Patents

Literature

211results about How to "Extrude quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

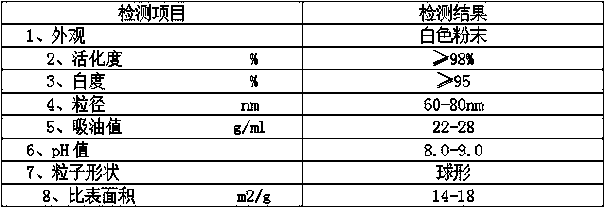

Method for preparing special nano calcium carbonate for plastic master batch

ActiveCN103897434AThe melt index will not changeImprove performanceCalcium/strontium/barium carbonatesPigment treatment with macromolecular organic compoundsDispersityPolyolefin

The invention provides a method for preparing special nano calcium carbonate for a plastic master batch. According to the method, on the basis of calcium carbonate and characteristics thereof in application in plastics, internal indicators, such as crystal form, particle size, whiteness, pH value and the like, of nano-CaCO3 are controlled, meanwhile, the agglomeration and second-time surface coating of nano-CaCO3 particles caused by dry-activation modification are avoided by adopting wet activation, the dispersity of nano-CaCO3 is improved by one-time conventional coating, the oil absorption value of nano-CaCO3 is lowered by the one-time conventional coating, the compatibility of nano-CaCO3 with polyolefin plastics is improved by second-time coupling coating, and the processability and compatibility of nano-CaCO3 in the master batch are effectively improved, so that the prepared nano master batch has reinforced, toughened, high-dispersion and high-extrusion characteristics.

Owner:SHANXI XINTAI HENGXIN NANO MATERIALS TECH CO LTD

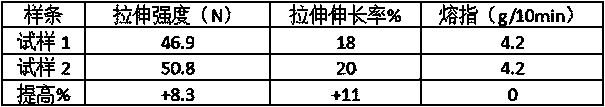

High-toughness high-modulus polypropylene composite material and preparation method thereof

The invention discloses a high-toughness high-modulus polypropylene composite material and a preparation method thereof. The high-toughness high-modulus polypropylene composite material consists of 50-62.5 parts of a polypropylene base body, 10-12 parts of high-density polyethylene, 12-15 parts of a polyolefin elastomer, 6-9 parts of modified wollastonite, 0.5-2 parts of nano modified particles, 1-2 parts of modified boron nitride, 5-6 parts of a compatibilizer, 1-1.5 parts of an antioxidant and 2-2.5 parts of a lubricating agent, wherein the nano modified particles are obtained by mixing a silane coupling agent and nano titanium dioxide in a weight ratio of 1 to 100. The preparation process is simple and convenient, the adopted materials are cheap, the comprehensive cost is lower than that of conventional toughness-modified polypropylene, and the produced high-toughness high-strength high-modulus polypropylene is excellent in performance. A composite system disclosed by the invention forms a polymer / flexible interface layer / inorganic particle three-phase composite system.

Owner:HENAN UNIV OF SCI & TECH

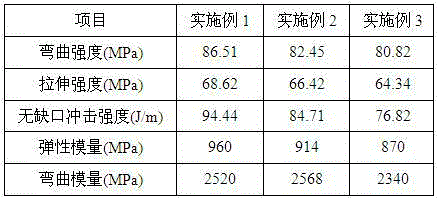

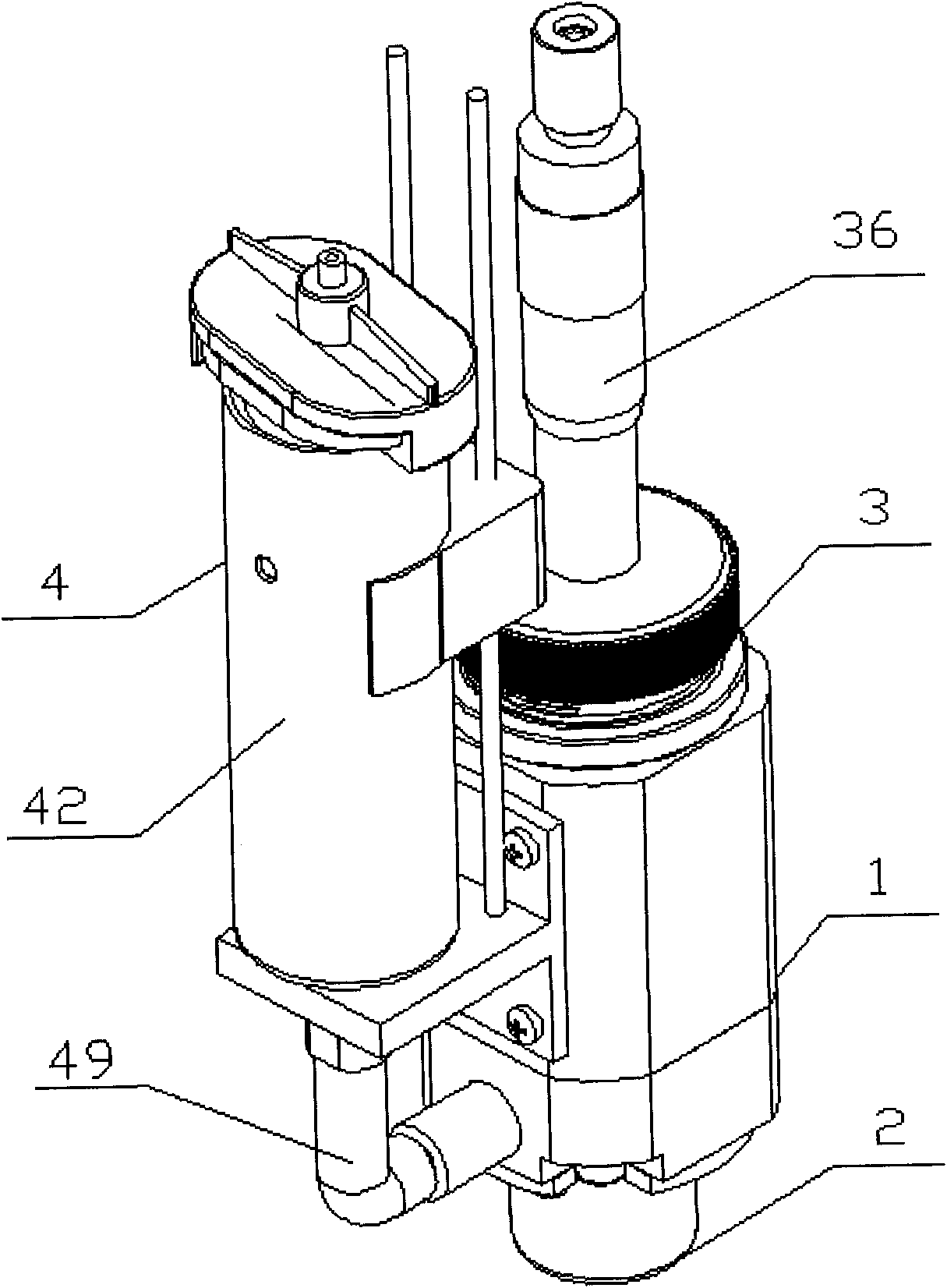

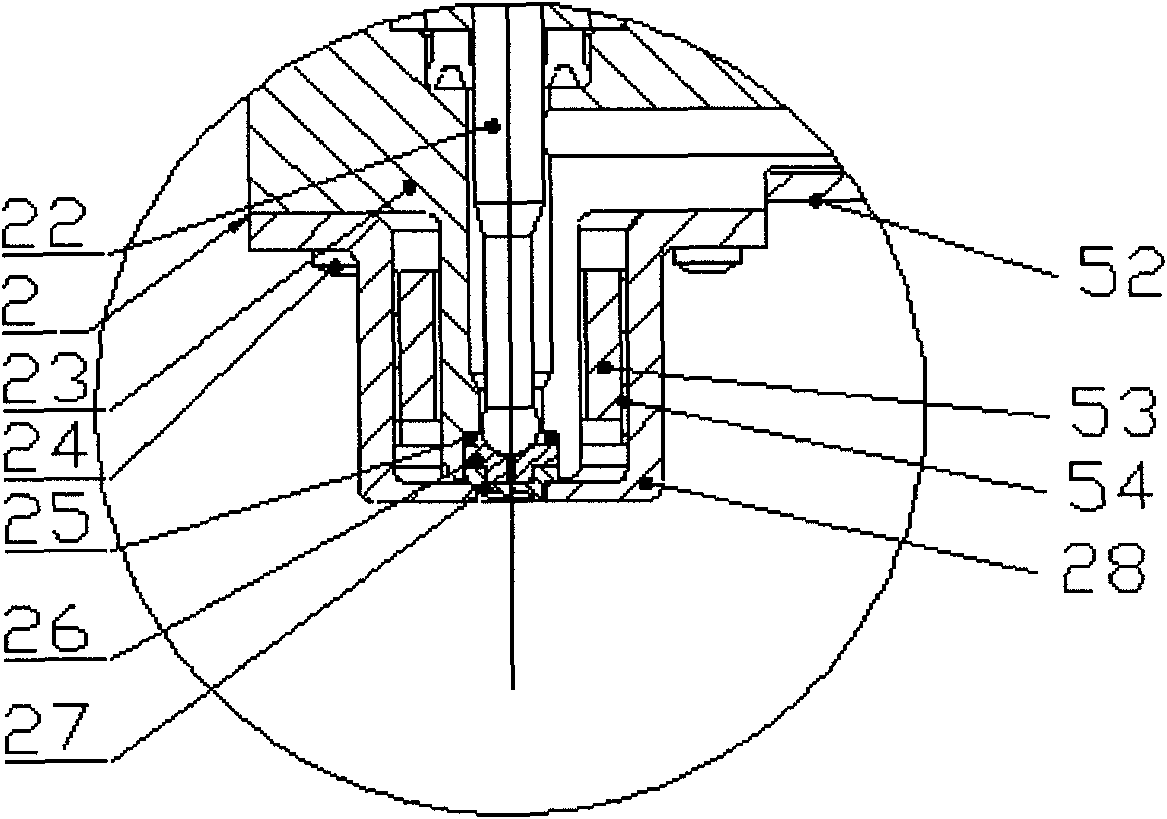

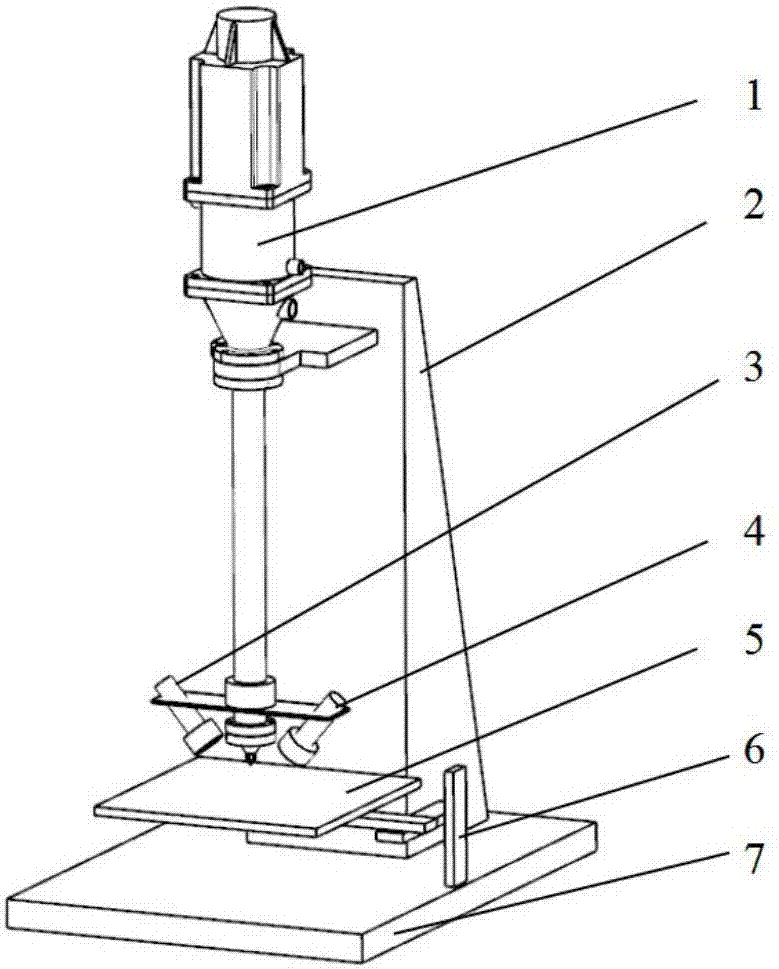

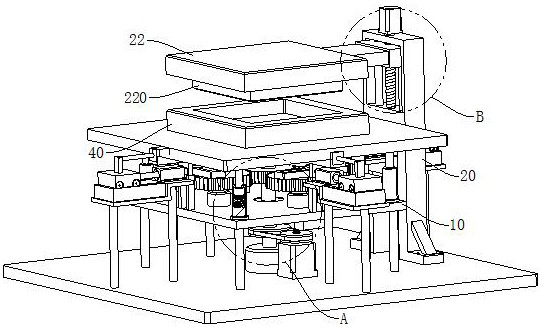

Ejecting adhesive dispenser based on dual-function cylinder

InactiveCN101844124AExtrude quicklyIncrease supplementLiquid surface applicatorsCoatingsThree stageDual function

The present invention provides an ejecting adhesive dispenser based on a dual-function cylinder, which comprises a driving mechanism, an ejecting mechanism, an adhesive supplying mechanism and a heating device. A device for a fine route tuning and a pre-pressure adjustment is arranged on the upper portion of the driving mechanism; the lower end of the driving mechanism is connected with the ejecting mechanism; the adhesive supplying mechanism is arranged on the side wall of the driving mechanism and connected with the ejecting mechanism via a feeding pipeline; and a three-stage heating device is provided around the head of the ejecting mechanism, the feeding pipeline and a feeding container. The driving mechanism comprises a dual-function cylinder and a returning spring; the ejecting mechanism comprises an ejecting needle integrated with the piston rod of the cylinder, a lower valve body and an ejecting head; and the ejecting head comprises an ejecting nozzle base, an ejecting nozzle and a clamping sleeve cup. The invention realizes the dispensing of high-viscosity fluid and has the advantages of micro amount, high speed, high frequency, no contact, high precision, high reliability, low cost and low requirements on processing precision.

Owner:SHANGHAI UNIV

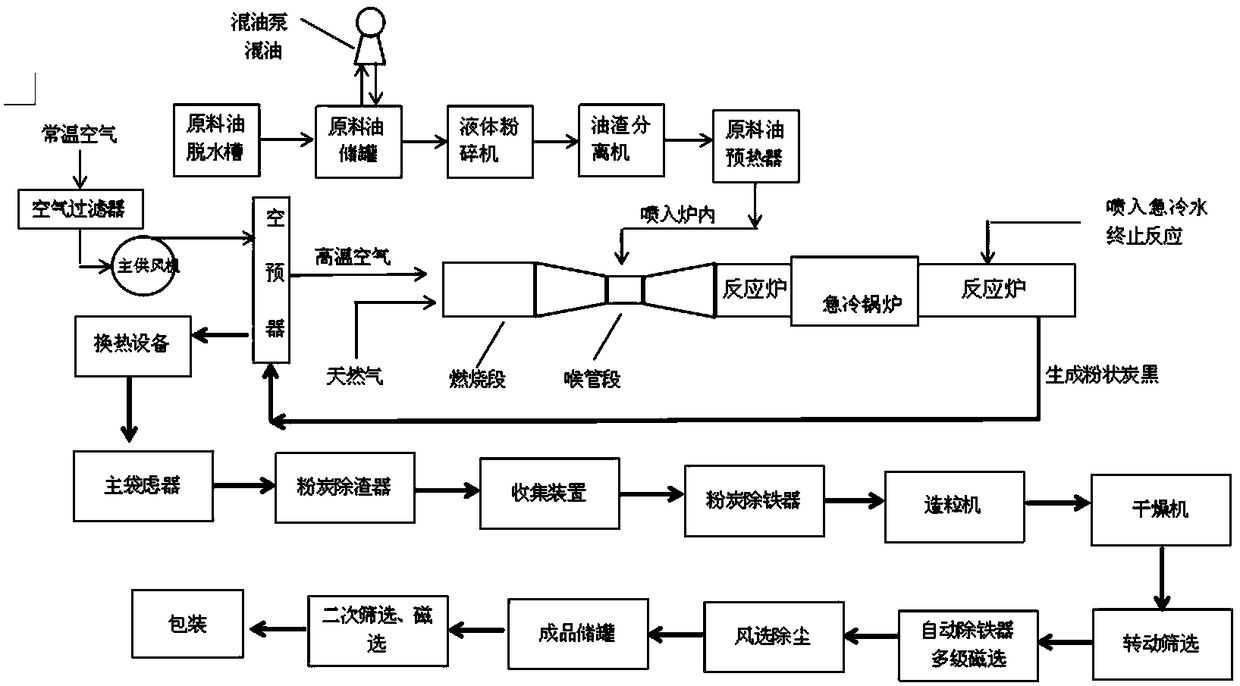

Production method for high-purity carbon black

ActiveCN109321005AImprove purityExtend your lifePigmenting treatmentCombustion chamberCrack resistance

The invention discloses a production method for a high-purity carbon black, which comprises the following steps: (Step 1) anthracene oil with a moisture content less than or equal to 0.2 percent and ethylene tar are sufficiently mixed according to the proportion of 8:2, and the mixed material is sequentially injected into a liquid pulverizer and an oil-residue separator and refined, so that refined material oil is obtained; (Step 2) natural gas and air are respectively filtered and then injected into the combustion chamber of a reaction furnace, wherein, after being filtered, the air is heatedto 900 DEG C, so that the temperature of the reaction furnace reaches 1800 DEG C to 2200 DEG C, wherein the refined material oil is heated to 250 DEG C to 300 DEG C, and the refined material oil andadditive are injected into a carbon black reactor of the reaction furnace to rapidly react for pyrolysis, so that the powdery carbon black is produced. The carbon black product produced by the invention has high purity and low ash, heavy metal, polycyclic aromatic hydrocarbon and sulfur contents, and can be highly dispersed to be completely combined with ingredients, the applicability, wear resistance, extrusion property, crack resistance, insulating property and conductivity of the product are increased, and the life of the product is greatly prolonged.

Owner:山东联科新材料有限公司

High specific gravity tungsten alloy material and preparation method thereof

The invention relates to a high specific weight tungsten alloy material and a preparation method thereof, and relates to a tungsten alloy material and a preparation method thereof. The invention solves the problems of poor plasticity, low strength, small deflection, large residual force of the prior high specific weight tungsten alloy product, and large equipment tonnage required, long demoulding time, tightly hermetical die and high cost in the method. The high specific weight tungsten alloy material is prepared by tungsten powder, nickel powder, iron powder and cobalt powder. The preparation method comprises the following steps: firstly, preparation of mixed powder A; secondly, preparation of a blank; thirdly, sintering of the blank; fourthly, preparation of mixed powder B; fifthly, preparation of a lubricating medium; and sixthly, acquisition of the high specific weight tungsten alloy material by placing the blank and the lubricating medium into the die for extrusion forming. The high specific weight tungsten alloy material has good plasticity, large strength, large deflection and small residual force. The preparation method is simple, has small equipment tonnage required, short demoulding time and low cost, and has no strict requirement on the die.

Owner:于洋

Server information processing equipment based on internet big data

InactiveCN112000186AImprove the effect of cooling and heat preservationExtrude quicklyDigital processing power distributionModifications using gaseous coolantsInformation processingThe Internet

The invention relates to the technical field of servers. The invention further discloses server information processing equipment based on the internet big data. The equipment comprises a shell, an endcover is fixedly connected to the upper end of the shell, a compressed air bag is fixedly installed on the side wall of an inner cavity of the shell, a framework body is fixedly connected to the inner cavity of the shell, a processor is fixedly installed in the inner cavity of the framework body, and heat storage rings are fixedly connected to the front wall and the rear wall of the inner cavityof the framework body. The invention discloses server information processing equipment based on internet big data. Thermal expansion or cold contraction is carried out through the hot air bag; the heat conduction rod is controlled to be in corresponding contact with the heat storage ring; and the piston rod moves at high temperature to drive the pressing plates on the two sides to move in the opposite directions, the springs are used for extruding the pressing air bags, and then the sealing plates are matched to reasonably seal and open the heat dissipation holes, so that the cooling and heatpreservation effects of the equipment during normal operation are improved, and the heat dissipation effect of the equipment at high temperature is improved.

