Patents

Literature

1769results about How to "Improve coaxiality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

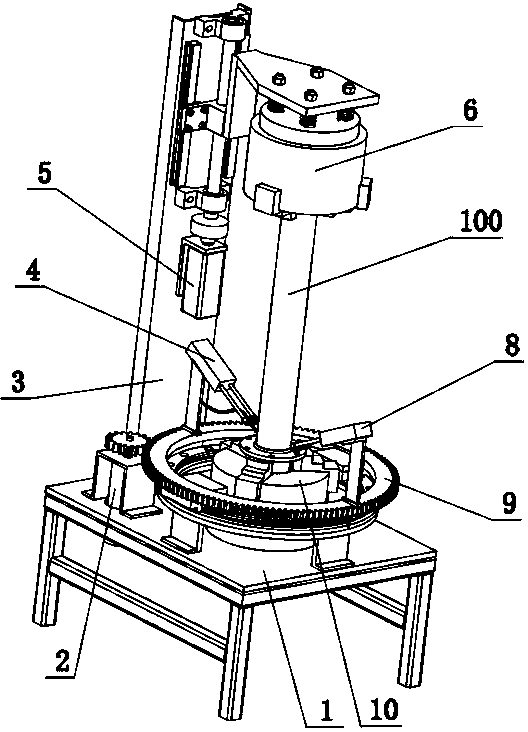

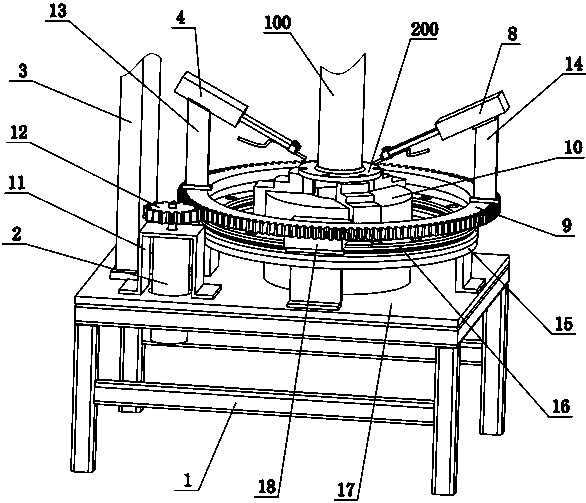

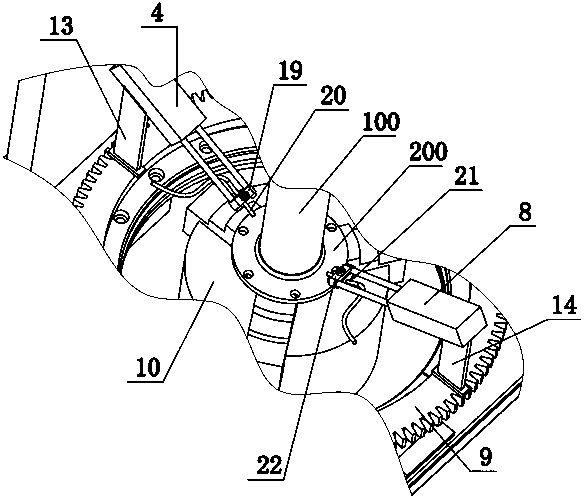

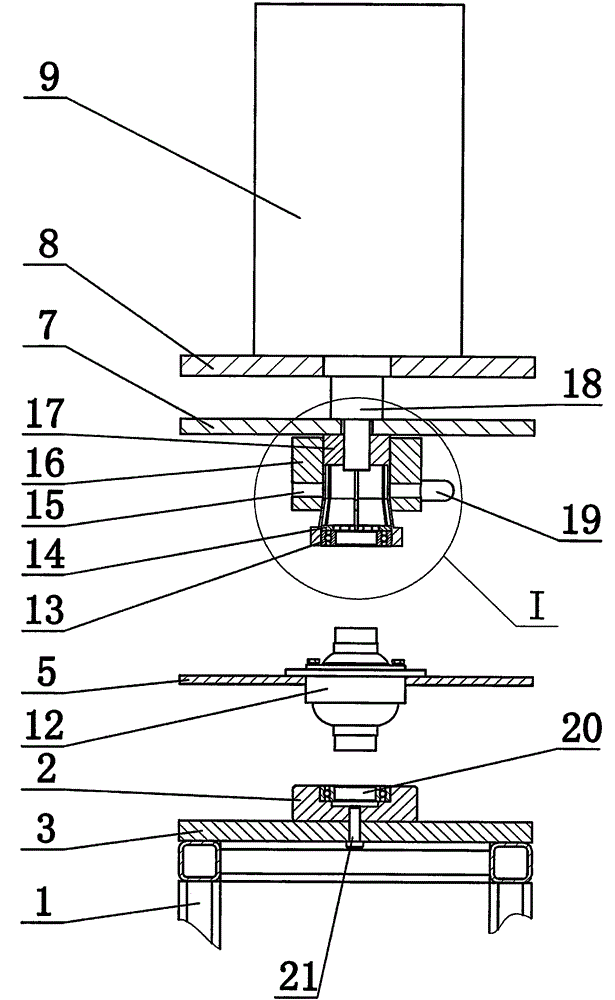

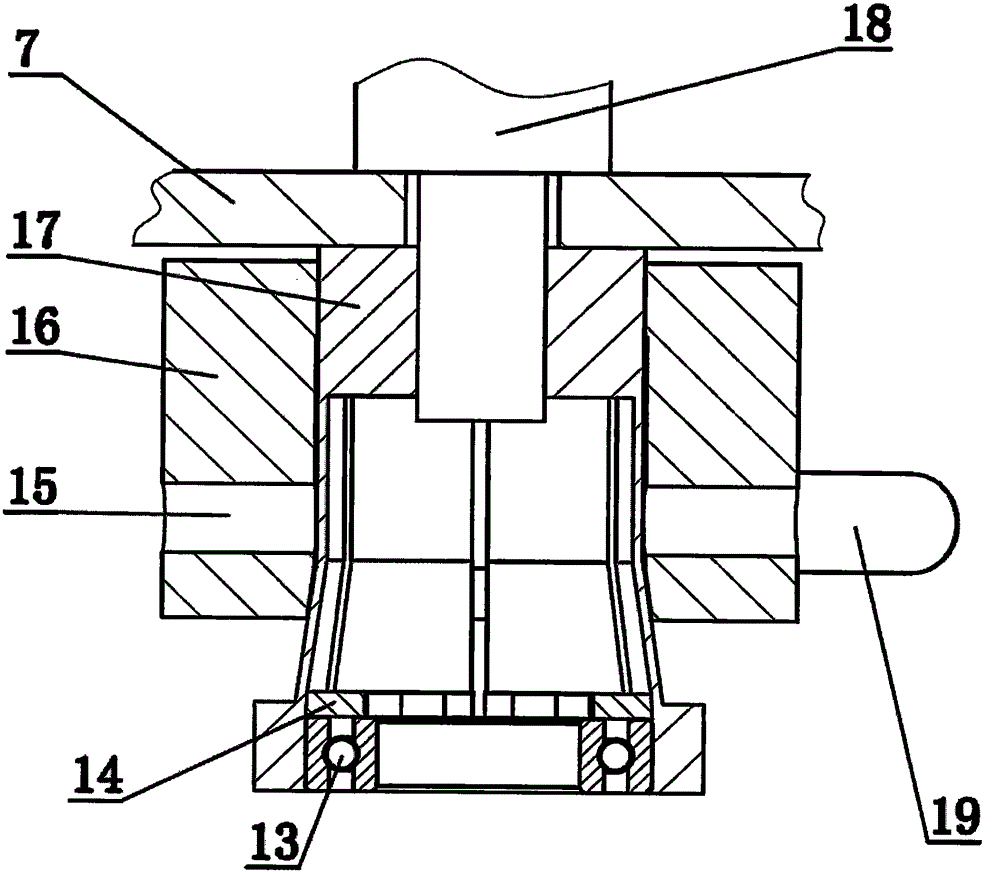

Vehicle supporting bridge pipe and end face flange welding machine and welding method thereof

ActiveCN108032027AReduce welding distortionImprove coaxialityWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationFlange

The invention provides a vehicle supporting bridge pipe and end face flange welding machine and a welding method thereof. The welding machine comprises a welding seat, a supporting flange plate is fixed at the upper end of the welding seat, a second three-claw chuck is fixed on the supporting flat plate, a circumferential rotating device coaxial with the second three-claw chuck is arranged on thesupporting flat plate, two welding guns are fixed on two sides of the center of the circumferential rotating device, a vertical beam is fixed on the supporting flat plate, a lifting mechanism is fixedon the vertical beam and fixed to a first three-claw chuck through elastic connection, a second three-claw chuck and the first three-claw chuck are fixed to a flange and a supporting bridge pipe respectively, and the welding guns weld the flange and the bridge pipe when rotating. The welding guns with two circumferential sides in symmetry are adopted to weld a welding position at the same time, welding deformation of the supporting pipe and the flange caused by welding stress is reduced, and coaxiality between the supporting pipe and the flange is improved.

Owner:ANYANG INST OF TECH

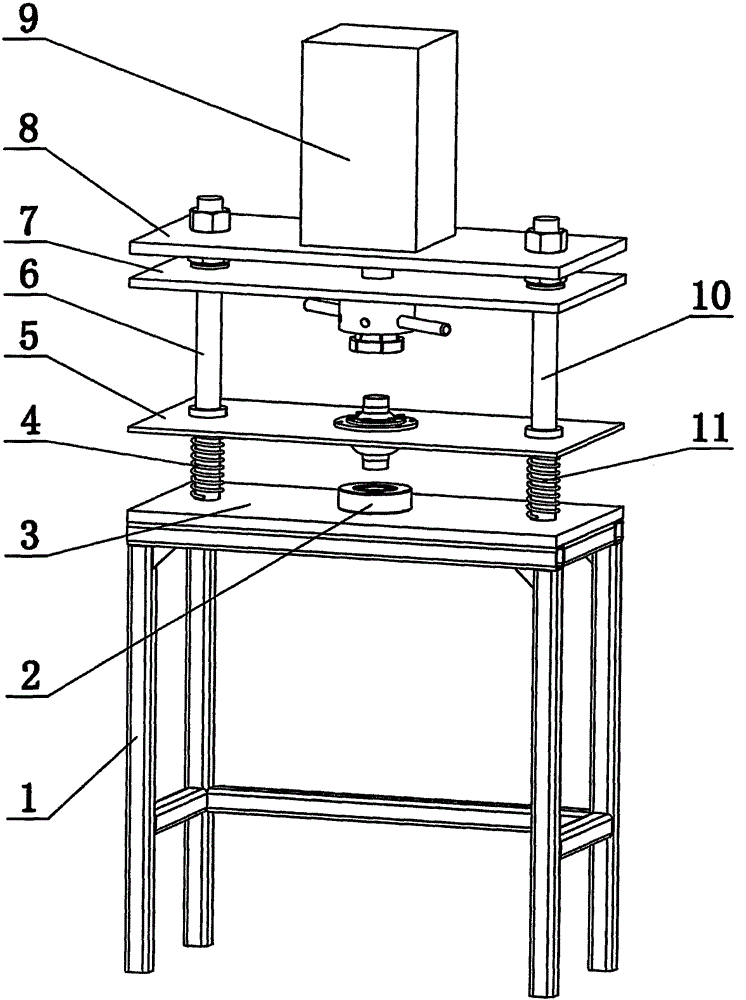

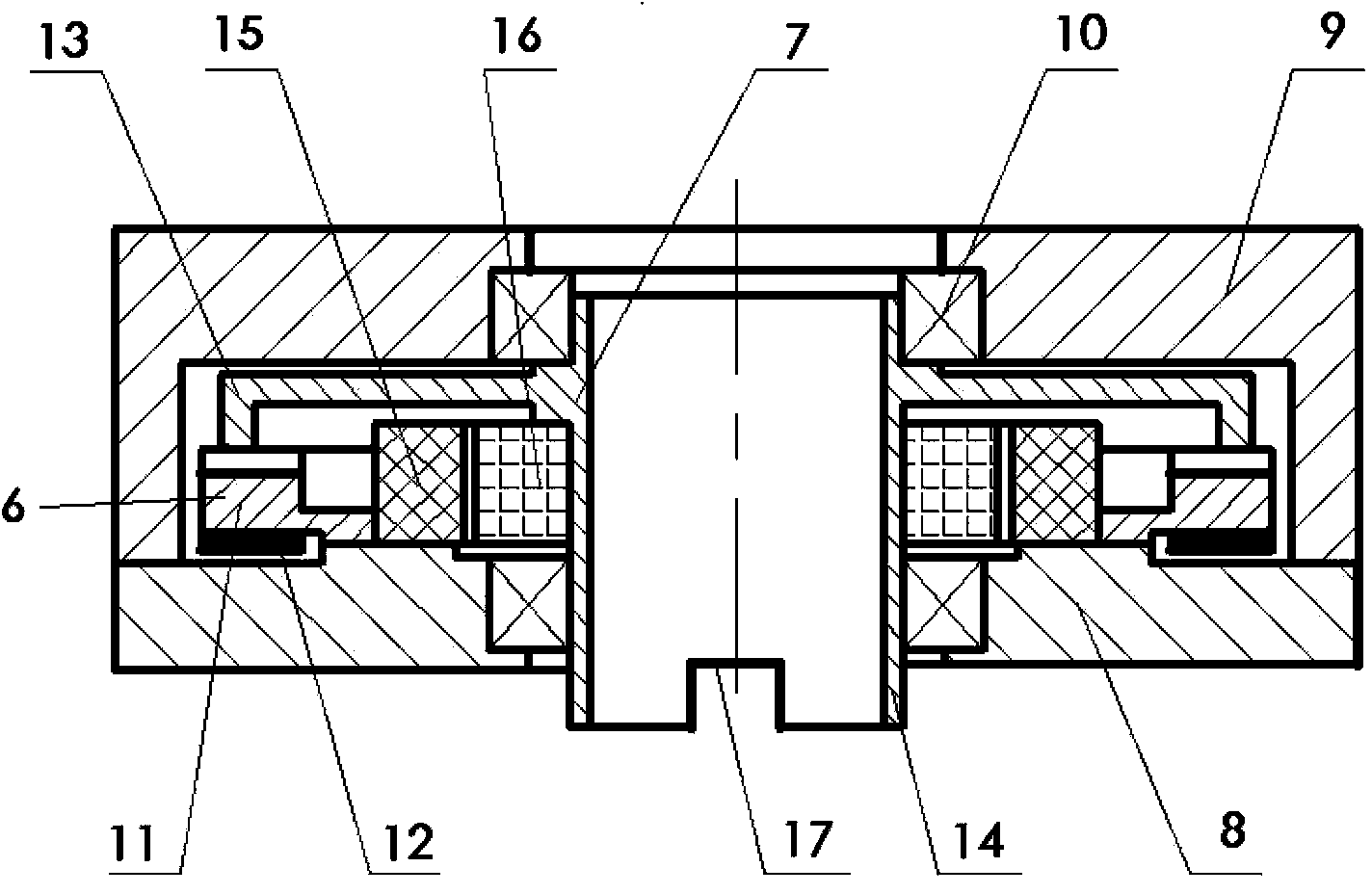

Press mounting device for bearing of rear axle differential of small vehicle

InactiveCN105081739AIncrease productivityLow costVehicle componentsMetal working apparatusControl theoryPiston rod

The invention provides a press mounting device for a bearing of a rear axle differential of a small vehicle. The device comprises a bracket; a horizontally-arranged supporting plate is fixed to the upper surface of the bracket; the lower ends of a first vertical column and a second vertical column are respectively fixed to the left end and the right end of the upper surface of the supporting plate, wherein the first vertical column and the second vertical column are vertical and arranged in parallel, and the first vertical column and the second vertical column are glidingly connected with two ends of a differential fixing plate and a downward-pressing plate from bottom to top in a sequence; the upper ends of the first vertical column and the second vertical column are fixedly connected with a cylinder fixing plate; a cylinder of which a piston rod downwards extends out is fixed to the cylinder fixing plate; the downward-pressing plate and a fixing device for the bearing at the upper side of the differential are fixed below the piston rod of the cylinder; a second circular through hole for mounting the differential is formed in the differential fixing plate; a bearing fixing seat for mounting a pressing-in bearing at the lower side of the differential is fixed to the supporting plate. The device is simple in structure, and small in cost; the efficiency of press-mounting of the bearing of the differential can be improved.

Owner:ANYANG INST OF TECH

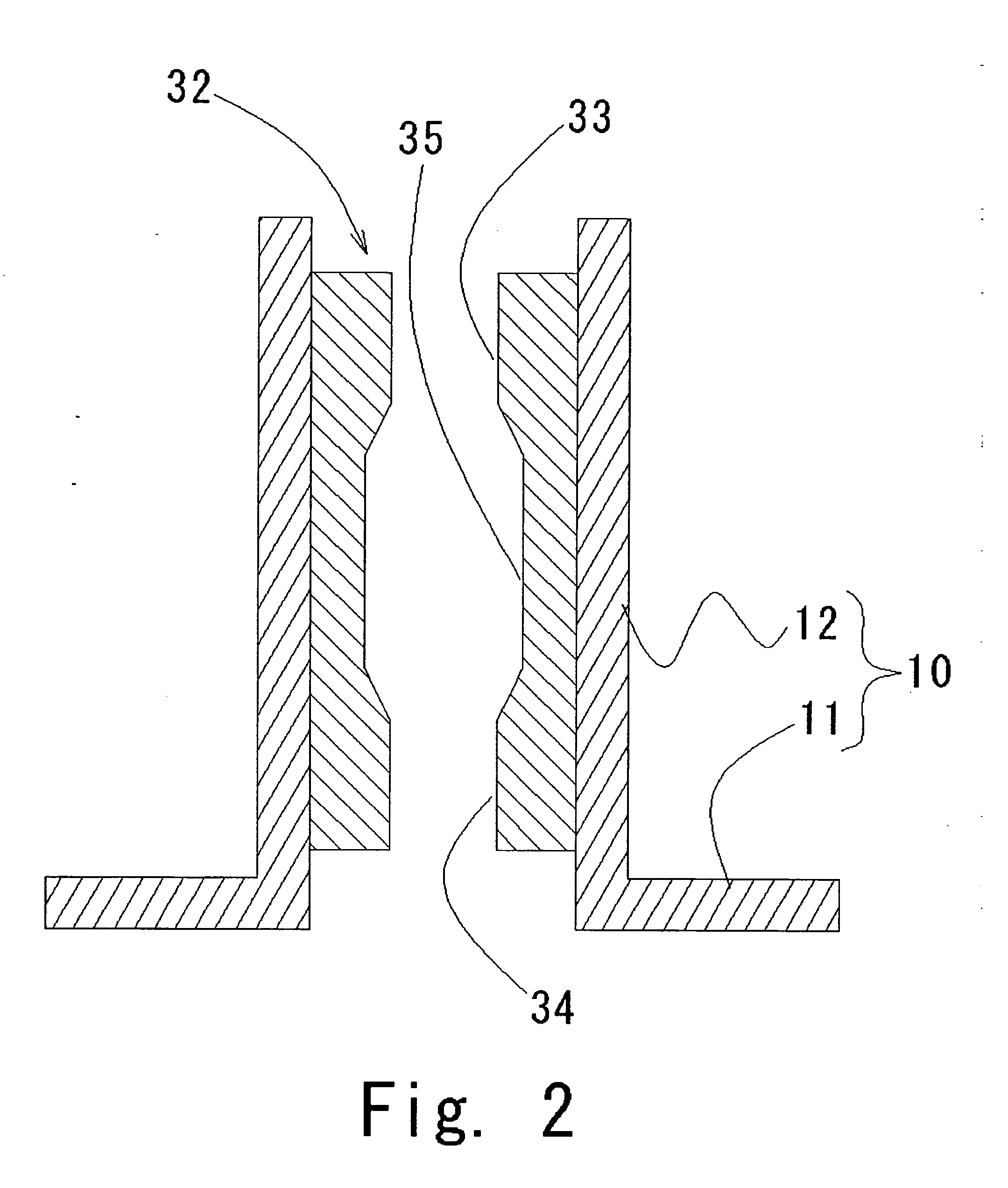

Brushless motor

ActiveUS20060071563A1Improve accuracyReduce the overall heightAssociation with control/drive circuitsMagnetic circuitBrushless motorsElectric motor

Owner:NIDEC CORP

Drive device assembled by an interference fit

InactiveUS20160036299A1Improve assembly accuracyAvoid leaningPropulsion by batteries/cellsVehicular energy storageInterference fitEngineering

A drive device is assembled with a fitting outer wall of a heat sink and a fitting inner wall of a frame combined by an interference fit. The drive device allows for a sufficient assembly accuracy of coaxiality, and may prevent a pulsation of motor torque and a vibration sound caused by a tilt of a shaft. Further, heat conductivity at a contacting portion is improved for heat dissipation from an electronic element in a controller section via the heat sink, the frame, and a bottom plate.

Owner:DENSO CORP

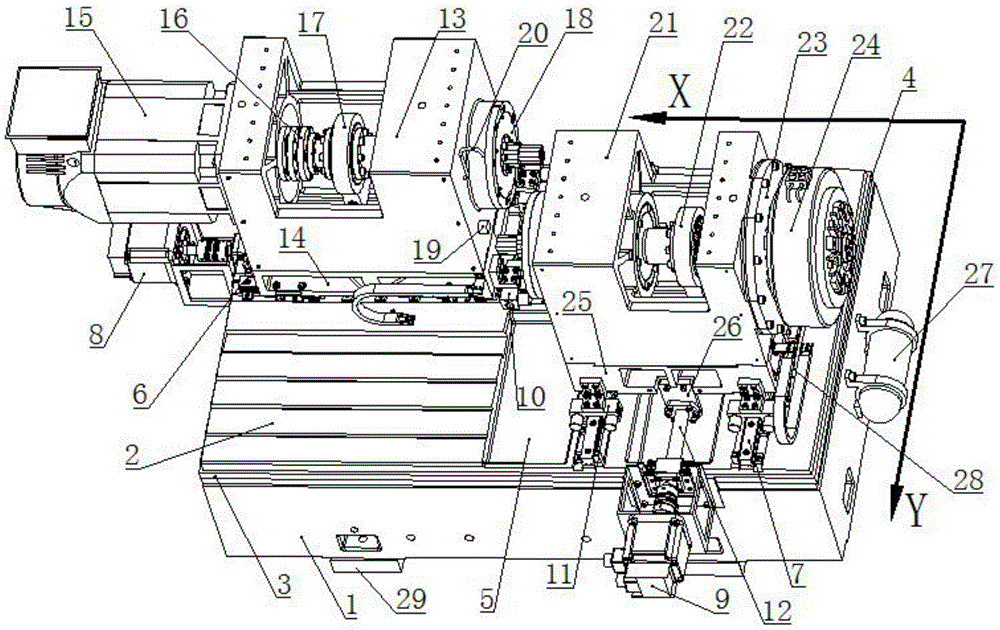

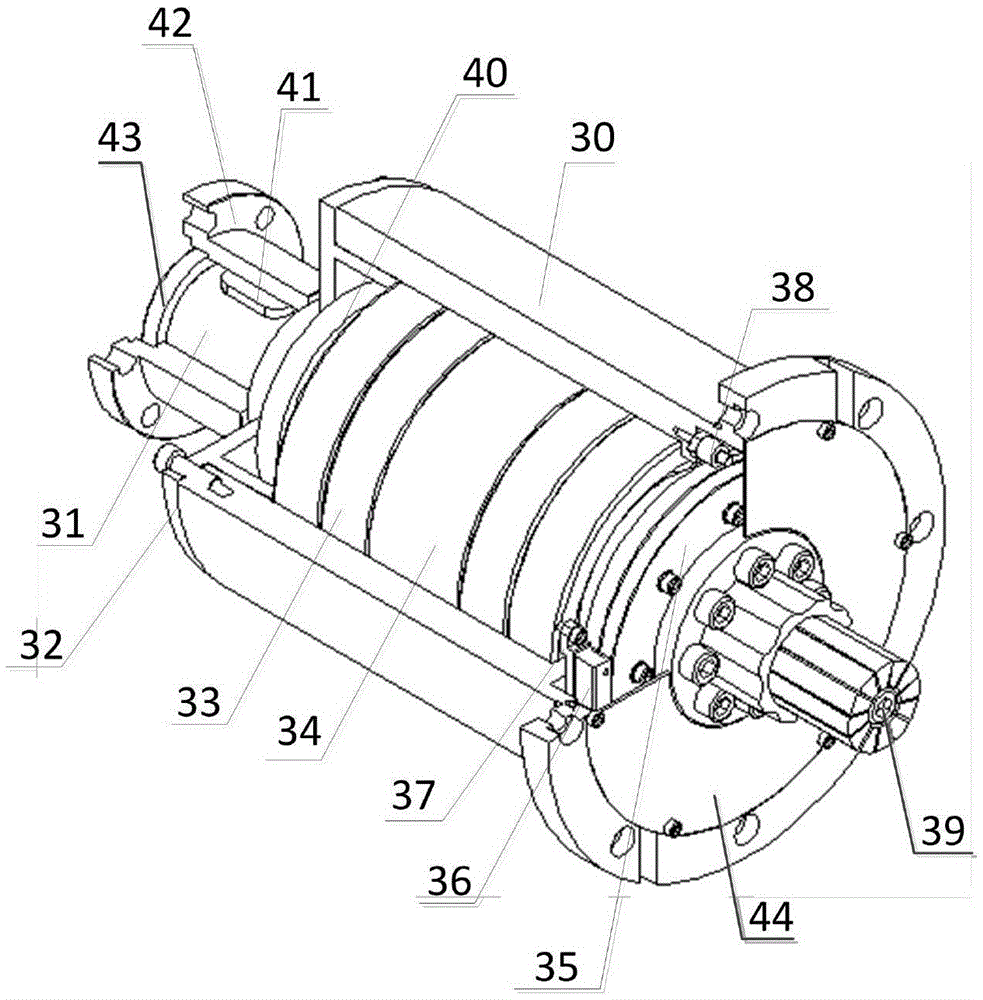

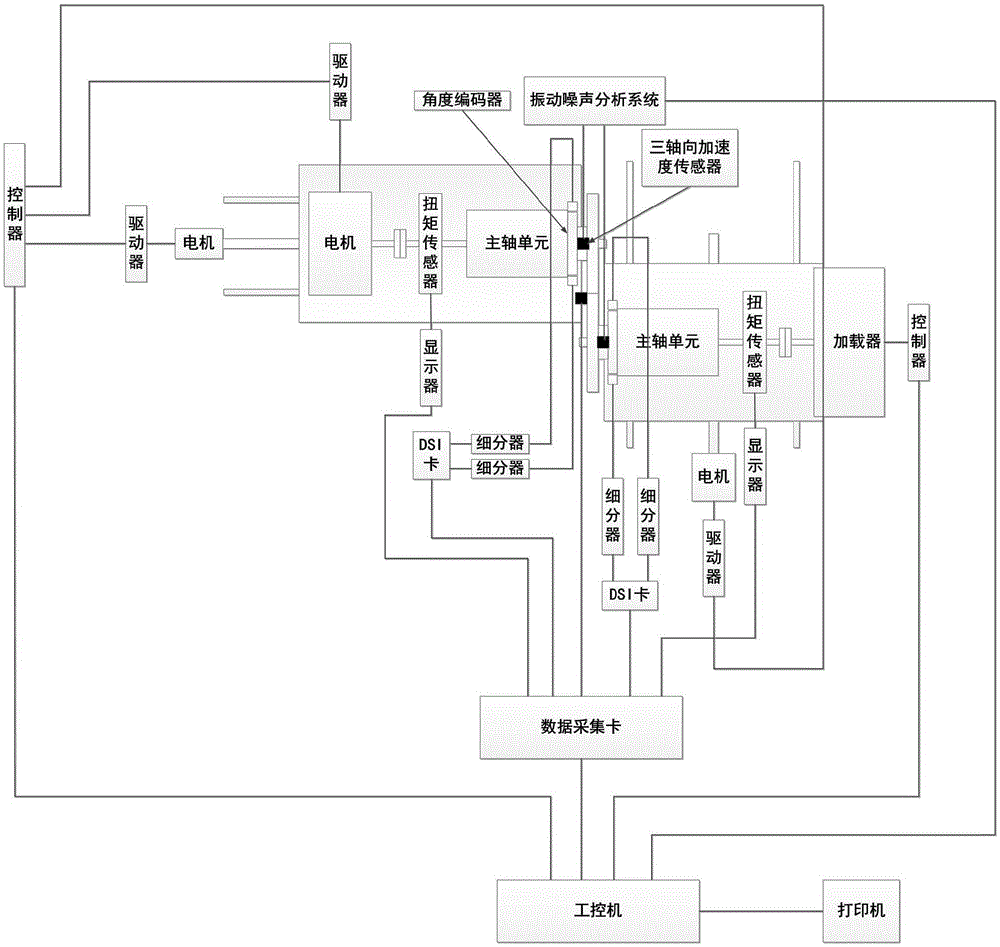

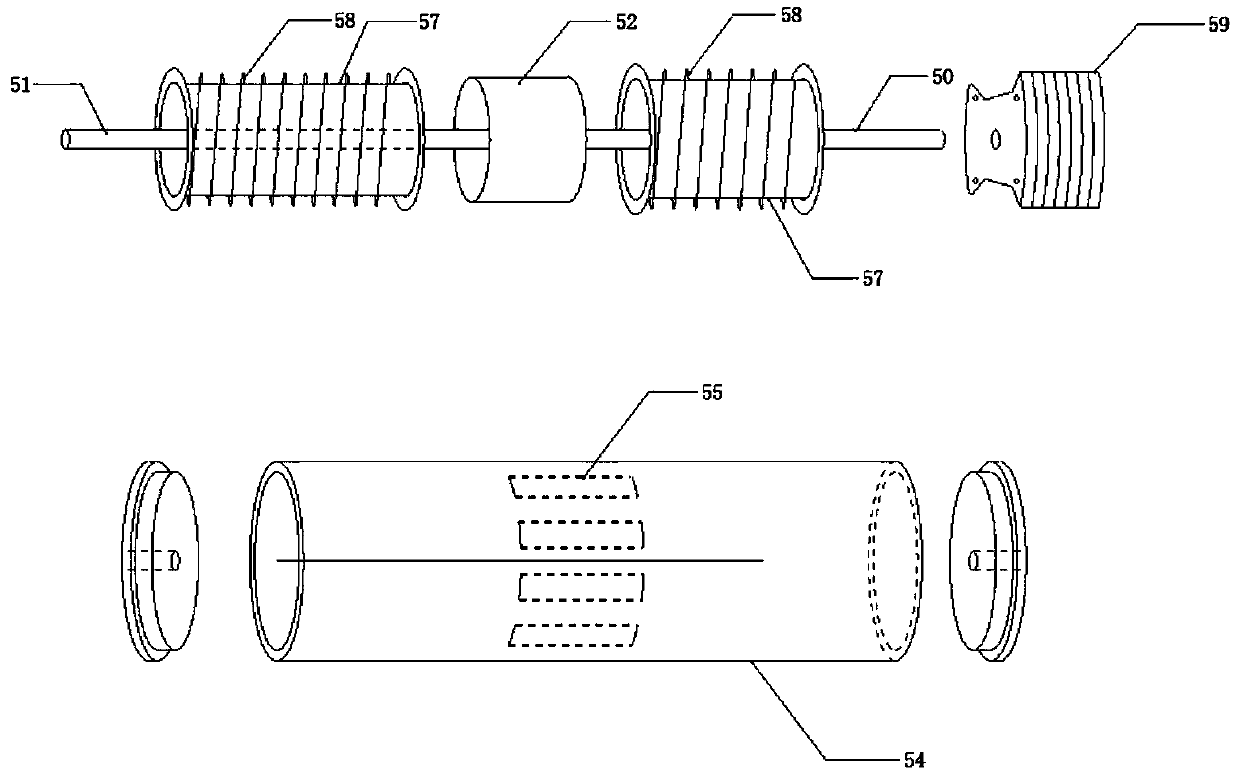

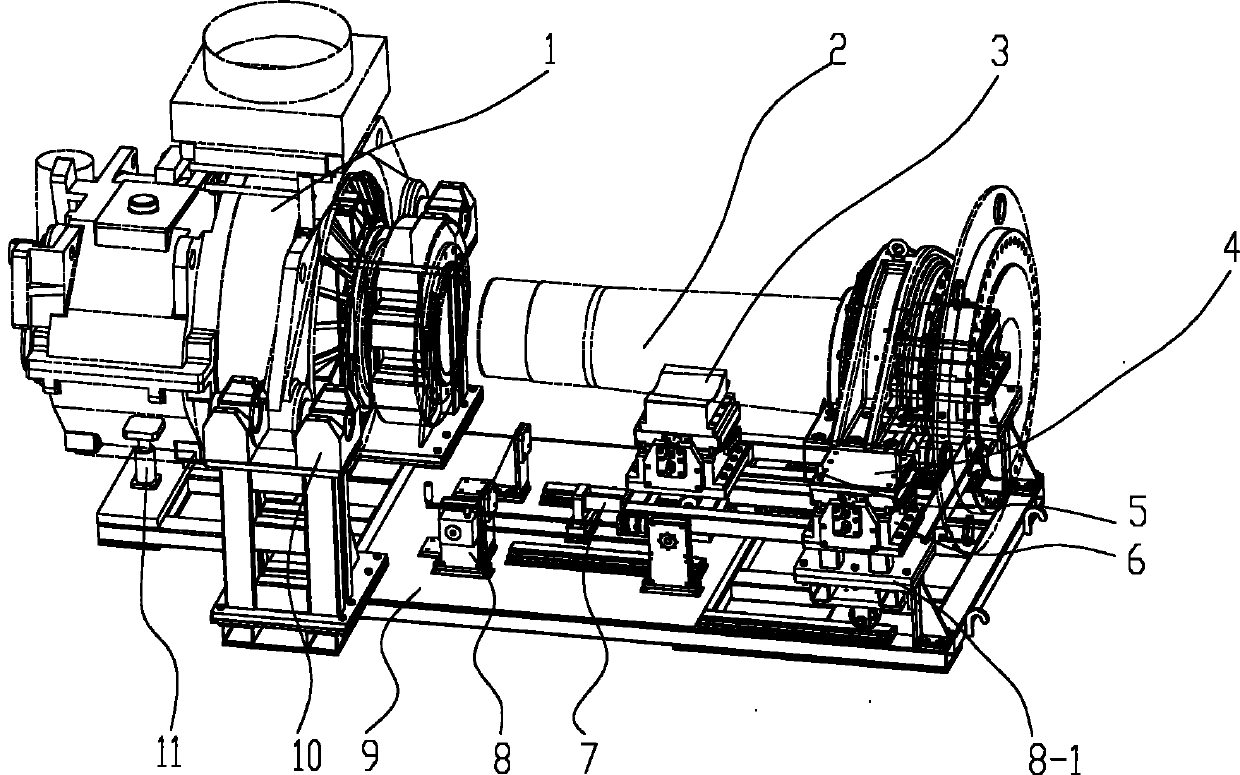

Experimental apparatus for dynamic performances of cylindrical gear

InactiveCN105651511AHigh degree of automationHigh precisionMachine gearing/transmission testingElectricityGear drive

The invention discloses an experimental apparatus for the dynamic performances of a cylindrical gear. The apparatus comprises a precision lathe bed and a precision spindle unit. A spindle unit, a torque sensor and a motor are fixed on a drive-end box body. A driven shaft spindle unit, a torque sensor and a loader are fixed on a load-end box body. A gear clamp and a spindle are connected via a lolley needle. In this way, the installation of gears is facilitated, and the gear clamp is ensured to be good in interchangeability. Meanwhile, the dimension range of experimental gears is enlarged. The experimental apparatus is provided with multiple sensors, thus integrating mechanical functions, optical functions and electrical functions as a whole. The experimental apparatus enables various common experiments on cylindrical gears, such as the measurement on the transmission error profiles of gears, the analysis on the meshing vibration noises of gears, the measurement on the contact spots of gears, the measurement on the transmission efficiencies of gears and the like. The experimental apparatus is high in precision, large in rigidity, extremely good in stability and high in degree of automation, which can meet the requirements of dynamic and static tests on gears.

