Patents

Literature

142results about How to "Fast loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

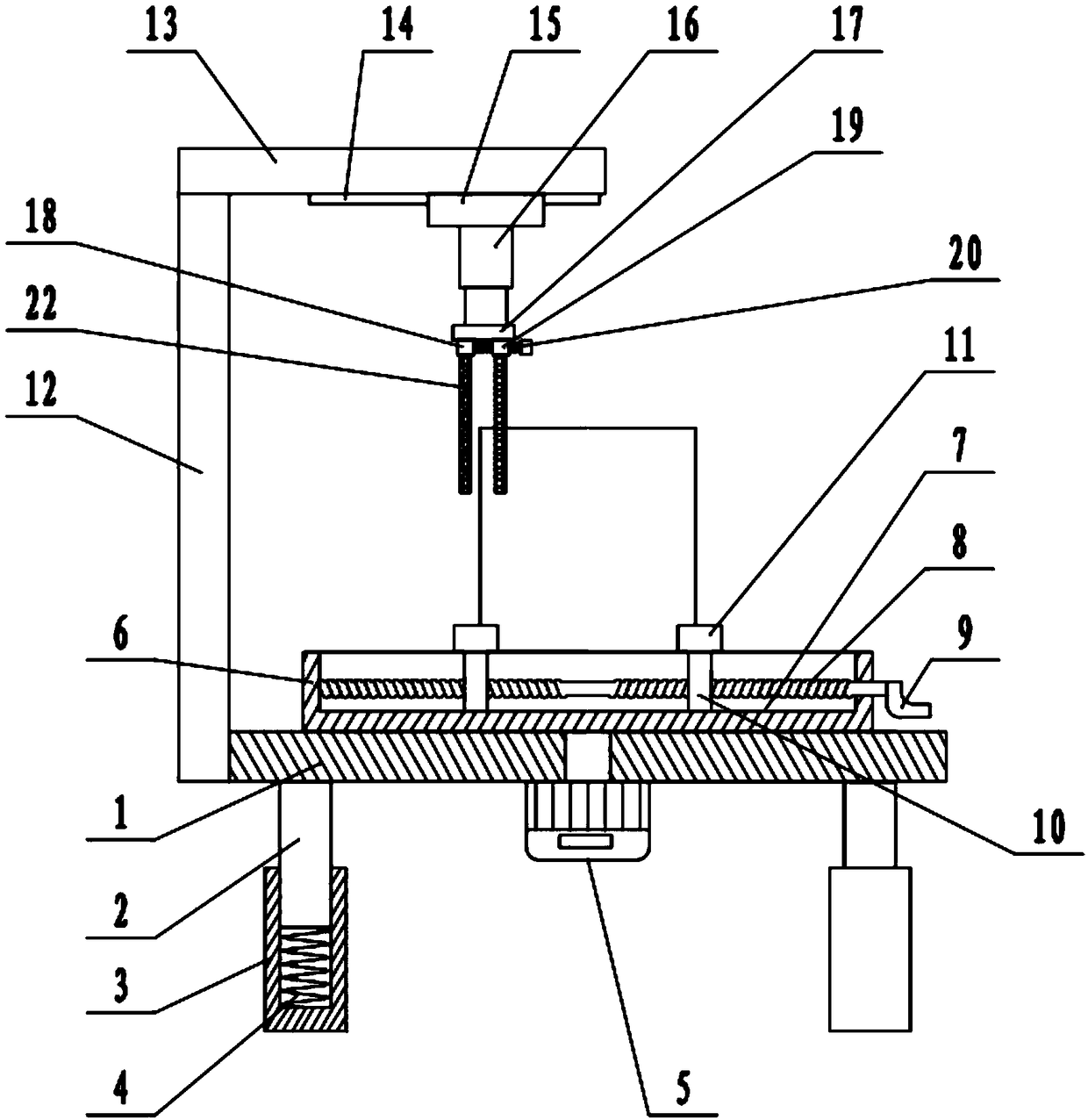

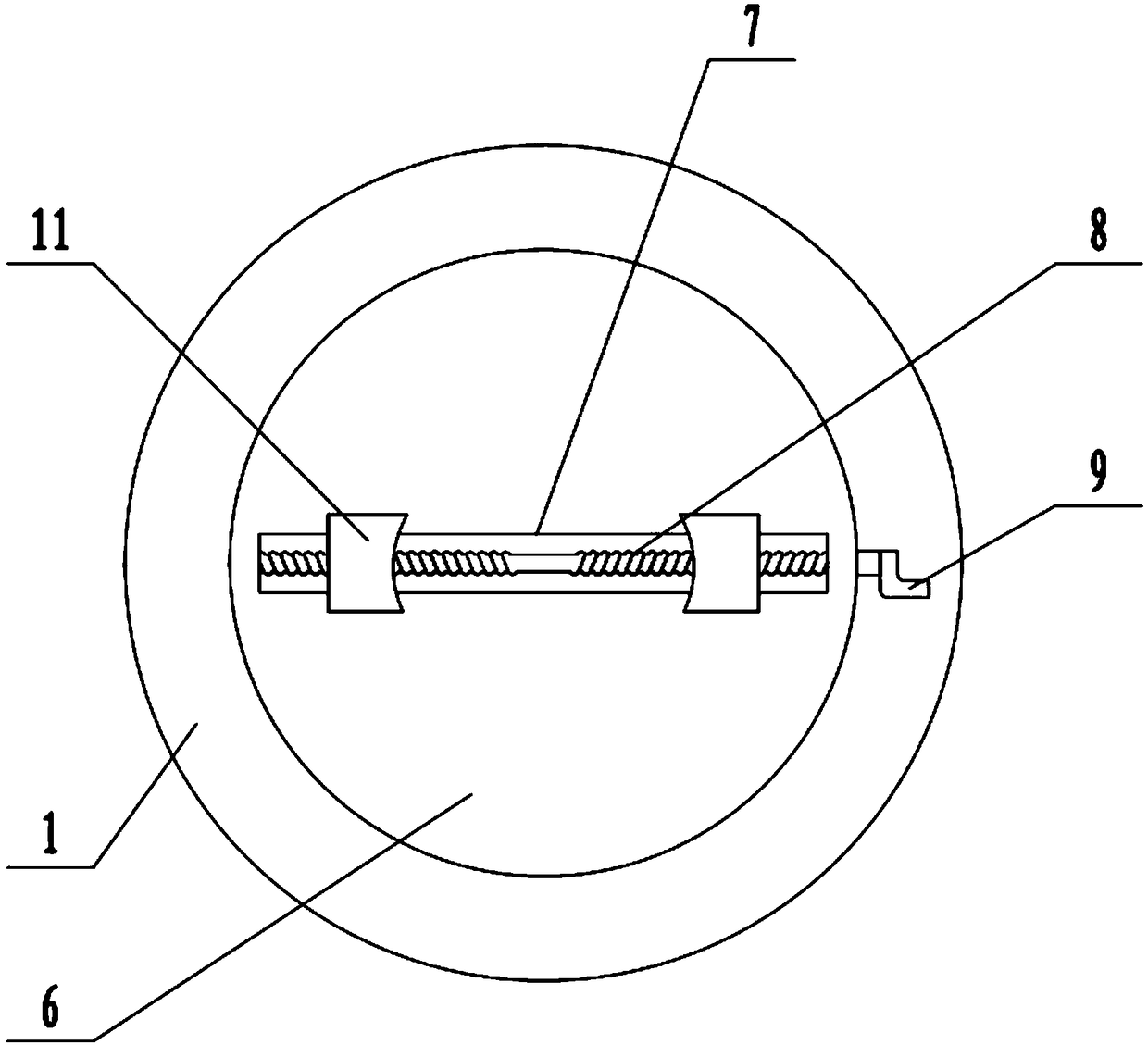

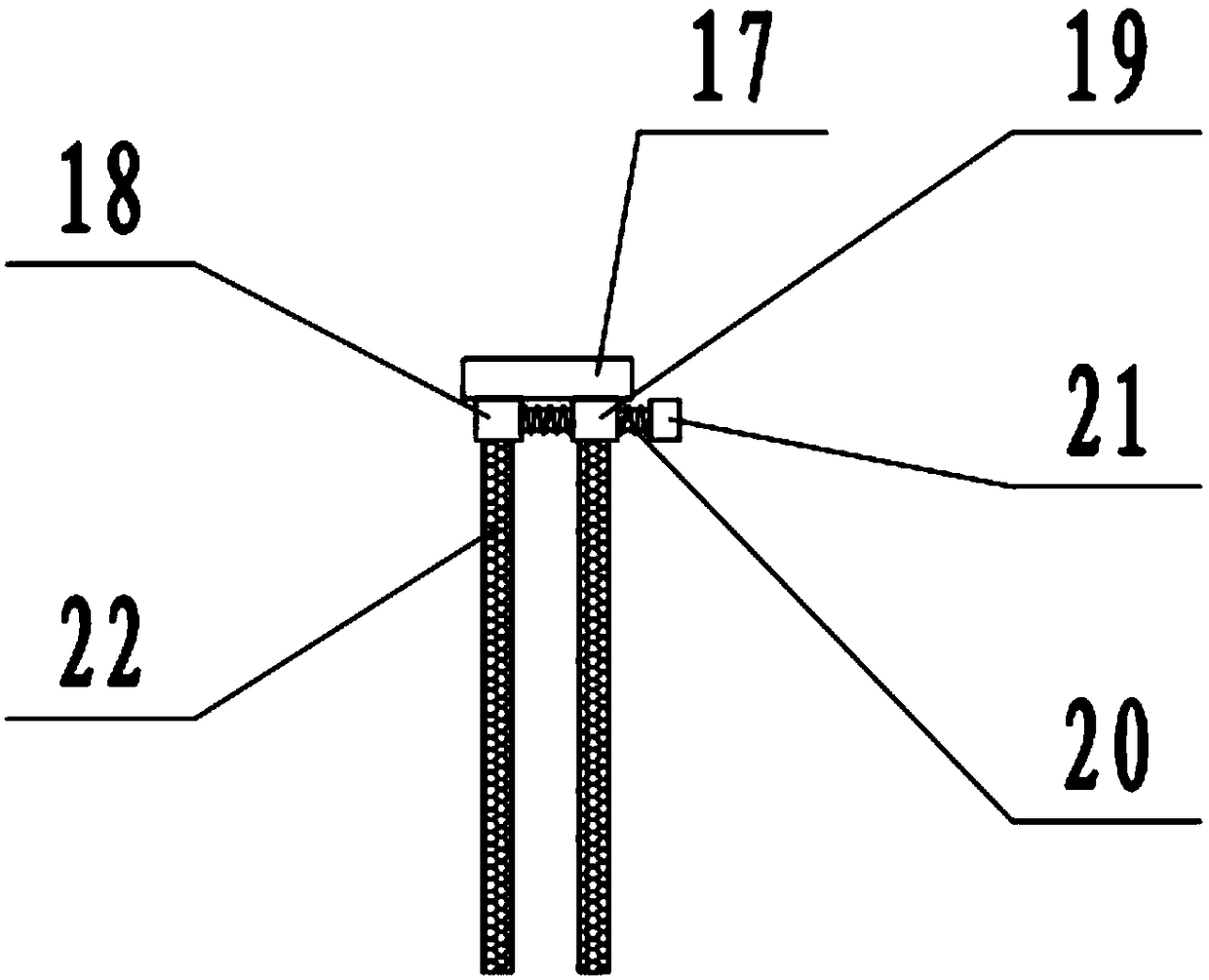

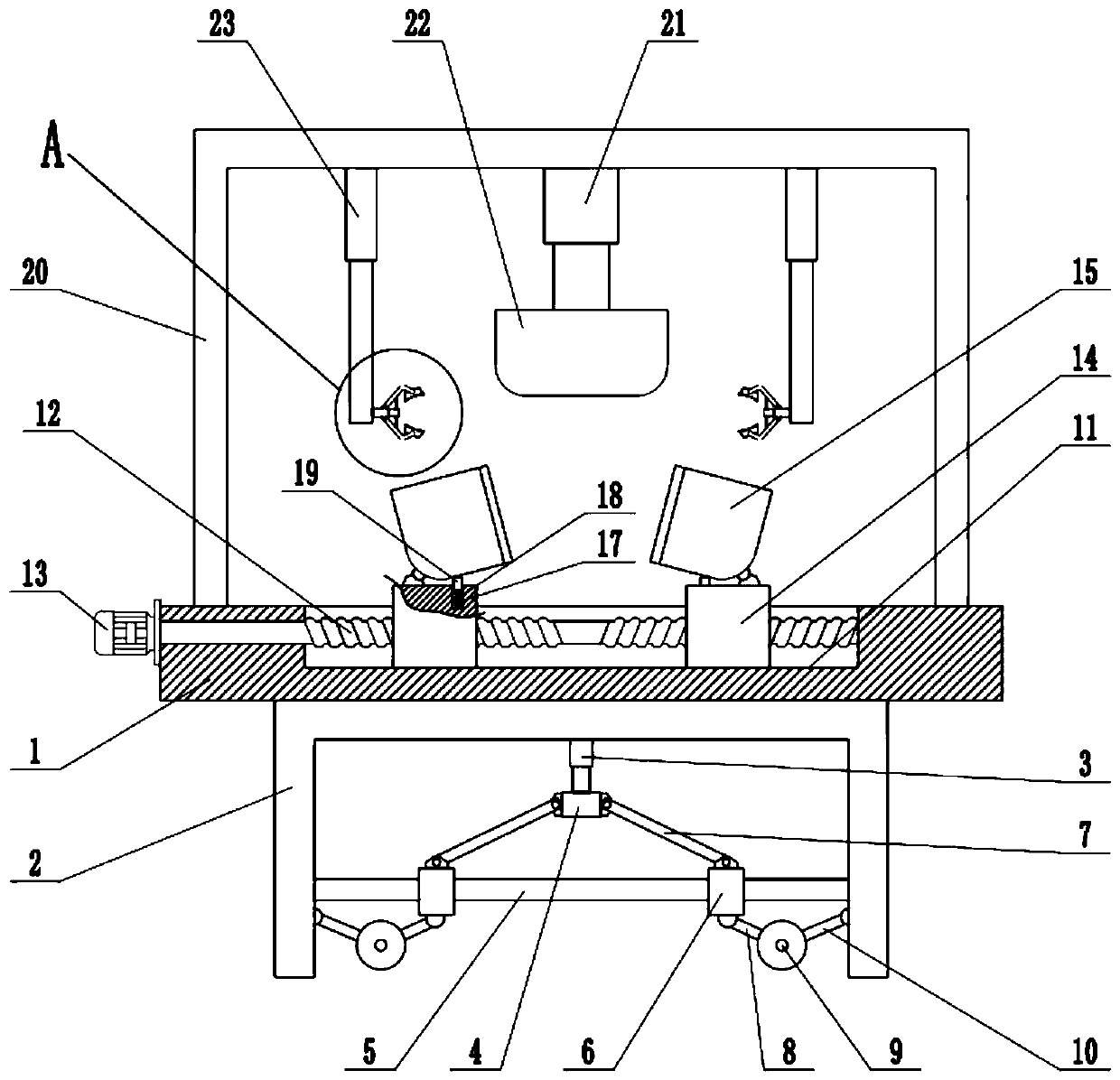

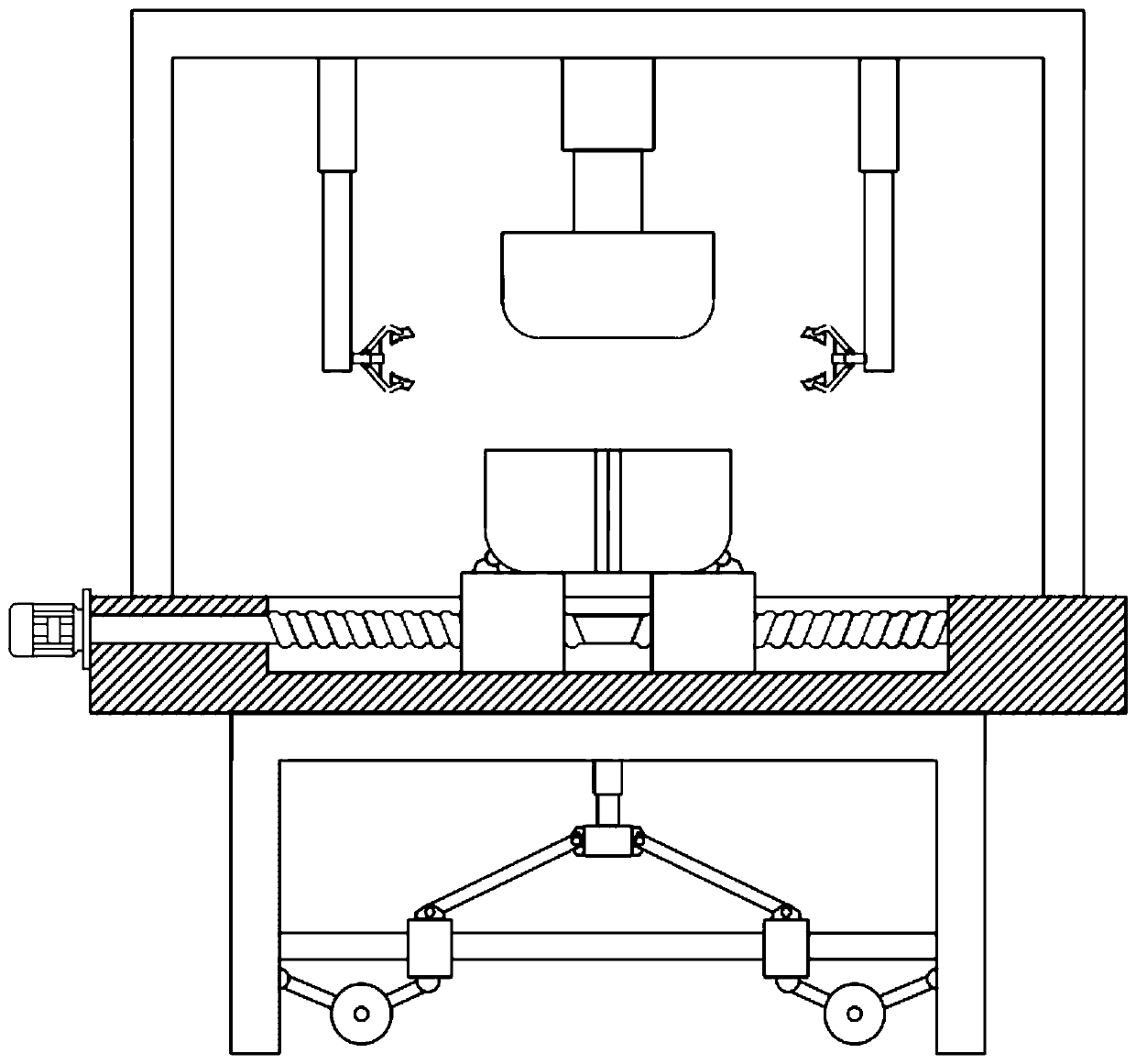

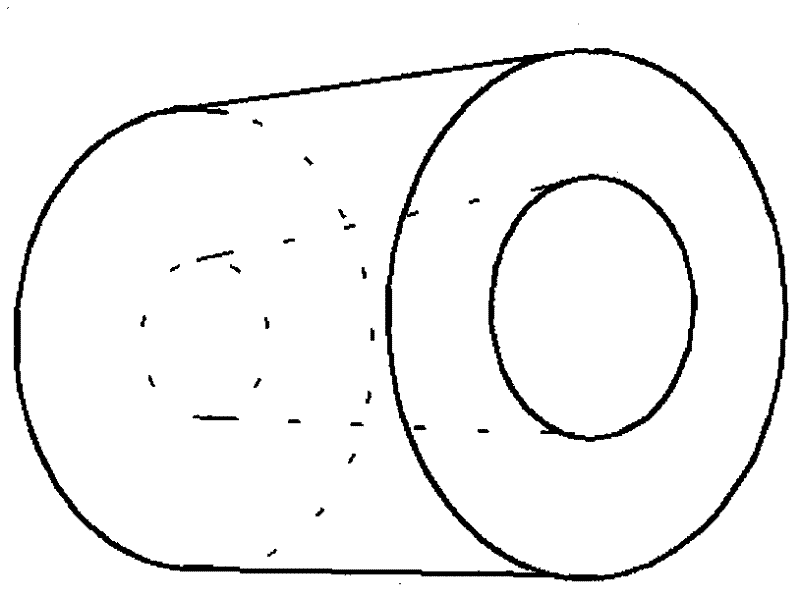

Rotary steel-pipe grinding device

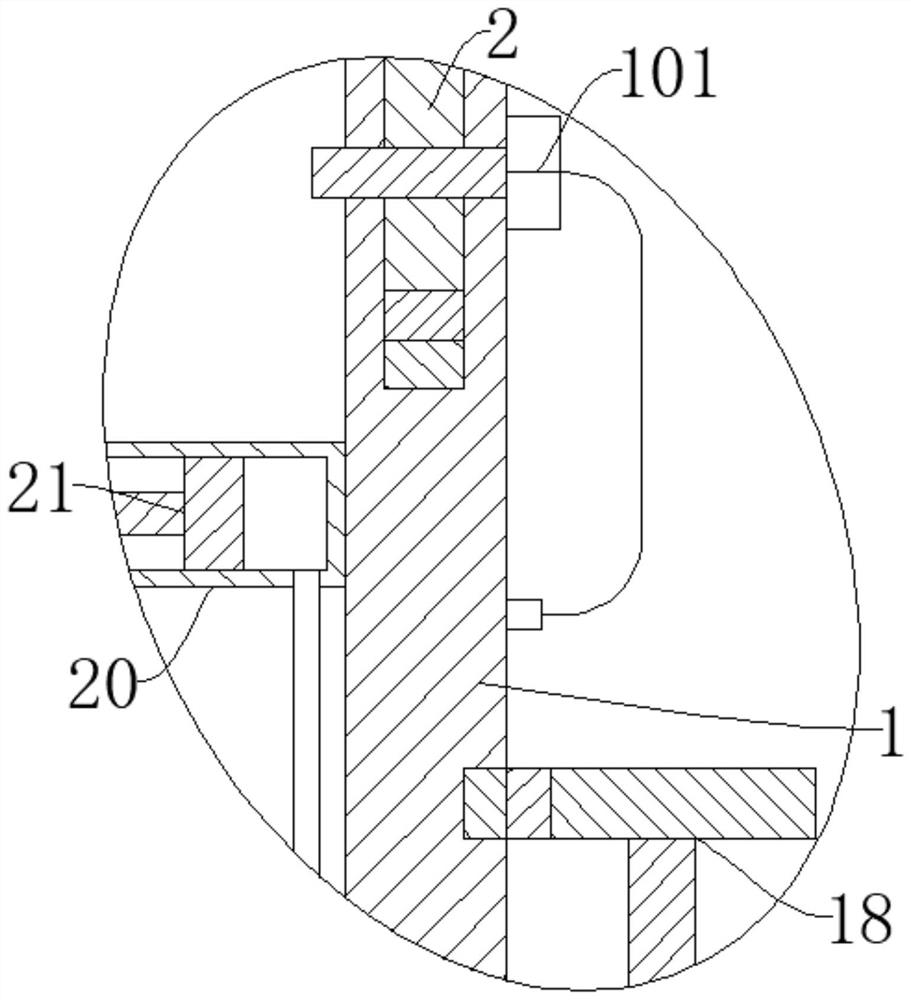

InactiveCN108972172AFast loading and unloadingImprove grinding efficiencyRevolution surface grinding machinesGrinding drivesSlide plateHigh loading

The invention discloses a rotary steel-pipe grinding device which comprises a workbench, support legs, a rotary disc, a fixing pillar and grinding rods. The rotary disc is rotatably connected to the upper surface of the workbench, the fixing pillar is fixedly connected to the left side wall of the workbench, a top plate is fixedly connected to the top of the fixing pillar, a guide rail is mountedon the lower surface of the top plate, a sliding plate is slidably connected on the guide rail, a telescopic mechanism is fixedly connected to the lower surface of the sliding plate, a mounting plateis fixedly connected to the lower surface of the telescopic mechanism, a fixing block is fixedly connected to the lower surface of the mounting plate, a threaded rod is rotatably connected to the sidewall of the fixing block, the threaded rod is sleeved with a movable block, and the grinding rods are fixedly connected with the lower surface of each of the fixing block and the movable block. A steel pipe clamped rapidly through clamping blocks, high loading and unloading speed is achieved, the inner wall and the outer wall of the steel pipe are ground simultaneously by the aid of the grindingrods, grinding efficiency is improved greatly, time is saved, certain damping effect is achieved by the aid of a spring, and vibration of the grinding device in operation is reduced.

