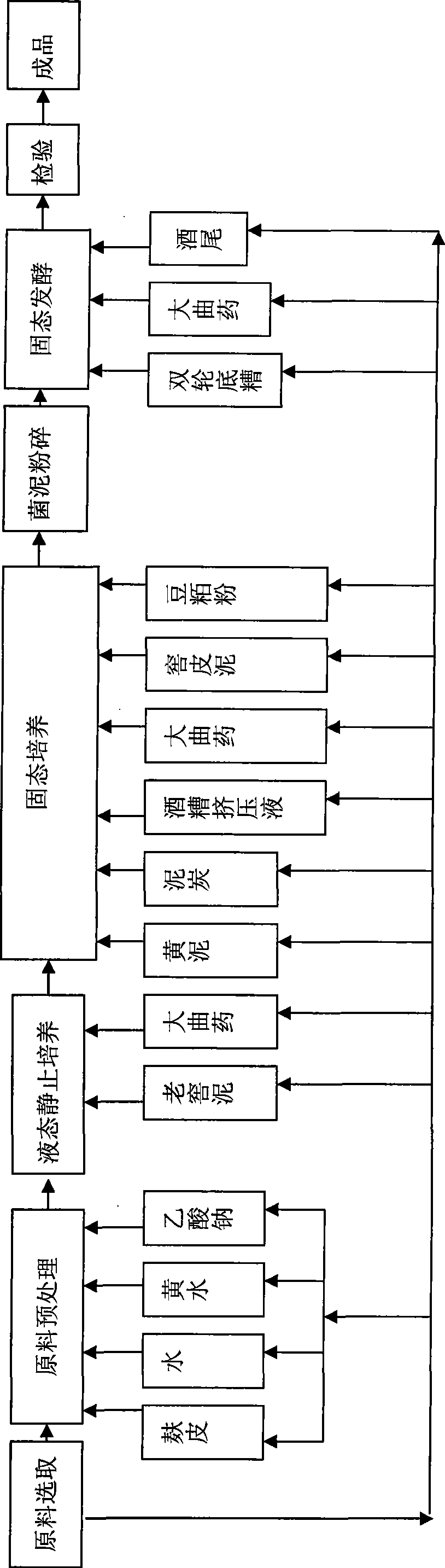

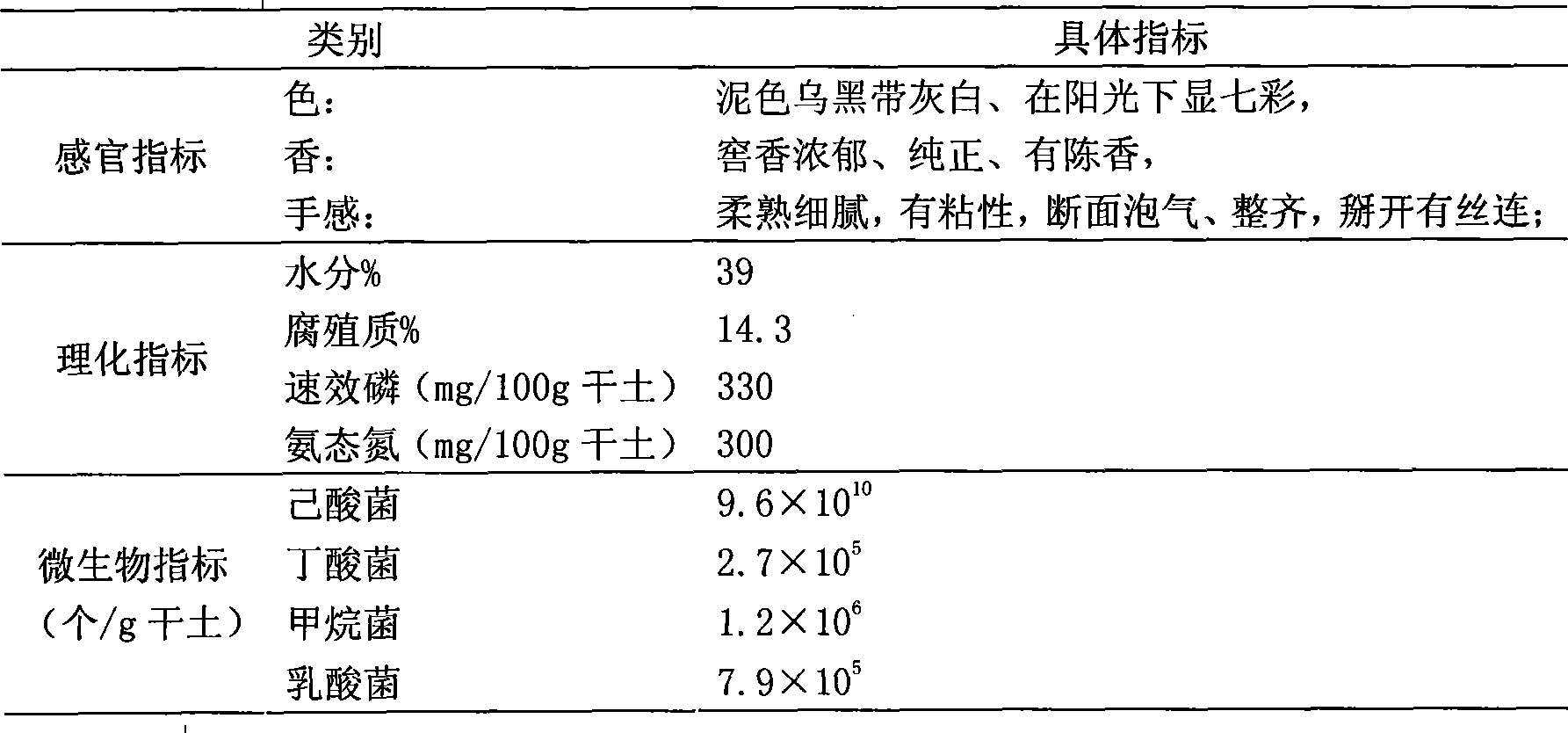

Preparation of artificial pit mud for improving aged aroma of aroma type white spirit

ActiveCN101503655AComfortable scentReach functional levelAlcoholic beverage preparationSodium acetatePeat

The invention discloses an artificial pit mud preparation method capable of improving the stale flavor of highly-concentrated fragrance white spirit, which comprises the following steps: mixing qualified bran, water, yellow water and sodium acetate in a proper proportion, and filling the mixture in a fermentation tank for sterilization; and when the temperature of the materials in the fermentation tank drops to 36 DEG C, adding a proper amount of aged pit mud and a Daqu drug into the fermentation tank, uniformly mixing the material and the aged pit mud and the Daqu drug, adjusting the pH value, covering the surface of material liquid with grease for isolating the material liquid from oxygen, standing the materials in the fermentation tank at 32 to 35 DEG C for anaerobic culture for 72 hours, taking out a bacterium solution, adding yellow mud, peat, vinasse squeezed fluid, the Daqu drug, pit surface mud and bean dreg powder in a proper proportion into the bacterium solution, culturing the mixture at room temperature for 7 to 10 days after uniform mixing, grinding bacterium mud, adding a certain amount of double bottom grains, the Daqu drug and ending beer, stacking the materials after uniform mixing for natural fermentation at normal temperature for 30 to 40 days, and obtaining the artificial pit mud. The 'aging degree' of the artificial pit mud is the same as that of aged pit mud naturally aging for more than 10 years, and the stale flavor of the freshly brewed liquor is the same as that of white spirit stored for more than three years in a ceramic jar.

Owner:SICHUAN TUOPAI SHEDE WINE

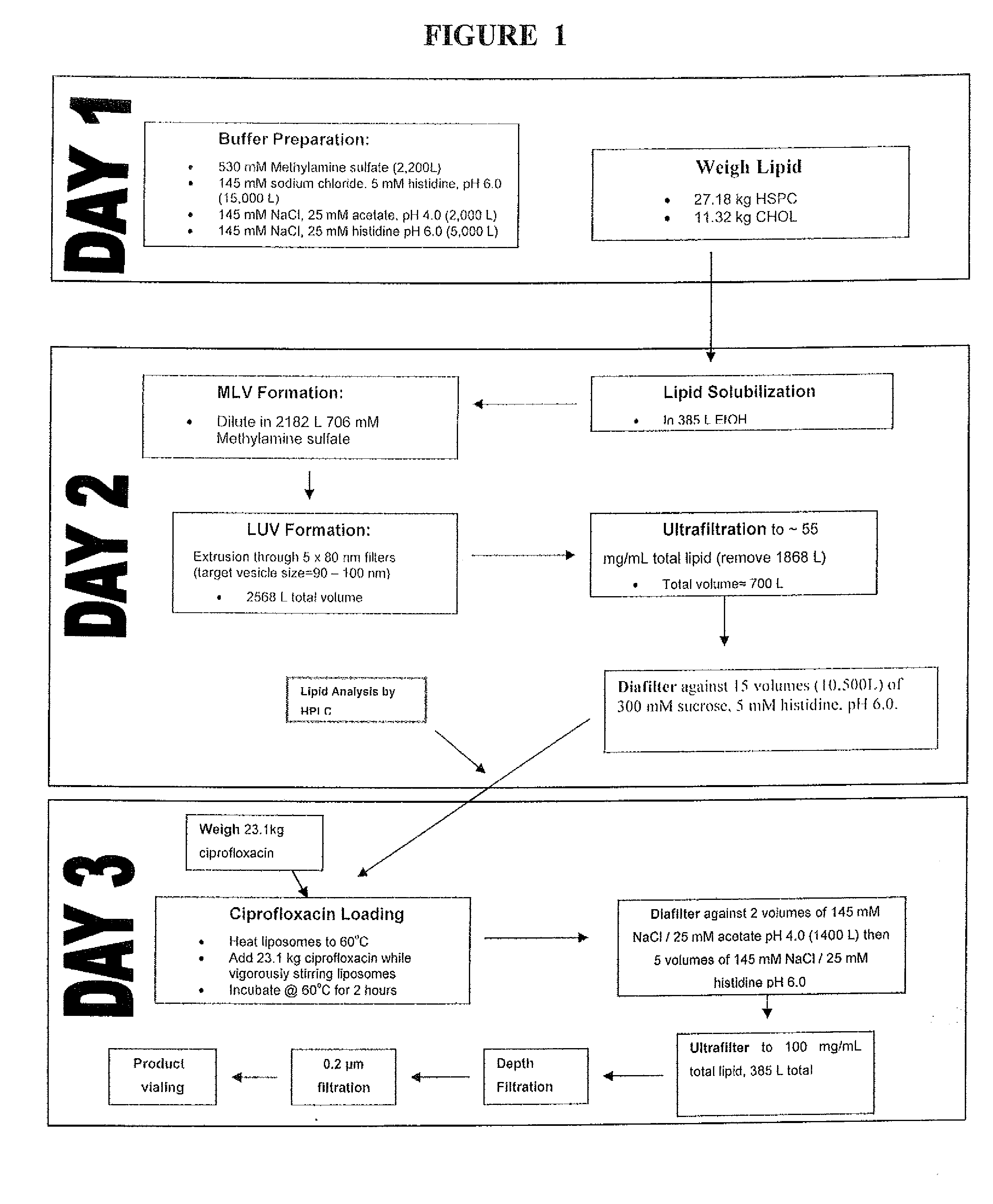

Concentrated, inhalable antibiotic formulation

InactiveUS20110064796A1Improve treatmentSustained release of anti-infective over timePowder deliveryOrganic active ingredientsSodium acetateLiposome

A concentrated inhalable formulation of an antibiotic drug such as ciprofloxacin is disclosed. The antibiotic is formulated with sodium acetate and liposome which incorporate antibiotic. The formulation is aerosolized and inhaled for treatment of respiratory tract infections and other medical conditions.

Owner:GRIFOLS

Electrodynamic method for removing fluorine contaminant in soil

InactiveCN101786099AWell mixedImprove removal efficiencyContaminated soil reclamationSodium acetateSodium acetrizoate

The invention discloses an electrodynamic method for removing fluorine contaminant in soil, which is as follows: an anion-exchange membrane is arranged between the anode and the contaminated soil to prevent the H+ generated by the anode from entering the electrolyzer so as to avoid the increase of the acidity of the contaminated soil; sodium acetate solution is put in an anode chamber to be used as electrolyte, deionized water is put in a cathode chamber to be used as electrolyte, and the liquid levels of the anode chamber and the cathode chamber are maintained to be parallel; in the rehabilitating process, the electrolytes circulate constantly to be stirred evenly so as to bring away the H2 and O2 which are generated by the anode and the cathode; the sodium acetate solution added in the anode chamber supplies OH- which neutralizes the H+ generated by the anode, and the surplus OH- and the OH- generated by the cathode promote the adsorbed fluorine in the soil to be desorbed to be free fluorinions; and the fluoride in the soil is removed through the electrodynamic approaches of electromigration, electroosmosis and the like. The method can effectively promote the adsorbed fluoride to be desorbed from the surface of the contaminated soil particles, remarkably improves the fluorine contaminant removal efficiency, reduces overpotential and saves energy consumption, and after the soil is rehabilitated, the pH value of the soil is basically maintained at the original state.

Owner:HENAN UNIV OF SCI & TECH

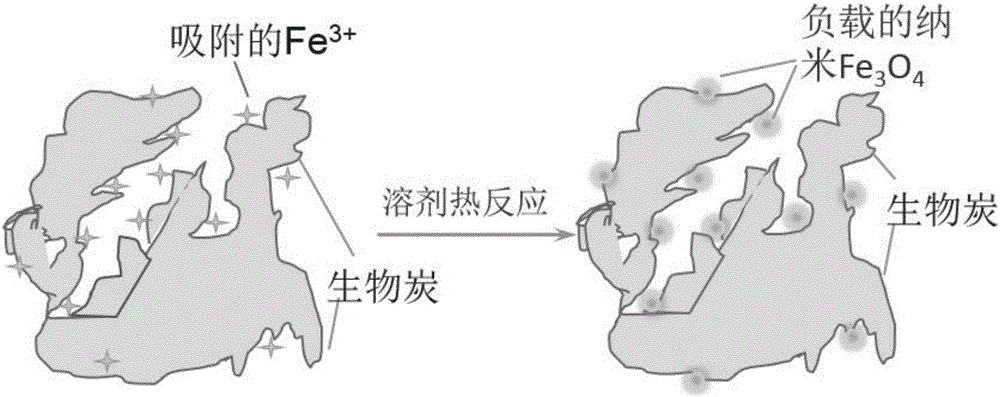

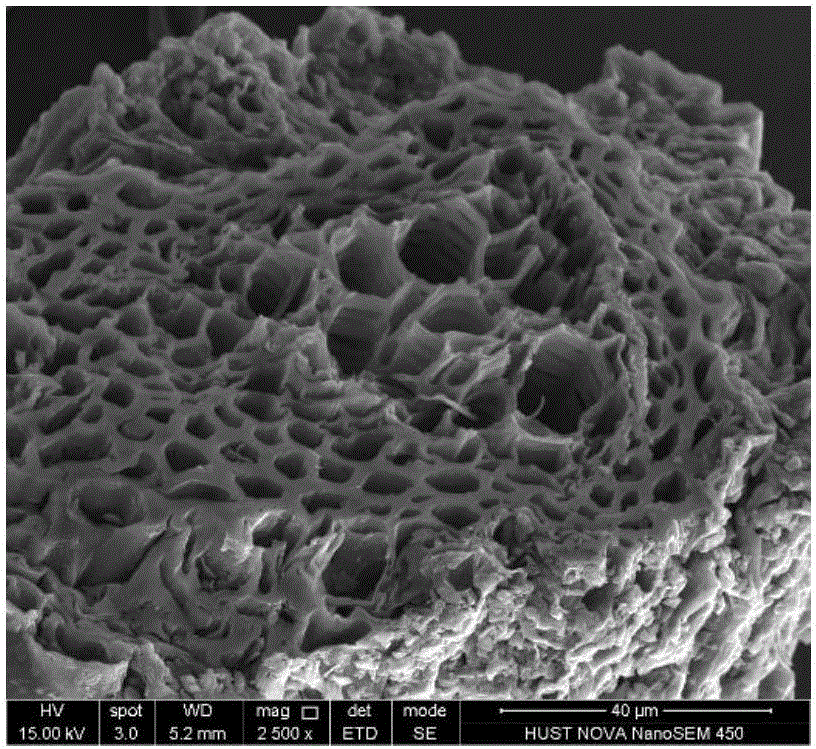

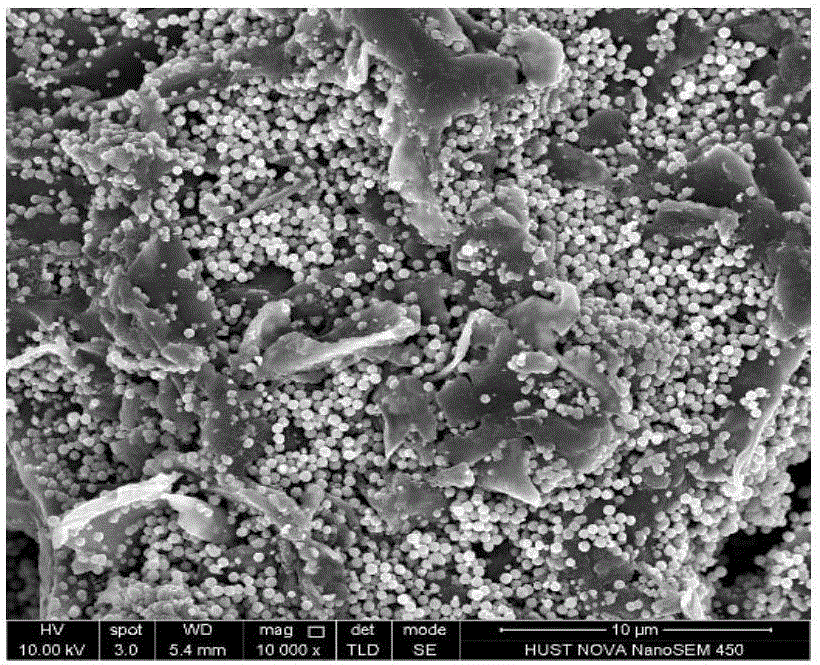

Magnetic biochar adsorbing material and preparation method thereof

InactiveCN106362690AGood lookingSimple structureOther chemical processesWater contaminantsSodium acetateSodium acetrizoate

The invention discloses a magnetic biochar adsorbing material and a preparation method thereof. The preparation method comprises the following steps: (1) preparation of biochar: by using powder obtained by treating plant biomass as a raw material, roasting under oxygen-free conditions to obtain porous biochar; (2) preparation of ferric iron precursor liquid: by using ethanediol as a dispersing agent, adding a solid-state ferric iron salt, continuing adding sodium acetate and a surfactant into the ethanediol, and stirring to form a disperse system which is the ferric iron precursor liquid; and (3) solvothermal reaction: uniformly mixing the biochar and ferric iron precursor solution to obtain a mixture, putting the mixture into a teflon hydrothermal reaction kettle, and carrying out solvothermal reaction to obtain the magnetic biochar adsorbing material. The pretreatment technique of the key biomass raw material and the specific conditions of solvothermal reaction in the preparation method are improved, thereby effectively solving the problem of poor connection stability between the magnetic biochar material magnetic particles and biomass.

