Patents

Literature

240results about How to "Fine and uniform particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Palladium/graphene nano electro-catalyst and preparation method thereof

InactiveCN101740785AGood chemical stabilityLarge specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetatePalladium nanoparticles

The invention discloses a palladium / graphene nano electro-catalyst which takes graphene as a carrier and palladium as an active component, wherein the mass fraction of the palladium in the catalyst is 10 to 40 percent. A preparation method of the palladium / graphene nano electro-catalyst comprises the following steps of: (1) ultrasonically dispersing graphite oxide nano sheets in liquid polyalcohol, then adding a palladium salt solution and a sodium acetate solution, and fully and evenly mixing, wherein the content of the graphene oxide nano sheets in the mixture is 0.48 to 1.3g / L, the concentration of palladium salts is 0.0005 to 0.005mol / L, and the sodium acetate concentration is 0.0033 to 0.012mol / L; and (2) transferring the mixture into a microwave hydro-thermal reaction kettle, carrying out microwave heating and reacting for 5 to 10 minutes, then filtering, washing and drying to obtain the palladium / graphene nano electro-catalyst. The preparation method has the advantages of energy saving, high speed, simple process, and the like; and palladium nanoparticles in the prepared palladium / graphene nano electro-catalyst have even particle sizes. The catalyst has high electro-catalysis activity to formic electrooxidation and has wide application in fuel cells.

Owner:ZHEJIANG UNIV

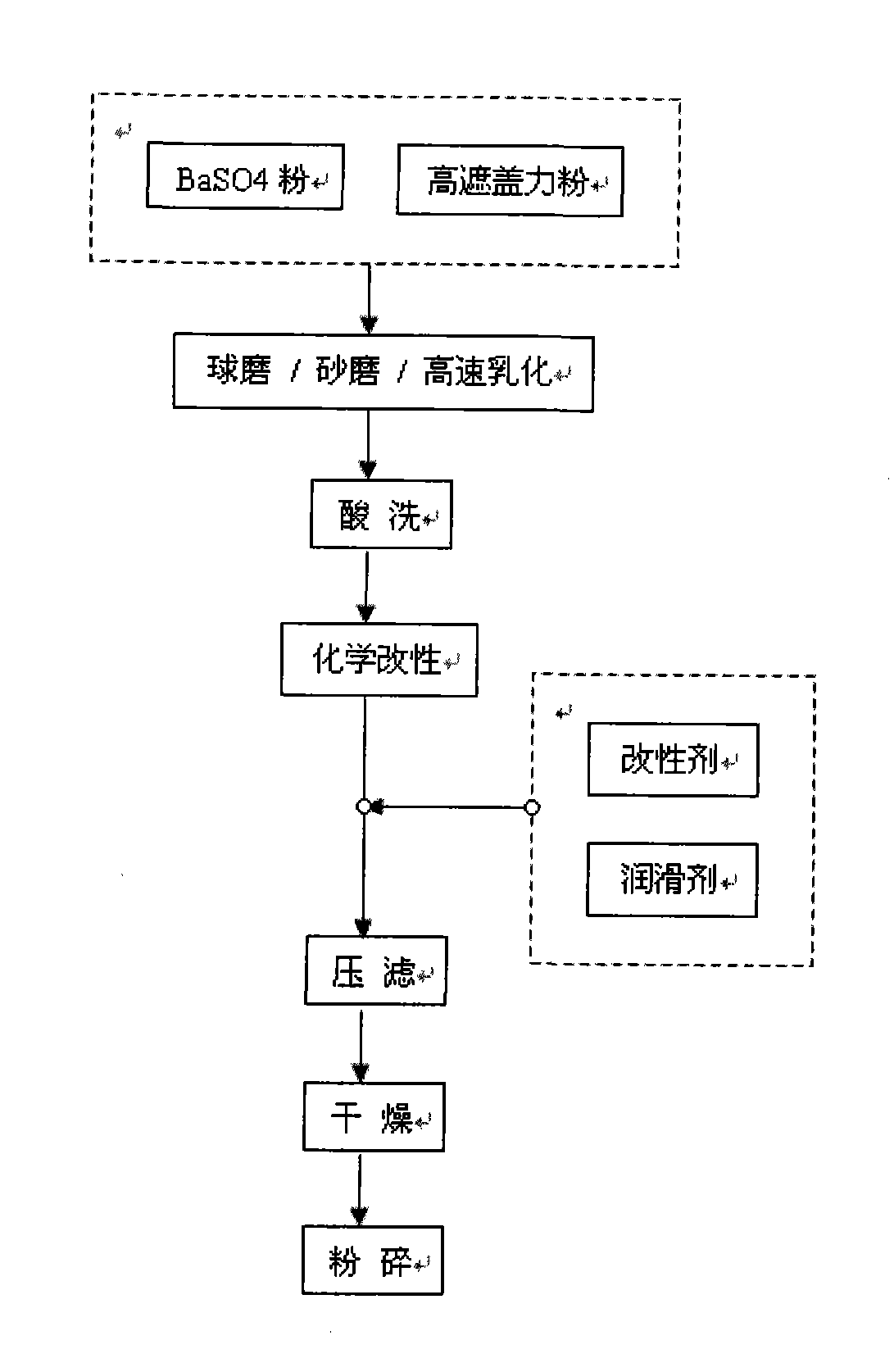

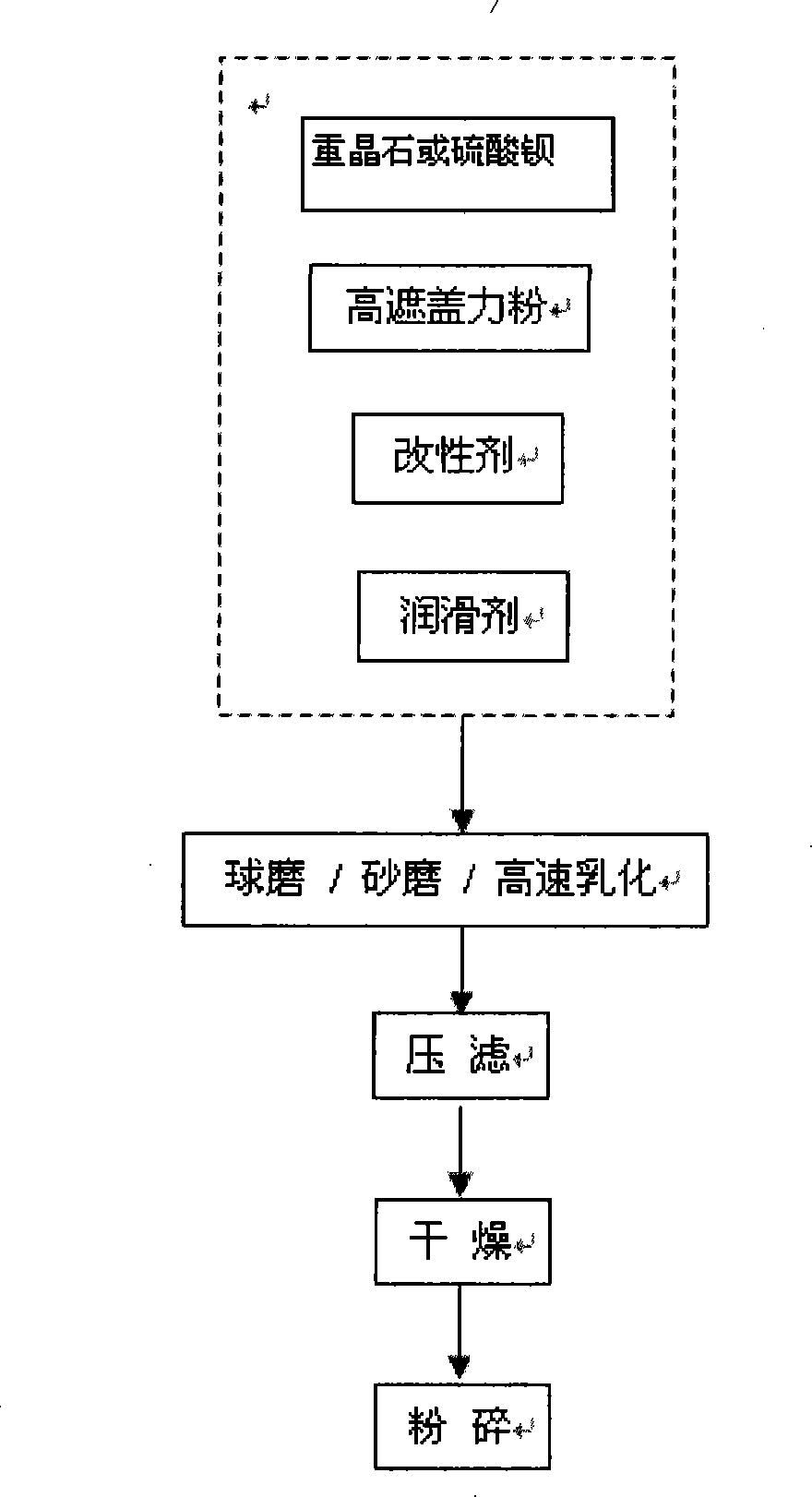

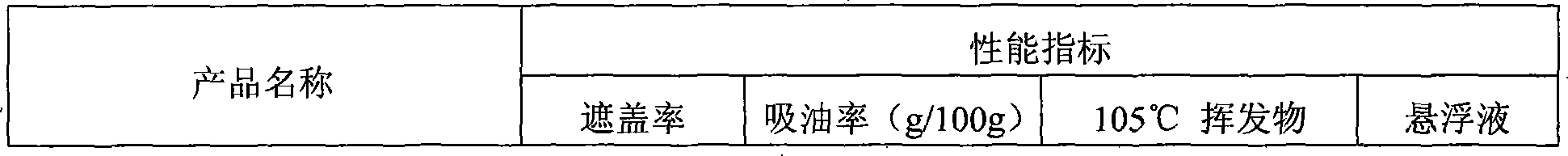

Barium sulfate based polybasic composite white pigments and method for preparing same

InactiveCN101250336AFine and uniform particle sizeHigh whitenessInorganic pigment treatmentBarium sulfatePigment

The invention discloses barium sulfate group multi-composite white pigment, which is characterized in that the invention comprises components with parts by weight: 100 parts of powder with barium sulfate, 0.1-10 parts of dispersant, 0.1-90 parts of powder with high covering power, 0.1-10 parts of modifier and 0.01-20 parts of lubricating agent. The barium sulfate group multi-composite white pigment has fine and even particle diameter, high whiteness, excellent dispersing ability, strong covering powder and wonderful weather-ability, and has the advantages of low production cost, simple technique and suitable industrial production.

