Patents

Literature

106results about How to "Improve the separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for separating anthocyanins monomer from lycium ruthenicum fruits

ActiveCN103626814AImprove the separation effectShort analysis timeSugar derivativesNatural dyesFormic acidMedicinal chemistry

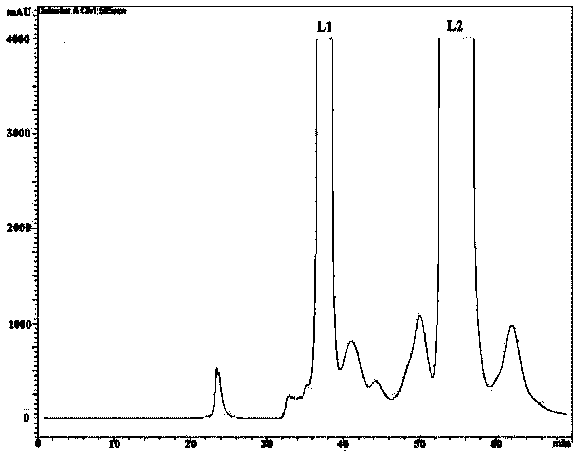

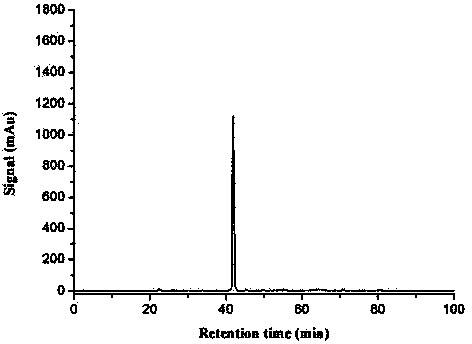

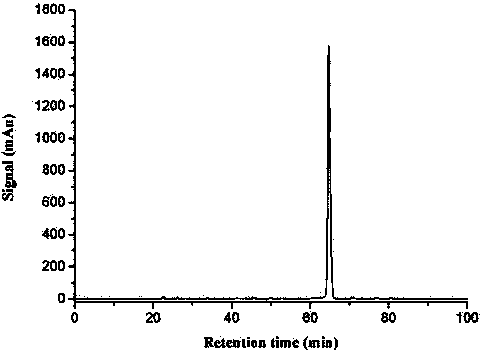

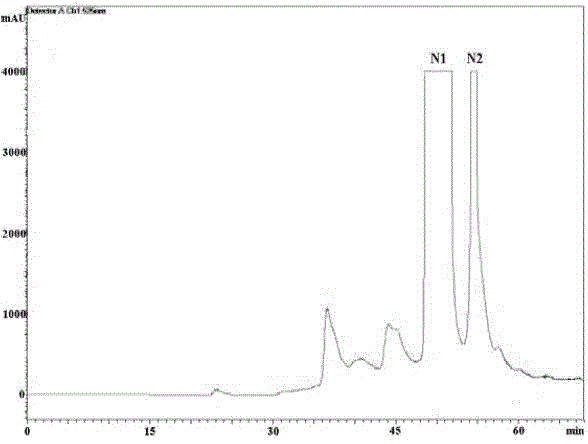

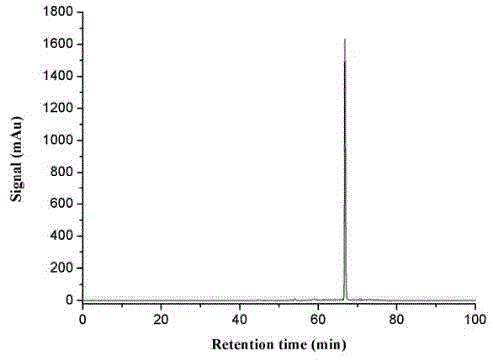

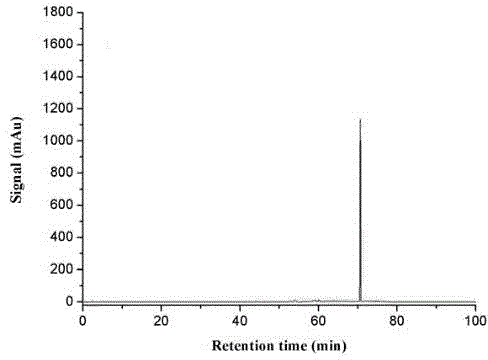

The invention relates to a method for separating an anthocyanins monomer from lycium ruthenicum fruits. The method comprises the following steps: (1) pretreating raw materials: removing impurities from lycium ruthenicum fruits, washing the lycium ruthenicum fruits with water to obtain the treated lycium ruthenicum fruits; (2) preparing a formic acid-methanol solution at a volume concentration of 2%; (3) adding the formic acid-methanol solution into the lycium ruthenicum fruits for extraction at room temperature to obtain an extract; (4) filtering, and concentrating the extract by evaporating to obtain an lycium ruthenicum anthocyanins extract; (5) treating macroporous adsorption resin; (6) redissolving the lycium ruthenicum anthocyanins extract, applying the redissolved lycium ruthenicum anthocyanins extract to the treated macroporous adsorption resin, and collecting effluent; (7) concentrating the effluent under reduced pressure to obtain crude anthocyanins; (8) injecting the crude anthocyanins into a high-performance semipreparative chromatographic column, and separating to obtain the anthocyanins monomer with the purity of higher than or equal to 90%; concentrating the anthocyanins monomer under reduced pressure, and performing freeze drying in vacuum to constant weight to obtain finished anthocyanins monomer. The method is good in separating effect, short in time consumption and low in cost.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Content detection method for Naoxintong capsule

ActiveCN103207255AImprove the separation effectThe test result is accurateComponent separationSafflower yellowCarthamus

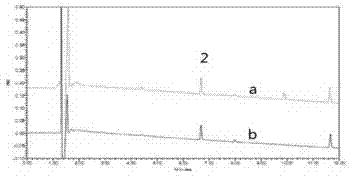

The invention relates to a content detection method for the Naoxintong capsule. The Naoxintong capsule comprises 66 parts of astragalus root, 27 parts of red peony root, 27 parts of root of red-rooted salvia, 27 parts of Chinese angelica, 27 parts of Szechuan lovage rhizome, 27 parts of peach kernel, 13 parts of safflower, 13 parts of prepared Frankincense, 13 parts of prepared myrrh, 20 parts of suberect spatholobus stem, 27 parts of twotooth achyranthes root, 20 parts of cassia twig, 27 parts of mulberry twig, 27 parts of earthworm, 13 parts of scorpion, and 27 parts of leech. The main chemical components, namely hydroxy safflower yellow A, paeoniflorin, ferulic acid, salvianolic acid B and ligustilide, in the Naoxintong capsule are simultaneously measured by the UPLC (ultra-performance liquid chromatography) technique. Single chromatographic analysis can be completed in 24 minutes. Chromatographic peaks of the main components are well separate, RSD (relative standard deviation) in both precision and receptiveness is smaller than 2.0%, and the quality of Naoxintong capsule can be controlled comprehensively.

Owner:SHAANXI BUCHANG PHARMA

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove yieldImprove the separation effectFluid removalFilm coatingFilm-coated tablet

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

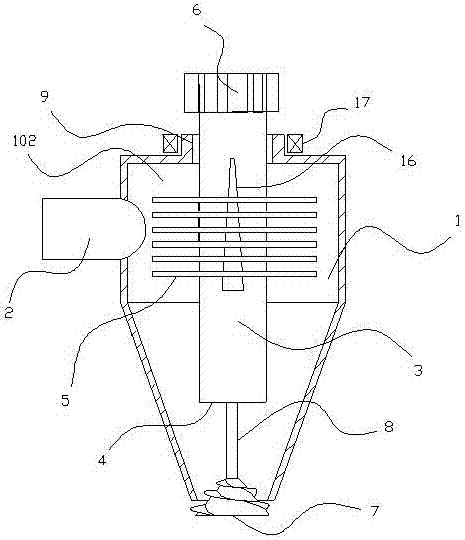

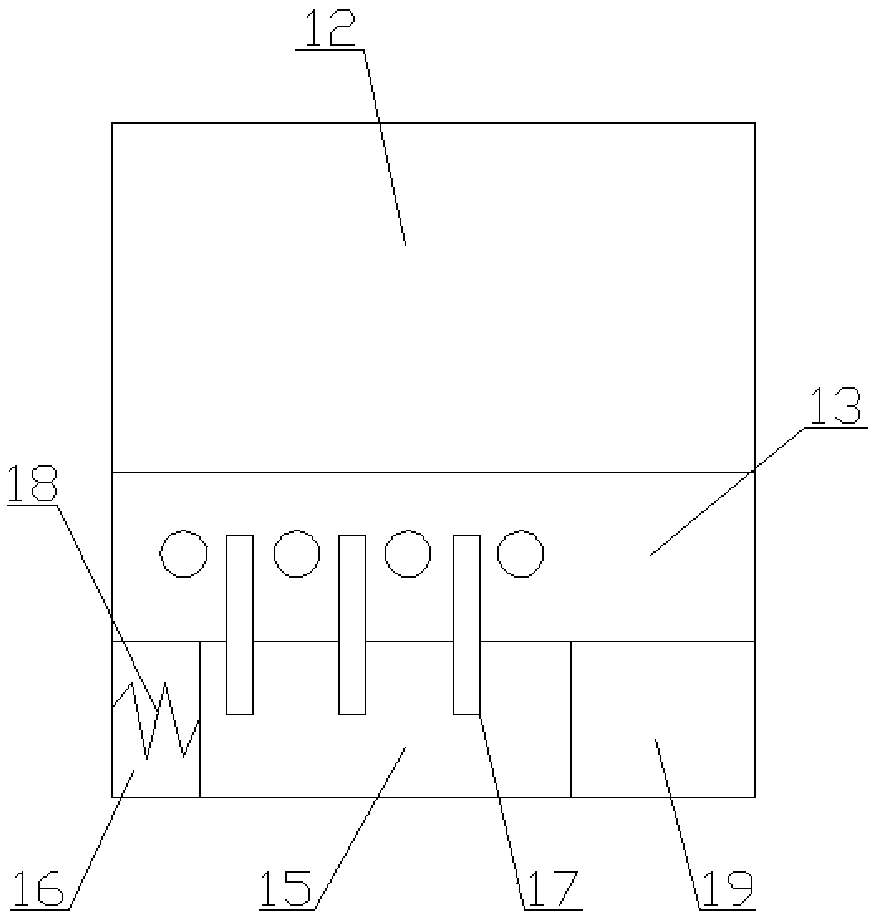

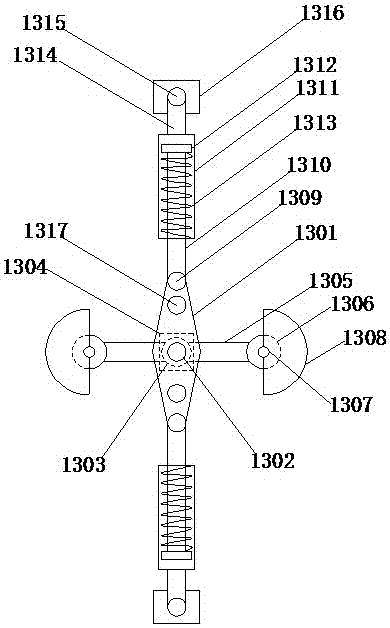

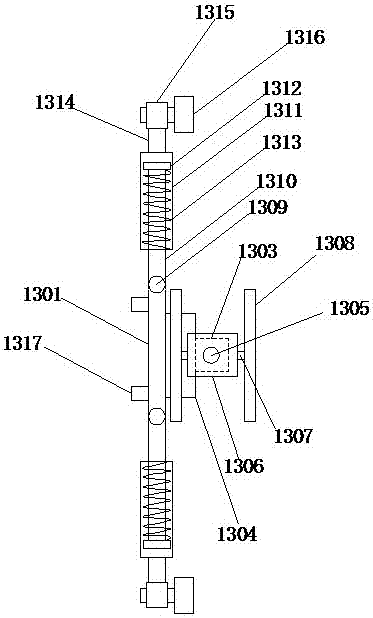

Adjustable cyclone separator

PendingCN106975576AImprove the separation effectEasy dischargeReversed direction vortexAirflowEngineering

The invention provides an adjustable cyclone separator, relates to a cyclone separator, and solves the problem of more discharged gas impurities caused by airflow fluctuation in the prior art. The adjustable cyclone separator comprises a cyclone cylinder formed by communicating a cylinder cavity with a cone cavity, an intake pipe, an exhaust pipe and a cyclone cylinder lower port, and is characterized in that the exhaust pipe is rotationally matched with the cyclone cylinder; spiral blades are arranged on the exhaust pipe; and a centrifugal wind wheel is arranged in an upper end outlet of the exhaust pipe. The adjustable cyclone separator uses the rotation controllable exhaust pipe for reducing the influence on air currents in the cyclone separator by the intake airflow fluctuation, reduces the discharge quantity of impurities along with the air currents, and improves the separation effect.

Owner:SHENTONG TECH GRP CO LTD

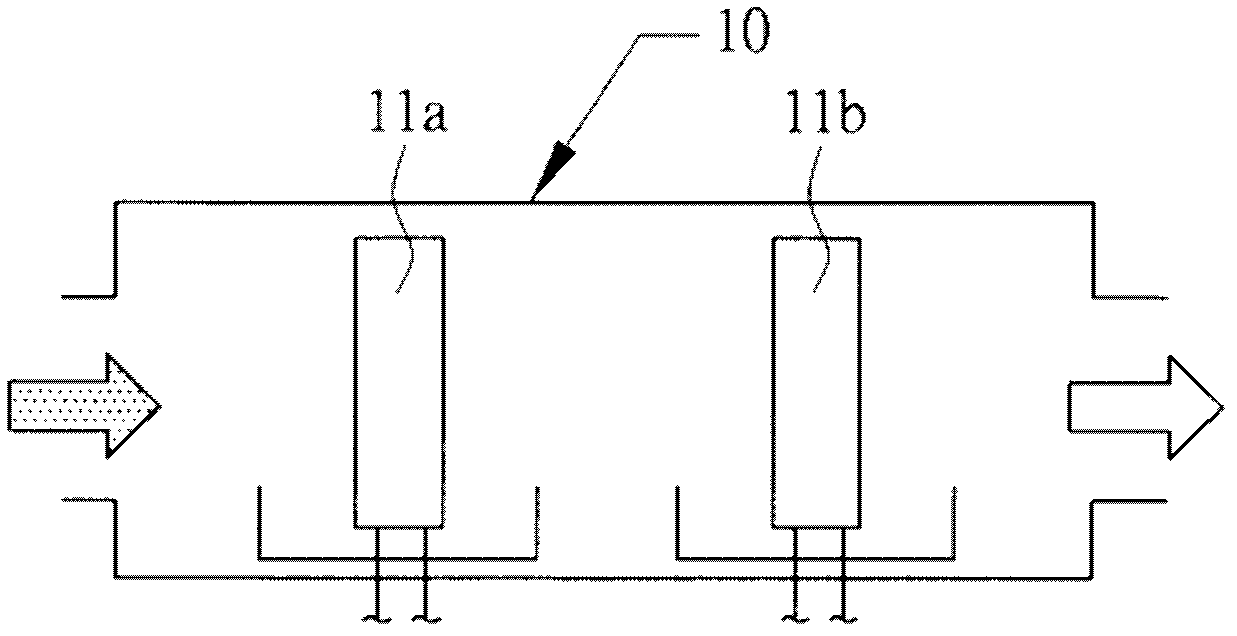

Microfluidic chip for cell separation and application thereof in tumor cell separation, and cell separation and identification method

PendingCN109852544AExquisite structure designImprove the separation effectBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic chipChemistry

The present invention relates to a microfluidic chip for cell separation and an application thereof in the tumor cell separation, and a cell separation and identification method. The microfluidic chipcomprises an fluid inlet flow channel, a capture zone and a fluid outlet flow channel, the fluid inlet flow channel is provided with a fluid inlet, the fluid inlet flow channel correspondingly communicates with a fluid inlet side of the capture zone, the fluid outlet flow channel is provided with a fluid outlet, and the fluid outlet flow channel correspondingly communicates with a fluid outlet side of the capture zone; and the capture zone is provided a plurality of capture units and each capture unit is provided with a plurality of flow dividing columns. The microfluidic chip uses a column sorting method, the flow dividing columns play functions of flow dividing and blocking in the flow channels of the capture zone, the blocking of the flow dividing columns respectively forms capture flow channels and passing-through flow channels, target cells to be captured can be trapped in the capture flow channels, while other non-target cells can flow out through the passing-through flow channels, and the whole microfluidic chip is exquisitely designed in structure, can be used for separating the target cells form a cell mixture of a plurality of cells with different cell diameters, is highin separation effect and simple in operation, and can be widely promoted and applied.

Owner:欧阳东方

Method for separating and preparing anthocyanin monomer from Nitraria tangutorum Bobr

ActiveCN103601771AImprove the separation effectShort analysis timeSugar derivativesNatural dyesChromatographic columnFormic acid

The invention relates to a method for separating and preparing anthocyanin monomer from Nitraria tangutorum Bobr, which comprises the following steps: (1) raw material pretreatment: roguing dry Tangut Nitraria tangutorum Bobr, and washing with water to obtain the treated Nitraria tangutorum Bobr; (2) preparing a formic acid methanol solution of which the volume concentration is 2%; (3) adding the formic acid methanol solution into the Nitraria tangutorum Bobr, and carrying out normal temperature leaching to obtain an extract; (4) filtering the extract, and concentrating by evaporation to obtain a Nitraria tangutorum Bobr anthocyanin extractum; (5) treating with a macroporous adsorbent resin; (6) redissolving the Nitraria tangutorum Bobr anthocyanin extractum, passing through the treated macroporous adsorbent resin, and collecting the effluent liquid; (7) concentrating the effluent liquid under reduced pressure to obtain an anthocyanin crude product; (8) injecting the anthocyanin crude product into a high-performance semipreparative chromatographic column to perform separation, thereby obtaining the anthocyanin monomer with the purity of at least 90%; and finally, concentrating the anthocyanin monomer reduced pressure, and drying to constant weight, thereby obtaining the anthocyanin monomer finished product. The method has the advantages of favorable separating effect, short time consumption and low cost.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

