Patents

Literature

208results about How to "Fully vaporized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

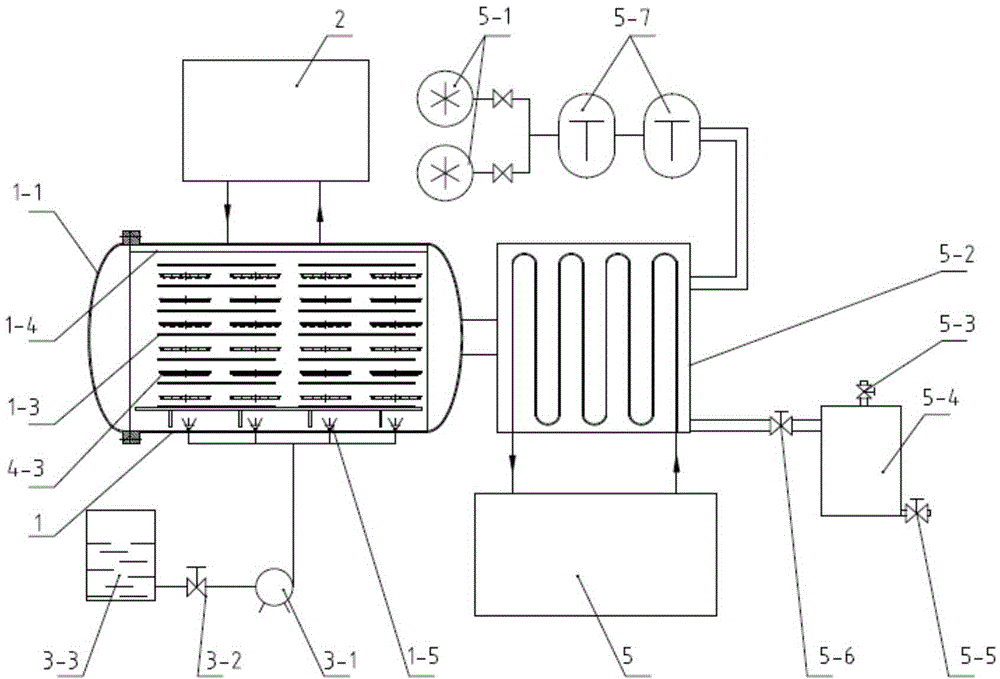

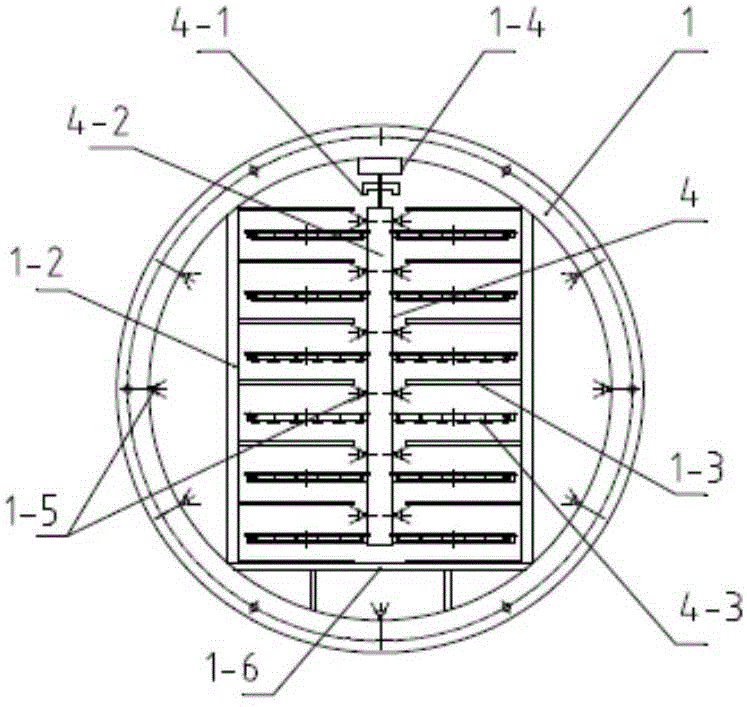

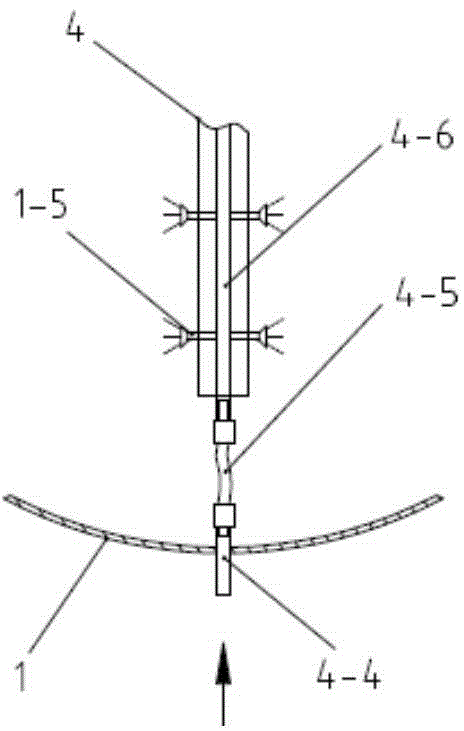

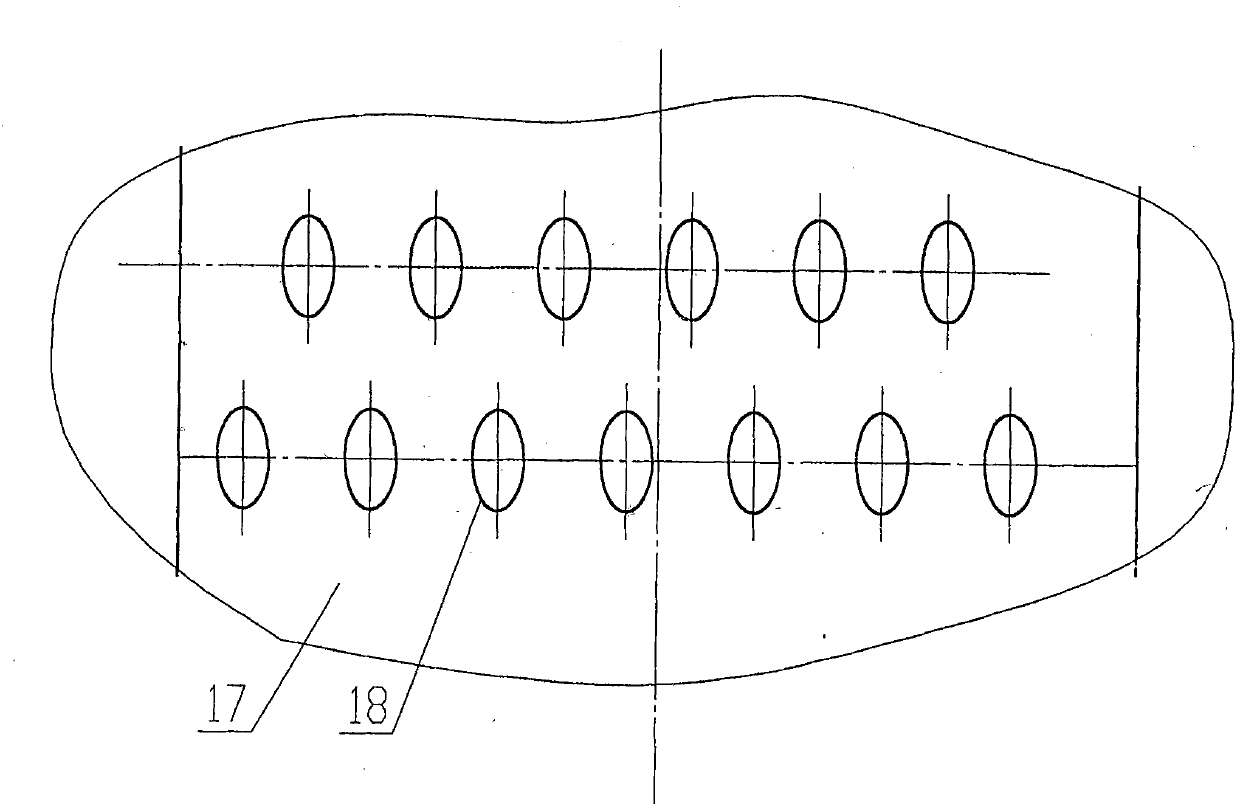

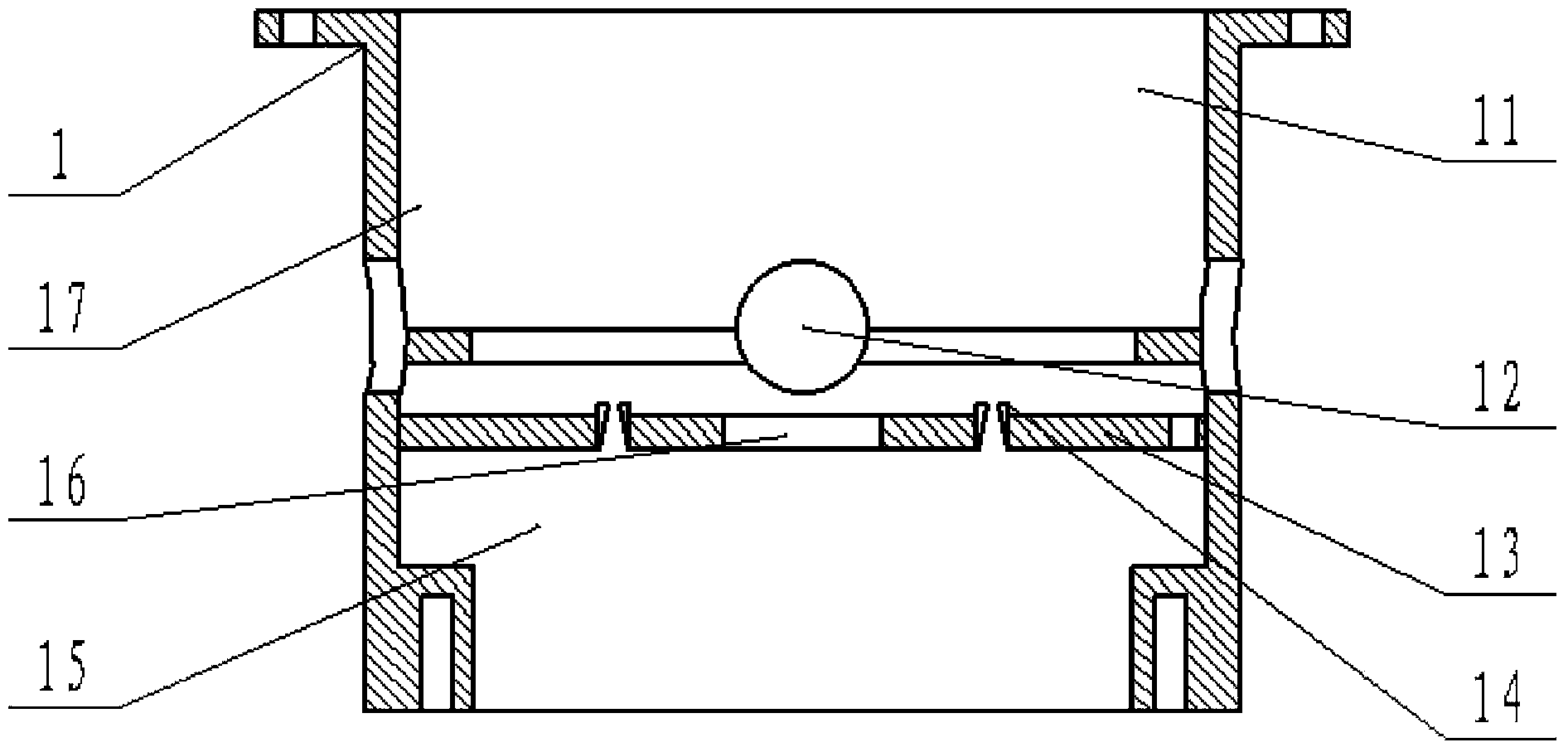

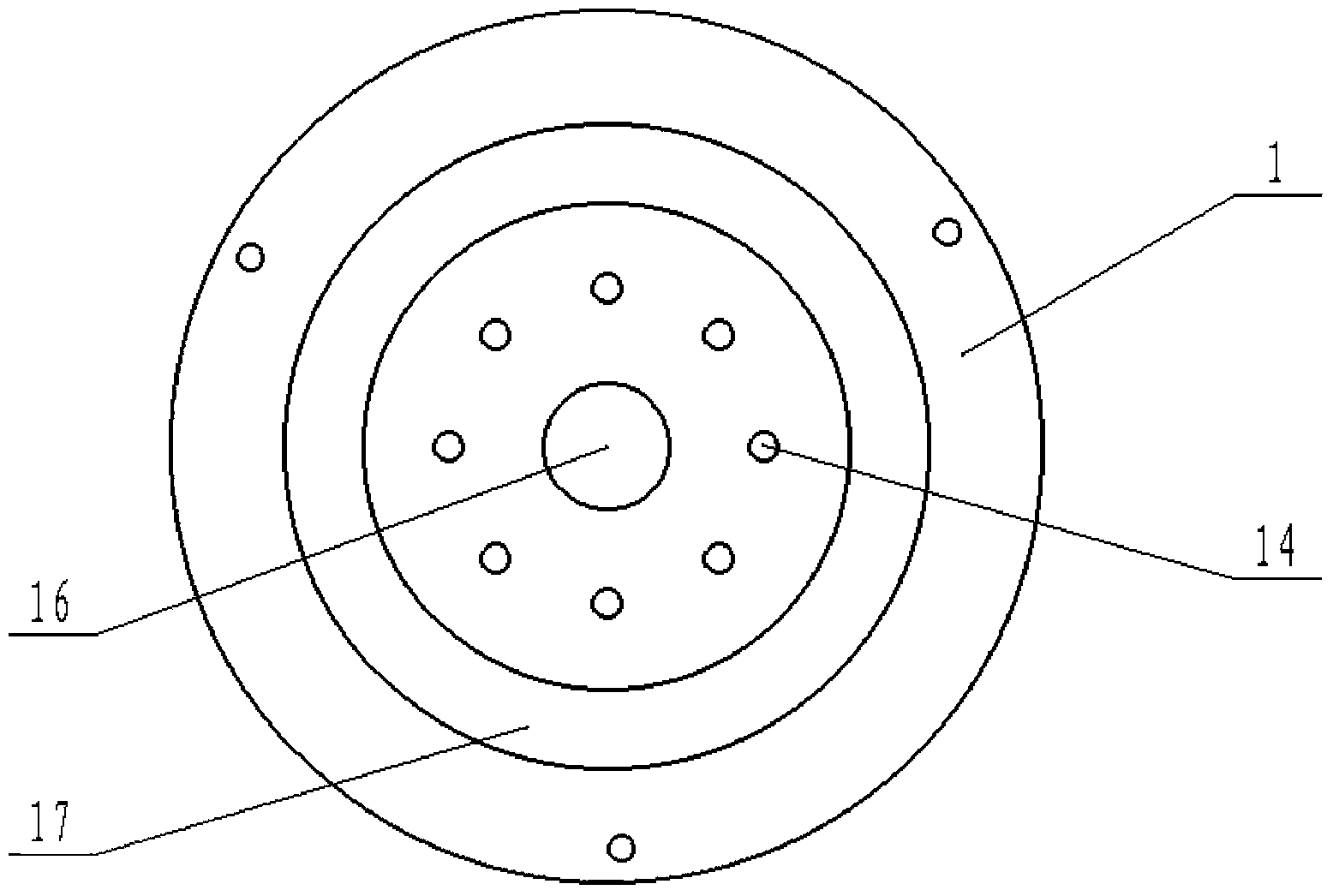

Trickle falling film type evaporator device and use method

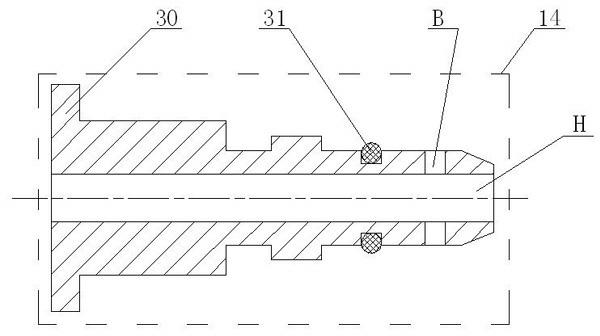

ActiveCN101382359AReduce chargeLiquid evenlyEvaporators/condensersStationary conduit assembliesVena contracta diameterPressure decrease