Owner:汪彩云

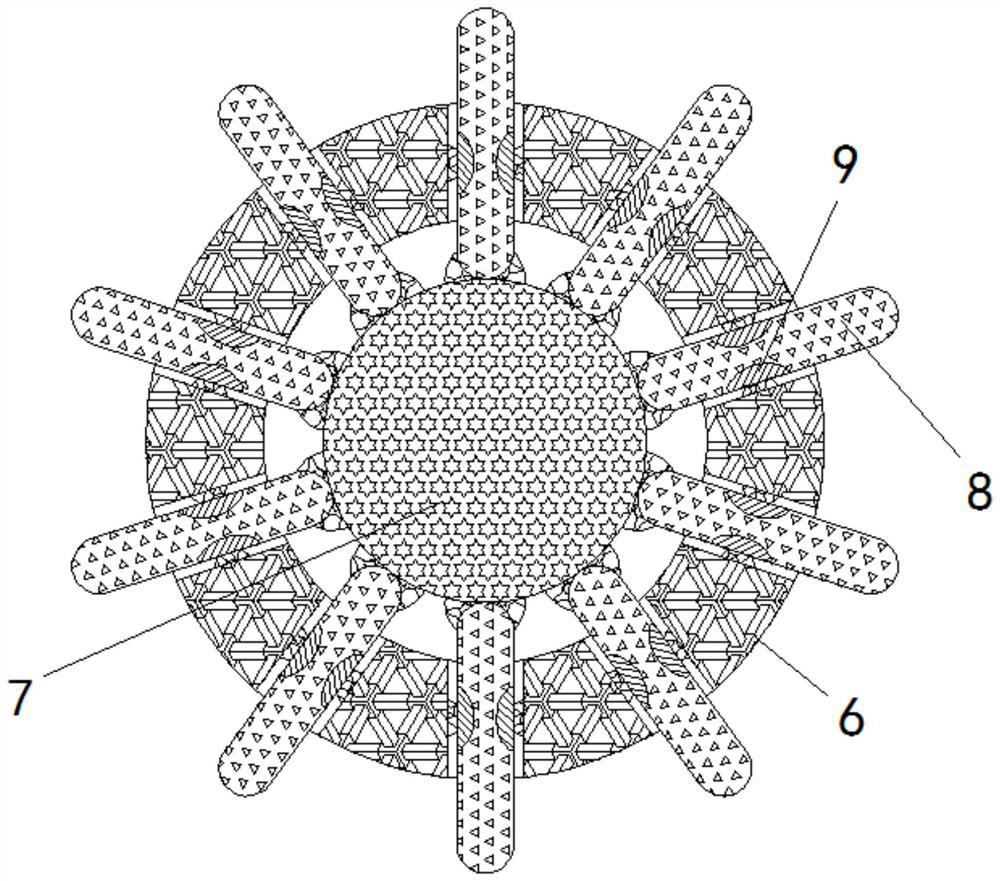

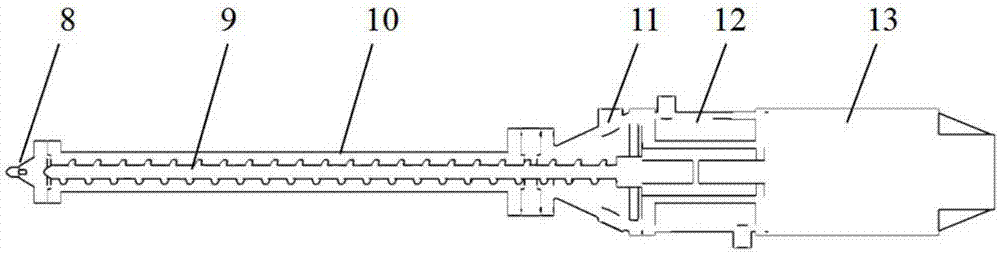

Screw type additive manufacturing spray head

InactiveCN106217867AEasy to useLow costAdditive manufacturing apparatusHeater RodPulp and paper industry

The invention discloses a screw type additive manufacturing spray head. Particles of the conventional size can be used as a raw material, the material extrusion process is stable, the extrusion force is large, and the forming efficiency is high. The screw type additive manufacturing spray head comprises a machine barrel, a nozzle fixed to the front end of the machine barrel, a screw arranged in the machine barrel and a drive motor fixed to the rear end of the machine barrel. The tail end of the screw is arranged in a cone shape. The front end of the screw is connected with the output end of the drive motor. The part, provided with a thread, of the screw is sequentially provided with a feeding segment, a compression segment and a metering segment from the front end to the tail end according to threaded groove depths. The groove depth of the feeding segment is the maximum, and the feeding segment is arranged in an equal groove depth manner. The groove depth of the metering segment is the minimum, and the metering segment is arranged in an equal groove depth manner. The groove depth of the compression segment is gradually changed into the minimum groove depth from the maximum groove depth. A feeding opening is formed in the position, corresponding to the feeding segment of the screw, of the machine barrel. A first heating ring is arranged at the position, corresponding to the compression segment, of the machine barrel, and a second heating ring is arranged at the position, corresponding to the metering segment, of the machine barrel. The interior of the nozzle is arranged in the manner of a conical face matched with the tail end of the screw. A set of heating bars is arranged on the nozzle in an inserted manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

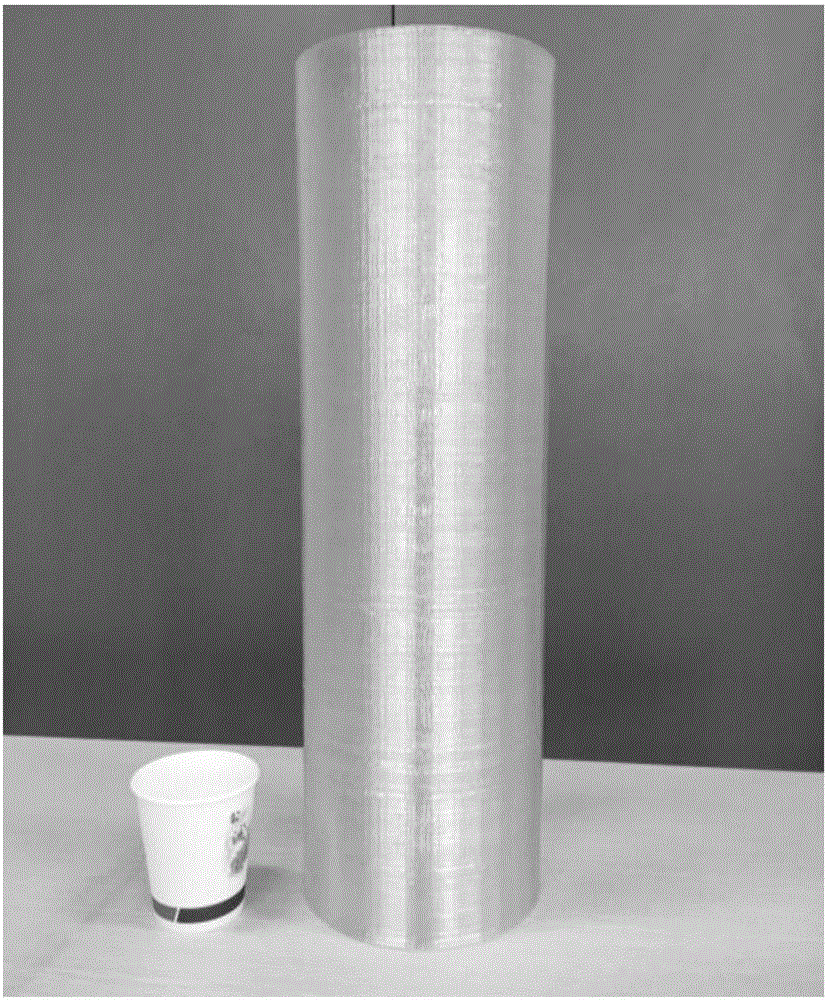

3D printing device and method for high-molecular-weight silicone rubber

ActiveCN107283819AExtended service lifeQuality improvementAdditive manufacturing with liquidsApplying layer meansEngineeringUltimate tensile strength

The invention discloses a 3D printing device and method for high-molecular-weight silicone rubber. A hundred-micron-level micropore nozzle with the high shearing rate and high extruding strength and for screw extruding force is adopted in a 3D printing head system, the flowing viscosity of the high-molecular-weight silicone rubber is greatly reduced, and 3D printing forming of a high-molecular-weight, high-compression-modulus and long-service life silicone rubber material is achieved. The extrusion and expansion stability of the material on the hundred-micron-level micropore nozzle is improved, the dimensional precision of a 3D printing fluid line is accurately controlled, and high quality, high precision and high efficiency in the 3D printing process are achieved. A photo-thermal two-order curing material 3D printing manner is adopted, the curing rate and dimensional precision of the 3D printing material are greatly increased, the high quality and stability of the 3D printing high-molecular-weight silicone rubber material are improved, and the macro-performance and structure adjustability of the 3D printing material are achieved.

Owner:XIAN LIANCHUANG ADVANCED MFG A SPECIALIZED INCUBATOR CO LTD

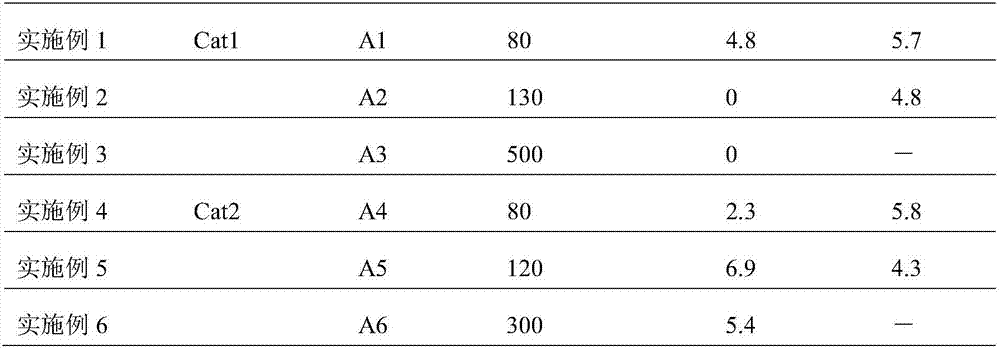

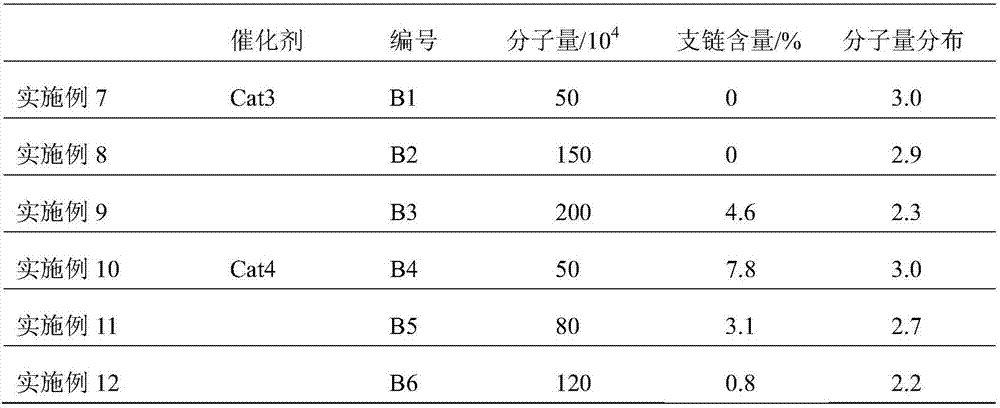

Powder for preparing polyethylene microporous membrane and its preparation method and application

InactiveCN106947154AEasy to processImprove performanceSemi-permeable membranesPolymer scienceSolvent

The invention relates to powder for preparing a polyethylene microporous membrane and its preparation method and application. The powder comprises, by weight, 1-99 parts of polyethylene A and the balance of polyethylene B. The polyethylene A has viscosity average molecular weight of 0.8 to 5 million, molecular weight distribution greater than 3 and branched chain content of 0 to 20%. The polyethylene B has viscosity average molecular weight of 0.5 to 2 million, molecular weight distribution of 1-3 and branched chain content of 0-10%. Compared with the existing powder, the powder provided by the invention has the characteristics of adjustable molecular weight and distribution, processing easiness and good product performances. In processing, a use amount of the solvent can be adjusted according to powder molecular weight and distribution so that a high processing rate is guaranteed and processing benefits are improved. The preparation method is simple, greatly improves processing performances in the preparation of a microporous membrane from ultra-high polyethylene, reduces a solvent use amount, reduces pollution, reduces a cost and has a good application prospect.

Owner:SHANGHAI RES INST OF CHEM IND

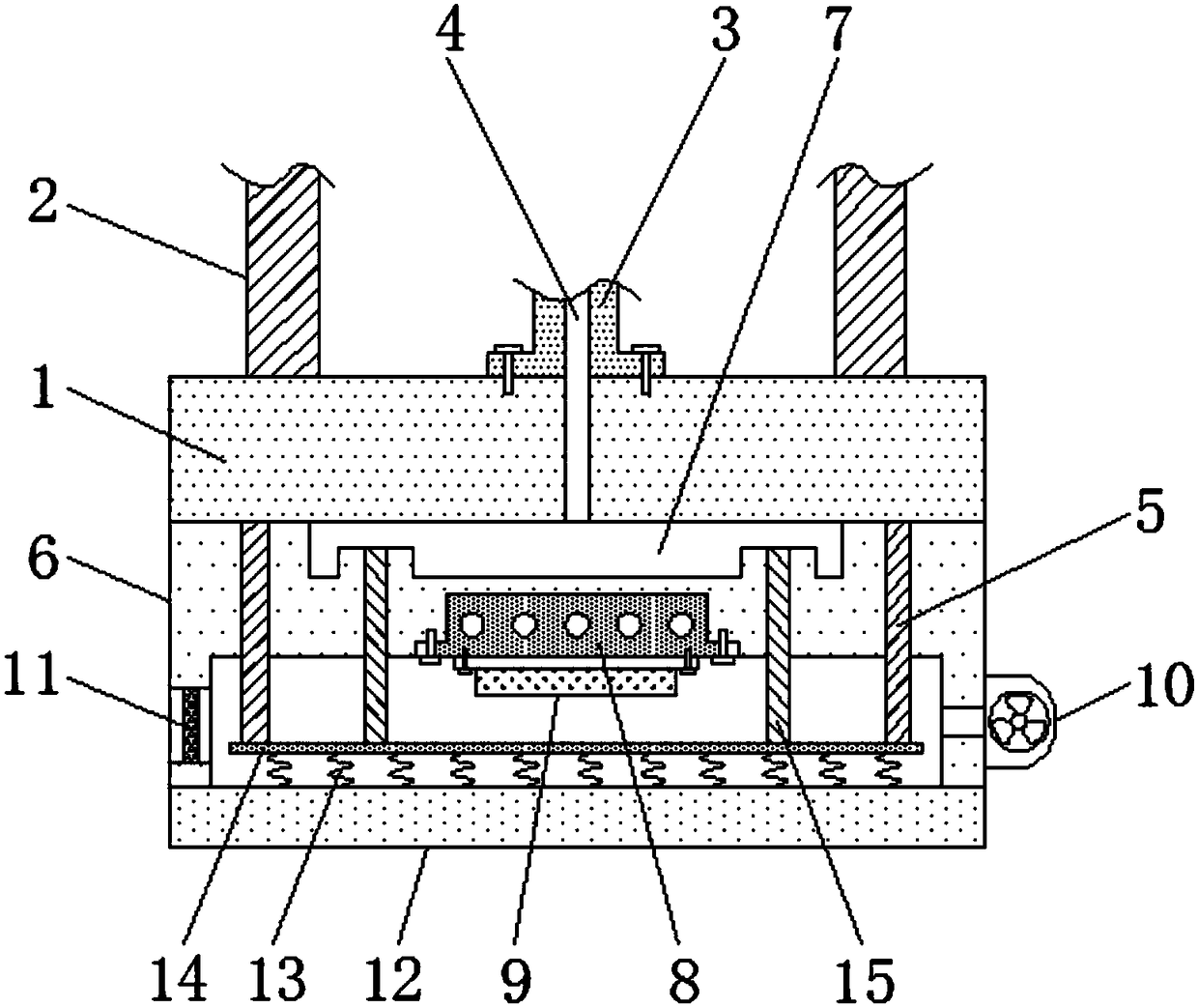

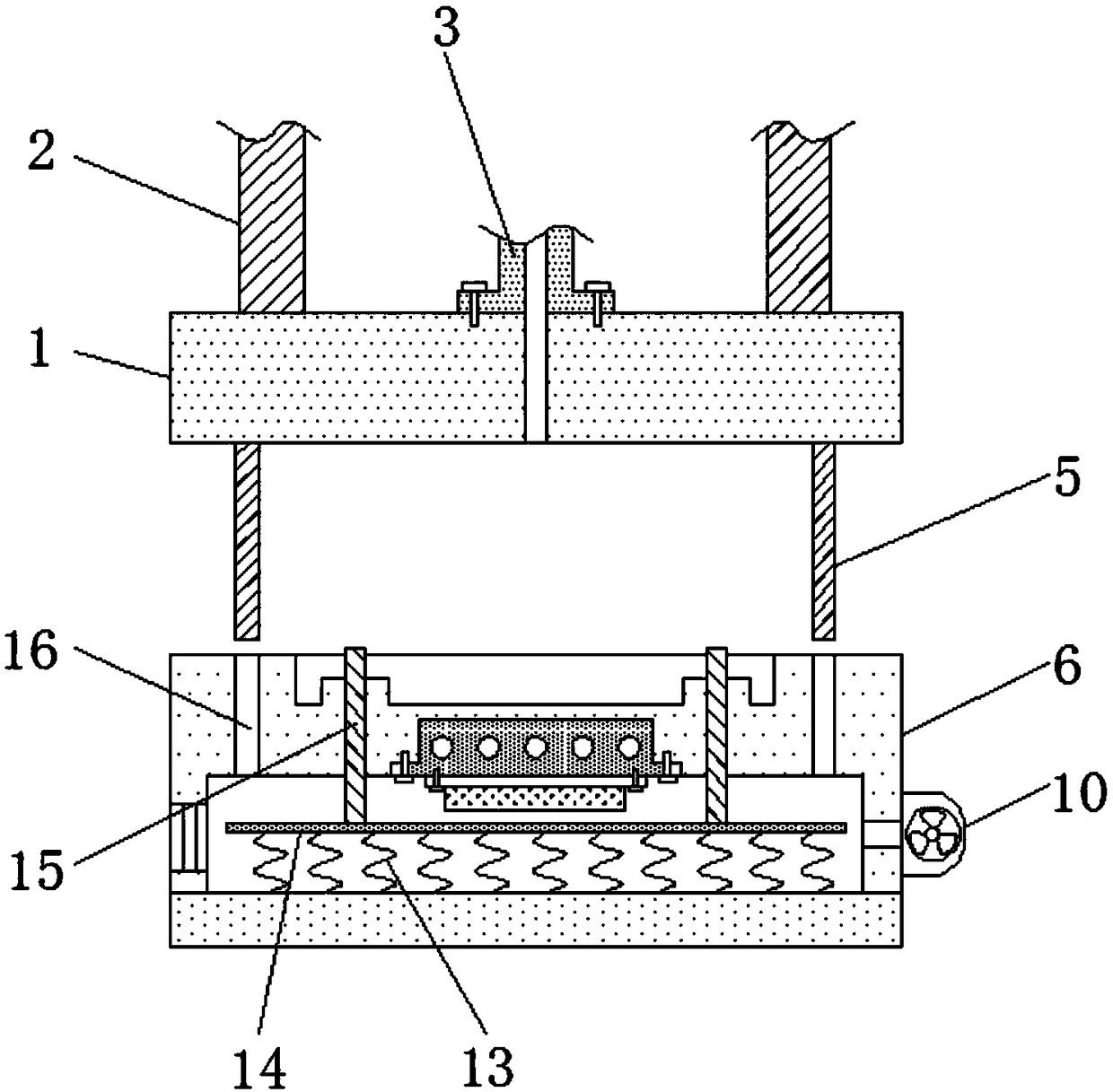

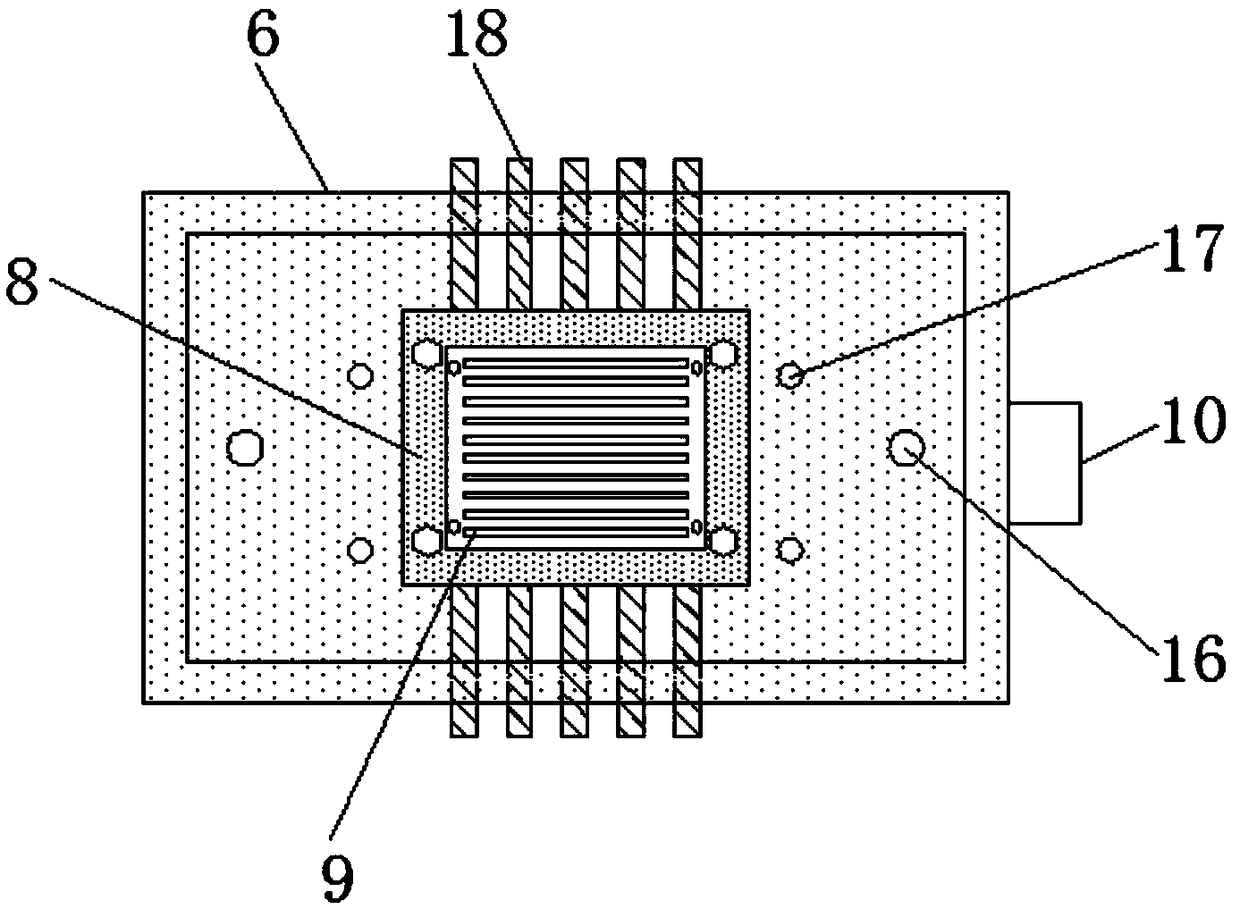

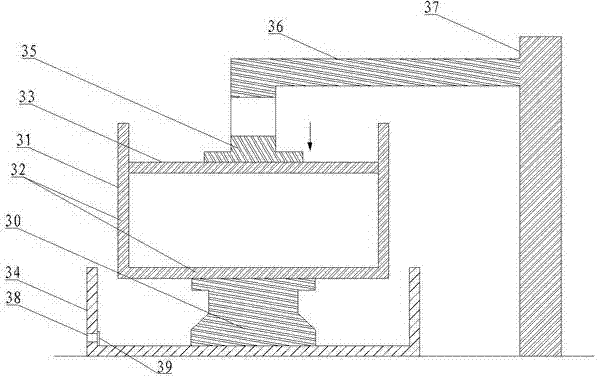

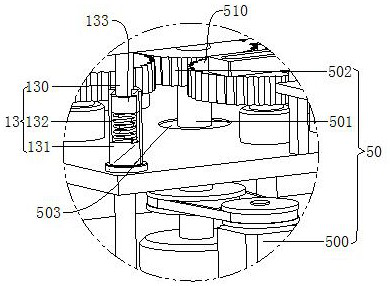

Injection mold capable of achieving fast cooling and demolding

The invention discloses an injection mold capable of achieving fast cooling and demolding. The injection mold comprises an upper mold body, a lower mold body and a base; pressing rods are connected tothe two sides of the upper end of the upper mold body correspondingly; injection molding flow channels are pre-reserved inside the upper mold body and an injection molding head; the lower mold body is located at the lower end of the upper mold body; a heat conducting plate is disposed inside the lower end of the lower mold body; fins are connected to the lower end surface of the heat conducting plate; a fan is mounted at the right end of the outer side of the lower mold body; the base is located at the lower end of the lower mold body; demolding rods are disposed on the two sides of the upperend of a connecting plate correspondingly and penetrate through the lower mold body through second guiding holes; connecting pipes are connected to the front side and the rear side of the heat conducting plate correspondingly; and a heat dissipation flow channel is pre-reserved inside the heat conducting plate. By means of the injection mold capable of achieving fast cooling and demolding, duringinjection molding of plastic products, fast cooling and demolding of the plastic products can be achieved, the manufacturing time of the plastic products can be shortened, and the economic benefits are improved.

