Patents

Literature

2997results about How to "Guaranteed work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

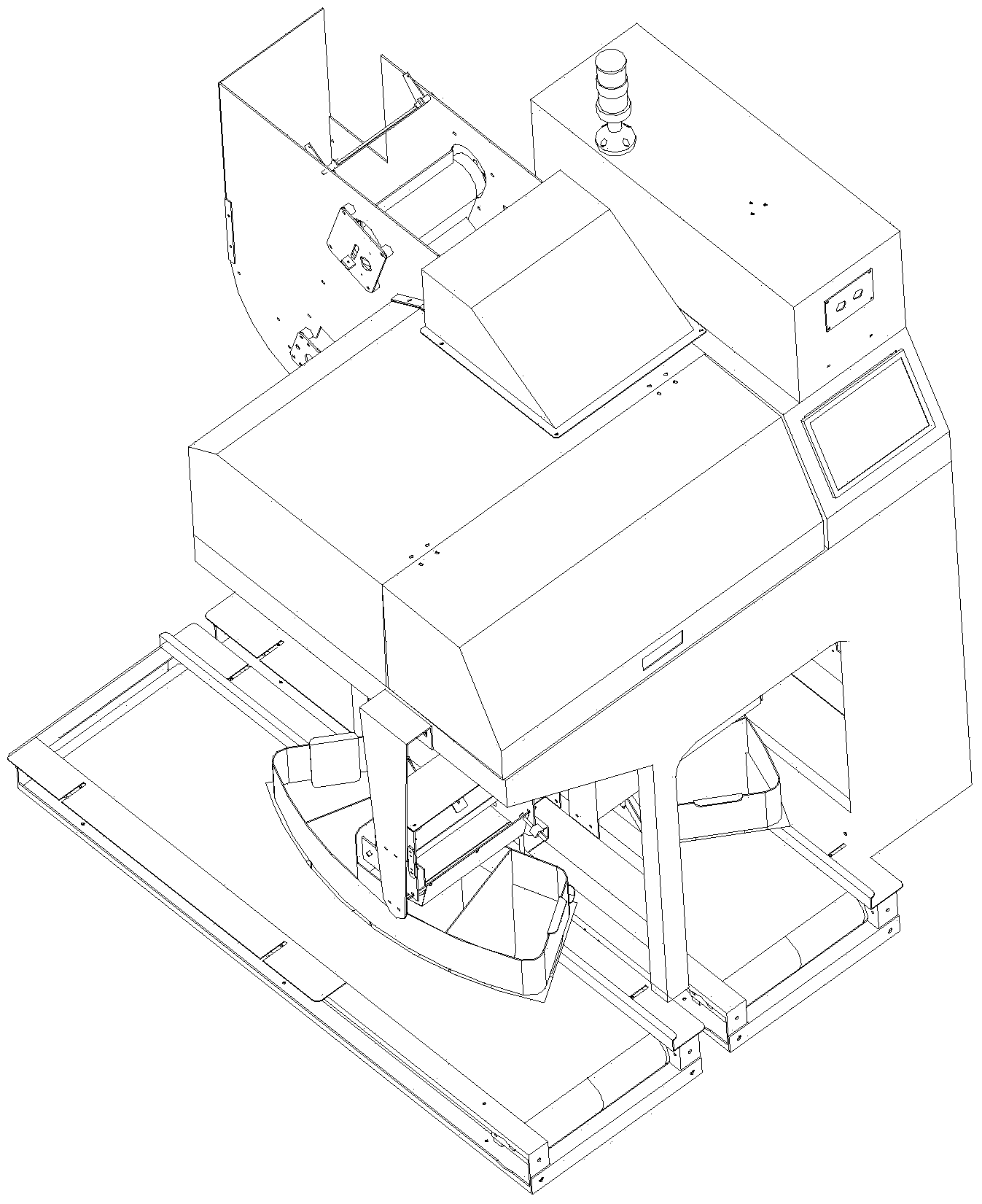

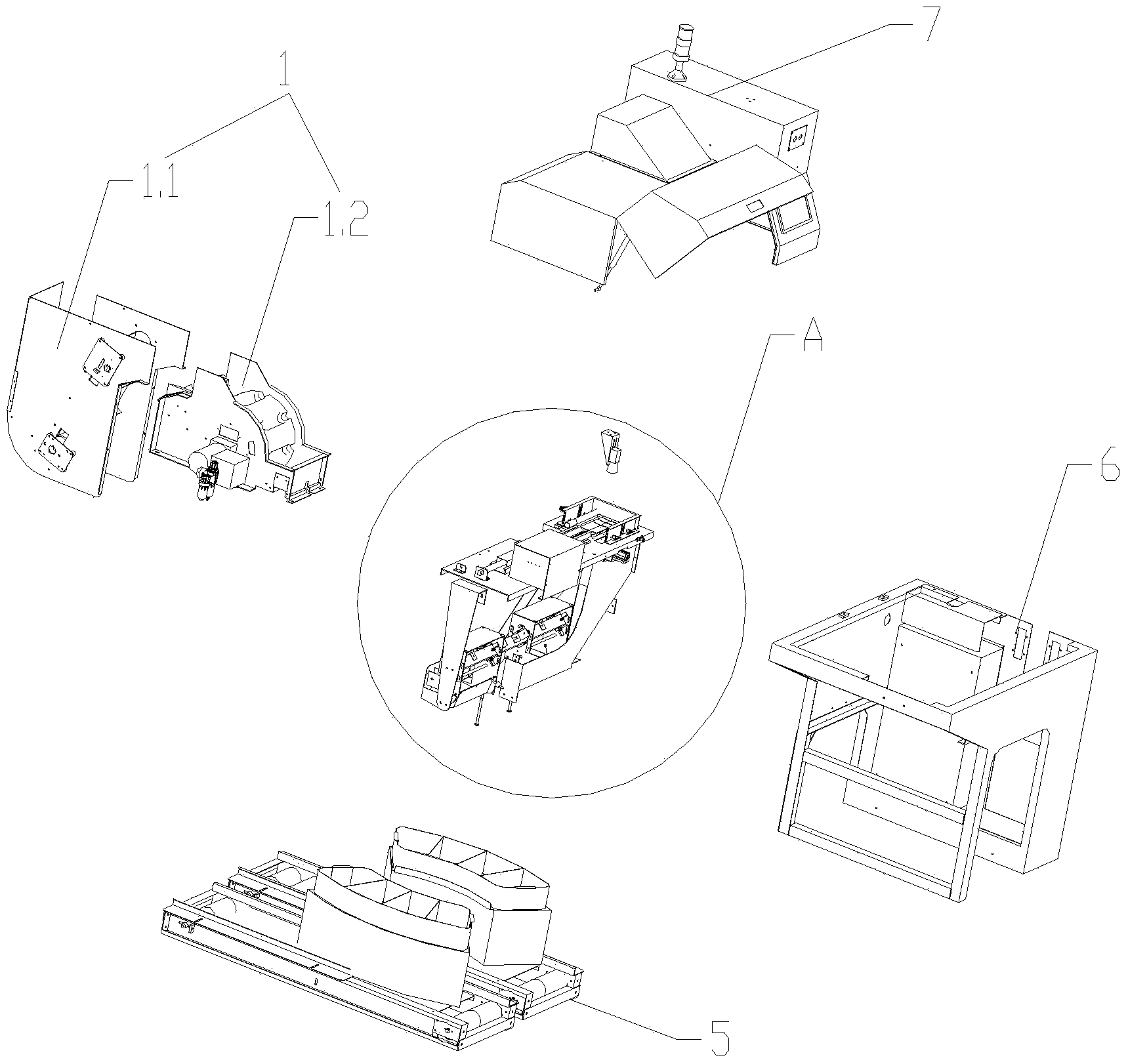

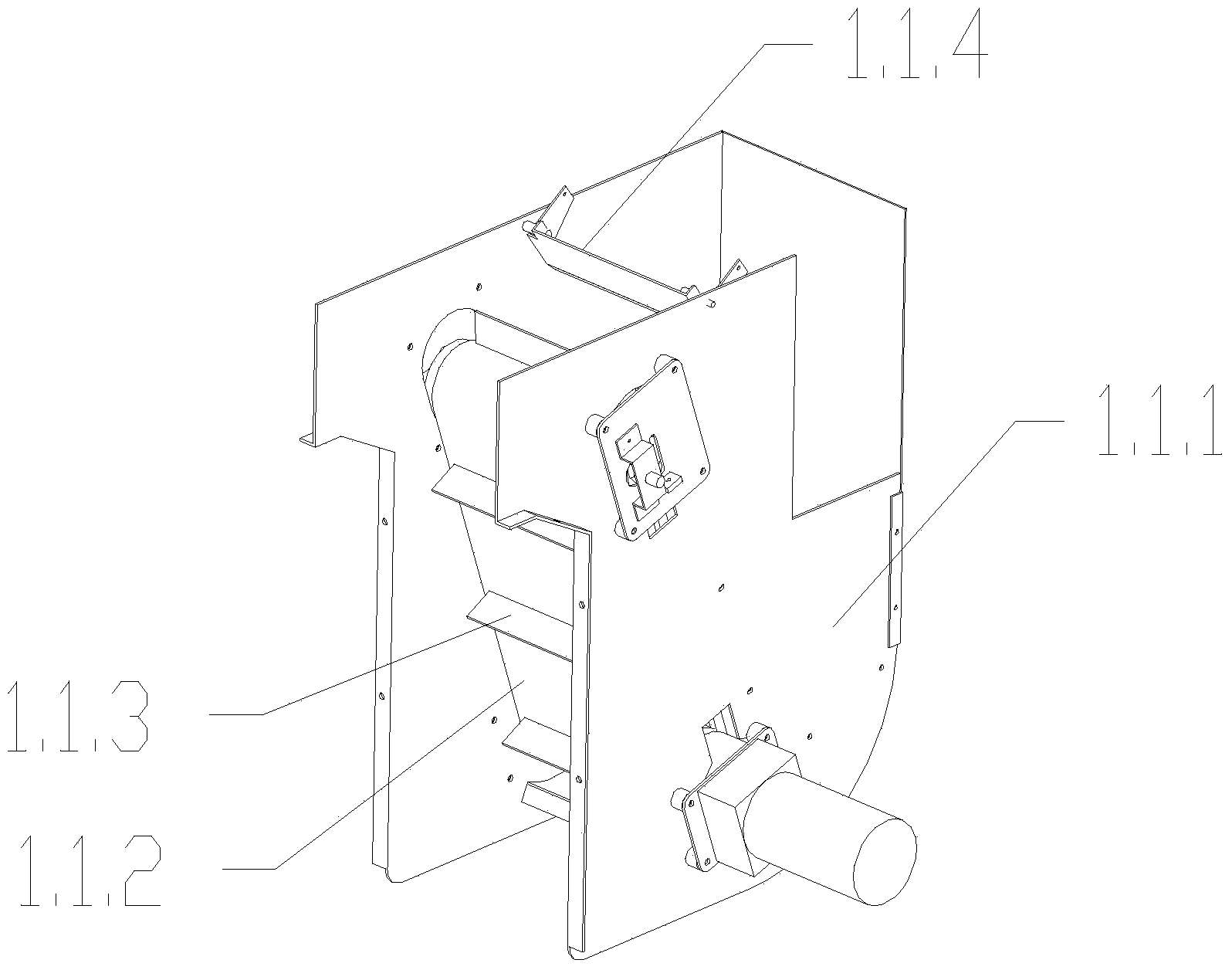

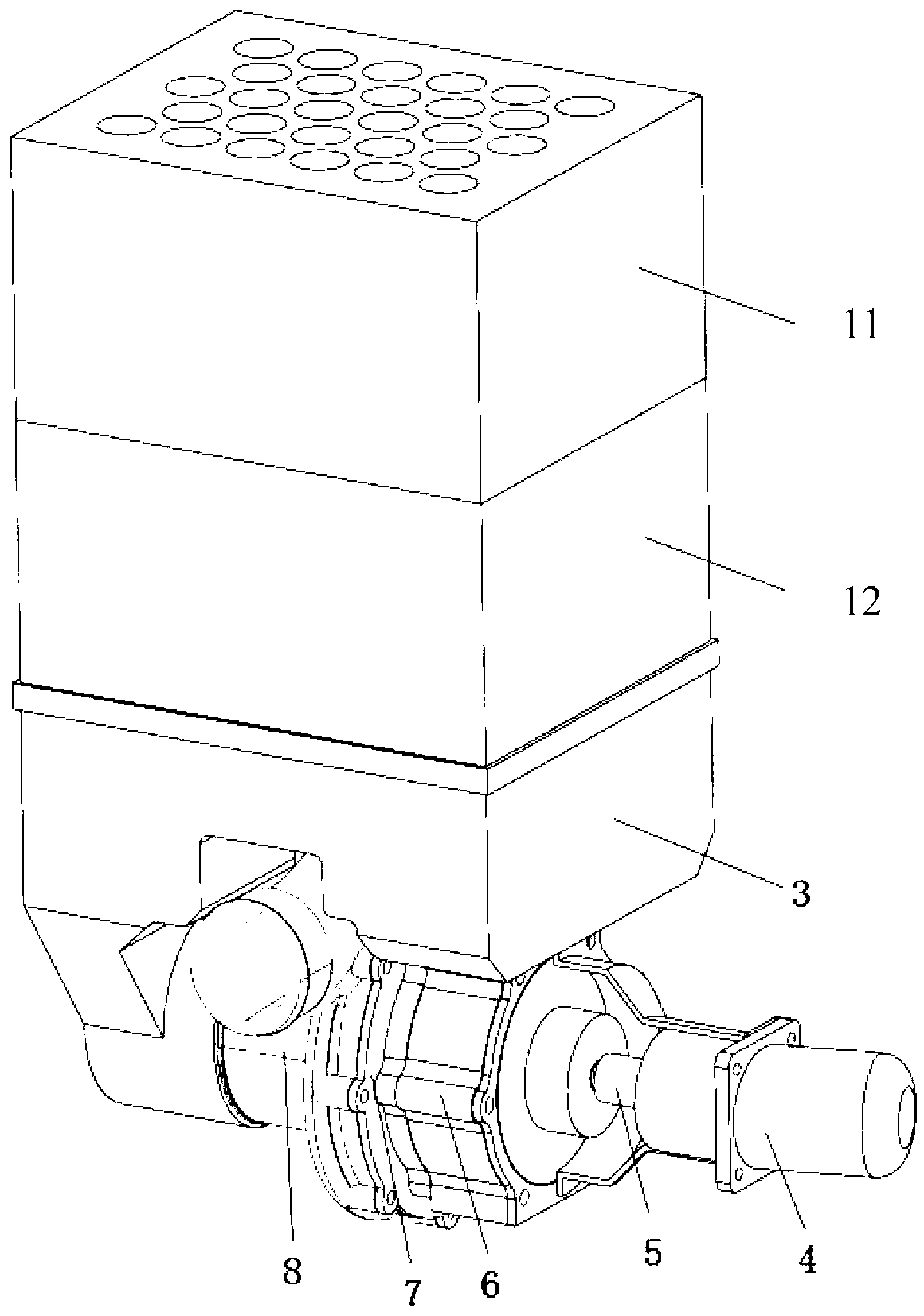

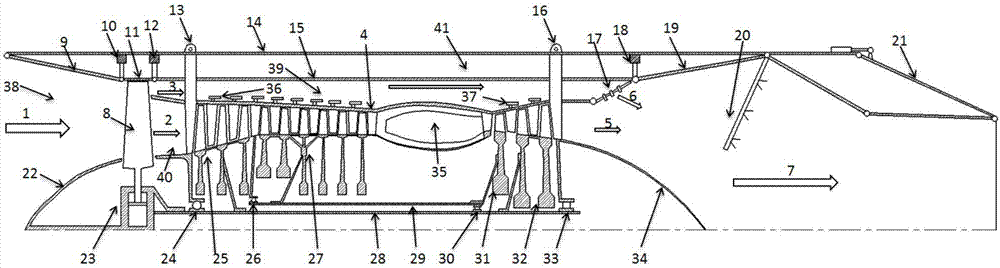

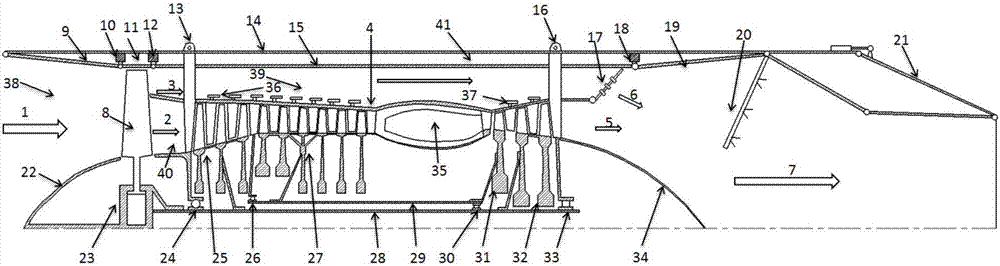

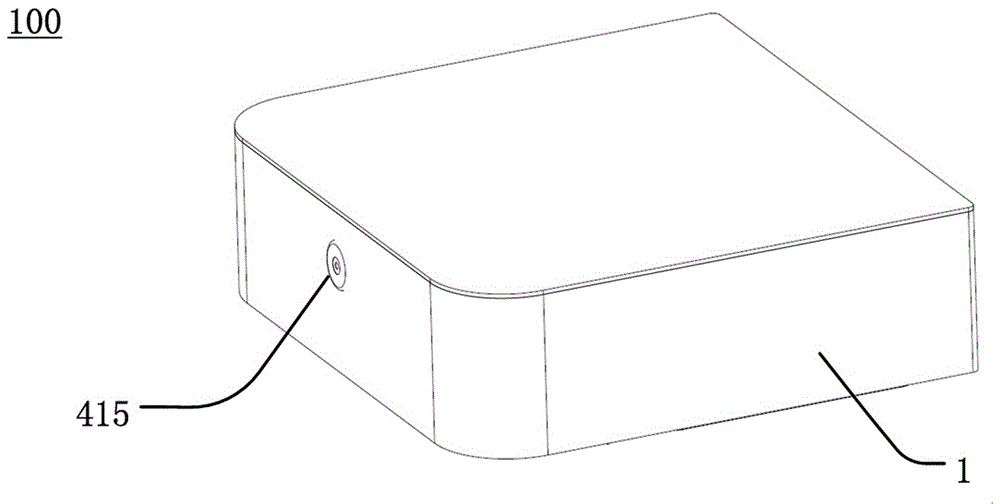

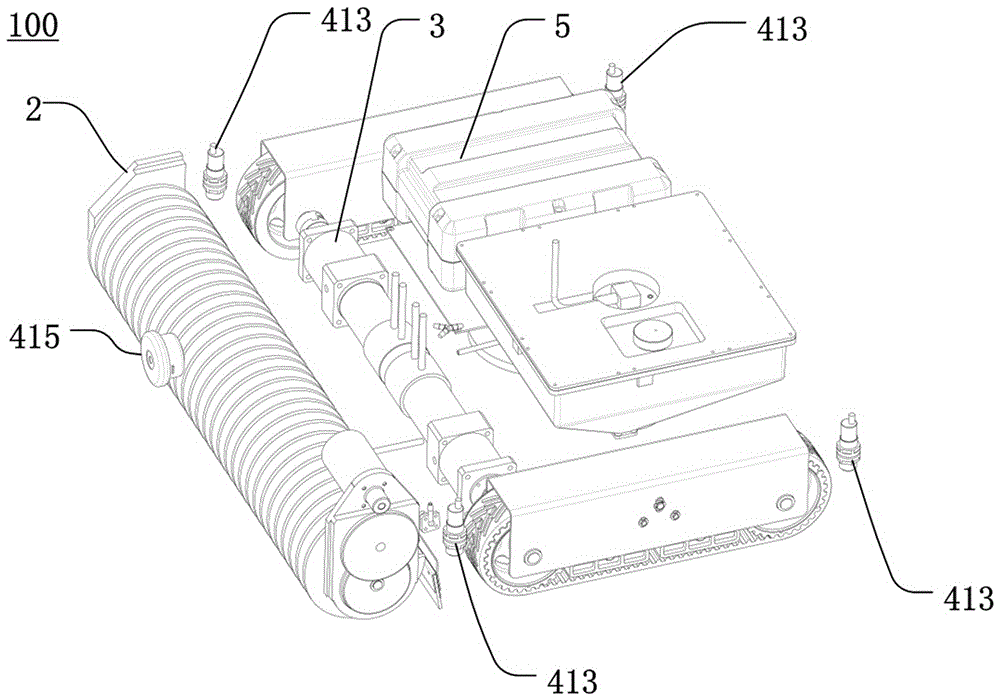

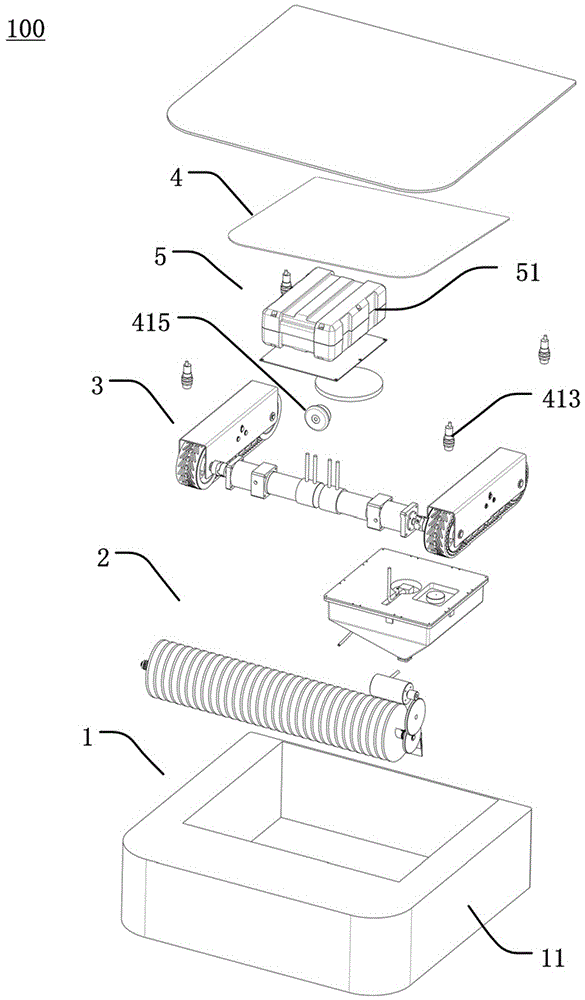

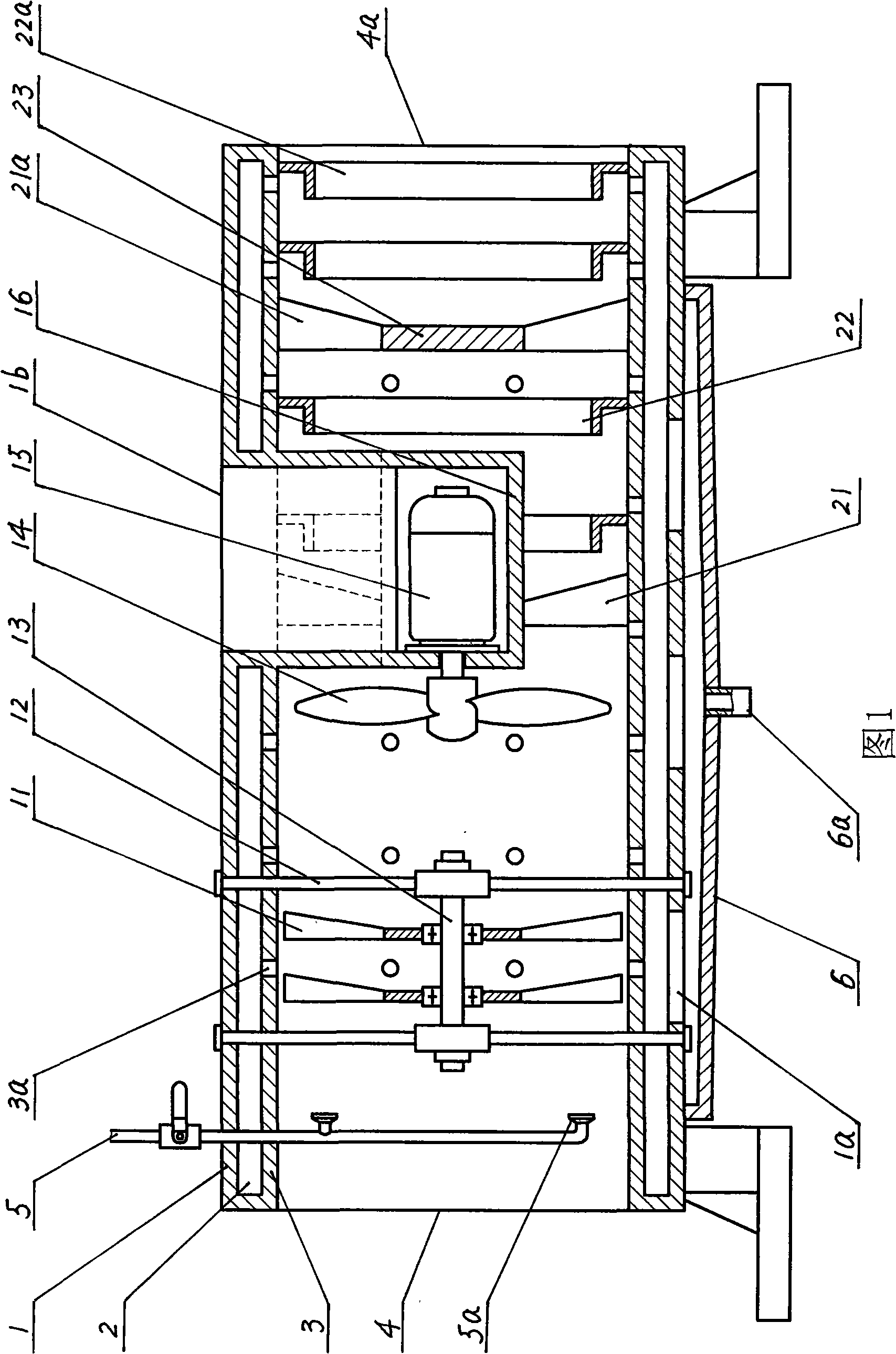

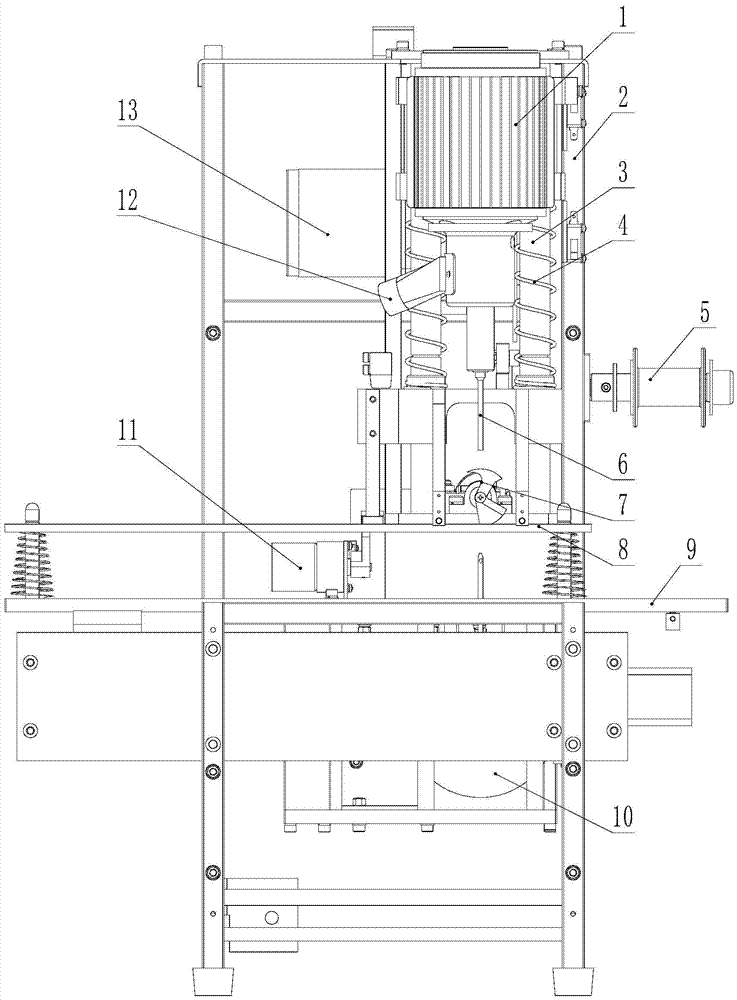

Bobbin burying machine

The invention relates to a bobbin burying machine. The bobbin burying machine is characterized by comprising a bobbin storage mechanism (1), a bobbin separating mechanism (2), a bobbin falling mechanism (3), a bobbin connecting buffer mechanism (4), a bobbin connecting mechanism (5), a rack (6) and an outer shell (7). The bobbin storage mechanism (1), the bobbin separating mechanism (2), the bobbin falling mechanism (3) and the bobbin connecting buffer mechanism (4) are arranged on the rack (6), the outer shell (7) covers the top of the rack (6), and the bobbin connecting mechanism (5) is arranged below the bobbin connecting buffer mechanism (4). According to the bobbin burying machine, whether bobbins contain yarn or not can be distinguished, the colors of empty bobbins are distinguished, the big ends and the small ends of the bobbins without the yarn are straightened out, automation is achieved in the whole process, the manual operation is not needed, the manual operation difficulty of workers is greatly relieved, the number of employees of enterprises can be effectively saved, the employment pressure of the enterprises can be effectively relieved, and the bobbin burying machine has the advantages of improving work efficiency, and being high in automation degree and capable of being applied to arc-shaped recycle cases.

