Patents

Literature

289 results about "Low temperature sterilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Temperature Sterilization. Low temperature sterilization is a sterilization process best used for heat-sensitive devices that may be damaged by the conditions of a steam sterilization cycle. Ethylene oxide (EO) and vaporized hydrogen peroxide (VHP) are the two most common types of low temperature sterilization.

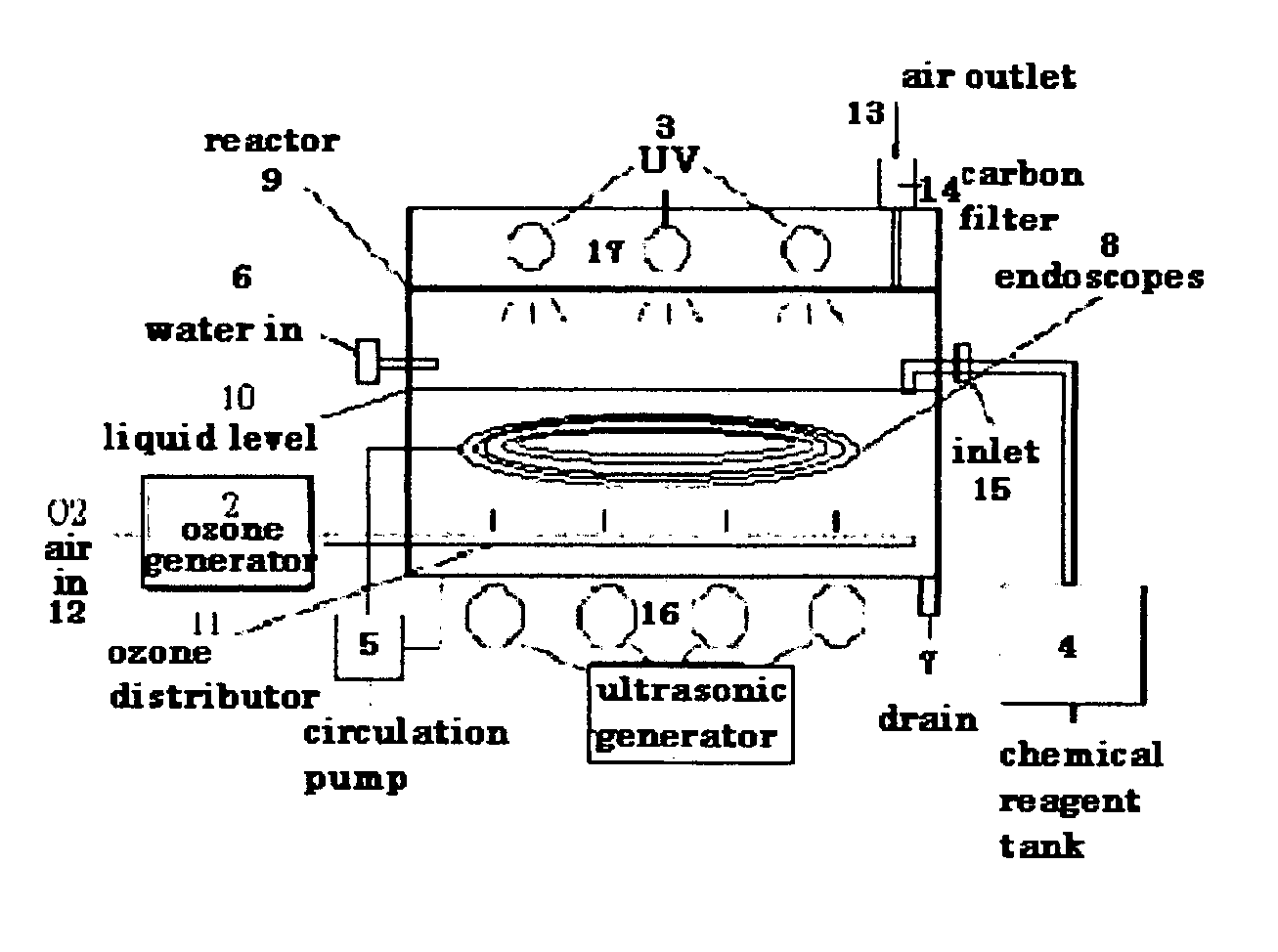

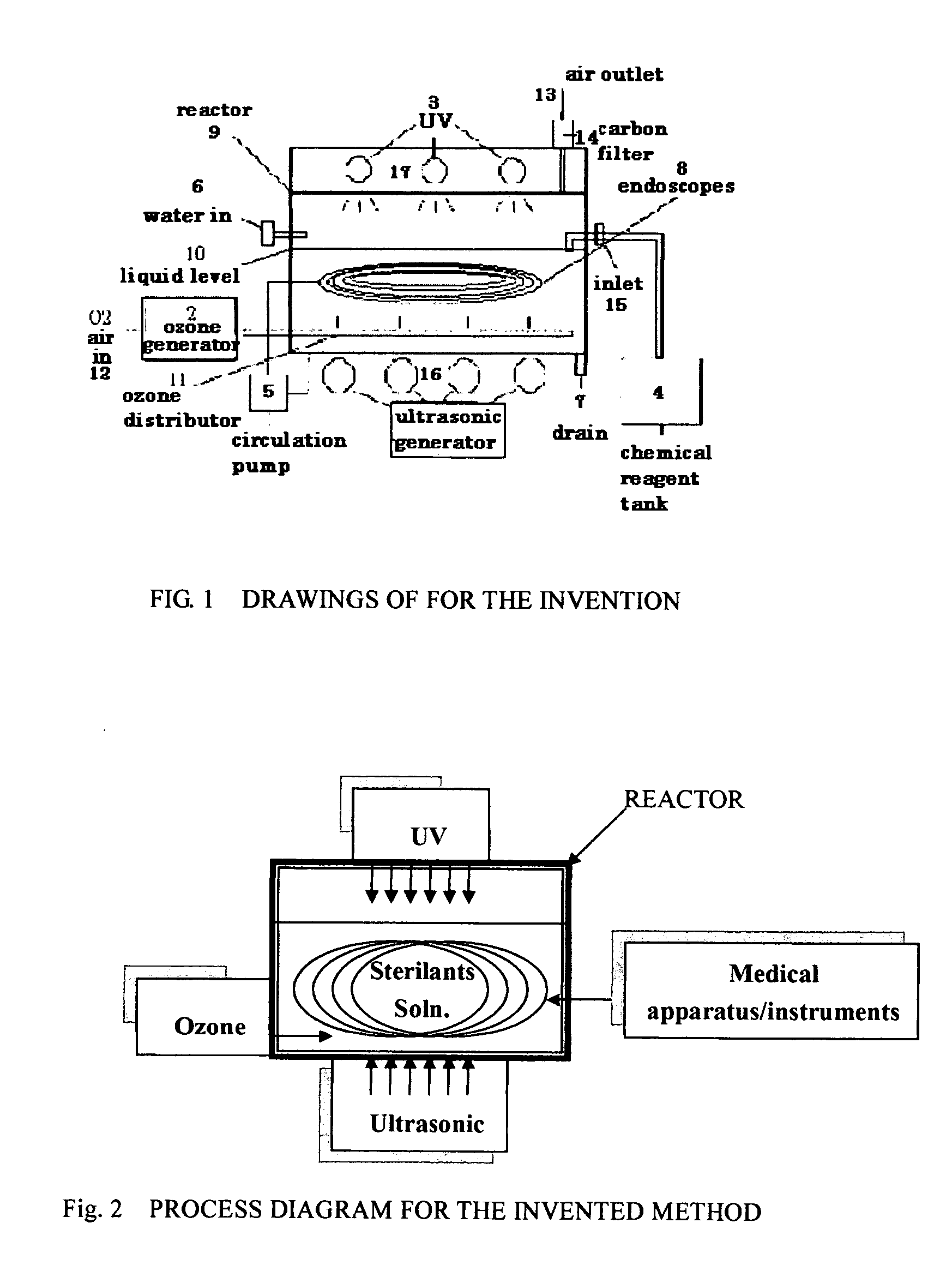

Low temperature sterilization and disinfections method and apparatus for medical apparatus and instruments

A method and apparatus for the low temperature sterilization and disinfections to be applied to medical apparatus / instruments. This invention perfects the use of ultrasonic, UV, ozone in a liquid bath with at least one chemical reagent which can be either sterilant or disinfectant solution for reprocessing many classes of medical equipment / instruments especially those which do not withstand high temperature sterilization process and require sterilization or high level disinfections. The invented method can effectively remove and destroy contaminates, particularly living organisms, bacterial spores, virus, and organics from used or contaminated medical apparatus / instruments surface, inner hollow lumen tube, joints and crevices. Having greatest immediate application for the cleaning, disinfecting and sterilizing all in one simple process for reprocessing used or contaminated medical apparatus / instruments after treating patients.

Owner:DING LAMBERT LISHING

Fermentation method for production of nutritionally balanced natural fruit enzyme

ActiveCN103609985AReduce lossesRetain activityFood ingredient functionsFood preparationLactic acid bacteriumAcetic acid

The invention relates to a fermentation method for production of nutritionally balanced natural fruit enzymes. The method comprises the following steps: (1) pretreatment on raw materials; (2) a first bacterium inoculation: inoculating a saccharomyces cerevisiae liquor with concentration of 106 CFU / ml into a pulp according to an inoculation proportion of 5%; (3) early stage fermentation; (4) a secondary bacterium inoculation: after the early fermentation, inoculating acetic acid bacterium liquid and lactic acid bacterium liquid in a weight ratio of 1:1 for a secondary bacterium inoculation according to an inoculation amount of 5%; (5) middle-term fermentation; (6) coarse filtration; (7) secondary fermentation; (8) ripening; and (9) fine filtration to obtain the natural fruit enzyme. The fermentation method provided by the invention through low-temperature sterilization and strict control on the fermentation temperature retains the enzyme activity to the maximum; and twice inoculation of dominant bacteria effectively inhibits breeding of other infectious microbes, so as to realize stable product quality.

