Patents

Literature

35 results about "Long fingers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

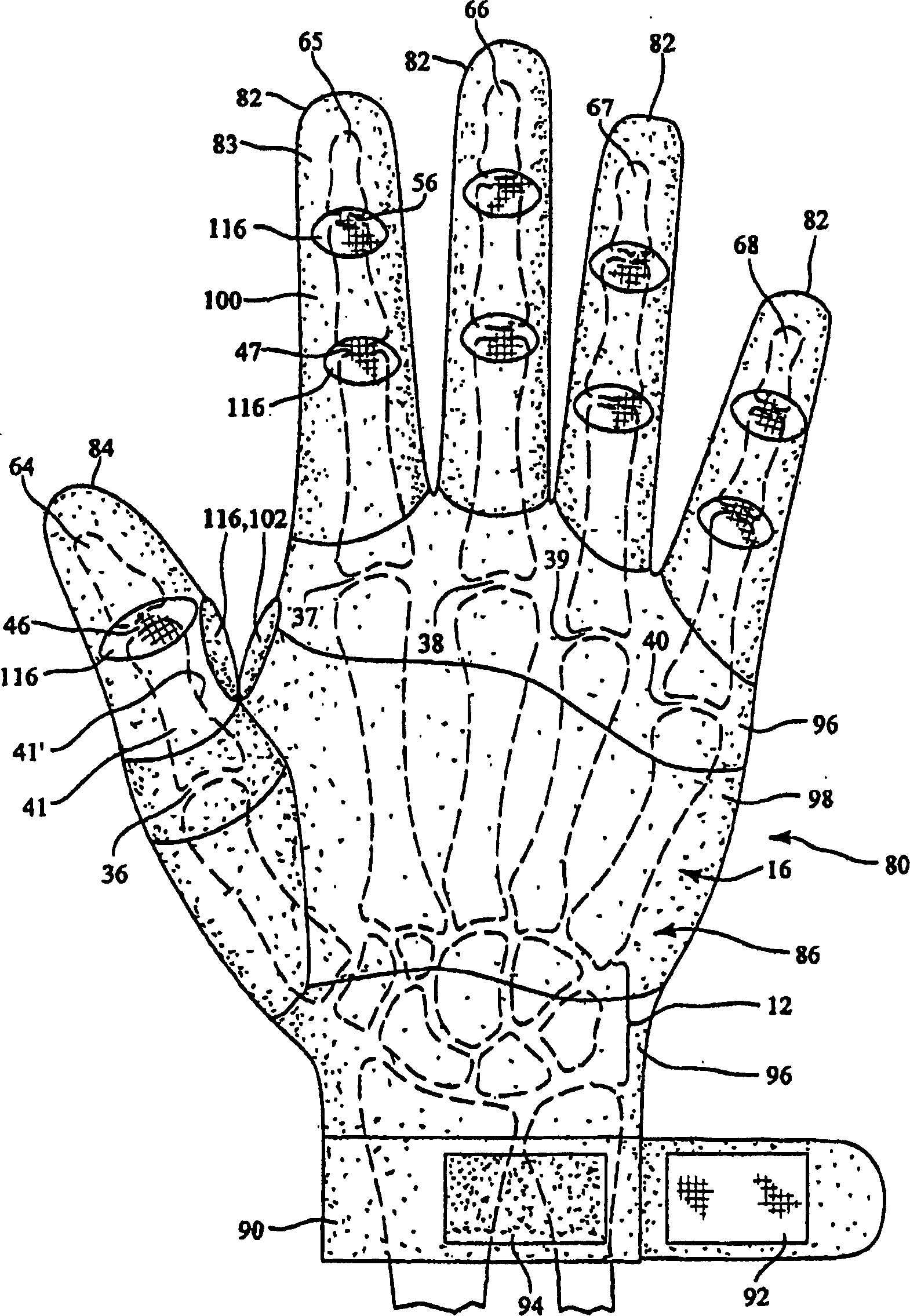

Work glove

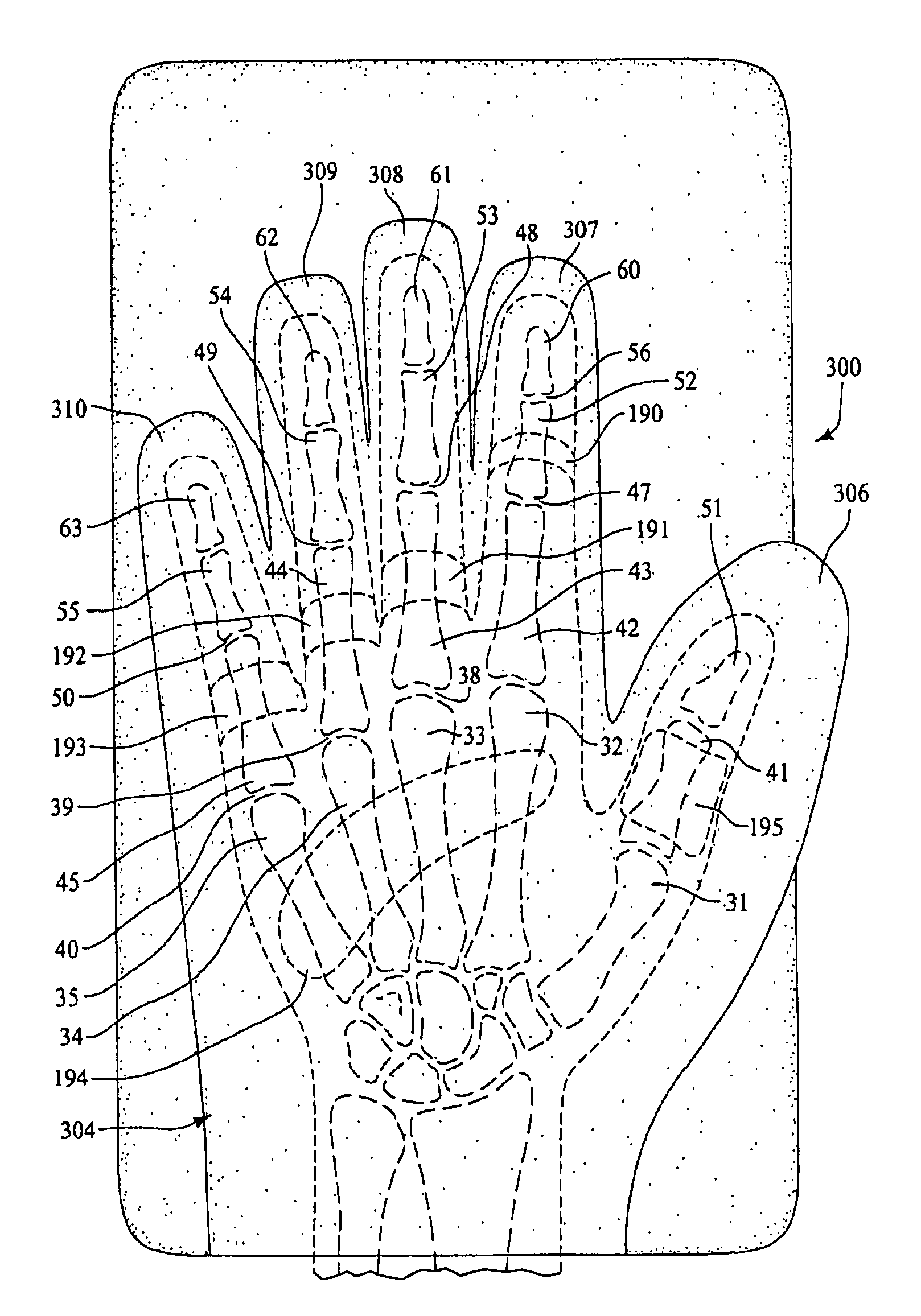

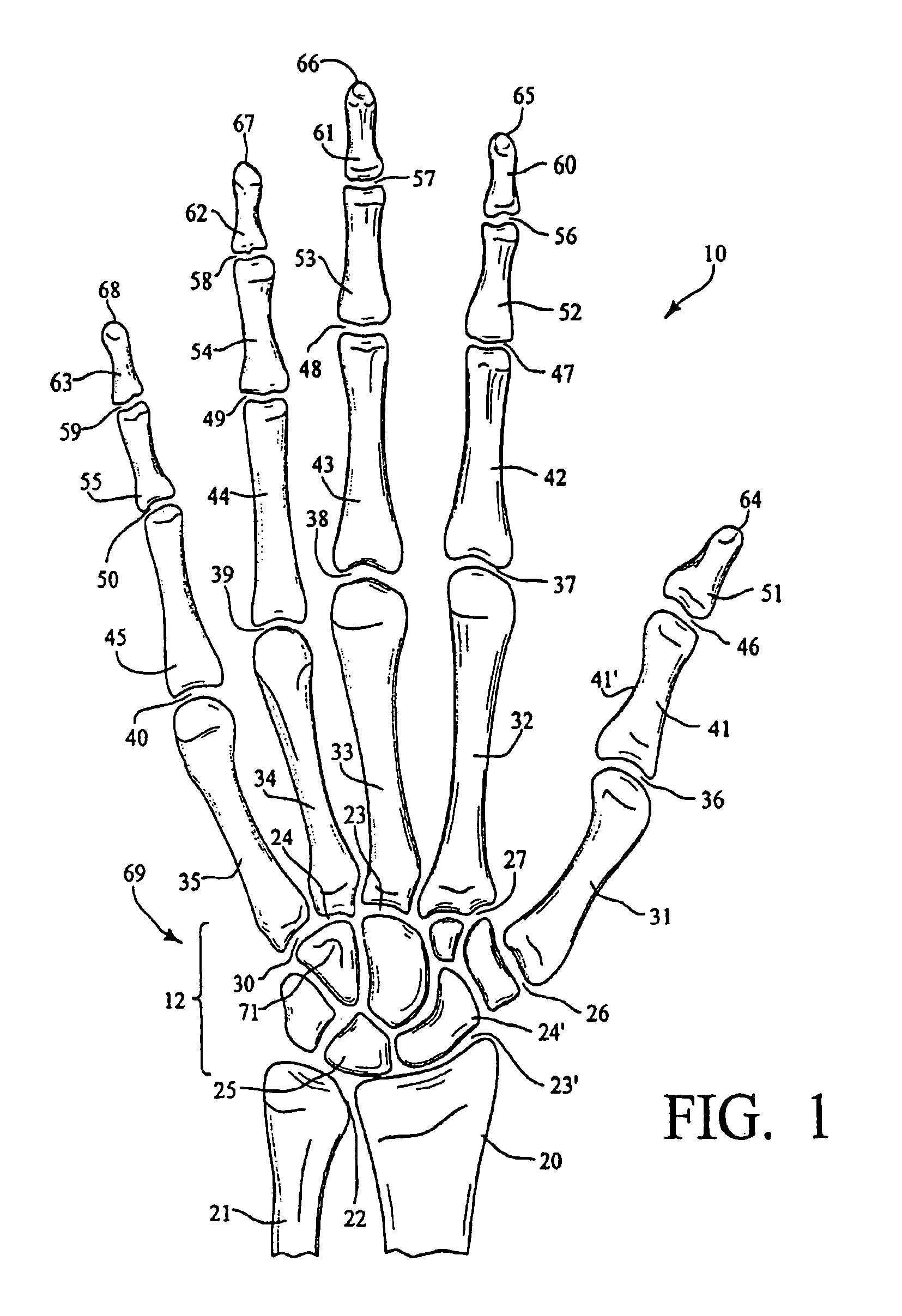

InactiveUS7000256B2Increase flexibilityPromote respirationGlovesBall sportsInterphalangeal joints of the handEngineering

