Patents

Literature

47results about How to "Increase scrolling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Regulation of navigation speed among displayed items and tilt angle thereof responsive to user applied pressure

InactiveUS20110193881A1Increase scrolling speedReduce scrolling speedCathode-ray tube indicatorsInput/output processes for data processingMarine navigationGraphics

An electronic device can include a touch sensitive display screen and a controller circuit. The touch sensitive display screen identifies a location where a user is pressing and generates a force signal that indicates how hard the user is pressing. The controller circuit controls a speed at which information items are scrolled across the screen and controls a tilt angle of the displayed information items responsive to the force signal. The controller circuit graphically renders the tilt angle on the screen by tapering width of the displayed information items in a defined direction and regulates the tapered width responsive to the force signal. No tilt angle is rendered when the force signal indicates that the user is not pressing the screen. The scrolling speed and the tilt angle of the displayed information items are increased, to provide a visual indication to the user of the increased scrolling speed, responsive to the force signal indicating that the user is pressing harder against the screen.

Owner:SONY ERICSSON MOBILE COMM AB

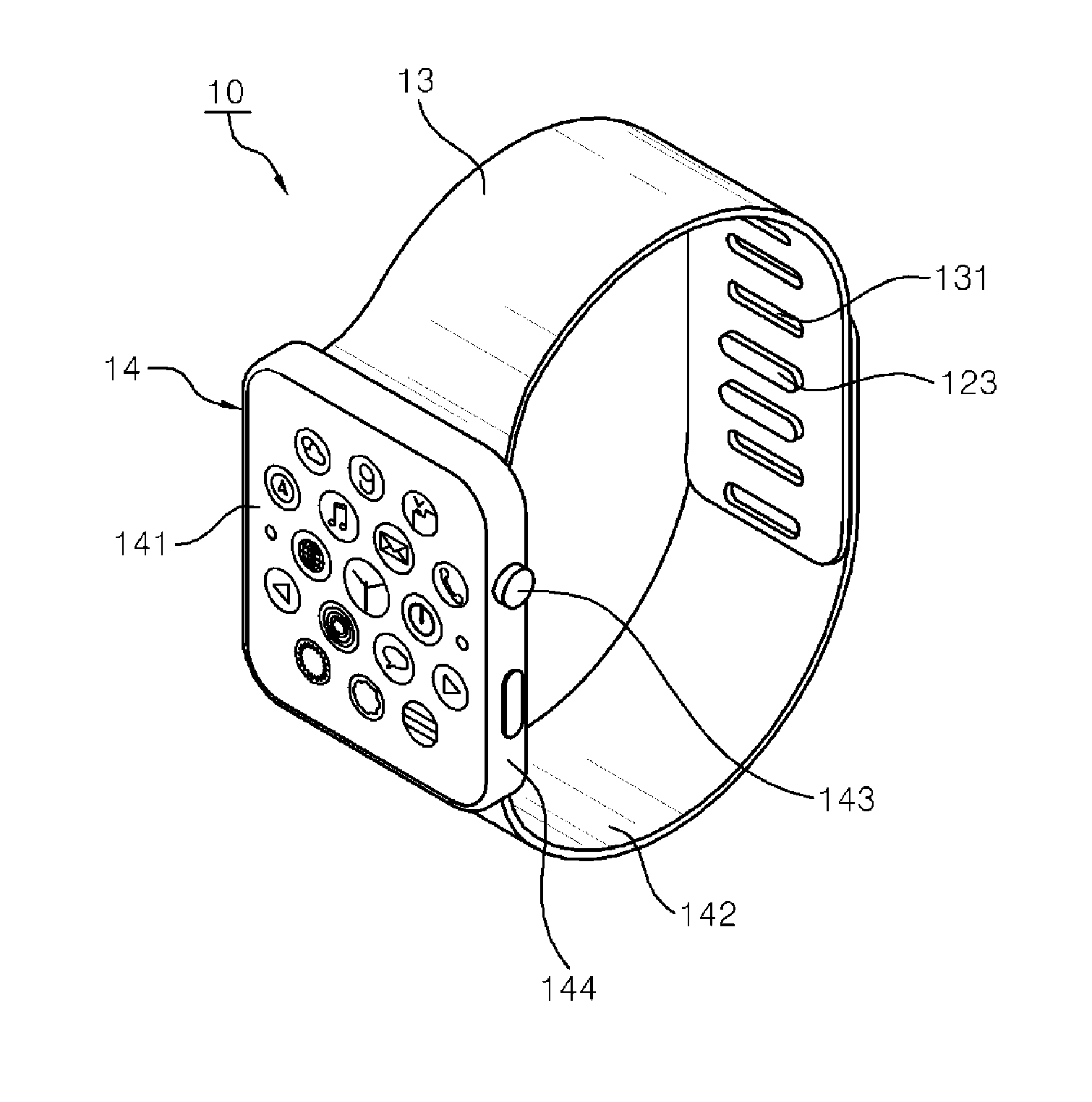

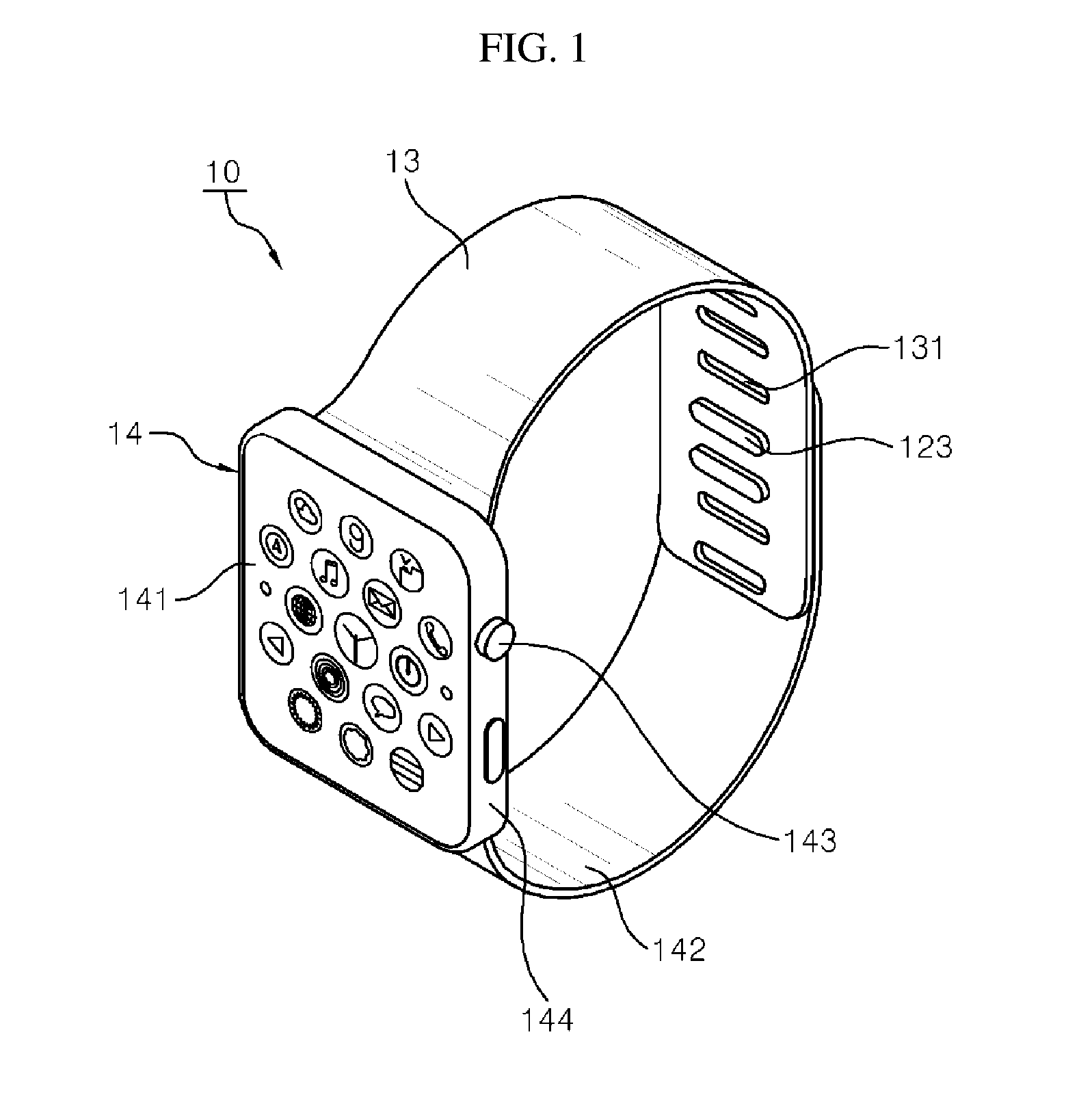

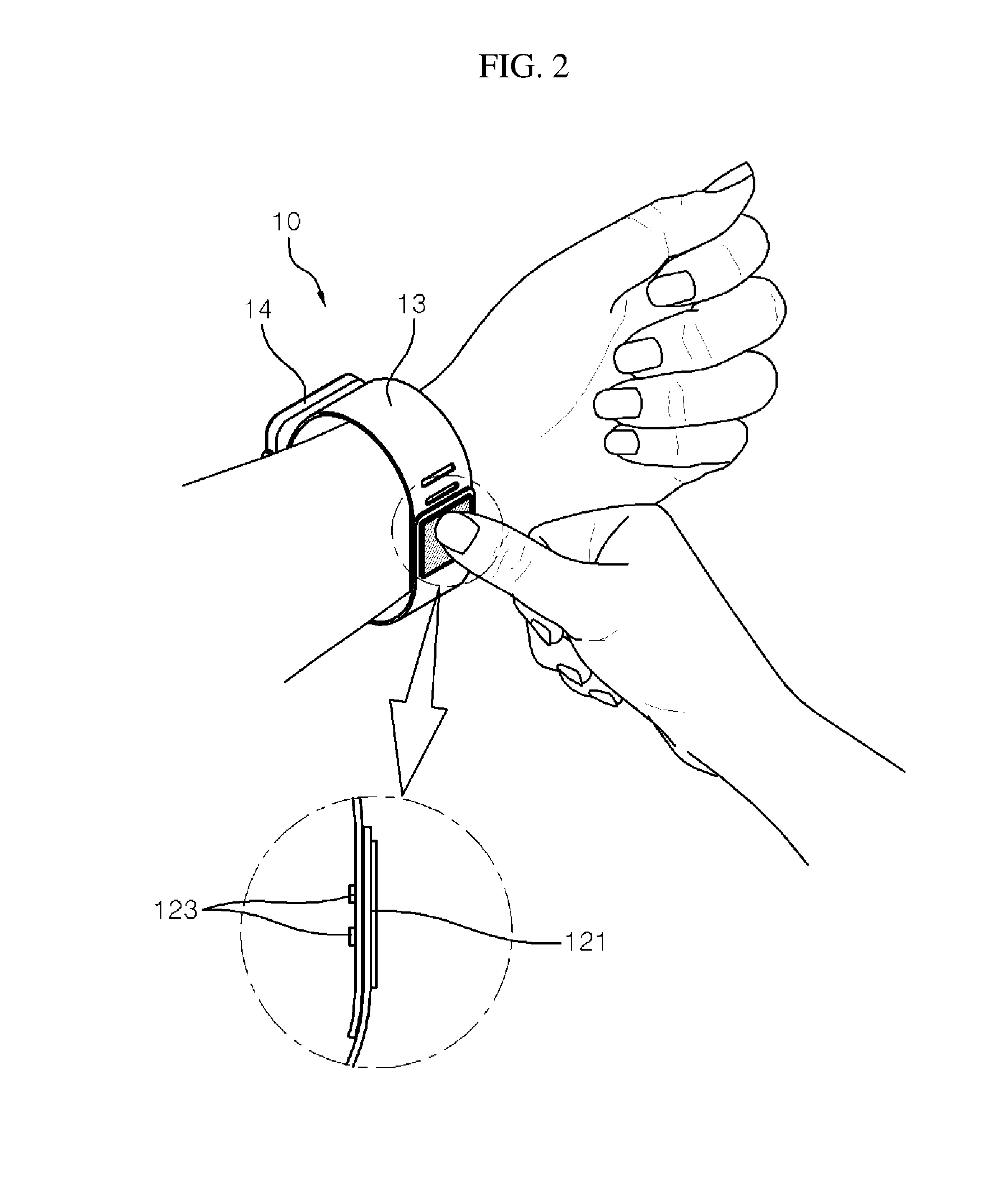

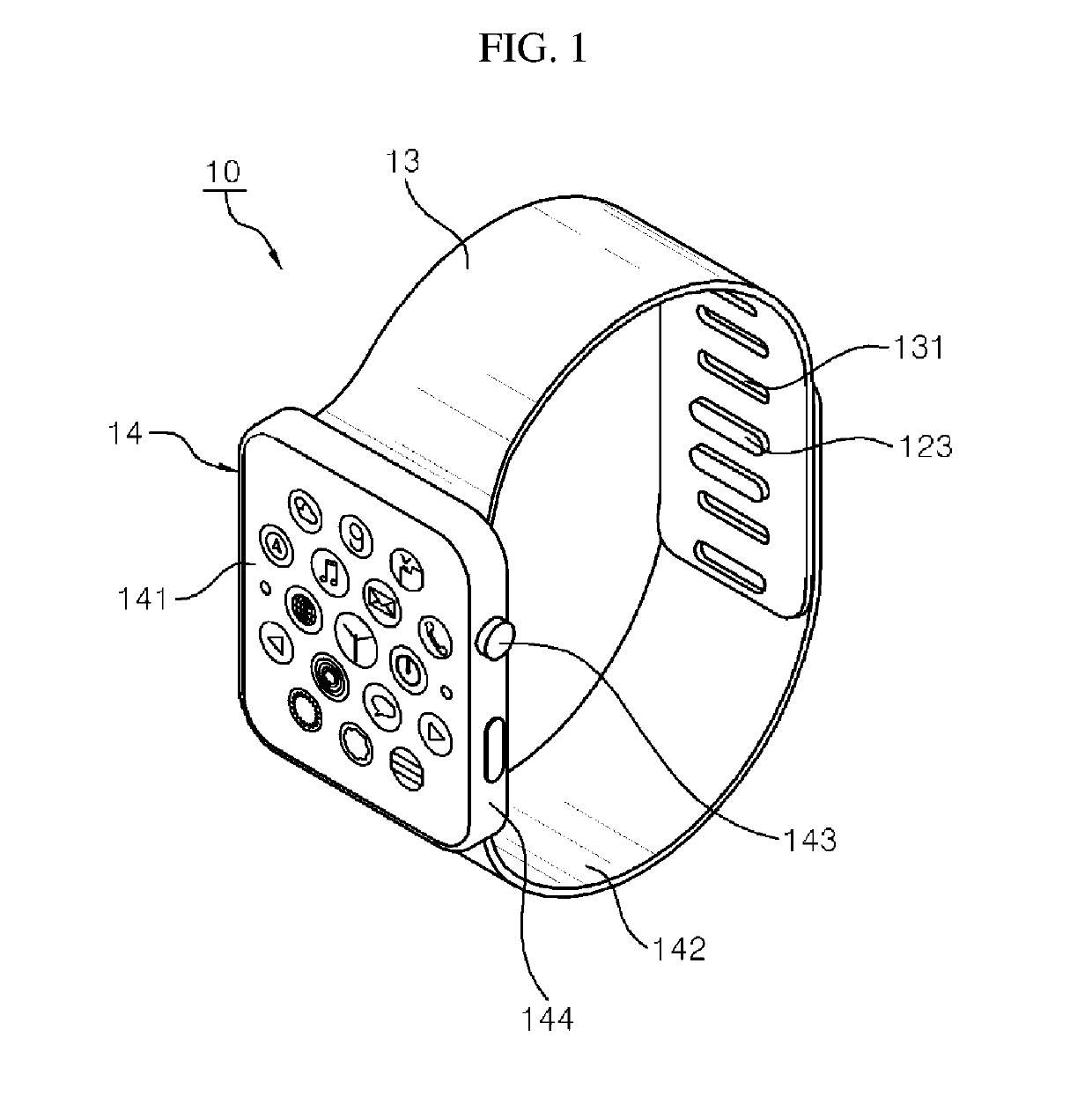

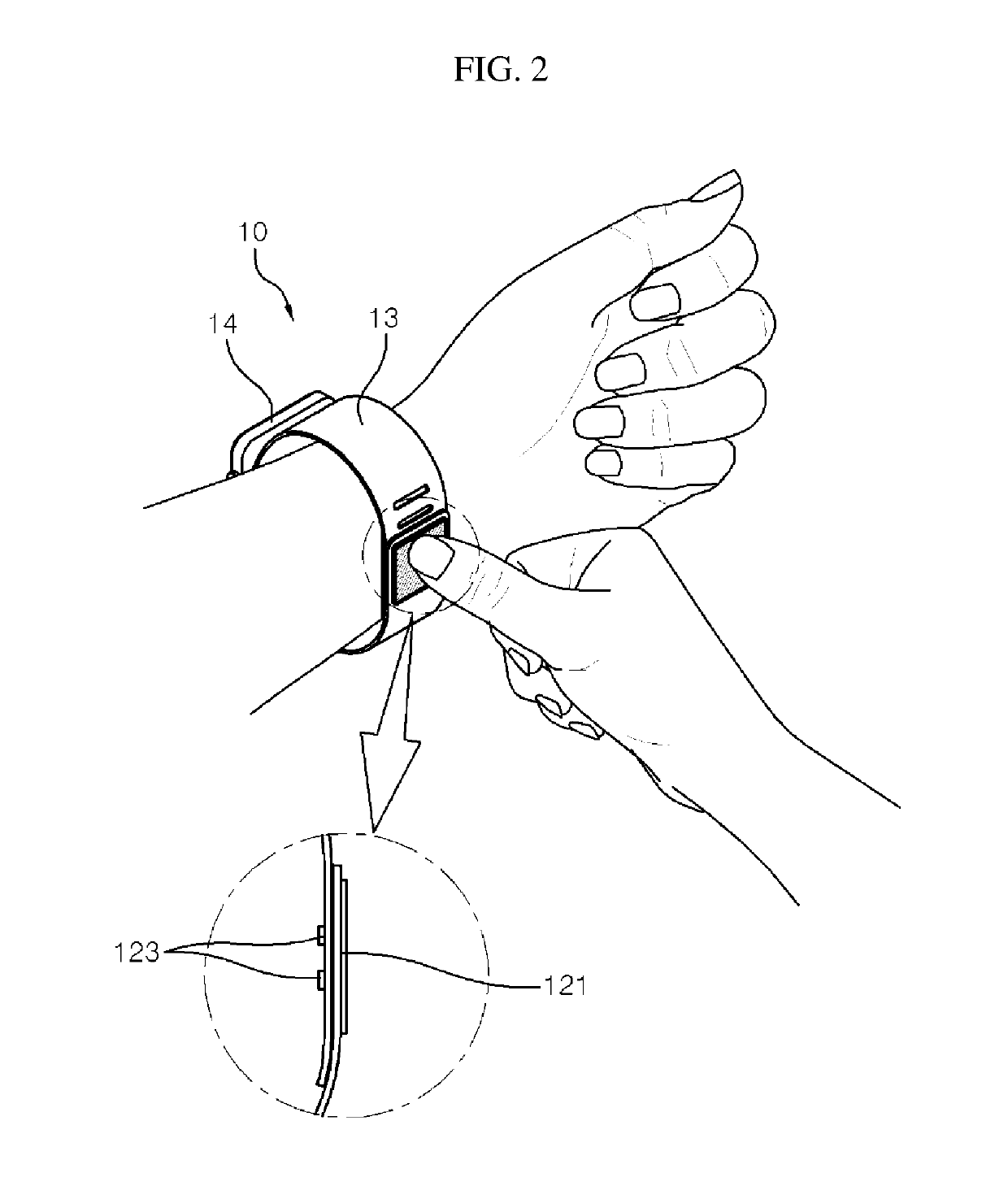

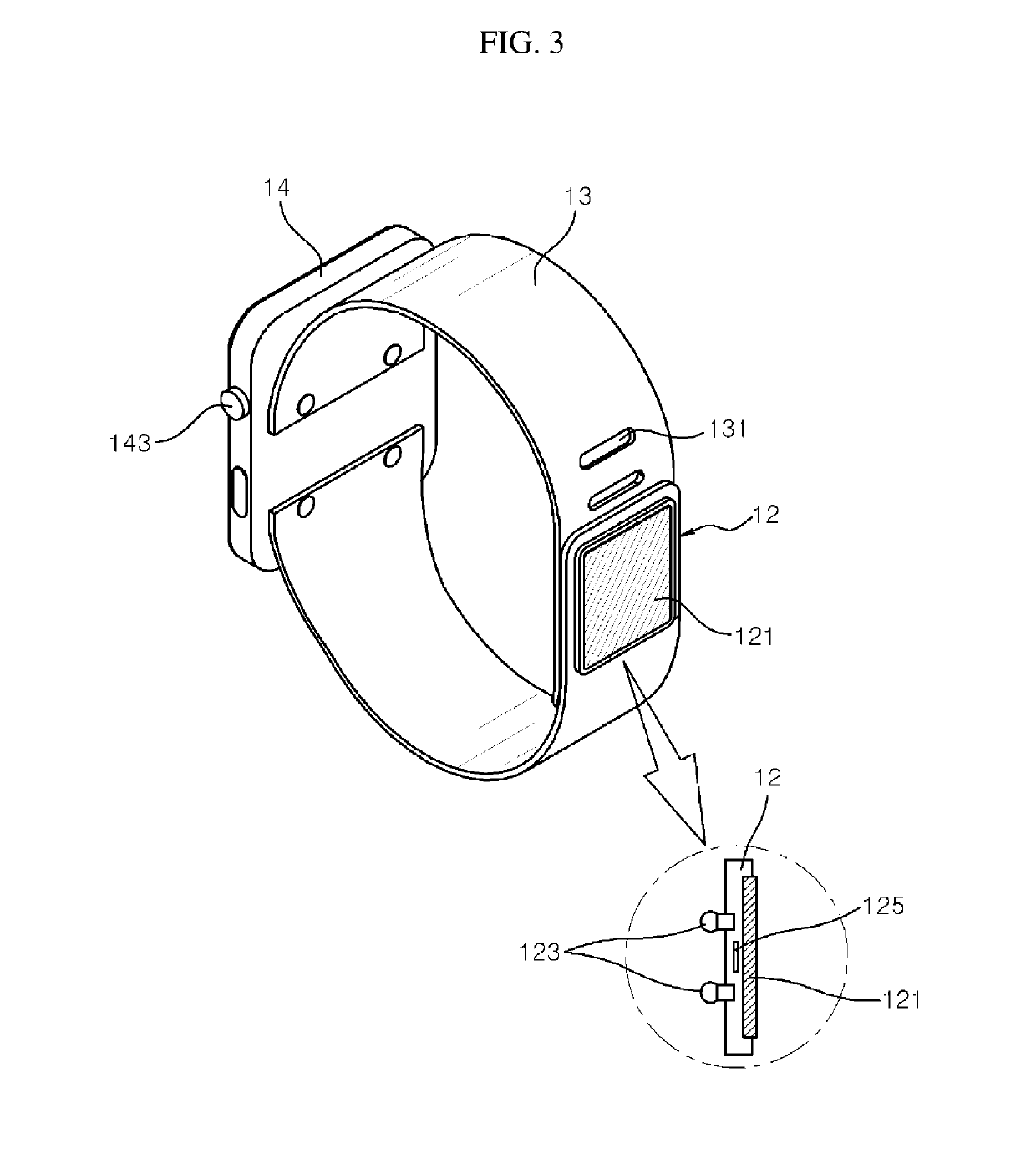

Smart watch and operating method using the same

InactiveUS20170032168A1Improve security levelHigh authentication levelTime-pieces with integrated devicesDigital data authenticationUser authenticationComputer science

Disclosed are a smart watch and a method of operating the same, in which fingerprint information and biometric information are measured by a single motion, a certain duration is set such that biometric information measured in the duration is generated into authenticated information or secured information, and transmitted or output to the outside. The smart watch includes a body, a fingerprint information acquisition unit provided on one surface of the body and configured to acquire fingerprint information about a user by a touch pressure applied from an outside, a biometric information acquisition unit provided on the other surface of the body, opposite to the one surface of the body, and configured to acquire biometric information about the user while contacting the skin of the user, and a control unit provided in the body and configured to acquire the fingerprint information and the biometric information for a predetermined period of time based on a point in time at which the touch pressure is applied if the touch pressure is greater than a reference pressure, and to generate user authentication information by using the acquired fingerprint information and biometric information.

