Patents

Literature

163 results about "Food sterilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The time and temperature required for the sterilization of foods are influenced by several factors, including the type of microorganisms found on the food, the size of the container, the acidity or pH of the food, and the method of heating. The thermal processes of canning are generally designed to destroy the spores of the bacterium C. botulinum.

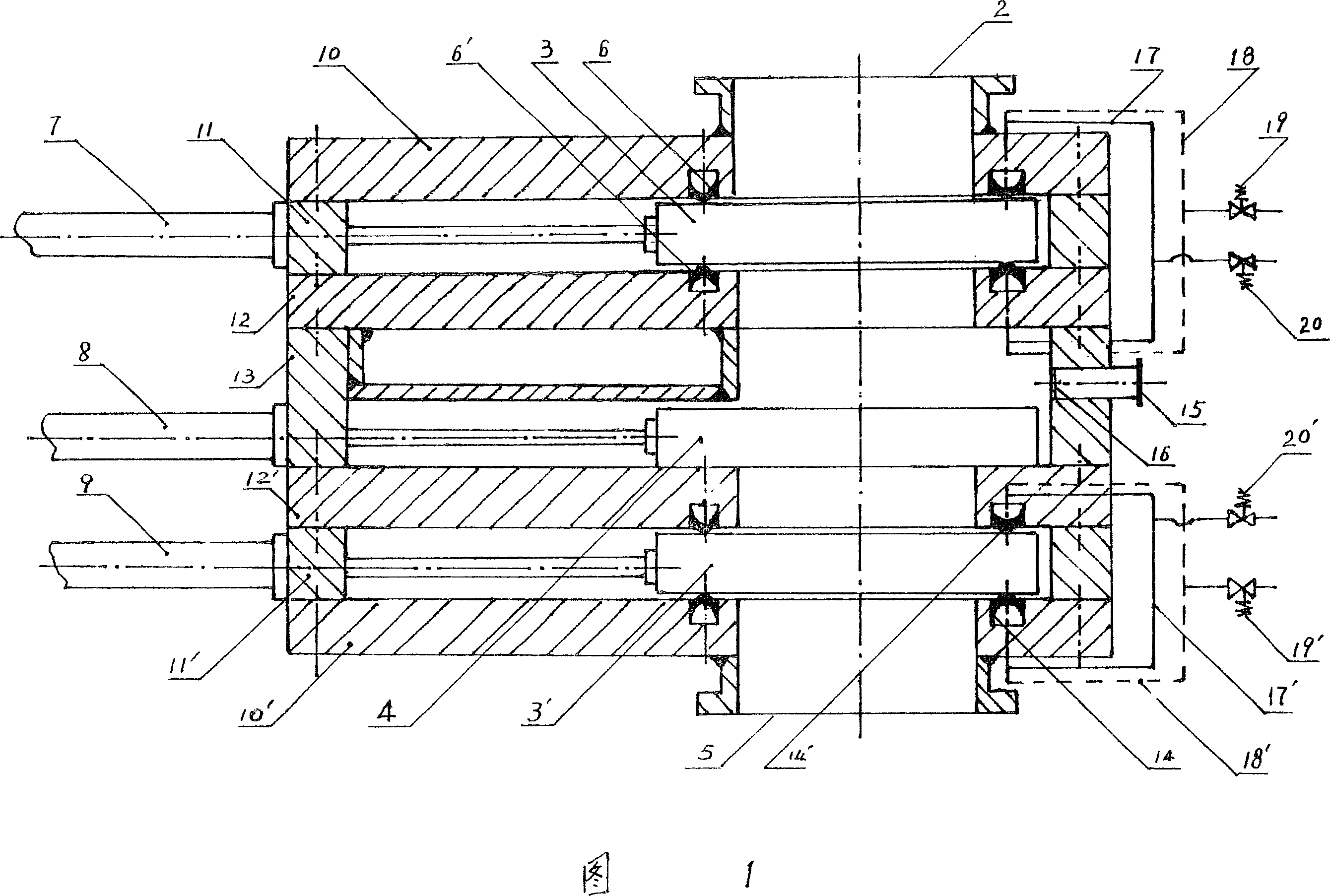

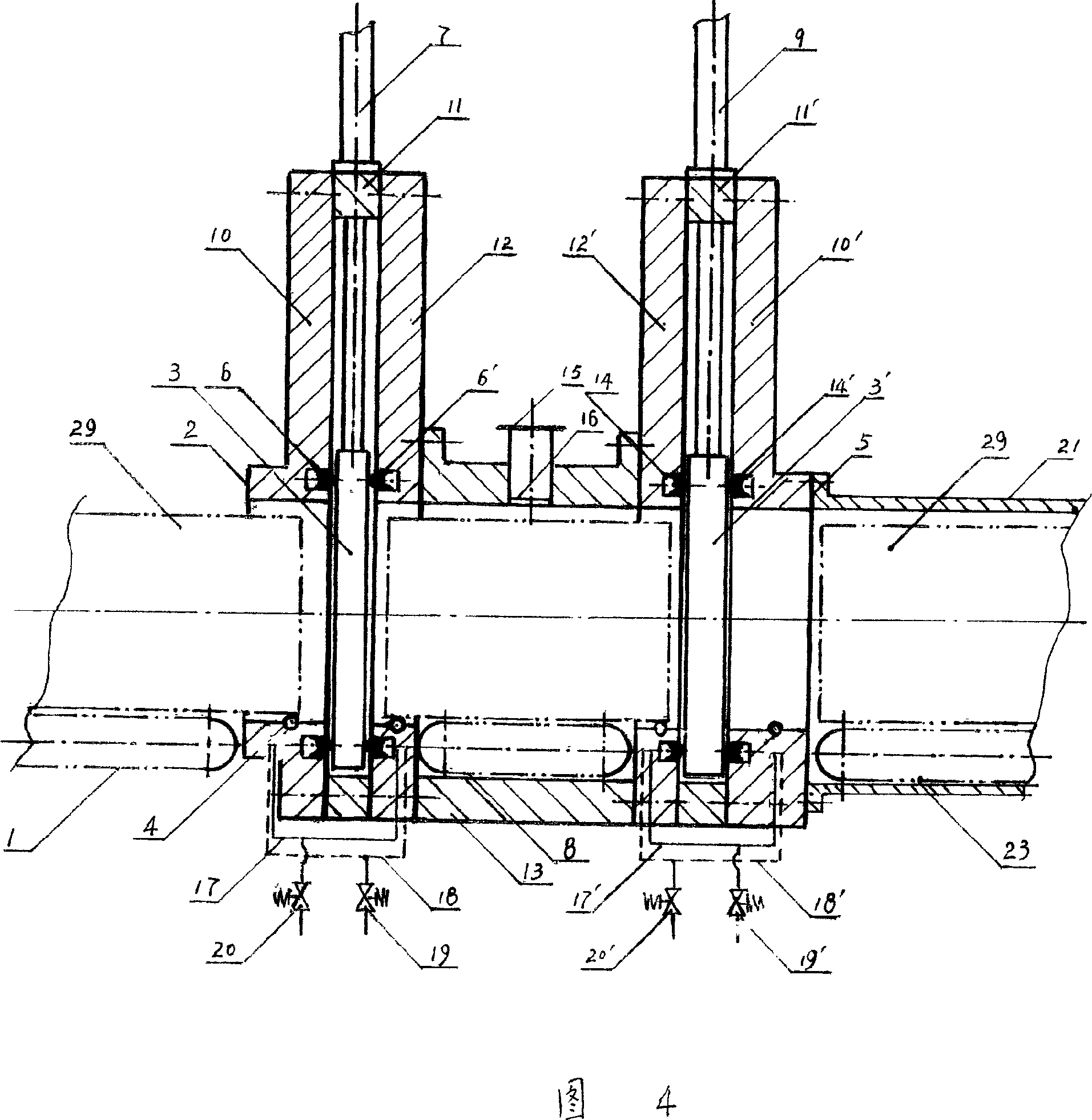

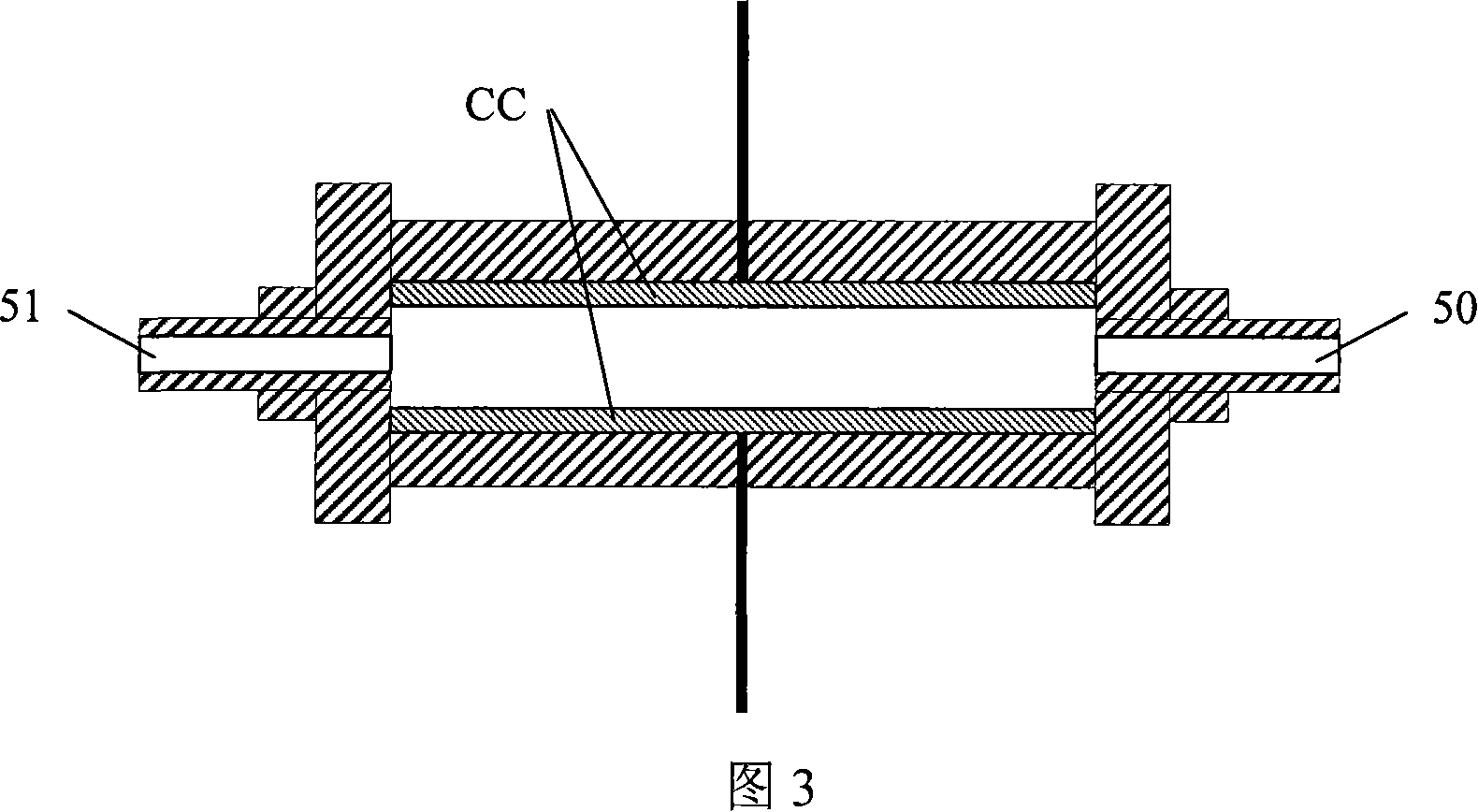

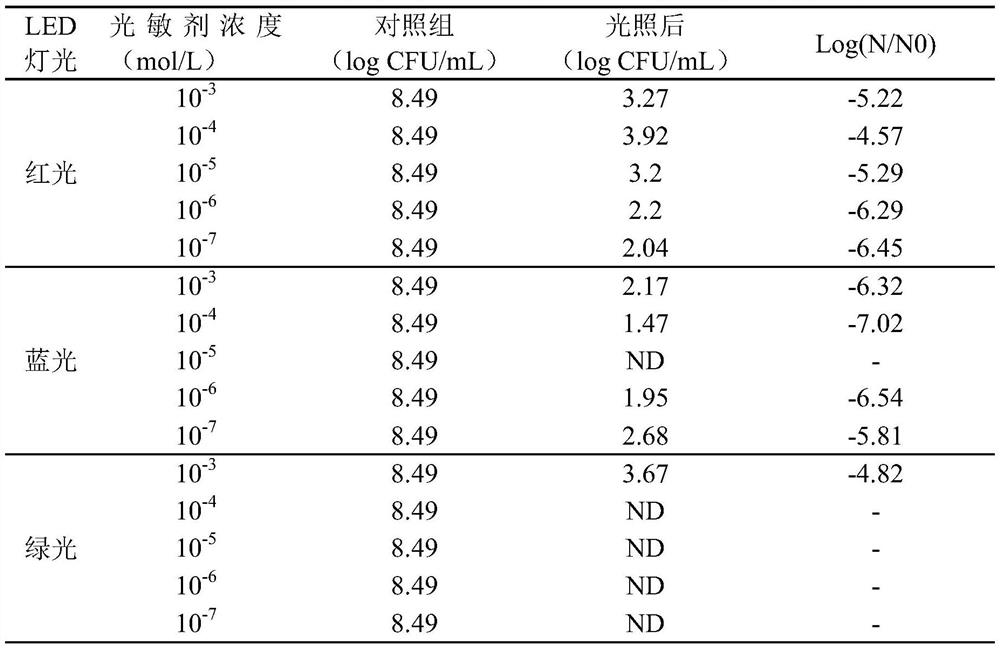

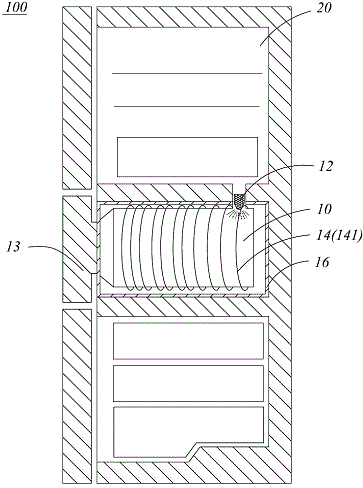

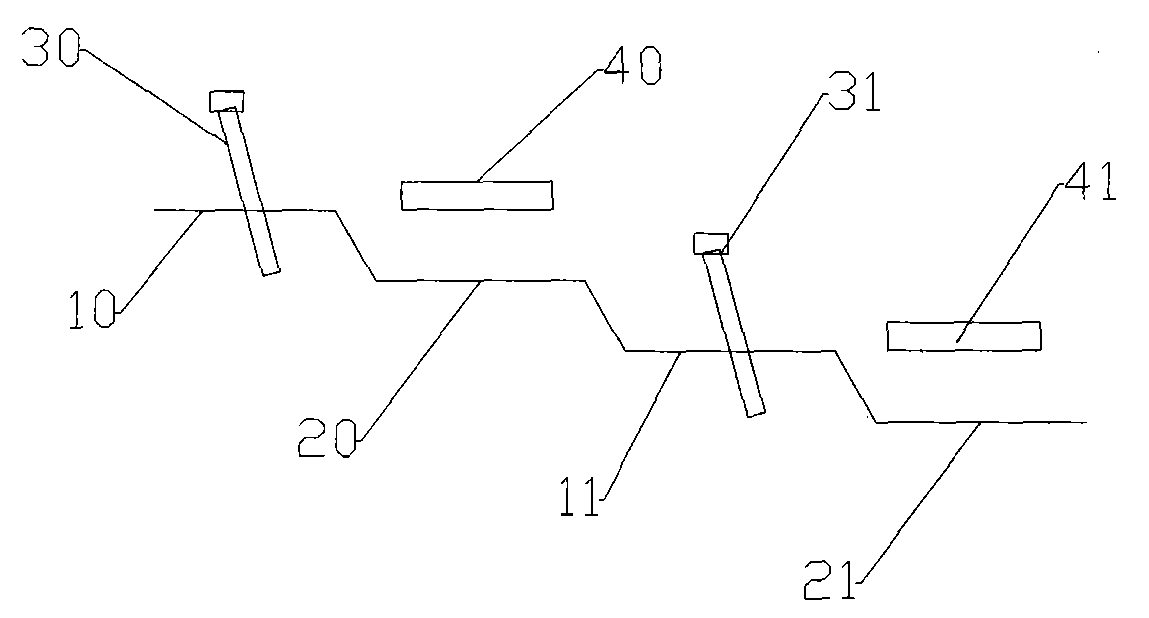

Sealing device for gate type continuous vacuum/pressurized charging and discharging treatment

InactiveCN1995783ASimple structureImprove sealingEngine sealsConveyor partsMicrowaveFood sterilization

The invention relates to a flashboard sealing device for charge and discharge machining in vacuum and pressure continuously, belonging to mechanical equipment machining area such as food, traditional chinese medicinal materials, chemical engineering and wood so on, mainly comprising charge (discharge) port, pressing board of charge (discharge) port, charge (discharge) pressing board, charge (discharge) middle frame, middle frame, collecting device, charge (discharge) sealing plate, reciprocating cylinder, U-shape sealing ring, charge (discharge) pressure fluid pipe, electromagnetic valve and forvacuum port so on. It is the sealing device that can maintain the vacuum degree / pressure under continuous charge and discharge of materials. It can applied in various equipments with different purposes such as food sterilization, fried deoiling machining, freezing machining in deep cold and precooling machining so on. It is adapted in various machining processes.

