Patents

Literature

2302 results about "Ultra high pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra high pressure is defined by the National Fire Protection Agency (NFPA) as pump pressures above 1100 psi.

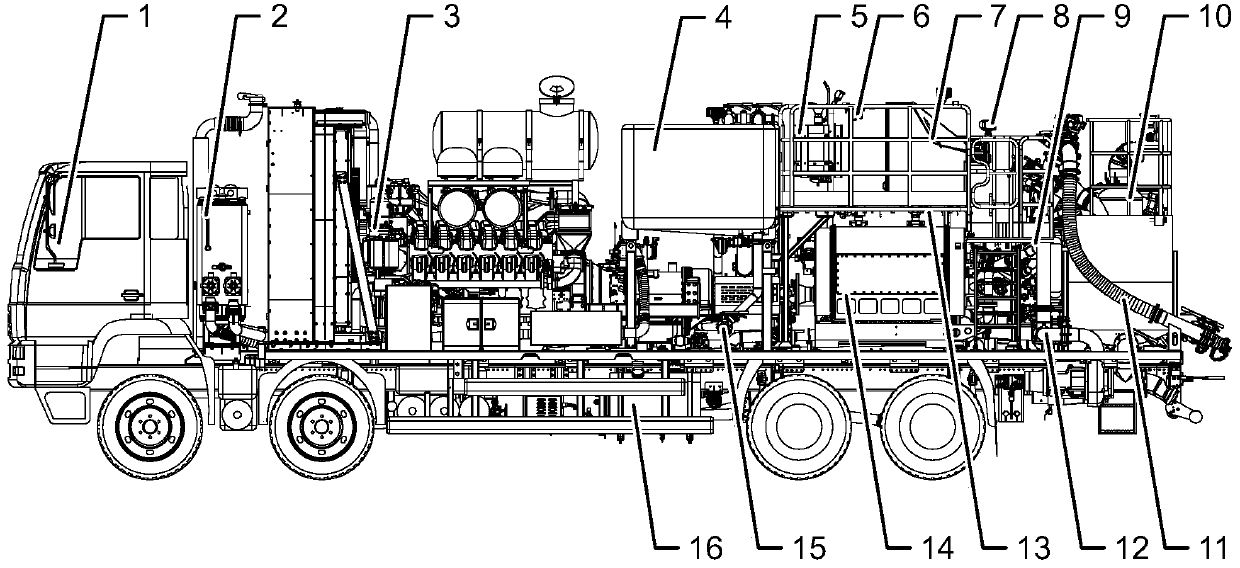

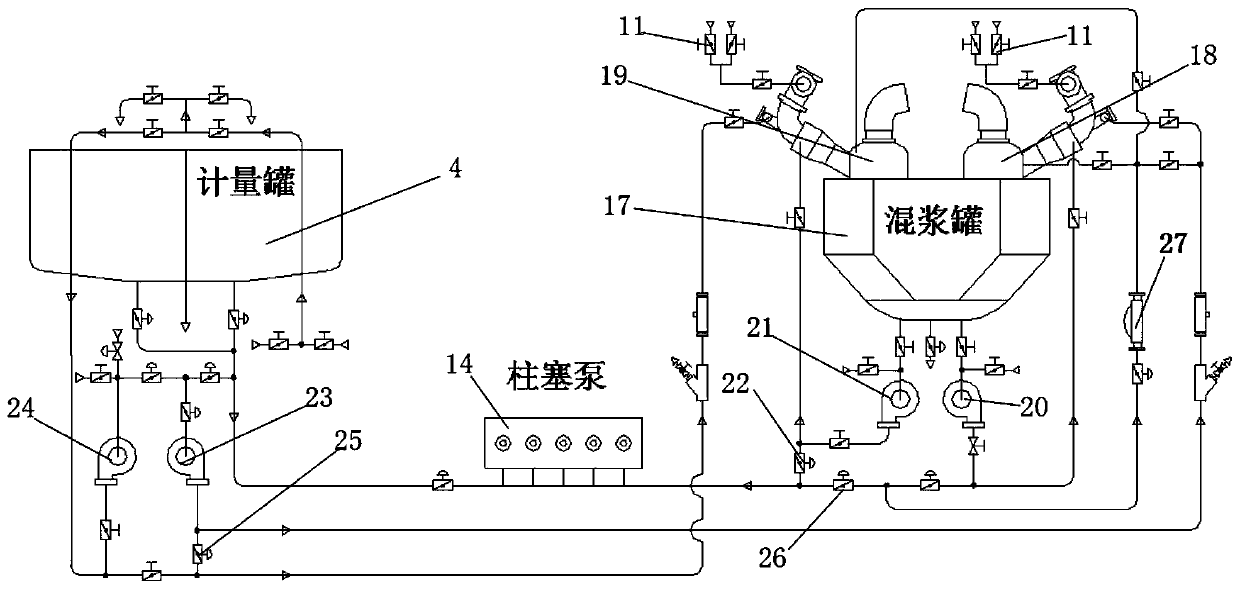

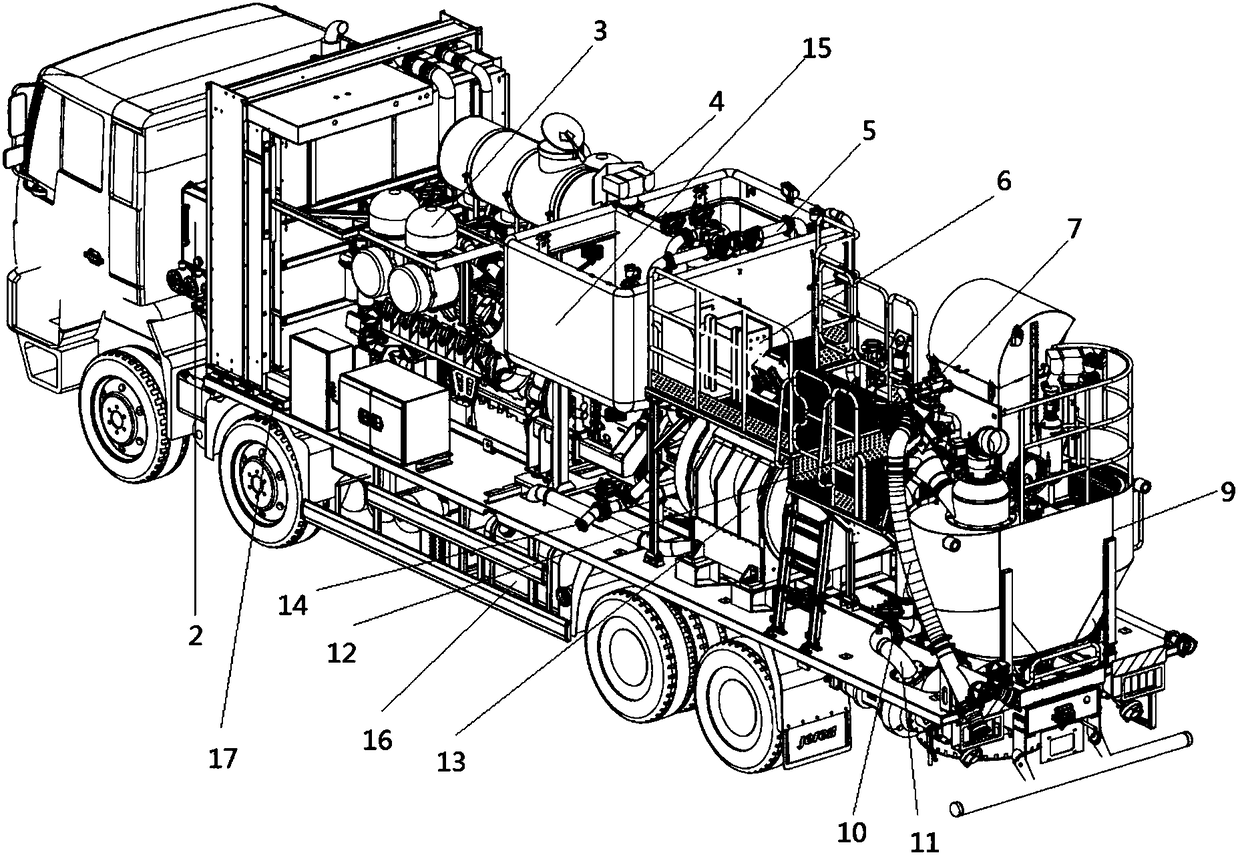

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

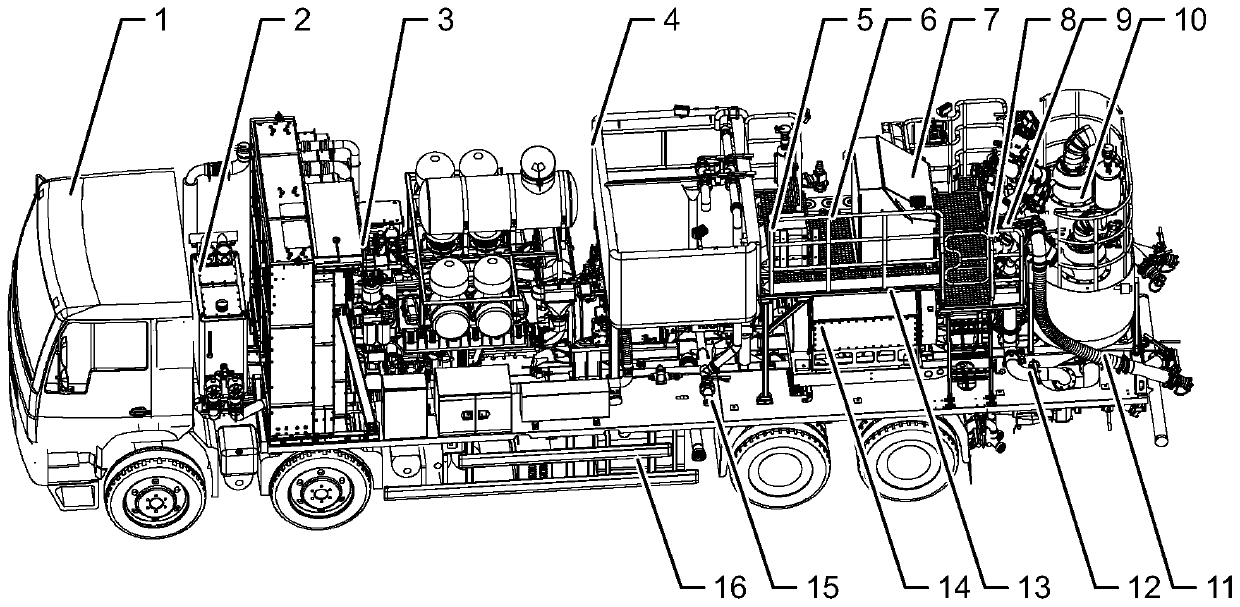

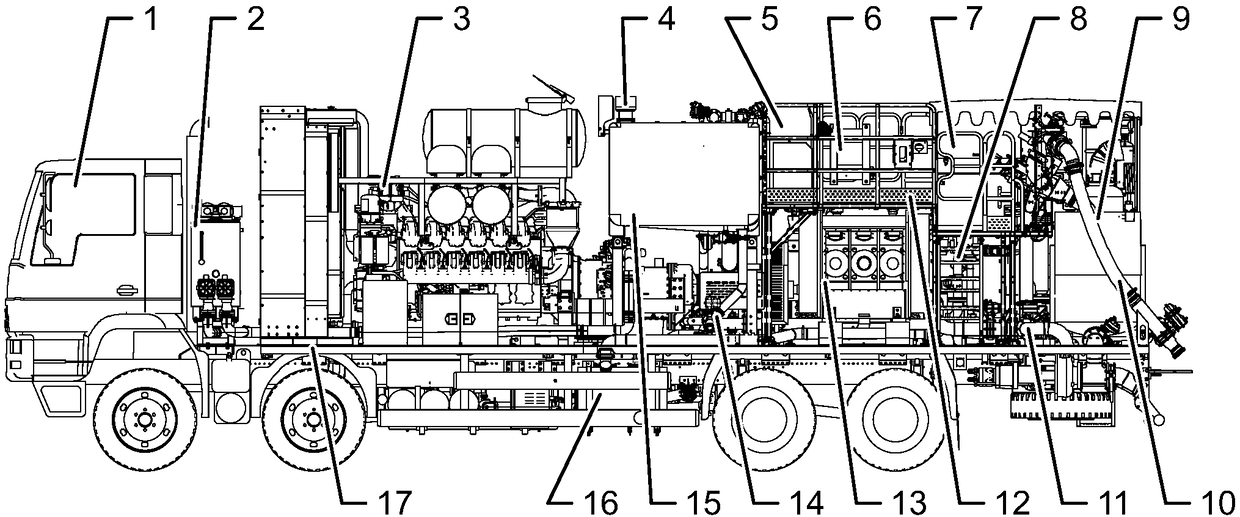

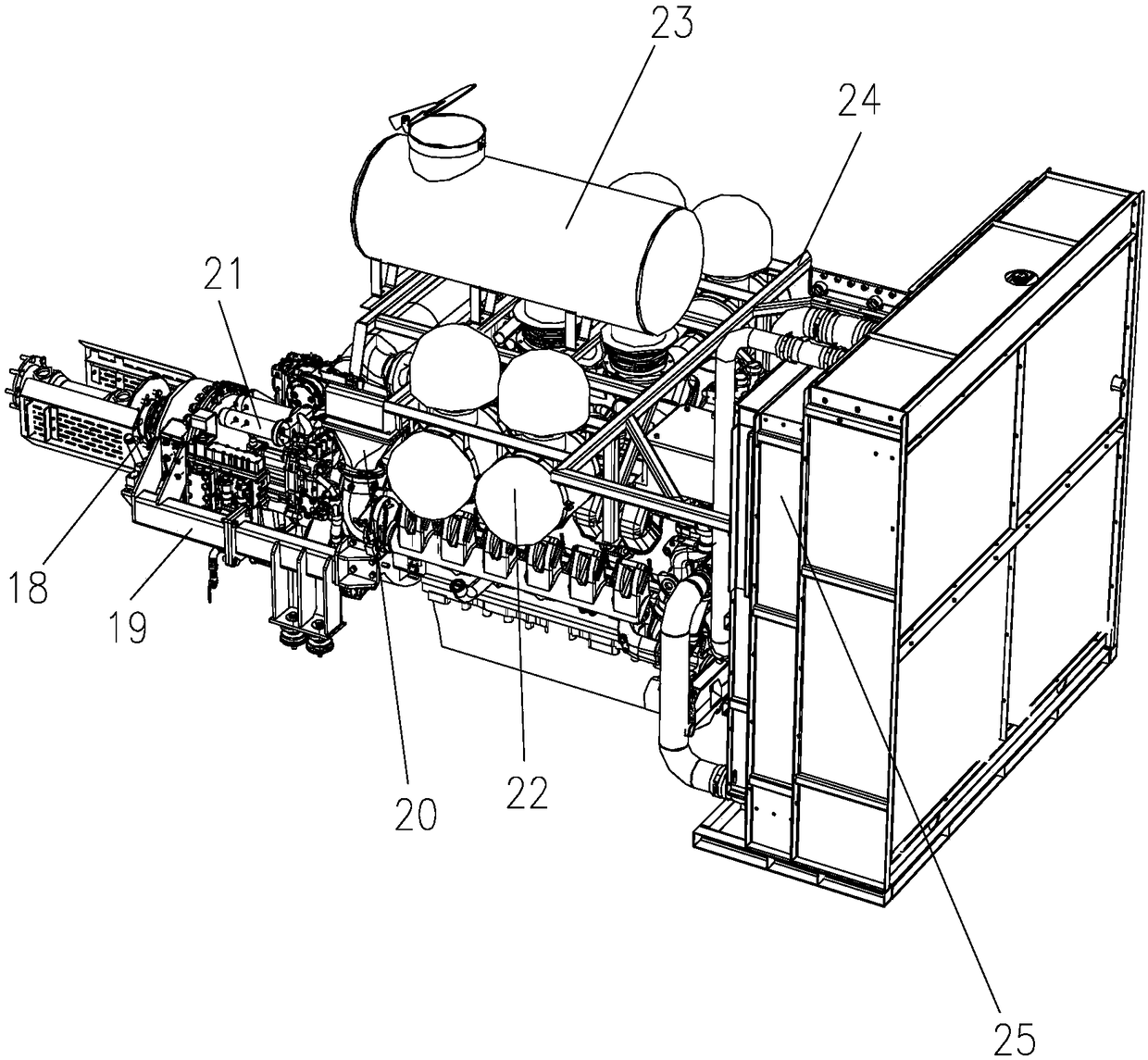

Novel ultra-high-power cementing equipment integrated with remote control

PendingCN108561098AQuick arrangementSave work spacePositive displacement pump componentsPumpsUltra high pressureDrivetrain

The present invention relates to the technical field of petroleum equipment, in particular to novel ultra-high-power cementing equipment integrated with remote control. The novel ultra-high-power cementing equipment integrated with remote control comprises a loading system and a secondary beam, wherein the secondary beam is connected with a hydraulic system, a power transmission system, a meteringtank, an electrical system, a gas circuit system, a control system and a mixing system from front to rear in sequence, the lower portion of the gas circuit system is provided with a plunger pump, theplunger pump is connected with a high-pressure discharge system; a control platform is arranged at the lower part of the electrical system; the control system is positioned above the control platform; and the control system is connected with the remote control system. The novel ultra-high-power cementing equipment integrated with remote control meets the requirements of high pressure, large displacement, long time and continuous uninterrupted operation during the ultra-deep cementing operation and the ultra-high pressure gas well operation; and the occupied area is small, the pipeline connection is simple, and the maintenance frequency is low.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

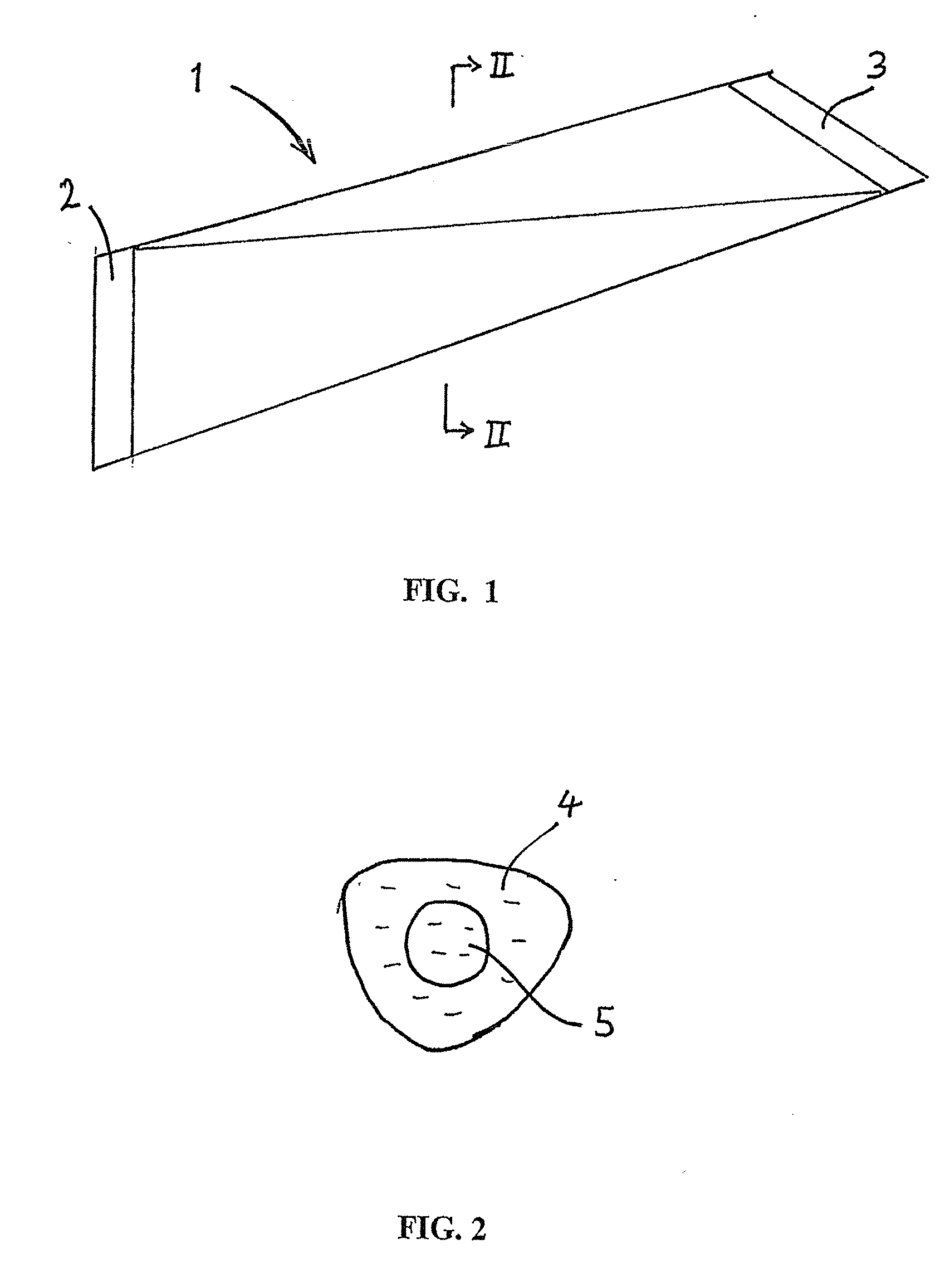

Process for the synthesis of diamond

InactiveUS6129900ALess inclusionReduce the impactUltra-high pressure processesUltra high pressureDiamond crystal

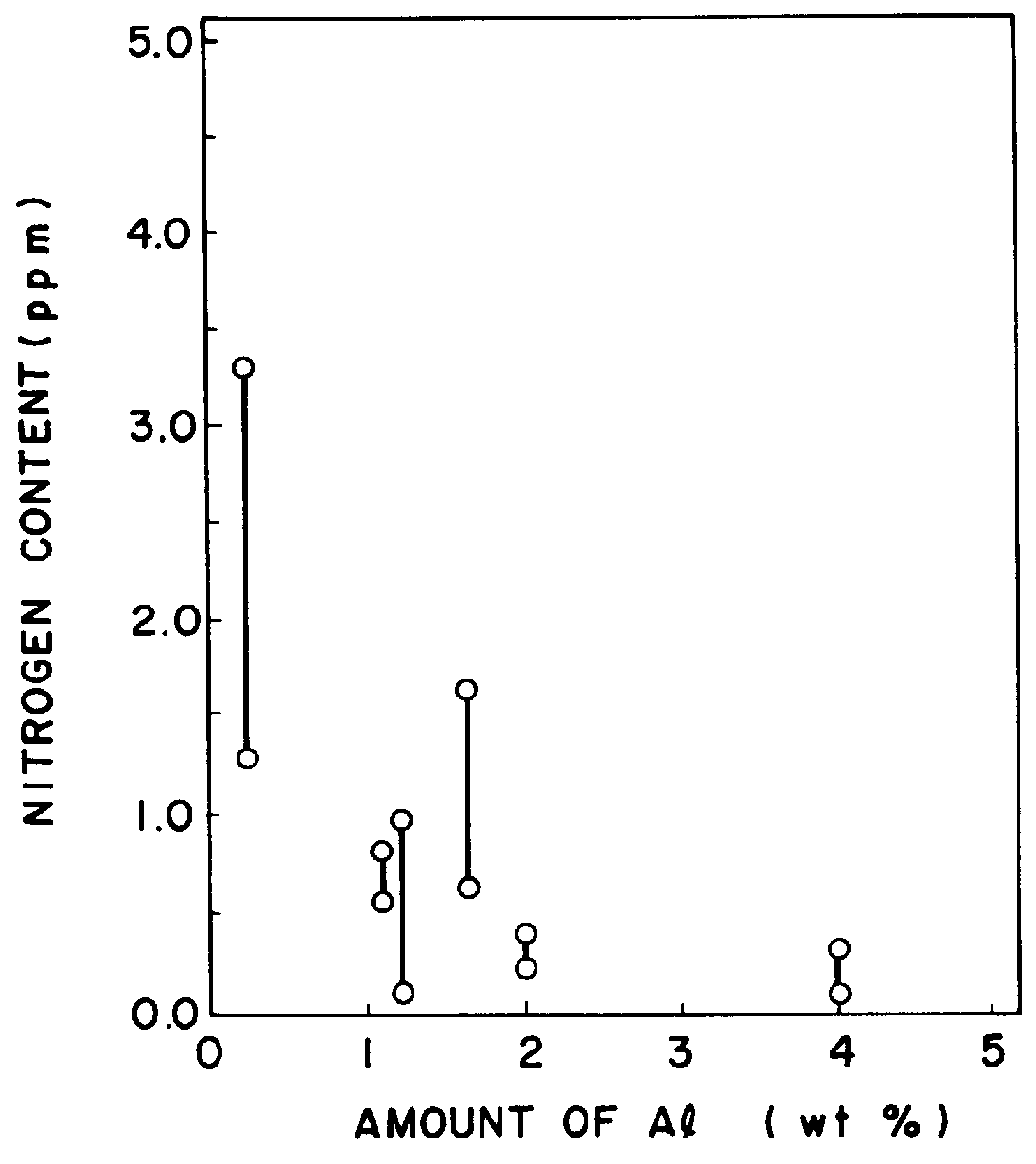

PCT No. PCT / JP92 / 00149 Sec. 371 Date Oct. 14, 1992 Sec. 102(e) Date Oct. 14, 1992 PCT Filed Feb. 14, 1992 PCT Pub. No. WO92 / 14542 PCT Pub. Date Sep. 3, 1992A colorless and transparent, substantially inclusion-free diamond crystal which can be applied to decorative uses and optical parts is synthesized by a process using a temperature gradient method in an ultra-high pressure apparatus. This process comprises using, as a solvent for the growth of the crystal, at least one metal selected from the group consisting of Fe, Co, Ni, Mn and Cr (at least two metals in the case of containing Fe) and as a nitrogen getter for the removal of nitrogen in the solvent, at least one metal selected from the group consisting of Al, Ti, Zr, Hf, V, Nb and Ta in a proportion of 0.5 to 7% by weight (at most 2% by weight when using only Al) to the solvent metal.

Owner:SUMITOMO ELECTRIC IND LTD

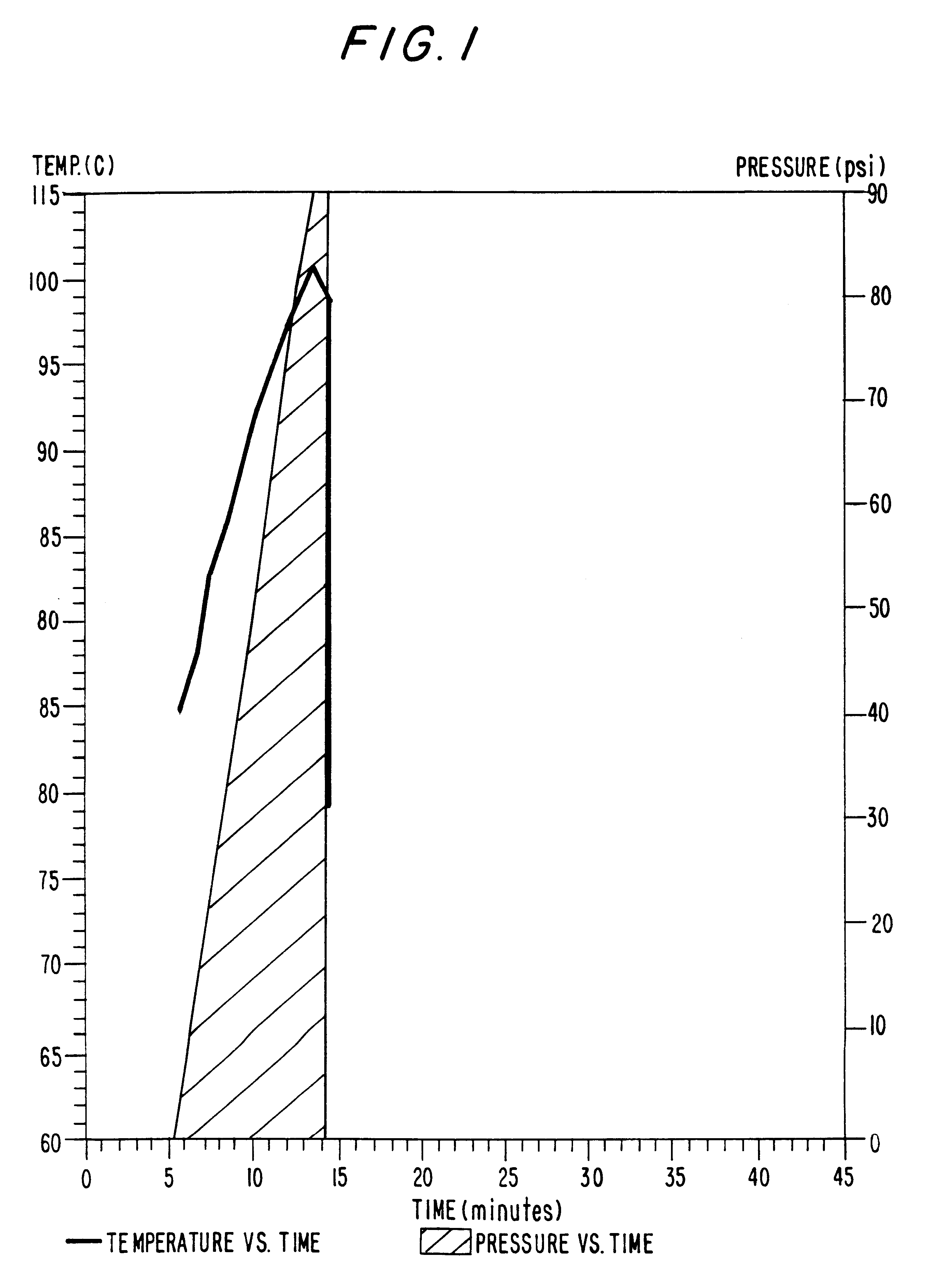

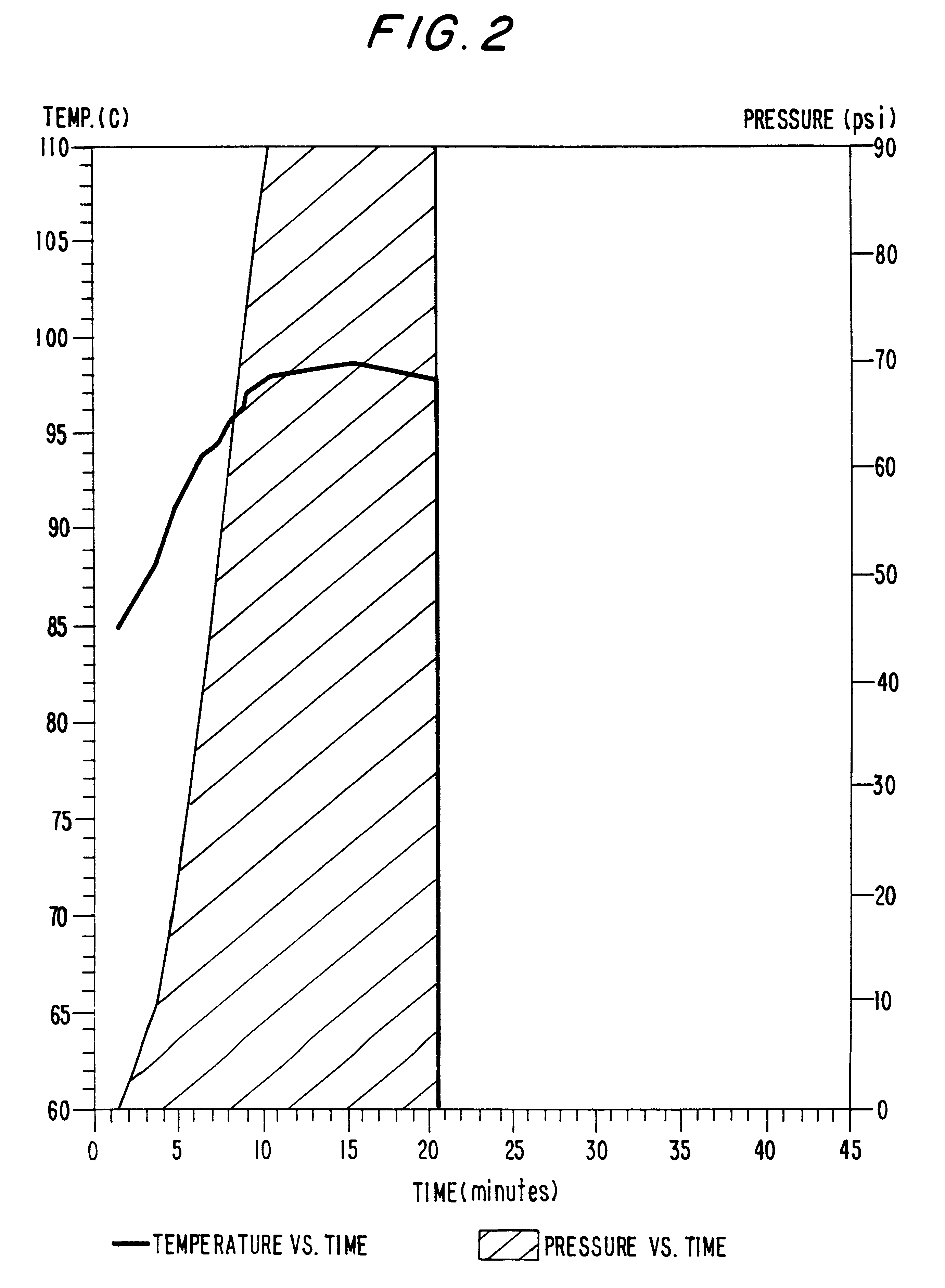

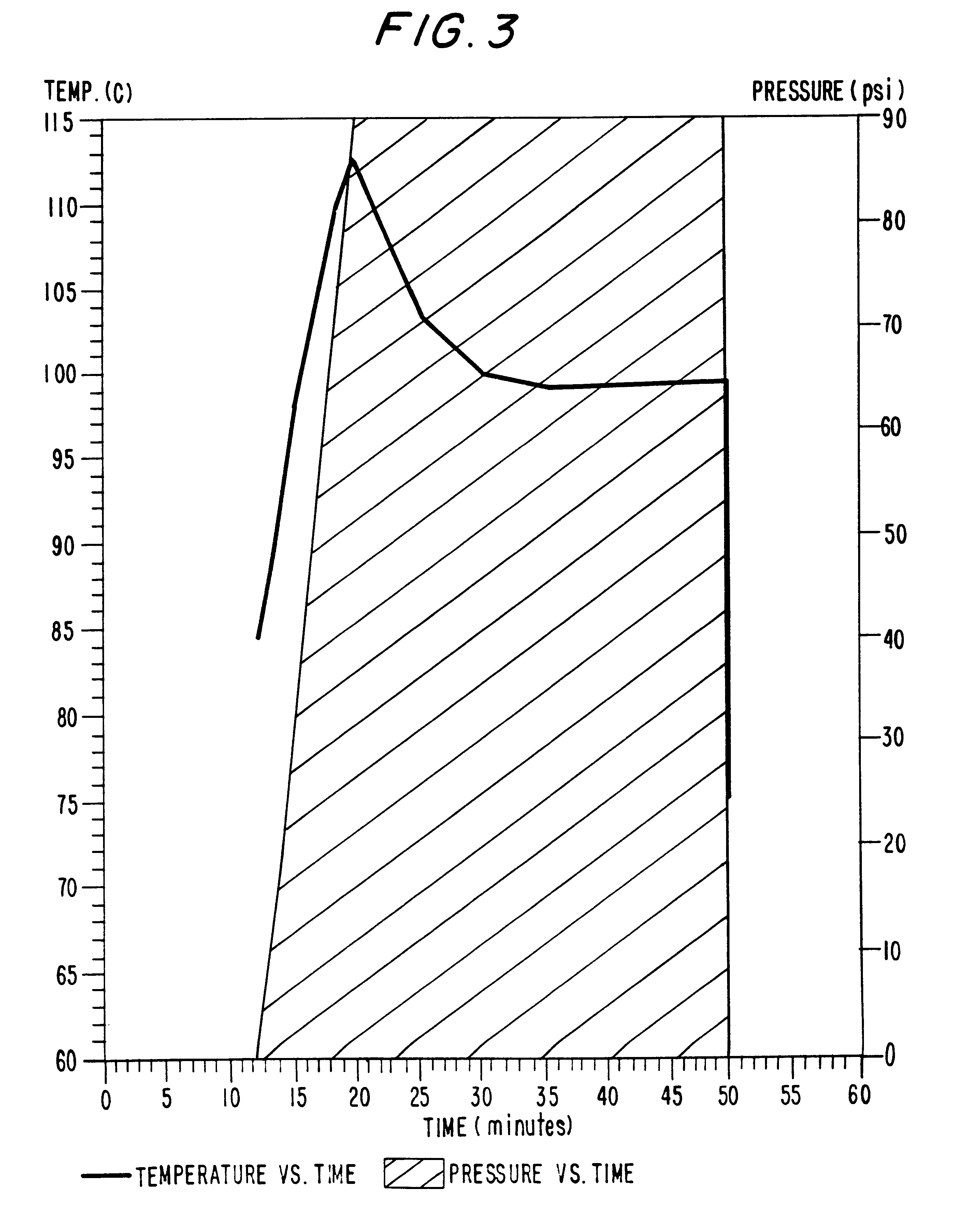

High temperature/ultra-high pressure sterilization of foods

InactiveUS6086936AImprove efficiencyFaster and more energy efficientMilk preservationMeat/fish preservation by heatingUltra high pressureProcess engineering