Owner:KIM JONG HO

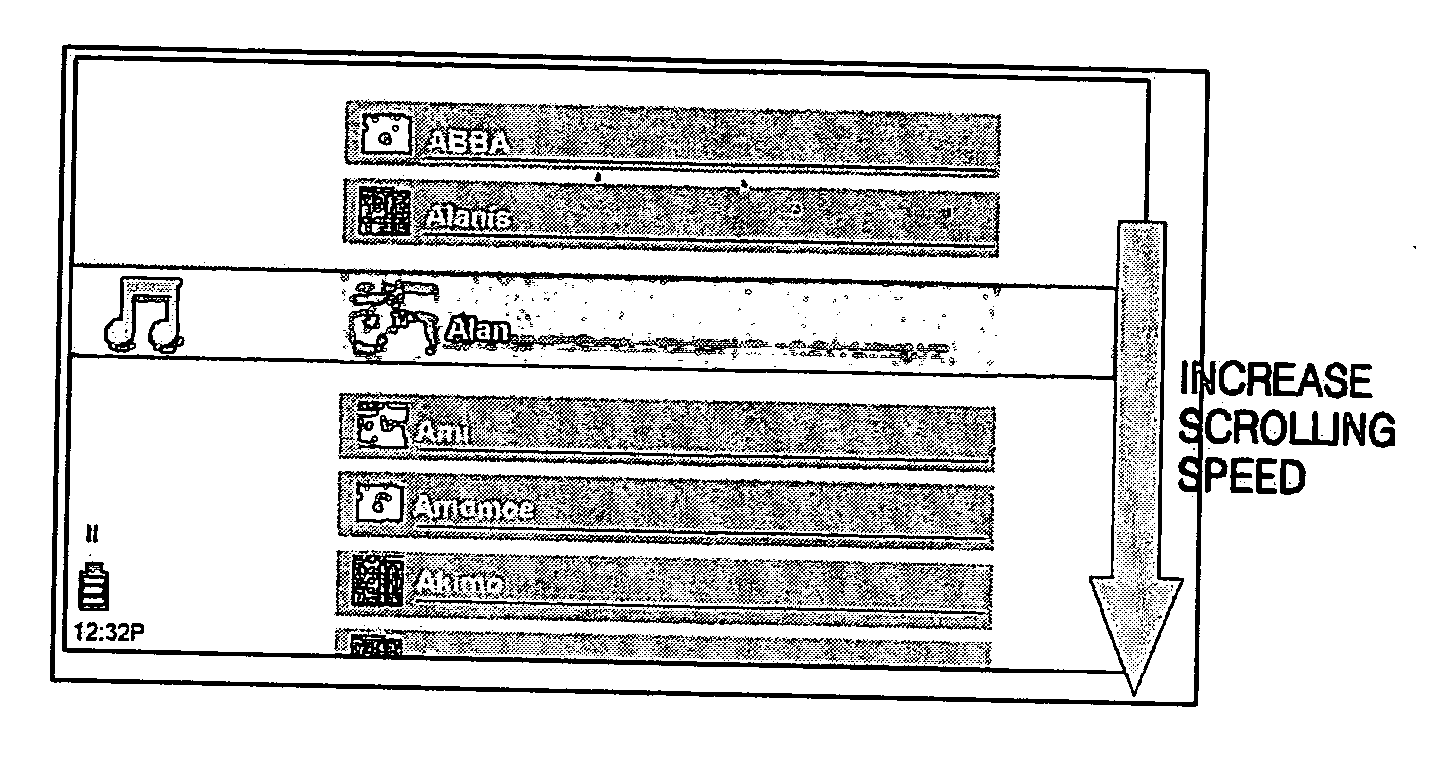

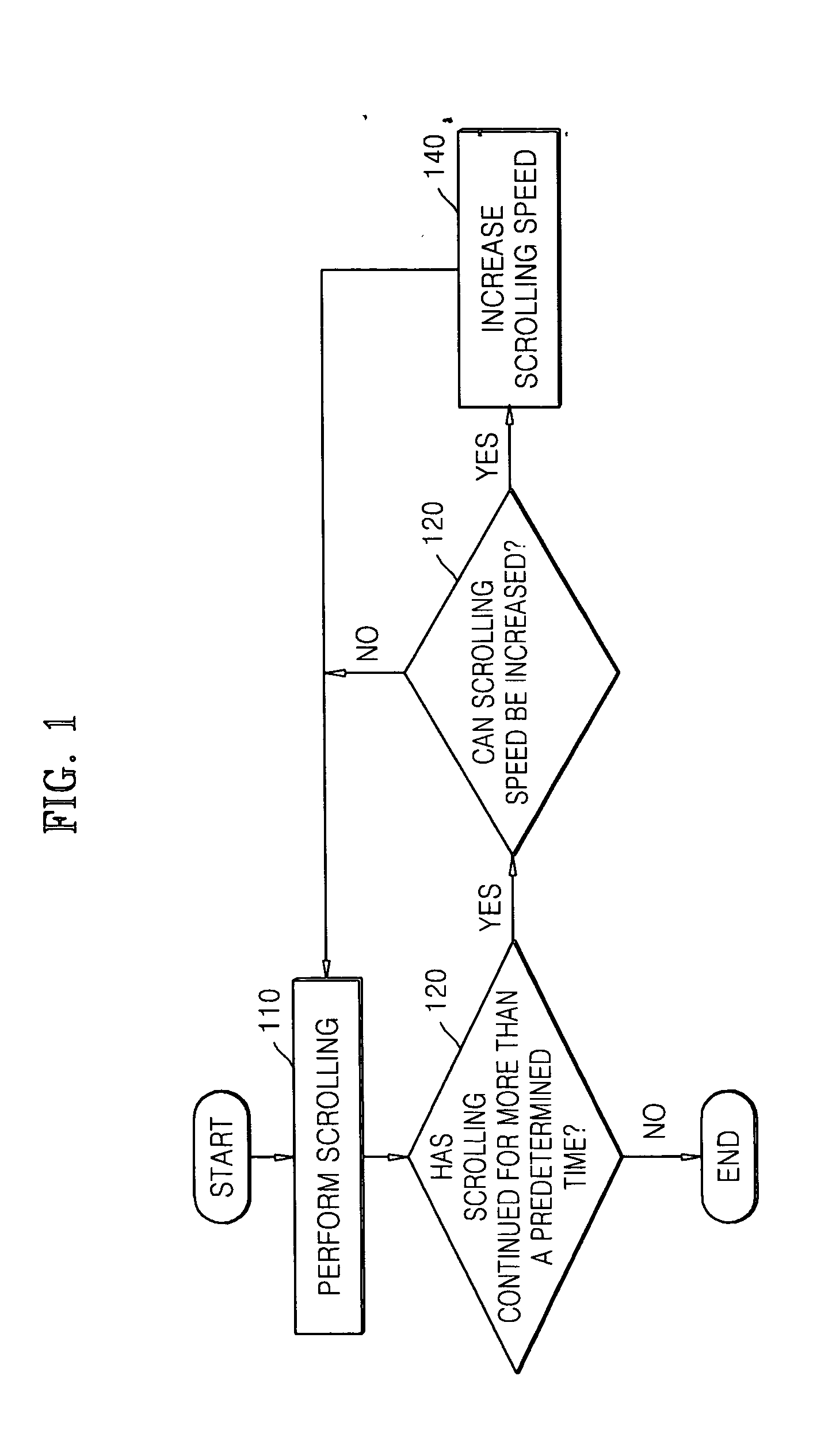

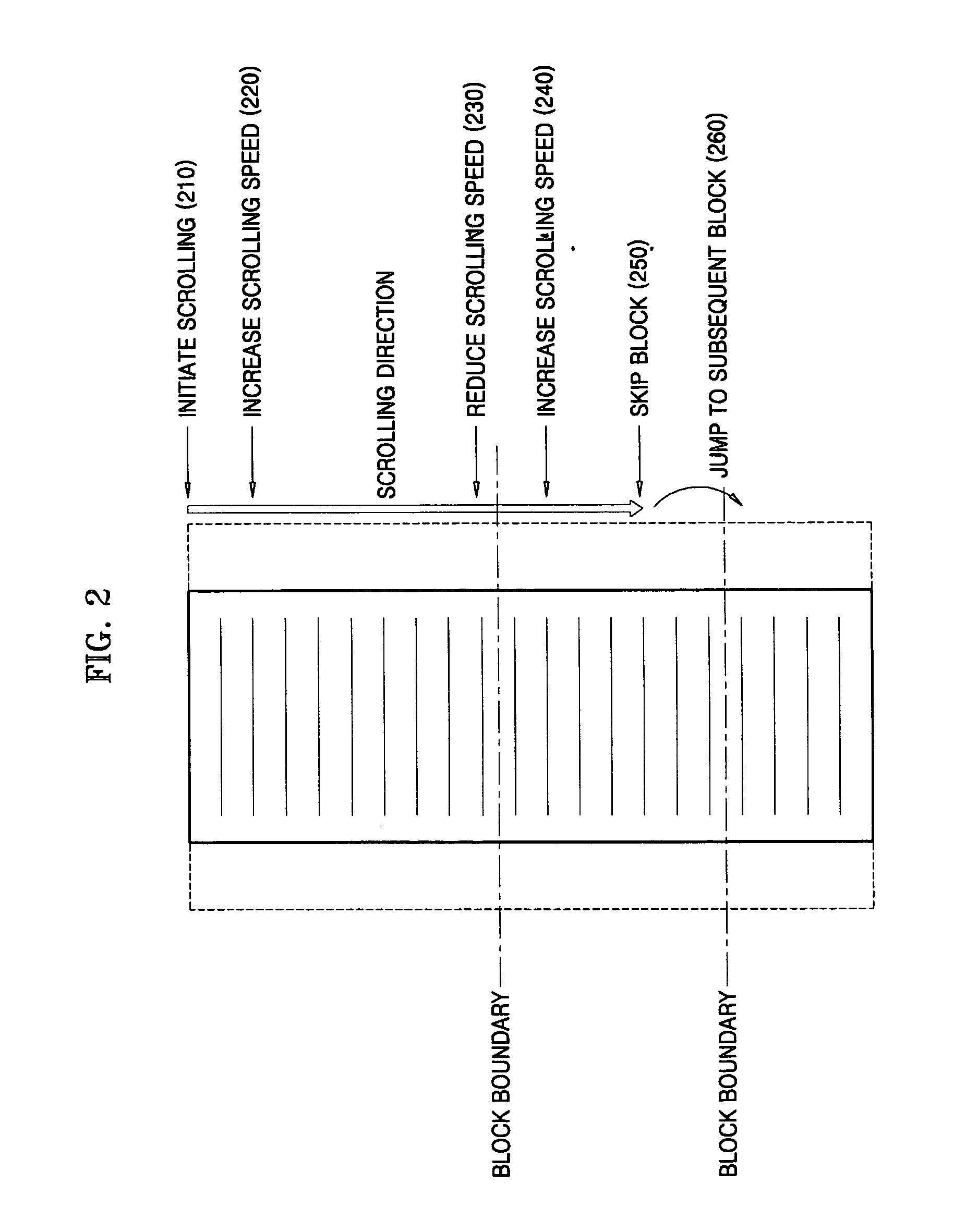

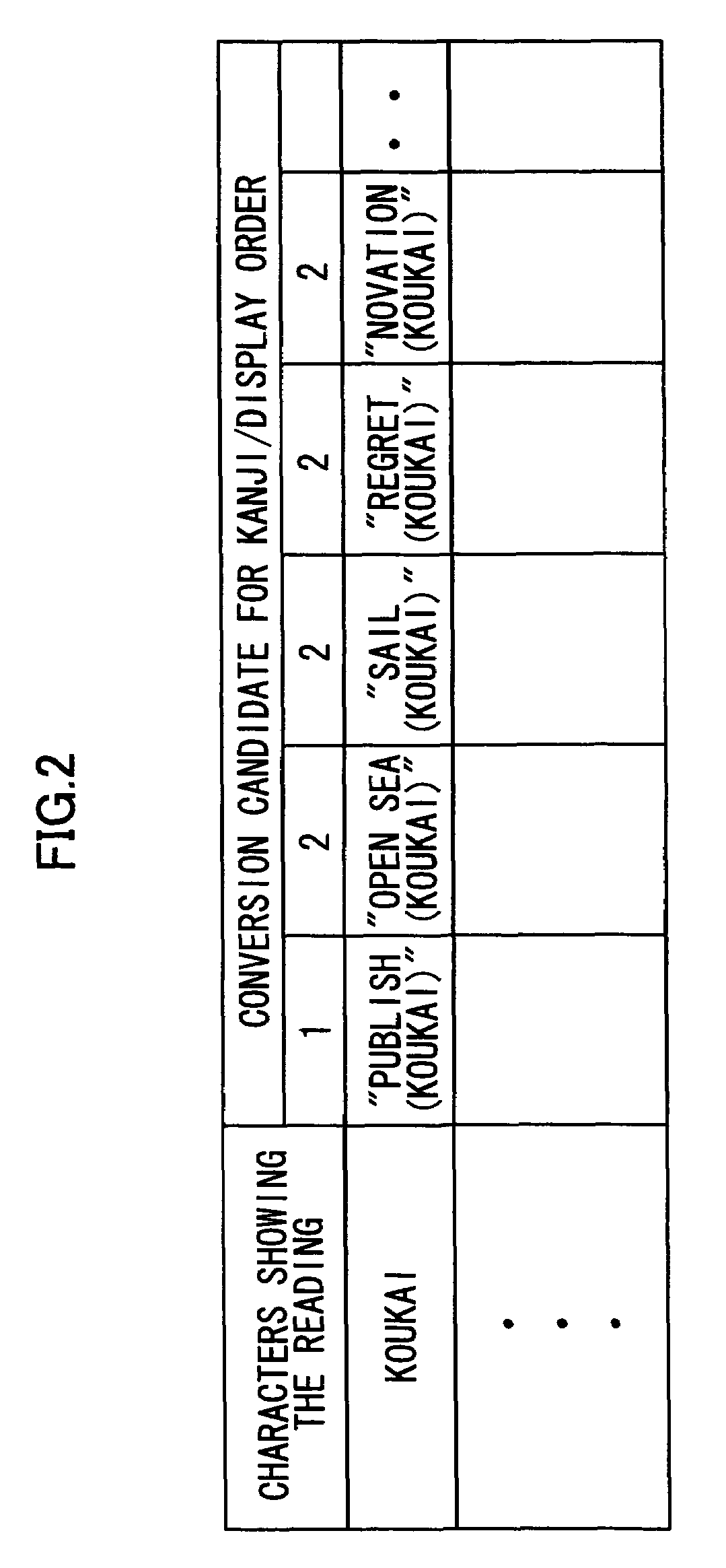

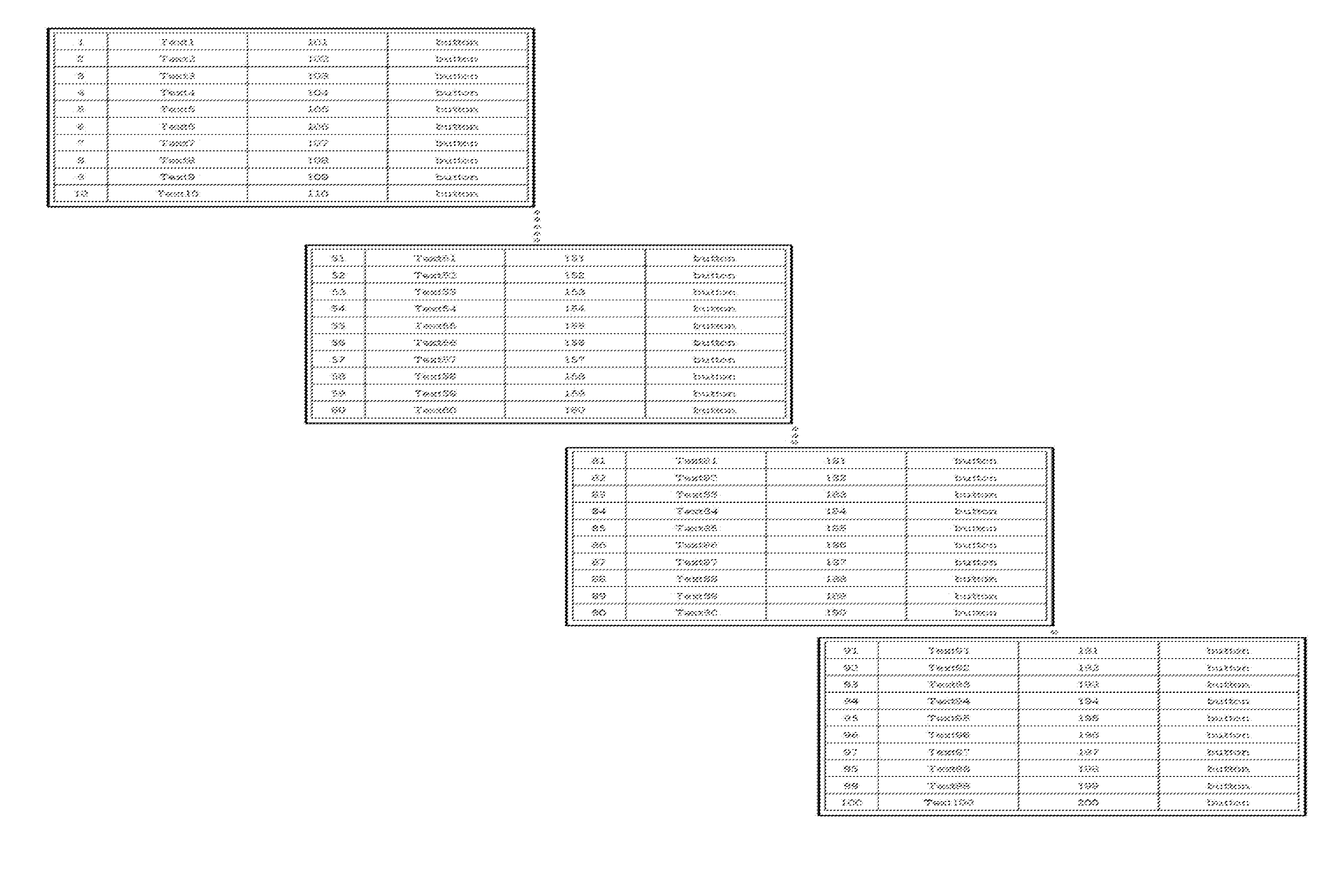

Scrolling method and apparatus using plurality of blocks into which items are classified

InactiveUS20060268020A1Increase scrolling speedReduce scrolling speedCathode-ray tube indicatorsInput/output processes for data processingScrolling

A method and apparatus for adjusting scrolling speed according to the location of an item currently being highlighted on a screen in a block containing the item. The method includes: measuring a distance between the item currently being highlighted on the screen and a last item of the block containing the item; and reducing the scrolling speed if the measured distance is smaller than a predefined value. Therefore, it is possible for a user to identify the location of desired data while quickly scrolling through a considerable amount of data on a screen.

Owner:SAMSUNG ELECTRONICS CO LTD

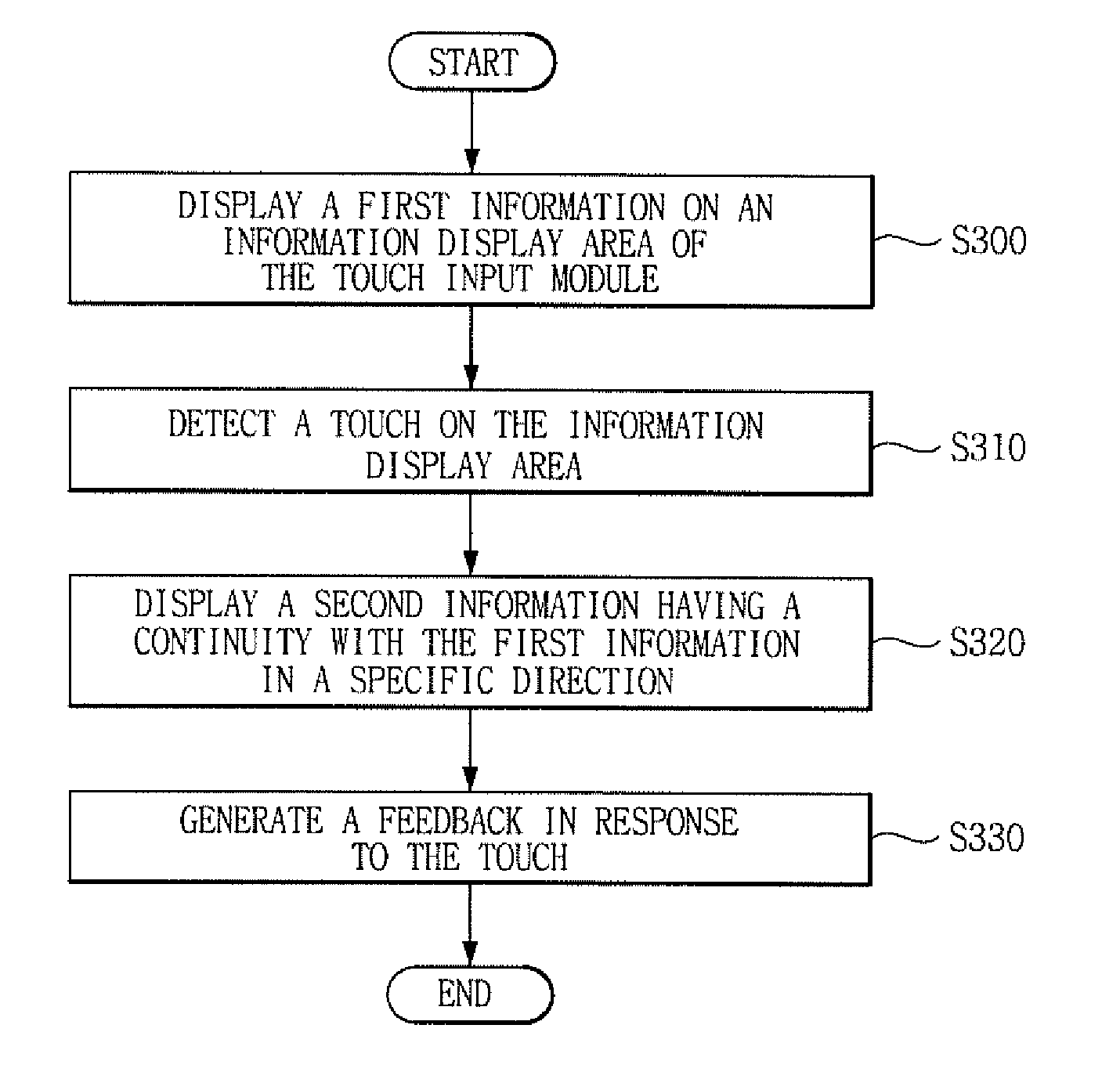

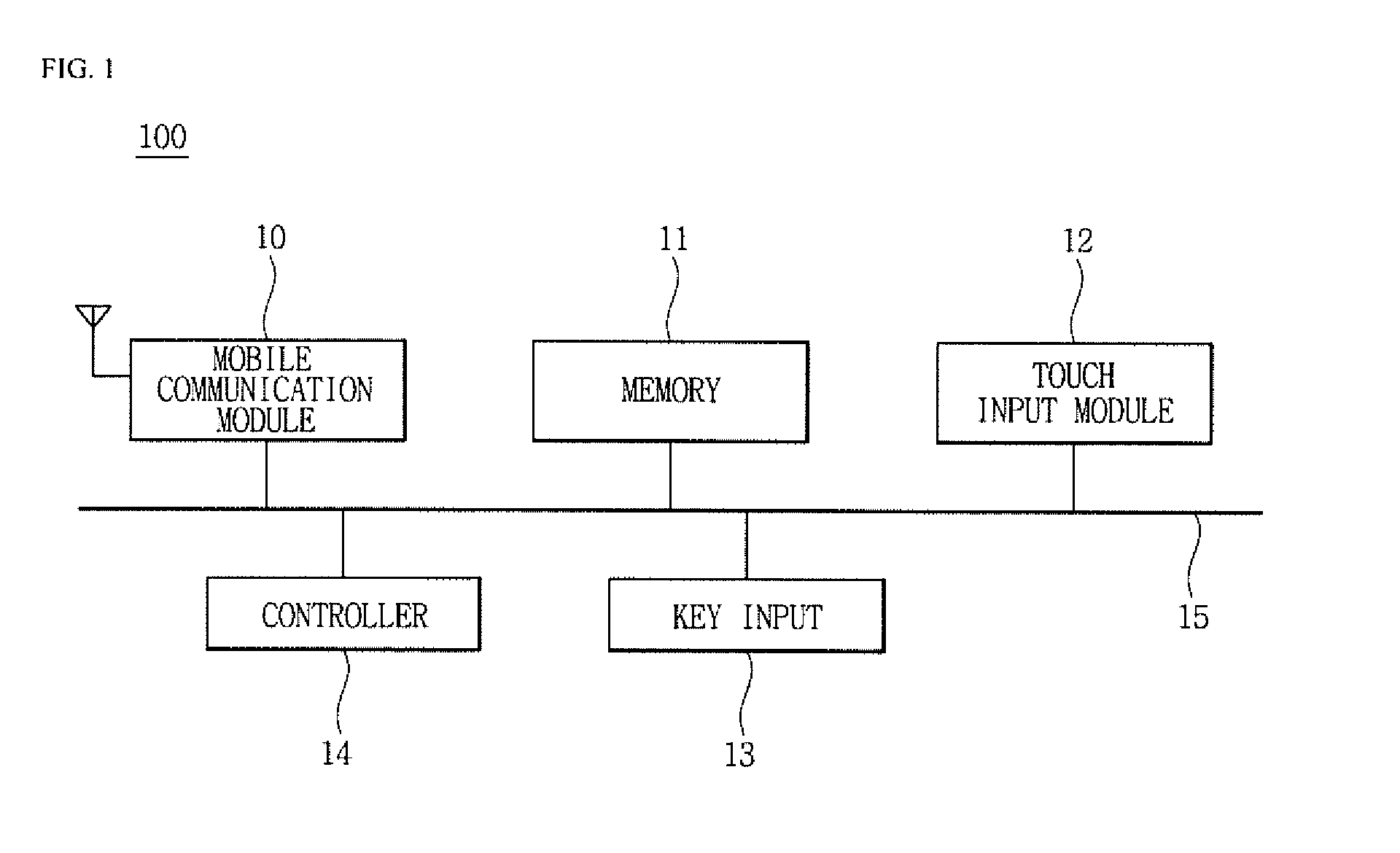

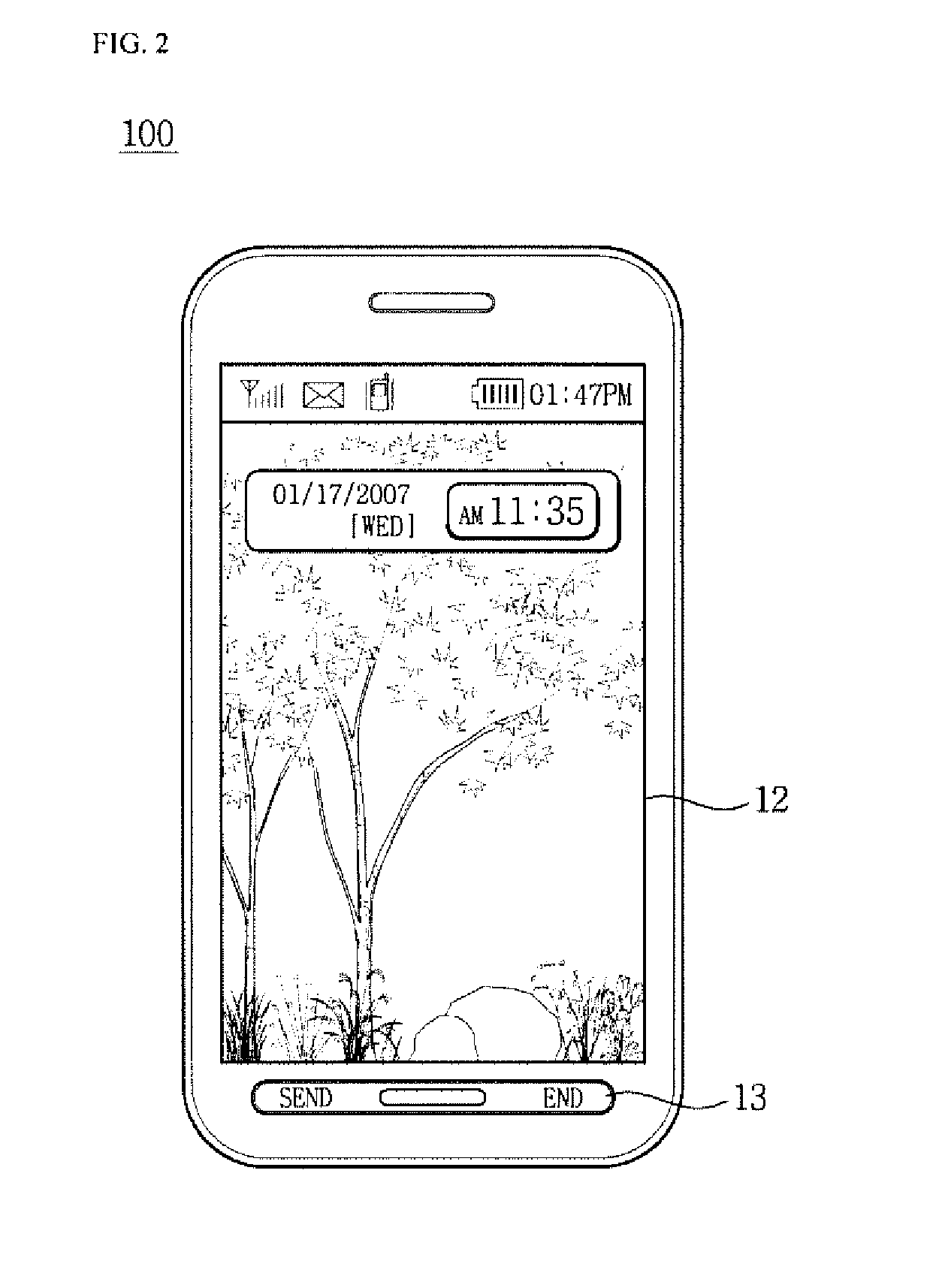

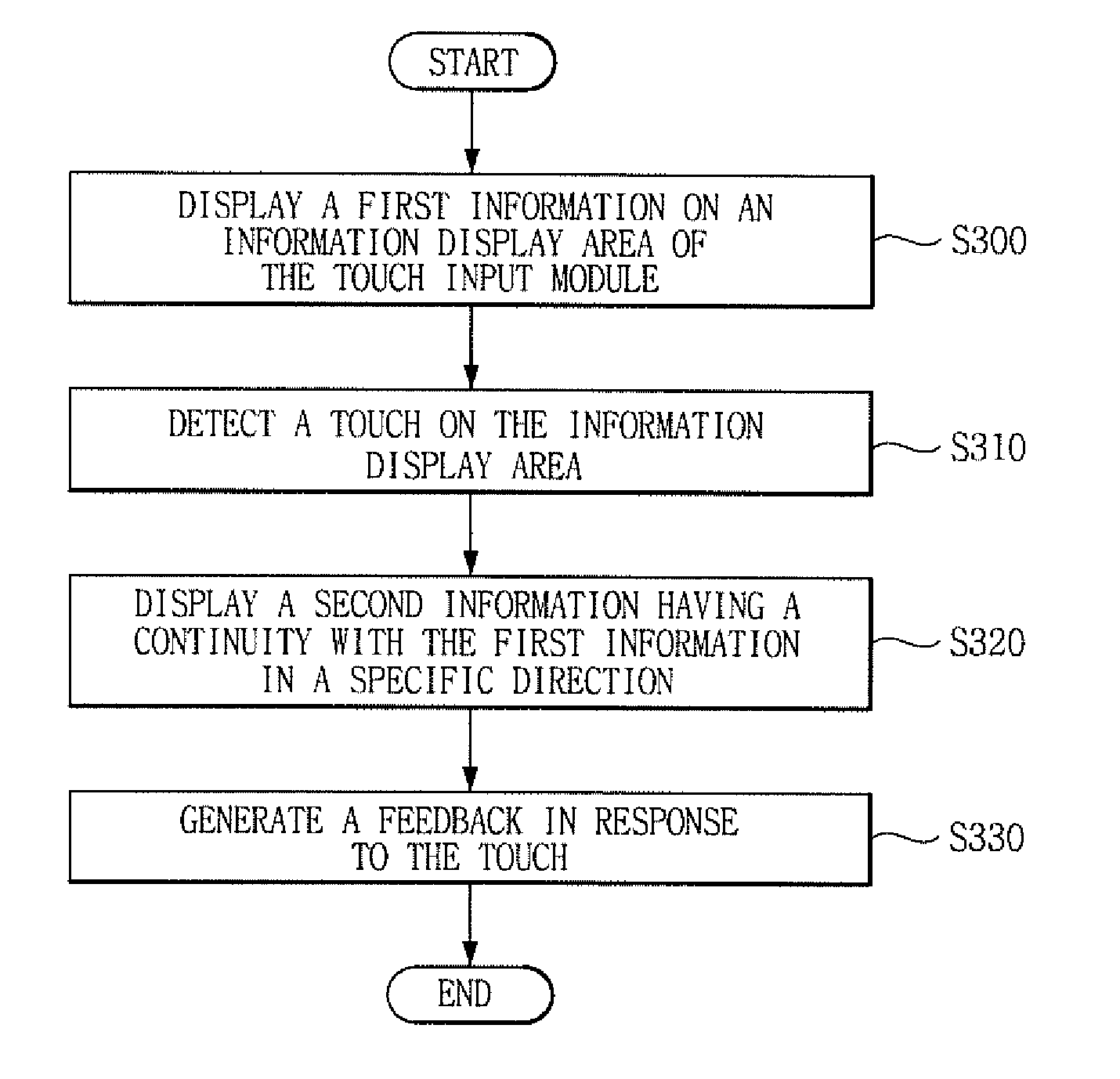

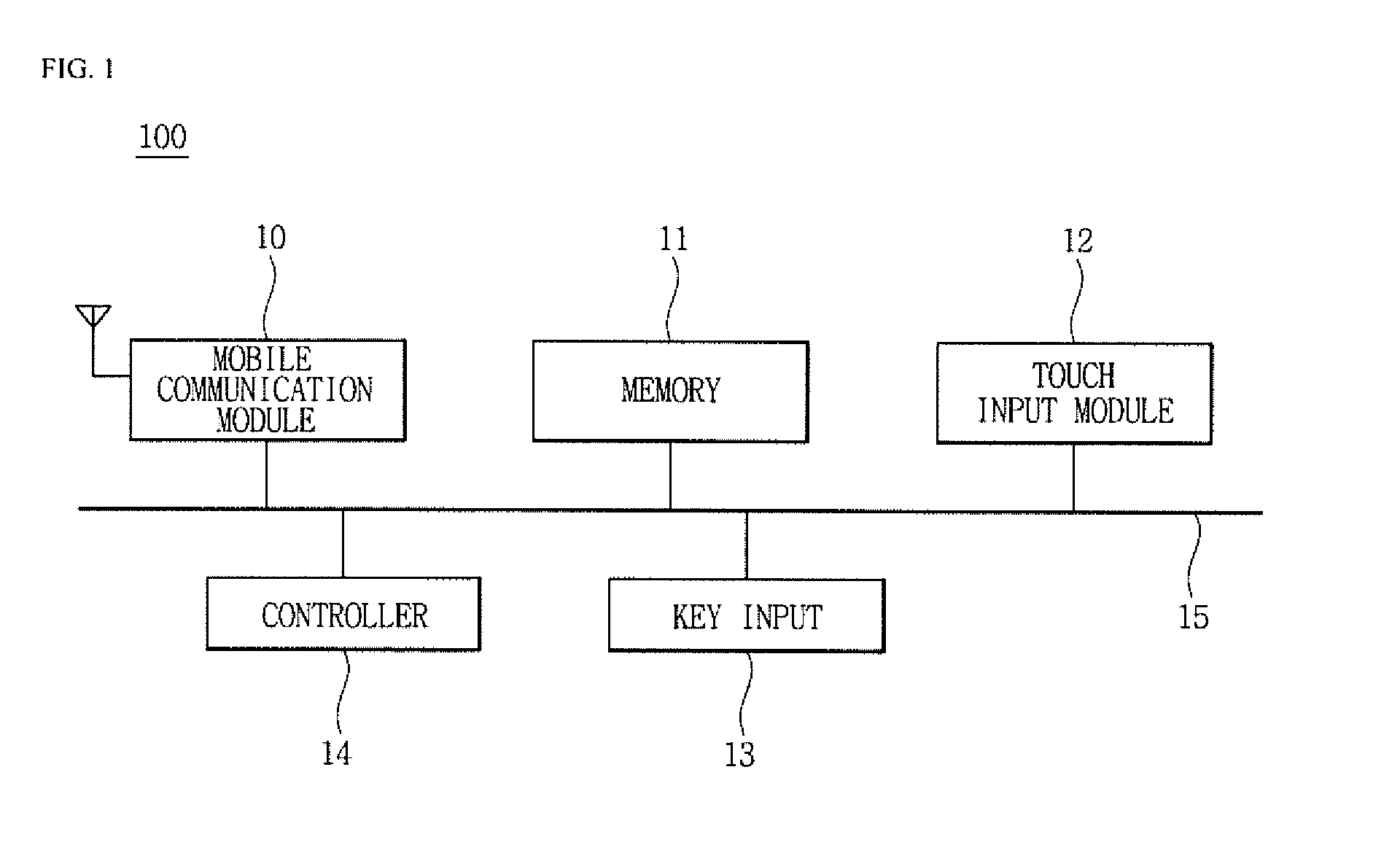

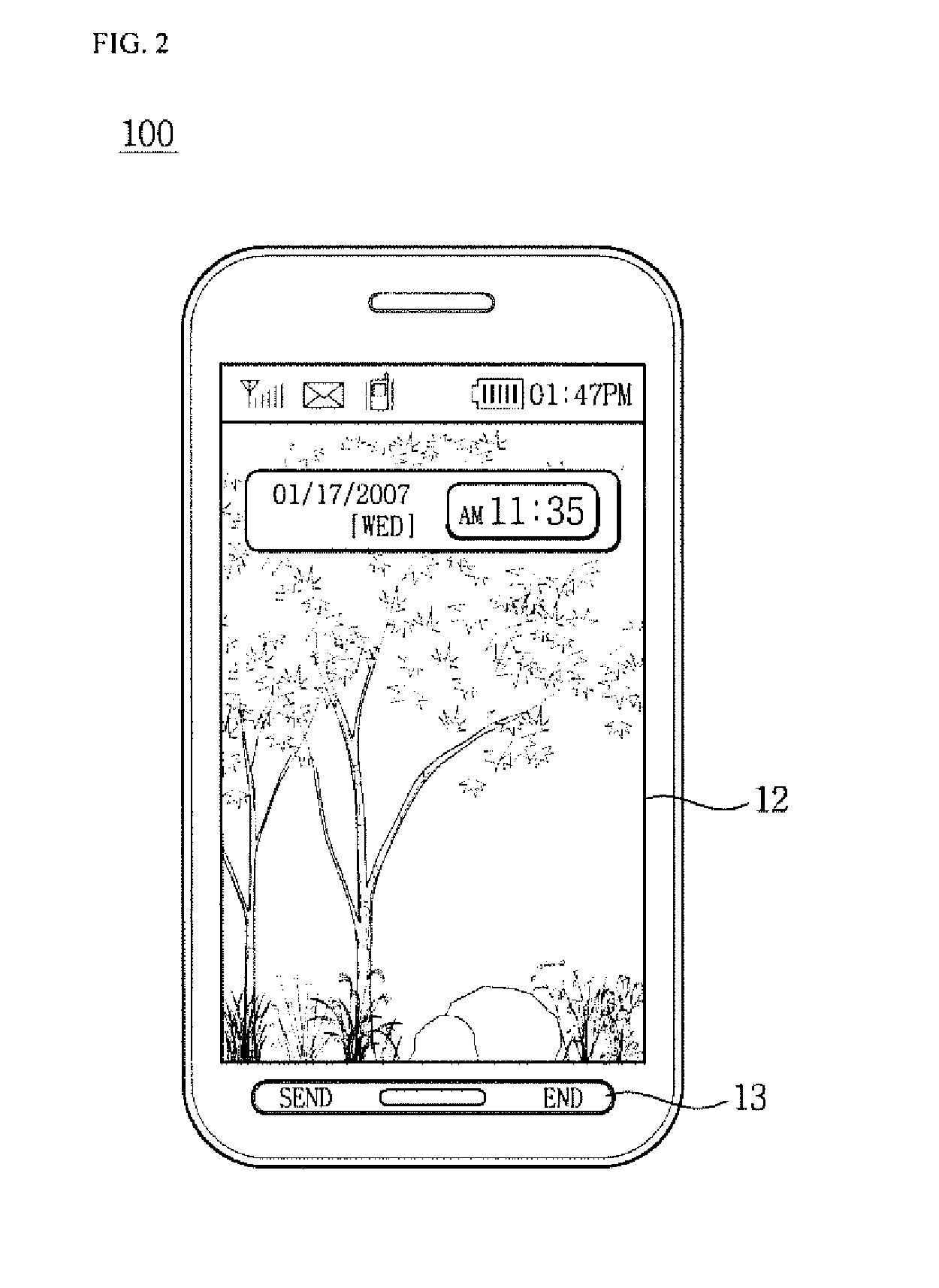

Mobile electronic apparatus with touch input device and display method using the same

ActiveUS20080174562A1Reduce message entry timeSpeed up entryDigital output to display deviceData informationTouchscreen

A mobile terminal having a touch input device and a method using the same are provided. The mobile terminal includes a display unit having a touch screen for displaying a data information, the touch screen having a display area configured for a touch input area, and a controller for controlling movement of at least part of the data information on the display area configured in response to a touching location on the touch input area, wherein the touch input area corresponds to an area where the data information is displayed.