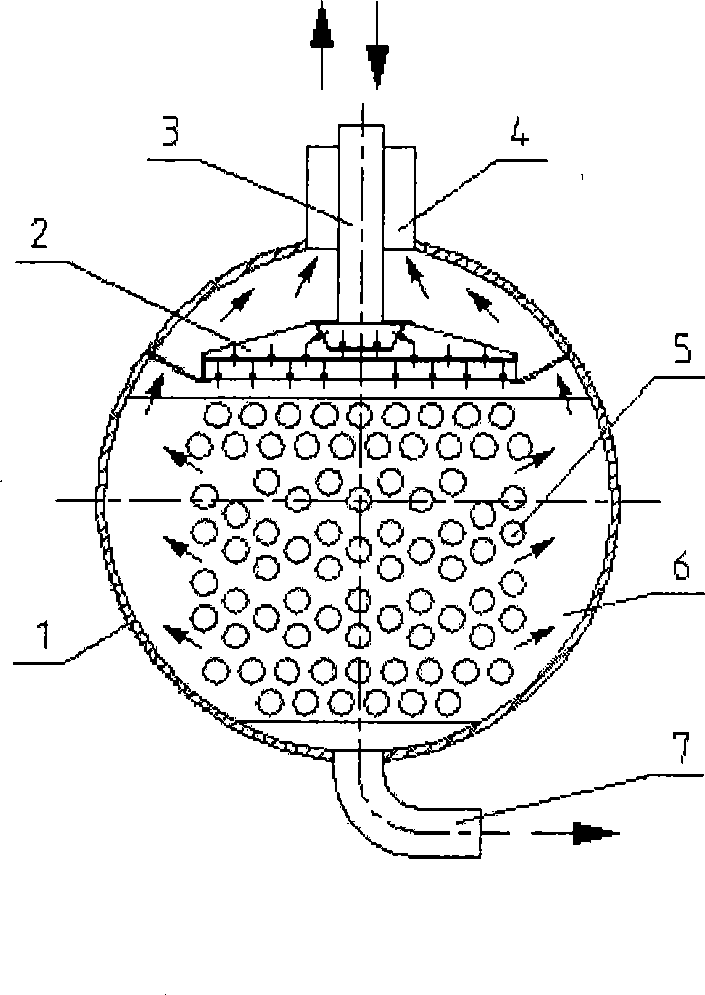

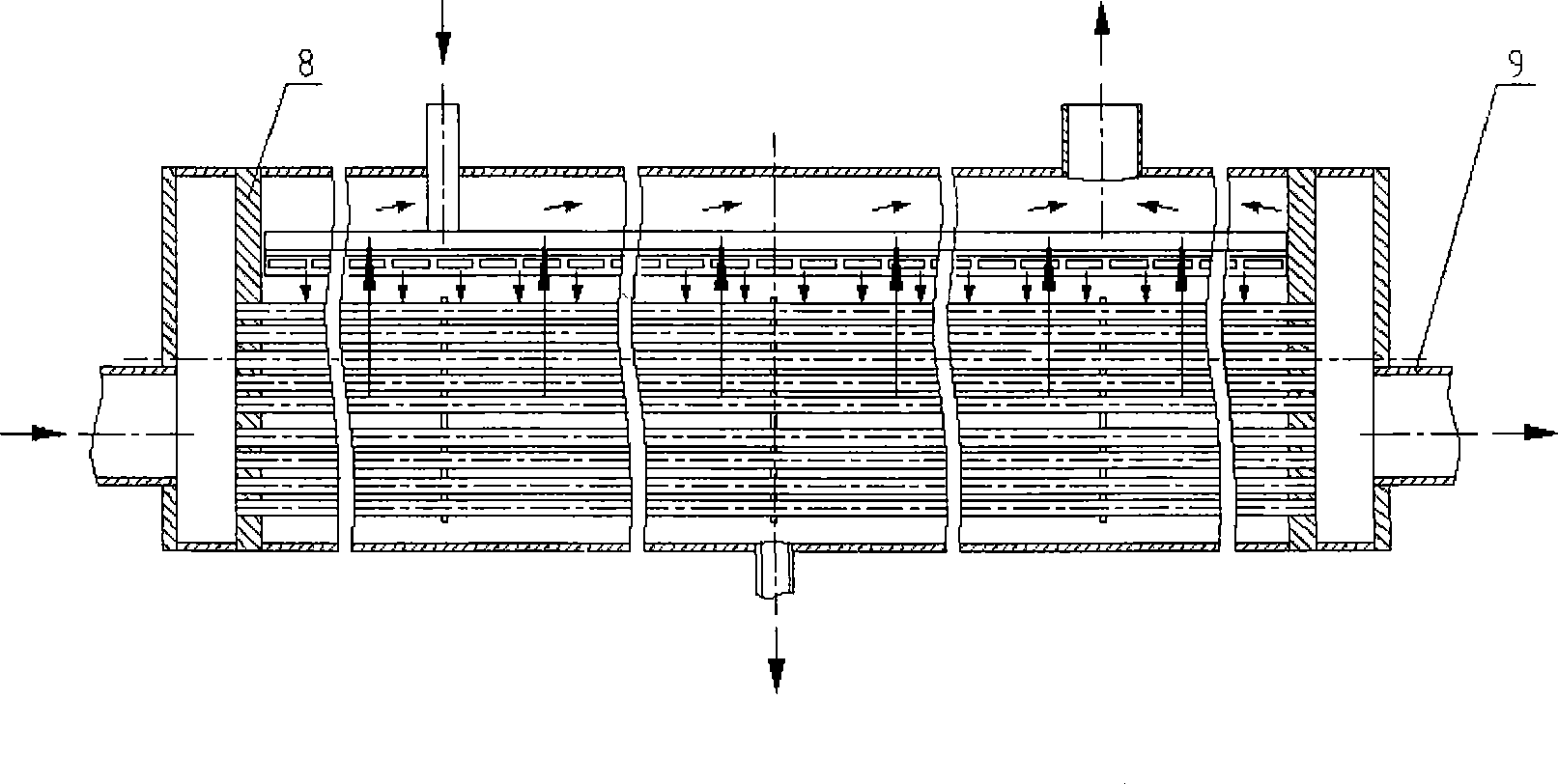

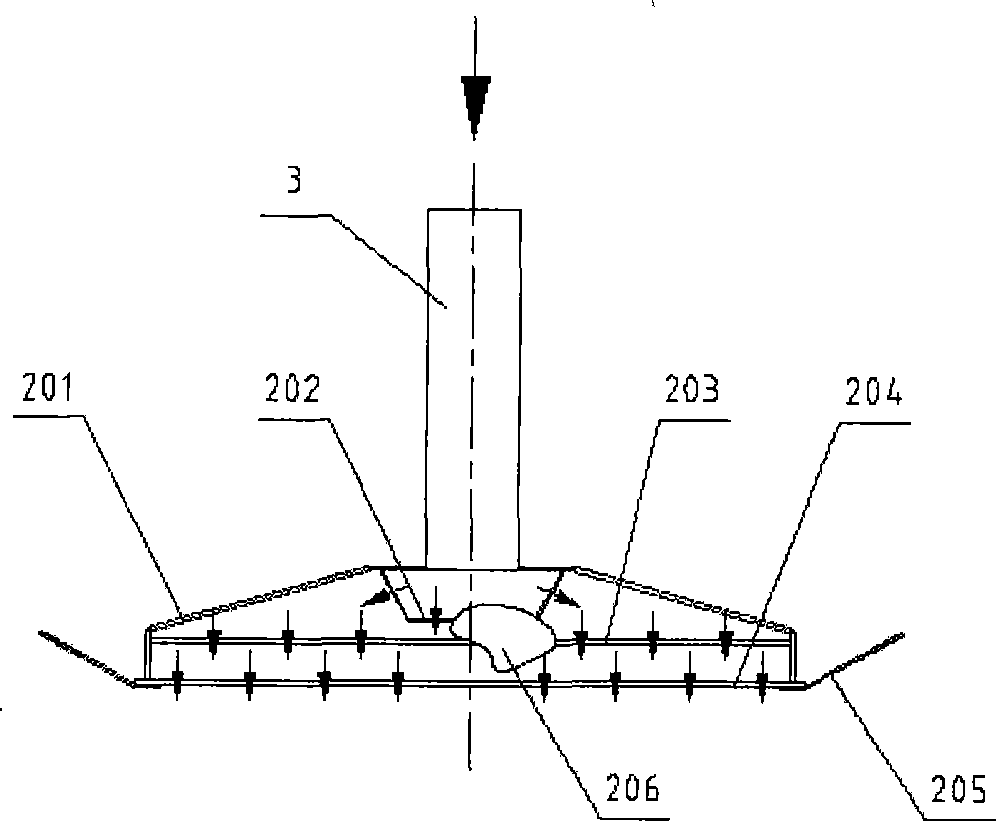

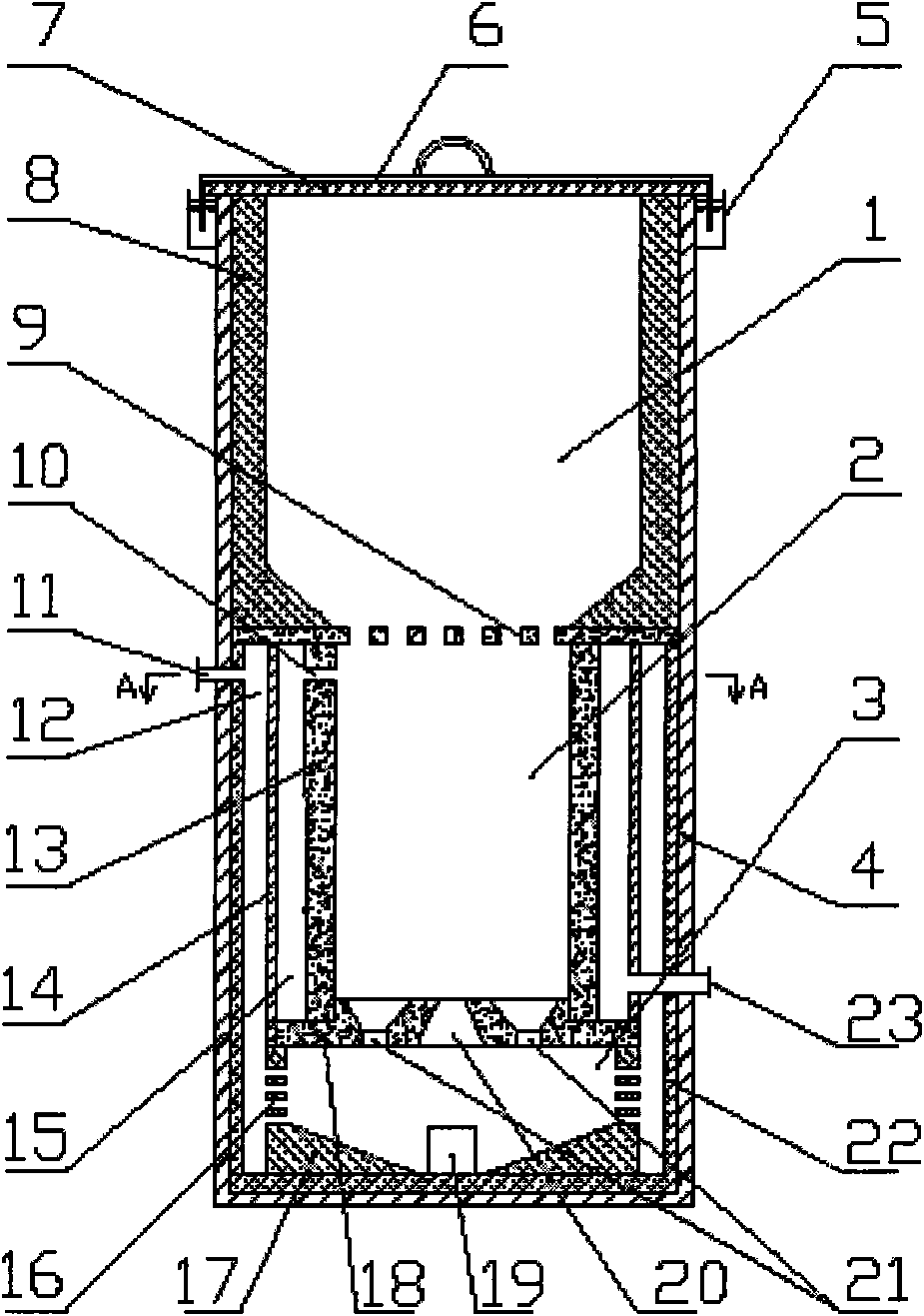

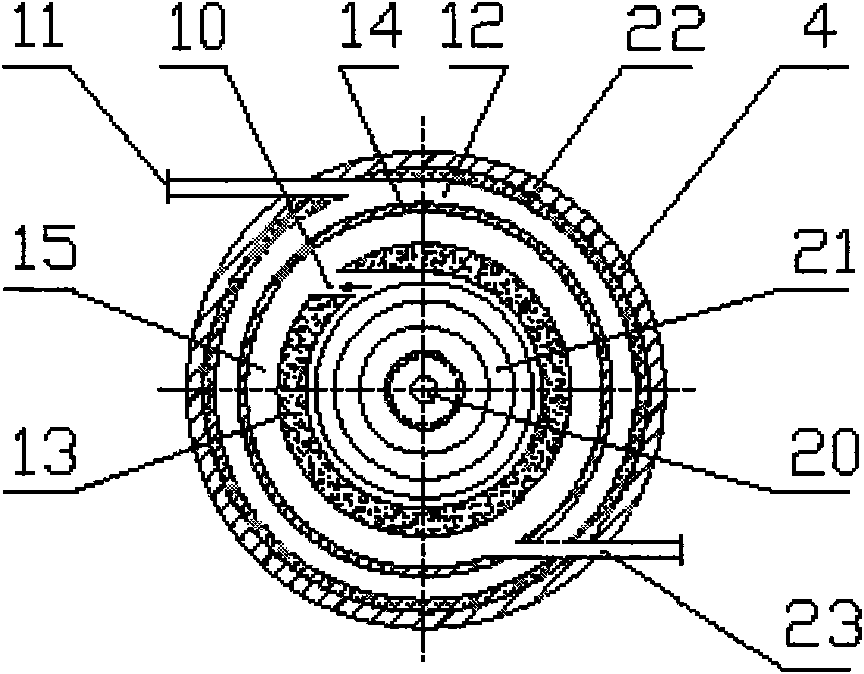

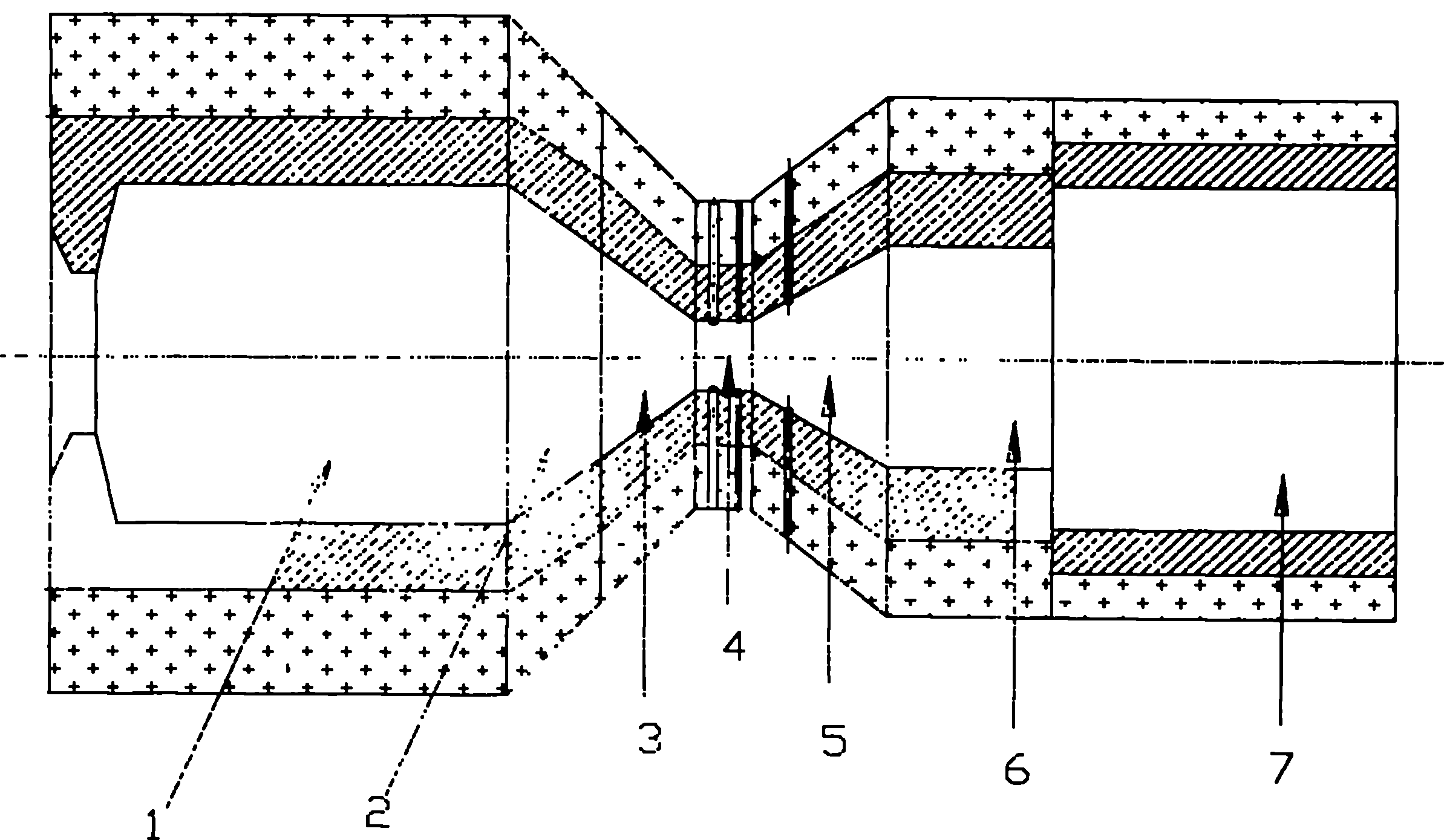

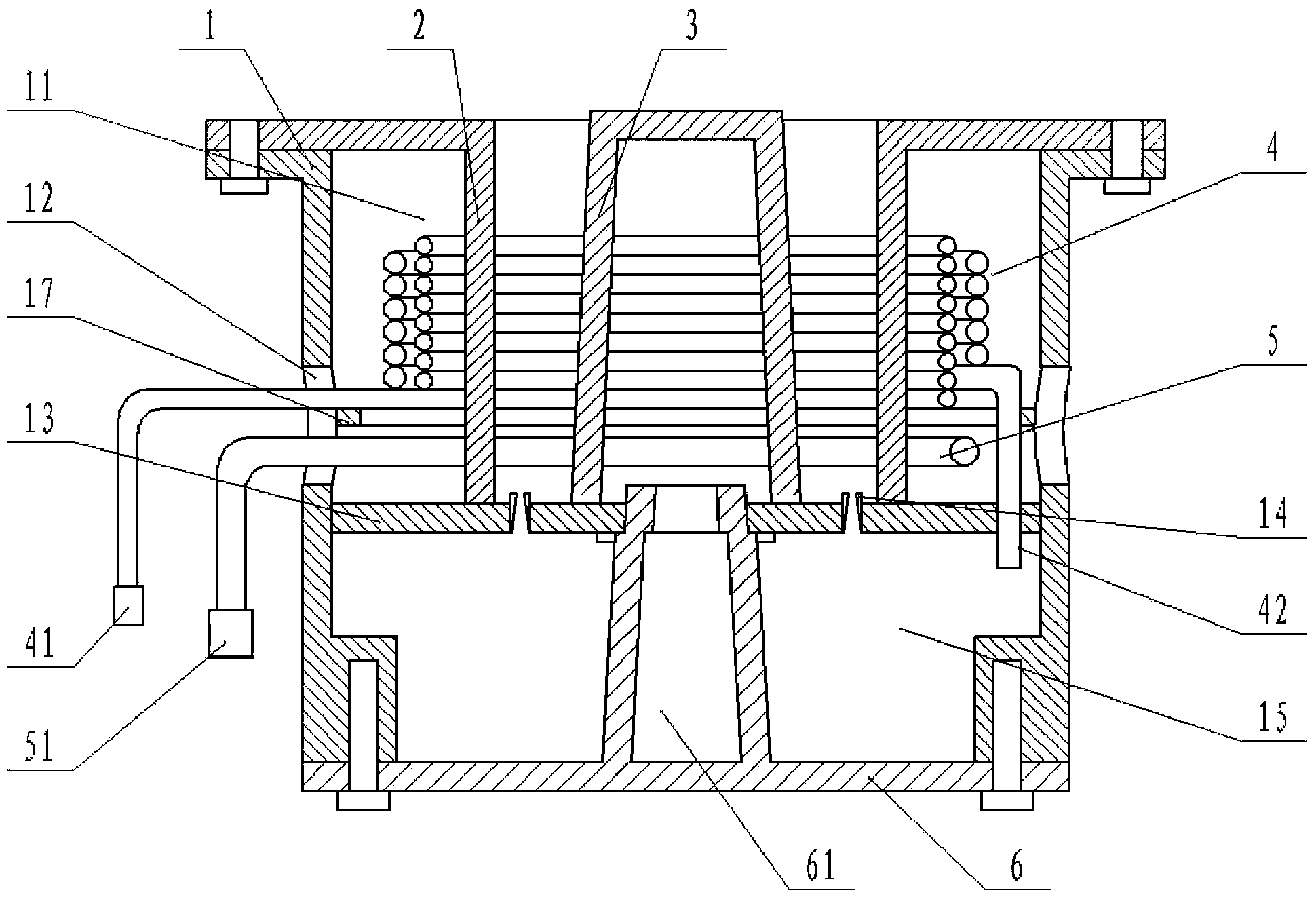

The invention relates to a trickle downward film type evaporator device and a using method thereof; the downward film type evaporator of the prior art which is the two-phase refrigerant distributor technology has a five-layer orifice plate structure and a capillary structure, as the structure is more complicated and the processing and assembling difficulty is high, the uneven liquid distribution is easily caused, the heat transfer performance is decreased and the energy efficiency is lowered. The trickle downward film type evaporator device adopts the technical proposal of a multi-directional two-grade pressure decrease distribution device, a two-phase refrigerant distributor which consists of a trapezoidal shell body, a multi-directional flow distribution plate, a grade-one distribution orifice plate, a grade-two distribution orifice plate, a gas absorption distribution plate and an end seal plate is used for carrying out the multi-directional two-grade pressure decrease distribution, thereby leading a gas-liquid refrigerant to be evenly and effectively trickled at the outer surface of the pipe wall of an evaporation pipe bundle and further carry out the full heat exchange. The trickle downward film type evaporator device has the advantages that: the two-phase refrigerant distributor technology has simple structure, easy production, even liquid distribution of the gas-liquid refrigerant and improved heat transfer performance. Compared with the existing flooded evaporator, the energy is saved by 15-20 percent, and the filling amount of the refrigerant is reduced by 20-30 percent, thereby being economic and energy-saving.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

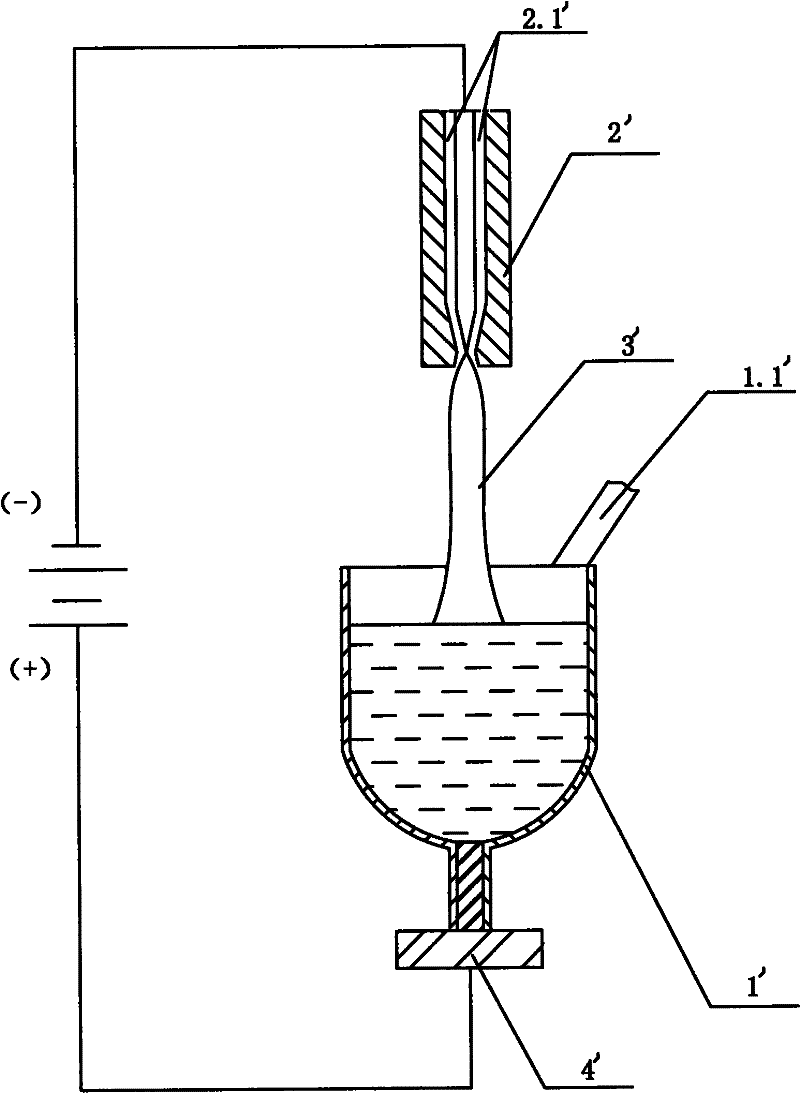

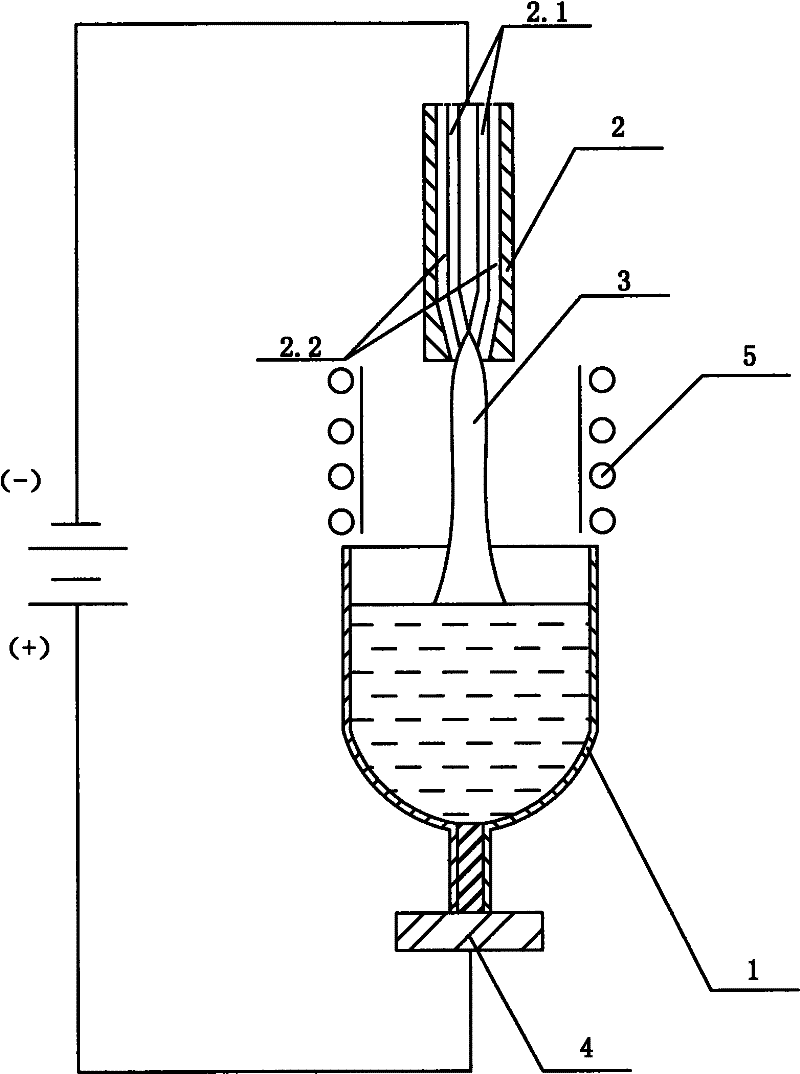

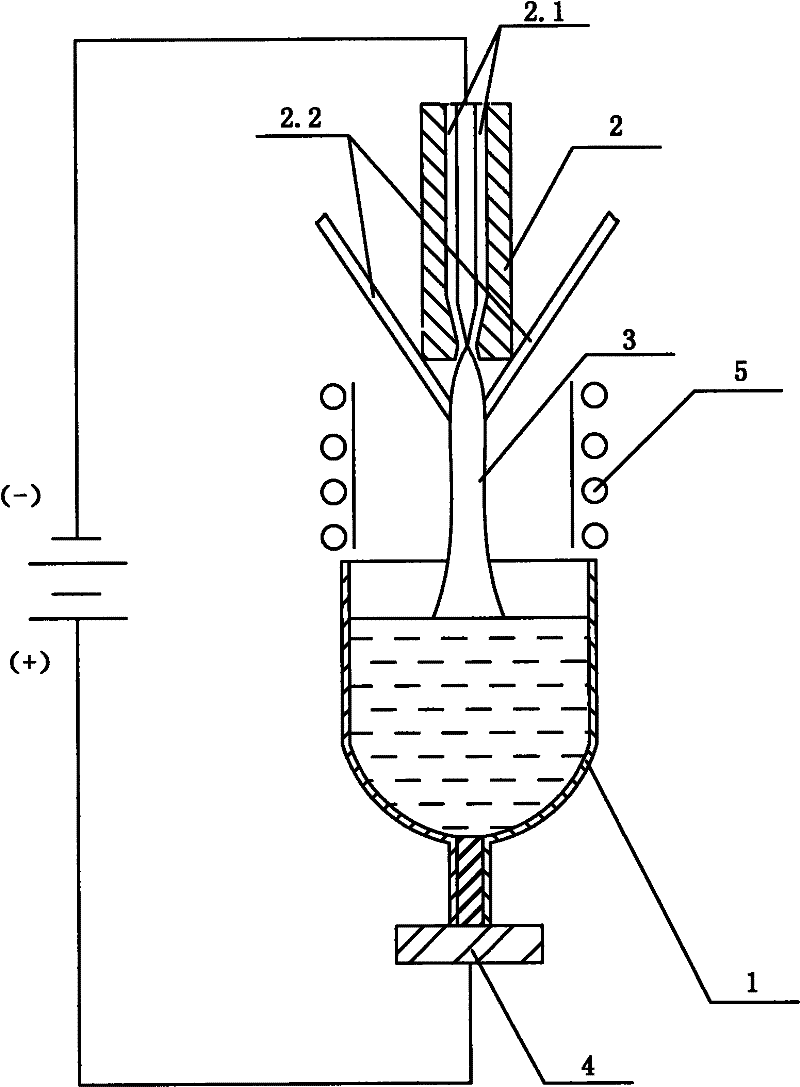

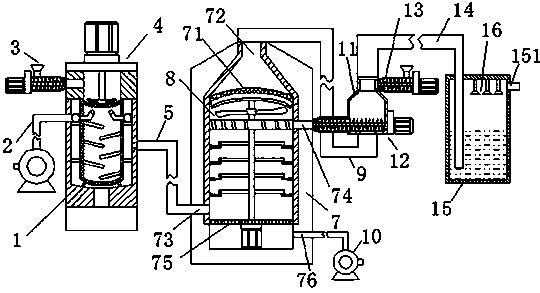

Metal evaporating device and method for preparing ultrafine metal powder by using same

The invention discloses a metal evaporating device and a method for preparing ultrafine metal powder by using the same. The device comprises a crucible (1), a plasma transferred arc torch (2), a plasma transferred arc (3), a graphite (4), a power supply and a lead, which form an electric loop, wherein an air inlet pipe (2.1) from which air enters, is arranged in the plasma transferred arc torch (2); the plasma transferred arc (3) is arranged between the plasma transferred arc torch (2) and the crucible (1); the graphite (4) is arranged on the bottom of the crucible (1); and a feed pipe (2.2) which is used for feeding metal raw materials is arranged above the plasma transferred arc (3). The structure of the metal evaporating device has the advantages that the energy of the plasma transferred arc is fully utilized, the metal output and the metal evaporating efficiency are increased, the energy consumption is lowered, and the ultrafine metal powder which has uniform particle size and is free from large particle metal residual is acquired.

Owner:JIANGSU BOQIAN NEW MATERIALS

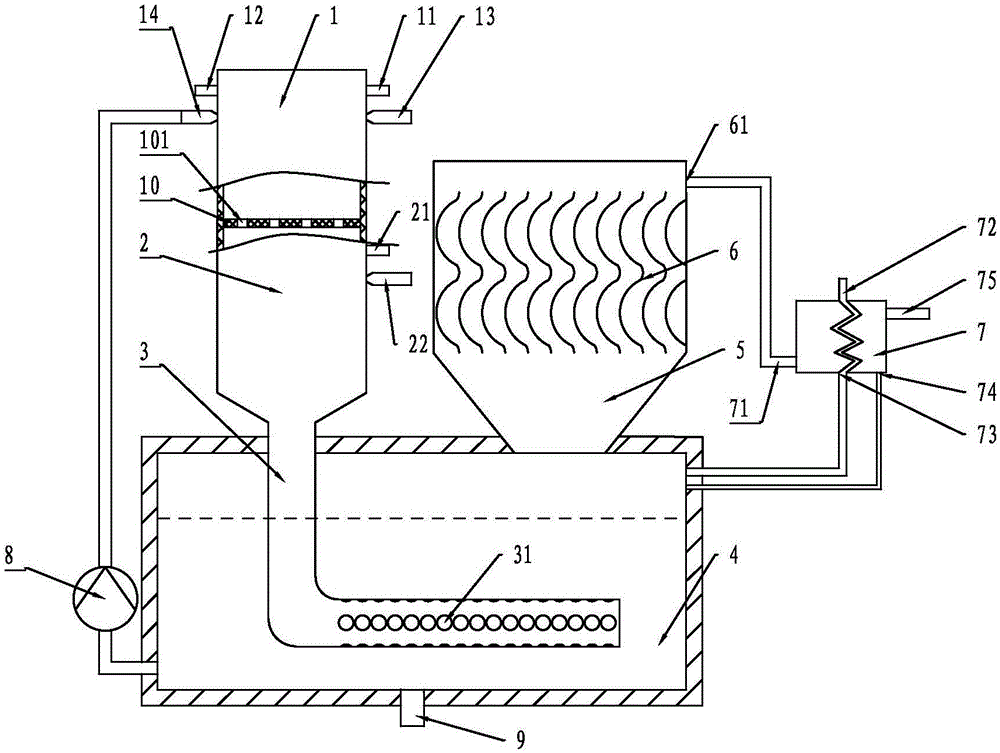

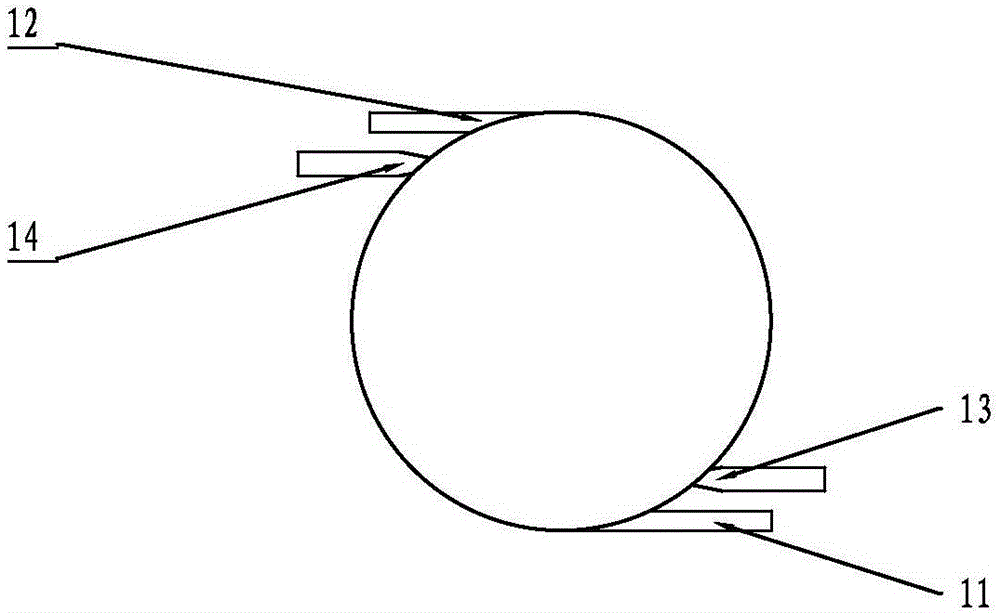

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

Integrated radiation vacuum freeze-dry device and method

ActiveCN104596206ALow costSimple processFruit and vegetables preservationDrying solid materials without heatWaxFreeze-drying

The invention relates to an integrated radiation vacuum freeze-dry device and method, further relates to a corresponding method, and belongs to the technical field of food devices. The freeze-dry device is characterized in that a vertical side bracket is fixed in a vacuum warehouse body, the side bracket extends out of heating shelves, and the heating shelves and a heat carrying agent heater form a heat exchange cycle system; an accommodating interval of a hanging material vehicle is formed between the two heating shelves on both sides, the hanging material vehicle comprises a vertical suspension which extends out of level trays which are positioned between the two adjacent level hollow heating shelves; spraying nozzles are distributed in the vacuum warehouse body, and are connected to a high pressure water conveying system through a pipeline. Through the adoption of the freeze-dry device disclosed by the invention, the low cost food freezing is realized, and all of the technological processes namely freezing and drying are completed once in the same device, so that the technological processes are simplified, the efficiency is obviously improved, and the freeze-dry device is suitable for various food materials, such as food materials which contain less water, are compact in texture or have wax coat surfaces.

Owner:JIANGSU BOLAIKE FROZEN TECH DEV CO LTD

Double distillation type multiple-effect distilled water machine

InactiveCN1569300AFully vaporizedEven distribution of waterDistillation in pipe stillsWater/sewage treatment by heatingDistillationDistilled water

The invention is a double-distillation type multiple effect distilled water machine, belonging to water distillation device. Its features lie in: the evaporator is divided into two segments, the upper one is steam-water separation segment, the lower is evaporating segment, the steam inlet arranged on the evaporating segment of the first effect evaporator is connected to industrial boiler steam source, the water condensing port is connected to preheater, the condensing ports of the following effect evaporator are connected to the condenser, there arranges a material condensed water discharging port on the last effect evaporator, the water pipe is connected to the water inlet of the first evaporator through condenser pipe and preheater. The invention can use the residue heat generated by the device, upgrades the use factor of heat and the reclaiming rate of distilled water, and the structure is compact.