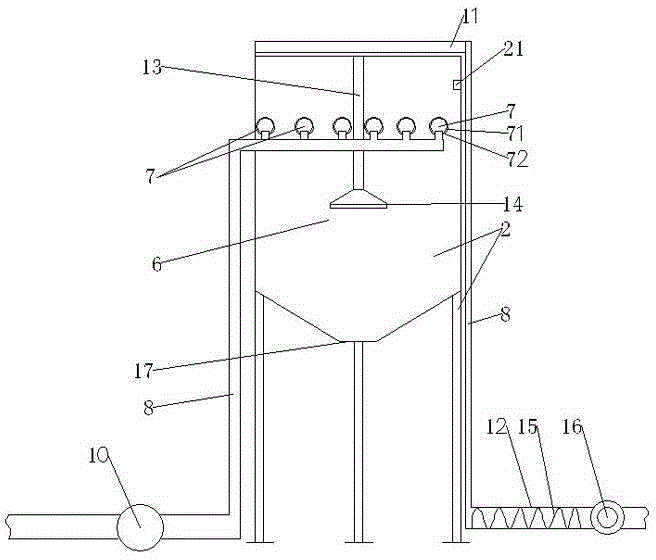

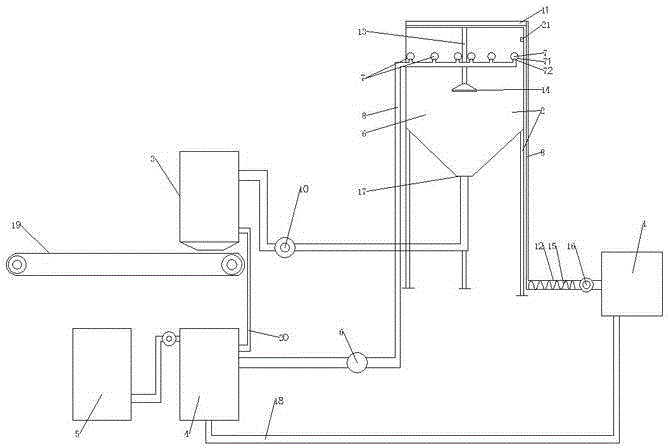

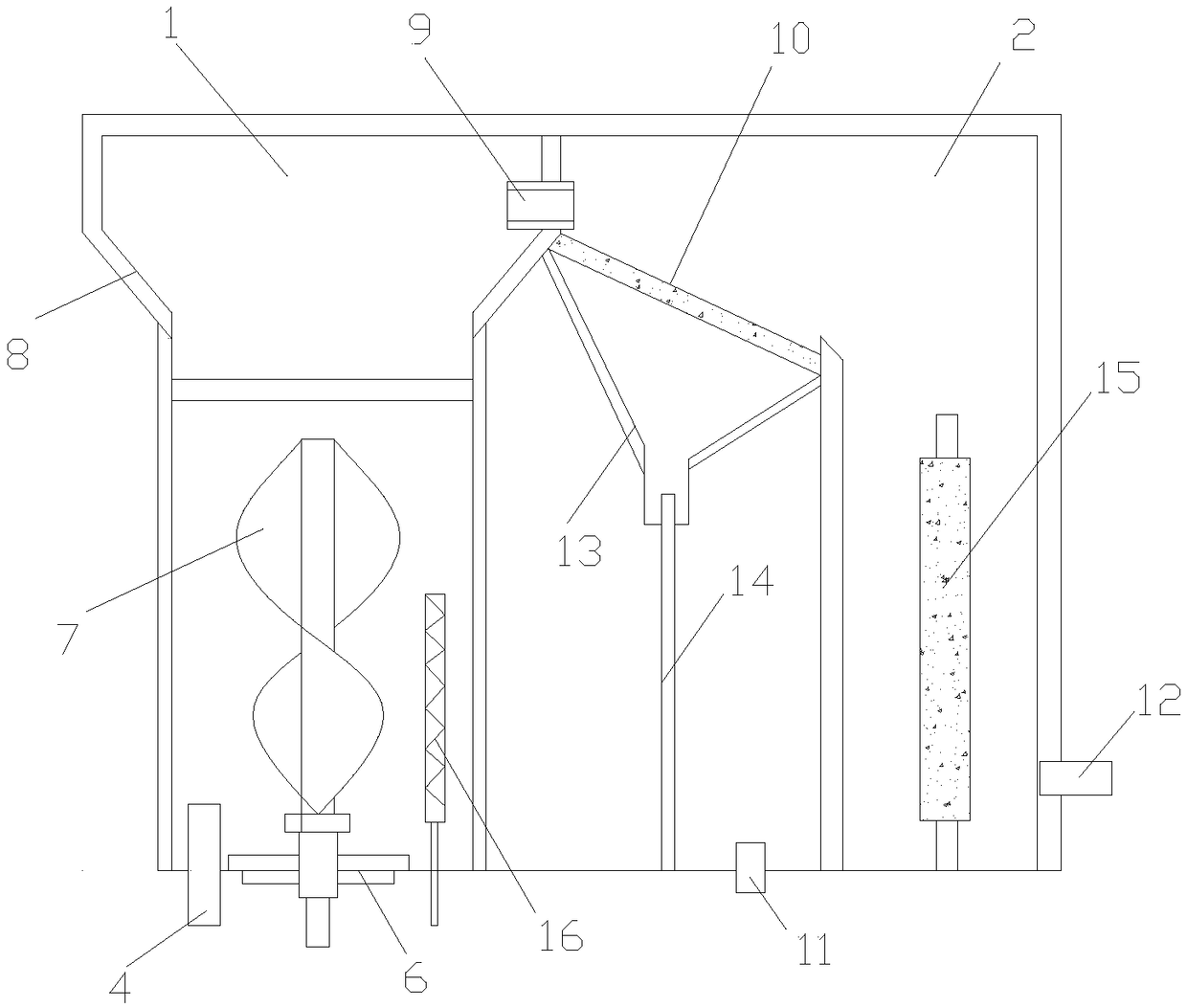

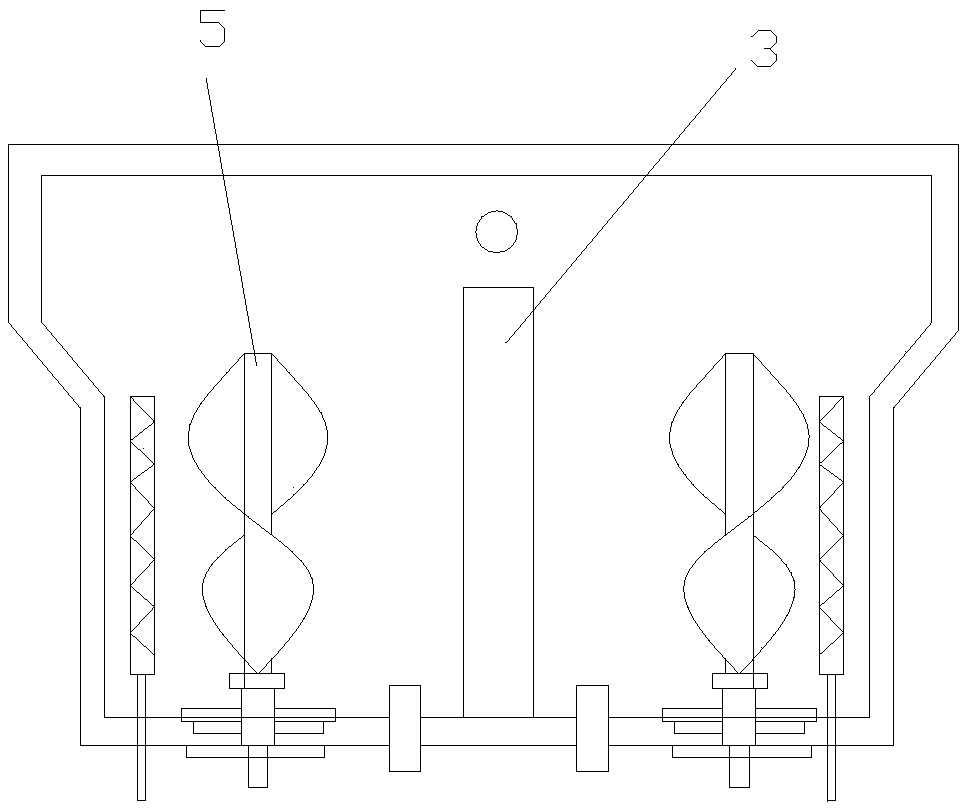

Mud-water separation system and slurry circulation mud-water separation method

ActiveCN104961321AImprove the separation effectImprove efficiencySludge treatment by de-watering/drying/thickeningSlagSeparation method

The present invention discloses a mud-water separation system including a mixing device, a mud-water separation tank, a pressure filtration device, a sedimentation tank and a purification pool; the upper part of the main tank body inner cavity is provided with a plurality of filter water suction ends, the plurality of filter water suction ends are in parallel connection on a water suction pipe, the upper end of the main tank body is provided with a helical surrounding coil, the outer end of the coil and a first slurry delivery tube are communicated, a down-feed pipeline which is connected with the inner end of the coil is fixedly arranged in the main tank body, a spiral conveyor belt is fixedly arranged in the first slurry delivery tube, the outer end of the spiral conveyor belt is provided with a slurry delivery pump, the lower end of the main tank body is provided with a mud discharge outlet; the mixing device and the first slurry delivery tube are in connection, the water suction pipe is connected with the sedimentation tank, the lower part of the sedimentation tank is connected with a second slurry delivery tube, the mud discharge outlet is connected with the pressure filtration device through a pipe, and a slag discharge port of the pressure filtration device directly faces a mud block conveyor belt. The present invention also provides the slurry circulation mud-water separation method using the mud-water separation system, the mud-water separation system can achieve automatic and continuous mud-water separation of the slurry, the mud-water separation efficiency is higher, operation is more convenient, and minimal labor is required.

Owner:温州市工业设计院有限公司

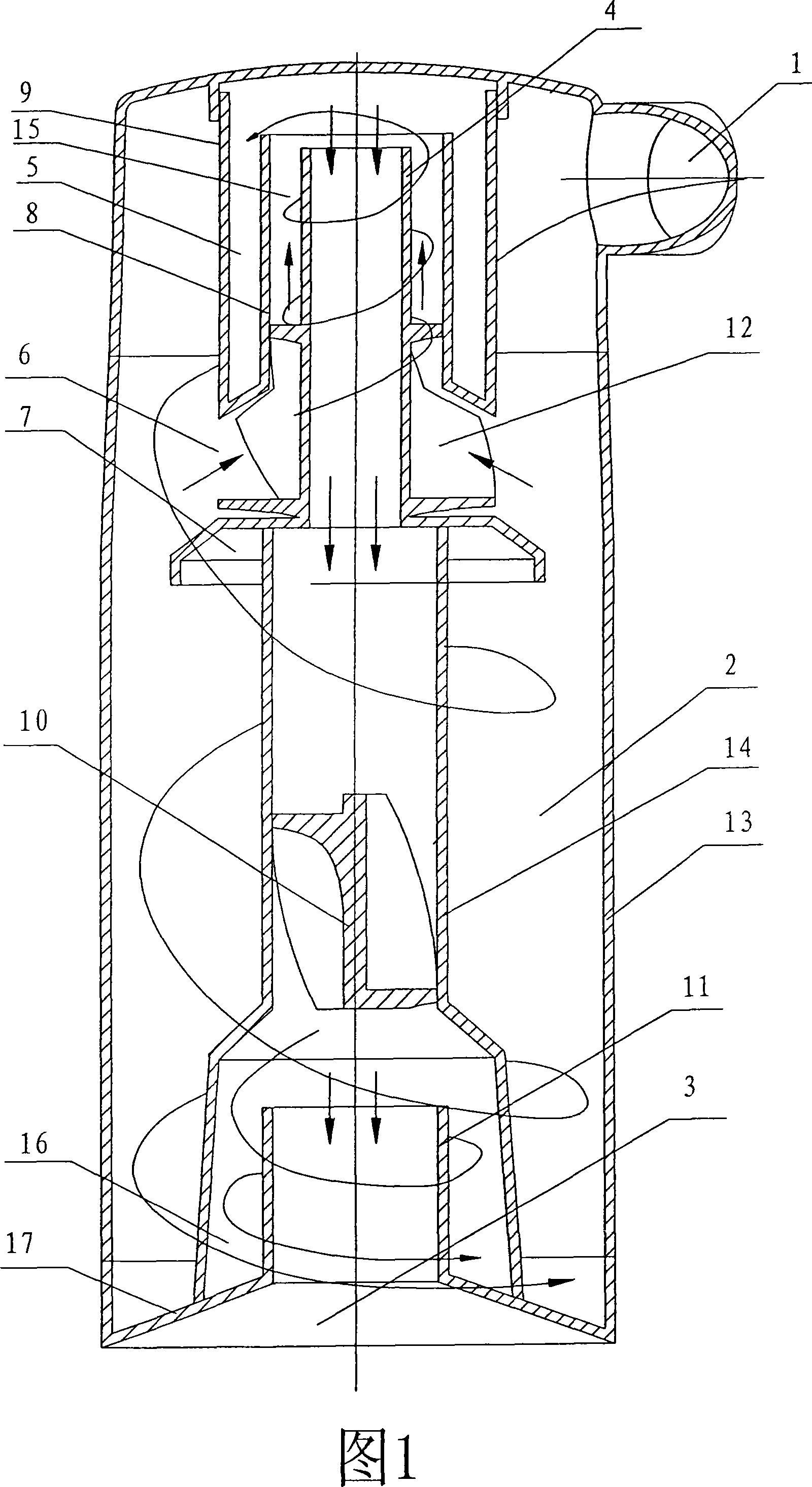

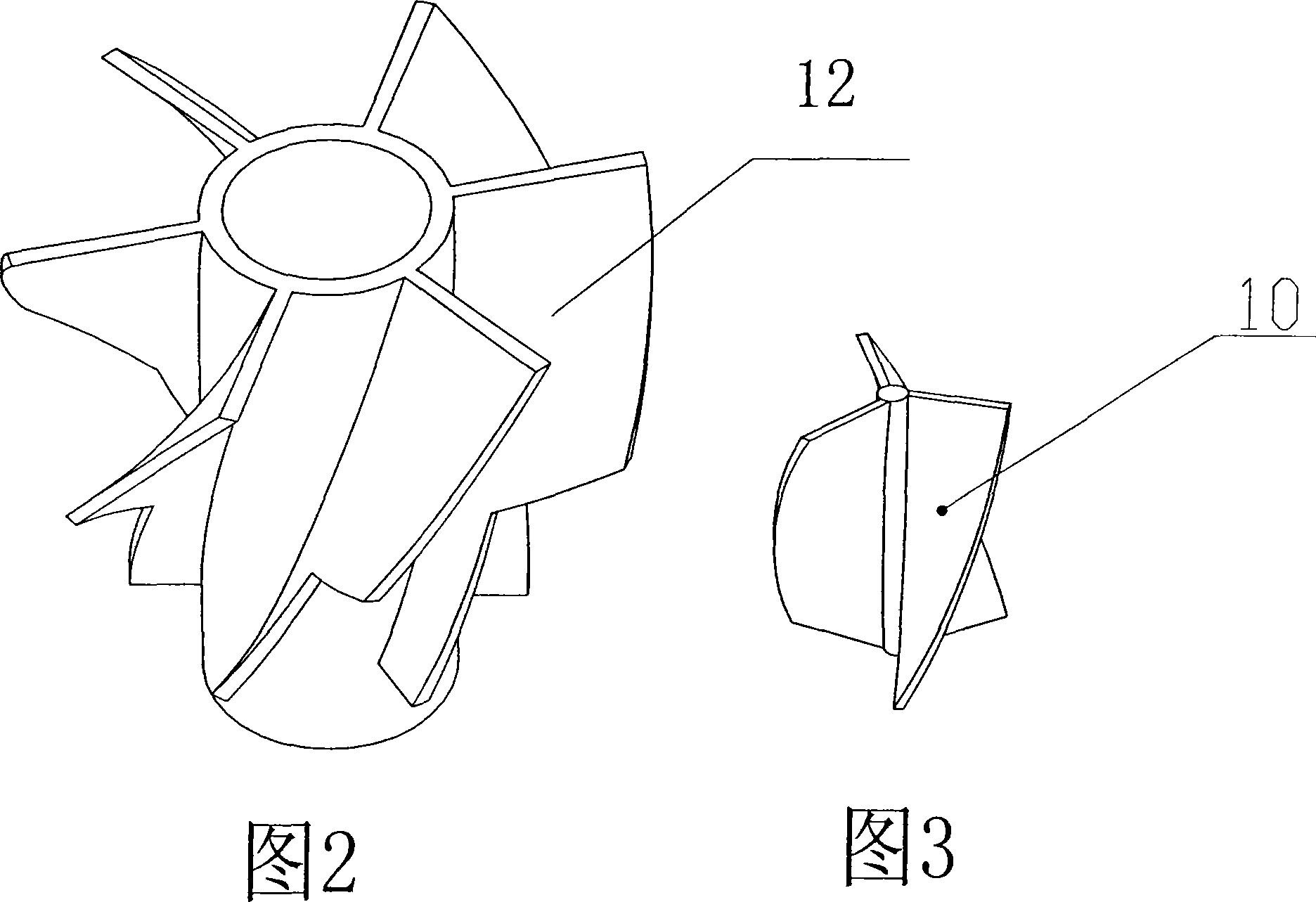

Vacuum cleaner cyclone dust cup with tri-separation function

InactiveCN101143083AImprove the separation effectReduce wind pressureSuction filtersInternal cavityCyclone

A vortex type dust cup of a dust collector with the function of thrice separating includes a crust body, an air inlet that is arranged at the crust body and is tangent with the crust body and a separator, which is arranged inside the crust body. Certain fall height is arranged between the level position of the top of the air inlet of the separator and the central position of the dust cup air inlet. The separator is provided with two pieces of an internal pipe and an external pipe, which are coaxially installed. The bottoms of the internal pipe and the external pipe are in close connection. The height of the internal pipe is lower than the height of the external pipe. The air inlet of the separator is an annular body and is formed by the screw-thread-shaped rotary arrangement of screw panels, and the bottom of the separator is fixed at a separating cover. The middle of the internal pipe above a central hole of the separator is connected with a central pipe, which is coaxial with the internal pipe. The central pipe is put through the separating cover and extends downwards to form an extending pipe, which is provided with a small top and a big bottom. A short pipe is arranged inside the lower part of the extending pipe and links the extending pipe, the short pipe and the bottom of the crust body as a dust cup air outlet, which is provided with a trumpet-shaped convex edge. The extending pipe under the separator is provided with a three-vane rotating plate inside. The separation effect towards the air with dust can be further strengthened by thrice separating through the dust cup internal cavity.

Owner:NINGBO FUJIA IND

Method for separating trivalent actinide and lanthanide ions based on synergistic effect

ActiveCN107958717AImprove applicabilityImprove the separation effectRadioactive decontaminationIonActinide

The invention discloses a method for separating trivalent actinide and lanthanide ions based on the synergistic effect. Fat-soluble dithiophosphiic acid is used as an extracting agent and is diluted with a diluent to form an organic phase, and the organic phase and an aqueous phase are subjected to an extraction reaction, wherein the aqueous phase is an acidic aqueous solution containing the trivalent actinide and lanthanide ions, and a water-soluble organic weak acid complexing agent is added into the acidic aqueous solution. The trivalent actinide and lanthanide ions are extracted through the synergistic effect of the extracting agent and the complexing agent, the volume ratio of the organic phase to the aqueous phase is 0.2-2, and the pH value of the acidic aqueous solution is 2-4. Themethod is good in separation performance, good in stability and easy and convenient to operate.

Owner:TSINGHUA UNIV

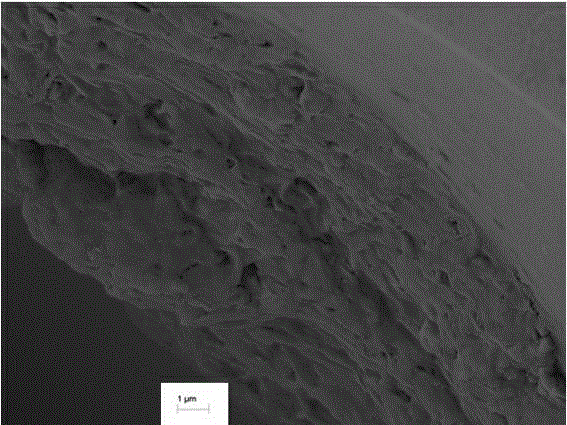

Preparation method of gold nanoparticle modification based open tubular column

InactiveCN103336081AGood chromatographic performanceImprove the separation effectComponent separationPhase ratioChemical bond

The invention discloses a gold nanoparticle modification based open tubular column, and a preparation method and application thereof, and belongs to the technical field of chromatography. The preparation method comprises the following steps: (1) synthesis of a gold nanoparticle solution by a chemical reduction method; (2) pretreatment on the capillary; (3) silanization of the capillary; and (4) modification on inner wall of capillary. The preparation method provided by the invention employs 3-mercapto propyl-trimethoxy silane as a silanization reagent, so that the gold nanoparticles and mercapto groups are modified on the inner surface of the quartz column by chemical bonding; then lauryl mercaptan is added, and the mercapto group in the lauryl mercaptan can react with gold nanoparticles as well, thereby bonding on the inner wall of the capillary. The invention uses gold nanoparticles easily characteristics and SH groups covalently bonded, gold nanoparticles were prepared by modified open tubular capillary column. The invention utilizes the characteristic of gold nanoparticles of easy covalent bonding with -SH groups to prepare the gold nanoparticle modified open tubular column. The technology of using gold nanoparticles as a stationary phase of the open tubular capillary column improves the disadvantages of low volume and small phase ratio of the open tubular capillary column.

Owner:FUZHOU UNIVERSITY

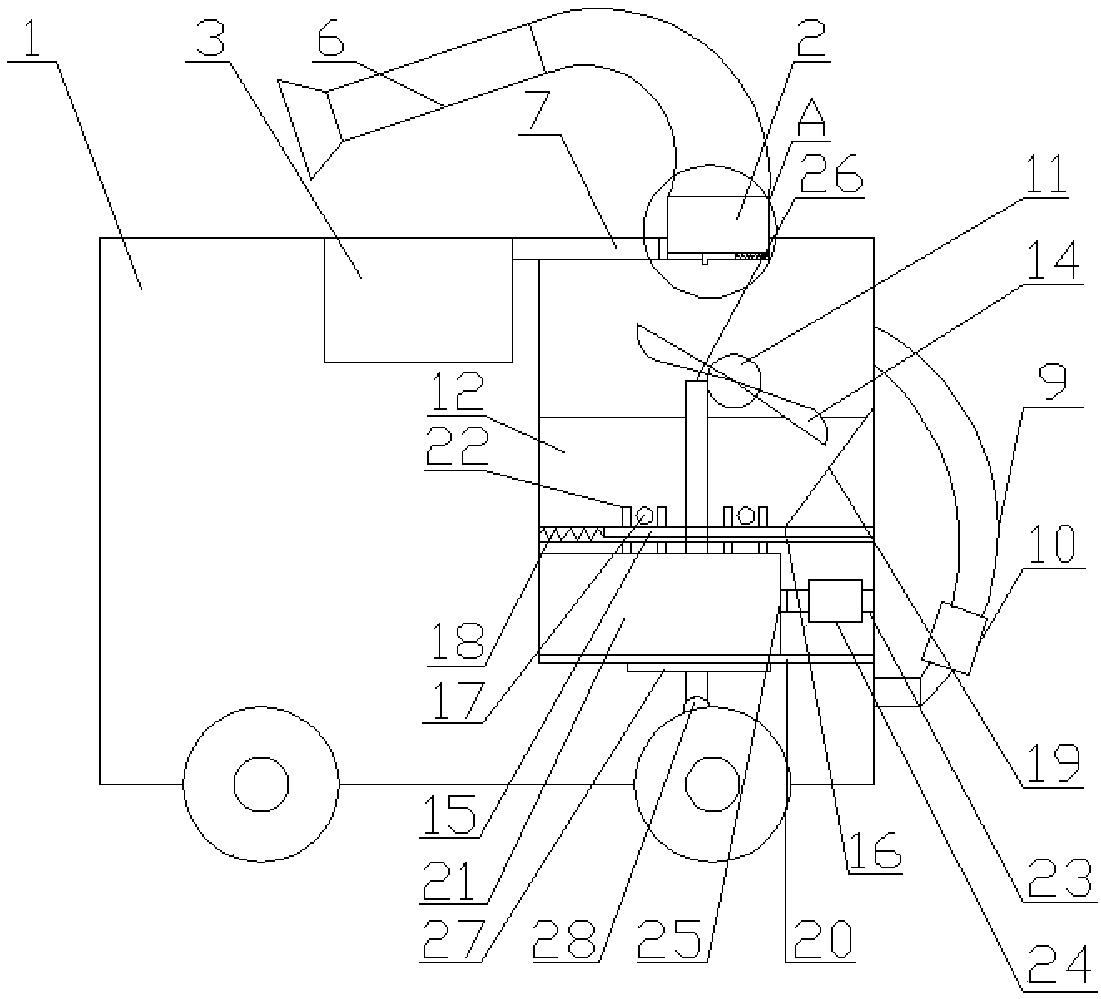

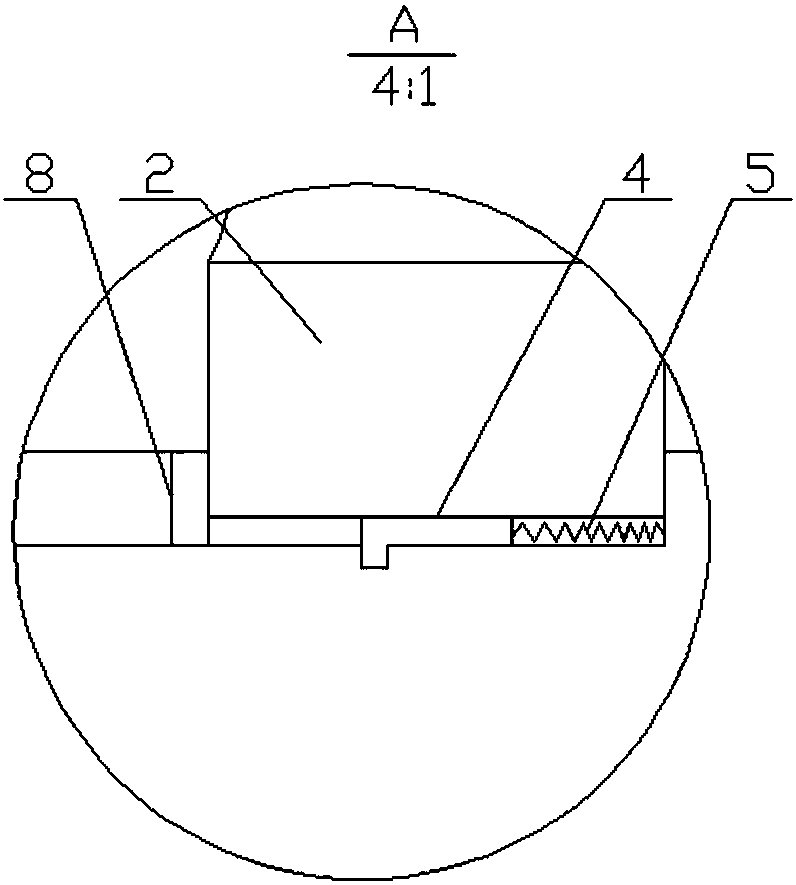

Vehicle for collecting dead leaves

The invention discloses a vehicle for collecting dead leaves and specifically relates to the technical field of municipal landscaping. The vehicle for collecting the dead leaves comprises a working vehicle, wherein a charging tube is provided with a sliding groove and a first sliding block; a first spring is connected between the sliding groove and the first sliding block; the charging tube is connected with an air suction tube; an air suction pipe is connected between the charging tube and a vacuum pump; an air inlet pipe is connected between a drying chamber and an exhaust pipe of the working vehicle; a rotating shaft is provided with blades; an inclined guard board is fixed at the inner wall of the drying chamber; a holding board is provided with a plurality of through holes; a compression board is connected to the interior of a box body; an air bag is arranged on the compression board; iron pipes communicate with the air bag; iron pipes are provided with dust holes; an air outlet pipe communicates the air bag with the inner wall of a dust suction chamber; the air outlet pipe is provided with a check valve; a driving mechanism comprises a cam and a friction column; and the friction column is provided with a compression plate. The technical scheme of the invention overcomes the problem that the dust and moisture in the dead leaves can not be removed during the process of collecting the dead leaves and can be used for the pretreatment of collecting the dead leaves.

