Patents

Literature

1092results about How to "Good thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

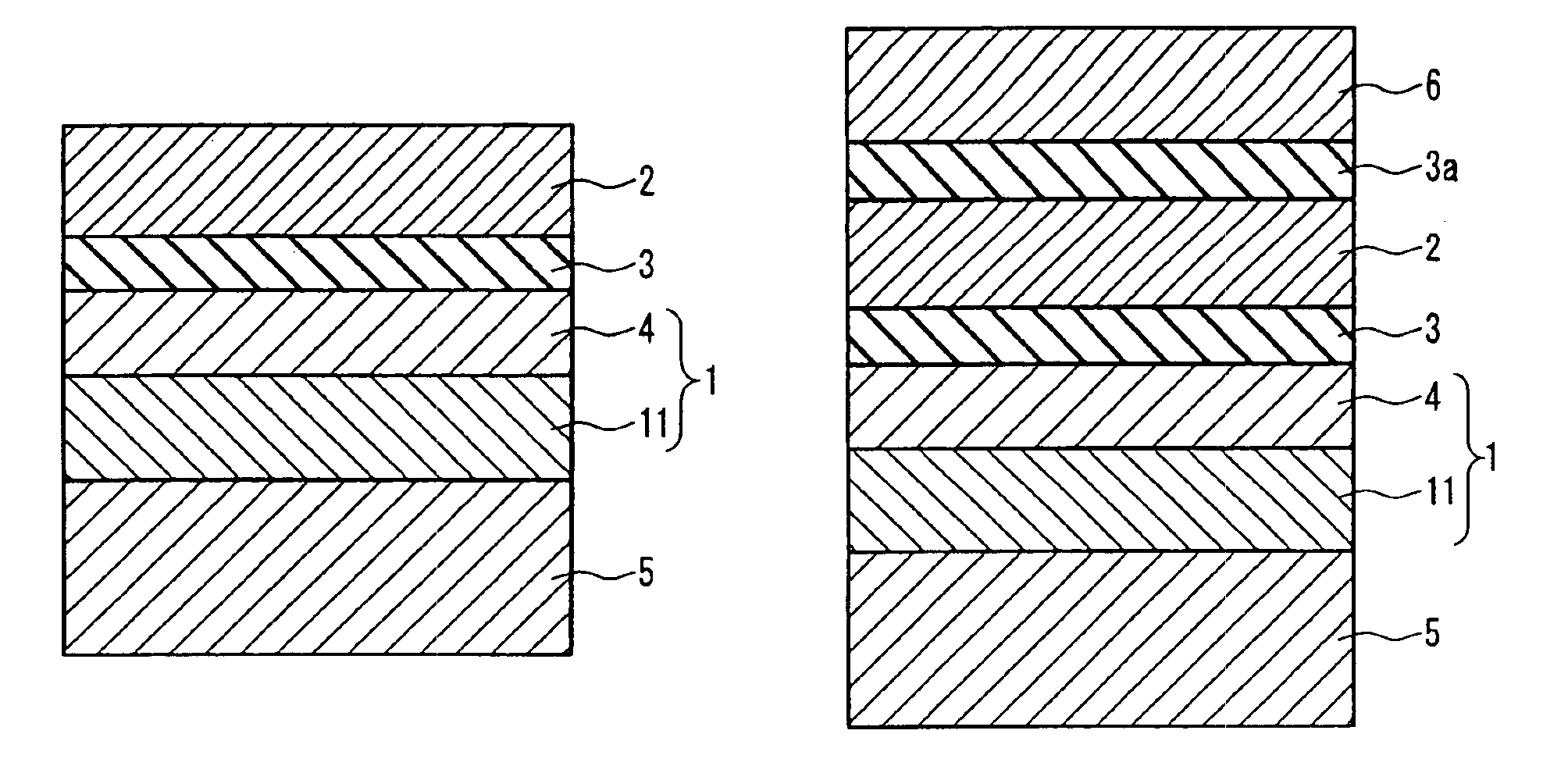

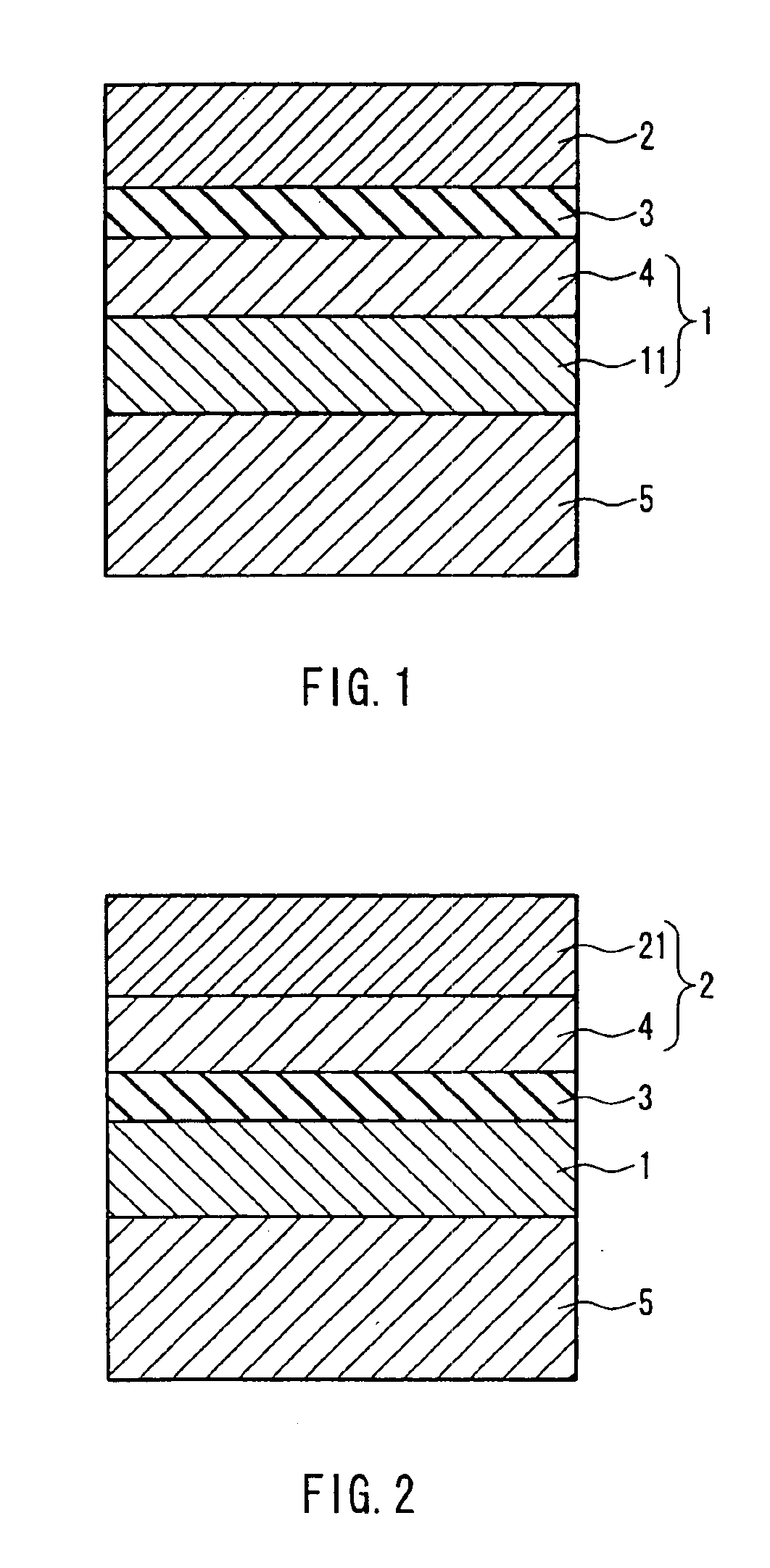

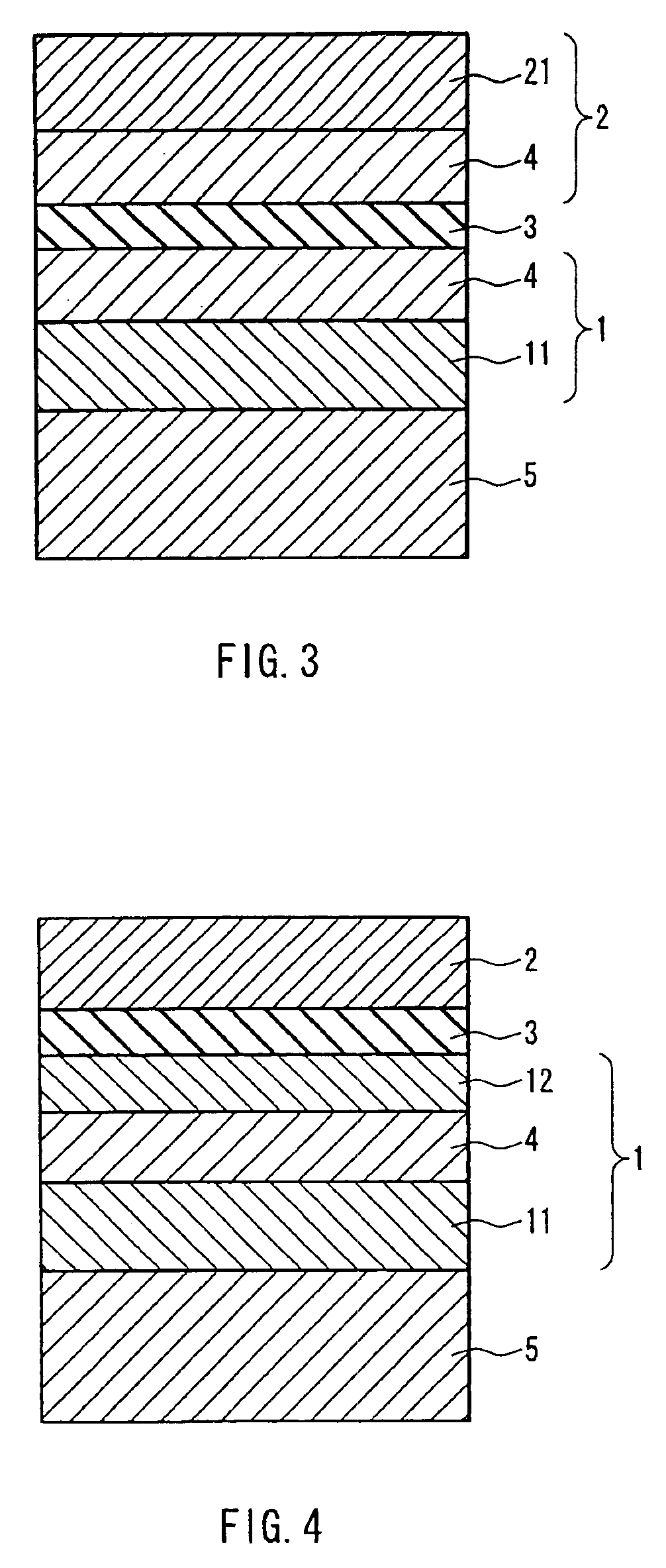

Magnetoresistive element, magnetic head, magnetic memory and magnetic recording apparatus using the same

InactiveUS6842317B2Good thermal stabilityImprove thermal stabilityNanomagnetismNanoinformaticsPhysicsMagnetic layer

A magnetoresistive element includes a multilayer film configuration including: a tunnel insulation layer; and a pair of magnetic layers that are laminated with the tunnel insulation layer interposed therebetween. A resistance value of the magnetoresistive element varies with a relative angle between magnetic orientations of both of the magnetic layers, and at least one of the magnetic layers includes a magnetic film having a thermal expansion coefficient not greater than a value obtained by adding 2×10−6 / K to a thermal expansion coefficient of the tunnel insulation layer. The thus configured magnetoresistive element can exert excellent thermal stability. The use of such a magnetoresistive element can realize a magnetic head, a magnetic memory element and a magnetic recording apparatus with excellent thermal stability.

Owner:PANASONIC CORP

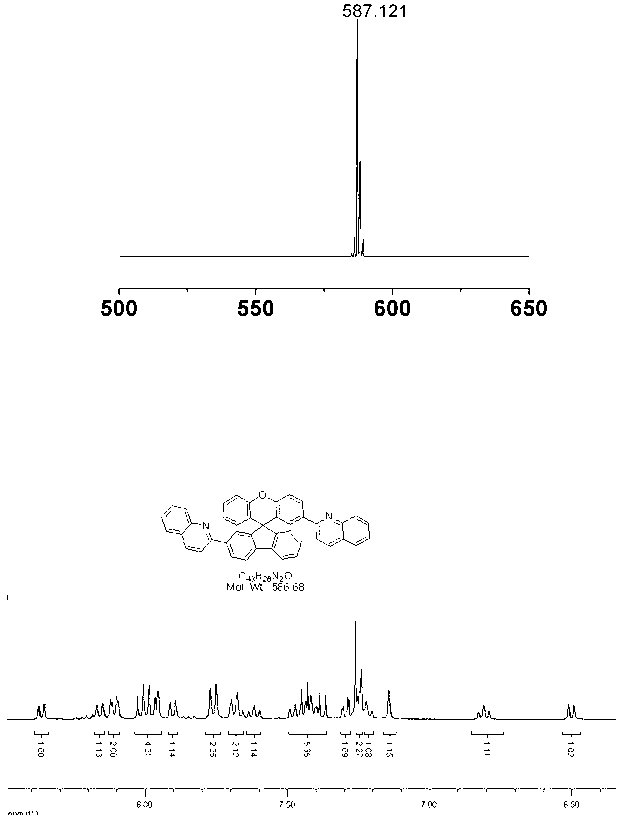

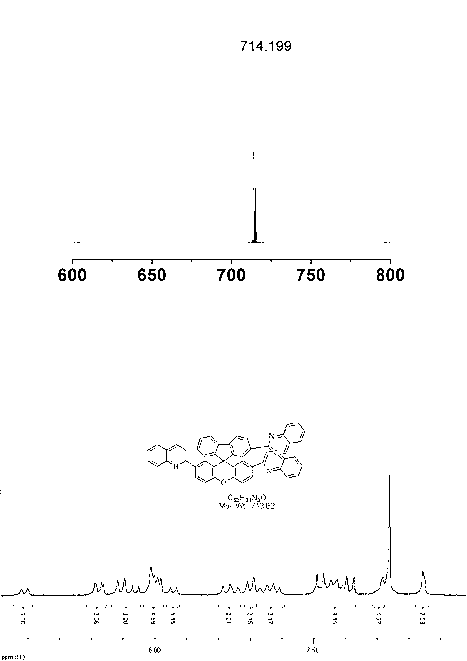

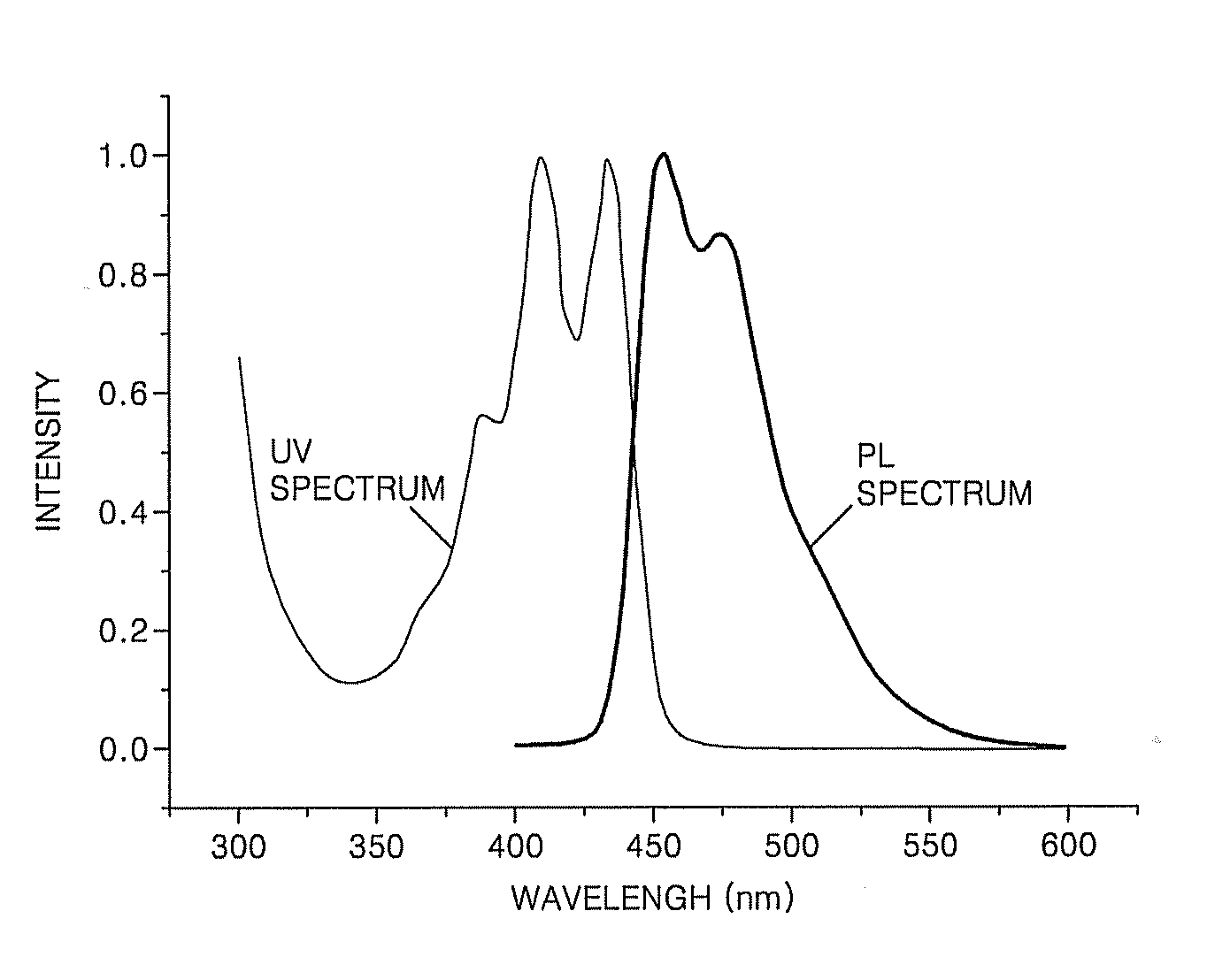

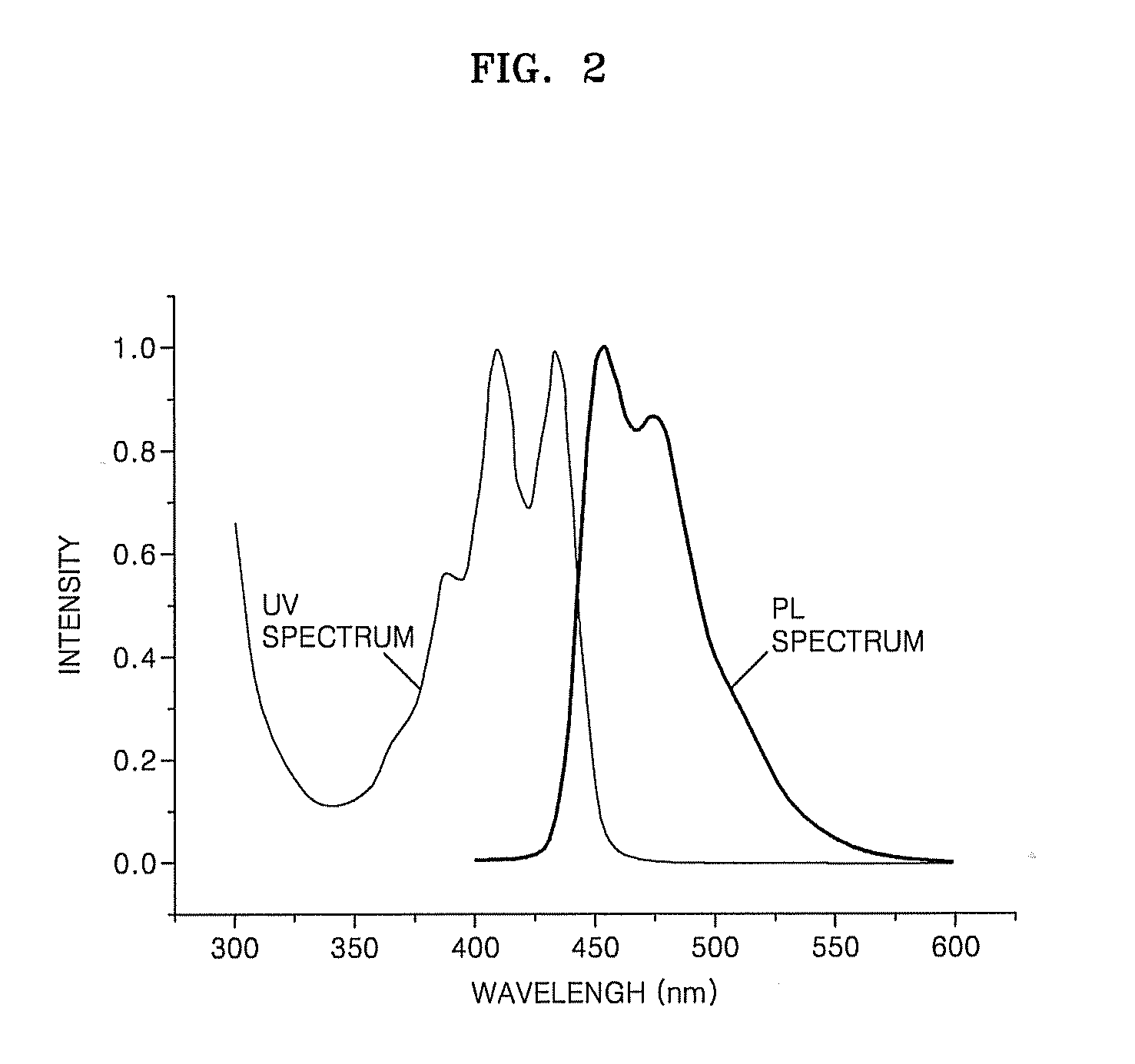

Spiro-fluorene-9,9-xanthene bipolar luminescent material, its preparation method and its application method