Owner:JIANGSU YUEFA CONSTR ENG CO LTD

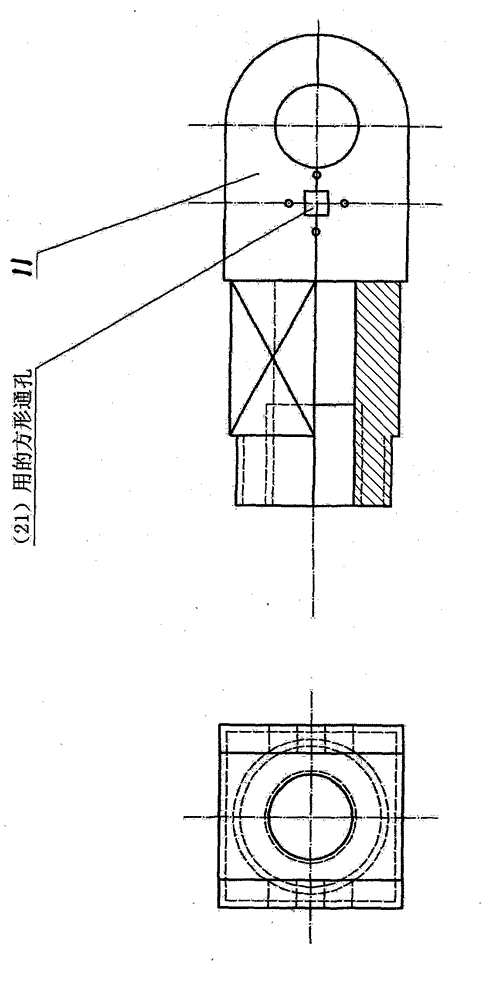

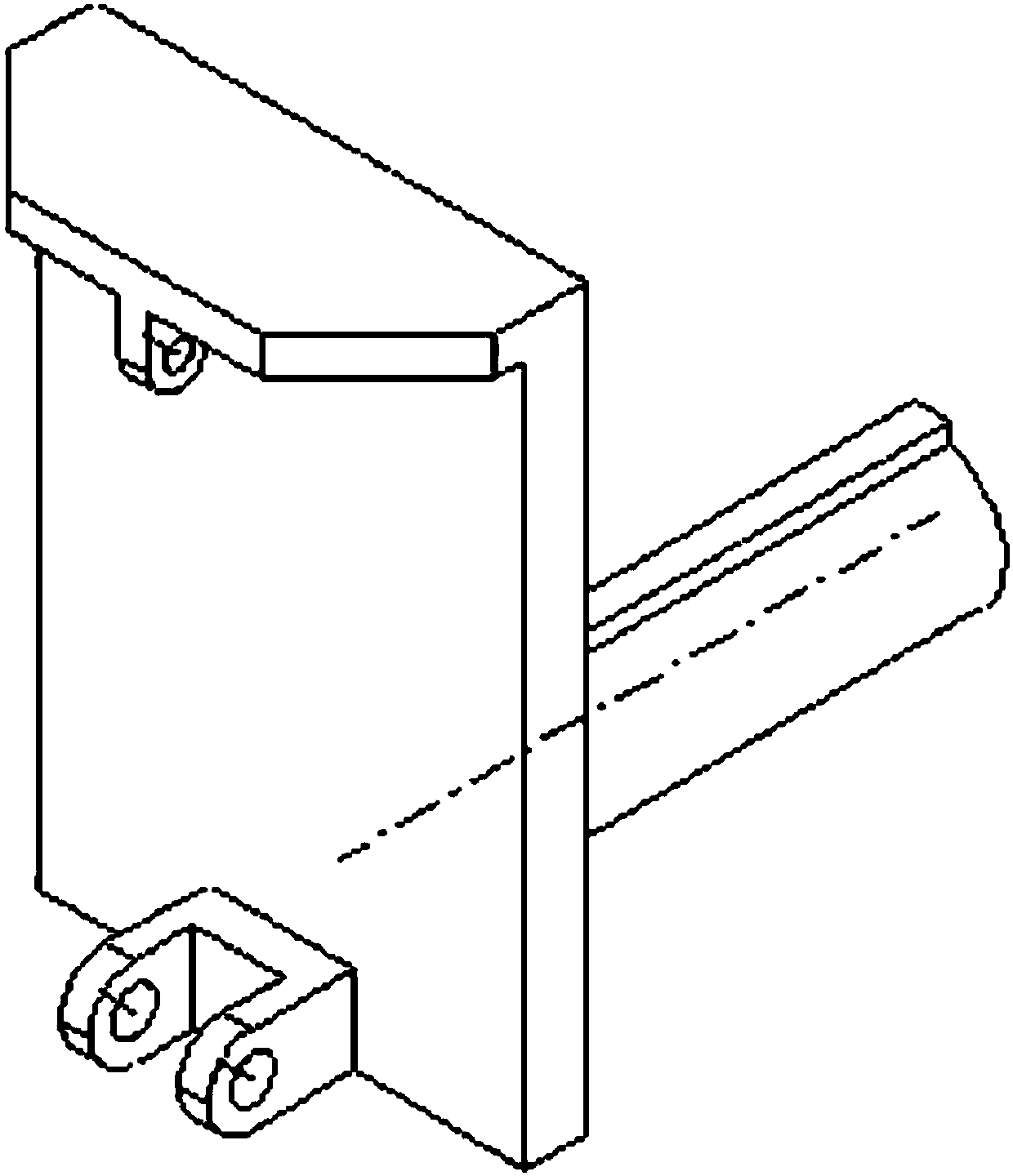

Automatic gravity gripper

ActiveCN104058182AStrong interchangeabilityFast loading and unloadingExternal framesEngineeringMechanical engineering

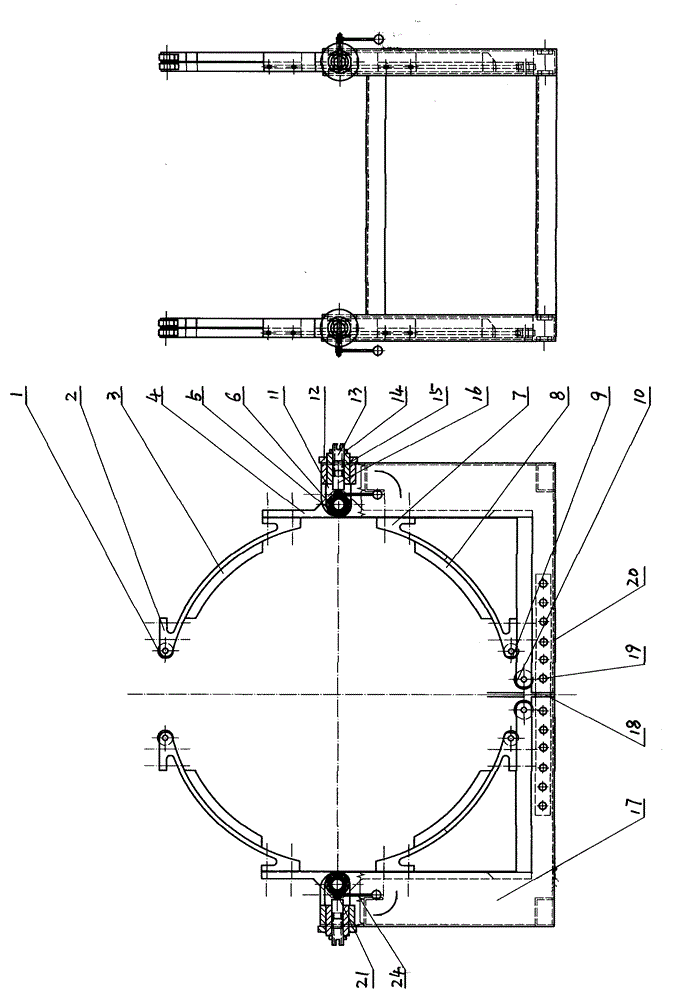

The invention relates to a gripper for transportation and storage. The gripper consists of a gripper seat assembly, a square shaft assembly, groove-shaped movable gripping head assemblies and a spine lock assembly, wherein the gripper seat assembly looks like a square with a half capable of being separated and combined, and the gripper seat assembly is fastened integrally through screws and adjusting connecting plates; the square shaft assembly is fastened on square holes for square shafts of the gripper seat assembly through fastening nuts; each groove-shaped movable gripping head assembly looks like a bow, the left and right groove-shaped movable gripping head assemblies can be matched to form a sleeved ring which can be opened and closed, and the groove-shaped movable gripping head assemblies are mounted in hinge pin holes in front ends of the square shafts through hinge pins and can be freely opened at 45 degrees-135 degrees; the spine lock assembly penetrates through round spine lock assembly through holes above the front side of the gripper seat assembly and is fastened on the square shafts through screws. The automatic gravity gripper is generally applicable to transportation and storage, and parts are high in interchangeability and can be produced in batches in a standard manner (the automatic gravity gripper can also be assembled on a liftable trolley and is quick, convenient and safe in object transportation, loading and unloading).