Owner:江阴市凯业纺织机械制造有限公司

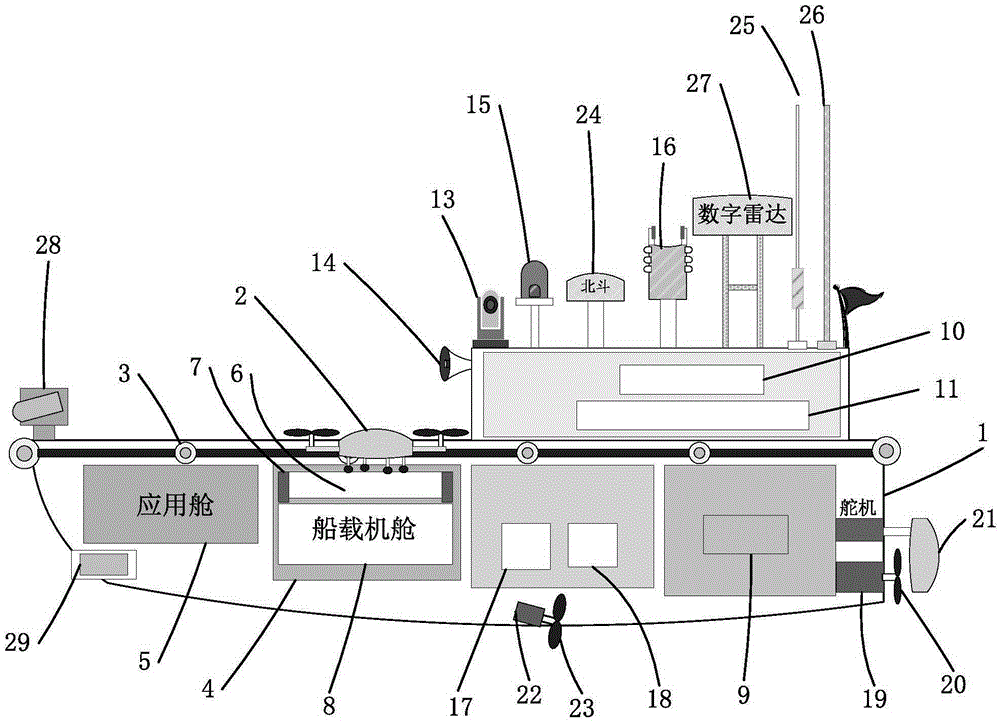

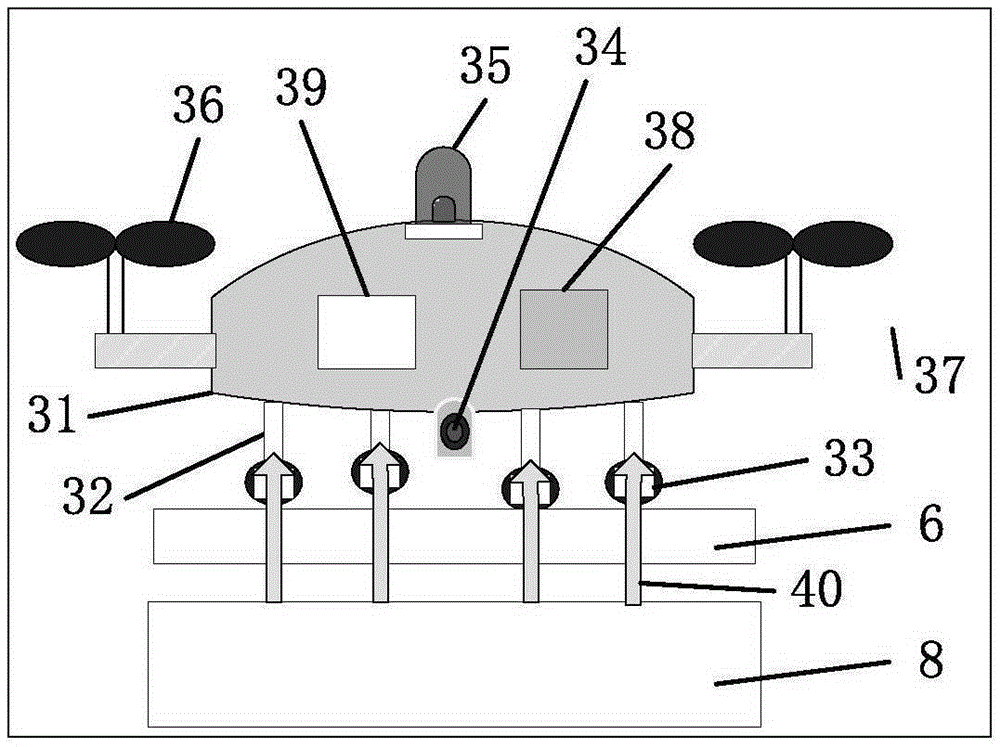

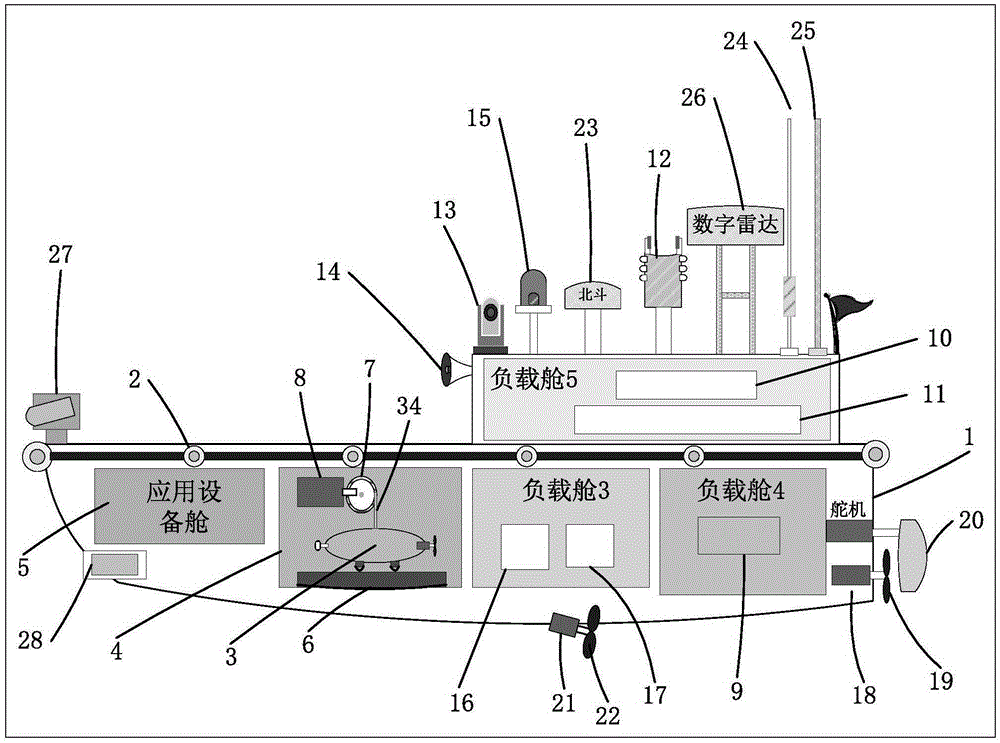

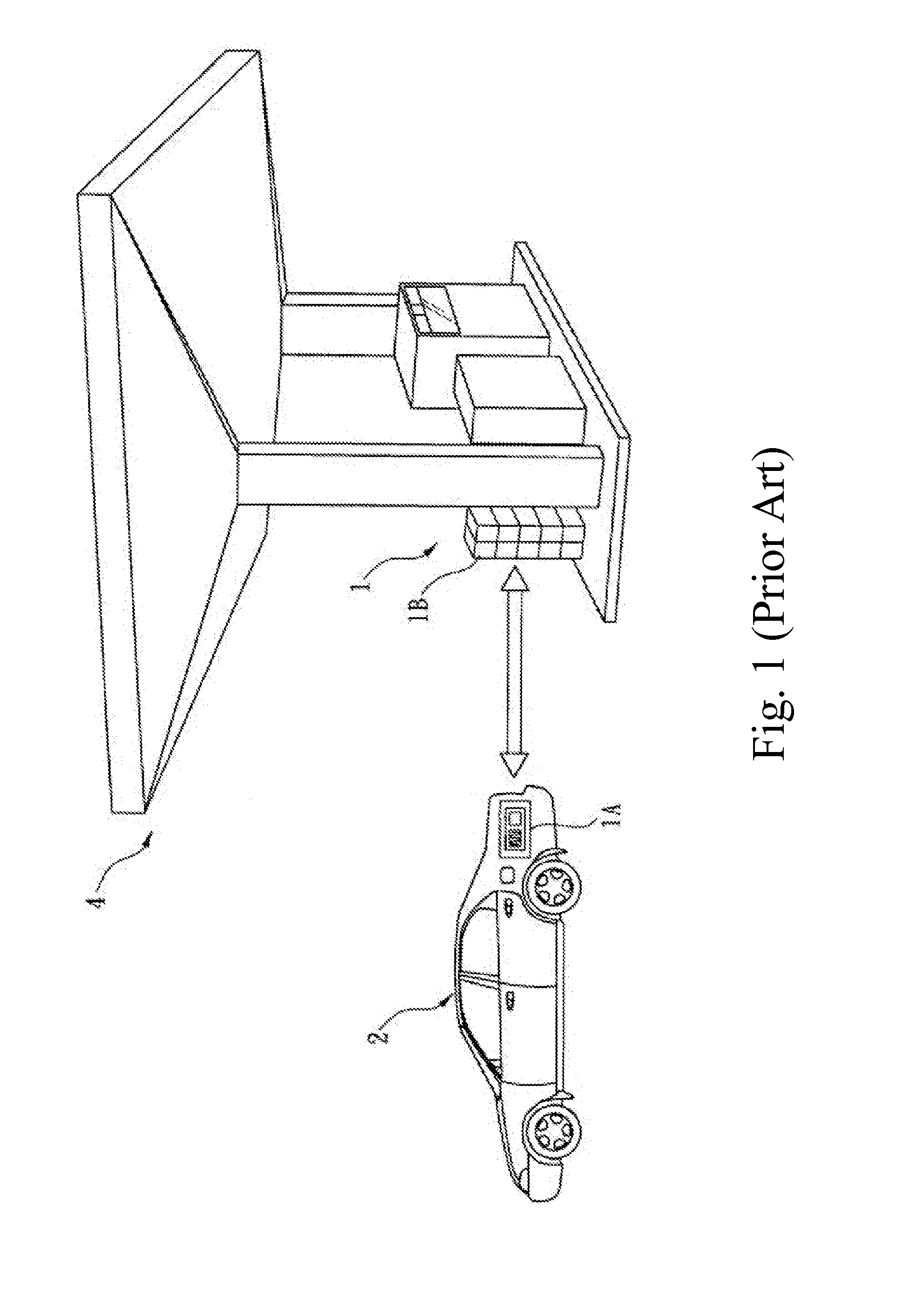

Unmanned aerial vehicle mixed system carried by unmanned ship

ActiveCN105292398AFully utilize the loadMake the most of your communication skillsAircraft componentsAuxillariesHybrid systemCommunications system

The invention provides an unmanned aerial vehicle mixed system carried by an unmanned ship. The system comprises the unmanned ship, an unmanned aerial vehicle and a mixed communication system. The unmanned ship serves as a water domain movable platform for the unmanned aerial vehicle, and mainly comprises a ship body, a ship-borne control system arranged on the ship body, a ship-borne power device and a ship-borne application device. The unmanned aerial vehicle comprises an unmanned aerial vehicle body and a vehicle-mounted coordinating system. The unmanned aerial vehicle body is provided with a vehicle-mounted navigation device, a vehicle-mounted obstacle-avoiding device, a vehicle-mounted control device, a vehicle-mounted power device and a vehicle-mounted application device. The mixed communication system comprises a ship-borne communication device and a vehicle-mounted communication device. The ship-borne control system of the unmanned ship and the vehicle-mounted control device of the unmanned aerial vehicle body exchange data through the mixed communication system; the ship-borne control system serves as the core for the mixed communication system, and the unmanned ship and the unmanned aerial vehicle are controlled uniformly by an internal bus and a communication board card to work in cooperation. By means of the mixed system, the unmanned ship and the unmanned aerial vehicle can effectively supplement each other in water domain and space domain functions, and meanwhile the disadvantages of the water domain unmanned ship during space domain perpendicular work are compensated for.

Owner:SIFANG JIBAO WUHAN SOFTWARE CO LTD +2

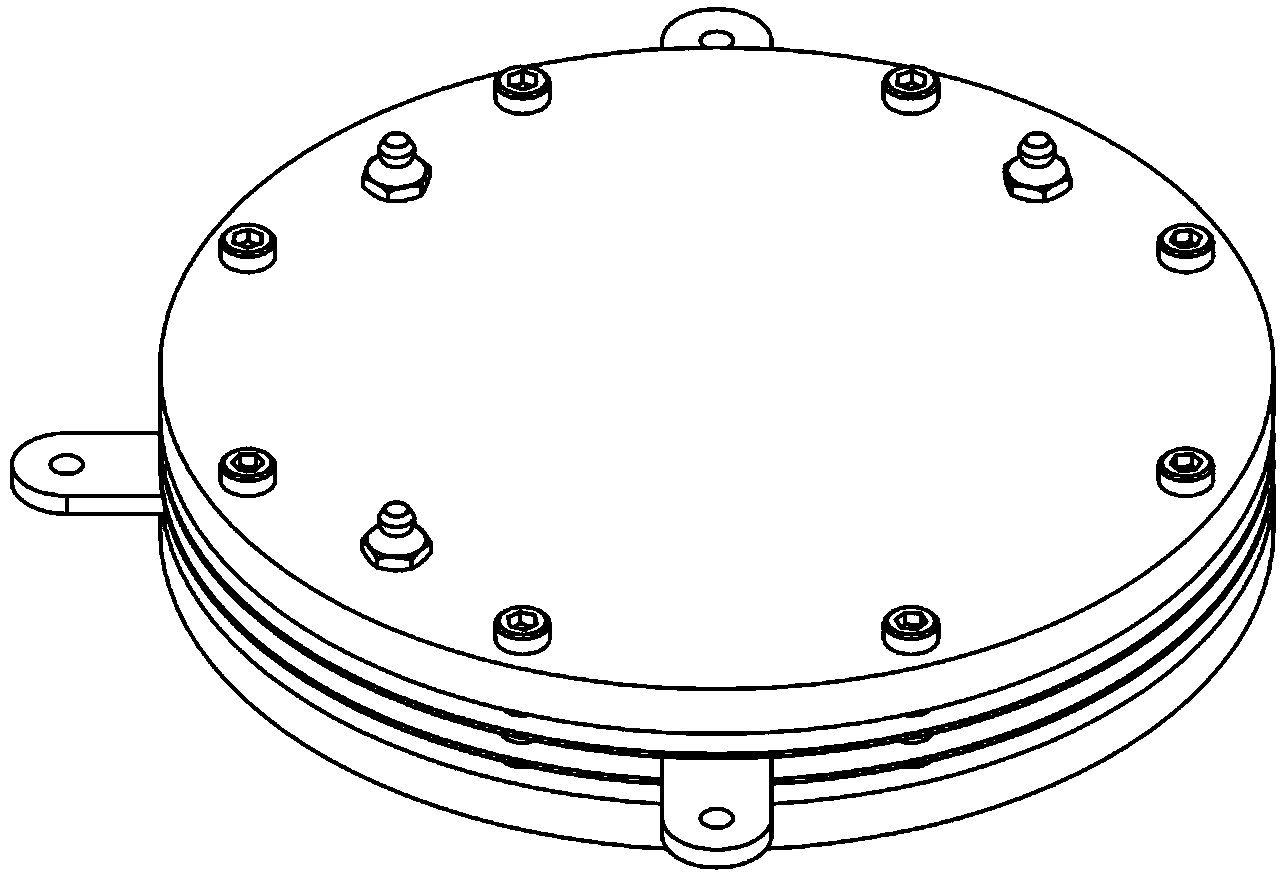

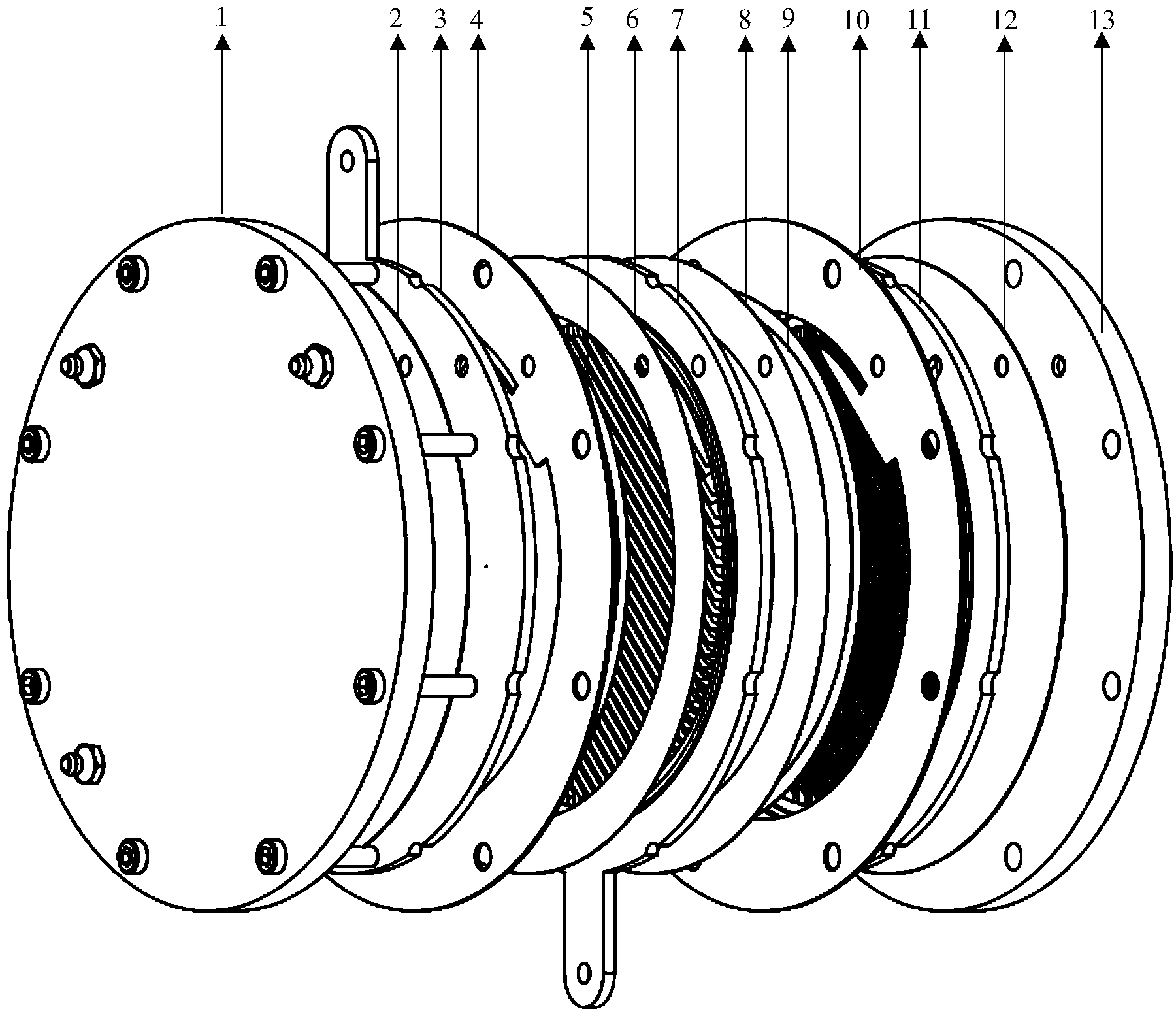

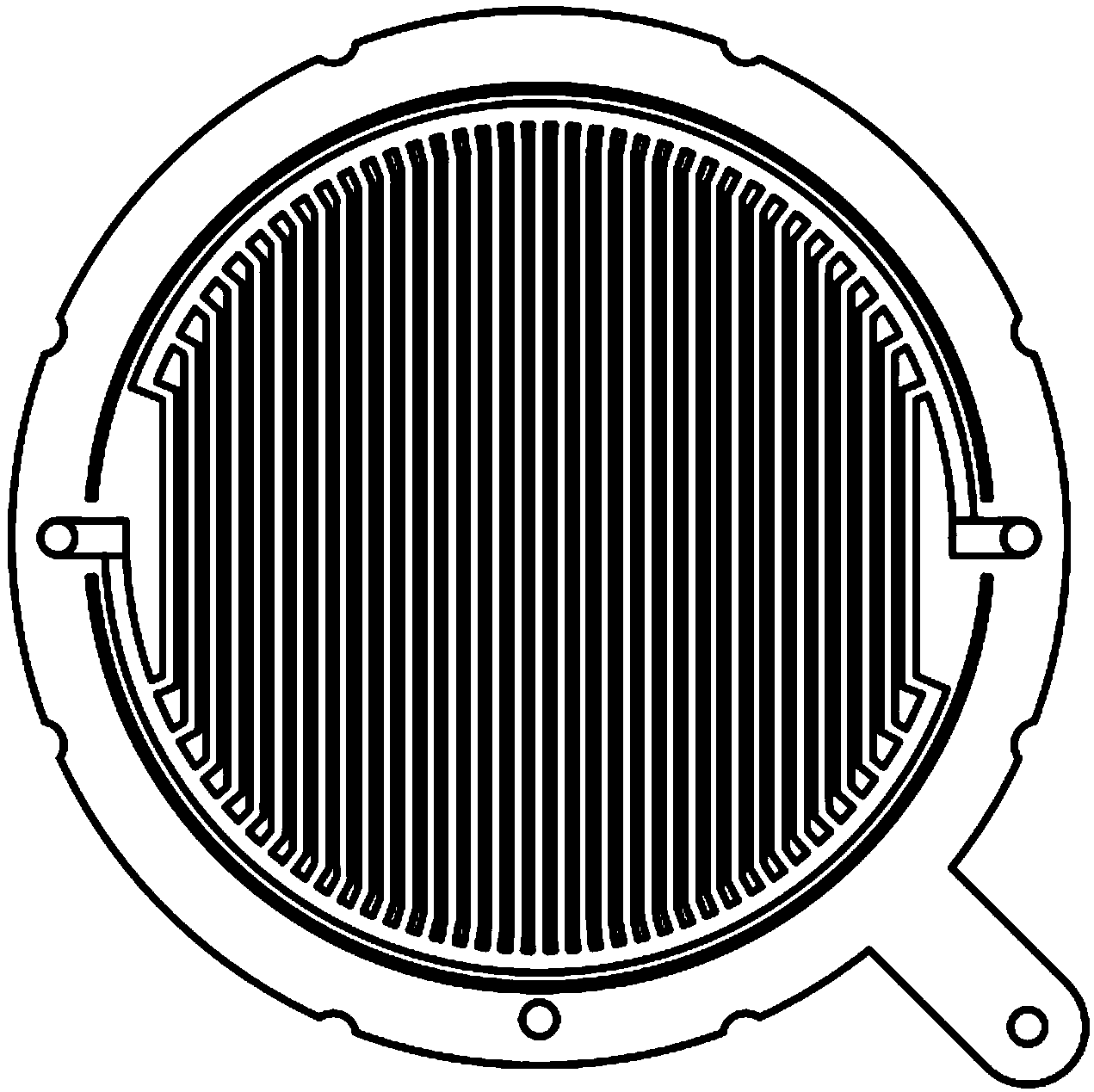

Proton exchange membrane water electrolysis device

InactiveCN103806014ADoes not affect workLarge water electrolysis scaleElectrolysis componentsEnergy inputElectrolysisElectrical battery

The invention provides a proton exchange membrane water electrolysis device which is a small hydrogen / oxygen generating device. The proton exchange membrane water electrolysis device comprises two anode plates, a negative bipolar plate and a membrane electrode between two anode plates and the negative bipolar plate; moreover, an anode end plate and an insulation spacer are sequentially arranged at two ends of the anode plate, sealing gaskets are respectively arranged between the anode plate and the membrane electrode and between the membrane electrode and the negative bipolar plate, and screw rods and nuts are used for fastening into the sealing gaskets, the anode plate, the membrane electrode and the negative bipolar plate into one body. The adopted working medium is pure water, the proton exchange membrane water electrolysis device has the characteristics of mild working conditions and high electrolytic efficiency, the purity of the produced gas is high, the operation is simple, and the proton exchange membrane water electrolysis device can be combined with a solar cell and a fuel cell to form a high-efficiency renewable energy utilization system.

Owner:UNIV OF SCI & TECH BEIJING

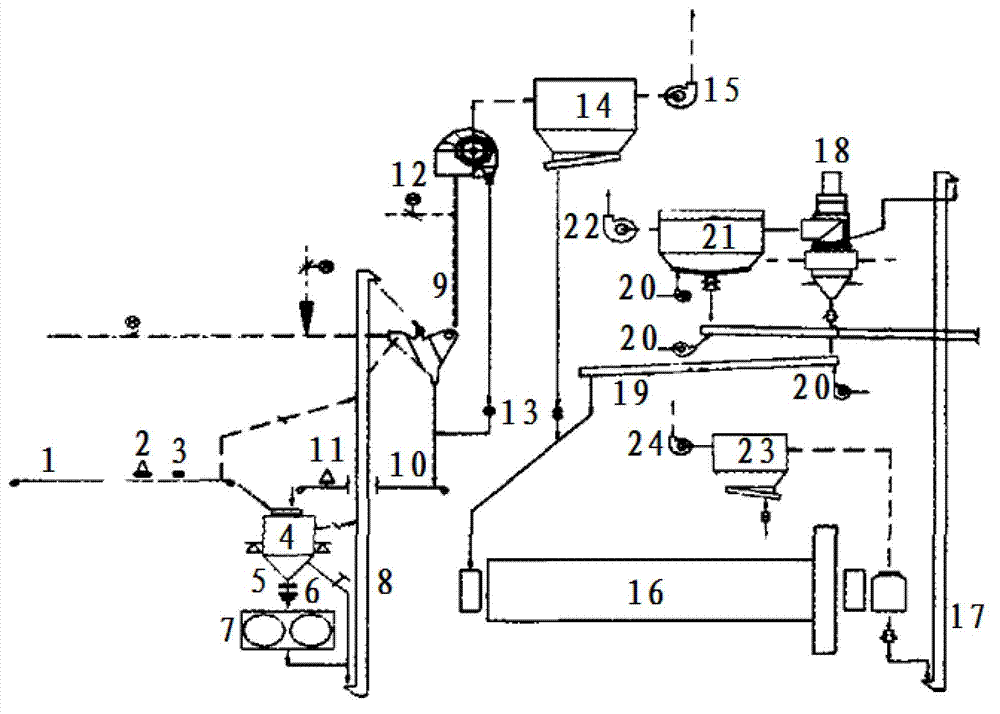

Slag micropowder grinding system and technology

The invention discloses a slag micropowder grinding system and a technology. The system consists of a roller press, an air flow classifier, a dynamic classifier, a ball mill and a high-efficiency powder concentrator. Slag is subjected to de-ironing by a de-ironing separator, sent into the roller press by a belt conveyor for high-pressure treatment, and then sent into the air flow classifier by a cake elevator for separation; if the particle size of the slag is large, the slag returns to the roller press for extrusion again; fine powder with a small particle size enters the dynamic classifier along with an air flow for the separation; coarse powder separated by the dynamic classifier returns to the roller press for the extrusion again; the fine powder is sent to the ball mill for grinding; the ground material is sent to the high-efficiency powder concentrator for the separation; the separated coarse powder is returned to the ball mill for the grinding again; and the separated fine powder enters air box pulse bag dust collectors along with the air flow for collection, and then serves as the finished slag for warehousing. According to the slag micropowder grinding system and the technology, the roller press, the air flow classifier and the dynamic classifier form a circle flow, and the ball mill and the high-efficiency powder concentrator form a circle flow, so that slag micropowder can be subjected to repeated crushing and grinding, and the particle shape of the finished micropowder is good.

Owner:湖南三泓建材有限公司

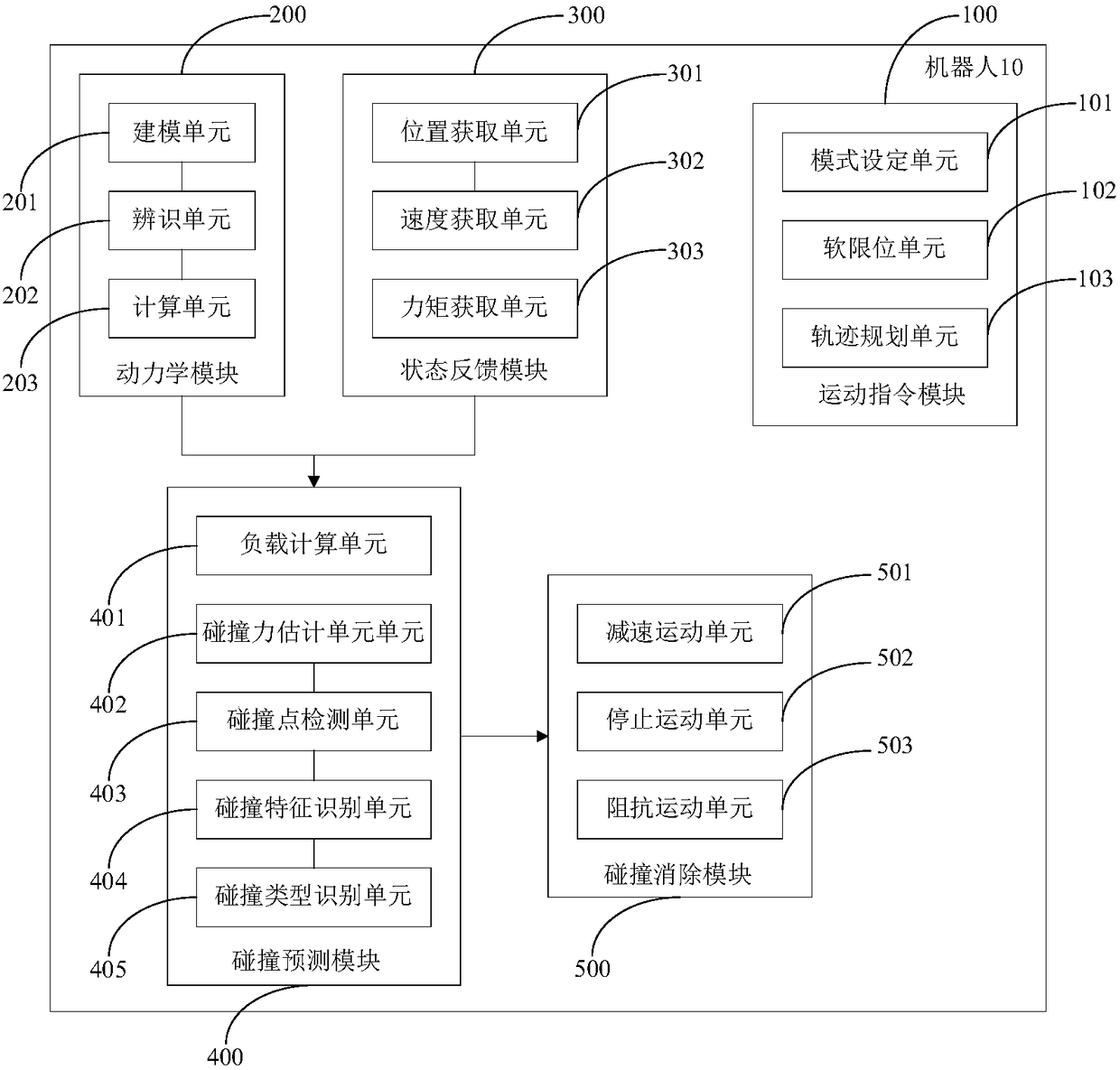

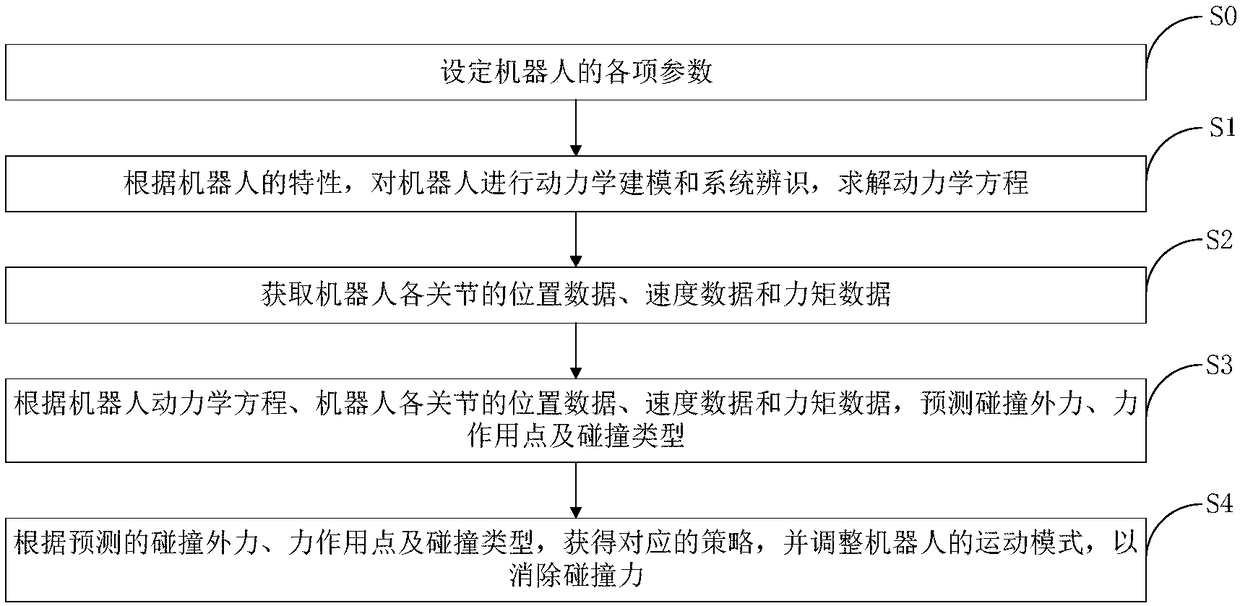

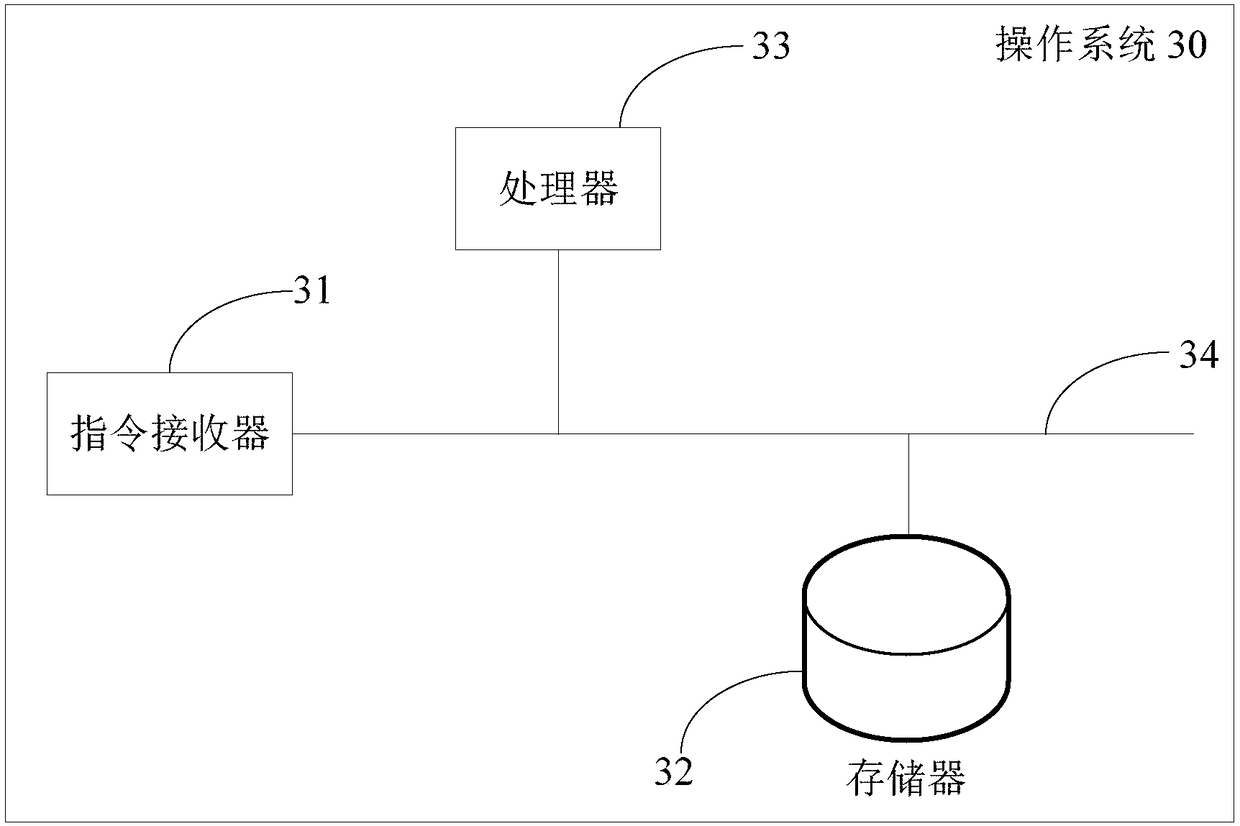

Robot collision detecting system and method, storage medium and operation system

InactiveCN108582070AEliminate CollisionsGuaranteed work efficiencyProgramme-controlled manipulatorMovement controlRobot dynamic

The invention discloses a robot collision detecting system and method, a storage medium and an operation system. The collision detecting system comprises a motion instruction module, a dynamic module,a state feedback module and a collision predicating module, wherein the motion instruction module is used for performing motion control on a robot; the dynamic module is used for performing dynamic modeling and system identifying on the robot according to characteristics of the robot, and solving a dynamic equation; the state feedback module is used for obtaining position data, speed data and force moment data of each joint of the robot; and the collision predicating module is used for predicating collision external force, a force acting point and a collision type according to the robot dynamic equation, and the position data, the speed data and the force moment data of each joint of the robot. Based on collision detection of current ring feedback, the robot collision detecting system canreduce complexity and cost of a robot structure, can detect whether a user collides or not when the robot works, and safety of the user when the robot and the user are effectively guaranteed to be cooperatively work.

