Patents

Literature

350results about How to "No manual adjustment required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

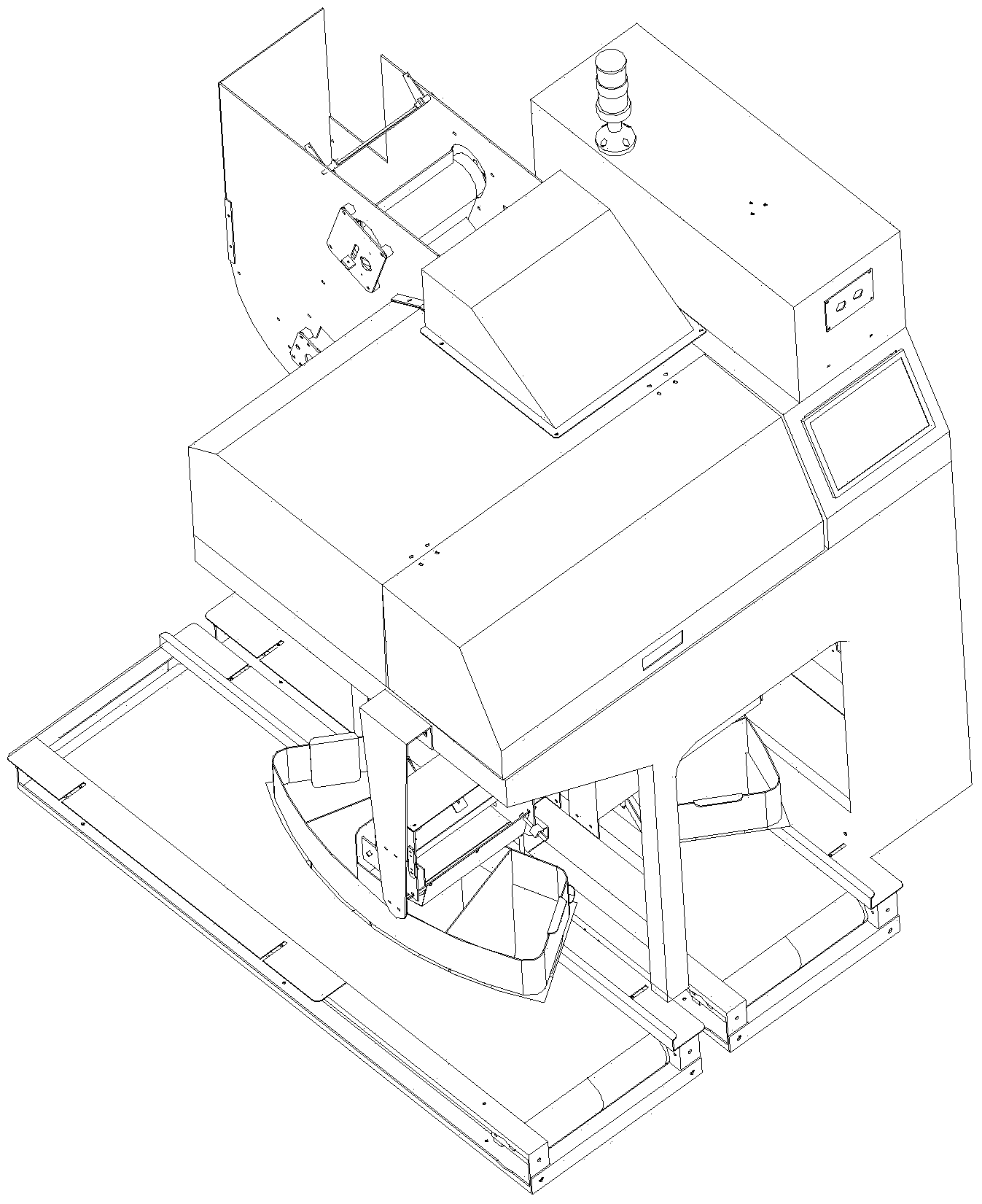

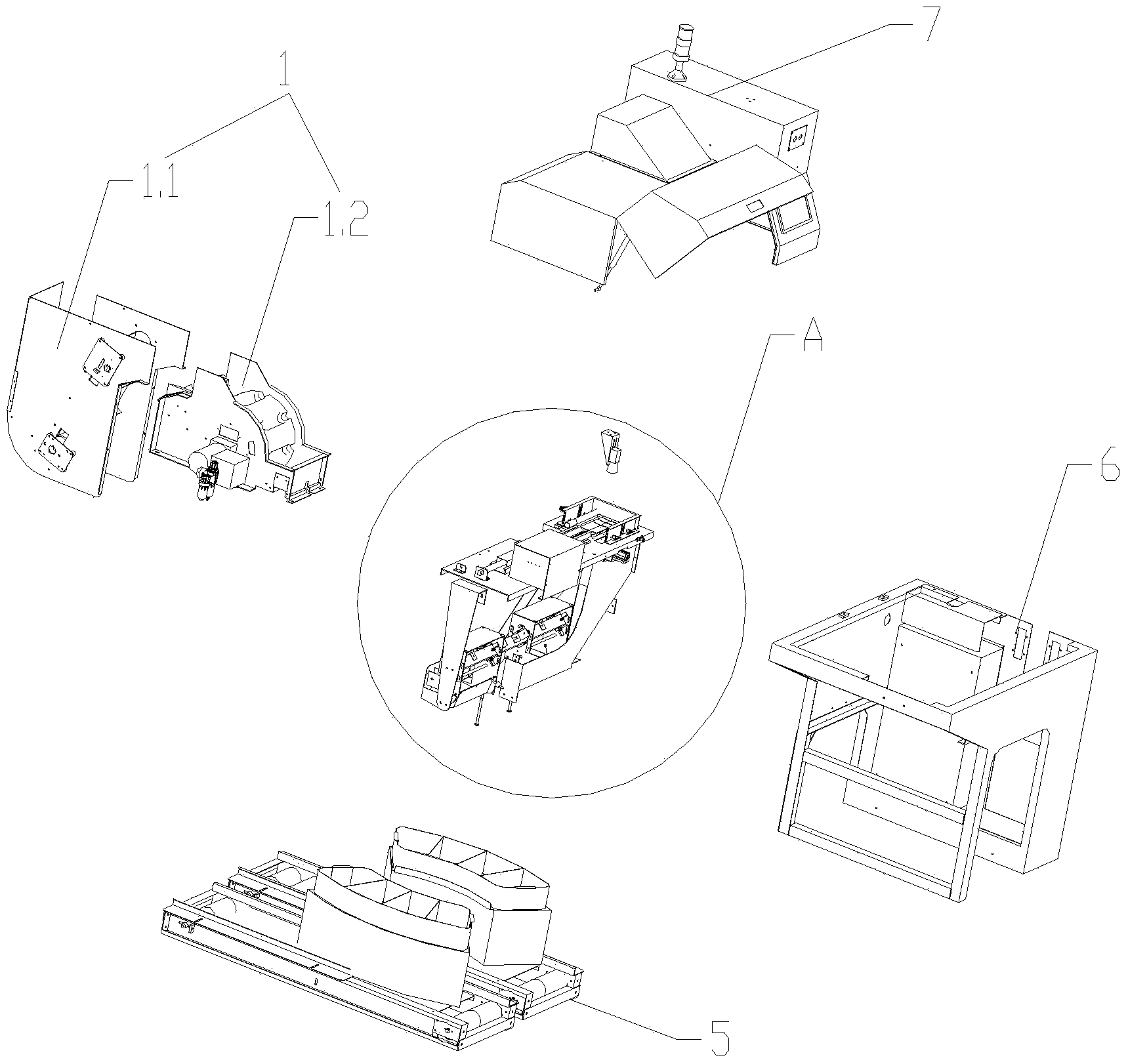

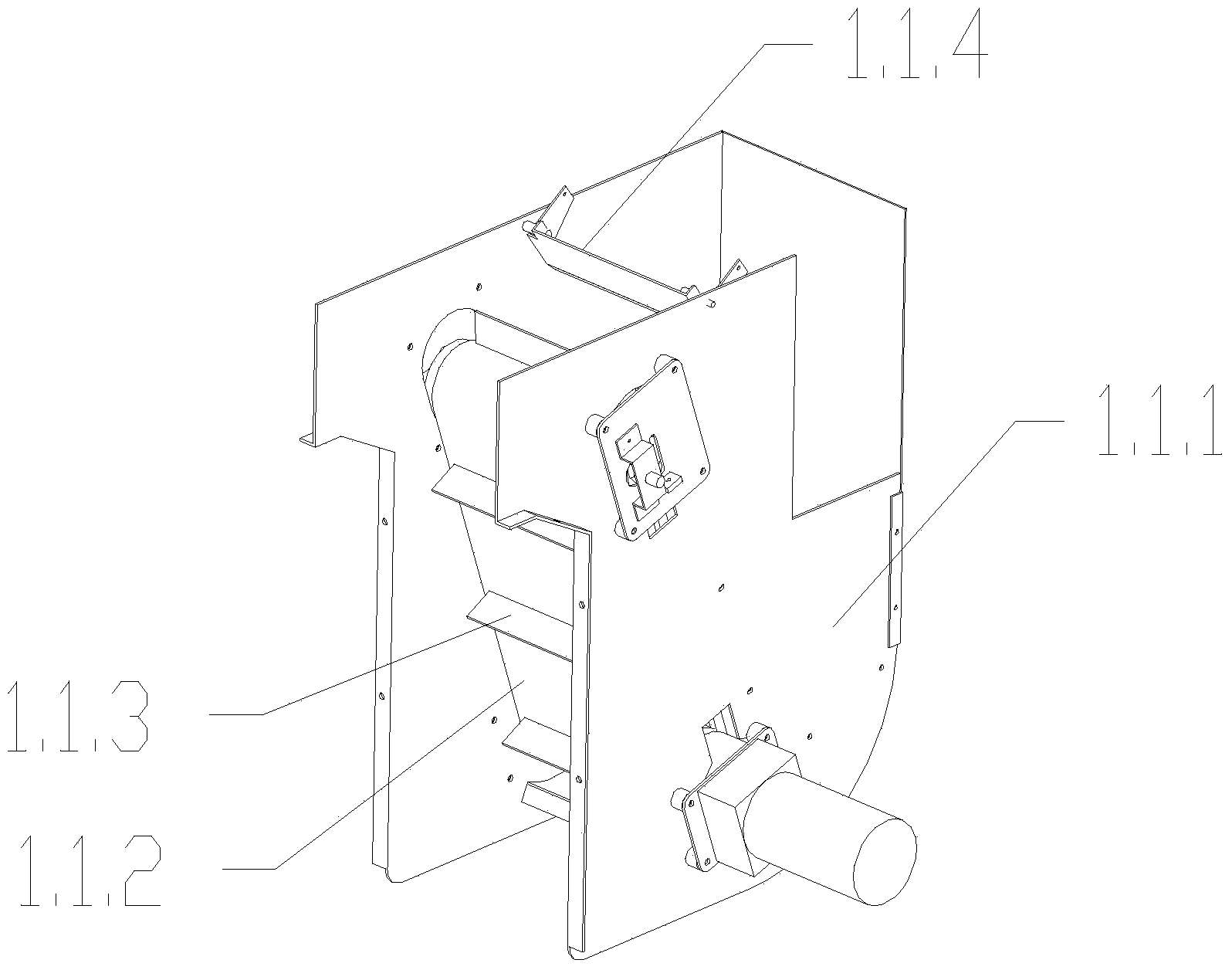

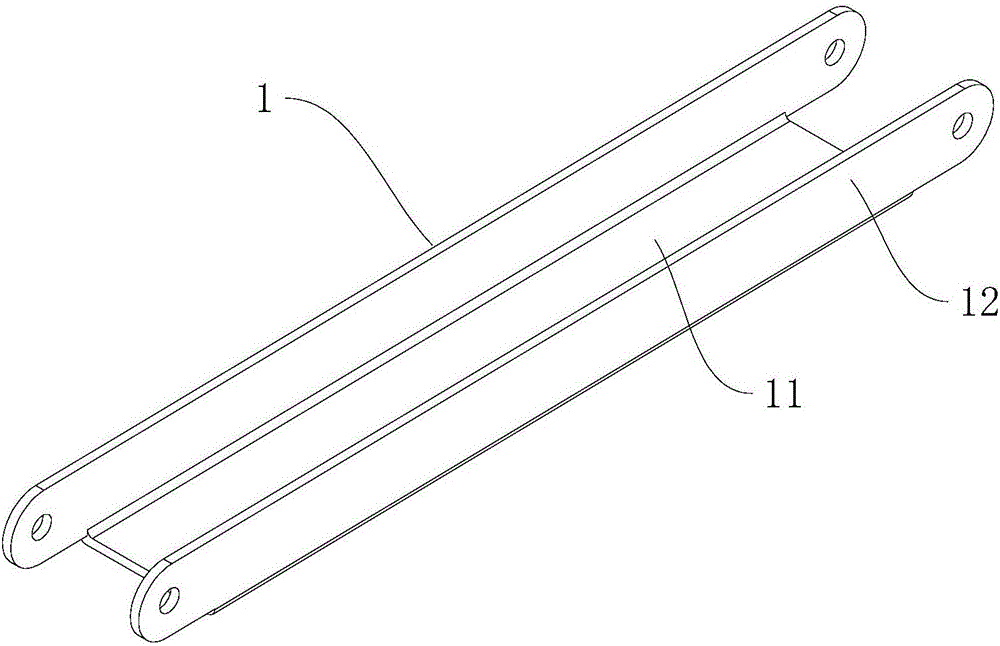

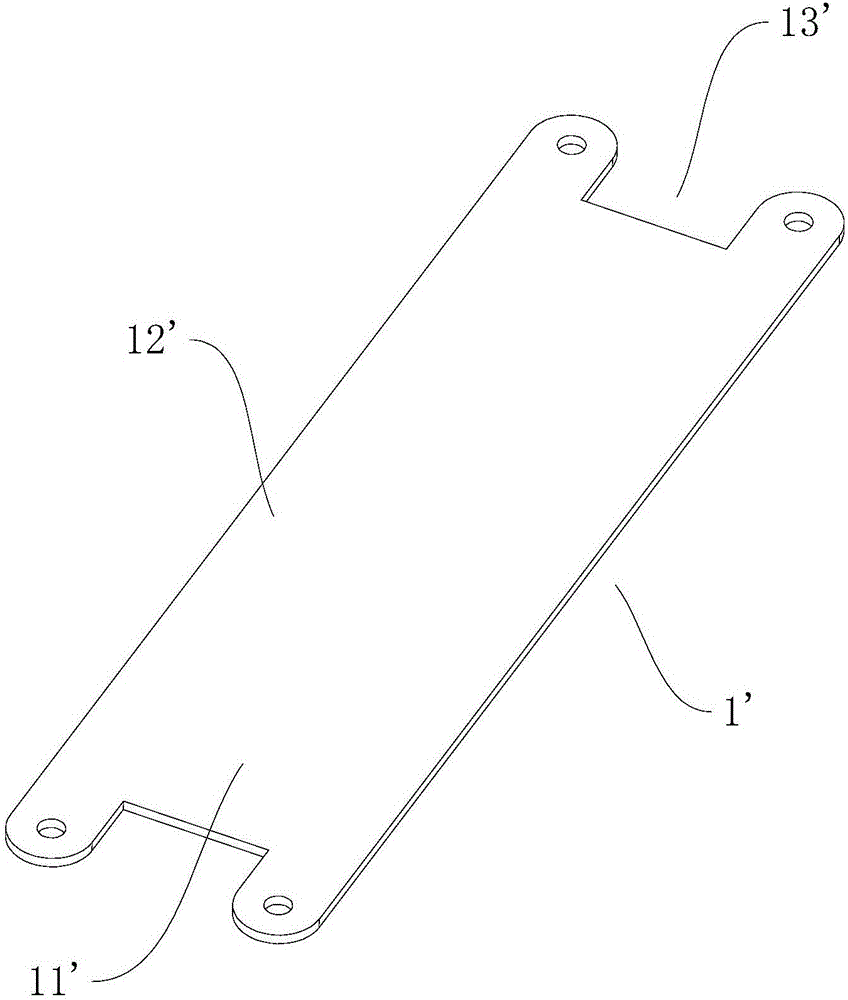

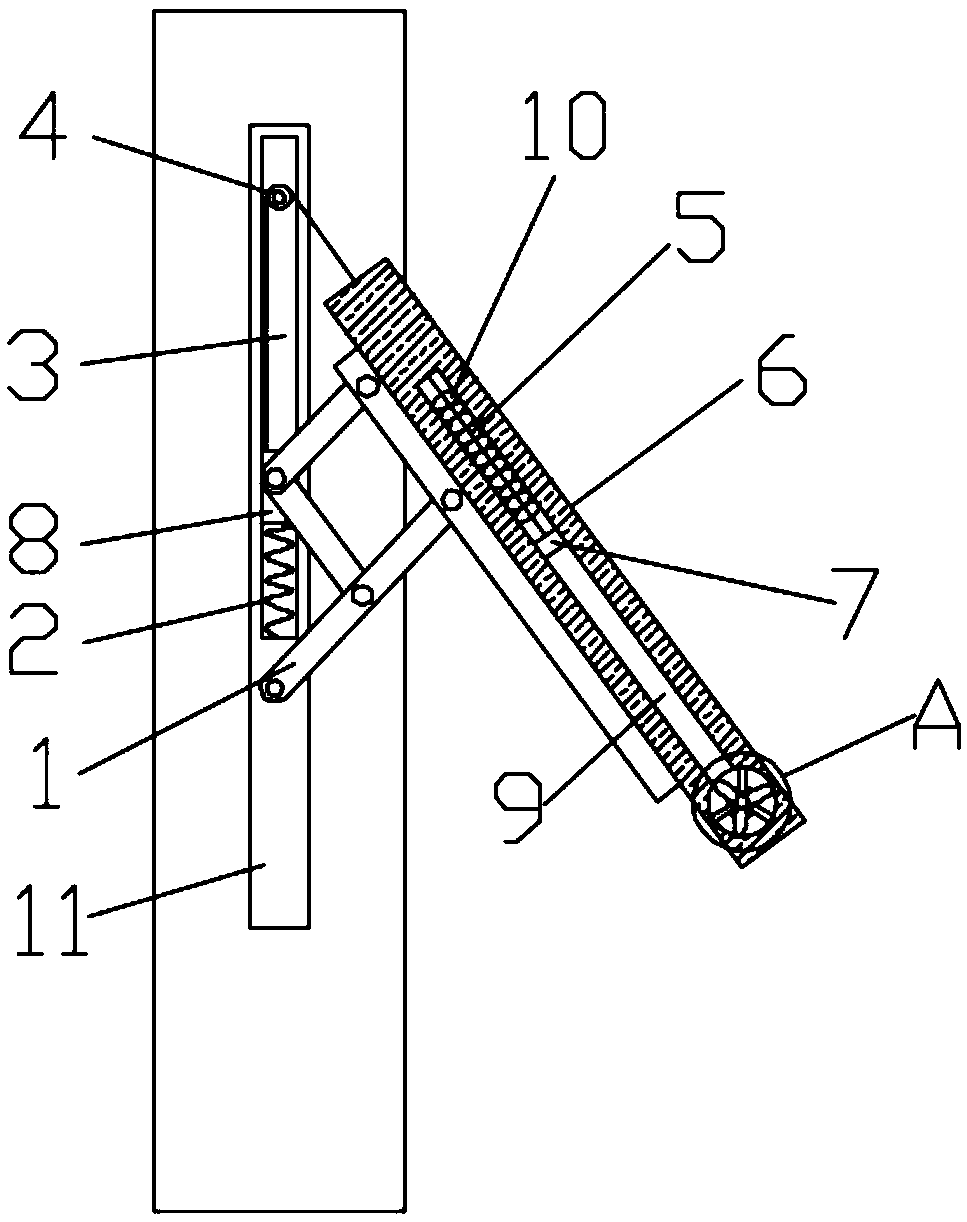

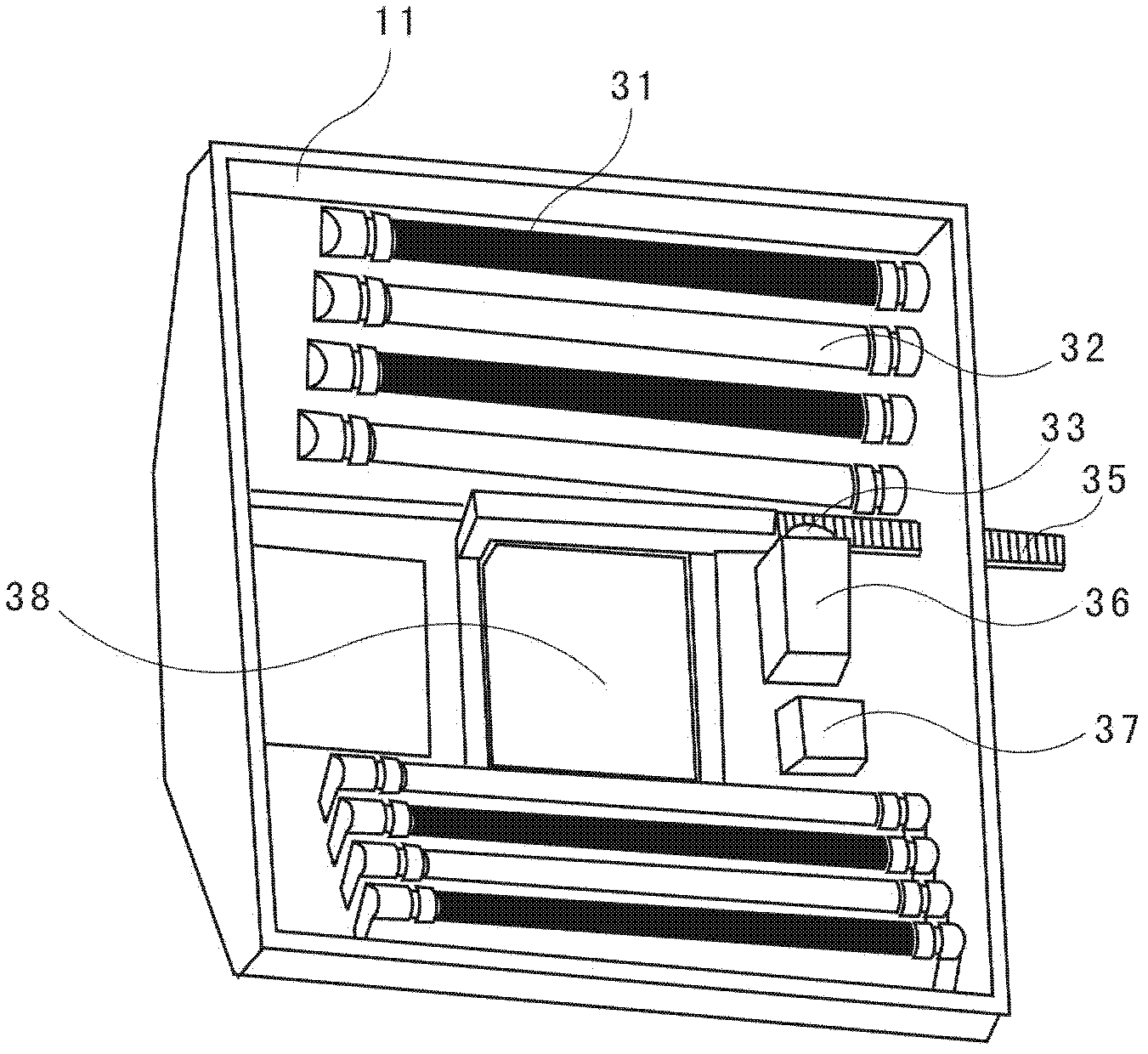

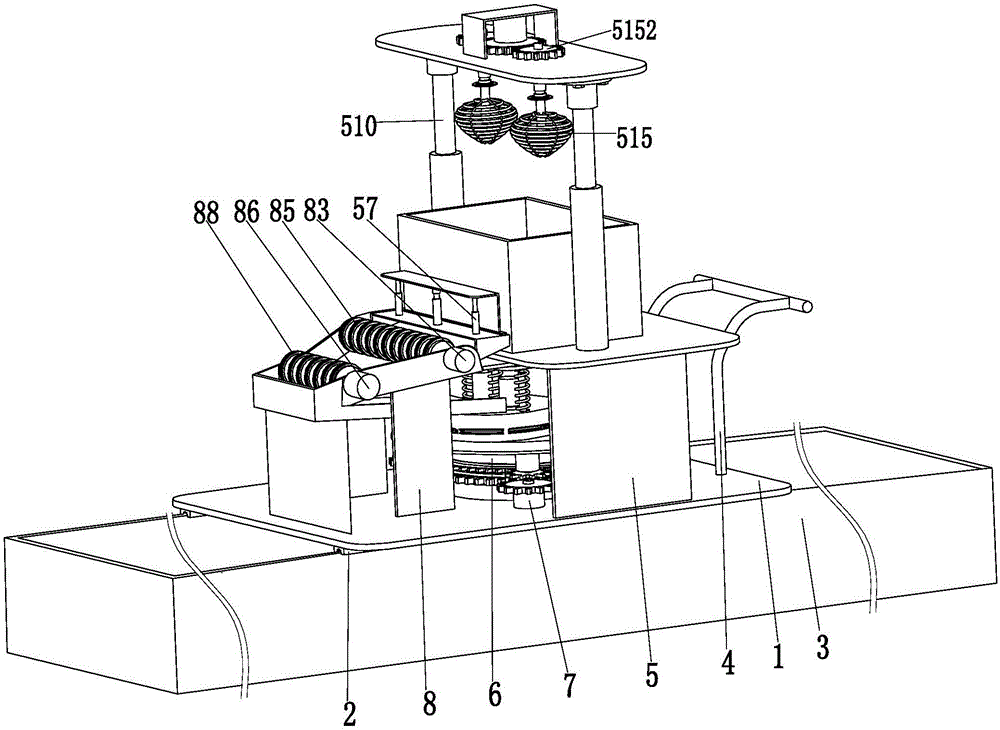

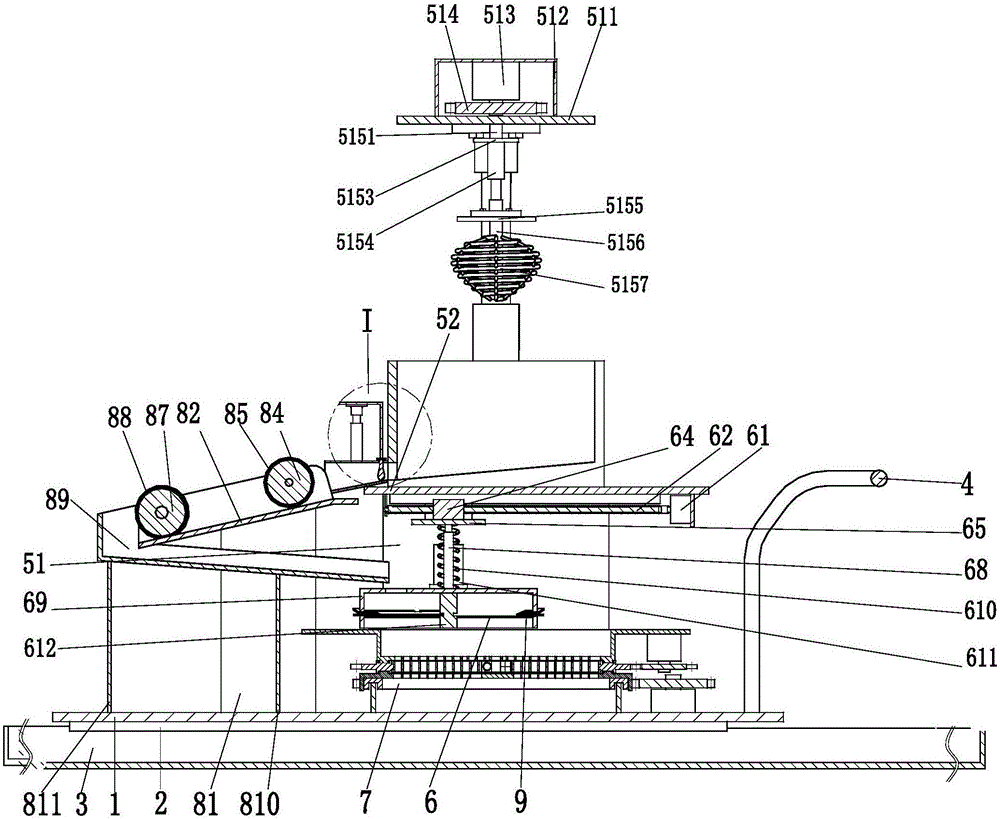

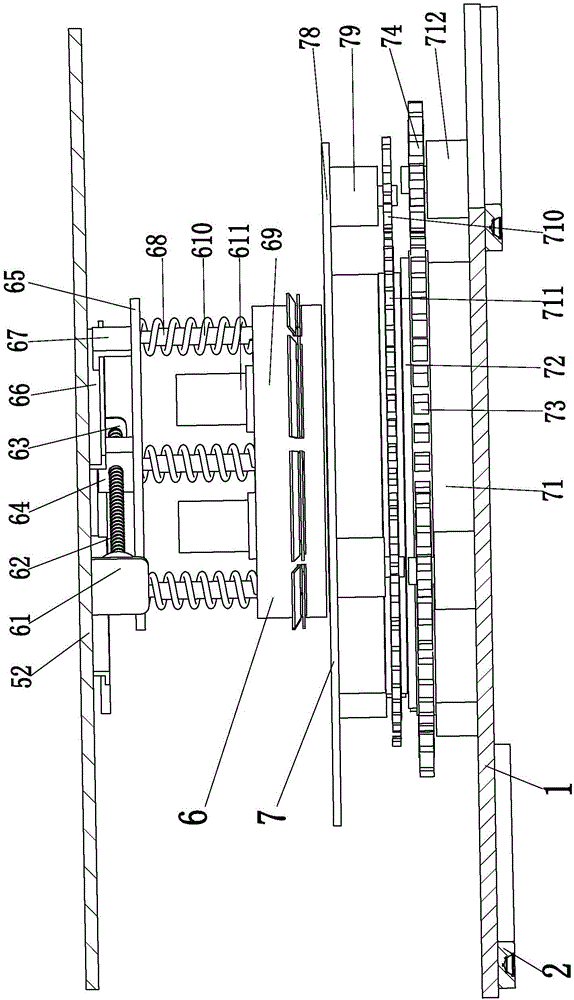

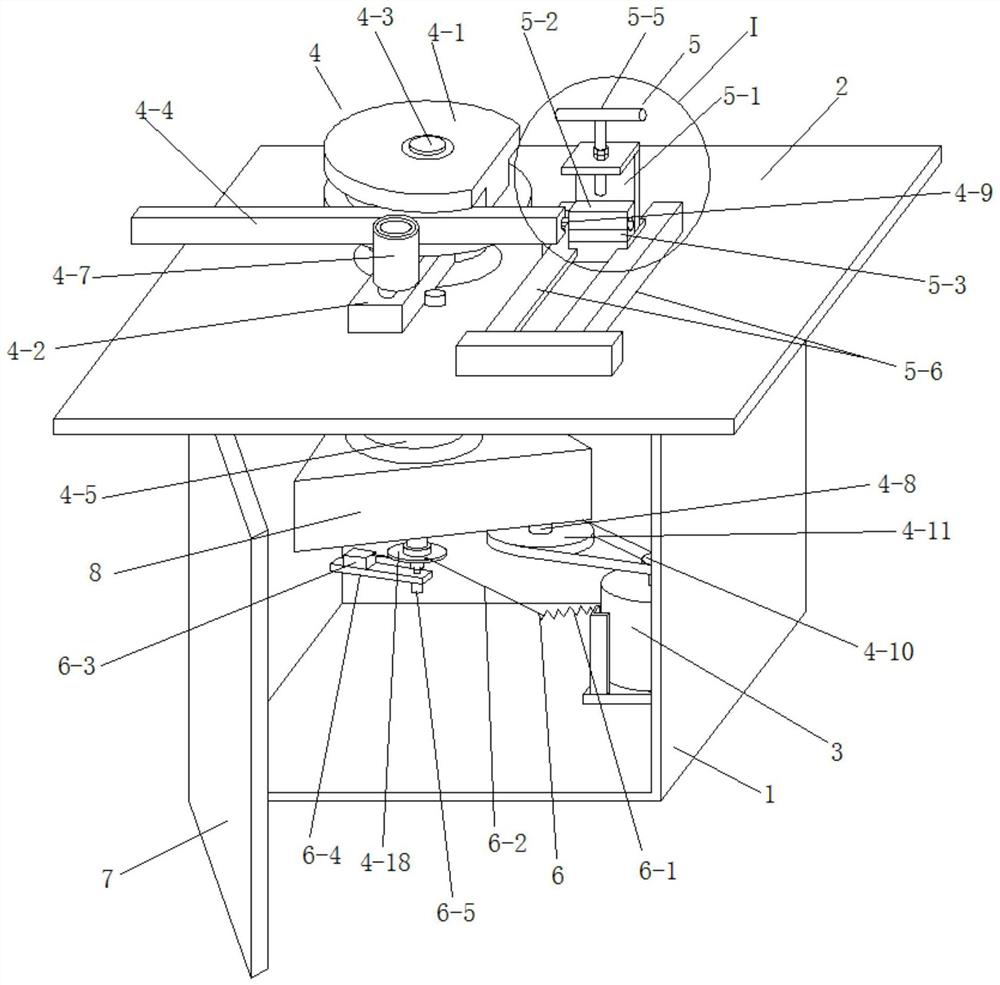

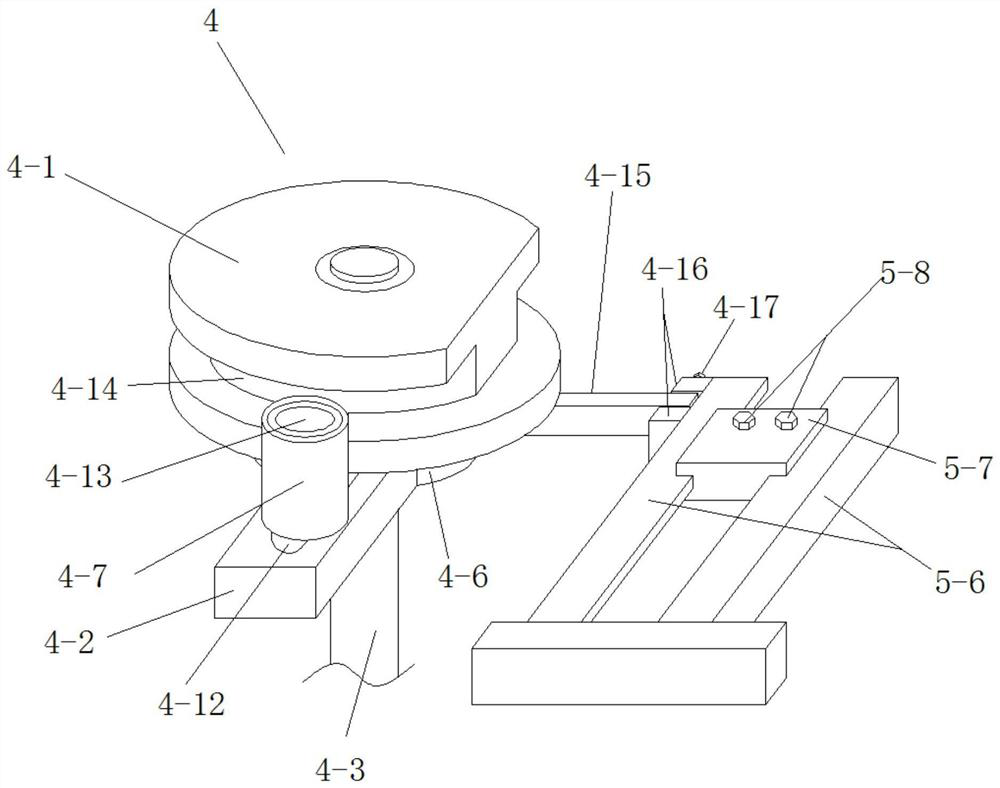

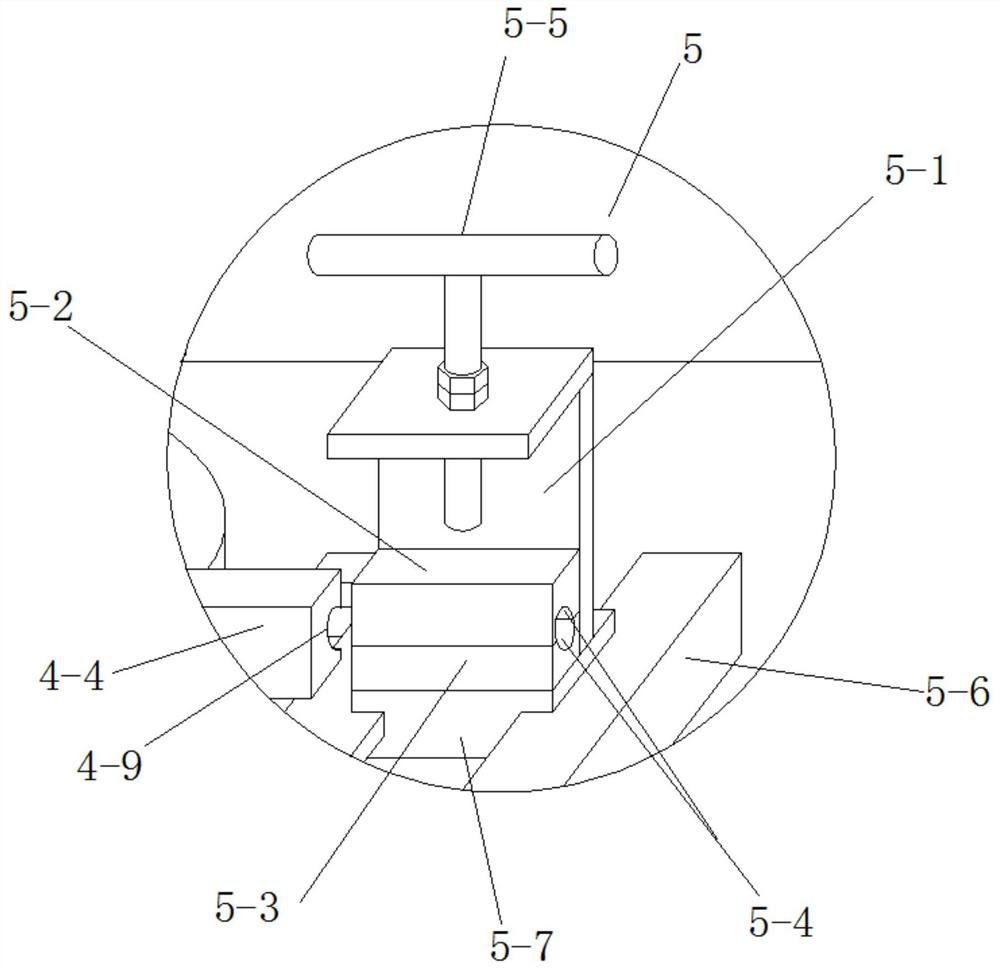

Bobbin burying machine

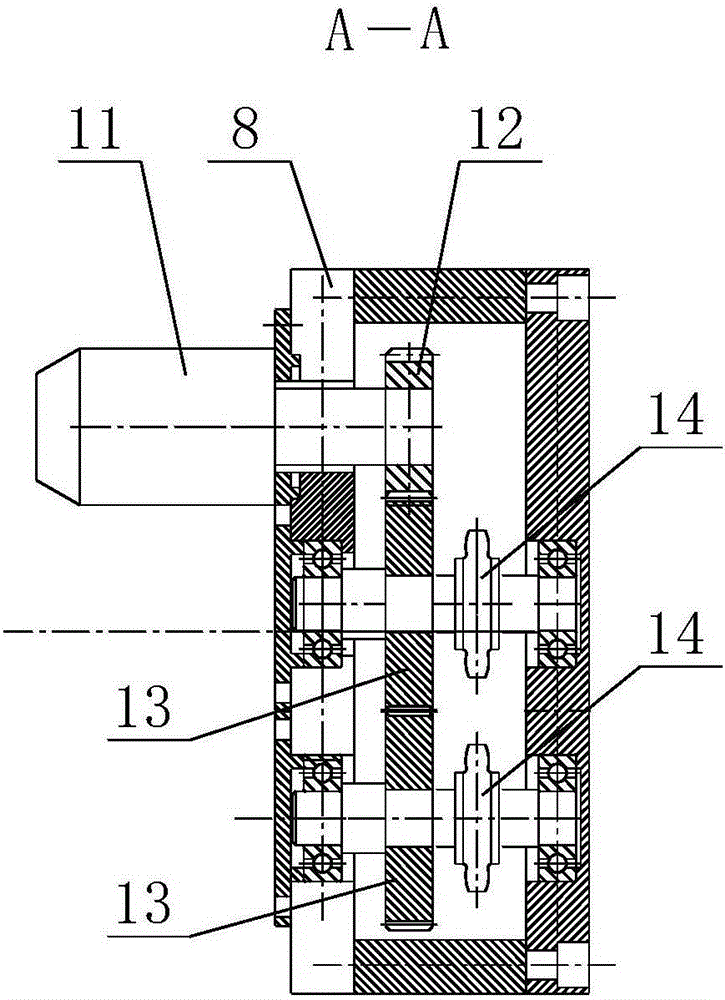

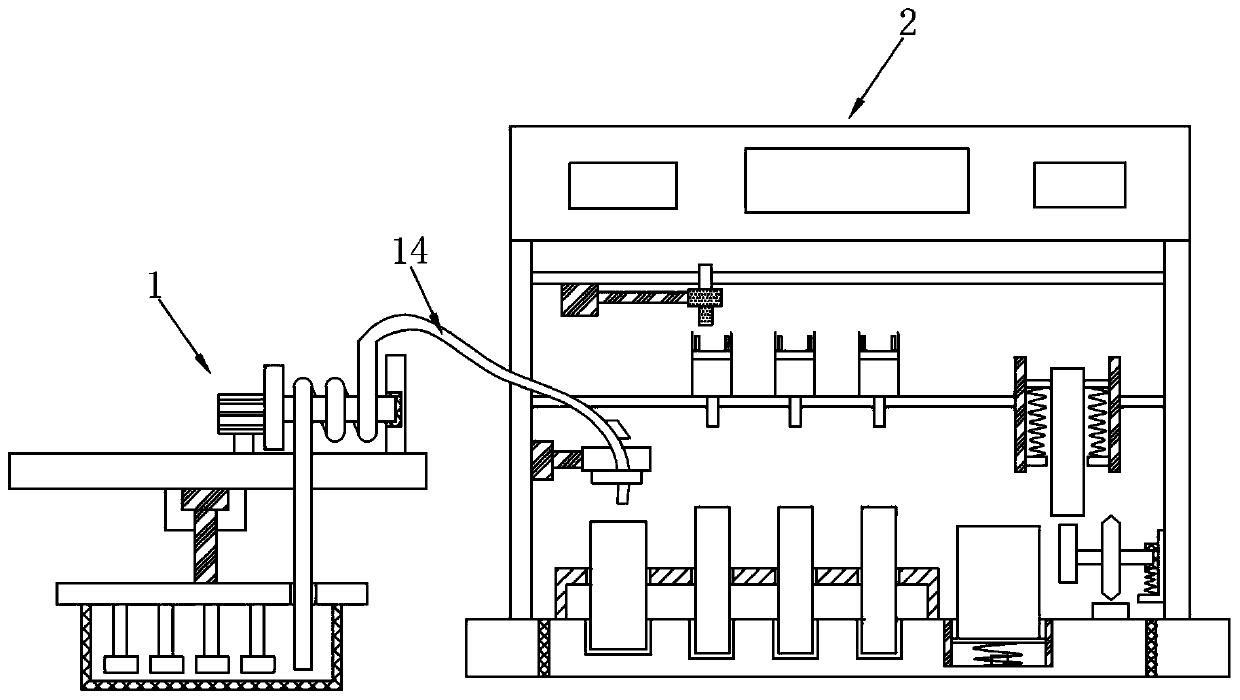

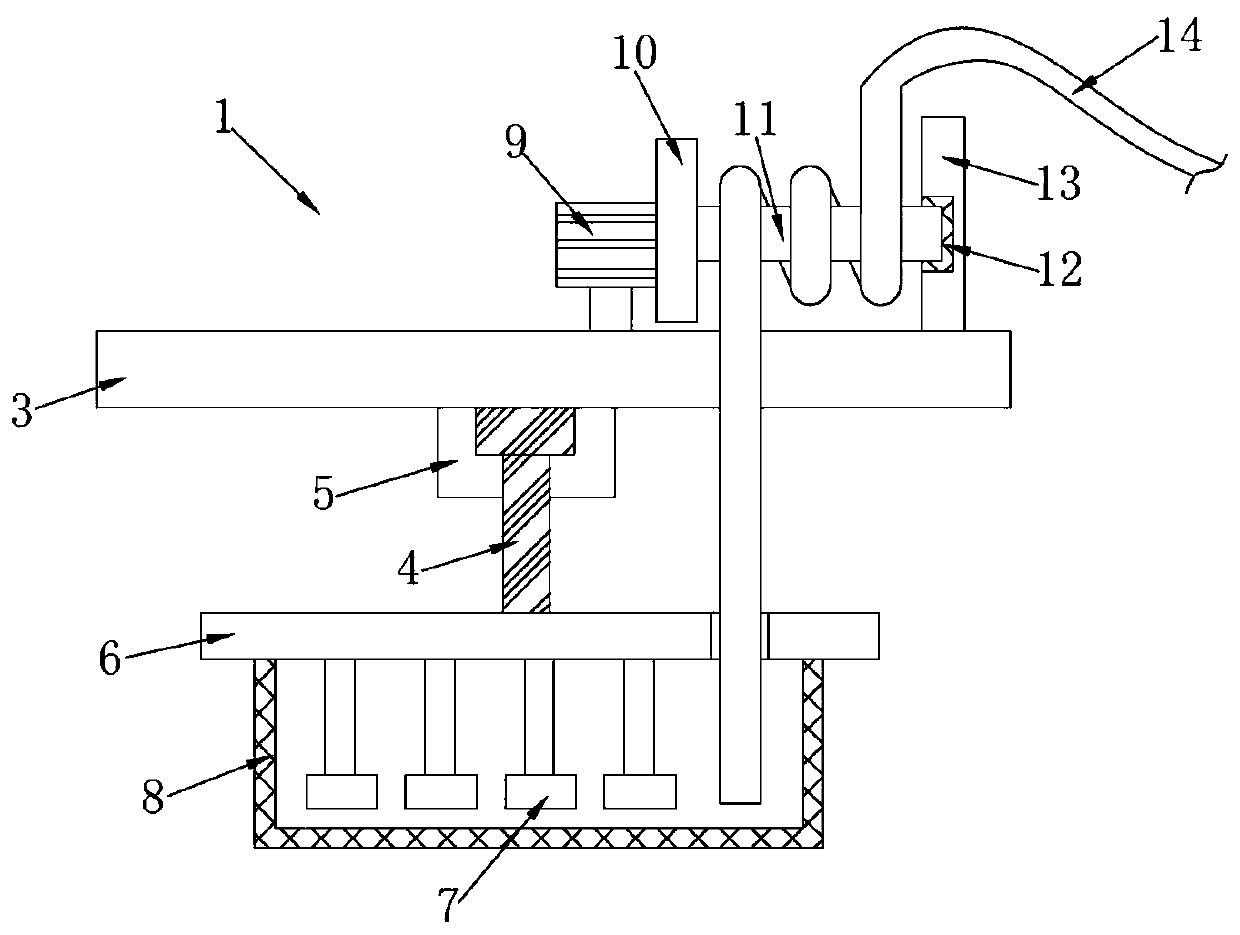

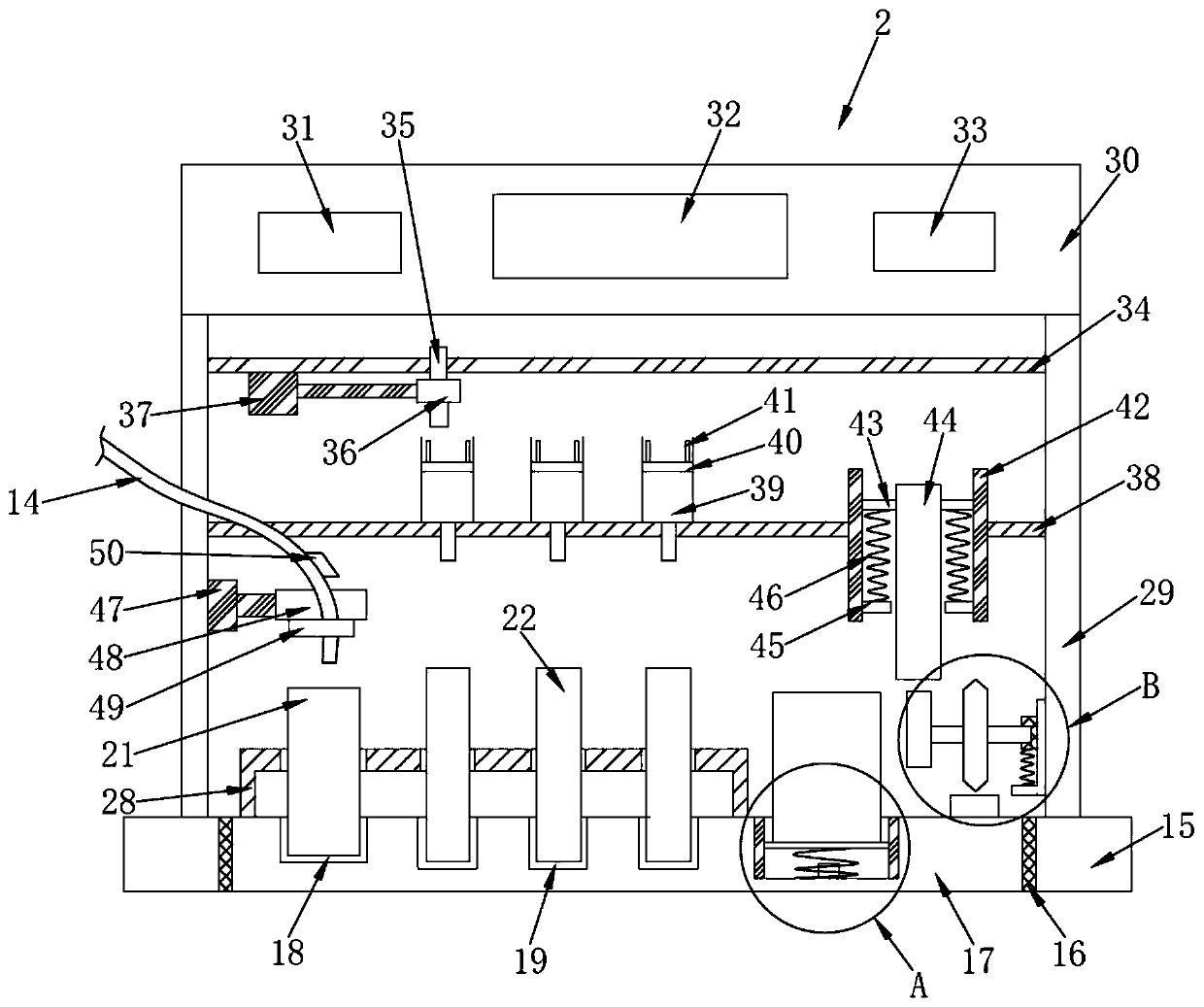

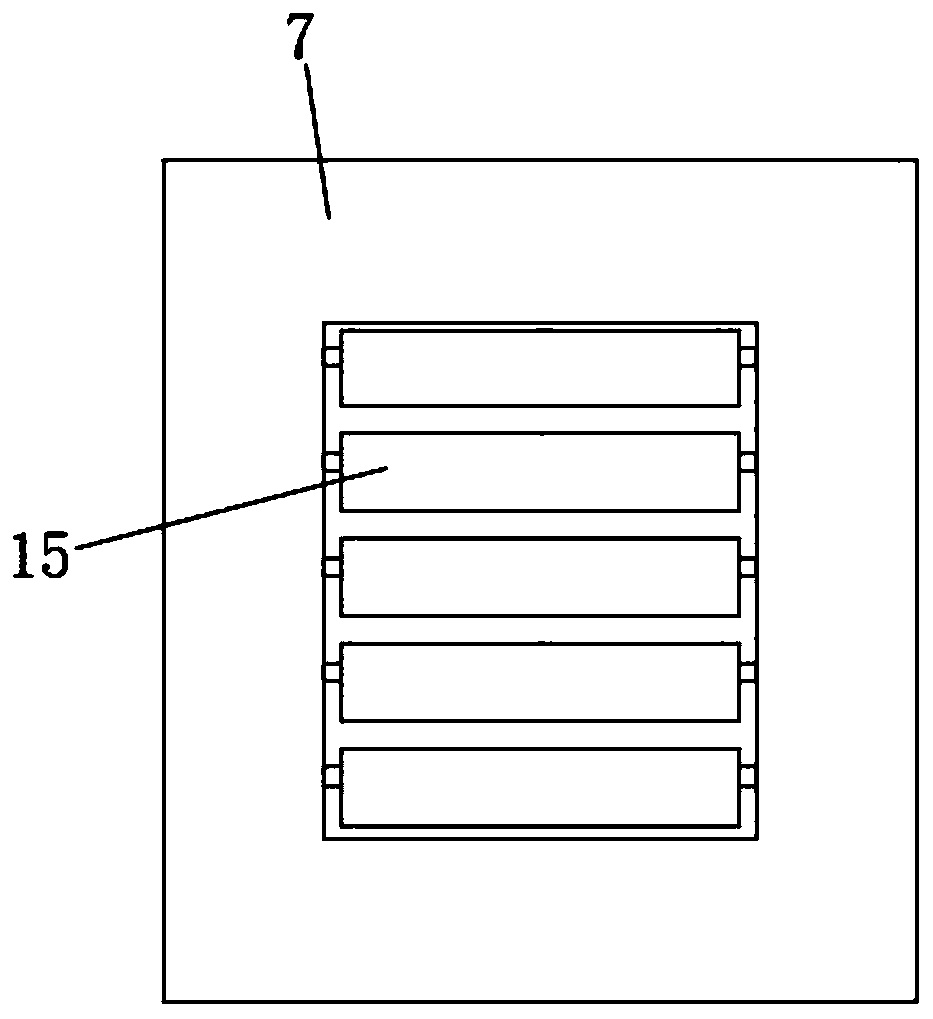

The invention relates to a bobbin burying machine. The bobbin burying machine is characterized by comprising a bobbin storage mechanism (1), a bobbin separating mechanism (2), a bobbin falling mechanism (3), a bobbin connecting buffer mechanism (4), a bobbin connecting mechanism (5), a rack (6) and an outer shell (7). The bobbin storage mechanism (1), the bobbin separating mechanism (2), the bobbin falling mechanism (3) and the bobbin connecting buffer mechanism (4) are arranged on the rack (6), the outer shell (7) covers the top of the rack (6), and the bobbin connecting mechanism (5) is arranged below the bobbin connecting buffer mechanism (4). According to the bobbin burying machine, whether bobbins contain yarn or not can be distinguished, the colors of empty bobbins are distinguished, the big ends and the small ends of the bobbins without the yarn are straightened out, automation is achieved in the whole process, the