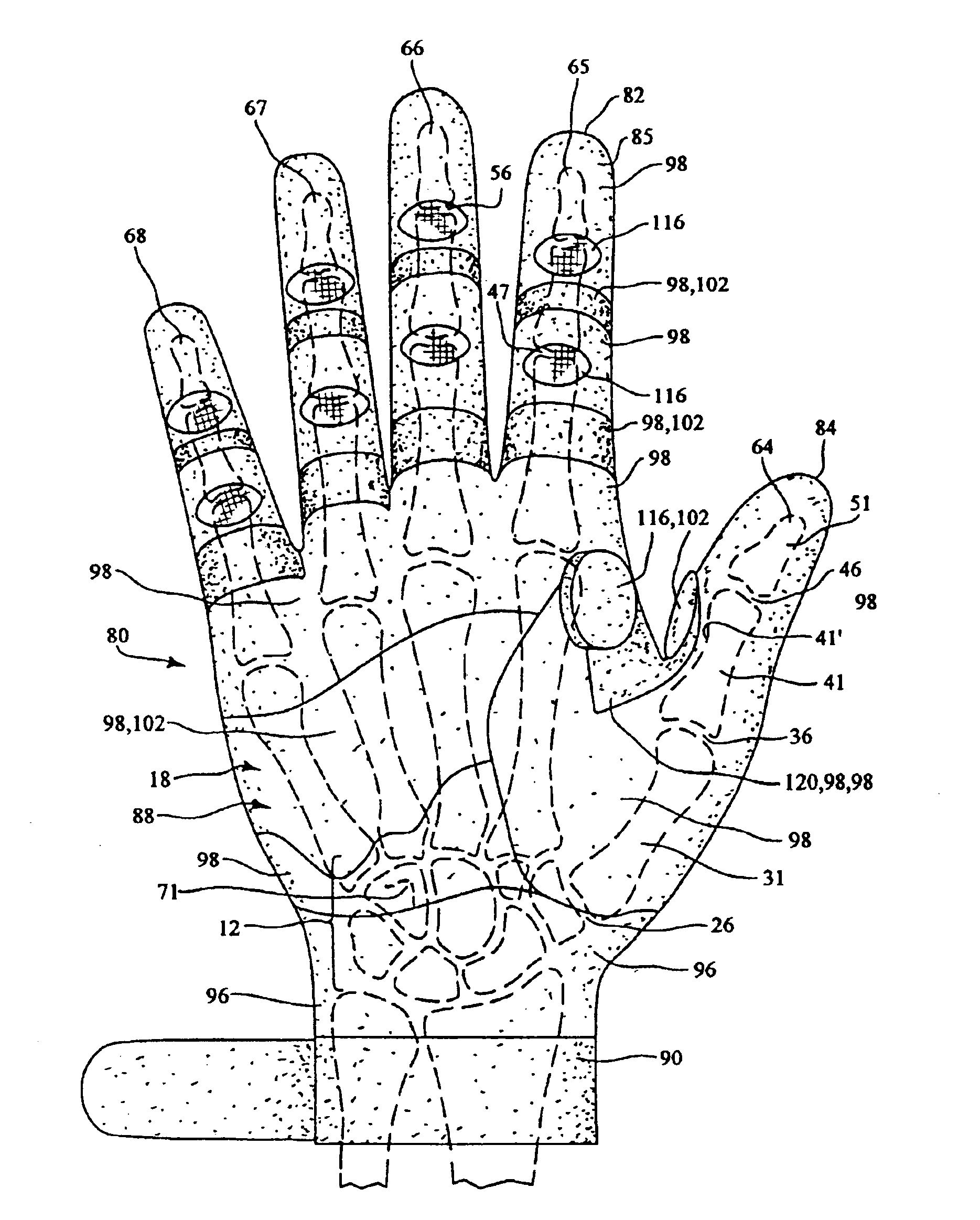

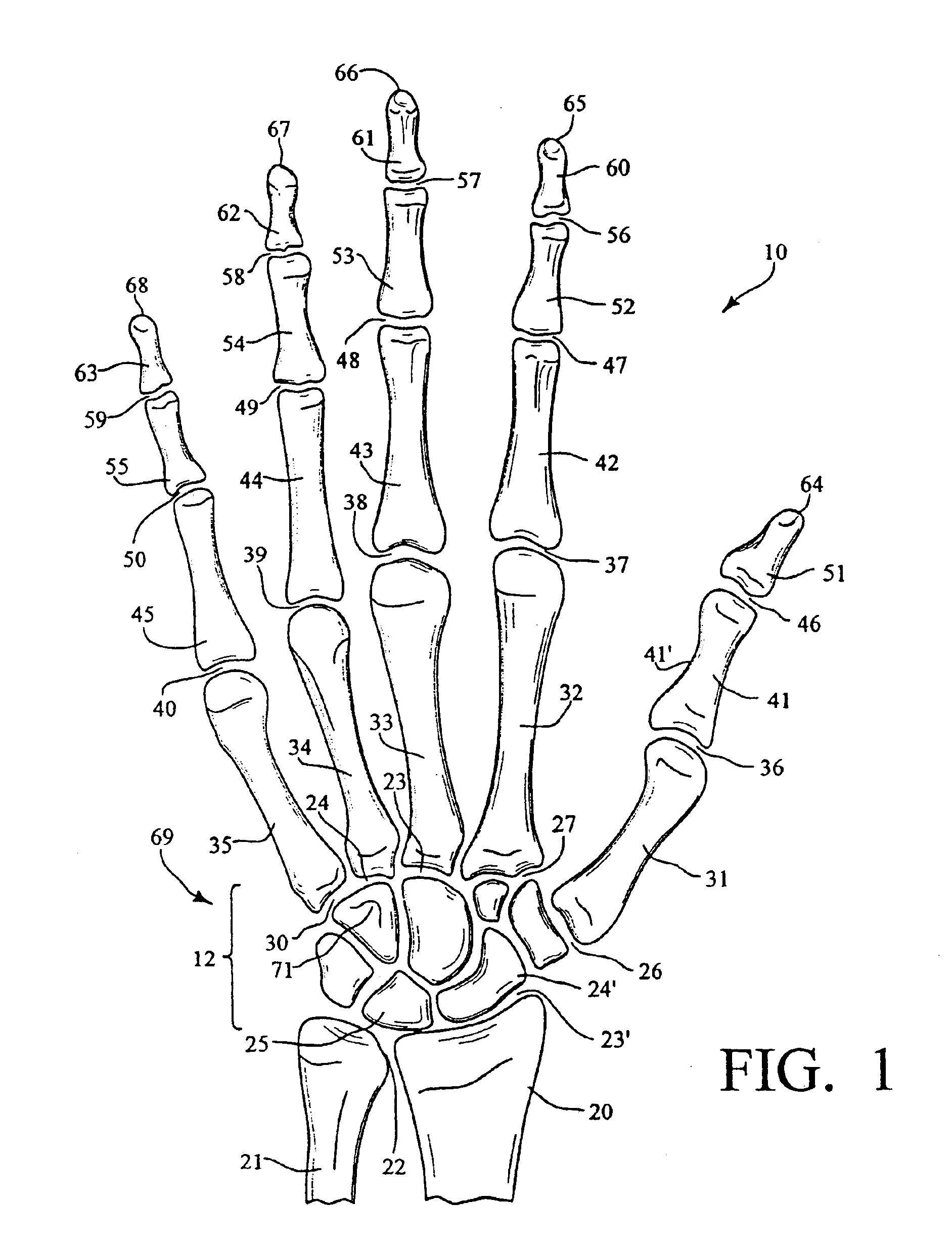

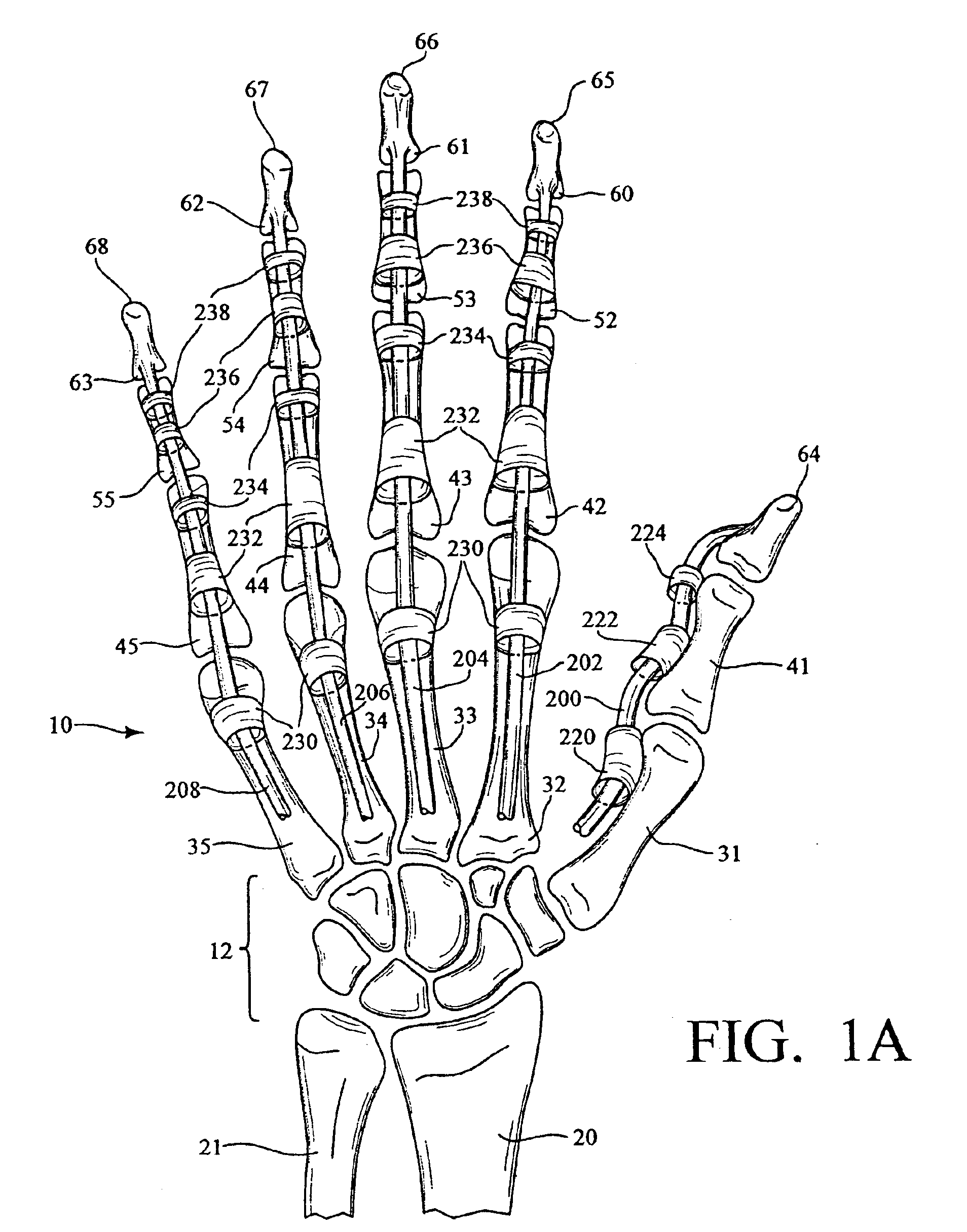

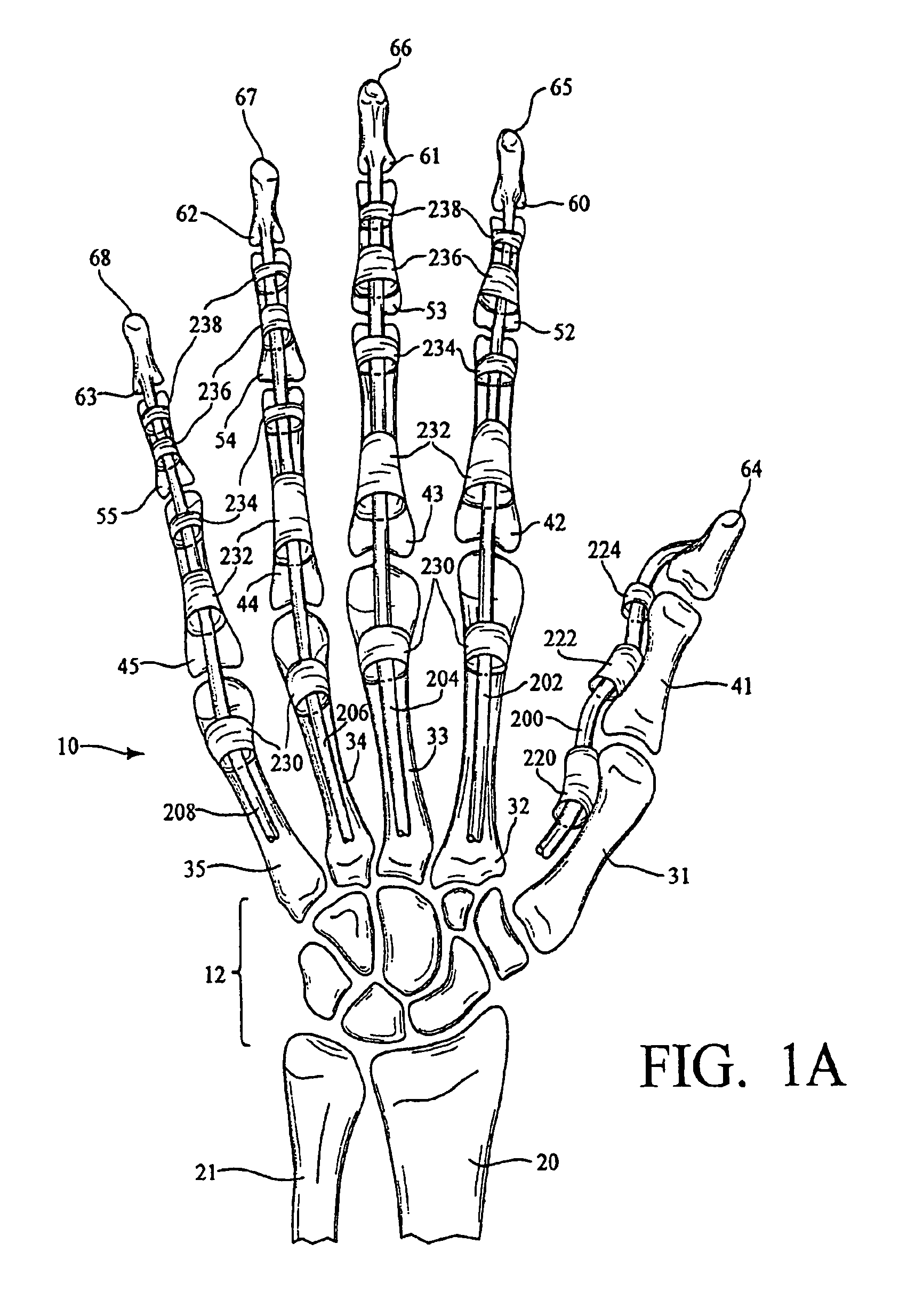

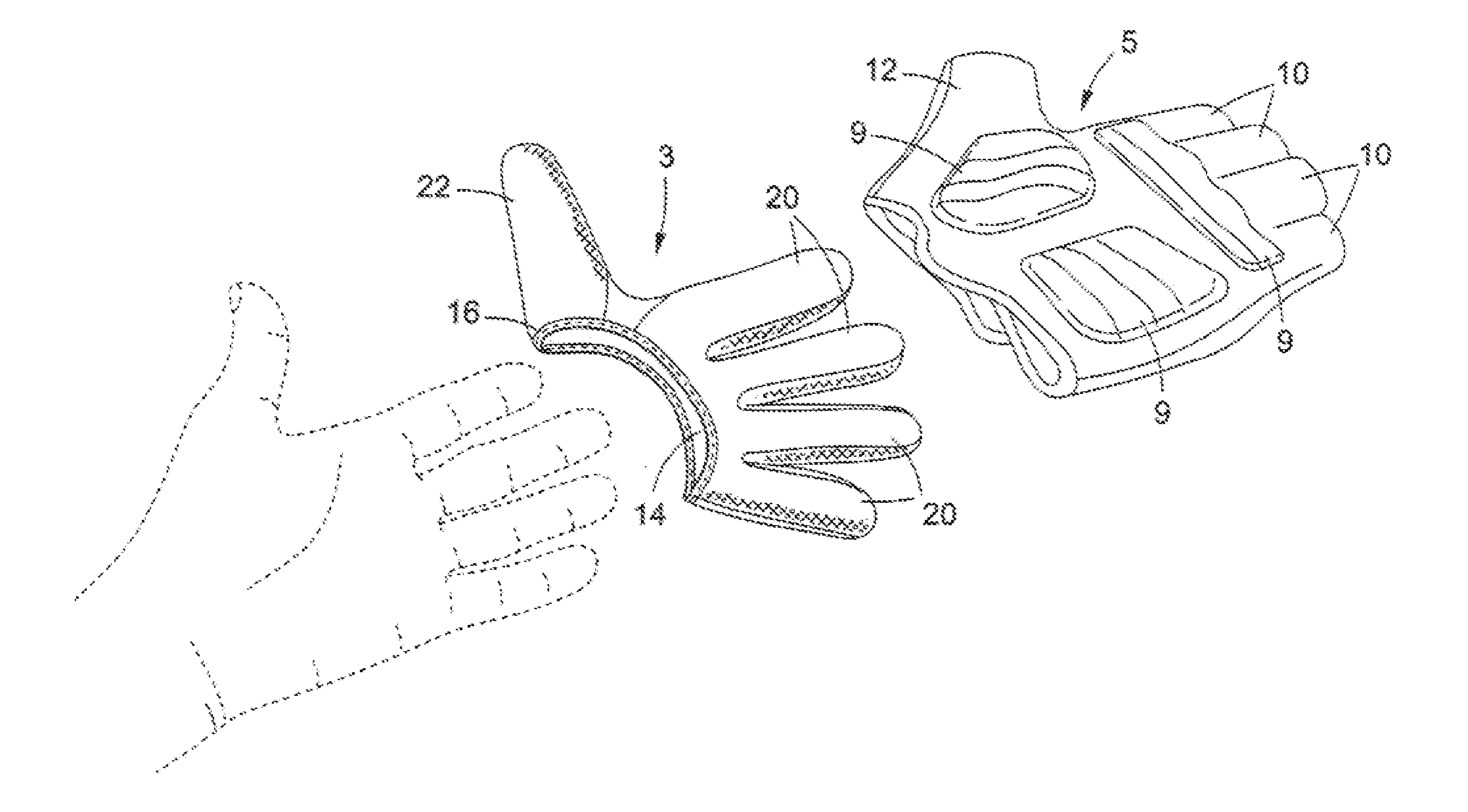

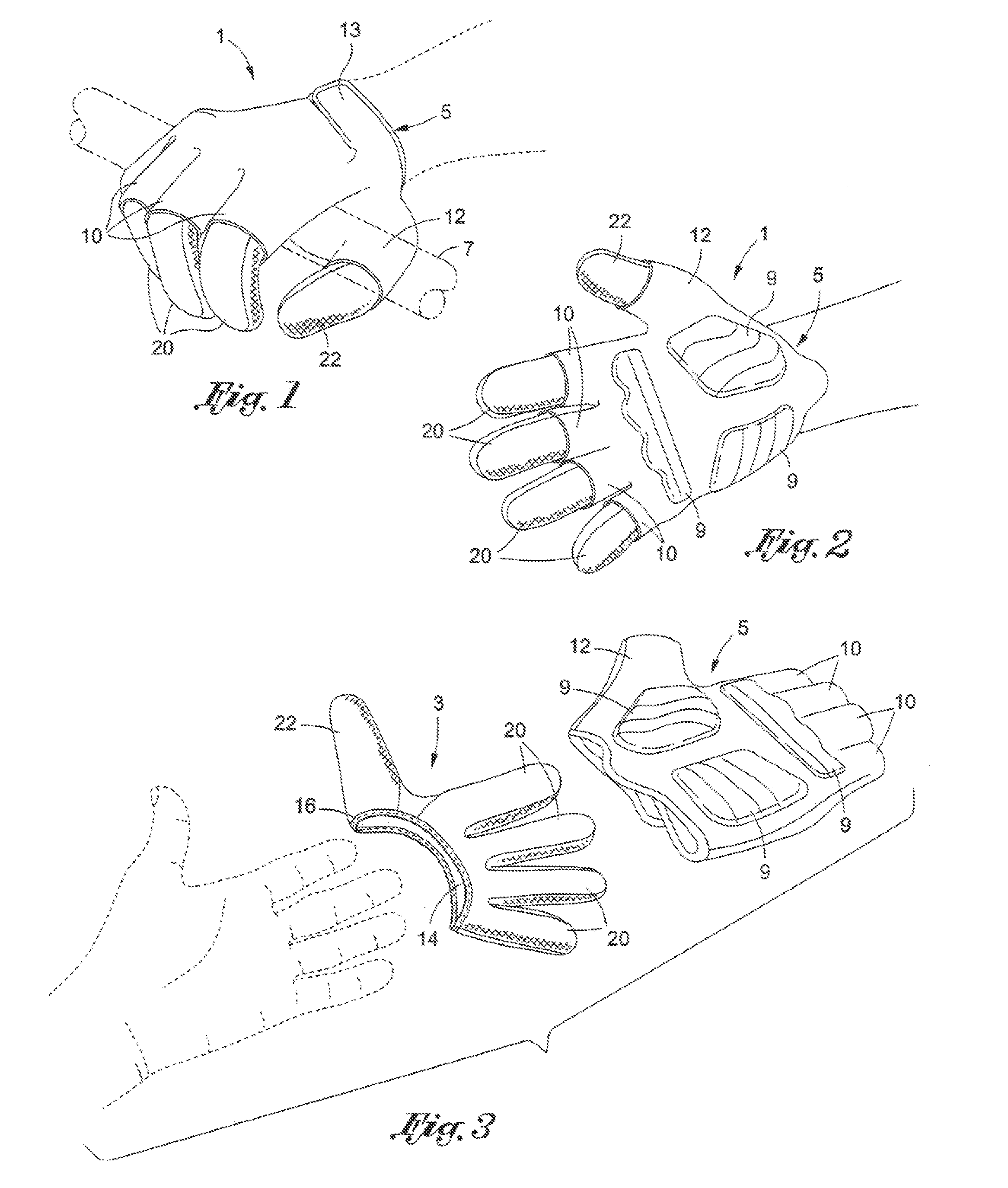

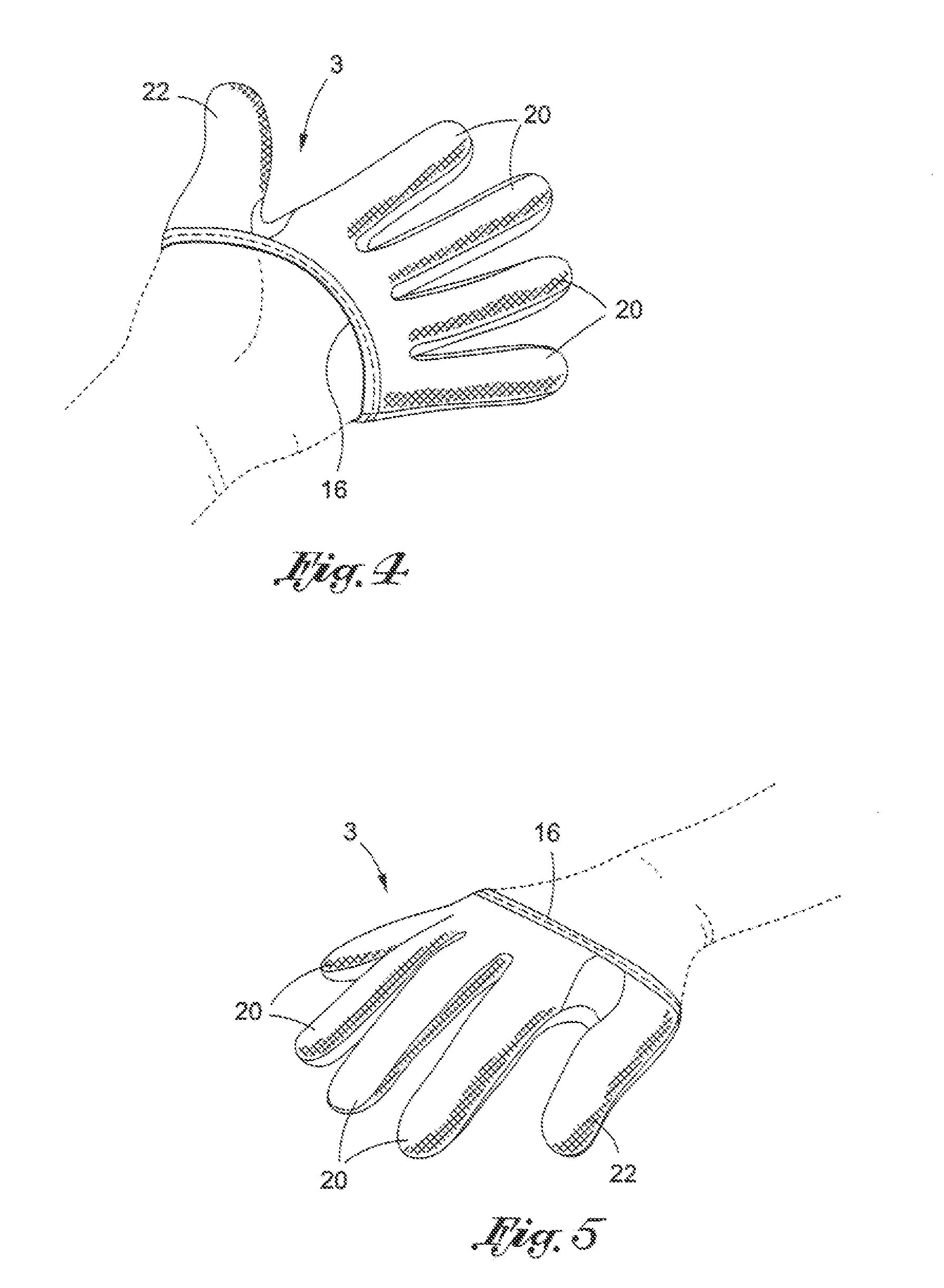

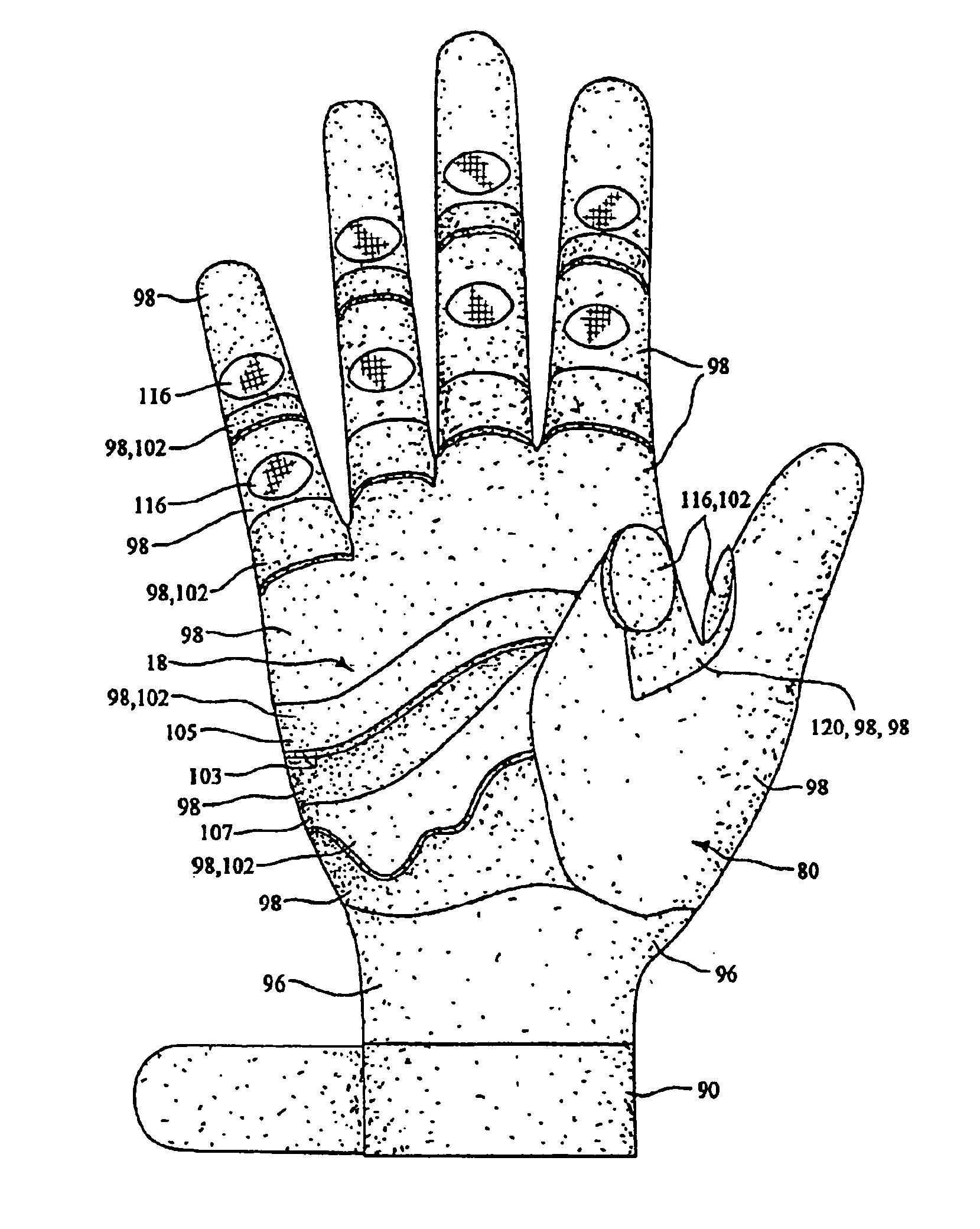

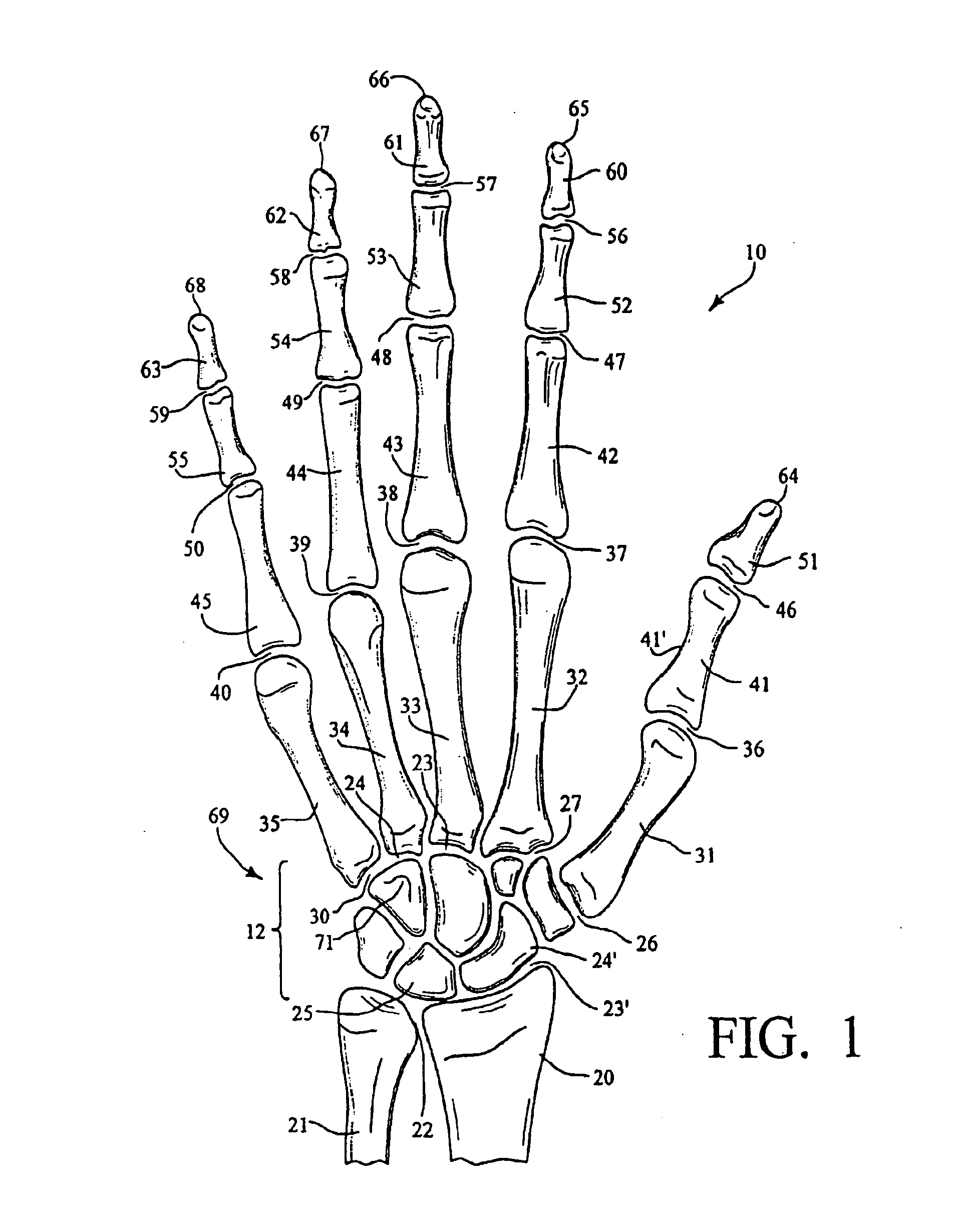

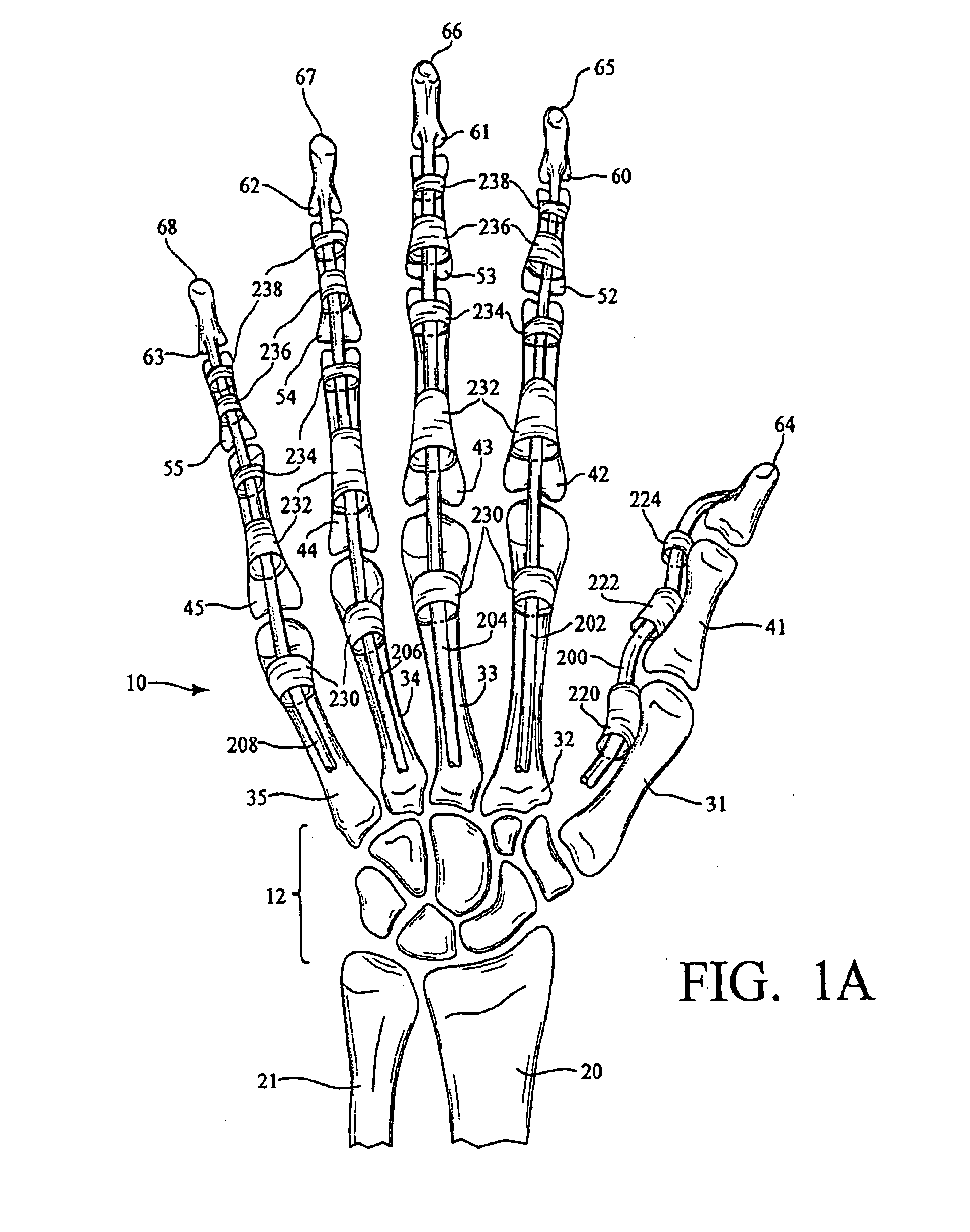

A work glove particularly useful for gardening, automobile mechanical work and any other type of use which brings the palmar side of the hand in contact with work or the like which may result in stinging, bruising, or blistering of the fingers, thumb and palm of a human hand is provided with protective padding disclosed or positioned for overlying at least the distal halves of the index finger and long finger metacarpals excluding the metacarpalphalangeal joints of the index finger and the long finger. Preferably, the glove also includes protective padding disposed along a thumb stall of the glove at a location adapted to be along an ulnar border as well as the A2 pulleys of the thumb's proximal phalanx between the metacarpalphalangeal joint and the interphalangeal joint.

