Optical resin for optical protective film and preparation method thereof

A technology of optical resin and protective film, applied in optics, optical components, instruments, etc., can solve the problems of reduced mechanical properties, transparency, and low transparency, so as to avoid degradation and phase separation, reduce melting processing temperature, and improve thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

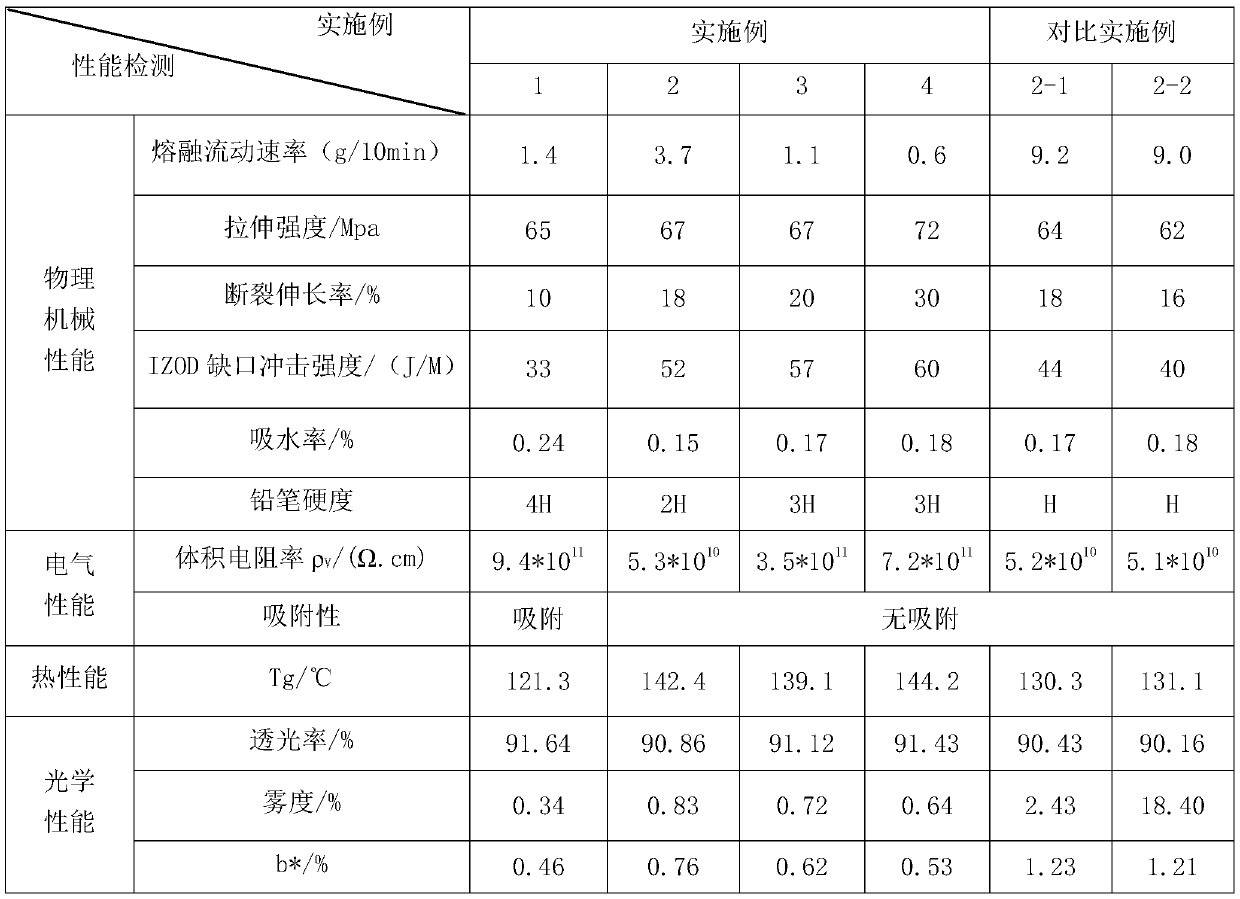

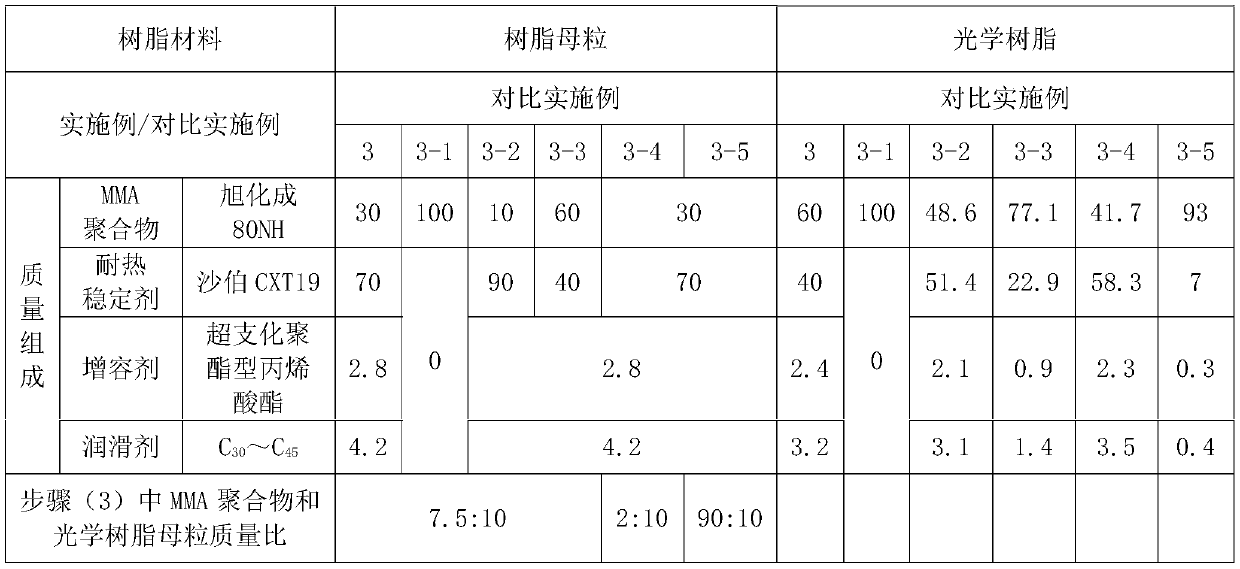

Examples

preparation example Construction

[0095] The application also provides a preparation method of an optical resin for an optical protective film, comprising the steps of:

[0096] (1) Preparation of heat-resistant stabilizer

[0097] The copolycarbonate resin is melted and sprayed by a melt spinning machine, stretched and spun, clustered by a bundler, chopped by a fiber cutter, coarsely pulverized on a coarse pulverizer and ground by a fine mill to obtain copolycarbonate micropowder.