Owner:BEIJING UNIV OF TECH

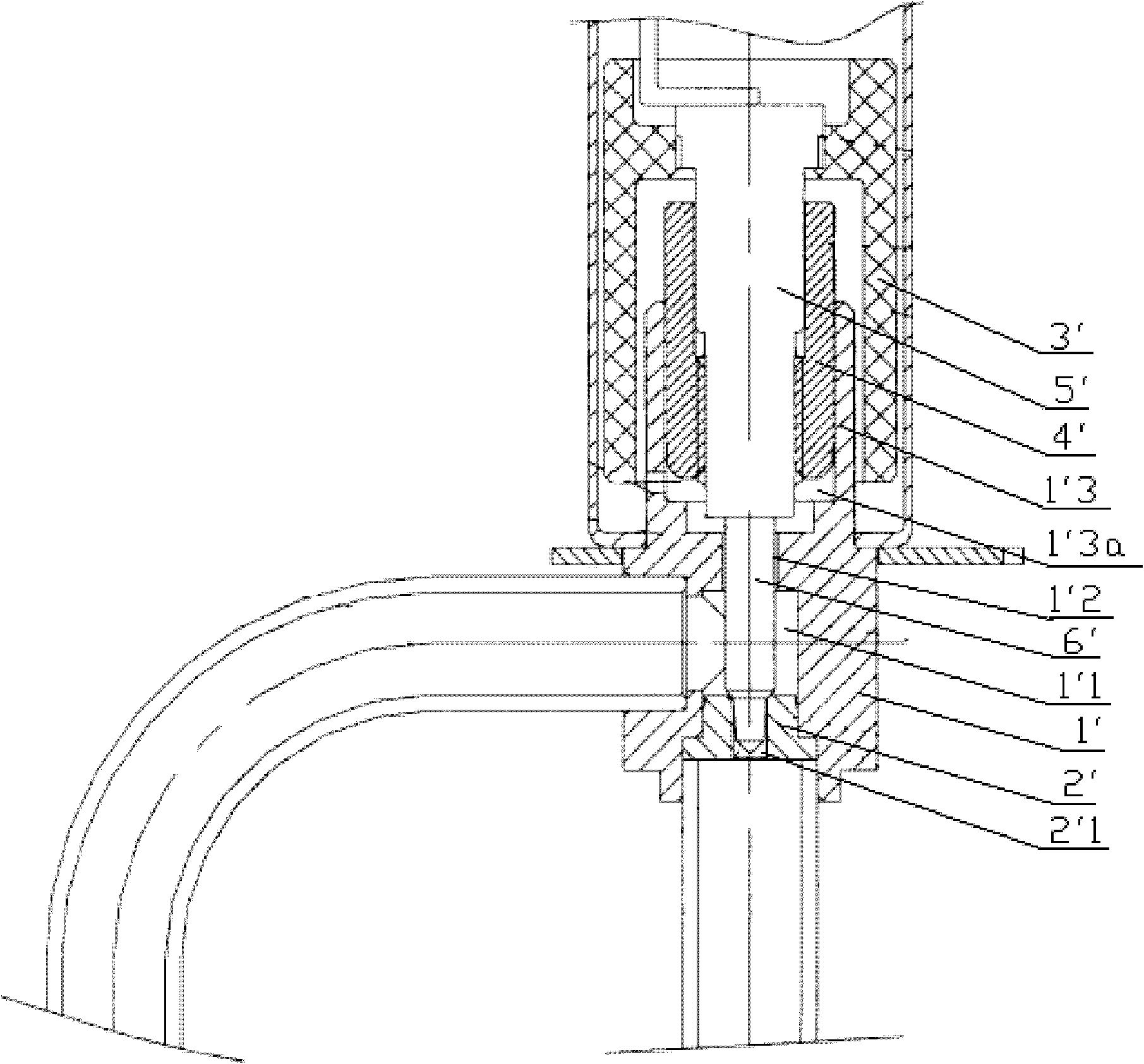

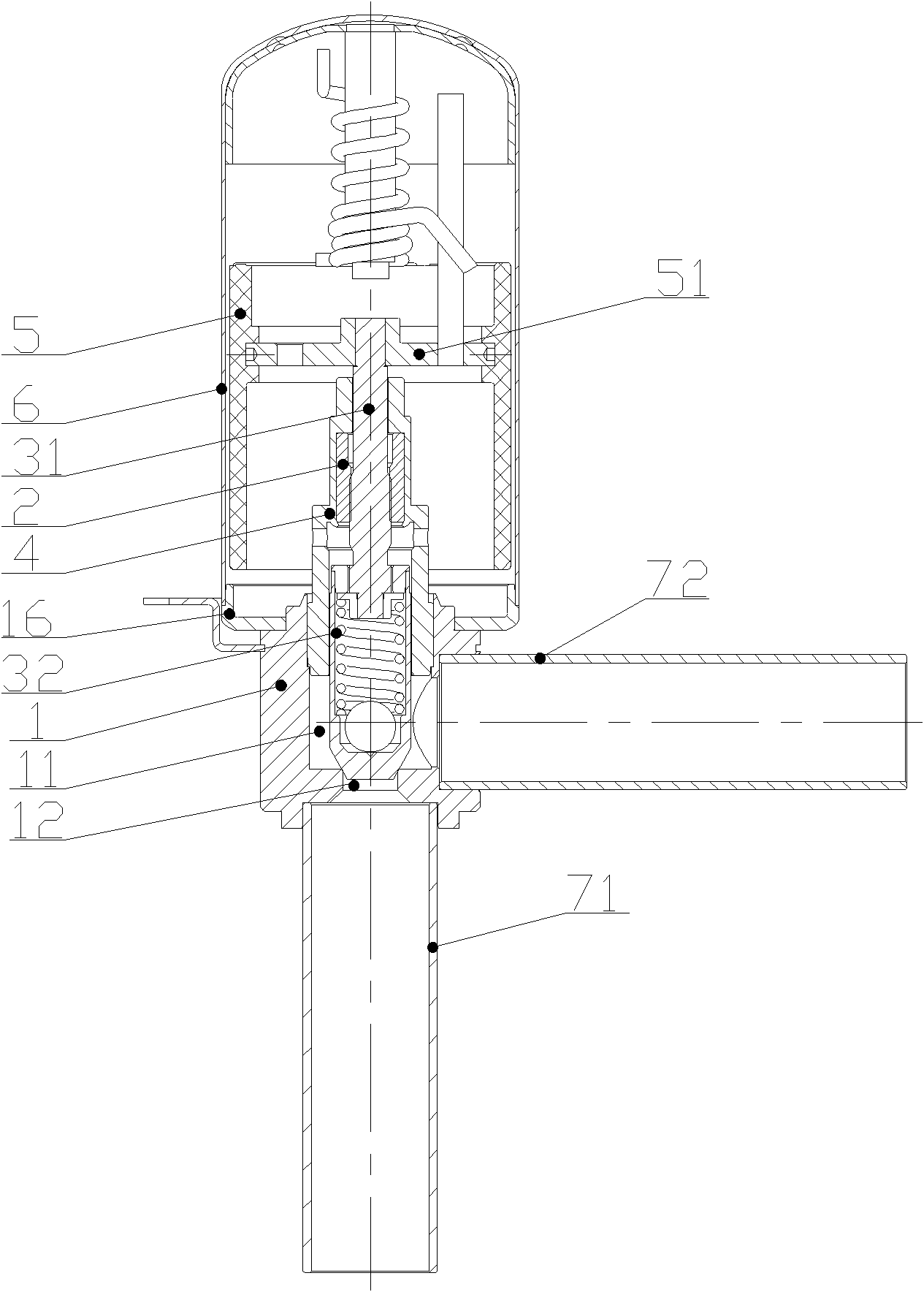

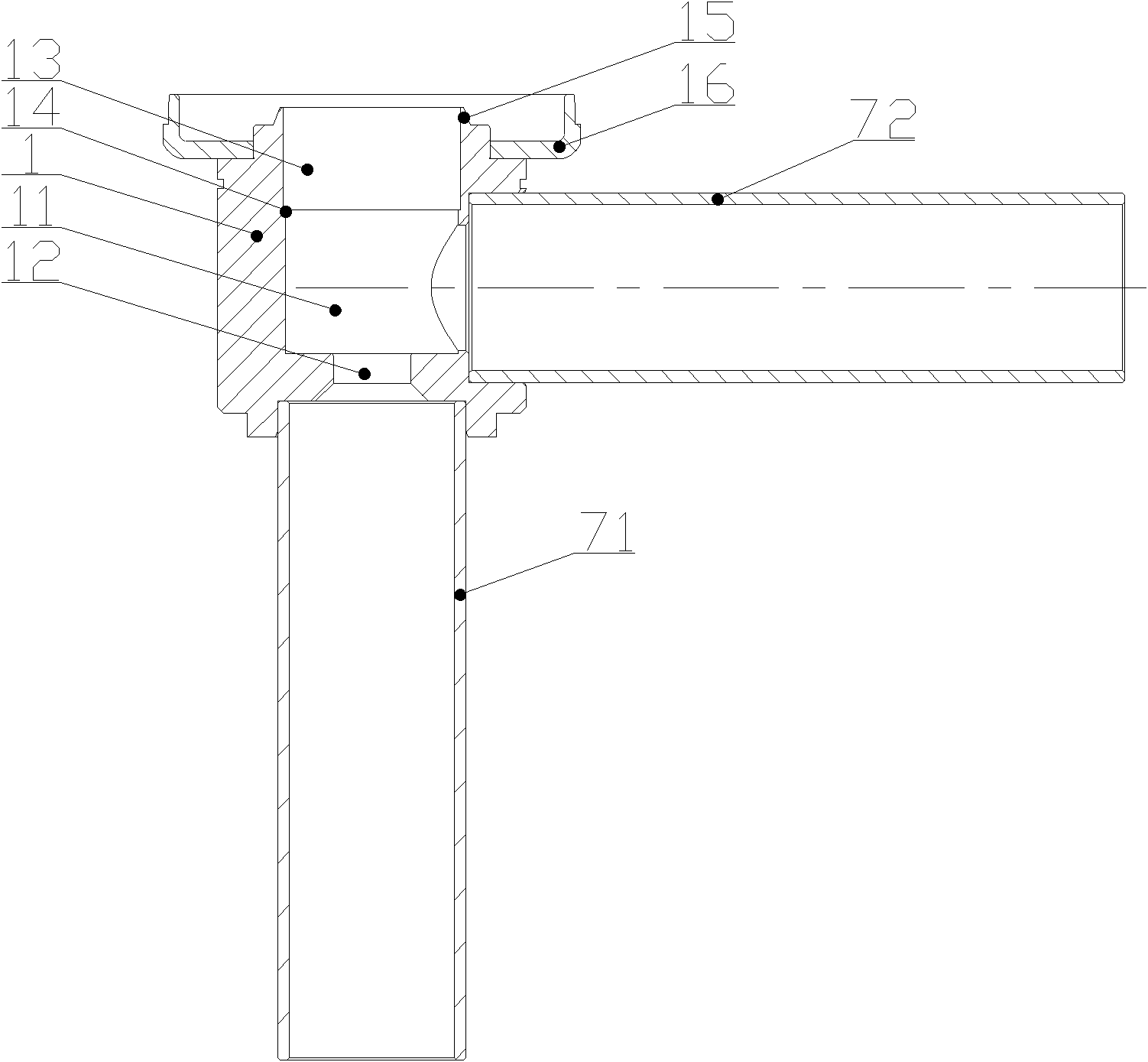

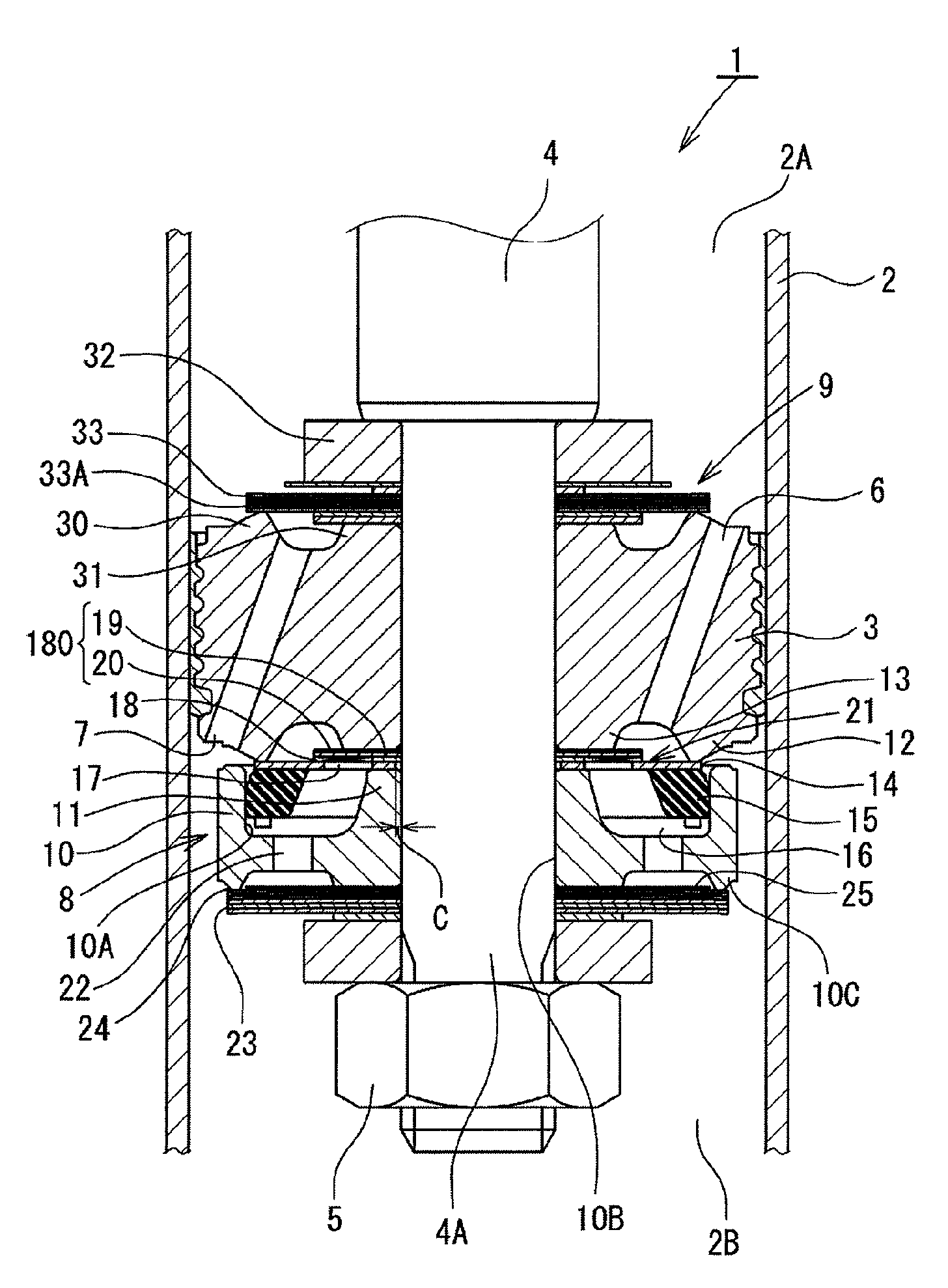

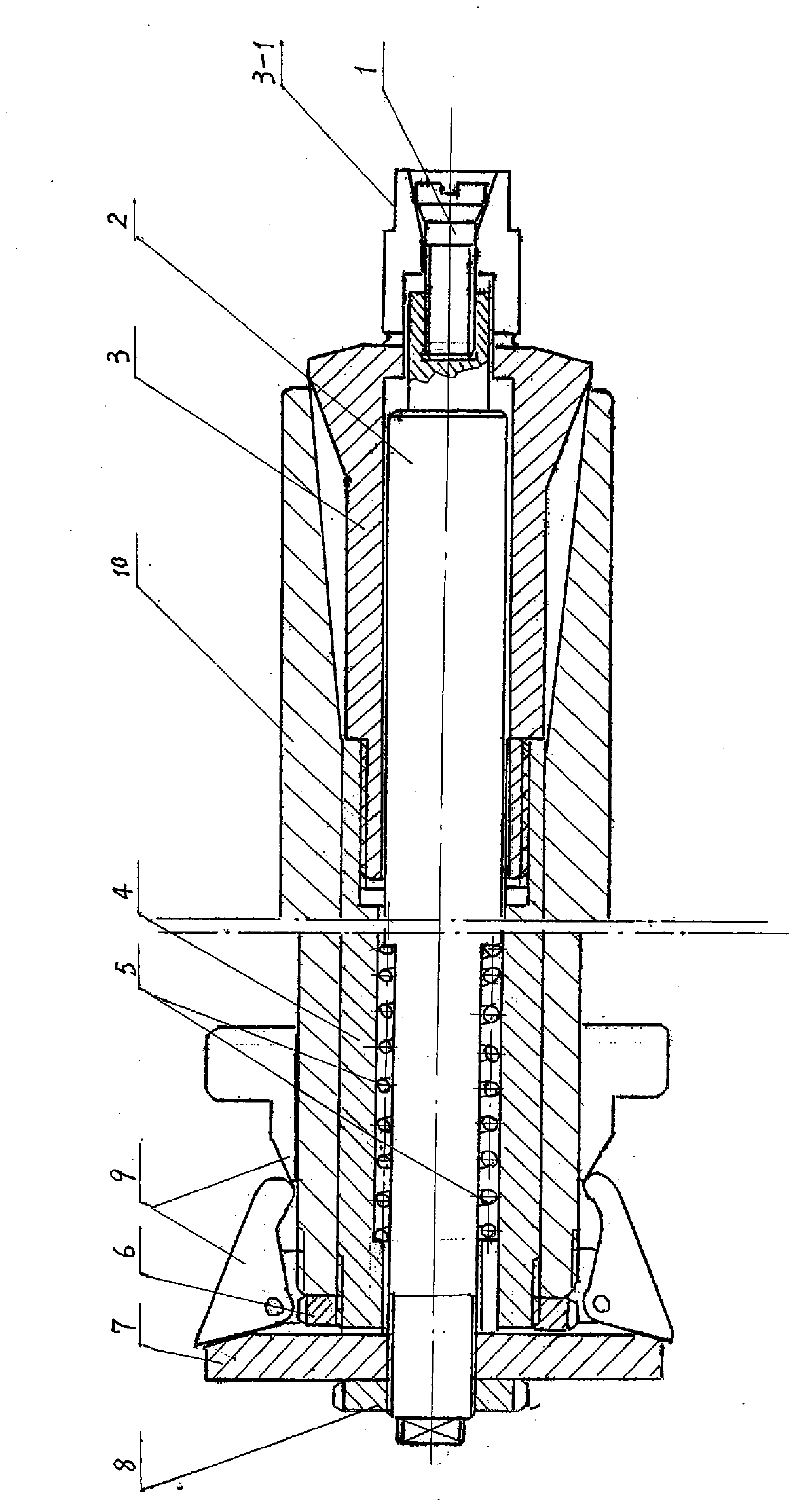

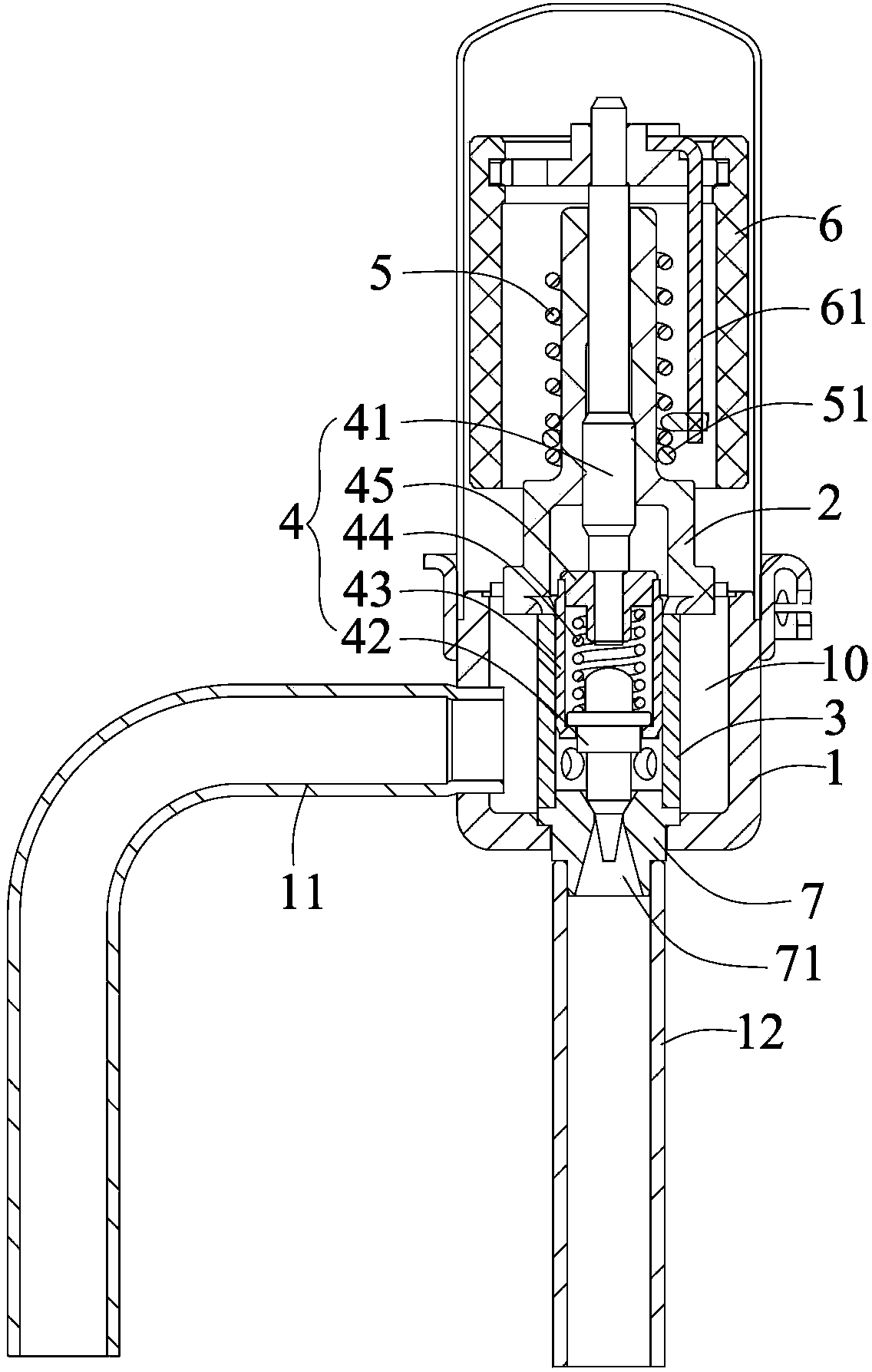

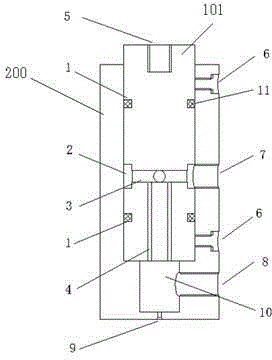

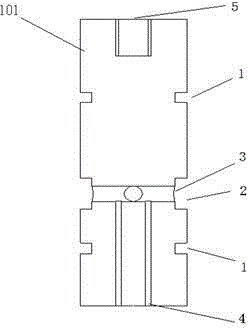

Electronic expansion valve

ActiveCN102734476AReduce material costsGuaranteed coaxialityEfficient regulation technologiesFluid circulation arrangementNeedle guideElectronic expansion valve

The invention discloses an electronic expansion valve which comprises a valve seat (1), a nut (2) and a valve needle assembly and also comprises a bearing block (4), wherein the valve seat (1) is provided with a valve cavity (11) and a valve port (12); the nut (2) is connected with the valve seat (1); the valve needle assembly is matched with the nut (2) through a screw (31) via a thread; a bearing block mounting hole (13) for installing the bearing block (4) is formed on the valve seat (1); the nut (2) is connected with the valve seat (1) through the bearing block (4); and a valve needle guide hole (41) is formed on the bearing block (4), and a valve needle (32) of the valve needle assembly passes through the valve needle guide hole (41) and is matched with the valve port (12). According to the structure design of the electronic expansion valve, on one hand, the coaxiality between corresponding holes of the valve seat (1) can be improved, on the other hand, the processing efficiency of the valve seat (1) can be improved, and the expenditure of material cost is reduced.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

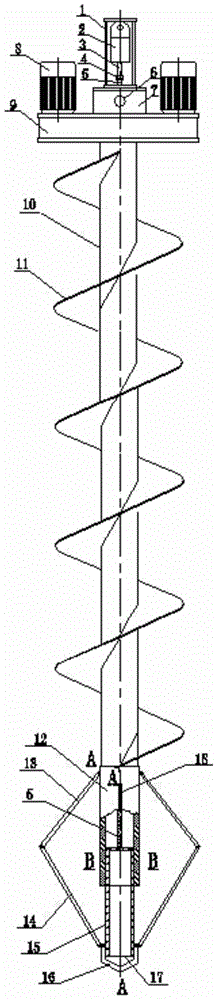

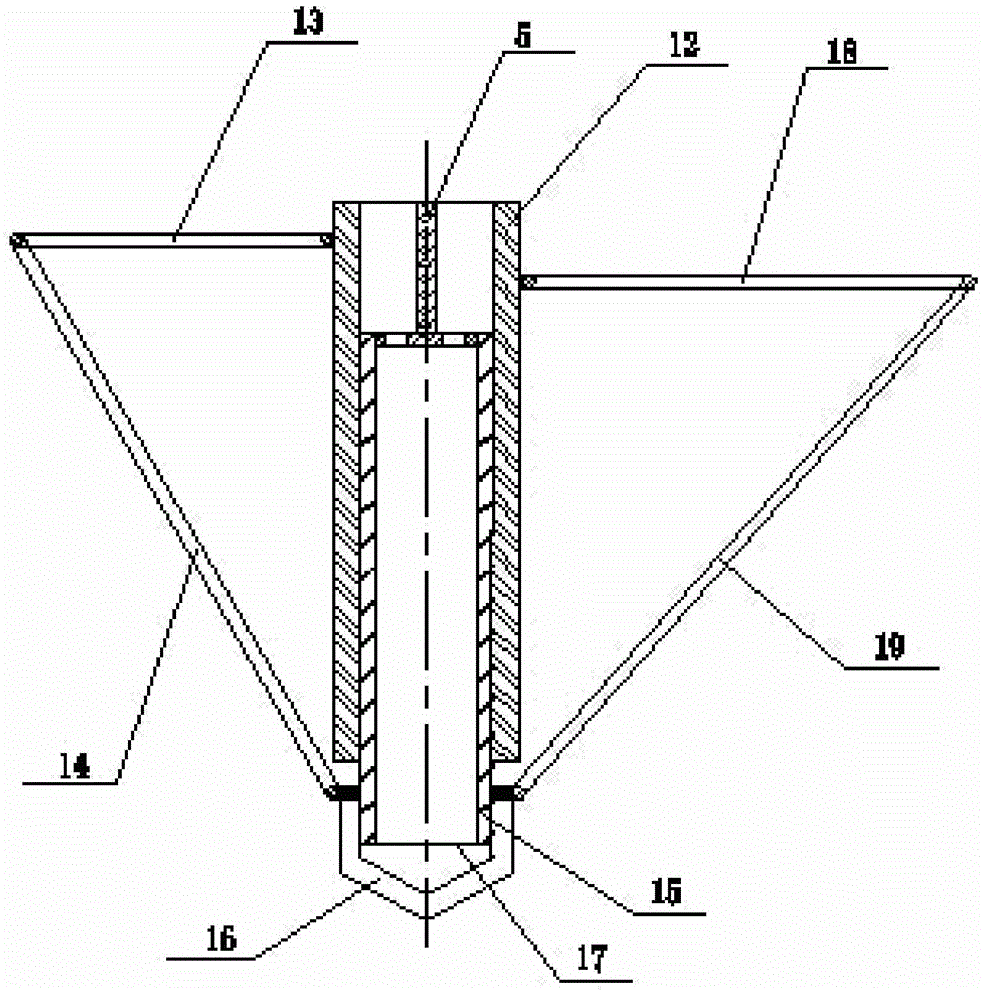

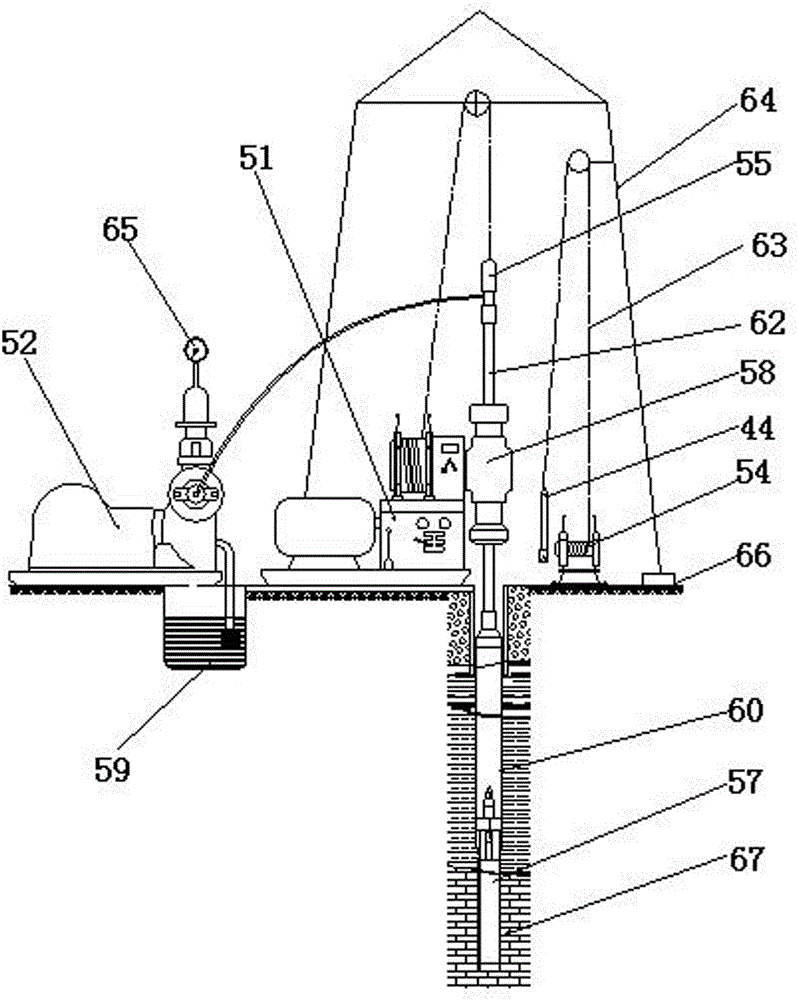

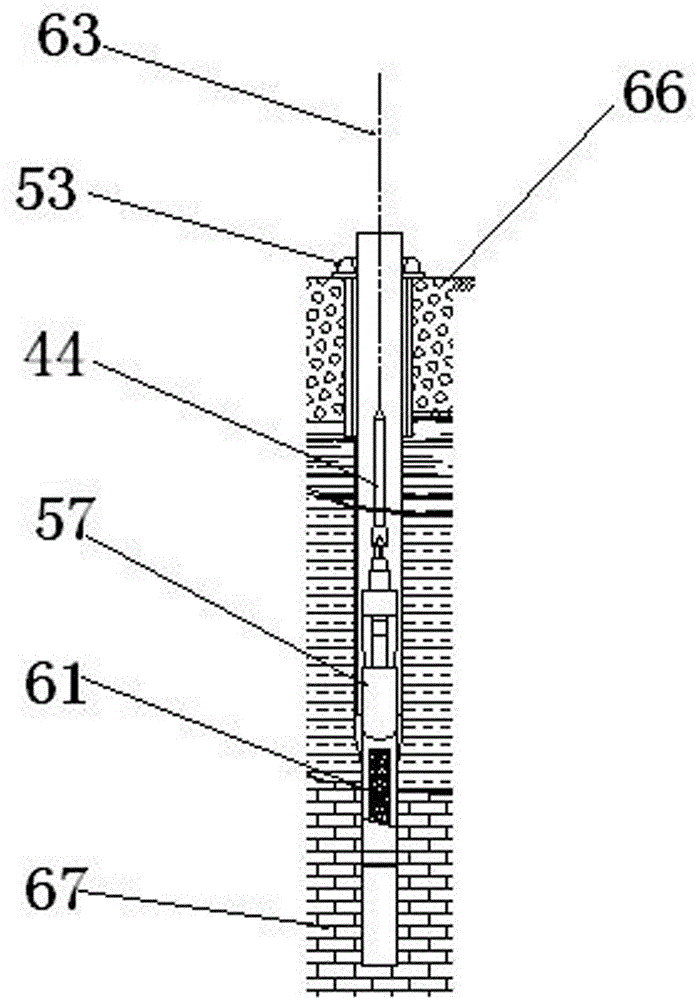

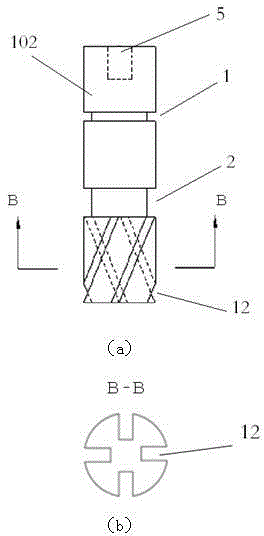

Long auger drilling and bottom expanding device and expanded anchor rod construction method

ActiveCN104453717AImprove the pull-out capacityImprove bearing capacityDrill bitsBulkheads/pilesSlurryUltimate tensile strength

The invention relates to a long auger drilling and bottom expanding device and an expanded anchor rod construction method. The long auger drilling and bottom expanding device comprises an auger drilling rod with an auger blade and a front guide drill bit. The upper portion of the auger drilling rod is connected with a power box of a pile machine through a rotary connector, a slurry inlet is formed in the rotary connector, motors are arranged on the two sides of the upper portion of the power box, a broaching oil cylinder support and a broaching oil cylinder are arranged in the middle of the upper portion of the power box, a connecting lug is arranged in the middle of the upper portion of the oil cylinder support, the broaching oil cylinder is hinged to the broaching oil cylinder support through the connecting lug, the lower end of a piston rod of the broaching oil cylinder is connected with the top of a broaching connecting rod through a transfer connector, the lower portion of the broaching connecting rod is arranged in an axial central through hole of the auger drilling rod, a rotary broaching device is arranged between the front guide drill bit and the auger drilling rod, the lower end of the broaching connecting rod is connected with the rotary broaching device, and the lower portion of the rotary broaching device is connected with the front guide drill bit. According to the long auger drilling and bottom expanding device and the expanded anchor rod construction method, noise, vibration and slurry are avoided in the construction process, an anchoring body is high in strength, good in quality, low in cost, high in working efficiency and good in environmental friendliness, and the uplift bearing capability of an anchor rod is high.