Owner:OPTIS CELLULAR TECH LLC

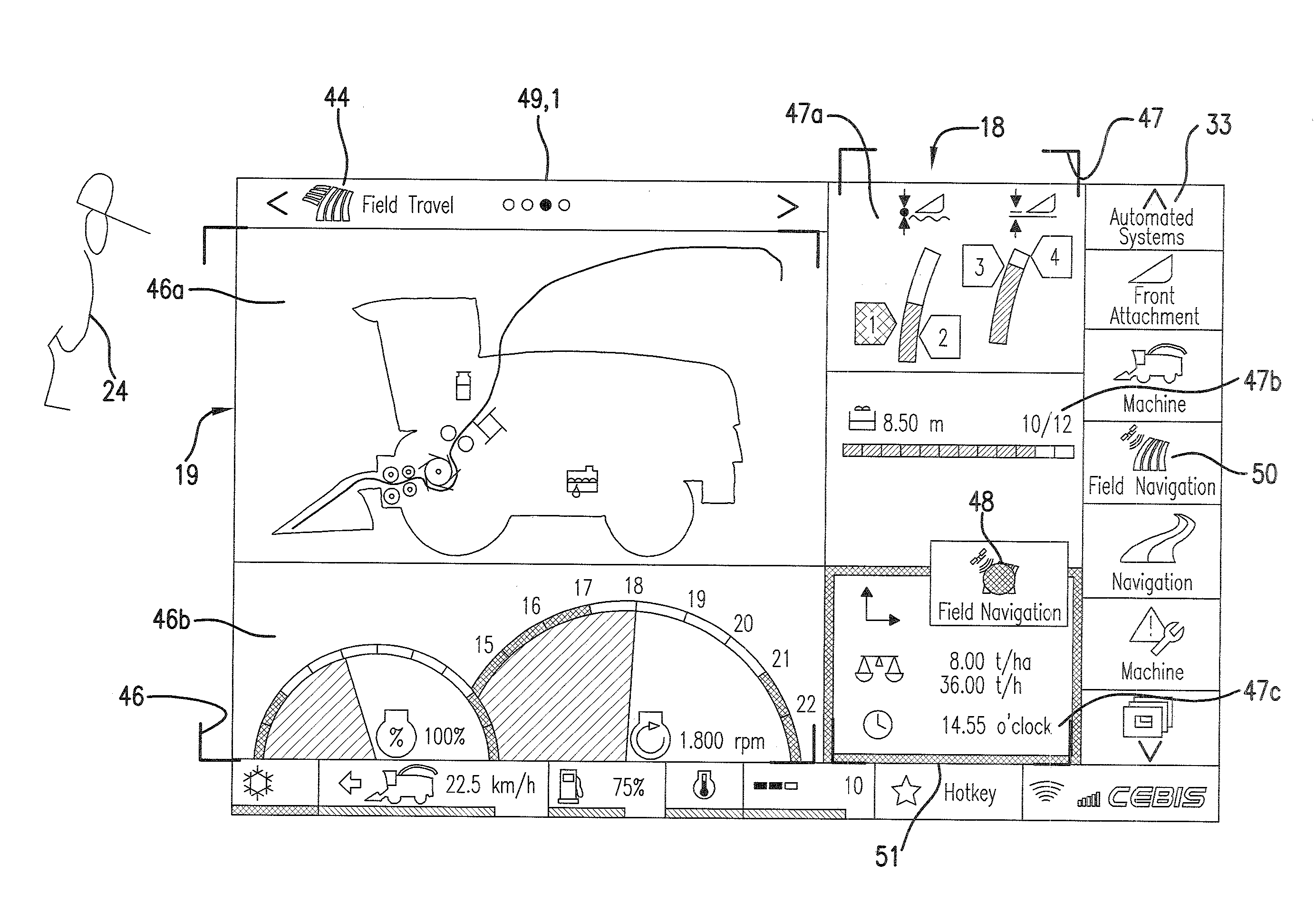

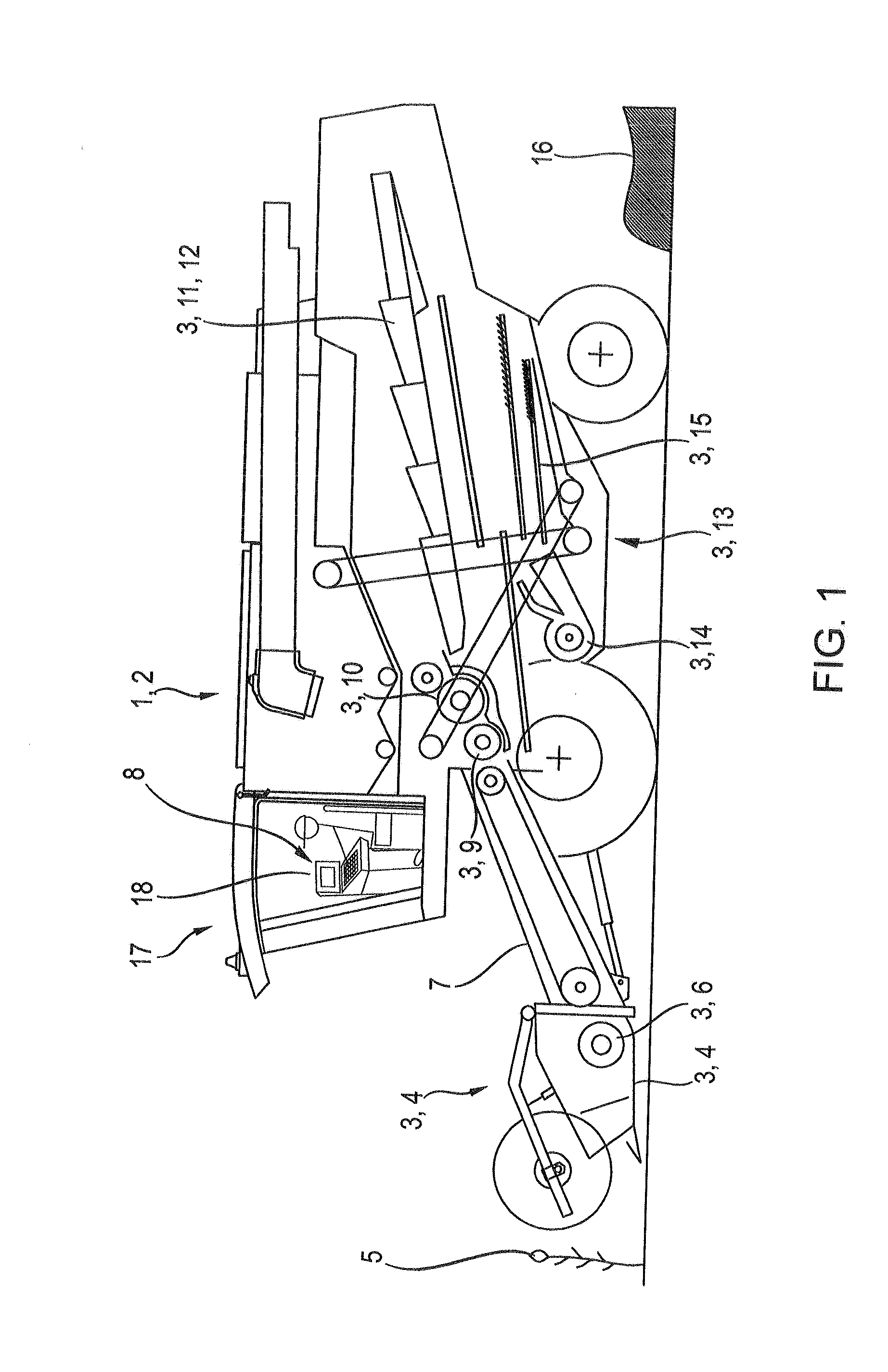

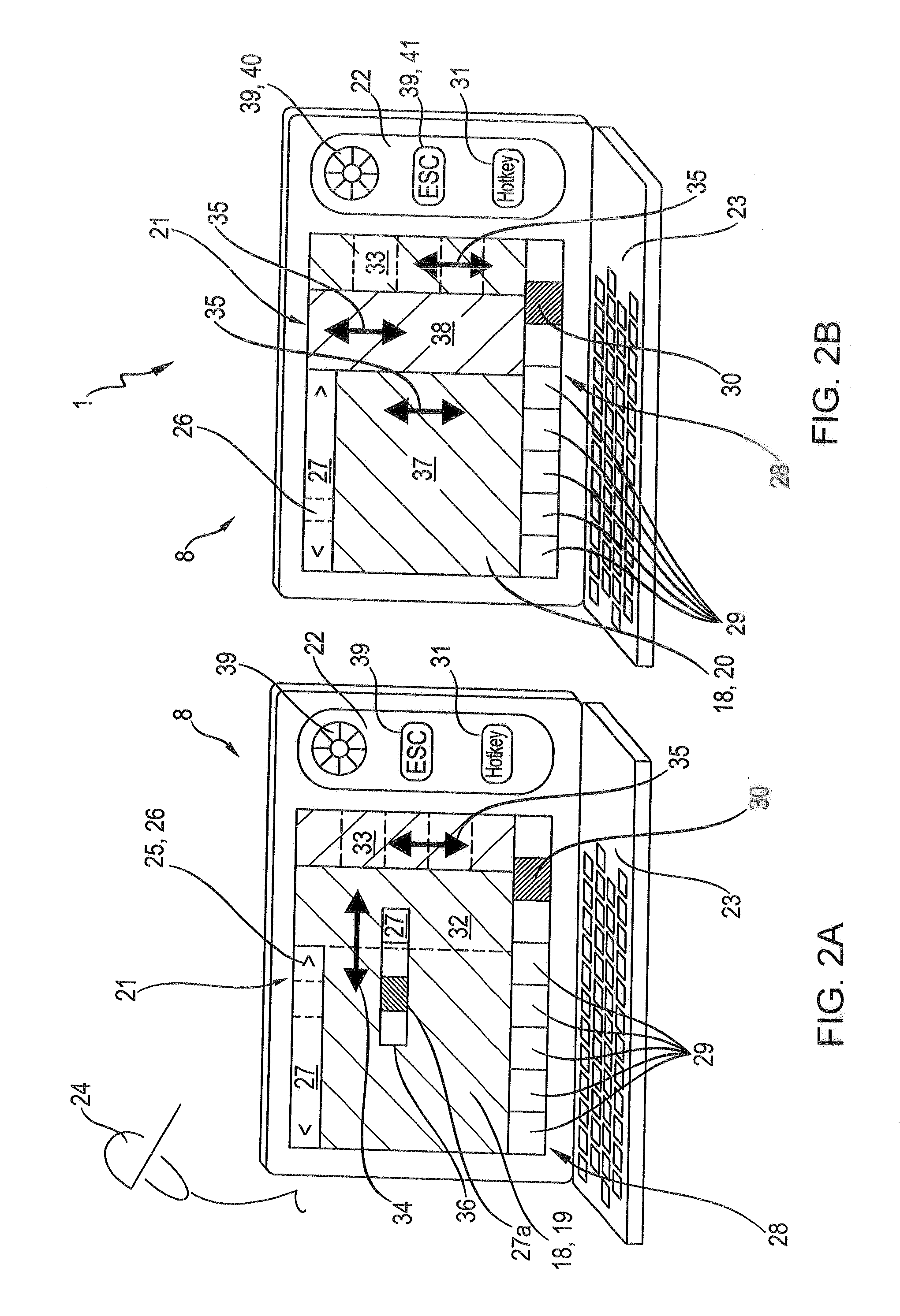

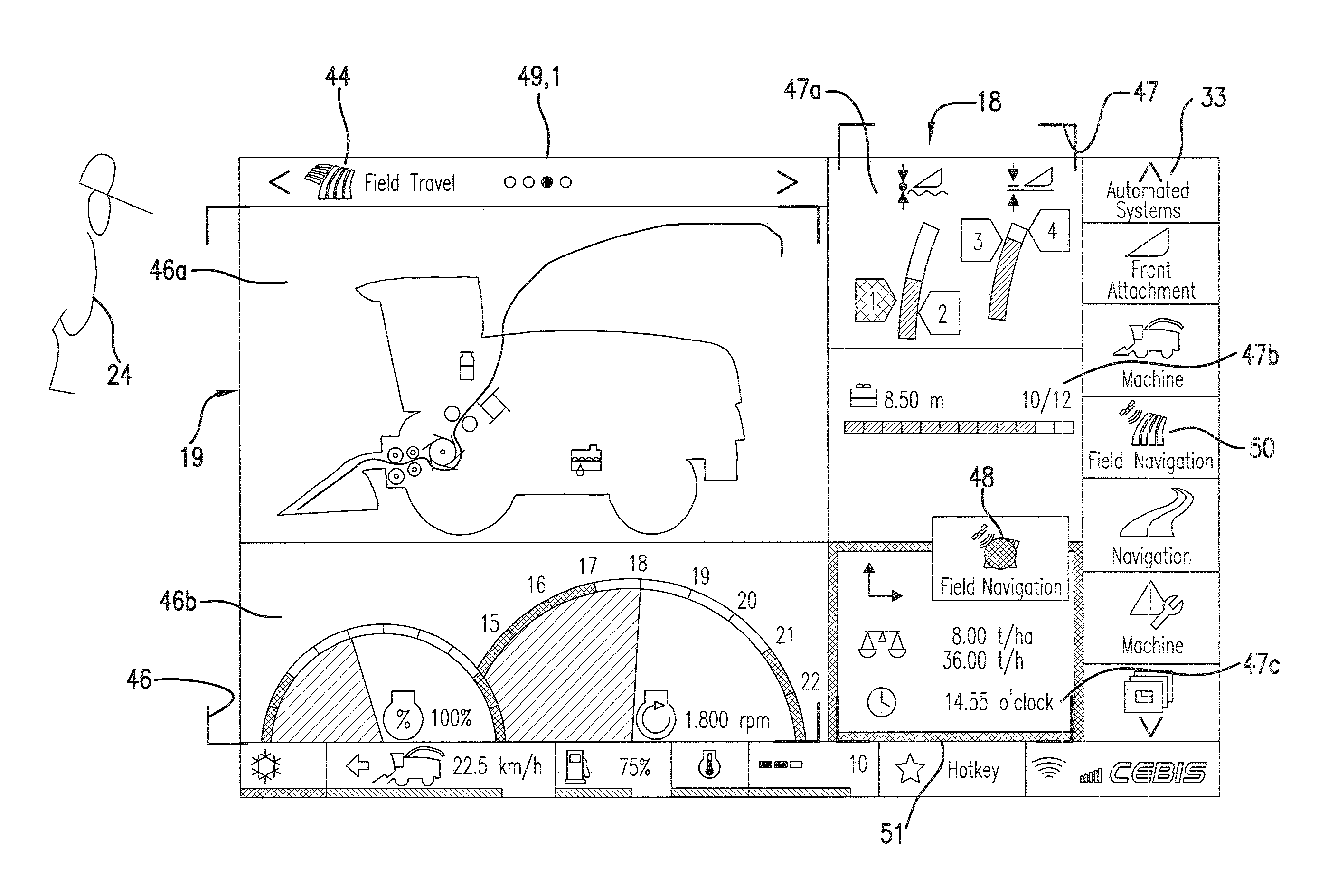

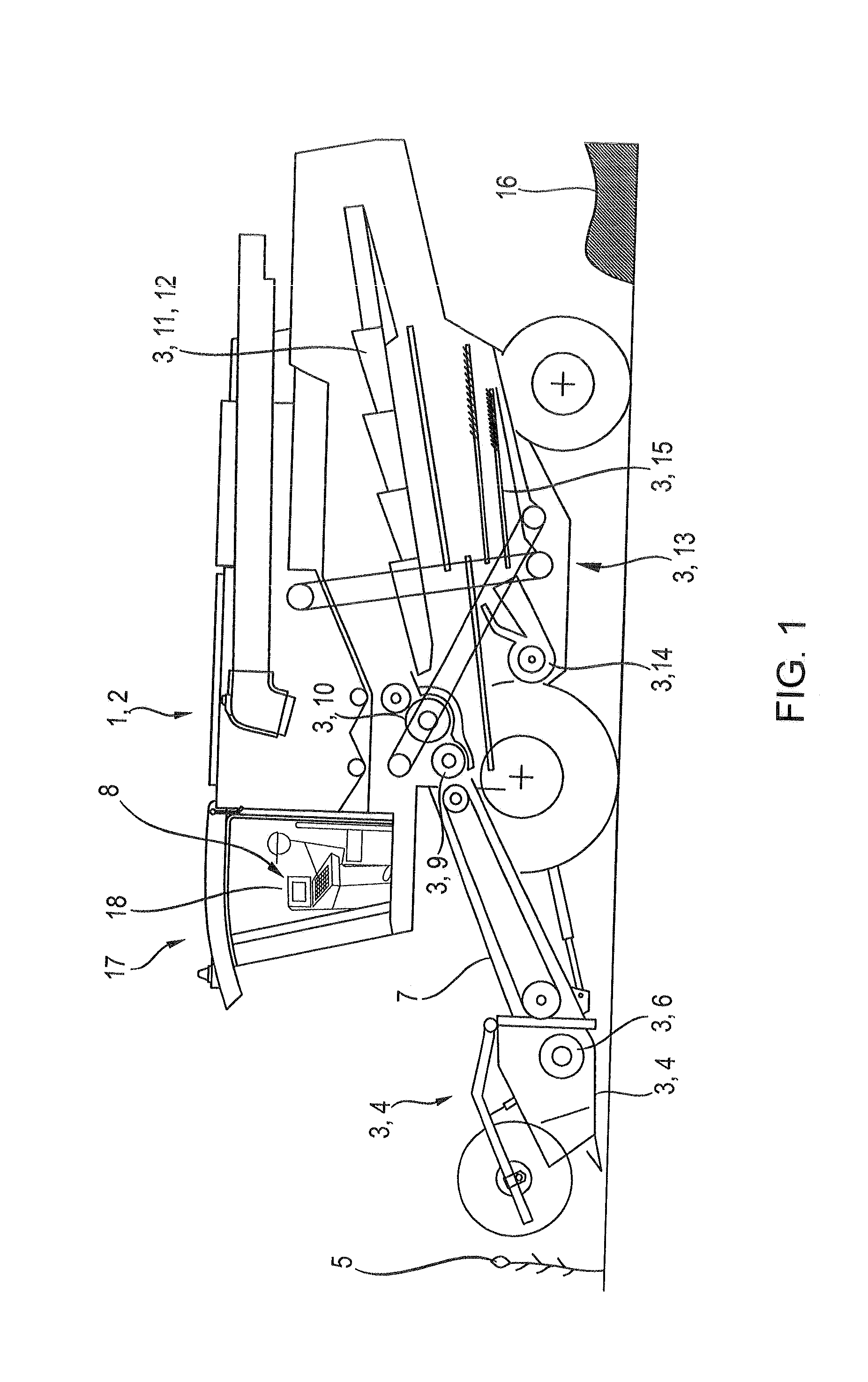

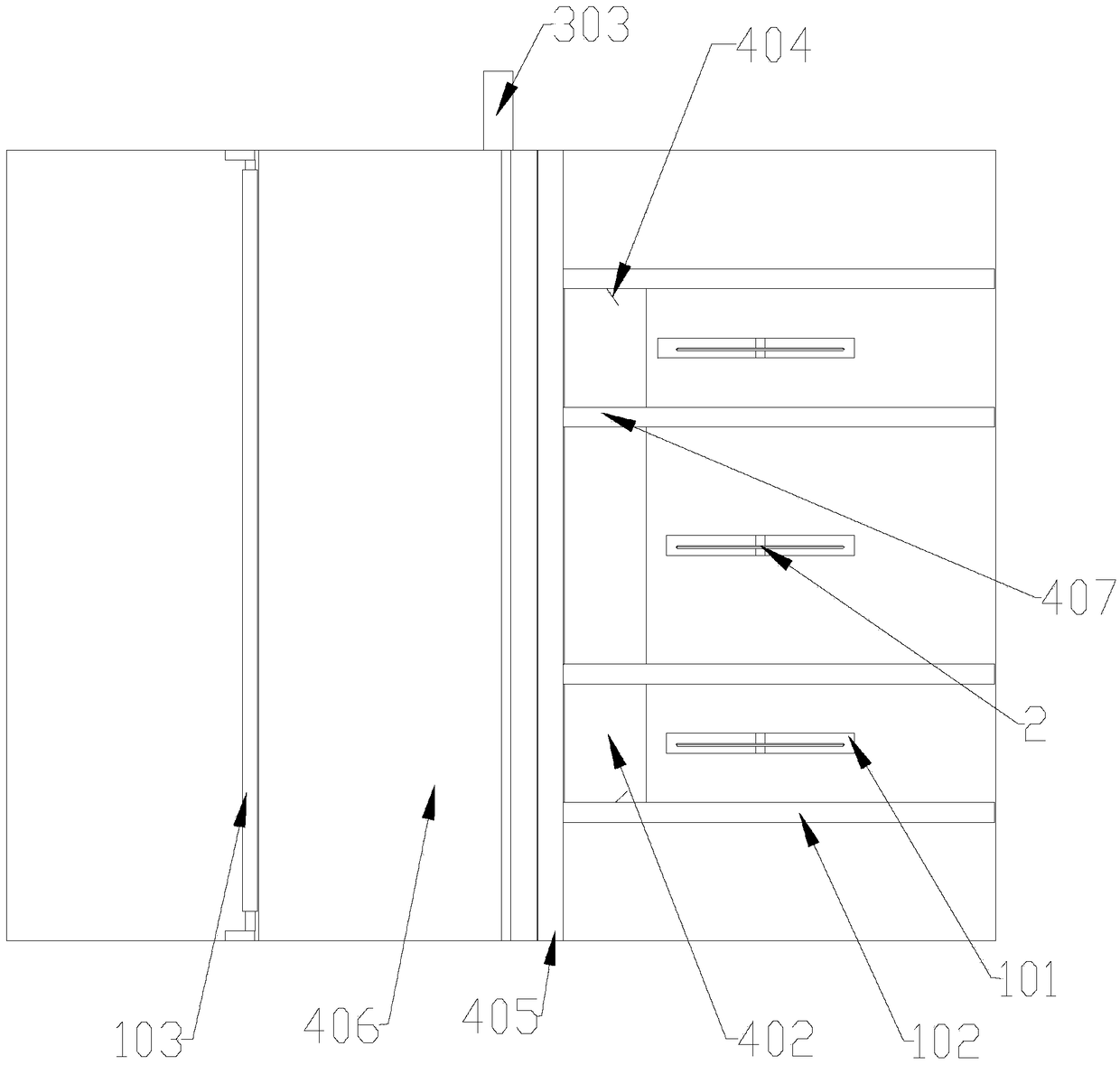

Electronic control and display unit

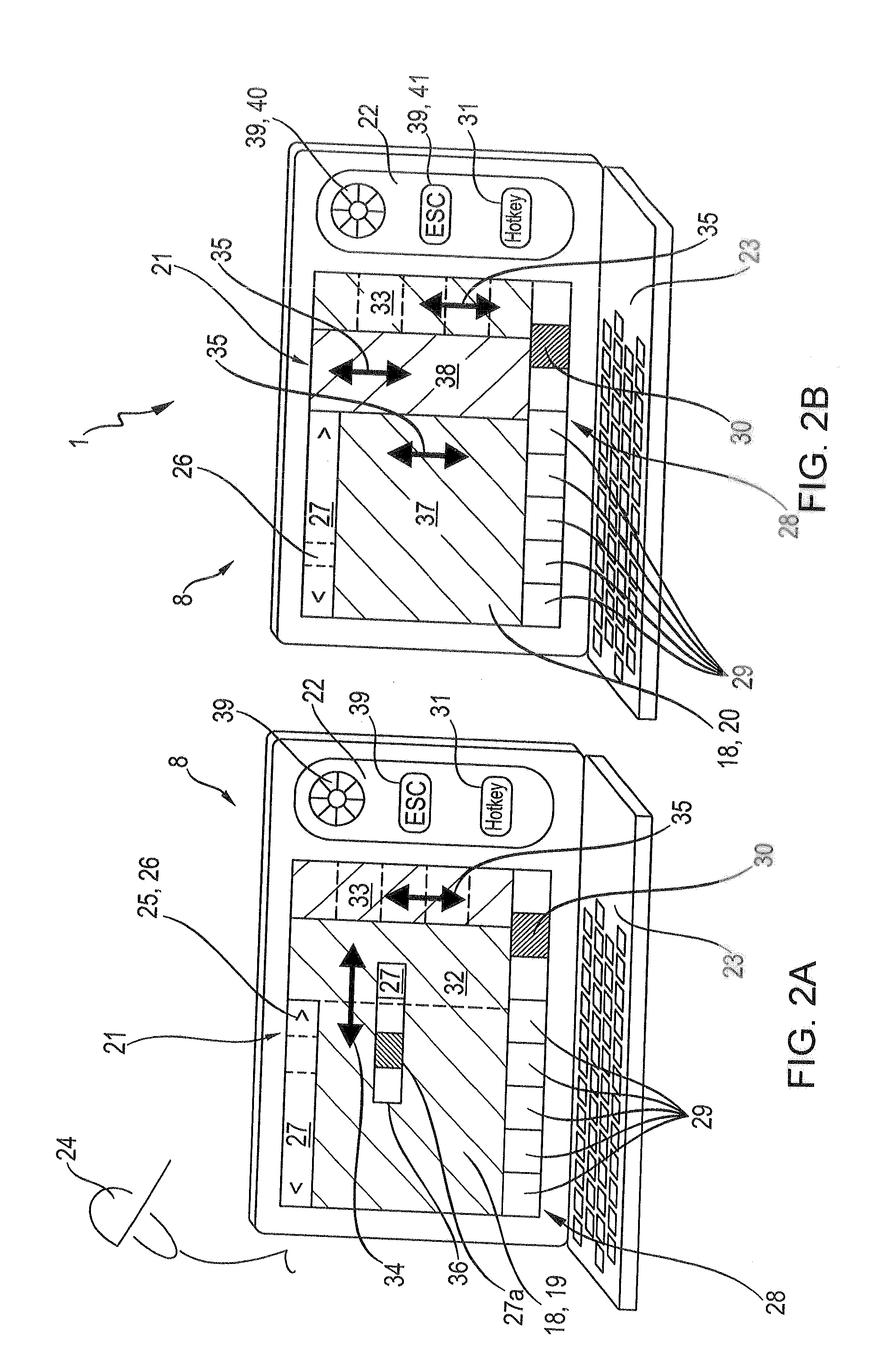

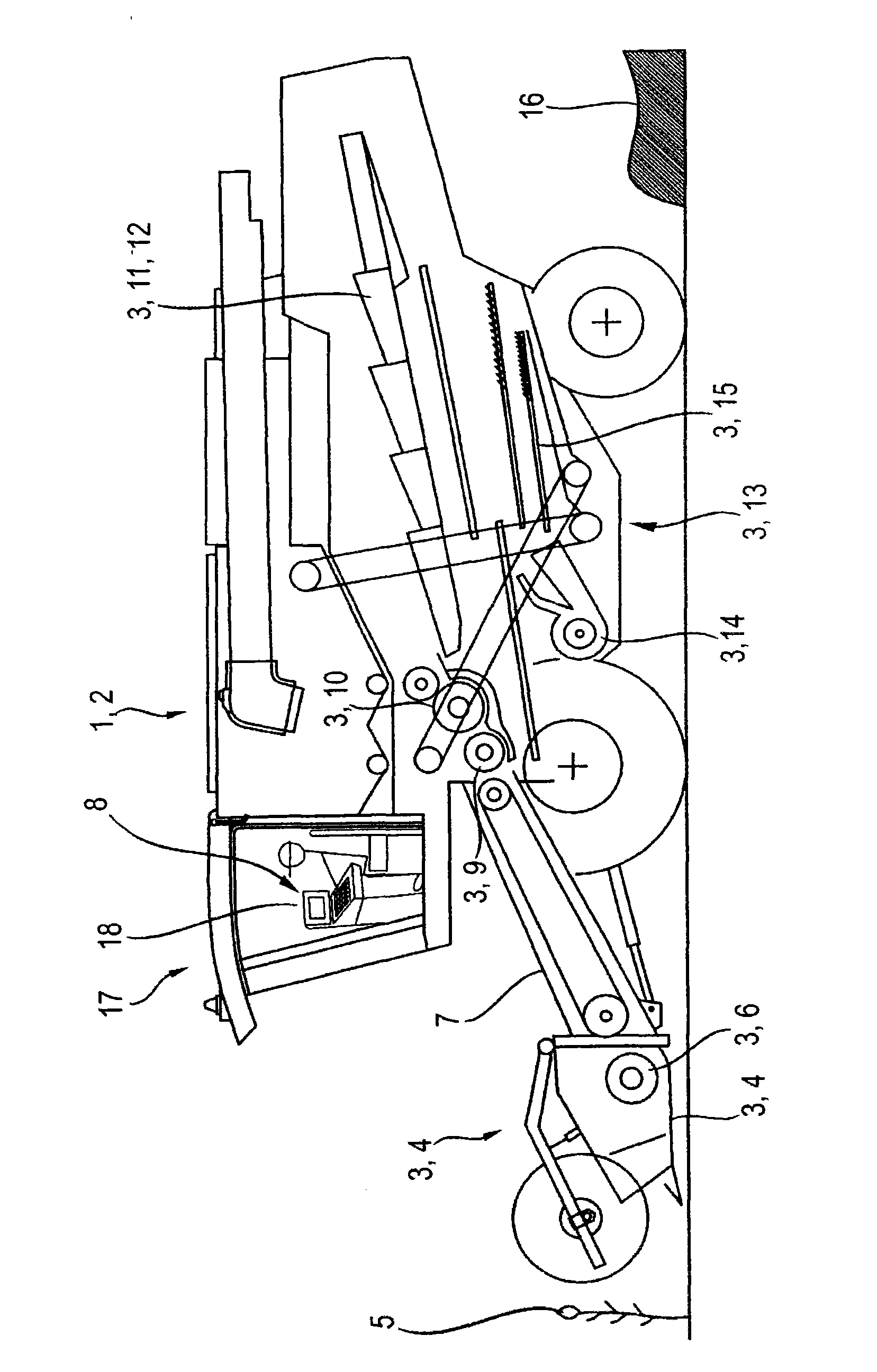

InactiveUS20140053092A1Quick navigationIncrease scrolling speedMowersInput/output processes for data processingMarine navigationDisplay device

An electronic control and display unit includes a display and at least one control unit. The display has a set of visualization regions and can be operated in navigation levels. The display is subdivided into visualization regions within a navigation level and at least a portion of the visualization regions are movable relative to others of the visualization regions.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Experience digitally recorded book

InactiveUS20060075354A1Speeded up and downLarge data capacityElectrical appliancesInput/output processes for data processingData displayComputer graphics (images)

Disclosed is software and a method that has the following steps: inputting a text book into a data base for sequential display onto a computer screen; programing the data display, the data for sequential display of experiences; the sequential display of experiences comprises story text and movie clips associated with said story text material; the speed at which one must read the text material may be controlled and the text may be speeded up or slowed down; the speed of the movie clip is held at a constant whereas the text speed of the display may be controllably varied; the text material is combined with narration; the text material is read by the narrator simultaneously as the text is displayed; the control is by a first software which is contained on a first disc and the story data and the movie clip is contained on a second disc.

