Patents

Literature

57results about How to "Won't sag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

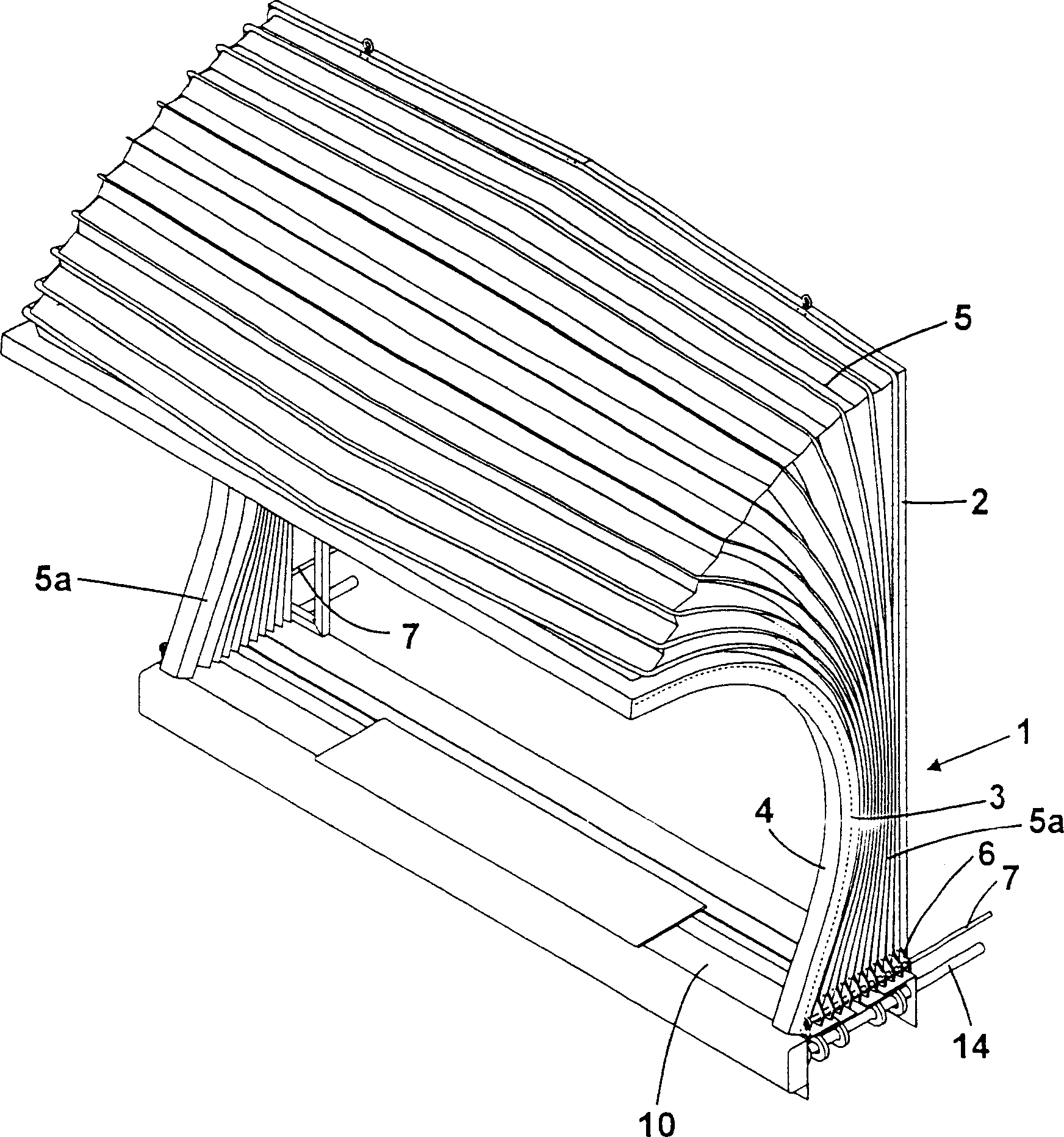

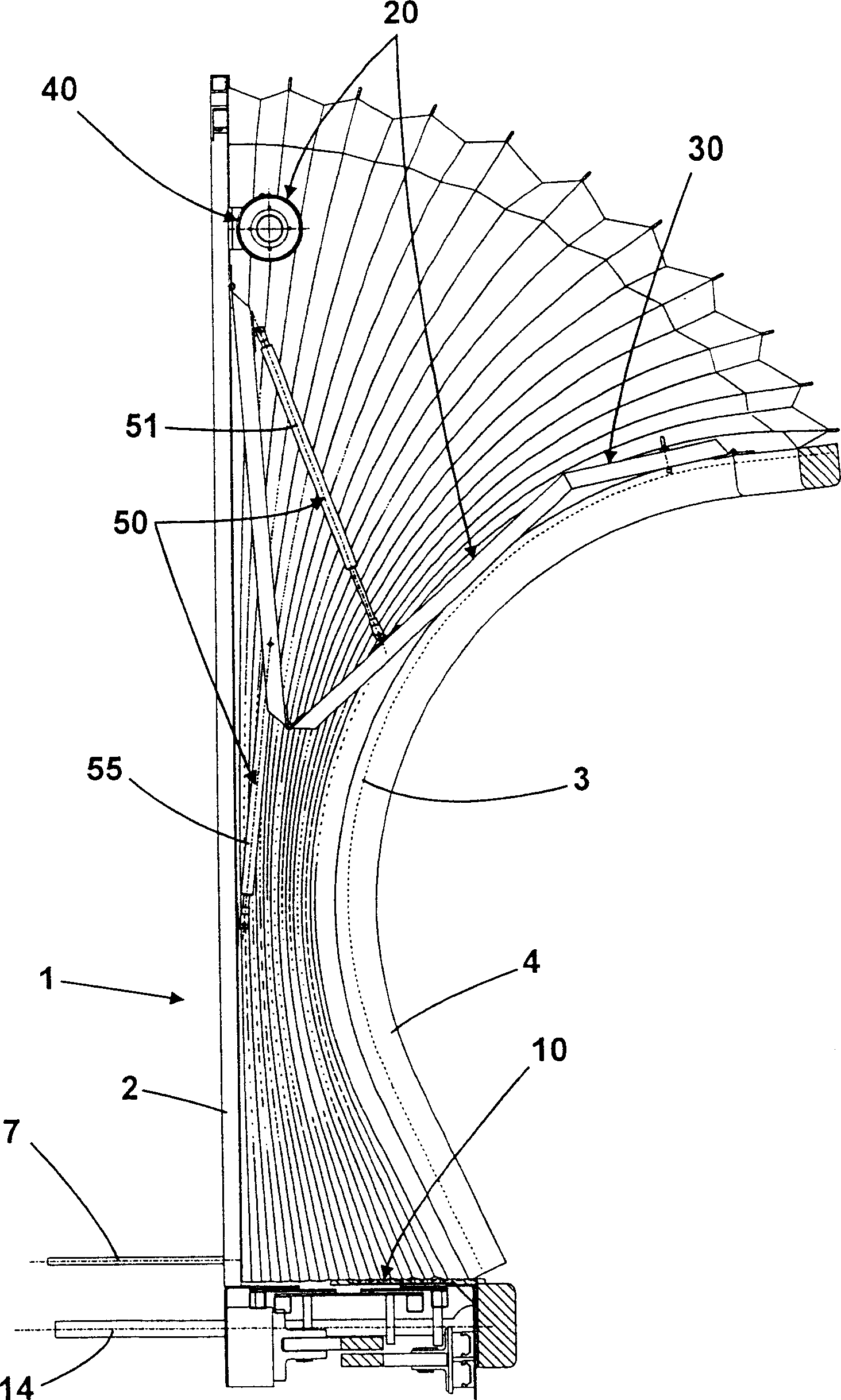

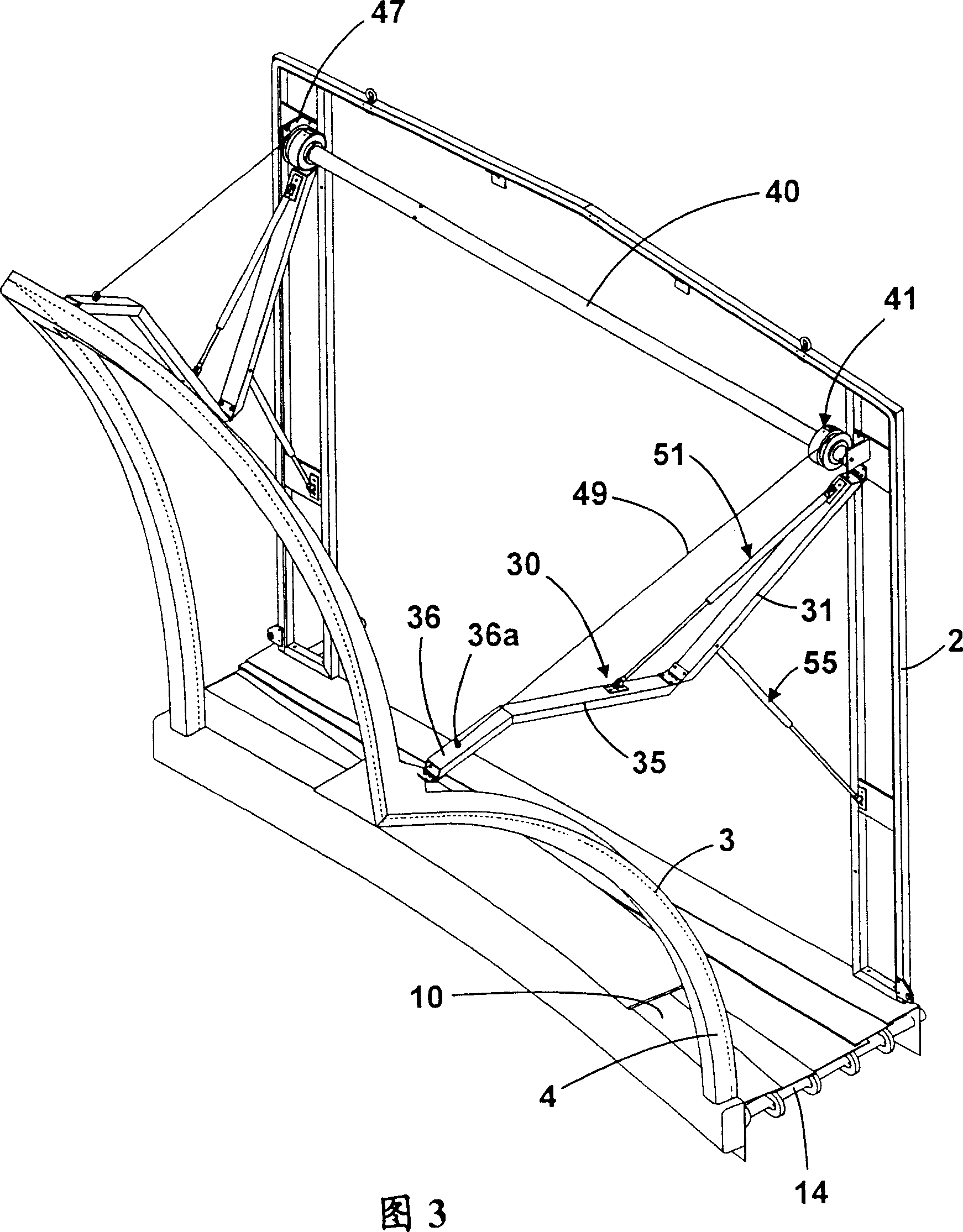

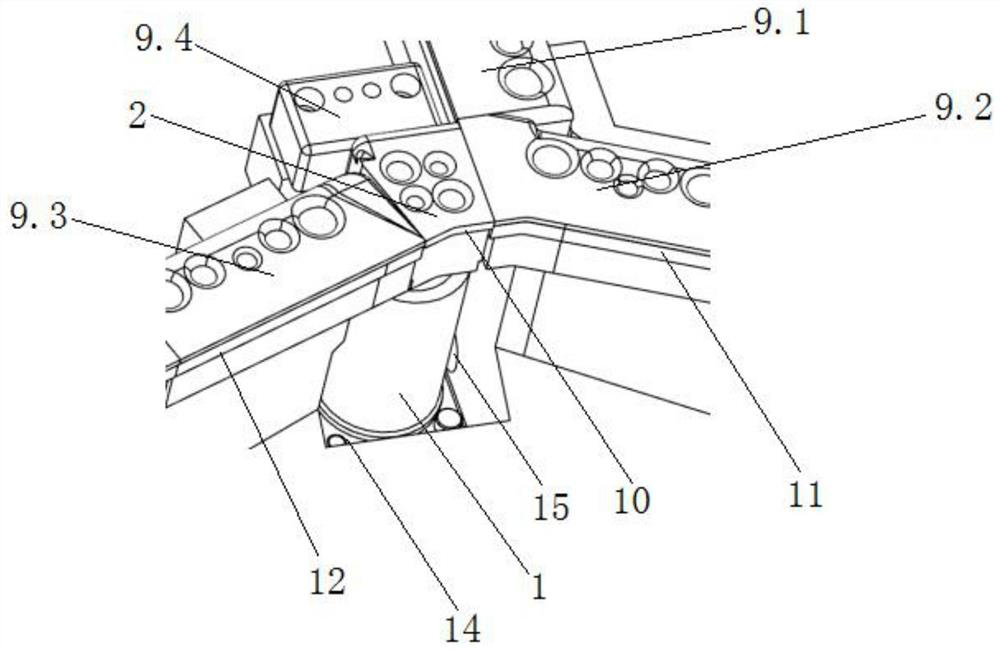

Aircraft boarding bridges and stairs or sealing device for the bridge

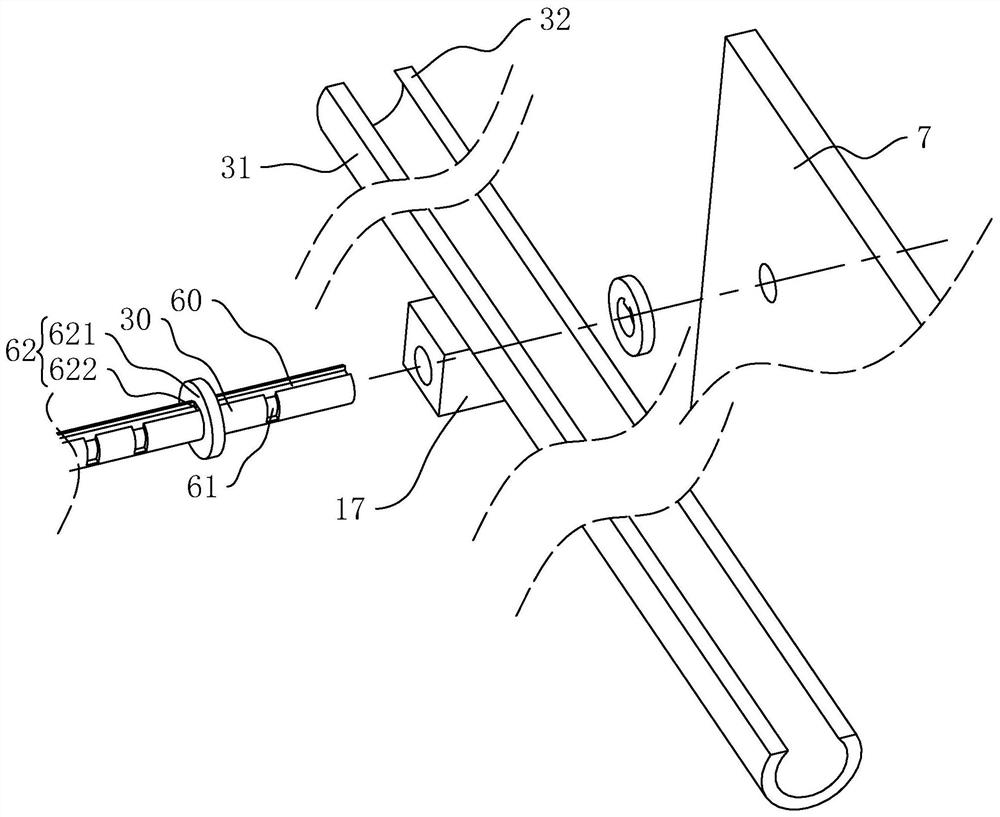

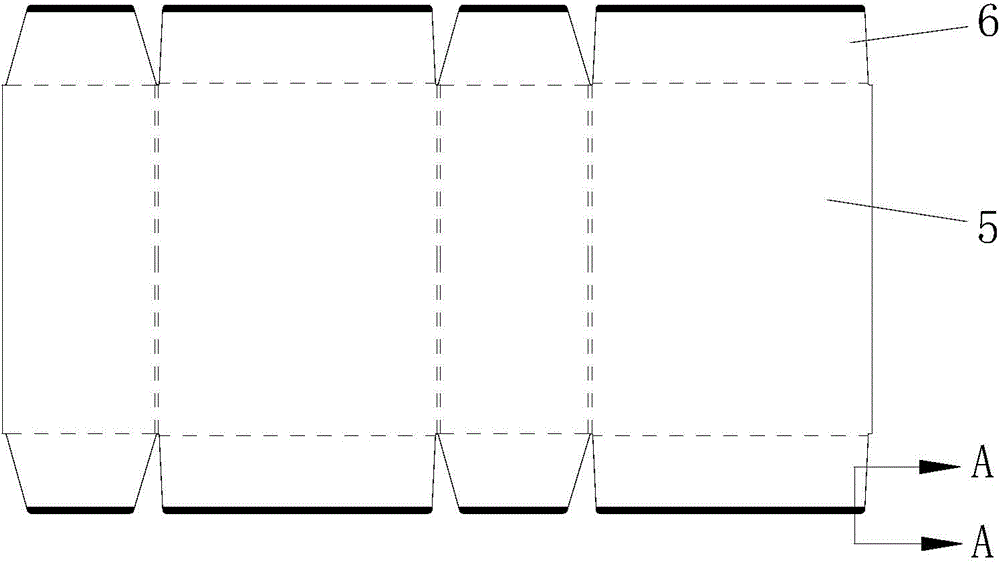

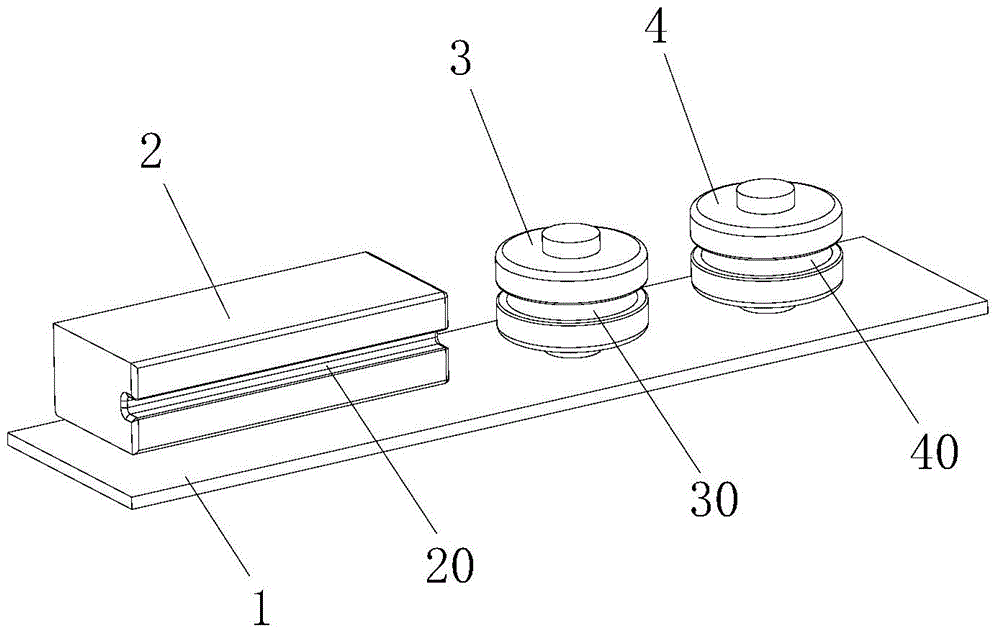

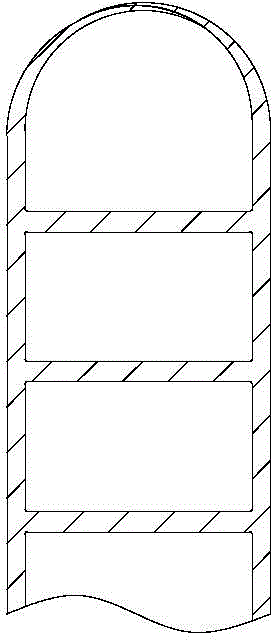

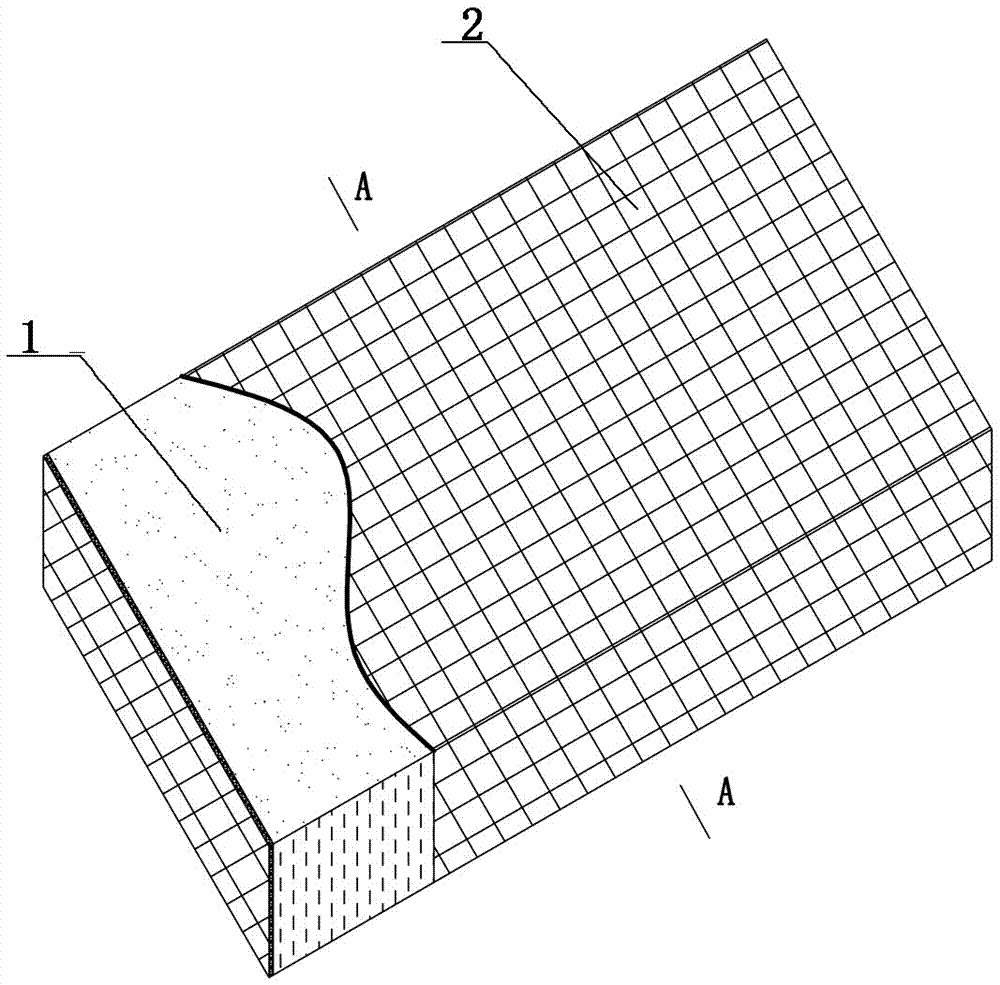

The invention is directed to a seal for aircraft boarding stairs or for an aircraft boarding bridge, said seal comprising a bellows ( 5 ) that spans a gangway bottom plate ( 10 ), said bellows comprising a flexible frame ( 3 ) at its one open end and having at its other end a gantry frame ( 2 ) intended to be fastened to the aircraft boarding stairs or to the aircraft boarding bridge, the flexible frame ( 3 ) resting against the outer skin of the aircraft when the bellows is deployed and an actuation device for actuating the bellows being provided for extending and retracting the bellows, said actuation device comprising a rotatable shaft equipped with a drive, said rotatable shaft ( 40 ) permitting to wind and unwind a traction means connected to the flexible frame, the actuation device ( 20 ) comprising two articulated arms ( 30 ) arranged in a spaced-apart relationship, each articulated arm ( 30 ) comprising an upper arm member ( 31 ) and a lower arm member ( 35 ) coupled to said upper arm member by a hinge, said upper arm member ( 31 ) of the articulated arm ( 30 ) being hinged to the gantry frame ( 2 ) in the roof region of the bellows ( 5 ) and the lower arm member ( 35 ) being hinged to the flexible frame ( 3 ), extension means ( 51, 55 ) being provided for extending the bellows ( 5 ).

Owner:HUBNER GMBH

Production method of vehicle top using wet treatment

ActiveCN101332791AReduce weightMeet the requirements of lightweight designSuperstructure subunitsEnvironmental resistanceHeat resistance

The invention relates to a production method for vehicle top wet processing, in particular to a vehicle top which is mounted at the top part of the vehicle, plays the roles of heat isolation, sound isolation and beautification as well as belongs to the technical field of the interior decorating piece of the vehicle. The invention is characterized by selecting a PU material as the base material of the top, heating, rolling glues on the front surface and the back surface as well as spraying soft water on the PU material; laying a combination layer and cutting a roll type material; then pressing and forming, cooling and shaping, cutting by a water cutter and packaging into a box and warehousing after inspection. The production method of the invention realizes the performance indexes of the sound suction, heat resistance, light weight and high intensity of a top assembly, reaches the international top level of Grade three, greatly reduces the weight of the top, meets the requirements of the light weight design of the whole vehicle; during the working procedure of rolling glues, the PU material is adopted to carry out flow operation of glue rolling on the front surface and back surface, heating and shaping; the technique is stable; the rigidness of a product is high; besides, the product can not be broken or droop; no semi-finished products are accumulated during the process, thus saving the manufacturing cost; the whole production process of the product does not generate harmful matters; besides, the product belongs to environment-friendly product.

Owner:广州吉兴汽车内饰件有限公司

Method for producing decorating part of car boot cover

InactiveCN101654080AReduce weightProcess stabilitySynthetic resin layered productsLaminationWork in processEnvironmental resistance

The invention relates to a method for producing a decorating part of a car boot cover, which belongs to the technical field of interior parts of cars. A low-density PP plate molding material is mainlyadopted as a decorating part basal body of a boot cover and is subjected to press molding, water-jet cutting and inspection to obtain a finished product. The invention solves the problem of meeting the performance indexes of sound absorption, heat resistance, light weight, high strength, and the like of a decorating part assembly of the boot cover and the three-grade international advanced level,greatly reduces the weight of the decorating part of the boot cover, meets the requirement on the lightweight design of the whole car and has stable molding process; a product has high rigidity and can not be broken and sagged; the product is produced by an automatic production line in the whole production process, thereby greatly reducing the labor intensity of workers in the production processand improving the production efficiency; no semi-finished product is stacked in the process, and the manufacture cost is saved; and the product does not generate harmful substances in the whole production process and belongs to an environmental-friendly product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Production method of automobile skylight sun-shield

