Mechanical and automatic feeding and discharging mechanical device

A technology of mechanical devices and servo motors, which is applied to machine tools, grinders, and metal processing equipment designed for grinding the rotating surface of workpieces. It can solve the problem of difficulty in ensuring the consistency of processed workpieces, the harsh working environment of production personnel, and the difficulty in ensuring product consistency. and other problems, to achieve the effect of convenient wireless remote control operation, saving manpower, and moderate equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

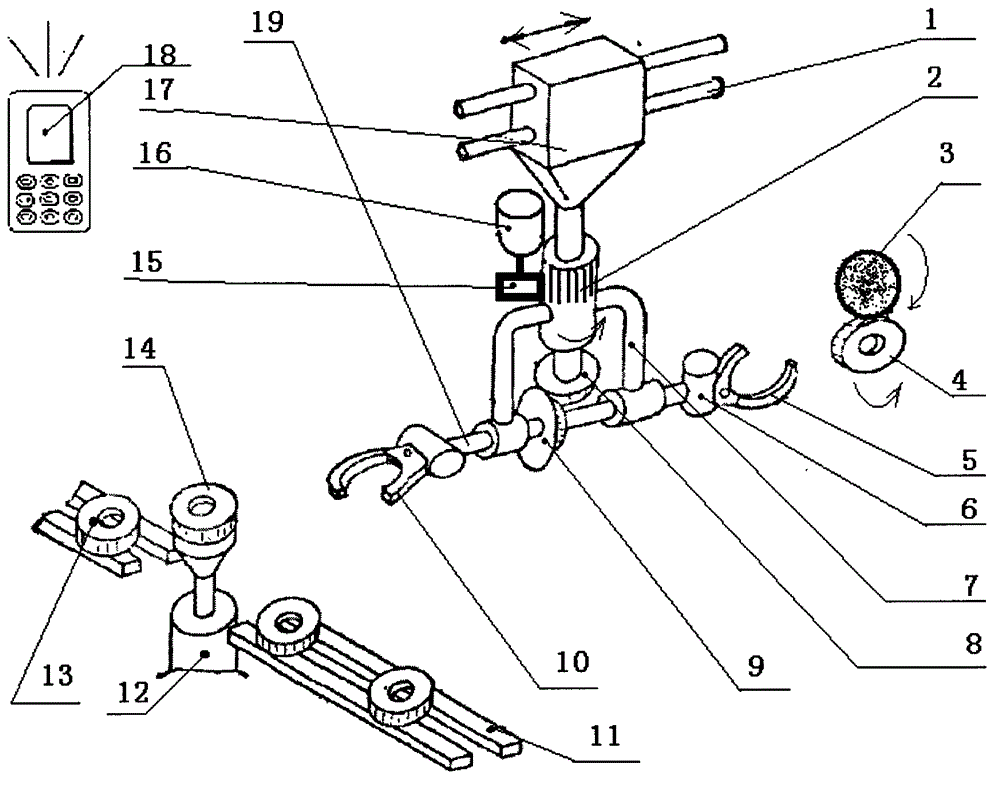

[0023] Such as figure 1 As shown, when the mechanical parts need to grind the outer circle, the parts 14 waiting to be ground can be placed on the conveying line 11, and the transmission device can transfer the parts 14 waiting to be ground to the lifting cylinder 12, and the lifting The oil cylinder 12 has an automatic lifting function. The upper surface of the lifting oil cylinder 12 is provided with a photoelectric sensor. Once the parts 14 waiting for grinding are placed on the upper surface of the lifting oil cylinder 12, the lifting oil cylinder 12 will automatically lift. Once the parts 14 waiting for grinding Taken away by manipulator, lifting oil cylinder 12 descends automatically. Because the moving large slider 17 is controlled by the programmable controller, the moving large sliding block 17 can automatically slide to the left after completing the last working cycle, and at the same time, the servo motor 16 drives the pinion 15 to rotate, and the pinion 15 drives t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com