Owner:JINYES QINGDAO BIOTECH CO LTD

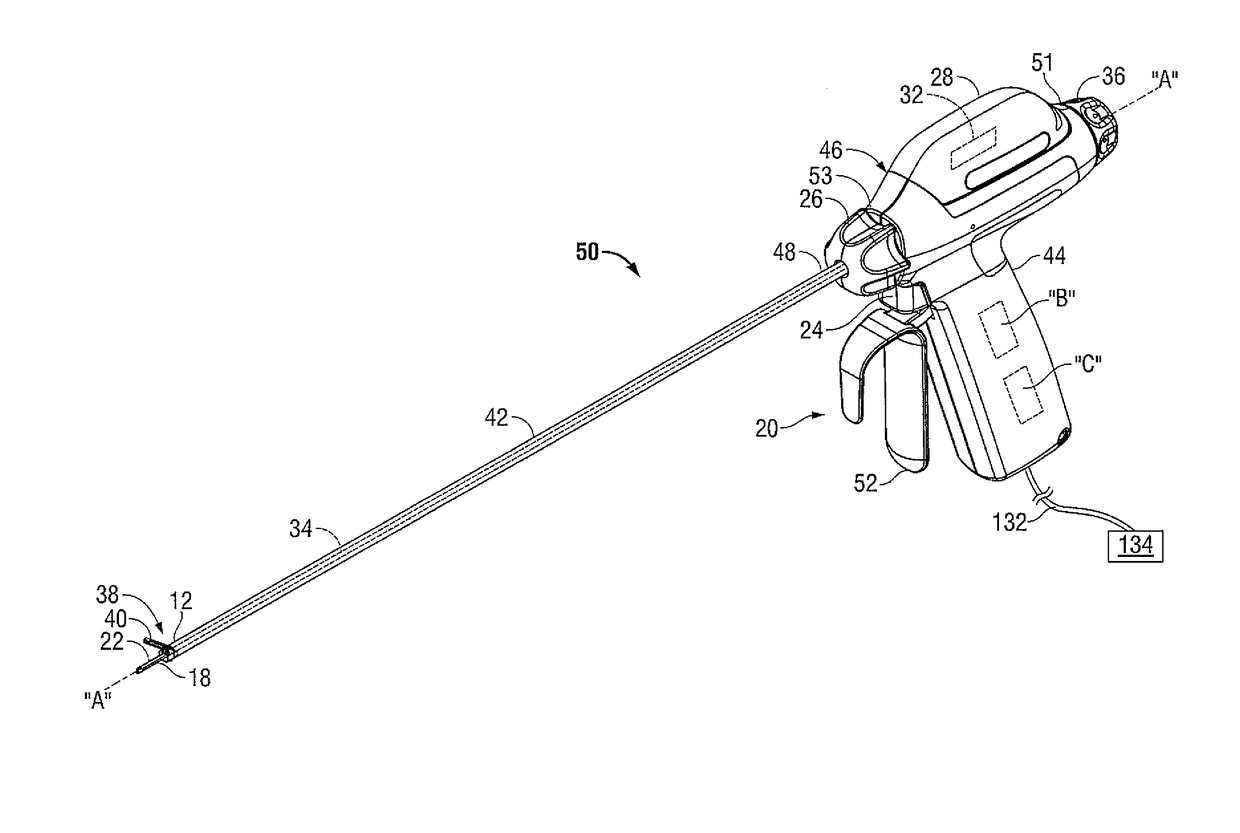

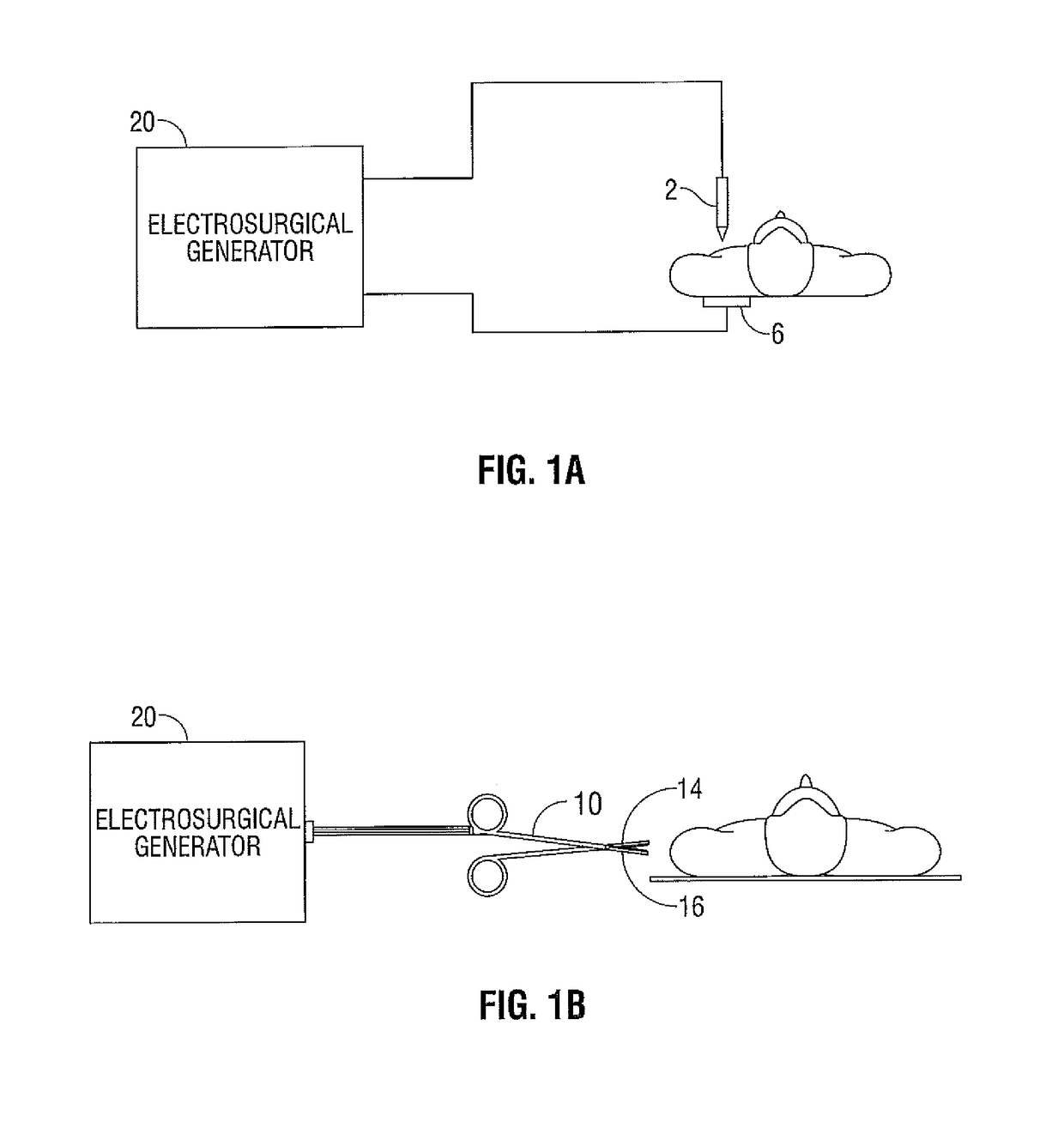

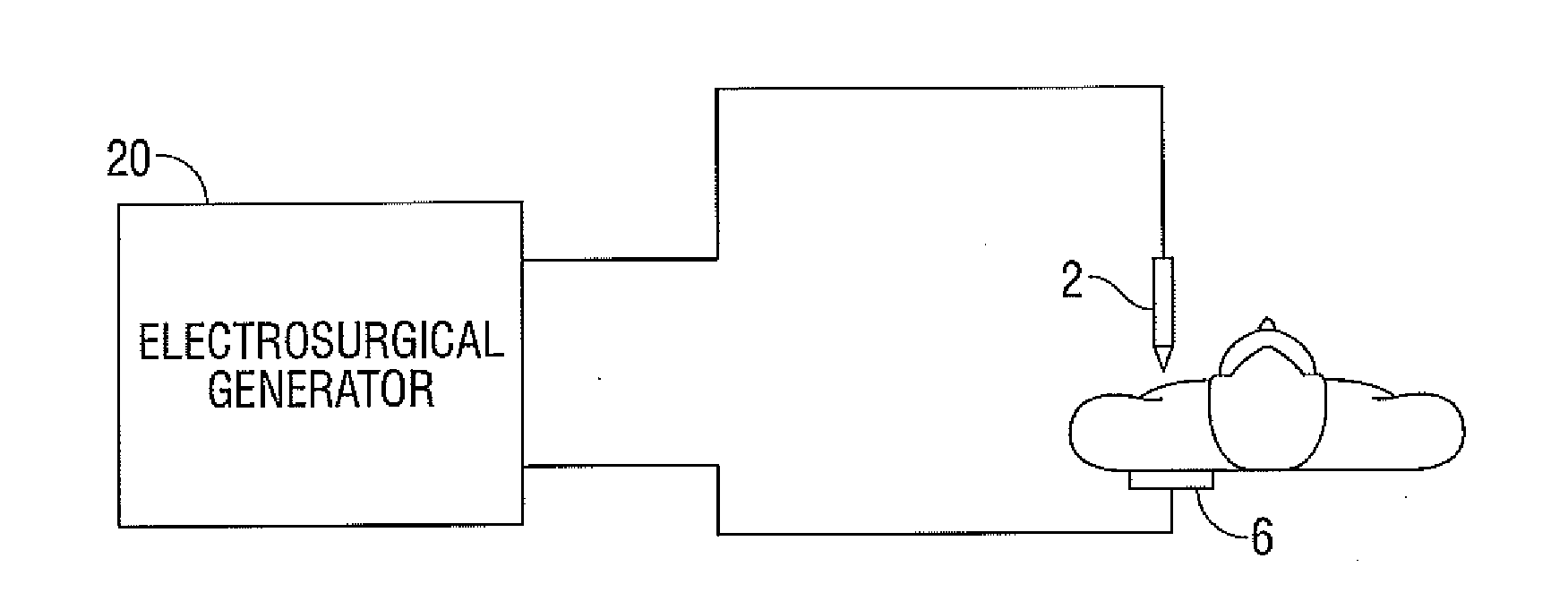

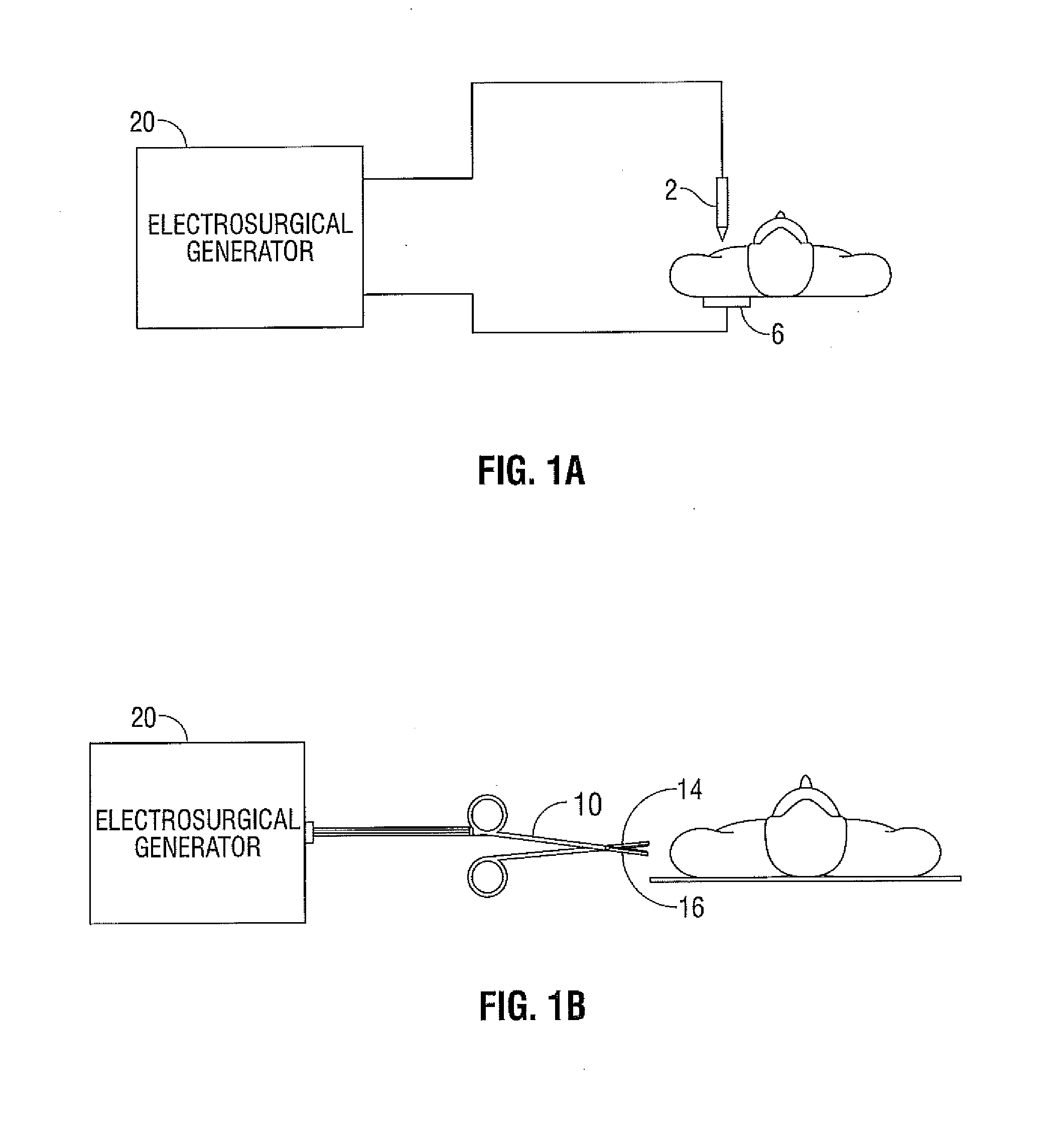

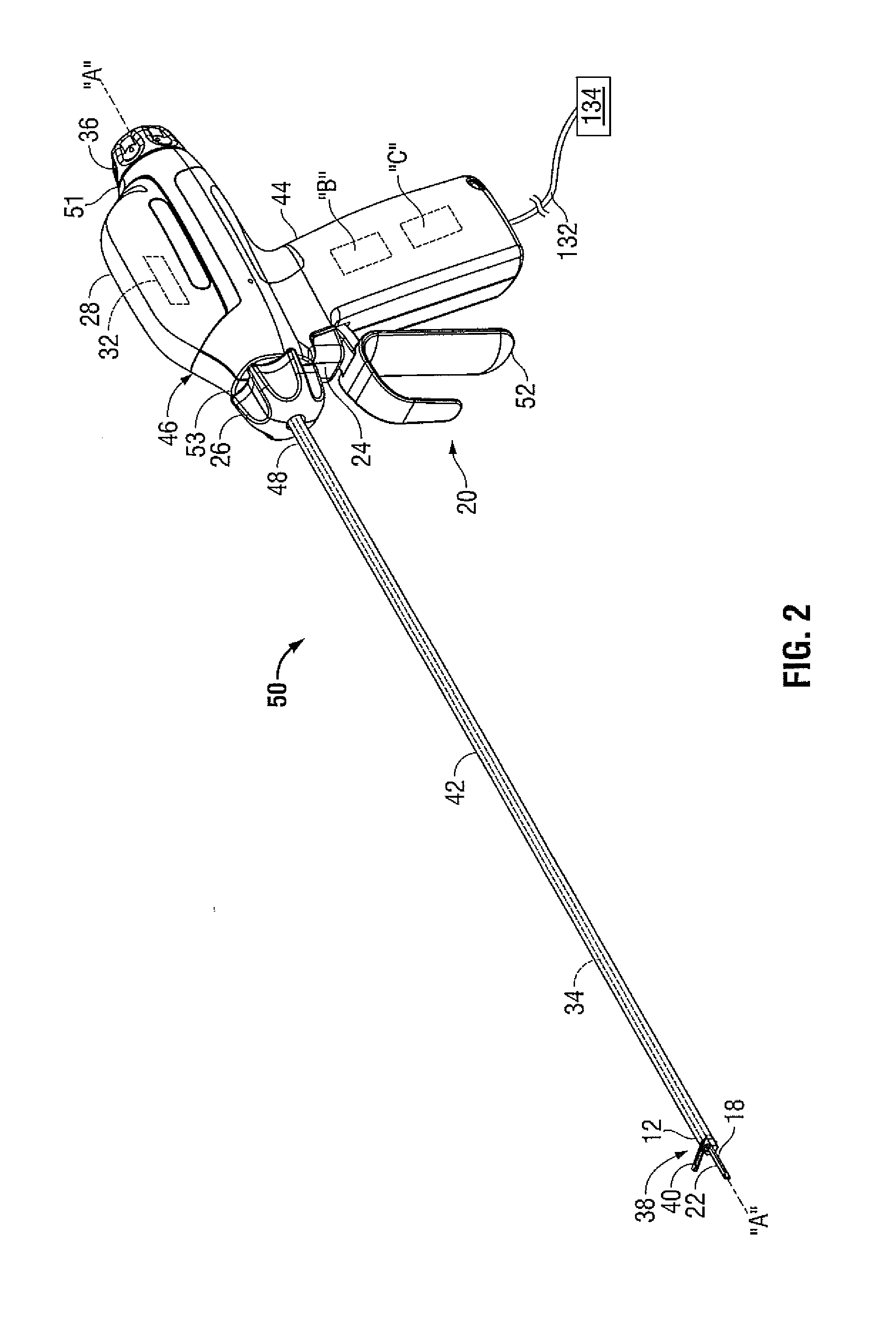

Surgical device with DC power connection

ActiveUS9636167B2Convenient power supplySurgical instruments for heatingSurgical forcepsElectrical batteryElectrosurgery

A system and method for providing additional power to a hand-held surgical device from a supplemental DC power supply. The hand-held surgical device includes a generator and an internal power supply. The internal power supply is a battery or a capacitor either which can withstand a high-temperature and / or a low-temperature sterilization procedure while within the hand-held surgical device. The supplemental DC power supply can provide alone or in combination with the internal power supply sufficient power to the generator to perform an electrosurgical procedure. The supplemental DC power supply is connected through a detachable cord to the hand-held surgical device. The DC power supply may be outside a sterile surgical environment.

Owner:TYCO HEALTHCARE GRP LP

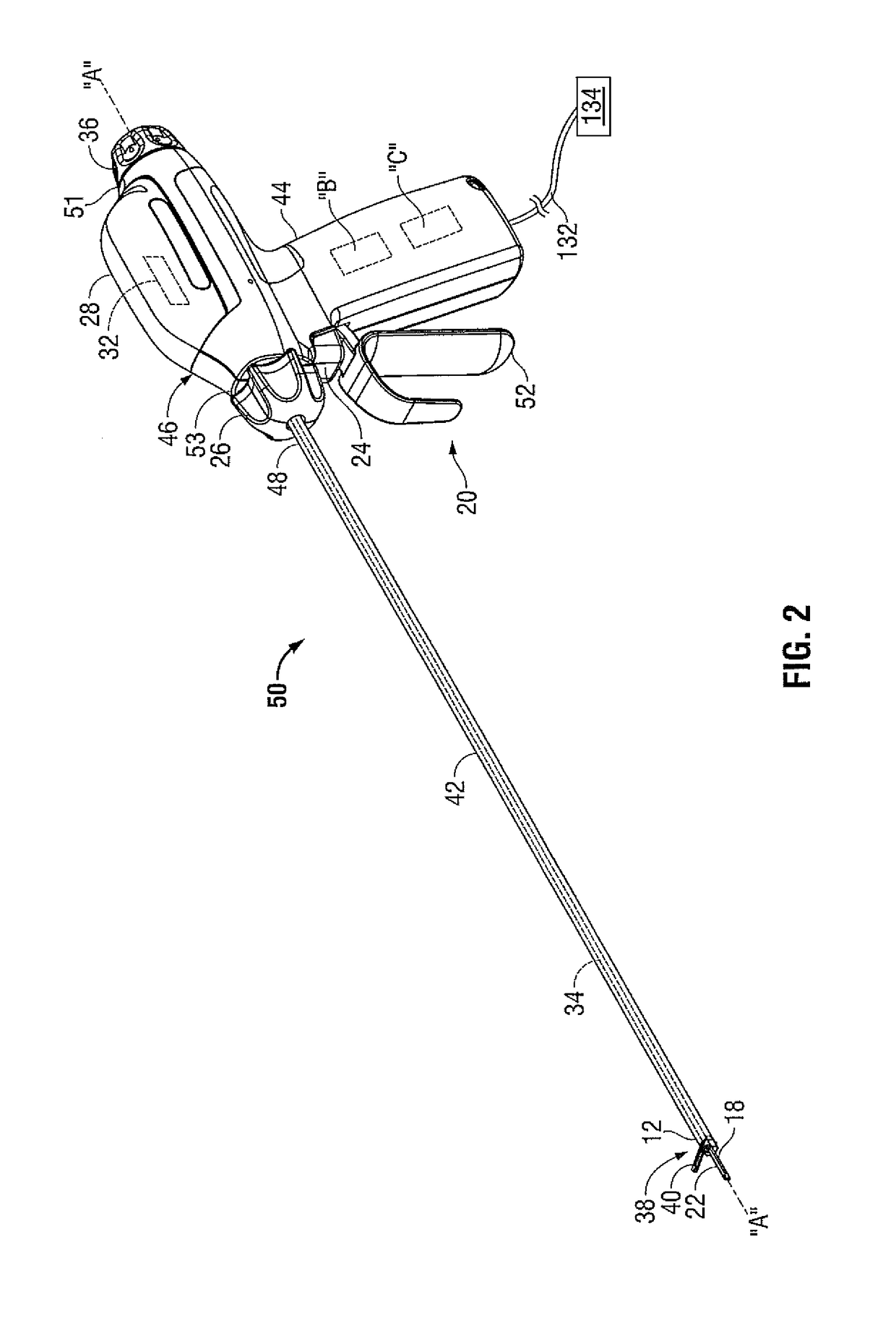

Surgical Device with DC Power Connection

ActiveUS20120310229A1Convenient power supplySurgical instruments for heatingSurgical forcepsElectrosurgeryHand held

A system and method for providing additional power to a hand-held surgical device from a supplemental DC power supply. The hand-held surgical device includes a generator and an internal power supply. The internal power supply is a battery or a capacitor either which can withstand a high-temperature and / or a low-temperature sterilization procedure while within the hand-held surgical device. The supplemental DC power supply can provide alone or in combination with the internal power supply sufficient power to the generator to perform an electrosurgical procedure. The supplemental DC power supply is connected through a detachable cord to the hand-held surgical device. The DC power supply may be outside a sterile surgical environment.