Owner:陈长清

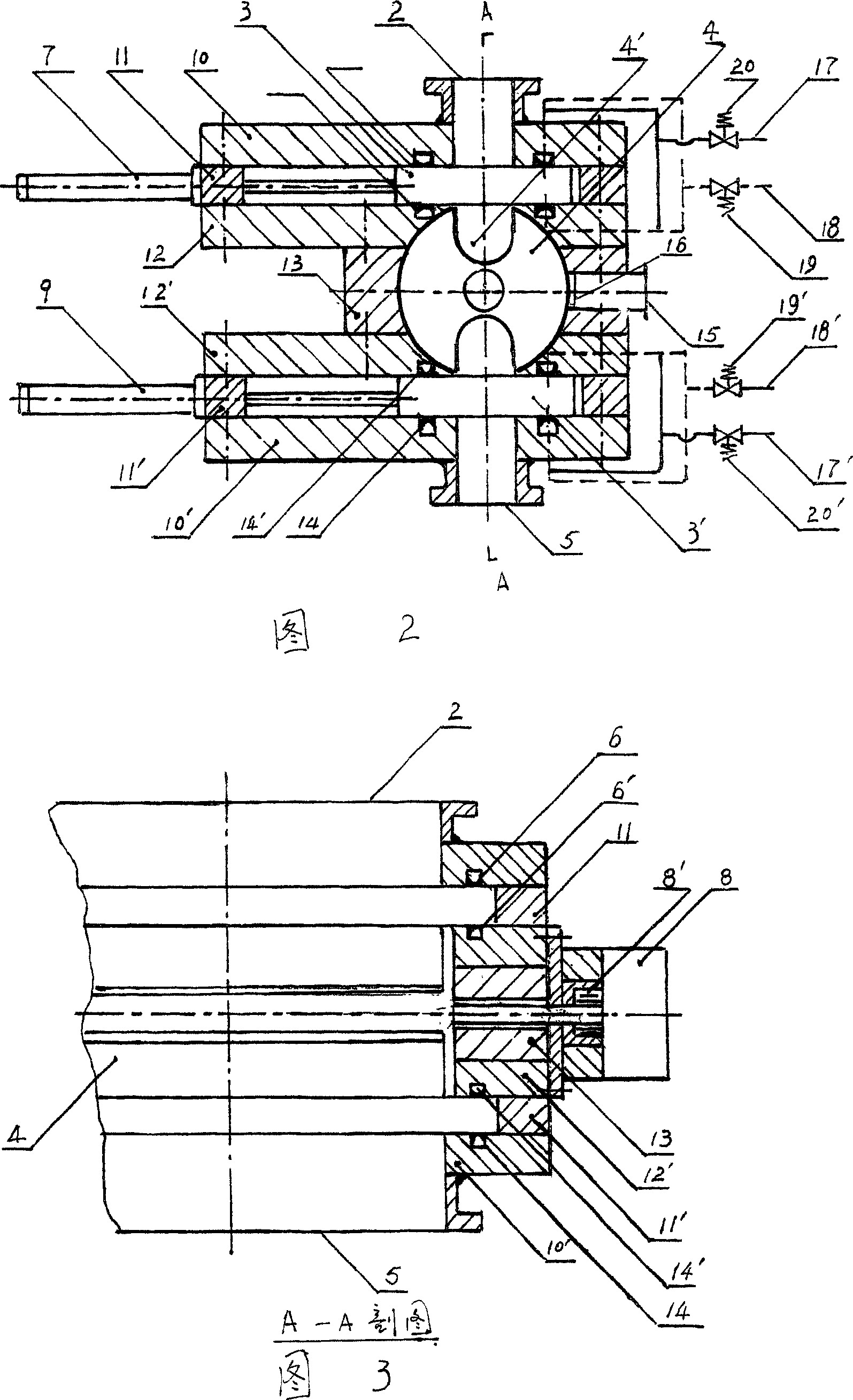

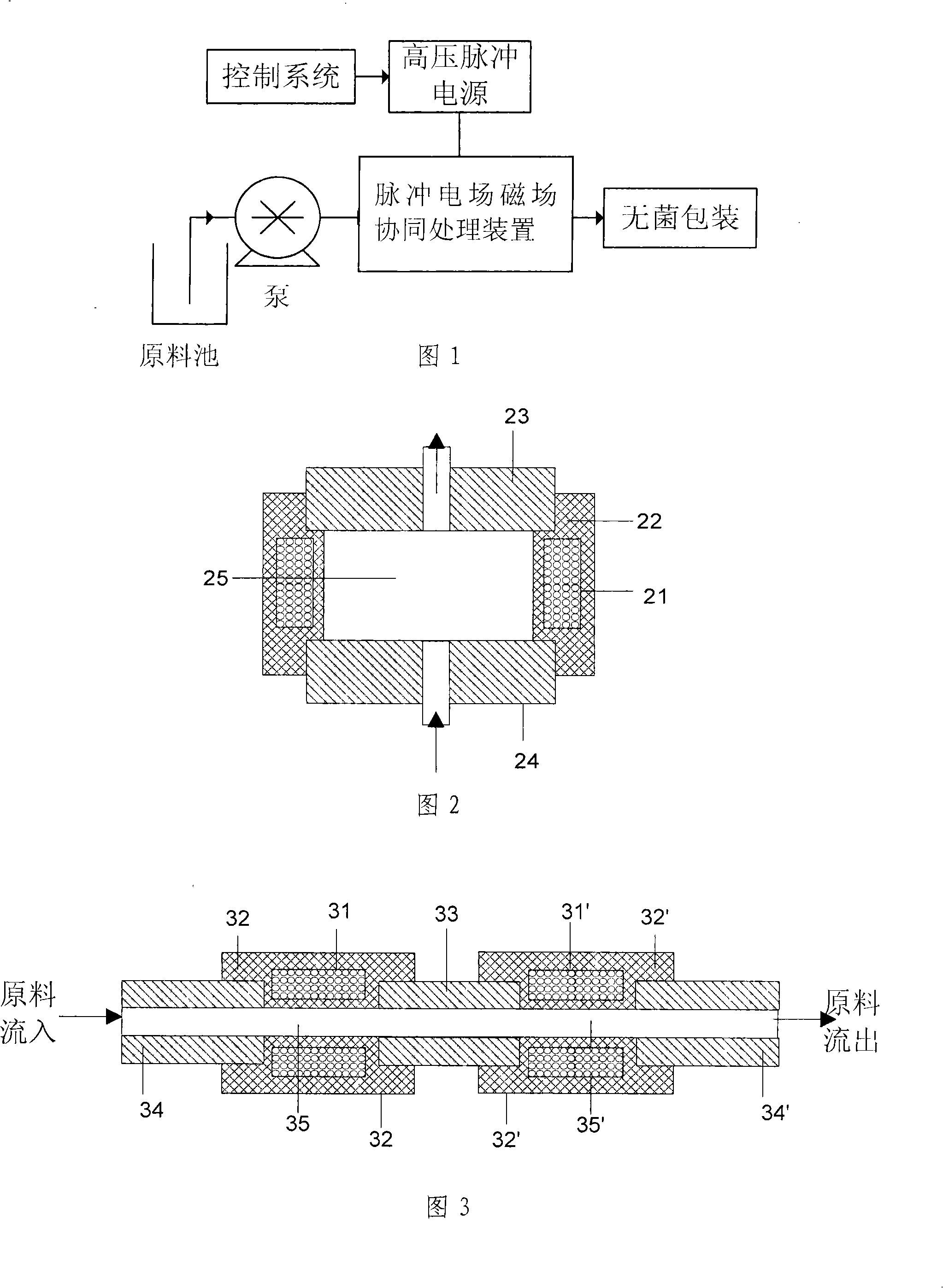

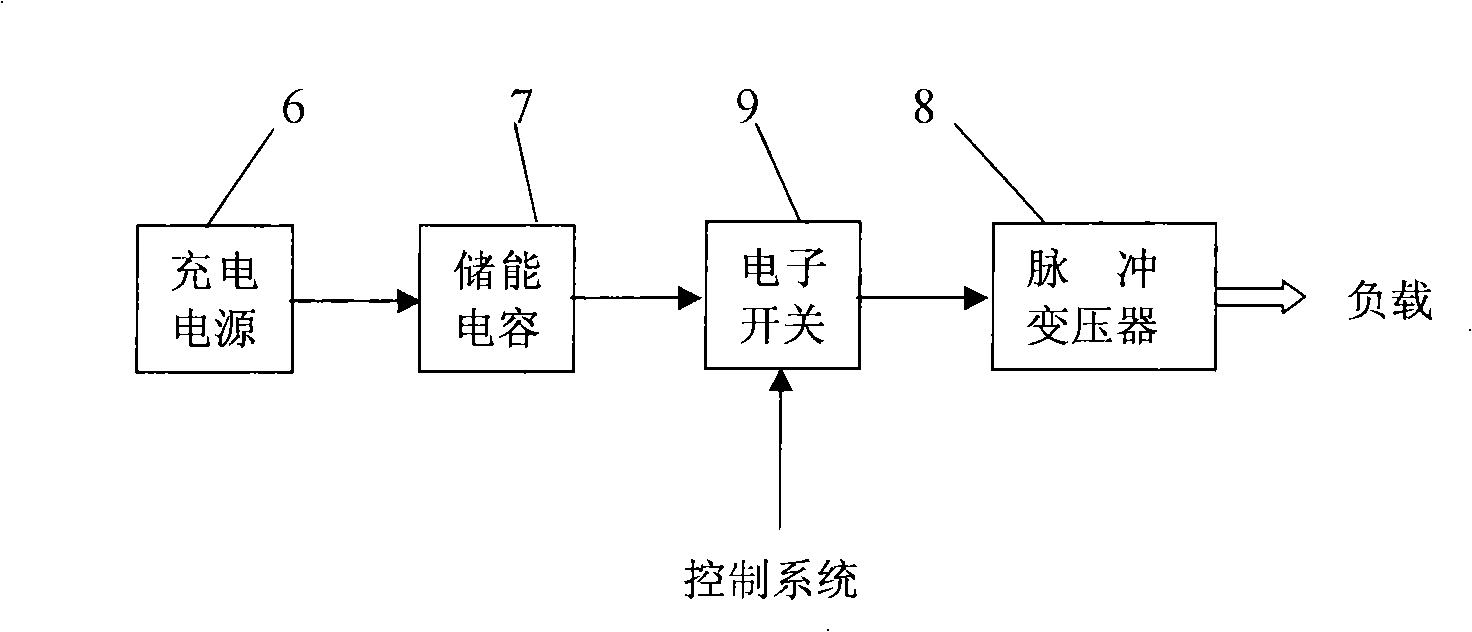

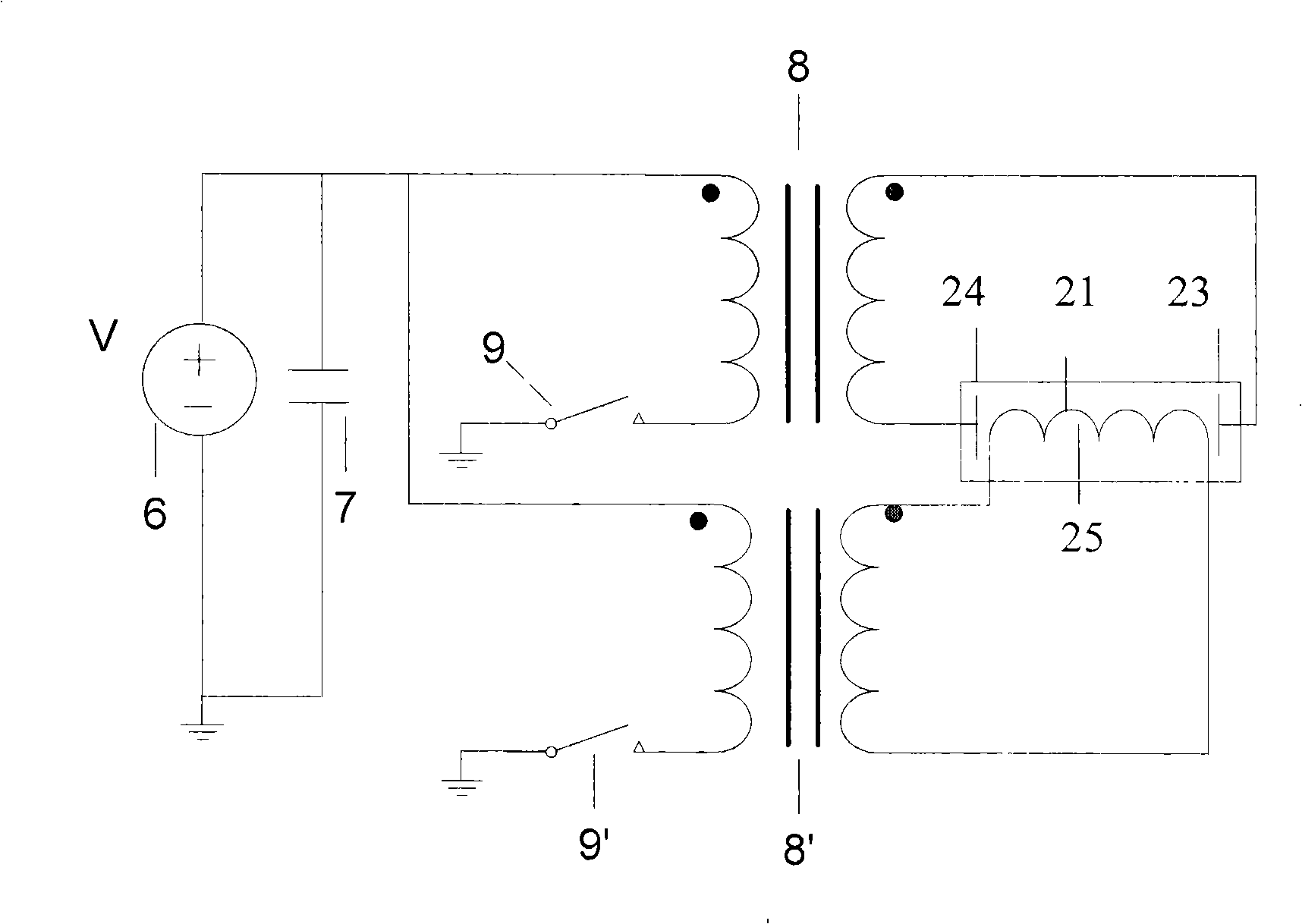

Method and apparatus for materials cooperation disinfection and enzyme dulling with impulse electric field and magnetic field

InactiveCN101292769AMaintain nutritional valueKeep the flavorMilk preservationFood preservationNutritive valuesElectromagnetic field

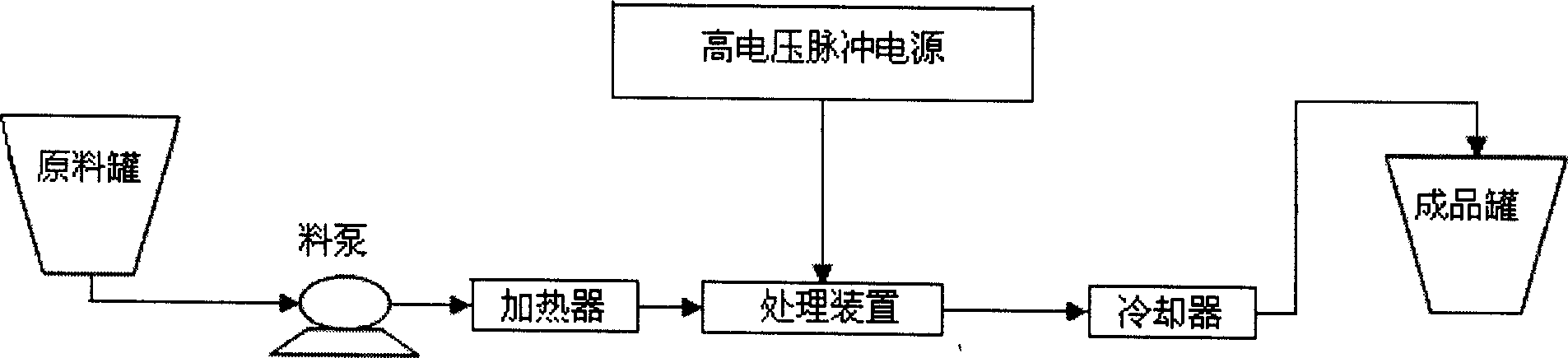

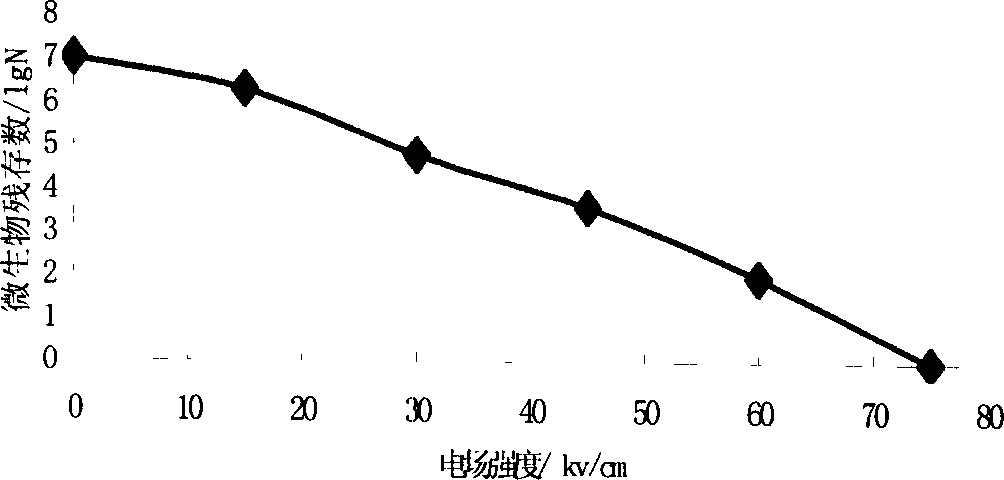

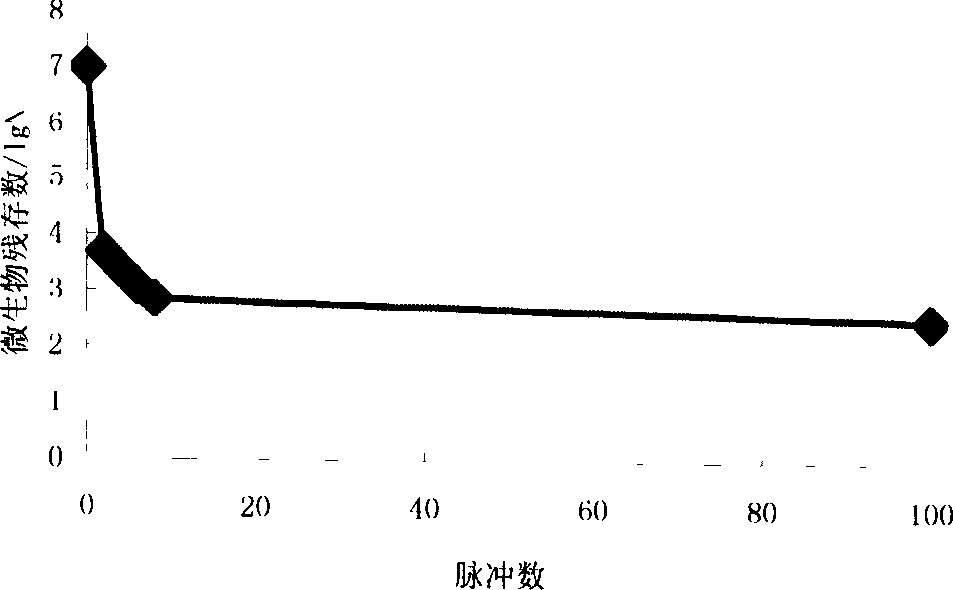

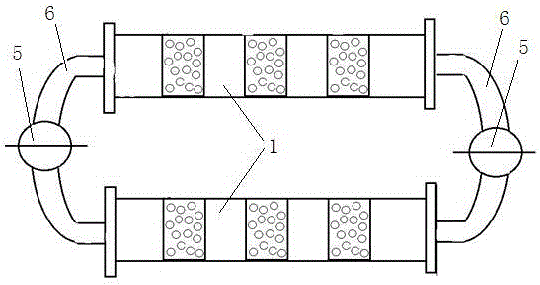

The invention provides a method that a pulsed electric field and a magnetic field cooperatively sterilize materials and inactivate enzyme and a device. The method comprises: materials to be processed continuously or discontinuously flow through the processing area of the cooperative processing device with the pulsed electric field and the magnetic field; a high pressure pulse power source imposes a pulsed magnet field of 0.1T-50T by the field coils which circle the processing area and a pulsed electric field of 5-100kV / cm by electrode plates at two sides of the processing area to carry out electric-magnetic-field cooperative processing of the materials in the processing area; the electric-magnetic-field cooperative processing device has novel conception, combines the magnetic field and the pulsed electric field, is convenient in installation and application and suitable for being adapted and used in a food sterilization processing system; the cooperative processing of materials by the pulsed electric field and the magnetic field takes a short time; the temperature of materials rises a little during the whole sterilizing course; the effect of sterilization and enzyme inactivation is increased, meanwhile, the original nutritive value and flavor of food are preserved to the maximum degree.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Food hyperpressure low-temperature sterilization method

InactiveCN101356990AAdapt and guarantee bactericidalFood preservationUltra high pressureFood sterilization

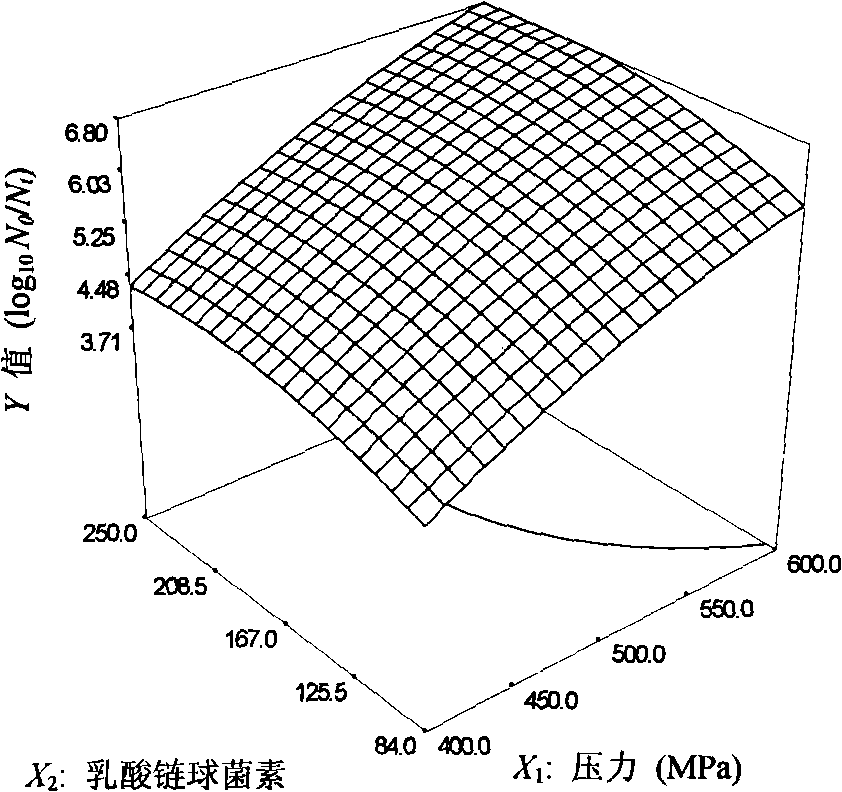

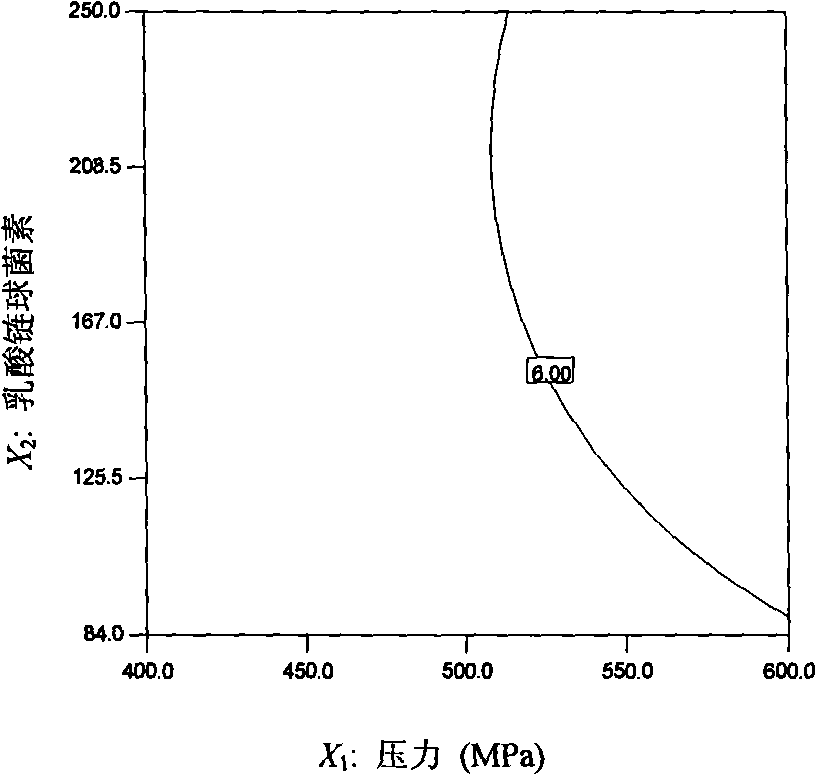

The invention discloses a superhigh pressure and low-temperature food sterilization method. The method comprises the following steps: streptostacin of lactic acid is added to fluid food at the temperature of 30 DEG C-70 DEG C under the pressure of 300MPa-700MPa for 7.5min-17.5min treatment, wherein, the concentration of the streptostacin of the lactic acid in the fluid food is 0IU / ml-333IU / ml. The process condition determined by the food sterilization method can kill 100000-order of magnitude bacteria basically without affecting the main components of the fluid food, and even can kill more than 100000-order of magnitude bacteria under the optimized condition, which absolutely adapts to and guarantees the antibacterial performance of the fluid food.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Method for refreshing fresh foods by adopting electrolytic water treatment with modified atmosphere packaging

The invention discloses a method for refreshing fresh foods by adopting electrolytic water treatment with modified atmosphere packaging. By adopting the method provided by the invention, strong-speed, weakly acidic or alkaline electrolytic water, which is high-efficiency and wide-spectra for sterilization, safe, environment-friendly and relatively lower in production cost, is adopted for sterilizing the fresh goods, such as fresh (fresh cut) fruits and vegetables, fresh fishes and shrimps, fresh meat products and the like; furthermore, with the help of the modified atmosphere packaging, the quality guarantee periods of the fresh foods under a refrigeration condition can be prolonged. The method disclosed by the invention is low in production cost and simple in process and has wide application prospect.

Owner:JIANGNAN UNIV

Sterilization and fresh-keeping method of fruits and vegetables

InactiveCN102475121AGood kill controlSuitable for industrial applicationsFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingFood sterilizationNutritional quality

Belonging to the technical field of food sterilization and fresh-keeping, the invention specifically relates to a sterilization and fresh-keeping method of fruits and vegetables. The method comprises the steps of: conducting irradiation pre-treatment to fruits and vegetables, and carrying out sterilization and fresh-keeping treatment to the fruits and vegetables by electron beam irradiation, and storing an irradiated fruit and vegetable sample. The method of the invention can substantially prolong the freshness keeping time of fruits and vegetables, enhance their commercial value, and well maintain their nutritional quality. The method provided in the invention is characterized by safety, environmental protection, high efficiency and rapidity, strong bactericidal power, wide application scope, and is easy for application in industrial production.