Owner:遵义湘江园林工程有限责任公司

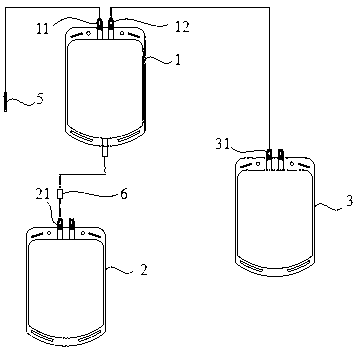

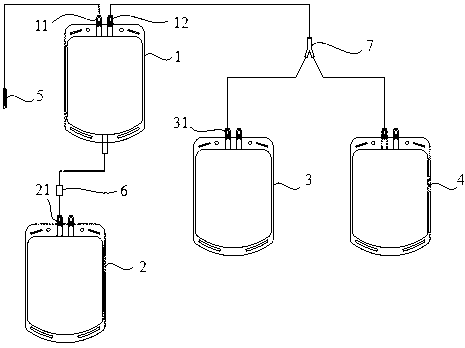

Platelet separation bag and method for manually separating platelet

ActiveCN103028154AImprove the separation effectMeet the needs of clinical patientsBlood transfusionChemistryBlood plasma

The invention discloses a platelet separation bag and a method for manually separating platelet, belonging to the field of medical instruments and apparatuses and separation of blood. The method comprises the steps of: after whole blood is heavily centrifuged, respectively extruding blood plasma from the upside and separating erythrocytes from the downside, then lightly centrifuging, and extracting leukocytes and residual erythrocytes to obtain concentrated platelet. The platelet separation bag comprises a blood collecting bag, a blood plasma collecting bag and an erythrocyte collecting bag which are mutually connected, and a transfer bag capable of being used for secondarily centrifuging and separating residual erythrocytes in the blood plasma. According to the invention, a white film layer is remained in the original blood collecting bag, thus the loss of the white film in a transfer process is greatly reduced, the complete white film layer is remained, and thus the high-concentration platelet is obtained, and the recycling rate of the platelet is remarkably higher than that of the platelet by other manual recycling methods. According to the invention, the erythrocytes and the blood plasma can be better extracted, thus the waste of blood components is avoided, the cost is far lower than that of the apheresis platelet, and the economic load of a patient is favorably reduced.

Owner:NANJING SHUANGWEI BIOTECH +1

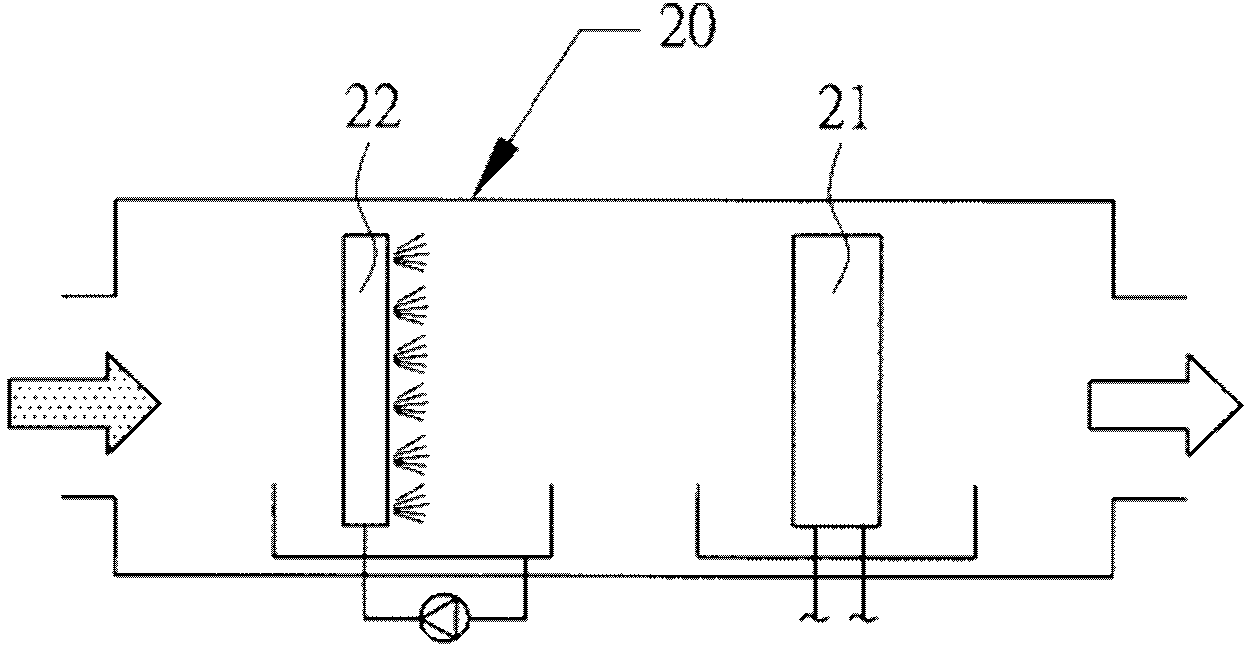

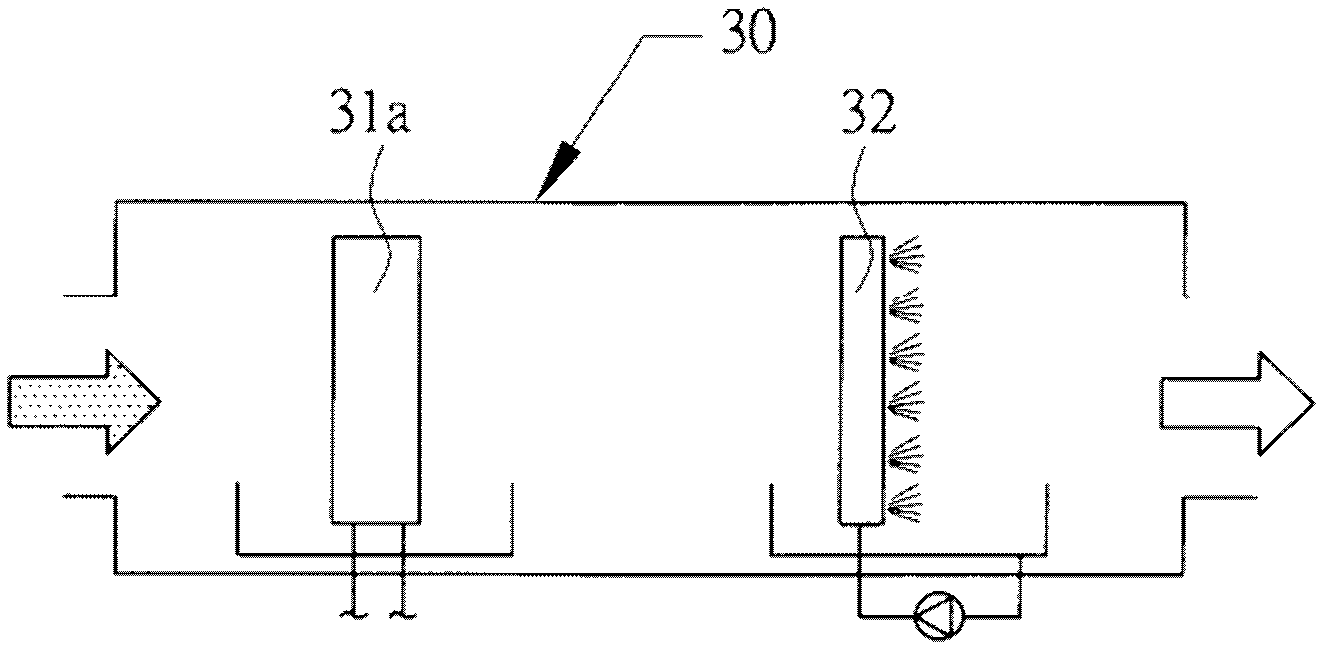

Volatile organic matter condensing device

InactiveCN103028269AImprove recycling qualityImprove the separation effectVapor condensationVolatile organic compoundWater soluble

The invention relates to a volatile organic matter condensing device; a first condenser is disposed inside a waste gas flow channel; a water sprinkler is disposed at the downstream end of the first condenser; most water-soluble volatile organic matter is separated by the first condenser, and then water mist is sprinkled to waste gas flow passing through by the water sprinkler so as to separate residual water-soluble volatile organic matter by using the absorption effect of water drop; a second condenser is further disposed at the downstream end of the water sprinkler. Therefore, the volatile organic matter condensing device is provided which has the effects of improving recovery quality and separation effect of volatile organic matter.

Owner:CHENG YUAN ENVIRONMENTAL TECH

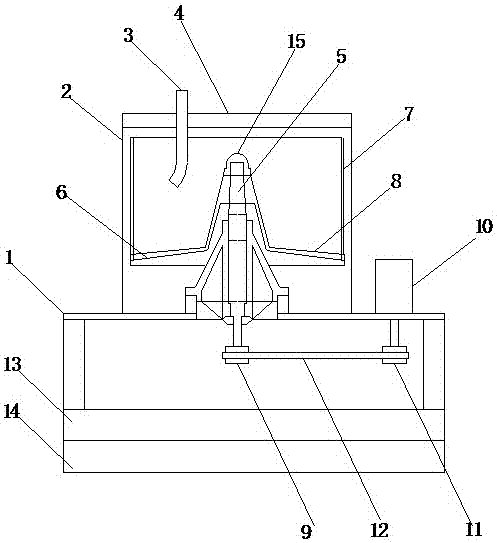

Centrifugal machine for food processing

InactiveCN107511271AImprove the separation effectIncrease productivityFood shapingCentrifugesEngineeringFood processing

The invention discloses a food processing centrifuge, which comprises a frame, an organic casing is arranged at the upper end of the frame, an upper cover is arranged at the upper end of the casing, a feeding port is arranged on one side of the upper cover, and a rotating spindle is arranged at the middle position inside the casing , the lower end of the rotating main shaft runs through the upper end surface of the frame and is fixedly connected with the center of the driven wheel. The cylinder body is a hollow structure, and one side of the upper end of the frame is equipped with a motor one. The output shaft of the motor one runs through the upper end surface of the frame and is fixedly connected with the center of the driving wheel. It is fixedly connected with the shock absorbing mechanism. Beneficial effects: by setting the vibration mechanism, the centrifuge for food processing can more fully separate raw materials, thereby improving the separation effect of the centrifuge for food processing and improving the production efficiency of the enterprise.