Owner:HILLERICH & BRADSBY

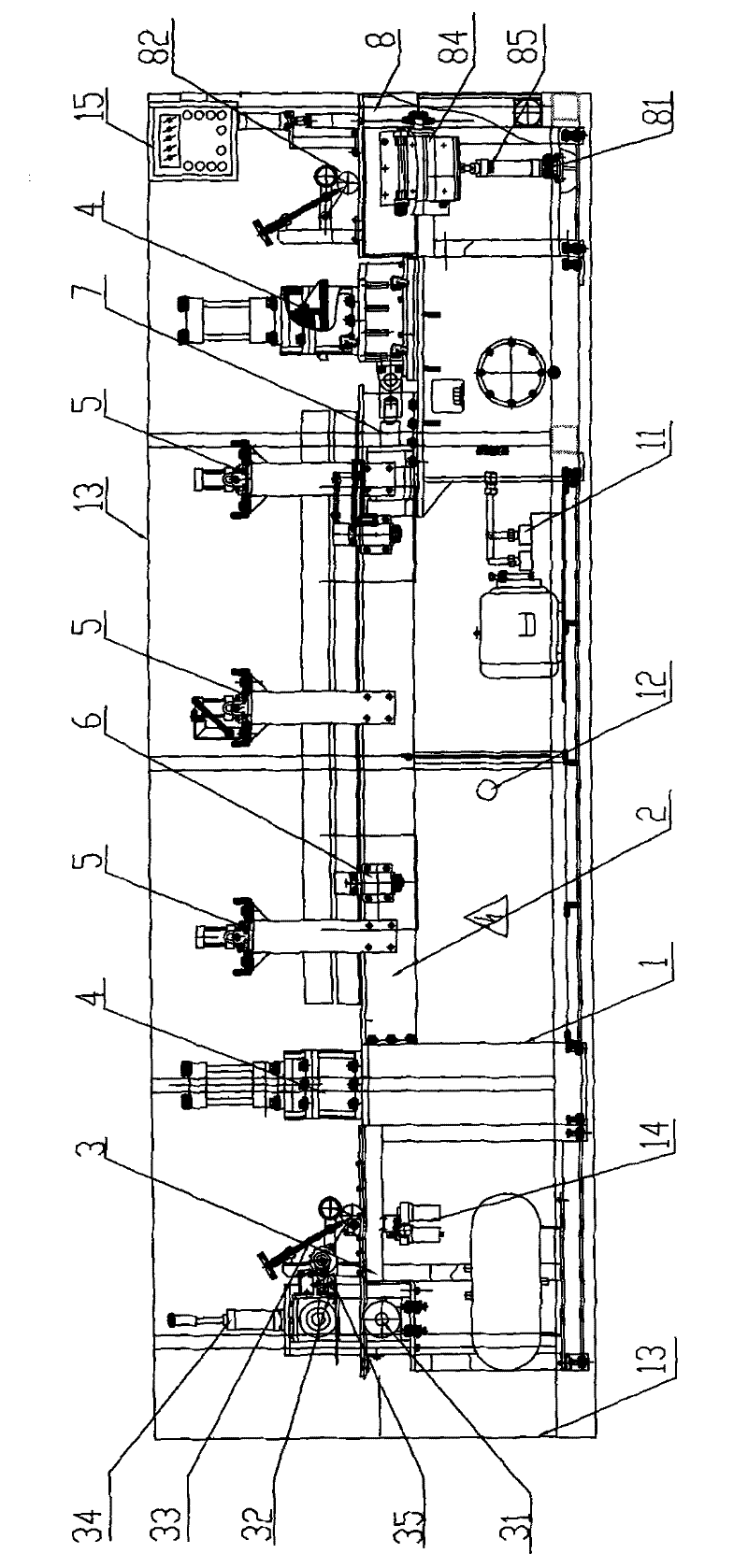

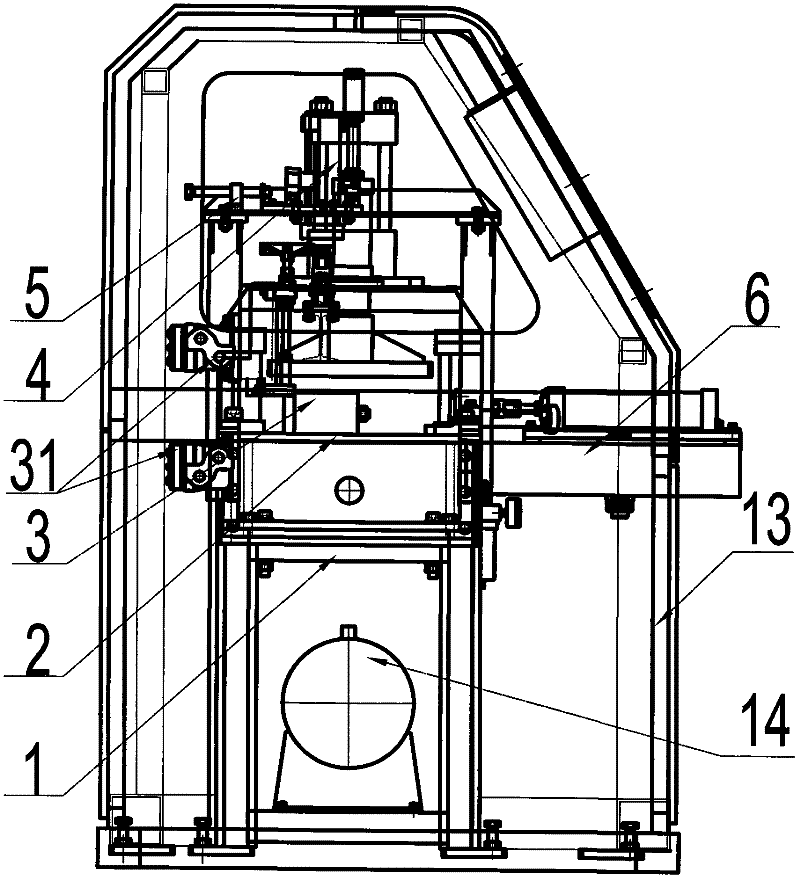

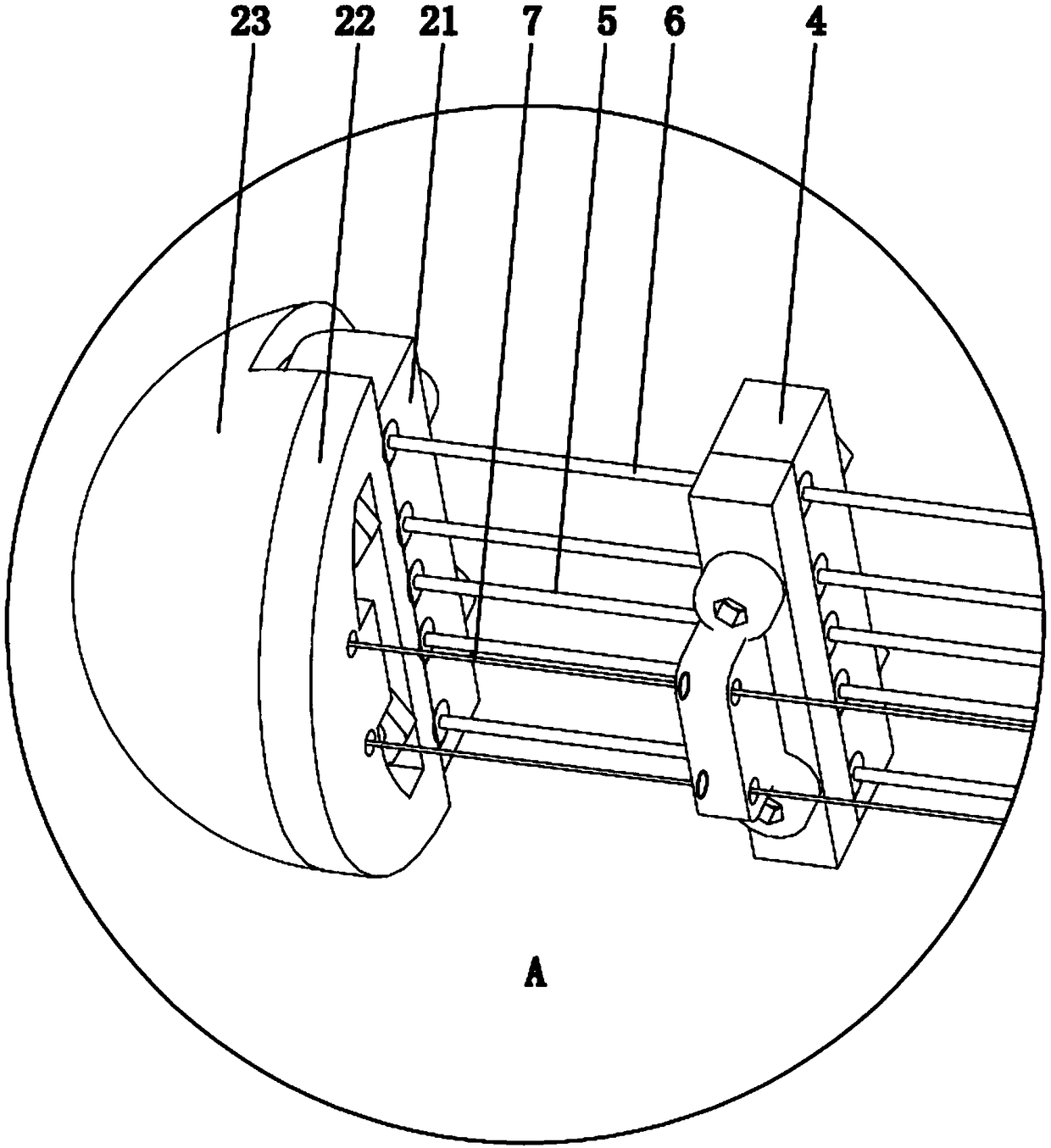

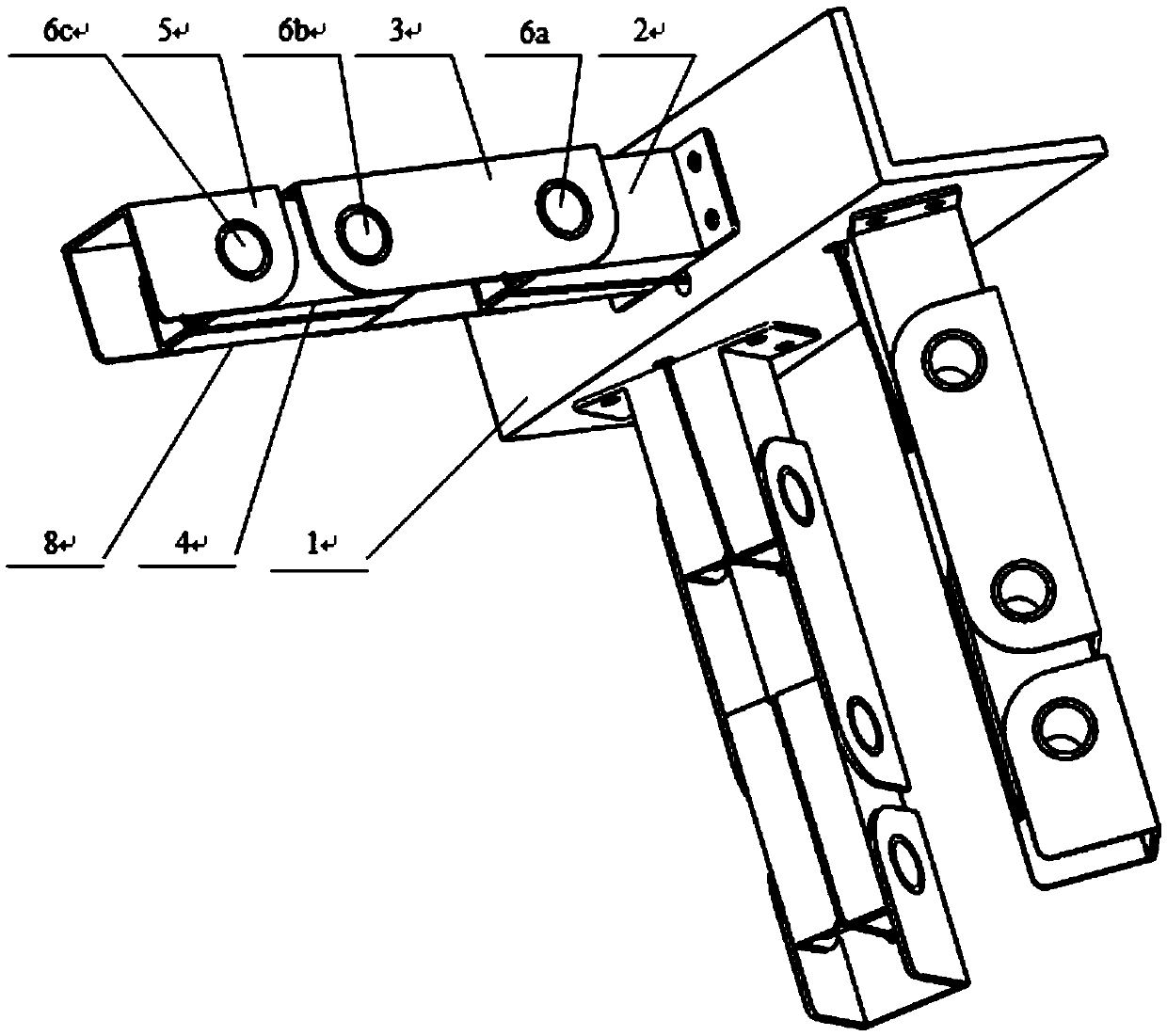

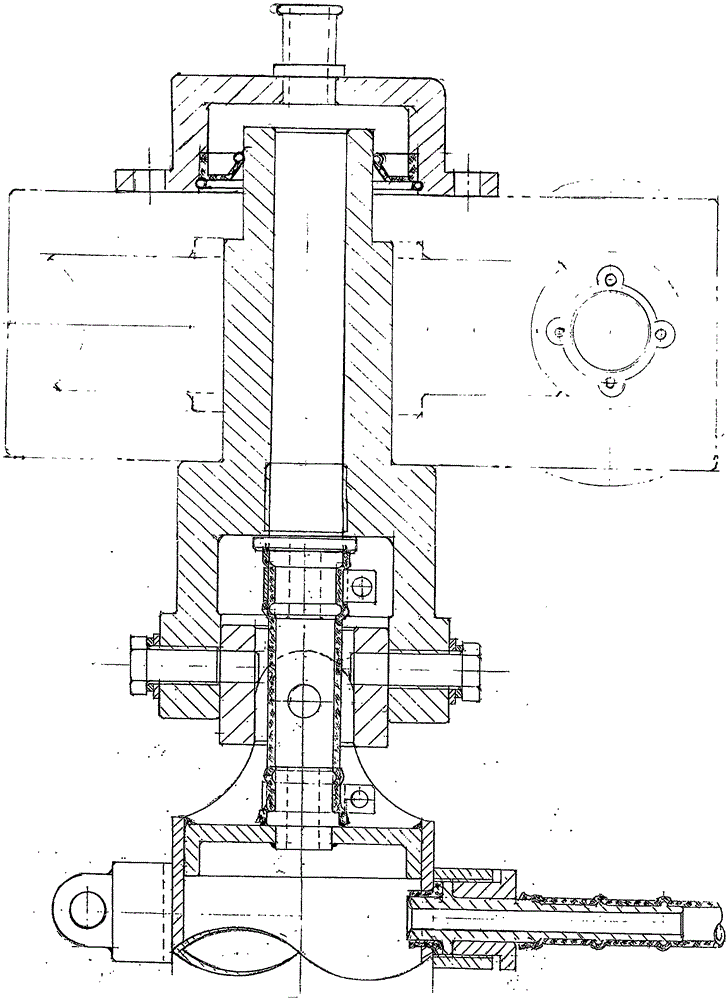

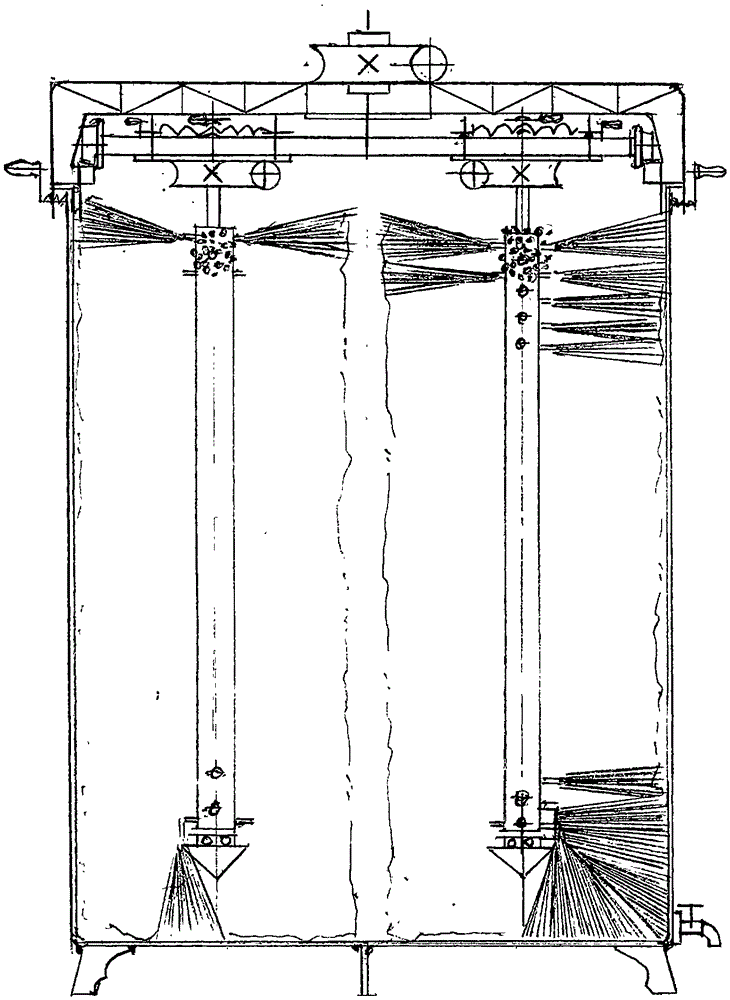

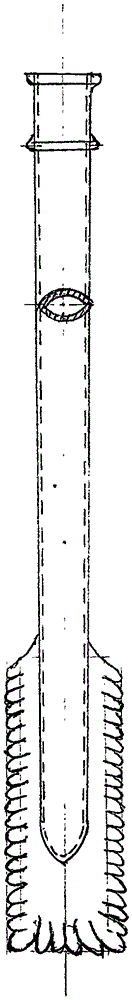

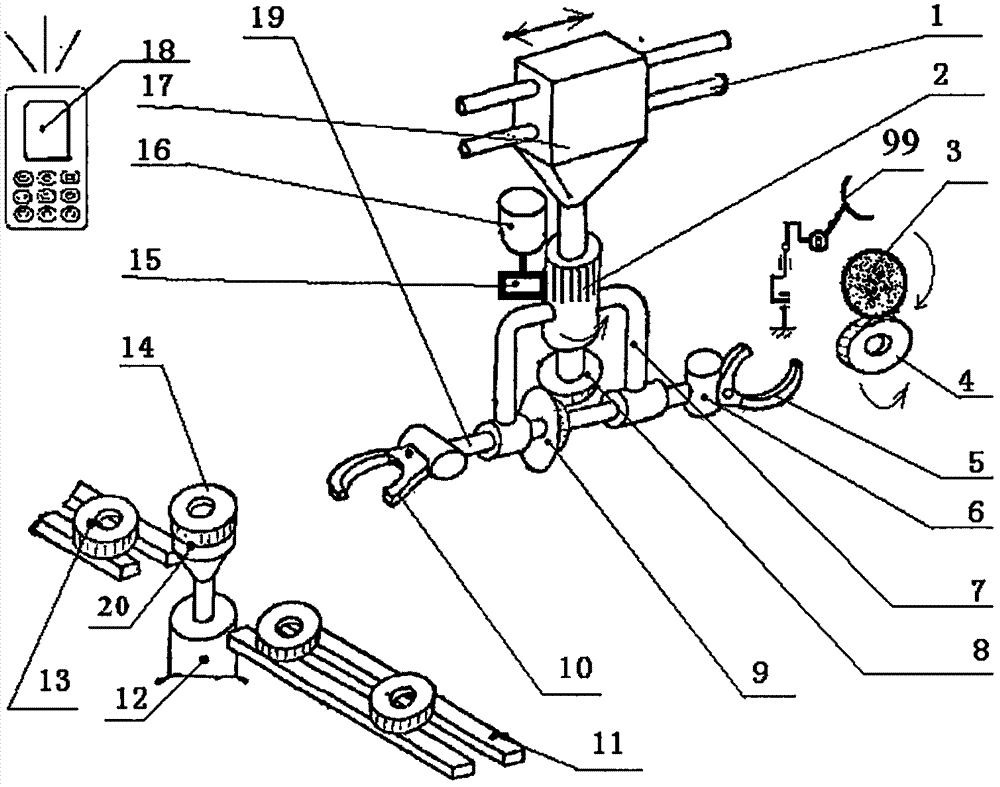

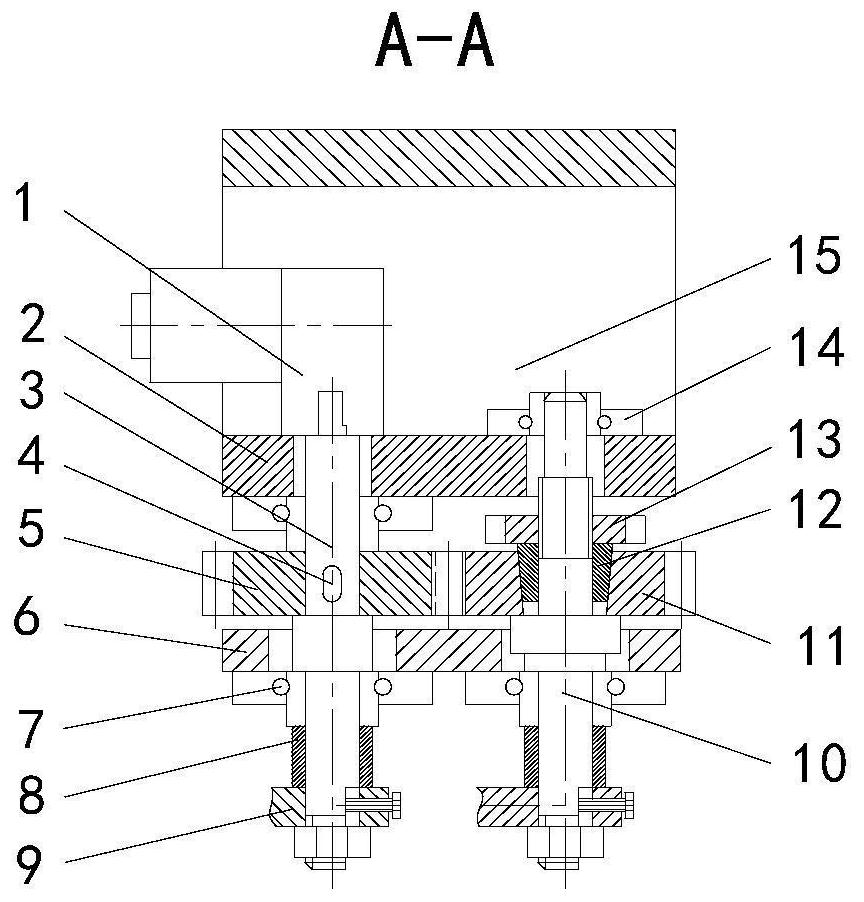

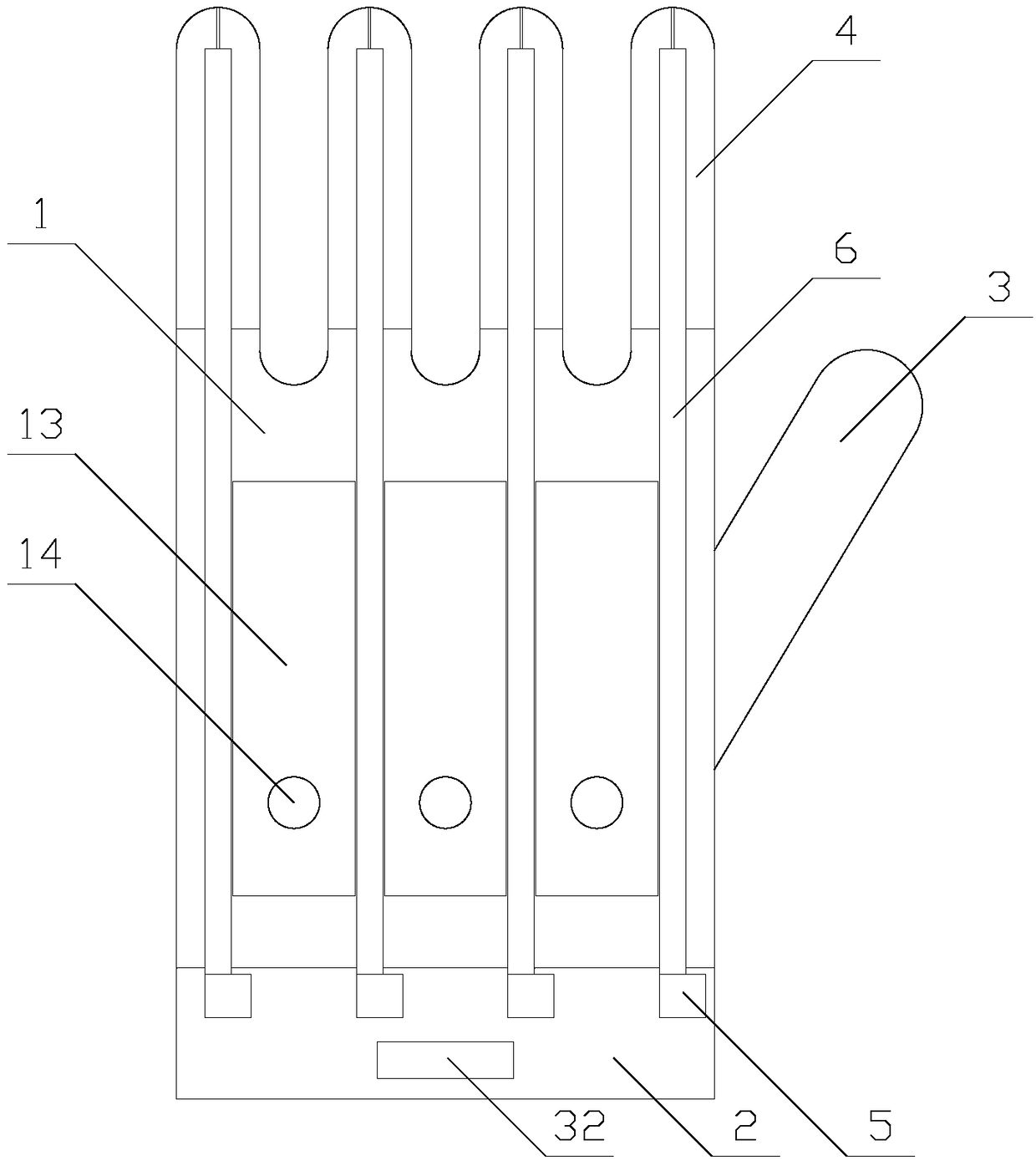

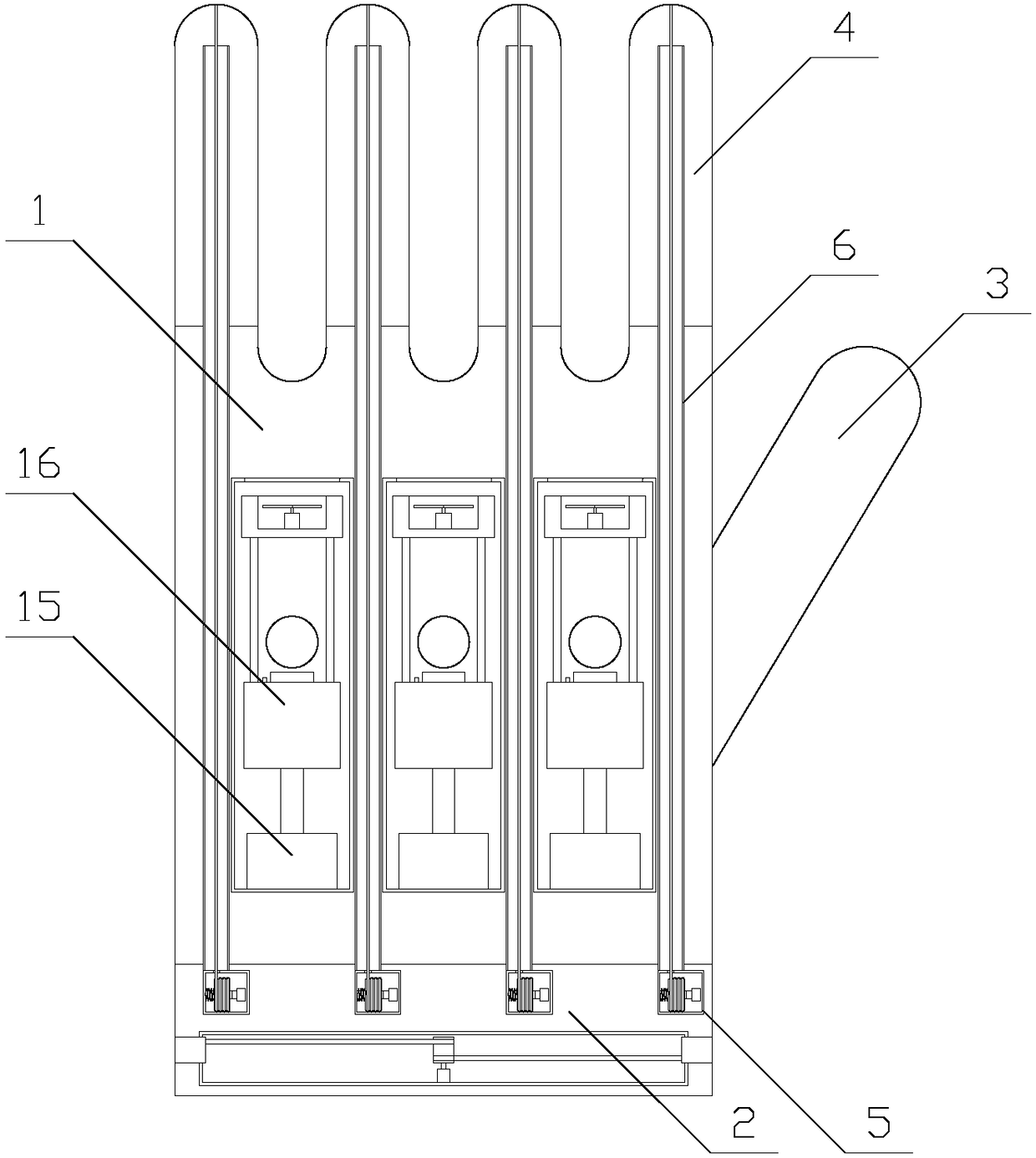

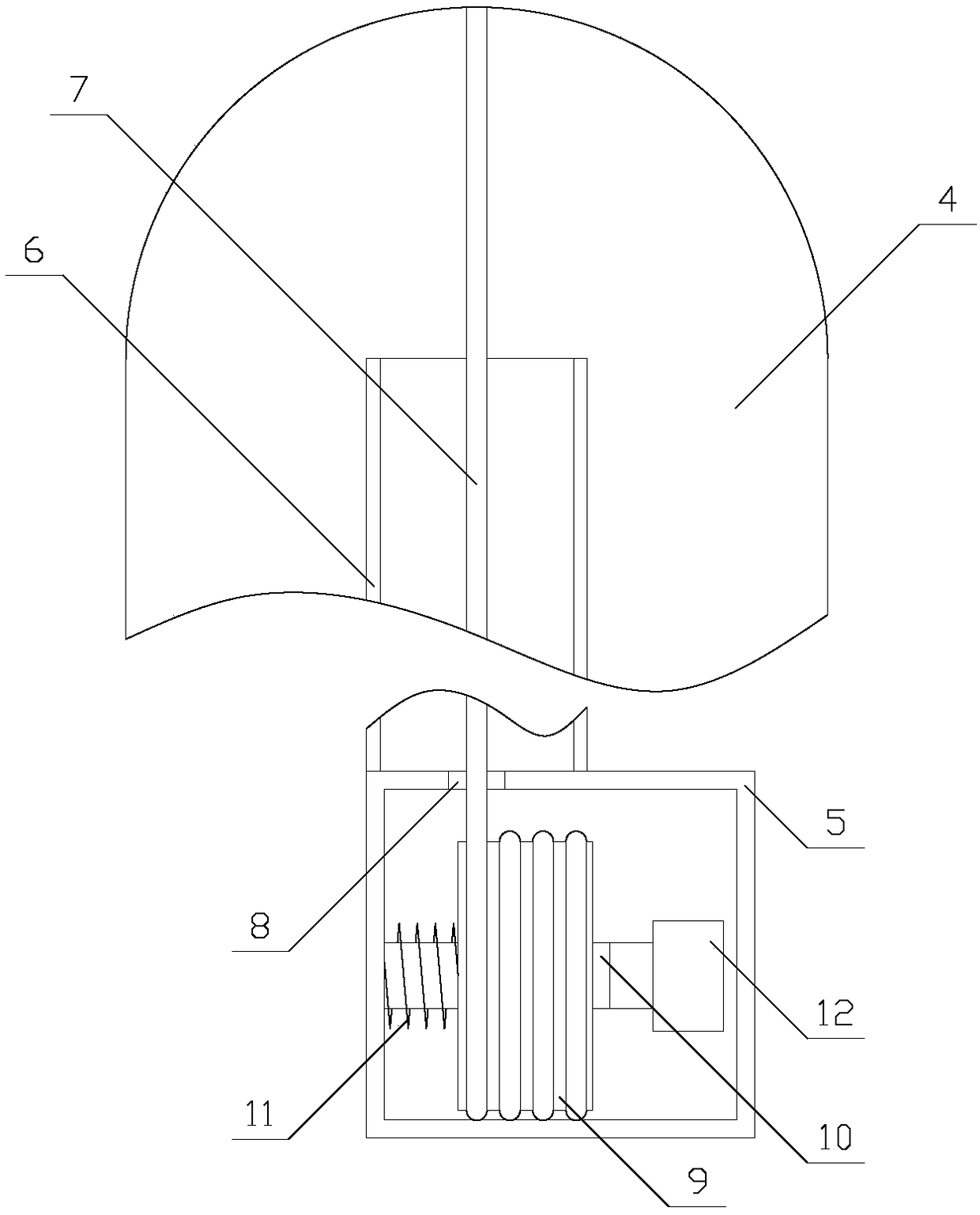

Full-automatic infinitely-long finger jointing machine

InactiveCN102225562AAccurate and reliable length dimensionReduce frictional resistanceWood veneer joiningLong fingersAutomatic control

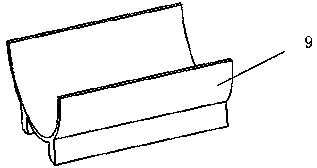

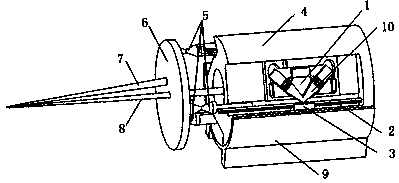

The invention discloses a full-automatic infinitely-long finger jointing machine. The finger jointing machine comprises a frame (1). The finger jointing machine is characterized in that: a workbench (2), a feeding pre-extension mechanism (3), a hydraulic positive pressure leg (4), a pneumatic upper pressure lever (5), a pneumatic lateral pressure lever (6), a hydraulic longitudinal finger jointing cylinder (7), the frame (1), a protective shell cover (13) and a touch screen button station (15) form an infinitely long continuous finger jointing machine host; the feeding end pre-extension mechanism (3) is assembled and connected with a variable speed feeding table (9) to form a photoelectric length measurement adaptive variable speed feeding table; a fixed length cut-off saw (8) is combinedand connected with a receiving discharge table (10) to form an automatic fixed size cut-off discharge table; and the host, the feeding table, the discharge table, a hydraulic system (11) and an electric automatic control system (12) form the full-automatic infinitely-long (continuous) finger jointing machine for automatically identifying material end joints, automatically measuring the length, adapting to speed adjustment and automatically cutting off the discharge in fixed size according to the preset length. The finger jointing machine is optical, mechanical, electric and liquid integrated technical equipment for longitudinal continuous finger joint of large-section wood with full automation, high efficiency, high quality and random length.

Owner:烟台黄海木工机械有限责任公司

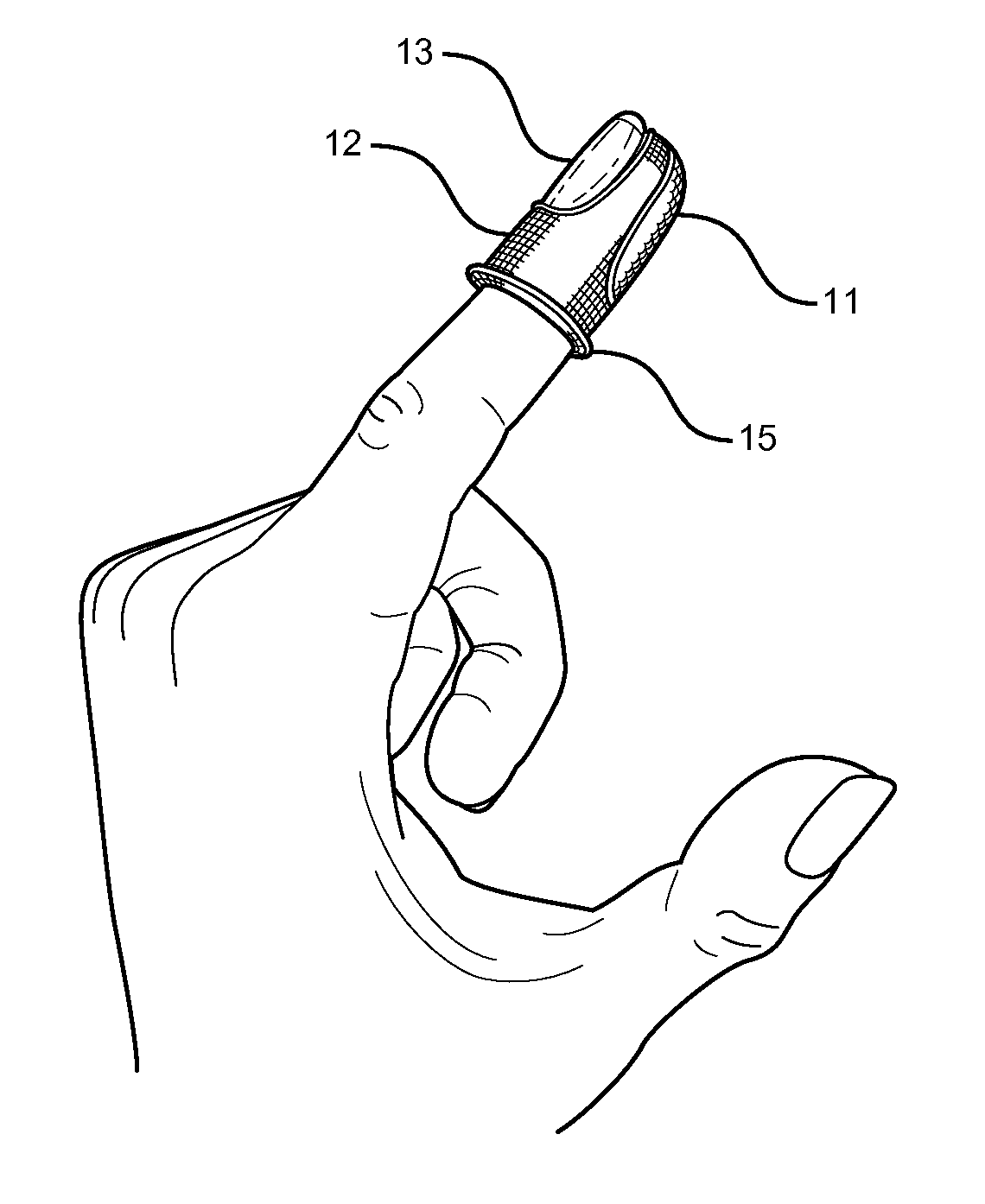

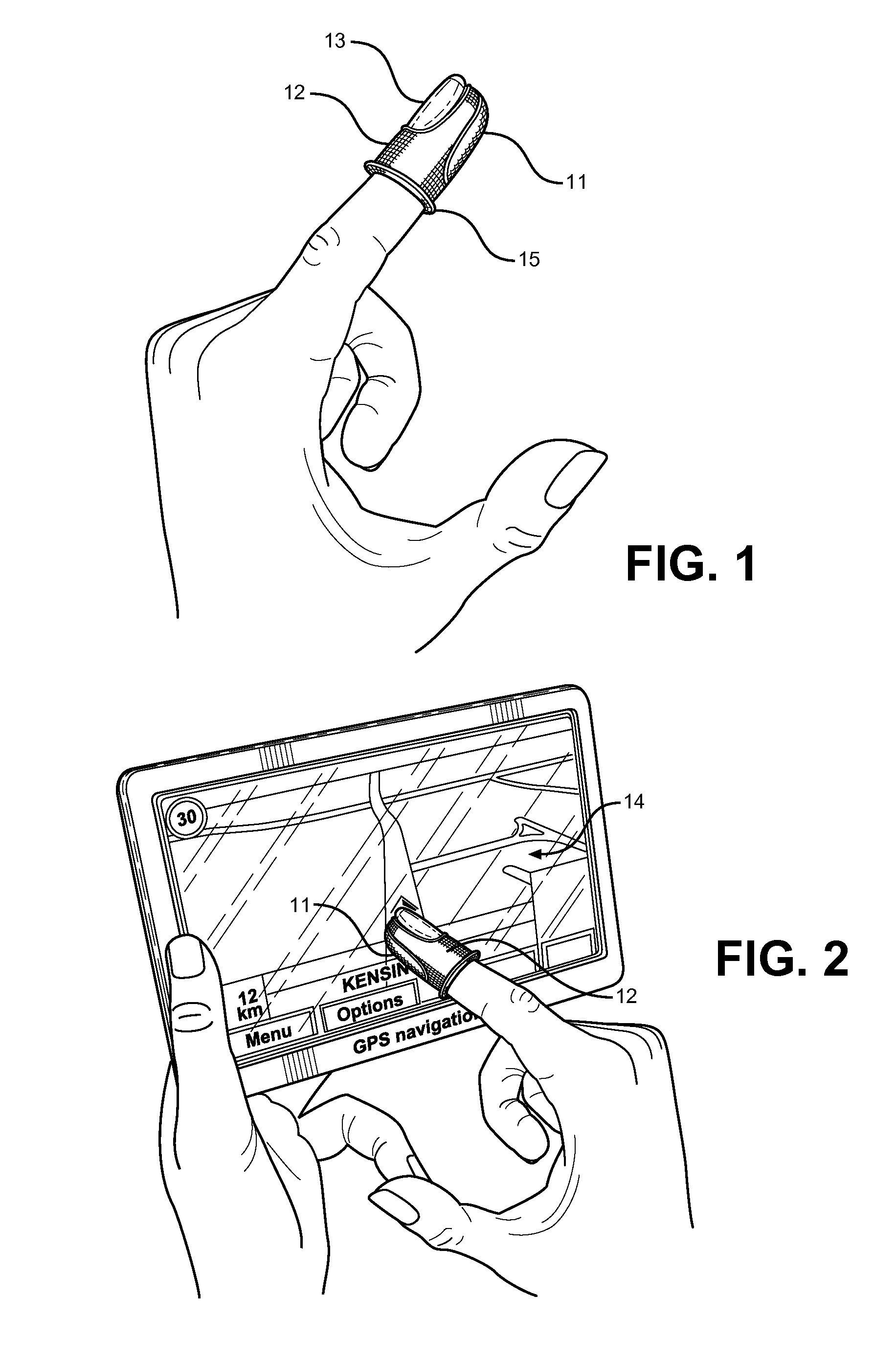

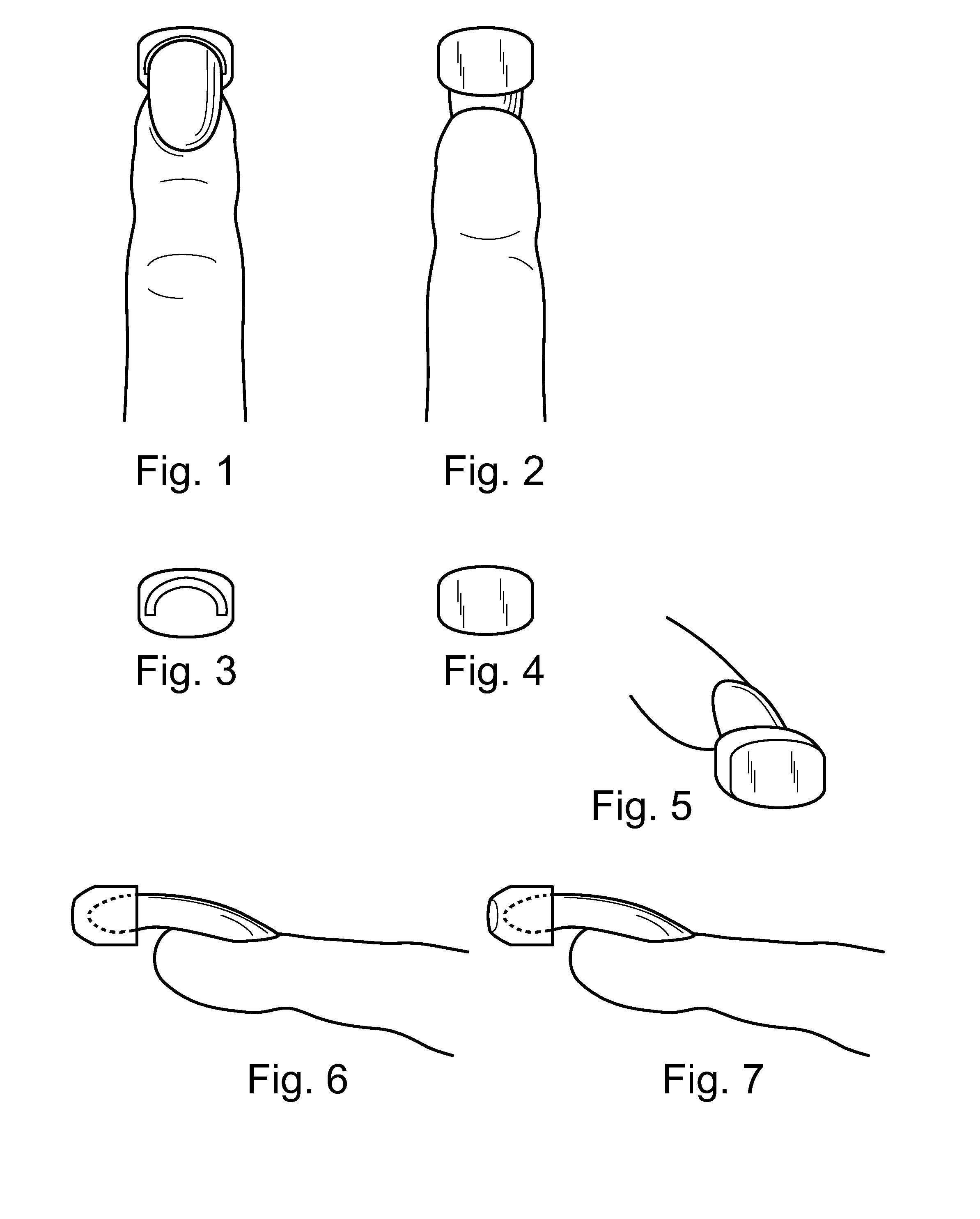

Touch Screen Stay-Clean Finger Mitten

InactiveUS20120137403A1Inhibit transferGlovesInput/output processes for data processingDisplay deviceEngineering

A fingertip covering for prevention of smudges, dirt accumulation and germ transfer to and from an electronic touchscreen device. The covering comprises a cylindrical section with an open end and a closed end, and a two-part construction. An antistatic microfiber material comprises the contact region and interface with the touchscreen, while an elastic material comprises the body of the covering. The use of a microfiber contact region provides a conductive interface for use with multiple touchscreen technologies. A fingernail opening is provided to accommodate users with longer finger nails, while the elastic body region conforms to different size fingers. The disclosed invention is an alternative to touchscreen covers that dull the display, reduce feedback and are prone to imbedded air bubbles that erode touch sensitivity. The coverings may be used with capacitive and resistive touchscreen without reduction in performance, and to provide a means that eliminates unwanted smudging or fingerprints on the screen.