Owner:HARPEL ELIZABETH

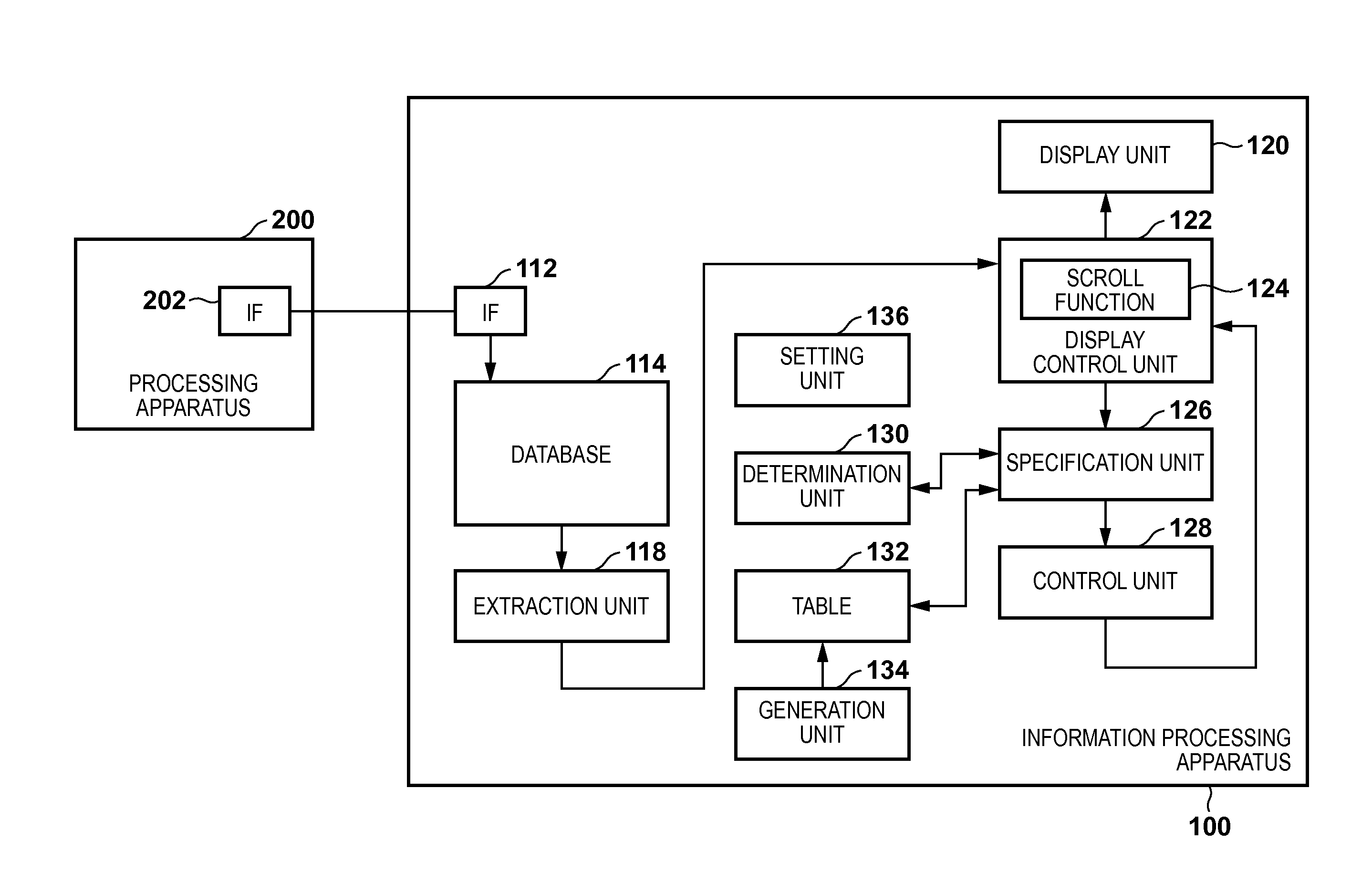

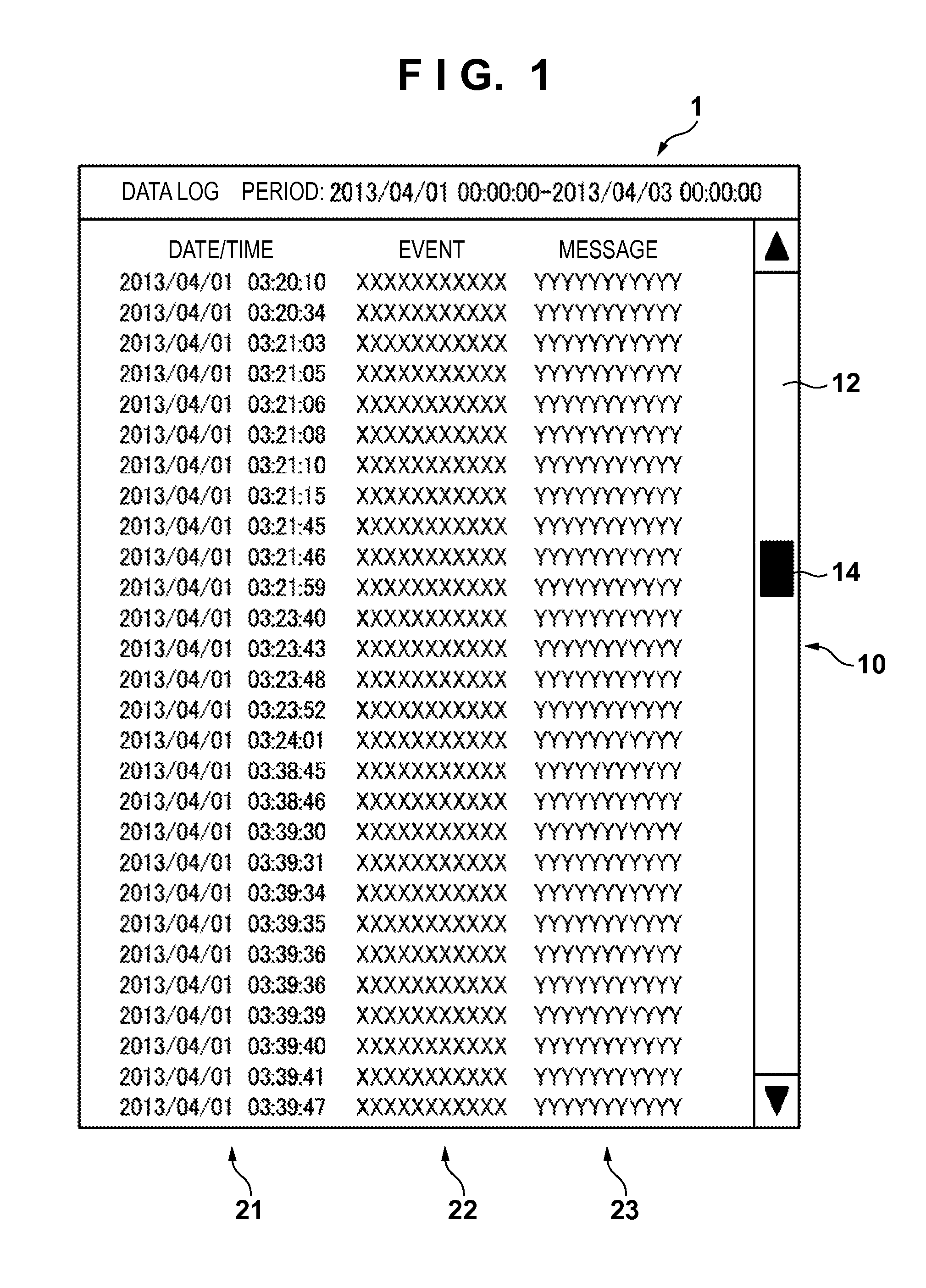

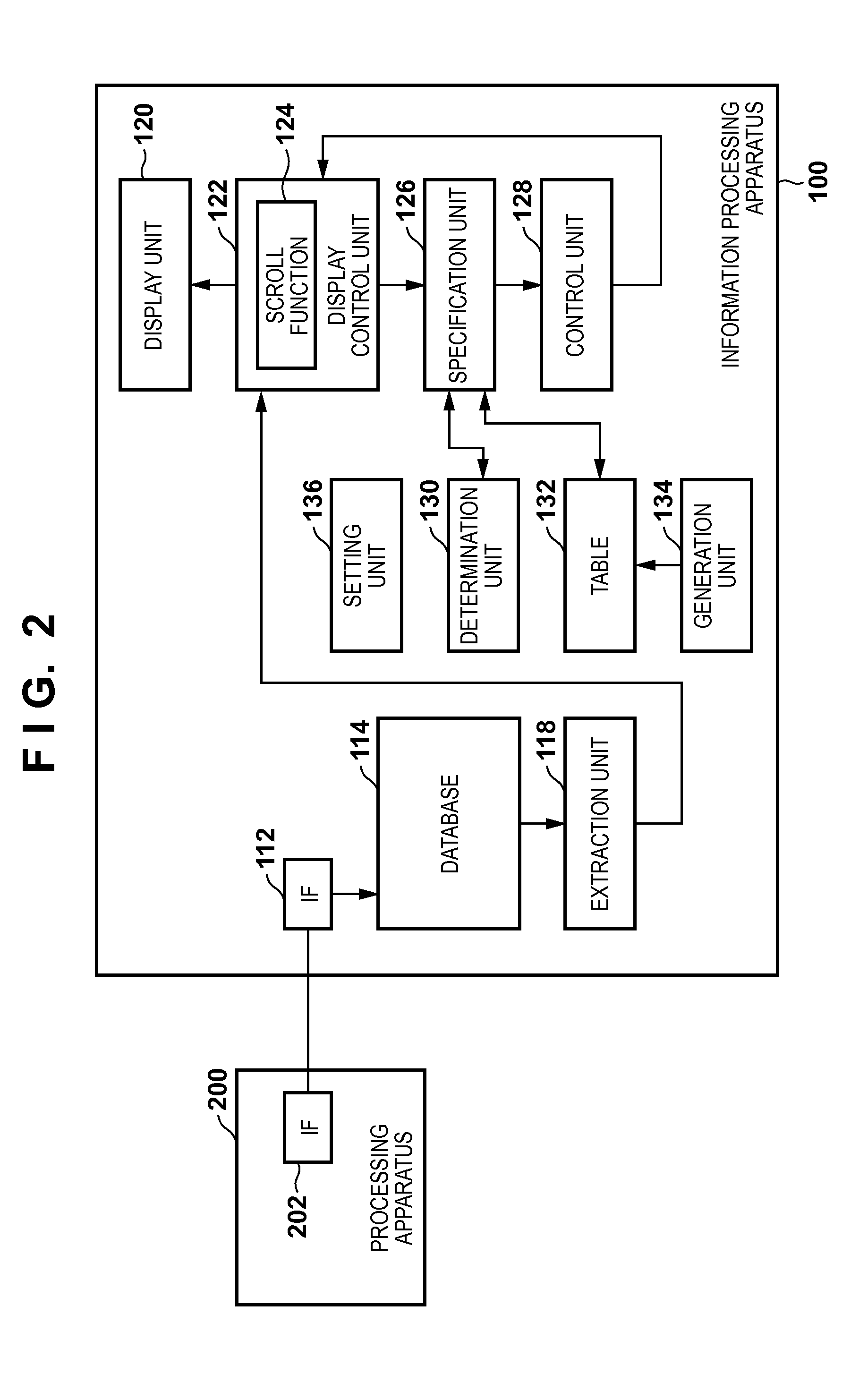

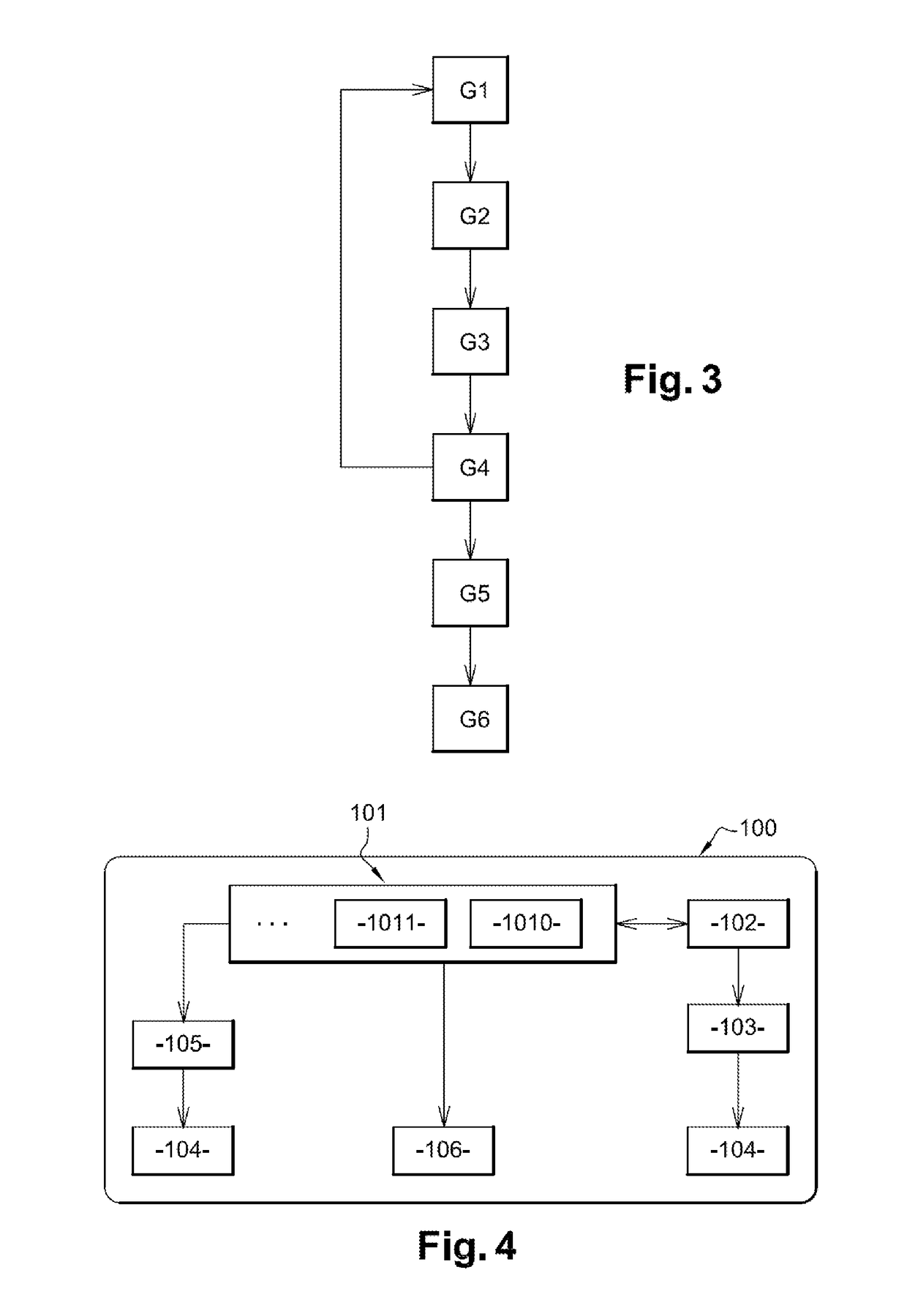

Information processing apparatus for processing plural event data generated by processing apparatus

ActiveUS20140351747A1Increase scrolling speedInput/output processes for data processingInformation processingEvent data

An information processing apparatus for processing a plurality of event data generated by a processing apparatus for processing a member, includes a determination unit which determines at least two event data existing at a preset interval in a time-series sequence of the plurality of event data, a specification unit which acquires a scroll request containing designation information for designating a position in the sequence from a scroll function incorporated in the information processing apparatus, and specify, as jump destination event data, event data at a position close to the position designated by the designation information in the sequence, among the at least two event data determined by the determination unit, and a control unit which causes the scroll function to start scrolling from or near the jump destination event data.

Owner:CANON ANELVA CORP

Electronic control and display unit

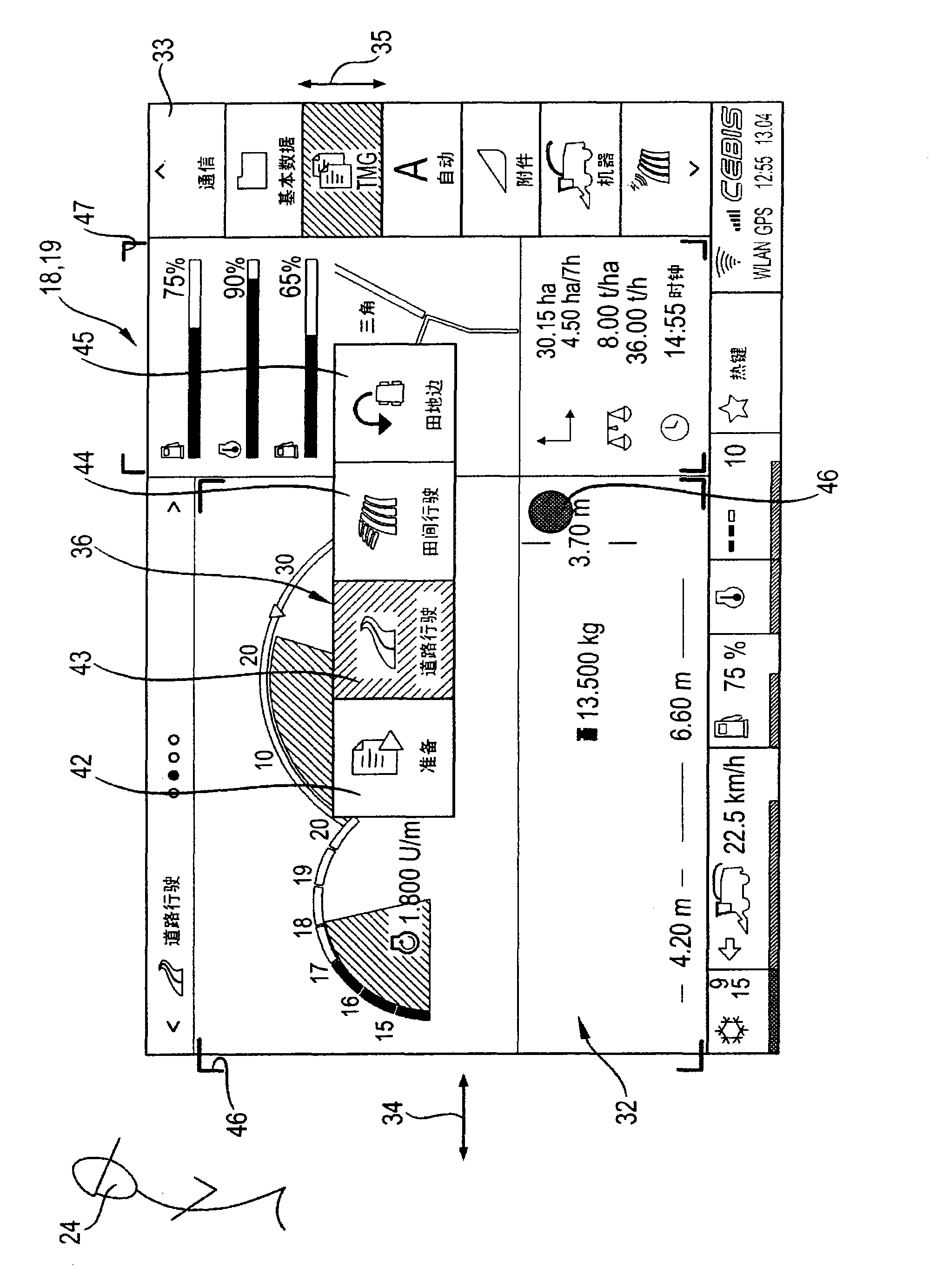

ActiveUS20140053093A1Quick navigationIncrease awarenessMowersInput/output processes for data processingComputer graphics (images)Display device

An electronic control and display unit includes at least one display that has a touchscreen monitor and at least one control unit. The display has a plurality of visualization regions having visualization content. The touchscreen monitor associated with the display is subdivided into visualization regions and the visualization content of each visualization region is editable independently of the visualization content of the remaining visualization regions using available touchscreen functions.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

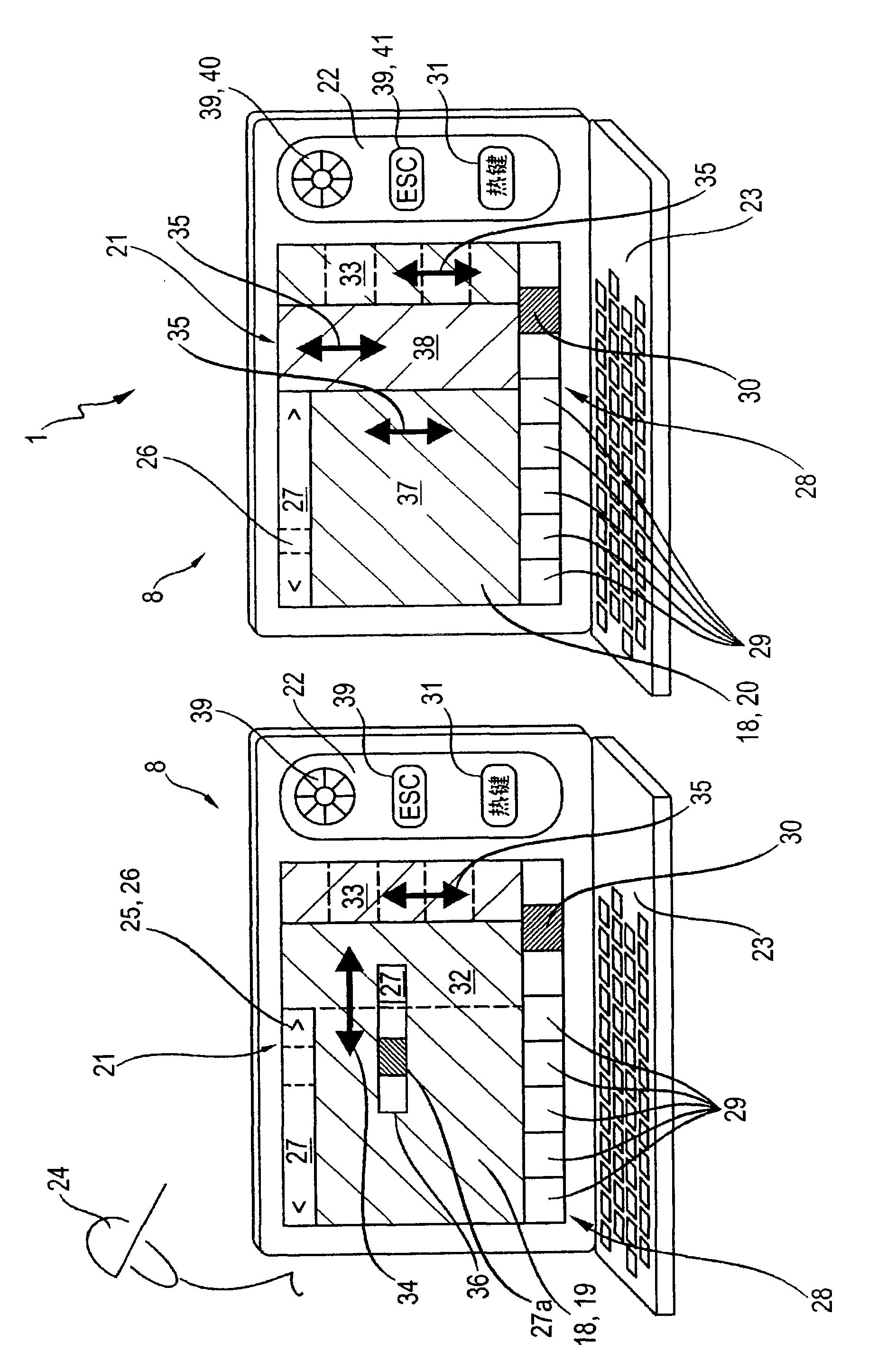

Display device for agricultural machines

ActiveCN103593117AOriginal display preservedIncrease scrolling speedMowersInput/output processes for data processingAgricultural scienceComputer graphics (images)

An electronic control and display unit includes a display and at least one control unit. The display has a set of visualization regions and can be operated in navigation levels. The display is subdivided into visualization regions within a navigation level and at least a portion of the visualization regions are movable relative to others of the visualization regions.

Owner:克拉斯自行式收获机械有限公司

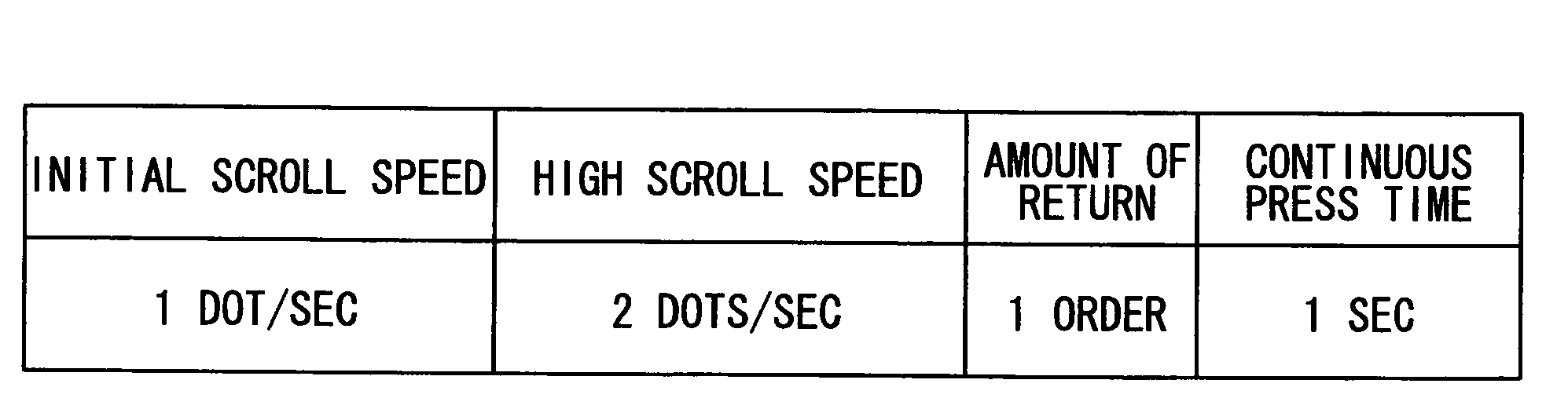

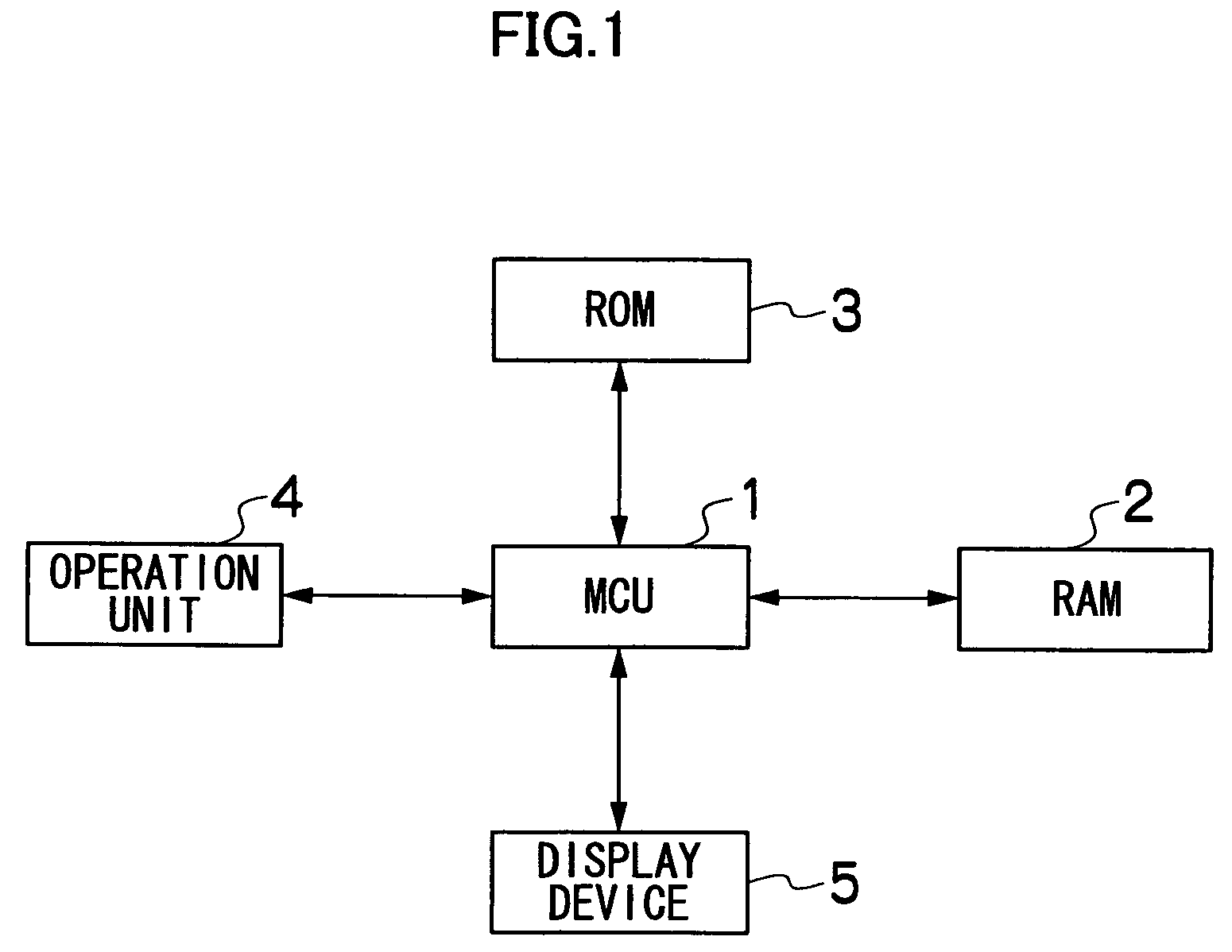

Display processing apparatus

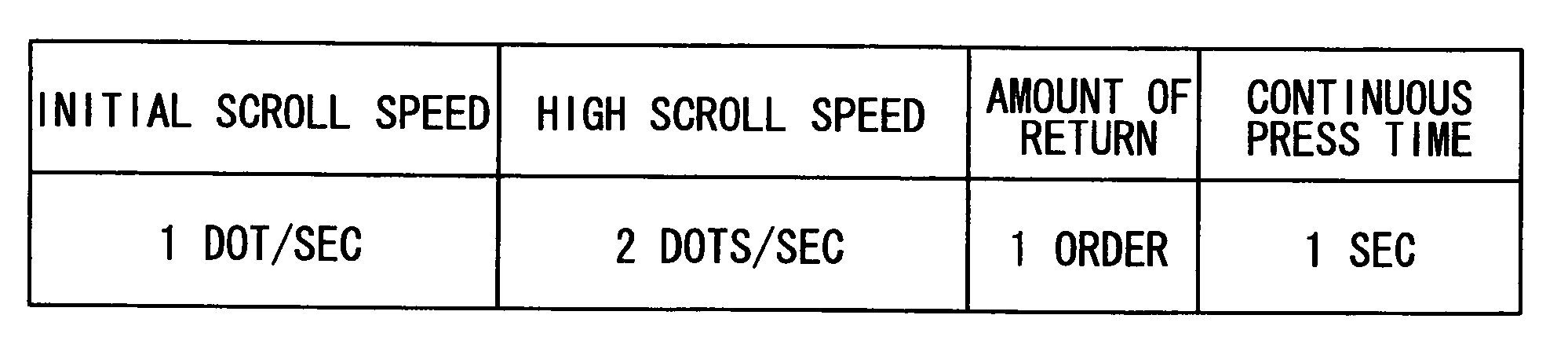

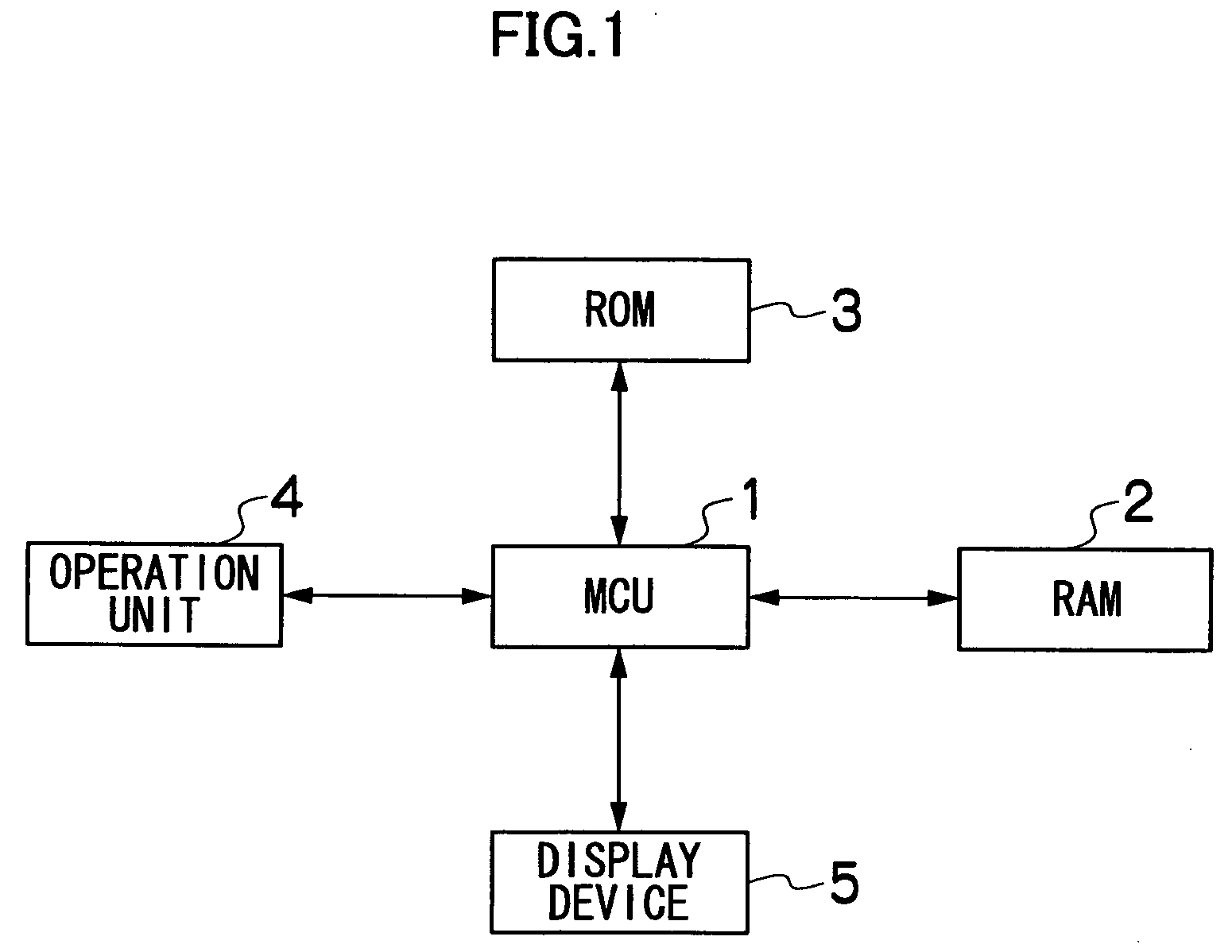

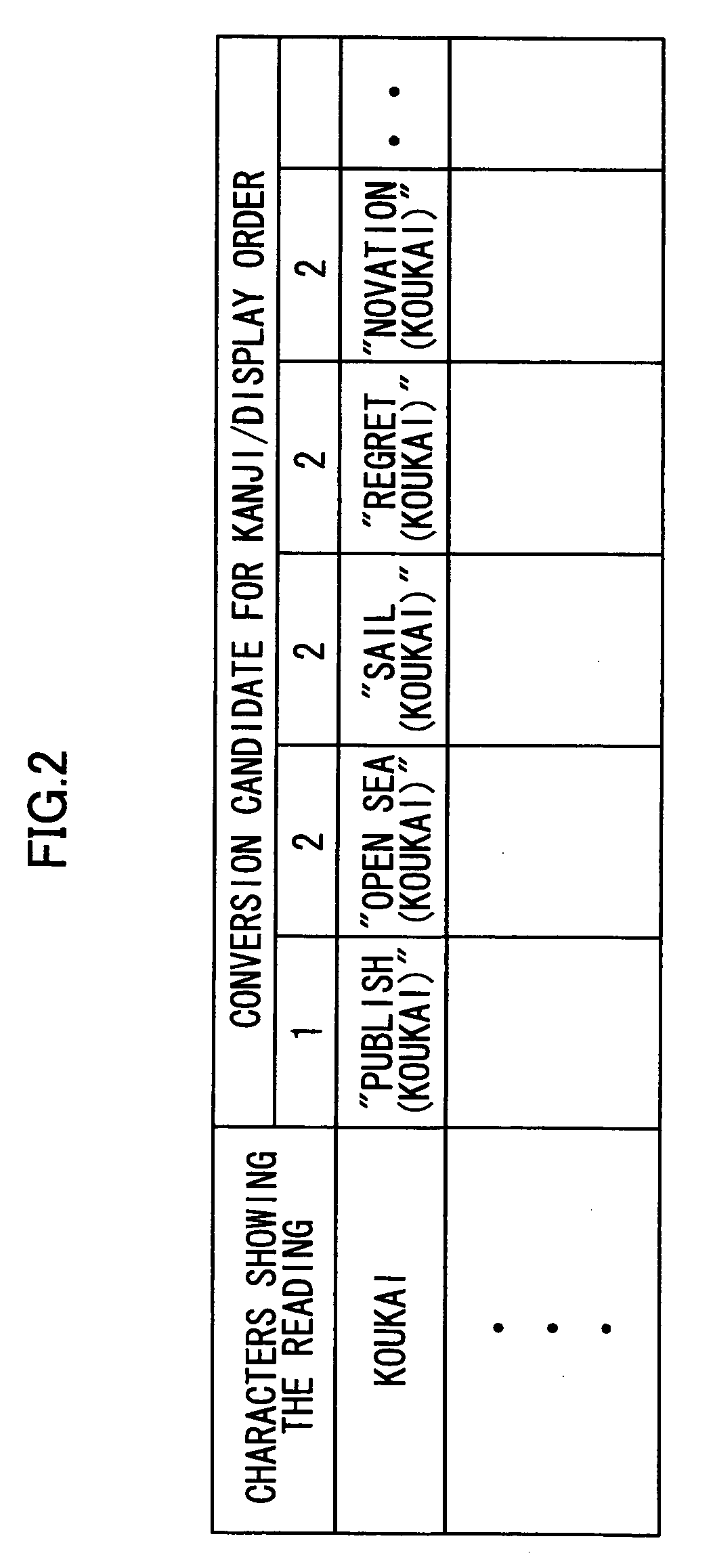

ActiveUS20050195222A1Increase scrolling speedCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceScrolling

According to the display processing apparatus of the present invention, when an instruction to perform scrolling and displaying of information terminates, the information is returned by a predetermined scroll amount in the reverse direction of the scrolling and displaying direction. That is, although the user-desired information has passed the display range on the display device while scrolling, the information is returned by a predetermined amount. As a result, it is not necessary for the user to return all the way to the desired candidate.

Owner:FUJIFILM HLDG CORP +1

Mobile electronic apparatus with touch input device and display method using the same

ActiveUS8300017B2Shorten entry timeSpeed up entryDigital output to display deviceData informationTouchscreen

Owner:OPTIS CELLULAR TECH LLC

Display processing apparatus

ActiveUS7605827B2Increase scrolling speedCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceScrolling

According to the display processing apparatus of the present invention, when an instruction to perform scrolling and displaying of information terminates, the information is returned by a predetermined scroll amount in the reverse direction of the scrolling and displaying direction. That is, although the user-desired information has passed the display range on the display device while scrolling, the information is returned by a predetermined amount. As a result, it is not necessary for the user to return all the way to the desired candidate.

