Stator and rotor combined assembling device

A stator-rotor and equipment technology, applied in the field of stator-rotor combined equipment, can solve the problems of bearing damage, production safety and efficiency problems, rotor and stator assembly with different shafts, etc., to achieve stable coaxiality, ensure production rhythm, The effect of saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

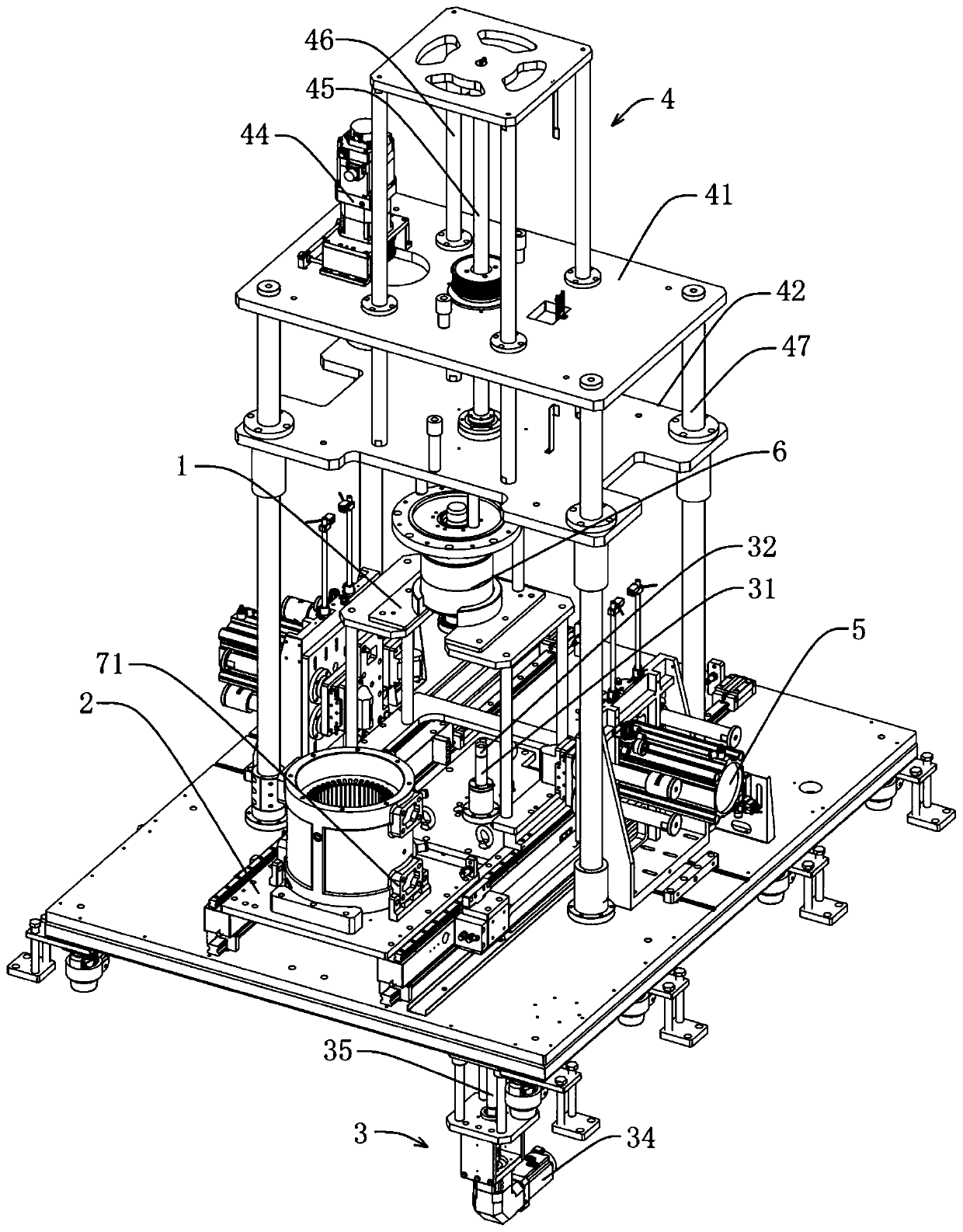

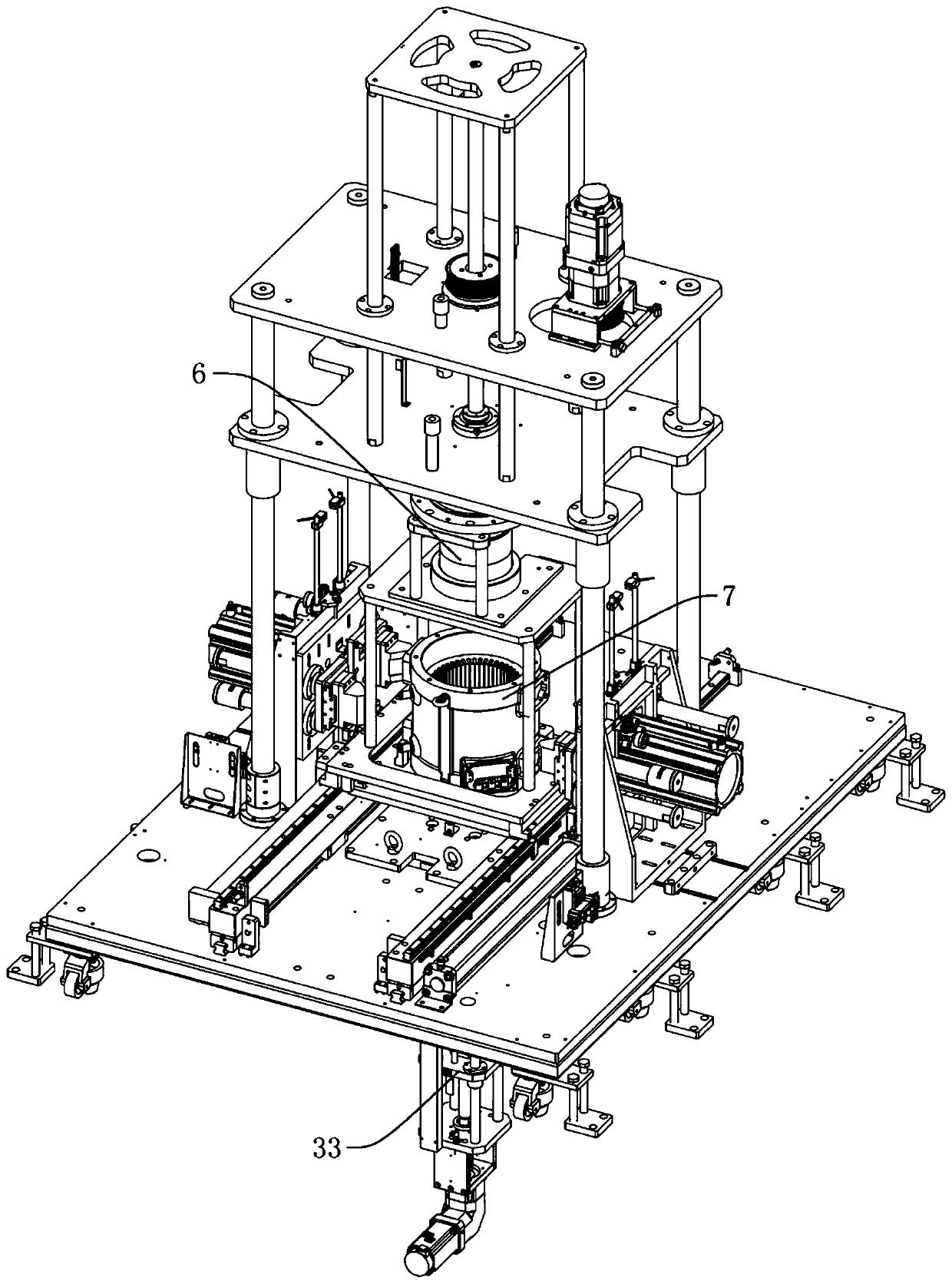

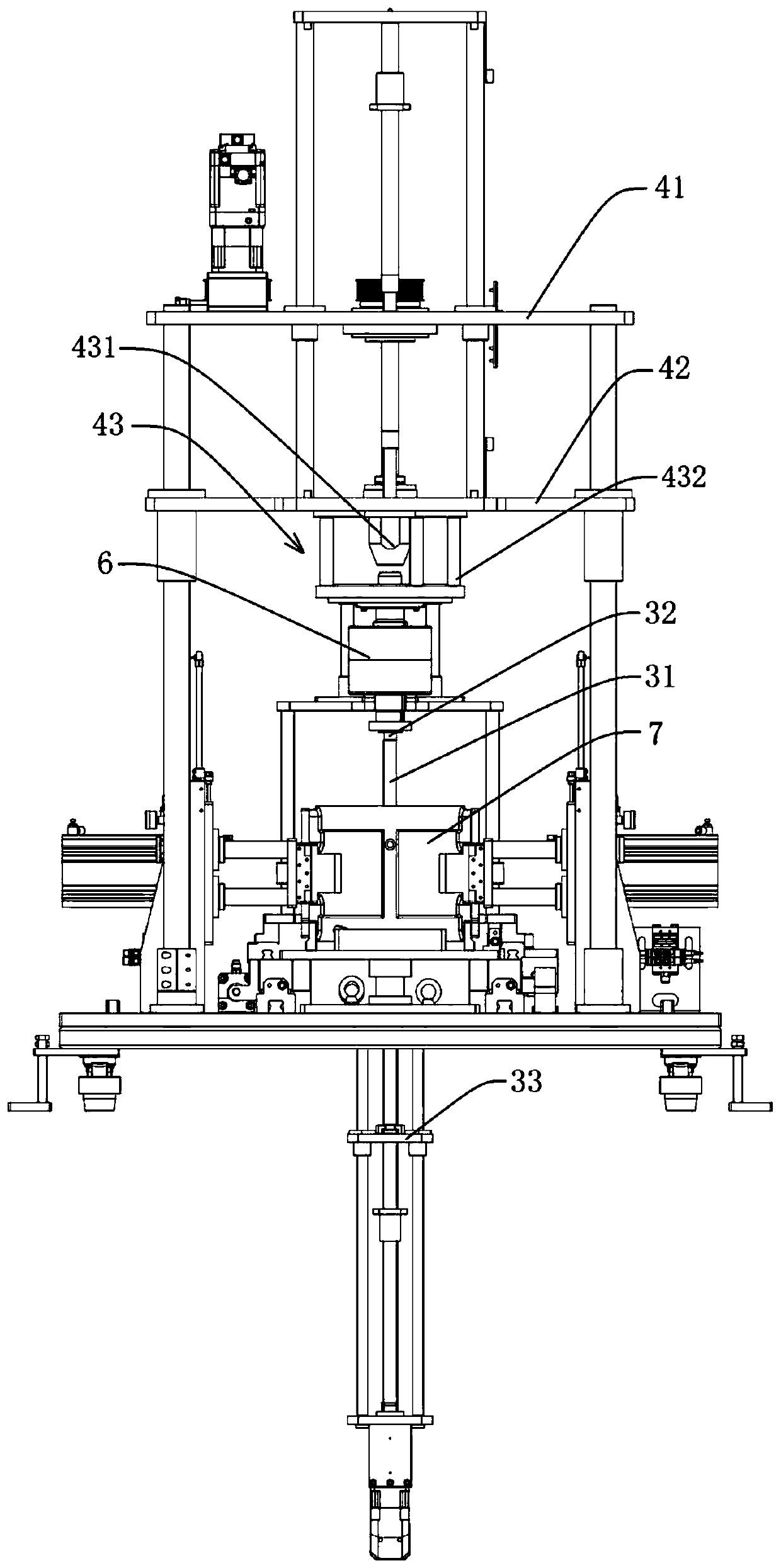

[0049] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, this embodiment is provided with: a first feeding and conveying mechanism 1 , a second feeding and conveying mechanism 2 , a jacking and guiding mechanism 3 , a pressing mechanism 4 and a lateral clamping mechanism 5 .

[0050] The first feeding conveying mechanism 1 comprises a first linear displacement mechanism 11, the first linear displacement mechanism is provided with a first linear displacement moving part, the first linear displacement moving part is provided with a first feeding base 13, the first linear displacement moving part is provided with a first feeding base 13, and A feeding base 13 positions and fixes the rotor end cover assembly; the first feeding base is provided with a evacuation avoidance opening 131 and an end cover positioning part 132, and the evacuation avoidance opening 131 is convenient for the first feeding base to move from the closing position during the jacking and guidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com