Owner:BONE JOHN +1

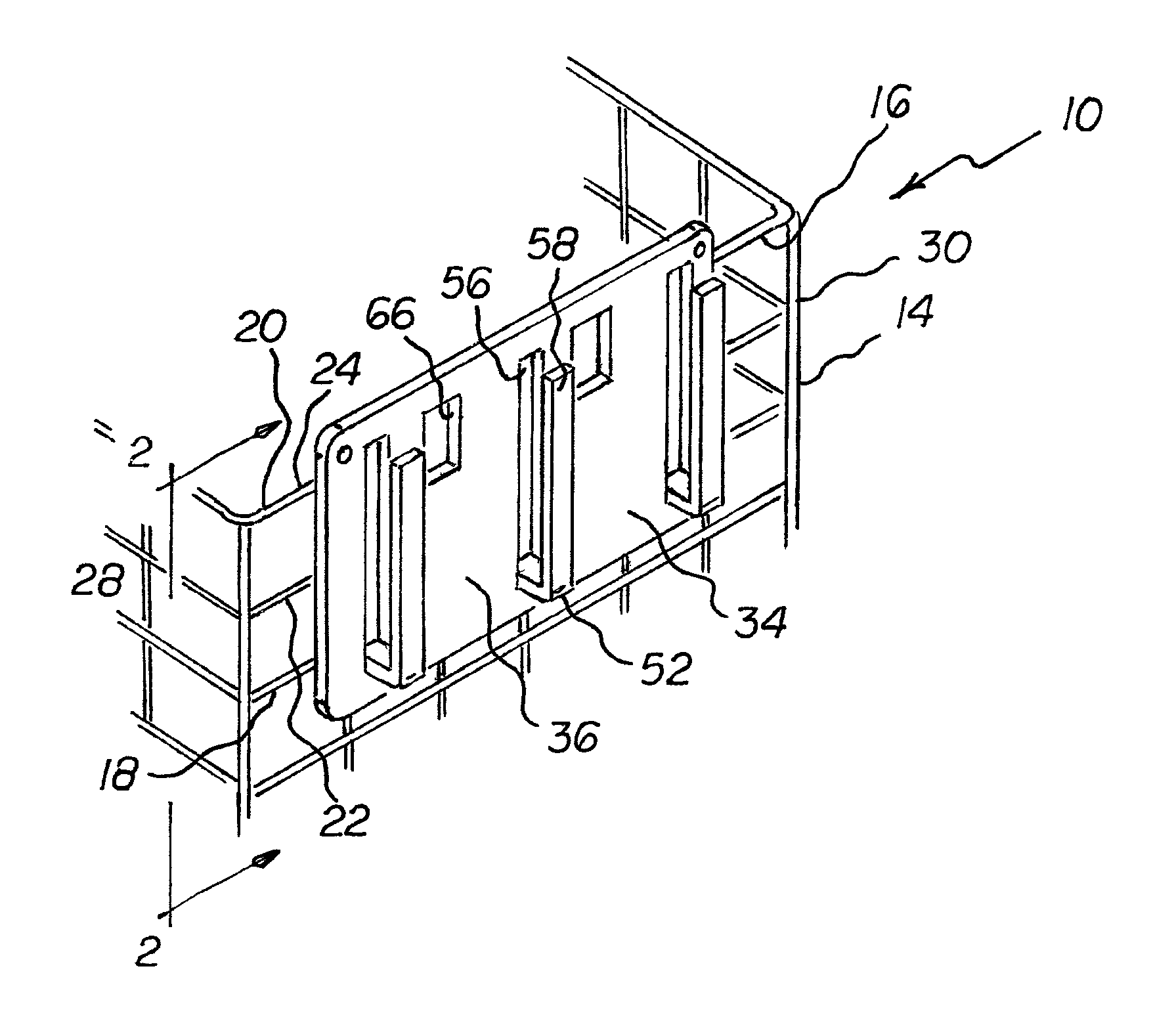

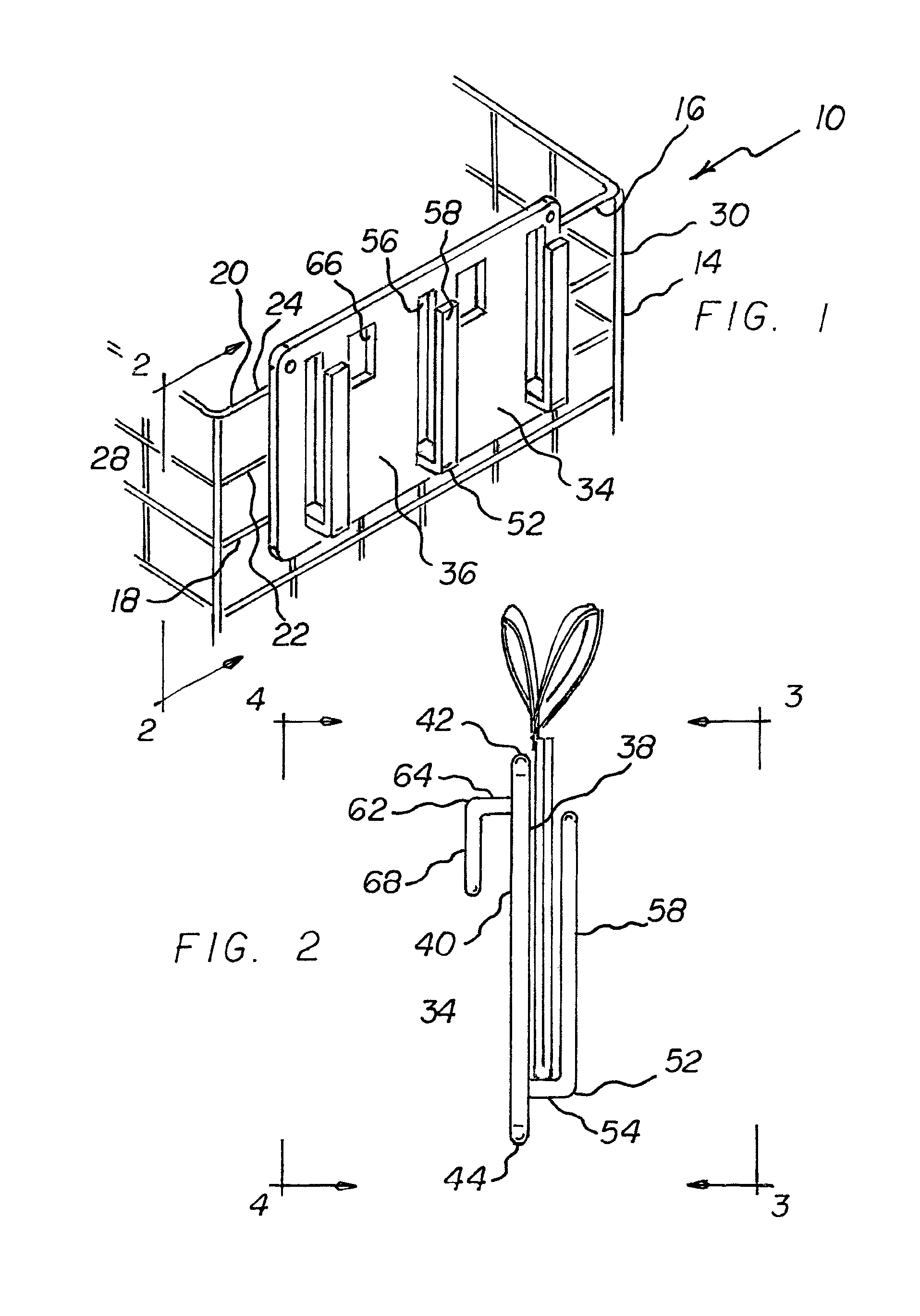

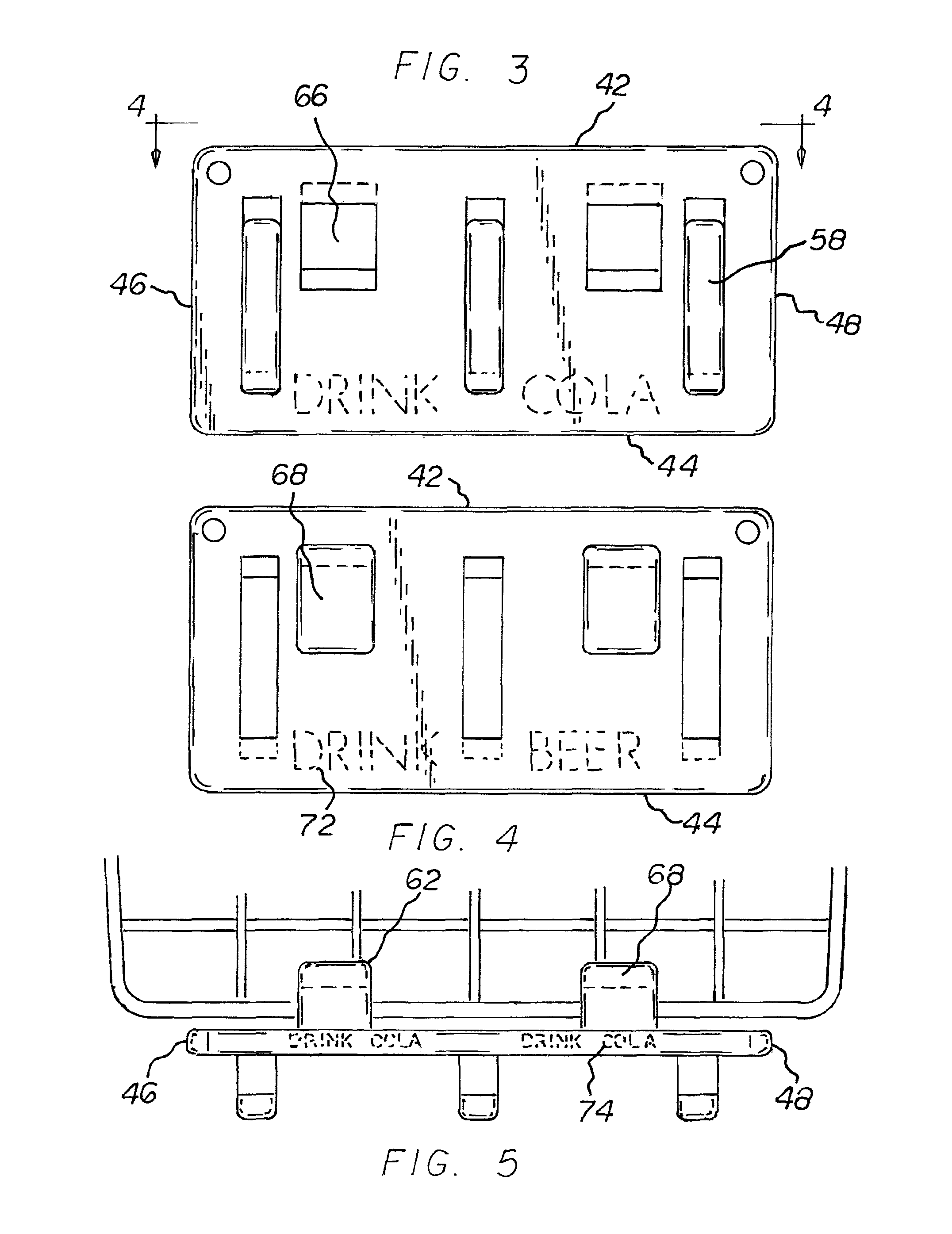

Product promotion storage rack and caddy system

InactiveUS8668207B1Easy and efficient to manufactureDurable and reliable constructionSupplementary fittingsDisplay meansLong fingersShort finger

A product promotion storage rack is formed of a base plate having a front surface and a rear surface. The base plate has upper and lower edges. The base plate has parallel left and right edges. A plurality of laterally spaced long fingers extend forwardly from the front surface. Each long finger has a horizontal first short leg and an upwardly extending vertical first long leg. A plurality of laterally spaced inverted short fingers extend rearwardly from the rear surface. Each short finger has a horizontal second short leg and a downwardly extending vertical second long leg.

Owner:GILLIAM JAMES R

Structure decoupling driven variable-stiffness soft hand

InactiveCN108177156AAchieving Variable StiffnessReduce riskProgramme-controlled manipulatorGripping headsVariable stiffnessShape-memory alloy

The invention relates to the technical field of intelligent robots, in particular to a structure decoupling driven variable-stiffness soft hand, which comprises a palm base. A long finger and two short fingers are arranged on three electrical interfaces in the front end of the palm base; each finger comprises a fingertip, a plurality of finger knuckles and a finger root arranged sequentially at intervals; a framework structure is connected among the fingertip, the plurality of finger knuckles and the finger root; muscle-like structures and muscular tissues are arranged on the fingers; and theframework structures, the muscle-like structures and the muscular tissues are made of SMA (shape memory alloy) materials. The structure decoupling driven variable-stiffness soft hand provided by the invention is reasonable in structure; and the SMA drives various parts of the fingers to act, and meanwhile, an electric current changes a temperature of the shape memory alloy so as to control a Youngmodulus, so that the stiffness of the fingers is variable, a more accurate grabbing action can be obtained; and the structure decoupling driven variable-stiffness soft hand has a simpler structure and solves the problems of mechanical fatigue and wear, and risks caused during an interaction process of a manipulator and people can be further reduced, so that a practicable structure model for softhand development is provided.

Owner:WUHAN UNIV OF TECH

Work glove

InactiveCN1870954AUnloadPromote sportsGlovesBall sportsInterphalangeal joints of the handLong fingers

A work glove particularly useful for gardening, automobile mechanical work and any other type of use which brings the palmar side of the hand in contact with work or the like which may result in stinging, bruising, or blistering of the fingers, thumb and palm of a human hand is provided with protective padding disclosed or positioned for overlying at least the distal halves of the index finger and long finger metacarpals excluding the metacarpalphalangeal joints of the index finger and the long finger. Preferably, the glove also includes protective padding disposed along a thumb stall of the glove at a location adapted to be along an ulnar border as well as the A2 pulleys of the thumb's proximal phalanx between the metacarpalphalangeal joint and the interphalangeal joint.

Owner:HILLERICH & BRADSBY

Three-finger mechanical paw

The invention discloses a three-finger mechanical paw and belongs to the technical field of robots. The three-finger mechanical paw comprises three fingers and a palm. The two side faces of the palm form a right angle, wherein one finger is installed on one side face, and two fingers are installed on the other side face. Each finger is provided with three segments of finger joints which are connected through three joints, and each finger joint can be bent by 0-90 degrees around the corresponding joint. Each finger joint is bent under driving of one flexible rope, and resetting straightening of each finger joint is driven by a spring. When the fingers are sleeved with rubber sleeves, friction force can be increased, article grasping is more stable, and the fingers are more close to human fingers in appearance. When the mechanical paw is used for grasping articles, the mechanical paw can be in various states, articles within a large size range can be grasped, the 100-milimeter-long fingers in the embodiment can be used for grasping articles with the length of 5-150 mm, the three-finger mechanical paw can adapt to articles in various shapes such as a cylinder, a prism, a sphere and an irregular shape.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

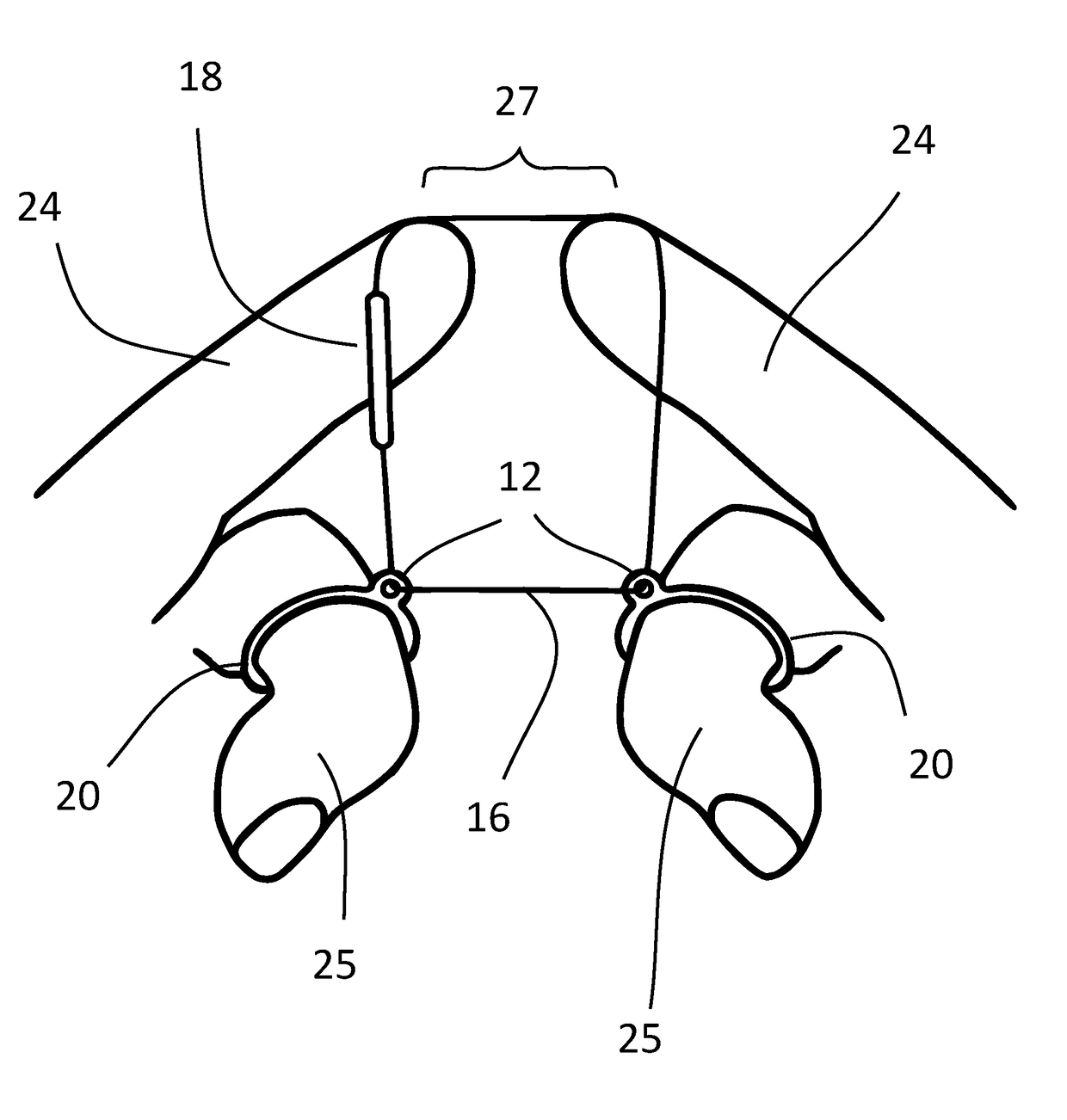

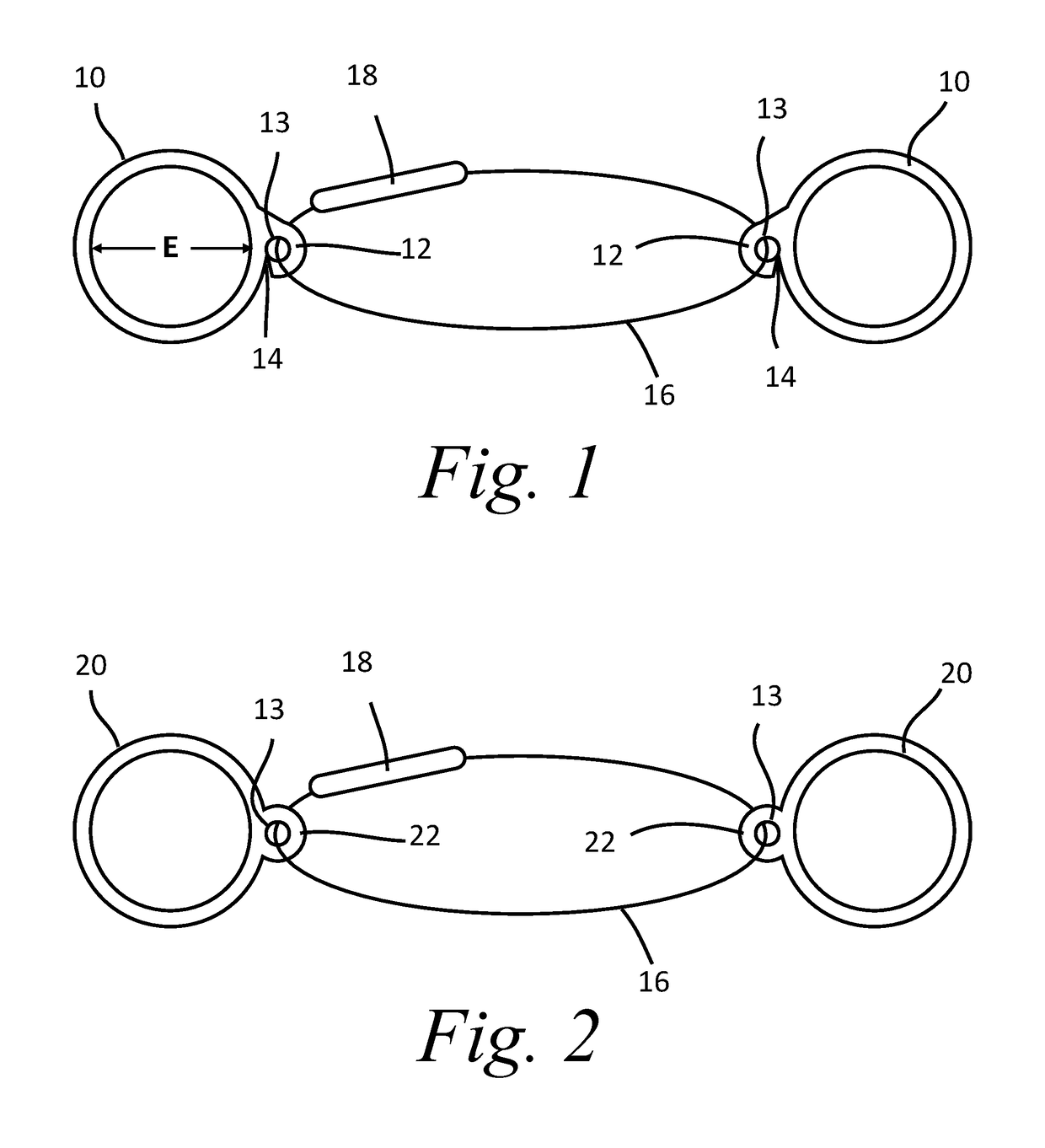

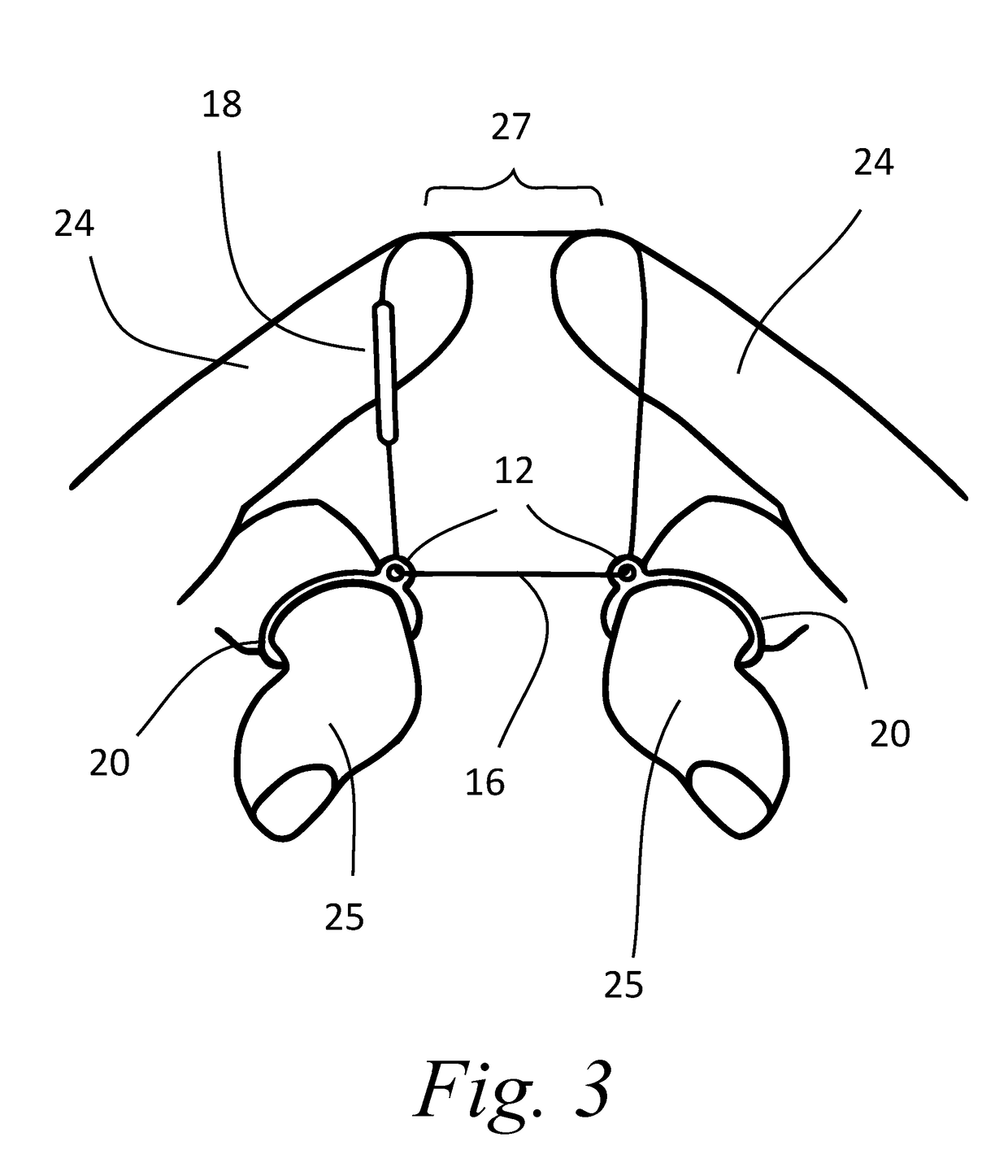

Oral hygiene device for the flossing of teeth

A dental flossing apparatus having a single continuous loop of dental floss passing freely through and held by apertures, which may be located either within the body of each of two rings, or in an eyelet on each of the rings, the rings being suitable for placing on the long fingers of both hands. One or both eyelets may have one end fixed to and continuous with the ring, and one sharply pointed end contiguous with, but not continuous with, the ring, with the pointed end pointing inwards such that its external side lies at an acute angle to the outer circumference of the ring, so that the floss can enter the aperture by being pulled through the contact point between the pointed end of the eyelet and the ring, but can't easily exit the aperture once inside.

Owner:DARGAN DENTAL LTD

Work glove

InactiveUSRE42729E1Increase flexibilityPromote respirationGlovesEye treatmentLong fingersProximal phalanx

A work glove particularly useful for gardening, automobile mechanical work and any other type of use which brings the palmar side of the hand in contact with work or the like which may result in stinging, bruising, or blistering of the fingers, thumb and palm of a human hand is provided with protective padding disclosed or positioned for overlying at least the distal halves of the index finger and long finger metacarpals excluding the metacarpalphalangeal joints of the index finger and the long finger. Preferably, the glove also includes protective padding disposed along a thumb stall of the glove at a location adapted to be along an ulnar border as well as the A2 pulleys of the thumb's proximal phalanx between the metacarpalphalangeal joint and the interphalangeal joint.

Owner:HILLERICH & BRADSBY

Glove with optional insert

A riding glove having particular application to be worn over the hand of one riding a bicycle to warm the fingers and thumb of the rider in cold or windy weather conditions. The riding glove includes an optional inner insert having relatively long finger and thumb sleeves into which the rider slides his fingers and thumb. A conventional outer glove member having relatively short finger and thumb sleeves, through which the longer finger and thumb sleeves of the inner insert are received, is pulled over the inner insert. The outer conventional glove member can be worn over the rider's hand in combination with or independently of the inner insert.

Owner:HILL LLOYD R

Multifunctional worm wheel rotation-friction arm

InactiveCN106740710ALower center heightCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsLong fingersWire rod

The invention discloses a multifunctional worm wheel rotation-friction arm. The multifunctional worm wheel rotation-friction arm is divided into two types of automatic inflation and non-inflation styles. A shaft head of the automatic inflation type hollow worm wheel is provided with a convex shape compression lid which is externally welded with a gas inlet nozzle and is internally provided with an air chamber, and embedded with an oil seal at the upper part, the convex shape compression lid is connected to a shell of a worm decelerating machine, the inner hole of the oil seal and the shaft head of the worm wheel are sealed, a left connecting lug and a right connecting lug which are arranged on the lower shaft and are in an inverted concave shape are provided with two nuts in the same diameter respectively, the nuts movably connected to two holes of the diameter of a hollow cylindrical universal coupler through bolts, the two holes in the diameter of a lower cross are movably connected with two symmetrical hanging lugs arranged on the pipe top of the inflation rotation-friction arm through the bolts, and a water cage canvas pipe, a PPR hard plastic pipe, an alloy pipe, a stainless steel tube or a galvanized tube is adopted in the inflation rotation-friction arm. A zero damage inflation type glass cowhells latex fish tail fin type long finger is adopted to wipe various bright outer surfaces of limousines, buses, metros, trains, passenger cars, motor cars and high-rise buildings, a high resilience wear-resisting nylon wire rod or an alloy steep wire is adopted as a container, acid, alkali, salt and calcium in the inner wall of a jar or a pot is polished and cleaned in a water spraying process and then discharged from a pollution discharge valve, and a mushroom type foxtail type rotation-friction arm can conduct wiping in various kinds of ways such as a horizontal tilting mode.

Owner:昝士录 +1

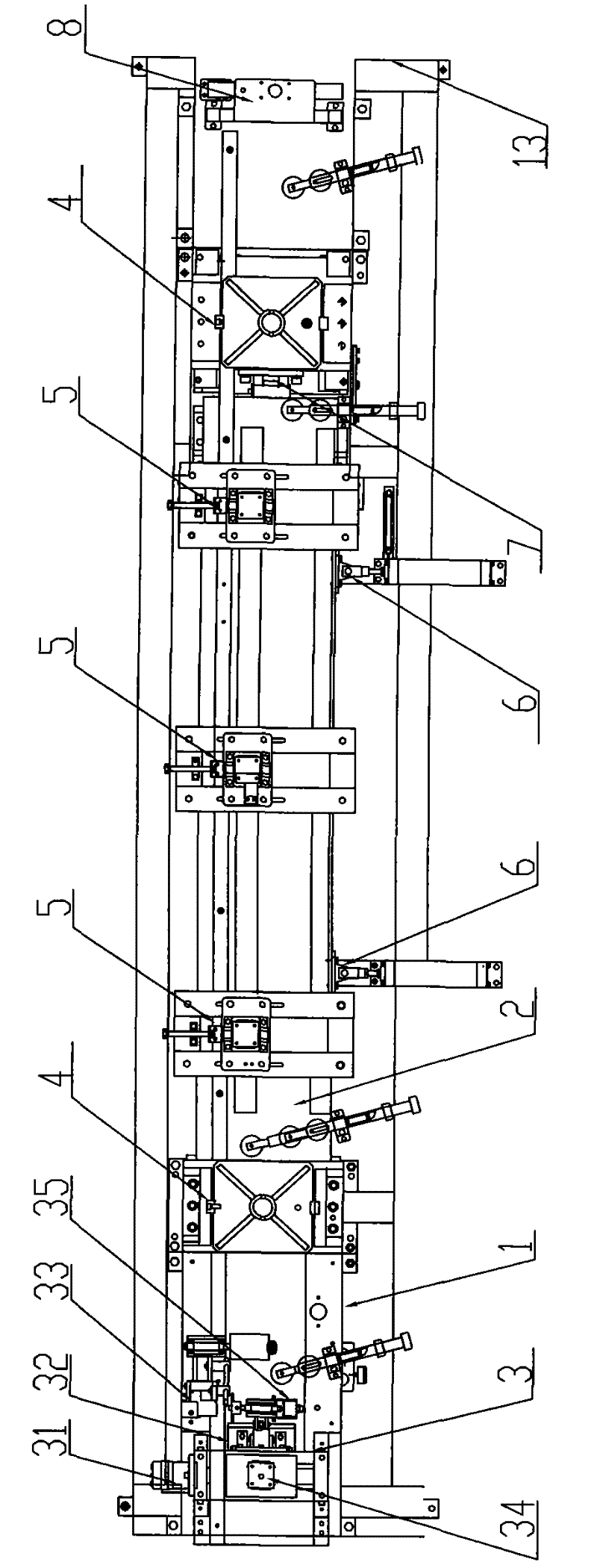

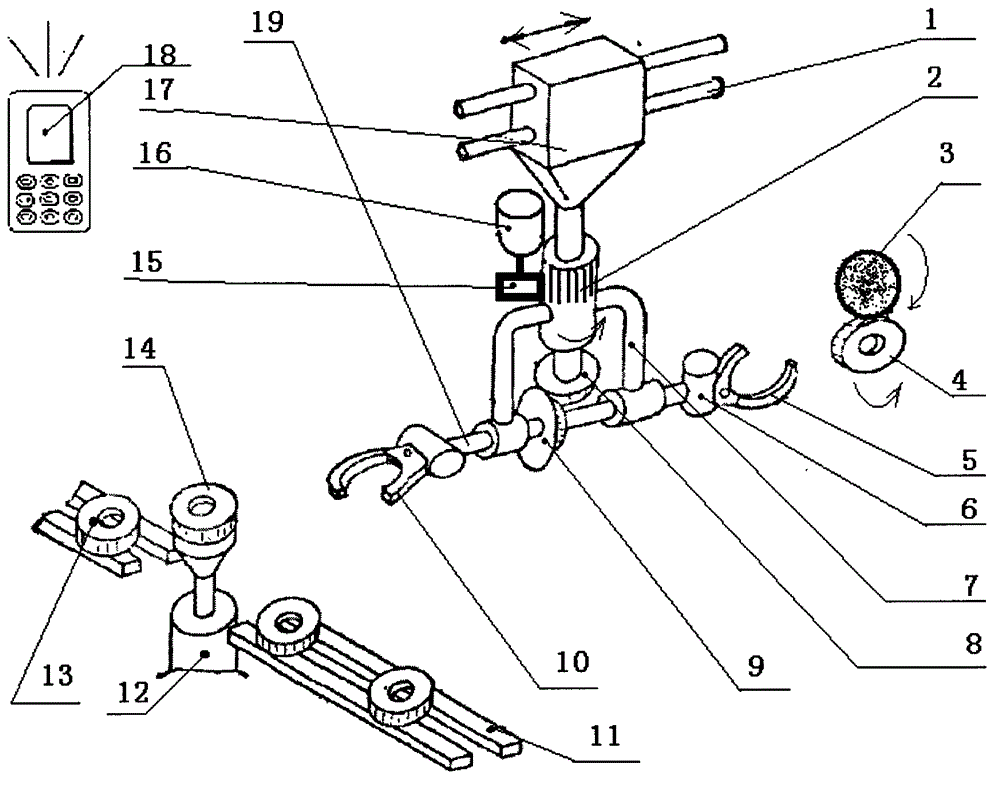

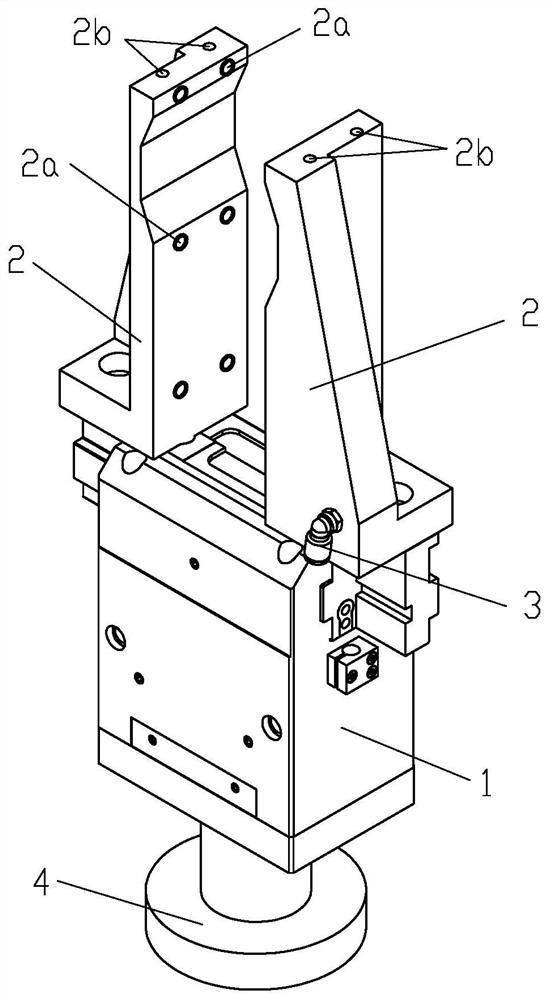

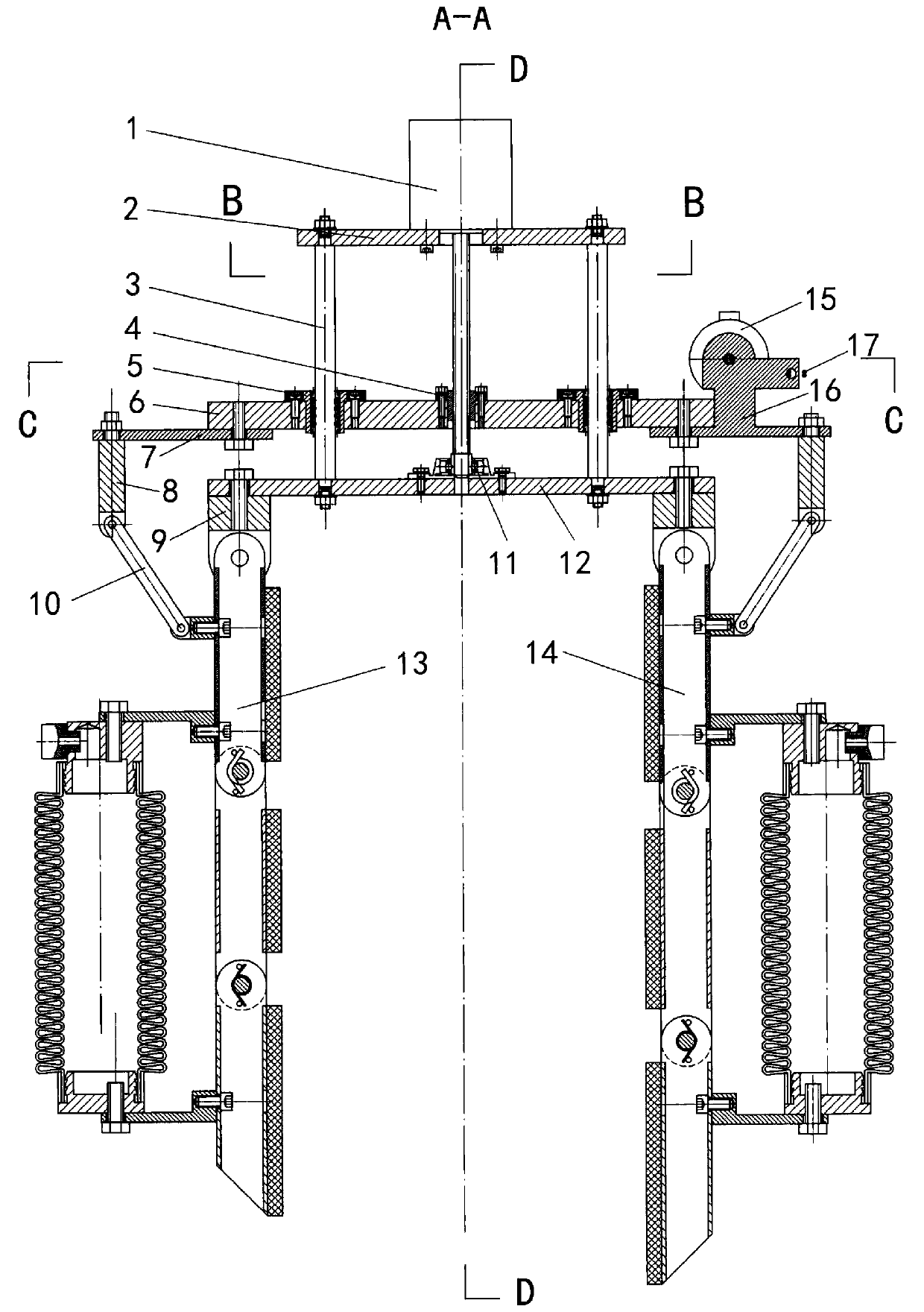

Mechanical and automatic feeding and discharging mechanical device

InactiveCN104526477AReduce workloadSave human effortRevolution surface grinding machinesProduction lineLong fingers

The invention relates to a mechanical and automatic feeding and discharging mechanical device. The mechanical and automatic feeding and discharging mechanical device is composed of arm moving slide bars, a turning gear, long fingers of grasping hands, a horizontal shaft and the like; two arm moving slide bars are horizontally arranged on a wallboard of a machine above a conveying production line, and a movable large slide block has movable fit with the arm moving slide bars; the output shaft of a servo motor is connected with a pinion through a flat key; the pinion is externally engaged to the turning gear, the turning gear has stationary fit with a turning arm, when the turning gear rotates, the turning arm rotates, a fixed gear is arranged on a fixed shaft below the turning gear, and a planetary conical gear is arranged on the horizontal shaft and forms a pair of externally engaged conical gears with the fixed gear. The mechanical and automatic feeding and discharging mechanical device is capable of greatly reducing the workload of operators and saving manpower. The mechanical and automatic feeding and discharging mechanical device realizes mechanical and automatic feeding and discharging. The mechanical and automatic feeding and discharging mechanical device is especially suitable for grinding disc type mechanical parts, realizes to mechanically, automatically and remotely conducting an operation site in a wireless mode, is fast in feeding and discharging speed, and is precise in position.