Owner:TYCO HEALTHCARE GRP LP

Coconut-water beverage and preparation method thereof

The invention discloses a method for preparing a coconut-water beverage. The method comprises the following steps: (1) breaking coconuts and then getting coconut water, adding an ascorbic acid the weight of which accounts for 0.1-0.15% of that of the coconut water into the coconut water, then stirring the obtained mixture so as to dissolve the ascorbic acid; (2) adding water into the solution obtained in the step (1), then stirring the obtained mixture, wherein the weight ratio of the water to the coconut water is (0.5-1.2): (4-5); (3) adding cane sugars into the aqueous solution obtained in the step (2), adjusting the sugar degree of the obtained mixture to 7.0-8.00 Brix, then adding a citric acid into the obtained product, and adjusting the pH value of the obtained mixture to 4.6-4.8; and (4) carrying out membrane filtration sterilization and ultrahigh-pressure low-temperature sterilization on the aqueous solution obtained in the step (3) so as to obtain the coconut-water beverage. The invention also discloses a coconut-water beverage. The coconut-water beverage and preparation method thereof disclosed by the invention have the advantages that because of changing the traditional heat treatment technology for sterilization and adopting the combination of low temperature membrane filtration sterilization and high pressure low temperature sterilization, the purposes of sterilization and refreshment are achieved, the unique flavor, nutrition and functional components of the coconut water are effectively kept, and the quality guarantee period of the prepared coconut-water beverage is long; and through filtering large particles in the coconut water through centrifugal filtration and membrane filtration, the prepared coconut-water beverage is clear, soft, delicate, pure and fresh.