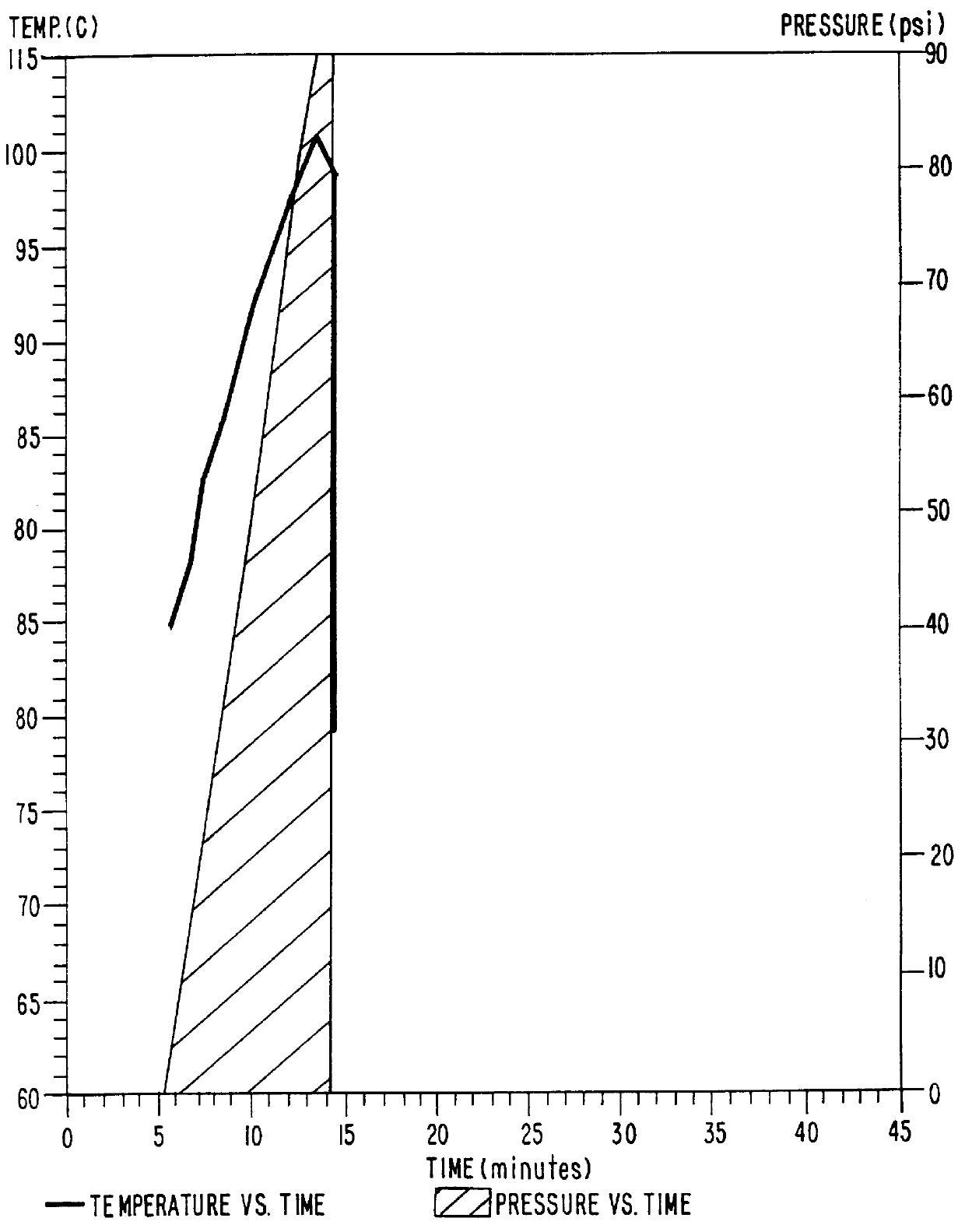

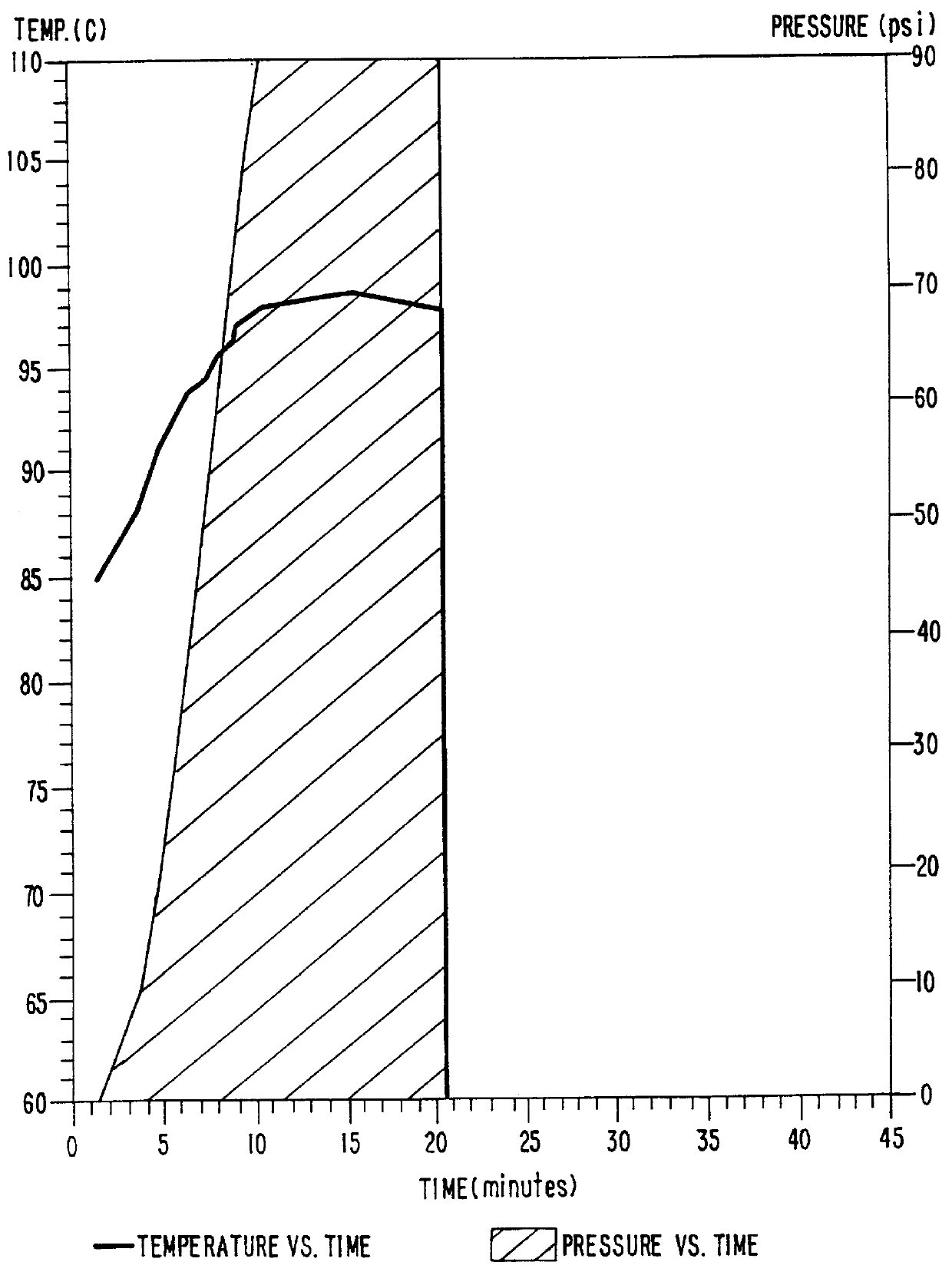

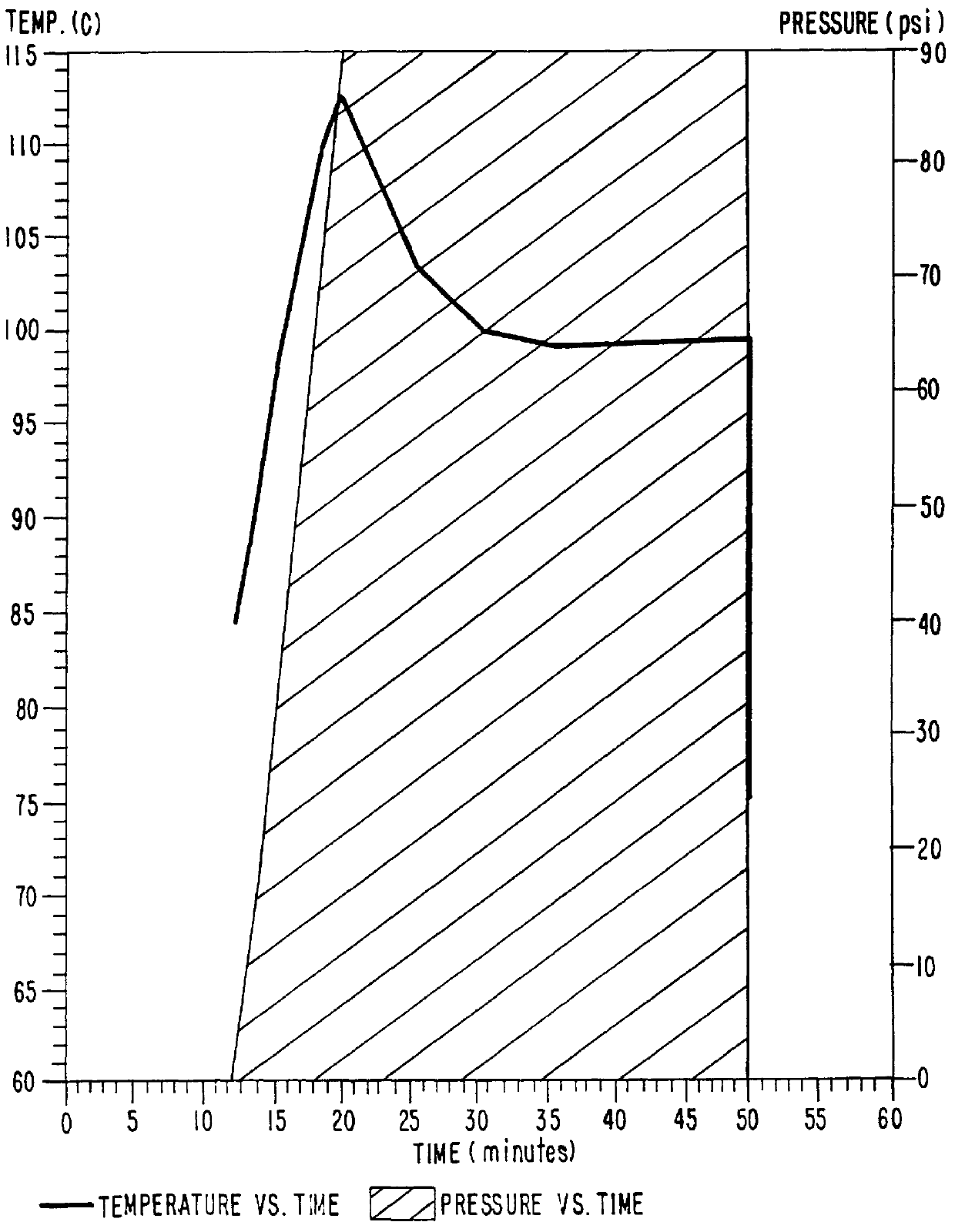

Method for sterilizing foods using both ultra-high pressures and high temperatures. The instantaneous temperature change that occurs when pressure is applied combines a high-temperature short-time process with ultra-high pressure to deliver a fast and therefore gentle thermal process to a pre-packaged product. The process involves heating a food to a pre-pressurized temperature, subjecting the food to ultra-high pressure, which instantaneously raises the temperature of the food, and then releasing the pressure so that the temperature returns to the original pre-pressurized temperature. The method leverages the adiabatic temperature rise which occurs when the food is hydrostatically pressurized, coupled with the lethality of the pressure, to achieve appropriate sterilization conditions.

Owner:KAL KAN FOODS

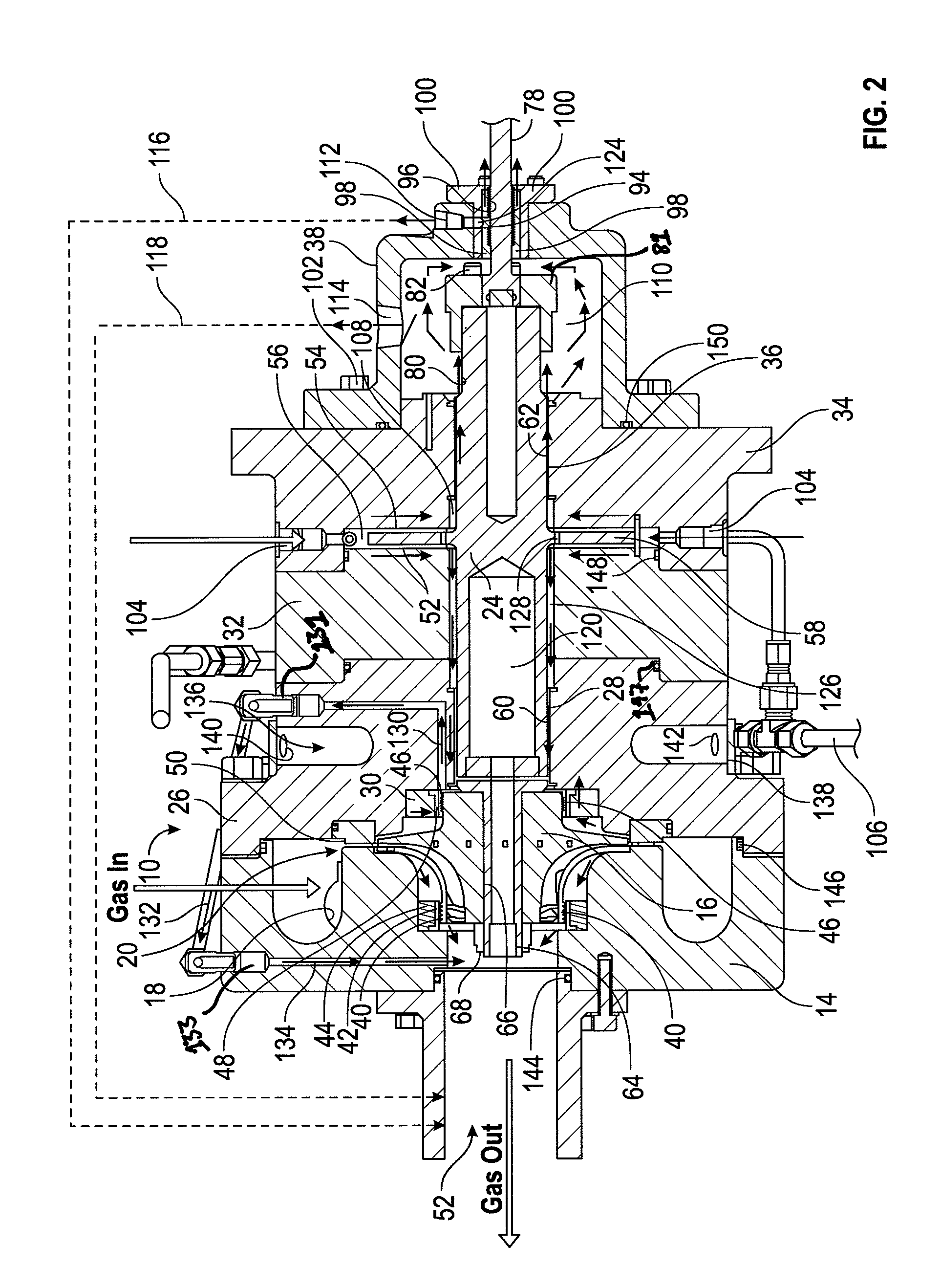

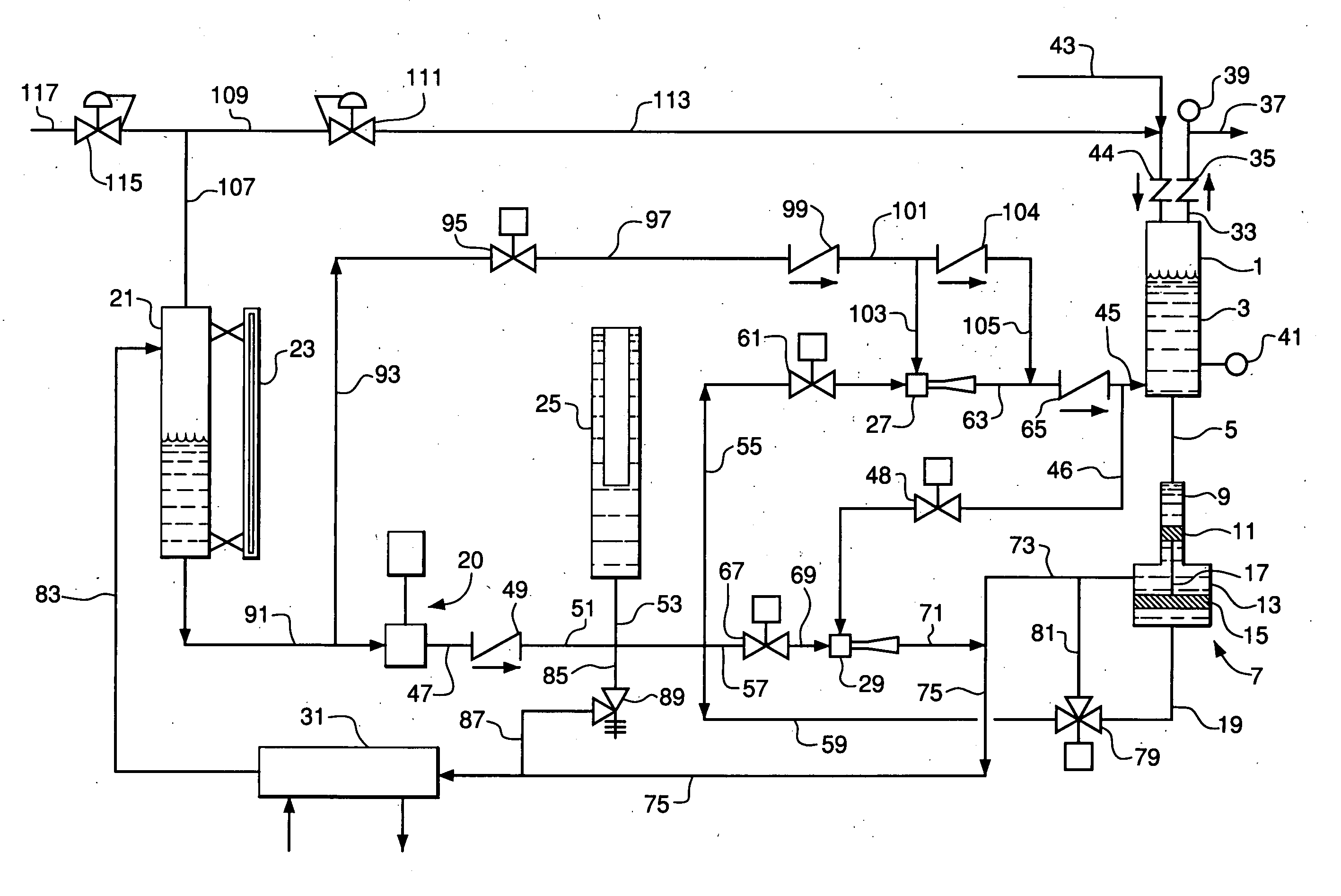

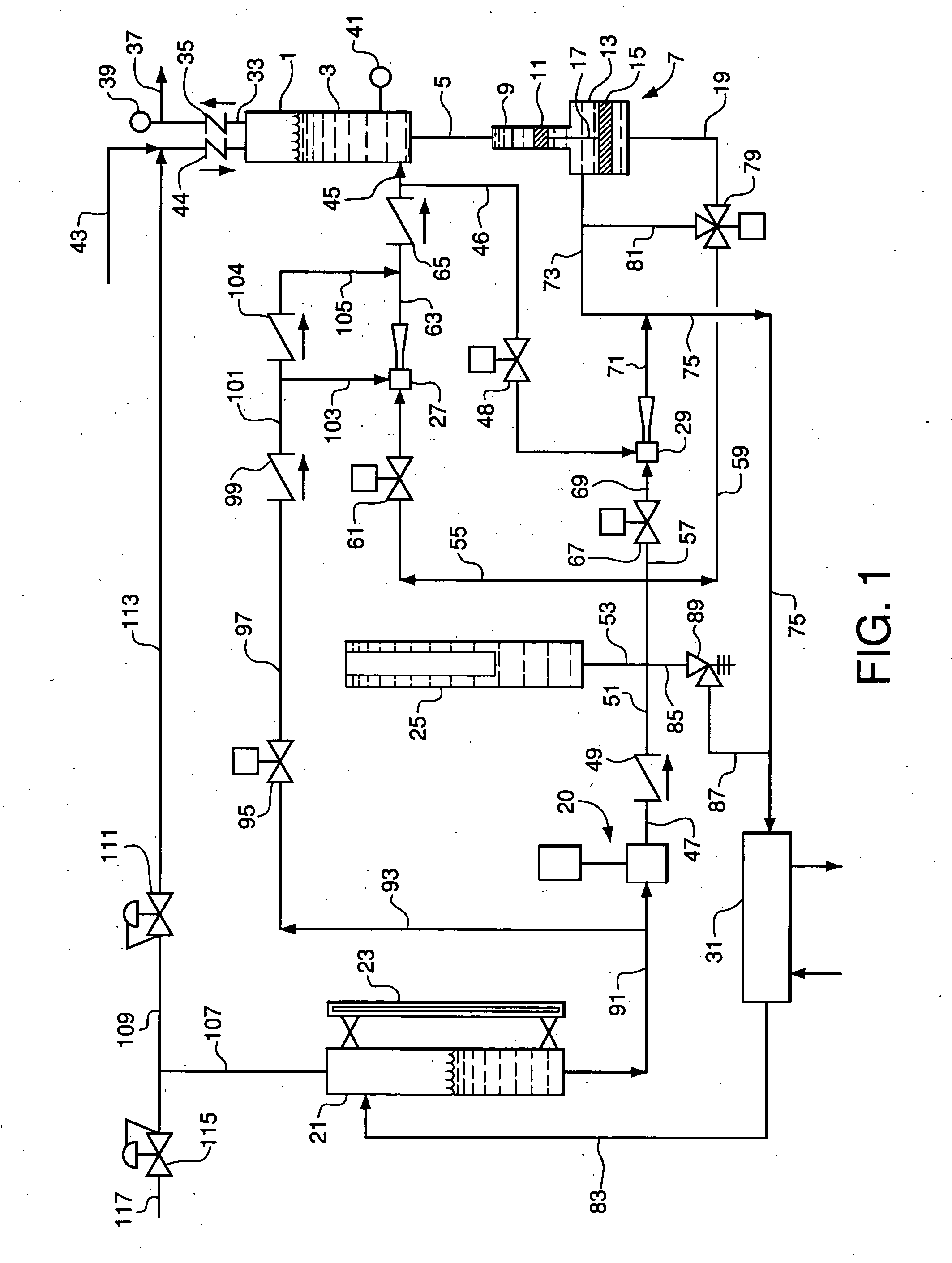

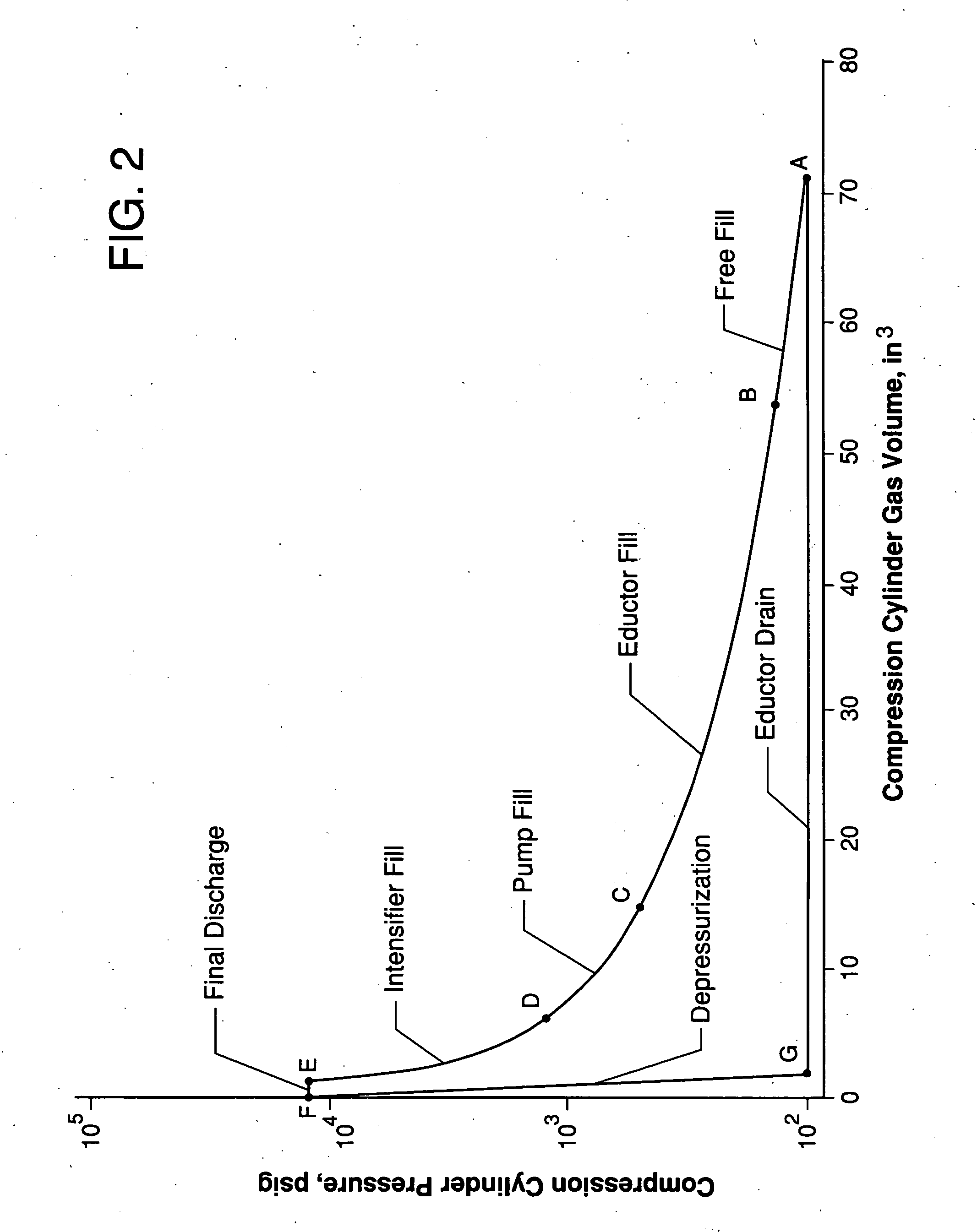

Zero-clearance ultra-high-pressure gas compressor

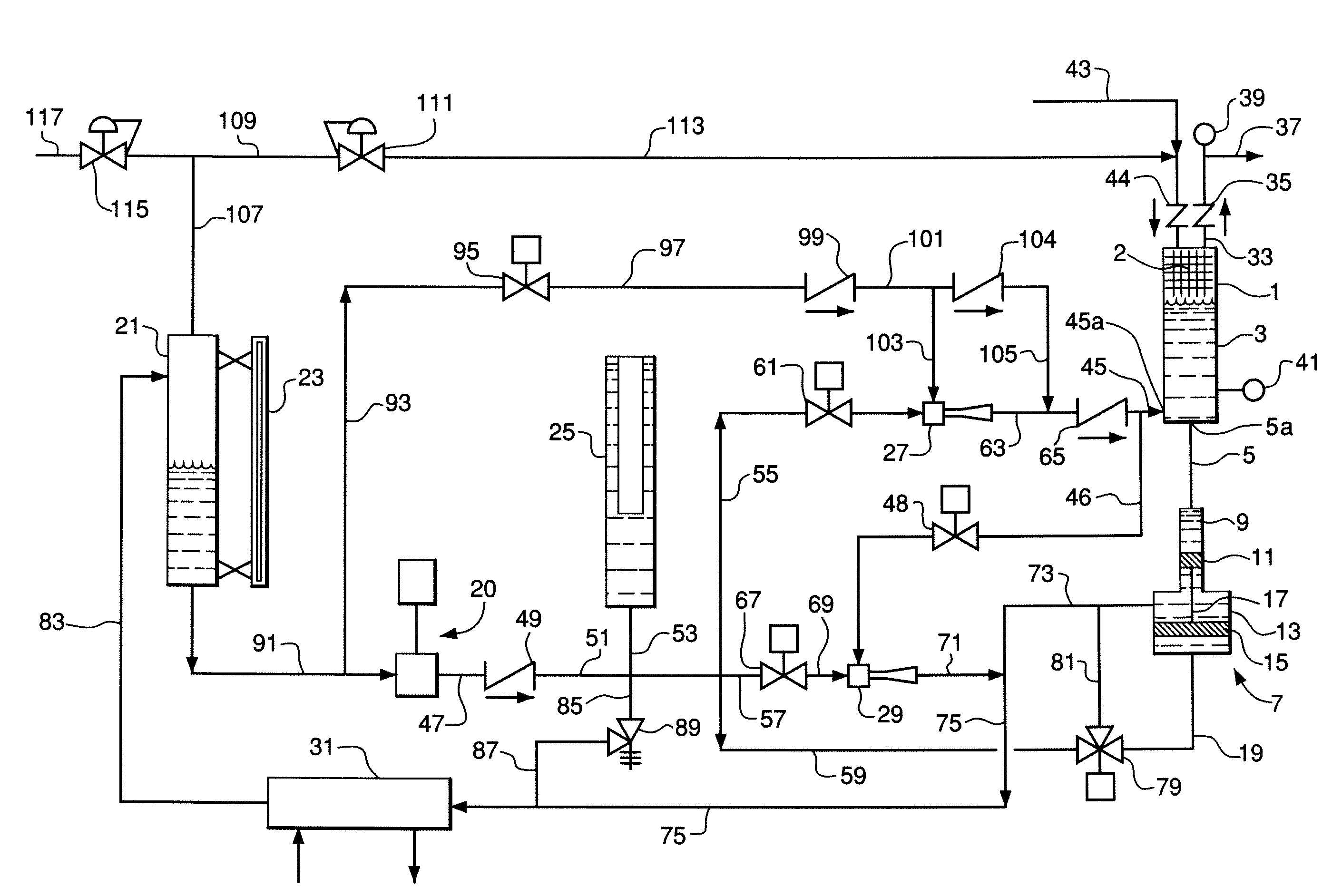

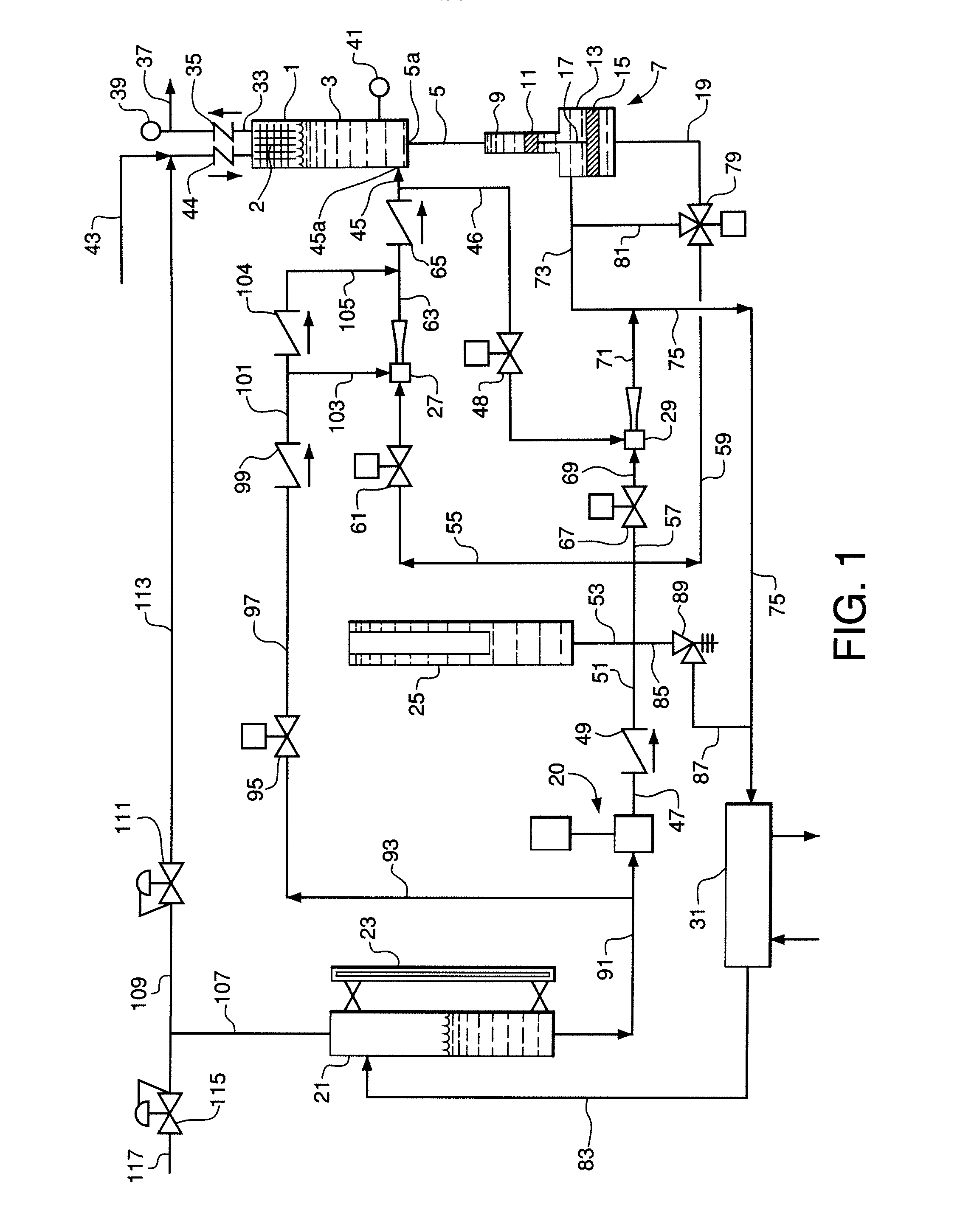

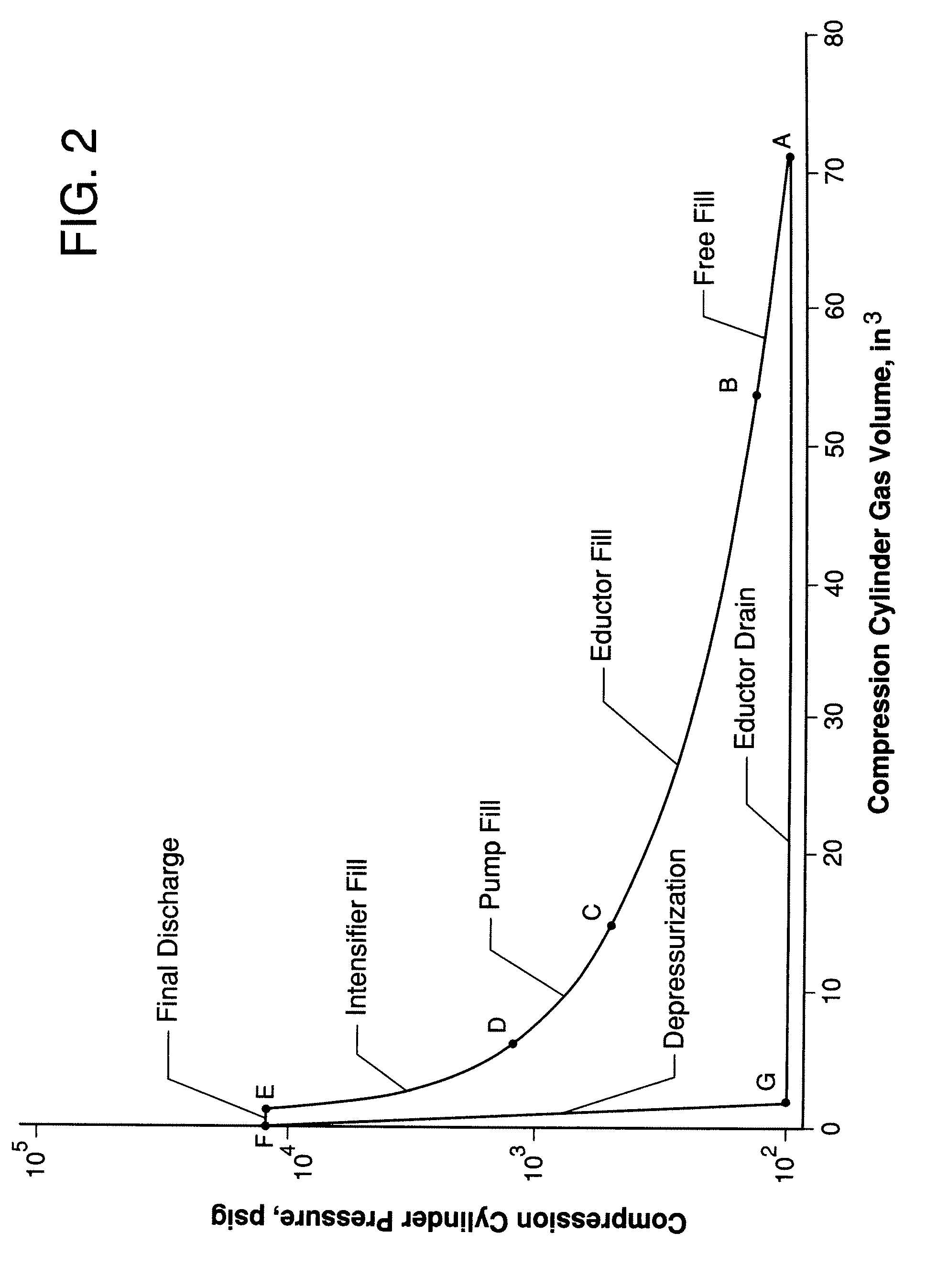

Gas compression system comprising a compression cylinder having a gas inlet, a compressed gas outlet, and one or more liquid transfer ports; a pump having a suction and a discharge; and a compressor liquid. The system also includes any of the following: a pressure intensifier having an inlet in flow communication with the pump and an outlet in flow communication with the compression cylinder; a feed eductor in flow communication with the discharge of the pump, with a reservoir containing a portion of the compressor liquid, and with the compression cylinder; a drain eductor in flow communication with the discharge of the pump, with the compression cylinder, and with a reservoir containing a portion of the compressor liquid; and a variable-volume compressor liquid accumulator in flow communication with the discharge of the pump.

Owner:AIR PROD & CHEM INC

Fruit Snack

ActiveUS20080014303A1Minimally processedMinimal additiveHydrolasesPackaging protectionUltra high pressureEnzyme

The present invention is directed to a packaged, shelf-stable, gelled natural fruit pulp, in which the natural pectins of the fruit pulp have been substantially demethoxylated by the action of a pectinmethylesterase enzyme under ultra-high pressure (UHP) conditions. Also provided is a method of preparation of the packaged, ambient-stable, natural fruit product.