ActiveCN101337434ASolve sound absorptionSolve heat resistanceOther domestic articlesSoftened waterHazardous substance

The invention relates to a method for producing a sunroof window visor for an automobile. The method comprises the following steps: substrate PU material pretreatment, sunroof window visor material combination and laying, pressure molding, cooling shaping and waterjet cutting, and the step of substrate PU material pretreatment comprises a substep of rubber rolling and a substep of softened water spray. The method solves the problems of performance indices of sound absorption, heat resistance, light weight and high strength of a sunroof window visor assembly; the weight of the sunroof window visor is greatly reduced, and the requirement on lightweight design of a complete automobile is met; during the PU material pretreatment process, the flow operations of heating of the double-sided PU rolled rubber and softened water treatment are adopted, the technology is stable, the operation security and accuracy are guaranteed, and simultaneously, the operation efficiency is improved; the rigidity of the product is high, without break and sagging; the stack of half-finished products can not happen during the process, and thus the production cost is saved; no harmful substance is generated during the entire production process.

Owner:WUXI GISSING AUTO PARTS CO LTD

Automobile ceiling producing process

InactiveCN1887597AReduce weightMeet the requirements of lightweight designLaminationLamination apparatusHazardous substanceHeat resistance

The present invention relates to automobile inner decoration technology, and is especially automobile ceiling producing process. The present invention adopts low density foamed polyurethane material as the base material, and the automobile ceiling producing process includes the steps of rolling glue, spraying softening water, pressing to form, cooling to fix, adhering facing material, cooling to fix for the second time, cutting with water cutter, mounting fittings and inspection. The automobile ceiling assembly has high performance and light weight.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

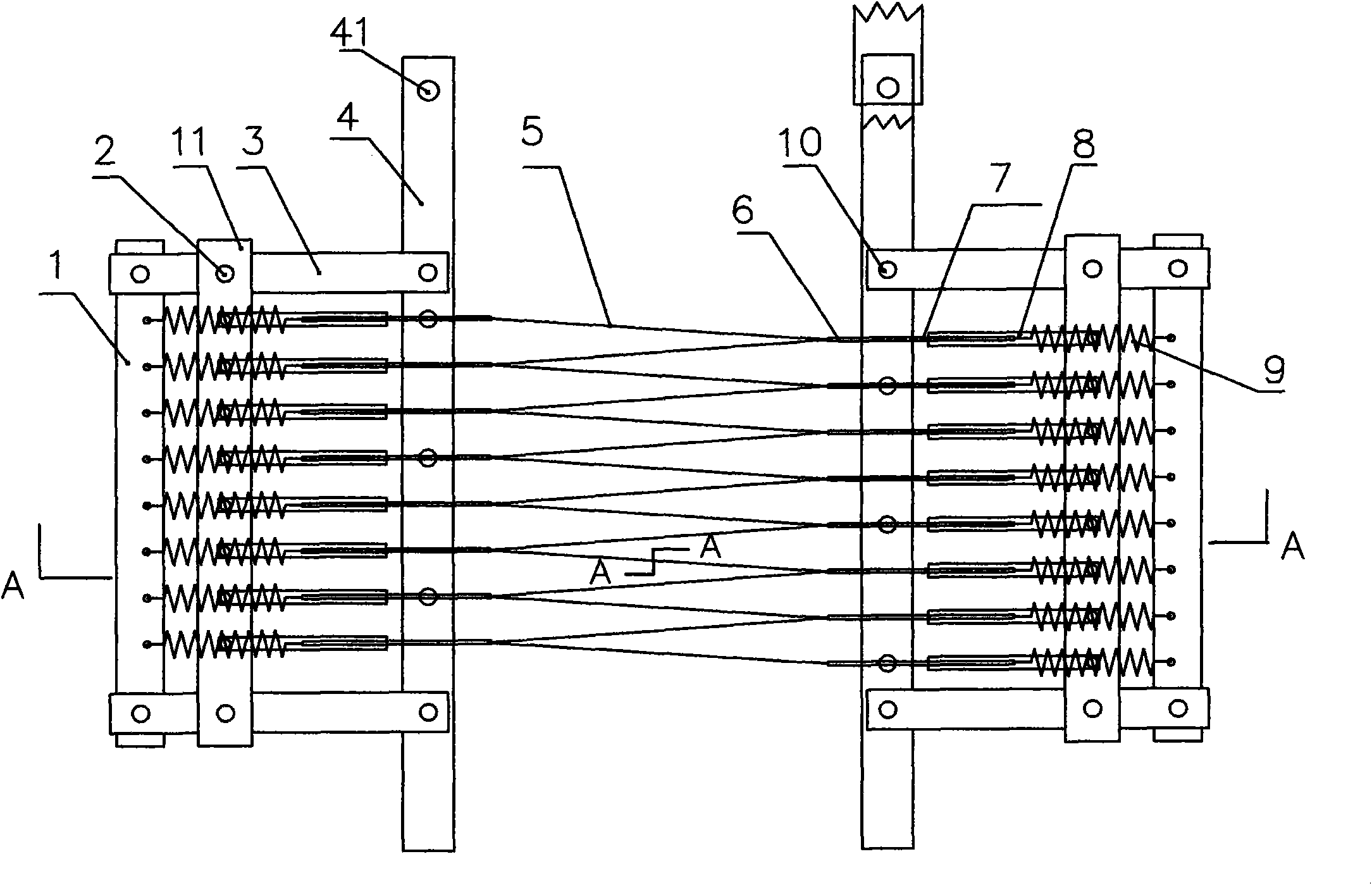

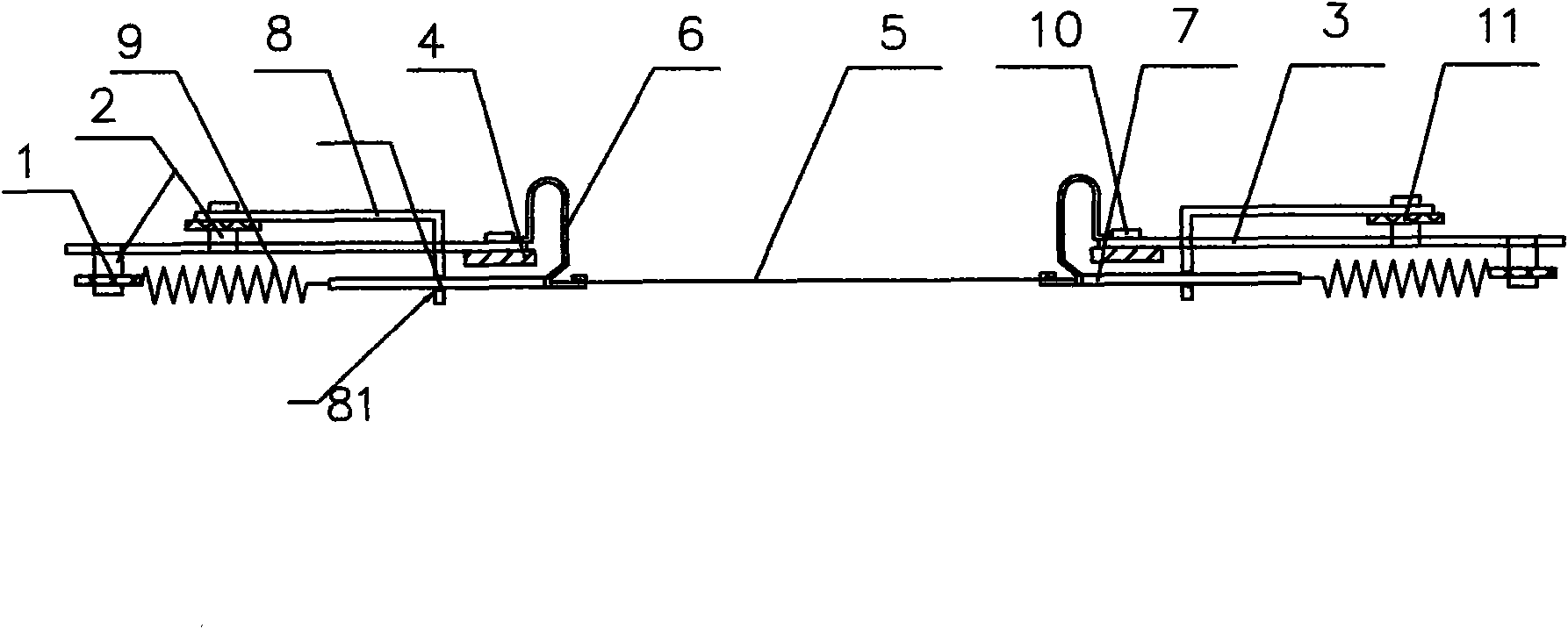

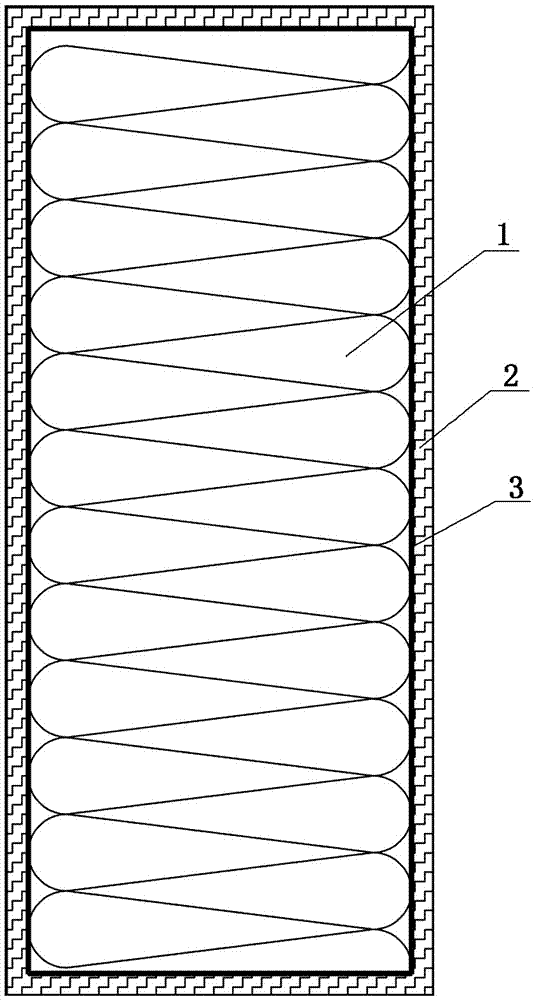

Tensile spring structure for preparing diamond film

InactiveCN102140626AMechanical vibration absorptionArrange staticChemical vapor deposition coatingPower flowEngineering

The invention discloses a tensile spring structure for preparing a diamond film, which overcomes the defects that the tensity of all heating wires can not be adjusted independently and the heating wires are vibrated due to current fluctuation in the prior art. The invention provides a device which can automatically and finely adjust the tensity of all the heating wires independently. The device comprises a left insulating board, a right insulating board, a left electrode and a right electrode, wherein the left insulating board and the right insulating board are arranged on a base, the left electrode and the right electrode are made of molybdenum bars, a heating wire device is arranged between the two insulating boards and comprises a group of heating wires arranged in a multi-turning way and in the shape like a Chinese character zhi, left turning parts and right turning parts of the heating wires are hooked on a group of left elastic hooks and a group of right elastic hooks connected with the left insulating board or the right insulating board, each hook is provided with a guiding and limiting structure, and all the turning parts of the heating wires are electrically connected with one of the left electrode and the right electrode made of molybdenum bars through hooked electrodes. The tensile spring structure can adjust the tensity of the heating wires automatically, independently and finely, can ensure that all the sections of the heating wires do not droop and are positioned in the same plane in the whole growing process of diamond, enables the tensile force to be uniform and the tensity to be compensated automatically in the whole process.

