Patents

Literature

1095results about How to "Guaranteed straightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

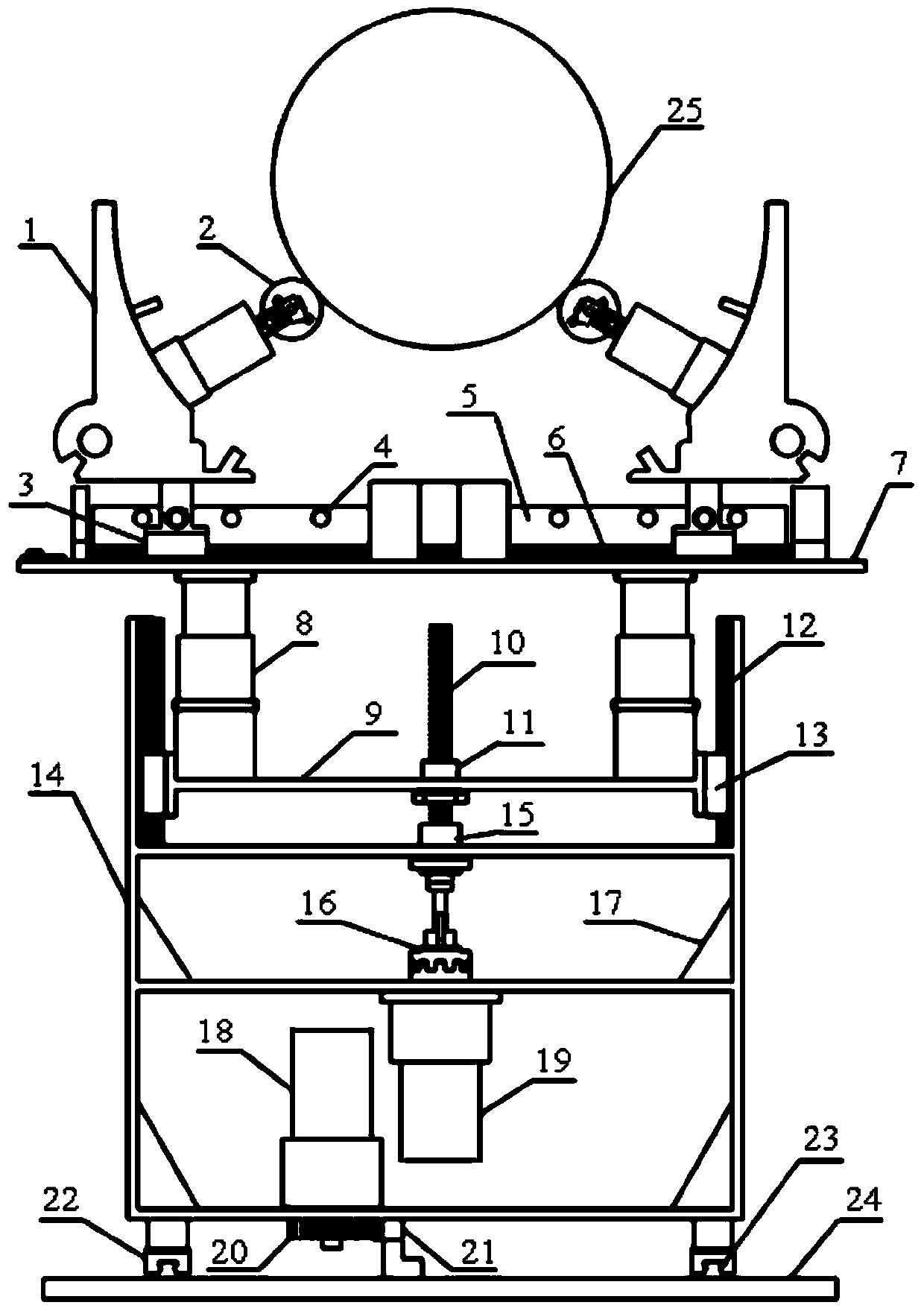

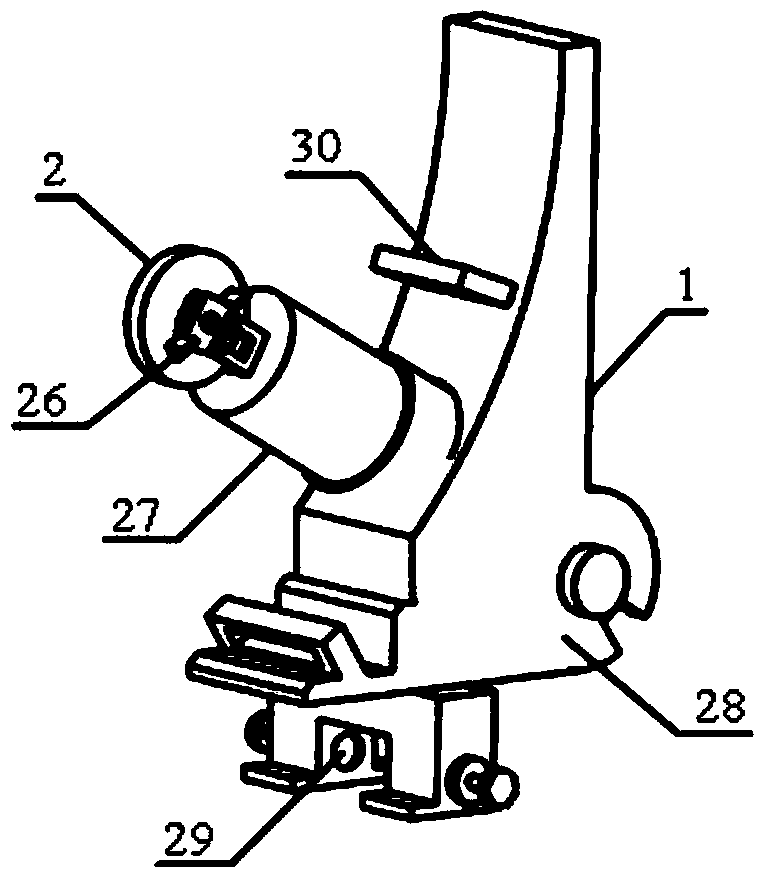

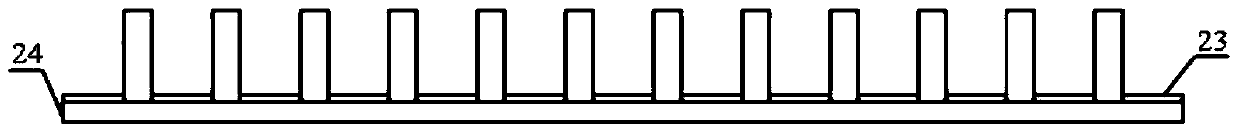

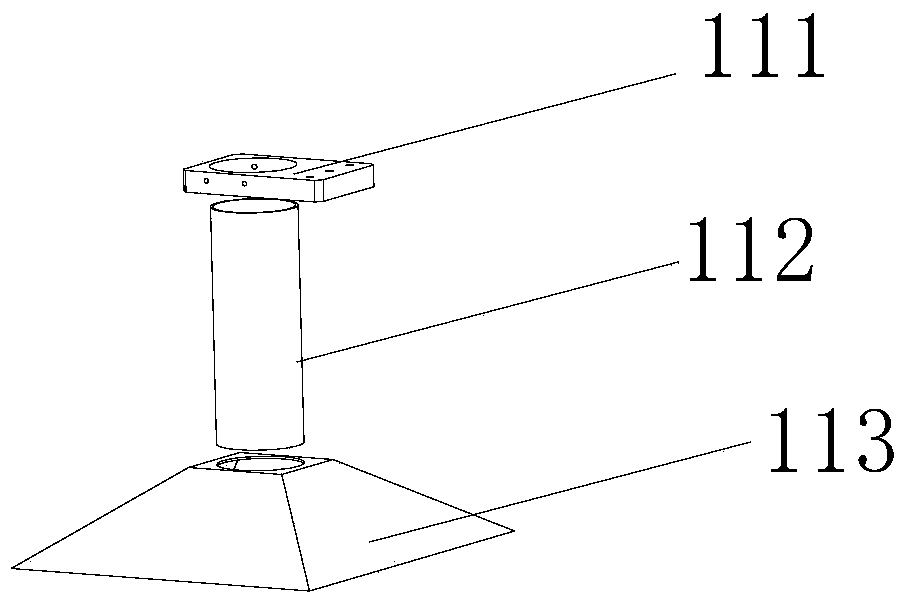

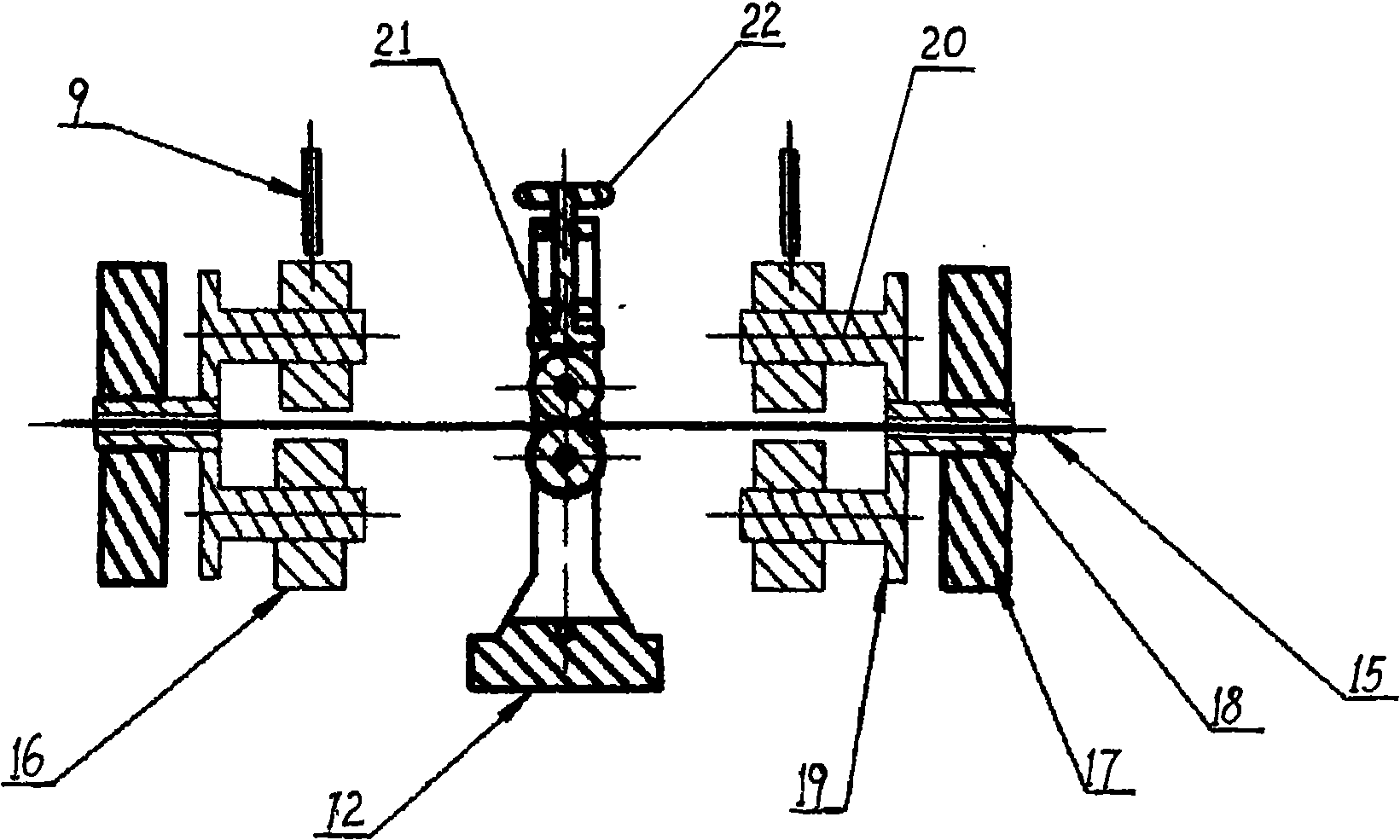

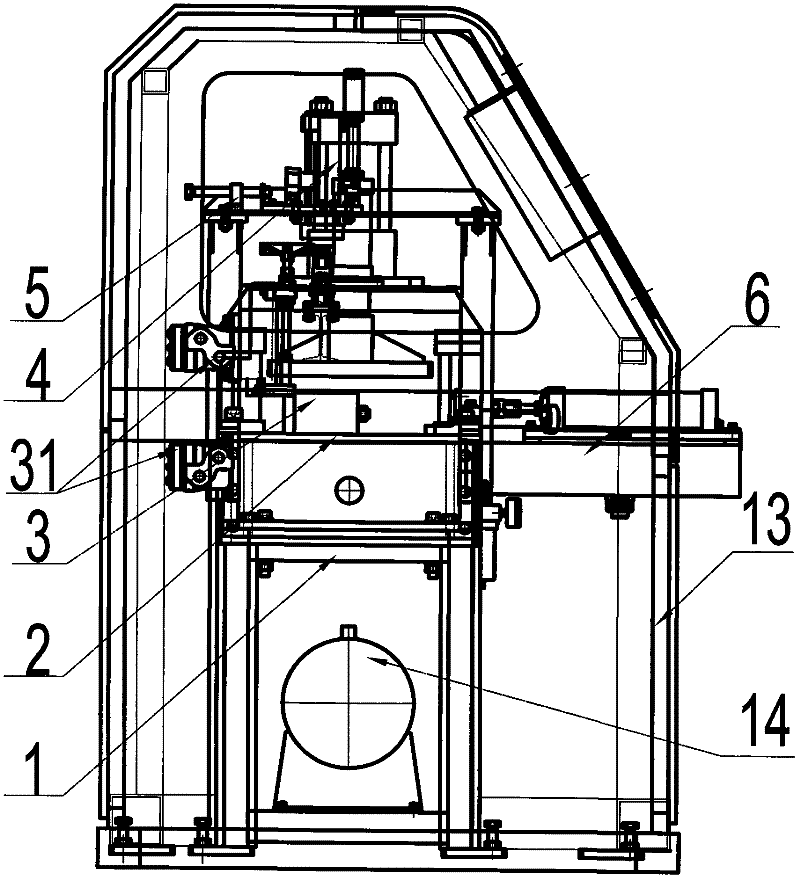

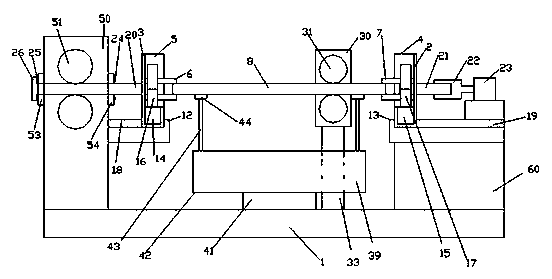

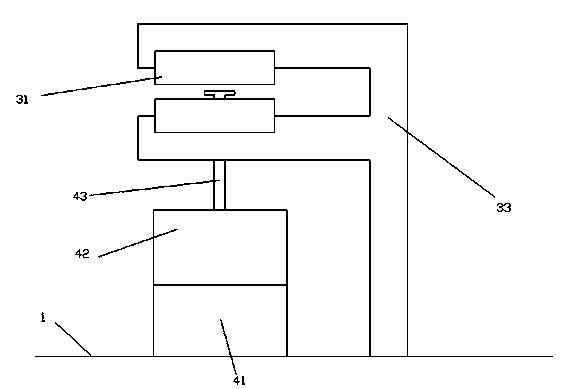

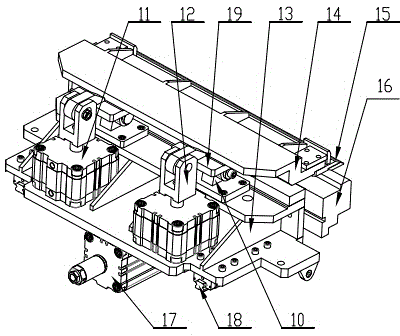

Cylindrical cabin docking assembly

InactiveCN103737310AGuaranteed dockingGuaranteed straightnessMetal working apparatusPositioning apparatusMotor driveGear wheel

The invention discloses a cylindrical cabin docking assembly comprising an open and close movement mechanism, a lifting mechanism, a horizontal movement mechanism, a frame and a computer. The lifting mechanism and the horizontal movement mechanism are arranged in the frame, and the open and close movement mechanism is arranged above the frame. The lifting mechanism comprises a vertical support rod, a lifting support plane, a lifting sliding block, a lifting guide rail, a lead screw and a lifting motor. The lifting motor drives the lead screw to rotate to enable the lifting sliding block of the lifting support plane to move on the lifting guide rail. The open and close movement mechanism comprises two open and close support devices, a position control plate, an open and close sliding block, an open and close guide rail and a horizontal platform deck. The open and close support devices slide symmetrically on the guide rail via manual labor and are fixed by a locating pin. The horizontal movement mechanism comprises a horizontal motor, a rack, a gear, a rack, a horizontal sliding block and a horizontal guide rail. The horizontal motor drives the gear and the rack to mesh to drive the docking assembly to move on the horizontal guide rail; the horizontal motor and the lifting motor are controlled by the computer to realize automatic docking of the devices.