Owner:SHANDONG ZHENGYUAN CONSTR ENG

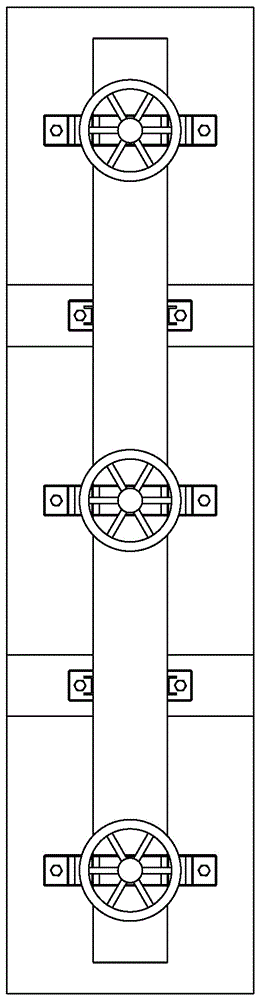

Thin-wall tube body fastening device

The invention discloses a thin-wall tube body fastening device which relates to a tool for processing a thin-wall tubular work piece on a lathe, and comprises a mandrel; a spacer is arranged in the center of the mandrel; a left baffle, a left conical sleeve, a left pressure block and a retaining ring are sequentially arranged on the mandrel on the left side of the spacer; a right baffle, a right conical sleeve and a right pressure block are sequentially arranged on the mandrel on the right side of the spacer; the spacer, the left baffle, the left conical sleeve, the left pressure block, the right baffle, the right conical sleeve and the right pressure block can slide on the mandrel; axial gaps are respectively arranged between the left baffle and the left conical sleeve and between the right baffle and the right conical sleeve; the retaining ring is fixedly arranged on the mandrel; a fastening nut is arranged on the mandrel on the right side of the right pressure block; and circular Half blocks which are provided with conical inner holes, and comprise a plurality of semi-rings are respectively arranged on the outer peripheral conical surfaces of the left conical sleeve and the right conical sleeve in a matching way. First, a thin-wall tube body is fastened on the thin-wall tube body fastening device, the thin-wall tube body can be fixed only after the mandrel is fixed on the lathe, the fixation to the thin-wall tube body is simple, the axiality of both ports of the tube body is high, the tube body does not deform when in processing, and the processing precision is high.

Owner:SHANDONG SHUANGLUN

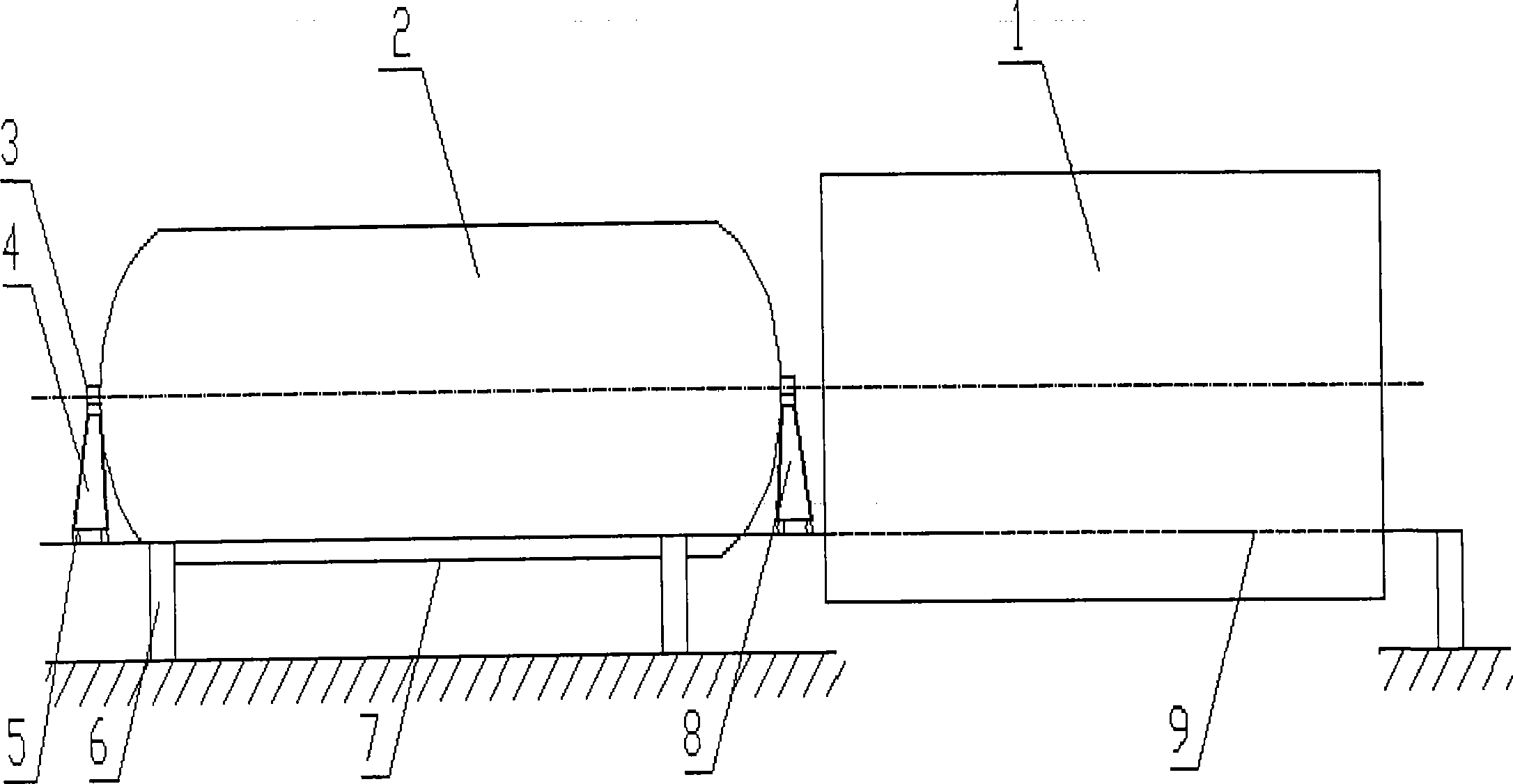

Liquefied natural gas tanker container nesting method

InactiveCN101187442APrecise positioningSwallowing process is smoothPressure vesselsInsulation layerEngineering

The invention discloses a package packing method of a liquefied natural gas tanker container. An inner tank is set up on the positions of assembly process pipes on the two ends through special supports, the lower section of each support is provided with four concave wheels which are engaged with outer cylinder guide rails, two support pipe which are engaged with the assembly process pipes on the two ends of the inner tank are arranged on the upper end of the support, the support is arranged on the outer cylinder guide rails whose heights are decided by the center shaft of the inner tank overlapping the center shaft of the outer cylinder. The inner tank and the support are pushed by a truss hoist and other devices on the far end from the inner tank to the outer cylinder, and the inner tank is slowly sleeved in the outer cylinder to the assembly position. The invention can precise the center positioning of the inner tank through adopting double supports, and the axialities of the inner tank and the outer cylinder are high, which are specially used to pack assembly under the condition that the distance between the outer surface of the inner tank and the inner surface of an outer cylinder is smaller. The double support enables the inward swallowing process of the inner tank much smoother, which avoids that the inner tank skews to hit the outer cylinder result in damaging an insulation layer in the packing process, and largely reduces the packing operation time, and the safety is much higher.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

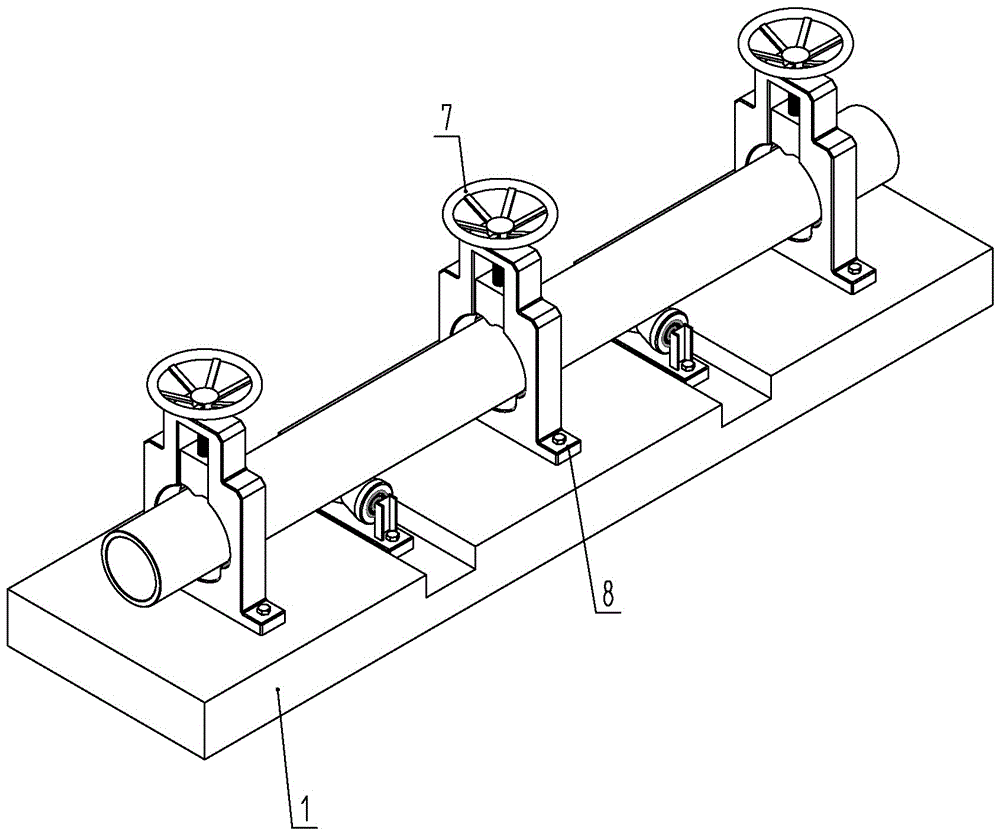

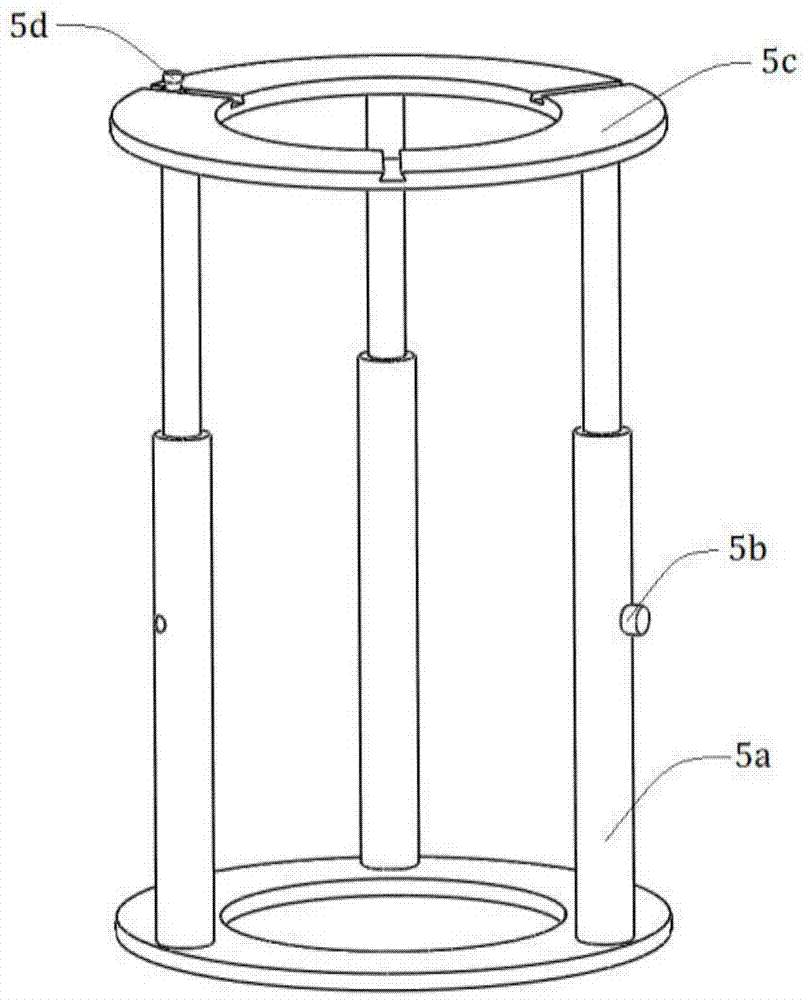

Auxiliary clamping mechanism for tubular and rod workpieces

InactiveCN105710677AAvoid bending deformationAvoid vibrationPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention discloses an auxiliary clamping mechanism for tubular and rod workpieces. The auxiliary clamping mechanism comprises a base, at least two positioning mechanisms which are coaxially arranged and assembled on the base in a sliding manner, and a locking mechanism capable of fixing the positioning mechanisms and a conveying mechanism to the base. The auxiliary clamping mechanism has the beneficial effects that through a tool, auxiliary positioning clamping of tubular and rod workpieces can be achieved, the workpieces are prevented from bending and deforming due to gravity, and coaxiality is improved; and the machining precision is improved, and vibration generated by high-speed rotation can be prevented. In addition, the beneficial effects of being simple in structure, high in practicability and the like are achieved.

Owner:句容五星机械制造有限公司

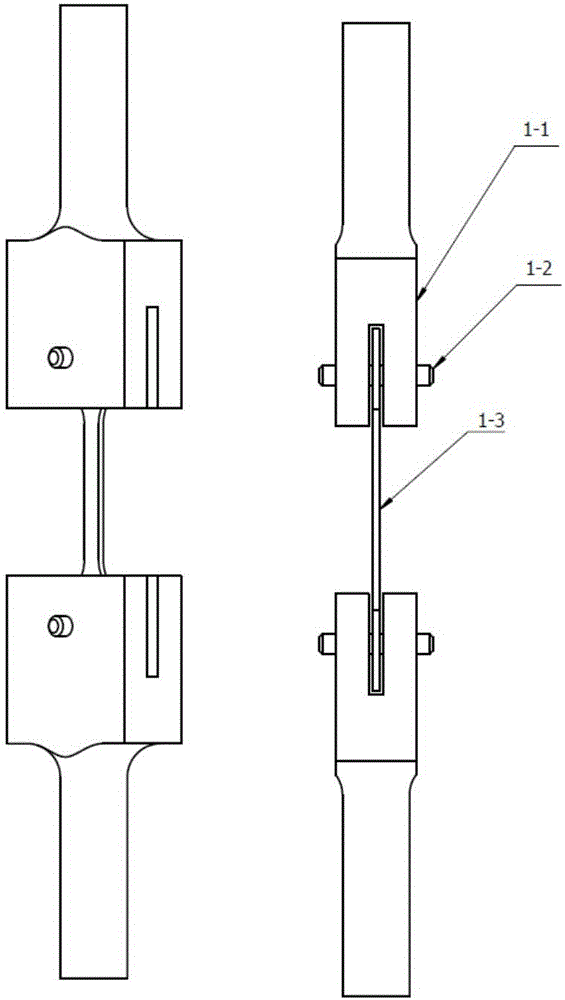

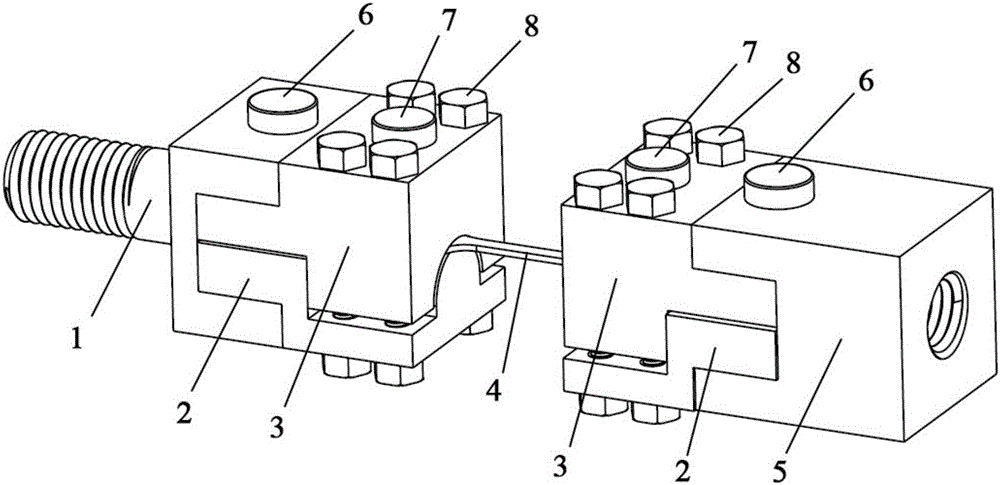

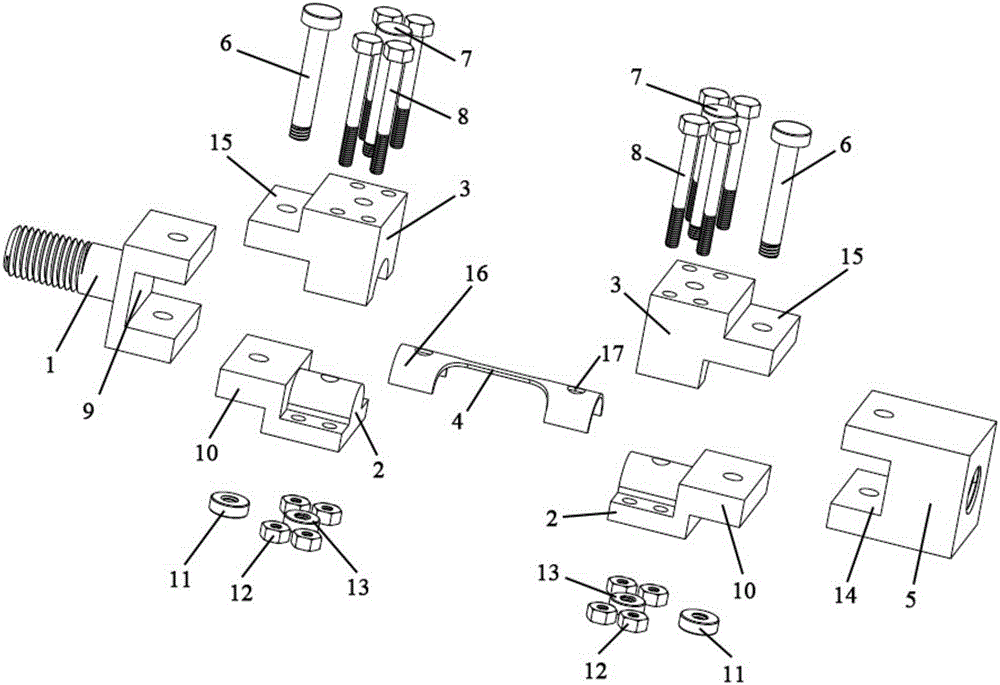

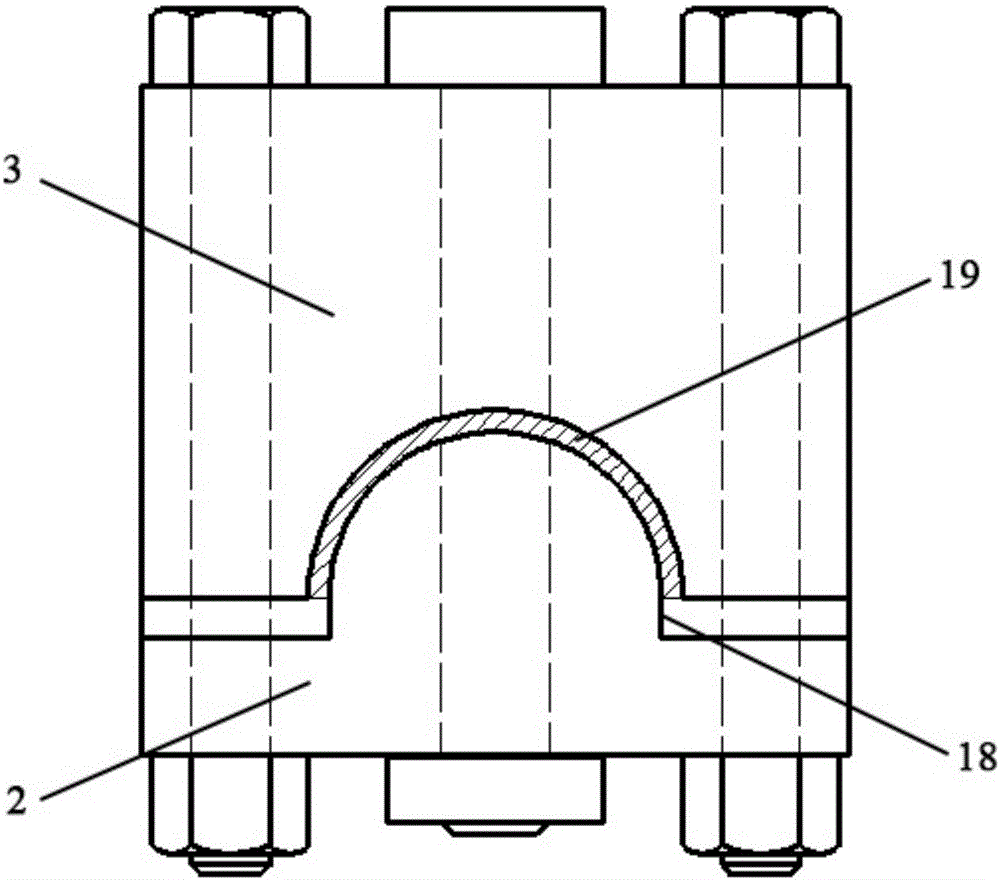

Test clamp suitable for high-temperature lasting creep deformation of plate-like test sample

ActiveCN106769423AReduce chance of trial failureAvoid inaccurate dataStrength propertiesTensile fatigueEngineering

The invention belongs to the technical field of mechanical performance test, and relates to a test clamp suitable for high-temperature lasting creep deformation of a plate-like test sample. The clamp comprises two portions, namely, a clamp main body and a cushion block assembly, wherein the clamp main body is a cuboid shaped like the Chinese character Hui, a cavity is formed in the clamp main body, the cushion block assembly is divided into two elements, and longitudinal axes of the clamp main body, the cushion block assembly and the plate-like test sample stay on a same straight line; and the plate-like test sample is installed and clamped, a parallel section of the plate-like test sample is arranged between the two elements and fixed together by virtue of bolts, and then the test sample is integrally placed into the cavity of the clamp main body. The test sample and the clamp are connected in a clamping end suspension manner, so that the defect that a clamped end of the test sample is broken due to the pin connection can be overcome, the test failure probability is reduced, and the problems such as data inaccuracy, resource waste and the like can be avoided. The structure of the test sample is not only suitable for the high-temperature lasting and creep deformation of the plate-like test sample, but also suitable for testing mechanical performances of the plate-like test sample such as single-shaft tensile at a room temperature and high temperature, tensile fatigue and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