InactiveCN102786508AGood thermal stabilityGood photoelectric performanceOrganic chemistrySolid-state devicesOrganic electroluminescenceLarge applications

Spiro-fluorene-xanthene bipolar main materials have vertical spiral structures, so the main materials can effectively inhibit intermolecular actions, thereby the main materials can inhibit the intermolecular actions and dimer luminescence, and have good thermal stabilities and stable amorphous states. The invention relates to a spiro-fluorene-9,9-xanthene main material having a concrete designed structure shown in the specification, and concretely relates to a preparation method of the spiro-fluorene-9,9-xanthene main material, and an application of the spiro-fluorene-9,9-xanthene main material in organic light-emitting diode devices. The material has the following advantages: 1, the material has a high thermal stability and a stable amorphous state; 2, the material has a steric hindrance effect, so the material can effectively inhibit the dimer luminescence; and 3, the preparation method and the synthetic condition of the material are simple and are easy to implement, and the luminescent efficiency of the material is high. Preliminary research results of the structures of devices of the material and the properties of the material show that the material can be used in red and green light organic electroluminescent devices. Research results show that the material has a large application value and a wide application prospect in organic light-emitting diodes as the main material.

Owner:NANJING UNIV OF POSTS & TELECOMM

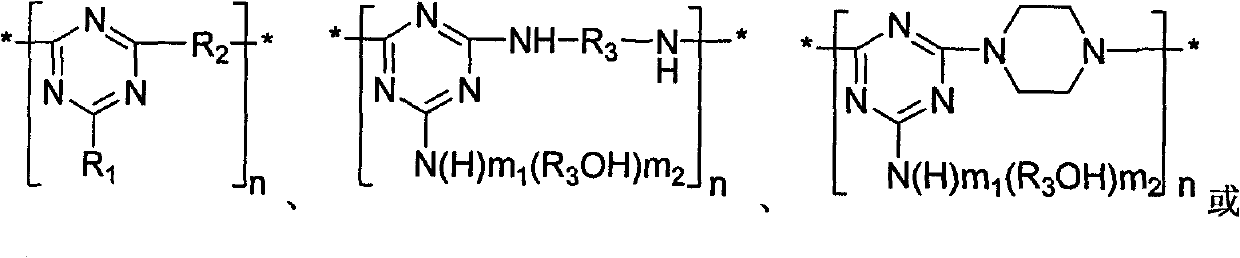

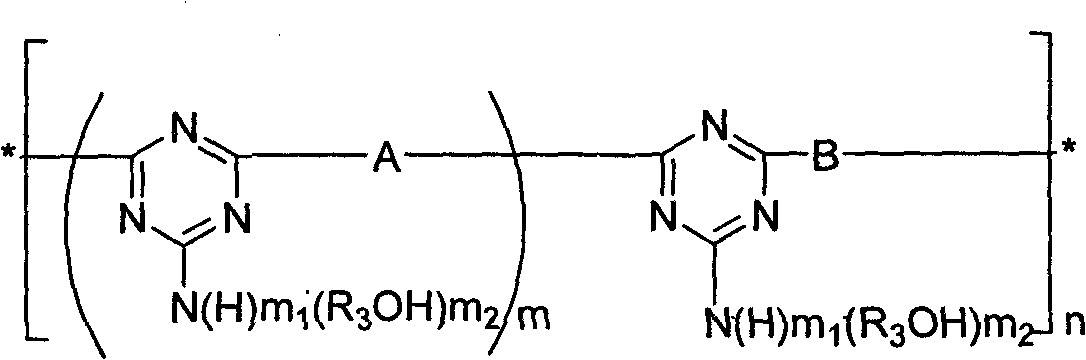

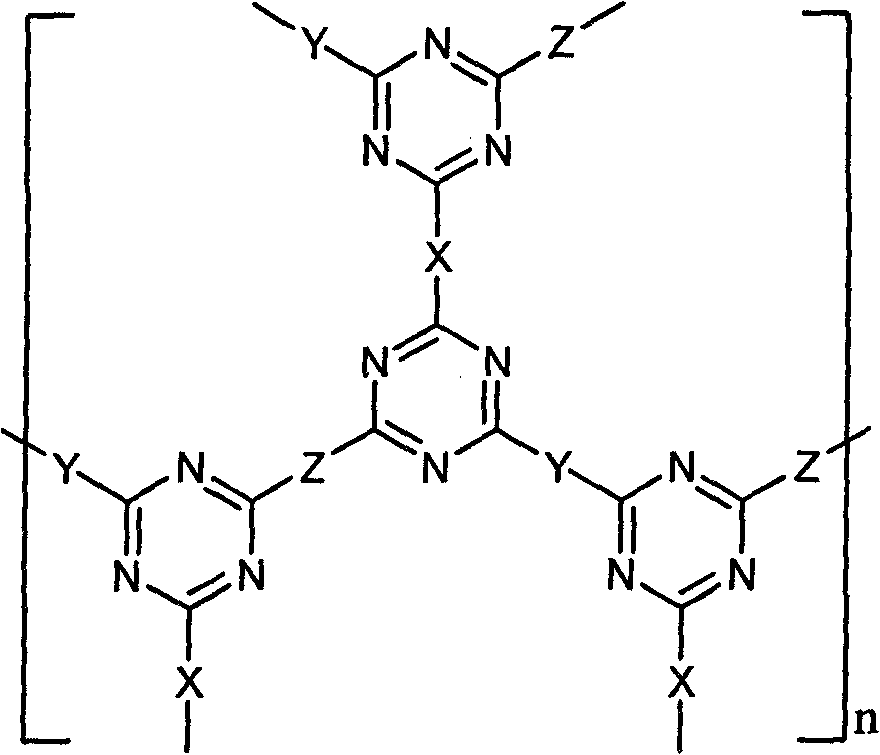

Halogen-free expansible flame-retardant thermoplastic resin composition

The invention discloses a halogen-free expansible flame-retardant thermoplastic resin composition, which is prepared by fusing and blending the following components in percentage by weight: 40 to 80 percent of thermoplastic resin, 18 to 25 percent of halogen-free expansible flame retardant, 0 to 5 percent of flame-retardant synergetic agent, 0 to 30 percent of glass fiber, 0 to 2 percent of coupling agent and 0.5 to 1 percent of antioxidant, wherein the thermoplastic resin is any one of polyamide 6, polyamide 66 and polylactic acid or glass fiber reinforced product thereof. The halogen-free expansible flame retardant in the flame-retardant thermoplastic resin composition has low additive amount and good flame retardancy, and the compound flame-retardant synergetic agent does not affect various inherent properties of the resin and can improve the flame retardancy of the material and reduce the cost of the material so as to fill the blank that the prior art has no thermoplastic resin compositions of halogen-free expansible flame-retardant polyamide, polylactic acid and the like.

Owner:SICHUAN UNIV

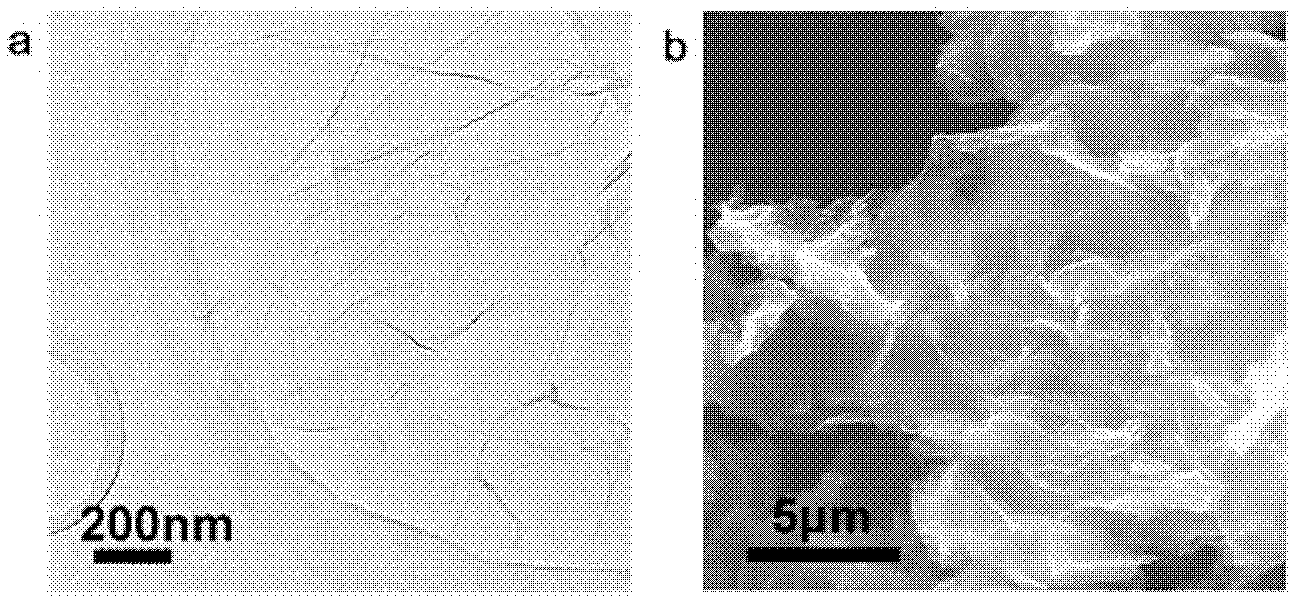

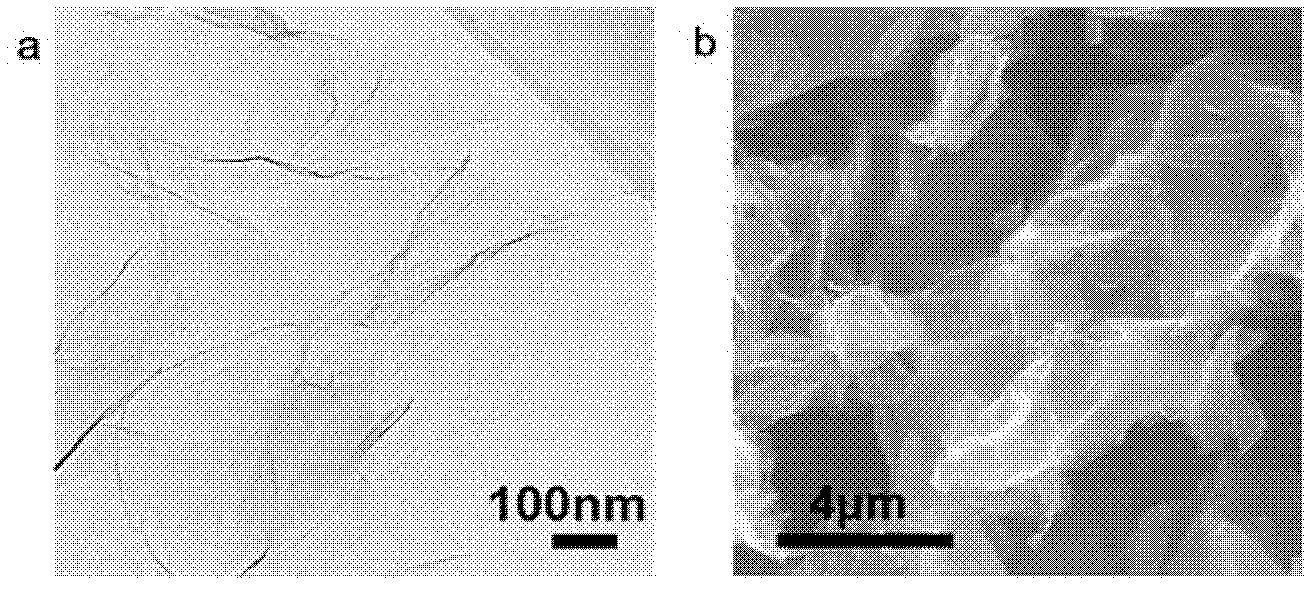

Doped graphene electrode material, macro preparation method and application of doped graphene electrode material

InactiveCN102306781AImprove conductivityGood thermal stabilityCell electrodesHigh current densityDoped graphene

The invention relates to the field of graphene electrode materials, and in particular relates to a doped graphene electrode material, a macro preparation method as well as an application of the doped graphene electrode material in a high-capacity high-multiplying-power lithium ion battery. In the invention, graphene is taken as a raw material. The preparation method comprises the following steps: controlling the temperature rising speed rate through shielding gas; introducing gas containing nitrogen or boron elements in different concentrations at high temperature so as to realize the doping of heteroatoms of the graphene, and get the nitrogen or boron doped graphene; mixing the doped graphene, conductive carbon black and a bonding agent; adding a solvent; coating the mixture on a current collector after grinding; taking the mixture after drying, shearing and tabletting as a working electrode; adding electrolyte containing a lithium salt by taking a lithium plate as a counter electrode / reference electrode; assembling into a button-type lithium ion half-battery in a glove box; and carrying out constant current charge and discharge tests under the condition of high current density. According to the invention, the electrode stability of the material under the condition of high current density is improved, and the fact that the doped graphene has higher specific capacity and excellent cycle performance in a shorter time is realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Organic light-emitting compound, organic light-emitting device including the compound, and method of manufacturing the organic light-emitting device

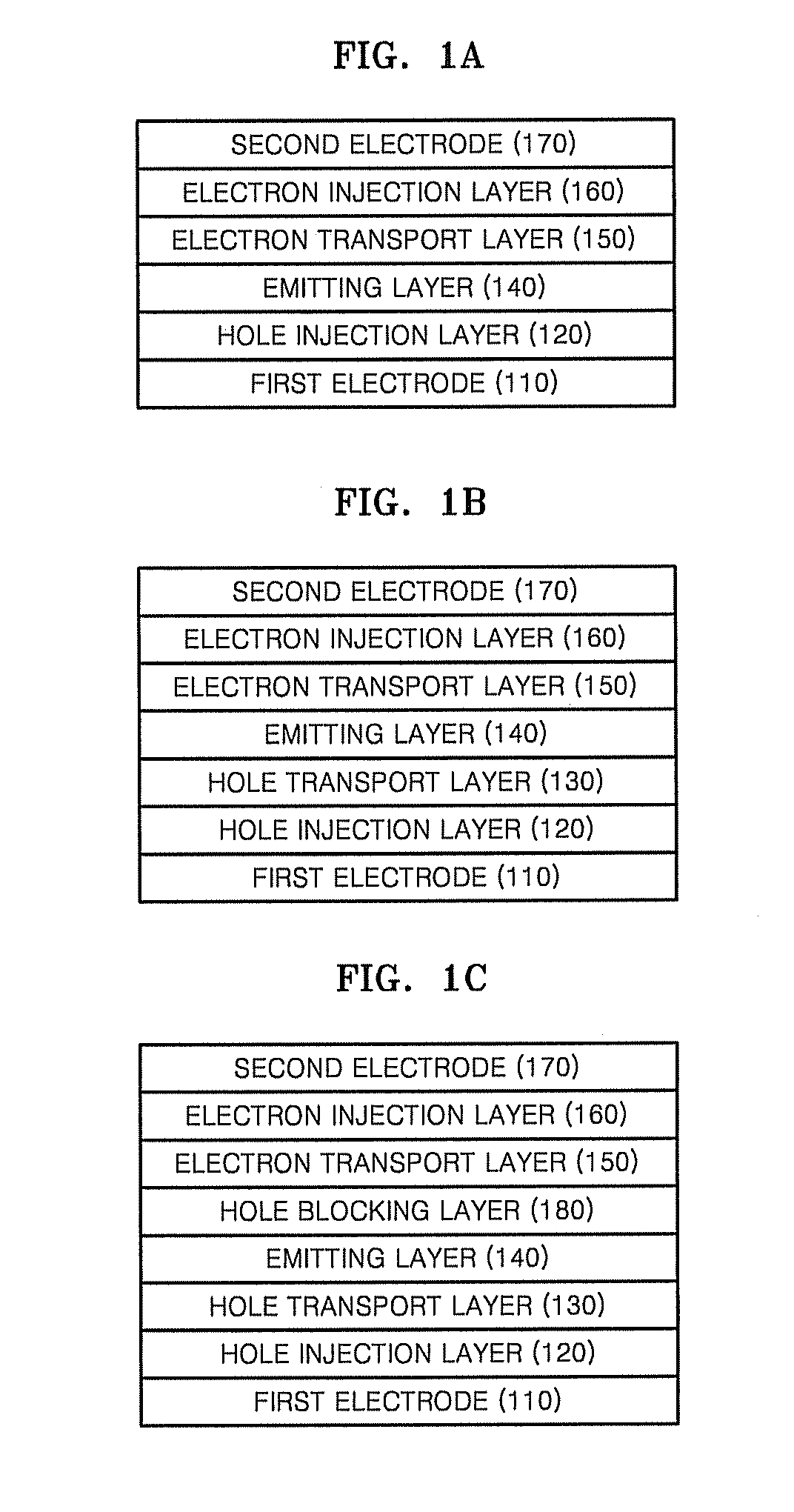

InactiveUS20080100208A1Good thermal stabilityImprove thermal stabilitySilicon organic compoundsDischarge tube luminescnet screensOrganic groupPhotochemistry

Provided are a compound represented by Formula 1 below and an organic light-emitting device including the same:wherein X is a C, Si, or Ge atom disubstituted with H or C1-60 organic groups, Ra-Rj are C1-60 organic groups, CY1 is a substituted or unsubstituted C5-C60 aromatic ring or a substituted or unsubstituted C2-C60 heteroaromatic ring, and n is 0 or 1. The use of the compound provides an organic light-emitting device having a low operating voltage and good efficiency and brightness.