Owner:XIDIAN UNIV

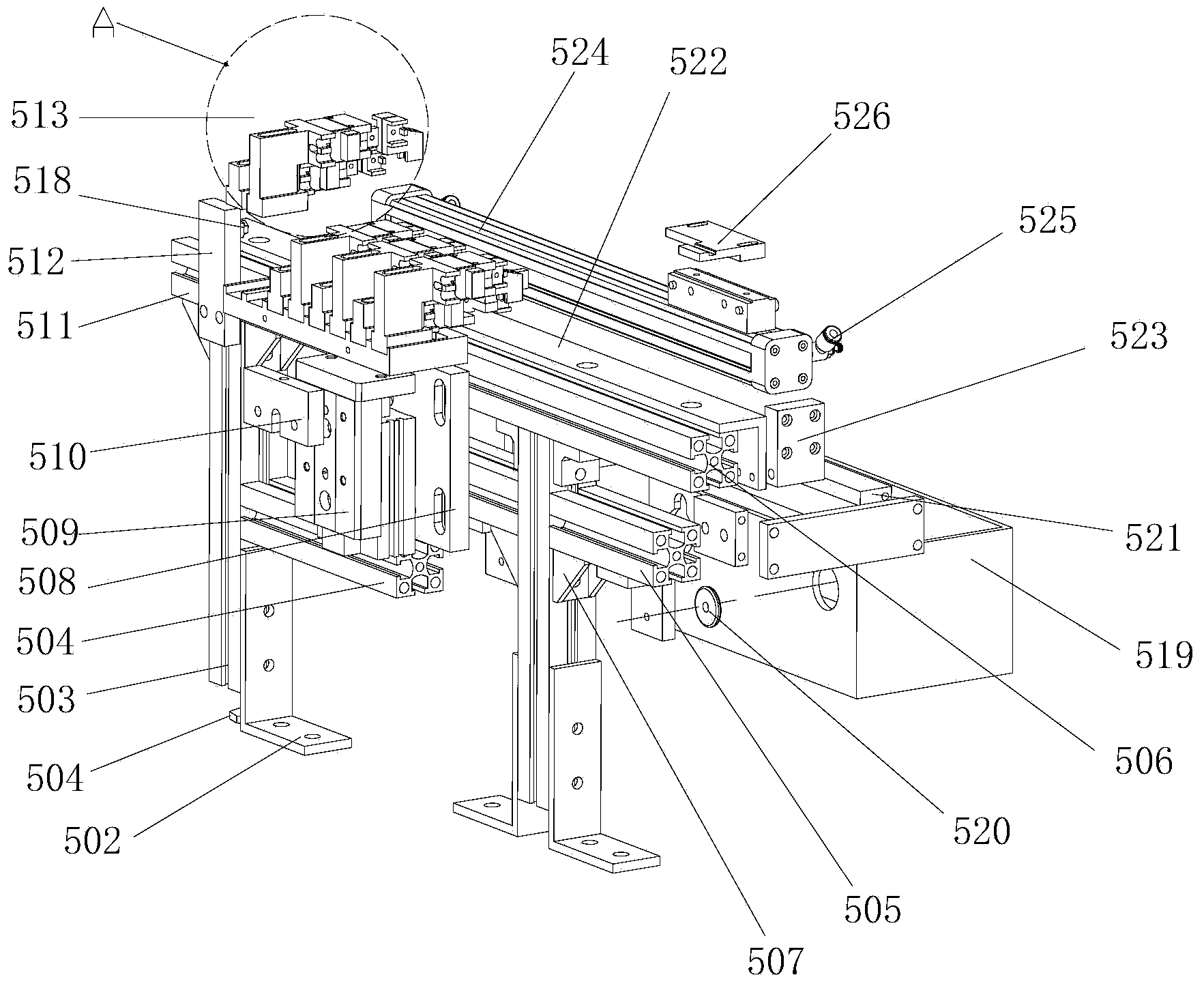

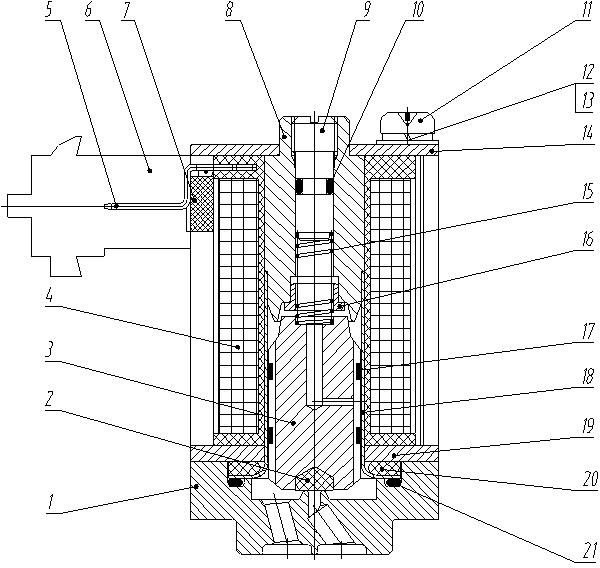

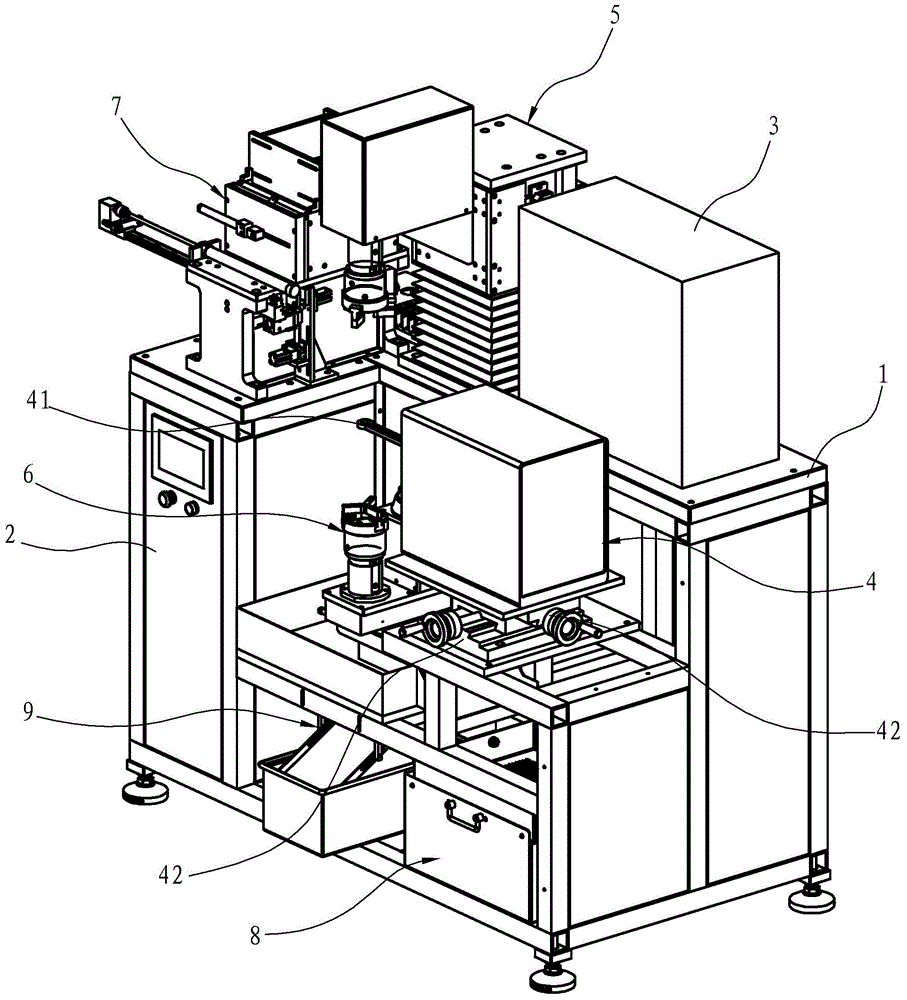

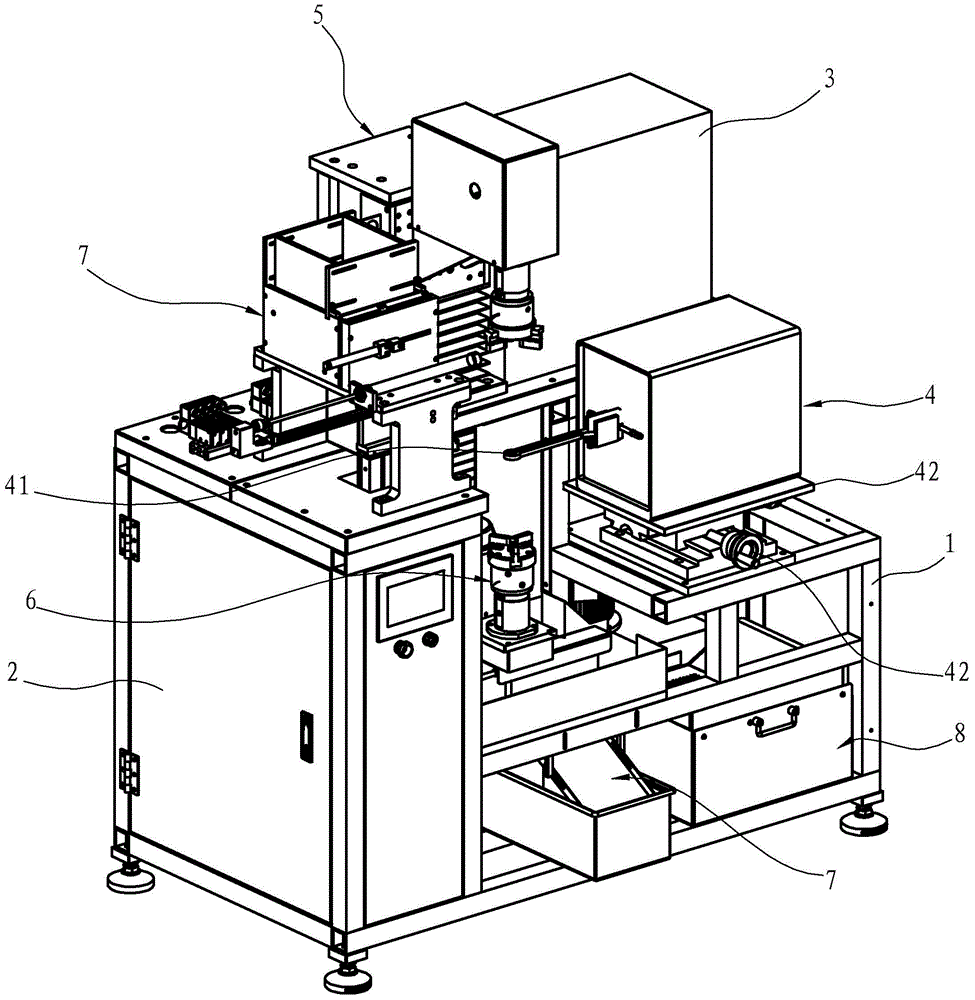

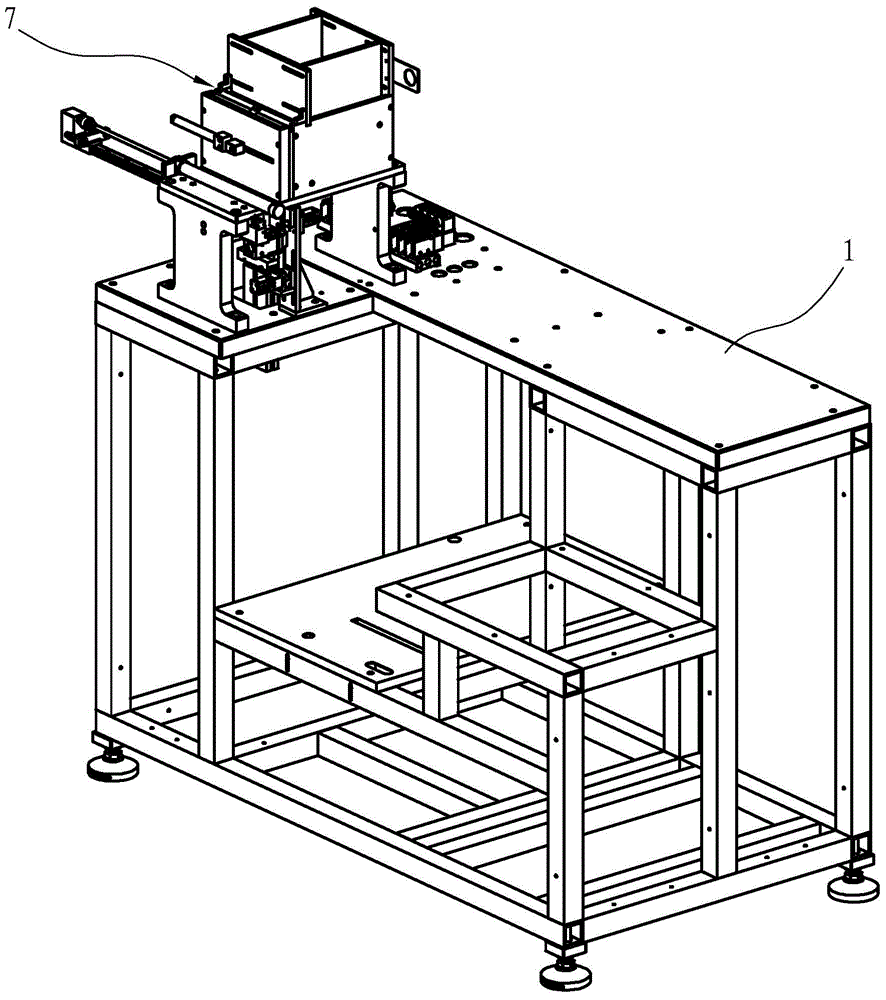

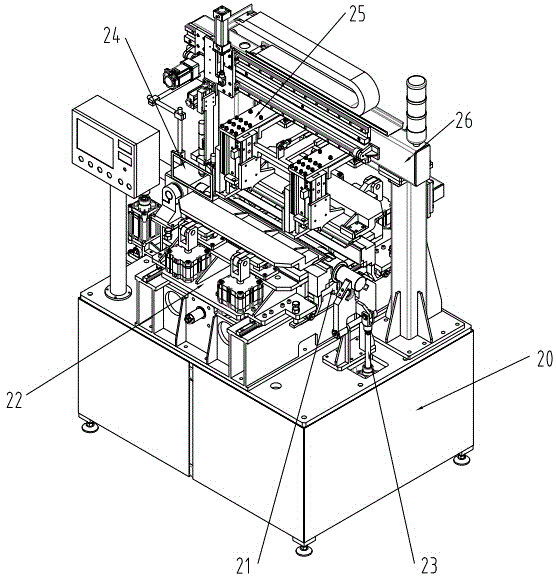

Automatic tin soldering machine

ActiveCN103447649AGuaranteed straightnessRealize mechanical automationMetal working apparatusSolder feeding devicesEngineeringRosin

The invention discloses an automatic tin soldering machine. The automatic tin soldering machine comprises a machine base, a soldering tin wire passing mechanism, a control box, an automatic feeding mechanism, a soldering tin assembly mechanism, a soldering tin testing mechanism, a rosin infiltration mechanism, a tin soldering mechanism and a sliding table mechanism, wherein the automatic feeding mechanism, the soldering tin assembly mechanism, the soldering tin testing mechanism, the rosin infiltration mechanism, the tin soldering mechanism and the sliding table mechanism are connected with the control box; the automatic feeding mechanism is connected with the soldering tin assembly mechanism, and the soldering tin wire passing mechanism is connected with the sliding table mechanism; the control box is arranged on the front end face of the machine base; the automatic feeding mechanism, the soldering tin assembly mechanism, the soldering tin testing mechanism, the soldering tin wire passing mechanism and the tin soldering mechanism are sequentially arranged at the top of the machine base from left to right; the sliding table mechanism is arranged at the side edge of the soldering tin wire passing mechanism, a wire material is sequentially conveyed to the soldering tin testing mechanism, the rosin infiltration mechanism and the tin soldering mechanism by the sliding table mechanism after the wire material is conveyed to the soldering tin assembly mechanism by the automatic feeding mechanism, so as to be subjected to an automatic tin soldering process, and automatic discharging is realized. According to the automatic tin soldering machine, mechanical automation for charging, processing and the final discharging can be realized, the production efficiency is increased greatly, and the product quality can be guaranteed.