manual operation is not needed, the manual operation difficulty of workers is greatly relieved, the number of employees of enterprises can be effectively saved, the employment pressure of the enterprises can be effectively relieved, and the bobbin burying machine has the advantages of improving work efficiency, and being high in automation degree and capable of being applied to arc-shaped recycle cases.

Owner:江阴市凯业纺织机械制造有限公司

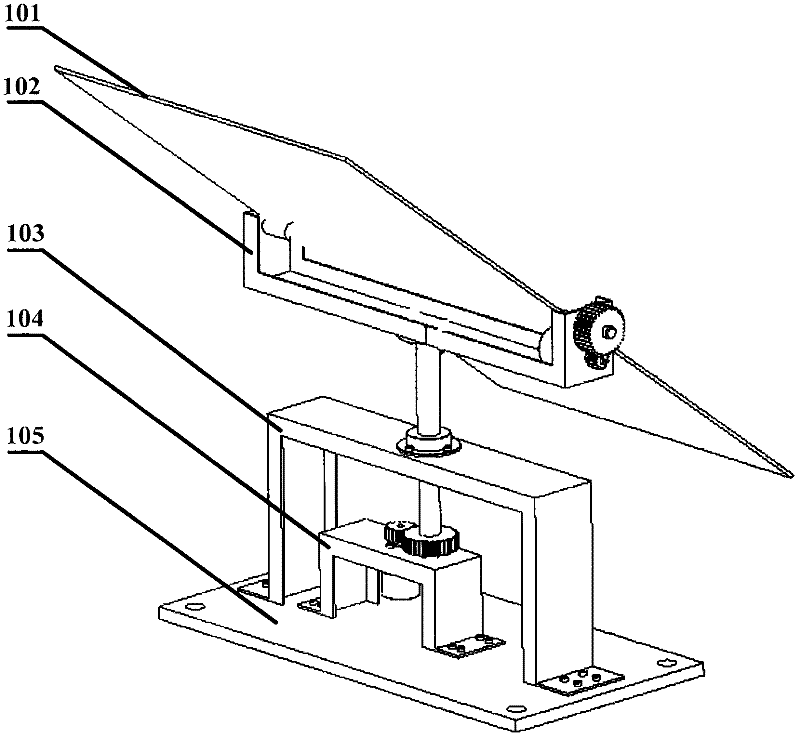

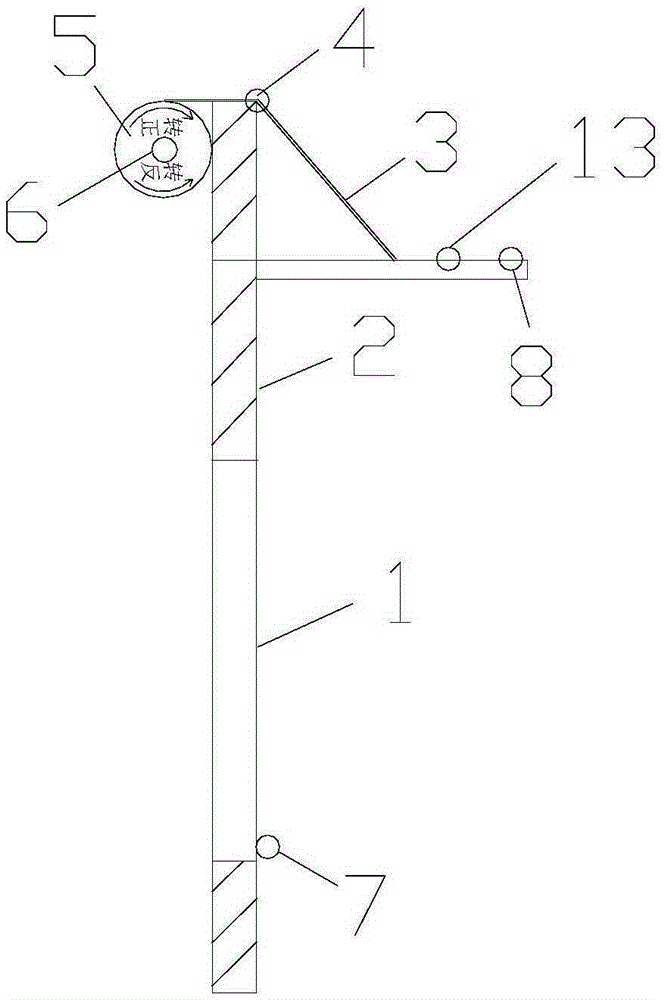

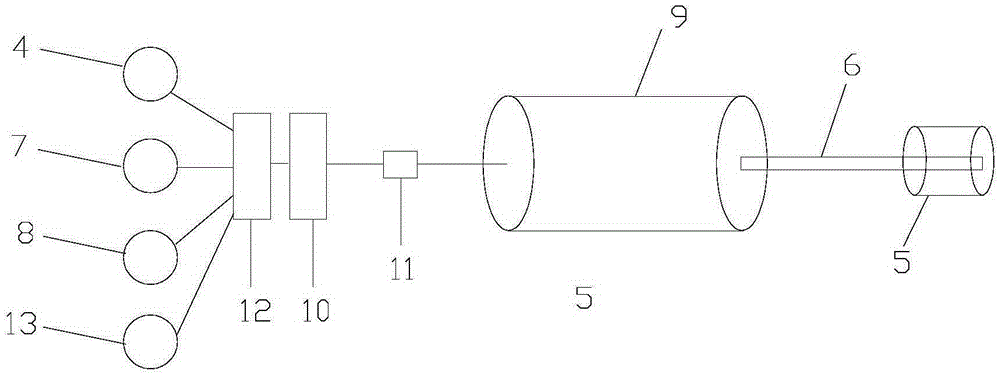

Sun auto-tracking device and tracking method thereof

InactiveCN102411377AExtended TrackingRealize three-dimensional omni-directional trackingControl using feedbackMotor driveAutomatic control

The invention discloses a sun auto-tracking device and a tracking method thereof. The device comprises a solar energy pole plate, a horizontal fixed shaft, a horizontal bracket, an upright shaft, a pedestal, an upright direct current motor, a horizontal direct current motor and an automatic control circuit, wherein the horizontal bracket is used for fixing the solar energy pole plate and the horizontal fixed shaft, the upright shaft is used for supporting the horizontal bracket, the upright direct current motor is used for driving the upright shaft to rotate, the horizontal direct current motor is used for driving the horizontal fixed shaft to rotate, and the automatic control circuit is composed of STC (Sensitivity-Time Control) single chip machine, a GPS (Global Positioning System) chip, a tilt sensor module, an electronic compass and a direct current motor driving module. The sun auto-tracking device provided by the invention has the characteristics of large tracking range, automation and wide applicable area and the like.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

