Pt-CeO2/graphene electro-catalyst and preparation method thereof

An electrocatalyst, pt-ceo2 technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as the difficulty of metal nanoparticles and affect the electrocatalytic performance of catalysts, and achieve energy-saving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

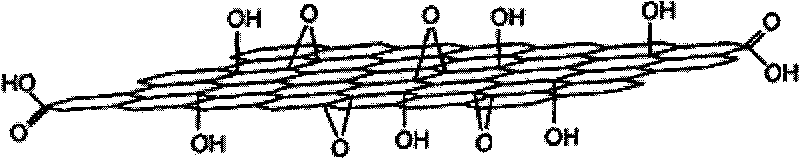

Image

Examples

Embodiment 1

[0020] 148 mg of graphite oxide nanosheets were dispersed in 150 mL of ethylene glycol by ultrasonic treatment, then 4 mL of 0.05 M chloroplatinic acid solution and 20 mL of 10 mM cerium ammonium nitrate aqueous solution were added, the molar ratio of platinum and cerium was 1:1, Then add 1.5 milliliters of 1 mol / L sodium acetate aqueous solution, the concentration of sodium acetate in the synthesis solution is 0.01 mol / L, fully stir and mix evenly. The homogeneous mixture was transferred to a microwave hydrothermal reaction kettle, and the reaction was heated by microwave radiation for 8 min. After cooling, filter, wash thoroughly with acetone and deionized water, and dry at 80°C to obtain Pt-CeO 2 / graphene catalyst. The platinum nano-particles in the catalyst were observed by a transmission electron microscope to have a uniform particle size, with an average particle size of 2.8 nanometers. EDX analysis showed that the mass fraction of platinum in the catalyst was 19.3% ...

Embodiment 2

[0024] 336 mg of graphite oxide nanosheets were dispersed in 300 mL of ethylene glycol by ultrasonic treatment, then 8 mL of 0.05 M chloroplatinic acid solution and 20 mL of 10 mM cerium ammonium nitrate aqueous solution were added, and the mol ratio of platinum and cerium in the solution was 2: 1. Then add 4 ml of 1mol / L sodium acetate aqueous solution, the concentration of sodium acetate in the synthesis solution is 0.013mol / L, stir well and mix well. The homogeneous mixture was transferred to a microwave hydrothermal reaction kettle, and the reaction was heated by microwave radiation for 10 min. After cooling, filter, wash thoroughly with acetone and deionized water, and dry at 80°C to obtain Pt-CeO 2 / graphene catalyst. The platinum nano-particles in the catalyst were observed by a transmission electron microscope to have a uniform particle size, with an average particle size of 3.0 nanometers. EDX analysis showed that the mass fraction of platinum in the catalyst was 2...

Embodiment 3

[0028] 430 milligrams of graphite oxide nanosheets are dispersed in 400 mL of ethylene glycol with ultrasonic treatment, then 10 mL of 0.05 M chloroplatinic acid solution and 20 mL of 10 mM ammonium cerium nitrate aqueous solution are added, and the mol ratio of platinum and cerium in the solution is 2.5: 1. Then add 10 ml of 1mol / L sodium acetate aqueous solution, the concentration of sodium acetate in the synthesis solution is 0.025mol / L, stir well and mix well. The homogeneous mixture was transferred to a microwave hydrothermal reaction kettle, and the reaction was heated by microwave radiation for 10 min. After cooling, filter, wash thoroughly with acetone and deionized water, and dry at 80°C to obtain Pt-CeO 2 / graphene catalyst. The platinum nano-particles in the catalyst were observed by a transmission electron microscope to have a uniform particle size, with an average particle size of 3.2 nanometers. EDX analysis showed that the mass fraction of platinum in the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Peak current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com