Owner:东莞市威元电子科技有限公司

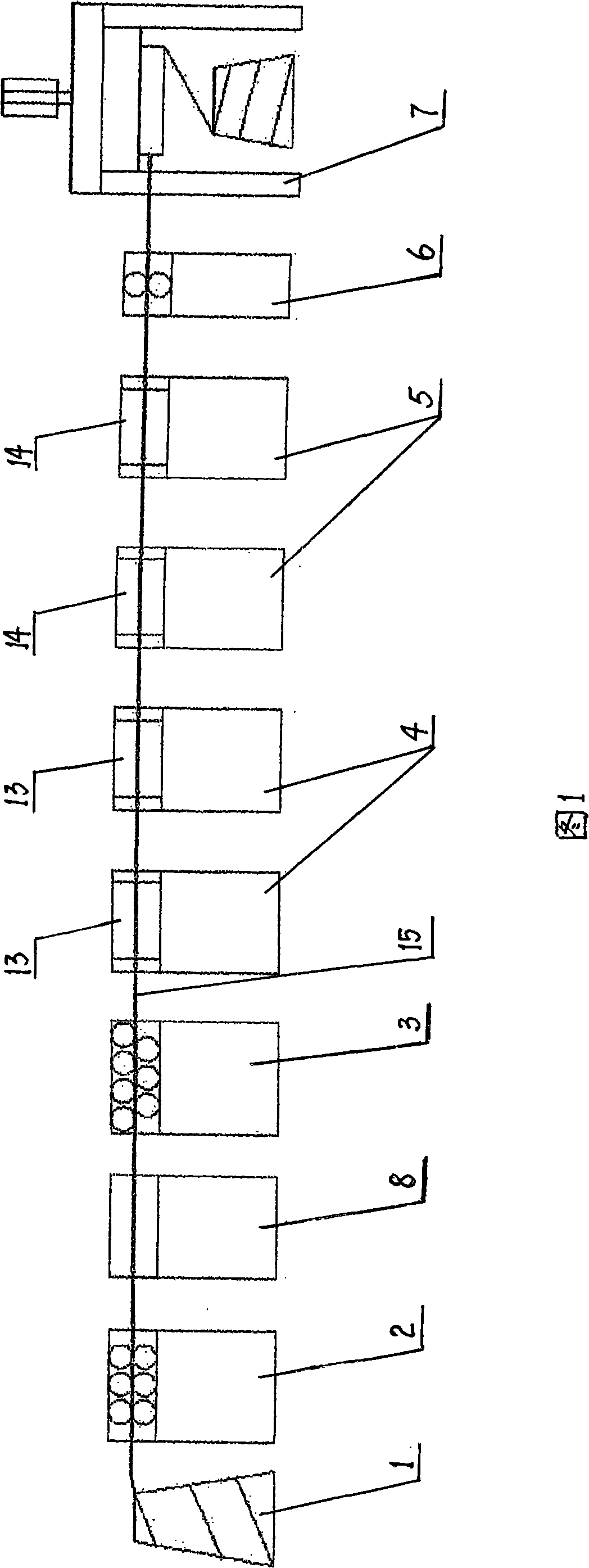

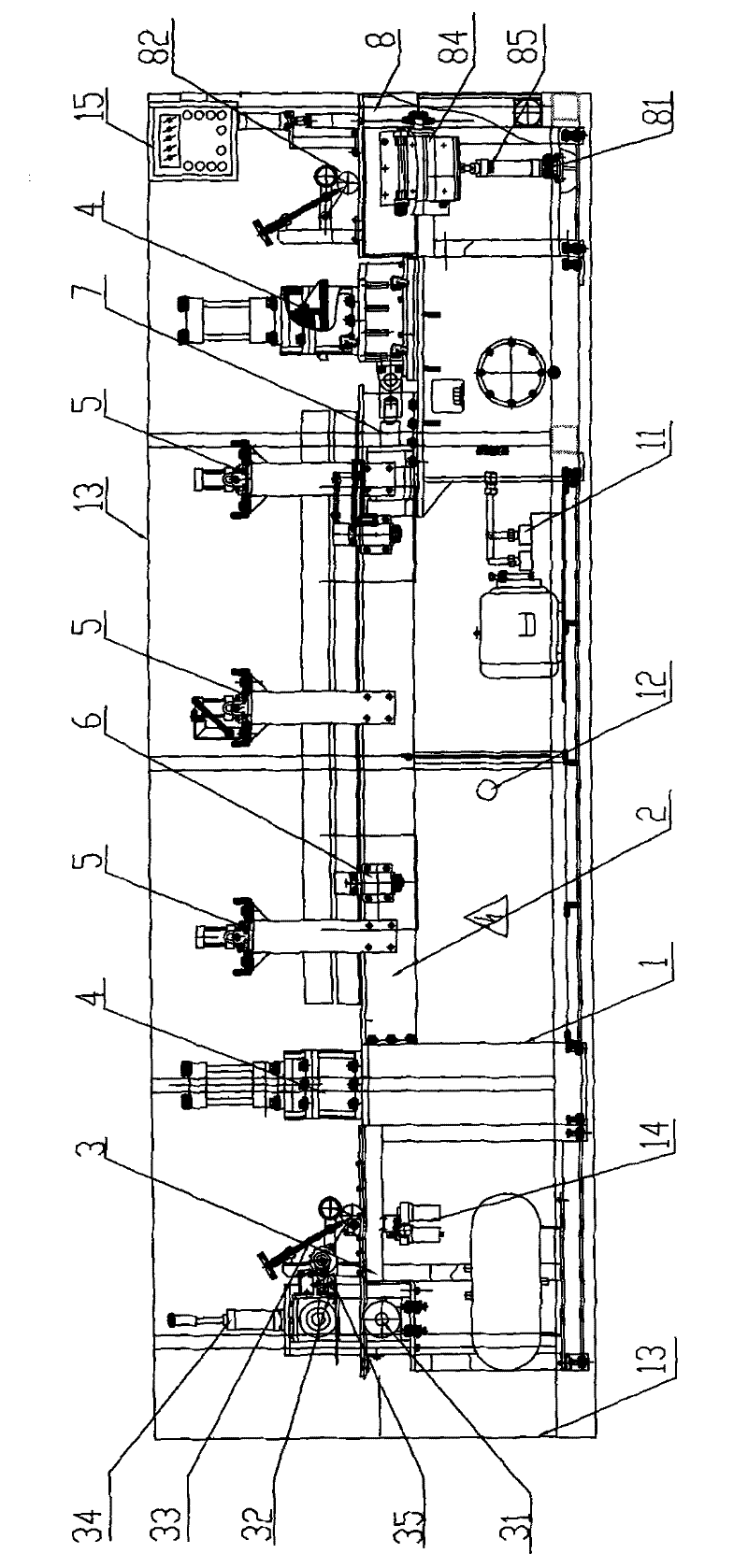

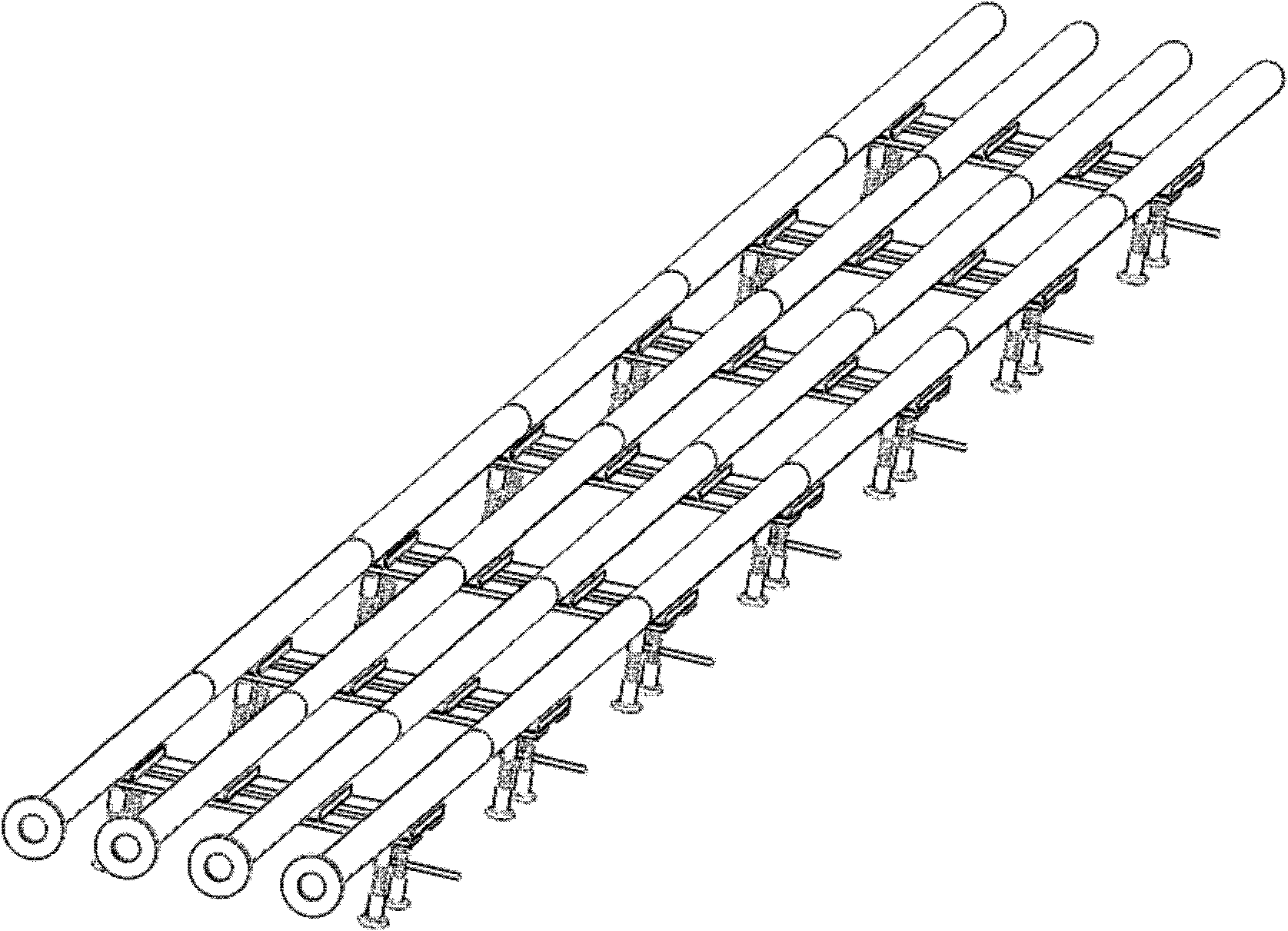

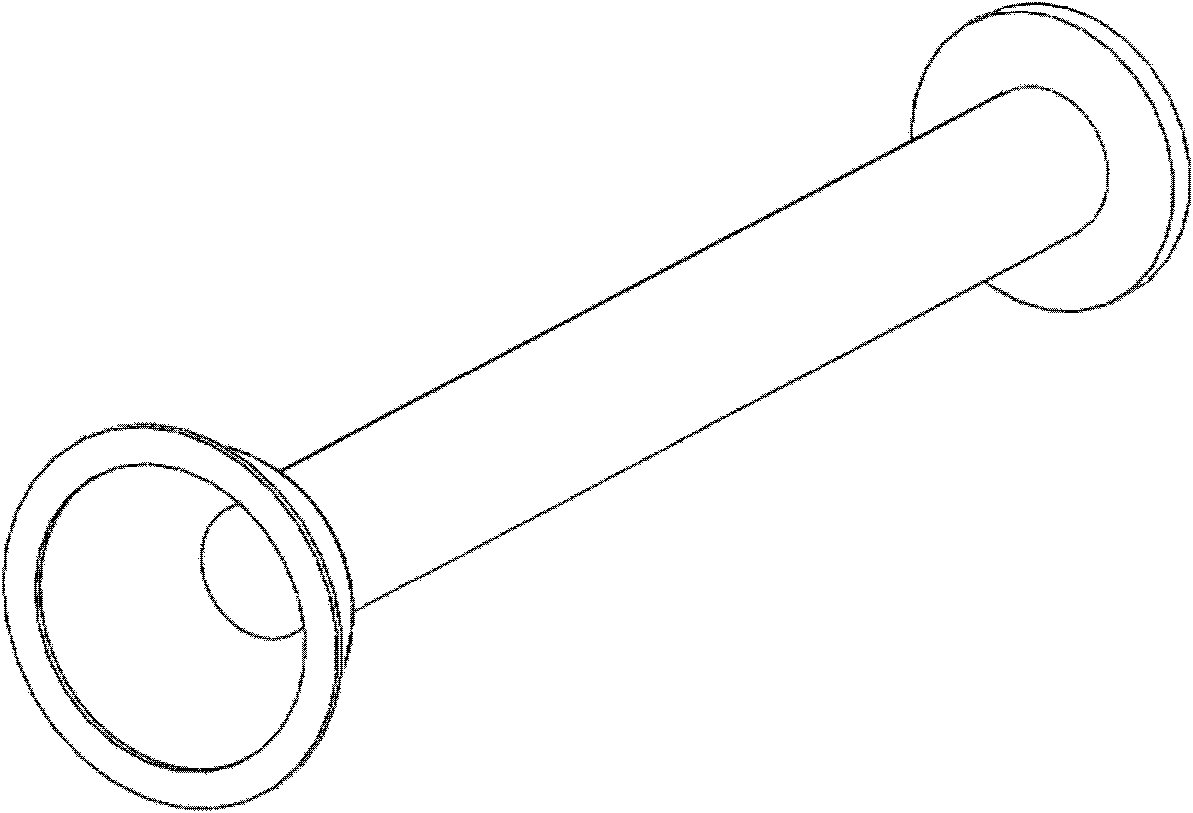

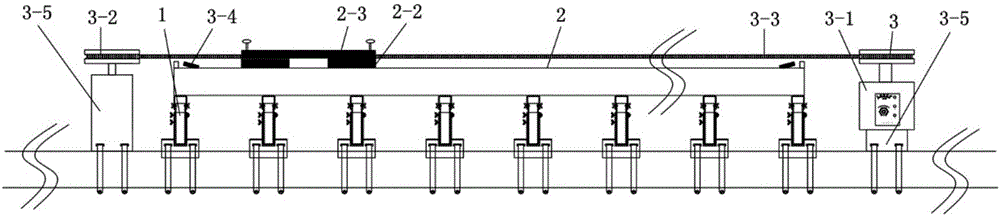

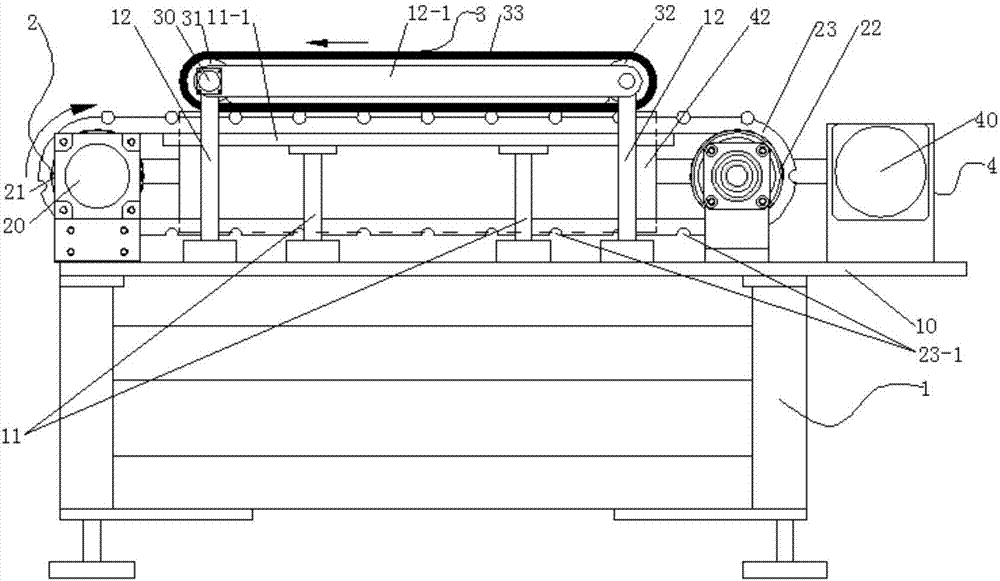

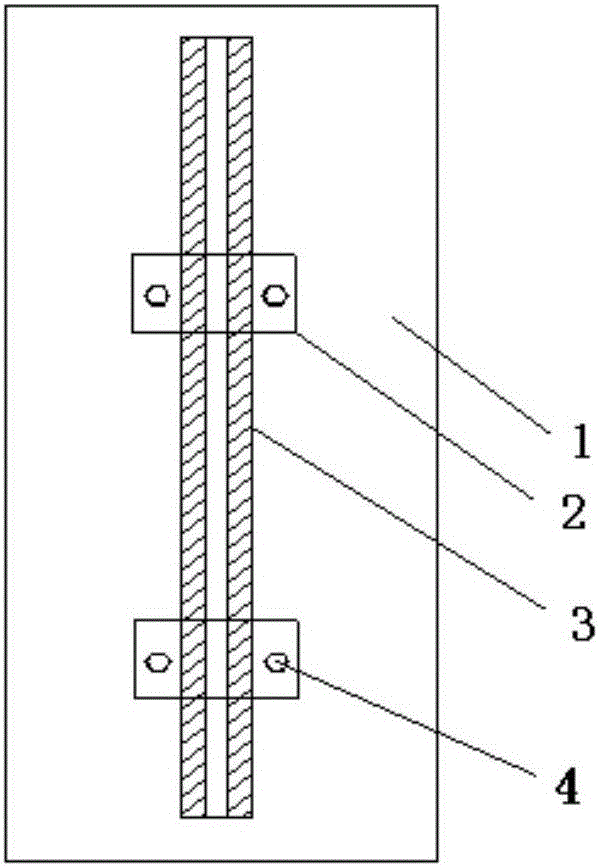

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

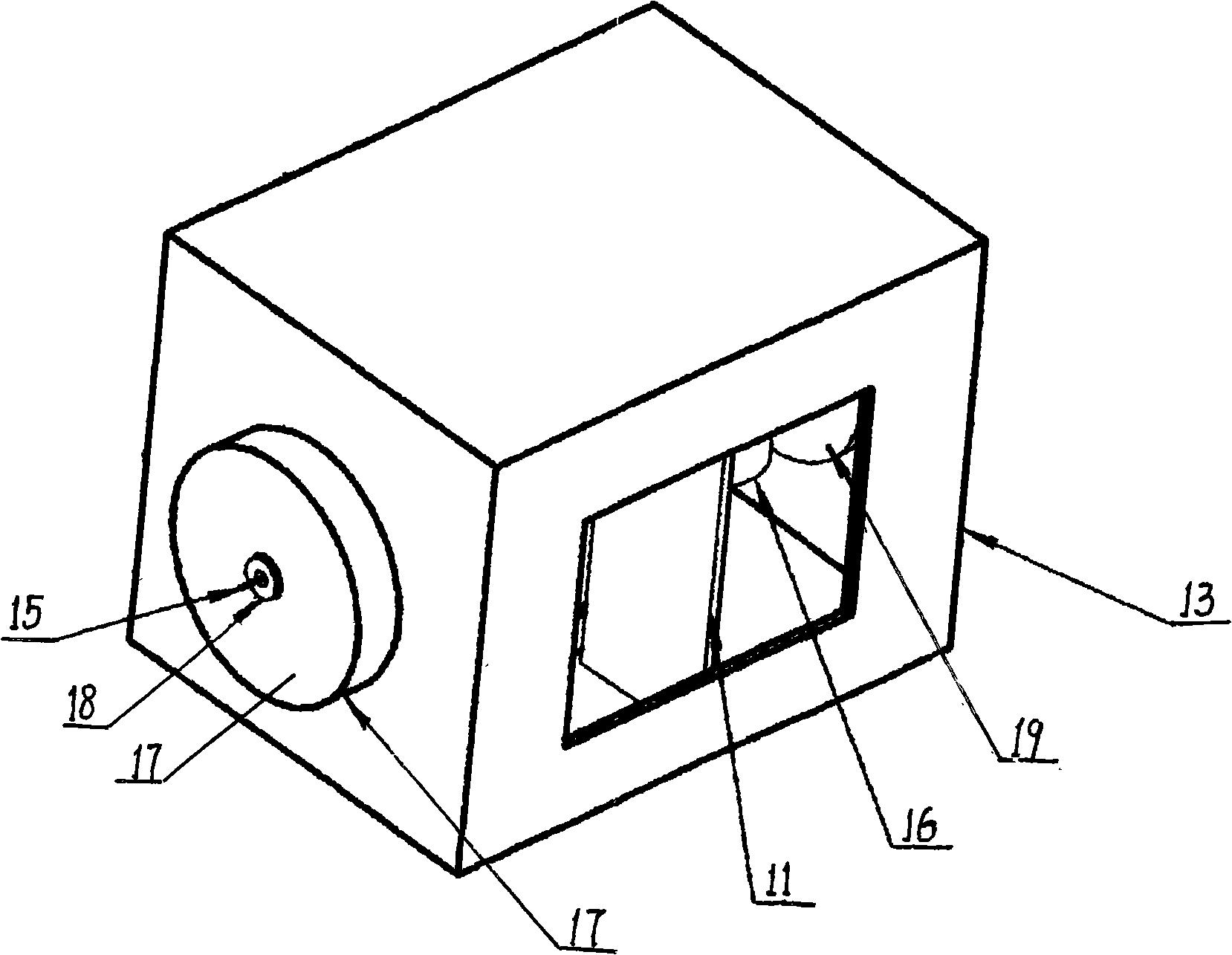

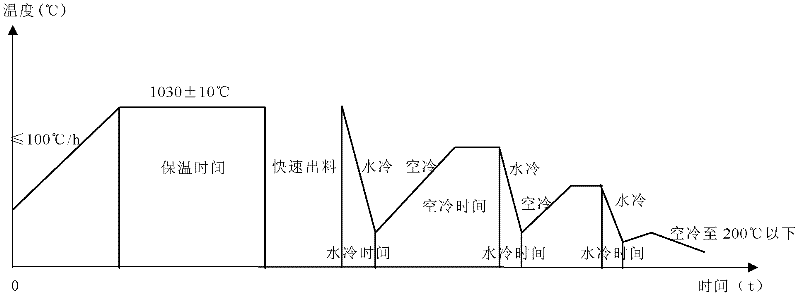

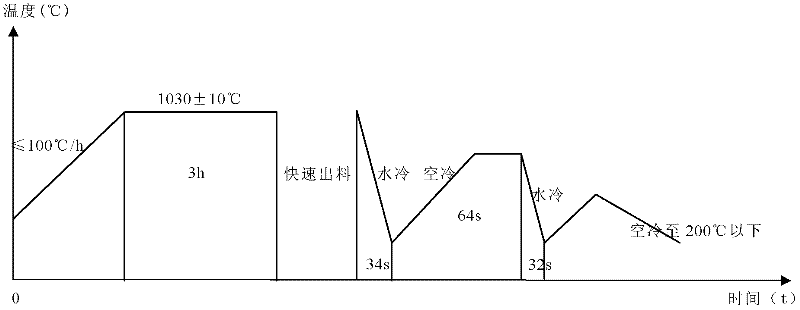

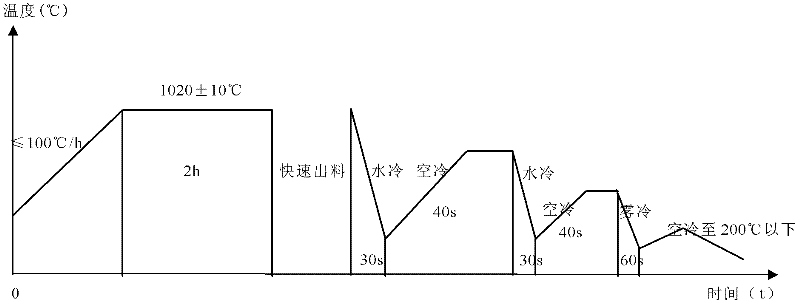

Continuous type alloy steel heat treatment line

The invention discloses a continuous type alloy steel heat treatment line, solving the problem existing in small-section ultra-long material workpiece heat treatment. The continuous type alloy steel heat treatment line is formed by connecting a continuous type roller hearth heating furnace, a roller hearth type quenching groove and electric heating continuous type roller hearth furnace in series.The heat treatment process comprises the following steps of: carrying out austenitization heating on a workpiece in the continuous type roller hearth heating furnace, rapidly discharging after reaching the process time and then entering into the roller hearth type quenching groove; automatically generating a non-continuous water cold process according to the chemical components and different standards of the workpiece, and rapidly cooling through an immersion or spray mode; and tempering the workpiece which is cooled to room temperature according to the process requirement. The continuous type alloy steel heat treatment line has the advantages that: 1, the quenching, solid solution and normalizing continuous heat treatment of the small-section ultra-long material workpiece are achieved, and the heat treatment is completed on roller beds which are located on the same height and axis; 2, a quenching medium is stable in the rising process, and the workpiece can be simultaneously cooled in the length direction; and 3, fire danger and lamp black pollution are precluded by adopting non-continuous water quenching.

Owner:FUSHUN SPECIAL STEEL SHARES

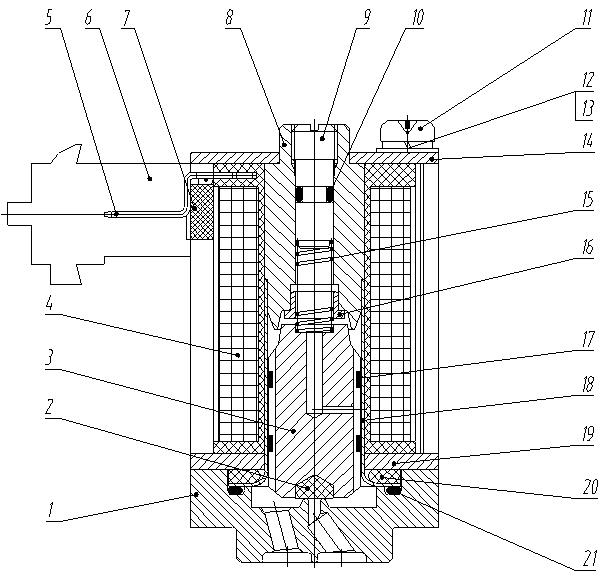

Proportional electromagnetic valve for electrically controlled high-pressure common-rail fuel injection system of diesel engine

InactiveCN102506217AMeet the use requirementsControl on and offOperating means/releasing devices for valvesFuel injection apparatusDriving currentCommon rail

The invention discloses a proportional electromagnetic valve for an electrically controlled high-pressure common-rail fuel injection system of a diesel engine and relates to an electromagnetic valve. A position at which a fixed iron core (8) and a movable iron core (3) of the electromagnetic valve attract each other is a conical polar plane. The fixed iron core (8), the movable iron core (3), a guide pipe (18), a spiral spring (15), an electromagnetic coil (4), a square iron core (19), a shell (14) and a valve body (1) jointly form the electromagnetic valve in an assembling way. When driving current is input into the electromagnetic coil, a magnetic field is generated through a magnetic path in the valve, electromagnetic force with magnitude which is in proportion with the magnitude of the driving current and is not related to a stroke is generated relative to the movable iron core, the movable iron core is enabled to overcome spring force to move, the movable iron core stops moving at a balance point of the two kinds of force and therefore is kept at a stable position, and the movable iron core can proportionally and continuously move according to the magnitude of the driving current to control the opening of the valve. Under complex working conditions under which the diesel engine works, the electromagnetic valve not only can stably control the on / off of a fuel path, but also can accurately and proportionally control the flow of the fuel path according to the driving current.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Compression spring processing process

InactiveCN102248097AShorten the lengthGuaranteed straightnessFurnace typesWire springsSand blastingMechanical property

The invention relates to a compression spring processing process. The compression spring processing process is characterized by comprising the following process steps of: rolling, cutting into rings, reducing diameters, quenching, performing primary tempering, inspecting mechanical properties, setting, grinding end faces, correcting the length and the concentricity of springs, performing secondary tempering, setting, performing primary heating and loading aging treatment, grinding the end faces, detecting, performing sand blasting, performing magnetic powder inspection, performing sand blasting, performing surface treatment, performing secondary heating and loading aging treatment, and detecting finished products. By the process, the deformation of the springs in the processing process can be reduced, the geometric dimension of the springs is ensured, and production efficiency is greatly improved.