Owner:SHANGHAI ACAD OF AGRI SCI

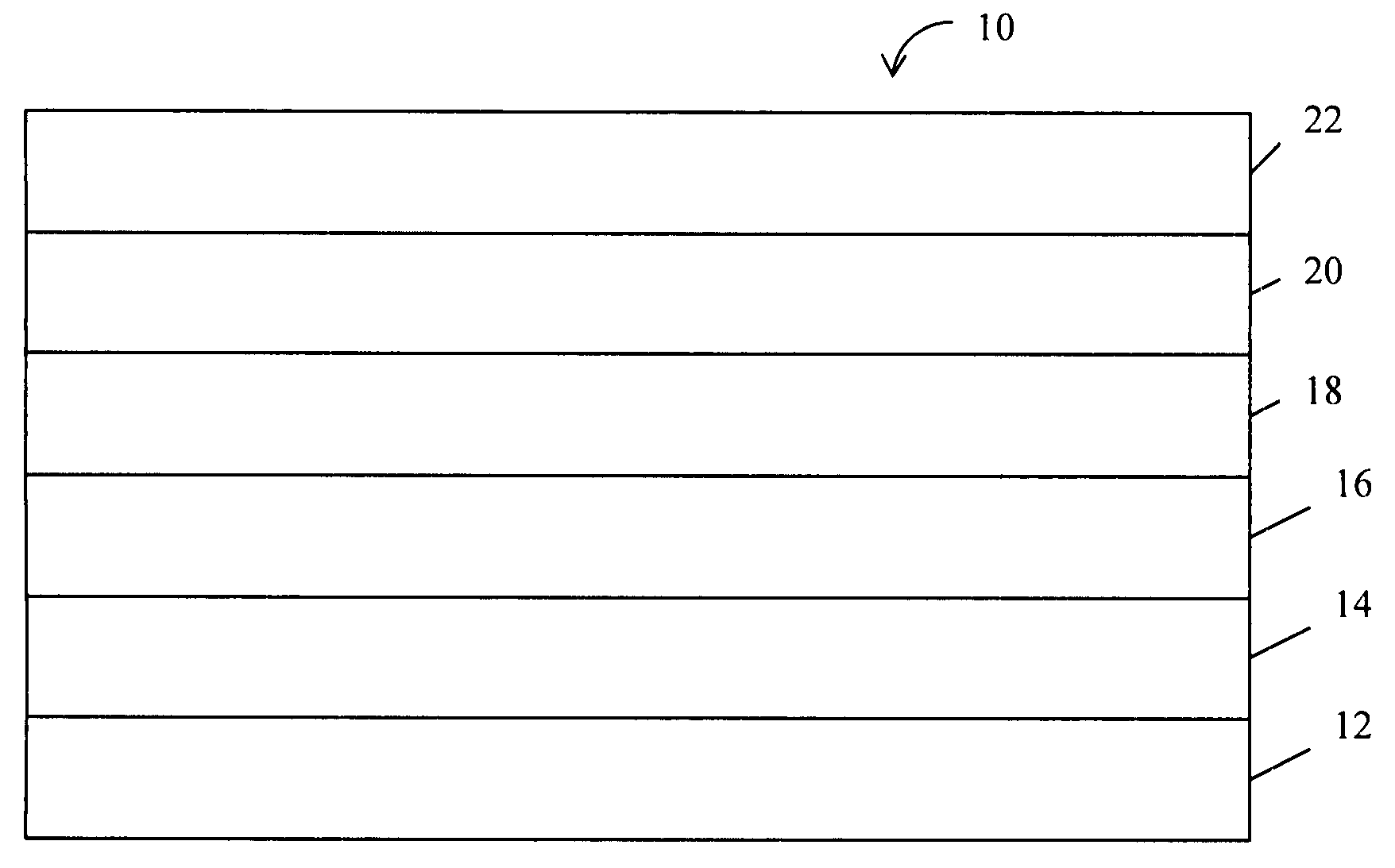

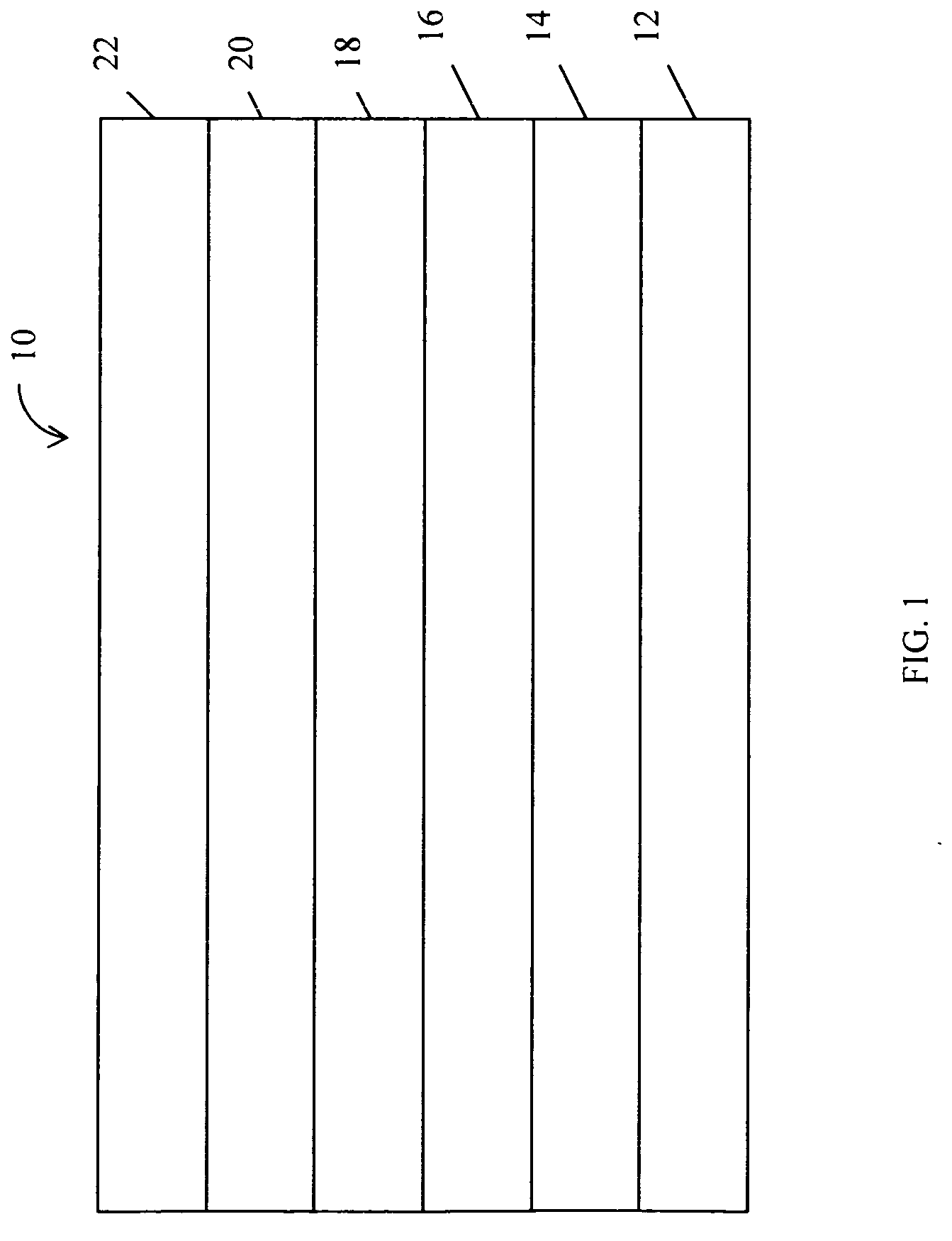

Food sterilization dosage indicator

InactiveUS20080014117A1High selectivityImprove stabilityMaterial analysis by observing effect on chemical indicatorDisinfectionMedicineProton

A multilayer food sterilization dosage indicator having (a) an indicator layer including an ion-sensitive ink, an ionic photoinitiator, a proton source; (b) a substrate, and an overlayer including a UV-absorber. The ink undergoes a color change upon exposure to a known amount of sterilizing radiation. A method for indicating the amount of exposure to sterilizing radiation using the dosage indicator.

Owner:QUESTEL ADHESIVES

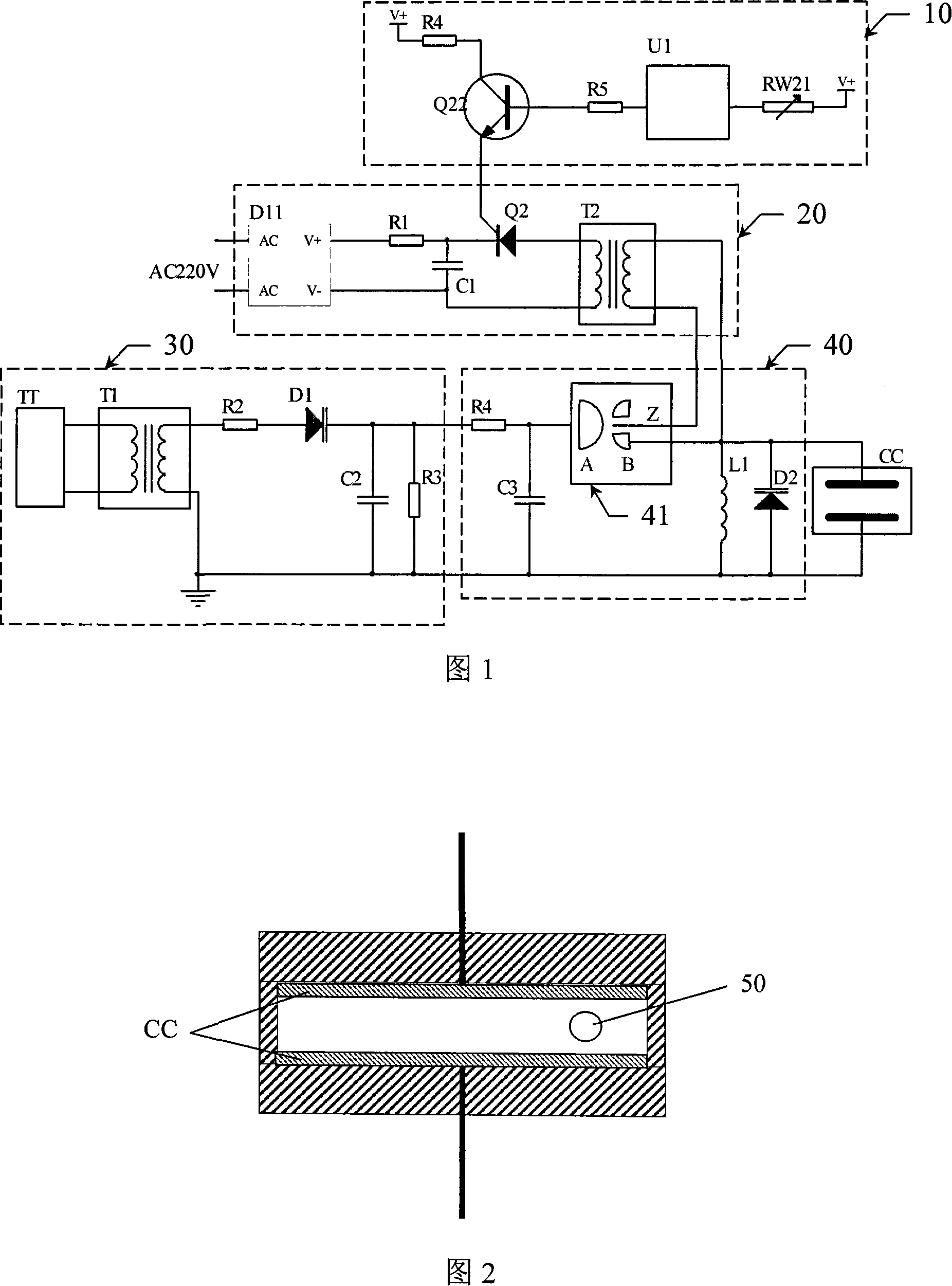

High-pressure pulse electric sterilization process device for liquid food

The present invention relates to a high-voltage pulse electric-field sterilization treatment equipment for liquid food. It is characterized by that the pulse signal output end of its pulse signal generation circuit is connected with control signal input end of pulse generation circuit, two pulse signal output ends of said pulse generation circuit are connected with two pulse control signal input ends of its discharge circuit, the voltage signal input end of said discharge circuit is connected with voltage signal output end of its boost up circuit, two electrode plates of its sterilization condenser are respectively connected with discharge signal output end of discharge circuit and power supply, and its treatment chamber is a sealed rectangular space, two electrode plates of sterilization condenser are respectively fixed on two large-area opposite inner walls of said treatment chamber interior, and on a side wall of said treatment chamber a material inlet is opened. It can be used in the field of liquor food sterilization.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

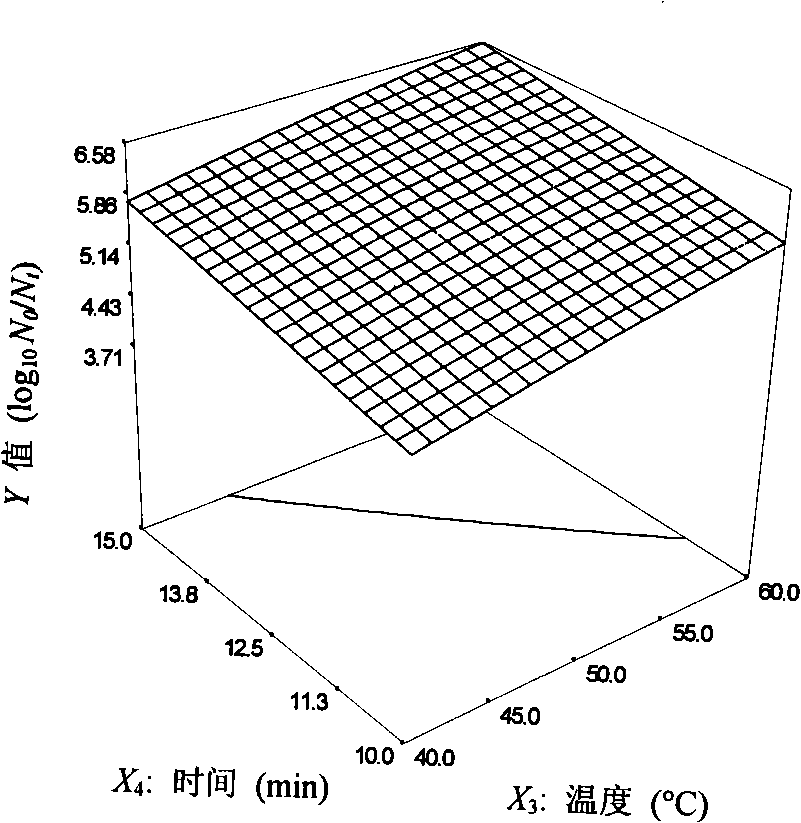

Soft sterilization method of mixed fresh cut root vegetables in small packages

InactiveCN105557976AShorten the timePreserve sensory qualitiesFood thermal treatmentFruits/vegetable preservation by irradiation/electric treatmentFood sterilizationRoom temperature

The invention discloses a soft sterilization method of mixed fresh cut root vegetables in small packages, and belongs to the technical field of vegetable and fruit sterilization. According to the method, mixed fresh cut root vegetables are soaked in fresh-keeping liquid with a low pH value to inhibit bacterium growth, and at the same time, nano zinc oxide, radio frequency, and hot wind are used together to kill bacteria. The method comprises the following steps: soaking root vegetables in sodium hypochlorite (100 mg / L) for 3 to 5 minutes, washing root vegetables by deionized water, cutting root vegetables into blocks, blanching the vegetable blocks by calcium salt containing hot water to kill the enzymes, then immediately soaking the vegetable blocks in the fresh-keeping liquid for 8 to 10 minutes, fishing out the vegetable blocks, adding nano zinc oxide dispersion liquid, evenly mixing, packing the vegetable blocks into small packages; processing the packed vegetables by radio frequency and hot wind, and storing the vegetables at a room temperature. The provided method can effectively prolong the shelf life to 9 months. The total number of bacterial colony of finished product is less than 1000 CFU / g, and no pathogenic bacterium (eg. salmonella) has been found. Moreover, good texture, color and luster can be maintained during the storage period.