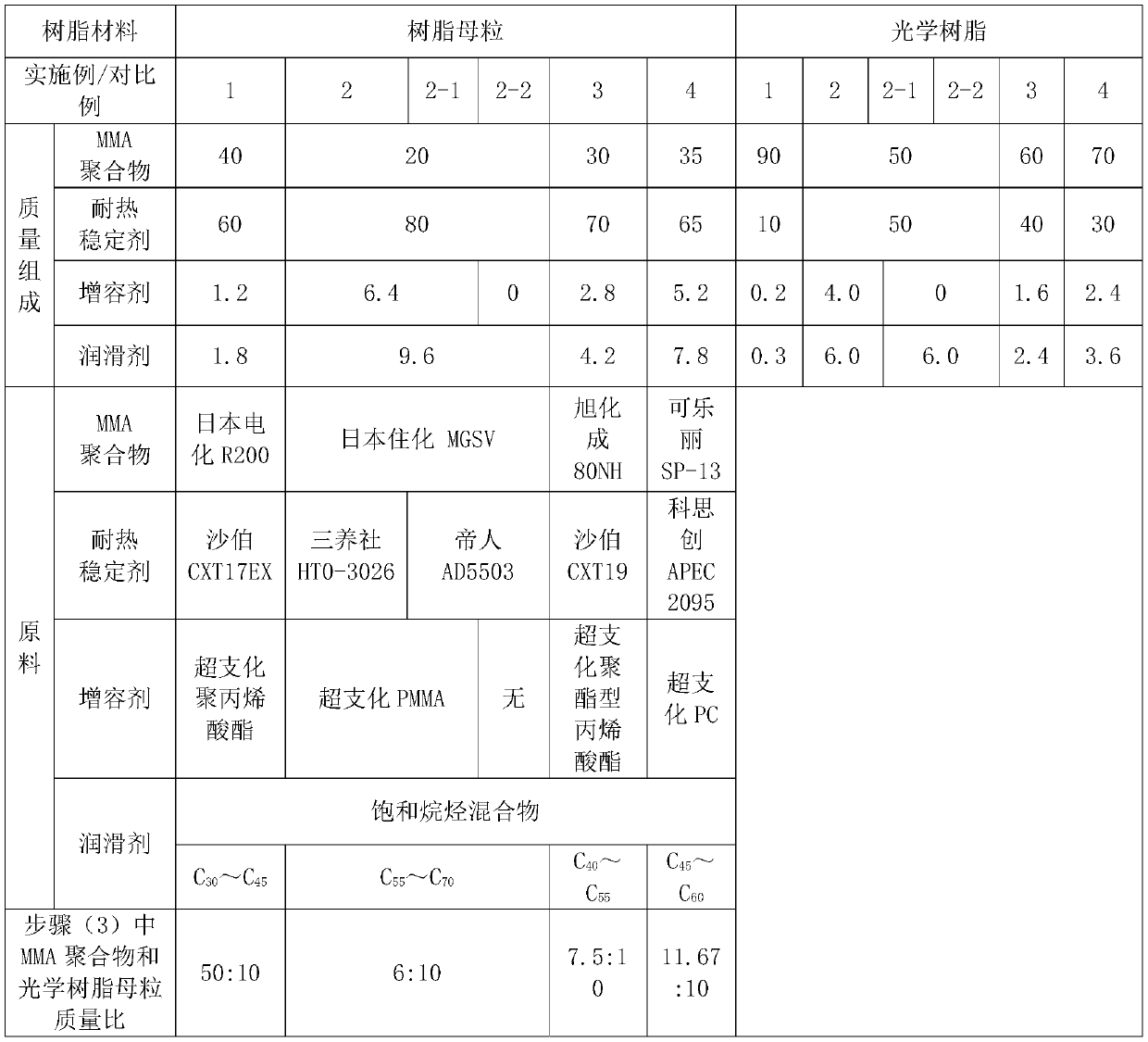

[0098] (2) Preparation of optical resin masterbatch

[0099] Add 20-40 parts of methyl methacrylate polymer, 60-80 parts of heat-resistant stabilizer, 1.2-6.4 parts of compatibilizer and 1.8-9.6 parts of lubricant into a high-speed mixer and mix thoroughly, and extrude through twin-screw Machine blending granulation, melt plasticization, extrusion granulation, vacuum drying to obtain optical resin masterbatch.

[0100] Preferably, add 30 to 35 parts of methyl methacrylate polymer, 65 to 70 parts of heat-resistant stabilizer, 1.8...

Embodiment 1

[0109] Embodiment 1, the concrete steps of the preparation method of optical resin for optical protection film are:

[0110] (1) Preparation of heat-resistant stabilizer

[0111] The copolycarbonate resin is melted and sprayed by a melt spinning machine, stretched and spun, clustered by a bundler, chopped by a fiber cutter, coarsely pulverized on a coarse pulverizer and ground by a fine mill to obtain copolycarbonate micropowder.

[0112] (2) Preparation of optical resin masterbatch

[0113] Add 40 parts of methyl methacrylate polymer, 60 parts of heat-resistant stabilizer, 1.2 parts of compatibilizer and 1.8 parts of lubricant into a high-speed mixer and mix thoroughly, then blend and granulate through a twin-screw extruder, melt plasticize Chemical, extruded, pelletized, and vacuum-dried to obtain optical resin masterbatches.

[0114] (3) Preparation of optical resin

[0115] The methyl methacrylate polymer and the optical resin masterbatch are added to a high-speed mixer...

Embodiment 2

[0123] Embodiment 2, the specific steps of the preparation method of optical resin for optical protective film are:

[0124] (1) Preparation of heat-resistant stabilizer

[0125] The copolycarbonate resin is melted and sprayed by a melt spinning machine, stretched and spun, clustered by a bundler, chopped by a fiber cutter, coarsely pulverized on a coarse pulverizer and ground by a fine mill to obtain copolycarbonate micropowder.

[0126] (2) Preparation of optical resin masterbatch

[0127] Add 20 parts of methyl methacrylate polymer, 80 parts of heat-resistant stabilizer, 6.4 parts of compatibilizer and 9.6 parts of lubricant into a high-speed mixer and mix thoroughly. Chemical, extruded, pelletized, and vacuum-dried to obtain optical resin masterbatches.

[0128] (3) Preparation of optical resin

[0129] The methyl methacrylate polymer and the optical resin masterbatch are added to a high-speed mixer according to the mass ratio of 6:10 and mixed thoroughly, blended and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com