Owner:FUJIFILM HLDG CORP +1

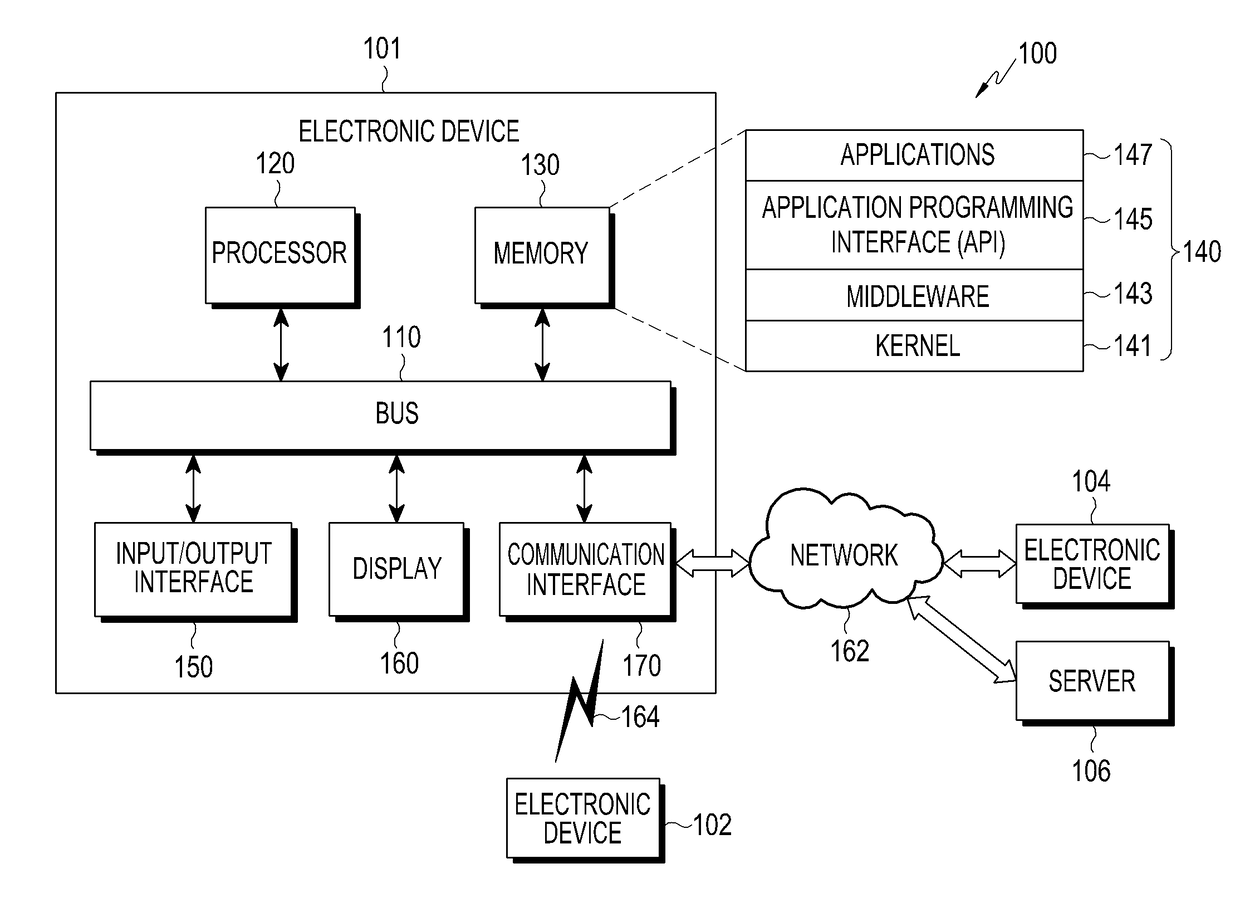

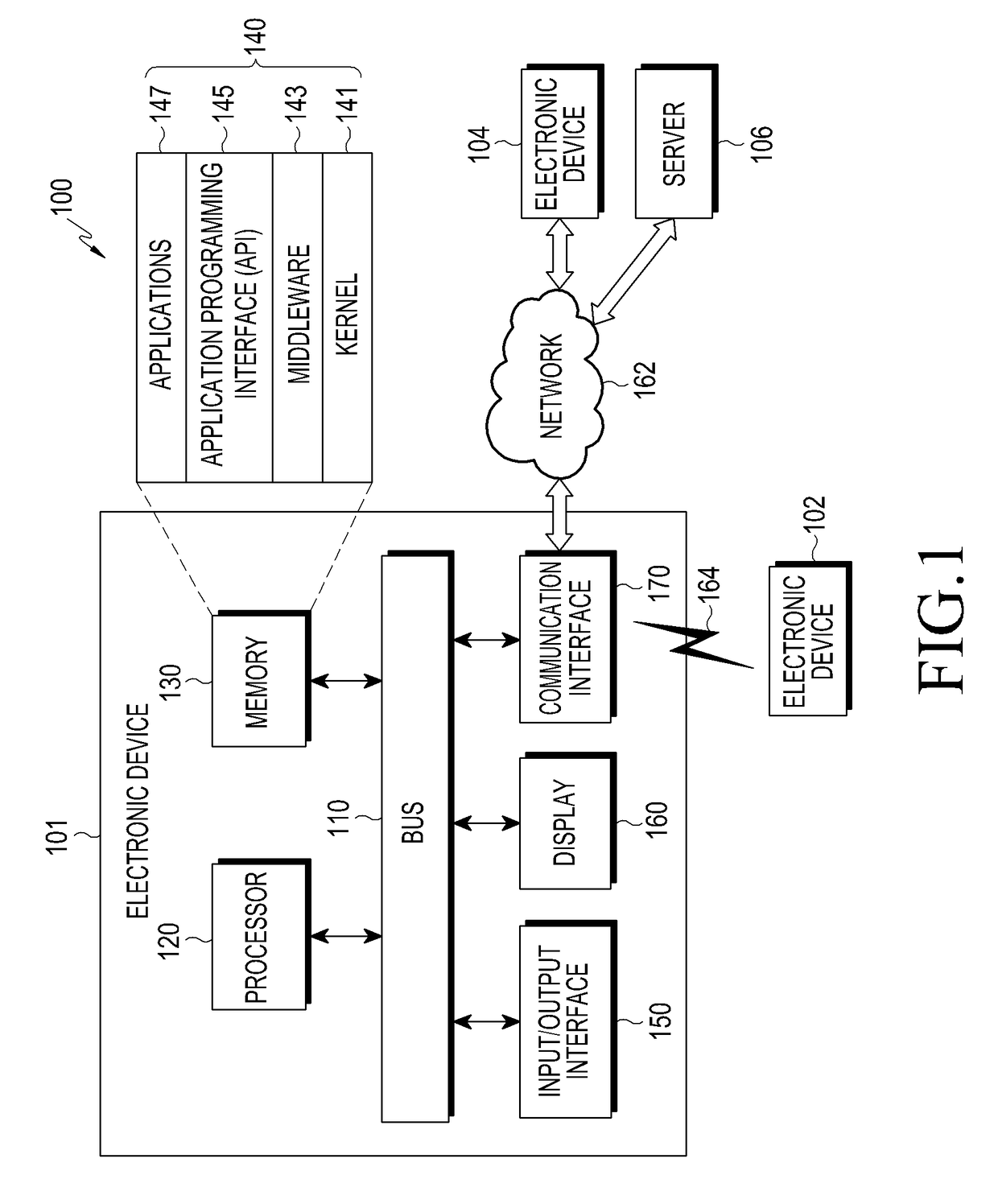

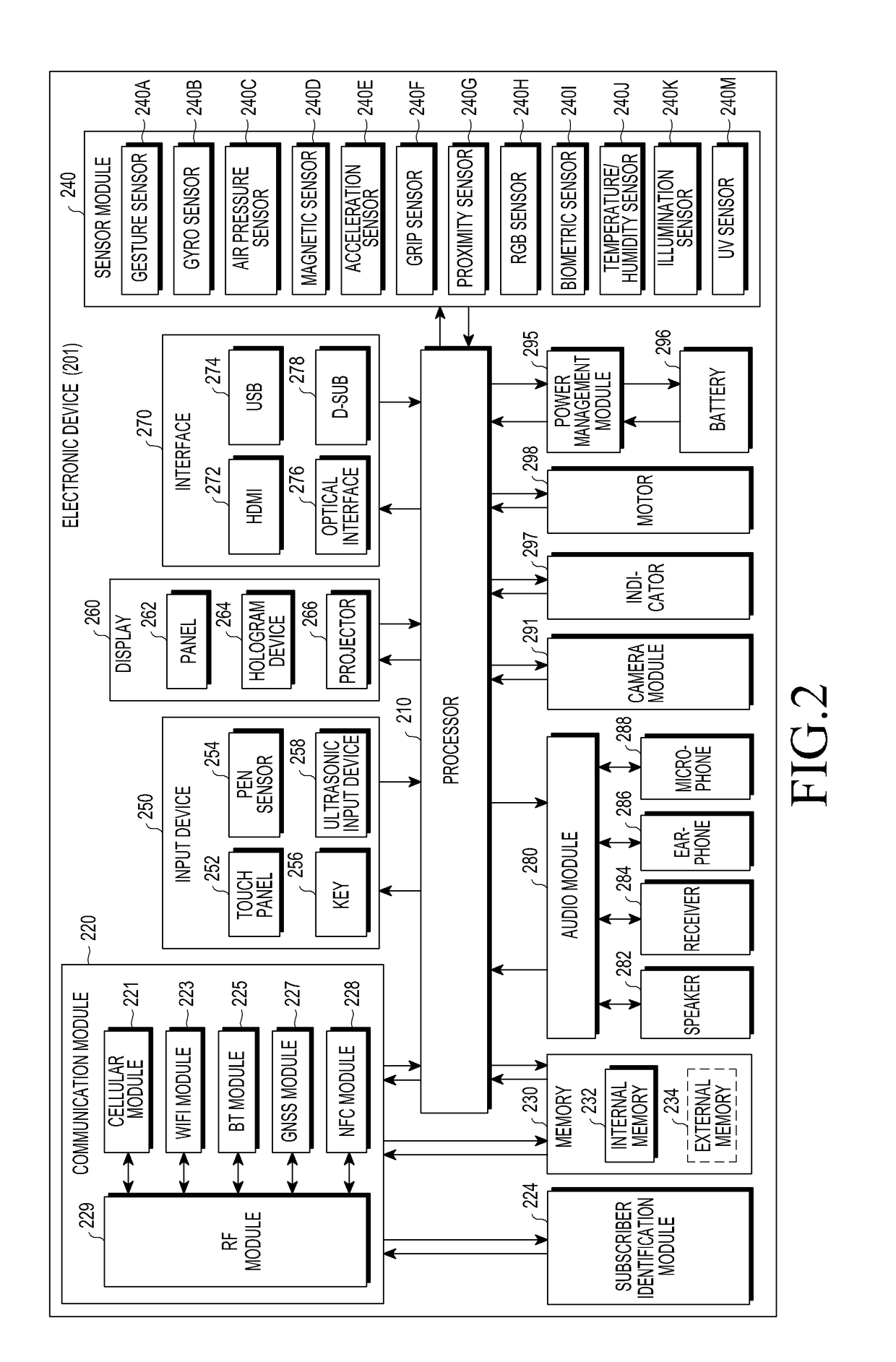

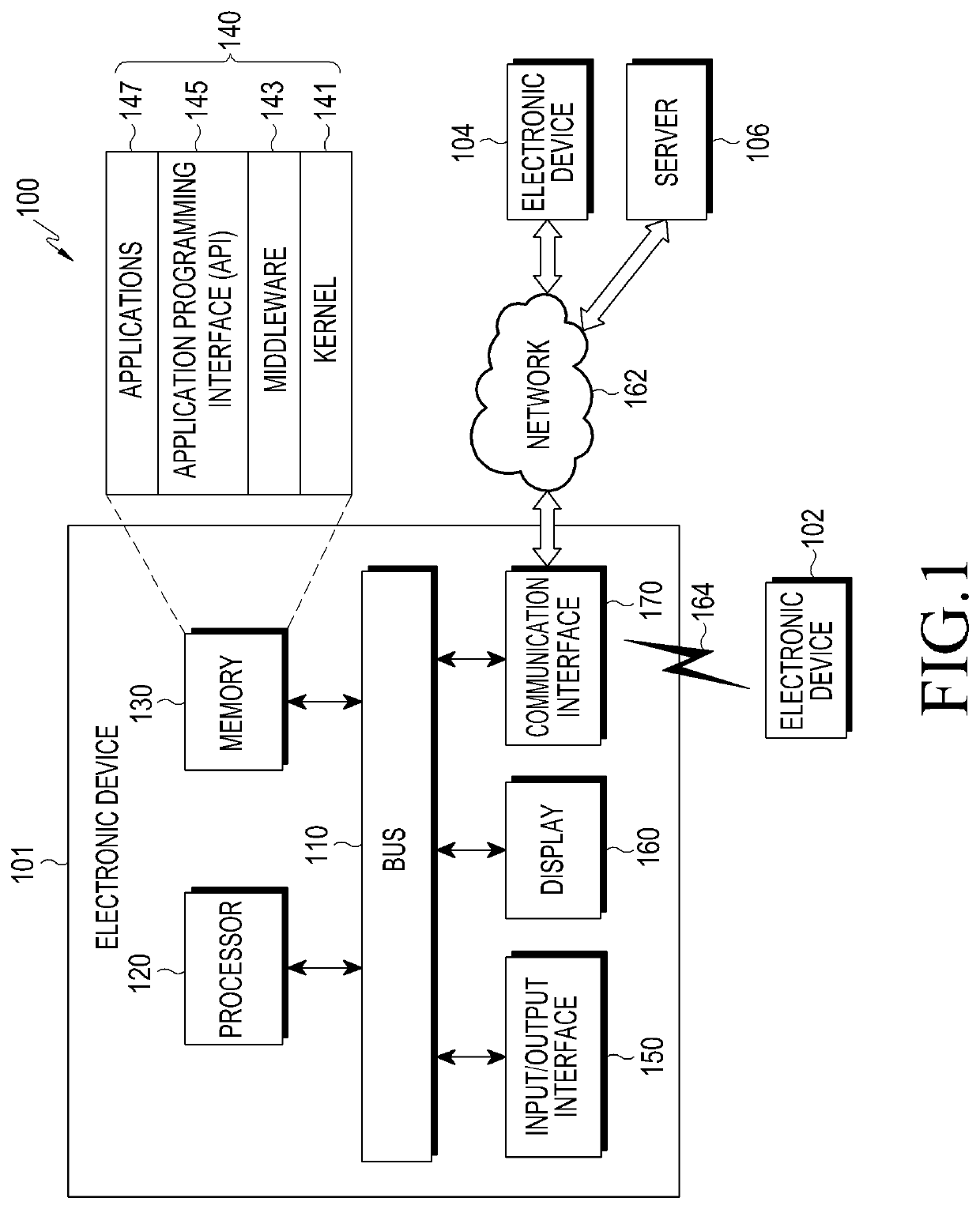

Electronic device and method for displaying screen by the same

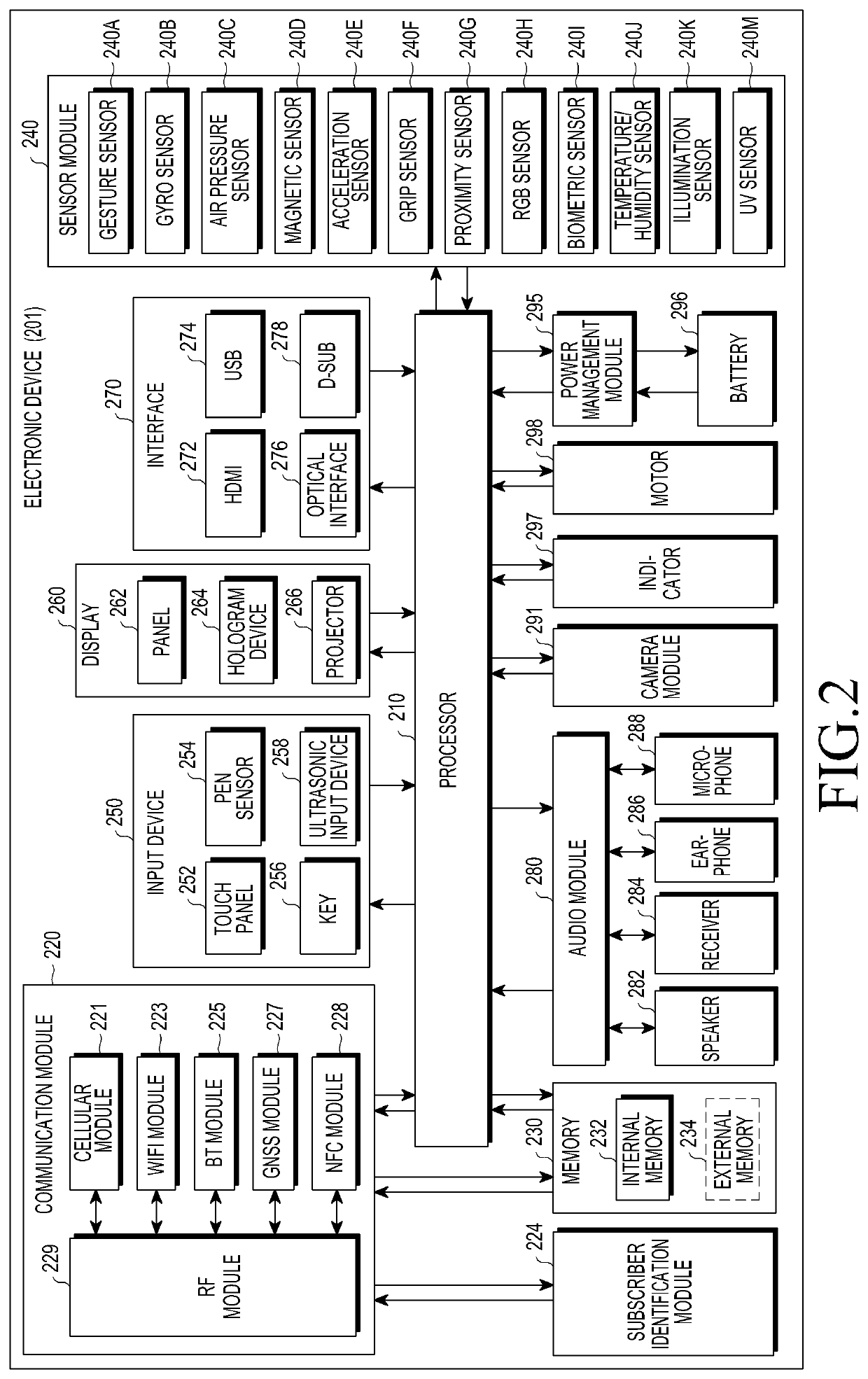

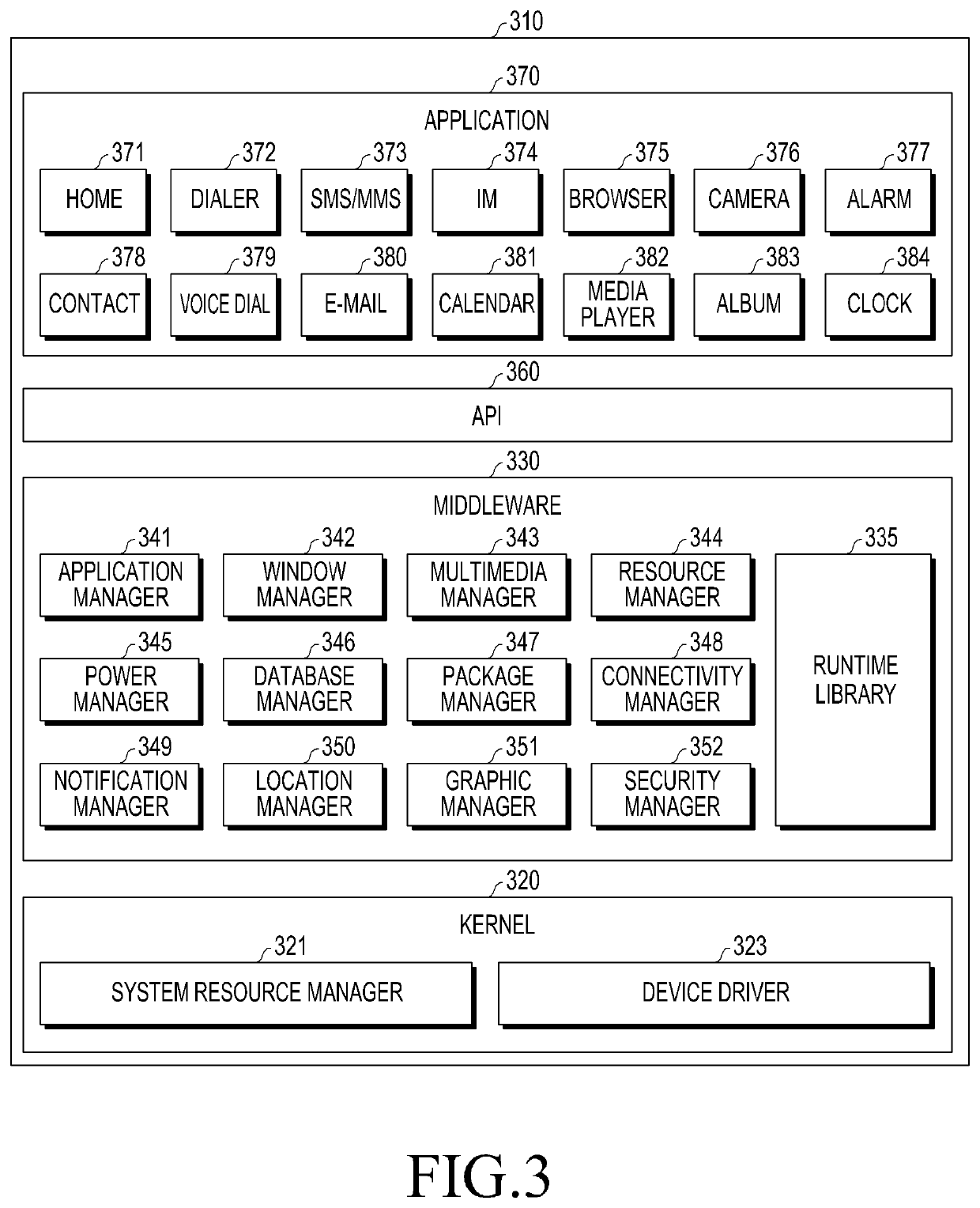

ActiveUS20180210621A1Increase scrolling speedInput/output for user-computer interactionGraph readingComputer graphics (images)

Owner:SAMSUNG ELECTRONICS CO LTD

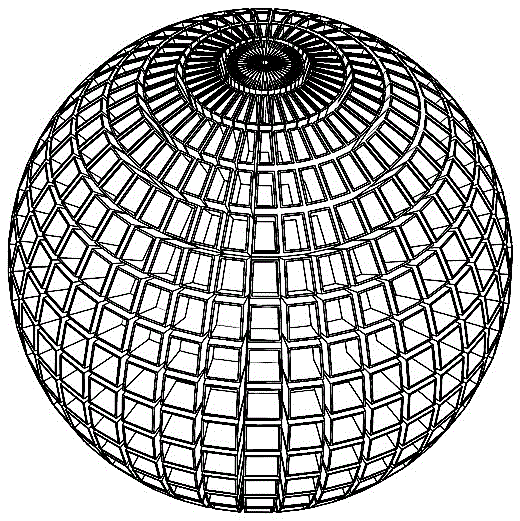

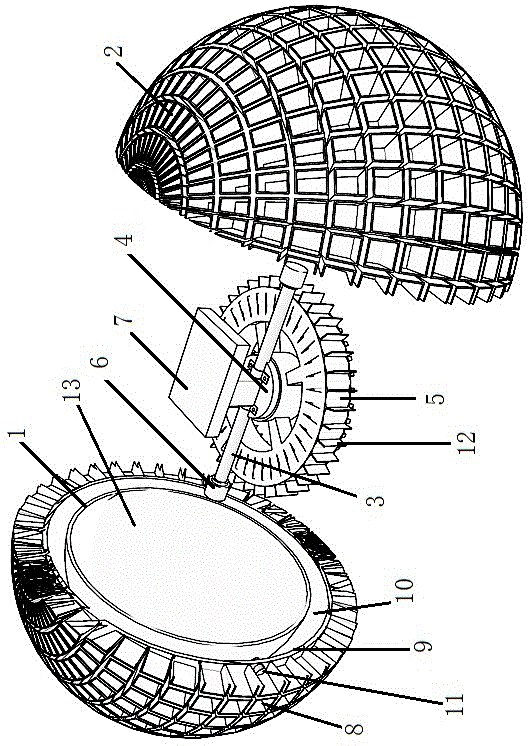

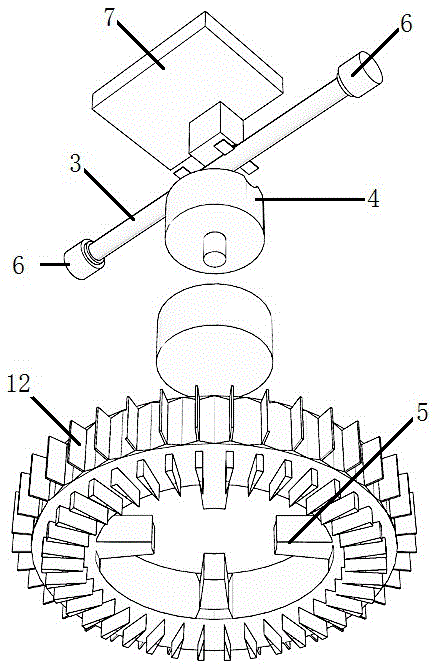

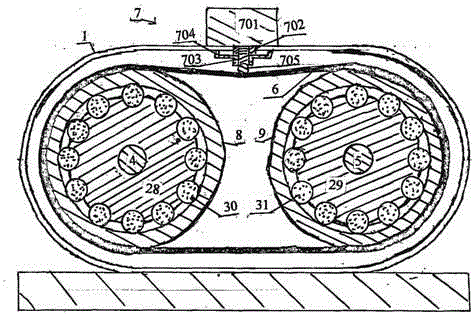

Spherical self-rotating type cleaning robot

InactiveCN105521974AIncrease scrolling speedIncrease rotation speedHollow article cleaningManipulatorDrive motorEngineering

The invention discloses a spherical self-rotating type cleaning robot, and relates to the technical field of cleaning robots. The spherical self-rotating type cleaning robot comprises a hard spherical packaging housing, a soft spherical cleaning sleeve which sleeves the outer part of the hard spherical packaging housing, and an acting unit which is mounted in the hard spherical packaging housing, wherein the acting unit comprises a main shaft which is radially arranged along the hard spherical packaging housing, an A driving motor which is fixed in the middle part of the main shaft, and an inertial wheel which is driven by the A driving motor; axes of the A driving motor and the inertial wheel are positioned in the same radial direction of the hard spherical packaging housing; B driving motors are mounted at two ends of the main shaft, and output ends of the B driving motors are connected to the end part of the main shaft; a base of each B driving motor is fixedly connected to the hard spherical packaging housing; wireless control modules for controlling the A driving motor and the B driving motors are arranged in power supplying circuits. The spherical self-rotating type cleaning robot is ingenious in structure, convenient to arrange inside, rich in rotating action after being arranged in a small-opening container, and high in cleaning efficiency.

Owner:福州环亚众志计算机有限公司

Smart watch and operating method using the same

InactiveUS10318958B2Increase scrolling speedImprove security levelTime-pieces with integrated devicesDigital data authenticationUser authenticationComputer science

Disclosed are a smart watch and a method of operating the same, in which fingerprint information and biometric information are measured by a single motion, a certain duration is set such that biometric information measured in the duration is generated into authenticated information or secured information, and transmitted or output to the outside. The smart watch includes a body, a fingerprint information acquisition unit provided on one surface of the body and configured to acquire fingerprint information about a user by a touch pressure applied from an outside, a biometric information acquisition unit provided on the other surface of the body, opposite to the one surface of the body, and configured to acquire biometric information about the user while contacting the skin of the user, and a control unit provided in the body and configured to acquire the fingerprint information and the biometric information for a predetermined period of time based on a point in time at which the touch pressure is applied if the touch pressure is greater than a reference pressure, and to generate user authentication information by using the acquired fingerprint information and biometric information.