Owner:BEIJING TIANDI ORIENT SUPERHARD MATRIALS

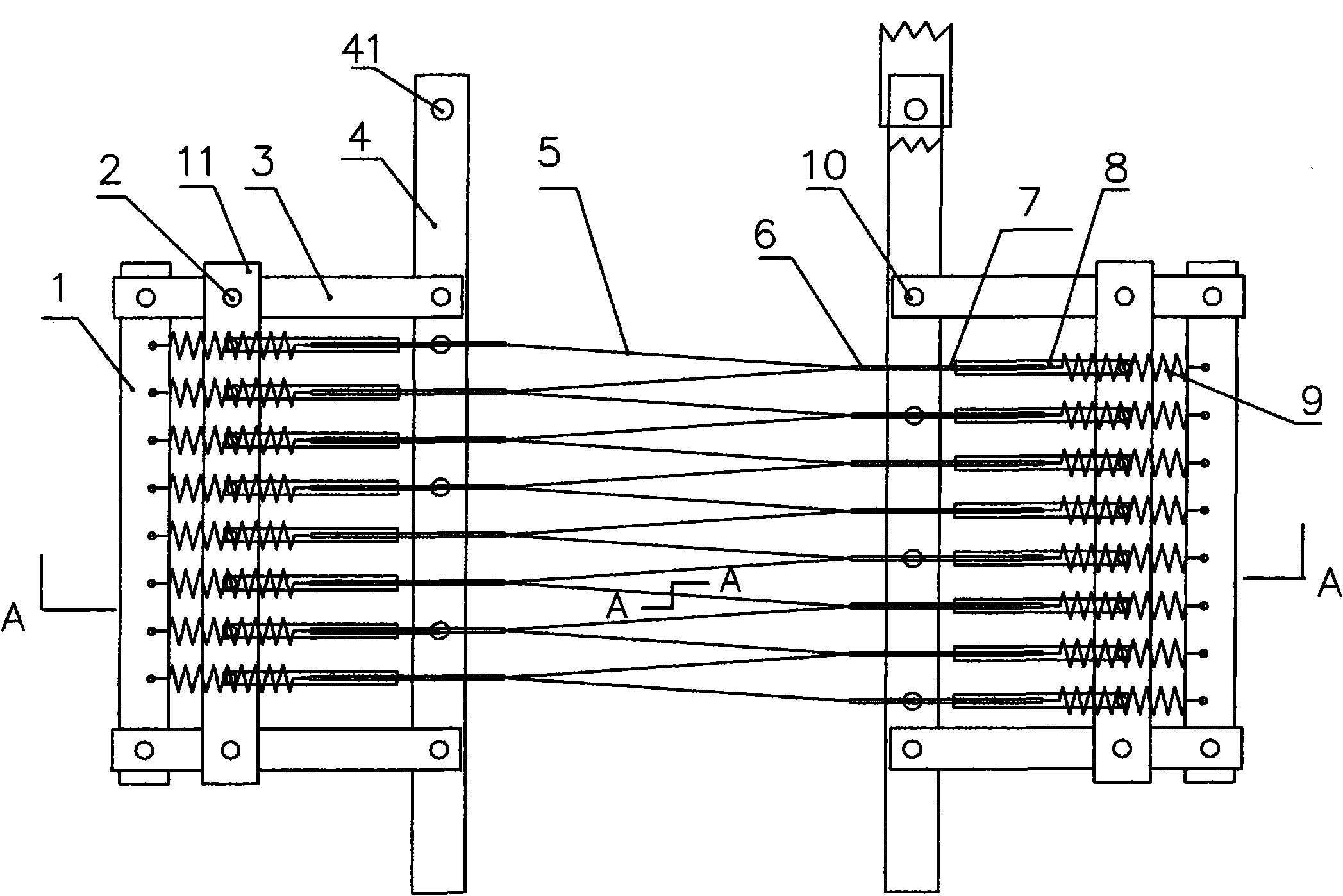

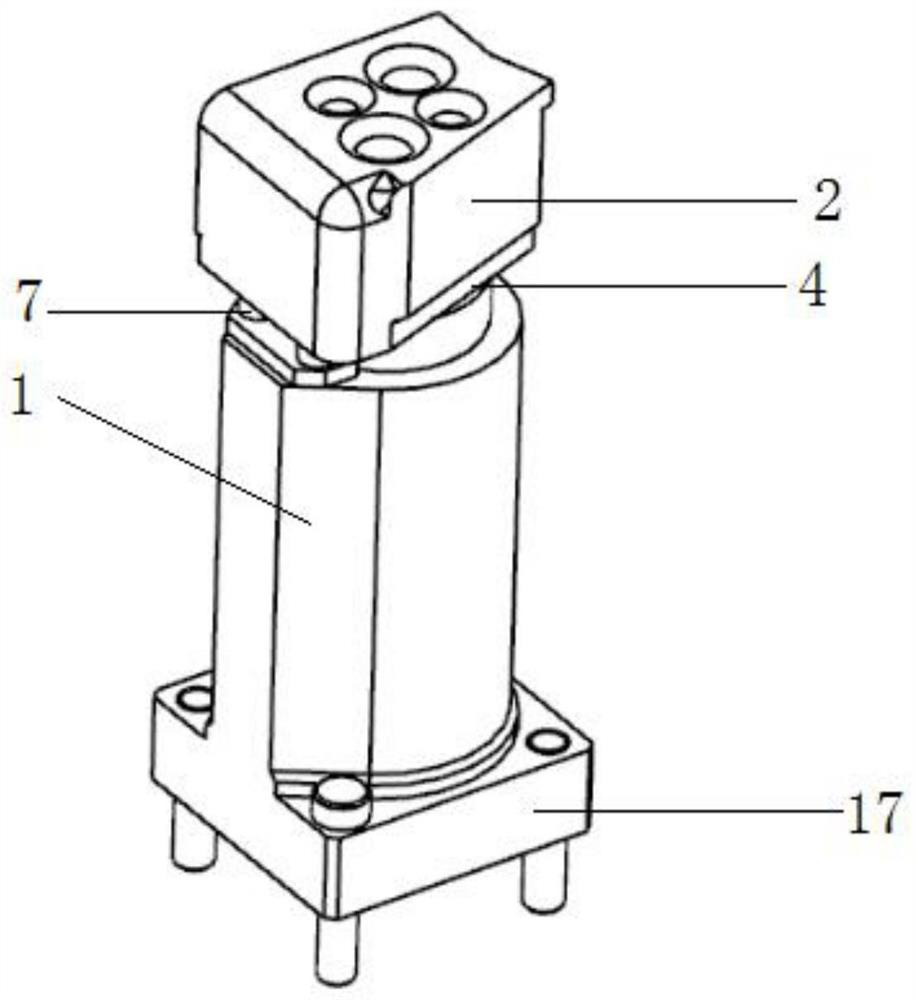

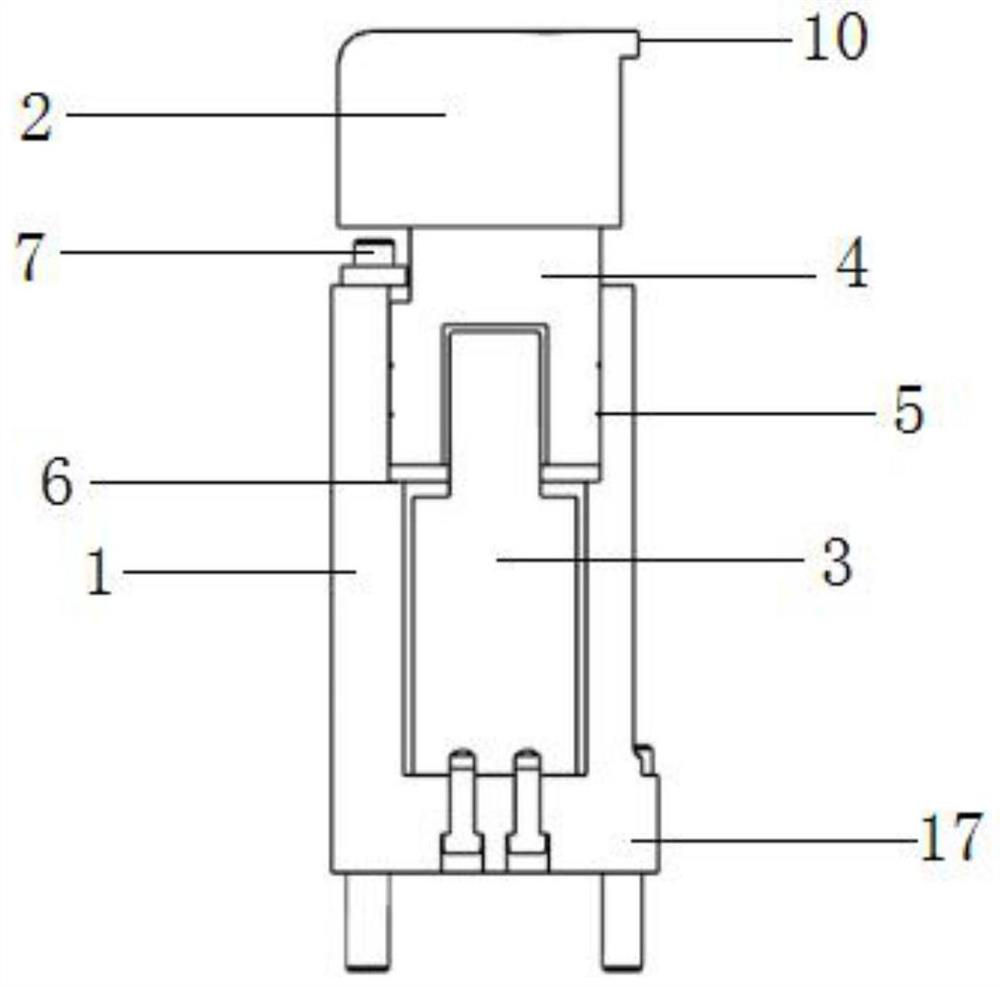

Mounting structure of wire electrode of honeycomb electric field

The invention discloses a wirelike electrode assembling structure of a honeycomb electric field, which enables a wirelike electrode to keep straight all the time, and comprises a wirelike electrode arranged in a tubular electrode, wherein, the two ends of the wirelike electrode are fastened on a pair of supports positioned on the two sides of the wirelike electrode through a pair of springs. The wirelike electrode assembling structure is characterized in that the wirelike electrode can be fastened on a pair of supports through a pair of springs, so the straightness of the wirelike electrode can be ensured, namely, the wirelike electrode cannot droop, thereby guaranteeing the reliable operation of the electrode of the honeycomb electric field, and also preventing the periodic correction carried out to the wirelike electrode and the correction carried out to the wirelike electrode after the cleaning process.

Owner:江苏保丽洁环境科技股份有限公司

Special core material for exterior wall external insulation fire-proof insulation and decoration plates and preparation method thereof

A special core material for exterior wall external insulation fire-proof insulation and decoration plates and a preparation method thereof are provided. The core material comprises a blocky vertical silk rock wool plate blank. The six sides of the vertical silk rock wool plate blank are each coated with a layer of flexible building structure adhesive to form a sealing layer. The outer side of the sealing layer is reinforced with basalt fiber mesh cloth, and the basalt fiber mesh cloth closely wraps the vertical silk rock wool plate blank to form a new mesh-bar composite body. Therefore, the joint stress of the pasting material and the vertical silk rock wool plate blank is enhanced, the tensile resistance, compressive resistance and shearing resistance of the rock wool insulation plate are increased, and the strength, stiffness, crack resistance and integrity of the rock wool insulation plate are improved. The surface of the vertical silk rock wool plate is sealed, so that the plate is effectively prevented from aging or becoming damp, and the service life is prolonged greatly. The core material has a simple structure, and is easy to manufacture. The technical scheme is applicable to the special core material for exterior wall external insulation fire-proof insulation and decoration plates.

Owner:北京东华绿源建筑装饰工程技术有限公司

Wet process technique of PU flexible foam top-liner

ActiveCN101337526AMeet the requirements of lightweight designNo generationSuperstructure subunitsDomestic articlesGlass fiberHazardous substance

The invention relates to a wet producing process for PU soft foam roof lining. The process comprises the following steps: rubber coating, glass fiber sprinkling, pressure molding, cooling to shape, fabric fitting, cooling to shape, water jet cutting and accessory mounting. The wet producing process has the advantages that the weight of the roof lining produced by the method of the invention is greatly reduced, the requirement of the lightweight design for the complete machine is met, the rigidity of the product is good, the nearly 3 meter long product cannot be broken nor droops, and the harmful substances cannot be generated during the overall production process.

Owner:WUXI GISSING AUTO PARTS CO LTD

Rigid reinforced automobile bottom protection plate and production method thereof

ActiveCN104149860AReduce weightNothing producedSuperstructure subunitsGlass fiberHazardous substance

The invention relates to a rigid reinforced automobile bottom protection plate and a production method thereof. The rigid reinforced automobile bottom protection plate is of a structure with five layers, namely, the polypropylene resin layer, the glass fiber mat layer, the polypropylene resin layer, the glass fiber mat layer and the polypropylene resin layer from top to bottom in sequence. The production method comprises the steps of heating the polypropylene resin layers and the glass fiber mat layers in a drying oven, laying and locating the polypropylene resin layers and the glass fiber mat layers in a closed forming mold, starting a forming press and carrying out pressing formation. The production steps of the rigid reinforced automobile bottom protection plate are simple, the produced automobile bottom protection plate is light in weight and high in strength, the weight of finished automobile equipment is greatly lowered, the rigidity of the automobile bottom protection plate is high, the automobile bottom protection plate will not be broken or droop, and the whole production process is free of hazardous substances and is friendly to environment.

Owner:WUXI GISSING AUTO PARTS CO LTD

Wet process technique of PU flexible foam top-liner

ActiveCN101337526BMeet the requirements of lightweight designNo generationSuperstructure subunitsDomestic articlesGlass fiberHazardous substance

The invention relates to a wet producing process for PU soft foam roof lining. The process comprises the following steps: rubber coating, glass fiber sprinkling, pressure molding, cooling to shape, fabric fitting, cooling to shape, water jet cutting and accessory mounting. The wet producing process has the advantages that the weight of the roof lining produced by the method of the invention is greatly reduced, the requirement of the lightweight design for the complete machine is met, the rigidity of the product is good, the nearly 3 meter long product cannot be broken nor droops, and the harmful substances cannot be generated during the overall production process.

Owner:WUXI GISSING AUTO PARTS CO LTD

Plastic temperature-adjustable pack

A cold and hot pack capable of being plasticized comprises: a bag member made of an impermeable soft sealing material; plural particle-like supporters disposed in the bag member, each of the particle-like supporters is formed with at least a pore; and a fluid filled and accommodated in the pores of the particle-like supporters, and a negative pressure status is formed inside bag member, thereby enabling the particle-like supporters and the fluid to be pressed and secured by the atmospheric pressure so as to prevent sag. The present invention is able to be applied in various fields such as a cold and hot pack, a sitting pad, a water bed, an anti-bedsore mattress and a temperature keeping pack, and provides better functions and quality comparing to prior art.