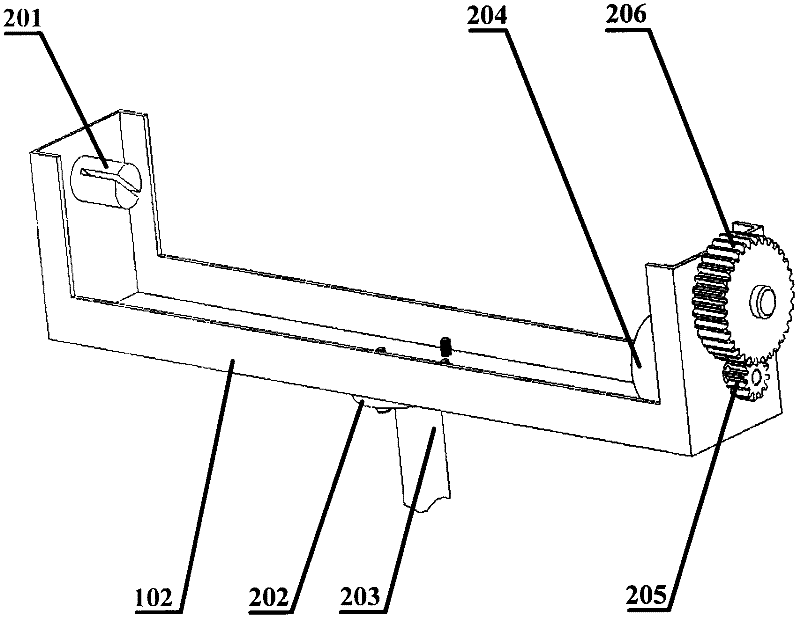

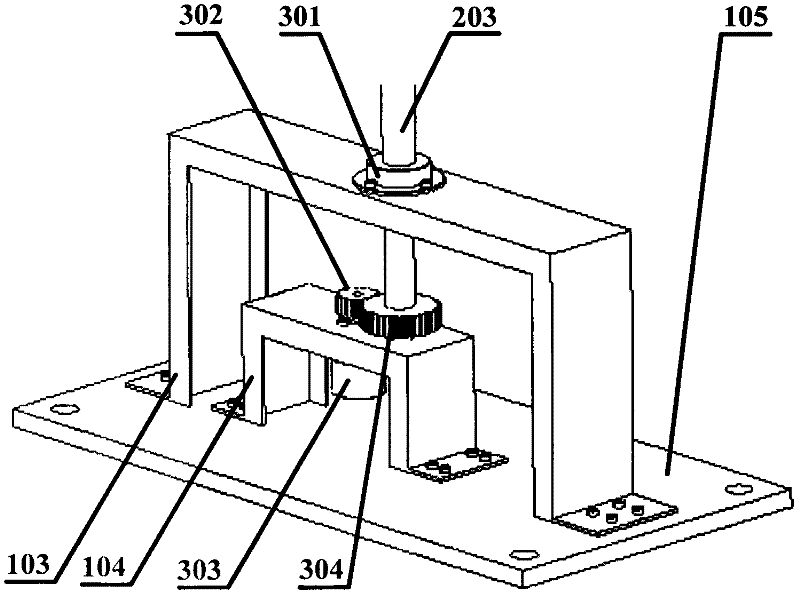

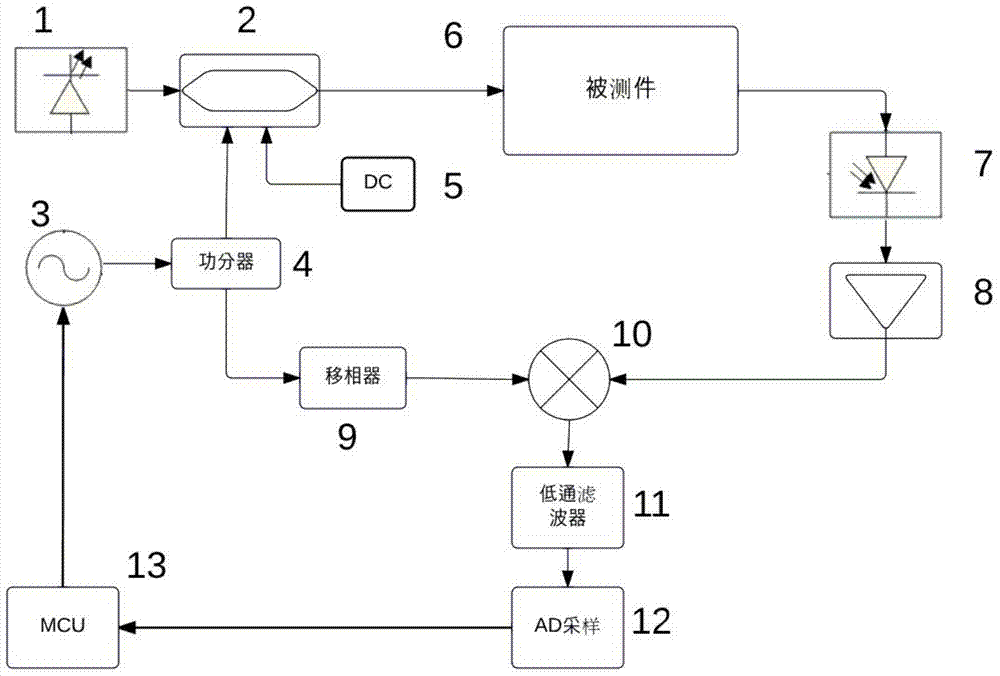

Measuring device for interferential sensor arm length difference

The invention discloses a measuring device for an interferential sensor arm length difference. The measuring device comprises a broadband light source, a Mach-Zehnder intensity modulator, a microwave frequency sweeping source, a power divider, a direct-current stabilized power supply, a high-speed photoelectric detector, a radio-frequency amplifier, a phase shifter, a frequency mixer, a low-pass filter, an AD sampler and a measuring processer. The measuring device breaks through a thinking mode of measurement in a pure light domain, a microwave signal is led in, and a signal of the arm length difference is modulated on a light load microwave phase by the aid of an original light path structure of a sensor without damaging the sensor, so that the arm length difference is measured by demodulating the microwave phase. The measuring device mainly has the advantages that the measuring device is low in implementation cost, wide in measuring range, high in accuracy and high in speed, does not need to be supported by a special instrument and can fully automatically measure, manual adjustment is omitted, and a measuring result can be outputted only by connecting a measured sensor on the measuring device.

Owner:ZHEJIANG UNIV

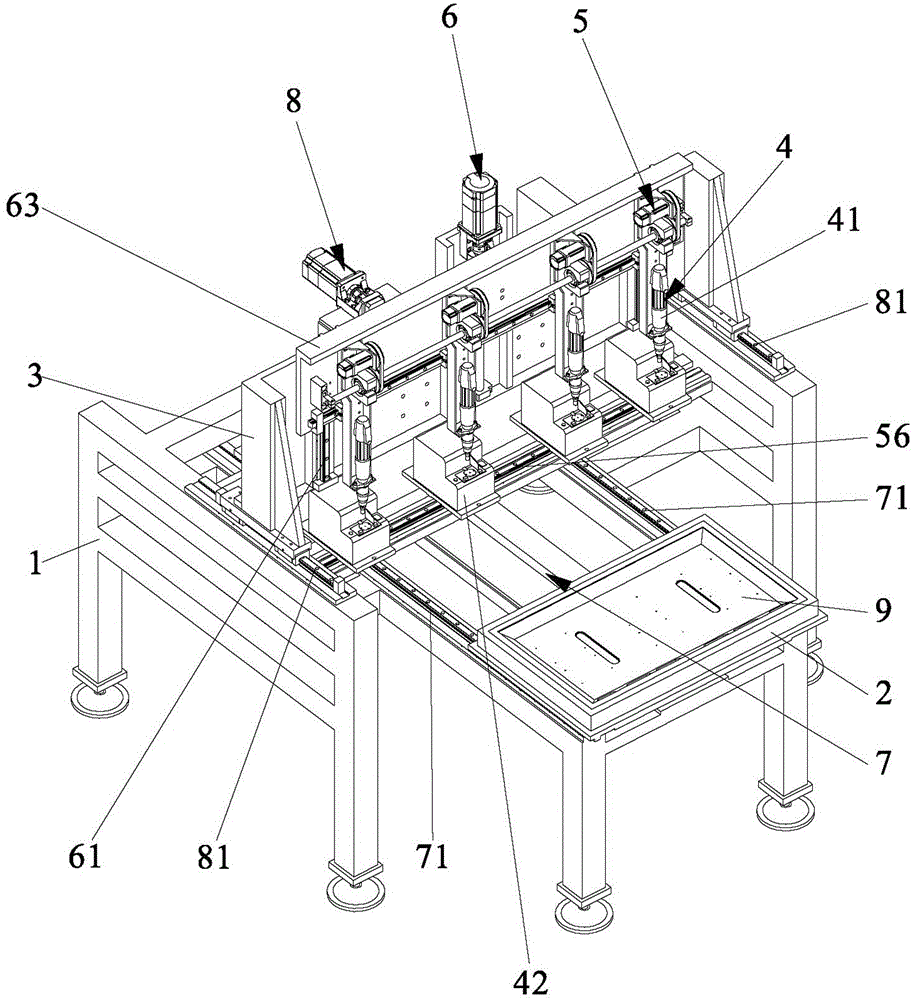

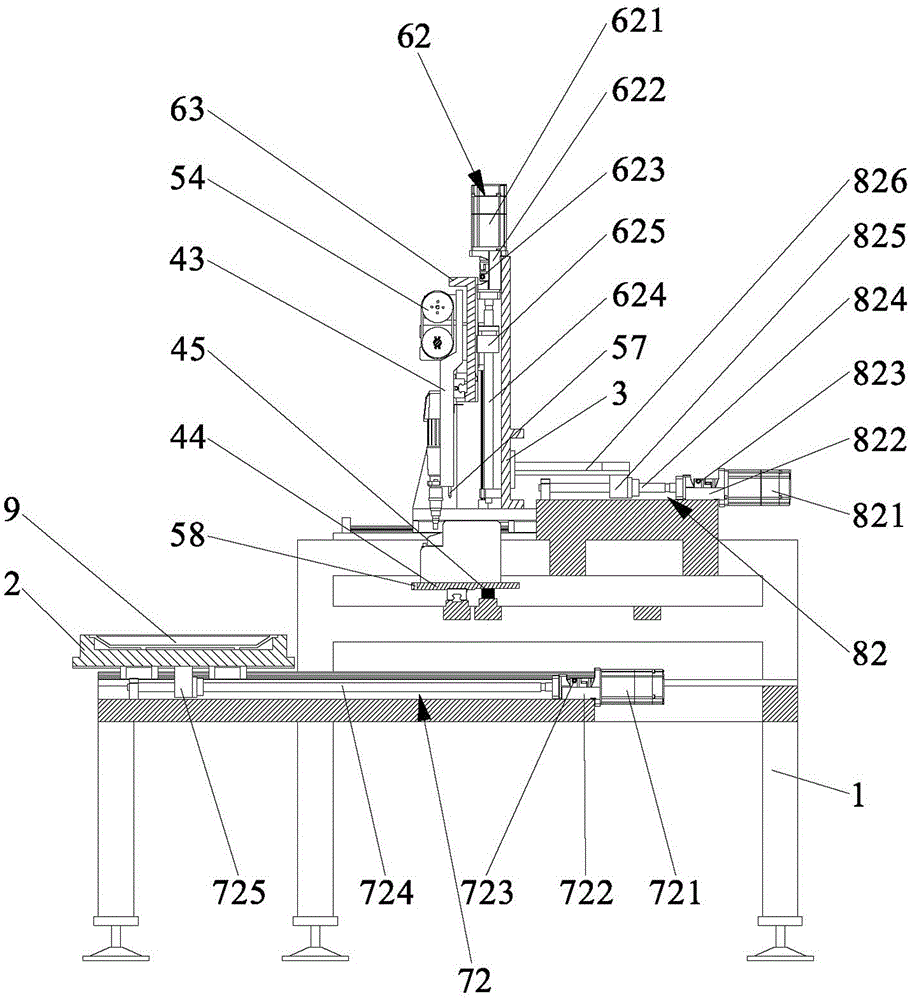

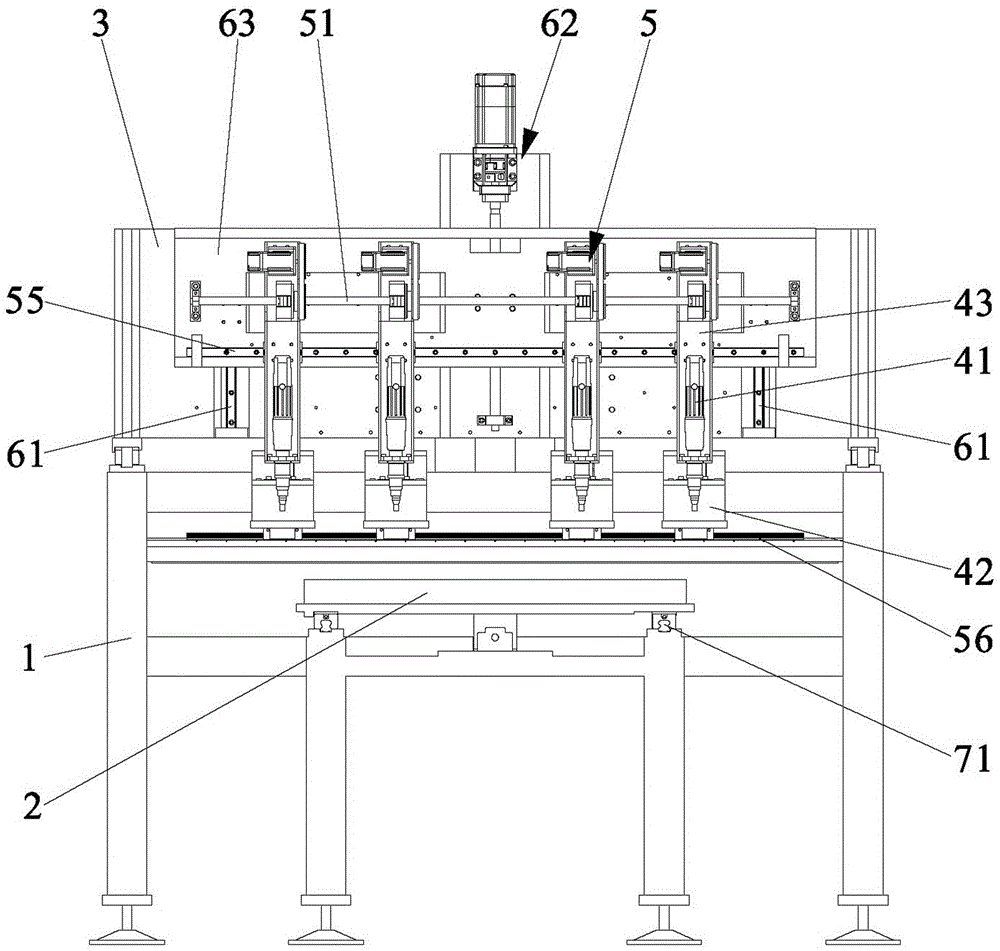

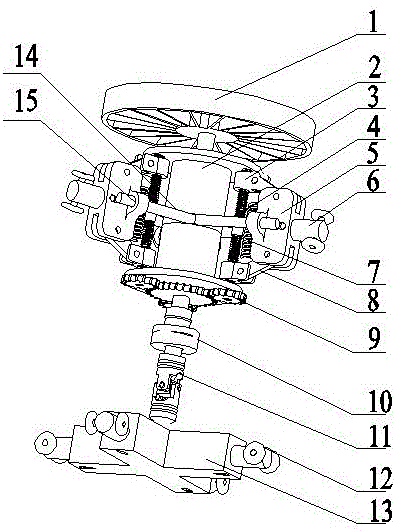

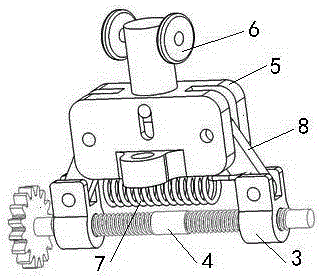

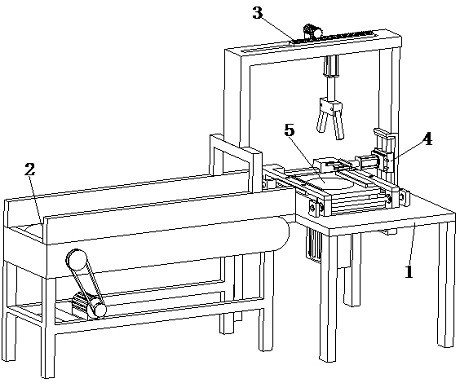

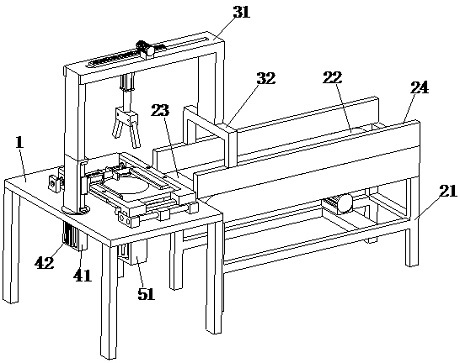

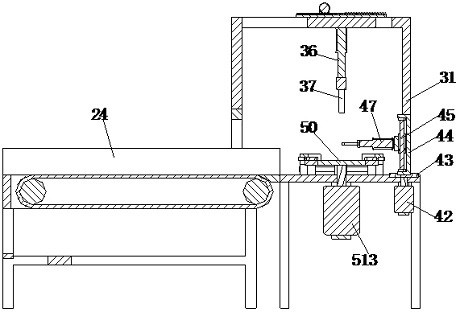

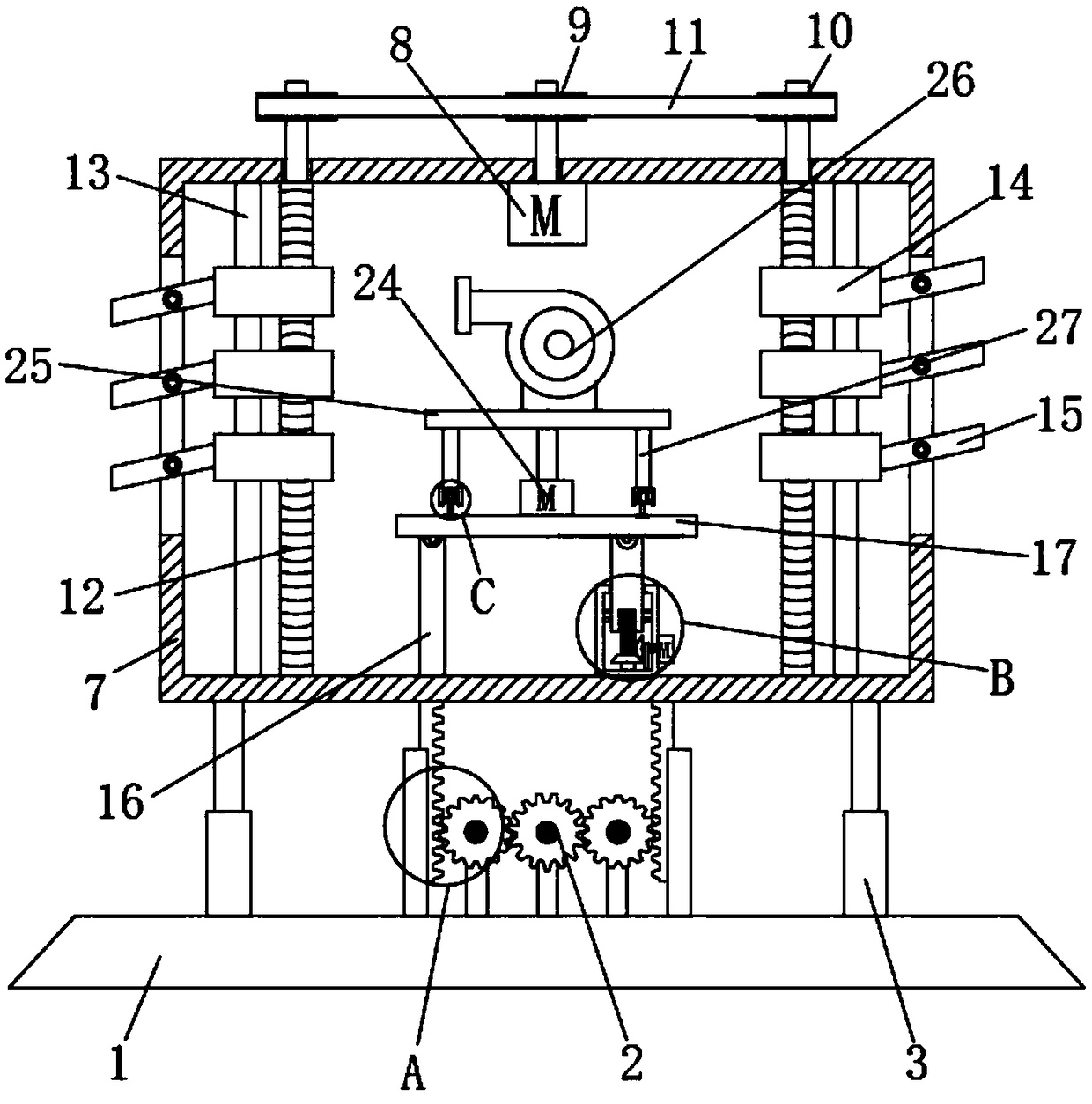

Adjustable multi-shaft automatic screwing machine and position adjustment method thereof

ActiveCN105014368ARealize synchronized movementEasy to adjustMetal working apparatusEngineeringMechanical engineering

The invention discloses an adjustable multi-shaft automatic screwing machine and a position adjustment method thereof. The screwing machine comprises a machine frame, an object containing table, a portal frame, a plurality of screwing mechanisms, a position adjustment mechanism capable of adjusting movement of the screwing mechanisms in the X axis direction, a Z-axis movement mechanism capable of driving the screwing mechanisms to vertically move, a Y-axis movement mechanism capable of driving the object containing table or the screwing mechanisms to move and a control mechanism. The position adjustment mechanism comprises a nut-rotating-type lead screw pair fixed to the portal frame. A plurality of nuts are arranged on the nut-rotating-type lead screw pair according to the number of the screwing mechanisms. Each nut is provided with an X-axis nut base which is fixedly linked with the corresponding screwing mechanism. Each screwing mechanism is provided with an X-axis motor to be connected with the corresponding nut in a transmission manner through a transmission mechanism. According to the adjustable multi-shaft automatic screwing machine and the position adjustment method, the relative positions among the screwing mechanisms can be adjusted to adapt to screw hole positions in a to-be-screwed workpiece, and therefore the multiple screw hole positions in a row in the workpiece can be screwed at the same time.

Owner:XIAMEN UNIV OF TECH

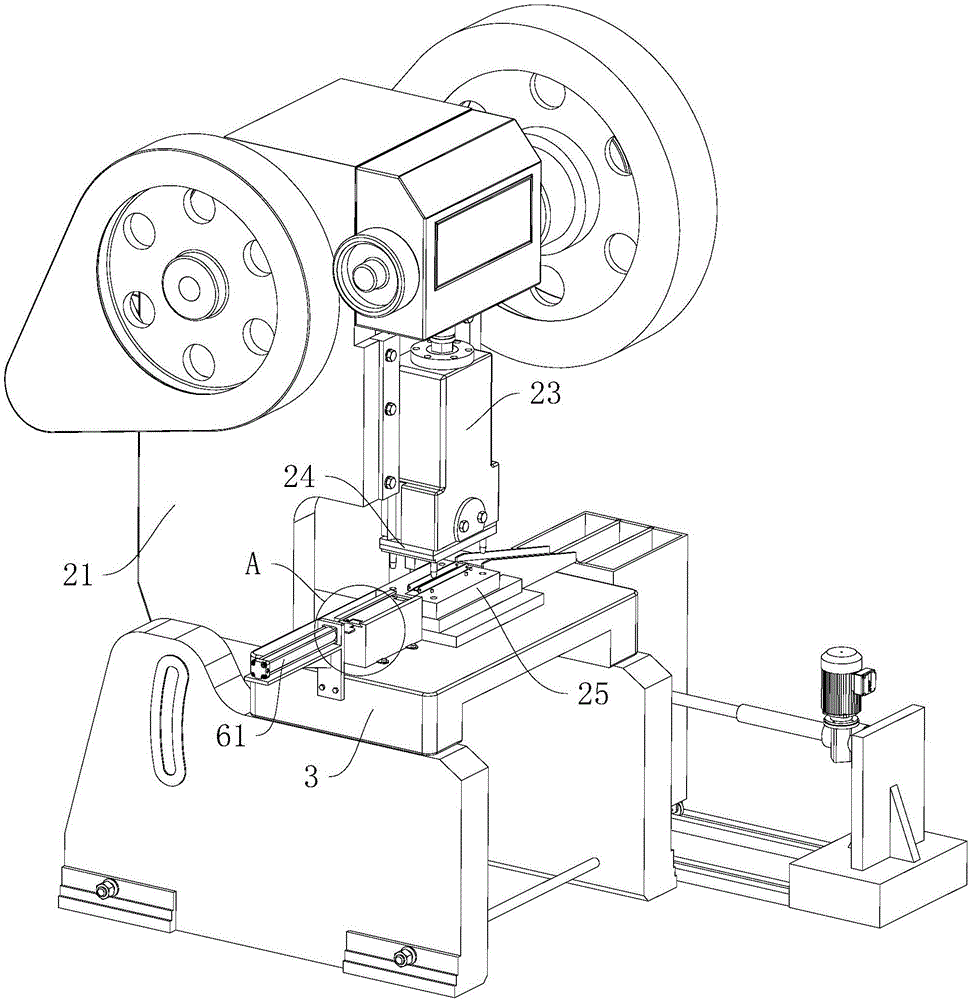

Automatic feeding and discharging punch

ActiveCN107520306AImprove work efficiencyReduce operational riskMetal-working feeding devicesPositioning devicesPunch pressWork in process

The invention discloses an automatic feeding and discharging punch. The problems that in the prior art, manpower is wasted for feeding and discharging of a punch, and potential safety hazards exist are solved. According to the technical scheme, the automatic feeding and discharging punch is characterized in that the automatic feeding and discharging punch comprises a workbench and a punching lower die, a feeding box is arranged on the part, on one side of the punching lower die, of the workbench, the upper end face of the feeding box is flush with the upper end face of the punching lower die, and the feeding box is provided with an elevating mechanism elevating a semi-finished fixing piece; the workbench is further provided with a pushing mechanism pushing the semi-finished fixing piece; the punching lower die is further provided with a first positioning column abutting against the end portion of a side plate of the semi-finished fixing piece in the punching process, and a collecting box for containing a television support fixing piece is arranged on the workbench part on the side, away from the pushing device, of the punching lower die; and according to the punch, semi-finished punched part feeding and television support fixing piece discharging can be achieved without manpower, the manpower is saved, and meanwhile operation risks of operators are reduced.

Owner:宁波臣力五金科技有限公司

A suspension window capable of prevent crosswind from opening and close

InactiveCN108894633AAuto shut offReduce heatWind motor combinationsMachines/enginesBoiling pointMetal sheet

A suspension window capable of prevent crosswind from opening and close, includes a window frame fixedly attached to the wall, A sliding groove is arranged on the opposite side of the window frame, Aslide block is slidably connected in the sliding groove, A window frame is installed on the inner side of the window frame through a wind support, the sliding part of the wind support is slidably connected with the sliding groove through a sliding block, The slider is fixedly connected with the inner bottom of the sliding groove through a tension spring, a ventilation chamber is arranged through the left and right side walls of the lower end of the window frame along the horizontal direction, axial flow blades are installed at both ends of the ventilation chamber, and two axial flow blades areconnected and rotated synchronously through a connecting shaft. As that axial flow wind blade, the friction roller, the friction plate, the memory metal sheet, the slide plug and the low boiling point evaporating liquid are arranged so as to make the window automatically close when the wind blow out of the window, people do not need to close the windows one by one, the safety performance of the window is improved, and the window is automatically opened without manual adjustment when the external wind force becomes small, and the window is convenient to use.

Owner:程坤

Apparatus for acquiring images of rock core and rock debris, method for acquiring and processing images

ActiveCN102221550AClear captureAccurate collectionImage enhancementMaterial analysis by optical meansRock coreControl signal

The invention discloses an apparatus for acquiring images of rock core and rock debris, which comprises a lamp bracket, a master control circuit system and a sample shift mechanism. A light conversion device, a filter lens and a filter lens shift mechanism are provided within the lamp bracket, the filter lens and the filter lens shift mechanism are connected; the sample shift mechanism comprises stepping motors and reduction boxes along two directions of X shaft and Y shaft in a horizontal plane, the control signal input terminal of the stepping motors, light conversion equipment and the filter lens shift mechanism are respectively connected with the corresponding signal output terminal of the master control circuit system. The present invention also discloses a method for acquiring images of rock core and rock debris, the clearest image can be found by automatically searching a clear focal length direction for realizing an automatic focusing. The invention also discloses a method forprocessing the images of rock core and rock debris, an automatic splicing of the images can be completed by successively finding the optimum splicing line in an overlap area. Small rock core (plungertype rock core and the like) and rock debris images can be collected according to the invention, which has the advantages of light mass and small size, high intelligent degree.