Owner:FOSHAN ONMILLION NANO MATERIALS

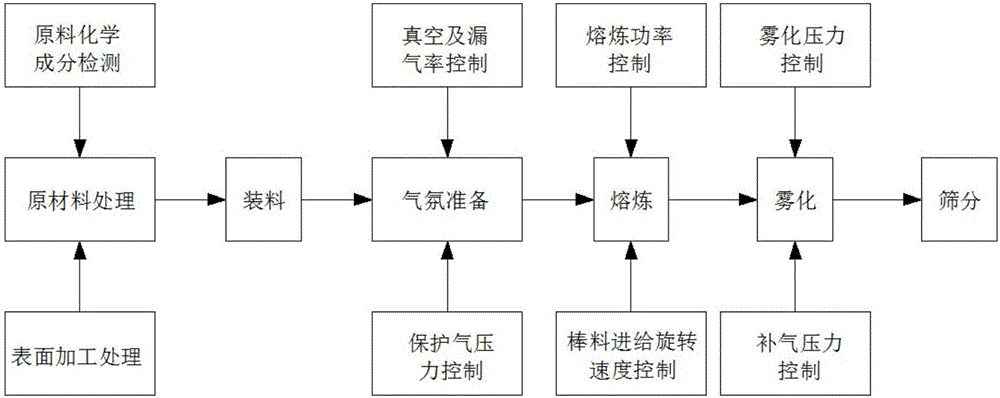

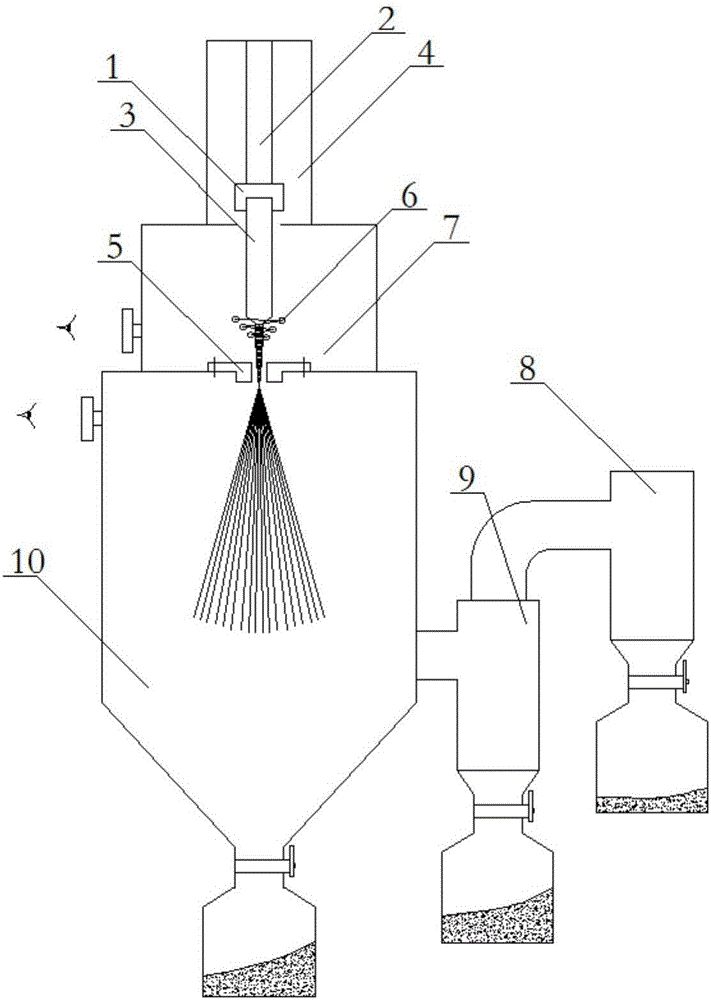

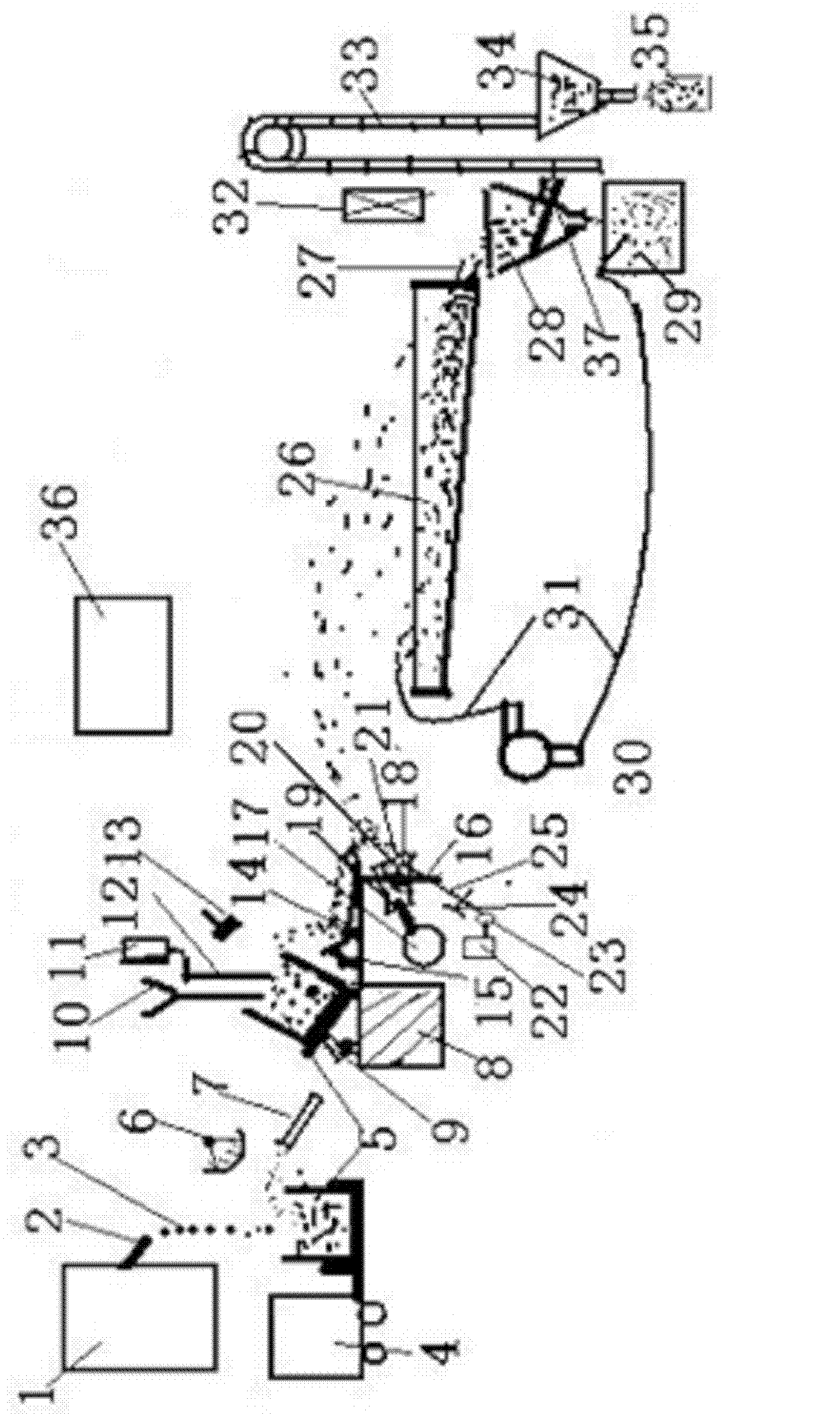

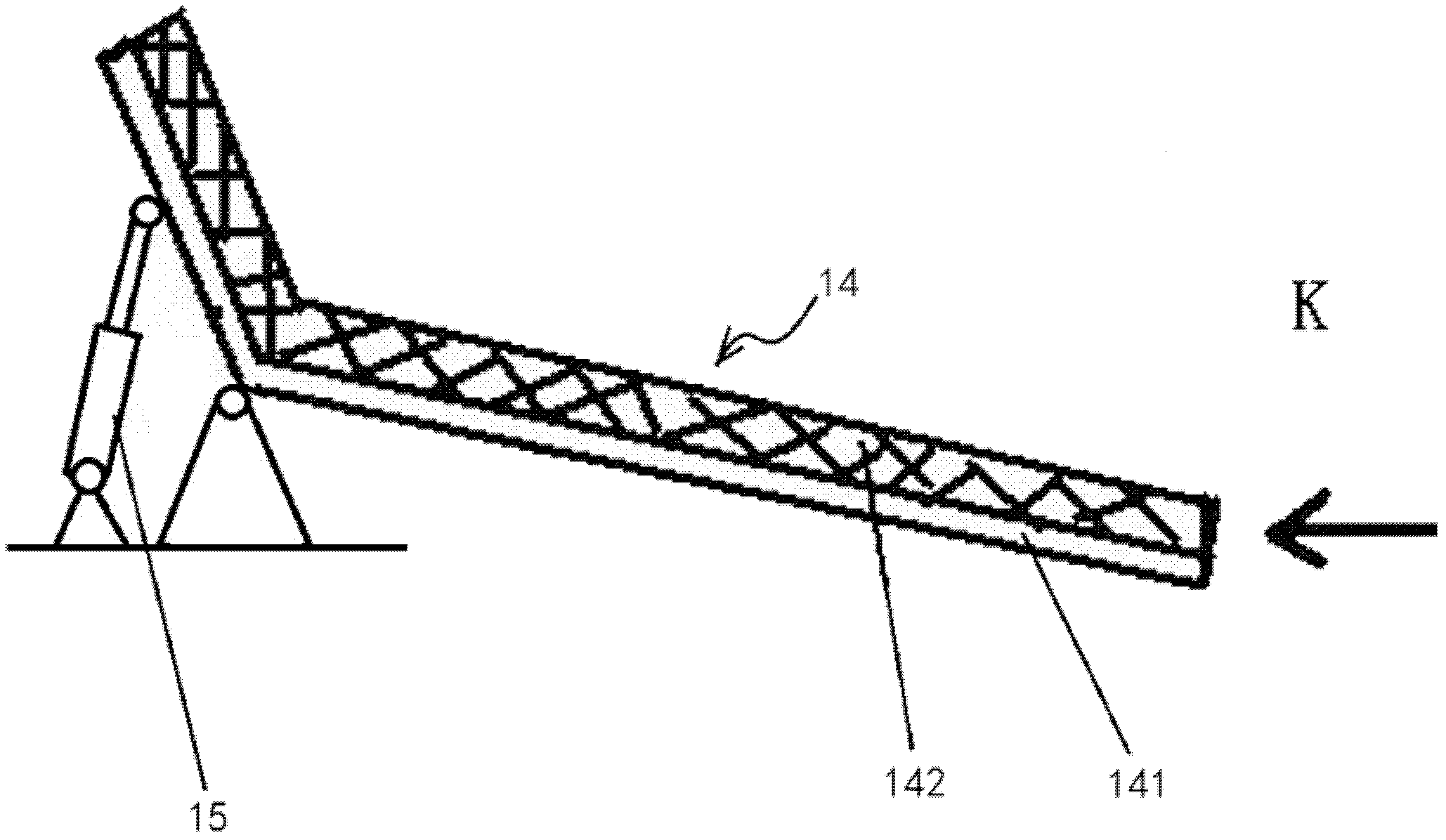

Preparation method of titanium alloy powder for 3D printing

ActiveCN106166617AEffective introductionIncrease productivityAdditive manufacturing apparatusTitanium alloyImpurity

The invention discloses a preparation method of titanium alloy powder for 3D printing, and belongs to the technical field of 3D printing / material additive manufacturing. The method comprises the specific steps that raw materials are loaded and clamped after being treated; pre-vacuum-pumping treatment is carried out on a smelting chamber and an atomization furnace, and high-purity argon is introduced into the smelting chamber and the atomization furnace when the vacuum degree reaches 10<-5>-10<-3> Pa; a gate valve is opened, a feeding mechanism is turned on, and bar materials are heated at the temperature of 1550-1700 DEG C; metal molten drop or liquid flow is atomized through a supersonic speed tight coupling gas atomization nozzle, and finally screening is carried out. The preparation method has the advantages that impurities introduced in the smelting and atomization process can be effectively reduced, and it is ensured that power oxygen content is controlled to be below 200 ppm; continuous production can be carried out after bar materials are replaced, and the powder is uniform in granularity, good in degree of sphericity and good in flowability.

Owner:中航迈特增材科技(北京)有限公司 +1

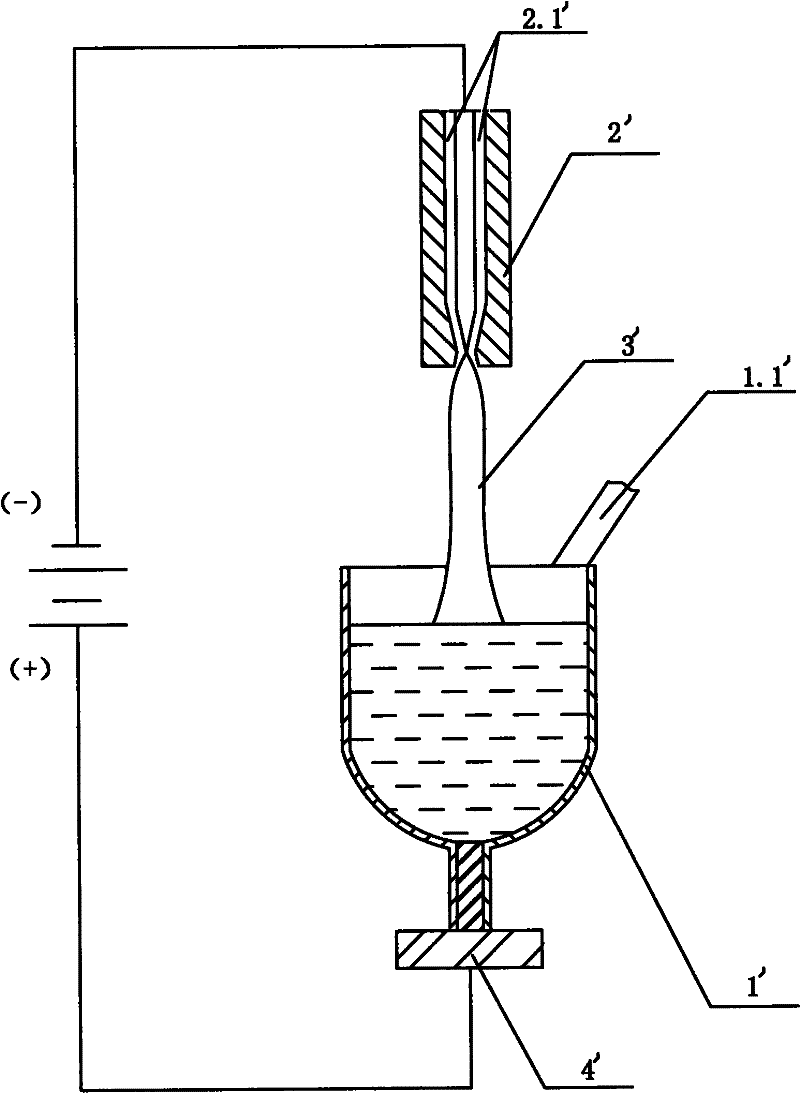

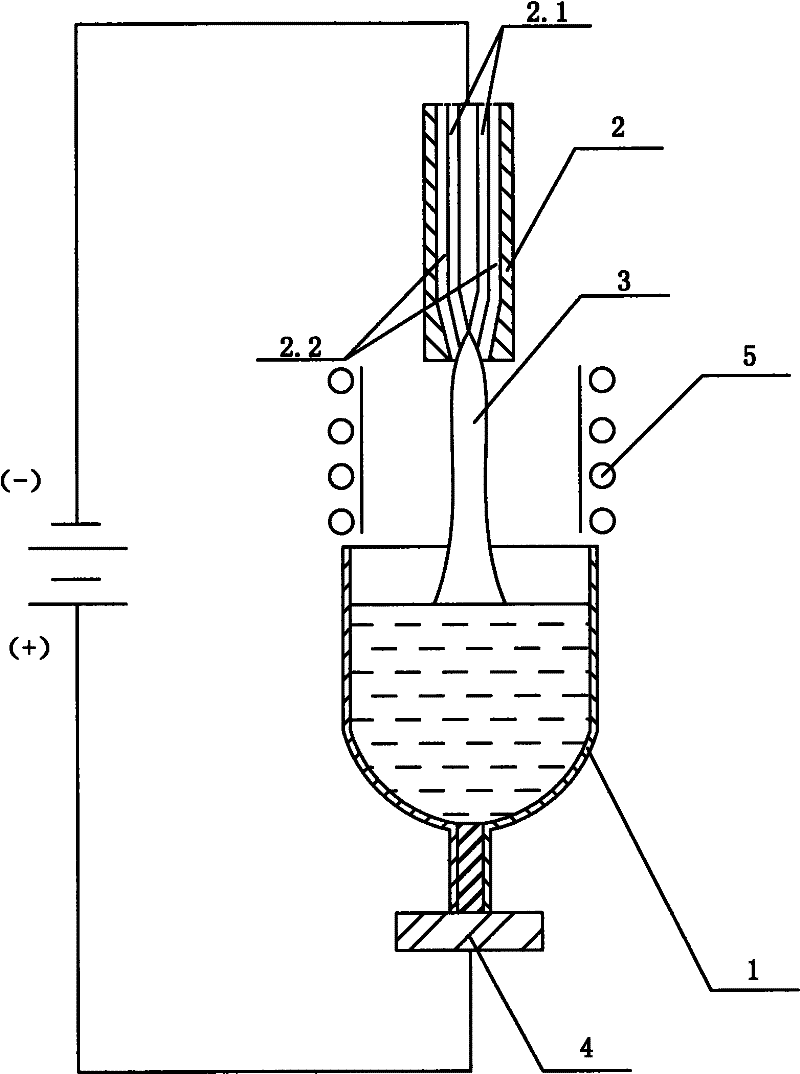

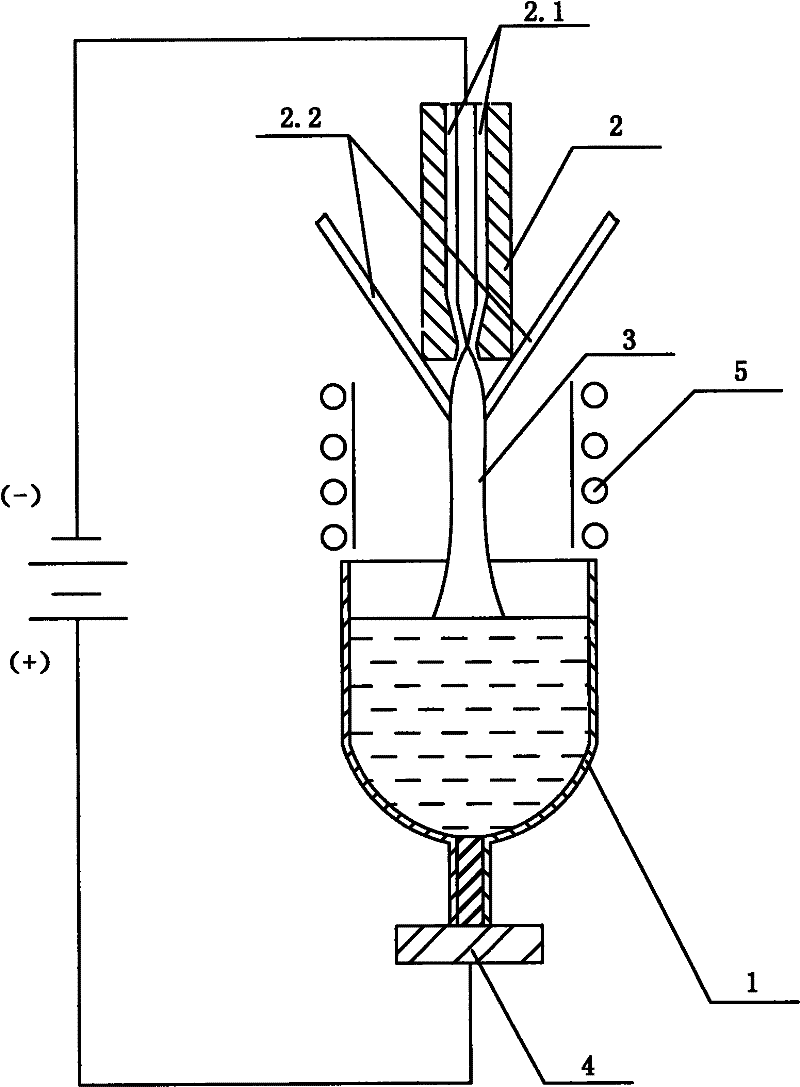

Metal evaporating device and method for preparing ultrafine metal powder by using same

The invention discloses a metal evaporating device and a method for preparing ultrafine metal powder by using the same. The device comprises a crucible (1), a plasma transferred arc torch (2), a plasma transferred arc (3), a graphite (4), a power supply and a lead, which form an electric loop, wherein an air inlet pipe (2.1) from which air enters, is arranged in the plasma transferred arc torch (2); the plasma transferred arc (3) is arranged between the plasma transferred arc torch (2) and the crucible (1); the graphite (4) is arranged on the bottom of the crucible (1); and a feed pipe (2.2) which is used for feeding metal raw materials is arranged above the plasma transferred arc (3). The structure of the metal evaporating device has the advantages that the energy of the plasma transferred arc is fully utilized, the metal output and the metal evaporating efficiency are increased, the energy consumption is lowered, and the ultrafine metal powder which has uniform particle size and is free from large particle metal residual is acquired.