Owner:MARS INC

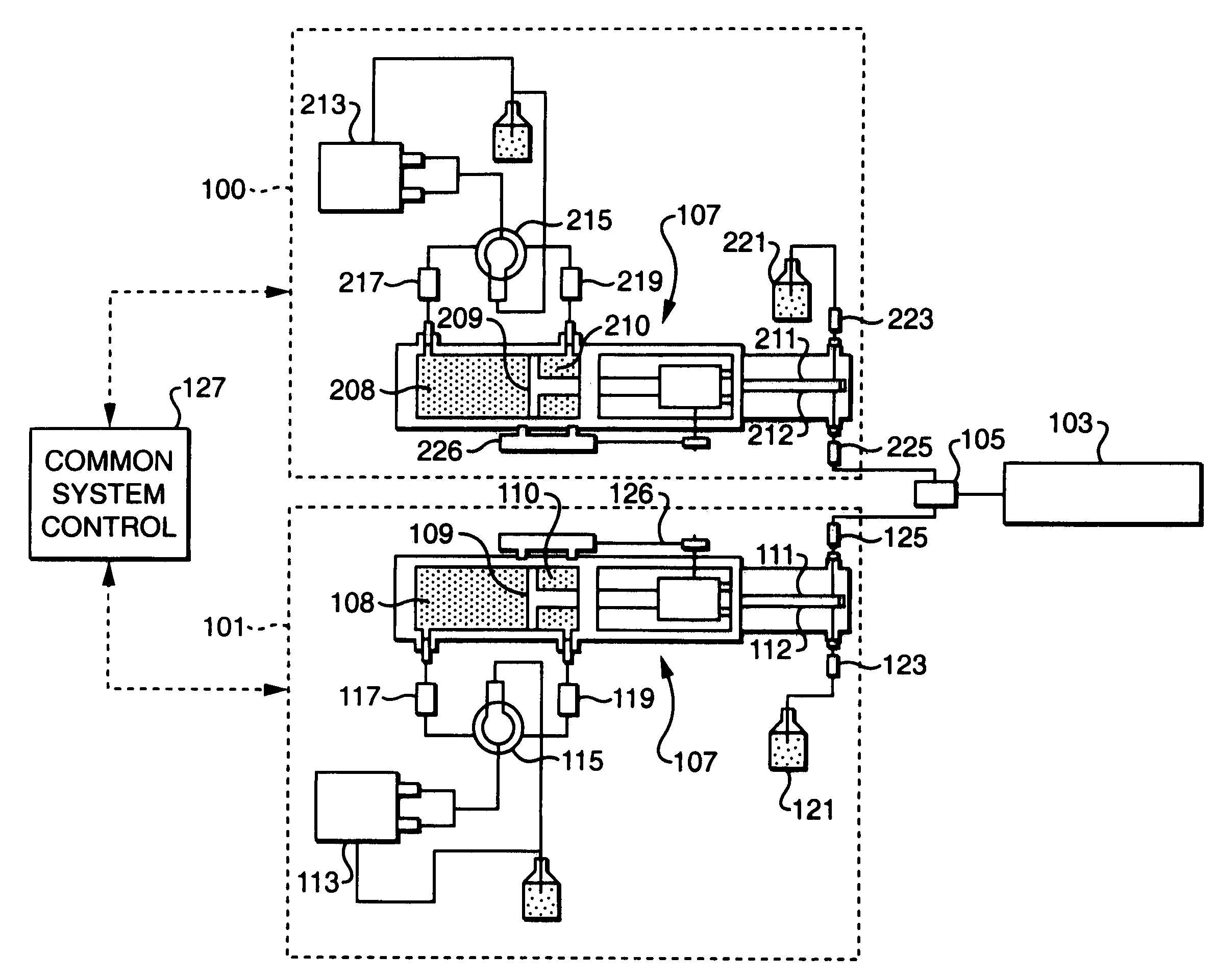

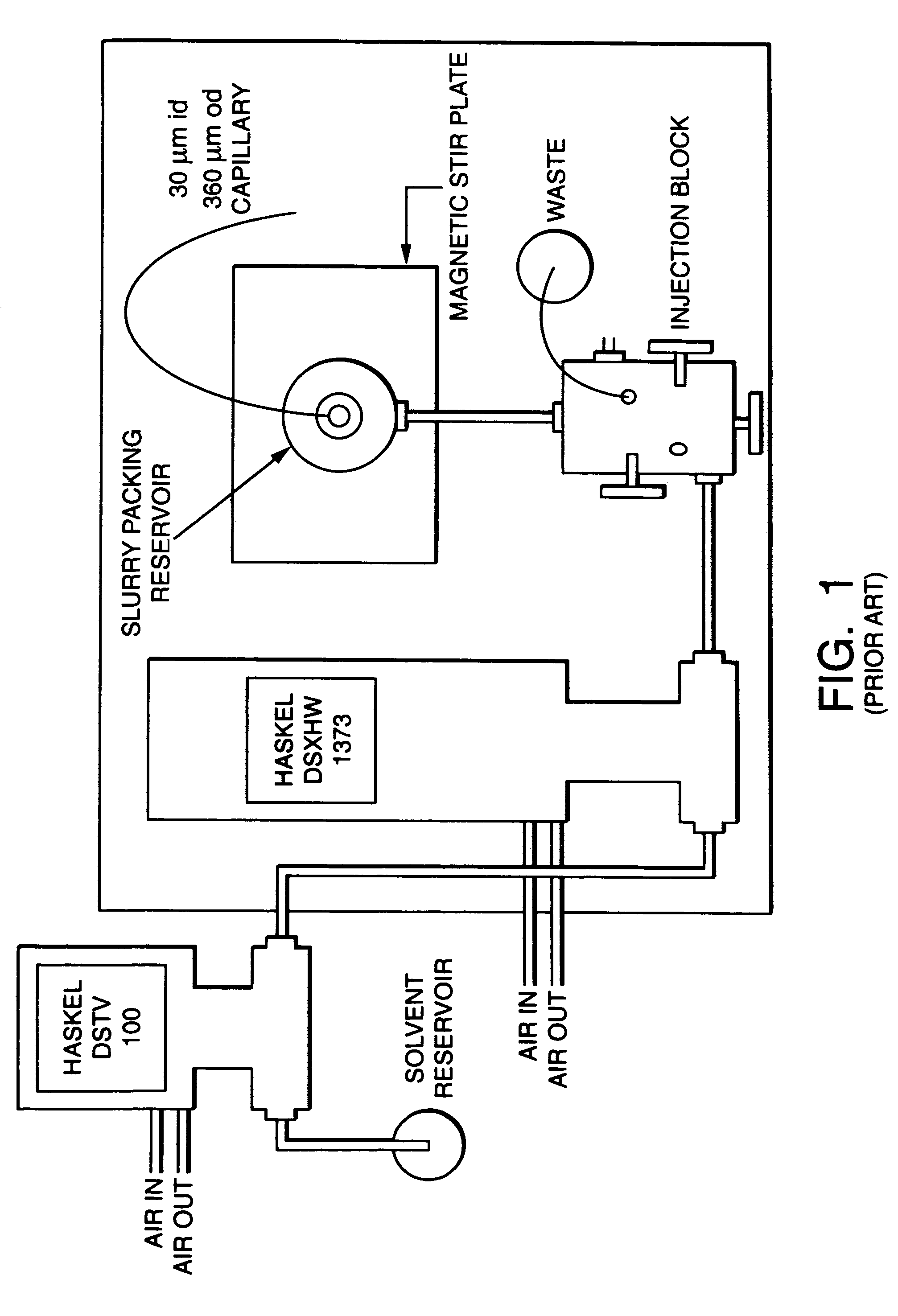

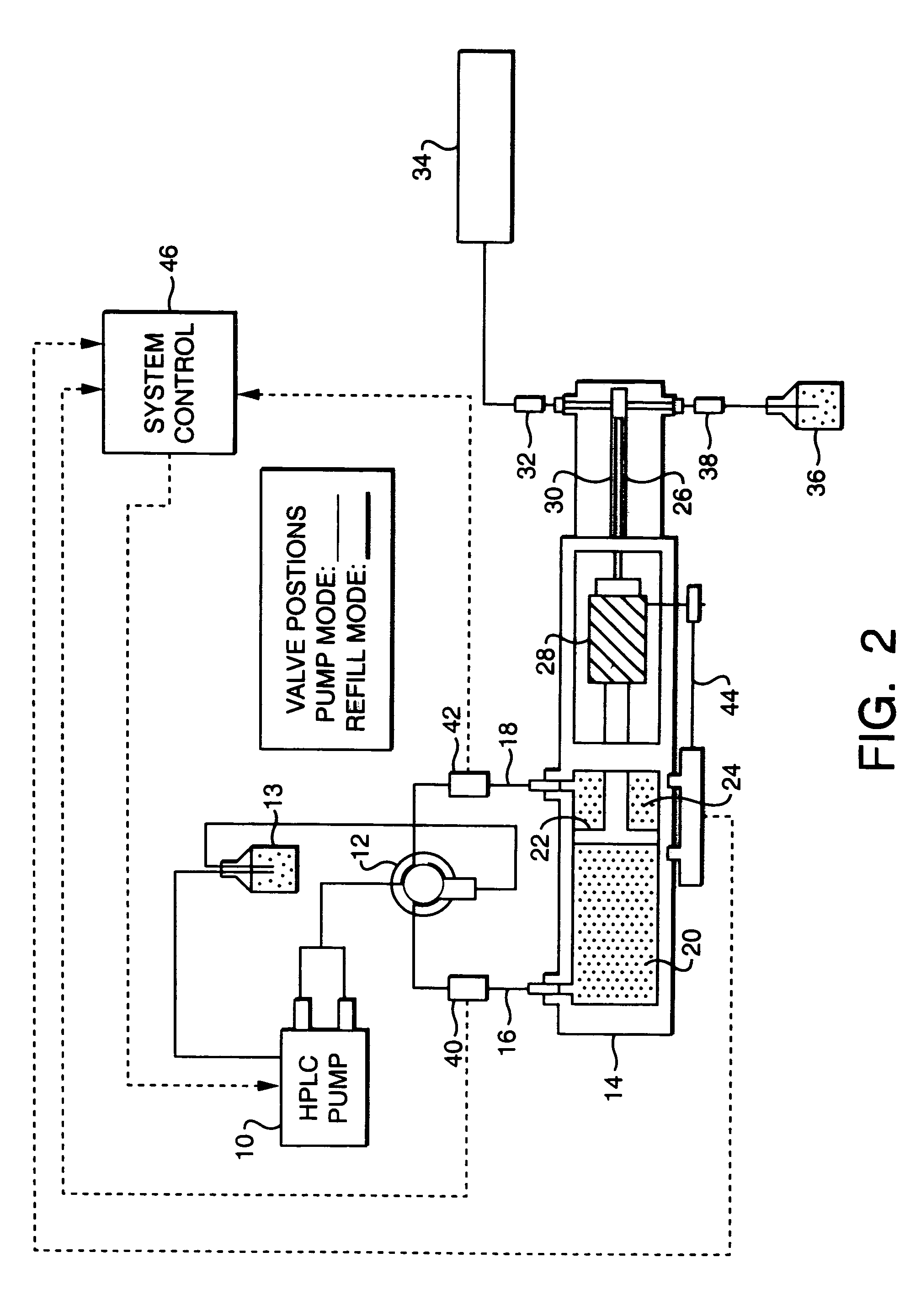

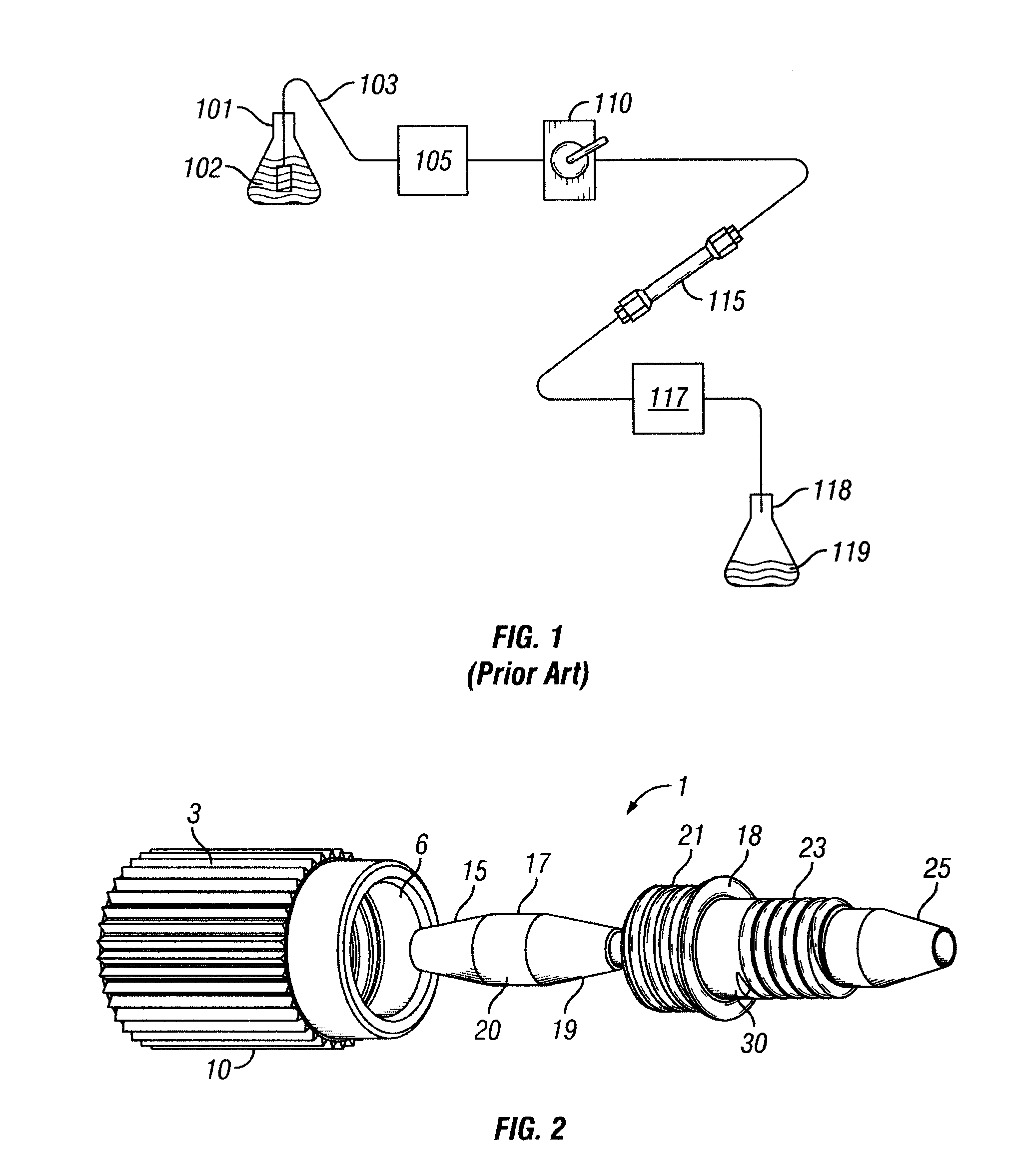

Method for using a hydraulic amplifier pump in ultrahigh pressure liquid chromatography

ActiveUS7311502B2Sufficient pressureConstant flowComponent separationPump controlHydraulic cylinderUltra high pressure

A method for supplying solvent to an ultra-high pressure liquid chromatography system using a hydraulic amplifier. The hydraulic amplifier system includes a hydraulic cylinder comprising a primary piston chamber in which a primary piston is disposed and a secondary piston chamber in which a secondary piston is disposed. The cross-sectional area of the primary piston is larger than the cross-sectional area of the secondary piston. The difference in the cross-sectional areas of the pistons creates an amplification of the pressure in the primary piston chamber and a reduction in flow rate.

Owner:WATERS TECH CORP

High temperature/ultra high pressure sterilization of foods

InactiveUS6207215B1Fresh lookAchieves commercial sterility of low acid food productsMilk preservationMeat/fish preservation by heatingUltra high pressureEngineering

Method for sterilizing foods using both ultra-high pressures and high temperatures. The instantaneous temperature change that occurs when pressure is applied combines a high-temperature short-time process with ultra-high pressure to deliver a fast and therefore gentle thermal process to a pre-packaged product. The process involves heating a food to a pre-pressurized temperature, subjecting the food to ultra-high pressure, which instantaneously raises the temperature of the food, and then releasing the pressure so that the temperature returns to the original pre-pressurized temperature. The method leverages the adiabatic temperature rise which occurs when the food is hydrostatically pressurized, coupled with the lethality of the pressure, to achieve appropriate sterilization conditions. The disclosure also includes foods which have been sterilized using both ultra-high pressures and high temperatures.

Owner:KAL KAN FOODS

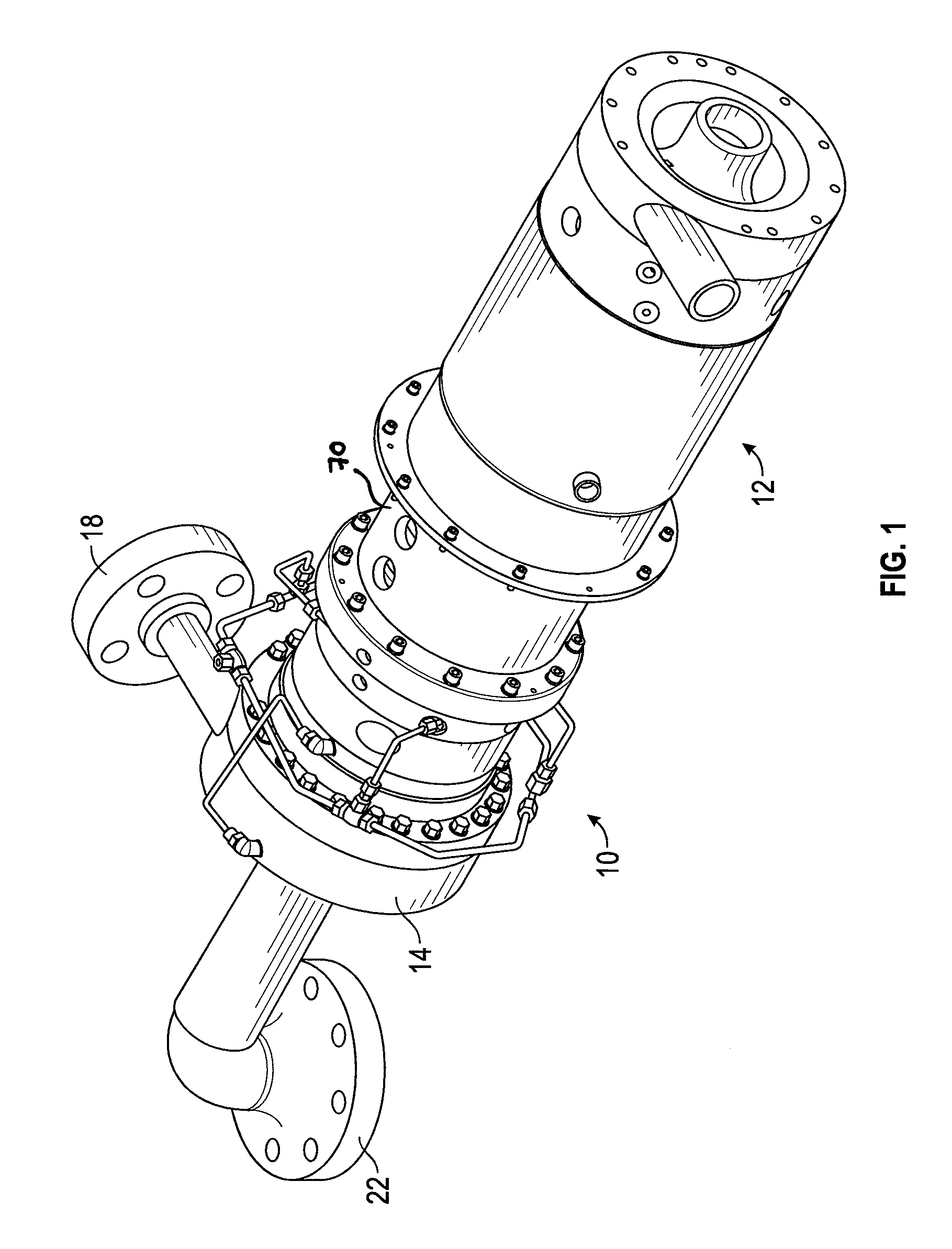

Ultra high pressure turbomachine for waste heat recovery

ActiveUS20120306206A1Prevent leakageReduce lossesMagnetic circuit rotating partsPump componentsRotational axisUltra high pressure

A turbine-driven alternator (i.e., a turbomachine) suitable for generating electrical power from process gas waste energy. In particular suitable for very high density process gases such as super critical CO2, R134a, R245fa, etc. The turboalternator comprises two separate machines, specifically, a turbine device and an alternator device operatively connected together by a coupling shaft. The rotating shaft assemblies for each machines on the turbine side and the alternator side are supported by hydrodynamic foil gas bearings. The foil gas bearings use process gas at the turbine side, enabling high-pressure operation (˜3000 psia) and thrust load balancing. At the alternator side, cooling fluid is used in the foil gas bearings, enabling high-speed (˜40,000 rpm), low-windage, oil-free operation with closed-loop shaft cooling.

Owner:R & D DYNAMICS

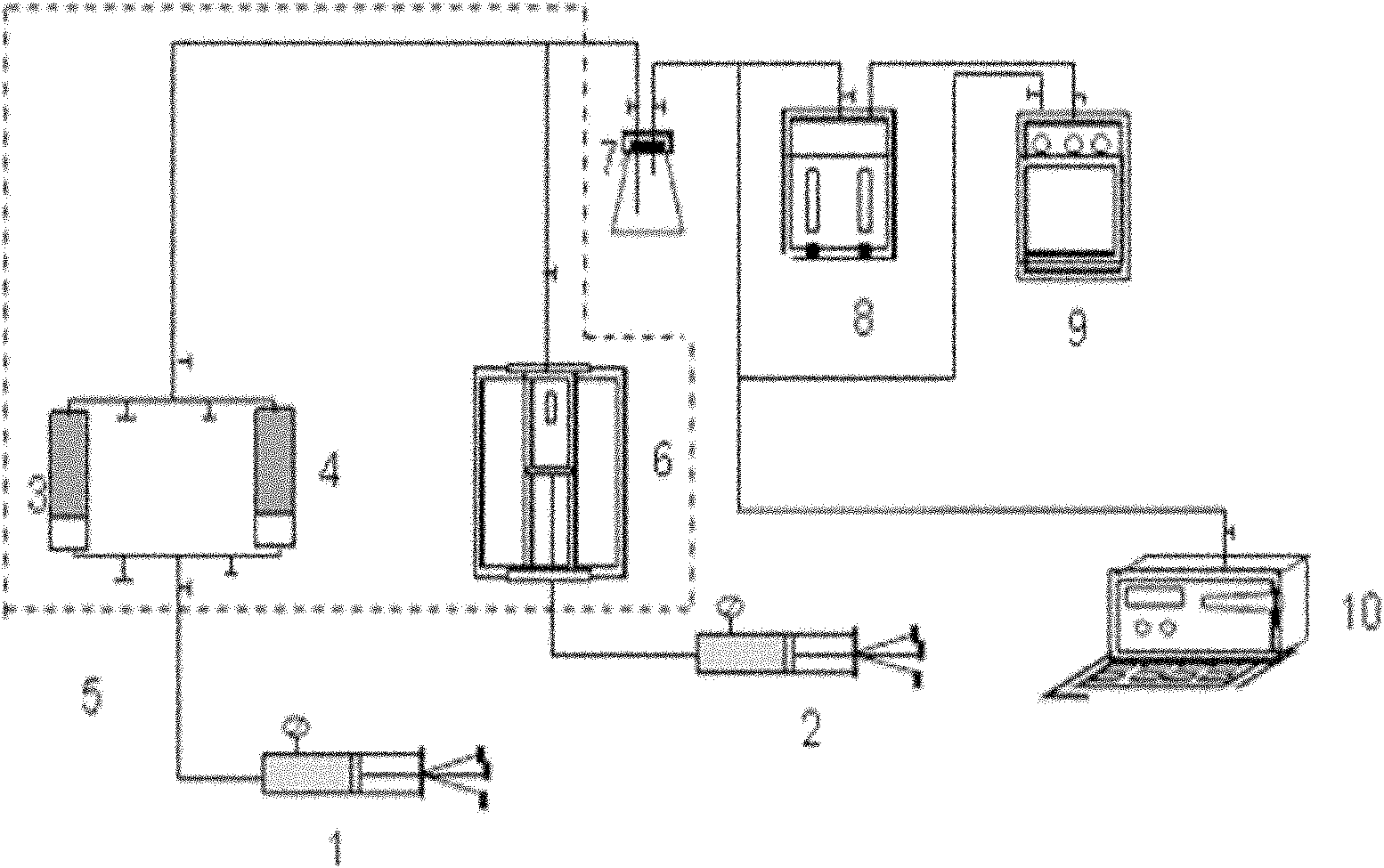

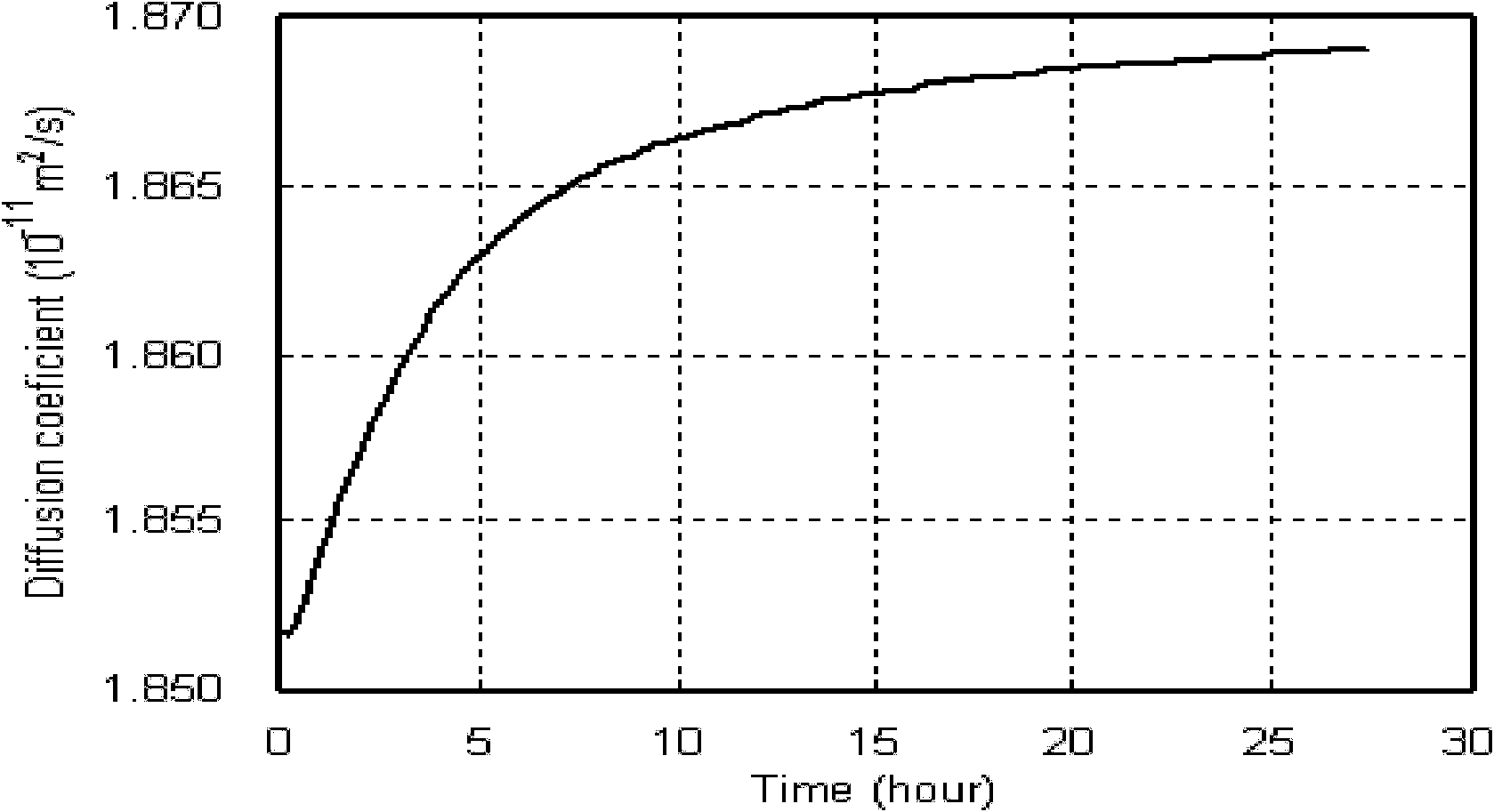

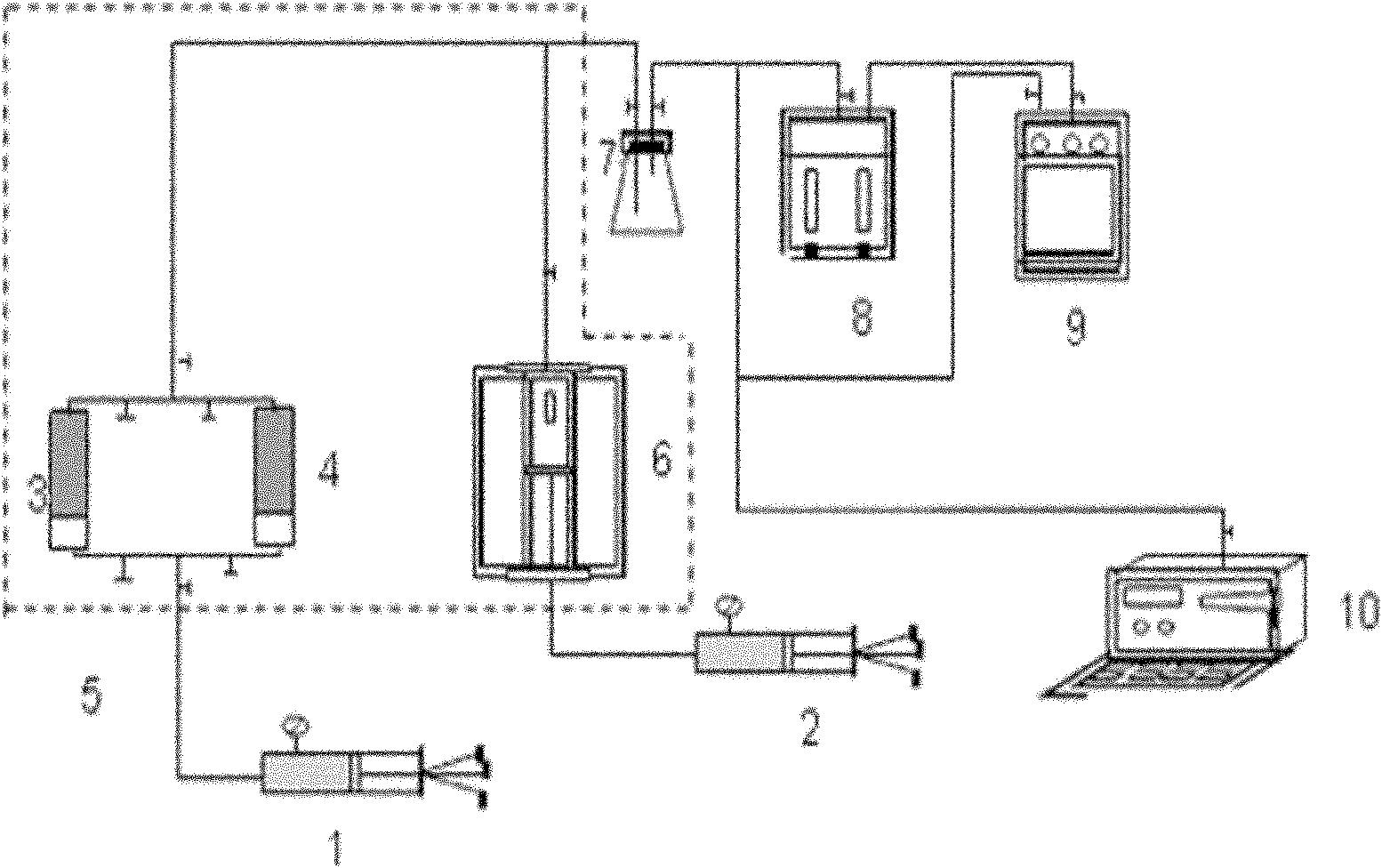

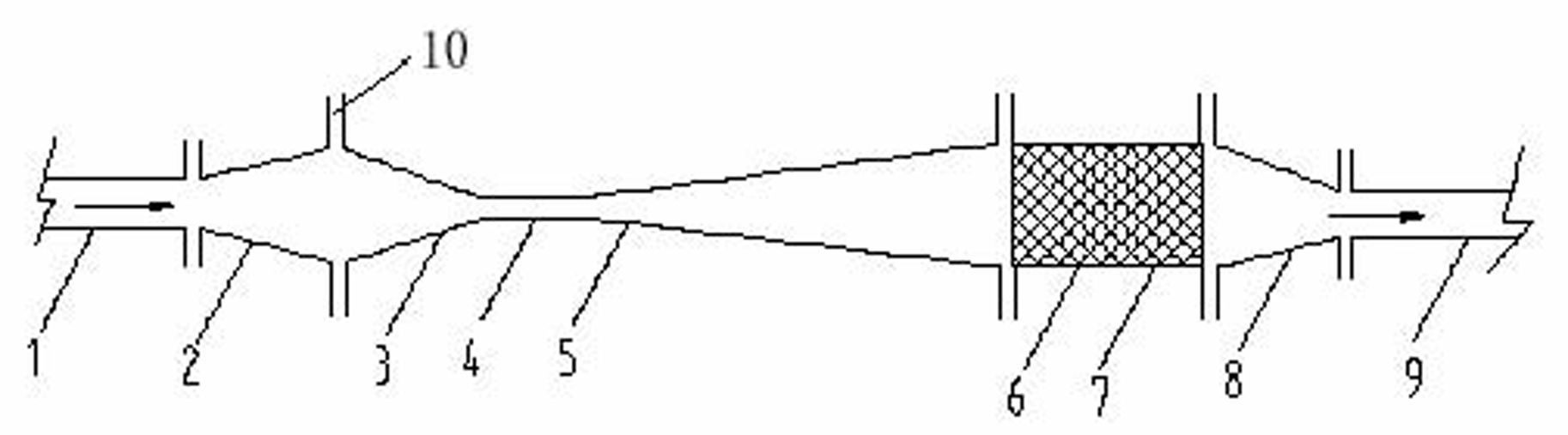

Device and method for testing molecular diffusion coefficients in multi-component oil-gas system under high temperature and high pressure

InactiveCN102121891AReliable principleGuaranteed accuracySurface/boundary effectUltra high pressureGas phase

The invention relates to a device and method for testing molecular diffusion coefficients in a multi-component oil-gas system under high temperature and high pressure. The device consists of an inlet pump 1, an outlet pump 2, an intermediate container, a PVT (pressure-volume-temperature) cylinder 6, an oil-gas separator 7, a gas volume flow meter 8, a liquid phase density analyzer 10 and a chromatographic analyzer 9, wherein, one end of the intermediate container is connected with the inlet pump 1, and the other end of the intermediate container is connected with the PVT cylinder 6; the PVT cylinder is connected with the oil-gas separator 7; the separator is connected with the gas volume flow meter 8 and the liquid phase density analyzer 10; the gas volume flow meter and the liquid phase density analyzer are respectively connected with the chromatographic analyzer 9; and the other end of the PVT cylinder is connected with the outlet pump 2. The device has the advantages of reasonable principle and simple structure, and is convenient in operation; and by utilizing the method, the molecular diffusion coefficients of each component in a multi-component injected gas and actual crude oil system in gas phase and oil phase under the conditions of different reservoir temperature and pressure can be determined, thereby providing reasonable basic data for quantitative evaluation of influence of molecular diffusion effect on the enhancement of the recovery ratio by means of gas injection.

Owner:SOUTHWEST PETROLEUM UNIV

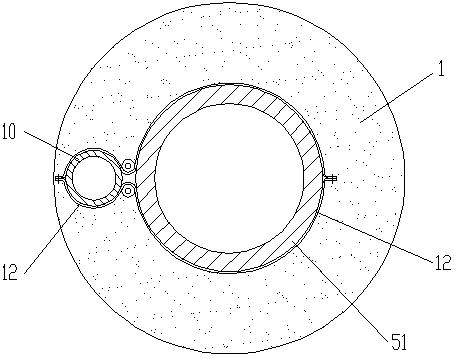

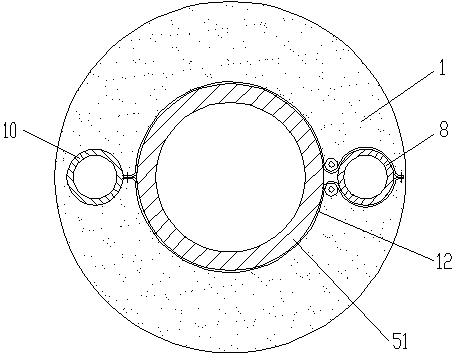

Drilling and sealing method and sealing device for ultra-high pressure fracturing holes in underground coal mines

The invention discloses a drilling-sealing method and a sealing device of a coal mine underground ultrahigh pressure fracturing hole. The drilling-sealing method comprises the following steps: drilling a plugging hole on coal rock body; going on drilling a fracturing hole forward in the plugging hole; transmitting the sealing device into the plugging hole, enabling a water outlet hole of a fracturing pipe to stretch into the fracturing hole and enabling a taper sleeve sleeved on the fracturing pipe and made of soft material to plug on a hole opening of the fracturing hole; sealing by using polyurethane and solidifying for 30 minutes for 1 m length section at the hole opening of the plugging hole; and grouting cement slurry greater than 425 into the plugging hole with pressure by a grouting pipe, and solidifying for 48 hours after finishing grouting. The device comprises a grouting pipe and a slurry returning pipe and a fracturing pipe. The grouting pipe and the slurry returning pipe are arranged in the plugging hole. The grouting pipe, the slurry returning pipe and the fracturing pipe are connected integrally. A soft taper sleeve is arranged on the fracturing pipe. The soft taper sleeve is plugged at the hole opening of the fracturing hole. The invention has the advantages that the sealing method has high sealing success rate, good effect and wide application range; and the sealing device has simple structure and convenient operation.