Owner:杨传平

Easily-processed polyethylene composition

InactiveCN104558789AFast processingProcessed polyethylene compositions can be produced rapidly using existing film making equipmentPhosphoric Acid EstersPolymer science

The invention provides an easily-processed polyethylene composition, and belongs to the technical field of processing of polyethylene films. The easily-processed polyethylene composition is characterized by being prepared from the following components in parts by weight: 100 parts of polyethylene, 0.03 to 0.1 part of an antioxidant, 0.05 to 0.08 part of an acid acceptor, and 0.05 to 0.5 part of a processing auxiliary; a hydroxystearic acid salt compound is used as the processing auxiliary; a mixture of an hindered phenol antioxidant, a phosphite ester antioxidant and a thioester antioxidant is used as the antioxidant. Compared with the existing polyethylene film, the easily-processed polyethylene composition has the advantages of being small in shearing viscosity and screw torque, high in critical shearing rate, fast to produce the film, and outstanding in optical performance.

Owner:CHINA PETROLEUM & CHEM CORP

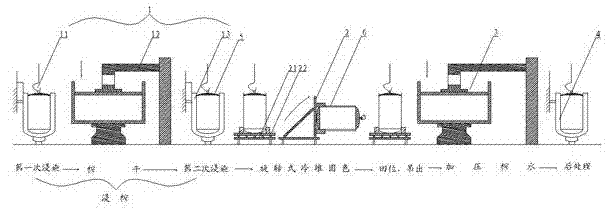

Cold-pad batch dyeing process for loose fibers

ActiveCN103774363AEvenly distributedPromote absorptionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberPolymer science

The invention belongs to the technical field of loose fiber dyeing and relates to cold-pad batch dyeing process for loose fibers. The cold-pad batch dyeing process for loose fibers comprises the steps of soaking and squeezing, rotating type cold-patch treatment, pressing and water squeezing and post-treatment. The loose fibers are soaked and squeezed in a twice soaking and once squeezing mode, the rotating type cold-patch treatment is then conducted, the loose fibers are pressed and water is squeezed out after the rotating type cold-patch treatment is conducted, and after the water and dye in a loose fiber cake or loose fibers are squeezed out, the loose fiber cake or loose fibers are sent for post-treatments of drying and the like. The cold-pad batch dyeing process for loose fibers is applied to cold-pad batch dyeing of the loose fibers and has the advantages of being uniform in dyeing, small in water consumption and the like. In addition, procedures are simple.

Owner:绍兴国周针织科技有限公司

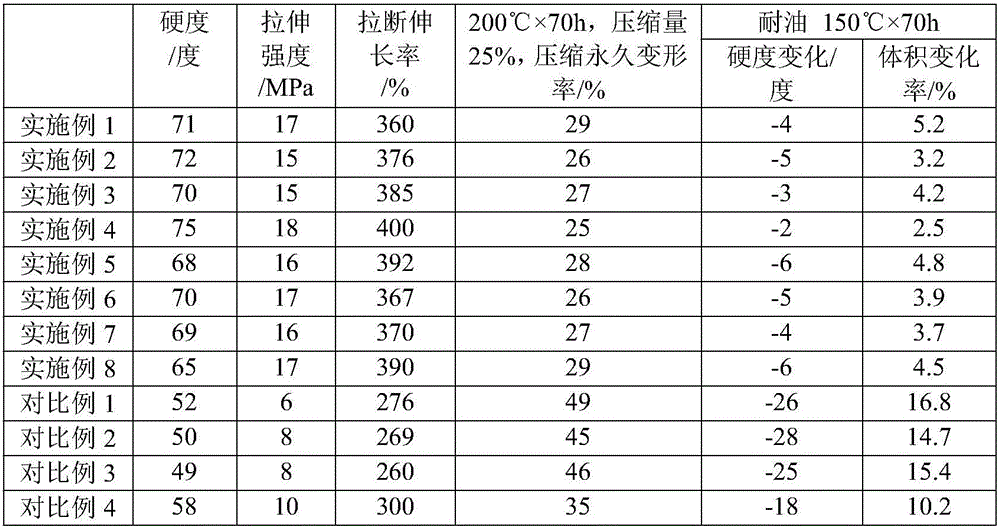

Seal ring for special fluororubber motor for nuclear power and preparation method of seal ring

ActiveCN106589709AGood oil resistance at high temperatureImprove performanceNuclear powerEngineering

The invention discloses a seal ring for a special fluororubber motor for nuclear power and a preparation method of the seal ring. The seal ring for the special fluororubber motor for the nuclear power is prepared from the following raw materials in parts by weight: 85 to 90 parts of fluororubber, 5 to 8 parts of acid-acceptor, 2 to 5 parts of compound vulcanizing agent, 8 to 10 parts of reinforcing agent and 1 to 2 parts of additive. The fluororubber motor seal ring is high in mechanical strength, excellent in oil resistance under high temperature, and suitable for a motor of a nuclear-powered ship.

Owner:南阳天一密封股份有限公司

Granules Comprising Bitumen and a Thermoplastic Polyurethane Elastomer, Method for its Preparation and its Uses

ActiveUS20150291798A1Good dispersionReduce preparation timeWorking-up pitch/asphalt/bitumen by solidifying/disintegratingTextiles and paperFiberThermoplastic polyurethane

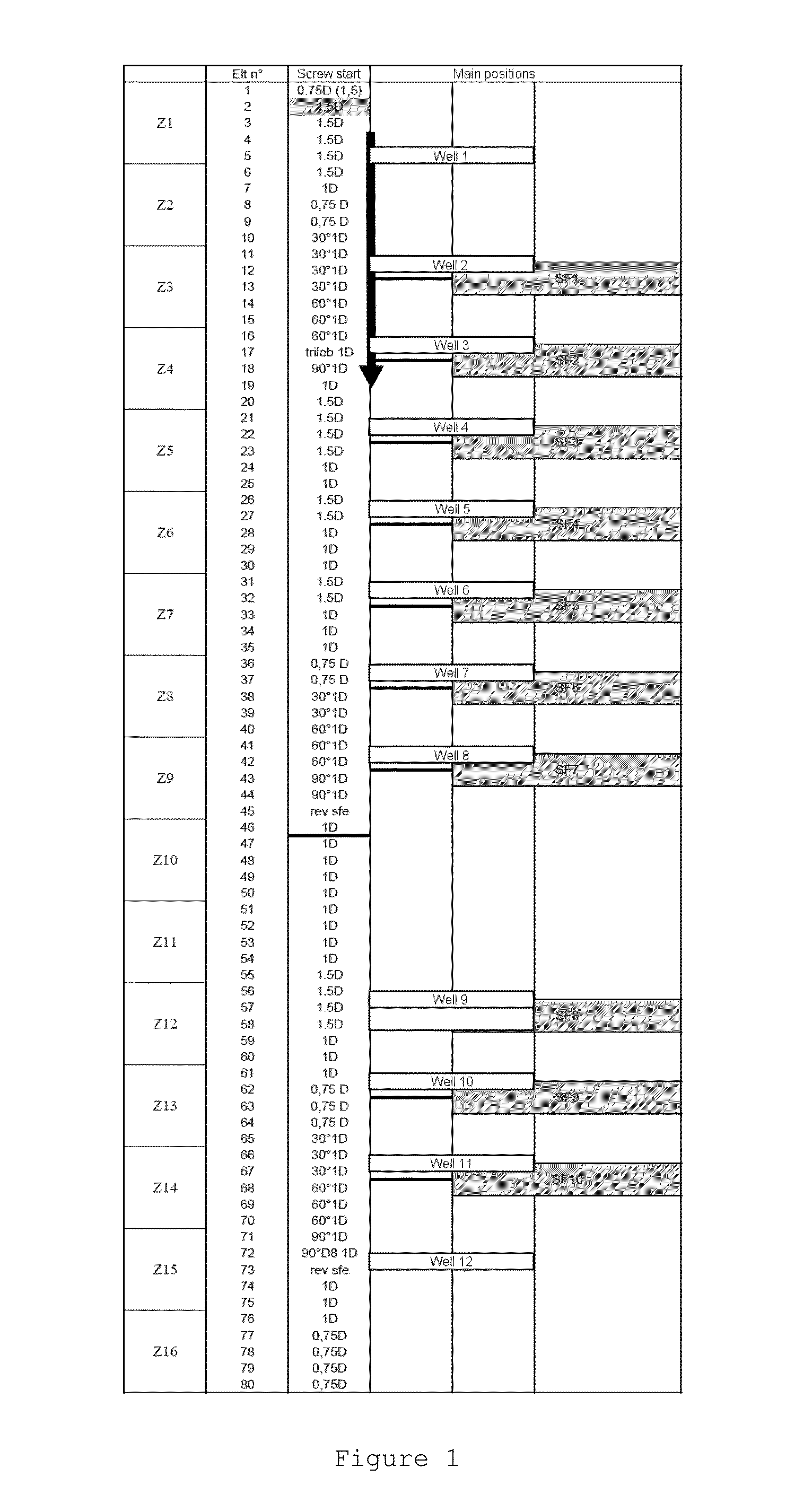

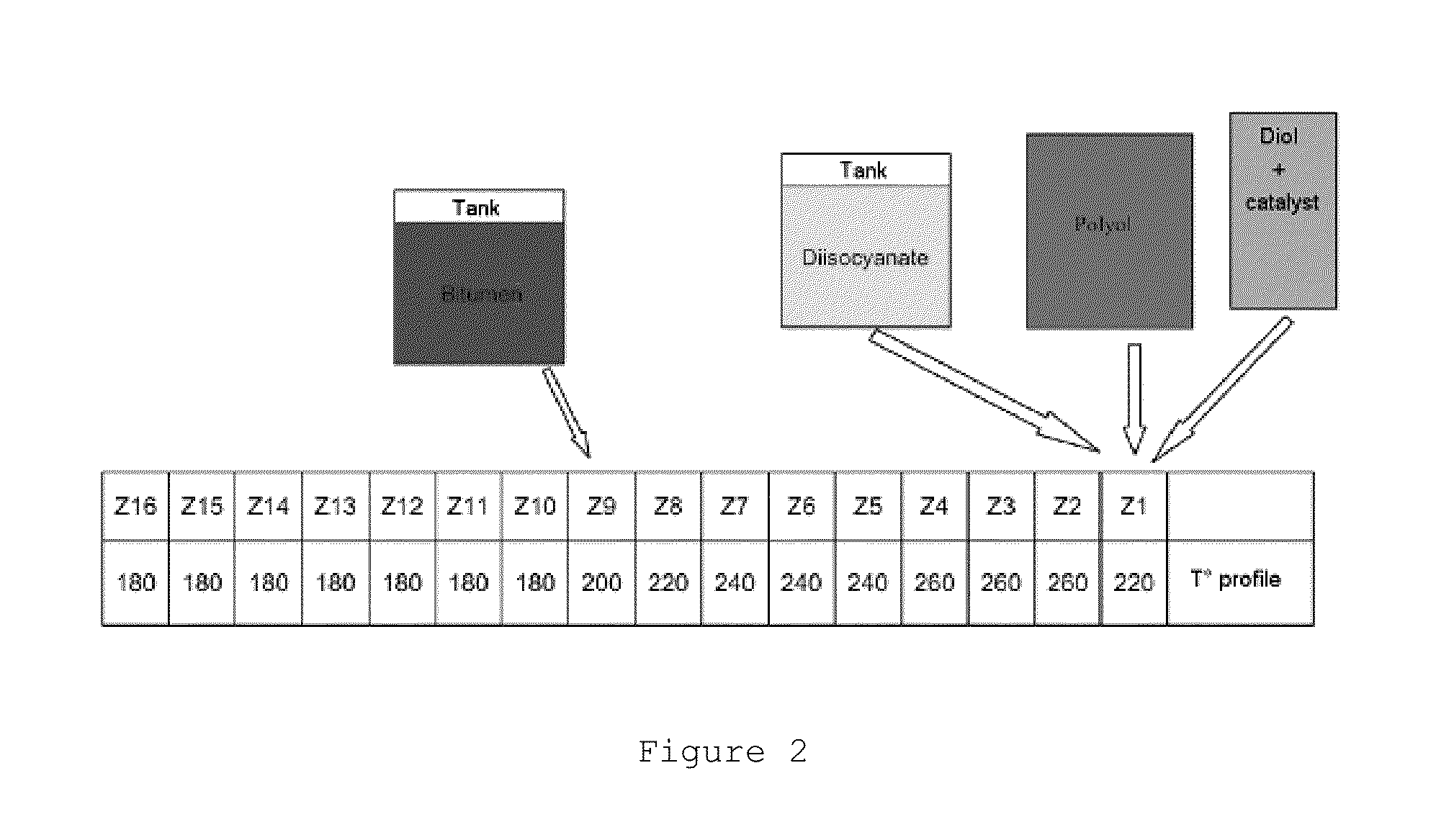

Disclosed are granules comprising an elastomeric polyurethane and bitumen, processes for preparing the granules in an extruder and to their use for preparing a bituminous binder, which may especially be used for producing prefabricated sealing membranes by depositing said bituminous binder onto a fibrous support.

Owner:SOPREMA SA

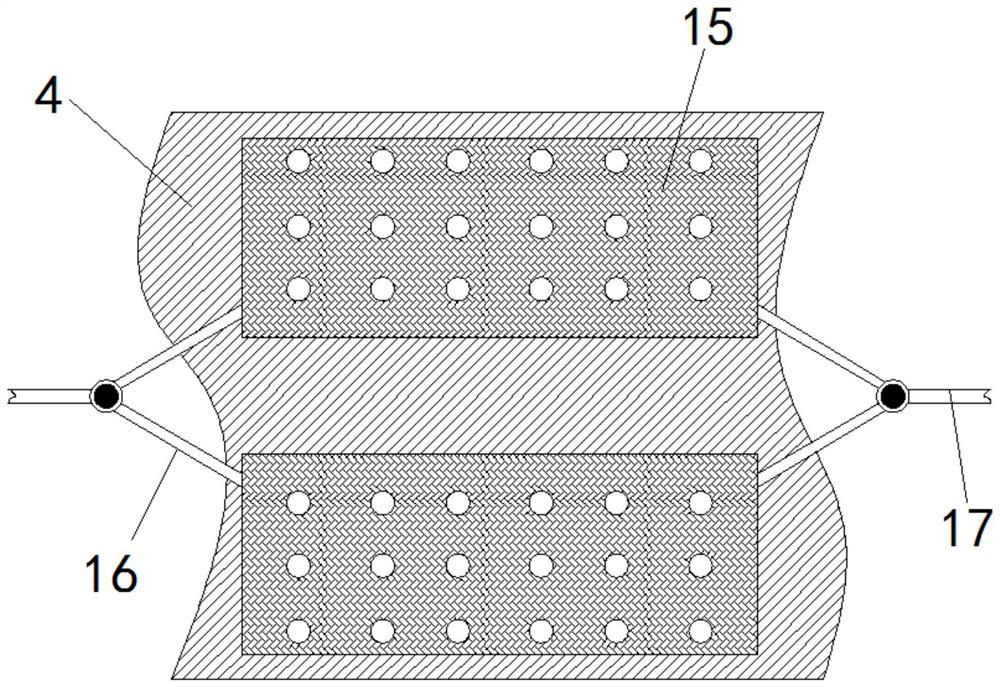

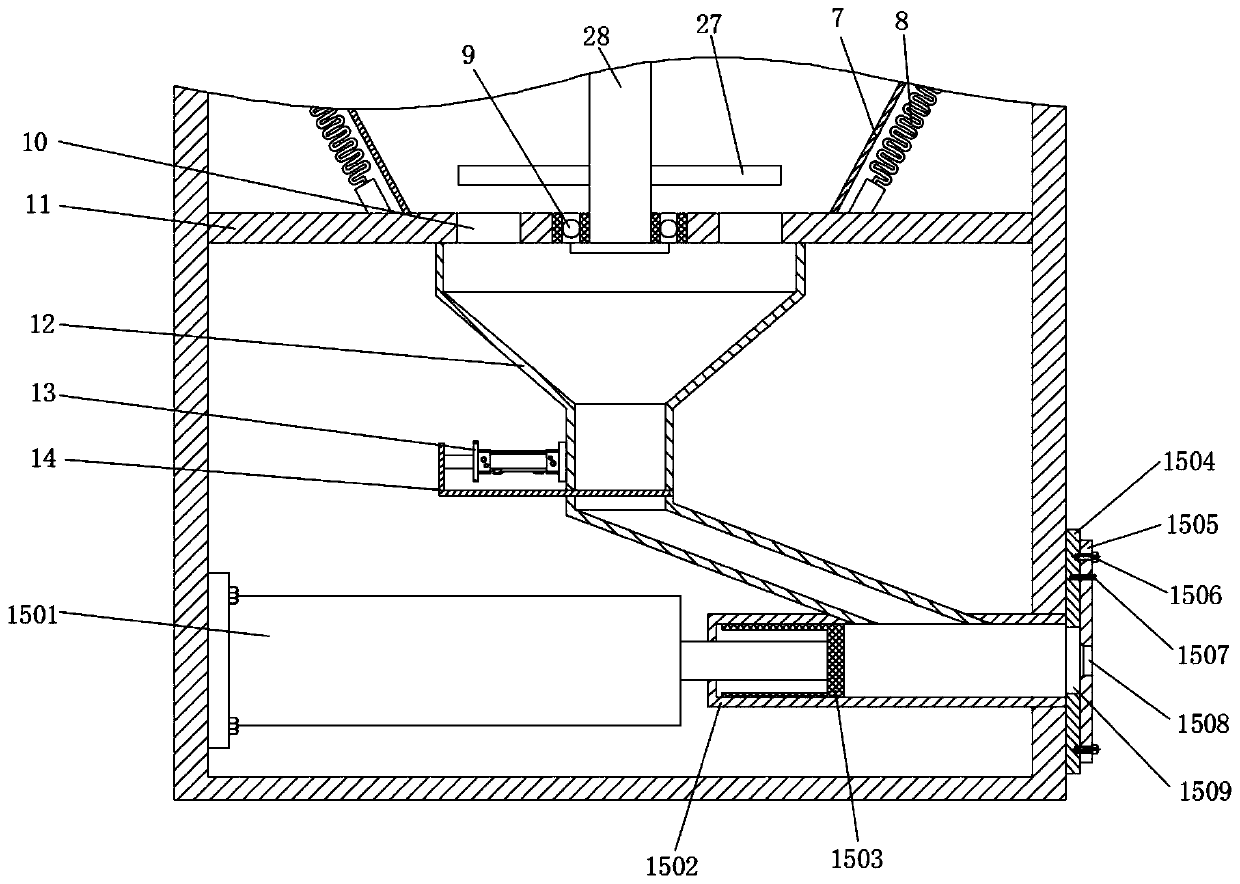

Dual-pressure waterproof roll material coating device

ActiveCN111054578AAvoid deformationImprove finished product qualityPretreated surfacesCoatingsBituminous waterproofingEngineering