Owner:周朝木 +1

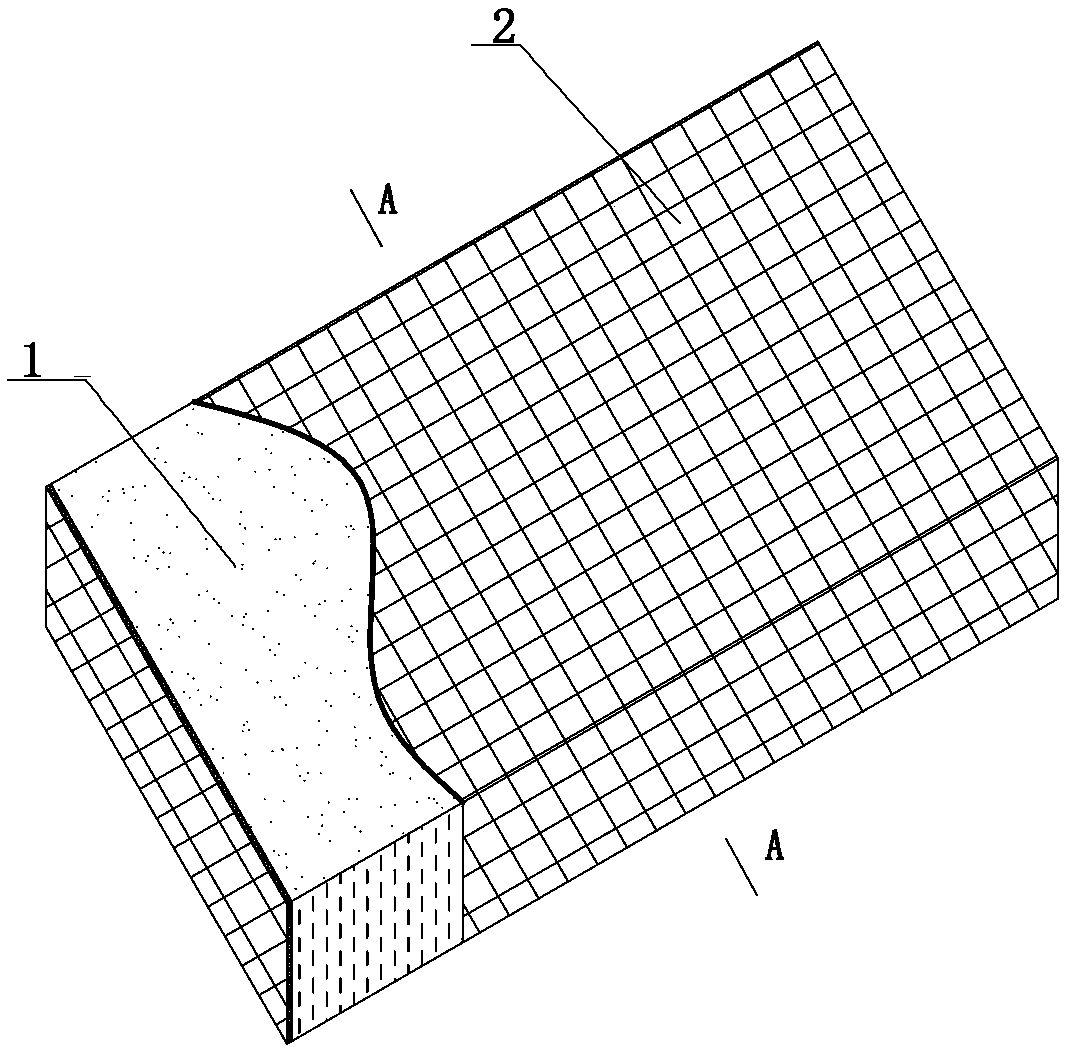

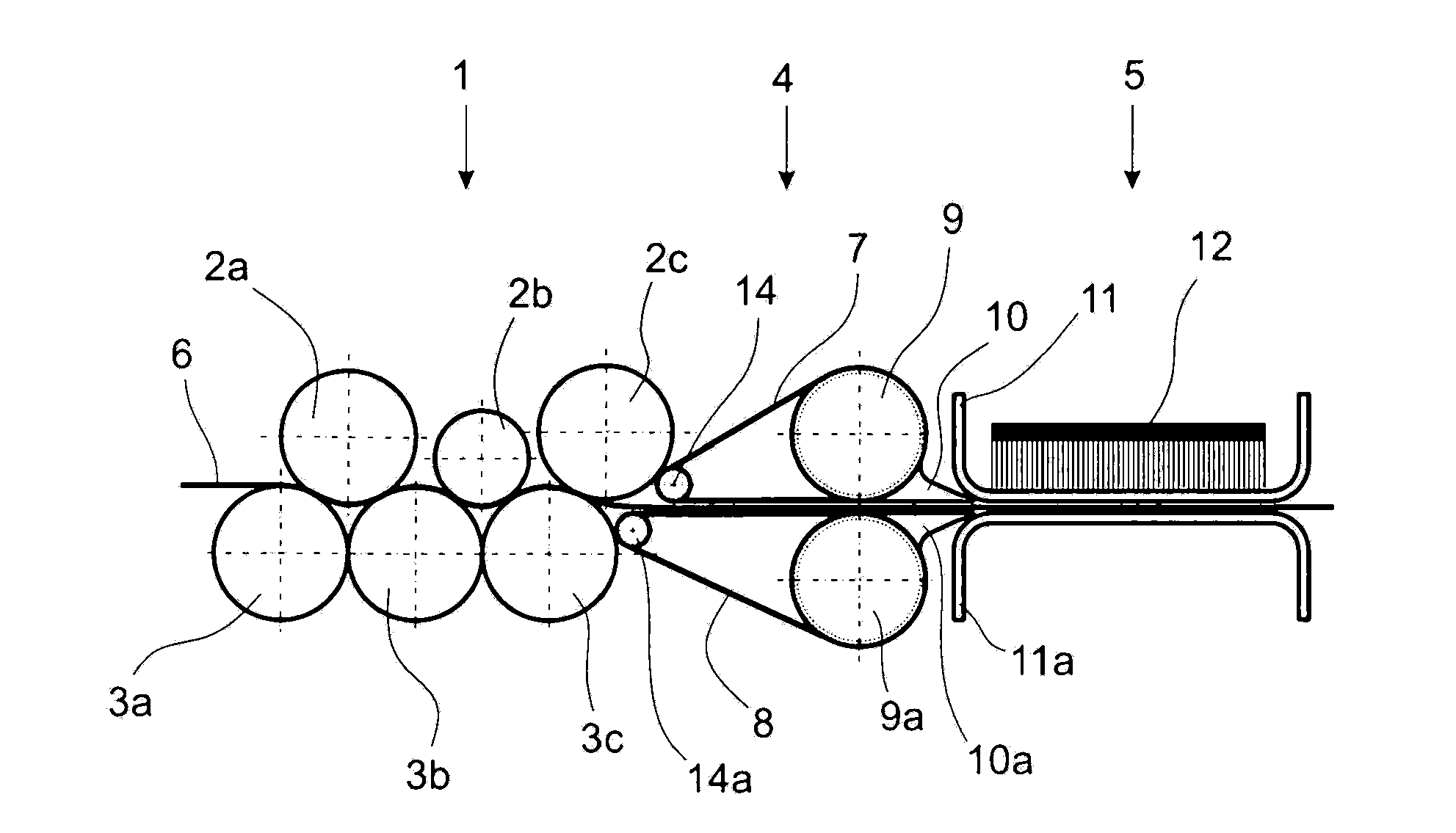

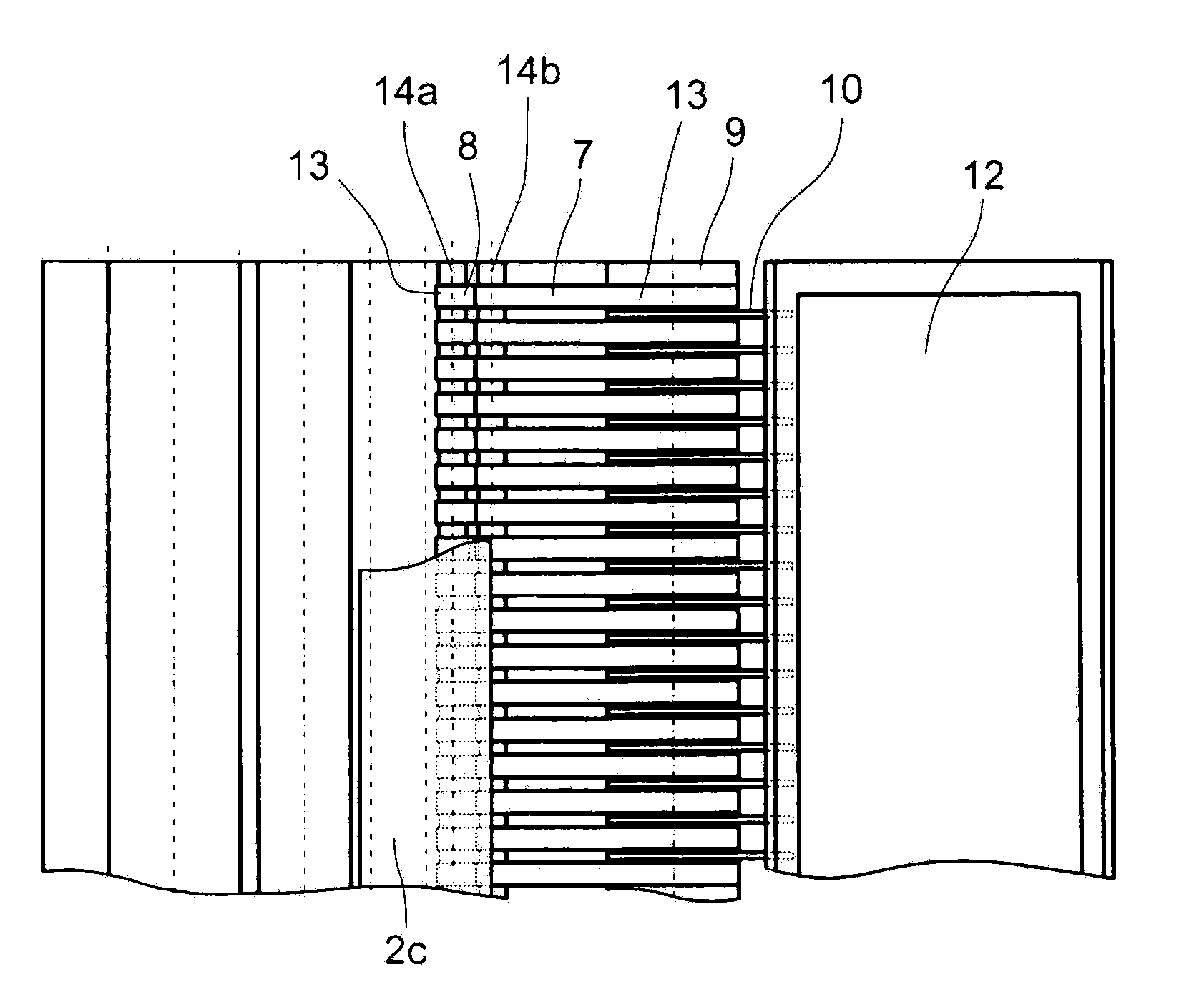

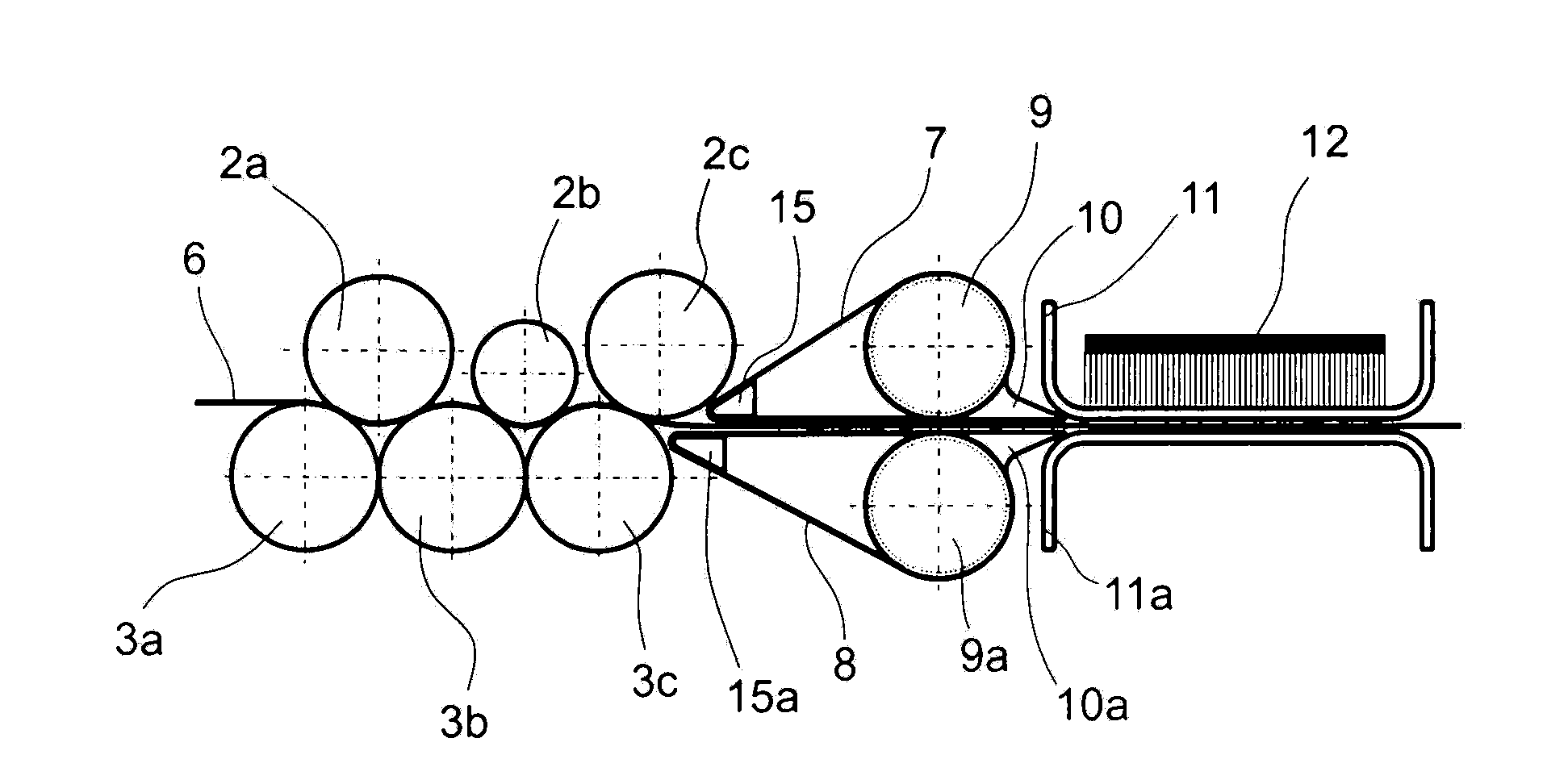

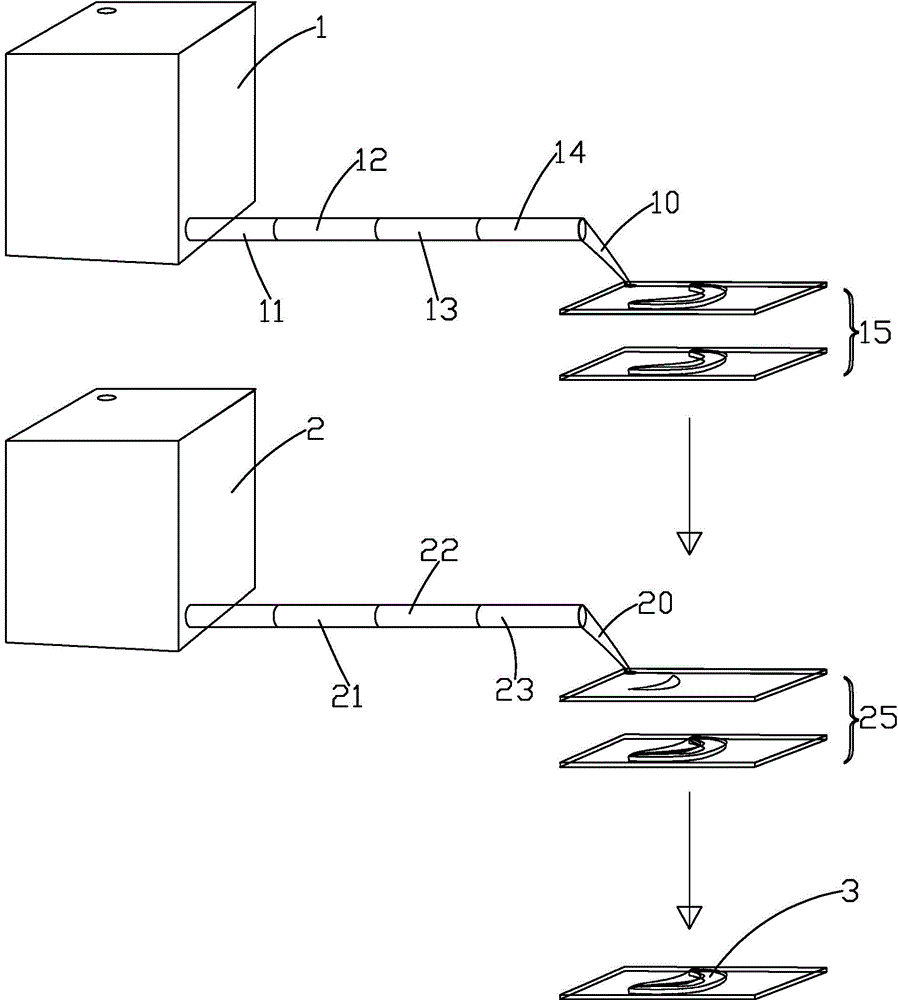

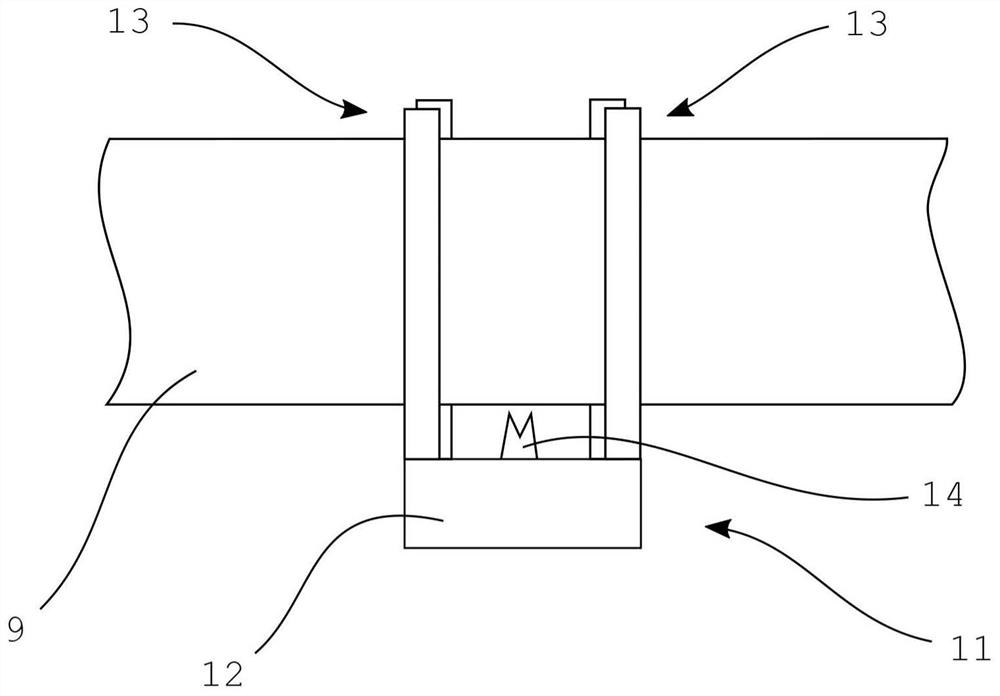

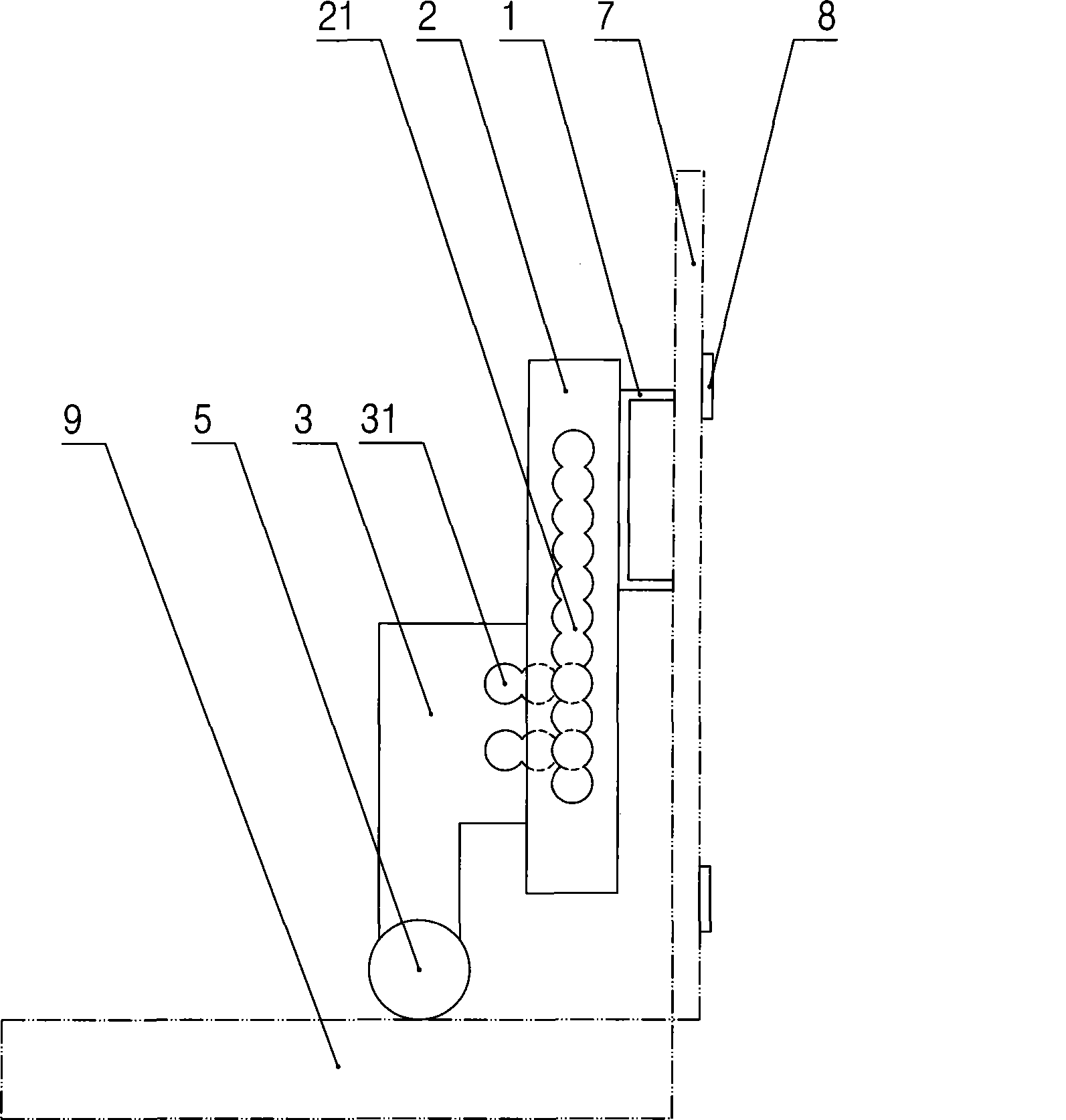

Feed system for textile processing machine

InactiveCN103668574AReliable deliveryReliable bootFibre feedersNeedling machinesYarnTextile processing

The invention relates to a feed system for a textile processing machine. The feed system includes at least one circling conveyer belt (8) and another conveying device, a non-woven fabric belt (6) is conveyed and guided between the conveyer belt and the other conveying device, and the feed system is characterized in that the conveyer belt (8) includes at least two belt strips, and a yarn guide (10a) is arranged between every adjacent belt strips.

Owner:TRUETZSCHLER GMBH & CO KG

Production method of automobile back seat decoration part

InactiveCN102897109AReduce labor intensityMeet the requirements of lightweight designVehicle seatsEngineeringHydroforming

The invention discloses a production method of an automobile back seat decoration part, comprising the following steps: putting the material of the automobile back seat decoration part between an upper oven heating plate and a lower oven heating plate of an oven to dry, controlling the temperature of the upper oven heating plate at 300-310 DEG C, controlling the temperature of the lower oven heating plate at 400-410 DEG C, and controlling the time for drying in 100-120 seconds; and putting the dried material of the automobile back seat decoration part on a hydraulic forming machine, controlling forming pressure of the hydraulic forming machine at 4.5-5.5MPa and controlling the time for forming in 75-85 seconds to obtain finished products of the automobile back seat decoration part. The method provided by the invention has the advantages that the weight of the produced product is greatly reduced, the product is provided with high rigidity, and no harmful substance is produced in the whole production process of the product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Producing method of automobile skylight sun louver

InactiveCN104999769AWon't breakWon't sagLaminationLamination apparatusSoftened waterHazardous substance

The invention relates to a producing method of an automobile skylight sun louver, and belongs to the technical field of automotive upholstery. The method includes the steps of preprocessing a base body PU material, combining and laying a skylight sun louver material, conducting pressing and forming, conducting cooling and shaping, and conducting cutting through a water jet scalpel, wherein the step of preprocessing the base body PU material includes the substeps of rolling the material in rubber and spraying softened water. By means of the method, the high strength performance index of a skylight sun louver assembly is achieved, the requirement for high strength design is met, the assembly line work of heating double-sided PU, rolling the PU in rubber and conducting processing through the softened water is adopted in the PU material preprocessing step, the process is stable, operation safety and accuracy are ensured, and meanwhile the work efficiency is improved; the product is high in rigidity, no breaking or drooping can occur; no semi-finished products are accumulated in the way, bad products caused by insufficient rigidity are reduced, and the manufacturing cost is saved; no harmful substances are produced in the whole producing process of the product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