Owner:SHENYANG AIRCRAFT CORP

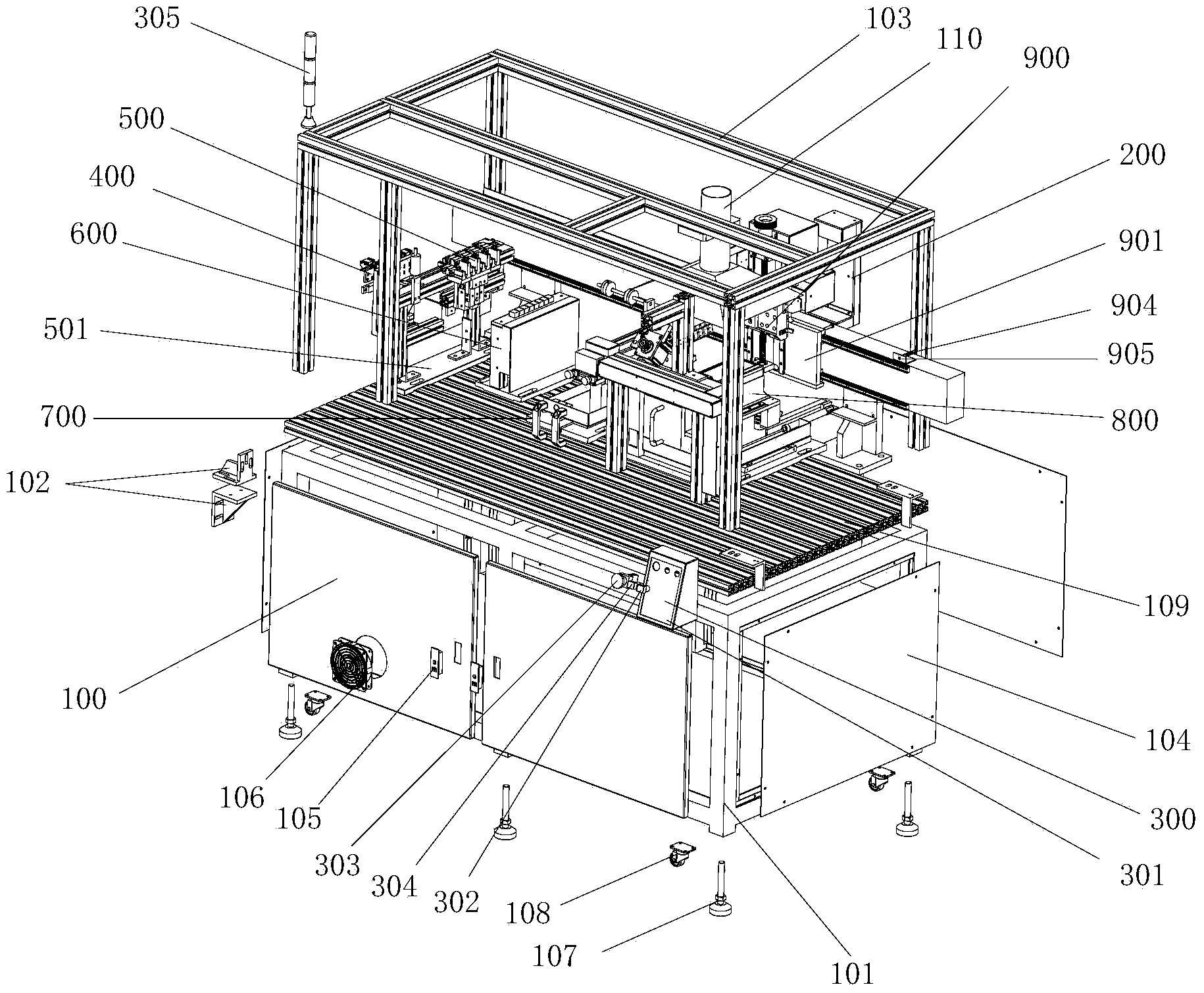

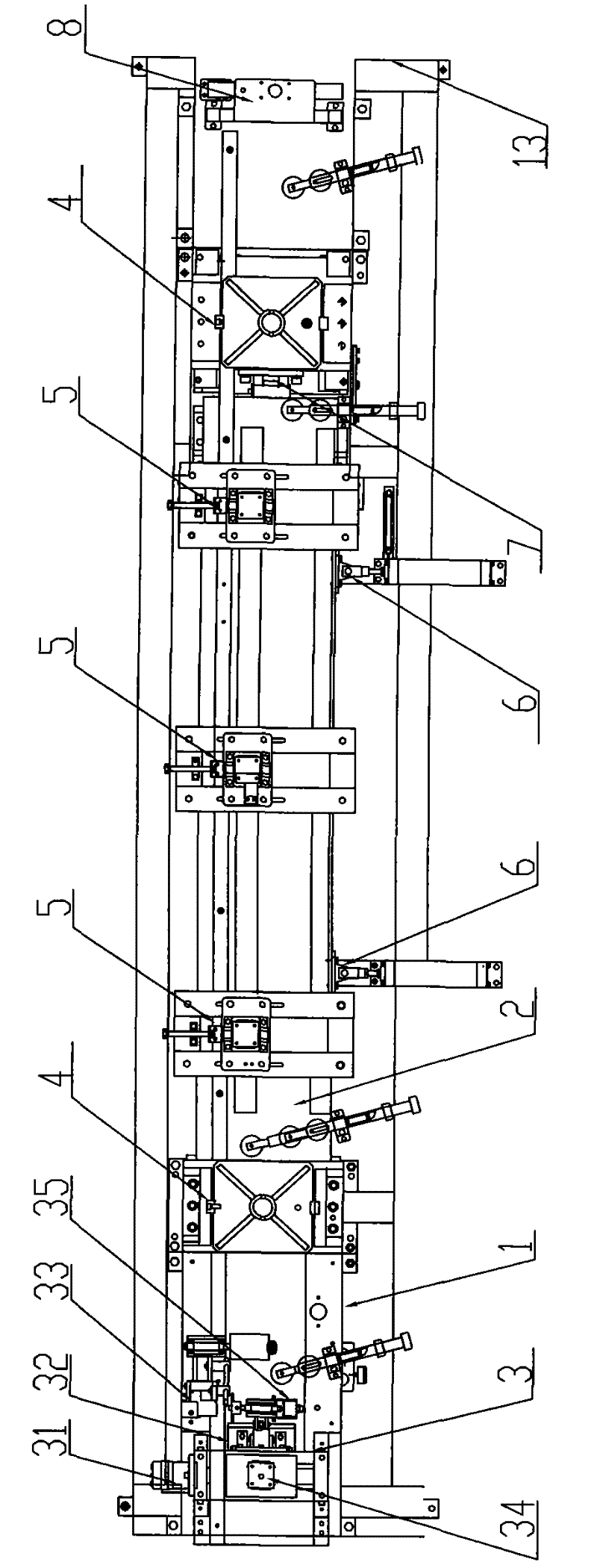

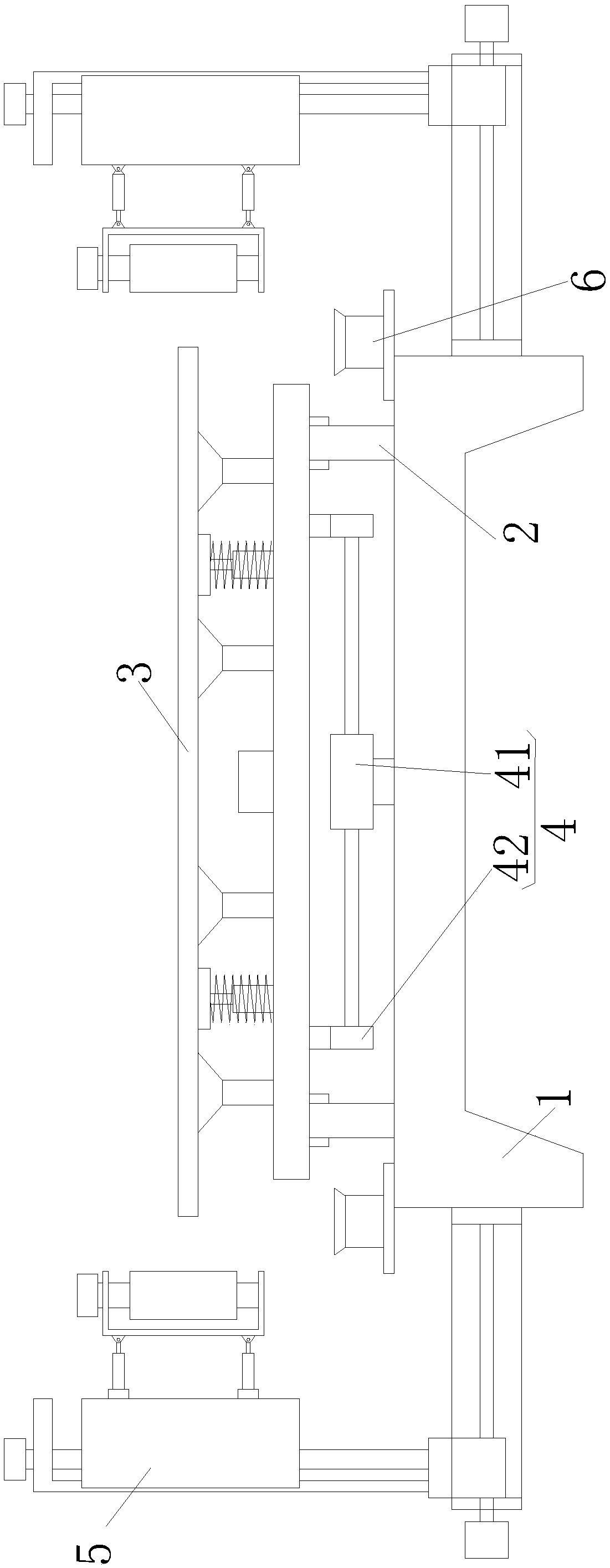

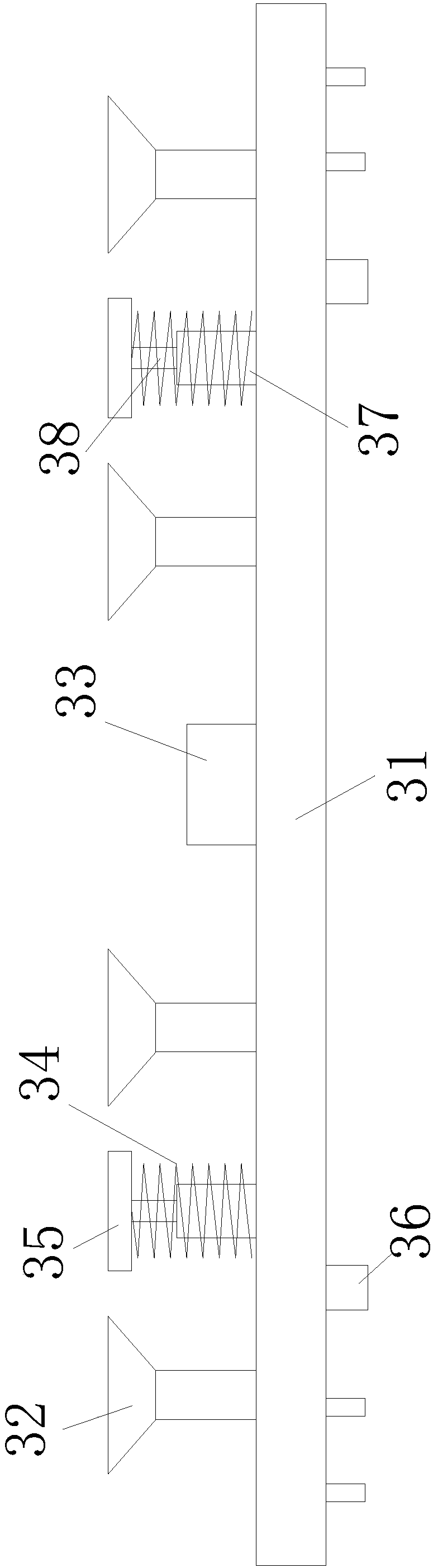

Full-automatic infinitely-long finger jointing machine

InactiveCN102225562AAccurate and reliable length dimensionReduce frictional resistanceWood veneer joiningLong fingersAutomatic control

The invention discloses a full-automatic infinitely-long finger jointing machine. The finger jointing machine comprises a frame (1). The finger jointing machine is characterized in that: a workbench (2), a feeding pre-extension mechanism (3), a hydraulic positive pressure leg (4), a pneumatic upper pressure lever (5), a pneumatic lateral pressure lever (6), a hydraulic longitudinal finger jointing cylinder (7), the frame (1), a protective shell cover (13) and a touch screen button station (15) form an infinitely long continuous finger jointing machine host; the feeding end pre-extension mechanism (3) is assembled and connected with a variable speed feeding table (9) to form a photoelectric length measurement adaptive variable speed feeding table; a fixed length cut-off saw (8) is combinedand connected with a receiving discharge table (10) to form an automatic fixed size cut-off discharge table; and the host, the feeding table, the discharge table, a hydraulic system (11) and an electric automatic control system (12) form the full-automatic infinitely-long (continuous) finger jointing machine for automatically identifying material end joints, automatically measuring the length, adapting to speed adjustment and automatically cutting off the discharge in fixed size according to the preset length. The finger jointing machine is optical, mechanical, electric and liquid integrated technical equipment for longitudinal continuous finger joint of large-section wood with full automation, high efficiency, high quality and random length.

Owner:烟台黄海木工机械有限责任公司

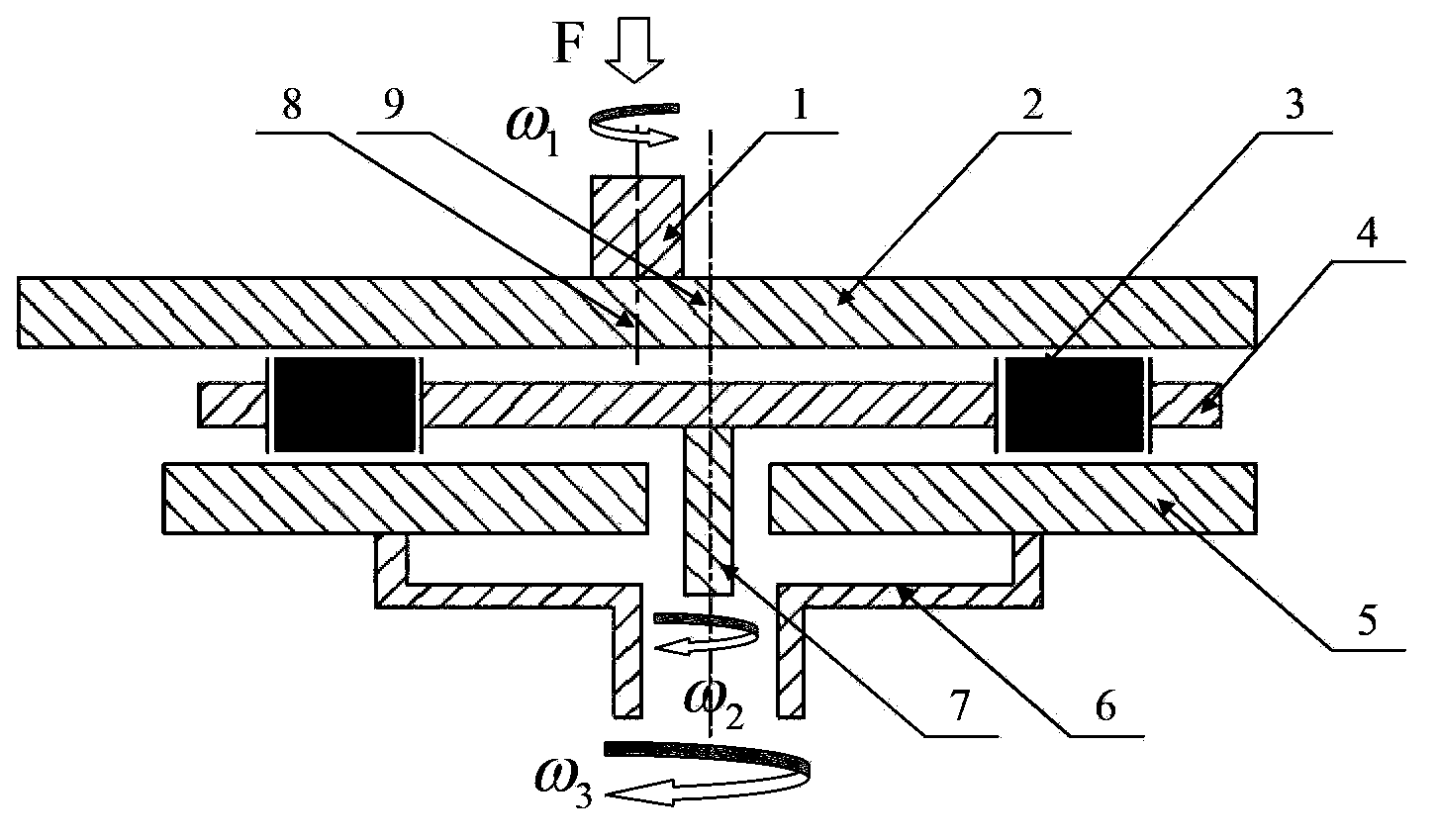

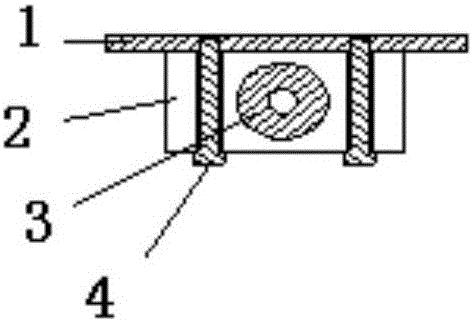

Method for processing outer circle of cylindrical part based on upper plate eccentric pressurizing

ActiveCN103522166AHigh precisionImprove consistencyLapping machinesWork carriersOffset distanceMechanical engineering

A method for processing an outer circle of a cylindrical part based on upper plate eccentric pressurizing. A processing device for achieving the processing method comprises an upper grinding plate, a holder and a lower grinding plate. The upper grinding plate is located above the lower grinding plate, the holder is located between the upper grinding plate and the lower grinding plate, a rotating shaft of the holder and a rotating shaft of the lower grinding plate are coaxial, and a definite offset distance exists between a rotating shaft of the upper grinding plate and the rotating shaft of the holder. In the process of processing, a loading device eccentrically acts on the cylindrical part through the upper grinding plate, and the outer circle of the cylindrical part is processed through the cooperation of a plane of the upper grinding plate, a plane of the lower grinding plate and matched abrasive materials. The method for processing the outer circle of the cylindrical part is high in precision and good in consistency.

Owner:ZHEJIANG UNIV OF TECH

Monolithic multi-way valve body casting piece casting method

ActiveCN105903910ADefect control such as sticky sandAvoid overheatingFoundry mouldsFoundry coresCasting defectLinearity

The invention discloses a monolithic multi-way valve body casting piece casting method which comprises the following steps: preparing a core preparing mold, and checking and cleaning the mold; preparing a main core by mold sand, and after the shape of the main core is finalized, spraying a mold release agent, and demolding; preparing small cores, and drilling exhaust holes in the small cores; finishing to remove burrs on the main core and the small cores, and removing a transition jet nozzle on the main core; fixing the main core by a sand core bonding preparation tooling, firstly assembling the small core at one side, and then assembling the small core at the other side; mounting the assembled sand core into a shell body; and casting a valve body: performing a pouring process at two sides of a side thin gate at the same time, using an exothermic riser with the diameter of 120 mm and the height of 220 mm, and placing special cold iron at the bottom face of the shell body. The monolithic multi-way valve body casting piece casted by the casting method has the advantages that the linearity of a main valve hole casting blank is controlled to be less than or equal to 1.0 mm, and the valve hole linearity is ensured; the casting piece pore shrinkage, shrinkage porosity, internal gas holes and other casting defects, especially defects of micropores in the casting piece, are solved; and the compactness of the internal structure is improved.

Owner:南通华东油压科技有限公司

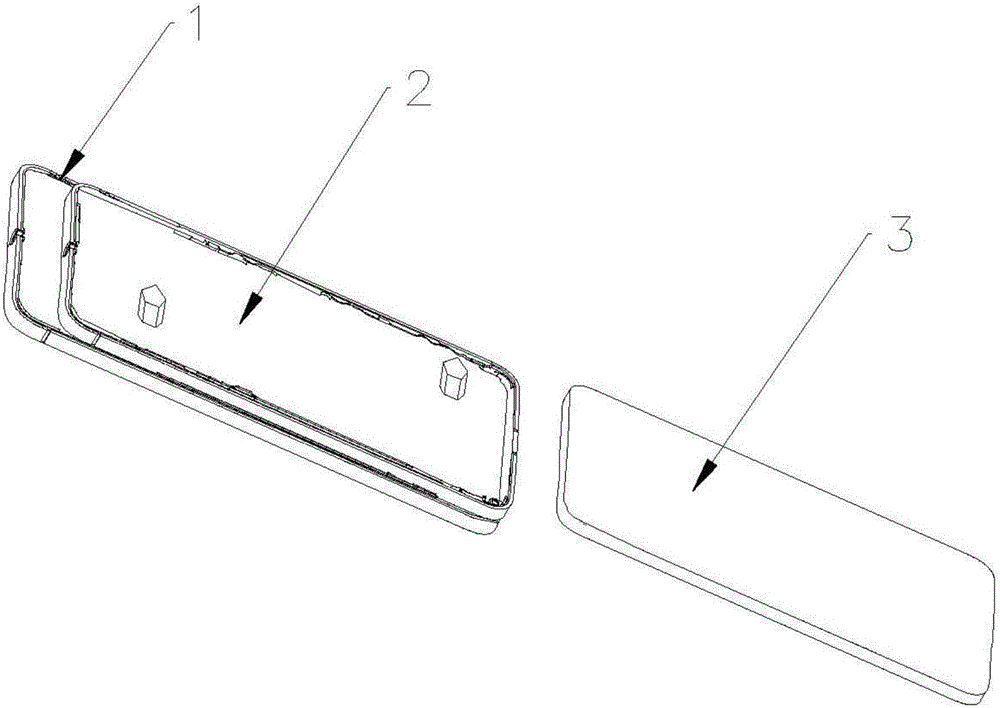

Surface treatment method for highlight edge of aluminum alloy mobile phone shell

ActiveCN106400083ANot easy to fadeImprove yieldSurface reaction electrolytic coatingInksSand blastingPrinting ink

The invention belongs to the technical field of aluminum alloy surface treatment, and particularly relates to a surface treatment method for the highlight edge of an aluminum alloy mobile phone shell. The surface treatment method comprises the following steps of machining of the counter and an inner cavity of the aluminum alloy mobile phone shell, CNC highlight treatment carried out on a frame after surface polishing, surface alkaline washing, surface sand blasting and first-time anodic oxidation, oil removal and cleaning, spraying of printing ink after shielding of the mobile phone shell, printing ink baking, ultraviolet exposure treatment, developing treatment, baking, UV radiation for curing printing ink, second-time anodic oxidation treatment, printing ink removal and third-time anodic oxidation treatment. After the highlight edge of the aluminum alloy mobile phone shell is subjected to three times of anodic oxidation treatment, the portion, close to a display screen, of a longitudinal frame of the mobile phone shell has the same color as the display screen, a frame-free visual sense is formed, the straightness of a color junction edge in second-time anodic oxidation and third-time anodic oxidation is ensured by the adoption of a three-dimensional exposure mode, the production yield reaches up to 90% or above, the cost is low, and production efficiency is high.