Owner:CHENGDU WESTIMAGE TECH

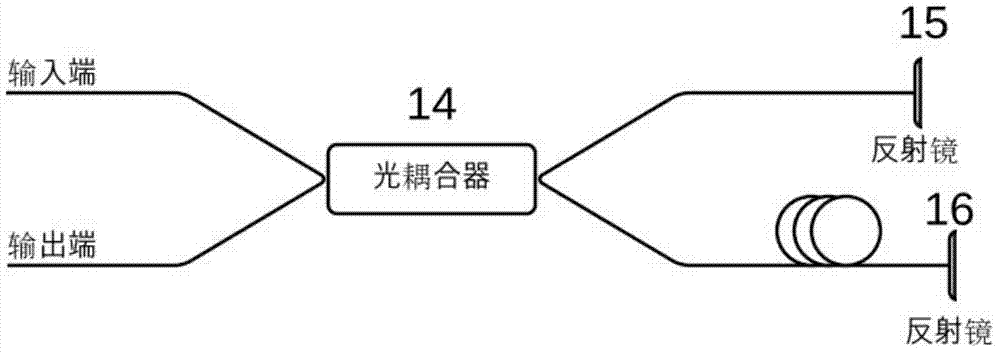

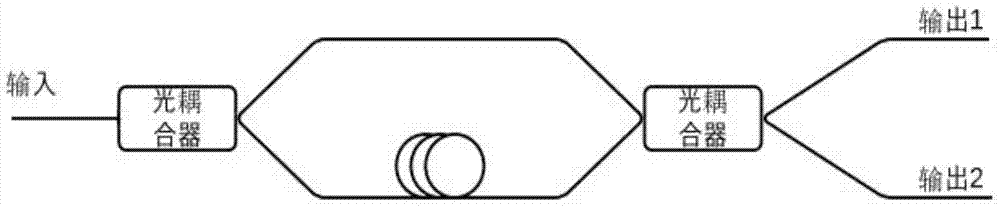

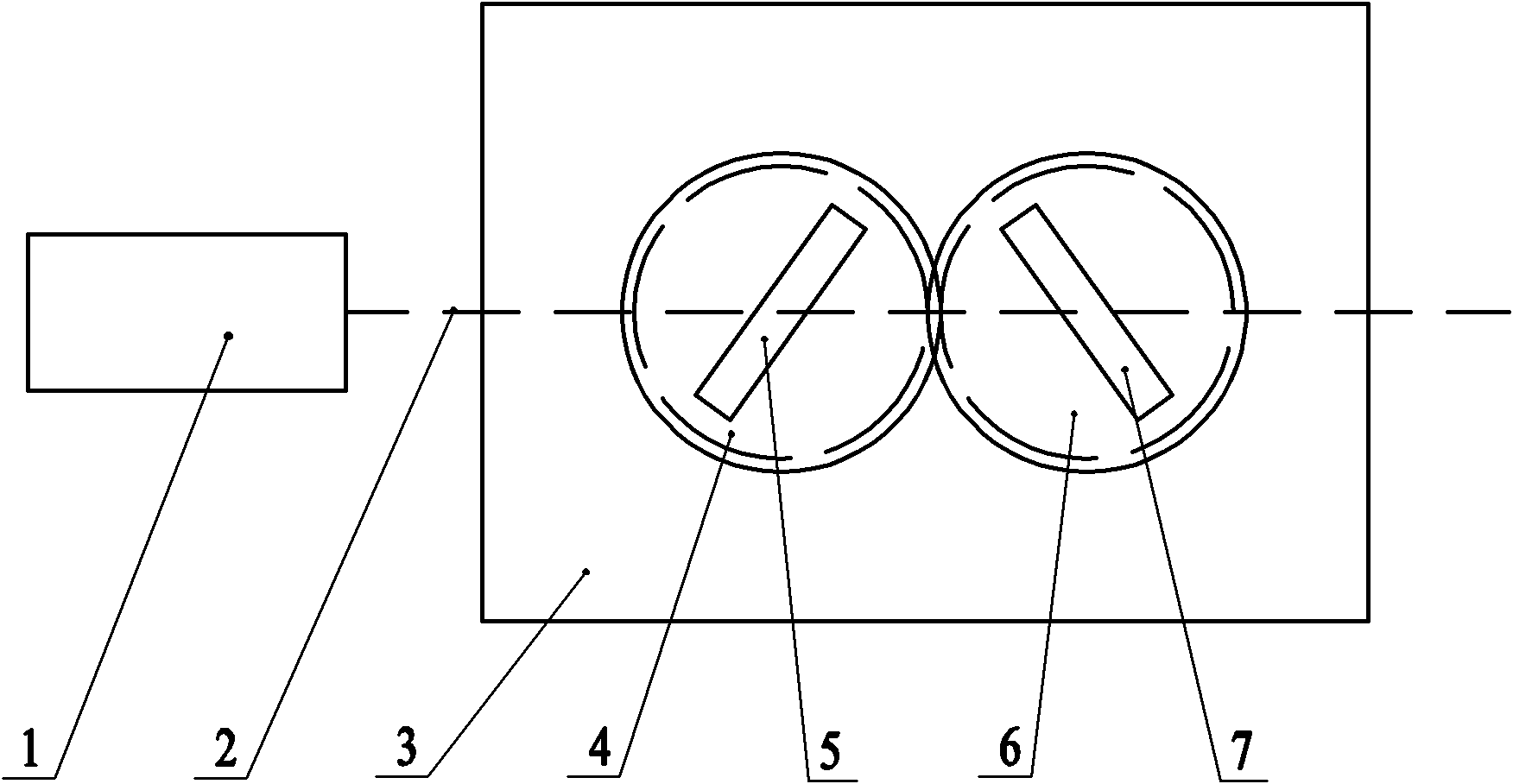

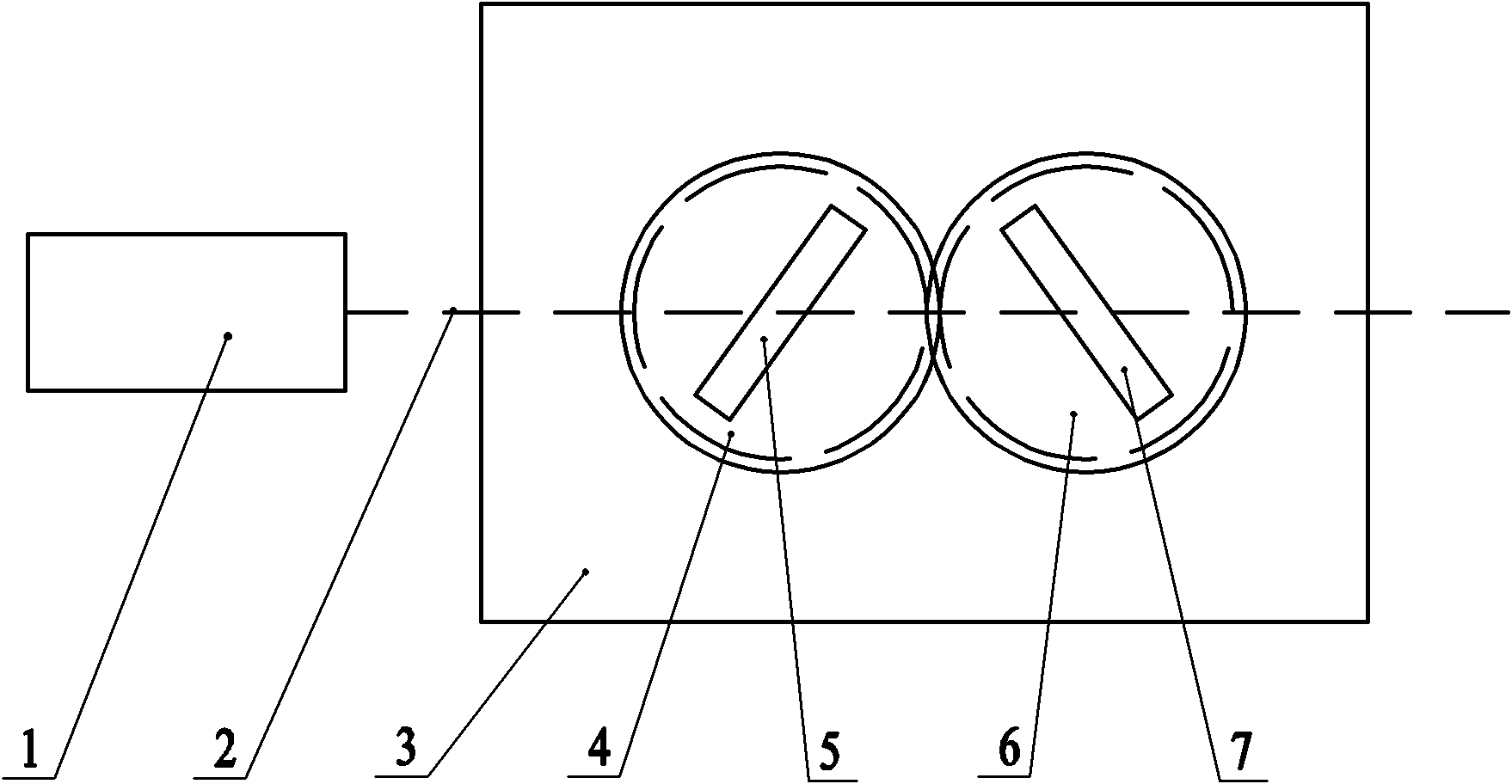

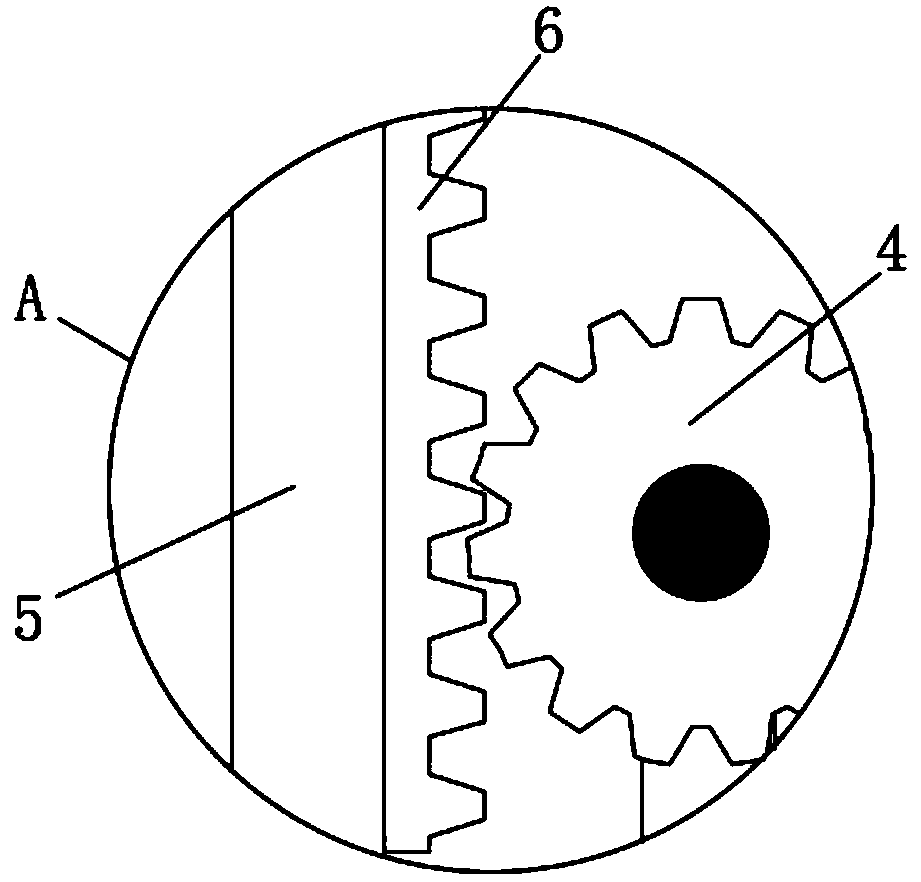

Continuous and adjustable type optical attenuator

InactiveCN102096186AEasy to makeReduce manufacturing costOptical elementsUltrasound attenuationLight energy

The invention relates to a continuous and adjustable type optical attenuator, comprising a light source capable of emitting light beams. The continuous and adjustable type optical attenuator is characterized in that a first plate optical element and a second plate optical element are arranged in the forward directions of the light beams; the first plate optical element and the second plate optical element are respectively placed on a first rotary platform and a second rotary platform which are arranged on an operating platform and are associated mutually in a gear-meshing manner; and the rotating angles of the first rotary platform and the second rotary platform are equal, and the rotating directions are reverse. In the continuous and adjustable type optical attenuator, the structure is simple, smart and reasonable, continuous and adjustable light energy attenuation can be realized, the applicable waveband range is wide, the adjustment of light paths is not carried out when an attenuation value of the light energy is changed, manual adjustment is not needed due to adopting computer control, the adjusting accuracy is high and the manufacturing cost is low.

Owner:无锡荣兴科技有限公司

Integrated processing equipment of dry lime powder for breeding silkworms

ActiveCN106830717AImprove crushing efficiencyReduce labor intensityGrain treatmentsAnimal husbandryEngineeringIntegrated processing

The invention relates to integrated processing equipment of dry lime powder for breeding silkworms. The integrated processing equipment comprises a bottom plate, wherein an annular opening structure is arranged at the lower end of the bottom plate; two sliding rails are symmetrically mounted at the lower end of the bottom plate; a crushing mechanism with adjustable height is mounted on the bottom plate; a screening mechanism is mounted at the lower end of the crushing mechanism; a quantifying mechanism is mounted in the middle of the upper end face of the bottom plate; the quantifying mechanism is located just below the screening mechanism; a conveying and grinding mechanism is mounted at the front end of the bottom plate; the crushing mechanism, the conveying and grinding mechanism, the screening mechanism and the quantifying mechanism are matched to finish an integrated processing process of the dry lime powder. By adopting the integrated processing equipment provided by the invention, the difficulties in an existing silkworm breeding and mulberry leaf water absorption process that the requirements of silkworms with different ages on dry lime powder grains are different, the dry lime powder grains need to be manually distinguished, manual scattering is not uniform, the labor intensity is great, the working efficiency is low and the like can be solved; an integrated function of crushing the dry lime powder, grinding, screening and quantitatively scattering can be realized.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

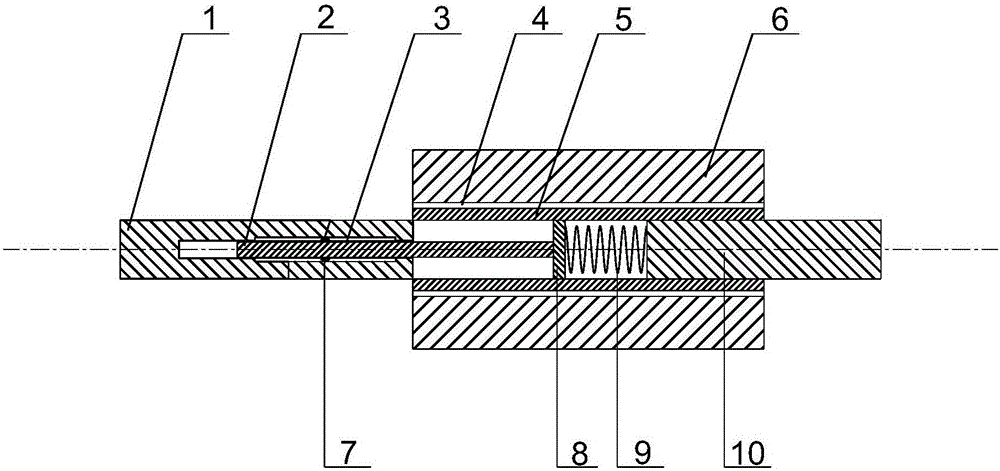

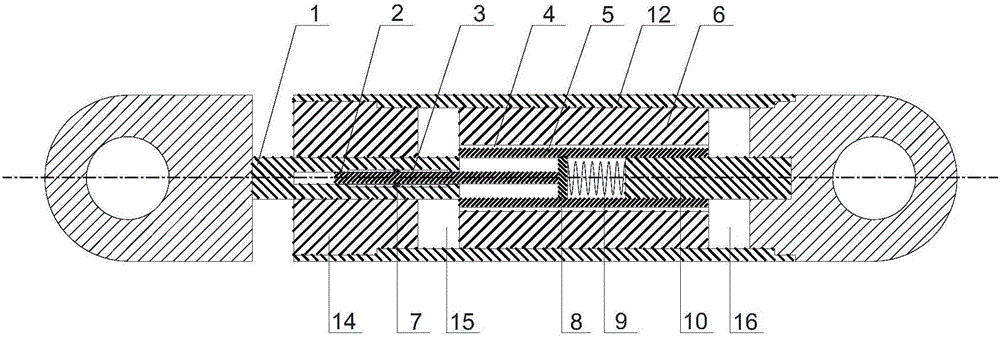

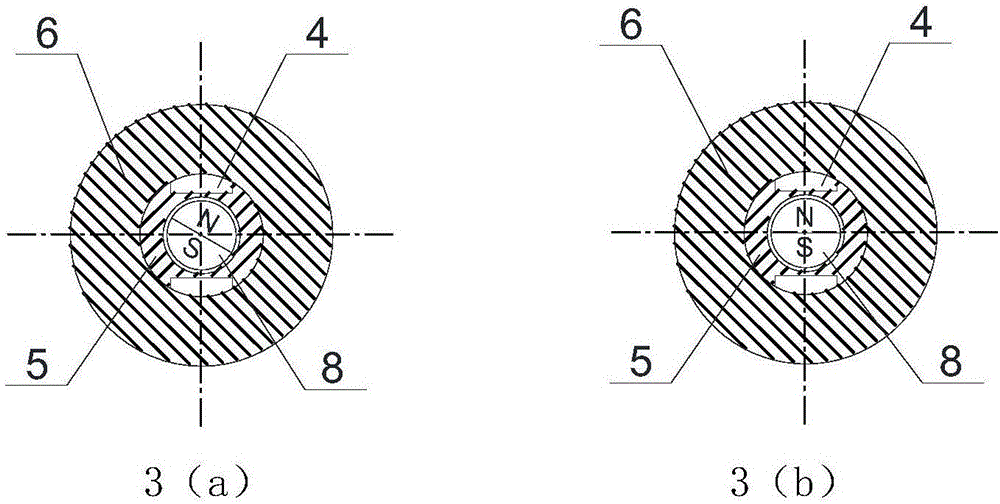

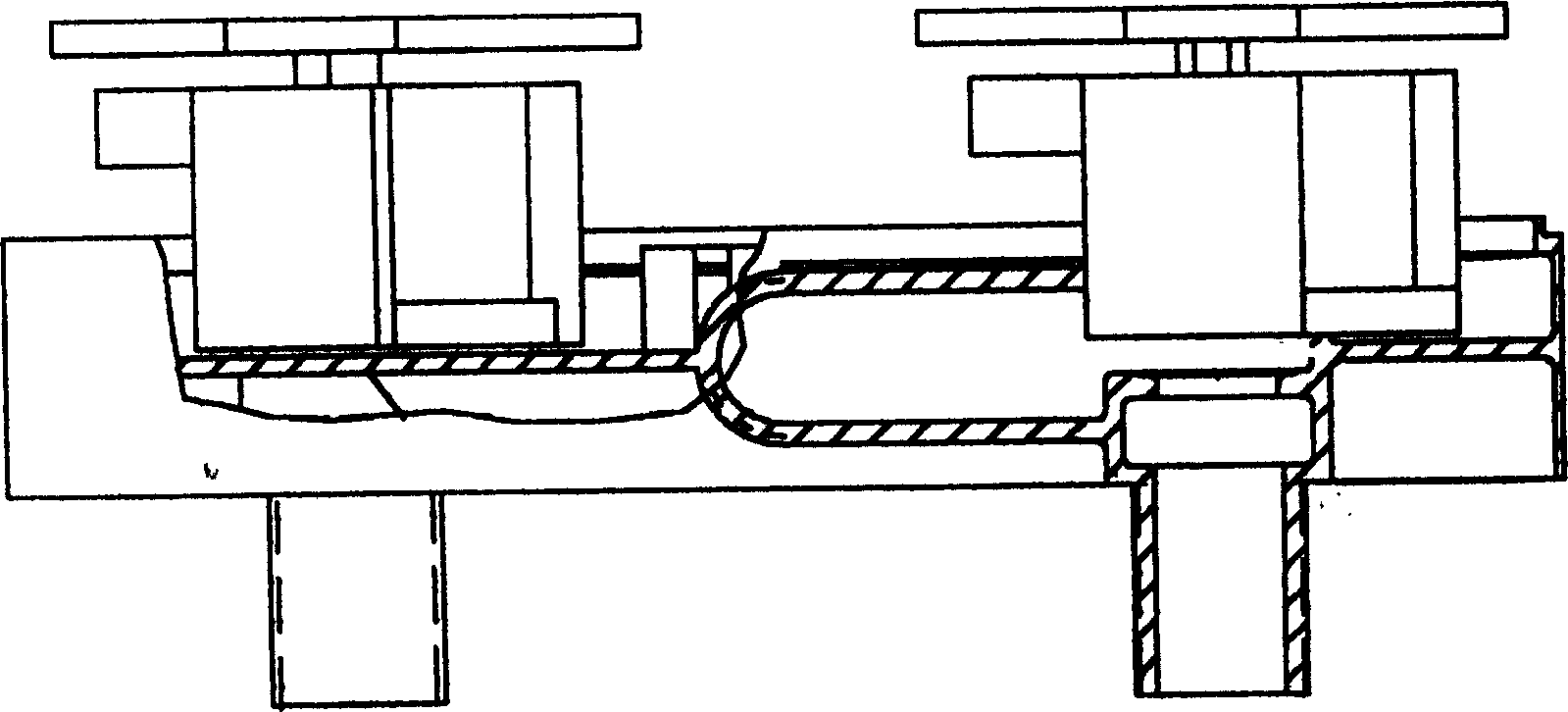

Piston and self-adaptive damping adjustment type permanent-magnet magneto-rheological fluid damper

ActiveCN107435706AWide range of applicationsReduce labor intensitySpringsNon-rotating vibration suppressionSelf adaptiveMagnet

The invention belongs to the field of dampers and discloses a piston and a self-adaptive damping adjustment type permanent-magnet magneto-rheological fluid damper. The piston body comprises an inner piston and an outer piston, the outer piston externally sleeves the inner piston, the inner piston is axially provided with a through hole along the center line direction, and a magnet is arranged in the through hole. A piston rod is connected with the piston body coaxially and is axially provided with a blind hole along the center line direction, an adjusting rod connected with the magnet is arranged in the blind hole, the outer surface of the adjusting rod is provided with a convex ball, and the position, matched with the ball, of the inner wall of the piston rod is provided with a corresponding curved rail composed of three sections, wherein a first section and a third section are arc and symmetrical relative to a middle section which is straight. The piston and the self-adaptive damping adjustment type permanent-magnet magneto-rheological fluid damper have advantages that self-adaptive adjustment of damping force according to load sizes and slide strokes can be realized; due to a pure mechanical structure, wide application range, structural simplicity and high reliability are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

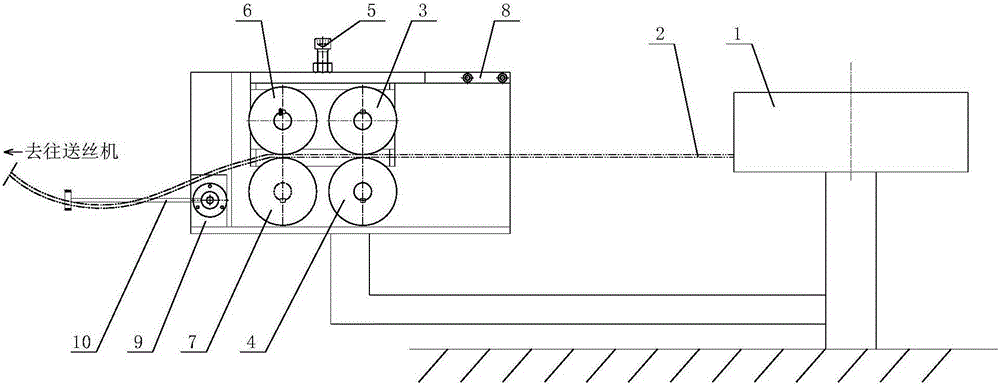

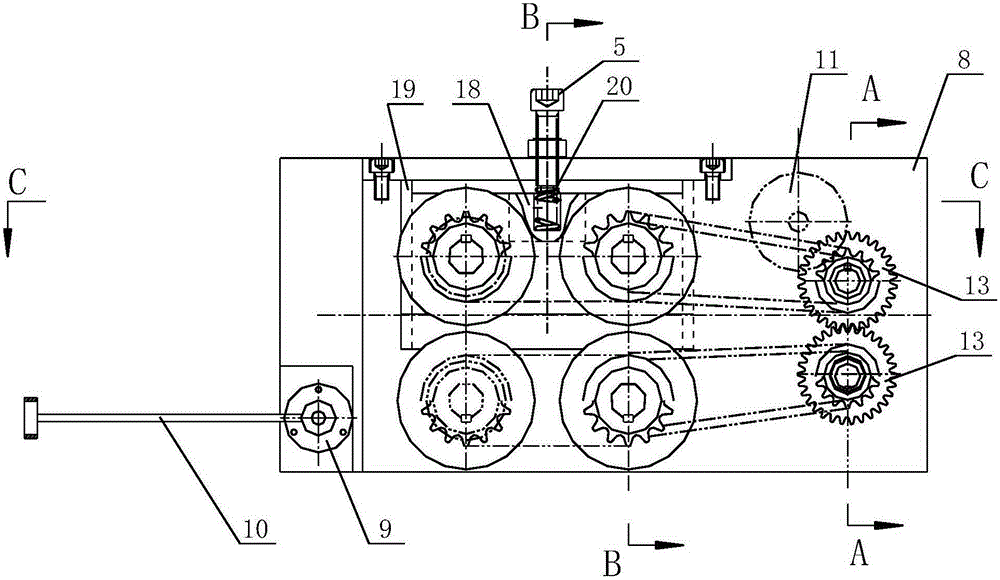

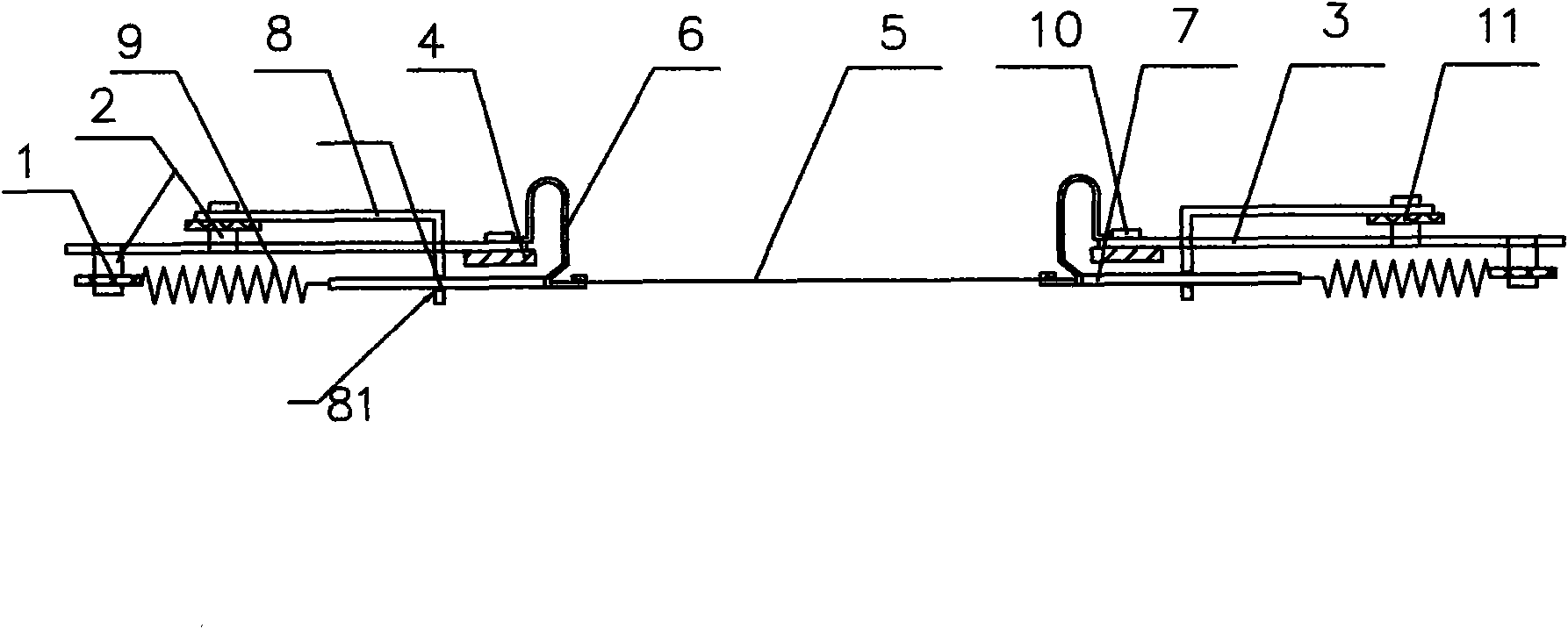

Auxiliary wire feeding process and device for submerged-arc welding

ActiveCN105234530AHigh precisionImprove stabilityArc welding apparatusEngineeringMechanical engineering

The invention relates to an auxiliary wire feeding process and device for submerged-arc welding. Welding wires drawn out of a wire reel enters the auxiliary wire feeding device and is fed to a wire feeder after the conveying speed is adjusted through a wire pressing wheel set in the auxiliary wire feeding device, and a certain amount of stock of the welding wires is ensured to be reserved between the auxiliary wire feeding device and the wire feeder, namely the welding wires are continuously conveyed in an arc-shaped state between the two devices. The pressing force can be automatically compensated and adjusted through upper wire pressing wheels of the wire pressing wheel set, so that the traction of the welding wires in the conveying process is kept to be constant and it is ensured that the welding wires are not damaged. According to the auxiliary wire feeding process and device for the submerged-arc welding, the auxiliary wire feeding device are flexibly connected between the wire feeder and the wire reel, and the wire feeding speed can be adjusted automatically, so that the precision and stability of the wire feeding are effectively improved. The locating positions of the wire feeder and the wire reel are more flexible, and the coil weight of the welding wires of the wire reel can be increased, so that the replacing times of the welding wires is reduced and the efficiency is improved. The pressure of pressing wheels of the wire feeder is reduced, and the damage to the welding wires can be avoided.

Owner:中冶辽宁德龙钢管有限公司

Water quality detection device and detection method

PendingCN110361516AComprehensive detectionAffect accuracyTesting water hardnessWater storageEnvironmental engineering

The invention discloses a water quality detection device and detection method. The water quality detection device comprises an in-water real-time detection device and a ground water quality analysis box; a plurality of detection probes are arranged on an installation plate; a waste fluid tube is arranged in a waste fluid tube groove; test tubes are arranged in test tube grooves; one end of a slideplate, which is far away from a change-over switch, is provided with a standby water storage barrel; a plurality of reagent needle tubes are embedded in a cross plate in a clamped manner; a toothed bar A is fixedly arranged between slide rods; a rotating rod is fixedly provided with a linkage gear in a manner that the linkage gear passes through the rotating rod; and one side of a center plate, which is close to the linkage gear, is fixedly provided with a toothed bar B. The water quality detection device provided by the invention can be used for carrying out in-water real-time detection andground chemical analysis detection on water bodies in different water layers, has functions such as multi-layer detection, automatic water storage and the like, and can automatically add different types and quantities of chemical reagents and automatically switch the detection of the next water layer after detection. The invention further discloses a detection method of the water quality detectiondevice. The detection method is simple to operate and worthy of popularization.

