Pulsed intensive light sterilization method for betel nuts

A technology of pulsed strong light and sterilization method, which is applied in the field of food processing, can solve problems such as weight loss, and achieve the effect of small quality change, guaranteed sterilization effect, and uniform flashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

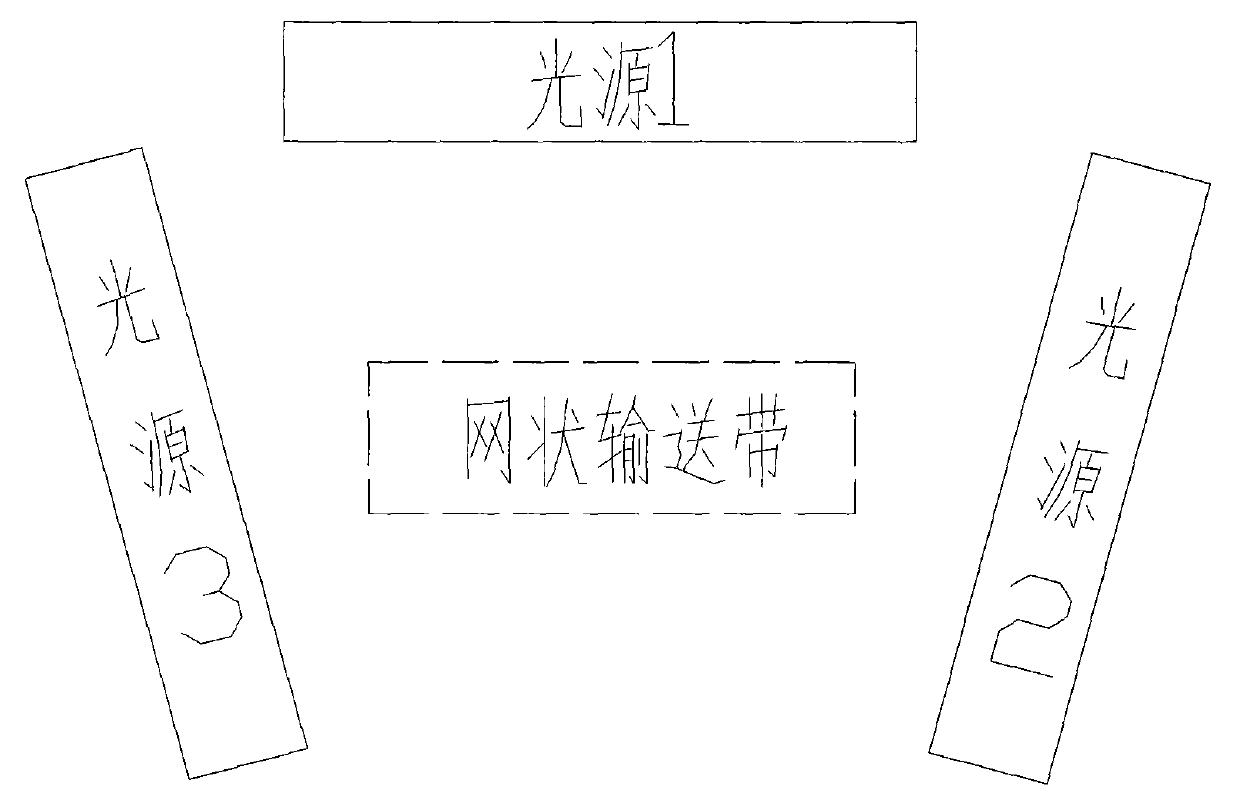

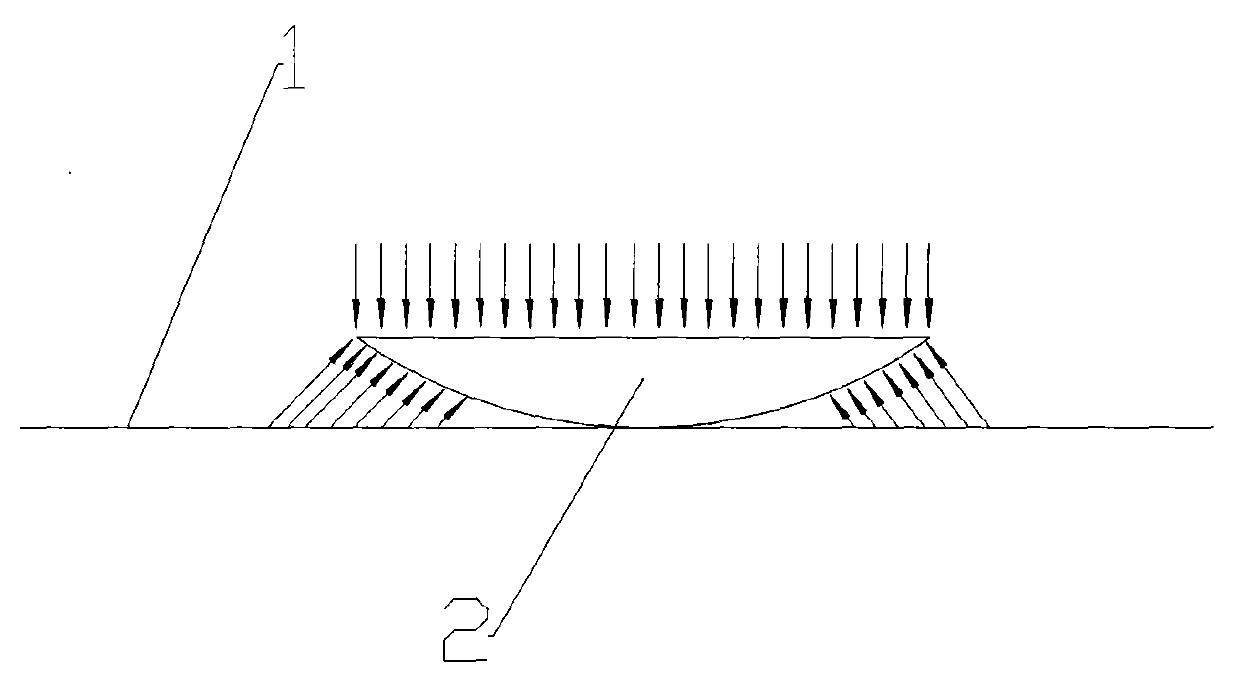

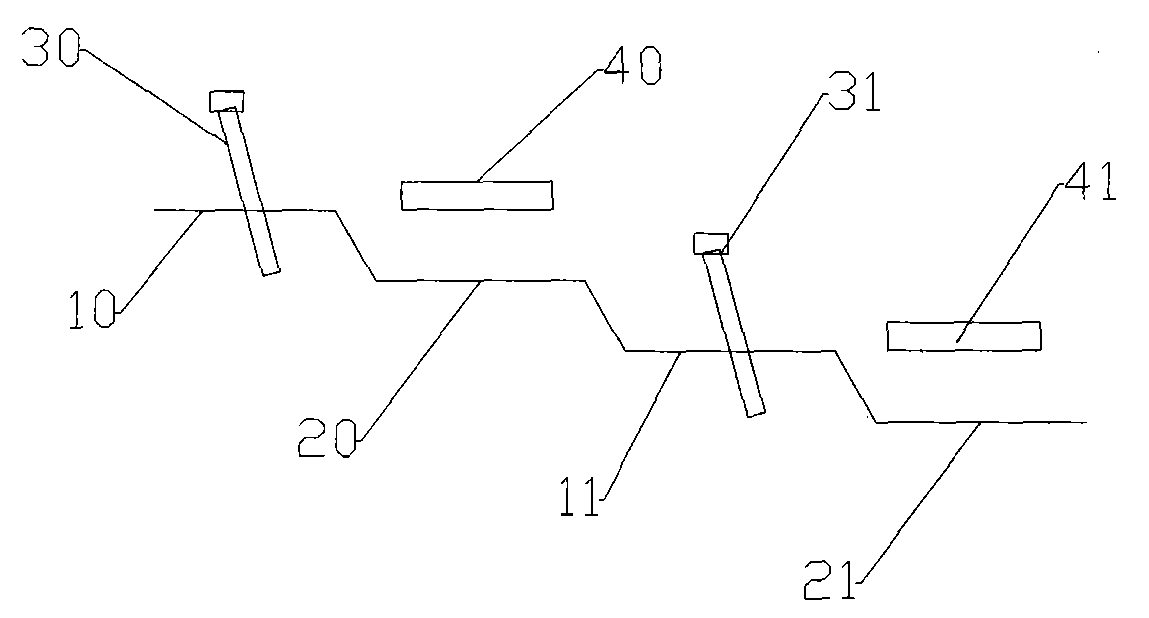

[0017] During the betel nut production process, the sliced betel nut slices are transported to the pulse light source for processing with the conveyor belt, and the pulse light intensity is adjusted to 1kJ / cm 2 , the pulse width is 10us, and the number of flashes is 9 times. Such as image 3 As shown, there are two kinds of conveyor belts where betel nut sheets pass through the pulsed strong light: mesh surface and mirror belt, which pass through the first three-sided pulsed flash light source 30, the first horizontal flashed light source 40, and the second three-sided pulsed flashed light source. The light source 31 and the second horizontal flash light source 41 . When the betel nut passes through two horizontal flash light sources, the mirror surface vibrates, the betel nut jumps up, and the mirror surface reflects strong light for sterilization. Three-sided pulsed light source such as figure 1 As shown, the three-sided pulsed light source is irradiated directly above ...

Embodiment 2

[0020] During the production process of betel nuts, after being sliced, they are treated with brine, and the three pulsed light intensities are adjusted to 8kJ / cm 2 , the pulse width is 3us, and the number of flashes is 4 times. Such as image 3 As shown, there are two kinds