Owner:岳睿

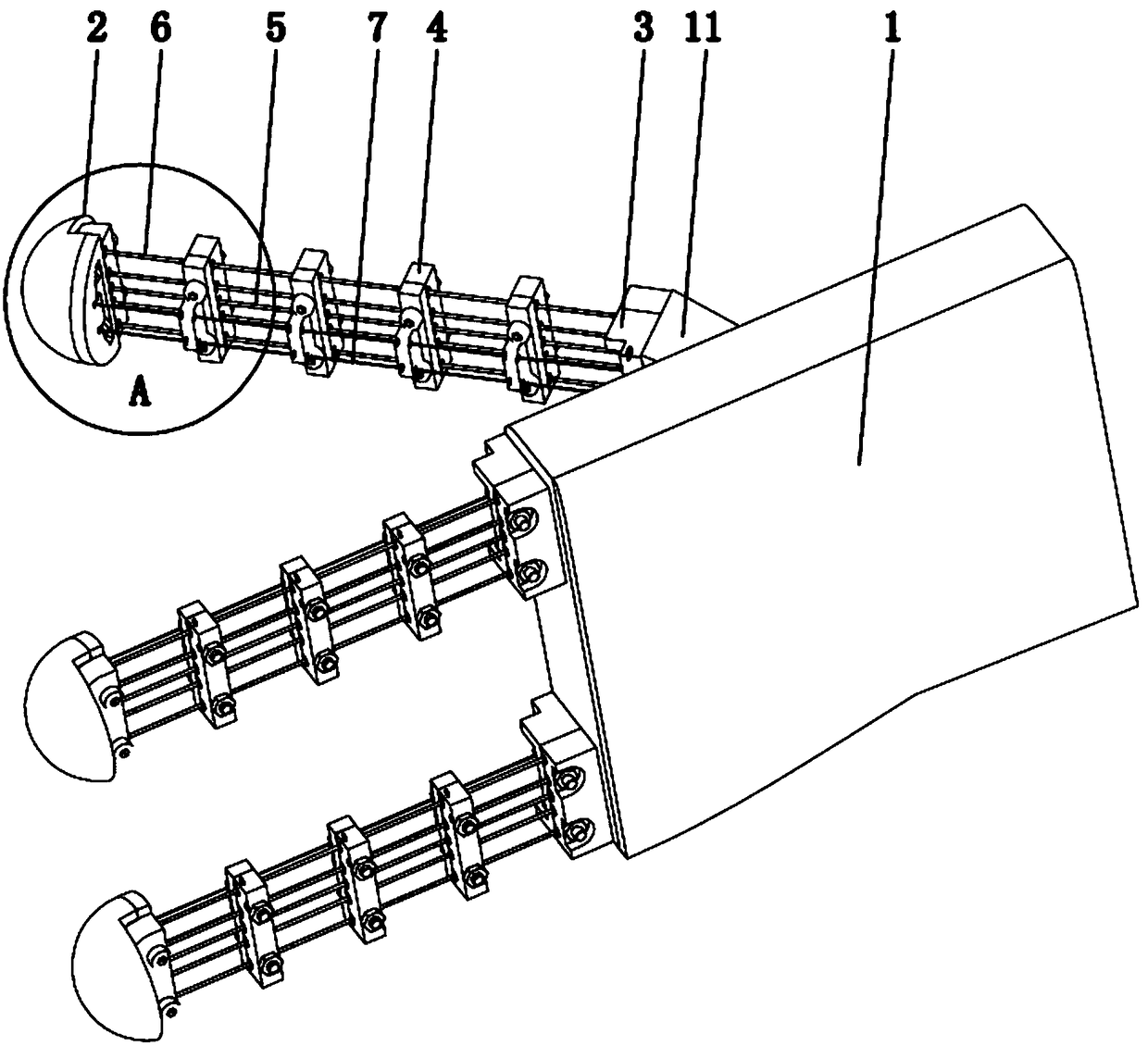

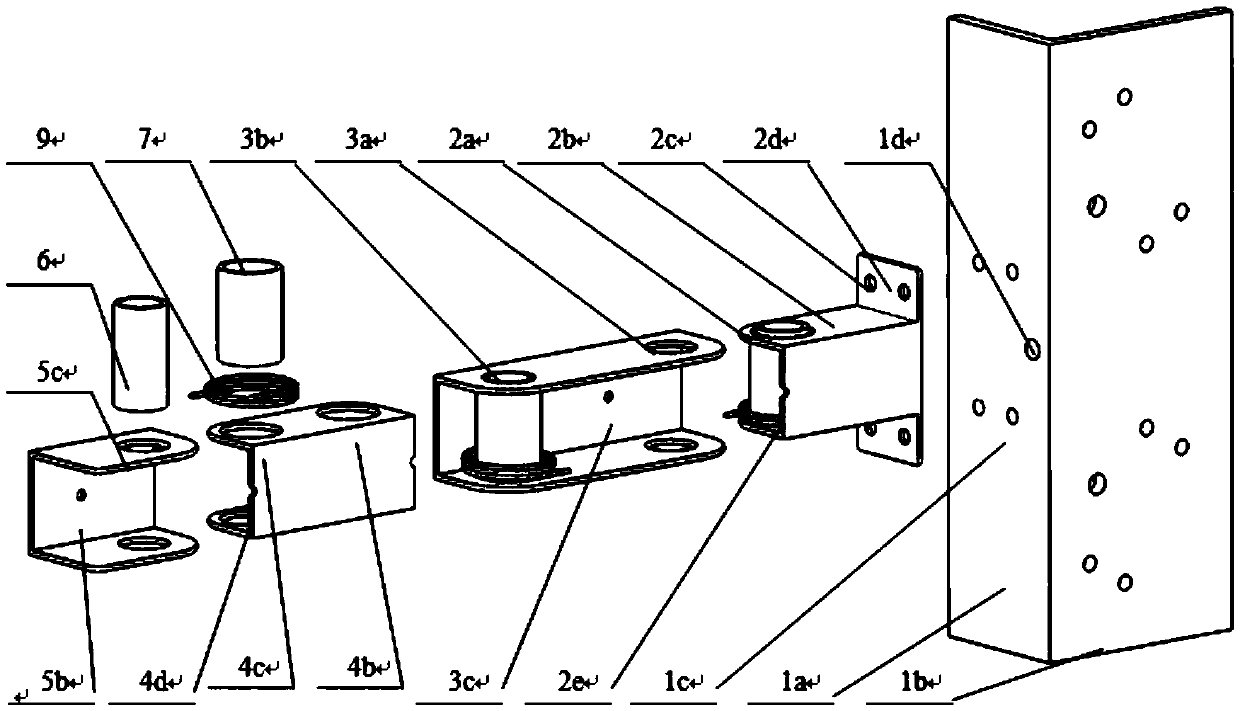

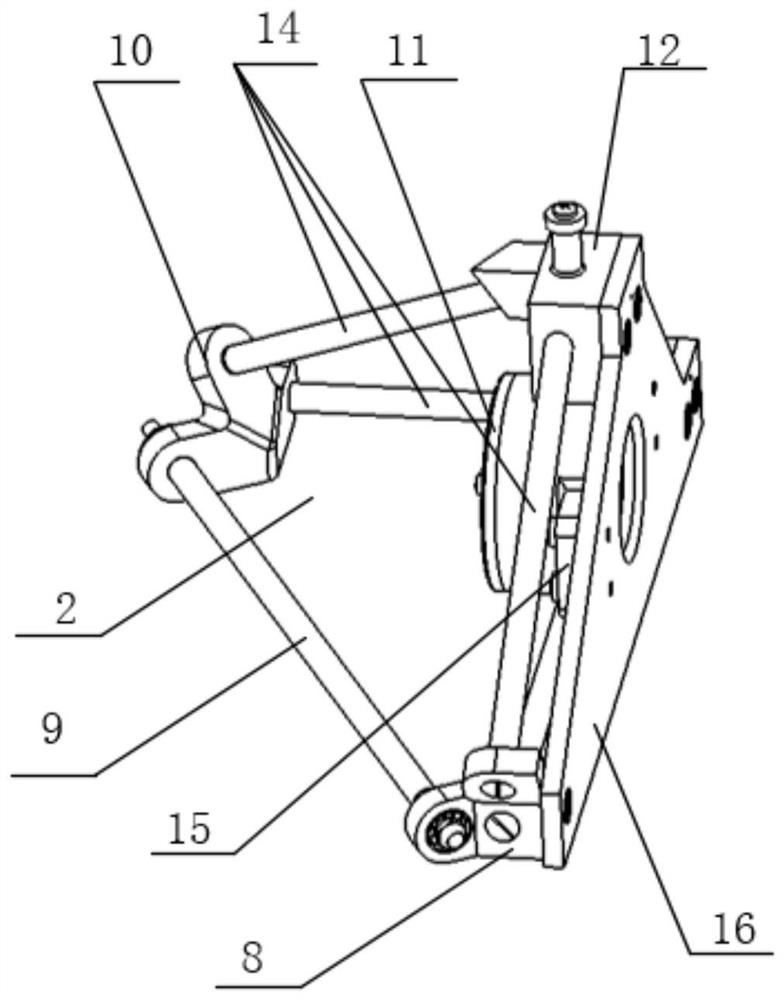

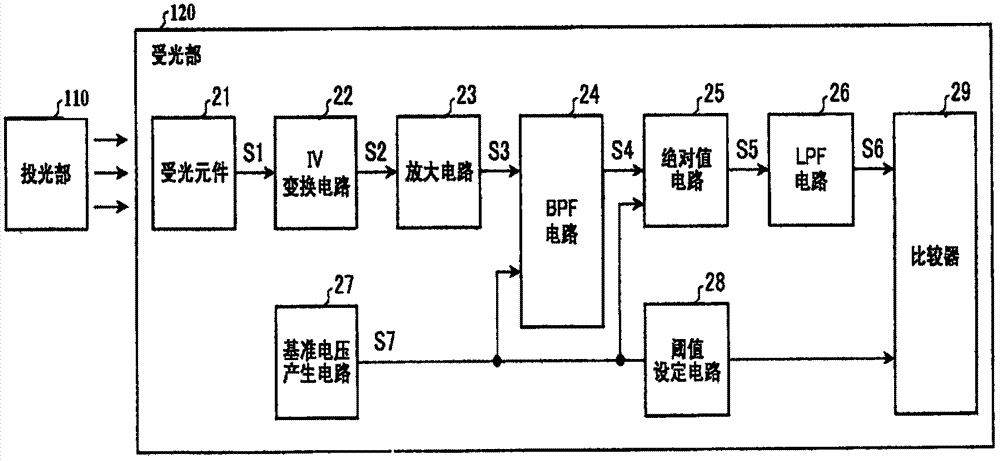

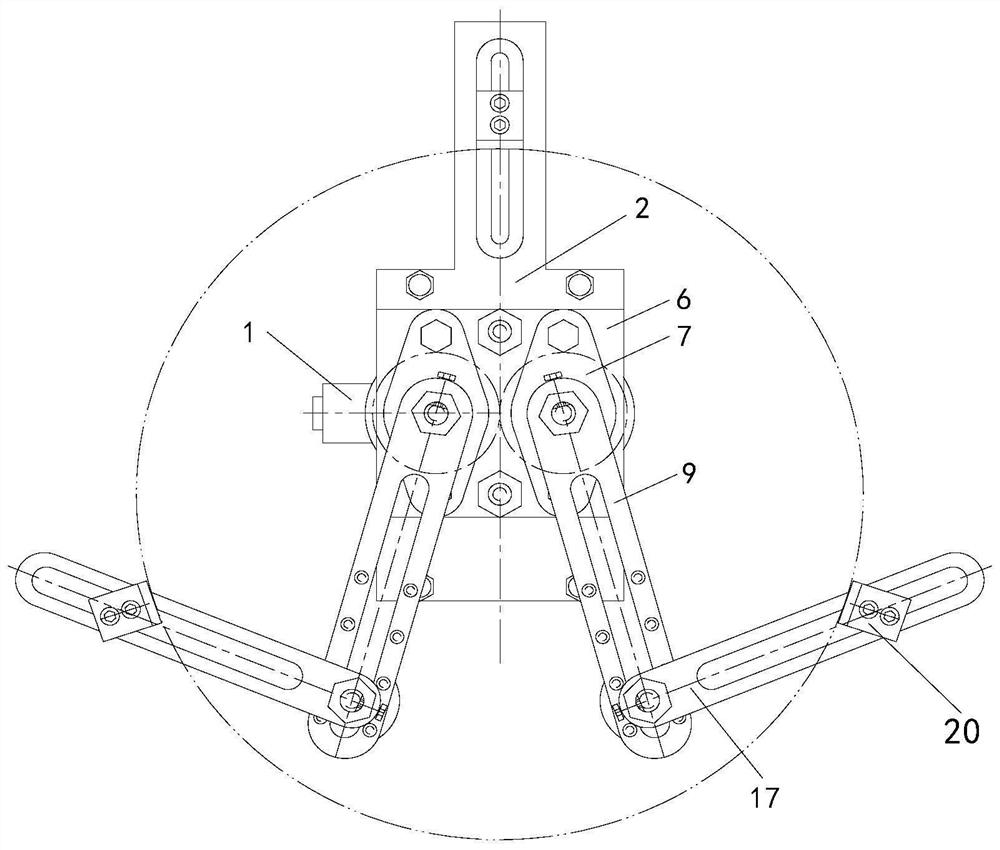

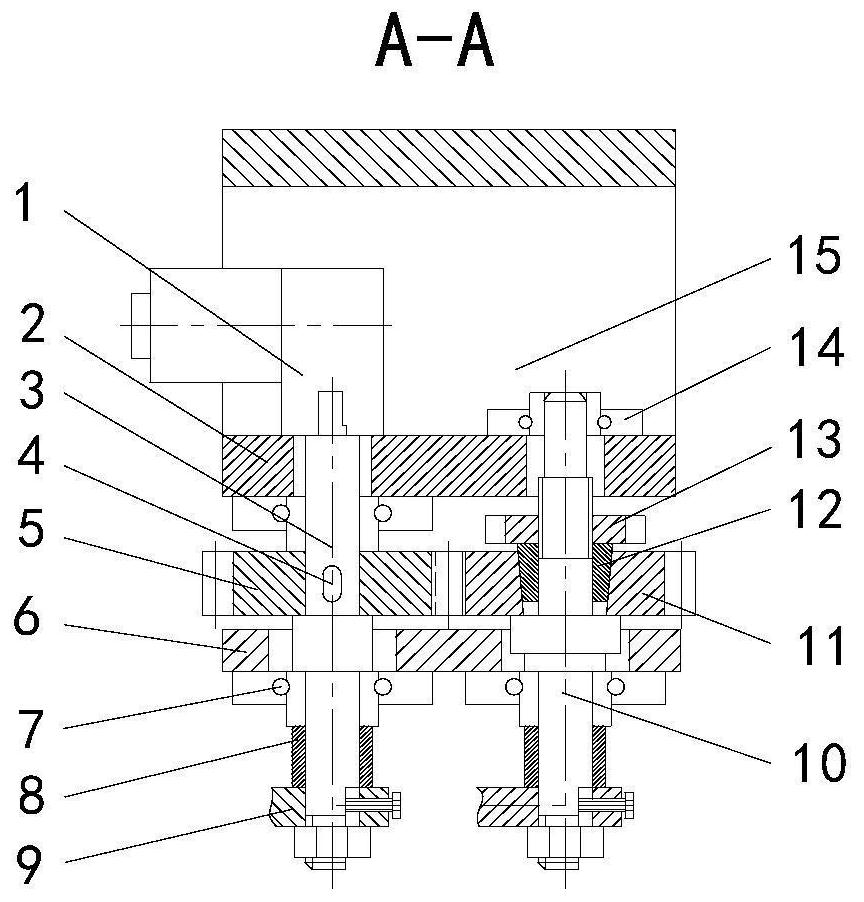

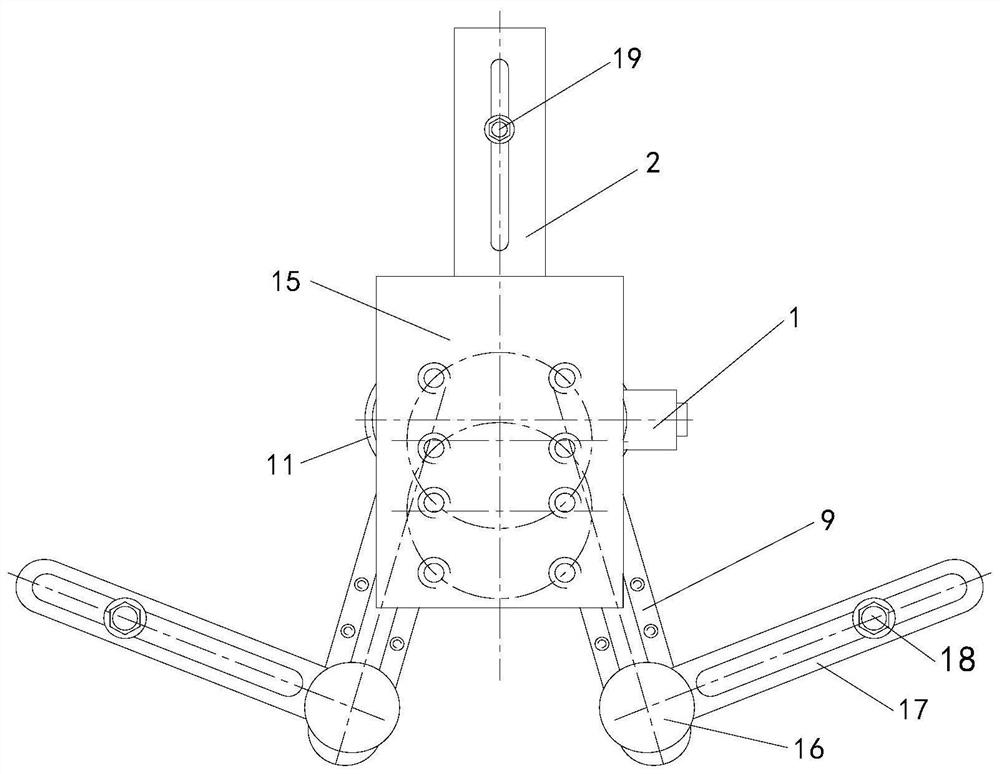

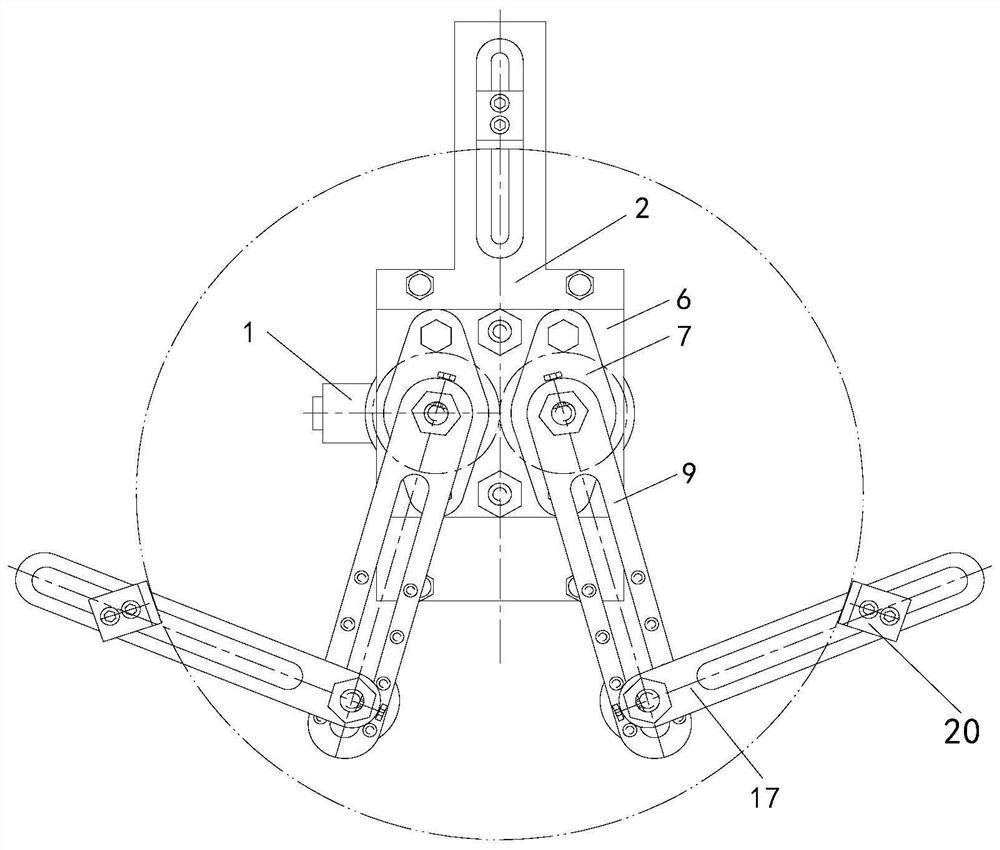

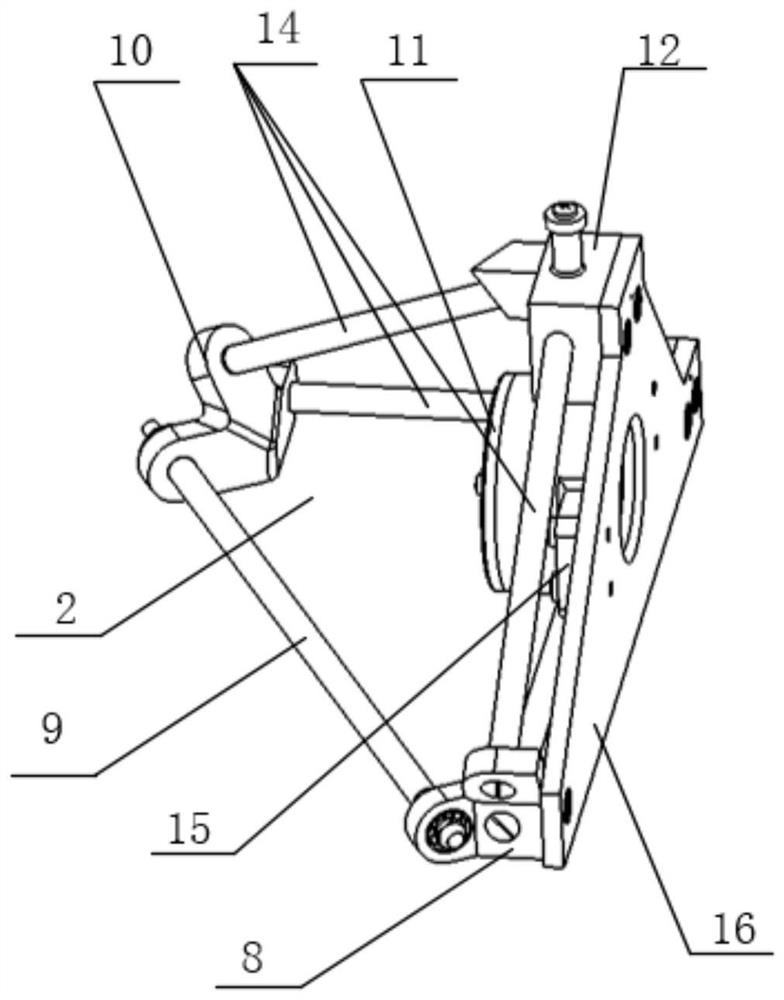

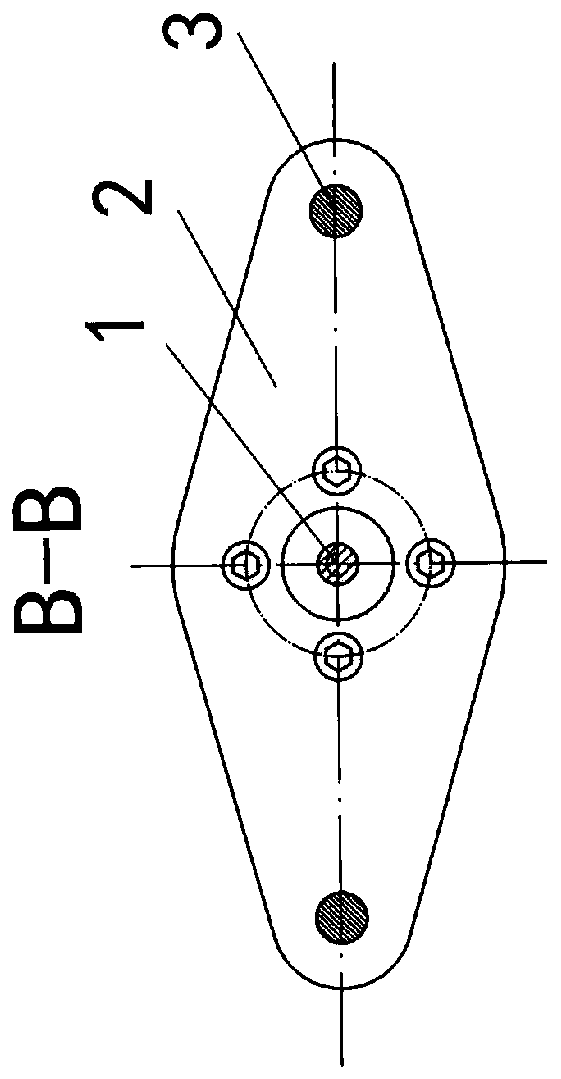

Linear supersonic motor-based two-finger parallel connection micro operation hand and operation method

InactiveCN103950027AQuick responseFlexible grabbingProgramme-controlled manipulatorMicromanipulatorLong fingersMicro-operation

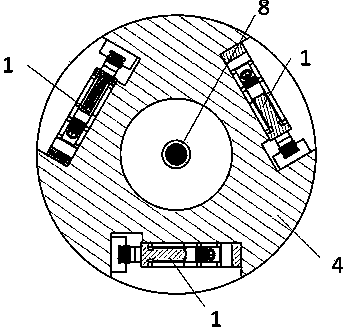

The invention discloses a linear supersonic motor-based three-freedom degree two-finger parallel connection micro operation hand method and belongs to the field of biomedical engineering. An operation hand comprises an arm, linear supersonic motors, flexible joints, a disc, a long finger, a short finger and a base, wherein the arm is fixed on the base, the three linear supersonic motors are all formed by stators and sliders which are fixed on the arm as well as linear guide rails positioned between driving feet of the stators and the sliders; the three linear supersonic motors are uniformly distributed around the middle axis of the arm and are differenced by 120 degrees two by two. The disc is arranged at the tail ends of the guide rails of the linear supersonic motors by the flexible joints; the long finger is fixed on the arm, and the fingertip of the long finger penetrates through a central hole in the disc; the finger root of the short finger is fixed on the disc. The operation hand is compact in structure and simple in control method, and has larger operation range and higher location precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Work Glove

InactiveUS20110314582A1Increase flexibilityPromote respirationGlovesBall sportsLong fingersProximal phalanx

A work glove particularly useful for gardening, automobile mechanical work and any other type of use which brings the palmar side of the hand in contact with work or the like which may result in stinging, bruising, or blistering of the fingers, thumb and palm of a human hand is provided with protective padding disclosed or positioned for overlying at least the distal halves of the index finger and long finger metacarpals excluding the metacarpalphalangeal joints of the index finger and the long finger. Preferably, the glove also includes protective padding disposed along a thumb stall of the glove at a location adapted to be along an ulnar border as well as the A2 pulleys of the thumb's proximal phalanx between the metacarpalphalangeal joint and the interphalangeal joint.

Owner:HILLERICH & BRADSBY

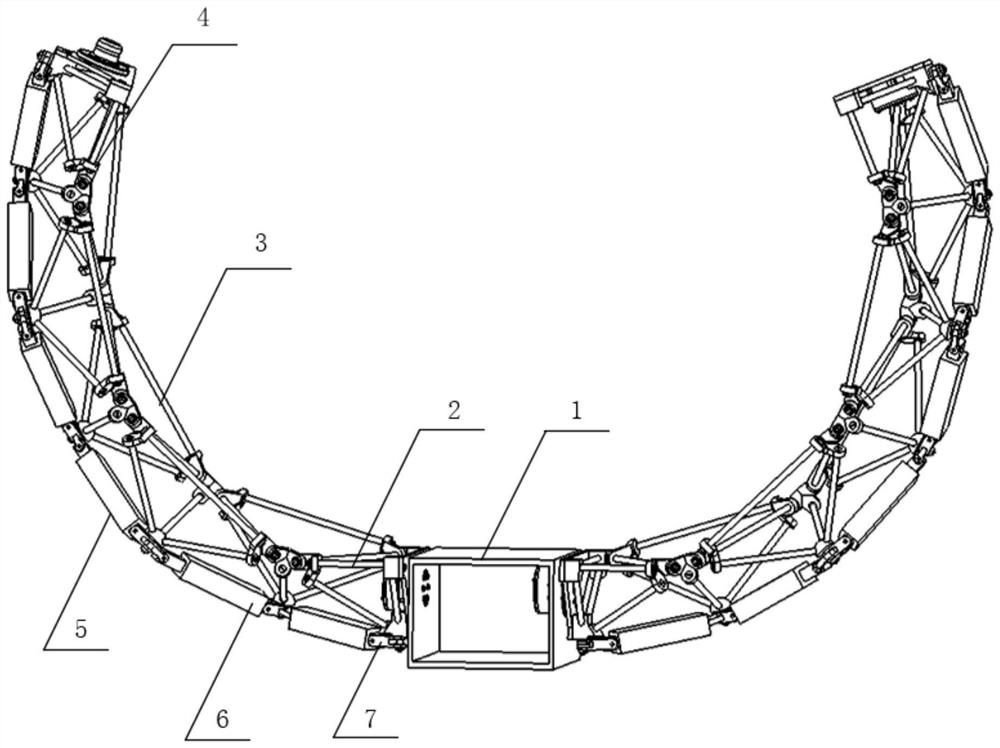

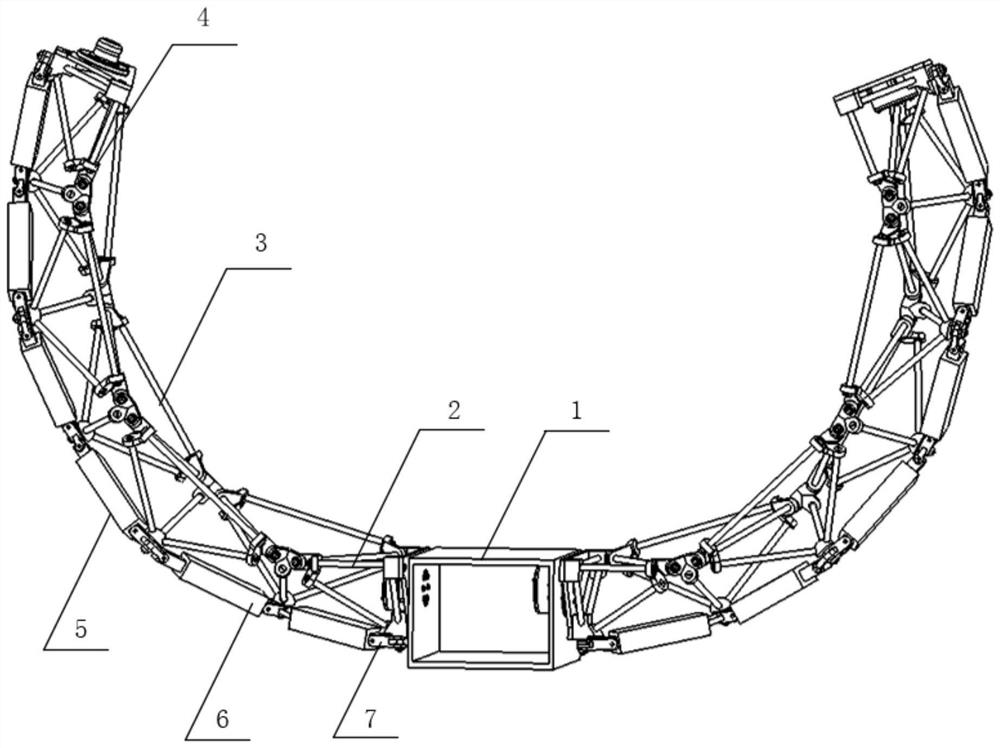

Space reconfigurable truss type capturing mechanism and capturing method thereof

The invention provides a space reconfigurable truss type capturing mechanism and a capturing method thereof.The space reconfigurable truss type capturing mechanism comprises a base and two reconfigurable truss type capturing fingers, and each reconfigurable truss type capturing finger comprises a butt joint plug truss unit, a butt joint connector truss unit, a plurality of modular extensible trussunits and a plurality of linear driving devices; the butt joint plug truss unit, the modular extensible truss units and the butt joint connector truss unit of each reconfigurable truss type capturingfinger are connected in sequence, and a linear driving device is connected between every two adjacent truss units of each reconfigurable truss type capturing finger. Butt joint or separation betweenthe capture fingers and the base and butt joint or separation between the two fingers can be achieved, and capture can be completed by selecting a two-finger cooperation mode or a mode that the two fingers are in butt joint to form a lengthened finger according to different requirements of capture tasks; butt joint expansion is achieved, the structure is simple, the weight is light, the capturingspace is large, and adaptability to captured objects is good.