Owner:HUAZHONG UNIV OF SCI & TECH

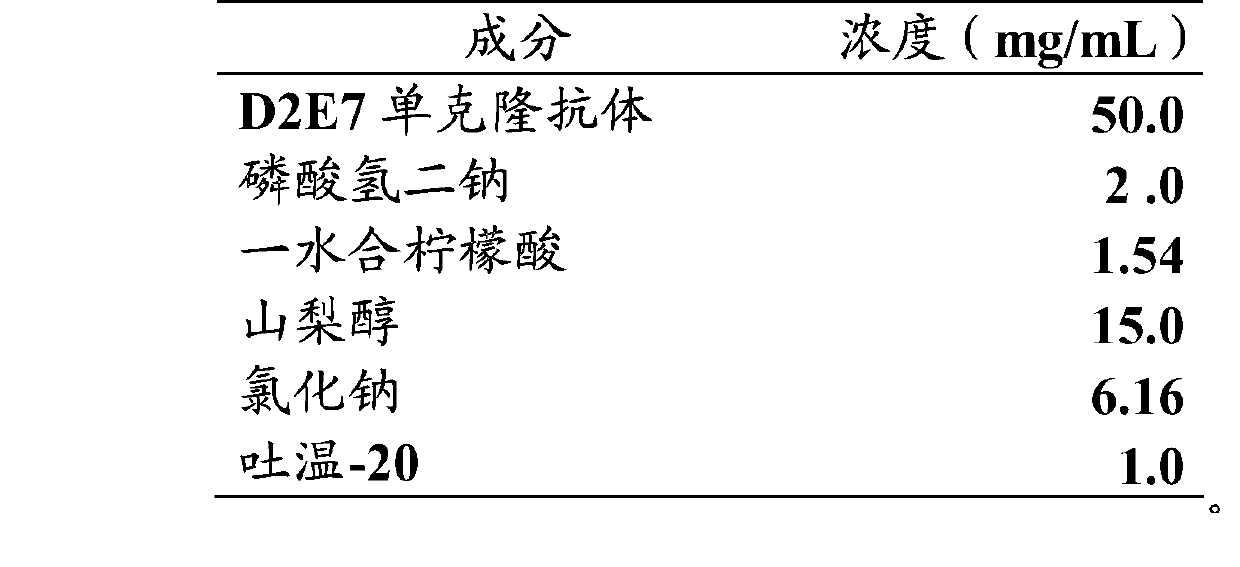

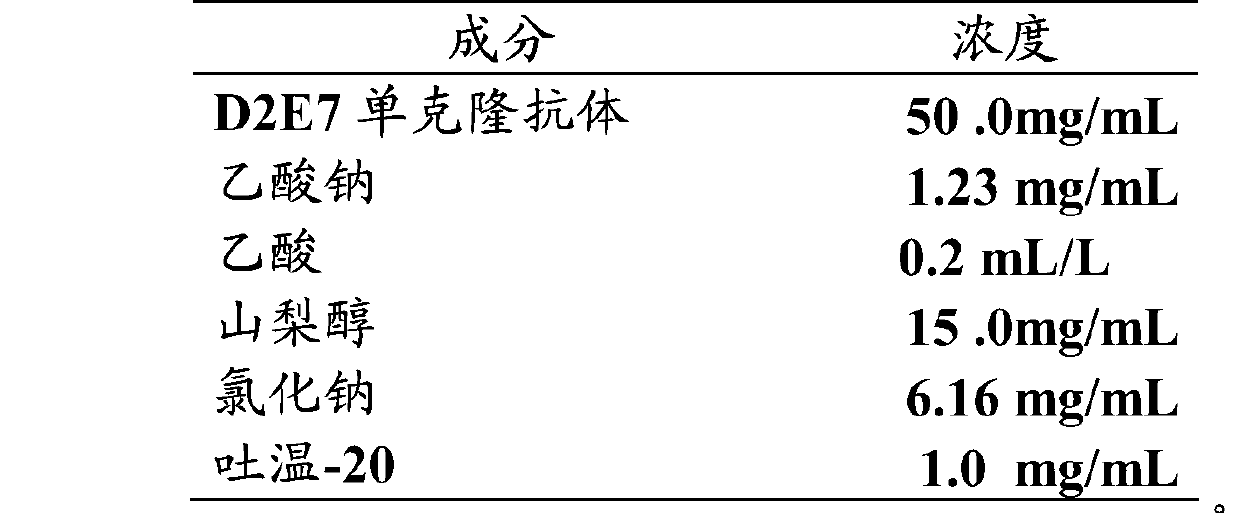

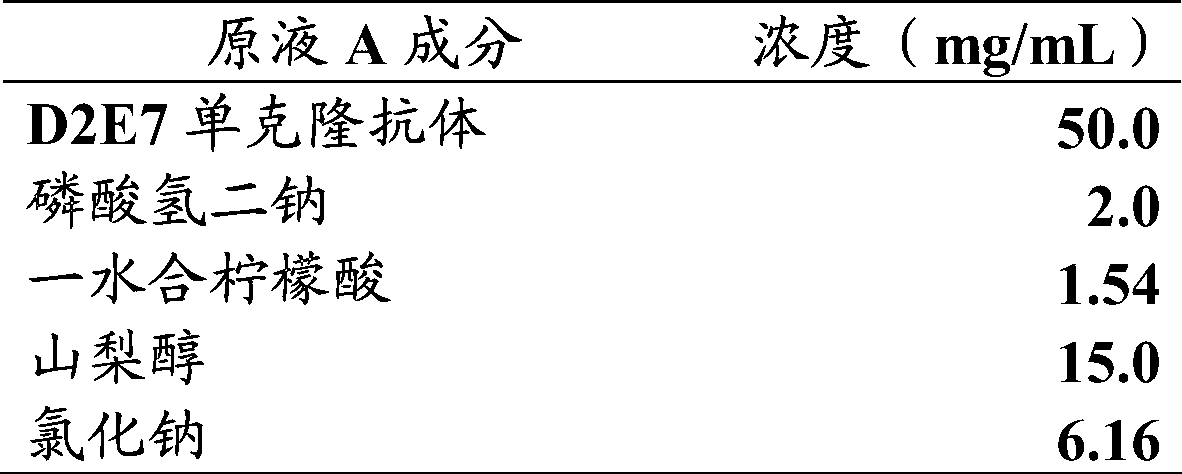

Aqueous drug preparation of anti-TNF (tumor necrosis factor)-alpha human monoclonal antibody for strengthening stability

ActiveCN102988984AEasy to prepareLong storage timeSkeletal disorderPharmaceutical delivery mechanismSodium acetateRetention time

The invention provides a new liquid aqueous drug preparation of an anti-TNF (tumor necrosis factor)-alpha human monoclonal antibody for strengthening the stability, wherein antibody solution is stabilized and osmotic pressure is regulated by sorbitol; disodium hydrogen phosphate / citric acid monohydrate or sodium acetate / acetic acid is taken as a buffer agent, and preferably, the disodium hydrogen phosphate / citric acid monohydrate is taken as the buffer agent; and tween-20 is taken as a surfactant, so that antibody preparation is stable, and long in retention time, meanwhile, preparation components are simplified, and the preparation is prepared simply and conveniently.

Owner:GENOR BIOPHARMA +1

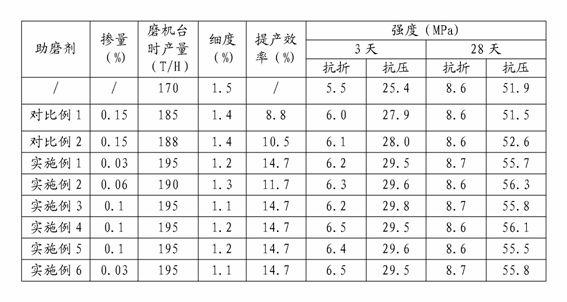

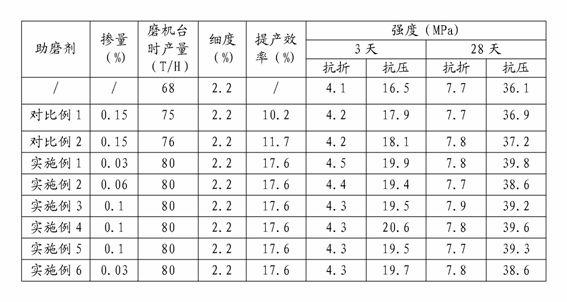

Liquid cement grinding aid

The invention discloses a liquid cement grinding aid. The liquid cement grinding aid comprises the following components by weight percent: 10-24% of triethanolamine, 10-16% of polymeric polyol, 10-13% of molasses, 1-3% of calcium formate, 3-5% of sodium acetate, 5-10% of sodium thiosulfate and the balance water. Compared with the prior art, the liquid cement grinding aid has the advantages that the grain composition of a cement material is changed, the strength of cement is improved, enhancing effect of the cement mixed with a large quantity of limestone is improved obviously; the cost is lower as the using amount of triethanolamine is reduced; the cement output in the unit time is increased effectively, and the power consumption of per unit output is reduced as the mixing amount in the cement finishing process is low; the liquid cement grinding aid is green and environmental-friendly and cannot hurt people, or cannot damage buildings and the like as chloridion content is not contained.