Owner:李惠妙

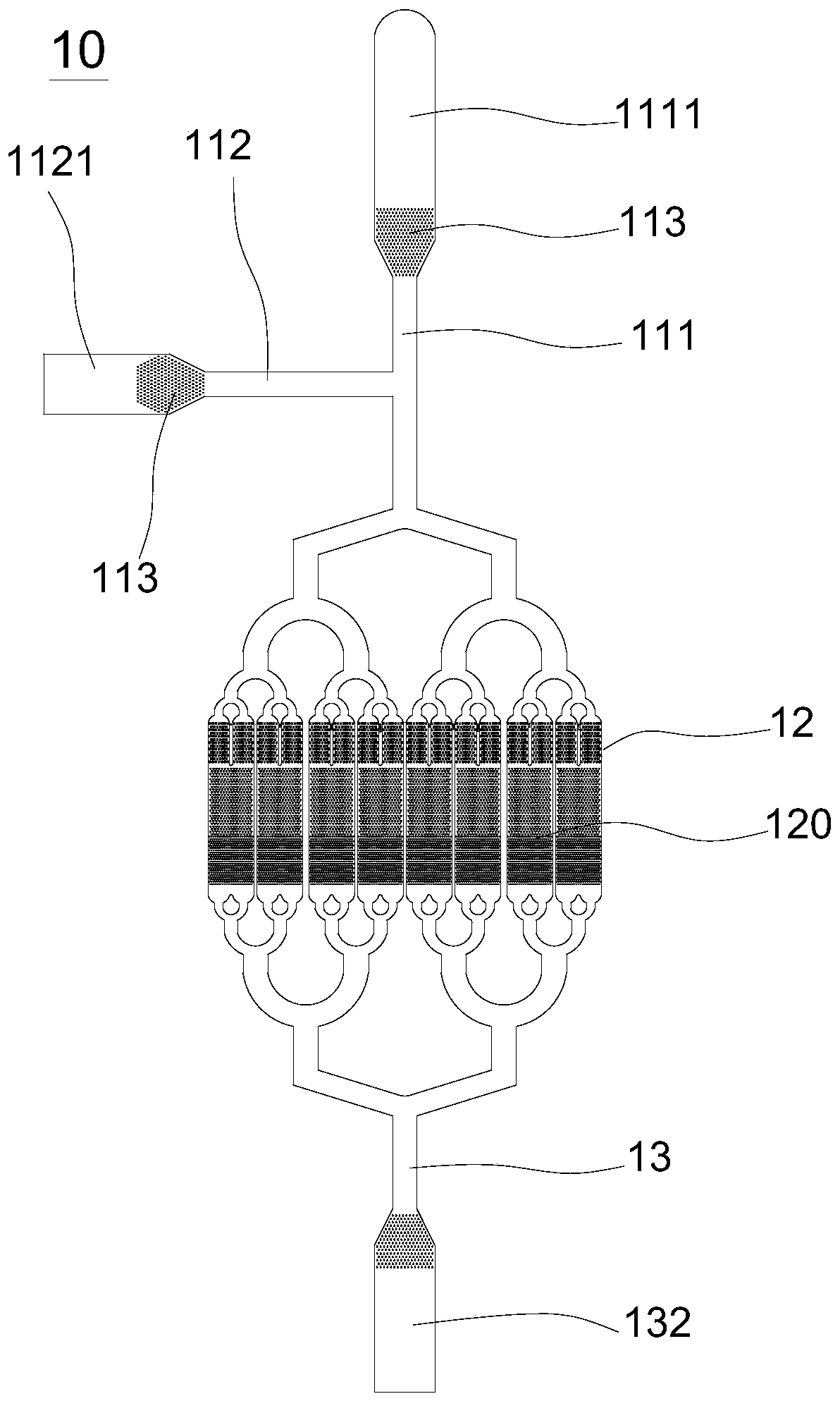

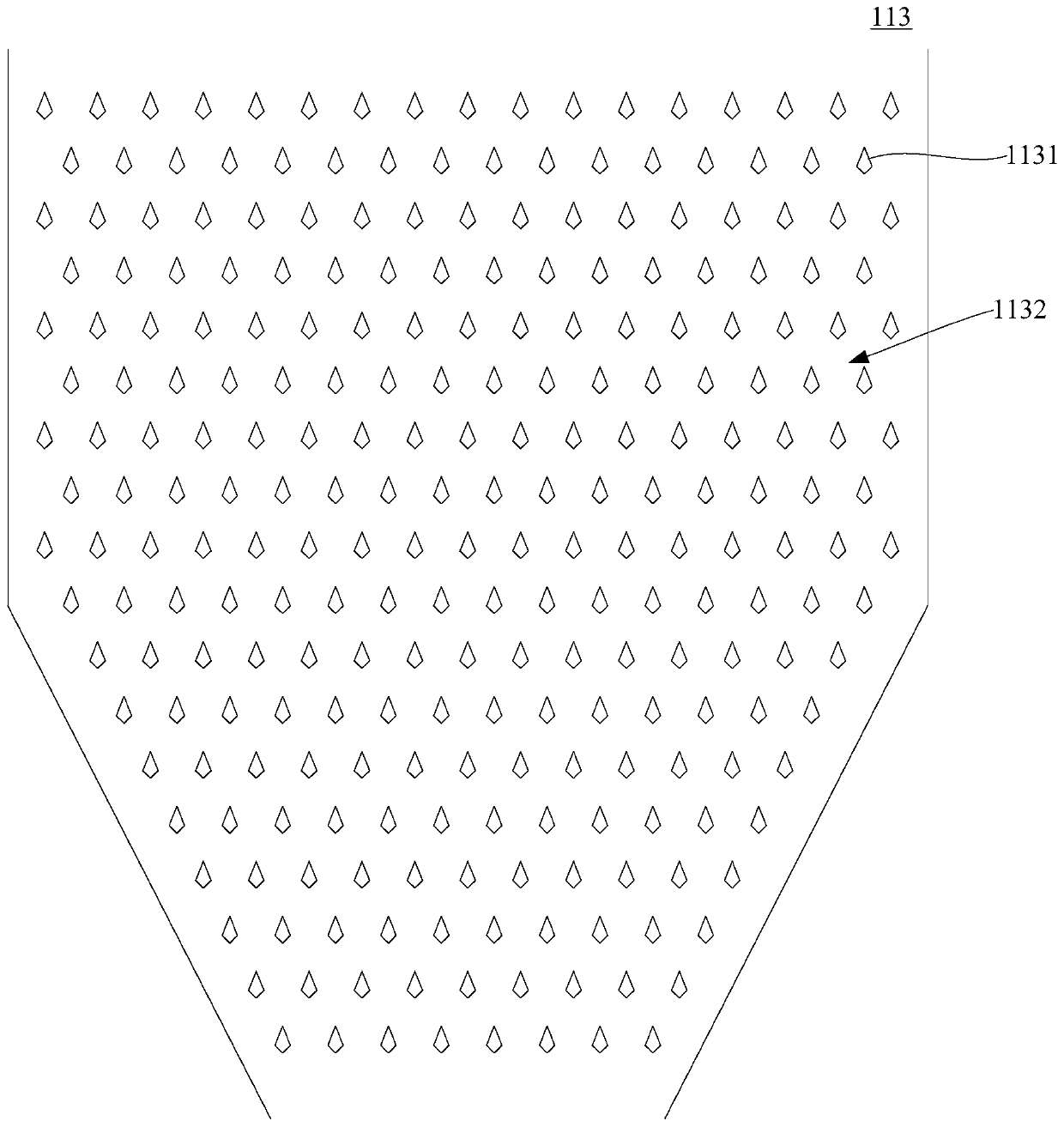

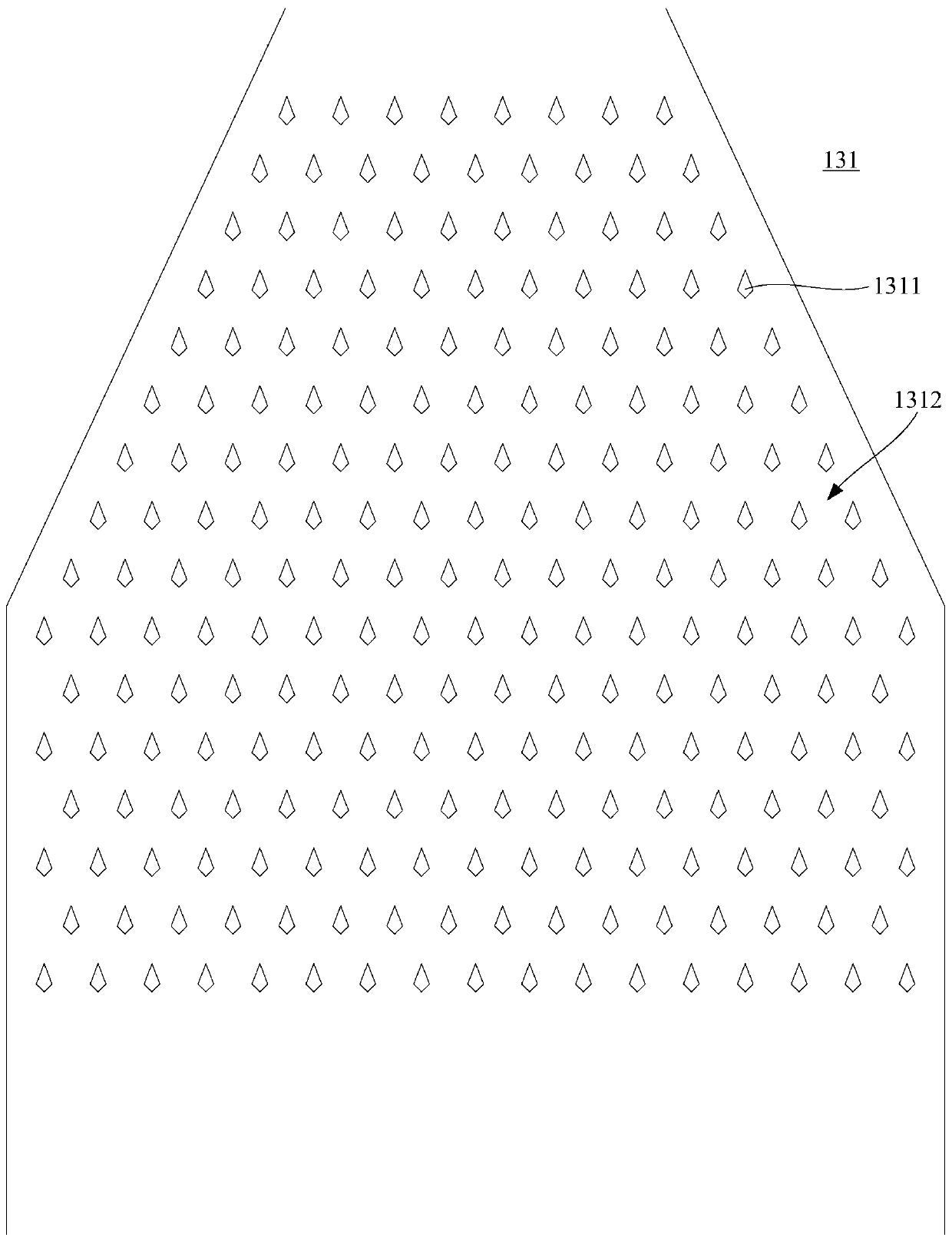

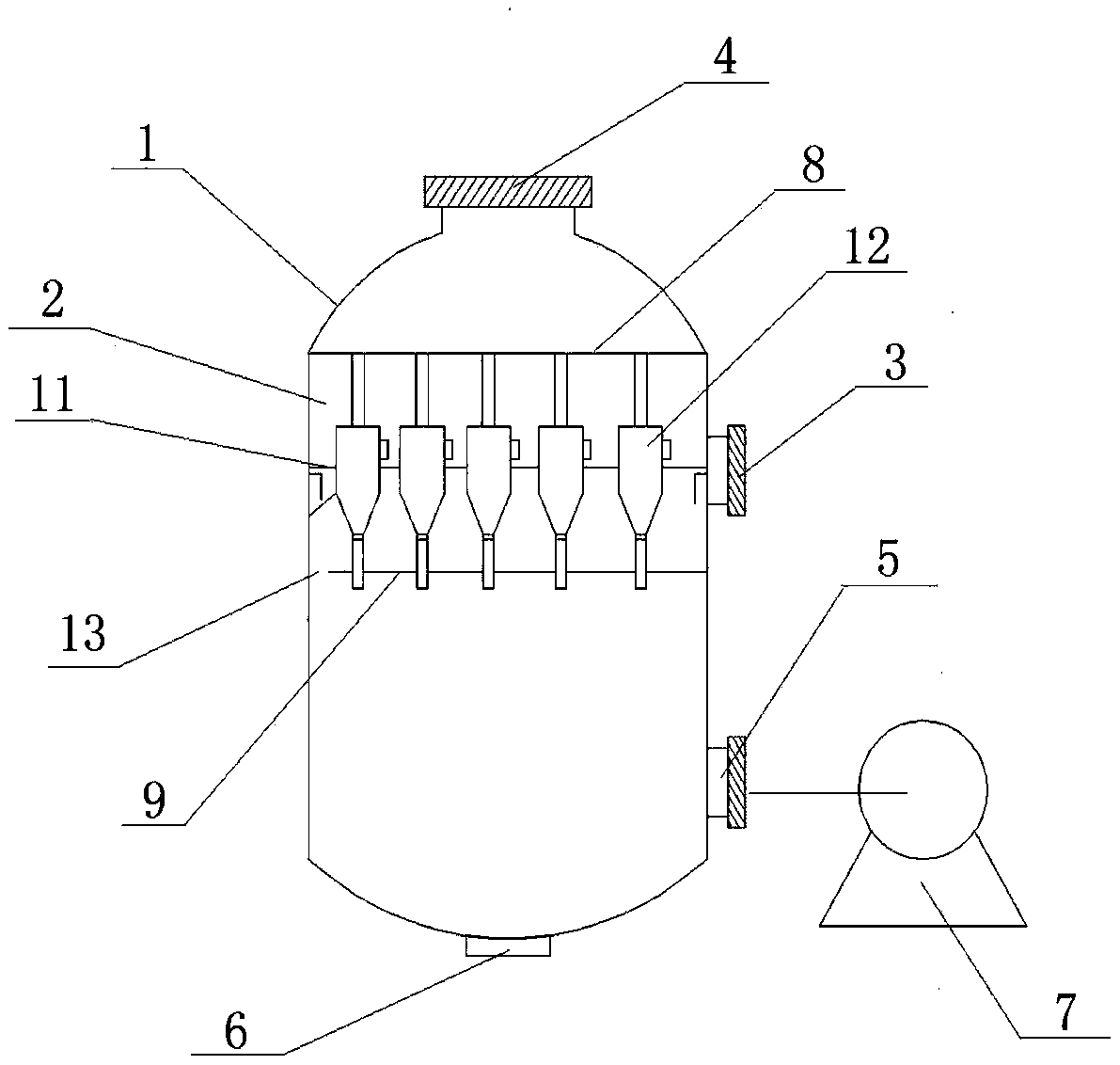

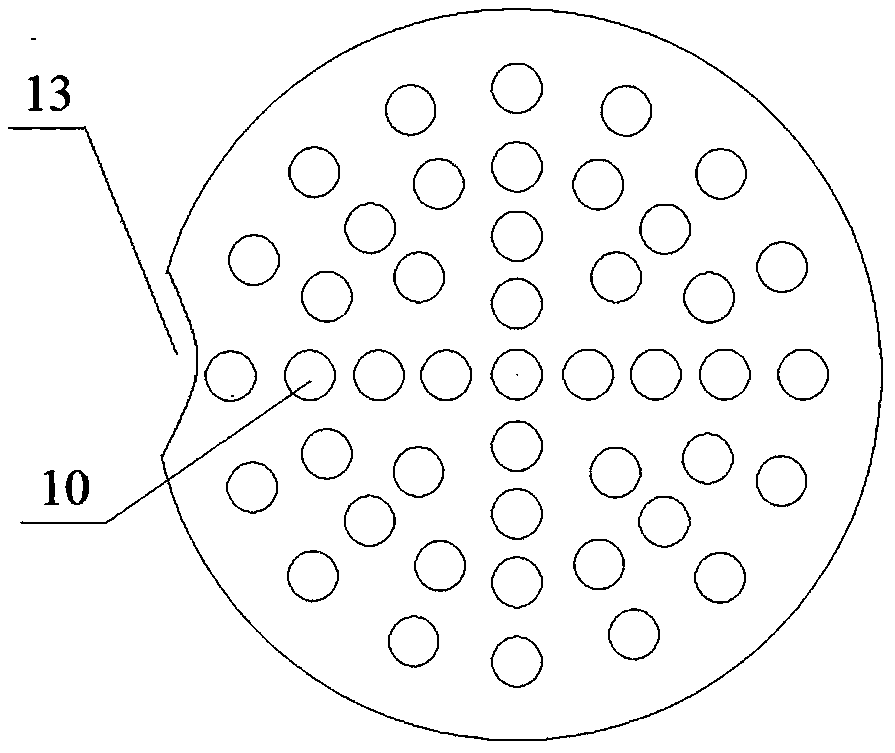

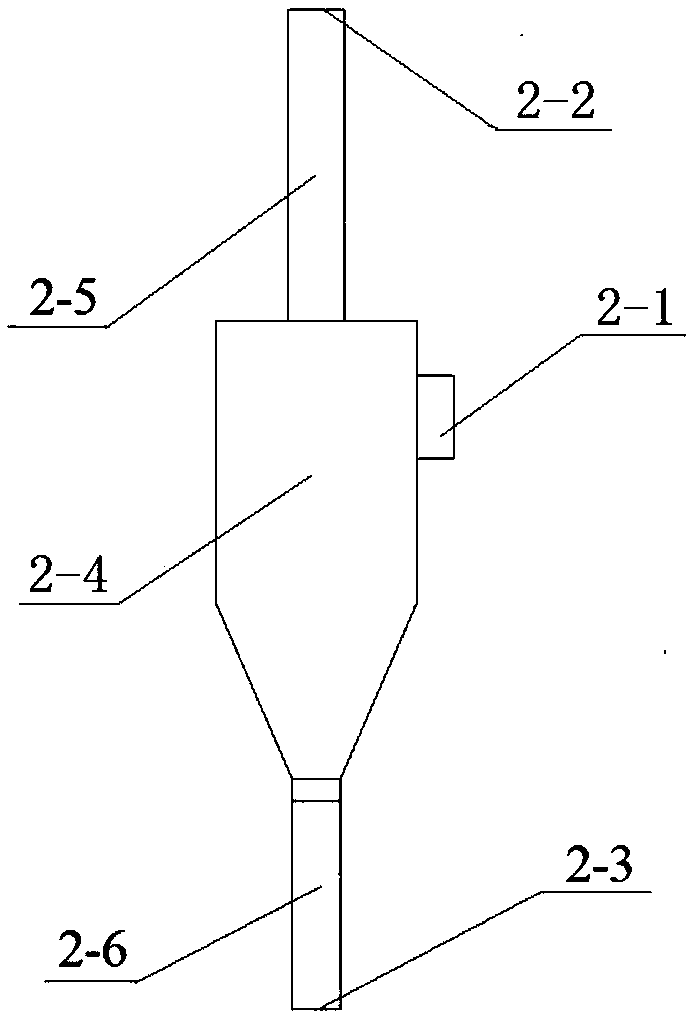

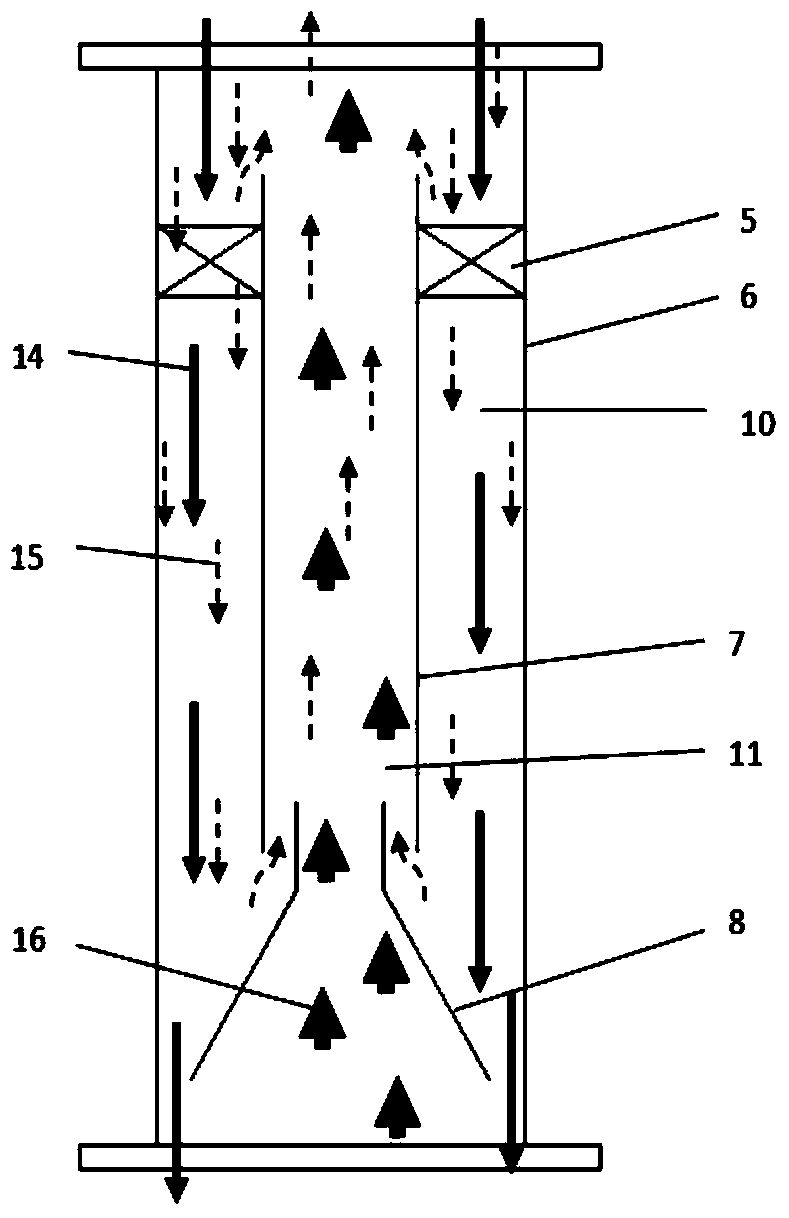

Separation equipment for Fischer-Tropsch slurry bed reactor products

ActiveCN108815929AEfficient separationImprove the separation effectReversed direction vortexDispersed particle separationSolid phasesProcess engineering

The invention discloses separation equipment for Fischer-Tropsch slurry bed reactor products. The separation equipment comprises a casing and a cyclone separator unit, wherein the casing comprises a casing inner cavity, and a mixed solution feed port is formed in the side wall of the casing; the cyclone separator unit comprises a plurality of cyclone separators, feed ports of the cyclone separators are used for receiving the Fischer-Tropsch slurry reactor products input from the mixed solution feed port, and a gas-phase component outlet and a liquid-phase component outlet are formed in the topand the bottom of each cyclone separator respectively; a gas discharge port is formed in the top of the casing; an area, located below the liquid-phase component outlets of the cyclone separators, inthe casing inner cavity is a liquid-phase component accommodating area; an impurity discharge port is formed in the bottom of the casing; a liquid-phase discharge port is formed in the position, corresponding to the liquid-phase component accommodating area, of the side wall of the casing. According to the separation equipment and technology, gas-phase, liquid-phase and solid-phase separation ofslurry bed reaction is realized, internal parts of the separators are prevented from being blocked by the solid-phase particles, and filter products meet the following system production demands.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

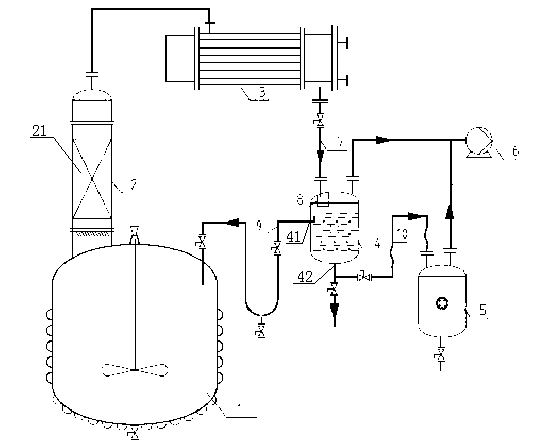

Reaction vessel negative pressure distilled water separating apparatus

InactiveCN103055789AStrong operabilityImprove the separation effectFatty/oily/floating substances removal devicesVapor condensationReaction timingProcess engineering

The invention discloses a reaction vessel negative pressure distilled water separating apparatus which comprises a reaction vessel body. A separating apparatus is arranged in the reaction vessel body and comprises a distillation column, a condenser, a separator, a reception tank and a vacuum pump, wherein the reaction vessel body is communicated with the distillation column through a pipeline, the distillation column is communicated with an inlet of the condenser through a pipeline, an outlet of the condenser is communicated with the separator through a discharging pipe, one side of the separator is provided with a reflux inlet, the reflux inlet is communicated with the reaction vessel body through a reflux pipe, the bottom of the separator is provided with a water rising opening, the water rising opening is communicated with the reception tank through a water rising pipe, and the tops of the separator and the reception tank are respectively connected with the vacuum pump through pipelines. The apparatus provided by the invention overcomes the following problems in usage of a traditional reaction vessel separator: water is taken back to a reaction vessel with a solvent during two-phase separation by the traditional separator under the condition of a negative pressure, and a separation effect of a solvent and water is poor, which causes reduction in product yield, delay of reaction time, reduction in production efficiency and the like.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