Owner:上海禾野智能科技有限公司

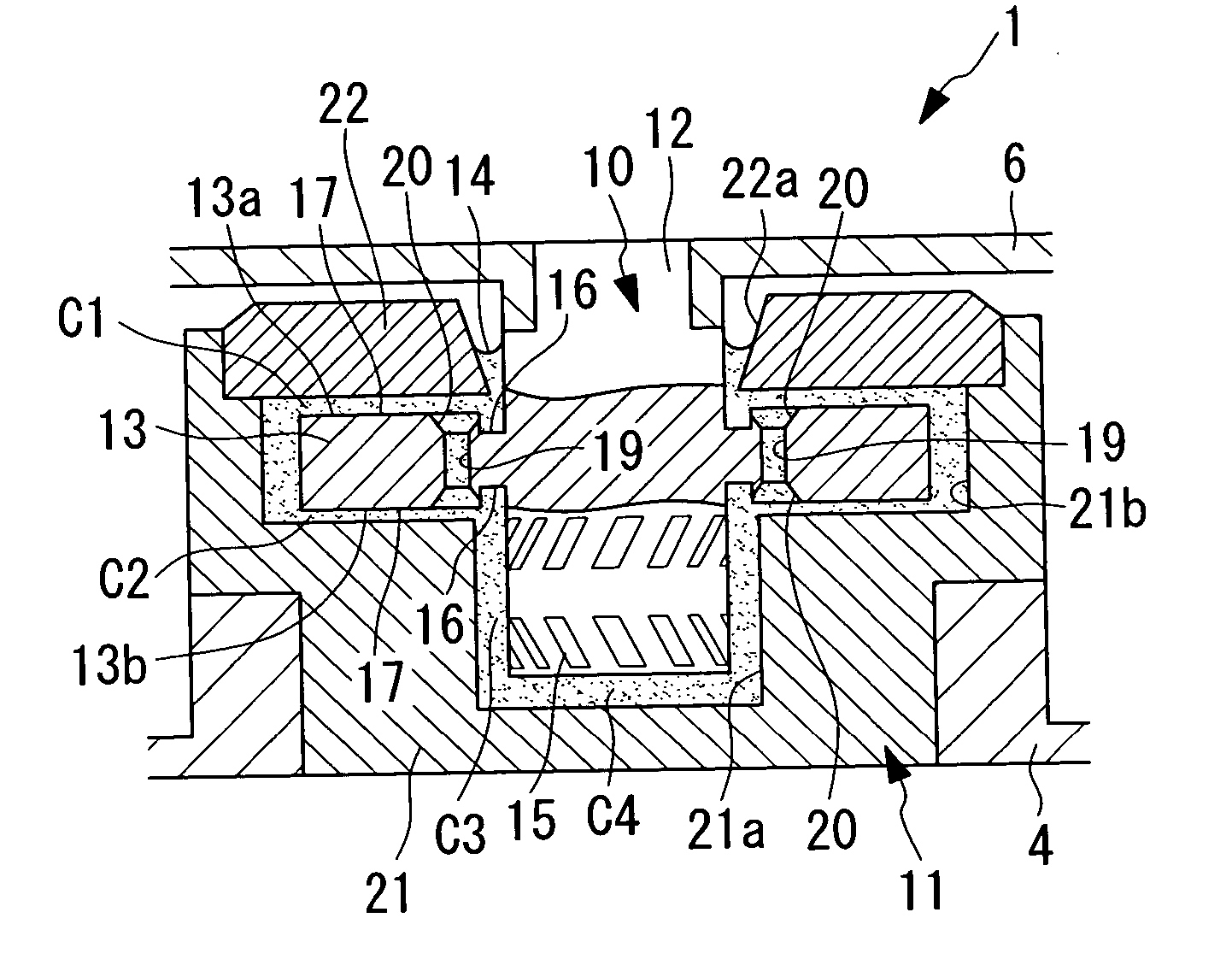

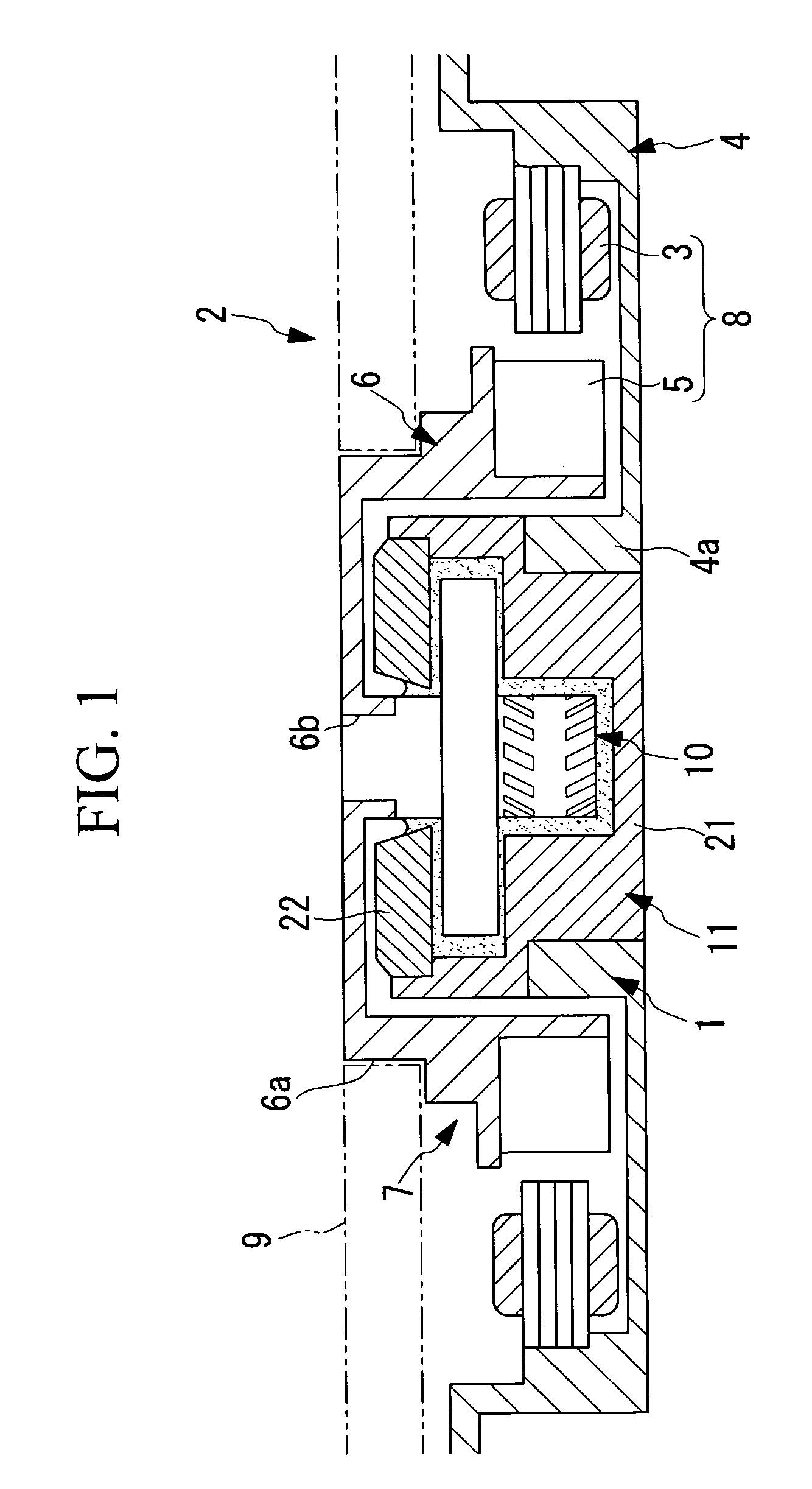

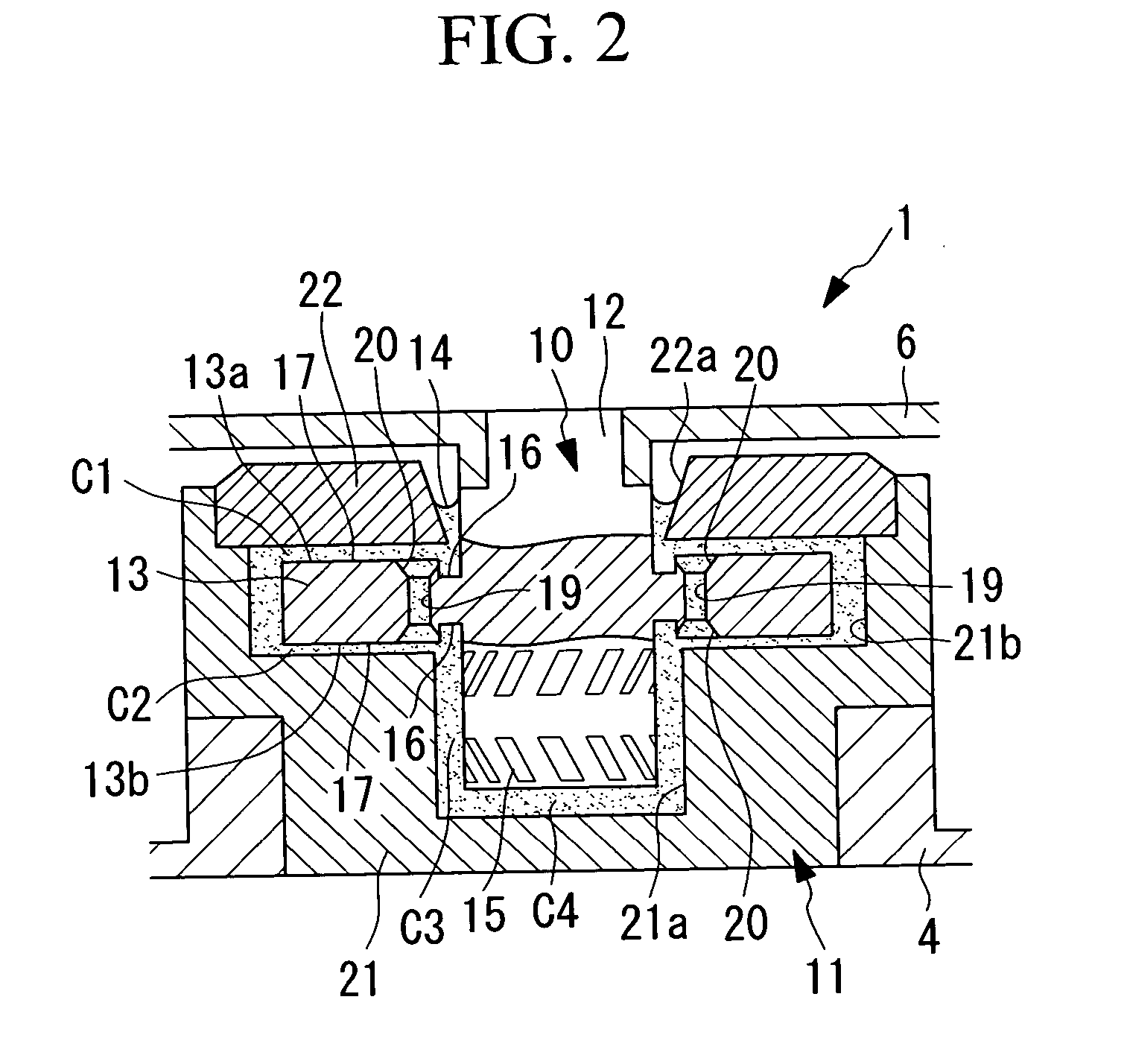

Fluid dynamic pressure bearing, motor, and recording medium driving device

InactiveUS20070177832A1Avoid mistakesAvoid bubblingShaftsRecord information storagePressure generationWorking fluid

The generation of bubbles can be suppressed by enabling a stable supply of working fluid to a dynamic pressure generating groove, and oscillation at the time of rotation and leakage of working fluid can be prevented effectively by efficiently releasing any bubbles generated. There is provided a fluid dynamic pressure bearing 1 provided with an annular dynamic pressure generating face 17 made by forming a dynamic pressure generating groove, which draws a working fluid 14 toward a midway position in the radial direction from the inside and outside of a thrust bearing plate 13 in the radial direction, when a shaft 10 and a housing 11 are rotated relative to each other about the axis, on thickness direction end faces 13a, 13b of the thrust bearing plate 13, or on an inner surface of the housing 11, and an inner groove section 16, which is located on an inner peripheral side thereof and that is depressed more than the dynamic pressure generating face 17 in the thickness direction, on the end faces 13a, 13b. Moreover there is provided a through hole 19 which passes through the thrust bearing plate 13 in the thickness direction so as to open to the dynamic pressure generating face 17, and there is provided a communicating cavity 20 which connects the opening portion of the through hole 19 and the inner groove section 16.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

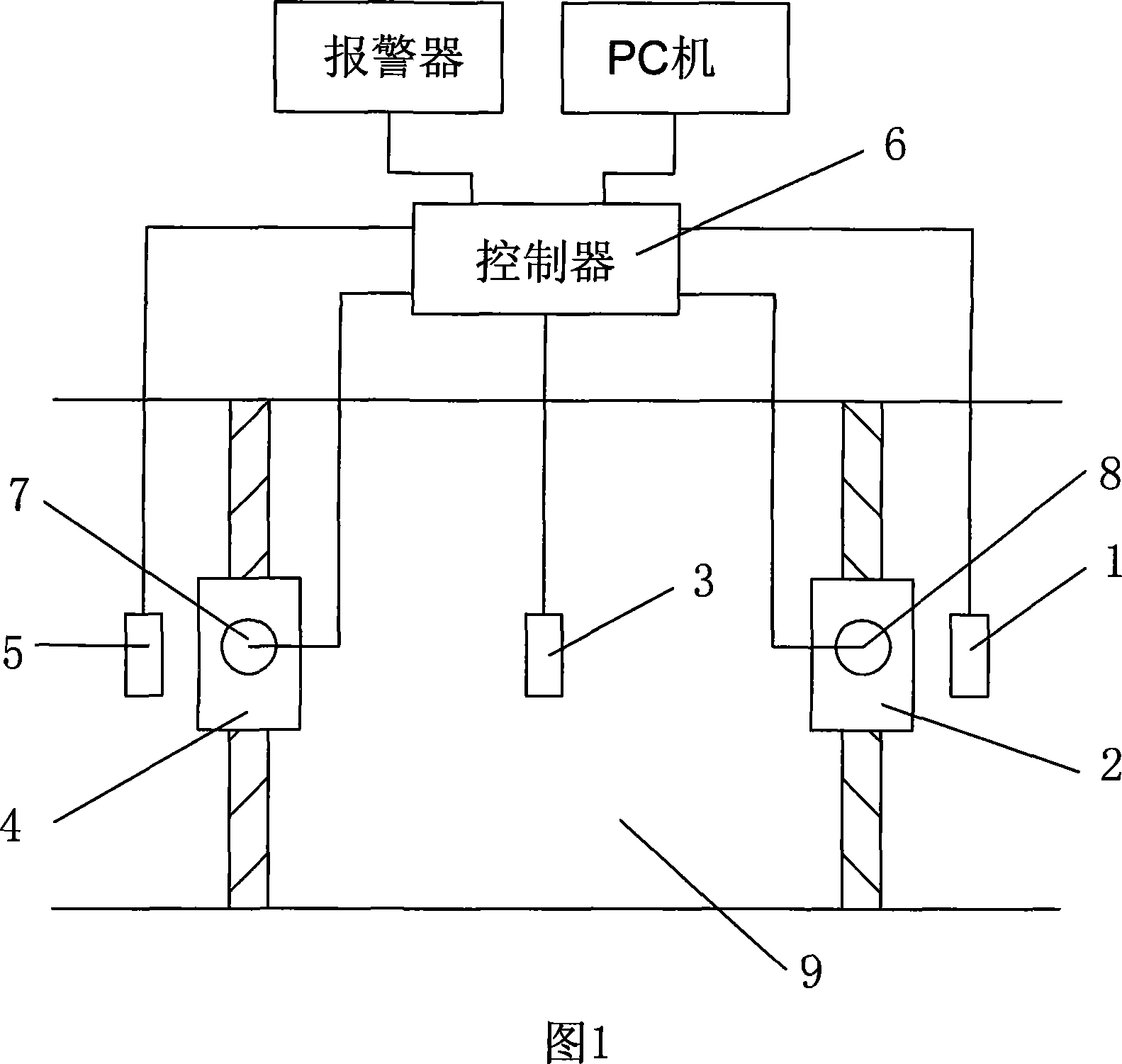

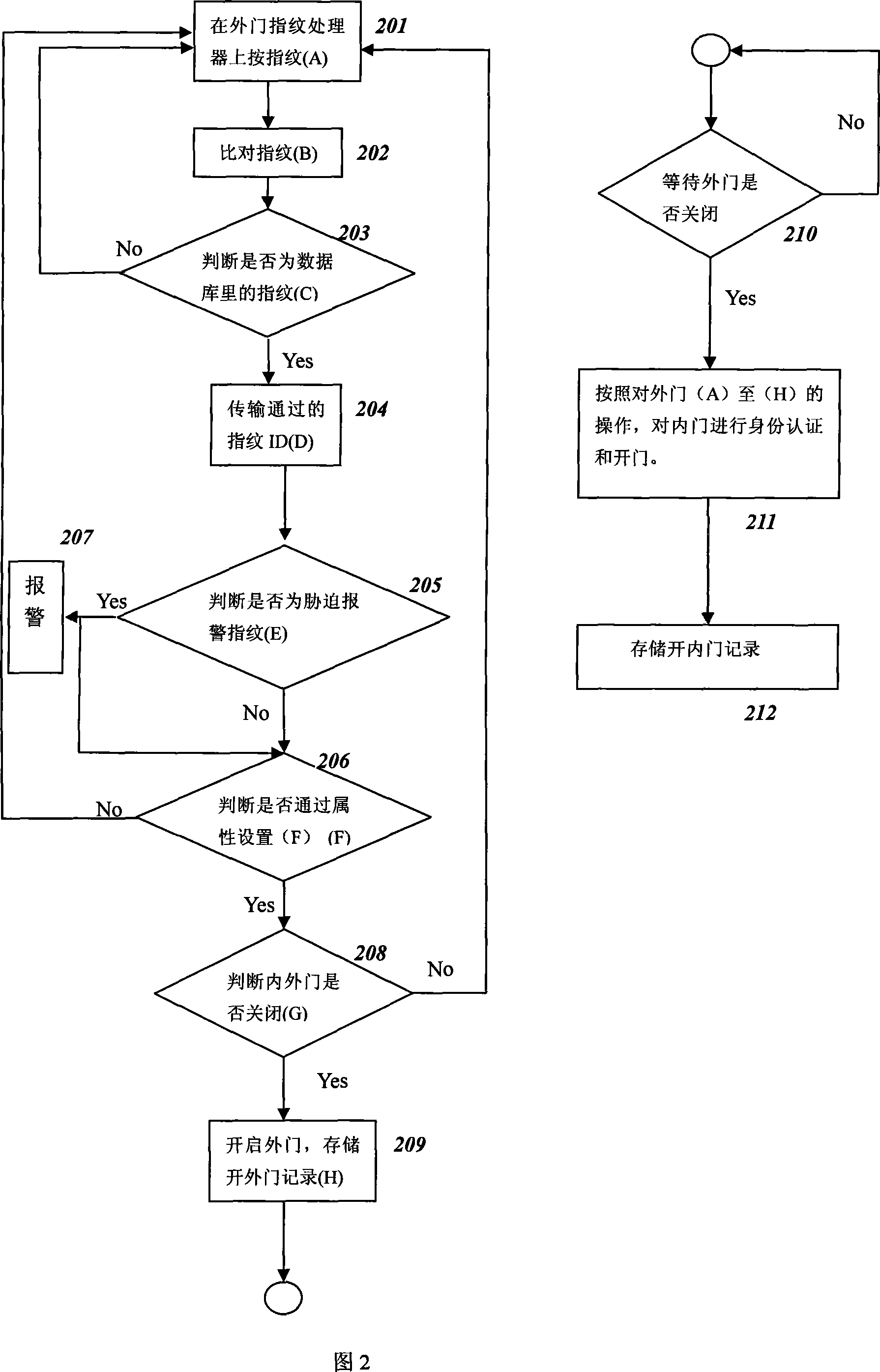

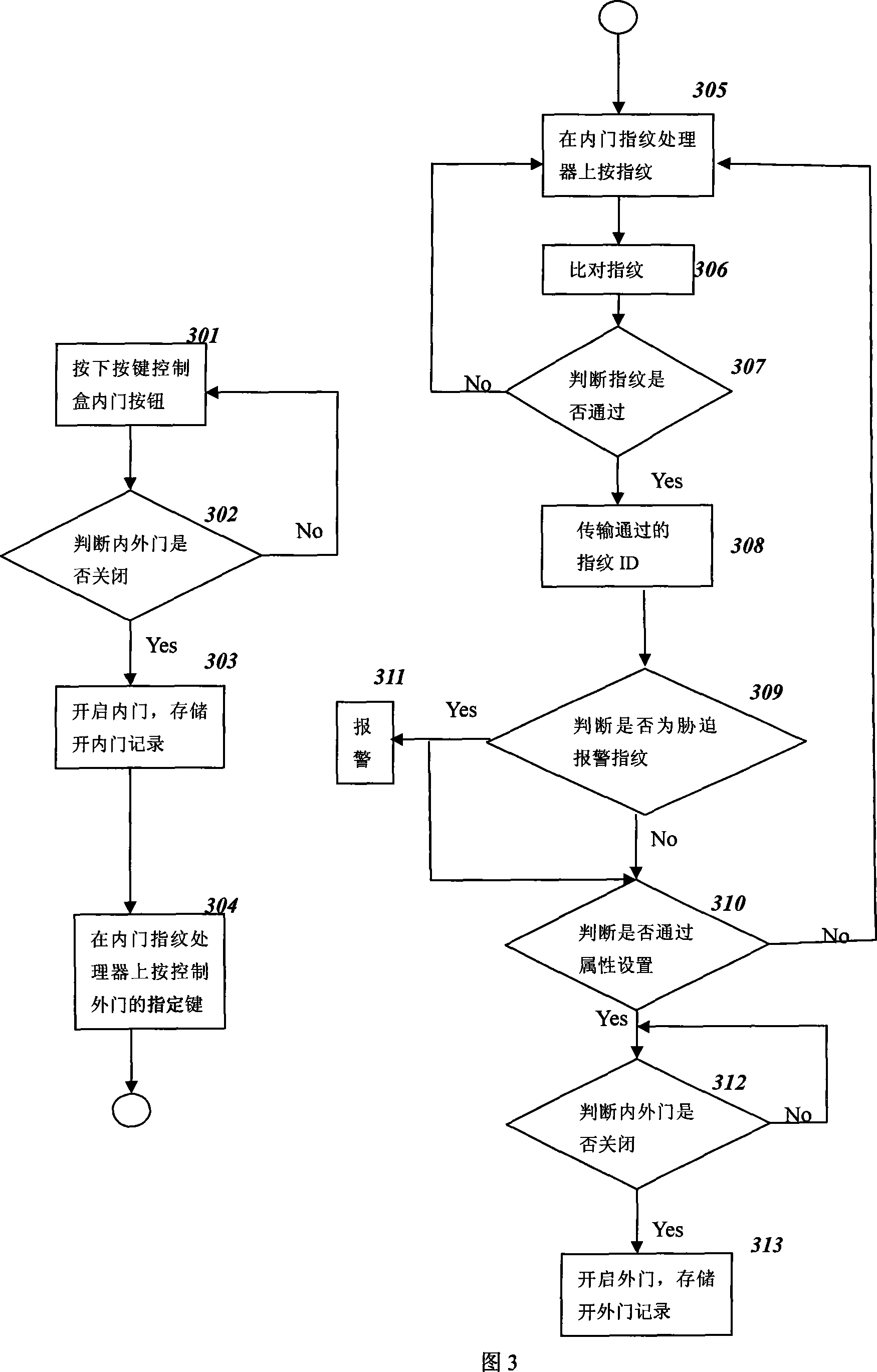

Secondary door access system adopting biological character identification technology and control method

InactiveCN101059878AEnsure safetyGuaranteed accuracyCharacter and pattern recognitionIndividual entry/exit registersGeneral biologySwitch box

The invention relates to a two-door gate inhibition system and a control method, based on biology character recognize technique, comprising a biology character gate inhibition device, a controller, an electric lock, a switch box, a biology character register terminal, and a gate inhibition system server, wherein the biology character register terminal registers the biology character information, to record and build database for general biology character and alarm biology character, when passes two doors, the gate inhibition device checks and receives biology character, to extract and compare the biology character information, and when the biology character information is authorized one, to send an outer door open request to the controller, and when the biology character information is alarm biology character, send out an outdoor door open request and an alarm signal. The invention provides forced alarm method, to open door with starting alarm response, to alarm on time and protect owner.