Owner:柳州宝能建材科技有限公司

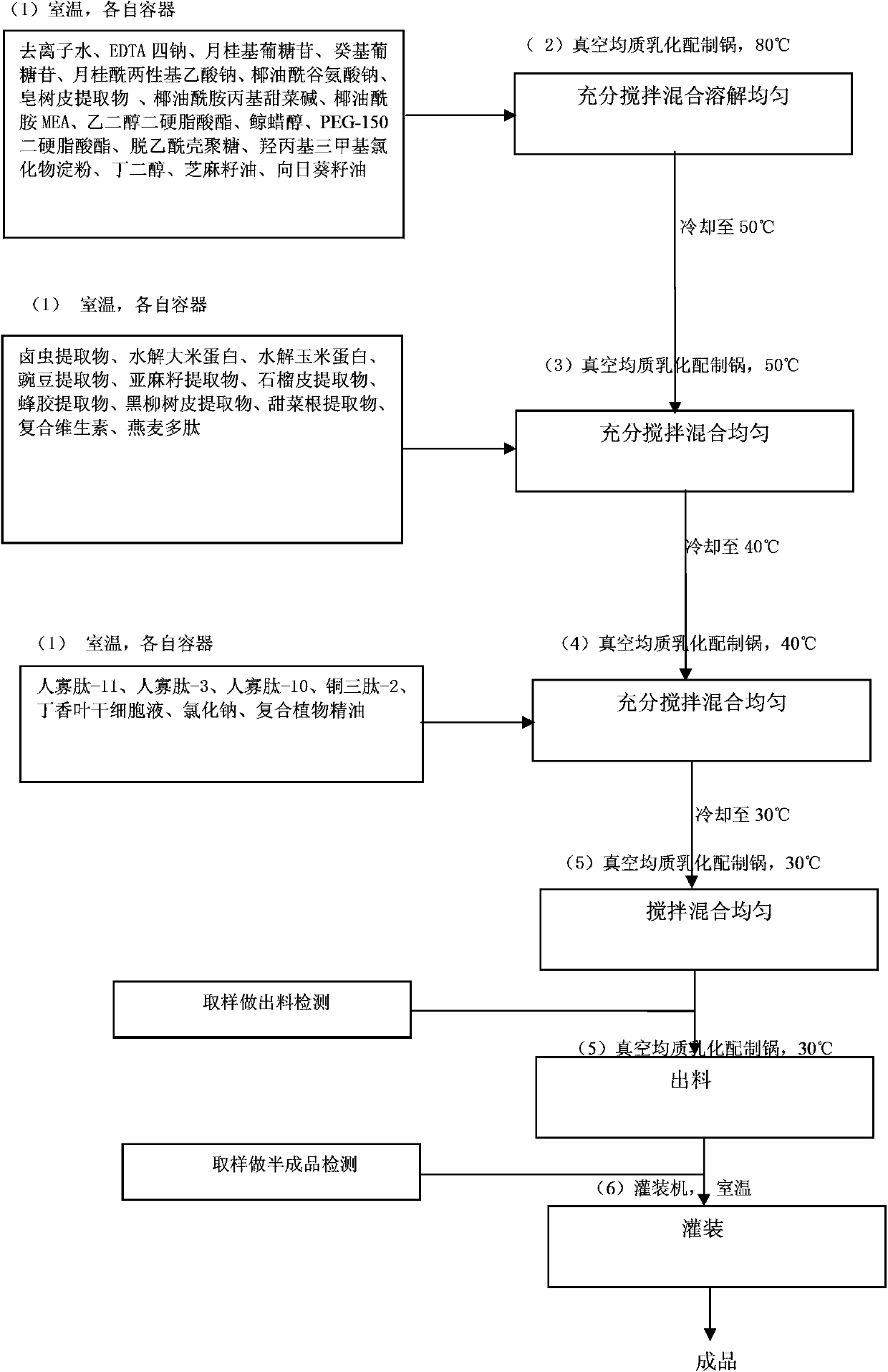

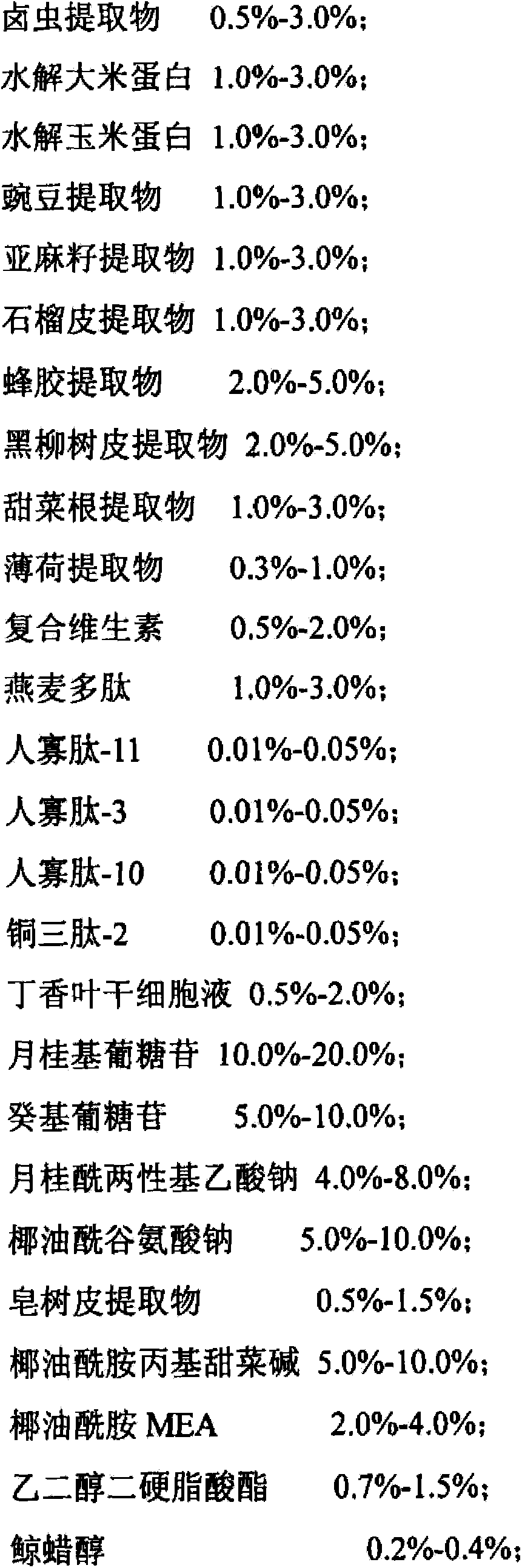

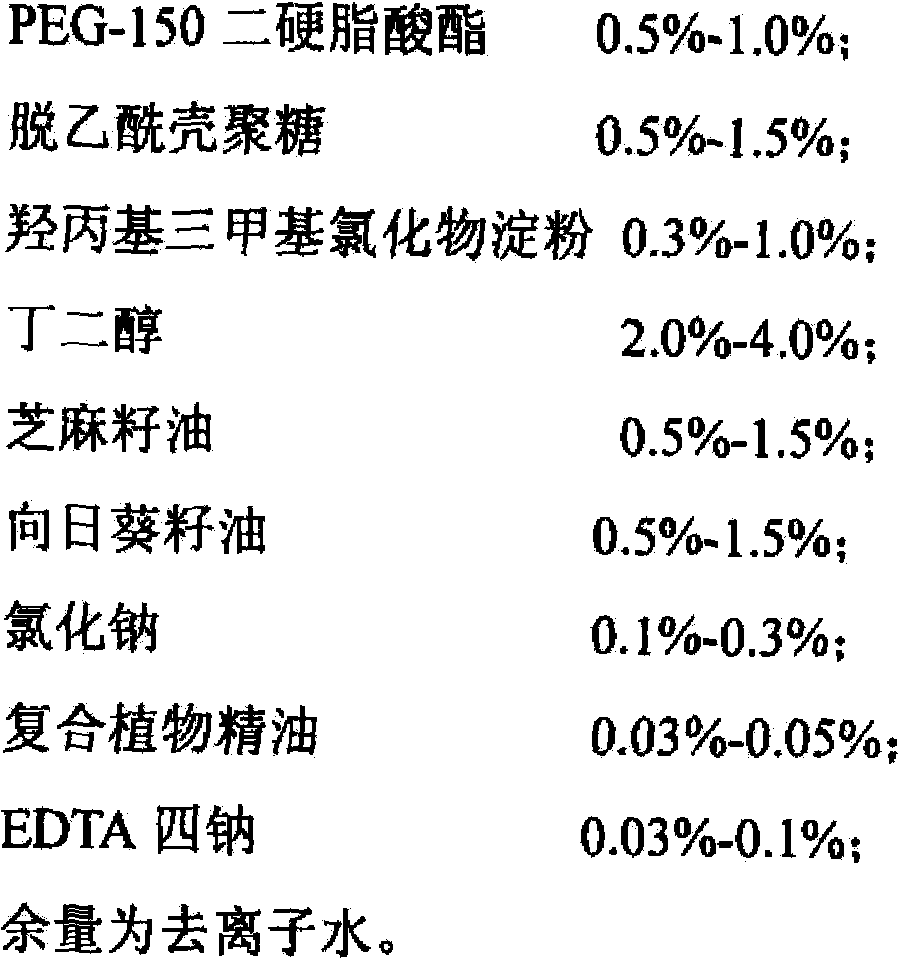

Anti-hair loss and hair-regeneration shampoo prepared from herbal essence and biochemical components and preparation method thereof

ActiveCN103494754AMoisturizingWith sun protectionCosmetic preparationsHair cosmeticsBiotechnologyNatural source

The invention relates to the technical field of cosmetics for hair and especially relates to anti-hair loss and hair-regeneration shampoo prepared from herbal essence and biochemical components and a preparation method thereof. The preparation method scientifically adopts the modern herbal essence such as artemia extract, hydrolyzed rice protein, hydrolyzed corn protein, pea extract, flaxseed extract, pomegranate rind extract, propolis extract, black willow bark extract, beet root extract and mint extract, also adopts the modern biochemical components such as human oligopeptide-11, human oligopeptide-3, human oligopeptide-10, copper tripeptide-2, clove leaf stem cell fluid and oat polypeptide, and also adopts natural source surfactants such as lauryl glucoside, decyl D-glucopyranoside, sodium cocoyl glutamate, sodium lauroamphoacetate and soapbark extract. Compared with the prior art, the preparation method breaks through traditional plant (Chinese herbal medicine) use and traditional formula use, realizes formula design and raw material optimization based on the modern care conception and scientific raw materials, and does not use any chemical source surfactants, antiseptics, pigments and perfume. The anti-hair loss and hair-regeneration shampoo obtained by the preparation method is natural, safe and effective anti-hair loss and hair-regeneration shampoo satisfying the modern health concept.

Owner:杨跃飞

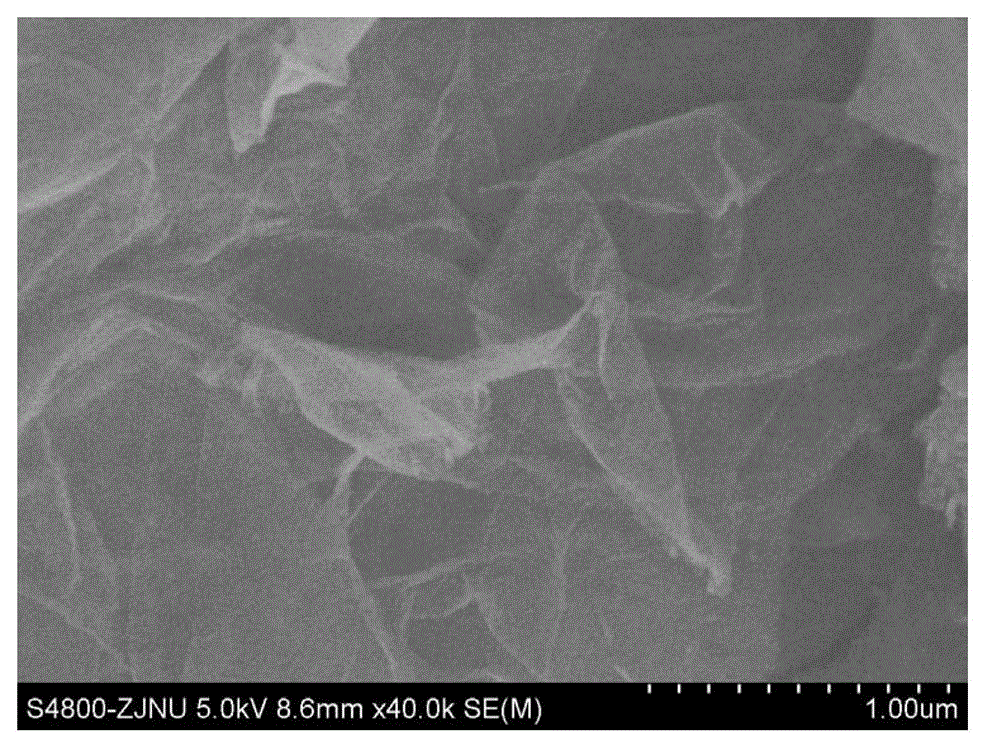

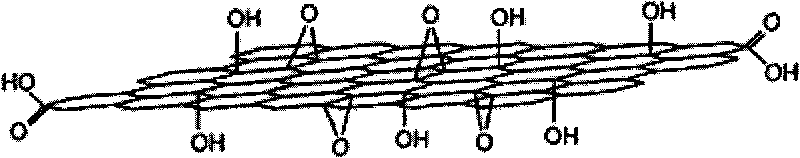

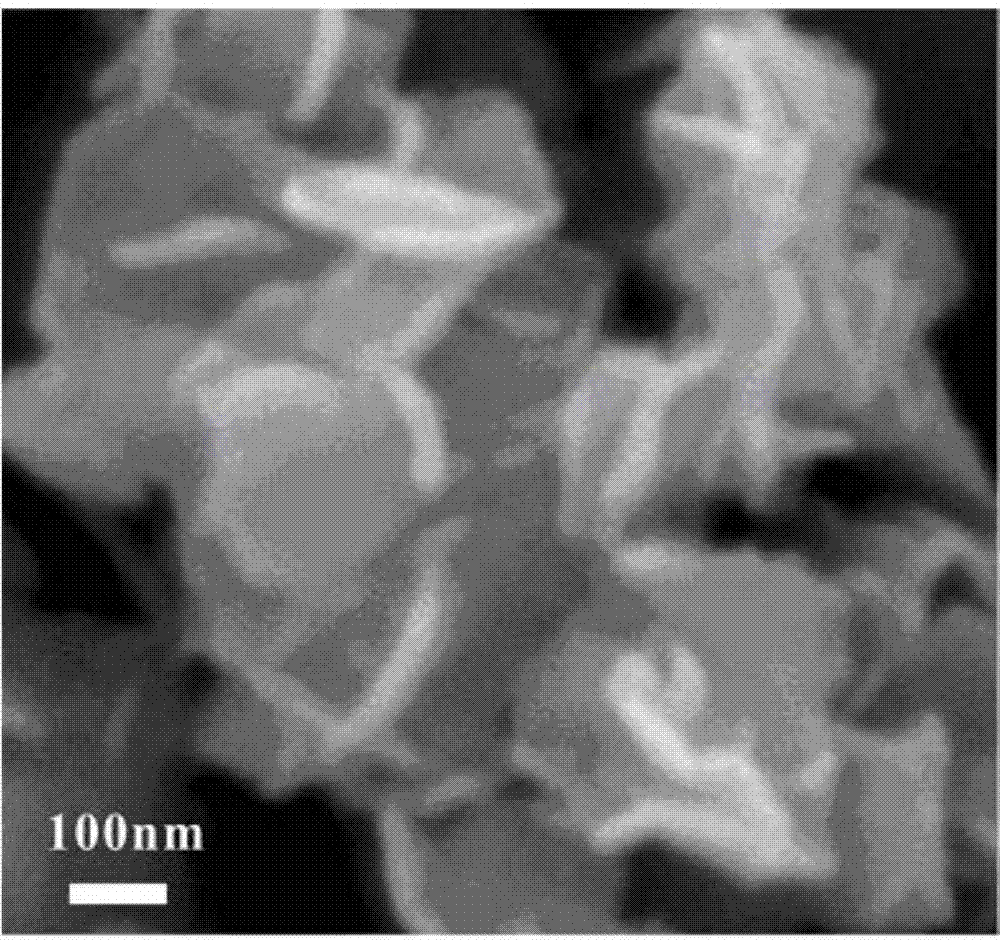

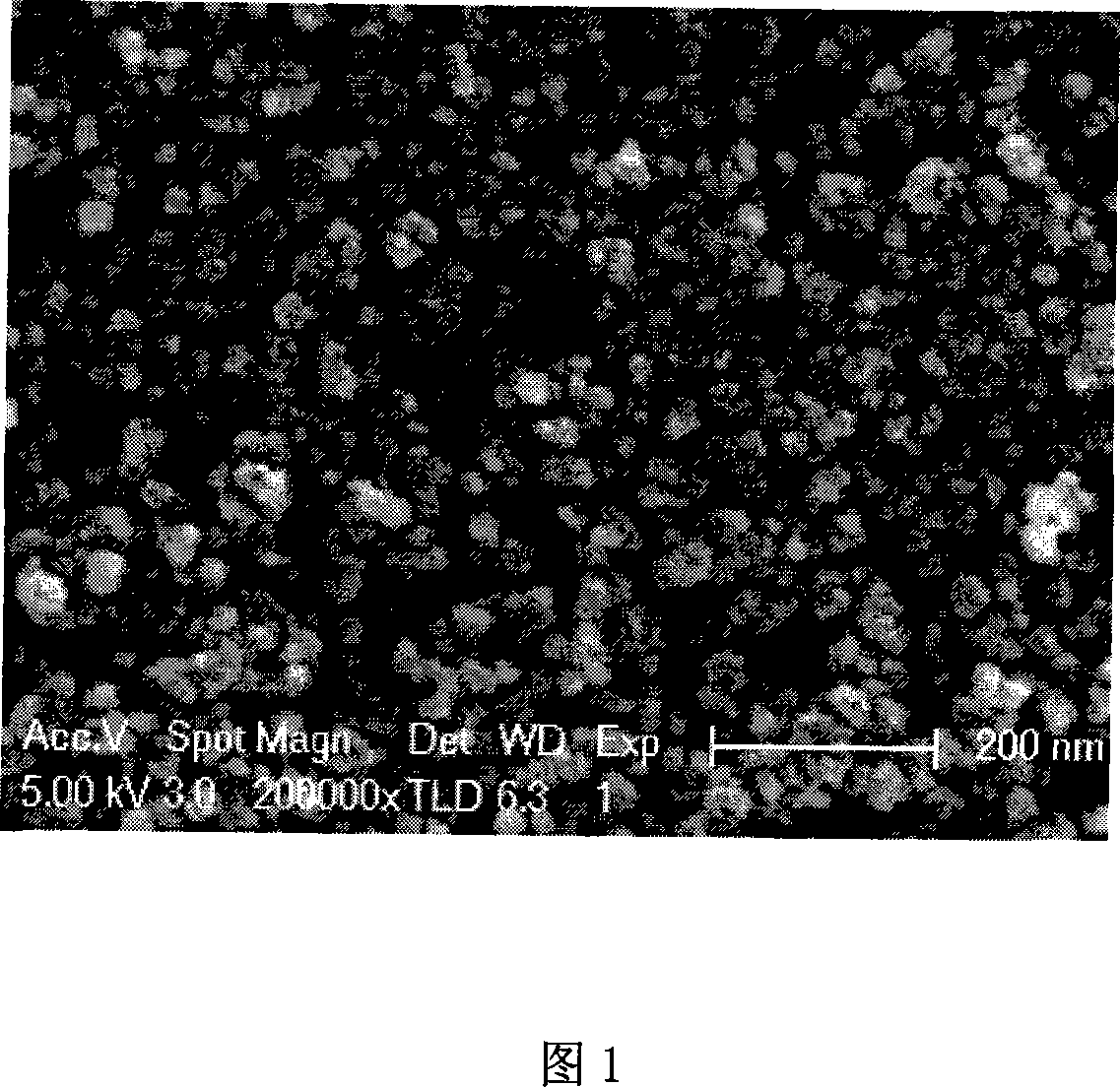

Platinum/graphene nano electro-catalyst and preparation method thereof

InactiveCN101745384AReductiveGood dispersionCell electrodesCatalyst activation/preparationSodium acetatePt element

The invention discloses a platinum / graphene nano electro-catalyst. The platinum / graphene nano electro-catalyst uses graphene as a carrier and uses platinum as an active component, wherein the mass fraction of the platinum in the catalyst is 10 to 40 percent. A preparation method comprises the following steps: 1) ultrasonically dispersing an oxidized graphite nano sheet into liquid polyalcohol, then adding chloroplatinic acid solution and sodium acetate solution into the liquid polyalcohol, and fully mixing the solution uniformly, wherein the content of the oxidized graphite nano sheet in the mixture is between 0.48 and 1.3 g / L, the concentration of the chloroplatinic acid is between 0.0005 and 0.005 mol / L and the concentration of the sodium acetate is between 0.007 and 0.013 mol / L; and 2) transferring the mixture to a microwave hydrothermal reaction kettle, heating the mixture by microwave to react for 5 to 10 minutes, and then filtering, washing and drying the reaction product to obtain the platinum / graphene nano electro-catalyst. The preparation method of the invention has the advantages of energy conservation, quickness, simple process and the like. The particle diameters of the platinum nano particles in the prepared platinum / graphene nano electro-catalyst are uniform. The catalyst has good electro-catalysis performance, and has wide application in a fuel cell.