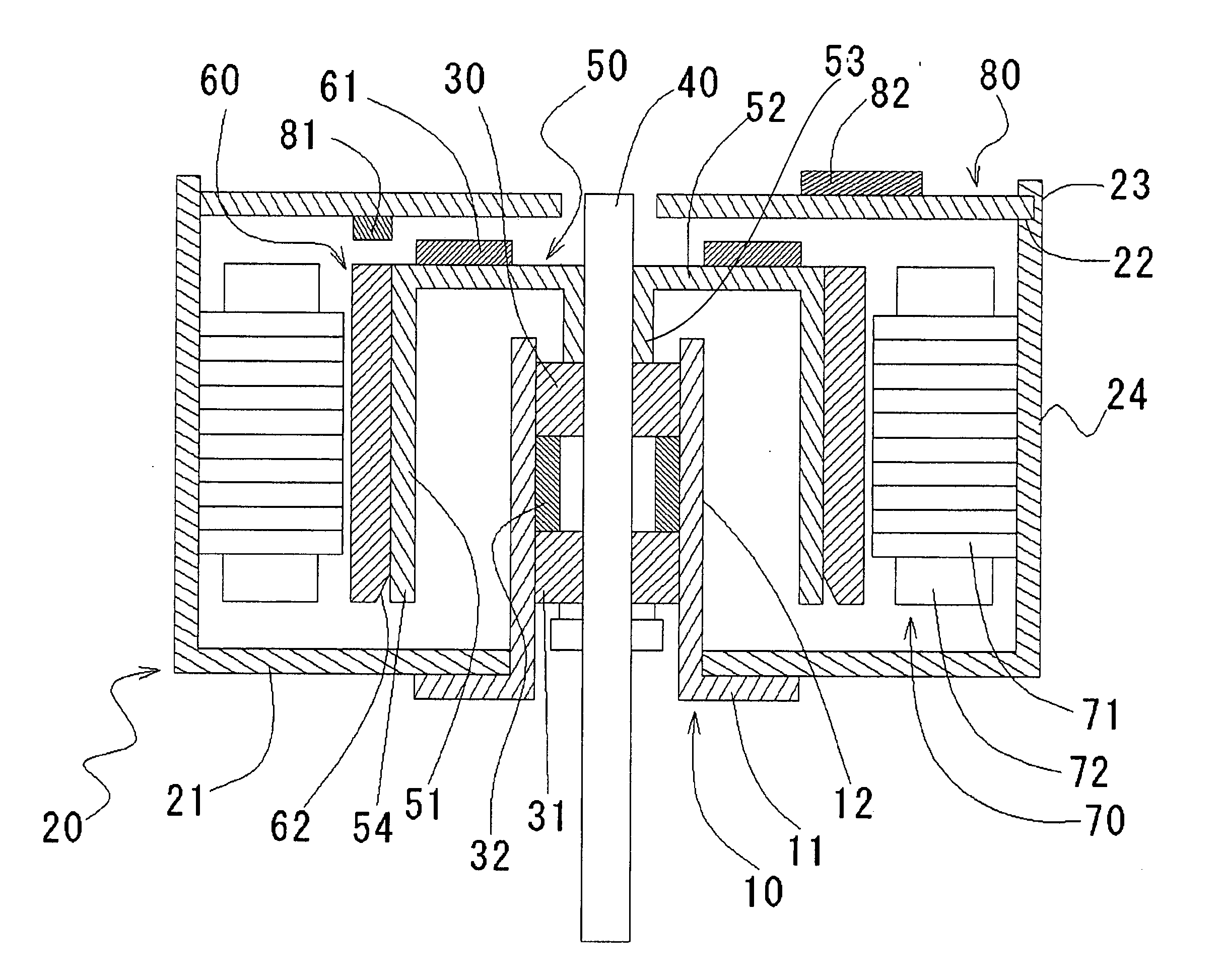

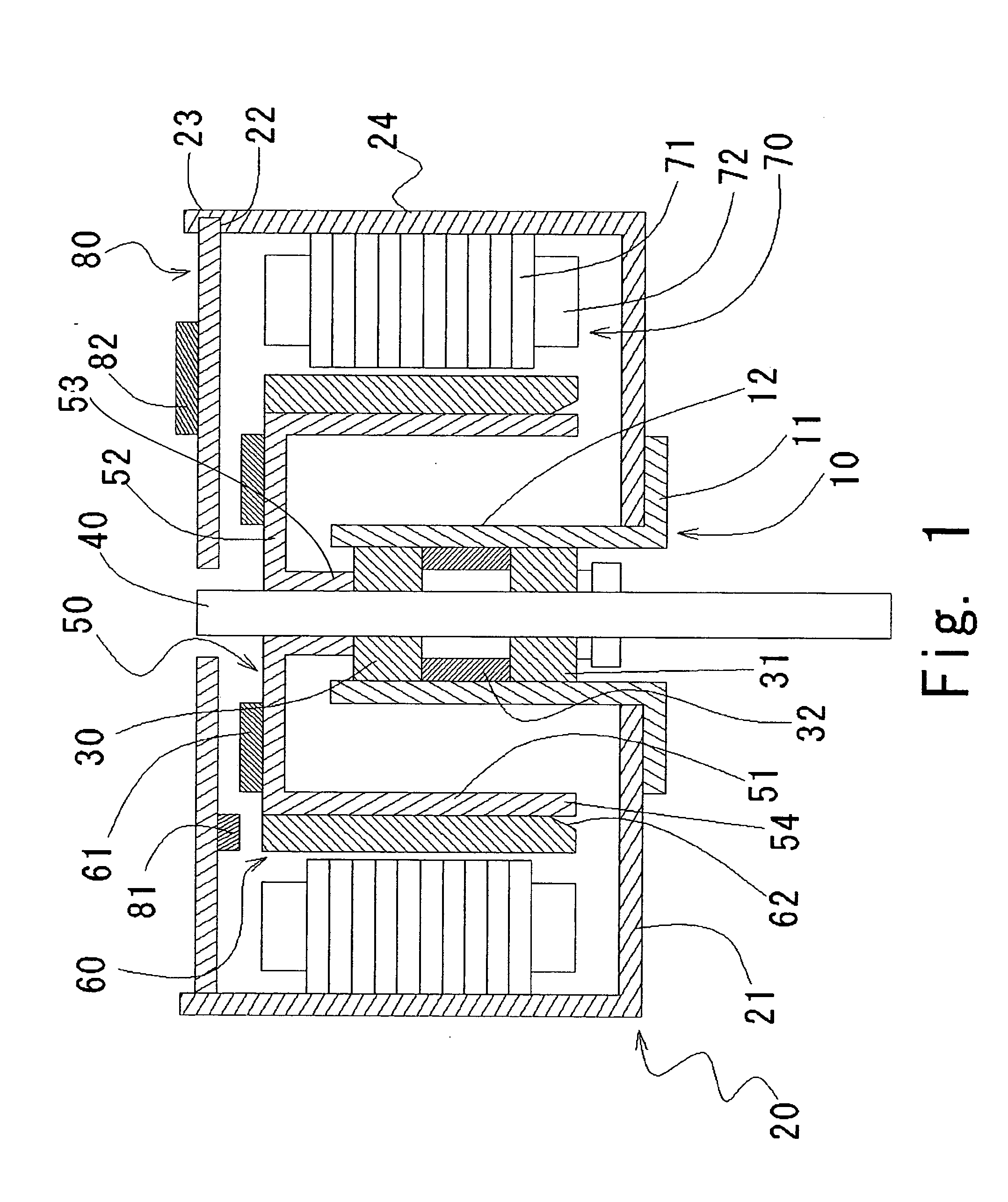

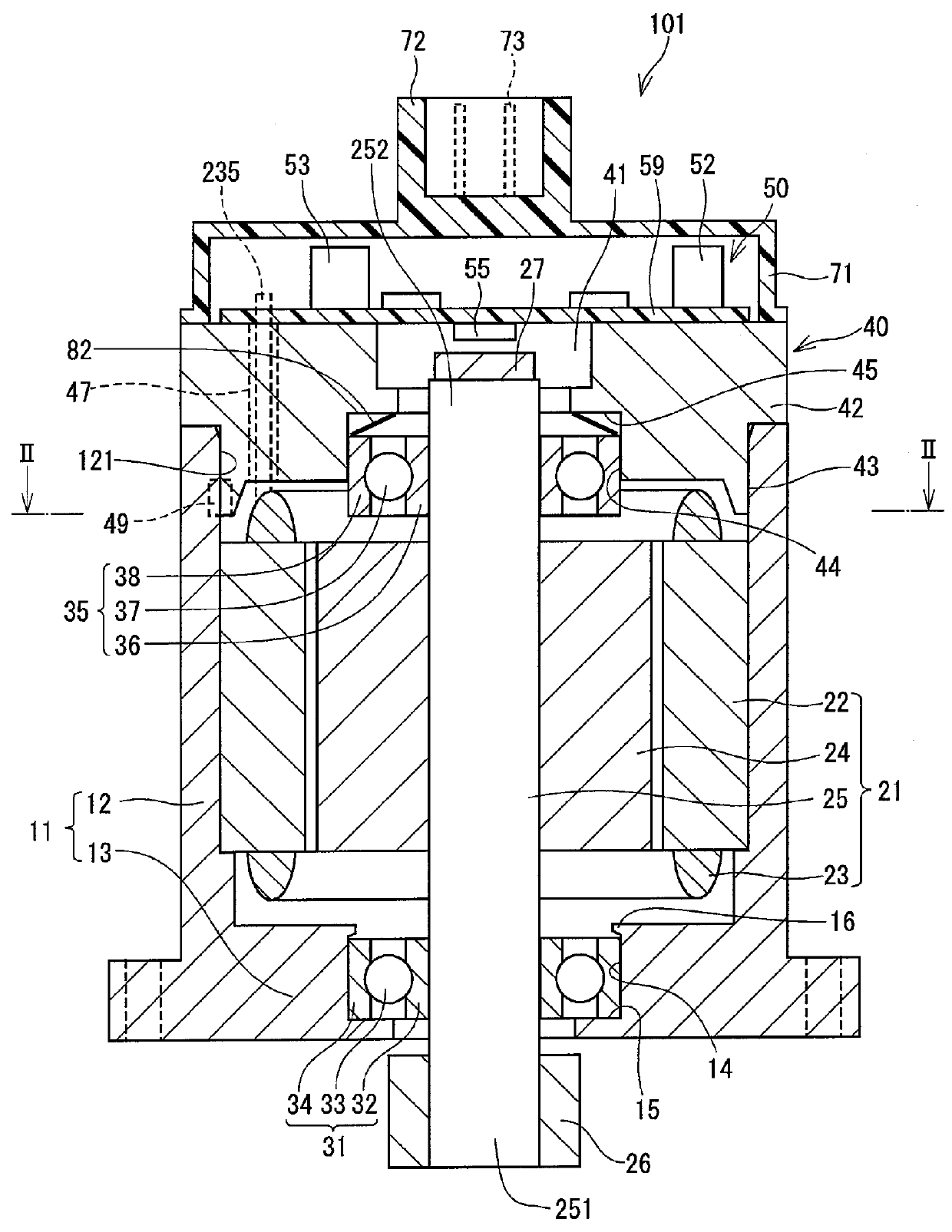

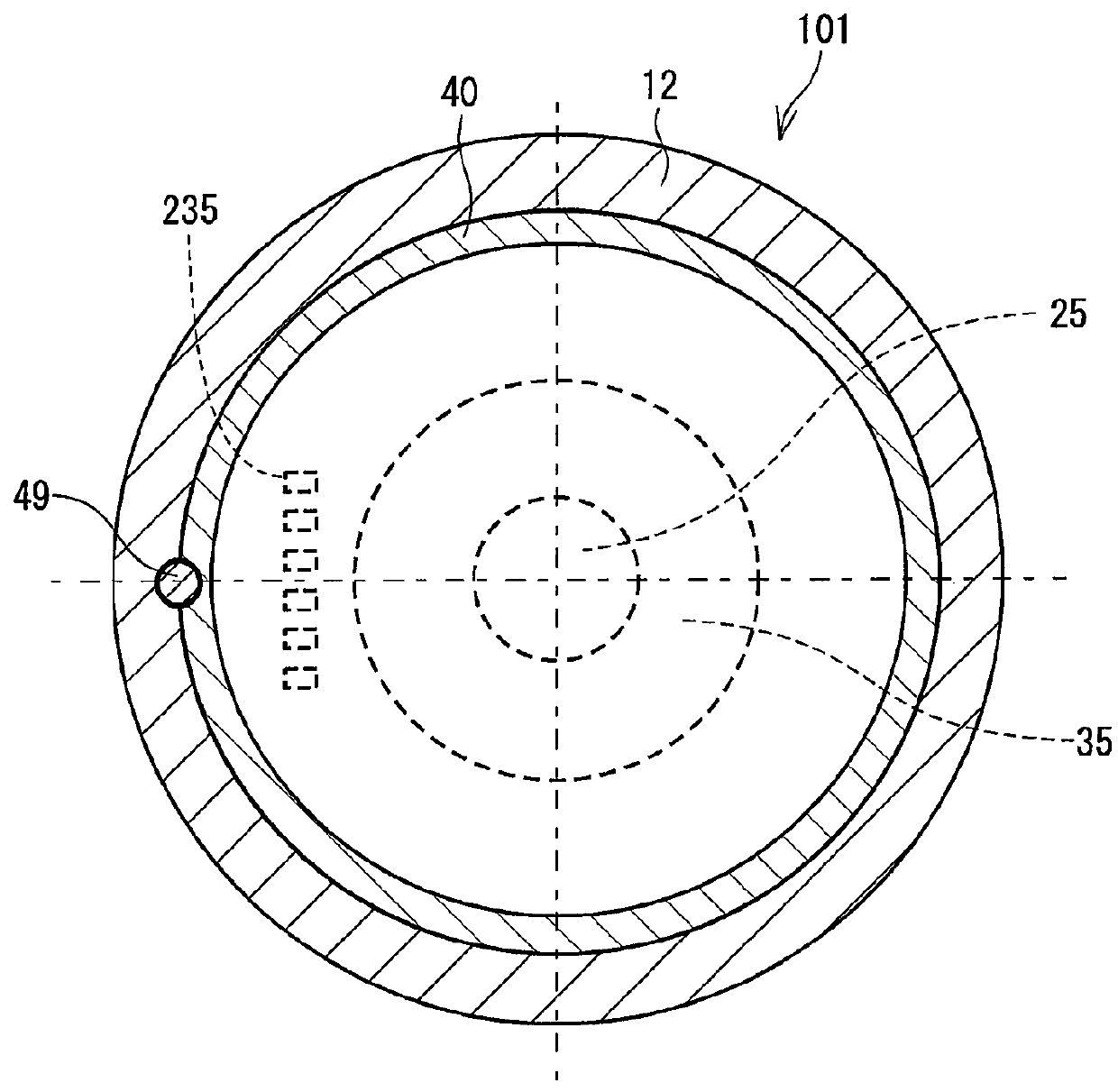

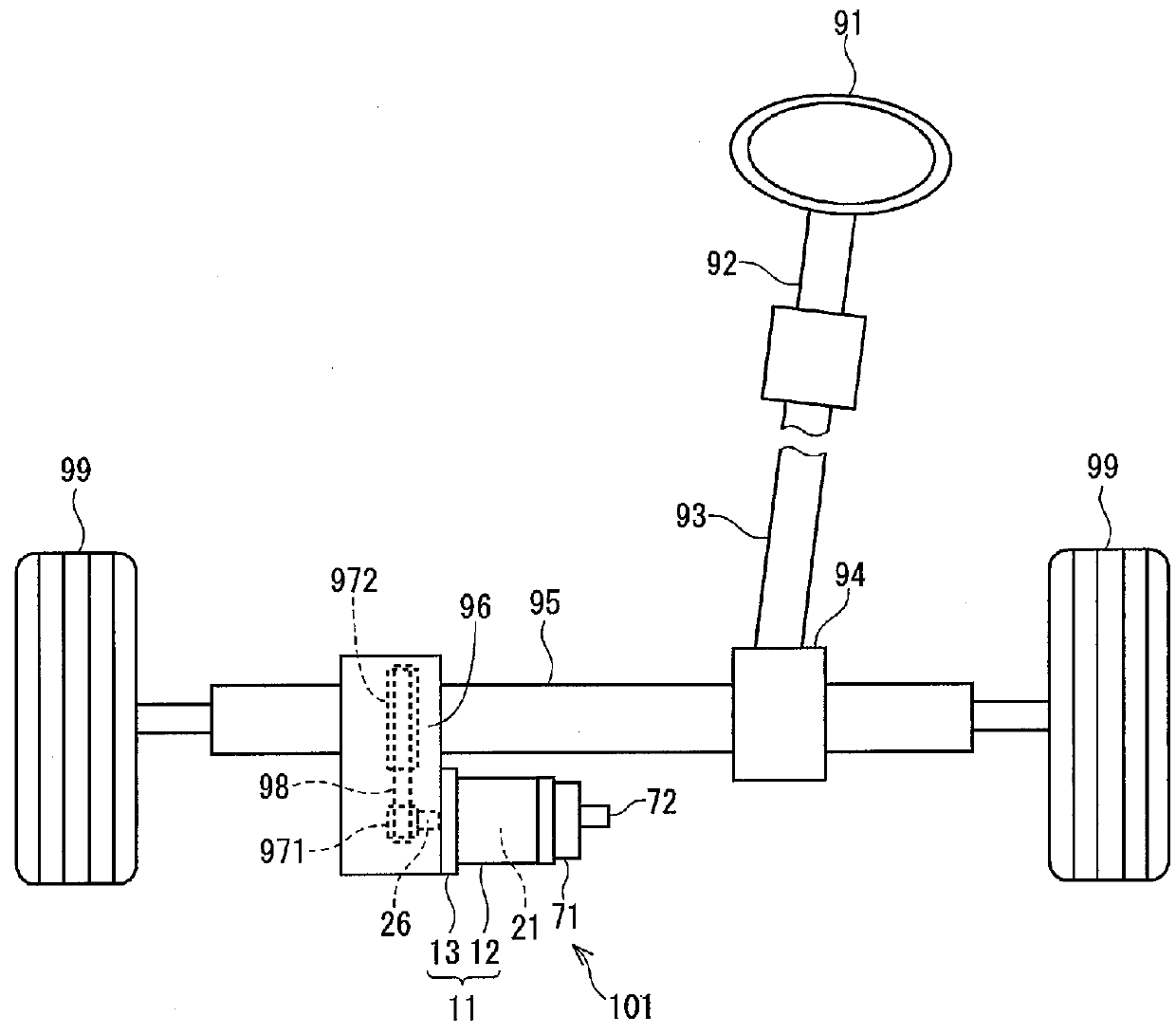

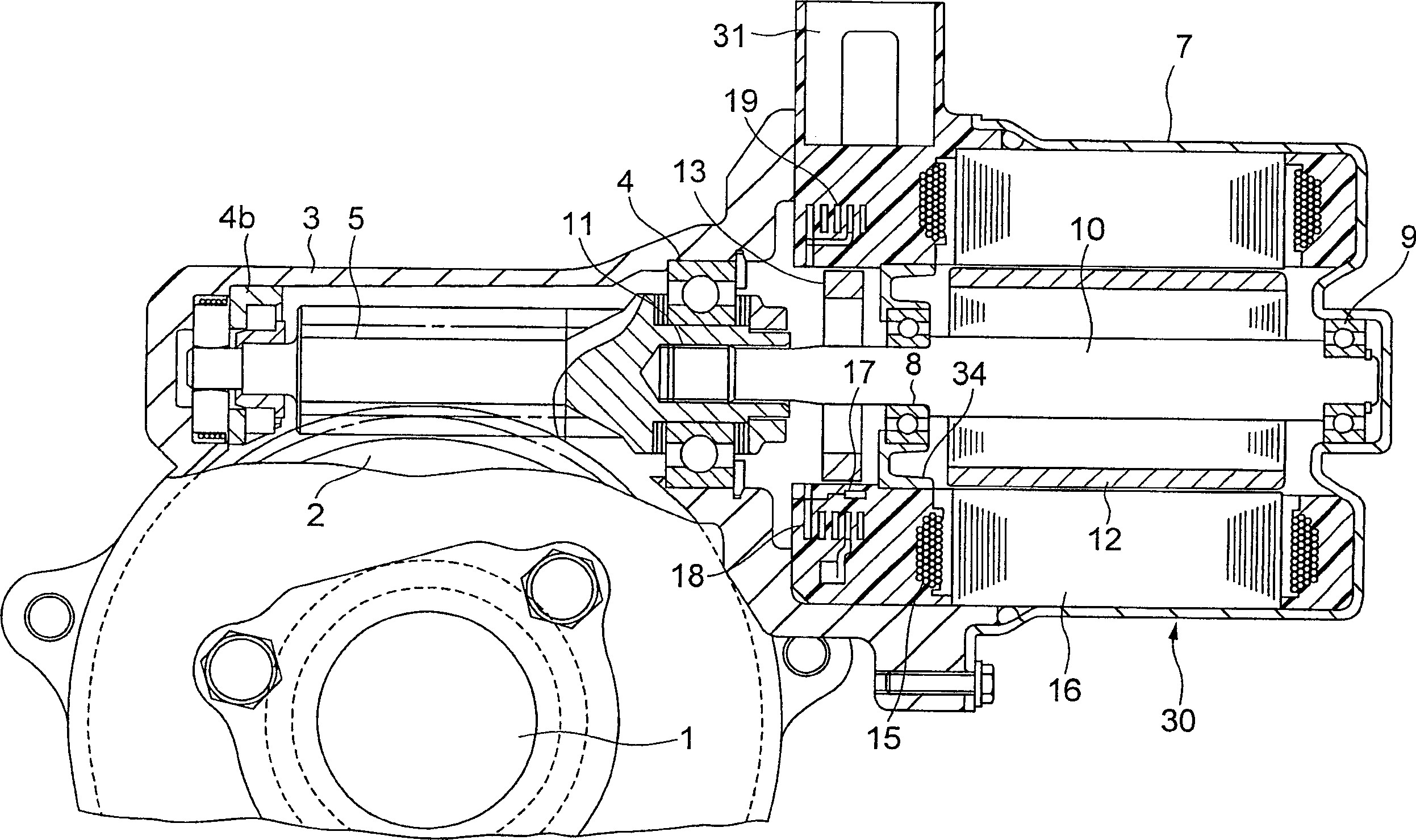

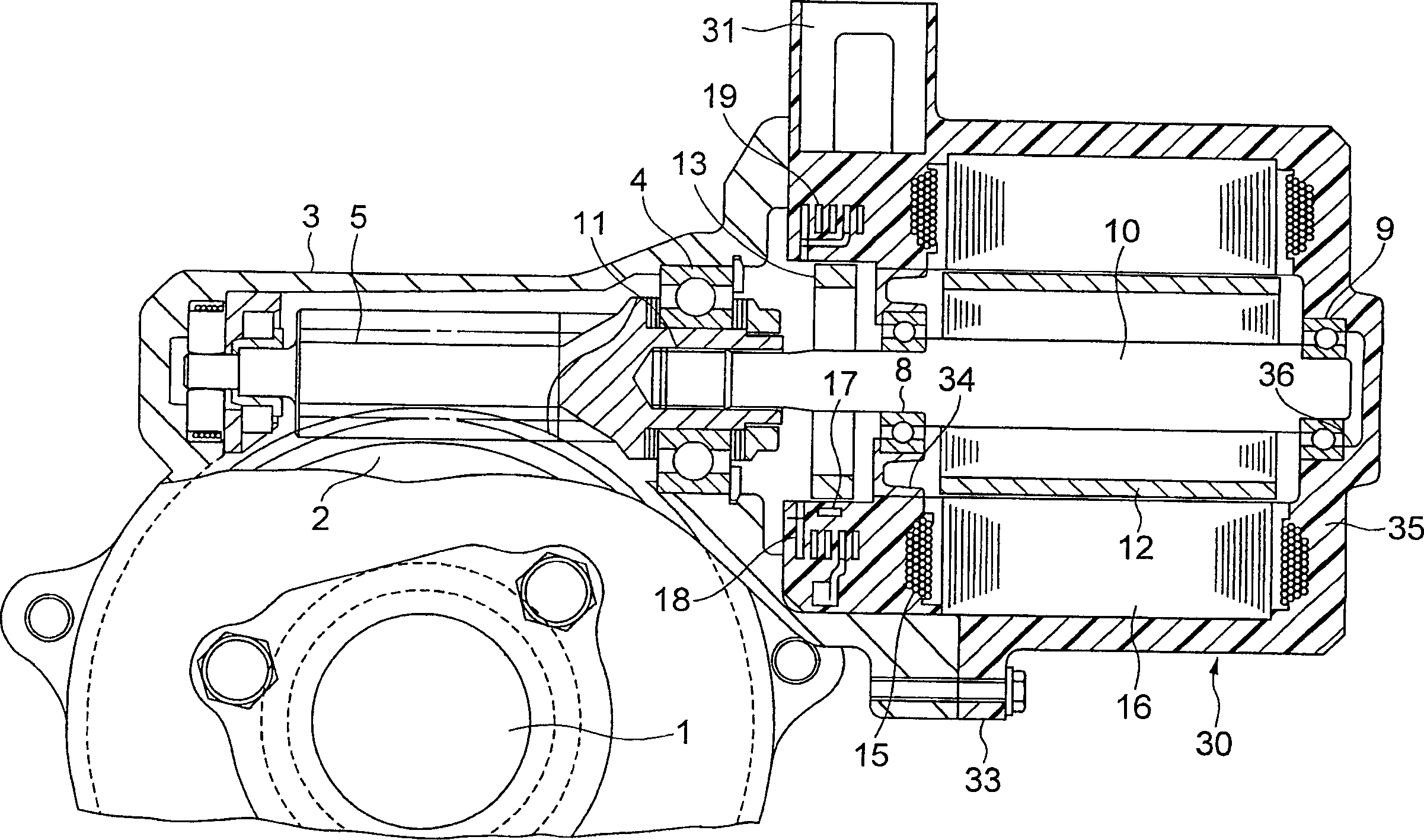

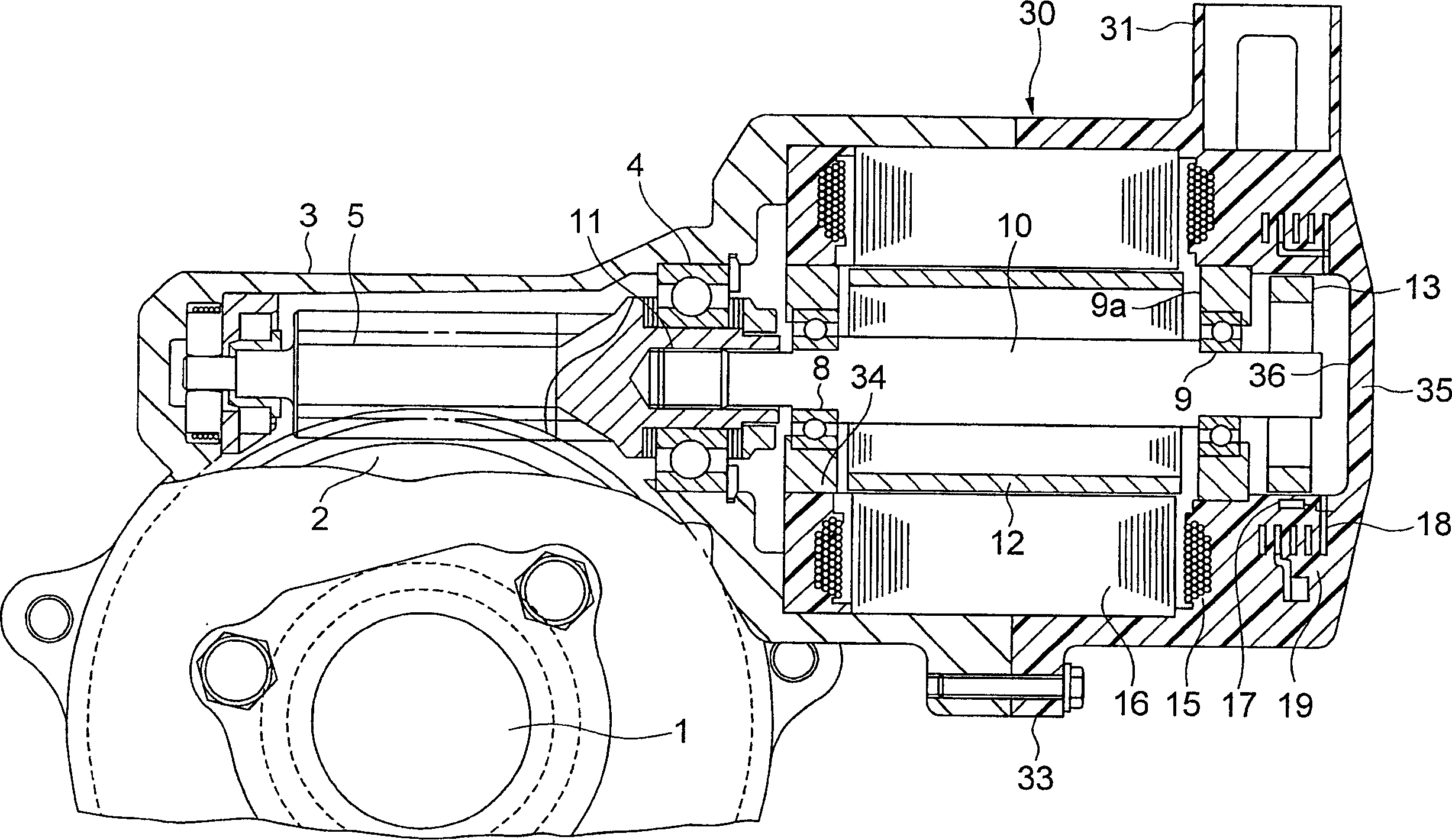

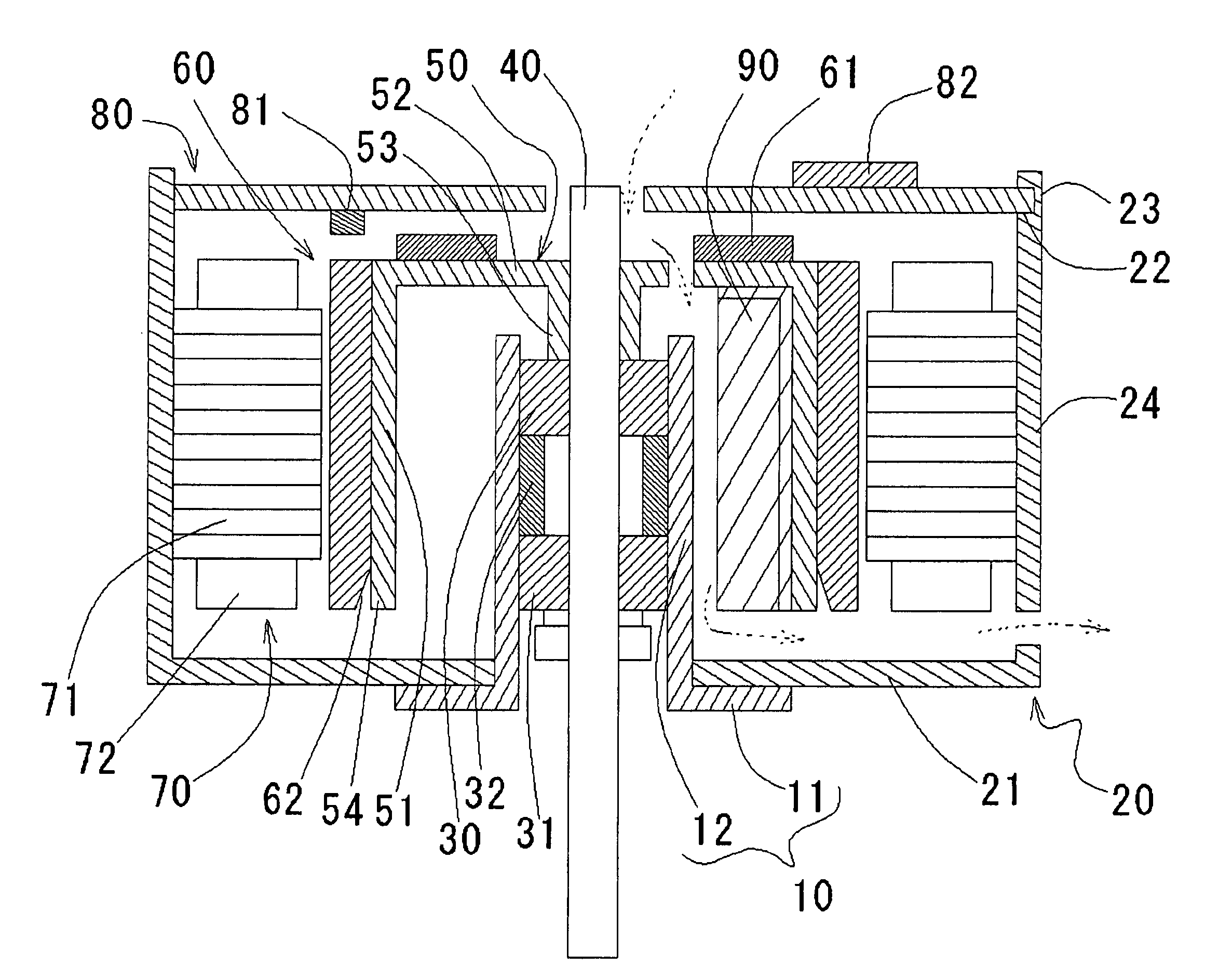

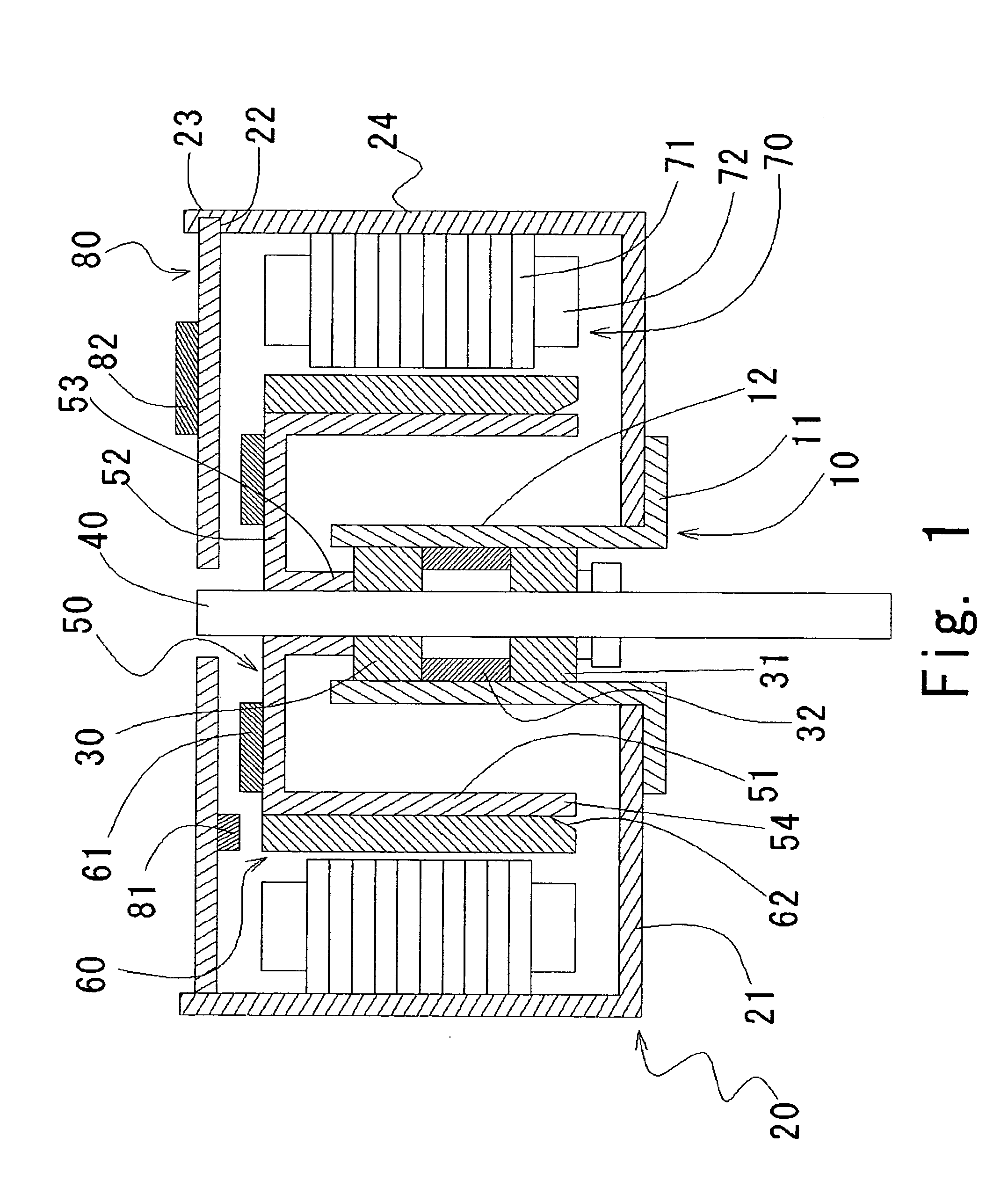

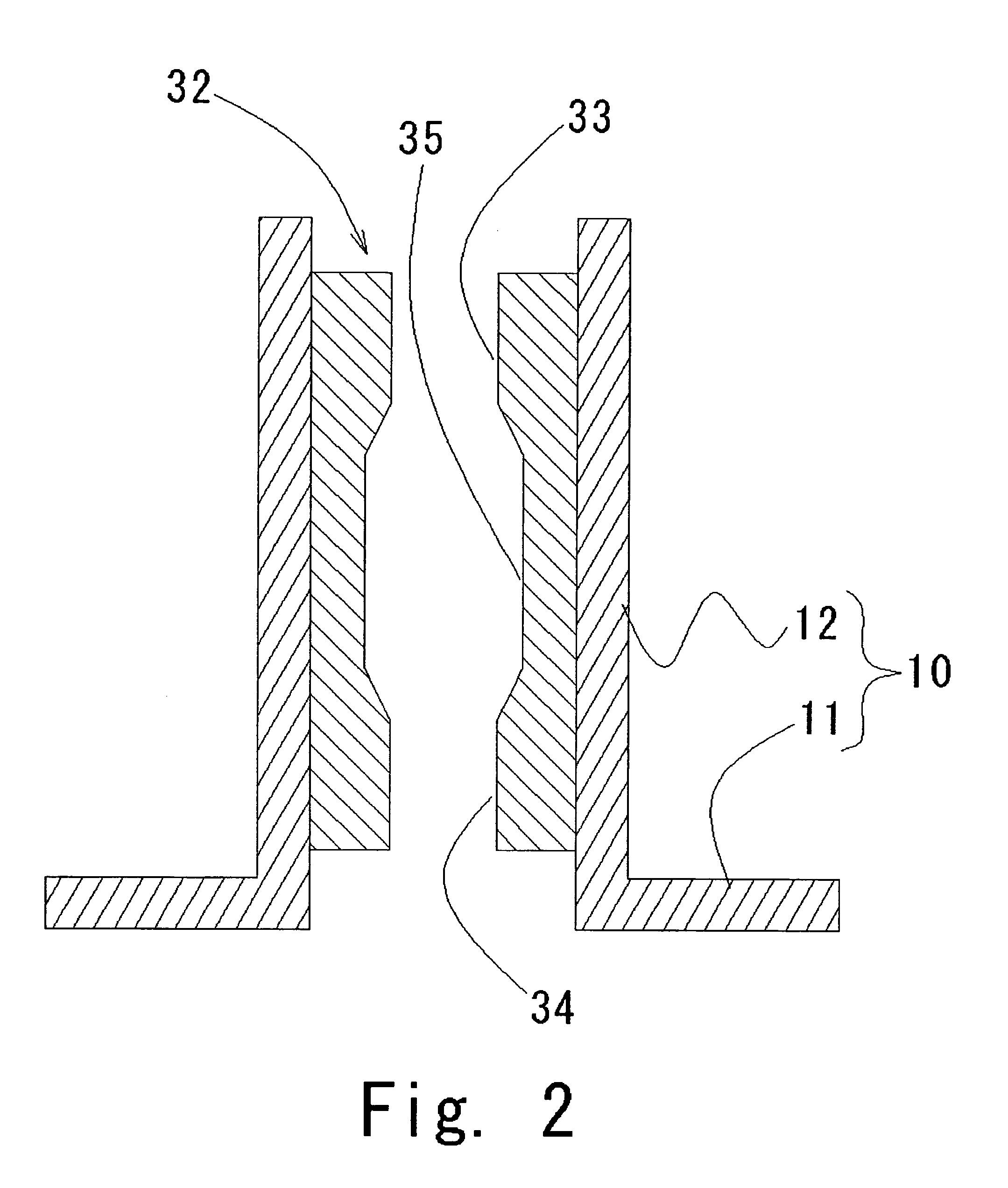

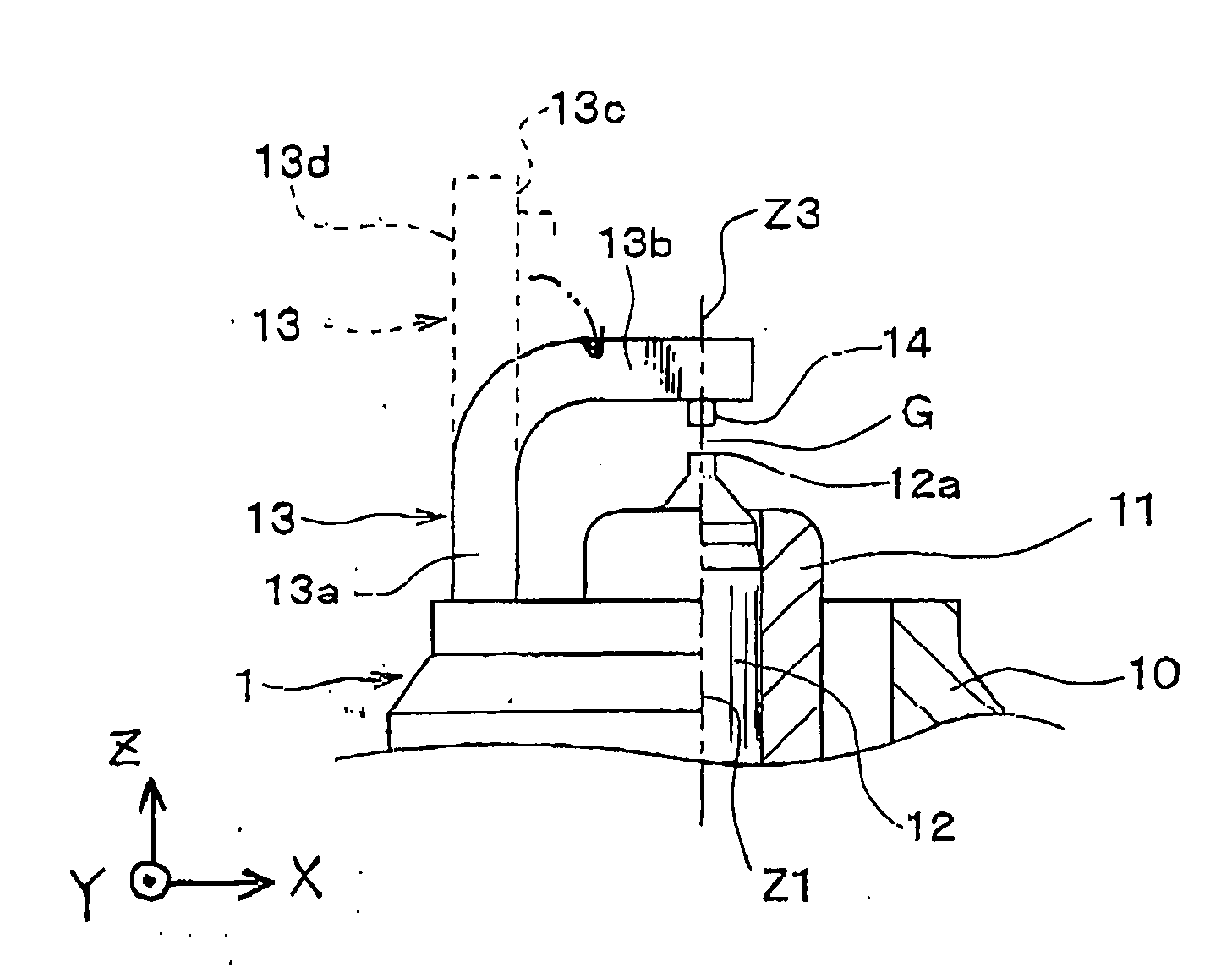

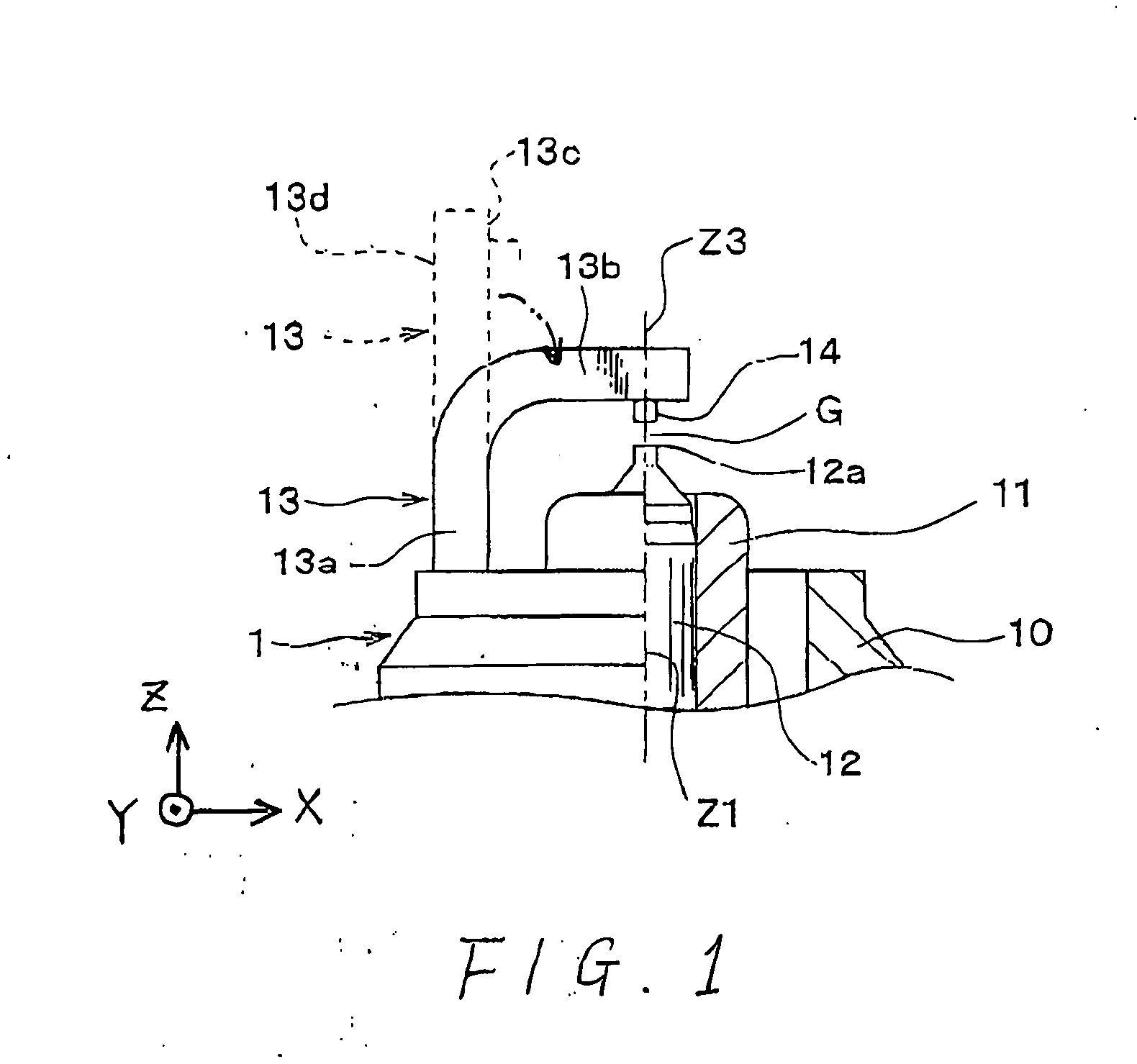

Electric power steering device

InactiveCN1736014AShorten the lengthHigh sensitivityElectrical steeringMechanical energy handlingElectric power steeringBrushless motors

In an electric power steering apparatus that generates an auxiliary steering torque by a brushless motor in response to a steering torque applied on a steering wheel and transmits it to an output shaft of a steering mechanism while reducing it by means of a reduction gear, the apparatus comprises a rotor ( 10 ) to which a cylindrical permanent magnet for rotational driving ( 12 ) and a member to be detected ( 13 ) for detection of a rotational angle of the rotor are attached and a cylindrical stator ( 30 ) opposed to the rotor in which a laminated core ( 16 ) on which a coil is wound, detection means ( 17 ) for detecting the rotational angle of the rotor by the member to be detected and a terminal ( 19 ) for providing connection to the coil are integrally formed by resin molding. At least one bearing ( 8, 9 ) for rotatably supporting the rotor is disposed radially inside the stator and between the permanent magnet for rotational driving and the member to be detected.

Owner:NSK LTD +1

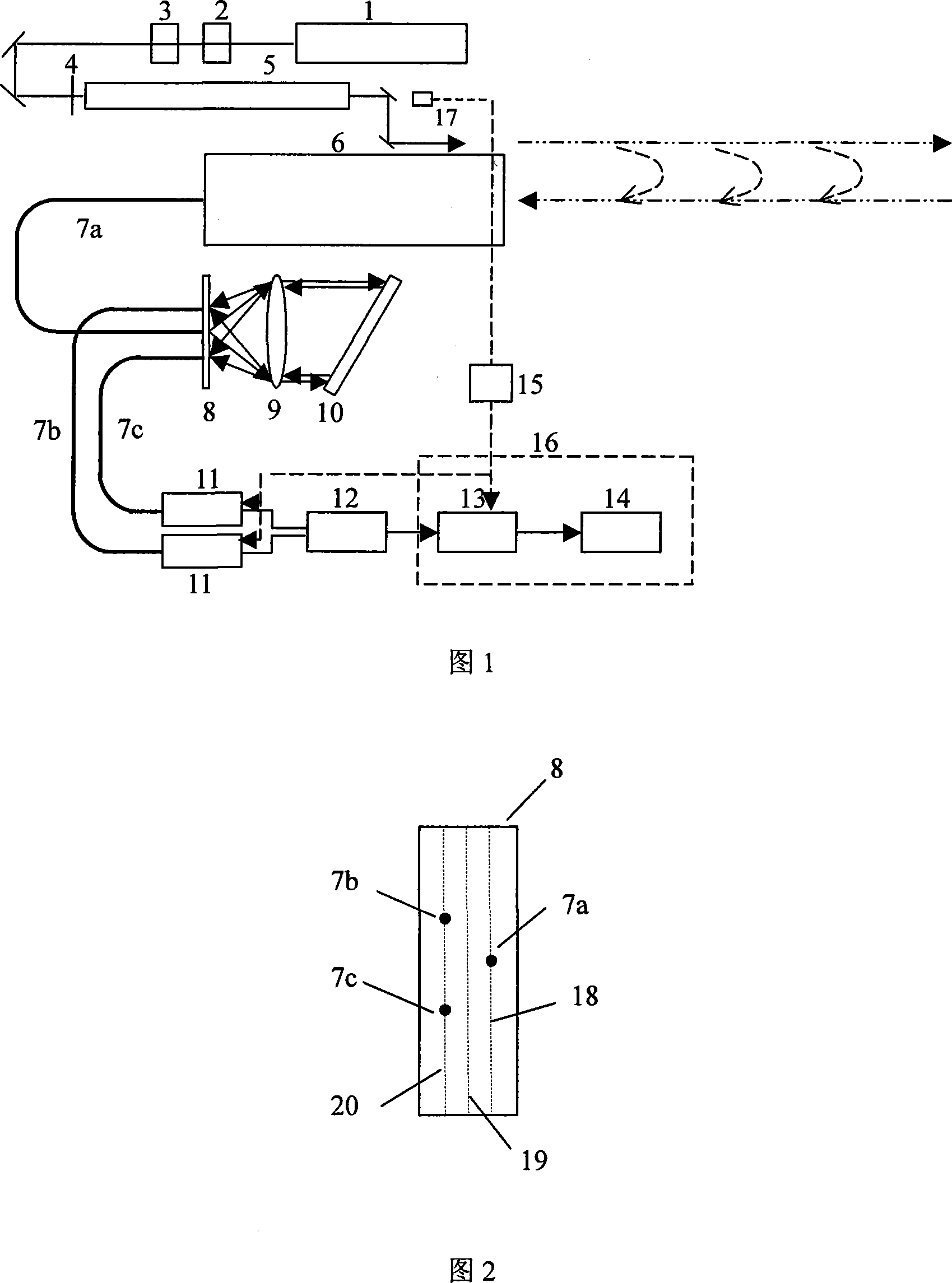

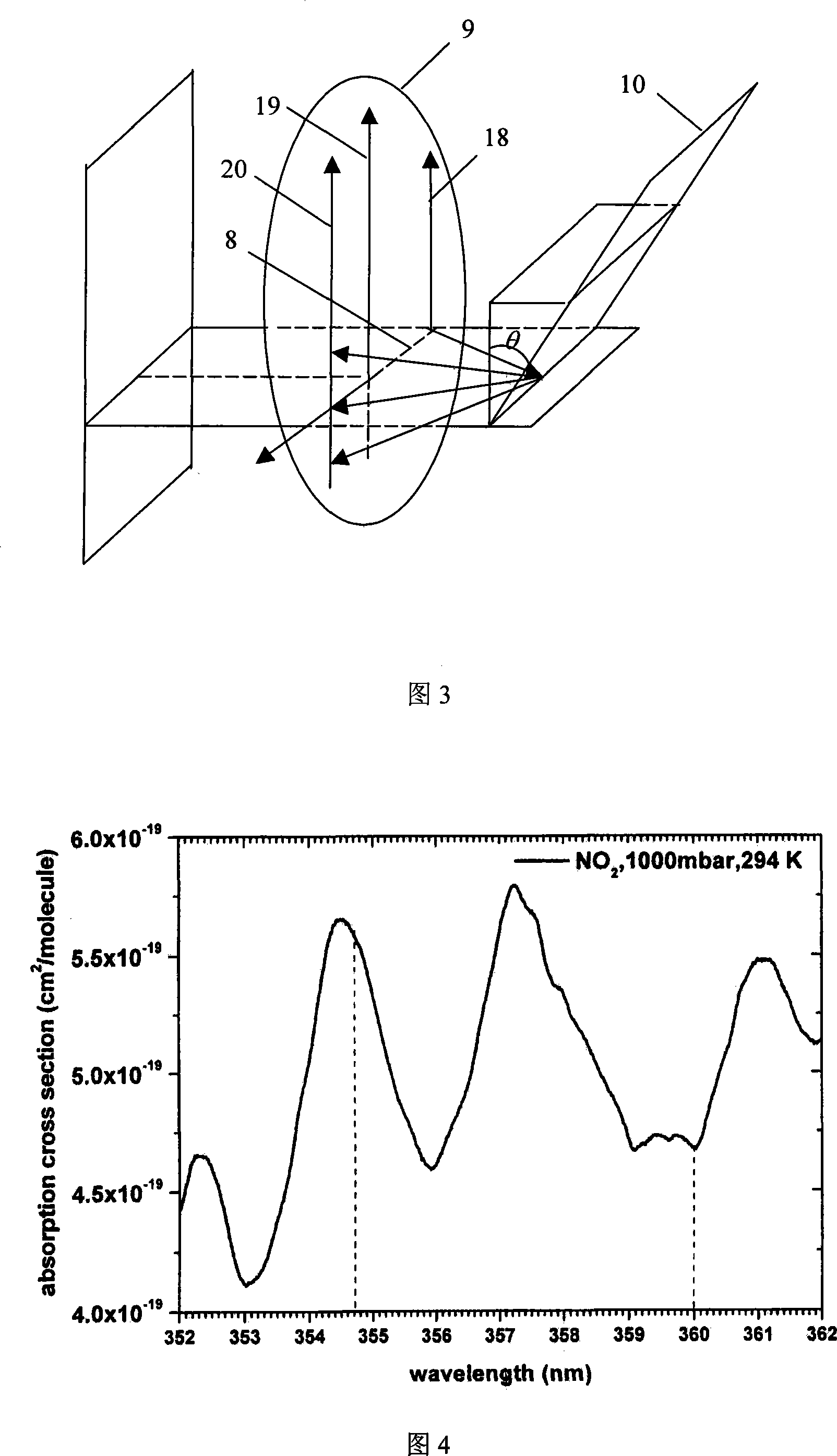

Laser radar for determining atmosphere NO2 concentration based on raman light source differential absorption method

InactiveCN101101261AHigh wavelength resolutionImprove signal-to-noise ratioRaman scatteringColor/spectral properties measurementsFiberData acquisition

The invention discloses a laser radar is based upon lame light source difference absorption process to test thickness of NO2 in the atmosphere, it includes lame light source, light incept and spectrum components, photo-detection and control transaction components, the characteristic is that the light incept and spectrum components accepts the scattered light from atmosphere backward by telescope tube of incept light, after coupling of light fiber, making the light to lay in the focal plane of lens, ripping into the raster by collimation lens, after section out the wave length of light 354.71nm and 360.00nm,recepted by the two emergent light fiber on the focal plane of lens. The raster is blazed grating, it has definite included angle with lens; the photo-detection and control transaction part includes microcomputer, data acquisition card, chronotron, enlarge shaping circuit, photomultiplier and photo-electricity probe. The invention has the beneficial purpose of easy structure, low cost, high diffraction efficiency, good flexibility, convenient using and vindicate etc.