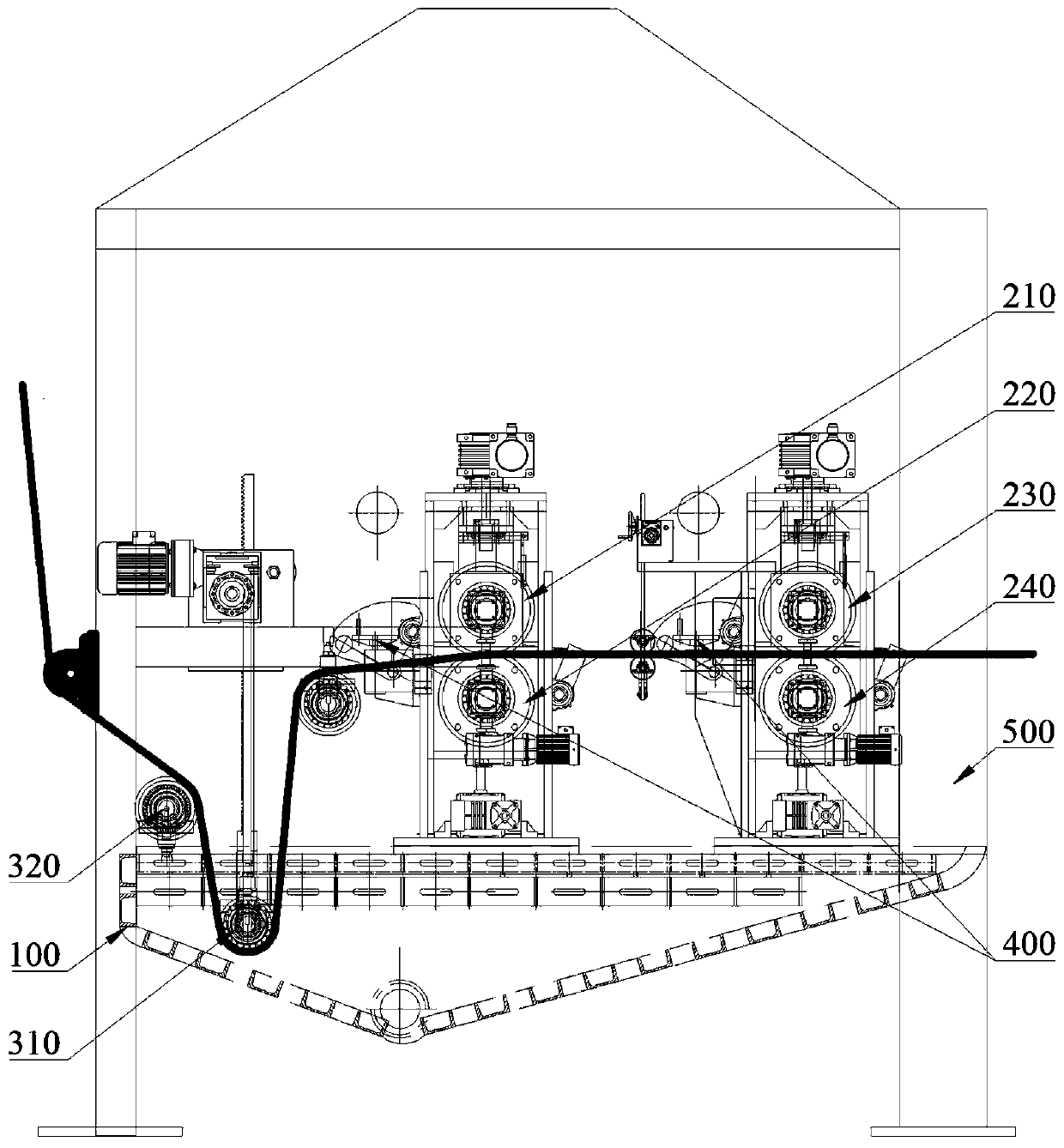

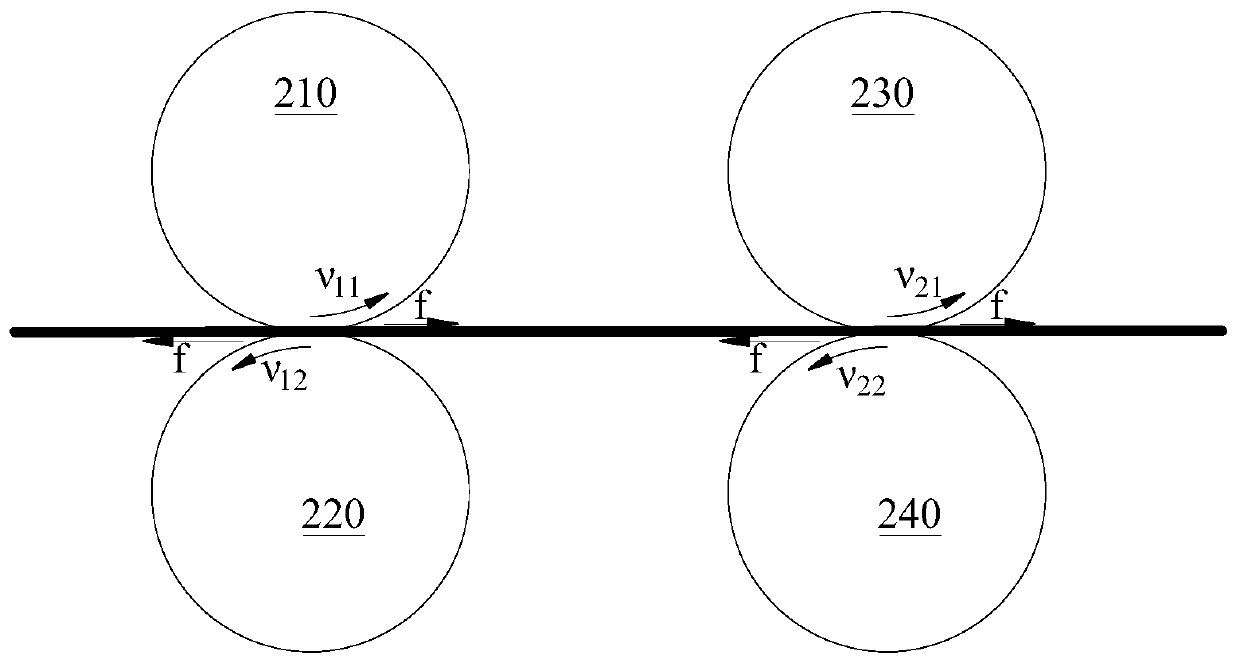

The invention relates to the technical field of bituminous waterproof roll material production equipment and discloses a dual-pressure waterproof roll material coating device. The dual-pressure waterproof roll material coating device comprises a coating tank used for containing and / or receiving bitumen and a dual straight row extrusion forming mechanism arranged above the coating tank. The dual straight row extrusion forming mechanism comprises two pairs of extrusion rolls arranged in pairs, and the two pairs of extrusion rolls have heat and are spaced and used for the first upper extrusion roll and the first lower extrusion roll which are used for coarse pressing and the second upper extrusion roll and the second lower extrusion roll which are used for finish pressing. The rotating speedof the first upper extrusion roll is higher than that of the second upper extrusion roll. The dual-pressure waterproof roll material coating device is provided with the dual straight row extrusion forming mechanism, and each extrusion roll has heat; the dual-pressure waterproof roll material coating device further softens bitumen at the contact position to squeeze air and fill seams more rapidly to prevent generation of bubbles while conducting extrusion. Through combination of the coarse pressing process and the finish pressing process, the extrusion compactness and uniformity are improved. At least the first upper extrusion roll and the second upper extrusion roll are driven by different driving mechanisms, and the probability of deformation is greatly reduced.

Owner:重庆科顺新材料科技有限公司

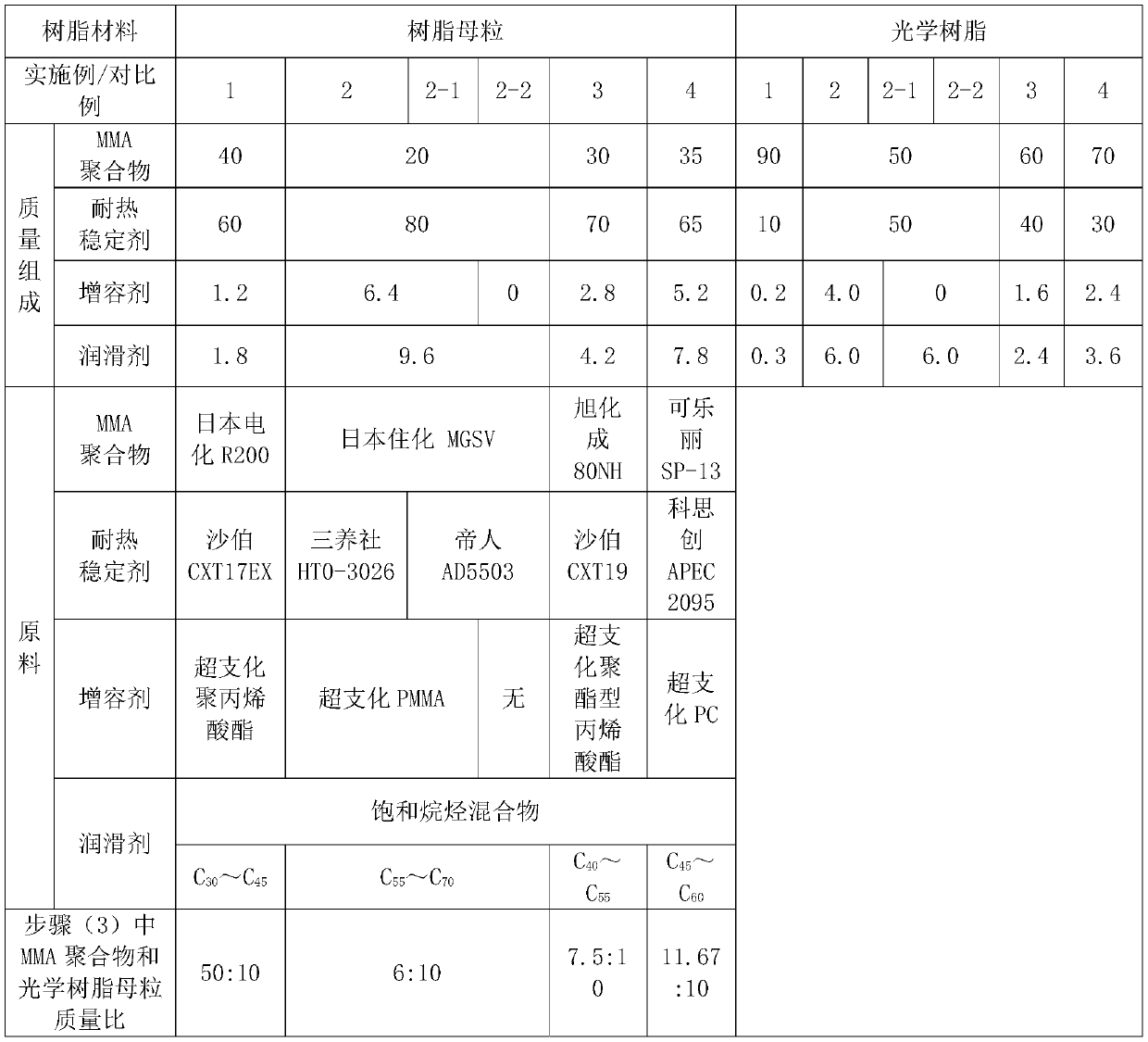

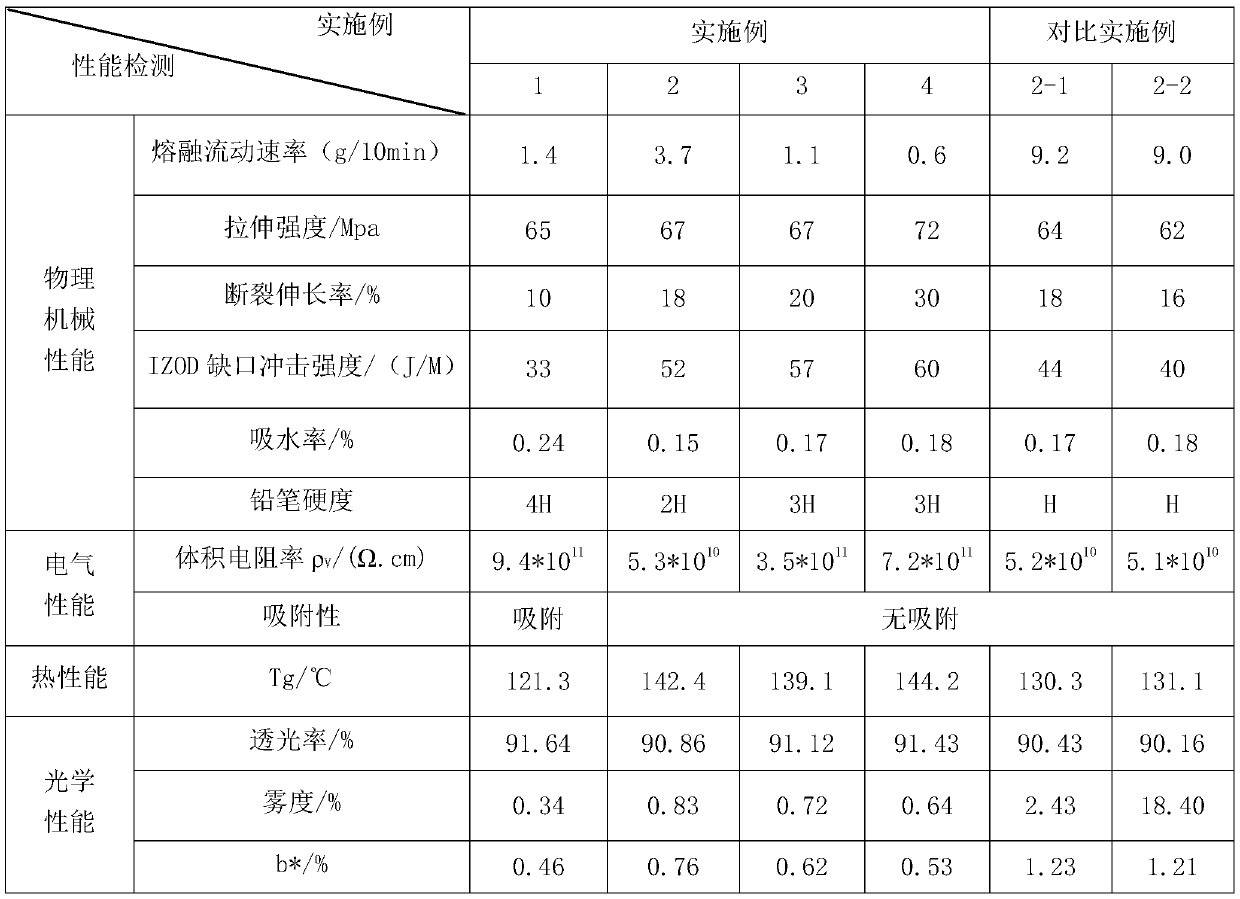

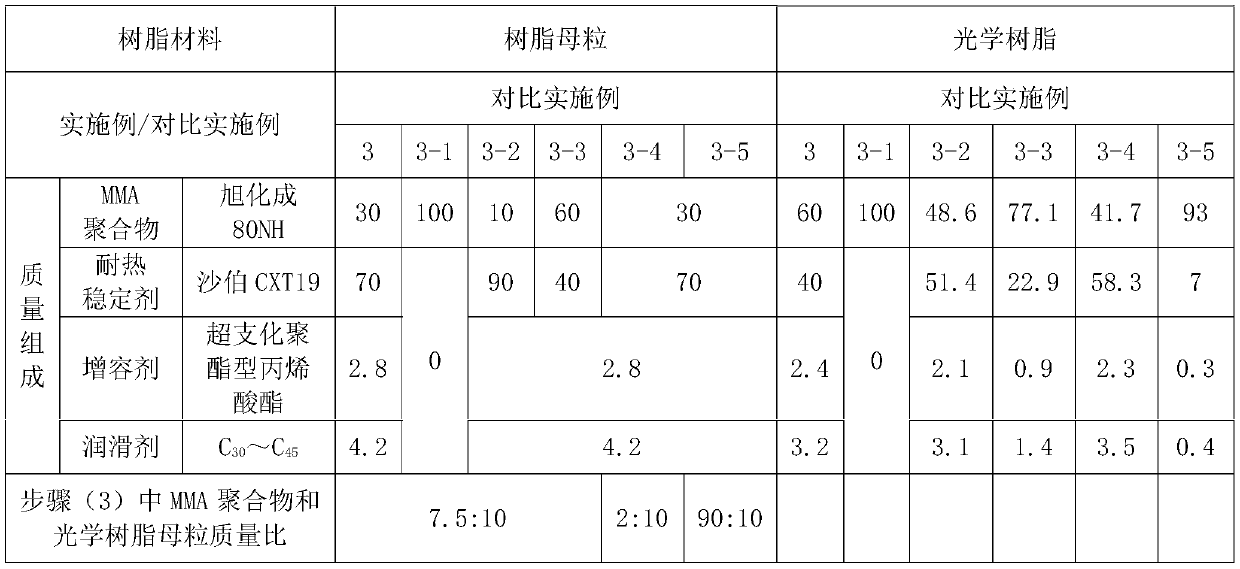

Optical resin for optical protective film and preparation method thereof

ActiveCN111423683AImprove thermal stabilityPlasticized wellOptical elementsPolymer scienceOptical property

The invention relates to an optical resin for an optical protective film and a preparation method thereof. The optical resin for the optical protective film is prepared from the following components in parts by mass: 50-90 parts of a methyl methacrylate polymer, 10-50 parts of a heat-resistant stabilizer, 0.2-4.0 parts of a compatibilizer and 0.3-6.0 parts of a lubricant. The heat-resistant stabilizer is copolycarbonate micro powder. The preparation method of the optical resin for the optical protective film comprises the steps of preparation of the heat-resistant stabilizer, preparation of anoptical resin master batch, preparation of the optical resin and the like. The method is simple in process, low in energy consumption and easy to realize industrialization. Compared with PMMA opticalresin produced in the prior art, the prepared optical resin for the optical protective film has outstanding heat-resistant stability and toughness, relatively low hygroscopicity and volume resistivity and less surface static electricity and is not easy to adsorb dust on the premise of ensuring basic physical and mechanical properties and optical properties.

Owner:聚纶材料科技(深圳)有限公司 +1

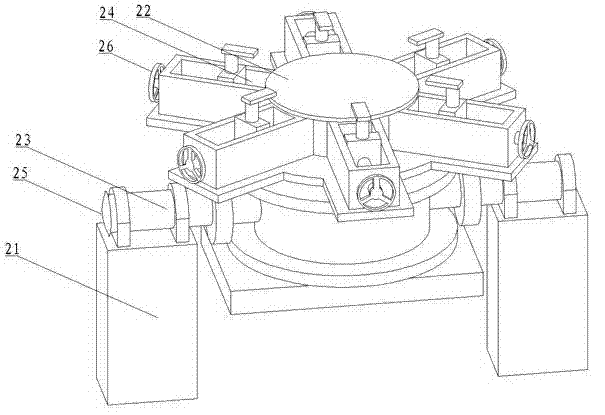

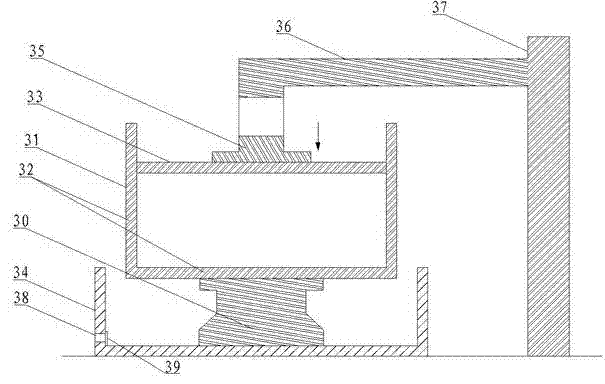

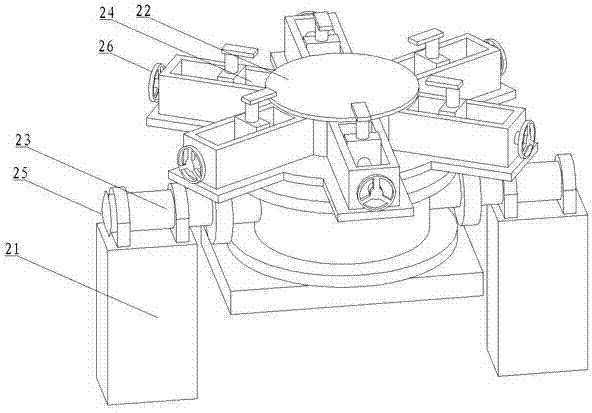

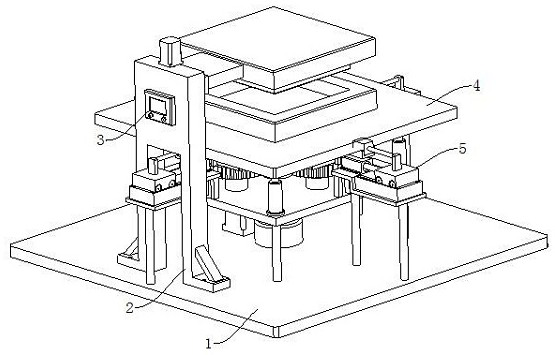

Wringer suitable for loose fiber or loose fiber cake dehydration

InactiveCN103774367AReduce the difficulty of washingReduce water consumptionLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentPistonPower component

The invention relates to a wringer suitable for loose fiber or loose fiber cake dehydration and belongs to the technical field of loose fiber dyeing. The wringer comprises a base, a cylindrical cylinder body and a top plate. The cylindrical cylinder body is arranged on the base. A leakage hole is formed in the cylindrical cylinder body. The top plate is movably connected with the cylindrical cylinder body. The upper portion of the top plate is connected with a pressure component. A power component drives the top plate to carry out piston motion in the cylindrical cylinder body, so that moisture in loose fibers in the cylindrical cylinder body is squeezed out. The wringer is used for loose fiber cold rolling stack dyeing and has the advantages that dyeing is even, the amount of used water is small, and procedures are simple.