Owner:重庆市能源投资集团科技有限责任公司 +1

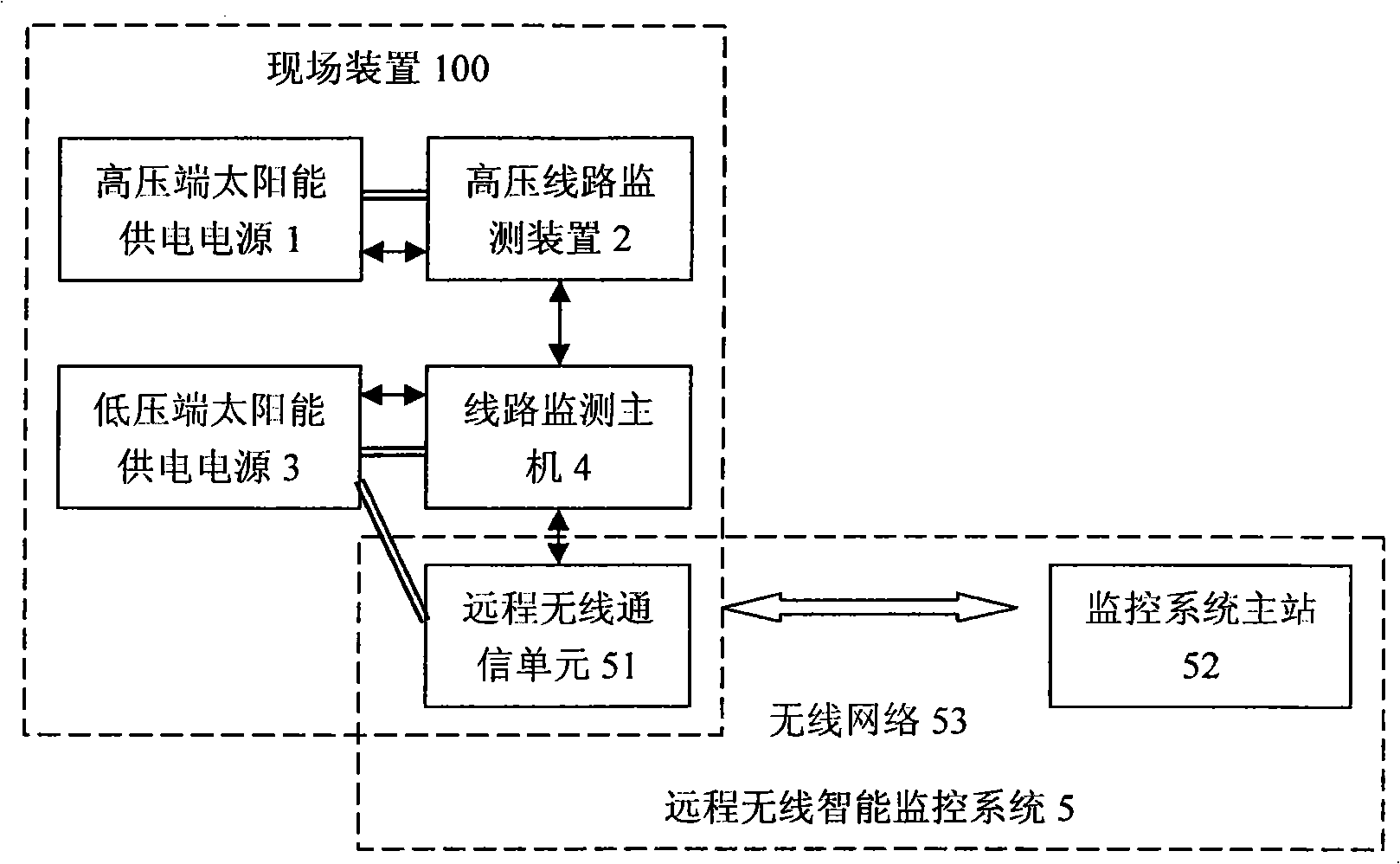

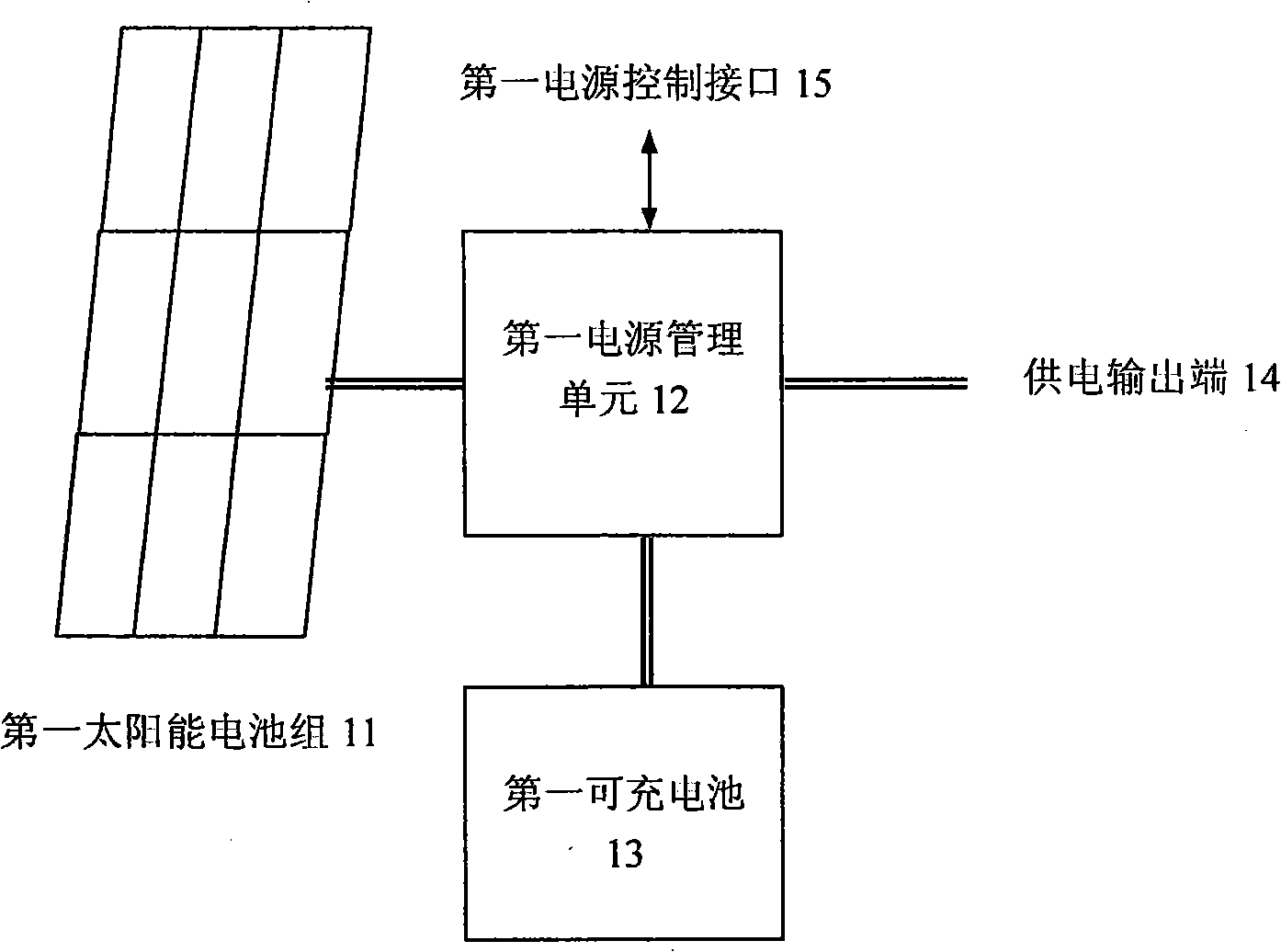

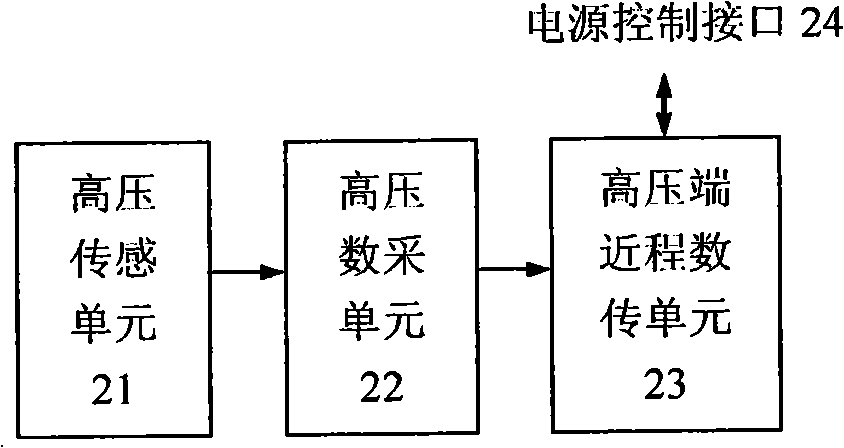

Ultra-high pressure circuit monitoring system for solar power generation

InactiveCN101359022ARealize long-term online operationSolve power problemsData switching by path configurationFault locationTime informationUltra high pressure

The invention relates to a solar-powered ultra-high voltage line monitoring system, comprising a high-voltage side solar power supply, a high voltage line monitoring device, a low-voltage side solar power supply, a line monitoring host computer and a remote wireless intelligent monitoring system. The high-voltage side solar power supply and the low-voltage side solar power supply comprise solar batteries, rechargeable batteries and power management units; the high voltage line monitoring device and the line monitoring host computer comprise sensing units as well as data acquisition and recording units for detecting and processing field parameters of various lines; and the remote wireless intelligent monitoring system comprises a wireless communication unit and a monitoring system master station. The high-voltage side solar power supply, the high voltage line monitoring device, the low-voltage side solar power supply, the line monitoring host computer and the remote wireless intelligent monitoring system compose a field device which collects and records the running status and fault information of high-voltage lines through solar power and transmits the running status and fault information to the monitoring system master station through the remote wireless communication unit so as to provide real-time information for power line monitoring.

Owner:SOUTHEAST UNIV +2

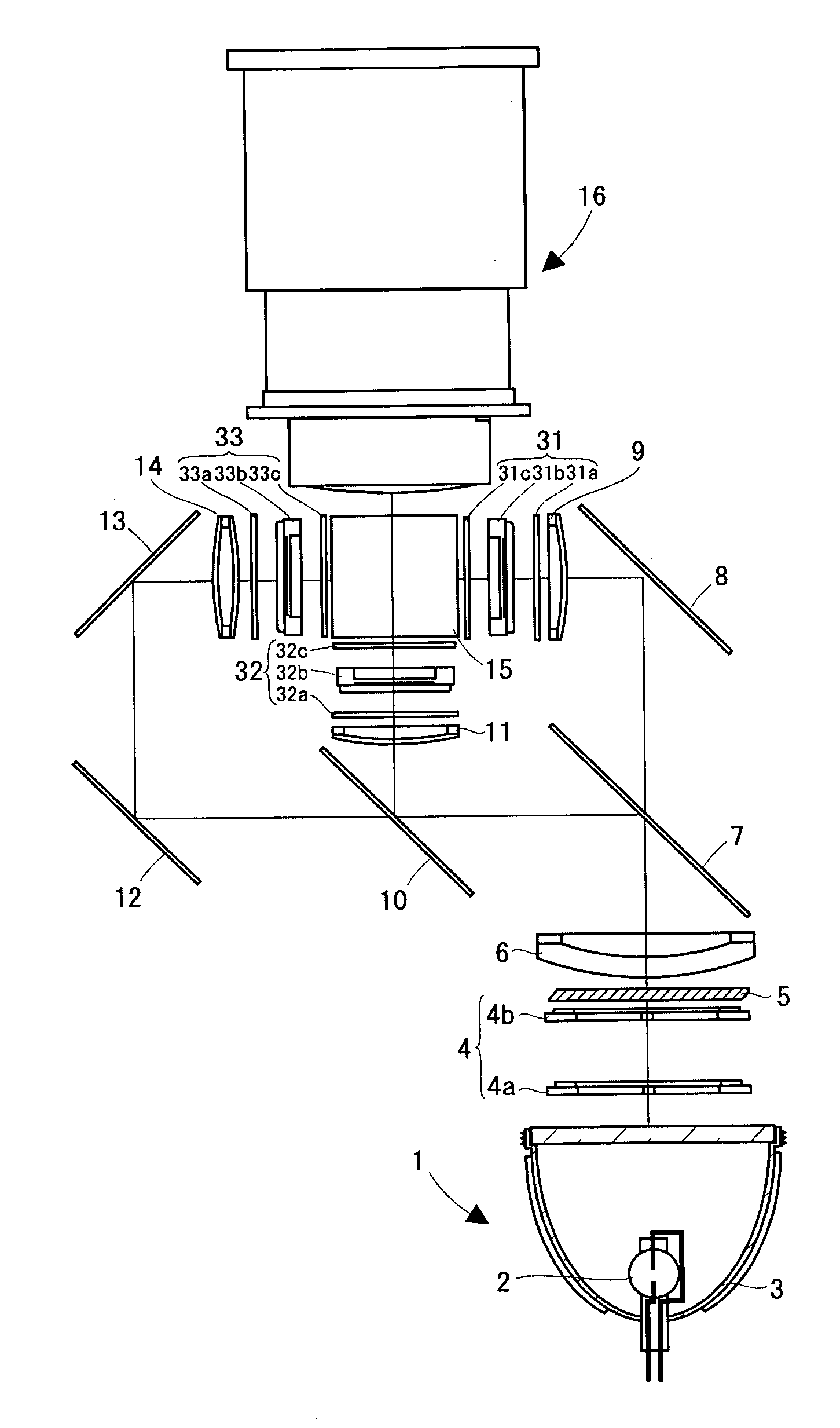

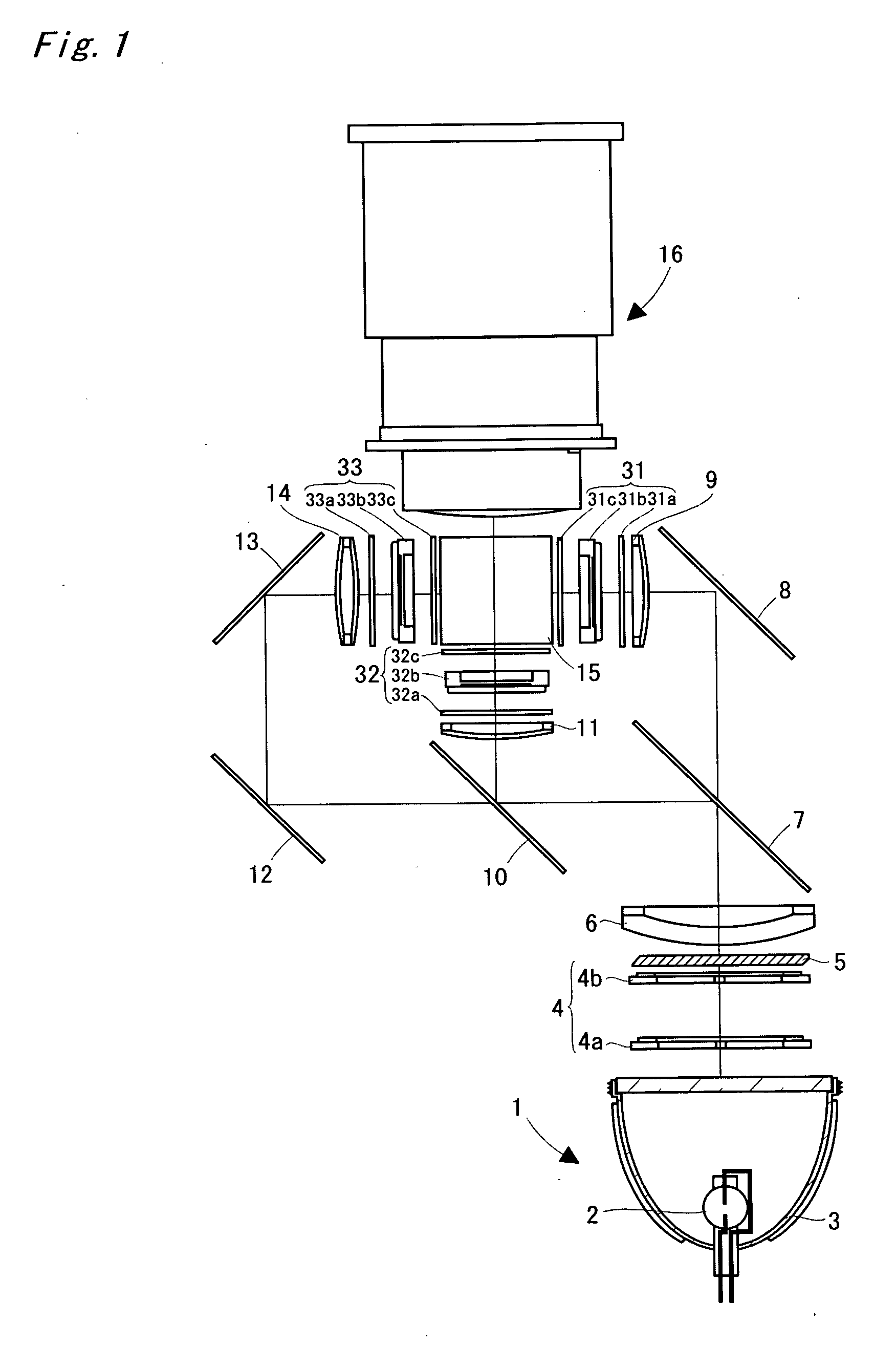

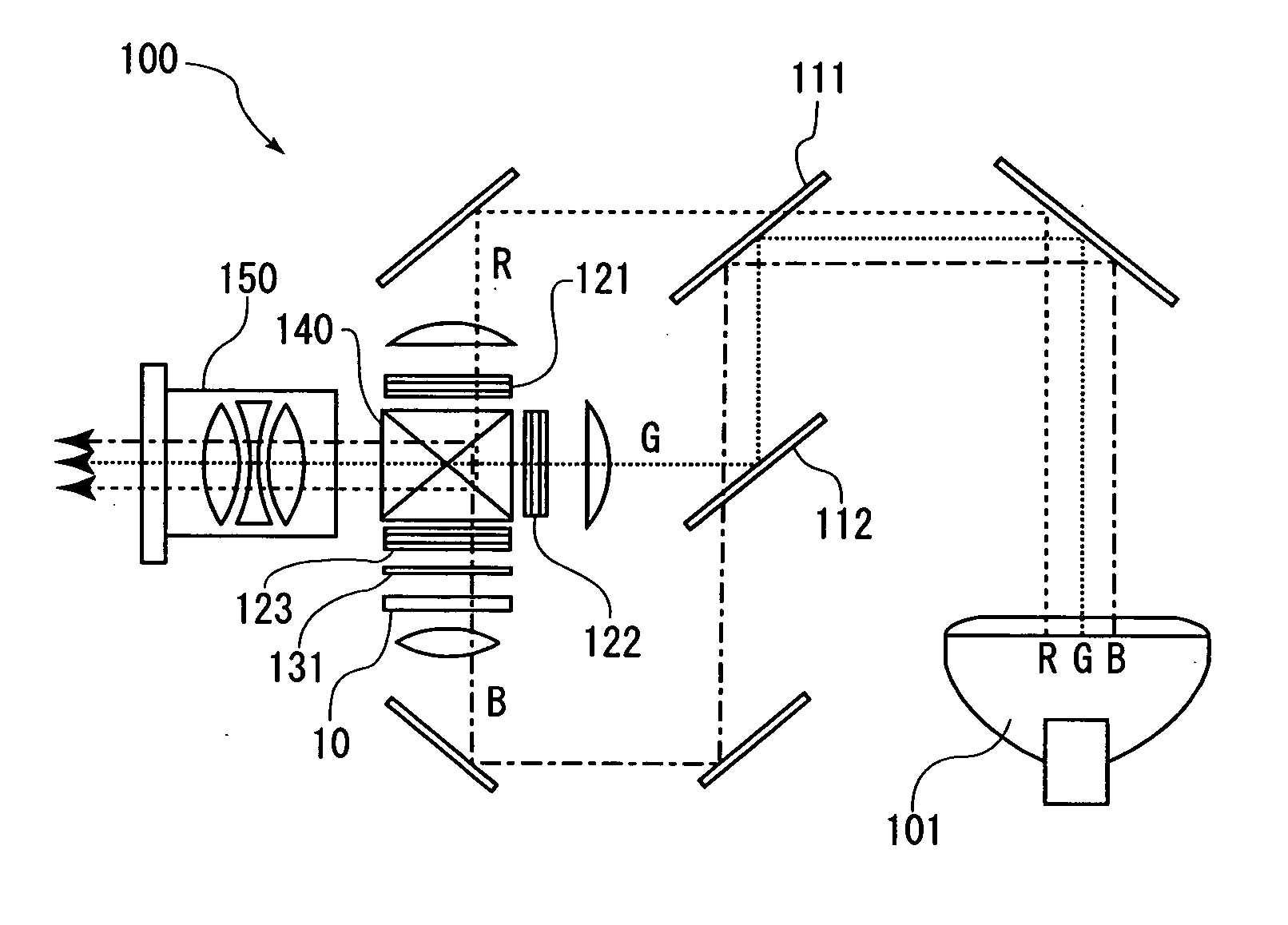

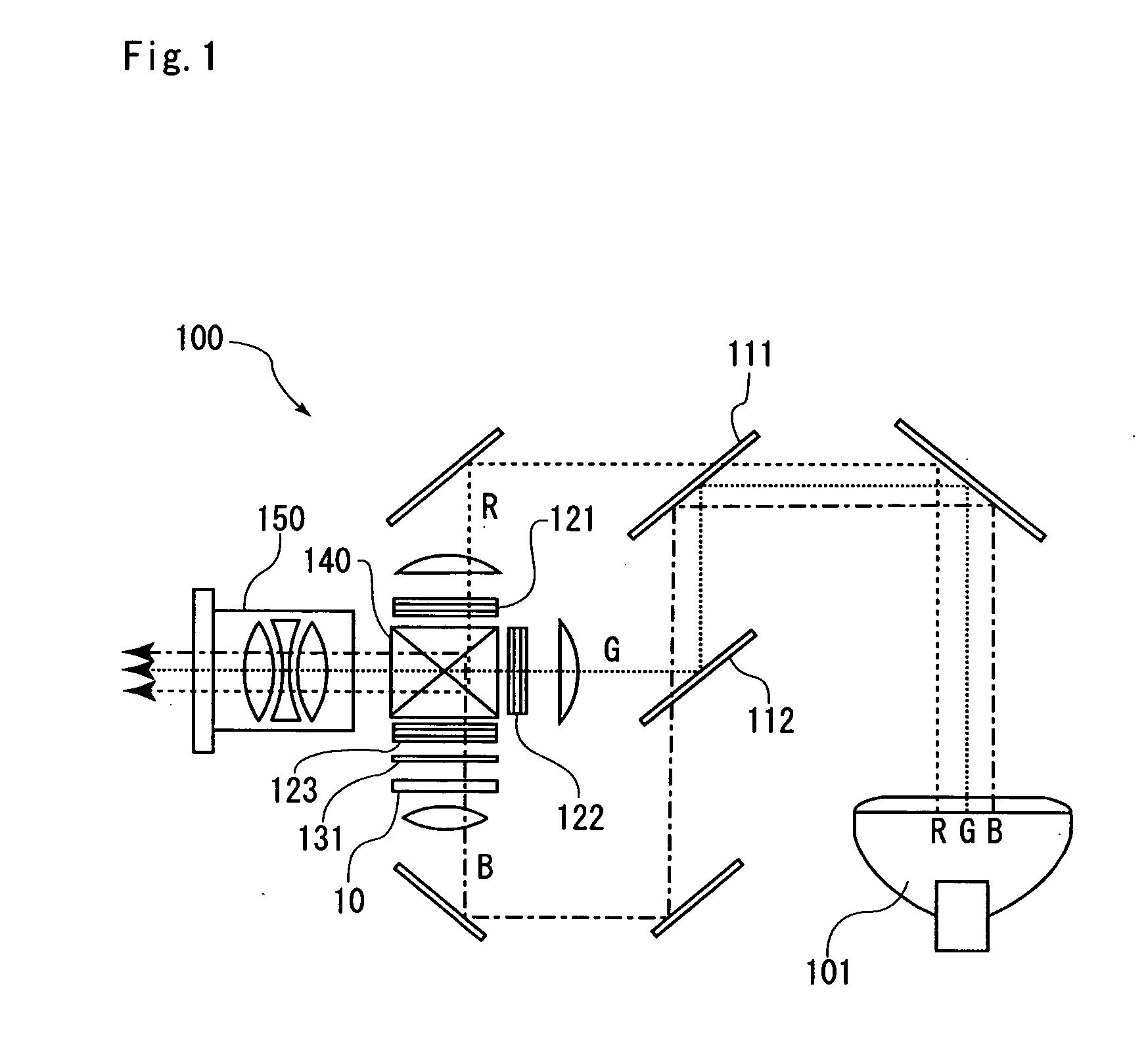

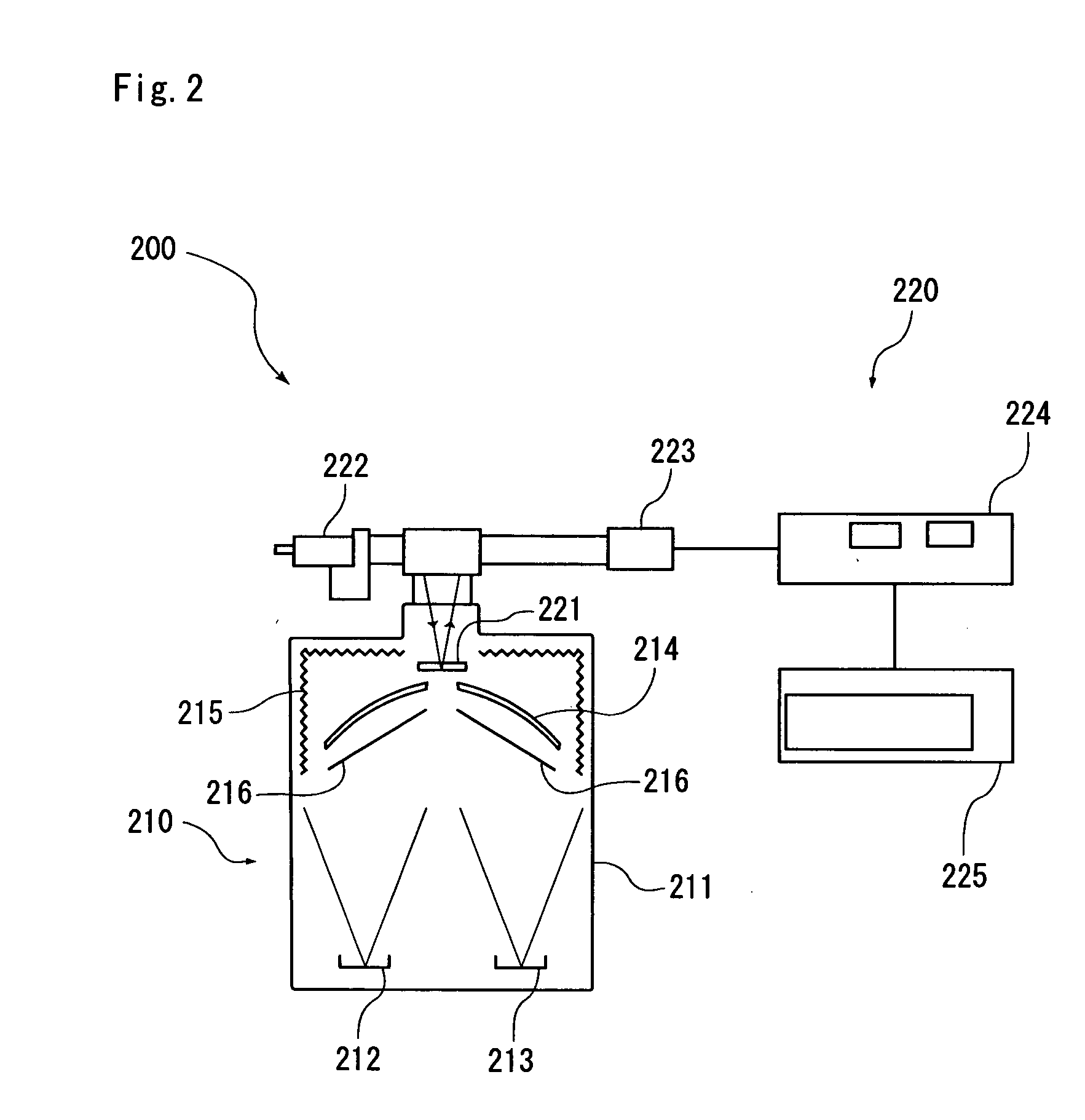

Projection type video display

InactiveUS20050231962A1High efficiency of heat radiationTelevision system detailsNon-electric lightingUltra high pressureMetal-halide lamp

A light source comprises a lamp such as an ultra-high pressure mercury lamp or a metal halide lamp and its irradiated light is emitted after being parallelized by a parabolic reflector. The parabolic reflector is made by pressing metal such as stainless and its light exit side aperture is covered with a transparent plate made of glass, etc. The transparent plate prevents fragments of glass of the lamp and the like from scattering when the lamp bursts. The parabolic reflector does not have an aperture (cut-out) for ventilation, but heat radiation fins are formed on the outer surface of it.

Owner:SANYO ELECTRIC CO LTD

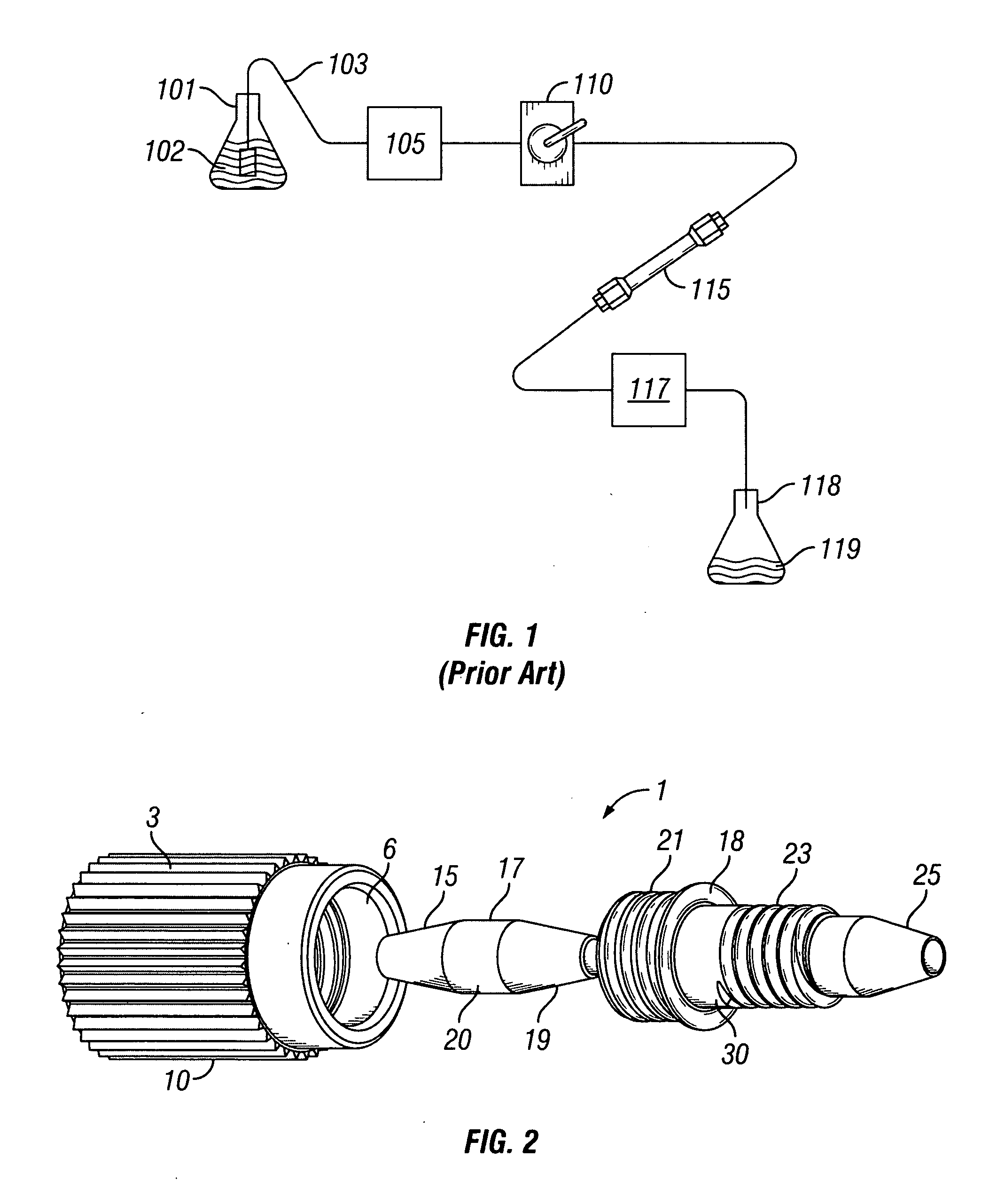

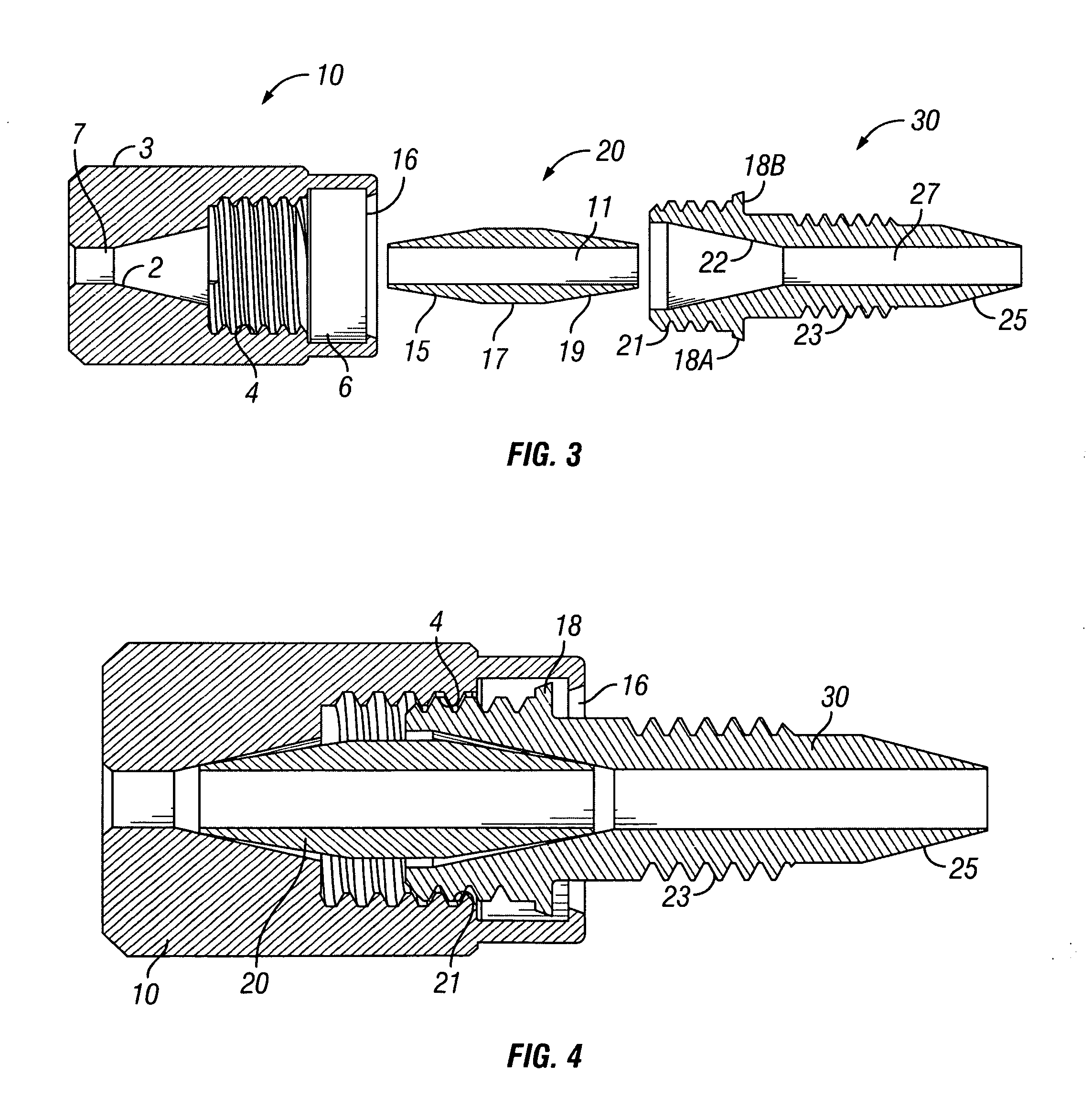

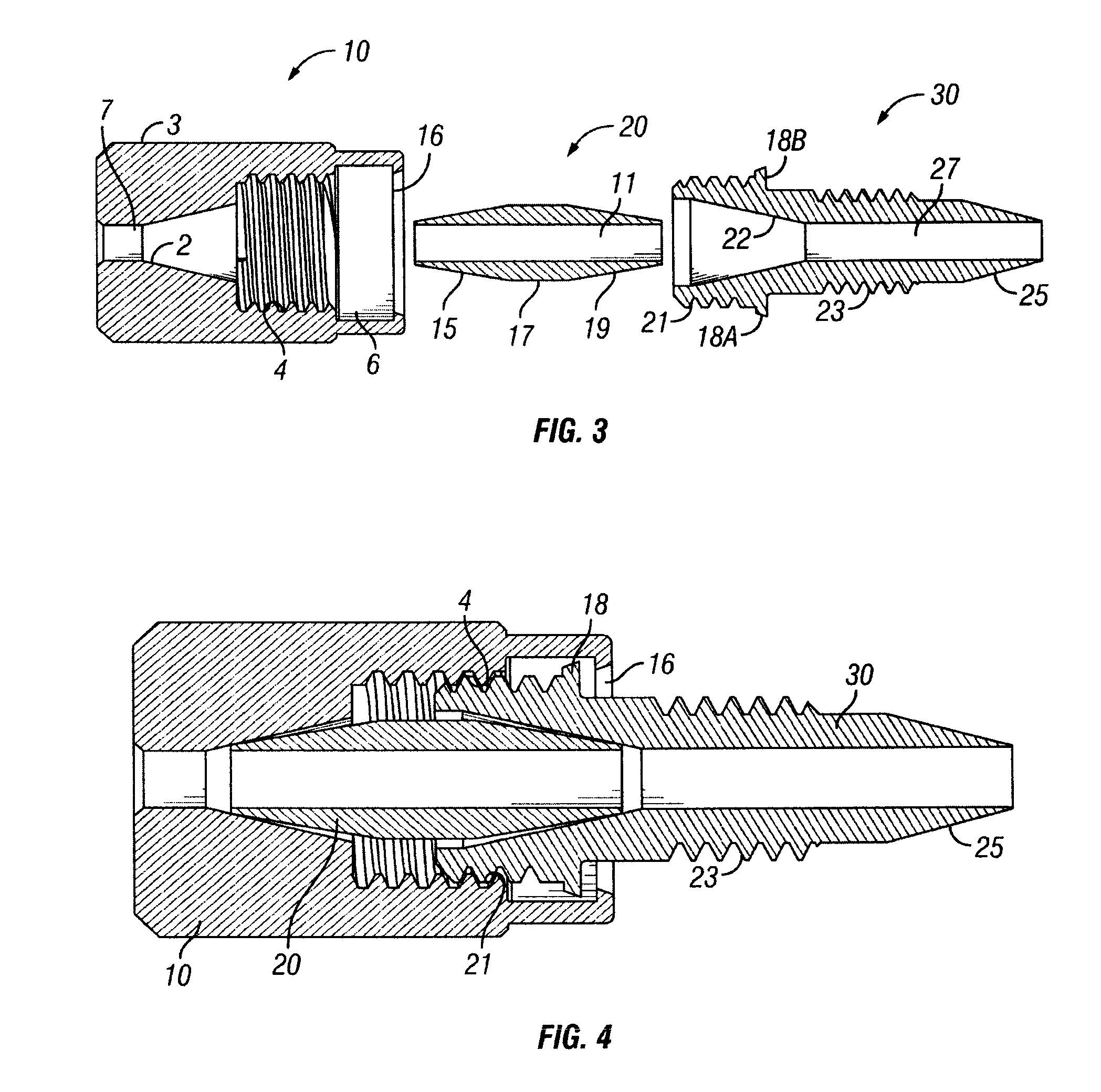

Connection assembly for ultra high pressure liquid chromatography

InactiveUS20100224543A1Firmly connectedIon-exchange process apparatusSleeve/socket jointsUltra high pressureEngineering

A fitting assembly having a double-headed ferrule, a nut, and a fitting that may be assemble or dissembled by an operator. The fitting assembly includes a nut with first and second ends, with the second end have an internally tapered portion adapted to receive the first end of a ferrule, and further includes a fitting with a first end having an internally tapered portion adapted to receive the second end of the ferrule and a second end adapted to be removably connected to a component or fitting of a liquid chromatography system. The nut, ferrule and fitting of the fitting assembly have passageways therethrough for receiving and removably holding tubing.