Owner:CHINA JILIANG UNIV

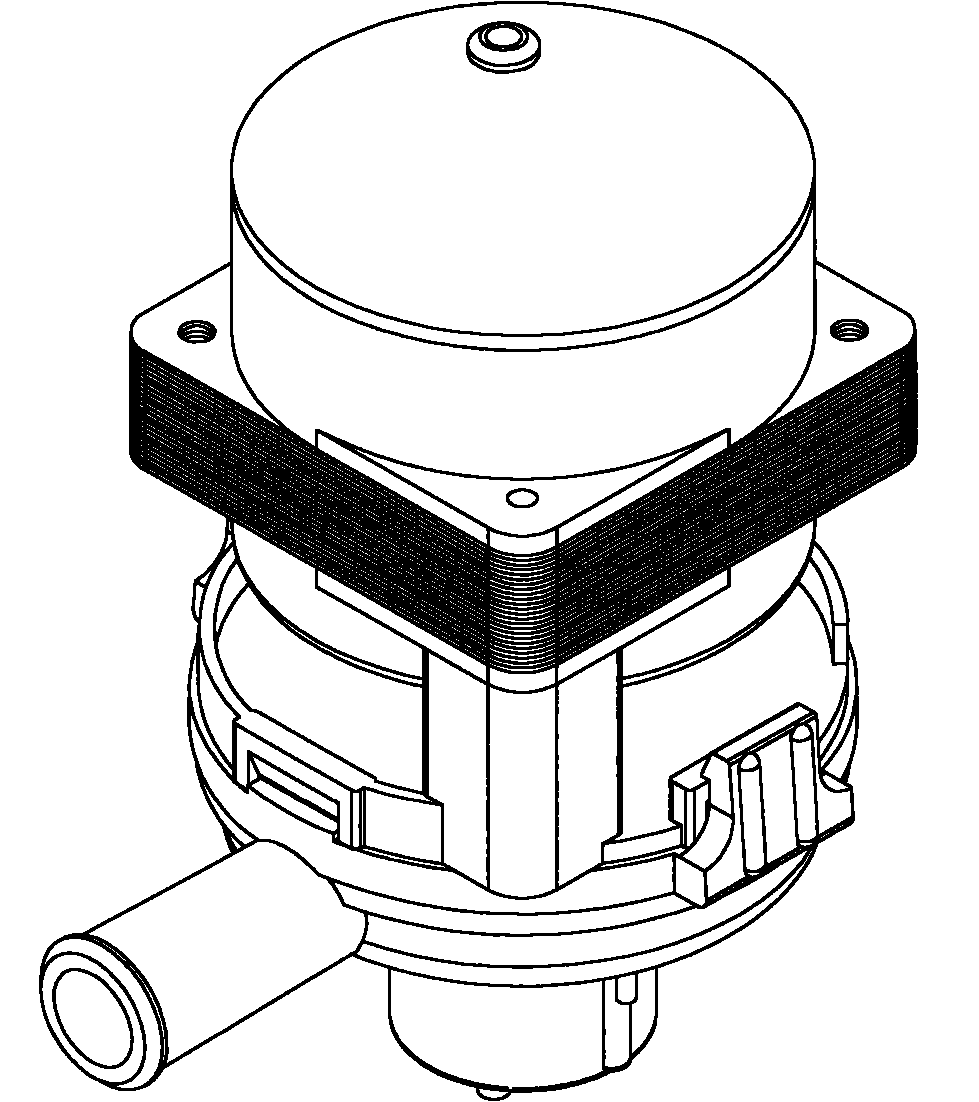

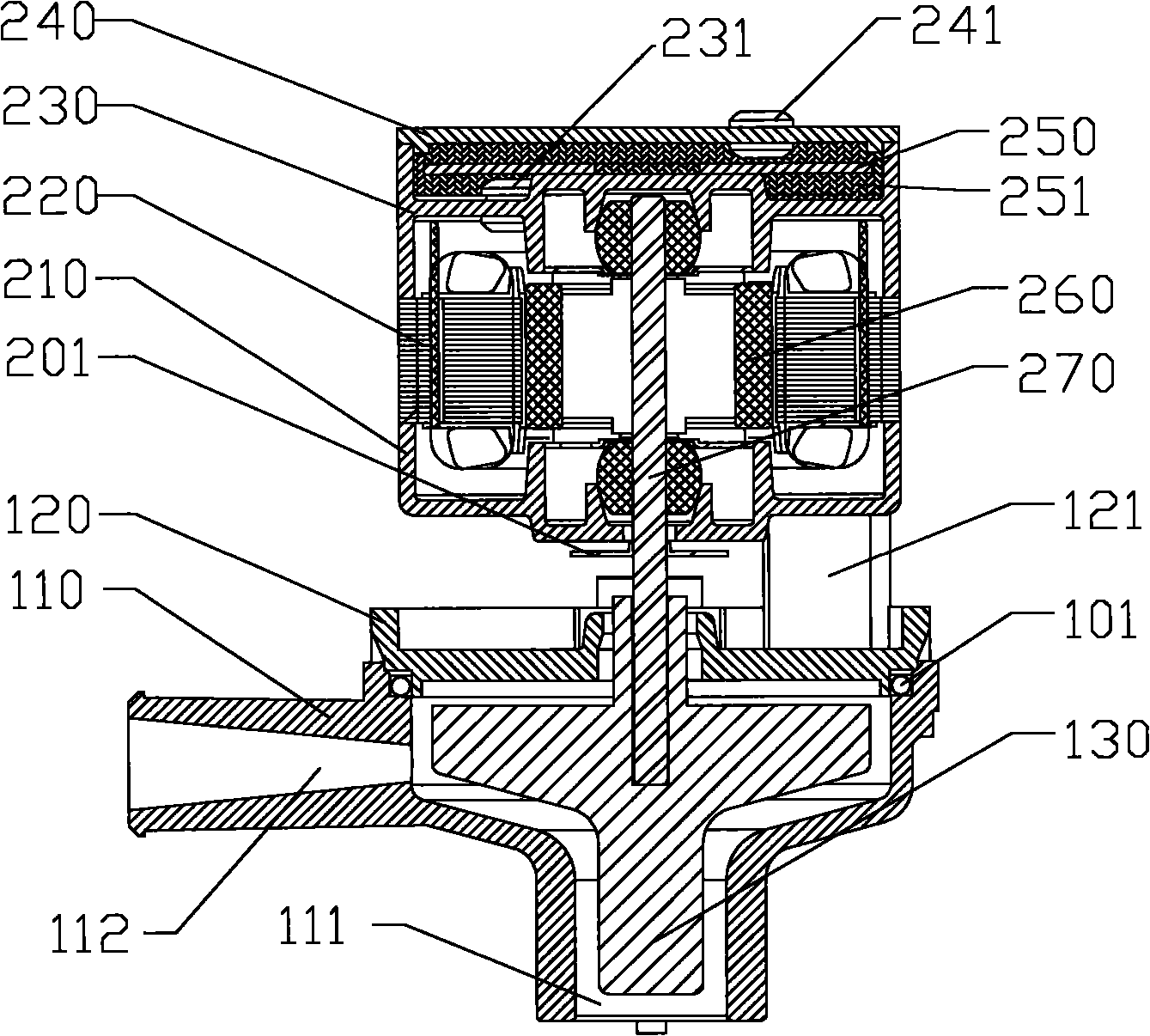

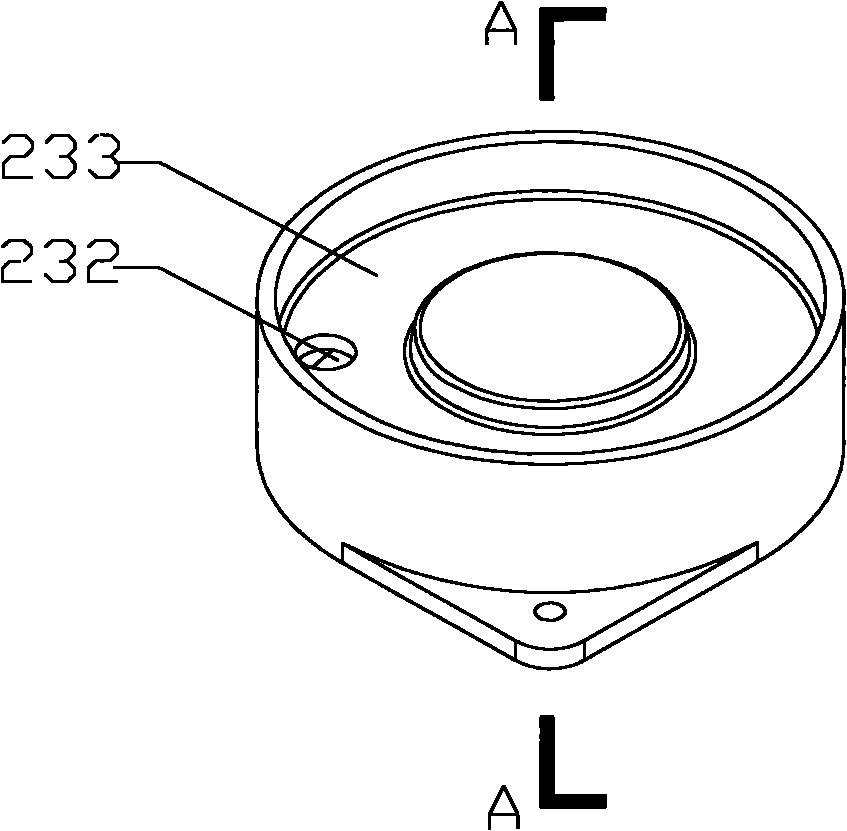

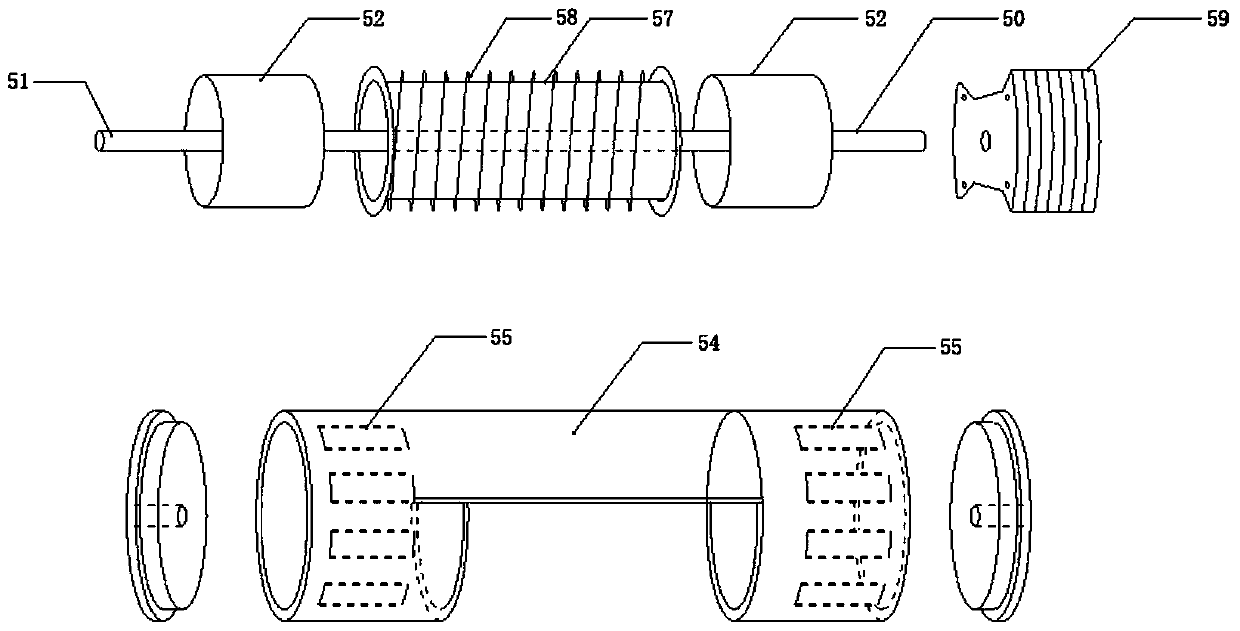

Brushless direct current motor for pump and manufacturing method thereof as well as pump equipped with same

ActiveCN102158034AImprove reliabilitySimple structureManufacturing dynamo-electric machinesPump installationsMotor controlControl circuit

The invention discloses a pump driven by a brushless direct current motor, a pump equipped with the brushless direct current motor as well as a manufacturing method of the brushless direct current motor for driving the pump. The brushless direct current motor of the pump comprises a motor shell and a motor shaft, wherein the motor shell comprises a lower end cover and an upper end cover, a statorpart is fixed between the lower end cover and the upper end cover, the motor shaft passes through the lower end cover and extends downwards, surrounding edges extending upwards are arranged at the periphery of the upper end cover, a circuit board chamber is arranged at the upper side of the upper end cover and is internally provided with a control circuit board and an encapsulating body made of encapsulating material, an internal lead of the control circuit board is connected with a connecting wire of the motor after passing through an internal lead hole on the upper end cover, and an external lead of the control circuit board passes through the encapsulating body and extends outwards. The control circuit board is sealed in the circuit board chamber in the way of encapsulating, and the encapsulating body can protect the control circuit board, ensure the reliability of motor control and operation, simplify the structure of the motor and facilitate the assembly of the motor.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

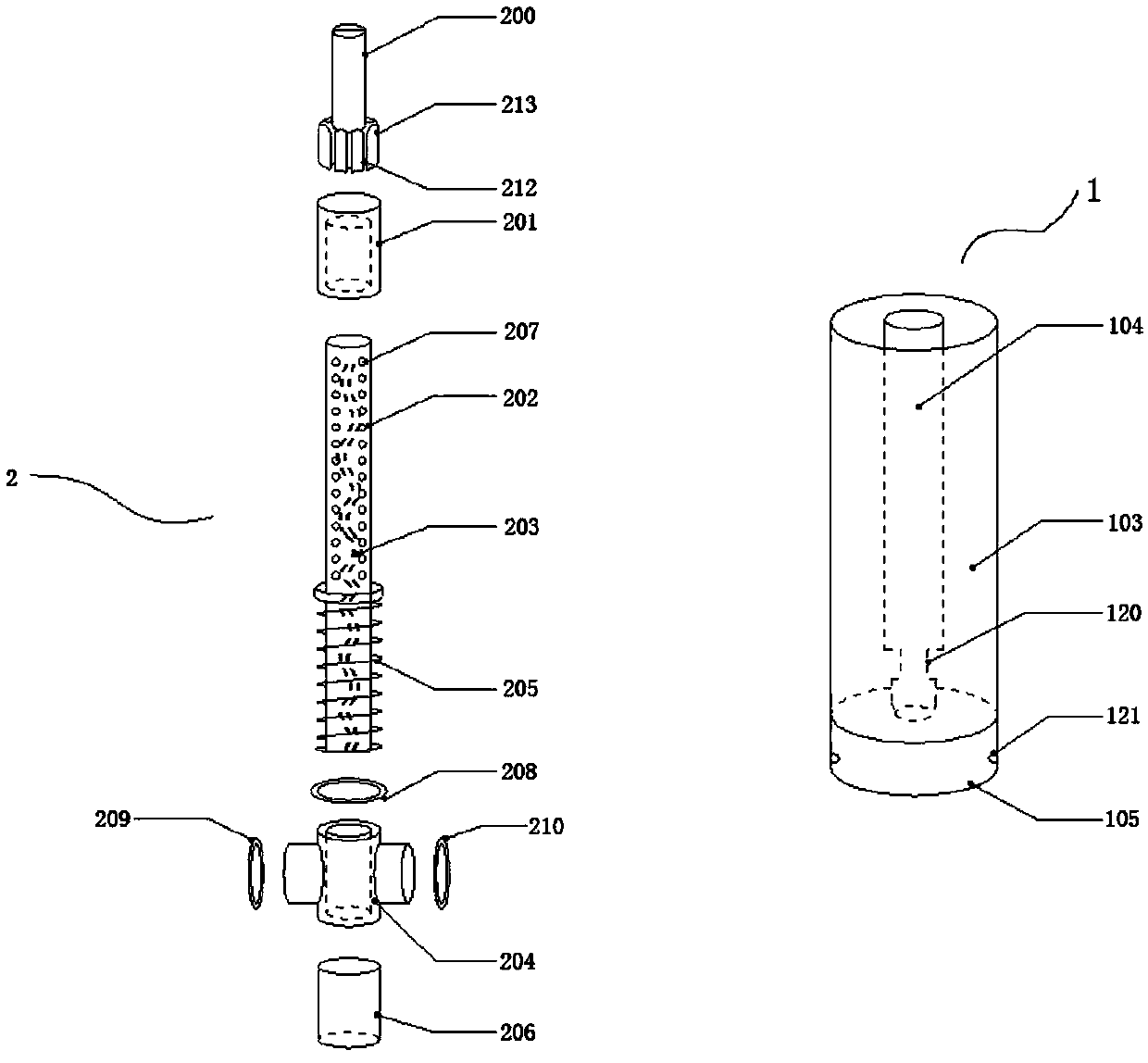

A type of oil storage atomizer with vibration

The invention discloses an accompanying vibration type oil storage atomize which comprises the following components: an oil storage element (1) and a porous vibration element (2), wherein the oil storage element (1) comprises a central passage (104) and an oil tank (103) surrounding the central passage; a base (105) is arranged at the bottom of the oil storage element (1); two inwards-raised oil inlets (120) are formed in the sidewall of the central passage (104); air inlets (121) are formed in the base (105), and are communicated with the central passage (104) through an airflow; the porous vibration element (2) is positioned in the central passage (104), and comprises a vibration cavity (202) and an oil guide element (203) positioned in the vibration cavity (202); a plurality of micropores (207) are formed in the sidewall of the vibration cavity (202); an upper end cover (201) is arranged at the upper part of the vibration cavity (202), and a lower end cover (204) and a vibration source connecting end (206) connected with the lower end cover (204) are arranged at the lower part; the vibration cavity (202) is sleeved with a spring (205).

