Porous-particle-doped polyimide hollow fibrous membrane, preparation method thereof, and application thereof

A technology of polyimide and fiber membranes, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve the problems of low gas transmission rate of organic membranes and low separation effect of inorganic membranes, and achieve high permeability. Overselectivity and transmission rate, good thermal stability, and the effect of improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

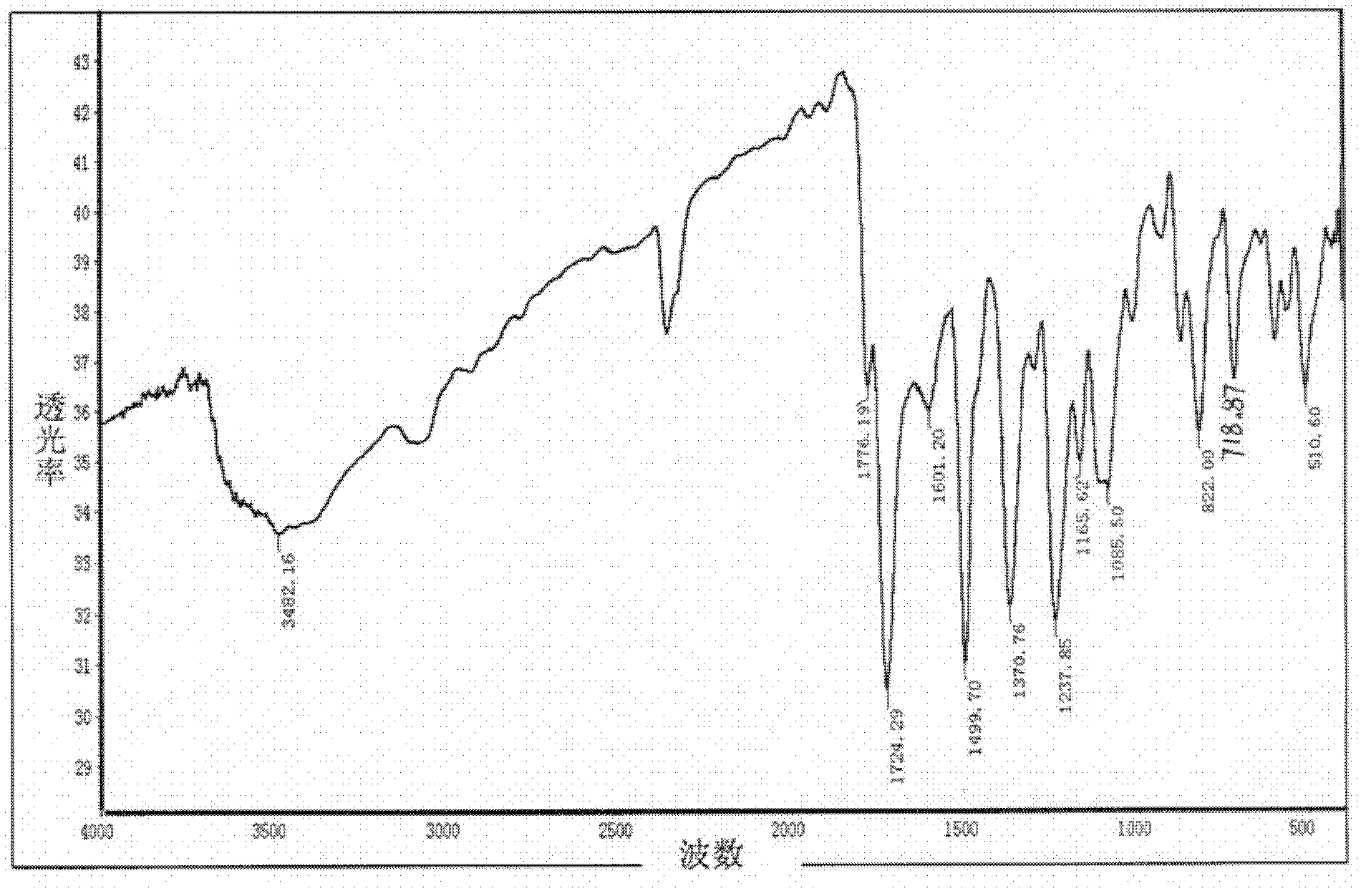

[0039] Example 1 metal organic framework material Cu 3 (BTC) 2 Synthesis of particles

[0040] Get 1 gram of trimesic acid and dissolve it in 15 milliliters of N, N'-dimethylformamide and 15 milliliters of ethanol, get 2 grams of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 15 mL of deionized water. Mix both well. React at 85°C for 8 hours, filter under reduced pressure to obtain a solid, and wash with ethanol three times. Add 100 milliliters of ethanol and reflux at 80°C for 6 hours, filter under reduced pressure, and dry the product in an oven at 100°C for 4 hours. 14 The reported method was compared, and the final product was determined to be Cu 3 (BTC) 2 . After testing, its pore size is 0.8 nanometers, and its BET specific surface area is 1035cm 2 / g, Cu at 300°C 3 (BTC) 2 structure remains stable. CO at room temperature 2The adsorption capacity can reach 4.0 mmol / g.

Embodiment 2

[0041] The synthesis of embodiment 2MCM-41 particle

[0042] Take 1 g of cetyltrimethylammonium bromide, dissolve it in 480 ml of deionized water, stir to dissolve completely, heat to 80°C, add 3.5 ml, 2 mol / L NaOH and stir for about 5 minutes, slowly add 5 ml dropwise Ethyl orthosilicate was reacted in the above solution at 80°C for 2 hours. The solid was filtered under reduced pressure and washed with 500 ml of deionized water and 250 ml of ethanol respectively. The product is dried in an oven at 60°C for 6 hours, then heated to 550°C at a rate of 2°C / min, and kept at 550°C for 6 hours. The XRD pattern of the obtained product was compared with the method reported in the references D.R.Radu, C.Lai, J.W.Wiench, et al., J.Am.Chem.Soc., 2004, 126, 1640-1641, and the final product was determined to be MCM-41. Its pore size was detected to be 2.5 nanometers.

Embodiment 3

[0043] The synthesis of embodiment 3SBA-15 particles

[0044] Take 1 gram of tri-block copolymer P123 in an Erlenmeyer flask, add 25 ml of deionized water, stir vigorously at room temperature, then slowly add 25 ml of 4 mol / L hydrochloric acid, and mix well. Slowly add 2 ml of tetraethyl orthosilicate to the above solution, and keep stirring and aging at room temperature for 24 hours. After 48 hours, the solid was filtered under reduced pressure and washed with 500 ml of deionized water and 250 ml of ethanol respectively. The product is dried in an oven at 60°C for 6 hours, then heated to 550°C at a rate of 2°C / min, and kept at 550°C for 6 hours. Gained product XRD figure and reference J.S.Lee, J.H.Kim, J.T.Kim, J.K.Suh, J.M.Lee, C.H.Lee, J.Chem.Eng.Data, 2002, 47, 1237-1242 report method contrast, determine that final product is SBA -15. Its pore diameter was detected to be 6.5 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com