Owner:SAMSUNG ELECTRONICS CO LTD

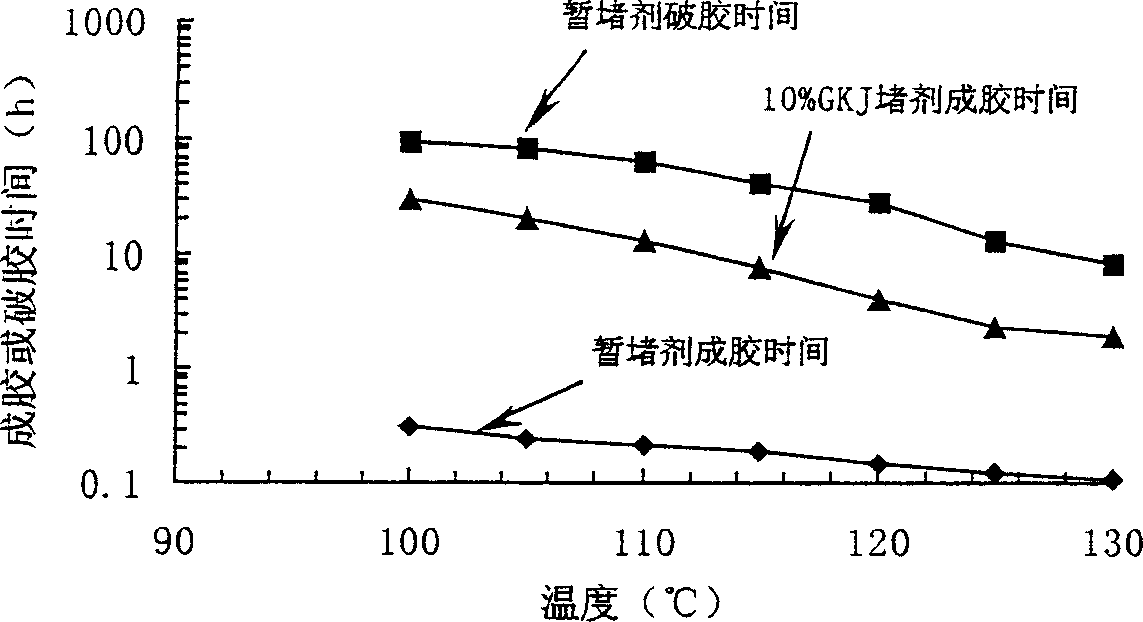

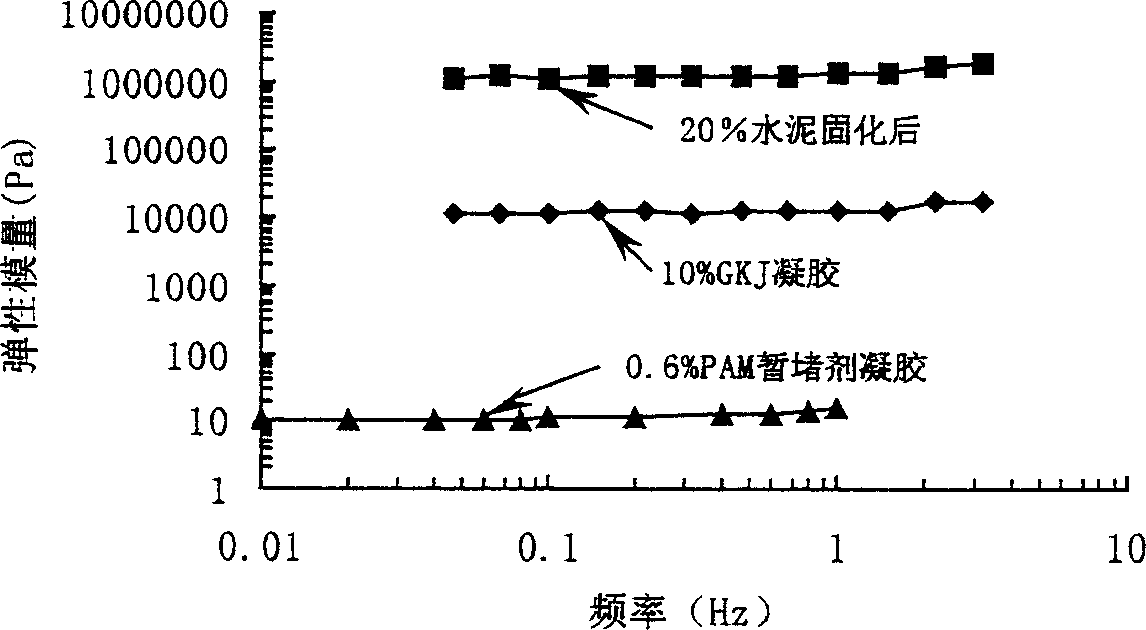

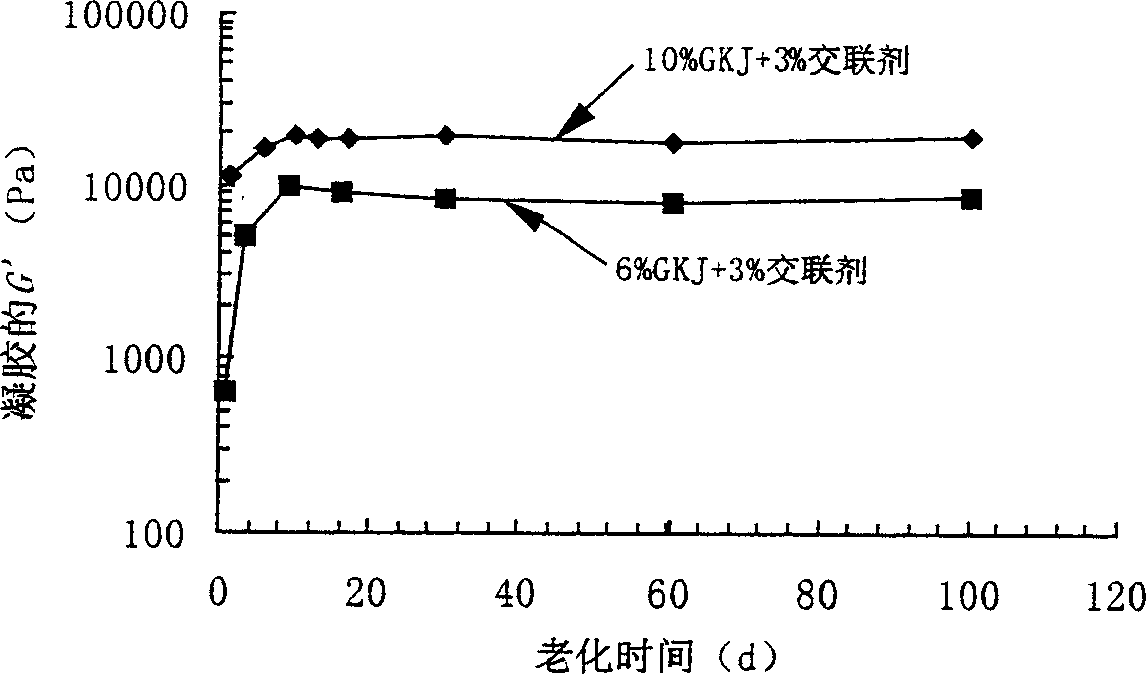

High-temperature and High-Salt resisting gel water packing-off method

The present invention relates to a high-temperature-resistant and high-salt-resistant gel water-plugging method for raising petroleum recovery efficiency. Said invention adopts three-slug injection water-plugging method, and provides the concrete steps of said three-slug injection water-plugging method. These steps are as follows: first slug, adding temporary blocking agent, its added quantity is 10-20% of total injection amount, after the temporary blocking agent is injection for 0.5-1.5 hr, closing well, the temporary blocking agent can be formed into gel, can be used for temporarily blocking the oil layer; then making second slug, injecting low-viscosity gel which is easily injected and can be formed into gel with high viscoelasticity under the condition of stratigraphic temperature, its injected quantity is 70-80% of total injection amount; and third slug, injecting cement as sealing agent, its injected quantity is 10-20% of total injection amount.

Owner:PETROCHINA CO LTD

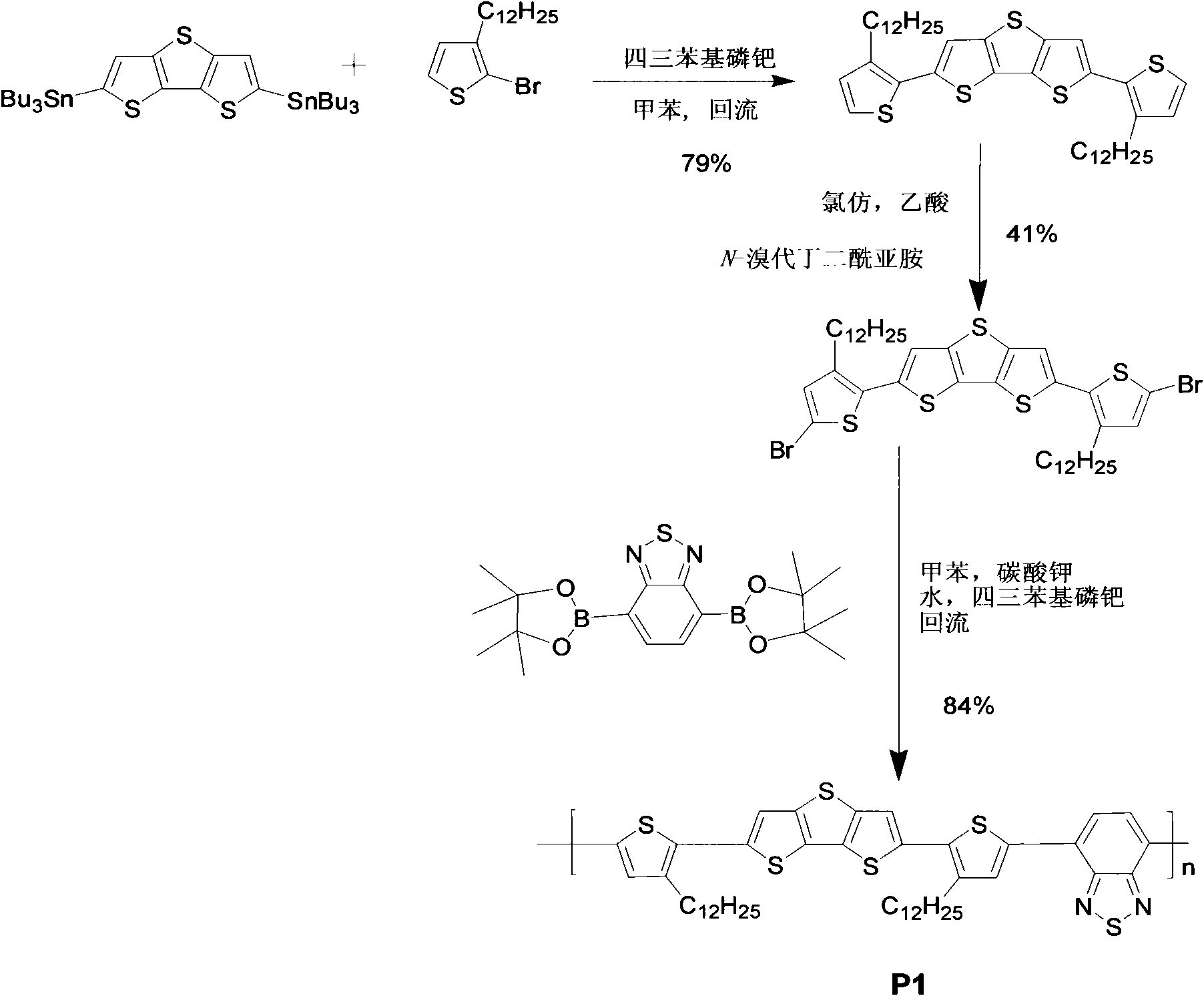

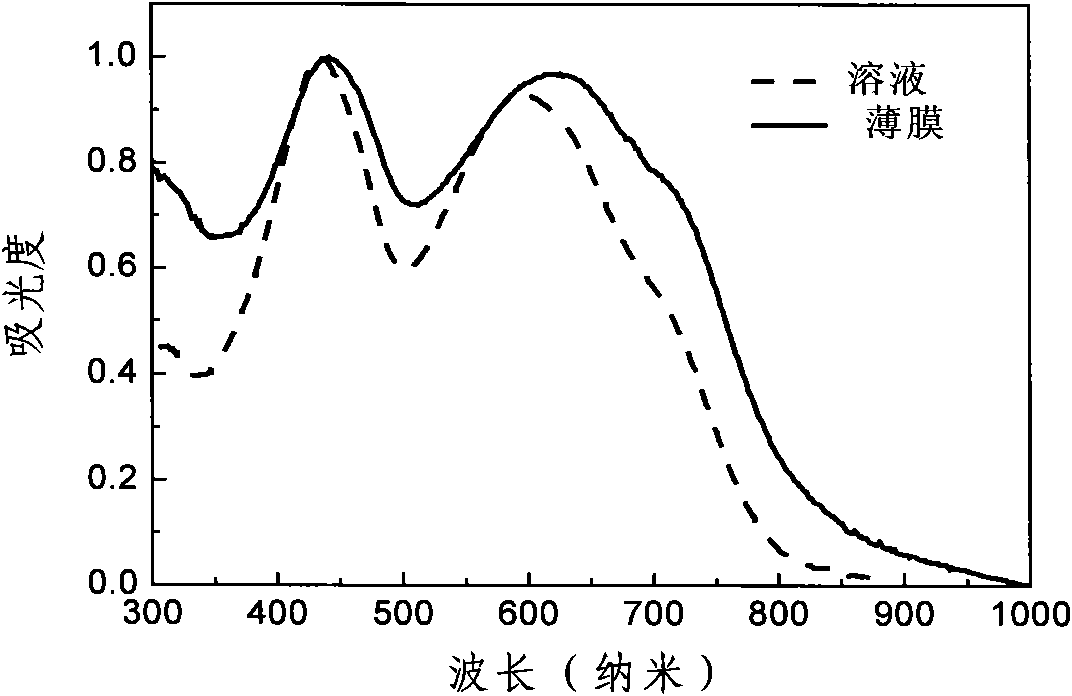

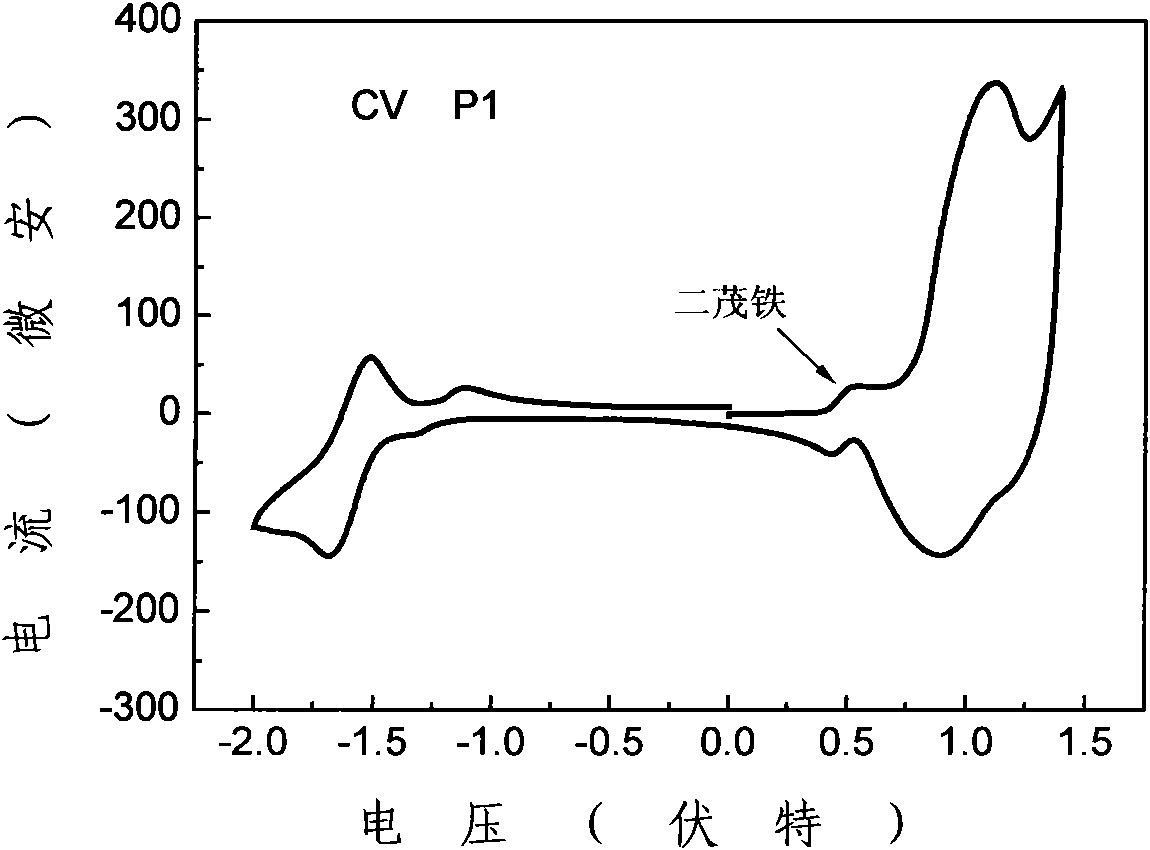

Conjugated polymer based on condensed ring thiophene and diazosulfide as well as preparation method and application thereof

ActiveCN101671428AGood processabilityGood thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingTransmission performanceOrganic semiconductor

The invention relates to a conjugated polymer based on condensed ring thiophene and diazosulfide, a preparation method and an application of the conjugated polymer as an active layer material in organic optoelectronic devices, such as polymer solar energy cells, organic field effect transistors and organic light emitting diodes. The conjugated polymer based on condensed ring thiophene and diazosulfide has an excellent sunlight capture ability and a hole transmission ability, and the conjugated polymer solution has good processability, thermostability, charge transmission performance and lightadsorption and is an ideal organic semiconducting material in the organic electronic devices, such as solar energy cells, field effect transistors and light emitting diodes. A general formula of the conjugated polymer is shown as above.