Owner:CHINA TOBACCO YUNNAN IND

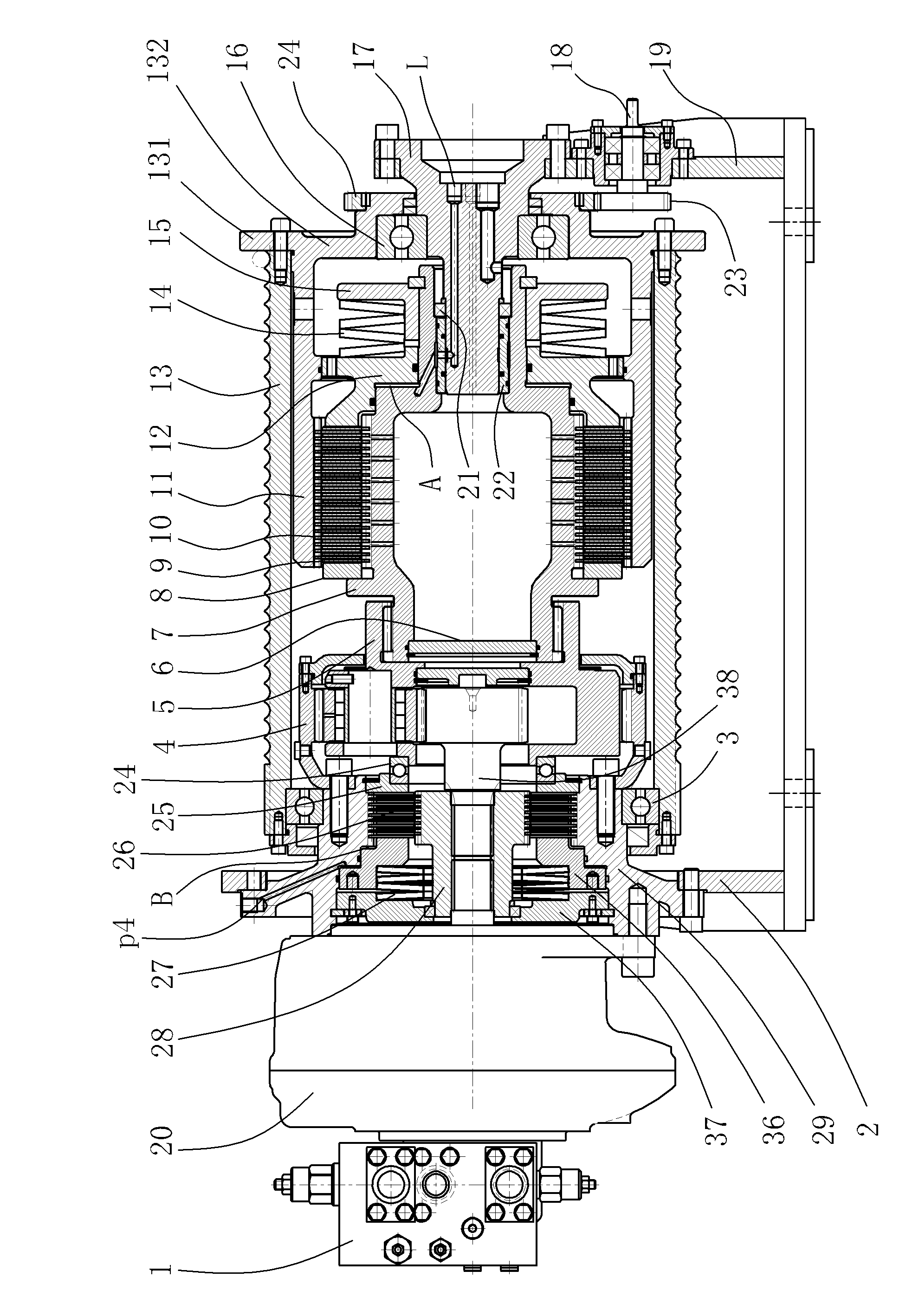

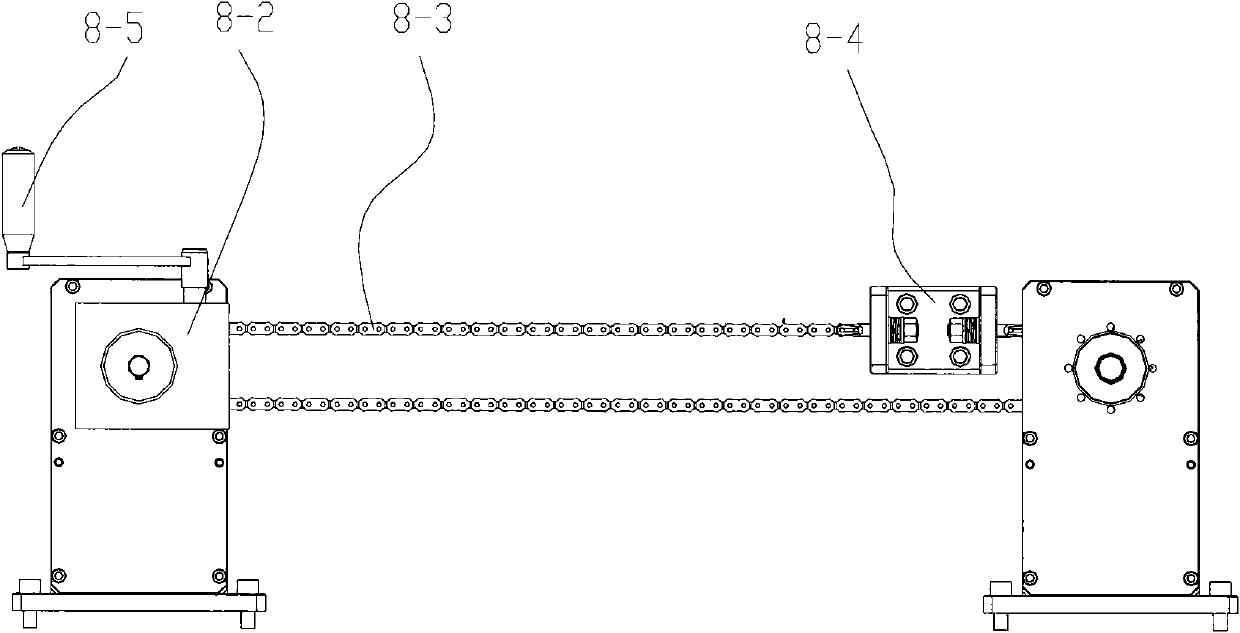

Hydraulic winch

ActiveCN102718161AImprove coaxialityImprove parallelismWinding mechanismsHydraulic motorReduction drive

The invention relates to a hydraulic winch, comprising a machine frame, a winding barrel, a hydraulic motor, and a hydraulic brake, a planet gear speed reducer and a hydraulic clutch which are arranged in the winding barrel. The hydraulic clutch comprises an outer barrel, a clutch friction plate and a clutch oil cylinder. A bearing shaft is fixed on the machine frame. The outer barrel and a piston of the clutch oil cylinder are fixed on the bearing shaft through bearings respectively. The piston is in transmission connection with an output end of a planet carrier of the planet gear speed reducer. The outer barrel and the piston are fixed on the bearing shaft, so that the outer barrel, the piston and the bearing shaft have a relatively high coaxiality, and a dynamical friction plate and a static friction plate which are arranged on the outer barrel and the piston respectively have relatively high parallelism. The dynamical friction plate and the static friction plate can be well contacted with each other and completely separated from each other as well so that the hydraulic winch has more stable and reliable clutch performance, and the abrasion and the heat generation of the clutch friction plate are reduced. In the hydraulic winch, transmission efficiency and operational reliability can be improved, and service life can be prolonged. The hydraulic winch has a simplified integral structure and higher machining and assembling manufacturability.

Owner:INI HYDRAULIC

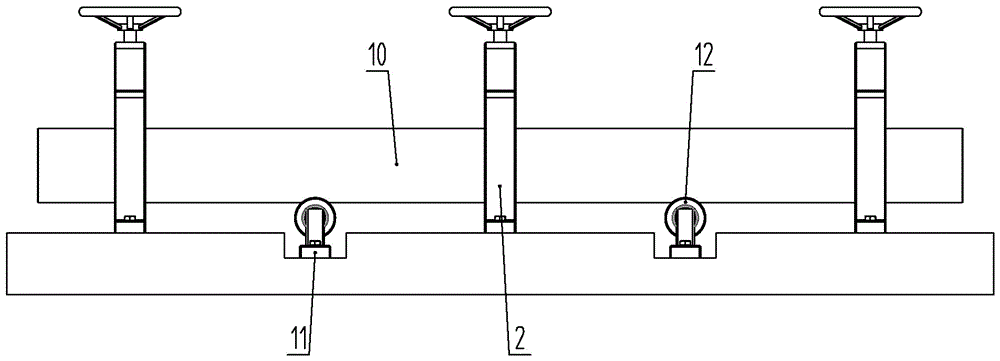

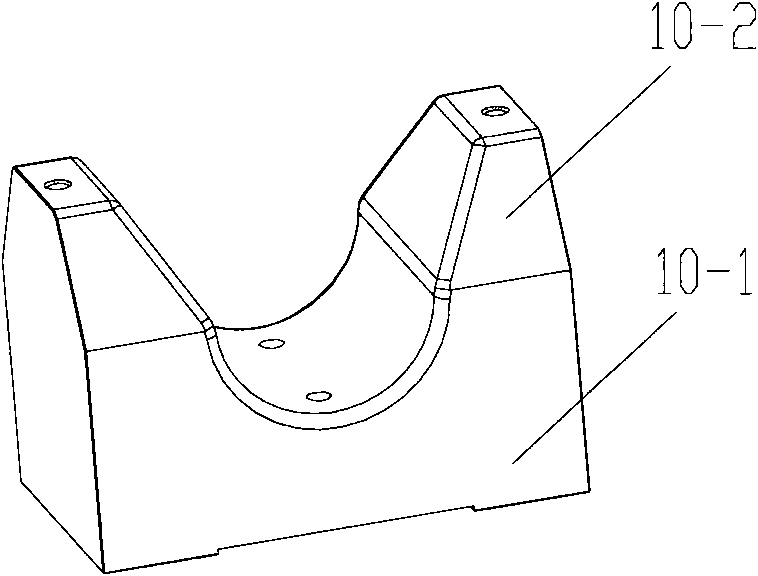

Installation device

ActiveCN101905414AImprove coaxialityAssembly precisionMetal working apparatusEngineeringMechanical engineering

The invention discloses an installation device, relating to the technical field of mechanical assembly. The installation device is used for installing a shaft in a shaft hole of a shaft hole part and comprises a shaft hole part fixing device, a shaft fixing device and a support seat, wherein the shaft hole part fixing device is used for horizontally fixing the shaft hole part; the shaft fixing device is used for horizontally fixing the shaft; and the support seat is used for supporting the shaft hole part fixing device and the shaft fixing device; and the shaft hole center line of the shaft hole part fixed by the shaft hole part fixing device is aligned with the center line of the shaft fixed by the shaft fixing device. The shaft fixing device moves along the horizontal direction under the drive of a driving device. The installation device can accurately assemble the shaft and the shaft hole part and prevent collisions and gouges between the shaft and the shaft hole part in the installation process.

Owner:SANY ELECTRIC CO LTD

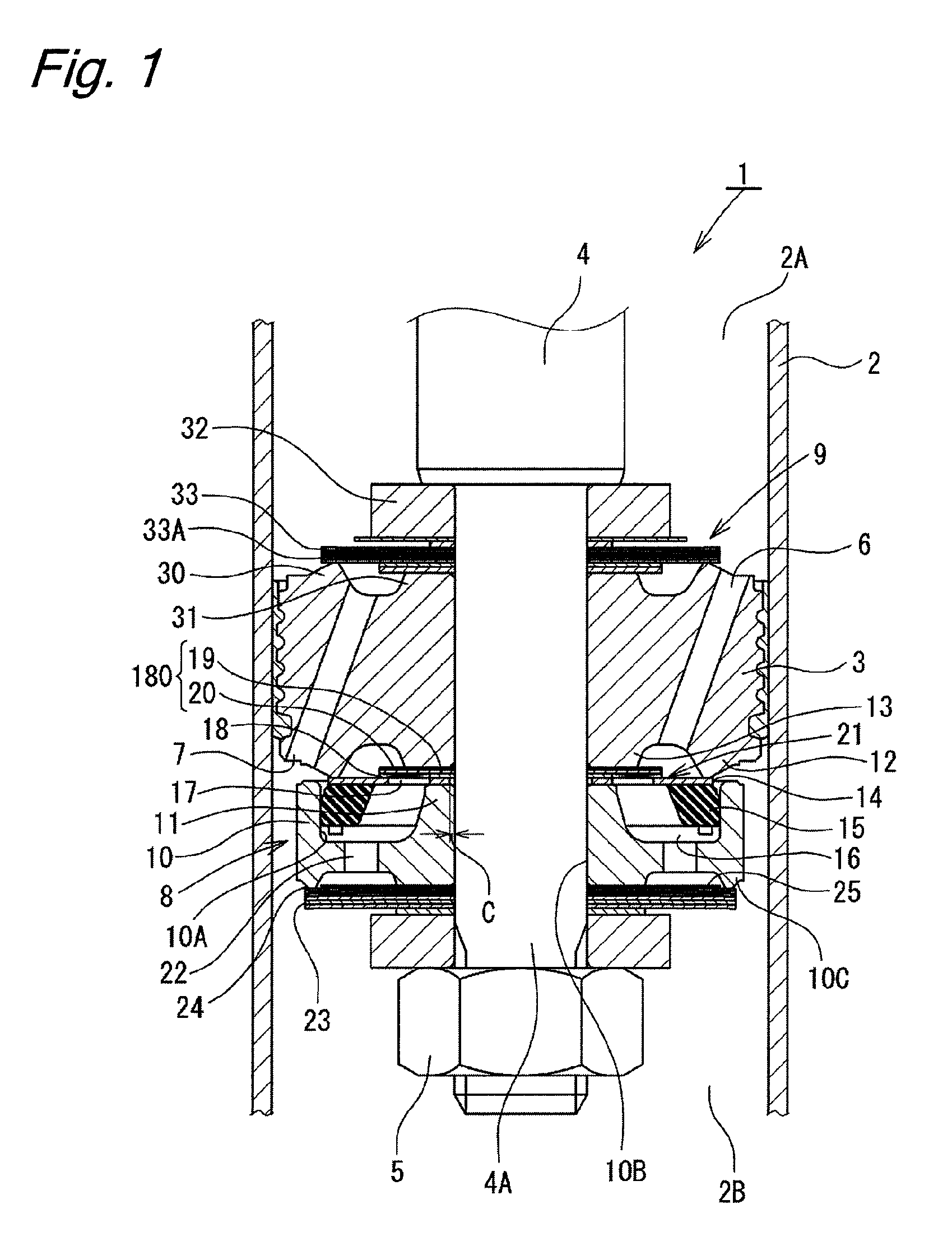

Shock absorber

ActiveUS8584818B2Improve coaxialityReduce distractionsSpringsShock absorbersSliding contactPiston rod

A piston connected to a piston rod is fitted in a cylinder having a hydraulic oil sealed therein. Flows of hydraulic oil induced by sliding movement of the piston are controlled by extension and compression damping force generating mechanisms and to generate damping force. In the extension damping force generating mechanism, the valve-opening pressure of a disk valve is controlled by the pressure in a back pressure chamber. An elastic seal member fixed to the disk valve is brought into sliding contact with an inner peripheral surface of a cylindrical portion of a valve member to seal the back pressure chamber. The disk valve is self-aligned by fitting between the elastic seal member and the inner peripheral surface of the valve member and secured by being axially clamped at an inner peripheral portion thereof in a state where a clearance is formed between the inner peripheral portion of the disk valve and a shaft portion of the piston rod, thereby reducing the requirements for coaxiality.

Owner:HITACHI ASTEMO LTD

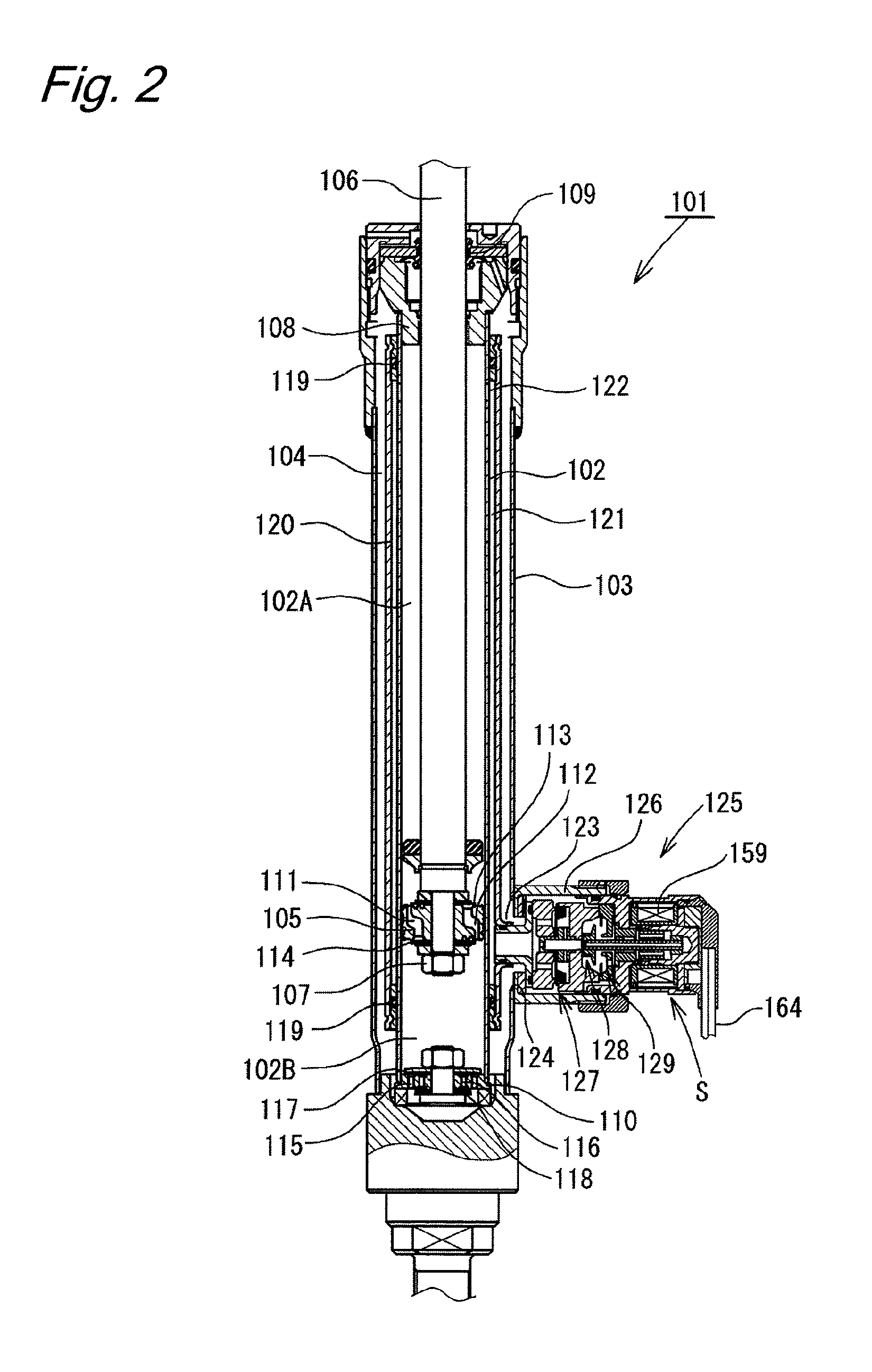

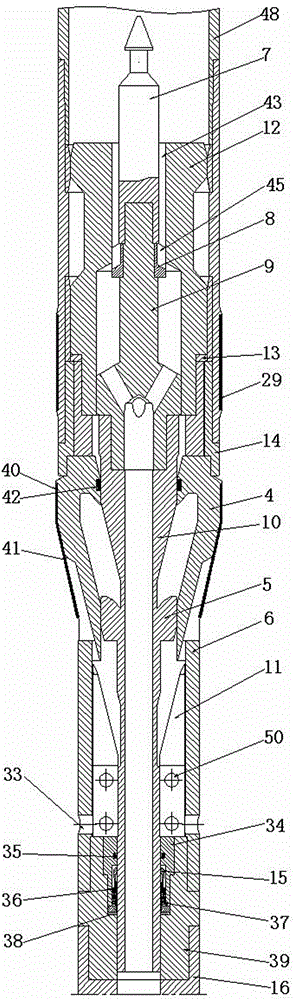

Casing coring drill and casing coring drilling method

InactiveCN103603625AImplementation checkAchieve replacementDrill bitsCore removalGeological explorationCoring

The invention discloses a casing coring drill applied to a core drilling project in geological exploration, and a casing coring drilling method. The casing coring drill is a hole bottom drilling device for carrying out coring drilling without lifting the drill to replace a drilling bit, and is mainly composed of an inner pipe drill capable of feeding and fishing and an outer pipe drill connected with a casing. The casing coring drilling method is characterized by comprising the following main process flows: replacing an inner hole drill stem with the casing; drilling for coring; fishing with a core; inspecting or replacing the drilling bit; feeding a coring drill; and lifting an inner pipe drill so as to finish the casing drilling operation. The casing coring drilling method disclosed by the invention adopts the casing instead of the drill stem to transfer drilling loads. The coring drilling without lifting the drill to replace the drilling bit is carried out by the casing coring drill, and running casing along with the drill is achieved; drilling is quickly and effectively achieved, and reaches the expected hole depth as a complex formation or the casing is isolated. Thus, the technical problems including but not limited to coring drilling of the complex formation are solved.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

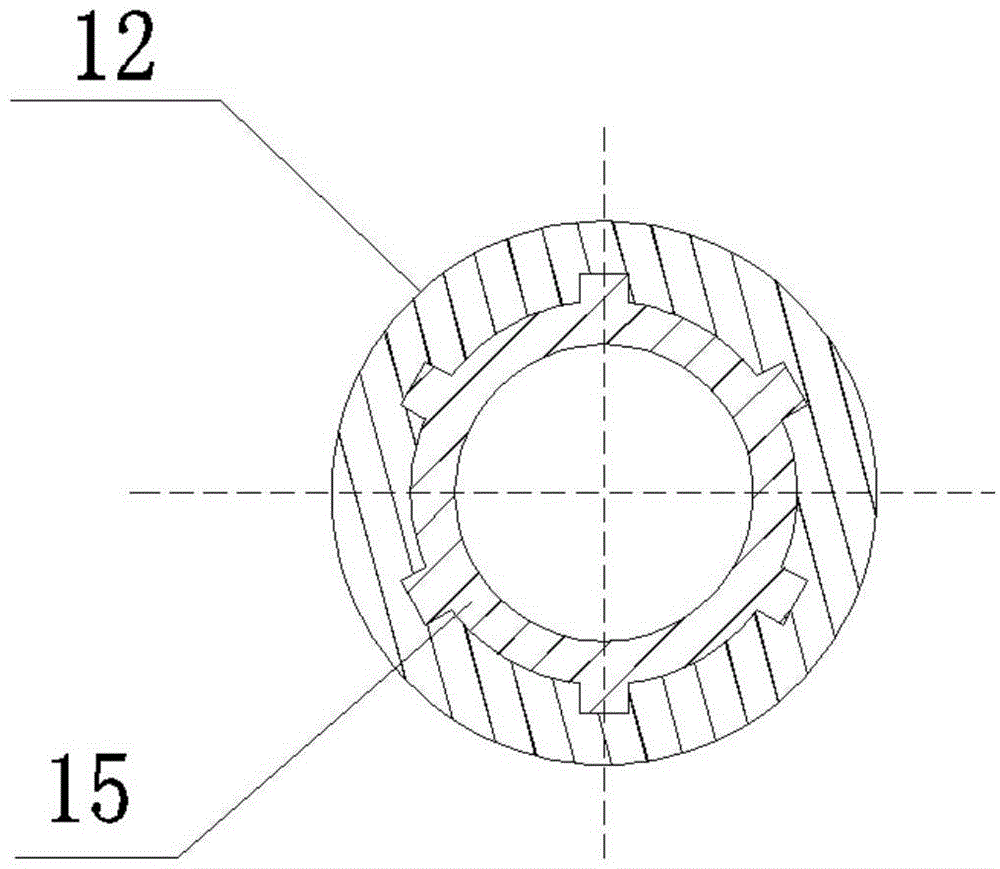

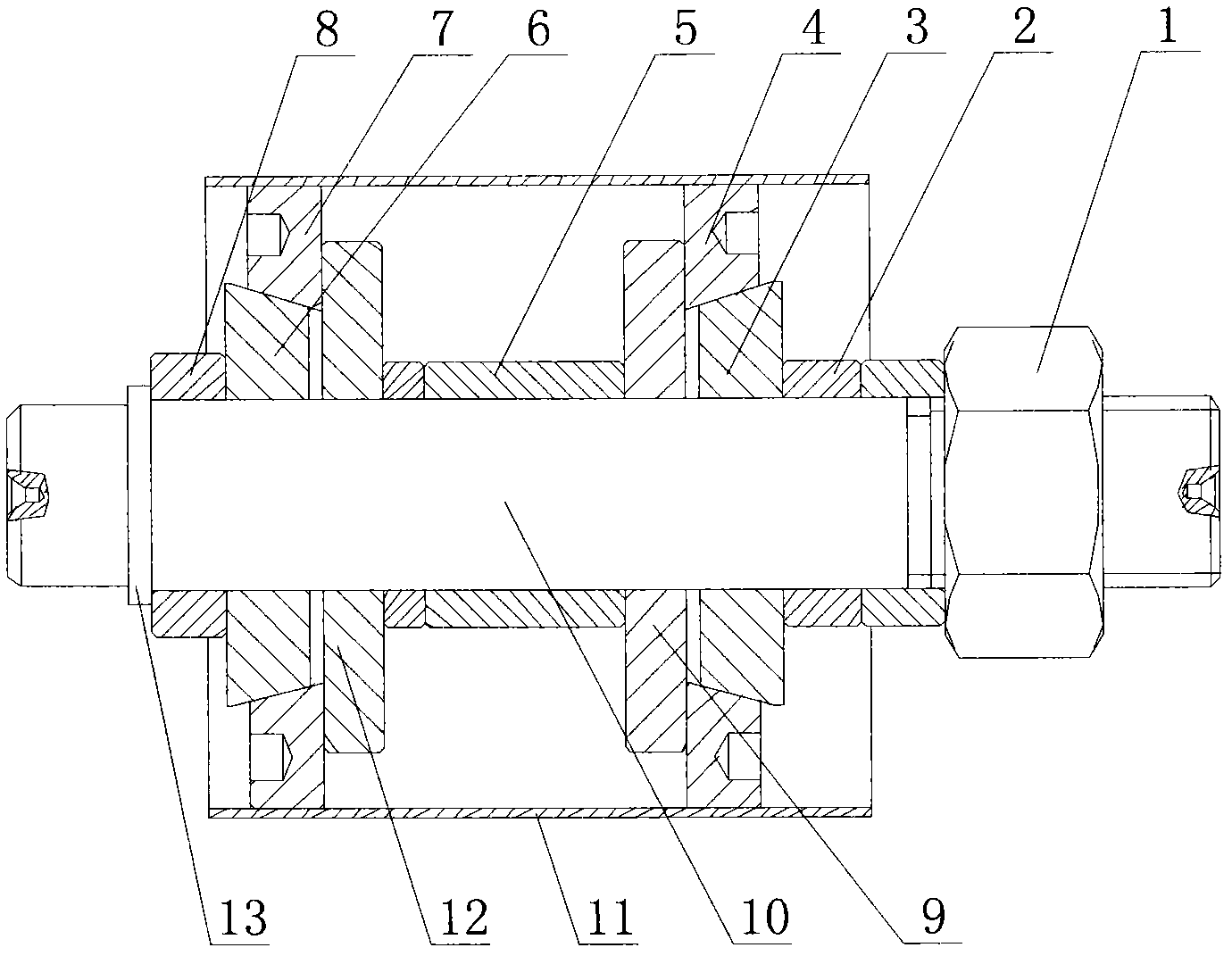

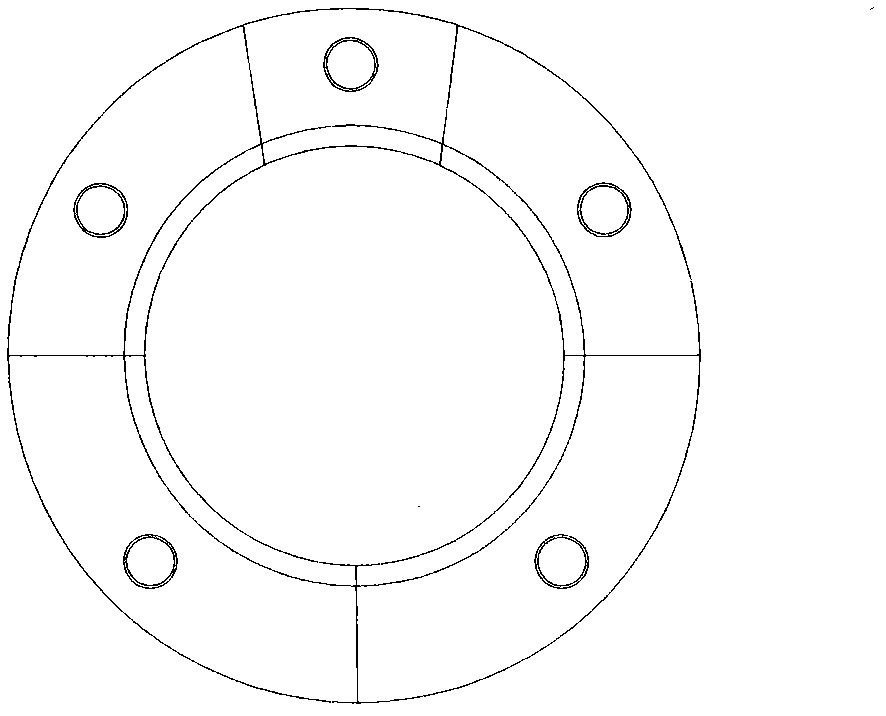

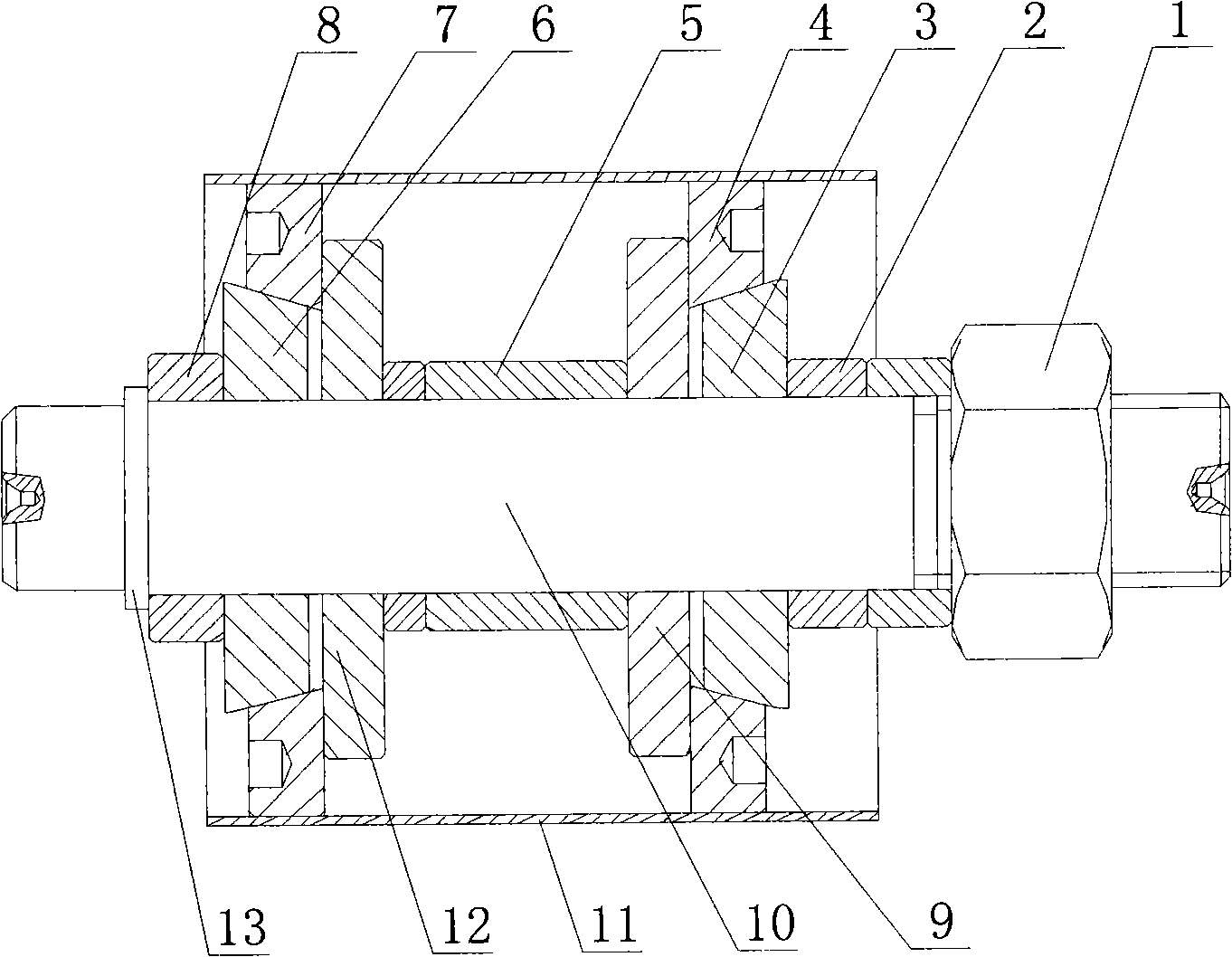

Expanding type clamp used on lathe and machining method thereof

The invention discloses an expanding type clamp used on a lathe and a machining method thereof. A workpiece is usually clamped from outside to inside when being machined on the lathe. However, for a short thin-wall workpiece which has a cone-shaped outer surface, does not have a cylindrical surface and has high requirements for machining accuracy and coaxiality, when machining of one end of the workpiece is finished and the other end needs to be machined, a universal clamp can not meet the requirements due to the fact that the universal clamp is low in clamping force and prone to deformation. The expanding type clamp used on the lathe and the machining method thereof are suitable for being used in the situation that machining of one end of a short thin-wall workpiece, with a small inner diameter and a cone-shaped or angular outer surface and having high requirements for machining accuracy and coaxiality and free of a cylindrical surface, is finished and the other end needs to be machined. A hole of the machined workpiece is sleeved on an expanding type clamping head first, and then the circumference of the clamp expands outwards evenly in a clamping process to stretch the inner diameter of the workpiece to be machined to carry out lathe work. The clamp is loosened after the machining is finished, the expanding type clamping head contracts elastically, and then the machined workpiece is taken down easily.

