Metal evaporating device and method for preparing ultrafine metal powder by using same

A metal evaporation and metal powder technology, applied in the field of preparing ultra-fine metal powder, can solve the problems of small contact surface, large energy consumption, low metal vapor output, etc., and achieve stable plasma transfer arc, fine and uniform particle size, The effect of improving product efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawings and specific implementation, but the present invention is not limited to the following examples, and any modification within the protection scope of the present invention is considered to fall within the protection scope of the present invention.

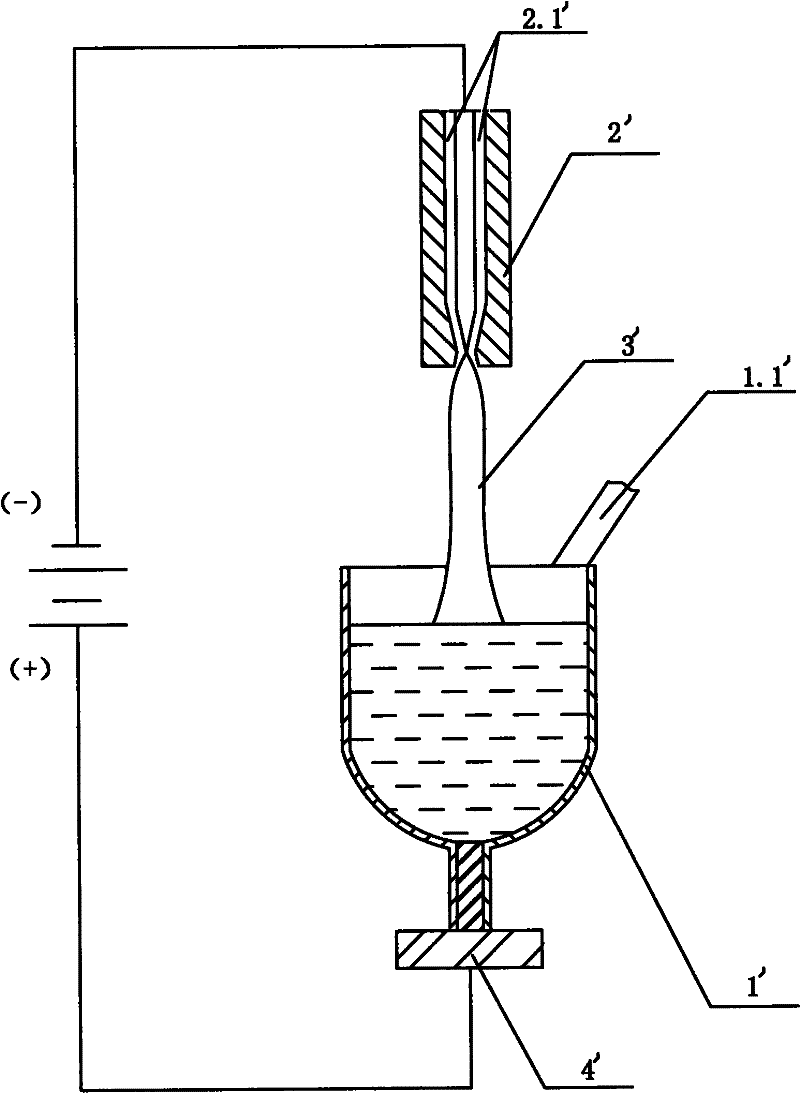