Owner:绍兴国周针织科技有限公司

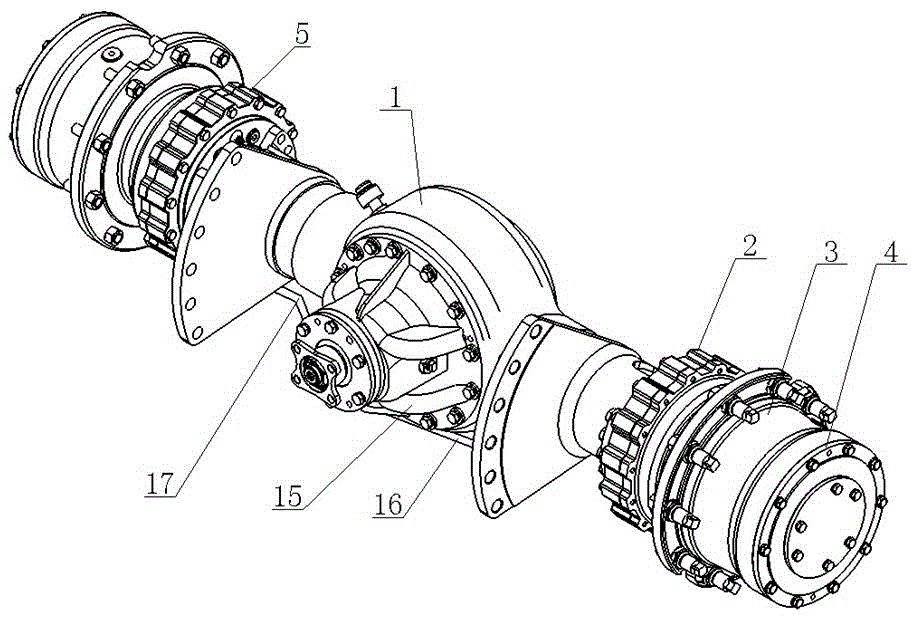

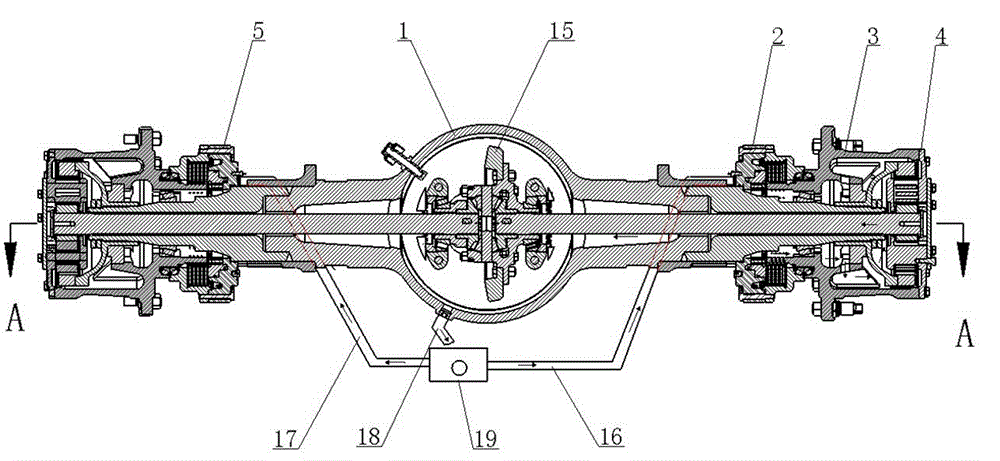

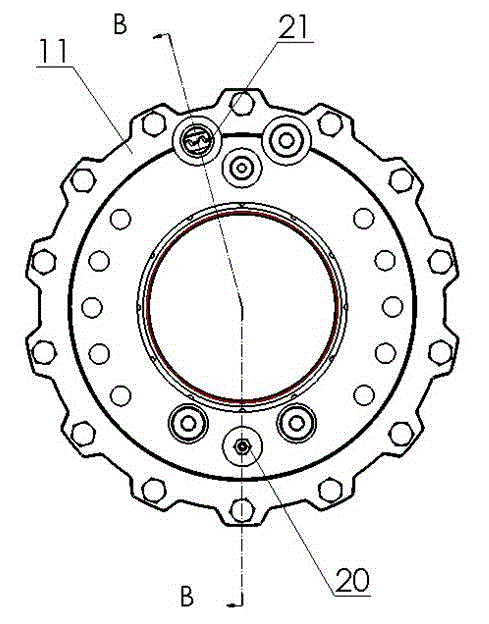

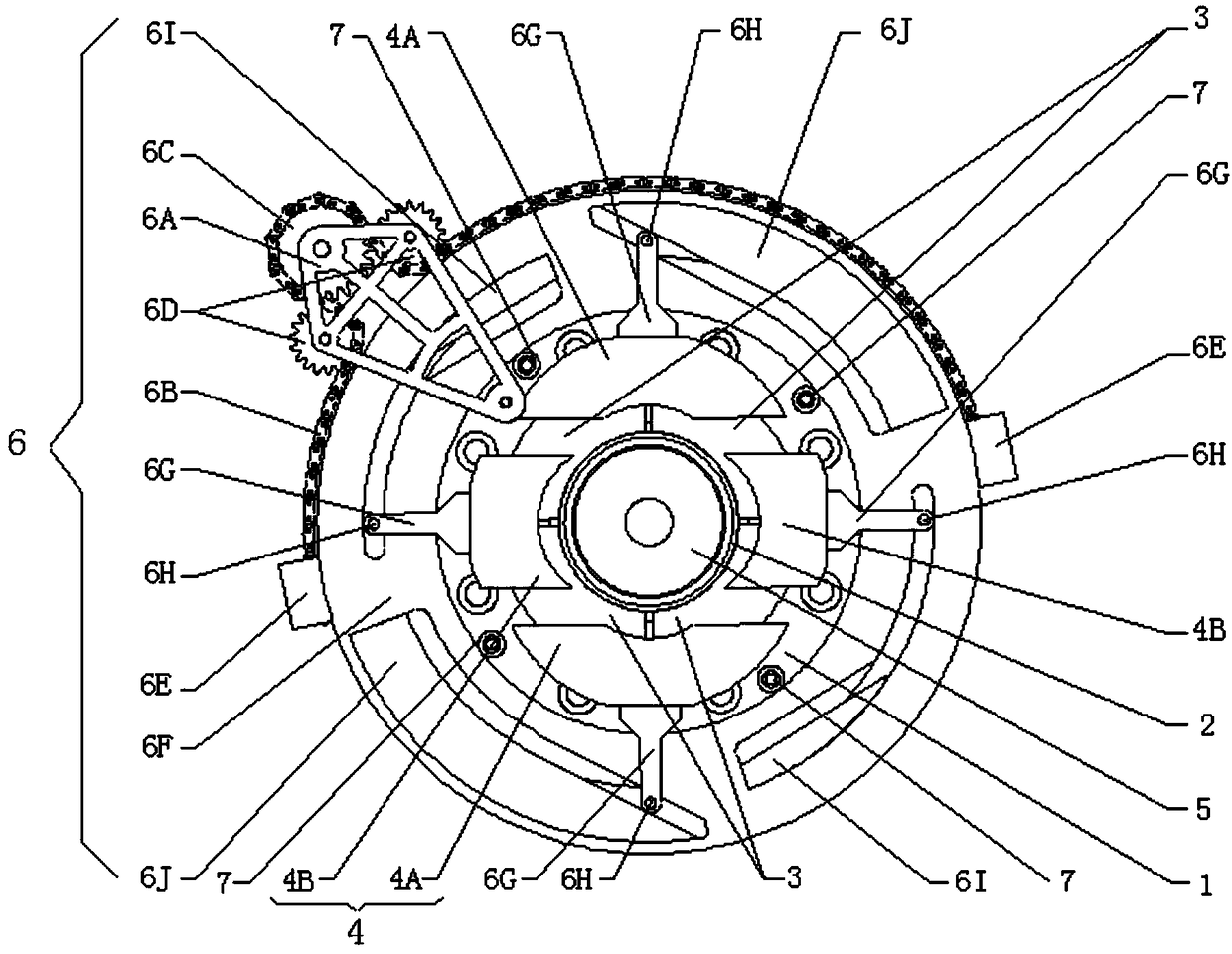

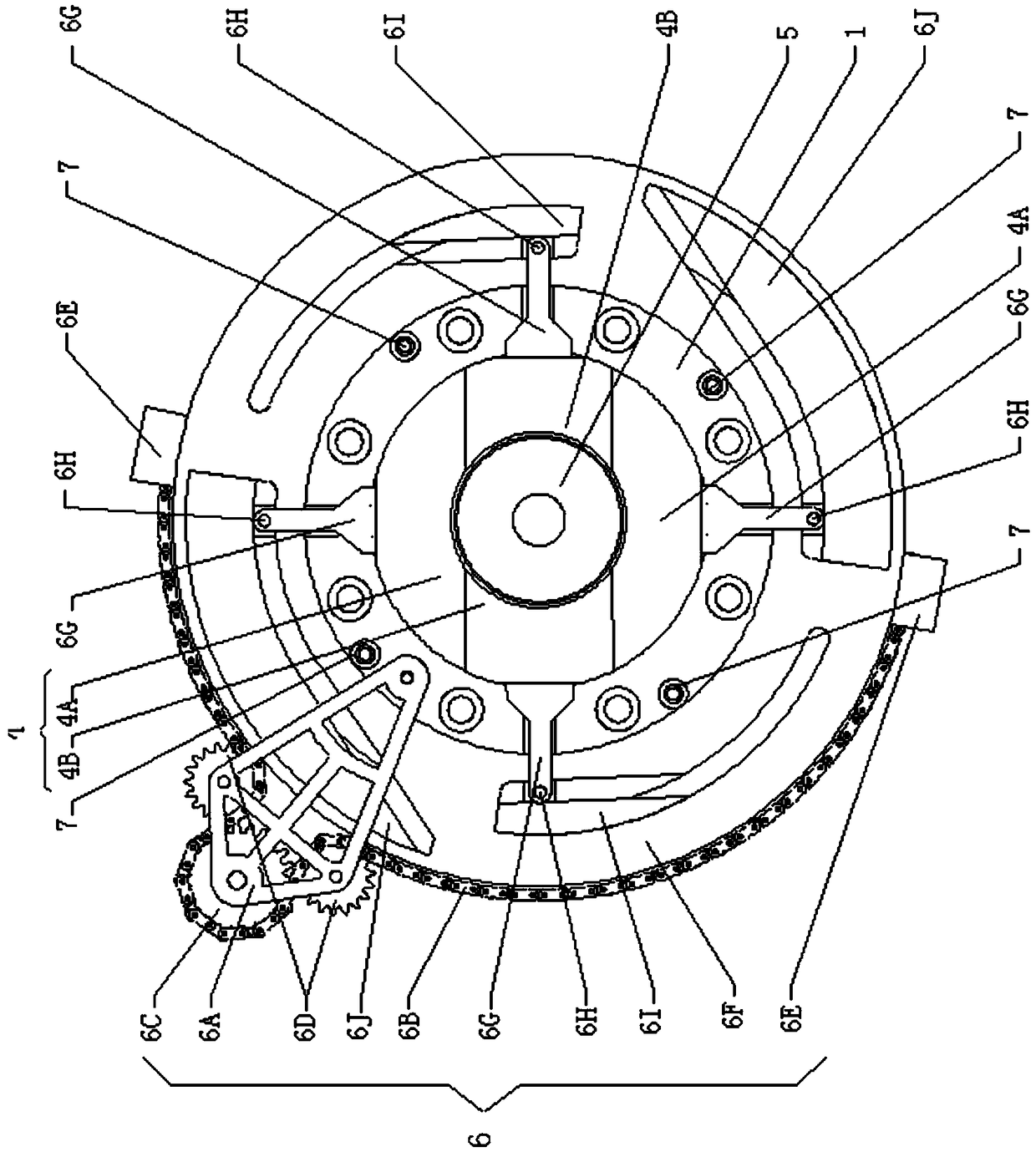

Multi-functional wet axle of 5-10 T fork-lift truck

The invention relates to a multi-functional wet axle of a 5-10 T fork-lift truck. Service brakes of the drive axle are wet brakes; inner shells of the left brake and the right brake are provided with a first lubricating oil passage respectively; the first lubricating oil passages on the two sides are communicated with one ends of a right cooling oil pipe and a left cooling oil pipe respectively; the other ends of the right cooling oil pipe and the left cooling oil pipe are connected with a first port and a second port of a three-way pipe respectively; a cooling oil outlet pipe is arranged at the bottom of a drive axle shell corresponding to a main speed reducer assembly; a wheel hub body is provided with an oil drainage hole, a second lubricating oil passage and a third lubricating oil passage respectively; a third port of the three-way pipe and the cooling oil outlet pipe are communicated with an outlet and an inlet of a lubricating pump respectively; and thus, a forced circulatory lubrication system is formed. The service life of the wet axle is 3-5 times the service life of normal drum brakes, and the brake performance does not decline after the wet axle is used for more than three years; and the problem of insufficient engine power supply caused by large size of a hydraulic oil tank and additional arrangement of a cooling fan due to sharing of a cooling mechanism with a hoisting system is solved.