Owner:NANJING JIANGGAO DRYING EQUIP CO LTD +1

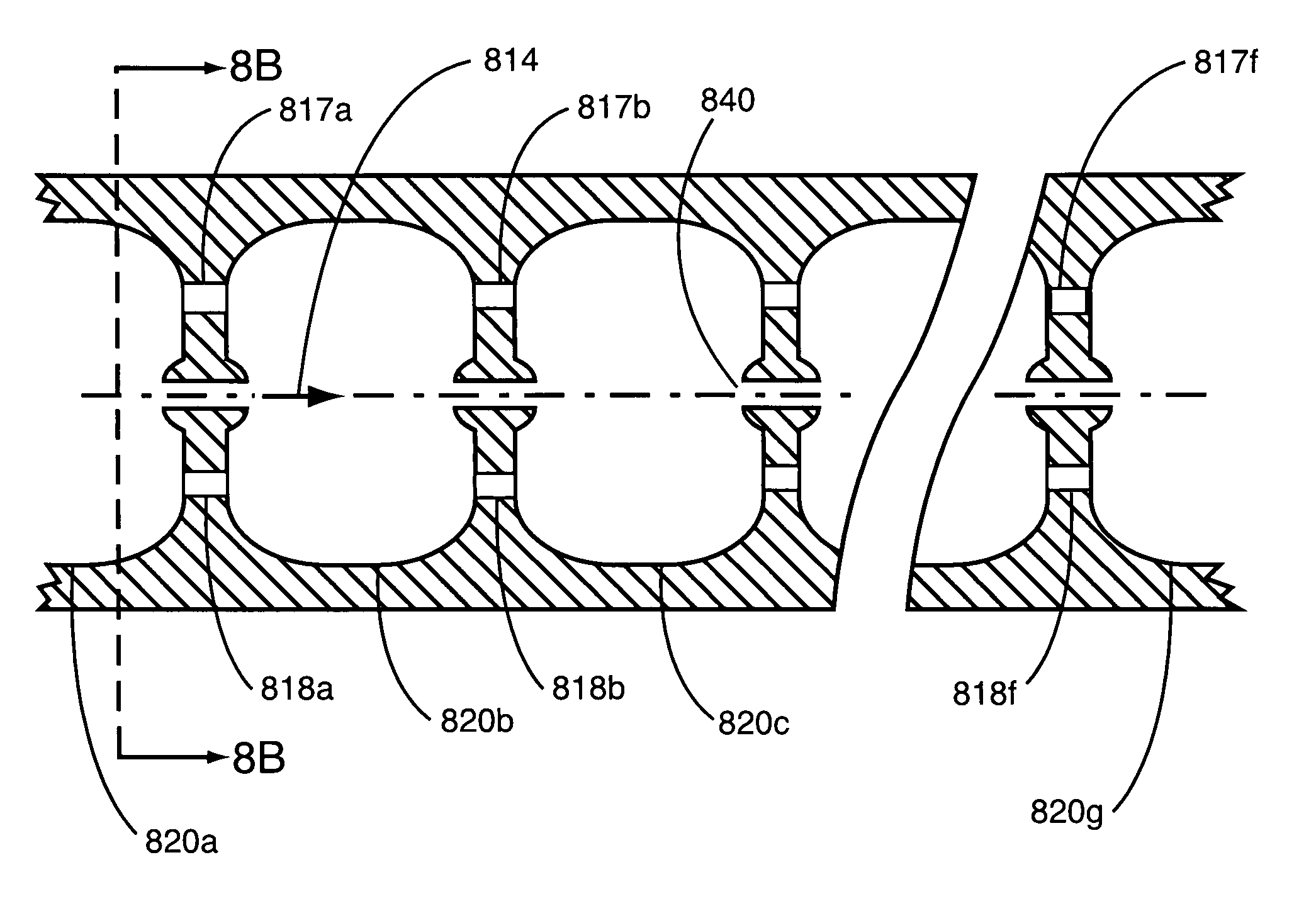

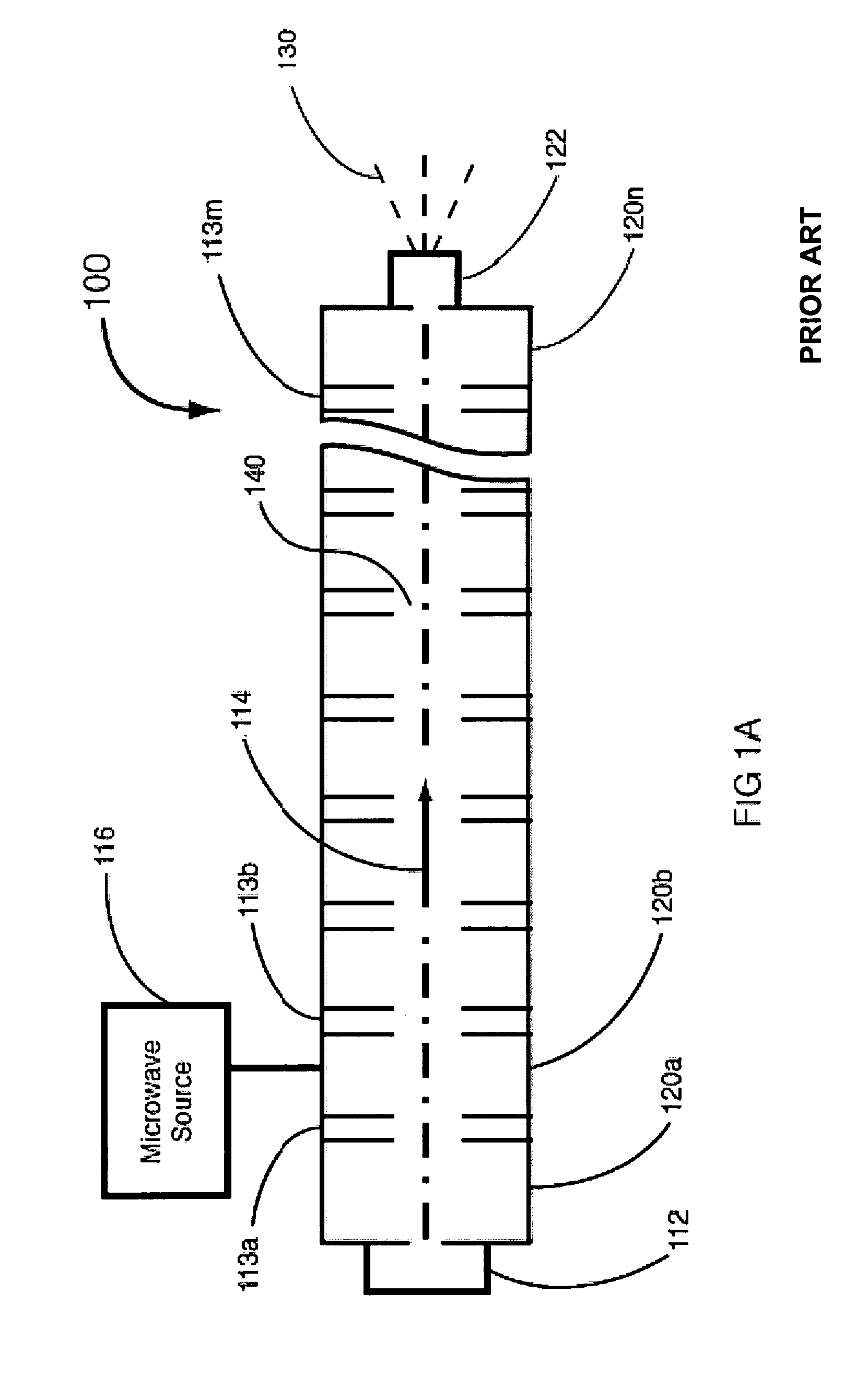

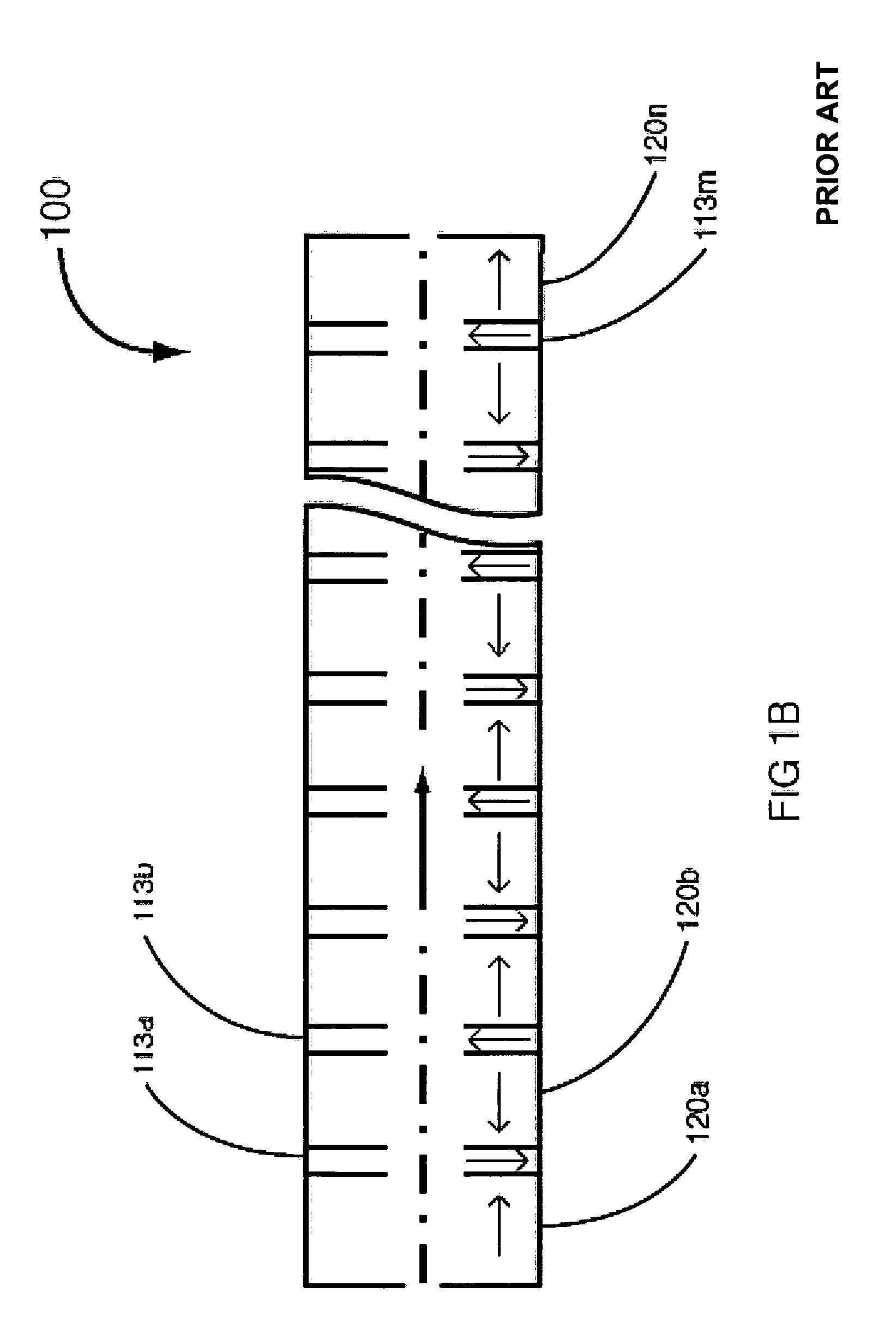

Particle accelerator and methods therefor

Standing-wave linear accelerators (linac) having a plurality of accelerating cavities and which do not have any auxiliary cavities are provided. Such linacs are useful for industrial applications such as radiography, cargo inspection and food sterilization, and also medical applications such as radiation therapy and imaging. In one embodiment, the linac includes an electron gun for generating an electron beam, and a plurality of accelerating cavities which accelerates the electron beam by applying electromagnetic fields generated by a microwave source. At least two adjacent accelerating cavities of the plurality of accelerating cavities are coupled together by at least one resonant iris. The electromagnetic fields resonate through the plurality of accelerating cavities and the at least one resonant iris.

Owner:HANNA SAMY M

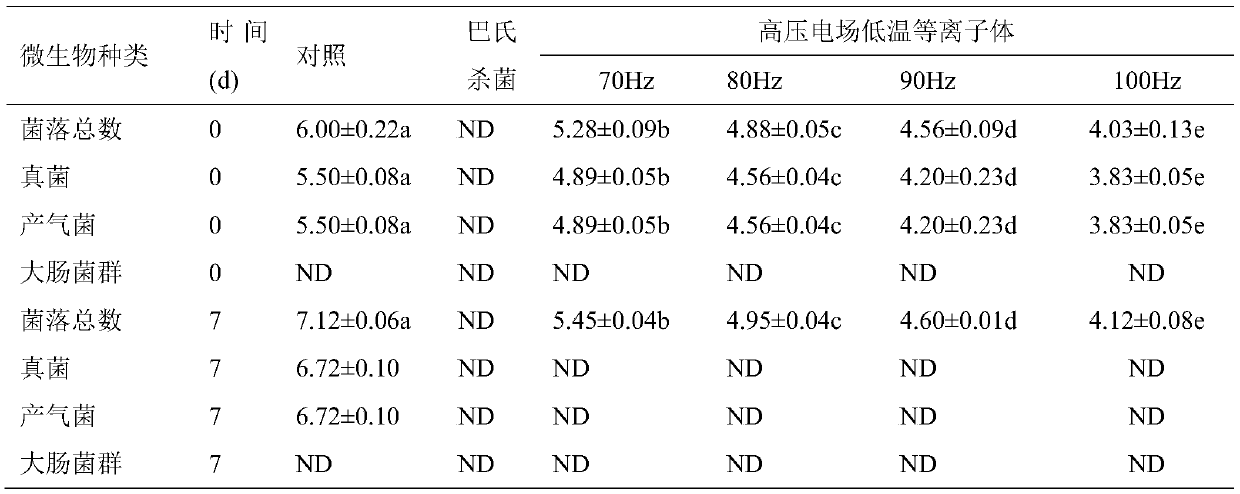

Cold sterilization and fresh-keeping technology and method with high-voltage electric field low-temperature plasma for low-salt pickled vegetables

PendingCN111165566AControl quantityExtended shelf lifeFruits/vegetable preservation by irradiation/electric treatmentClimate change adaptationLow temperature plasmaMaterials science

The invention relates to a cold sterilization and fresh-keeping technology and method with high-voltage electric field low-temperature plasma for low-salt pickled vegetables and belongs to the field of food sterilization and fresh keeping. According to the technical scheme, the cold sterilization and fresh-keeping technology and method with the high-voltage electric field low-temperature plasma for low-salt pickled vegetables comprises the following steps: putting pickled and fermented low-salt pickled vegetables into a packaging bag (box), adjusting the concentration of a pickling and fermentation broth NaCl of the pickled vegetables to 2.5-4.0%, adjusting the total acidity to 0.4-0.6%, putting the pickling and fermentation broth into the packaging bag (box) according to a ratio of the pickled vegetables to the pickling and fermentation broth being 1:1(w / v), introducing a gas, and performing packaging; and under conditions that the temperature is 15-20 DEG C and the relative humidityis 50-70%RH, placing the packaging bag (box) between two electrodes of a high-voltage electric field low-temperature plasma sterilization device, and performing repeated treatment for 2-5 times in a short time-interval-multi-time sterilization mode, so as to complete the sterilization process, wherein t he voltage intensity is 55-65kV / cm, the frequency is 70-120Hz, the current is 0.3-0.8mA, the action time of a single time of an electric field is 20-60 seconds, and the interval time is 20-60 seconds. By adopting the method, the short time-interval-multi-time sterilization mode of the low-temperature plasma is adopted for the low-salt pickled vegetables, on premise that sensitive quality of the pickled vegetables is ensured, a function of killing flatulence reduction fungi can be achieved,the sterilization effect is remarkably improved, the shelf fresh keeping period can be remarkably prolonged, and large-scale automatic production requirements of local special pickled vegetables can be met.

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI +1

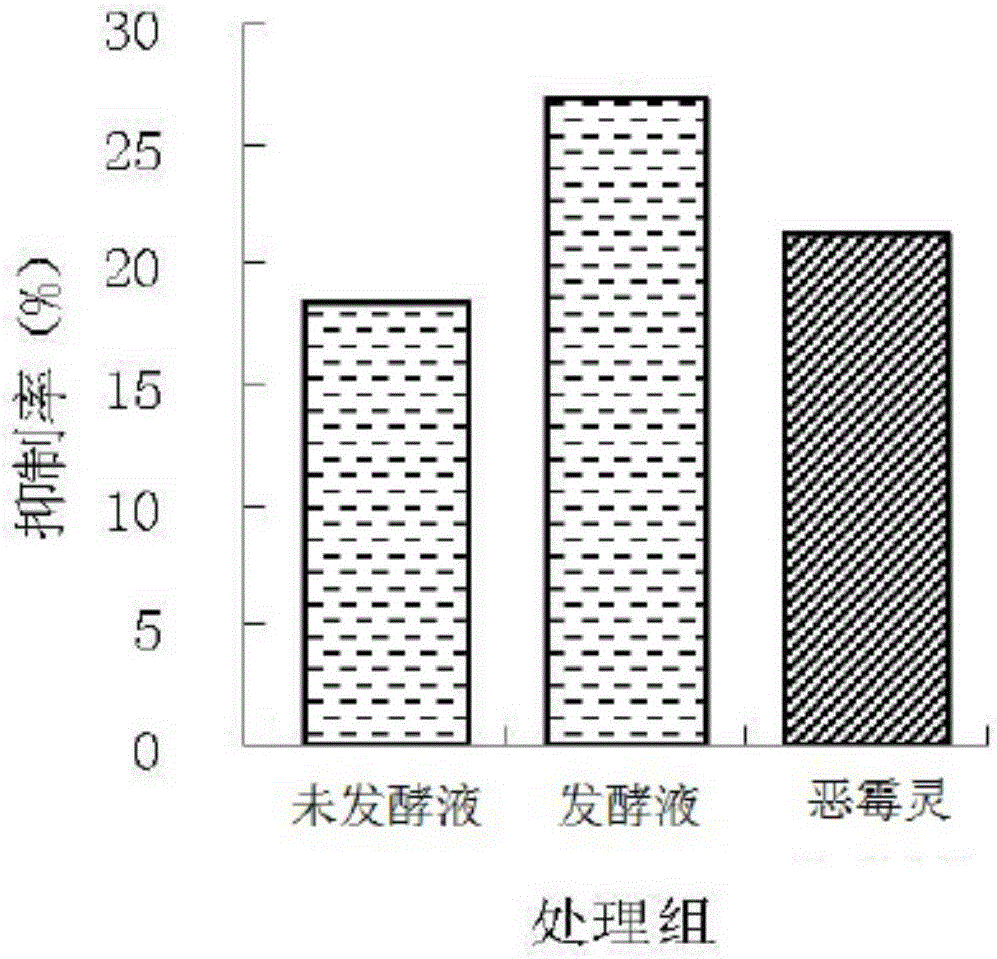

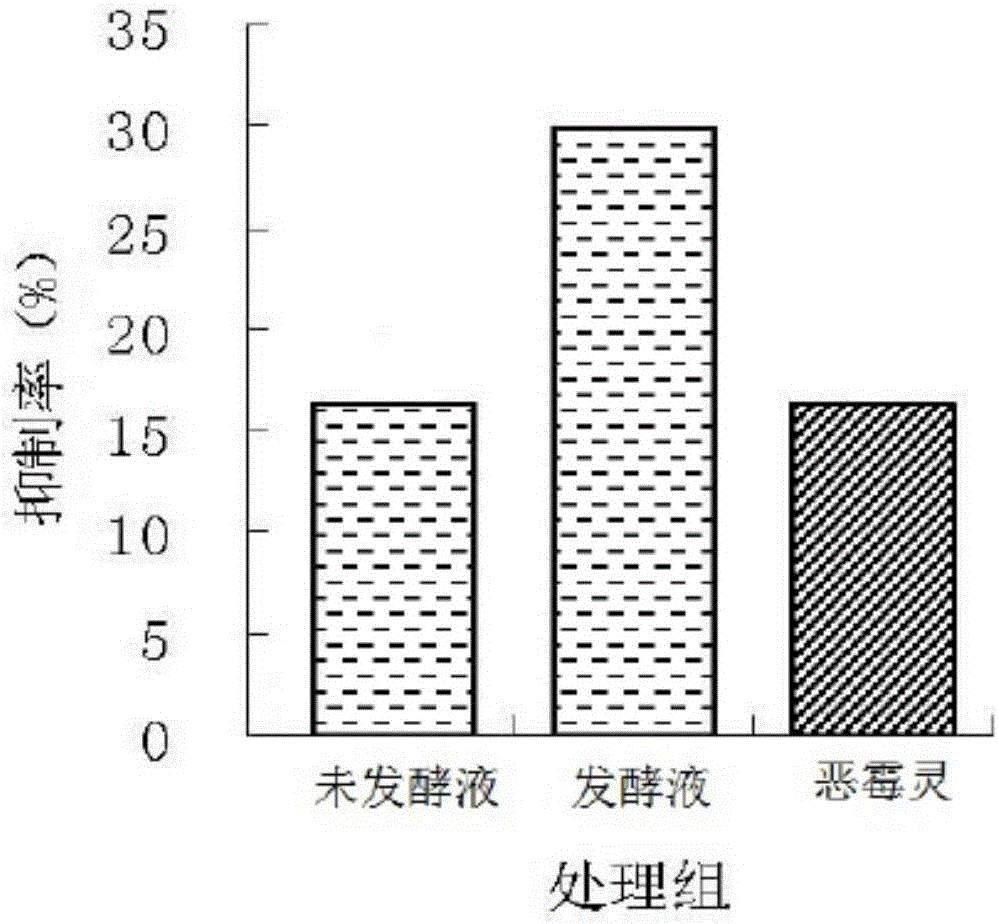

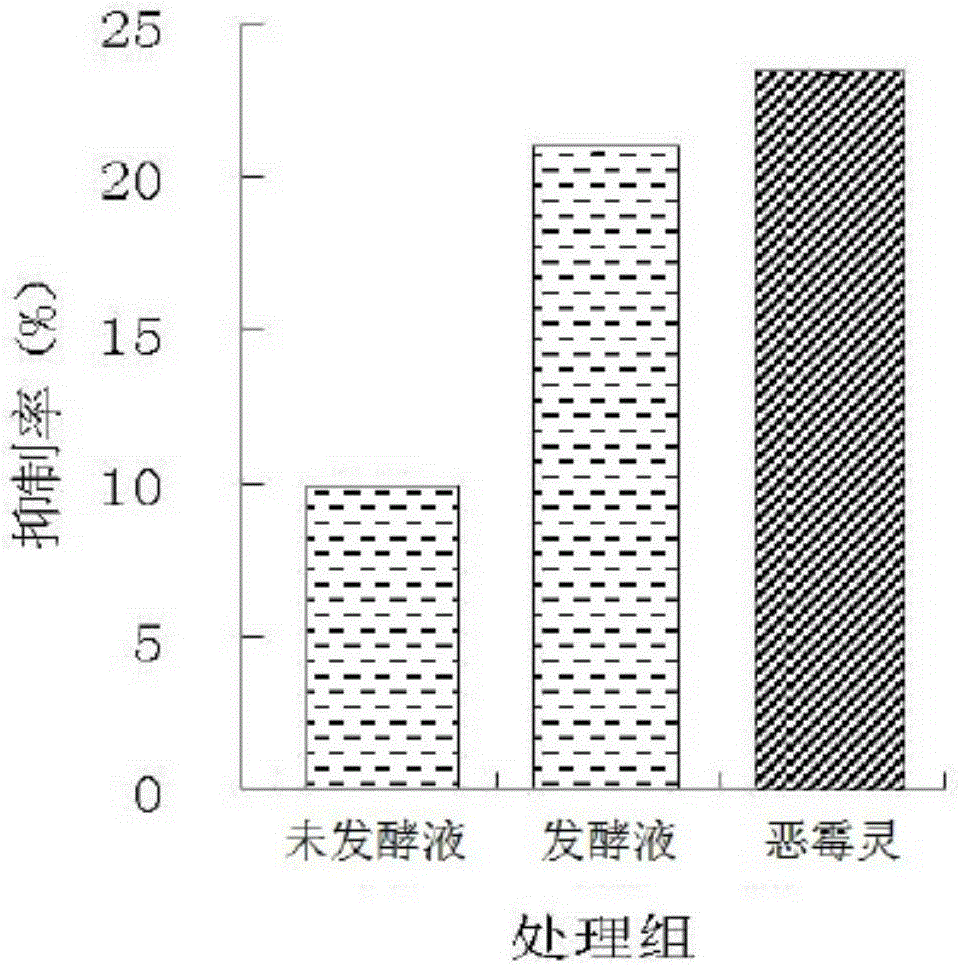

Eurotium cristatum LS1 strain

ActiveCN105861333AHas broad-spectrum antibacterial activityDisease controlBiocideFungiEscherichia coliSclerotinia

An eurotium cristatum LS1 strain is classified and named as EurotiumCristatum LS1 and preserved in China Center for Type Culture Collection on June 17, 2015, and the preservation number is CCTCC NO:M 2015379. The strain LS1 can grow on kudzuvine roots and conduct bioconversion, when the strain LS1 is used for fermenting kudzuvine roots, an obtained fermenting product has stronger inhibiting effects on cowpea anthracnose, tomato early blight, sclerotinia sclerotioru and Chinese cabbage leaf spots, and the inhibiting effects on five putrefactive bacteria of staphylococcus aureus, bacillus cereus, escherichia coli, bacillus subtilis and salmonella are all improved than those before fermentation is conducted. It is shown that a product obtained by fermenting kudzuvine roots through the strain LS1 has broad-spectrum antibacterial activity, can inhibit pathogenic fungi and the putrefactive bacteria to some extent, is expected to be developed into biopesticides to prevent and control crop diseases and is expected to serve as a food sterilizing agent to be used for food preservation.

Owner:HUNAN AGRICULTURAL UNIV

Ultrahigh-pressure vegetable food processing method

The invention relates to an ultrahigh-pressure vegetable food processing method, which comprises the following steps: (1) washing vegetables; (2) soaking the vegetables; (3) reshaping the vegetables; (4) pre-boiling the vegetables; (5) cooling the vegetables; (6) filling the vegetables into bags for seasoning, and packaging under vacuum; (7) performing ultrahigh-pressure cold sterilization; and (8) storing and selling the finished products. In the invention, the physical properties, such as color, fragrance and flavor, of the vegetable food subjected to the ultrahigh pressure treatment are changed without generating peculiar smells, the pressured food still retains the original raw and fresh flavor and nutrients, and thus, food sterilization is uniform, instant and efficient. The protein denaturation and starch paste state of the vegetable food subjected to ultrahigh pressure treatment are different from those of vegetable food subjected to heat treatment, so food of new physical properties is obtained.