Owner:ZHEJIANG MIAXIS TECH CO LTD

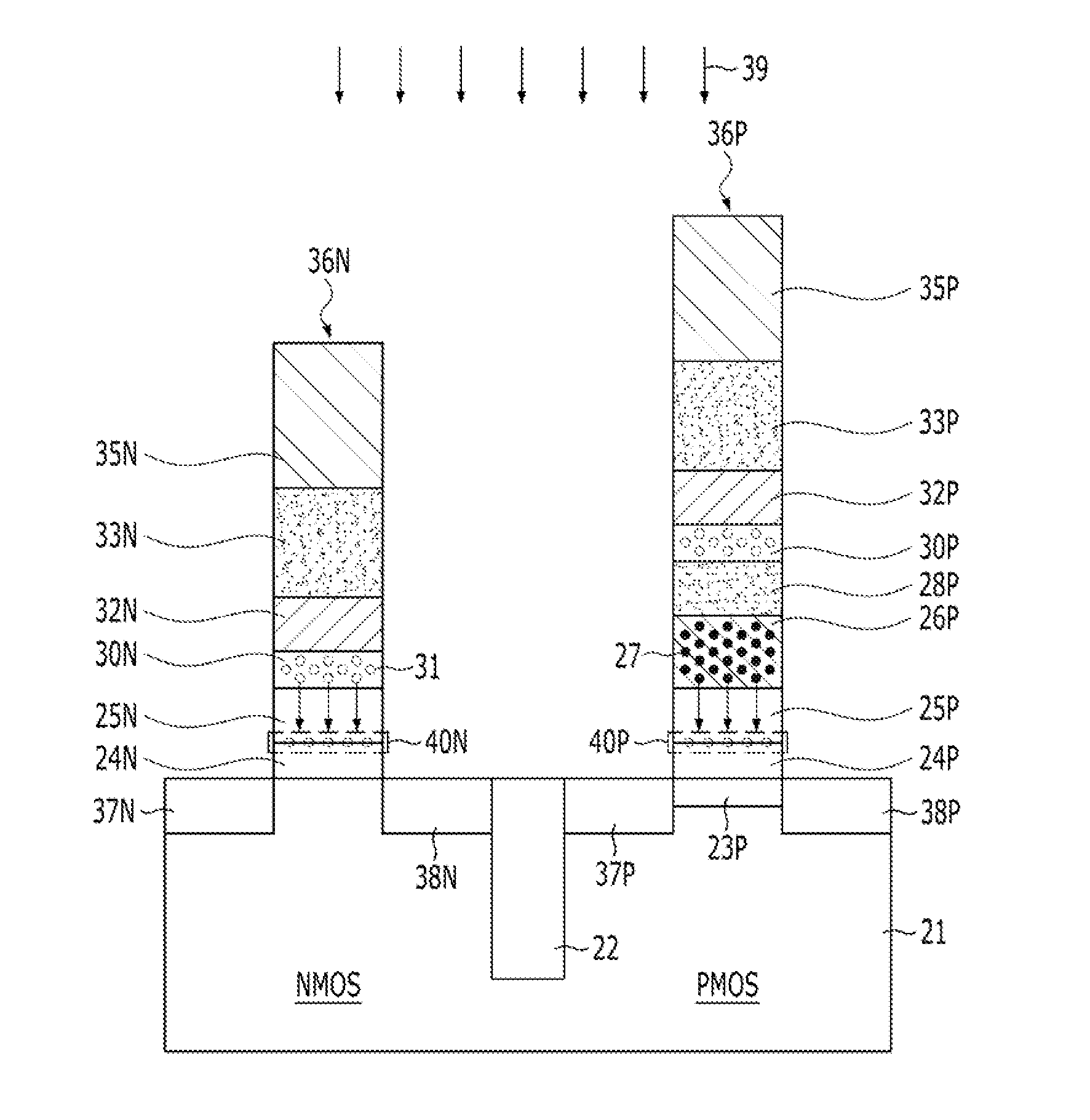

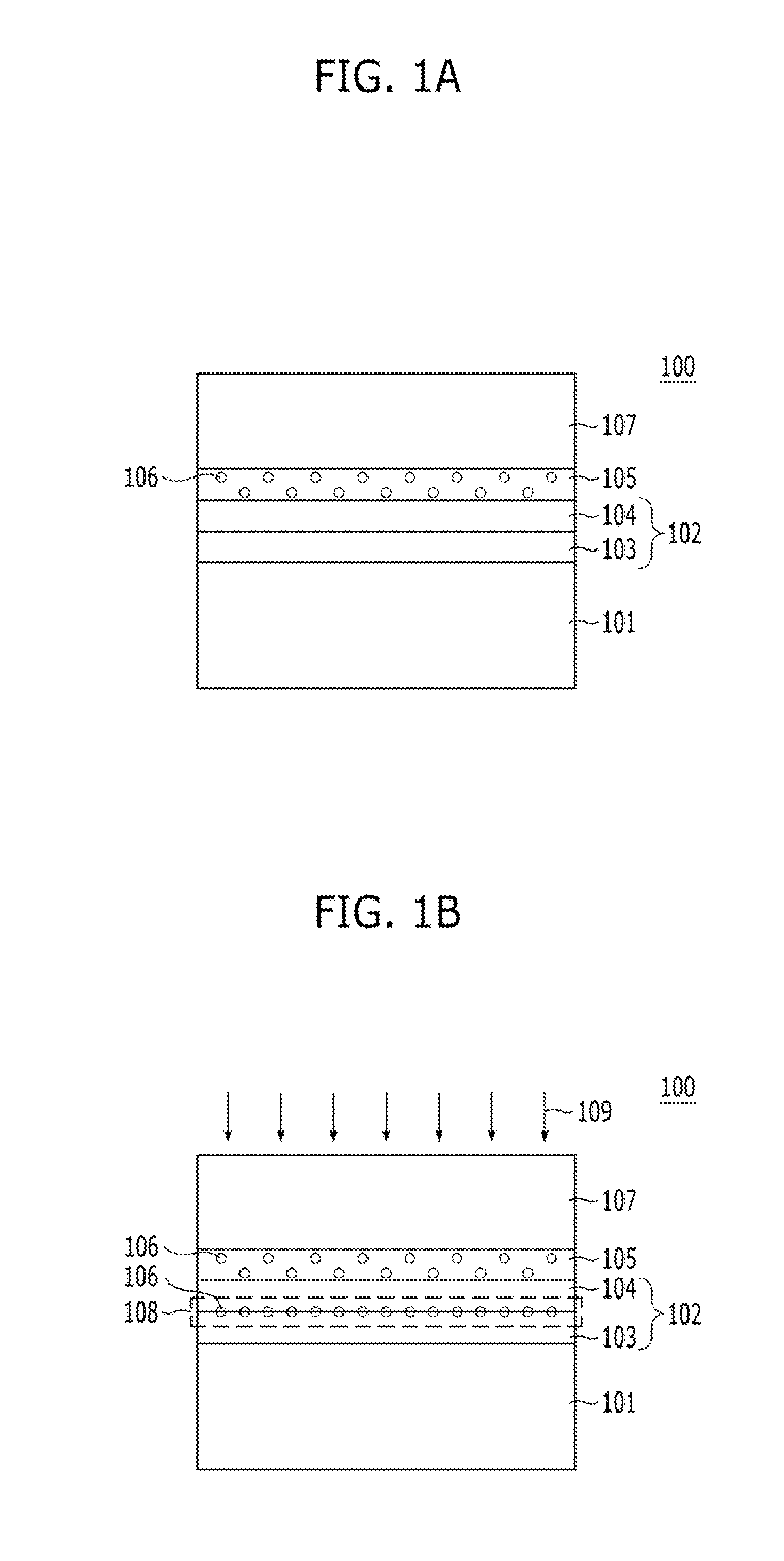

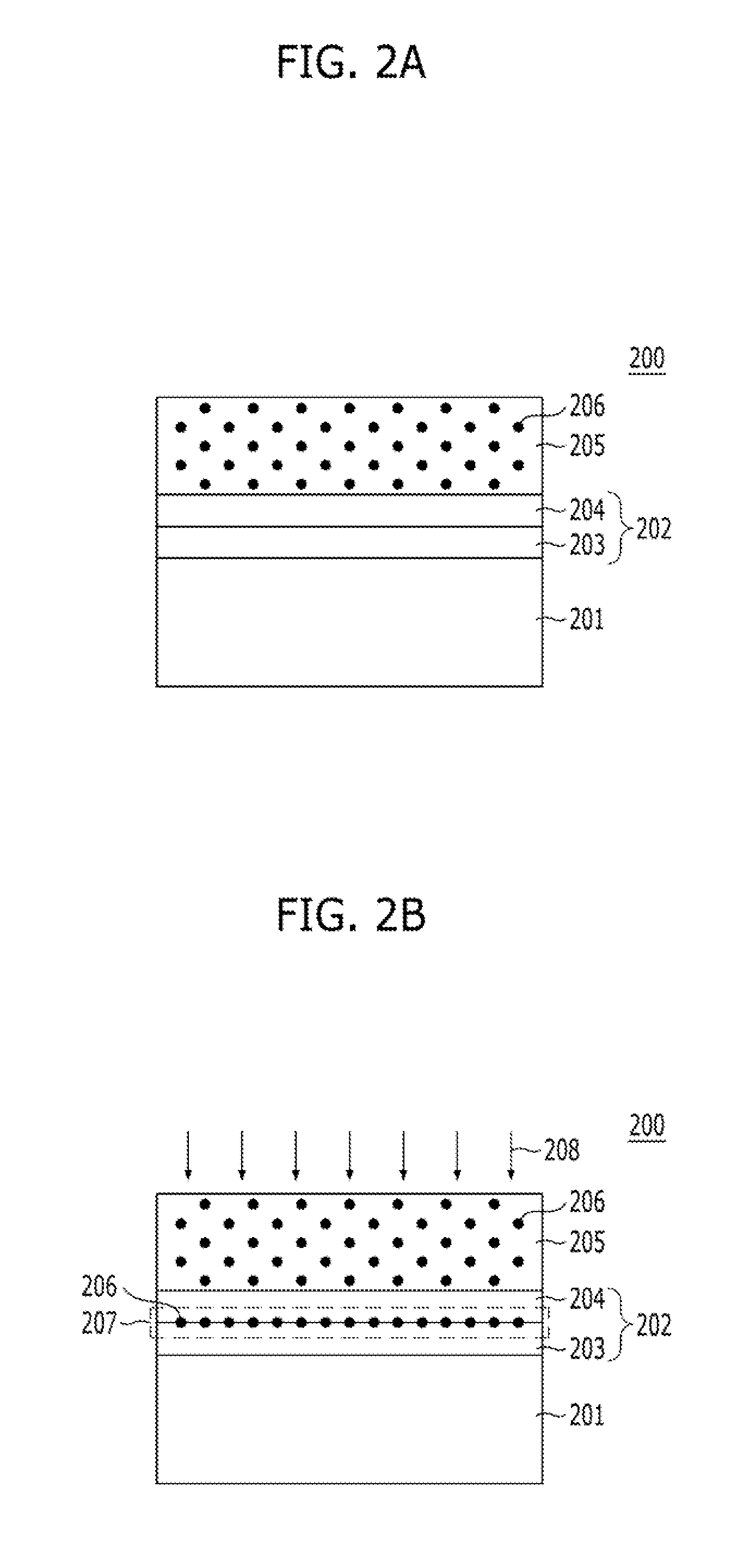

Semiconductor device including gate structure for threshold voltage modulation in transistors and method for fabricating the same

ActiveUS20150129973A1Lower threshold voltageGuaranteed work efficiencyTransistorSolid-state devicesPower semiconductor deviceGate dielectric

A method for fabricating a semiconductor device includes forming an NMOS region and a PMOS region in a substrate, forming a first stack layer including a first gate dielectric layer and a first work function layer that is disposed over the first gate dielectric layer and contains aluminum, over the PMOS region of the substrate, forming a second stack layer including a second gate dielectric layer, a threshold voltage modulation layer that is disposed over the second gate dielectric layer and contains lanthanum, and a second work function layer that is disposed over the threshold voltage modulation layer, over the NMOS region of the substrate, and annealing the first stack layer and the second stack layer, thereby forming a first dipole-interface by diffusion of the aluminum in the first gate dielectric layer and a second dipole-interface by diffusion of the lanthanum in the second gate dielectric layer, respectively.

Owner:SK HYNIX INC

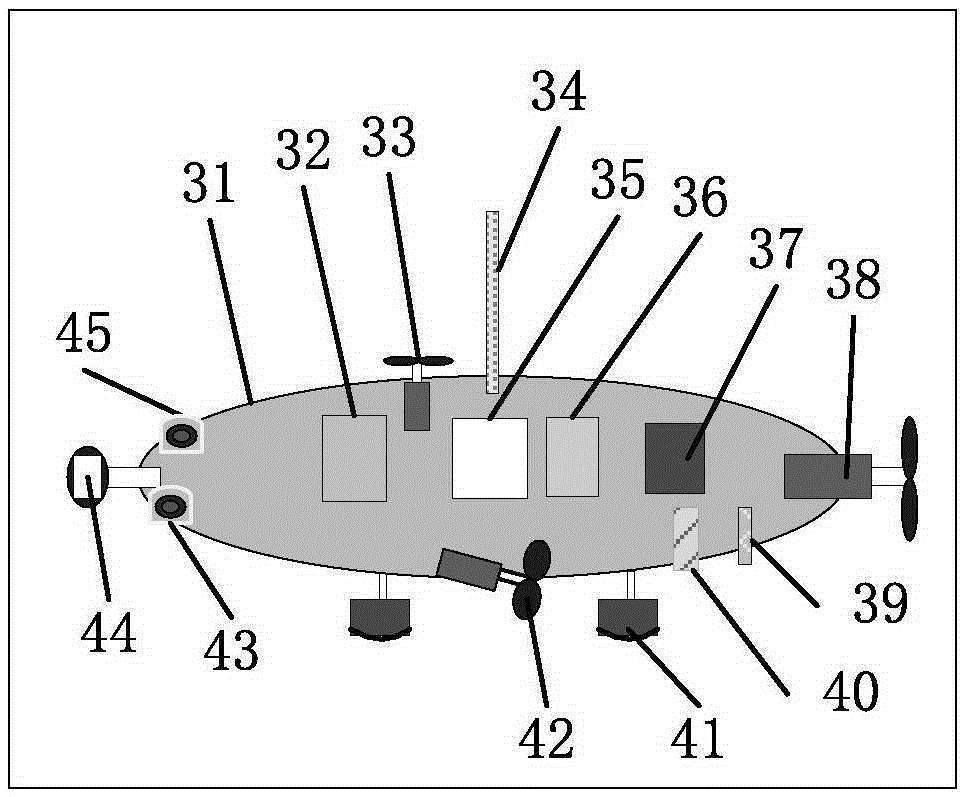

Unmanned-ship-mounted underwater robot mixing system

ActiveCN105329418AEnsure work efficiency and duty frequencyBroaden the field of applicationAircraft componentsAuxillariesPower equipmentControl equipment

The invention provides an unmanned-ship-mounted underwater robot mixing system which comprises an unmanned ship, an underwater robot and a connection system. The unmanned ship mainly comprises a ship body and a ship-mounted control system, ship-mounted power equipment and ship-mounted application equipment which are arranged on the ship body. The underwater robot comprises an underwater robot body and underwater application equipment, and the underwater robot body is provided with underwater control equipment, underwater power equipment and operation equipment. The connection system comprises a connection cable and a communication system, the connection cable is formed by binding communication cable, a charging cable and a dragging cable. The unmanned ship and the underwater robot are connected through the connection cable and exchange data through the communication system. According to the mixing communication system, the ship-mounted control system serves as the core, and an internal bus and a communication board card are adopted to control the unmanned ship and the underwater robot to conduct cooperative work in a unified mode; the unmanned ship serves as a water transport platform and a communication replay platform, and response is made to requirements of carrying, inward journey, parking, communication, power supply and the like of the underwater robot.

Owner:SIFANG JIBAO WUHAN SOFTWARE CO LTD

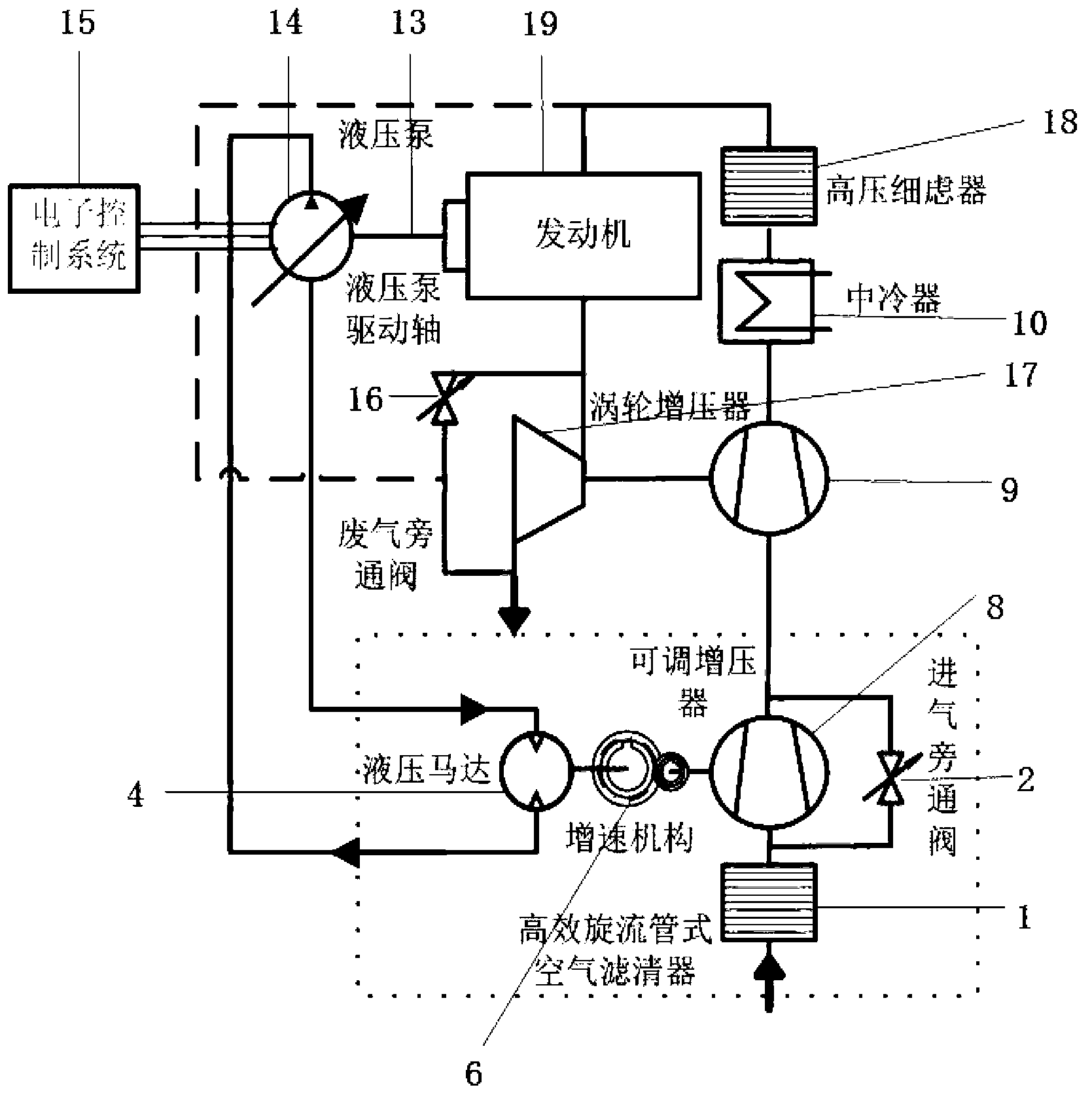

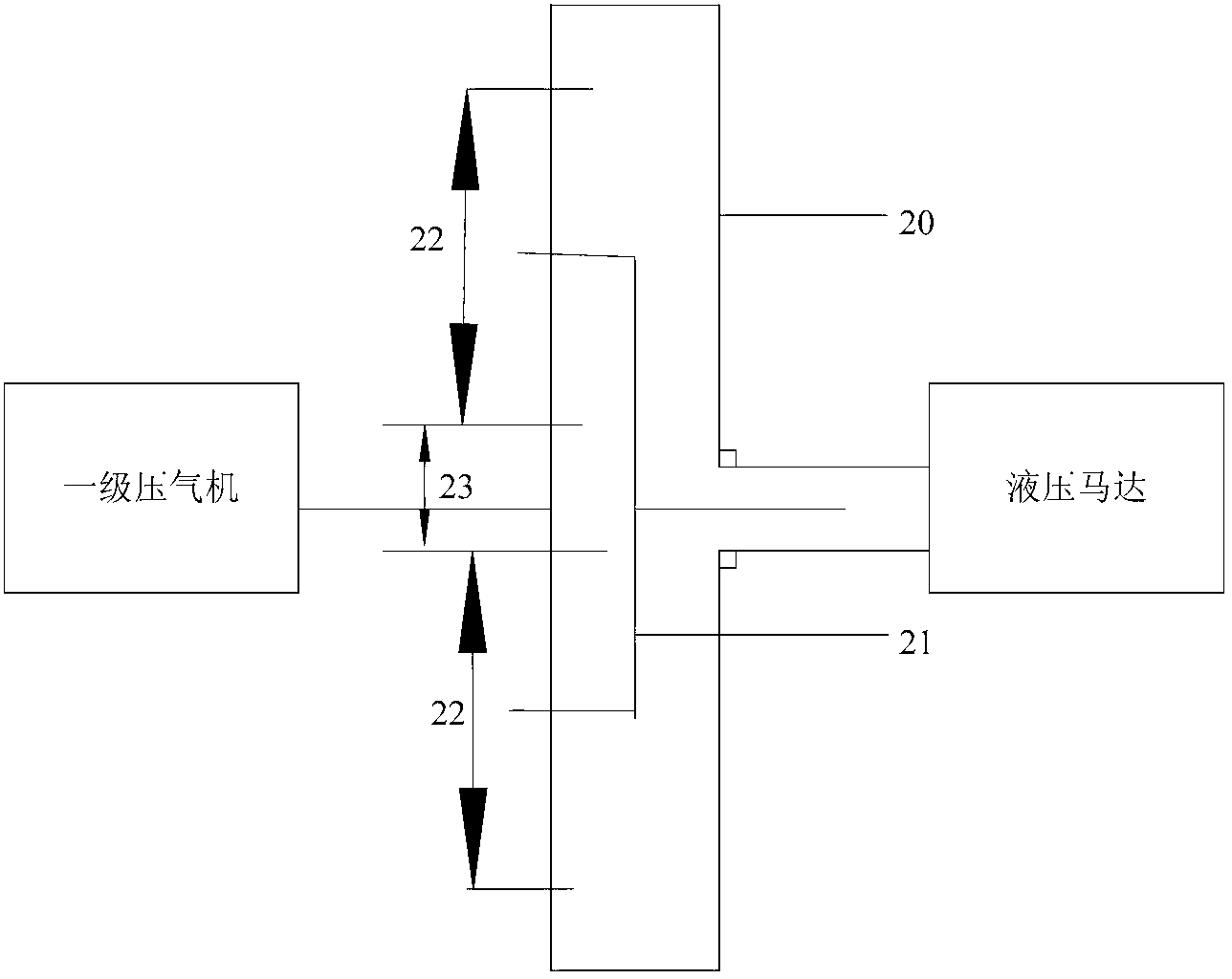

Adjustable composite pressure-boosting air intake system

InactiveCN103306805AGuaranteed work efficiencyImproved low-speed torque characteristics and acceleration response characteristicsInternal combustion piston enginesCombustion-air/fuel-air treatmentForced inductionBypass valve

The invention provides an adjustable composite pressure-boosting air intake system which comprises two stages of pressure boosters, that is, an adjustable pressure booster and a turbine pressure booster respectively, wherein the adjustable pressure booster comprises a first-stage compressor, an air intake bypass valve, an acceleration mechanism, a driving device and an electronic control system; the first-stage compressor is connected with the air intake bypass valve in parallel; the first-stage compressor is connected with the acceleration mechanism; the acceleration mechanism is connected with the driving device; and the driving device is connected with the electronic control system. The rotation speed of the adjustable pressure booster can be correspondingly adjusted according to the change of altitude and engine speed, so as to realize reasonable distribution of the pressure ratio of the two stages of the pressure boosters and ensure the working efficiency. Therefore, by utilizing the system, the problem of recovering the power of a variable-altitude vehicle is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

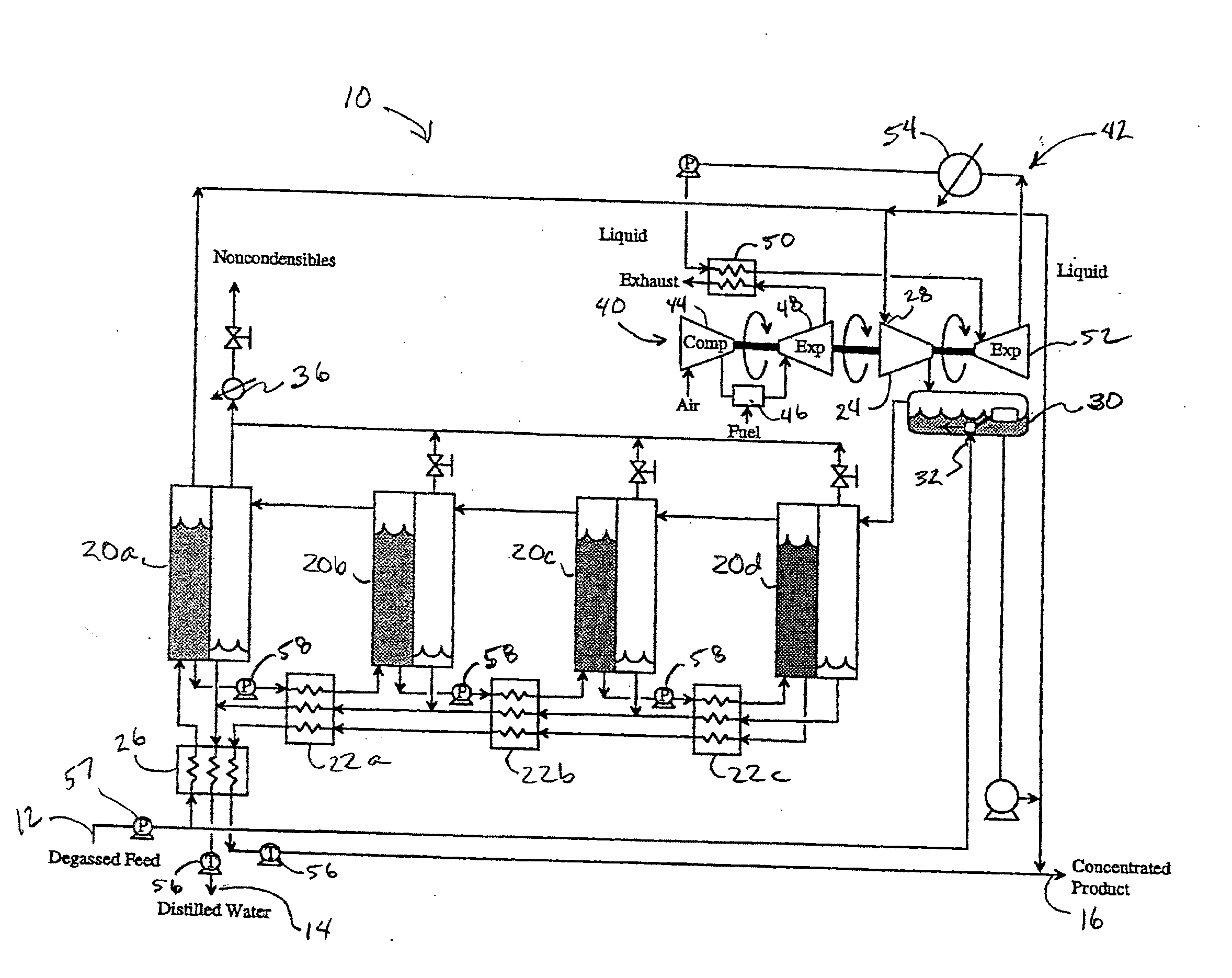

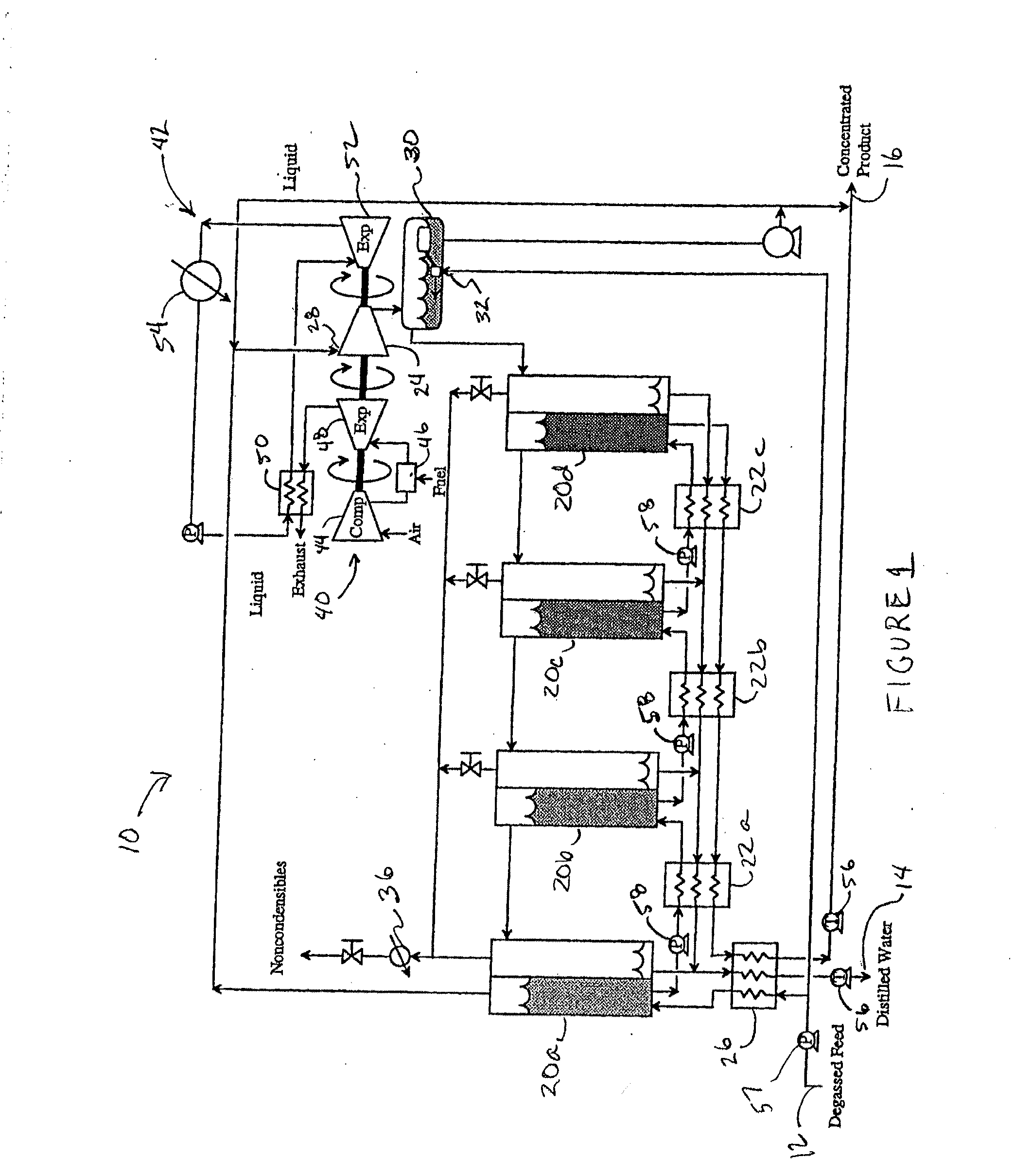

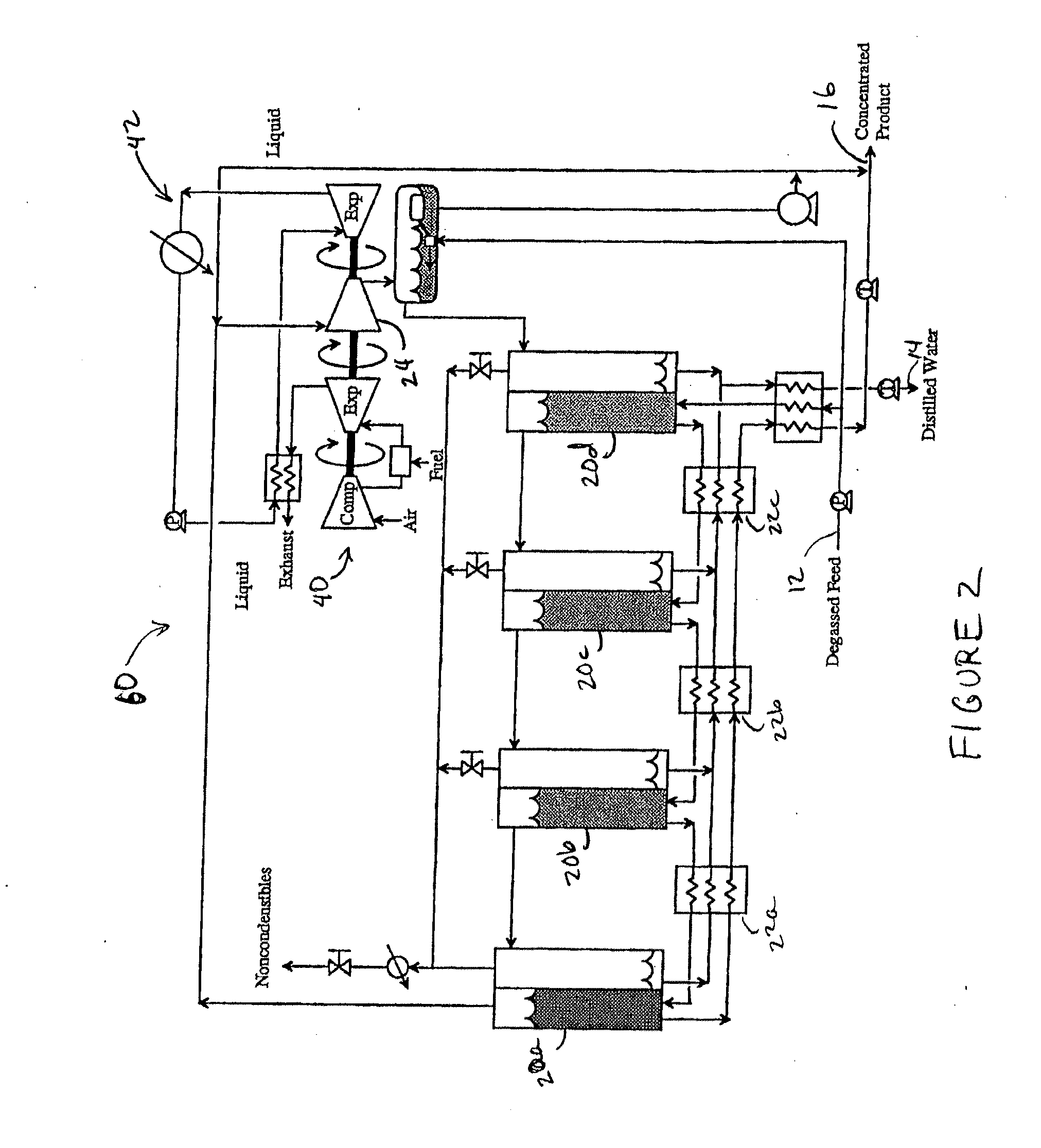

Desalination methods

InactiveUS20120199534A1EfficientlyReduce workloadGeneral water supply conservationAuxillariesDesalinationEngineering

In accordance with particular embodiments, a desalination system includes a plurality of evaporators. The plurality of evaporators includes at least a first evaporator and a last evaporator. The plurality of evaporators are arranged in cascading fashion such that a concentration of salt in a brine solution increases as the brine solution passes through the plurality of evaporators from the first evaporator towards the last evaporator. The desalination system also includes a plurality of heat exchangers. An input of each evaporator is coupled to at least one of the plurality of heat exchangers. The system also includes a vapor source coupled to at least one of the plurality of evaporators.