Owner:ANHUI HELI CO LTD

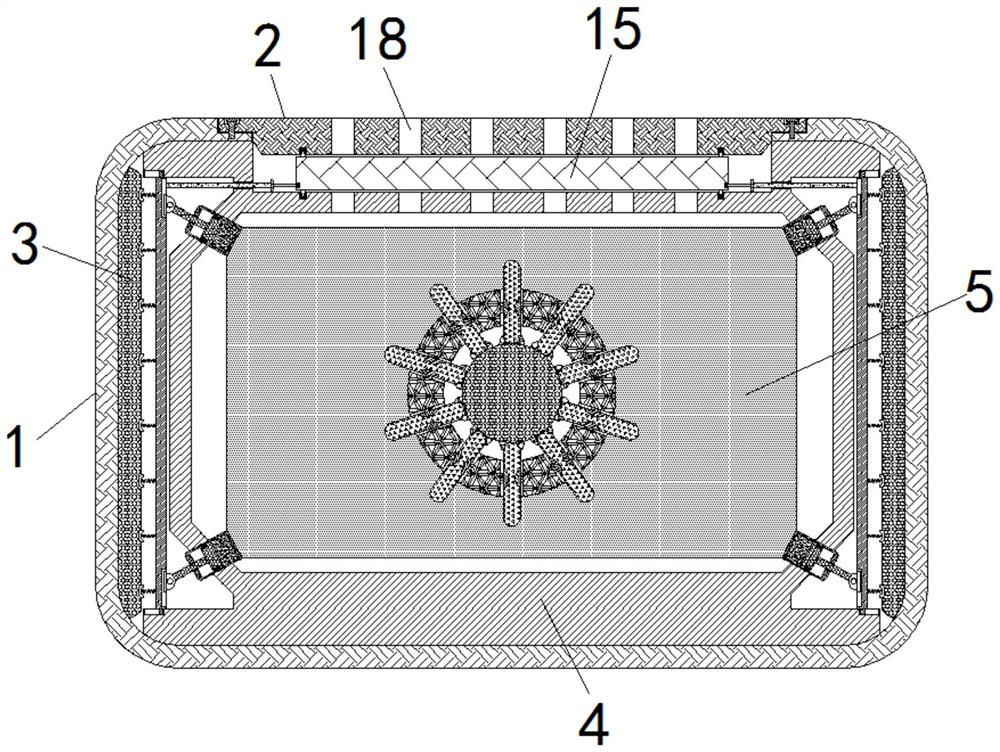

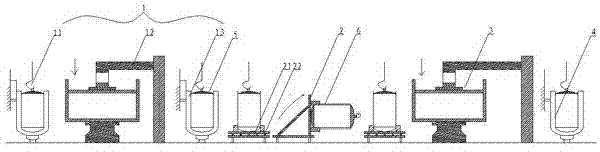

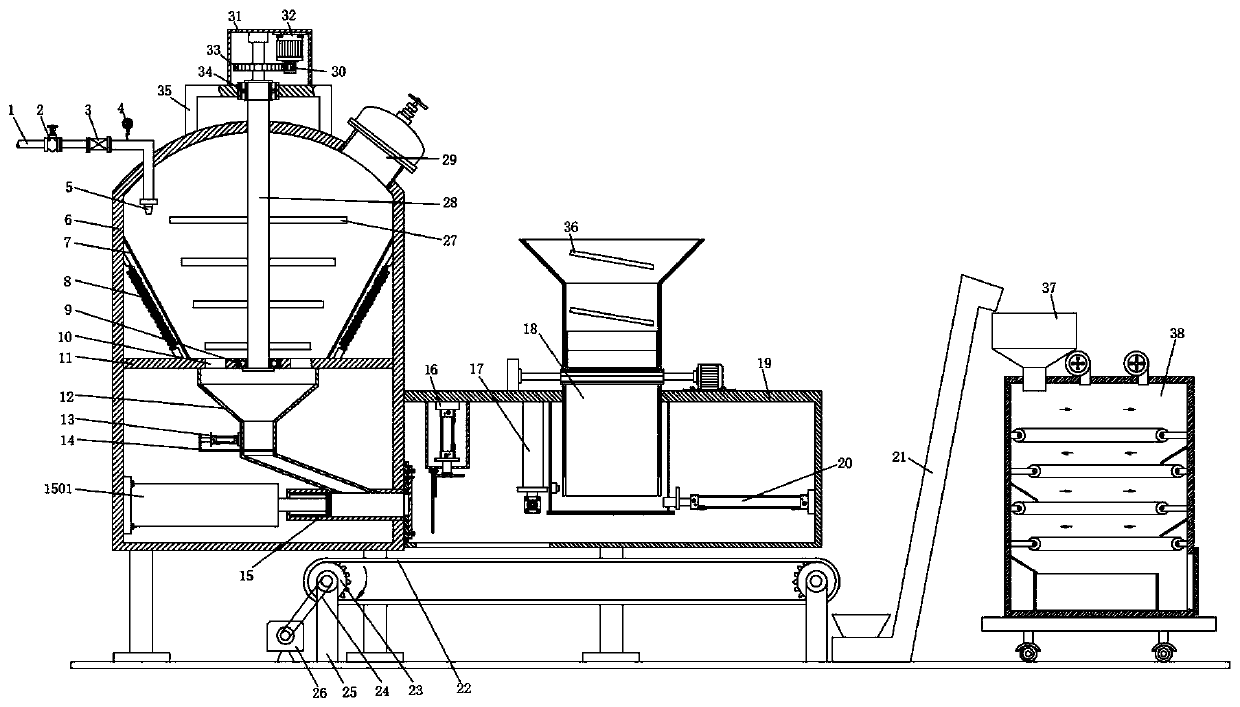

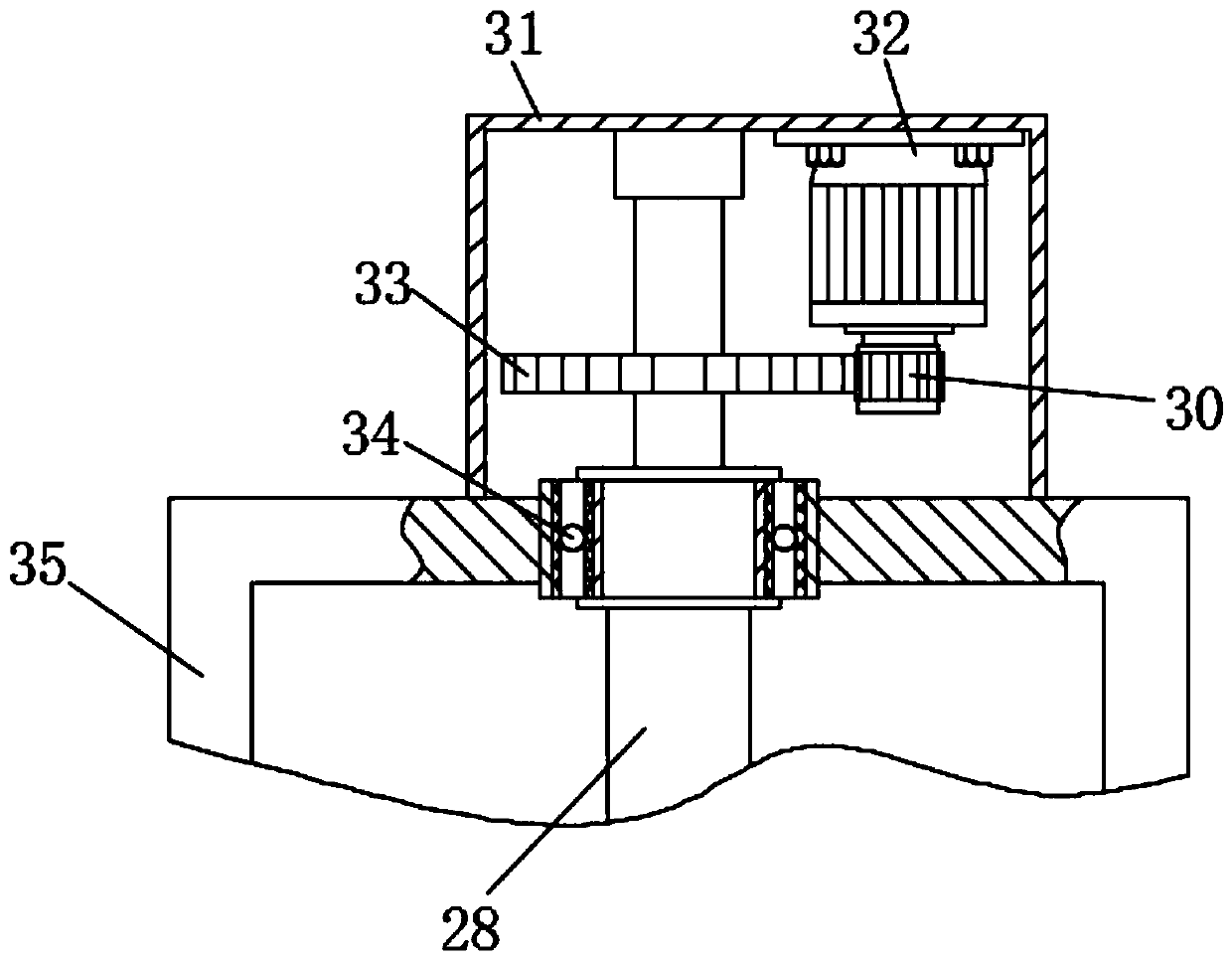

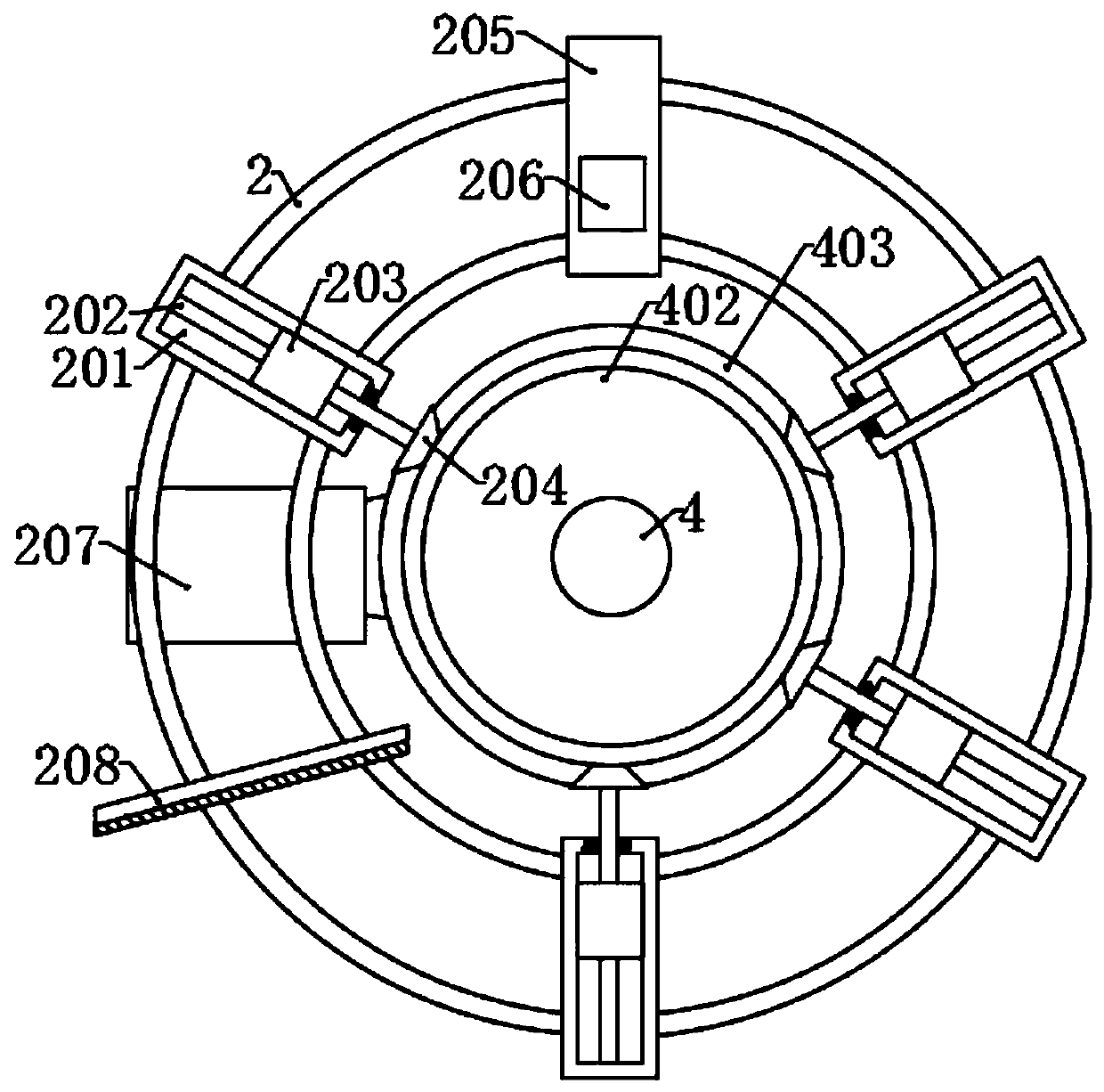

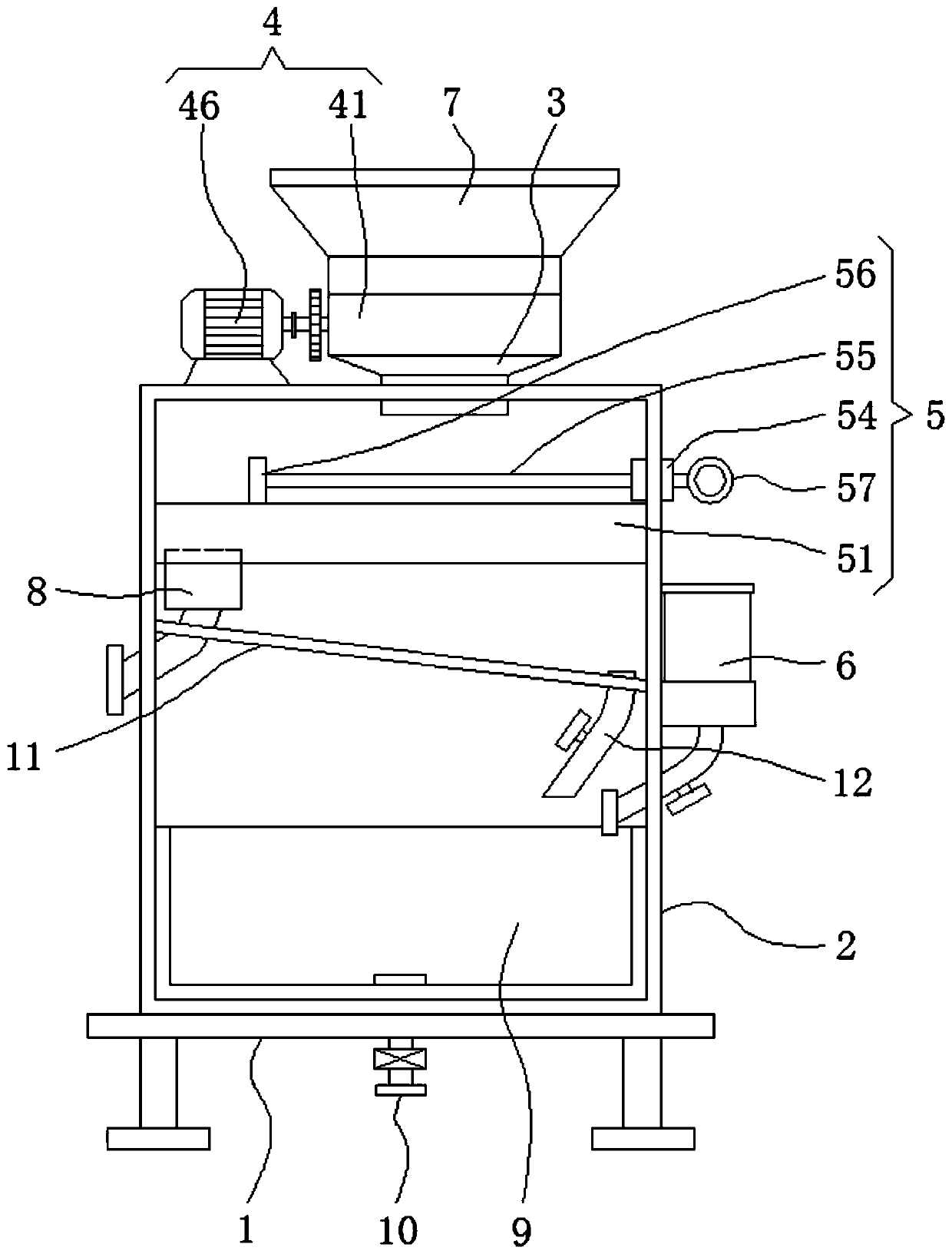

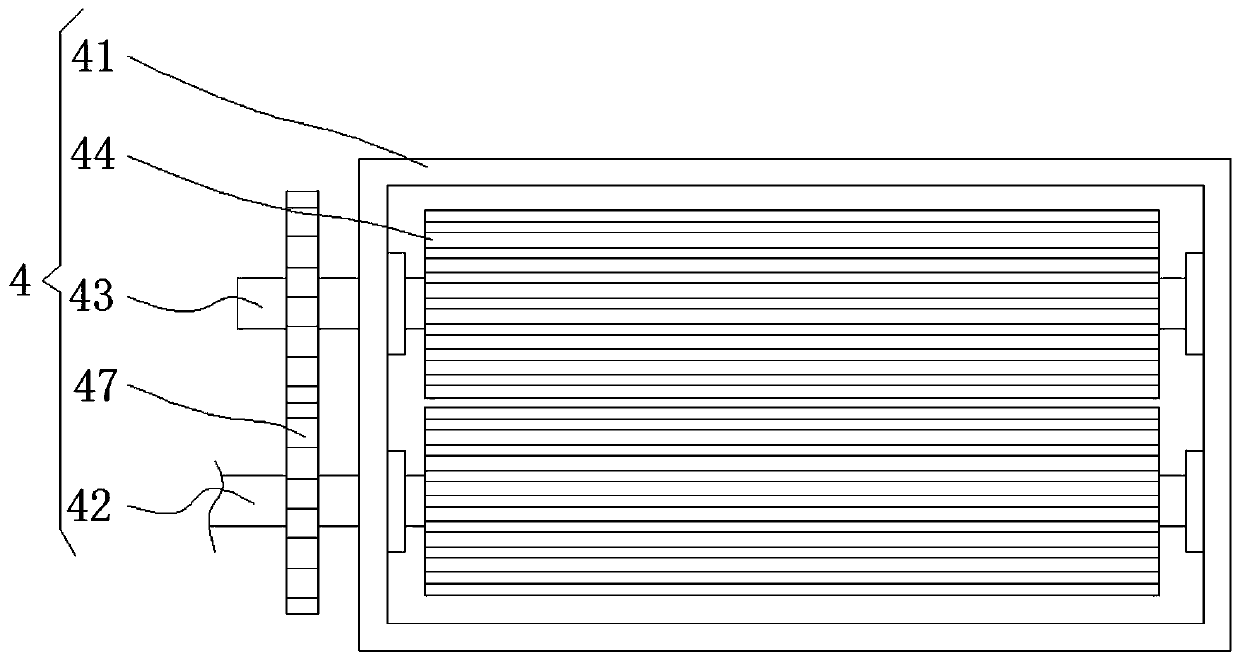

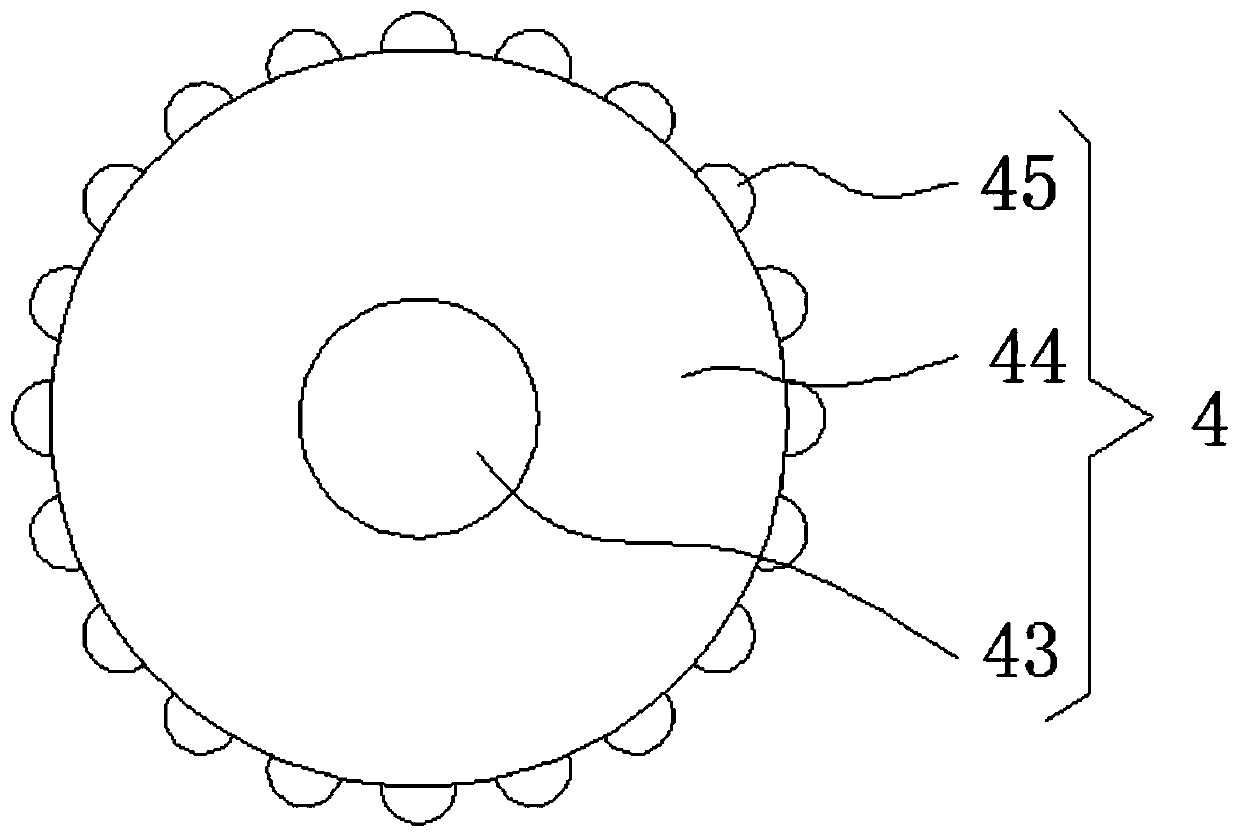

Full-automatic biomass stick incense production line

ActiveCN110497645AReduce labor intensityImprove labor efficiencyRotary stirring mixersTransportation and packagingBiomassMarket needs

The invention discloses a full-automatic biomass stick incense production line which comprises a first shell and a second shell. The top of the first shell is provided with a feeding opening, a fixingframe and a water input pipe. A third shell is arranged on the top of the fixing frame. A stirring motor is arranged in the third shell. The output shaft end of the stirring motor is in transmissionwith a driven gear on a stirring shaft through a driving gear. Stirring rods are arranged on the stirring shaft at intervals. A material receiving hopper is arranged on the bottom of a fixing plate. Aforming device used for extrusion forming is arranged on an outlet in the lower end of the material receiving hopper. A cutting-off device, a clamping device, a bamboo stick discharging device and abamboo stick pushing device are sequentially arranged on the right side of the forming device. According to the production line, stirring, forming, bamboo stick inserting and cutting off operation canbe carried out on biomass powder automatically, labor intensity is low, the labor efficiency is high, the biomass powder can be stirred uniformly, the water flow and the temperature can be monitored,drying operation can be carried out, manufactured sticks are regular in length and uniform in color, and the market needs are met.

Owner:湖南清泉生物科技有限公司

Meatball extrusion molding machine for food processing

InactiveCN110934173AAvoid obstructionEasy to adjust the positionMeat processing devicesMolding machineEngineering

The invention discloses a meatball extrusion molding machine for food processing in the technical field of food processing. The molding machine includes a first driving mechanism, a second driving mechanism, an extrusion component, a scraping mechanism, a cleaning mechanism, a starch brushing mechanism, a feeding mechanism, an extrusion mechanism and a material discharge plate. According to the molding machine, the first driving mechanism makes corresponding scraping plates, a cleaning brush, a starch brush and an extrusion block move inwards into a corresponding extrusion cylinder for work ormove outwards when a rotating frame rotates; when the starch brushing mechanism works, a starch outlet is eccentrically arranged in the top surface of a rotating tube, when the rotating tube rotates,the rotating tube intermittently communicates with the starch outlet tube, so that starch enters the rotating tube and enters the extrusion cylinder through the powder outlet, and the starch is uniformly brushed on the side wall of the extrusion cylinder through the brushing effect during rotating; feeding is performed on the extrusion cylinder through the feeding mechanism, and extrusion moldingis performed on raw materials through the extrusion mechanism; and the scraping mechanism and the cleaning mechanism thoroughly clean the inner side wall of the extrusion cylinder.