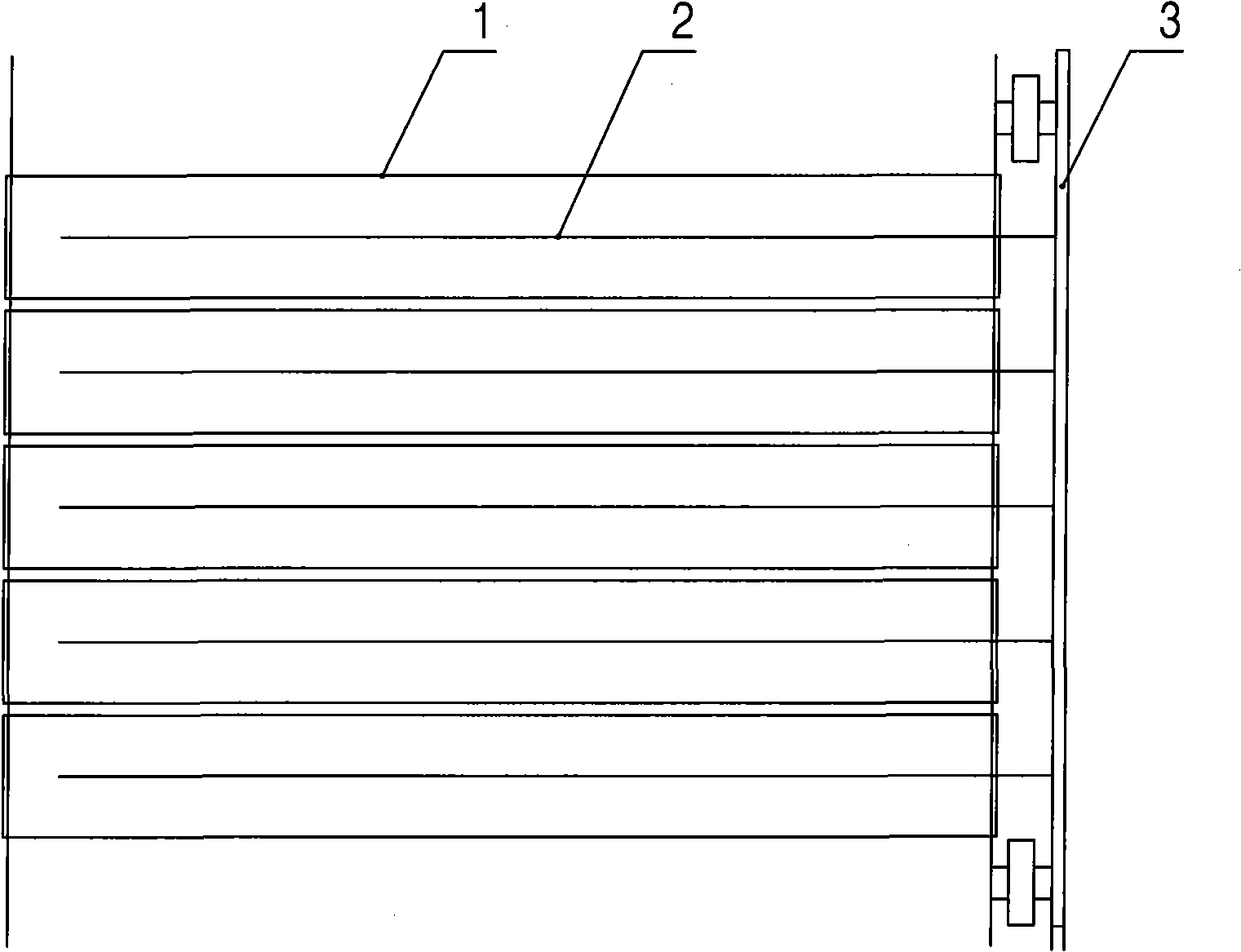

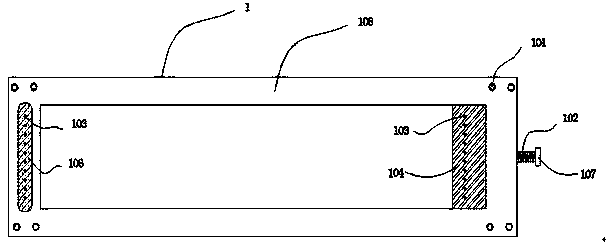

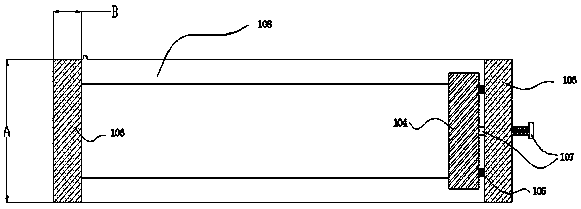

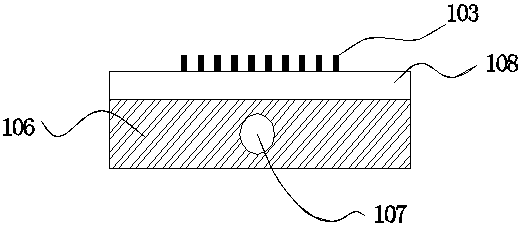

Gluing device for ultra-long flexible LED light source

The invention provides a gluing device for an ultra-long flexible LED light source and belongs to the field of manufacturing of LED lighting products. The gluing device for the ultra-long flexible LEDlight source consists of a gluing bottom plate and a gluing support. The gluing support is used for straightening during gluing of a FPC (flexible printed circuit) substrate of the ultra-long flexible LED light source and glue baking and setting after dispensing. A movable stretching mechanism is arranged on the gluing support and can strengthen the flexible substrate of the ultra-long flexible LED light source to facilitate dispensing of the dispensing process. The gluing base provides accurate positioning and bearing functions for the gluing support. Platform type support tables and semicircular groove support channels of the FPC substrate of the ultra-long flexible LED light source product are arranged on the gluing base. The flexible substrate of the ultra-long flexible LED light source product is strengthened under the action of the movable stretching mechanism of the gluing support and placed on the platform type support tables and the semicircular groove support channels of thegluing base, so that the FPC substrate is ensured to be in a horizontal straight state, and gluing operation of an automatic machine is facilitated.

Owner:黄琴

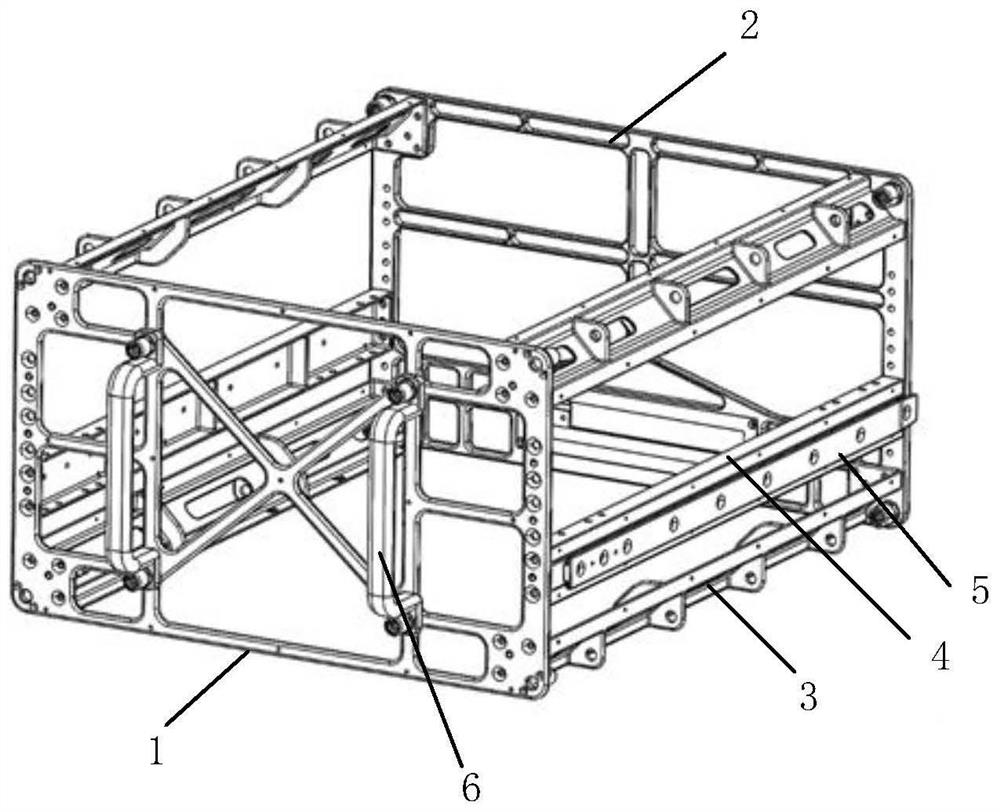

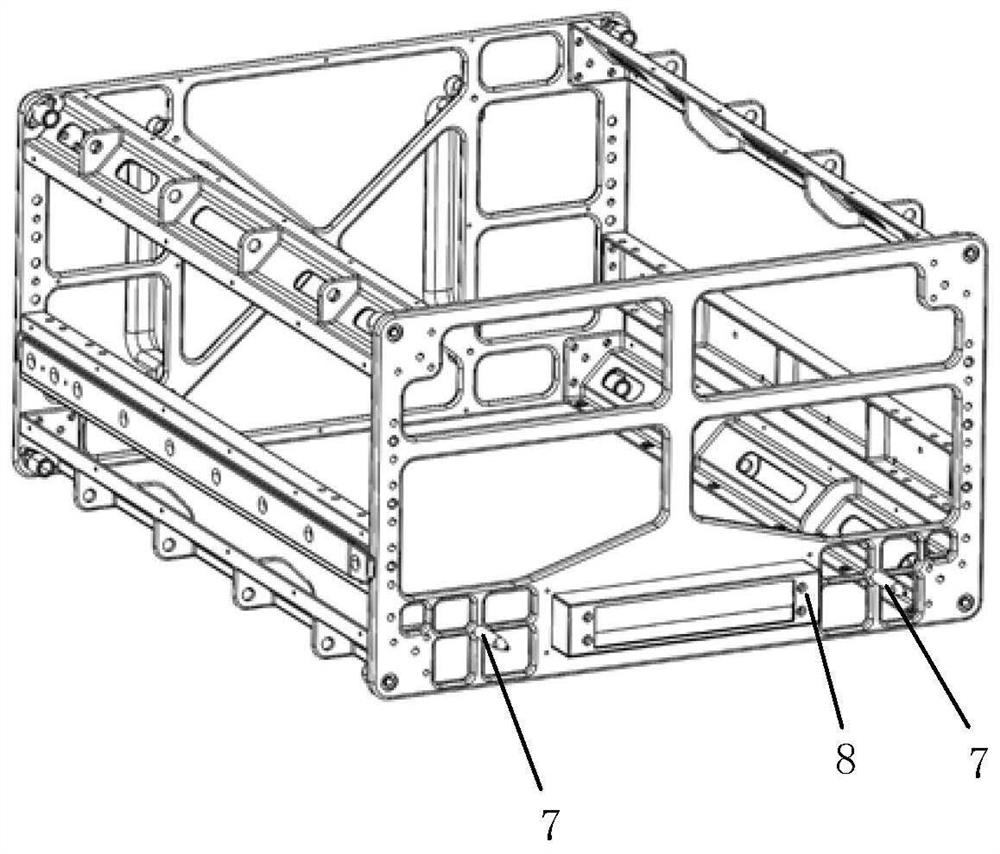

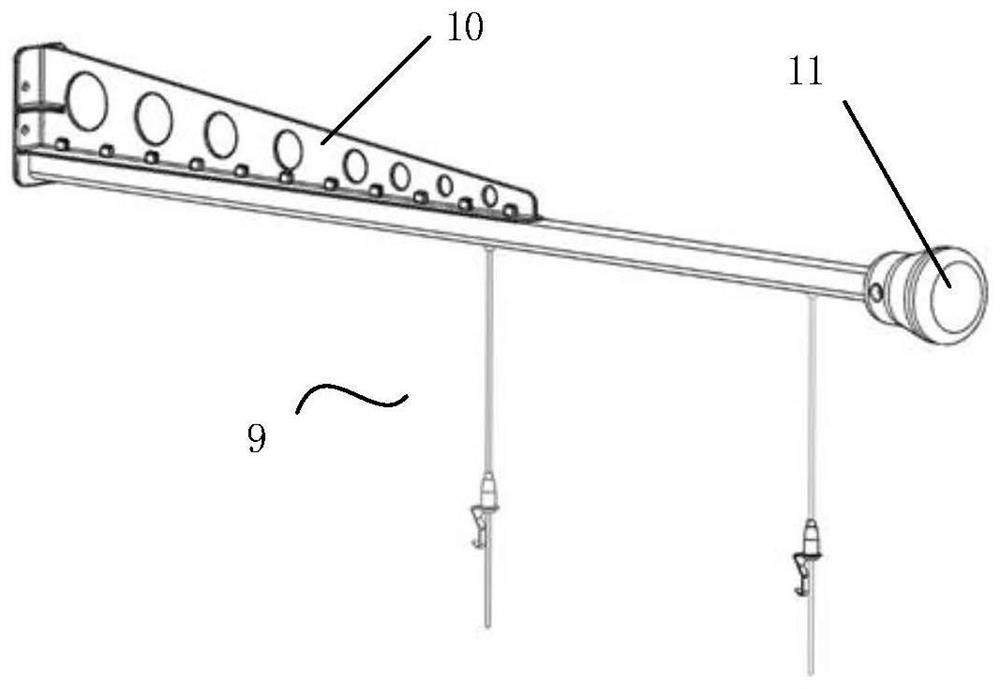

Scientific experiment load light simulation device for experiment cabinet

The invention relates to a scientific experiment load light simulation device for an experiment cabinet, and relates to the technical field of space, the scientific experiment load light simulation device comprises an experiment cabinet main body, a scientific experiment load light part and a steel wire rope assembly, one side of the scientific experiment load light part is fixedly provided with a guide rail, the side wall of the experiment cabinet main body is fixedly provided with a guide groove, and the guide rail is slidably connected with the guide groove; the steel wire rope assembly is fixedly connected with the experiment cabinet body, and the lower end of the steel wire rope assembly is connected with the scientific experiment load light part and used for counteracting the gravity of the scientific experiment load light part. The device has the advantages that the scientific experiment load light part is suspended by the steel wire rope assembly, it can be guaranteed that the scientific experiment load light part cannot droop under the action of gravity, the space use environment of the guide rail and the guide groove is simulated, and therefore whether the installation positions of the guide rail and the guide groove are reasonable or not can be verified, and the feasibility of the device is verified. And meanwhile, an astronaut can practice and operate the experiment load conveniently.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