Owner:JIANGSU XINGHE VALVE +1

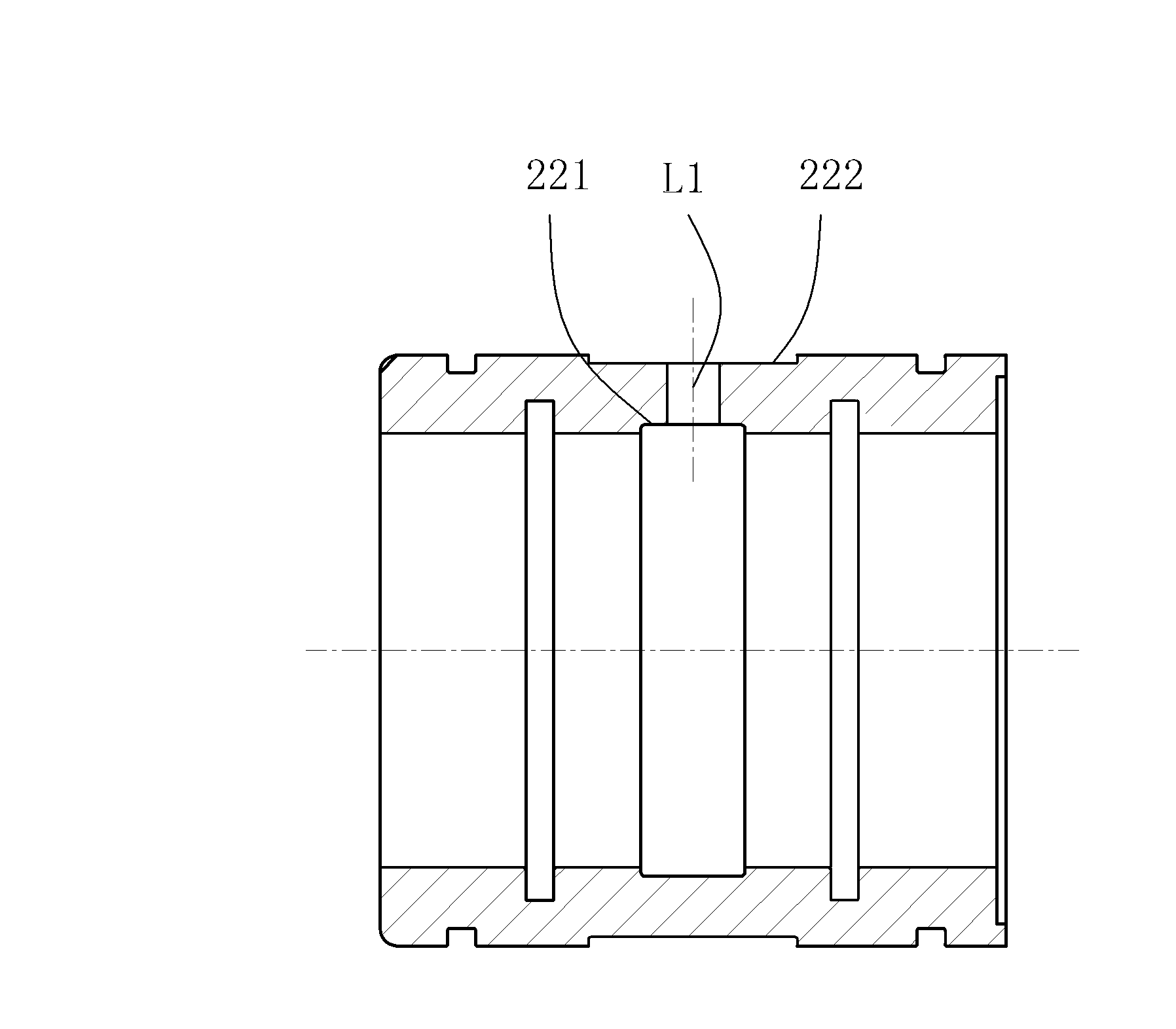

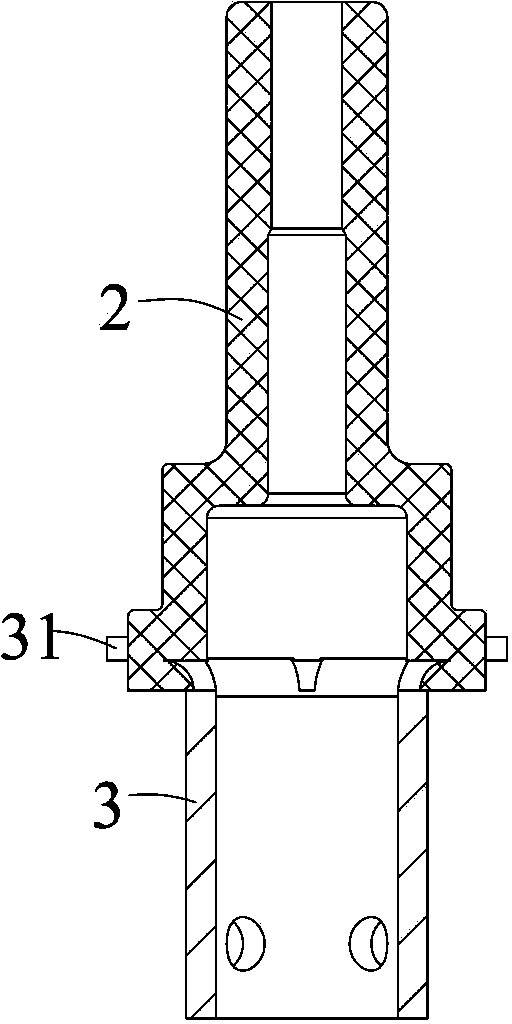

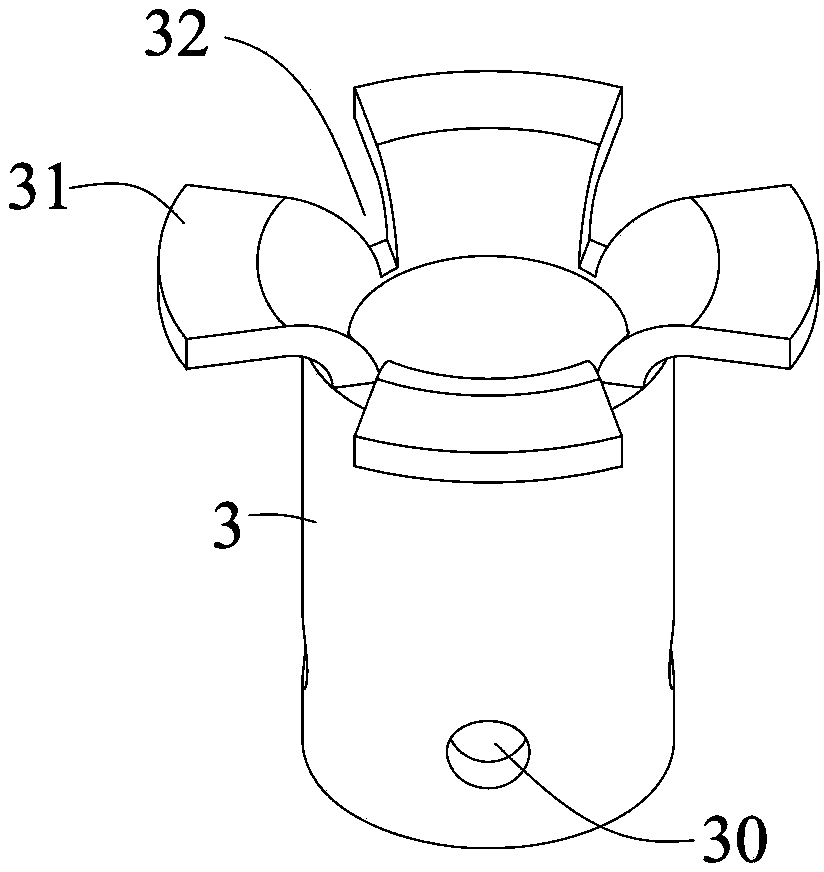

Electronic expansion valve

InactiveCN104279342AReduce wearImprove coaxialityEfficient regulation technologiesFluid circulation arrangementInjection mouldingRefrigeration

The invention discloses an electronic expansion valve, belongs to the technical field of refrigeration system control, and solves the technical problem of wear caused by the coaxiality difference between the existing electronic expansion valve nut and a valve needle assembly. The electronic expansion valve comprises a valve body, a nut, a valve needle assembly and a guide sleeve, wherein the nut and the guide sleeve are assembled on the valve body, and the valve needle is arranged on the nut; the nut and the guide sleeve are integrally molded by injection.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

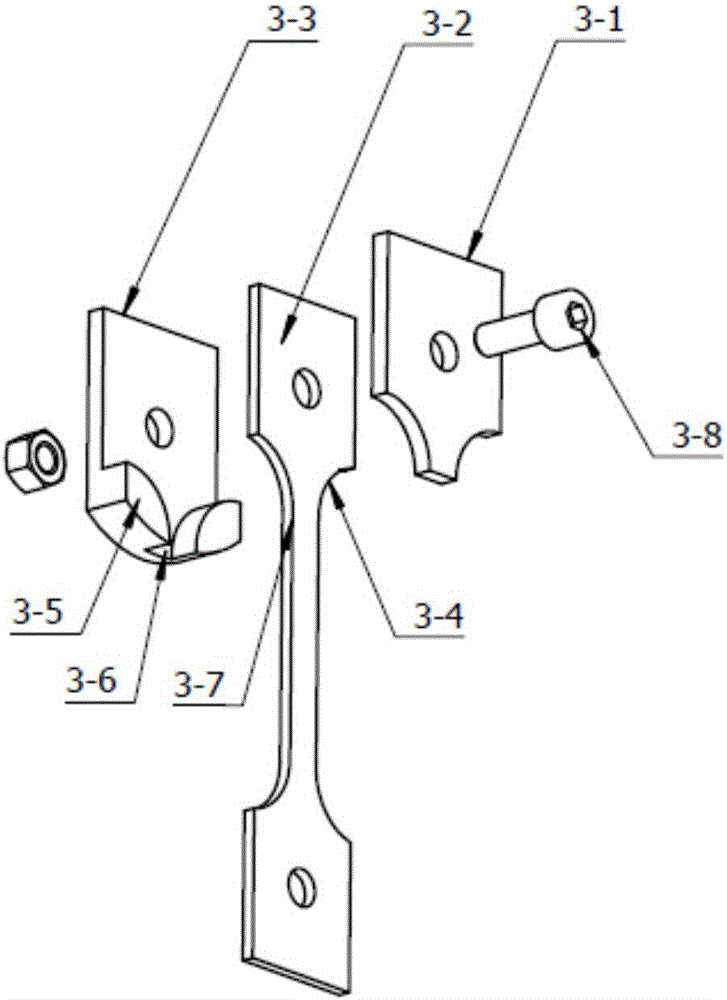

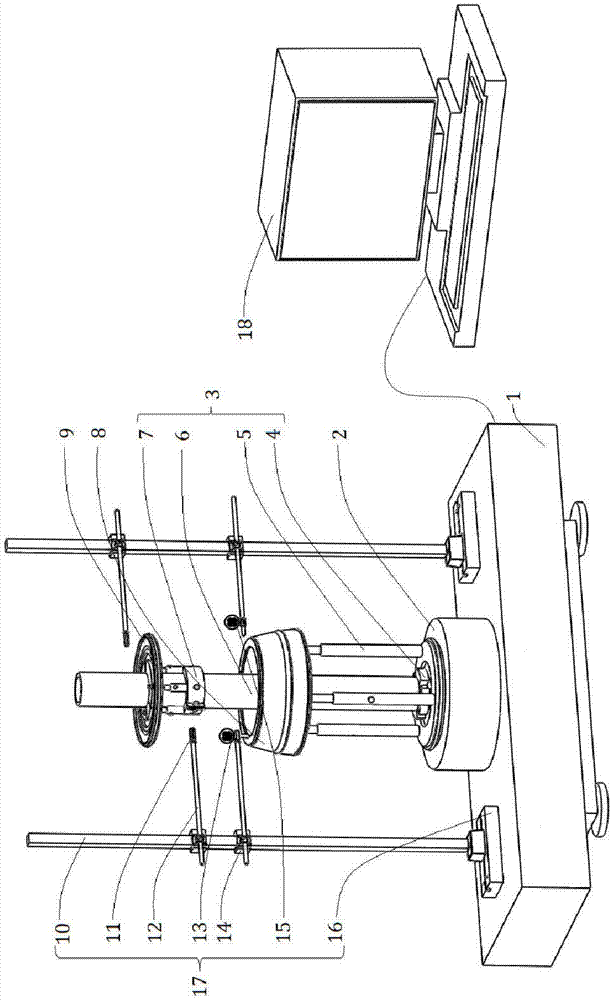

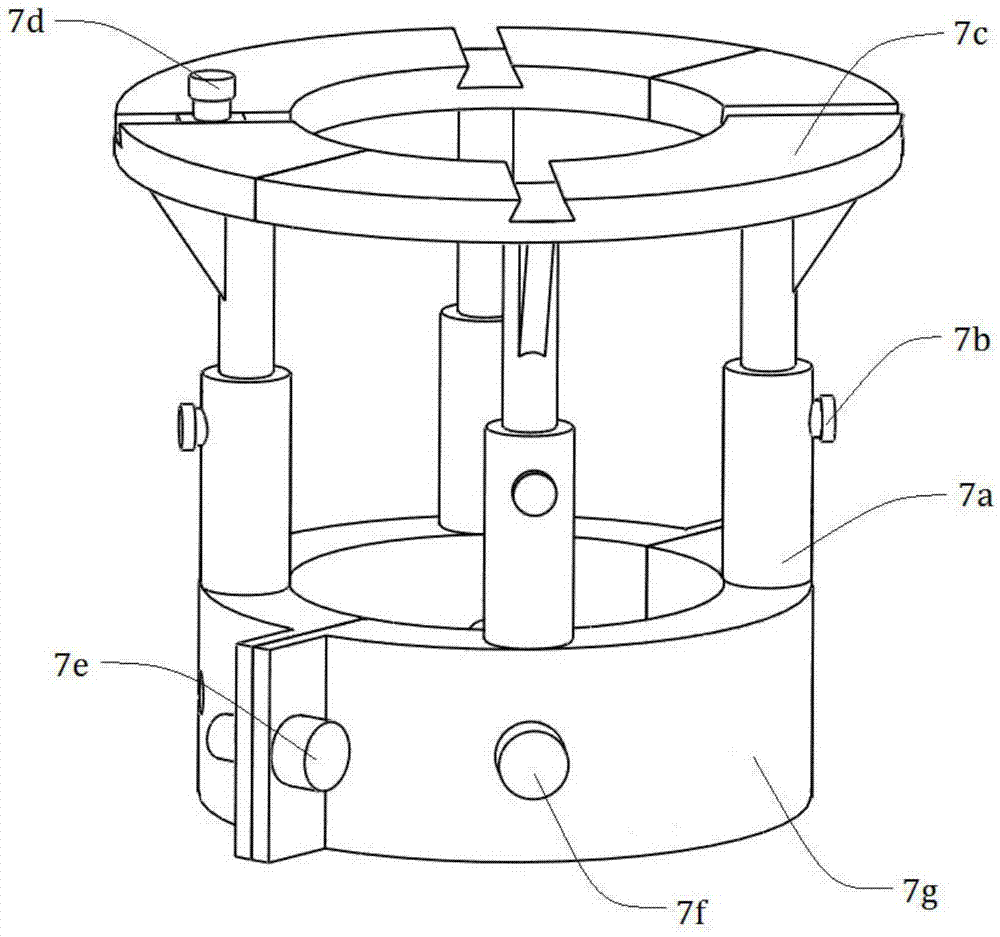

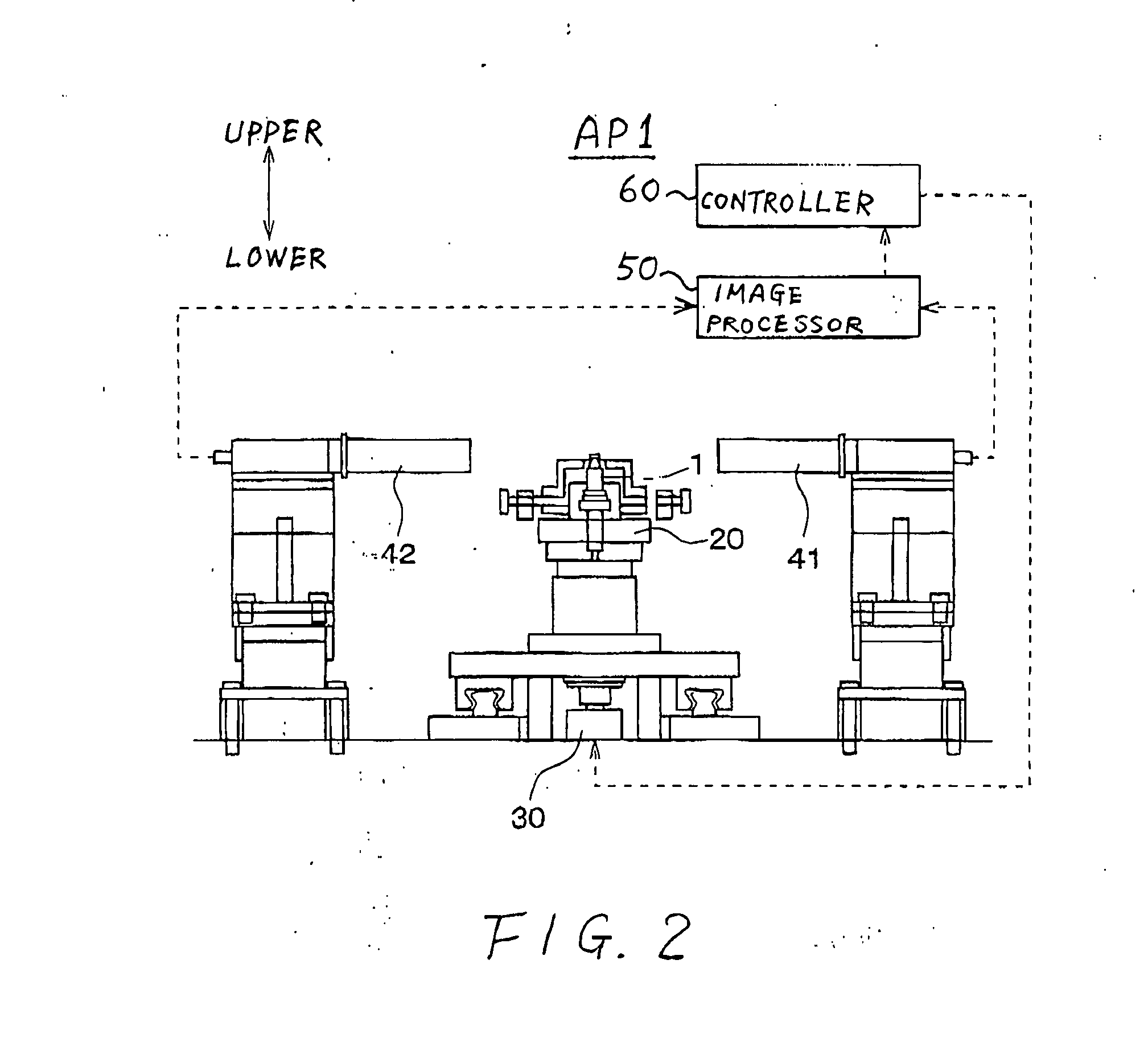

Device and method for assembling multi-stage drum type rotor of aero-engine

ActiveCN105443169AImprove coaxialityContinuous assemblyMachines/enginesSafety/regulatory devicesControl systemEngineering

The invention provides a device and method for assembling a multi-stage drum type rotor of an aero-engine. The device comprises a base, an air-floating rotary table, a clamp device, measuring devices and a computation control system, wherein the air-floating rotary table is fixed to the center of the base, the clamp device is mounted on the air-floating rotary table, and the measuring devices are mounted on the base and arranged on the two sides of the air-floating rotary table; the computation control system is connected with the air-floating rotary table and used for transmitting driving, center-regulating and tilt-regulating information, and the computation control system is connected with the measuring devices and used for collecting morphology information of assembled parts. By means of the device and method, coaxiality of all parts of the rotor can be guaranteed, continuous assembling can be carried out, and the situation that the parts are dismounted and then measured, marked and assembled one by one is avoided; universality is high, operation is easy, and assembling precision and assembling efficiency are high.

Owner:SHANGHAI JIAO TONG UNIV

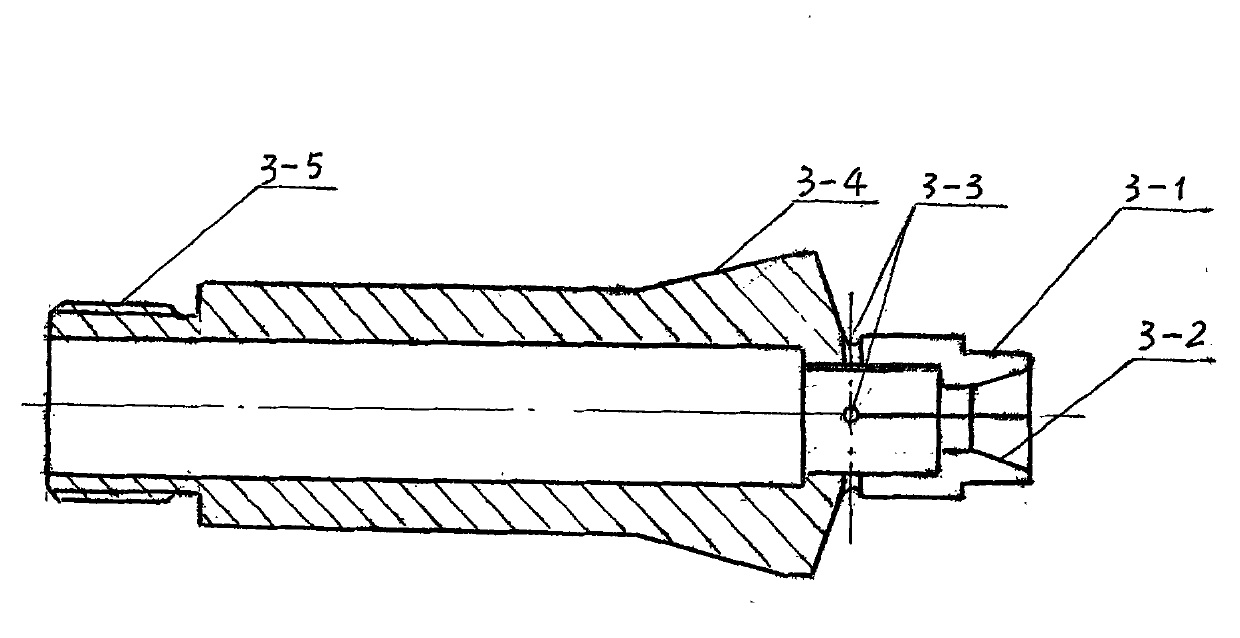

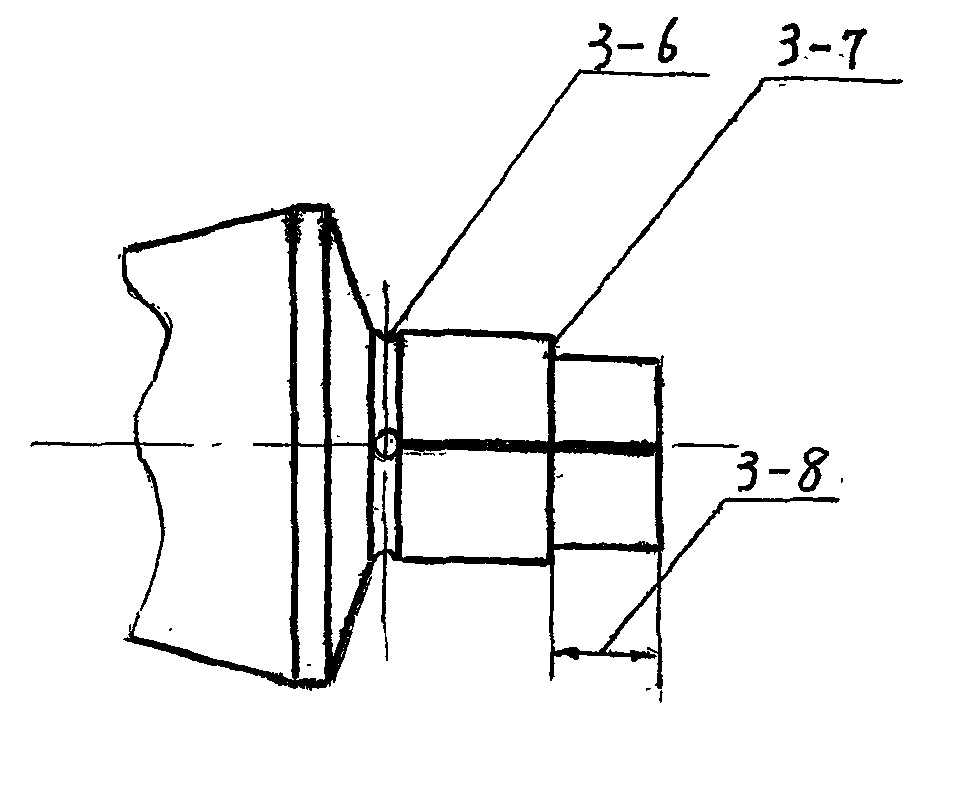

Bubble atomizing nozzle and adjusting method of bubble atomizing nozzle

The invention relates to a bubble atomizing nozzle and an adjusting method of the bubble atomizing nozzle. The bubble atomizing nozzle comprises a multi-channel air intake structure consisting of two or more layers of sealing rings, or an external part of an air intake structure of a swirl groove, and an external part having a diffusion conical spray hole, a jackscrew hole and an air-liquid inlet quick mounting joint, wherein the internal part is directly inserted in the external part to assemble the nozzle; the internal part and the external part are sealed by an O-shaped rubber ring and fixed by a jackscrew; and a space between the internal part and the external part is a mixing chamber. The flowing resistance of the internal part is lower, so that the pressure of the mixing chamber can be kept in a higher range, and the atomizing efficiency of the nozzle is higher; a bubble flow formed in the air-liquid two-phase mixing process in the mixing chamber is uniform and stable, so that the stable atomizing effect is realized under the low-air-liquid mass flow ratio (between 0.07-0.1); and the working pressure is low, and the liquid flow is low, so that the stable atomization can be kept under the liquid flow of 3.5-6.0 kg / h and the absolute air-liquid inlet pressure of 0.36-0.40 MPa. The bubble atomizing nozzle is applied to such fields as chemical engineering, motive power and heating and ventilation.

Owner:HEBEI UNIV OF TECH +1

Brushless motor

ActiveUS7294944B2Improve accuracyReduce the overall heightAssociation with control/drive circuitsMagnetic circuitBrushless motorsEngineering

Owner:NIDEC CORP

Method and apparatus for manufacturing spark plug

ActiveUS20050039332A1Improve accuracyImprove coaxialitySpark gapsElectrically conductive connectionsEngineeringGrounding electrodes

A spark plug is provided, for a provisional bending process for manufacturing the spark plug, as a work in a condition where an earth electrode is straight and substantially in parallel with an axial line of a center electrode. In the provisional bending process, two searchers individually facing the tip of the center electrode with the tip located therebetween are arranged, positions of the searchers in a first direction perpendicular to the axial line being adjusted for every spark plug. Then a bending punch is driven to press a second end-surface of the other end of the earth electrode down to the searchers so that the earth electrode is provisionally bent at a substantially perpendicular angle to the axial line, the second end-surface being opposite to the first end-surface. Preferably, before the provisional bending process, positioning the work and correcting the position and tilt of the work are performed.