Owner:淄博华周制药设备有限公司

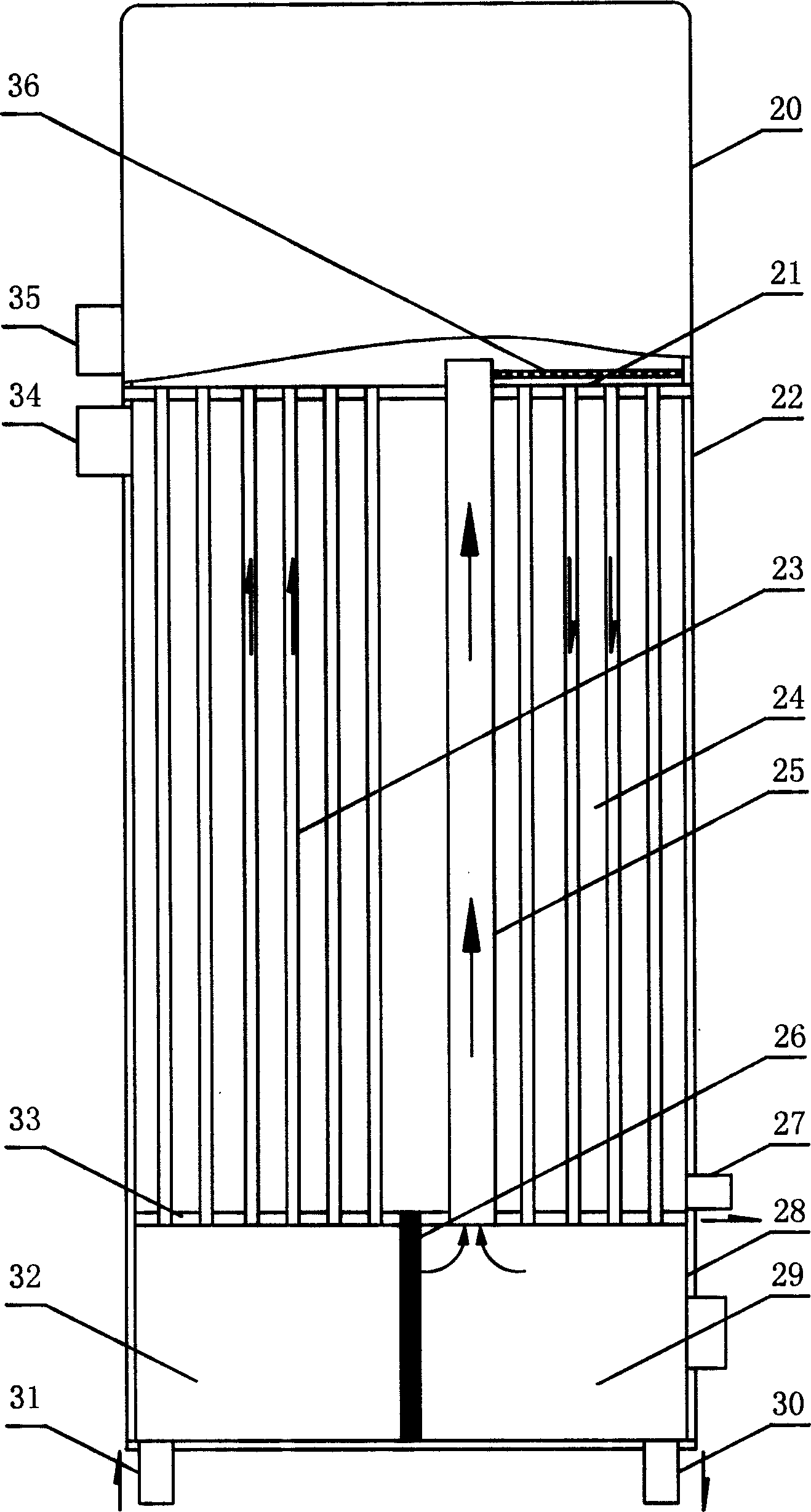

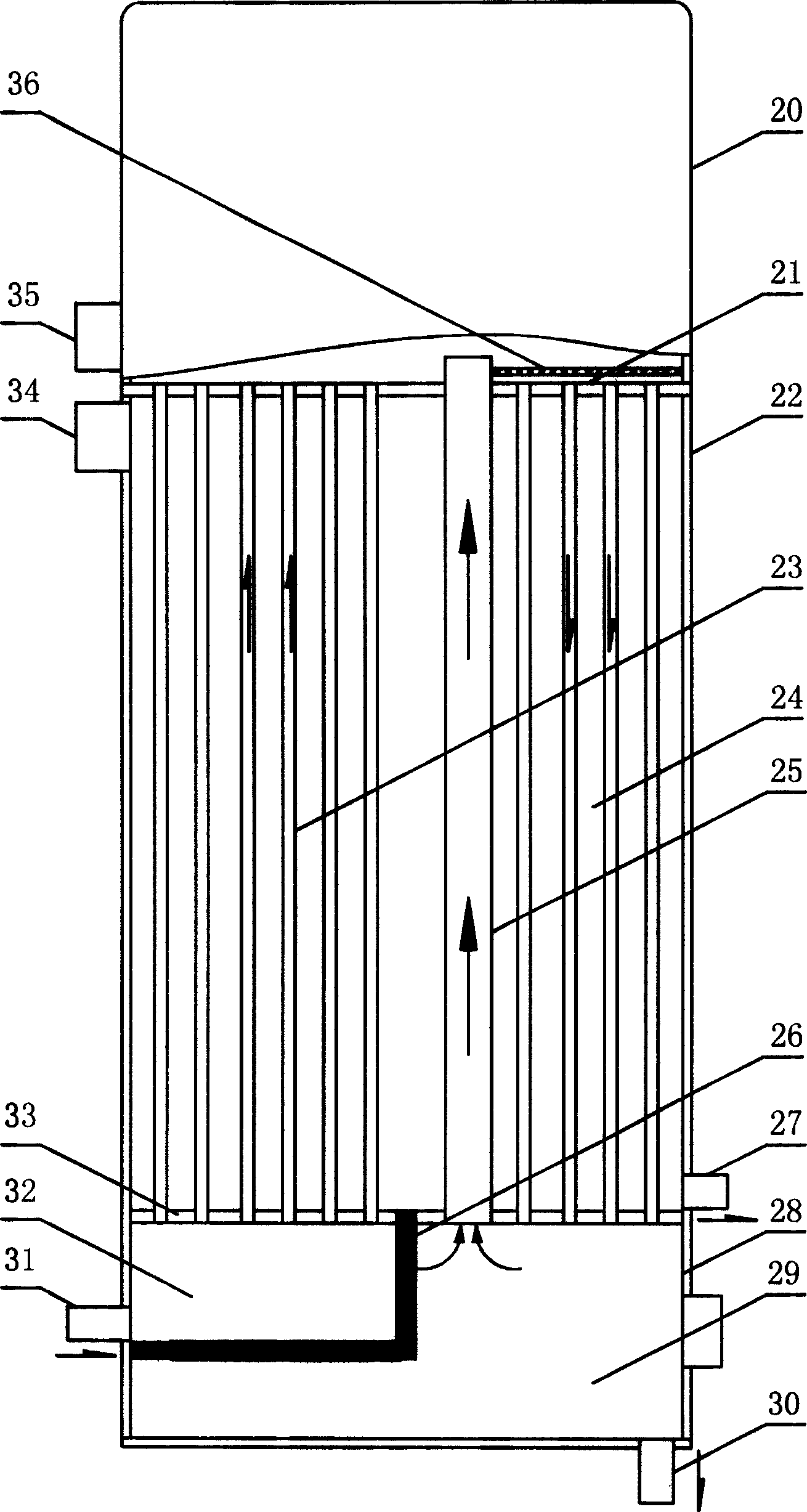

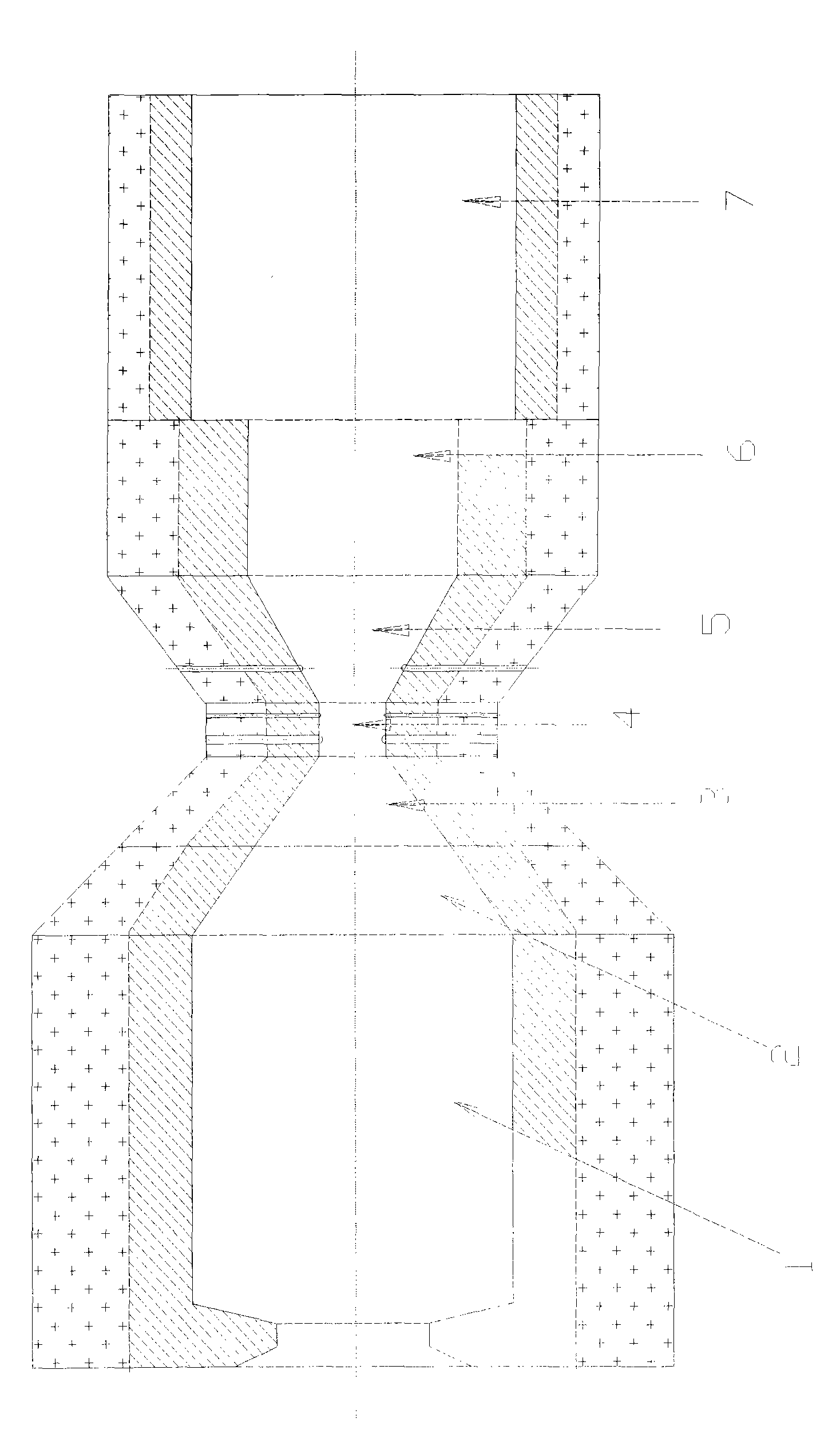

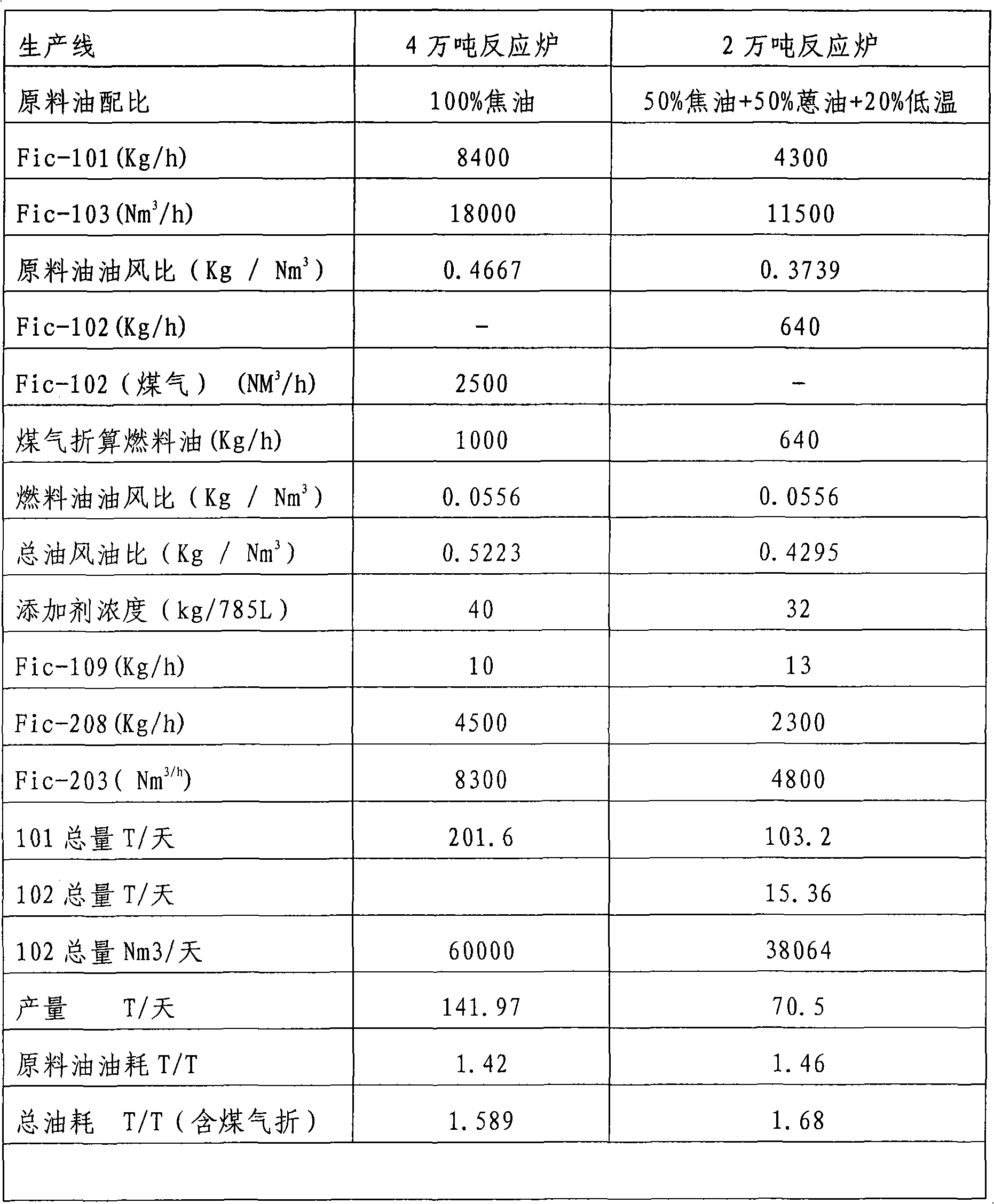

40-thousand-ton hard carbon black reaction furnace and production process of carbon black

The invention discloses a 40-thousand-ton hard carbon black reaction furnace and a production process of carbon black. The carbon black reaction furnace comprises a combustion chamber, a venturi tube, a reaction chamber, and a quench zone. The uniquely designed combustion chamber of the reaction furnace ensures that the distribution of the temperature field of the carbon black production is more reasonable, the appropriate angle, length and inner diameter of the venturi tube ensure that raw oil is fully vaporized and sheared on the venturi tube part; and the reasonably designed reaction section and the matched quench zone ensure that the carbon black cracking reaction can be performed quickly, and the side reaction can be inhibited. Coal gas or natural gas is used as a fuel, the range of the raw oil is wider, the production capacity of the carbon black is high, unit consumption is low, a small amount of polluted product is discharged and the quality of the carbon black is high.

Owner:WUHAI BLACK CAT CARBON BLACK

Double-medium circulation humidifying air conditioner capable of cooling and heating

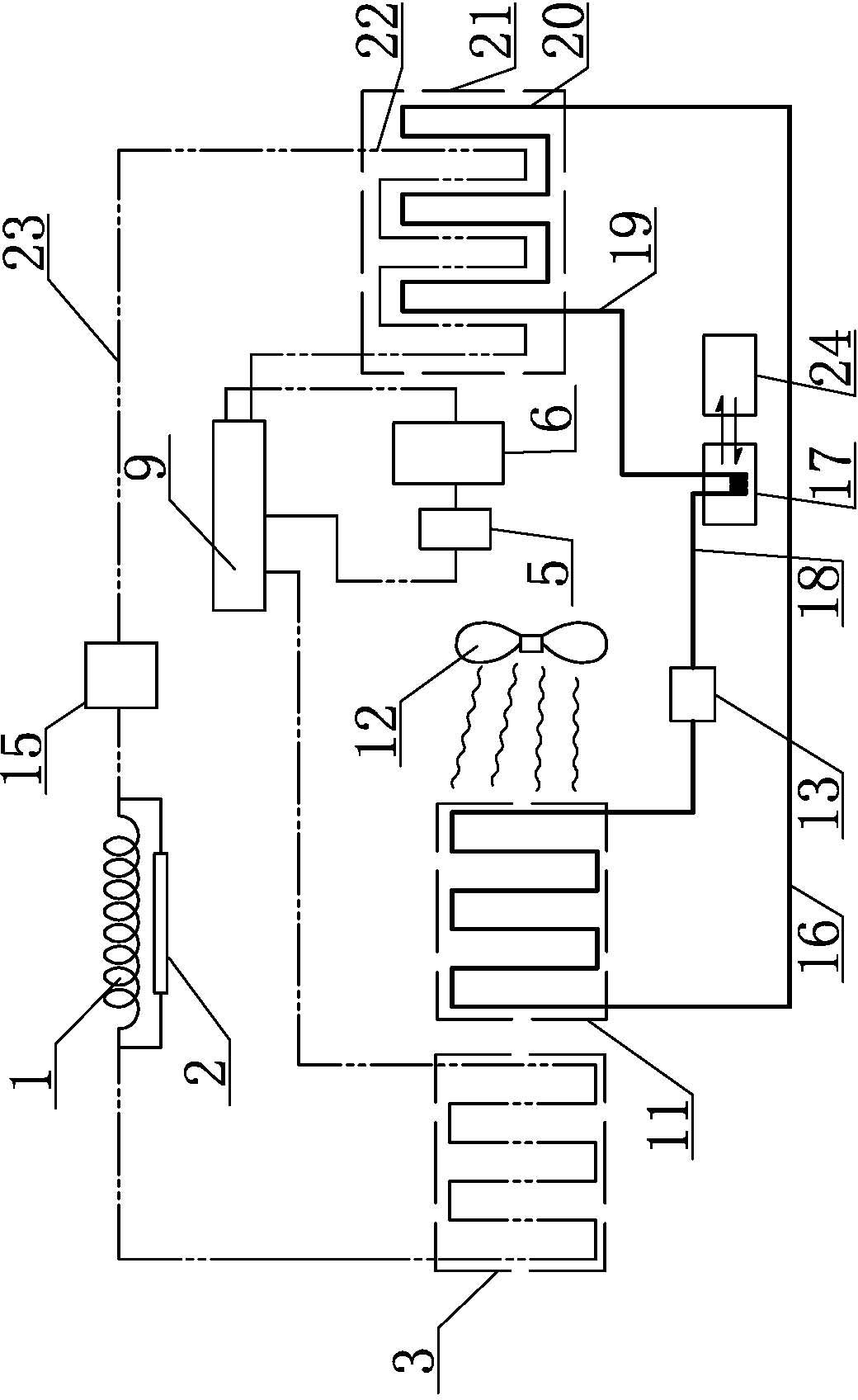

ActiveCN102589072AThere will be no loss of adjustment abilityImprove thermostat efficiencySpace heating and ventilation safety systemsOther heat production devicesTemperature controlWater source

The invention relates to a double-medium circulation humidifying air conditioner capable of cooling and heating, belonging to the field of indoor temperature regulation devices. The double-medium circulation humidifying air conditioner comprises a conditioner body which is provided with an air inlet and an air outlet, and is characterized in that a heat exchange fan, a water circulation system, arefrigerant circulating system and a heat exchanger are arranged in the conditioner body, wherein the heat exchanger comprises a water heat exchange tube and a refrigerant heat exchange tube, the twogroups of pipelines are twined mutually or stacked together, but are not communicated with each other; and the water circulation system is communicated with the water heat exchange tube of the heat exchanger, and the refrigerant circulation system is communicated with the refrigerant heat exchange tube of the heat exchanger. The double-medium circulation humidifying air conditioner combines the advantages of a water air conditioner and a refrigerant circulation air conditioner, utilizes the heat exchanger to replace an air cooling heat exchange part of an outdoor unit of a traditional refrigerant circulation air conditioner, conducts the heat exchange through an underground water source with relatively constant temperature, overcomes the air drying problem under the normal running of the refrigerant air conditioner due to the independent humidifying system, simultaneously realizes the temperature control, humidify control and remote control, and is humanized in control.

Owner:SHANDONG YICUN AIR CONDITIONING

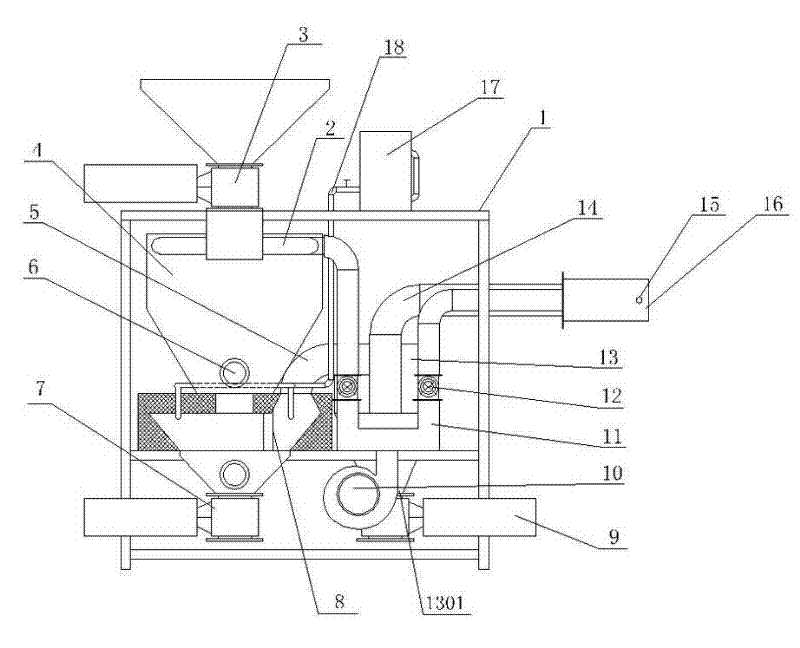

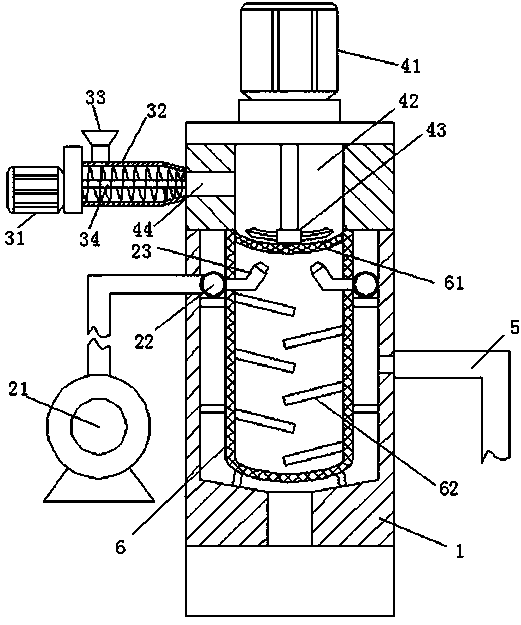

Gasification combustor for biomass granules

ActiveCN102252317APrevent compactionFully vaporizedSolid fuel combustionCombustion apparatusCombustorCarbonization

The invention relates to a gasification combustor for biomass granules. The gasification combustor comprises a shell, wherein a filler device is arranged on the shell; an inner container and a blast blower are arranged in the shell; and an ignition tuyere and a fire grate is formed on the lower part of the inner container. The gasification combustor is characterized in that: an annular air diffuser is arranged on the upper part in the inner container; a carbonization area corresponds to the ignition tuyere in the inner container, a reduction area is positioned between the carbonization area and the fire grate, and a gasification area is positioned outside the fire grate; the gasification area is connected with a filter by a connection pipe; a gas pipe is arranged at an outlet of the filter; an ash discharge opening is formed at the bottom of the filter; a burner and an ignition device are arranged at the lead-out end led out of the filter and the shell on the gas pipe; and the blast blower is connected with the air diffuser and the burner respectively by a pipeline and a valve arranged on the pipeline. The gasification combustor can gasify the biomass granules fully, is good in combustion effect, high in heat efficiency and heat value, energy-saving, low-carbon, environment-friendly and low in discharge, can replace fuel oil, gas and fire coal, and does not have oil tar, wastewater and smoke dust; and the gasification combustor has a compact structure, and is easy and convenient to mount, small in space occupation and wide in application range.