Owner:INST OF CHEM CHINESE ACAD OF SCI

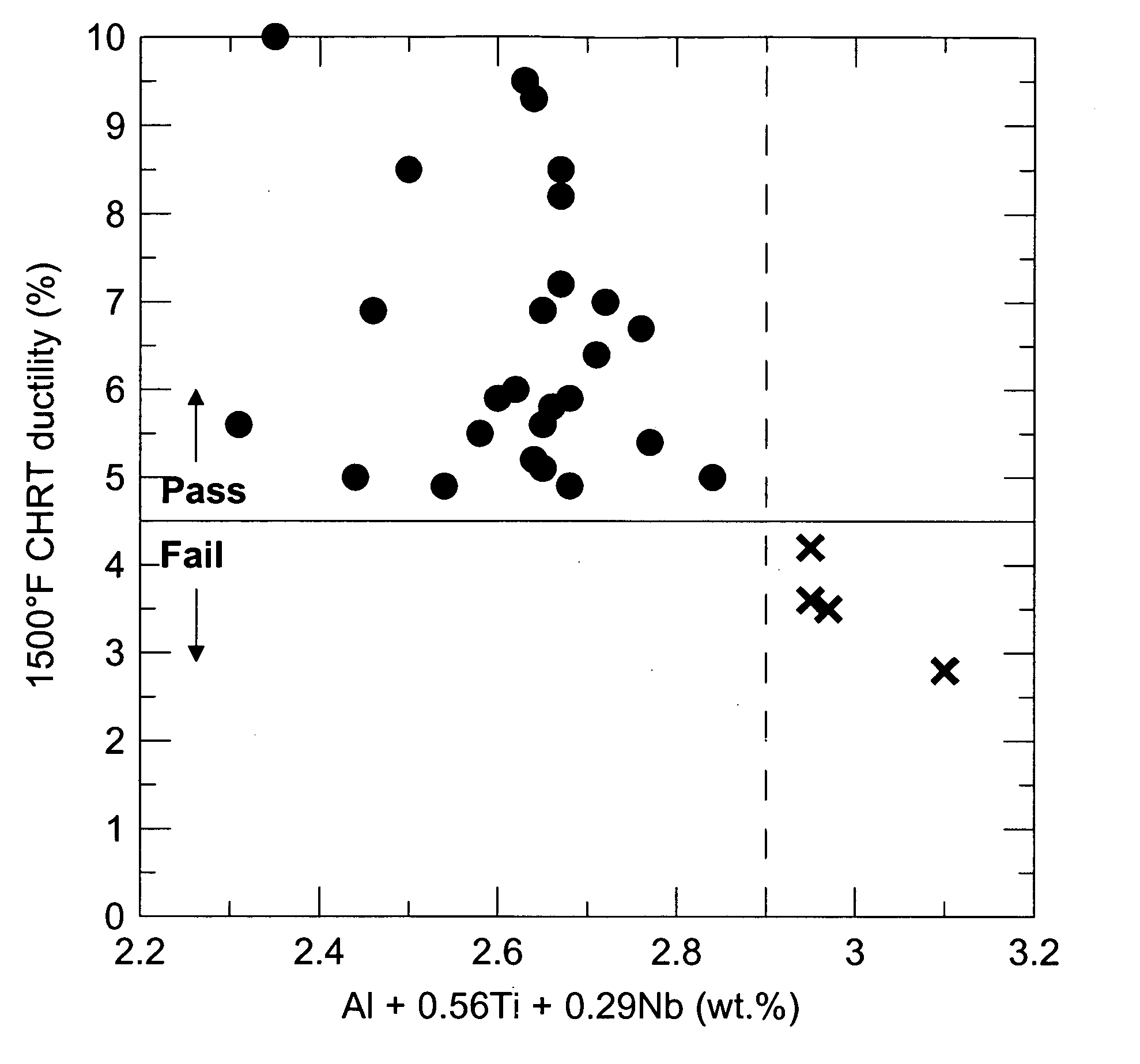

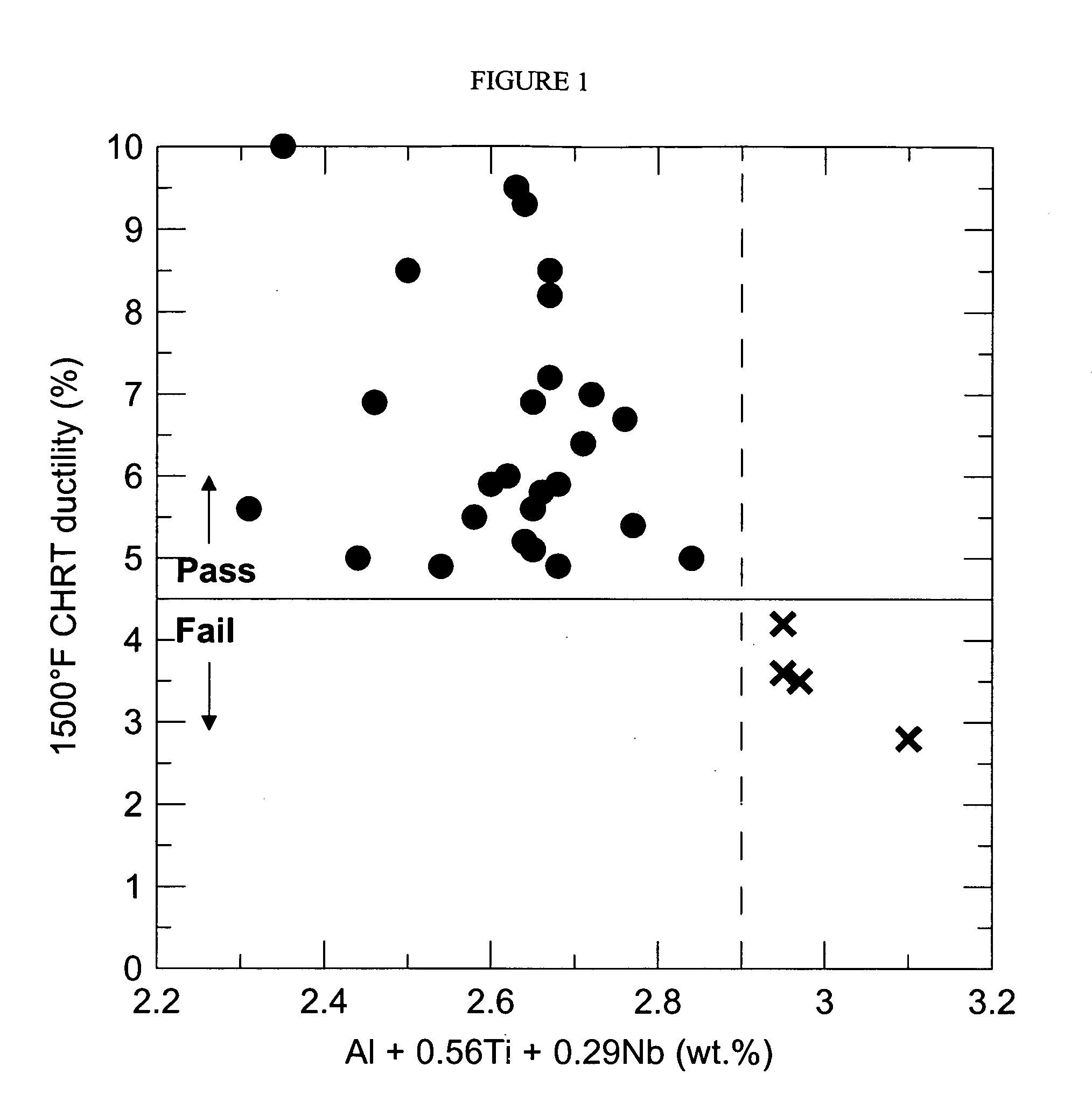

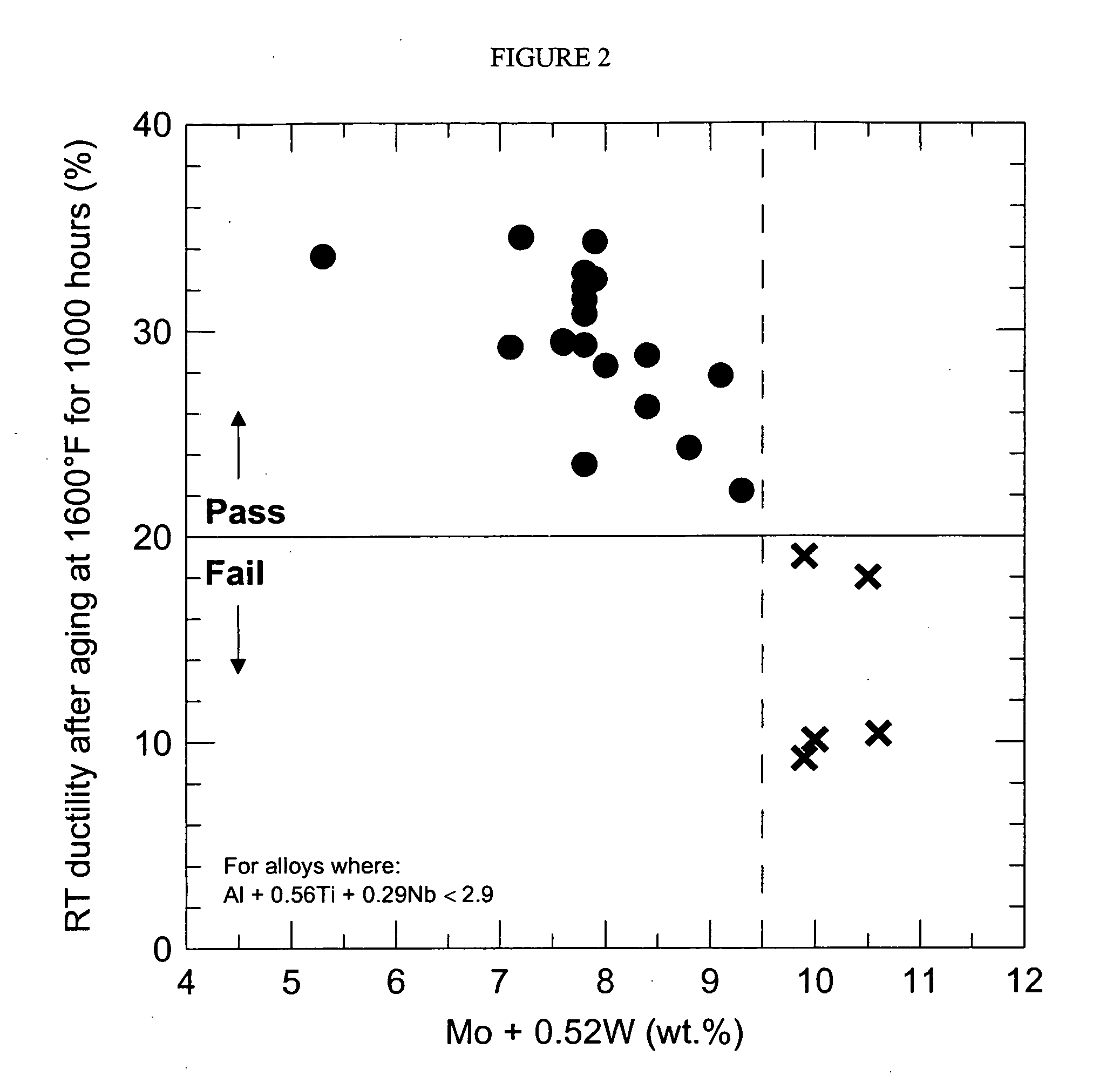

Ni-Cr-Co alloy for advanced gas turbine engines

A wrought age-hardenable nickel-chromium-cobalt based alloy suitable for use in high temperature gas turbine transition ducts possessing a combination of three specific key properties, namely resistance to strain age cracking, good thermal stability, and good creep-rupture strength contains in weight percent 17 to 22 chromium, 8 to 15 cobalt, 4.0 to 9.5 molybdenum, up to 7 tungsten, 1.28 to 1.65 aluminum, 1.50 to 2.30 titanium, up to 0.80 niobium, 0.01 to 0.2 carbon, up to 0.01 boron, and up to 3 iron, with a balance of nickel and impurities. Certain alloying elements must be present in amounts according to two equations here disclosed.