Owner:淮北暴风工业设计有限公司

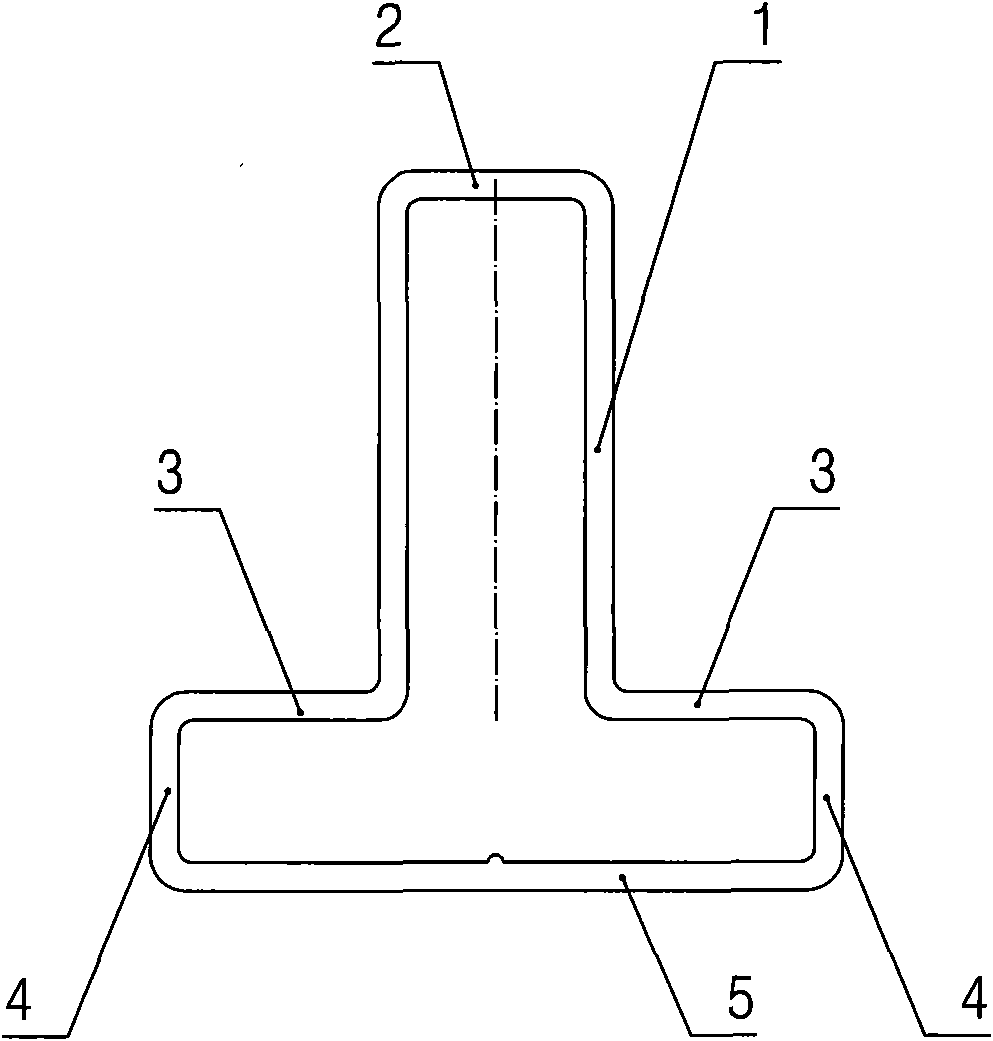

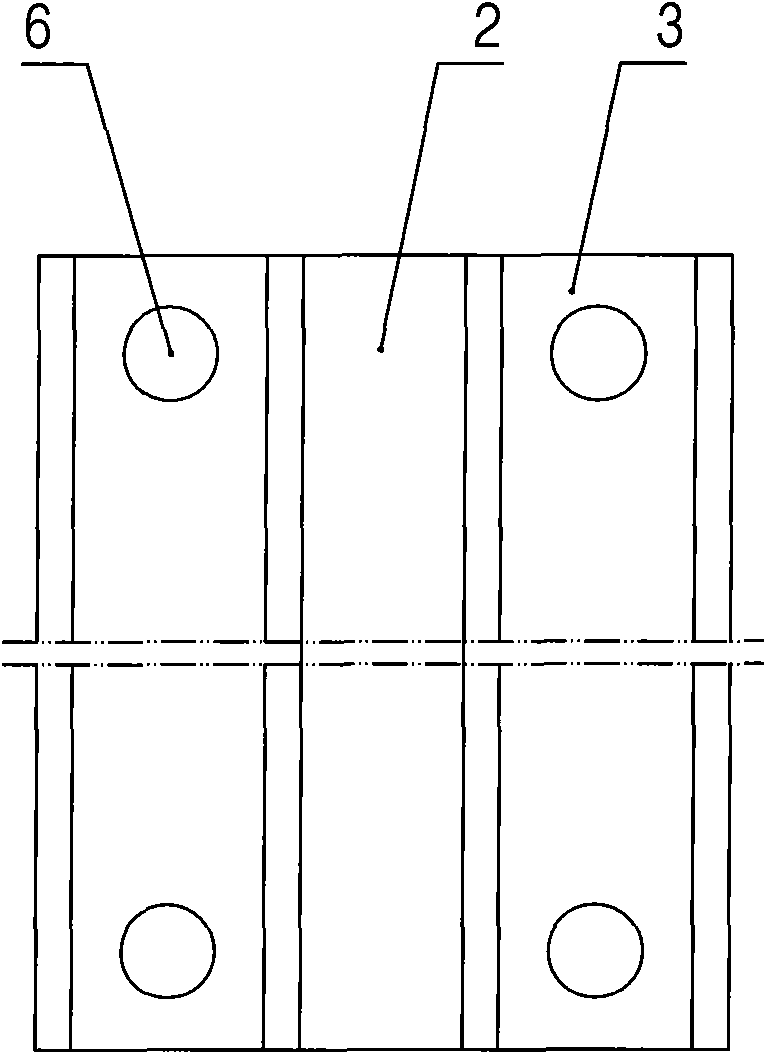

Hollow cage guide

The invention discloses a hollow cage guide, which can save materials and has strong torsion deformation resistance and convenient installation. The hollow cage guide comprises a guide rail seat and a hollow guide rail body connected with the guide rail seat, wherein the guide rail body comprises a pair of parallel guide rail sides and a guide edges connected with the pair of guide rail sides. The cross section of the hollow cage guide encircles into a sealed hollow structure of the Chinese character tu. The invention is mainly used in low speed elevators.

Owner:ZHANGJIAGANG TONGDA ELEVATOR DECORATION

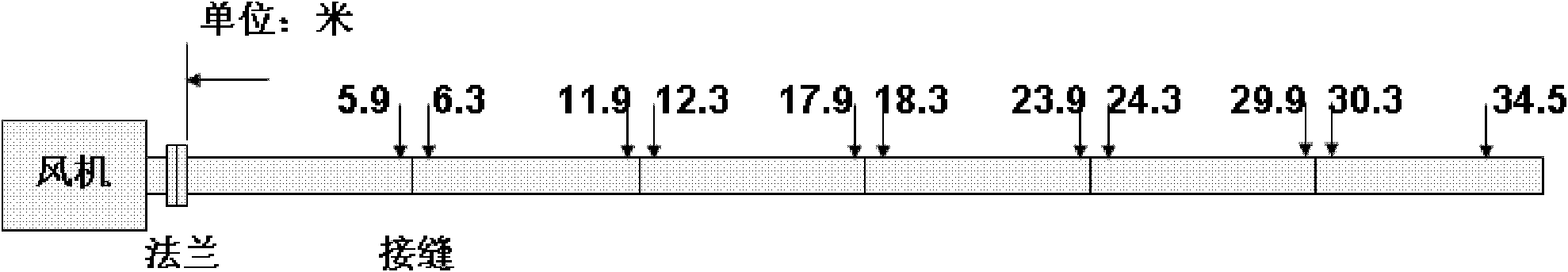

A method and device for testing the frictional resistance coefficient of the inner wall of a pipeline

InactiveCN102269690ATest the coefficient of frictional resistanceGuaranteed turbulence intensityMachine part testingUsing mechanical meansEngineeringDrag coefficient

The invention discloses a device for testing a frictional drag coefficient of an inner wall of a pipeline. The device consists of a high speed fan, a frequency converter, a turbulence smoothening section, a pipeline bracket, the pipeline, a multitube pressure gauge, a Pitot tube and a slanting leg manometer, wherein the frequency converter is connected with the high speed fan; the front end of the turbulence smoothening section is connected with the outlet of the high speed fan, and the rear end is connected with the pipeline; the pipeline is arranged on the pipeline bracket with an adjustable mechanism; pressure testing holes are processed at different positions of the pipeline and are connected with the multitube pressure gauge through tee joints and hoses; and at the tail end of the pipeline, the wind speed in the pipeline is tested by the Pitot tube, and the Pitot tube is connected with the slanting leg manometer. A method for testing the frictional drag coefficient of the inner wall of the pipeline comprises the following six steps of: 1, selecting a testing scheme; 2, selecting a testing means; 3, distributing the pressure testing holes; 4, analyzing the experimental accuracy; 5, designing and manufacturing the pipeline bracket; and 6, assembling the testing device, wiring and debugging. The invention has application value in the technical field of pipeline pressure and friction drag testing.

Owner:BEIHANG UNIV

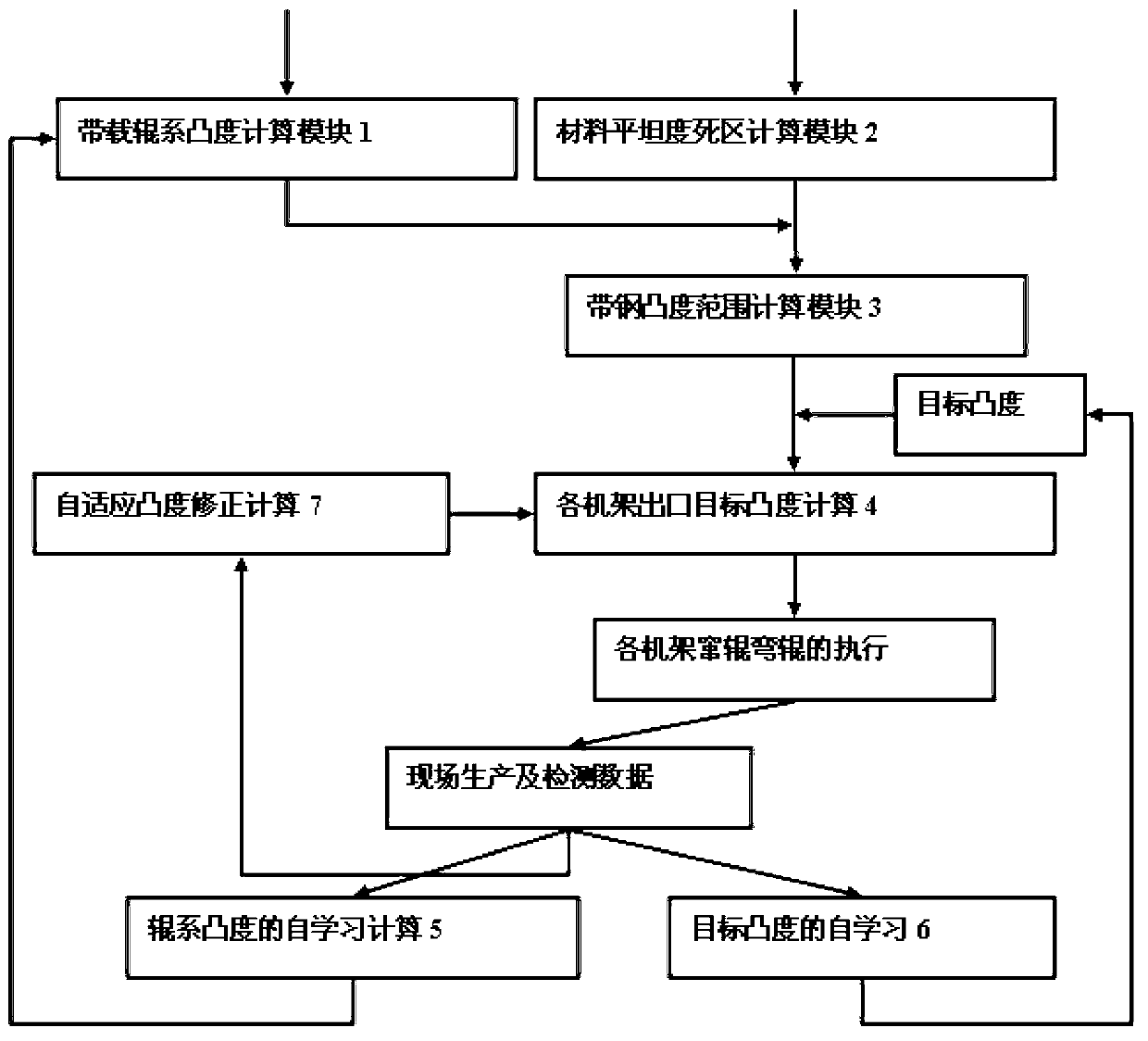

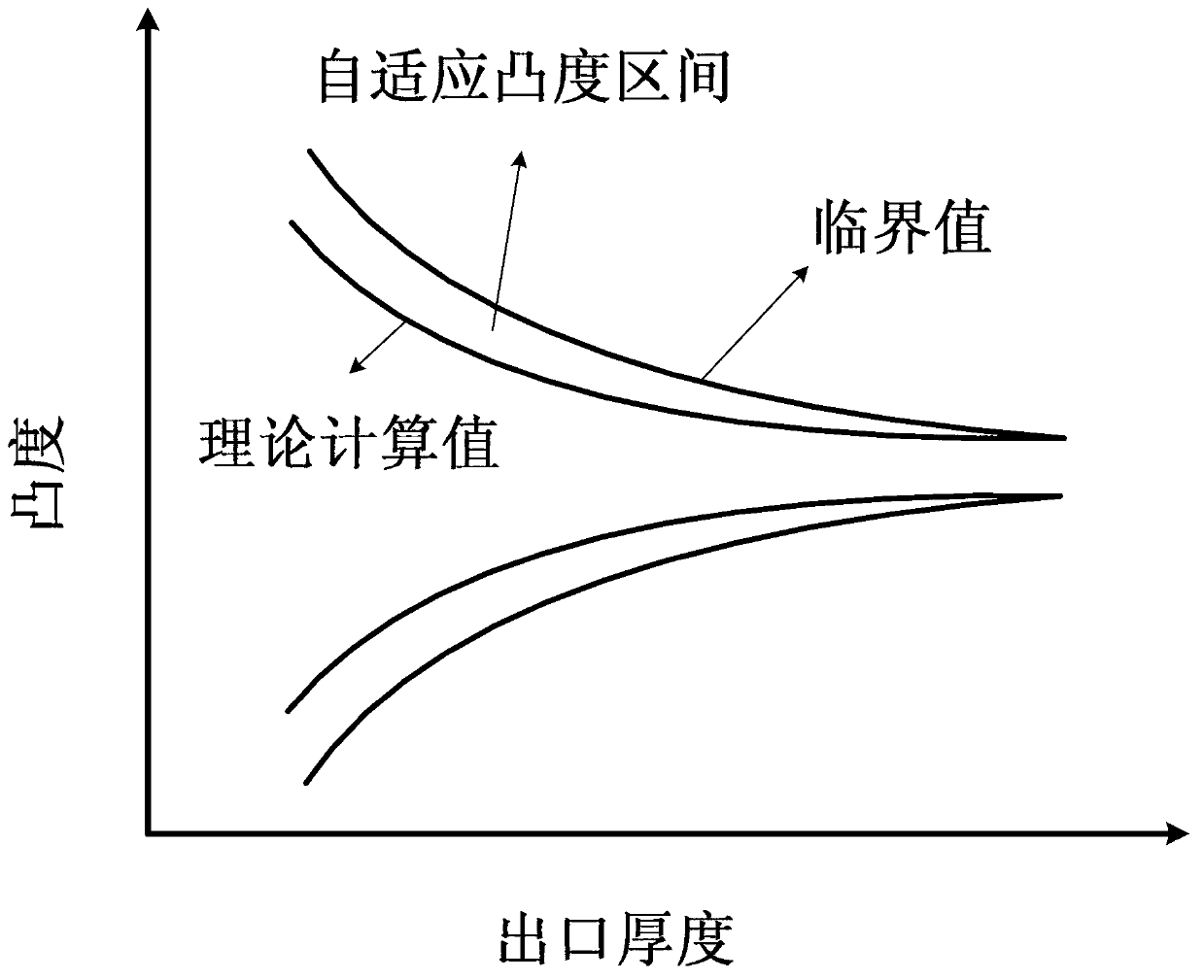

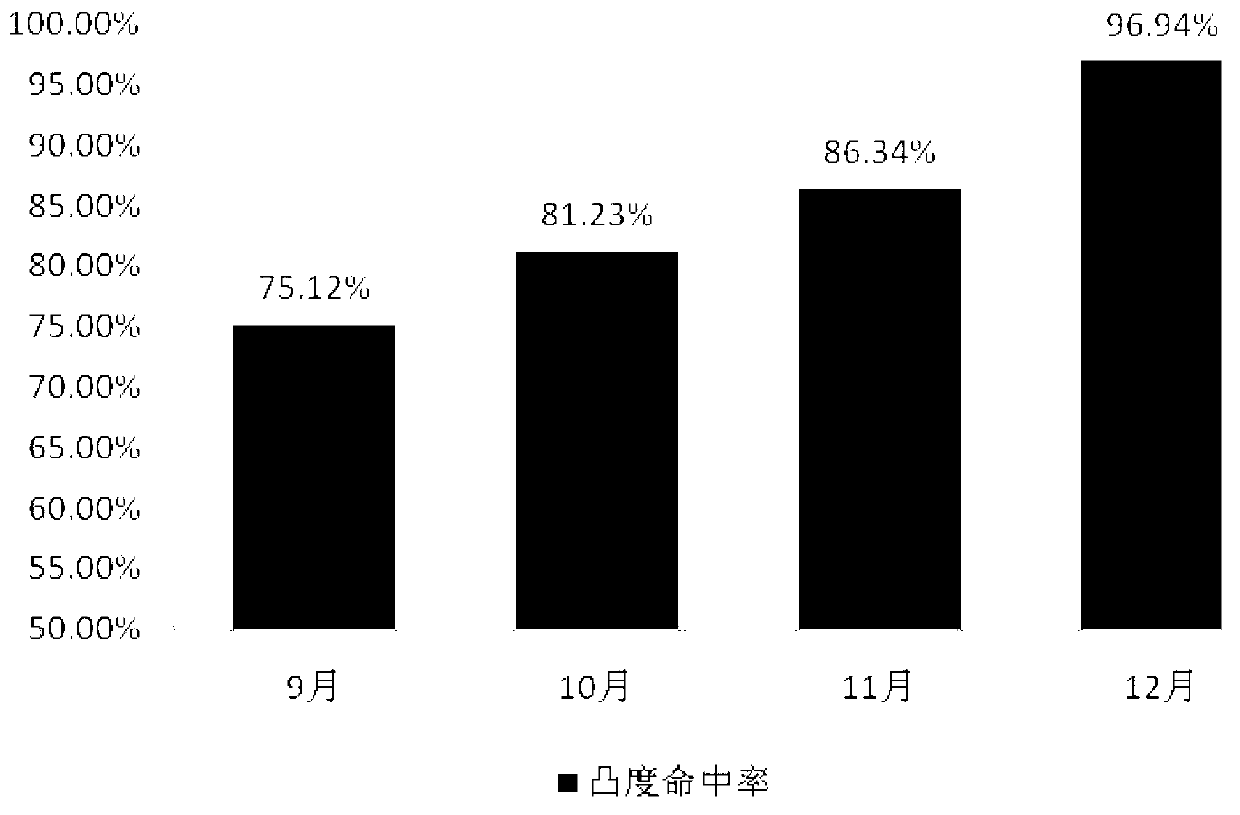

Self-adaptation convexity change hot rolled plate shape control model

ActiveCN103341503AGuaranteed straightnessImprove hit rateProfile control deviceStrip steelMixed mode

A self-adaptation convexity change hot rolled plate shape control model belongs to the technical field of plate and strip hot rolling process analysis and control. The self-adaptation convexity change hot rolled plate shape control model comprises a strip-loaded roller system convexity computation module, a material flatness dead zone computation module, a strip steel convexity range computation module, outlet convexity computation modules of various racks, a roller system convexity self-learning computation module, a target convexity self-learning computation module and a self-adaptation convexity correction computation module. The self-adaptation convexity change hot rolled plate shape control model has the advantages that straightness of hot rolling strip steel is acted as a priority target, ,on the premise that the target convexity is guaranteed, strip steel convexity change of the racks are optimized through self-adaptation convexity correction computation according to rolling parameters provided by a rolling model and with the combination of roller system characteristics of the racks, and therefore under the condition that wide strip steel, narrow strip steel, thin strip steel and thick strip steel are rolled in a mixed mode, strip steel straightness and target convexity control are stable, and the hit rate of strip steel target convexity control is improved.