Owner:合肥市宇驰检测技术有限公司

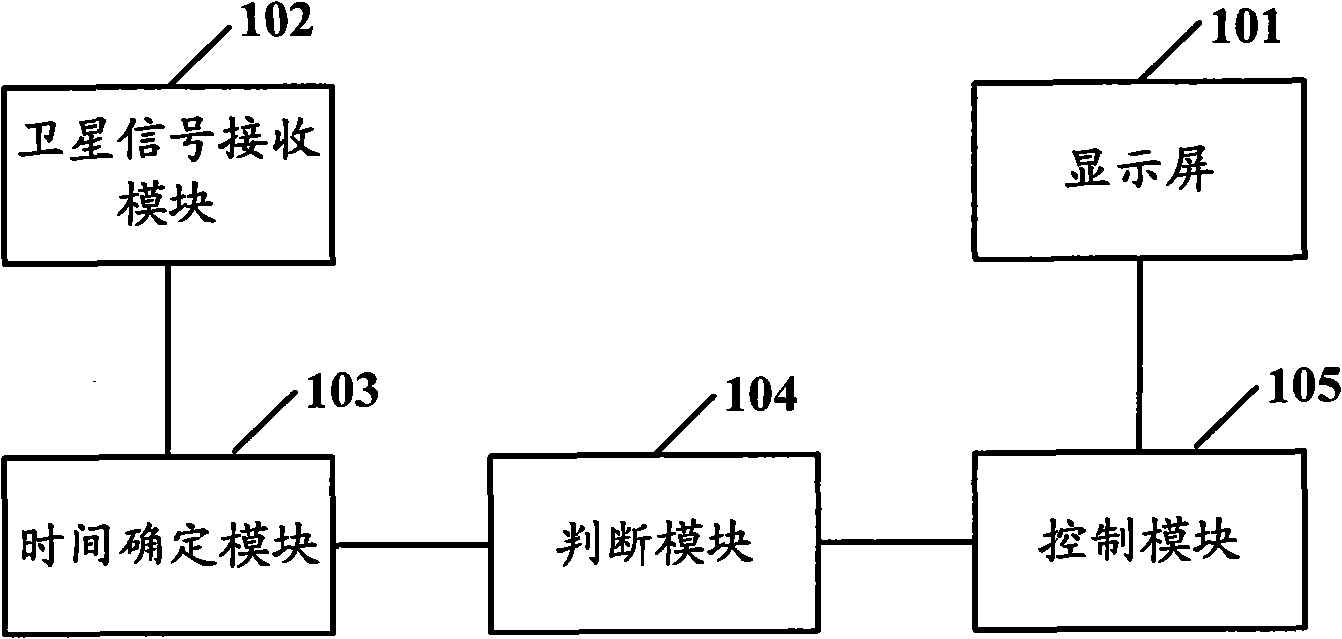

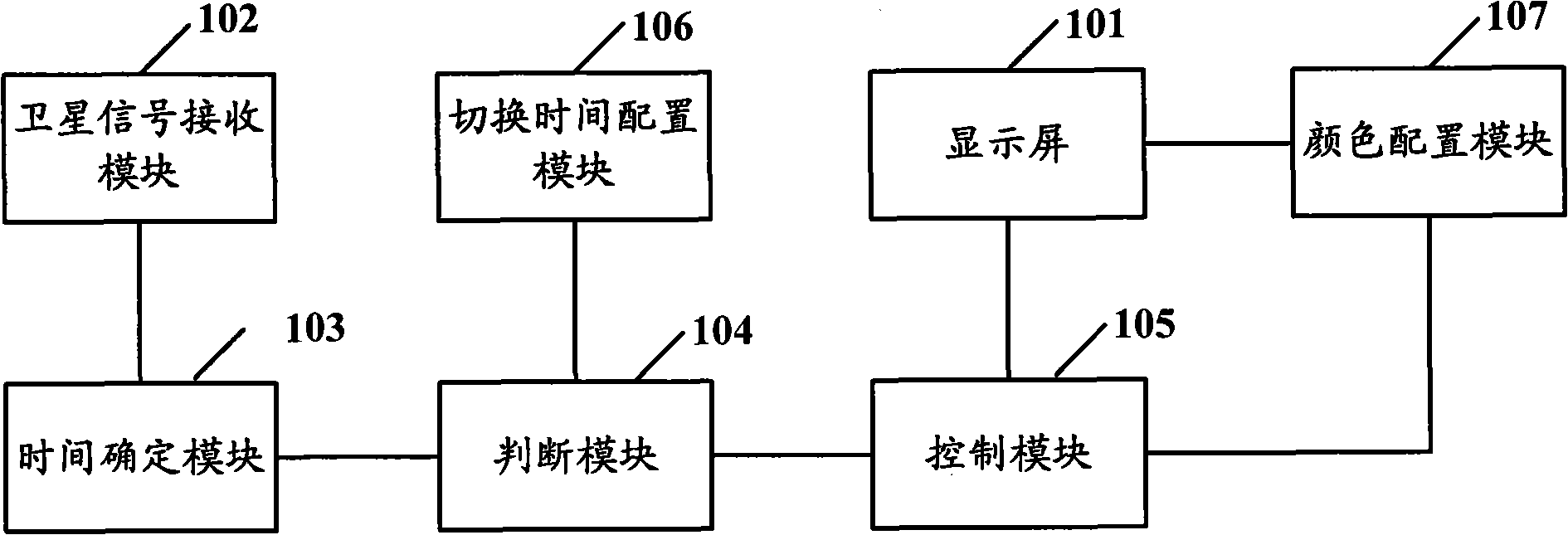

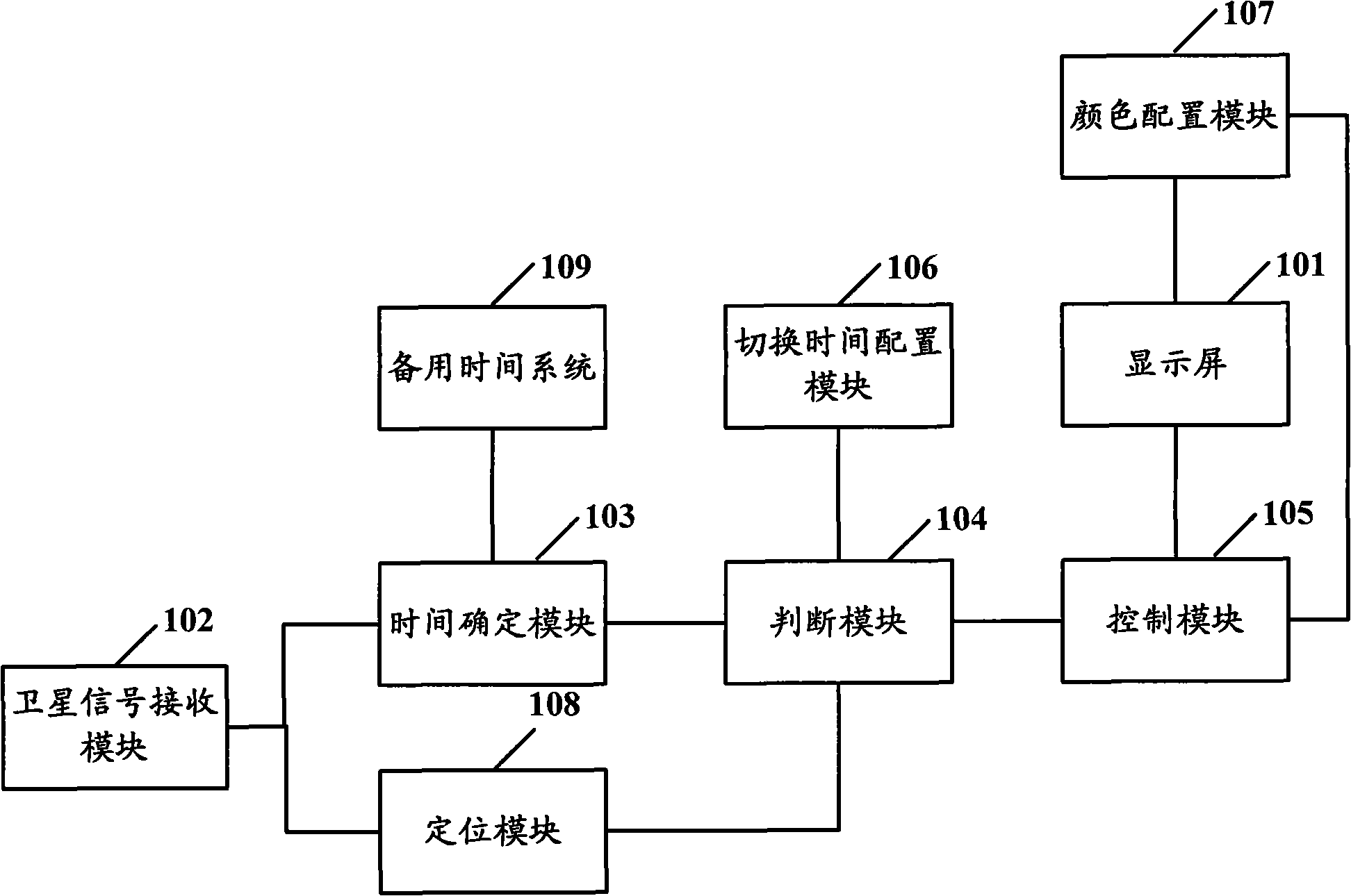

Navigation equipment and navigation mode-switching method

InactiveCN101539620ARealize automatic switchingImprove experienceInstruments for road network navigationBeacon systems using radio wavesSwitching timeMarine navigation

The invention provides a navigation equipment and a navigation mode-switching method. The navigation equipment comprises a satellite signal receiving module, a display screen, a time ensuring module, a judging module and a control module, wherein, the time ensuring module is used for ensuring a current time; the judging module is used for judging whether the current time is a daytime or nighttime navigation mode-switching time; and the control module is used for controlling the navigation content which is displayed by the display screen to be under a daytime navigation mode when the current time is the daytime navigation mode-switching time and controlling the navigation content which is displayed by the display screen to be under a nighttime navigation mode when the current time is the nighttime navigation mode-switching time. The invention can realize automatic switch from the daytime navigation mode to the nighttime navigation mode so as to improve the experience of users.

Owner:NAVINFO

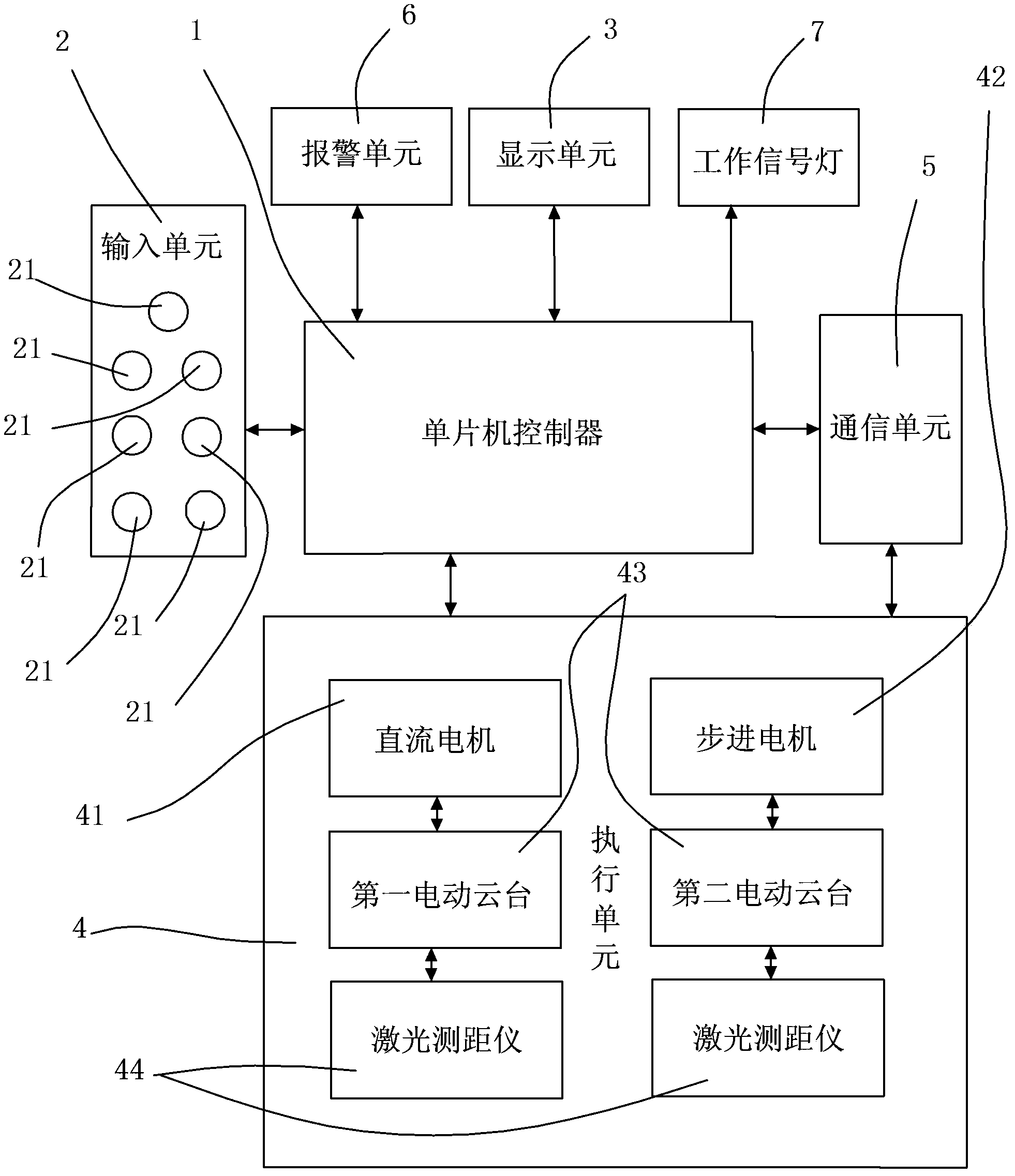

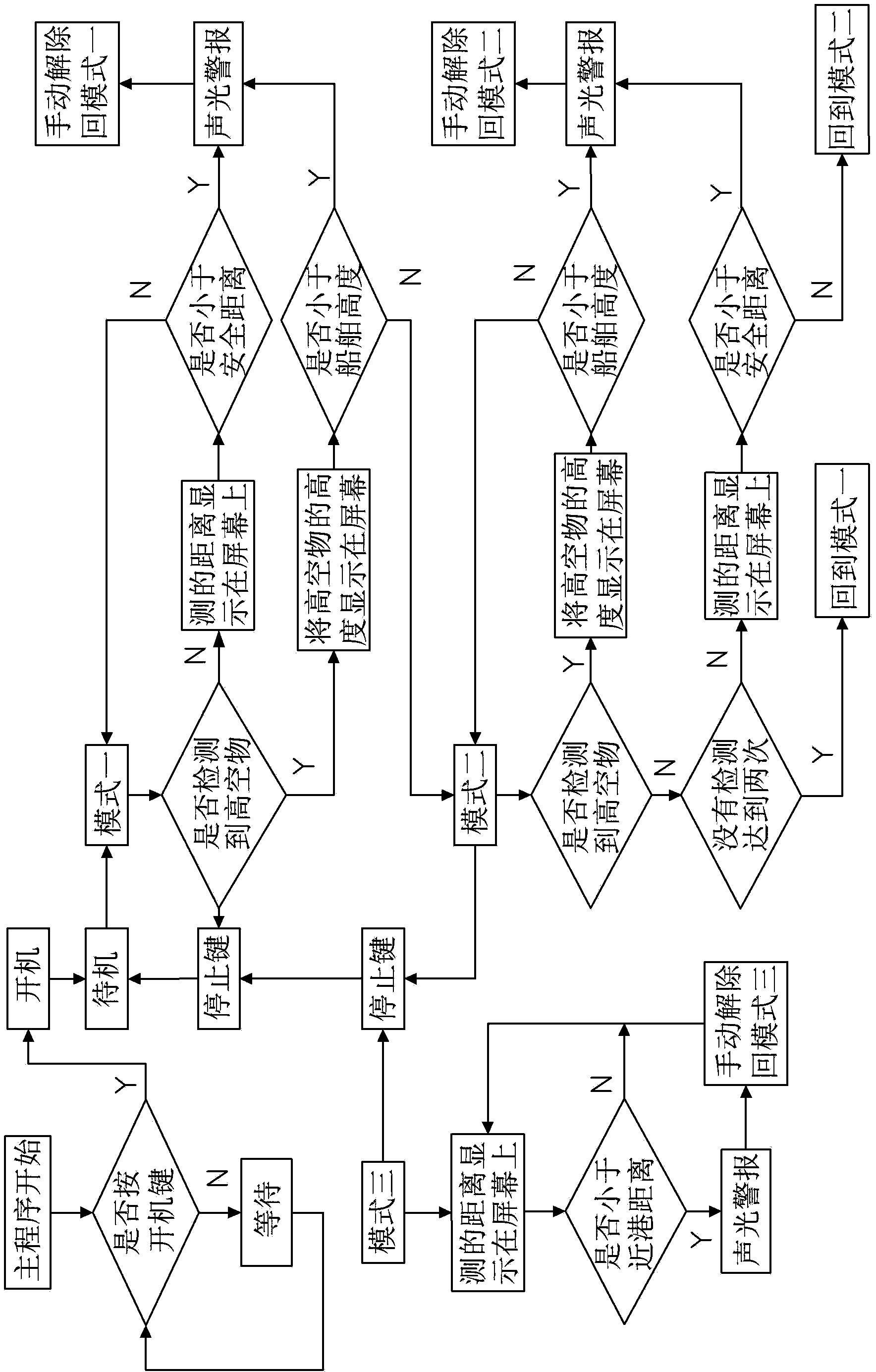

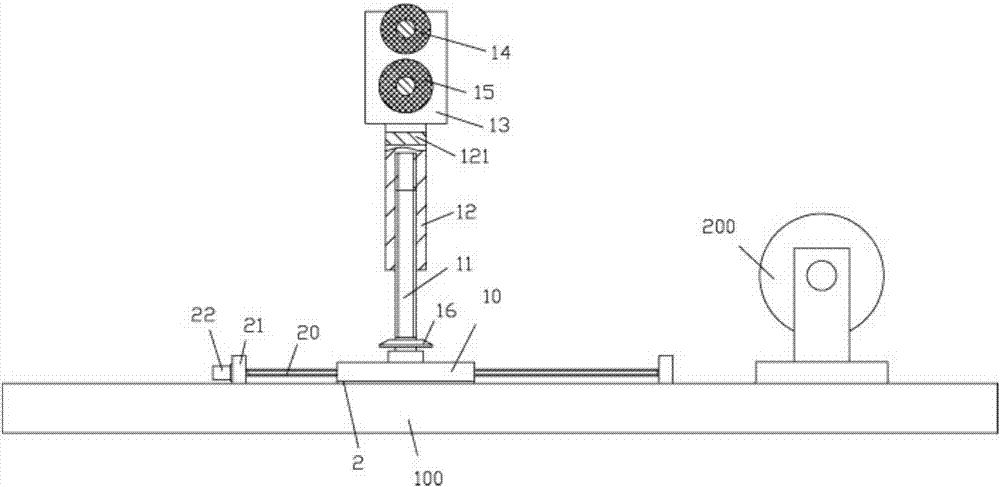

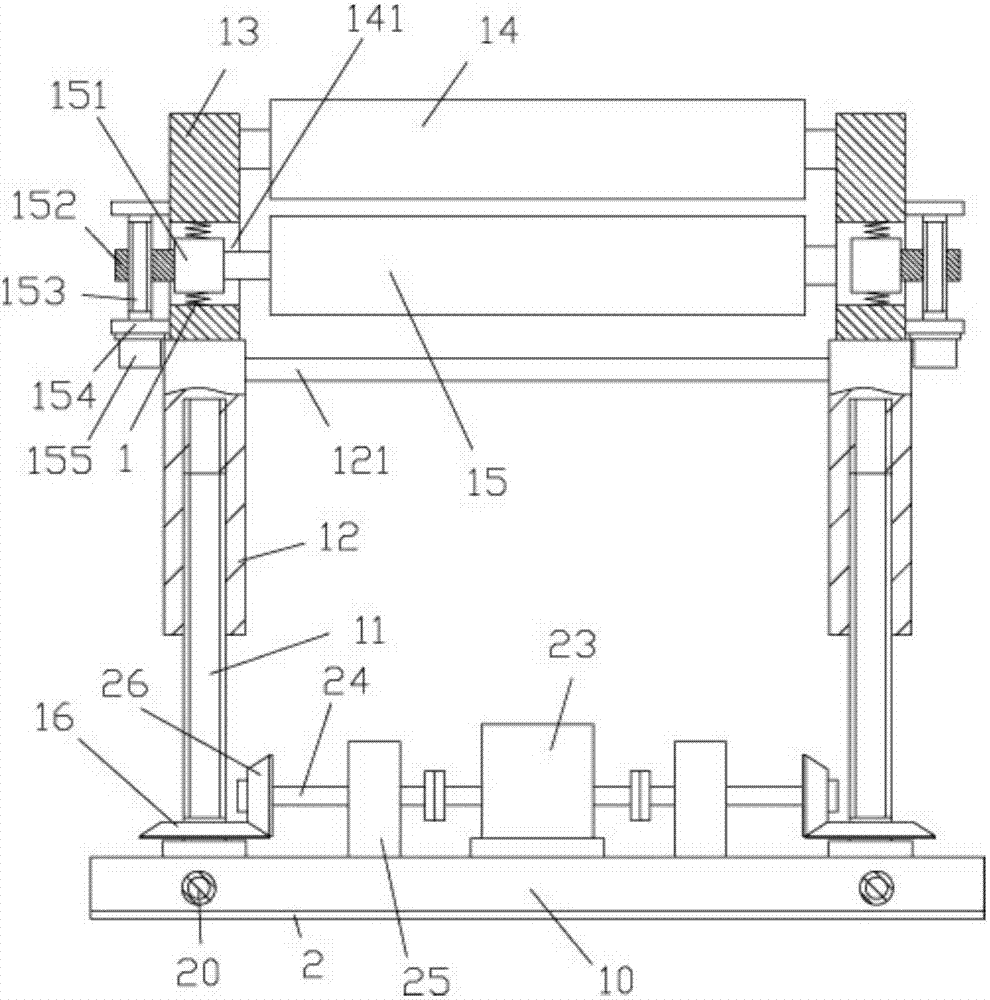

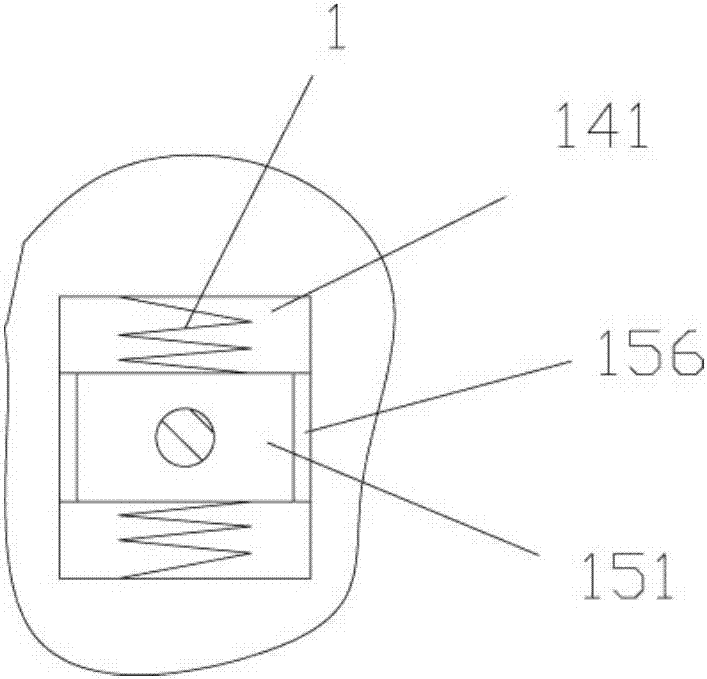

Ship collision avoidance early-warning device and intelligent early-warning method thereof

InactiveCN103440786ACost-effectiveLow priceMarine craft traffic controlMotor driveCommunication unit

The invention relates to a ship collision avoidance early-warning device which comprises a single-chip microcomputer controller, an input unit, a display unit, an execution unit, a communication unit, an alarm unit and a working signal light. The execution unit comprises a direct-current motor, a motor drive matched with the direct-current motor, a stepping motor, a motor drive matched with the stepping motor, two two-degree-of-freedom electrical platforms, and two laser range finders placed on the electrical platforms respectively. The invention further relates to an intelligent early-warning method of the ship collision avoidance early-warning device. According to the method, the distance between an obstacle in the horizontal direction and a ship and the height of a bridge ahead are detected, transmitted and displayed, early-warning against danger signals is carried out, and conversion of work systems in different modes can be achieved. The ship collision avoidance early-warning device can be installed in various types of ships, and is high in detection and early-warning precision and high in cost-performance ratio.

Owner:ZHEJIANG OCEAN UNIV

Cloth transition transferring and winding mechanism

The invention discloses a cloth transition transferring and winding mechanism. The cloth transition transferring and winding mechanism comprises a bottom main plate. A drive support base plate is arranged above the middle of the bottom main plate. A winding mechanism body is fixed to the top face of the right end of the bottom main plate. The front side and the rear side of the drive support base plate are connected into corresponding movable screw rods in a screw joint mode correspondingly. The two ends of the movable screw rods are hinged to corresponding vertical main supporting plates which are fixed to the top face of the bottom main plate. One of the vertical main supporting plates corresponding to the two ends of the movable screw rods is fixedly provided with a movable fine adjustment motor. Vertical studs are hinged to the two sides of the top face of the drive support base plate. The top ends of the vertical studs are connected into center screw holes of lifting thread sleeves in a screw joint mode. The top ends of the lifting thread sleeves are fixed to upper supporting plates. According to the cloth transition transferring and winding mechanism, an upper driving roller and a lower driving roller can be adjusted up and down as well as left and right, and thus the tension degree can be adjusted; and the space between the upper driving roller and the lower driving roller can be automatically adjusted through operation of the adjustment motor, adjustment is made convenient, no manual operation and adjustment are required, and safety is achieved.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