Owner:江苏北华微电子科技有限公司

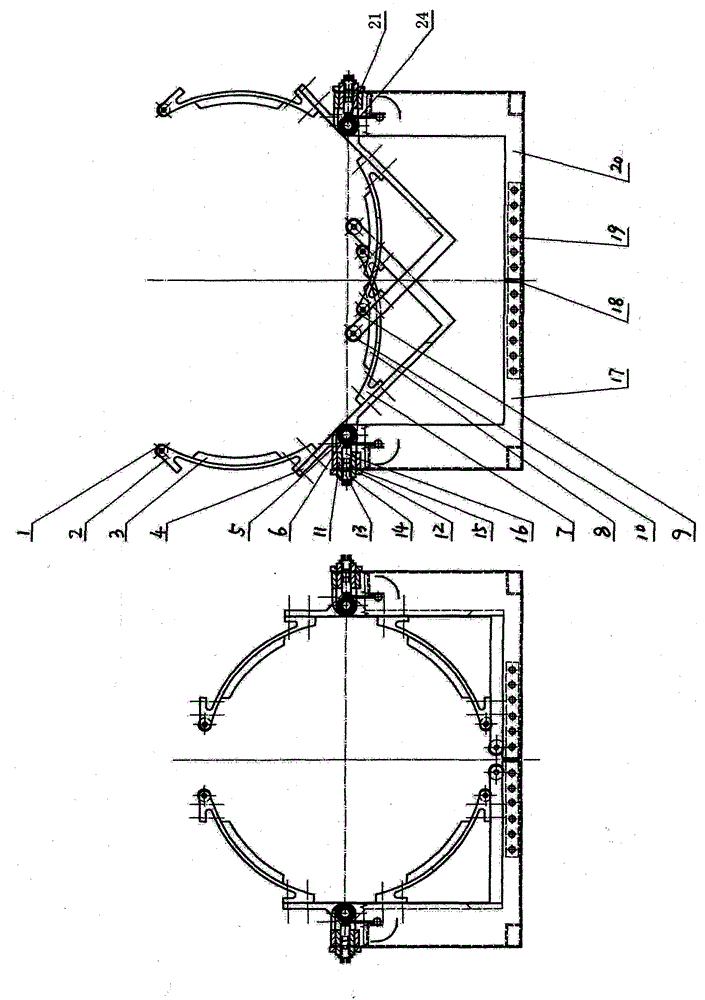

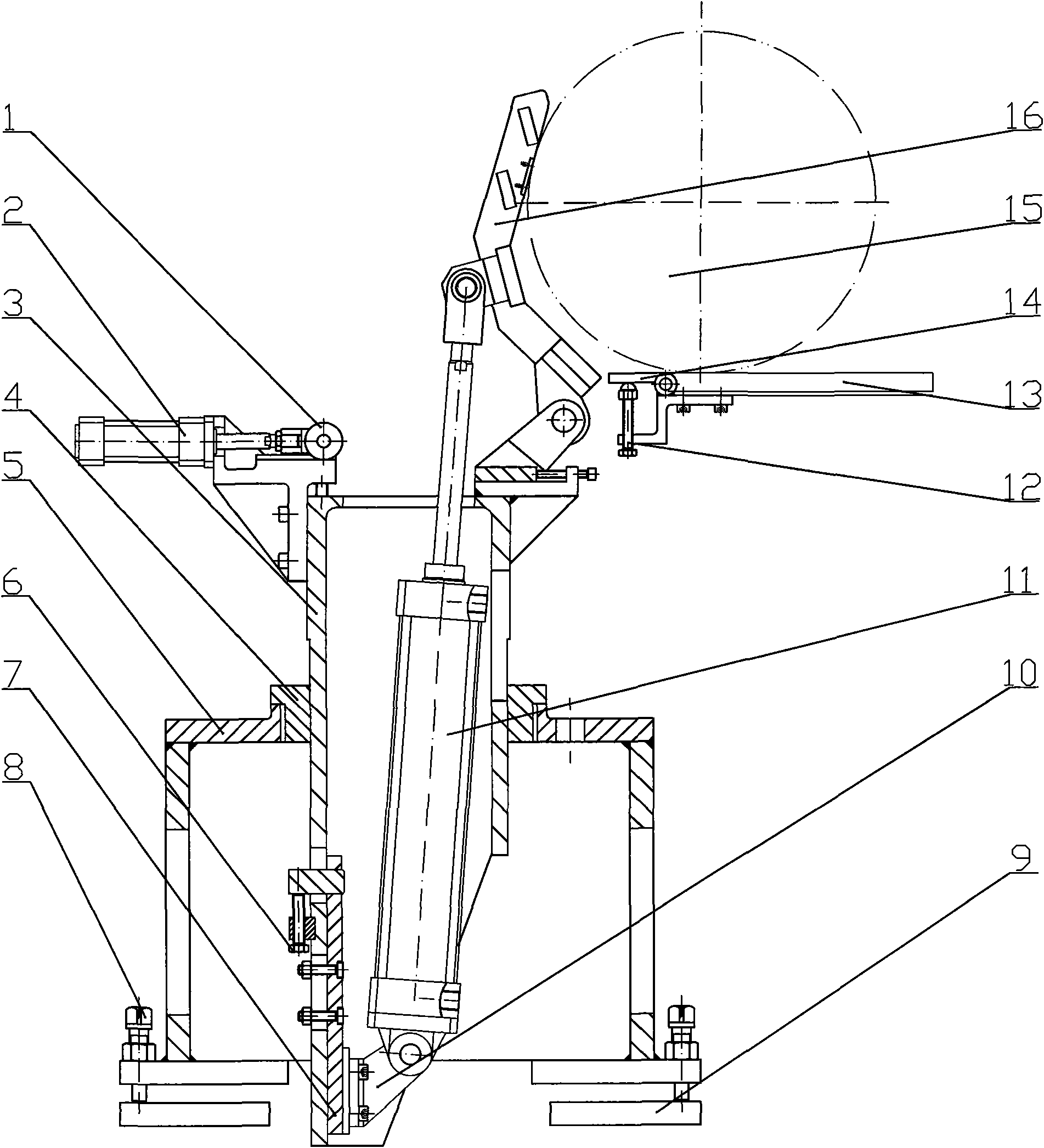

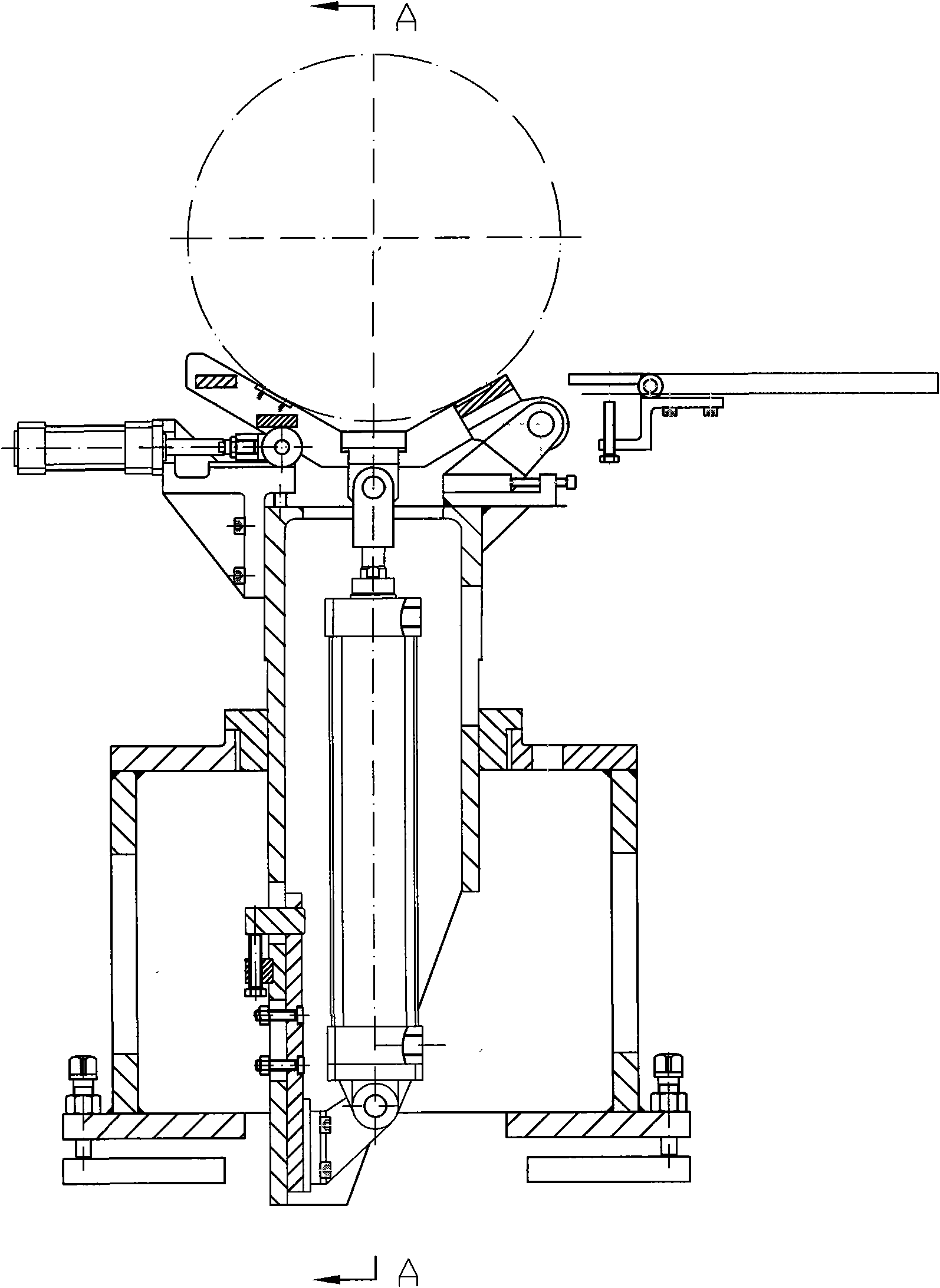

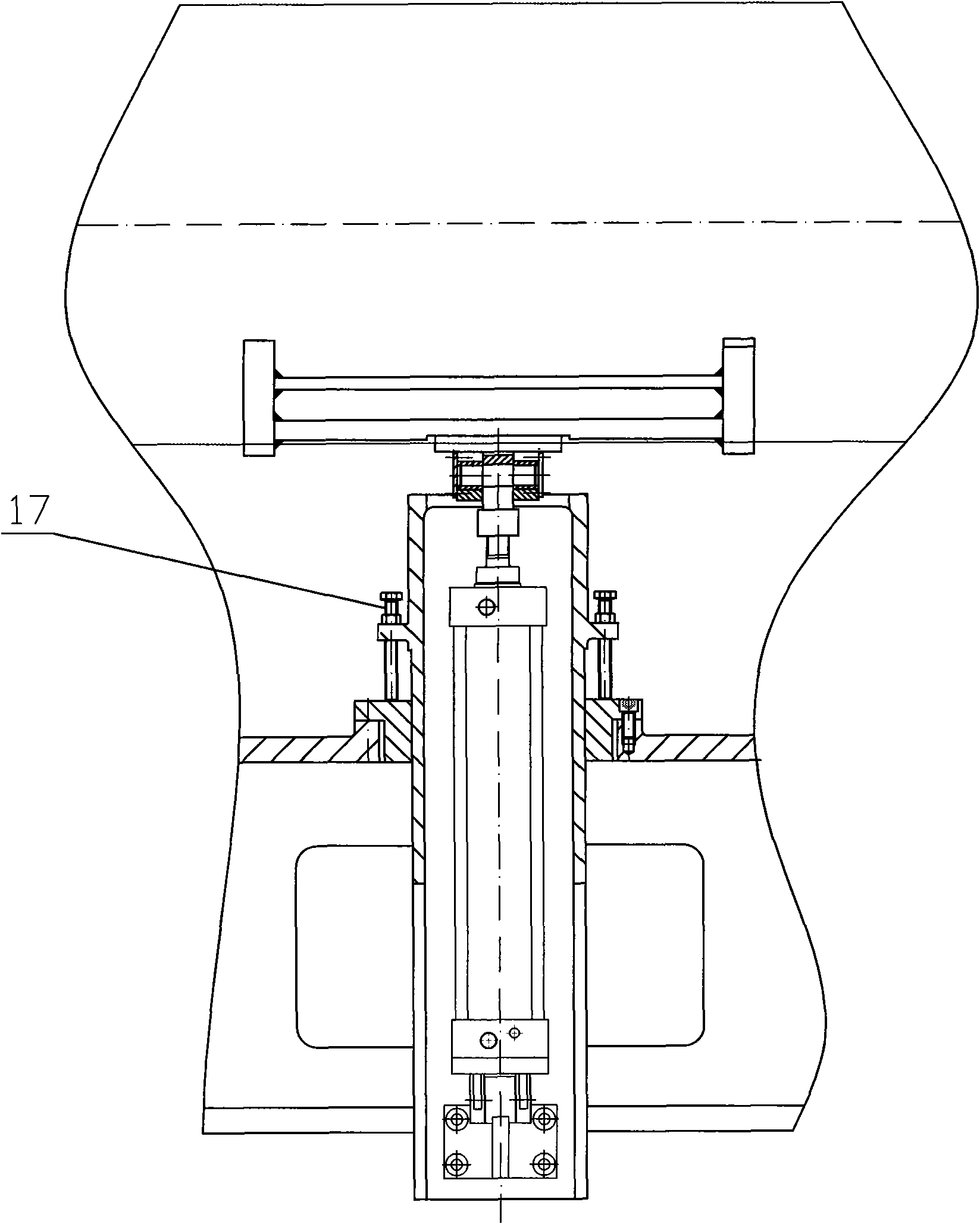

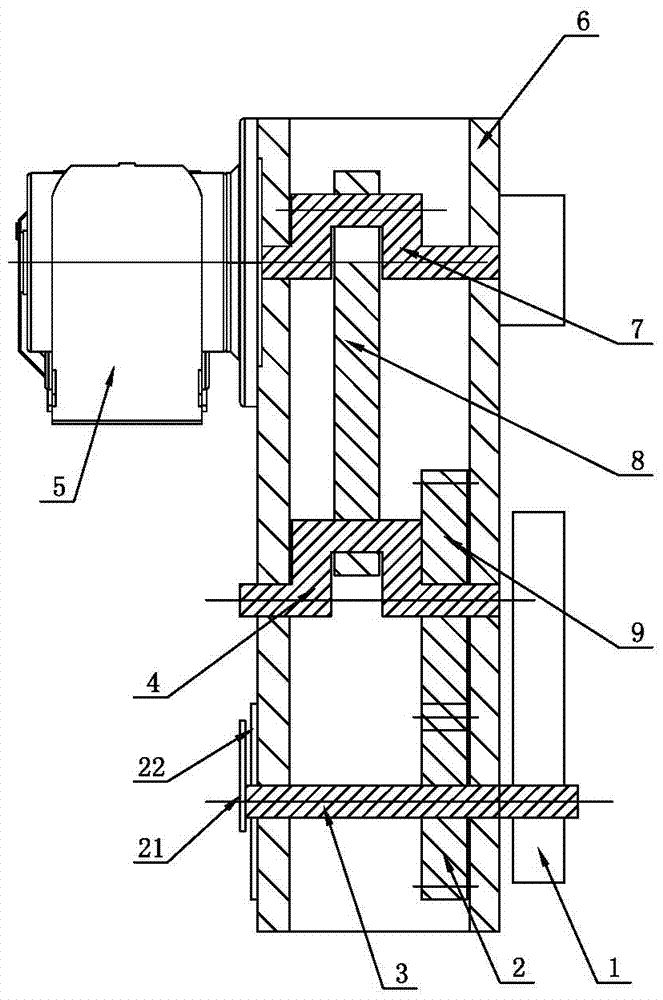

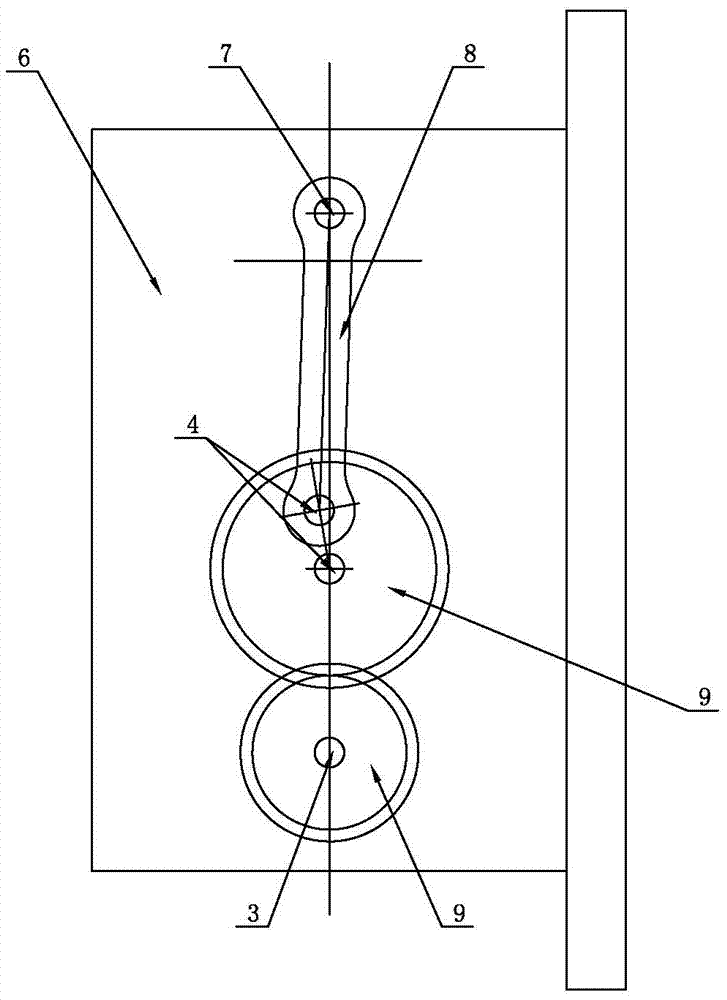

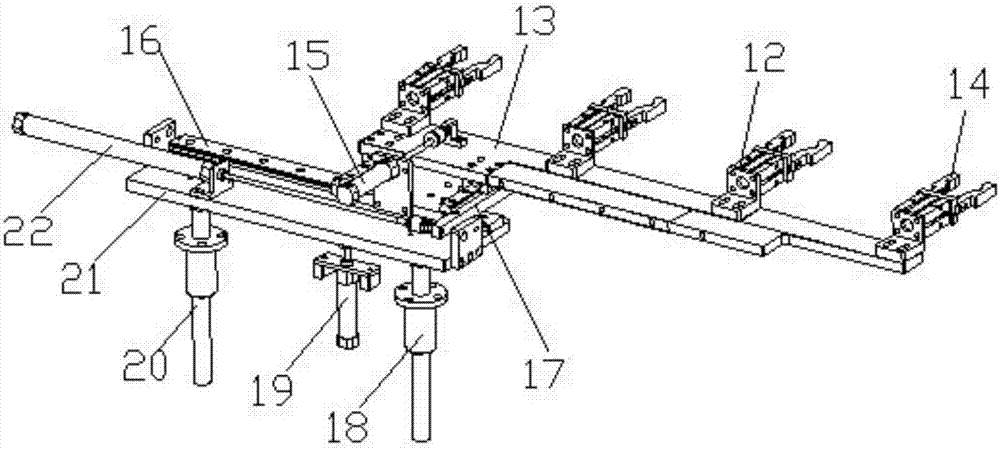

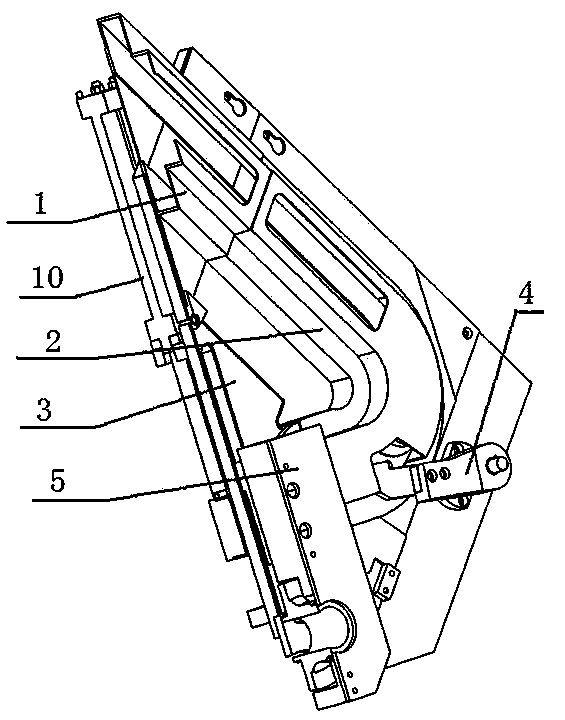

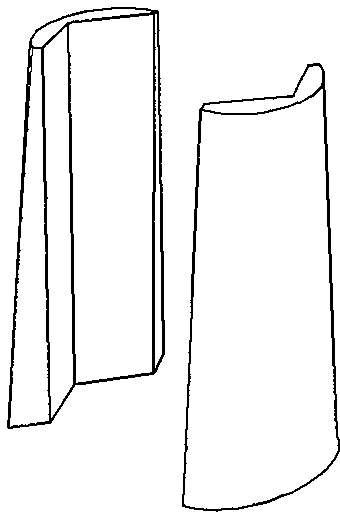

Automatic loading and unloading mechanism of cylindrical workpieces

InactiveCN101670406AHigh positioning accuracyFast loading and unloadingMetal-working feeding devicesPositioning devicesThin walledHinge point

The invention discloses an automatic loading and unloading mechanism of cylindrical workpieces. The automatic loading and unloading mechanism comprises a support, a bracket, a moving support and an overturning and driving mechanism. One end of the bracket is hinged with the support; the bracket is connected with the overturning and driving mechanism capable of driving the bracket to overturn around a hinge point, and the moving support is movably arranged on the support and has two positions in the moving process, wherein one position is away from the bracket and the other position supports the free end of the bracket when the bracket is overturned to a horizontal position. The automatic loading and unloading mechanism has high positioning precision on the workpieces, quick loading and unloading, simple structure, high efficiency, easy realization of automation, high repeat positioning precision, good reliability and wide range of application, and can be suitable for thin-wall cylinders of different diameters as well as the loading and the unloading of a plurality of workpieces.