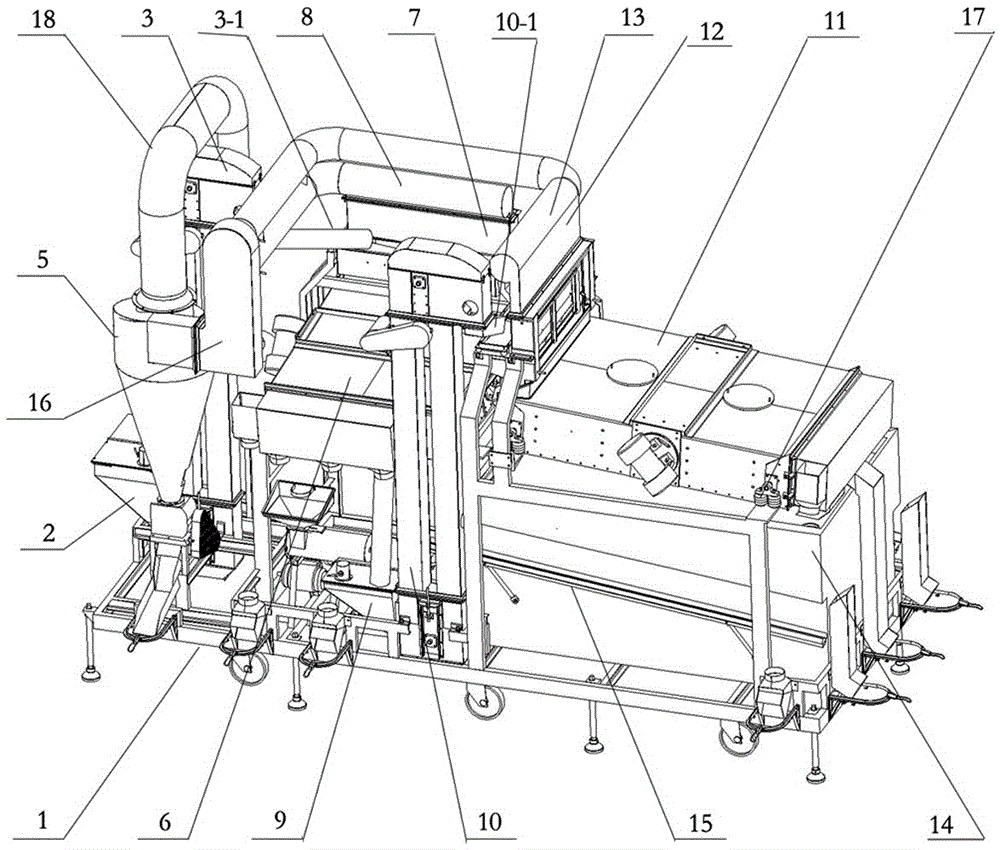

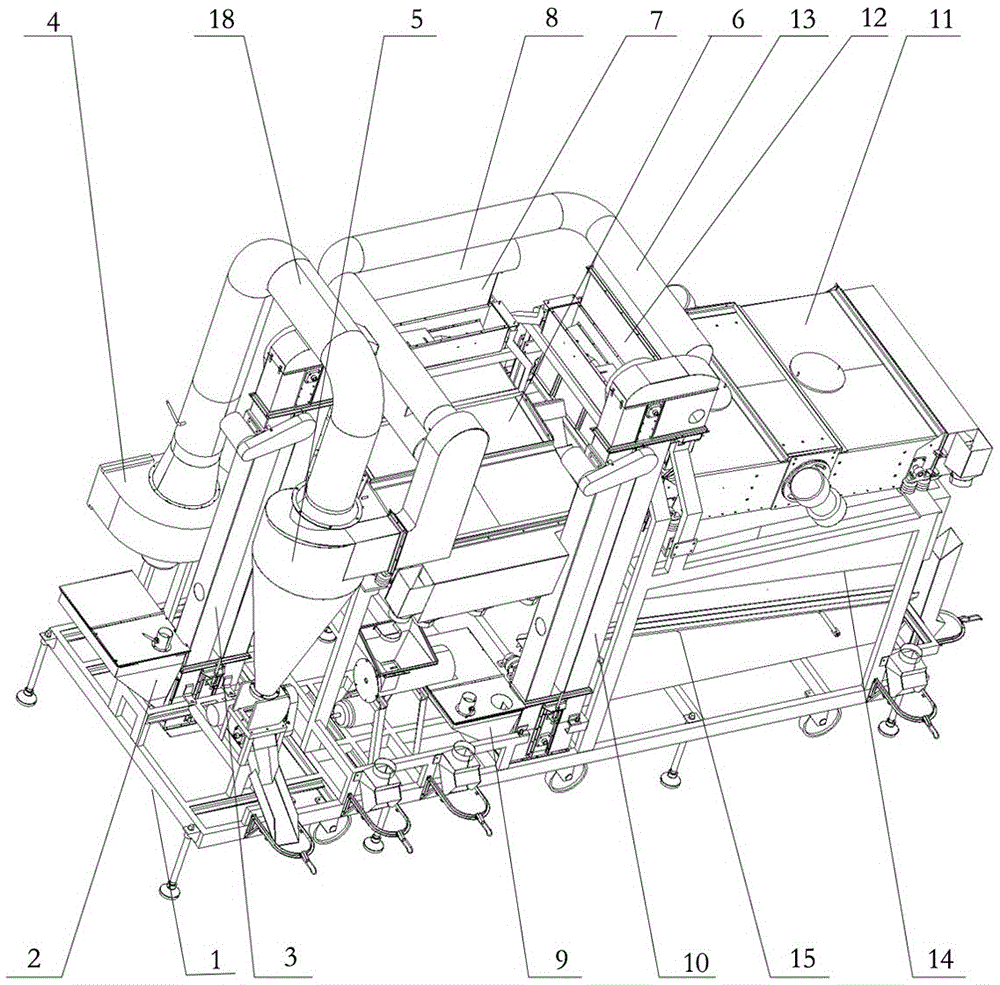

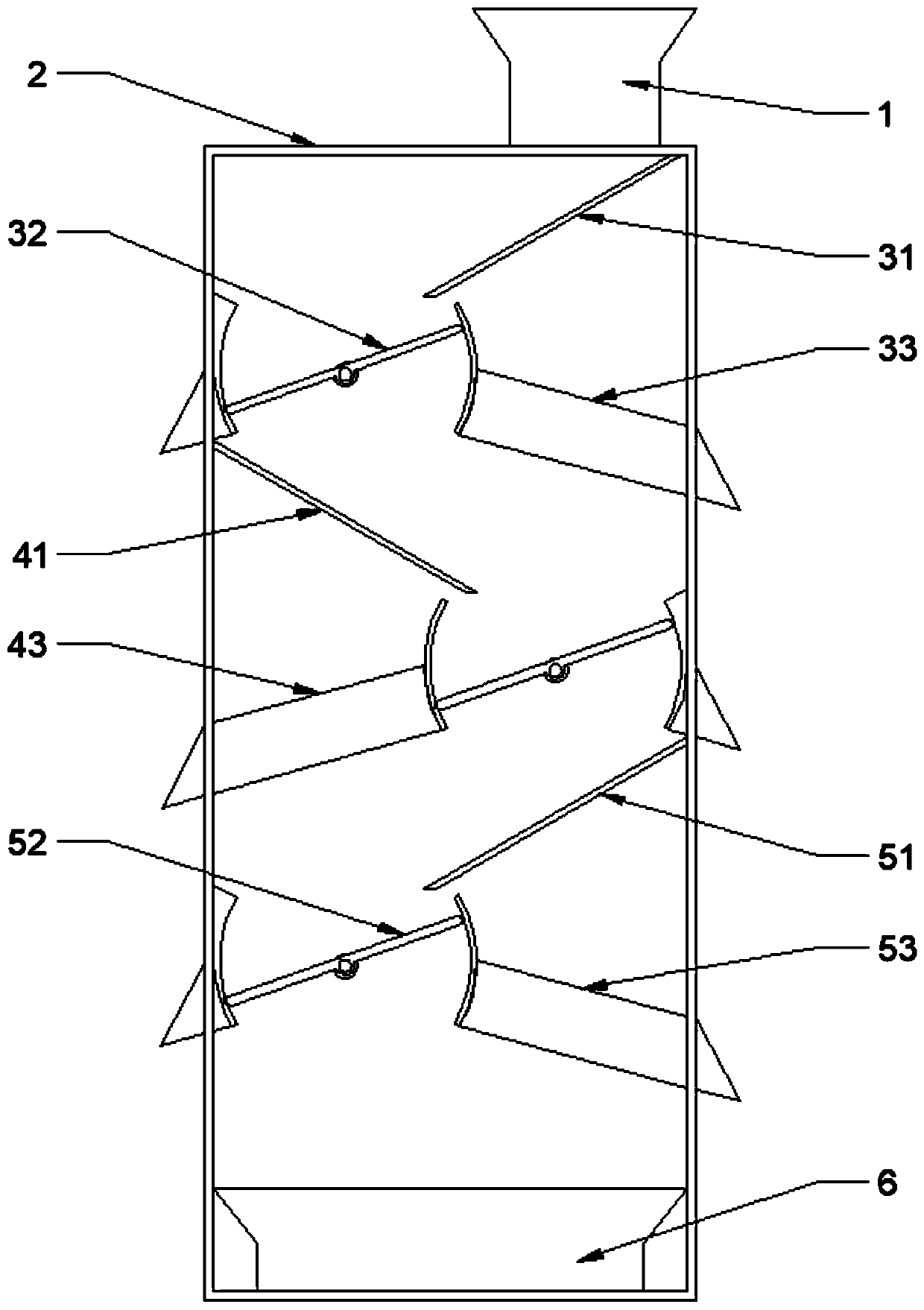

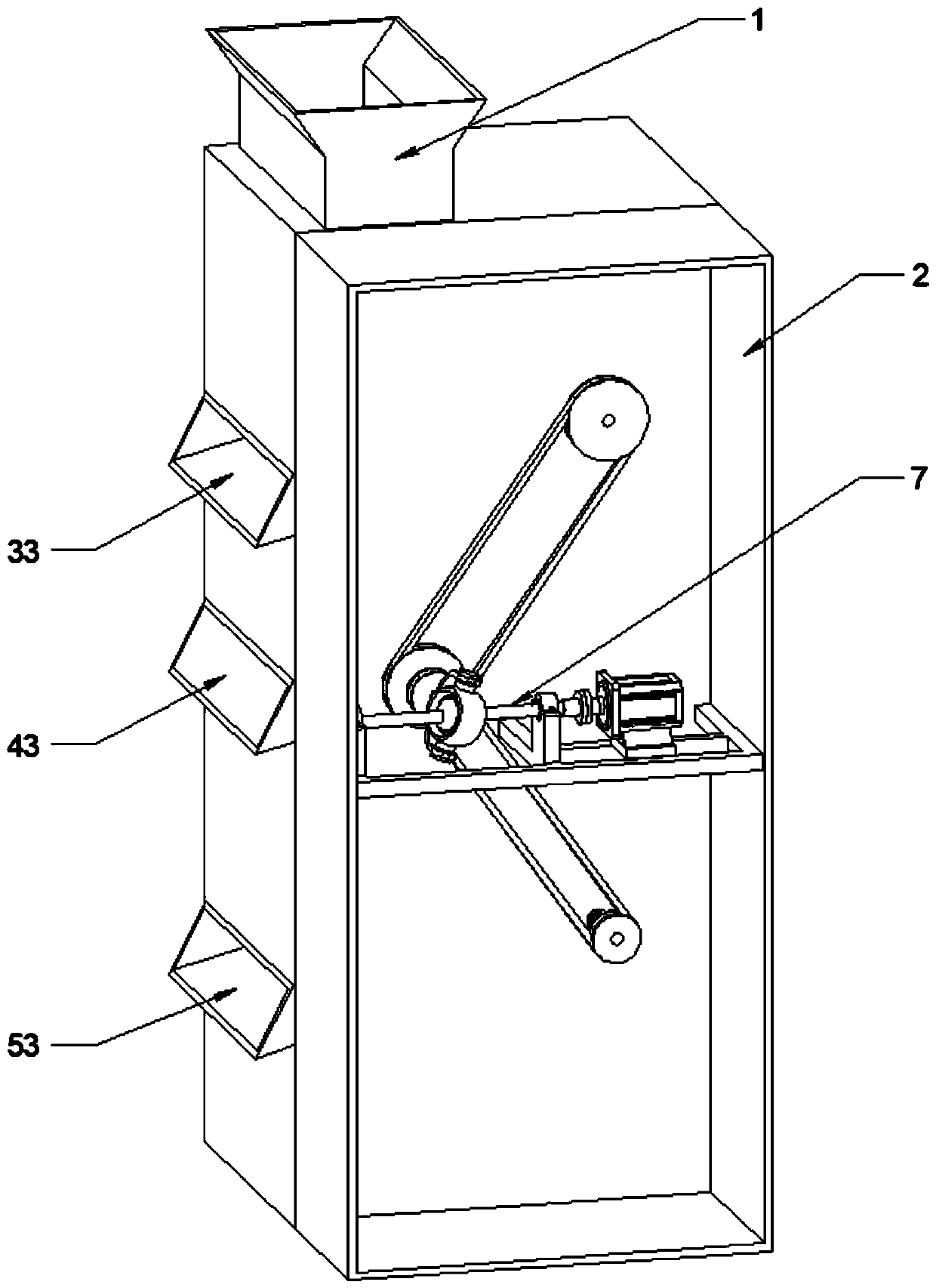

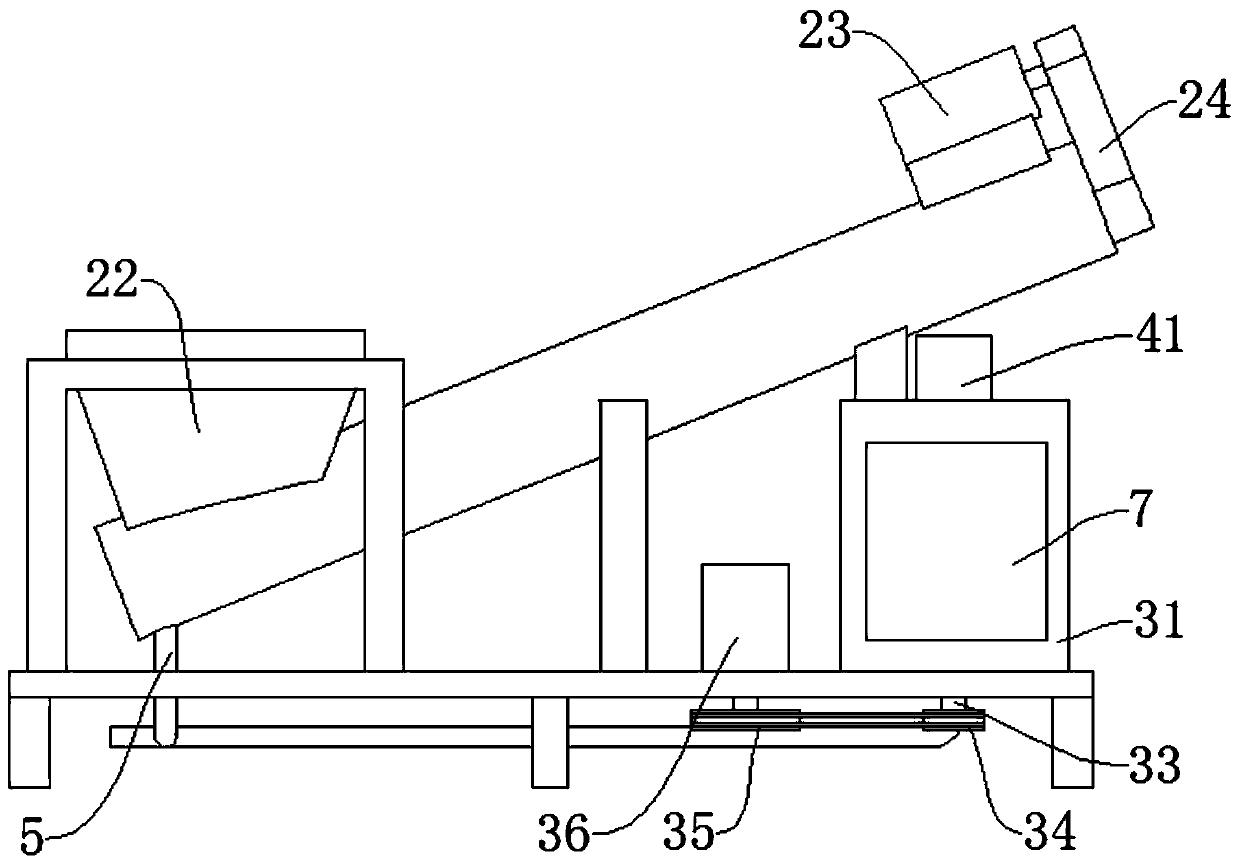

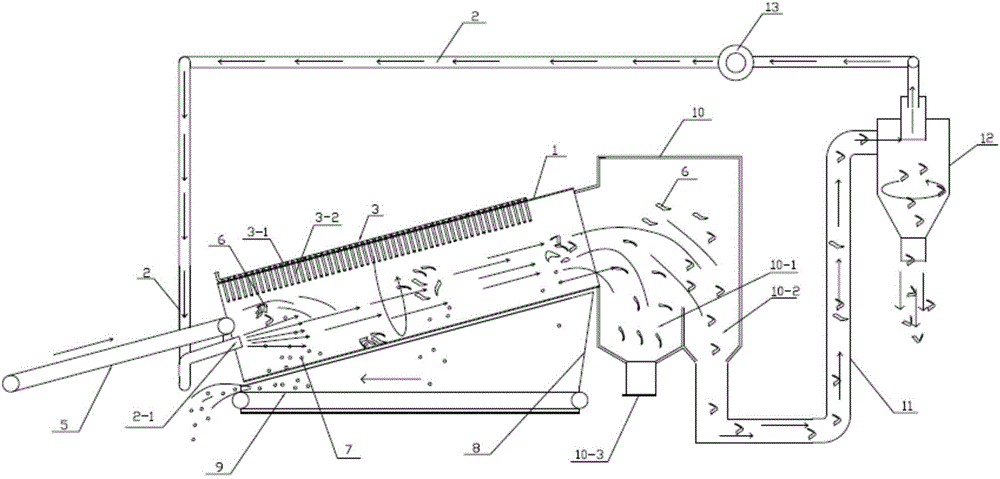

Multi-stage efficient grain cleaner

PendingCN106583252AImprove the separation effectImprove cleaning effectSievingGas current separationSpecific gravityEngineering

The invention provides a multi-stage efficient grain cleaner which comprises a first material feeding device, a fan dust removal device, a first air screening device, a second material feeding device, a second air screening device, a specific gravity separator and a rack, wherein the first material feeding device and the fan dust removal device are arranged at the same end of the rack; the first material feeding device comprises a first material feeding hopper and a first lifting machine communicating with the first material feeding hopper; the fan dust removal device comprises an induced draft fan and a dust remover communicating with the induced draft fan; the first air screening device comprises a first vibration sieve, a first debris suction box and a first air suction pipe; the second material feeding device comprises a second material feeding hopper and a second lifting machine; the second air screening device comprises a second vibration sieve, a second debris suction box and a second air suction pipe; and the specific gravity separator is arranged under the second vibration sieve. By the adoption of the modularized design for combining the first air screening device, the second air screening device and the specific gravity separator, the multi-stage efficient grain cleaner can meet different requirements of clients, and maintenance and equipment replacement are facilitated.

Owner:河北茂恒机械有限公司

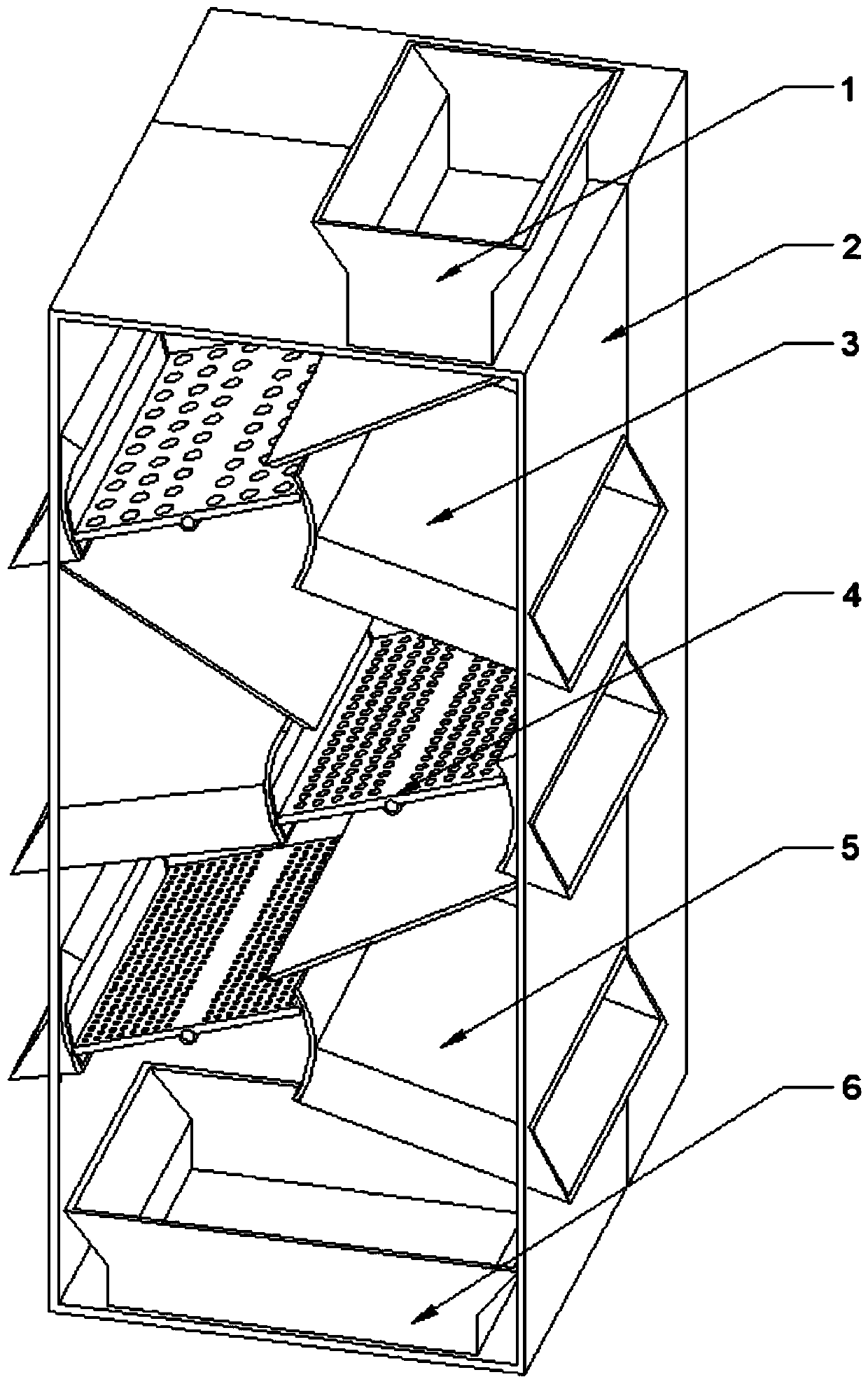

Screening device for construction waste treatment

ActiveCN110433960AImprove filtering effectImprove the separation effectSievingScreeningMagnetEngineering

The invention discloses a screening device for construction waste treatment. The screening device comprises a box body and a screening mechanism arranged in the box body. The screening mechanism comprises a first screening mechanism, a second screening mechanism and a third screening mechanism; the first screening mechanism is located above one side of the second screening mechanism. The third screening mechanism is located below the other side of the second screening mechanism and arranged in the box body in a staggered mode from top to bottom; the screening mechanism rotates through a driving mechanism, an eccentric rotating shaft is arranged in the driving mechanism, the eccentric rotating shaft is fixedly connected with the screening mechanism, and the eccentric rotating shaft rotatesto drive the screening mechanism to swing in a reciprocating mode. Three-stage screening is adopted, and multiple sets of permanent magnets are arranged, so the step-by-step screening and layer-by-layer separation are achieved, and the screening effect is greatly improved; a swing rod, a swing lantern ring and the eccentric rotating shaft are matched, and the eccentric rotating shaft performs circular motion to drive the swing rod to perform reciprocating swing through the swing lantern ring, so the rotation is stable, and the motion is coherent without dead points.

Owner:国闰建设集团有限公司

Oil-containing wastewater treatment agent

InactiveCN105399183AReduce processing costsImprove the separation effectWaste water treatment from quariesFatty/oily/floating substances removal devicesChemistryZeolite

The present invention provides an oil-containing wastewater treatment agent comprising the following components: dihydroxyethyl octadecyl amine oxide, peppermint extract, sulfosuccinate sodium, polymeric ferric sulfate, polyethyleneimine, zeolite, nano titanium dioxide and dimethyl silicone. The oil-containing wastewater treatment agent is capable of treating a large number of oil-containing wastewater, is low in processing cost, and can improve the separation effect of oil and water to recover oil in the wastewater, and on the one hand, environmental pollution is reduced, and on the other hand oil recycling can be realized.

Owner:TIANJIN OUPAN TECH DEV CO LTD

Scrap iron pressing device of machining center

PendingCN110802864AImprove the separation effectImprove environmental qualityMaintainance and safety accessoriesPressesScrapProcess engineering

The invention discloses a scrap iron pressing device of a machining center. The scrap iron pressing device comprises a conveying device arranged above a supporting device and further comprises a rotating device arranged on one side of the conveying device, and a compressing mechanism arranged on the inner side of the rotating device. Cooling liquid is subjected to preliminary separation while theconveying device collects waste, sweeps subjected to preliminary separation enter the rotating device through a discharging hopper and then are subjected to thorough separation again, the separation effect of scrap iron and cooling liquid can be improved, separation is carried out in the seal environment, environment quality is improved, operation space is saved, then, the scrap iron is compressedand recycled through a compression mechanism, direct participation by manual work is avoided, and manual labor intensity is reduced.