Owner:HAYNES INTERNATIONAL

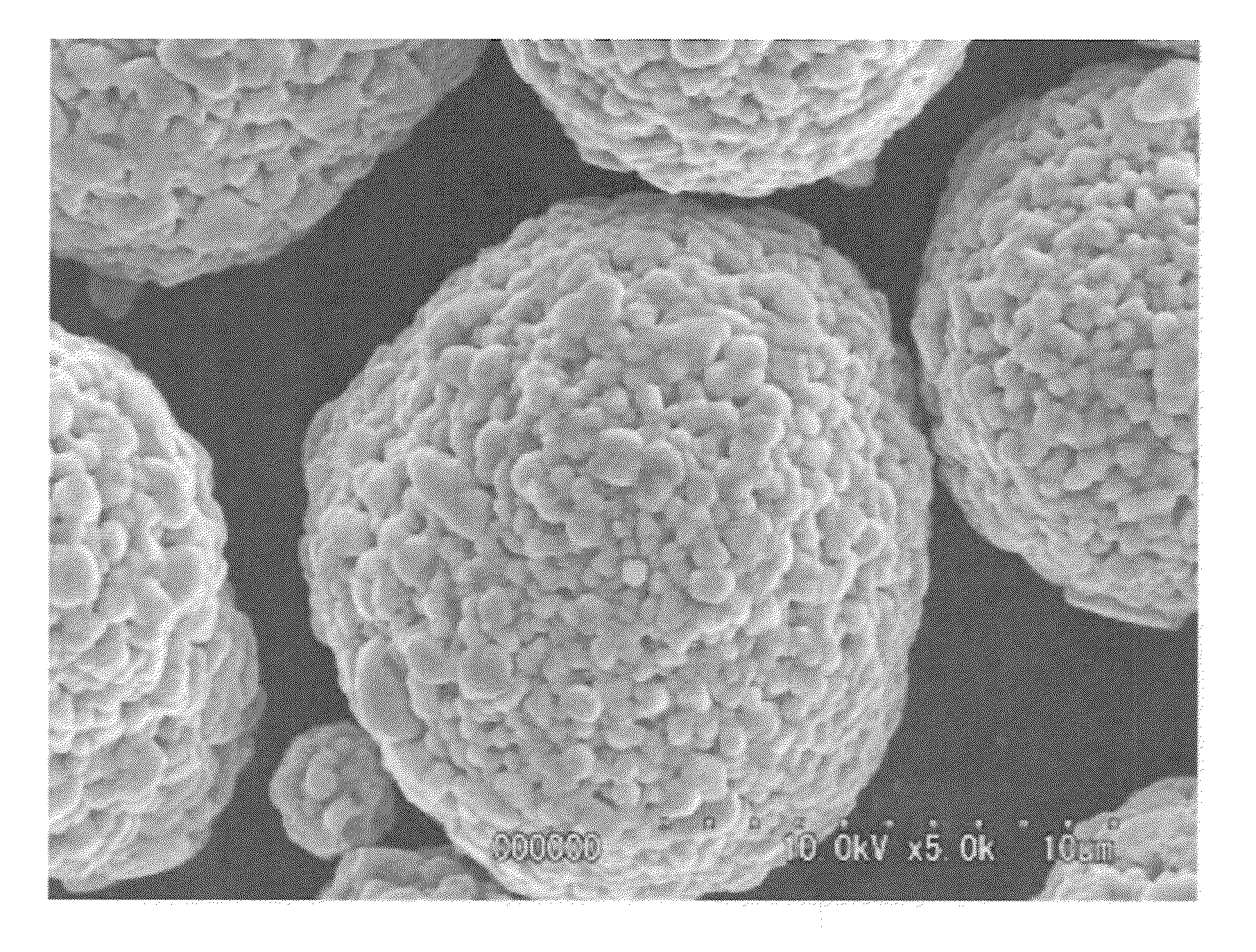

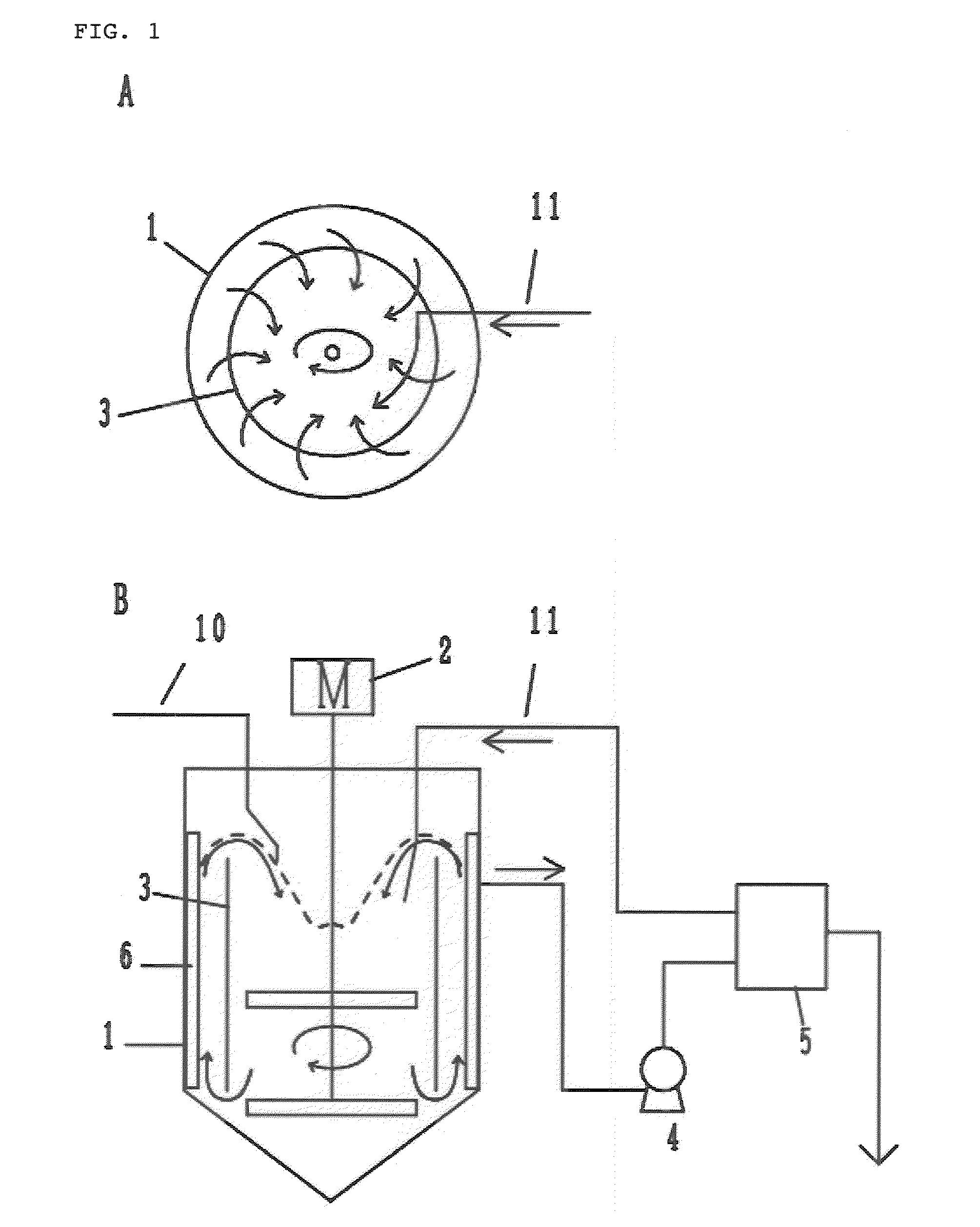

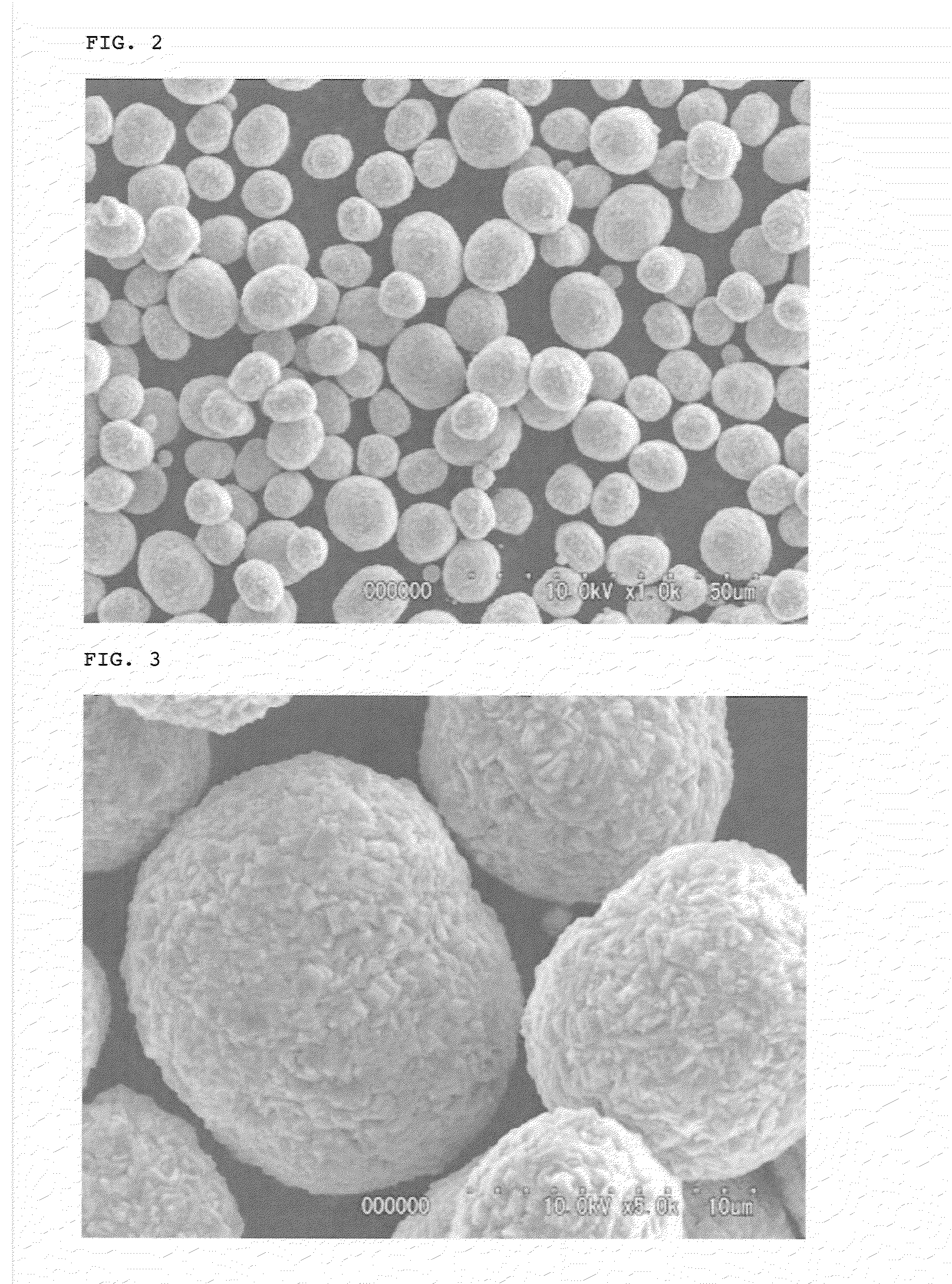

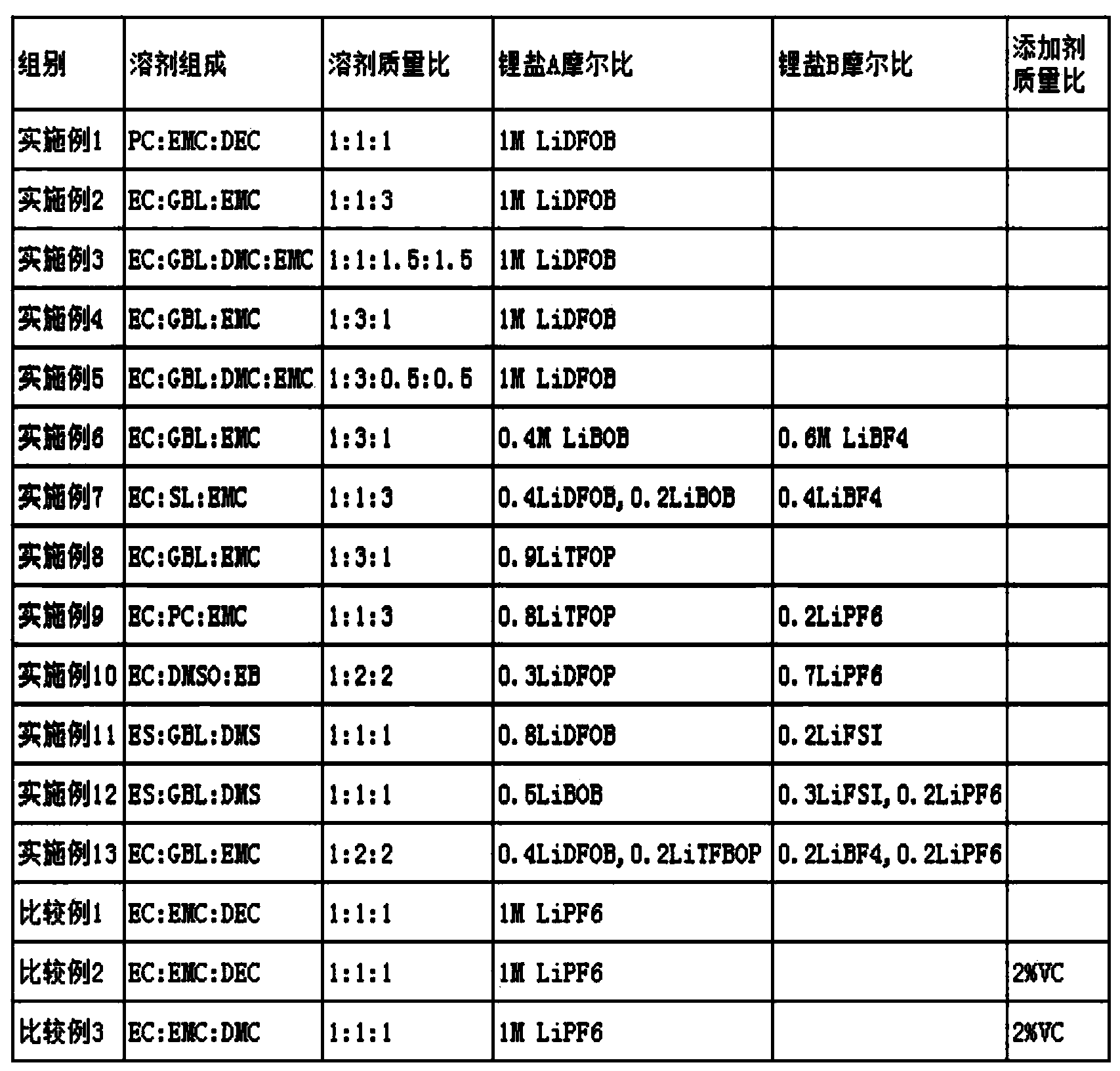

Nickel-cobalt-maganese-based compound particles and process for producing the nickel-cobalt-manganese-based compound particles, lithium composite oxide particles and process for producing the lithium composite oxide particles, and non-aqueous electrolyte secondary battery

ActiveUS20130045421A1Good thermal stabilityLess thermal stabilitySynthetic resin layered productsCellulosic plastic layered productsComposite oxideChemistry

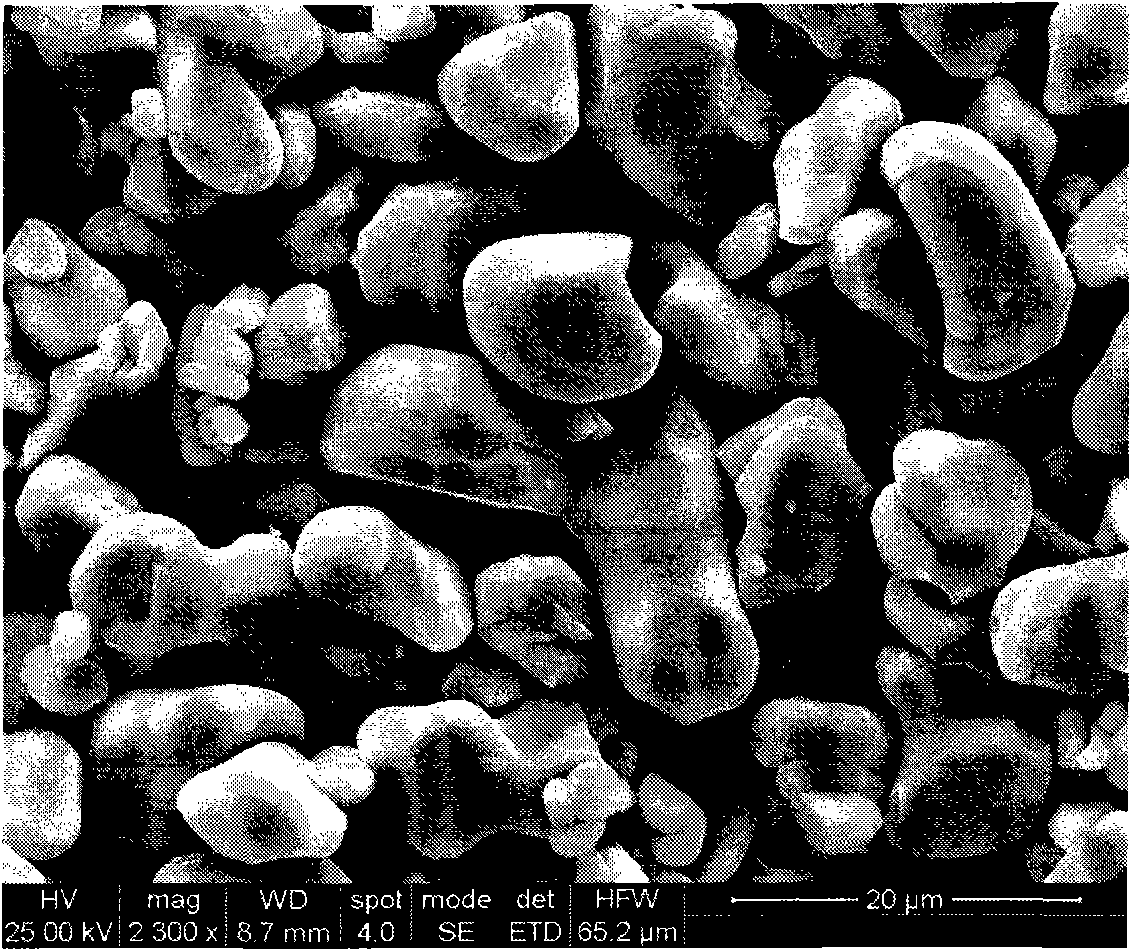

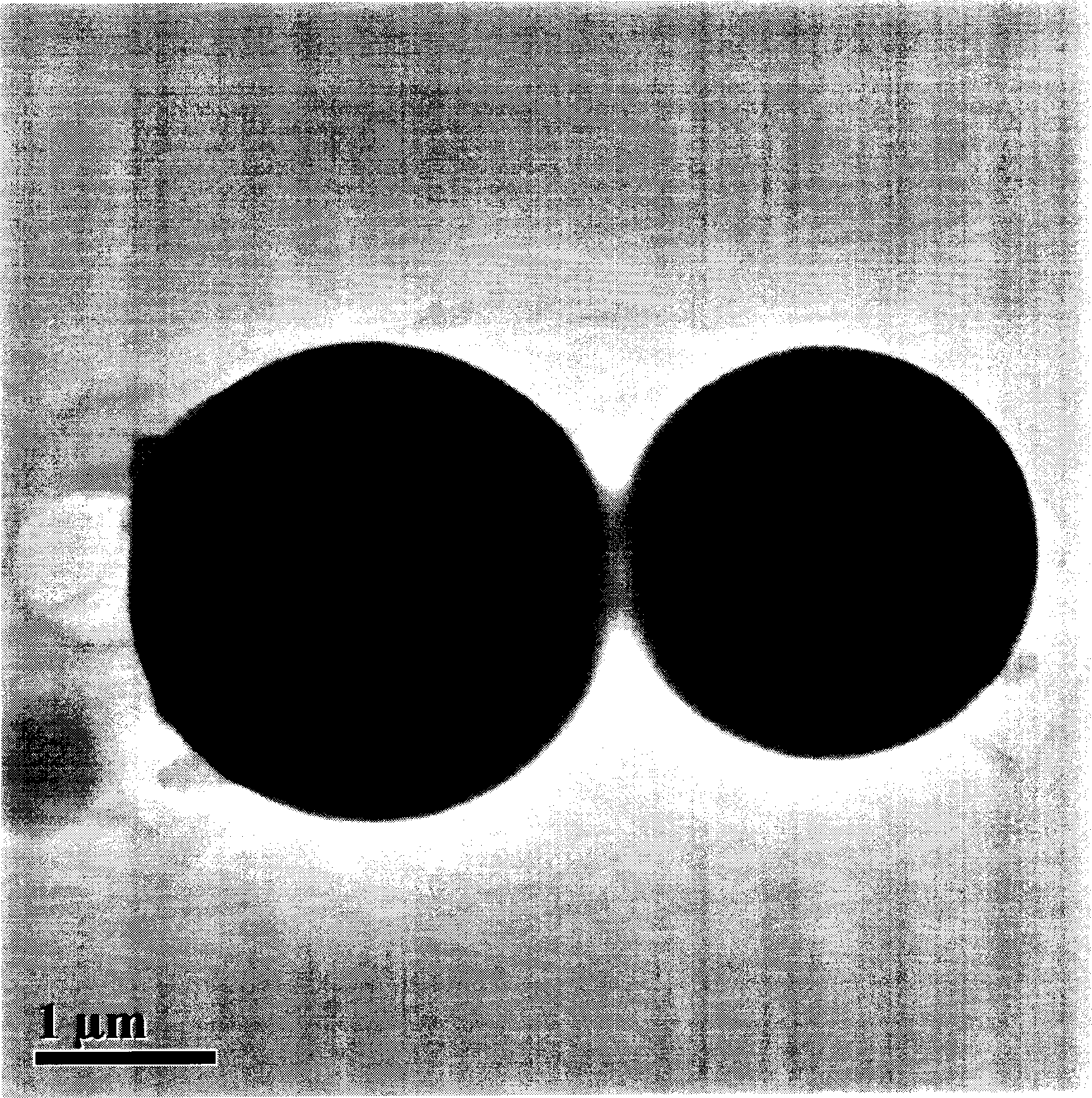

The present invention relates to nickel-cobalt-manganese-based compound particles which have a volume-based average secondary particle diameter (D50) of 3.0 to 25.0 μm, wherein the volume-based average secondary particle diameter (D50) and a half value width (W) of the peak in volume-based particle size distribution of secondary particles thereof satisfy the relational formula: W≦0.4×D50, and can be produced by dropping a metal salt-containing solution and an alkali solution to an alkali solution at the same time, followed by subjecting the obtained reaction solution to neutralization and precipitation reaction. The nickel-cobalt-manganese-based compound particles according to the present invention have a uniform particle size, a less content of very fine particles, a high crystallinity and a large primary particle diameter, and therefore are useful as a precursor of a positive electrode active substance used in a non-aqueous electrolyte secondary battery.

Owner:TODA IND

Preparation method of protective lubricating grease for high-temperature-resistant steel wire rope

InactiveCN102102047AImprove adhesionImprove anti-friction and anti-wear propertiesLubricant compositionWire ropeHigh adhesion

The invention discloses a protective grease composition with high performance for a high-temperature-resistant steel wire rope and a preparation method thereof. The protective lubricating grease composition for the steel wire rope is prepared from base oil (high-viscosity mineral oil or synthetic oil), a thickening agent, an additive and a covering agent. The ordinary protective lubricating grease for the steel wire rope is prepared by thickening the base oil with a solid hydrocarbon thickening agent. The thickening agent disclosed by the invention is bentonite. A high-molecular-weight tackifier and a lubricating grease solid filler are adopted, so that the performance of bentonite lubricating grease is further improved, the protective lubricating grease for the steel wire rope has extremely high high-temperature resistance and extremely high adhesion strength, and low-cost protective grease with excellent combination property for the steel wire rope is provided. The protective grease for the steel wire rope is specially used for protecting the steel wire rope used in an extreme high temperature environment.

Owner:益田润石(北京)化工有限公司

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

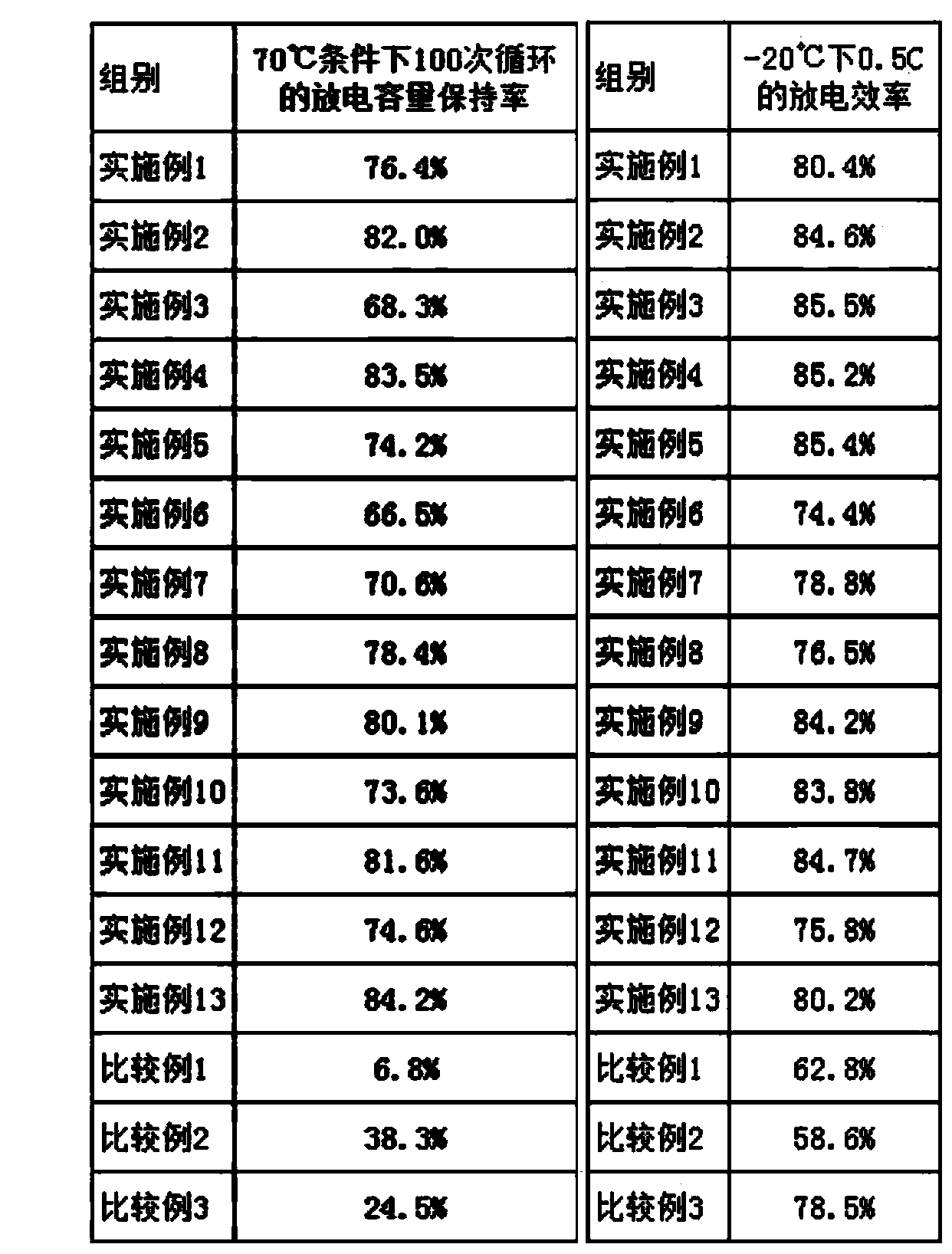

Lithium ion battery electrolyte solution

InactiveCN103943884AImprove conductivityGood thermal stabilitySecondary cellsOrganic electrolytesSulfoneEther

The invention discloses a lithium ion battery electrolyte solution which comprises a lithium salt and a non-aqueous organic solvent, wherein the lithium salt is a lithium salt A or a mixture of the lithium salt A and a lithium salt B; the lithium salt A contains oxalate groups, and the lithium salt B does not contain oxalate groups; the lithium salt A comprises one or mixture of several of lithium bis(oxalate)borate (LiBOB), lithium difluoroborate (LiDFOB), lithium difluorophosphate (LiDFOP) and lithium tetrafluorophosphate (LiTFOP); the non-aqueous organic solvent is one or mixture of several of common carbonate, carboxylate, ethers, sulfone compounds and the like. Due to the lithium ion battery electrolyte solution, the safety and the high-low-temperature performance of a lithium ion battery can be greatly improved, and the use temperature range of the lithium ion battery can be expanded.