Owner:SHANDONG FIN CNC MACHINE

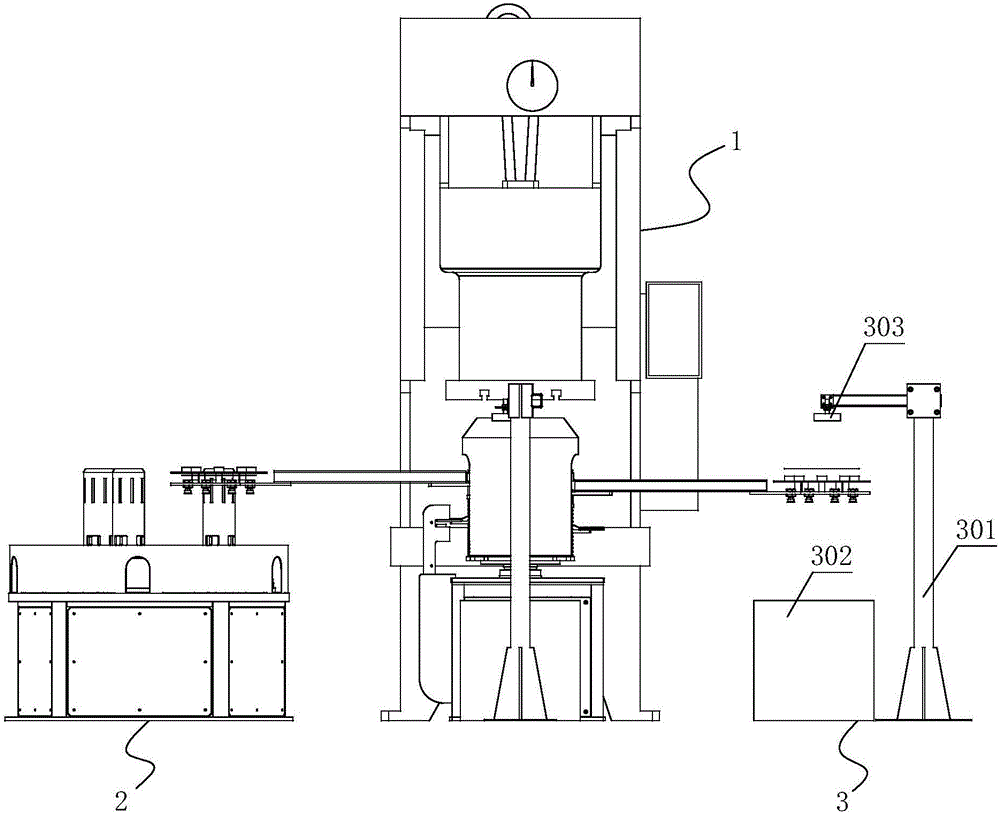

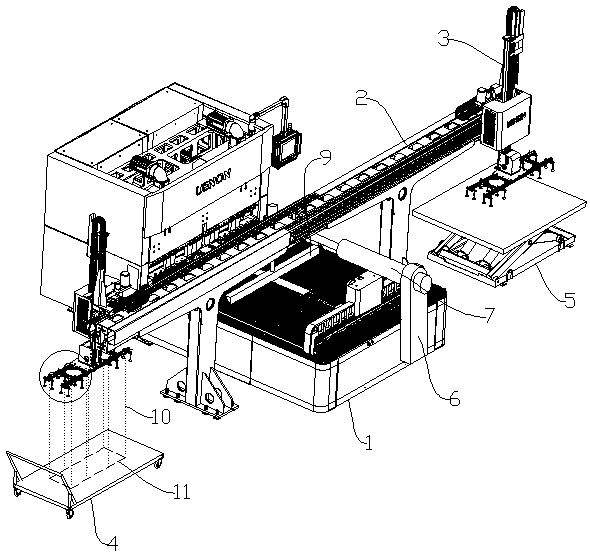

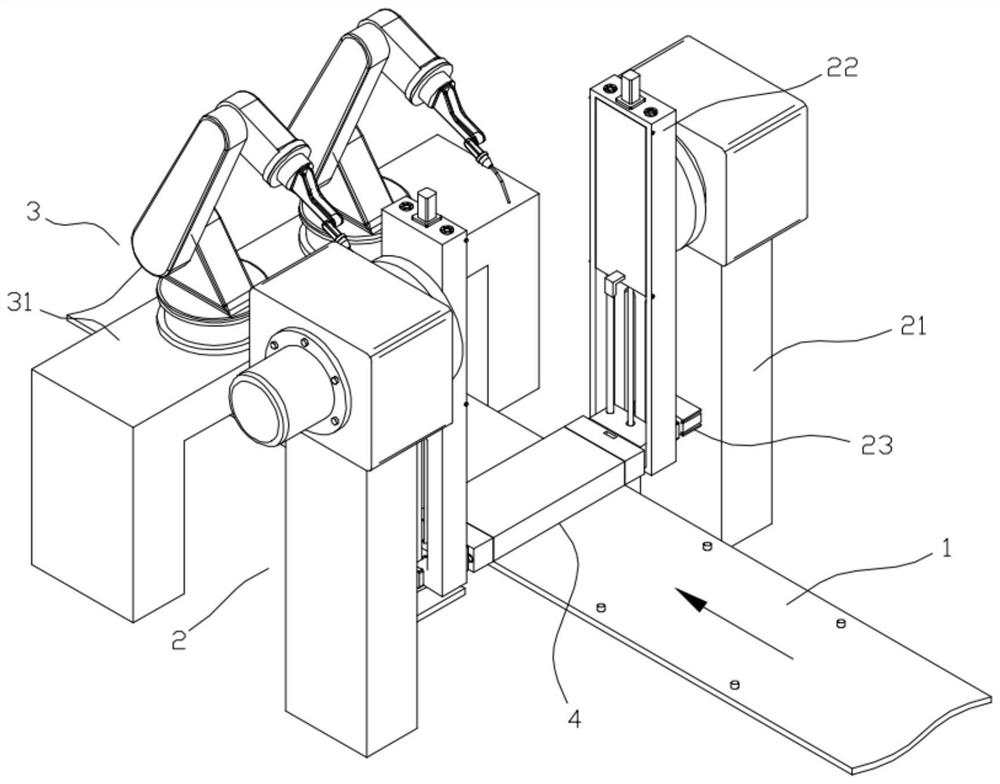

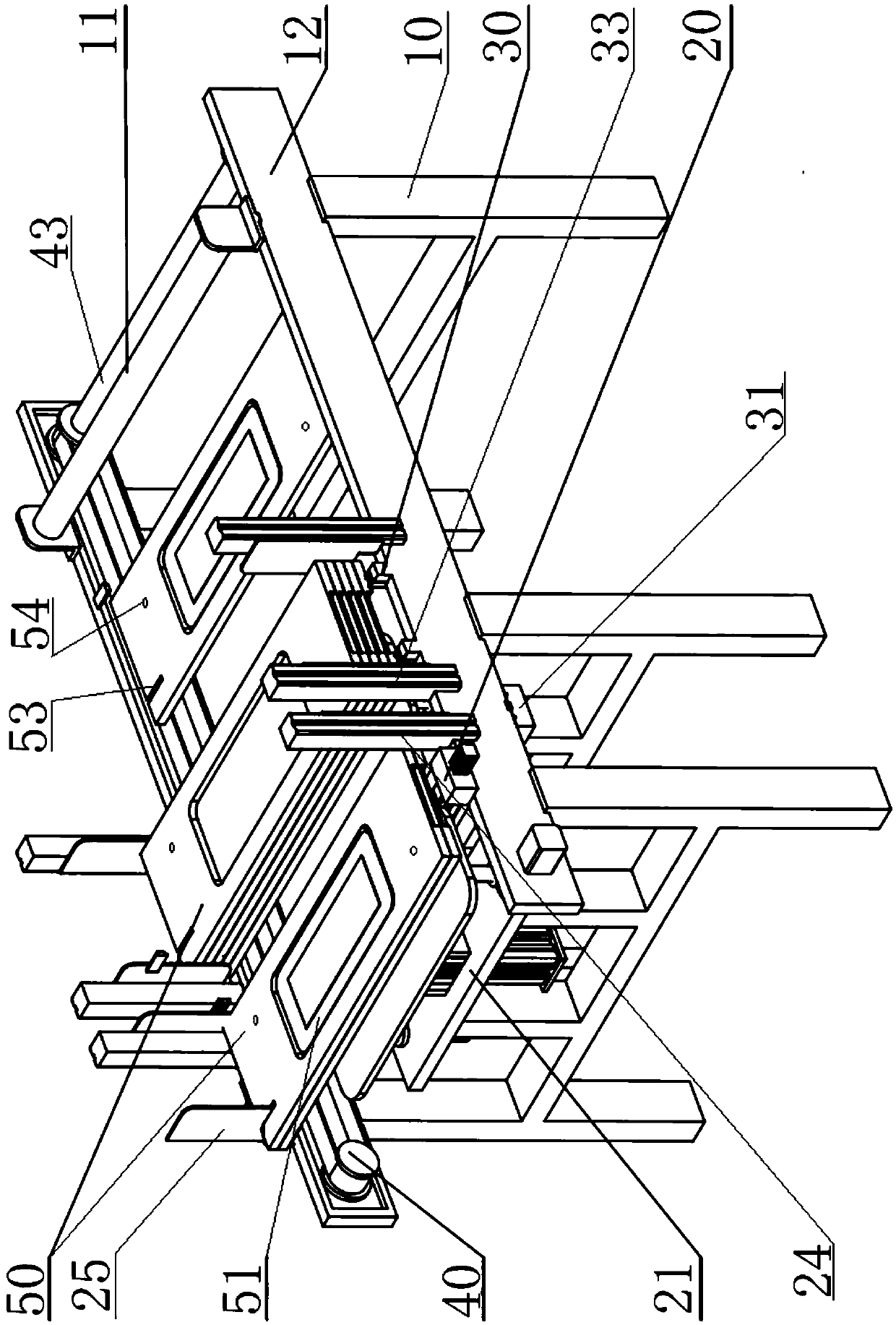

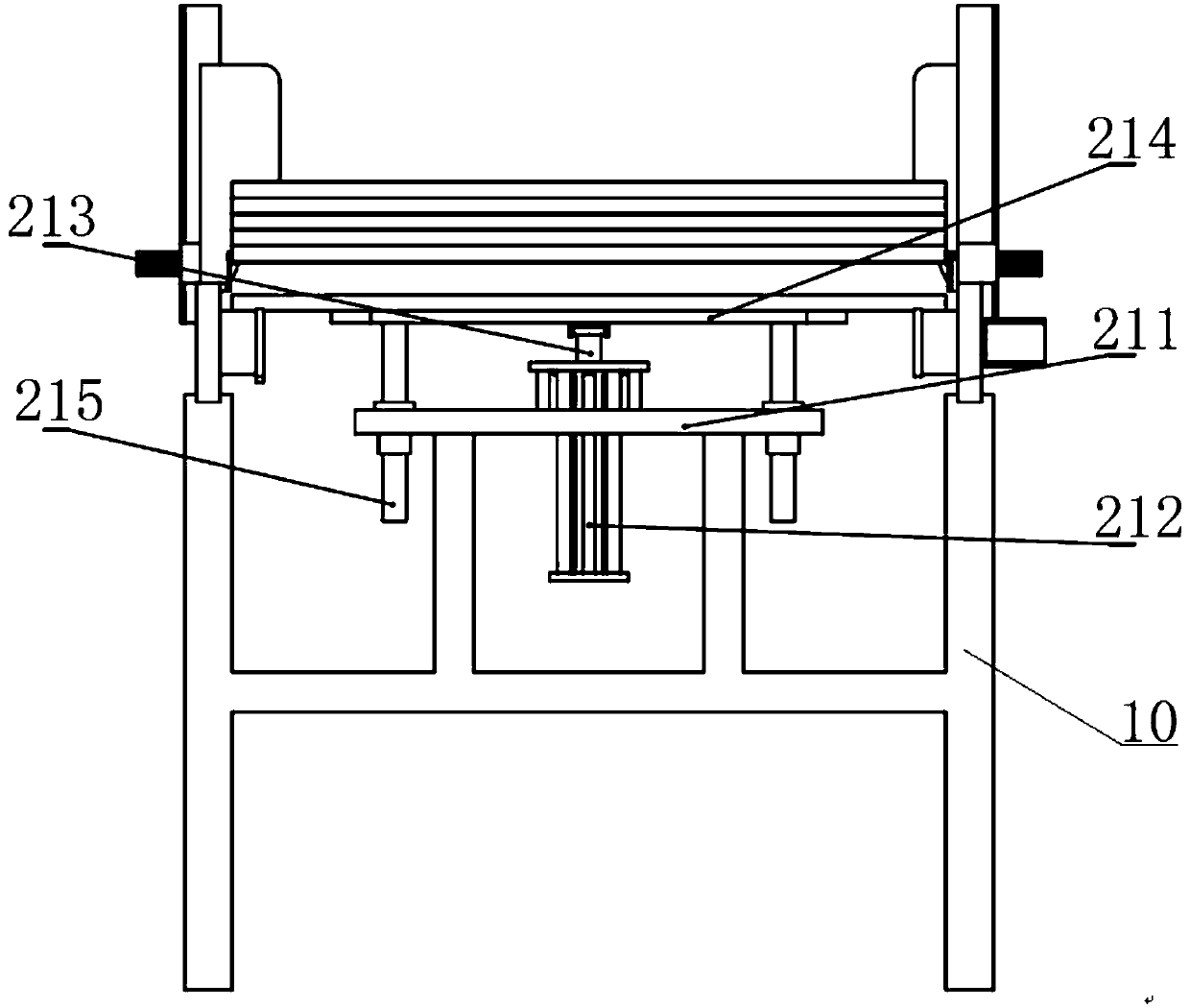

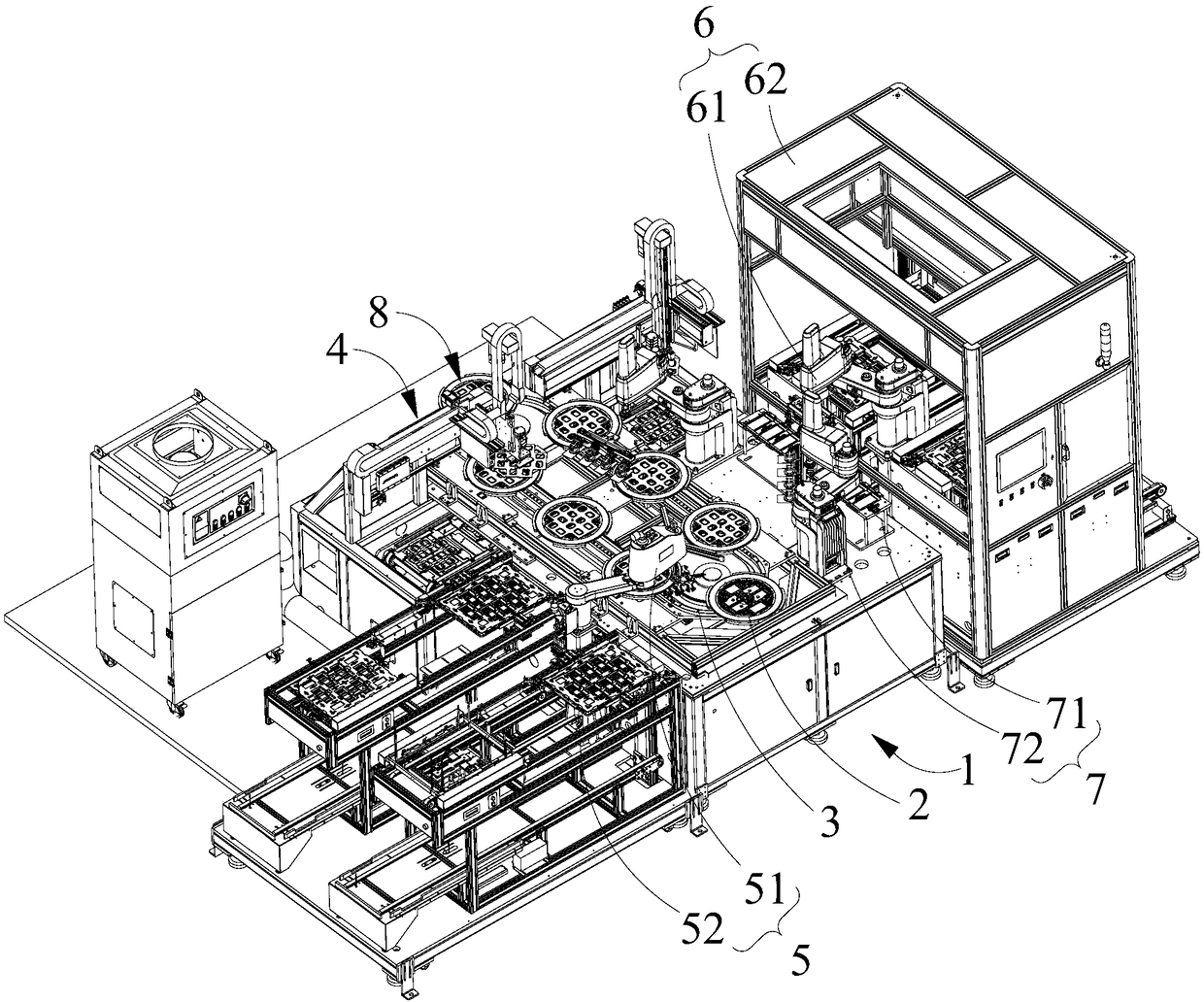

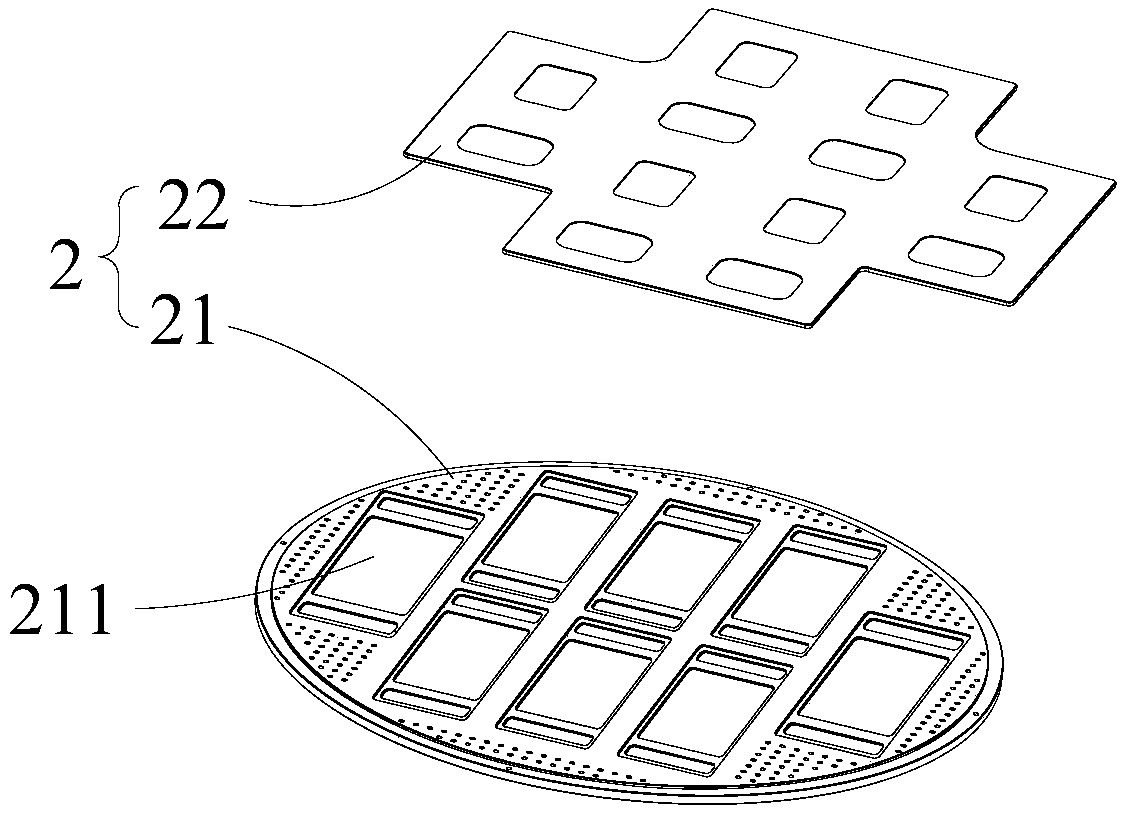

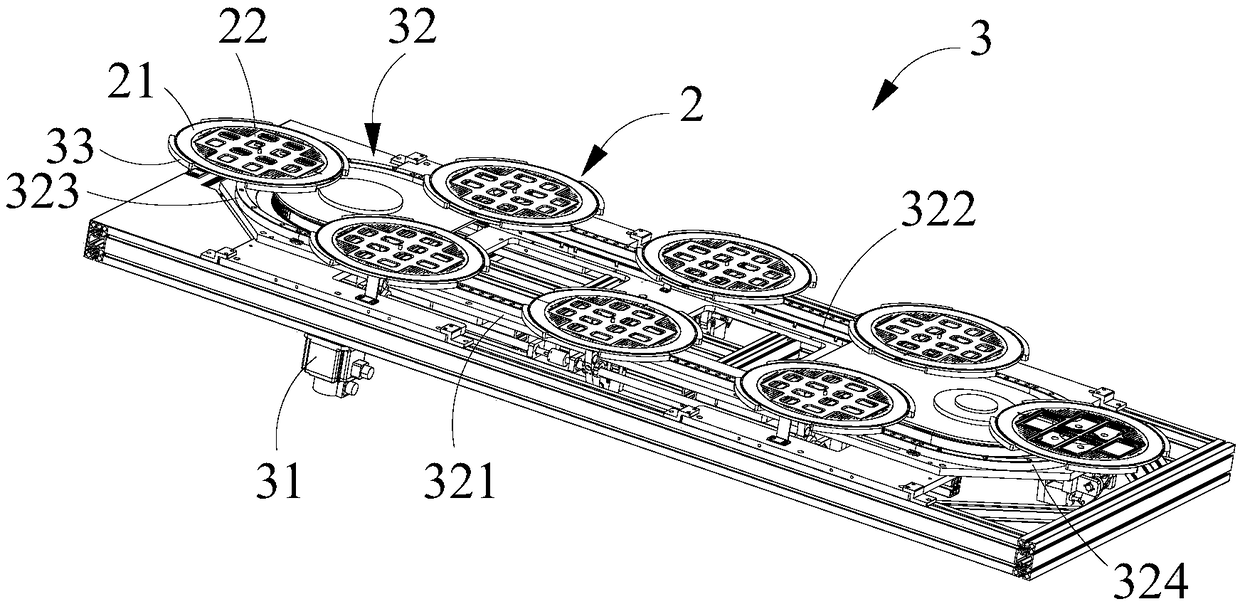

Silicon steel plate stamping production line

ActiveCN106311844AFast loading and unloadingSimple structureMetal-working feeding devicesStripping-off devicesProduction linePunch press

The invention discloses a silicon steel plate stamping production line. The silicon steel plate stamping production line comprises a stamping transfer robot as well as a loading station, a stamping station and an unloading station which are arranged at the periphery of the stamping transfer robot; the loading station, the stamping station and the unloading station are sequentially distributed in a circumferential direction; a multi-station loading device is arranged on the loading station; a punch is arranged on the stamping station; a stamping mould is mounted on the punch; the stamping mould comprises an upper mould and a lower mould; a sucking device used for sucking the silicon steel plate is arranged on the upper mould; the unloading device is arranged on the unloading station; the stamping transfer robot comprises a rack; the rack is rotatably connected with a rotary frame; the rotary frame is driven by a rotary motor; at least one mechanical arm is arranged on the rotary frame; and a clamping device used for sucking the silicon steel plate is mounted on the mechanical arm. The silicon steel plate stamping production line is simple in structure and is reasonable in arrangement; and the stamping transfer robot rotates in a one-way mode, so that the mechanical arm does not need to return, and therefore, quick loading and unloading for the silicon steel plate can be realized.

Owner:WUXI IDO SCI & TECH CO LTD

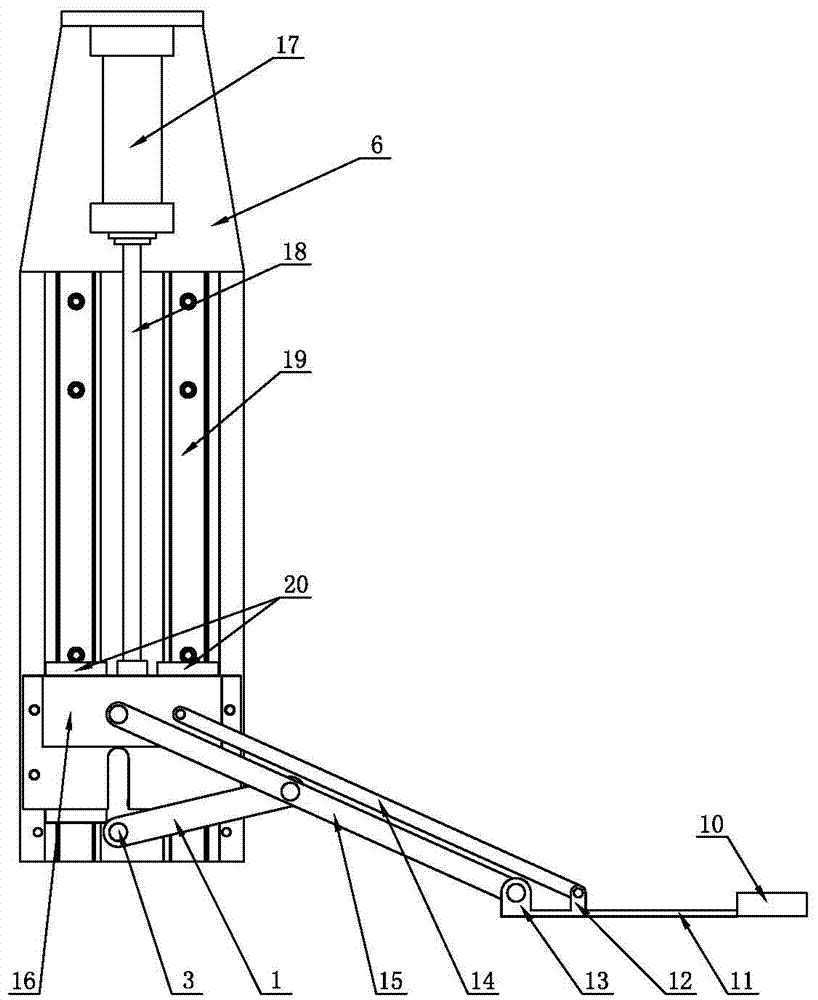

Feeding and discharging device and method thereof

PendingCN106945024ASolve the technical problem of low loading and unloading efficiencyReduce labor intensityProgramme-controlled manipulatorMetal-working feeding devicesAutomatic controlDrive shaft

The invention discloses a feeding and discharging device and a method thereof in the technical field of automatic control of press machines. The feeding and discharging device comprises a motor, a connection base capable of sliding up and down and a material conveying mechanism. The motor is in transmission connection with a drive crankshaft, the drive crankshaft is connected with the upper end of a drive connecting rod, and the lower end of the drive connecting rod is connected with a driven crankshaft. The driven crankshaft is further in transmission connection with a drive gear. The connection center of the drive connecting rod and the driven crankshaft is arranged eccentrically relative to the connection center of the drive gear and the driven crankshaft. The drive gear is in transmission connection with a driven gear. The driven gear is connected to one end of a drive shaft, and the other end of the drive shaft is connected with one end of a driven connecting rod. One end of a main swing arm and one end of an auxiliary swing arm are hinged to a connection base, and the other end of the driven connecting rod is hinged to the main swing arm. The material conveying mechanism comprises a base, the other end of the main swing arm and the other end of the auxiliary swing arm are hinged to the base, and the end portion of the base is connected with a material placement part used for bearing materials. According to the feeding and discharging device and the method thereof, the structure is ingenious, automatic feeding and discharging are achieved, the conveying efficiency is improved, and time and labor are saved.

Owner:YANGLI GRP CORP LTD

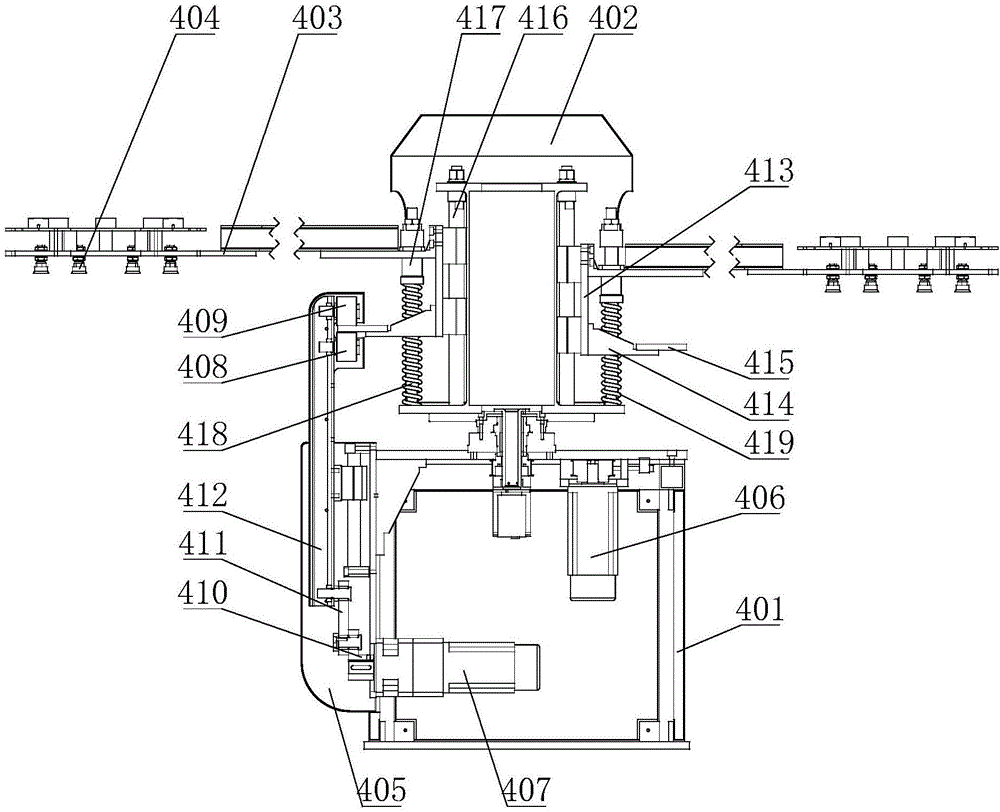

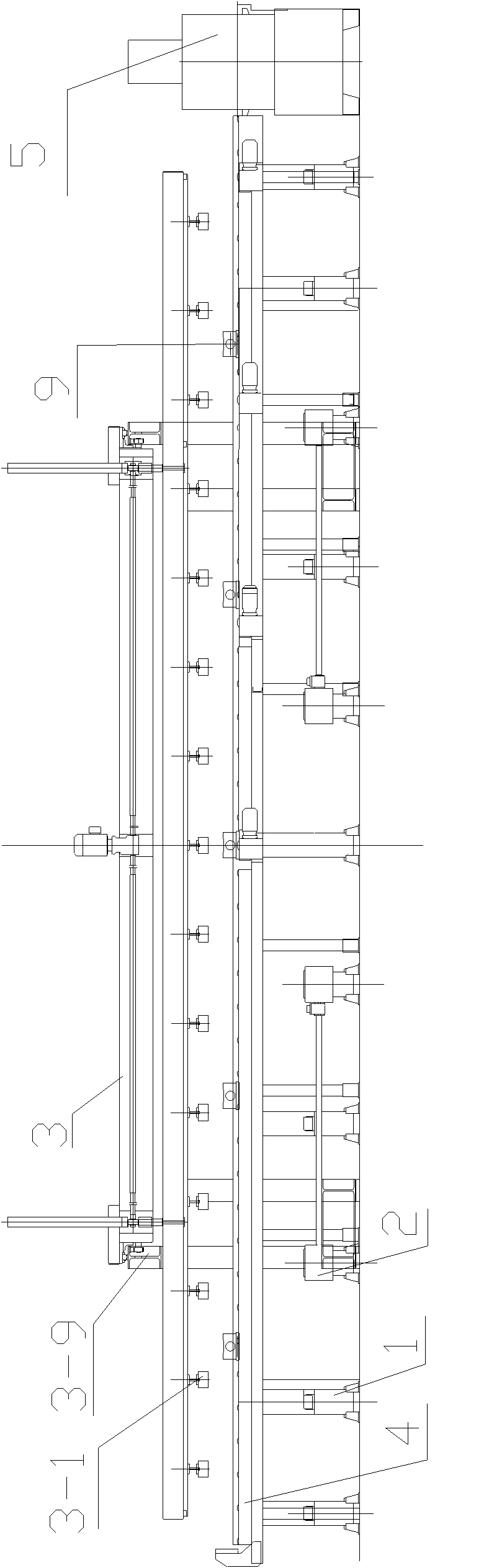

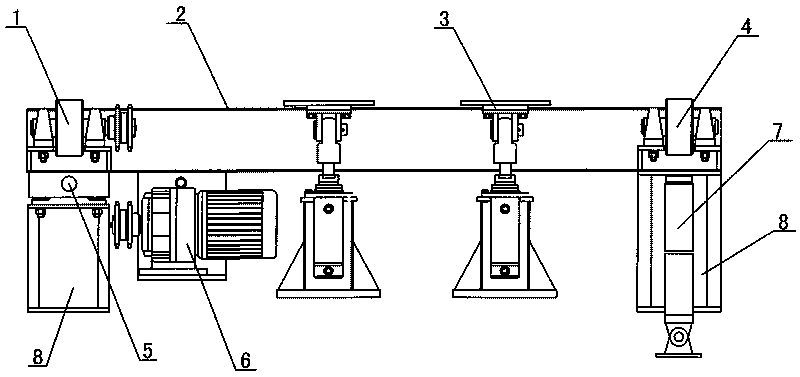

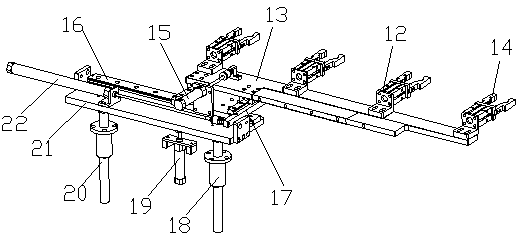

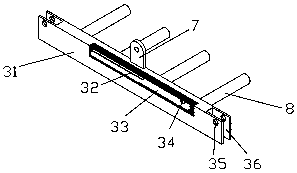

Full-automatic loading and unloading device for large vehicle longitudinal beam hydraulic machine

InactiveCN101985144APrecise positioningFast loading and unloadingMetal-working feeding devicesPositioning devicesEngineeringAutomation

The invention relates to a full-automatic loading and unloading device for a large vehicle longitudinal beam hydraulic machine, an outer input mechanism comprises a roller table frame, a plurality of driving rollers mounted on the roller table frame, lower supporting plates positioned between the adjacent driving rollers and side baffle plates mounted on the roller table frame, wherein the lower supporting plates are mounted on the roller table frame, a material blocking side bent plate which gradually approaches the central line of the roller table frame along the output direction of a blank is fixedly connected on one side of the output end of the roller table frame, and the plurality of the driving rollers include a magnetic driving roller. The full-automatic loading and unloading device can lead plate materials to automatically smoothly reach the set position for realizing accurate positioning, realize automatic loading and unloading of the plate materials with different specifications, lead the irregular plate materials to smoothly enter into a die, and further realize automatic operation by controlling all actions through an electrical program; and the full automation can lead the operation to be convenient, save a large amount of manpower and time and improve production efficiency. The full-automatic loading and unloading device can realize accurate positioning of the plate materials, fast loading and unloading speed and conveying of the plate materials with the different specifications.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Device for automatically coating lubricants on hot-expanding seamless steel tubes

InactiveCN101700512AChange the shortcomings that are difficult to flow intoChange manual applicationLiquid surface applicatorsCoatingsHydraulic cylinderUniform rotation

The invention relates to a device for automatically coating lubricants on hot-expanding seamless steel tubes, comprising bases, a platform frame, tube holding mechanisms, a hydraulic lifting system and a rotating mechanism, wherein both ends of the platform frame are respectively connected with a rotating bracket and the hydraulic lifting system; a drive roller at the left side of the device is driven by a drive motor and drives steel tubes to rotate; the hydraulic lifting system is fixed on the ground with the base at the right side and lifts and inclines the right side of a platform by virtue of extension of a hydraulic cylinder; and both the left and right tube holding mechanisms are installed next to the rollers at both sides. The tube holding mechanisms are used for holding the rolling steel tubes and placing the steel tubes on the drive roller and a driven roller. The hydraulic lifting system is used for jacking up the platform frame to enable the steel tubes to incline a certain angle and then to be driven by the drive motor to rotate at constant speed. The lubricants are evenly distributed on the inner surfaces of the steel tubes, then the platform is restored, and the tube holding mechanisms are used for holding the steel tubes to roll out of the platform and enter a rack. Being adopted to produce the hot-expanding steel tubes, the device features high production efficiency and high yield, and can obtain high quality hot-expanding steel tubes with ultra-large apertures.

Owner:DEXIN STEEL PIPE CHINA

Recyclable motorcycle engine transportation bracket

InactiveCN101823600AQuick disassemblyGuaranteed reliabilityPackage recyclingPackaging vehiclesCircular economyEngineering

The invention relates to a recyclable motorcycle engine transportation bracket; the bottoms of the corners of a frame are supported by bottom pillars, and the tops of the corners of the frame are fixed with locating pillars, each of which is connected with a folding support pillar; the frame is internally provided with bases distributed in a matrix way, a spring hook is positioned besides each base, and each base is provided with a groove-shaped bracket; the tops of the two sides of the groove-shaped bracket are symmetrically provided with through holes; and the lower part of one side of the groove-shaped bracket is connected with a lock pin by a first chain, and the lower part of the other side thereof is connected with a penetrating pin by a second chain. The recyclable motorcycle engine transportation bracket has the structure of high-density loading and high-density folding recyclable structure, and is the product advocating 'low-carbon economy' and 'circular economy'; an engine can be conveniently and rapidly assembled and folded on the bracket; and the bracket is firm, safe and reliable in the transportation process, and can greatly reduces the loading and transporting costs of the engine.