Owner:广州市永汇自动化设备有限公司

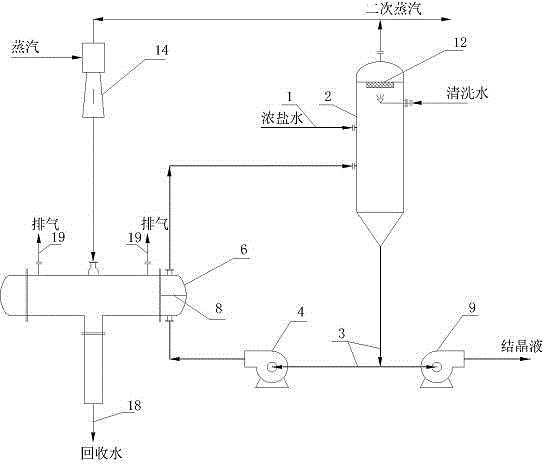

Forced circulating and crystallizing device for industrial wastewater treatment

InactiveCN104671302AImprove the separation effectImprove efficiencyWater/sewage treatment by heatingIndustrial wastewater treatmentSaline water

The invention discloses a forced circulating and crystallizing device for industrial wastewater treatment, and relates to the wastewater treatment devices of the environment-friendly technical field. The forced circulating and crystallizing device comprises a crystallizer and a horizontal type double-tube-pass circulation heat exchanger. A charge hole of concentrated saline water is formed in the side wall of a crystallizer housing, the bottom of the crystallizer is connected with a discharge tube; and concentrated saline water from the discharge tube passes through a circulating pump and a forced circulating heat exchanger in sequence and then is returned to the crystallizer. Steam in the crystallizer is extracted from the top of the crystallizer through a thermal compressor after passing through a demister, and enters the forced circulating heat exchanger for heating and concentrating the concentrated saline water. Compared with the prior art, the double-tube-pass circulation heat exchanger is adopted for returning crystallized concentrated saline water into the crystallizer and separating, so that the separating effects are strengthened, the efficiency is improved, the blockage is avoided, and the normal operation of the compressor is guaranteed.

Owner:TONGFANG ENVIRONMENT

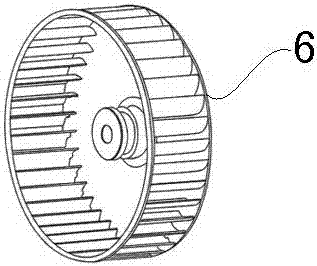

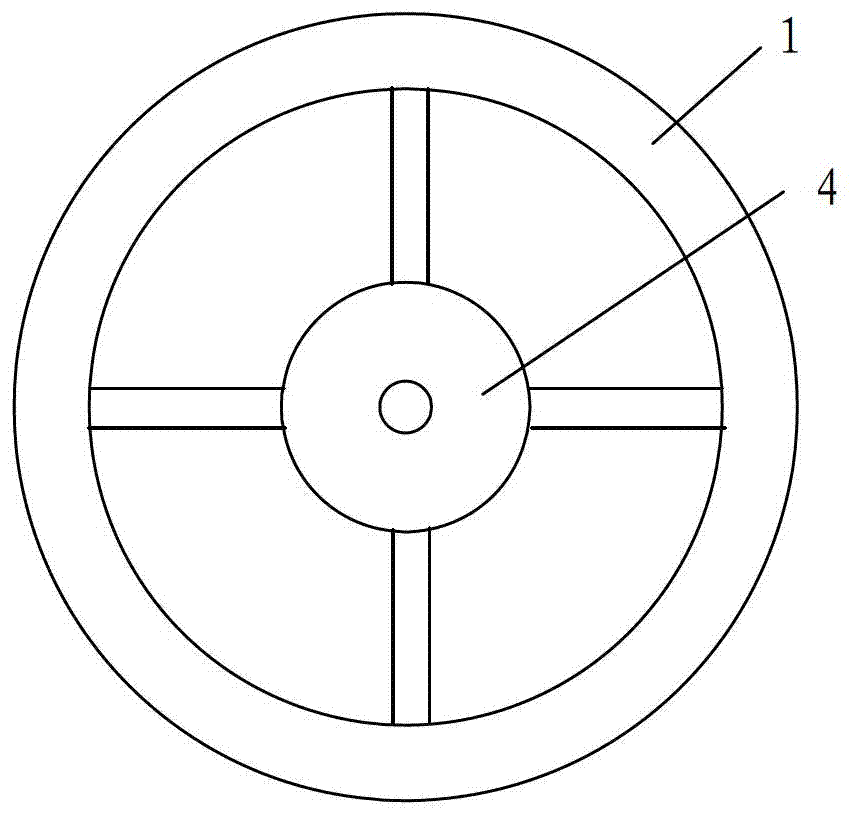

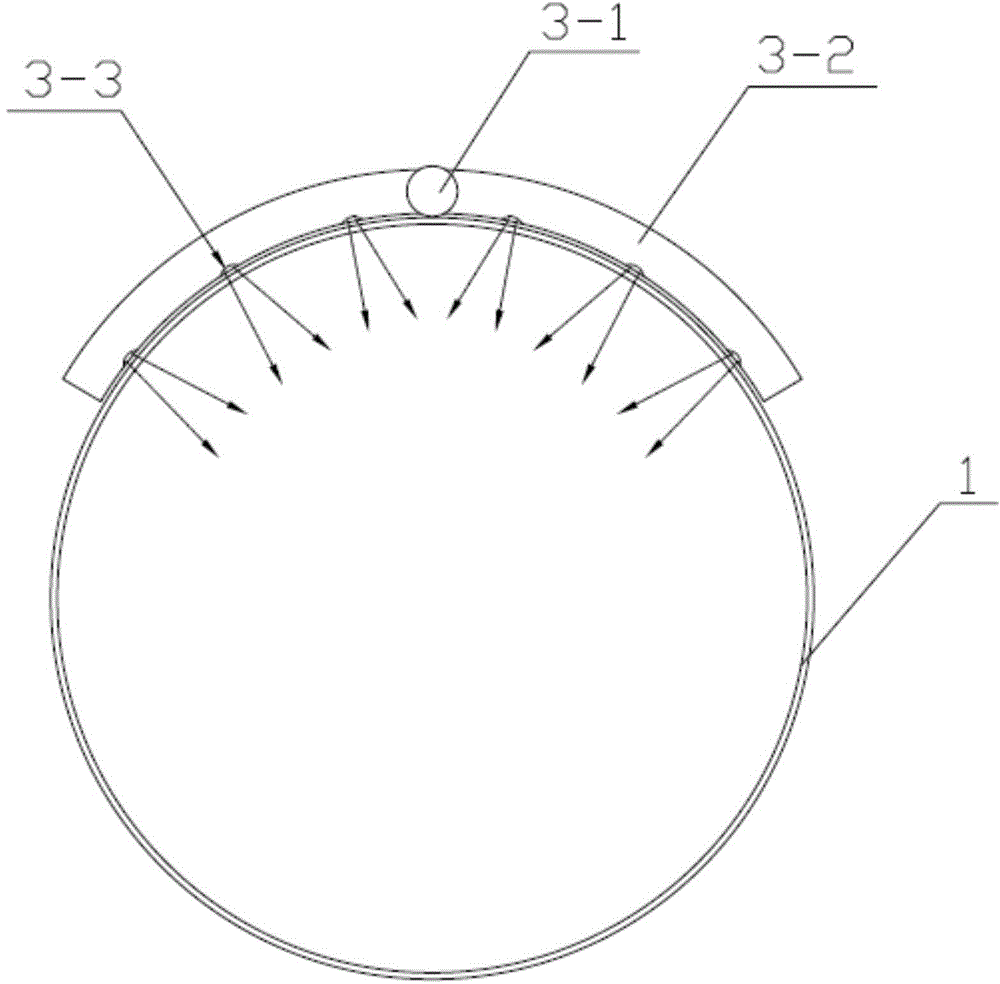

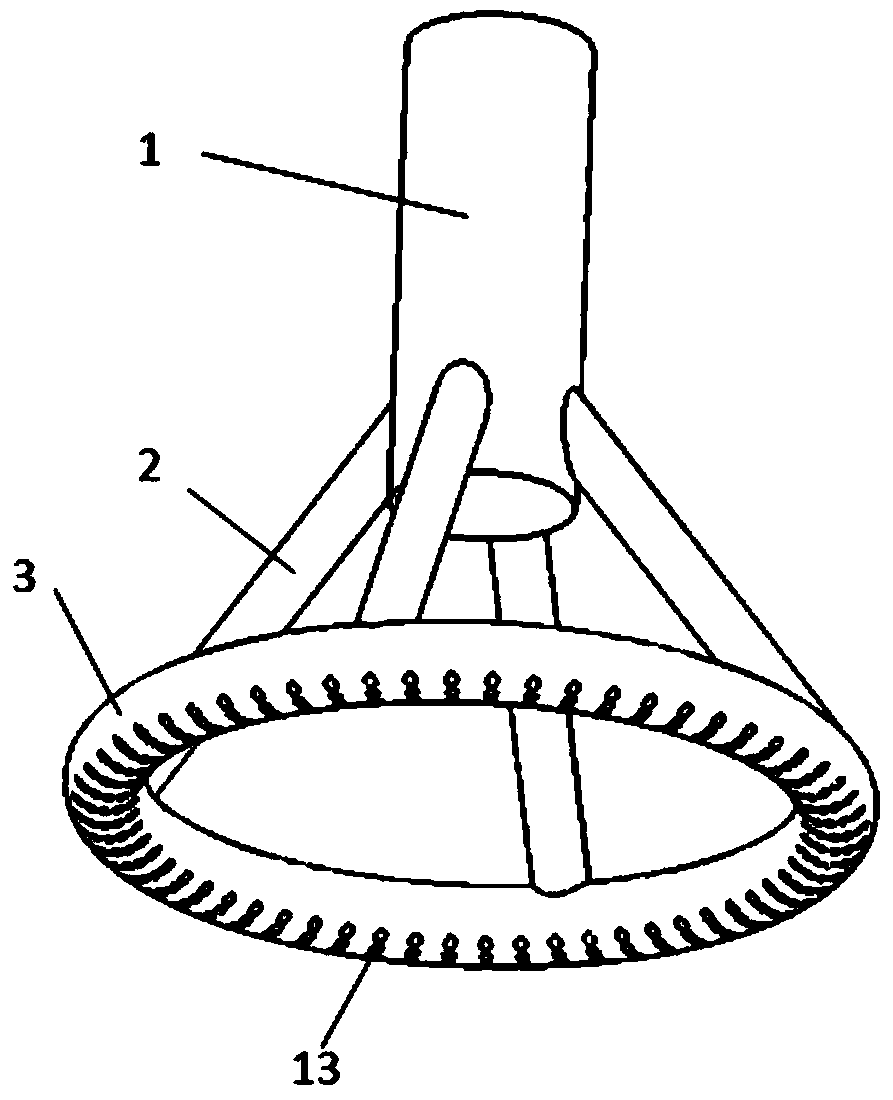

Wind wheel (with filter screen) for range hoods

InactiveCN102759137AGood separation rateImprove the separation effectDomestic stoves or rangesLighting and heating apparatusEngineering

The invention discloses a wind wheel (with a filter screen) for range hoods, which comprises a first support ring and a second support ring, wherein the first support ring and the second support ring are connected by blades arranged at a certain interval along the circumferential direction, the second support ring is connected with a filter screen, and the filter screen covers a ring hole of the second support ring. According to the invention, as the wind wheel is provided with the filter screen, when the wind wheel rotates, grids of the filter screen rotate and impact the lampblack, and then the lampblack is centrifugally separated, so that an effect of lampblack separation can be achieved before the lampblack reaches the blades of the wind wheel for range hoods, thereby avoiding the adherence of oil stains on a motor and the blades, reducing the cleaning of the motor and the blades of the wind wheel, and ensuring the lampblack extracting, discharging and separation effects of range hoods after being used for a long time.

Owner:武汉力诺王力科技有限公司

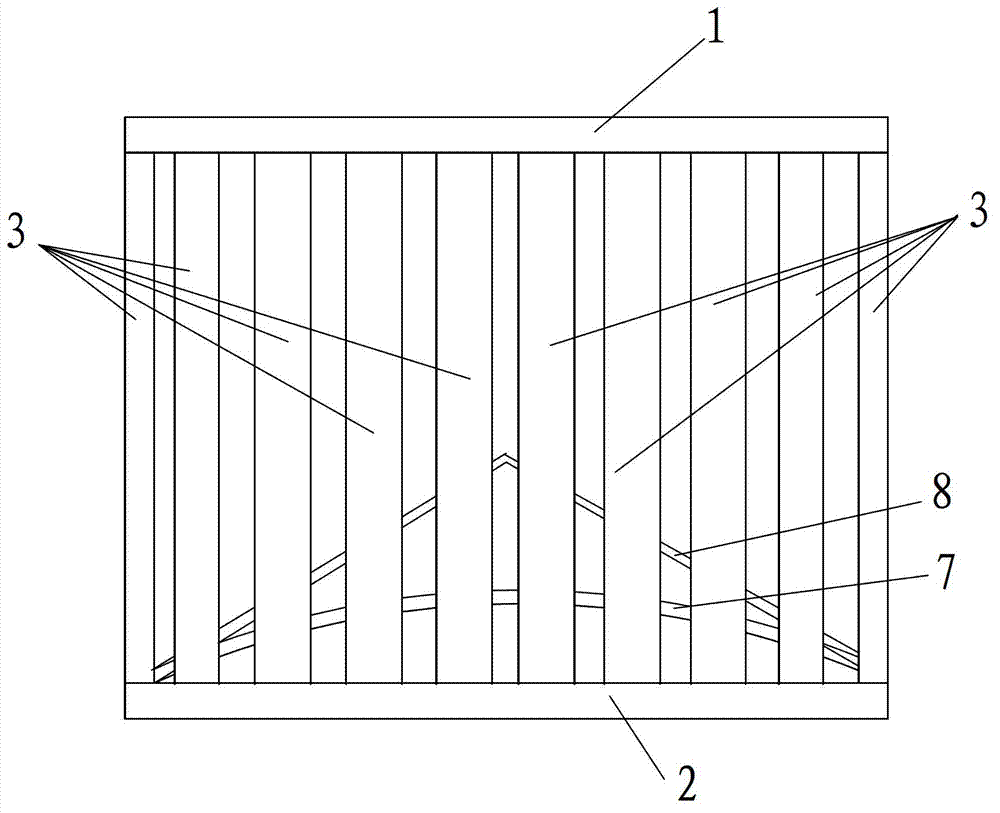

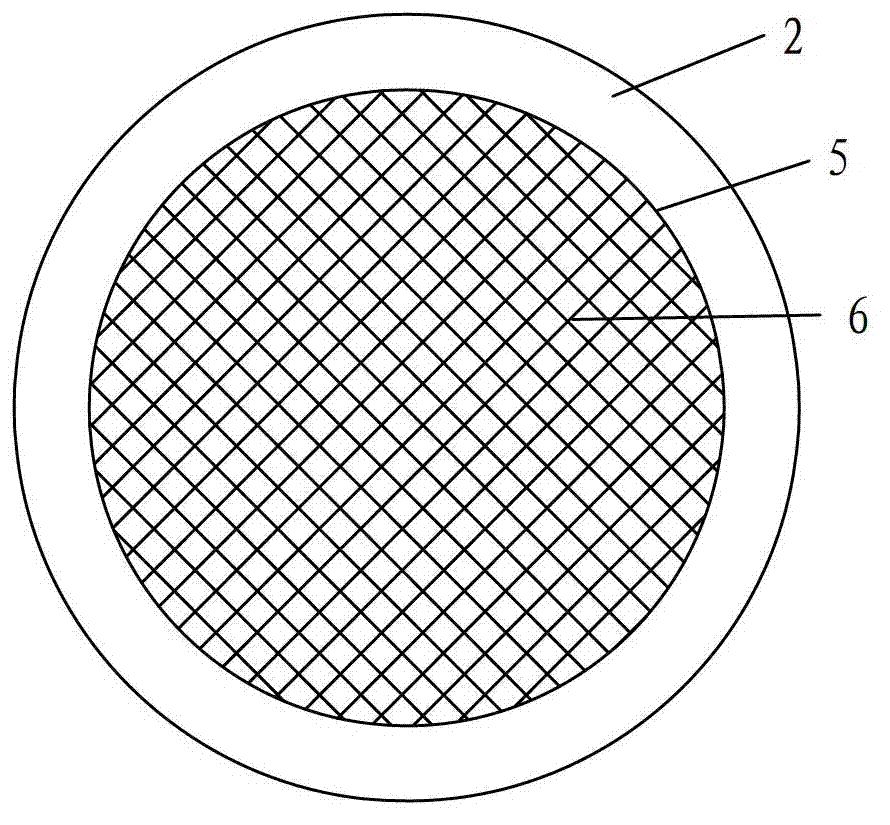

Impurity separating equipment for soft sheet material

ActiveCN104815795AImprove separation rateImprove the separation effectGas current separationProcess engineeringProduct gas

The invention discloses impurity separating equipment for soft sheet material. The impurity separating equipment comprises an air supply device, a separating barrel, a separating barrel drive device, a feeding mechanism, a secondary soft sheet separating device and a soft sheet gas separating device, wherein the air supply device comprises a fan and an air pipe connected with the fan; sieve holes are formed in the wall of the separating barrel, and two ends of the separating barrel are opened; the secondary soft sheet separating device comprises a separating box connected with the discharge end of the separating barrel, and a high-density soft sheet gathering box and a small-density soft sheet gathering box are arranged in the separating box; the soft sheet gas separating device comprises a cyclone separator, the feed hole of the cyclone separator is connected with the bottom of the small-density soft sheet gathering box, and the top exhaust hole is connected with an air pipe in the air supply device. The impurity separating equipment has advantages of good impurity separating effect and high separating rate, and moreover, the separated soft sheet material can be classified, and the gas can be separated from the separated soft sheet material to recycle.

Owner:冯愚斌

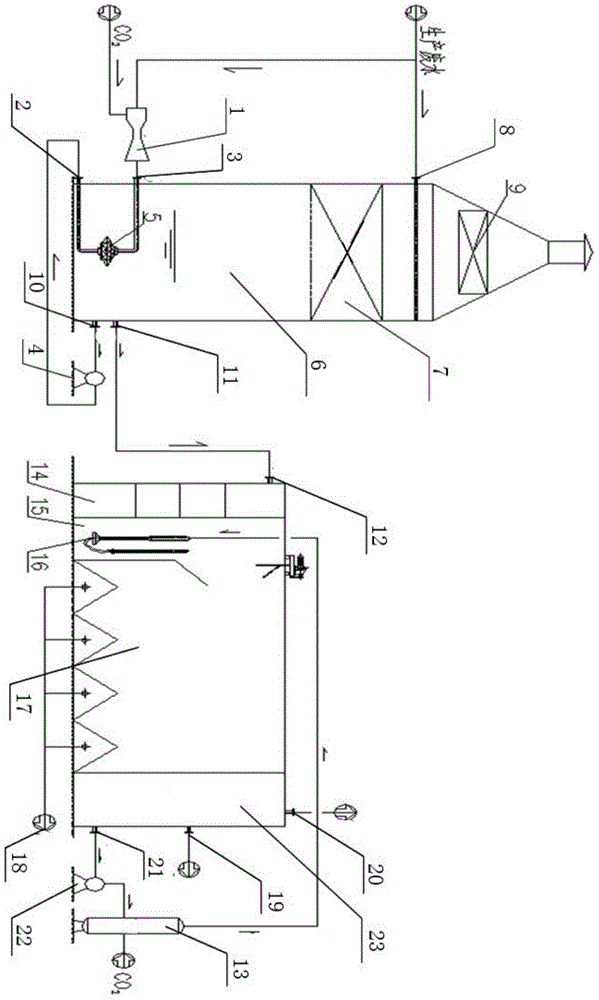

Carbon dioxide gas floatation treatment system for coal chemical industrial wastewater

ActiveCN104909420AImprove the separation effectIncreased mixing contact surfaceFatty/oily/floating substances removal devicesWater/sewage treatment by neutralisationIonChemistry

The invention discloses a carbon dioxide gas floatation treatment system for coal chemical industrial wastewater. The carbon dioxide gas floatation treatment system for coal chemical industrial wastewater comprises a conditioner and a gas floatation device, wherein the conditioner takes carbon dioxide as a gas source; and the gas floatation device is connected with the conditioner by a pipeline. According to the invention, by taking original waste carbon dioxide as a gas source, after the carbon dioxide is dissolved in water, wastewater is converted into acidic wastewater, and the PH value of the wastewater is adjusted, so that the original alkali wastewater is converted into acidic wastewater, thereby greatly improving the separation effect of subsequent gas flotation; and because carbon dioxide is taken as a gas source, the increasing of a COD value and the occurrence of bubbles caused by the fact that air as an air source easily oxidizes organic pollutants in wastewater, are avoided, so that the biodegradability of the wastewater is reduced. Because carbon dioxide is difficult to be dissolved in water, the gas source increases the pressure, and a disc-type jet aerator (a patent of our company) is applied for increasing a mixed contact surface, so that an effect of increasing the solubility is achieved, therefore, the carbon dioxide gas floatation treatment system for coal chemical industrial wastewater disclosed by the invention effectively improves the removal rate of oil materials in wastewater, and the introduction of other harmful ions is avoided.