Owner:SHOUGANG CORPORATION

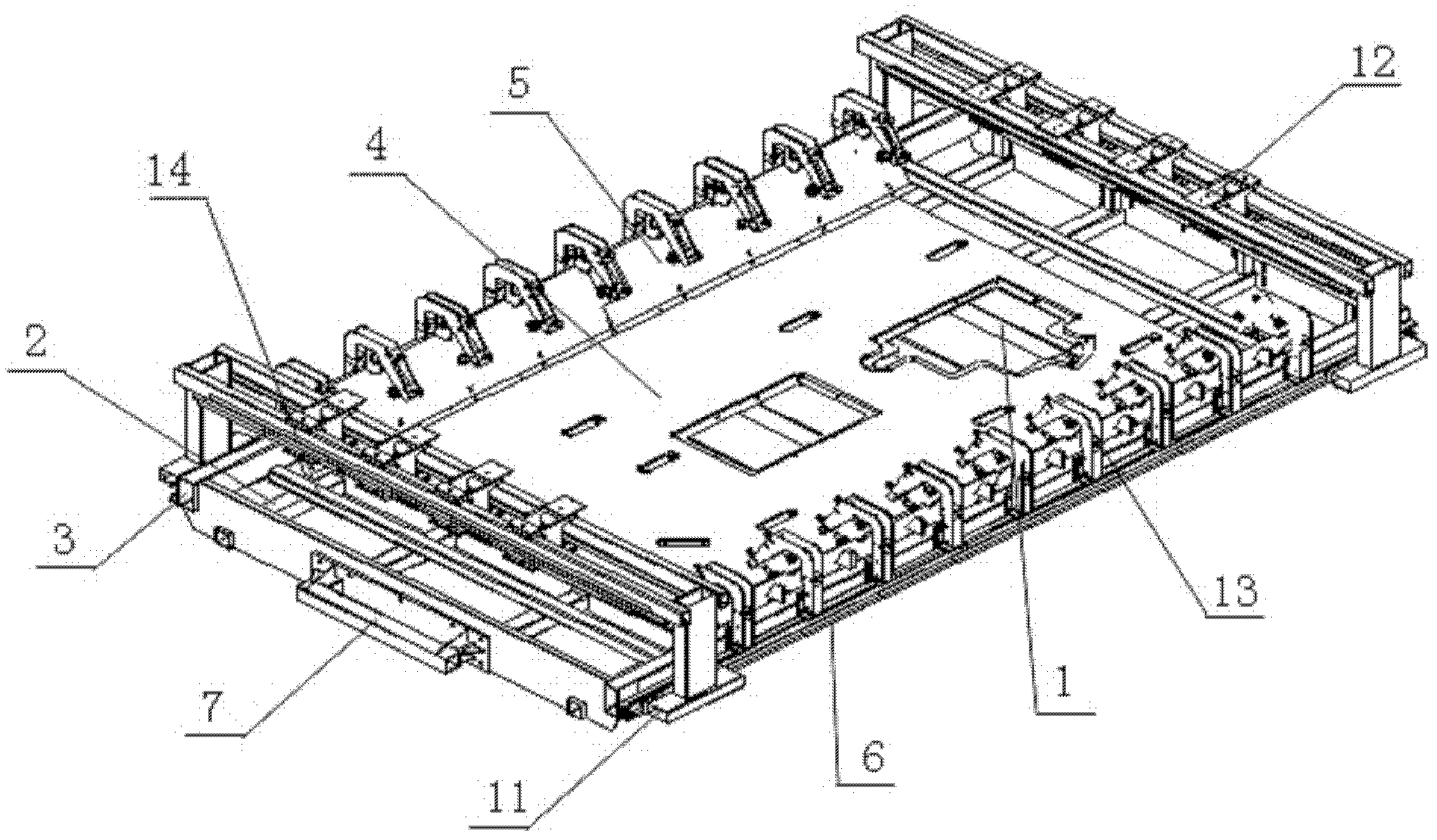

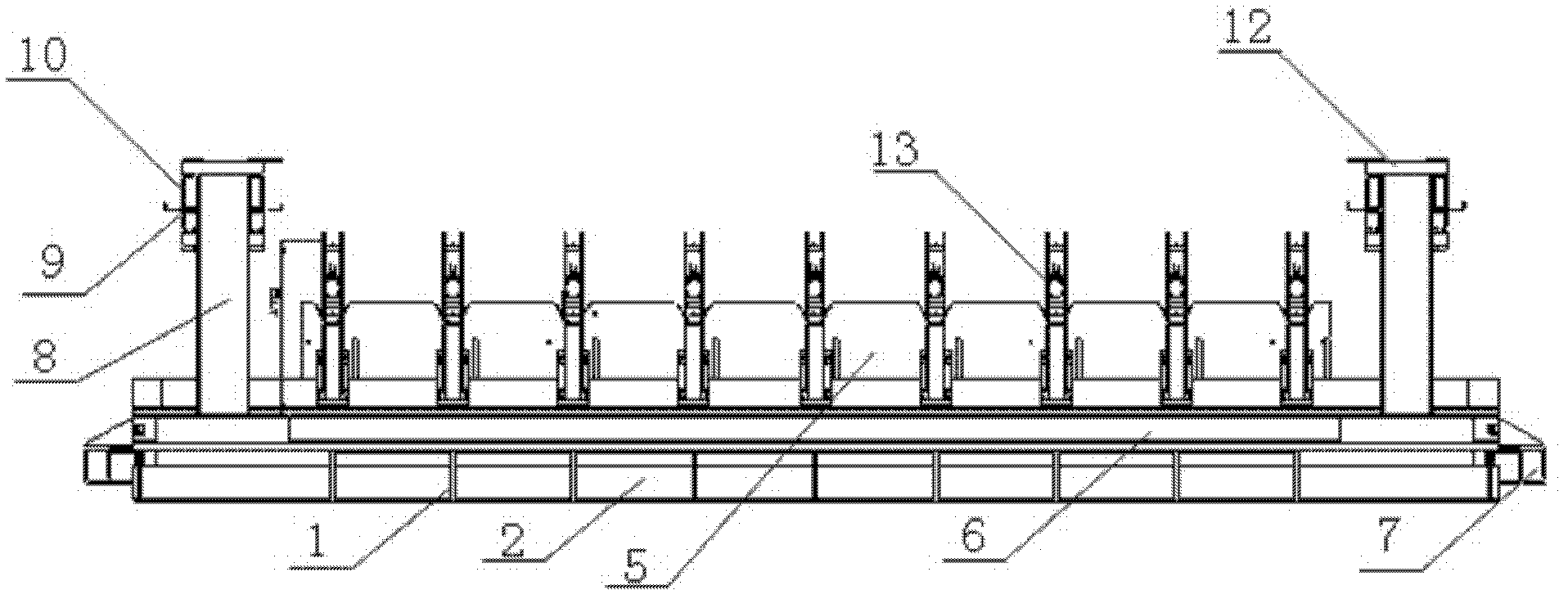

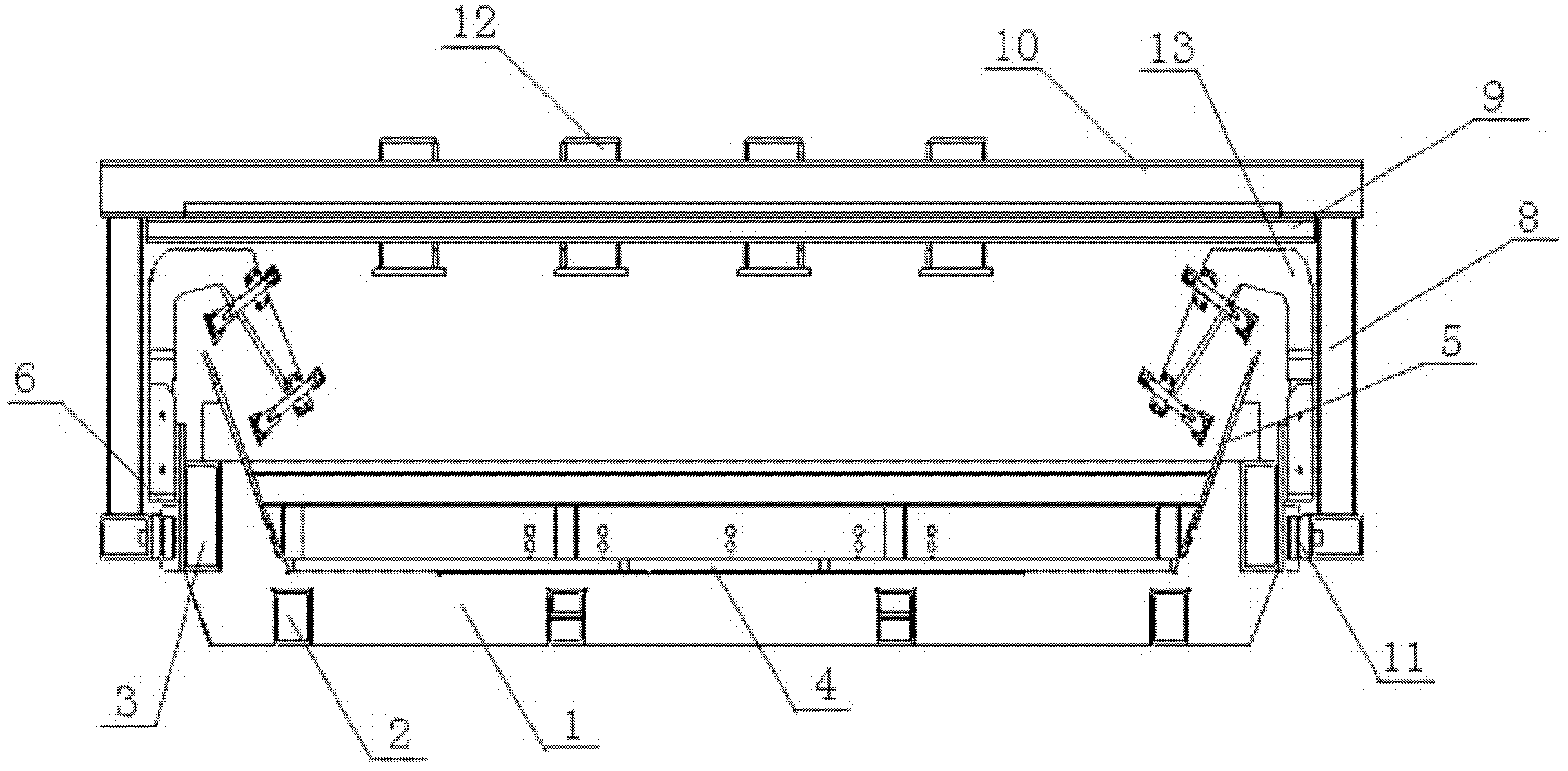

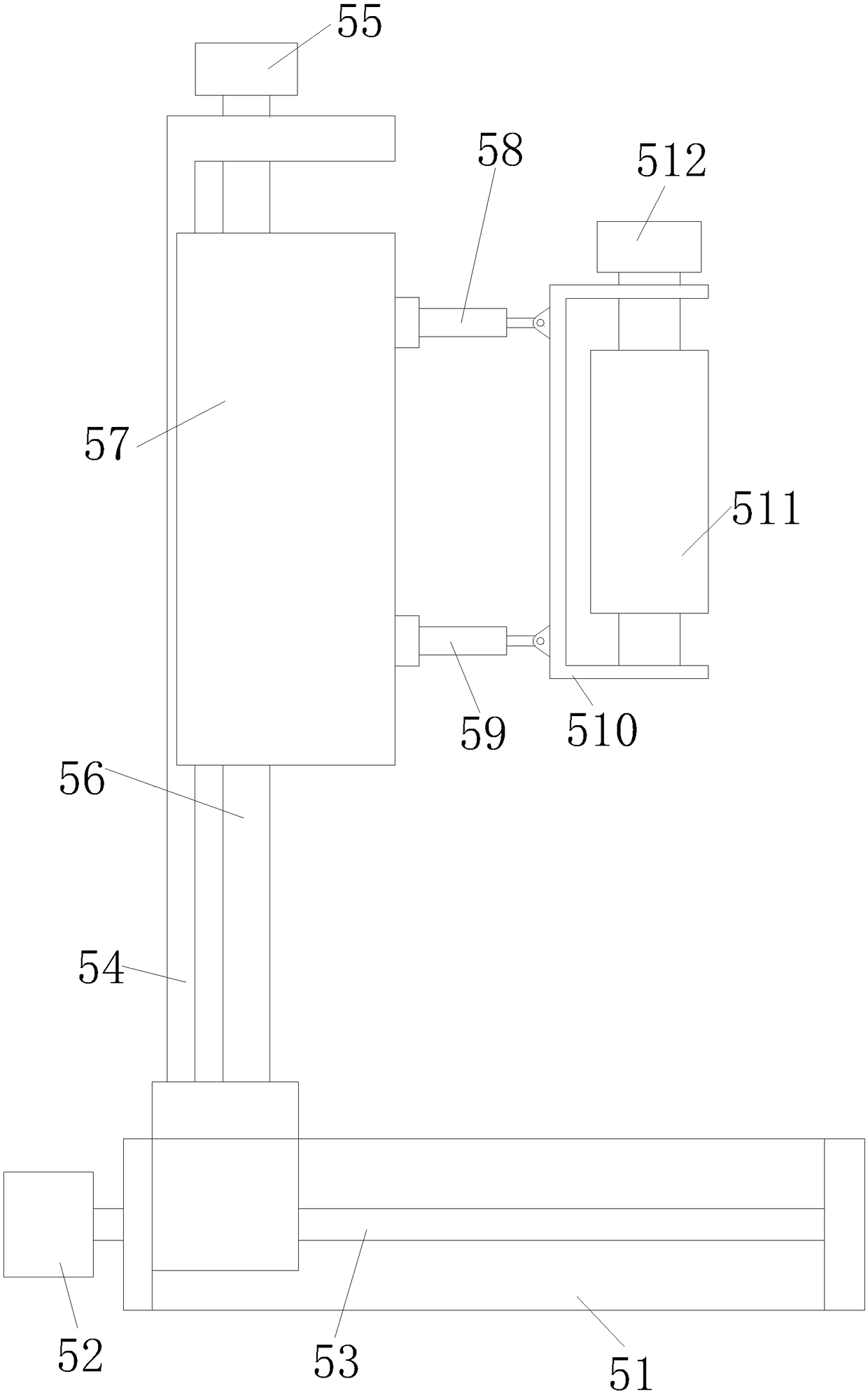

Electric locomotive roof assembly and welding tool

ActiveCN102500985ASolve the sinking deflectionGuaranteed validityWelding/cutting auxillary devicesAuxillary welding devicesCantileverElectric power

The invention relates to an electric locomotive roof assembly and welding tool, which comprises an integral frame, a gantry and a cylinder, wherein the integral frame consists of a reinforcing ribbed plate, a main beam, an edge beam, a bottom plate and a side wall board; the side wall board and the bottom plate form an inclination angle; a sliding track for mounting the gantry is arranged outside the side wall board; the gantry is provided with a movable cylinder fixing frame and is used for eliminating welding gap between an aluminum plate and the frame to guarantee welding quality; and the effect of reducing welding deformation is reduced by forming rigid fixing force for the aluminum plate and the frame. Side wall pressing cantilevers are uniformly distributed outside the edge beam; and the reinforcing ribbed plate is provided with a positioner connecting pipe. The interference between a product and the tool is eliminated in a movable pressing and fixed pressing combined mode, so that all products can be welded on the tool at one time. The working efficiency is increased. All positioning devices are used for quick and accurate positioning. The stability of the tool is effectively guaranteed, and the product quality requirements are met.

Owner:ZHUZHOU POWER LOCOMOTIVE PREUMATIC EQUIPOMENT

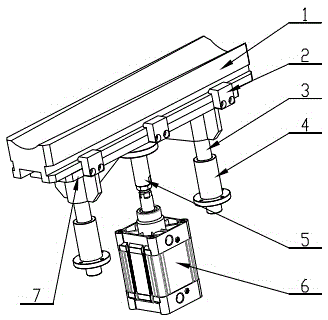

Auto quenching device and auto quenching method

ActiveCN104831030ARealize automatic quenching functionGuaranteed straightnessFurnace typesHeat treatment furnacesHigh frequency powerEngineering

The invention discloses an auto quenching device which includes a rack and an induction coil connected to a high-frequency power supply circuit. The auto quenching device is characterized by including: a rotary lifting mechanism including a pneumatic gripper which is arranged longitudinally and used for clamping a shaft workpiece and can be rotated with the axial line itself and lifted vertically; an automatic material feeding mechanism arranged beside the rotary lifting mechanism, wherein the automatic material feeding mechanism is used for sending the shaft workpiece into the rotary lifting mechanism from a material arranging box so that the shaft workpiece can be clamped by the pneumatic gripper of the rotary lifting mechanism; a material receiving mechanism arranged under the rotary lifting mechanism and used for receiving a quenched shaft workpiece; and the induction coil which is arranged transversally and is matched with the pneumatic gripper clamping the shaft workpiece in the rotary lifting mechanism, wherein cooling liquid flows through the induction coil. The auto quenching device can achieve an automatic quenching function on the shaft workpiece. The shaft workpiece is cooled by spraying water thereon directly, so that heat is effectively prevented from transferred into the interior of the workpiece. The pneumatic gripper in the rotary lifting mechanism clamps the shaft workpiece longitudinally, thereby ensuring linear degree of the shaft workpiece.

Owner:宁波美德威机械科技有限公司

Preparation method and application of heat-resistant titanium alloy wires

ActiveCN109355530ADifferent tensile strength matchingPlastic different matchingTitanium alloyHeat treated

The invention provides a machining and manufacturing method and application of heat-resistant titanium alloy Ti60 wires. The method comprises the steps that Ti60 titanium alloy ingot castings are smelted by adopting a vacuum consumable smelting technology; the smelted Ti60 titanium alloy ingot castings are forged into rods by adopting a free forging technology; the Ti60 titanium alloy rods are finish-forged into thick rod blanks by adopting a finish forging technology; the Ti60 titanium alloy thick rod blanks are rolled into straight strip wire blanks by adopting a hot rolling technology; surface treatment is conducted on Ti60 titanium alloy annealing wire blanks, and pre-oxidation oxidation film hanging treatment is conducted after defects on the surfaces of the wire blanks are removed; continuous high-temperature drawing deformation is conducted on the Ti60 titanium alloy wire blanks obtained after surface treatment by adopting a straight wire drawing machine; the drawn wires are straightened by adopting electric heating tension; and annealing heat treatment is conducted on the straightened wires, and finally centerless grinding is conducted. According to the machining and manufacturing method and application of the heat-resistant titanium alloy Ti60 wires, through combination of different heat machining and heat treating technologies, different matching combinations of the tensile strength, the plasticity and the shearing strength can be obtained, and the heat-resistant titanium alloy Ti60 wires can be used for manufacturing advanced aerospace fasteners such as rivets, bolts and nuts and are used in the temperature range of 600-650 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

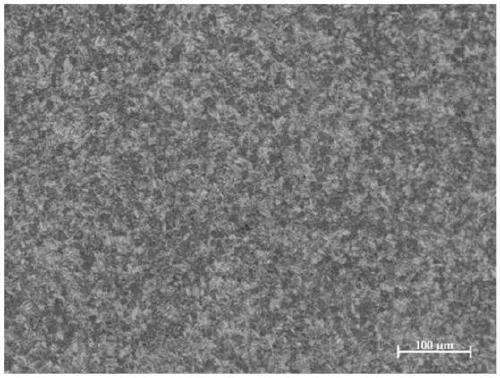

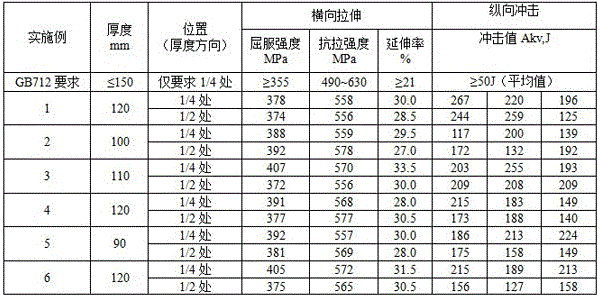

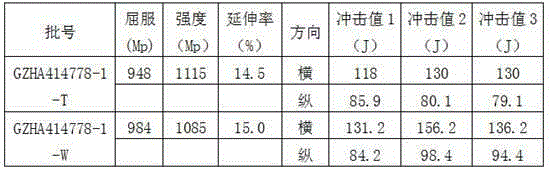

Super-thick EH36 steel for offshore wind power pipe pile and preparation method thereof

The invention relates to super-thick EH36 steel for an offshore wind power pipe pile. The super-thick EH36 steel for the offshore wind power pipe pile comprises the following chemical components in percentage by mass: .015 to 0.18 percent of C, 0.15 to 0.30 percent of Si, 1.40 to 1.60 percent of Mn, less than or equal to 0.0070 percent of P, less than or equal to 0.0030 percent of S, 0.050 to 0.070 percent of Nb, 0.015 to 0.030 percent of V, 0.08 to 0.020 percent of Ti, 0.030 to 0.050 percent of Al, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and the balance of Fe. A production process flow comprises the following steps: performing converter operation, performing LF refining, performing vacuum degasifying, performing Ca treatment, performing continuous casting, dehydrogenizing, rolling, performing air cooling, performing high-temperature hot straightening, and normalizing. According to the production process flow, the super-thick EH36 steel of 90 to 120 mm for the offshore wind power pipe pile, which is high in unit weight, high in strength, high in impact toughness, small in thickness tolerance and high in straightness and does not have a surface defect is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