Owner:JIANGSU BOQIAN NEW MATERIALS

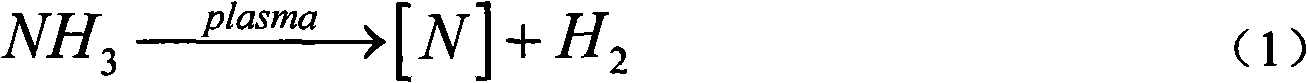

Method for preparing superfine spherical iron nitride powder

InactiveCN101891163AReduce Oxidation ProblemsFine and uniform particle sizeNitrogen-metal/silicon/boron binary compoundsIron nitrideRadio frequency

The invention provides a method for preparing superfine spherical iron nitride powder, and belongs to the technical field of powder preparation. In the method, the superfine spherical iron nitride powder is synthesized and prepared by taking carbonyl iron liquid as a raw material, ammonia (or nitrogen) plasma as nitridation atmosphere and radio frequency (RF) plasma as a heat source for the reaction. The method comprises the following steps of: evaporating the carbonyl iron liquid; feeding the liquid steam into the nitrogen plasma by carrier gas; and reacting decomposed carbonyl iron steam with the nitrogen plasma to obtain the superfine spherical iron nitride powder. The method is characterized in that the nitridation and spheroidization of the carbonyl iron liquid steam are finished in one step by taking the radio frequency (RF) plasma as the heat source so as to prepare the superfine spherical iron nitride powder. The superfine spherical iron nitride powder produced by the method has fine and uniform particle size, high sphericity and high spheroidization rate; the process is simple; and magnetic fluid prepared by the method has high saturation magnetization.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of high-quality white carbon black for rubber

The invention relates to a preparation method of high-quality white carbon black for rubber, which comprises the following steps: introducing CO2 gas into sodium silicate solution, heating up, stirring, and reacting till the pH value of solution is reduced to be 9-10.5, stopping carbonation, and conducting solid-liquid separation; conducting cocurrent and carbonation of residual liquid and the CO2 gas till the pH value of the solution is reduced to be 7-8, conducting solid-liquid separation, and obtaining the high-quality white carbon black for rubber by washing and drying solids; and soaking or heat cooking solid sediment separated in first carbonation with strong acid to remove impurities, and also obtaining the high-quality white carbon black for rubber by washing and drying. The white carbon black prepared by the method has high purity, fine and uniform granularity, good whiteness, and higher values of specific surface area and oil absorption of SiO2 particles, and can be directly used as high-quality white carbon black for rubber, with application performance meeting the performance index requirements of national standard white carbon black for rubber products.

Owner:CHINACOAL PINGSHUO GRP

Preparation method of aluminium hydroxide micro powder

ActiveCN1927719APerfect crystal developmentFine granularityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

The present invention relates to technological process of producing fine aluminum hydroxide powder as fire retardant stuffing, and is especially technological process of producing fine aluminum hydroxide powder with high crystallization degree. The gel seed prepared with sodium aluminate solution through CO2 introducing carbon process and with sodium aluminate solution through aluminum sulfate neutralization process is converted via a special process into fine pure alpha-aluminum hydroxide powder without beta-aluminum hydroxide. The fine pure alpha-aluminum hydroxide powder is coated, modified and stoved to obtain submicron level pure alpha-aluminum hydroxide powder. Or, the completely converted fine powder slurry is added into sodium aluminate solution directly or after being concentrated and further decomposed to obtain fine aluminum hydroxide powder with excellent fire retarding performance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

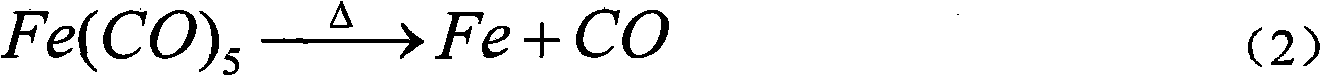

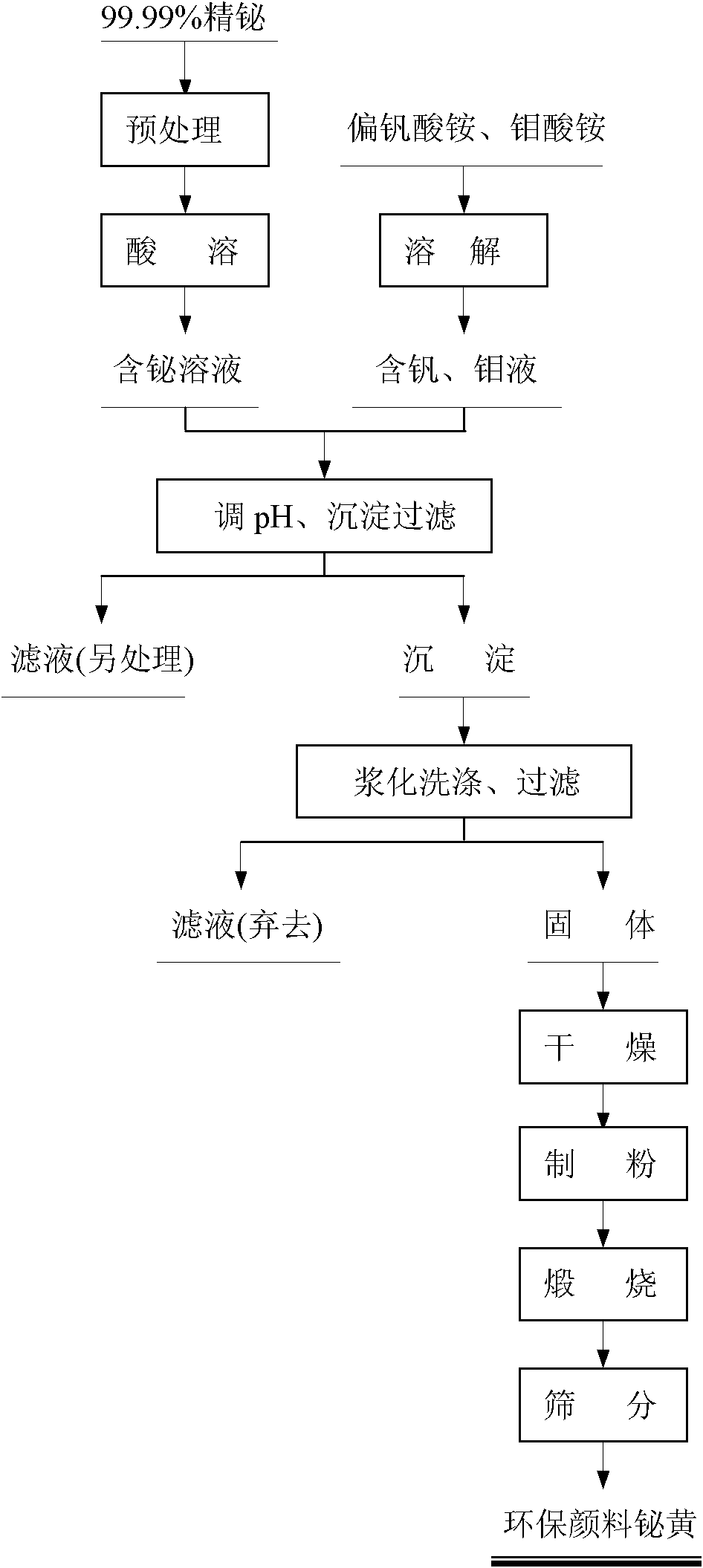

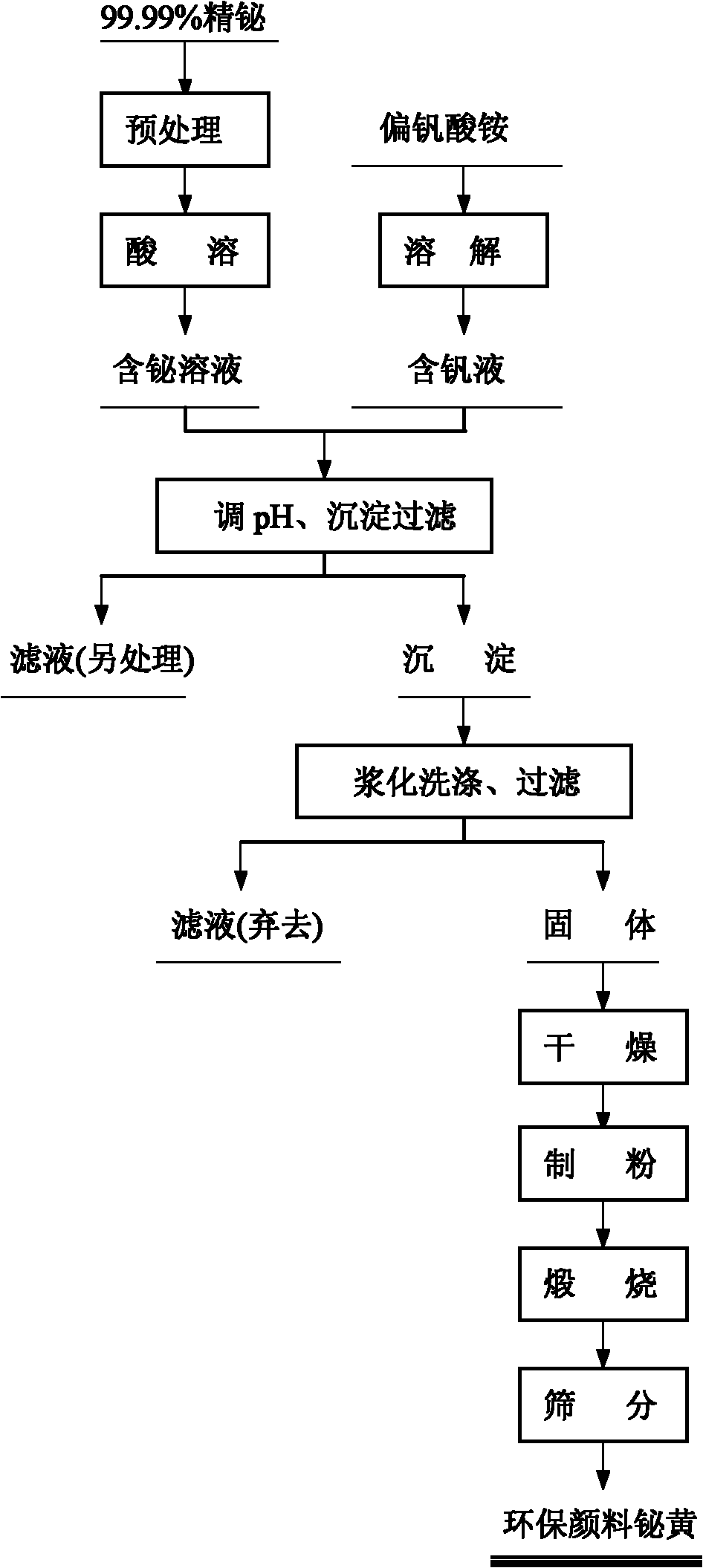

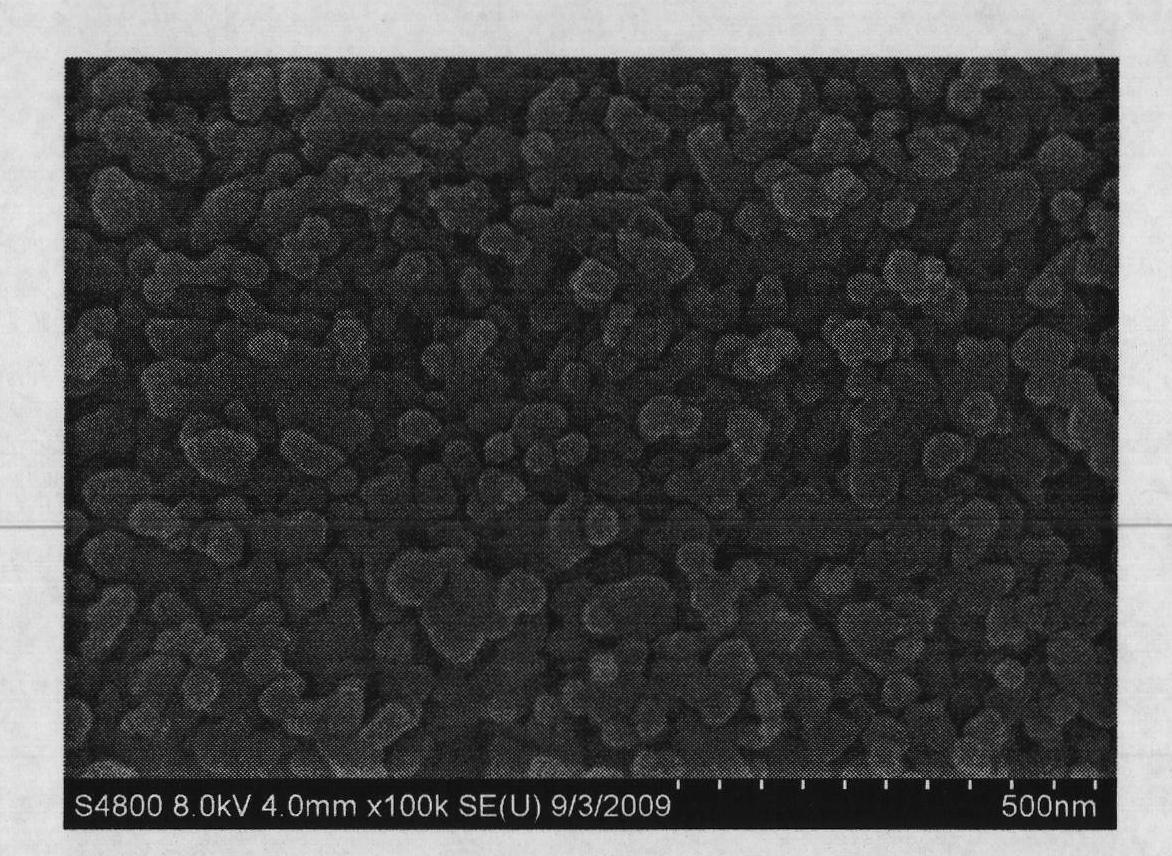

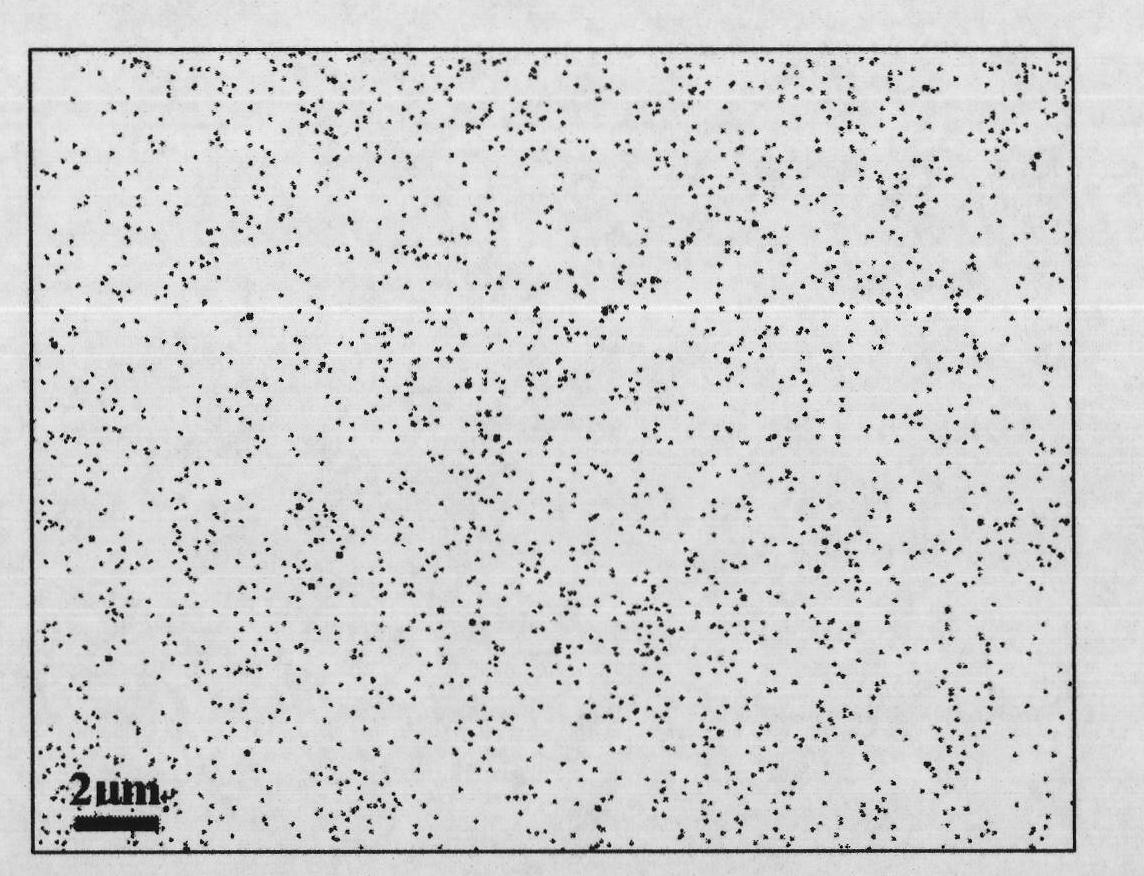

Environmental-friendly pigment bismuth yellow and production method thereof

ActiveCN101914310AProcess conditions are easy to controlImprove uniformityPigment physical treatmentPigment treatment with non-polymer organic compoundsDispersityAmmonium metavanadate