Owner:海南品香园食品有限公司

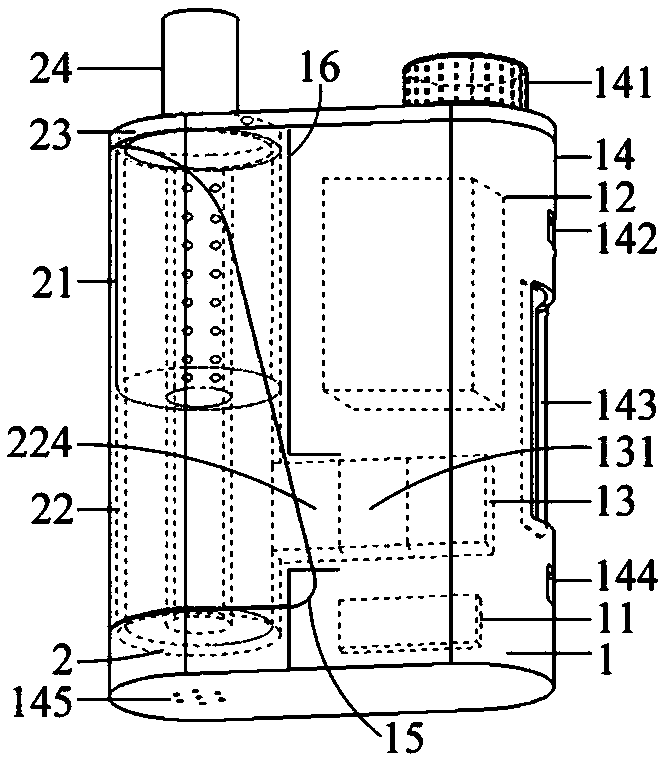

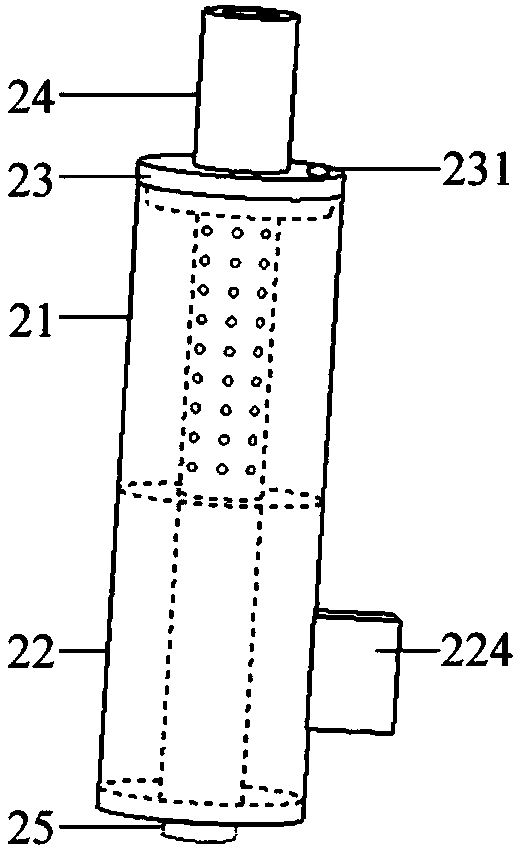

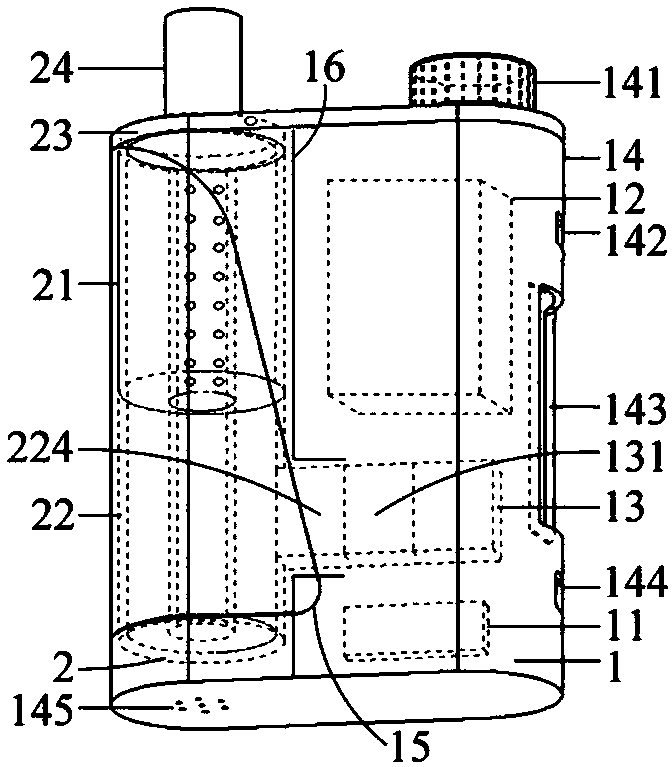

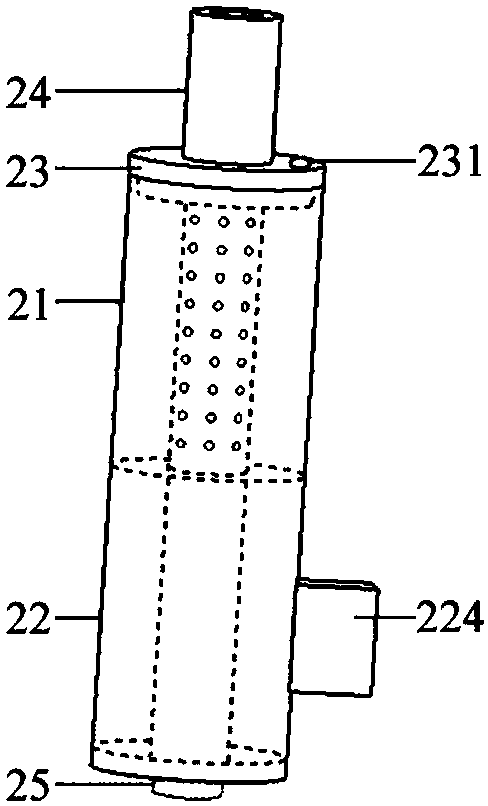

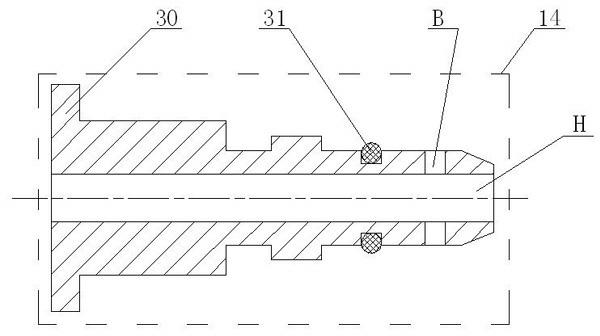

Electronic cigarette for atomizing by microwave resonance

InactiveCN108552613AAvoiding the Risk of Patent InfringementIncrease energy densityTobacco devicesTarMicrowave resonance

The invention discloses an electronic cigarette (1) for atomizing by microwave resonance, comprising a main shell (14), a battery (11), a controller (12) and a microwave generator (13) which are located in the main shell (14), and an accommodating chamber (16) used for placing a microwave resonance atomizer (2), wherein a gear switch (141) capable of performing microwave power strength adjustment,a master control switch (142), a display screen (143) and a charging interface (144) are arranged on the outer wall of the main shell (14), and an air inlet (145) is formed in the bottom of the outerwall of the main shell (14); the microwave resonance atomizer (2) comprises a tar storage unit (21), an atomizing unit (22), an upper cover plate (23), a suction nozzle (24) and a base (25) used forfixing the microwave resonance atomizer (2) in the accommodating chamber (16); and the microwave resonance atomizer (2) is enveloped by a detachable auxiliary shell (15). The atomizing mechanism of the electronic cigarette disclosed by the invention is different from that of electrothermic type electric cigarettes, and the electronic cigarette disclosed by the invention has the advantages of beinginstant in heating, high in efficiency, and good in thermal uniformity, realizing non-contact atomizing, and being capable of realizing low temperature sterilization of tobacco tar.

Owner:CHINA TOBACCO YUNNAN IND

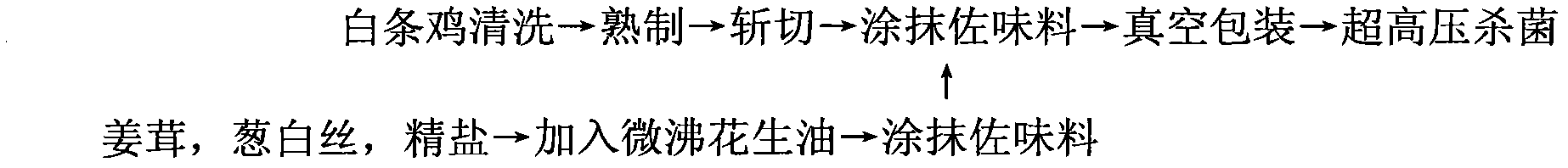

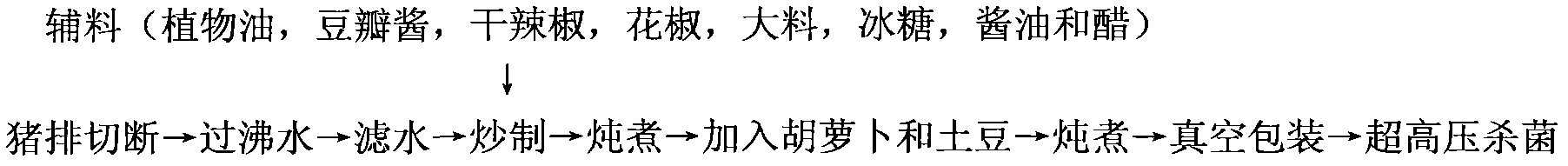

Ultrahigh-pressure low-temperature sterilization method for processed meat product and application thereof

ActiveCN102008084AIncrease nutritionExtended shelf lifeMeat/fish preservation by heatingFood preparationAquatic productFood flavor

The invention discloses an ultrahigh-pressure low-temperature sterilization method for processed meat products and application thereof. The method is suitable for directly edible foods or foods which are edible after being heated and cooked and are made of edible livestock, aquatic products and aquatic byproducts serving as major raw materials. The defects of degraded eating quality, flavor and nutrition of the conventional high-temperature meat product are overcome, high eating quality of the processed meat products is kept well, the meat products has high elasticity and good chewing mouthfeel and are fresh, tender and juicy and the shelf life of the meat products is far longer than the processed meat products which are not sterilized under an ultrahigh pressure. The method can be applied to ultrahigh-pressure low-temperature sterilization of packaged processed meat products which are mainly made of livestock and aquatic raw materials and need heating and cooking before being eaten as well as cooked processed meat products which are mainly made of livestock and aquatic raw materials.

Owner:SOUTH CHINA AGRI UNIV

Fully-fresh cubilose stewing method

InactiveCN107198087AHigh removal rateImprove food safetyFood preservationUltra high pressure food processesMegasonic cleaningBottle

The invention discloses a fully-fresh cubilose stewing method. The method includes steps: S1, soaking in magnetized water; S2, cleaning, to be more specific, shredding soaked cubilose, cleaning by an ultrasonic cleaning machine, and adopting a centrifugal spin dryer for spin drying of the cubilose; S3, secondary soaking and cleaning, to be more specific, soaking the cubilose in magnetized water for 30min after spin drying, adopting the ultrasonic cleaning machine for cleaning for 20min during soaking, and adopting the centrifugal spin dryer for spin drying of the cubilose; S4, vacuum sealing and filling, to be more specific, subpackaging the cleaned cubilose into cleaned glass bottles, adding pre-dissolved rock candy, and performing vacuum sealing; S5, first-stage sterilization stewing, to be more specific, performing low-temperature sterilization stewing; S6, second-stage sterilization stewing, to be more specific, performing high-temperature sterilization stewing; S7, cooling, taking out and packaging. The fully-fresh cubilose stewing method has advantages that the cubilose manufactured according to the method is great in sterilization effect, high in safety, low in nutrition loss, great in taste and visual effect, portable and convenient to eat and is available for nationwide express delivery with guarantee of quality and freshness.