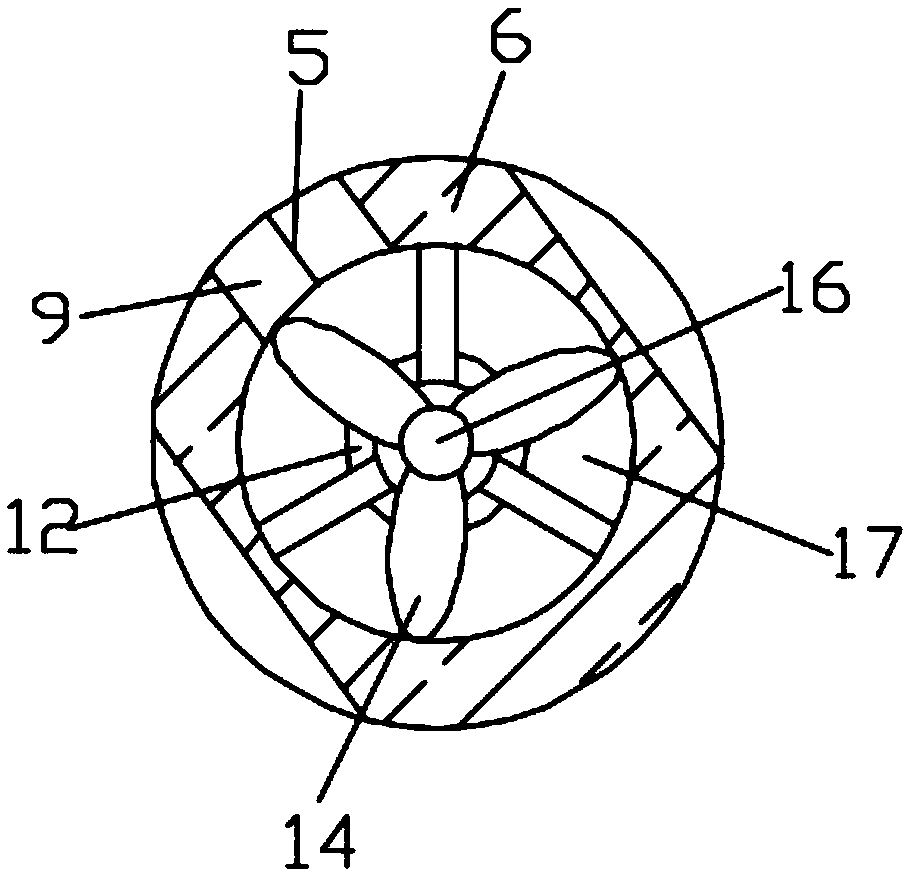

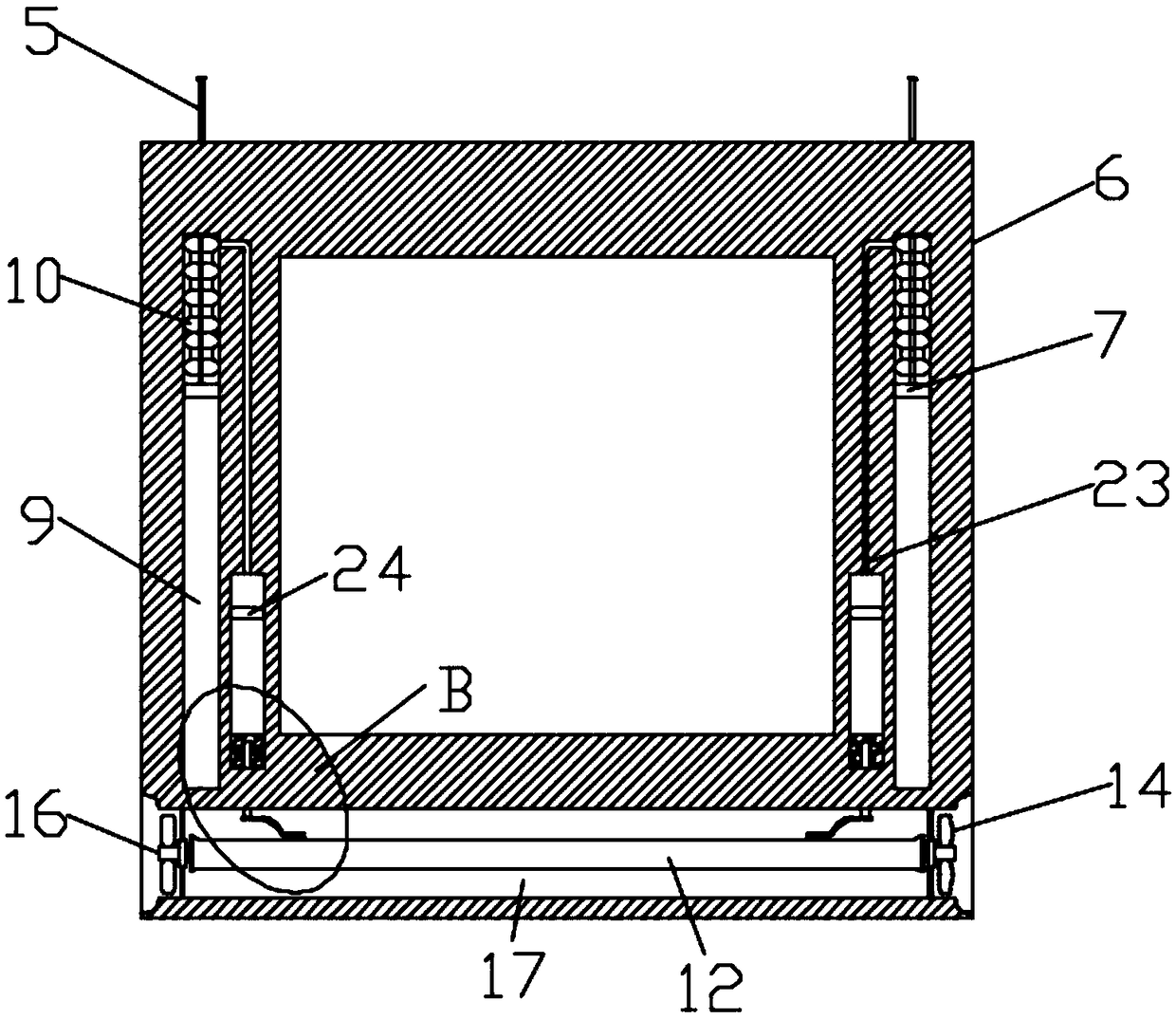

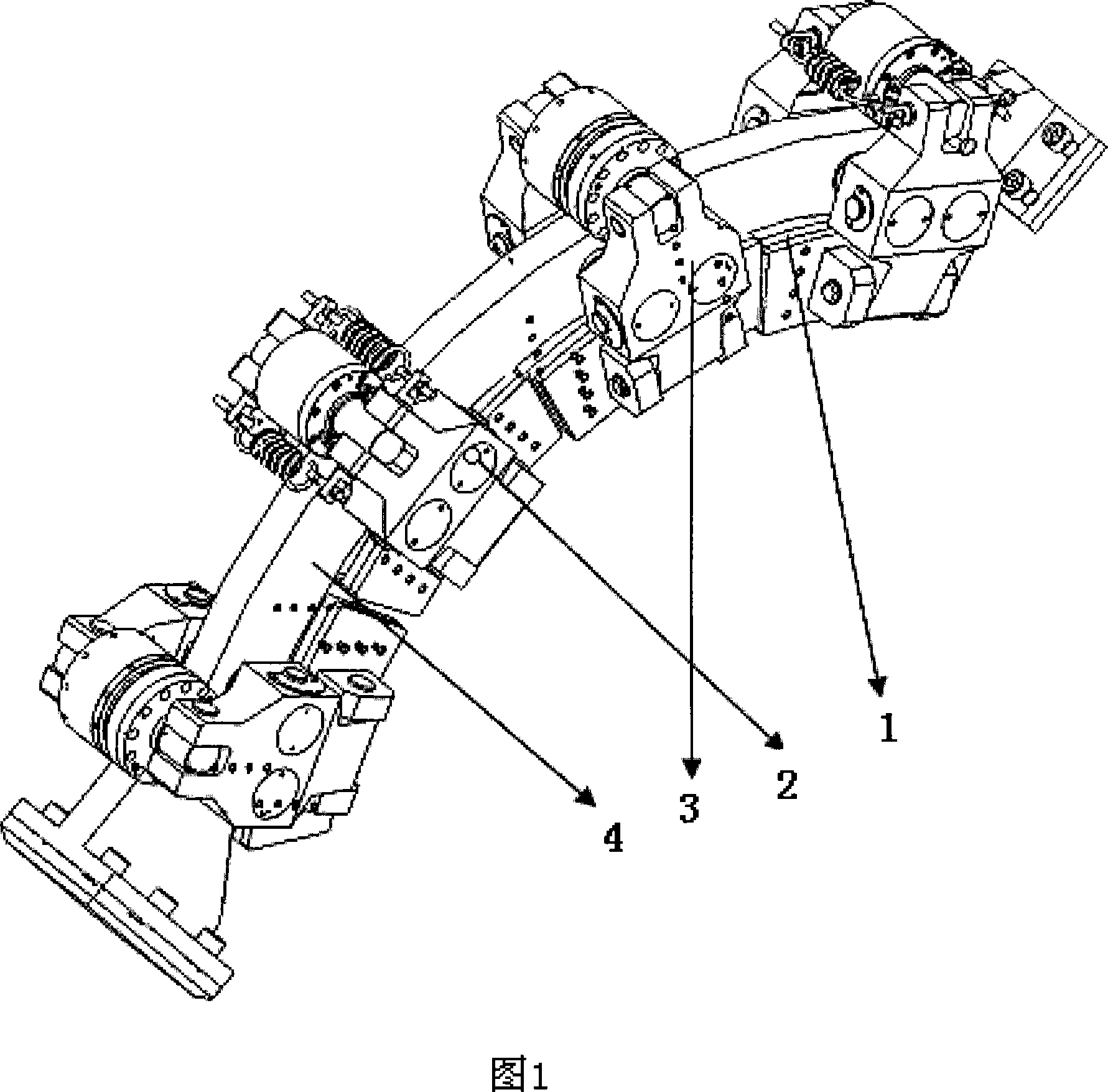

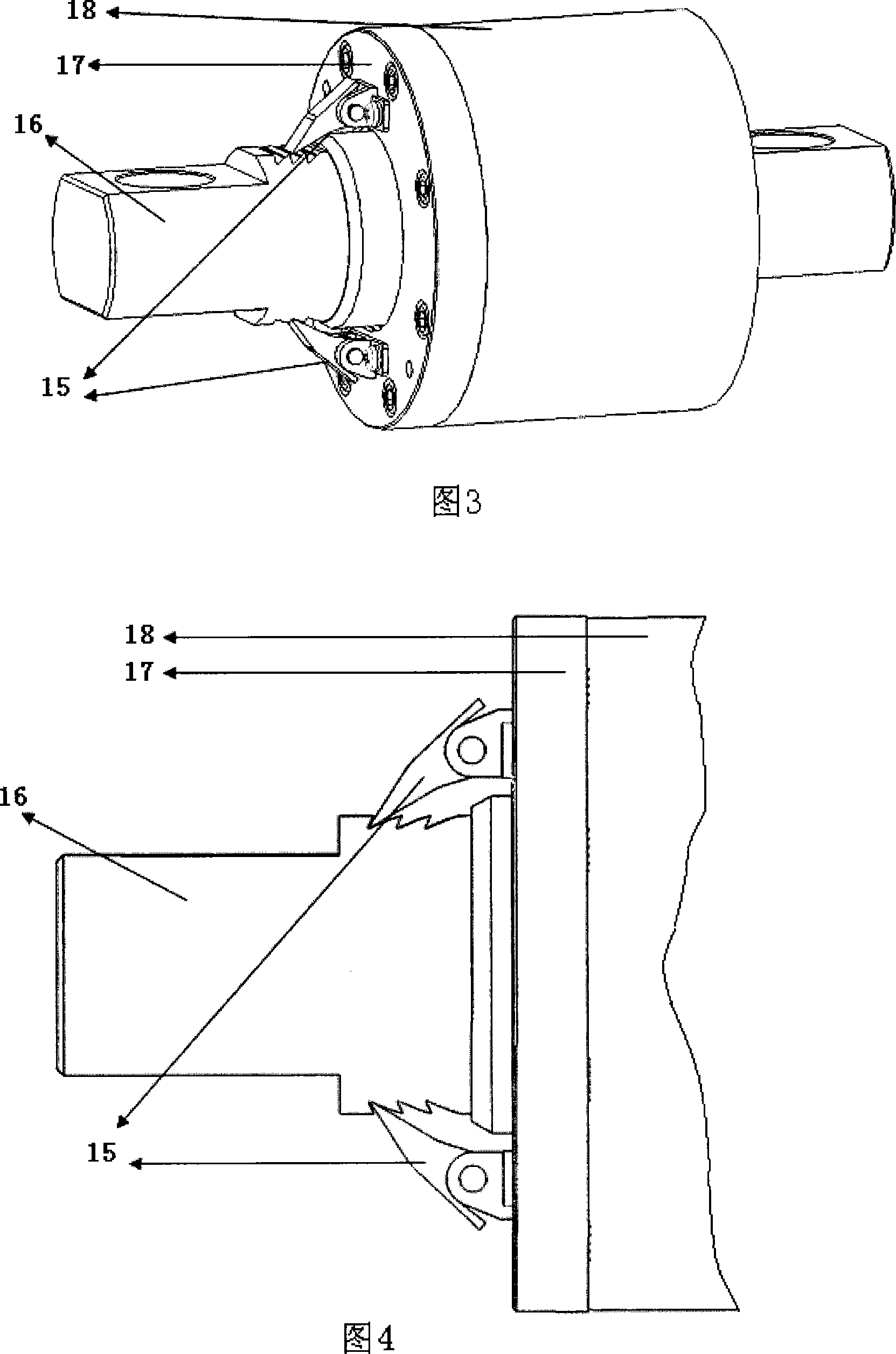

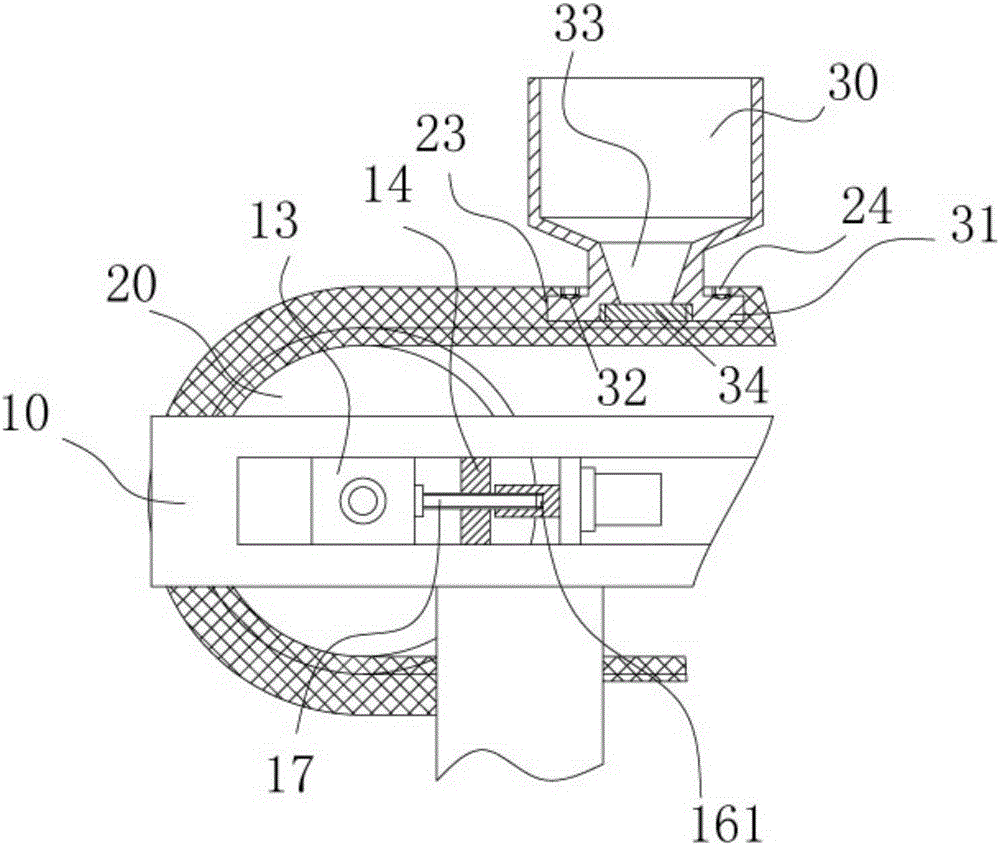

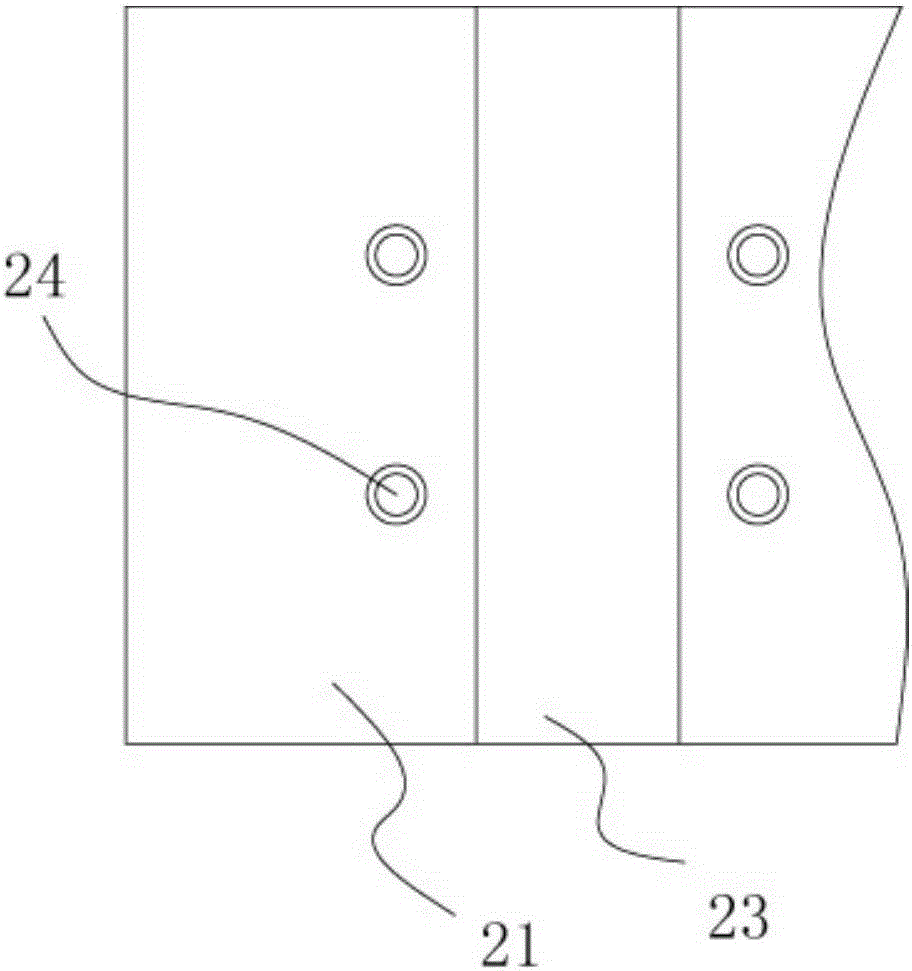

Pipeline robot with pipe diameter self-adaption function

A pipeline robot with the pipe diameter self-adaption function comprises a planetary reducer, the input end of the planetary reducer is connected with a driving impeller, the output end of the planetary reducer is connected with a fixed guiding mechanism through a cardan joint, and a safety clutch is arranged between the planetary reducer and the cardan joint; ball screws with two end thread directions opposite are arranged on a shell of the planetary reducer, the two ends of the ball screws are sleeved with nut pairs, and the nut pairs are connected together through tension springs; each nut pair is connected with a wheel seat through a connecting rod, and driving wheels are arranged on the wheel seats; the output end of the planetary reducer is connected with the input ends of the ball screws through a gear system. The pipeline robot with the pipe diameter self-adaption function is simple in structure, low in machining cost and capable of automatically adjusting the own size according to the size of an obstacle to overcome the obstacle without manual adjustment; after the obstacle is overcome, the own size of the driving wheels can be automatically increased to move forward in a pipeline conveniently.

Owner:CHINA PETROLEUM & CHEM CORP +2

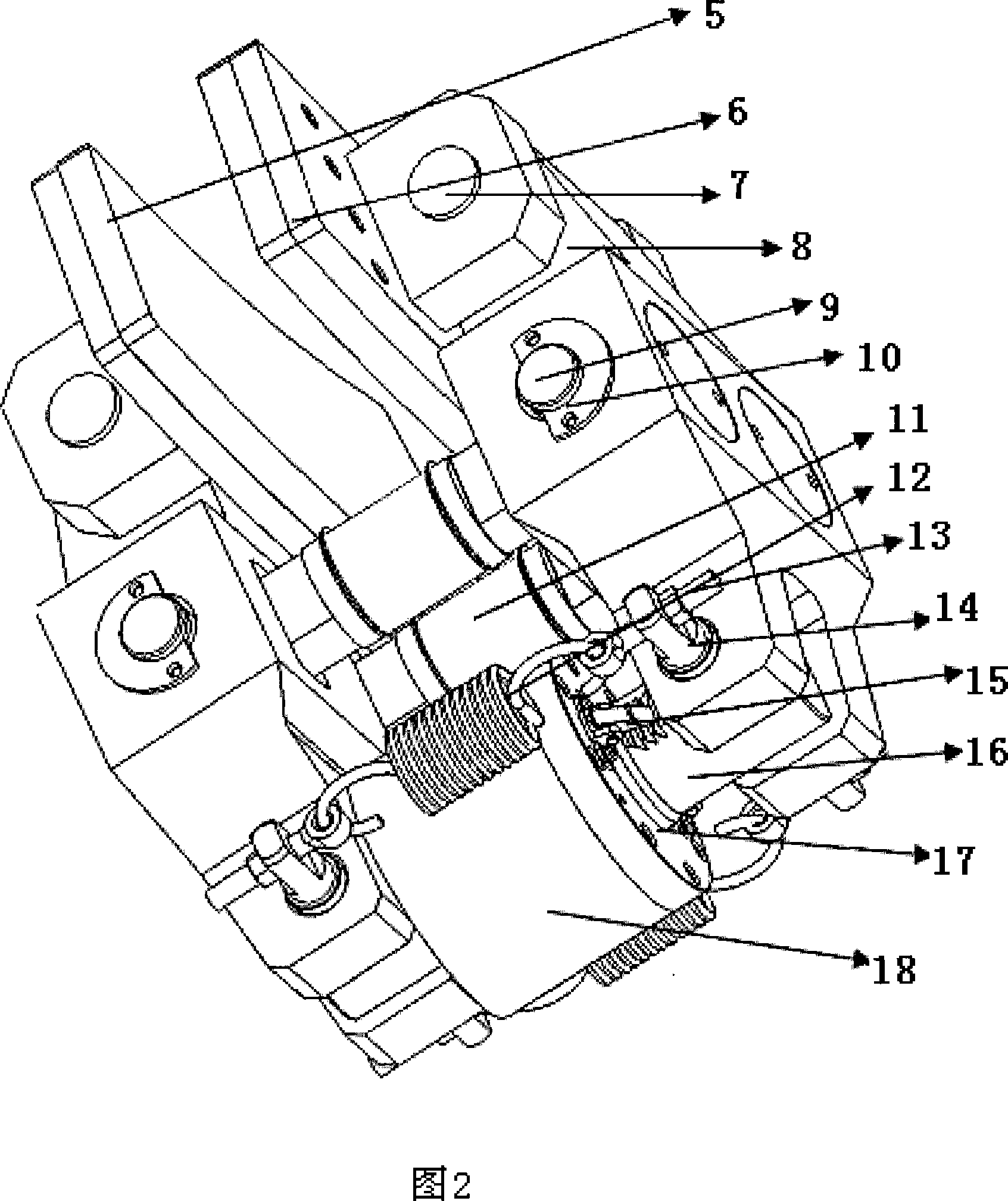

Disc type brake automatic compensation gap braking clamp

ActiveCN101169164ASafe and convenient adjustmentTroubleshoot gap adjustment issuesAxially engaging brakesBrake actuating mechanismsCoil springEngineering

A caliper with automatic gap compensation for a disk brake applies to a brake device of an oil drilling rig. The invention is characterized in that the caliper comprises essentially a working cylinder, a piston rod, working levers, caliper bodies, spiral springs, a support axle and brake blocks, wherein, the brake blocks are respectively fixed at the inner sides of the two caliper bodies; the two caliper bodies connect respectively with ends of the two working levers via pin rolls; the other ends of the two working levers are respectively provided with a fixed clip-cylinder pin roll; the working cylinder is connected between the two clip-cylinder pin rolls; two ends of the two clip-cylinder pin rolls respectively have a spring tensioning screw; the spiral springs are connected between two opposite spring tensioning screws; the working cylinder comprises essentially a cylinder body, the piston rod and a cylinder cover; a pawl mechanism is arranged between the piston rod and the cylinder cover. The invention has the advantages that the caliper can compensate the gap between a brake block and a brake disc; the gas compensation can be safely and quickly carried out after the brake block is worn, thereby guaranteeing the safety and the reliability of the brake system; the gap compensation can be done automatically, conveniently and quickly.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

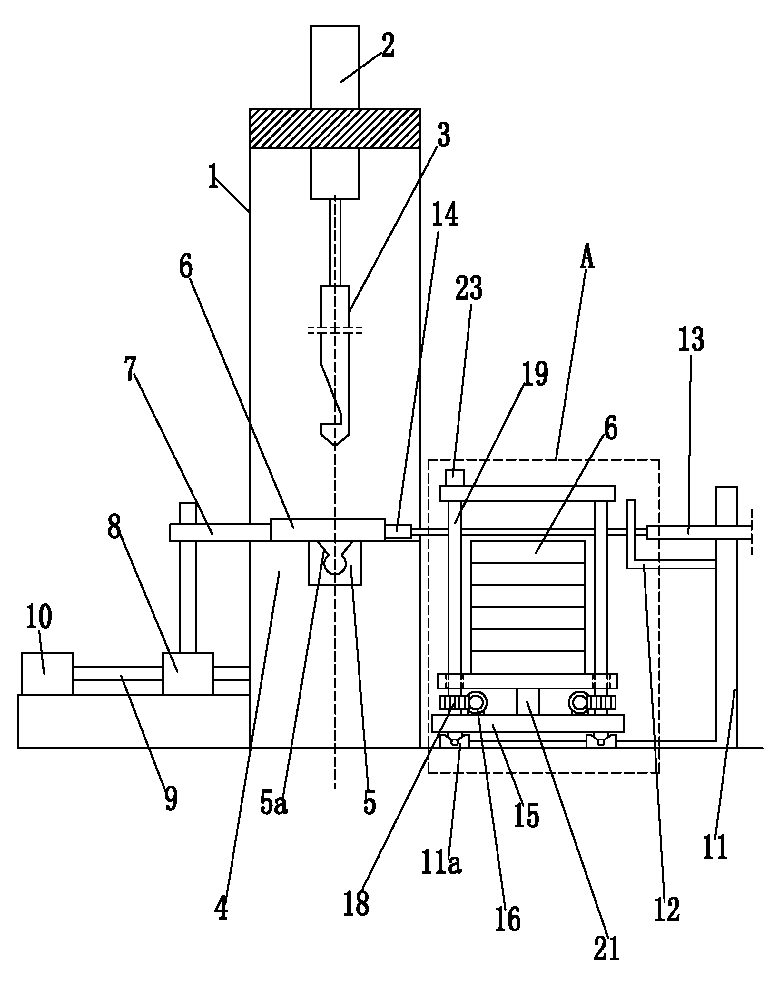

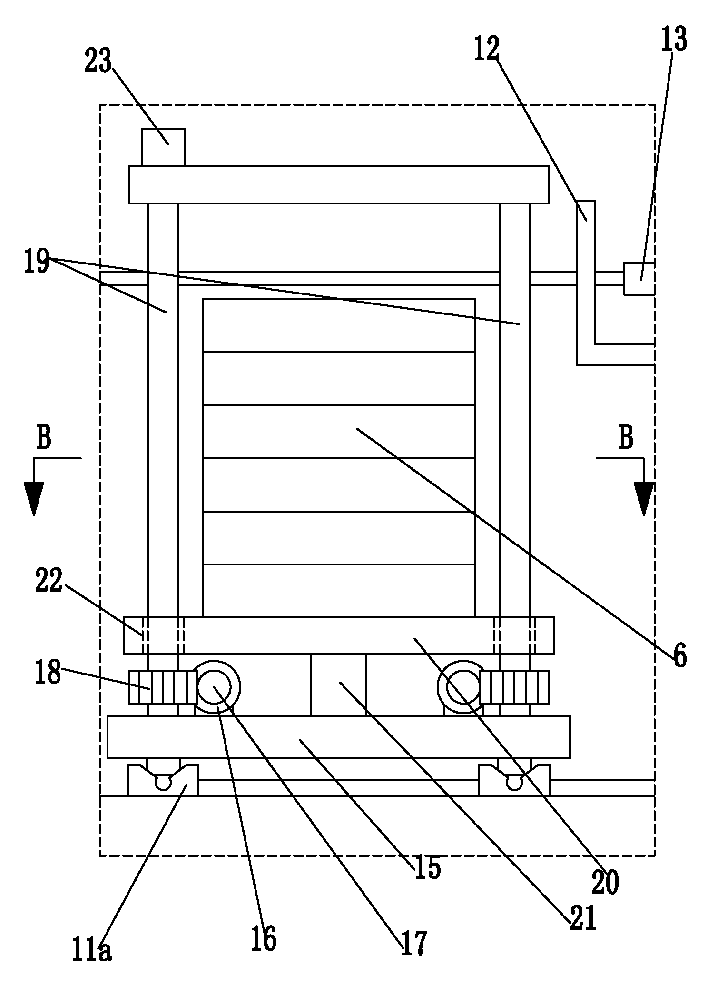

Automatic metal plate bending equipment

InactiveCN107931375AHigh precisionNo manual adjustment requiredMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses an automatic metal plate bending equipment in the technical field of metal plate machining. The automatic metal plate bending equipment comprises a main base, a material storing table, a bending die, a vertical drive mechanism, a female die block and a PLC. The equipment further comprises a material pushing unit for pushing a plate workpiece onto the female die block, and amovable limiting mechanism used for limiting the bending position of the plate workpiece. The vertical drive mechanism is controlled by the PLC. The movable limiting mechanism comprises a limiting follow block used for limiting the plate workpiece and further comprises a limiting nut base, a transverse moving lead screw, and a limiting motor controlled by the PLC. The limiting nut base is installed on the lower side of the material storing table in the manner of being capable of sliding horizontally. The limiting nut base and the transverse moving lead screw are matched, the limiting follow block and the limiting nut base are installed into one, in the bending process, the limiting follow block can abut against one side of the plate workpiece, and the plate workpiece can be conveyed to the bending station accurately.

Owner:镇江倍斯特曼新材料研究有限公司

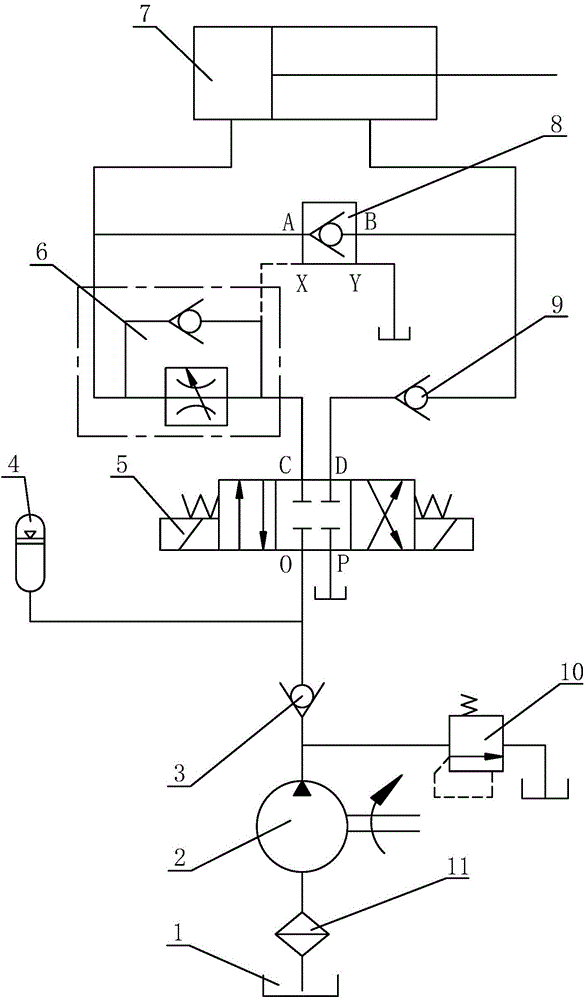

Hydraulic control system for reciprocating test beds

InactiveCN104421226AReasonable designEasy to useServomotor componentsAccumulator installationsHydraulic cylinderControl system

The invention discloses a hydraulic control system for reciprocating test beds. The hydraulic control system comprises a reversing valve, a one-way speed control valve and a hydraulic control one-way valve. A first working port and a second working port of the reversing valve are respectively communicated with a rodless cavity and a rod cavity of a hydraulic cylinder, a third working port and a fourth working port of the reversing valve are respectively communicated with oil outlets of an oil tank and a hydraulic pump, an accumulator is mounted on the oil outlet of the hydraulic pump, the one-way speed control valve is mounted on a pipe arranged between the first working port of the reversing valve and the rodless cavity of the hydraulic cylinder, the rodless cavity and the rod cavity of the hydraulic cylinder are respectively communicated with an oil inlet and an oil outlet of the hydraulic control one-way valve, a hydraulic control oil port of the hydraulic control one-way valve is respectively communicated with the first working port of the reversing valve and the oil tank. The hydraulic control system for reciprocating test beds has the advantages of reasonable design, good using effects, high automation level, low cost, mechanic-electric-hydraulic integrative design, high intelligent level, stable and reliable operation and long service life.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

Clamping device for producing transformer

ActiveCN112091359AAutomatic clampingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to the technical field of transformers, in particular to a clamping device for producing a transformer. The clamping device comprises a machining table, a conveying device, a feeding device, a turnover device and a clamping device body, wherein the machining table is arranged on the ground; the top of the machining table is provided with a rectangular groove in sliding fit with the clamping device body; the conveying device is arranged beside the machining table; the feeding device is arranged on the machining table and the conveying device and is located above the clamping device body; the turnover device is arranged above the clamping device body; and the clamping device body is arranged at the top of the machining table. According to the clamping device for producing the transformer, through the mutual operation among the arranged conveying device, the feeding device, the turnover device and the clamping device body, the transformer can be automatically clamped, and pins of the transformer can be welded while the transformer is clamped, so that the welding quality and the production efficiency are improved; and the clamping device can be automatically adjusted, and can clamp transformers with different specifications, so that the use range is enlarged, and wide application and use are facilitated.