Owner:IDEX HEALTH & SCI

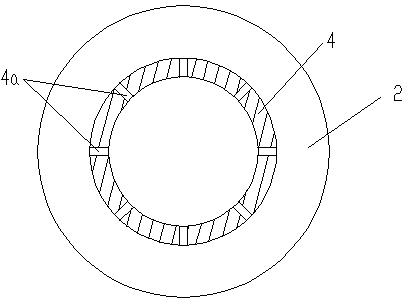

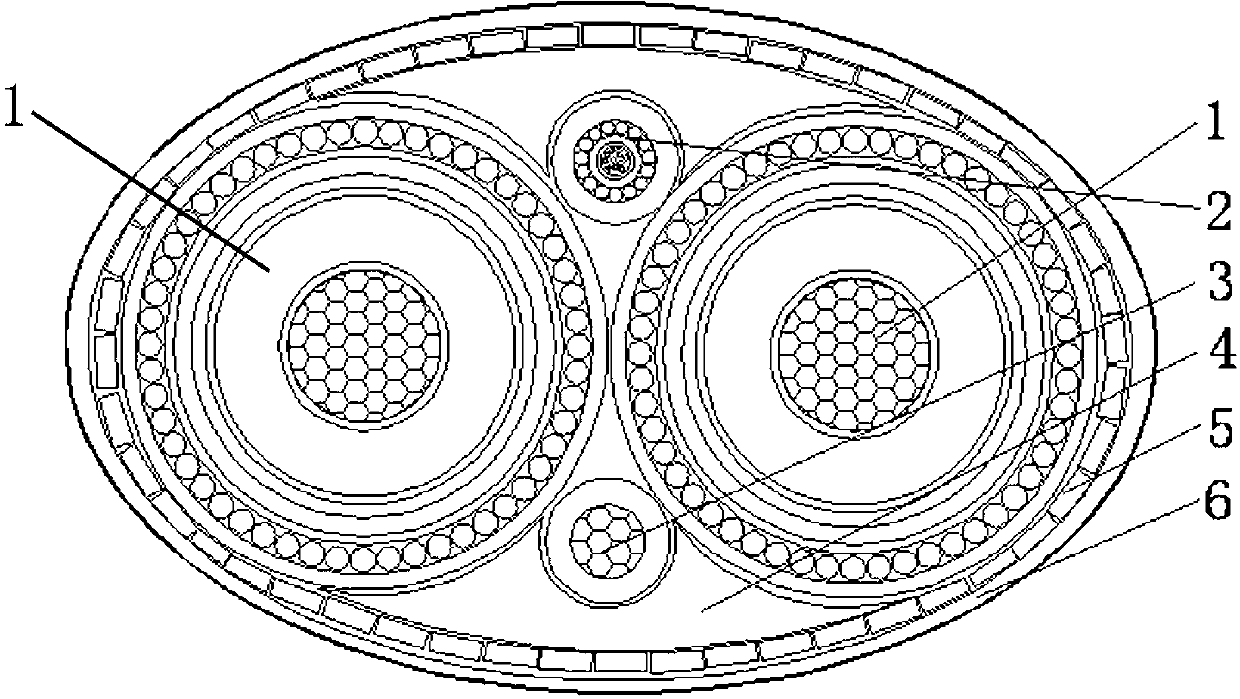

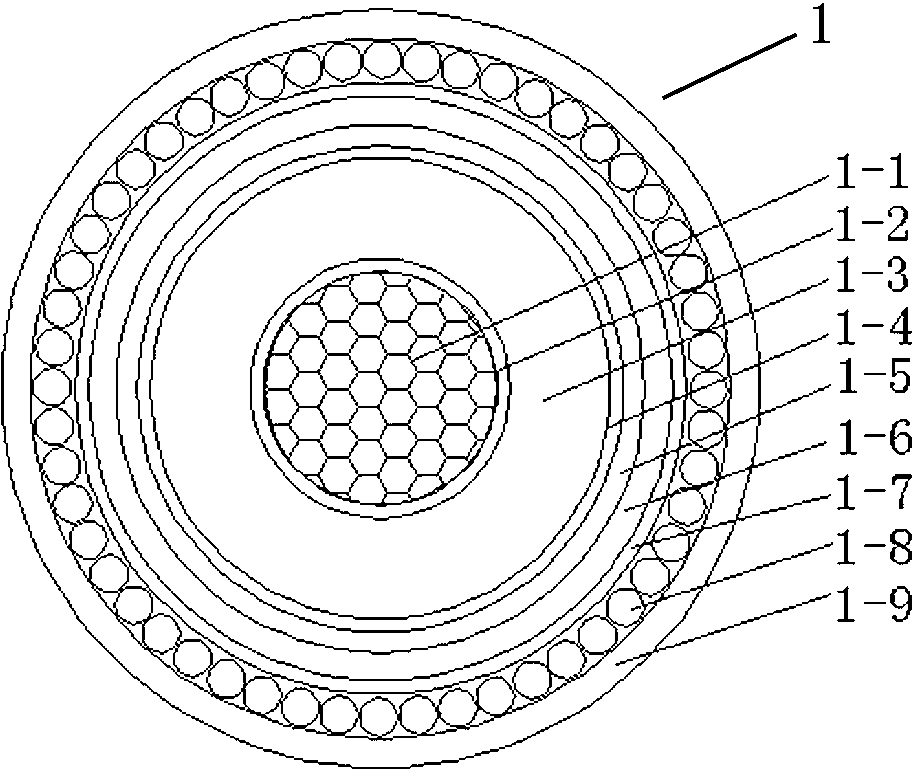

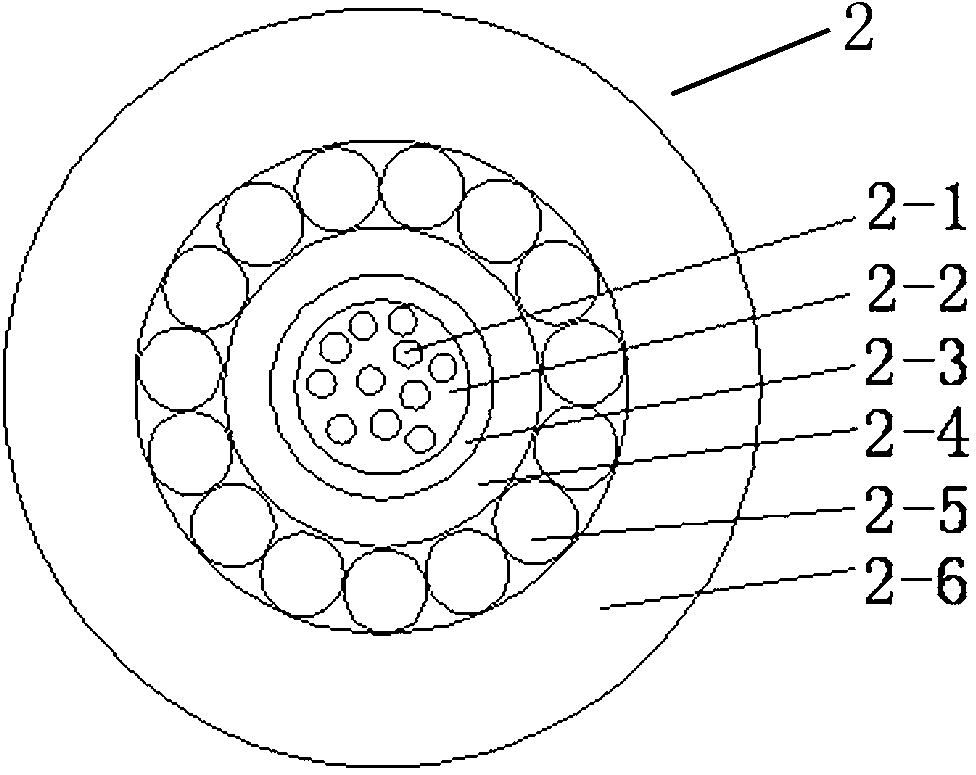

Ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable

ActiveCN103000292AImprove workplaceImprove work field strength in insulation work fieldCommunication cablesOcean bottomUltra high pressure

The invention discloses an ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable and relates to a direct-current cable. The ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable is particularly used in large-power remote submarine power transmission in a flexible direct-current power consumption system of the vacuum control switch (VCS) current-switching technology and grid-tied connection among new energy alternating current systems of aperiodic operating wind power generation, tidal power generation and the like. The ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable comprises direct-current cables, an optical fiber unit, a grounding feeder, filling strips, a main armor layer and an outer protective layer, wherein the two direct-current cables are respectively arranged on the left side and the right side, the optical fiber unit is arranged above the middle of the two direct-current cables, the grounding feeder is arranged under the middle portion of the two direct-current cables, and the cable is formed in a flat-supporting non-stranding mode; cable forming gaps are filled through arc-shaped filling strips; the direct-current cables, the optical fiber unit and the grounding feeder form the cable and then are armored through the main armor layer, the outer protectively layer is arranged on the surface of the main armor layer, anti-corrosion insulating glue is coated on each layer of polypropylene rope, and high-strength self-adhesive tapes are twisted outside the anti-corrosion insulating glue.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Filtration Control Agent And A Drilling Fluid Containing The Same

ActiveUS20130079256A1Good filter loss reduction effectLow viscosity effectFlushingDrilling compositionUltra high pressurePolymer science

The present invention provides a filtration control agent and a drilling fluid containing the same. The filtration control agent comprises the product obtained from the reaction of water, lignite, aldehyde and sulfonate polymer at 180-220° C. and the units containing sulfonate groups in the molecular chains of sulfonate polymer are at least 30 wt %. The filtration control agent provided by the present invention features a good filtration loss reduction effect and a low viscosity effect and can improve the rheological behavior of the drilling fluid, thereby meeting the requirements of the drilling of deep wells, ultra-deep wells and ultra high pressure formations.

Owner:CHINA PETROCHEMICAL CORP +1

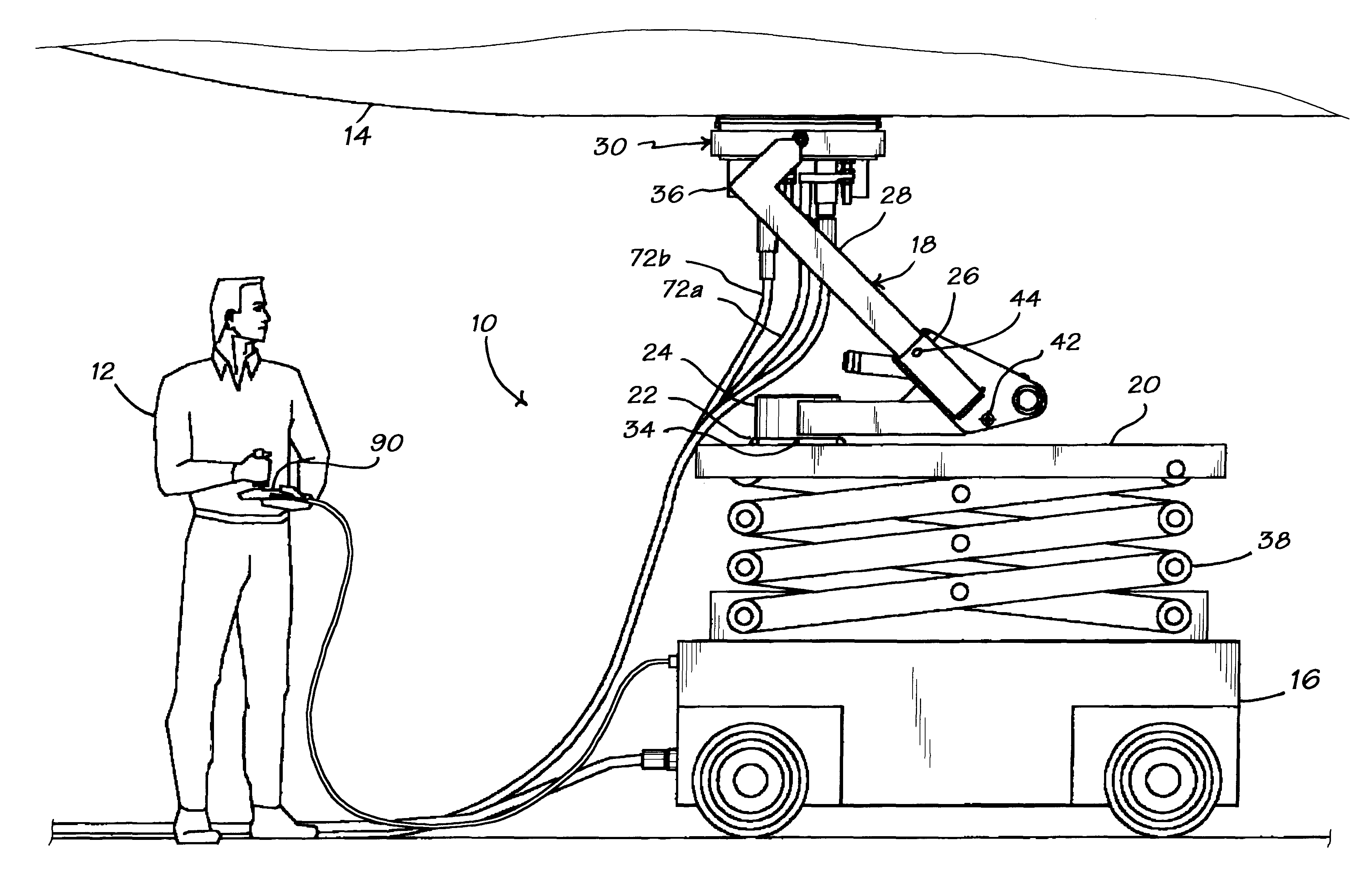

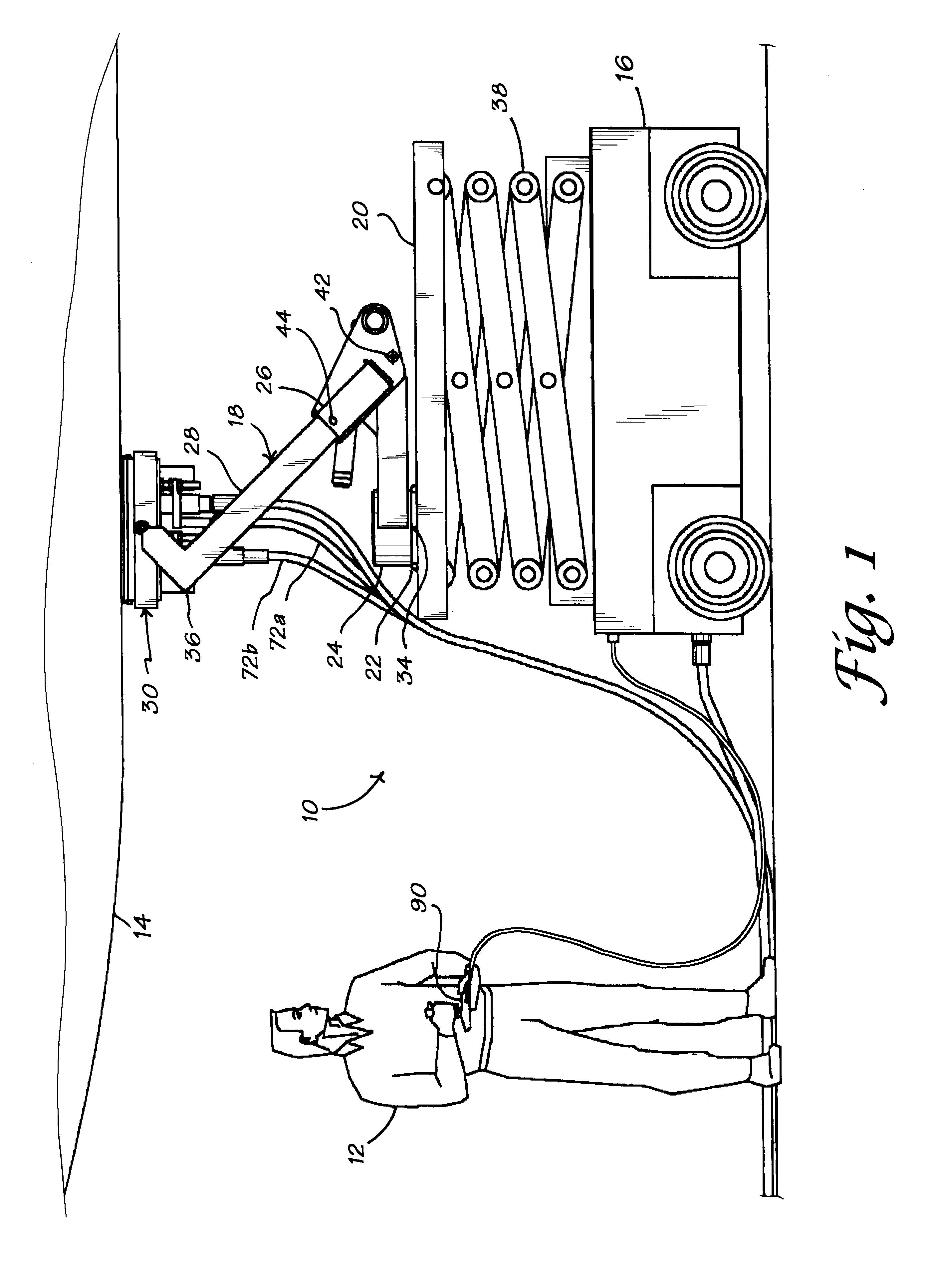

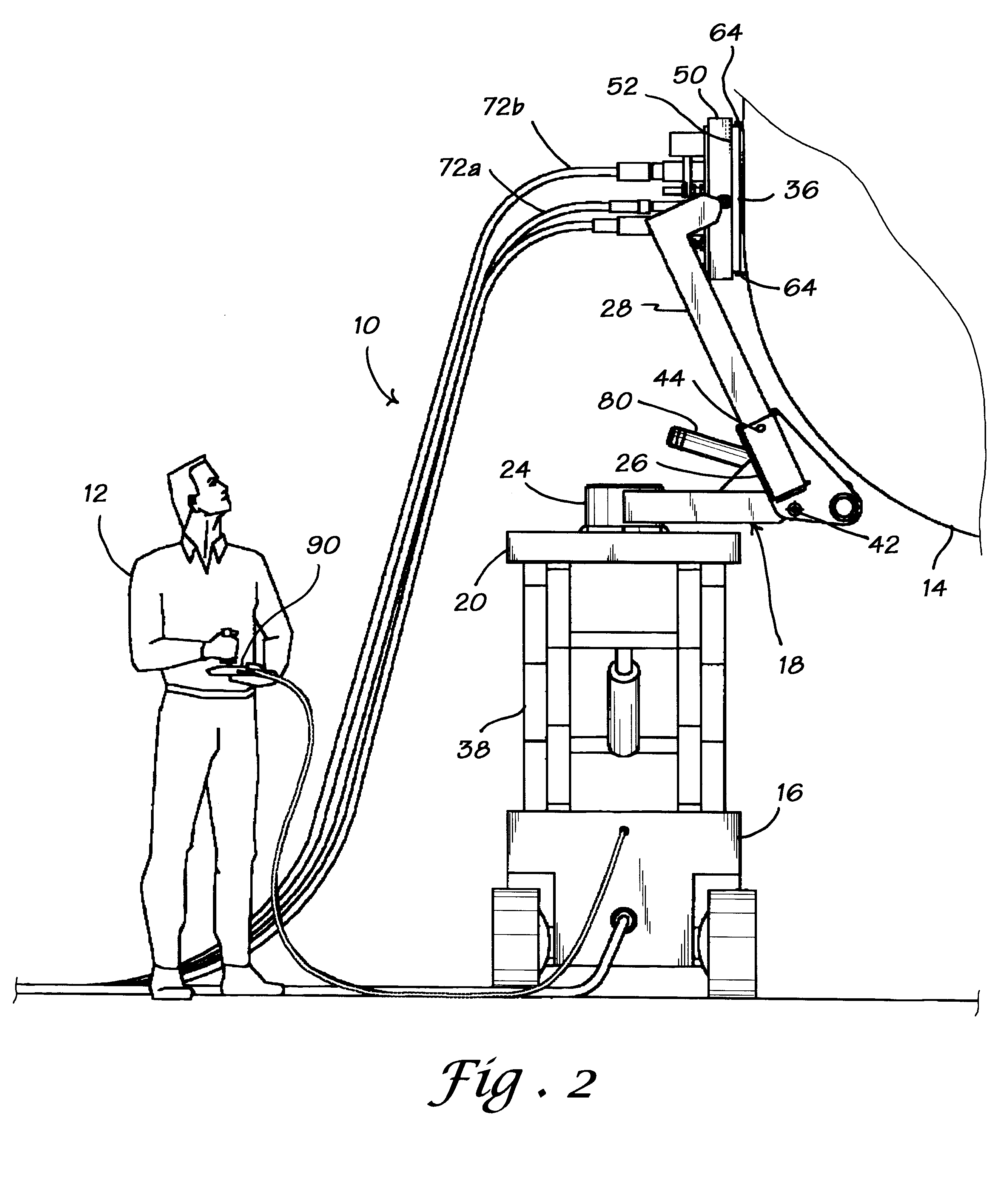

Contour-following apparatus for cleaning surfaces

InactiveUS6189473B1Furthering alignment with work surfaceEasy to cleanVessel cleaningHullsUltra high pressureContour following

A modular apparatus for supporting and guiding a tool such as an ultra-high pressure water jet along a work surface, including a contour following assembly attached to a motorized lift vehicle. The contour following assembly includes a gimbals assembly with an instrument or tool carriage assembly, a positioning assembly that urges the gimbals assembly and the instrument carriage against the surface, and, optionally, a hydraulic, mechanical, or pneumatic pressure system that applies pressure to the positioning assembly. A scissors lift, hydraulic lift, telescoping arm, or other suitable device raises and lowers the apparatus. In operation, the gimbals assembly and the positioning assembly cooperate to maintain the instrument carriage in a user-selected position with respect to a work surface such as a ship hull, aircraft fuselage, storage tank, or the like. Depending on the type of tool selected, the apparatus may be used for cleaning or stripping surface coatings, buffing, painting, washing, and so forth. The apparatus is mobile, compact, cost-effective, and can be operated by a single operator.

Owner:REMOTE TOOLS

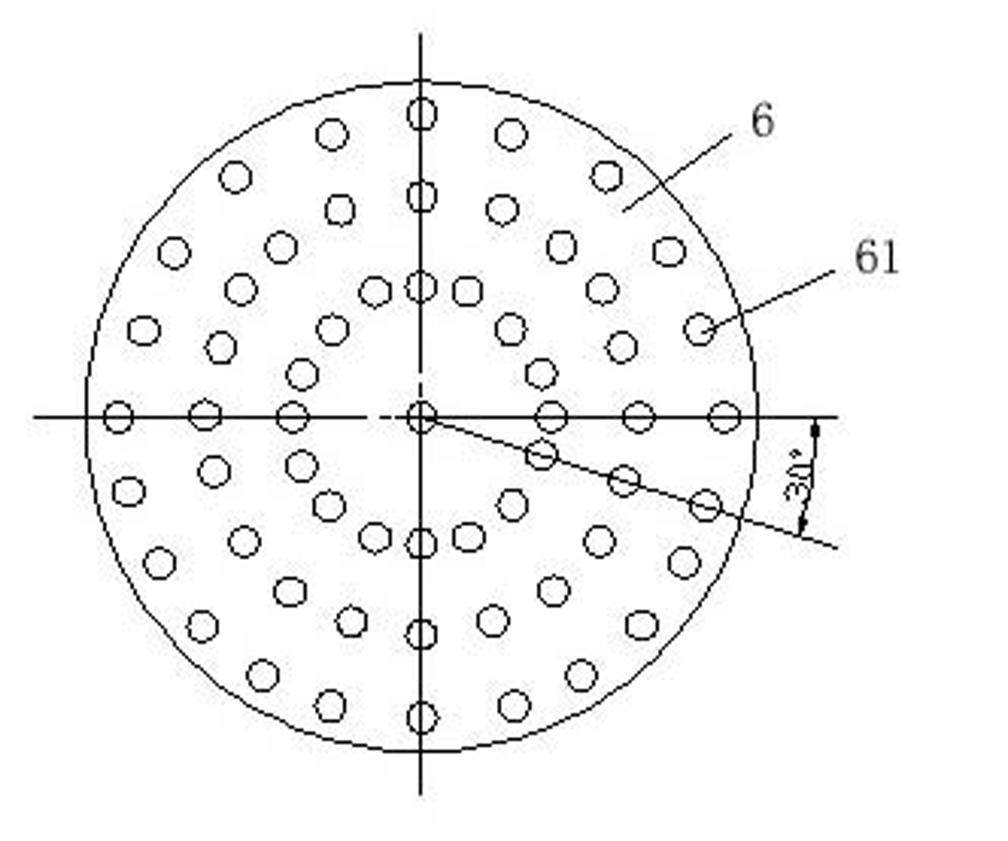

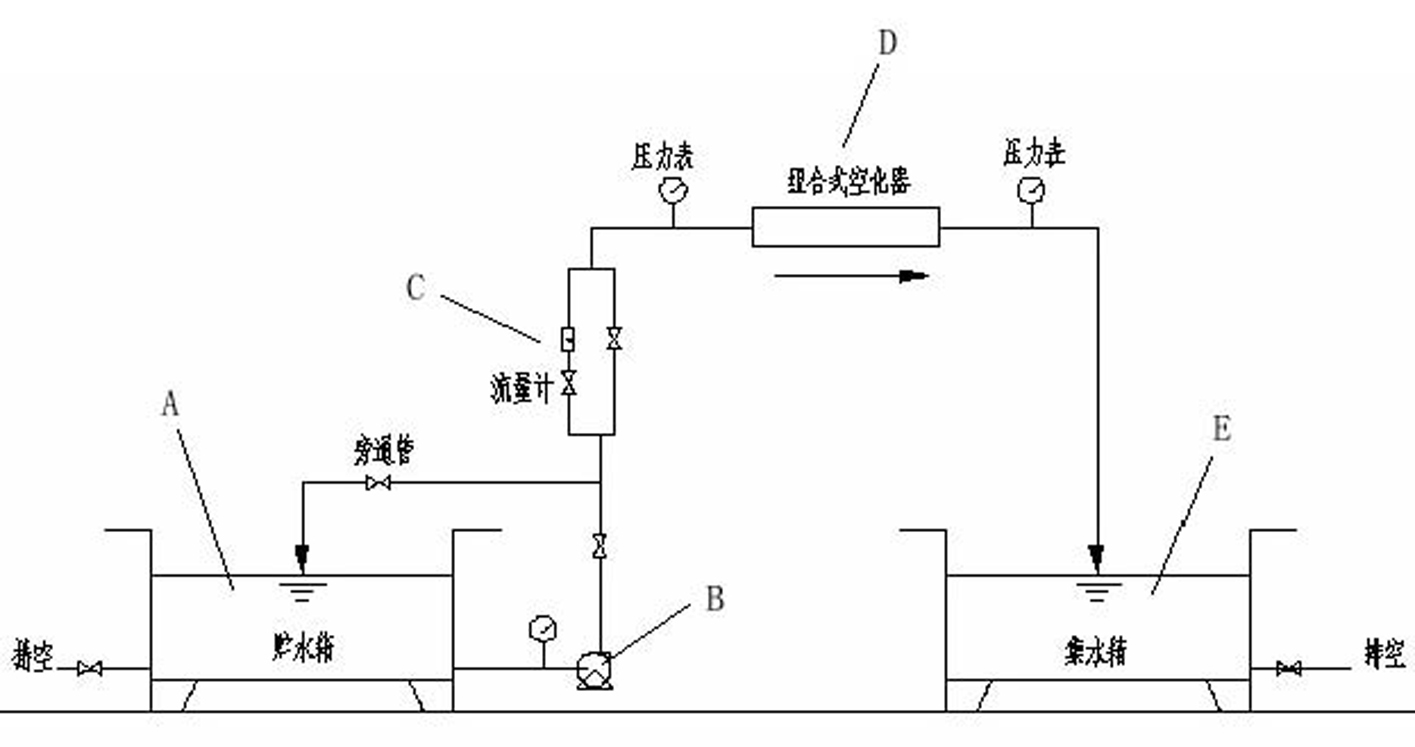

Device for degrading waste water organic matters by combined type hydraulic power cavitation

InactiveCN102531146ABOD/COD improvementImprove subsequent biochemical effectsWater/sewage treatment by oxidationHigh concentrationShock wave

The invention relates to a device for degrading waste water organic matters by combined type hydraulic power cavitation. The device comprises a Venturi tube component and a sieve mesh plate component which are connected in series and communicated with each other, wherein the water inlet end of the Venturi tube component is connected with a high-pressure pump waste water device; and the water outlet end of the sieve mesh plate component is connected with a water outlet pipeline. According to the device, due to the adoption of the structure, ultra-high pressure and high temperature which are similar to the condition of 'wet air oxidation' are generated and accompanied with strong shock waves and jet flows at the moment of collapsing cavitation bubbles after cavitation by utilizing the hydraulic power cavitation principle, so that part of organic matters in waste water are decomposed into CO2, H2O and inorganic oxides to degrade chemical oxygen demands (COD) and biochemical oxygen demands (BOD). The device is suitable for the pretreatment of the high-concentration organic waste water which is insusceptible to biochemical degradation, and the pH value of the waste water is not limited.