Owner:TIANJIN GUANGHUI FOOD

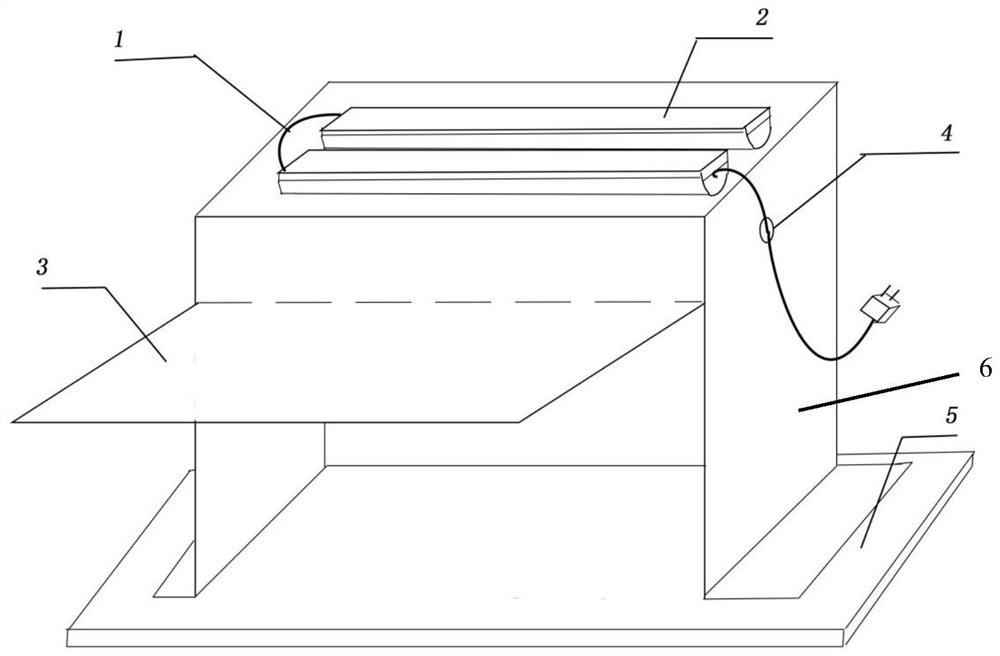

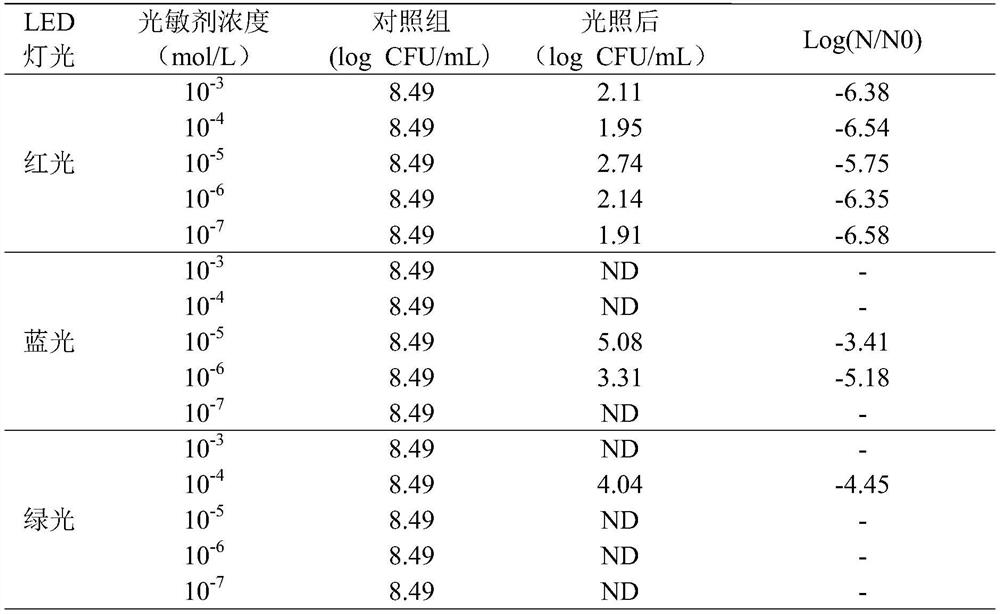

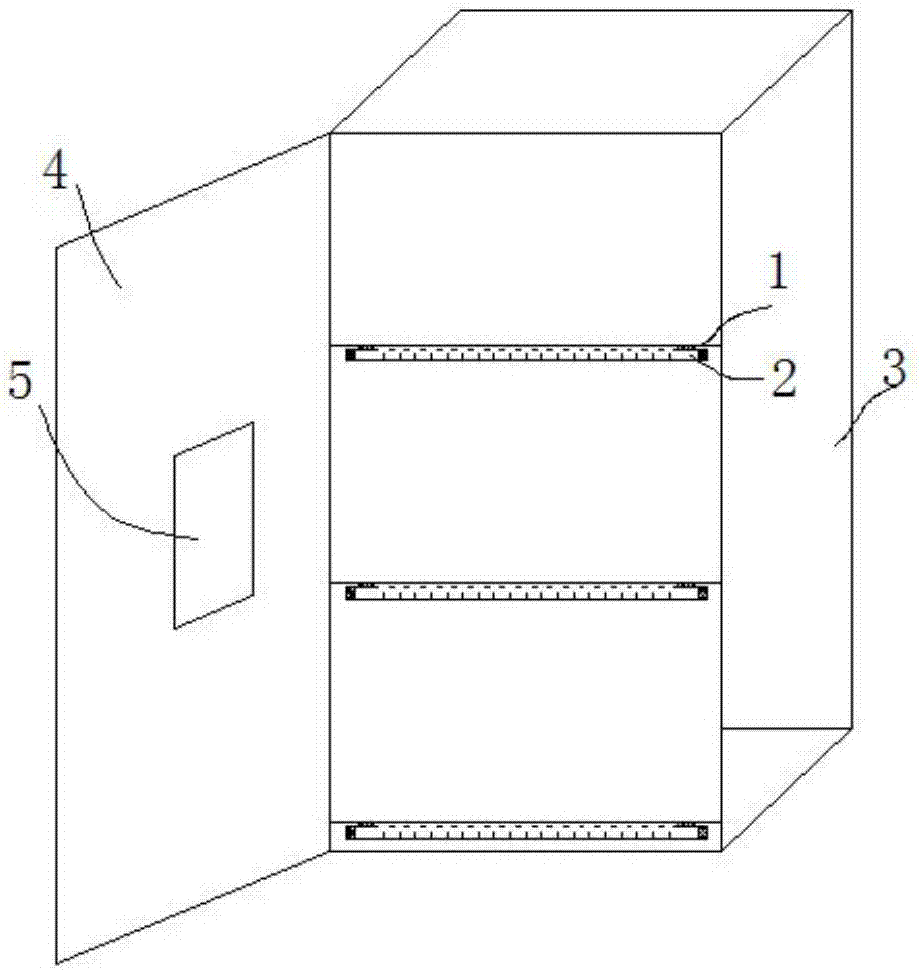

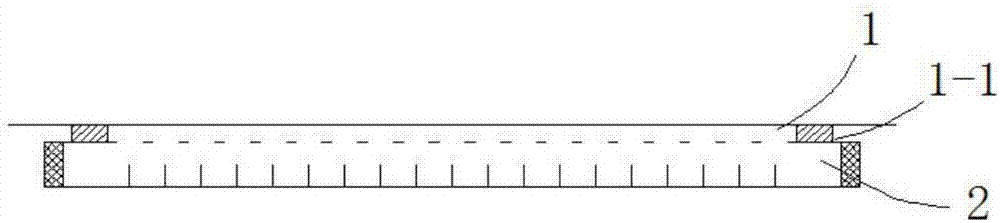

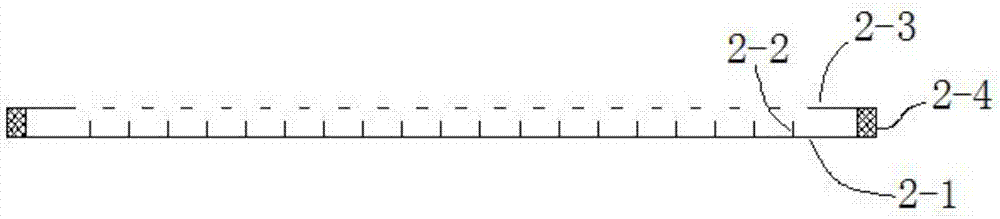

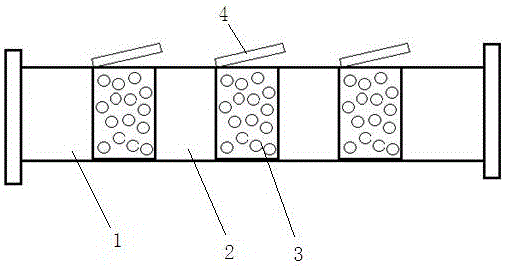

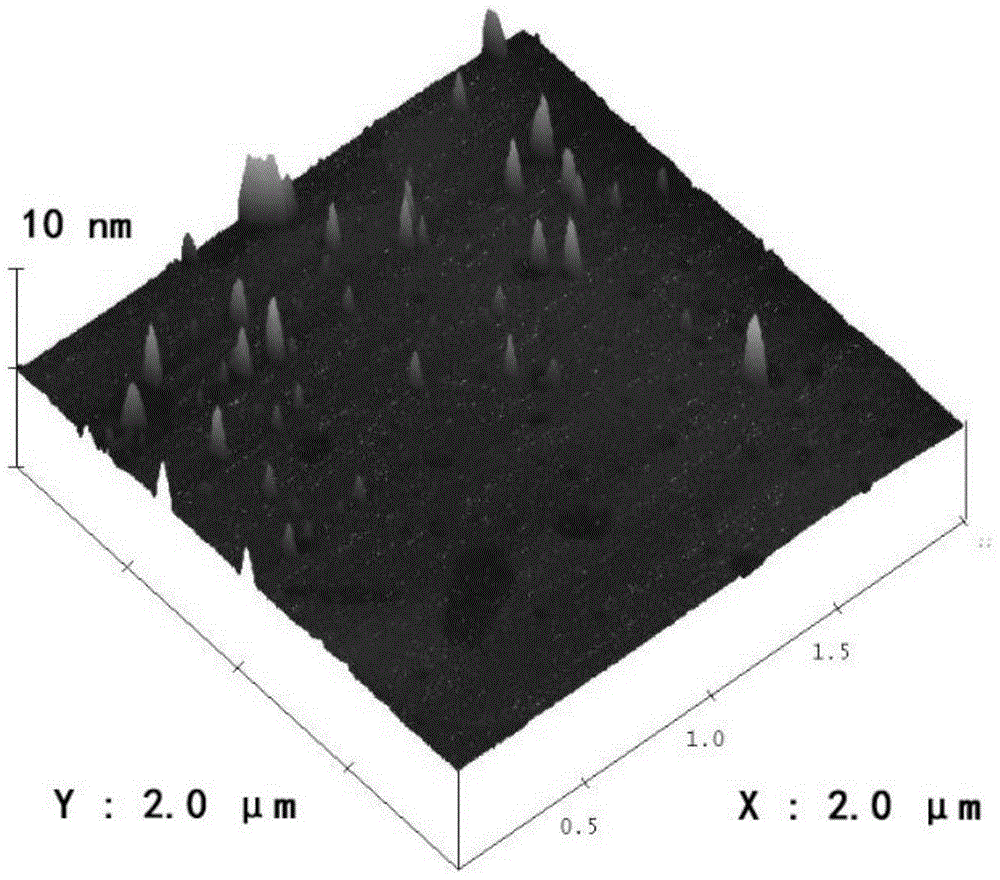

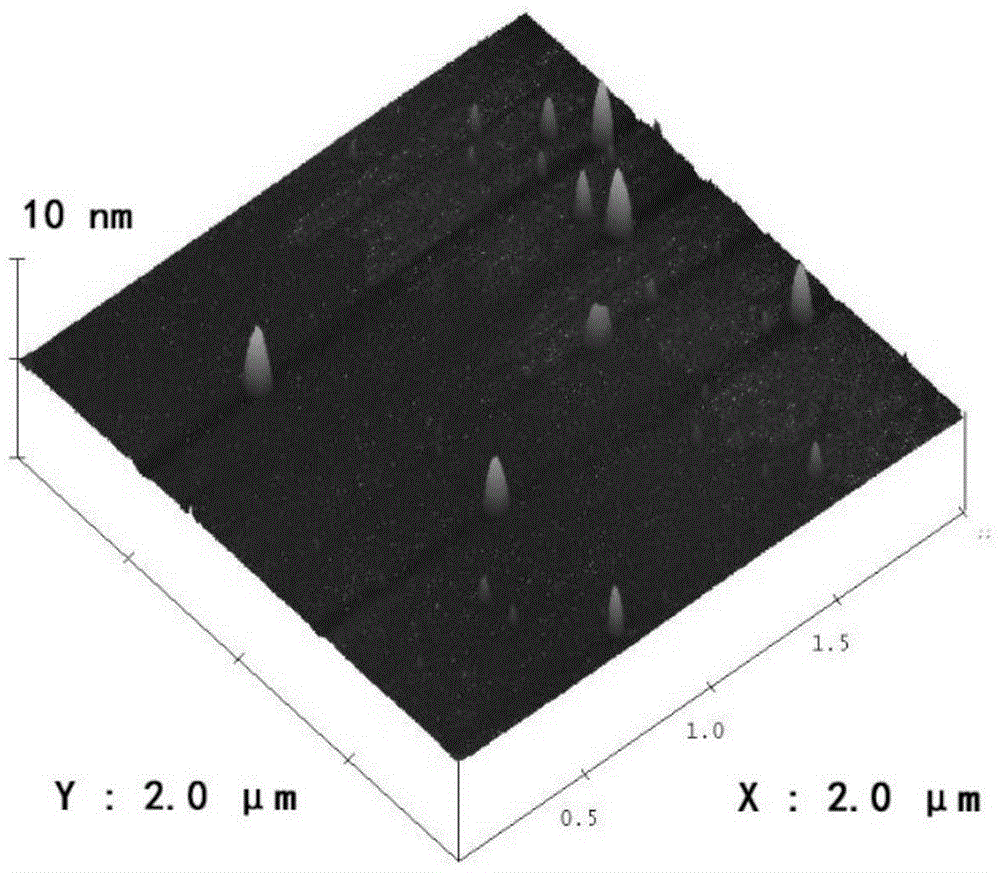

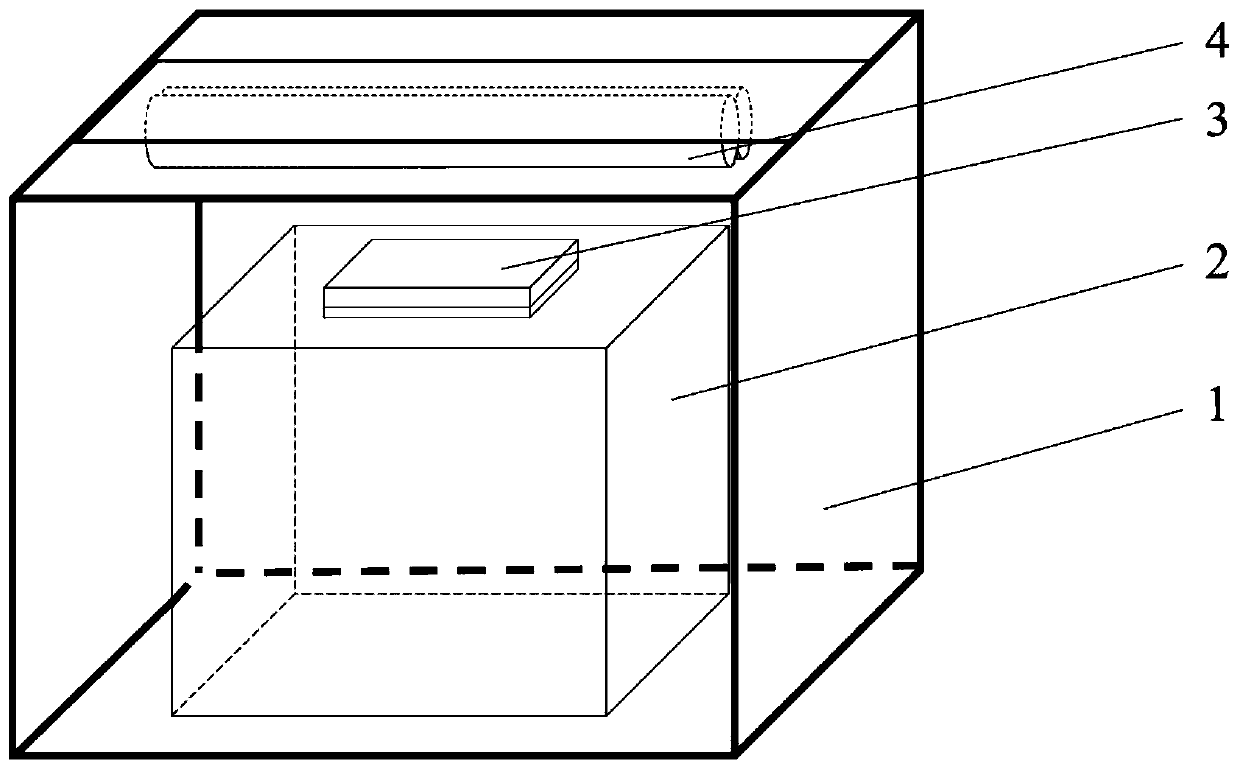

Photodynamic sterilizing device for foods and application of photodynamic sterilizing device for foods

PendingCN112293643ASmall difference in resultsFlavor destructionFood preservationLuminous intensityNutrition

The invention belongs to the technical field of food sterilization and discloses a photodynamic sterilizing device for foods and application of the photodynamic sterilizing device for foods. The photodynamic sterilizing device for the foods comprises a hollow box body, wherein an openable / closeable front door or door curtain is arranged on one side face of the box body, a plurality of LED lamp tubes are arranged at the internal top of the box body, all the lamp tubes are connected in series, and each lamp tube can be disassembled freely; the device further comprises a photosensitizer; the LEDlamp tubes are LED lamp tubes emitting red light or LED lamp tubes emitting blue light; and the photosensitizer is either sodium magnesium chlorophyll or curcumin. According to the device disclosed bythe invention, the intensity and stability of output light are good, and the light intensity of all places of the same horizontal plane inside the device is unified and uniform; and the LED lamp tubes in the device can be disassembled freely, and the LED lamp tubes of different light emitting strength can be selected. The device disclosed by the invention is simple and is relatively low in cost.According to the device disclosed by the invention, the efficiency of sterilization is high, and original flavors, texture and nutrients of foods are not destroyed. The device disclosed by the invention is applied to the field of food sterilization.

Owner:FOSHAN UNIVERSITY

Soft package food sterilization machine

InactiveCN101161132AWon't hurtSmall footprintFood processingFood preservationWater savingFruit juice

A soft casingfood sterilizing machine, is suitable to sterilize for all model and specification, various shape soft casing can, fruit cup, syrup which weight is between 25 to 3000g. The machine includes frame, feeding mechanism, sterilization box, cooling box, hot water cycle device, cold water cycle device, the characteristics is that setting floating-proof device; the feeding mechanism transports material with net belt; the sterilization box and the cooling box is arranged with clapboard for locating holes; the floating-proof device connects drive transmission shaft to a second driven shaft through transmission chain, the second driven shaft connects with the main axis of the floating-proof through gear and to the driven shaft of the floating-proof through floating-proof chain, setting pressing board on the floating-proof chain, the pressing board is arranged with perforations. The present invention can be used widely, saves working time; can not damage packing surface during running; sterilization effect is good, energy as well as water saving; the whole structure is compact, the ground area occupied is small, space using efficiency is high, throughput is big.

Owner:象山双鱼轻工机械有限公司

Solid hydrogen peroxide sustained release preparation and preparation method thereof

ActiveCN102144664AEasy to useConvenient storage and transportationFruit and vegetables preservationFood sterilizationAdduct

The invention relates to a sustained release preparation and a preparation method thereof and particularly discloses a solid hydrogen peroxide sustained release preparation and a preparation method thereof. The solid hydrogen peroxide sustained release preparation is characterized by being prepared by taking a solid hydrogen peroxide adduct as a main agent and adding solid weak acid, water absorbing materials and auxiliaries according to a certain proportion, wherein the weight percentages of all the components are as follows: 0.1-99% of the solid hydrogen peroxide adduct, 0.1-98% of the solid weak acid, 0-98% of the water absorbing materials and 0-98% of the auxiliaries. The solid hydrogen peroxide sustained release preparation and the preparation method thereof which are provided by the invention have the beneficial effects that: the solid hydrogen peroxide sustained release preparation can be conveniently used for food sterilization and fruit and vegetable preservation and can be stored for a long term and the solid hydrogen peroxide adduct releases hydrogen peroxide when encountering water and is easy to control; the release speed and the sustained-release period of the hydrogen peroxide can be regulated according to needs; the sustained release preparation is simple in production and has small investment and low cost; and the solid hydrogen peroxide sustained release preparation is a solid powdered product and can be conveniently stored and transported.