Owner:ZHEJIANG UNIV

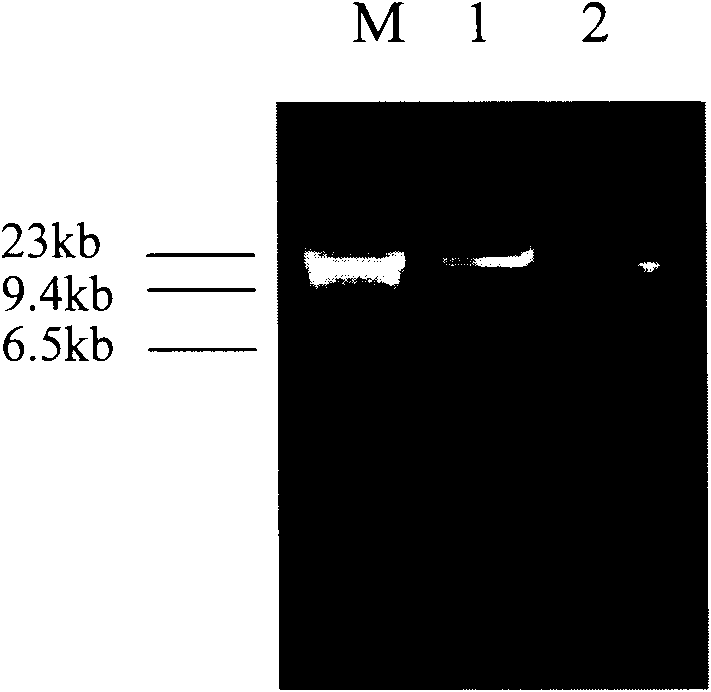

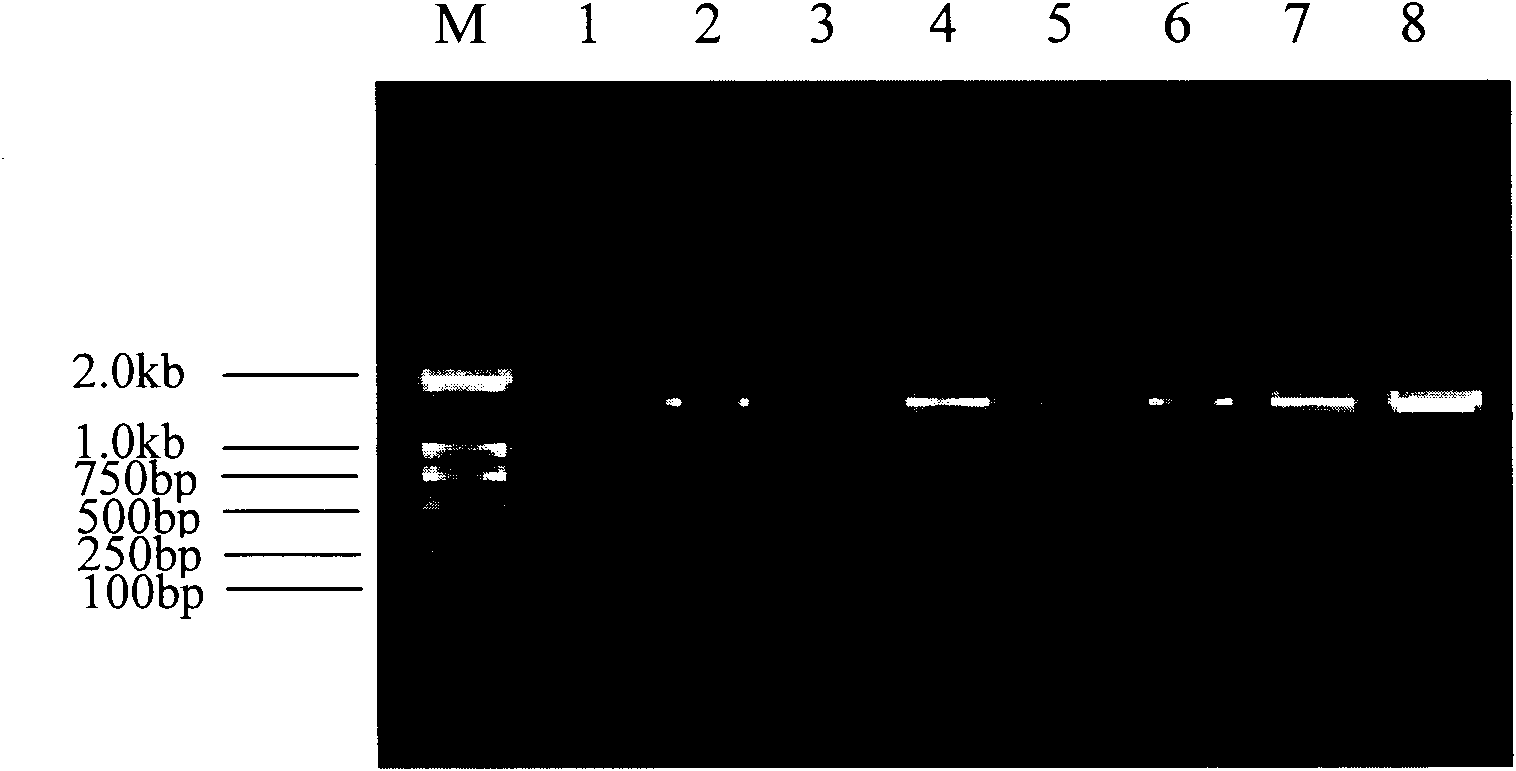

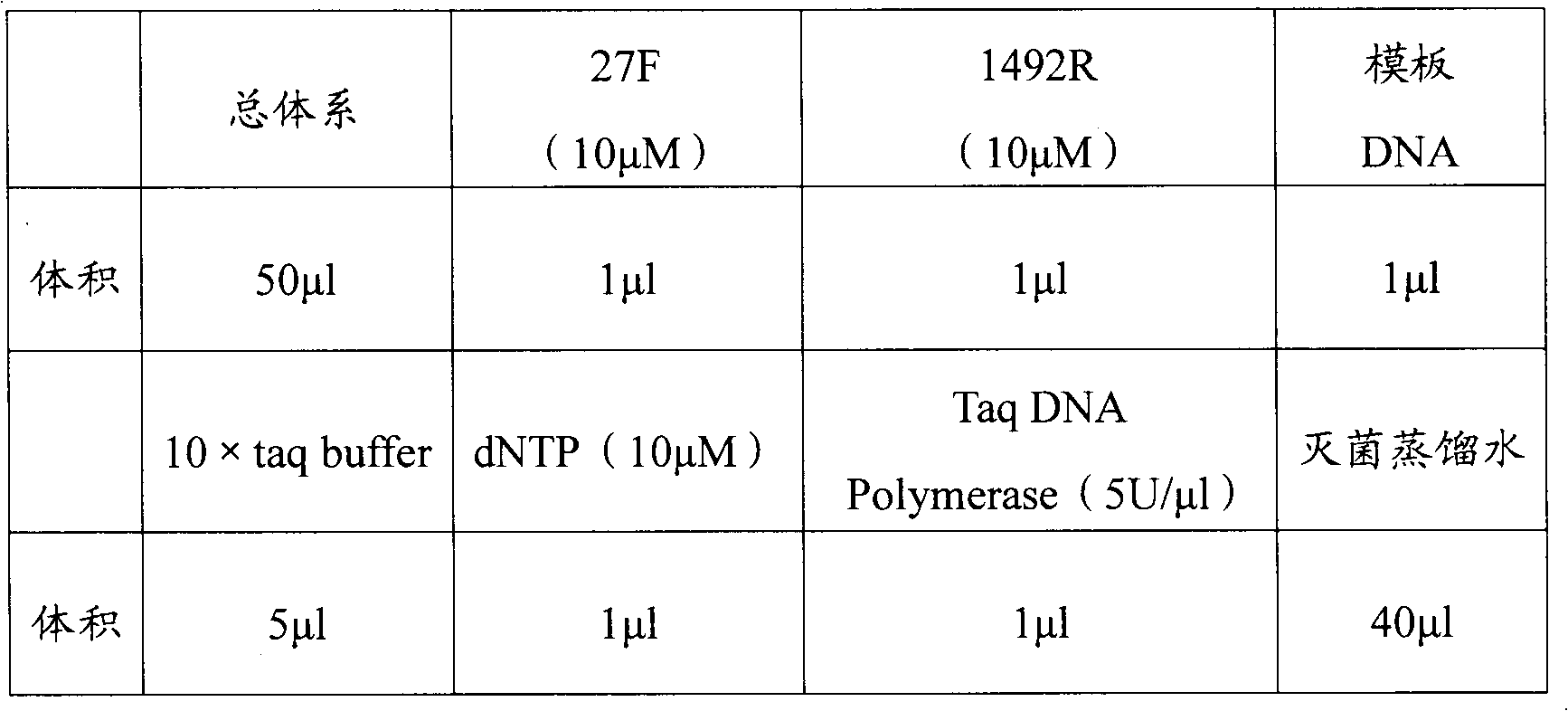

Kit and method for extracting microbial DNA

ActiveCN101935647AImprove bindingReduce adsorptionDNA preparationSodium acetateAluminum ammonium sulfate

The invention relates to the field of molecular biology and discloses a kit and a method for extracting microbial DNA. The kit comprises lysis solution, inhibitor removal solution and binding solution, wherein the lysis solution comprises 50 to 200mM of Tris-HCl, 50 to 150mM of EDTA, 0.5 to 3M of NaCl, 0.5 to 2 percent of CTAB, 0.5 to 2 percent of PVP and 0.5 to 2 percent of SDS; the inhibitor removal solution comprises 100 to 300mM potassium acetate, sodium acetate or ammonium acetate and 50 to 200mM aluminum sulfate, ammonium sulfate or aluminum ammonium sulfate; and the binding solution comprises 3 to 6M guanidine hydrochloride, 10 to 50mM Tris-HCl and 5 to 50 percent isopropanol. The kit and the method for extracting the microbial DNA have the advantages of high purity, high universality, high extraction speed, direct use for a downstream experiment, and application to extracting DNA from a microbe-containing sample.

Owner:中生方政生物技术股份有限公司

Method for performing electroless nickel plating on surface of aluminum nitride ceramic

ActiveCN101962760AHigh bonding strengthImprove high temperature resistanceLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention provides a method for performing electroless nickel plating on the surface of aluminum nitride ceramic, belonging to the ceramic thin-film metallization field. The method comprises the following specific steps: 1) polishing the surface of aluminum nitride with a machinery; coarsening the aluminum nitride substrate with mixed acid or alkali, completely cleaning away the residual acid or alkali; 3) sensitizing the coarsened substrate in stannous chloride solution, activating in palladium chloride solution or performing activation without palladium; 4) weighting a certain amount of nickel sulphate, sodium hypophosphite, sodium citrate, sodium acetate, lactic acid, thiourea and sodium dodecyl sulfate in sequence to prepare a chemical plating solution; and 5) adjusting the pH value of the solution to 4.0-6.0 with acid or alkali, heating the solution to 70-95 DEG C, and placing the prepared substrate in the solution to perform electroless nickel plating. The invention is characterized in that the electroless nickel plating can be performed on the surface of the aluminum nitride ceramic substrate which is difficult to plate; and a certain amount of surfactant is added so that the plating becomes denser and smoother, the binding force between the plating and the substrate is increased, and the solderability of the plating is better.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for coal combustion improver

The invention relates to a preparation method for a coal combustion improver. After common coal is added with coal additives for combustion, the effect of energy saving and emission reduction is obvious and effective. The preparation method comprises the following steps that: 1. high-stability sodium chlorate and potassium chloride react with each other to produce potassium chlorate when water is added and the sodium chlorate and the potassium chloride are dissolved; 2. leavening agent sodium acetate is introduced to conduct base exchange with humate in coal, low ignition point humate is produced and the ignition performance of the coal is reduced; and 3. ferric oxide required by the formula is compound insoluble in water. Thereby, ferric chloride and calcium oxide are used to react with each other to produce ferric oxide when water is added and the ferric chloride and the calcium oxide are dissolved. Other products in the market do not at all have the preparation and application characteristics of the three compounds.