Owner:穆壮荣

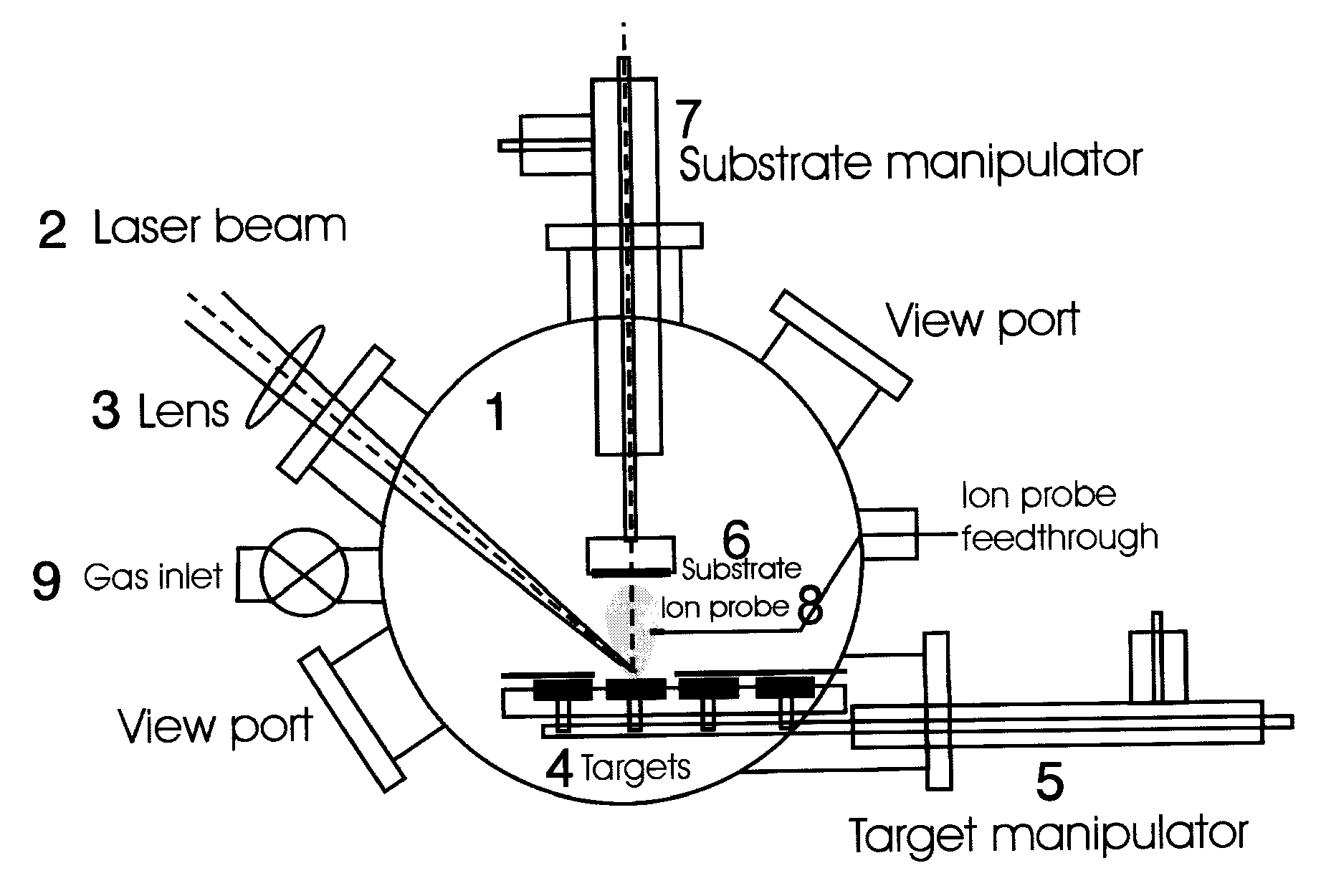

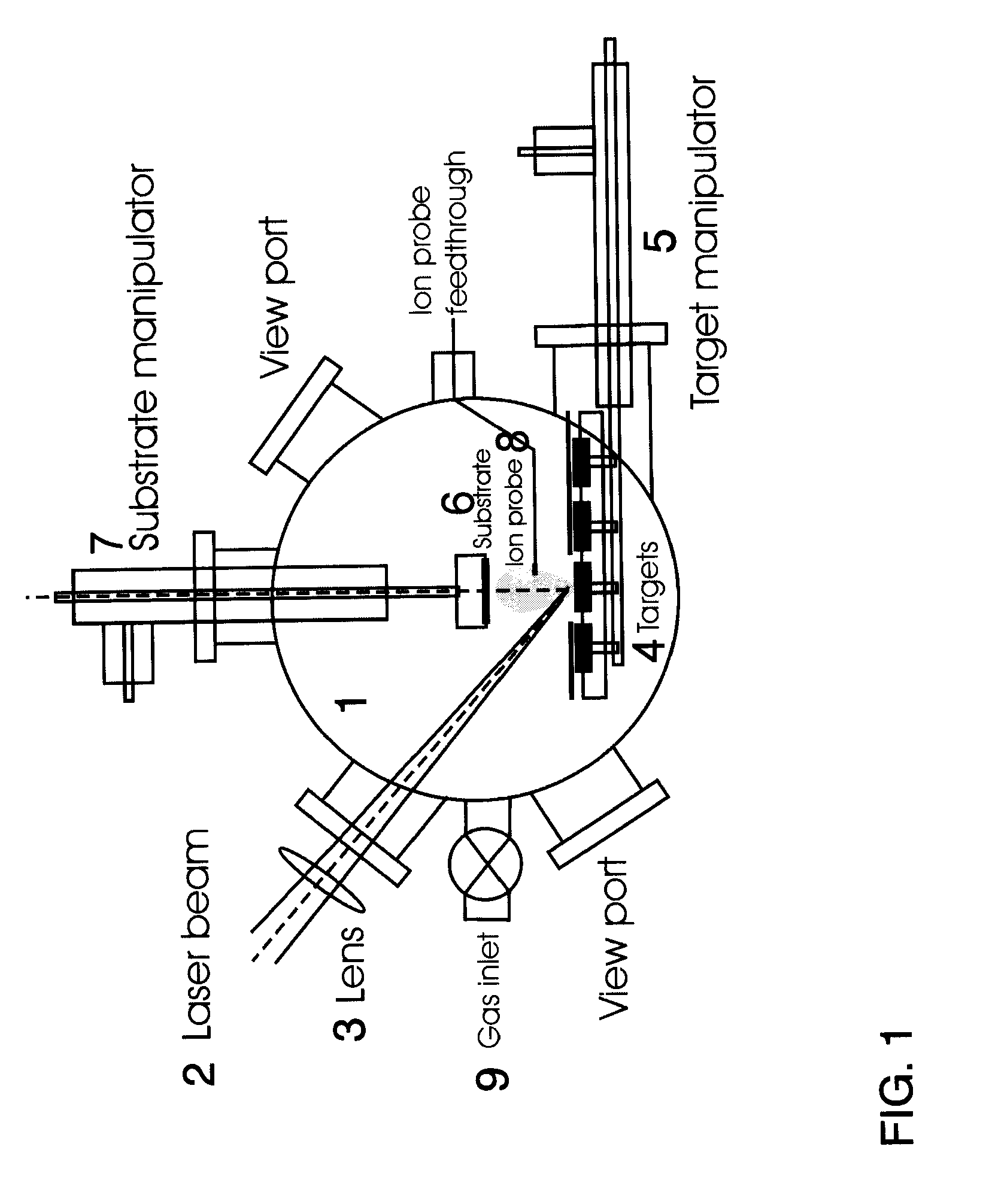

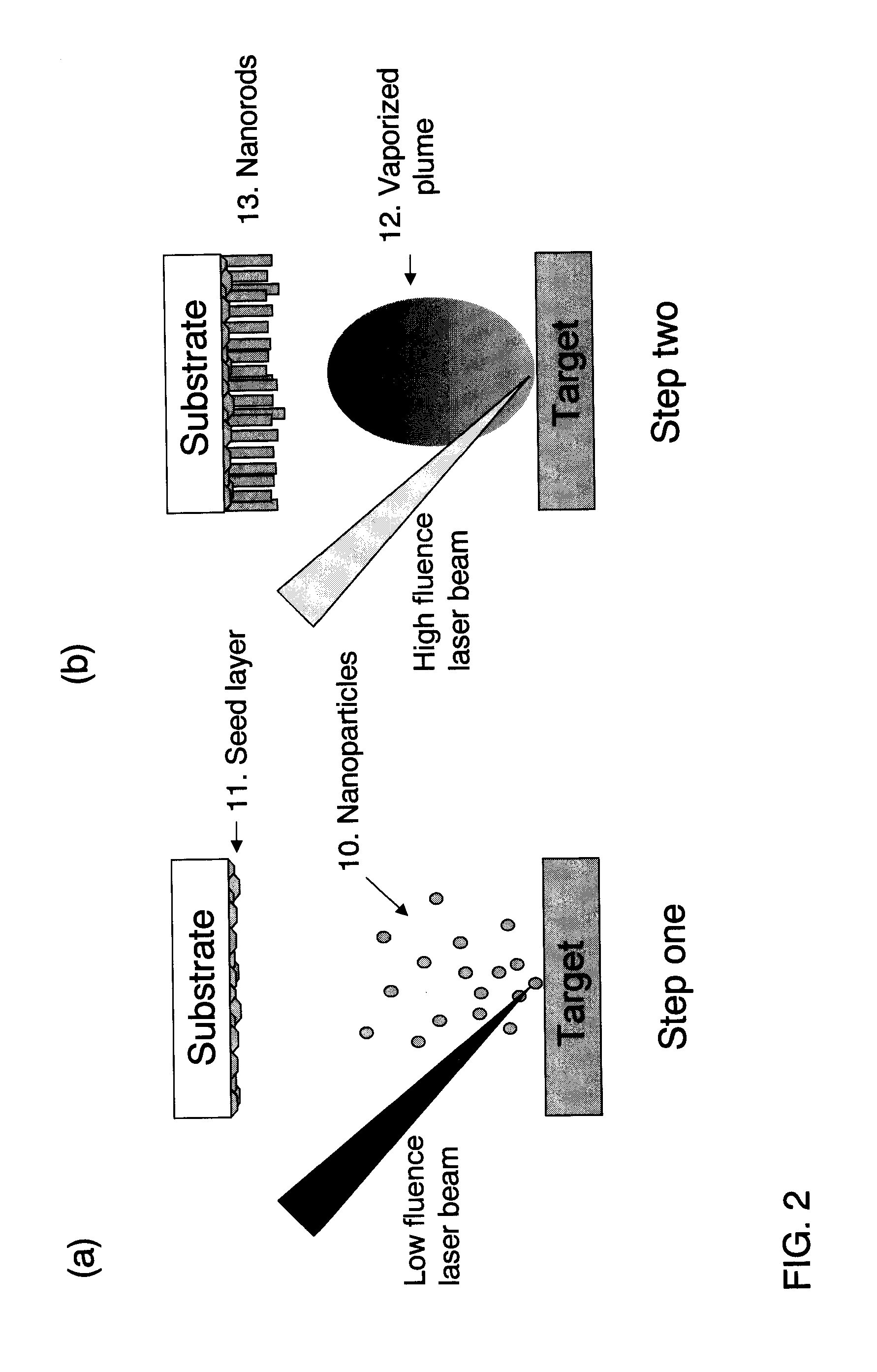

Method of producing compound nanorods and thin films

InactiveUS20080292808A1High energy density of laserImprove throughputMolten spray coatingRadiation applicationsSelf formingNanoporous membrane

A method of producing compound nanorods and thin films under a controlled growth mode is described. The method involves ablating compound targets using an ultrafast pulsed laser and depositing the ablated materials onto a substrate. When producing compound nanorods, external catalysts such as pre-deposited metal nanoparticles are not involved. Instead, at the beginning of deposition, simply by varying the fluence at the focal spot on the target, a self-formed seed layer can be introduced for nanorods growth. This provides a simple method of producing high purity nanorods and controlling the growth mode. Three growth modes are covered by the present invention, including nanorod growth, thin film growth, and nano-porous film growth.

