Ore dressing production automatic control system

An automatic control and control system technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as belt deviation and affect production efficiency, achieve stable operation, realize automatic deviation correction, and solve frequent load changes. Effect

Inactive Publication Date: 2010-08-25

ANHUI FUSITE INTELLIGENT TECH CO LTD

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, the deviation of the belt is also very serious, and frequent manual adjustments are also required, which directly affects the production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

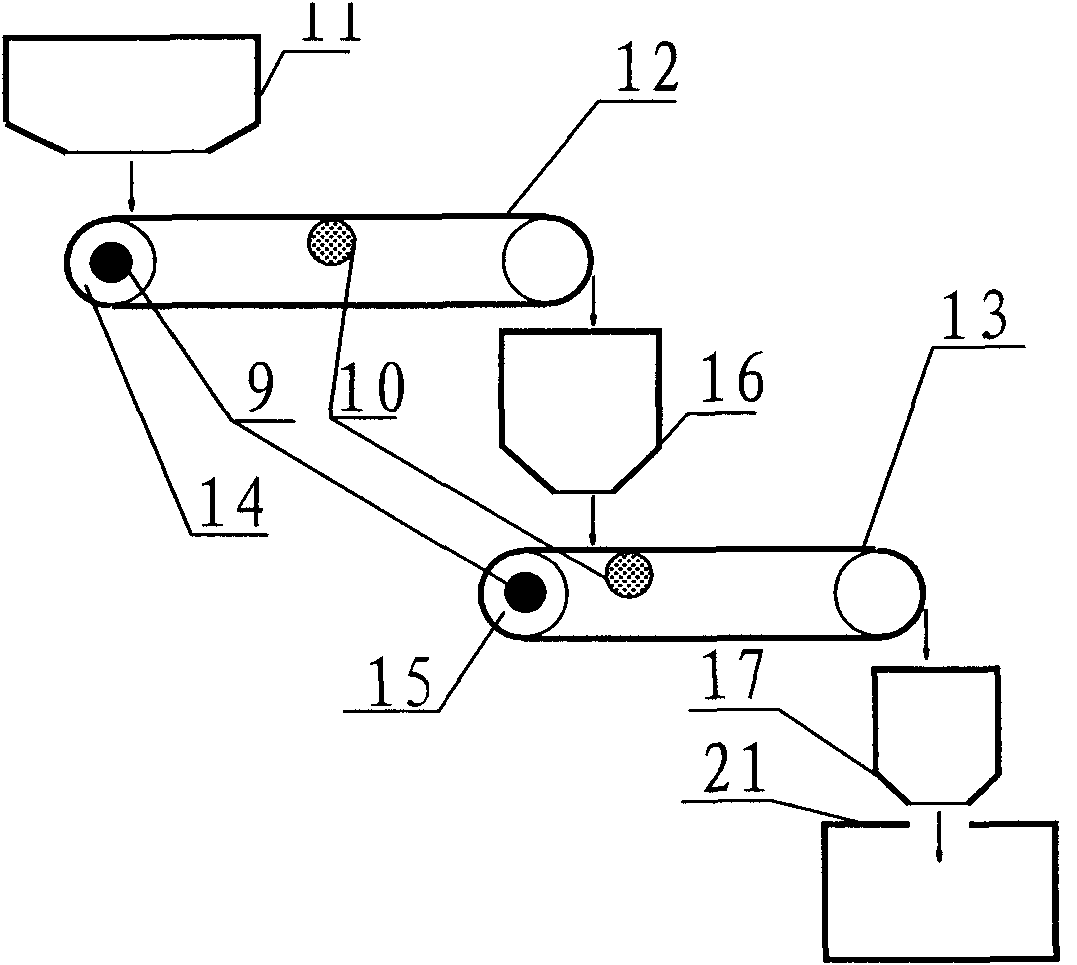

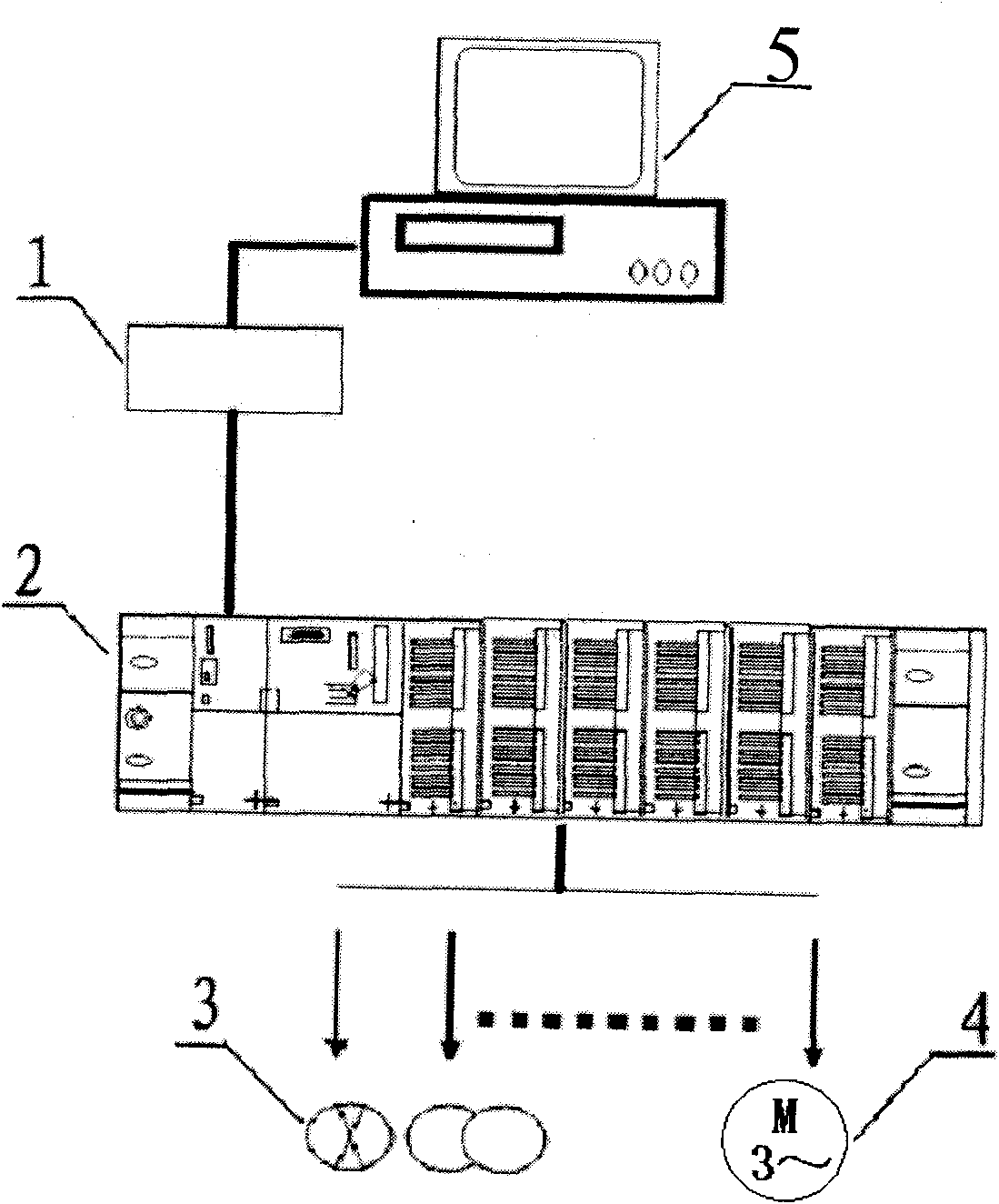

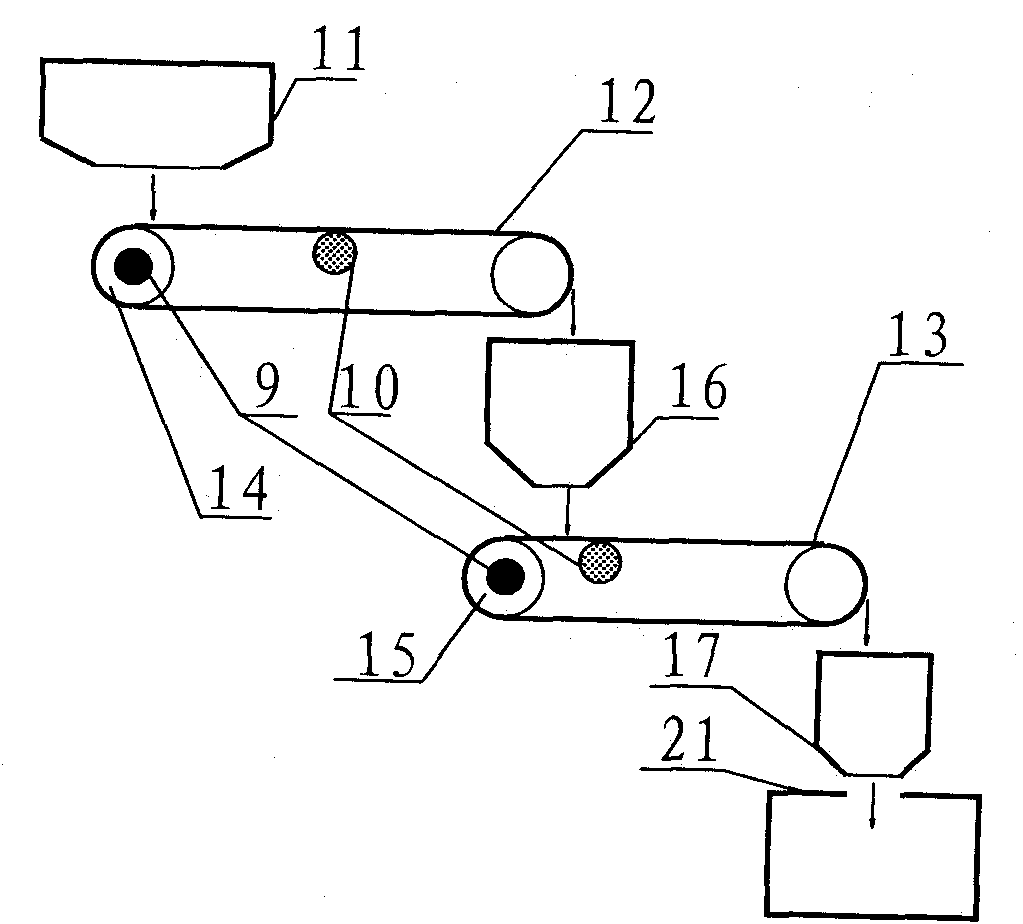

The invention discloses an ore dressing production automatic control system, which comprises an operator station 5 of a control system, an Ethernet bridge 1, a system controller 2, an in-site detection switch 3, a motor 4 and a crushing and conveying device, wherein slide switches 9 are arranged on driven rolls of belt