Owner:安徽麦壳科技有限公司

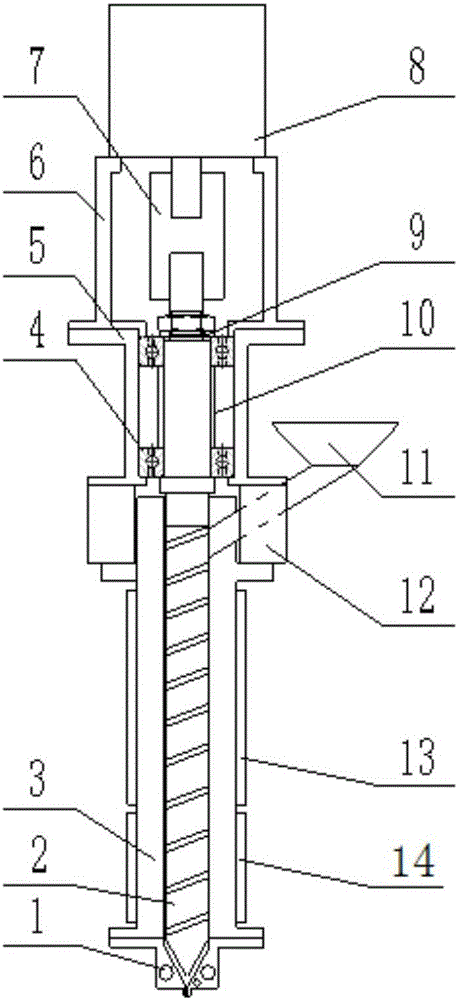

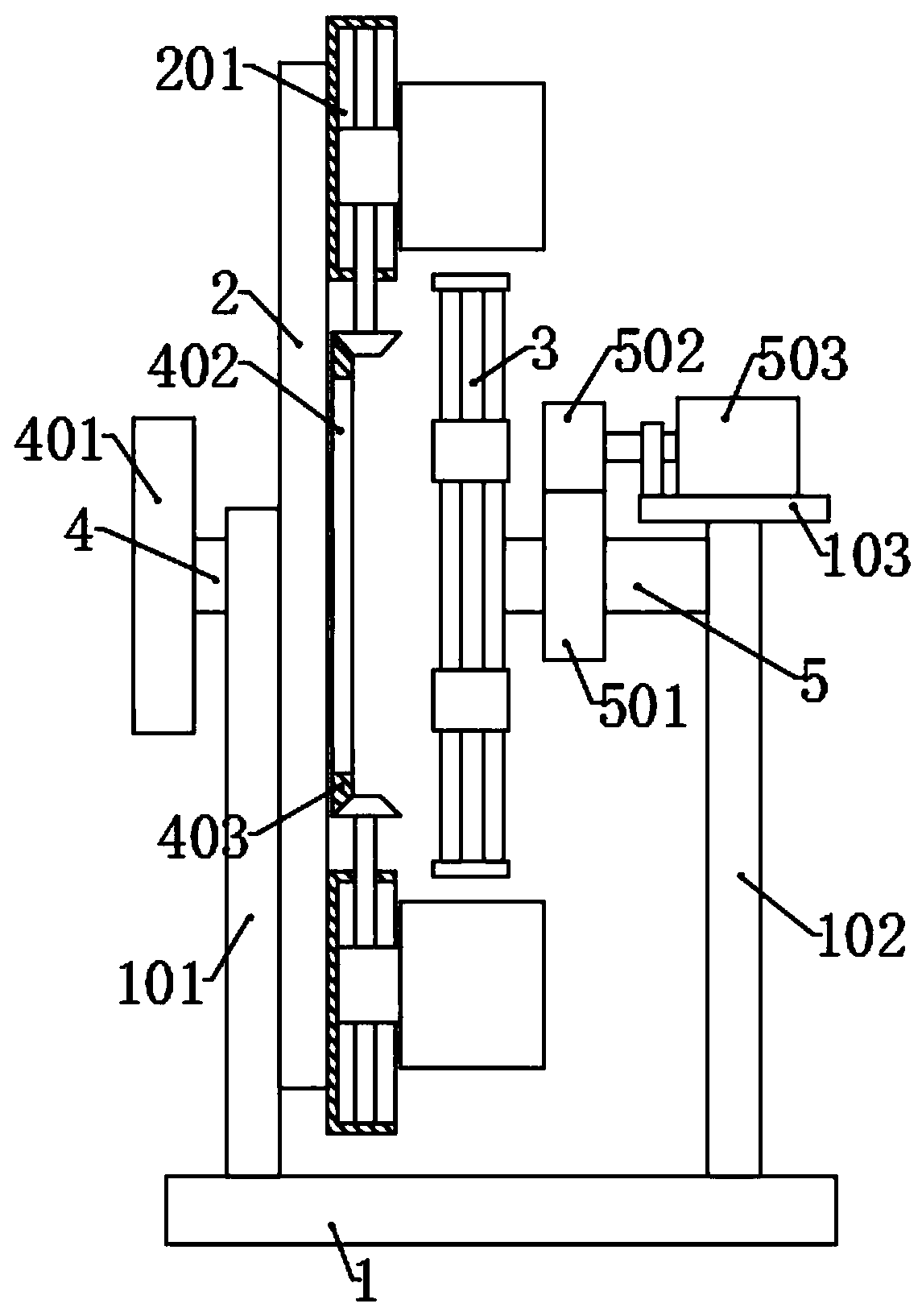

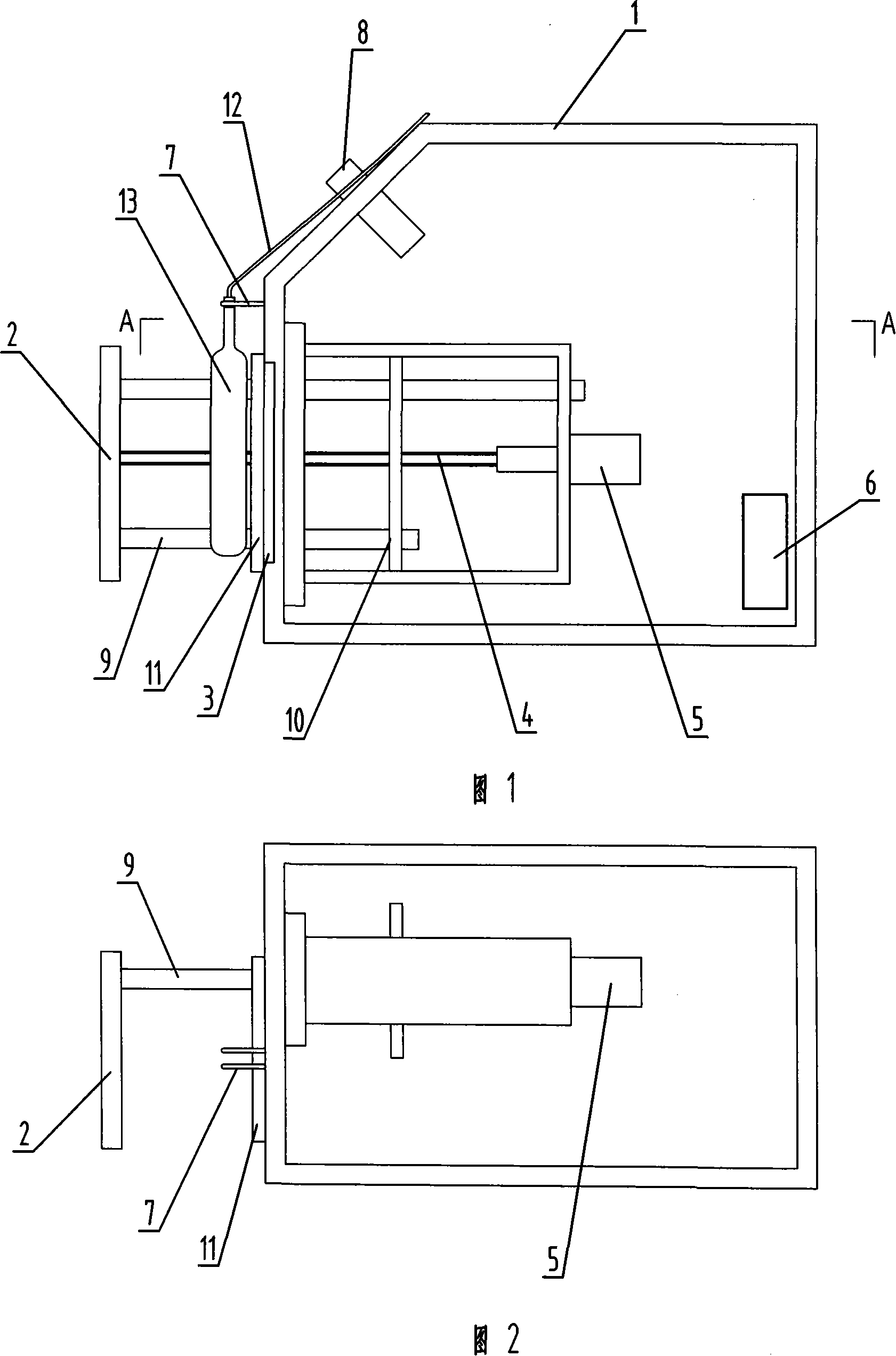

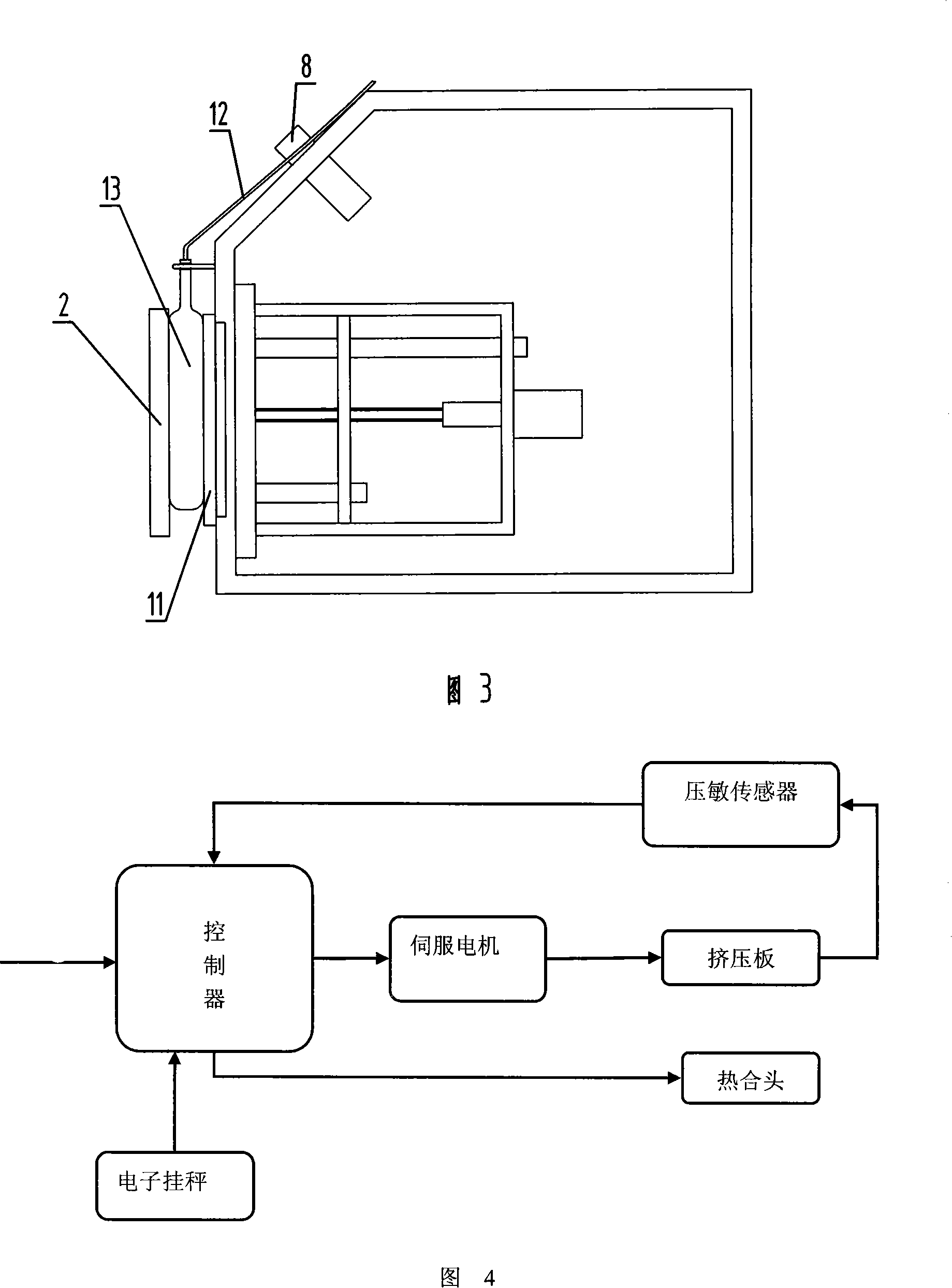

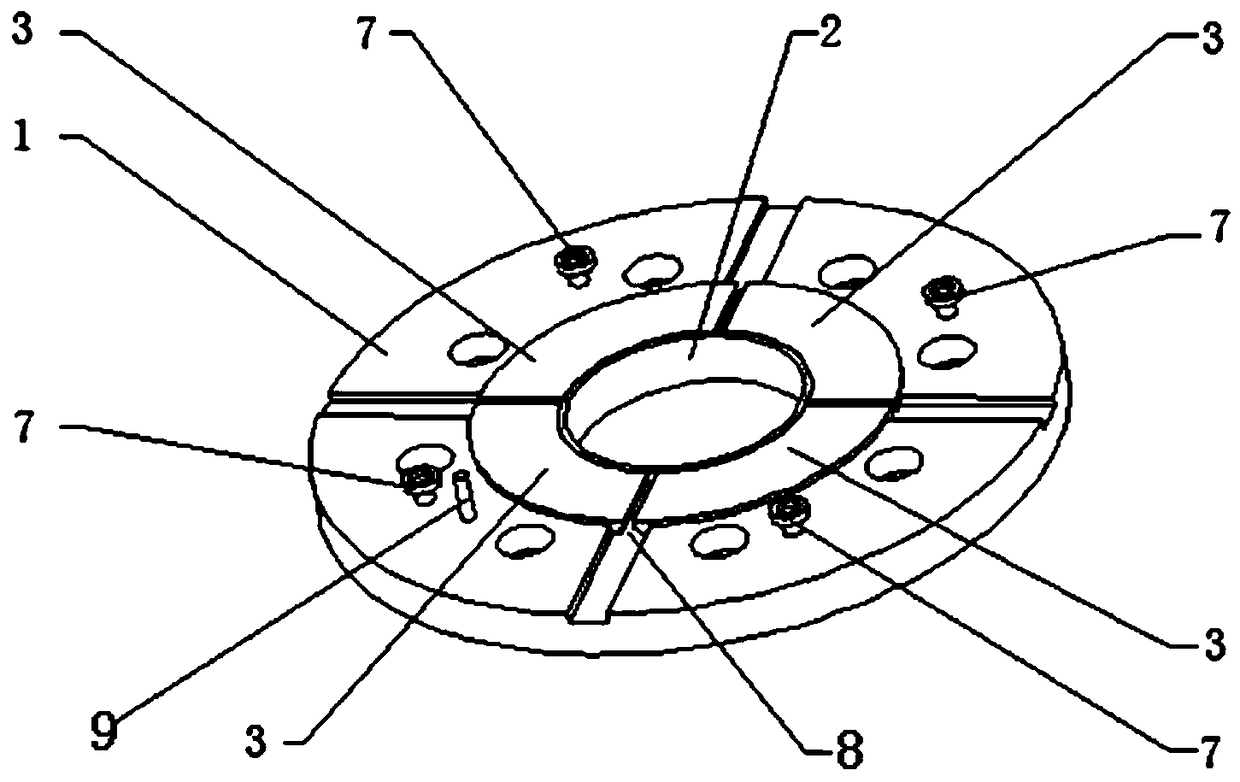

Blood plasma bag air blister squeezer

InactiveCN101157277AExtrude quicklyControl extrusionOther blood circulation devicesPress ramPlasma bagEngineering

The invention relates to a bubble extrusion machine used for plasma bags, and comprises a shell (1), a extrusion plate (2), a screw pulling mechanism used for pulling the extrusion plate (2), and a controller (6); the screw pulling mechanism comprises a screw (4), and a motor (5) used for pulling the screw (4); one end of the screw (4) is connected with the extrusion plate (2); the motor (5) is arranged in the shell (1) and controlled by the controller (6); the extrusion plate (2) is arranged outside the shell (1). By adopting the extrusion plate and the screw pulling mechanism, the invention can quickly squeeze air out of the plasma bags.

Owner:WUHAN BMS MEDICALTECH

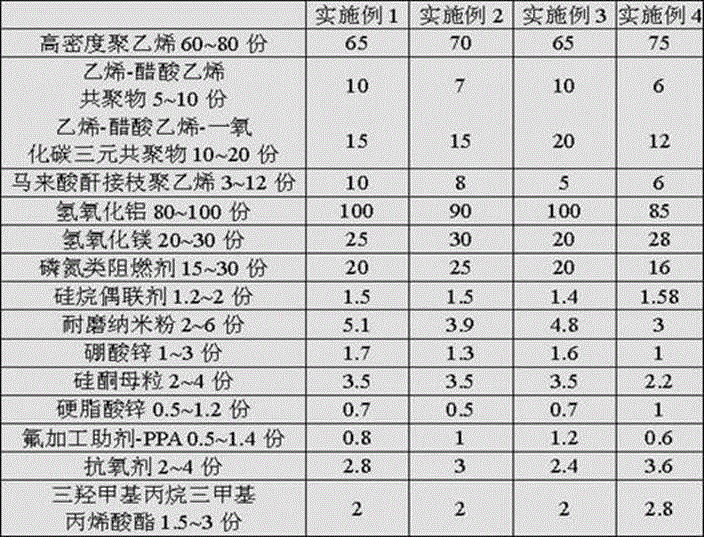

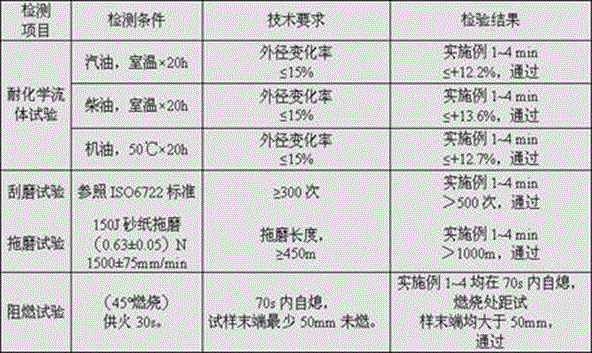

High-wear-resistant irradiation crosslinked halogen-free flame-retardant automotive wire cable material and preparation process thereof

InactiveCN105400045ADifficult to disperseImprove wear resistancePlastic/resin/waxes insulatorsMeth-Vinyl acetate

The invention relates to a high-wear-resistant irradiation crosslinked halogen-free flame-retardant automotive wire cable material composed of the following components in parts by weight: high density polyethylene, an ethylene-vinyl acetate copolymer, an ethylene-vinyl acetate-carbon monoxide terpolymer, maleic anhydride grafted polyethylene, aluminum hydroxide, magnesium hydroxide, a phosphorus-nitrogen flame retardant, a silane coupling agent, a wear-resistant nano-powder, zinc borate, silicone master batch, zinc stearate, a fluorine processing auxiliary agent-PPA, an antioxidant, and trimethylolpropane trimethacrylate. The wear-resistant nano-powder comprises a main component of a nitrogen-silicon-oxygen compound, the melt flow index of high density polyethylene is 0.08-2 g / 10 min, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 20-40%, and the melt flow index of the ethylene-vinyl acetate copolymer is 0.2-5 g / 10 min. The high-wear-resistant halogen-free flame-retardant cable material has the characteristics of high mechanical strength, low smoke, no poison, excellent wear resistance, good high-temperature resistance, good oil resistance and the like, and has the tensile strength of more than 17 MPa and the elongation at break of more than 600%.

Owner:中广核三角洲(苏州)高聚物有限公司

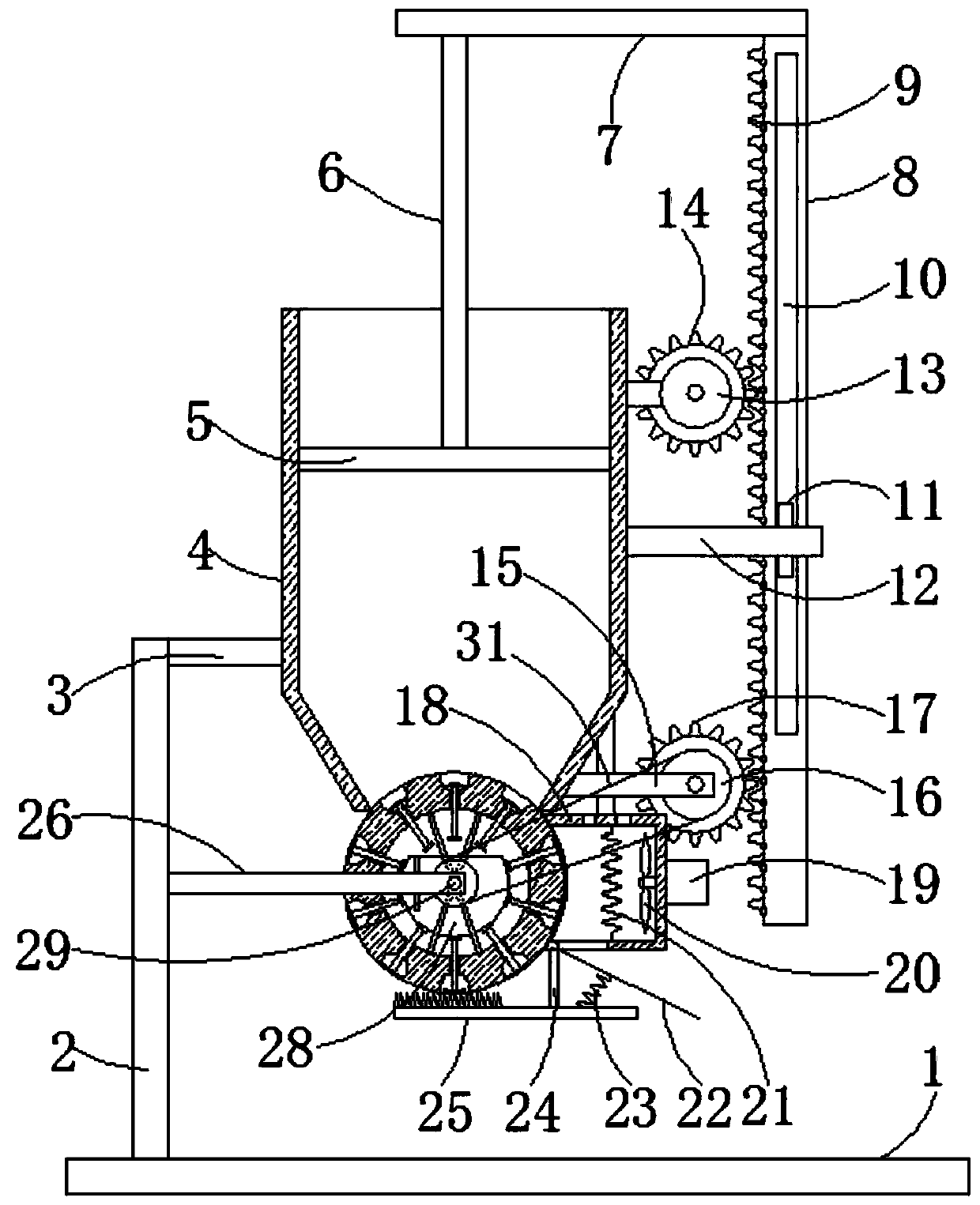

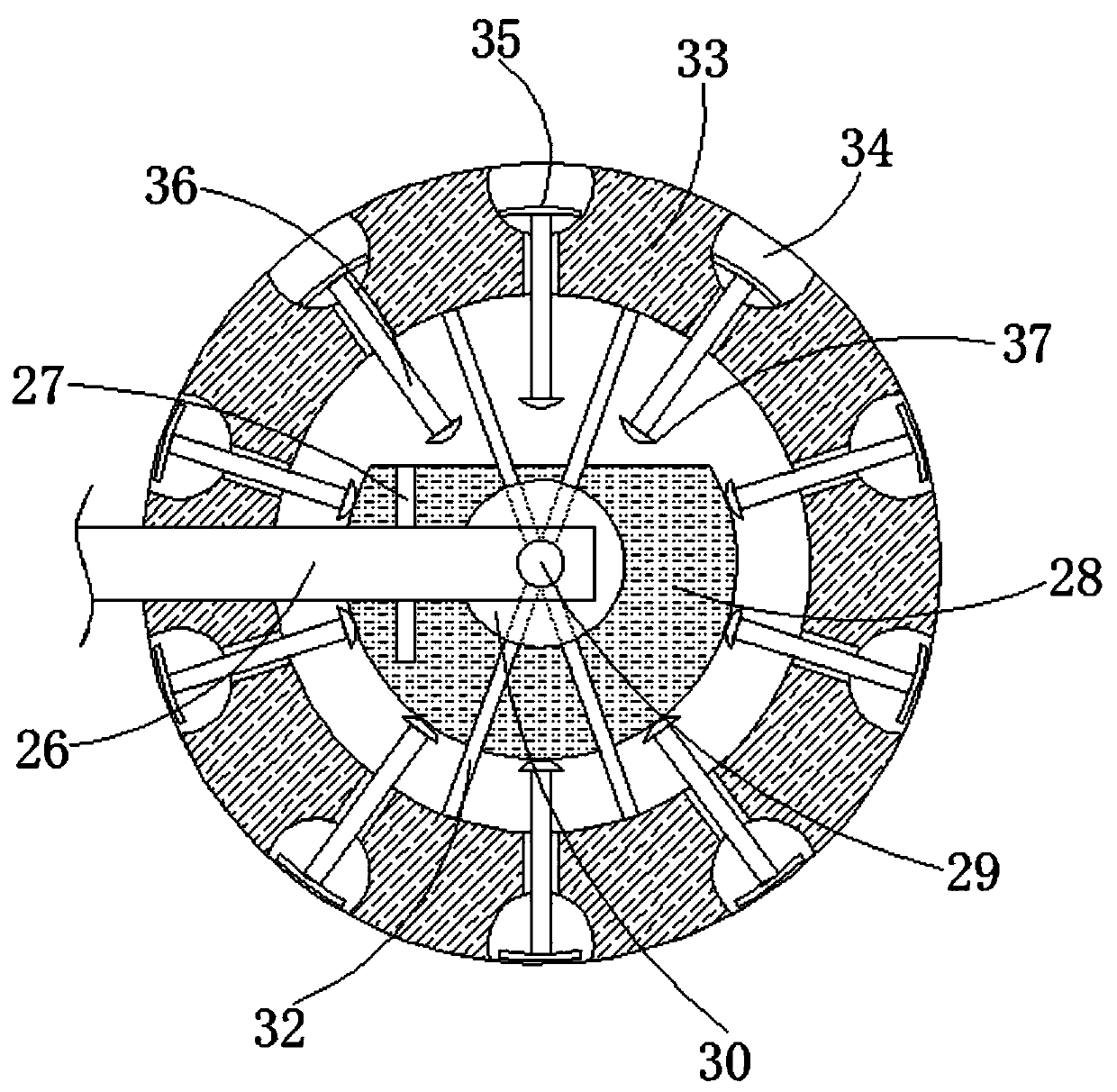

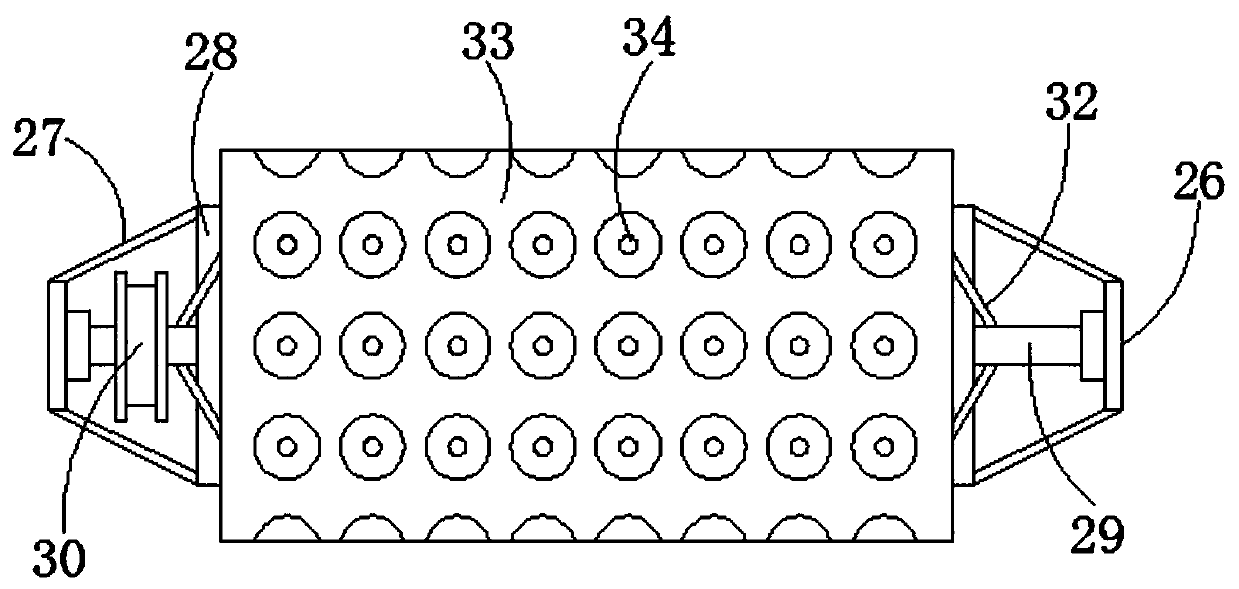

Granulation equipment for feed production

InactiveCN110917992AEasy to squeeze inEase of ejectionFeeding-stuffGranulation by pressingGear wheelElectric machinery

