New type equipment for producing super high pressure

A new type of ultra-high pressure technology, applied in the field of pressure equipment, can solve the problems of complex structure of the equipment, heavy maintenance workload, high energy consumption in operation, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

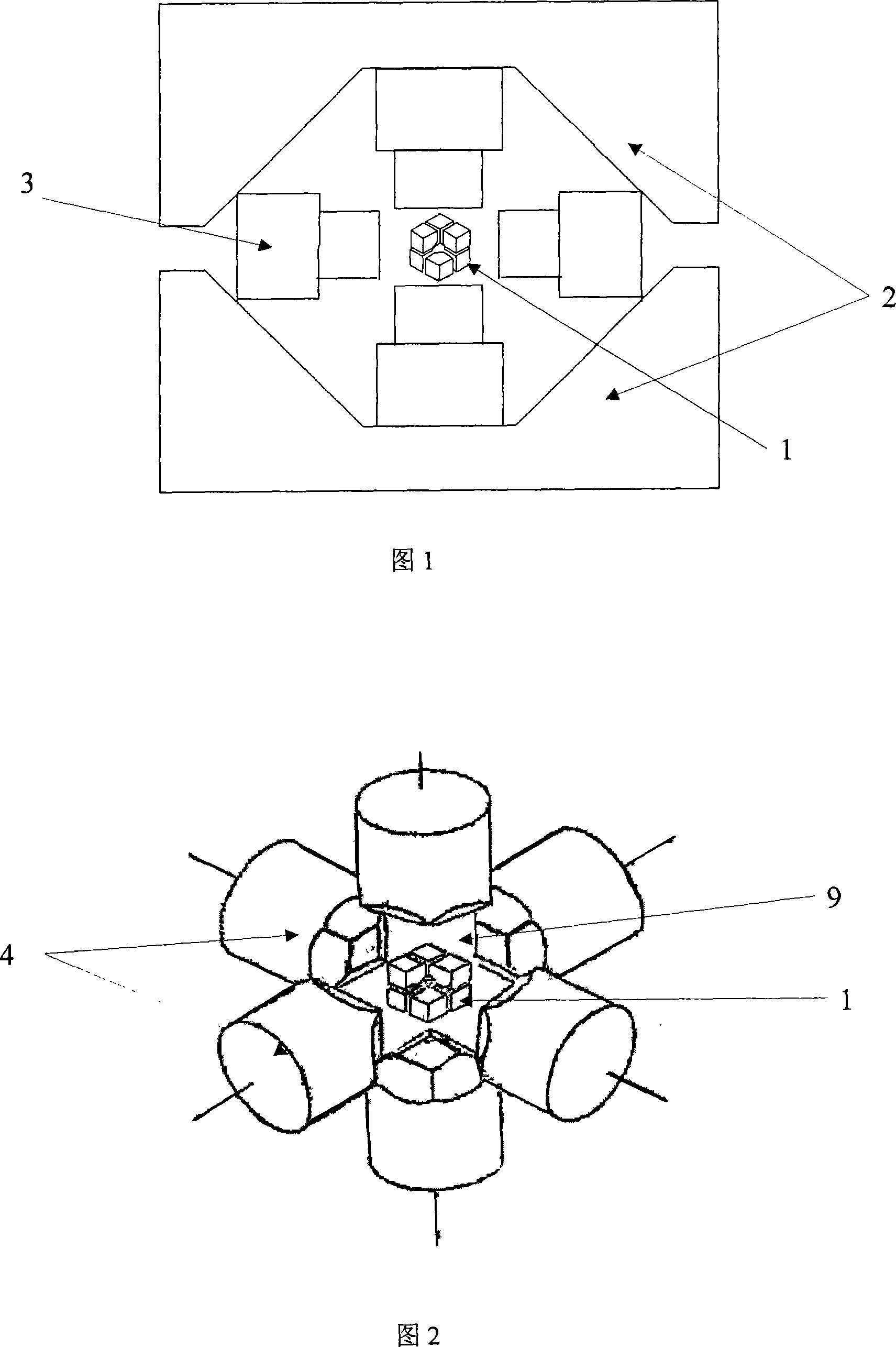

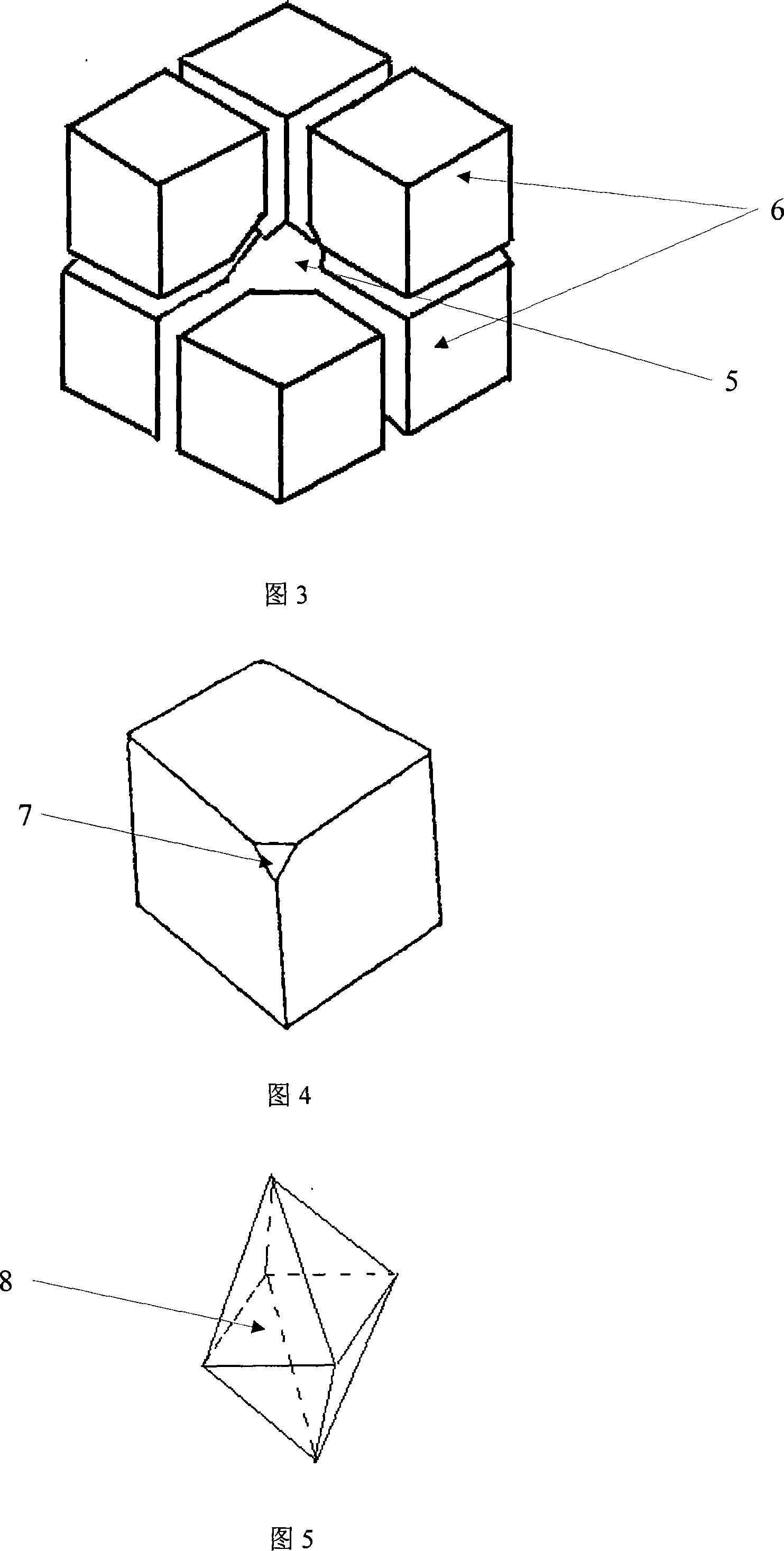

[0021] A new type of device for generating ultra-high pressure. Its structure is shown in Figures 2, 3, and 4. It is an octahedral large-cavity static high pressure device with a hinged six-sided pressing mechanism frame. The device includes a six-sided pressing machine synchronously An octahedral pressurizing unit 1 composed of six driven top hammers 4, eight cut-off cubes 6 and an octahedral composite block 8 used to contain synthetic materials. The top hammer 4 is made of hard alloy steel, The booster unit 1 is placed in a matching hexahedral high-pressure chamber 9 surrounded by six top hammers 4, and an octahedral composite block 8 is placed in a matching cube 6 surrounded by a WC material In the octahedron high-pressure cavity, wood supports are filled between the eight cubes forming the pressurizing unit. In order to enable the six top hammers of the six-side top press to continue to move forward to pressurize the pressure boosting unit after contacting the pressure boostin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com