Owner:IMRA AMERICA

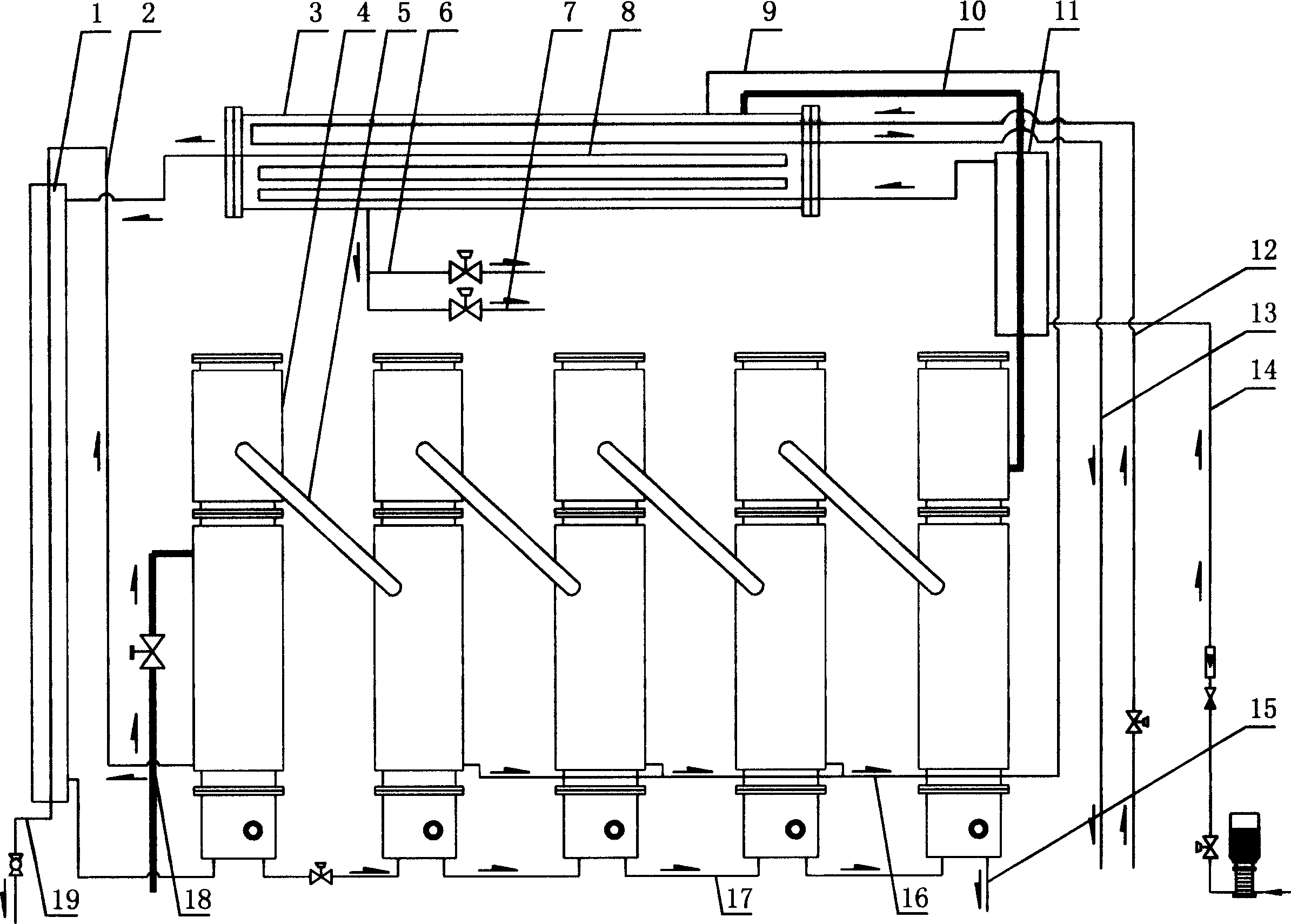

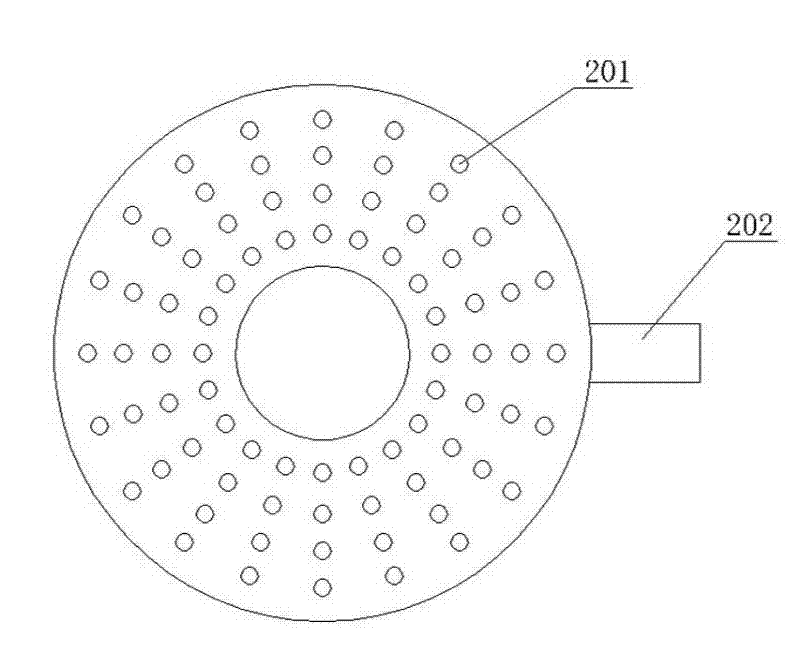

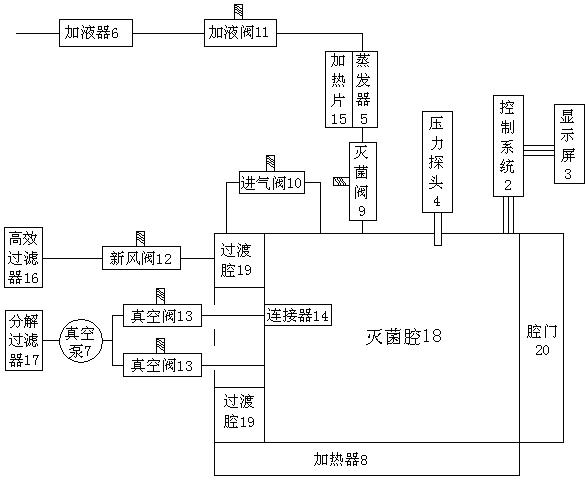

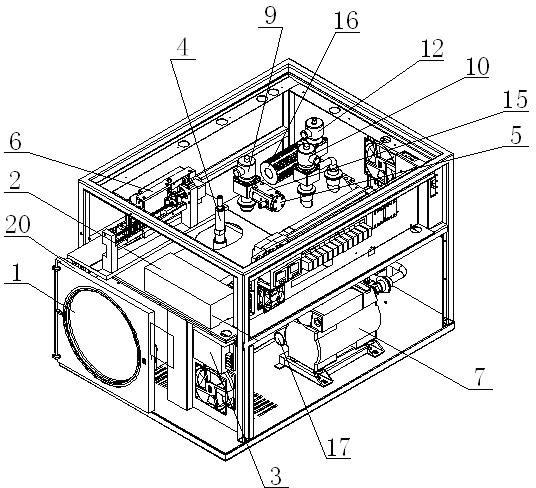

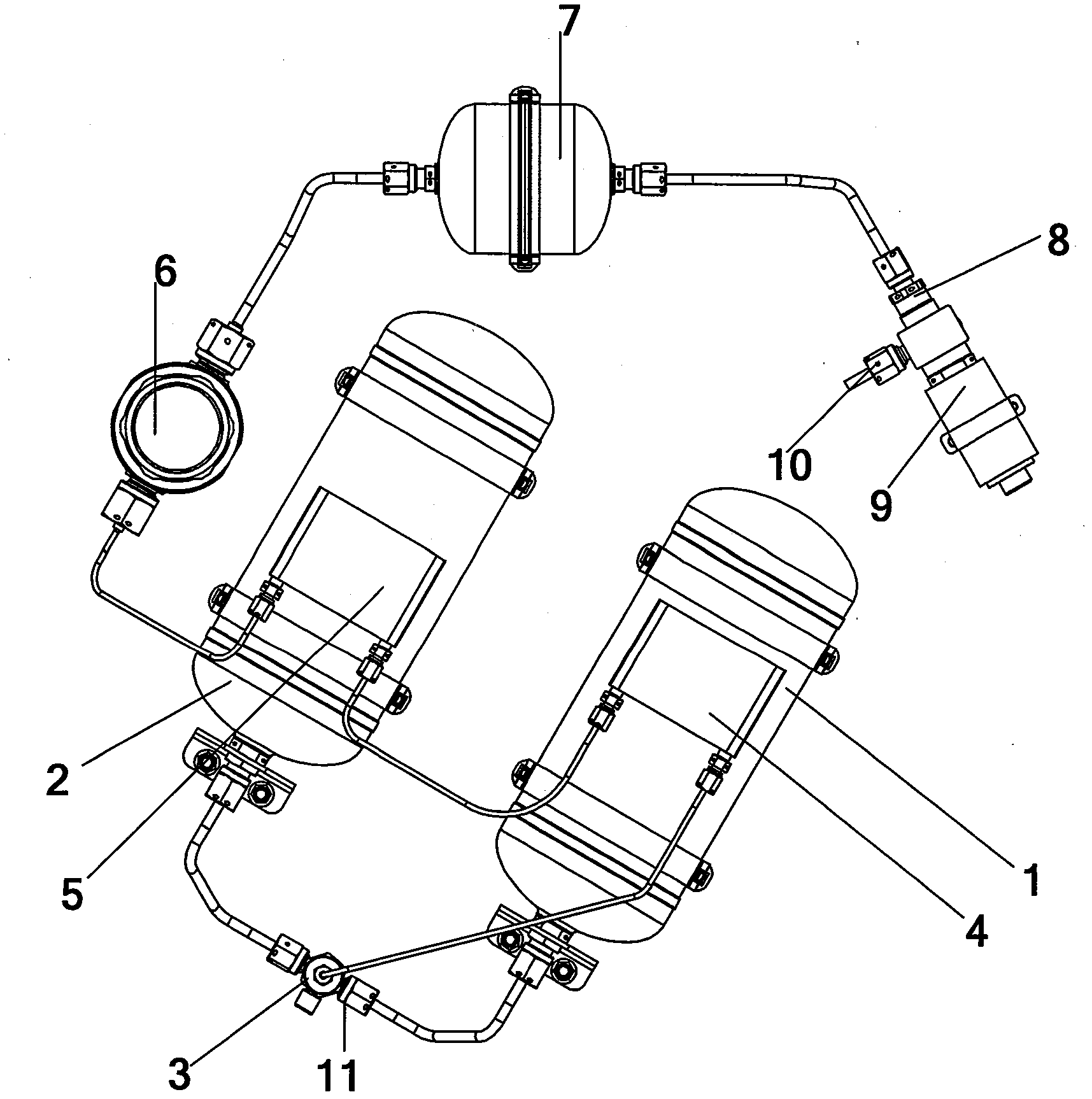

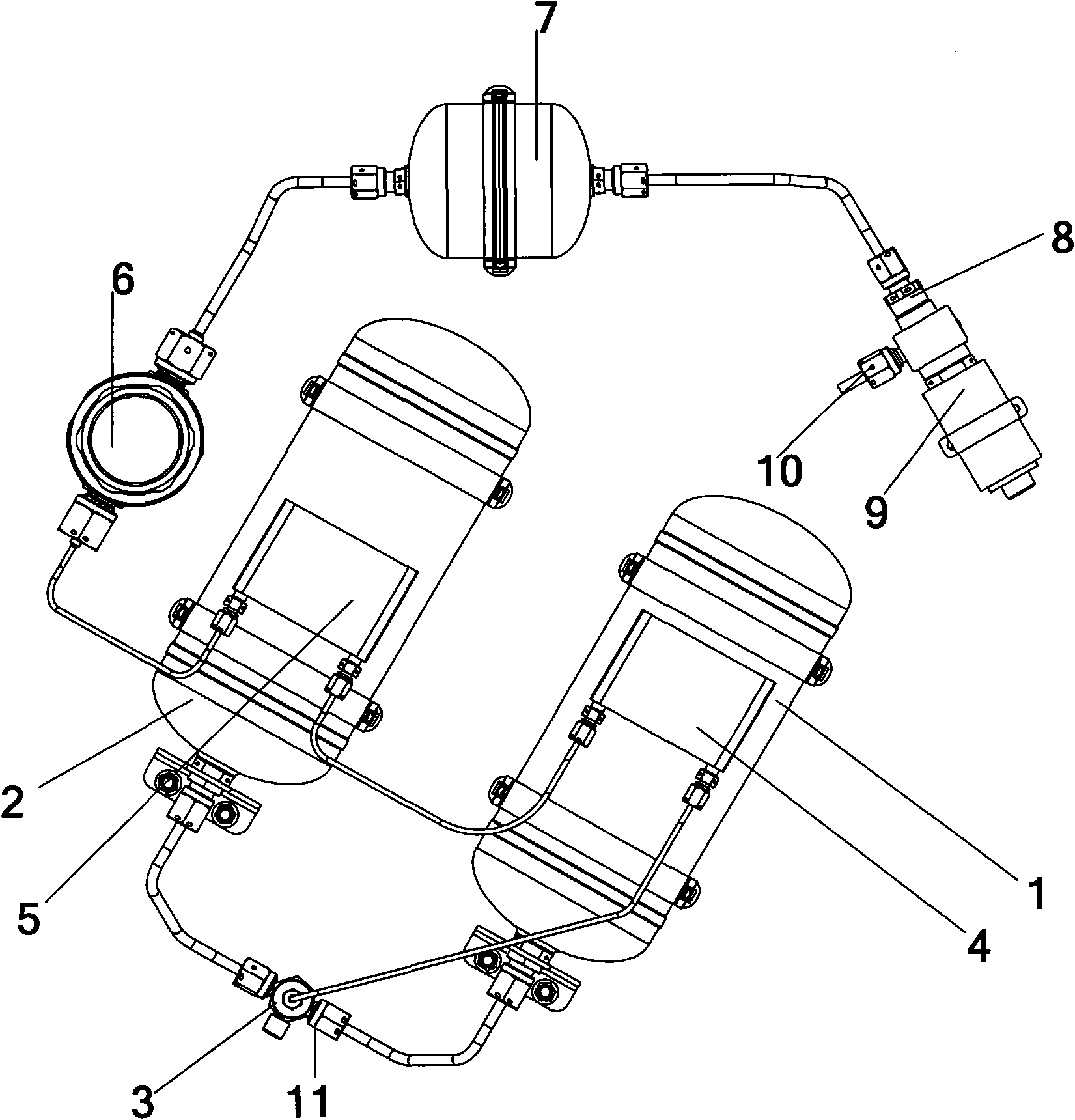

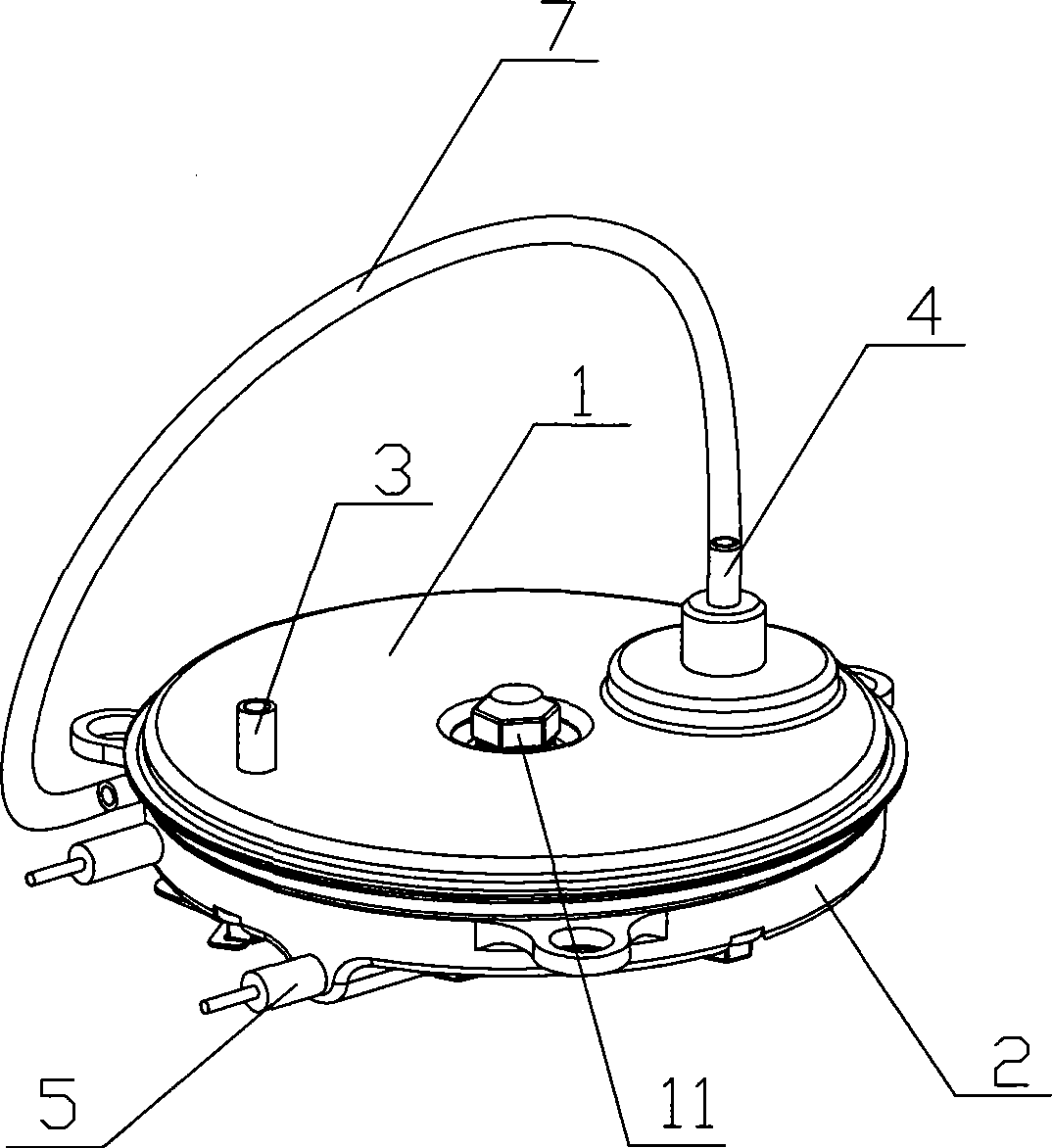

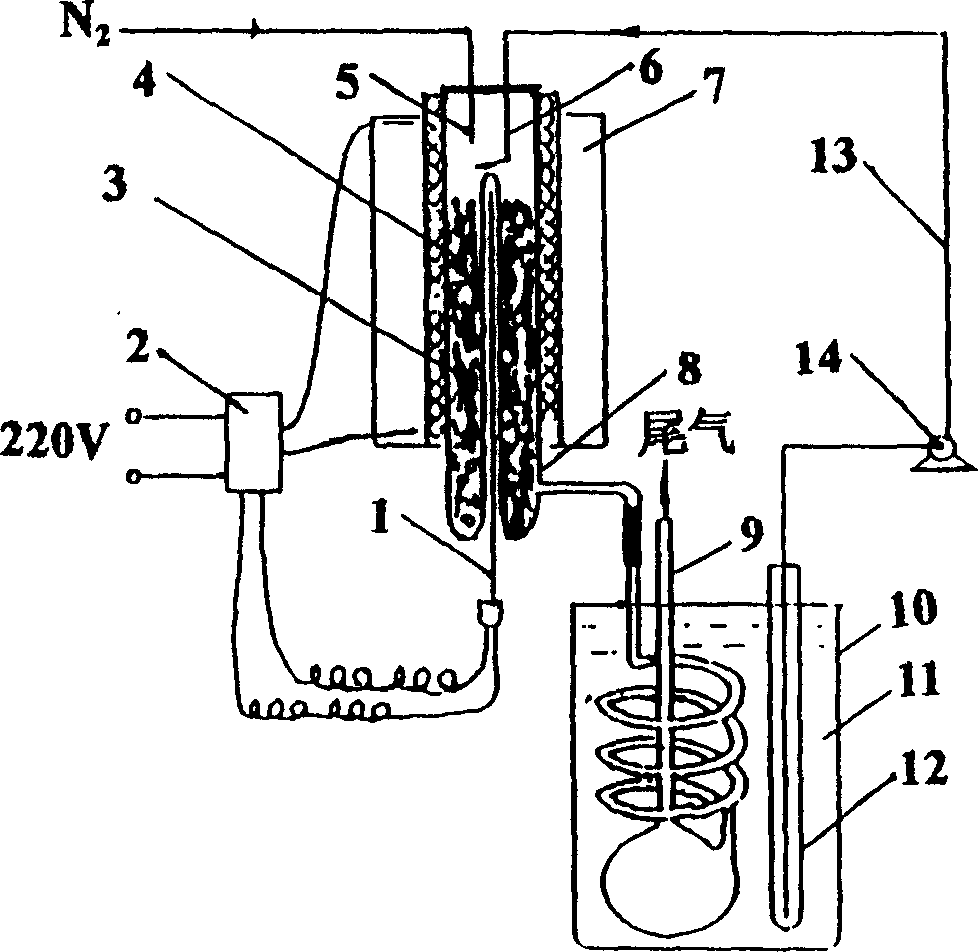

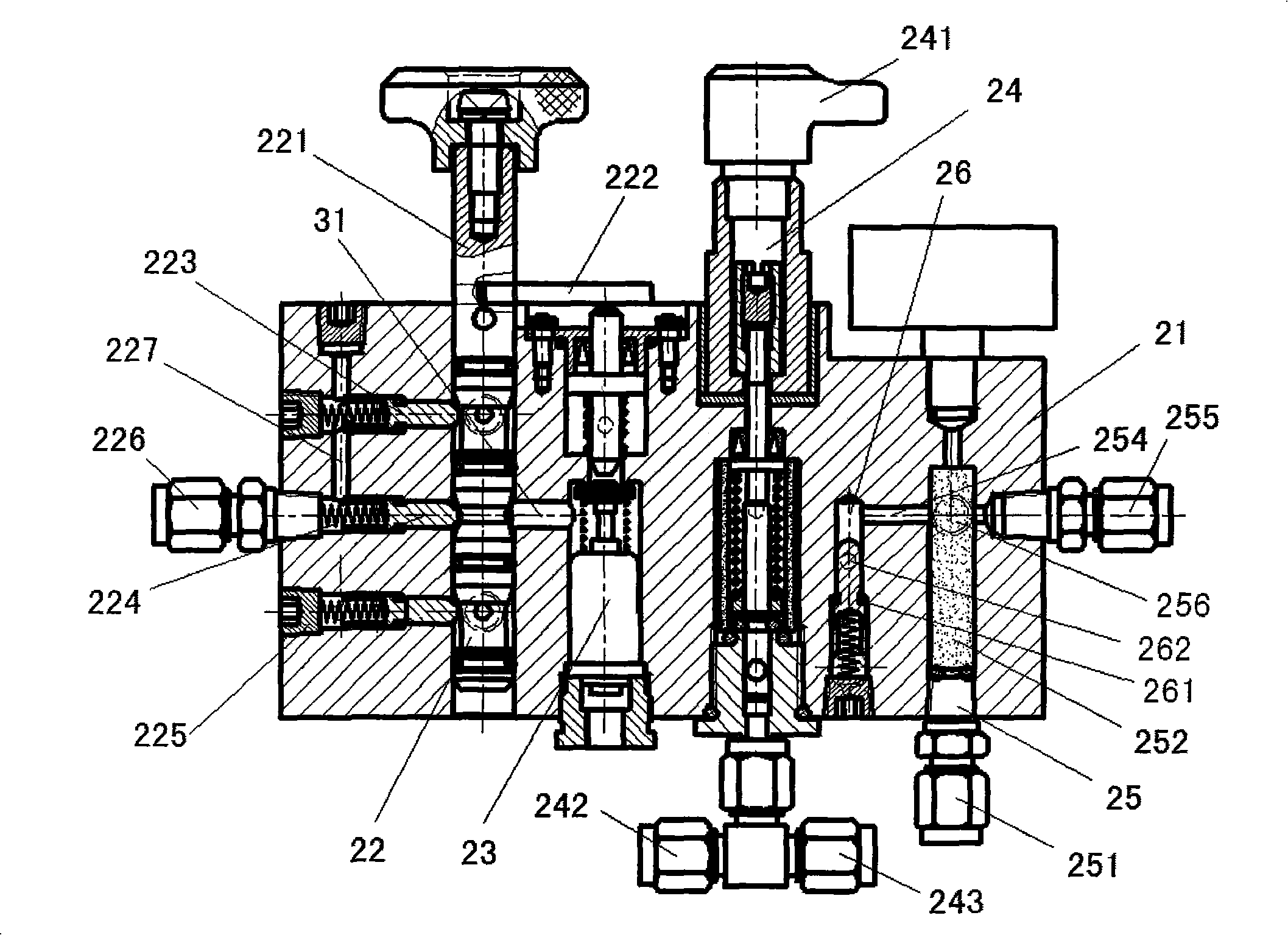

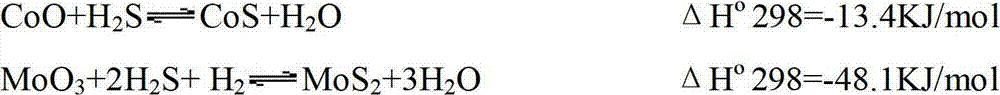

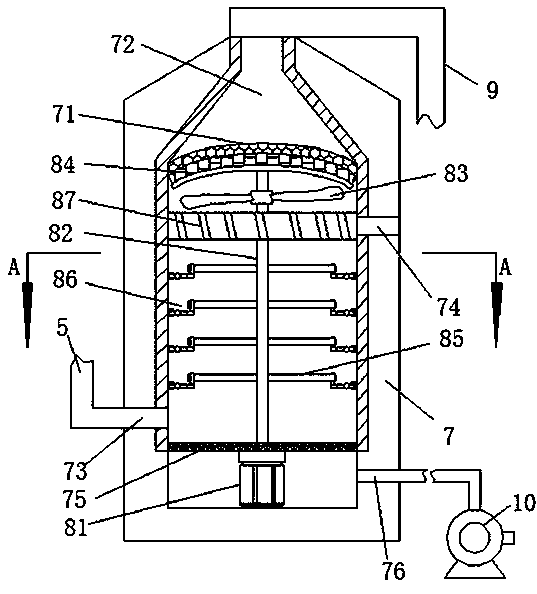

Hydrogen peroxide low-temperature sterilizing equipment and use method thereof

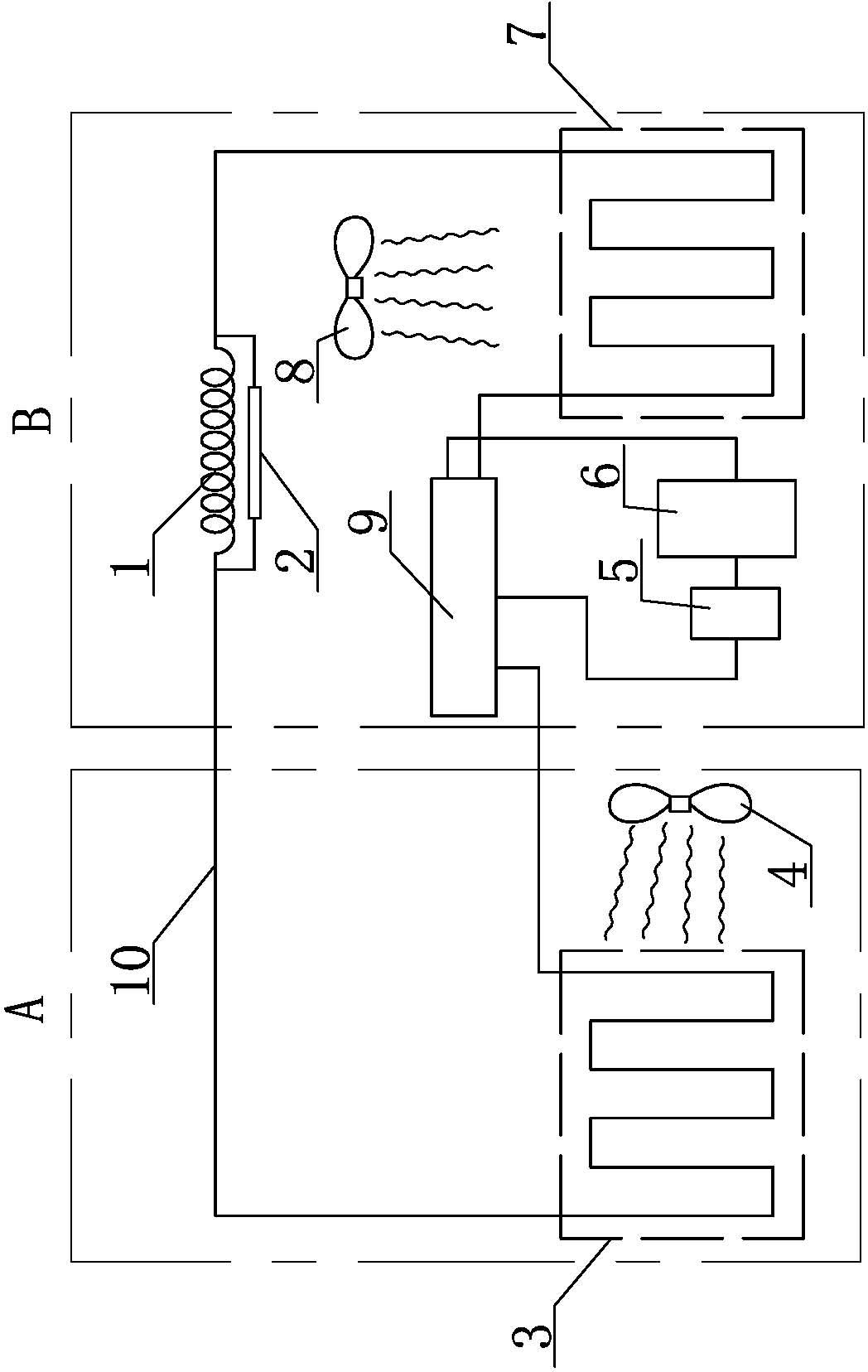

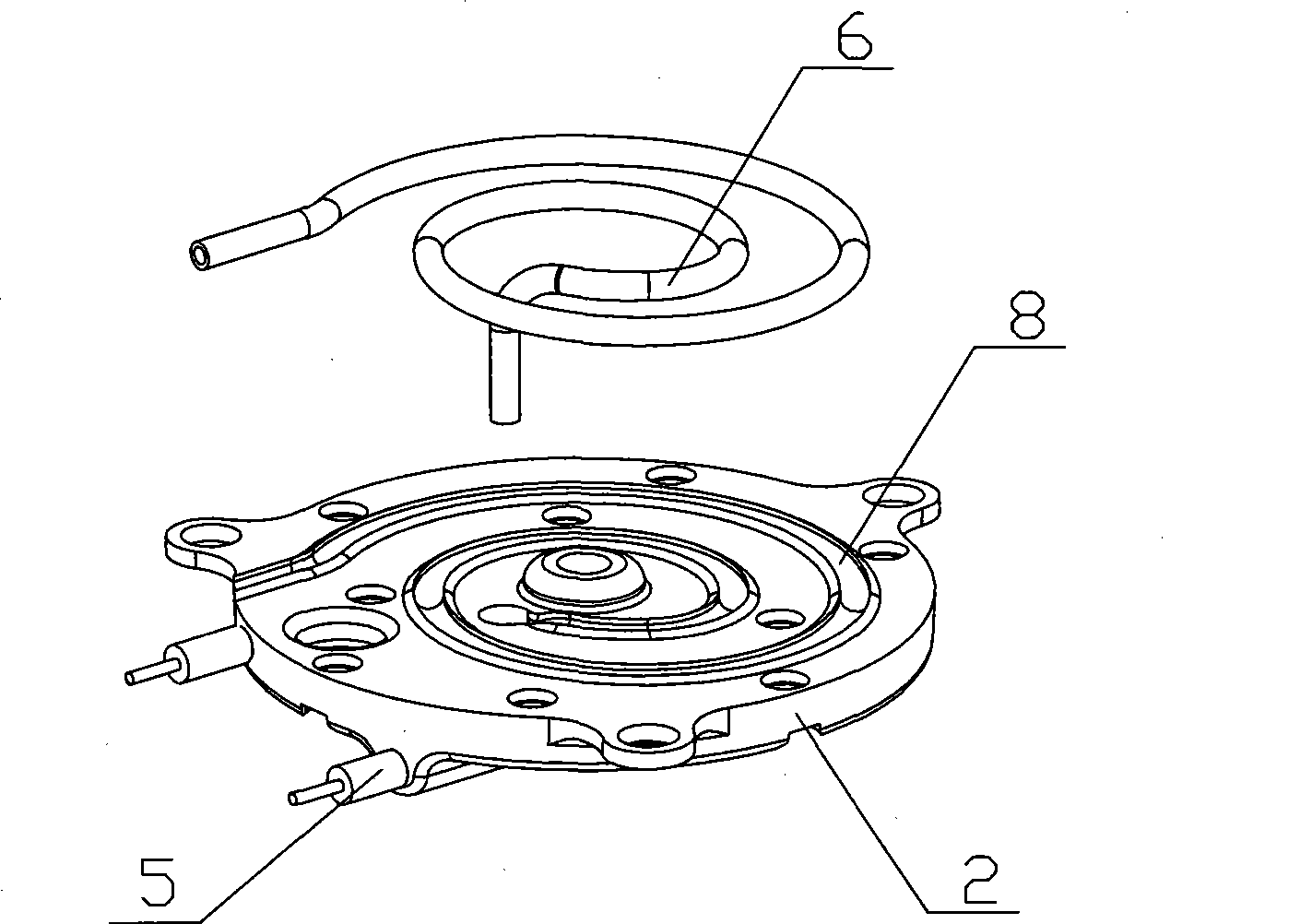

ActiveCN102350003AImproved vaporizationEasy dischargeChemicalsVacuum pumpLow temperature sterilization

The invention discloses hydrogen peroxide low-temperature sterilizing equipment and a use method thereof. The sterilizing equipment comprises a cavity body (1), an evaporator (5), a liquid feeder (6), a vacuum pump (7), a heater (8) and a high-efficiency filter (16), wherein the cavity body (1) is divided into a sterilizing cavity (18) and a transition cavity (19); the sterilizing cavity (18) is connected with the outlet end of the evaporator (5) through a sterilizing valve (9); the inlet end of the evaporator (5) is connected with the liquid feeder (6) through a liquid feeding valve (11); a heating sheet is arranged on the evaporator (5); the air suction end of the vacuum pump (7) is connected with the sterilizing cavity (18) through a vacuum valve (13); and the air outflow end of the vacuum pump (7) is connected with a decomposition filter (17). The sterilizing equipment can sterilize medical appliances at a low temperature, can carry out sufficient sterilization on the pipelines of the medical appliances with slender holes, and can also carry out filtration and decomposition on the used hydrogen peroxide vapor.

Owner:LAOKEN MEDICAL TECH

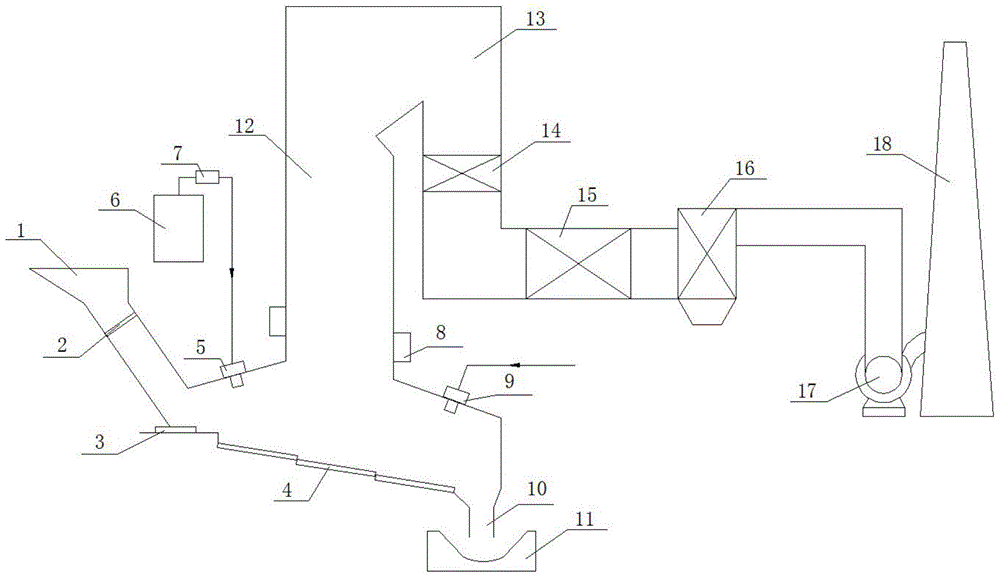

Low-corrosion and high-efficiency city garbage combusting system and method

InactiveCN105570898AIncrease moisture contentAvoid the phenomenon of lowering the combustion temperatureIncinerator apparatusCombined combustion mitigationCombustion chamberSlag

The invention discloses a low-corrosion and high-efficiency city garbage combusting system and method. The low-corrosion and high-efficiency city garbage combusting system comprises a boiler system and a marsh gas auxiliary combusting system. The boiler system comprises a combusting room with a cavity. The combusting room is provided with a feeding port, a slag discharging port, an air inlet and an exhaust opening. The marsh gas auxiliary combusting system comprises a combusting device, a dehumidifying device and a fermenting device used for fermenting kitchen garbage. The combusting device is connected to the combusting room, and the combusting device, the dehumidifying device and the fermenting device are communicated in sequence and in series. By means of the low-corrosion and high-efficiency city garbage combusting system, the difference of the water content of garbage is small, the combustion heat value and the water content are uniform, and corrosivity is low.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