Owner:陈琛

Positive material for lithium ion battery and its preparation method

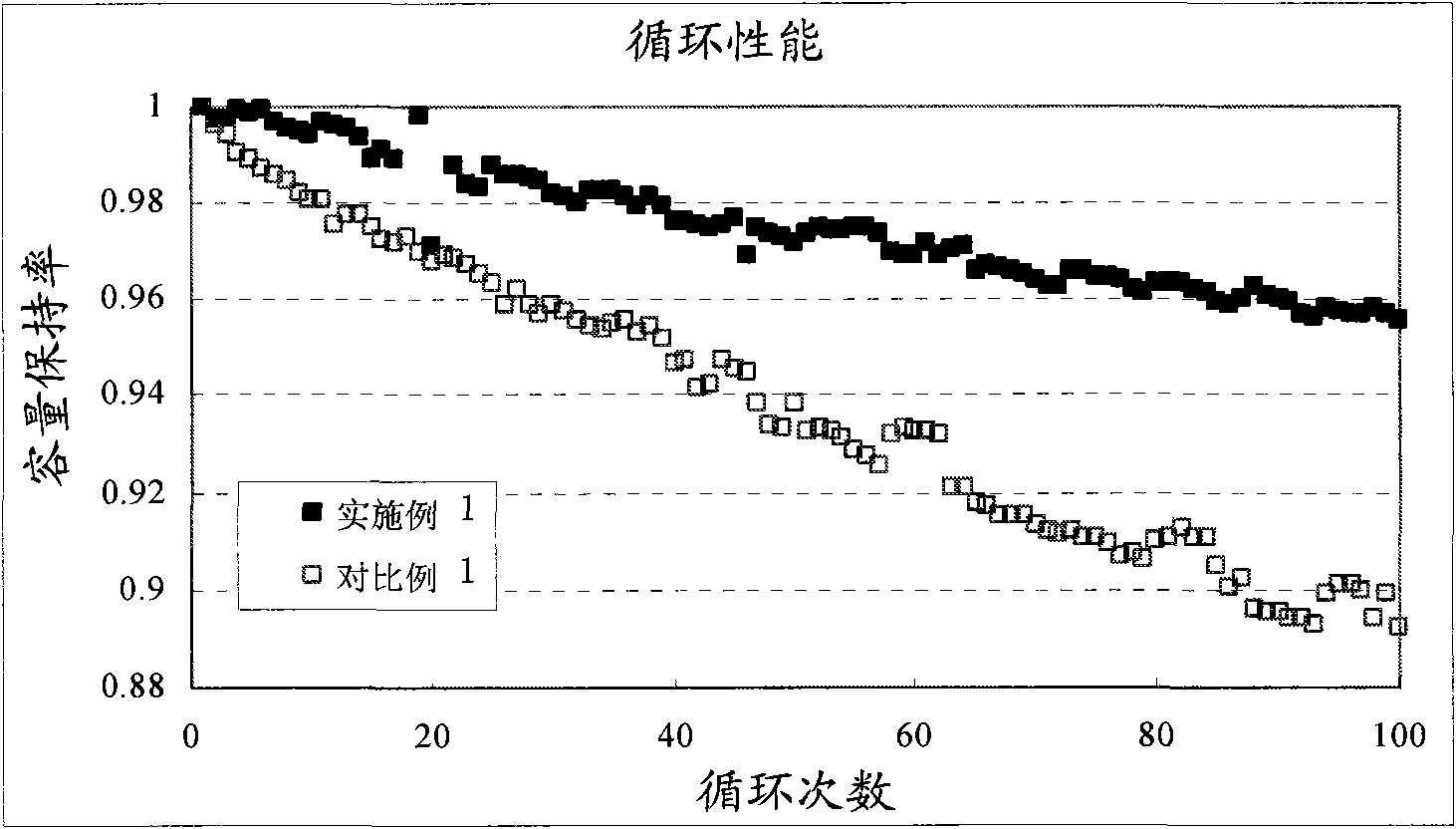

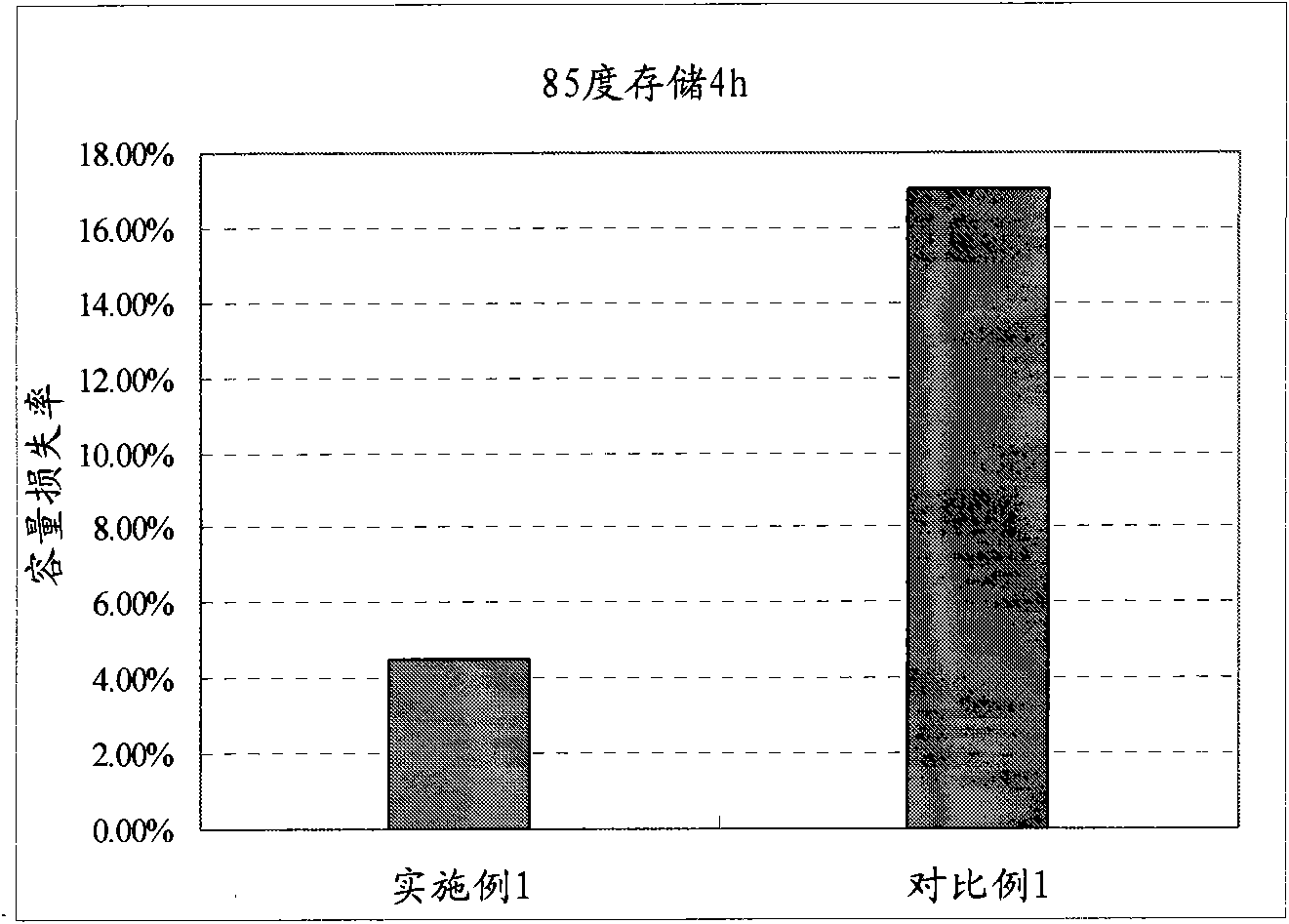

ActiveCN102339998AInhibit swellingImprove cycle performanceCell electrodesSecondary cellsHeat stabilityLithium-ion battery

The invention discloses a positive material for a lithium ion battery and its preparation method, concretely relates to a modified cobalt acid lithium material and its preparation method, and relates to a lithium ion battery containing the material. The general formula of the material is LiMxLyNwCozO2, wherein 0.001<=x<=0.1, 0.005<=y<=0,05, 0<=w<=0.05, 1-x-y-w<=z<=1, M is one or more transition metals selected from Mn, Ni, Ti, Zr, Cr, Fe, Cu, Zn, Y, Ce, Sm, Pr, La, Mo or Nb and the like, L is one or more main group metal elements selected from Na, K, Ca, Mg, Sr, Ba, B, Ga, Sn, Sb, Bi or Al and the like; N is one or more of Li, Mn, Ni, Zr, Ti, Y, Ce, Sm, Mo, Nb, Na, K, Ca, Mg, Sr, Ba, B or Al. The material has the advantages of high specific capacity, excellent cycle performance and heat stability, simple preparation method and easy industrialization production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

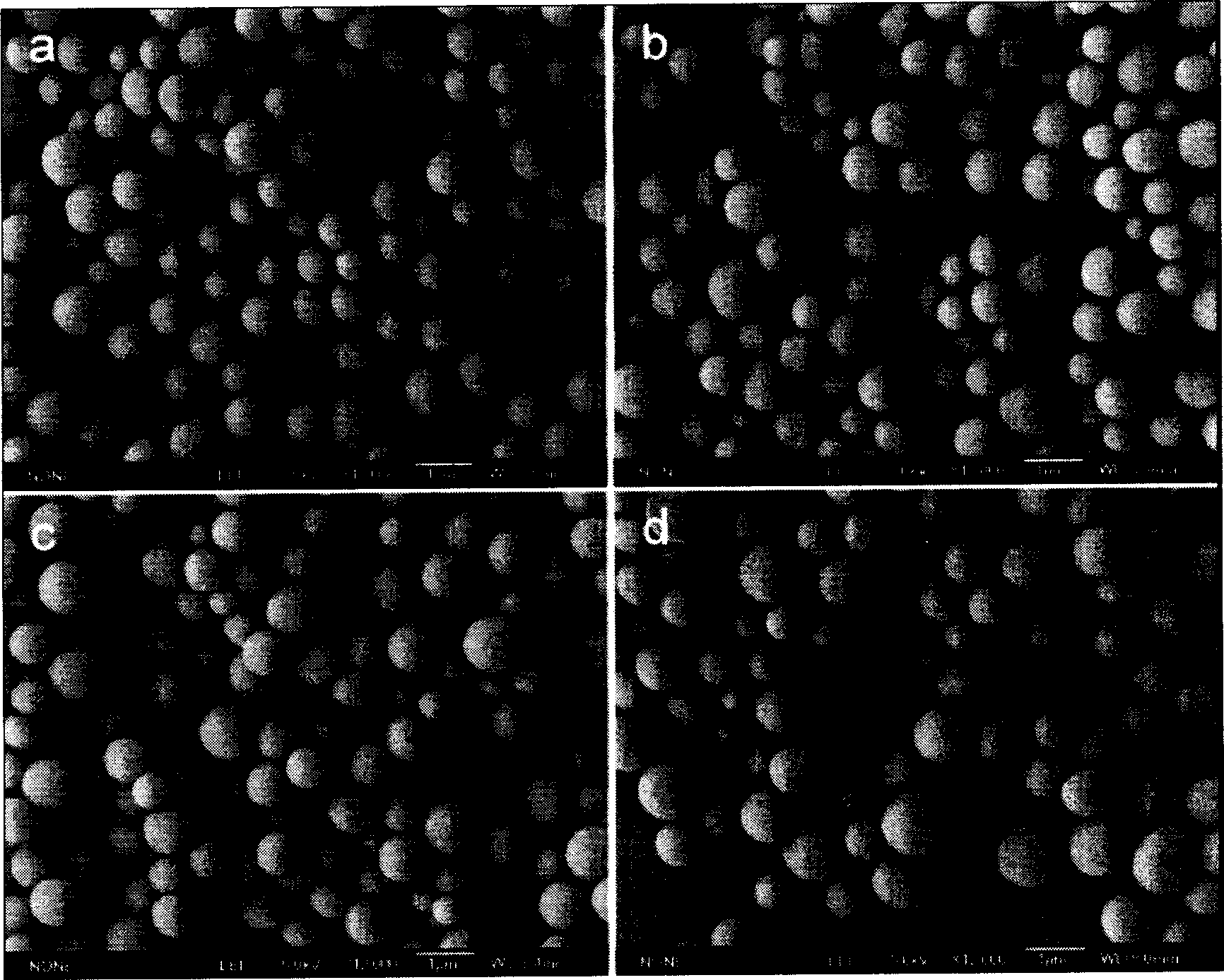

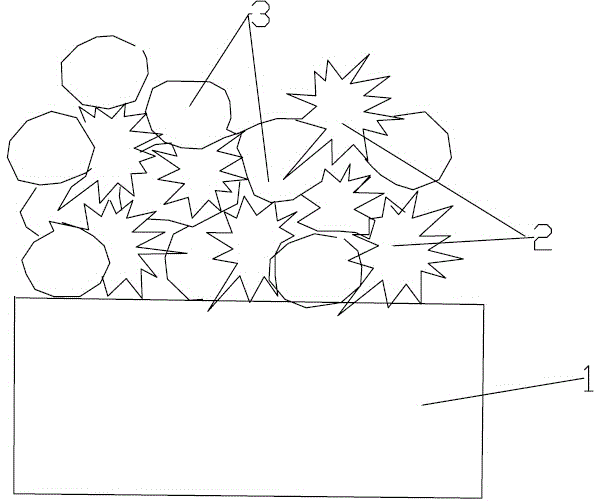

Crosslinking poly(organophosphazenes) microsphere and preparation method thereof

InactiveCN1908033AGood thermal stabilitySimple processCatalyst carriersPharmaceutical non-active ingredientsChemistryChromatography column

the invention discloses a crosslinking polyphosphine-nitrile microball and preparing method, which is characterized by the following: the diameter is 0.4-5 um ; the chemical structural formula is displayed on the right; the microball surface is flat solid structure, which adopts hexachloride cycotrinitrilephosphine and 4, 4'-dihydroxy diphenyl sulfone to crosslink and condense under the action of trimethylamine.