Owner:HARBIN INST OF TECH

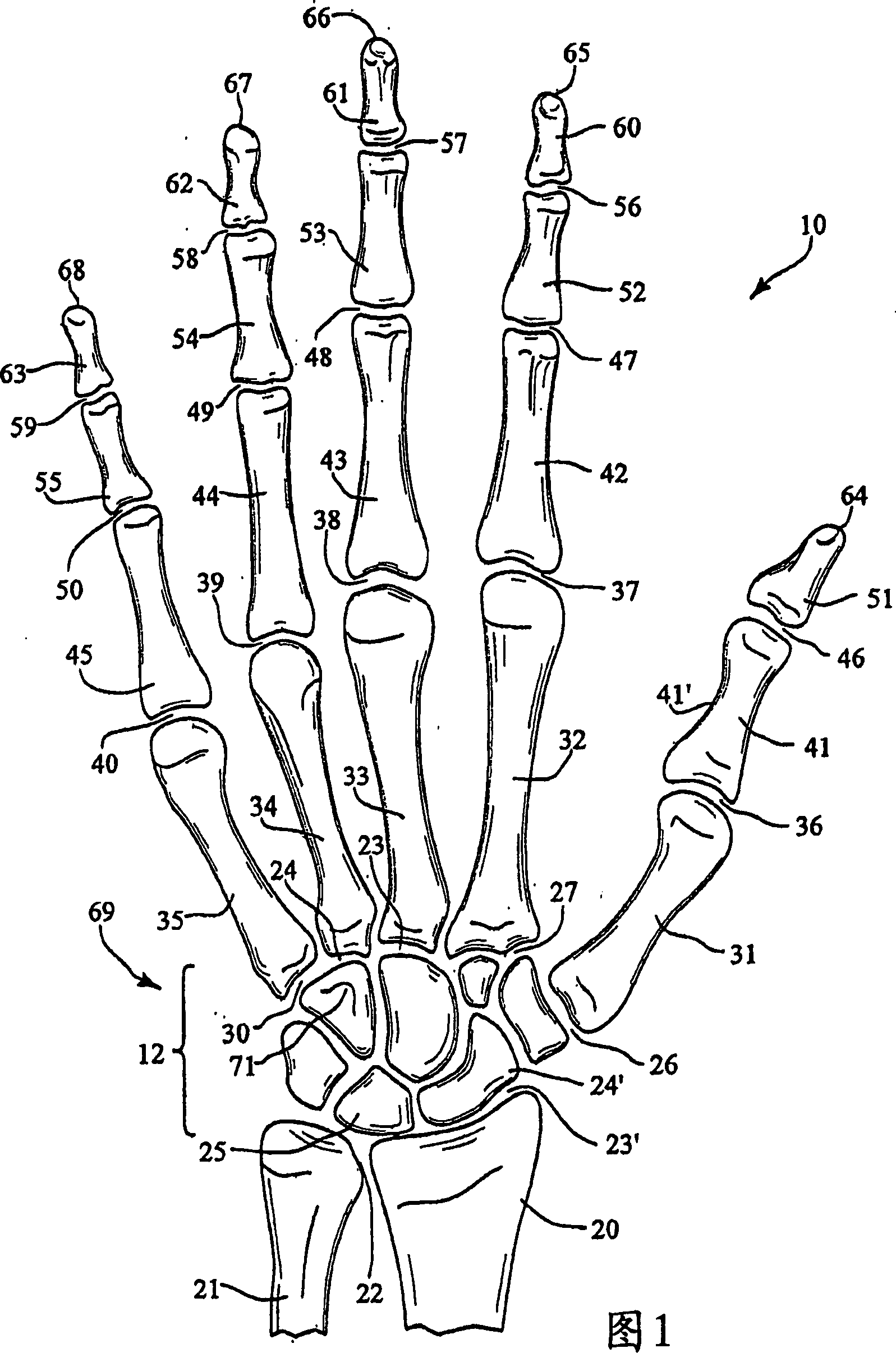

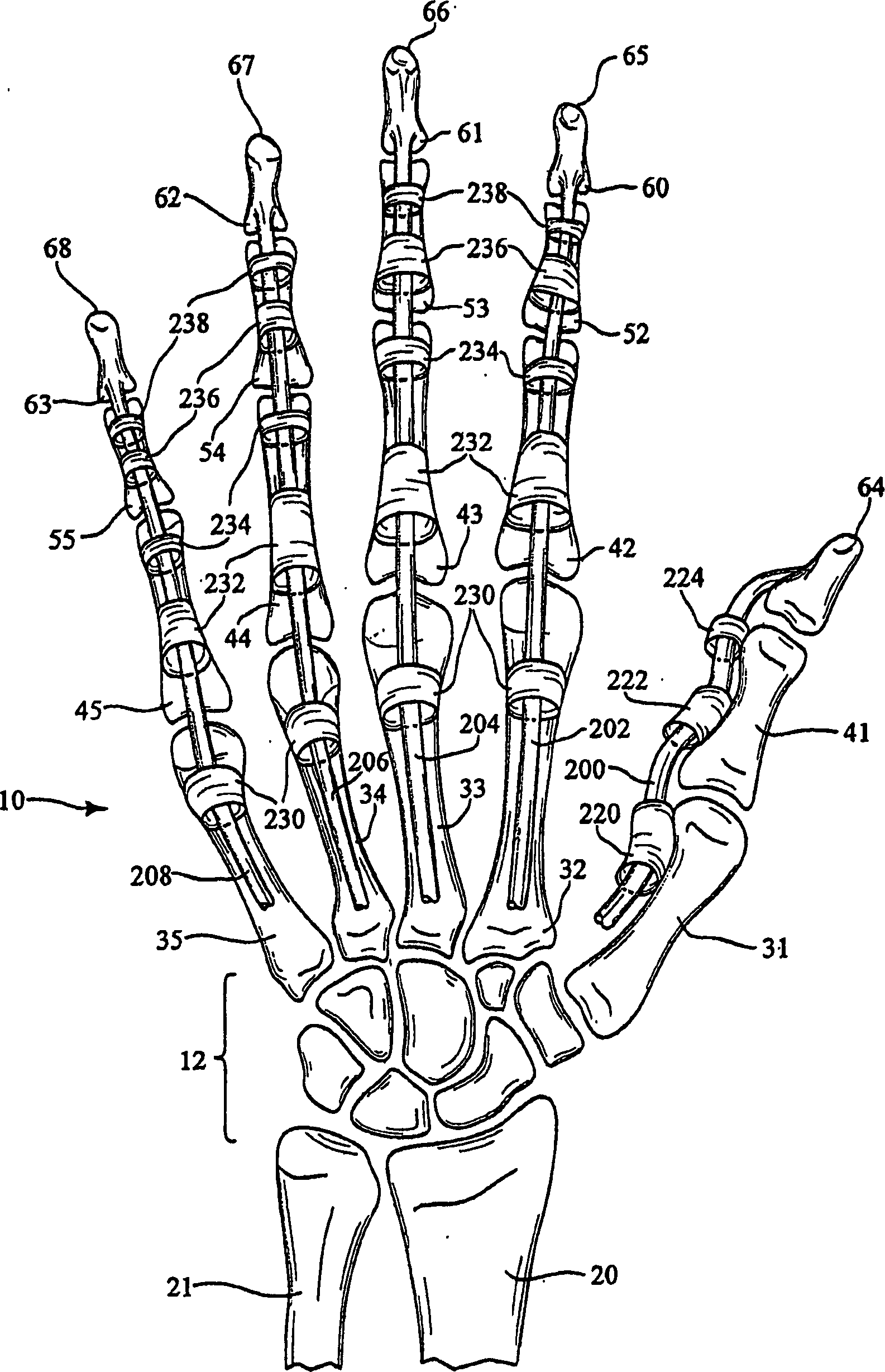

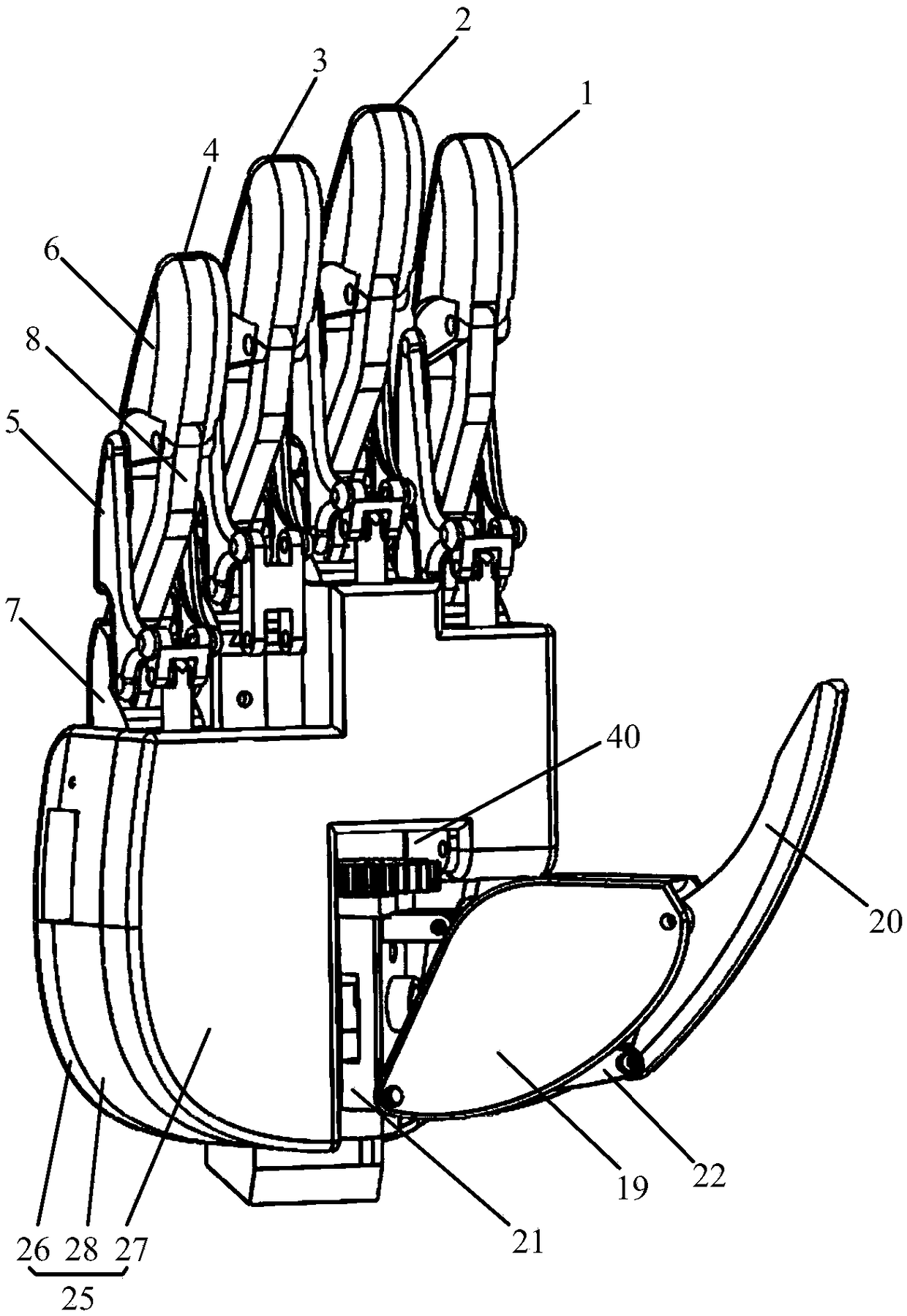

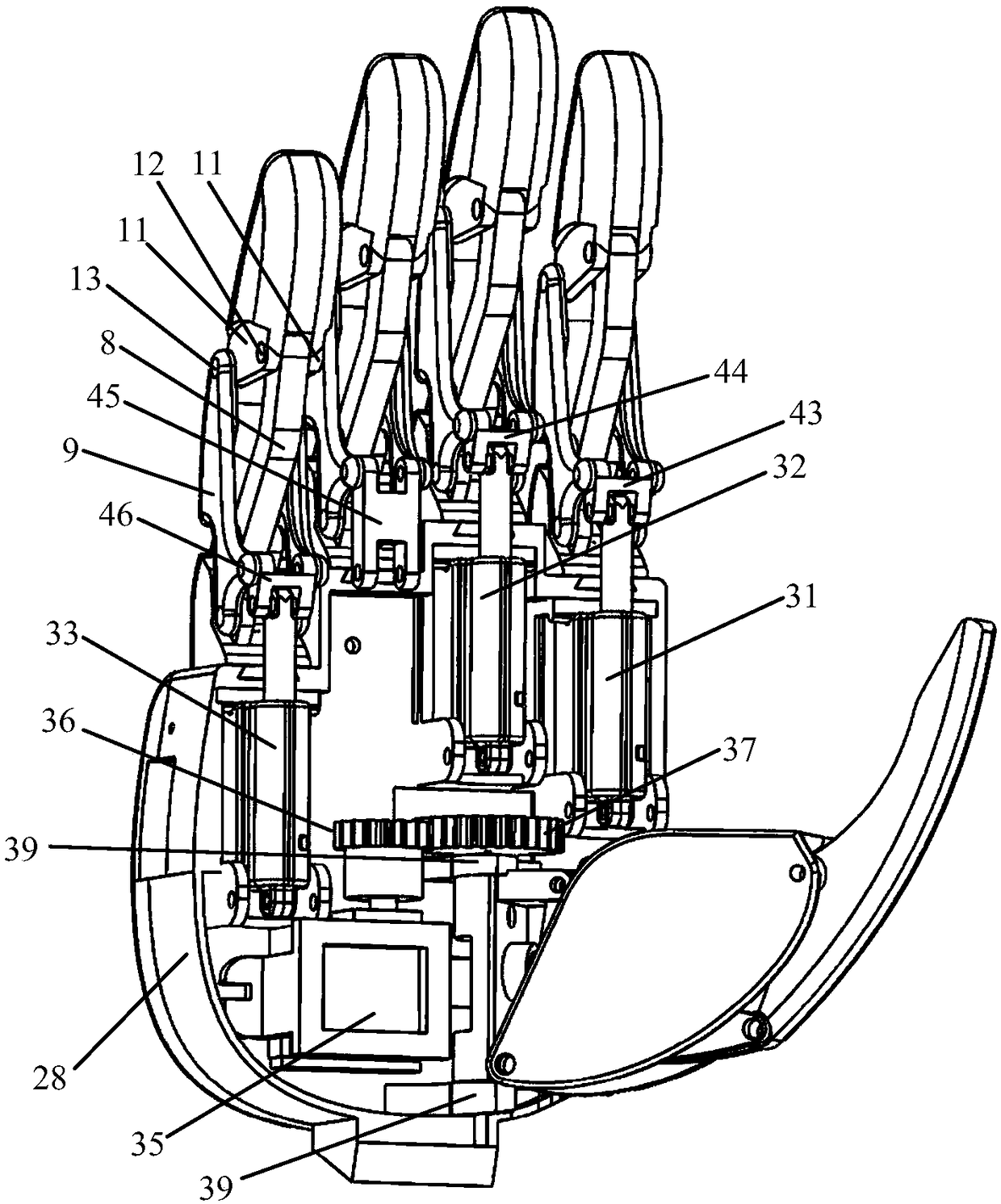

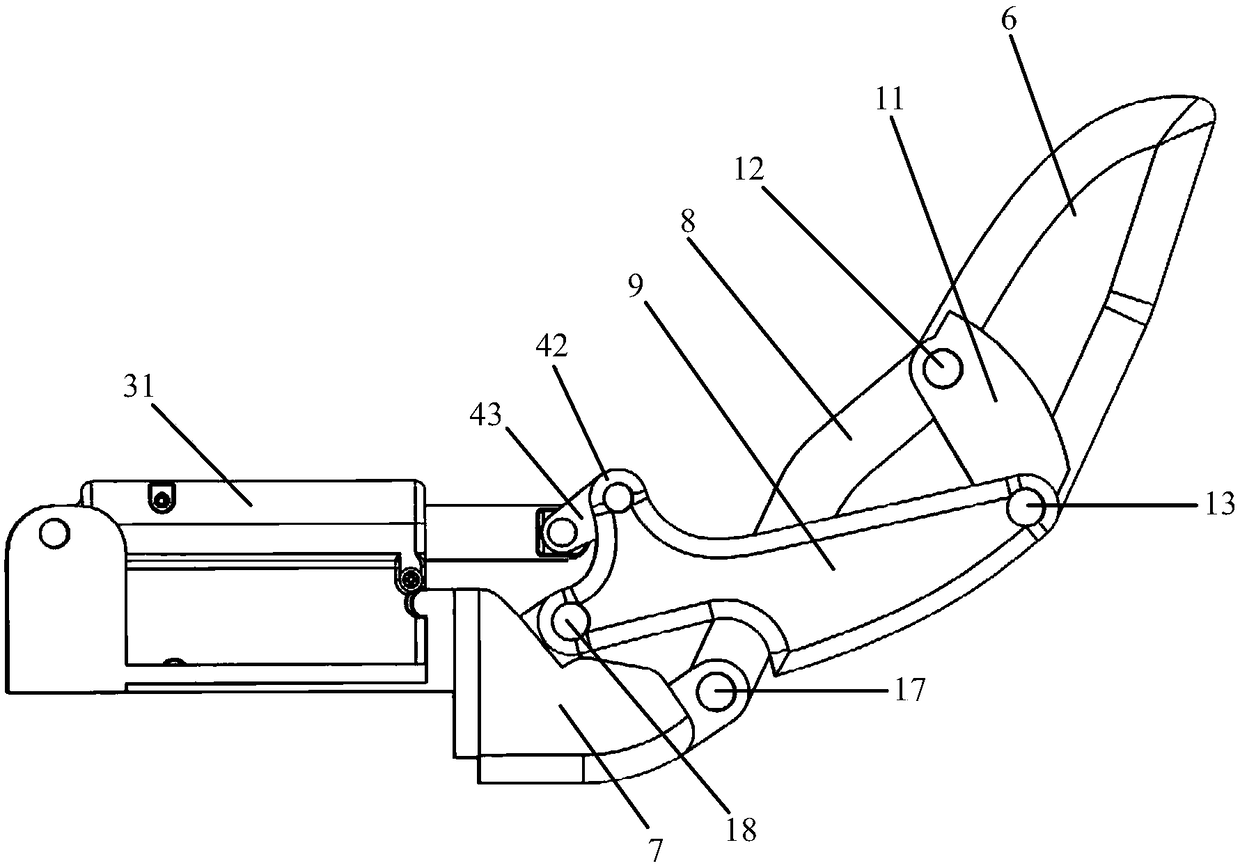

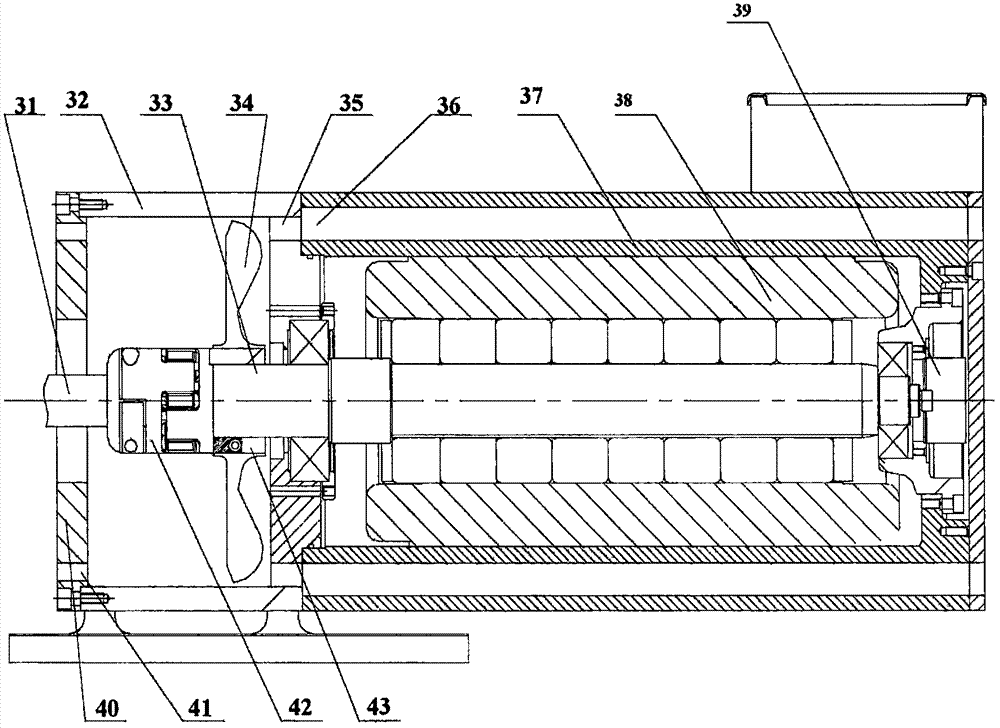

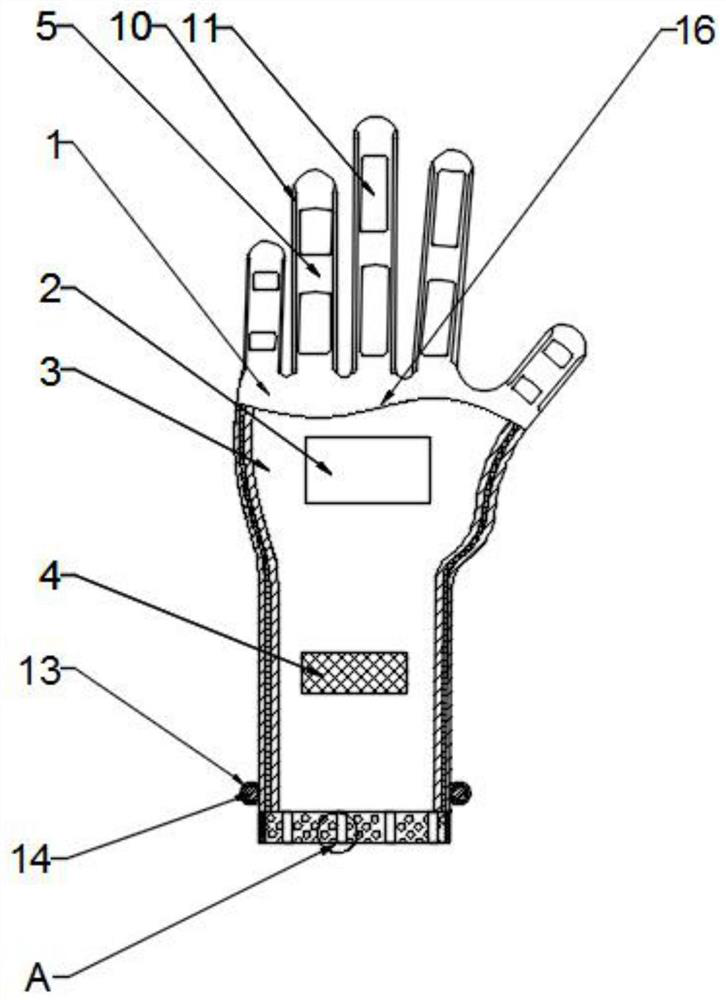

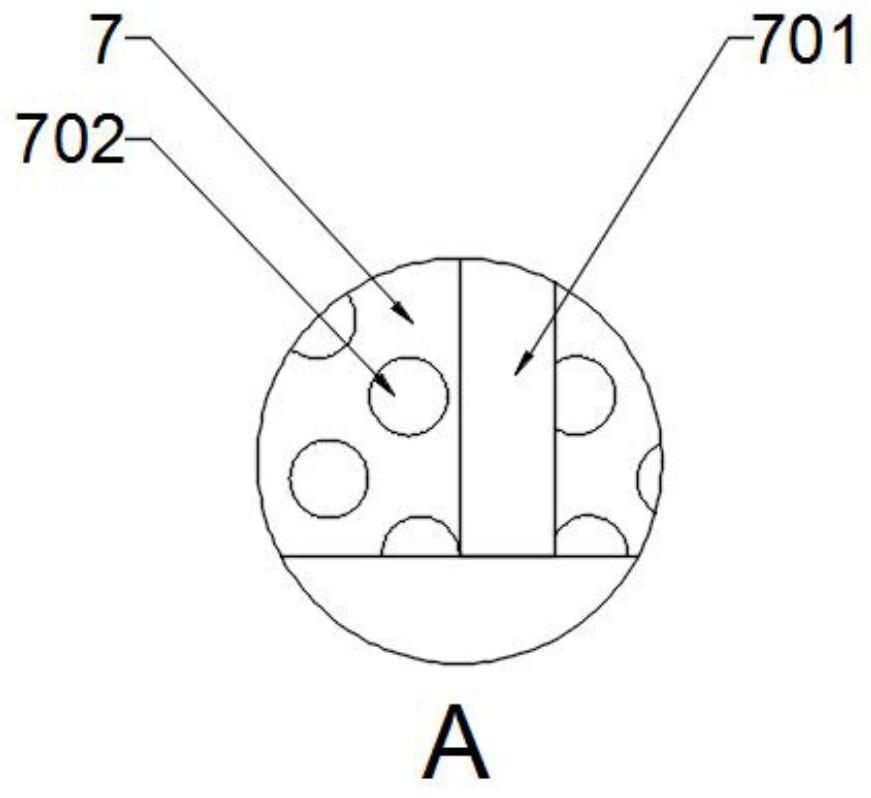

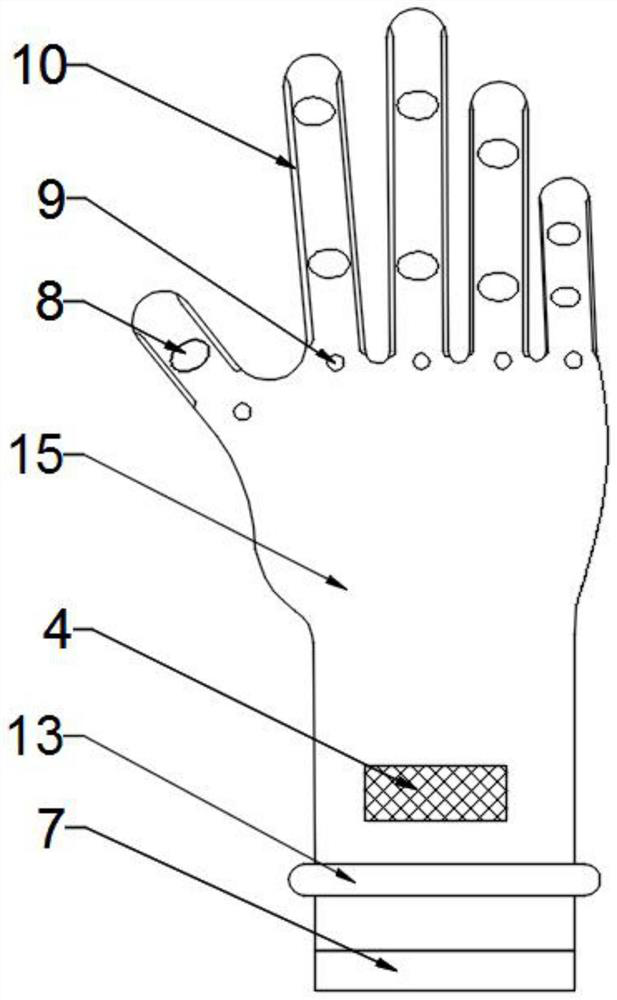

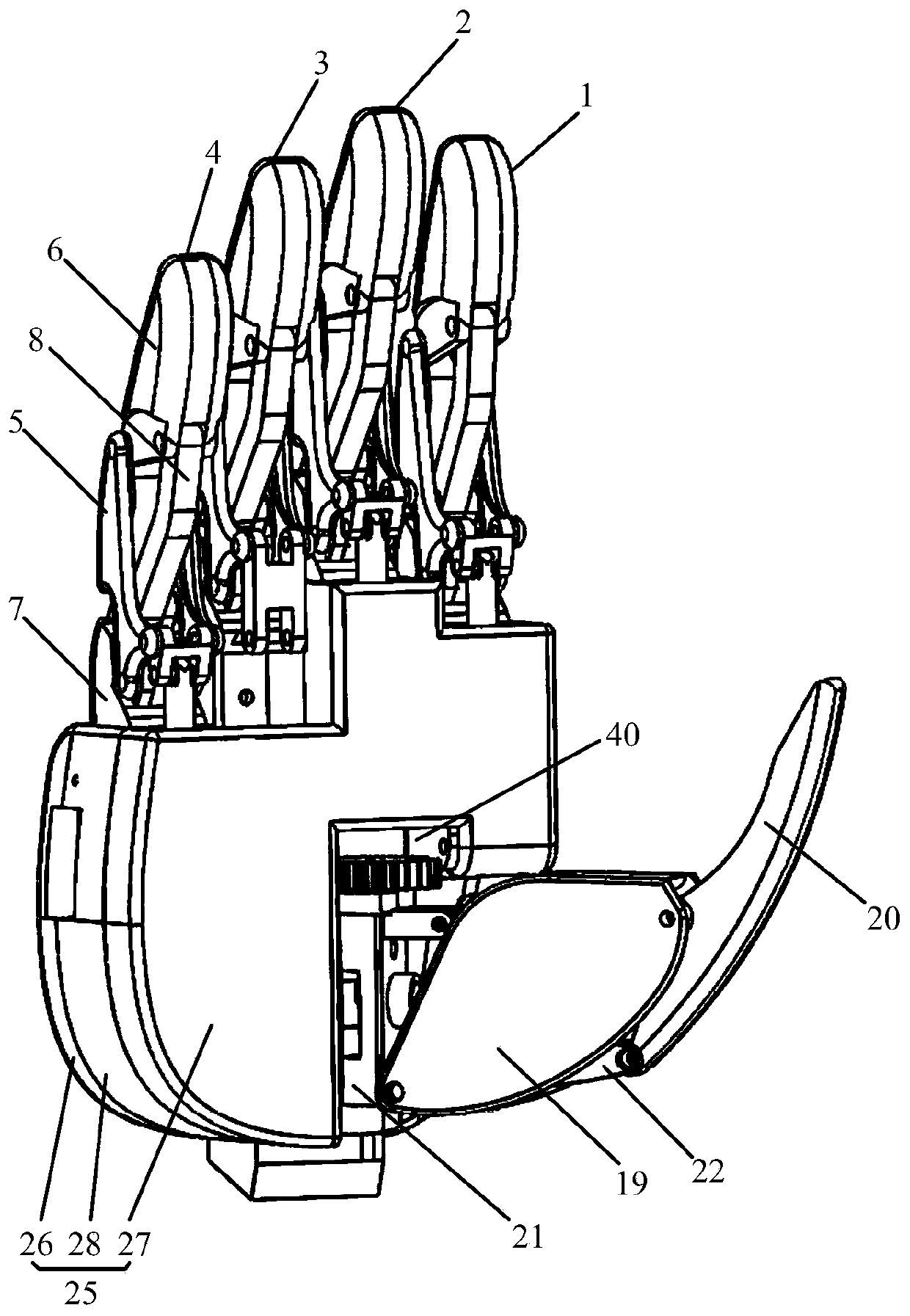

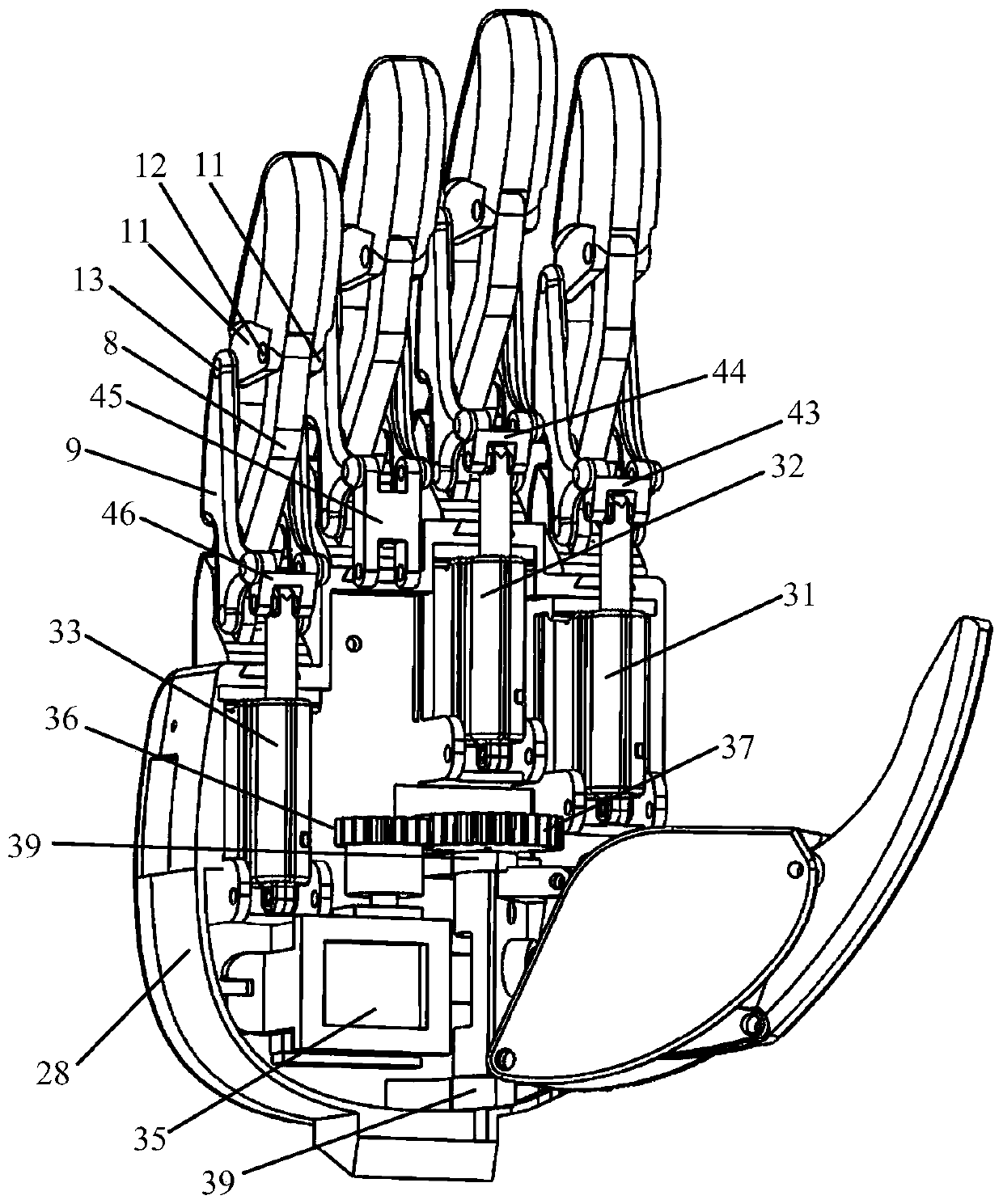

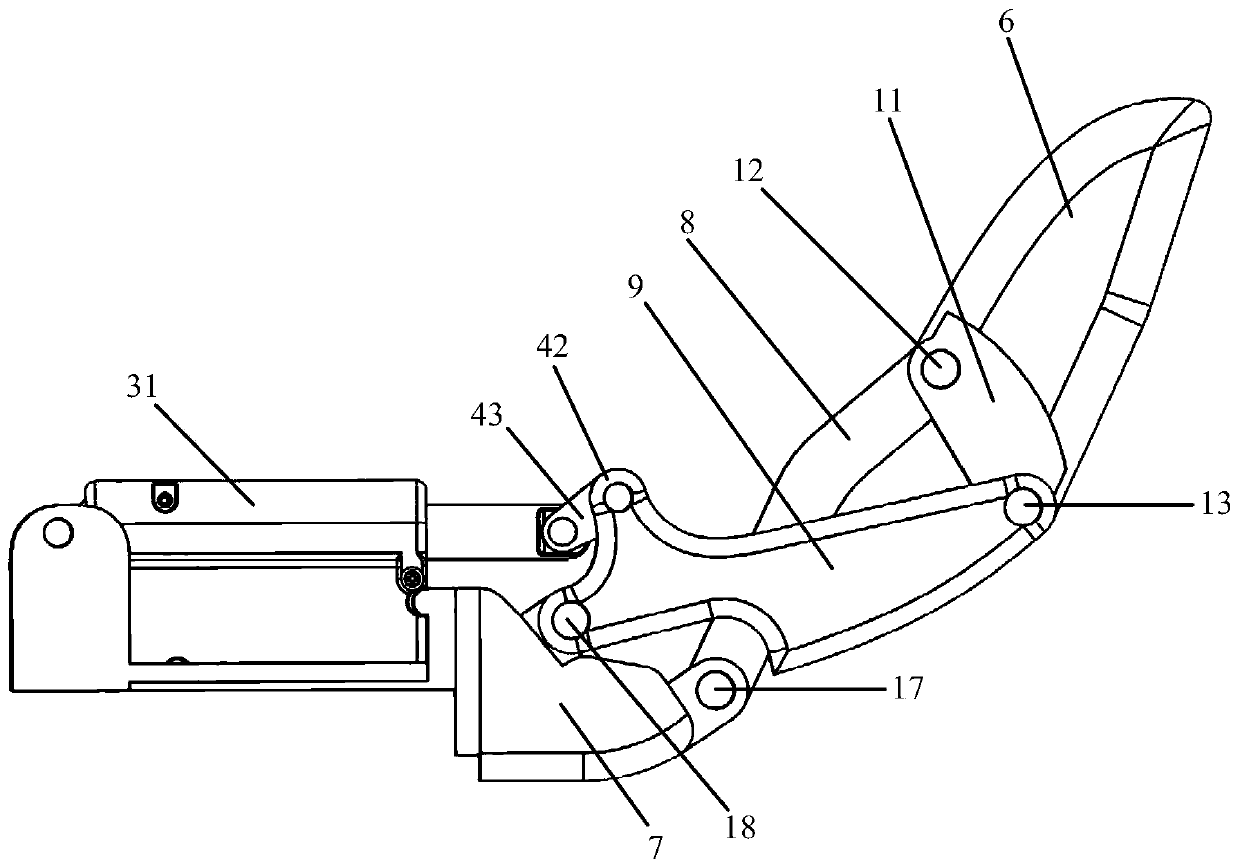

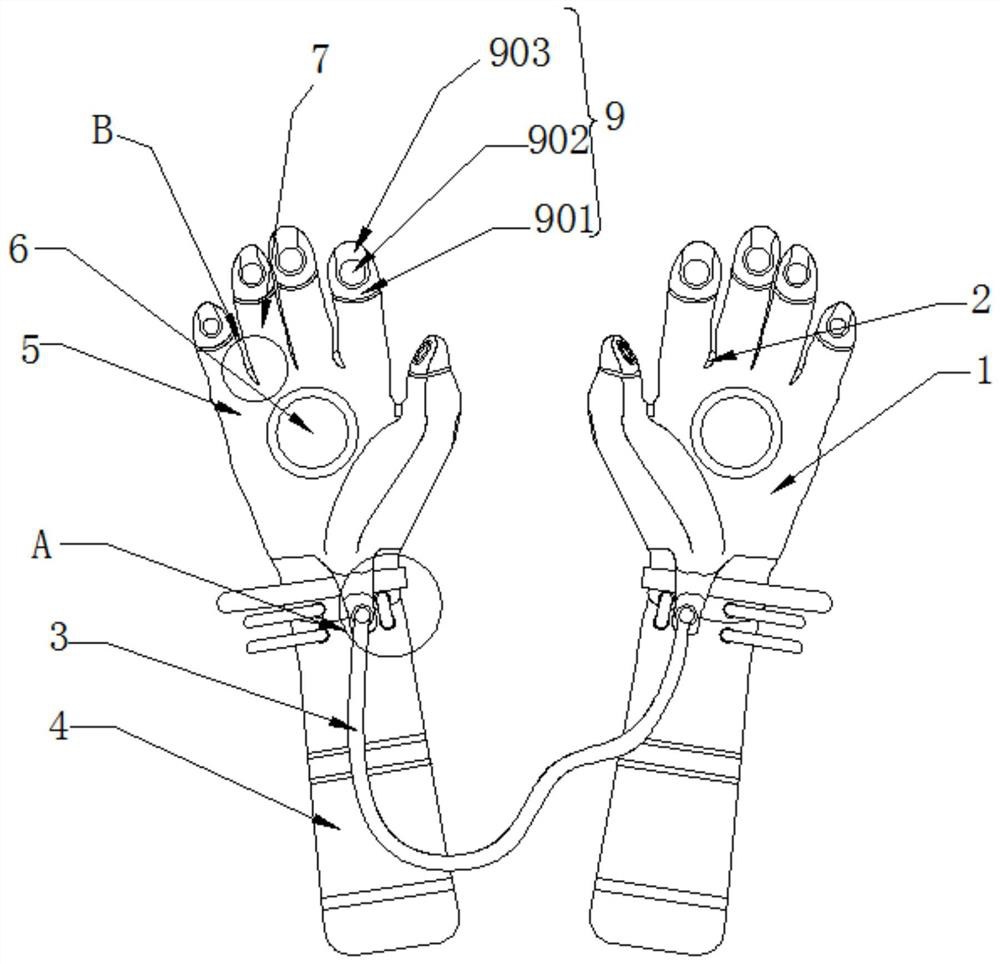

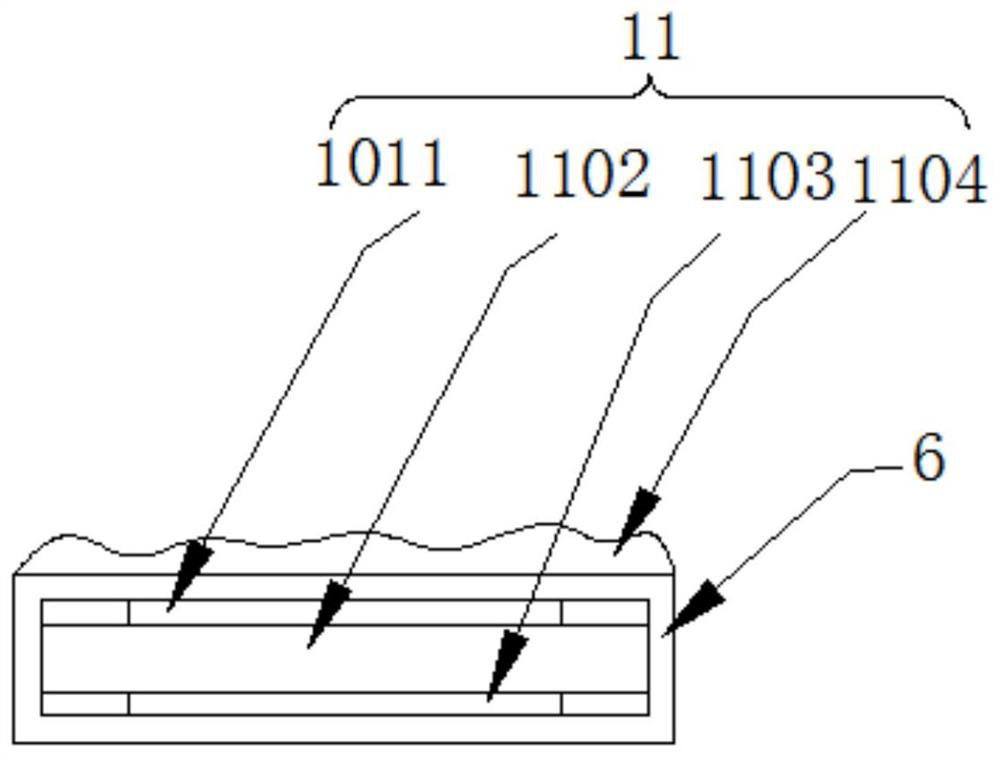

Prosthetic hand sensing mechanism and system supporting cloud fusion

The invention relates to a prosthetic hand sensing mechanism and system supporting cloud fusion, belonging to the technical field of biomimetic prosthetic hands. The prosthetic hand sensing mechanismcomprises a long finger part, a thumb part, four connecting blocks, a palm part and a printed circuit board. The long finger comprises four long finger mechanisms, namely, an index finger mechanism, amiddle finger mechanism, a ring finger mechanism and a pinky finger mechanism. Each long finger mechanism comprises a proximal knuckle and a middle finger, a distal phalangeal joint, a first metacarpophalangeal joint seat, and a first connector; and the thumb portion includes a proximal phalangeal segment, a distal phalangeal segment, a second metacarpophalangeal joint seat, and a second connector. The thumb portion includes a proximal phalangeal segment, a distal phalangeal segment, and a second metacarpophalangeal joint seat. Each proximal finger of the long finger mechanism is articulatedwith a connecting block; the palm part comprises a housing, a rotating driving mechanism installed in the housing and four linear driving mechanisms; and a main control module, a driving module and adata communication module are integrated on the print circuit board. The prosthetic hand sensing mechanism can make corresponding gestures according to the recognition results of the gestures recognized by the upper computer on the cloud end.

Owner:SOUTHEAST UNIV

Automatic conveying mechanical device for disc-sleeve-type grinding parts

InactiveCN106891210AReduce workloadEasy to passProgramme-controlled manipulatorRevolution surface grinding machinesLong fingersGear wheel

The invention relates to a conveying device, in particular to an automatic conveying mechanical device for disc-sleeve-type grinding parts. The automatic conveying mechanical device is composed of a mechanical arm, a rotation gear, a long finger of a hand grab, a horizontal shaft and the like. Arm moving slide bars are horizontally arranged and installed on a machine wallboard above a conveying assembly line, and a big moving sliding block and the arm moving slide bars are in movable fit. An output shaft of a servo motor is connected with a pinion through a flat key. The pinion is externally engaged with the rotation gear. The rotation gear is fixedly matched with a rocking arm, so that when the rotation gear rotates, the rocking arm rotates. A fixed gear is installed on a fixed shaft below the rotation gear. A planet bevel gear is installed on the horizontal shaft, and the planet bevel gear and the fixed gear form a pair of externally-engaged bevel gears. By the adoption of the automatic conveying mechanical device, the workloads of operators can be reduced, and manpower is saved. Mechanical and automatic feeding and discharging can be achieved. The automatic conveying mechanical device is particularly suitable for conveying the disc-sleeve-type grinding parts, automation and wireless remote control commanding of an operational site can be achieved, the feeding and discharging speed is high and the position is accurate.