Owner:SHANDONG AOWEITE BIOTECH CO LTD

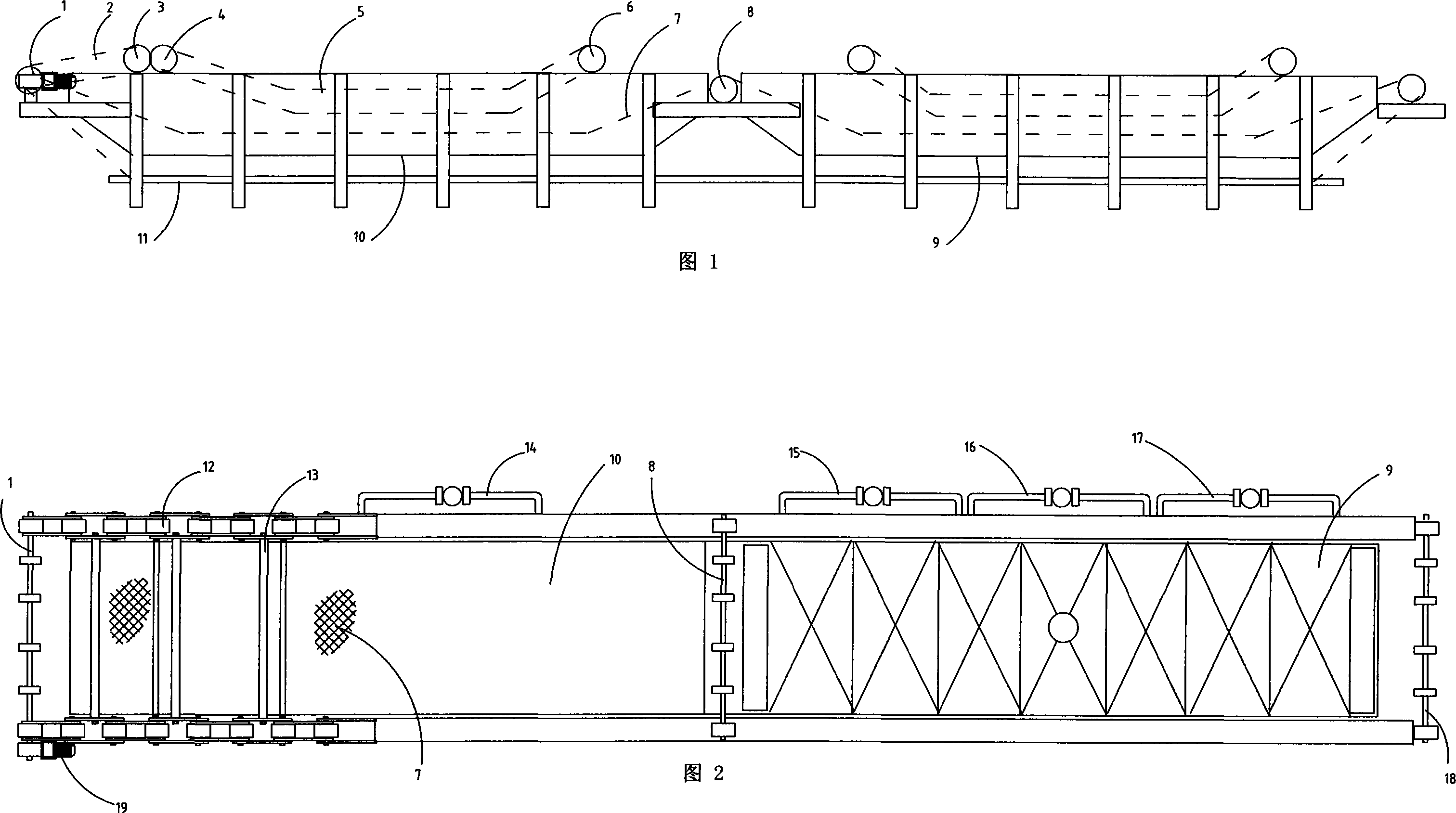

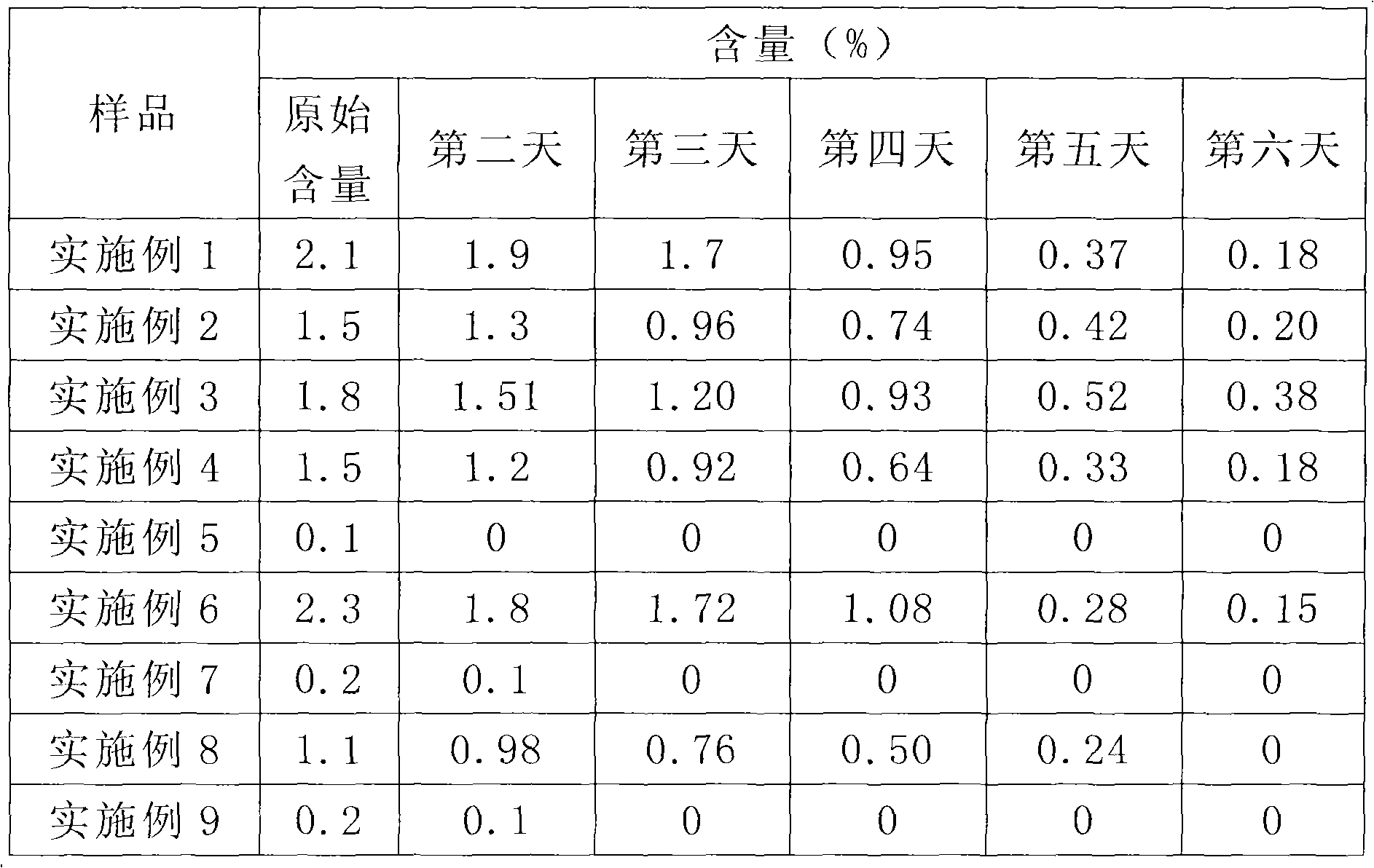

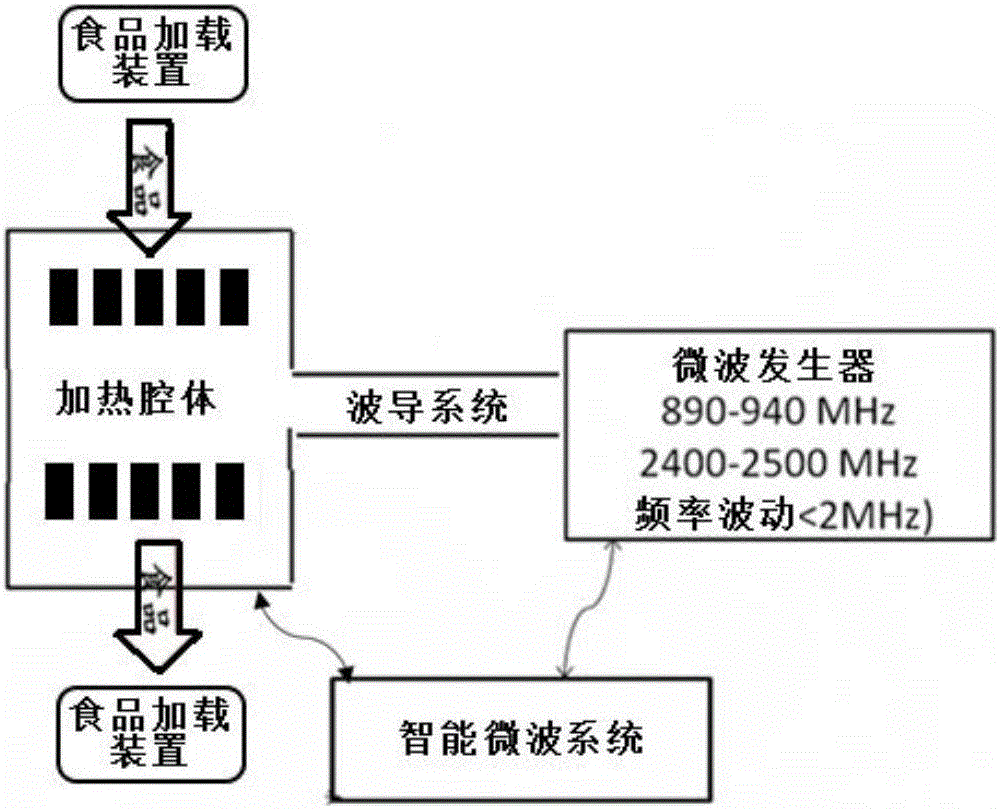

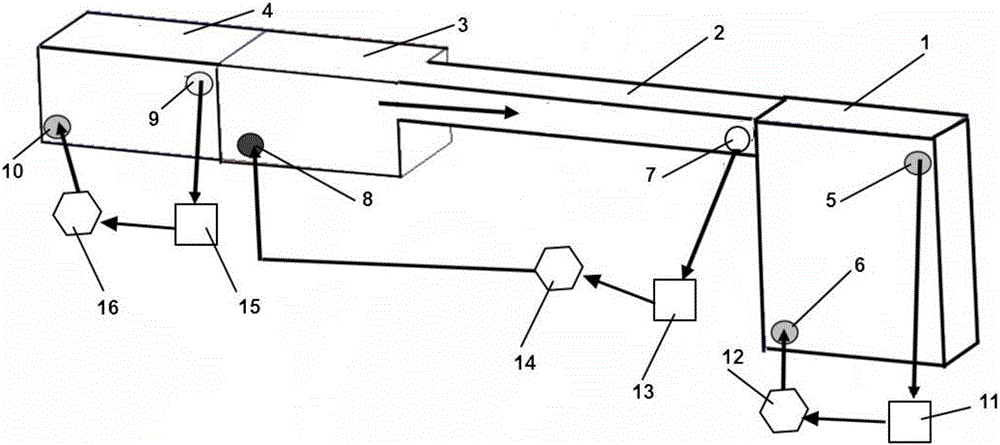

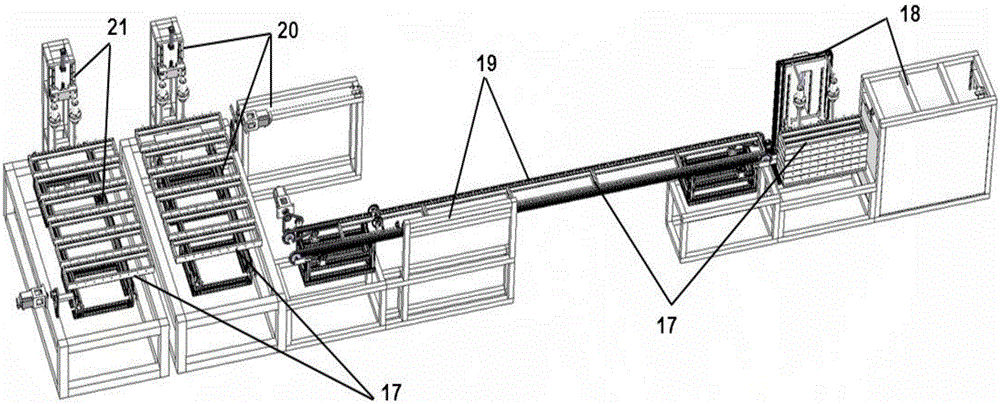

Microwave heating method and intelligent microwave system

InactiveCN106472947AImprove food heating qualityImprove heating qualityFood preservationWater circulationCooling temperature

The invention relates to the technical field of food processing, and discloses a microwave heating method and an intelligent microwave system. The method comprises the following steps of through a first water circulation system, heating water in a preheating cavity to a preheat temperature, and preheating foods; through microwaves, heating water in microwave heating cavities to heating and sterilizing temperature, and heating foods; through a second water circulation system, maintaining water temperature to be the heating and sterilizing temperature, and sterilizing the foods; and through a third water circulation system, heating water in a cooling cavity to cooling temperature, and cooling the foods. The intelligent microwave system is used for controlling a food loading device to remove foods into and out of a working cavity body and move the foods in the cavity body, performing real-time monitoring on the flow speed and the water temperature of the water in the cavity body, and controlling microwave generation power. The industrialized application of microwave heating is realized through the food loading device and the intelligent microwave system, and independent water circulation systems are used, so that food heating quality is improved.

Owner:SHANGHAI OCEAN UNIV

Food fresh-keeping method by using biological bacteriostatic agent in combination with ultra high pressure-assisted thermal treatment

ActiveCN103750497AInhibition of germinationEffective passivationFood preservationSpore germinationUltra high pressure

The invention belongs to the field of food preservation and fresh keeping and in particular relates to a food fresh-keeping method by using a biological bacteriostatic agent in combination with ultra high pressure-assisted thermal treatment. The food fresh-keeping method comprises the following steps: (1) carrying out thermal treatment on low acid food; (2) adding the biological bacteriostatic agent to the low acid food subjected to thermal treatment, wherein the biological bacteriostatic agent comprises the following components of 0.1-0.5g / kg of nisin, 0.1-0.5g / kg of chitosan, 0.1-0.5g / kg of muramidase, 0.1-0.4g / kg of epsilon-polylysine, 0.2-1g / kg of allicin and 20-250g / kg of sodium chloride; and (3) carrying out temperature and ultrahigh pressure treatment. By using the food fresh-keeping method, bacterial spores in the low acid food can be effectively passivated and spore germination can be inhibited at 4 DEG C when the low acid food is stored within a shelf life of 20 days, and meanwhile, the losses of textures, flavor, nutrition and color caused by a conventional high temperature and high pressure food sterilization method can be avoided; and the food fresh-keeping method is especially advantageous to the low acid food with pH not less than 4.5.

Owner:INST AGRO PROD PROCESSING ANHUI ACADEMY AGRI SCI

Method of sterilizing and enzyme-eliminating for fluid food

The present invention relates to a sterilization enzyme-inactivating method for fluid foods. Said fluid foods includes liquid or semi-solid foods, such as fresh milk, watermelon juice, apple juice, orange juice, tomato juice, strawberry juice, vegetable juice, pulpy fruit juice and vegetable paste, etc. It is characterized by that said invention adopts combination of pasteurization and high-voltage pulse electric field to make sterilization and inactivate enzyme. Its electric field intensity is 75-50 kV / cm.

Owner:殷涌光

Refrigerator

InactiveCN105805999AEnsure safetyExtended shelf lifeLighting and heating apparatusDomestic refrigeratorsPreservativeControl system

The invention discloses a refrigerator. The refrigerator comprises a sterilization chamber, a magnetic field generating piece, a preservative module and a control system. The magnetic field generating piece can form a magnetic field in the sterilization chamber. The preservative module can spray preservatives to the sterilization chamber. The control system is at least used for controlling starting and stopping of the preservative module. Compared with the prior art, the refrigerator provided by the invention has the following beneficial effects that the magnetic field is adopted for 360-degree sterilization without dead corners, the refrigerator has no harmful chemical substance, the eating safety of food is guaranteed, and the food sterilization efficiency is improved; and while sterilization is conducted, the preservatives are sprayed to the surface of the food, so that the preservatives play roles in preservation and isolation, the dual functions of preservation and sterilization are achieved at the same time, and accordingly the quality guarantee period of the food is prolonged to a great extent.

Owner:HAIER SMART HOME CO LTD

Low-temperature plasma device used for food sterilization and freshness retaining

PendingCN107241849AInhibitory activityReduce decomposition rateFood preservationPlasma techniqueDecompositionEngineering

A low-temperature plasma device used for food sterilization and freshness retaining includes a supporting plate for placing food, a plasma generation device, a shell, a door and a circuit control module. The supporting plate and the plasma generation device are connected through an insulating medium, spray points of the plasma generation device are welded on a metal plate, the metal plate and a ground electrode are connected through an insulating medium, the spray pints are arranged in centers of circular holes of the ground electrode, the metal plate is connected with a high voltage end which is connected with a high voltage power supply, and the ground electrode is connected to the ground. The device generates plasma through a special discharge structure, utilizes ionic wind to drive flow of air, some active ingredients in the plasma react with microorganisms on the surface of food, thereby killing the microorganisms, the active ingredients react with some enzymes inside the food, thereby inhibiting activity of the enzymes, the decomposition rate of organic matter is slowed down, food and daily utensils are sterilized, and the shelf life of food can be prolonged, thereby realizing sterilization and freshness retaining of food under a low-temperature condition.

Owner:YUNNAN AEROSPACE IND

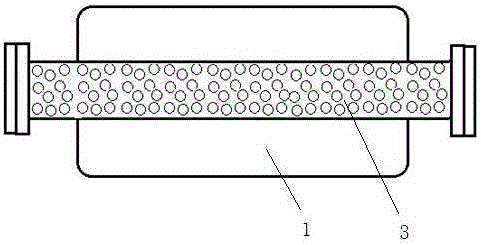

Liquid food sterilizing and disinfecting method and apparatus thereof

InactiveCN105831551ASimple structureContinuous effective sterilization and disinfectionMilk preparationFood preservationLysozymeLiquid food

The invention relates to a liquid food sterilizing and disinfecting method. Bacteria in a liquid food are instantly killed by adopting a catalytic reaction; a catalyst adopted in the invention is a biological bactericide, the biological bactericide is one of or a combination of an antibacterial peptide, lysozyme and lysostaphin, the temperature in the use process of the antibacterial peptide is controlled to be -80 - 120DEG C, and the pH value is 4-9; and the temperature in the use process of the lysozyme and lysostaphin is controlled to be 2-50DEG C, and the pH value is controlled to be 5-7. The invention also provides a liquid food sterilizing and disinfecting apparatus. The liquid food sterilizing and disinfecting apparatus adopts a reactor, the reactor is a tubular reactor or a barrel reactor, and a grid or a nozzle is arranged in the reactor. The method and the apparatus have the advantages of concise structure, high convenience and practicality, and realization of continuous and effective sterilization and disinfection of liquid foods.

Owner:GENLOCI BIOTECH

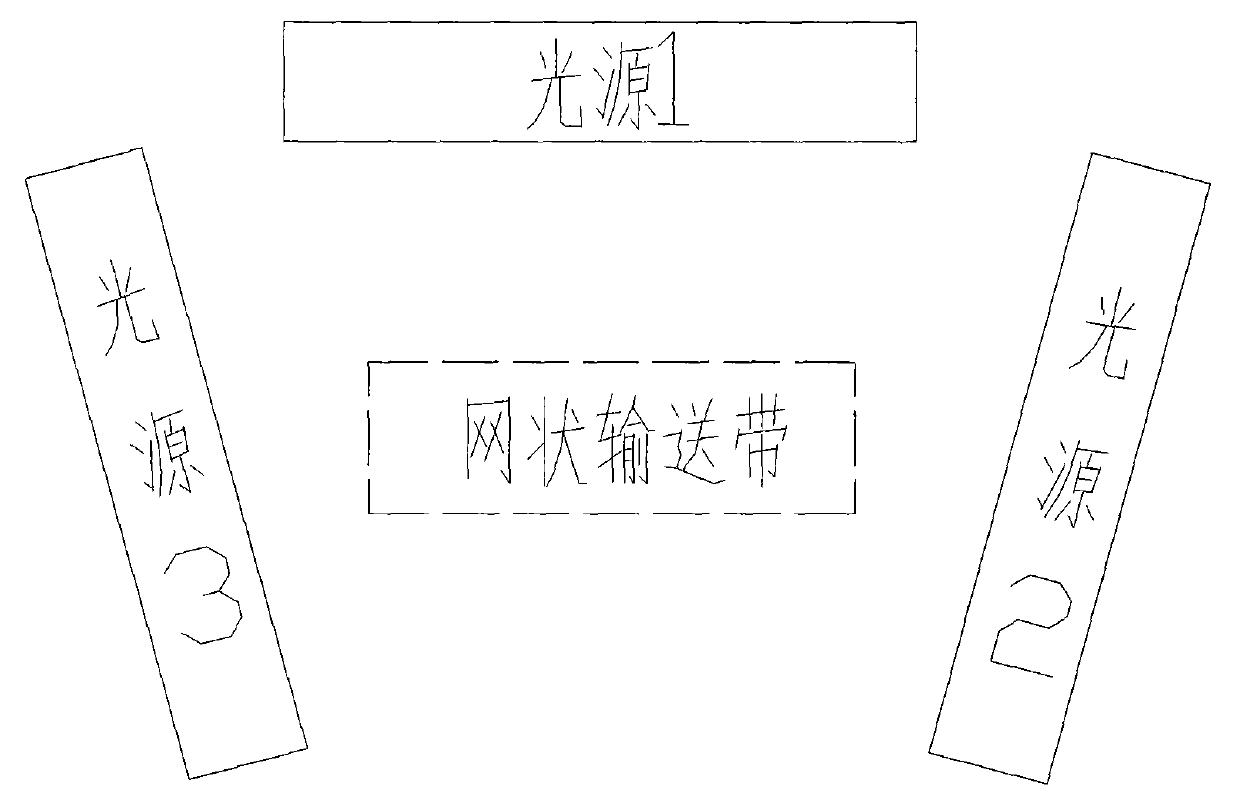

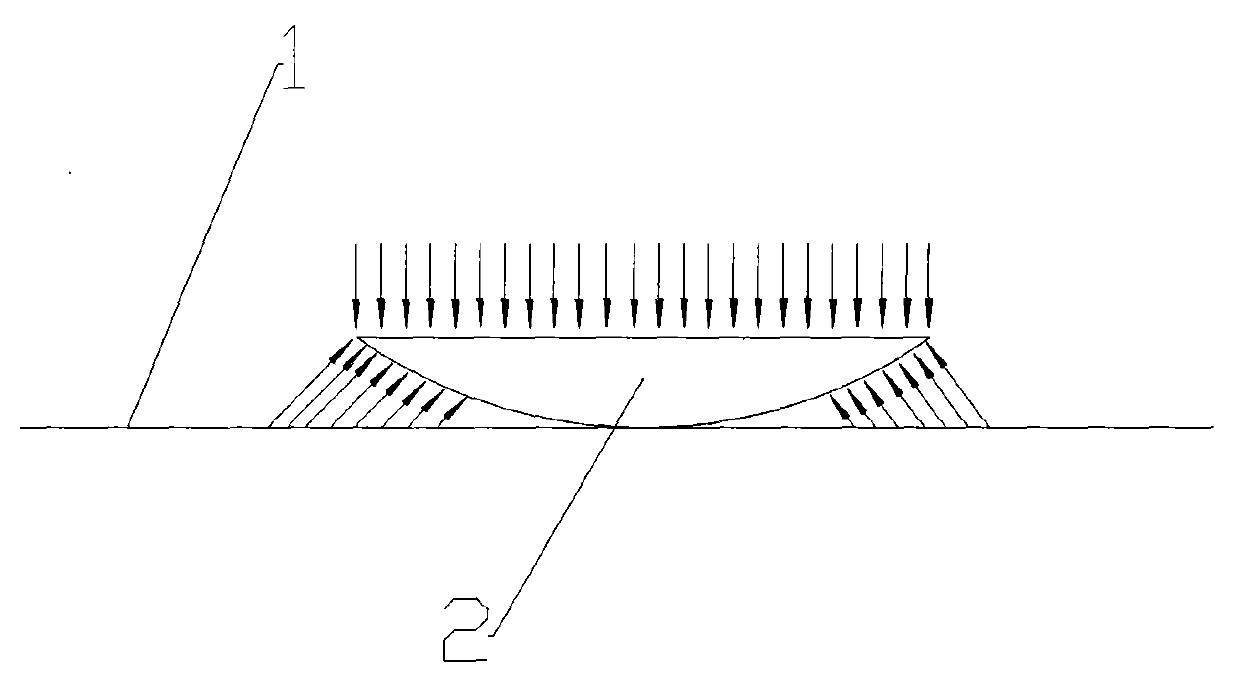

Pulsed intensive light sterilization method for betel nuts

InactiveCN104188047AGuaranteed radiation effectLittle change in qualityFood preservationProduction lineBetel nuts

The invention belongs to the technical field of food processing, relates to a food sterilization method and in particular relates to a pulsed intensive light sterilization method for betel nuts. The method is characterized in that a pulsed intensive light processing process is increased on a betel nut processing production line, wherein pulsed light source irradiation is adopted in the pulsed intensive light processing process, the light intensity is 1-8kJ / cm<2>, the pulse width is 3-10 microseconds, and the flash frequency is not less than 4 times. The pulsed intensive light processing process is performed after a betel nut processing and slicing process, the sterilized betel nuts penetrate through the pulsed intensive light processing process along with conveyor belts before a packaging process, and the conveyor belts comprise a meshed belt and a mirror surface belt which are sequentially arranged at an interval, the meshed belt adopts a three-sided light source irradiation mode comprising 180-degree horizontal top irradiation for betel nut shells and 75-85-degree irradiation on two sides, and the mirror surface belt adopts a top horizontal flash light source. The method has the beneficial effects of uniform irradiation, good sterilization effect, high production efficiency, capability of obviously prolonging the quality guarantee period of the betel nut products, slight influence on quality of the betel nut products and the like.