Owner:SHANGHAI JIAO TONG UNIV

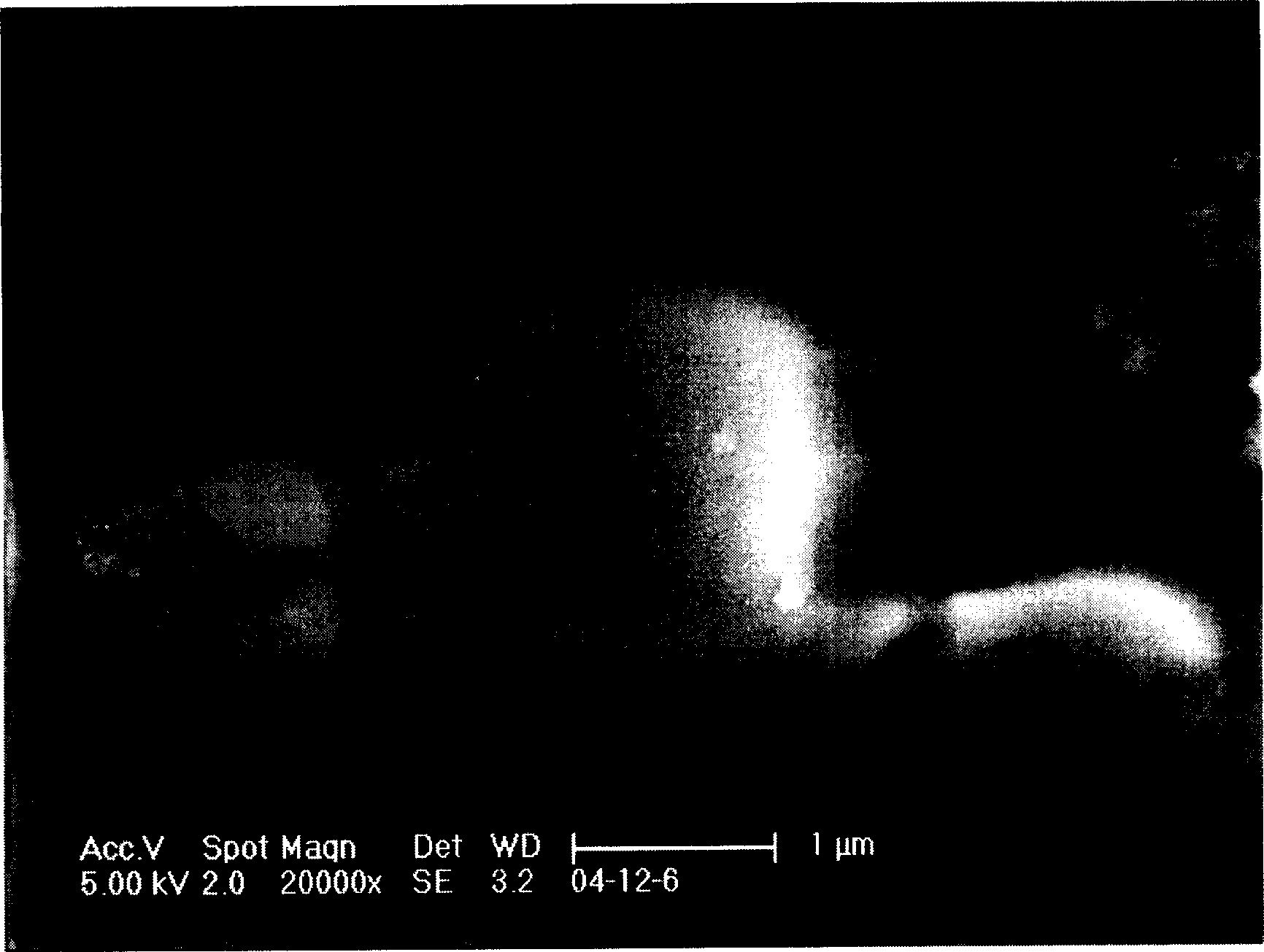

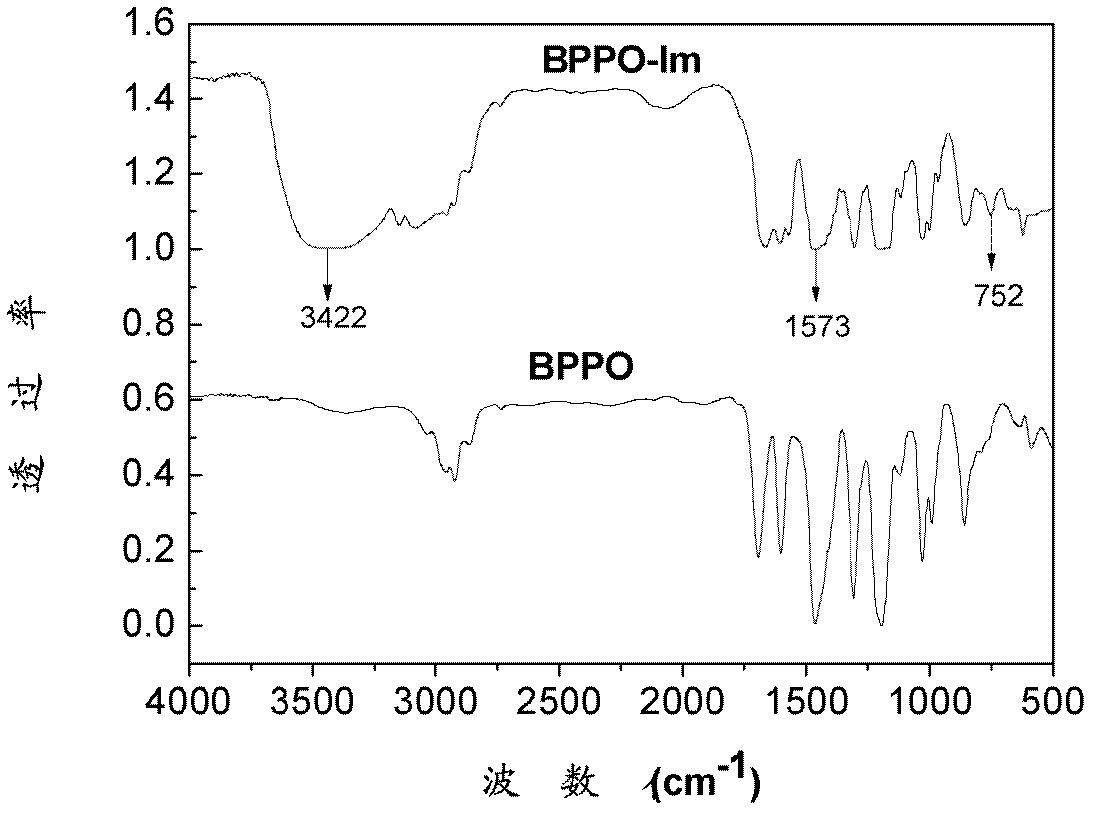

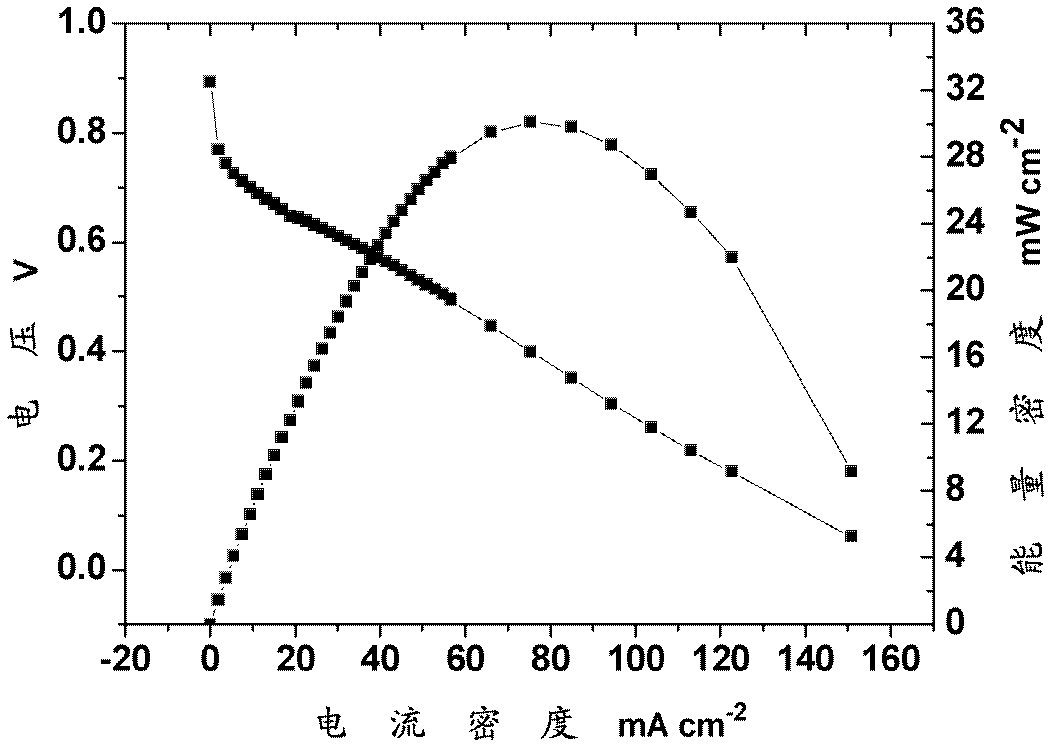

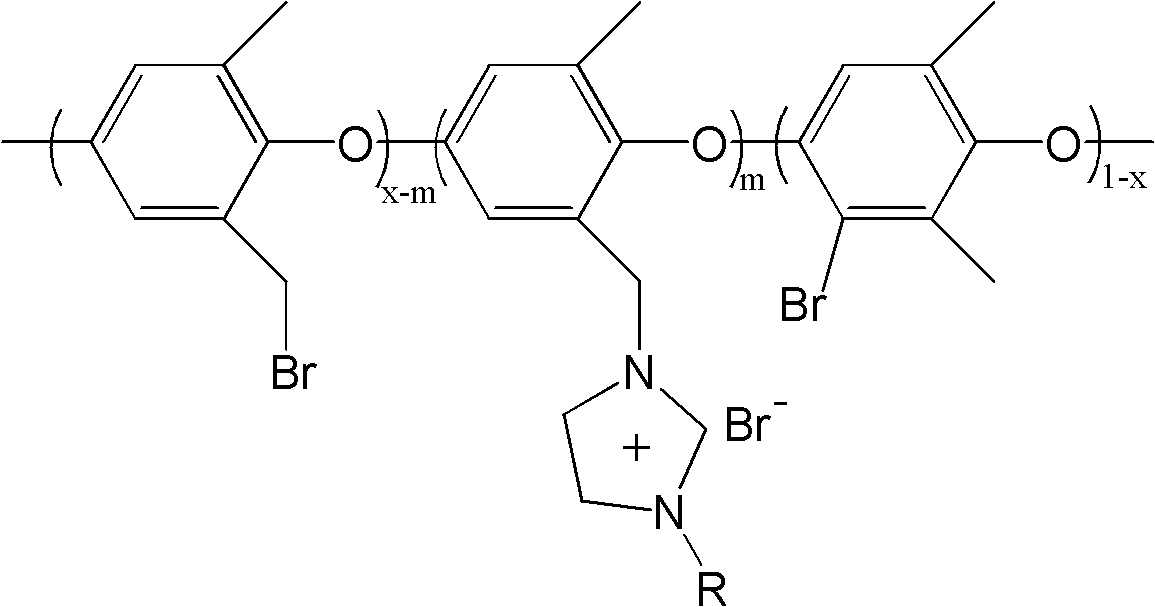

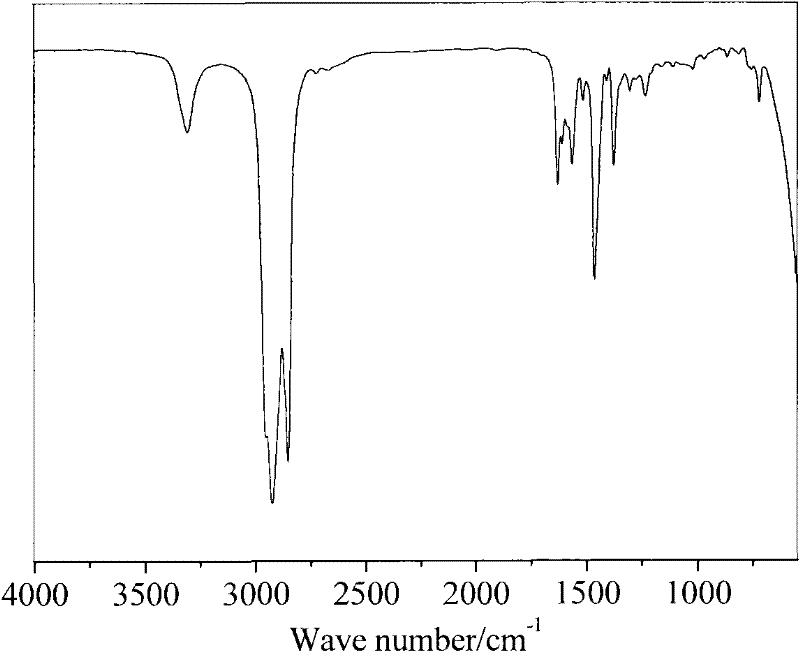

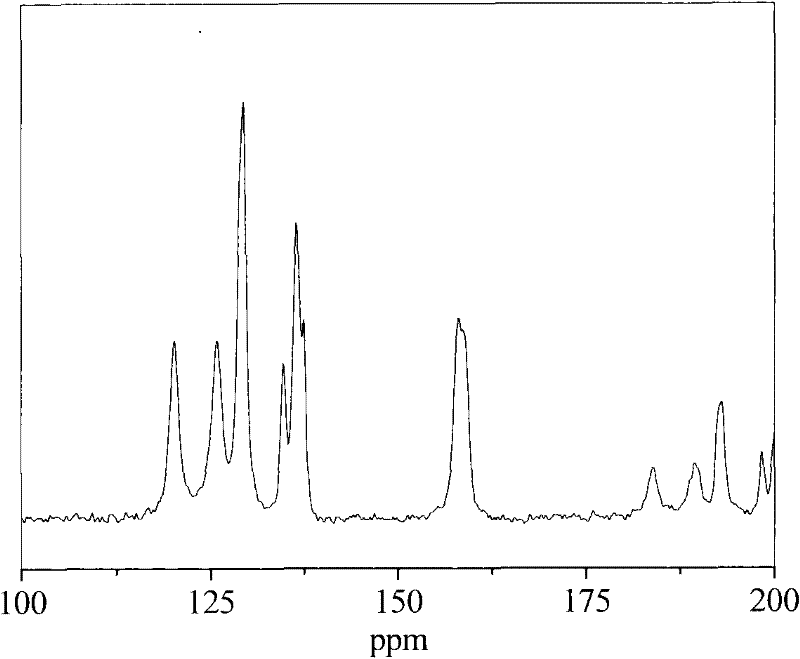

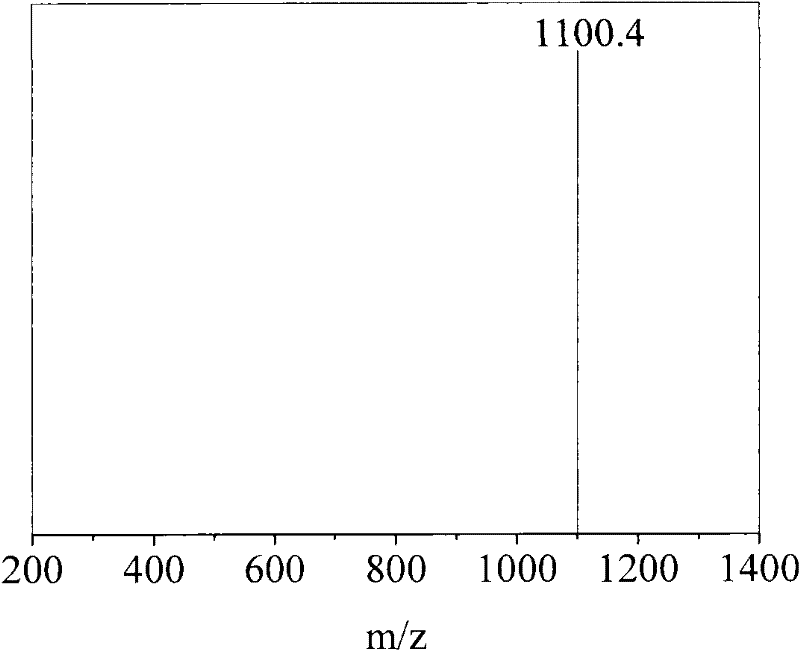

Anion-exchange film, preparation method thereof and fuel cell

ActiveCN103372381AOH-high conductivityGood thermal stabilitySemi-permeable membranesAnion exchangersIon-exchange membranesChemistry

The invention provides an anion-exchange film, a preparation method of the anion-exchange film and a fuel cell. The anion-exchange film comprises imidazole functionalized brominated polyphenylene oxide with the structure shown in the specification. The preparation technology of the film is simple, the obtained imidazole functionalized brominated polyphenylene oxide has excellent film properties, such as high anion-exchange film OH-conductivity, good heat stability and good alkaline resistance, and the performance of the film can be adjusted and controlled by simply changing the adding amount of N-substitution imidazole micromolecules.

Owner:UNIV OF SCI & TECH OF CHINA

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

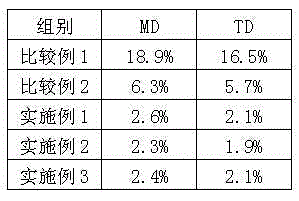

Microporous polymer isolating film for Li-ion battery and method for producing the same

ActiveCN101212036AIncrease surface areaHigh porositySolid electrolytesFinal product manufactureHydrophilic monomerPolymer science

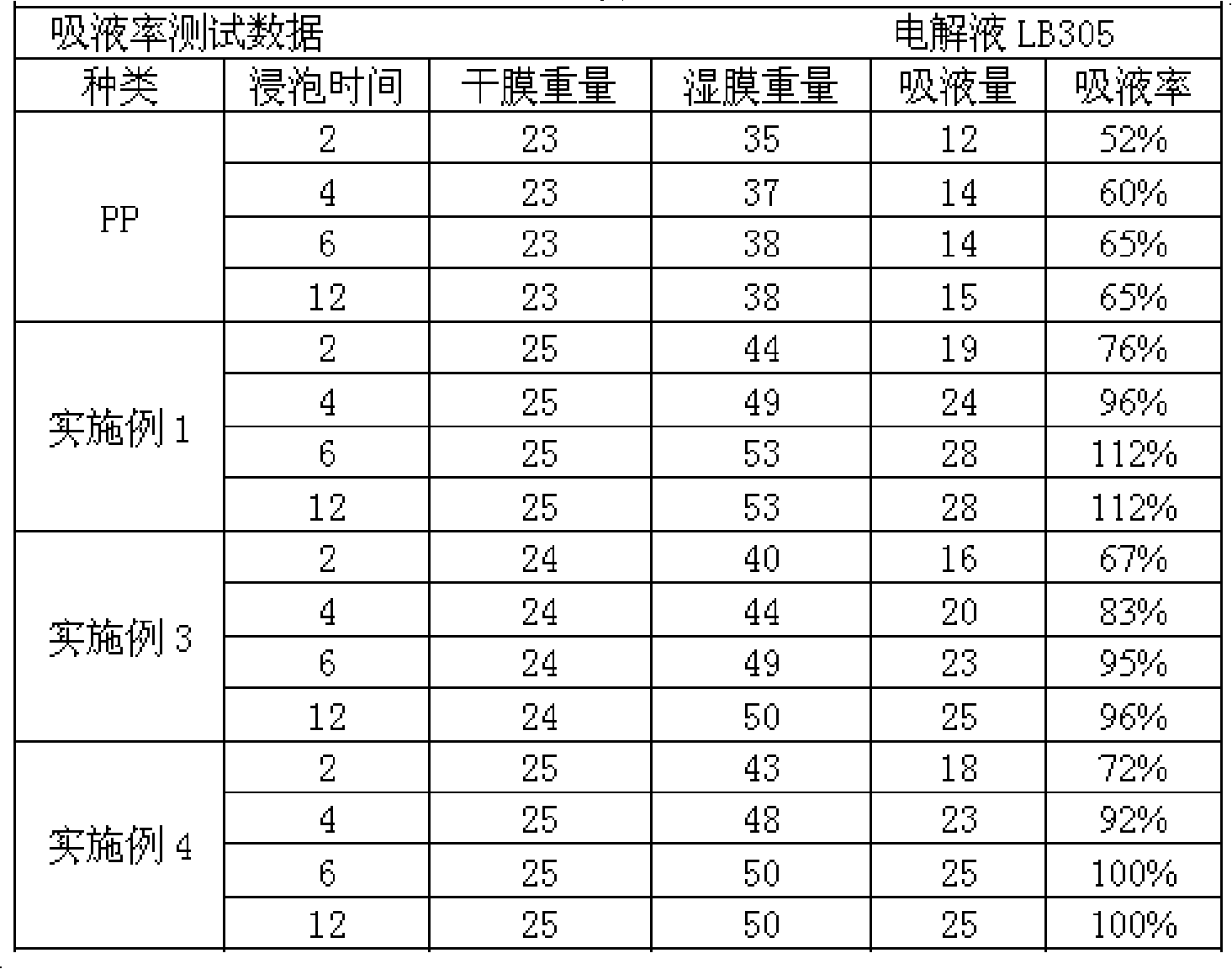

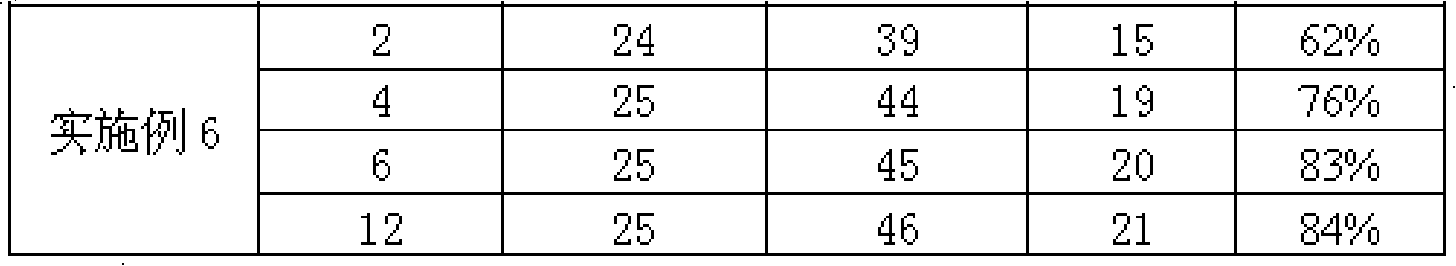

The invention relates to a diaphragm used for power maintaining device as a lithium ion secondary battery and a preparation method thereof, which belongs to a field of manufacturing battery and capacitor. The diaphragm of the invention takes water as reaction medium; polymers colloid and emulsion are obtained through polymerization reaction generated by polyvinyl alcohol, hydrophobic monomer and hydrophilic monomer with an initiator in water solution; by adopting tape-casting and coating process, the polymers colloid and emulsion are coated on a plastic baseband; the diaphragm is obtained through stripping after drying. The diaphragm has good liquid absorbability, high liquid absorption rate and retention, low resistivity, good mechanical strength and good thermal stability (little thermal shrinkage and little size distortion) as well as electrochemical stability; and the prepared lithium ion battery is characterized by good cycle stability and long service life.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