Owner:KIM JONG HO

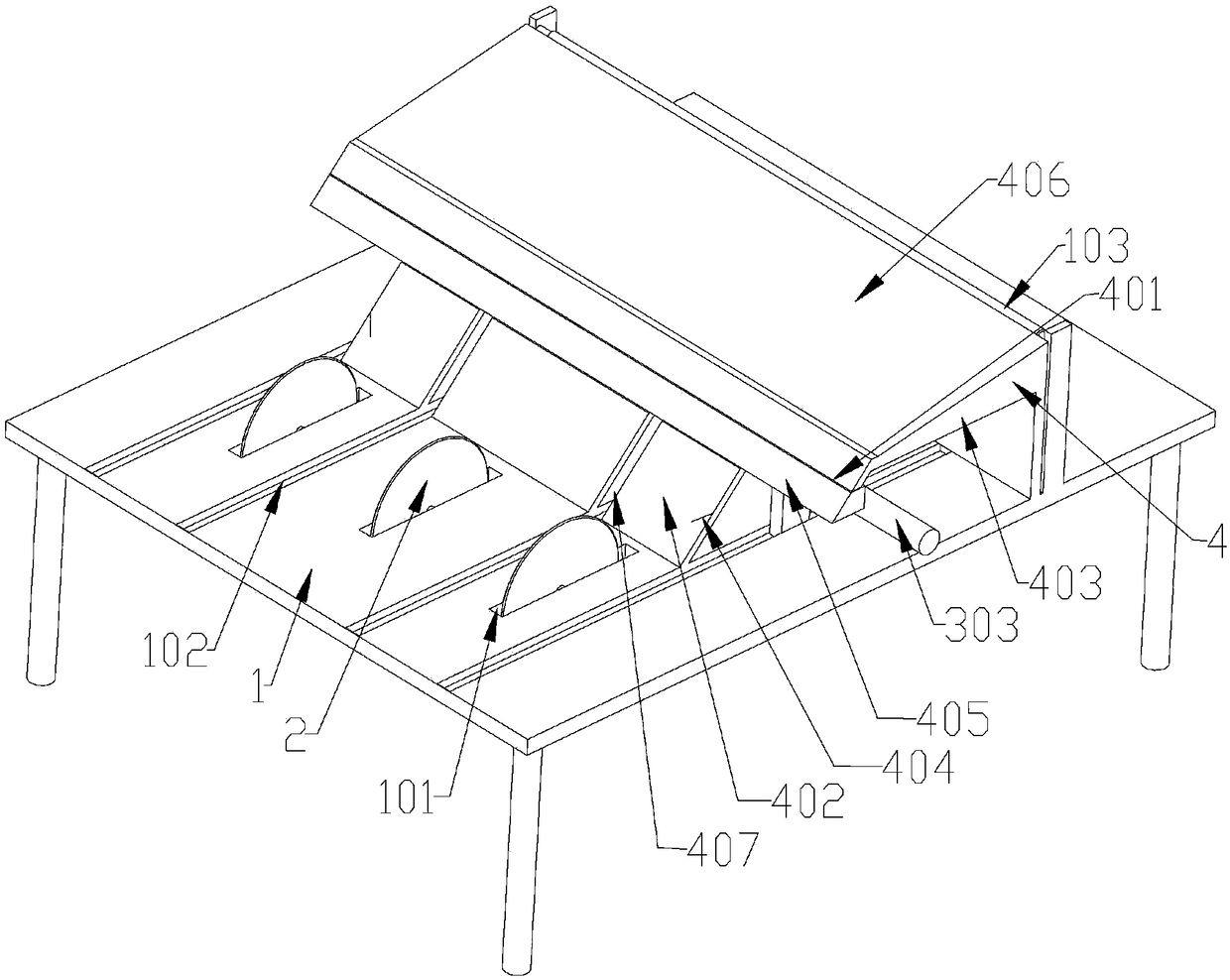

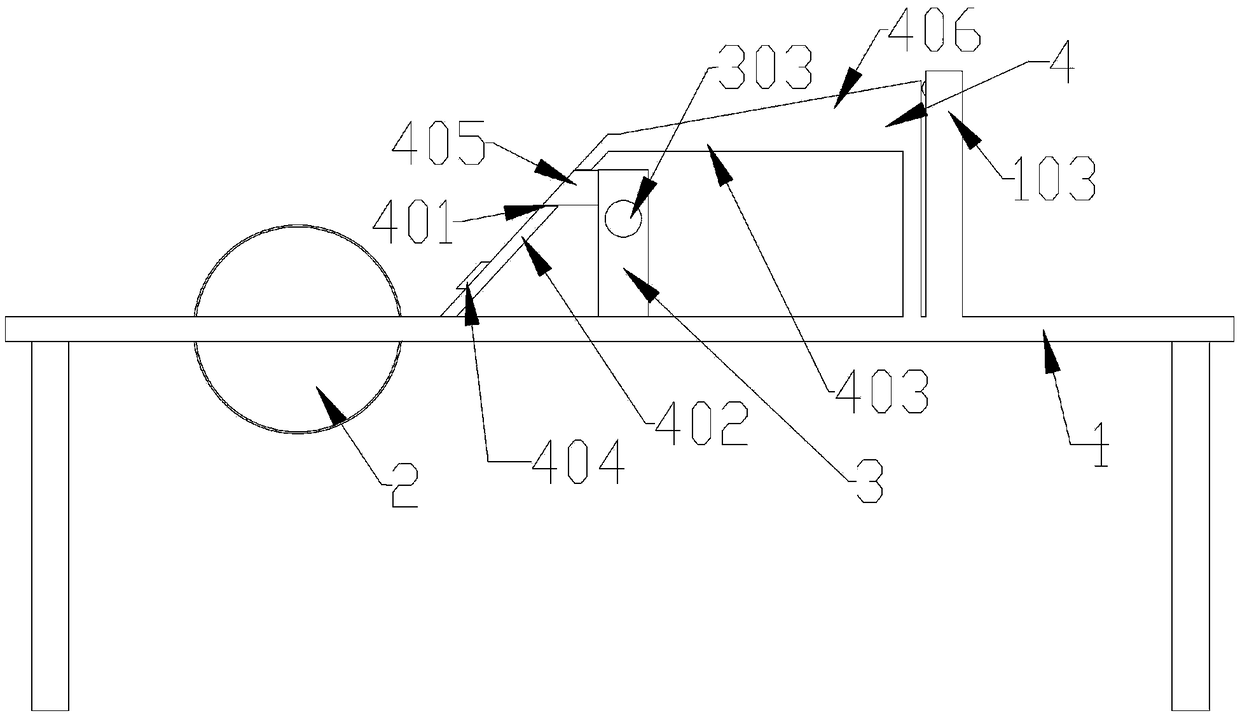

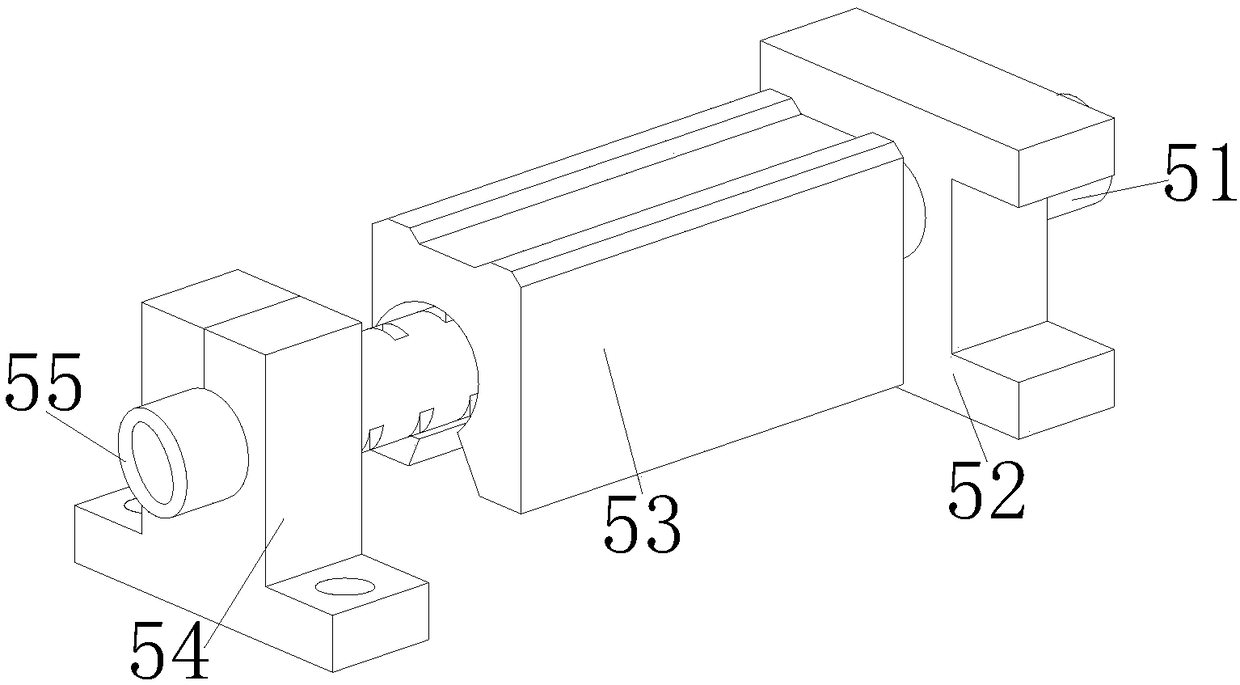

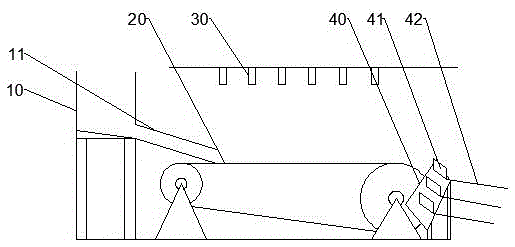

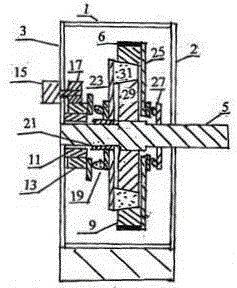

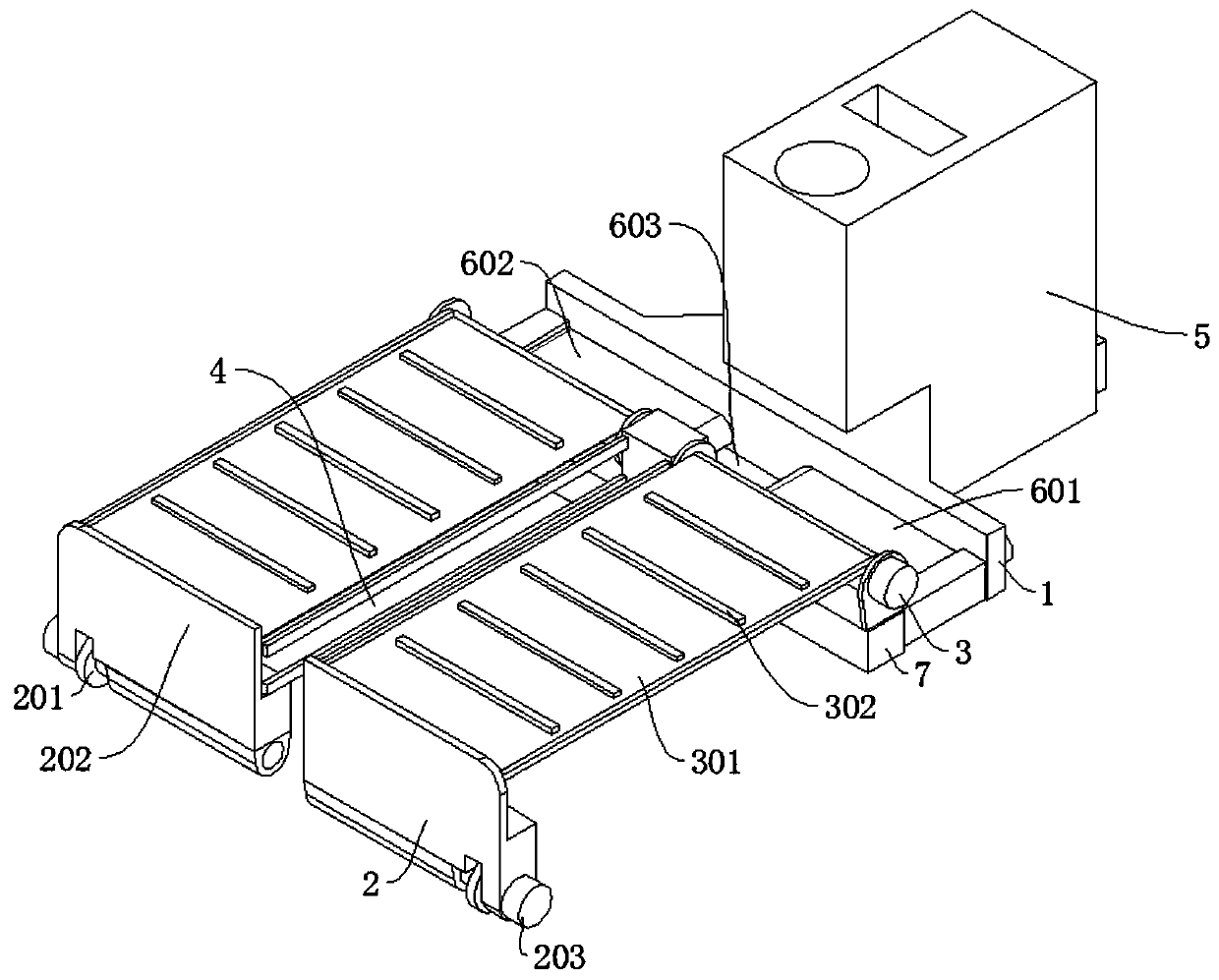

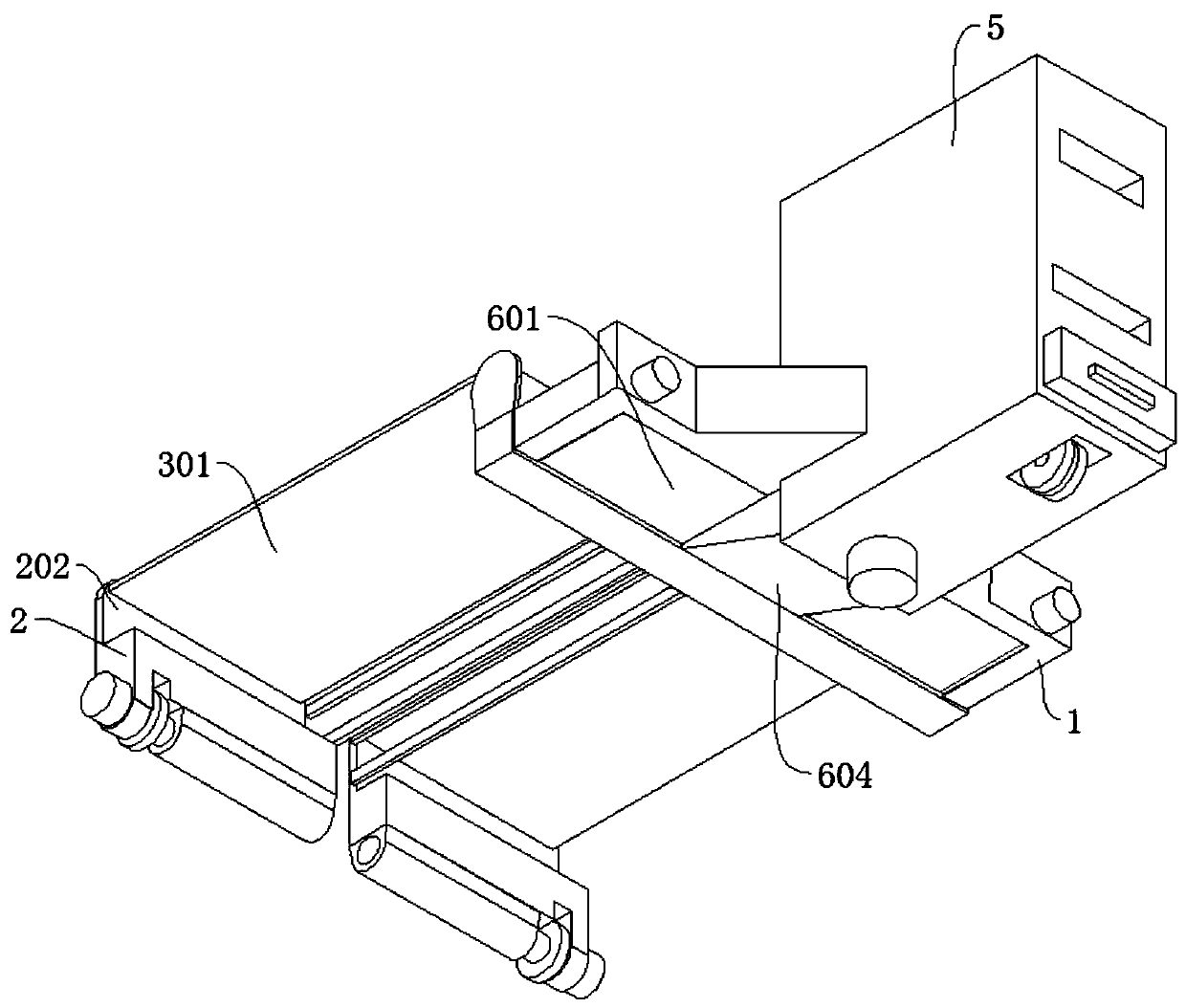

Cutting device for paper fireworks roll

ActiveCN109079882AReduce the probability of handImprove work efficiencyMetal working apparatusFireworksRolling sliding

The invention discloses a cutting device for a paper fireworks roll. The device comprises a tabletop, and a cutting mechanism which is arranged on the tabletop, wherein a first through hole through which the cutting mechanism passes is formed in the upper end surface of the tabletop; a first groove and a propping mechanism are arranged on the upper end surface of the tabletop; the propping mechanism is glidingly connected into the first groove and is used for propping the paper firework tube; a guide plate through which the paper fireworks roll slides is arranged on the upper end surface of the tabletop; a second through hole through which the propping mechanism passes is formed in one side, close to the cutting mechanism, of the guide plate.

Owner:李强

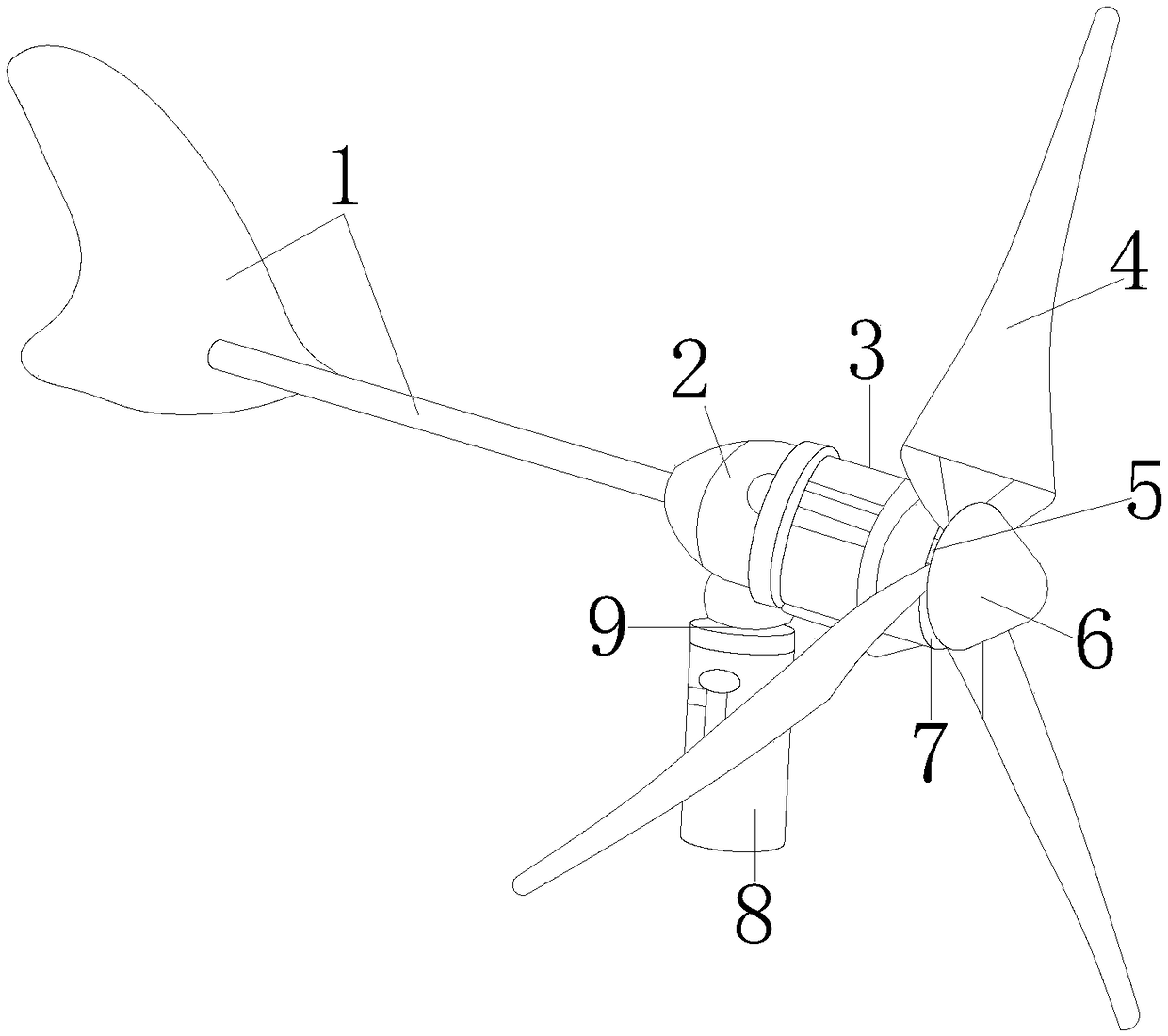

Horizontal axial wind following high-speed rotation wind power generator

InactiveCN109404214AIncrease scrolling speedAvoid damageWind motor controlMachines/enginesEngineeringTower

The invention discloses a horizontal axial wind following high-speed rotation wind power generator. The horizontal axial wind following high-speed rotation wind power generator structurally comprisesa tail wing, a power generator body, a cabin shell, windmill blades, a blade navigation mechanism, a fairing, a hub, a tower frame and a rotation shaft. Through installation and connection of the front end of a main direction shaft and an inner rod of the fairing, the main direction shaft follows rotation when the windmill blades are pushed by wind, an inner rotation rod and the main direction shaft can stably do the rotation movement through an insert at the time; meanwhile, an outer barrel directionally overturns through cooperation of equal-distance groove holes in the edge wall and obliqueteeth on the surface of a double-face winch, a retainer in an intermediate joint is used for conducting forward pushing, the main direction shaft rolls back and forth through fine balls so that an outer gear can be driven to accelerate to twist the integral mechanical power of a shaft piece in a gear case, the equipment can sufficiently utilize wind energy for volatilization, the blade rolling speed is increased, rapid power generation is conducted, and if the wind direction changes and reverse running happens, a spiral winch rod can brake the main direction shaft through the outer wall double-face winch, and the situation that the outer end of an inner shaft reversely rotates and is fractured or the gear case is damaged is prevented.

Owner:XIANGSHAN HONGQIANG ELECTRIC MFG CO LTD

Tangerine cleaning and sorting machine

InactiveCN105476044AIncrease the number ofGuaranteed work efficiencyFood treatmentGradingEngineeringMechanical engineering

The invention discloses a tangerine cleaning and sorting machine. According to the scheme, the tangerine cleaning and sorting machine comprises a feeding box and a conveying belt, a discharge port is formed in one side of the bottom of the feeding box, a channel which inclines to the conveying belt in a guiding mode is connected to the discharge port, sprayers are arranged above the conveying belt, the bottom of the feeding box is arranged obliquely, the obliquely arranged bottom guides tangerines to the discharge port, a buffer plate inclining downwards is arranged at the rear end of the conveying belt, guide plates perpendicular to the buffer plate are arranged on the buffer plate, sorting rods are evenly arranged on the buffer plate, and a collection frame is arranged below the sorting rods. Through the large tangerine cleaning and sorting machine, tangerines can be conveyed out of the sorting machine in time, and subsequent sorting work is not affected.

Owner:CHONGQING HENGHE AGRI TECH CO LTD

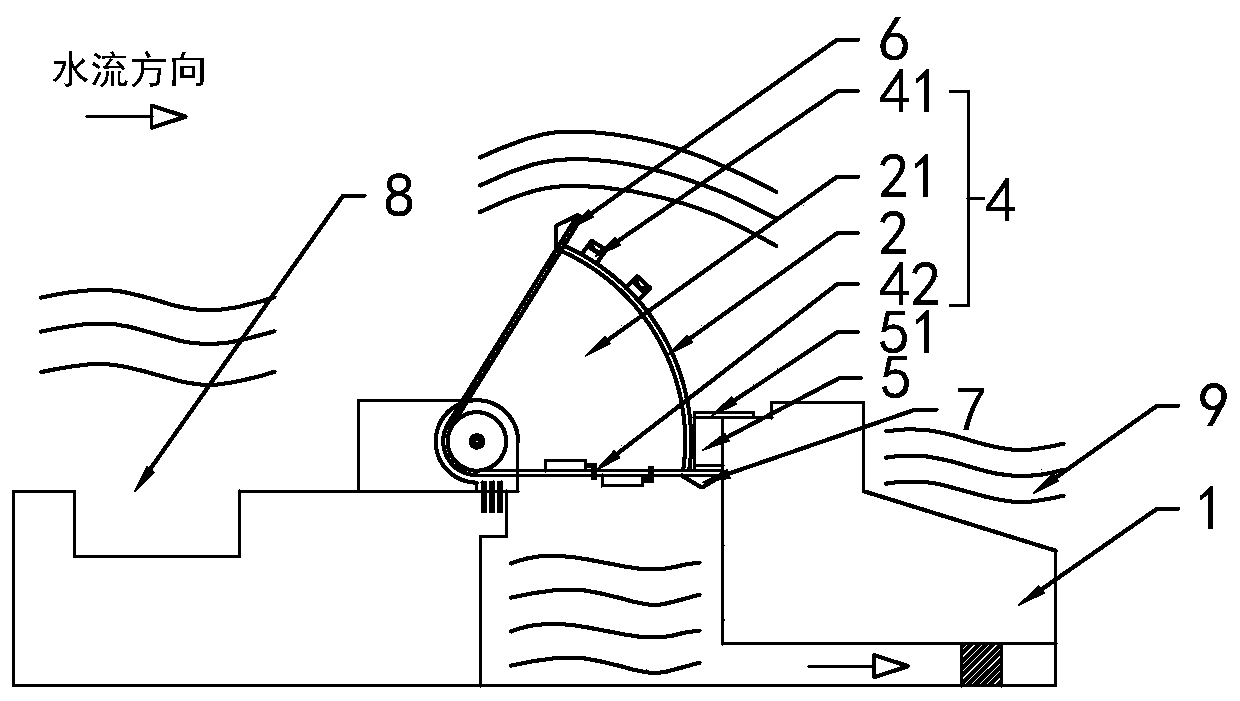

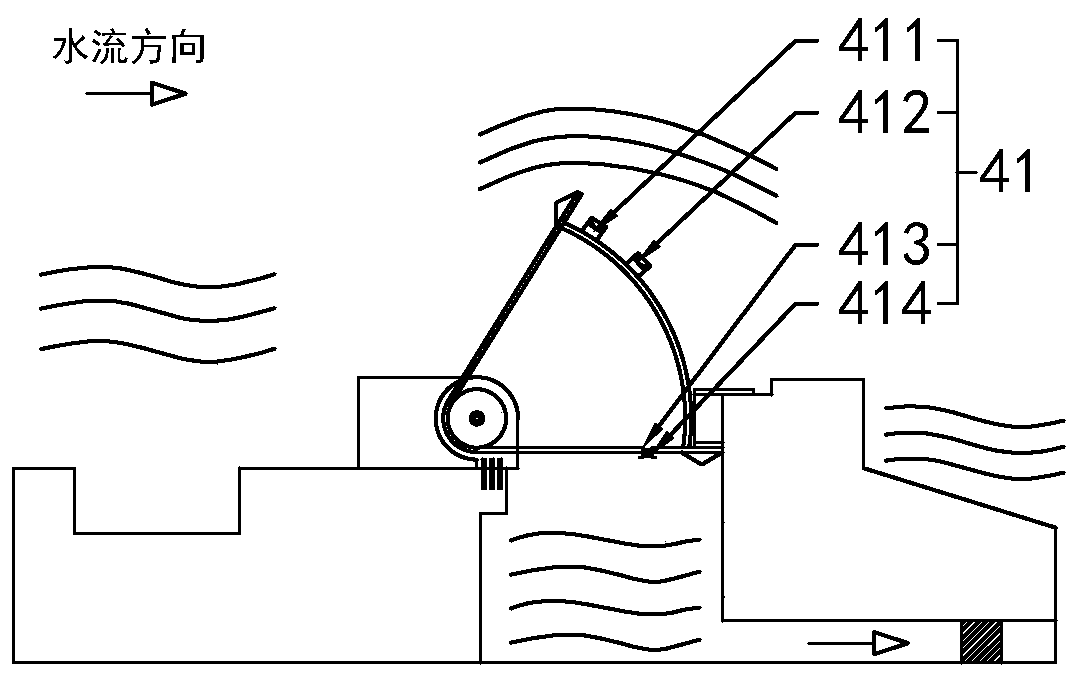

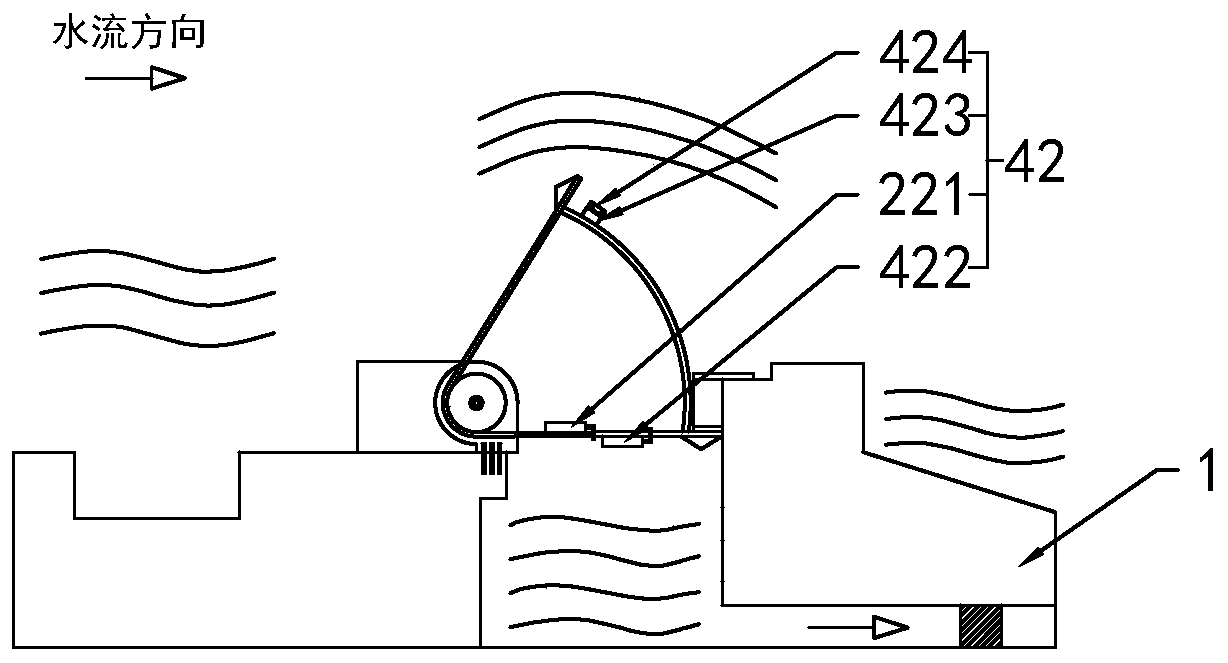

Water retaining dam and water flow regulation and control method thereof

PendingCN110847128APrecise height controlPrecise speed controlBarrages/weirsWater flowEnvironmental engineering

The invention relates to the technical filed of water retaining dams, in particular to a water retaining dam and a water flow regulation and control method thereof. According to the technical scheme,the water retaining dam comprises a dam body and a gate rotationally arranged on the dam body and is characterized in that a power unit is installed on the gate and is used for driving the gate to overturn on the dam body; the power unit comprises an air exchange cavity and an air exchange device, the air exchange cavity is arranged on the gate and is used for exchanging water and air, and the airexchange device is used for conducting water and air exchange in the air exchange cavity; the air exchange cavity controls overturn of the gate in water through inside water and air exchange; and thewater retaining dam and the water flow regulation and control method thereof have the beneficial effects that the water retaining dam is high in stability, high in safety performance and convenient to maintain.

Owner:QUZHOU CITY RIVER HOLY WATER POWER AUTOMATIC FLAPGATE

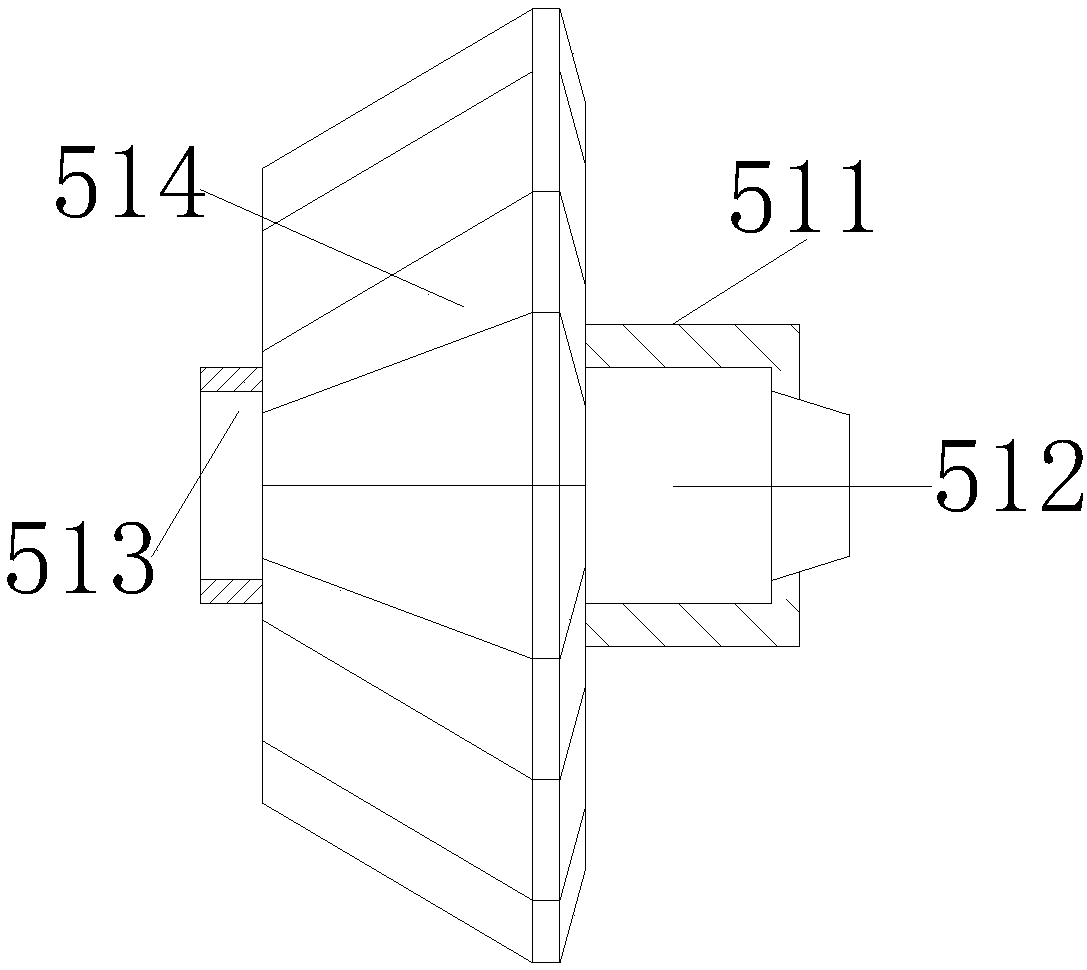

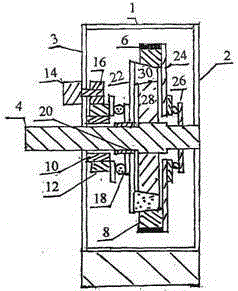

CVT stepless speed changer

The invention discloses a CVT stepless speed changer. A clamping speed reduction motor rotates to drive a clamping nut to rotate, so that a clamping screw and a roller are driven to move upwards or downwards to adjust the tightness degree and the slipping degree of a metal belt, and the rotating speed ratio of a driving rotating shaft to a driven rotating shaft is adjusted. If the needed rotating speed is not reached through a roller type clamping device, the rotating speed will be adjusted through two AT stepless speed changers. The adjusting process of the AT stepless speed changer on the driving rotating shaft includes the steps that an input speed reduction motor rotates and drives an input gear nut to rotate on an input annular screw through an input driving gear, and the input gear nut drives an input spline to move through an input rear thrust bearing, so that an input thrust disc on the input spline moves to adjust pressure exerted on input conical rollers, the rolling speed of the input conical rollers is adjusted, and then the rotating speed difference between a driving grooved wheel and a driving belt wheel is adjusted. The adjusting process of the AT stepless speed changer on the driven rotating shaft is the same as that of the AT stepless speed changer on the driving rotating shaft.

Owner:张英华

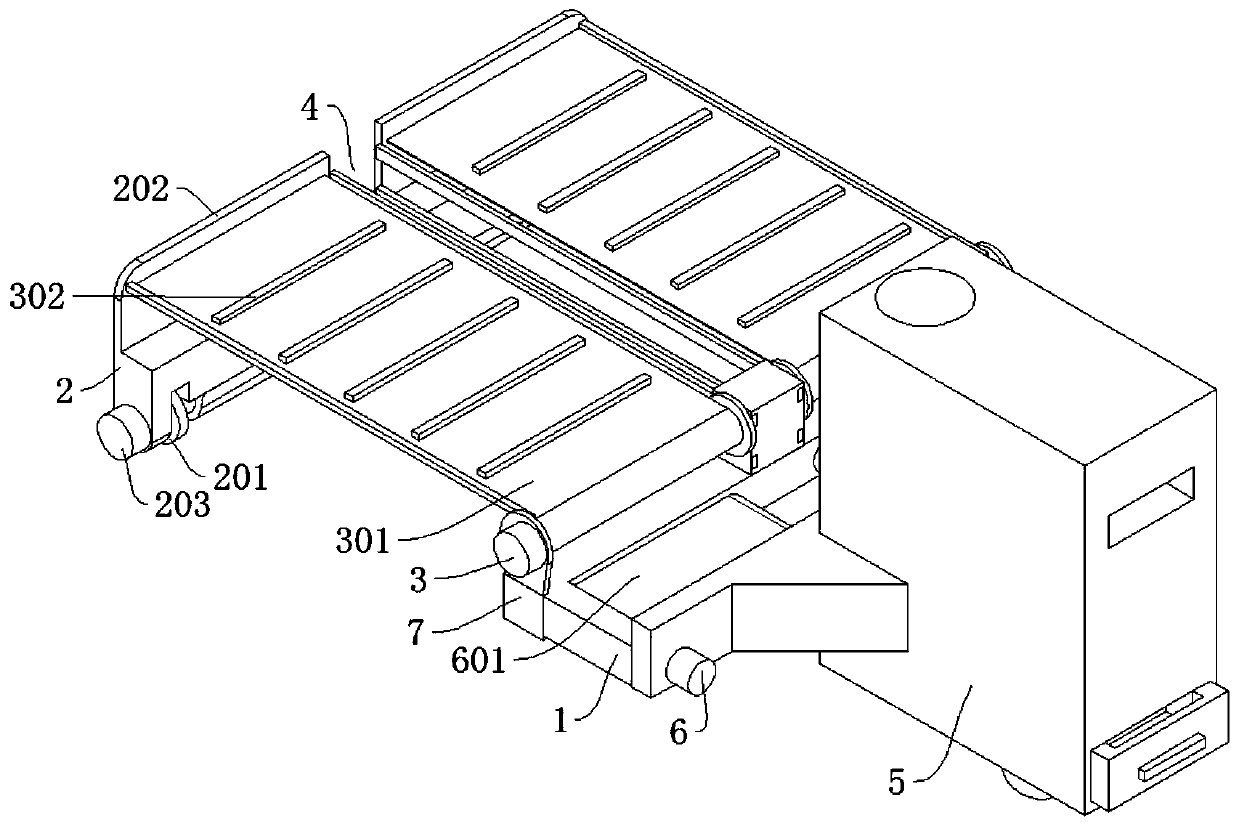

Efficient jujube harvesting robot

ActiveCN111386857AIncrease scrolling speedImprove the separation effectGas current separationFruits/vegetable preservation by irradiation/electric treatmentAgricultural engineeringChinese Jujube

The invention discloses an efficient jujube harvesting robot, and belongs to the technical field of agricultural machinery. The efficient jujube harvesting robot comprises a base; a collecting cloth,wherein one end of the collecting cloth is connected with the base, and the other end is connected with a moving seat; the moving seat is connected with a driving part for driving the moving seat to move; a material collecting opening is formed in the base; a crawler belt assembly is used for being connected to the base to convey the jujubes to the material collecting opening; a separation box isconnected to the base, and the bottom of the separation box communicates with the material collecting opening through a material collecting channel; a lifting assembly is connected into the separationbox and used for lifting the jujubes and the sundries; a separation plate A is obliquely connected into the separation box; a separation plate B is obliquely connected into the separation box; and afirst sundry outlet corresponding to the separation plate A and a second sundry outlet corresponding to the separation plate B are formed in the separation box. According to the red date picking device, falling red dates can be collected in a centralized mode through the collecting cloth, fruit leaves are further separated through the separating box, and compared with traditional manual picking, the working efficiency is improved, and manual fatigue is reduced.