Owner:赵永庆

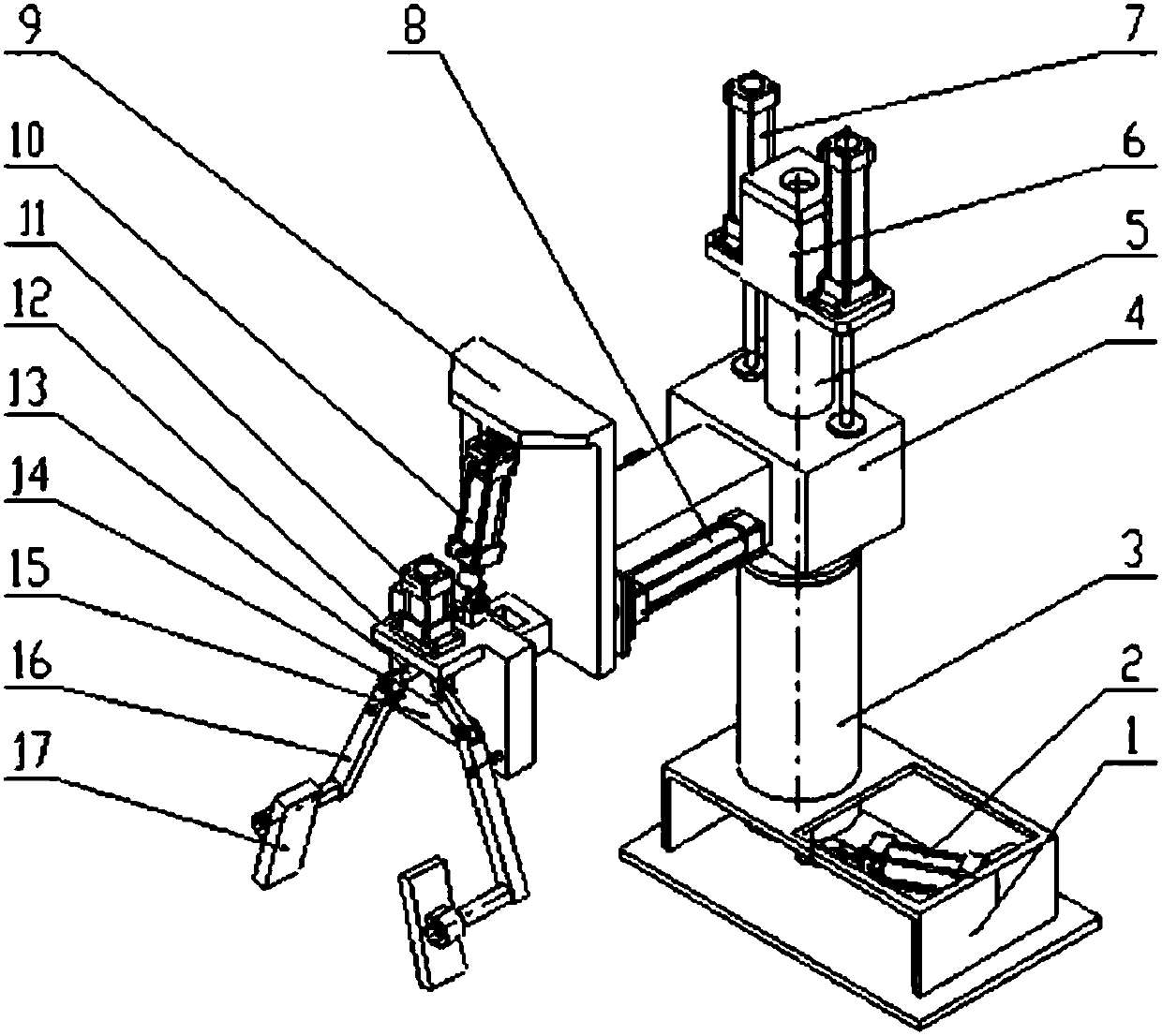

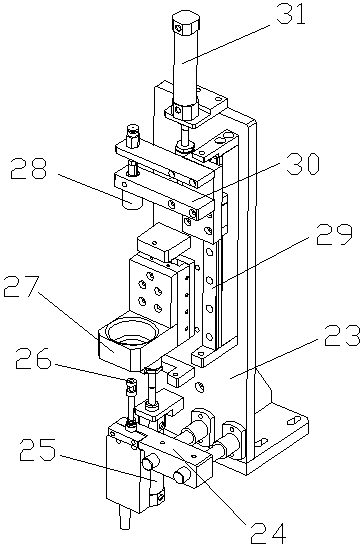

Automatic workpiece feeding and discharging robot

InactiveCN107696027AHigh positioning accuracyImprove efficiencyProgramme-controlled manipulatorGripping headsRotational axisEngineering

The invention provides an automatic workpiece feeding and discharging robot. The automatic workpiece feeding and discharging robot comprises a robot base, a rotary shaft, a lifting frame, a telescopicframe, a turnover support and a manipulator, wherein the rotary shaft is rotationally arranged on the robot base and connected with a drive device I for driving the rotary shaft to rotate; the lifting frame is arranged on the rotary shaft in a vertical sliding mode and connected with a drive device II for driving the lifting frame to slide vertically; the telescopic frame is arranged on the lifting frame in a horizontal sliding mode and connected with a drive device III for driving the telescopic frame to slide horizontally; the turnover support is arranged on the telescopic frame in a vertical turning mode and connected with a drive device IV for driving the turnover support to turn over; and the manipulator is arranged on the turnover support and connected with a drive device V for driving the manipulator to conduct grapping and releasing actions. The automatic workpiece feeding and discharging robot can accurately feed workpieces to the set position, is high in workpiece positioning precision, replaces manual labor with the machine, and is high in feeding and discharging speed.

Owner:郑州欧尚德电子技术有限公司

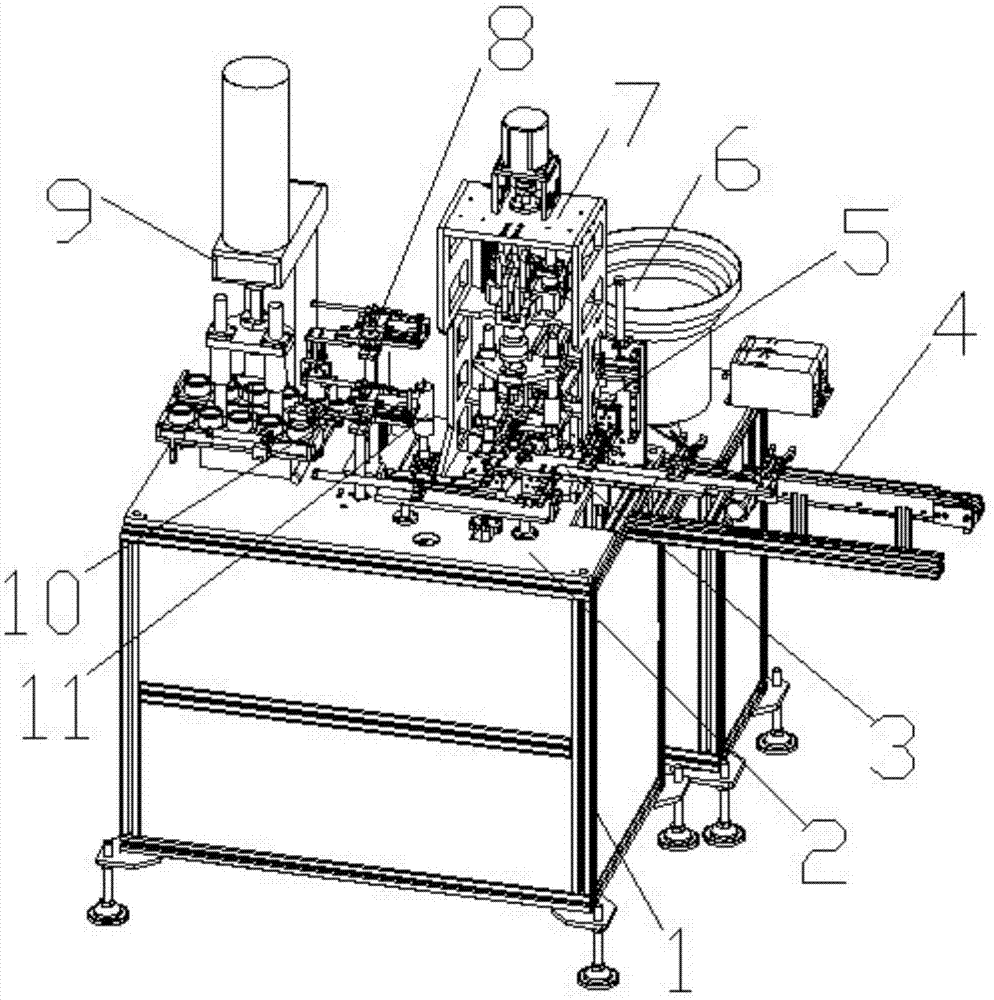

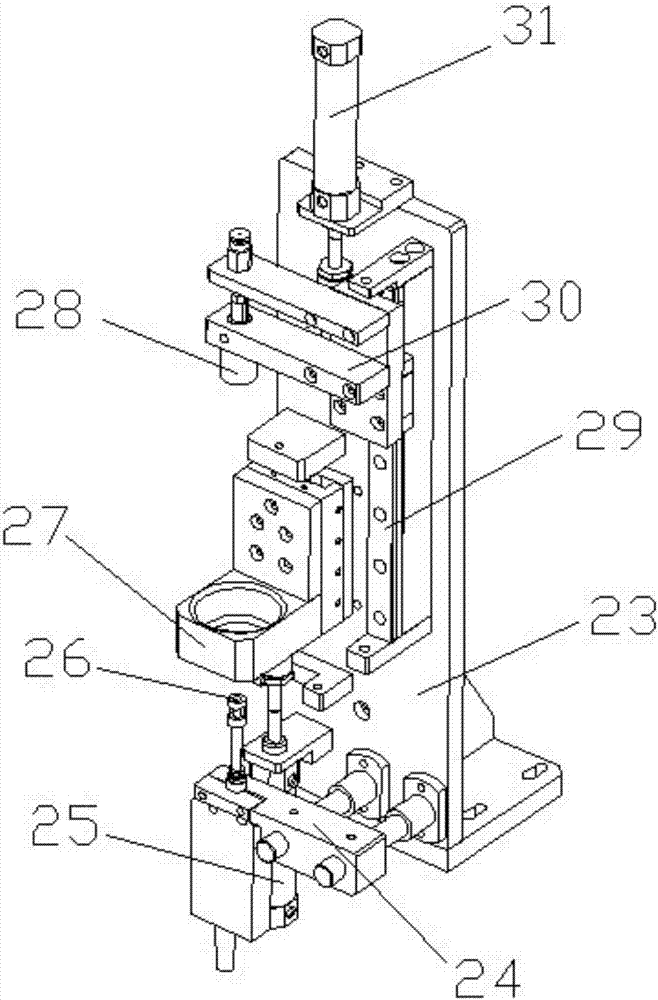

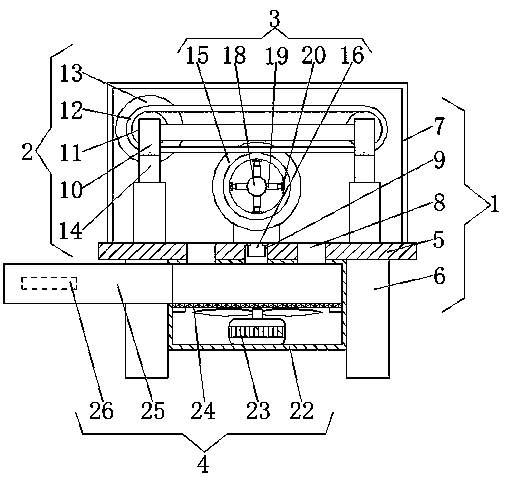

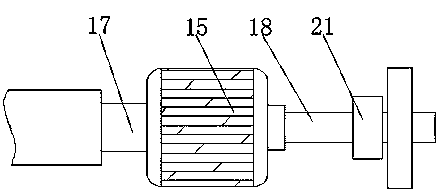

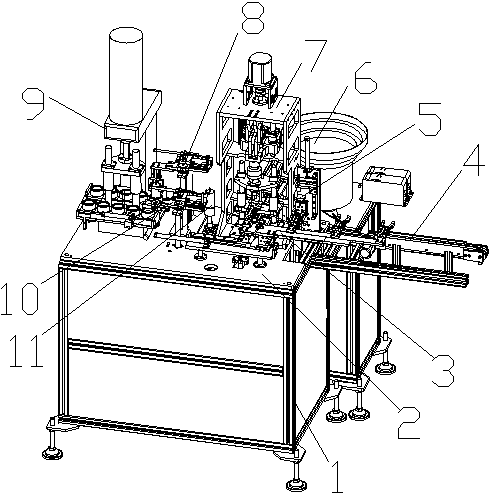

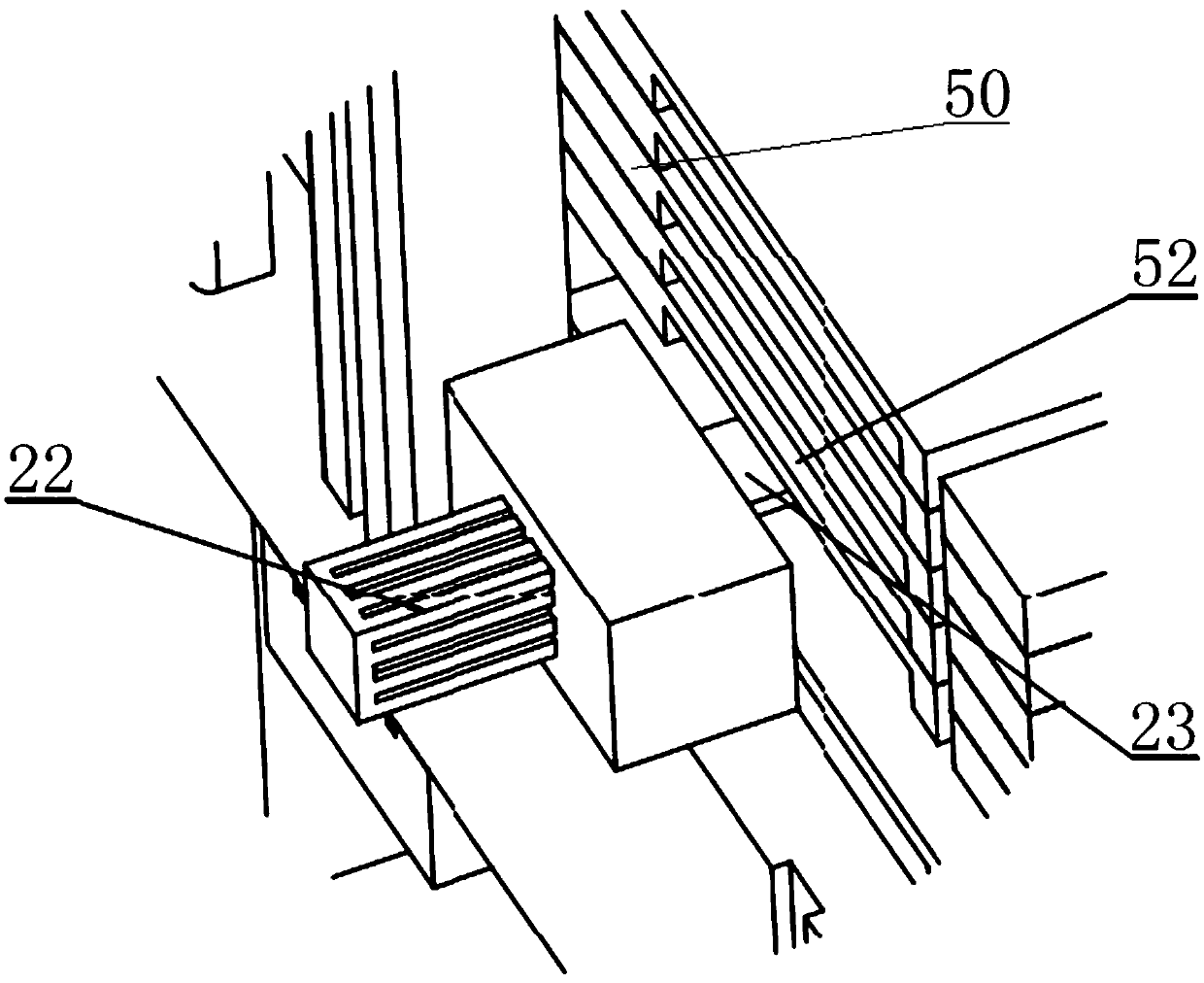

Motor synchronous wheel assembling equipment

ActiveCN107538202AImprove assembly qualitySolve crackingMetal working apparatusElectric machineryEngineering

The invention relates to the field of motor assembling, in particular to motor synchronous wheel assembling equipment. The motor synchronous wheel assembling equipment comprises a control cabinet anda machine frame arranged on the control cabinet. A motor conveying device and a pressing wheel mechanism which are matched with each other are arranged on the machine frame. A synchronous wheel feeding device matched with the pressing wheel mechanism is arranged on the part, on the machine frame, of the rear side of the pressing wheel mechanism. The motor conveying device, the pressing wheel mechanism and the synchronous wheel feeding device are connected with the control cabinet. A motor is limited through a positioning device of the pressing wheel mechanism, meanwhile, a synchronous wheel ispositioned by the positioning device, the positioning device is pressed by a slow pressing head to drive a motor product on the positioning device to push downwards, the synchronous wheel on the positioning device is arranged on a shaft of the motor in a sleeving mode, and the problem that cracks of the synchronous wheel are caused during press-assembling due to the fact that the synchronous wheel is placed obliquely is solved, so that the motor assembling quality is greatly improved.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG

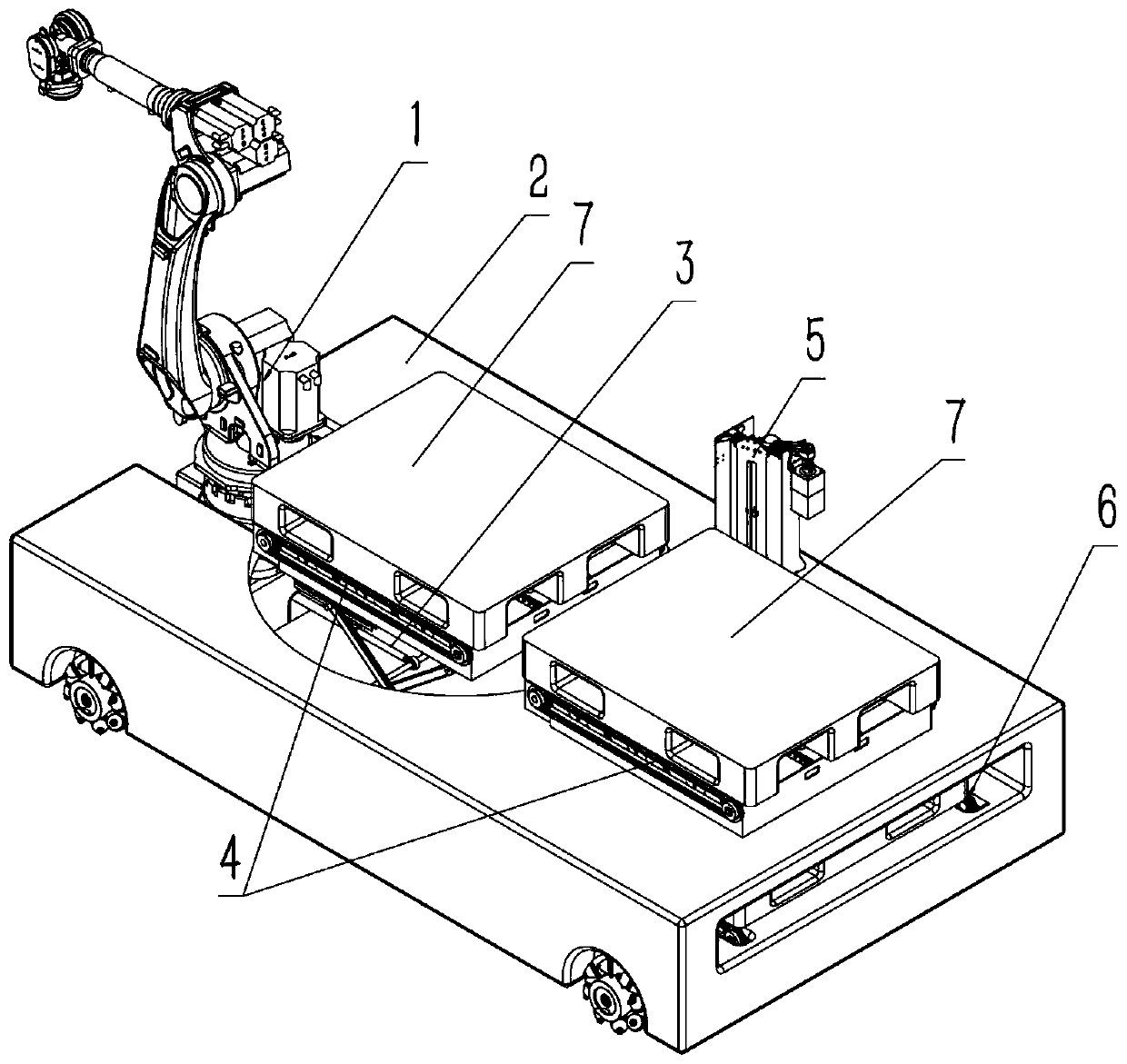

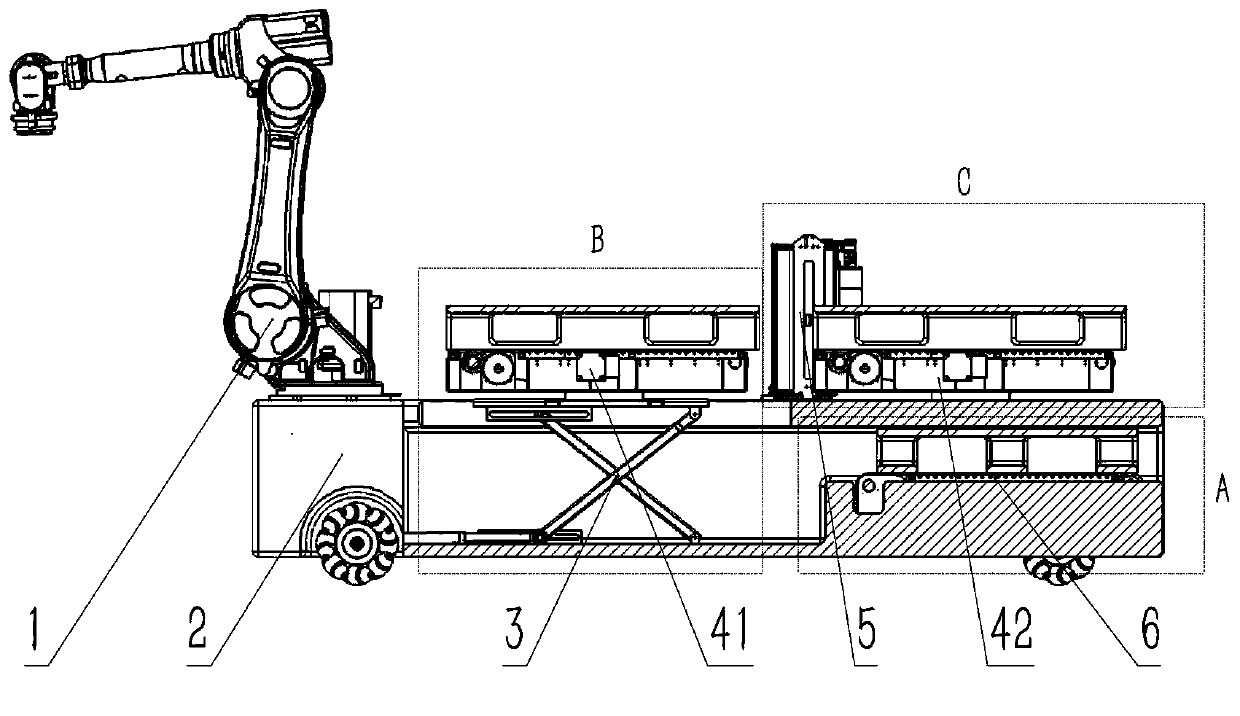

Compact loading and unloading mobile robot and loading and unloading method

PendingCN110239966AEfficient use ofShorten the lengthWrapping with article rotationStacking articlesEngineeringManipulator

The invention belongs to the technical field of loading and unloading robots and particularly discloses a compact loading and unloading mobile robot and a loading and unloading method. The compact loading and unloading mobile robot comprises an omnidirectional mobile platform, a manipulator arranged on the omnidirectional mobile platform, a pallet changer, a pallet lifting device, a pallet rotary delivering device and a film winding device, wherein the manipulator is positioned on one side of the omnidirectional mobile platform; the pallet changer is positioned on the other side of the omnidirectional mobile platform; the pallet lifting device is positioned between the manipulator and the pallet changer; the pallet rotary delivering device comprises a palletizing rotary delivering unit and a film winding rotary delivering unit; the palletizing rotary delivering unit and the film winding rotary delivering unit are respectively positioned above the pallet lifting device and the pallet changer; the film winding device is positioned on the side of the palletizing rotary delivering unit. The compact goods loading and unloading mobile robot can realize loading and unloading. The compact loading and unloading mobile robot disclosed by the invention has the advantages of simple structure, high efficiency and the like, and is suitable for loading and unloading goods in a narrow space.