of conveyor belts where betel nut sheets pass through the pulsed strong light: mesh surface and mirror belt, which pass through the first three-sided pulsed flash light source 30, the first horizontal flashed light source 40, and the second three-sided pulsed flashed light source. The light source 31 and the second horizontal flash light source 41 . When the betel nut passes through two horizontal flash light sources, the mirror surface vibrates, the betel nut jumps up, and the mirror surface reflects strong light for sterilization. Three-sided pulsed light source such as figure 1 As shown, the three-sided pulsed light source is irradiated directly above the betel nut shell at 180° horizontally, and the...

Embodiment 3

[0022] During the production process of betel nuts, after being sliced, they are treated with brine, and transported to the pulse light source for processing. The three pulse light intensities are adjusted to 7kJ / cm respectively. 2 , the pulse width is 4us, and the number of flashes is 5 times. Such as image 3 As shown, the processed betel nut slices are transported to the three-sided pulsed light source along with the conveyor belt for processing. The conveyor belts where the betel nut slices pass through the pulsed strong light are two types: mesh surface and mirror belt, and pass through the first three-sided pulsed flash light source 30 successively. , the first horizontal flash light source 40 , the second three-sided pulse flash light source 31 , and the second horizontal flash light source 41 . When the betel nut passes through two horizontal flash light sources, the mirror surface vibrates, the betel nut jumps up, and the mirror surface reflects strong light for ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com