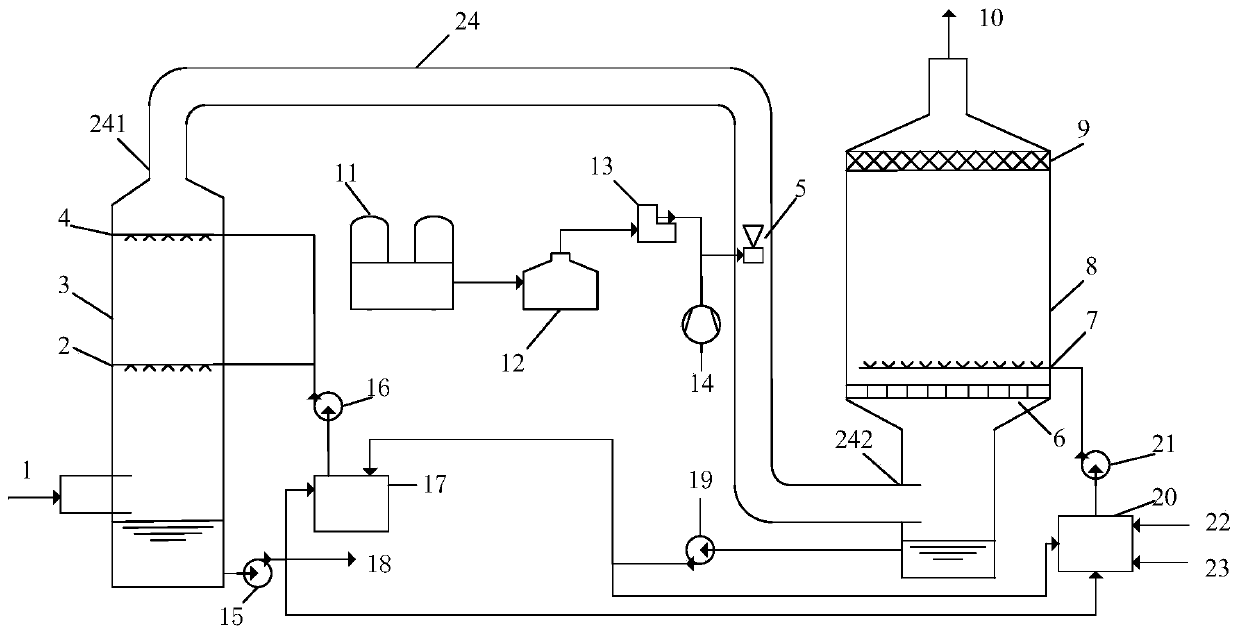

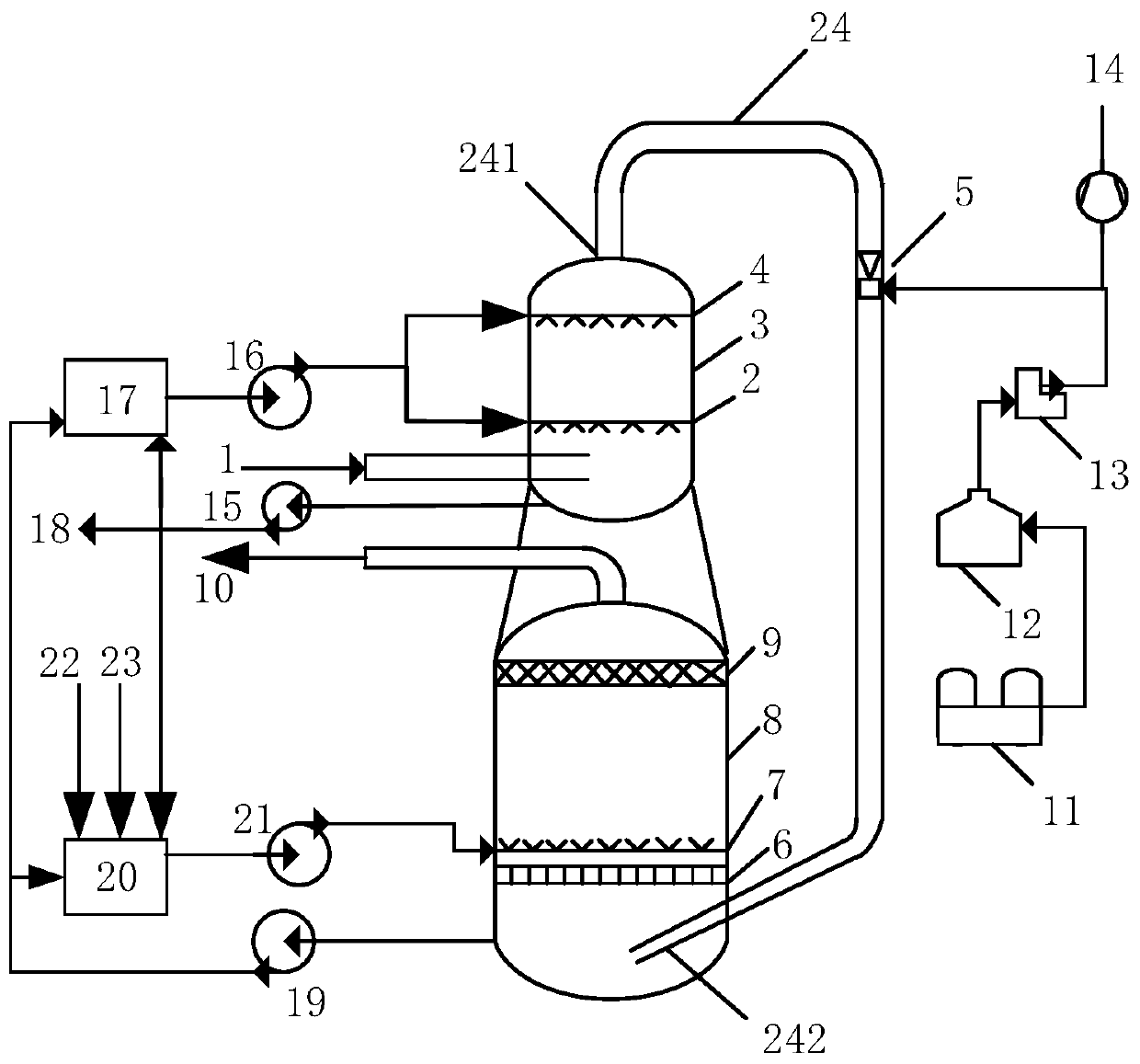

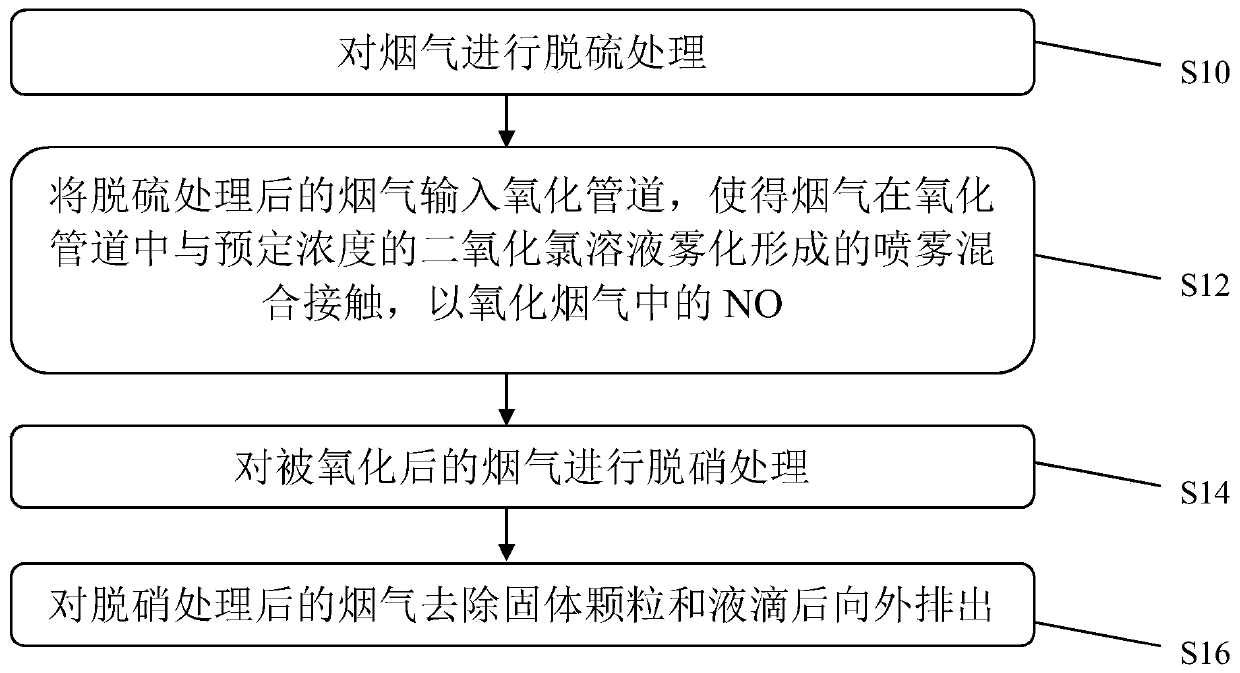

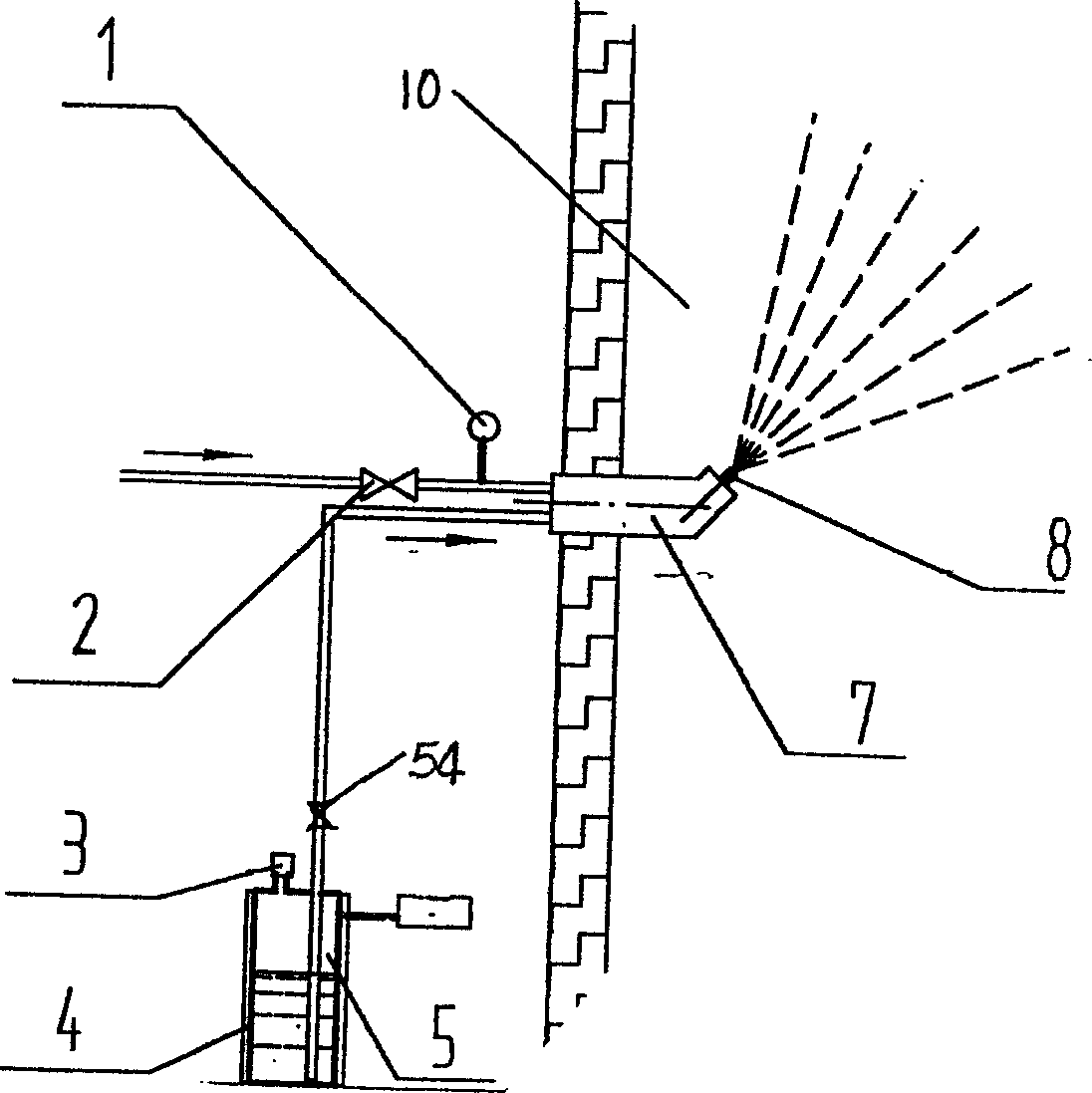

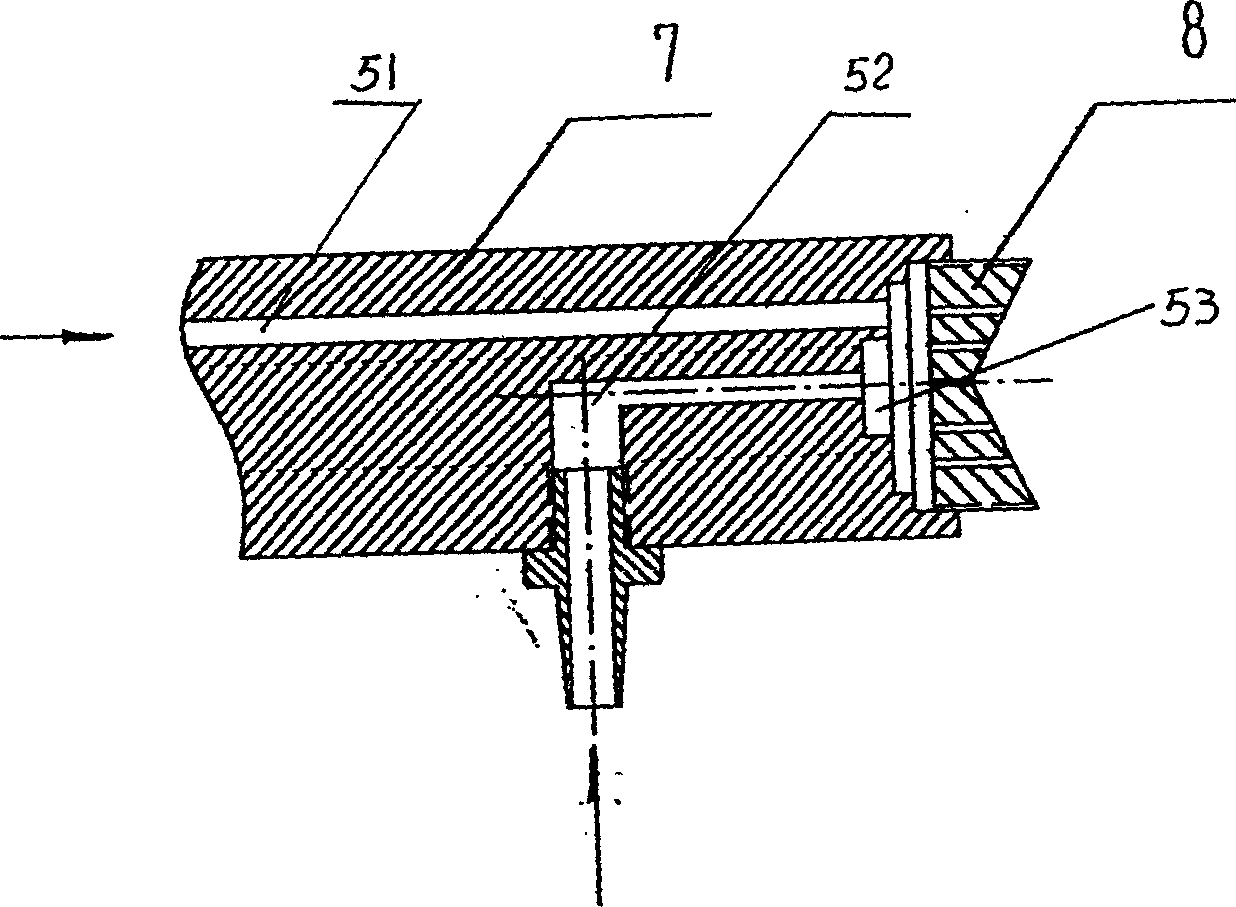

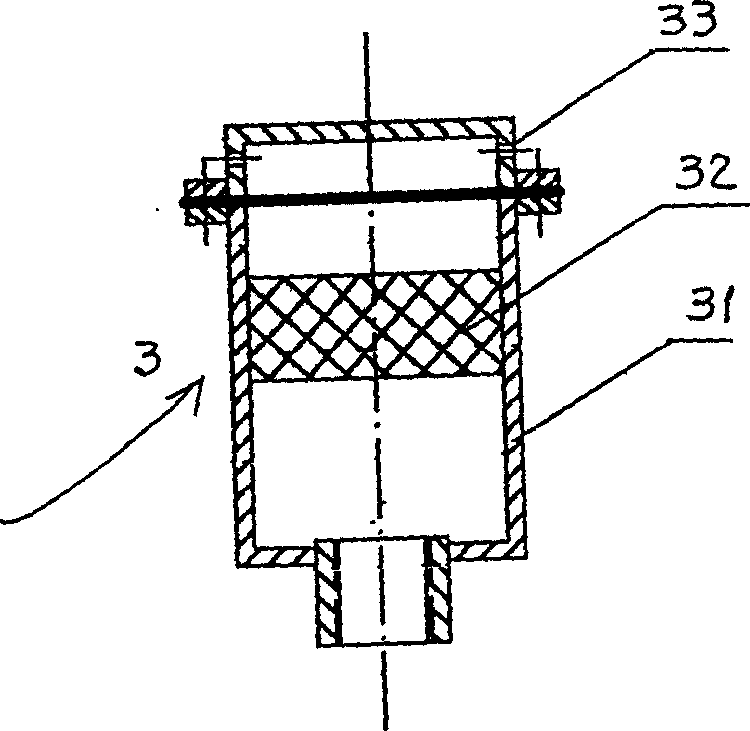

Flue gas desulfurization and denitration device and method

ActiveCN109718653AHigh gas velocityOxidation achievedDispersed particle separationChlorine dioxideFlue gas

The invention discloses a flue gas desulfurization and denitration device and method. The device comprises: a desulfurization container, the bottom of which is equipped with a desulfurization liquid material storage area, above which a flue gas inlet is disposed, with a flue gas washing and desulfurization structure being arranged above the flue gas inlet; a denitration container, the bottom of which is equipped with a denitration liquid material storage area, above which a flue gas washing and denitration structure is arranged, with a separation structure for removing solid particles and liquid drops being disposed above the flue gas washing and denitration structure, and a gas outlet being disposed at the top of the denitration container; an oxidization pipeline for communicating the desulfurization container and the denitration container; an atomization spray structure that is disposed in the oxidization pipeline and capable of providing structure connection together with chlorine dioxide, with the chlorine dioxide mist sprayed by the atomization spray structure being mixed with the flue gas in the oxidization pipeline. The flue gas desulfurization and denitration device and method provided by the invention can realize high efficiency and high utilization oxidation of ClO2 to NO, are safe and convenient to operate, and are convenient for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

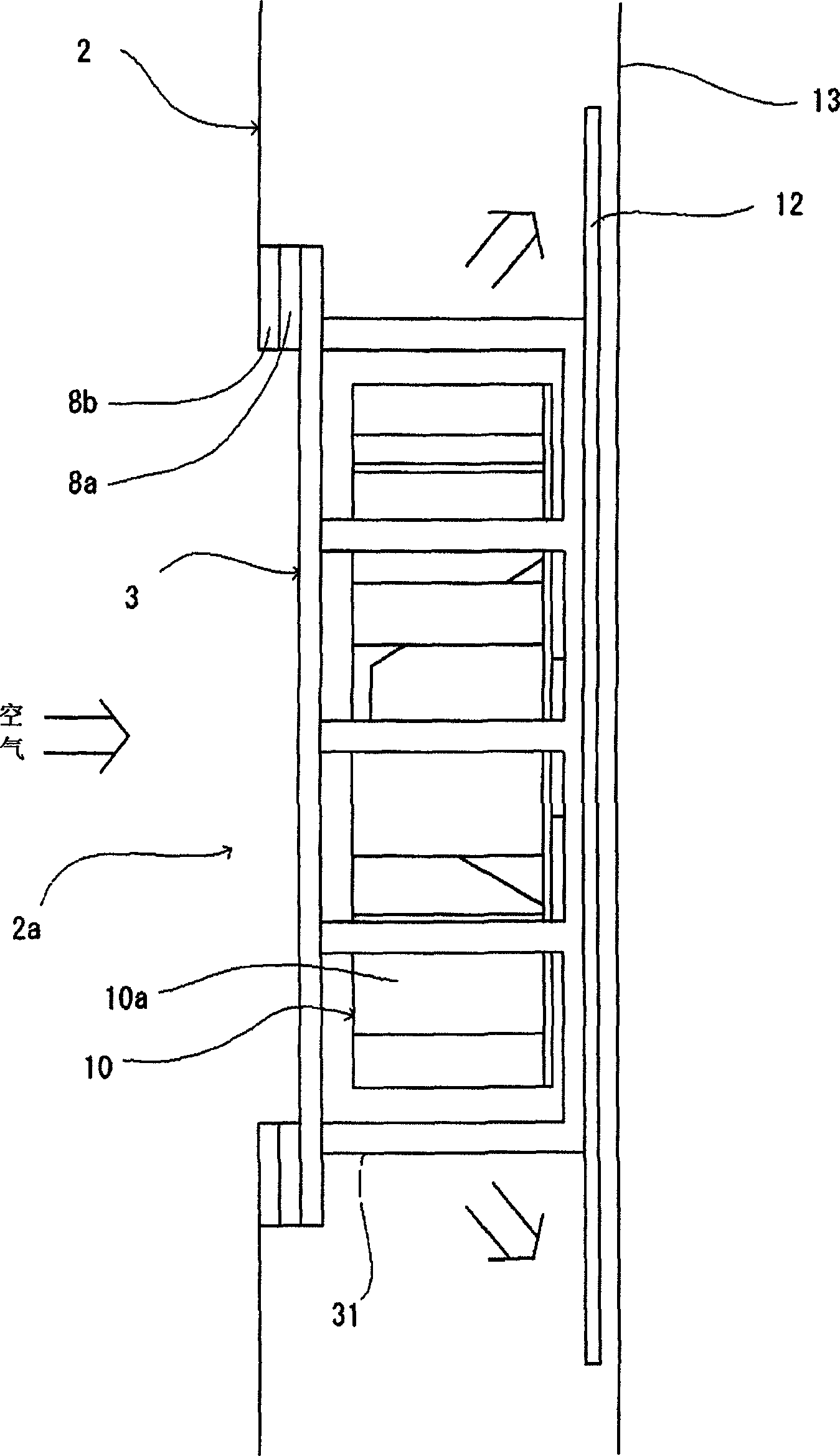

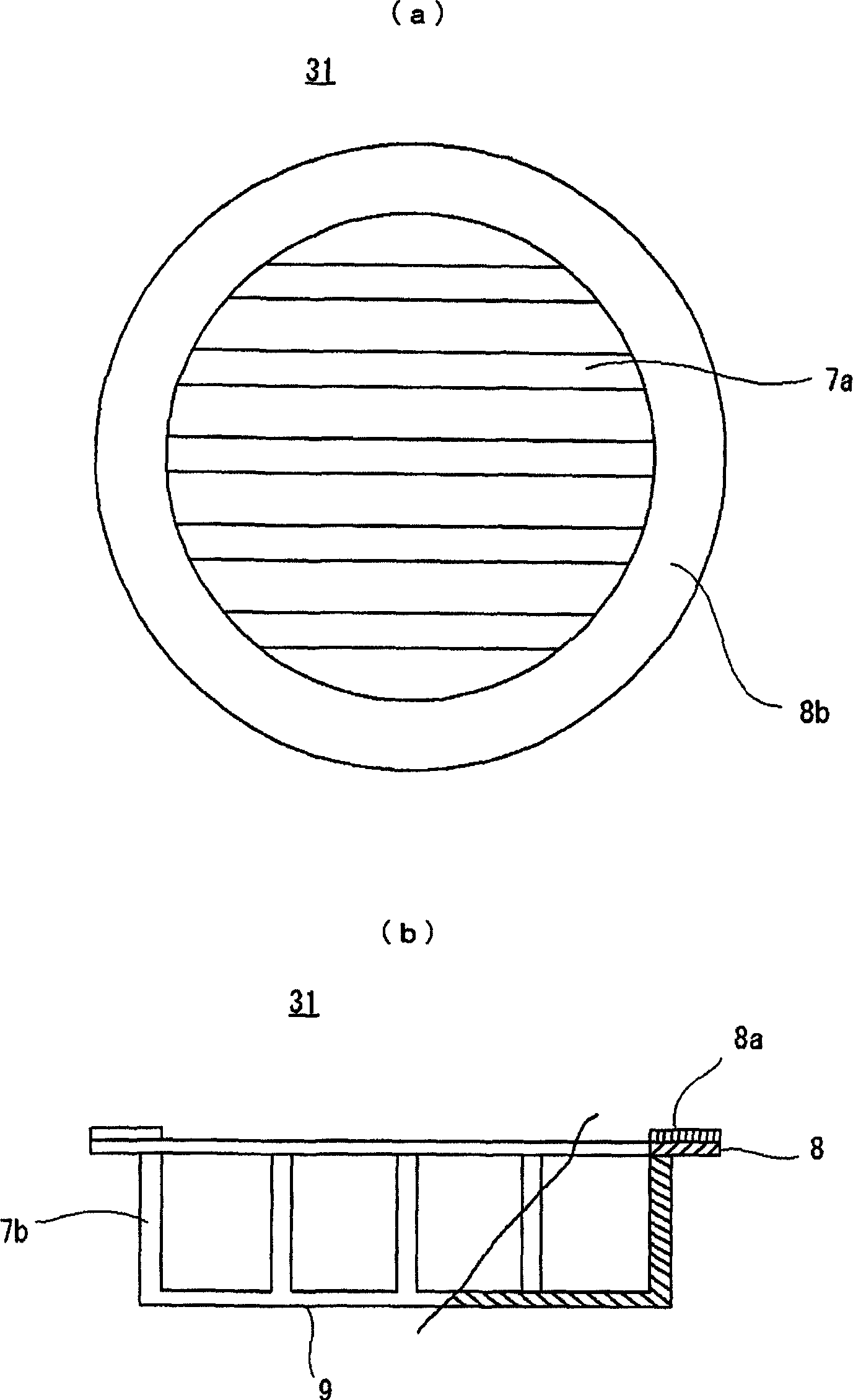

Dsinfectedf humidified liquid vaporization generating apparatus for air conditioning system

InactiveCN1508484AEvenly spacedGood sterilization and humidification effectLighting and heating apparatusAir conditioning systemsAir filtrationAir filter

The invention is disinfection and damping liquid evaporation generating device in air-conditioner system, which comprises liquid storing pot, the blender and the atomization spray on the inner wall of wind transmitting segment, there have air channel, liquid channel and the compound channel all of which are connected together in the blender, the atomization is set by the output of the compound channel; the air channel connects with compressor through air pipe, the liquid channel connects with the liquid storing pot; the air inlet of the pot sets a air filtering respirator; the pot also has a temperature control and heating device; the spray angel can be adjusted.

Owner:LIAONING YISHENG BIOLOGY PHARMACY

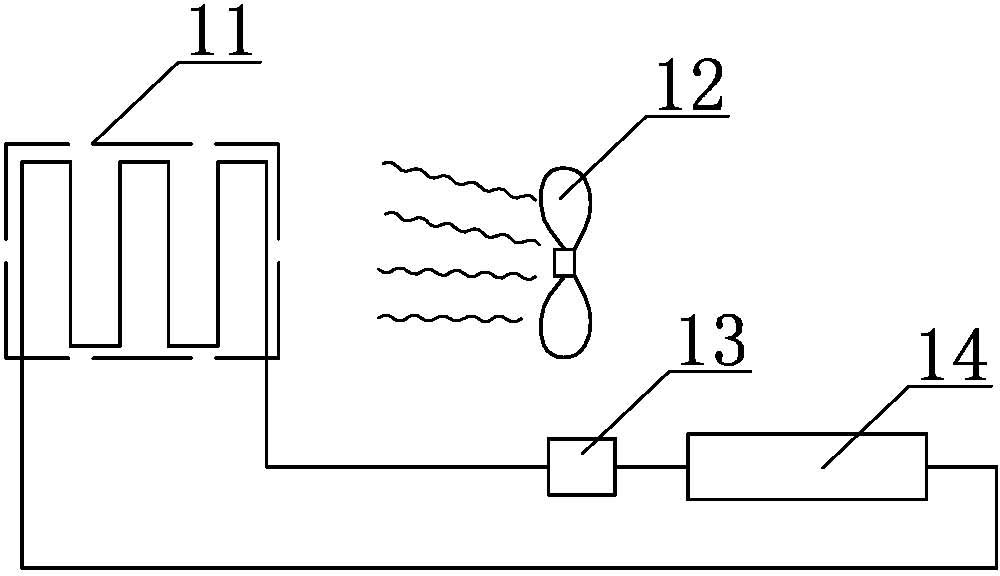

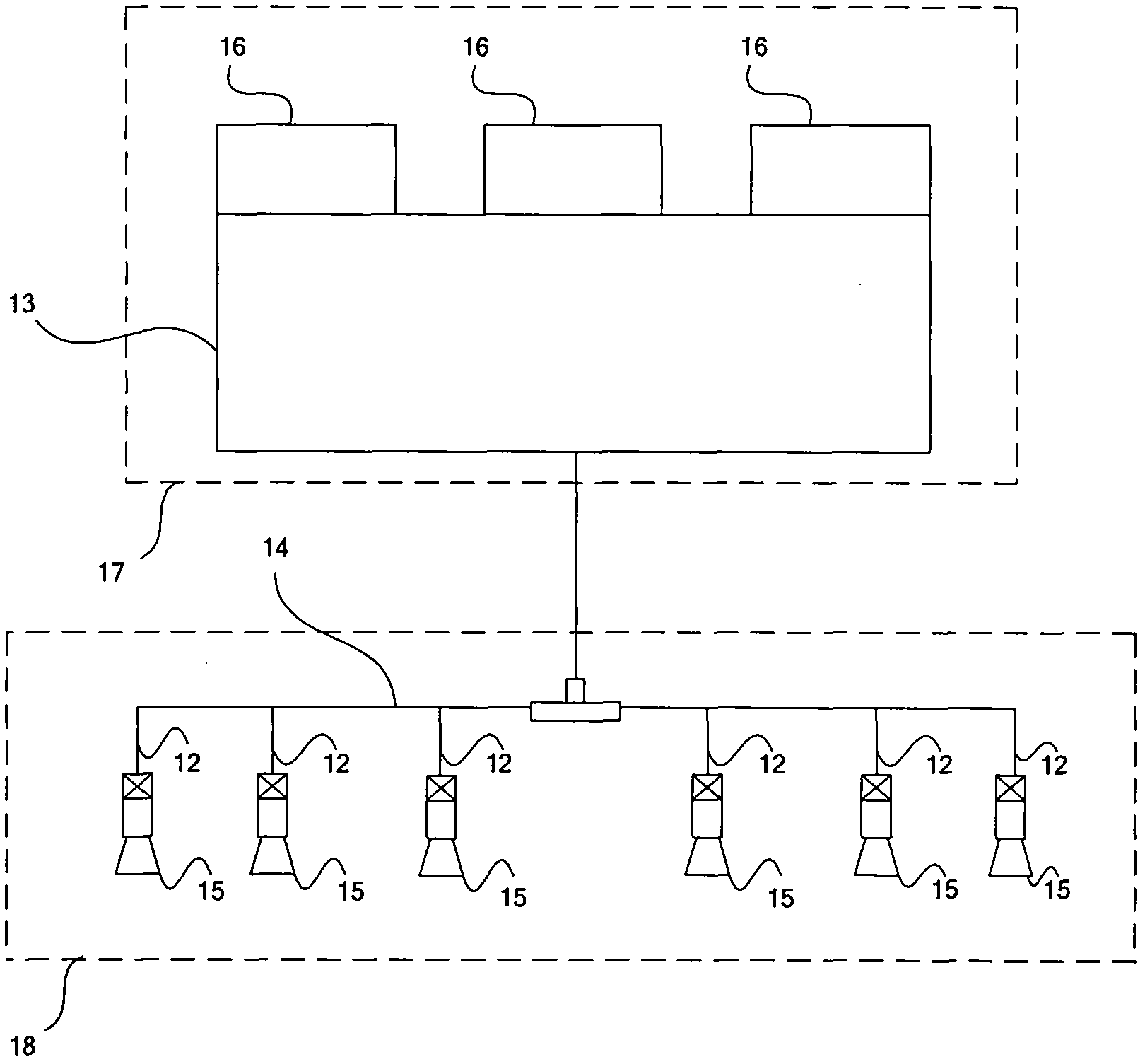

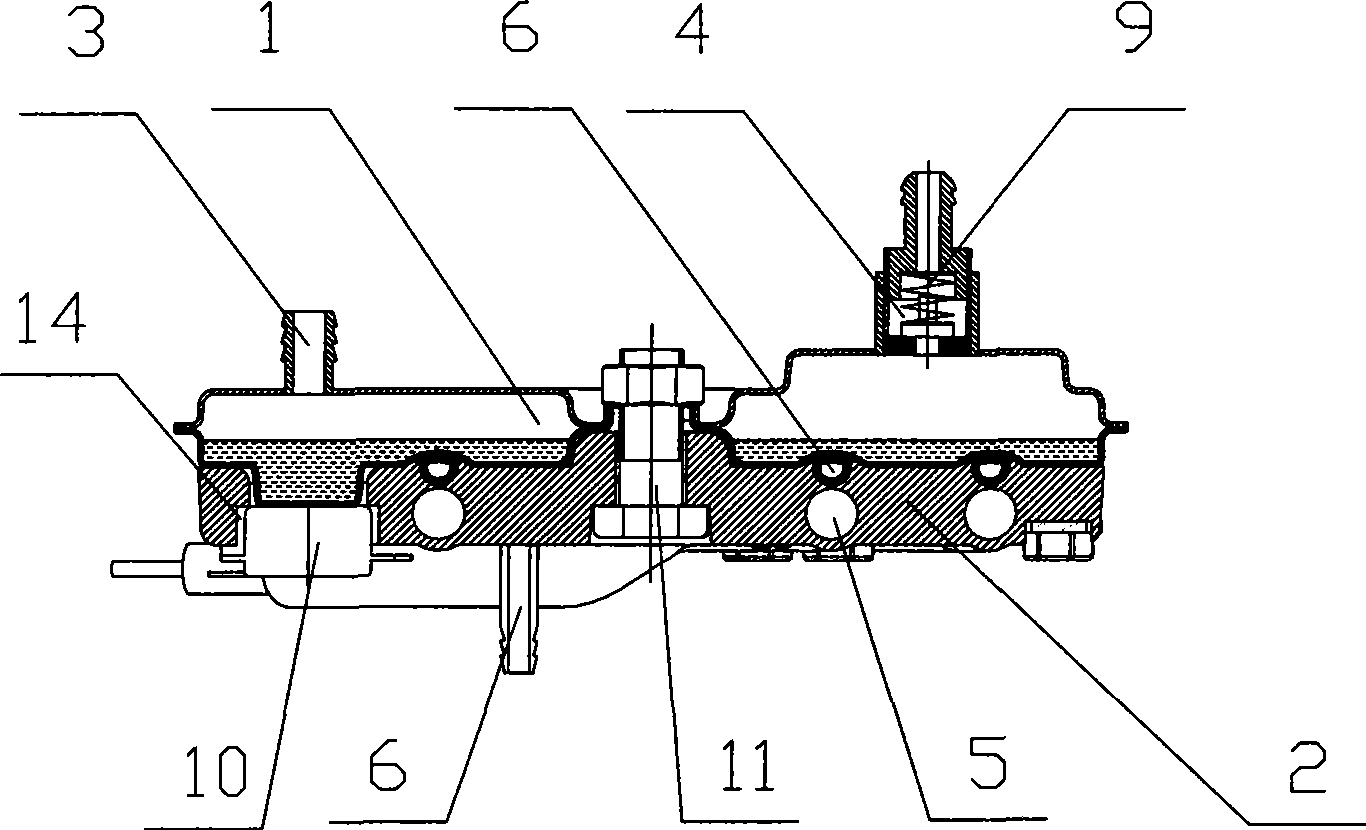

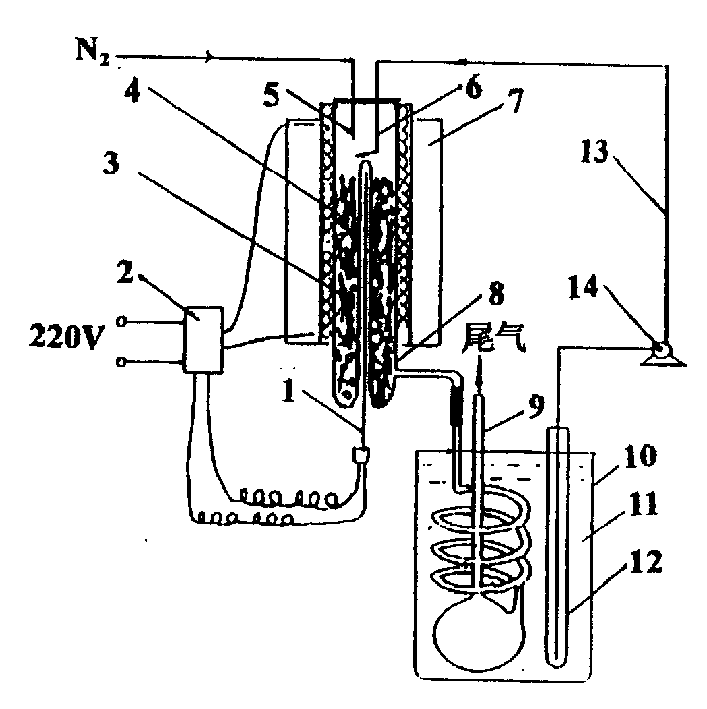

Heating gasification device for liquefied gas micro-propulsion system

InactiveCN101943082ASimple structureLight in massCosmonautic propulsion system apparatusRocket engine plantsPassive heatingHeat conducting

The invention discloses a heating gasification device for a liquefied gas micro-propulsion system. The device comprises a first propellant storage box, a second propellant storage box, a first heat conducting module, a second heat conducting module, a pressure reducer, a pressure stabilizing tank, a safety valve, a pressure sensor and a filter. In the device, a passive heating mode is adopted, and a satellite internal heat dissipation unit is used as a heat source, so that extra power consumption is not needed; and the gasification device has the advantages of reducing the production cost, fully gasifying the propellant and ensuring that the propellant completes work in the form of gas state, along with simple structure, a few elements and devices and high reliability and safety.