Owner:HUAZHONG UNIV OF SCI & TECH

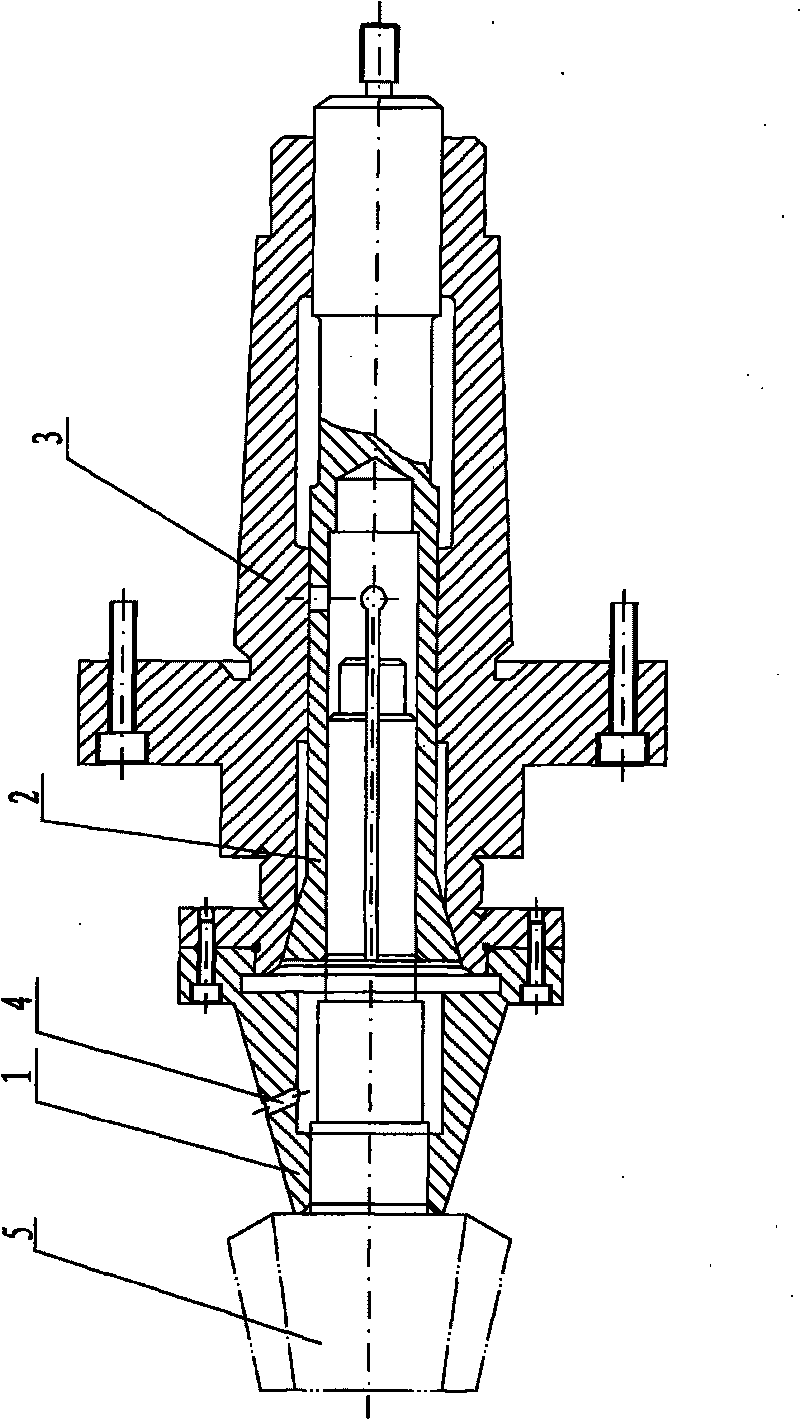

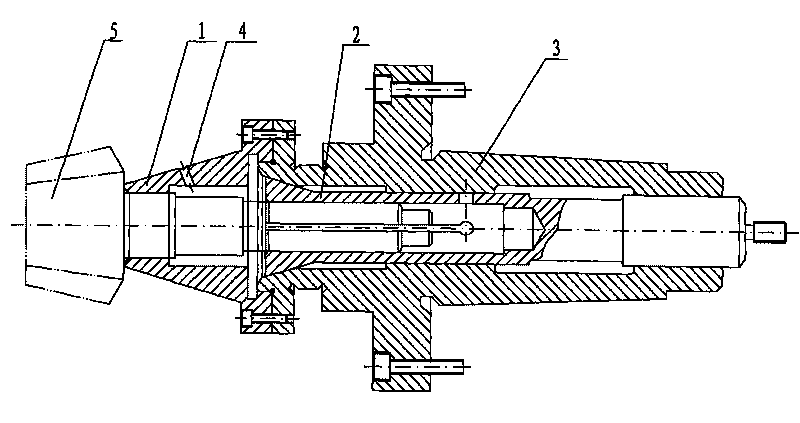

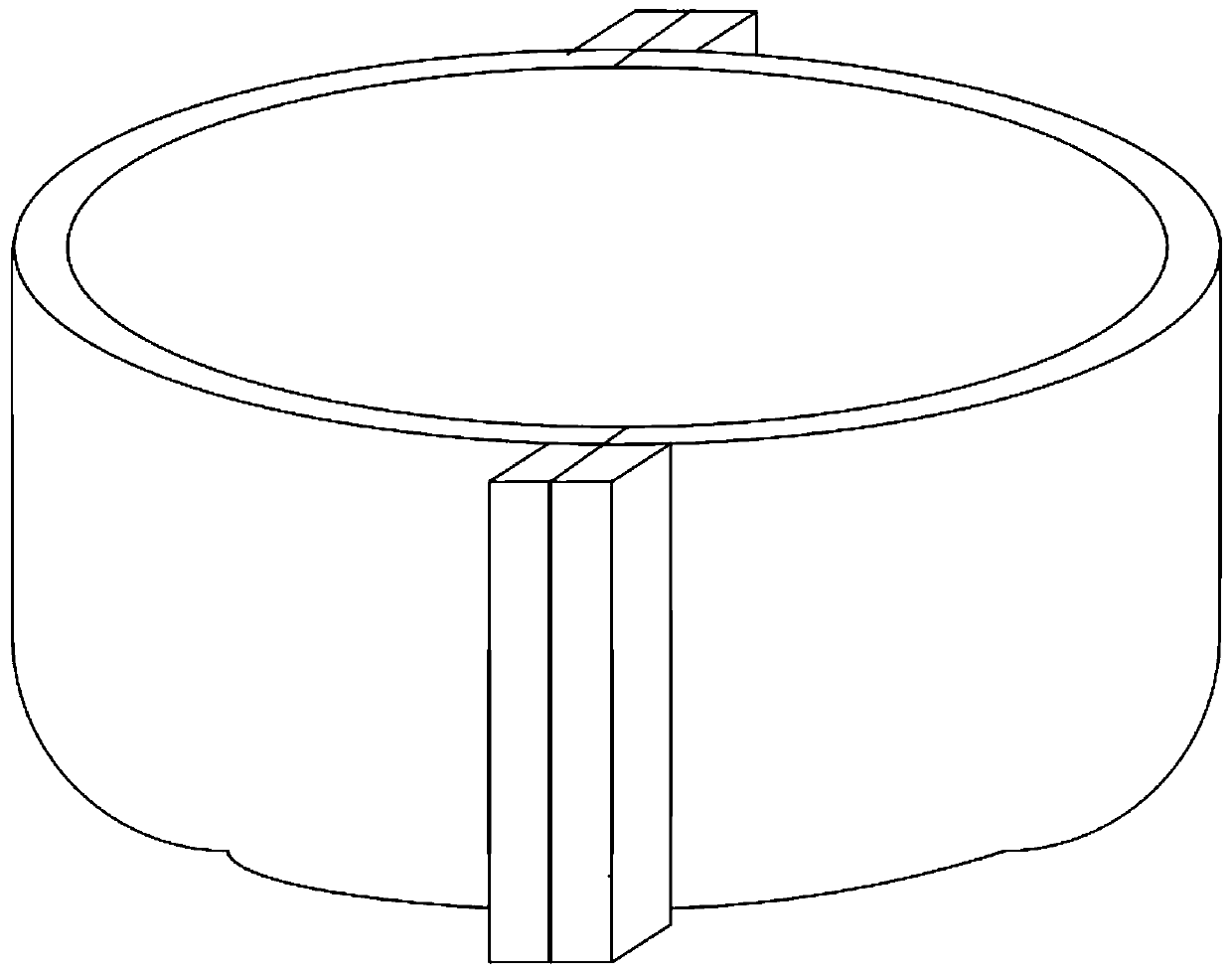

Gear milling positioning fixture for spiral bevel gear

InactiveCN101722339ASimple structureEasy to manufactureGear-cutting machinesGear teethEngineeringClosed cavity

The invention discloses a gear milling positioning fixture for a spiral bevel gear, which comprises a draw bar coaxially matched with an inner bore of a mandrel, and a chuck coaxially connected with the left end of the mandrel. The outer wall of the left end of the draw bar and the inner bore of the mandrel have a tapered expansion sleeve structure; the inner bore of the draw bar is in clearance fit with the shaft section of a workpiece; the inside of the chuck is provided with stepped holes; the inner bore at the left end is in clearance fit with the shaft neck of the workpiece; the chuck is provided with a through hole which pass through a large-diameter outer wall, because the through hole directly communicates the inside and outside of the chuck, the workpiece cannot form a closed cavity after being arranged, thus, the workpiece is easy to be disassembled and installed. The gear milling positioning fixture is particularly suitable to be matched with the fixture of the mandrel positioning structure.

Owner:JIANGSU AIRSHIP GEAR

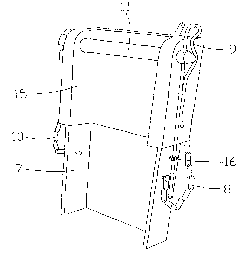

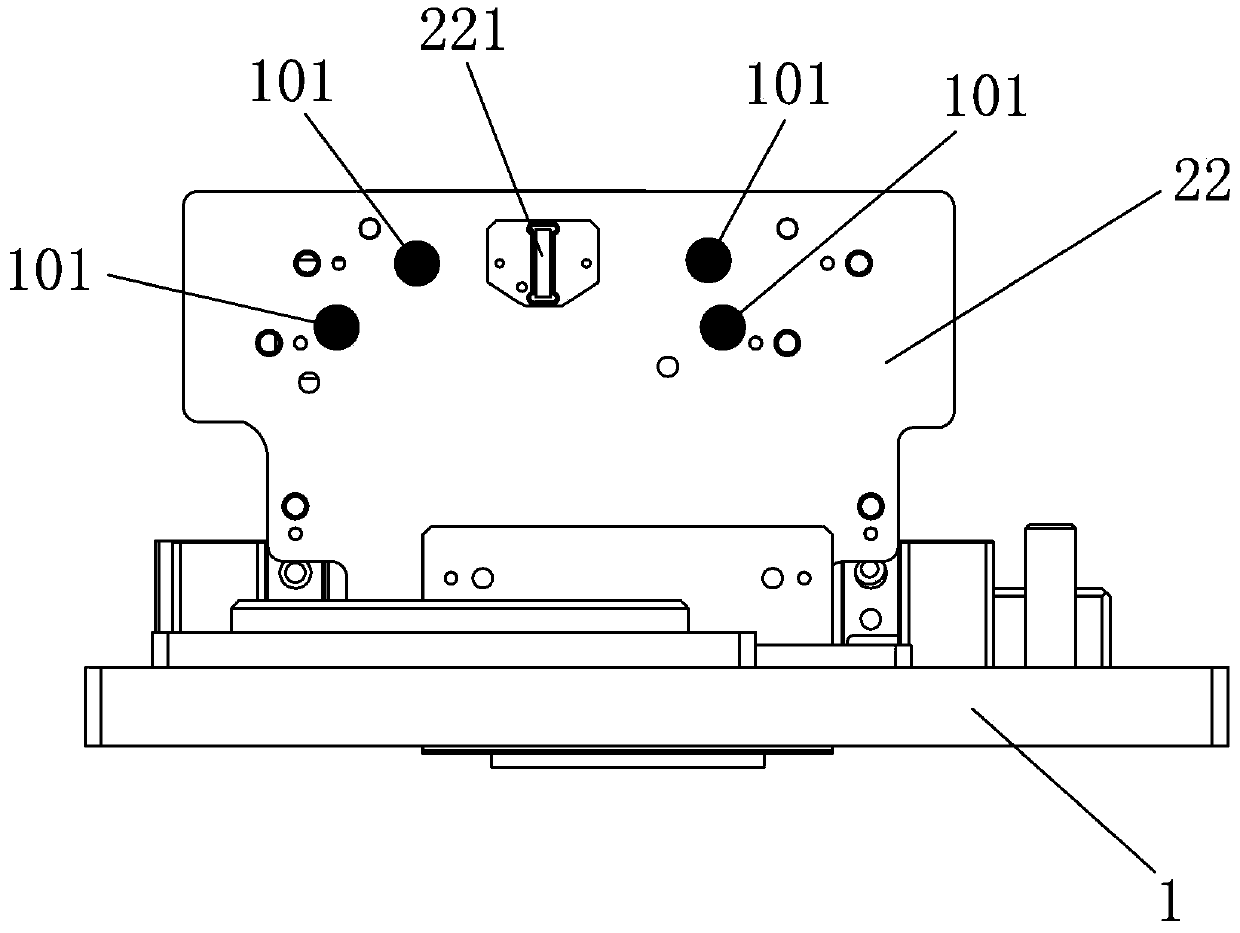

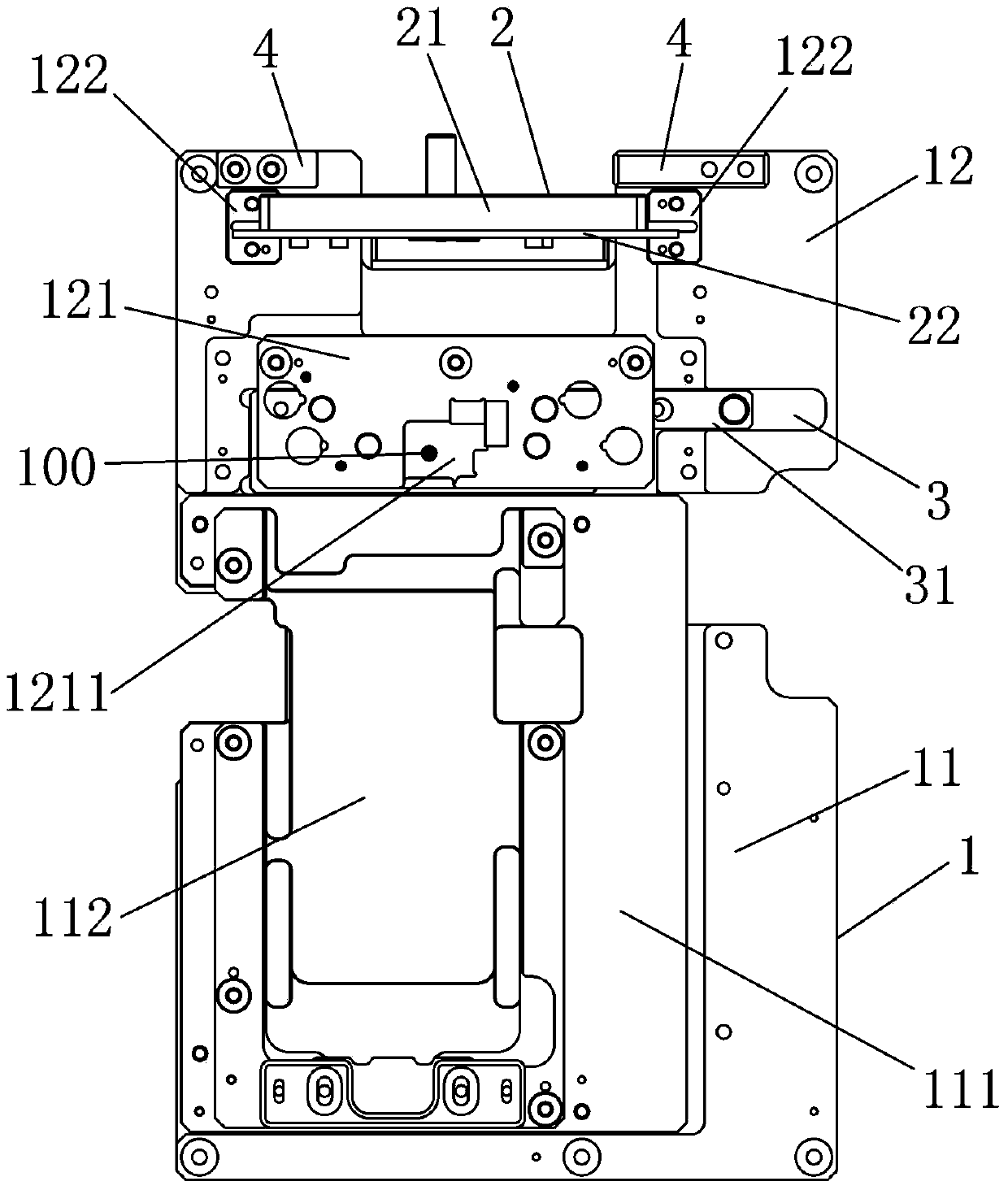

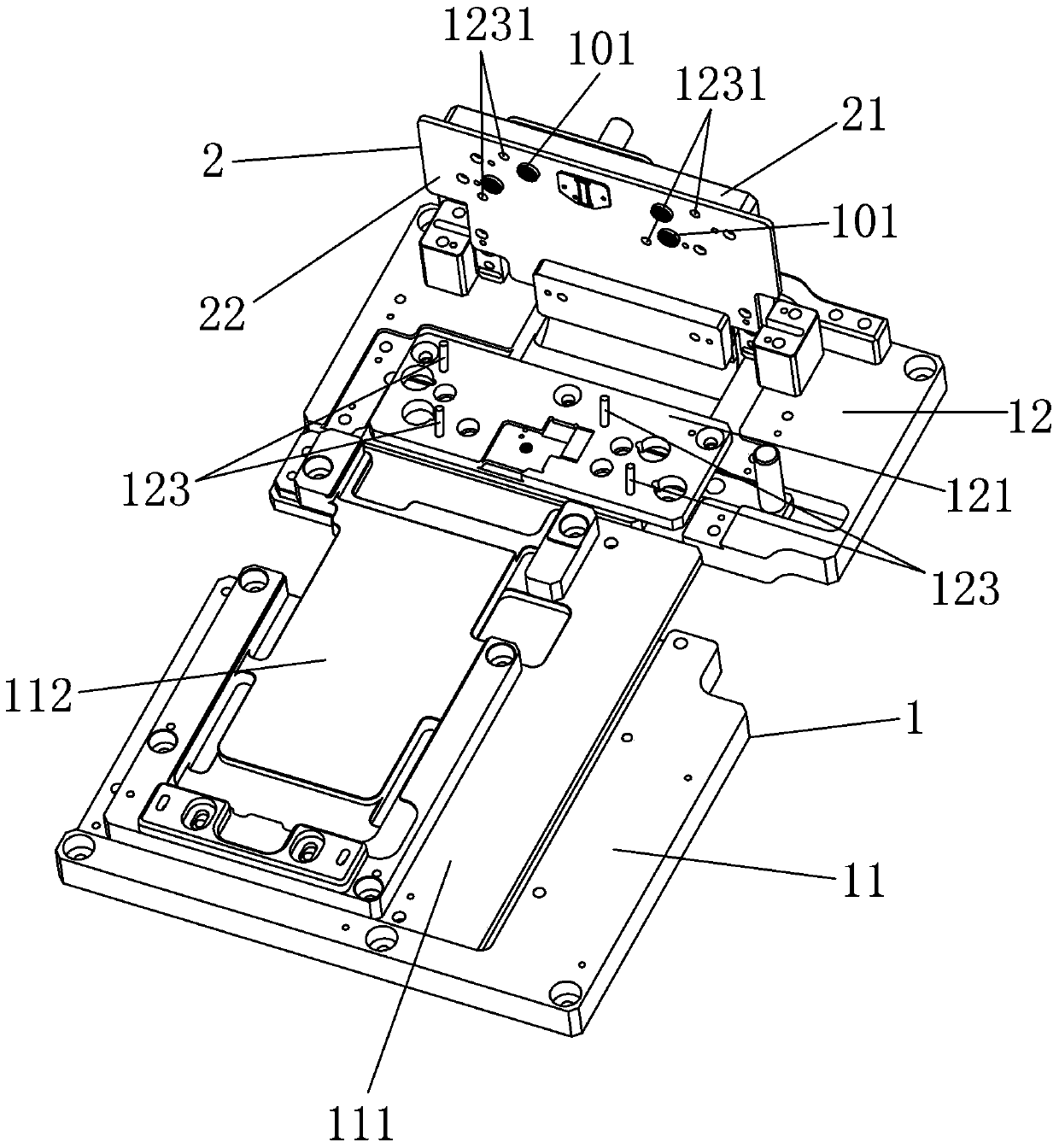

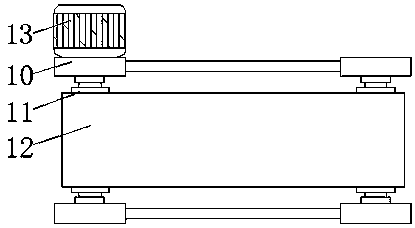

Detector for detecting liquid crystal module

ActiveCN103424902AEasy to operateHighly miniaturizedEngagement/disengagement of coupling partsMeasurement instrument housingEngineeringLiquid crystal

The invention discloses a detector for detecting a liquid crystal module. The detector comprises top plates and an overturn assembly, wherein the top plates comprise the first top plate and the second top plate, the first top plate is used for carrying the module to be detected, and the overturn assembly is arranged on the second top plate in a turnover mode; the overturn assembly comprises at least one substrate fixing plate, wherein at least one detection substrate is arranged on the substrate fixing plate, and the detection substrate is provided with at least one connector detection port used for detecting a connector of the module to be detected. According to the detector for detecting the liquid crystal module, the module to be detected is convenient to replace in the operation process, the fault rate of the connector detection ports on the module to be detected is reduced, the service life of the connector detection ports on the detection substrates is prolonged, production efficiency is effectively improved, and production cost is reduced.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