Owner:GUANGHUA SCI & TECH SHANGHAI +1

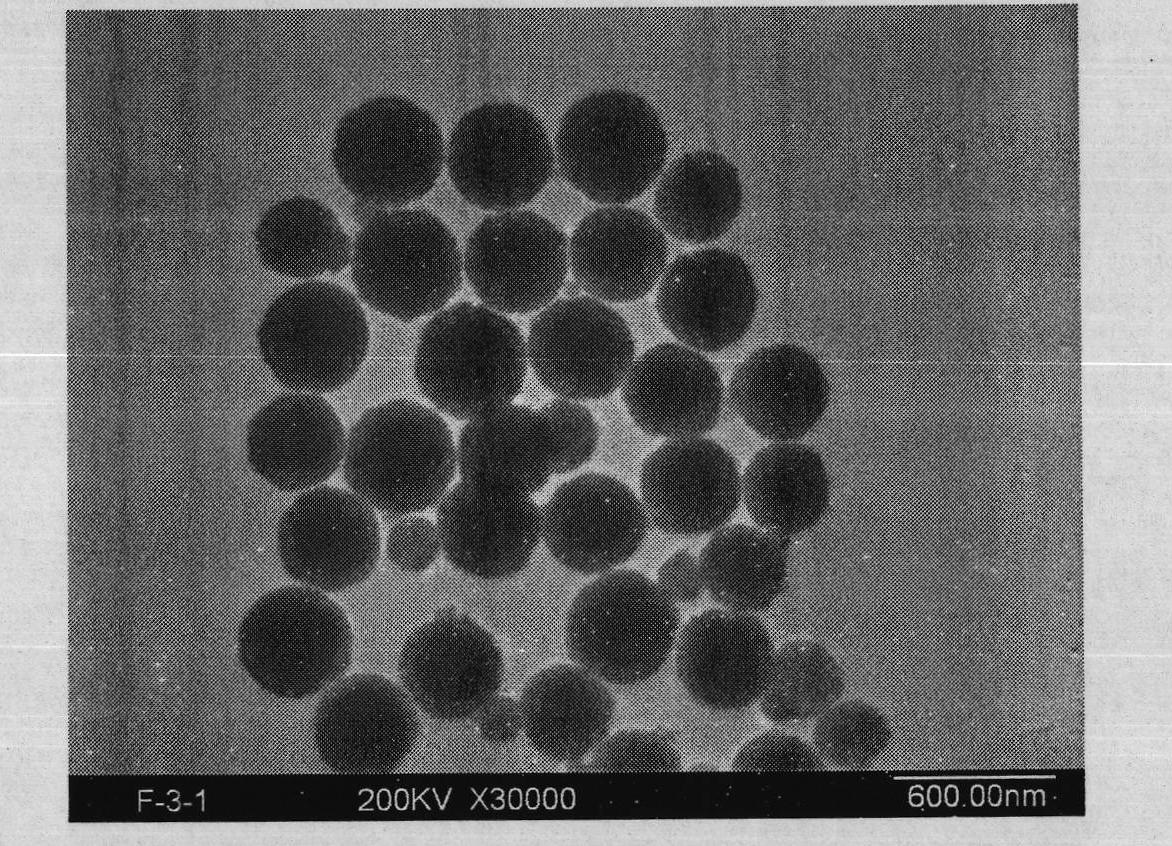

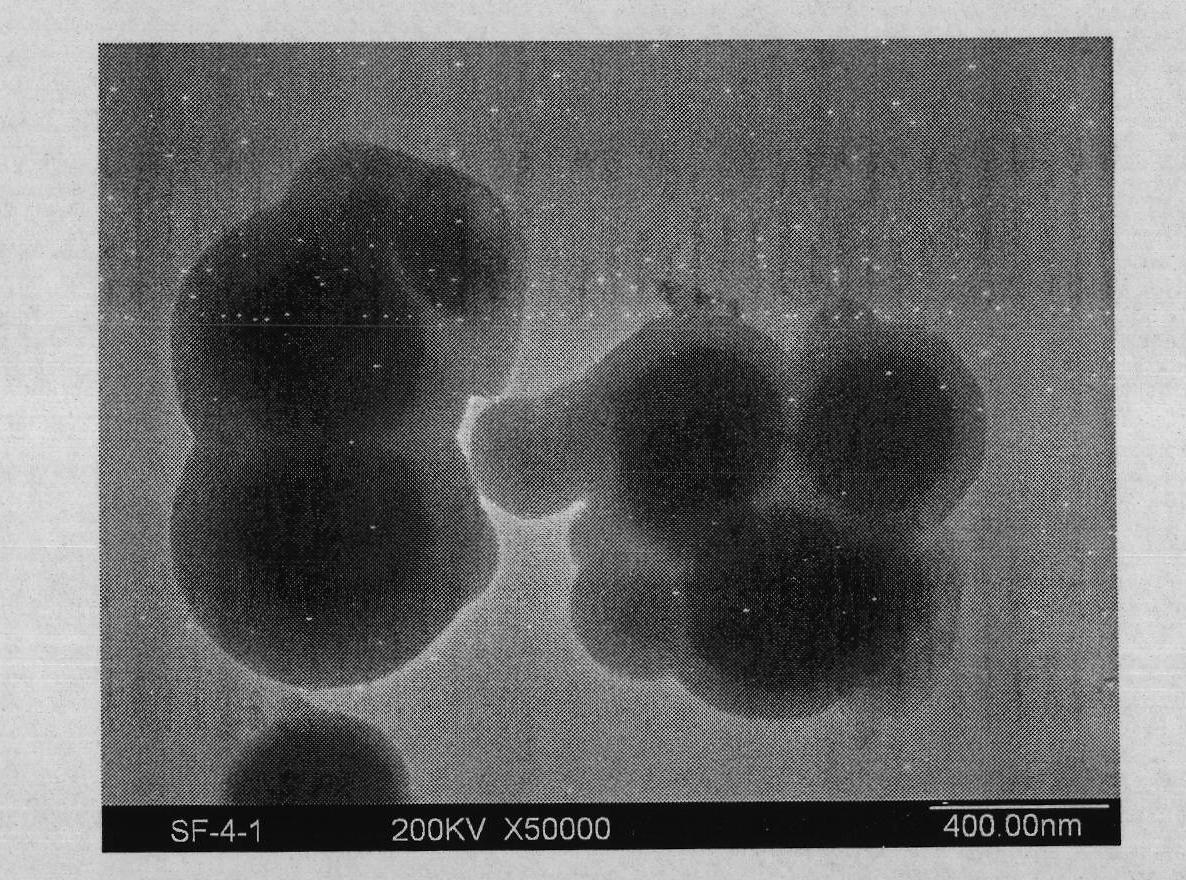

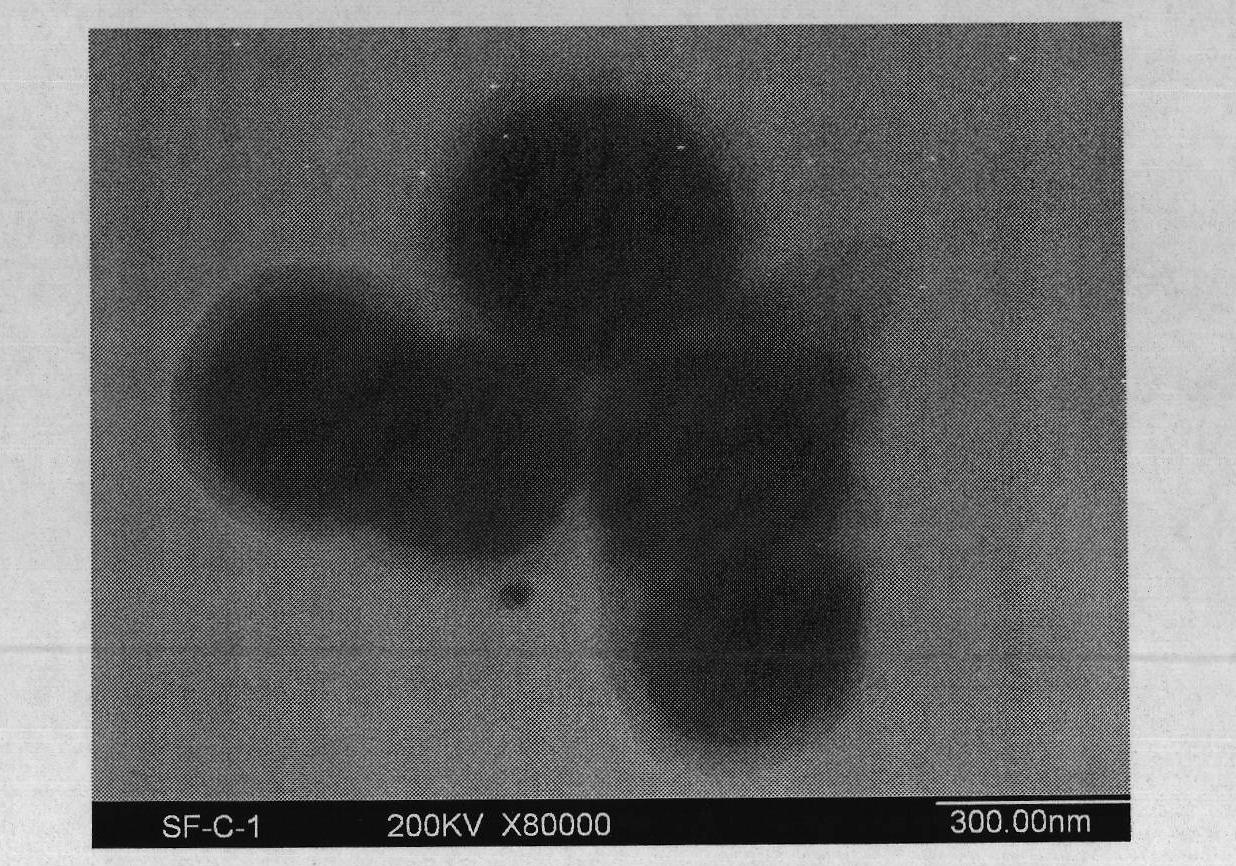

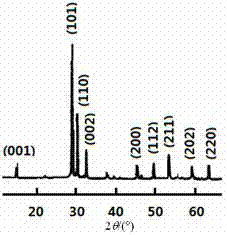

Method for preparing core-shell structured SiO2/Fe3O4 compound magnetic particle

InactiveCN102097194AUniform particlesGood dispersionMagnetic materialsSodium acetatePolyethylene glycol

The invention discloses a method for preparing a core-shell structured SiO2 / Fe3O4 magnetic particle. The core-shell structured SiO2 / Fe3O4 magnetic particle is characterized in that Fe3O4 is used as the magnetic core and SiO2 is used as the shell to form the SiO2 / Fe3O4 core-shell covering structure. The method comprises the following steps: under the heat condition of a solvent glycol, taking ferric chloride as the Fe source, sodium acetate as a reducing agent and a right amount of polyethylene glycol as a dispersing agent, heating the system to 150-180 DEG C and then preserving heat for several hours; and after washing and drying, mixing the synthesized Fe3O4 powder with a right amount of absolute ethyl alcohol, deionized water and surfactants, dropwise adding a certain amount of stronger ammonia water, after ultrasonic dispersion, slowly dropwise adding tetraethoxysilane under the condition of stirring, continuing stirring for reaction for several hours and then washing and drying the product, thus obtaining the SiO2 / Fe3O4 compound particle. The method has the following advantages: the process is simple; the cost is low; the reaction conditions are easy to control; the core-shell structured SiO2 / Fe3O4 magnetic particle can be produced in a large scale; and therefore, the method has a good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

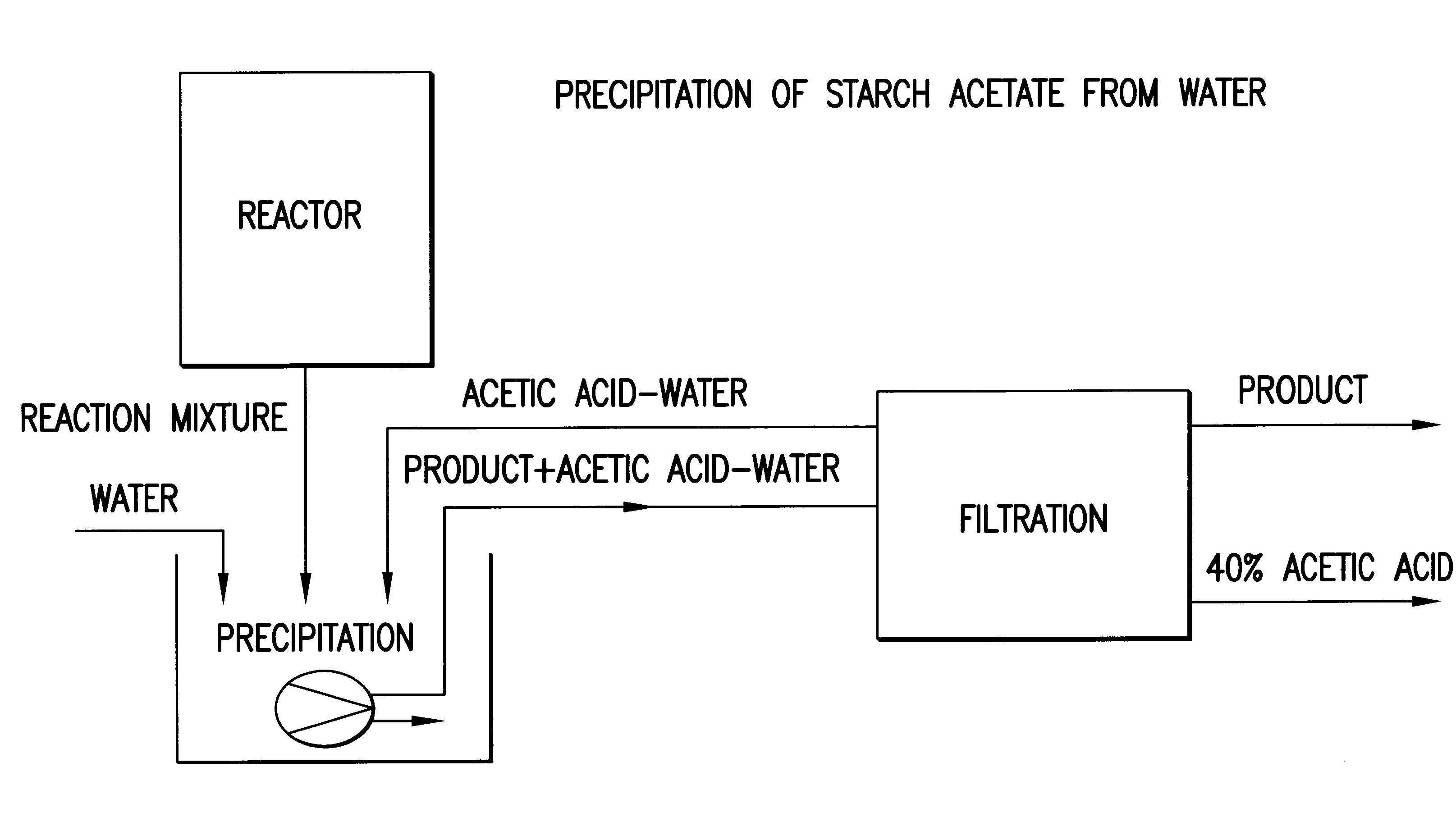

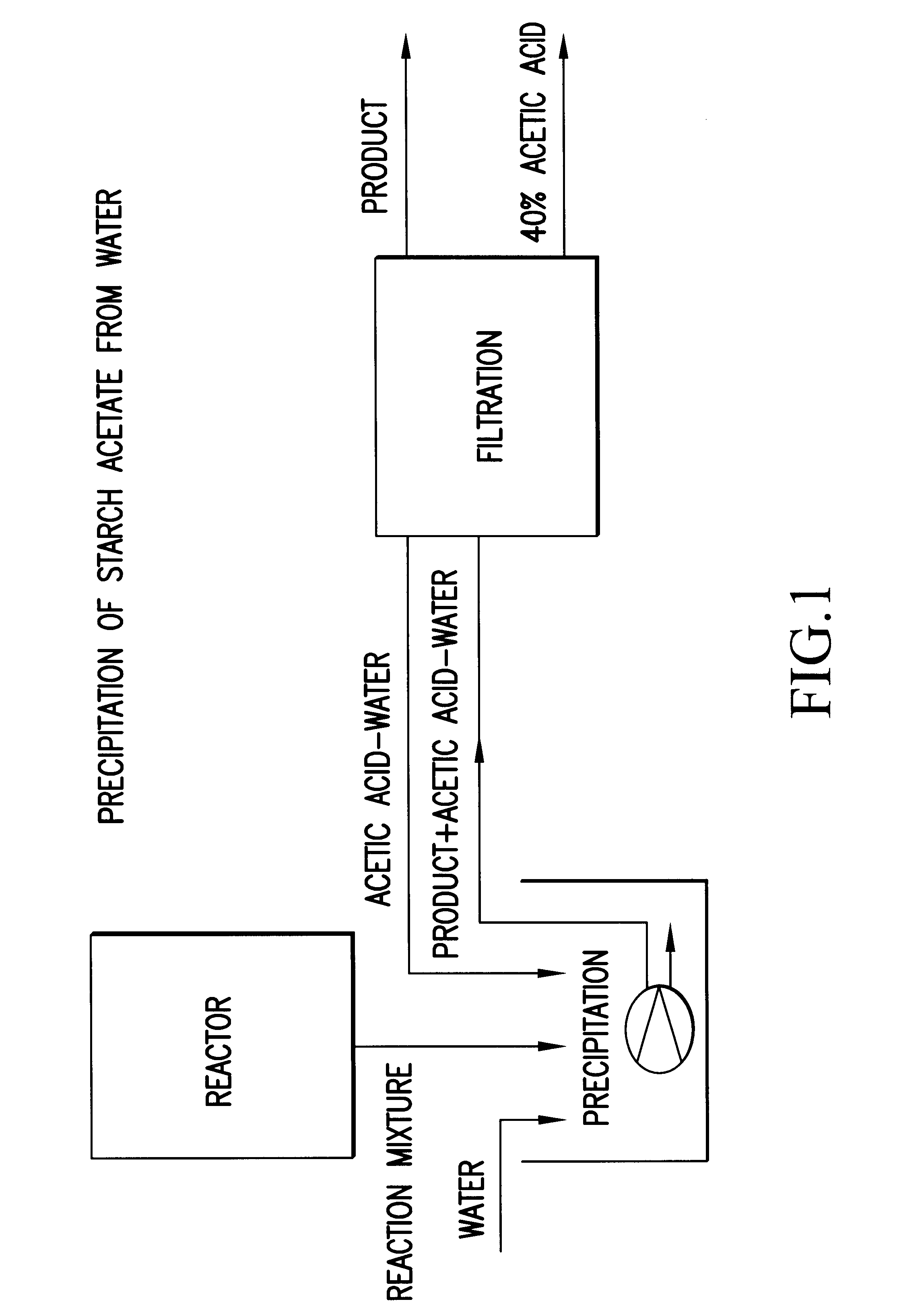

Process for the preparation of a starch ester

InactiveUS6605715B1Easy to controlDelayed reaction timeEsterified saccharide compoundsSugar derivativesSodium acetateAcetic acid

Process for the preparation of a starch ester, in particular a starch acetate, wherein a starch-based feedstock is reacted with an organic carboxylic acid anhydride in the presence of a catalyst. The reaction of the starch-based feedstock and the anhydride is performed at an excess pressure of about 0.1 to 50 bar in an essentially anhydrous medium containing 10% by weight of water at the most. As catalyst, sodium acetate, sodium hydroxide or sulphuric acid is used, and as the reaction medium, acetic acid or excess acetanhydride is used. By means of the invention, the duration of the esterification reaction can be significantly shortened, the separation of the product can be facilitated, and the recirculation of the waste solutions can be rendered more efficient.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

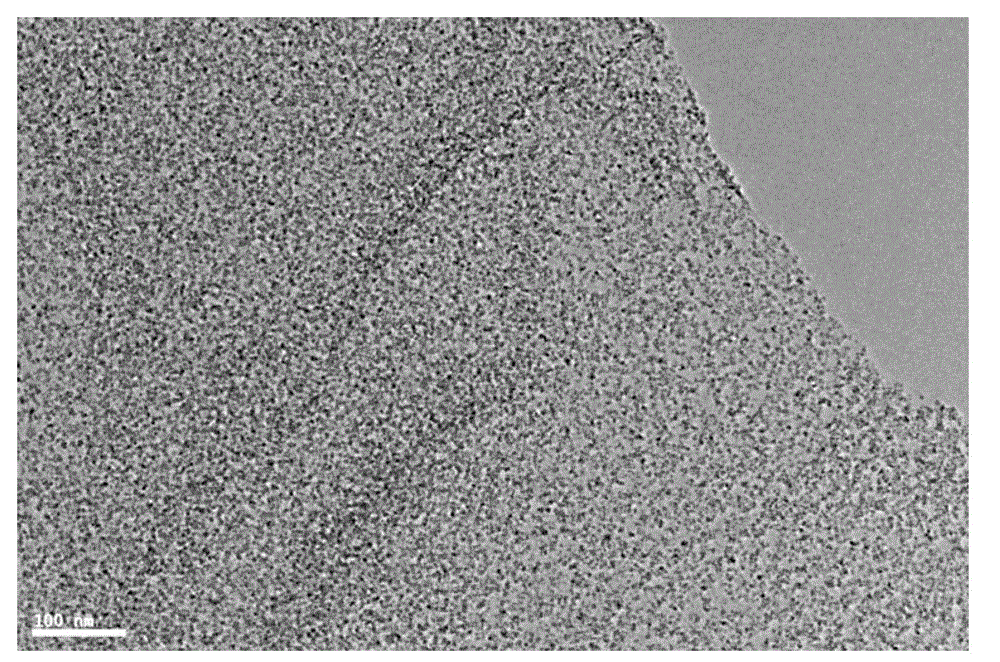

Preparation method for cerium oxide/graphene oxide nanocomposite

InactiveCN102716734AShort reaction timeReduce energy consumptionMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsSodium acetateNano composites

The invention relates to a preparation method for cerium oxide / graphene oxide nanocomposite. The invention aims at providing a preparation method of cerium oxide / graphene oxide nanocomposite, and the preparation method is low in equipment requirement, simple to operate and fast in reaction speed, and is capable of saving energy consumption and uniformly dispersing metal nanoparticles on the surface of graphene. The method comprises the steps of: based on cerate, sodium acetate, urea and graphite oxide as raw materials, placing graphite oxide and water into a container, and carrying out ultrasonic treatment so that graphite oxide form a suspension in the water; placing cerate, sodium acetate and urea into the container for dissolving cerate, sodium acetate and urea into the water; and placing the container into a reactor with a backflow device for reaction until the reaction is finished, so as to obtain a black precipitate namely cerium oxide / graphene oxide nanocomposite.