Owner:常德创亿电子元件有限公司

Bending device for thin-walled snake-shaped heat exchange tubes

Provided is a bending device for thin-walled snake-shaped heat exchange tubes. A box body is of an upper-end-open structure defined by a bottom plate, three side plates and a box door hinged to one side plate, and a bending platform is fixed to the upper end opening of the box body; a driving motor is installed in the box body, the driving motor is connected with a bending mechanism through a transmission piece, the lower half part of the bending mechanism is arranged in the box body, the upper half part of the bending mechanism is installed on the bending platform, and a feeding port positioning mechanism arranged on the surface of the bending platform is located on the right side of the bending mechanism; a resetting mechanism connected with the lower end of the bending mechanism is arranged in the box body; and after the driving motor drives the bending mechanism to rotate by a certain angle, bending of a to-be-bent rod piece which penetrates through the feeding port positioning mechanism and is inserted into the bending mechanism is achieved. The bending device overcomes quality defects caused by the deformation of the bending positions of the thin-walled snake-shaped heat exchange tubes, filling is not needed, the bending efficiency is improved, the uniformity of bent finished products is good, the bending process is mechanically completed, the labor intensity of staff isgreatly reduced, and the use value is high.

Owner:宝鸡特钢钛业股份有限公司

Conveying mechanism for cement materials

The invention discloses a conveying mechanism for cement materials. The conveying mechanism comprises a conveying frame body, wherein the conveying frame body comprises two adjustment cross beams; support legs are fixed at the bottoms of the two adjustment cross beams; the bottoms of the support legs are fixed on bottom connection parts respectively; a long slide through groove which extends along a length direction is formed in the middle part of each adjustment cross beam; slide grooves are formed in the upper inner sidewall and the lower inner sidewall of each long slide through groove; two slide blocks are bushed in the two ends of each long slide through groove; bulged blocks are arranged on the upper top surface and the lower bottom surface of each slide block; each bulged block is bushed in the corresponding slide groove; a middle adjustment plate and an adjustment motor connection plate are fixed in each long slide through groove and close to the two ends; a fine adjustment motor is fixed on each adjustment motor connection plate; one end of each adjustment screw is hinged on the corresponding slide block, the other end of each adjustment screw is screwed in a screwing hole formed in the output shaft of the corresponding fine adjustment motor, and the middle part of the adjustment screw is screwed to the corresponding middle adjustment plate. The conveying mechanism is capable of adjusting the tensioning degree of a conveying belt through the fine adjustment motors, the adjustment is accurate, and manual adjustment is not needed.

Owner:中材萍乡水泥有限公司

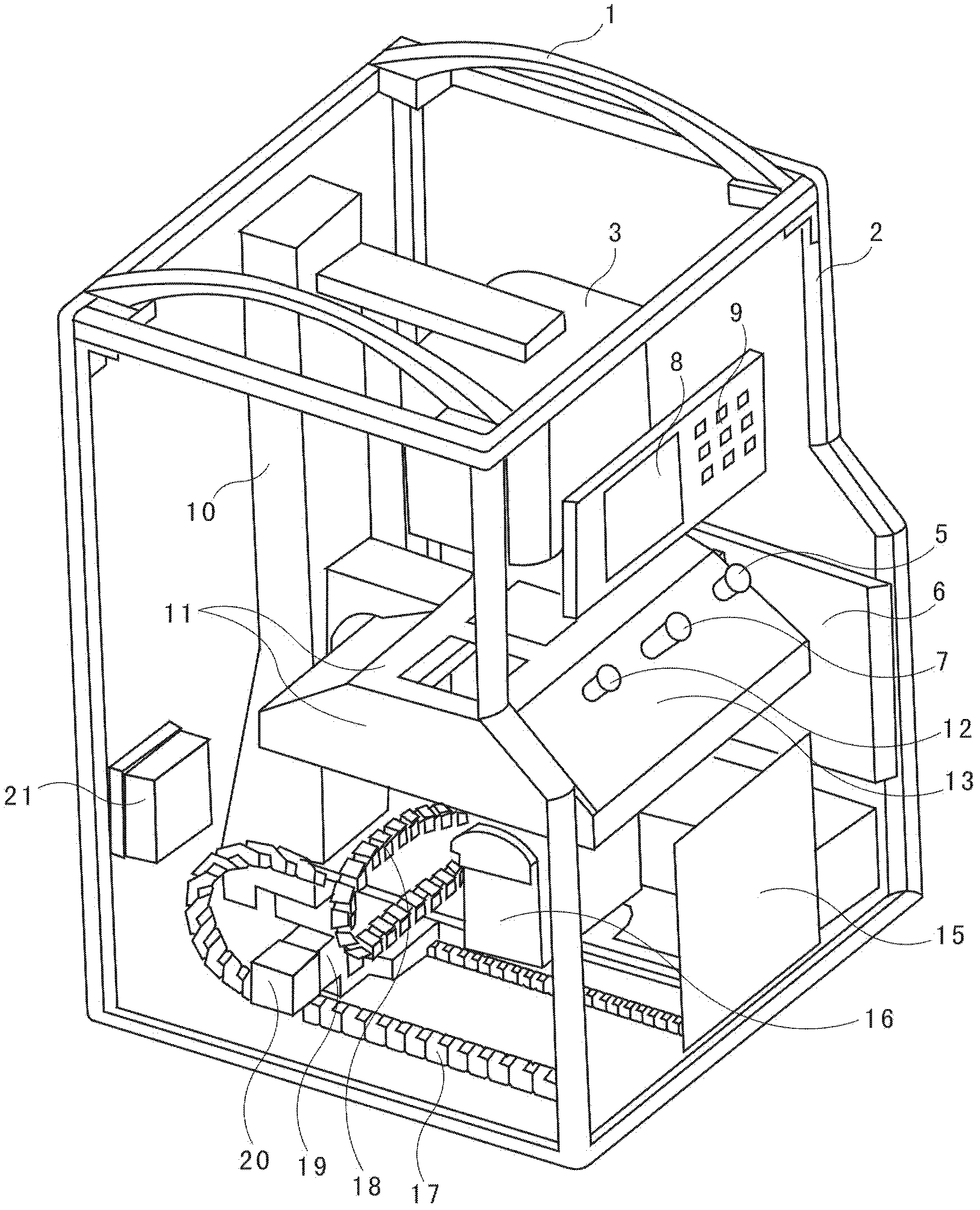

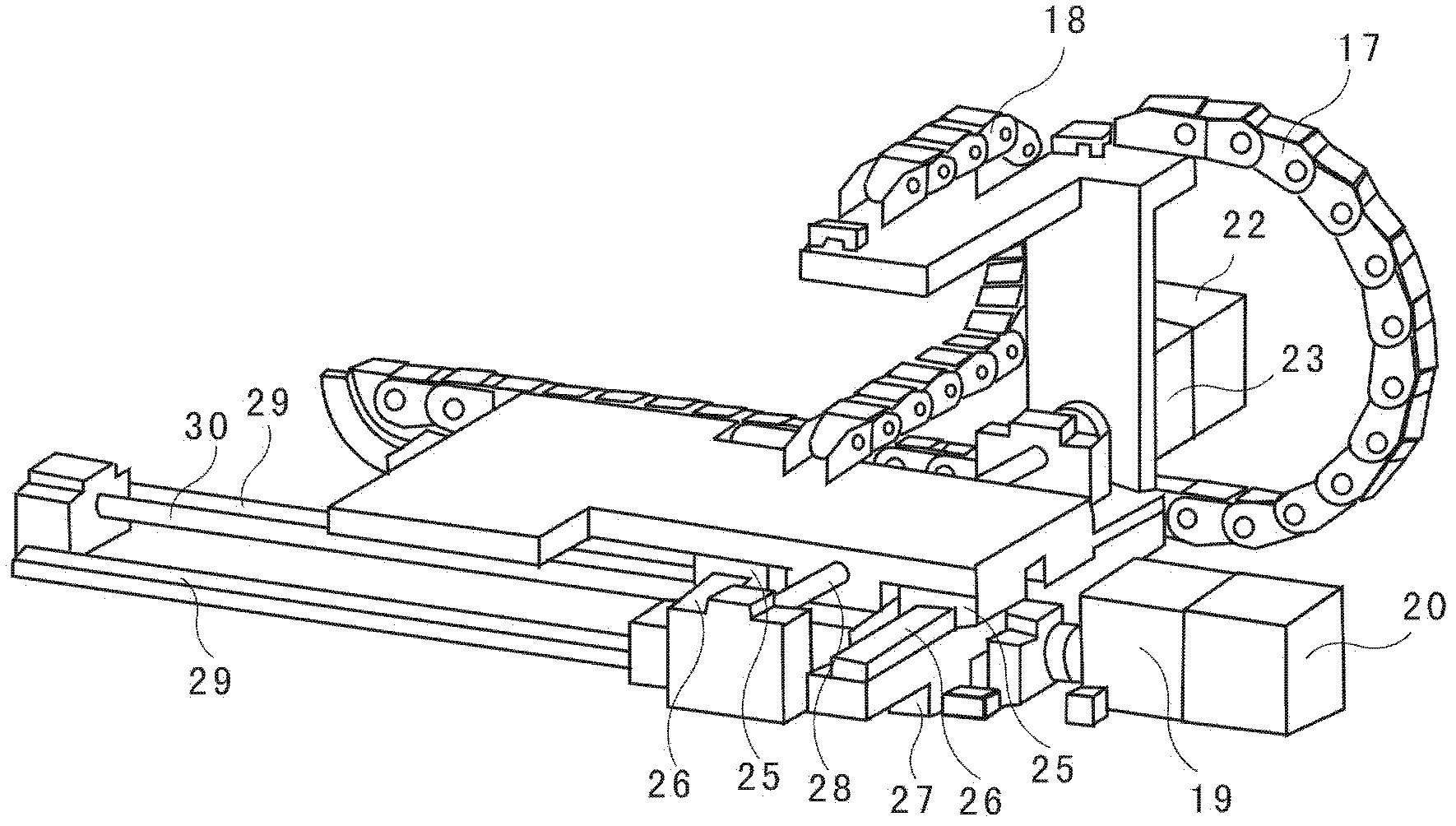

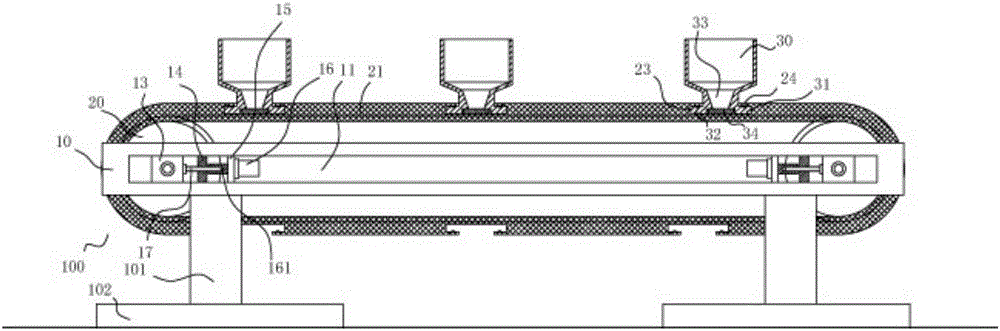

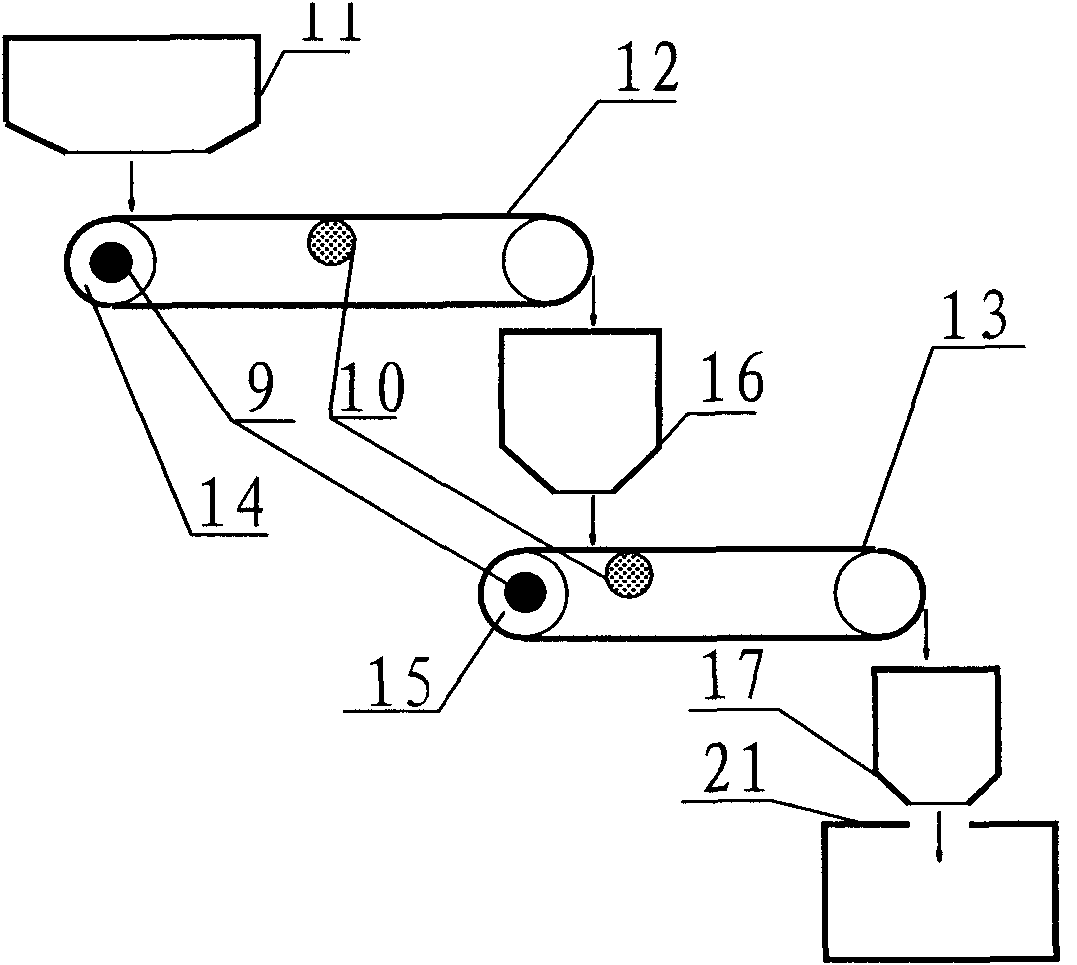

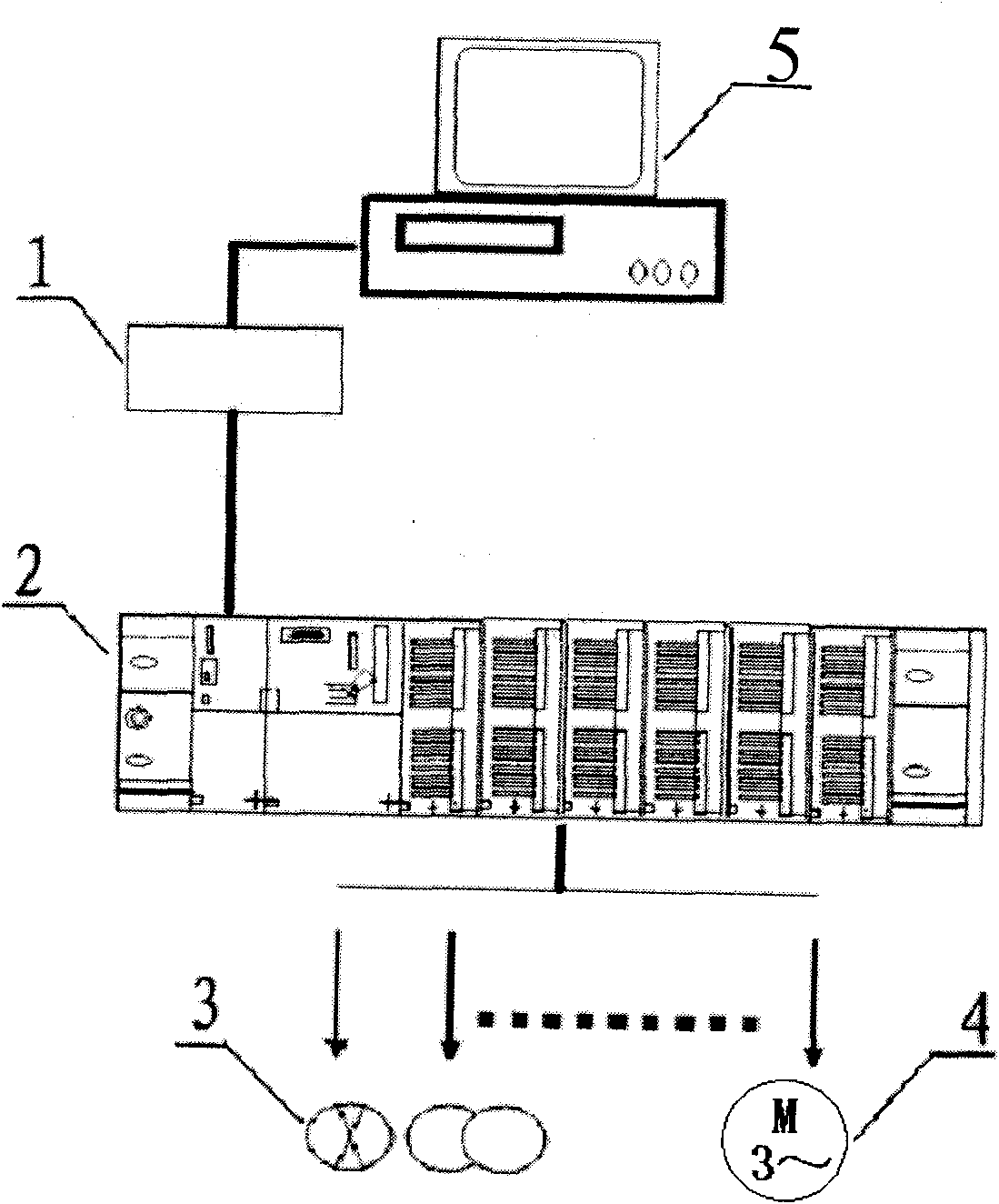

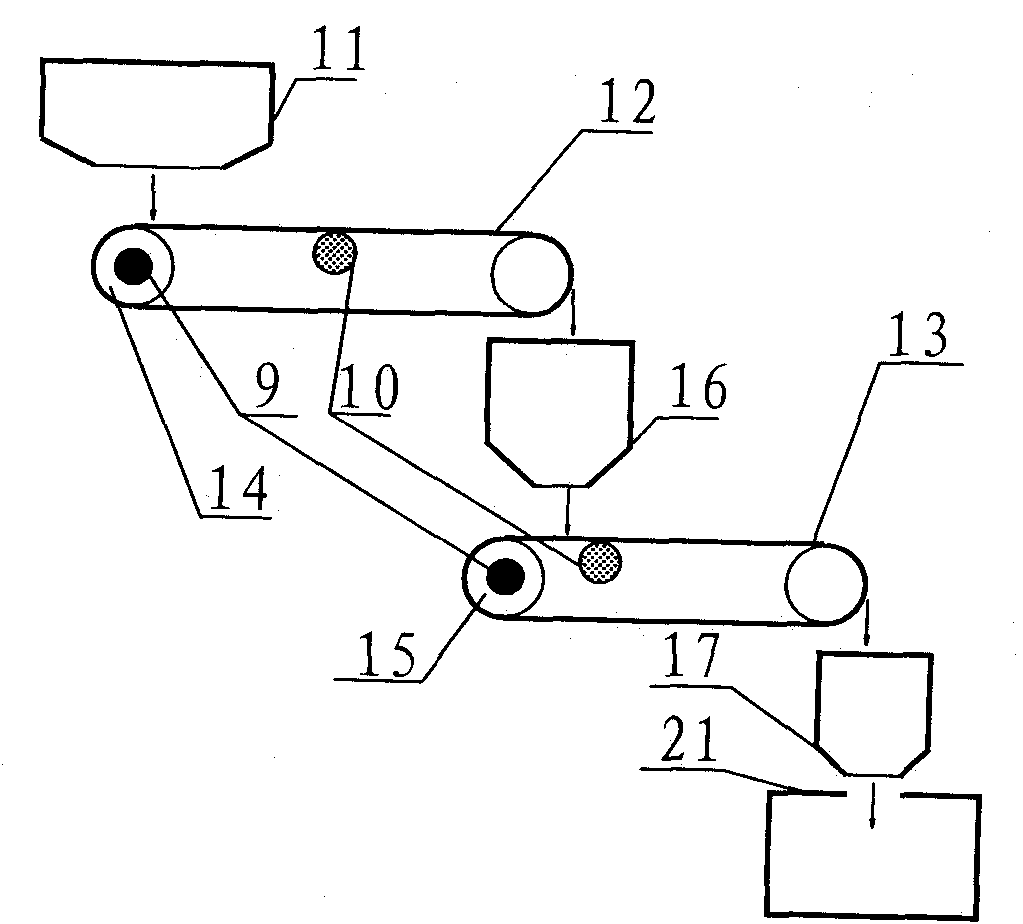

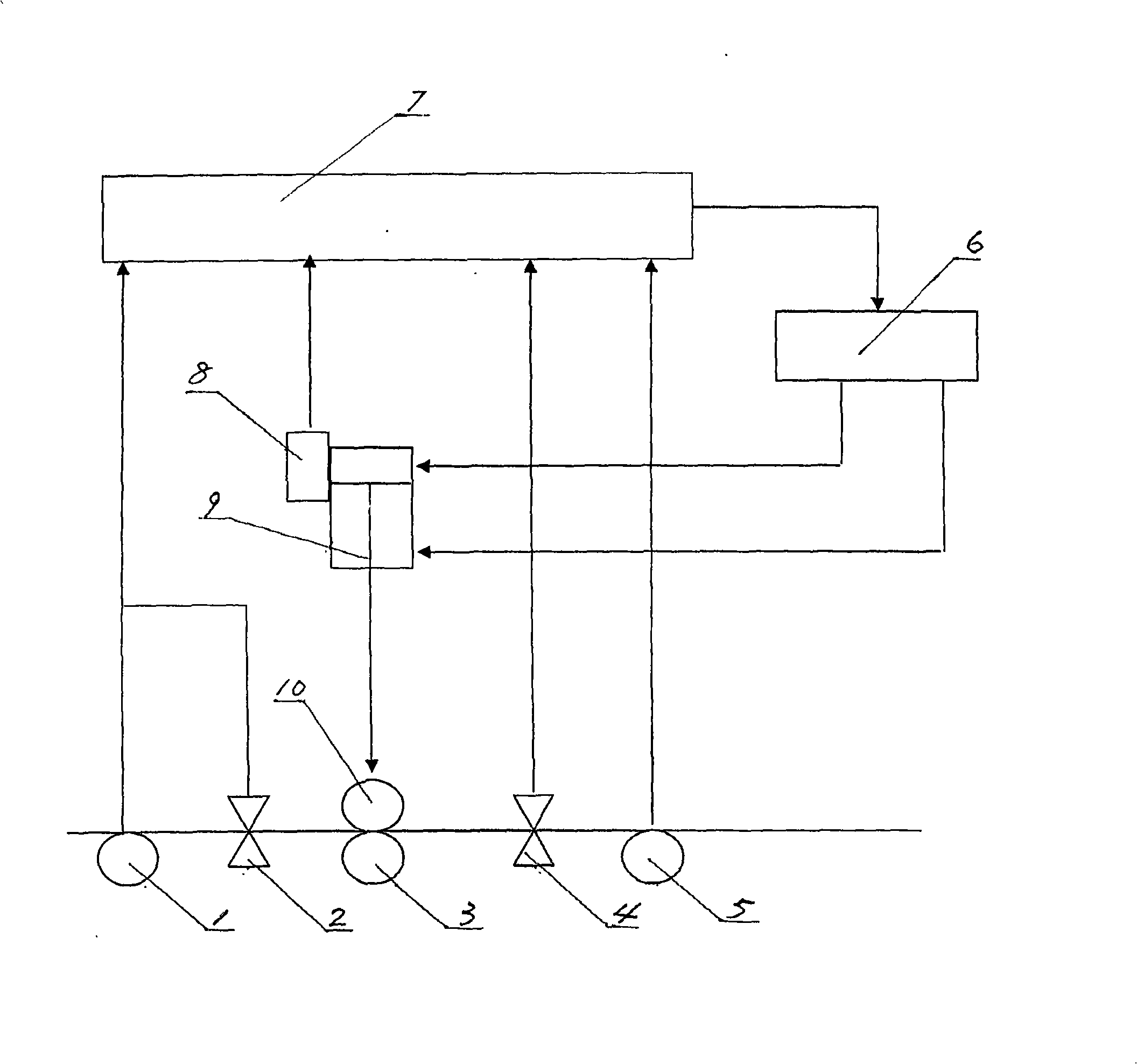

Ore dressing production automatic control system

The invention discloses an ore dressing production automatic control system, which comprises an operator station 5 of a control system, an Ethernet bridge 1, a system controller 2, an in-site detection switch 3, a motor 4 and a crushing and conveying device, wherein slide switches 9 are arranged on driven rolls of belt conveyers arranged in the crushing and conveying device, i.e. the slide switches 9 are arranged on the driven rolls of the belt conveyers 14 and 15 of the crushing and conveying device of the crude crushing work section; a slide switch 9 is arranged on the driven roll of the belt conveyer 24 of the crushing and conveying device of the fine crushing work section; and the control system is a DCS or PLC system. The DCS or PLC system of the invention can be used for judging whether the speed of the belt conveyers is in a normal state or in a speed lack state through detecting the states of the slide switches 9 arranged on the driven rolls of the belt conveyers of the crude crushing work section and the fine crushing work section, so the belt conveyers can be started or stopped for automatically increasing or decreasing the material amount. Thereby, the invention realizes the automatic control of the material feeding and material reducing of ores without manual regulation.

Owner:ANHUI FUSITE INTELLIGENT TECH CO LTD

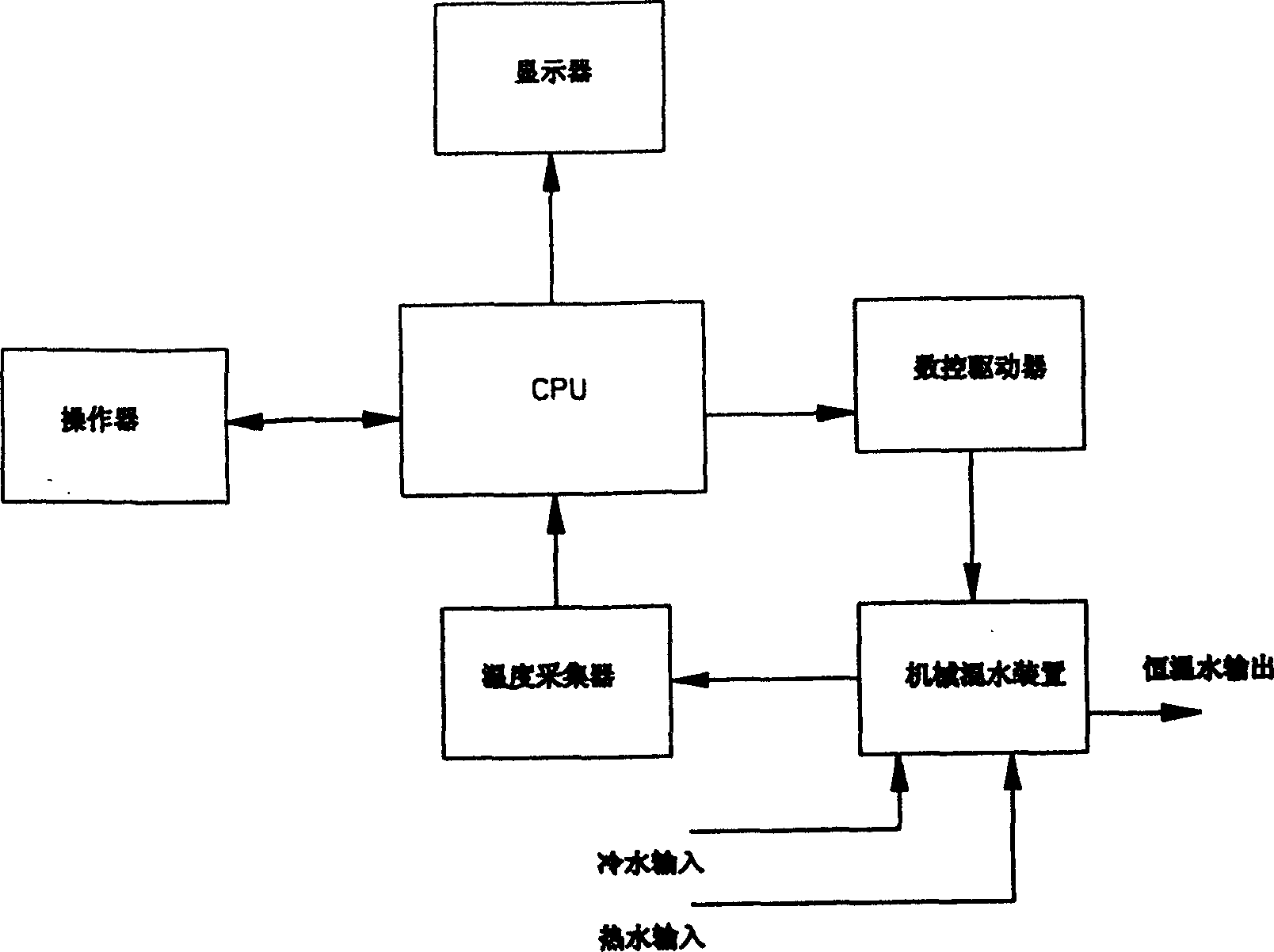

Digital control constant temperature water delivery apparatus

The numerically controlled constant-temperature water conveying device is one device to make water heater output constant-temperature hot water. The technological scheme includes connecting CPU to operating unit, display, temperature collector and numerically controlled driver; and connecting the mechanical water mixer to the temperature collector and the numerically controlled driver. The temperature collector consists of non-shielded anti-jamming amplifier, temperature sensor connected to the input of the amplifier and A / D converter connected to the output of the amplifier. The mechanical water mixer consists of water mixing seat, water mixing chamber, cold water inputting controller and hot water inputting controller. The present invention has the functions of controlling the temperature of the electric water heater and outputting constant-temperature hot water, and may be used to replace available electric control board.