The invention relates to environmental-friendly pigment bismuth yellow and a production method thereof. The production method is characterized by comprising the steps of: firstly placing solid bismuth into a mixed acid solution made of nitric acid and hydrochloric acid for soaking, then taking out for reacting with a nitric acid solution to obtain a bismuth nitrate solution; keeping the nitric acid in an excessive state, then mixing and dissolving ammonium metavanadate or ammonium metavanadate and ammonium molybdate into ammonia water to obtain a vanadium-containing or vanadium and molybdenum-containing ammonia water mixed solution; under the condition of continuously stirring, simultaneously adding the bismuth nitrate solution and the mixed solution into a reactor containing a dispersing agent and a bottom fluid to obtain a light yellow sediment; and washing, drying and pulverizing according to a conventional method, finally, calcining and sieving to obtain the environmental-friendly pigment bismuth yellow with uniform granularity. The invention has the advantages of easy control of process conditions, good product dispersity, fine and uniform granularity, good powder activity, wide source and high utilization ratio of raw materials and better economic feasibility.

Owner:ZHUZHOU SMELTER GRP

Method for preparing zinc oxide-based sputtering target material

ActiveCN101845614AHigh densityInhibit migrationMolten spray coatingVacuum evaporation coatingRoom temperatureVolumetric Mass Density

The invention discloses a method for preparing a zinc oxide-based sputtering target material. The method comprises the following steps of: performing die pressing on doped zinc oxide nano-powder at the pressure of between 30 and 150 MPa and maintaining the pressure for 30 to 300 seconds; performing isostatic cool pressing on the doped zinc oxide nano-powder at the pressure of between 120 and 300 MPa and maintaining the pressure for 60 to 600 seconds; heating the doped zinc oxide nano-powder to the temperature of between 950 and 1,300 DEG C at a heating rate of between 5 and 10 DEG C per minute, and maintaining the temperature for 1 to 30 minutes; cooling the doped zinc oxide nano-powder to the temperature of between 650 and 1,100 DEG C at a cooling rate of between 10 and 100 DEG C per minute and maintaining the temperature for 2 to 40 hours; and finally, cooling the doped zinc oxide nano-powder to the room temperature at a cooling rate of between 0.5 and 10 DEG C per minute, and performing cutting and polishing on the doped zinc oxide nano-powder to obtain the zinc oxide-based sputtering target material. By adopting specific two-step sintering parameters, the method is used for preparing the target material of which the density is over 98 percent, the grain size is very small and uniform and is between 0.5 and 20 mu m, and the doped components are uniform at a low sintering temperature.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

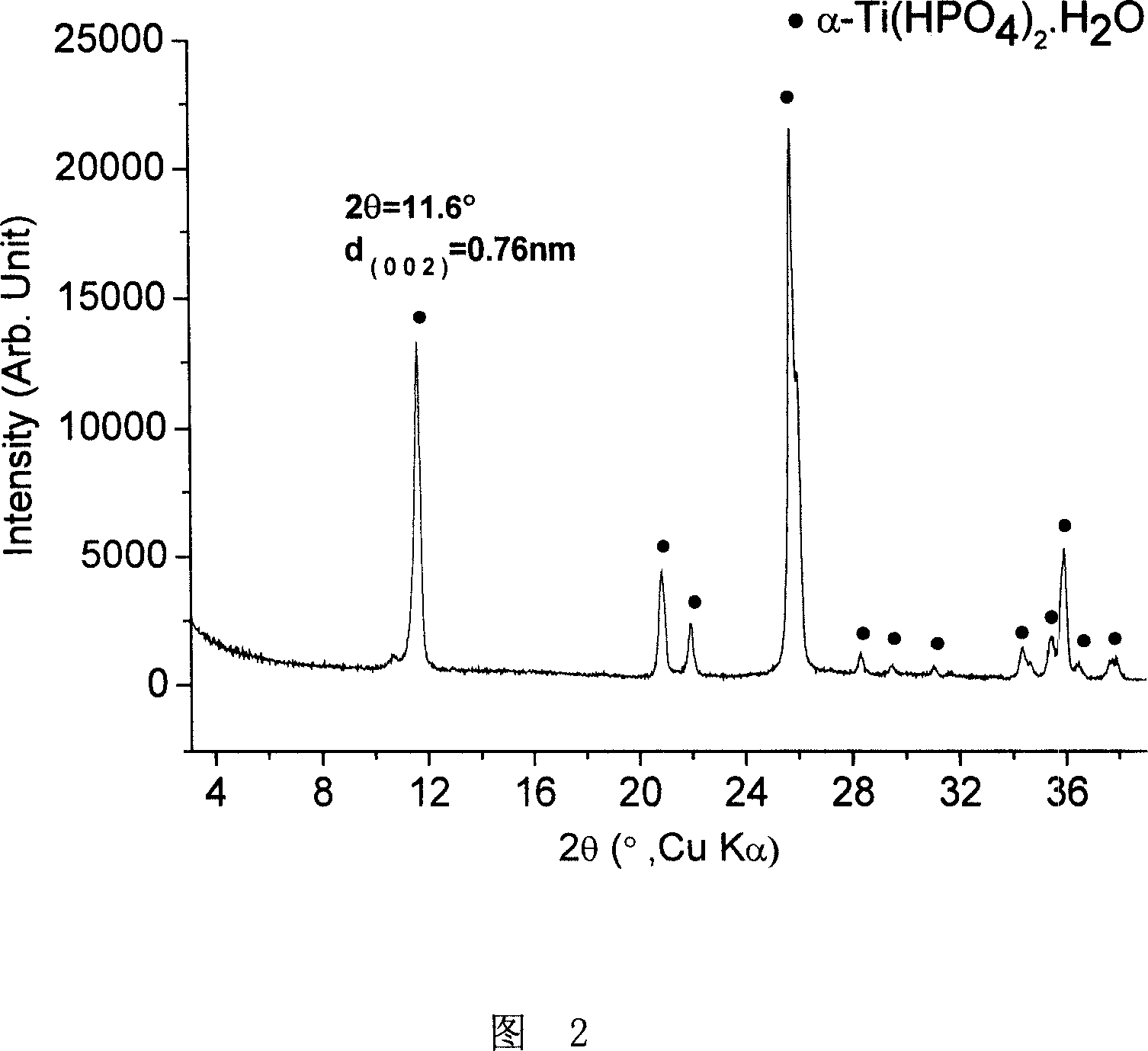

Method of preparing layered alpha-titanium phosphate

InactiveCN101033062AHigh crystallinityUniform shapePhosphatesTitanium compoundsTitanium phosphatePhosphoric acid

This invention discloses a method for preparing laminated alpha-Ti3(PO4)2, which mixes Ti salt with deionized water in the proportion of 1 :4-10 to get deposit after being hydrolyzed fully to be cleaned and mixed in the proportion of 1 : 20-30 : 3-15, then the concentration of H3PO4 in the mixed solution is 4-12mol / L, then transfers the mixed solution into a high pressure kettle and reacts for 4-24 h under 150-200deg.C to be cooled to room temperature t obe cleaned to 3-7 pH value to be dried to get laminated alpha-Ti3(PO4)2.

Owner:TSINGHUA UNIV

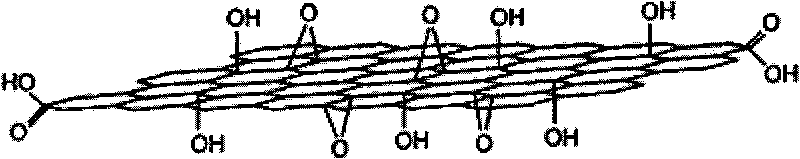

Graphene/Ru nano-composite material for supercapacitor and preparation method thereof

InactiveCN101714463AHigh specific capacitanceGood chemical stabilityElectrolytic capacitorsHybrid capacitor electrodesSodium acetateCapacitance

The invention discloses a graphene / Ru nano-composite material for a supercapacitor. The mass fraction of Ru is between 10 and 50 percent, and the mass fraction of graphene is between 90 and 50 percent. A preparation method comprises the steps of: ultrasonically dispersing oxidized graphite nano-plates into liquid polylol, and then adding solution of ruthenium chloride and solution of sodium acetate into the liquid polylol, wherein in the mixture, the content of the oxidized graphite nano-plates is between 0.5 and 1.5g / L, the concentration of the ruthenium chloride is between 0.0008 and 0.006mol / L, and the concentration of the sodium acetate is between 0.003 and 0.013mol / L; and transferring the mixture into a microwave hydrothermal reaction kettle, performing a microwave heating reaction for 5 to 10 minutes, and then obtaining the graphene / Ru nano-composite material through filtration, washing and drying. The preparation method has the advantages of energy conservation, quickness, simple process and the like; and the graphene / Ru nano-composite material which is taken as an electrode material of an electrochemical supercapacitor has high specific capacitance.

Owner:ZHEJIANG UNIV

Manufacturing method of nano yttrium oxide powder

InactiveCN1410353AFine and uniform particle sizeGood dispersionRare earth metal compoundsIonActive agent

A process for preparing nano-class yttrium oxide powder features that under the existance of surfactant, the solution of yttrium ions reacts on the alkaline solution under normal temp. and pressure. Its advantages are fine granularity (10-60 nm), high dispersity and low cost.

Owner:JINAN UNIVERSITY

Polyimide foam plastic and preparation method thereof

ActiveCN103275319AImprove mechanical propertiesGood flexibilityAdhesivesPolymer scienceHeat resistance

The invention provides a preparation method of polyimide foam plastic. The method comprises the steps as follows: firstly, after dianhydride is mixed with low-level aliphatic alcohol, an esterification reaction is performed, and a diacid diester solution is obtained; then the obtained diacid diester solution is mixed with polymerized monomer amine and polyamic acid powder to obtain a mixed solution; and finally, the obtained mixed solution is sequentially subjected to foaming and thermal imidization after concentration to obtain the polyimide foam plastic. The invention further provides the polyimide foam plastic and the preparation method thereof, and the method comprises the step that polyamic acid powder is added when dianhydride and isocyanate are used for preparing the polyimide foam plastic. According to the invention, the polyamide acid powder serves as a nucleating agent, so that a cell of an objected formed by foaming of polyimide is fine and smooth, that is, the size distribution of the cell is improved, the cell uniformity is better, then the flexibility performance and the like of the polyimide foam plastic are improved; meanwhile, the heat resistance is not influenced; and besides, the preparation method of the polyimide foam plastic is concise in processing, and low in energy consumption and production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Novel attapulgite supported palladium hydrogenation catalyst and preparation method thereof

InactiveCN101711980ASmall particle sizeLow costCatalyst carriersOrganic compound preparationActive carbonCarbon nanotube

The invention discloses a novel attapulgite supported palladium hydrogenation catalyst and a preparation method thereof. Acidized attapulgite clay is used as a carrier, potassium borohydride or hydrazine hydrate is used as a reducer, and a soluble palladium salt is reduced to palladium nano particles which are loaded on the acidized attapulgite clay. In the attapulgite loaded palladium hydrogenation catalyst prepared by the method of the invention, the palladium nano particles are fine and uniform and are highly dispersed on the surfaces of carbon nano tubes, and compared with the active carbon or graphite loaded palladium catalyst, the attapulgite loaded palladium hydrogenation catalyst has high activity and selectivity for hydrogenating cinnamyl aldehyde to prepare phenylpropyl aldehyde.

Owner:赵杰 +2

Palladium-cobalt/graphene nano electro-catalyst and preparation method thereof

InactiveCN103022521AFine and uniform particle sizeUniform particle sizeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetateBULK ACTIVE INGREDIENT

The invention discloses a palladium-cobalt / graphene nano electro-catalyst and a preparation method thereof. According to the palladium-cobalt / graphene nano electro-catalyst, palladium serves as an active ingredient, cobalt serves as a cocatalyst, and graphene serves as a carrier; and in the catalyst, the mass fraction of the palladium is 10-40%, the mass fraction of the cobalt is 5-30%, and the balance is the carrier. According to the preparation method of the catalyst, graphite oxide nanosheets are ultrasonically dispersed into polylol, palladium salt liquid, cobalt salt liquid and sodium acetate liquid are then added and fully mixed uniformly, the mixture is then transferred into a microwave hydrothermal reaction kettle, and the filtering, washing and drying processes are carried out after reaction, thereby obtaining the palladium-cobalt / graphene nano electro-catalyst. The preparation method disclosed by the invention has the advantages of energy saving, high speed, simple process and the like; and the particle sizes of palladium and cobalt nanoparticles in the prepared palladium-cobalt / graphene nano electro-catalyst are uniform. The catalyst has high electro-catalytic activity to the electrooxidation of formic acid and is widely applied to fuel cells.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Method of synthesizing Pt-CeO*/C electro-catalyst with one-step method microwave

InactiveCN101108346AImprove efficiencyFine and uniform particle sizeElectrolysis componentsElectrolytic organic productionSodium acetateAlcohol fuel

The invention discloses a one-step microwave compounding Pt-CeO2 / C catalyst method, which dissolves chloroplatinic acid in ethylene glycol, the concentration of the chloroplatinic acid in the solution is between 0.002 to 0.005mol / L; then adding ammonium ceric nitrate water solution with certain volume and make the mol ratio of Pt and Ce in the solution is 1 / 1 to 2.5 / 1; then add small volume sodium acetate water solution in the solution as stabilizer, the concentration of the sodium acetate in solution is between 0.01 to 0.03mol / L. Add a certain volume Nami carbon as carrier, use supersonic process to dissolve the Nami carbon material in the solution fully. Heat the even mixture with microwave for 6 to 12min under the situation of reflow, compound to achieve Pt-CeO2 / C catalyst, the quality per centage of Pt in the catalyst is 20 per cent, the mol ratio of Pt and Ce is between 1 / 1 to 2.5 / 1, the Nami carbon as the carrier is XC-72 Nami carbon or carbon Nami tube. The Pt-CeO2 / C catalyst compounded by the method in the invention has higher electrocatalysis activity and better anti-CO poisoning performance to the oxidizing of methanol, which has wide application in direct alcohols fuel battery.