Owner:ZHEJIANG NORMAL UNIVERSITY

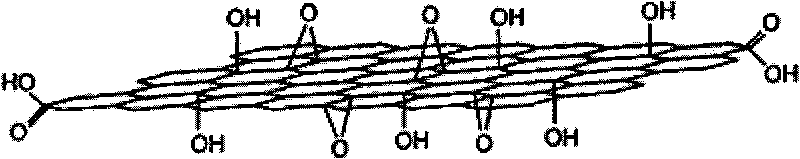

PtRu/graphene nano electro-catalyst and preparation method thereof

InactiveCN101740786AReductiveGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetrizoateSodium acetate

The invention discloses a preparation method of PtRu / graphene nano electro-catalyst, comprising the following steps of: ultrasonically dispersing oxidized nano graphite sheets into liquid polylol; then adding a chloroplatinic acid solution and a sodium acetate solution, sufficiently mixing, wherein the content of the oxidized nano graphite sheets contained in a mixture is 0.3-1.1 g / L, the concentration of chloroplatinic acid is 0.0004-0.002 mol / L, the concentration of ruthenium chloride is 0.0004-0.0013 mol / L, and the concentration of sodium acetate is 0.005-0.027 mol / L; transferring the mixture to a microwave hydro-thermal reaction kettle for microwave hydro-thermal reaction for 5-10 minutes; and filtering, washing and drying to obtain the PtRu / graphene nano electro-catalyst, wherein the mass fraction of a PtRu alloy contained in the PtRu / graphene nano electro-catalyst is 20-40 percent, the mass fraction of graphene is 80-60 percent, the atomic ratio of the PtRu alloy is Pt:Ru=1:2-1.5:1, and the liquid polylol is propanetriol or glycol. The preparation method has energy saving, fastness, simple process, and the like; and in addition, the prepared PtRu / graphene nano electro-catalyst has good electrocatalysis property for the oxidation of methanol and ethanol and is widely used as anode catalysts of direct methanol fuel cells.

Owner:ZHEJIANG UNIV

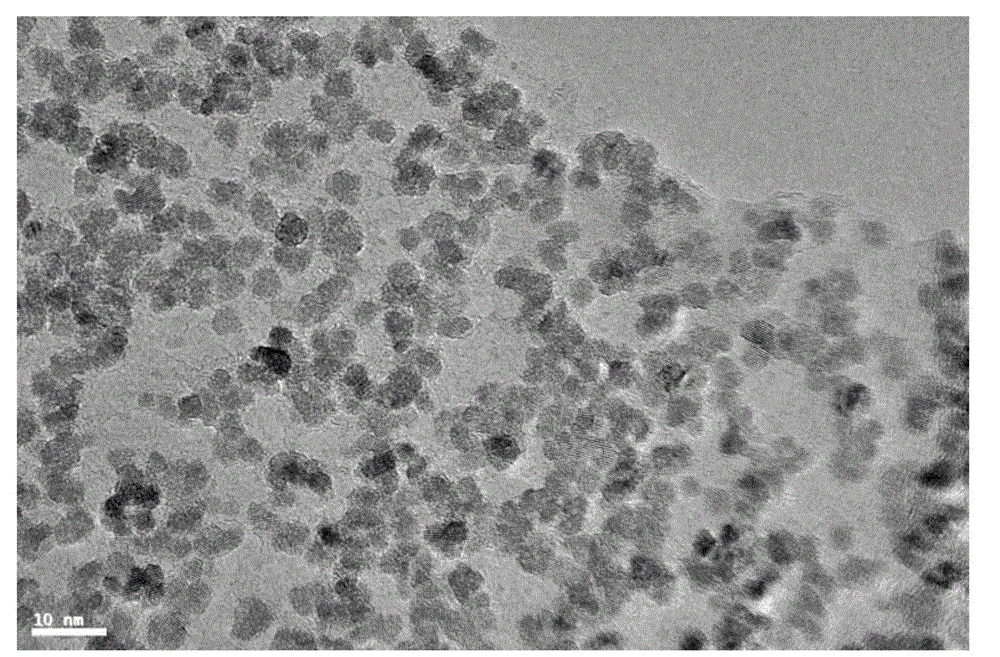

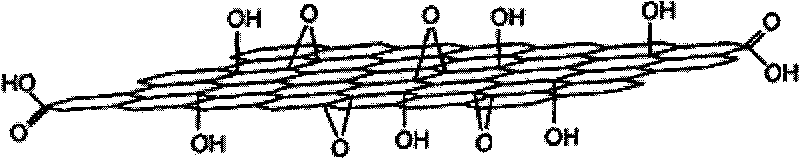

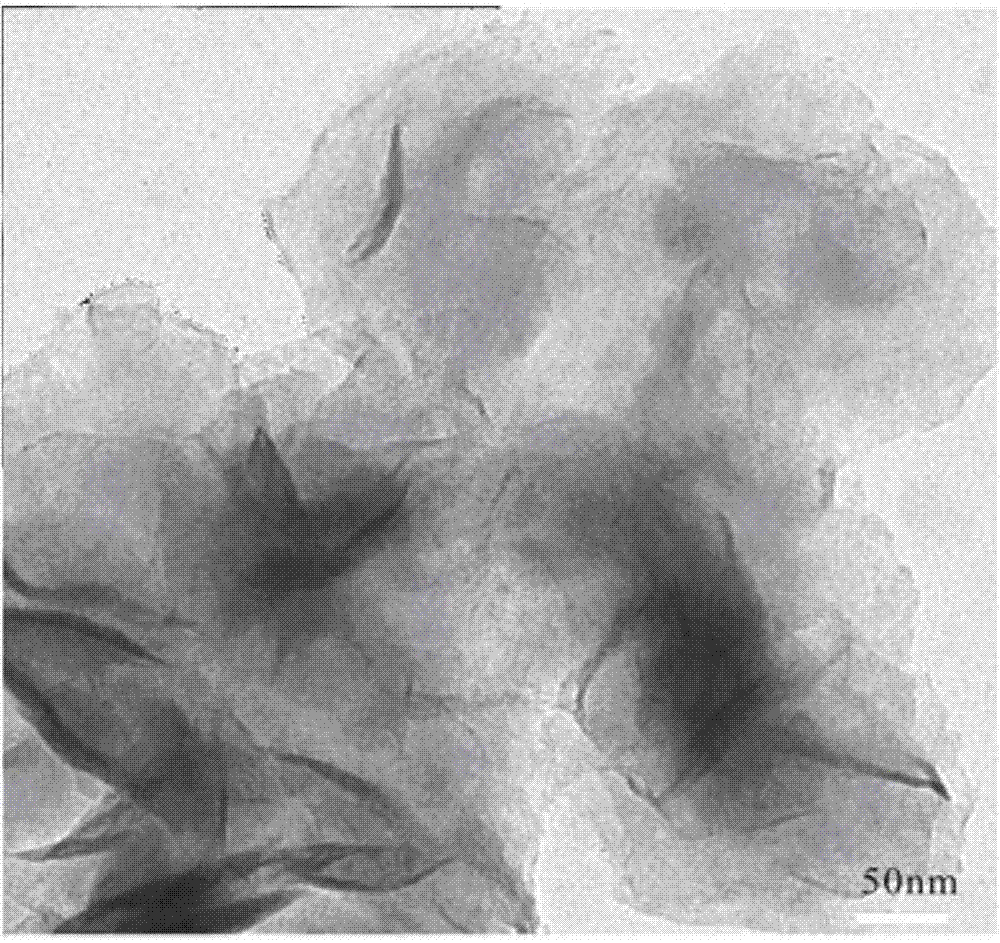

Palladium/graphene nano electro-catalyst and preparation method thereof

InactiveCN101740785AGood chemical stabilityLarge specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetatePalladium nanoparticles

The invention discloses a palladium / graphene nano electro-catalyst which takes graphene as a carrier and palladium as an active component, wherein the mass fraction of the palladium in the catalyst is 10 to 40 percent. A preparation method of the palladium / graphene nano electro-catalyst comprises the following steps of: (1) ultrasonically dispersing graphite oxide nano sheets in liquid polyalcohol, then adding a palladium salt solution and a sodium acetate solution, and fully and evenly mixing, wherein the content of the graphene oxide nano sheets in the mixture is 0.48 to 1.3g / L, the concentration of palladium salts is 0.0005 to 0.005mol / L, and the sodium acetate concentration is 0.0033 to 0.012mol / L; and (2) transferring the mixture into a microwave hydro-thermal reaction kettle, carrying out microwave heating and reacting for 5 to 10 minutes, then filtering, washing and drying to obtain the palladium / graphene nano electro-catalyst. The preparation method has the advantages of energy saving, high speed, simple process, and the like; and palladium nanoparticles in the prepared palladium / graphene nano electro-catalyst have even particle sizes. The catalyst has high electro-catalysis activity to formic electrooxidation and has wide application in fuel cells.

Owner:ZHEJIANG UNIV

Pt-CeO2/graphene electro-catalyst and preparation method thereof

InactiveCN101733094AReductiveGood dispersionCell electrodesCatalyst activation/preparationSodium acetateCerium

The invention discloses a Pt-CeO2 / graphene electro-catalyst which uses graphene as a carrier, platinum as an active component and CeO2 as an auxiliary component, wherein the mass fraction of the platinum contained in the Pt-CeO2 / graphene electro-catalyst is 20 percent; and the mole ratio of the platinum and cerium is 1:1-2.5:1. A preparation method of the Pt-CeO2 / graphene electro-catalyst comprises the following steps of: ultrasonically dispersing oxidized nano graphite sheets into glycol; then adding a chloroplatinic acid solution, an aqueous ammonium ceric nitrate solution and an aqueous sodium acetate solution, and sufficiently mixing; transferring a mixture to a microwave hydro-thermal reaction kettle; and after microwave hydro-thermal reaction, filtering, washing and drying to obtain the Pt-CeO2 / graphene electro-catalyst. The preparation method has energy saving, fastness, simple process, and the like; and in addition, the prepared Pt-CeO2 / graphene electro-catalyst has high electrocatalysis activity for the electrochemical oxidation of methanol and is widely used for direct methanol fuel cells.

Owner:ZHEJIANG UNIV

Anti-freeze aerated concrete brick

The invention discloses an anti-freeze aerated concrete brick. The anti-freeze aerated concrete brick is prepared from the following raw materials in parts by weight: 35-40 parts of fly ash, 15-20 parts of cement, 15-20 parts of wollastonite powder, 5-10 parts of modified straw ash, 2-4 parts of gypsum, 0.05-0.1 part of aluminum powder, 2-4 parts of urea, 0.01-0.03 part of oxyparaffin soap, 1-2 parts of sugar calcium, 4-6 parts of calcium formate, 0.1-0.5 part of polyethylene wax powder, 4-6 parts of calcium carbonate, 0.2-0.4 part of calcium nitrate, 0.1-0.2 part of sodium acetate and right amount of water.

Owner:潘逸东

Enhanced liquid cement grinding aid

InactiveCN102115316AIncrease late strengthImprove grinding efficiencySodium acetateSodium lignosulfonate

The invention relates to an enhanced liquid cement grinding aid capable of improving the grinding efficiency of a cement grinding mill and enhancing the strength of cement. The liquid cement grinding aid comprises the components with the weight percentages as follows: 10 to 20 percent of triethanolmine, 5 to 10 percent of triisopropanolamine, 3 to 5 percent of diethylene glycol, 2 to 5 percent of sodium formate, 2 to 5 percent of sodium acetate, 1 to 3 percent of sodium lignosulfonate, 10 to 20 percent of desugarized molasses, 5 to 10 percent of glycerin, and water.

Owner:山东国元新材料有限公司

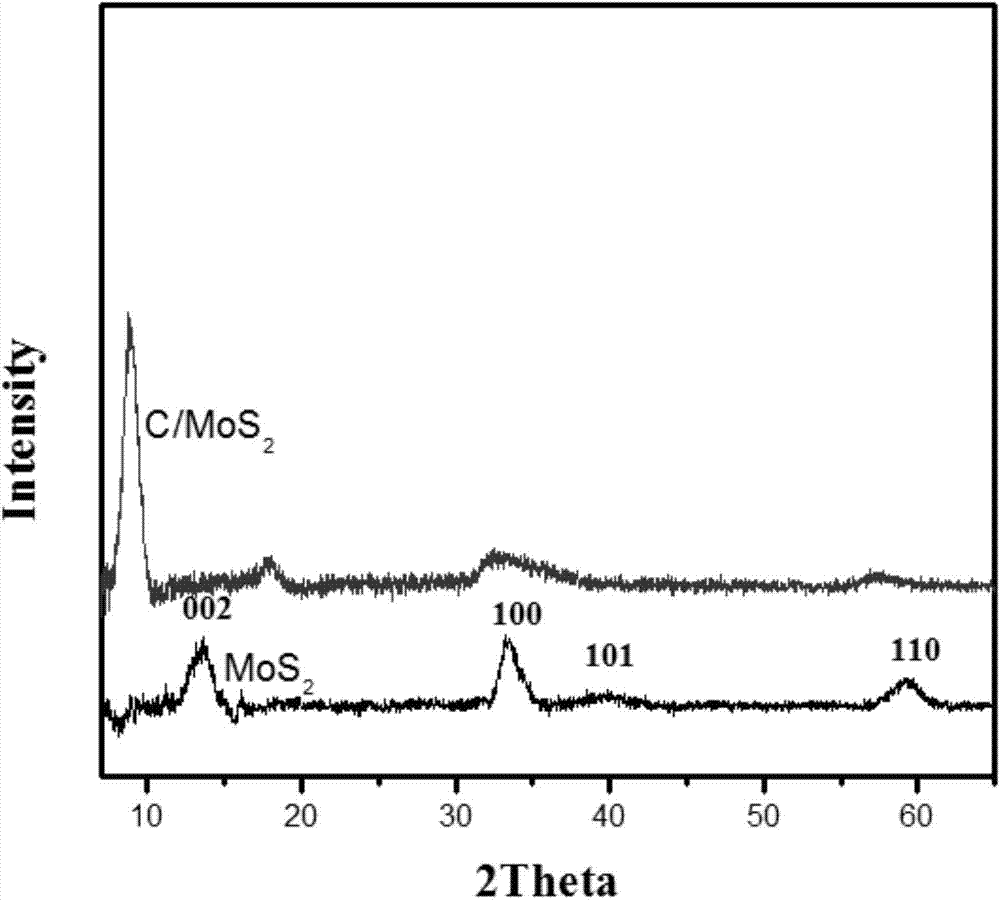

Preparation method of carbon-doped molybdenum disulfide nanometer material

InactiveCN104495937AImprove cycle stabilityLittle change before and afterMaterial nanotechnologyMolybdenum sulfidesSodium acetateDispersity

The invention provides a preparation method of a carbon-doped molybdenum disulfide nanometer material. The method comprises the following steps: weighing sodium molybdate, ammonium molybdate or molybdenum oxide and thiourea, sodium sulphide, potassium rhodanate or dithiocyano sodium acetate to be firstly dissolved into an ethylene glycol solution, then dissolved into ultrapure water, and fully stirring, so as to prepare a mixed solution; adjusting the pH value of a mixed solution with ammonia water and hydrochloric acid; transferring the mixed solution into a reaction kettle, and carrying out solvothermal reaction; taking out the mixed solution after reaction, and naturally cooling to room temperature; sequentially washing with ultrapure water and ethyl alcohol, and collecting a black substance; and drying the black substance in a vacuum drying oven, so as to prepare the carbon-doped molybdenum disulfide nanometer material. According to the carbon-doped MoS2 nanometer material prepared by the method, the sheet is uniform in size, good in dispersity, small in pollution in preparation process, and free of harmful air; and the molybdenum disulfide nanometer material with good dispersity can be greatly prepared.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