The invention discloses granulation equipment for feed production and relates to the technical field of feed production. The problems that existing granulation equipment for feed production has complex structure, unfavorable maintenance and popularization and a formed feed cannot be conveniently and quickly removed and dried are solved. The invention proposes the following scheme, the equipment comprises a placing plate, a supporting plate is mounted on one side of a top of the placing plate, a top of one side of the supporting plate is fixedly connected with a fixed rod, a storage box is installed at one end, away from the supporting plate, of the fixed rod, a driving motor is fixedly connected to an outer portion of a side, away from the fixed rod, of the storage box, a tail end of an output shaft of the driving motor is fixedly sleeved with a first gear, and a discharging device is arranged on a side, away from the storage box, of the first gear. By means of the equipment, the feedcan be conveniently and rapidly extruded and formed, the discharging is also facilitated after forming, the formed feed is rapidly dried, multiple processes are completed on the same equipment, the applicability of the equipment is improved, and the popularization is facilitated.

Owner:韩宜保

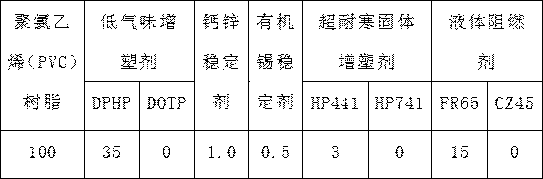

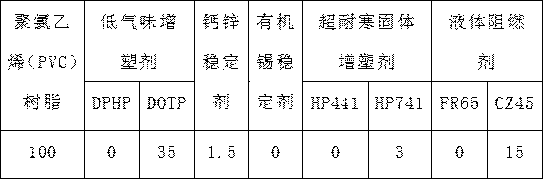

Double-85 (temperature of 85 DEG C and humidity of 85%) yellowing-resistant and low-odor flame-retardant transparent material for optical cable sheaths

InactiveCN108912559ARapid ExtrusionGood humidity and temperature resistancePlasticizerPolyvinyl chloride

The invention discloses a double-85 (the temperature of 85 DEG C and the humidity of 85%) yellowing-resistant and low-odor flame-retardant transparent material for optical cable sheaths, which is characterized by comprising the following components in parts by weight: 100 parts of polyvinyl chloride (PVC) resin, 25-35 parts of a low-odor plasticizer, 3-5 parts of a super-cold-resistant solid plasticizer, 1.0-1.8 parts of a calcium-zinc composite stabilizer, 0.5-1.0 part of an organotin stabilizer and 15-25 parts of a liquid flame retardant. According to the double-85 yellowing-resistant and low-odor flame-retardant transparent material for optical cable sheaths, a low-melt-index super-cold-resistant solid plasticizer additive is adopted to improve the rapid extrusion performance of a twin-screw extruder during extrusion granulation through an advanced formula and excellent process treatment, and the surface is smooth and free of particles, a stabilizer of the calcium-zinc composite stabilizer and the organotin stabilizer is added in proportion, good humidity and temperature resistance are achieved, after aging is conducted at 85 DEG C under the humidity of 85% for 168 h, the coloris basically unchanged, the flame-retardant transparent material has good temperature and yellowing resistance, and the environmental protection performance meets the requirements of ROHS and REACH standards.

Owner:ANHUI CHUZHO DEWEI NEW MATERIAL

Plastic pipe production model head with adjustable aperture specification

The invention discloses a plastic pipe production model head with the adjustable aperture specification. The plastic pipe production model head comprises a flange plate, a plastic extruding machine mouth model external die, a plurality of fan-shaped fixing pieces, an adjustment model group, an improved mouth model core die, a model adjustment driving device and a plurality of grooved rollers, theflange plate is connected with an extruder, and the plastic extruding machine mouth model external die coaxially sleeves with an inner ring of the flange plate; the fan-shaped fixing pieces are arranged as a guide rail T-shaped groove for guiding movement of the adjustment model group; the adjustment model group can move in the radial direction of the flange plate; the improved mouth model core die is arranged in the plastic extruding machine mouth model external die in a sleeved mode, the model adjustment driving device is responsible for driving the adjustment model group to move in the radial direction of the flange plate, so as to realize specification adjustment of the aperture. According to the plastic pipe production model head with the adjustable aperture specification, the specifications of extruding pipes can be quickly completed, the time of die changing is saved, meanwhile labor and material costs are reduced, the set range is flexible, and the adaptive capacity of a production line is high.

Owner:JIANGSU UNIV OF SCI & TECH

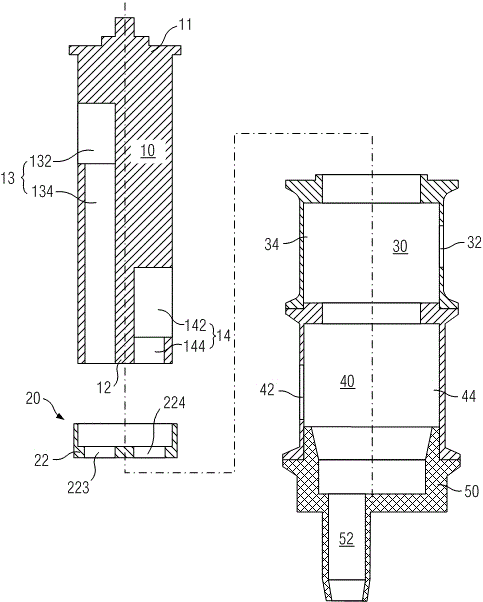

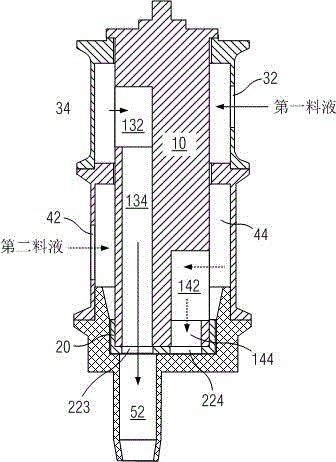

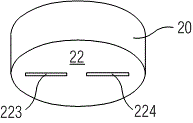

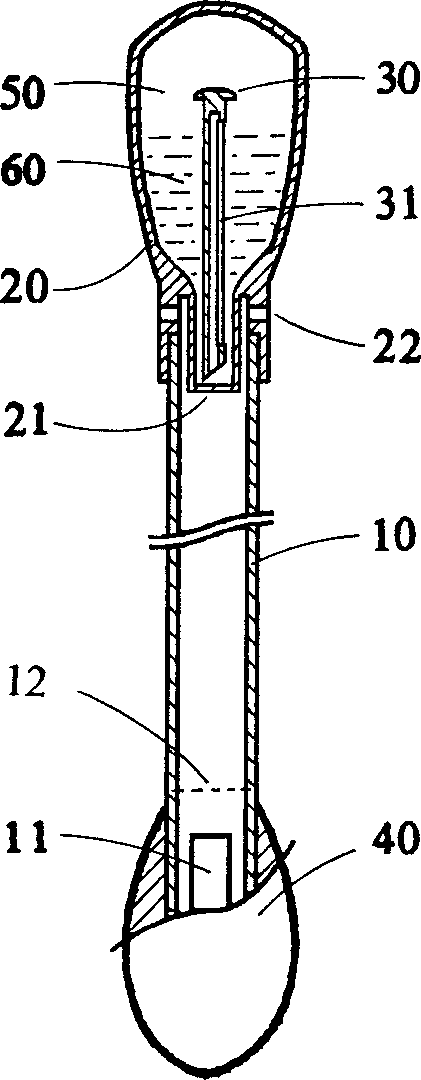

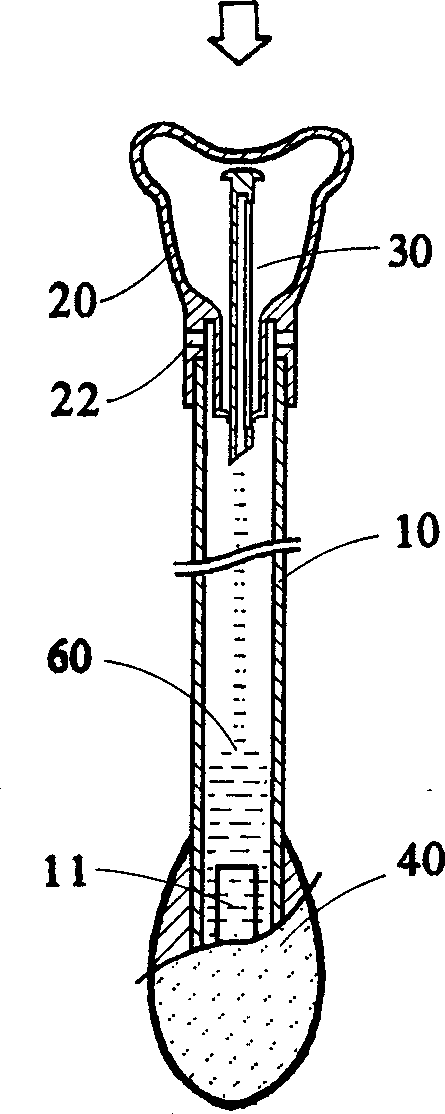

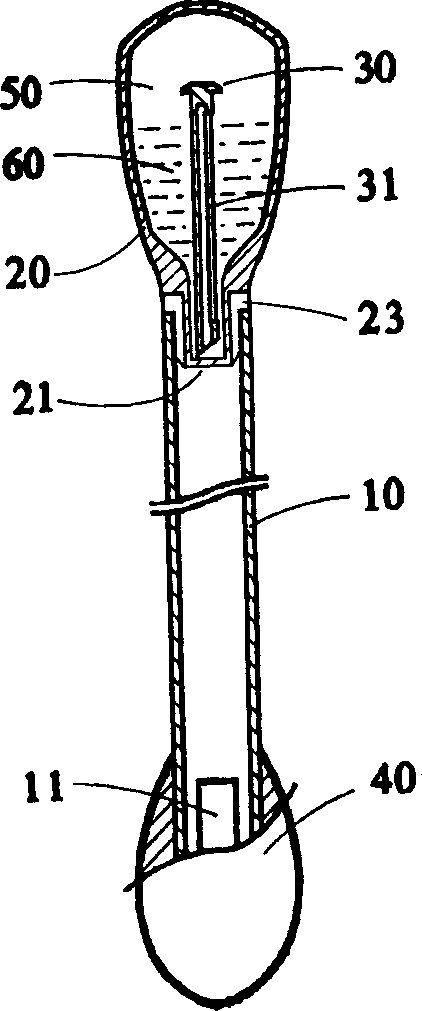

Lamellar ice cream extruding device

The invention relates to a lamellar ice cream extruding device. The lamellar ice cream extruding device comprises a conveying shaft (10), a shaping device (20), a first discharging barrel (30), a second discharging barrel (4) and an extruding cover (50). First material liquid enters a first material liquid cavity (34) from a first material liquid inlet (32), then flows to an opening (223) via a first radial passage (132) and a first axial passage (134), and finally is discharged from a discharge nozzle (52). Second material liquid enters a second material liquid cavity (44) via a second material liquid inlet (42) and then flows towards an opening (224) via a second radial passage (142) and a second axial passage (144), and since the second material liquid stays in the opening which is not communicated with the discharge nozzle (52), the second material liquid cannot be extruded. In the process of driving the shaping device by virtue of the conveying shaft, the first material liquid and the second material liquid can be sequentially and circularly extruded from the discharge nozzle, so an ice cream product formed by laminating the two material liquid can be formed.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

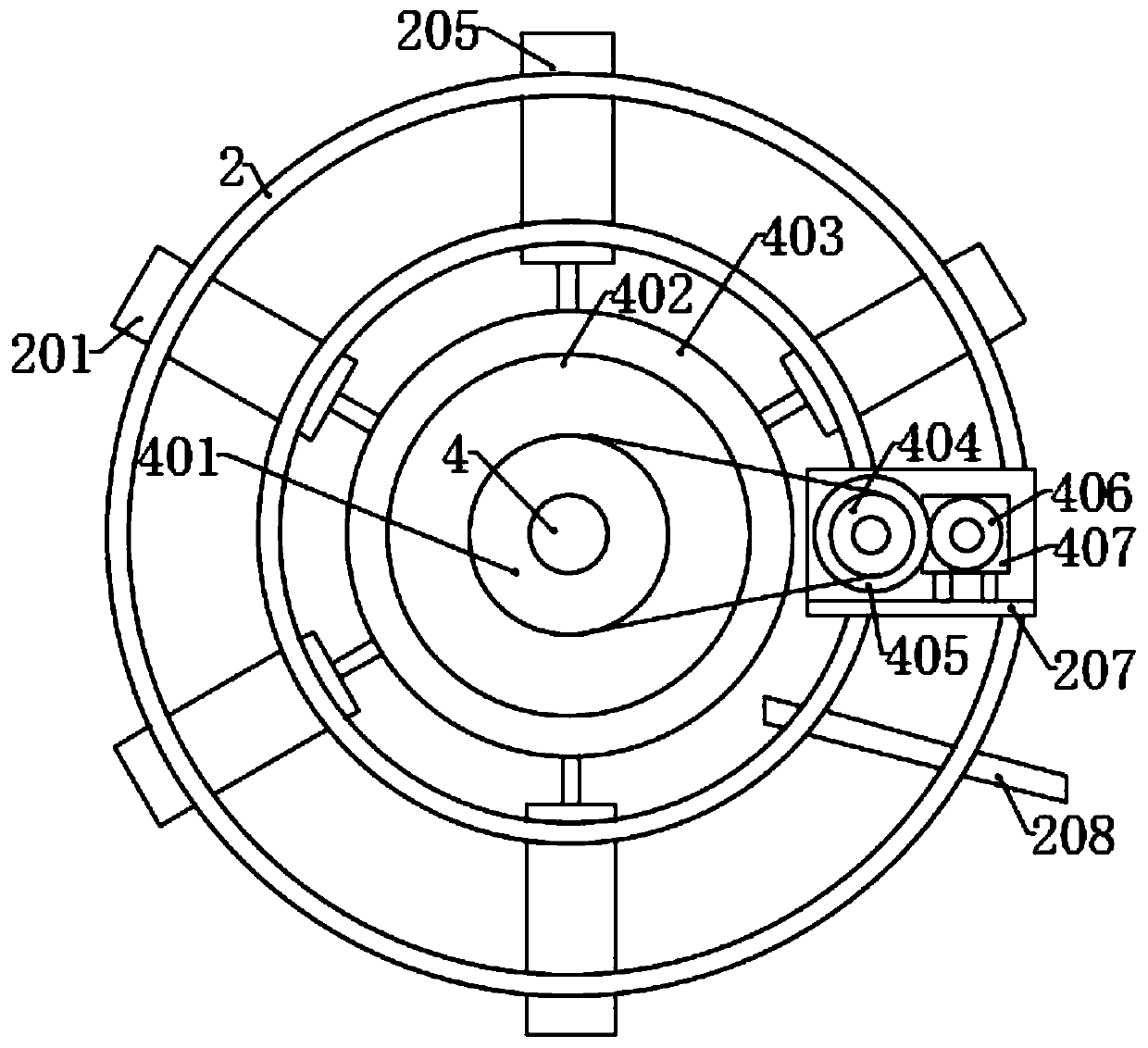

Fermentation system and fermentation method for strawberry wine

PendingCN111363652AReduce blind spotsSave operating timeAlcoholic beverage preparationFragariaProcess engineering

The invention provides a fermentation system and a fermentation method for strawberry wine. The fermentation system for the strawberry wine comprises: a base and a tank body, wherein the tank body isarranged at the top part of the base. According to the fermentation system and the fermentation method for the strawberry wine provided by the invention, through a crushing structure, a strawberry rawmaterial can be rapidly crushed; through arrangement of arc-shaped blocks, strawberries can be effectively ground, so juice in the strawberries can be conveniently and rapidly extruded out; through arrangement of two crushing wheels, the strawberries can be well rolled and crushed, and rolling and crushing are thorough, so the blind area of crushing is reduced, and the juice can be fully sucked;through arrangement of a filtering structure, pulp is prevented from existing to affect the taste of the strawberry wine; subsequent better cleaning is facilitated; the fermentation speed of the strawberry wine during brewing is effectively increased; fragrance of the strawberry wine is prevented from being emitted; and the original flavor is effectively reserved.

Owner:FUYANG NORMAL UNIVERSITY

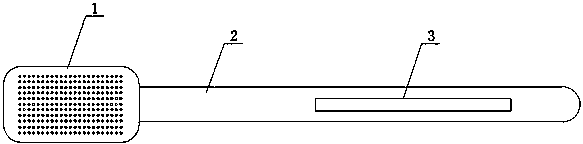

Toothbrush allowing convenient toothpaste squeezing

InactiveCN103844566AExtrude quicklyEasy to operateBrush bodiesHolders and dispensersToothpasteEngineering

The invention discloses a toothbrush allowing convenient toothpaste squeezing. The toothbrush allowing convenient toothpaste squeezing comprises a brush head and a brush handle; a slot is formed in the brush handle; the length of the slot is from 3 to 5 cm; the slot which is formed in the lower portion of the brush handle is in a rectangular shape. The toothbrush allowing convenient toothpaste squeezing has the advantages of enabling toothpaste to be rapidly squeezed, rapidly squeezing remaining toothpaste in a toothpaste casing due to the acting force of the toothbrush handle, being free of residual basically and simple and labor saving in operation, not needing squeezing manually and being simple in structure, small in process manufacturing difficulty and wide in application range.

Owner:何毅

Eraser carrying micro liquid by itself

InactiveCN1373469AEasy to openAvoid Seal FailureLiquid surface applicatorsCleaning recording headsEngineeringMechanical engineering

Owner:吴振东

Flow dividing type die for aluminum alloy extrusion forming and working method thereof

The invention relates to the field of machining, in particular to a flow dividing type die for aluminum alloy extrusion forming and a working method thereof. The flow dividing type die comprises a base and a lifting mechanism, the lifting mechanism comprises a vertical plate and a lifting assembly, a cantilever is arranged on the lifting mechanism in a sliding mode, an upper die is fixedly arranged at the bottom of the cantilever, the flow dividing type die further comprises a controller, a machining table and a pushing mechanism, a supporting plate is fixedly arranged at the top of the base,four telescopic rods are symmetrically arranged at the top of the supporting plate, a lower die is fixedly arranged at the top of the machining table, the pushing mechanism is arranged at the bottom of the machining table to achieve flow dividing of the die and comprises a driving assembly, a rotating assembly and four top wheel assemblies, and the lifting assembly and the driving assembly are electrically connected with the controller. According to the flow dividing type die for aluminum alloy extrusion forming and the working method thereof, it can be guaranteed that aluminum alloy materialsare evenly pressed, meanwhile, it can be guaranteed that the top wheel sufficiently extrudes a workbench, rapid forming of the aluminum alloy materials is facilitated, and the machining efficiency isimproved.

Owner:佛山市顺德区合力荣辉模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com