Owner:TEXAS A&M UNIVERSITY +1

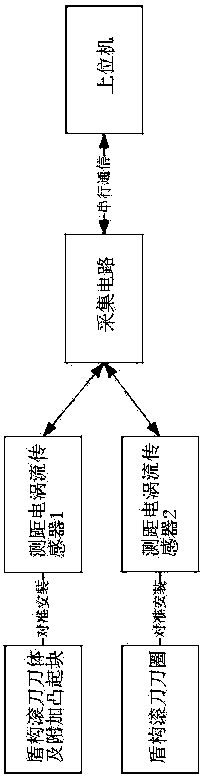

Working and abrasion state on-line detection method for shield hob

InactiveCN104111346ATimely monitoring of wear statusReal-time monitoring of wear statusUsing electrical meansDevices using time traversedEngineeringBuilding construction

Owner:SHIJIAZHUANG TIEDAO UNIV +2

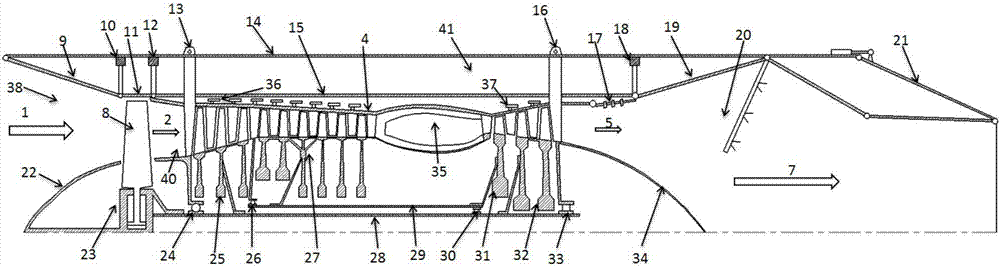

Intelligent engine adopting self-adaptive machine case and self-adaptive fan

ActiveCN108005812ALarge external duct flowAxial dimension shortJet propulsion plantsEngineeringFan blade

The invention provides an engine adopting a self-adaptive machine case and a self-adaptive fan. The engine comprises the self-adaptive machine case, the self-adaptive fan and a fuel gas generator; theself-adaptive machine case comprises a self-adaptive machine case driving execution part, an inlet section self-adaptive machine case, a fan section self-adaptive machine case, an engine middle section self-adaptive machine case and an outlet section self-adaptive machine case, wherein the inlet section self-adaptive machine case, the fan section self-adaptive machine case, the engine middle section self-adaptive machine case and the outlet section self-adaptive machine case are sequentially connected; the self-adaptive fan comprises self-adaptive fan blades and a fan driving execution part;a self-adaptive external duct is formed between the engine middle section self-adaptive machine case and an internal duct machine case of the fuel gas generator; an internal duct is formed in the internal duct machine case; the self-adaptive machine case driving execution part drives the self-adaptive machine case to move to control the cross section area of the external duct; and the fan drivingexecution part drives the self-adaptive fan blades to move in the axial direction to enable the self-adaptive fan blades to be matched with the fan section self-adaptive machine case.

Owner:AERO ENGINE ACAD OF CHINA

Control system for solar panel cleaning robot

InactiveCN106182015ALarge coverage areaGuaranteed cleanlinessProgramme-controlled manipulatorPhotovoltaicsControl systemEngineering

The invention provides a control system for a solar panel cleaning robot. The control system is used for the solar panel cleaning robot and comprises a data acquisition unit, a processor and at least one storage unit, wherein the data acquisition unit is used for acquisition of at least one working parameter in the proceeding process of the cleaning robot; the processor is connected to the data acquisition unit and used for sending out at least one proceeding control instruction or at least one cleaning control instruction; and the at least one storage unit is connected to the processor and used for storing the working parameters of the cleaning robot in the proceeding process.

Owner:SUZHOU RADIANT PHOTOVOLTAIC TECH

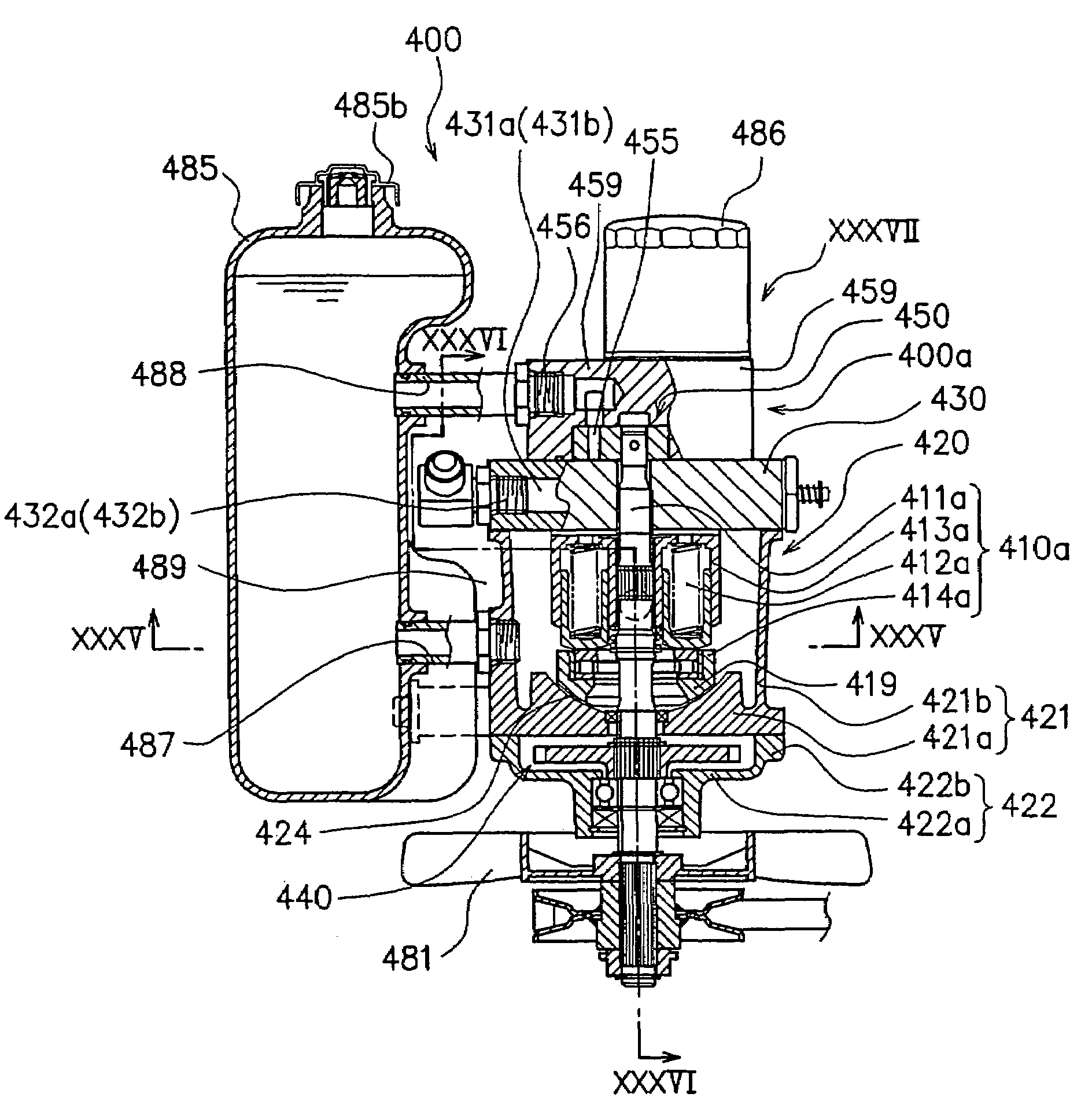

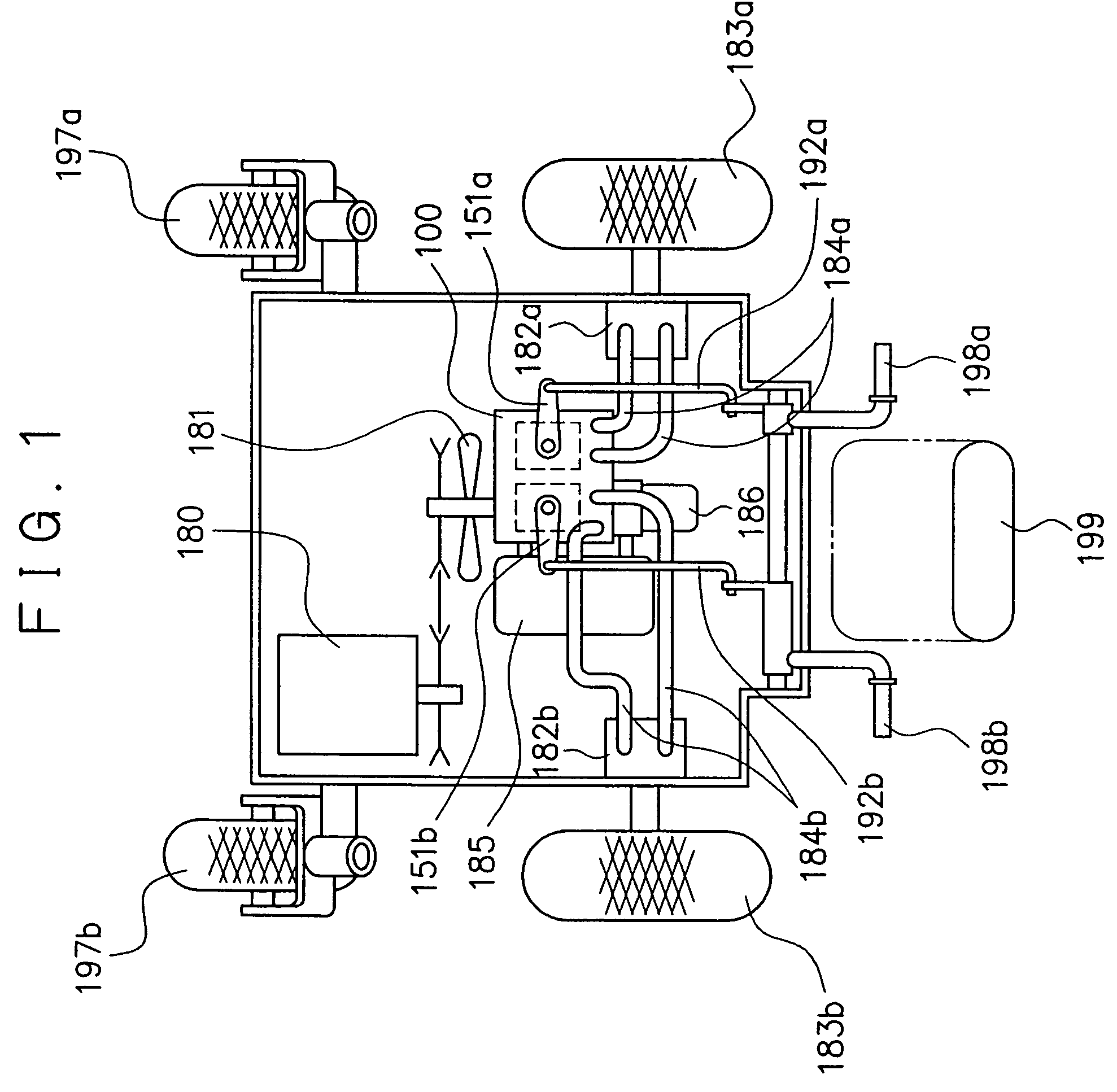

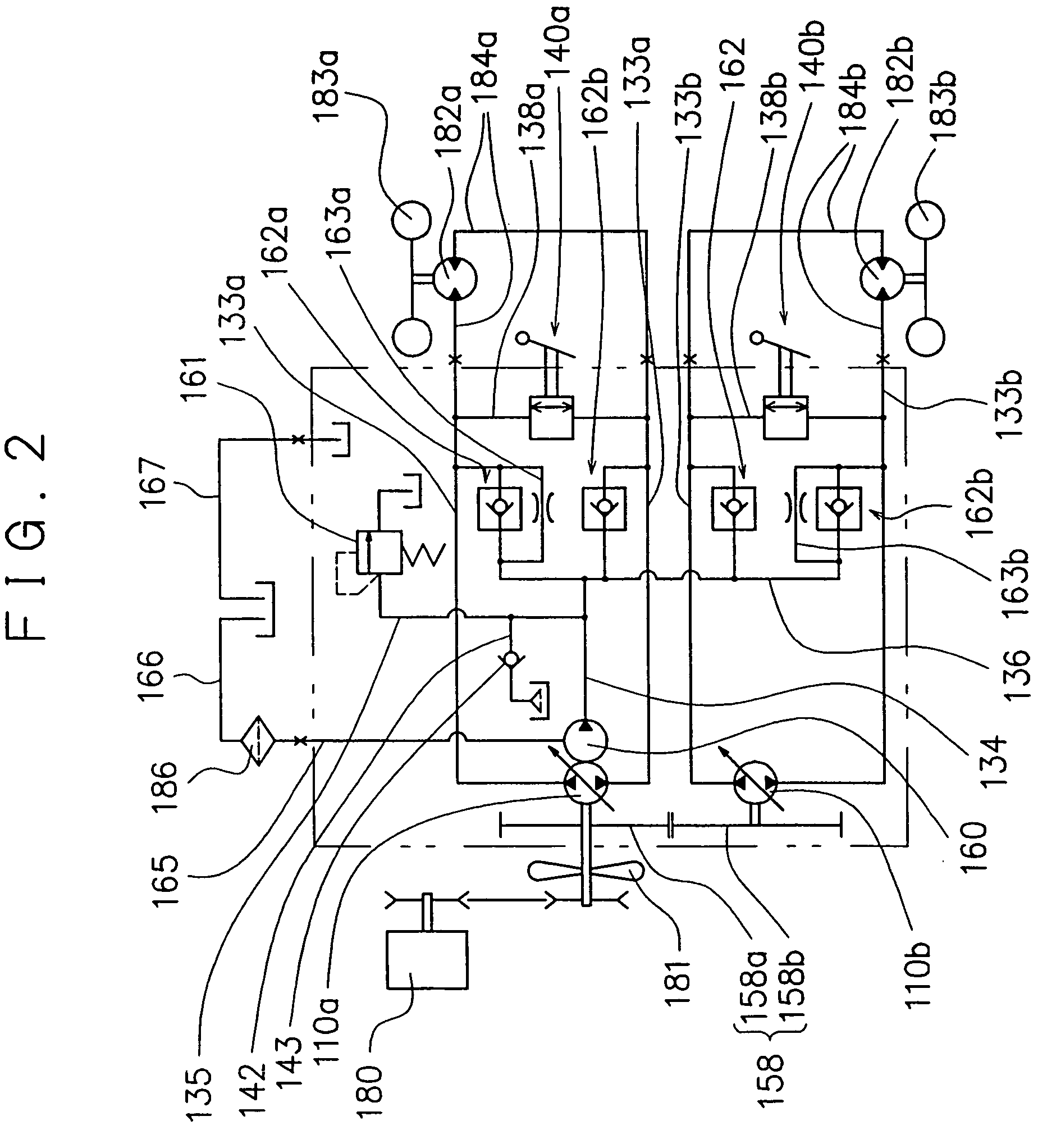

Pump unit

InactiveUS7028472B2Low sectionEasy to assembleFluid parameterFluid couplingsHydraulic pumpEngineering

The present invention provides a pump unit including at least one hydraulic pump with inlet and outlet ports, a pump case for accommodating the hydraulic pump having an opening through which the hydraulic pump is insertable, and a lid, called a center section, closing the pump case. The center section forms a pair of inlet / outlet passages communicating an end with the inlet and outlet ports of the hydraulic pump and an end opening through a pump case abutting surface of the center section, and a first charging passage by which hydraulic fluid is fed through the pump case abutting surface of the center section. At least one of the pump case and the center section communicates the first charging passage with the pair of inlet / outlet passages via a first hydraulic fluid feeding valve preventing the reverse flow into said first charging passage.

Owner:OHASHI RYOTA +1

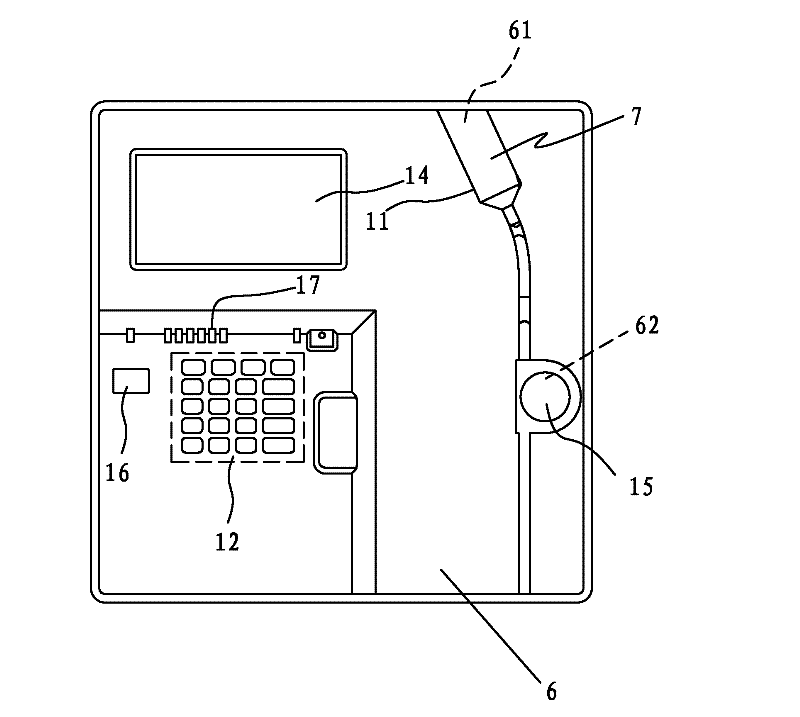

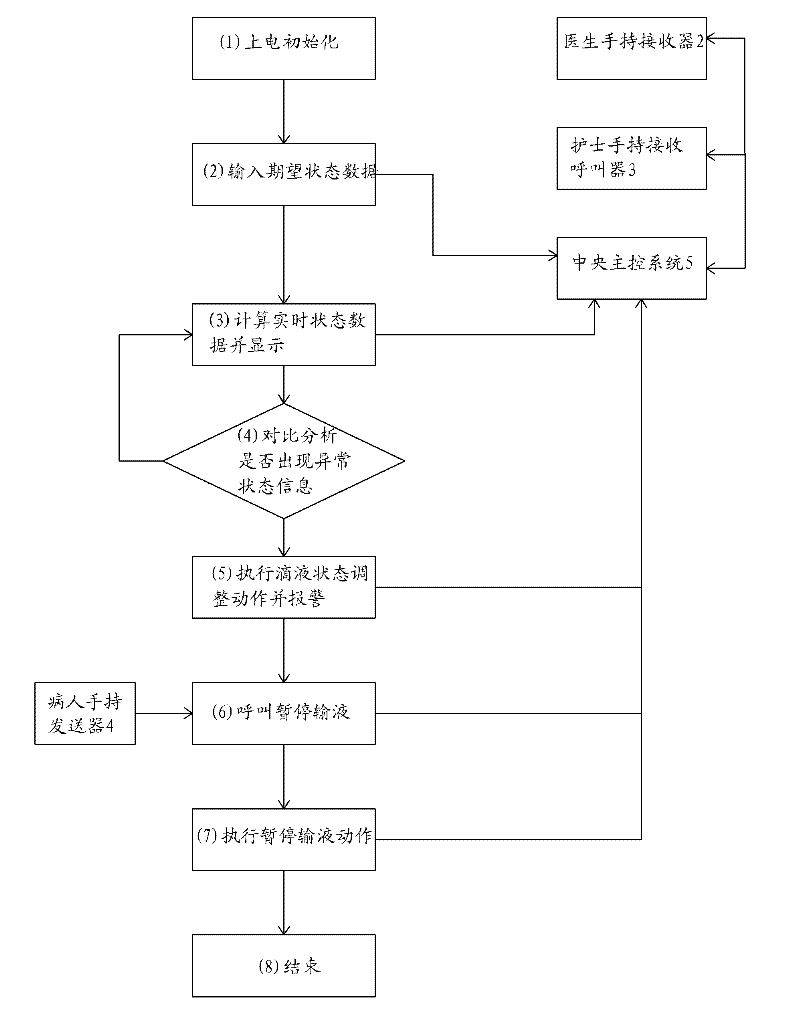

Infusion calling automatic control and medical care management system

InactiveCN102218170AAccurate detectionEasy to controlAlarmsFlow monitorsAutomatic controlControl system

The invention provides an infusion calling automatic control and medical care management system. The system comprises hospital bed intelligent terminals, a doctor handheld terminal, a nurse handheld terminal, a central master control system for patient handheld terminals and a nurse station, wherein the hospital bed intelligent terminals are arranged on hospital beds and can accurately detect abnormal status information and give the alarm in the infusion process and simultaneously carry out the adjustment on the dropping speed automatically; in the non-infusion process, the hospital bed intelligent terminals can remind nurses of carrying out a nursing procedure on patients at regular time; the patient handheld terminals are used for sending the information to the hospital bed intelligent terminals; and the wireless communication among the doctor handheld terminal, the nurse handheld terminals and the hospital bed intelligent terminals is completed by the central master control system.The system is capable of accurately detecting the abnormal status information and giving the alarm in the infusion process and simultaneously adjusting the dropping speed automatically; the system iscapable of reminding the nurses of carrying out the nursing procedure on patients at regular time in the non-infusion process; the central master control system is used for managing the information of the patients and the information of medical care personnel and carrying out the real-time control and management on the plurality of hospital bed intelligent terminals.

Owner:吴迪熙

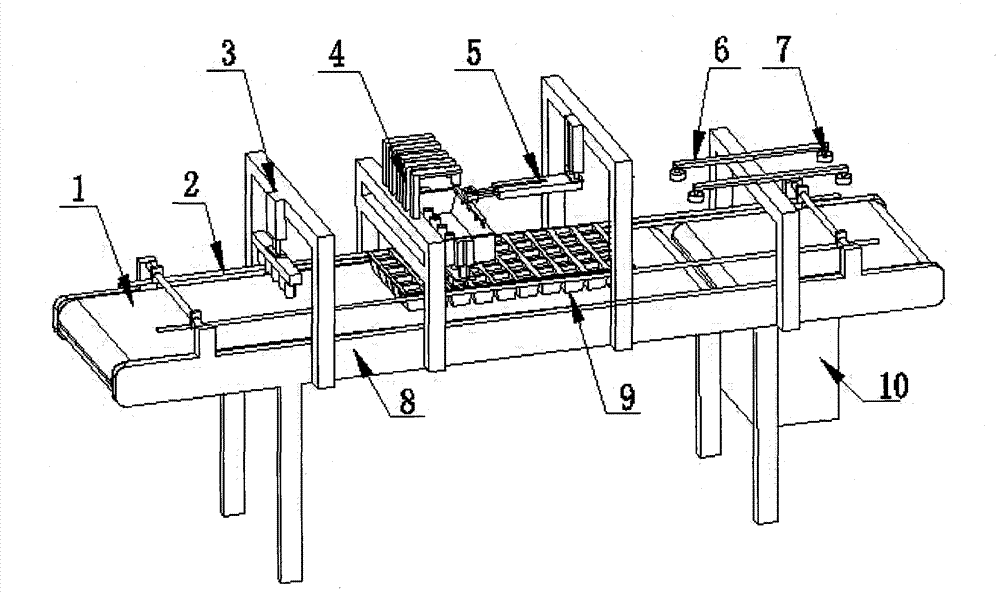

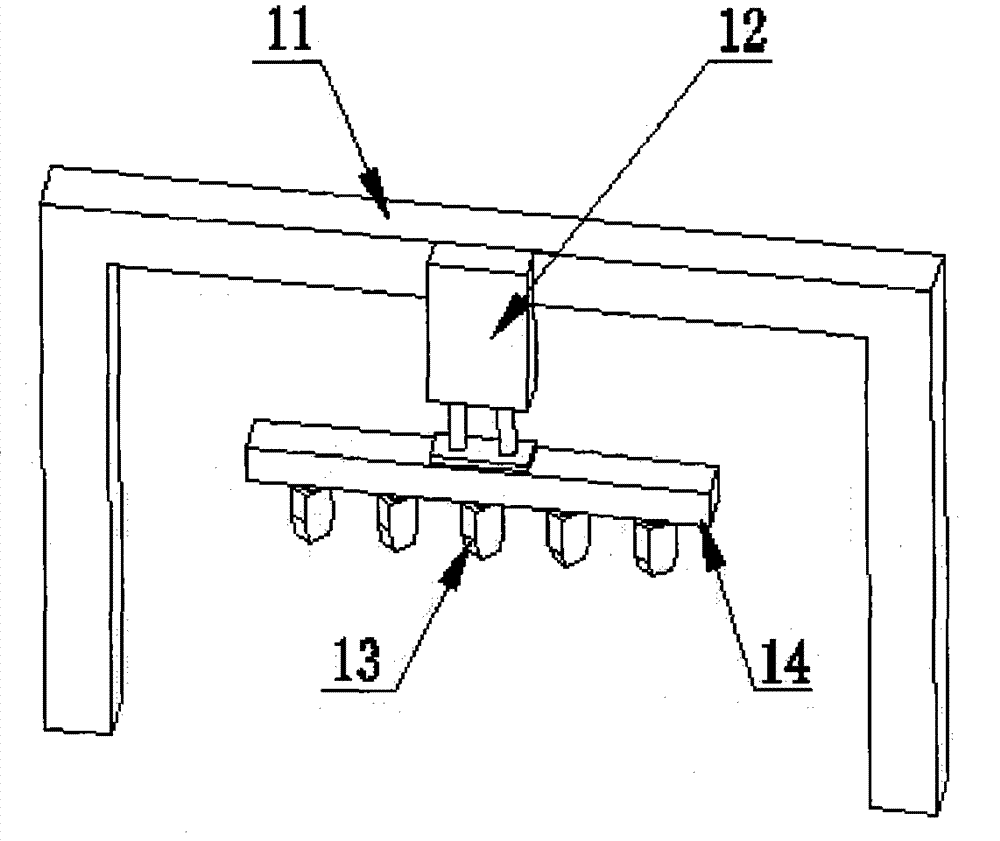

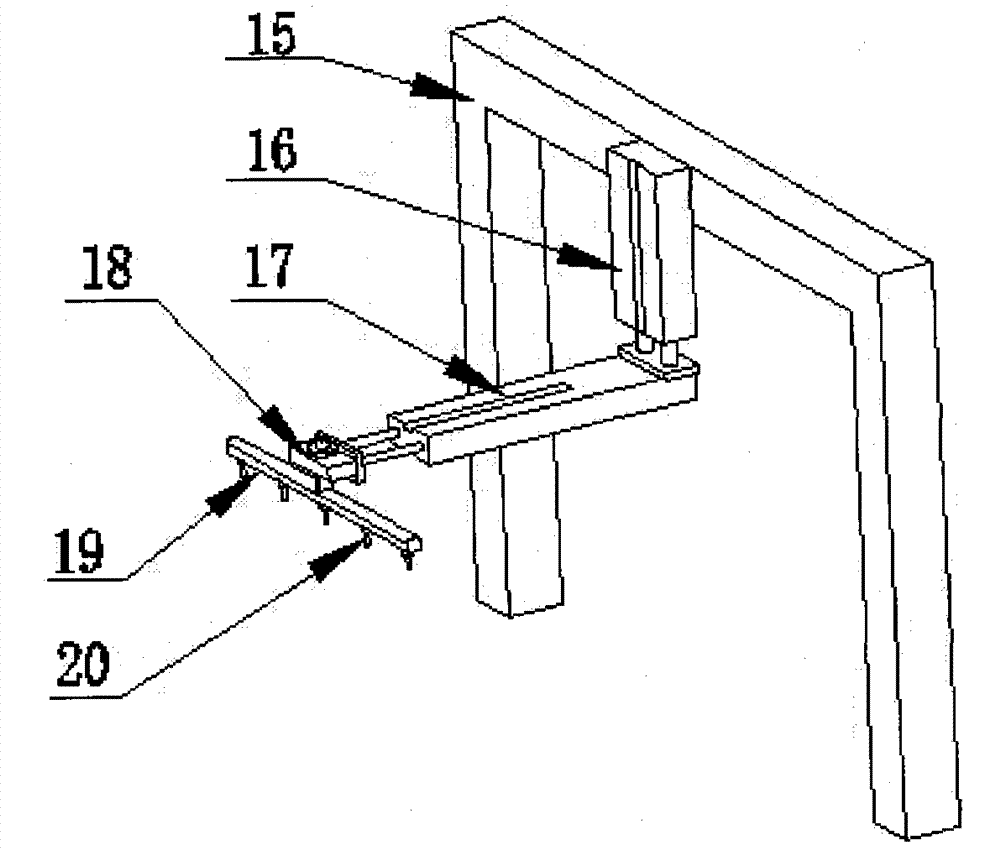

Orientation positioning seeder

InactiveCN104488418AConducive to unified managementReduce labor costsSeed depositing seeder partsBroadcast seedersEngineeringGrafting

The invention discloses an orientation positioning seeder. The orientation positioning seeder comprises a workbench, a conveying device, an aperture disk, an aperture pressing mechanism, an oriented seed aperture device, a negative pressure seed discharge device, a sprinkling device, a guide rod, a position sensor and a control case. The workbench comprises a frame and a workbench surface. The conveying device is installed on the workbench surface and is used for conveying the aperture disk according to a flow line working process so that the aperture disk goes through the aperture pressing mechanism, the oriented seed aperture device, the negative pressure seed discharge device and the sprinkling device, PLC is used for controlling the whole seeder, the oriented seed aperture device adopting a machine vision technology realizes seed direction adjustment, the negative pressure seed discharge device carries out orientation positioning sowing on the seeds subjected to direction adjustment, the sprinkling device is used for watering the apertures with the seeds, and the position sensor is used for accurately detecting and feeding back the work process. The orientation positioning seeder realizes 45 degree orientation positioning sowing of large seeds. The orientation positioning seeder solves the problem that the manual sowing method has low work efficiency and causes fatigue easily, can cultivate standard seedlings and provides favorable conditions for automatic grafting implementation.