Owner:HUNAN ONYEAR FOOD +1

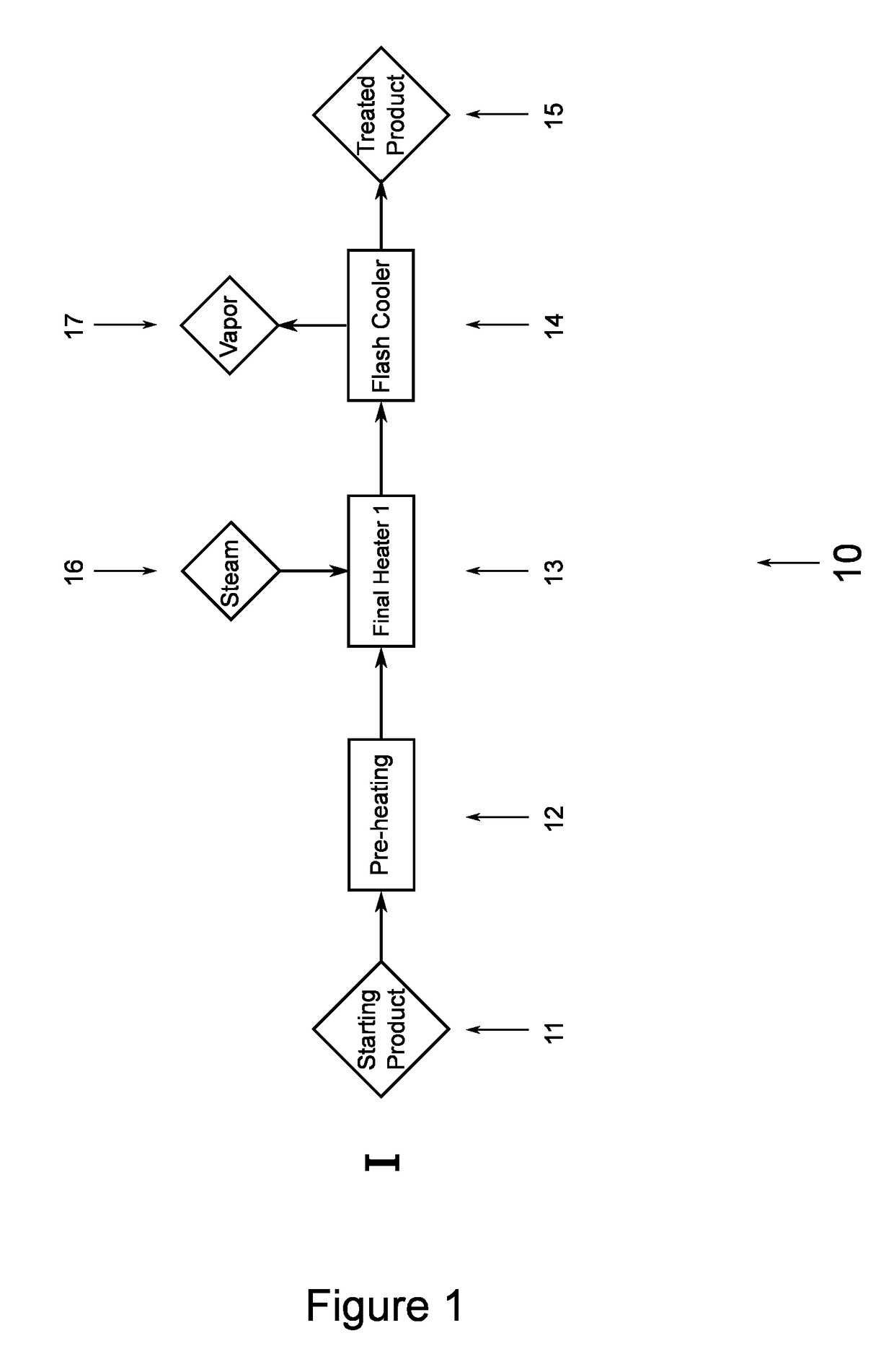

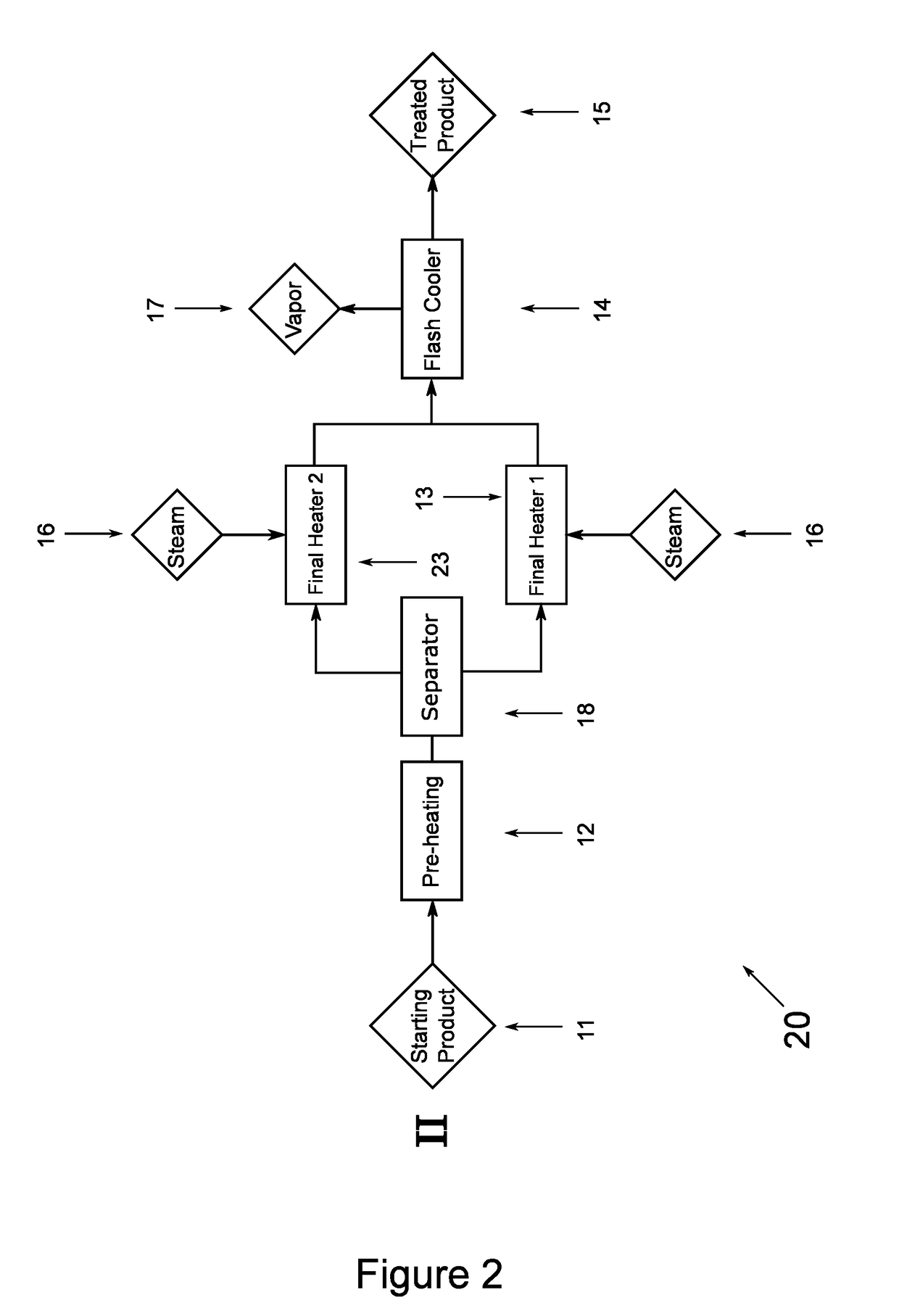

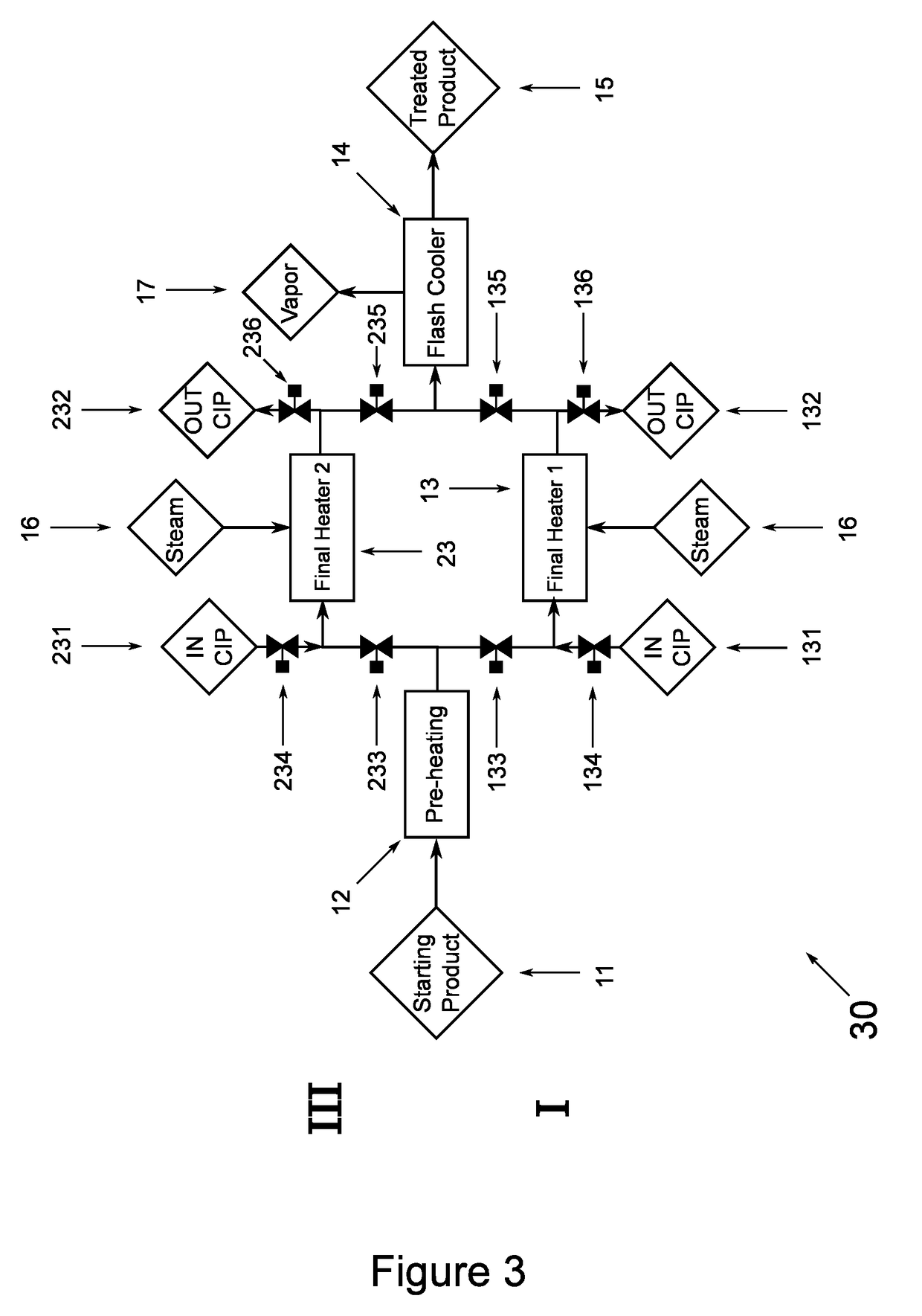

Method of cleaning a high temperature food processing line in place and food sterilization line

A high temperature food treatment method is disclosed wherein by alternatingly operating between a first final heater (13) and second final heater (23) arranged in parallel on a food processing line (30, 40, 50), it is possible to operate a continuous process, yet significantly reducing the overall downtime of the processing line (30, 40, 50), by performing a cleaning in place process on the final heater (13, 23), not currently being used in the high temperature food treatment process, thereby eliminating or significantly reducing the influence on the processing line (30, 40, 50) downtime by the process elements and / or processing equipment most easily contaminated.

Owner:SPX FLOW TECH DANMARK

Method for improving fruit and vegetable powder microwave sterilizing effect using steam pre-treatment

InactiveCN1899050AExtended sterilization methodsNo residueFruits/vegetable preservation by dehydrationElectricityMicrowave

The steam pre-treatment method for raising the microwave sterilizing effect of fruit and vegetable belongs to the field of dewatered fruit and vegetable sterilizing technology. The technological process includes the first steam heating on fruit and vegetable powder with water content of 2-7 wt% for 5-15 min to raise water content to 13-22 wt% and the subsequent microwave drying and sterilizing for 90-150 s. The fruit and vegetable powder through the said sterilizing process has ultimate water content of 2-7 wt%, 3-4 log order lowered bacteria amount and high sanitary quality. The steam pre-treatment can raise the dielectric constant of the fruit and vegetable powder so as to raise the microwave sterilizing effect greatly while providing certain sterilizing effect.

Owner:JIANGNAN UNIV

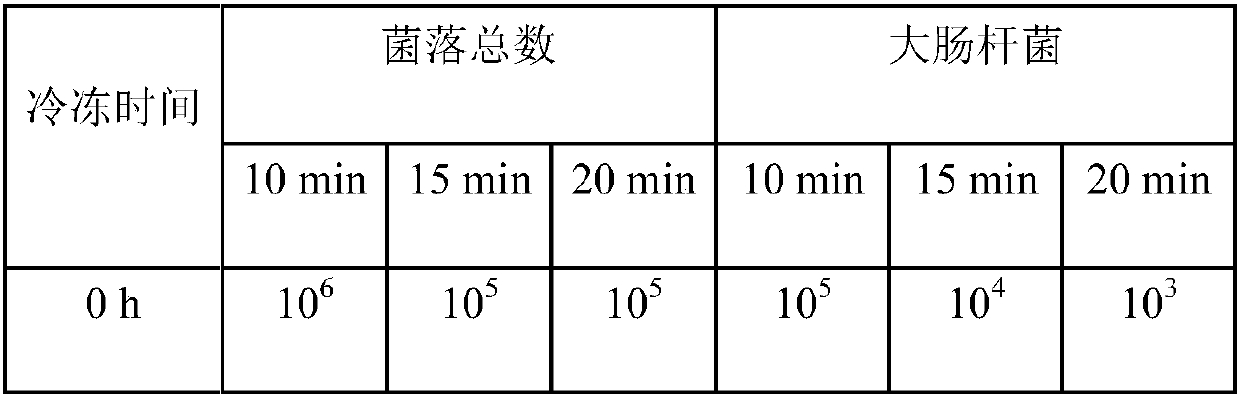

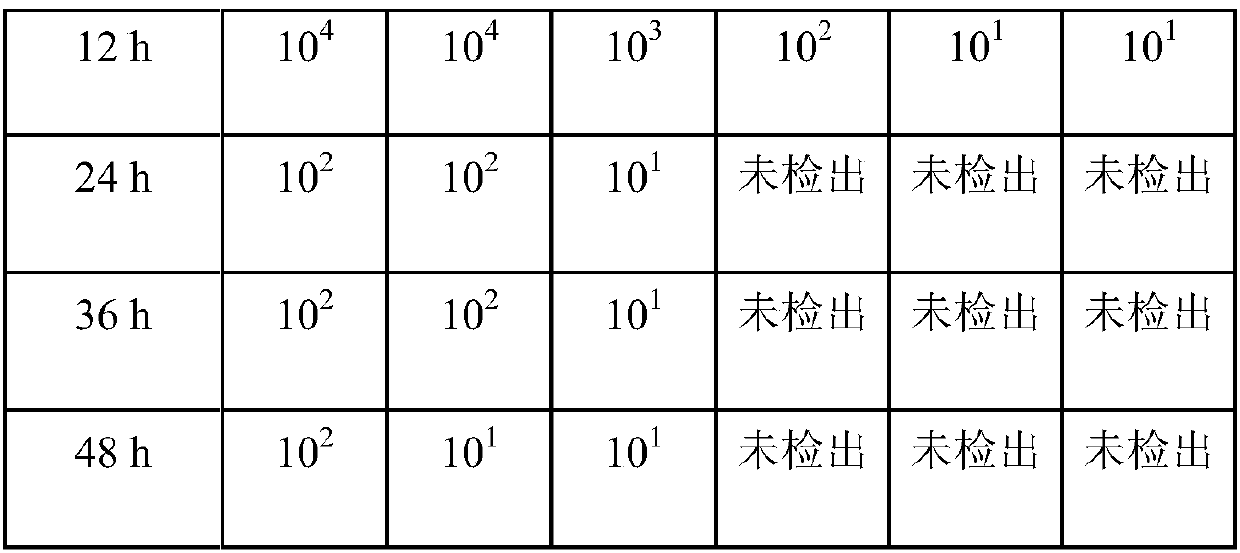

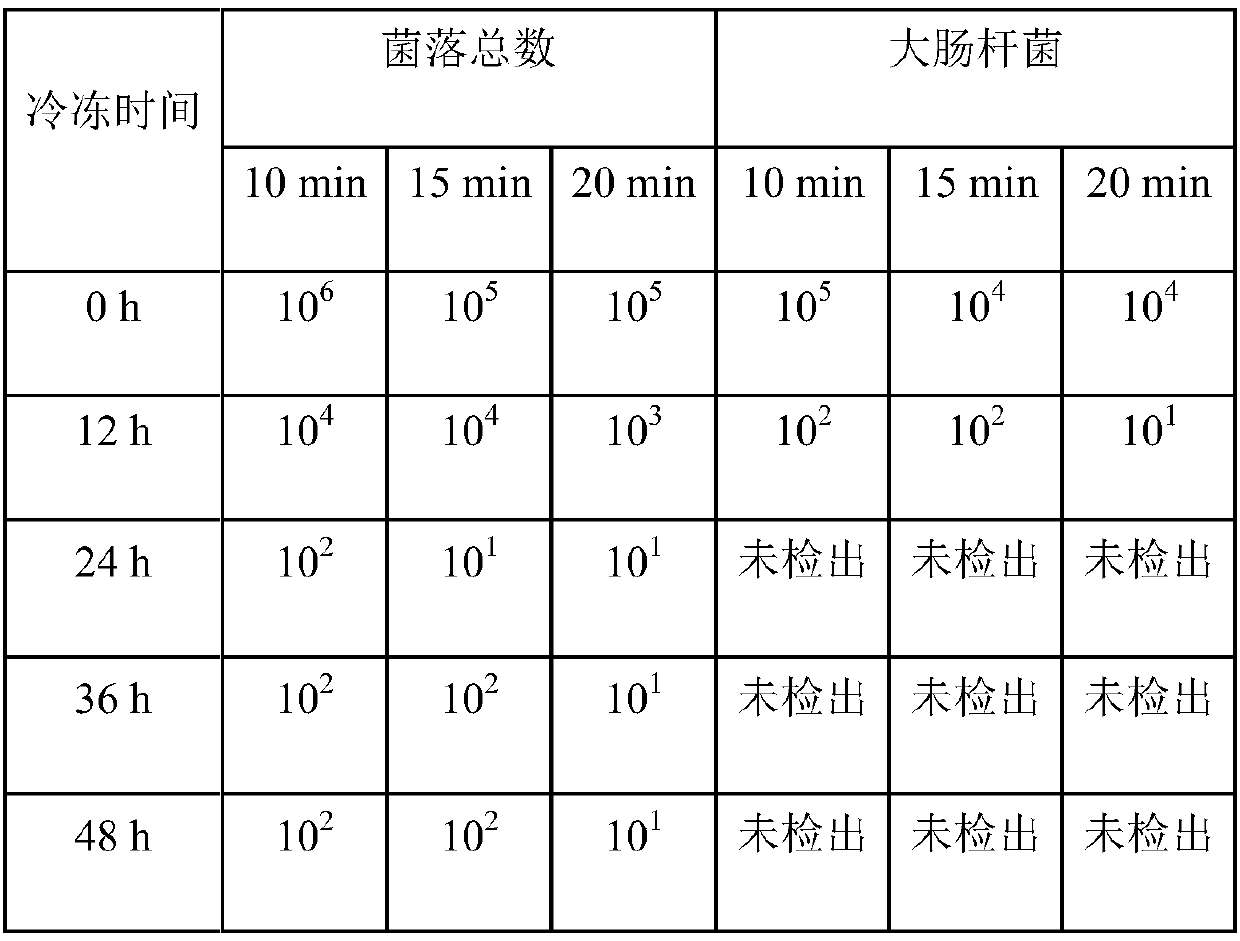

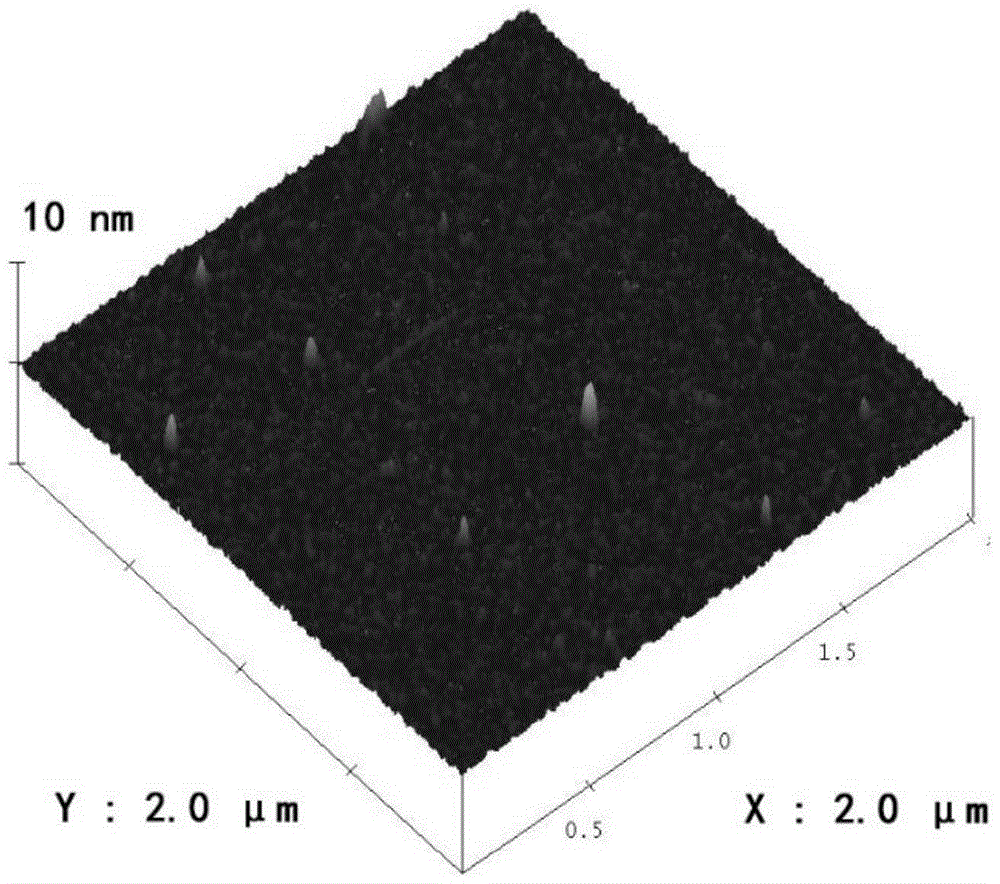

Method for sterilizing low-acid fruit and vegetable juice by cooperation of freezing pretreatment and ultrahigh pressure

InactiveCN109645296AFood freezingUltra high pressure food processesEscherichia coliUltra high pressure

The invention relates to a food sterilization treatment process, and aims to provide a method for sterilizing low-acid fruit and vegetable juice by the cooperation of freezing pretreatment and ultrahigh pressure. The method comprises the following steps of: placing fresh fruit and vegetable juice just processed in a container; freezing and storing at -20 DEG C for more than 24 hours; thawing thefrozen fruit and vegetable juice at room temperature; carrying out ultra-high pressure treatment of 400-600Mpa on the thawed fruit and vegetable juice; packaging and filling the ultra-high pressure treated fruit and vegetable juice to form commercial products. According to the invention, after freezing, thawing and ultrahigh pressure, the fruit and vegetable juice product can achieve commercial sterilization (the total number of colonies is less than 102CFU / ml, and the pathogenic bacteria-Escherichia coli are not detected) effect. And when the freezing time is more than 24 hours, the sterilization effect is basically unchanged, namely the freezing pretreatment is carried out for 24 hours. In addition, along with the improvement of pressure and pressure maintaining time in ultrahigh pressure processing, the sterilization effect is also gradually improved.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

Method for improving digestibility and reducing anaphylaxis of casein based on far infrared rays

ActiveCN105724578AReduce allergiesAllergenicity reductionMilk preparationCow milkingFood sterilization

The invention discloses a method for improving digestibility and reducing anaphylaxis of casein based on far infrared rays.According to the method, ordinary casein or a product containing ordinary casein is irradiated by far infrared rays.By the adoption of the method, processing steps are simple, processing time is short, processing temperature is low, energy consumption can be reduced, a dramatic leap is made in improving the digestibility of casein in cow milk and reducing the anaphylaxis of casein in cow milk, and the digestibility of casein in cow milk can be improved to 40% or more, which can not be realized with the current enzymolysis means, pasteurization means and other means.The conventional understanding of far infrared ray application is changed; far infrared rays are usually used for food sterilization currently, however, far infrared rays are used for changing the digestibility and anaphylaxis of casein in the method which has never been reported.Damage to the quality of cow milk is small, using is efficient and quick, environment friendliness is realized, and equipment maintenance and technology promotion are benefited.