Owner:上海银盏食品有限公司

Externally-used medicament for the sanitation and health-care of female vagina and for treating gynecology vagina diseases and method for making the same

ActiveCN101095895ANon-irritatingPromote absorptionAnthropod material medical ingredientsCapsule deliveryDiseaseDistillation

The invention provides an externally-used pharmaceutical composition for vaginal sanitation and treating gynaecologic diseases and its preparing process, wherein the medicament is prepared from bee glue extract, oil of aromatic turmeric, alkanna tinctoria extract and purple perilla seed as raw material through steps of supercritical CO2 separation and abstraction, molecular distillation, low-temperature sterilization and centrifugation, sound film separation. The medicament can be made into bottle-packed preparations or soft capsules.

Owner:陕西靓帝生物科技有限责任公司 +1

Micrometer sterilized Oviductus Ranae powder, preparation method and application thereof

InactiveCN102697813ASmall particlesAddresses Susceptibility to Microbial ContaminationAmphibian material medical ingredientsPowder deliveryPreservativePharmaceutical medicine

The invention discloses a micrometer sterilized Oviductus Ranae powder with particle diameter of 0.1-500 micrometer. The Oviductus Ranae powde is prepared from low-temperature sterilized Oviductus Ranae by ultra-micronizing. The invention also discloses preparation method and application of the Oviductus Ranae powder. The invention combines low-temperature sterilizing and ultra-micronizing to produce pure, preservative-free and easily-absorbable fine micrometer Oviductus Ranae powder in large scale, and the preparation method facilitates mass production of high-quality pharmaceutical, food or health food preparation.

Owner:INFINITUS (CHINA) CO LTD

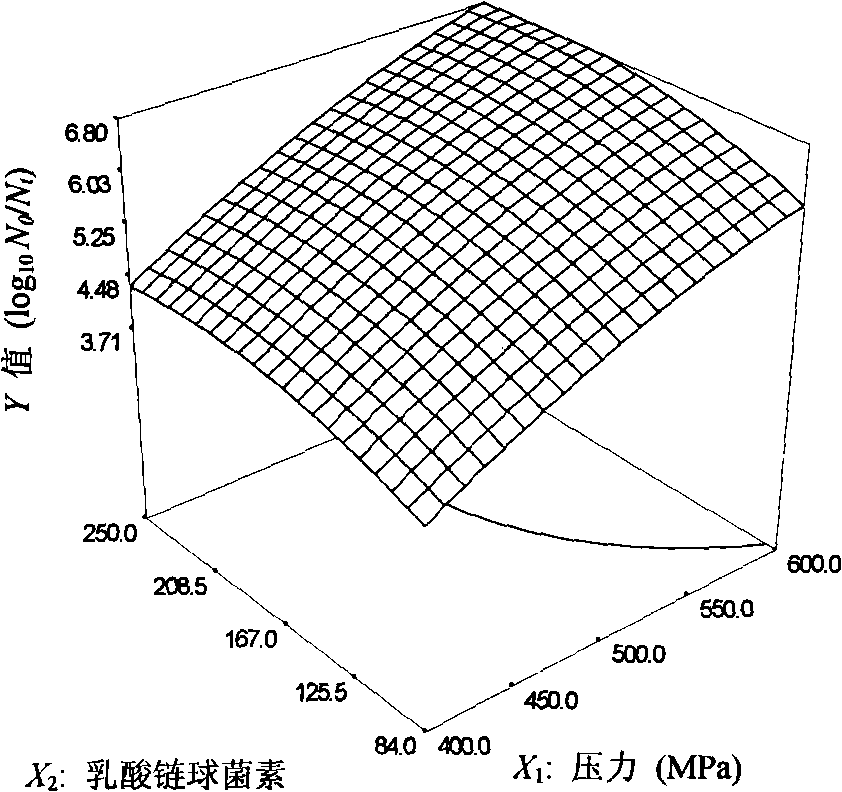

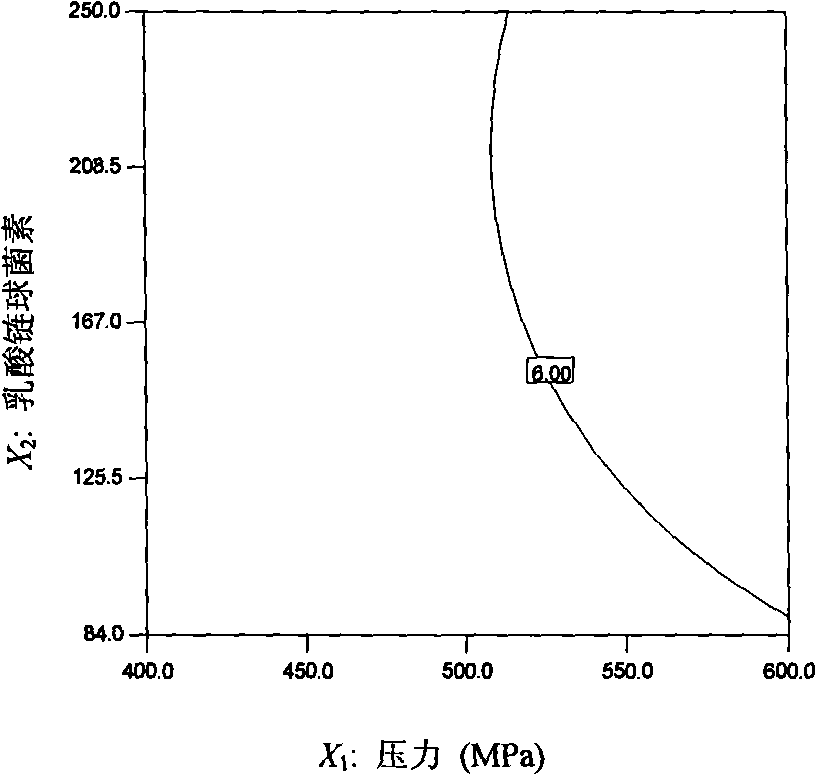

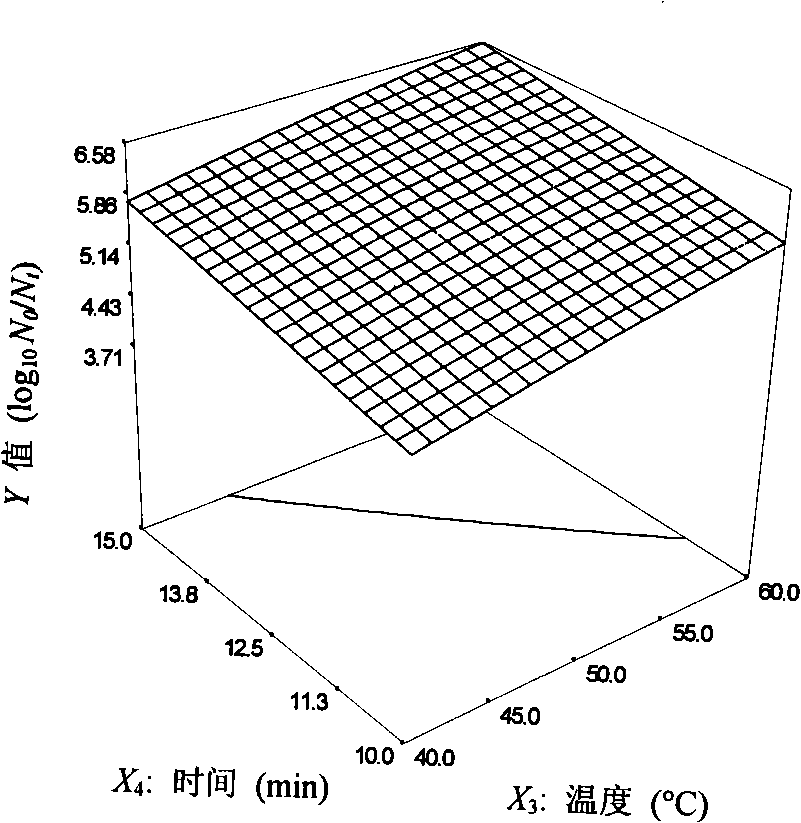

Food hyperpressure low-temperature sterilization method

InactiveCN101356990AAdapt and guarantee bactericidalFood preservationUltra high pressureFood sterilization

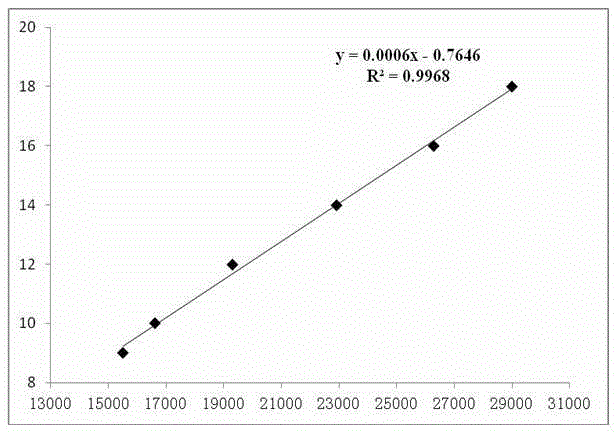

The invention discloses a superhigh pressure and low-temperature food sterilization method. The method comprises the following steps: streptostacin of lactic acid is added to fluid food at the temperature of 30 DEG C-70 DEG C under the pressure of 300MPa-700MPa for 7.5min-17.5min treatment, wherein, the concentration of the streptostacin of the lactic acid in the fluid food is 0IU / ml-333IU / ml. The process condition determined by the food sterilization method can kill 100000-order of magnitude bacteria basically without affecting the main components of the fluid food, and even can kill more than 100000-order of magnitude bacteria under the optimized condition, which absolutely adapts to and guarantees the antibacterial performance of the fluid food.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