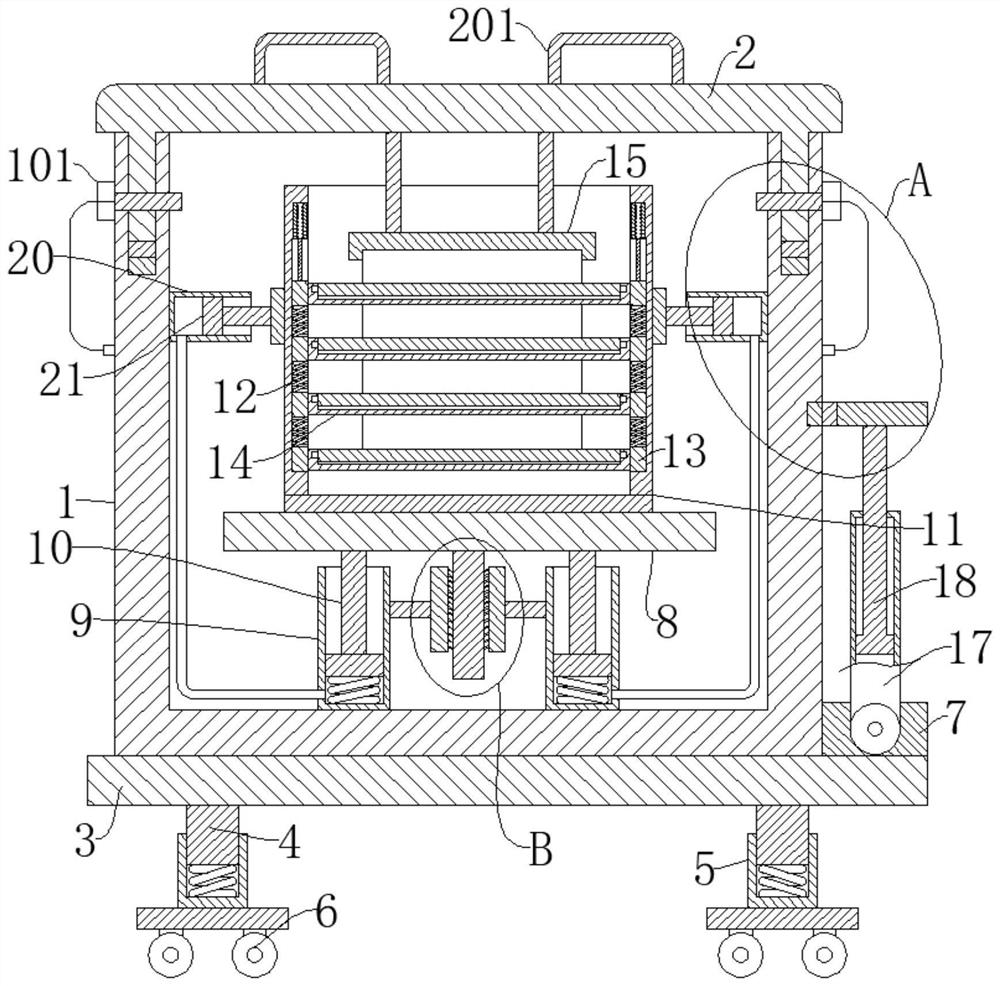

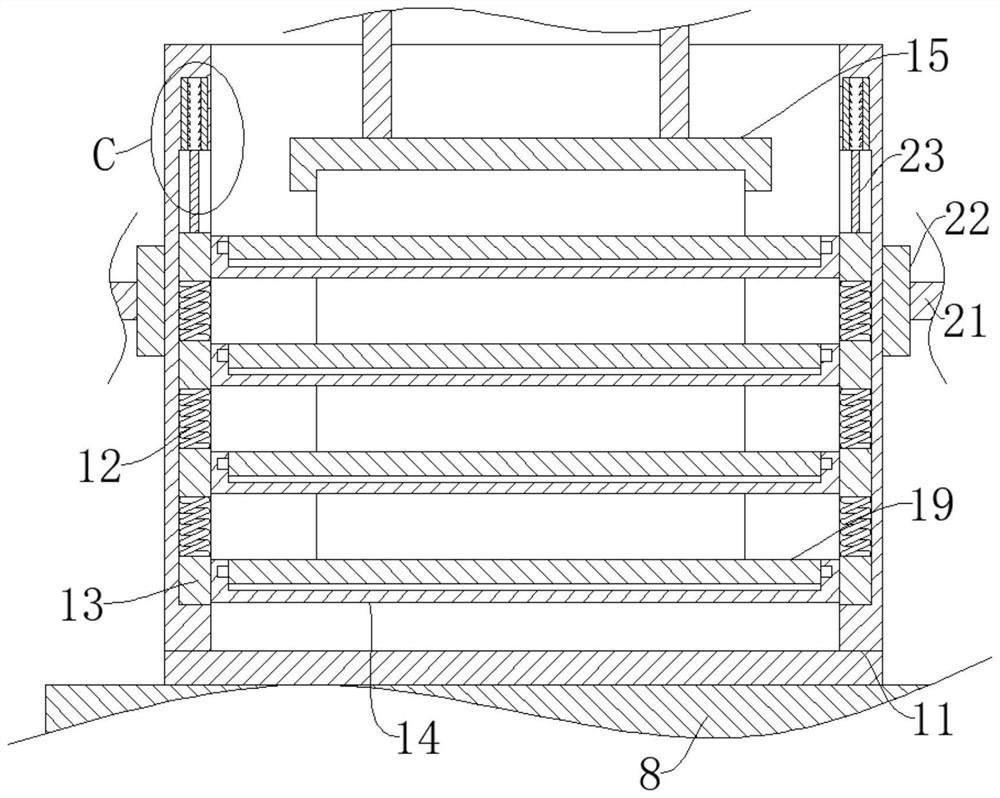

Mold conveying device for mechanical production

InactiveCN112407541AImprove stabilityPlay a shock absorbing roleClosure with auxillary devicesContainers to prevent mechanical damageProcess engineeringGas supply

Owner:深圳利朋技术研发有限公司

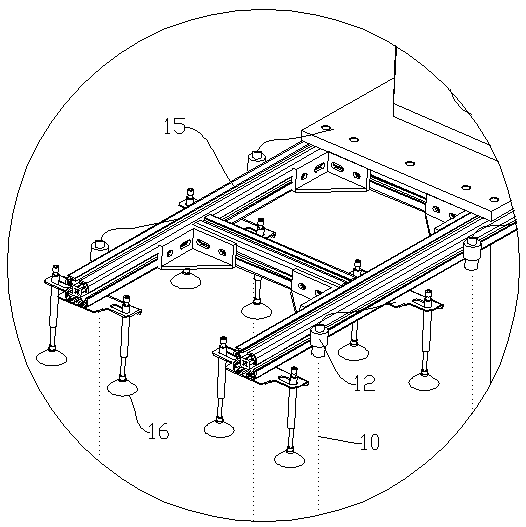

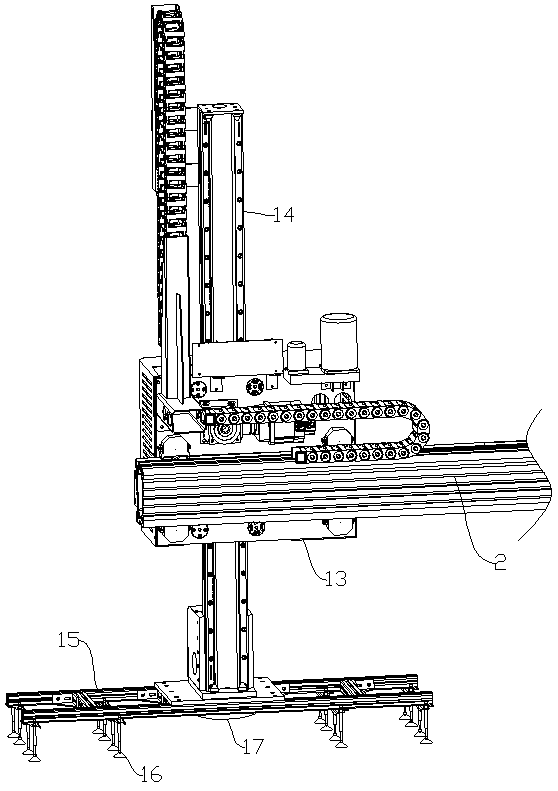

Automatic feeding and discharging bending machine

PendingCN111531055AReduce manufacturing costImprove efficiencyMetal-working feeding devicesPositioning devicesRobot handElectric machinery

The invention discloses an automatic feeding and discharging bending machine. A bending machine body and a feeding and discharging truss are included. The feeding and discharging truss comprises a beam and a sectional material mechanical arm arranged on the beam in a sliding manner. The sectional material mechanical arm comprises a vertical rod and two fixedly-connected linear motors, wherein onelinear motor slides on the beam, and the other linear motor slides on the vertical rod. A suction cup frame is arranged at the lower end of the vertical rod and provided with a plurality of suction cups. The automatic feeding and discharging bending machine has the beneficial effects that the bending machine can replace manual work for automatic feeding and discharging, the labor cost is effectively saved, meanwhile, the feeding and discharging speed is higher than the manual feeding and discharging speed, the production cost of enterprises is obviously reduced, enterprise benefits are improved, and practicability is good.

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

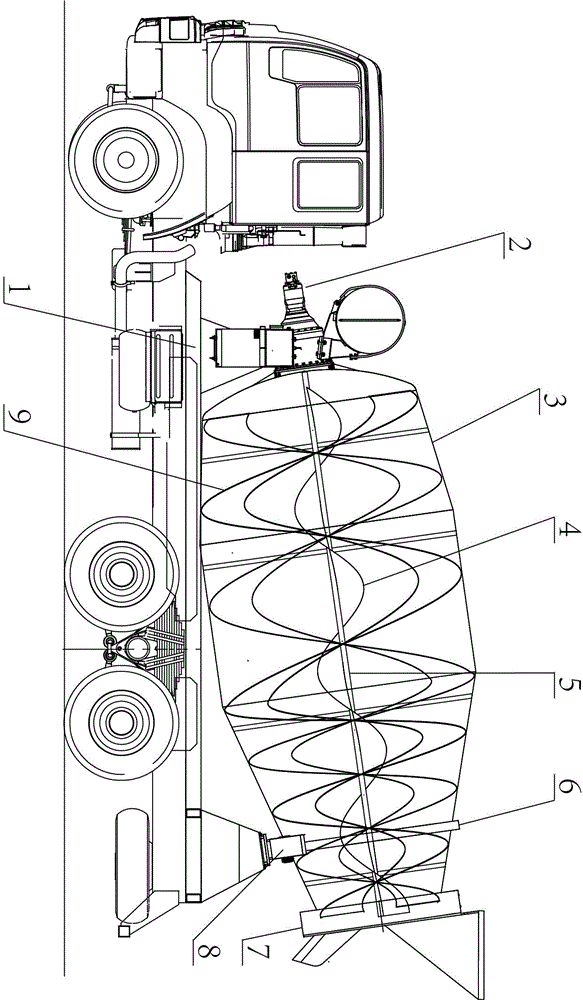

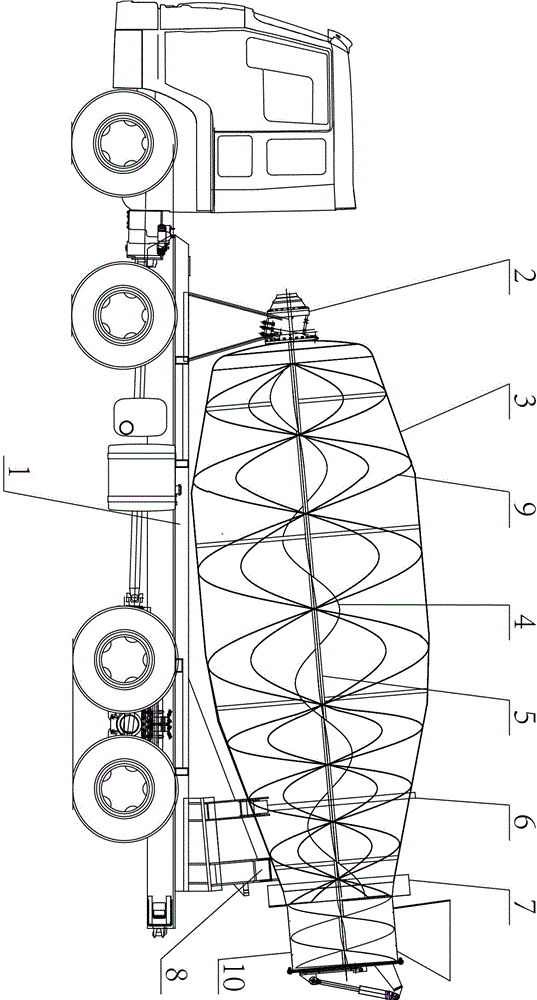

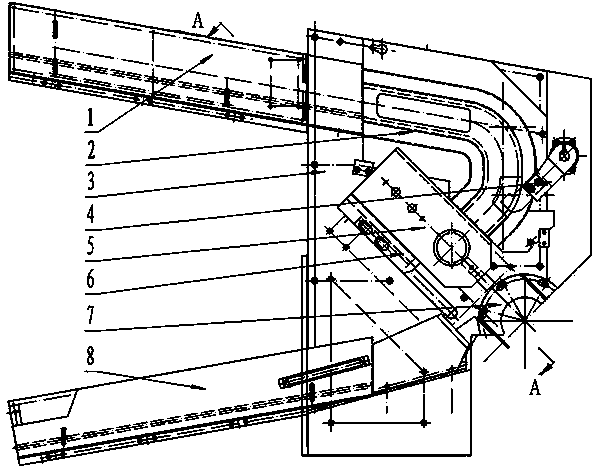

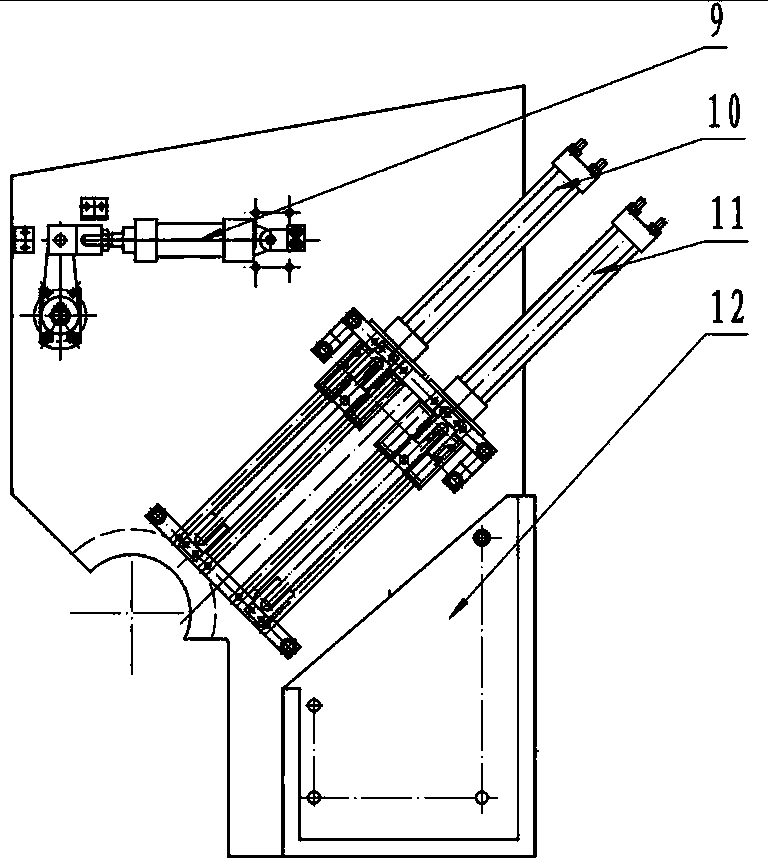

Composite screw transporting vehicle

ActiveCN104385462AStir wellImprove mixing uniformityDischarging apparatusCement mixing apparatusSludgeEngineering

The invention discloses a composite screw transporting vehicle. The rear end of a rotary material cylinder is connected with a rotary sealing mechanism, wherein a main screw blade is spirally mounted on the inner wall of the rotary material cylinder; a center shaft is arranged inside the rotary material cylinder; a secondary screw blade is mounted on the center shaft. The secondary blade and the main blade have synergistic effects. When the composite screw transporting vehicle is used as a high-viscosity concrete transporting vehicle or a sludge transporting vehicle, the loading and unloading rate is relatively high, and the utilization rate of the material cylinder is relatively high; when the composite screw transporting vehicle is used as a concrete transporting vehicle, the concrete is relatively uniformly stirred; the delamination is alleviated; the quality of the high-quality concrete is not influenced.

Owner:YANTAI SHENGLIDA ENG TECH

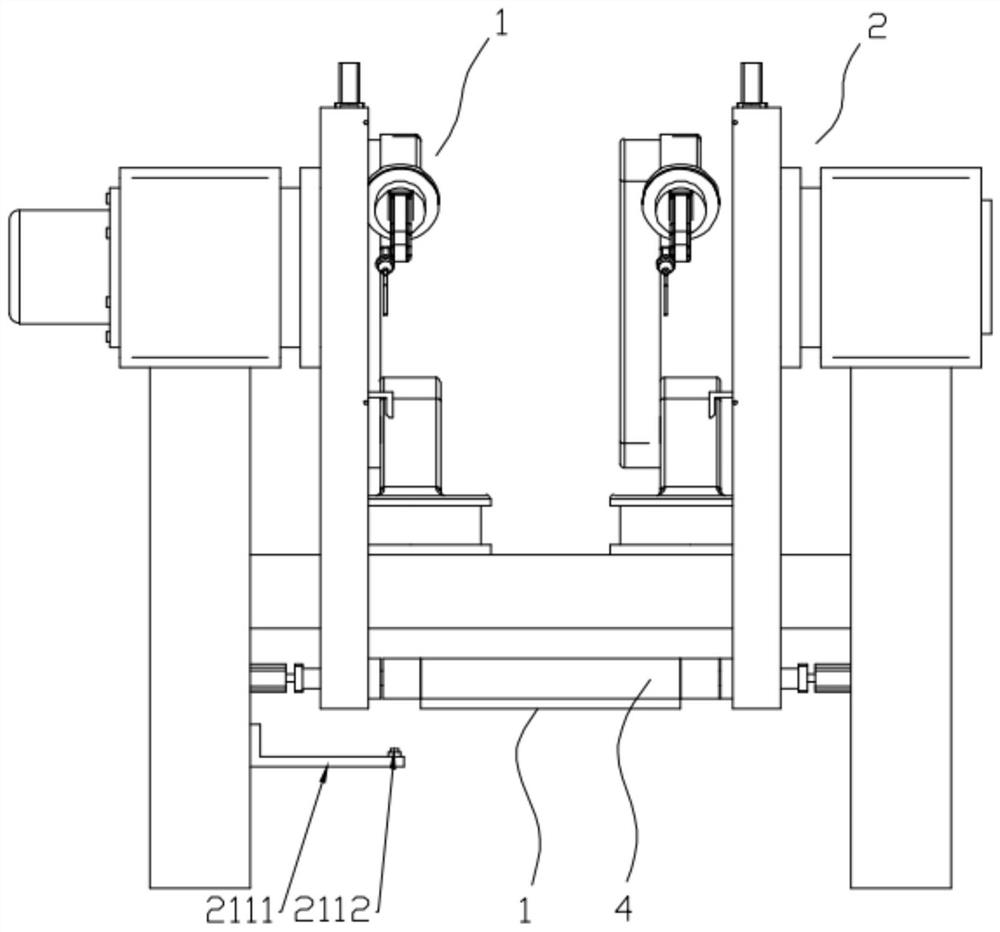

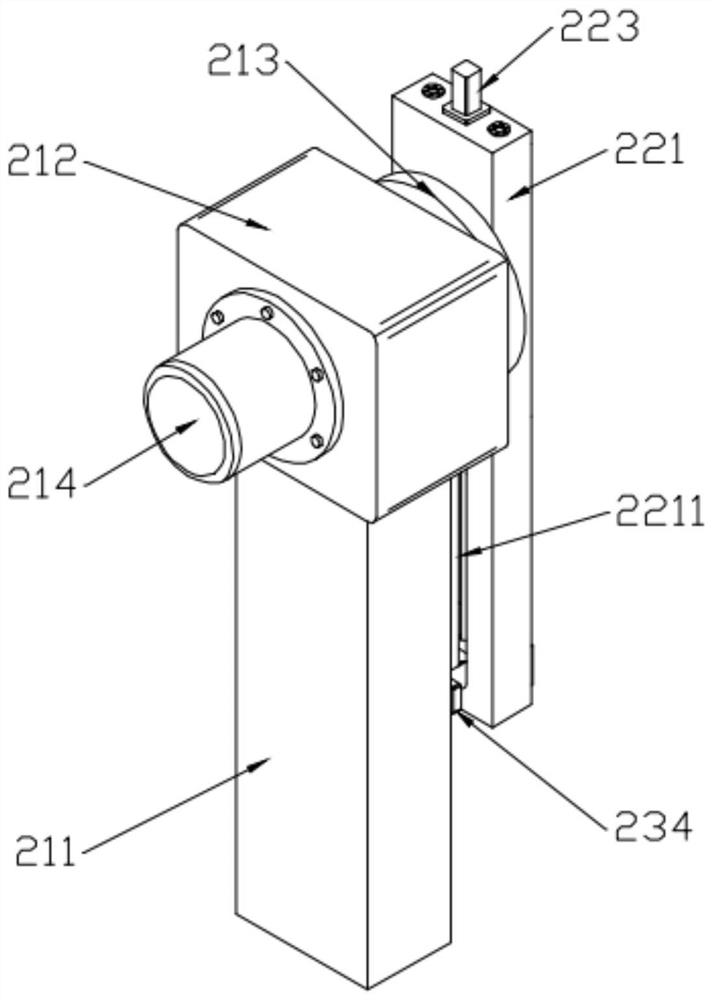

Charging and discharging device for outer circle groove grinder of automobile hub bearing unit, and application of device

ActiveCN103769977ALess mechanical actionFast loading and unloadingGrinding machinesGrinding feedersMachining timeBearing (mechanical)

The invention relates to a bearing grinder charging and discharging technology, in particular to a charging and discharging device for an outer circle groove grinder of an automobile hub bearing unit, and the application of the device. The charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit comprises a panel, wherein a charging channel, a transitional material channel, a discharging channel, a material separation oil cylinder, a main manipulator oil cylinder and an auxiliary manipulator oil cylinder are fixedly arranged on the panel; the charging channel is connected with the transitional material channel; a material separation manipulator is arranged on one side of the transitional material channel and is connected with the material separation oil cylinder; the main manipulator oil cylinder and the auxiliary manipulator oil cylinder are positioned at the tail end of the transitional material channel; a main manipulator is connected with the main manipulator oil cylinder; an auxiliary manipulator is connected with the auxiliary manipulator oil cylinder; a fan-shaped plate is arranged at a grinding station on the panel; the discharging channel is arranged at a position corresponding to the fan-shaped plate. Compared with a common charging and discharging device, the charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit has the advantages that waiting time for discharging and charging is not needed; the device is less in mechanical motion, high in charging and discharging speed and high in stability, the non-machining time is greatly shortened, and the efficiency is improved.

Owner:PUYANG BEAIN CNC MACHINERY & EQUIP

Automatic punching machine special for rice cooker inner container

ActiveCN110180964AFast clamping speedEasy to removeShaping toolsMetal-working feeding devicesPunchingEngineering

The invention relates to the field of rice cooker producing and machining equipment, in particular to an automatic punching machine special for a rice cooker inner container. The automatic punching machine special for the rice cooker inner container comprises a workbench, lower dies, a fixing frame, a second telescopic mechanism and an upper die; the upper surface of the workbench is provided witha sliding groove, a double-way screw is installed in the sliding groove and sleeved with supporting blocks, and the supporting blocks are in threaded connection with the double-way screw; the lower dies are hinged to the supporting blocks; and the fixing frame is fixedly connected to the upper surface of the workbench, the second telescopic mechanism is installed on the top of the fixing frame, and the upper die is fixedly connected to the lower end of the second telescopic mechanism. A to-be-punched part is clamped by a clamping mechanism, therefore, the to-be-punched part keeps stable, andthe clamping speed is high; punching operation is completed through cooperation of the lower dies and the upper die; the lower dies keep an inclination state through springs and ejection rods, therefore, people can conveniently take down the punched rice cooker inner container, and the assembling and disassembling speed is high; and a moving mechanism is arranged, and therefore the device can be conveniently pushed to move.