Owner:NORTHWEST A & F UNIV

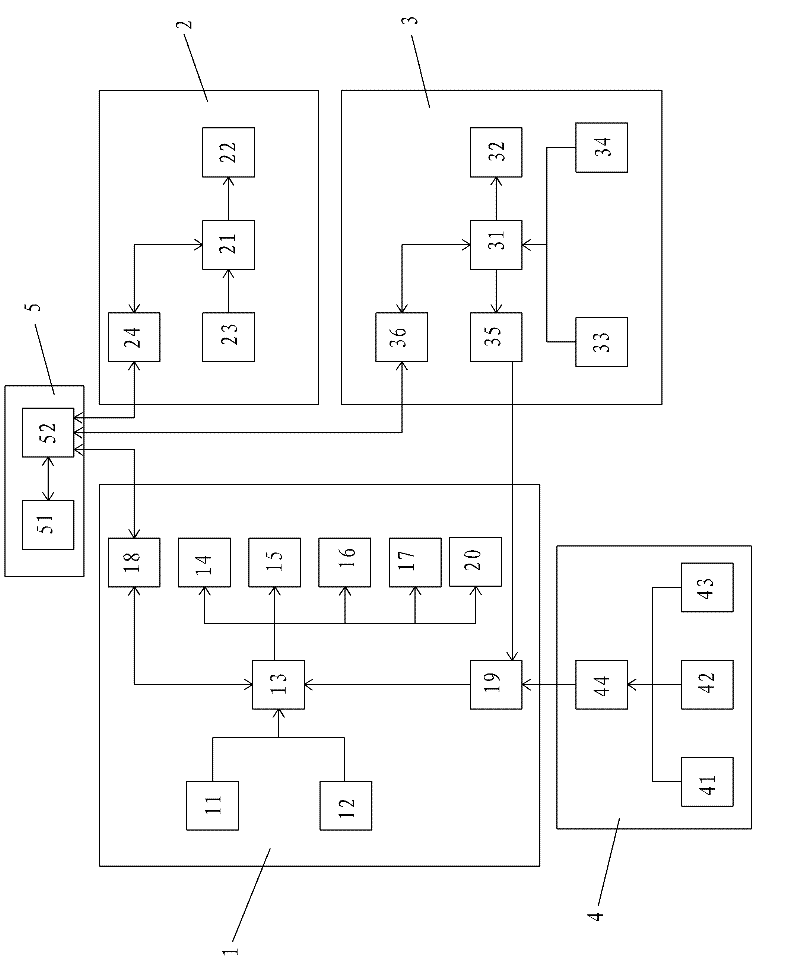

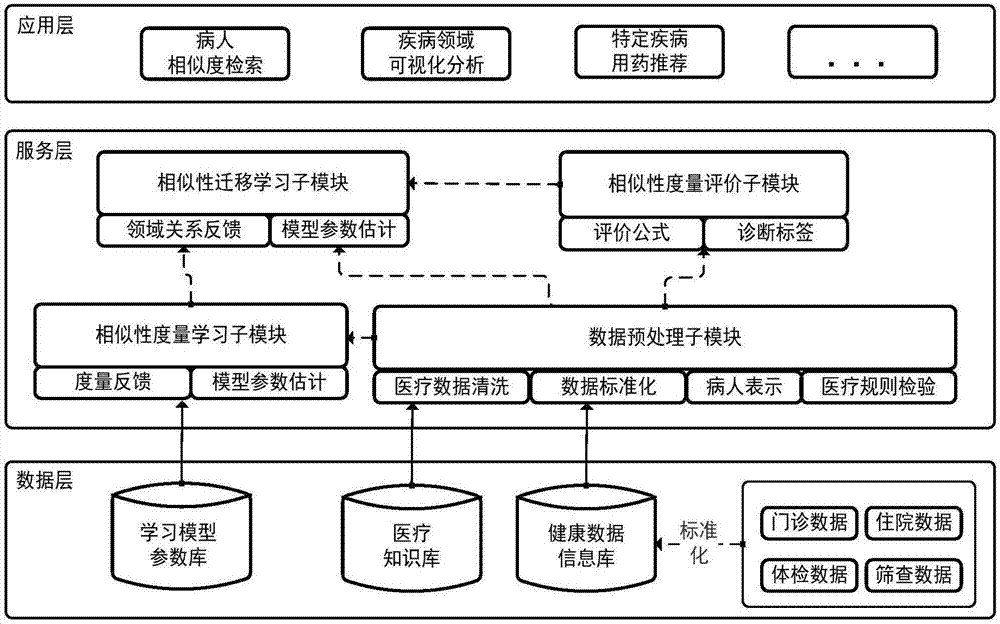

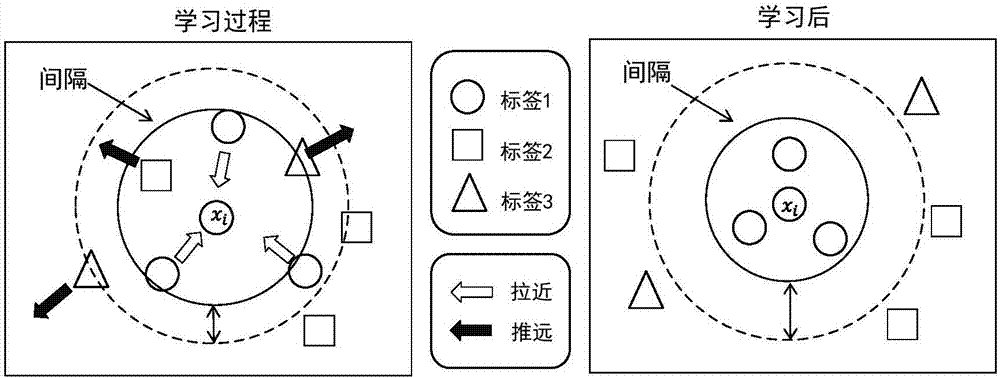

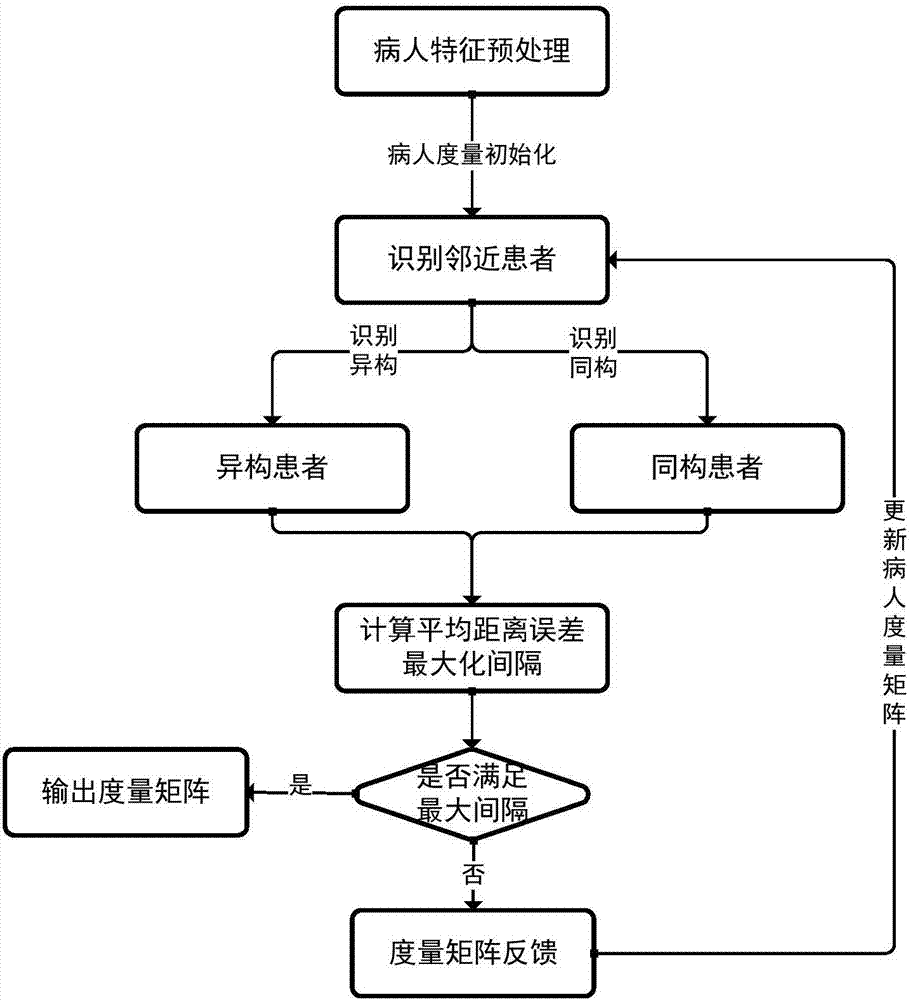

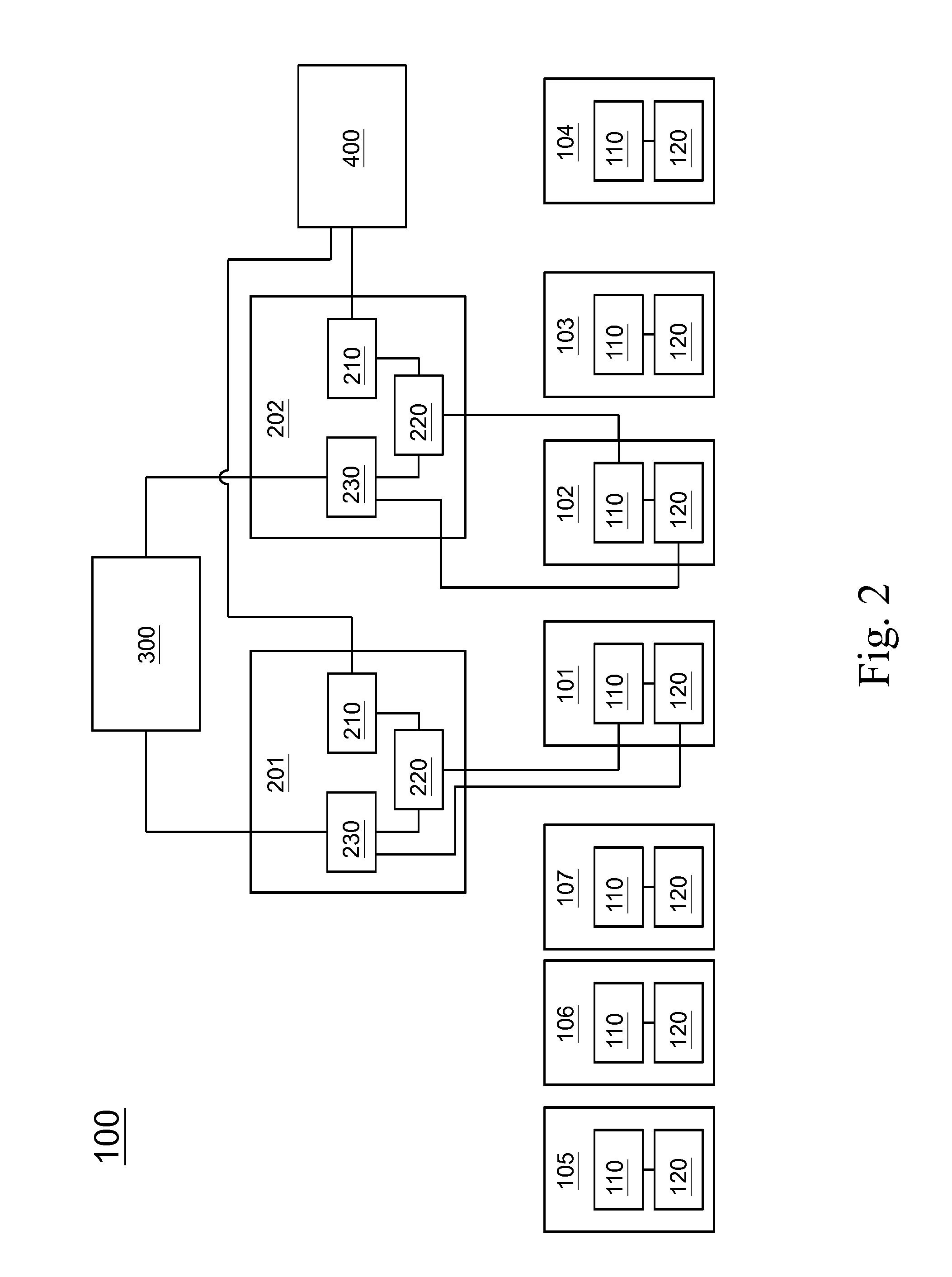

Patient similarity metric transfer system among disease domains on the basis of transfer learning

ActiveCN106934235ASolve access difficultiesSolve the problem of not being able to effectively obtain patient measurement informationMedical data miningMedical automated diagnosisTransfer systemInformation gain

The invention discloses a patient similarity metric transfer system among disease domains on the basis of transfer learning, and belongs to the technical field of the artificial intelligence software of computers. By use of the system, four submodules including a data preprocessing submodule, a similarity metric evaluation submodule, a similarity metric learning submodule and a similarity metric transfer submodule are constructed to finish similarity metric in a disease domain and patient similarity transfer among disease domains. The method aims to overcome the problem that traditional metric learning can not effectively work under a situation that supervisory information is difficult in acquisition and a patient sample amount in a specific disease field is small. The system can provide service support for a current accurate medical scene.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

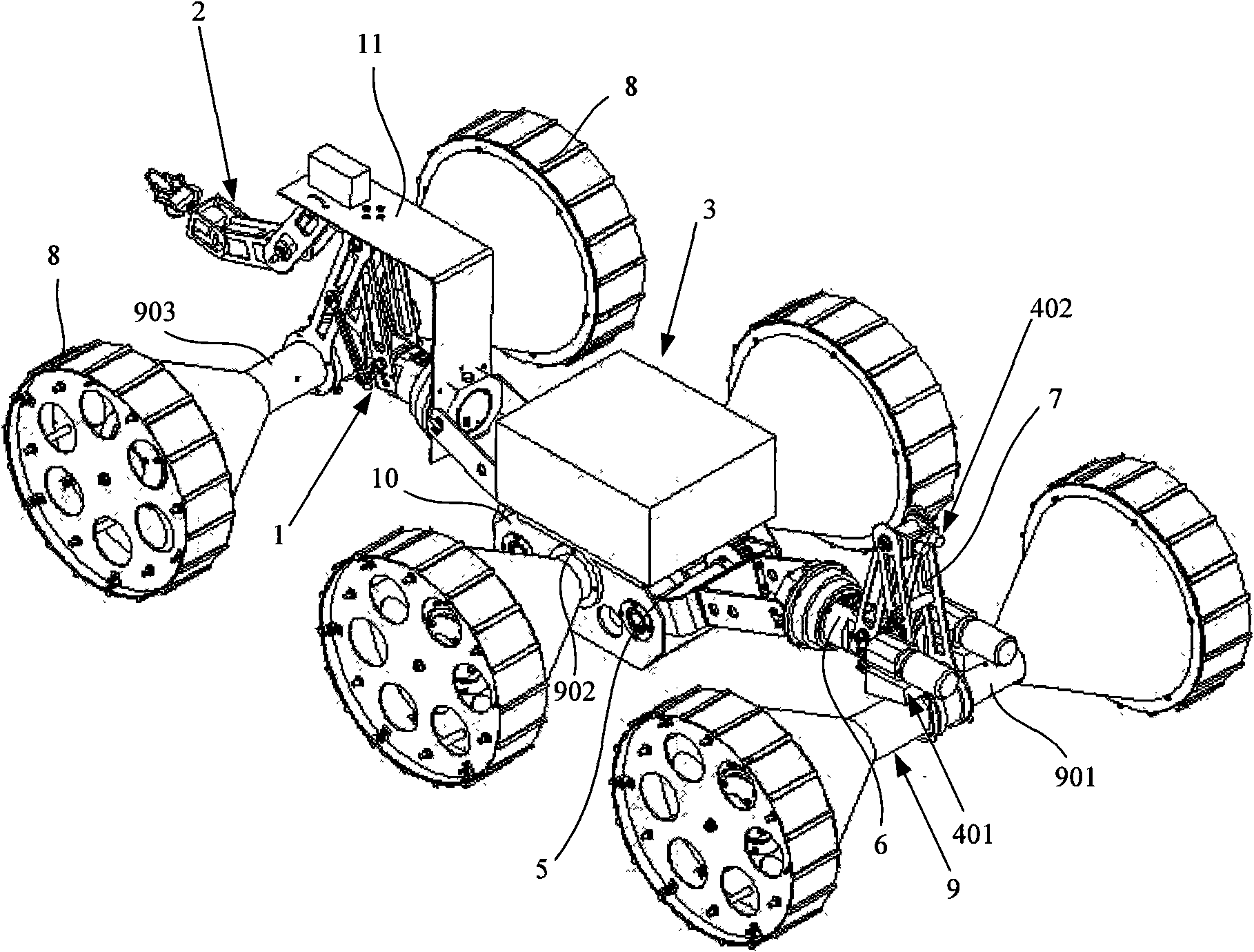

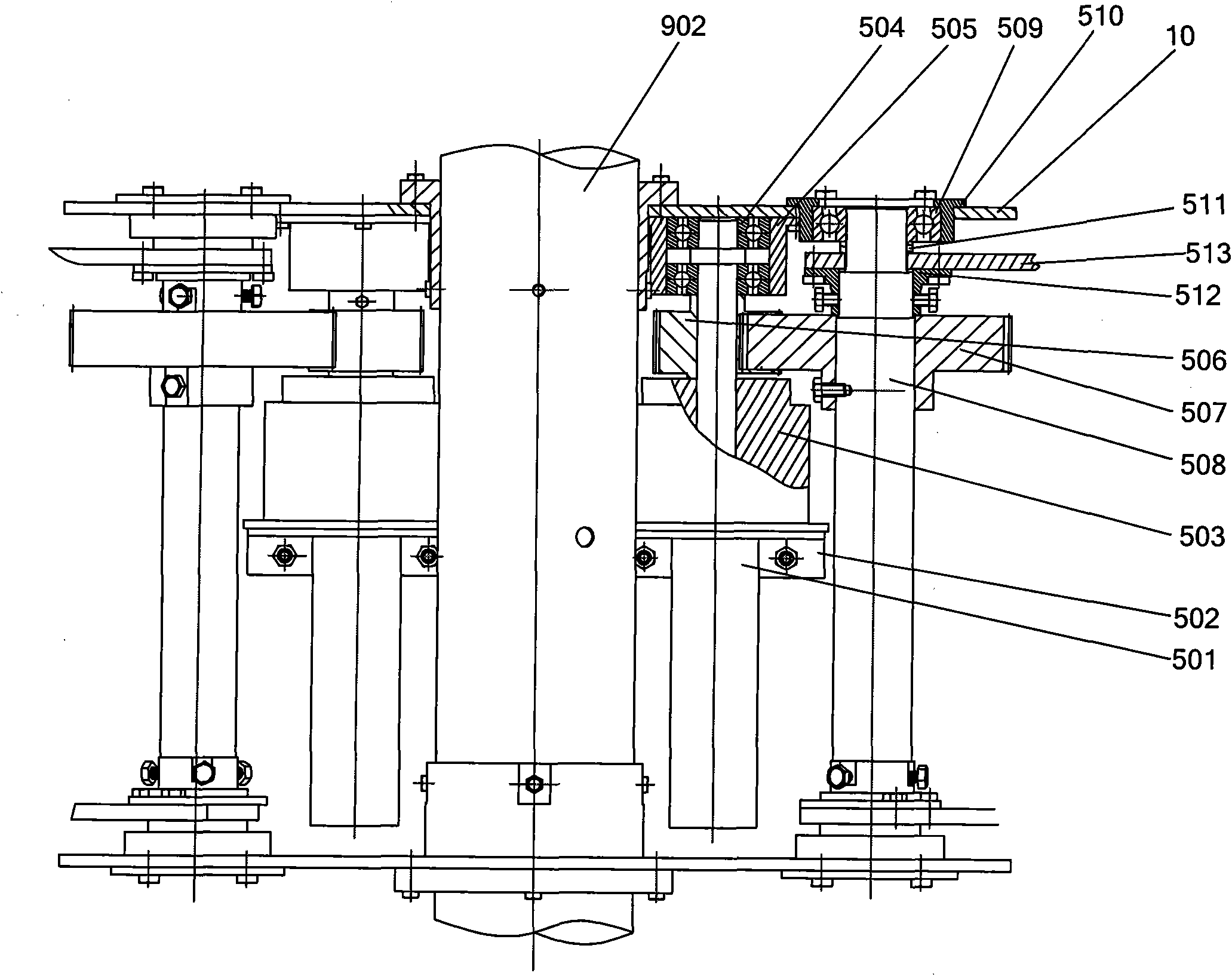

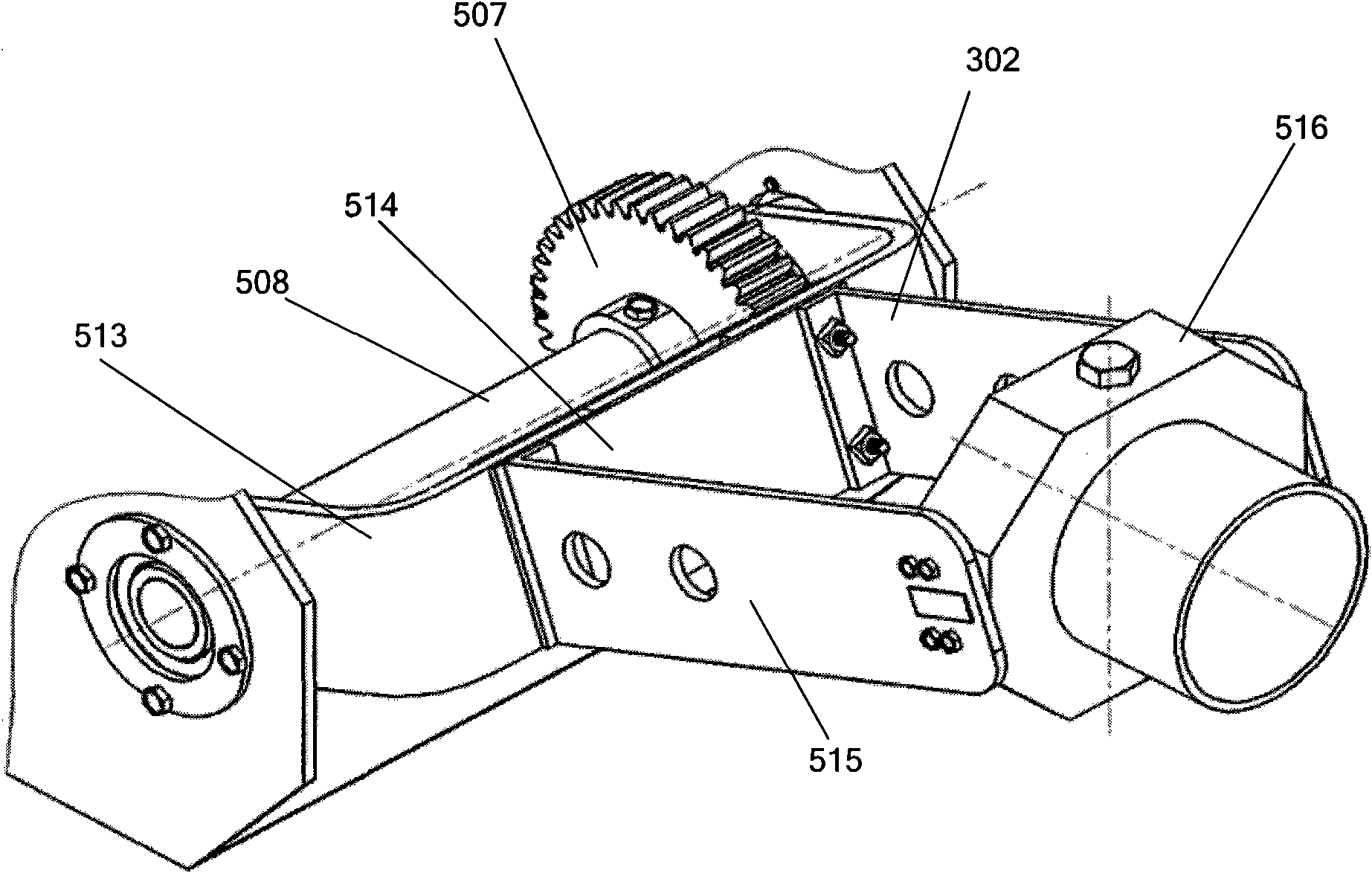

Multi-joint series wheeled mobile robot

InactiveCN101973028AGuaranteed work efficiencyThe control system is stableProgramme-controlled manipulatorArmsControl systemEngineering

The invention discloses a multi-joint series wheeled mobile robot. A middle box body is arranged on a middle axle of the robot, a control system is arranged above the middle box body, a pitching joint is fixed in the middle box body, each pitching joint is symmetrical to the middle axle and is respectively connected with a torsion joint, each torsion joint is respectively connected with a swinging joint which is respectively connected with a front axle and a rear axle, both ends of the front axle, the rear axle and the rear axle are provided with wheels, the torsion joint of the rear end is connected with a mechanical arm installing bracket, a mechanical arm is arranged on the mechanical arm installing bracket, and the front part of the robot is provided with a navigation system. The whole structure of the robot is in central axis symmetry by taking the middle axle as a symmetrical central axis. The gravity is evenly distributed on the wheels to furthest exert the work efficiency of a direct current motor. The multi-joint series wheeled mobile robot can measure and regulate the posture of the middle box body in real time, ensures the relative stabilization of the control system and has simple structure and light weight.

Owner:BEIHANG UNIV

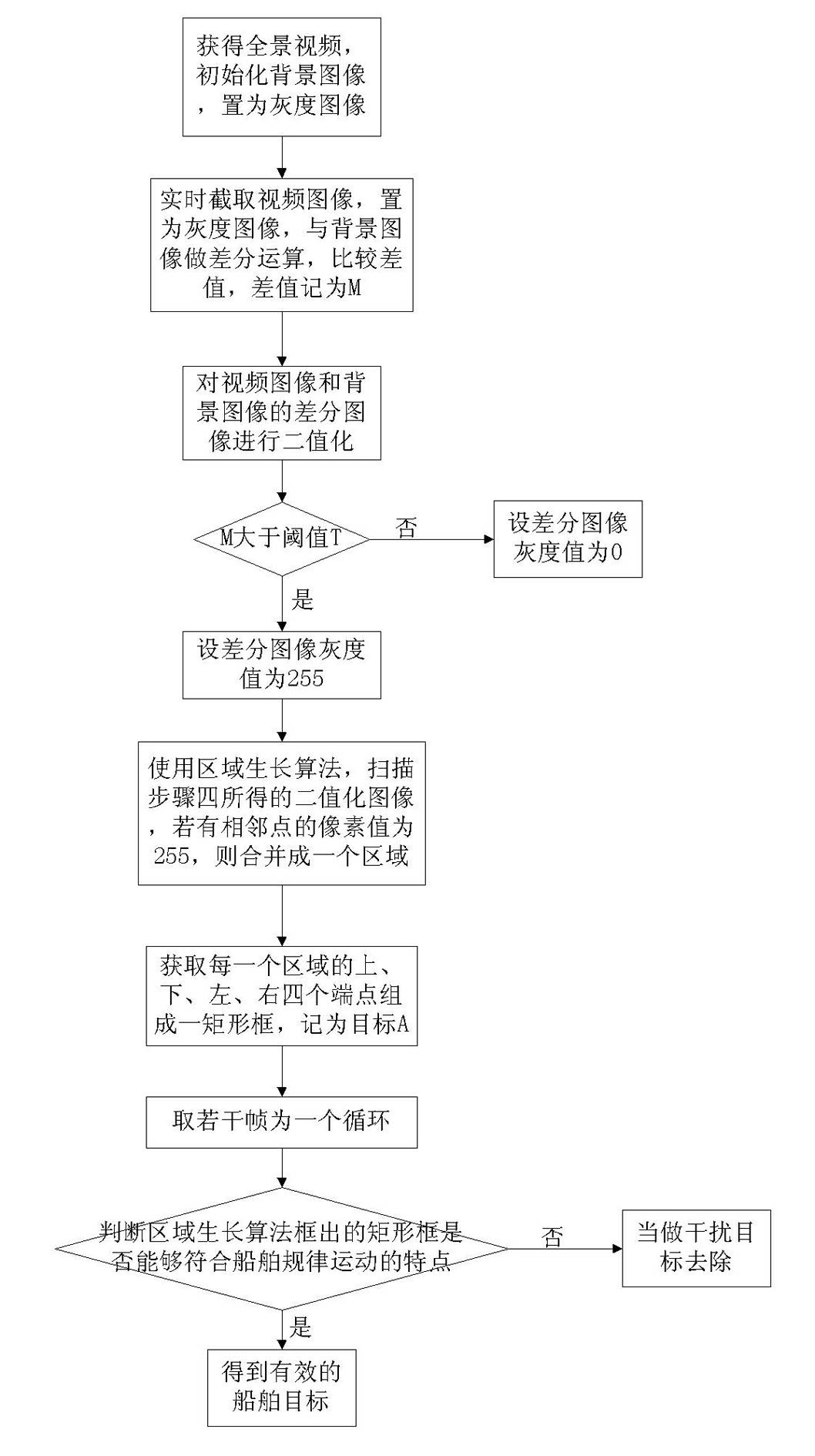

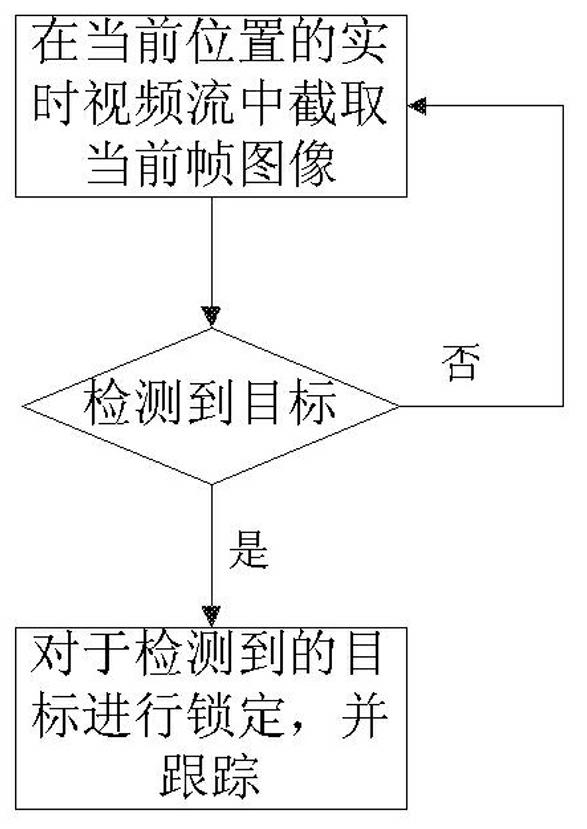

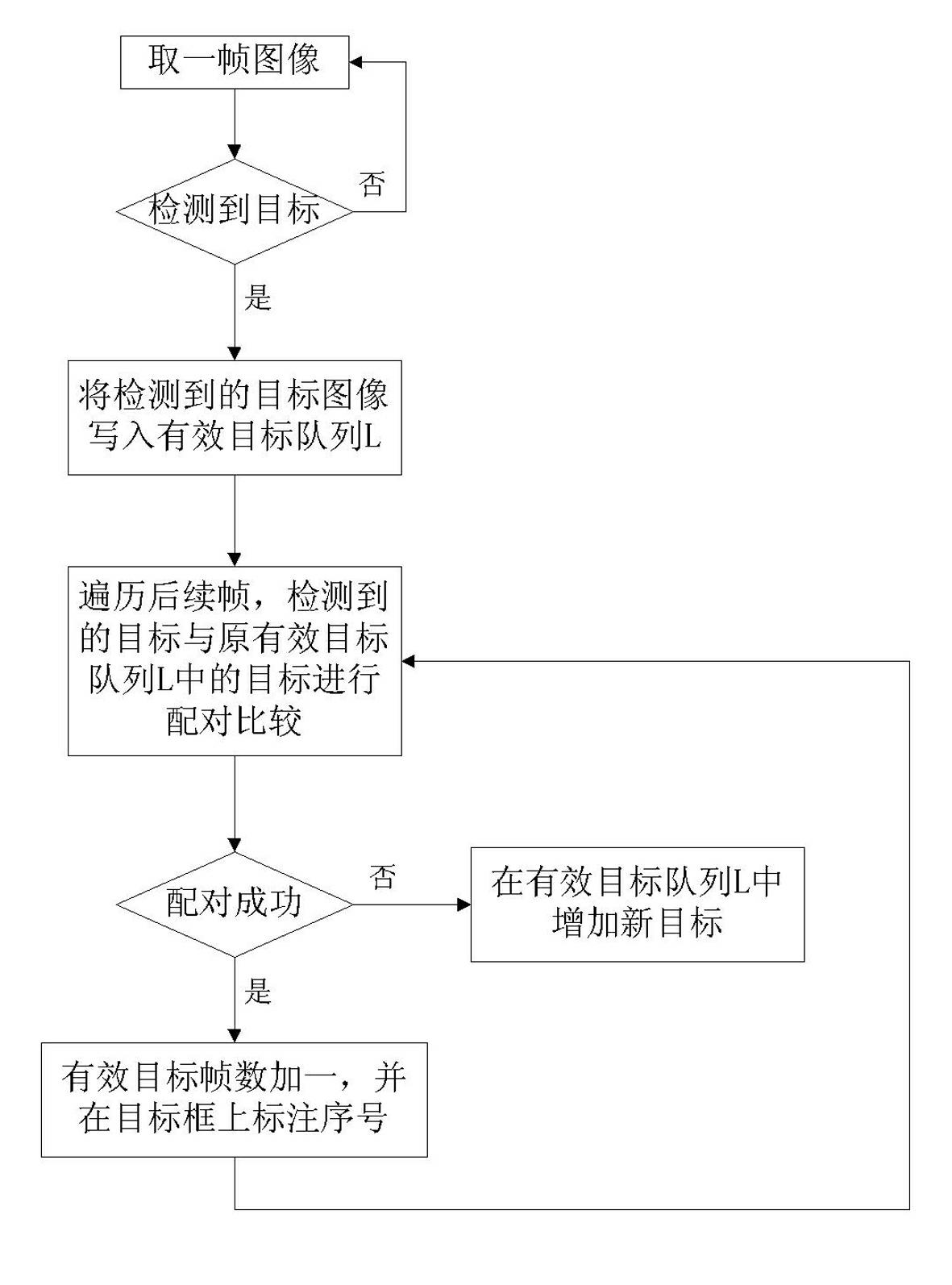

Ship monitoring method

ActiveCN102147859AEnsure safetyEasy to manage digitallyImage analysisCharacter and pattern recognitionData informationMonitoring system

The invention relates to a ship monitoring method. The monitoring method comprises a target identification method and a target tracking method, wherein in the target identification method, after an intercepted real-time video image and a background image are subjected to differential operation and binarization, a ship target is obtained by using a region growing algorithm, and the identified ship target is tracked and locked. By matching the target identification method, the target tracking method, a target locking method and a pairing comparison and database management method, a monitoring system can capture a ship and acquire continuous ship video under the condition of fog or night so as to realize all-weather monitoring of a shipping lane, ensure smoothness of the shipping lane and safety of the ship, reduce manual operation and realize automatic management; and the data information and the like acquired by monitoring are stored into a database, so that the data information and the like are convenient for digital management of the ship, can be timely called as required and can assist managers in learning more information about the ship.