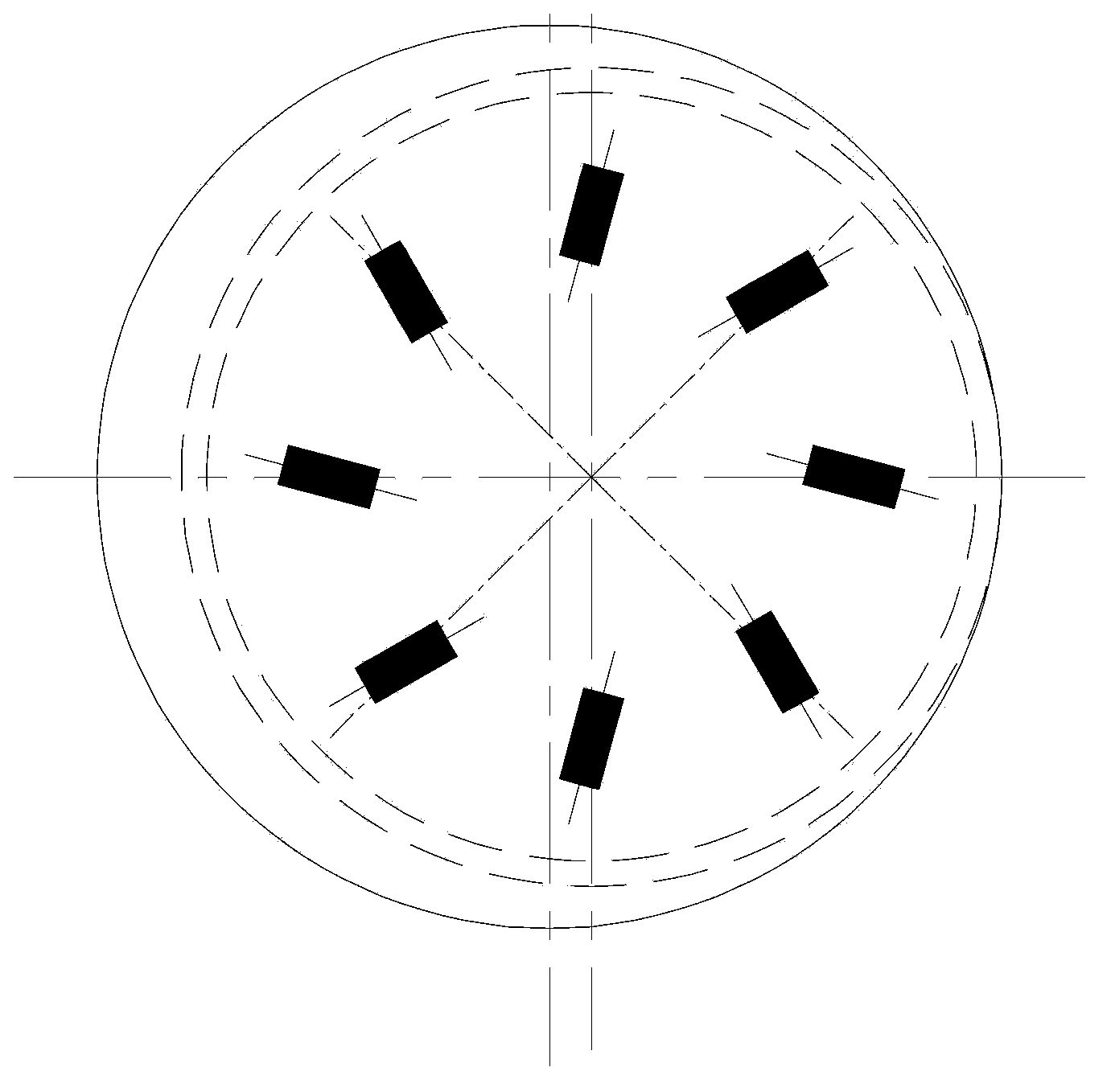

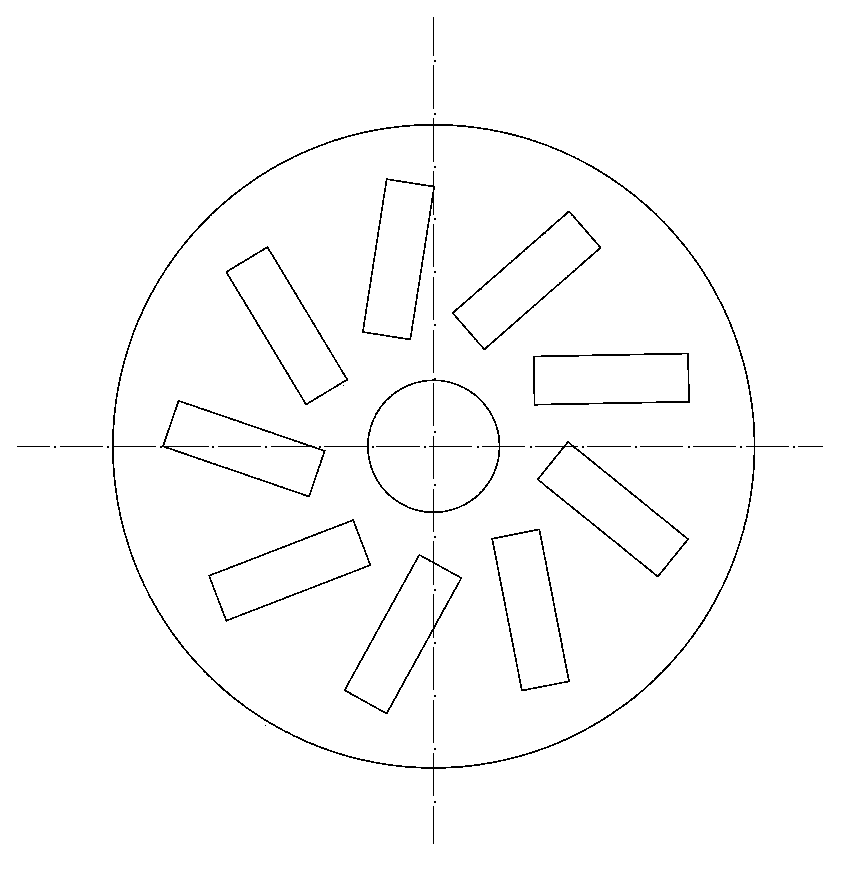

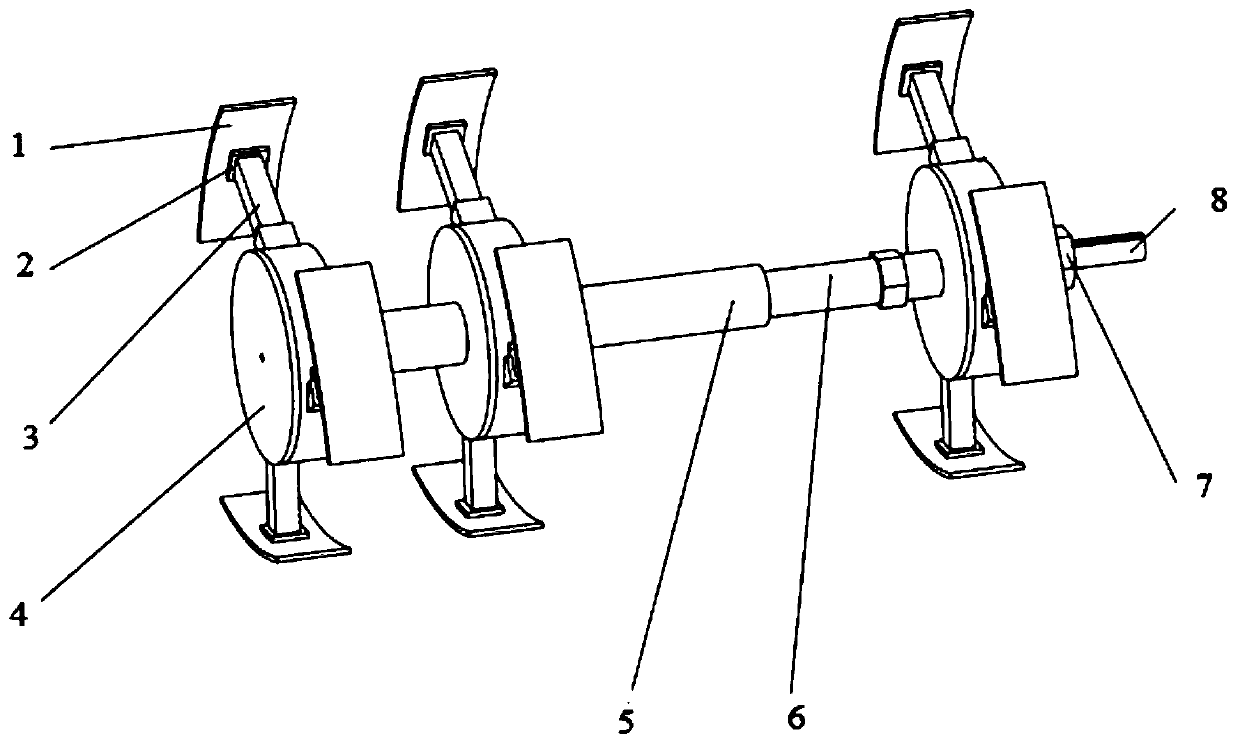

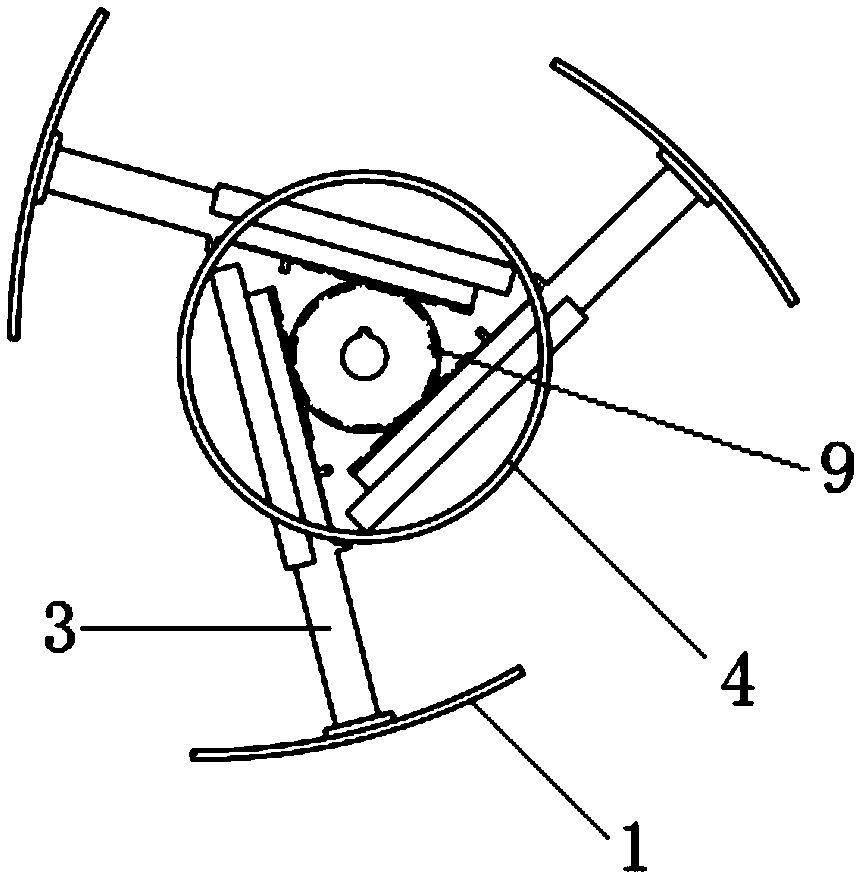

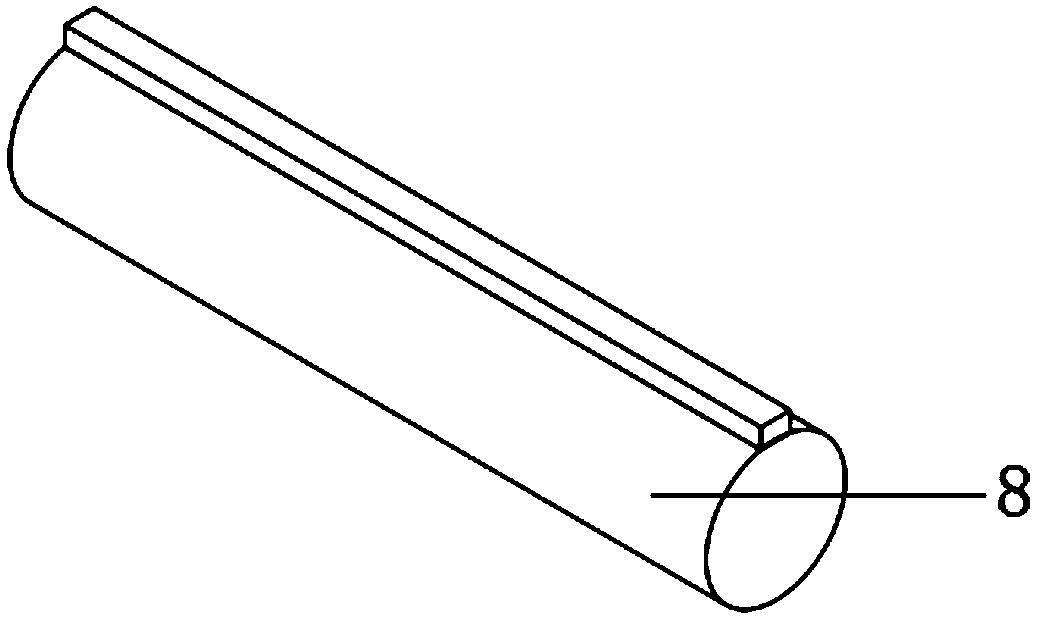

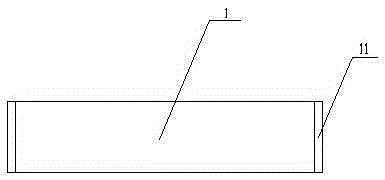

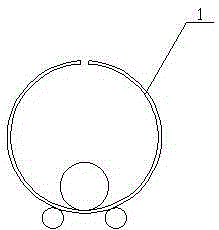

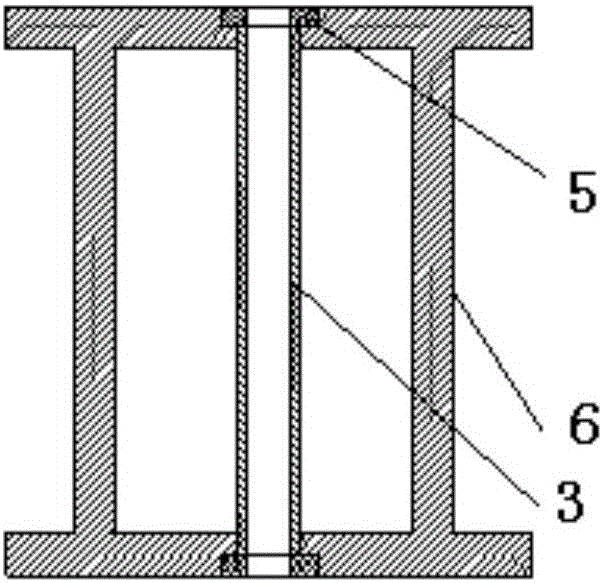

Internal supporting type fixture for turning external circles of thin-wall parts and application of fixture

InactiveCN109604659AGuaranteed straightnessGuaranteed roundnessExpansion mandrelsPipe fittingEngineering

The invention relates to an internal supporting type fixture for turning external circles of thin-wall parts and an application of the fixture. The fixture comprises multiple supporting device units;the supporting device units are connected through telescopic axial connecting components; each supporting device unit comprises a supporting device mounting disk, multiple supporting disks and radialtelescopic arms; a gear is arranged inside each supporting device mounting disk; a rack is arranged at one end of each radial telescopic arm; one end of each radial telescopic arm is inserted in the circumferential side surface of the corresponding supporting device mounting disk to mesh with the corresponding internal gear, and the other end of each radial telescopic arm is fixedly connected withthe corresponding supporting disk; the length of the radial telescopic arms is adjusted by the aid of a rocker arm inserted in the supporting device mounting disks, so that the supporting disks are controlled to support the inner walls of the thin-wall parts. Compared with the prior art, the fixture has the advantages that the roundness and the straightness of the parts can be well guaranteed, and machining of the external circles of different series of thin-wall pipe fittings can be met.

Owner:SHANGHAI UNIV OF ENG SCI

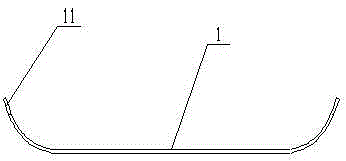

Building technology for pile leg of self-elevating wind power vessel

The invention relates to a building technology for a pile leg of a self-elevating wind power vessel. The building technology mainly comprises the following steps that cylinders are rolled, wherein rolling is carried out on the two ends, the middle part is rolled after the two ends are rolled in place, rolling is carried out in place again, longitudinal seam welding is carried out after positioned welding, and final roundness restoration is carried out; the cylinders are welded, wherein the cylinders are matched, an assembling machine is used for assembling, positioning welding is carried out, and finally welding is carried out; pre-assembling is carried out in a workshop, wherein the overall linearity of a reference section, the gap and the alignment tolerance are adjusted, technological flanges are assembled and welded in place, and the cross central line, the height reference line and the central line of a bolt hole are marked out on the reference section; bolt holes are cut, wherein an upper section and a lower section are rotated to the position of a saddle-shaped cutting machine, the central line of the pile leg is adjusted to be parallel to a track of the saddle-shaped cutting machine, and cutting is carried out according to the marked lines. The building technology has the advantages that various building requirements of the pile leg can be ensured, meanwhile, the building efficiency can be improved, and the building cost can be reduced.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

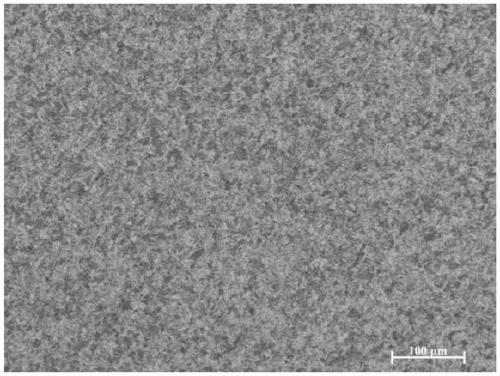

High-strength martensite stainless steel plate and production method thereof

ActiveCN105132820AGuaranteed straightnessImprove surface qualityMartensitic stainless steelSlow cooling

The invention discloses a high-strength martensite stainless steel plate and a production method thereof. The production method comprises a cogging process, a rolling process and a thermal treatment process. The steel plate consists of the following chemical components in percentage by mass: less than or equal to 0.06% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.015% of S, 15.00%-17.00% of Cr, 4.50%-5.50% of Ni, 0.80%-1.20% of Mo, less than or equal to 0.00025% of H, greater than or equal to 0.020% of N, and the balance of Fe and inevitable impurities. The rolling process adopts whole-process water-avoiding quick rolling without extruding by use of a vertical stick; after being cogged, steel ingot is introduced into a slow cooling pit to carry out slow cooling; the rolling process adopts multi-pass heating quick rolling with small rolling reduction; and the thermal treatment process adopts a quenching and tempering process. The steel plate is good in plate form and stable in performance, good in room-temperature tensile strength and yield strength, good in low-temperature impact toughness at a temperature of (-)40 DEG C and good in ductility.

Owner:WUYANG IRON & STEEL

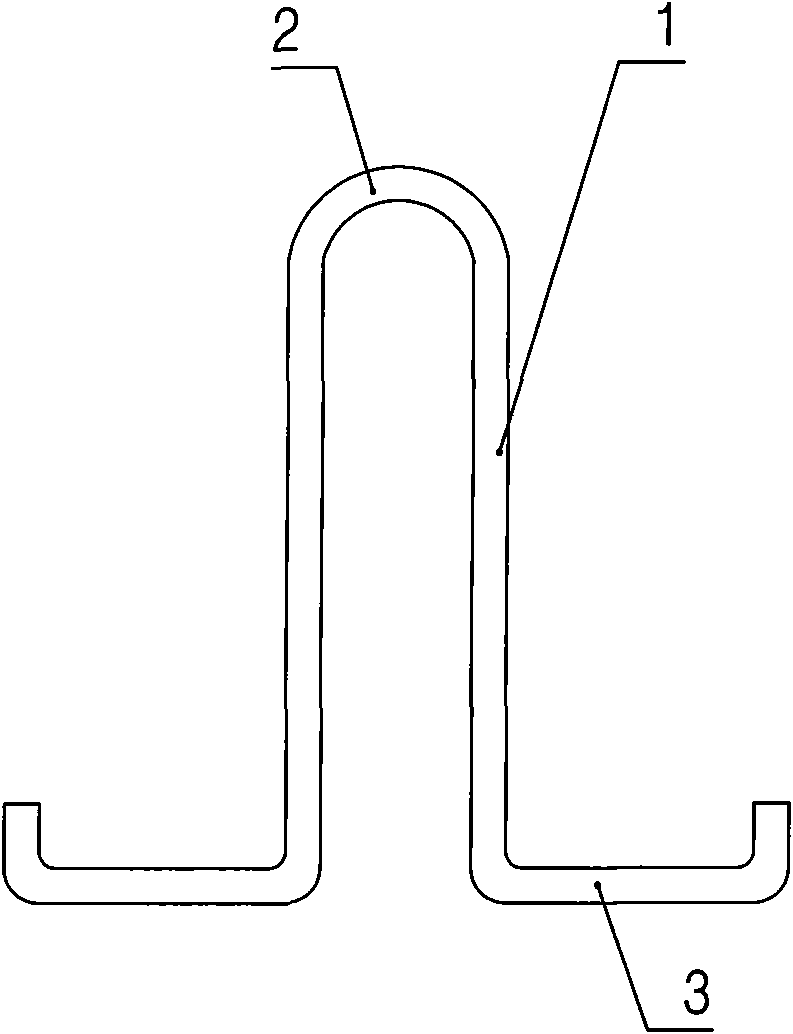

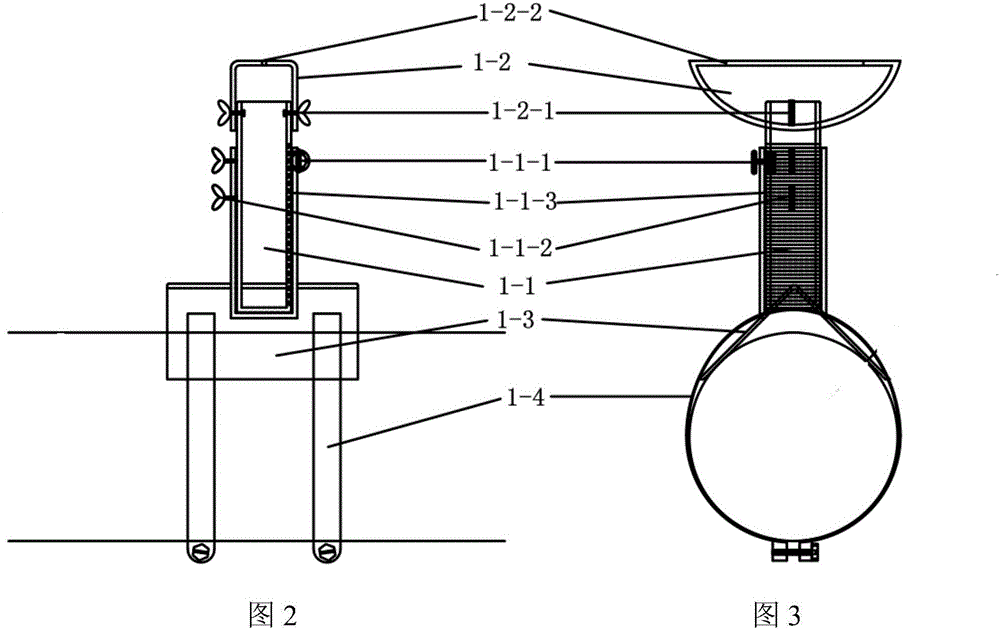

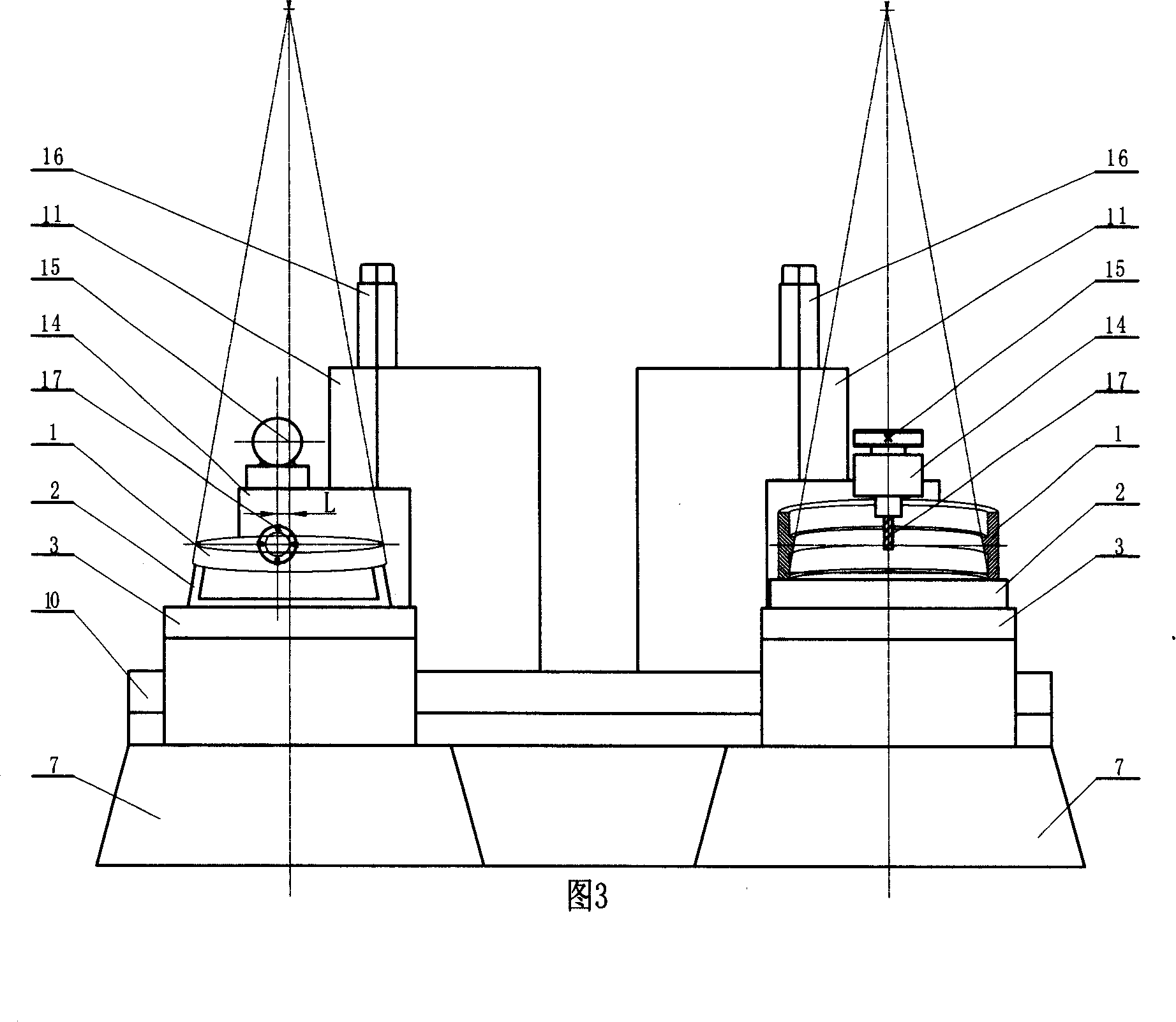

Testing platform for position and attitude precision of dual-antenna receiver and testing method thereof