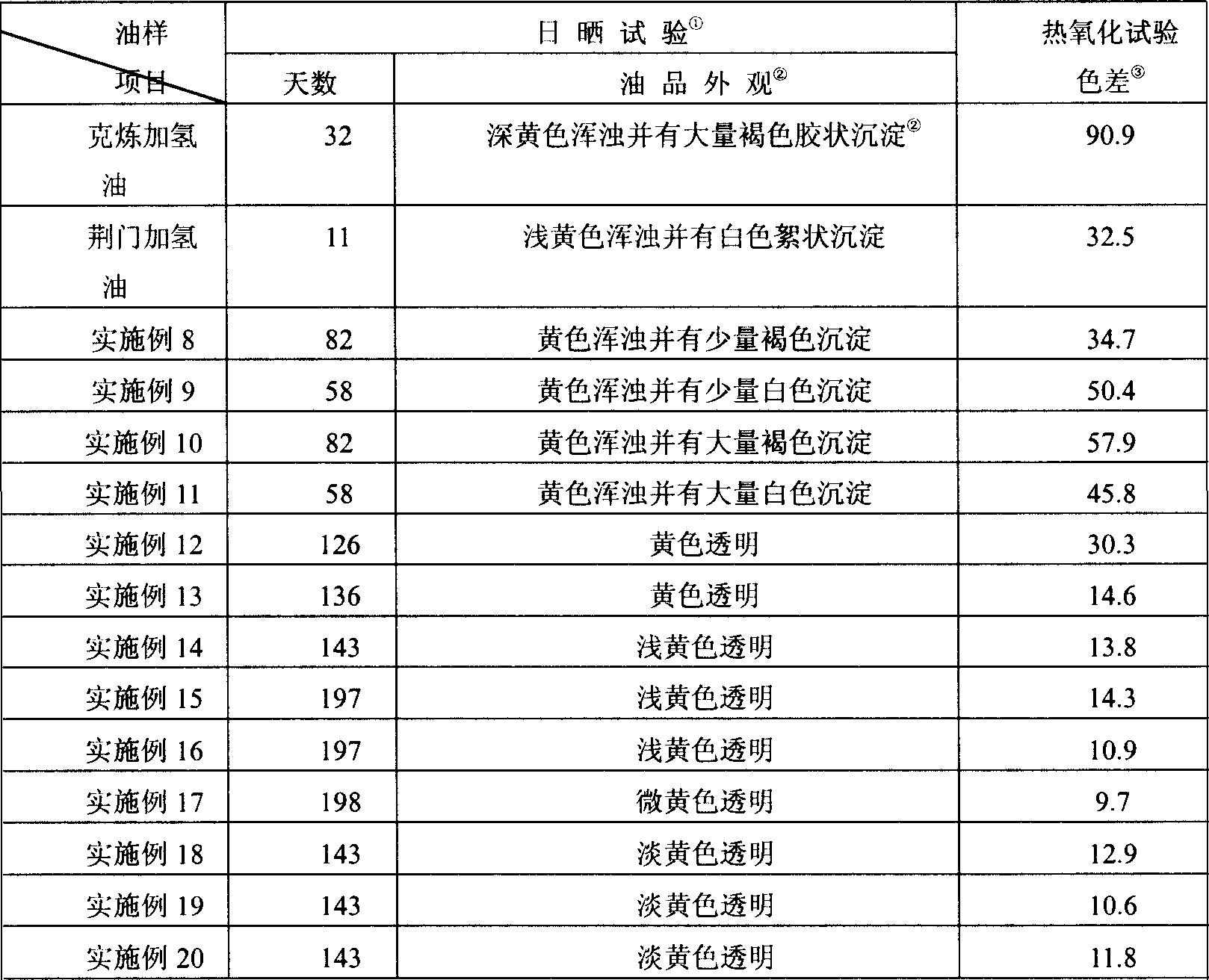

Lubricating oil composite stabilizer and stable hydrogenation lubricating oil composition

The composite lubricating oil stabilizer includes the following components: ultraviolet ray absorbent and light stabilizer of hindered amine in the weight ratio of 1-5 and total content inside the composite lubricating oil stabilizer of 40-80 wt%; antioxidant selected from the shielding phenol, aromatic amine, phenolic ester, metal phosphate-sulfate and carbamate sulfide in 15-45 wt%; and phenyl phosphite as chelating agent in 3-18 wt%. The composite lubricating oil stabilizer of the present invention may be added into the base oil of hydrogenated lubricating oil in the amount of 0.01-2.0 wt% to improve the light stability of the hydrogenated lubricating oil obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

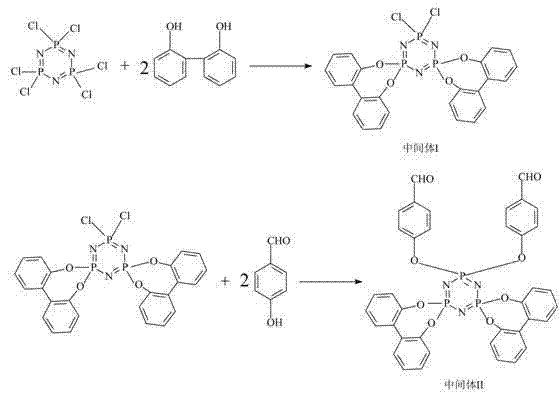

Oxa-phosphaphenanthrene flame retardant containing cyclotriphosphonitrile structure, and preparation method and application thereof

ActiveCN102757579AEasy to operateAdvanced technologyGroup 5/15 element organic compoundsEpoxyEngineering plastic

The invention relates to an oxa-phosphaphenanthrene flame retardant containing cyclotriphosphonitrile structure, and a preparation method and application thereof. The preparation method comprises the following steps: under the actions of K2CO3 and acetone, reacting hexachlorocyclotriphosphonitrile and 2,2'-diphenyldiphenol to obtain an intermediate I, reacting the intermediate I with p-hydroxybenzaldehyde to obtain an intermediate II, and reacting the intermediate II and DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) to obtain the target compound. The appearance of the compound is white, and the melting point is 186-188 DEG C; and the product has the advantages of favorable thermal stability, high flame retardancy and high purity (up to 99%). The invention has the advantages ofaccessible raw materials and advanced technique, and can easily implement industrial production. The flame retardant can be used as a reactive flame retardant to be connected to epoxy resin, polyurethane and other thermosetting resins, and can also be used as an additive flame retardant for halogen-free flame retardancy of ABS (acrylonitrile-butadiene-styrene), nylon and other engineering plastics with high heat resistance requirements.

Owner:HUBEI YAOMEI FLEXIBLE CERAMICS

Heat-proof purple sand ceramic mud and method for preparing the product

InactiveCN101134672AGood thermal stabilityExcellent thermal shock resistanceClaywaresShock resistanceRaw material

The present invention provides one kind of heat resisting violet sand earthenware material and its product making process. The heat resisting violet sand earthenware material consists of Si2O 60-73 wt%, Al2O3 15-38 wt%, CaO 2-6 wt%, MgO 6-12 wt%, Fe2O3 0-5 wt%, K2O 0-2 wt%, and Li2O 0-5 wt%; and its raw materials include violet sand 40-60 wt%, black clay 20-30 wt%, white clay 10-25 wt%, talcum 10-18 wt%, and Chinese medicinal stone 5-10 wt%. The heat resisting violet sand earthenware material may be used in making different kinds of heating utensils with thermal expansion coefficient of (1-2)x10<-6> / deg.c, high heat stability and high heat shock resistance. In addition, the utensil made of the violet sand earthenware material may be used in cooking food with good look, good smell, good taste and excellent health function.

Owner:朱绍波

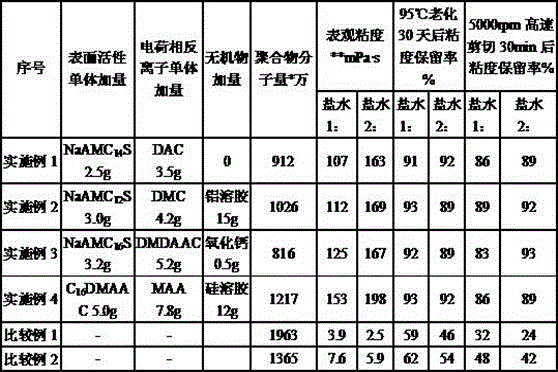

Polymer mobility control agent suitable for ultrahigh-salinity oil deposit and preparation method thereof

ActiveCN104448127AGood temperature and salt resistanceGood thermal stabilityDrilling compositionPolymer scienceWater soluble

The invention relates to a polymer mobility control agent suitable for an ultrahigh-salinity oil deposit and a preparation method thereof, and the polymer mobility control agent is mainly used for solving the problem that a polymer can not meet the requirement for tertiary oil recovery due to poor temperature resistant property, salt resistant property and shearing resistant property in the prior art. In order to better solve the problem, the technical scheme adopted by the invention is as follows: the control agent for an amphoteric hydrophobic associated polymer comprises the following components in parts by weight of the amphoteric hydrophobic associated polymer: 5-99.9 parts of nonionic water-soluble monomers, 0-50 parts of anionic monomers or / and cationic monomers, 0.1-10 parts of hydrophobic monomers with surface activity, 0.1-5 parts of inorganic substances and 1-20 parts of surface active agents. The preparation method disclosed by the invention can be used for the industrial production of the polymer mobility control agent suitable for the ultrahigh-salinity oil deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

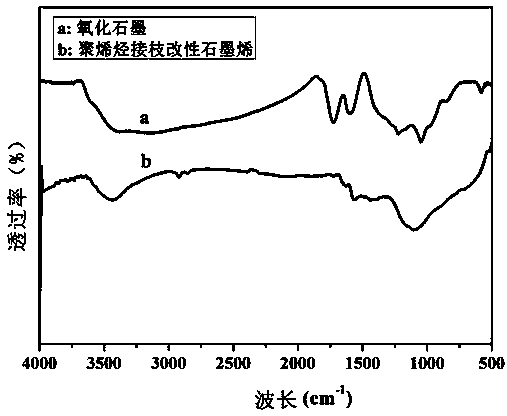

Polyolefin/graphene nanocomposite and preparation method thereof

ActiveCN104098816AGood dispersionOvercome wastePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolymer scienceGraphene nanocomposites

The invention discloses a polyolefin / graphene nanocomposite. According to the invention, two-dimensional nano-material graphene is used as a reinforcing agent, and through graft modification of polyolefin, polyolefin grafted-modified graphene is formed and uniformly dispersed in a polyolefin material. A preparation method for the polyolefin / graphene nanocomposite comprises the following steps: functionalized modification of graphene; preparation of polyolefin grafted-modified graphene; and preparation of the polyolefin / graphene nanocomposite. The preparation method overcomes the problems of easy agglomeration and difficult dispersion of graphene in graphene-enhanced non-polar polymers; in the prepared polyolefin / graphene nanocomposite, graphene is uniformly distributed; and the polyolefin / graphene nanocomposite has excellent flame retardation performance and mechanical properties.

Owner:HEFEI GENIUS NEW MATERIALS

A strain of Bacillus pumilus and its application in disease prevention and growth promotion

ActiveCN102296036AGood anti-effect and growth-promoting effectGood thermal stabilityPlant growth regulatorsBiocideLaboratory cultureNicotiana tabacum

The invention discloses a Bacillus pumilus. The Bacillus pumilus was preserved in China General Microbiological Culture Collection Center on August 23, 2010, and its preservation number is CGMCC NO.4117. The Bacillus pumilus disclosed in the invention can be used for preparing bactericides for biological control of tobacco or vegetable fungus diseases, and can be used for preparing growth promoting agents of tobacco or vegetable for promoting the growth of plants, especially tabocco. The bacterial strain has good stability, strong stress resistance, and excellent effect of promoting growth, is an excellent microbial pesticide and an excellent microbial pesticide resource. The bacterial strain has a wide application prospect.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

High-strength corundum ceramics and preparation method thereof

The invention discloses a high-strength corundum ceramics and a preparation method thereof. A ceramic blank comprises the following components: 18-22 parts of aluminum oxide, 12-15 parts of quartz, 0.5-1.0 part of talc, 27-30 parts of feldspar, 25-29 parts of kaolin, 10-14 parts of chinastone and 0.5-1.5 parts of blank body plasticizing agent. In sintered porcelain, the aluminum oxide content is higher than 30 percent. The method comprises the following steps: ball-milling and pulverizing a blank; adding water and mixing to obtain blank slurry; deironing and press-filtering the blank slurry into a mud cake and roughly smelting the mud cake; mildewing the roughly smelted mud cake and refining the mildewed mud cake; rolling and moulding the refined mud in a die to obtain a blank body; drying, washing and glazing the blank body and sintering at 1,280-1,320 DEG C for 15-18 hours to obtain a finished product. The product has favorable mechanical strength, and the impact resistant capability of the product is more than four times that of common ceramics; and the product has favorable thermostability, no crack after thermal shock at 200 DEG C / 20 DEG C three times, the water absorption rate of lower than 0.1 percent, is more dense, firm and durable and is particularly suitable for an oven, a microwave oven and a dish-washing machine.

Owner:江门市凌志餐厨用品有限公司

Light-color quenching oil complexing agent composition and preparation method thereof

ActiveCN101603118AImprove cooling effectExcellent high temperature cooling performanceQuenching agentsAntioxidantOxygen

The invention relates to a light-color quenching oil complexing agent composition and a preparation method thereof. The light-color quenching oil complexing agent composition comprises the following materials according to proportion by weight: 40 to 88 parts of refrigerant catalyst, 1 to 10 parts of brightener, 1 to 15 parts of antioxidant and 10 to 40 parts of anti-precipitation agent. The prepared composition product has high-temperature and low-temperature refrigeration catalysis functions and favorable brightness property and high-temperature and low-temperature anti-oxygen property and is suitable for preparing common and fast quenching oil with fast brightening.

Owner:锦州康泰润滑油添加剂有限公司

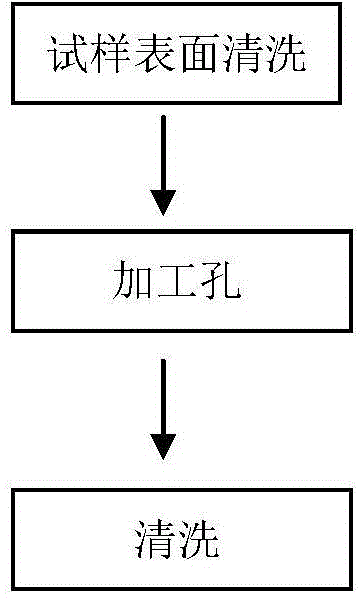

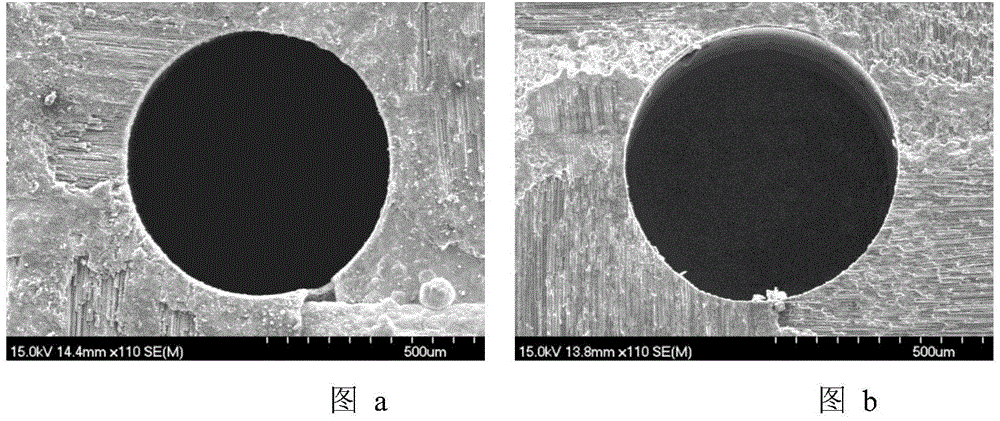

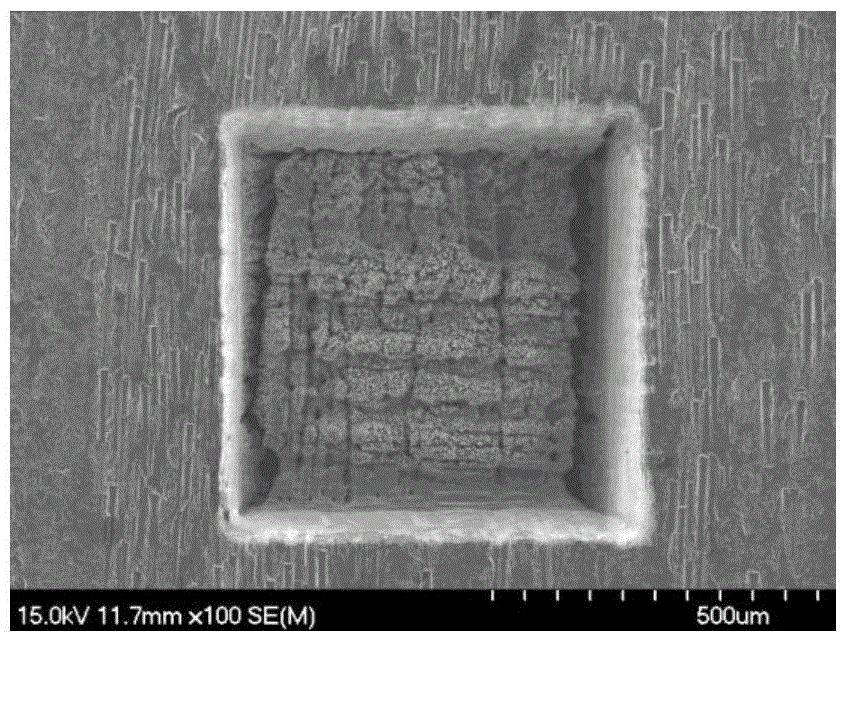

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ceramic membrane, preparation method of lithium ion secondary battery and battery

ActiveCN104064709AGood thermal stabilitySimple process controlFinal product manufactureSecondary cellsCeramic particleCeramic coating

The invention discloses a ceramic membrane. The ceramic membrane is formed by the following steps: synthesizing dendriform grafted copolymers by acrylate monomers and enol monomers in the presence of an initiator, then adding inorganic ceramic particles, uniformly dispersing to form a mixture, and then coating a single surface or two surfaces of a membrane base material with the mixture. The inorganic ceramic particles are adsorbed onto the copolymers and mutually bonded, so as to form compact ceramic coatings with three-dimensional network structures between the inorganic ceramic particles and between the copolymers, and the ceramic coatings are adsorbed together with the membrane base material by virtue of the copolymers, so that the three-dimensional network structure is formed by the inorganic ceramic particles, the copolymers and the membrane base material. The invention further discloses a preparation method of a lithium ion secondary battery and the battery. The ceramic membrane has the advantages of good thermostability, simplicity in process control and easiness in industrial production, in the process of using the lithium ion battery, the stability of the assembly process is kept, the safety performance of the battery is guaranteed, and the effects of environmental friendliness and energy conservation are achieved.

Owner:东莞市魔方新能源科技有限公司

Porous-particle-doped polyimide hollow fibrous membrane, preparation method thereof, and application thereof

InactiveCN102418168AGood thermal stabilityImprove permeation selectivity and permeation rateDispersed particle separationFilament/thread formingChemistryGas separation

The invention provides a porous-particle-doped polyimide hollow fibrous membrane, a preparation method thereof, and an application thereof. The hollow fibrous membrane provided by the invention comprises polyimide as a substrate and porous particles as adulterants. The preparation method provided by the invention comprises steps that: a hollow fibrous membrane green body is prepared through dry-wet spinning; and the porous-particle-doped polyimide hollow fibrous membrane is prepared through thermal imidization. The hollow fibrous membrane provided by the invention is applied in gas separation. Advantages of organic and inorganic membranes are combined in the hollow fibrous membrane provided by the invention. The hollow fibrous membrane has good thermal stability, good chemical stability, good mechanical strength, improved gas permeation selectivity, improved gas permeation speed, and improves gas separation effect.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of bacterial cellulose based carbon nanofibers

ActiveCN103820883AGood thermal stabilityImprove conductivityArtificial filament chemical after-treatmentNatural fibresFiberCarbon fibers

The invention discloses a preparation method of bacterial cellulose based carbon nanofibers and relates to a preparation technology of a carbon fiber material. The preparation method comprises the following steps: carrying out purification treatment on bacterial cellulose obtained by bacterial fermentation and carrying out freeze drying, carrying out carbonization treatment by putting the dried bacterial cellulose material into an atmosphere furnace and heating to 600-1200 DEG C, further heating the processed material to graphitize the material, and cooling to obtain the bacterial cellulose based carbon nanofiber material having a three-dimensional net structure. The preparation technology is simple and easy to carry out, is convenient to operate and has low cost. The obtained bacterial cellulose based carbon nanofiber has a good spatial net structure, has excellent mechanical property, thermal stability and conductivity, and can be applied in fields of electron devices, special composite materials, high efficient catalytic materials, biological materials and the like.

Owner:钟春燕

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AGood thermal stabilityIncreased carbonization yieldMonocomponent cellulose artificial filamentWater contentSolvent

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com