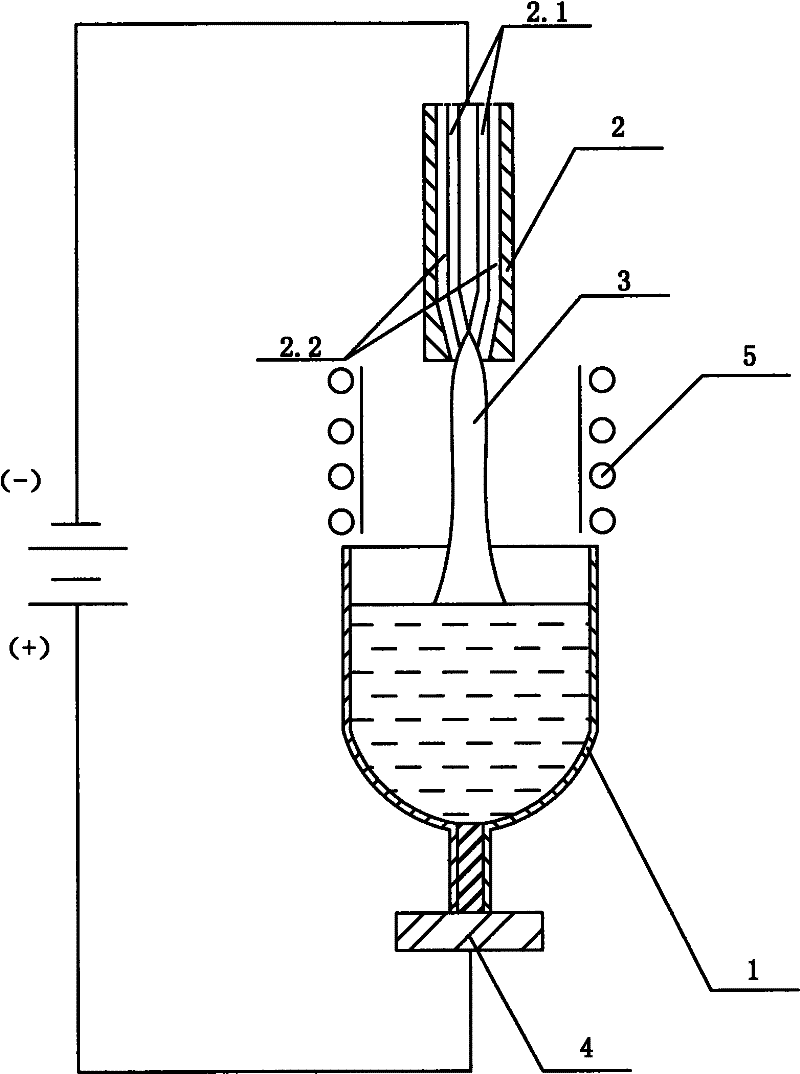

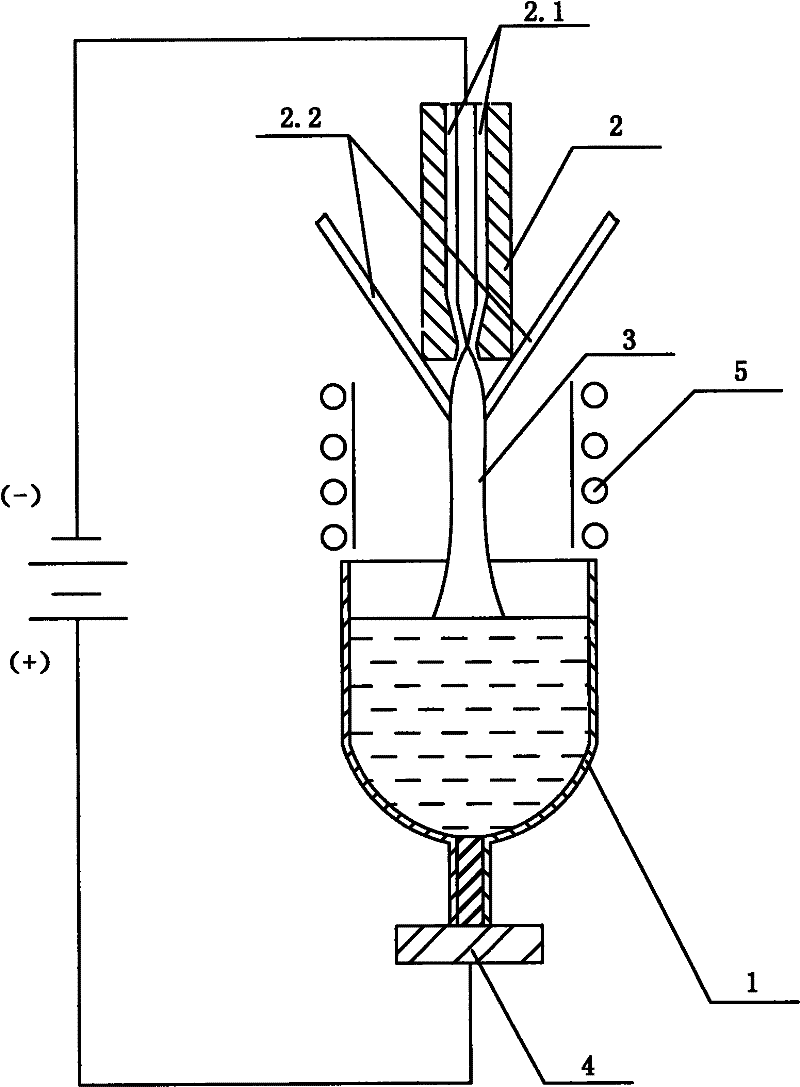

[0030] Such as figure 2 As shown, the metal evaporation device of the present invention includes a crucible 1, a plasma transfer arc torch 2, a plasma transfer arc 3, graphite 4, an external power supply and a lead for holding a metal block and molten metal liquid; The plasma transfer arc torch 2 is provided with an inlet pipe 2.1 for gas to enter; the plasma transfer arc 3 is placed between the plasma transfer arc torch 2 and the crucible 1; the graphite 4 is arranged at the crucible 1 Bottom; the crucible 1, the plasma transfer arc torch 2, the plasma transfer arc 3, the graphite 4, the external power supply and the wire form an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com