Owner:浙江华是科技股份有限公司

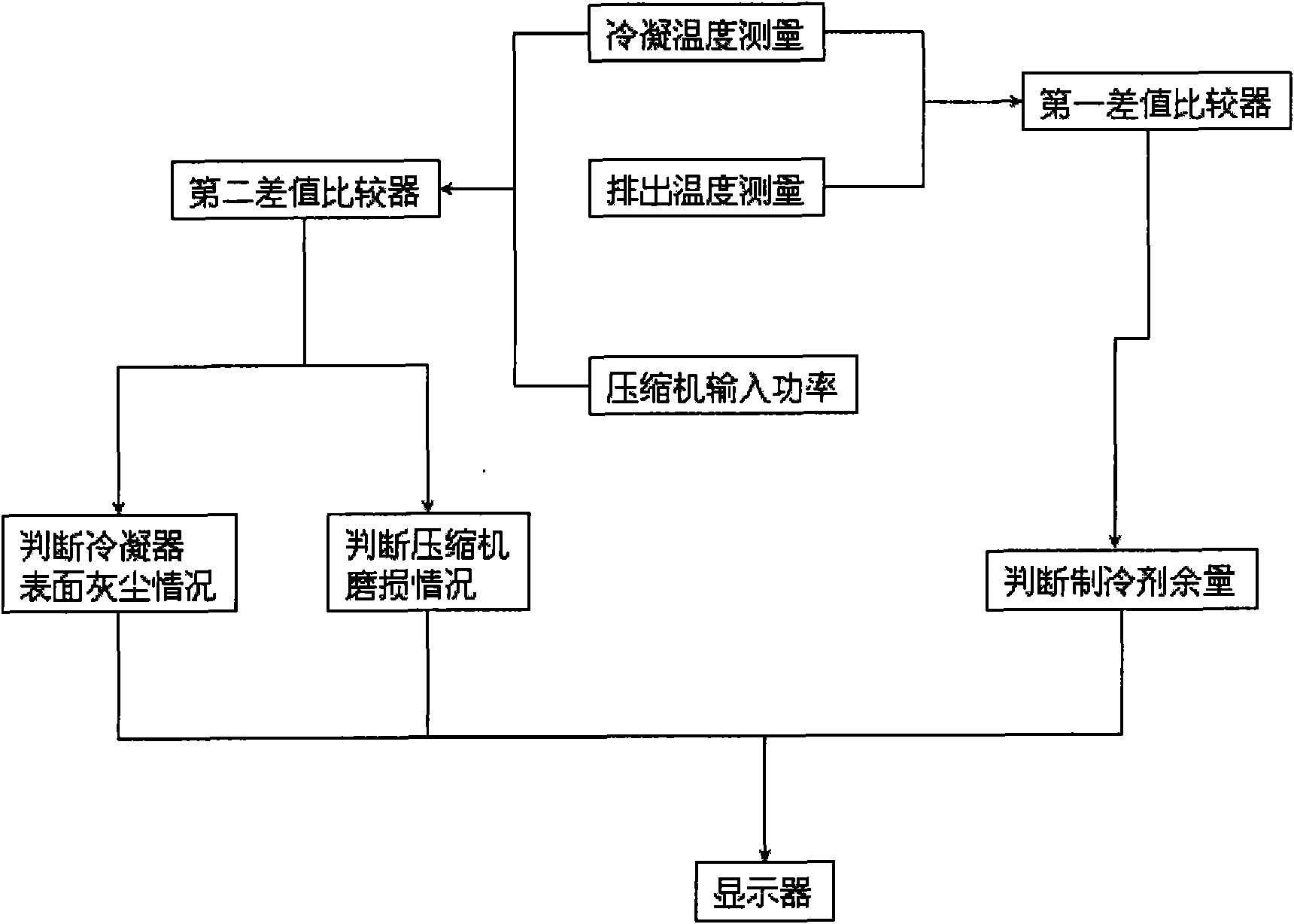

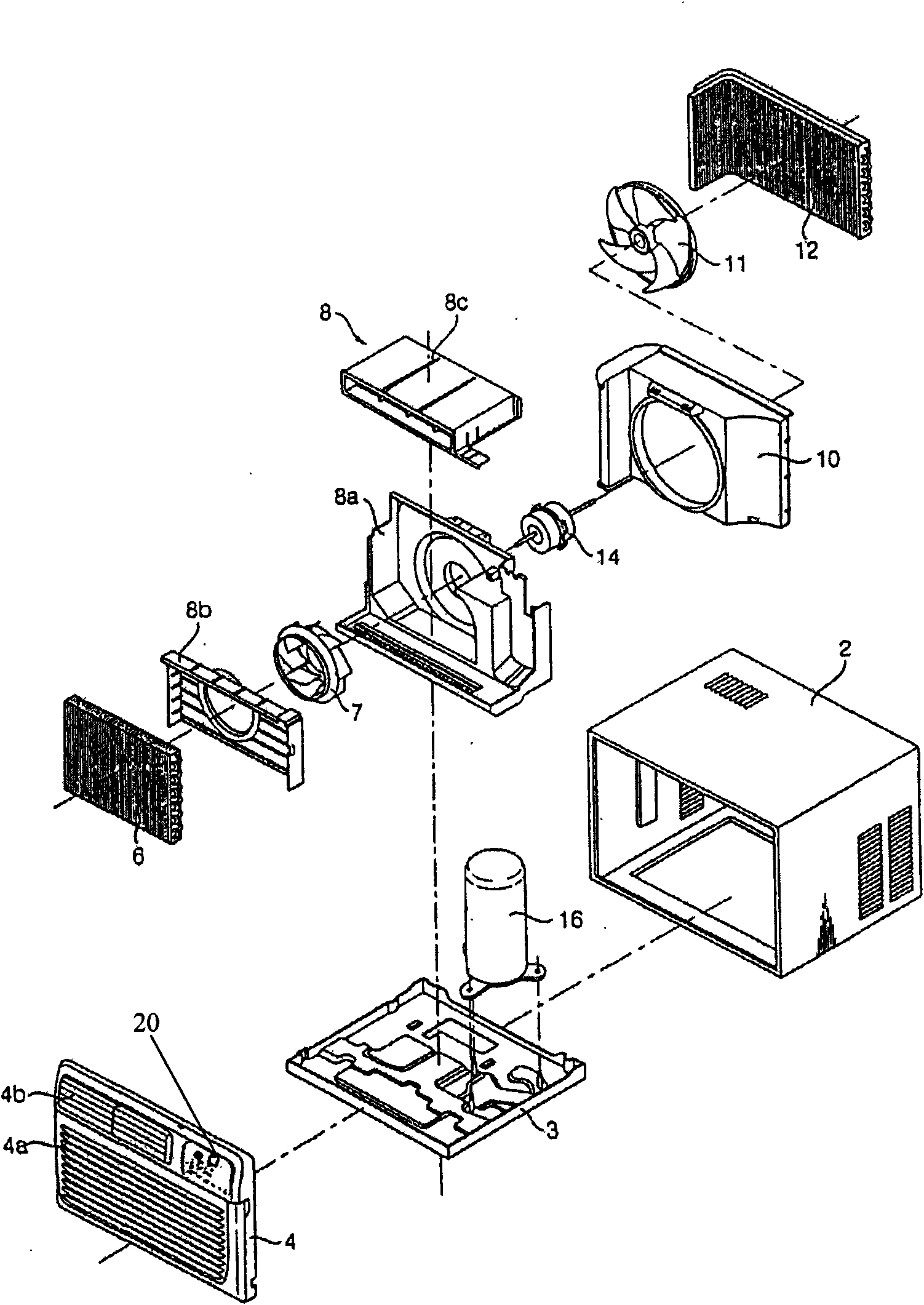

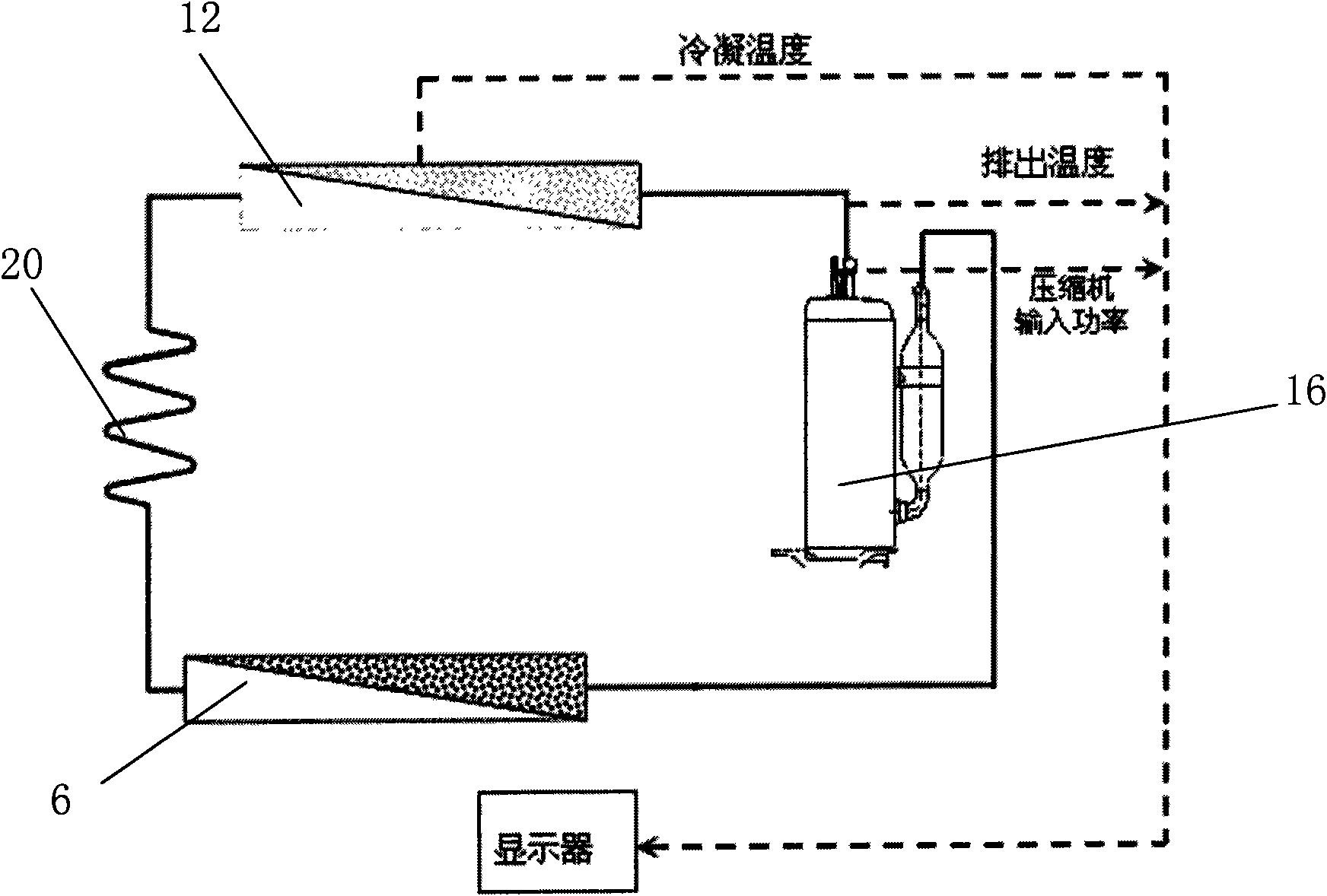

Air conditioning unit and method for detecting operation state thereof

InactiveCN101813358ATimely maintenanceImprove working conditionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsDisplay deviceEngineering

The invention relates to an air conditioning unit and a method for detecting the operation state thereof. A refrigerant outlet of a compressor and a condenser are respectively provided with a temperature sensor; the measured refrigerant discharge temperature, the condenser temperature and the compressor input power are respectively connected with a difference comparator; and each measured numerical value is compared with the standard value by the difference comparator so as to judge the working conditions of parts such as the condenser, the compressor and the like of the air conditioning unit, and then the working conditions are displayed to users directly by a display to enable the users to learn about the problems in the air conditioning unit intuitively and perform maintenance and partreplacement on the air conditioning unit timely according to the prompt of the display, thus ensuring the air conditioning unit to be a good working state, maintaining the working efficiency of the air conditioning unit in refrigeration and playing a role in saving energy source.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Wet-type dust-removal fan

ActiveCN101259355AHigh speed rotationIntensified conflictCombination devicesImpellerOperational costs

The invention discloses a wet dust removal fan, which comprises a wind-cone. The wind-cone consists of the wall of an outer cone and the wall of an inner cone which is provided with a plurality of through holes. A sandwich cavity is arranged between the wall of the outer cone and the wall of the inner cone; a flow port is opened at the bottom of the wall of the outer cone; a seeper box is connected with the lower part of the wall of the outer cone and is correspondent to the flow port; an outlet is arranged at the bottom of the seeper box; the inner wall of the inner cone is provided with a support which is equipped with an axle; the support is connected with the wind-cone and is arranged between a water injection nozzle and a fan wheel, and the axle is provided with at least a separating blade. The wet dust removal fan has the advantages of high purification efficiency in the practical application, low operational cost, notable energy saving effect and no frequent maintenance, which completely solves the problems that large resistance of the dust removing system exists owning to a filter screen, the handling ability of blast volume is bad, the increasing of the loading of a fan motor is directly affected by the dust capacity adsorbed of and the fan motor is burnt down easily owing to the phenomenon of blocking, thus ensuring the operation safety and work efficiency of the fan motor.

Owner:郭峰

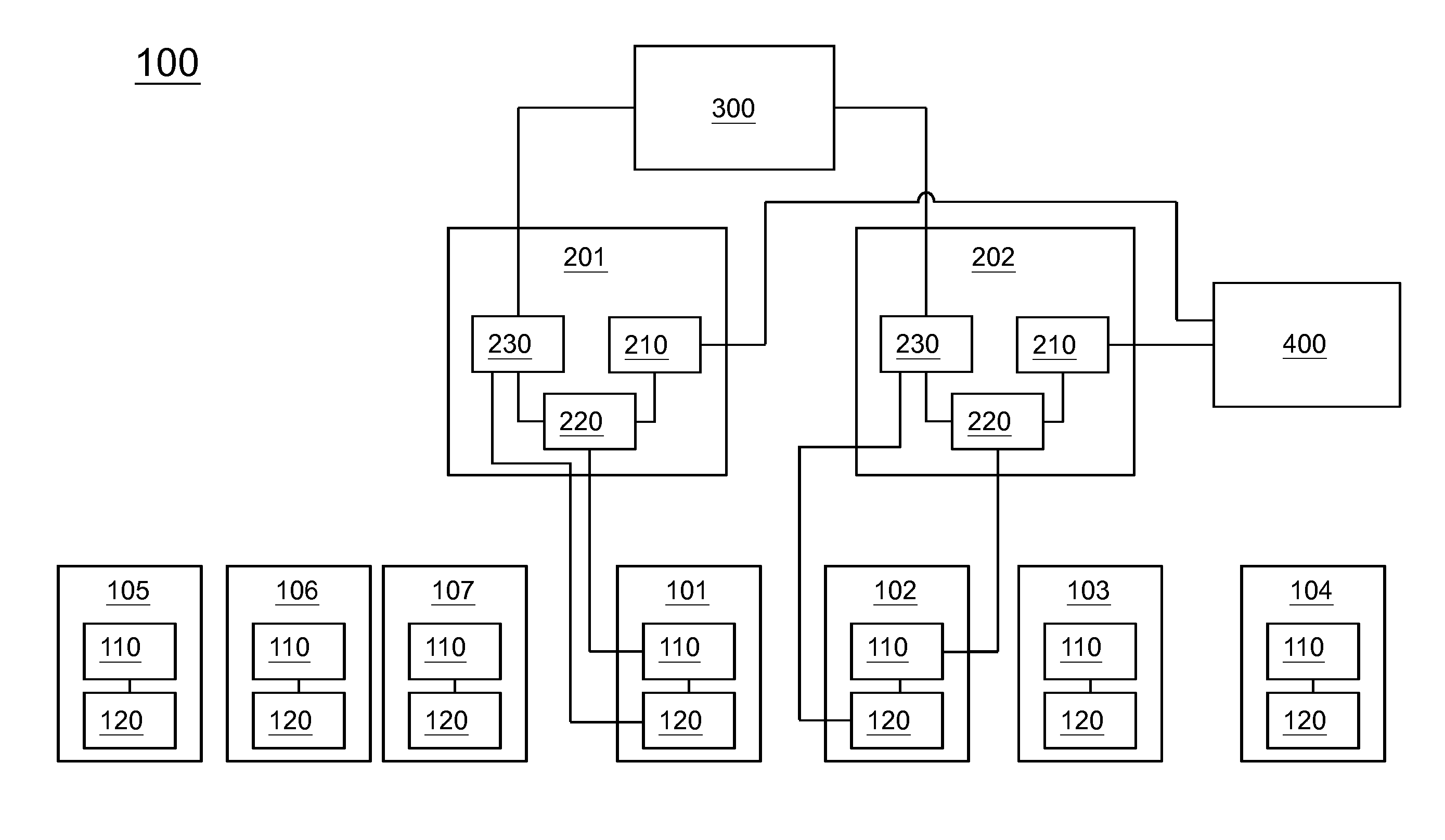

Battery sharing system

InactiveUS20150280465A1Effectively process monitoringGuaranteed work efficiencyCircuit monitoring/indicationIndicating/monitoring circuitsElectricityElectrical battery

A battery sharing system is disclosed in the present invention. The system includes a number of rechargeable battery packs, at least one charging device and a monitoring device. A portion of rechargeable battery packs are provided to users for use under a sharing mode. When one used rechargeable battery pack is in low status, the user exchanges the used rechargeable battery pack with another one of the rechargeable battery packs which is fully charged.

Owner:GO TECH ENERGY

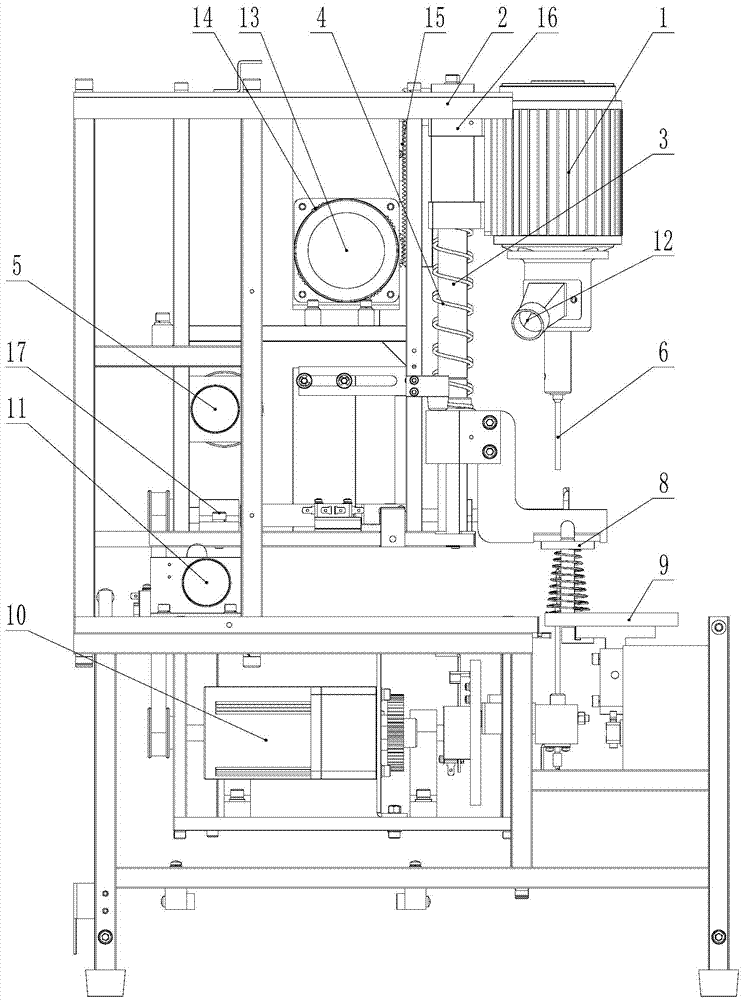

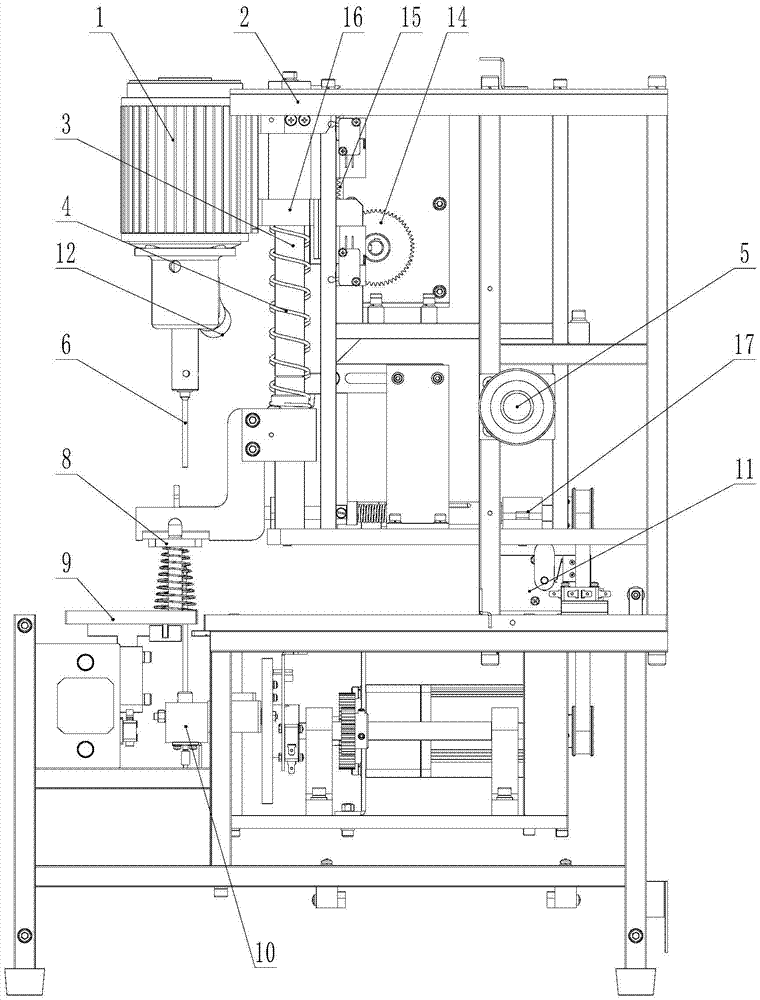

Wire type completely intelligent bookbinding machine

ActiveCN105437818AAvoid flying confettiReduce the use of laborSheet bindingMotor shaftBinding process

The invention relates to the field of binding machines and particularly relates to a wire type completely intelligent bookbinding machine. The wire type completely intelligent bookbinding machine comprises a machine frame, a central controller, a workbench, a drilling mechanism, a wire winding mechanism, a wire feeding mechanism and a sliding table component; the central controller, the workbench, the drilling mechanism, the wire winding mechanism, the wire feeding mechanism and the sliding table component are all arranged on the machine frame; the drilling mechanism, the wire winding mechanism, the wire feeding mechanism and the sliding table component are all connected with the central controller; both the drilling mechanism and the wire winding mechanism are arranged above the workbench; both the wire feeding mechanism and the sliding table component are arranged below the workbench; the drilling mechanism comprises a drilling motor, a drilling tool and a lifting device; the drilling tool is coaxially arranged on the motor shaft of the drilling motor; the drilling motor is fixed on the lifting device; and a through hole coaxial with the drilling tool is formed in the middle part of the drilling tool. During an entire binding process of the wire type completely intelligent bookbinding machine provided by the invention, full automatic and intelligent bookbinding is completely achieved, the use of manpower is reduced, work errors are reduced, and the work efficiency is improved.

Owner:ZHONGCHAUNGEN TIANJIN TECH CO LTD

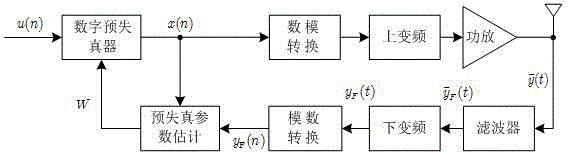

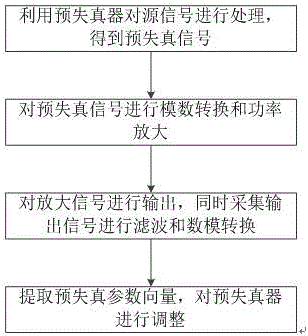

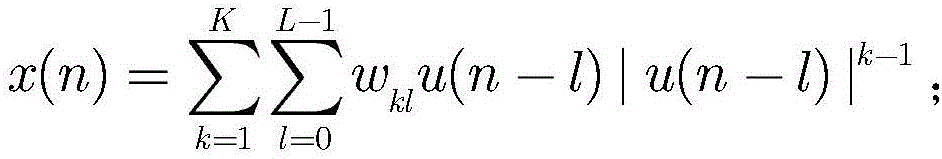

Narrow-band feedback digital pre-distortion system and method

ActiveCN106506417AReduce or counteract the effects of non-linear distortionGuaranteed work efficiencyAmplifier modifications to reduce non-linear distortionSynchronous/start-stop systemsFiltrationComputer module

The invention discloses a narrow-band feedback digital pre-distortion system and method. The narrow-band feedback digital pre-distortion system comprises a digital pre-distorter, a digital-analog conversion module, a power amplifier, a filter, an analog-digital conversion module and a pre-distortion parameter estimation module; the input end of the digital pre-distorter is connected with a signal source while the output end of the digital pre-distorter is respectively connected with the digital-analog conversion module and the pre-distortion parameter estimation module; the output end of the digital-analog conversion module is connected with the power amplifier, and the output end of the power amplifier is respectively connected with the signal output device and the filter; the output end of the filter is connected with the pre-distortion parameter estimation module through the analog-digital conversion module; the output end of the pre-distortion parameter estimation module is connected with the digital pre-distorter. By performing filtration processing on the signals output by the power amplifier, performing digital-analog conversion and pre-distortion parameter extraction after the signal bandwidth is reduced, and performing pre-distortion adjustment by the digital pre-distorter, the linearity index of the power amplifier is guaranteed on the basis that the feedback pass bandwidth is decreased and the analog-digital conversion rate, the system power and the cost are reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