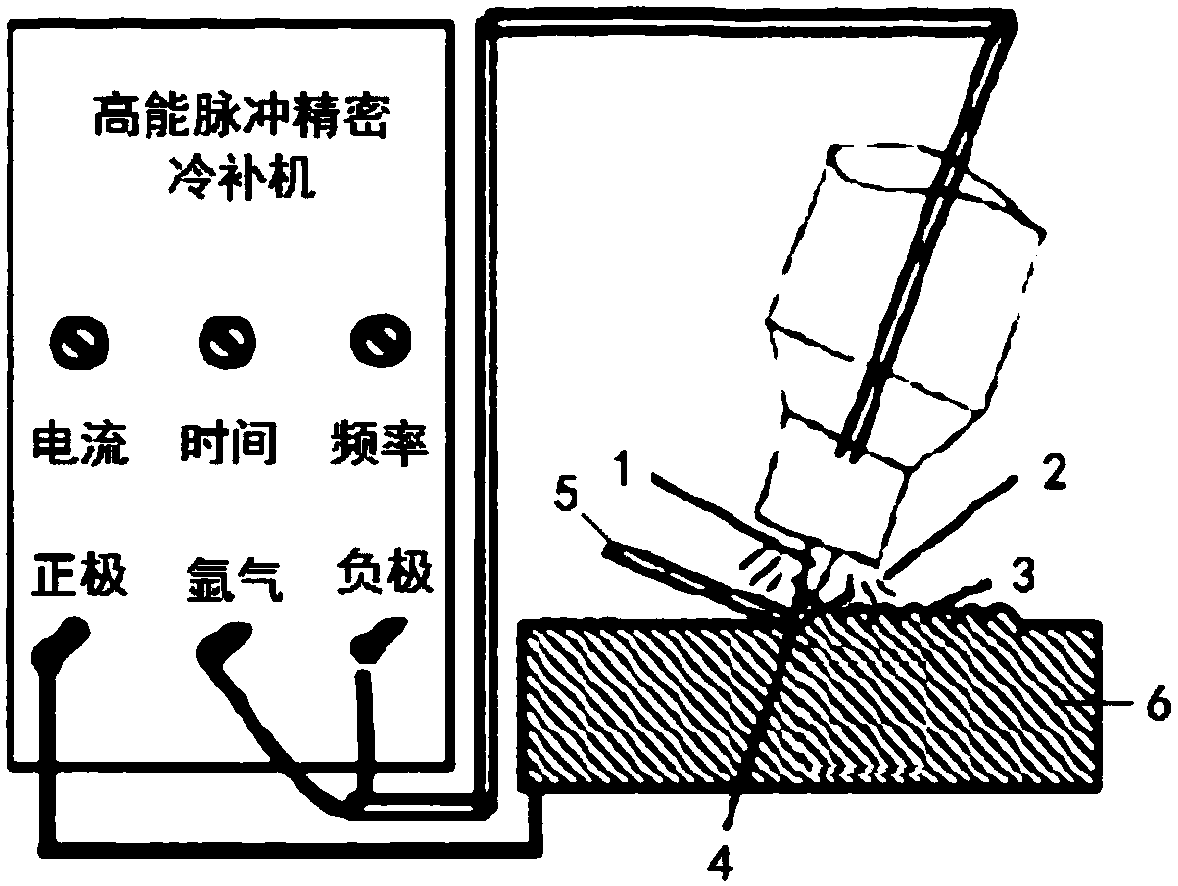

An online repair process for smooth shaft wear

The present invention relates to the field of blenders, and specifically relates to an on-line repair technology for smooth shaft abrasion of a blender. The repair technology comprises the following steps of (1) determining a repair scheme according to an abrasion degree of a smooth journal working surface of the blender during an operation process with an outer sealing ring, and inspection and confirmation of surface cleaning, abrasion loss, surface defects, shaft size precision and runout; (2) maintaining an abrasion part, determining materials for smoothing and repairing, and ensuring matching of corrosion resistance and mechanical properties of a repair region and a substrate; (3) machining the abrasion part after welding is performed, namely performing machining by using an axle end lathe after the welding is performed; and (4) performing a color nondestructive test on the repair part. By utilization of a high-precision pulse cold welding technology, the repaired binding part is more abrasion-resistant than the original substrate.

Owner:浙江翰德圣智能再制造技术有限公司

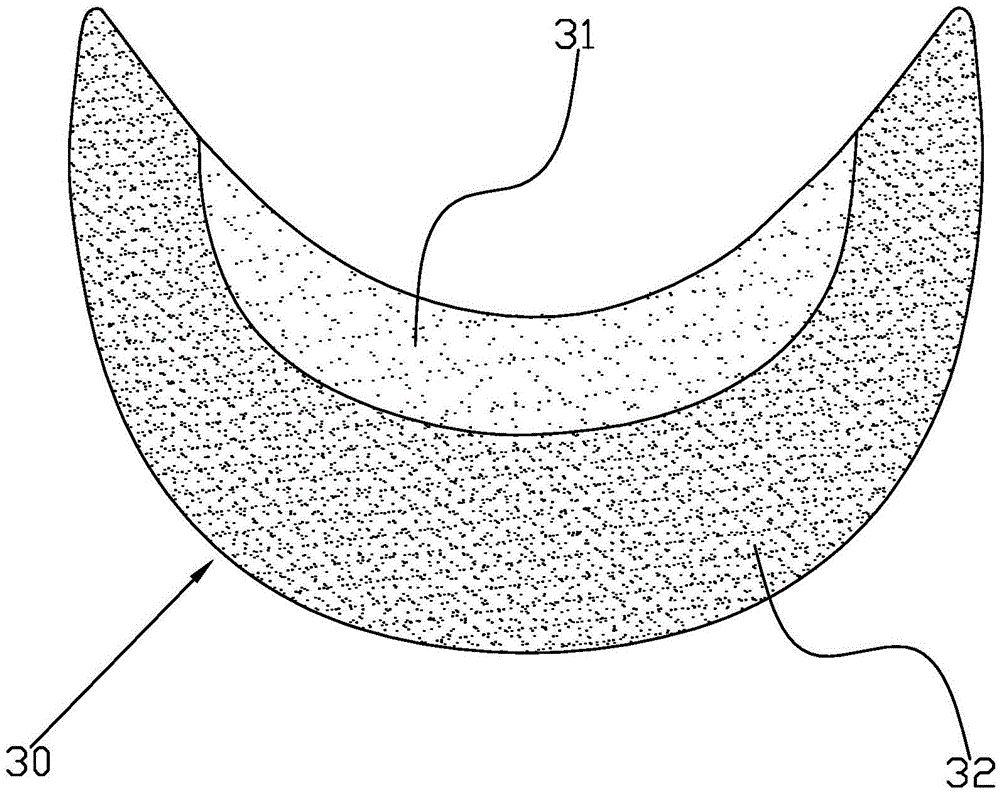

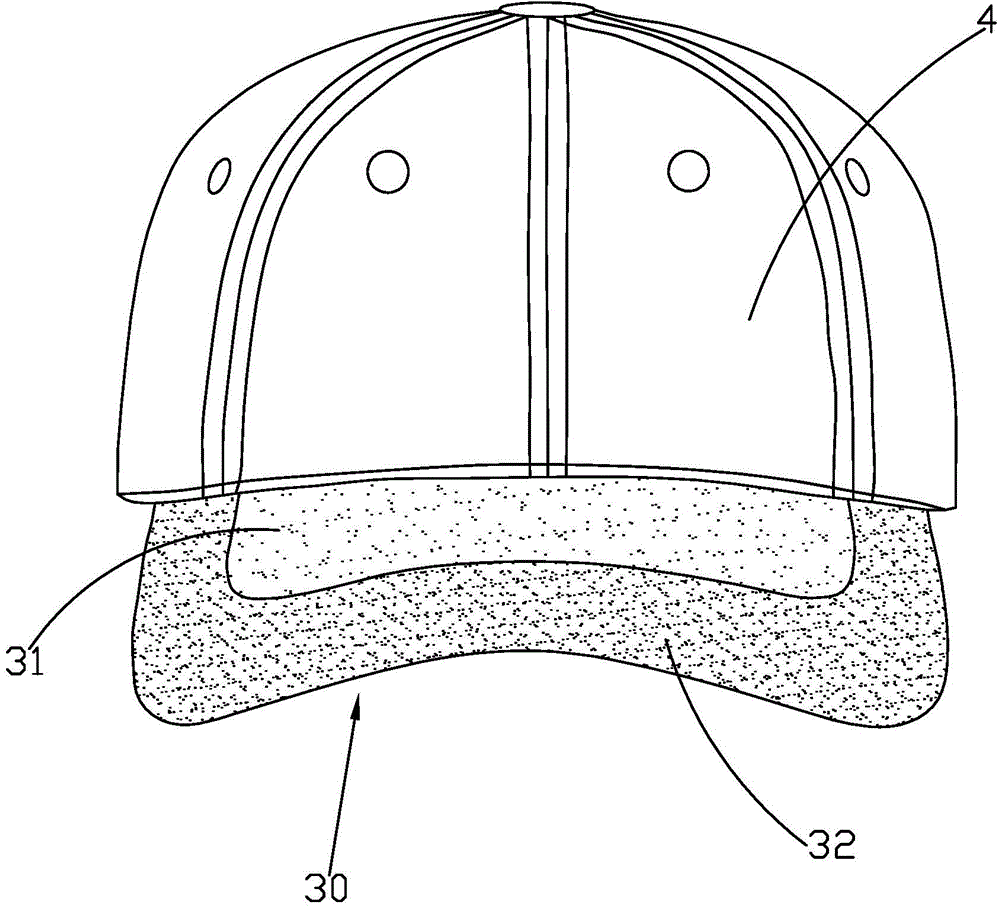

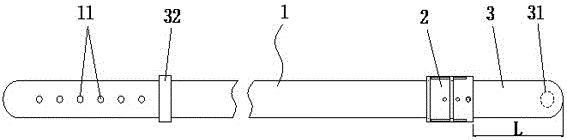

Method for manufacturing hat eye brow and eye brow manufactured by adopting method

The invention discloses a method for manufacturing a hat eye brow. The method comprises the following steps: 1) preparing a mold and molding materials; 2) carrying out primary injection molding; and 3) carrying out secondary injection molding. Additionally, the invention also discloses an eye brow comprising an eye brow main body, wherein the eye brow main body is composed of a first component and a second component, wherein the hardness of the first component is less than that of the second component. Because the first component and the second component are respectively manufactured on the injection molding mold by adopting the method provided by the invention, the hardness of the first component and the second component can be set to be different, and further the eye brow composed of the first component and the second component at different parts have different hardnesses.

Owner:ZHONGSHAN WEI LI TEXTILE

Movable support frame

Owner:JIANGSU YINHE ELECTRONICS

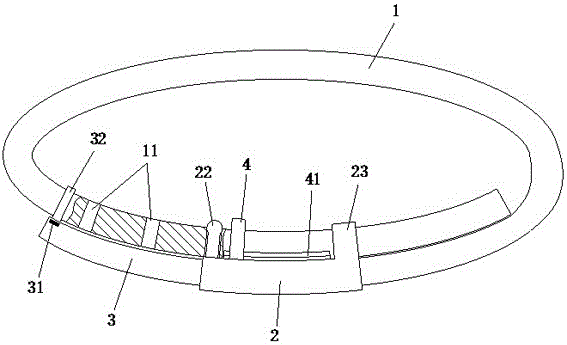

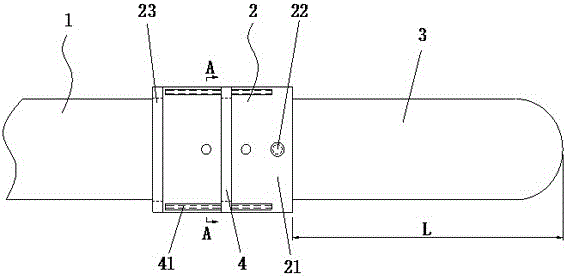

Plate buckle belt

InactiveCN106723559ANice appearanceAvoid embarrassmentBucklesGarment beltsEngineeringMechanical engineering

Owner:陈顺忠

Automobile ceiling producing process

InactiveCN100475528CReduce weightMeet the requirements of lightweight designLaminationLamination apparatusHazardous substanceHeat resistance

The present invention relates to automobile inner decoration technology, and is especially automobile ceiling producing process. The present invention adopts low density foamed polyurethane material as the base material, and the automobile ceiling producing process includes the steps of rolling glue, spraying softening water, pressing to form, cooling to fix, adhering facing material, cooling to fix for the second time, cutting with water cutter, mounting fittings and inspection. The automobile ceiling assembly has high performance and light weight.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