Owner:岳睿

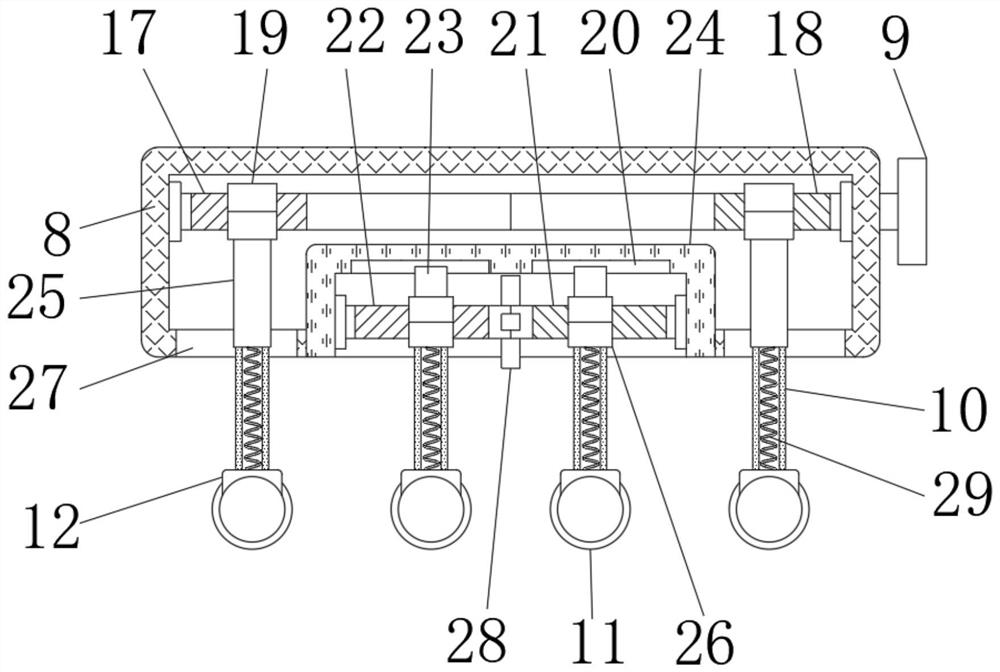

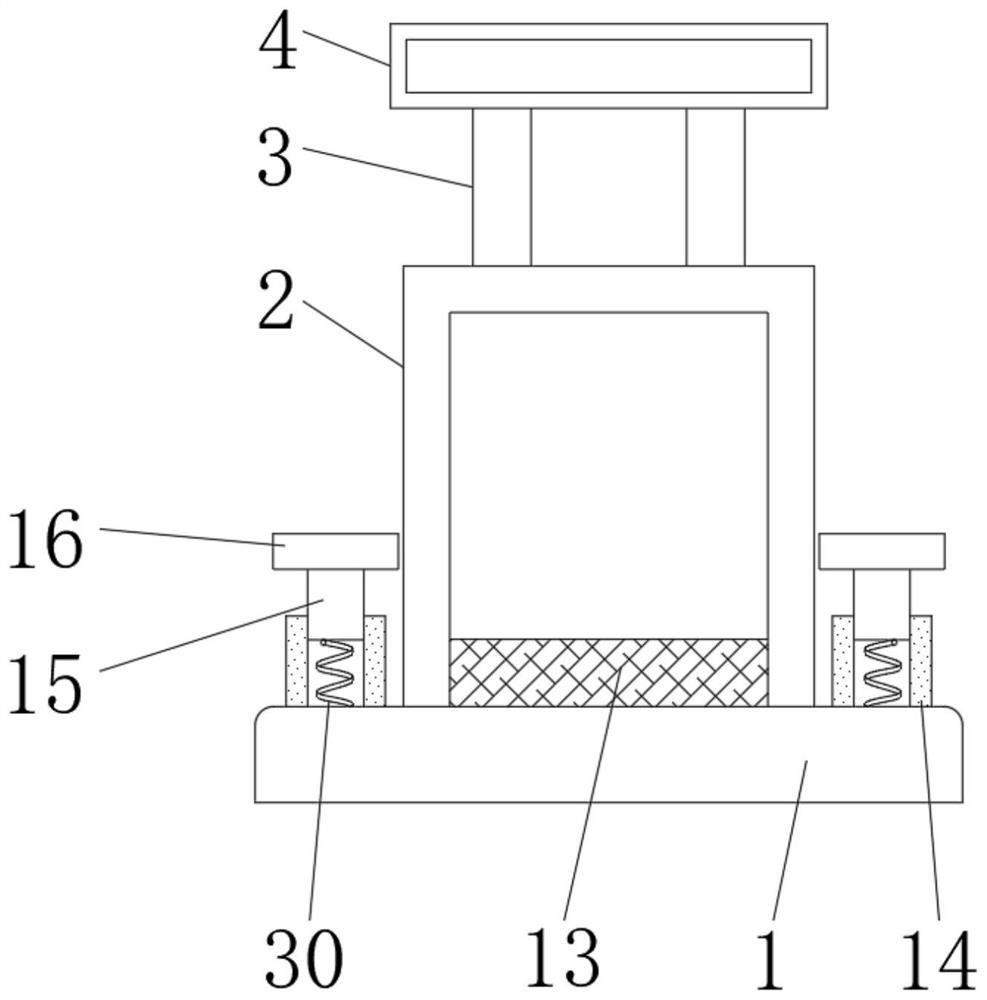

Finger joint movement device for electronic athletics to depressurize pre-racing activities

InactiveCN112842812AExercise flexibilityTo achieve the warm-up effectGymnastic exercisingChiropractic devicesLong fingersFinger joint

The invention discloses a finger joint movement device for electronic athletics to depressurize pre-racing activities, and relates to the technical field of finger joint movement instruments. The finger joint movement device comprises a bottom plate, a first U-shaped plate, two cylinders and a placement pad are fixedly connected to the upper surface of the bottom plate, and two supporting rods are fixedly connected to the upper surface of the first U-shaped plate; and the top ends of the two supporting rods are fixedly connected with the lower surface of the hollow plate. According to the finger joint movement device for electronic athletics to depressurize pre-racing activities, four long fingers are put into four elastic fingerstalls one by one, then the fingers of a player press the elastic fingerstalls downwards with force, and then the fingers of the player are subjected to certain tension under the action of a first spring and a natural latex tube; furthermore, the player can flexibly exercise the fingers, blood circulation of the finger parts is promoted, the effect of preheating the finger joints is achieved, the flexibility of the finger joints of the player is guaranteed, and normal playing of the player during a game is guaranteed.

Owner:SHANDONG SPORT UNIV

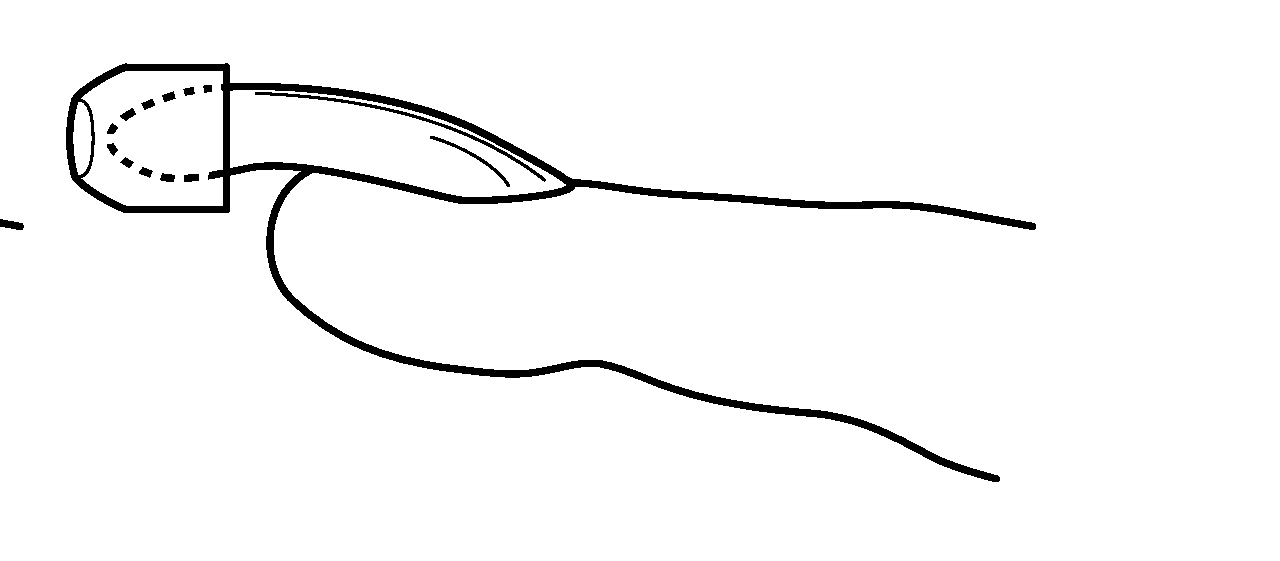

Typing-mate

A finger nail tip cover which acts as a typing aid for users when typing with long finger nails. It is made of rubber material and has one hard end, to prevent the nail tip from passing thru when typing and a semi-oval stretchy cavity at the other end where the finger nail tip is placed in.

Owner:FELICIANO YENNIFER

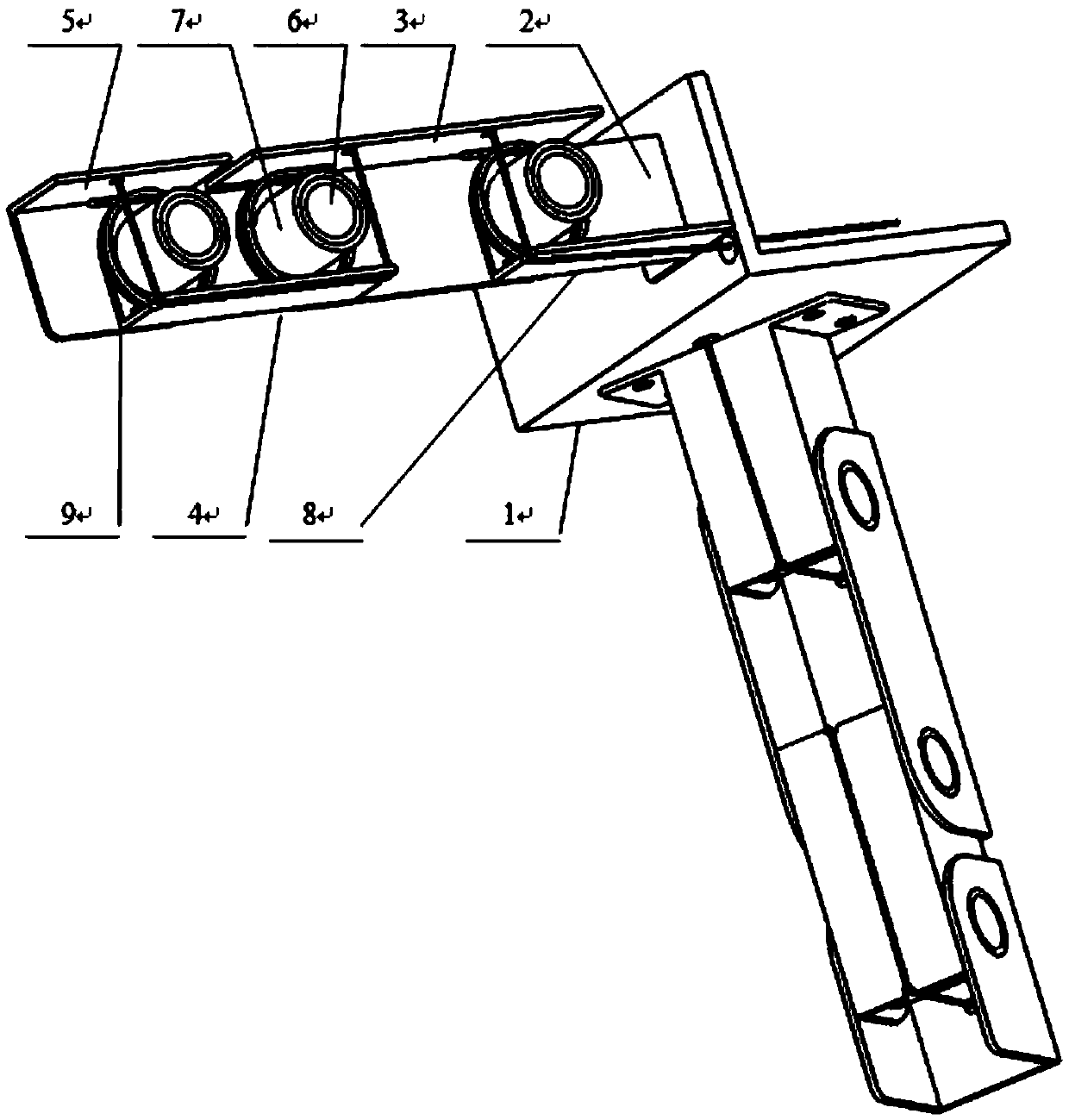

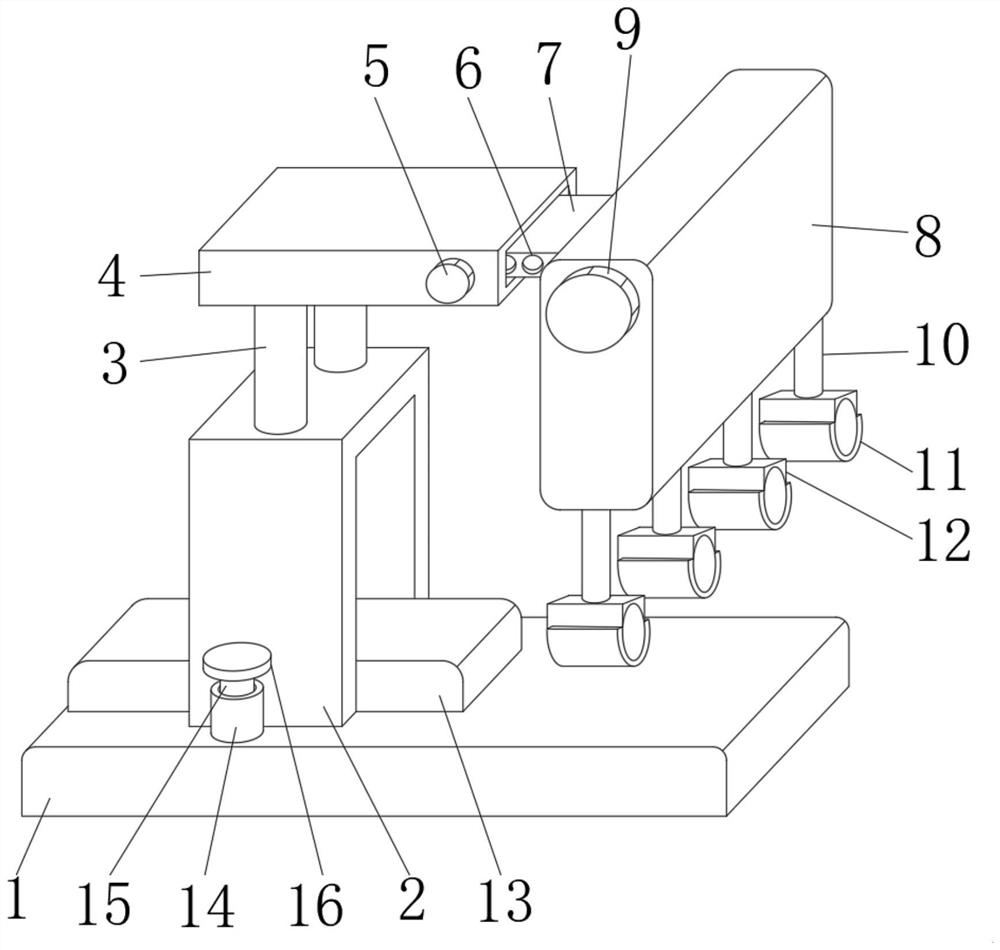

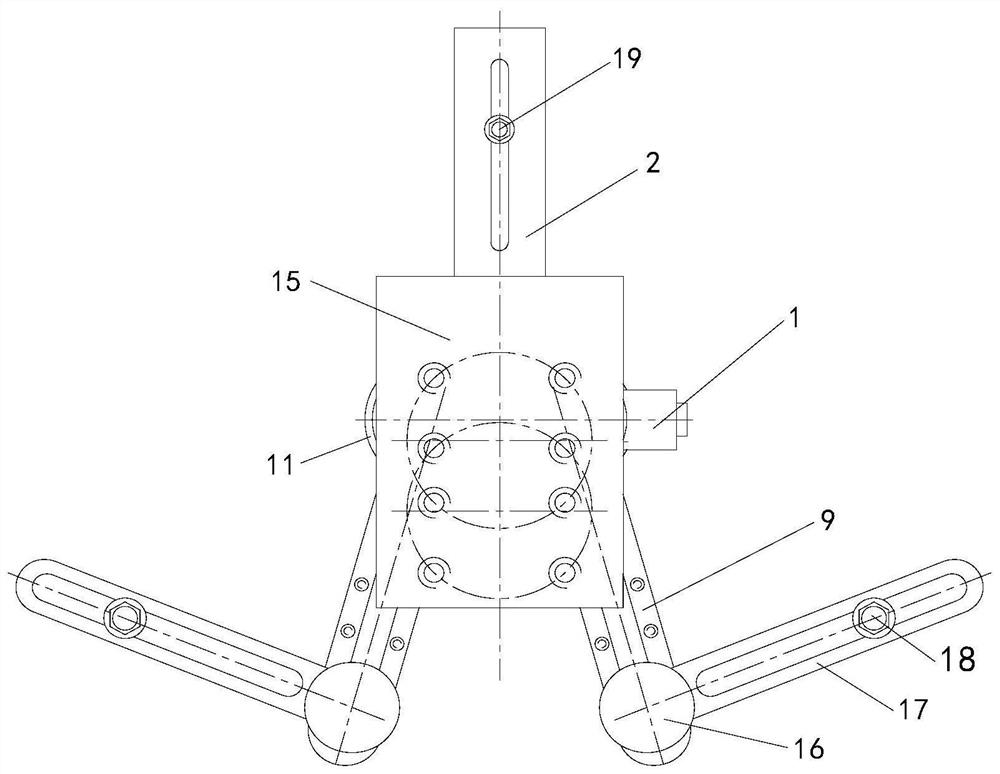

Three-finger smart end-effector for palm of three-motor-driven serial mechanism

ActiveCN112318536AGood synergyEasy to determine path planningGripping headsLong fingersReduction drive

The invention relates to the technical field of robots and automation, in particular to a three-finger smart end-effector for a palm of a three-motor-driven serial mechanism. A motor worm speed reducer drives a threaded head drive shaft to rotate; a drive gear on the threaded head drive shaft and a bevel hole gear on a threaded head driven shaft are engaged, are equal in rotation speed and are reverse in rotation directions; open slot rods I are separately and perpendicularly fixed at the outer end of the threaded head drive shaft and the threaded head driven shaft; a motor planetary wheel speed reducer is mounted at the other end of each open slot rod I; the output shafts of the motor planetary wheel speed reducers, the threaded head drive shaft and the threaded head driven shaft are parallel to each other; a long finger base is fixedly arranged on the bottom plate; short finger bases and long finger bases are separately mounted on the two open slot rods I or the two open slot rods I;and right-angled plate fingers are arranged on the two short finger bases. The three-finger smart end-effector is easy in determining a final grabbing posture and path planning of obstacle avoiding motion in a finger grabbing process, and is suitable for grabbing objects of different shapes and dimensions.