Owner:BEIHANG UNIV +1

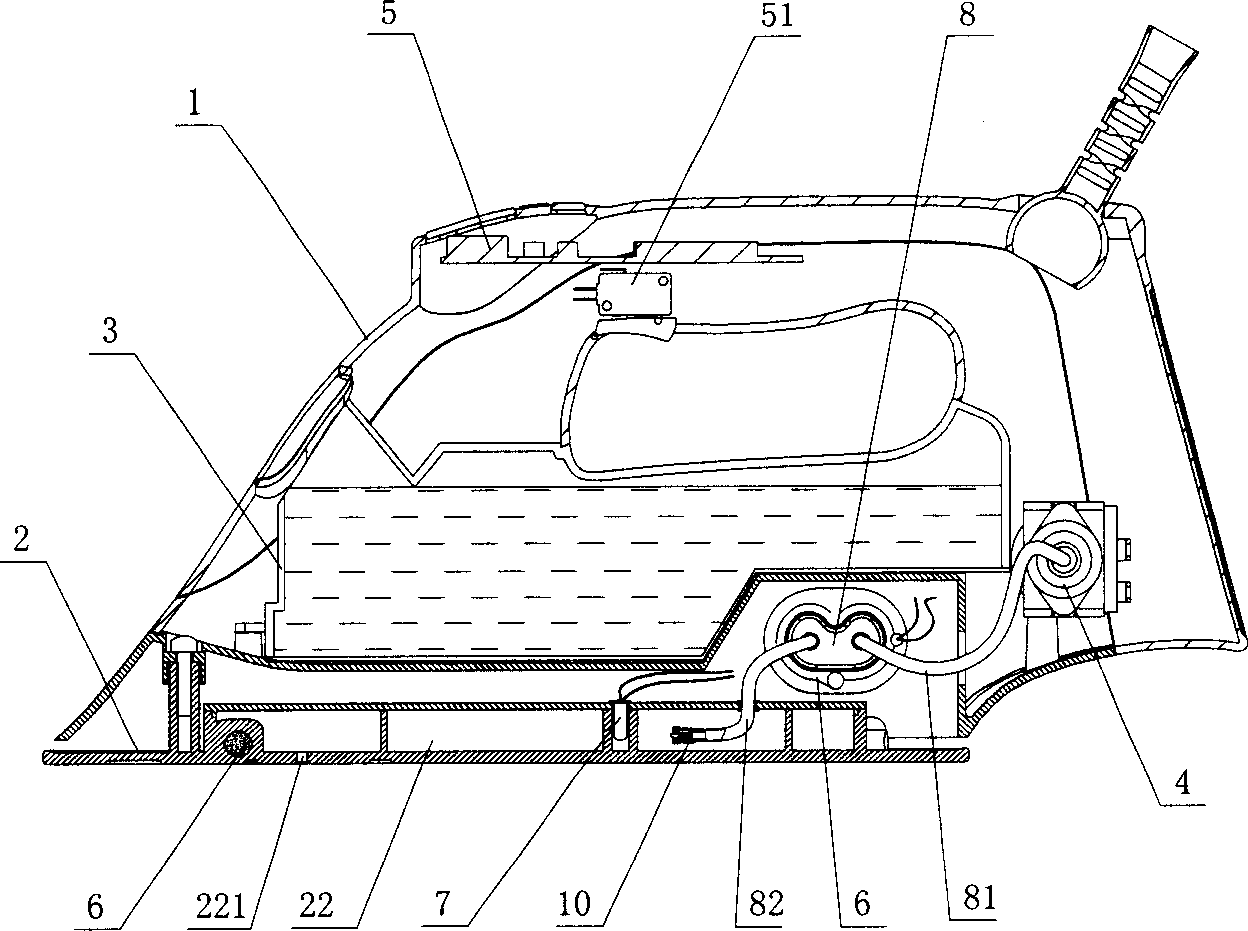

Novel steam generator

InactiveCN101387394AFully vaporizedReduce the chance of "dripping"Steam generation heating methodsIroning apparatusEngineering

Owner:ZHEJIANG HUAGUANG ELECTRIC APPLIANCE GRP

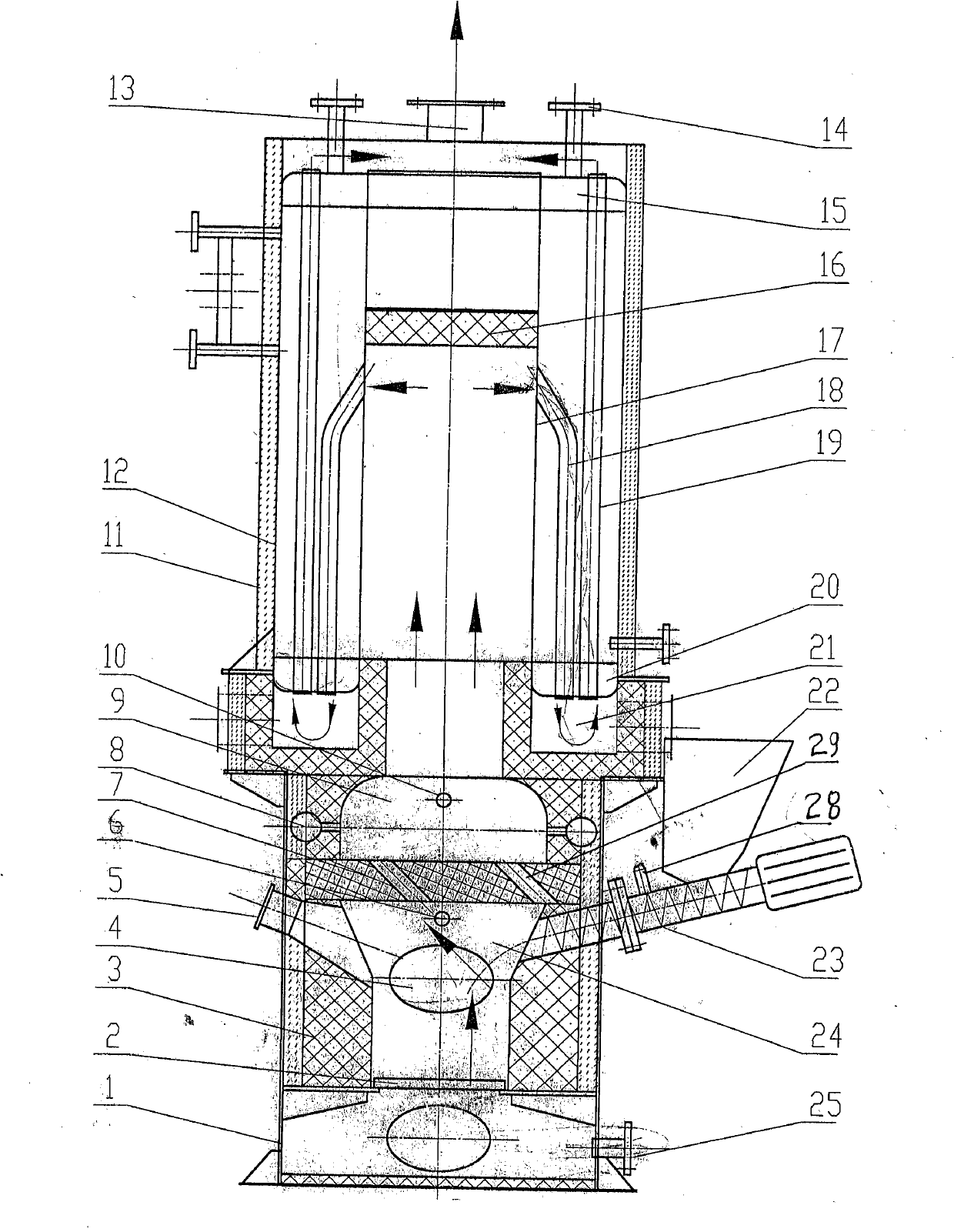

Vertical environment-friendly boiler for triple dedusting burning wood and biological particle fuel in boiler

InactiveCN101907292AFully embersFully vaporizedSolid fuel combustionCasings/liningsProduct gasEngineering

The invention relates to a vertical environment-friendly boiler for triple dedusting burning wood and biological particle fuel in a boiler, belonging to heating technology. The invention is used for burning wood and biological particles to obtain hot water or steam, and overcomes the defects of black smoke emission, low thermal efficiency, and the like of the similar traditional boilers. The boiler comprises a wind chamber, a fire grate, a carbon powder and gas burning hearth, a first wind inlet, a secondary wind inlet, and a heat exchanger above the hearth. The boiler is characterized in that the hearth is provided with a porous boiler crown of an inclined air vent; the upper end of an inner liner is provided with a smoke blocking wall; a downward screwed smoke tube is arranged between the wall of the inner liner and a lower end socket; an upward screwed smoke tube penetrates through an upper closing plate and a lower closing plate; and a heat exchanger seat of a smoke diversion dedusting chamber in the shape of a ring cavity is arranged on the circumference of the lower end of the heat exchanger. The invention has the advantages of sufficient burning of carbon powders, sufficient gasification and high thermal efficiency. Smoke is dedusted three times in the boiler, and the exhausted smoke has low dust capacity. The invention can be manufactured in a split mode, and is convenient to transport. The tonnage can be greatly increased.

Owner:袁福林

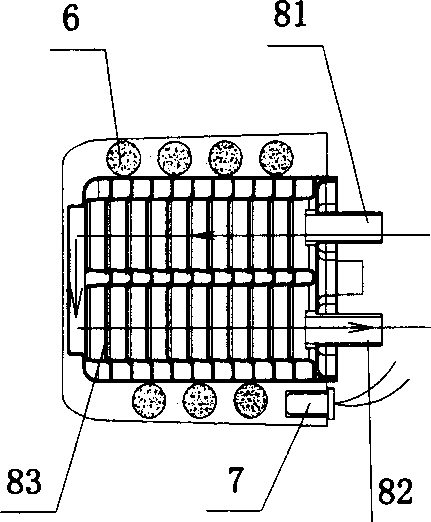

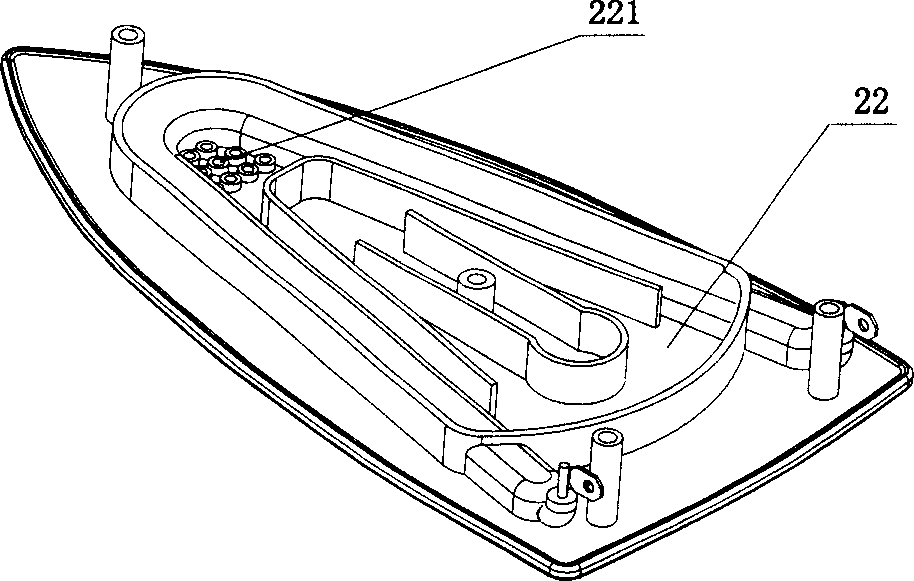

Improved structure of steam electric iron

InactiveCN1824882AEasy to manufacture and installGood conditionHand ironTextiles and paperMechanical engineering

The invention discloses an improved structure of steam iron that includes iron identity and base board. The base board has upper vaporizing chamber and down vaporizing chamber that connect with each other through a gas outlet tube. A one way valve is set at one end of the down vaporizing chamber and cascade conducting strips are set in the upper vaporizing chamber. The invention is simple structure, and is convenient to install. And the ironing quality is ensured.

Owner:徐建群

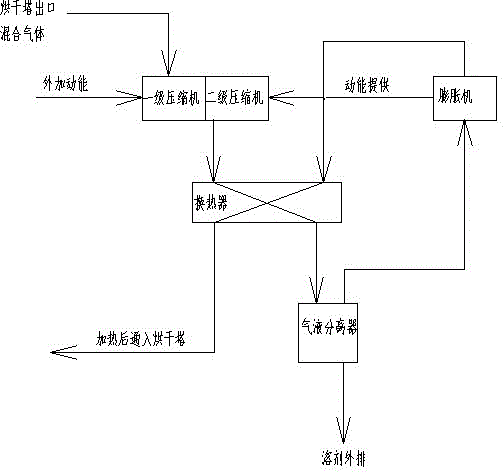

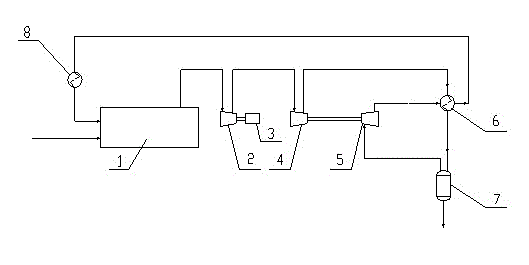

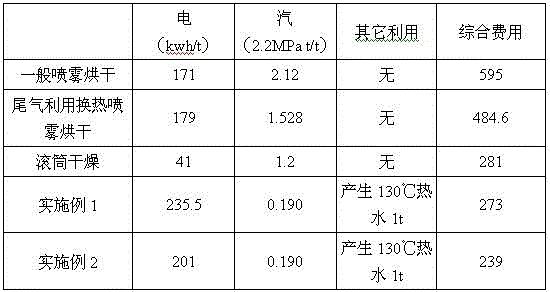

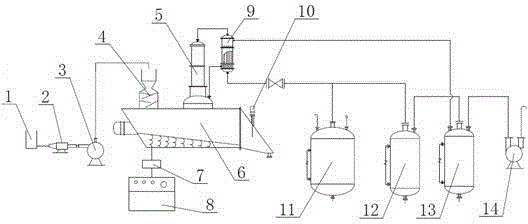

Energy-saving environment-friendly mist spray drying technology

The invention relates to an energy-saving environment-friendly mist spray drying technology which is realized through a corresponding mist spray drying system. The mist spray drying system mainly comprises a drying tower, a first-stage compressor, a second-stage compressor, an expansion machine, a heat exchanger and a gas-liquid separator. Tail gases exhausted from the drying tower are pressurized and heated stage by stage, the treated tail gases in the heat exchanger form a larger temperature difference and a larger pressure difference with a cold source gas, the heat exchanging effect is strengthened and particularly the release and the recycle of the condensation heat of a gaseous solvent in the mixed gases of high potential energy after pressurization can be promoted. After the condensation heat of the solvent is recycled, the mixed gases are transformed into a gas-liquid mixture to be subjected to gas-liquid separation; during the recycle of the condensation heat of the solvent, and the gas-liquid separation, which are performed in order, the pressure of the mixed gases is almost unchanged, the potential energy is not lost, the gases obtained through the gas-liquid separation still have higher potential energy, and the potential energy and the heat energy of the gases are transformed into kinetic energy through the expansion machine to be provided for the second-stage compressor, so that the recycle of the potential energy and the heat energy of the tail gases is realized, and the energy consumption of the system is reduced.

Owner:安徽瑞柏新材料有限公司

Liquid gasification burner

The invention discloses a liquid gasification burner, which comprises a stove body, an outer gas distribution cover, an inner gas distribution cover and a base, the four walls of the stove body are provided with air inlets, and the stove body is divided into a stove chamber and a gasification chamber by a partition; the outer gas distribution cover and the inner gas distribution cover are arranged in the stove chamber, and the four walls of each of the outer gas distribution cover and the inner gas distribution cover are provided with burning-supporting holes; the base is connected with the gasification chamber through bolts, and the liquid gasification burner also comprises a preheating coil and a gasification coil. Fuel respectively enters the preheating coil and the gasification coil, the heat produced by the burning liquid fuel flowing out of the preheating coil can gasify the fuel in the preheating coil, the gasified fuel enters the gasification chamber via the gas outlet of the gasification coil, and the gas flows out of the gasification chamber via flame nozzles on the partition to enter the stove chamber and burns. The fuel can be sufficiently burnt, the thermal efficiency is high, moreover, fire is evenly distributed, the environment cannot be polluted, and the safety performance is good.

Owner:苏志勇

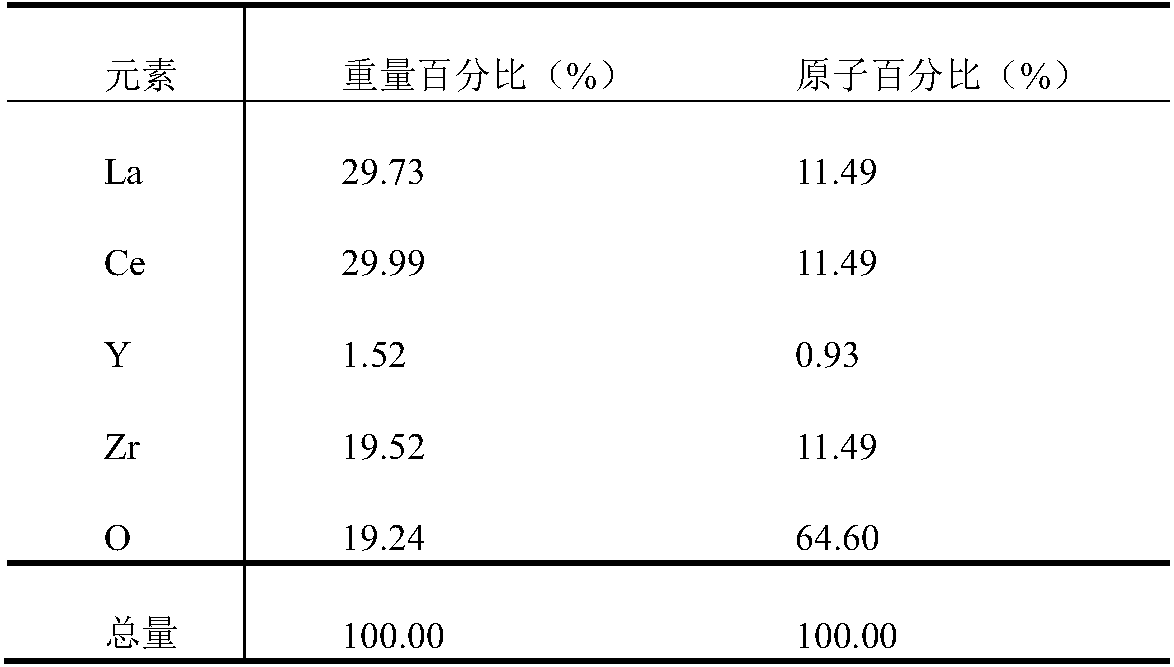

Yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for plasma physical vapor deposition and preparation method thereof and application

ActiveCN108546907AGood mechanical propertiesImprove fracture toughnessMolten spray coatingGas phaseLanthanum

The invention discloses yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for plasma physical vapor deposition and a preparation method thereof and application, and relates to the technical field of thermal barrier coating. The preparation method comprises the followings steps that lanthanum oxide, cerium oxide, yttrium oxide and zirconia are mixed in a molar ratio of (0.8-1.3):1:0.08:1 for ball-milling treatment, and ball-milling products are obtained; the products are filtered and dried, the products is performed ball milling with deionized water, binders and dispersants after drying to be mixed uniformly, and sizing agents are obtained; the sizing agents are performed spraying and drying treatment to obtain aggregates; and the aggregates are performed screening treatment after sintering to obtain the yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for the plasma physical vapor deposition. When a coating is prepared, the powder is heatedin a powder feeder to start plasma physical gas phase deposition equipment, and the vacuum is pumped to the pressure less than 0.08mbar and the vacuum chamber is filled with argon to 130mbar; and thenspraying is performed to obtain the coating. The yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for the plasma physical vapor deposition and the preparation method thereof and the application have simple steps and save cost, improve material performance and can be used in mass industrial production.

Owner:BEIHANG UNIV

Process for making combustable gas by external high temperature CO2 and biomass reducing reaction

The reduction reaction process of exogenic high temperature CO2 and biomass for preparing combustible gas includes setting biomass into furnace, and spraying high temperature CO2 and combustion promoting water vapor from external burner so as to gasify ligonocellulose and similar biomass into combustible gas with CO and H2 as main components. The said process can produce combustible gas of high heat value and capable of being used as civil fuel and industrial fuel in high gas producing rate, high carbon converting rate and adjustable gas components.

Owner:GUANGXI UNIV

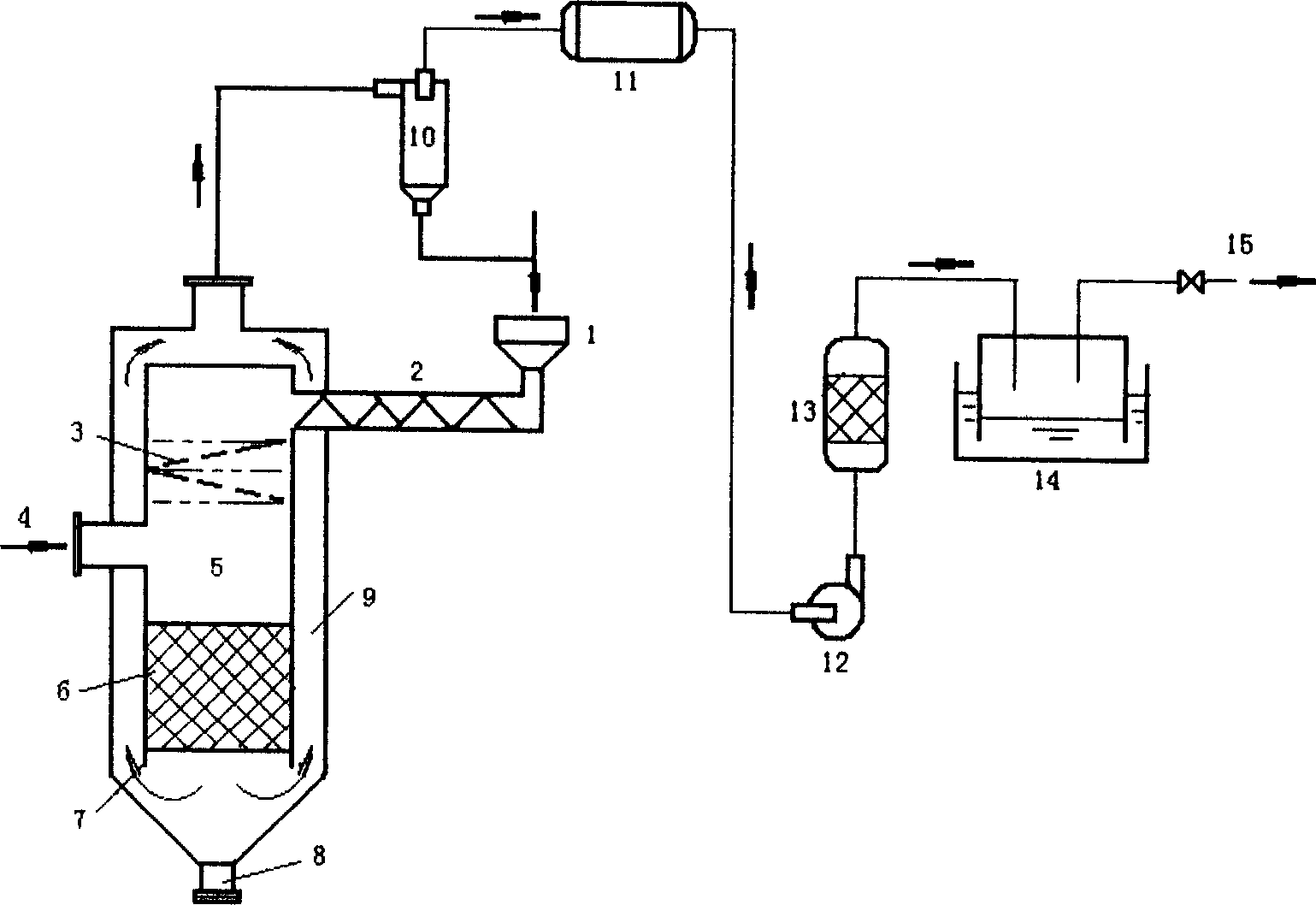

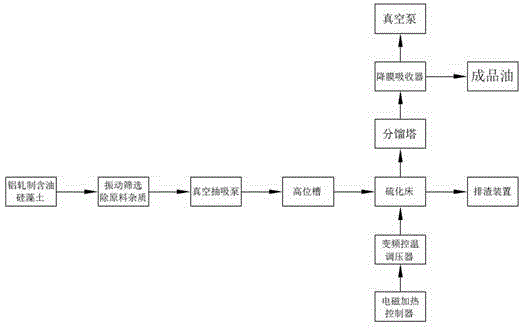

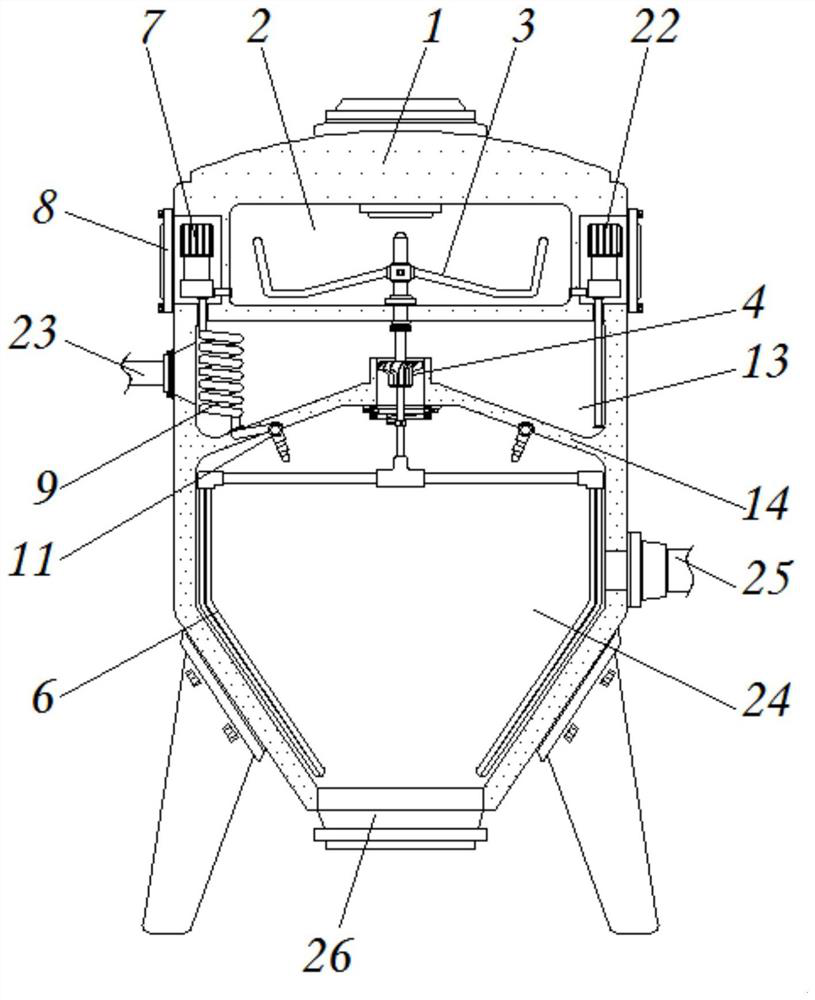

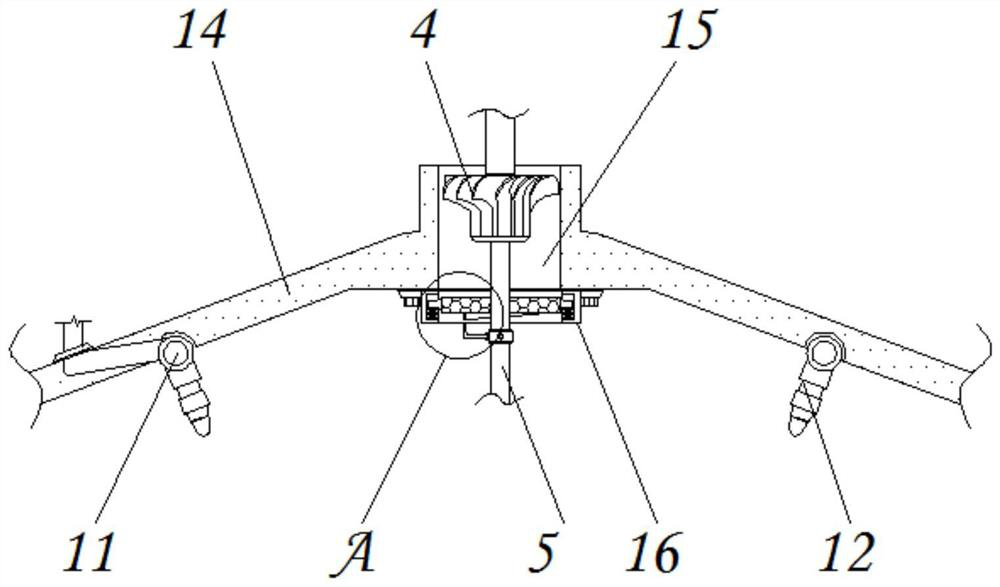

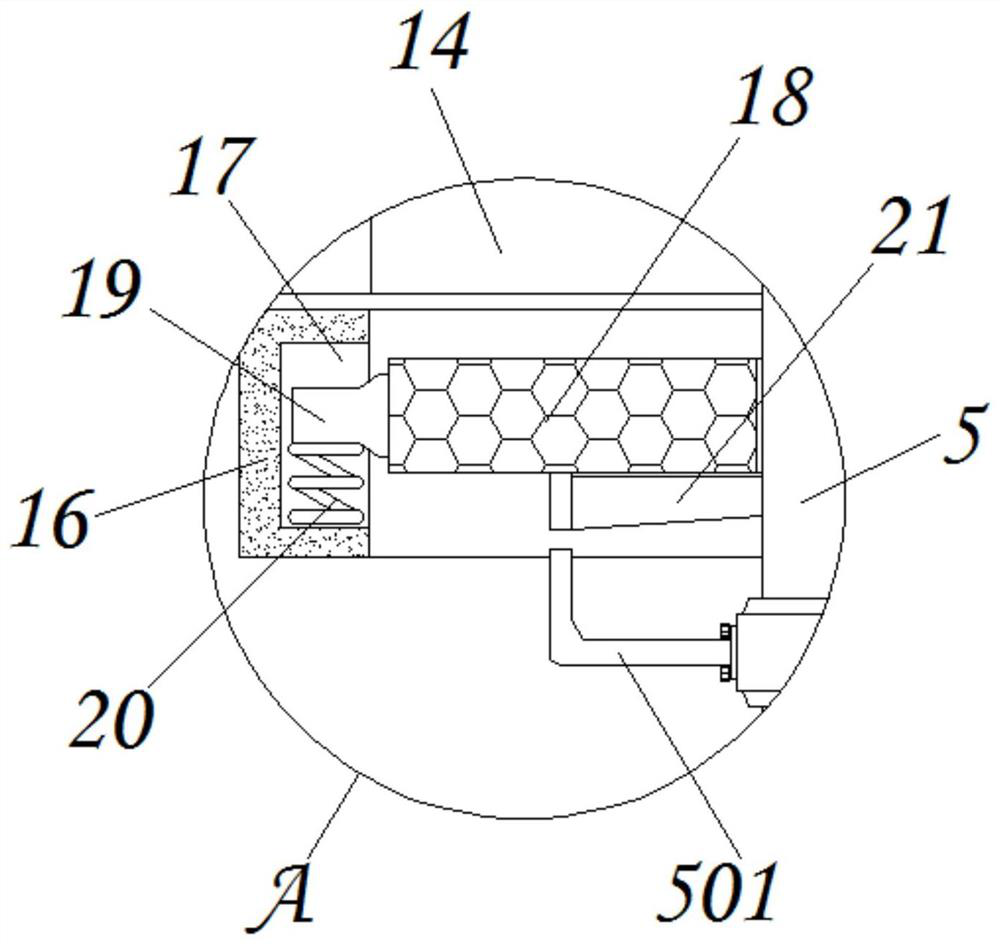

Fluidized bed heating device as well as oil-containing kieselguhr serialization oil extraction equipment and oil extraction method

ActiveCN104059761AEvenly heatedFully vaporizedCoil arrangementsLubricant compositionTemperature controlHazardous substance

The invention discloses a fluidized bed electromagnetic vortex heating device which comprises a fluidized bed and an electromagnetic heating controller connected with the fluidized bed, wherein an electromagnetic heating coil is arranged at the lower part of a bed body of the fluidized bed, and is connected with a frequency conversion and temperature control voltage regulator, and the frequency conversion and temperature control voltage regulator is connected with the electromagnetic heating controller. Oil-containing kieselguhr serialization oil extraction equipment comprises a feeding device, a heating device, an oil gas recovering device and a deslagging device, wherein the heating device is the fluidized electromagnetic vortex heating device, and the deslagging device is communicated with the discharging hole of the fluidized bed electromagnetic vortex heating device. An oil-containing kieselguhr serialization oil extraction method comprises the steps: feeding, heating, stirring, primarily distilling, extracting engine oil and hydraulic oil, and deslagging. Rolling oil and kieselguhr in oil-containing kieselguhr treated by adopting the oil-containing kieselguhr serialization oil extraction equipment are separated by using a physical method, without using acidic and basic or other harmful substances in the whole process, and the separation is performed under a vacuum condition, without exhaust gas emission.