Owner:江西盾牌化工有限责任公司

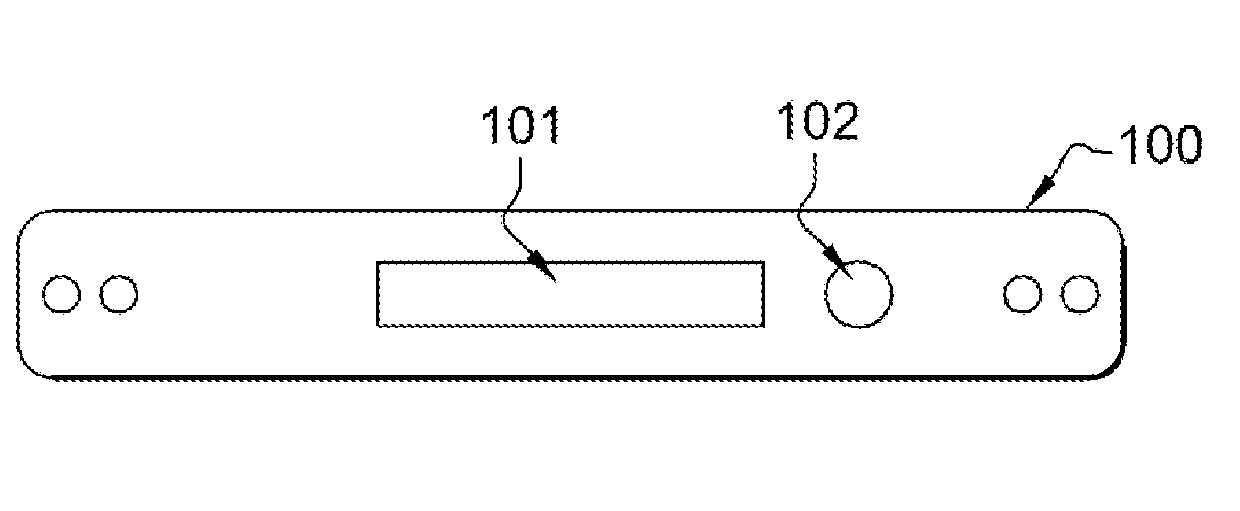

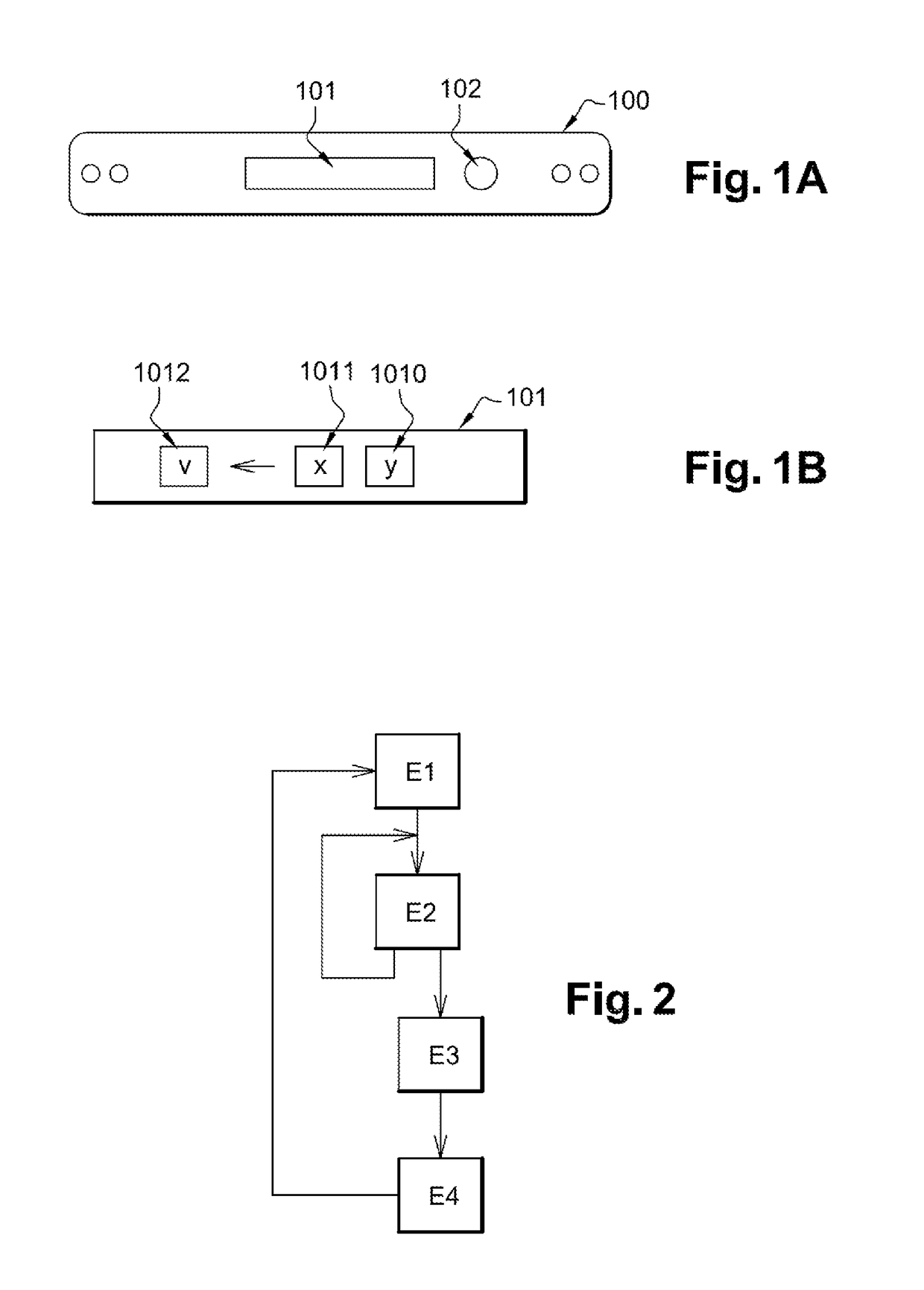

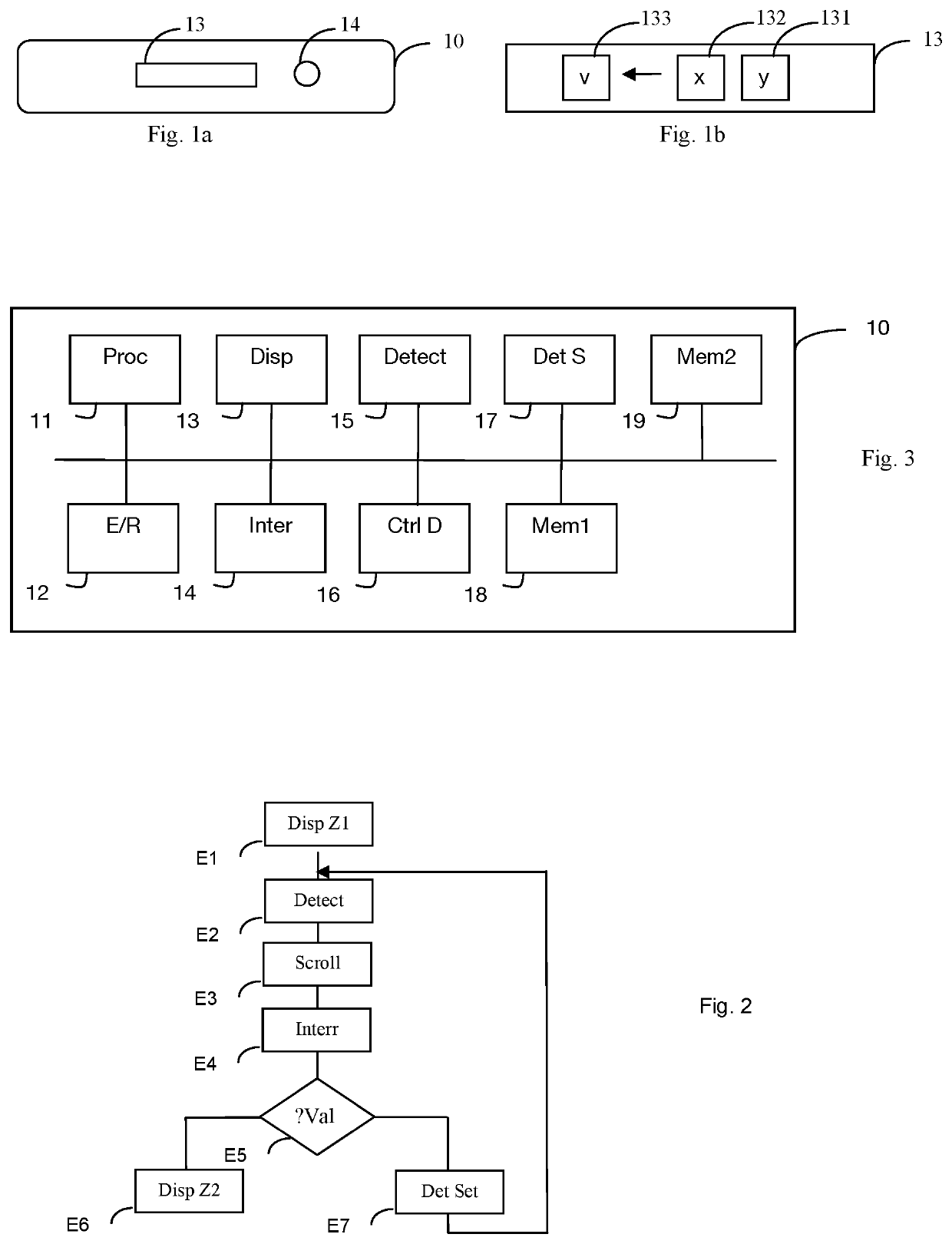

Method for inputting at least one alphanumeric character by using a user interface of an electronic device

InactiveUS20170131787A1Easy and fast inputGood autonomyDetails for portable computersInput/output processes for data processingScrollingHuman–computer interaction

A method for inputting at least one alphanumeric character by a user interface of an electronic device. The user interface has a display screen with a first display area for displaying at least one entered alphanumeric character, and a second display area for displaying an alphanumeric character that is being entered. The electronic device also has a command input element for inputting a scrolling control for scrolling alphanumeric characters displayed in the second display area. The method includes: detecting a scrolling command input by the command element triggering a scrolling of alphanumeric characters applied to a character in the second display area, displaying a current character in the second display area following the scrolling, detecting an event of entering the current alphanumeric character, displaying, following the detection of the event, the current character in the first display area, and deleting the current character from the second display area.

Owner:ORANGE SA (FR)

Material splitting barrel

InactiveCN104841633AIncrease scrolling speedImprove screening efficiencySievingScreeningEngineeringPore diameter

The invention provides a material splitting barrel which comprises a barrel body, a support, a first brush rod, a second brush rod and a driving mechanism. The barrel body can be rotatably installed on the support around the center axis and arranged in an oblique mode, and multiple sieve pores which are distributed according to the pore diameters from small to large are formed in the casing wall of the barrel body from the higher end to the lower end; the first brush rod and the second brush rod are installed parallel to the center axis of the barrel body and located on the two sides of the barrel body, brushes are arranged on the first brush rod and the second brush rod, and the length of the brushes is not less than that of the barrel body. According to the material splitting barrel, materials in the barrel body are distinguished by falling from the sieve pores, the barrel body is obliquely provided with the sieve pores which are beneficial for the materials to roll for sequentially penetrating through the sieve pores with different sizes to complete sieving of the materials with different diameters, and the rotatable arrangement mode of the barrel body is beneficial for increasing the rolling speed of the materials in the barrel body to improve the sieving efficiency. By means of the material splitting barrel, cleaning can be conducted on the sieve pores through the arrangement of the brushes, blocking is avoided, and the normal work of the material splitting barrel is guaranteed.

Owner:WUHU XILAIWANG AGRI

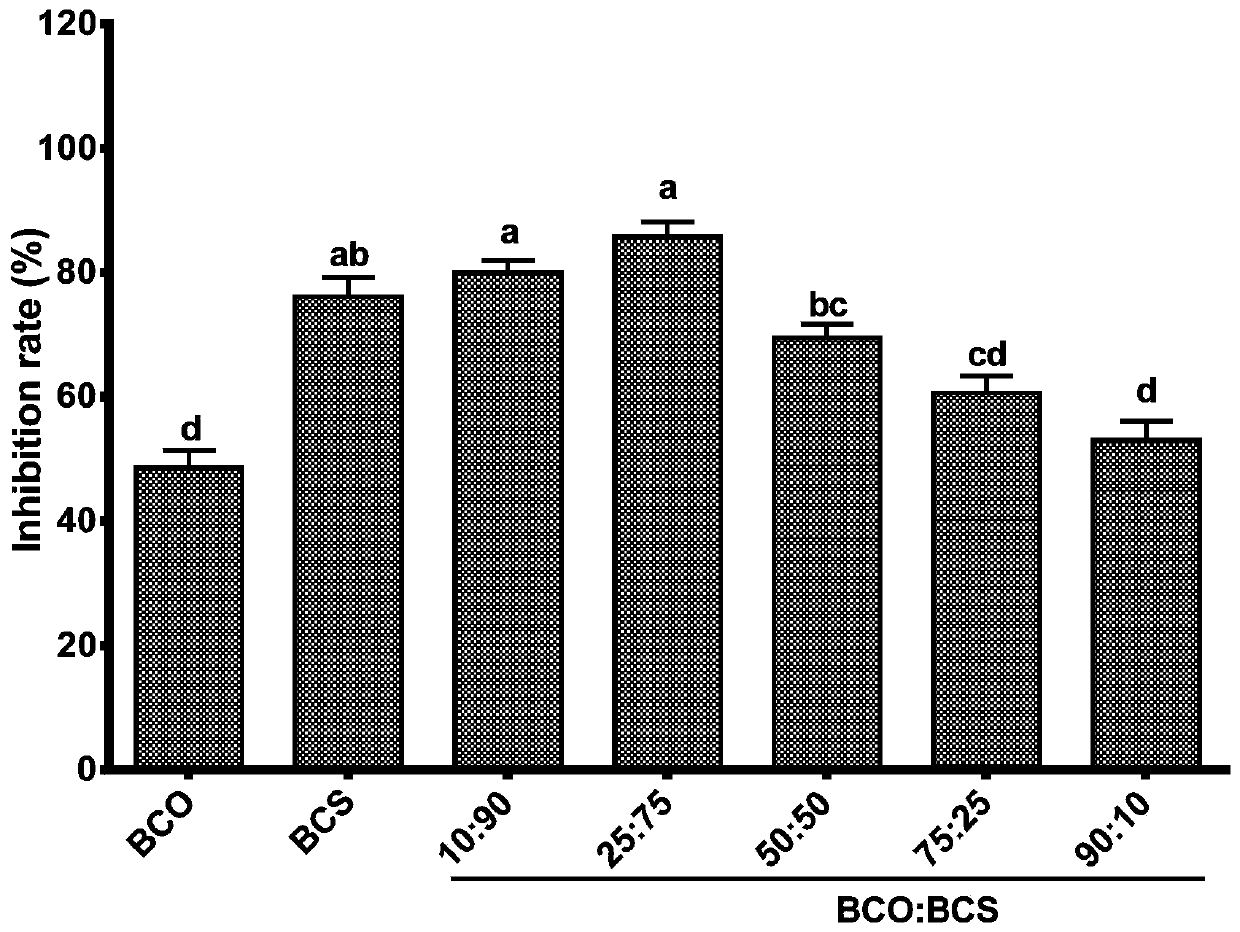

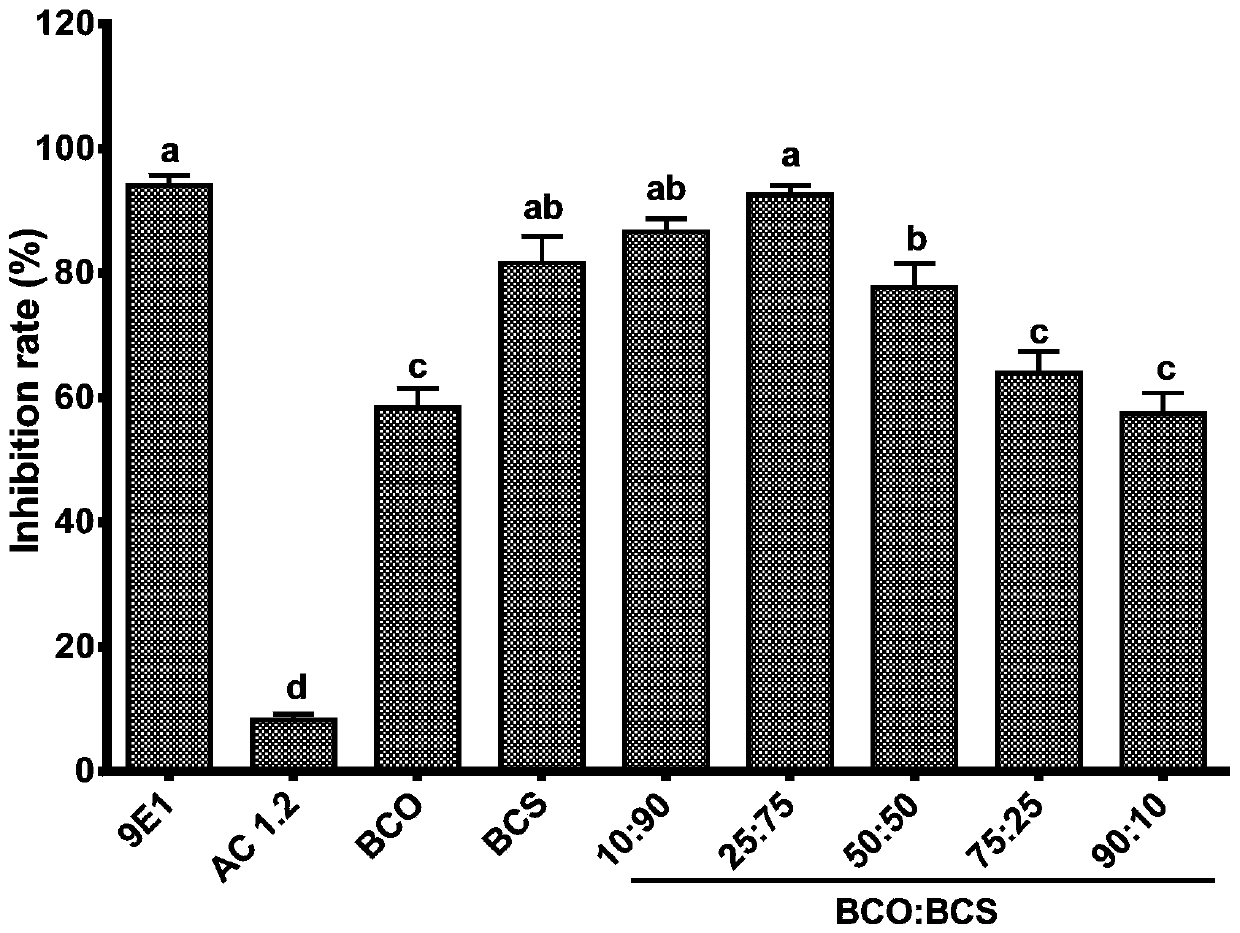

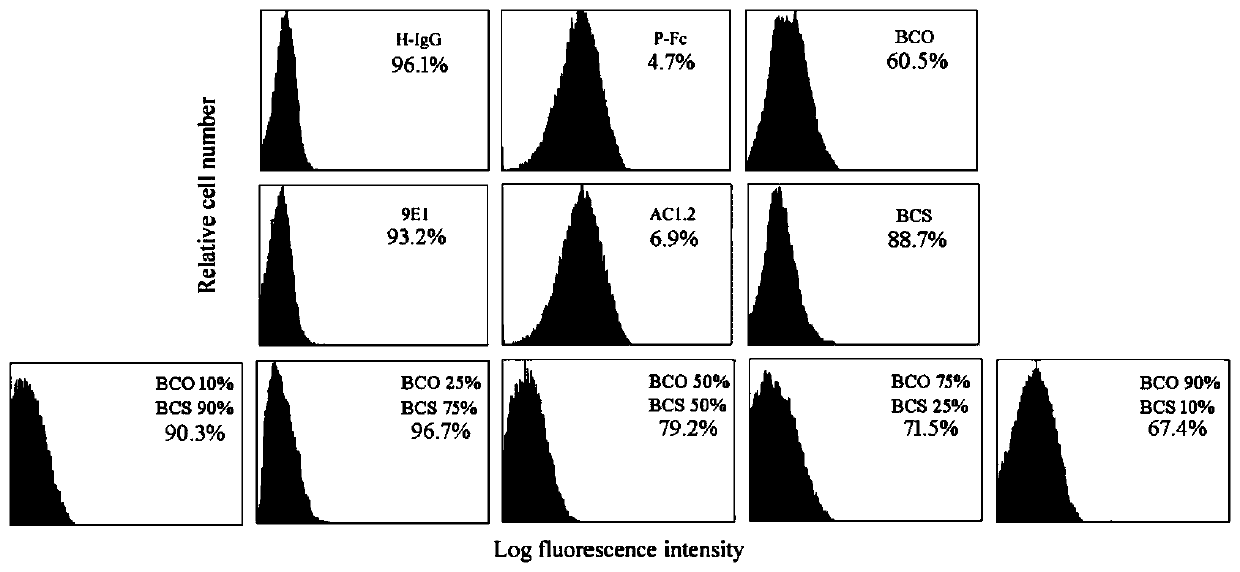

Anti-inflammatory active pharmaceutical composition based on radix bupleuri component and application of anti-inflammatory active medicinal composition

ActiveCN110123854AInhibition of exudationIncrease scrolling speedOrganic active ingredientsAntipyreticP-selectinPeritoneal fluid

The invention belongs to the field of traditional Chinese medicines, and particularly relates to an anti-inflammatory active pharmaceutical composition based on radix bupleuri components and a preparation method of the anti-inflammatory active pharmaceutical composition. The components of the composition are from the radix bupleuri, and particularly, the composition consists of the following components in percentages by mass: 10-50% of a radix bupleuri oligosaccharide fragment and 50-90% of radix bupleuri total saponins. According to pharmacological and activity experimental results, the composition can effectively inhibit exudation of white blood cells in the peritoneal fluid of an acute peritonitis mouse model, and shows good anti-inflammatory activity; and the acting mechanism of the composition is closely related to antagonizing leukocyte adhesion mediated by vascular endothelial P-selectin. The results show that the radix bupleuri composition can be used for preparing novel effective medicines for treating acute inflammation, and has wide application prospect.

Owner:WENZHOU UNIVERSITY

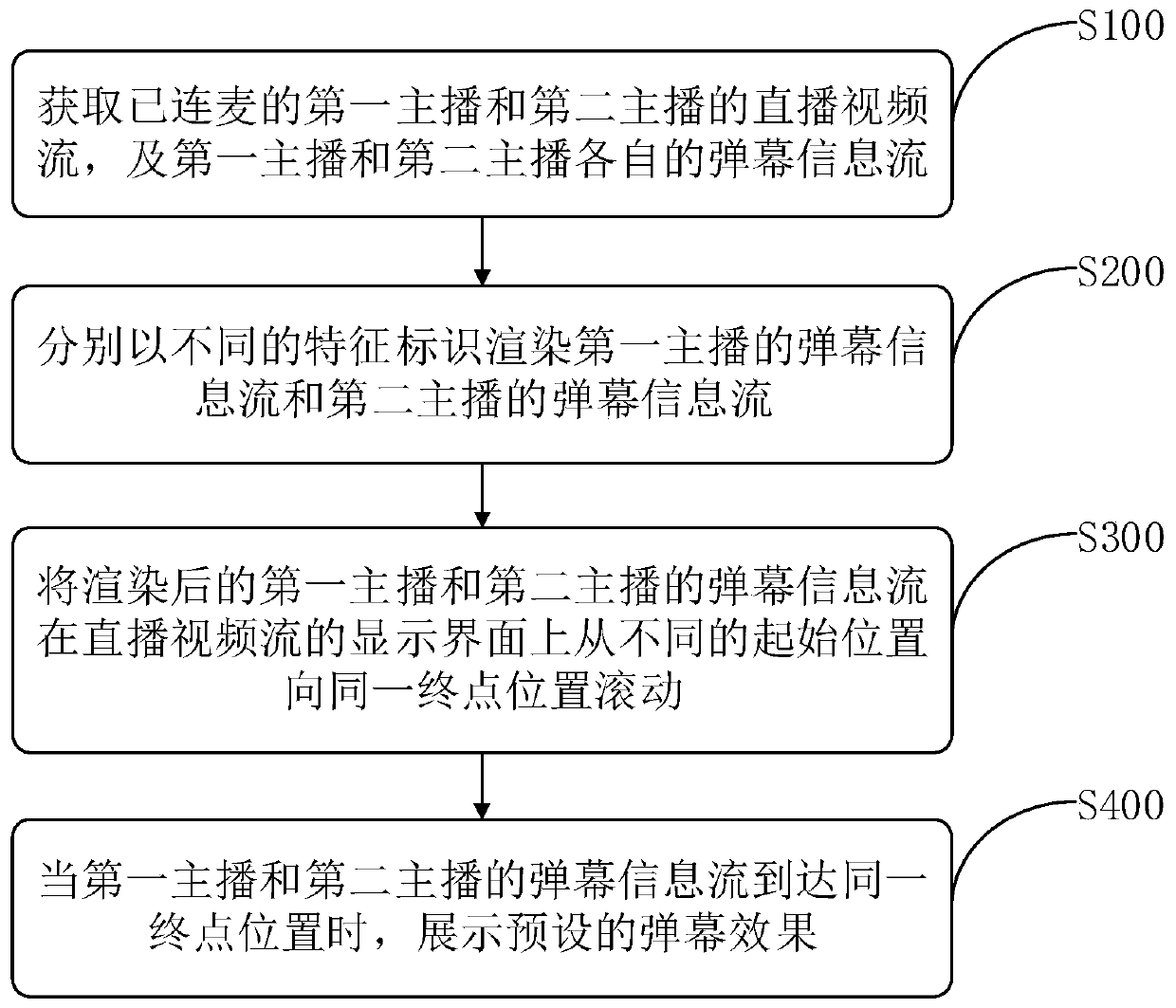

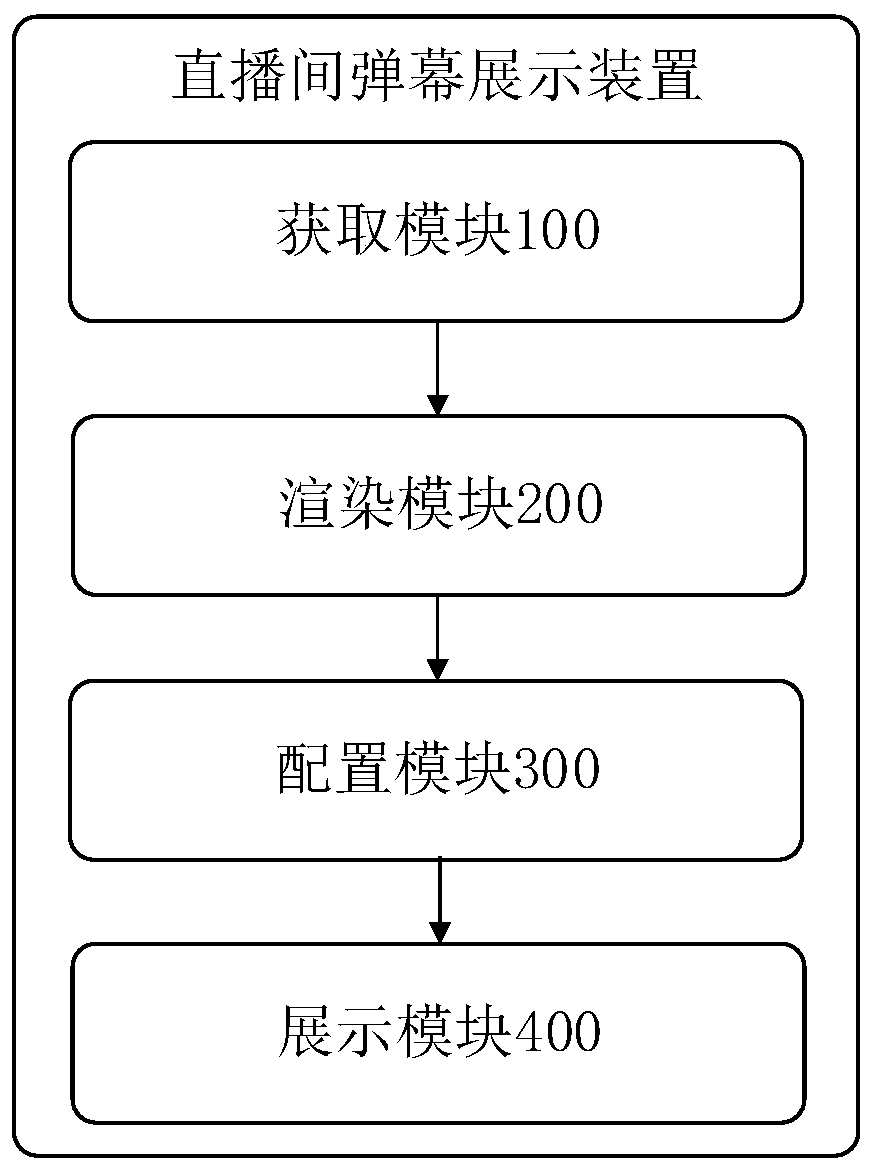

Barrage display method, device and corresponding terminal in live broadcast room

ActiveCN108055552BImprove visual effectsImprove viewing experienceSelective content distributionLiving roomComputer terminal

The invention relates to the field of a software application and specifically relates to a live broadcast room bullet screen display method and device and a corresponding terminal. The method comprises the steps of acquiring live broadcast video streams of a first anchor and a second anchor which are in microphone connection, and acquiring bullet screen information streams of the first anchor andthe second anchor; rendering the bullet screen information streams of the first anchor and the bullet screen information streams of the second anchor through utilization of different feature identities; scrolling the rendered bullet screen information streams of the first anchor and the second anchor from different initial positions towards the same final position on a display interface of the live broadcast video streams; and displaying preset bullet screen effects when the bullet screen information streams of the first anchor and the second anchor arrive at the same final position. Accordingto the method, the device and the terminal, the bullet screen information of live broadcast rooms of the anchors which are in microphone connected live broadcast is opened and shared and the bullet screen information and bullet screen effects of different live broadcast rooms are displayed through utilization of different feature identities in a microphone connected live broadcast video, so visual effects of the live broadcast rooms are improved, the watching experience of the live broadcast rooms is improved, and the atmosphere of the live broadcast rooms is activated.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

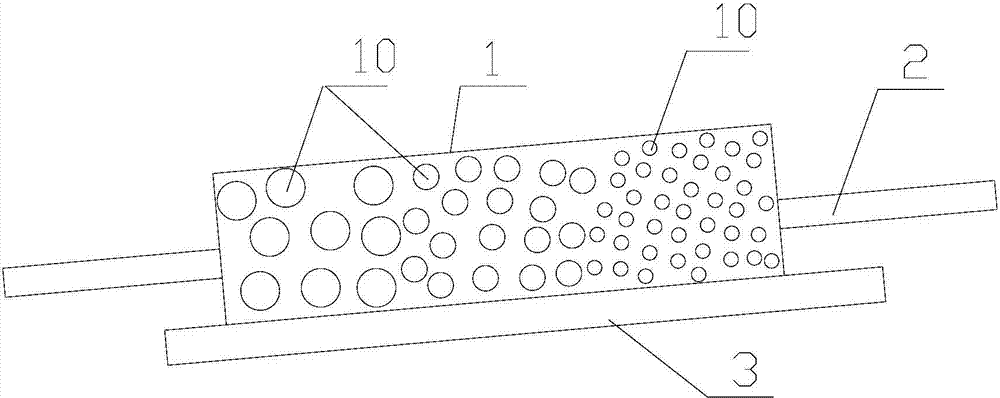

Mask and display screen

PendingCN111243455AGuaranteed installation efficiencyAvoid direct contactIdentification meansEngineeringMaterials science

The invention relates to a mask. The mask is used for being installed on a light-emitting assembly of a display screen. The light-emitting assembly comprises a circuit board and lamp beads. The mask comprises: a body part which is provided with a first surface and a second surface which face opposite directions, wherein the second surface is used for being attached to the circuit board, the body part is provided with a plurality of mounting holes which penetrate through the first surface and the second surface at the same time, the mounting holes are arranged in multiple rows and multiple columns, and the mounting holes are used for allowing the lamp beads to penetrate through; and protruding parts which are arranged on the first surface, wherein the protruding parts protrude by a set height relative to the first surface in the thickness direction of the body part, and the multiple protruding parts are arranged in multiple rows and multiple columns. Due to the interference effect of the protruding parts, when the mask is pressed on the circuit board through the rollers, the worry that the rollers may damage the lamp beads can be eliminated, and therefore the installation efficiencyof the mask is guaranteed on the basis that safety is guaranteed.

Owner:LEYARD VTEAM SHENZHEN CO LTD

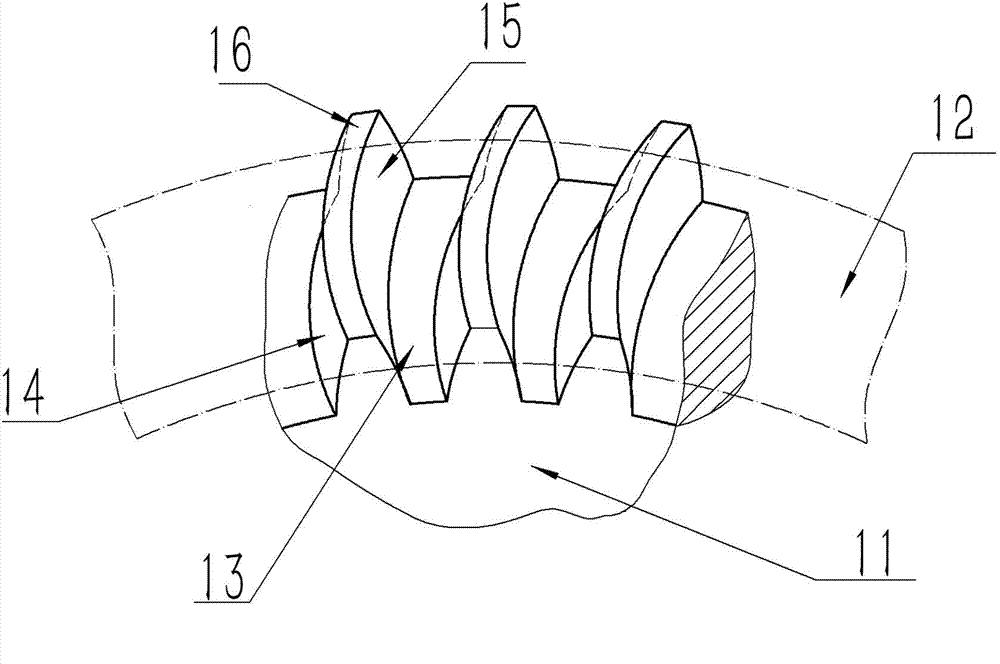

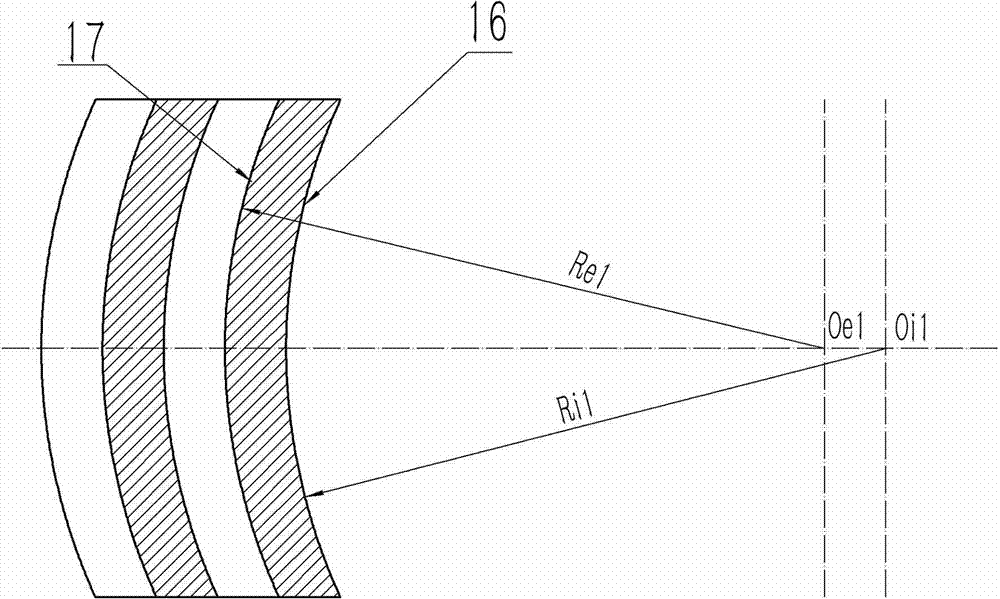

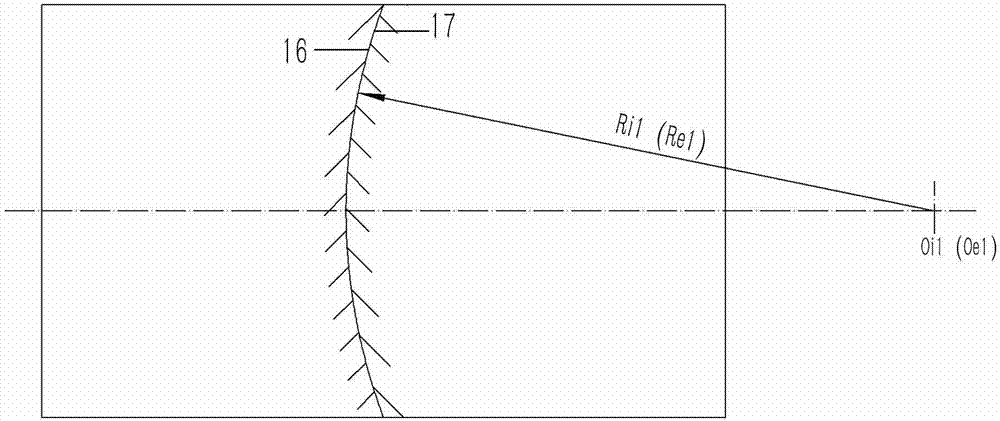

Arc gear and arc rack

ActiveCN104500695AIncrease scrolling speedEasy to assemblePortable liftingGearing elementsConvex sideEngineering

The invention discloses an arc gear and an arc rack. The maximum curvature radiuses of convexity tooth lines of wheel teeth and tooth bodies are smaller than the minimum curvature radiuses of concavity tooth lines; therefore, after two meshed gears or a gear and a rack are meshed and assembled, under an ideal condition, the convexity tooth lines and the concavity tooth lines are meshed by a point contact mode; during actual use, in a stage of starting meshing, the convexity tooth lines and the concavity tooth lines are still meshed by the point contact mode, and the difference is only that the point contact positions are different, that is, the convexity tooth lines and the concavity tooth lines are only instantly meshed and then are continuously abraded between the wheel teeth or between the wheel teeth and the tooth bodies; actually, quite long line segments of the concavity tooth lines and the convexity tooth lines are in contact, so that after two components subjected to meshing transmission are subjected to running in, the concavity tooth lines and the convexity tooth lines are meshed in a linear contact manner; therefore, the requirement on the error sensitivity of a center distance, a helical angle and the like in an assembling process is reduced, and the two components subjected to meshing transmission are more easily assembled.