Owner:JIANGNAN UNIV

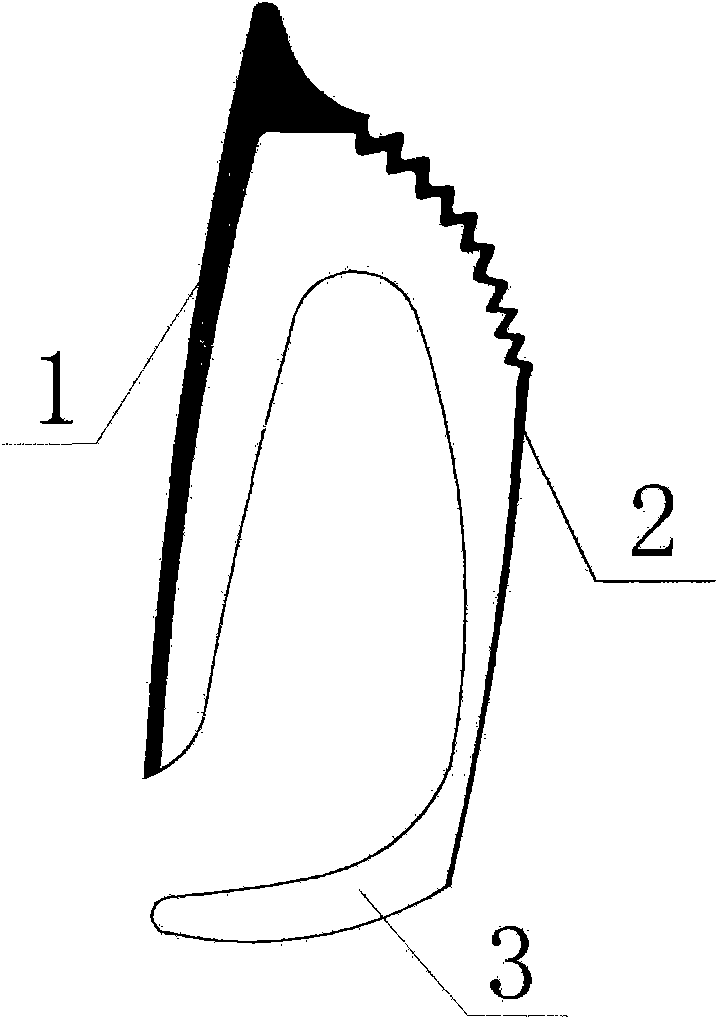

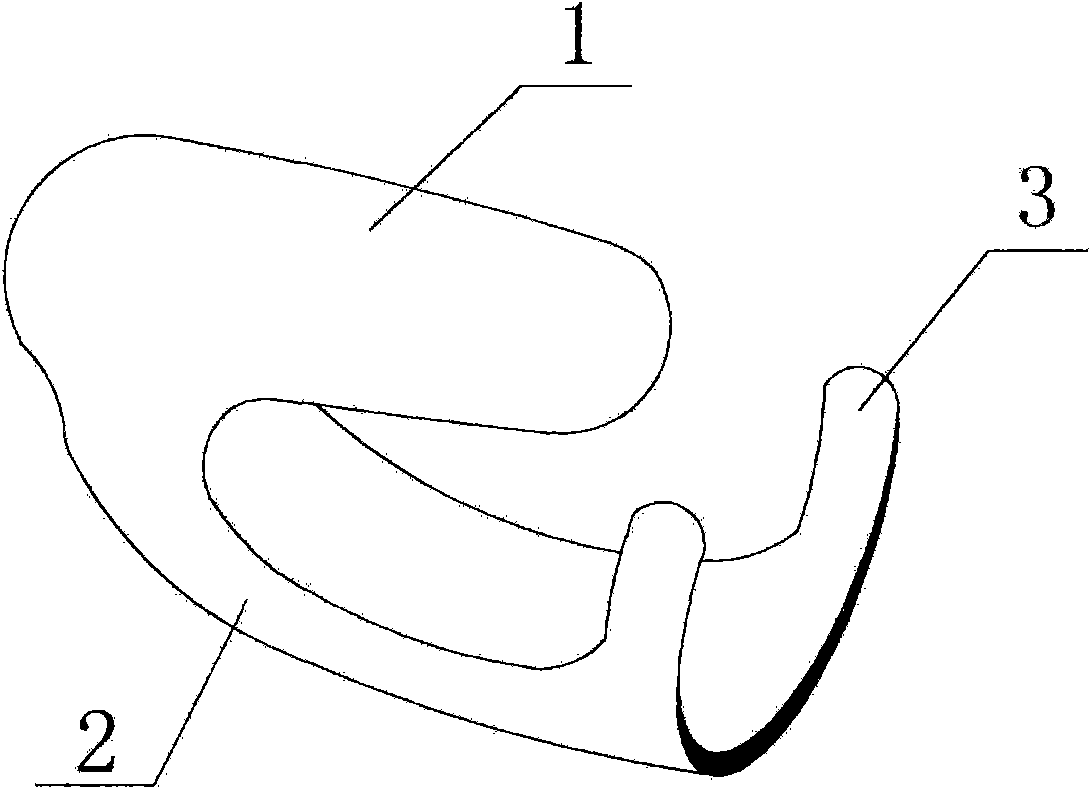

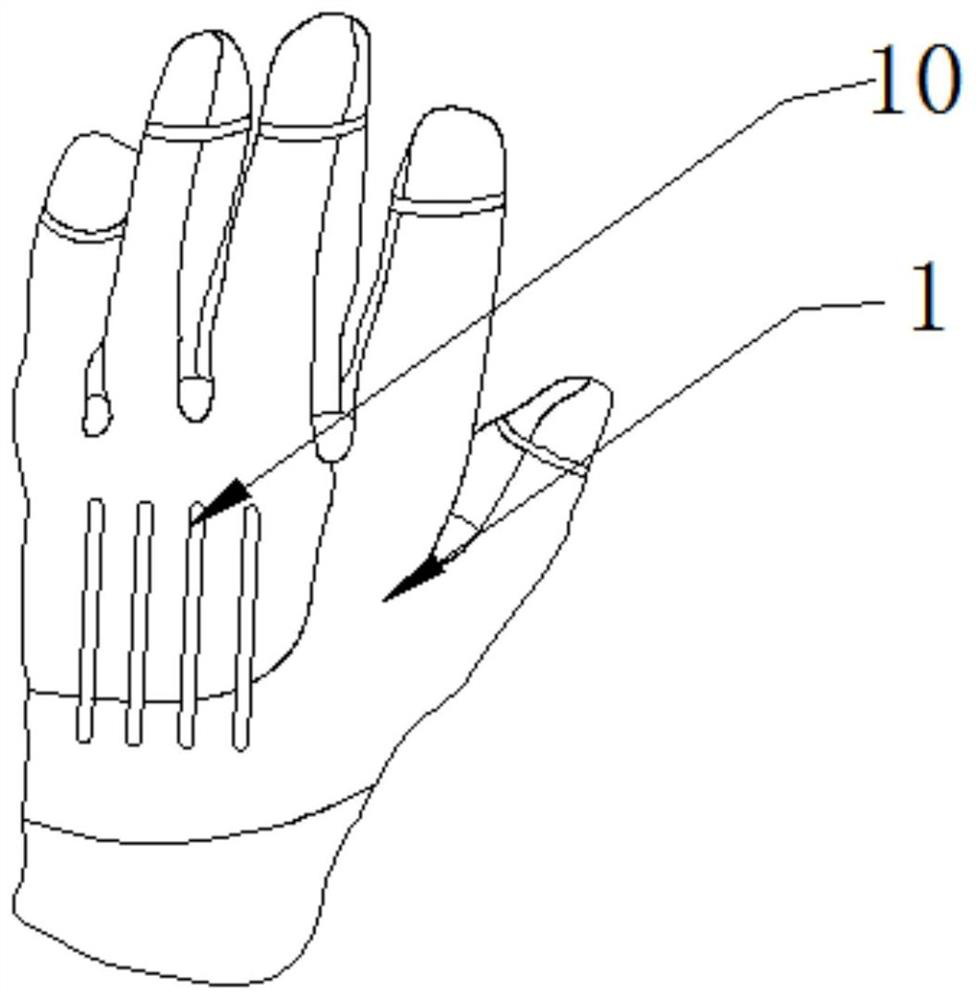

Finger stall with artificial nail

The invention discloses a finger stall with an artificial nail, which consists of an artificial nail 1, a finger pulp 2 and a finger pulp wing 3. The artificial nail 1 is connected with the finger pulp 2 in the fingertip. The root of the finger pulp 2 is provided with the thickened finger pulp wing 3 which is open along finger back direction. The long finger-shaped tool 1 is thickened gradually from the root to the fingertip direction and protrudes above 1mm at the tail end of the fingertip to form a circular fingernail tip. The finger pulp 2 is thickened gradually from the root to the fingertip direction and provided with antiskid veins. The finger stall with the long finger-shaped tool is suitable for fingers in different thicknesses by means of the adjusting capacity of the finger pulp wing. Fingers are flexible with the finger stall with the long finger-shaped tool and the finger stall with the long finger-shaped tool is suitable for work places such as hair washing, sorting, pick-up, massage and the like and convenient to wear or take off.

Owner:李耀强

A three-finger dexterous end effector in the palm of a three-motor-driven tandem mechanism

ActiveCN112318536BGood synergyEasy to determine path planningGripping headsReduction driveGear wheel

The invention relates to the technical field of robots and automation, in particular to a three-finger dexterous end effector driven by a three-motor series mechanism palm, wherein the motor worm gear reducer drives the drive shaft of the screw head to rotate, and the driving gear and the screw head on the drive shaft of the screw head The tapered hole gears on the driven shaft are meshed with the same speed and opposite direction. The outer ends of the threaded head drive shaft and the threaded head driven shaft are respectively vertically fixed with a slotted rod, and the other end of each slotted rod is respectively installed with a motor planet. Wheel reducer, the output shaft of the motor planetary gear reducer, the drive shaft of the threaded head, and the driven shaft of the threaded head are parallel to each other, and the long finger seat is fixed on the bottom plate, and installed on two slotted two rods or two slotted one rods respectively The short finger seat, the long finger seat, and the two short finger seats are all equipped with right-angle plate fingers. This application is easy to determine the final grasping pose and the path planning of the obstacle avoidance movement of the finger grasping process. It is suitable for grasping different shapes and sizes objects.

Owner:JIANGNAN UNIV

Spatial reconfigurable truss type arresting mechanism and its arresting method

The invention provides a spatially reconfigurable truss-type capture mechanism and a capture method thereof. The capture mechanism includes a base and two reconfigurable truss-type capture fingers, and each reconfigurable truss-type capture finger has Consists of a butt plug truss unit, a dock interface truss unit, several modular expandable truss units and a number of linear drives, one butt plug truss unit for each reconfigurable truss-type grabbing finger, several modular expandable truss units and A docking interface truss unit is connected in sequence, and a linear drive device is connected between two adjacent truss units of each reconfigurable truss type grabbing finger. The present invention can realize the docking or separation between the grasping finger and the base, and the docking and separation between the two fingers. According to the different requirements of the grasping task, the two fingers can be selected to cooperate to capture or the two fingers can be docked to form an extended finger. Complete capture; docking extension, simple structure, light weight, large capture space, good adaptability to capture objects.

Owner:HARBIN INST OF TECH

High-temperature flexible manipulator

PendingCN112140139AReduce temperature riseReduce the temperatureGripping headsLong fingersCooling effect

The invention discloses a high-temperature flexible manipulator which comprises two fingers. The two fingers are driven by a finger clamping cylinder and arranged oppositely, and a plurality of air blowing holes are formed in the fingers and communicate with a metal air pipe connector through an internal air channel. Preferably, at least two rows of the air blowing holes are distributed in the width direction of the fingers, and each row comprises at least two air blowing holes. The internal air channel is formed by drilling through a slender drill bit, the end parts where the fingers are dilled through are blocked through plugs, and the air blowing holes are in a horn shape. The high-temperature flexible manipulator has the beneficial effects that heat is taken away or blown away by usingair flowing, finger temperature rise is delayed, the cooling effect is enhanced, and the service life of the fingers is prolonged.

Owner:CHONGQING TENGHONG MACHINE

Puncture-proof medical rubber glove

PendingCN113331511AAvoid punctureMaintain stabilityGlovesSynthetic resin layered productsFiberLong fingers

The invention discloses a puncture-proof medical rubber glove. The puncture-proof medical rubber glove comprises a rubber glove body, a glove palm back and a glove palm center, wherein the rubber glove body is provided with the glove palm back and the glove palm center; a first rubber layer is arranged in the glove body; a fiber layer is arranged on the portion, close to the first rubber layer, of the glove body; and a second rubber layer is arranged on the fiber layer in the glove body. According to the invention, a wear-resistant layer is arranged in the fiber layer at the top of a long finger belt, a cut-resistant layer facing the glove palm center is arranged on the long finger belt, a wear-resistant plate is arranged on the long finger belt and close to the glove palm back, and the wear-resistant layer, the cut-resistant layer and the wear-resistant plate can protect key parts of fingers from being punctured; and the part, close to the long finger belt, of the glove palm back, is provided with protruding points, the first rubber layer is arranged in the glove palm center and the glove palm back, the fiber layer is arranged at the position, close to the first rubber layer, of the glove palm center and the glove palm back, the glove palm back is provided with a protective layer on the fiber layer, the second rubber layer is arranged on the inner side of the fiber layer , and the first rubber layer , the fiber layer and the second rubber layer prevent the glove palm center and the glove palm back from being punctured.

Owner:会同县龙凤皮制品有限责任公司

A prosthetic hand perception mechanism and system supporting cloud fusion

The invention relates to a prosthetic hand sensing mechanism and system supporting cloud fusion, belonging to the technical field of biomimetic prosthetic hands. The prosthetic hand sensing mechanismcomprises a long finger part, a thumb part, four connecting blocks, a palm part and a printed circuit board. The long finger comprises four long finger mechanisms, namely, an index finger mechanism, amiddle finger mechanism, a ring finger mechanism and a pinky finger mechanism. Each long finger mechanism comprises a proximal knuckle and a middle finger, a distal phalangeal joint, a first metacarpophalangeal joint seat, and a first connector; and the thumb portion includes a proximal phalangeal segment, a distal phalangeal segment, a second metacarpophalangeal joint seat, and a second connector. The thumb portion includes a proximal phalangeal segment, a distal phalangeal segment, and a second metacarpophalangeal joint seat. Each proximal finger of the long finger mechanism is articulatedwith a connecting block; the palm part comprises a housing, a rotating driving mechanism installed in the housing and four linear driving mechanisms; and a main control module, a driving module and adata communication module are integrated on the print circuit board. The prosthetic hand sensing mechanism can make corresponding gestures according to the recognition results of the gestures recognized by the upper computer on the cloud end.

Owner:SOUTHEAST UNIV

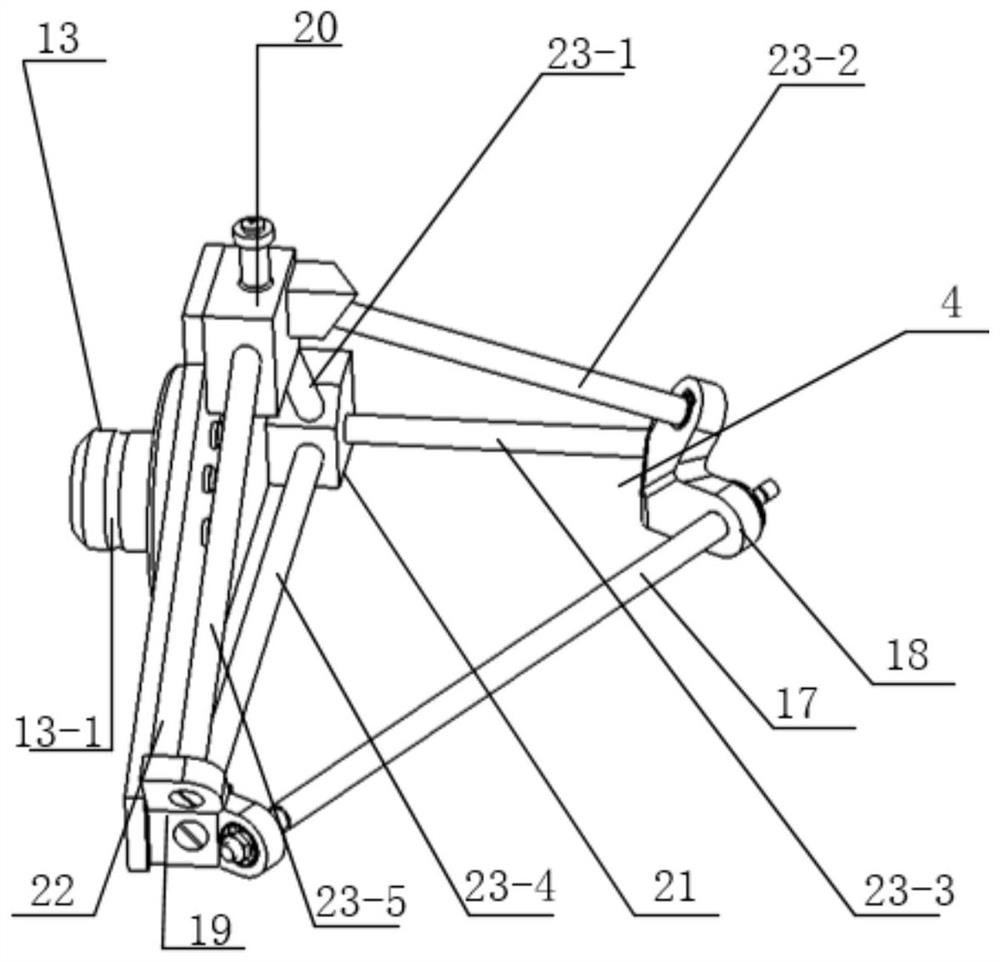

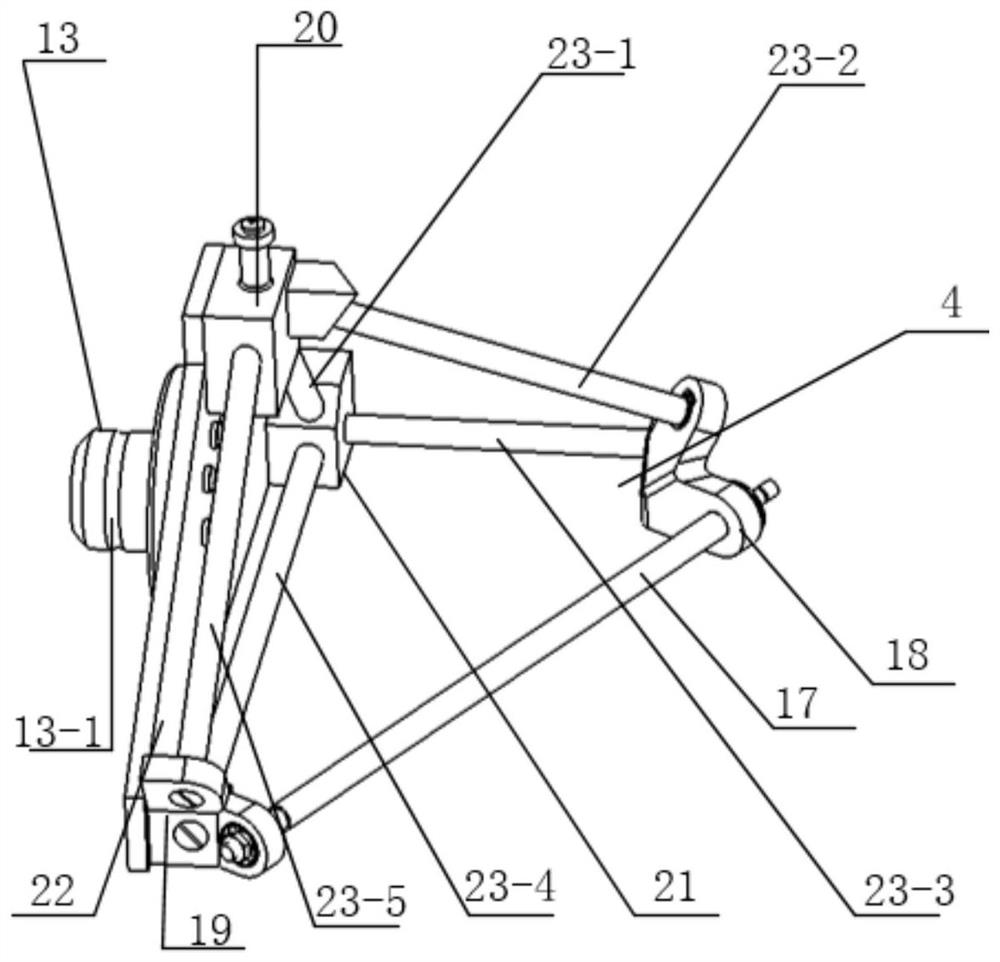

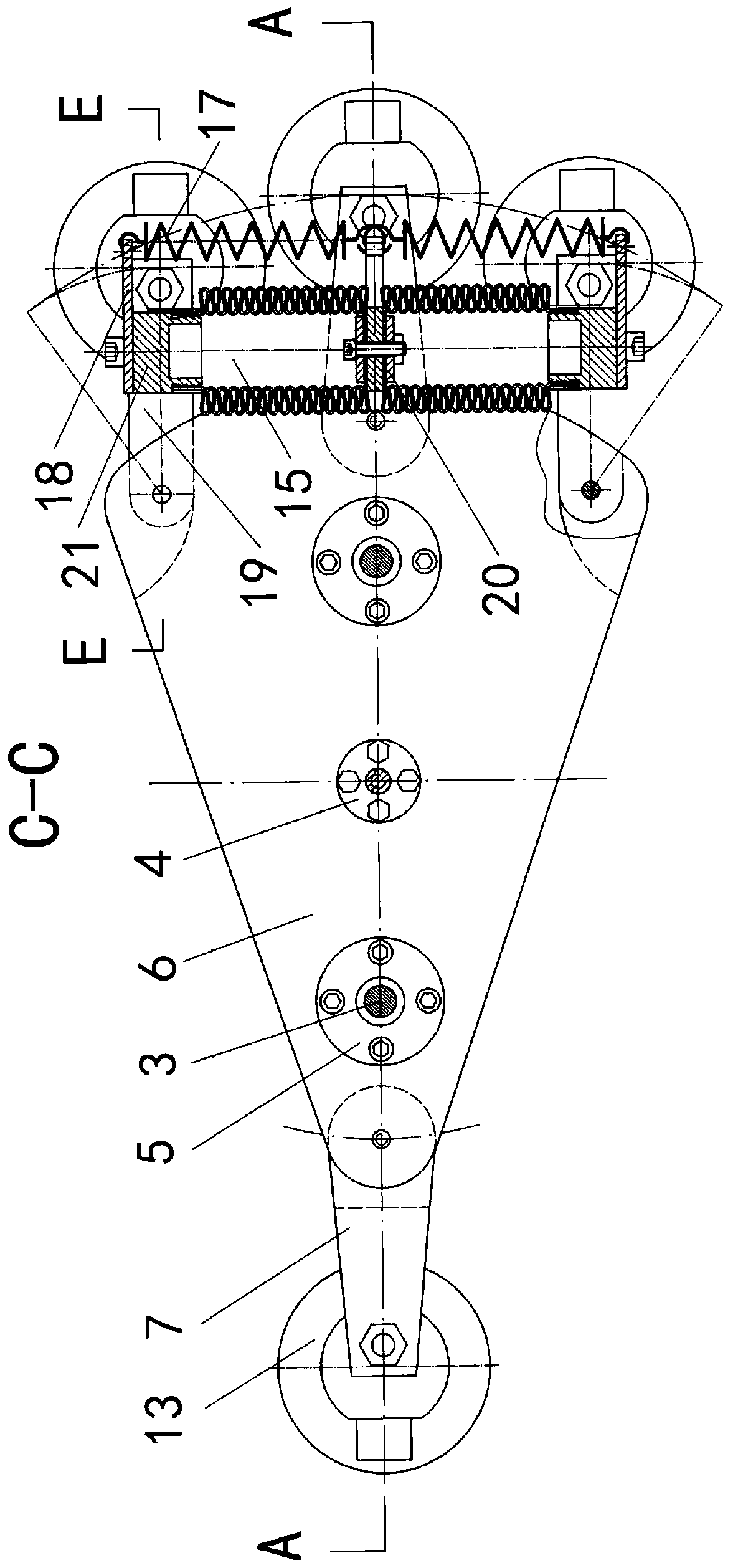

An electric-pneumatic composite drive flexible finger-like eagle claw logistics packaging manipulator

ActiveCN108436952BAchieve regulationPrecise and reliable grippingProgramme-controlled manipulatorGripping headsElectricityLong fingers

A claw-like logistics packaging mechanical arm with electric-gas hybrid drive flexible fingers, composed of a drive component and four identical finger components, and comprising a screw shaft motor (1), an upper base plate (2), a guide connecting rod (3), a screw nut seat (4), a linear bearing (5), a drive plate (6), a push plate (7), a push rod (8), a fixed finger base (9), a connecting rod (10), a bottom base plate (12), a short finger (13), a long finger (14), a single-head corrugated muscle (15), a ridged push plate (16), a pull spring (17), a small support base (18), a rotating drive plate (19), a round pressure plate (20), a seal head (21), a bushing (22), a rotating finger base (23), and a small belt seat bearing (24), the finger component being composed of a finger root section (13a), a finger middle section (13i), and a fingertip section (13k). The present packaging mechanical arm can select the action point of the contact force and the direction of the force according to the situation, such that no deformation or damage to the object is caused by the gripping process, and gripping is more precise and reliable. In addition, the angle between the finger root section and the object to be gripped can be adjusted to adapt to increases in size of the gripped objects and to adapt to changes to the shape and the vertical and horizontal placement of the gripped objects; the action point and magnitude of the gripping are flexible and adaptable, reactions are agile, and cushioning performance is good.

Owner:JIANGNAN UNIV

Winter sports outdoor sports glove

PendingCN113940470AImprove comfortEasy to storeConvertible garmentGlovesLong fingersStructural engineering

The invention discloses a winter sports outdoor sports glove, and relates to the technical field of gloves; thewinter sports outdoor sports glove comprises a right glove and a built-in pocket, the right glove is internally provided with a first hook-and-loop fastener, the lower end of the right glove is externally provided with a connecting belt, the tail end of the connecting belt is externally provided with a limiting buckle, and the limiting buckle is externally provided with a through hole. According to the winter sports outdoor sports glove, the length of the finger area of the glove can be flexibly adjusted according to the length of the fingers of a user, the finger bag and the upper layer can be connected through upward pulling, so that wrinkles reserved between the elastic layers connected with the upper layer can be stretched, and the user with long fingers can conveniently use the glove; and when the glove is used by a user with short fingers, the design of magnetic connection between the upper placement layer and the lower placement layer can be utilized, so that the upper placement layer is pressed downwards, the elastic layer connected with the upper placement layer can contract, the length of the finger area of the glove can be adjusted, and the use limitation is reduced.

Owner:HARBIN INST OF PHYSICAL EDUCATION

Internet-of-things-based comfortable intelligent wearable equipment with good ventilation effect

ActiveCN108491080AImprove practicalityWith charging functionInput/output for user-computer interactionGlovesLong fingersThe Internet

The invention relates to an Internet-of-things-based comfortable intelligent wearable equipment with a good ventilation effect. The equipment includes a palm sleeve, a wrist sleeve, a thumb sleeve andfour long-finger sleeves. The thumb sleeve is disposed on one side of the palm sleeve. The four long-finger sleeves are evenly disposed over the palm sleeve. The wrist sleeve is disposed below the palm sleeve. The wrist sleeve, the thumb sleeve and the long-finger sleeves are all in communication with the palm sleeve. A fastening mechanism is disposed on the wrist sleeve. A ventilation mechanismis disposed on the palm sleeve. The fastening mechanism includes a fastening component and four power generating components. According to the Internet-of-things-based comfortable intelligent wearableequipment with the good ventilation effect, tightening and relaxing functions of the wrist sleeve are realized through the fastening mechanism, comfort of user wearing is improved, in addition, functions of dehumidification and ventilation are also realized through the ventilation mechanism, and hand discomfort caused by being in a humid stuffiness environment for a long time can be avoided.

Owner:素泰智能科技(上海)有限公司

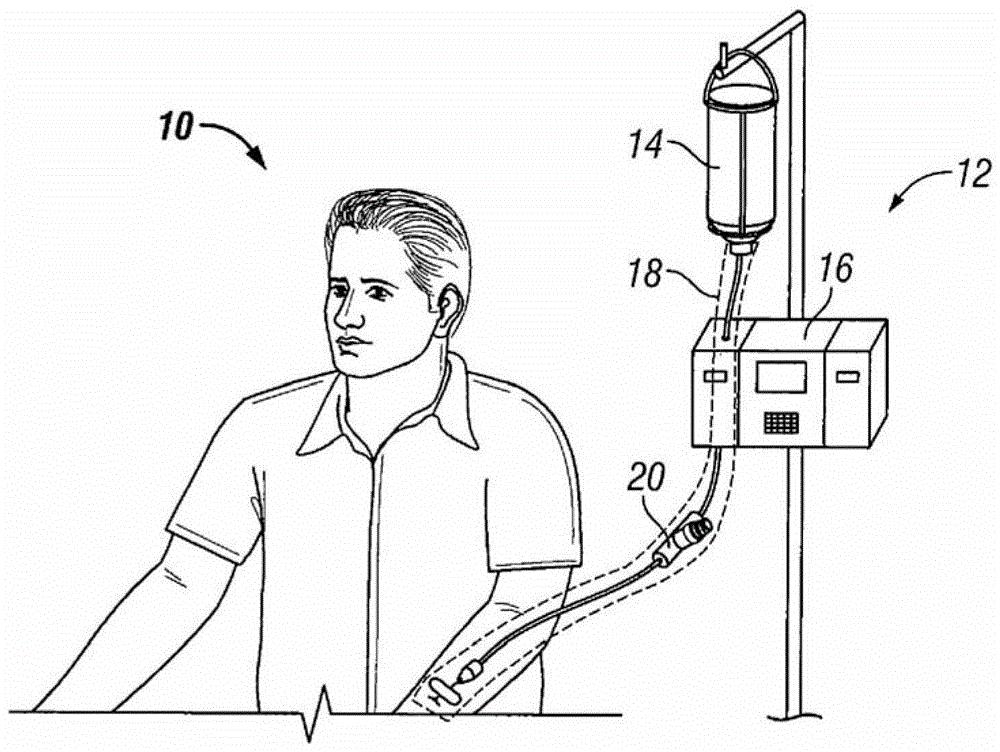

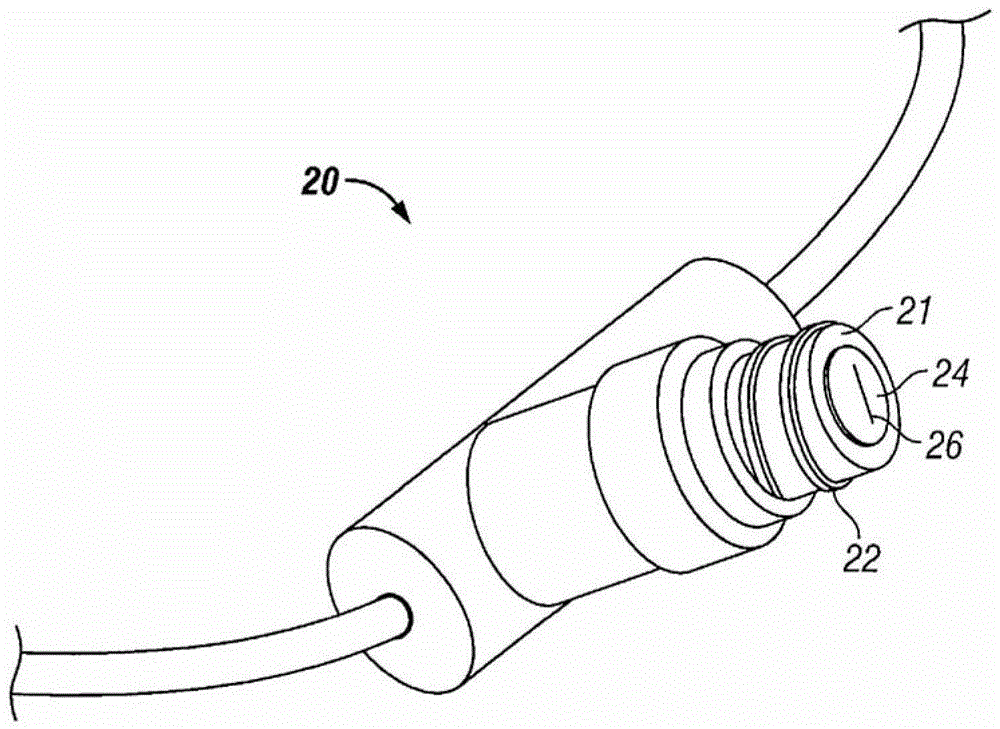

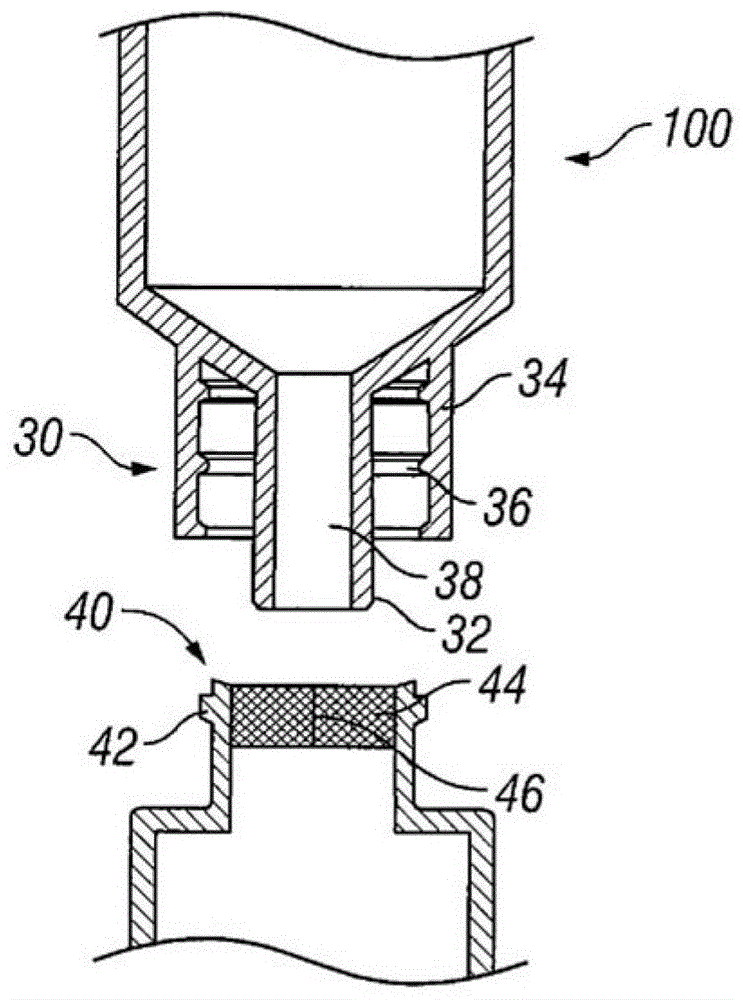

pinless connector

A sterilizing and pre-opening device for use with a female needleless connector is disclosed. The sterilization and pre-opening device includes a housing including a chamber having a distal opening and configured to fit over a female needleless connector, and a long finger attached to the housing on and configured in the chamber such that when the distal opening of the sterilizing and pre-opening device is arranged in close proximity to the septum and the sterilizing and pre-opening device is advanced in the distal direction, the long finger opens through the female needleless connection the fluid path of the device.

Owner:CAREFUSION 303 INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com