Owner:ZHEJIANG UNIV

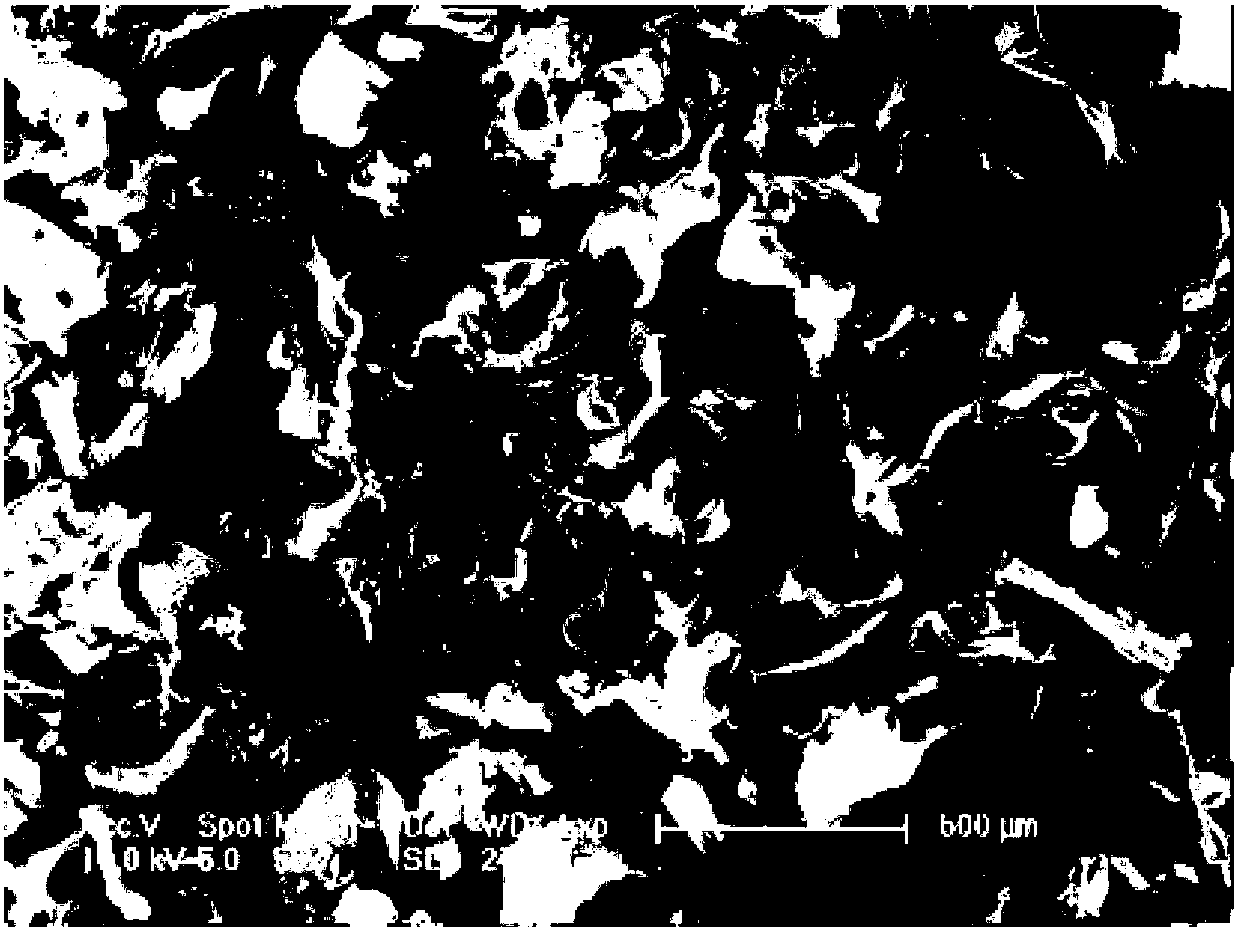

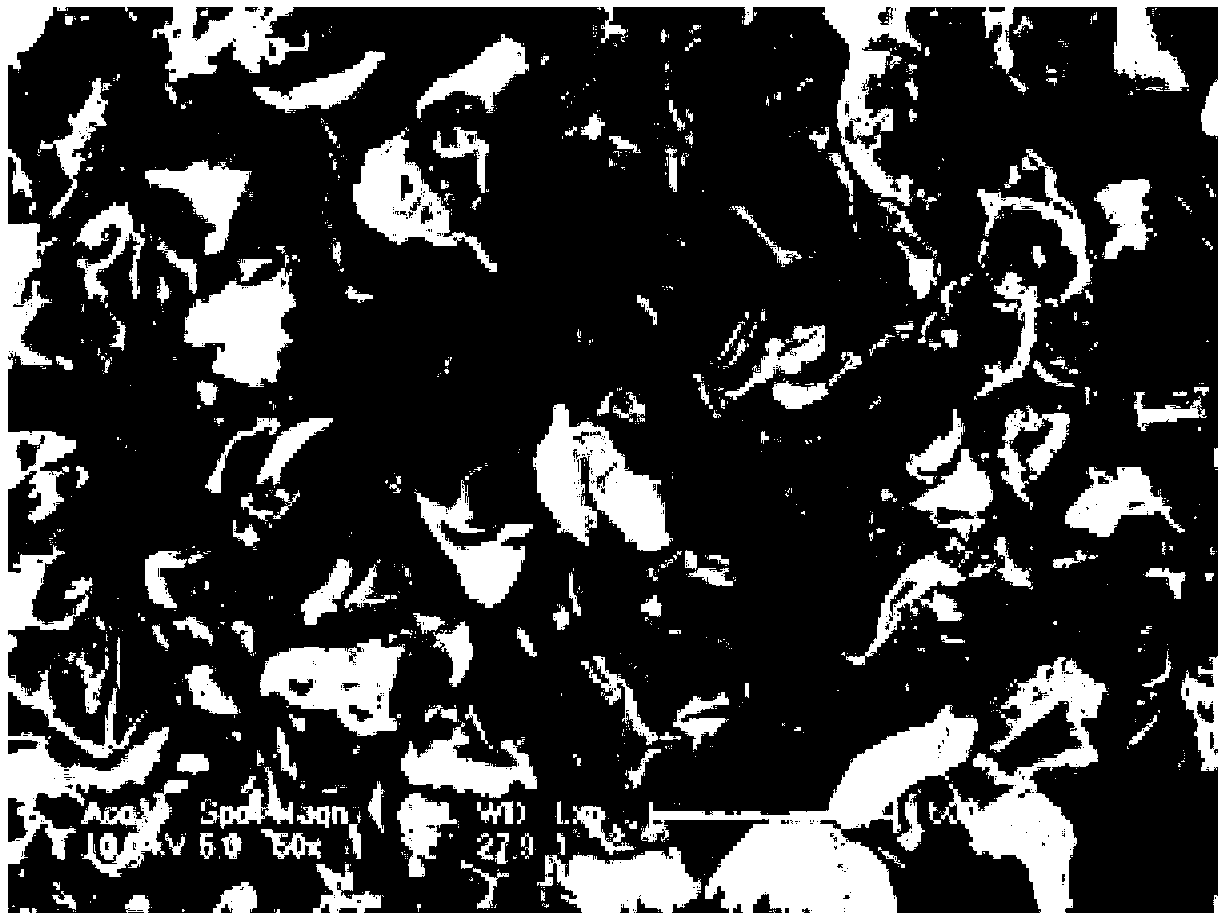

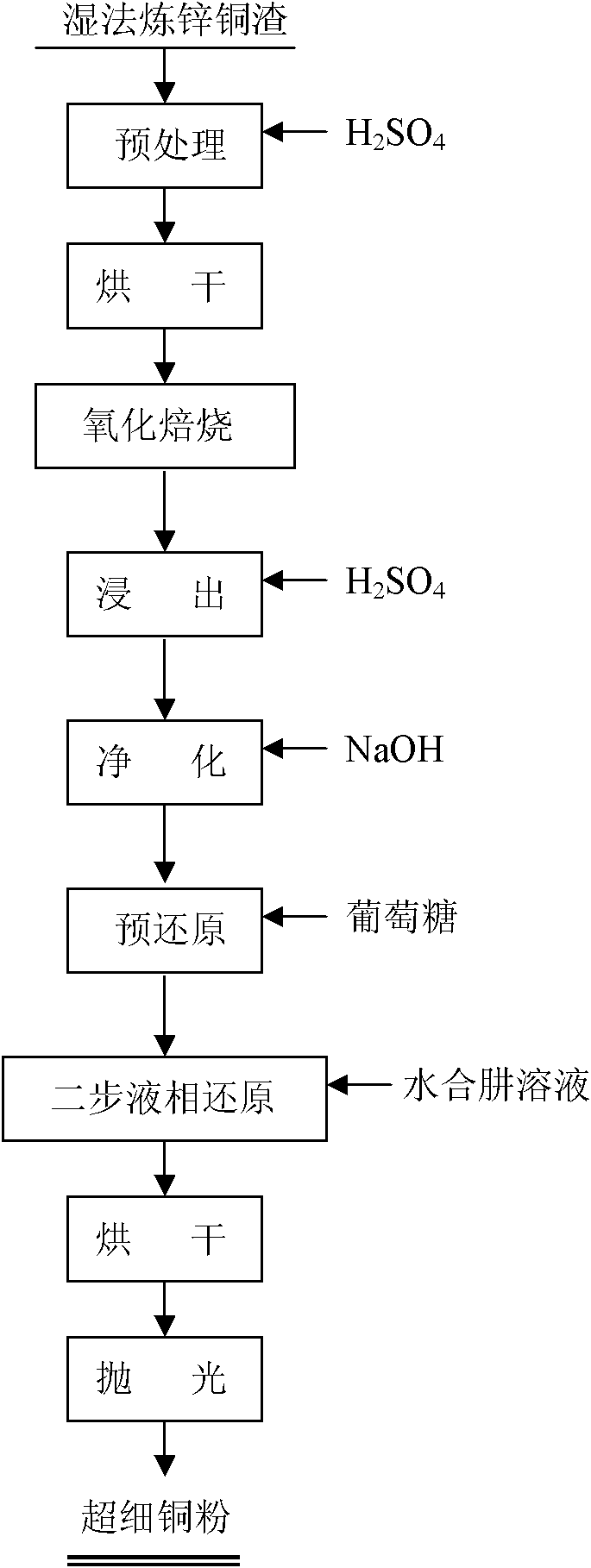

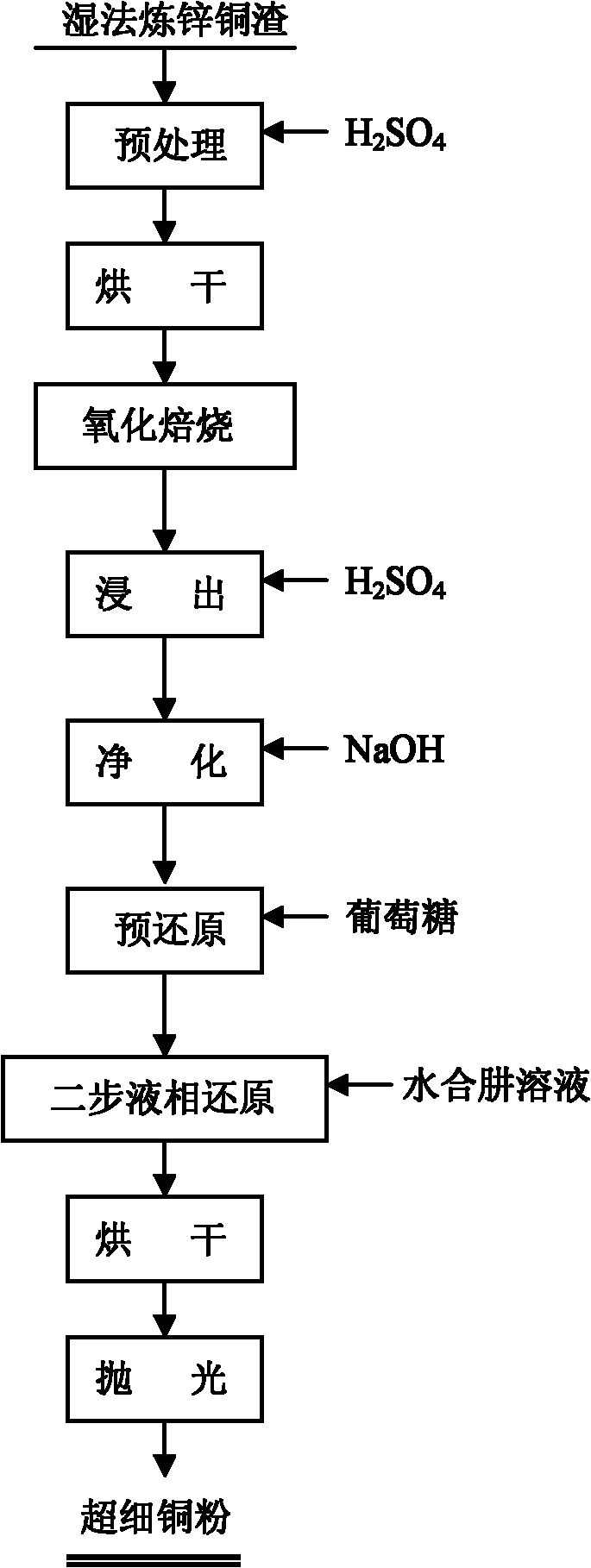

Superfine cupper powder and preparation method thereof

ActiveCN101890505AIncrease brightnessPrevent oxidationProcess efficiency improvementEconomic feasibilityOxide

The invention provides a preparation method of superfine cupper powder, which takes copper slag generated by hydrometallurgy of zinc as a raw material and is characterized by comprising the following steps: soaking the cupper slag in a sulfuric acid solution for pretreatment; filtering and drying; carrying out oxidization roasting to obtain roasted cupper slag; leaching the roasted cupper slag out by the sulfuric acid solution to obtain lixivium i.e. copper-bath; carrying out purification treatment on the copper-bath; and adjusting the pH value of the purified copper-bath; adding glucose in the copper-bath for pre-reduction to obtain the cuprous oxide sediment; adding a hydrazine hydrate solution in the cuprous oxide sediment to carry out reduction reaction to obtain solid reduced copper powder; and filtering the reduced copper powder, washing, drying and carrying out polished finish to obtain the superfine copper powder. The invention has the copper recovering rate as high as over 95% and simple process, produces the superfine cupper powder by hydrometallurgy of zinc with low cost and wide sources, and has the economic feasibility of industrialization production in a large scale.