Owner:深圳市宇力科技有限公司 +2

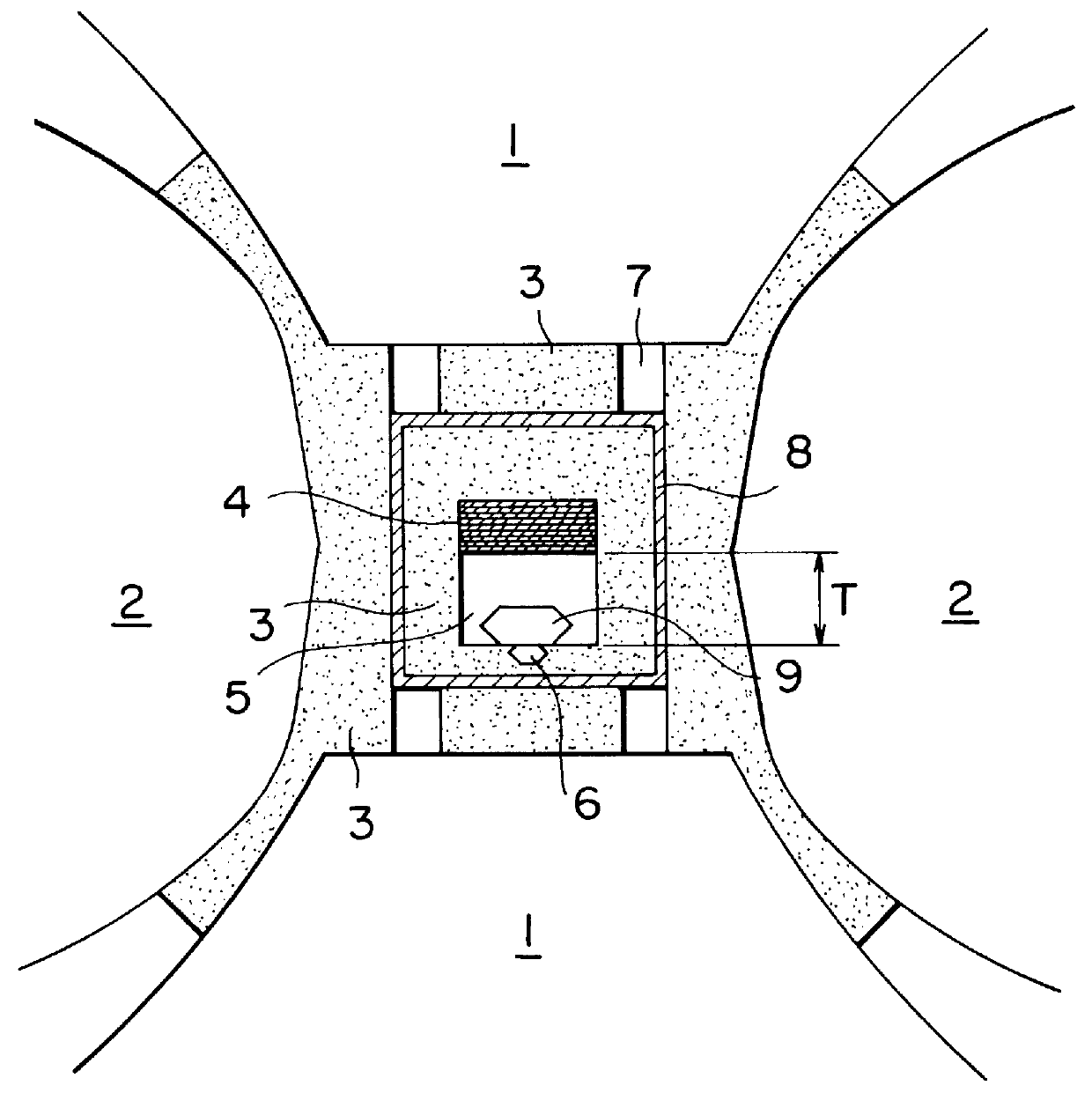

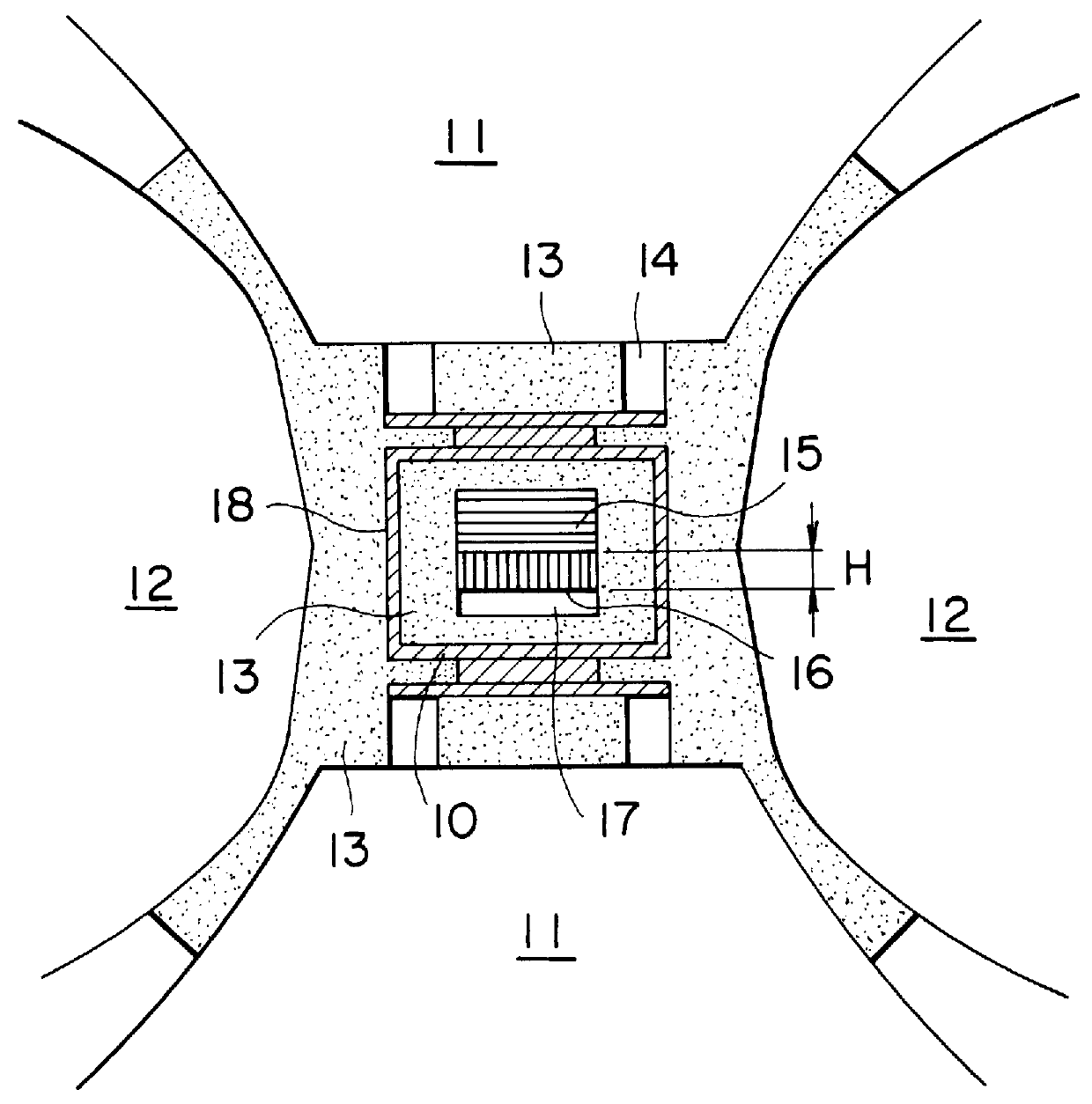

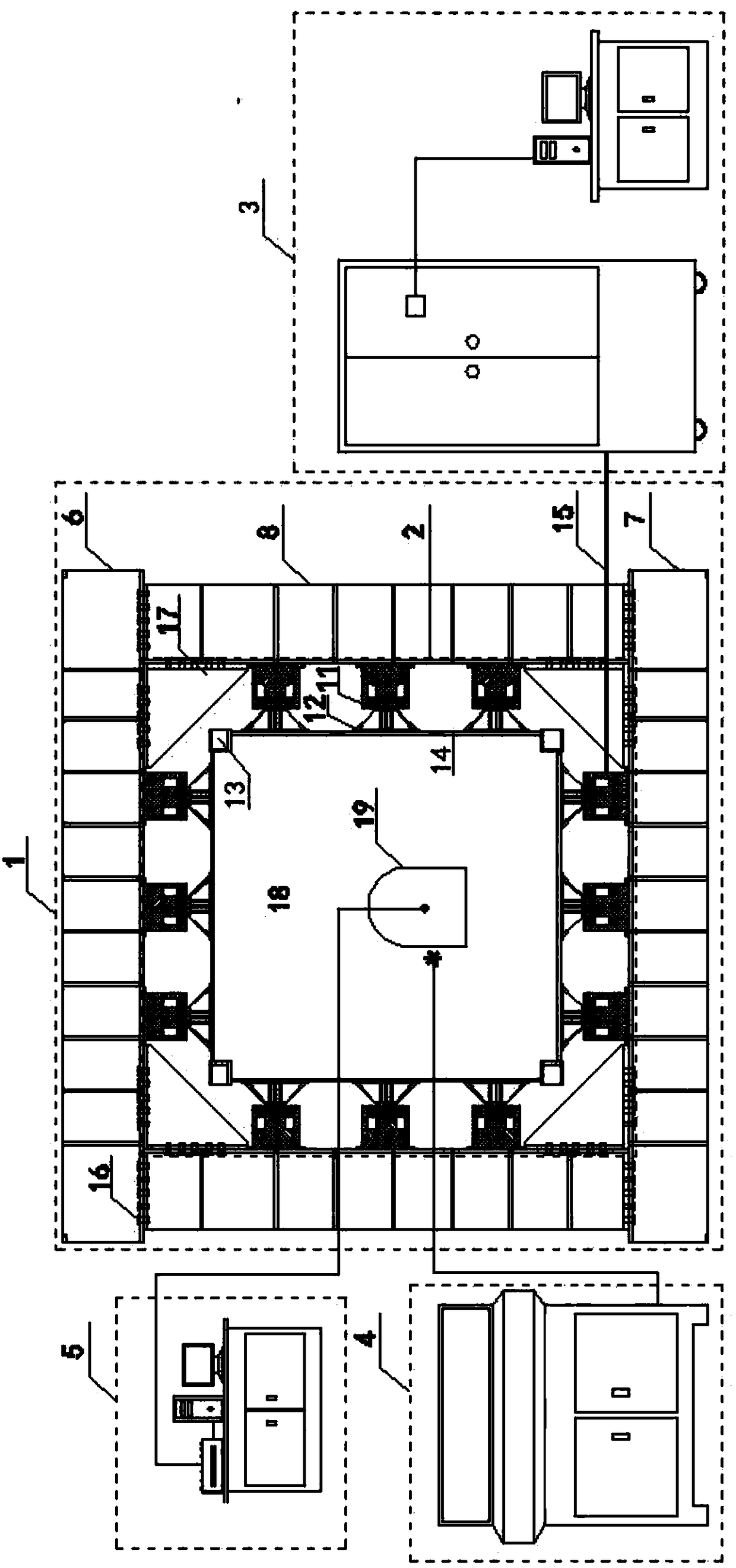

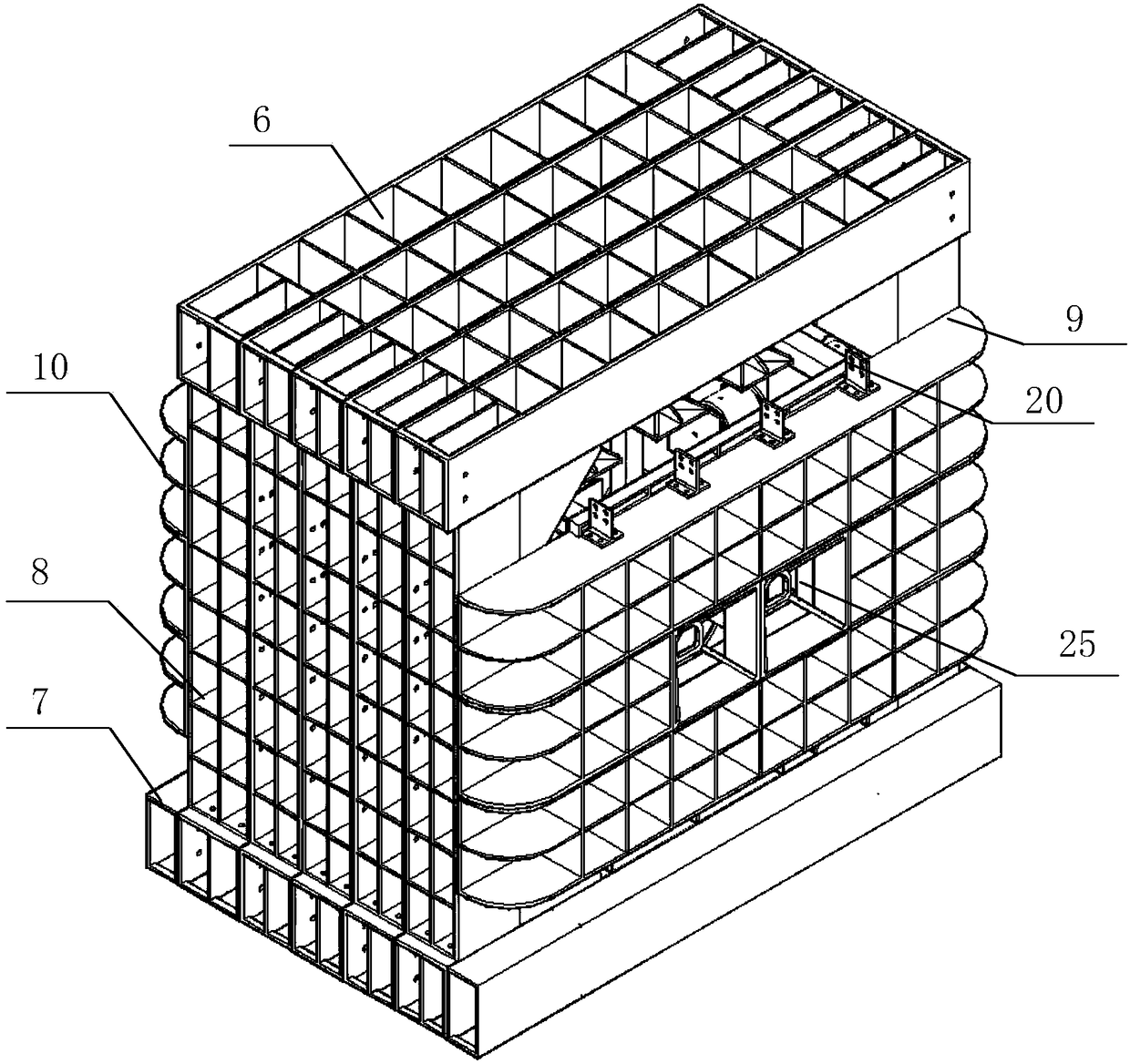

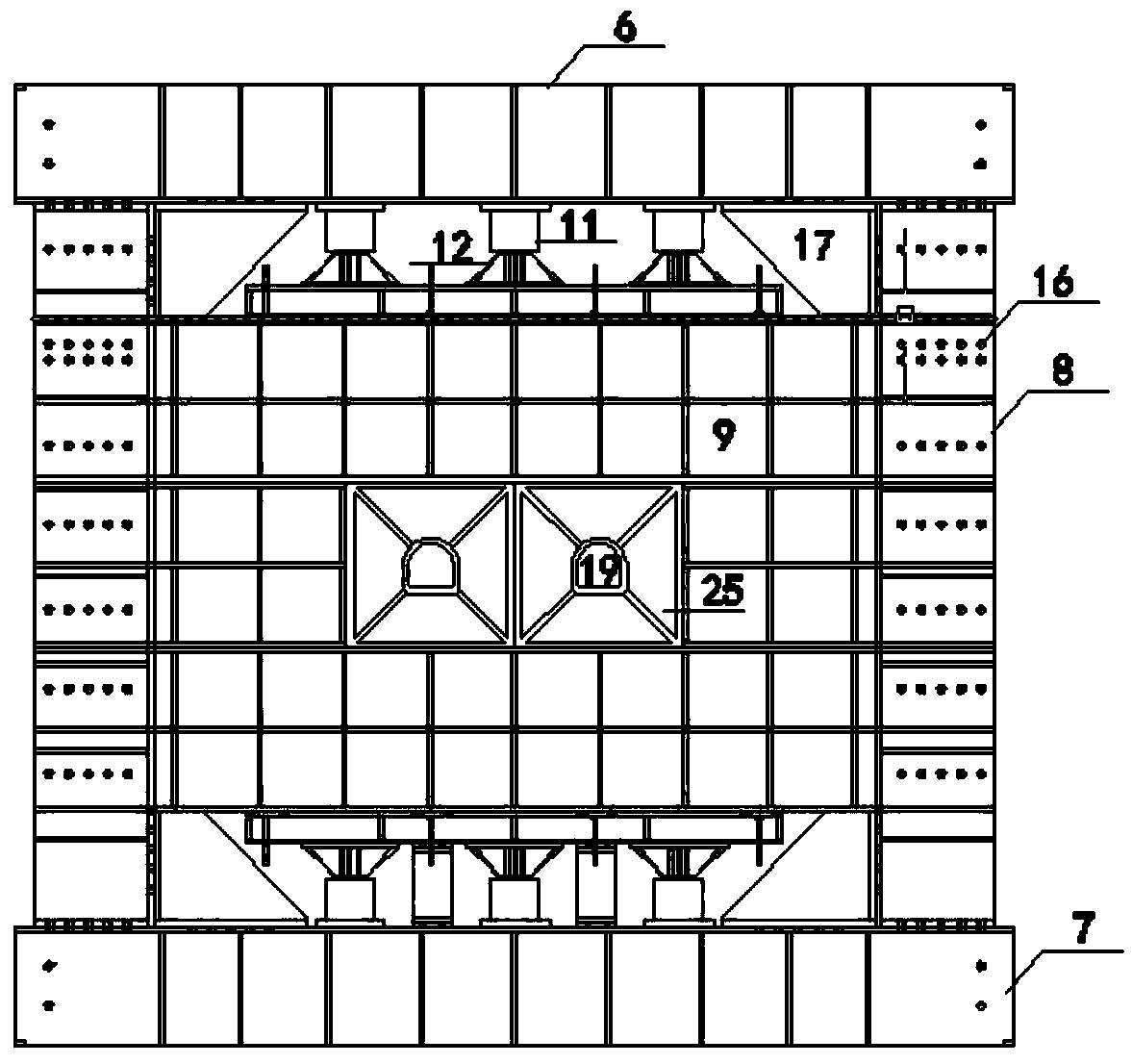

Intelligent NC super high pressure true 3D uneven loading and unloading and pressure stabilizing model test system

ActiveCN108124460AHigh loading accuracyLong stabilization timeUnderground chambersMaterial strength using tensile/compressive forcesUltra high pressurePilot system

The invention discloses an intelligent NC super high pressure true 3D uneven loading and unloading and pressure stabilizing model test system. The system includes a combined rack reaction device, a super high pressure true 3D uneven loading and unloading device, an intelligent hydraulic pressure unloading and pressure stabilizing NC system, a model displacement automatic test system and a high-definition multi-probe peeping system. The super high pressure true 3D uneven loading and unloading device is arranged in the combined rack reaction device for performing super high pressure true 3D uneven loading and unloading on a test model. The intelligent hydraulic pressure unloading and pressure stabilizing NC system is connected with the super high pressure true 3D uneven loading and unloadingdevice through a high pressure oil pipe. Through input commands of the intelligent hydraulic pressure unloading and pressure stabilizing NC system, digital servo control of the super high pressure true 3D uneven loading and unloading device for super high pressure true 3D gradient uneven loading and unloading and pressure stabilization control is realized. The model displacement automatic test system collects displacement of any parts in the model automatically. The high-definition multi-probe peeping system observes a tunnel digging, deforming and destruction processes dynamically in real time. The system has advantages of large and adjustable size of the reaction device, servo control of loading, large loading volume, high loading precision, good pressure stabilizing performance, unevenloading and the like. The scale and the performance are innovative home and abroad and non-continuous deformation and destruction processes of deep tunnel digging in a complex environmental conditions can be simulated and accurate information of multi-physical field evolution such as tunnel surrounding rock displacement, stress, strain and the like of tunnels can be acquired through automatic testing. The system has significant application prospects in simulating nonlinear deformation and destruction mechanisms of deep underground projects including energy, traffic, hydro-power and mine and the like.

Owner:SHANDONG UNIV

Multi-layer film cut filter and production method therefor, uv cut filter, dustproof glass, display panel and projection type display unit

A multi-layer film, wherein a ratio H / L or L / H, a balance in optical film thickness between a high-refractive-index layer H and a low-refractive-index layer L, is set within a range of 1.2-2.0 to bias a balance in thickness. A method of producing a dielectric multi-layer film, wherein, when a dielectric multi-layer film is formed, a proportion at which an optical film thickness is formed on a monitor substrate is made larger than usual. A UV reflection film, having a step difference in average transmittance of 70-90% at a specified half-power point and within a wavelength range of 430-450 nm, is provided on a substrate to form a UV cut filter. A UV reflection film at a specified half-power point, a step difference in average transmittance of 70-90% within a wavelength range of 430-450 nm, and a blue conditioning film having a transmittance of at least 90% within a wavelength range of 460-520 nm may be combined. This UV cut filter is applied to the projection type display unit of a ultra-high pressure mercury lamp light source. The UV reflection film may be provided on the dustproof glass of a display unit.

Owner:138 EAST LCD ADVANCEMENTS LTD

Zero-clearance ultra-high-pressure gas compressor

Gas compression system comprising a compression cylinder having a gas inlet, a compressed gas outlet, and one or more liquid transfer ports; a pump having a suction and a discharge; and a compressor liquid. The system also includes any of the following: a pressure intensifier having an inlet in flow communication with the pump and an outlet in flow communication with the compression cylinder; a feed eductor in flow communication with the discharge of the pump, with a reservoir containing a portion of the compressor liquid, and with the compression cylinder; a drain eductor in flow communication with the discharge of the pump, with the compression cylinder, and with a reservoir containing a portion of the compressor liquid; and a variable-volume compressor liquid accumulator in flow communication with the discharge of the pump.

Owner:AIR PROD & CHEM INC

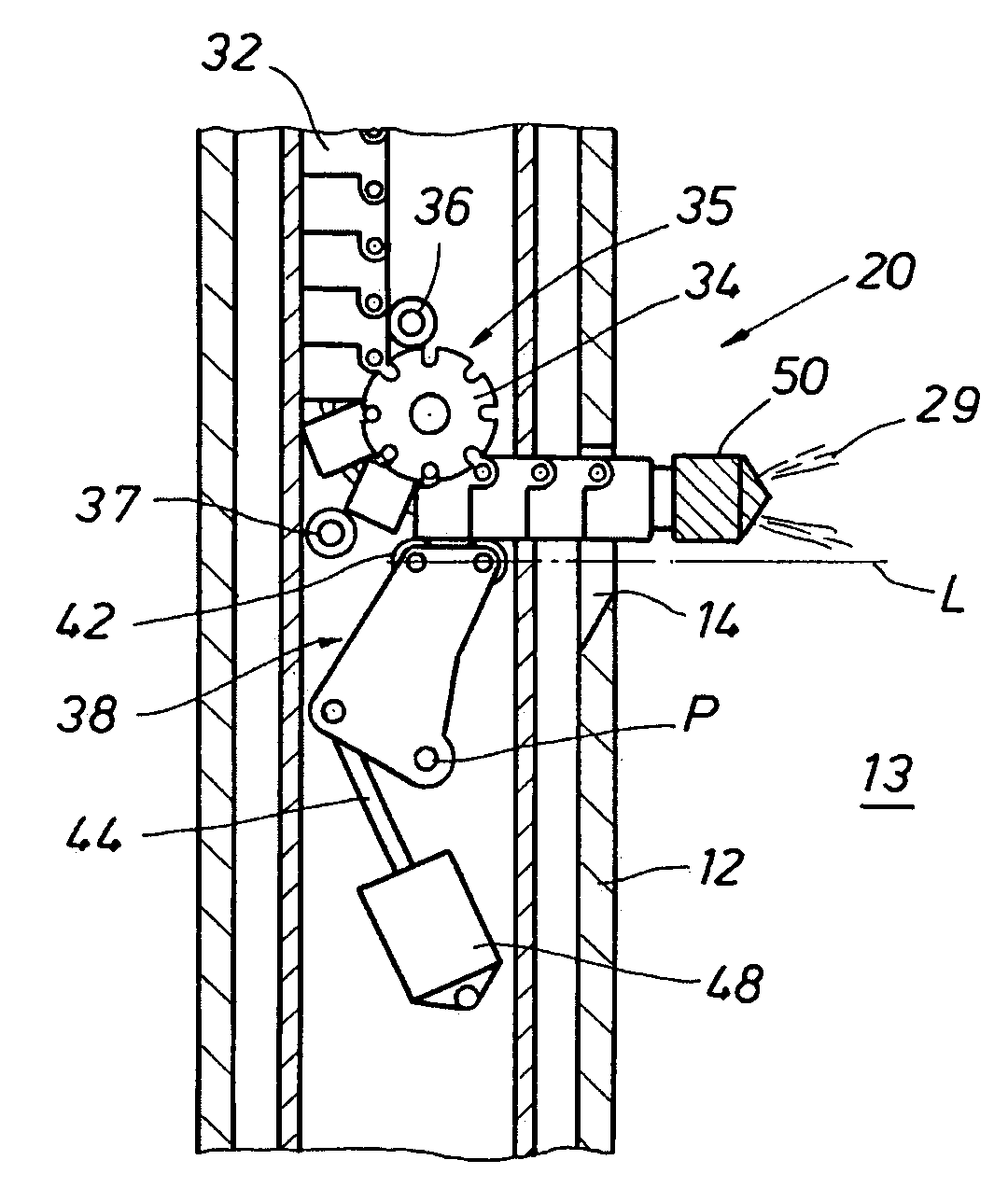

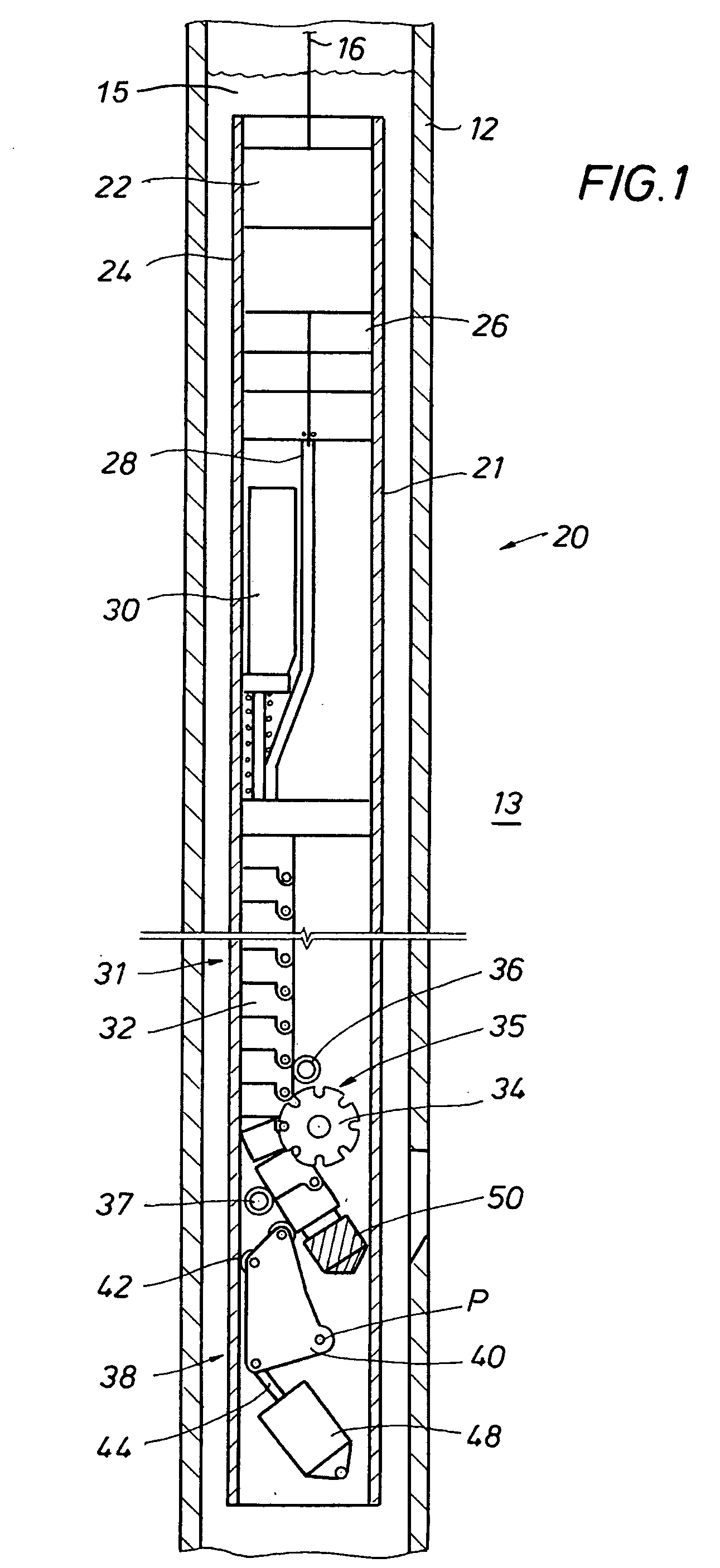

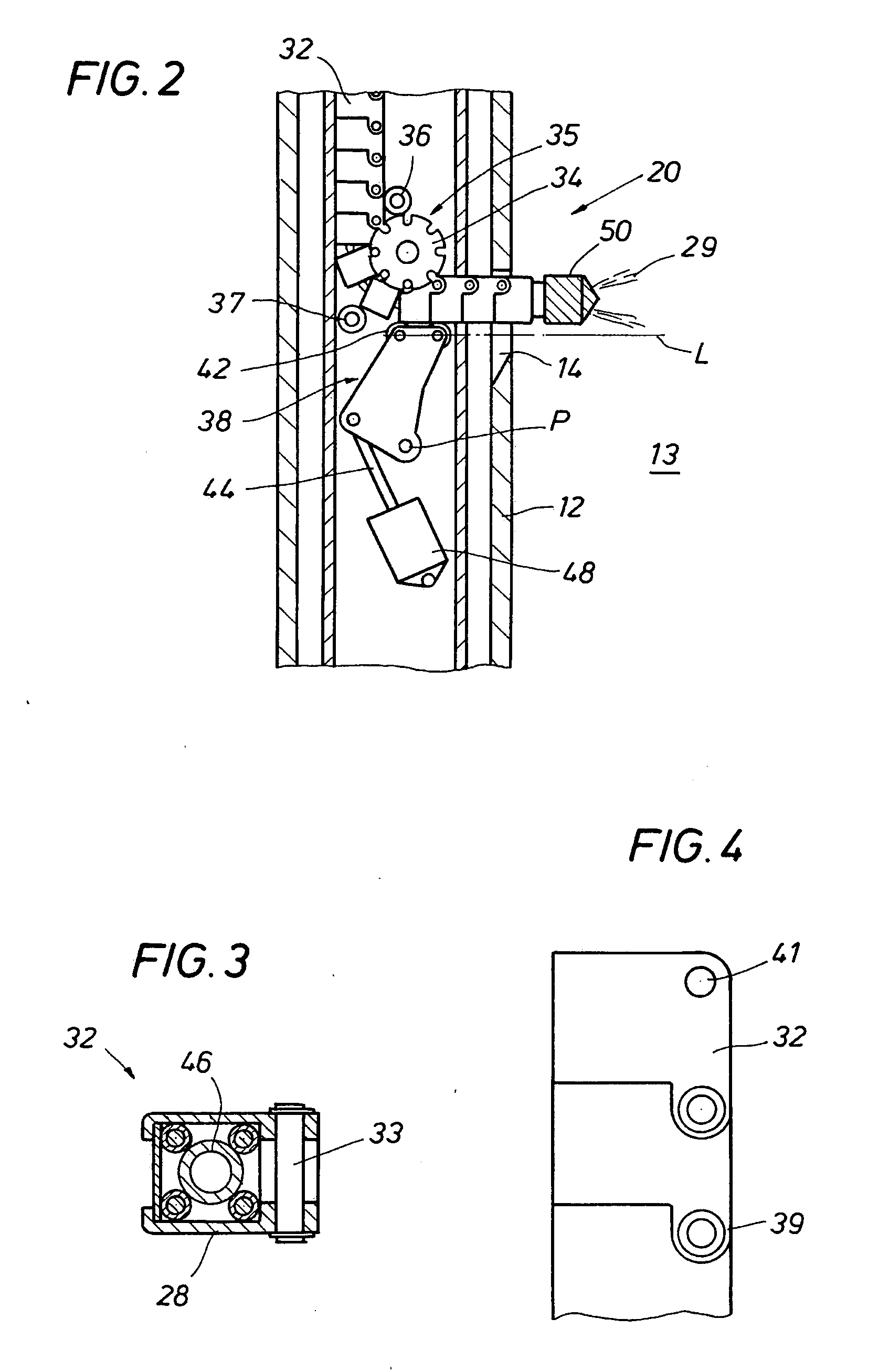

Mechanical and fluid jet horizontal drilling method and apparatus

InactiveUS20070151766A1Easy to createHigh pressureDerricks/mastsLiquid/gas jet drillingUltra high pressureWellbore

A device useful for conducting lateral or transverse excavating operations within a wellbore comprising a rotating drill bit with jet nozzles on a flexible arm. The arm can retract within the housing of the device during deployment within the wellbore, and can be extended from within the housing in order to conduct excavation operations. A fluid pressure source for providing ultra high pressure to the jet nozzles can be included with the device within the wellbore. The device includes a launch mechanism that supports the arm during the extended position and a positioning gear to aid during the extension and retraction phases of operation of the device.

Owner:BAKER HUGHES INC

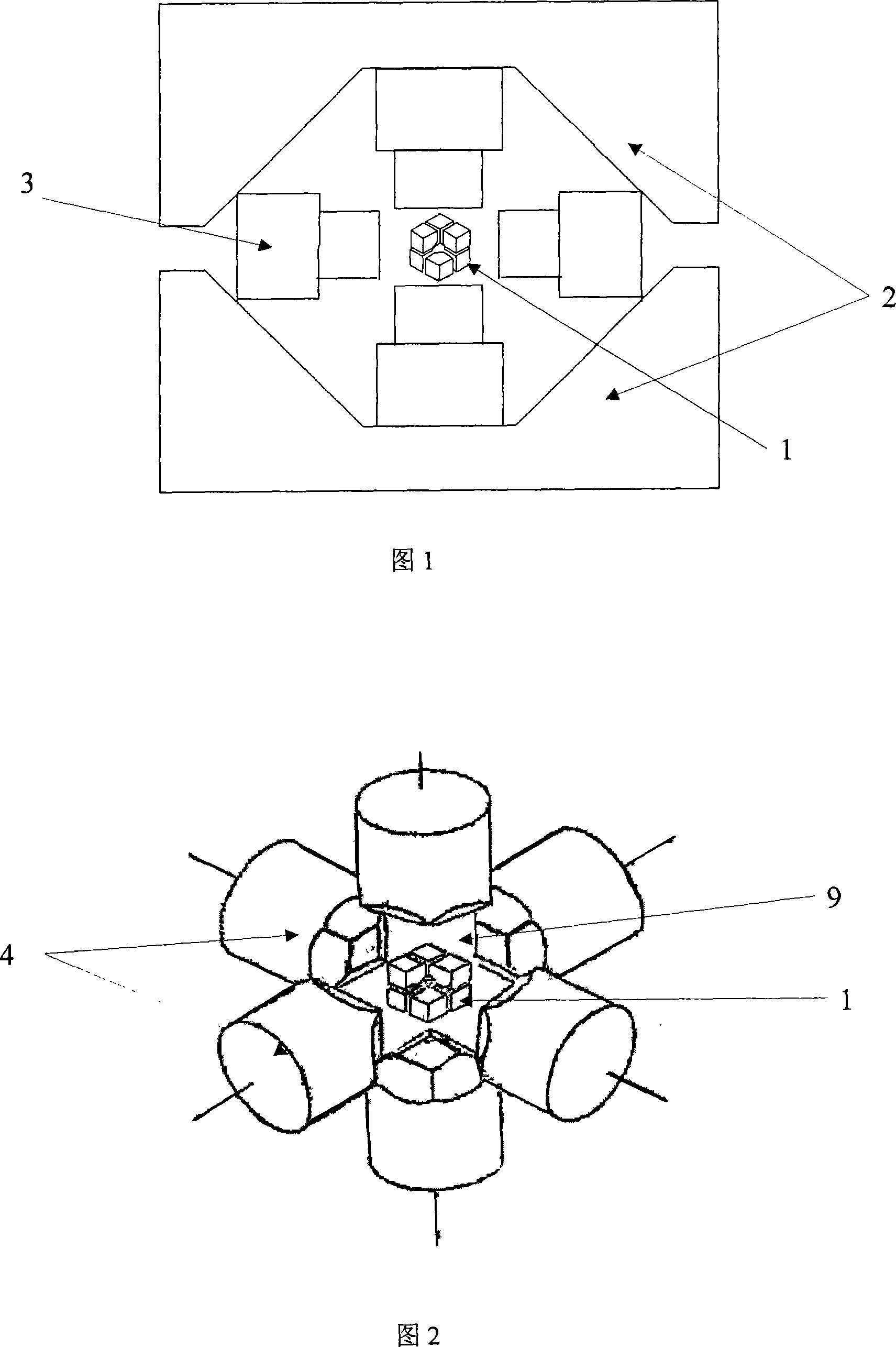

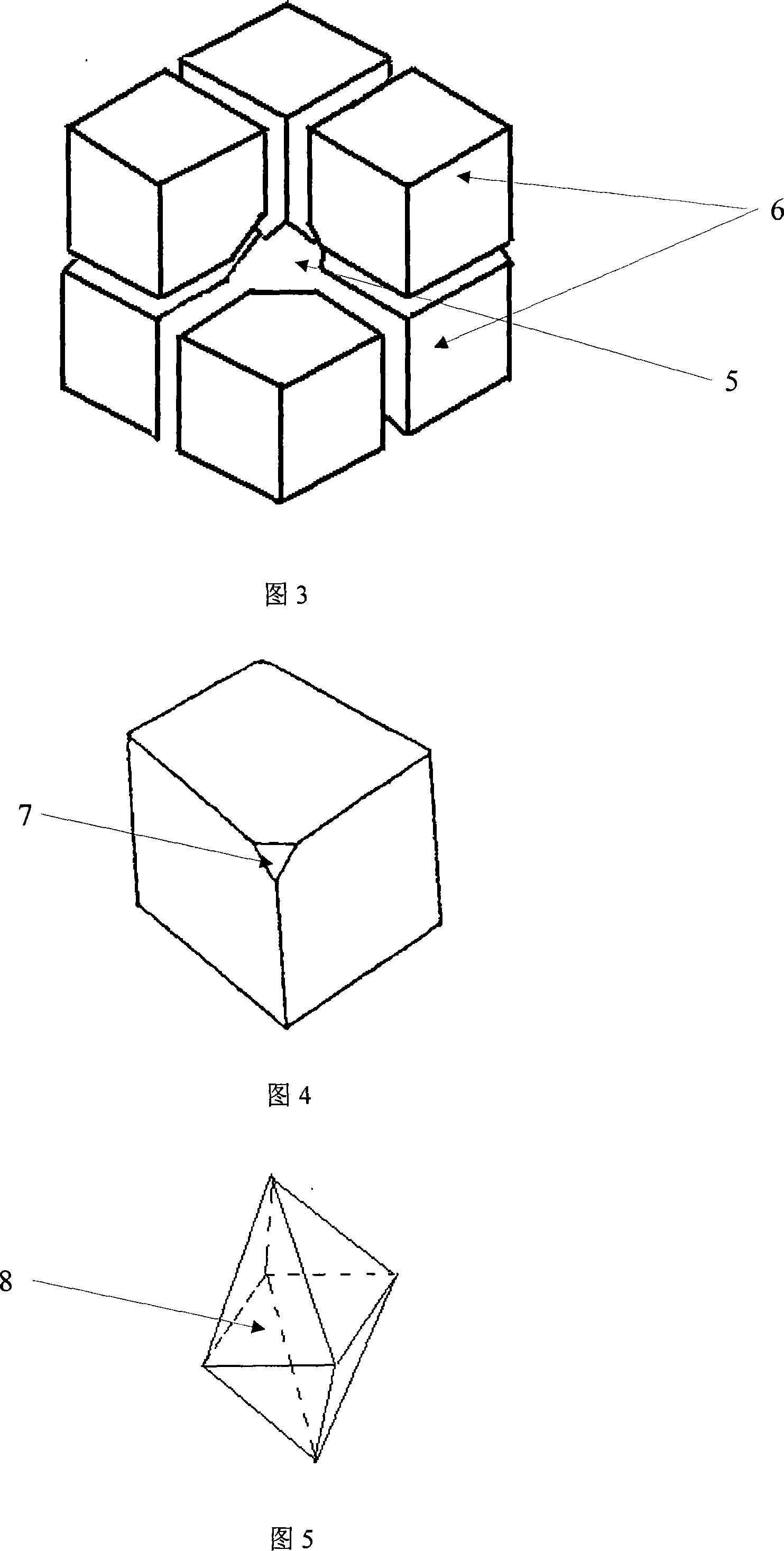

New type equipment for producing super high pressure

ActiveCN101091895ANo collisionImprove performanceUltra-high pressure processesUltra high pressureOctahedron

The invention relates to a new installment for having ultrahigh voltage. It includes 6 hammer heads (4) of 6 sides presser synchronization drive, supercharging unit (1) composed of 8 cubes (6) which cutting one corner each and octahedron synthesis blocks (8) used for holding the synthesis raw material in the internal. Thereinto, putting the turbo-charged unit (1) into the hexahedron high pressure octahedron cavity (9) made of cubes (6) which matches with the unit, and putting the octahedron synthesis block (8) into the octahedron high pressure cavity made of cubes which matches with the block, the deformation strutting whose hardness is smaller than the tangential angle cube is filled among the eight cubes (6) which compose the turbo-charged unit. Composed to the second-level six - octahedron static high pressure installment based on two sides skeleton heads in existence, it is simple structure, high intensity of pressure transfer ratio, few energy consumption of the movement, few service work load and so on.