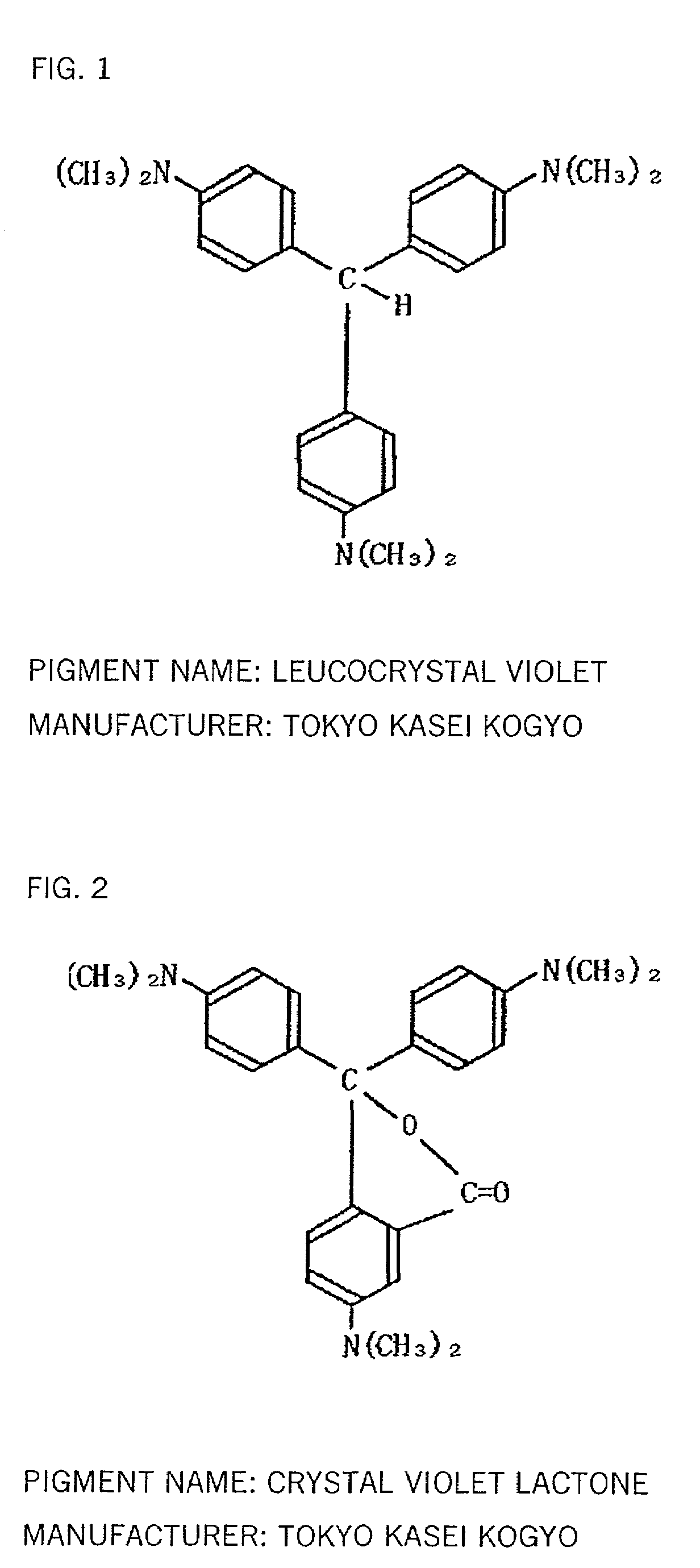

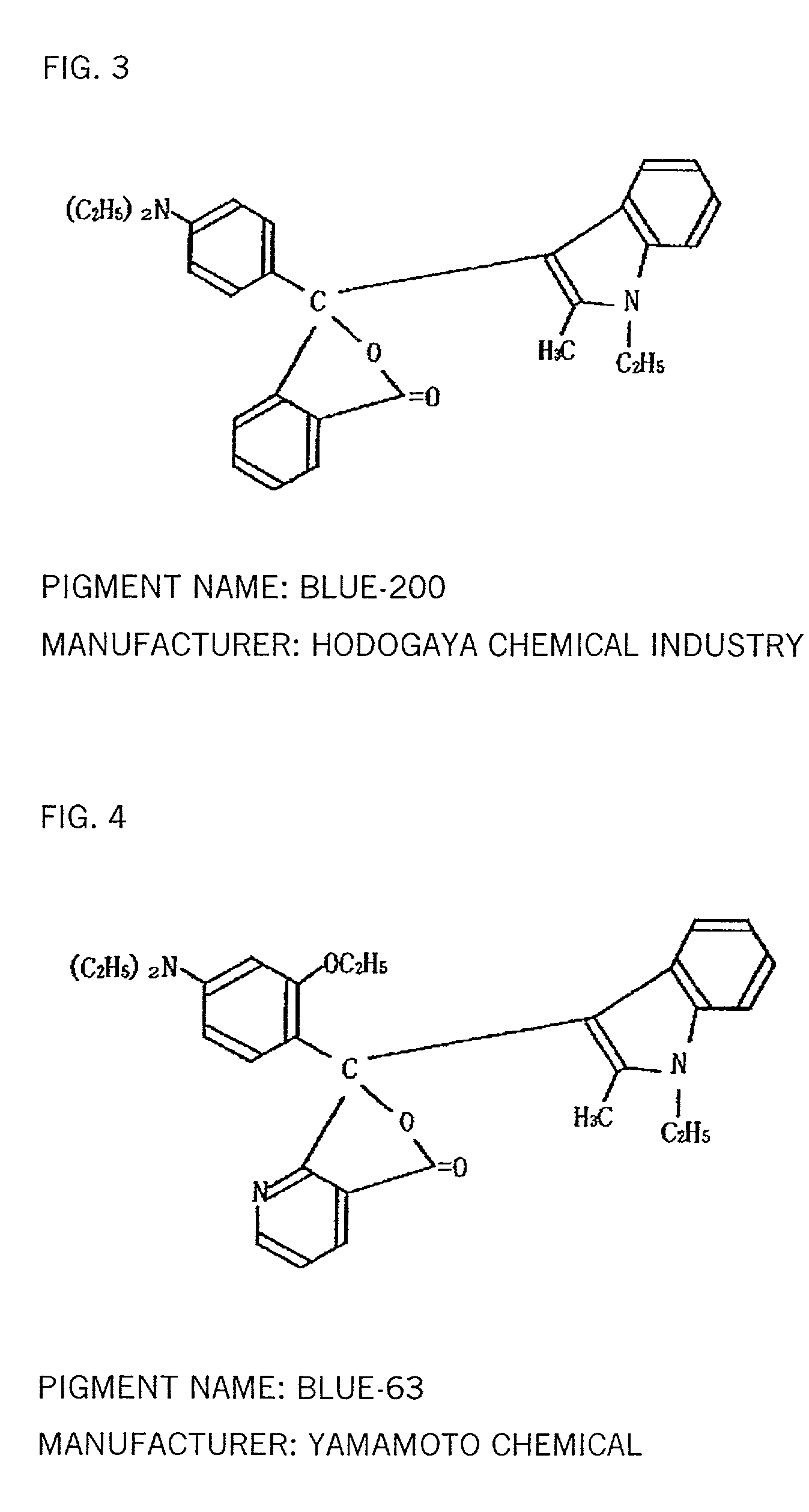

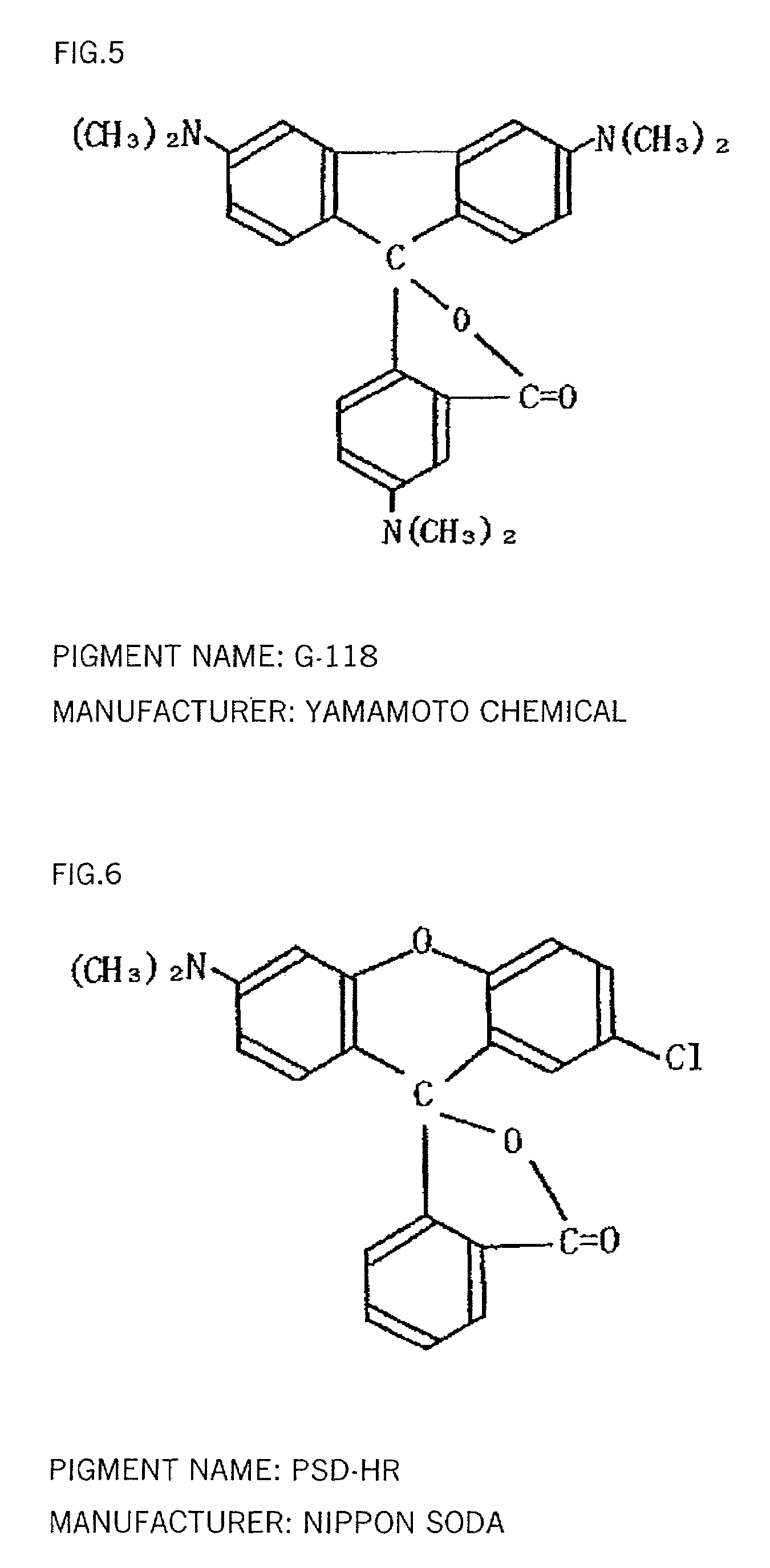

Indicator for plasma sterilization

InactiveUS7189355B2Good colorImproving and enhancing stability of color tone and color densityMaterial analysis by observing effect on chemical indicatorPhotometryPlasma sterilizationLow temperature plasma

The present invention relates to a chemical indicator that is used to determine whether instruments and other products to be sterilized have experienced a sterilization treatment process or to confirm whether sterilization has been efficiently performed, by the color tone change of the indicator when sterilizing medical instruments and other products and the like by a hydrogen peroxide low temperature plasma sterilizing method. The present invention provides an indicator for plasma sterilization, wherein an ink comprising a colorless chromogenic pigment, a coloring assistant, a binder (a binding agent) and a solvent for dissolving these, is applied to or printed on a base material, and wherein a color tone change of the indicator occurs by a hydrogen peroxide low temperature sterilization method.

Owner:HOGY MEDICAL CO LTD

Method for processing ready-to-eat leisure food by use of pleurotus eryngii head

The invention provides a method for processing ready-to-eat leisure food by use of pleurotus eryngii head, belonging to the field of deep processing of agricultural products. The method increases the varieties of the ready-to-eat leisure food on the market, and improves the utilization rate of the homogeneous non-commercial leftovers of the pleurotus eryngii in industrial production. According tothe invention, about 20% of the byproduct pleurotus eryngii head can be generated according to the pleurotus eryngii cultivated industrially; and the pleurotus eryngii head has the characteristics ofrich nutrition, cleanness and sanitation, crispy and tender texture and the like, and is suitable to be processed into ready-to-eat leisure food. The processing flow of the ready-to-eat leisure pleurotus eryngii head sequentially comprises the steps of: preparation of pleurotus eryngii head, cleaning, slitting, boiling, draining, baking, vacuum packing, and two-section low-temperature sterilization to obtain the finished product. According to the invention, the product has crispy and tender texture, does not contain oil and preservative, can maintain the inherent nutritional ingredients, flavor and color of pleurotus eryngii, is convenient to carry and can be used as ready-to-eat leisure food.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Production method of attapulgite compressed nutrient soil

ActiveCN104119168AReduce manufacturing costReduce shipping costsFertilizer mixturesEcological environmentPolyvinyl alcohol

The invention discloses a production method of attapulgite compressed nutrient soil. The point of the technical scheme is that the method comprises the following steps: acidifying attapulgite; and performing stirring, compression and microwave low-temperature sterilization of the ingredients of the attapulgite compressed nutrient soil, and packaging into a finished product. The attapulgite compressed nutrient soil consists of acidified attapulgite clay, instant sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, biogas residue, plant fiber, expanded vermiculite, expanded perlite, super absorbent resin and other materials. The attapulgite compressed nutrient soil contains a great quantity of nitrogen, phosphorus, potassium, organic matters and multiple trace elements and can provide necessary nutrient elements for the plant growth to reduce the harm to plants caused by pathogenic bacteria and pests, facilitate normal growth and development of the plants, protect the ecological environment and avoid secondary pollution to the surrounding environment; and the production method of the attapulgite compressed nutrient soil is suitable for producing compressed nutrient soil of different formulas.