Owner:DENSO CORP

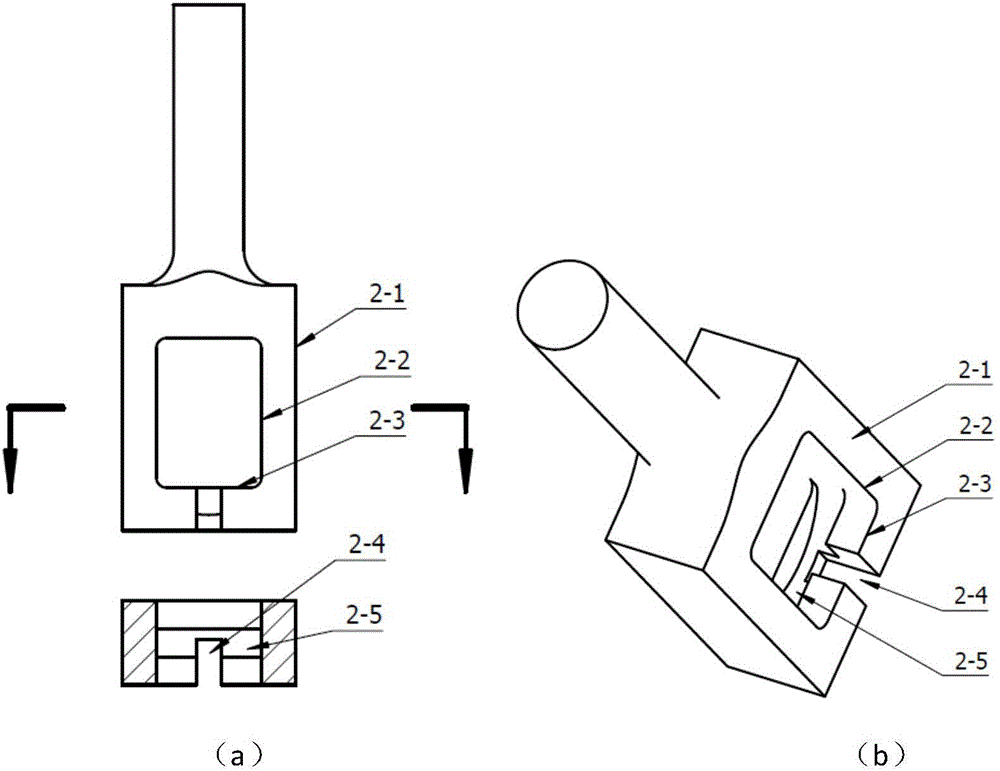

Thin-walled tube arc-shaped sample high-temperature high-pressure water slow tensile test clamp and application method thereof

PendingCN106483025APrecise positioningPrevent slippingMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceHigh pressure waterHigh pressure

The invention relates to the field of stress corrosion tests of metal and alloy thereof, in particular to a slow tensile test clamp of a thin-walled tube arc-shaped sample in a high-temperature high-pressure water environment and an application method of the slow tensile test clamp. The slow tensile test clamp is suitable for stress corrosion crack sensitivity study of a thin-walled tube in high-temperature high-pressure water. The clamp is composed of a sample clamping part and a clamp adaption part, the sample clamping part comprises a female die, a male die, a locating pin shaft and a fastening bolt, and the sample can be accurately located and completely fixed; the clamp adaption part comprises an external thread adaption part, an internal thread adaption part and a connecting pin shaft. The slow tensile test clamp can be fixed to an existing support and connected with a stretching shaft, and clamping and axial stretching of the thin-walled tube arc-shaped sample are achieved. The slow tensile test clamp is simple in structure and convenient to assemble, can achieve precise locating and completely fix the sample, and can achieve the slow tensile test of the thin-walled tube arc-shaped sample in the high-temperature high-pressure water environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

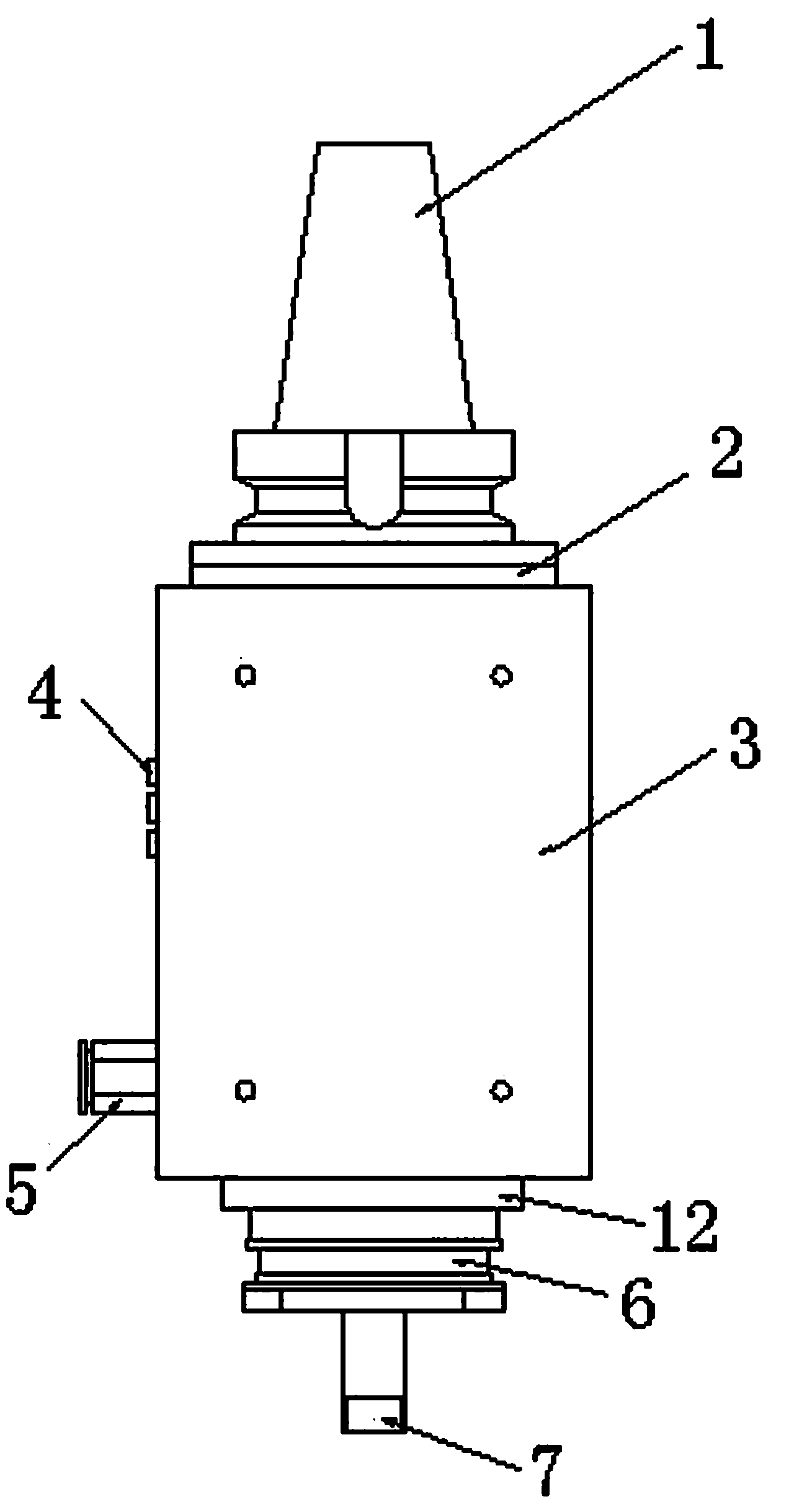

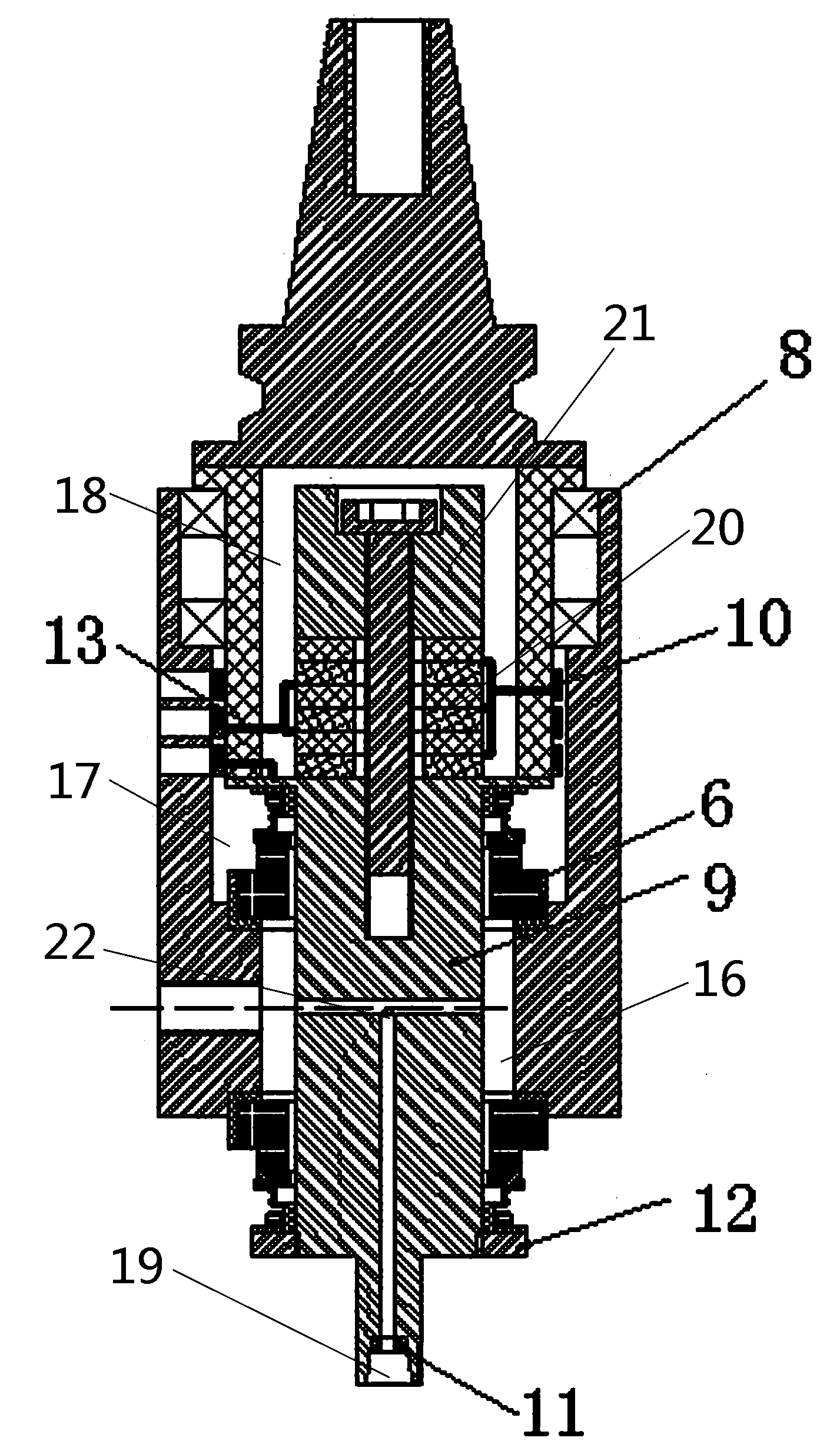

Universal ultrasonic-assisted inner jetted dielectric electric discharge machining (EDM) milling tool head and manufacturing method thereof

InactiveCN103920953AReduce frictional resistanceIncrease rotation speedDielectricUltrasonic assisted

The invention relates to the field of machinery, in particular to a universal ultrasonic-assisted inner jetted dielectric electric discharge machining (EDM) milling tool head. The universal ultrasonic-assisted inner jetted dielectric EDM milling tool head comprises an ultrasonic vibration portion, a knife handle and a knife bar. The knife handle is fixedly connected with an inner sleeve. The inner sleeve is fixedly connected with an amplitude-change pole. The bottom end o the amplitude-change pole is provided with the knife bar. An electrode is installed on the knife bar. The axis of the knife handle, the axis of the amplitude-change pole and the axis of the knife bar are coincident. An outer sleeve is arranged outside the inner sleeve and extends to the middle section of the amplitude-change pole. A cavity III is formed between the outer sleeve and the amplitude-change pole. The end of the cavity III is provided with a mechanical water seal. The interior of the amplitude-change pole is provided with a discharge medium circulating channel. The universal ultrasonic-assisted inner jetted dielectric EDM milling tool head has the advantages of being high in coaxiality, high in rotational speed and simple in structure.

Owner:SHANDONG UNIV

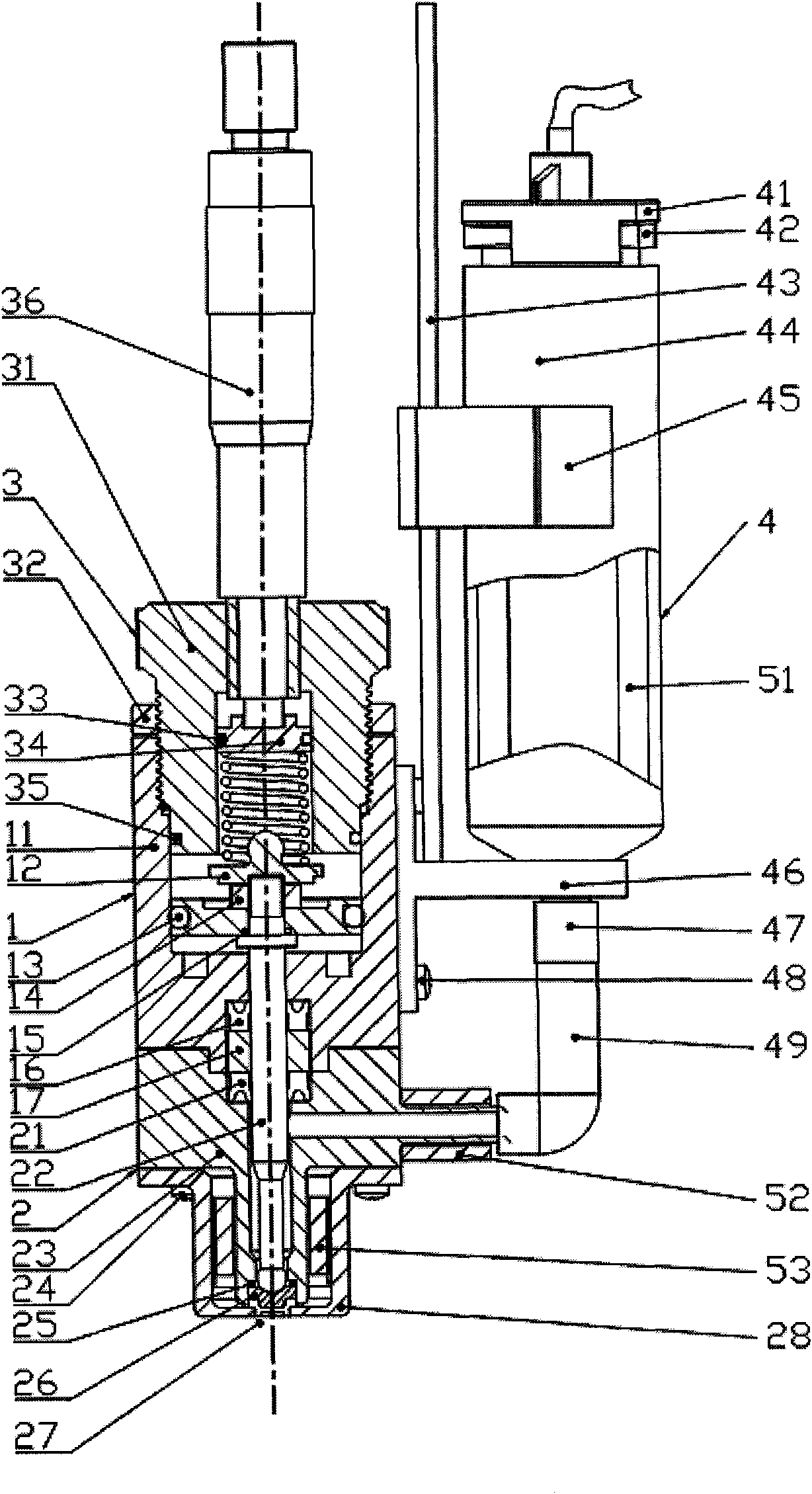

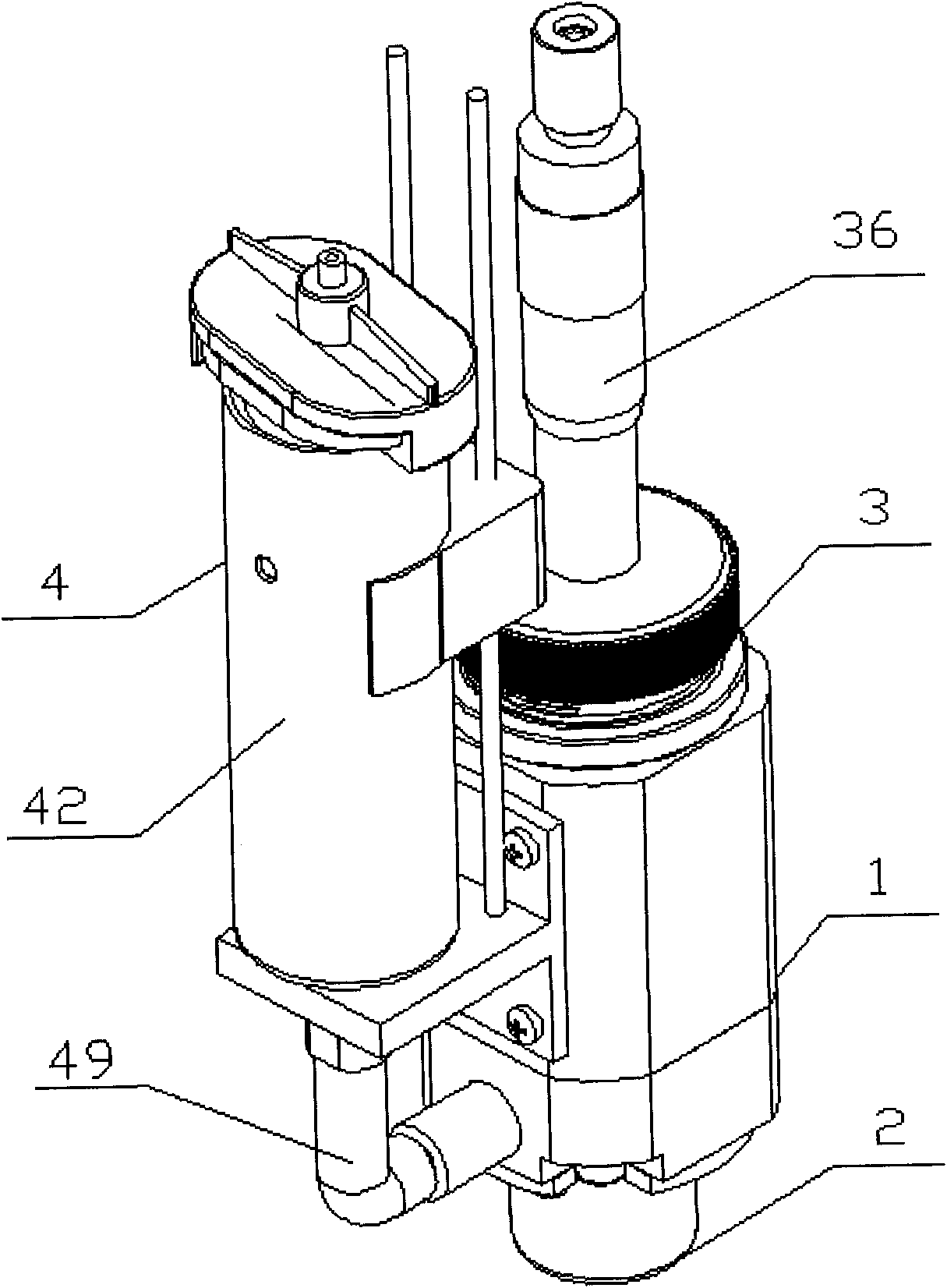

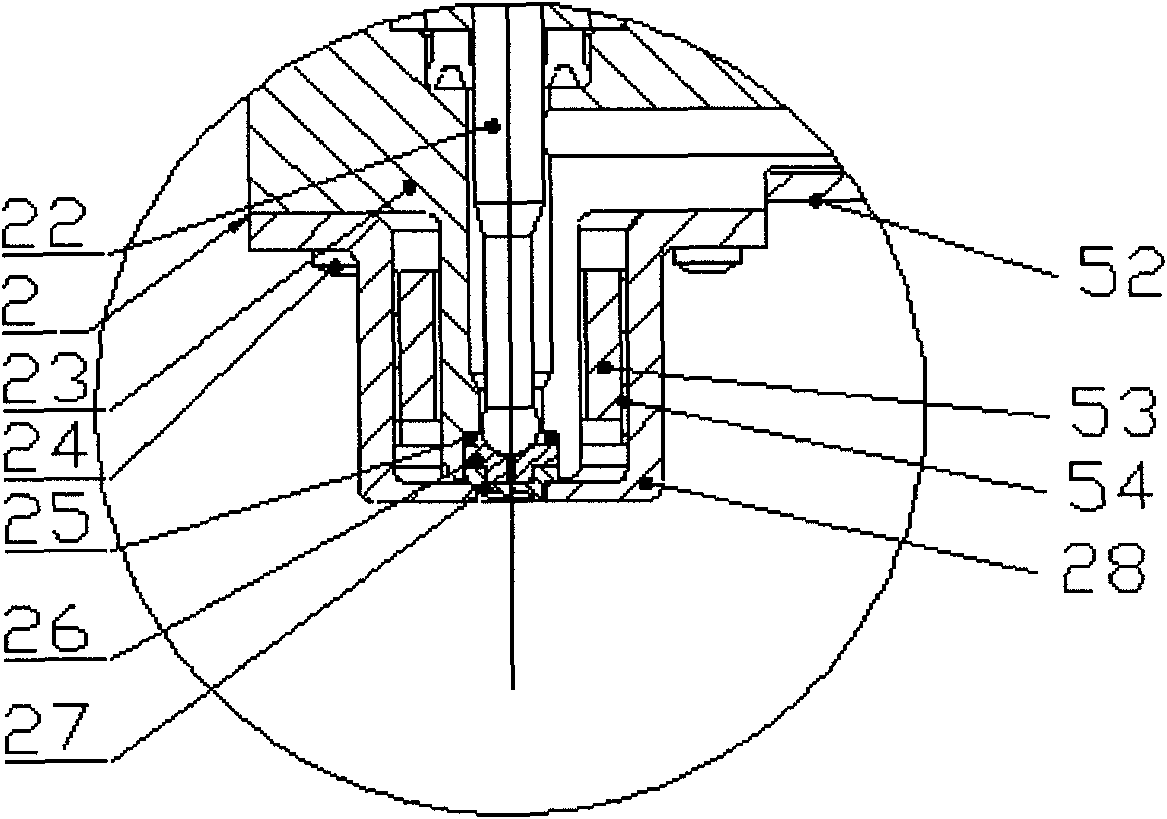

Ejecting adhesive dispenser based on dual-function cylinder

InactiveCN101844124AExtrude quicklyIncrease supplementLiquid surface applicatorsCoatingsThree stageDual function

The present invention provides an ejecting adhesive dispenser based on a dual-function cylinder, which comprises a driving mechanism, an ejecting mechanism, an adhesive supplying mechanism and a heating device. A device for a fine route tuning and a pre-pressure adjustment is arranged on the upper portion of the driving mechanism; the lower end of the driving mechanism is connected with the ejecting mechanism; the adhesive supplying mechanism is arranged on the side wall of the driving mechanism and connected with the ejecting mechanism via a feeding pipeline; and a three-stage heating device is provided around the head of the ejecting mechanism, the feeding pipeline and a feeding container. The driving mechanism comprises a dual-function cylinder and a returning spring; the ejecting mechanism comprises an ejecting needle integrated with the piston rod of the cylinder, a lower valve body and an ejecting head; and the ejecting head comprises an ejecting nozzle base, an ejecting nozzle and a clamping sleeve cup. The invention realizes the dispensing of high-viscosity fluid and has the advantages of micro amount, high speed, high frequency, no contact, high precision, high reliability, low cost and low requirements on processing precision.

Owner:SHANGHAI UNIV

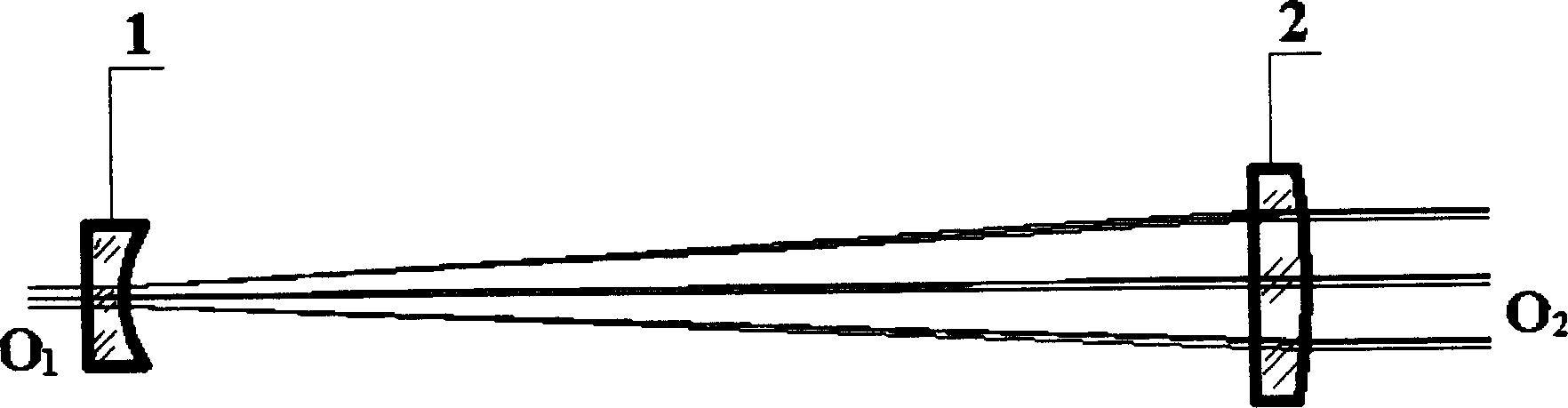

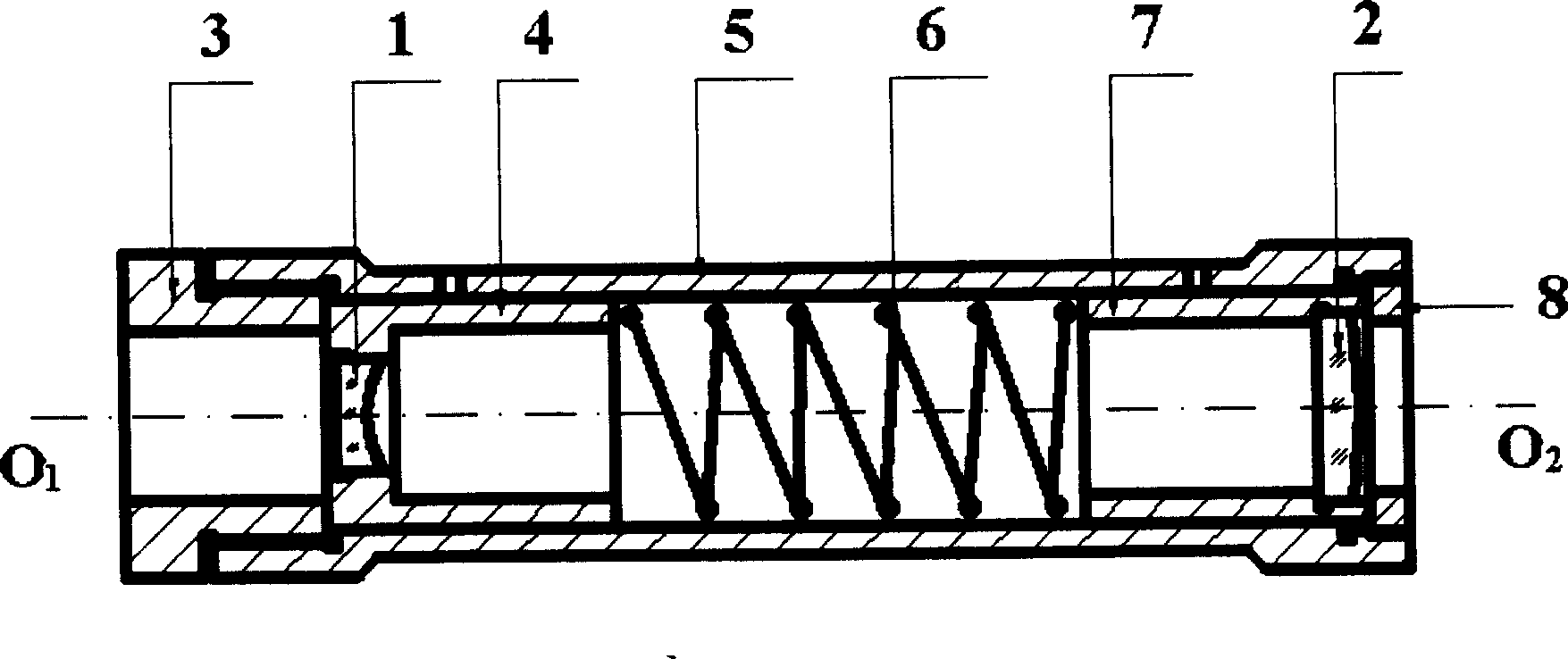

Light beam universal extending system

An universal extender system of light beam consists of extender negative mirror and extender positive mirror. The system is featured as having a mirror tube with regulation handwheel, extender negative mirror, negative mirror frame, spring, positive mirror frame, extender positive mirror and pressing ring setting in sequence along light axis O1O2 in the mirror tube; coordinating the mirror frames closely with mirror tube, pushing against the mirror frames by spring and connecting handwheel to mirror tube with thread.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

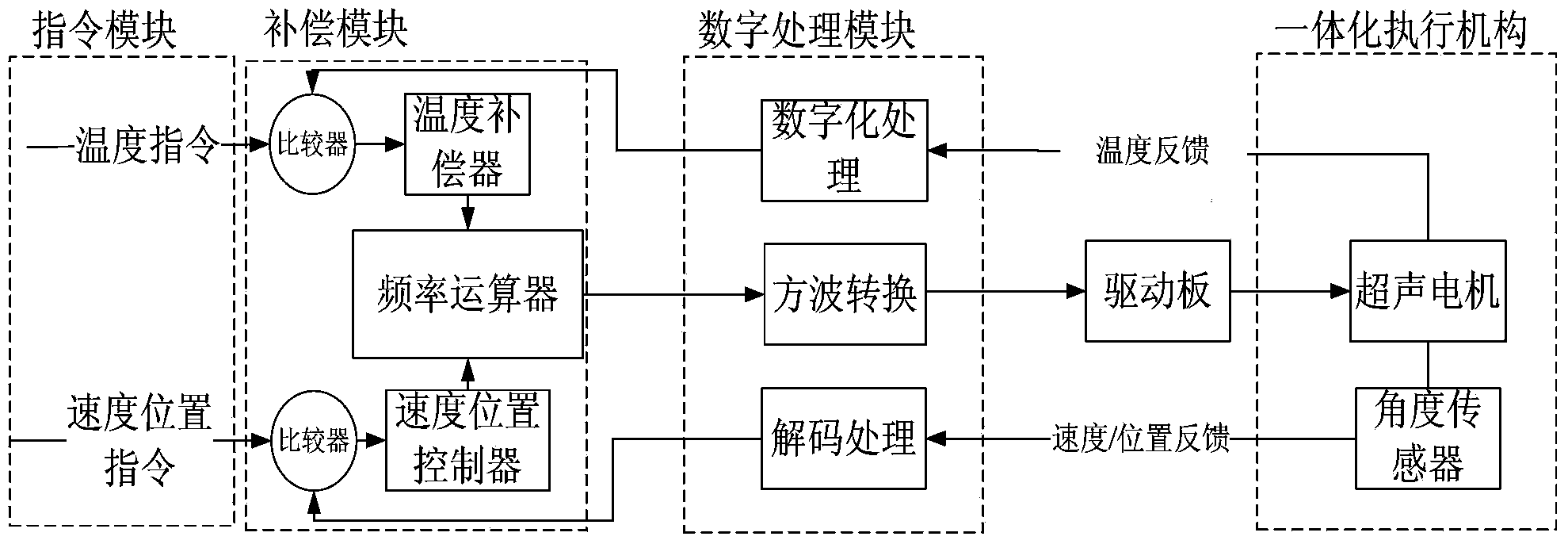

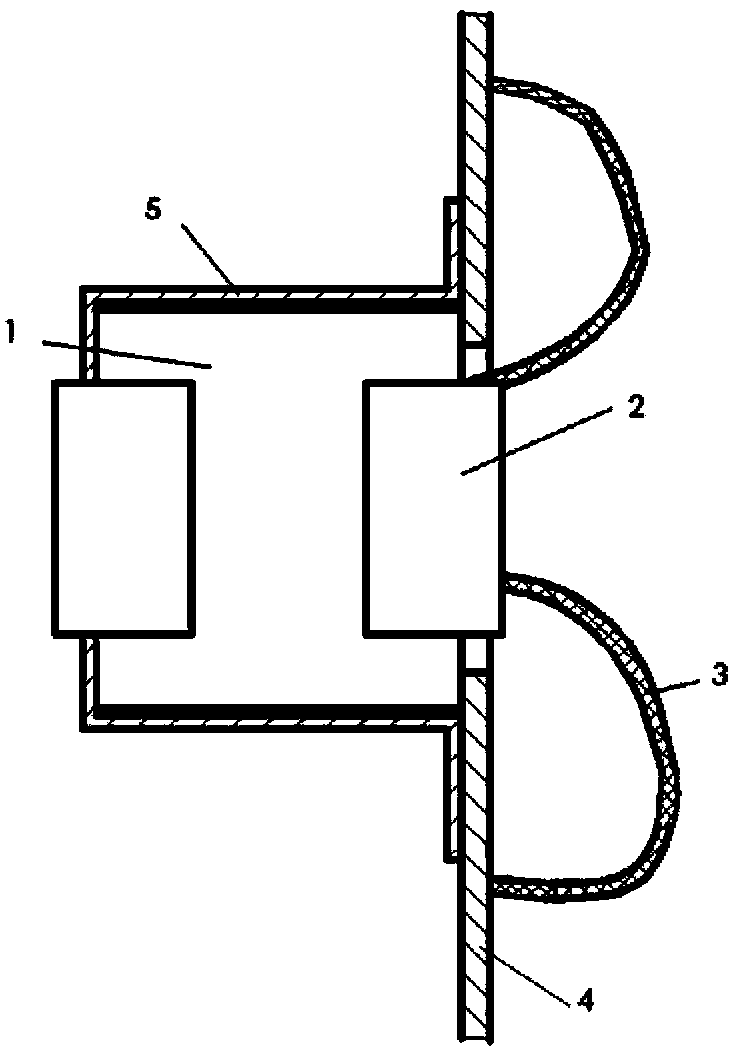

Internally-arranged angle sensor all-in-one ultrasonic motor servo control system

ActiveCN103414376APrecise closed-loop controlAffect speedPiezoelectric/electrostriction/magnetostriction machinesControl signalControl system

The invention discloses an internally-arranged angle sensor all-in-one ultrasonic motor servo control system and relates to servo control over ultrasonic motors. The internally-arranged angle sensor all-in-one ultrasonic motor servo control system comprises a command module, a compensation module, a digital processing module, a drive panel and an all-in-one actuating mechanism. The command module sends out commands to the compensation module, and the compensation module converts the commands into frequency control signals and transmits the frequency control signals to the digital processing module; the digital processing module processes the frequency control signals into square signals and transmits the square signals to the drive panel, the drive panel amplifies the square signals and then inputs the square signals to the all-in-one actuating mechanism, the all-in-one actuating mechanism is a hollow ultrasonic motor with an internally-arranged angle sensor, the angle sensor feeds back speed and position information, the speed and position information reaches the compensation module after passing through the drive panel and the digital processing module, through comparison, compensation and conversion, newly-generated frequency control signals are transmitted to the drive panel, and therefore closed-loop control is achieved. The internally-arranged angle sensor all-in-one ultrasonic motor servo control system has high reliability, high precision and good environmental suitability, and is especially suitable for being used as shaft end servo control systems of platforms with multi-degrees of freedom.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com