Owner:宜兴市荣盛达环保有限公司

Preparation method of wax phase change material

ActiveCN105778868AFast separationImprove the separation effectHeat-exchange elementsWaxProcess engineering

The invention discloses a preparation method of a wax phase change material. The method is characterized in that the surface of a wax layer is uniformly carpeted with metal particles before a heating and sweating process, and air forcedly flows through the wax layer in the heating and sweating process to take away liquid components, so the solid component and liquid component separation speed is accelerated, and the solid component and liquid component separation effect is enhanced. The forced solid component and liquid component separation process is set on the basis of a common sweating process, so the wax phase change material product can be produced through the solvent-free sweating and deoiling method. The method has the advantages of low device investment, simple production process, low operating cost and no solvent pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

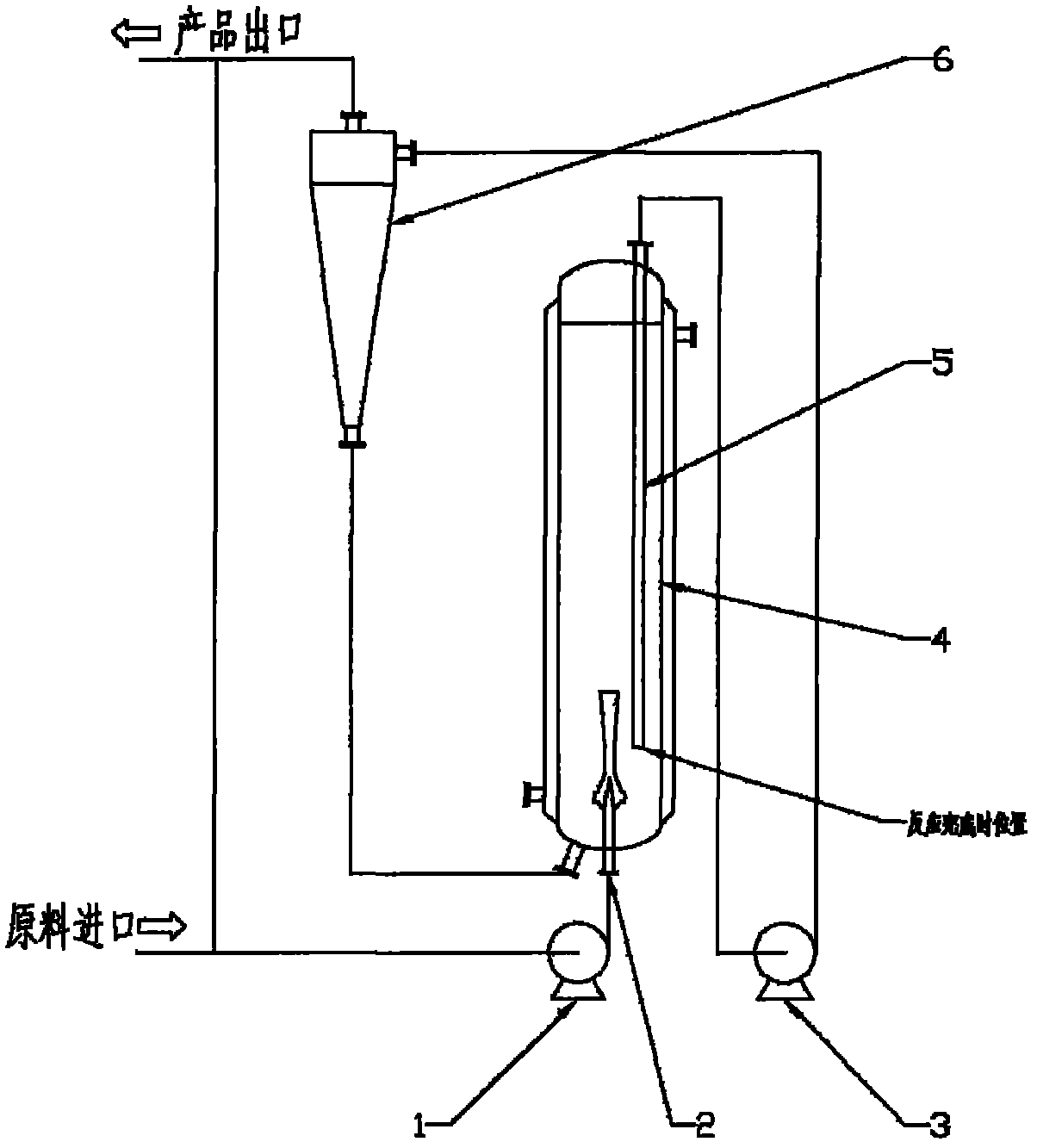

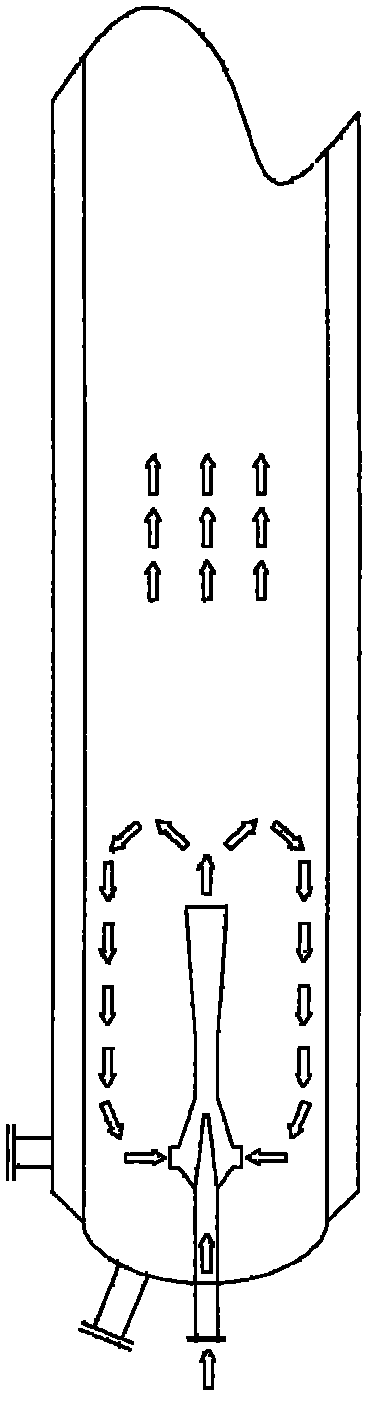

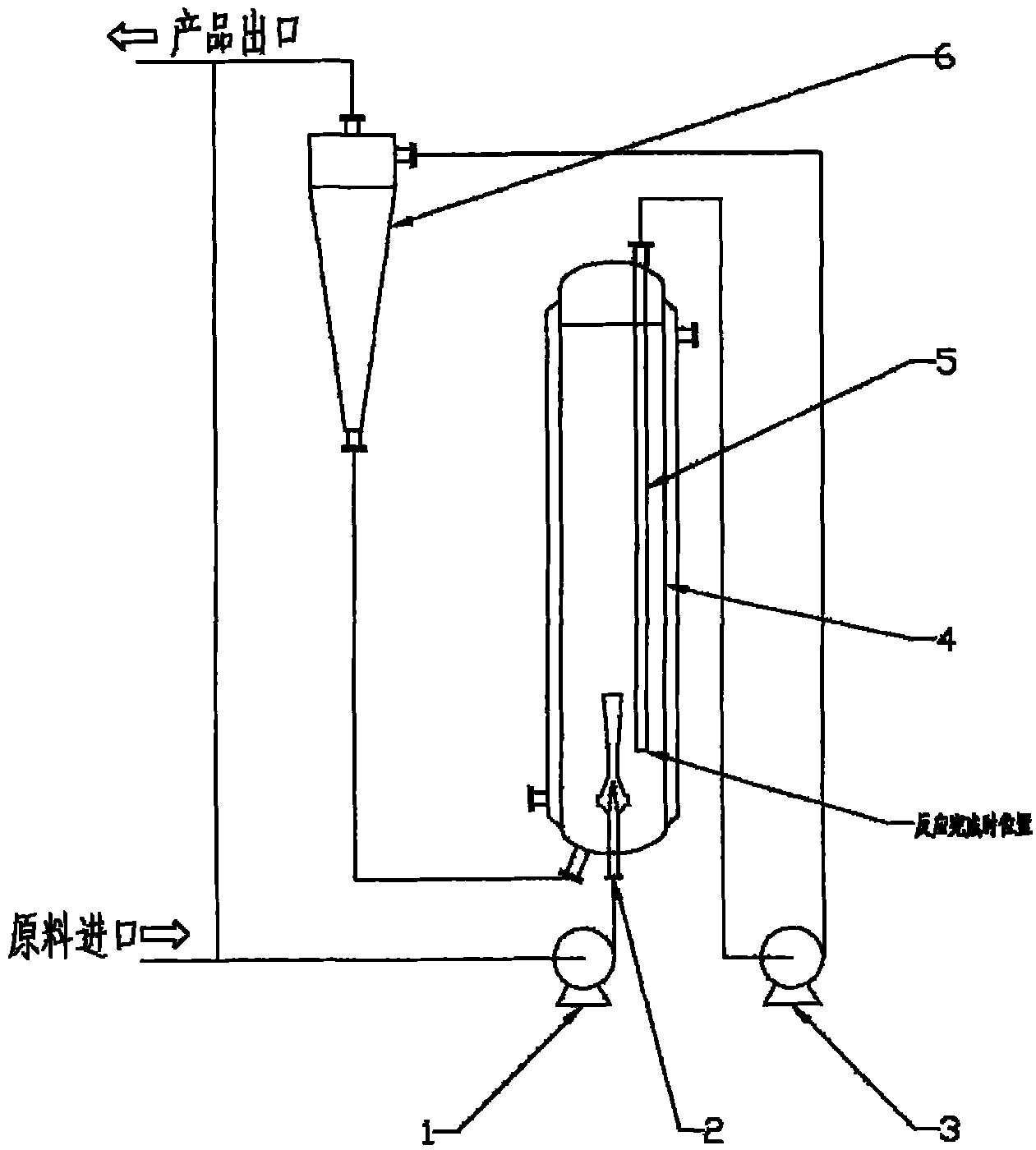

Esterification reactor and esterification reaction method based on solid catalyst

ActiveCN102093213AImprove the separation effectReduce wearOrganic compound preparationCarboxylic acid esters preparationLong chain fatty acidReaction tube

The invention relates to an esterification reactor based on a solid catalyst and a long-chain fatty acid esterification method using the same. The esterification reactor comprises a reaction tube, a feed pump, a circulating pump and a solid-liquid separator, wherein the outlet of the feed pump is connected to the bottom end of the reaction tube, so that the feed pump can send reaction raw materials and a reaction liquid part from a reaction chamber into the reaction chamber; the inlet of the circulating pump is connected with the reaction chamber, so that the circulating pump can be used for selectively outputting reaction products in multiple positions in the height direction of the reaction chamber; and the inlet of the solid-liquid separator is connected with the outlet of the circulating pump, so that the solid-liquid separator can be used for separating the reaction products from the circulating pump into the reaction liquid part and a solid catalyst-enriched slurry part. The light phase outlet of the solid-liquid separator is used as a crude product outlet and connected to the feed pump, so that the reaction liquid part flows back to the reaction chamber; and the heavy phaseoutlet of the solid-liquid separator is used as a solid catalyst recovery outlet and connected to the bottom end of the reactor, so that the slurry part flows back to the reaction chamber. The invention can greatly enhance the catalyst separation effect, reduce the circulating pump abrasion caused by the catalyst and enhance the esterification efficiency of the fatty acid.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Primary oil-water separation filtration structure

InactiveCN109432826AImprove the separation effectImprove separation efficiencyDispersed particle separationVapor condensationActivated carbonEngineering

The invention discloses a primary oil-water separation filtration structure which comprises a storage bucket, a separation cabin, an air tube and an exhaust mechanism arranged in a shell, wherein airtubes are arranged at tops of both the storage bucket and the separation cabin; the air tubes are communicated with the exhaust mechanism; the exhaust mechanism comprises an air blower and an activated carbon layer; one end of the air blower is connected with the air tube; the other end of the air blower is communicated with the activated carbon layer; the storage bucket is internally divided intotwo independent inner cavities by a partition plate; oil-water mixing liquids in the two inner cavities are mixed after overflowing the top of the partition plate; a stirring rod is arranged on the bottom surface of each inner cavity; the stirring rod is mounted on the storage bucket through an oil seal bearing; a flowing hole for an oil liquid to overflow is formed in the upper edge of a rotaryslope surface; the flowing hole is communicated with the separation cabin; the separation cabin is internally divided into a water cabin and an oil cabin; a hydrophilic and oleophobic separation layeris arranged at the outlet of the flowing hole; the separation layer is arranged in a manner of tilting downwards; the lower tilted end of the separation is communicated with the oil cabin; the lowerside of the separation layer is the water cabin; a water discharge hole is formed inside the water cabin; an oil discharge hole is formed in the oil cabin.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

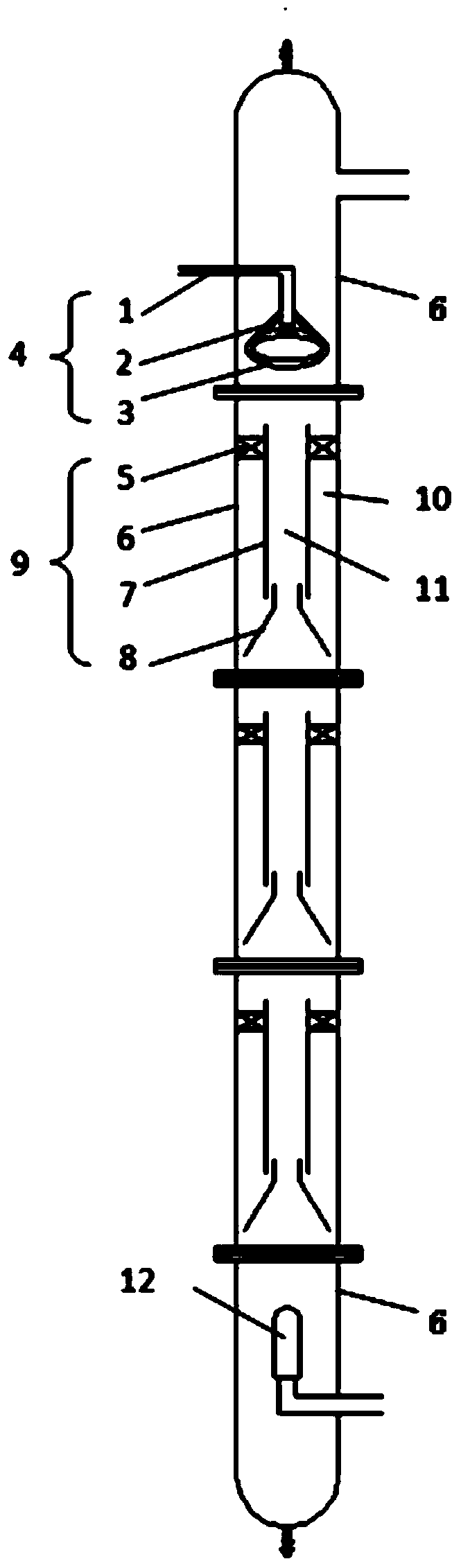

Oil-water separating tower

InactiveCN103691159AIncrease throughputImprove the separation effectLiquid separationOil dropletStaying time

The invention discloses an oil-water separating tower. The oil-water separating tower comprises a liquid distributor tower section, a plurality of circulating device tower sections and a microporous gas distributor tower section, wherein the circulating device tower sections are arranged below the liquid distributor tower section; the microporous gas distributor tower section is arranged below the circulating device tower sections; a microporous gas distributor is in threaded connection with a gas inlet pipe section and is positioned at the lower part of the oil-water separating tower; each circulating device comprises a metal outer barrel, a metal inner barrel, a tapered flow-guiding passage and an oil phase gathering filler; a space between the outer side of the metal inner barrel and the inner side of the metal outer barrel is a circulating flow passage; the oil phase gathering filler is arranged on the upper part of the circulating flow passage; the tapered flow-guiding passage is positioned on the lower part of the metal inner barrel; an upper outlet of the tapered flow-guiding passage is formed inside the inner barrel; and the diameter of a lower outlet is larger than that of the inner barrel. Independent flow passages are provided for separated oil droplets and separated water phase, so that the staying time and the flux of a liquid material can be increased, small-particle size oil droplets can be deeply removed, and the oil-water separating effect can be improved; therefore, the oil-water separating tower is especially suitable for an oil-water separating process with relatively large treatment amount.