Owner:江苏世澳非金属应用科技有限公司

Method for producing construction waste compressed nutrient soil

ActiveCN104109038AImprove protectionAvoid secondary pollutionFertilizer mixturesEcological environmentPolyvinyl alcohol

The invention discloses a method for producing construction waste compressed nutrient soil. According to key points of the technical scheme, the method comprises the following steps: acidizing construction wastes and sludge; stirring, compressing and performing microwave low-temperature sterilization on construction waste compressed nutrient soil; packaging to obtain the finished product. The construction waste compressed nutrient soil consists of acidized construction wastes, acidized sludge, instant sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, biogas residues, crushed plant fibers, expanded vermiculite, expanded perlite, super absorbent resins and other materials. The construction waste compressed nutrient soil contains lots of nitrogen, phosphorus, potassium, organic matters and multiple trace elements, can provide nutrient elements essential for plant growth and has the effects of reducing hazard of pathogenic bacteria and injurious insects to plants, promoting normal growth and development of plants and protecting the ecological environment, and the method for producing the construction waste compressed nutrient soil is suitable for producing construction waste compressed nutrient soil of different formulas.

Owner:江苏世澳非金属应用科技有限公司

Method for producing dragon fruit health drink

InactiveCN105410570AWith multiple characteristicsSweet and sour tasteFood ingredient functionsBiotechnologyMildew

The invention discloses a method for producing a dragon fruit health drink. The method comprises the steps of selecting and utilizing fully-grown fresh red core dragon fruit without mildew and rot or mechanical damage as a raw material; peeling the selected fresh dragon fruit and cutting the fresh dragon fruit into flakes with the thickness of 60 mm to 80 mm; mixing the flake dragon fruit, rock candy and brown sugar to ferment and stacking the fresh fruit and sugar in a fermentation barrel alternately, wherein the ratio of dragon fruit pulp to the rock candy to the brown sugar is 4 to 0.7 to 0.3, the fermentation temperature is 22 DEG C to 28 DEG C, and the fermentation time is 12 to 20 days; filtering the dragon fruit pulp, the rock candy and the brown sugar by a 100-mesh filter screen, performing standing and clarification for 10 to 15 days, performing bottling, and performing sealing and storage after low temperature sterilization. According to the method, a natural bacterial strain is utilized to perform fermentation, no chemical preservative is added, and the nutritional ingredient and the activity of enzyme of the dragon fruit are kept effectively. The fermentation time according to the method is short (12 to 20 days), the probability of bacterial contamination is reduced, the quality can be controlled easily, and the product quality is stable.

Owner:贵州省现代农业发展研究所

A kind of processing method of new flavor muscovy duck

InactiveCN102273645AGuaranteed damageShort drying time for dehydrationFood preparationFlavorCooking & baking

The invention relates to a processing method of a novel flavor Muscovy Duck, which is characterized in that it comprises the steps of slaughtering, cleaning, dry pickling, wet pickling, baking, fermentation, packaging, low-temperature sterilization and the like. The ripened muscovy duck is obtained by the processing method of the invention. Compared with the prior art, the present invention adopts low-temperature roasting process and subsequent fermentation and ripening process. The roasting process greatly shortens the dehydration and drying time in the traditional process. The fermentation and ripening process further matures the meat products and fully develops the flavor of the product. out; the low-temperature sterilization process not only ensures that the nutritional components of the product are destroyed as little as possible, but also ensures the quality of the product; the combination of appropriate anti-corrosion control measures is used to ensure the shelf life of the product; the unique product formula is used to make the product unique. flavor.

Owner:宁波市禽丰食品有限公司

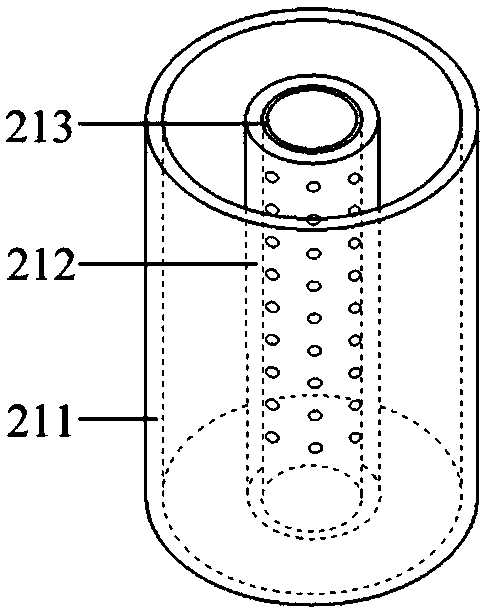

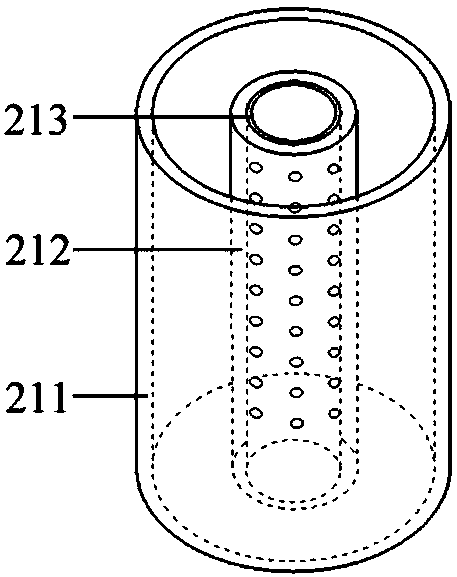

Microwave resonant cavity for electronic cigarette

InactiveCN108552612AAvoiding the Risk of Patent InfringementIncrease energy densityTobacco devicesResonant cavityMicrowave

The invention discloses a microwave resonant cavity (221) for an electronic cigarette. The microwave resonant cavity is of a cylinder shape, wherein a second oil guiding component (223) is arranged inthe microwave resonant cavity (221) along the axial direction; and a coupling hole (225) is formed in the side wall of the microwave resonant cavity (221). When being applied to the electronic cigarette, the microwave resonant cavity has the advantages that instant heating is realized, the efficiency is high, heat uniformity is good, non-contact atomization is realized, the low temperature sterilization of tobacco tar can be realized, and the like.

Owner:CHINA TOBACCO YUNNAN IND

Method for converting ginsenoside through plant complex enzyme

The invention discloses a method for converting ginsenoside through plant complex enzyme. The method comprises the following steps that ginseng is ground into powder, subjected to low-temperature sterilization and then cooled to the room temperature; the sterilized ginseng powder is evenly mixed with the plant complex enzyme, moisture is adjusted through a sterile LL liquid culture medium and distilled water, the mixture is fully mixed to be uniform, then sealed and put into a constant-temperature incubator for fermentation, and a ginseng fermentation product is obtained; an 80% methyl alcohol aqueous solution is used for ultrasonic extraction, filtering is carried out, filtrate is subjected to vacuum concentration, and coarse ginsenoside extract is obtained; the coarse ginsenoside extract is dissolved by adding deionized water, then subjected to extraction through a saturate n-butyl alcohol solution and subjected to vacuum concentration, and ginsenoside extract is obtained, wherein the ginsenoside extract contains rare ginsenoside with fewer sugar chains or an antineoplastic active material protopanoxadiol (PPD) without sugar chains. The method is simple in process and convenient to implement, and the product is easy to dry; most importantly, in the solid fermentation process, conversion of ginsenoside is achieved, and the rare ginsenoside or the antineoplastic active material protopanoxadiol (PPD) is obtained.

Owner:YANBIAN UNIV

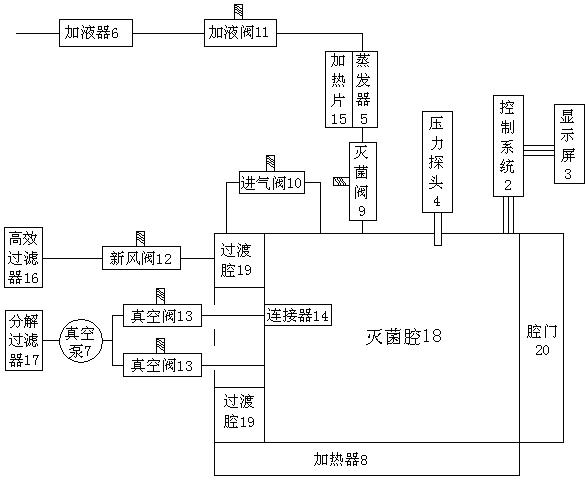

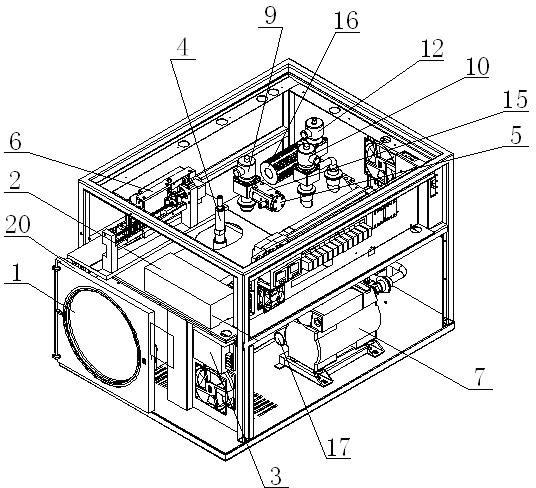

Hydrogen peroxide low-temperature sterilizing equipment and use method thereof

ActiveCN102350003AImproved vaporizationEasy dischargeChemicalsVacuum pumpLow temperature sterilization

The invention discloses hydrogen peroxide low-temperature sterilizing equipment and a use method thereof. The sterilizing equipment comprises a cavity body (1), an evaporator (5), a liquid feeder (6), a vacuum pump (7), a heater (8) and a high-efficiency filter (16), wherein the cavity body (1) is divided into a sterilizing cavity (18) and a transition cavity (19); the sterilizing cavity (18) is connected with the outlet end of the evaporator (5) through a sterilizing valve (9); the inlet end of the evaporator (5) is connected with the liquid feeder (6) through a liquid feeding valve (11); a heating sheet is arranged on the evaporator (5); the air suction end of the vacuum pump (7) is connected with the sterilizing cavity (18) through a vacuum valve (13); and the air outflow end of the vacuum pump (7) is connected with a decomposition filter (17). The sterilizing equipment can sterilize medical appliances at a low temperature, can carry out sufficient sterilization on the pipelines of the medical appliances with slender holes, and can also carry out filtration and decomposition on the used hydrogen peroxide vapor.