Owner:SICHUAN UNIV

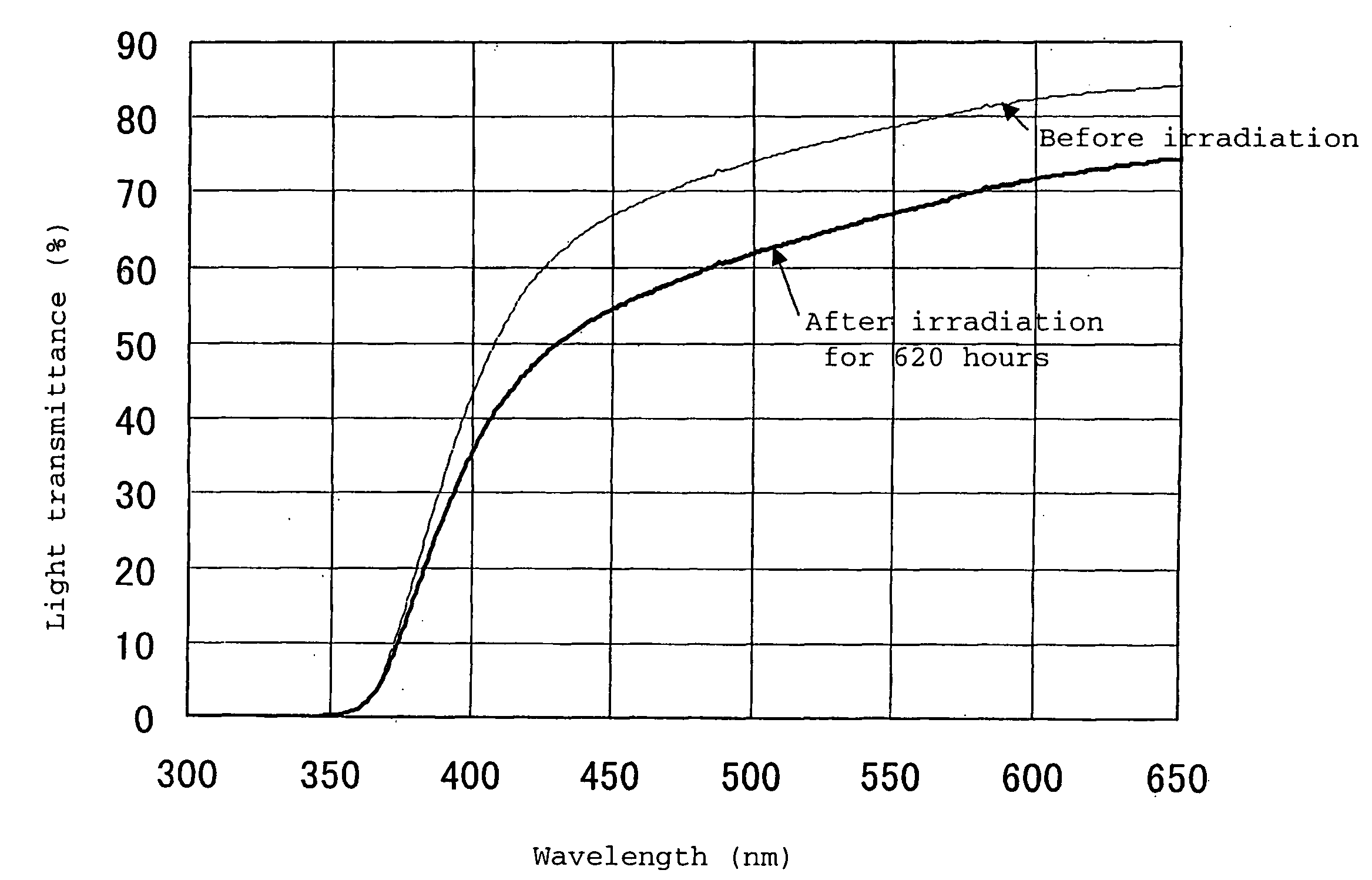

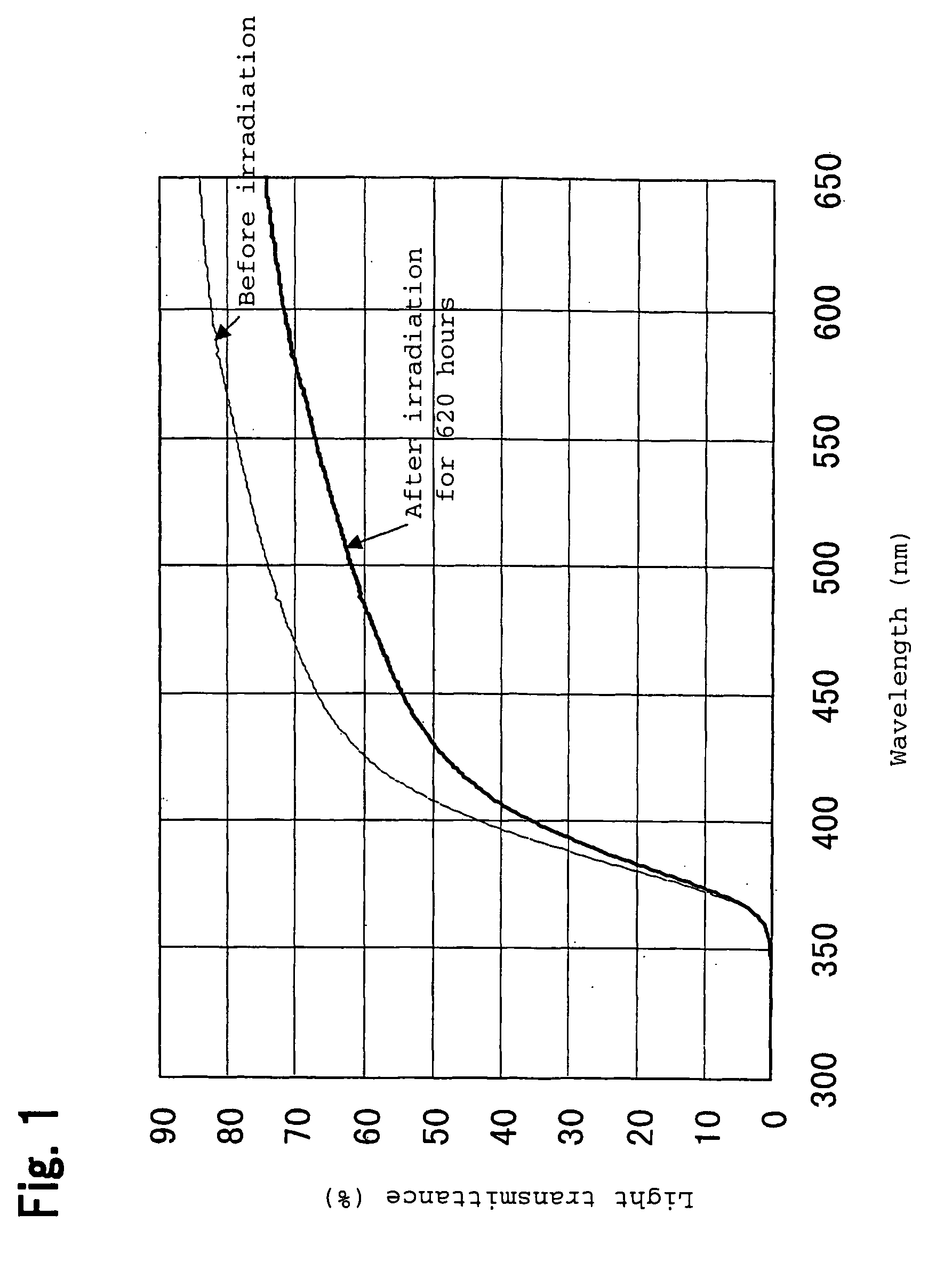

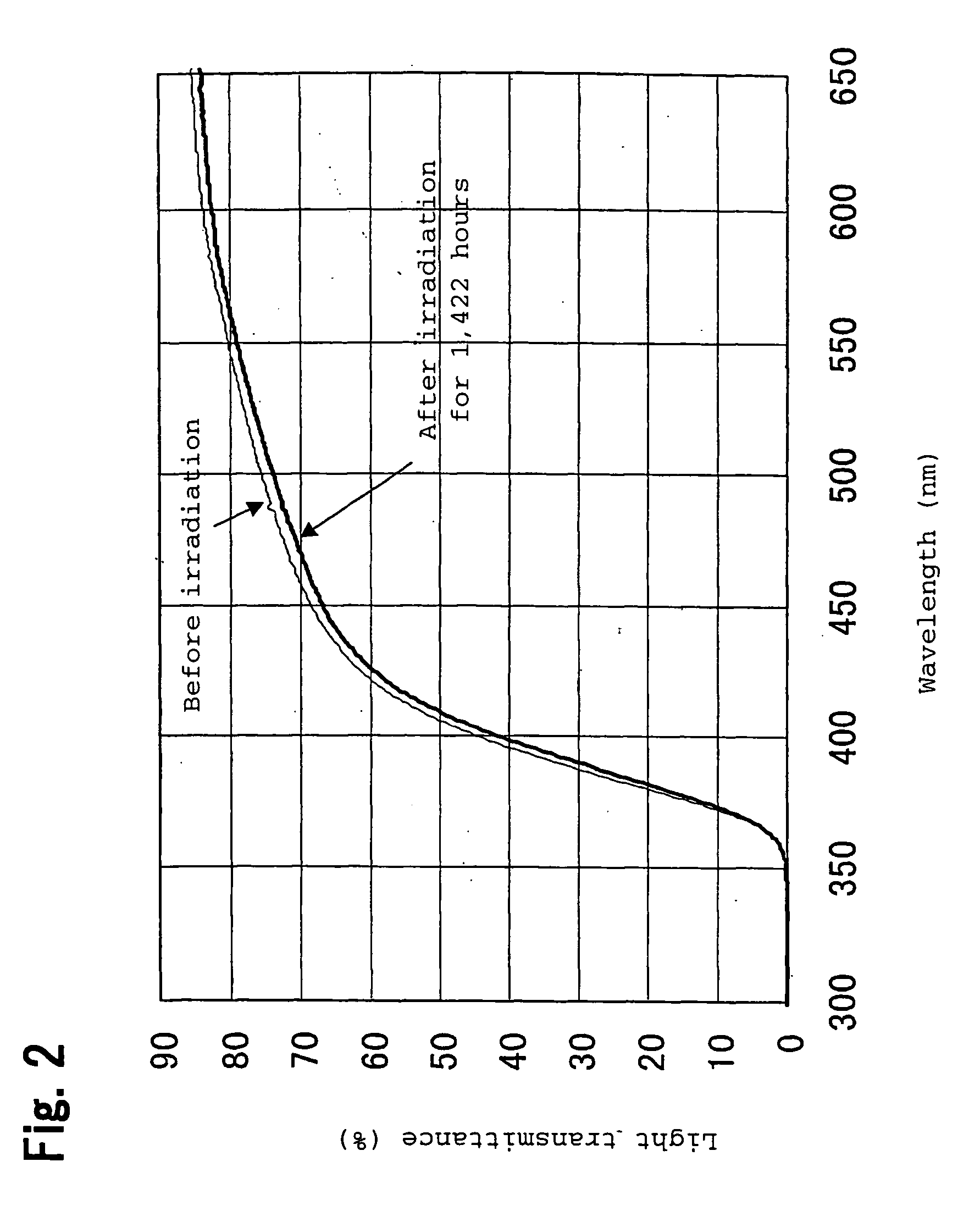

Thermoplastic resin composition and molded product employing it

InactiveUS20050170180A1Ultraviolet resistance improvedHigh light transmittanceSynthetic resin layered productsCellulosic plastic layered productsUltra high pressurePath length

A thermoplastic resin composition and a molded product, having excellent transparency, ultraviolet absorptivity and light resistance, are provided. A thermoplastic resin composition comprising from 0.001 to 10 wt %, based on the total resin composition, of a glass filler whose glass formulation consists mainly of a silicon oxide composition and exhibiting light transmittances at wavelengths of 340 nm and 400 nm of from 0 to 0.5% and from 30 to 99%, respectively, per mm of light path length. A molded product which is a molded product of a thermoplastic resin composition, characterized in that in a case where (1) an ultra-high pressure mercury lamp which does not substantially emit ultraviolet light having a wavelength of at most 250 nm, is used at such a distance that the intensity of ultraviolet light having a wavelength of 350 nm generated by the lamp would be 0.1 W / cm2 on the surface of the molded product, and (2) the molded product is irradiated for 72 hours in the air at the surface temperature thereof being 60° C., the light transmittance at a wavelength of 650 nm after the irradiation, is at least 70% per mm of light path length.

Owner:MITSUBISHI CHEM CORP

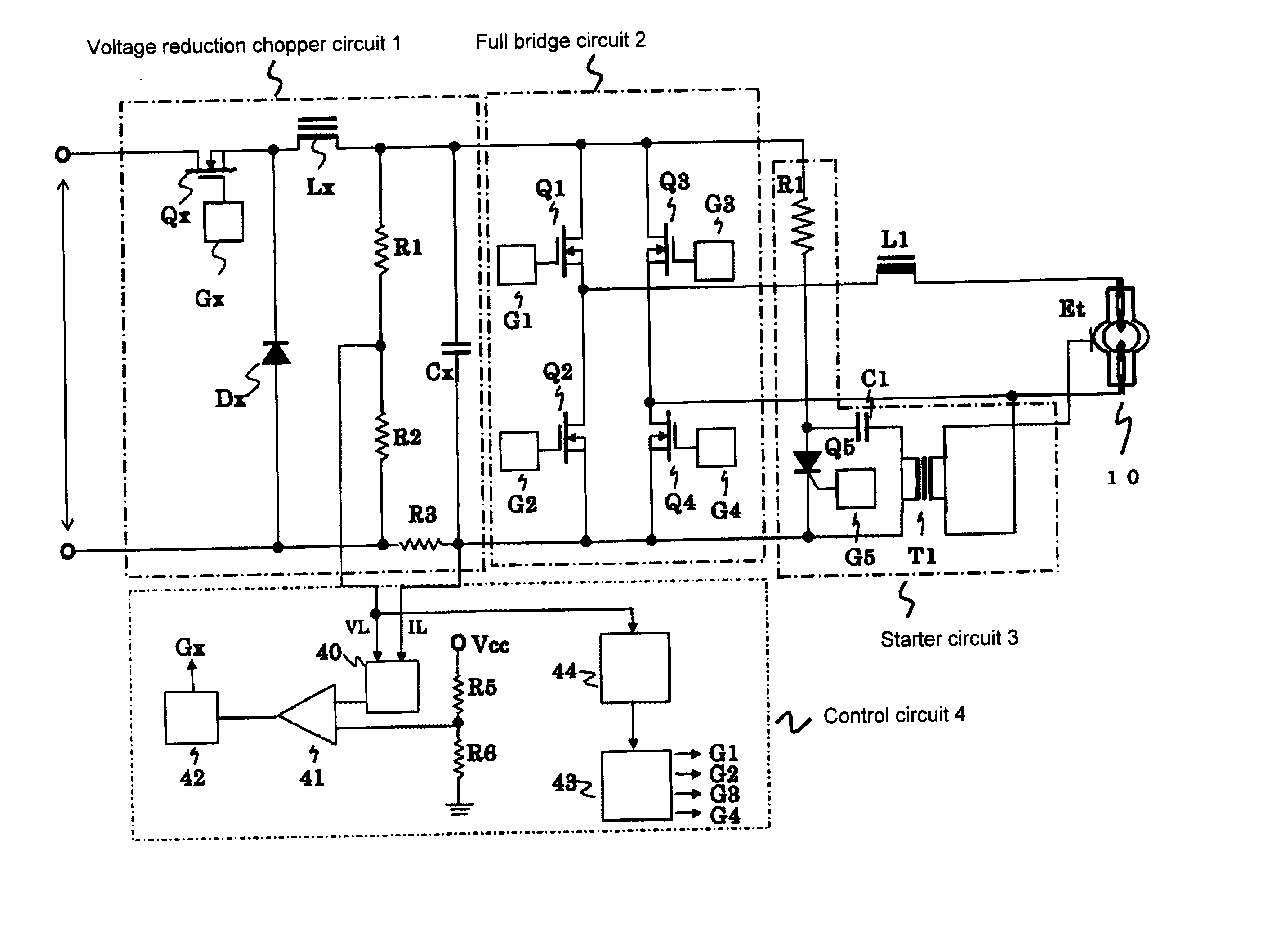

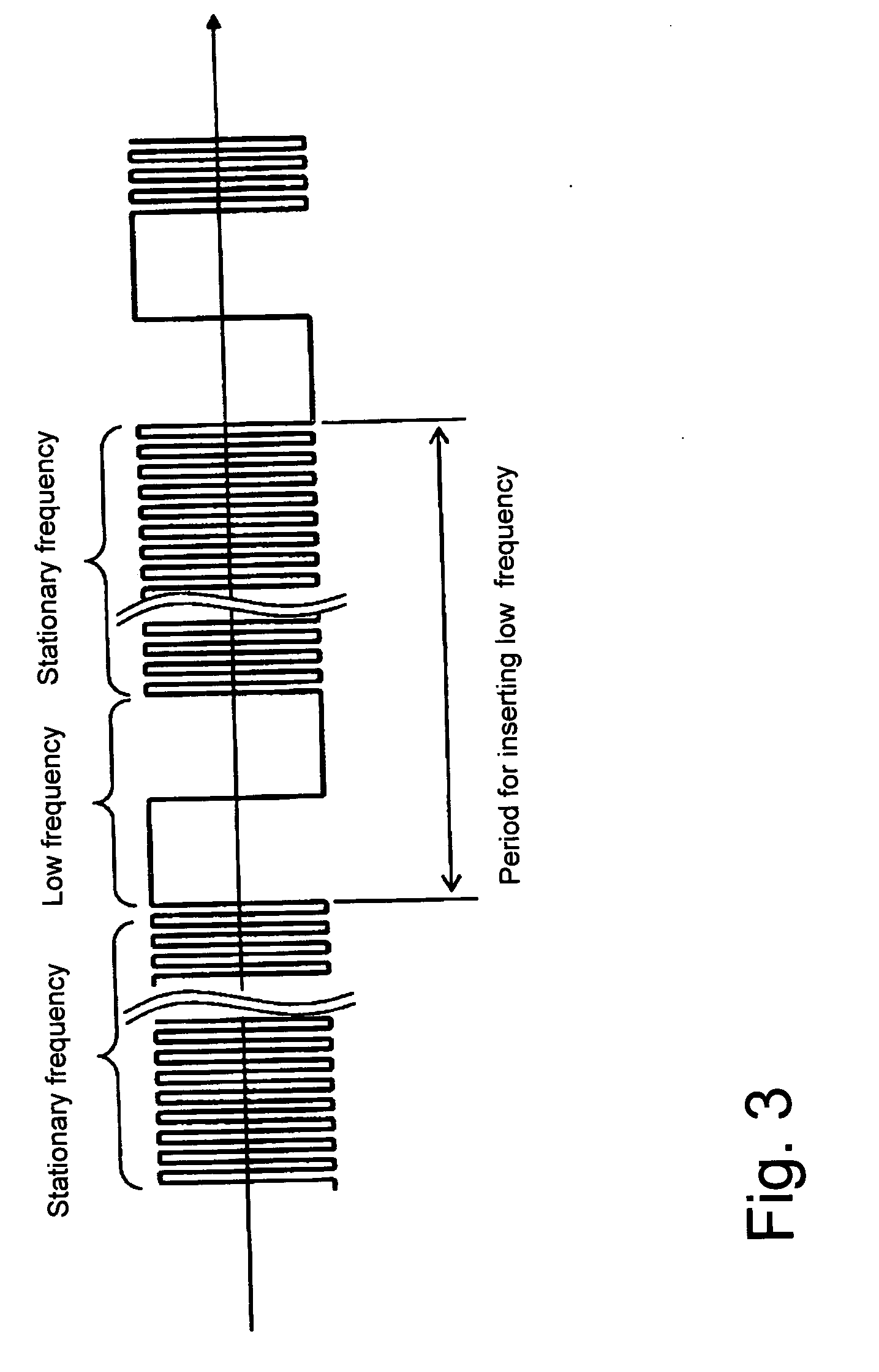

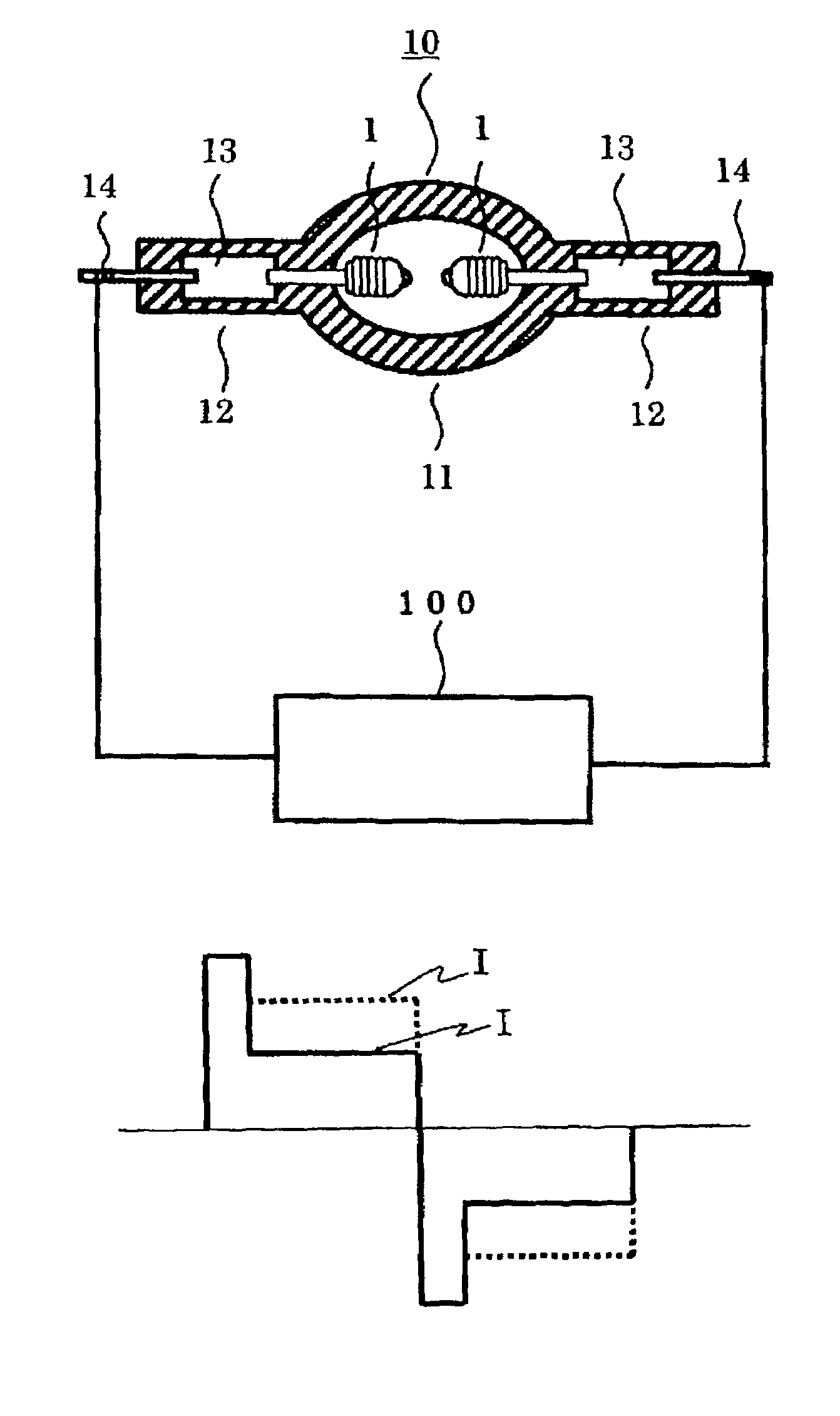

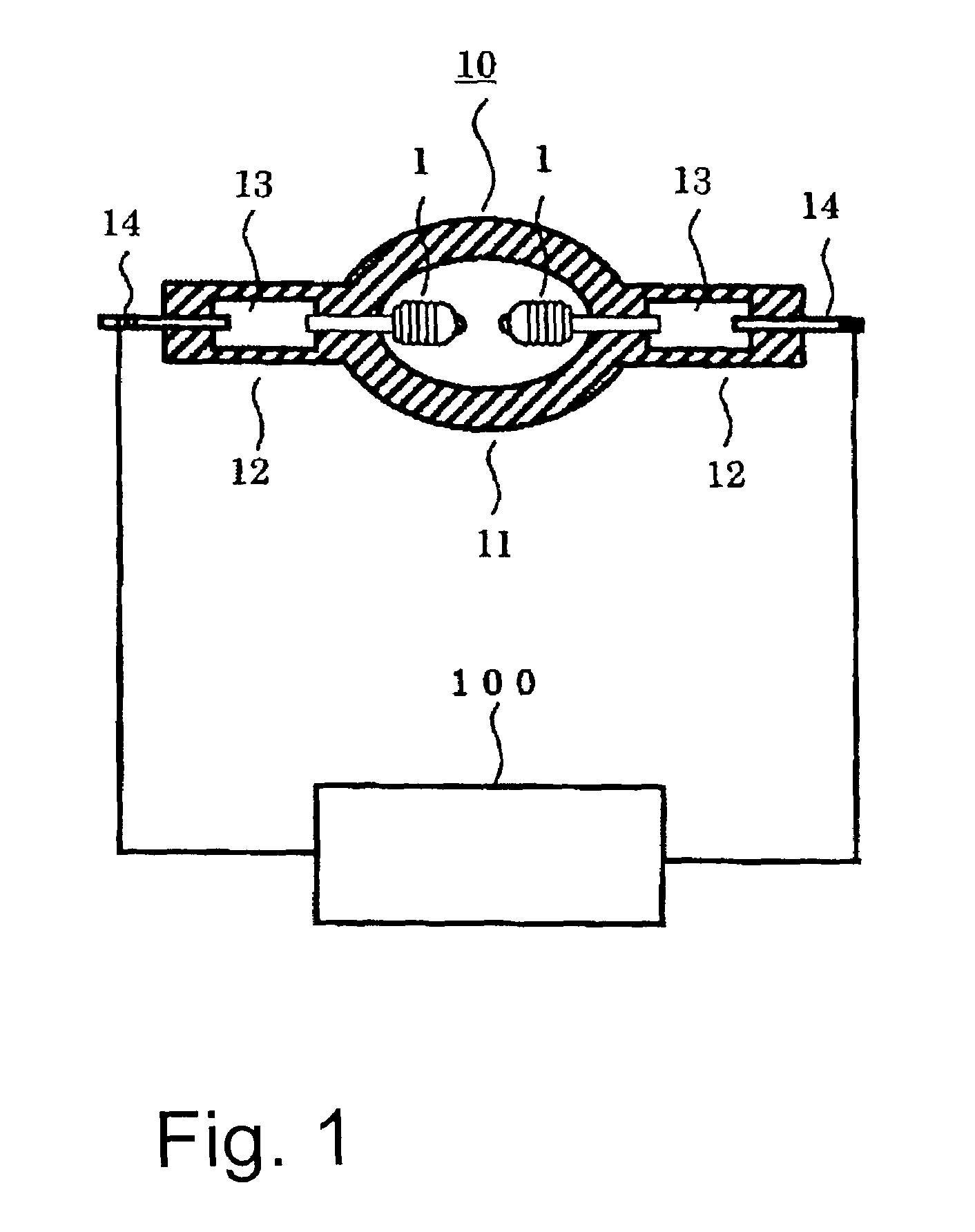

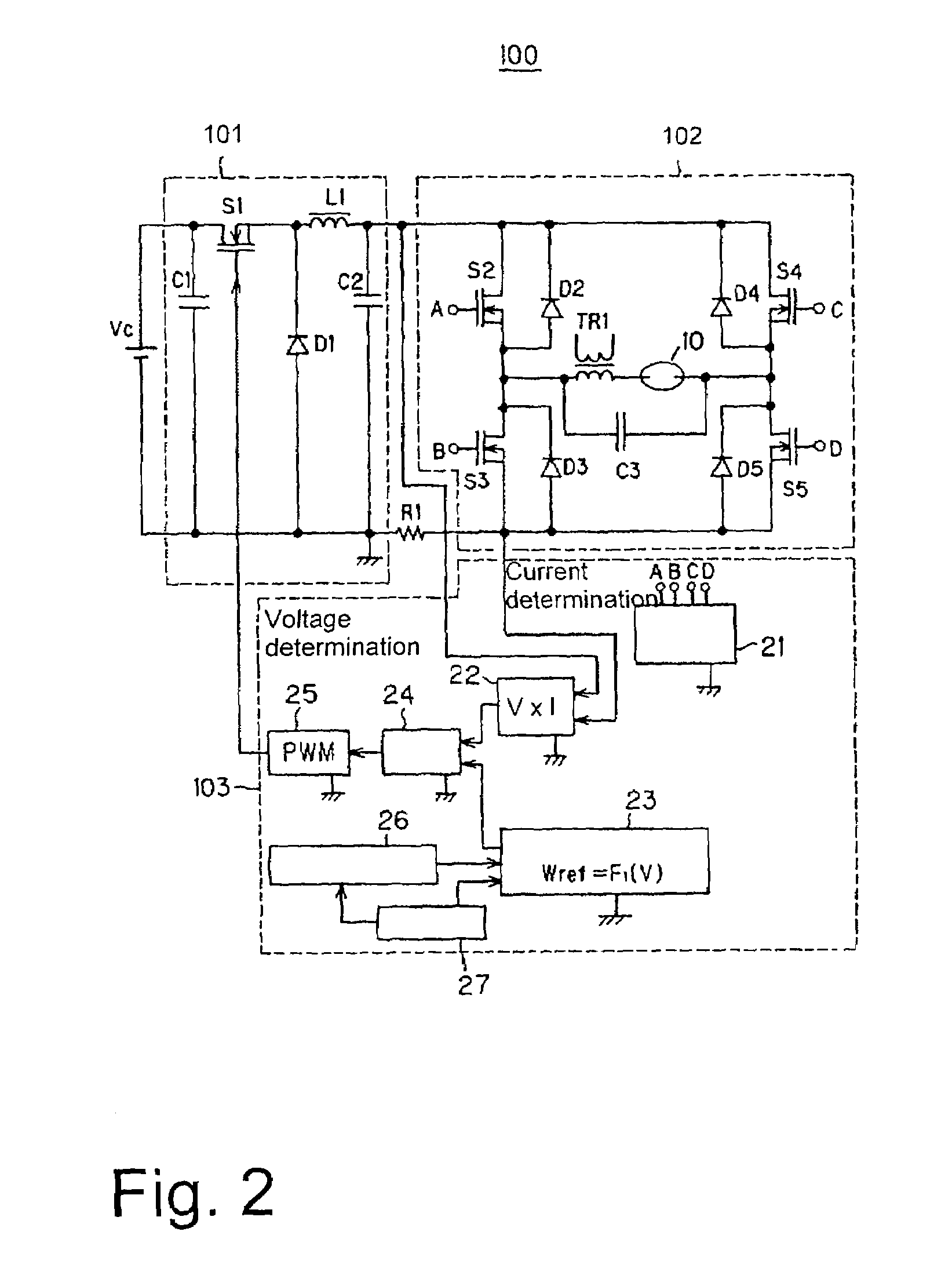

Device for operation of a high pressure discharge lamp

ActiveUS20060022613A1Inhibition formationIncrease in lamp voltageElectrical apparatusElectric light circuit arrangementUltra high pressureElectric light

To positionally stabilize the arc spot in a super-high pressure discharge lamp which is filled with at least 0.20 mg / mm3 of mercury and to prevent the formation of so-called flicker, in an operation device having a high pressure discharge lamp and a feed device, the feed device of the high pressure discharge lamp supplies a frequency in the range from 60 Hz to 1000 Hz as the stationary operating frequency and a low frequency, in a frequency range of from 5 Hz to 200 Hz is inserted which has an inserted length of from one half period to five periods, and an inserting period of from 0.01 seconds to 120 seconds, into the alternating current of the stationary operating frequency. Furthermore, the parameters of the low frequency are changed according to changes of the operating voltage of the discharge lamp.

Owner:USHIO DENKI KK

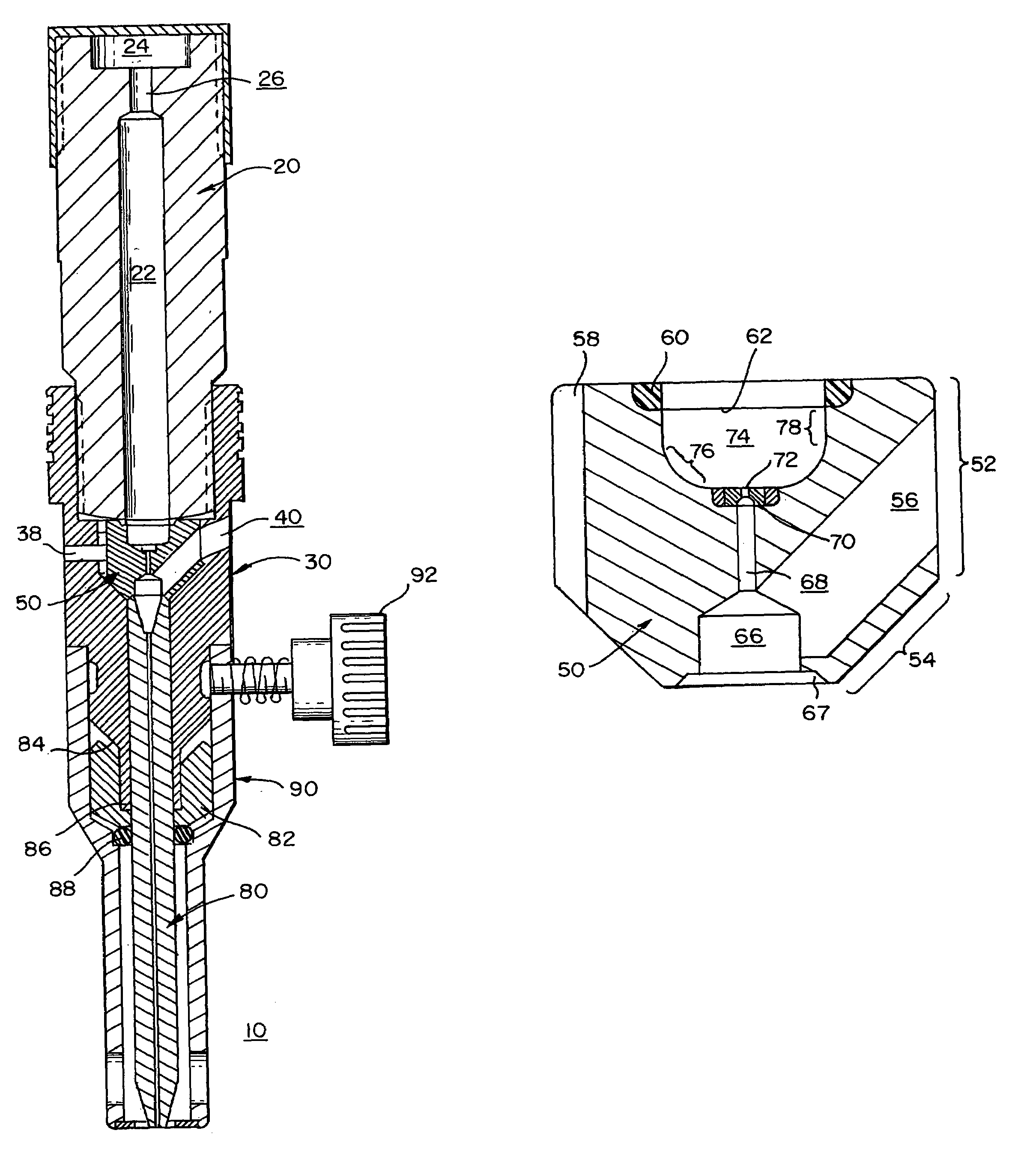

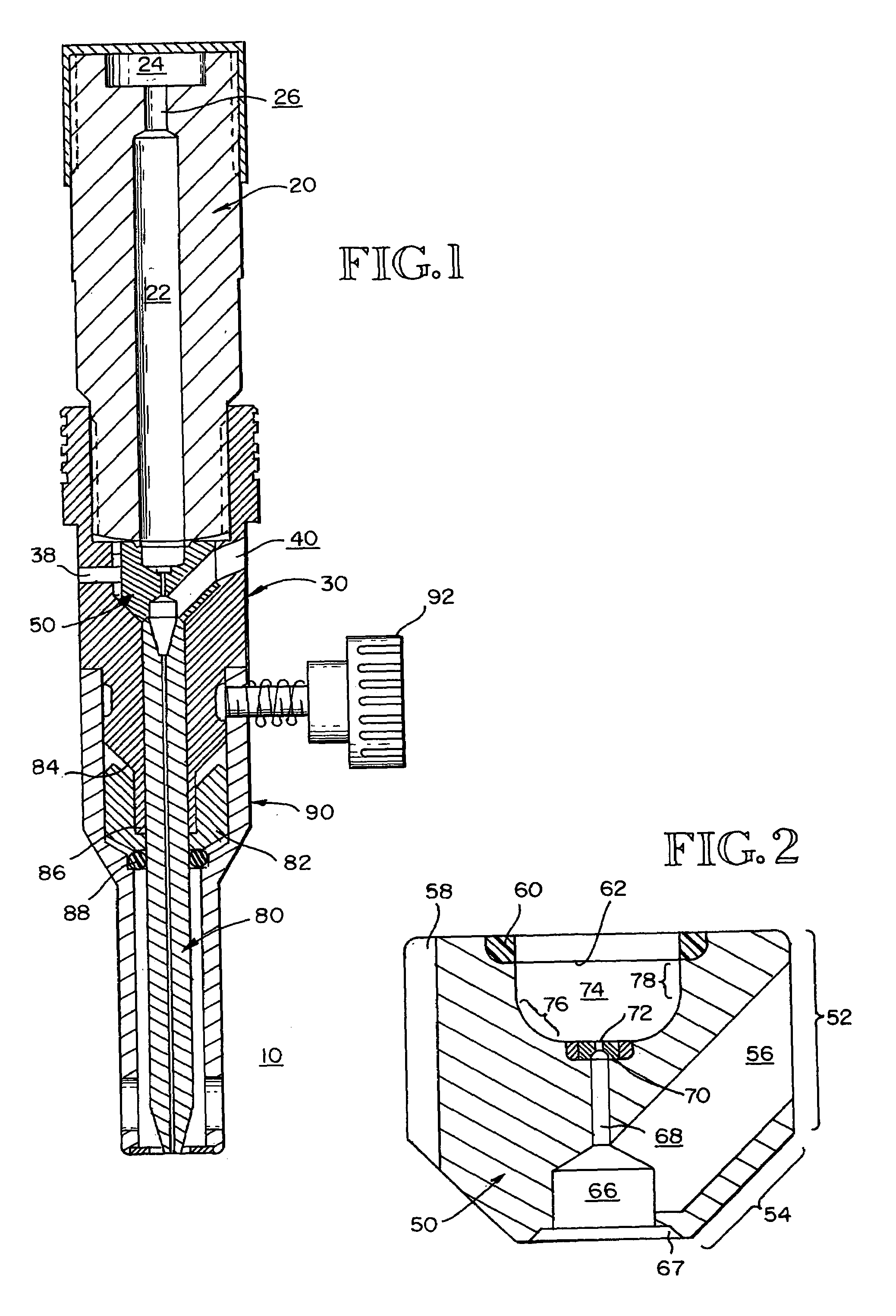

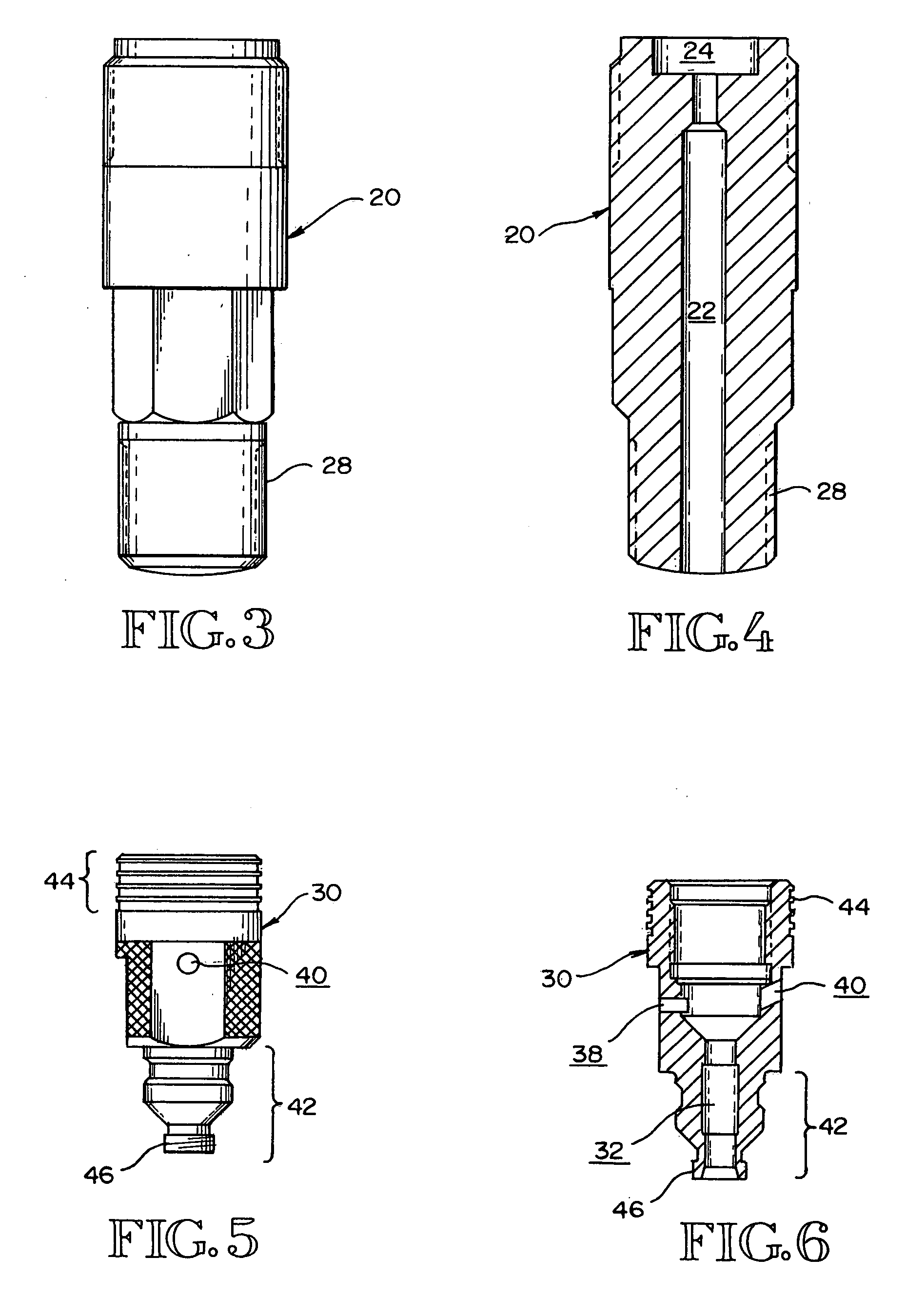

Orifice body with mixing chamber for abrasive water jet cutting

InactiveUS6932285B1Simple designImprove operationDrill bitsBlast gunsUltra high pressureHigh pressure

An improved orifice assembly for use with an ultra high pressure fluid jet cutting apparatus is disclosed. The improved orifice assembly generally includes an orifice body defining a central bore, a high pressure inlet cavity located at an upstream portion of the body, a mixing cavity located at a downstream portion of the body, and an abrasive material inlet bore that is in direct communication with the mixing cavity. The inlet or high pressure cavity preferably has a cylindrical cross section at the side wall portion and a generally flat bottom wall, with a constant radius transition portion between the side and bottom walls. A jeweled orifice is preferably located at the bottom wall and forms a portion thereof. A chamfer at the downstream portion of the mixing chamber permits appropriate coaxial alignment of a mixing tube with the jeweled orifice so as to preserve proper fluid flow characteristics. In addition, the incorporation of a soft seal between the mating surfaces of the inlet body and the orifice assembly permit easy user removal of these components from a cutting jet system.