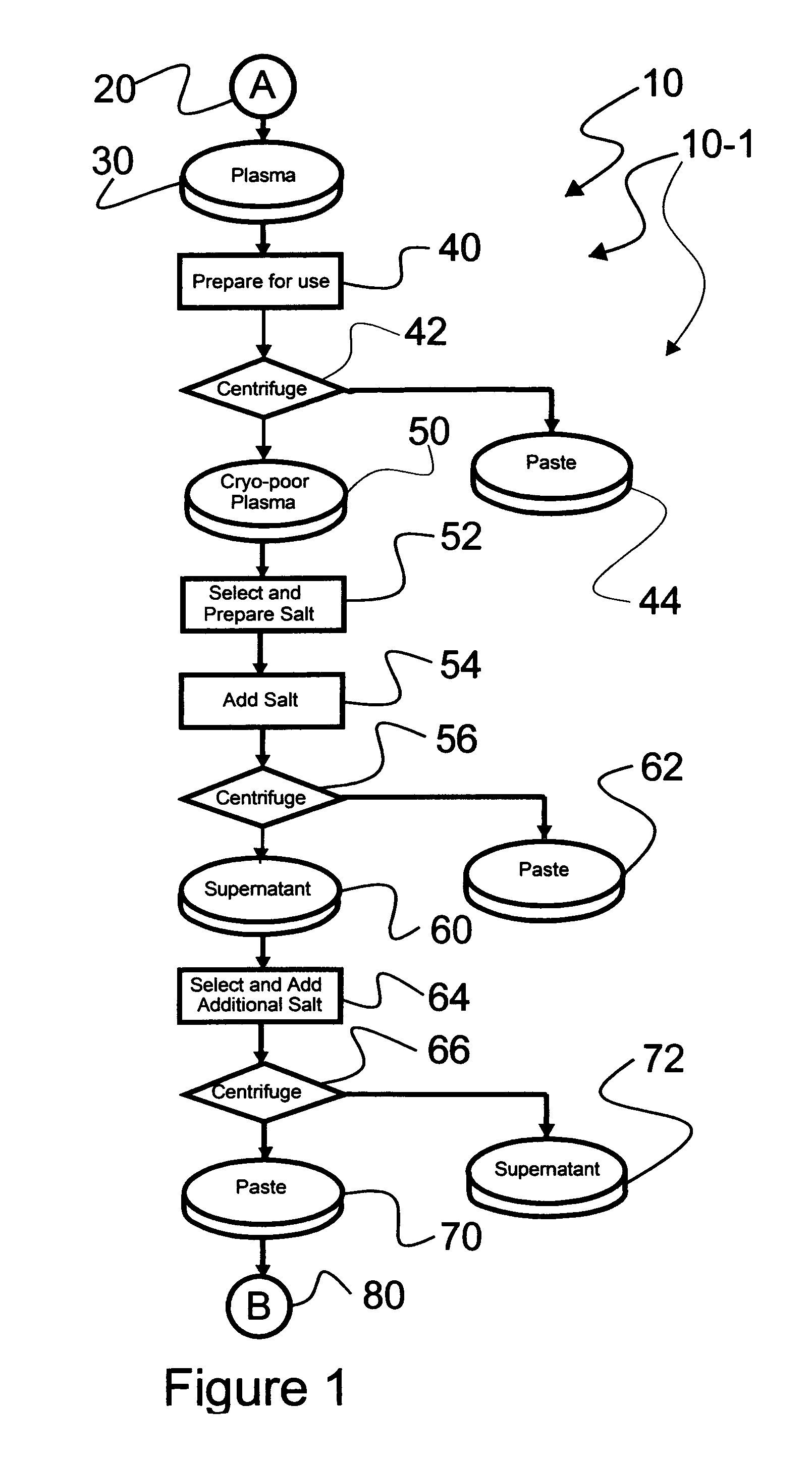

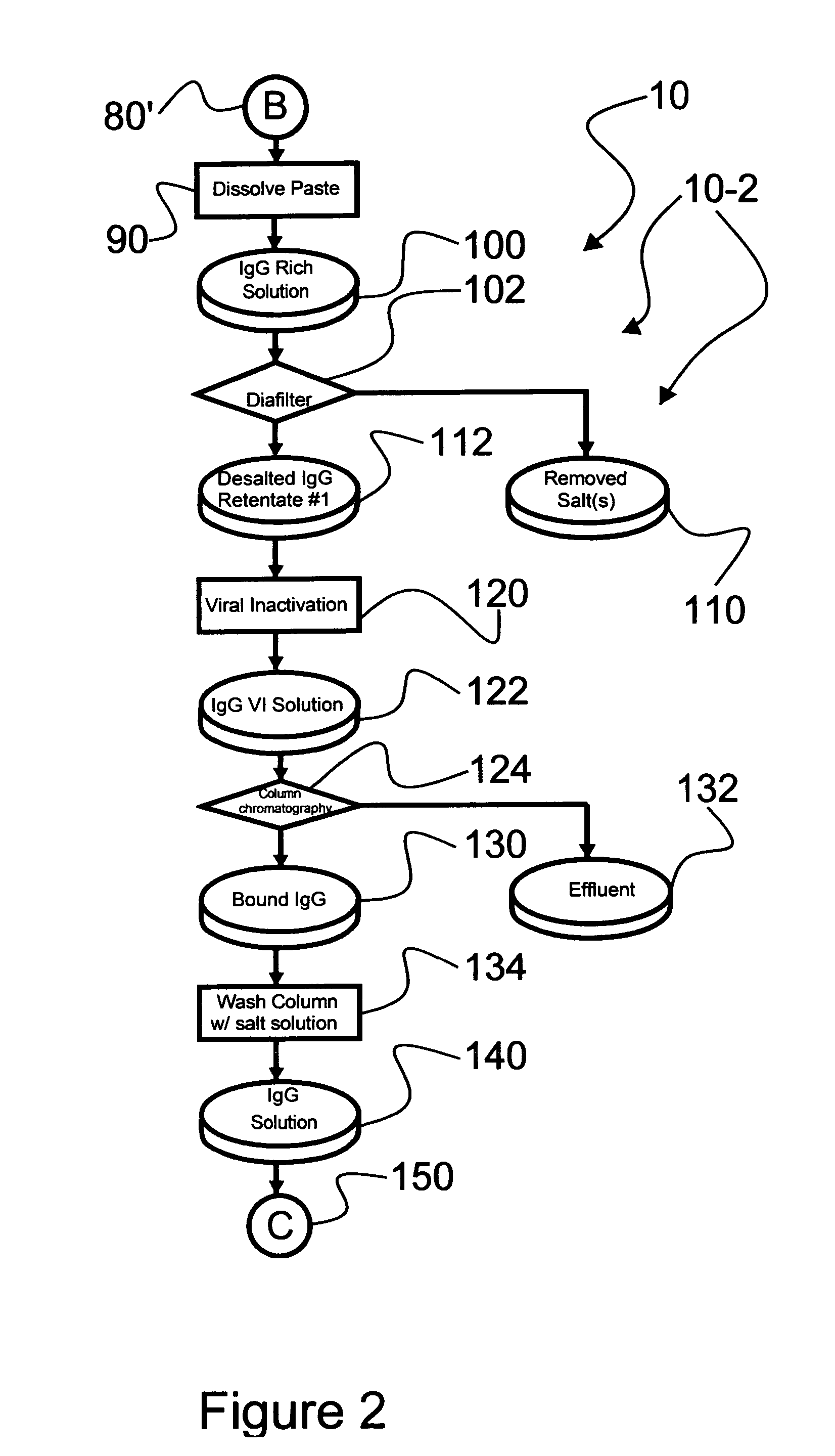

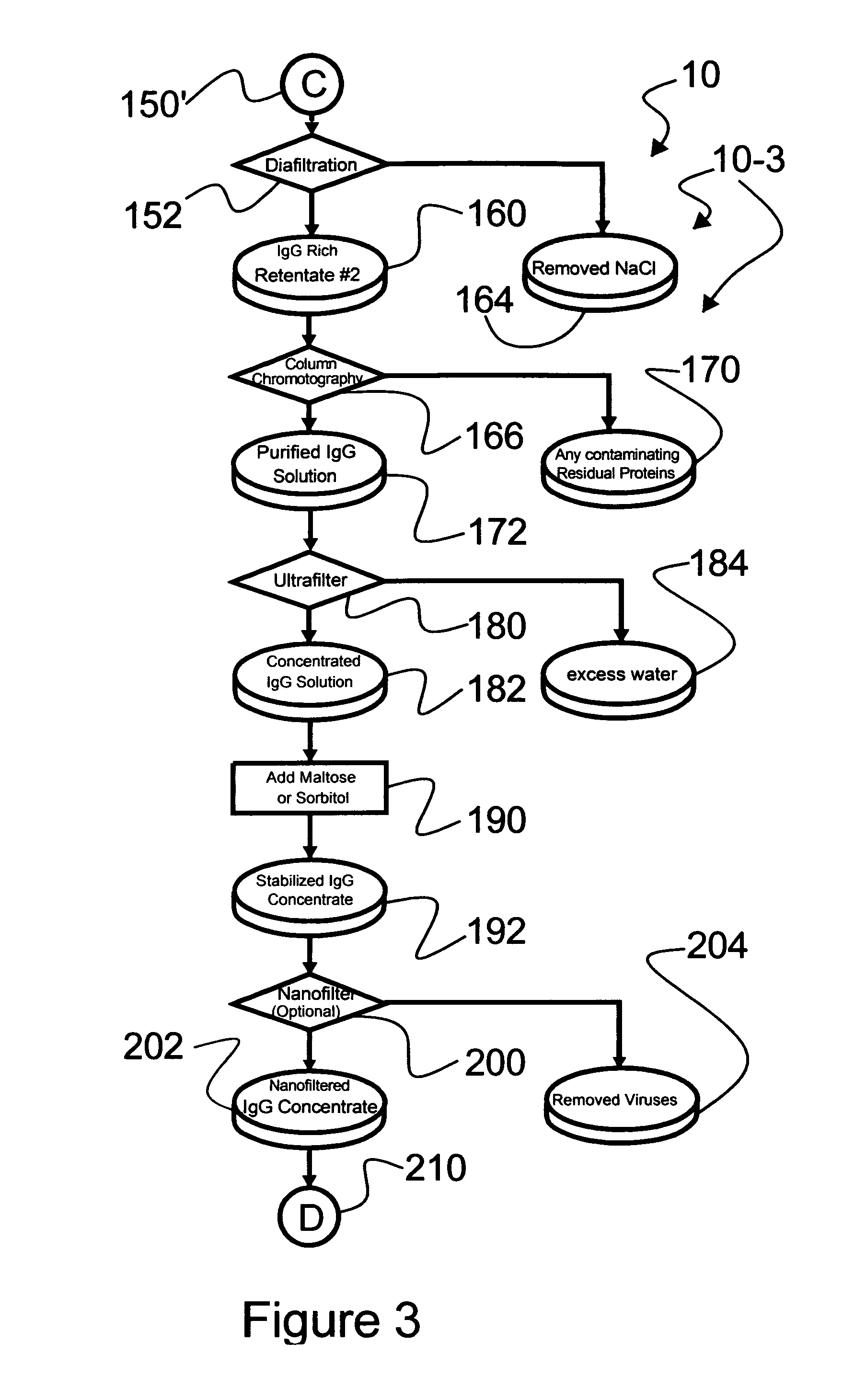

Ultra-high yield intravenous immune globulin preparation

ActiveUS7879332B2Quick restoration of the internal water moleculeReduce formationBiocideMedical devicesSodium acetateAlcohol free

An efficacious large-scale alcohol-free plasma fractionation production process which produces a high-yielding, non-denatured, double viral-inactivated intravenous human immune gamma globulin (IgG) product. The process employs one or more salts from a group of salts comprising sodium citrate, sodium acetate, sodium gluconate, ammonium sulfate, sodium chloride, sodium sulfate and ammonium chloride in two initial fractionation steps, followed by diafiltration to remove those salts employed. A process which employs alcohol via the process of the disclosed inventive method is also disclosed.

Owner:PLASMA TECH LLC

Method for preparing nano lead product by lead plaster of waste lead-acid storage batteries

ActiveCN102820496AHazard mitigationReduce pollutionWaste accumulators reclaimingProcess efficiency improvementSodium acetateAcetic acid

The invention relates to a method for preparing a nano lead product by lead plaster of waste lead-acid storage batteries. The method comprises the following steps of: mixing the lead plaster, sodium acetate, acetic acid and H2O2 according to a ratio, diluting the mixture by de-ionized water, agitating and reacting the diluted mixture at 20-30 DEG C for 6-10 hours, carrying out solid-liquid separation on the mixture after the reaction, adjusting the pH (Potential of Hydrogen) of the mixture to 7.1-7.3, standing the mixture for 1-2 hours, and filtering the mixture to obtain a lead acetate crystal; calcining the lead acetate crystal at 250-350 DEG C for 2-3 hours to obtain nano PbO powder; and mixing the lead acetate crystal, a sulfur source and a surfactant according to a ratio, adding a liquid medium in the mixture, mixing the mixture and the liquid medium uniformly, placing the obtained mixture into a reaction kettle at 120-130 DEG C for 10-15 hours, naturally cooling the mixture to a room temperature, carrying out solid-liquid separation on the mixture, and washing black sediments by water and ethanol to obtain the nano PbS product. The method disclosed by the invention not only provides a raw material and a method for manufacturing the nano lead product, and is good for relieving environmental damages which are possibly caused by a large amount of waste lead-acid storage batteries and realizing high efficiency and low pollution of a lead resource recycling process.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

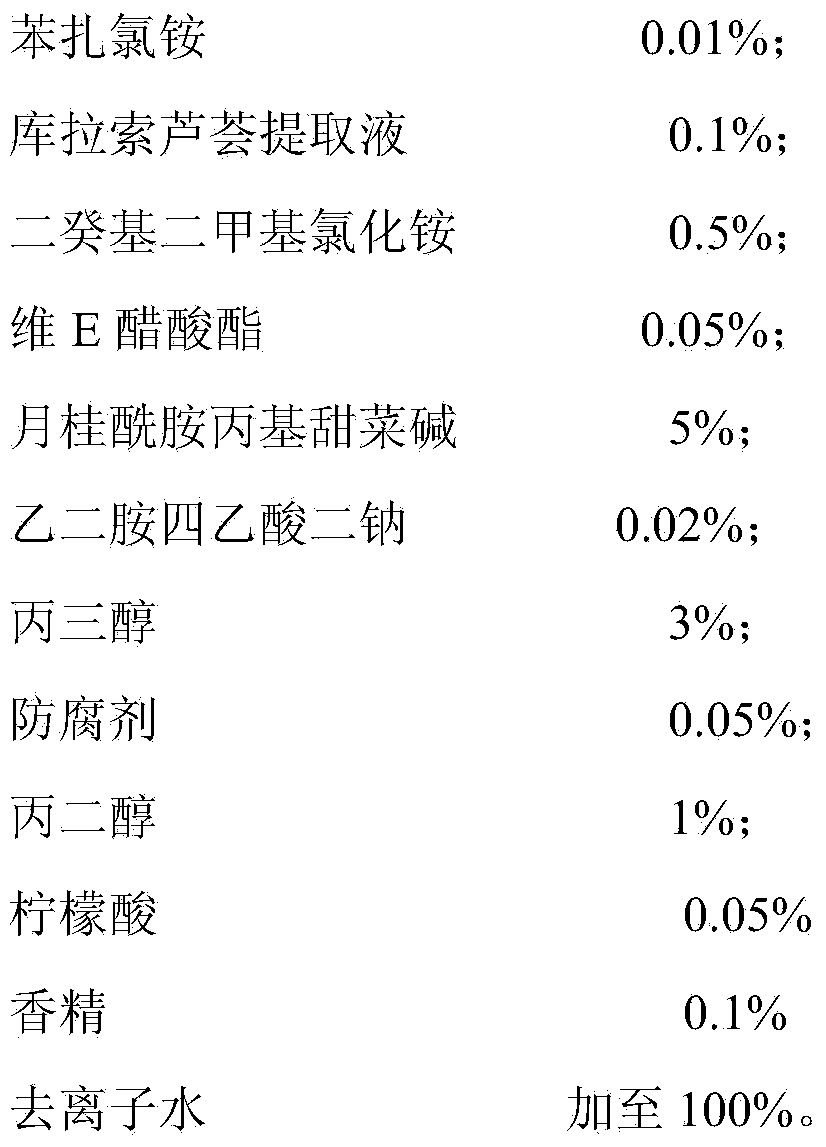

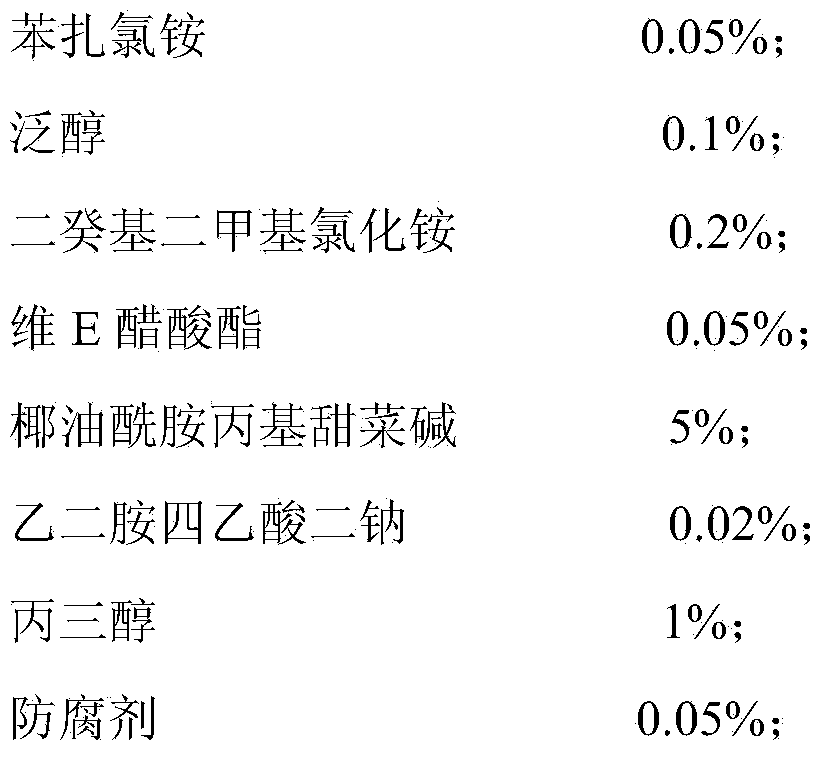

Foam type wash-free antibacterial liquid soap and using method thereof

InactiveCN104188811ALong-term antibacterial effectDelicate skinCosmetic preparationsToilet preparationsSodium acetateBetaine

The invention discloses foam type wash-free antibacterial liquid soap which comprises the following components based on the weight of the composition: A) 0.1-1.0wt% of anodic bactericide, wherein the anodic bactericide comprises benzalkonium chloride and didecyl dimethyl ammonium chloride; B) 0.1-10wt% of ampholytic surfactant, wherein the ampholytic surfactant is selected from at least one of alkyl amide propyl betaine and alkyl ampholytic sodium acetate or a mixture thereof; C) 0.1-5wt% of humectant; D) 0.02-0.5wt% of chelating agent; and E) the balance of deionized water. The foam type wash-free antibacterial liquid soap disclosed by the invention has to be matched with a foam pump head in use. After a product is pumped to form foam by virtue of the pump head, the foam is smeared in hands to achieve the best wash-free antibacterial using effect.