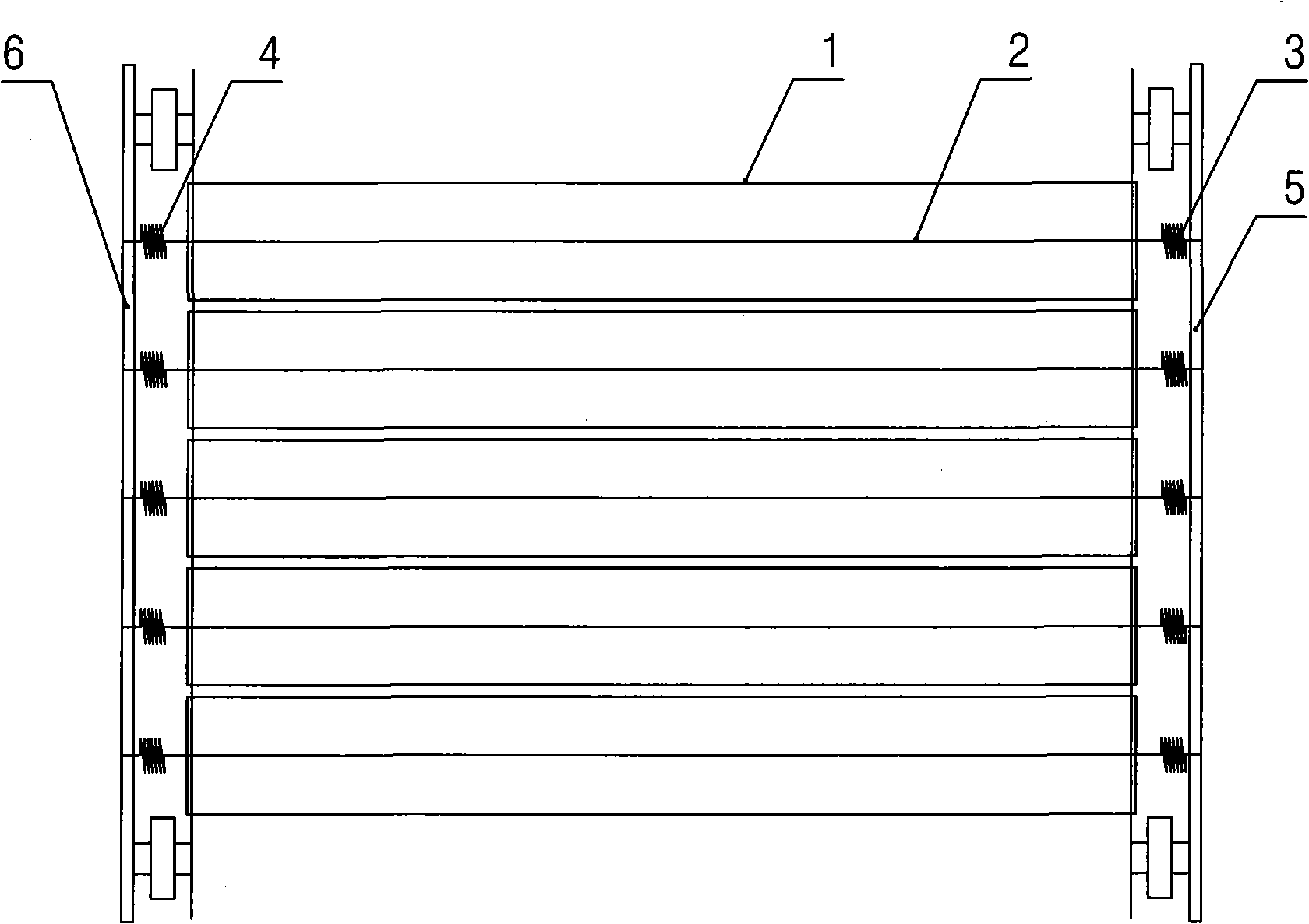

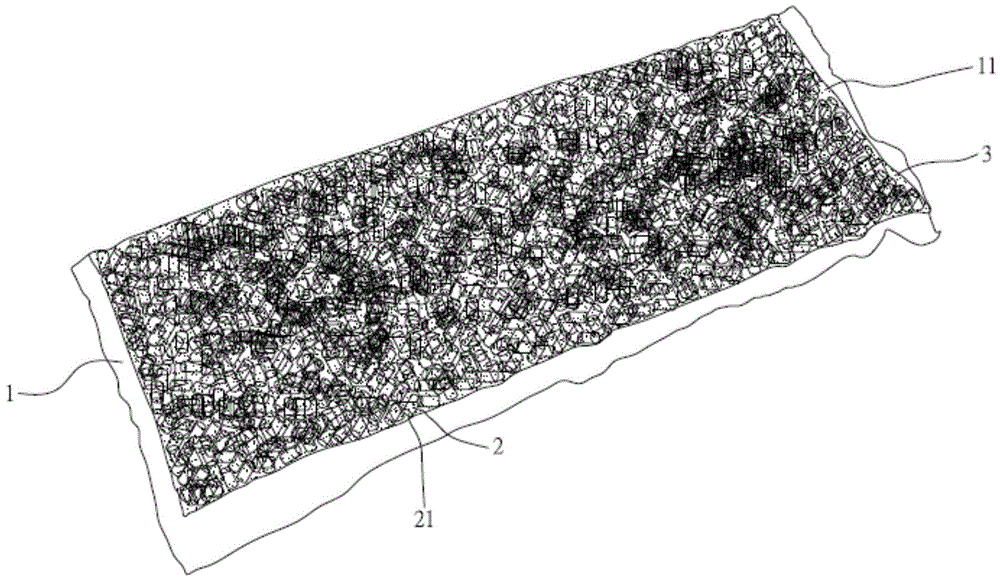

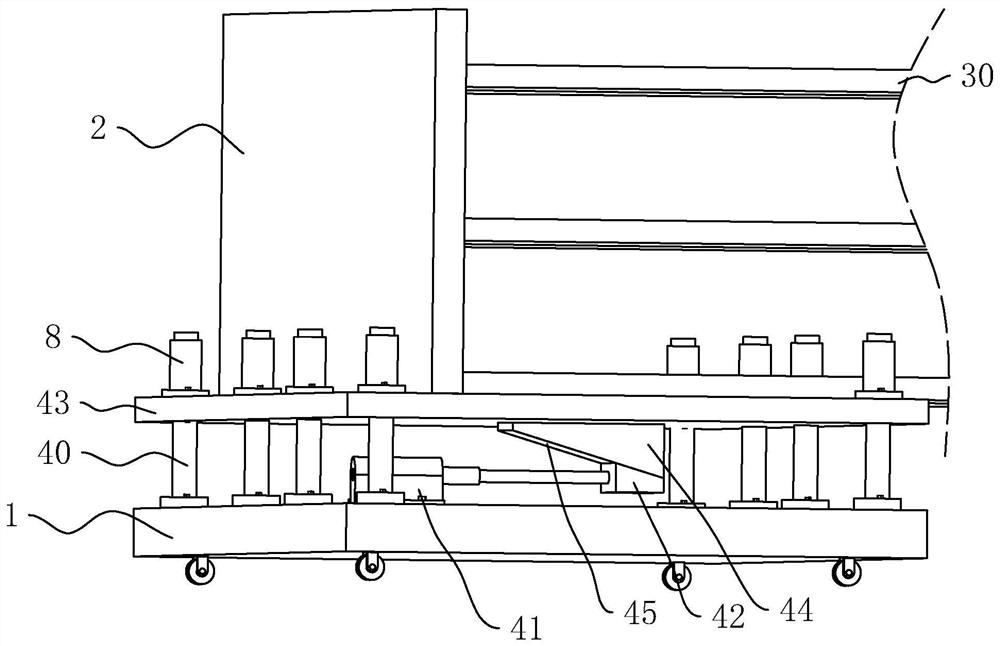

Steel bar prefabricating device for mold frame of aerated concrete plate

ActiveCN112847773AReduce the likelihood of saggingAchieve prefabricationCeramic shaping apparatusClassical mechanicsRebar

The invention relates to a steel bar prefabricating device for a mold frame of an aerated concrete plate. The steel bar prefabricating device for the mold frame of the aerated concrete plate comprises a moving part, a vertical mounting plate and a lifting mechanism used for driving the mounting plate to vertically ascend and descend are arranged on the moving part, a supporting mechanism is arranged on the side wall of the mounting plate, the supporting mechanism comprises at least two supporting rods which are located in the same horizontal plane and are parallel to each other, supporting pipes are arranged on the supporting rods, and material returning openings are formed in the tops of the supporting pipes. The steel bar prefabricating device has the advantage that a main reinforcement can be conveniently arranged between two inner end plates in a penetrating mode.

Owner:江阴天孚新型墙体材料有限公司

Method for producing reconstituted cotton type ceiling by high-temperature steam

InactiveCN101659242BReduce weightReduce labor intensityLaminationLamination apparatusEnvironmental resistanceCompression molding

The invention relates to an automatic production method of an auto ceiling steam technology, in particular to the method for producing a reconstituted cotton type ceiling by high-temperature steam, the ceiling is used for being mounted at the top of an auto to play the roles of environmental protection and beautification, and the method belongs to the technical field of auto inner garnish workpieces. According to the technical scheme, the method for producing the reconstituted cotton type ceiling by the high-temperature steam is as follows: a, steam heating; b, compression molding; c, coolingsolidification; d, primary water knife cutting; e, adhesive spraying; f, fabric bonding; g, wrapping and combination; h, secondary water knife cutting; and i, inspection: packing and warehousing after the inspection.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