Owner:ZHUZHOU SMELTER GRP

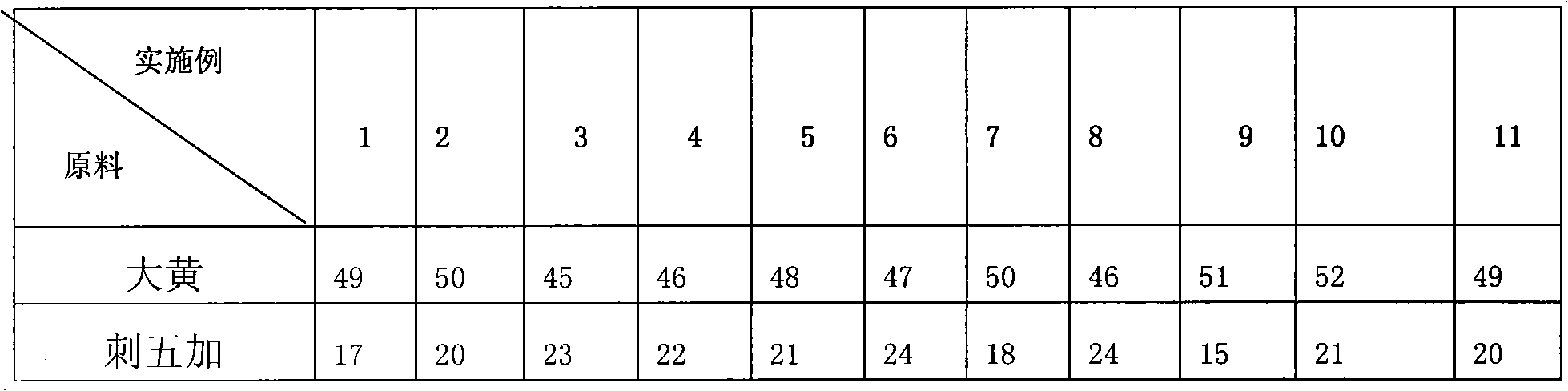

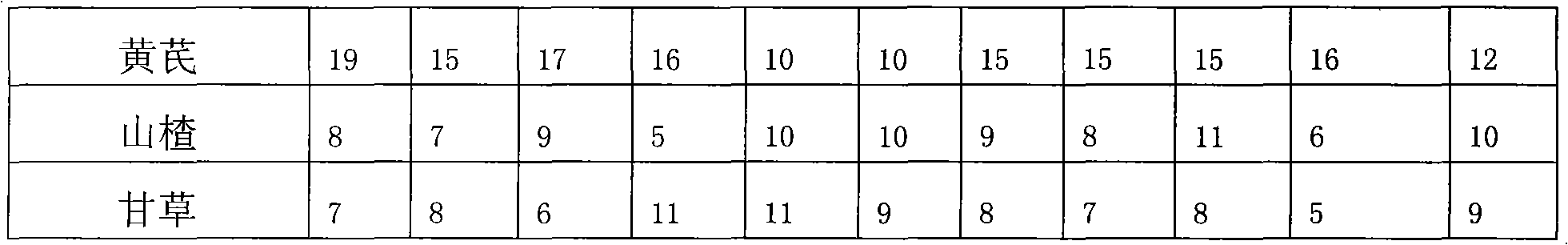

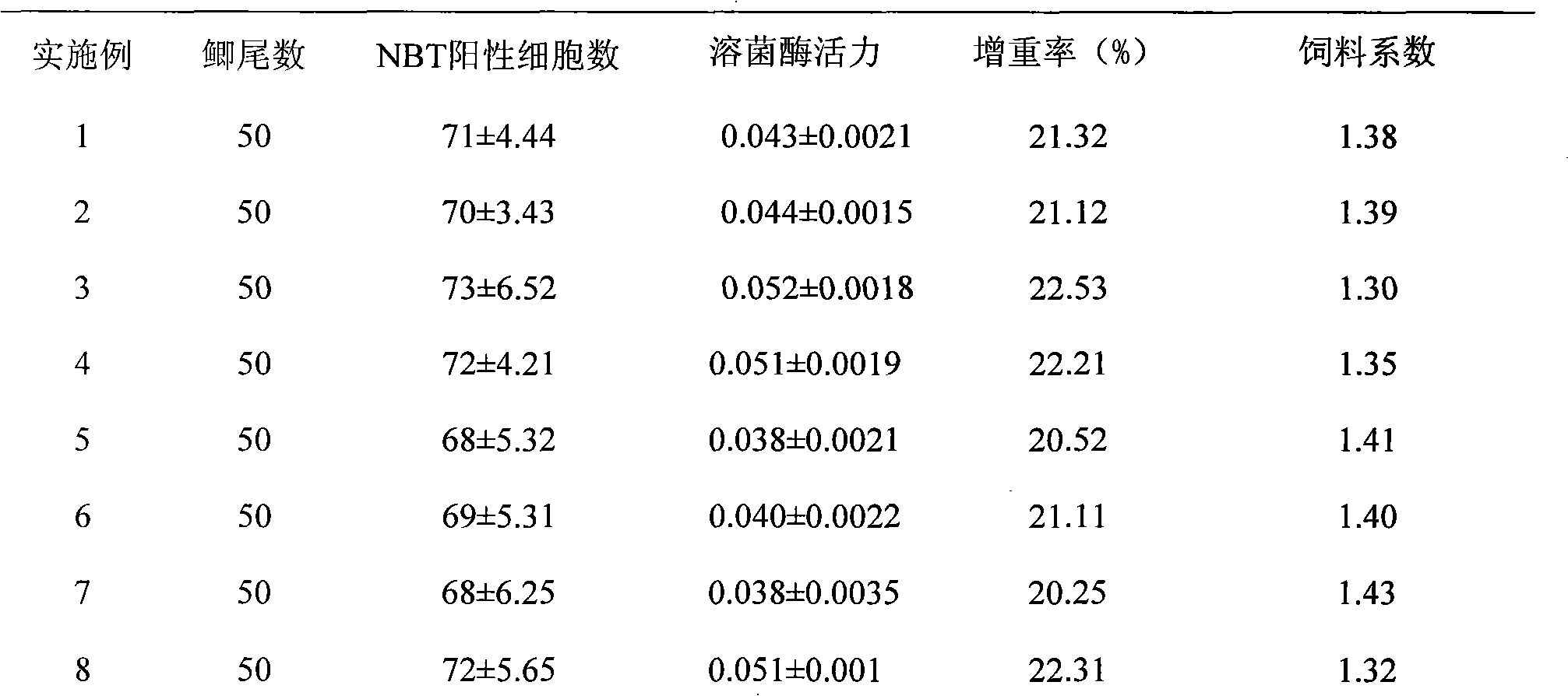

Fish compound traditional Chinese medicinal preparation and preparation method thereof

InactiveCN101829211ASolve the situation that there is no cure for intractable diseasesSolve the situation of no cureMetabolism disorderAntiinfectivesDiseaseHerbal preparations

The invention discloses a fish compound traditional Chinese medicinal preparation prepared from raw materials including rhubarb, acanthopanax, radix astragali, hawthorn and liquorice according a certain weight ratio. A method for preparing fish compound traditional Chinese medicinal preparation comprises the following steps of: A. washing and drying the rhubarb, the acanthopanax, the radix astragali, the hawthorn and the liquorice in the sun; B. respectively crushing and sieving the rhubarb, the acanthopanax, the radix astragali, the hawthorn and the liquorice to ensure the granularity reaches 140-200 mu; and C. weighing up the rhubarb, the acanthopanax, the radix astragali, the hawthorn and the liquorice according to the ratio and mixing and subpackaging after uniformly mixed to obtain the fish compound traditional Chinese medicinal preparation. The method has the advantages of feasibility, convenient operation, reasonable formulation and convenient use; traditional Chinese medicines have wide sources, low price, remarkable effects and no toxic or side effects; various components mutually act; and the invention simultaneously has two properties of nutrition and medicament, not only contains nutrient substances, but also has components with antibacterial activity and other bioactivities, can improve the metabolism of cultivated fishes, promote the growth and the development, improve the immunologic function, prevent and treat diseases and the like.

Owner:武汉中博水产生物技术有限公司

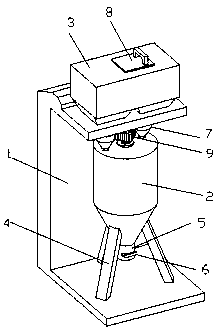

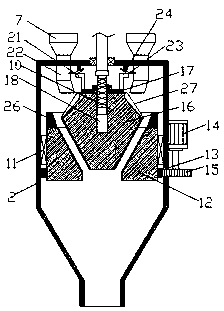

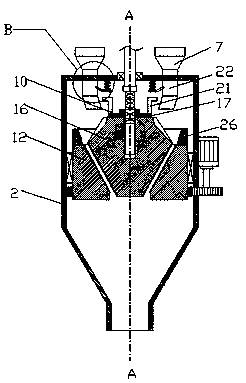

Ultra-fine grinding device for powder coating

InactiveCN110947447AFine and uniform particle sizeGood grinding effectGrain treatmentsElectric machineryEngineering

The invention relates to the technical field of coating grinding millers, in particular to an ultra-fine grinding device for powder coating. The ultra-fine grinding device comprises a fixing frame, agrinding cylinder and a storage bin. The lower end of the grinding cylinder is provided with supporting legs, the supporting legs are connected with the bottom of the fixing frame in a welded manner,the storage bin is arranged at the top end of the fixing frame, the left and right ends of the lower surface of the storage bin are connected with feed hoppers, the feed hoppers communicate with the upper surface of the grinding cylinder, a reduction motor is fixed to the lower surface at the top end of the fixing frame, and an output shaft of the reduction motor penetrates through the lower end at the center of the upper surface of the storage bin to be connected with a reciprocating lead screw. According to the ultra-fine grinding device for the powder coating, the reciprocating lead screw is driven by the reduction motor to rotate so as to realize the up-and-down movement of a movable round table grinding block, and the grinding gap is gradually reduced in the grinding process, so thatextremely fine grinding of the powder coating is realized, and the grinding effect of the ultra-fine grinding device for powder coating is excellent.

Owner:含山县领创新材料科技有限公司

Organic silicon acrylic acid modified waterborne epoxy emulsion and preparation method thereof

The invention provides an organic silicon acrylic acid modified waterborne epoxy emulsion and a preparation method thereof. The core layer consists of low-grade bisphenol A epoxy resin, reactive diluent, epoxy silane, a reactive emulsifier, an initiator, an assistant and an acrylic acid monomer; the shell consists of vinyl siliane, an acrylic acid monomer, a reactive emulsifier, an assistant, an initiator and de-ionized water. The obtained organic silicon acrylic acid modified waterborne epoxy emulsion is small and even in particle size and excellent in stability, is excellent in mechanical strength, environment-friendly and energy-saving after being formed to be films. The dry film matched with modified amine curing agent via the modified waterborne epoxy emulsion can reach the level of close to the film property of solvent-type epoxy resin.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Manufacturing method of nano iron oxide powder

InactiveCN1427042AFine and uniform particle sizeProduction equipment requirements are simplePigment treatment with macromolecular organic compoundsIonActive agent

A nanometre-class iron oxide powder with different shapes prepared through the reaction between Fe-ion solution and alkaline solution under the condition of introducing surfactant, and features that the shape of the said nanometre iron oxide particles can be controlled by regulating the proportion mix between the high-molecular and the low-molecular surfactants. Its advantages are fine and uniform granularity (10-30 nm), simple equipment and low cost.

Owner:JINAN UNIVERSITY

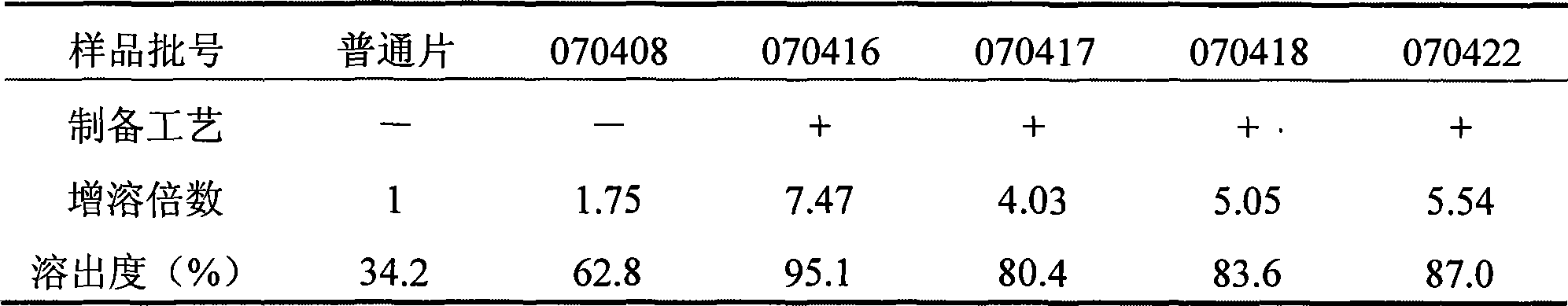

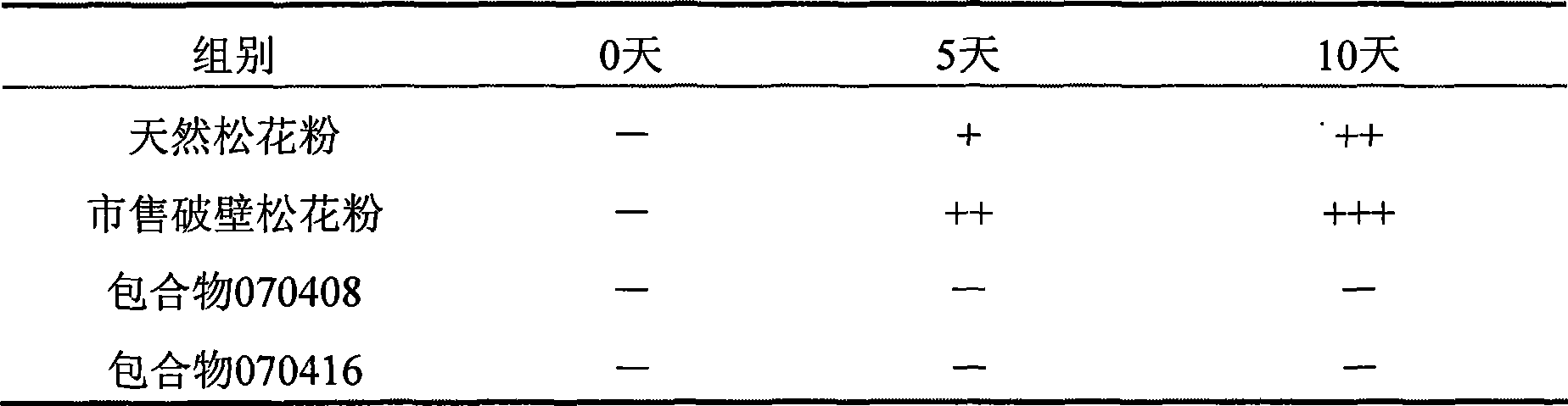

Pine pollen and cyclodextrin composition, method for preparing same, use of same in preparation of health-care products for resisting fatigue and improving immunity of organisms

InactiveCN101518552AHigh activitySolve the problem of easy oxidation and deterioration of nutrientsAntinoxious agentsPharmaceutical non-active ingredientsMass ratioAdditive ingredient

The invention disclose a pine pollen and cyclodextrin composition, a method for preparing the same and application of the same in the preparation of health-care products for resisting fatigue and improving immunity of organisms. The composition consists of extract of wall-broken pine pollen and cyclodextrin, and is characterized in that the mass ratio of the pine pollen or the extract of the pine pollen to the cyclodextrin is 1:0.6-5. The preparation method comprises the following steps of: adding pure water and the cyclodextrin into to the wall-broken pine pollen or the extract of the wall-broken pine pollen in an amount which are two times of that of the wall-broken pine pollen or the extract of the wall-broken pine pollen; uniformly stirring the mixture and grinding the mixture for 0.5 to 3 hours; drying the ground mixture under reduced pressure at a temperature below 50 DEG C; and crushing the mixture and passing the crushed mixture through a sieve to obtain the pine pollen and cyclodextrin composition. The application of the pine pollen and cyclodextrin composition in the preparation of the health-care products for resisting the fatigue and improving the immunity of the organisms has the advantages that: the composition is strong in stability; the preparations have good performance; the stability of active ingredients is obviously improved compared with the wall-broken pine pollen on the market; the products are long in storage time and convenient in transport; and the active ingredients of pine pollen can be absorbed by human bodies.

Owner:NANJING NORMAL UNIVERSITY +1

Preparation method of supported photocatalytic composite material

InactiveCN104475079AFine and uniform particle sizeGood dispersionMetal/metal-oxides/metal-hydroxide catalystsRare earthNanometre

The invention discloses a preparation method of a supported nano photocatalytic composite material, which comprises the following steps: preparing rare-earth-compound-doped titanium dioxide by a sol-gel process, wherein the rare-earth doping amount is 0.10-0.65%; and carrying out high-temperature calcination to support the titanium dioxide on zeolite, wherein the supporting amount of the zeolite is 10-55%. The wastewater treatment experiment detects that the COD chemical oxygen demand) degradation ratio of the supported nano photocatalytic composite material reaches 91% above.

Owner:青岛润国生态科技发展有限公司 +1

Production method of battery-grade iron phosphate

InactiveCN102050435AReduce dosageReduce manufacturing costPhosphorus compoundsIron sulfateIron salts

The invention relates to a production method of battery-grade iron phosphate, comprising the following steps of: dissolving polymeric iron sulfate into a solution with the iron ion concentration of 0.03-0.3 M; then adding a phosphate solution to generate an alkali iron phosphate sizing agent; then carrying out solid-liquid separation on the alkali iron phosphate sizing agent; adding separated alkali iron phosphate to a phosphoric acid solution for processing, and regulating a pH value; and then filtering, washing and drying to obtain the battery-grade iron phosphate. The invention reduces theusing amount of alkali in the producing process by utilizing the polymeric iron sulfate as ferric iron ions and the characteristics of lower acidity of the polymeric iron sulfate compared with iron salt, i.e. iron sulfate and the like, has the advantages of simple process flow, low production cost, high product purity, Fe content higher than 29 percent, purity higher than 99 percent and small anduniform grain diameter and is especially suitable for producing lithium iron phosphate, i.e. a positive pole material, of a lithium ion battery.

