Tensile spring structure for preparing diamond film

A technology of diamond film and wire stretching, which is applied in the field of materials, can solve problems such as inability to be easily independent and finely adjusted, and achieve the effect of reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

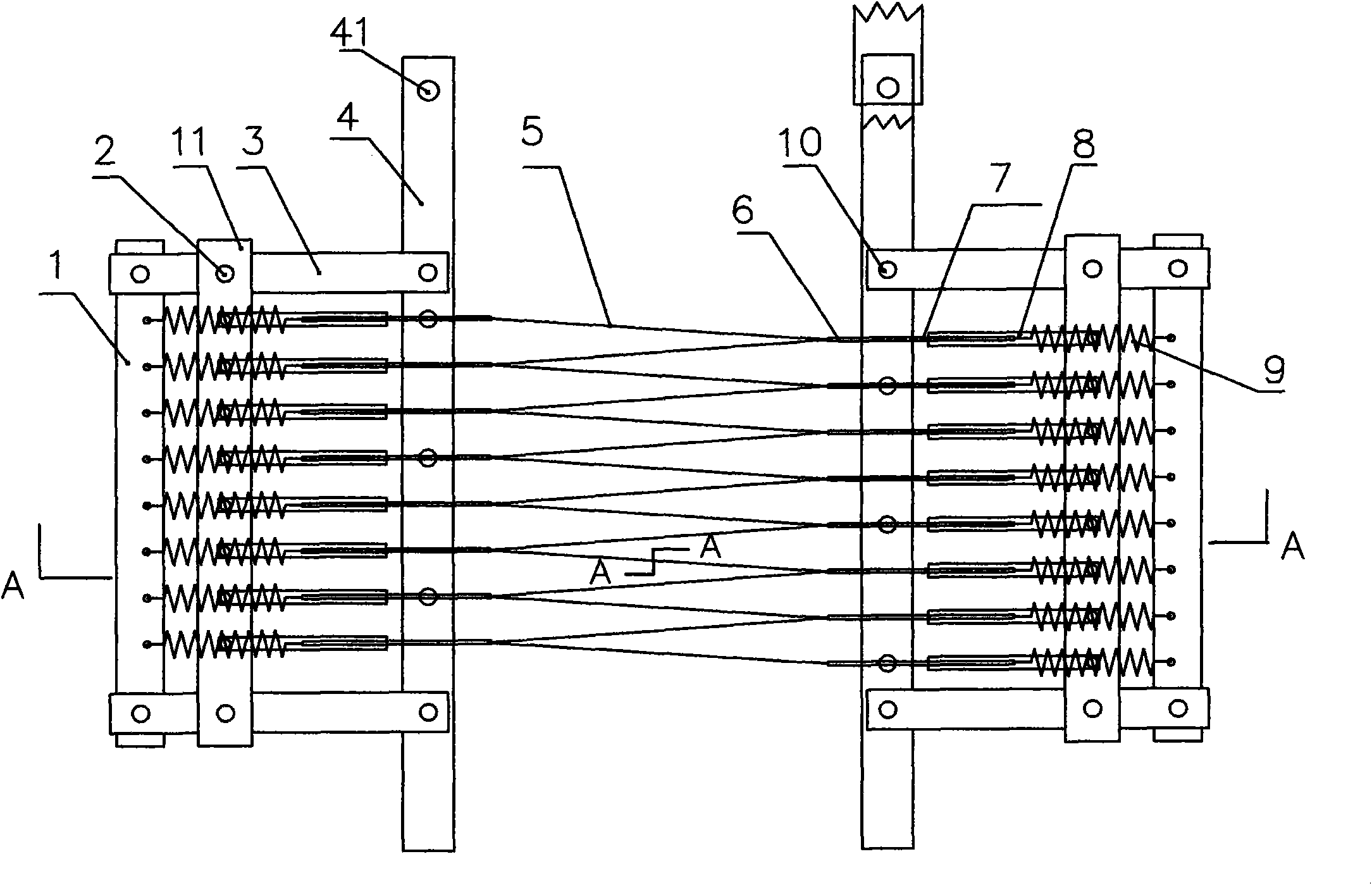

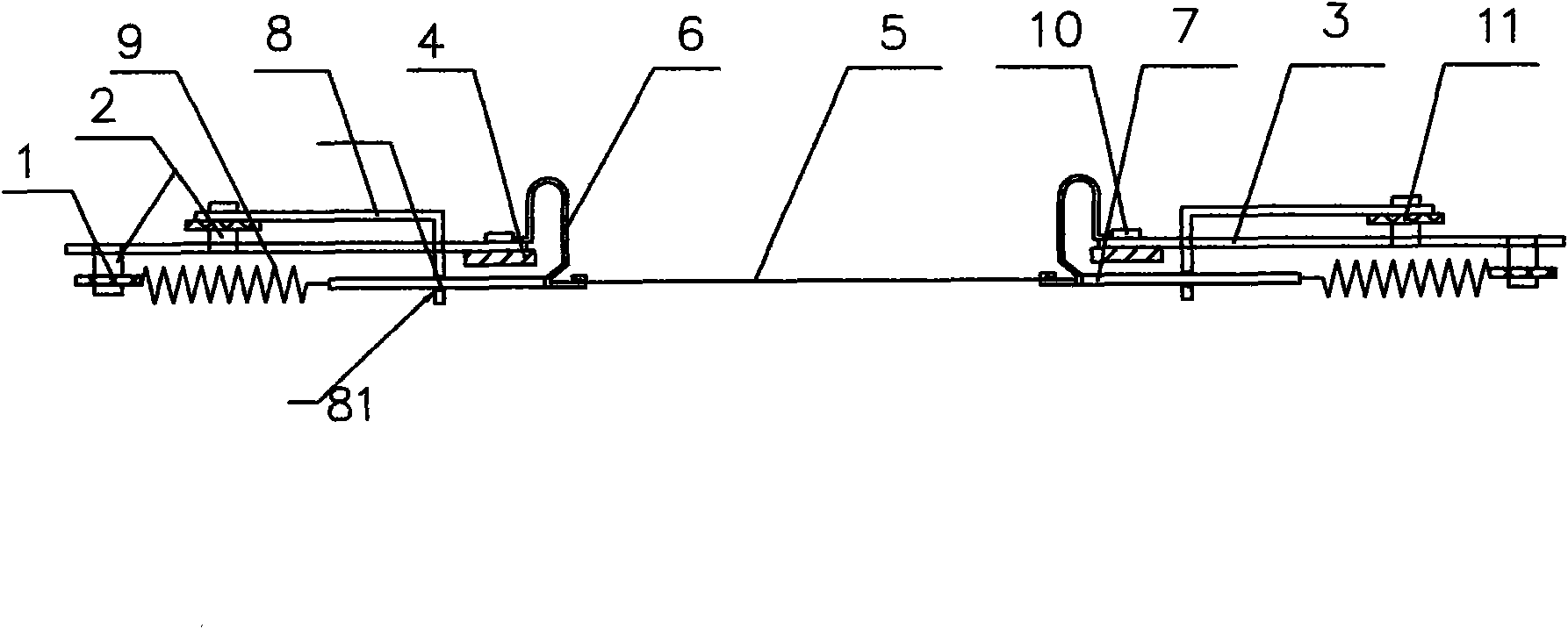

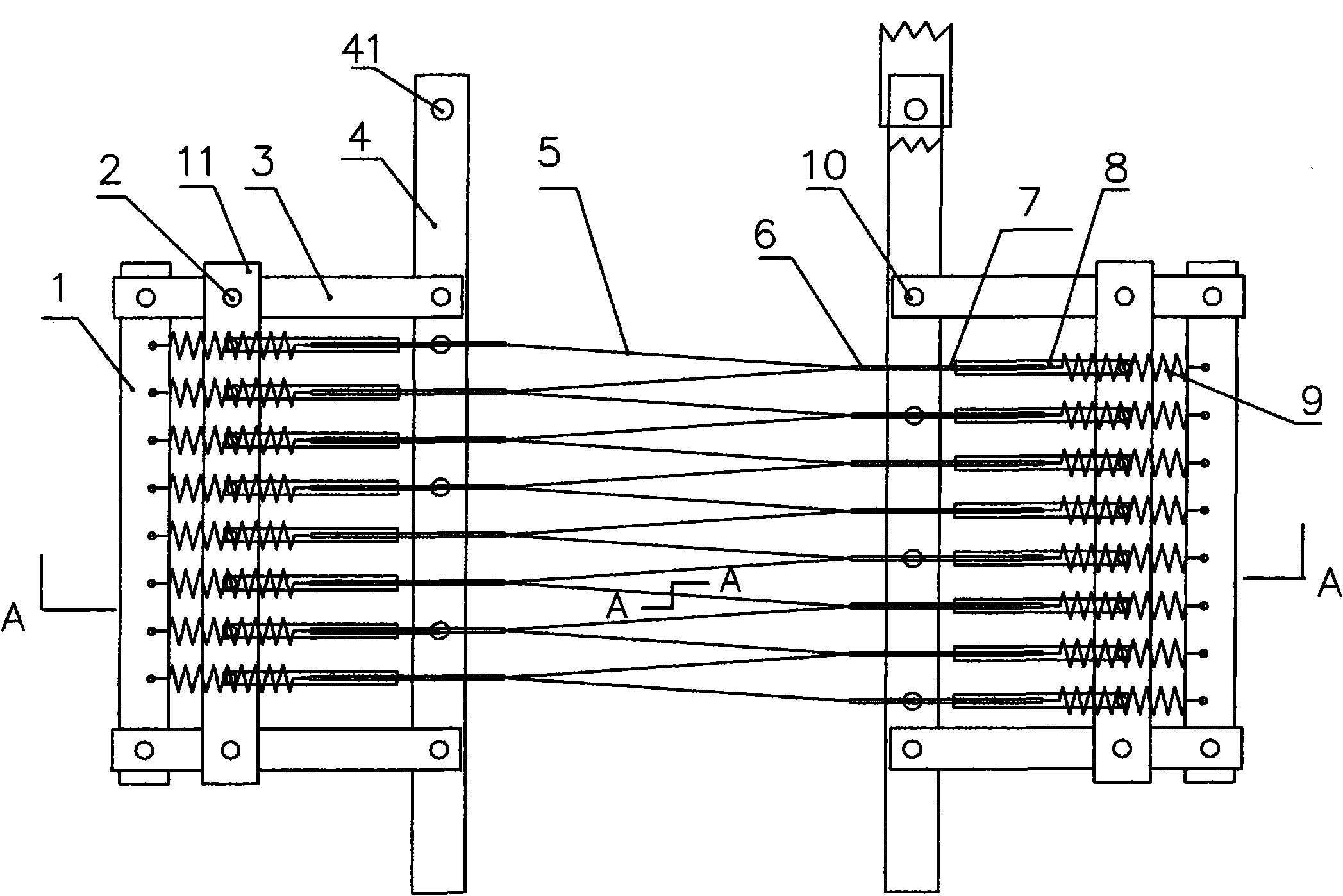

[0029] Embodiment 1: as figure 1 As shown in ~ 3, a wire structure for preparing a diamond film includes two left and right insulating plates 1 respectively arranged on the base and molybdenum strips 4 forming left and right electrodes, between the two insulating plates 1 A heating wire device is provided, and the heating wire device includes a group of heating wires 5 arranged in a zigzag shape with multiple turns. On the left or right two groups of hooks with elasticity, the hooks are provided with a guiding limiting structure; all turning points of the heating wire are electrically connected to the molybdenum strip 4 by a hook-shaped electrode 6 .

[0030] The heating wire is made of tantalum wire material. The set of heating wires arranged in zigzag multiple turns is composed of a whole long heating wire turning in zigzag, and each section of heating wires forming the zigzag has an electrical parallel connection relationship.

[0031]The elastic left and right two groups...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com