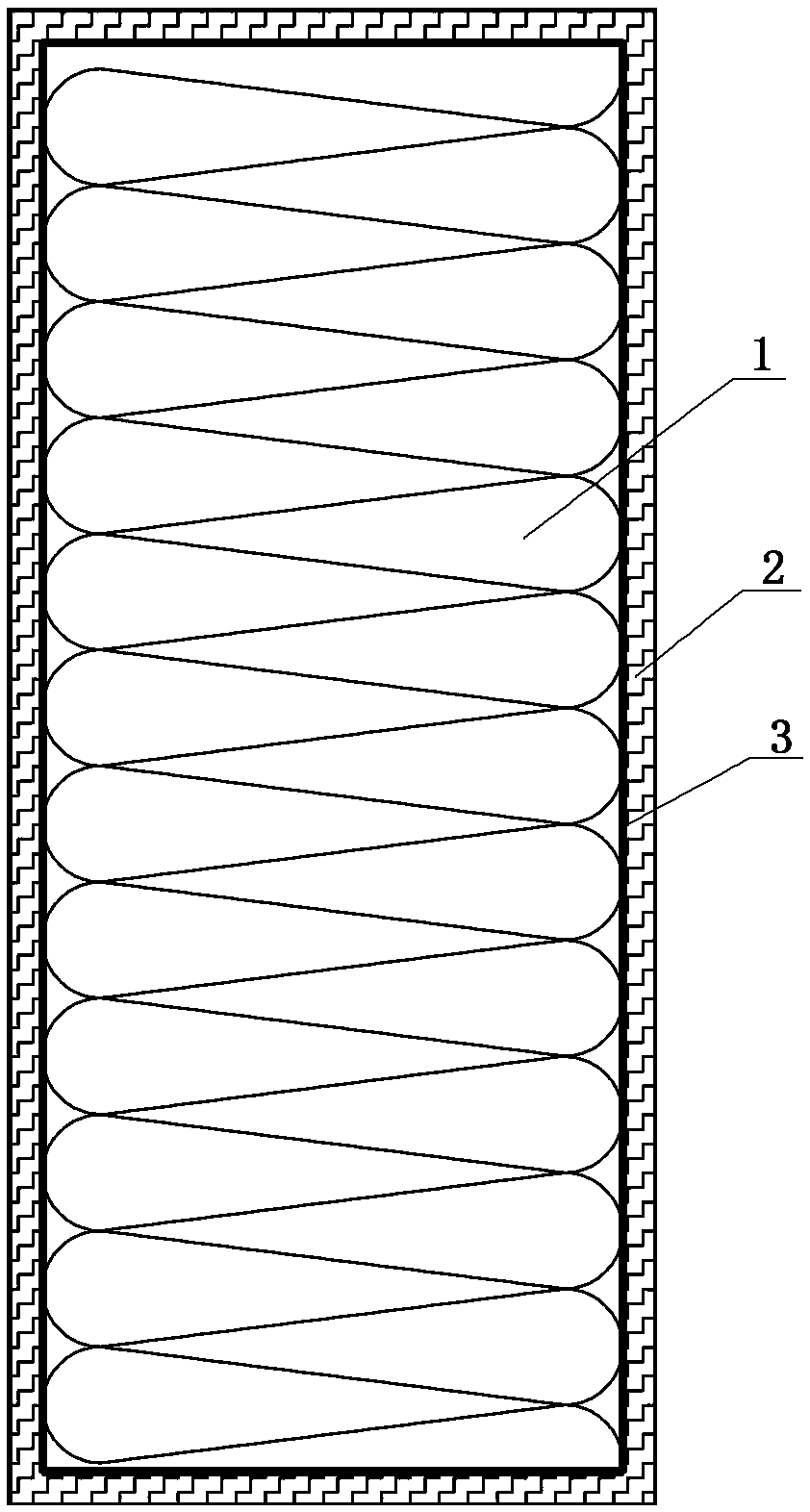

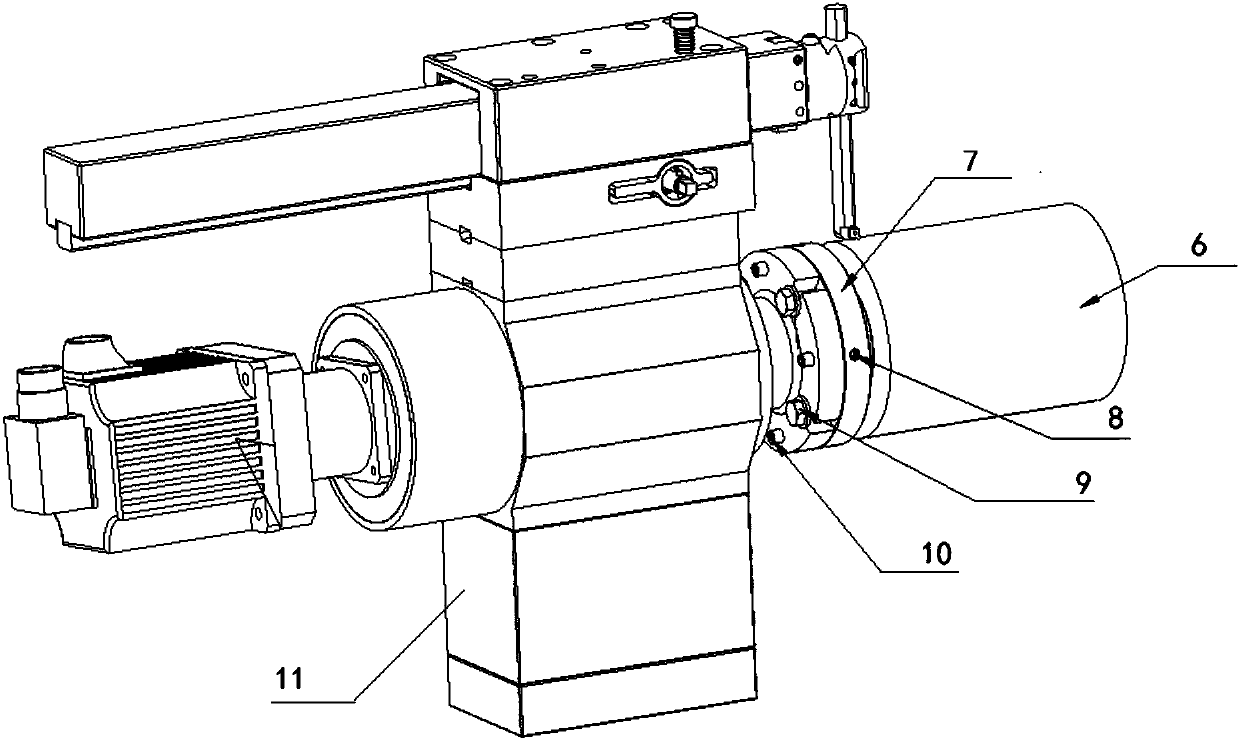

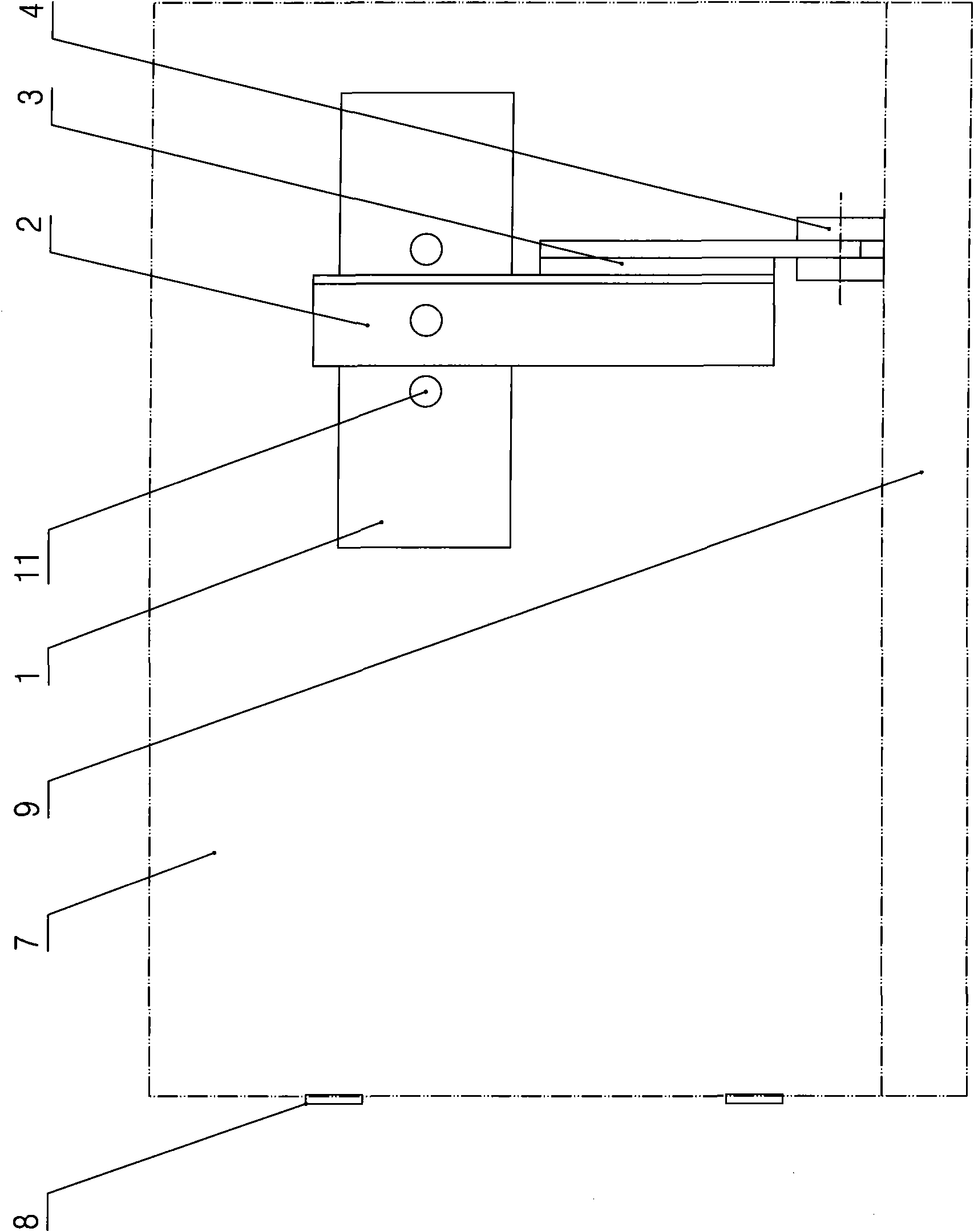

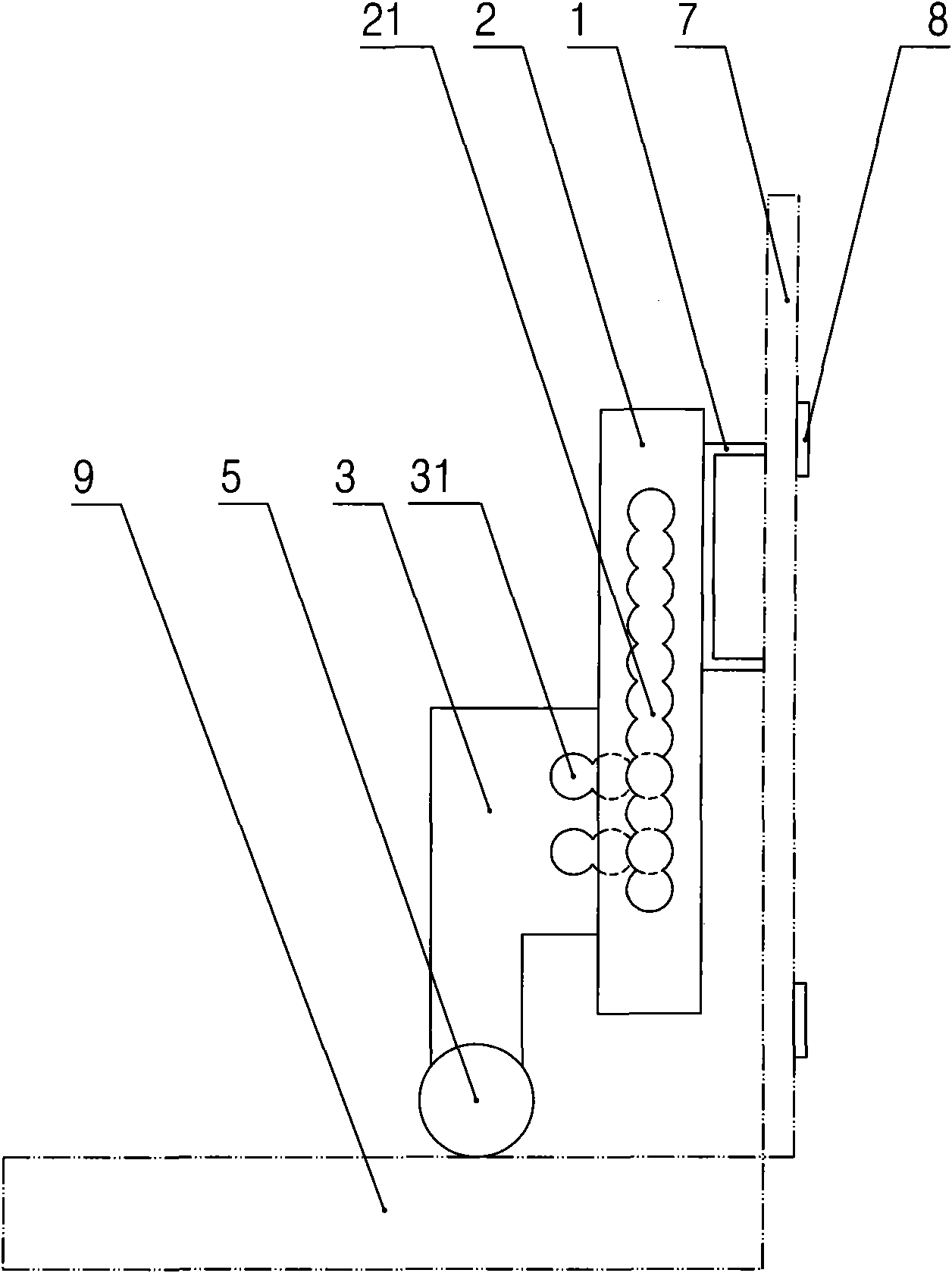

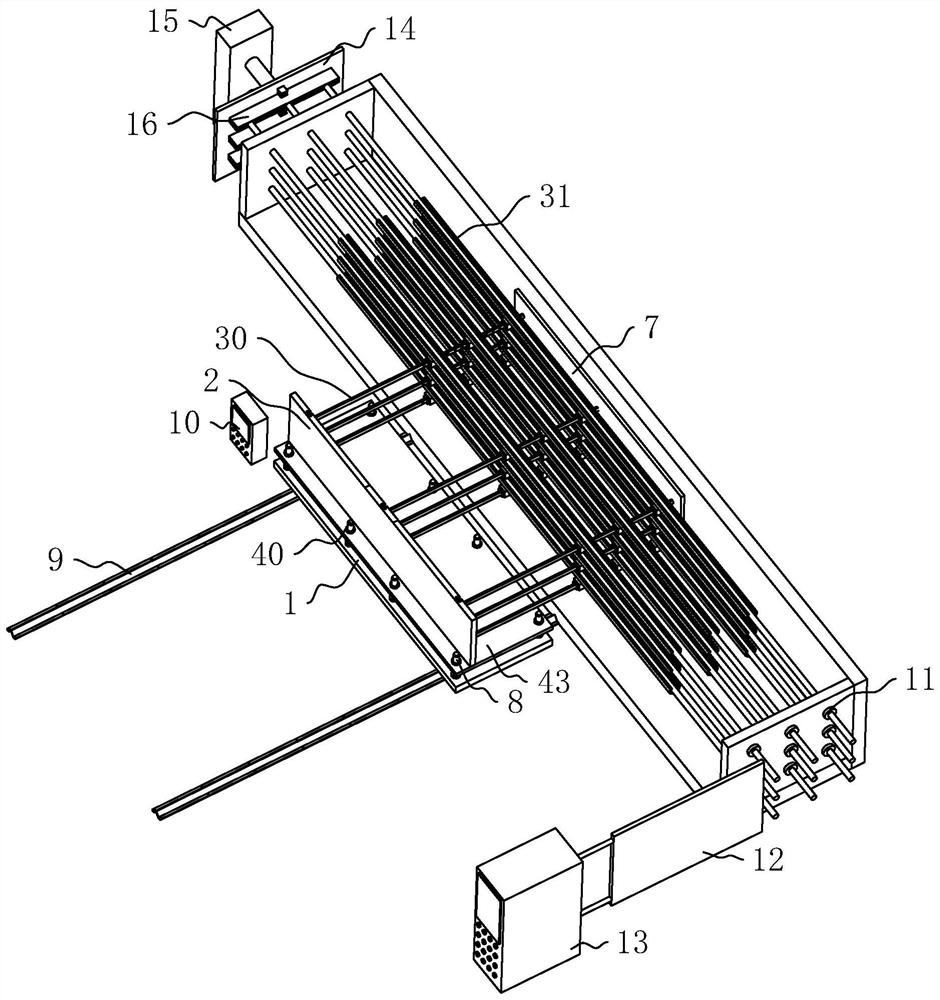

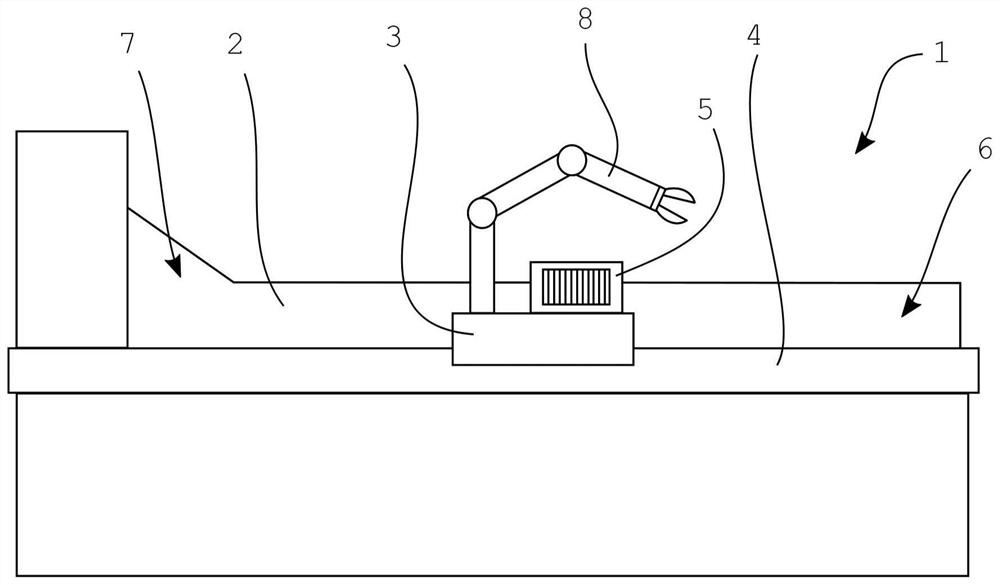

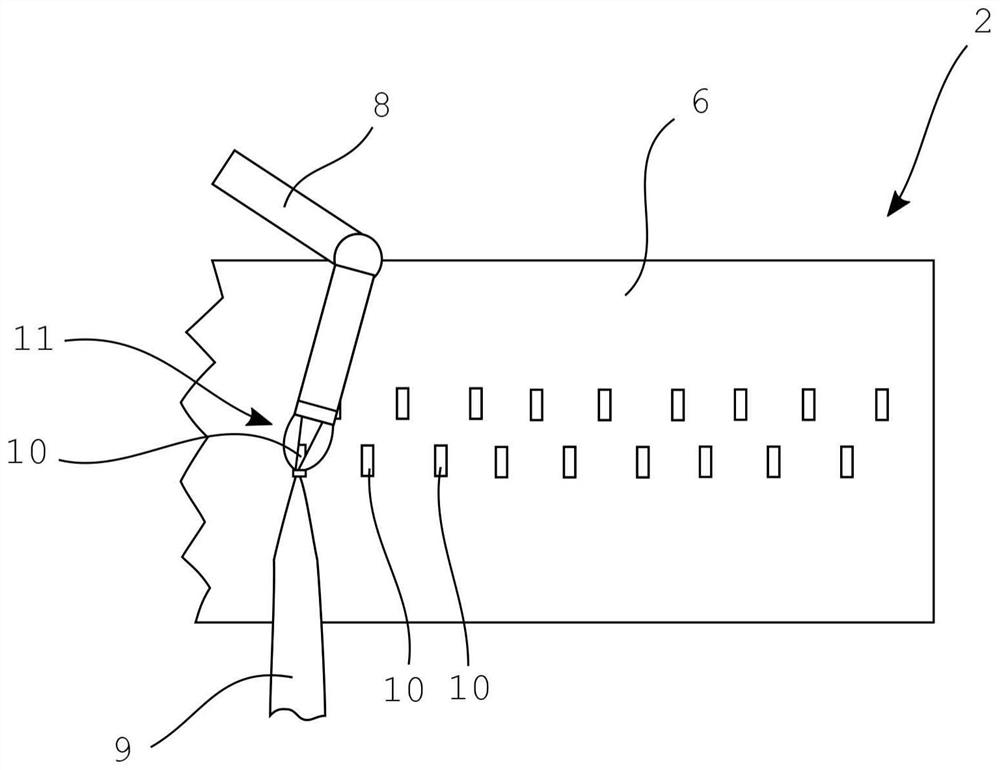

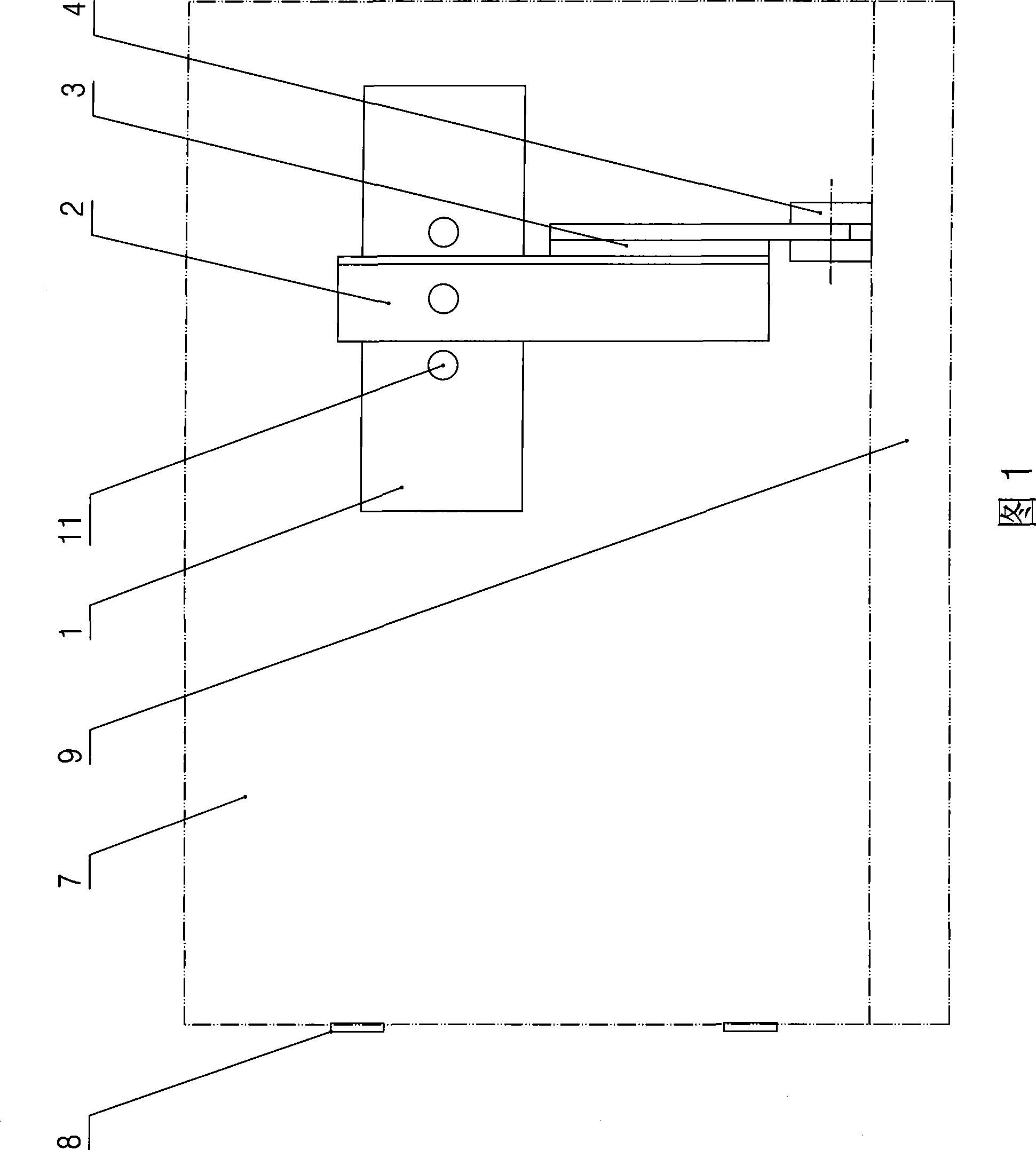

Cone warping machine and method for operating same

ActiveCN112080833AWon't sagWarping machinesOther manufacturing equipments/toolsYarnClassical mechanics

The invention relates to a cone warping machine and a cone warping machine operation method. The cone warping machine (1) is provided with a warping roller (2) and a warping table (3) arranged besidethe warping roller (2), a warping reed (5) used for yarn input is arranged on the warping table, the warping roller (2) and the warping table (3) can move relative to each other, and the cone warpingmachine (1) is provided with a mechanical arm (8). According to the invention, the mechanical arm (8) of the cone warping machine (1) has at least one means for actuating the warp slivers (9). The invention also relates to a method for operating the cone warping machine (1), comprising the following steps: moving the warping roller (2) of the cone warping machine (1) and the warping table (3) of the cone warping machine (1) relative to each other until the warping table (3) faces a warping start zone (6) of the warping roller (2), receiving a warp sliver (9) from the warping table (3) by meansof the mechanical arm (8) of the cone warping machine (1), and the warp sliver (9) is fixed on the warping roller (2) through the mechanical arm (8) in the warping start zone (6).

Owner:KARL MAYER STOLL R&D GMBH

Edge sealing method and device for soft plastic circulation box special for tobacco

PendingCN104626653AHigh strengthExtended service lifeContainer making machineryEngineeringMechanical engineering

The invention discloses an edge sealing method for a soft plastic circulation box special for tobacco. The soft plastic circulation box comprises a cuboid box body side wall and flap covers connected to the upper and lower ends of the box body side wall. The edge sealing method comprises the steps that heating and hot melting are carried out on the transverse edges and the end faces of the flap covers, and arc rolling wheels are adopted for rolling the edges and the end faces, obtained after hot melting is carried out, of the flap covers, and the formed transverse end faces of the flap covers are in a smooth arc shape. The edge sealing device comprises a support. A heating device, the first rolling wheel and the second rolling wheel are sequentially installed on the support linearly. The heating device is provided with an inward-concave heating groove. The circumferential face of the first rolling wheel and the circumferential face of the second rolling wheel are provided with a first rolling arc groove and a second rolling arc groove respectively. The transverse end faces of the flap covers with the sealed edges are in a smooth arc shape. On the one hand, the strength of the end faces of the flap covers can be enhanced, edge collapsing and deformation will not be caused, and the service life of the soft plastic circulation box is prolonged; on the other hand, the end faces of the flap covers with the sealed edges are smooth with no burrs, the wrist of a user will not be cut, and the using safety is improved.

Owner:有限会社林平

Preparation method of special core material for exterior thermal insulation, fireproof, thermal insulation and decorative integrated board

InactiveCN105369920BHigh strengthHigh tensile strengthHeat proofingCompressive resistanceCrack resistance

A special core material for exterior wall external insulation fire-proof insulation and decoration plates and a preparation method thereof are provided. The core material comprises a blocky vertical silk rock wool plate blank. The six sides of the vertical silk rock wool plate blank are each coated with a layer of flexible building structure adhesive to form a sealing layer. The outer side of the sealing layer is reinforced with basalt fiber mesh cloth, and the basalt fiber mesh cloth closely wraps the vertical silk rock wool plate blank to form a new mesh-bar composite body. Therefore, the joint stress of the pasting material and the vertical silk rock wool plate blank is enhanced, the tensile resistance, compressive resistance and shearing resistance of the rock wool insulation plate are increased, and the strength, stiffness, crack resistance and integrity of the rock wool insulation plate are improved. The surface of the vertical silk rock wool plate is sealed, so that the plate is effectively prevented from aging or becoming damp, and the service life is prolonged greatly. The core material has a simple structure, and is easy to manufacture. The technical scheme is applicable to the special core material for exterior wall external insulation fire-proof insulation and decoration plates.

Owner:北京东华绿源建筑装饰工程技术有限公司

Blanking floating cutter structure and blanking die with same

InactiveCN112872166AEliminate mutual interferenceWon't sagStructural engineeringMechanical engineering

The invention discloses a blanking floating cutter structure and a blanking die with the same. The blanking floating cutter structure comprises a sleeve; an elastic driving structure which can stretch out and draw back in the axial direction and reset automatically is coaxially arranged in the sleeve; the top of the elastic driving structure penetrates through the sleeve to be fixedly provided with a floating male die; the bottom of the elastic driving structure is fixed in the sleeve; a floating corner trimming face capable of being matched with a knife edge of a trimming knife is arranged on the surface of one side of the floating male die; and a radial limiting structure for limiting shaking of the elastic driving structure is arranged in the sleeve. By arranging the floating cutter structure, the problem that the trimming knife and the male die interfere with each other is solved, and meanwhile the problem of high cost of multi-step production and the quality problem caused by the height difference of the male die are solved. The floating cutter structure is small in size and is only located in the interference area of the trimming knife and the male die, so that the floating cutter structure is suitable for machining workpieces with different included angles, the distance between material brackets cannot be too large, and it is guaranteed that a plate does not droop.

Owner:DONGFENG MOTOR CORP HUBEI

Movable support frame

Owner:JIANGSU YINHE ELECTRONICS

Production method for rigidity-enhanced automobile coatrack

ActiveCN103434454BAddressing the strength to demandReduce weightRacks dispositionThermal ageingHazardous substance

The invention relates to a production method of a rigidity-enhanced automobile coat rack, which comprises the following steps: a heating process for the base material of the automobile coat rack, a process of embedding a rigidity-enhanced card seat, and a molding and punching process. The method of the present invention solves the strength requirements of the coat rack decoration in the normal state and heat-resistant aging process; and the product has performance indicators such as light weight and high strength; the weight of the interior decoration is greatly reduced, and the light weight of the whole vehicle is satisfied Quantitative design requirements; forming and assembly flow operation, stable process; automatic assembly tools are used during installation to ensure safety accuracy and improve work efficiency; the product has high rigidity and will not break or sag; The accumulation of semi-finished products saves manufacturing costs; no harmful substances are produced during the entire production process, which is an environmentally friendly production method.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com