Owner:易玲 +2

Method for preparing color fluorescent nanometer resin particle dispersion liquid

ActiveCN102718893AFine and uniform particle sizeAgglomeration and precipitation will not occurLuminescent compositionsTemperature resistanceFluorescence

The invention relates to a method for preparing color fluorescent nanometer resin particle dispersion liquid and aims at providing a preparation method with the advantages that concrete operation of experiments and scale production is convenient, the technical process is easy to control, the process stability is high, and the prepared color fluorescent nanometer resin particle has the effects that the particle size distribution is uniform, the glossiness is good, and meanwhile, better temperature resistance performance, sun-proof performance and acid-base resistance performance are realized. The method has the technical scheme that the method for preparing the color fluorescent nanometer resin particle dispersion liquid comprises the following steps of (1) polymerization medium initiating system preparation, (2) monomer emulsion system preparation and (3) polymerization reaction. According to the method for preparing the color fluorescent nanometer resin particle dispersion liquid, monomers in the step (2) are mixtures of drainable nonpolarity vinyl monomers, vinyl cyano monomers, polar vinyl monomers and sulfonic vinyl monomers, and the consumption of the monomers accounts for 20 to 50 percent of the weight of a monomer emulsion system.

Owner:ZHEJIANG JCOLOR TECH CO LTD

Palladium/carbon nanotube catalyst for hydrogenation of cinnamaldehyde and preparation method thereof

InactiveCN101703930AFine and uniform particle sizeHigh selectivityOrganic compound preparationCarbonyl compound preparationPalladium catalystCarbon nanotube

The invention discloses a palladium / carbon nanotube catalyst for the hydrogenation of cinnamaldehyde and a preparation method thereof. The carrier of the catalyst is carbon nanotubes, and the active ingredient of the catalyst is noble metal palladium nanoparticles with an average particle size of 5 to 6 nanometers. The catalyst contains 0.1 to 5 mass percent of palladium and the balance of the carbon nanotubes. The preparation method of the catalyst comprises: 1) dissolving a palladium salt in deionized water to prepare 0.01 to 0.2 mol / L aqueous solution of the palladium salt, adding the carbon nanotubes into the aqueous solution of the palladium salt and subjecting the solution to ultrasonic dispersion for 0.5 to 1 hour; 2) with magnetic stirring, dripping reducer-containing aqueous solution till the ratio of the reducer and the palladium is 1:1 to 2:1, and continuously stirring for 1 to 2 hours after the dripping is finished; and 3) finally, stirring the solution in an oil bath for 1 to 2 hours, and obtaining the palladium / carbon nanotube catalyst by filtering, washing and drying. Compared with active carbon supported palladium catalyst, the palladium / carbon nanotube catalyst has high selectivity for the preparation of benzenepropana by the hydrogenation of cinnamaldehyde.

Owner:葛昌华 +3

Steel slag ball production equipment and granulating system thereof

InactiveCN102690907AProlong the action timeFully oxidizedRecycling and recovery technologiesSlagAir compressor

The invention discloses steel slag ball production equipment and a granulating system thereof. The steel slag ball production equipment comprises the granulating system for spraying and cooling steel slag flowing out from a flowing groove by using high-pressure air water flow, wherein the granulating system comprises an air spraying mechanism and a cooling liquid spraying mechanism which are distributed up and down; the air spraying mechanism comprises an air compressor or a fan for supplying a high-pressure air source, and an air box for guiding air flow to be sprayed along a certain direction; the air box is provided with an air inlet and an air outlet; an air outlet of the air compressor or the fan is communicated with the air inlet of the air box through a pipeline; spraying panels are arranged at the front end of the air box; the spraying panels are provided with nozzles which are communicated with the air outlet of the air box; and more than two layers of spraying panels are arranged from top to bottom and each layer of spraying panel is horizontally provided with a plurality of nozzles in parallel. The granulating system of the steel slag ball production equipment adopts air and cooling liquid to commonly act on steel slag and the acting time in the air is long; the oxidization reaction is sufficient; the configuration of an organization is stable; and the granulating system can be used for grinding materials, building materials, water treatment, desulfurization agents and the like.