Owner:GUANGZHOU LIBY

Gemini quaternary-ammonium-salt water injection increasing agent

ActiveCN101705081AImprove seepage capacityReduce interfacial tensionDrilling compositionSodium acetatePotassium

The invention provides a gemini quaternary-ammonium-salt water injection increasing agent, which is an additive applied to injected water of oilfield injection wells. The parts by weight of the components are: 20 to 26 parts of N,N'-butylidene bislauroyl ammonium bromide, 5 to 8 parts of C12 fatty alcohol polyoxyethylene ether sodium acetate, 1.5 to 2.5 parts of ethylene glycol, 4.5 to 7.5 parts of polyoxyethylene (7) nonylphenol ether NPE-7, 4.5 to 8.5 parts of sorbitananhydride monostearate polyoxyethylene ether, 1 to 2.5 parts of ethyl ethylthio sulfonate, 12.5 to 16.5 parts of Monoethanolamine, 45 to 55 parts of distilled water, 0.5 to 1 part of sodium hydroxide, 2.5 to 4.5 parts of polyhydroxypropyl dimethyl ammonium chloride, and 0.05 to 0.1 part of perfluoroalkyl ether carboxylic acid potassium salt FC-5. The agent has the advantages that 0.05 to 0.2 percent of the agent added to the injected water can change the wettability of rock surfaces, enables oil reservoirs to be more hydrophilic, reduces blockage at well bottom and reservoirs, reduces damage to strata, and can drop the well-head pressure of the injection well by 5 to 15 percentage points.

Owner:PETROCHINA CO LTD

Pet foodstuff and method for making the same

InactiveCN101095470AEfficient killingKeep natural shapeAnimal feeding stuffAccessory food factorsSodium acetateVitamin C

The invention relates to a pet food mainly prepared from fowl meat, wherein the raw material comprises the following constituents (by weight ratio): chicken chest 100, potassium sorbate 0.05-0.1, dehydrogenated sodium acetate 0.01-0.03, sodium nitrite 0.001-0.003, vitamin C 0.01-0.02, table salt 0.02-0.04, glycerin 0.3-0.5. The preparing process consists of treating raw materials, proportioning quelite, low temperature pickling, drying, roasting, detecting and packaging.

Owner:WEIHAI WANGJIAWANG PET FOODSTUFF

A manufacture method of carbon-based metal nitrides, and carbonide supercapacitance material

InactiveCN101060037AHigh specific capacitanceEvenly dispersedElectrode manufacturing processesElectrolytic capacitorsSodium acetateCapacitance

The preparation method for super-capacitance material comprises: with meta-dihydroxybenzene and formaldehyde as the reacting material, with sodium acetate or sodium propionate or the mixture as additive, adding transition metal oxide during the gelling to obtain the uniform distributed RF aqueous gel with rich transition metal salt; then, with N2 or H2, drying on common pressure, and charring to obtain the final product with 400F / g-870F / g capacity.

Owner:HEFEI UNIV OF TECH

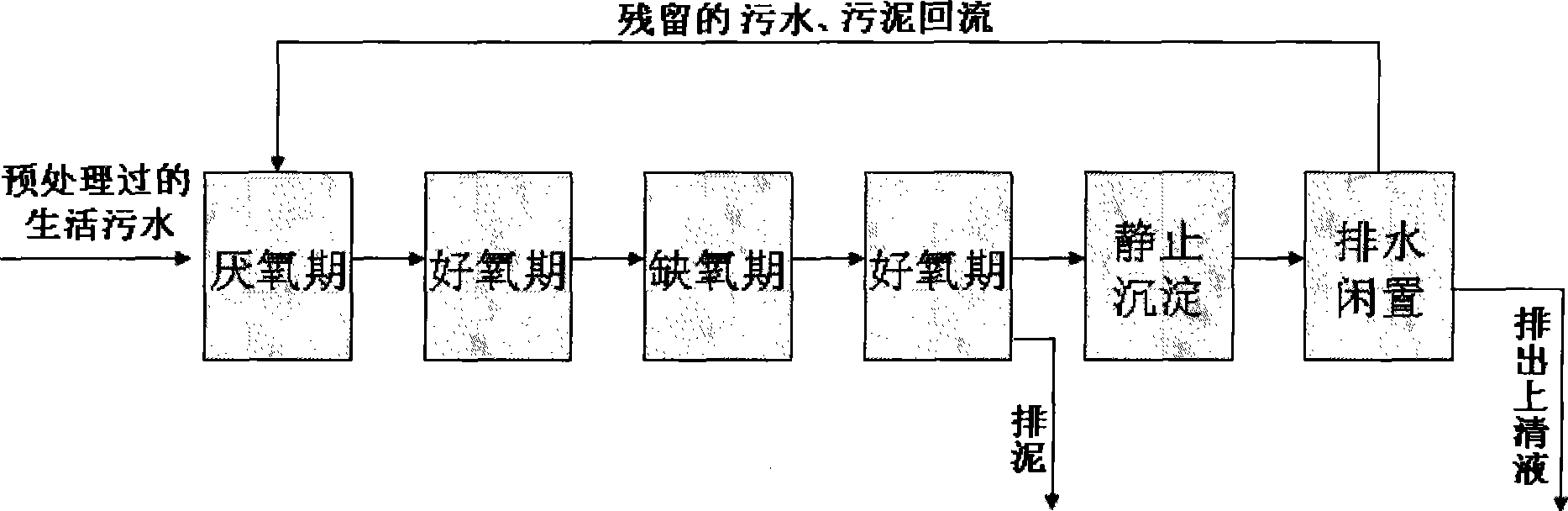

Simultaneous nitrogen and phosphorus removal (AO)2SBR sewage treatment process

InactiveCN101423294AExtended service lifeCarbon savingTreatment with aerobic and anaerobic processesSodium acetateNitrogen

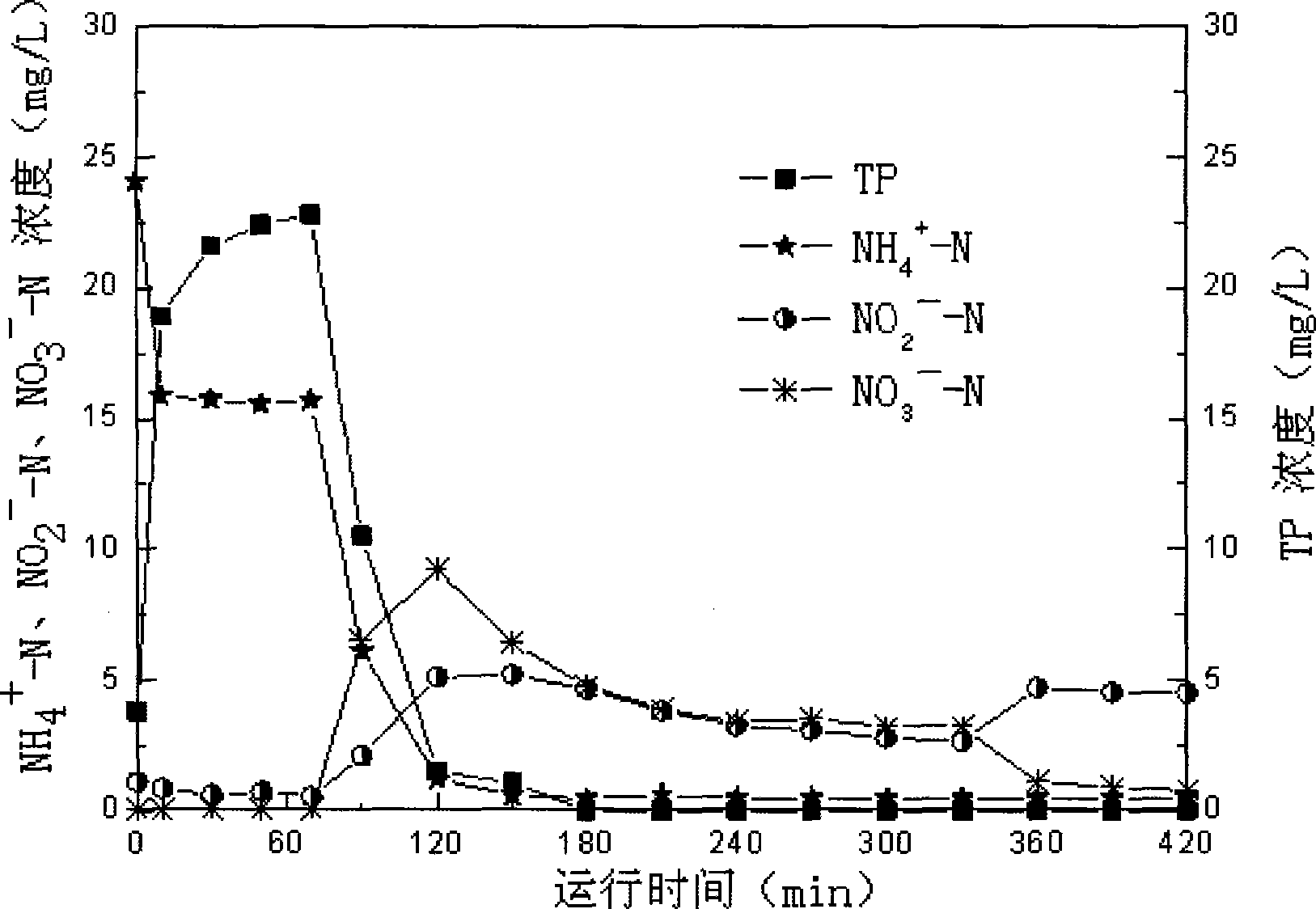

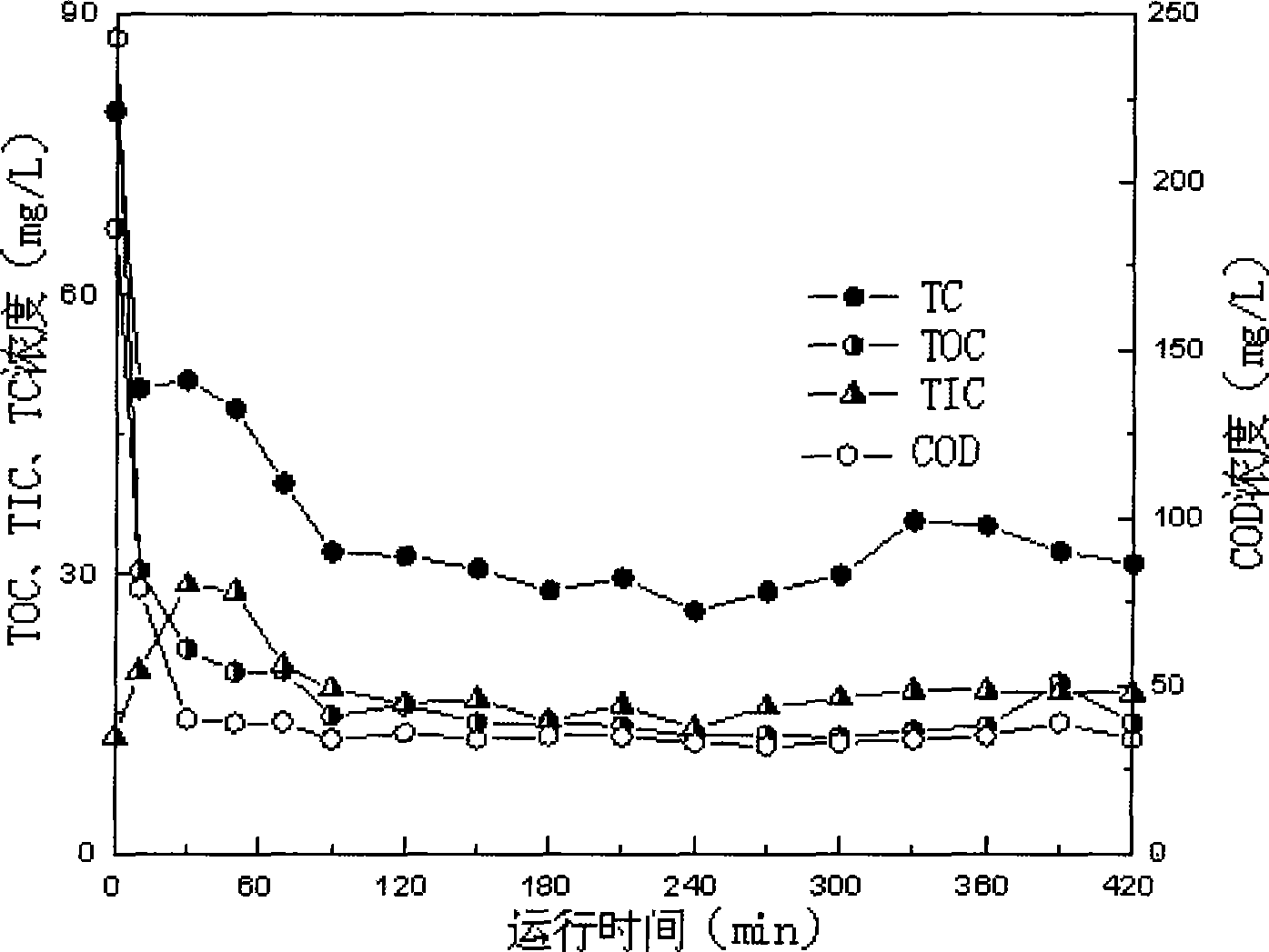

The invention relates to a sewage treatment process for removing the nitrogen and phosphorus simultaneously; the whole process reaction is carried out in a sequence batch type bioreactor, respectively undergoes six stages of an anaerobic period, an aerobic period, a hypoxia period, an aerobic period, static precipitation, and a water drainage idle period, namely an anaerobic section and an aerobic section are reduced on the basis of a (AO)3SBR process, so denitrifying phosphorus accumulating bacteria can be cultivated easily and become a advantageous bacteria type of the phosphorus accumulating bacteria; moreover, denitrifying phosphorus absorption is carried out on the denitrifying phosphorus accumulating bacteria in a 'one-carbon dual-use' of the reaction and no carbon source is needed to be added additionally, so the aim of carbon source conservation is achieved, one aerobic section is reduced, the aerobic time is decreased to 90min from 130min, and the energy consumption is reduced by about 31 percent; in addition, as (AO)2SBR process lacks an (A / O) alternate operation compared with the(AO)3SBR process, the service life of instrument is prolonged; the removal effect for TN, TP, COD, and TOC of the sewage is respectively 78.47 percent, 99.5 percent, 86 percent, and 79.3 percent; when part of sodium acetate is added to the sewage, the removal effects of the nitrogen and the phosphorus are both increased to a certain extent.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com