Process for activating CO sulfur-resistant shift catalyst before start-up of pulverized coal gasification device

A technology of sulfur-resistant conversion and coal gasification, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unsuitable control of bed temperature rise, large system pressure drop, and high start-up costs, and achieve The effect of shortening the activation time, reducing the amount of exhaust gas, and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

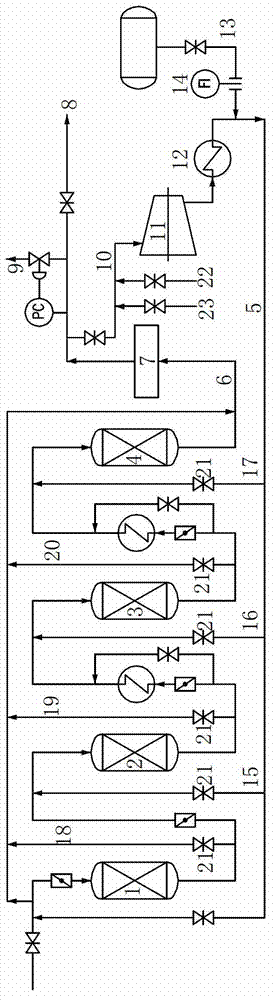

[0032] Such as figure 1 As shown, the equipment used in the CO shift catalyst activation process before the start-up of the pulverized coal gasification unit includes a pre-shift furnace 1 , a first shift furnace 2 , a second shift furnace 3 and a third shift furnace 4 connected in series. Wherein, the inlet of the pre-shift furnace 1 is connected to the vulcanization bus 5 , and the outlet of the third shift furnace is connected to the return pipeline 6 . A gas-liquid separation system 7 is provided on the return pipeline 6, and a three-way parallel pipeline is provided downstream of the gas-liquid separation system 7. One of them is connected to the downstream device 8 , one is connected to the atmosphere through the vent valve 9 , and one is connected to the inlet of the compressor 11 through the circulation line 10 . The outlet of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com