The invention provides a testing platform for position and attitude precision of a dual-antenna receiver and a testing method thereof. The testing platform comprises a supporting device, a linear guide rail and a traction system. The supporting device consists of a lifting support and a rotation support. The linear guide rail includes a U-shaped-groove guide rail with an upward opening, a sliding block, and a planar slipway, wherein the sliding block and the planar slipway are arranged above the U-shaped-groove guide rail; the U-shaped-groove guide rail is installed on a support platform; and two antennas are installed on the slipway. The traction system includes a speed regulating motor, a driving wheel, a gear belt, limit switches and a fixedly connection device; the speed regulating motor and the driving wheel are fixed on steel guard bar tubes at the two sides of the linear guide rail by the fixedly connection device; the gear belt is connected with the speed regulating motor and the driving wheel; one side of the gear belt is connected with the slipway fixedly; and the limit switches are arranged at the two ends of the linear guide rail. Therefore, the position and attitude precision of the dual-antenna receiver under different base line lengths and different speeds can be tested; and a problem of difficult positioning and attitude measuring precision evaluation of the dual-antenna receiver can be solved.

Owner:SOUTH CHINA AGRI UNIV

Panel processing method using vacuum chucks, left limiting sensor and right limiting sensor

The invention discloses a panel processing method using vacuum chucks, a left limiting sensor and a right limiting sensor. Devices used in the panel processing method comprise an underbed, a left rack and a right rack, wherein the left rack is arranged at the left end of the underbed, the right rack is arranged at the right end of the underbed, a panel conveying device and a rolling device are arranged between the left end and the right end of the underbed, panels borne by the panel conveying device can move on the underbed in the front and back direction through the panel conveying device, the rolling device can slide on the underbed in the left and right direction, and the front and back direction is the direction which is perpendicular to the left and right direction in a horizontal plane; the panel conveying device comprises a bearing frame, a lifting device and a front and back direction sliding device, and when processing is carried out, the bearing frame is used for bearing the panels, the bearing frame is connected with the lifting device, the bearing frame can ascend and descend through the lifting device, and therefore the vertical positions of the panels can be adjusted when the panels are borne by the bearing frame.

Owner:海安江理工技术转移中心有限公司

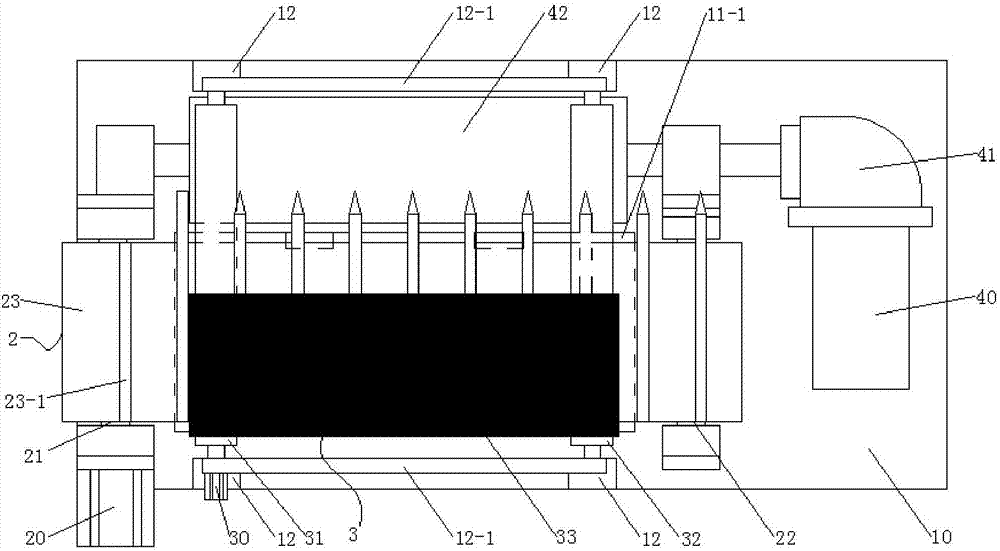

Pencil production polishing device

InactiveCN107225473AImprove automation production efficiencyEnables high-volume grinding operationsEdge grinding machinesGrinding carriagesReducerEngineering

Owner:许莲丽

High-strength glass edging device

InactiveCN108527062AAchieve grindingGuaranteed straightnessEdge grinding machinesHigh intensityEngineering

The invention discloses a high-strength glass edging device which comprises a rack. Two slide rails in parallel are arranged on two sides of the upper surface of the rack; a bearing assembly is arranged on the slide rails through a sliding joint way; a driving assembly for driving the bearing assembly to move is arranged between the bearing assembly and the rack, and is arranged on the rack; and two edging assemblies are symmetrically arranged on two sides of the rack. According to the high-strength glass edging device provided by the invention, through changing strokes of a No.1 electric cylinder and a No.2 electric cylinder, an included angle between a grinding roller and a glass side edge can be changed, so that the glass side edge can be ground at any angle without the need for manualoperation; and through arranging the slide rails, the moving straightness of the bearing assembly is ensured, and the edging quality is further ensured.

Owner:临泉县蓝天钢化玻璃有限公司

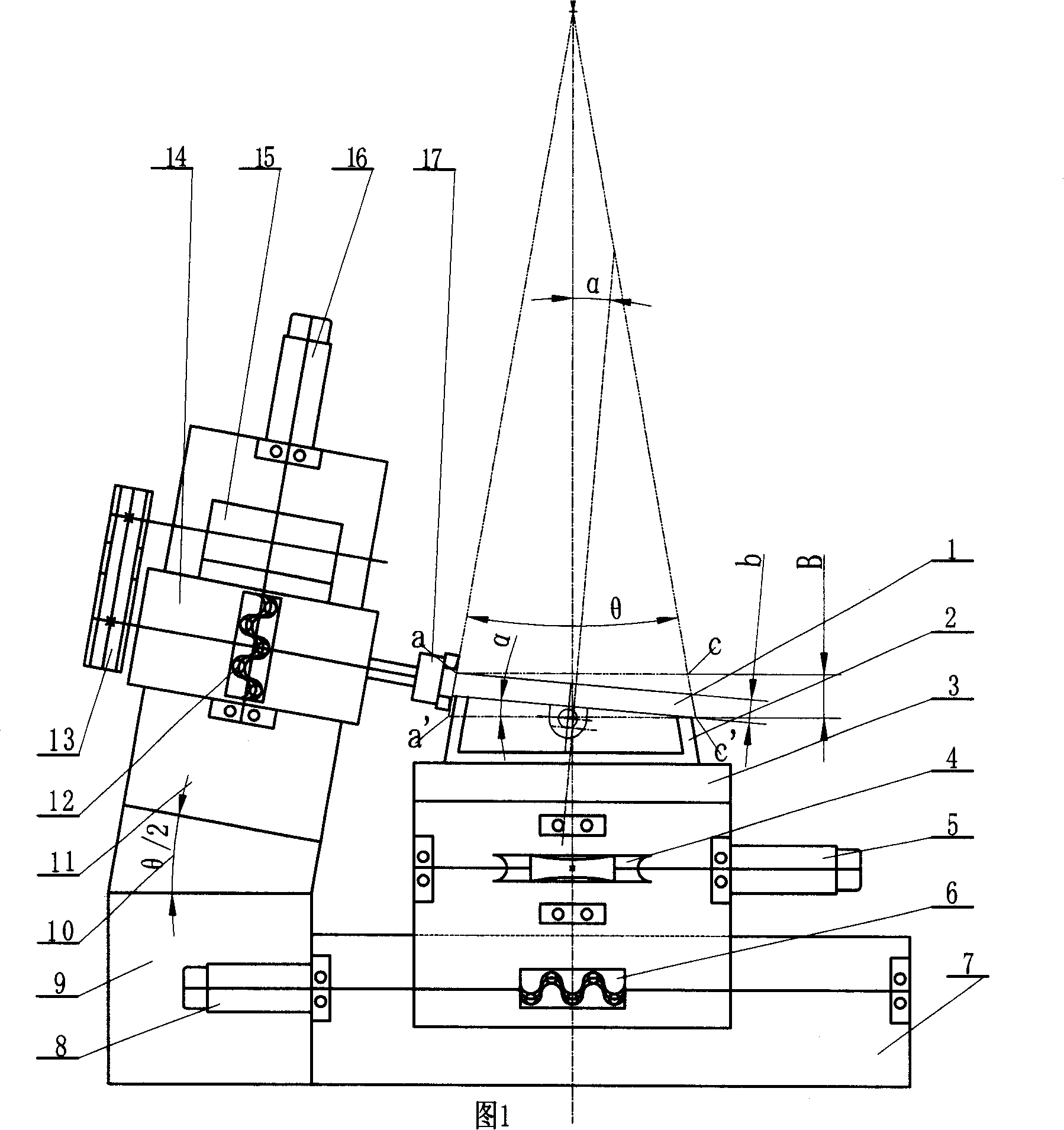

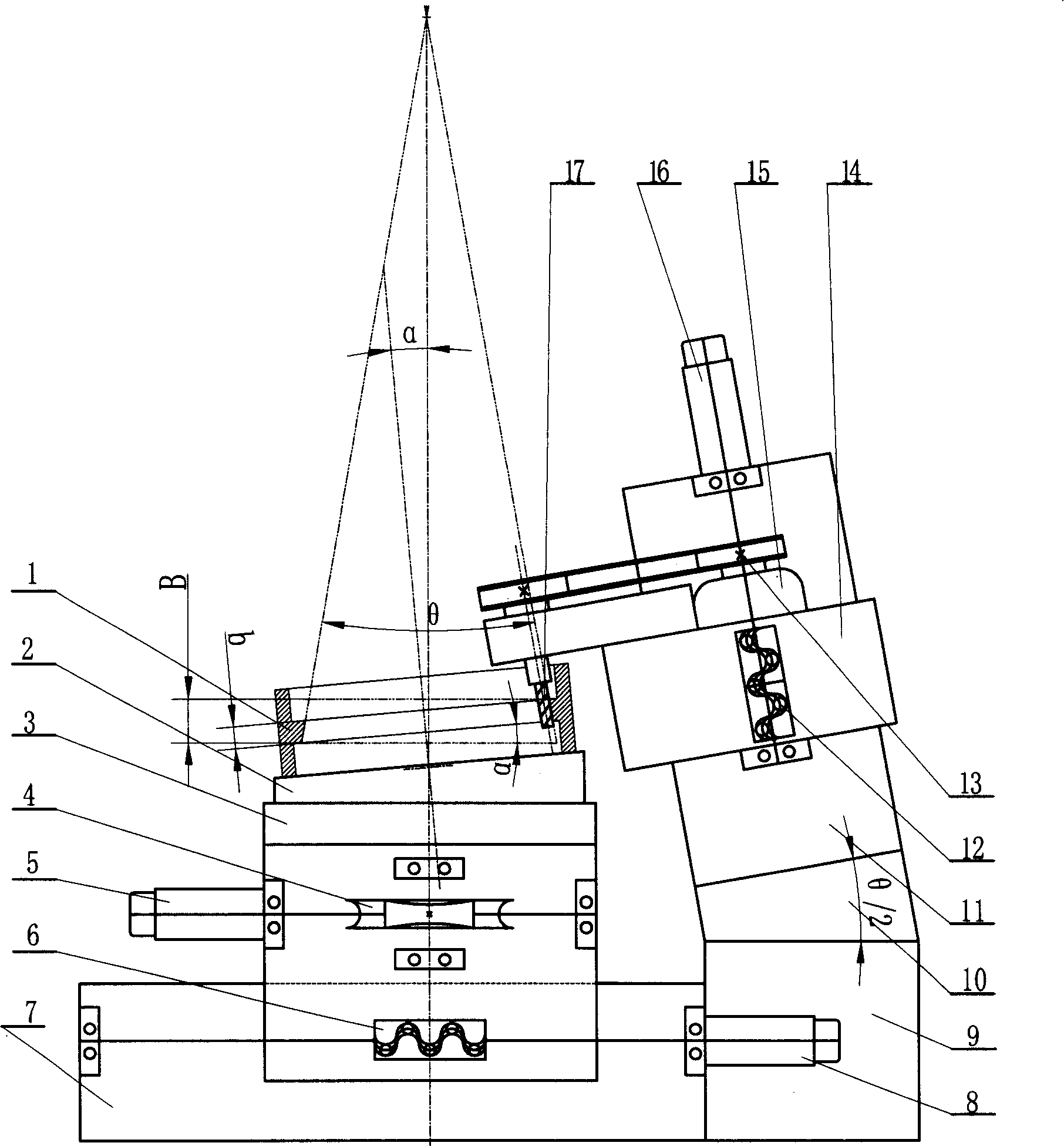

Longitudinal seam welding machine suitable for thin-wall small-diameter suspended single-face welding and double-face forming

ActiveCN104128736AGuaranteed straightnessAvoid positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention relates to welding equipment, in particular to a longitudinal seam welding machine suitable for thin-wall small-diameter suspended single-face welding and double-face forming. The longitudinal seam welding machine comprises a rack. The rack is provided with a work-piece locating device, folding and pressing devices, a central spindle supporting device, a central spindle device, a centering device and a walking gantry welding device. The first folding and pressing device and the second folding and pressing device are located on a sliding rail and connected with a horizontal air cylinder. The central spindle device is located above the locating device. According to the technical scheme, acting force is exerted on a longitudinal seam of a rolling pipe from left and right, under the effect of the misalignment-preventing centering device, seam alignment of a work-piece can be finished without manual adjustment, the straightness of butt seams can be ensured, and the phenomena that positions of the butt seams need to be manually adjusted many times and misalignment is corrected in the past production process can be avoided.

Owner:CHENGDU AIGRE TECH

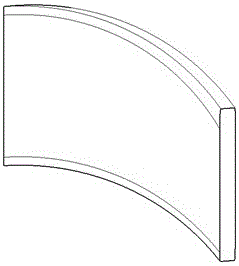

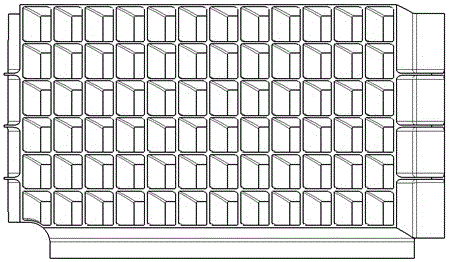

Forming method of carbon fiber composite material grille

InactiveCN106827585AGuaranteed straightnessSimplify the difficulty of demouldingDomestic articlesSurface finishFiber

The invention relates to a forming method of a carbon fiber composite material grille, the forming method of the carbon fiber composite material grille comprises the following steps: (1) core mold molding; (2) carbon fiber fabric paving; (3) mold assembly; (4) glue injection; (5) curing; (6) mold release, and mold core melting; (7) processing; on the basis of the existing method, the contradiction between the surface quality and demoulding difficulty is solved, the use requirements of pneumatic surface can be met; a low melting point alloy core mold used in the method can be repeatedly used, mold cost can be reduced, a RTM process is used for production, and the product is high in surface smooth degree, less in processing amount, and low in manufacturing cost.

Owner:HENGSHEN

Valve tri-eccentric seal surface milling processing special numerical control combination machine

InactiveCN101200009AGuaranteed straightnessImprove efficiencyMilling machinesMilling equipment detailsControl systemHigh intensity

The invention discloses a special digital combined machine tool in tri-eccentric sealing surface milling a valve; two independent turning worktables can process two workpieces of a butterfly plate and a valve body simultaneously; two milling driving heads are arranged on a base with the same inclination through each own upright column, ensuring the conformability on conicity and accuracy of the workpiece sealing surface of the butterfly plate and the valve body. Because the configuration of the main shaft servo motor realizes high-speed heavy cut and the two axis coupled digital feed control system realizes high intensity continuous milling for inclined cut cone surface at three dimensional direction with automatic precision feeding, the machine tool has simple structure, excellent performance, convenient adjustment and maintenance. Comparing with the common machine tool of the traditional technique, this machine tool not only improves the dimensional processing precision and production efficiency; but also greatly reduces the production cost.

Owner:SHANGHAI MAUD GROUP

High-strength steel plate and plate shape control method thereof

ActiveCN106987773AGuaranteed straightnessSimple processTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a high-strength steel plate and a plate shape control method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.4-1.5% of Mn, 0.015% or less of P, 0.005% or less of S, 0.015-0.03% of Als, 0.03-0.04% of Nb, 0.001-0.0015% of Ca, and the balance of iron and inevitable impurities. According to the method, through appropriate heating, rolling, cooling and straightening technology design, the straightness of the steel plate can be guaranteed to meet requirements, and the degree of unstraightness of the steel plate is smaller than 3.2mm / m; and a cold straightening machine for re-straightening is not needed, so that manufacturing cost is reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Manufacturing method of pup joint

InactiveCN101934469AAvoid quality problemsReduce restrictionsFurnace typesHeat treatment furnacesMedium frequencySharpening

The invention relates to a manufacturing method of a pup joint, which is characterized by comprising the following processing steps: (1) thermal treatment, straightening and flaw detection of a pipe body: the thermal treatment process comprises quenching and tempering; after thermal treatment is completed, carrying out full-length straightening on the pipe body with a six-roller straightener; and carrying out full-length flaw detection on the pipe body with a flaw detector; (2) saw-cutting: saw-cutting the pipe body after thermal treatment, straightening and flaw detection into a short material with a sawing machine; (3) initial machining: flattening the saw mouth of the end surface of the short material on the sawing machine, machining an excircle of the obtained short material into Phi132 plus or minus 0.3mm with the sawing machine, and then polishing the inner surface of the short material pipe body at 80-120mm from a port with an automatic sharpening machine to remove surface scale; (4) welding: directly welding a male joint and a female joint with two ends of the short material pipe body respectively on a continuous welding machine; (5) thermal treatment of welding seams: quenching and tempering the welding seams with a medium-frequency induction coil; and (6) machining. The manufacturing method has stable welding process and lower machining cost.

Owner:WUXI SEAMLESS OIL PIPE

Inner hole machining method for molybdenum alloy thin-walled long pipe

ActiveCN105750843ARealization of inner hole processingBrittleHoning machinesBoring/drilling machinesAlloyLinearity

The invention belongs to the technical field of molybdenum alloy machining, and discloses an inner hole machining method for a molybdenum alloy thin-walled long pipe of a reactor. The method is a combined machining method in which gun drilling, linear cutting and honing are organically combined, and comprises the following steps: (1) outer circle reference machining of a molybdenum alloy bar, (2) gun drilling of a threading hole, (3) linear cutting of an inner hole and (4) honing finish machining of the inner hole. The linearity of the machined inner hole of the molybdenum alloy thin-walled long pipe is higher than 0.03 mm, the cylindricity of the inner hole is higher than 5 [mu]m, and the roughness of the inner hole is better than 0.2 [mu]m.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com