Owner:SILICON VALLEY BANK

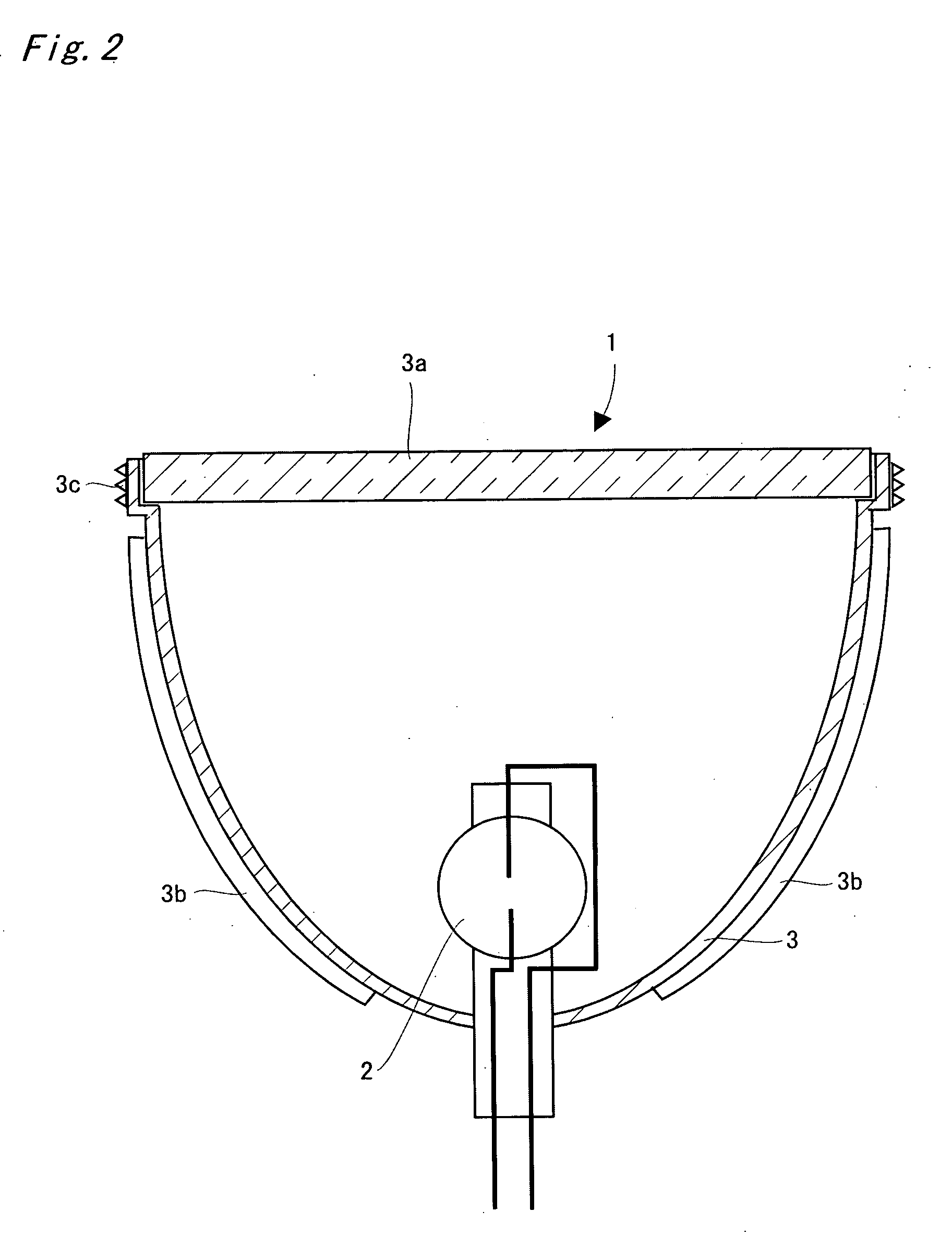

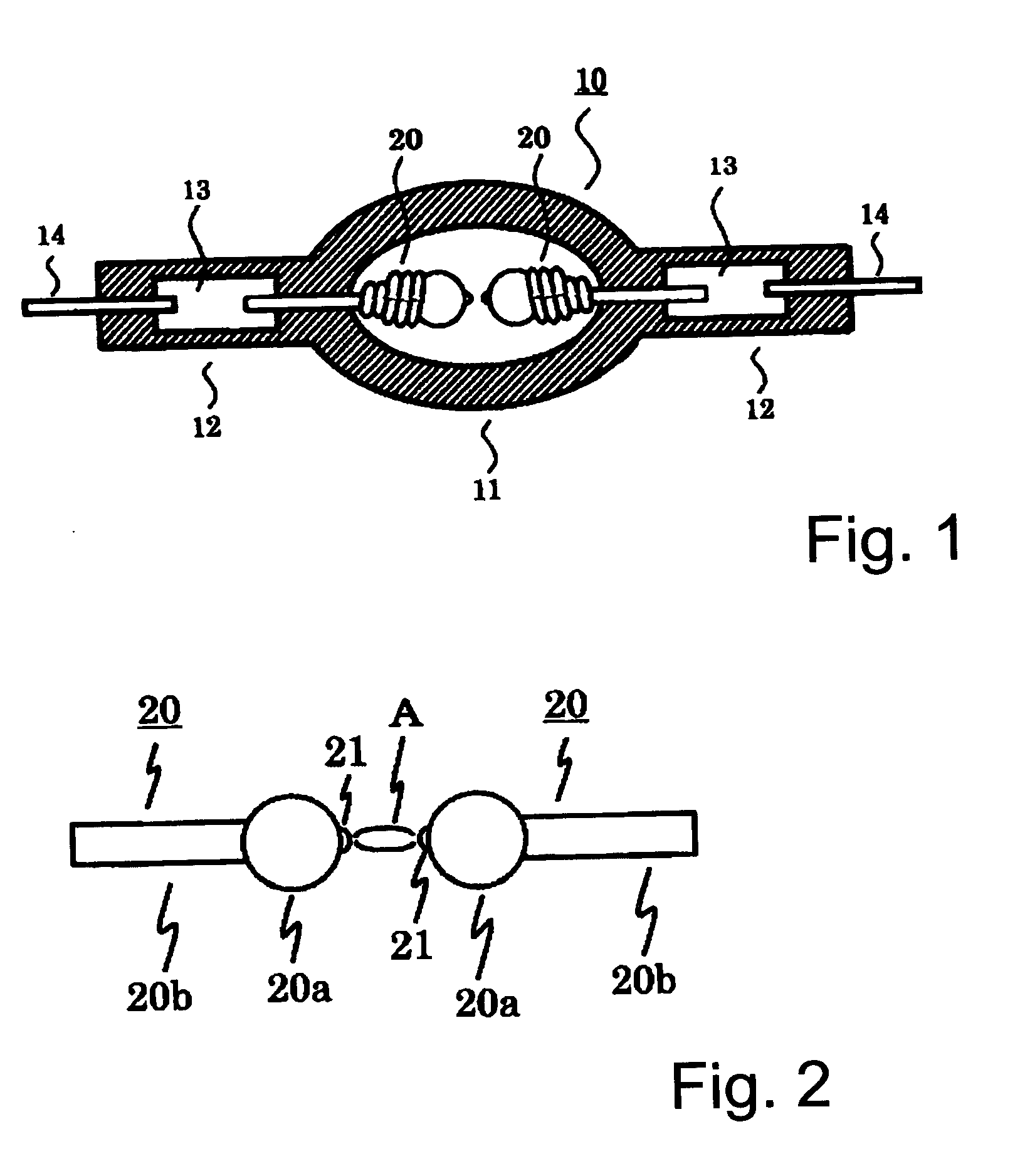

Emission device for an ultra-high pressure mercury lamp

ActiveUS7122960B2Inhibition formationElectric light circuit arrangementGas discharge lamp usageMolten stateUltra high pressure

An emission device for an ultra-high pressure mercury lamp which maintains an electrode tip shape by which a stable discharge can always be carried out is achieved for a short arc ultra-high pressure mercury lamp with silica glass arc tube containing a pair of opposed electrodes spaced apart a distance of at most 2 mm and in which the arc tube is filled with at least 0.15 mg / mm3 of mercury, a rare gas and a halogen in the range from 1×10−6 μmole / mm3 to 1×10−2 μmole / mm3; by providing an operating device which produces a current feed by which the surface of the tip of at least one of the electrodes is shifted into a molten state during lamp operation.

Owner:USHIO DENKI KK

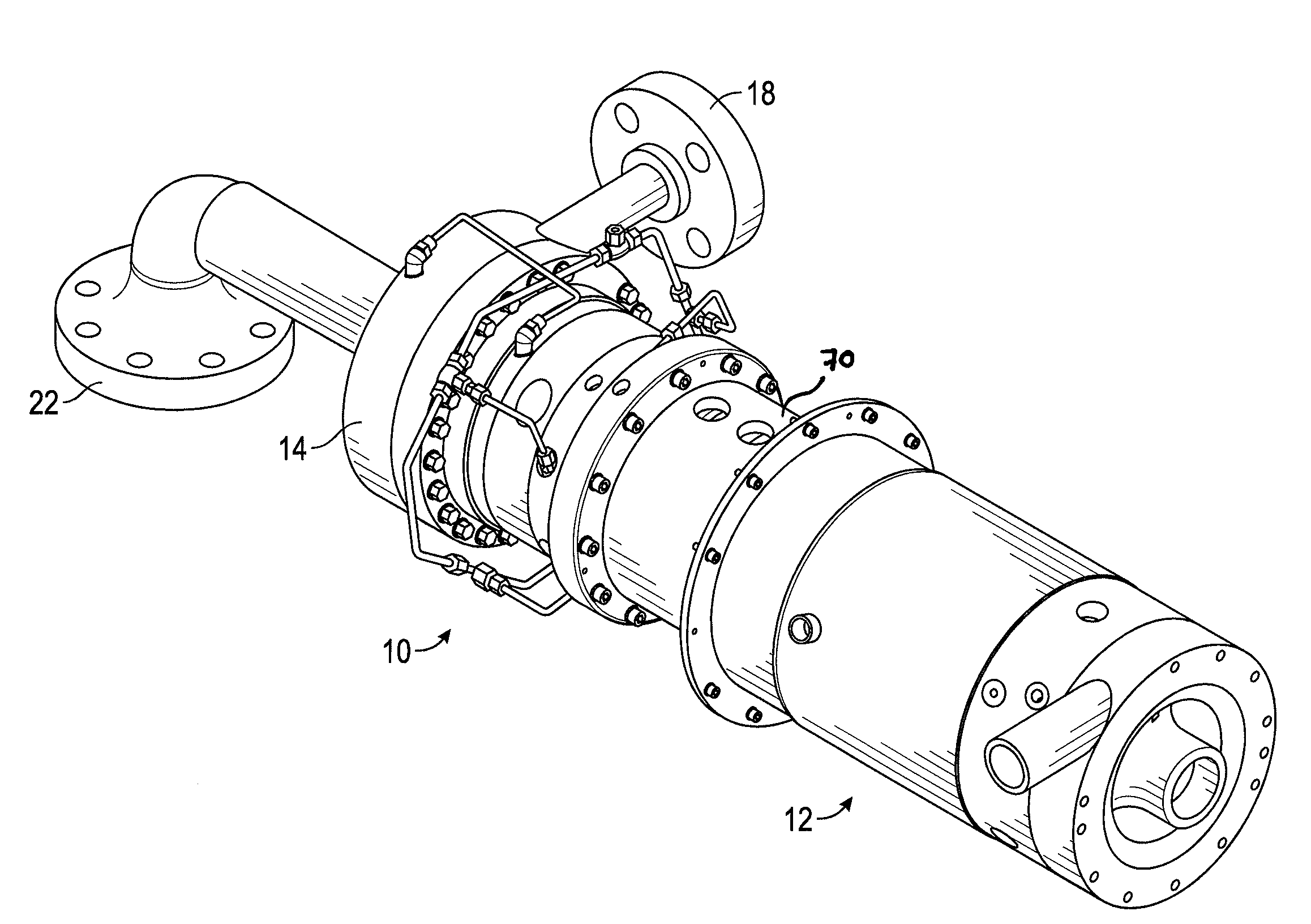

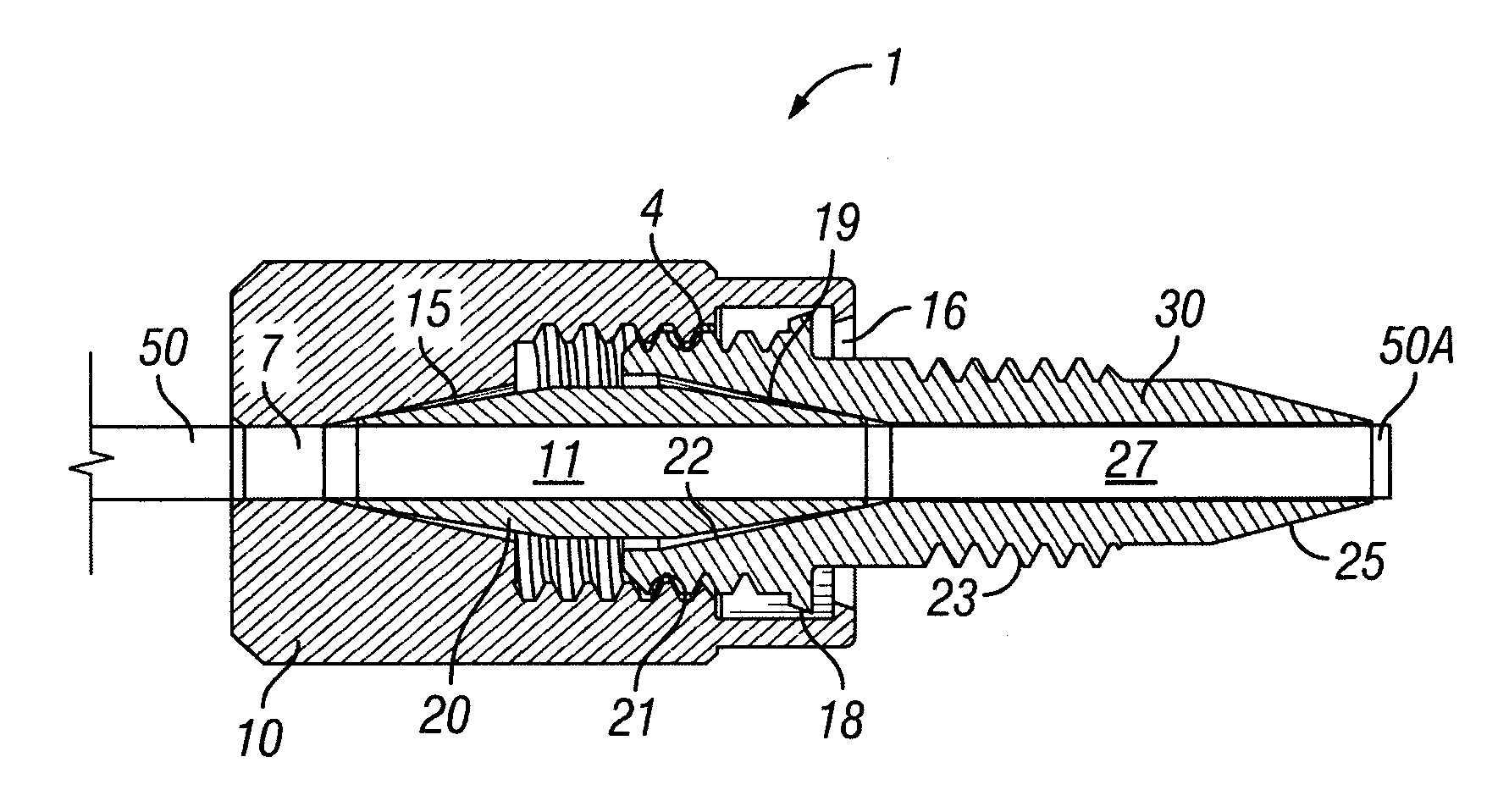

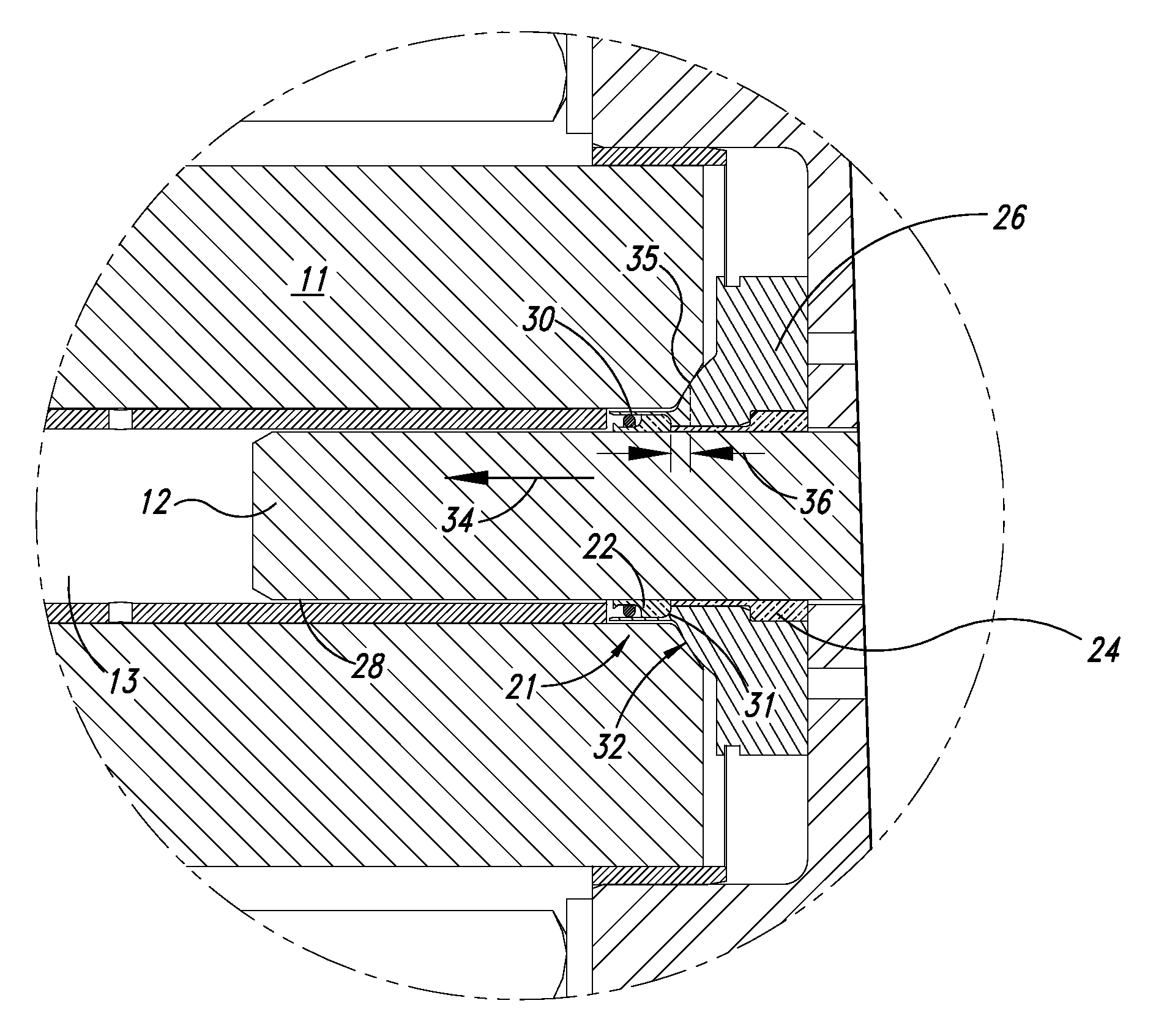

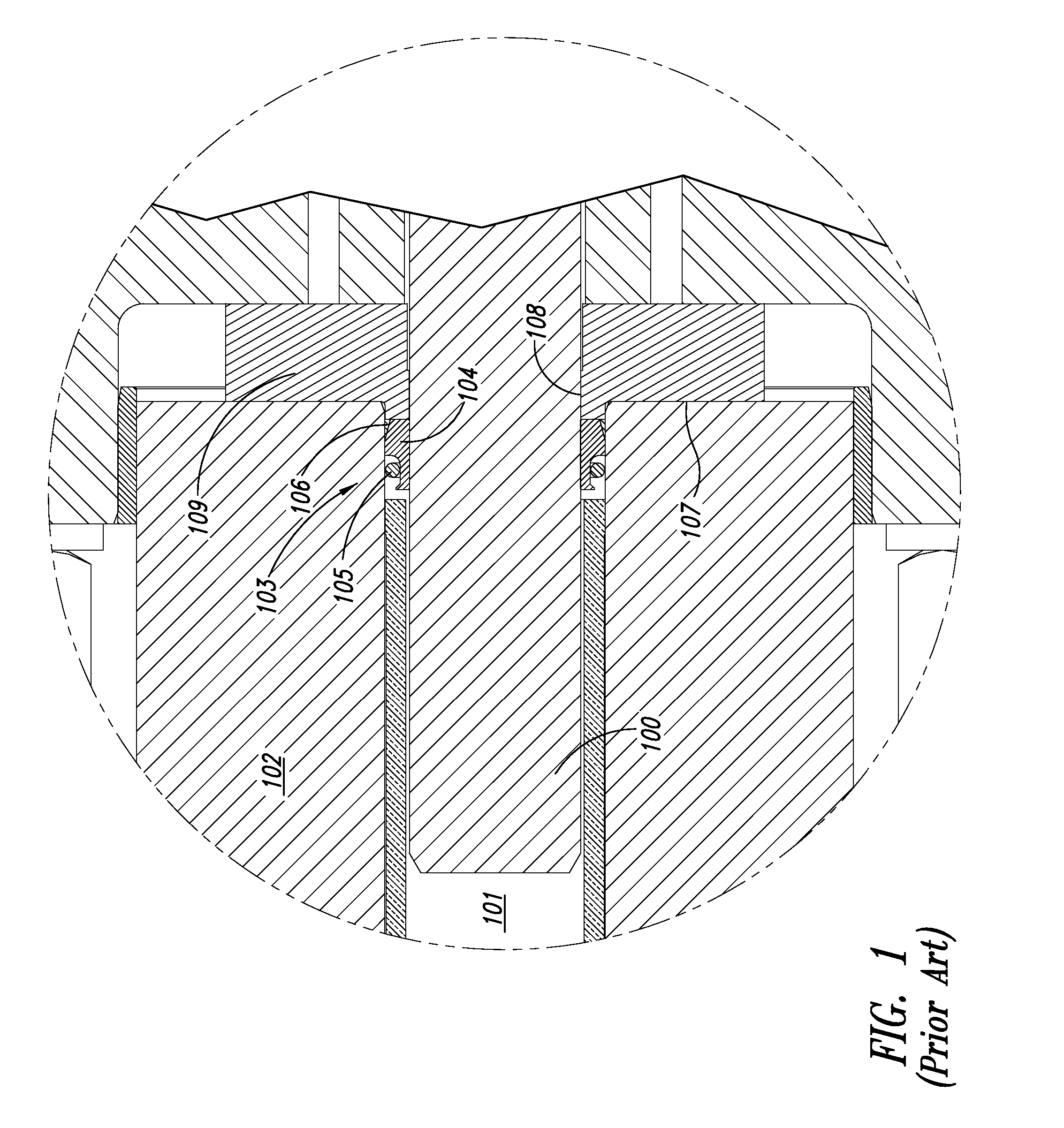

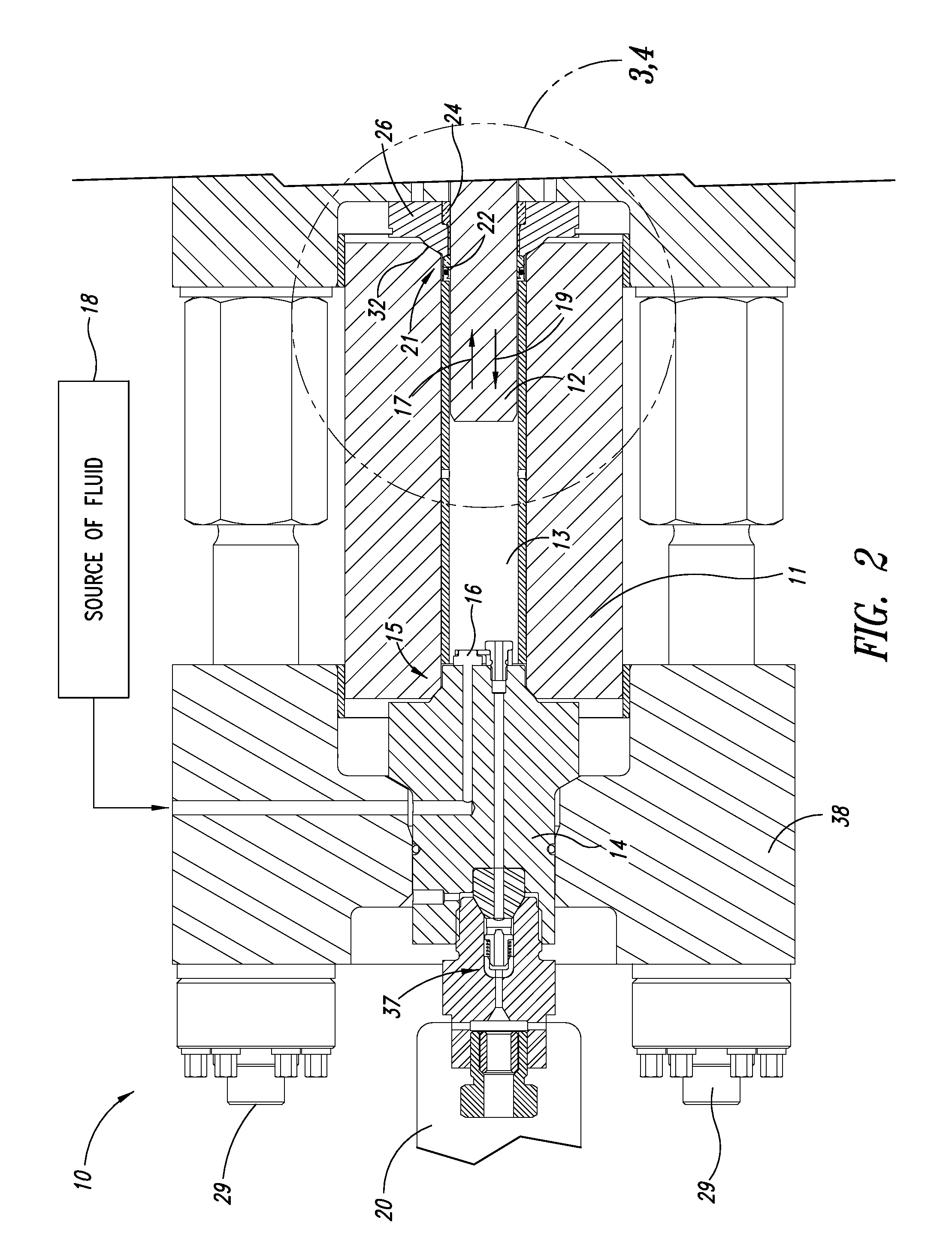

Method and apparatus for sealing an ultrahigh-pressure fluid system

InactiveUS20080019851A1Avoid displacementEngine sealsPositive displacement pump componentsUltra high pressureReciprocating motion

A seal carrier is provided for an ultrahigh-pressure fluid system having a plunger configured to reciprocate therein along a longitudinal axis when the ultra-high pressure fluid system is in operation, the seal carrier having an inner surface provided with a first portion configured to captively receive a seal, substantially preventing displacement of the seal in a direction substantially parallel to the longitudinal axis, and a second portion configured to circumferentially surround a bearing. The seal carrier is further provided with an outer surface having a recess formed along at least a portion of a circumference thereof, the recess at least partially positioned opposite the first portion of the inner surface along a lateral axis substantially perpendicular to the longitudinal axis.

Owner:FLOW INT

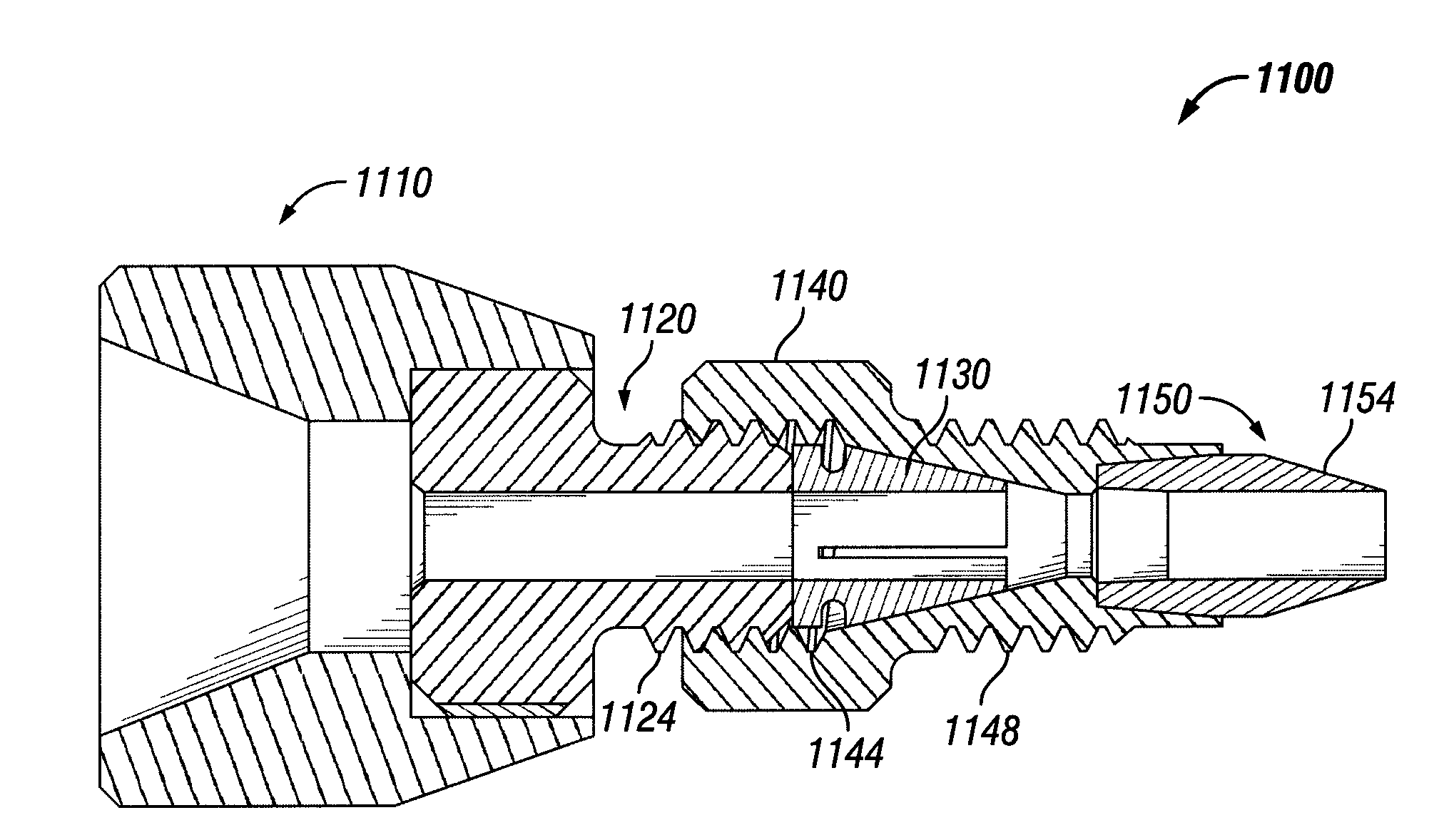

Connection Assembly for Ultra High Pressure Liquid Chromatography

ActiveUS20100224546A1Firmly connectedComponent separationFiltration separationUltra high pressureEngineering

A fitting assembly having a single- or double-headed ferrule, a nut, and a fitting that may be assembled or dissembled by an operator. The fitting assembly includes a nut with first and second ends, with the second end adapted to receive or abut the first end of a ferrule, and further includes a fitting with a first end having an internally tapered portion adapted to receive the second end of the ferrule and a second end adapted to be removably connected to a component or fitting of a liquid chromatography system. The nut, ferrule and fitting of the fitting assembly have passageways therethrough for receiving and removably holding tubing.

Owner:IDEX HEALTH & SCI

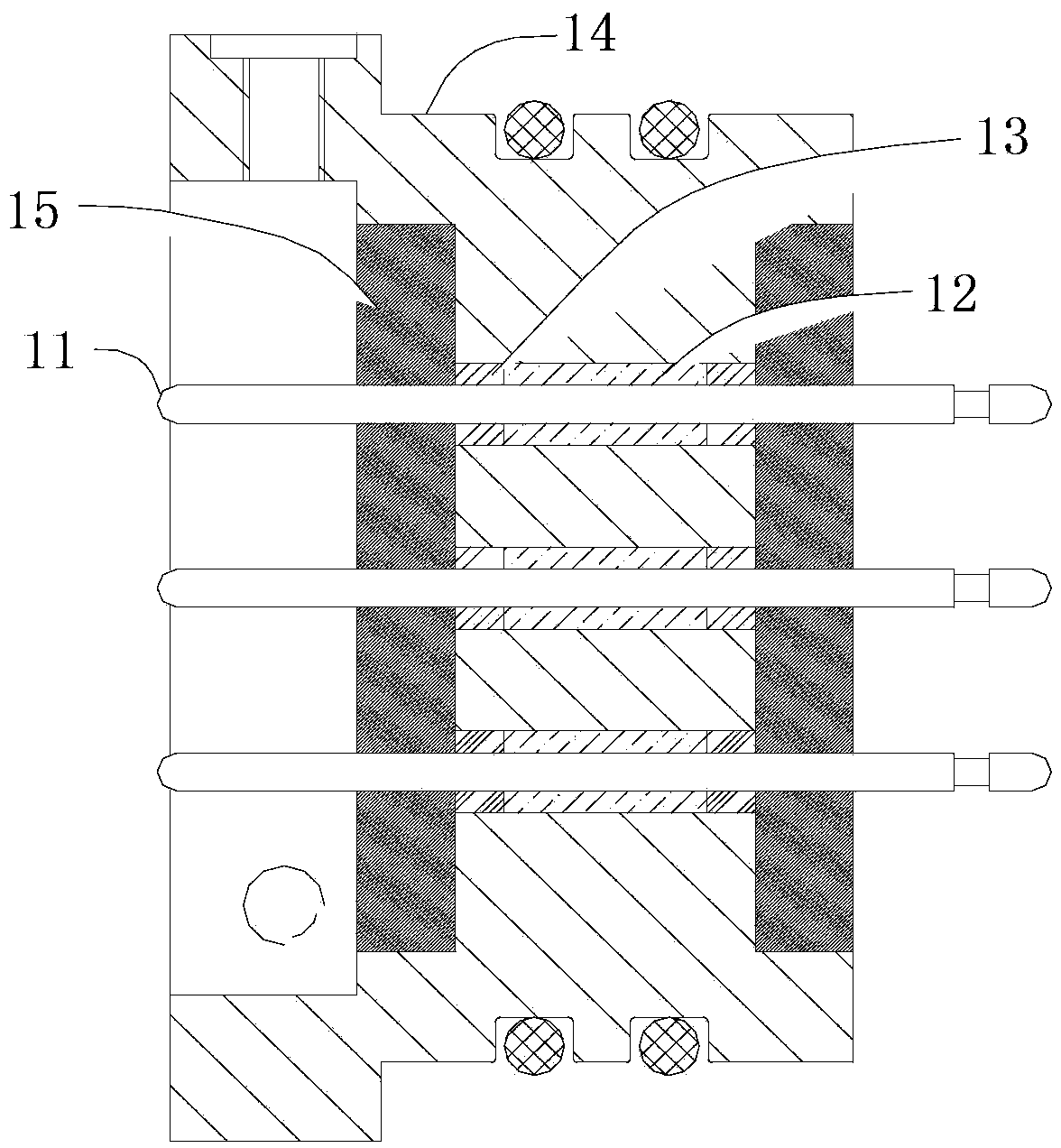

Glass sintered high temperature and high pressure sealing electric connector

ActiveCN103474831AHigh temperature resistanceProne to compressive stressSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorUltra high pressure

A glass sintered high temperature and high pressure sealing electric connector comprises conductor pins (11) used for transmitting currents, wherein a glass insulator (12) and a ceramic insulator (13) wrap each conductor pin (11), a metal outer shell (14) is arranged on the peripheries of the glass insulators (12) and on the peripheries of the ceramic insulators (13), the conductor pins (11), the glass insulators (12), the ceramic insulators (13) and the metal outer shell (14) are combined into a whole through the glass sintering process. The conductor pins (11) are made of expansion alloy, the glass insulators (12) are made of electronic seal glass, and the metal outer shell (14) is made of nickel-based superalloy. According to the electric sealing connector, pressure can be more easily produced between glass and a substrate, the micro combination degree of sealing between glass and metal is improved, and accordingly the probability that air leakage occurs in the sintering process or in the use process is greatly lowered.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com