conveyers arranged in the crushing and conveying device, i.e. the slide switches 9 are arranged on the driven rolls of the belt conveyers 14 and 15 of the crushing and conveying device of the crude crushing work section; a slide switch 9 is arranged on the driven roll of the belt conveyer 24 of the crushing and conveying device of the fine crushing work section; and the control system is a DCS or PLC system. The DCS or PLC system of the invention can be used for judging whether the speed of the belt conveyers is in a normal state or in a speed lack state through detecting the states of the slide switches 9 arranged on the driven rolls of the belt conveyers of the crude crushing work section and the fine crushing work section, so the belt conveyers can be started or stopped for automatically increasing or decreasing the material amount. Thereby, the invention realizes the automatic control of the material feeding and material reducing of ores without manual regulation.

Description

Mineral dressing production automation control system technical field The invention relates to the technical field of iron ore beneficiation production, in particular to an automatic production flow control system of an iron ore beneficiation plant. Background technique With the development of my country's iron and steel industry and the restriction of the price monopoly of international ore giants, my country's iron ore resources urgently need to tap the potential and expand production. At present, the beneficiation equipment of various small and medium iron ore mines in my country is outdated, basically in the stage of manual manual control, and the production efficiency is low. Especially in the coarse and medium crushing section of belt conveying, the belt load changes greatly, and the belt is easy to slip, so the feeding and reducing of ore must be controlled manually. At the same time, the deviation of the belt is also very serious, and frequent manual adjustments a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03B13/00B03B7/00

Inventor 吴宗霞孙章连

Owner ANHUI FUSITE INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com