Edge sealing method and device for soft plastic circulation box special for tobacco

A soft plastic, turnover box technology, used in transportation and packaging, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems affecting the service life of products, easy to cut workers' wrists, easy to collapse edges, etc., to prolong the use. Longevity, improved safety, enhanced strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

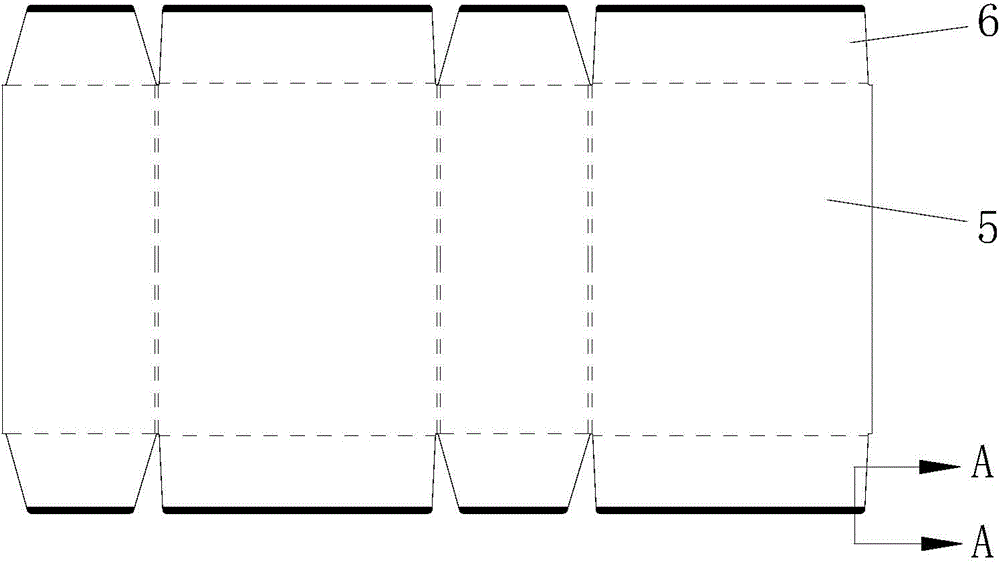

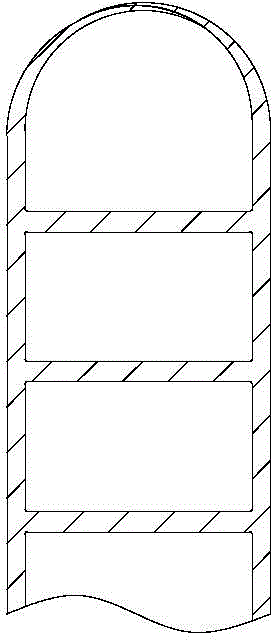

[0012] refer to figure 1 , a method for edge sealing of a soft plastic turnover box dedicated to tobacco, the soft plastic turnover box includes a cuboid box body side wall 5 and a flip cover 6 connected to the upper and lower ends of the box body side wall, the edge sealing method of the flip cover is: The lateral edge and end face of the flip cover 6 are heated and hot-melted, and the edge and end face of the hot-melted flip cover are rolled by an arc-shaped rolling wheel, and the lateral end face of the flip cover is shaped like image 3 The smooth arc shown ( figure 1 The black thick lines at the upper and lower ends of the center are the edge banding parts).

[0013] Since the two sides of the flip cover will not be easily touched, it is only necessary to seal the lateral edges of the flip cover. If the edge sealing is performed on both sides of the flip cover, it will increase the difficulty of edge sealing.

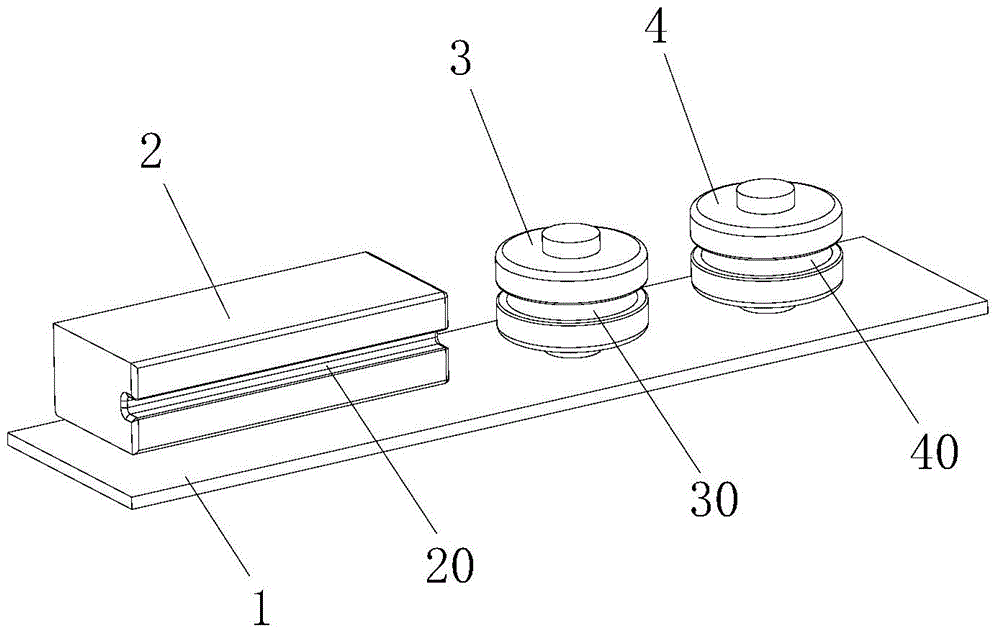

[0014] refer to figure 2 , an edge banding device for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com