Owner:TIANJIN UNIV

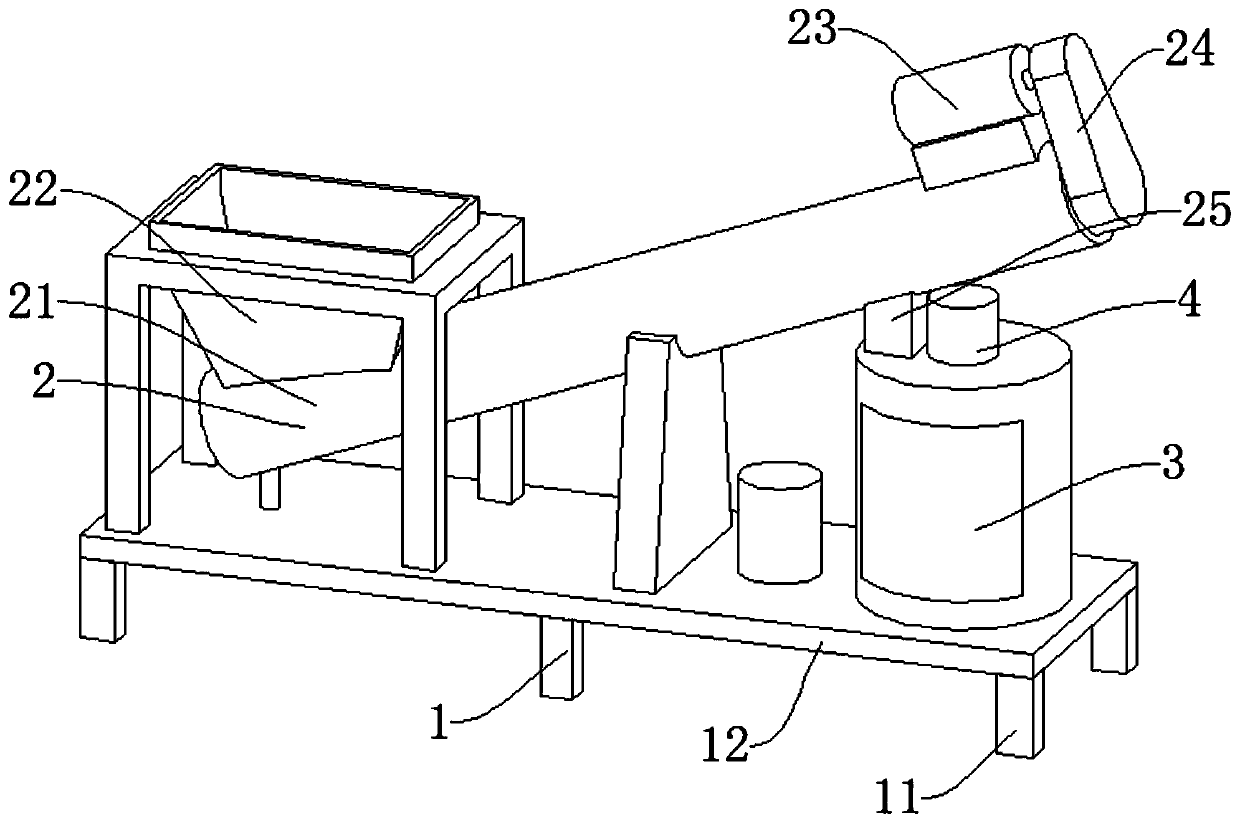

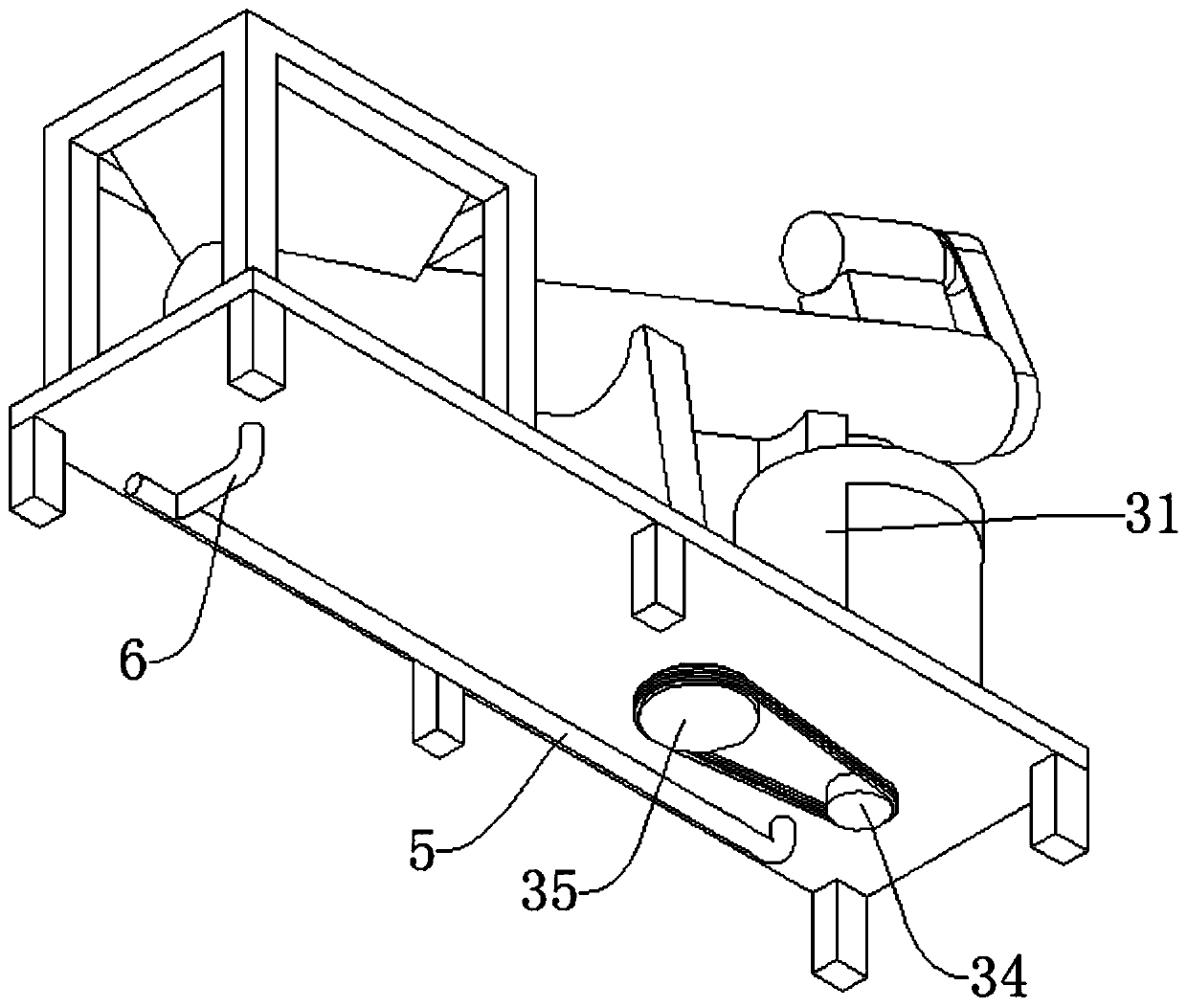

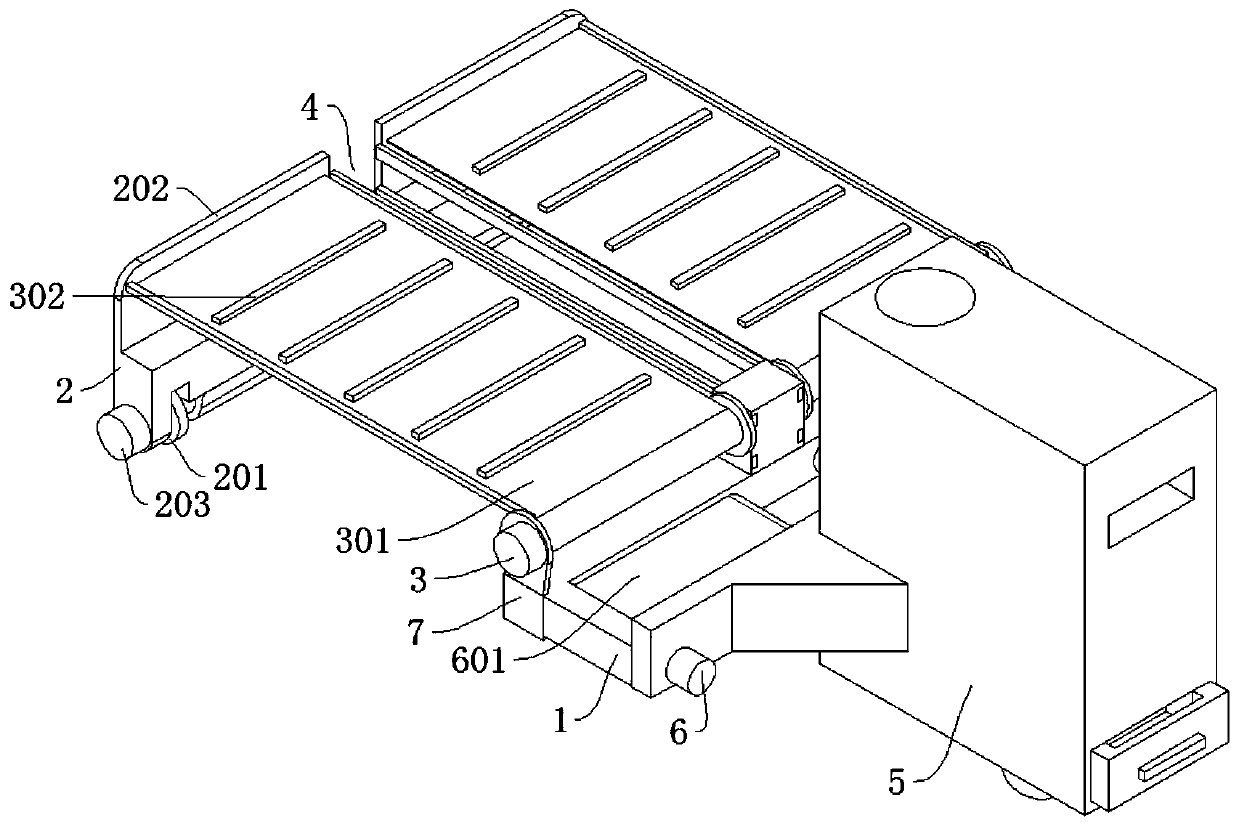

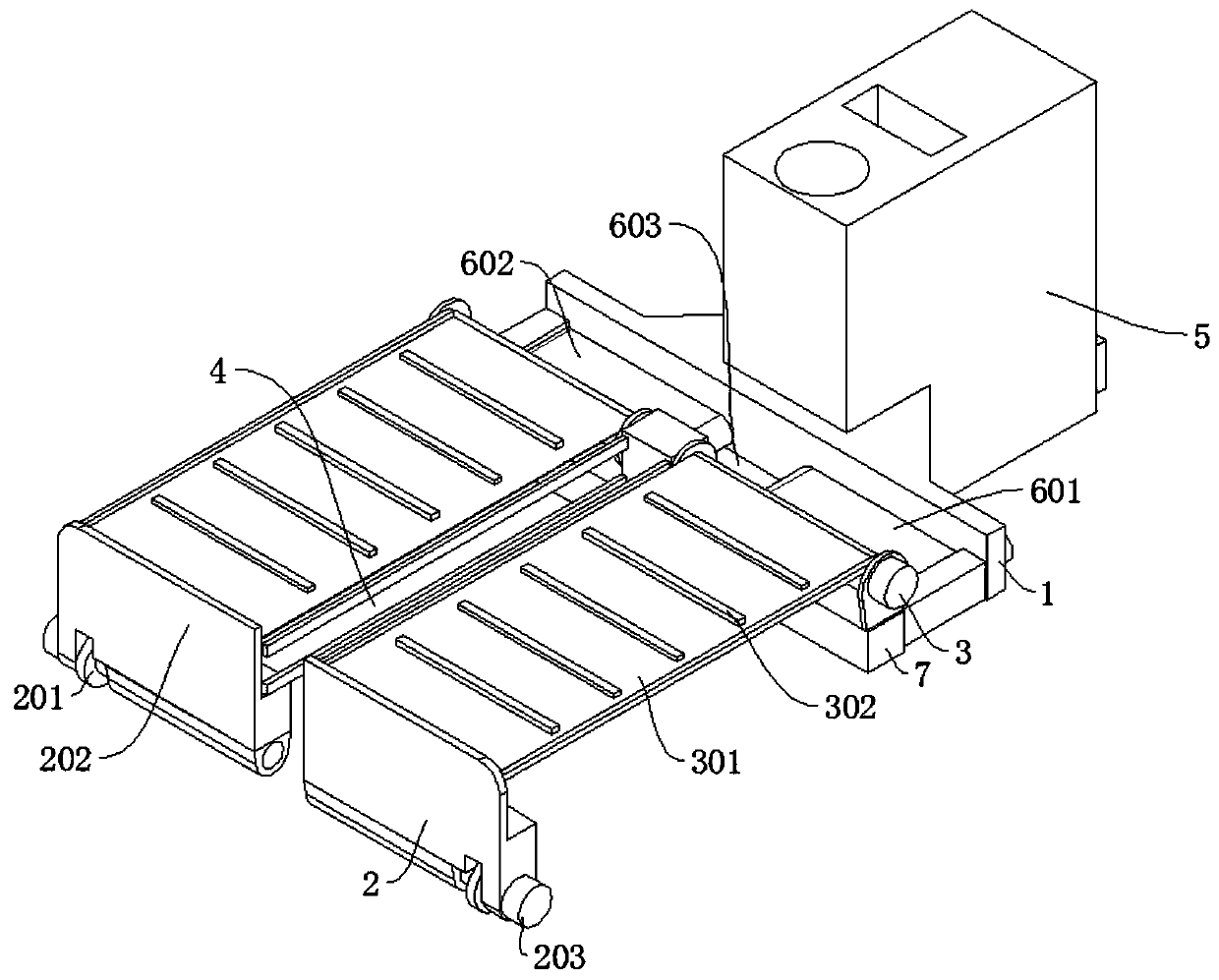

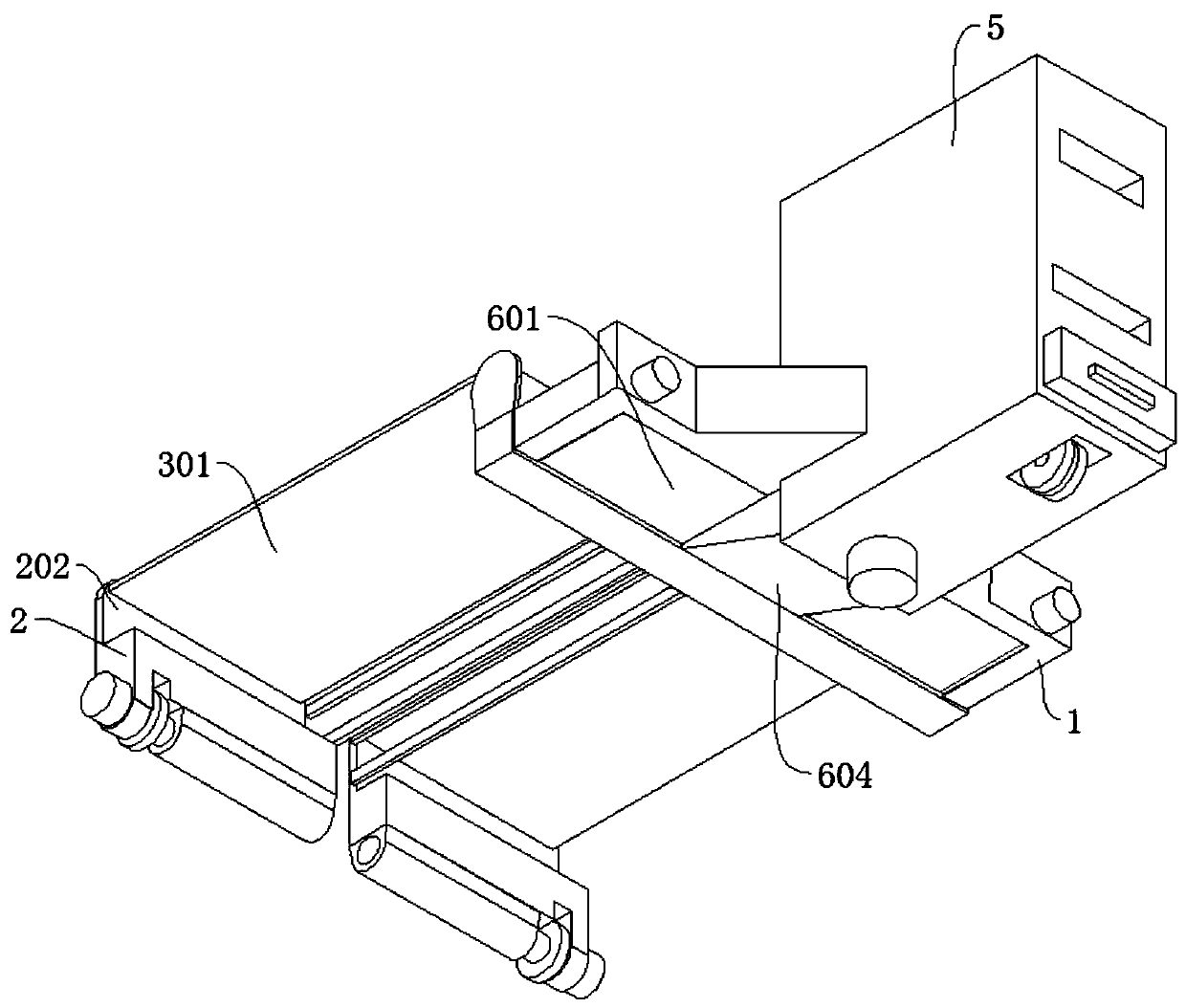

Efficient jujube harvesting robot

ActiveCN111386857AIncrease scrolling speedImprove the separation effectGas current separationFruits/vegetable preservation by irradiation/electric treatmentAgricultural engineeringChinese Jujube

The invention discloses an efficient jujube harvesting robot, and belongs to the technical field of agricultural machinery. The efficient jujube harvesting robot comprises a base; a collecting cloth,wherein one end of the collecting cloth is connected with the base, and the other end is connected with a moving seat; the moving seat is connected with a driving part for driving the moving seat to move; a material collecting opening is formed in the base; a crawler belt assembly is used for being connected to the base to convey the jujubes to the material collecting opening; a separation box isconnected to the base, and the bottom of the separation box communicates with the material collecting opening through a material collecting channel; a lifting assembly is connected into the separationbox and used for lifting the jujubes and the sundries; a separation plate A is obliquely connected into the separation box; a separation plate B is obliquely connected into the separation box; and afirst sundry outlet corresponding to the separation plate A and a second sundry outlet corresponding to the separation plate B are formed in the separation box. According to the red date picking device, falling red dates can be collected in a centralized mode through the collecting cloth, fruit leaves are further separated through the separating box, and compared with traditional manual picking, the working efficiency is improved, and manual fatigue is reduced.

Owner:江西盾牌化工有限责任公司

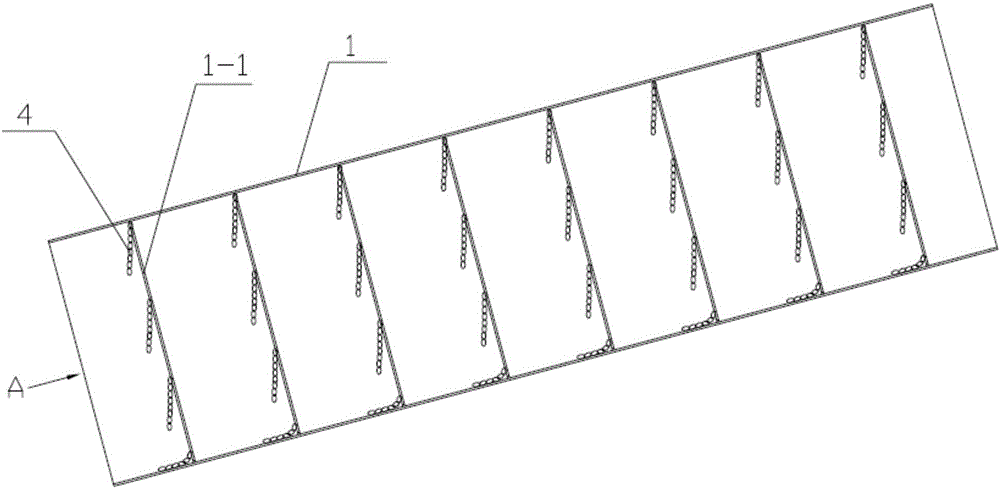

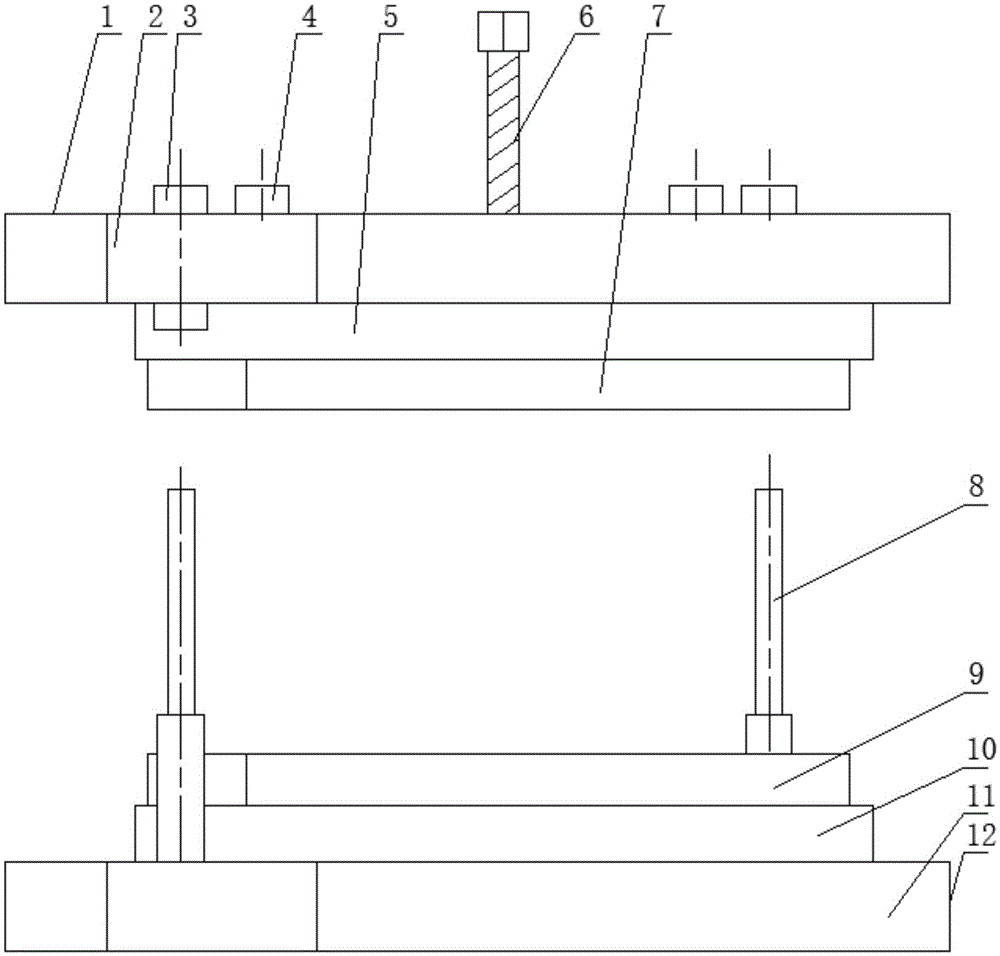

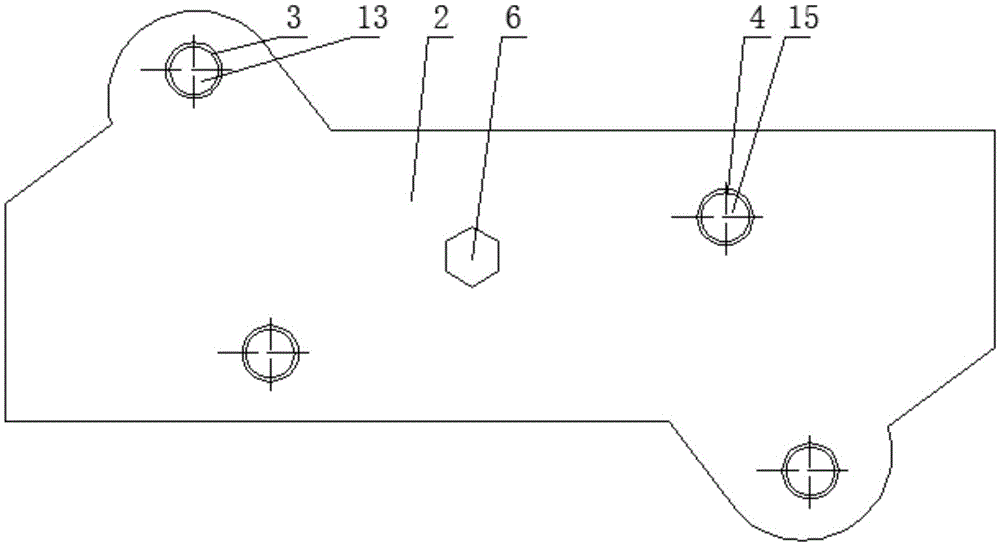

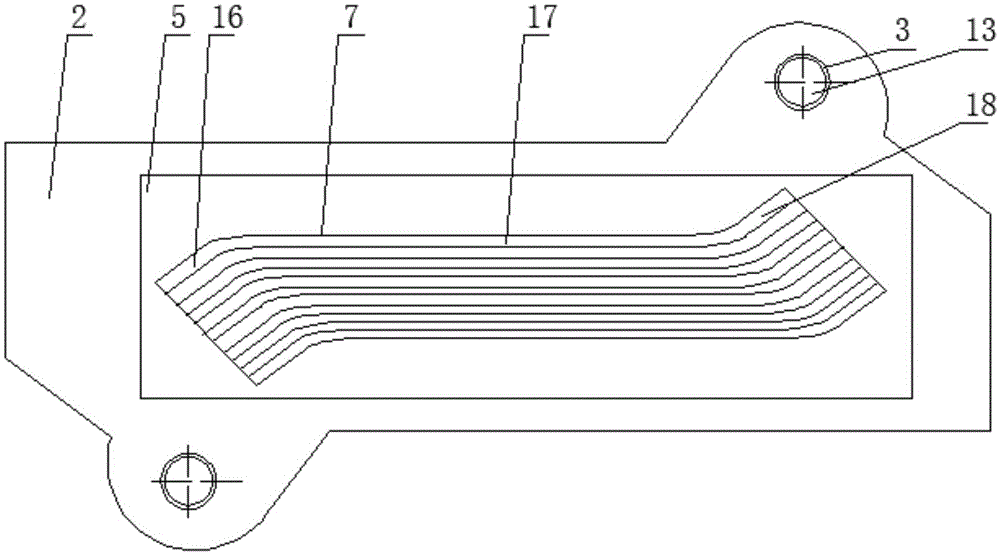

Hyperbolic filler bending mold

The invention relates to a hyperbolic filler bending mold. The mold comprises an upper die and a lower die, wherein the upper die is connected with a punching head; the lower die is detachably arranged on a worktable of a punch press; the upper die and the lower die are arranged oppositely along the vertical direction in use; the upper die comprises a punching head connecting part, an upper connecting plate and an upper die pressing plate which are sequentially connected in arrangement; the lower die comprises a base, a lower connecting plate and a lower die pressing plate which are sequentially connected in arrangement. According to the mold, the outer edge of metal gauze filler is bent, so liquid cannot flow out along the outer edge of the metal gauze filler, a good using effect is achieved, and the separation effect is improved; meanwhile, when hot air in the upper part inside a tower flows towards the metal gauze filler at the lower part, sputtering of the liquid above the metal gauze filler which has a hyperbolic structure is prevented, and no convection is generated inside the tower, so the separation efficiency is further improved, the production efficiency is improved, and the production cost of an enterprise is lowered.

Owner:TIANJIN NORTH EFFICIENT PETROCHEM EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com