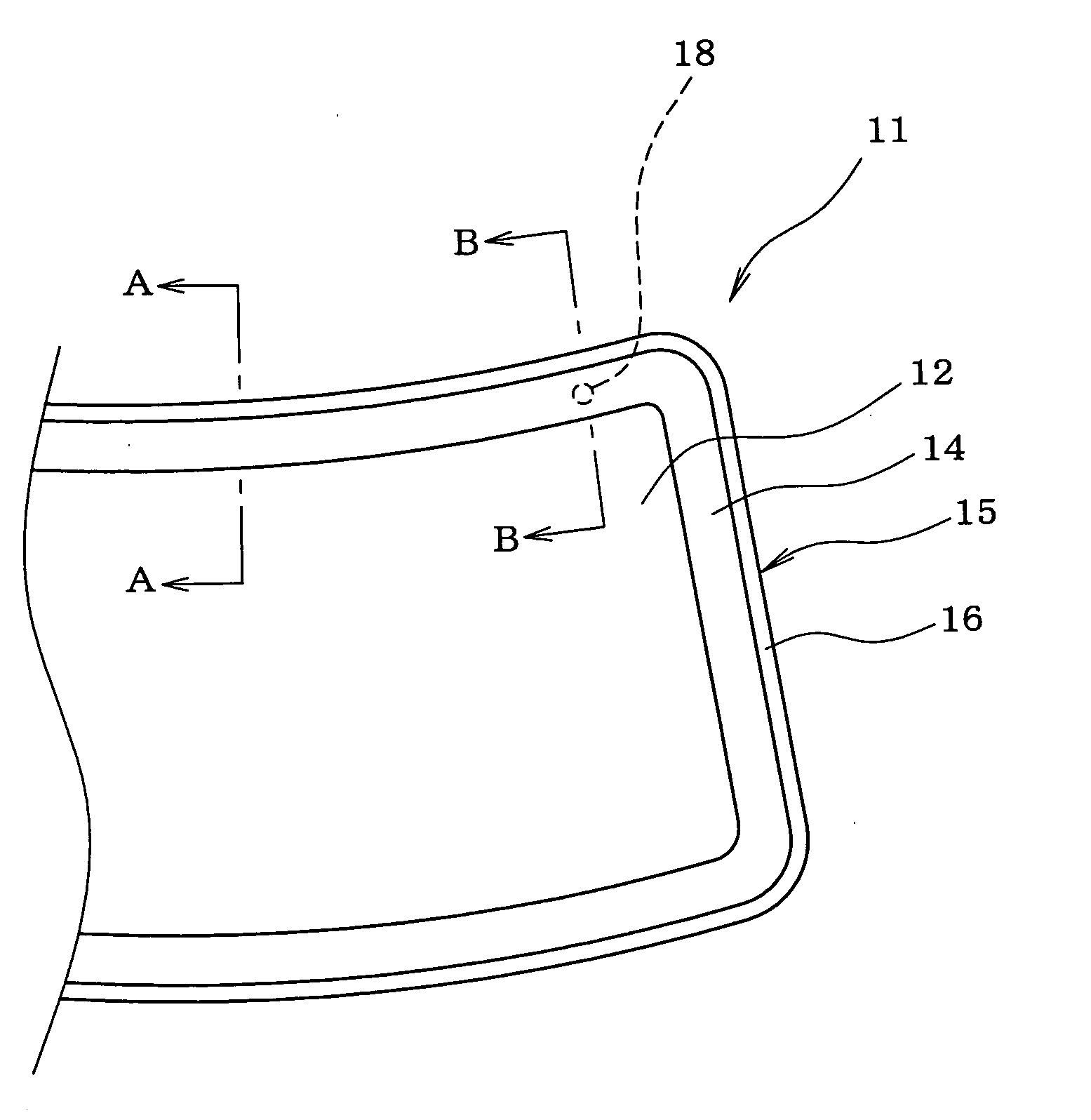

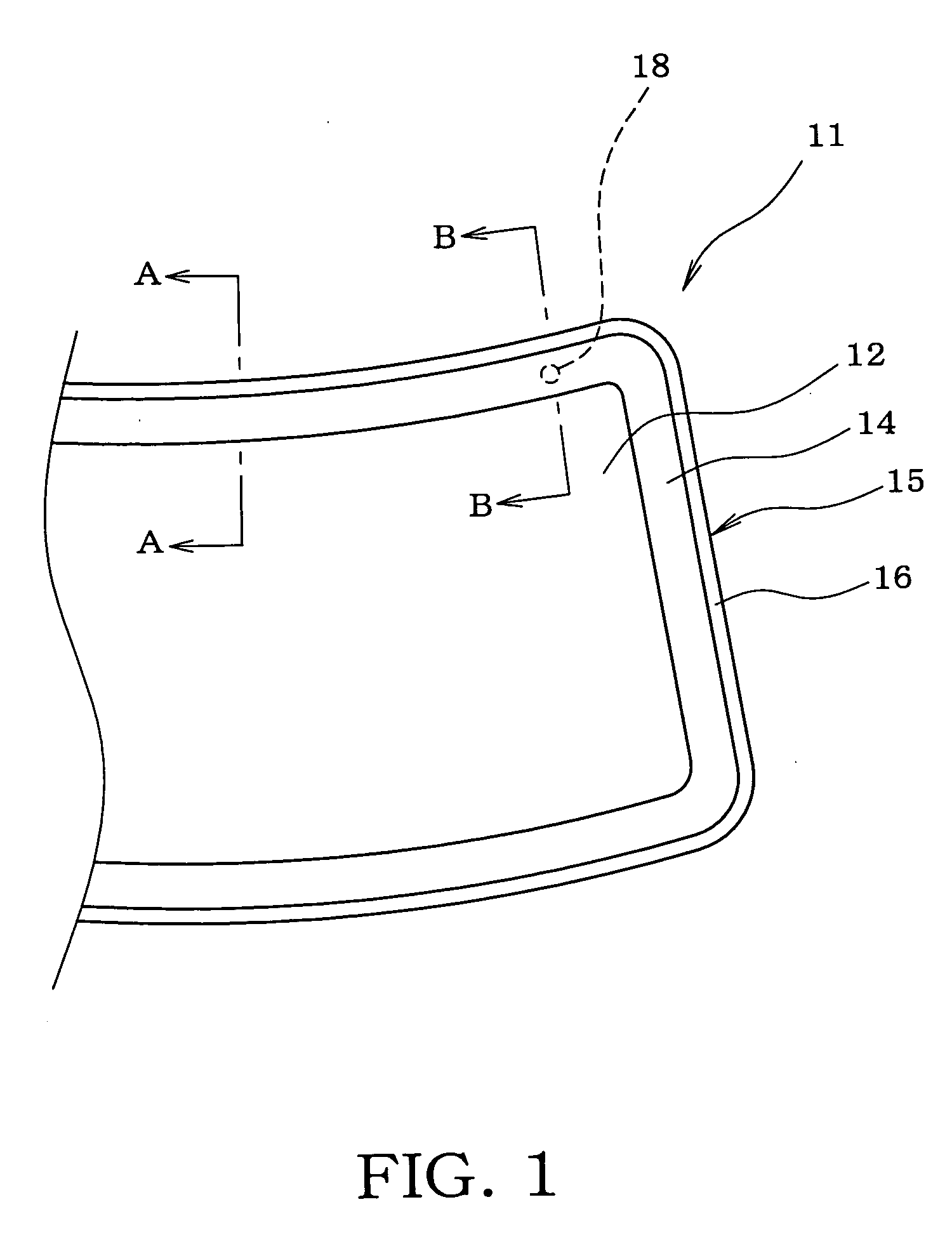

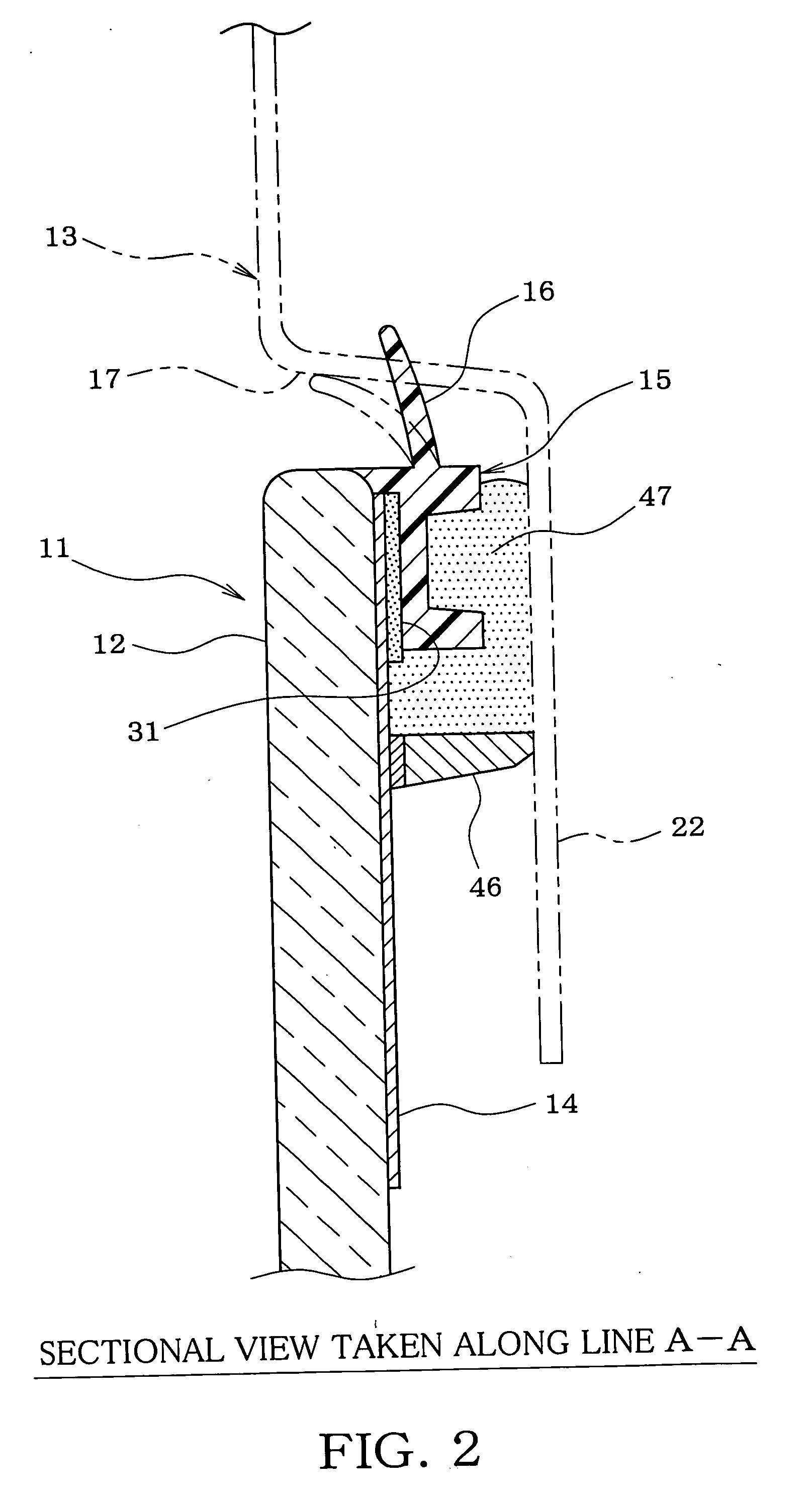

Window assembly-producing method and window plate

An adhesive agent is uniformly applied to a back surface of a window pane, the application made to an area where a covering member is planned to be adhered and to an area where a positioning fixture and a holding portion are planned to be adhered, the application is also made continuously such that adhesive agent layers of both planned adhesion areas being continuous with an adhesive agent continuous area in between. After that, the window pane and the positioning fixture are set in an injection mold and a polymer material is injected in the mold. This results that the covering member and the holding portion are formed into a shape where they are connected by a connection portion for material flow, which connection portion is formed at a position other than the adhesive agent continuous area. The forming results that the covering member and the holding portion are adhered and fixed to the back surface of the window pane with the adhesive agent layers in between. After the forming process above, the connection portion for material flow is removed.

Owner:TOKAI KOGYO CO LTD

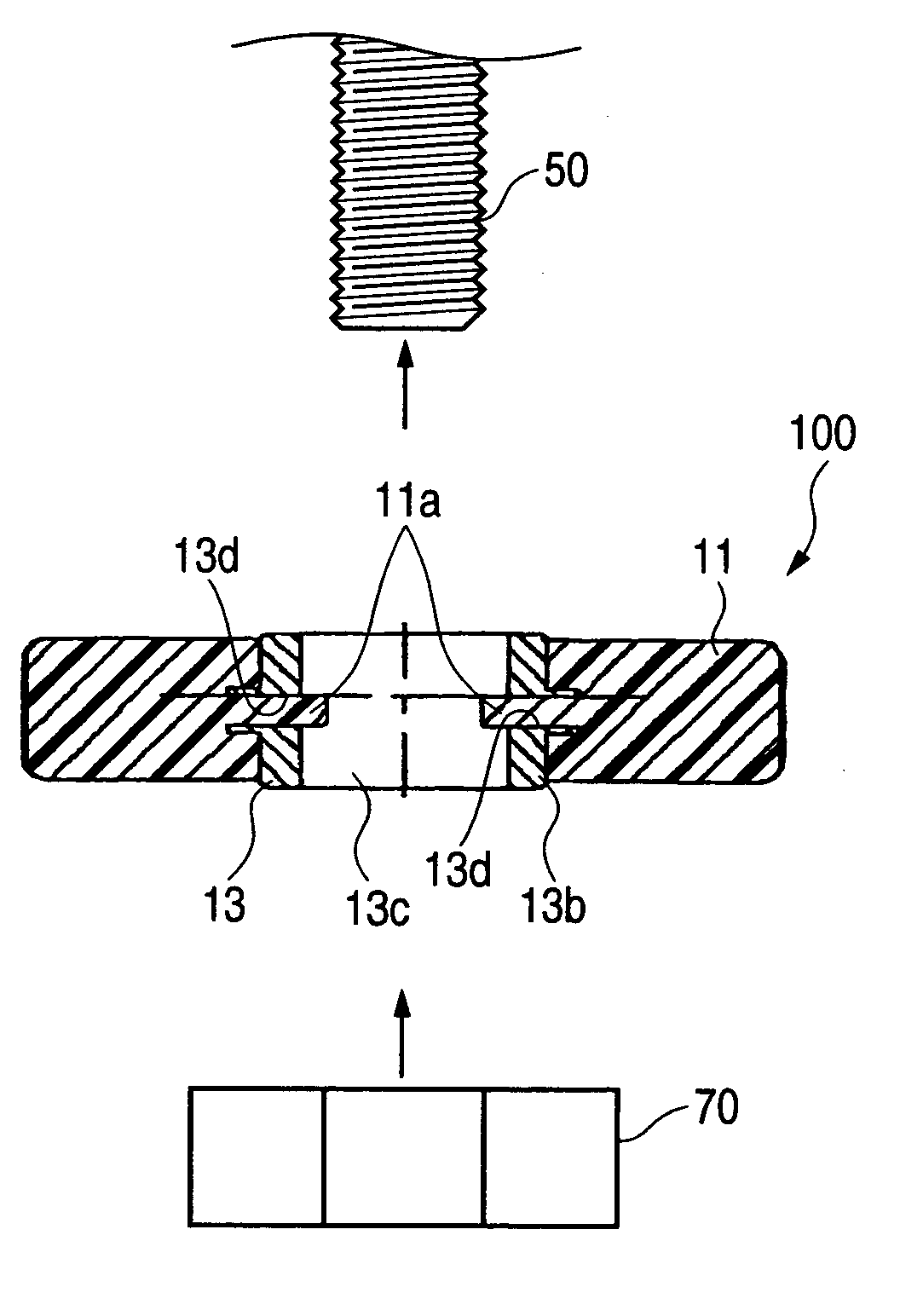

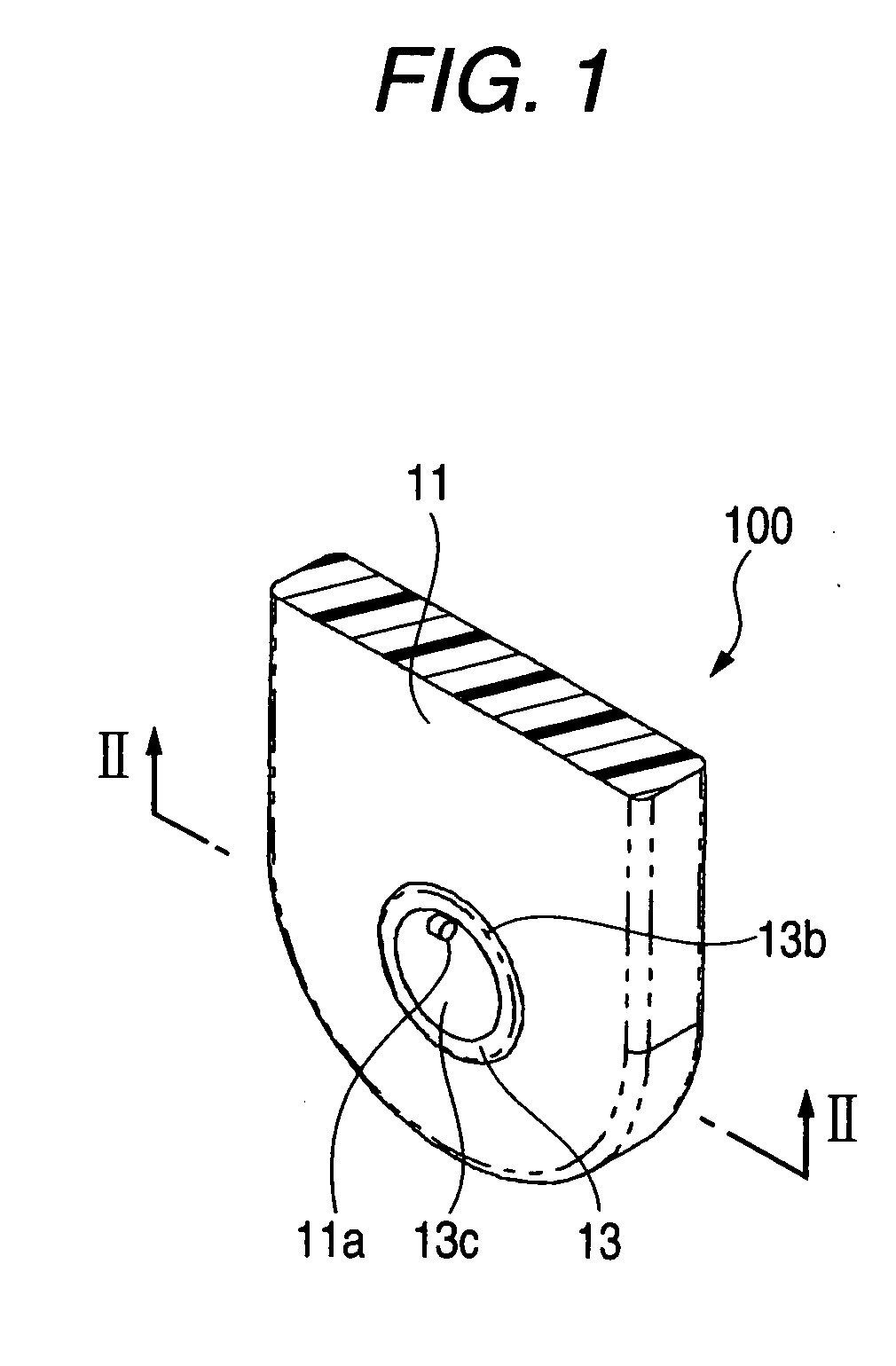

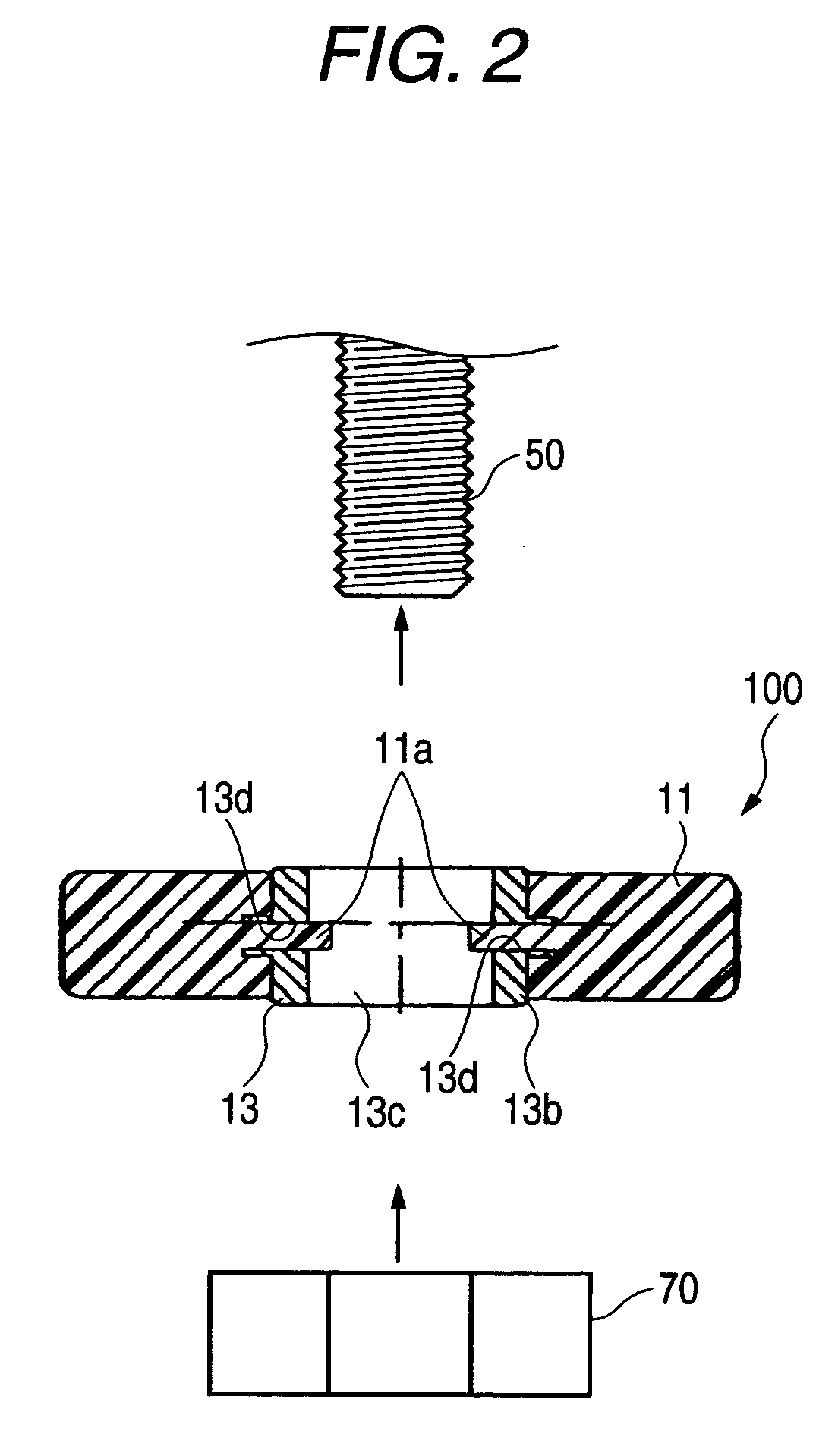

Fixing structure

InactiveUS20060056936A1Improve efficiencyGuaranteed work efficiencyPinsWashersEngineeringMechanical engineering

A fixing structure includes a synthetic resin fixing part that is formed on a fixed member, a metallic collar adapted to be fixed in the portion to be fixed and having a bolt insertion hole and two engaging protrusions which are formed integrally with the fixing part so as to protrude into an interior of the bolt insertion hole. Then, when a bolt is inserted into the bolt insertion hole, the inserted bolt is then engaged with the engaging protrusions, whereby the fixed member is provisionally fixed to the bolt. In this state, a nut is fittingly screwed on a distal end portion of the bolt which protrudes from the bolt insertion hole.

Owner:YAZAKI CORP

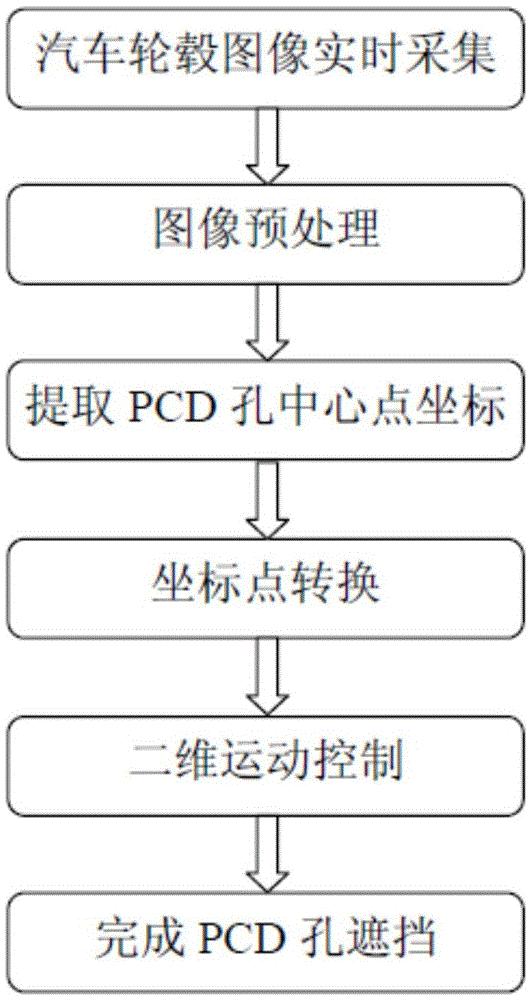

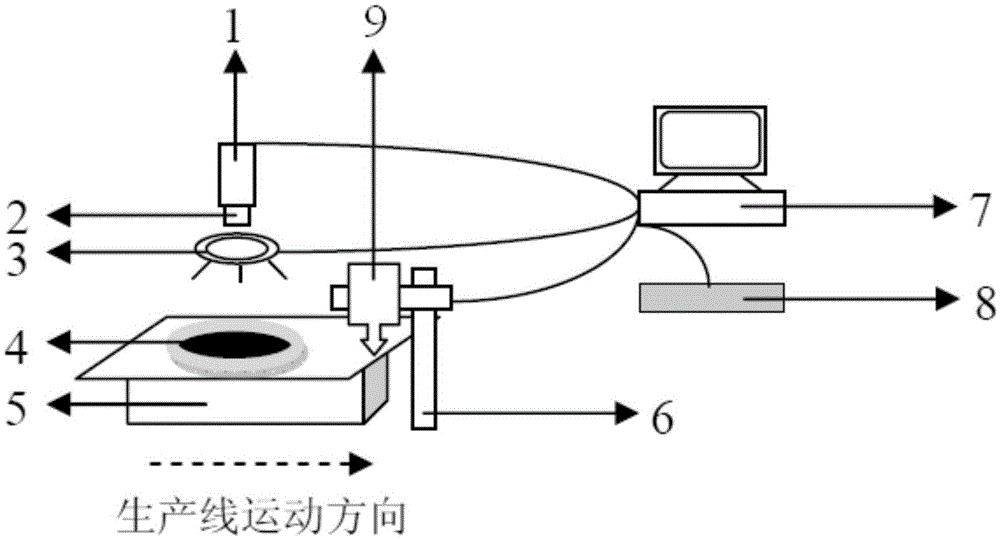

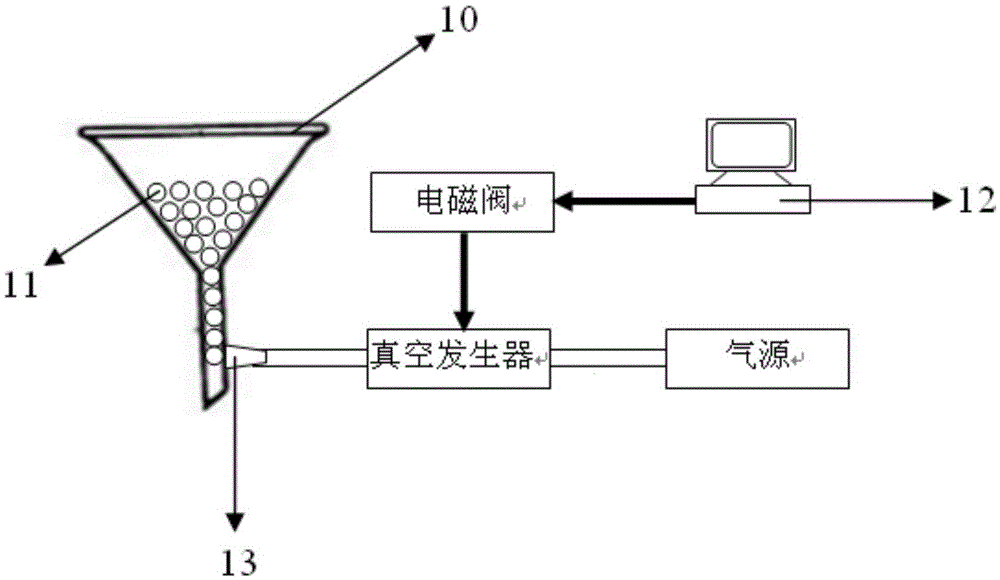

Automobile wheel hub screw hole recognition method based on machine vision and shielding method and system

ActiveCN105548185ARealize automatic controlNo damageSpraying apparatusMaterial analysis by optical meansMachine visionAutomatic control

The invention discloses an automobile wheel hub screw hole recognition method based on machine vision and a shielding method and system. The recognition method comprises the steps that a wheel hub image of a wheel hub to be detected is collected; the wheel hub image is preprocessed, edge information is extracted, screening is performed through the roundness characteristic, and the hole center coordinate of a PCD hole is primarily determined; a hole center coordinate value of the PCD hole is finally determined according to the distribution characteristic of the PCD hole in the wheel hub; the image coordinate is converted into the space coordinate, a two-dimensional manipulator is driven to drive a shielding spraying placer to move to the position over the PCD hole, shielding spraying balls are placed one by one, and automatic control over paint shielding spraying of automobile wheel hubs of various specifications is achieved. According to the recognition method, the wheel hub PCD hole positioning precision is high, automatic screw hole shielding can be achieved, the labor cost is reduced, and the automation and intelligentization degree of the production process is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

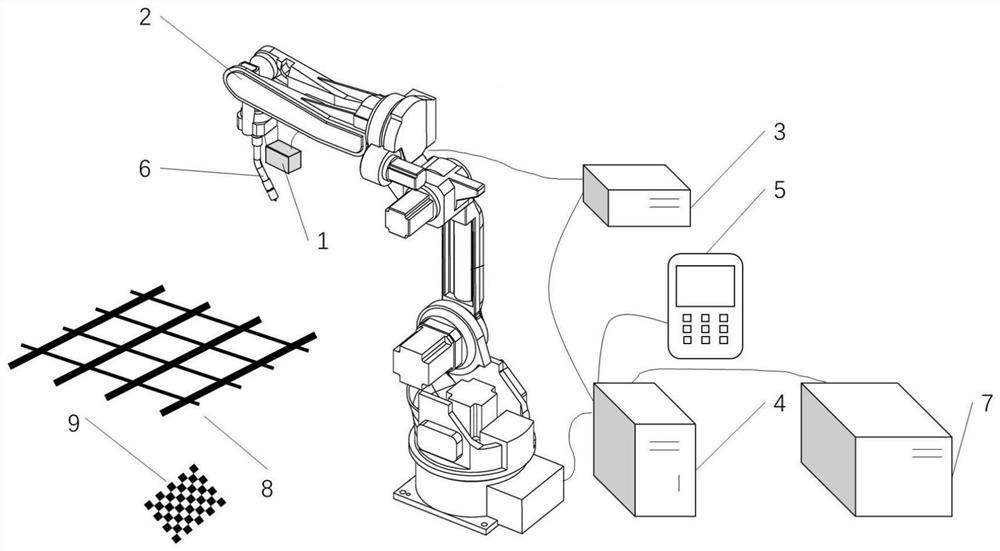

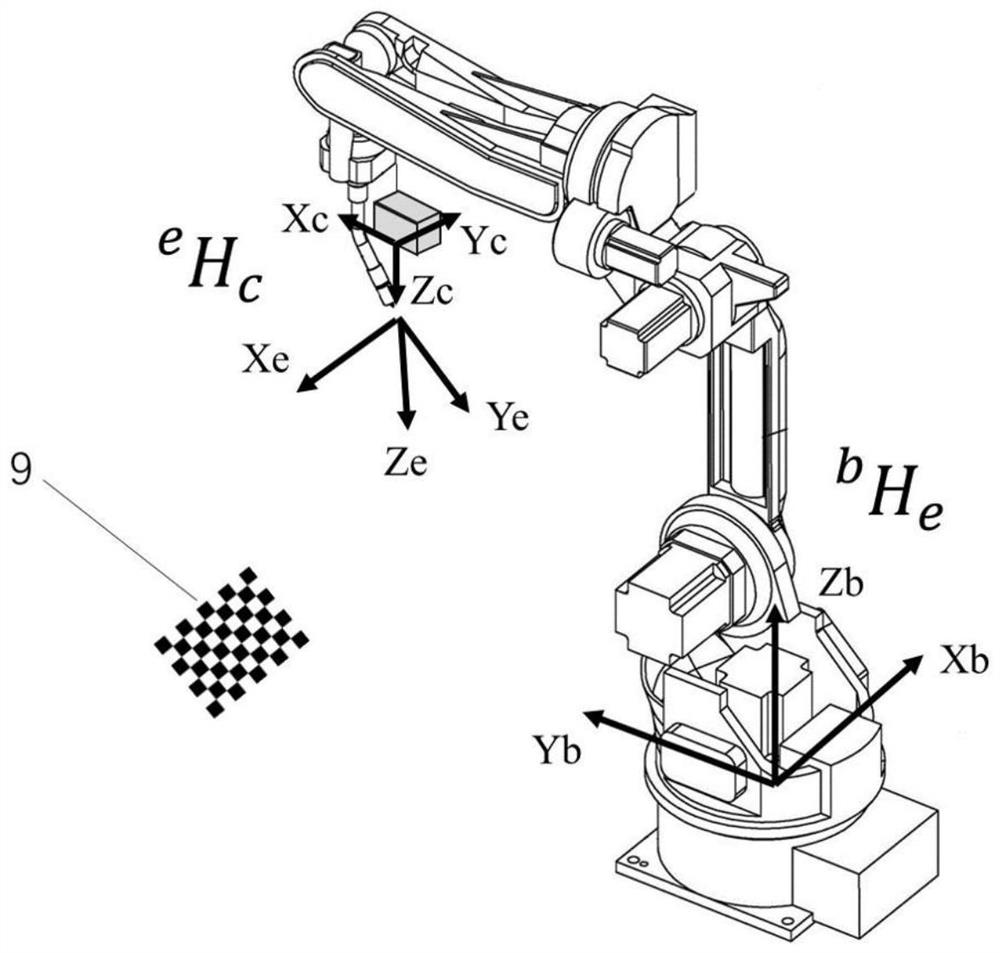

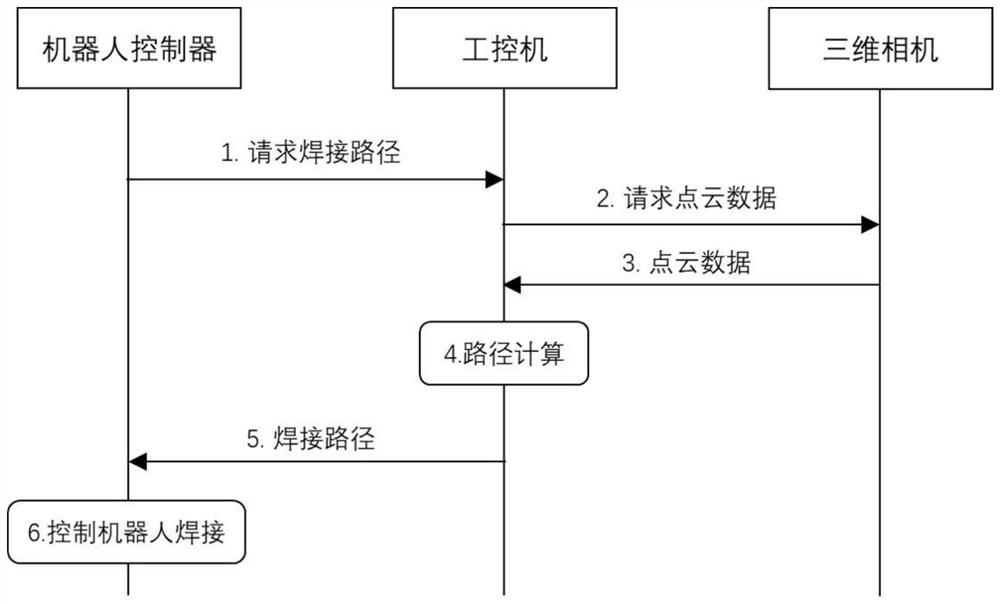

Visual location welding system and method based on robot welding

ActiveCN112122840ASimplify the teaching processFully automatedWelding/cutting auxillary devicesAuxillary welding devicesPoint cloudEngineering

The invention provides a visual location welding system and method based on robot welding. The visual location welding system is composed of a hand-eye calibration module, a photographing point location recording module and a welding execution module. The hand-eye calibration module is used for calculating a position and pose conversion relationship between a camera coordinate system and a robot coordinate system; three-dimensional information of crossed steel bars is acquired through the photographing point location recording module, and welding paths of the crossed steel bars are calculatedthrough a steel bar point cloud welding line extraction algorithm; and the welding paths are sent to the welding execution module, and the welding operation of steel bar crossing points is completed through the welding execution module . Through visual location of the crossed steel bars, the problem of poor precision of a workpiece and a clamp is solved, flexible and accurate welding is achieved,and the welding quality is guaranteed. According to the welding system, automatic calculation of the welding paths is achieved, and the demonstration of the welding paths is omitted; the robot demonstration process is simplified, and the requirement for operators is reduced; and the welding automation of the steel bars is achieved, and the welding effect and the production efficiency are improved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com