Owner:SHANGHAI JIAO TONG UNIV

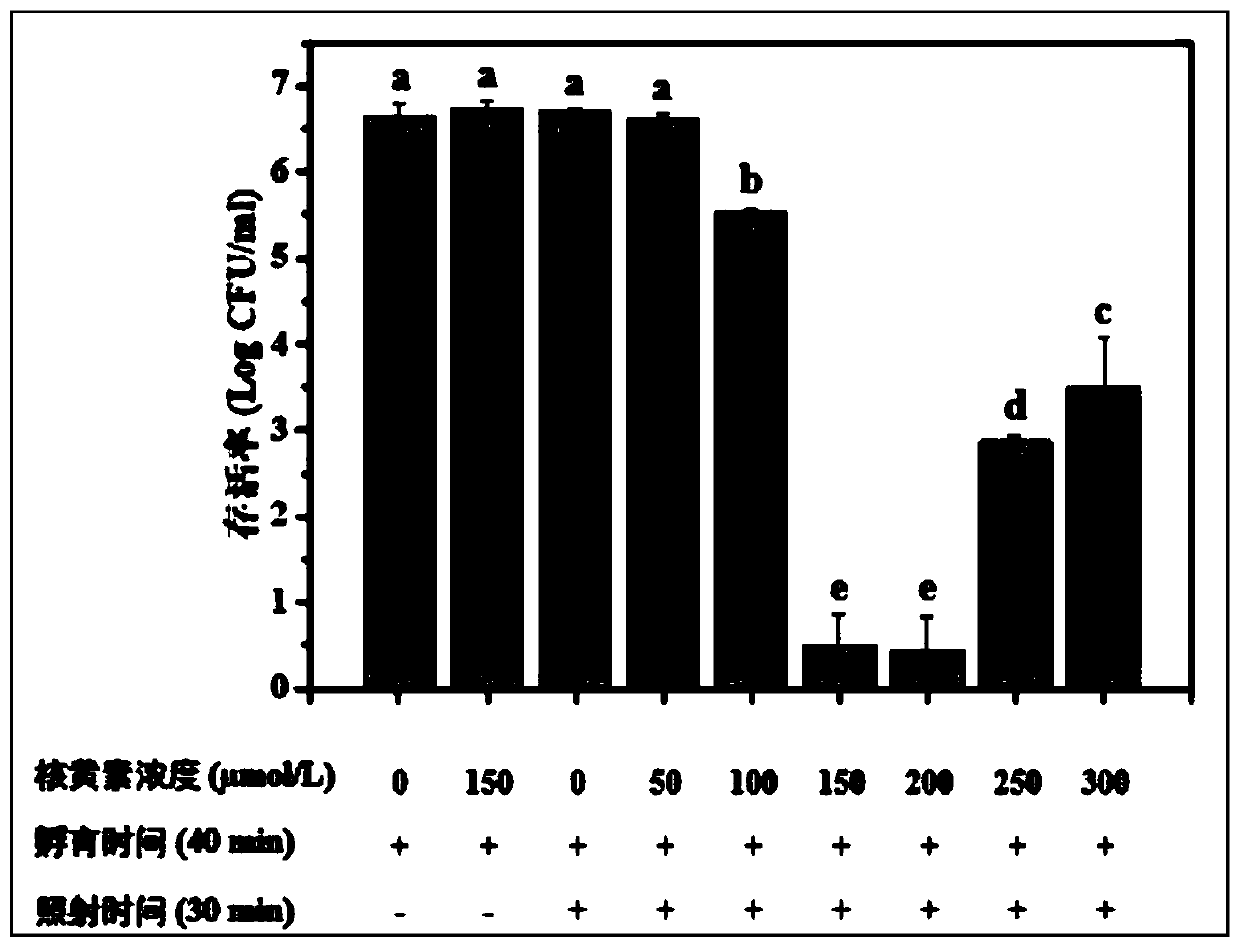

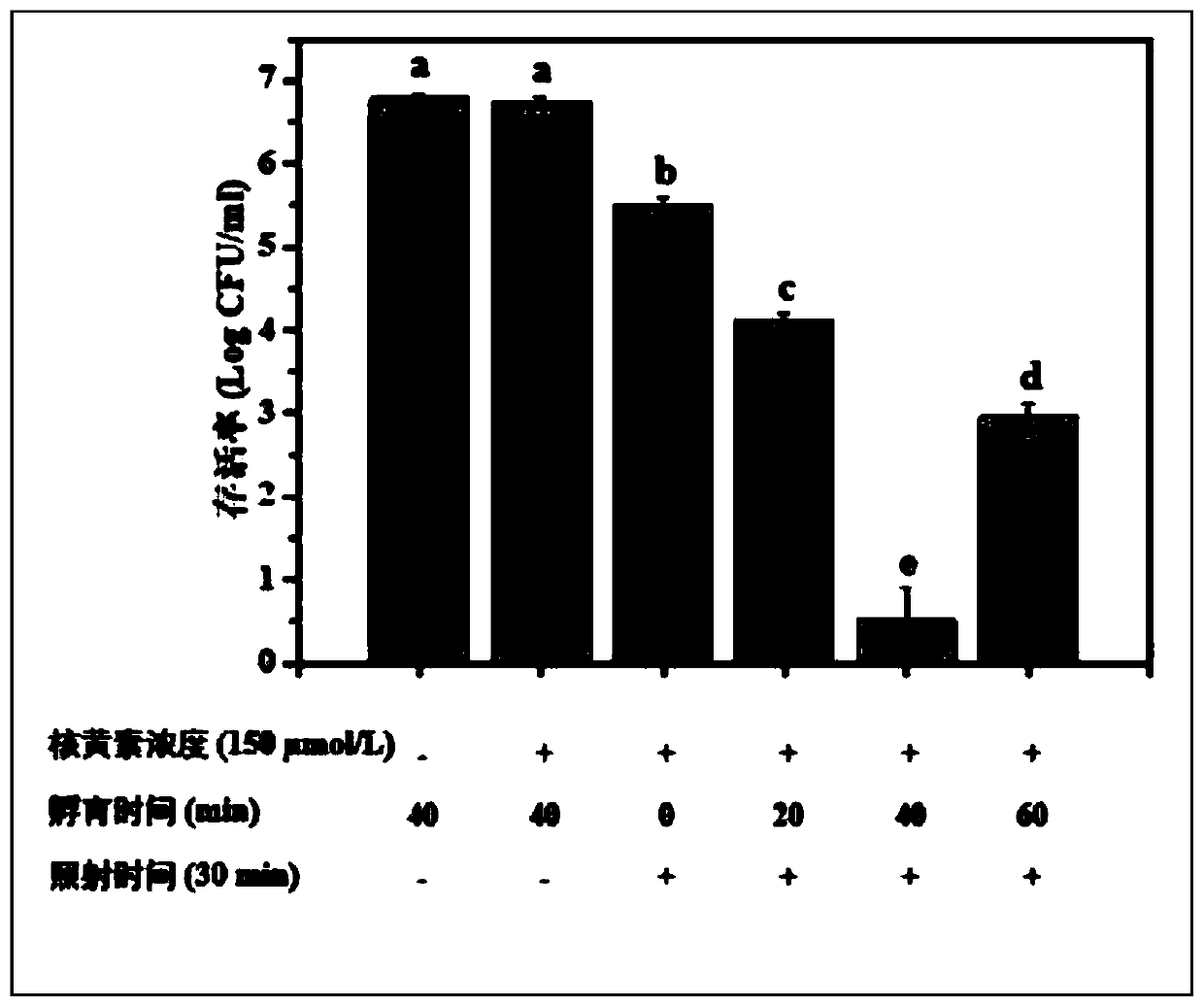

Method for killing salmonellas through photodynamics

PendingCN111067007AEasy to operateLow costEggs preservation by irradiation/electric treatmentBiotechnologySalmonella frintrop

Owner:SHANGHAI OCEAN UNIV

Food sterilization method

InactiveCN101455434ANot easy to appearImprove the bactericidal effectFood preservationExhaust valveFood sterilization

The invention relates to a food sterilizing method comprising the following steps: keeping the food under normal pressure for 15-20 minutes; heating the food to 80-95 degrees centigrade; closing all exhaust valves; heating the sterilization kettle to the temperature of 115-125 degrees centigrade in 15-30 minutes, and preserving the heat for 20-35 minutes; raising the pressure in the sterilization pressure kettle to 0.15MPa-0.2MPa in 3-7 minutes; then opening the cold water valve to make the temperature in the kettle to decrease suddenly, and closing the air compressor valve when the temperature in the kettle is under 50 degrees centigrade; finally, taking out the product. The method can kill the bacteria thoroughly, and causes no secondary pollution.

Owner:张志峰

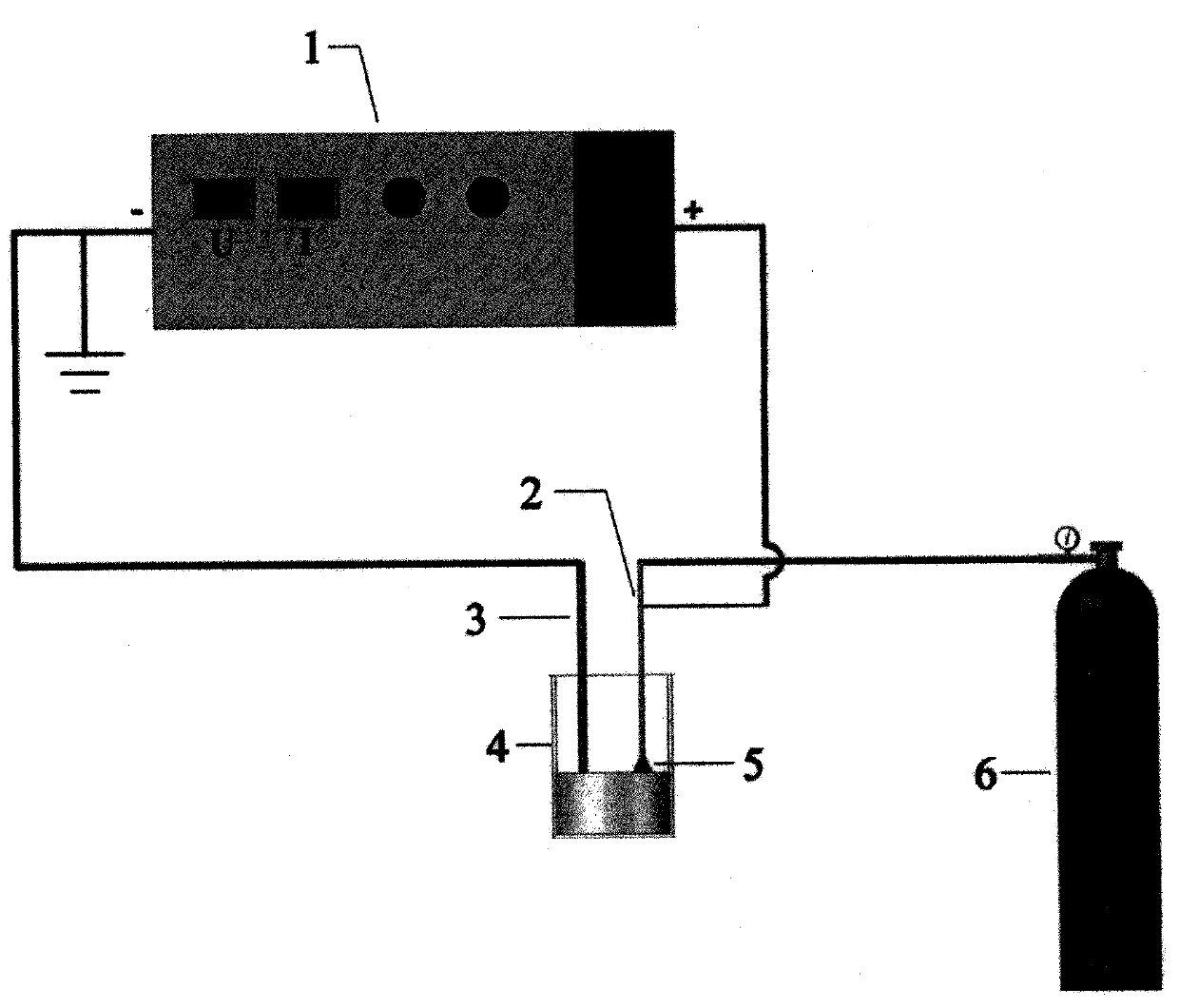

Method for sterilizing liquid food by virtue of micro plasma

InactiveCN104172429ARealize sterilizationLow costFood preservationFood electrical treatmentFood sterilizationEngineering

The invention discloses a method for sterilizing a liquid food by virtue of micro plasma. The method particularly comprises the steps: introducing the liquid food into a micro plasma device; opening an air source, regulating an air flow, starting a direct-current and high-voltage power supply after the air flow is stabilized, starting a discharge reaction, and forming micro plasma between an anode and a liquid level of the liquid food; discharging for 3-10min by using strong sterilizing oxidants such as OH, H2O2 and HO2 generated by the micro plasma so that harmful microorganisms in the liquid food can be effectively killed and the sterilization and disinfection on the foods are realized. According to the actual requirement, the method is capable of simply and conveniently killing the harmful microorganisms in the liquid food at low cost and high processing efficiency, realizes safe guarantee of the liquid food, and has a potential development prospect.

Owner:SUN YAT SEN UNIV

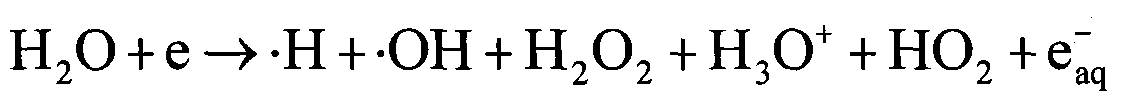

Method For Sterilization Of Food

InactiveUS20120082772A1Improve pressure resistanceDifficult to sterilizePre-baking dough/flour preservationSeed preservation by pressure variationBiotechnologyHigh pressure

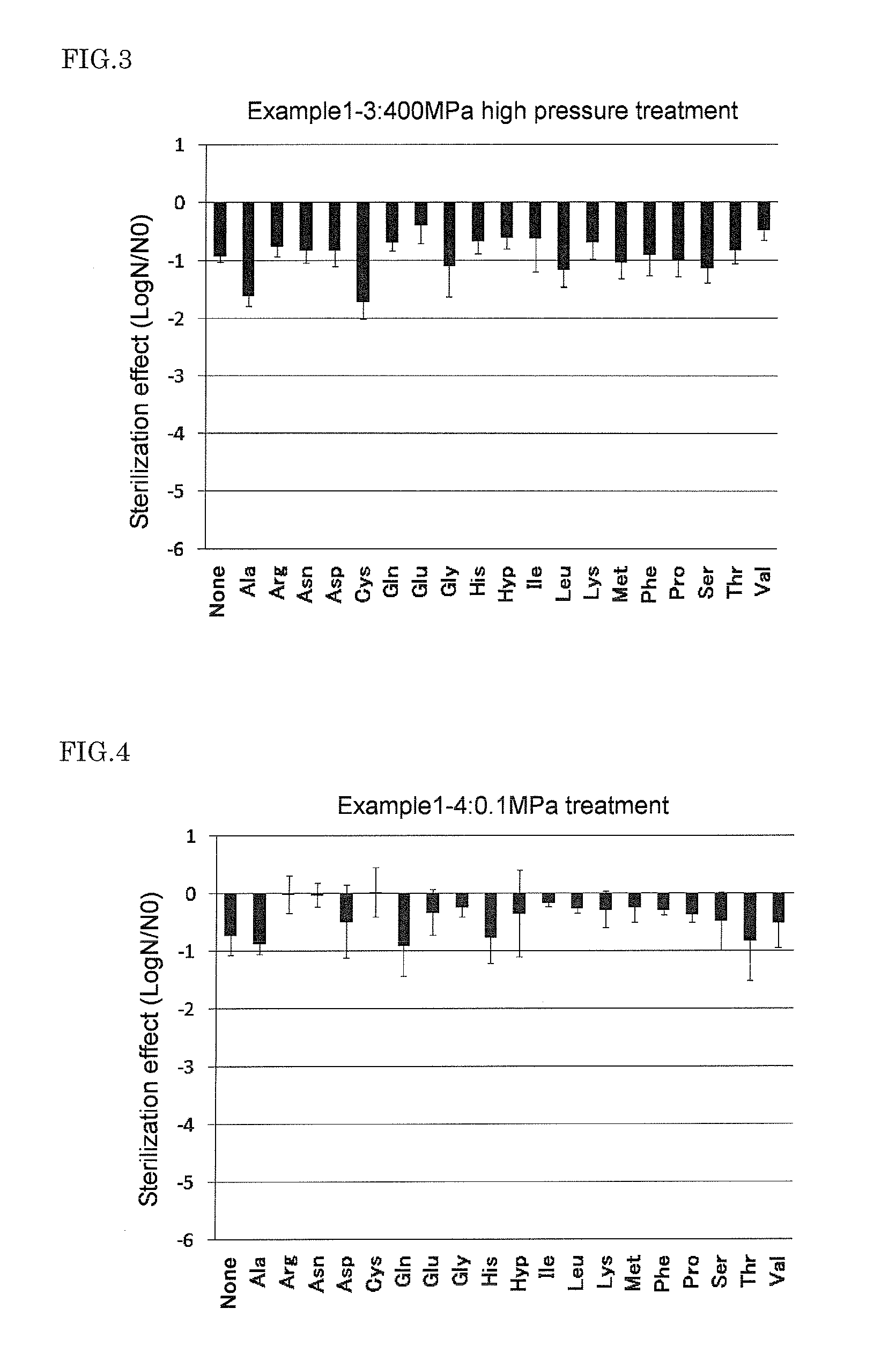

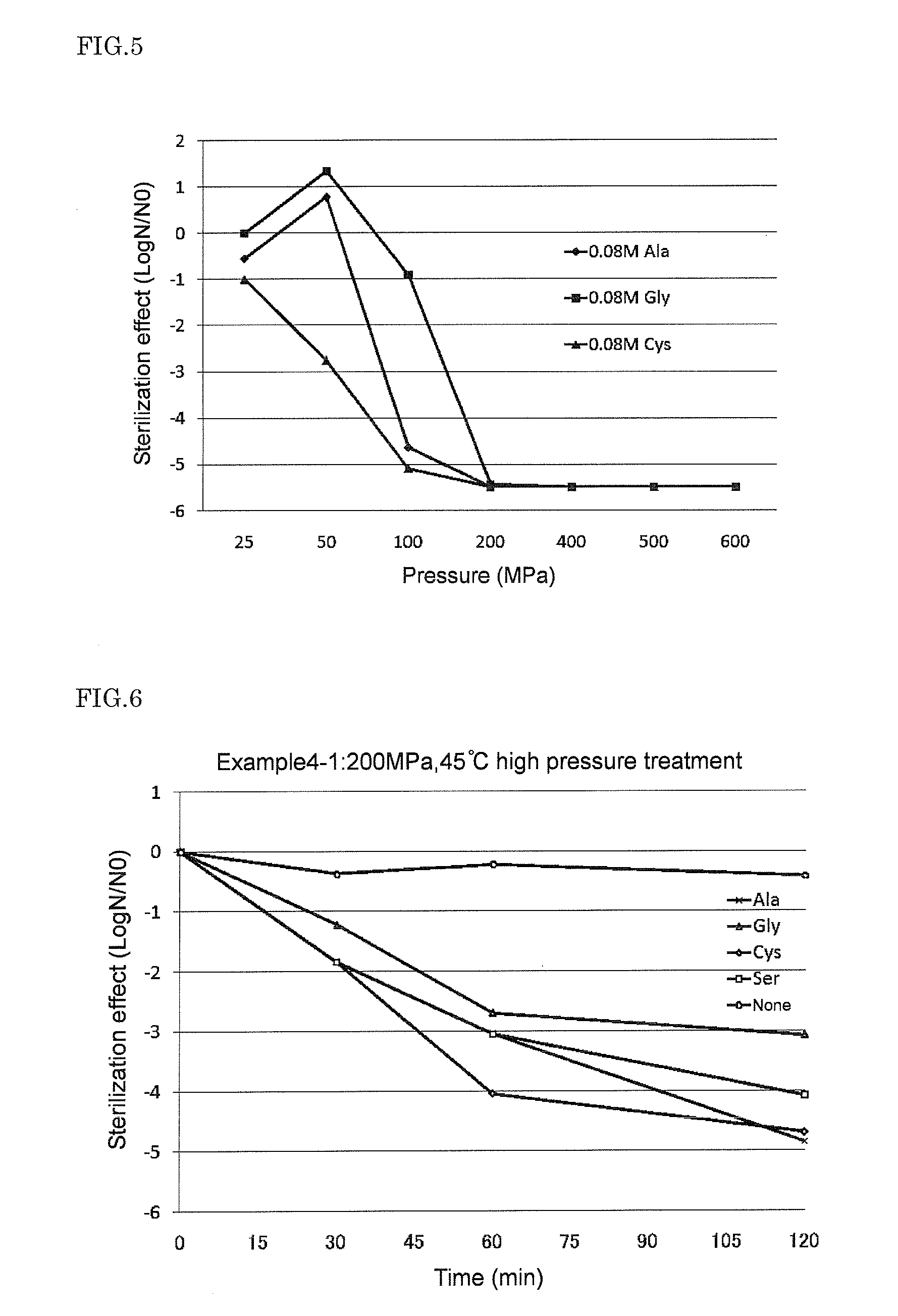

The present invention provides a food sterilization method by which the effective sterilization of the spore-forming bacteria having high heat resistance and high pressure resistance is possible without impairing the taste, flavor, and texture of food. A method for sterilization of food comprising: high-pressure treatment step in which one or more amino acids selected from the group consisting of cysteine, alanine, methionine, phenylalanine, serine, leucine, and glycine is added to a sterilization target food, and then the sterilization target food including the amino acid is treated at 50 to 600 MPa for 1 to 120 minutes; and low-temperature heating step in which the sterilization target food is heated at 60 to 100° C. for 5 minutes or more after the high-pressure treatment step.

Owner:DAIWA CAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com