Owner:三门峡骐达科技有限公司

Electronic device and method for displaying content in response to scrolling inputs

ActiveUS11119644B2Increase scrolling speedInput/output for user-computer interactionGraph readingComputer hardwareComputer graphics (images)

Owner:SAMSUNG ELECTRONICS CO LTD

Technique for inputting at least one character by way of a user interface of an electronic device

ActiveUS20190361583A1Input quickly and easilyIncrease scrolling speedInput/output processes for data processingScrollingHuman–computer interaction

A method and apparatus for inputting at least one character by way of a user interface of an electronic device. The method includes: detecting a scrolling command performed by way of a command input element; displaying a current character in a display area by scrolling through a current set of characters, triggered by the detection of the scrolling command; detecting a selection of the current character; determining a new restricted set of characters on the basis of the current set of characters, the new set including the selected character and a selection of characters surrounding the selected character and becoming the current set of characters for a following iteration of the display of the scrolling of characters; and detecting a confirmation of the current character by way of the command input element, putting an end to the iterations.

Owner:ORANGE SA (FR)

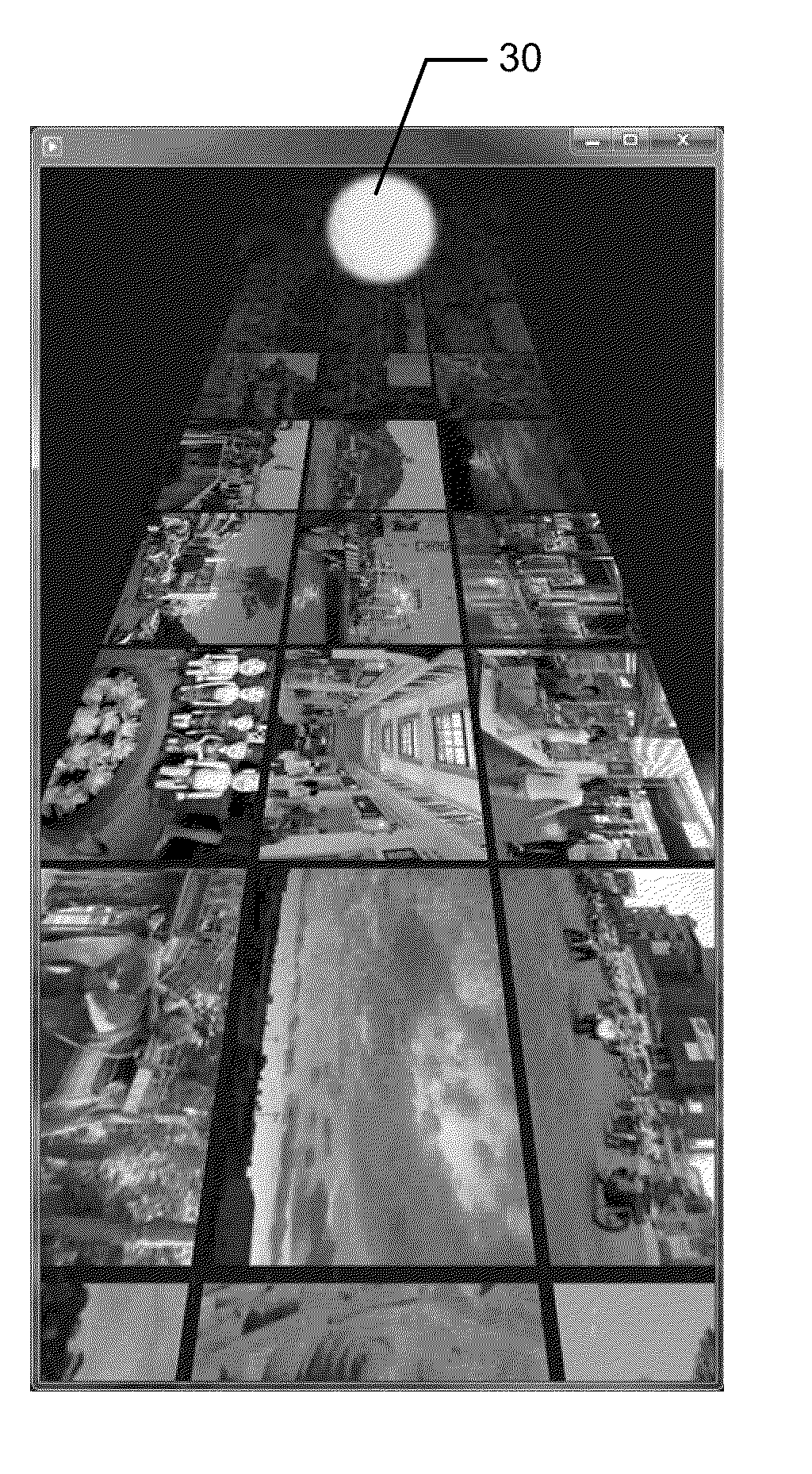

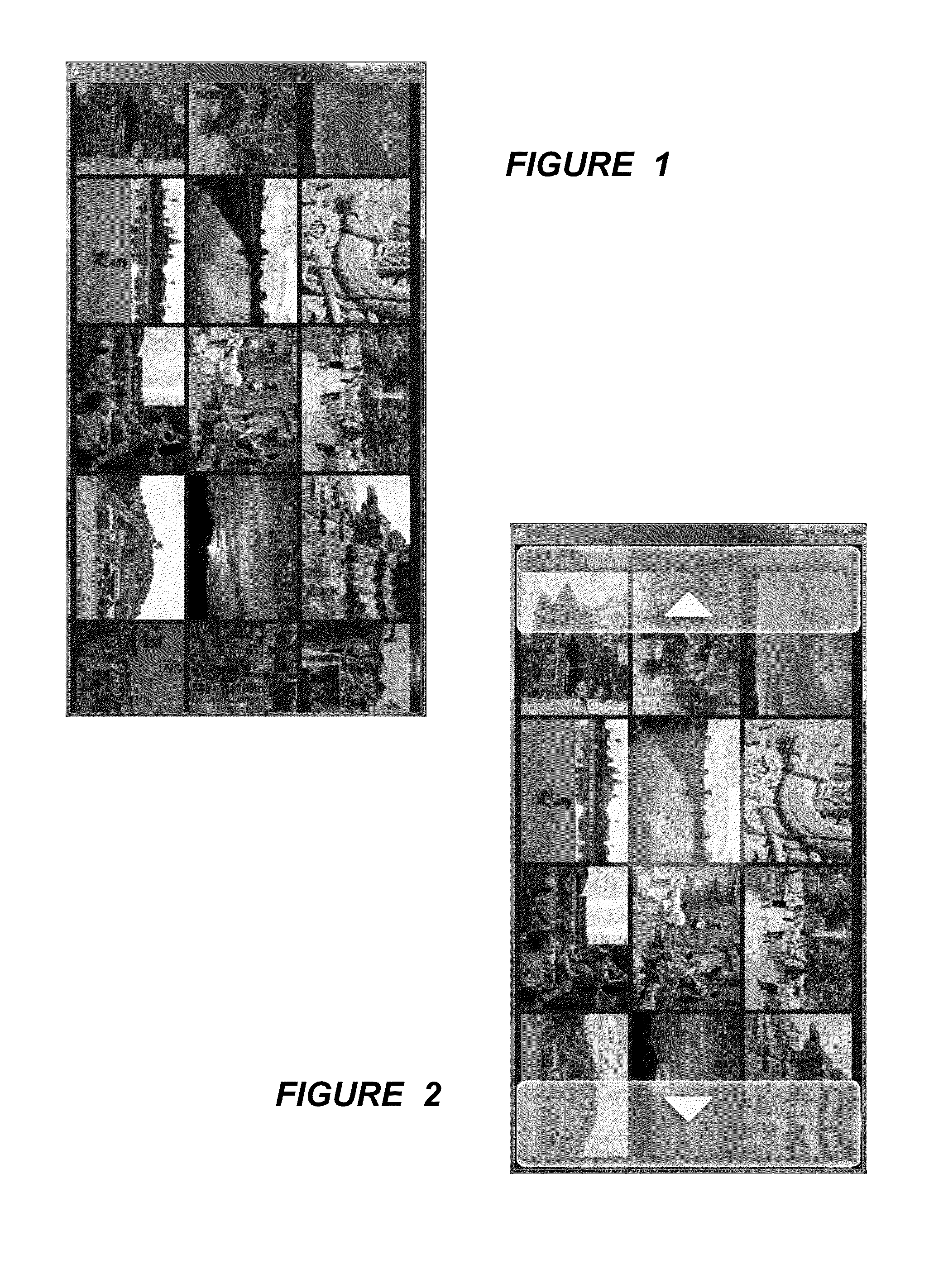

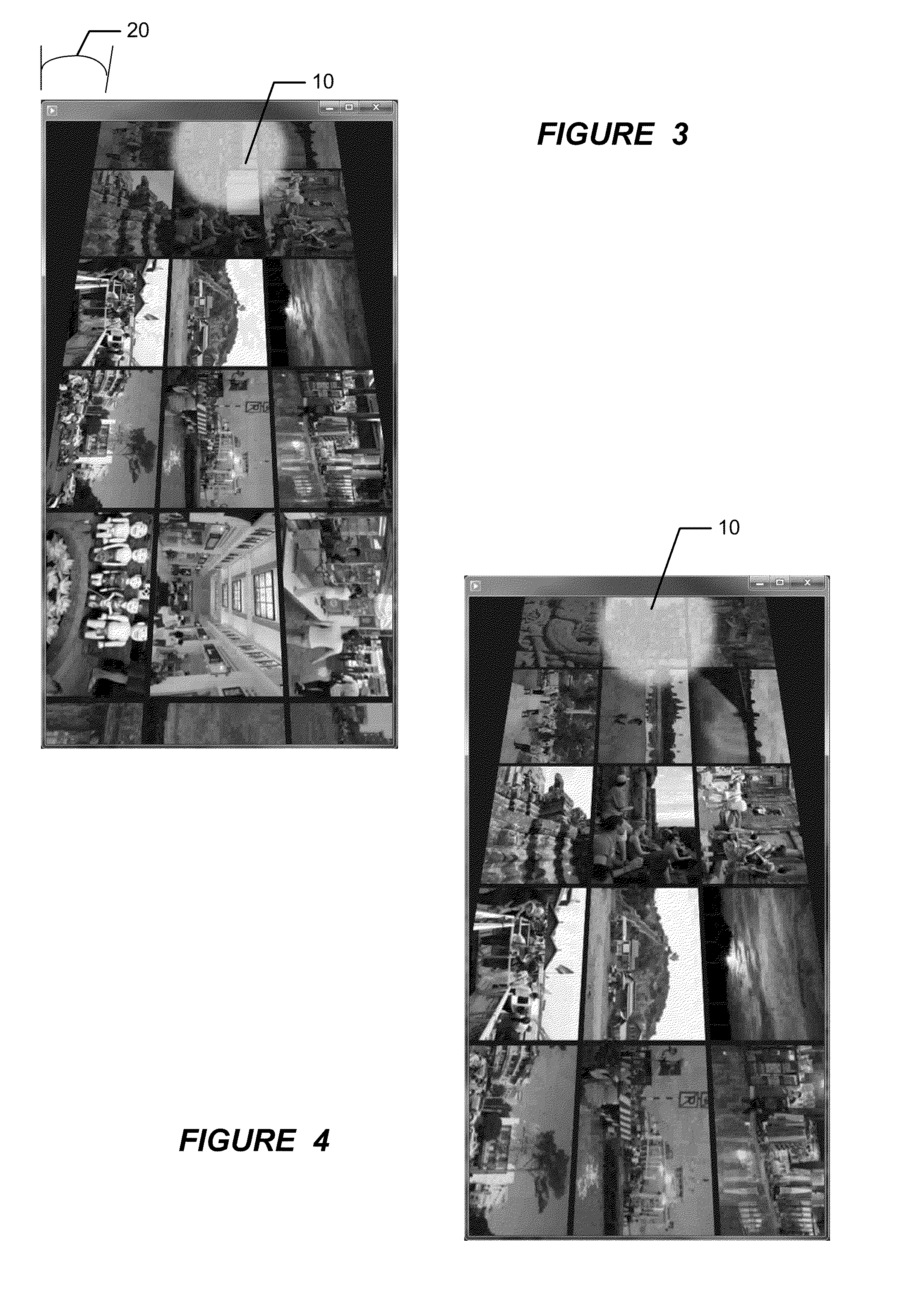

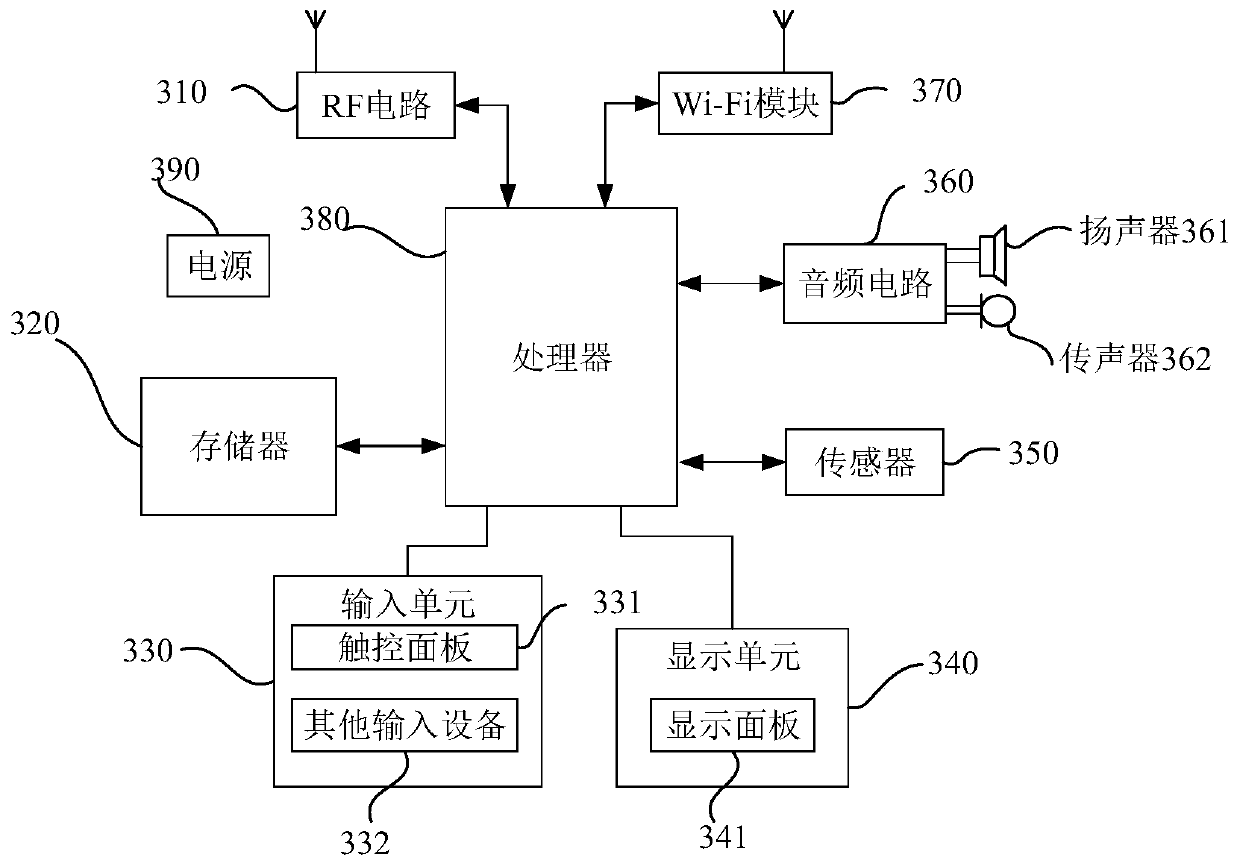

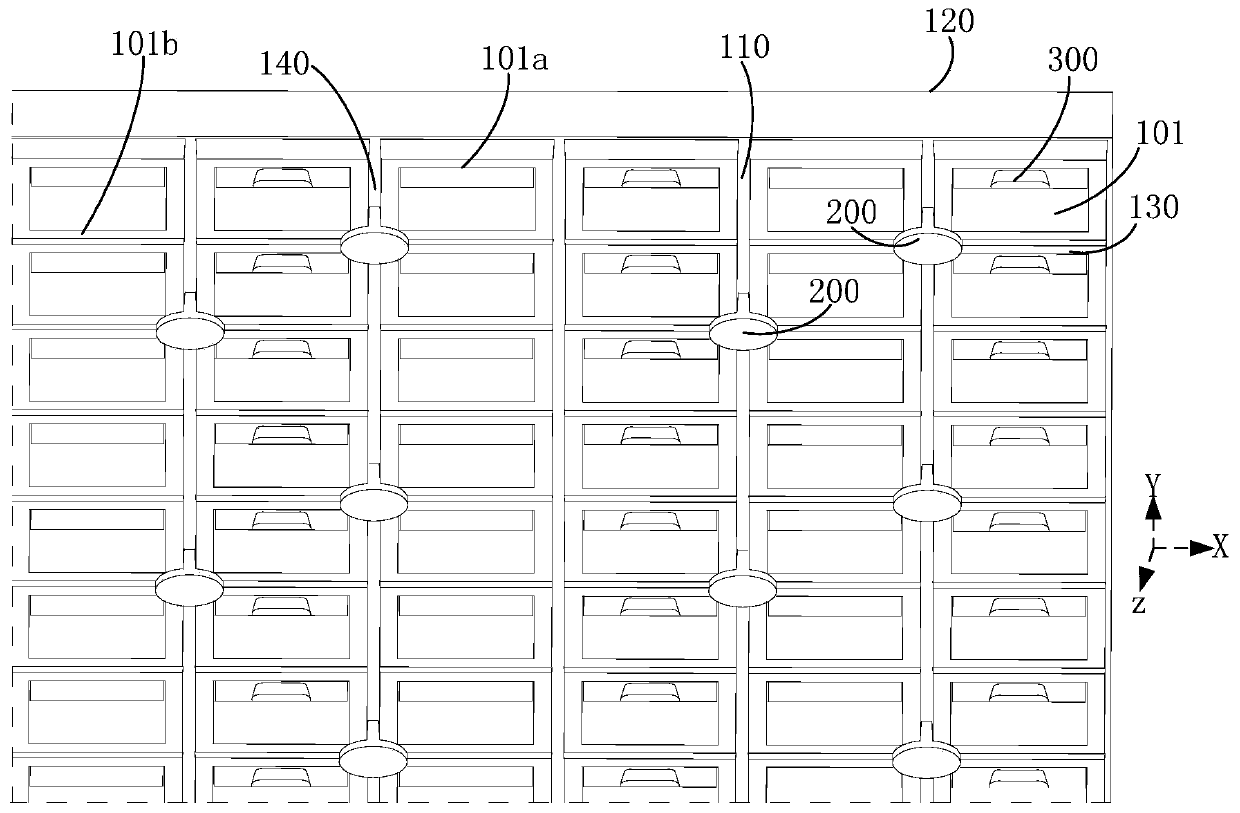

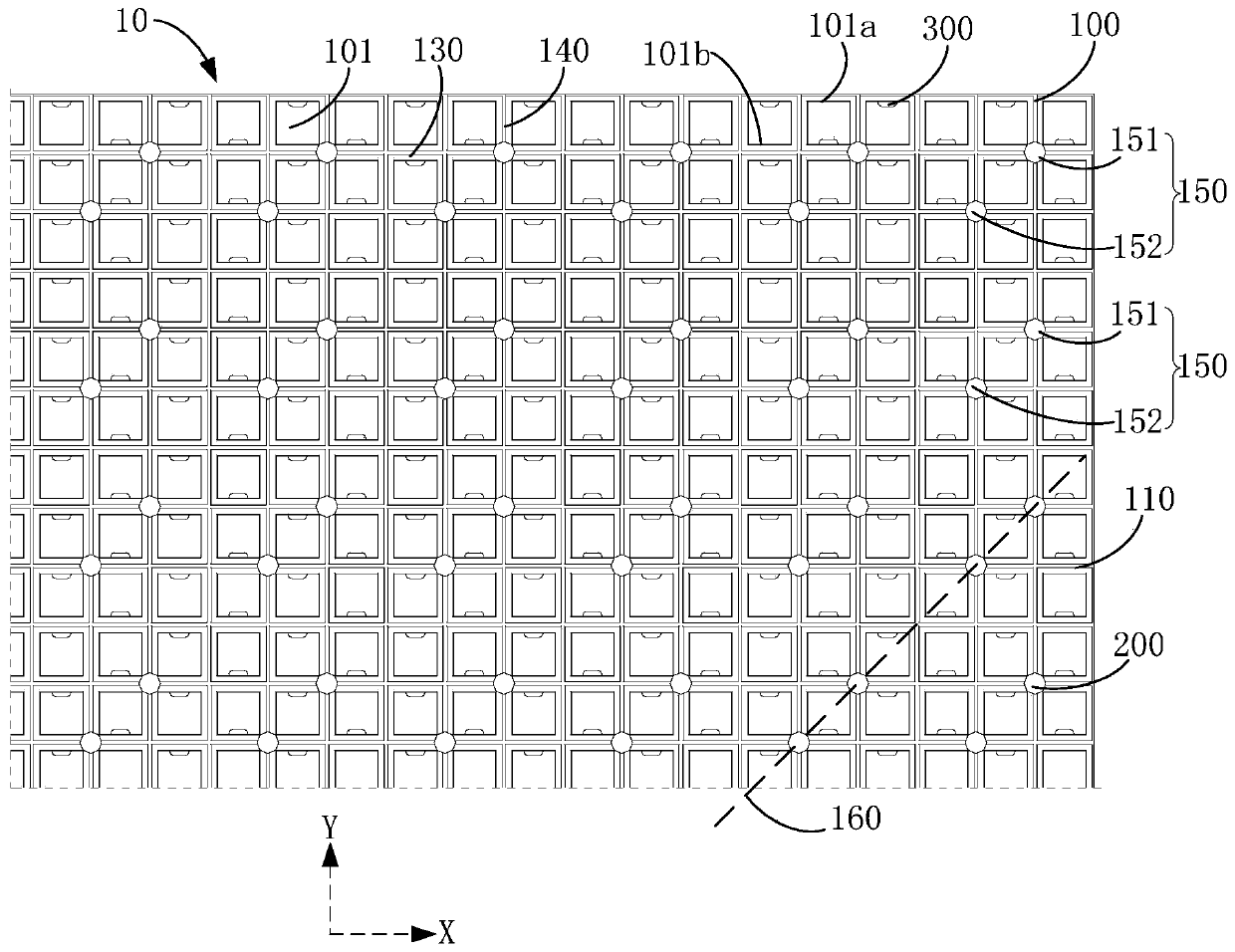

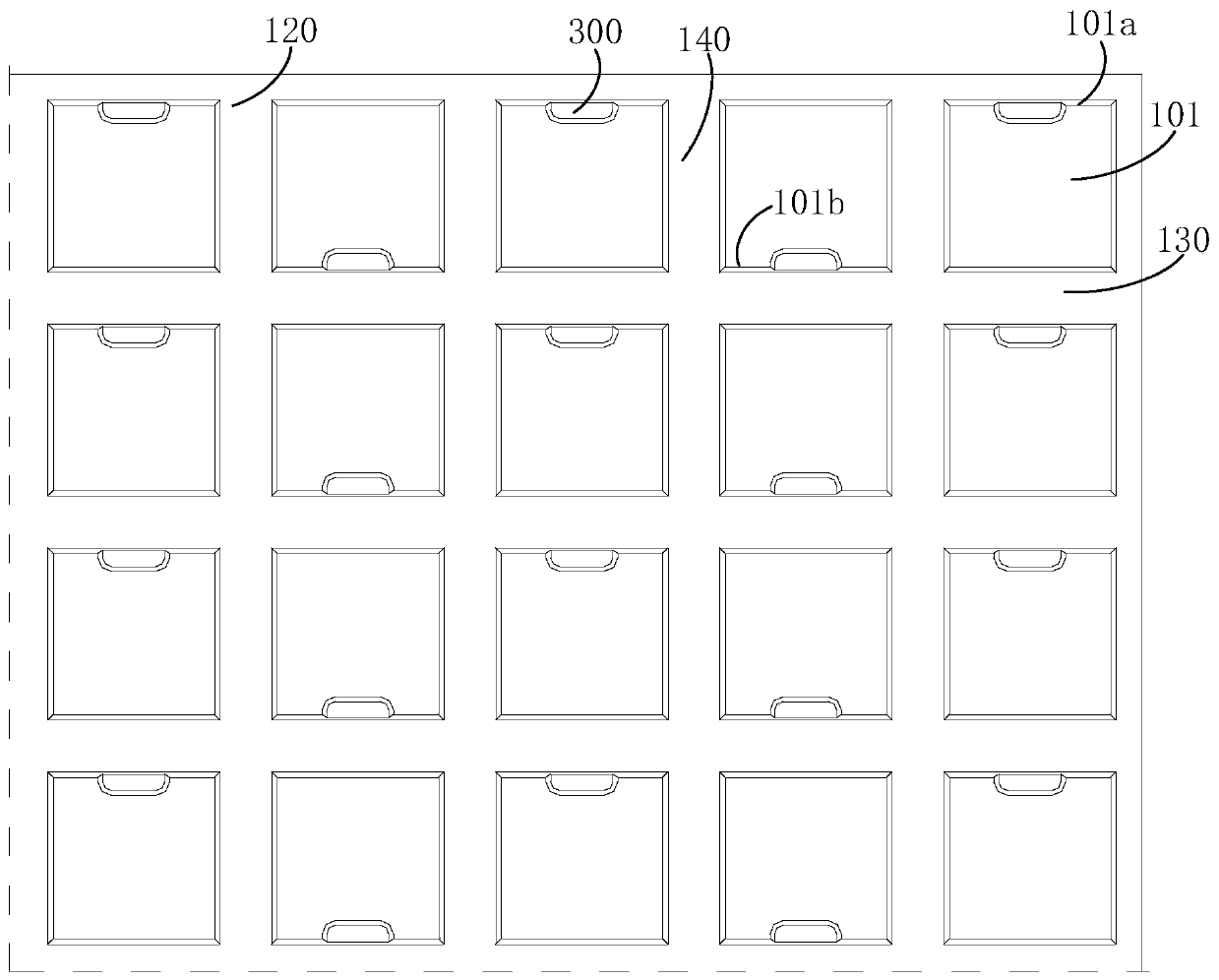

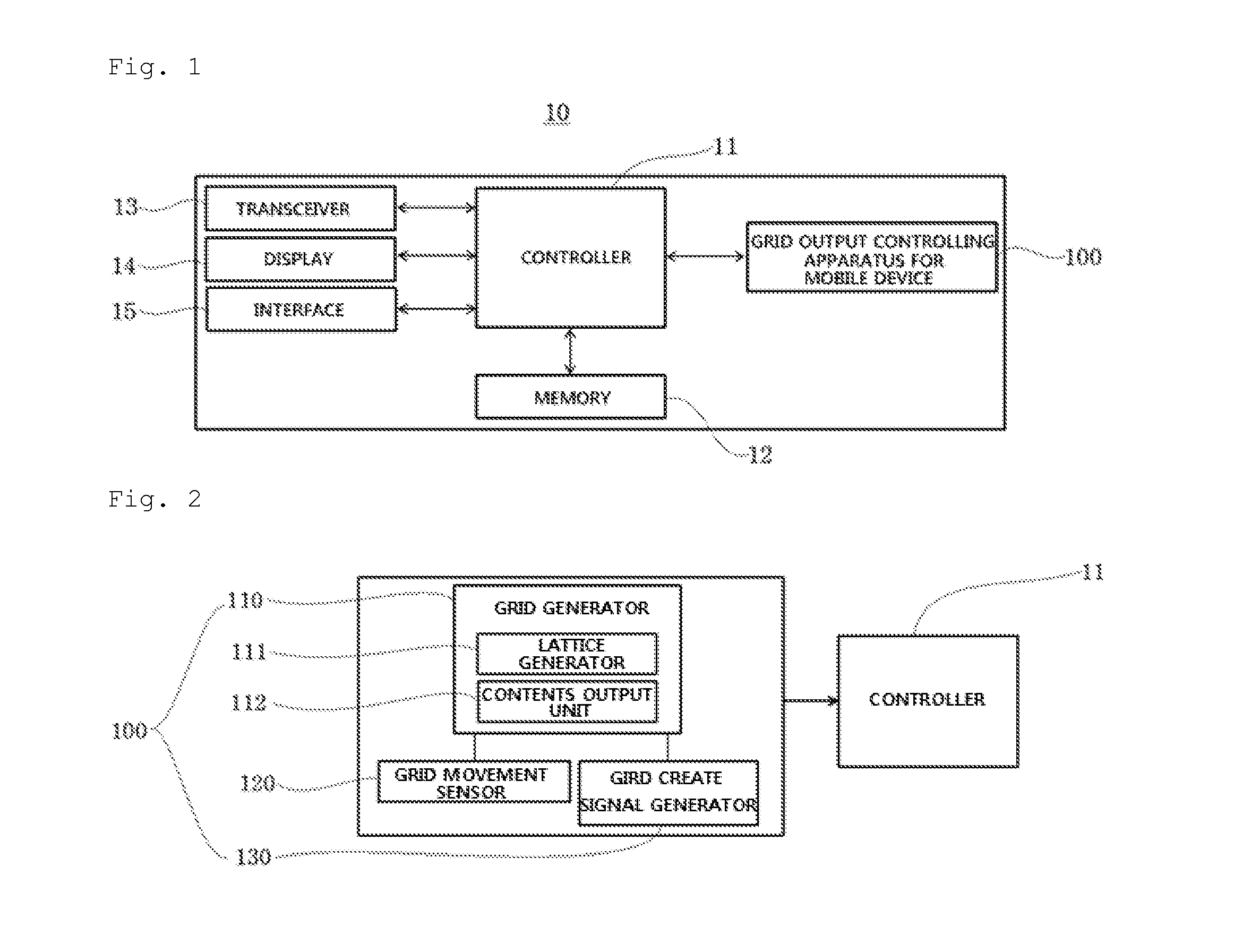

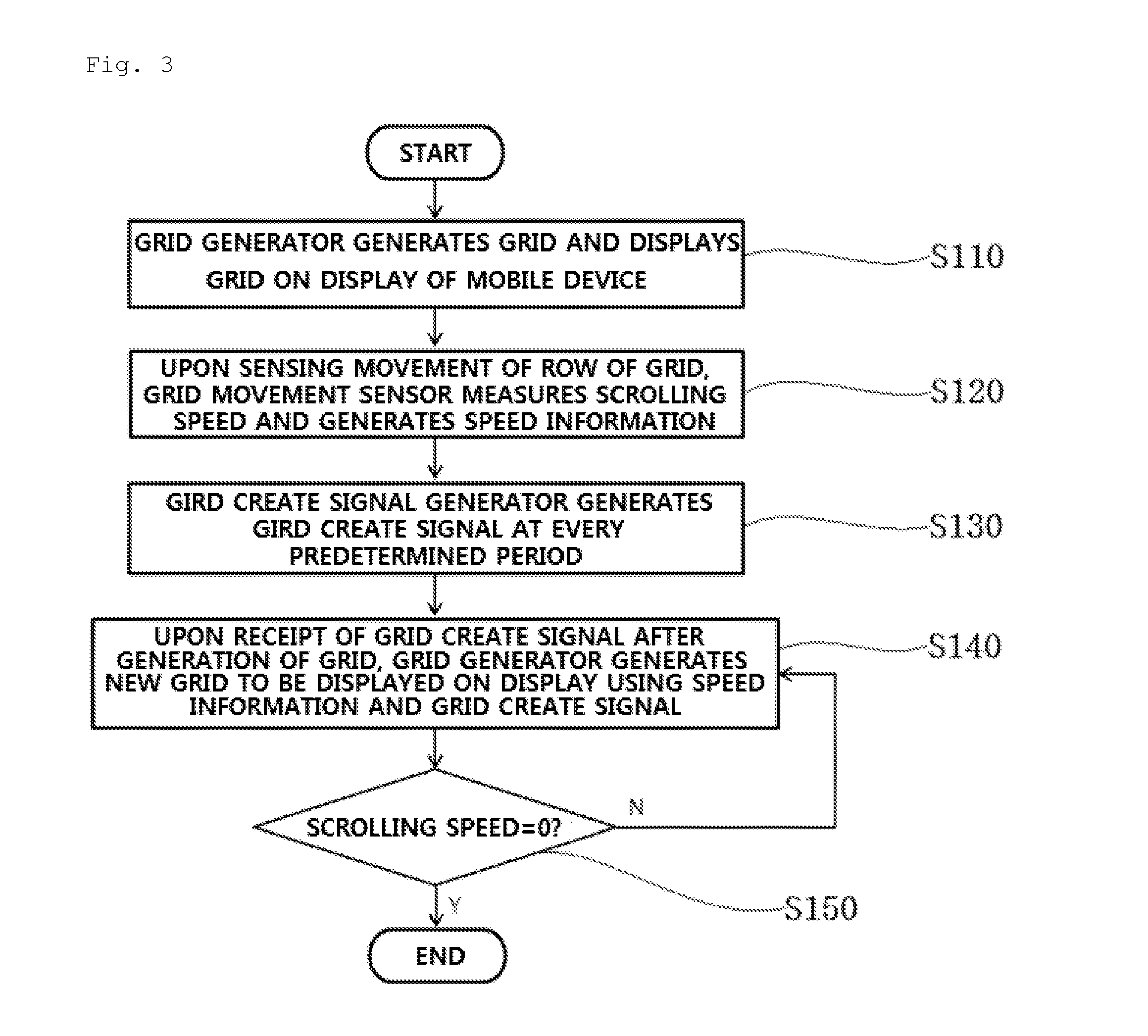

Apparatus for controlling grid output in a mobile device and method for controlling grid output using the same

InactiveUS20150116372A1Increase scrolling speedGeometric image transformationCathode-ray tube indicatorsDisplay deviceEngineering

The method includes generating a grid having a plurality of rows and displaying the grid on a display of a mobile device by a grid generator, sensing movement of a row of the grid, measuring a scrolling speed with respect to a speed of the row of the grid, and generating speed information based on the measured scrolling speed by a grid movement sensor, generating a grid create signal for a grid create command at every predetermined period by a grid create signal generator, and upon receipt of the grid create signal after the grid is generated, generating a new grid to be displayed on the display using the speed information by the grid generator.

Owner:TOBESOFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com