Owner:LAOKEN MEDICAL TECH

Processing method of garlic-fragrance instant crayfishes

The invention provides a processing method of garlic-fragrance instant crayfishes, belonging to the technical fields of foods and preserved aquatic products. According to the processing method, the fresh and alive fresh water crayfishes are taken as the raw materials and are subjected to pretreatment, cleaning, deep frying, frying, packaging, sealing, low-temperature sterilization and storage, and an instant crayfish product with a guarantee period of 60 days under a freezing condition is produced. By utilizing low-temperature water bath sterilization, the original flavor, texture, color and nutrients of the crayfishes are preserved, and the garlic-fragrance instant crayfishes do not contain any additive, are safe to eat and can be instantly, conveniently and rapidly eaten after a packaging bag is opened.

Owner:NINGBO UNIV

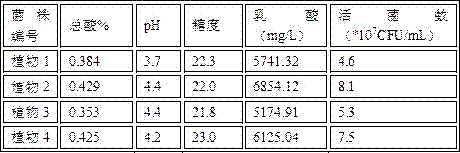

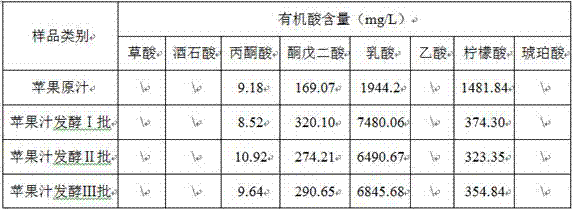

Method for fermenting concentrated apple juice with composite lactic acid bacteria and fermented fruit juice

InactiveCN107361275ASolve the problem of rapid fermentationBacteriaMicroorganism based processesFruit juiceFiltration

The invention discloses a method for fermenting concentrated apple juice with composite lactic acid bacteria and fermented fruit juice. The method comprises the following steps of disinfecting fresh apples free from damage and worms, performing cleaning, performing crushing, performing squeezing twice, performing heating enzymolysis, performing heating enzyme deactivation, performing cooling, performing centrifugation, performing filtration, performing fine filtration, performing vacuum concentration to 21-24 degree Bx so as to prepare the concentrated apple juice; performing low temperature sterilization at 98 DEG C on the concentrated apple juice for 5min, infiltrating the sterilized apple juice into a fermenter treated through steam sterilization, and performing inoculation with composite lactic acid bacteria, wherein the composite lactic acid bacteria are high-endurability lactobacillus plantarum of 2-5*10<6> CFU / mL, high-endurability rhamnose bacterium lacticum of 3-8*10<5> CFU / mL, and high-endurability lactobacillus acidophilus of 2-5*10<6> CFU / mL, and the total inoculum concentration of the composite lactic acid bacteria is controlled to be 0.5-2%; and under the temperature of 35-38 DEG C, and the speed of 30-50r / min, performing fermentation for 20-24h so as to prepare the fermented fruit juice. The sugar degree of the prepared fruit juice is 21-24 degrees Bx, pH is 4.0-4.5, the viable count of the lactic acid bacteria is greater than 5*10<7>CFU / mL, and the lactic acid is greater than 5g / L.

Owner:FUJIAN LVQUAN FOOD +1

Production method of attapulgite compressed nutrient soil

ActiveCN104119168BReduce manufacturing costReduce shipping costsFertilizer mixturesEcological environmentAdditive ingredient

The invention discloses a production method of attapulgite compressed nutrient soil. The point of the technical scheme is that the method comprises the following steps: acidifying attapulgite; and performing stirring, compression and microwave low-temperature sterilization of the ingredients of the attapulgite compressed nutrient soil, and packaging into a finished product. The attapulgite compressed nutrient soil consists of acidified attapulgite clay, instant sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, biogas residue, plant fiber, expanded vermiculite, expanded perlite, super absorbent resin and other materials. The attapulgite compressed nutrient soil contains a great quantity of nitrogen, phosphorus, potassium, organic matters and multiple trace elements and can provide necessary nutrient elements for the plant growth to reduce the harm to plants caused by pathogenic bacteria and pests, facilitate normal growth and development of the plants, protect the ecological environment and avoid secondary pollution to the surrounding environment; and the production method of the attapulgite compressed nutrient soil is suitable for producing compressed nutrient soil of different formulas.

Owner:江苏世澳非金属应用科技有限公司

Method for producing coal ash compressed nutrient soil

ActiveCN104119162AReduce manufacturing costReduce shipping costsFertilizer mixturesEcological environmentPolyvinyl alcohol

The invention discloses a method for producing coal ash compressed nutrient soil. According to key points of the technical scheme, the method comprises the following steps: acidizing coal ash and sludge, stirring, compressing and performing low-temperature microwave sterilization on ingredients of the coal ash compressed nutrient soil, and packaging to obtain the finished product. The coal ash compressed nutrient soil consists of acidized coal ash, acidized sludge, instant sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high viscosity attapulgite clay, biogas slurry, crushed plant fibers, expanded perlite, super absorbent resin and other materials. The coal ash compressed nutrient soil contains lots of nitrogen, phosphorus, potassium, organic matters and multiple trace elements, can provide necessary nutrient elements for plant growth and reduce harm of pathogenic bacteria and injurious insects to plants and contributes to normal plant growth and development, the ecological environment is protected, secondary pollution to a surrounding environment is avoided, and the method for producing the coal ash compressed nutrient soil is suitable for producing coal ash compressed nutrient soil of different formulas.

Owner:江苏世澳非金属应用科技有限公司

Method for producing kaolin tailing compressed nutritional soil

ActiveCN104119172AImprove protectionAvoid secondary pollutionFertilizer mixturesEcological environmentNutrition

The invention discloses a method for producing kaolin tailing compressed nutritional soil. The key point of the technical scheme of the invention is as follows: kaolin tailings and sludge are subjected to acidification treatment firstly, then, ingredients of the kaolin tailing compressed nutritional soil are subjected to stirring, compressing and microwave low-temperature sterilization, and then, packaging is carried out, so as to produce a finished product. The kaolin tailing compressed nutritional soil is prepared from materials, such as acidified kaolin tailings, acidified sludge, instant-dissolved sodium silicate, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite, biogas liquid, crushed plant fiber, expanded vermiculite, expanded perlite, super-absorbent resin and the like. The kaolin tailing compressed nutritional soil contains a large number of nitrogen, phosphorus, potassium, organic matters and a variety of microelements, so that nutrient elements necessary for the growth of plants can be provided, the harm to the plants caused by pathogenic bacteria and pests is reduced, and the normal growth and development of the plants and the protection to the ecological environment are facilitated. The method for producing the kaolin tailing compressed nutritional soil is suitable for producing kaolin tailing compressed nutritional soil of different formulations.

Owner:度测(上海)科技服务中心

Method for producing serpentine tailings compressed nutrient soil

ActiveCN104119182AImprove protectionAvoid secondary pollutionFertilizer mixturesFiberEcological environment

The invention discloses a method for producing serpentine tailings compressed nutrient soil. According to the technical scheme disclosed by the invention, the method is characterized by comprising the following steps of firstly acidifying serpentine tailings and sludge, and then stirring ingredients of the serpentine tailings compressed nutrient soil, compressing, carrying out microwave low temperature sterilization and packaging to obtain the finished product. The serpentine tailings compressed nutrient soil comprises acidified serpentine tailings, acidified sludge, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, crushed plant fibers, expanded vermiculite, expanded perlite, super absorbent resin and the like. Since the serpentine tailings compressed nutrient soil contains a large amount of nitrogen, phosphorus, potassium, organic matters and a plurality of trace elements, the serpentine tailings compressed nutrient soil can provide nutrients necessary for the growth of plants, reduces harms of pathogens and pests to plants and is conducive to the normal growth and development of plants, and the ecological environment is protected; the method for producing the serpentine tailings compressed nutrient soil is suitable for producing serpentine tailings compressed nutritive soil with different formulas.

Owner:盱眙欧佰特粘土材料有限公司

Method for producing red mud compressed nutrient soil

ActiveCN104119161AImprove protectionAvoid secondary pollutionEnergy inputFertilizer mixturesEcological environmentSlag

The invention discloses a method for producing red mud compressed nutrient soil. According to the technical scheme, the method comprises the following steps of firstly acidifying red mud and sludge, and then stirring ingredients of the red mud compressed nutrient soil, compressing, carrying out microwave low temperature sterilization and packaging to obtain the finished product. The red mud compressed nutrient soil comprises acidified red mud, acidified sludge, instant-soluble sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, biogas slag, crushed plant fibers, expanded vermiculite, expanded perlite and super absorbent resin. Since the red mud compressed nutrient soil contains a large amount of nitrogen, phosphorus, potassium, organic matter and a plurality of trace elements, the red mud compressed nutrient soil can provide nutrients necessary for the growth of plants, harms of pathogens and pests to plants are reduced, and red mud compressed nutrient soil is conducive to the normal growth and development of plants, the ecological environment is protected, the secondary pollution to the surrounding environment is avoided and the method for producing red mud compressed nutrient soil is suitable for producing red mud compressed nutritive soil with different formulas.

Owner:无锡锡东新农村投资发展有限公司

Production method of gangue compressed nutrient soil

ActiveCN104119190AReduce manufacturing costReduce shipping costsEnergy inputFertilizer mixturesFiberEcological environment

The invention discloses a production method of gangue compressed nutrient soil. According to the technical scheme, the production method is characterized by comprising the steps of firstly, acidizing gangue and sludge; then, stirring ingredients of the gangue compressed nutrient soil, compressing, carrying out low-temperature microwave sterilization, and then, packaging to obtain a finished product. The gangue compressed nutrient soil is composed of materials such as acidized gangue, acidized sludge, instant sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsites, high-viscosity attapulgite clay, biogas slurry, biogas residues, smashed plant fiber, expanded vermiculite, expanded perlite, super absorbent resin and the like. The gangue compressed nutrient soil contains a great number of nitrogen, phosphorus, potassium, organic matters and various trace elements, is capable of providing various nutrient elements necessary for growth of plants and reducing hazards of pathogenic bacteria and pests to the plants and is beneficial to the normal growth and development of the plants and the protection of the ecological environment. The production method of the gangue compressed nutrient soil is suitable for producing the gangue compressed nutrient soil according to different formulas.

Owner:平凉华晨非金属应用科技有限公司

Making method of stinky mandarin fish

The invention discloses a making method of stinky mandarin fish. The method comprises the following steps: (1) preparing a raw material: selecting live mandarin fish with weight of 400-800g, removing the gill of the mandarin fish, paunching to remove the internal organs, maintaining the scale, and then cleaning the fish with clear water; (2) keeping fresh and retaining water: putting the mandarin fish treated in the step (1) into an instant freezing warehouse with the temperature of -50 to -40 DEG C, quick-freezing for 4-5h, and carrying out low-temperature sterilization treatment; (3) pickling in water; (4) fermenting; (5) packaging; (6) refrigerating. The invention provides the making method of the stinky mandarin fish. The stinky mandarin fish, which is pickled according to the method, has the characteristics of being good in taste, free from additive, and the like.

Owner:安徽徽字一号投资有限公司

Red-color dragon fruit vinegar processing process

ActiveCN104560608AAvoid contactPale red colorMicroorganism based processesVinegar preparationAcetic acidFood grade

The invention relates to a red-color dragon fruit vinegar processing process which comprises the following five steps: treating raw materials, performing low-temperature alcohol fermentation, performing low-temperature acetic acid fermentation, performing low-temperature ageing and performing low-temperature sterilization and filling. In the processing process, containers, pipelines, valves and tools for the raw materials, half-finished products and finished products are all made of food-grade stainless steel, ceramic or high polymer materials and are prevented from contacting iron, aluminum or copper, optimally low-temperature bacteria are used, and a stabilizing agent is added in the fermentation and ageing process, so that the problems that pigment of the dragon fruit is damaged because of metal ion contact or high temperature and the quality is not easy to ensure are effectively solved, and the processed dragon fruit vinegar has the advantages of unique and fresh flavor, attractive color and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com