Owner:GONGYI CITY XINHUA MACHINERY FACTORY

Self-cleaning heat energy recovery energy-saving type combustion waste gas treatment device

InactiveCN111686571AVaporization fastFully vaporizedDispersed particle filtrationTransportation and packagingCombustionProcess engineering

The invention discloses a self-cleaning heat energy recovery energy-saving type combustion waste gas treatment device. The device comprises a warm-keeping tank body, an impeller, a scraping blade, a gas collecting plate and a fixing block. A storage bin is formed in the upper end of the warm-keeping tank body; a connecting shaft is welded at the lower end of the impeller; a first water pump is mounted in the left side of the upper end of the warm-keeping tank body; a preheating pipe is connected to the lower portion of the first water pump, a steam bin is formed in the middle of the interior of the warm-keeping tank body, an air vent is formed in the middle of the gas collecting plate, a filter screen is arranged on the inner side of a mounting base, a fixing block is arranged on the lowersurface of a filter screen, and a reaction bin is formed in the lower end of the warm-keeping tank body. According to the self-cleaning heat energy recovery energy-saving type combustion waste gas treatment device, heat in high-temperature combustion waste gas can be recycled, heat energy is converted into mechanical energy, and thus kinetic energy is provided for a mechanical structure of the device, the device does not need to be externally connected with power equipment, and the environmental protection performance of the device is improved.

Owner:徐科明

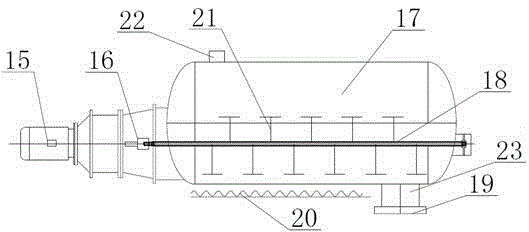

Gas phase catalytic esterification process for synthesizing butyl acetate

InactiveCN1184187CFully vaporizedWell mixedOrganic compound preparationCarboxylic acid esters preparationAcetic acidIt equipment

This invention relates to new technology of gaseous phase catalytic esterification and its equipment, it uses straight immobilized bed reactor with fluidic apparatus. The invented new technology is low in cost, higher raw material gas space velocity, uniform mixing of raw material, can reduce channeling and short circuit effectively. The ethyl butylate yield and selectivity can reach respectively to 85.41% and 95.43%.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

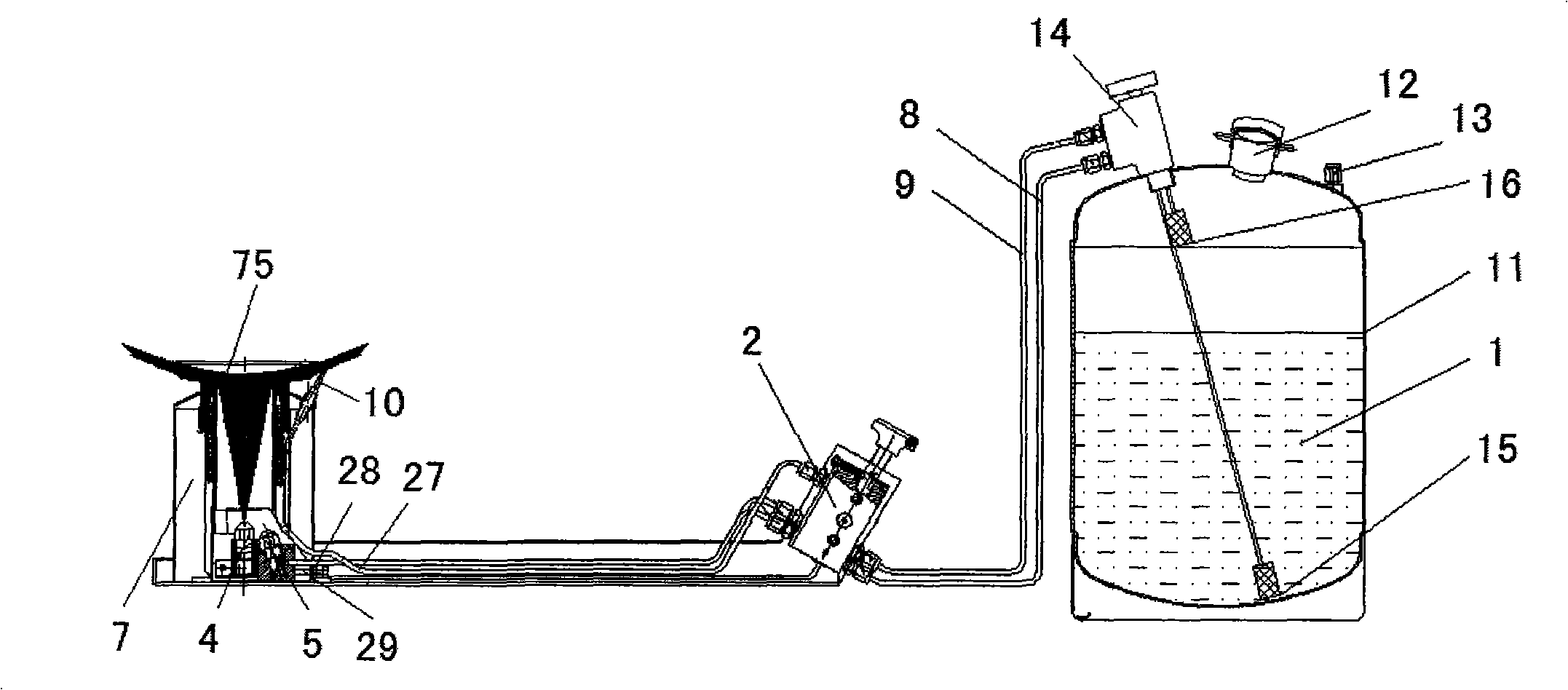

Mixed-oxygen preheating oil burning system

InactiveCN101539291AImprove combustion efficiencyBurn fullyCombustion using gaseous and pulverulent fuelBurnersCombustionEngineering

The invention relates to a mixed-oxygen preheating oil burning system. The system comprises an oil storage tank, a control valve, a combustion apparatus and corresponding connecting pipelines. The oil storage tank comprises a tank body. The top of the tank body is provided with an oil filling opening, a gas filling opening and an oil-gas switch. The inner end of the oil-gas switch is connected with an oil suction pipe extending to the bottom of the tank body and a gas transfer pipe at the upper part in the tank body. The outer end of the oil-gas tank is connected with an oil transfer pipeline and a gas transfer pipeline. The control valve comprises a valve body provided with a switch valve, an electromagnetic valve, an adjusting valve and a pressure maintaining valve thereon. The combustion apparatus comprises a grate, a heat-insulation cylinder, a preheating pipe, a fire cylinder, a fire distributing cylinder, a main oil burner, a preheating oil burner and a compressed air burner. The invention has the advantages of high preheating temperature, adequate combustion and safety. The invention can be widely used in the occasions needing oil burning stoves.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

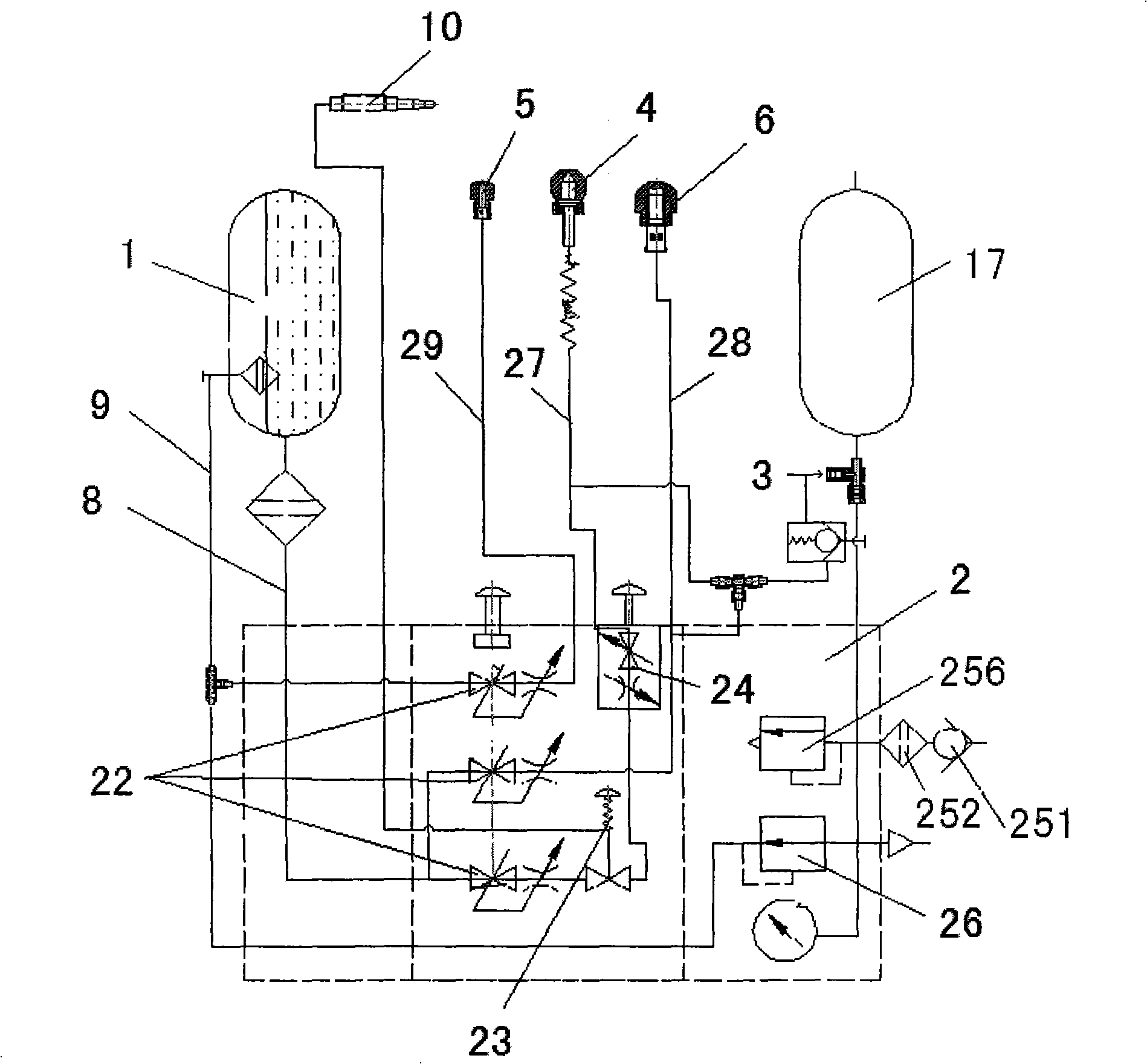

System and method for treating high-concentration organic waste liquid

ActiveCN105066146AEasy to handleReduce consumptionLiquid fuel feeder/distributionCombustion technology mitigationHigh concentrationLiquid waste

The invention belongs to the field of wastewater treating, and particularly relates to a system and a method for treating high-concentration organic waste liquid. The organic waste liquid can be efficiently processed in a low-consumption, energy-saving and environment-friendly manner. The system for treating the high-concentration organic waste liquid comprises a gasification chamber, a combustor, a smoke pipe, a waste liquid pump, a waste liquid tank, a settling chamber, demisting baffles and a condenser. The gasification chamber is located at the top of the combustor. A primary auxiliary fuel nozzle, a waste liquid nozzle and at least one air inlet are formed in the upper portion of the side wall of the gasification chamber. A secondary air inlet and a secondary auxiliary fuel nozzle are arranged at the upper portion of the side wall of the combustor. An exhausting opening of the combustor directly extends into the waste liquid tank through the smoke pipe. The settling chamber is installed at the top of the waste liquid tank. The multiple demisting baffles are installed at the upper portion of the interior of the settling chamber. A gas outlet in the top of the settling chamber is communicated with a gas inlet of the condenser through a pipe. An inlet of a condenser heat exchanging pipe is connected with a waste liquid delivery pipe. A waste liquid outlet in the waste liquid tank is sequentially communicated with the waste liquid pump and the waste liquid nozzle through a pipe.

Owner:南京赛佳环保实业有限公司 +1

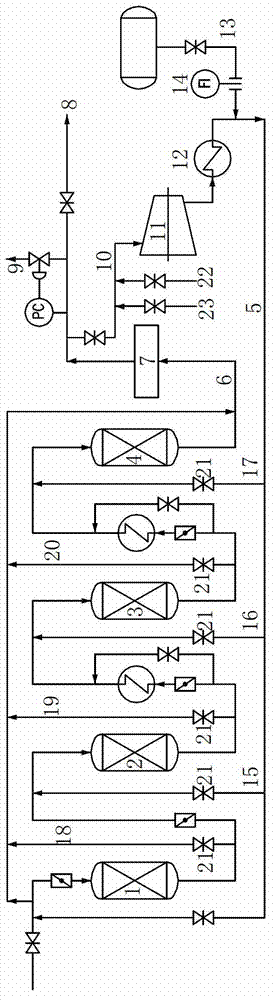

Process for activating CO sulfur-resistant shift catalyst before start-up of pulverized coal gasification device

ActiveCN102784668AShorten activation timeReduce consumptionCatalyst activation/preparationVulcanizationSulfur

The invention relates to a process for heating and activating a carbon monoxide sulfur-resistant shift catalyst. The catalyst is heated and activated by the process in a circulating vulcanization mode. A heating vulcanization line is arranged at an inlet of each shifter, and a drop-out line is arranged at an outlet of each shifter. Each shifter not only can be independently heated and perform vulcanization, but also can be heated and perform vulcanization in a series connection manner. During heating and vulcanization, the shifters which are heated or complete vulcanization can be disconnected from a system, and the follow-up shifters are directly heated or directly perform vulcanization. The process is further characterized in that after catalysts of a certain shifter are changed, the shifter can be disconnected from the system to be independently heated or independently perform vulcanization. By the aid of the process, start-up expense of a shifting device can be effectively reduced, and start-up time of the shifting device can be effectively shortened.

Owner:CHINA PETROCHEMICAL CORP +2

Garbage gasification and biomass combustion integrated system

PendingCN108916878AIncrease the calorific value of wasteImprove processing effectIncinerator apparatusIntegrated systemsCirculating fluidized bed boiler

The invention relates to the field of garbage treatment, in particular to a garbage gasification and biomass combustion integrated system. The garbage gasification and biomass combustion integrated system comprises a gasification furnace and a circulating fluidized bed boiler. An inner container is arranged in the gasification furnace. A pulverizing device for pulverizing garbage is arranged abovethe inner container. The gasification furnace is connected with a combustion chamber of the circulating fluidized bed boiler through a gas output pipe. The combustion chamber of the circulating fluidized bed boiler is internally provided with a scattering mechanism. The circulating fluidized bed boiler is connected with a drying furnace through a first smoke output pipe. The drying furnace is provided with a primary biomass feeding device and a secondary biomass feeding device, and the drying furnace is connected with a purification box through a second smoke output pipe. According to the garbage gasification and biomass combustion integrated system, the garbage is conveyed into the gasification furnace to be gasified, then, generated gas is conveyed into the circulating fluidized bed boiler to be combusted together with biomass, and generation of garbage toxic gas is greatly reduced; and the waste heat value is increased, comprehensive treatment is conducted on the garbage and the biomass, the treatment effect is improved, and the environment is better protected.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

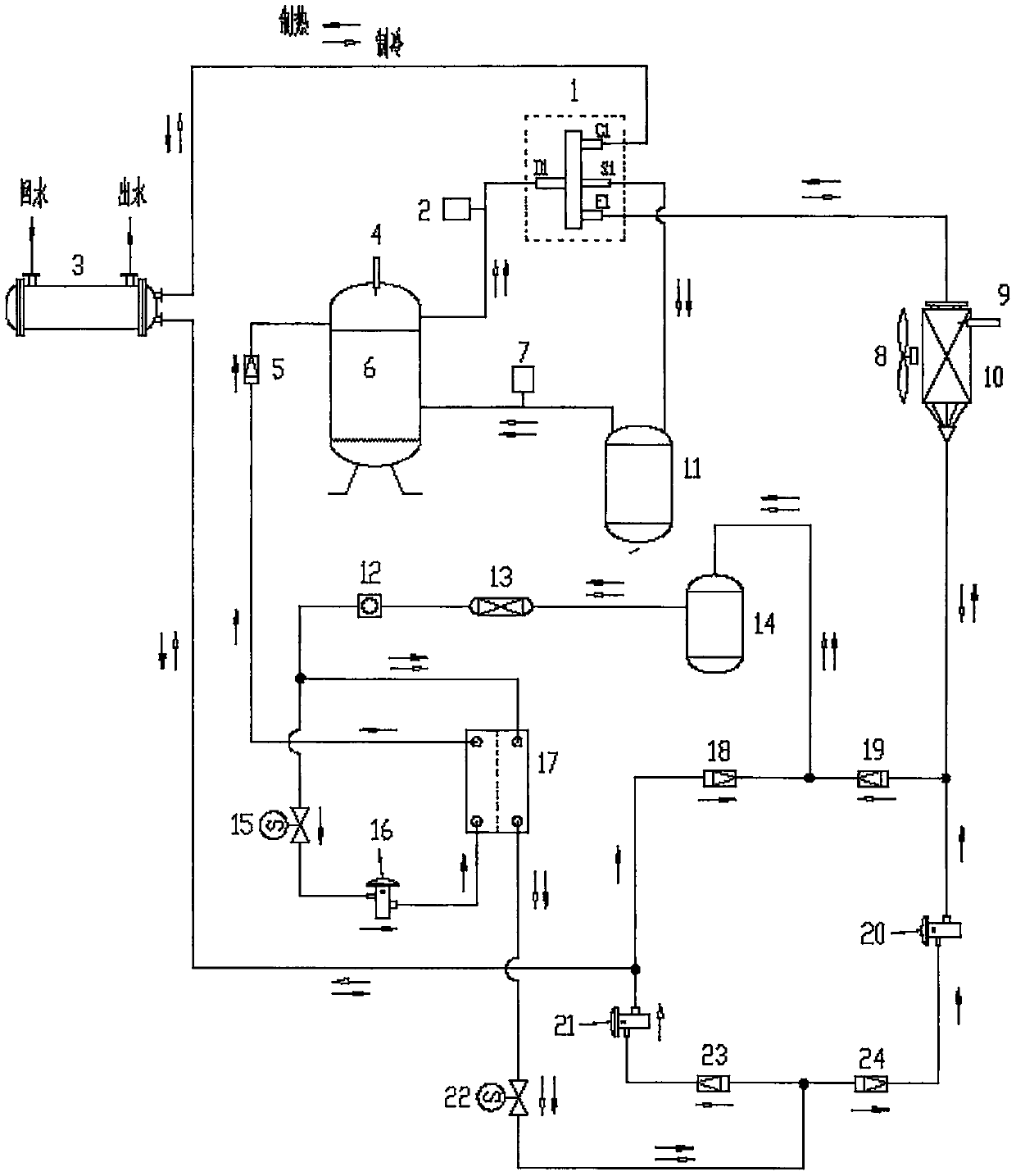

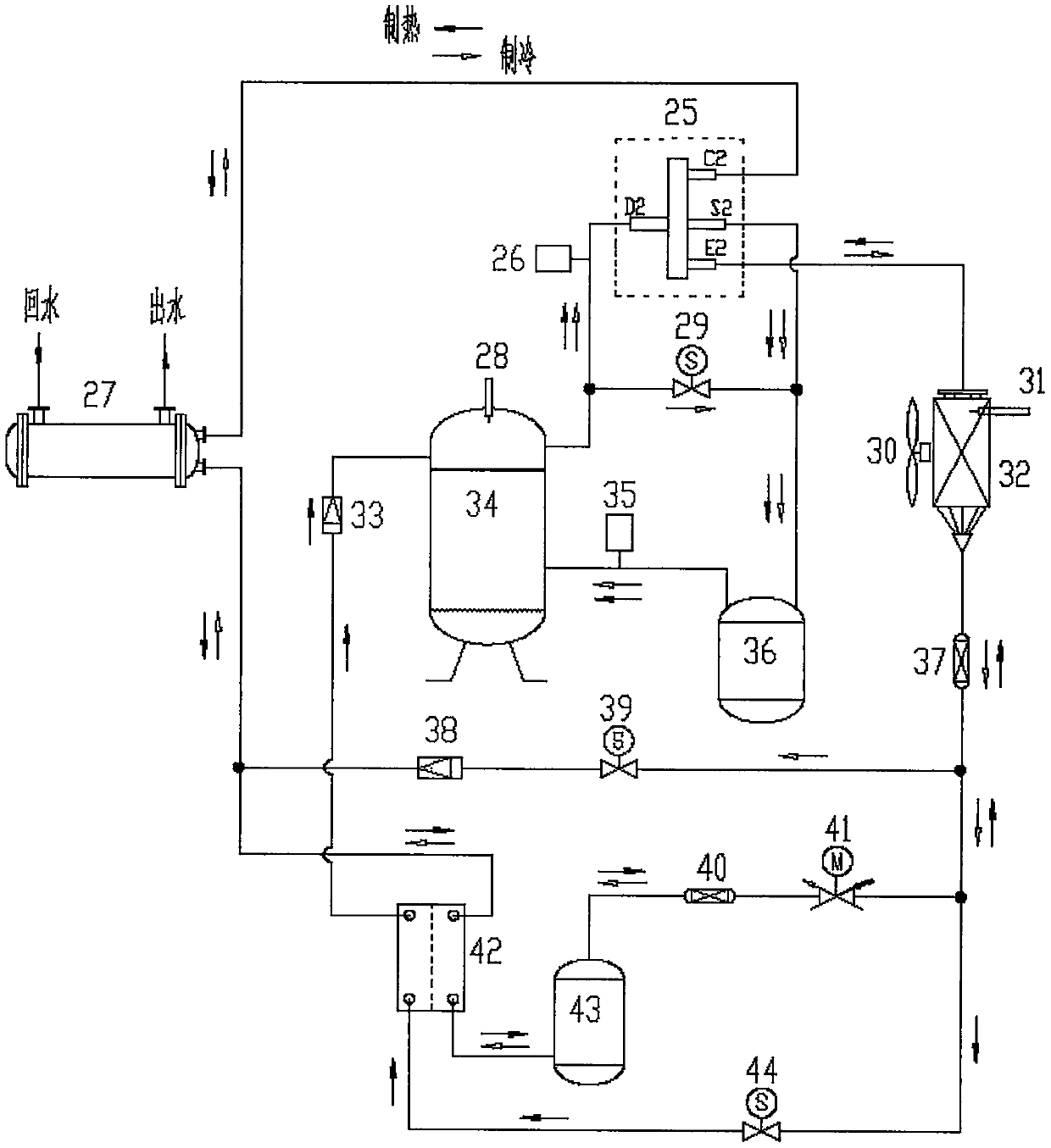

Heating and refrigeration vortex type air source heat pump system

PendingCN109631381AQuick responseFast actionMechanical apparatusFluid circulation arrangementShell and tube heat exchangerLiquid storage tank

The invention belongs to the field of steam compression type air source heat pumps and provides a heating and refrigeration vortex type air source heat pump system comprising a four-way reversing valve B, a high-pressure switch B, a water side shell and tube heat exchanger B, an exhaust temperature sensor B, an electromagnetic valve C, a fan B, a fin temperature sensor B, an air side fin heat exchanger B, a check valve F, an enhanced vapor injection compressor B, a low-pressure switch B, an air-liquid separator B, a pipeline filter, a check valve G, an electromagnetic valve D, a dry filter B,an electronic expansion valve, an economizer B, a liquid storage tank B, an electromagnetic valve E and other parts. With application of the heating and refrigeration vortex type air source heat pumpsystem, 1, the idea that refrigeration, heating and air supply of the heating and refrigeration vortex type air source heat pump system share the one electronic expansion valve is achieved, complexityand manufacturing cost are lowered, and full-working-condition refrigerating capacity and COP are promoted by 5% or above; and 2, during reverse cycle defrosting of the heating and refrigeration vortex type air source heat pump system, a refrigerant does not pass through the electronic expansion valve for throttling cooling and directly enters the water side shell and tube heat exchanger for heatexchange, room comfort is improved, and defrosting time is shortened by 5 seconds or above.

Owner:青岛沃润达新能源科技有限公司

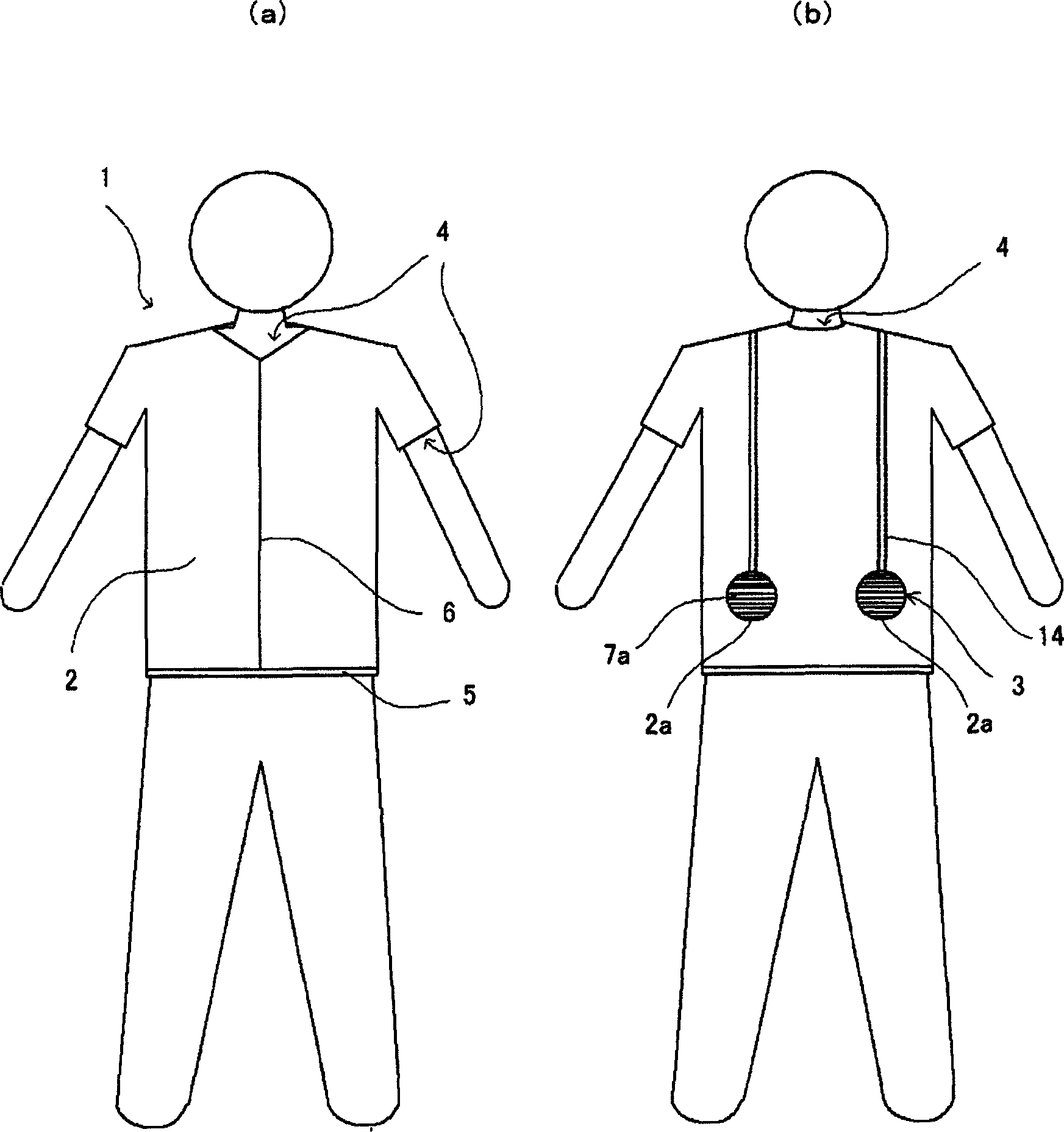

Cooling clothes

ActiveCN1829454ASimple structureFully vaporizedProtective garmentSpecial outerwear garmentsWater vaporFresh air

Owner:SEFT DEVMENT LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com