Owner:HENAN UNIV OF SCI & TECH

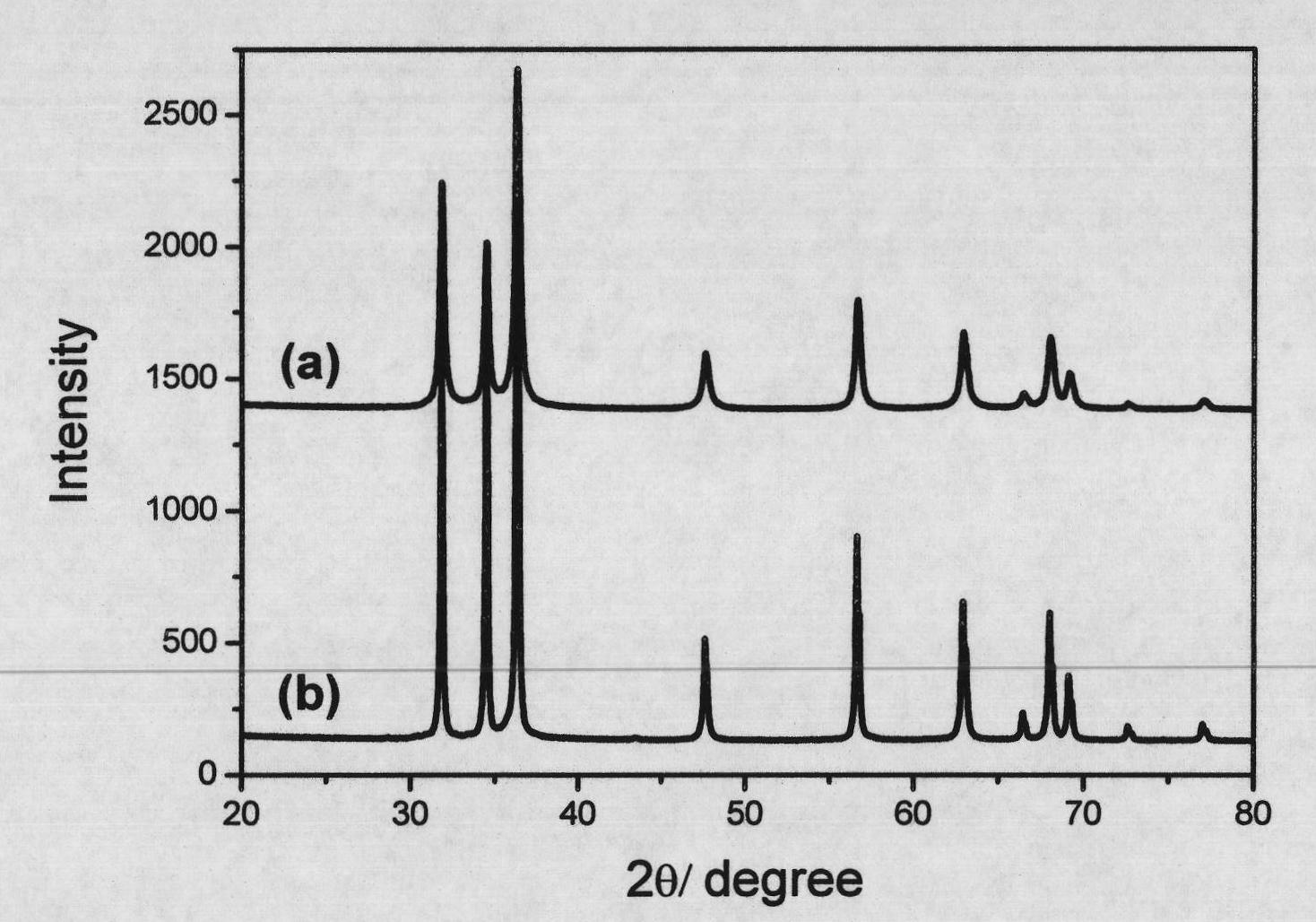

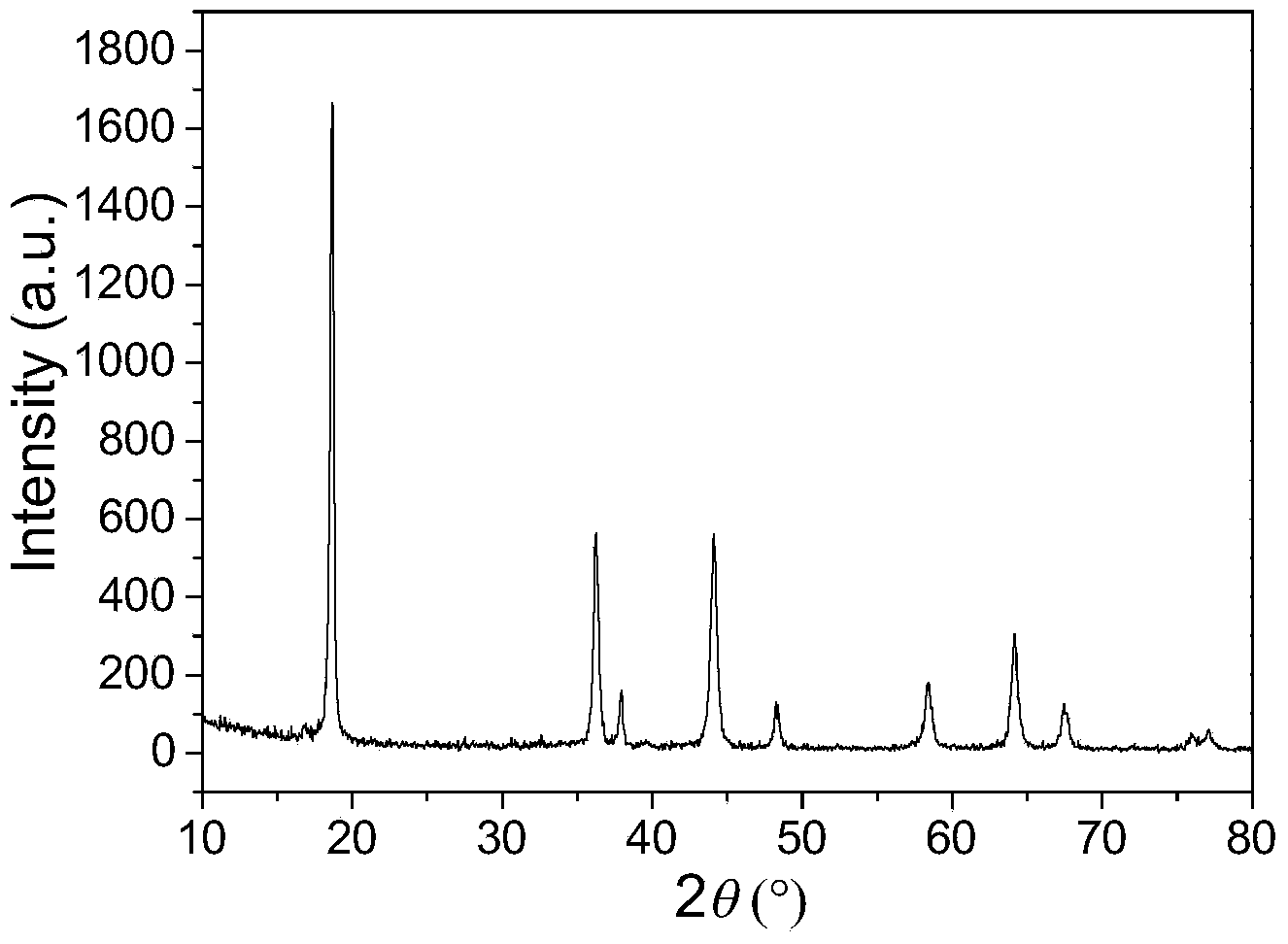

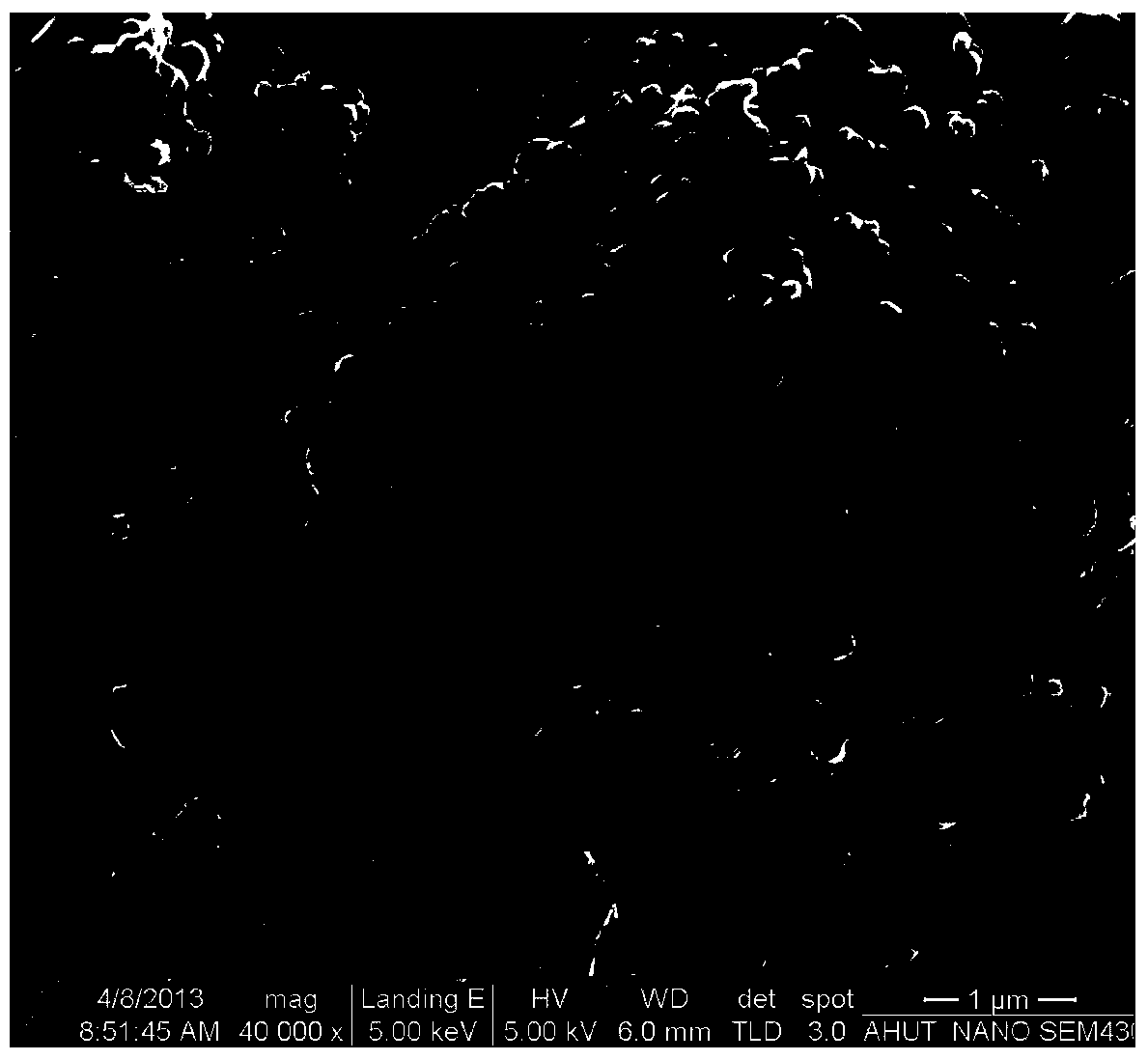

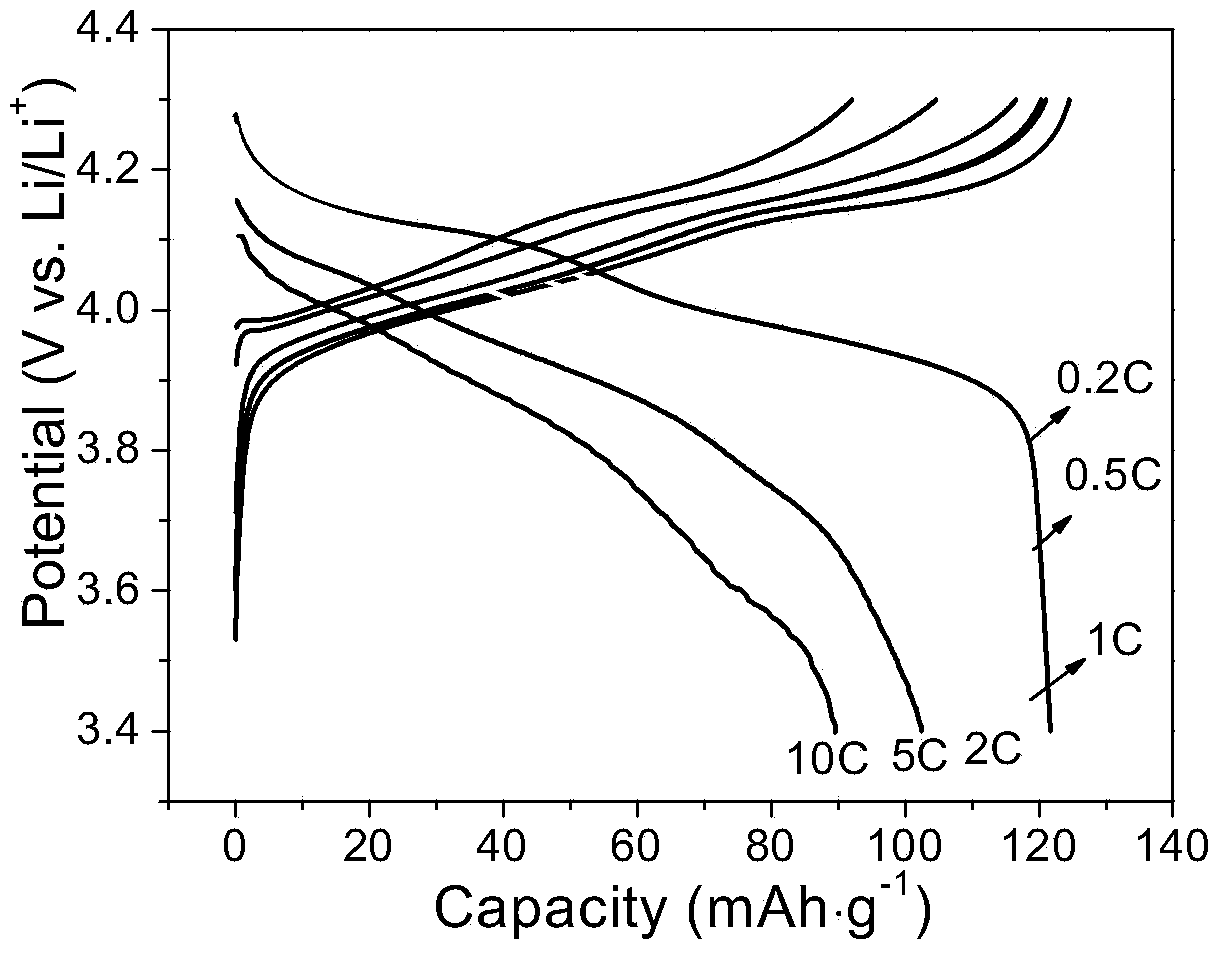

Doping modification method of spinel lithium manganate anode material

ActiveCN104319393APrecise control of stoichiometryPromote crystallizationCell electrodesManganateManganous-manganic oxide

The invention discloses a doping modification method of spinel lithium manganate anode material, and belongs to the field of nanotechnology. The method mainly comprises the following steps: respectively adding a saline solution of lithium-ion and doping ion into a citric acid solution, regulating pH values, adding ethylene glycol into the solution, heating and stirring the solution so as to form sol, mixing manganous-manganic oxide with the sol, performing ball milling, and performing microwave dehydration and subsequent heat treatment on products subjected to ball milling so as to obtain the doped spinel lithium manganate anode material. The method has the advantages that the prepared spinel lithium manganate anode material has high specific capacity, good rate capability and excellent cycling performance, meanwhile the technology is simple, the cost is low, the efficiency is high, and the method can be directly applied to industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

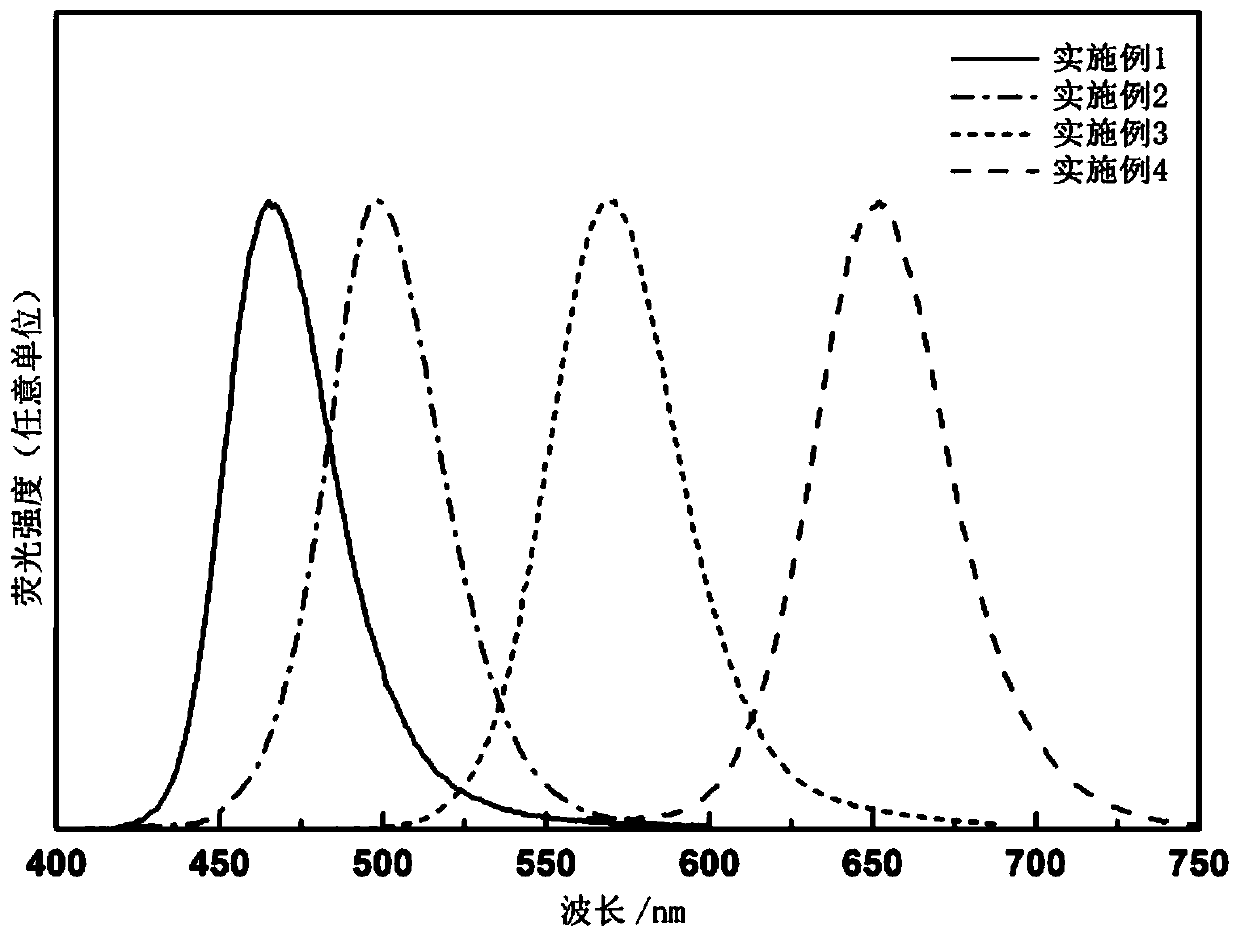

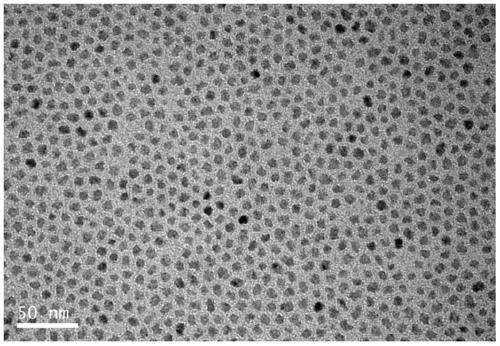

InP quantum dot and preparation method thereof

The invention discloses a preparation method of an InP quantum dot, relates to the field of quantum dot materials, comprising the following steps: firstly, water and oxygen are removed from a reactionvessel, then a homogeneous precursor solution of indium and zinc is prepared, a phosphorus precursor is added, a synthetic shell material is added, and then, an InP quantum dot structure with a shellstructure is prepared by increasing the shell thickness while raising the temperature. The InP crystal nucleus of the InP quantum dot prepared by the invention are nano-structures, and the shell layer composition comprises one or several of ZnS, ZnSe and ZnSeS; the fluorescence emission peaks range from 450 nm to 700 nm, and the half maximum width is less than 55 nm. The invention can effectivelycontrol crystal nucleus growth and fluorescence emission wavelength, and obtain InP quantum dots with small and uniform crystal nucleus diameter, wide luminous color gamut and narrow half-maximum width. At the same time, it can reduce the surface oxidation of the crystal nucleus, promote the thickness of the shell layer with high quality and low defects, and improve the luminescence efficiency ofInP quantum dot.

Owner:SHANGHAI JIAO TONG UNIV

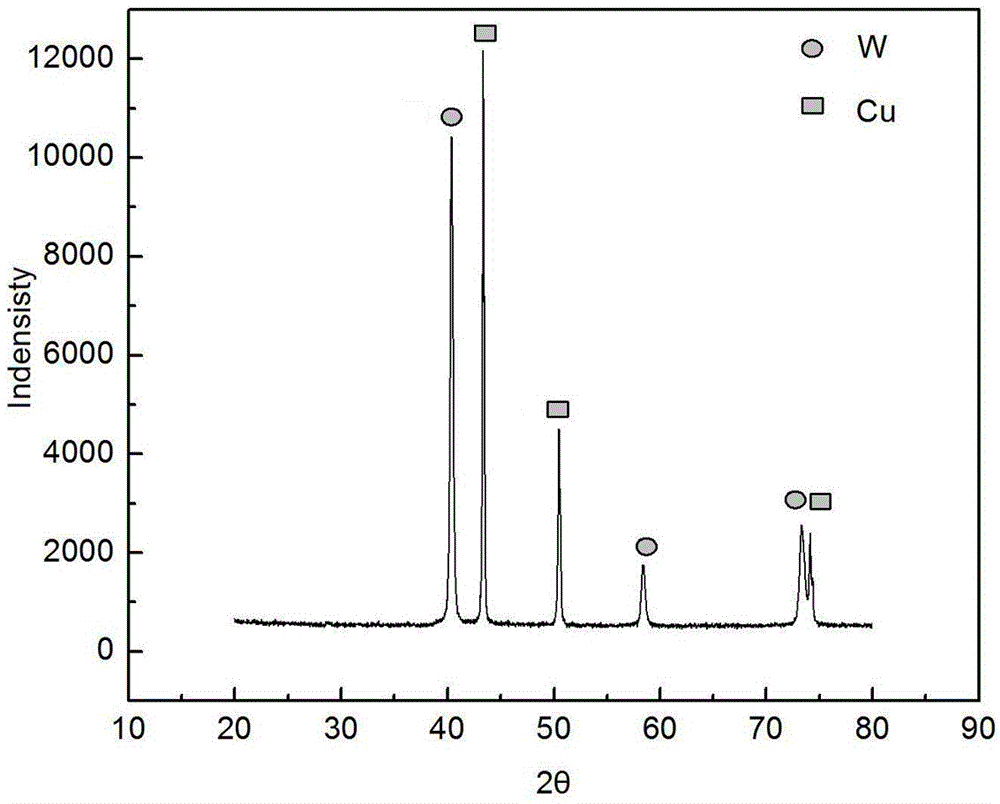

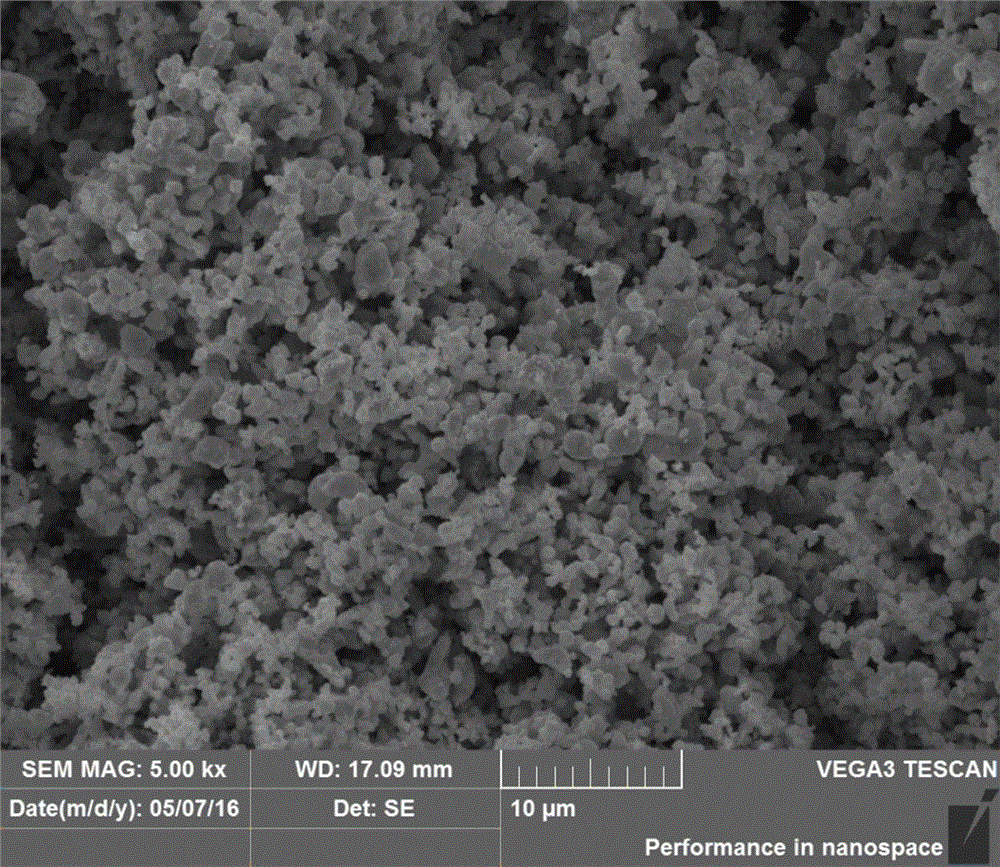

Preparation method for composite high-copper tungsten-copper nanopowder

ActiveCN106077695AInhibit aggregationFine and uniform particle sizeTransportation and packagingMetal-working apparatusMicro nanoTungstate

The invention discloses a preparation method for composite high-copper tungsten-copper nanopowder. The preparation method comprises the following steps: first preparing copper nitrate, ammonium meta-tungstate and oxalic acid solutions, then uniformly mixing the three prepared solutions according to the molar ratio of copper nitrate, ammonium meta-tungstate and oxalic acid of 1:(0.04-0.2):(1-1.5), adding dropwise an NaOH solution at a mass concentration of 30 to 60 percent into a mixed solution until the Ph value of the mixed solution is less than or equal to 3, performing reaction on the prepared mixed solution for 2 to 4h with stirring at 60 to 90 DEG C, filtering and washing a reaction product, drying the reaction product for 18 to 20h at 80 to 95 DEG C to obtain a precursor, and finally sequentially performing calcination, reduction and cooling on the prepared precursor to obtain granular high-copper tungsten-copper powder. The preparation method is easy to operate, and composite high-copper tungsten-based micro-nano powder with high dispersibility and uniformity can be effectively prepared.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com