Owner:曲波

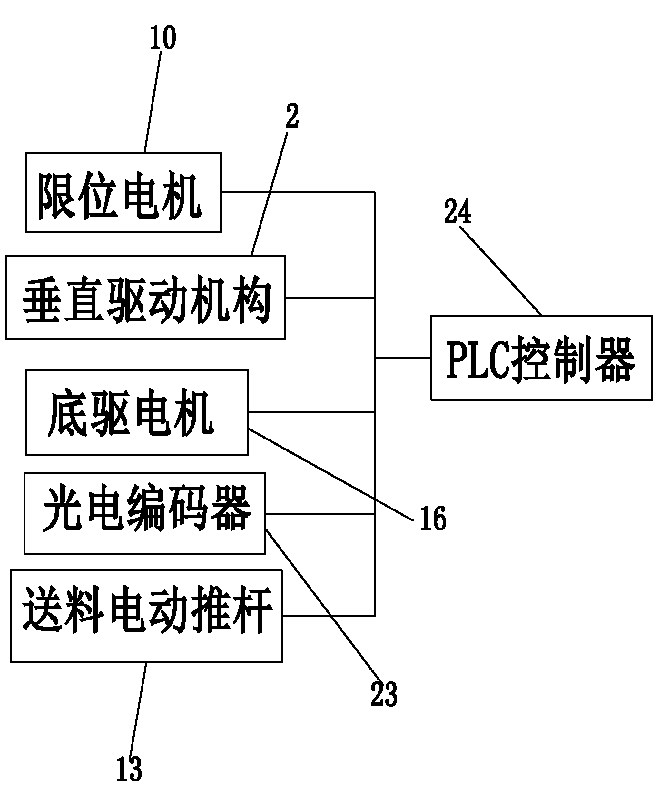

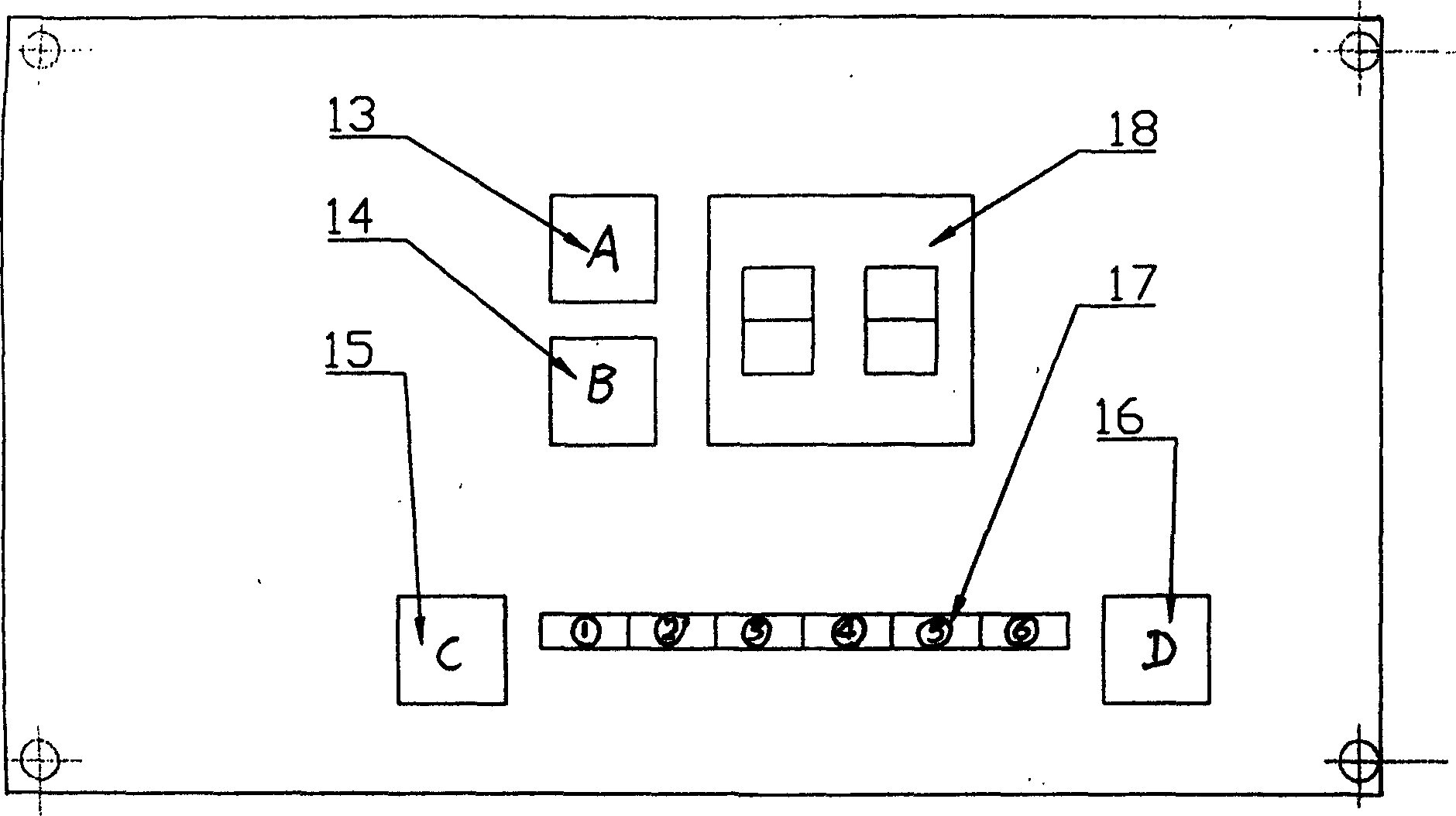

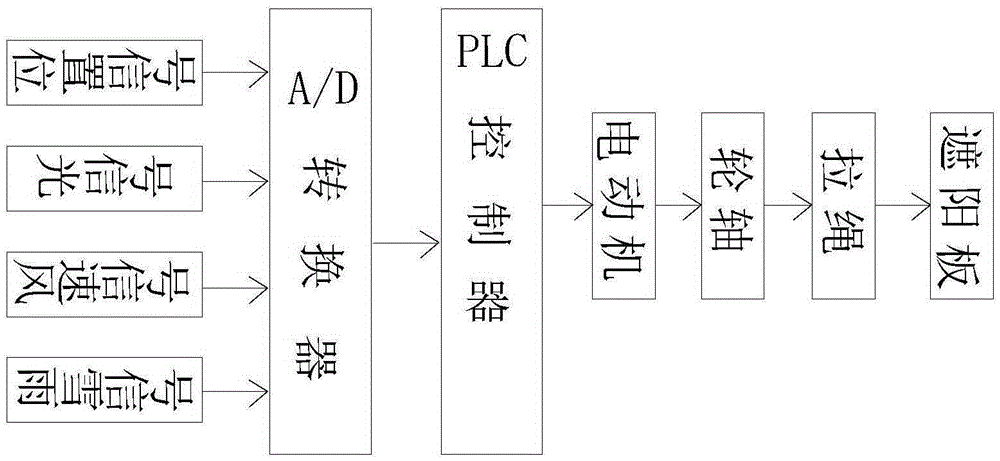

Building horizontal external shading angle regulation and control system based on PLC

InactiveCN105353779ANo manual adjustment requiredImprove accuracyControl using feedbackDigital signal processingEngineering

The invention discloses a building horizontal external shading angle regulation and control system based on a PLC. The system comprises an electric shading board, a PLC controller, a sensor component and an A / D converter. The sensor component acquires position signals, light signals, wind signals and rain and snow signals in real time and then converts analog signals into digital signals via the A / D converter and then transmits the digital signals to the PLC controller. The PLC controller sets the rotating tracks of the electric shading board according to change of the solar altitude angle and the azimuth of the latitude at which the shading board is positioned. The PLC controller performs logic signal processing according to the received real-time sensor signals and transmits control instructions to an electric motor via an output end. The electric motor rotates according to the output signals of the PLC controller so as to drive a wheel shaft and a pull rope to control change of the angle of the electric shading board. An automatic regulation and control function of the angle of the shading board changing according to time can be set according to the structural features and properties of a building and local sunlight conditions through programming of PLC internal programs with no requirement for artificial regulation.

Owner:江苏厚润新能源技术发展有限公司

Wind direction adjusting device of underground local ventilator of coal mine

InactiveCN108625890AAdjustable wind directionAdjustable tilt anglePump componentsTunnel/mines ventillationEngineeringCoal

The invention discloses a wind direction adjusting device of an underground local ventilator of a coal mine. The wind direction adjusting device comprises a base, a box is connected to an upper side of the base through a plurality of telescopic rods, the upper side of the base is connected with a lower side of the box through a lifting mechanism, ventilating windows are arranged on two sides of the box, the ventilating windows are provided with a plurality of wind-out blades in horizontal equidistant arrangement, and two sides of the wind-out blades are rotationally connected with inner wallsof the ventilating windows through rotating shafts. The wind direction adjusting device of the underground local ventilator of the coal mine has the advantages that the height of the box can be adjusted through the lifting mechanism, so that requirements on ventilation of wind outlets of different coal mines can be satisfied; through an arranged driving mechanism, the wind direction adjusting device can be driven to adjust angles of the wind-out blades, so that wind directions can be adjusted conveniently; through an arranged inclining mechanism, an inclining angle of the local ventilator canbe adjusted to correspond to the wind-out angles of the wind-out blades, and the wind direction adjusting device is convenient to use, free from manual adjusting and labor-saving.

Owner:张奇

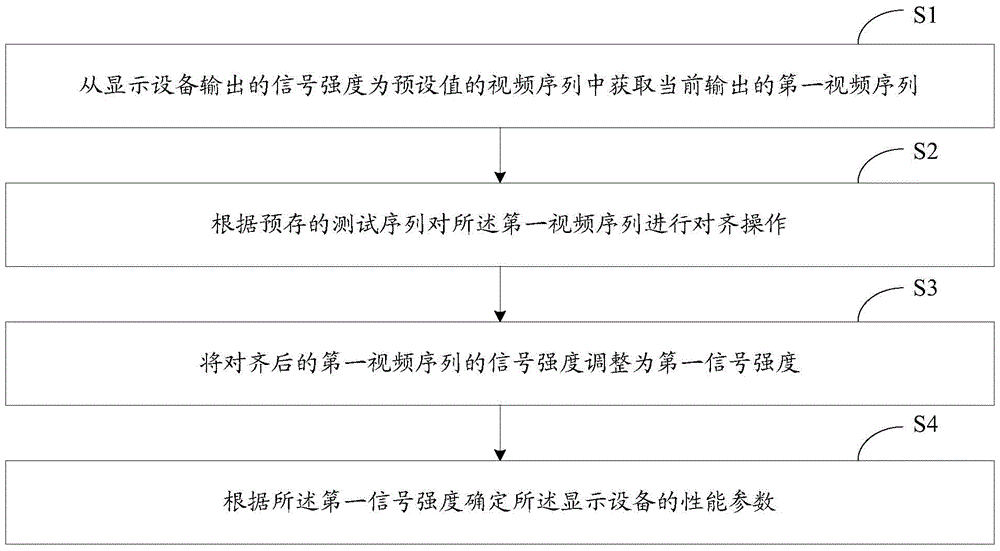

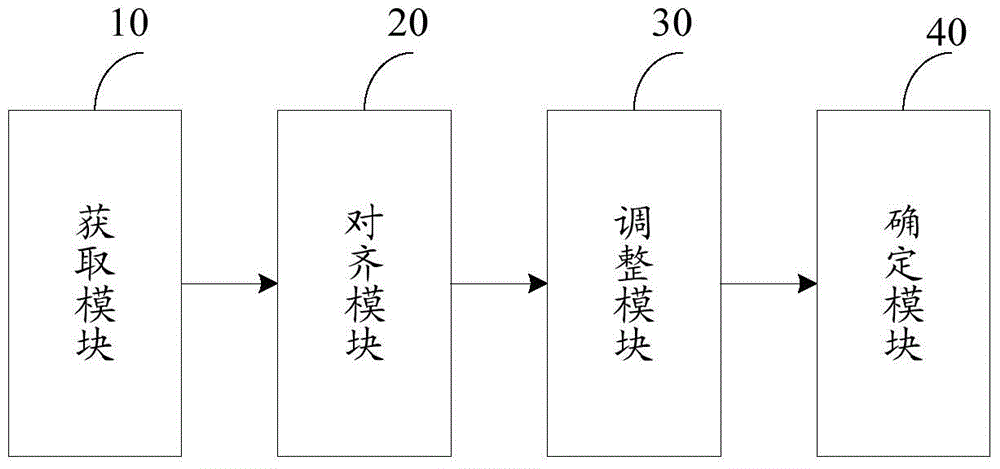

Display device performance parameter detection method and system

ActiveCN105704485AImplement automatic detectionNo manual adjustment requiredStatic indicating devicesTelevision systemsDisplay deviceVideo sequence

The invention relates to a display device performance parameter detection method and system. The method comprises the following steps: a first video sequence which is currently output is obtained from video sequences, output from a display device, of which the signal strength is a preset value; the first video sequence is subjected to aligning operation according to pre-stored test sequences; the signal strength of the aligned first video sequence is adjusted to a first signal strength; the first signal strength is a threshold signal strength, between a non-triggering strength for mosaic effect and a mosaic effect triggering strength, of the aligned first video sequence after the aligned first video sequence is output via the display device; performance parameters of the display device are determined according to the first signal strength. The display device performance parameter detection method and system can realize automatic detection of the performance parameters, manual adjustment is not needed, no extra hardware device is required, and low cost and high efficiency can be achieved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Automatic thickness control system for roller mill

InactiveCN101314166ANo manual adjustment requiredRoll mill control devicesMetal rolling arrangementsControl systemEngineering

The invention discloses an automatic thickness control system for a rolling mill, which comprises the rolling mill. The system is characterized in that: the system is also provided with a computer, a servo mechanism and a screwdown oil cylinder. The screwdown oil cylinder is positioned on the upper part of the rolling mill, a piston rod of the screwdown oil cylinder is downward and is connected with bearing supports at both ends of a working roll on the rolling mill, and an oil inlet and an oil outlet of the screwdown oil cylinder are respectively communicated with an oil inlet and an oil outlet of the servo mechanism. A control end of the servo mechanism is connected with the computer. The screwdown oil cylinder is provided with a position sensor which is connected with the computer by means of a conducting wire. An inlet side and an outlet side of the rolling mill are respectively provided with an inlet velocity measuring roll and an outlet velocity measuring roll which are both provided with encoders, and the two encoders are both connected with a tachometer circuit in the computer by means of conducting wires. The inlet side and the outlet side of the rolling mill are respectively provided with an inlet thickness tester and an outlet thickness tester which are both connected with a deviation port of the computer by means of conducting wires. The automatic thickness control system can guarantee the rolling quality of strip materials so that rolled strip materials have higher quality, and is applicable to control the rolling thickness of the strip materials.

Owner:WUXI HUANSHENG METAL PRODS

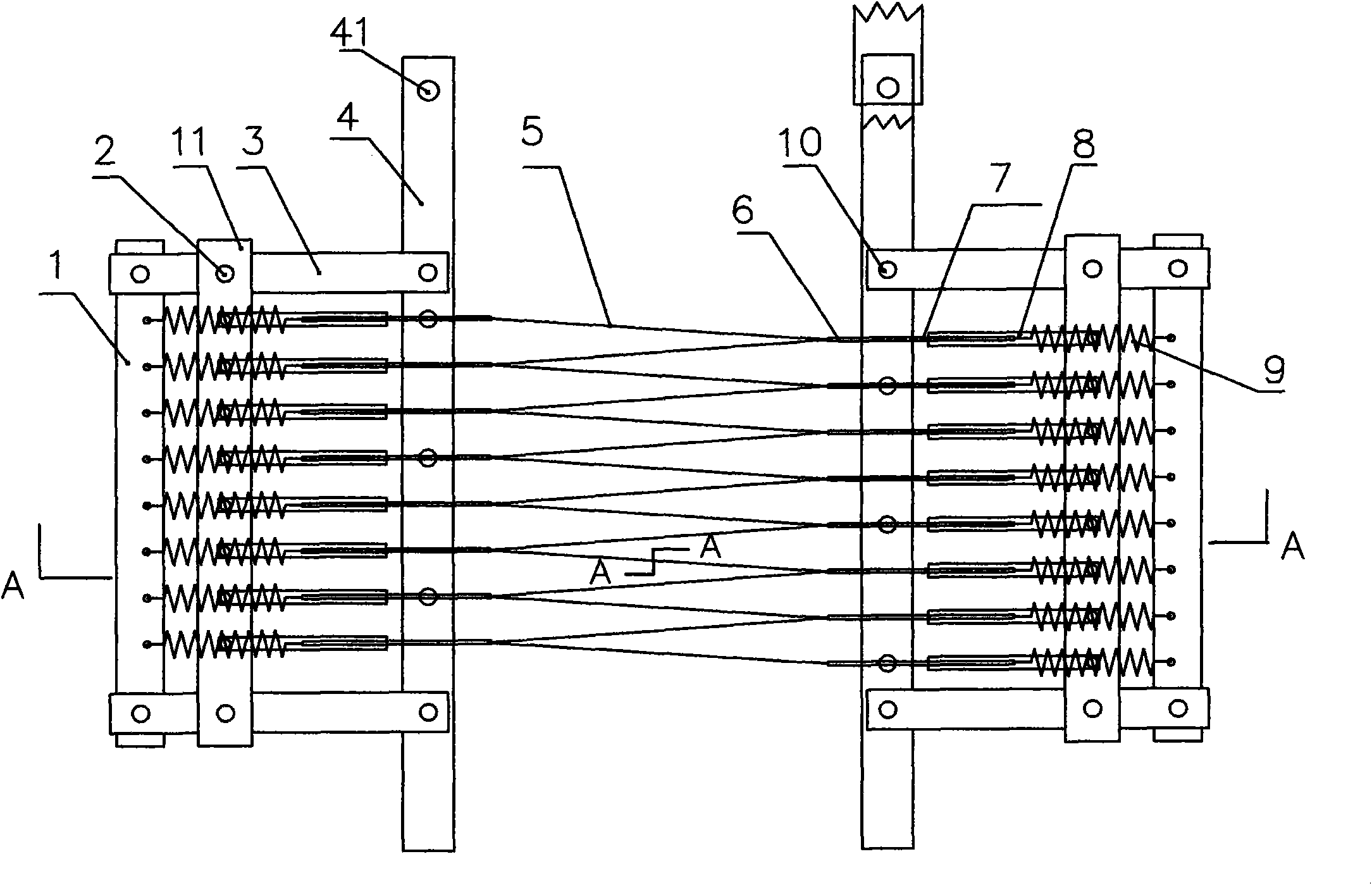

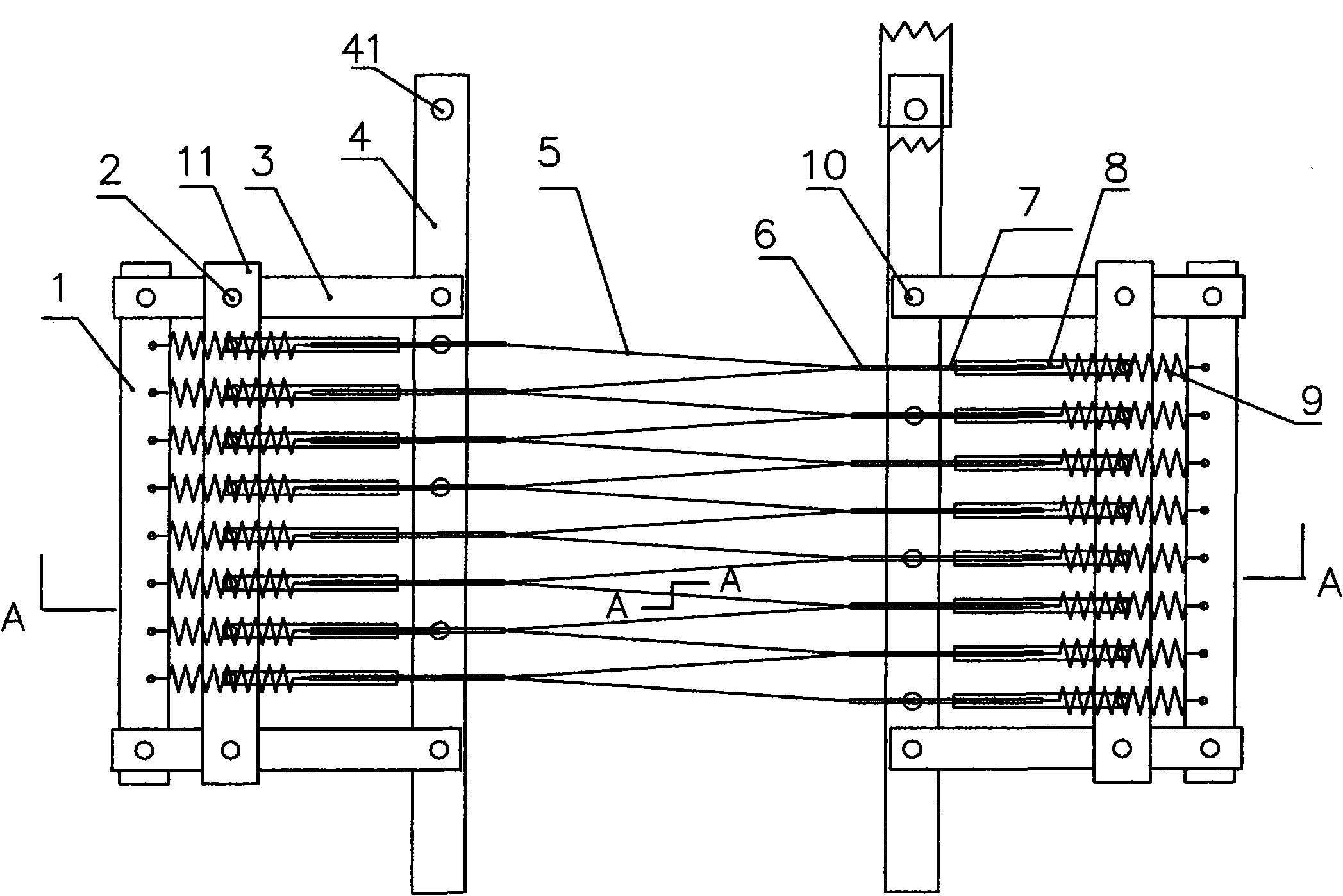

Tensile spring structure for preparing diamond film

InactiveCN102140626AMechanical vibration absorptionArrange staticChemical vapor deposition coatingPower flowEngineering

The invention discloses a tensile spring structure for preparing a diamond film, which overcomes the defects that the tensity of all heating wires can not be adjusted independently and the heating wires are vibrated due to current fluctuation in the prior art. The invention provides a device which can automatically and finely adjust the tensity of all the heating wires independently. The device comprises a left insulating board, a right insulating board, a left electrode and a right electrode, wherein the left insulating board and the right insulating board are arranged on a base, the left electrode and the right electrode are made of molybdenum bars, a heating wire device is arranged between the two insulating boards and comprises a group of heating wires arranged in a multi-turning way and in the shape like a Chinese character zhi, left turning parts and right turning parts of the heating wires are hooked on a group of left elastic hooks and a group of right elastic hooks connected with the left insulating board or the right insulating board, each hook is provided with a guiding and limiting structure, and all the turning parts of the heating wires are electrically connected with one of the left electrode and the right electrode made of molybdenum bars through hooked electrodes. The tensile spring structure can adjust the tensity of the heating wires automatically, independently and finely, can ensure that all the sections of the heating wires do not droop and are positioned in the same plane in the whole growing process of diamond, enables the tensile force to be uniform and the tensity to be compensated automatically in the whole process.

Owner:BEIJING TIANDI ORIENT SUPERHARD MATRIALS

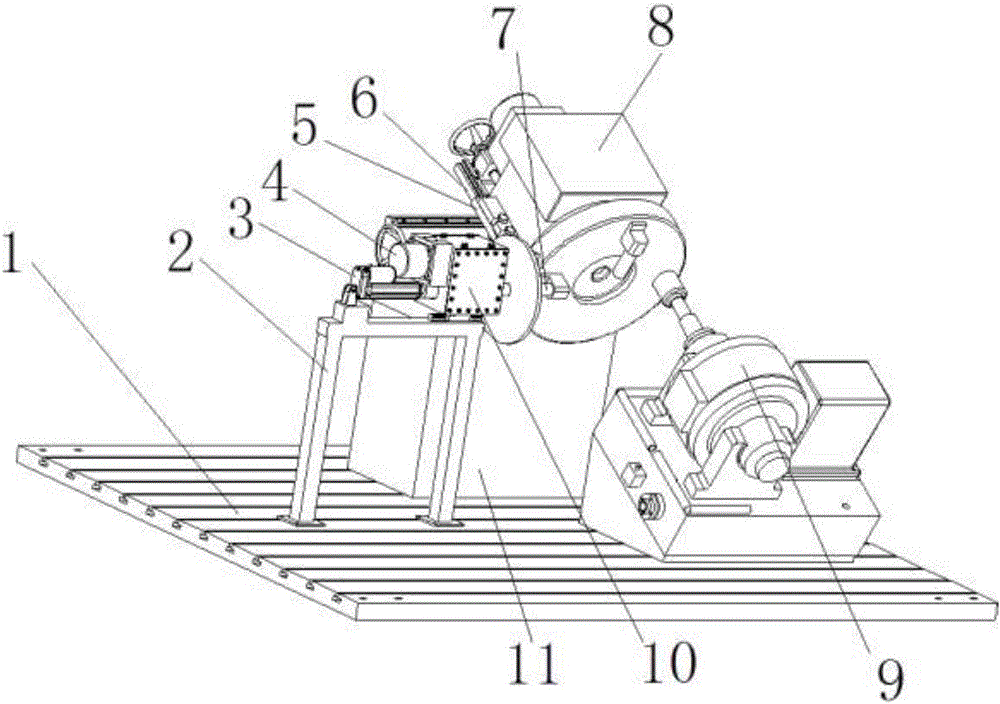

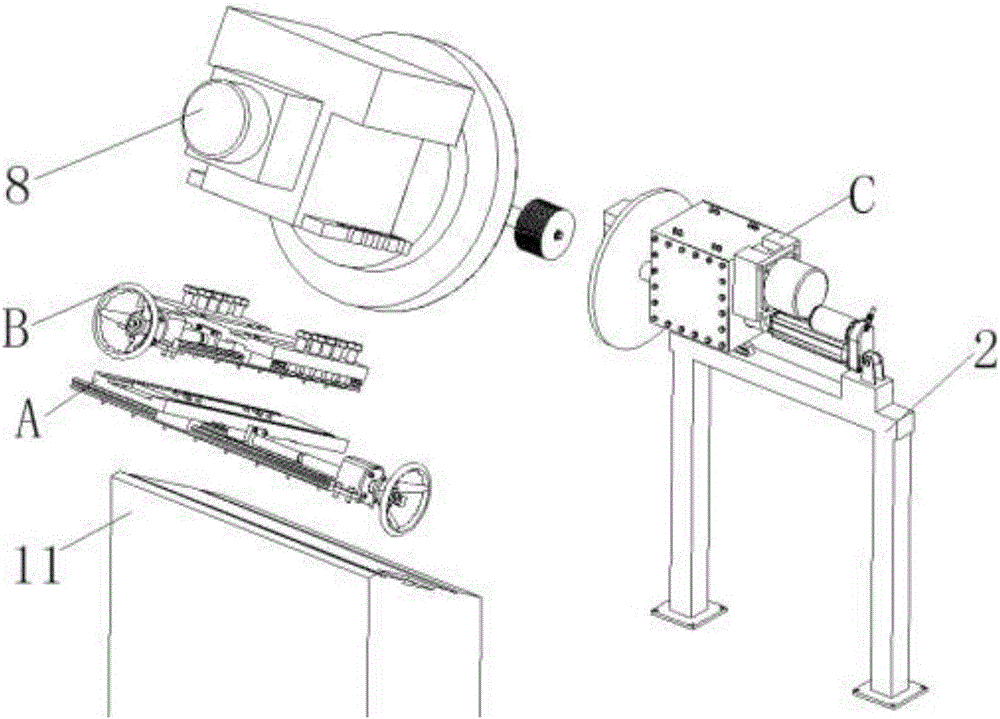

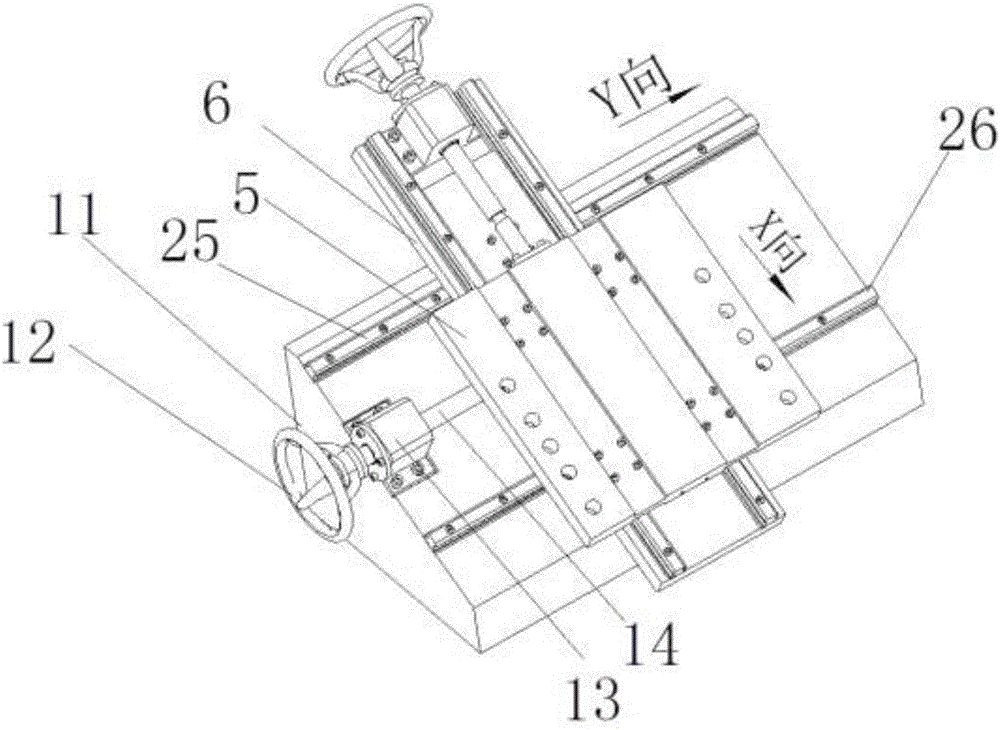

Electromagnetic and electric push rod mixed-loading tool rest reliability testbed

ActiveCN106840644AImprove versatilityAvoid Difficult AdjustmentsMachine part testingPower toolDynamometer

The invention discloses a reliability testing device of a machine tool power tool rest and particularly relates to an electromagnetic and electric push rod mixed-loading tool rest reliability testbed. The problem that the working condition of the tool rest on an oblique bed body cannot be simulated and three-directional tool rest loading cannot be simultaneously conducted on the tool rest in the prior art is solved. The electromagnetic and electric push rod mixed-loading tool rest reliability testbed consists of a tool rest supporting part, a cutting force loading part, a tool rod part and a torque loading part. The tool rest supporting part comprises an X-direction moving unit and a Y-direction moving unit. The tool rod part is fixed to the power tool rest. The power tool rest is fixed to the X-direction moving unit. The cutting force loading part is arranged on one side of the power tool rest. The cutting force loading part comprises X-direction and Y-direction electromagnetic loading units and a Z-direction electric push rod loading unit. A dynamometer in the torque loading part is connected with a power output shaft of the power tool rest. The electromagnetic and electric push rod mixed-loading tool rest reliability testbed is closer to an actual usage state of the tool rest and has the advantages of being high in universality, easy to adjust, simple in structure and small in size.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com