Owner:磐安途舛信息科技有限公司

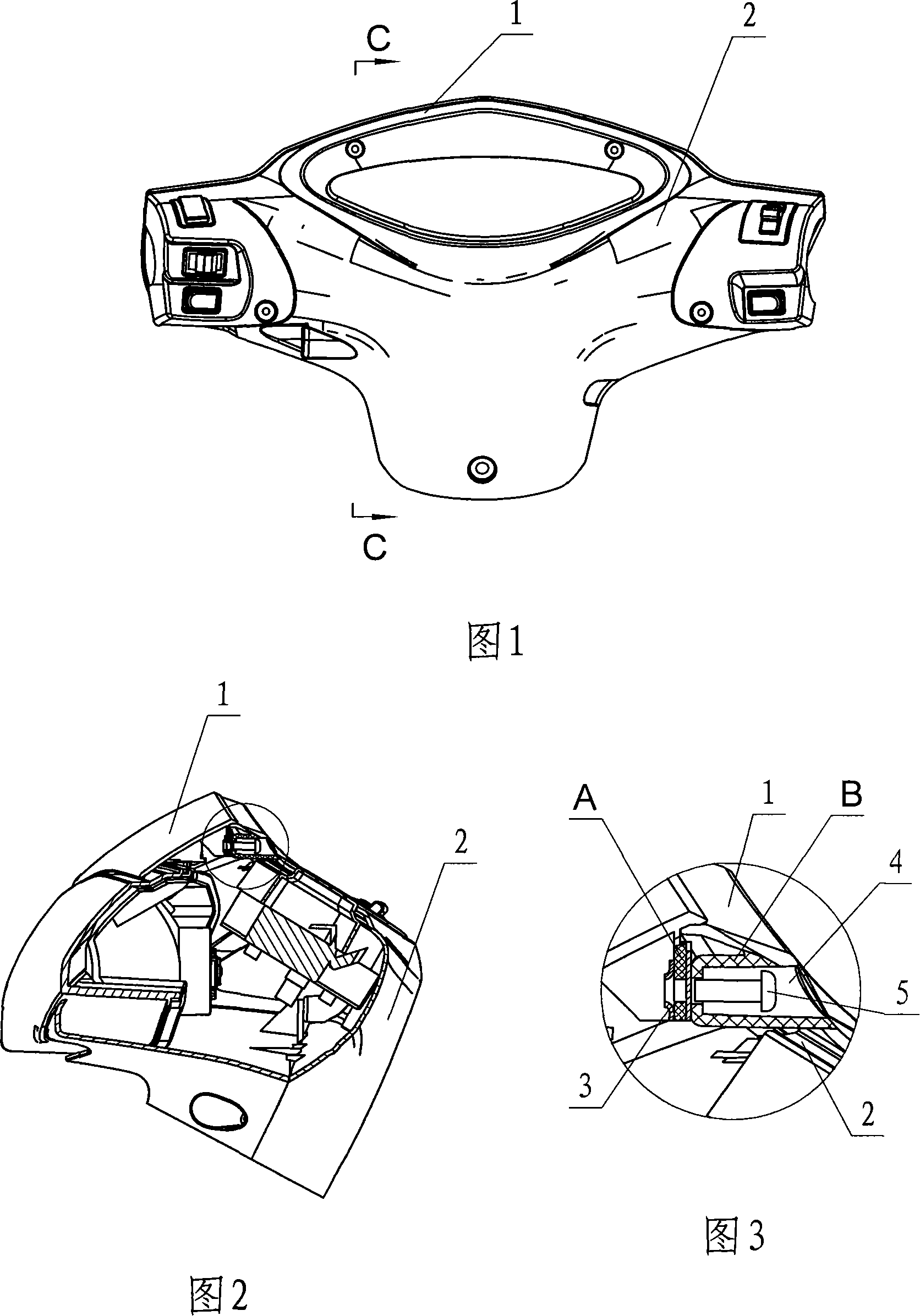

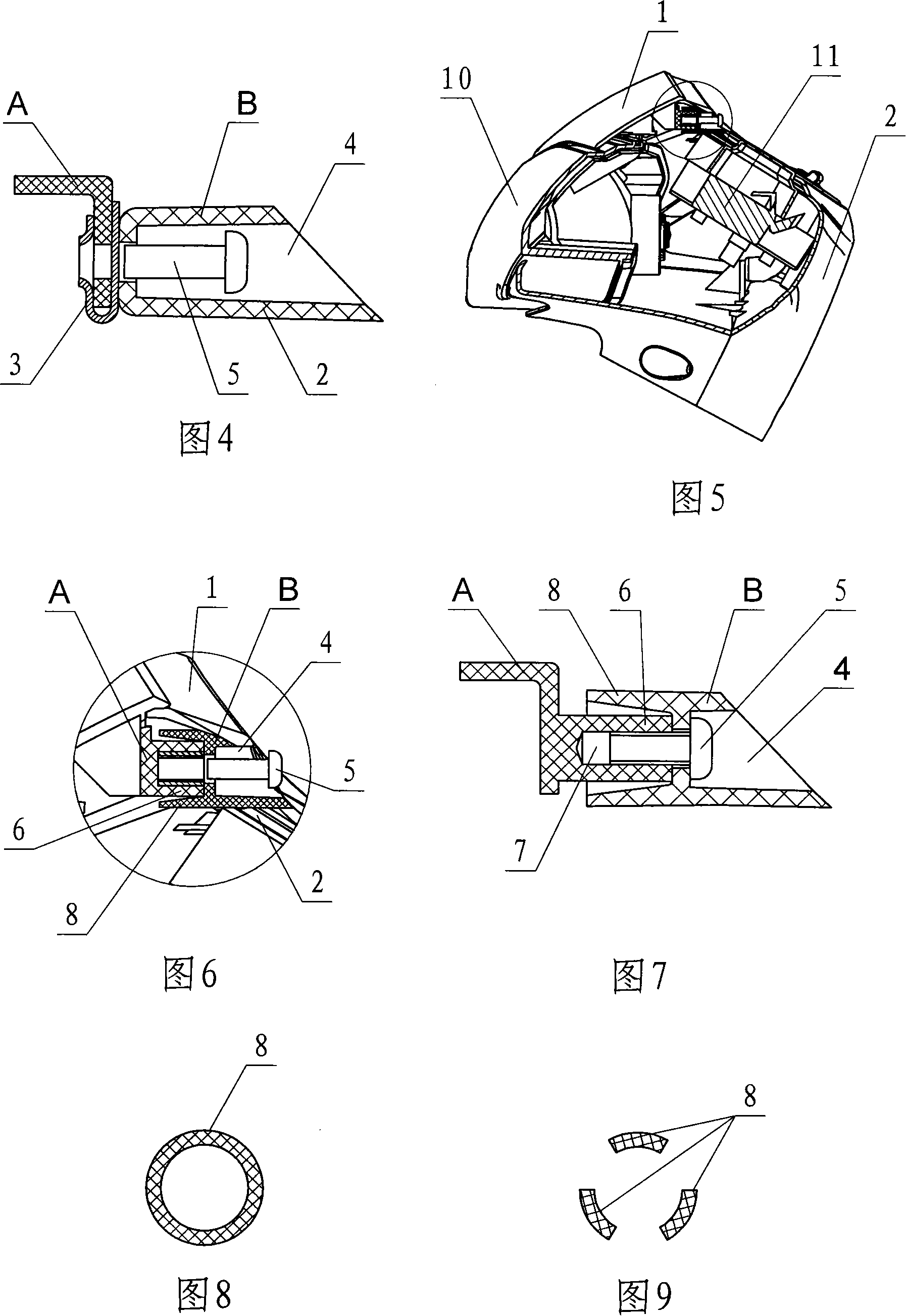

Motorbicycle lamp shade mounting and connection structure

InactiveCN101149138AEasy loading and unloadingFast loading and unloadingGlobesRoad vehiclesElectrical and Electronics engineering

This invention is a motor vehicle lamp shade assembly connecting structure. It includes connecting base on the lamp shade and connecting base on the meter shade. There is counter bore on the connecting base of meter shade. There is projection on the connecting base of lamp shade. Screws, which match the counter bores, are arranged in axial direction on the projection. The screw and counter bore are connected through bolt. Guiding element, which matches the said projection, is arranged on the connecting base of meter shade. This invention is simple and convenient.

Owner:CHONGQING LONCIN MOTOR

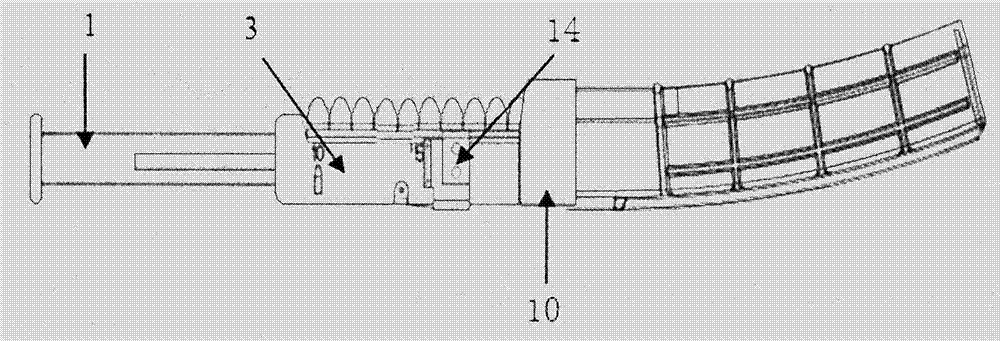

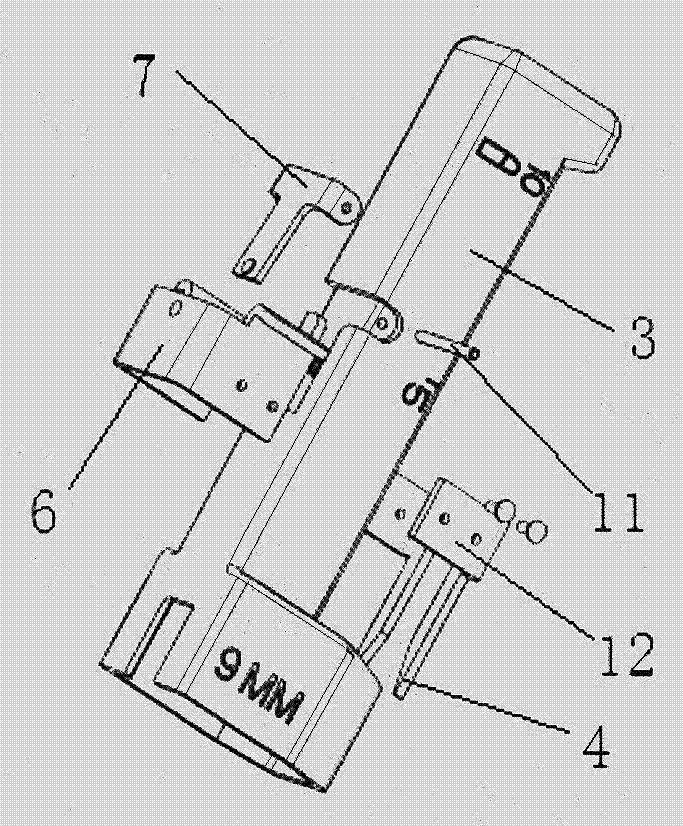

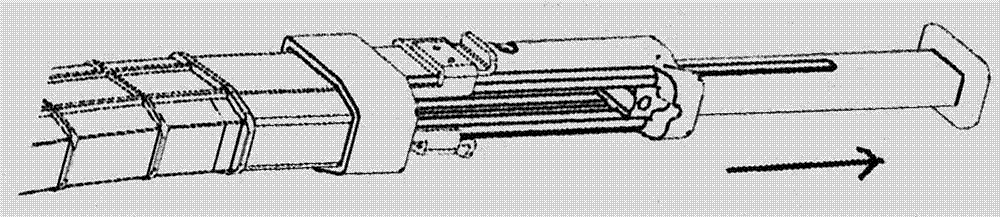

Bullet charging and discharging device and quick bullet charging and discharging method thereof

ActiveCN107228594AQuick to useSmall sizeCartridge extractorsAmmunition loadingEngineeringSlide plate

The invention provides a bullet charging and discharging device which comprises a bullet containing groove, a bullet push rod and a bullet discharging device. The bullet containing groove is provided with a front bag opening movably connected with a box magazine. Sliding grooves are formed in the two inner side walls of the bullet containing groove, the bullet push rod is a strip-shaped cube, and boss keys matched with the sliding grooves are arranged on the two outer side walls of the bullet containing groove. A back bag opening is formed in the back end of the bullet containing groove, a limiting groove is formed in the back bag opening, and a limiting clamping tenon is arranged at the front end of the bullet push rod and is movably matched with the limiting groove. The bullet discharging device comprises a T-shaped positioning bullet sheet, an L-shaped insertion needle and a U-shaped sliding plate. The invention further provides a quick bullet charging and discharging method for the bullet charging and discharging device. The bullet charging and discharging device has the beneficial effects that bullet charging and discharging are convenient, machining, assembling and adjusting are facilitated, the working state is stable and reliable, the manufacturing cost is low, carrying is easy, the bullet charging and discharging device is suitable for being used in all-weather environments, quick bullet charging is achieved, the failure rate is approximately zero, the bullet discharging device can be easily and stably used, and quick bullet discharging is achieved.

Owner:贺佳琪 +1

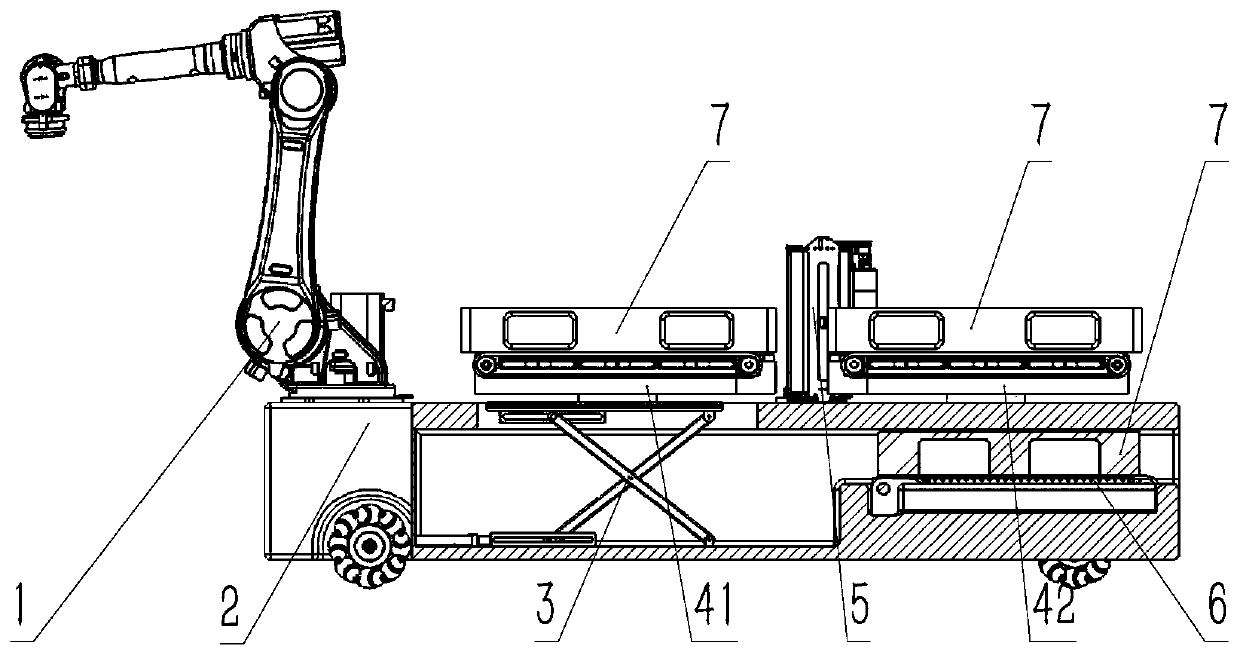

Automatic conveying flower basket buffer storage station based on AGV trolley

ActiveCN111115146AIncrease profitReduce waiting timeControl devices for conveyorsMechanical conveyorsAgricultural engineeringMechanical engineering

The invention discloses an automatic conveying flower basket buffer storage station based on an AGV trolley. The automatic conveying flower basket buffer storage station comprises a waiting position,a working position and a buffer storage position which are in butting connection in sequence. A waiting position conveying line used for conveying trays is arranged in the waiting position. A workingposition conveying line used for conveying the trays is arranged in the working position. A buffer storage position conveying line used for conveying the trays is arranged in the buffer storage position. The trays are used for loading flower baskets. A tray locating mechanism used for locating the trays is arranged in the working position. On the waiting position conveying line, the trays are input through the AGV trolley, and on the buffer storage position conveying line, the trays are output through the AGV trolley. There is no need to wait in the feeding and discharging process of the flower baskets from the AGV trolley to a manipulator. The feeding and discharging waiting time of the flower baskets is shortened. The feeding and discharging speed of the flower baskets is increased. Theconveying efficiency of the flower baskets is improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

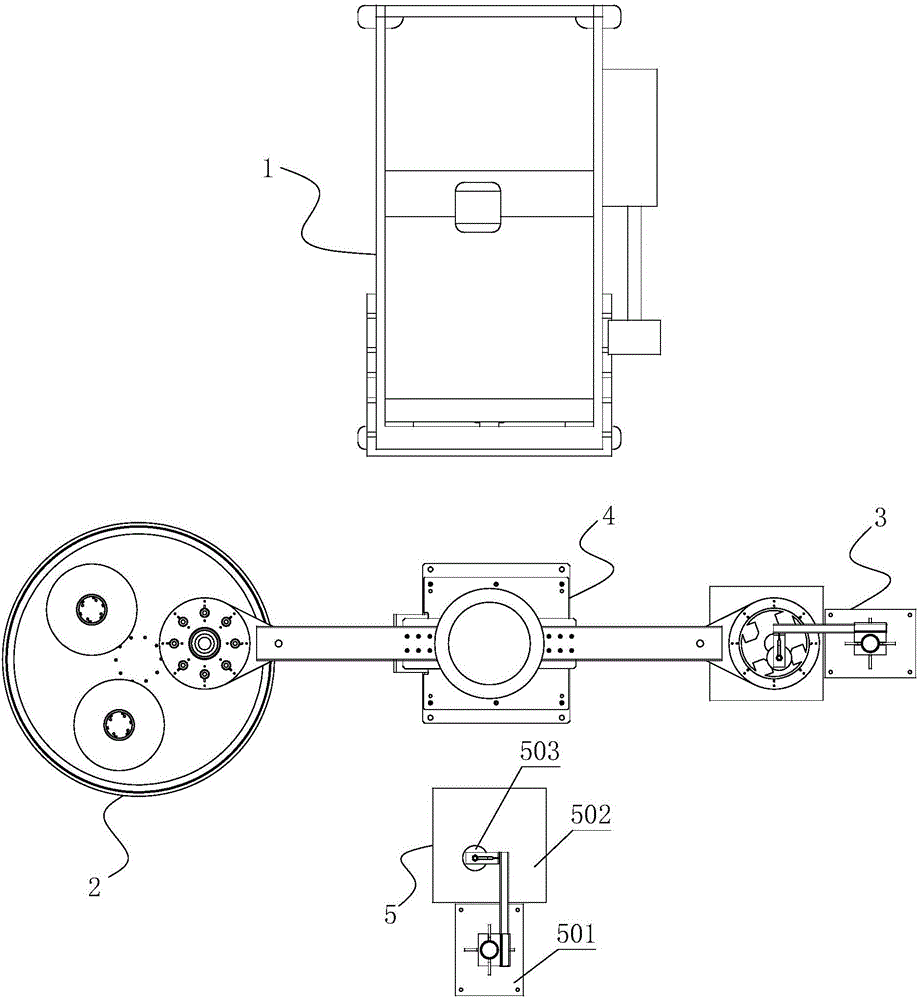

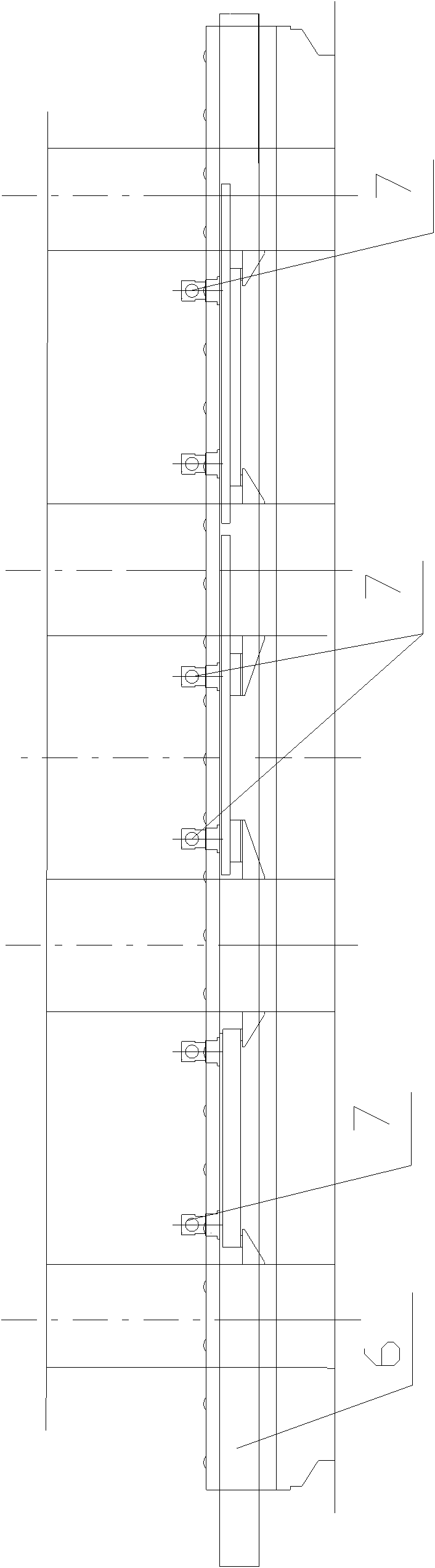

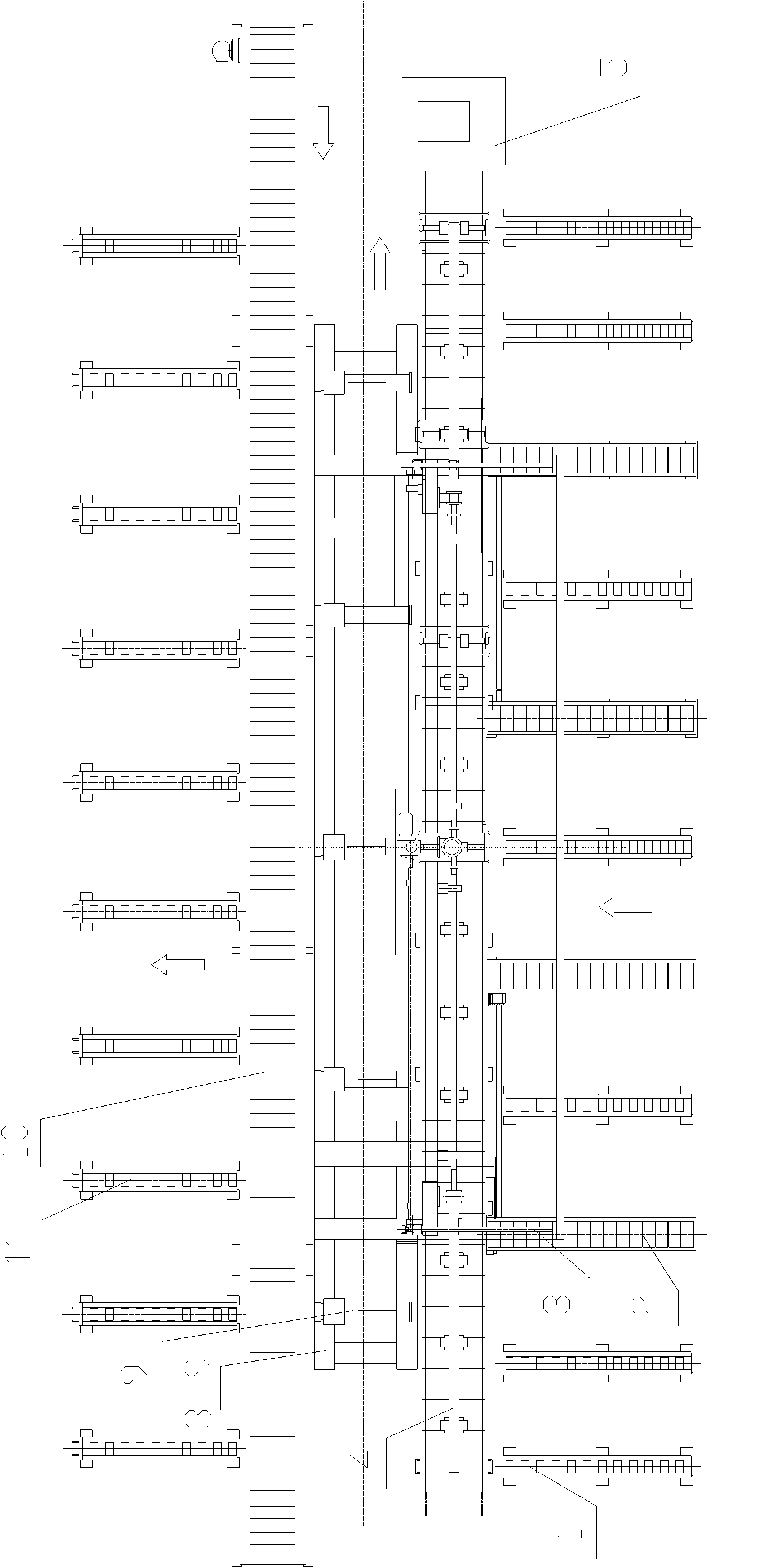

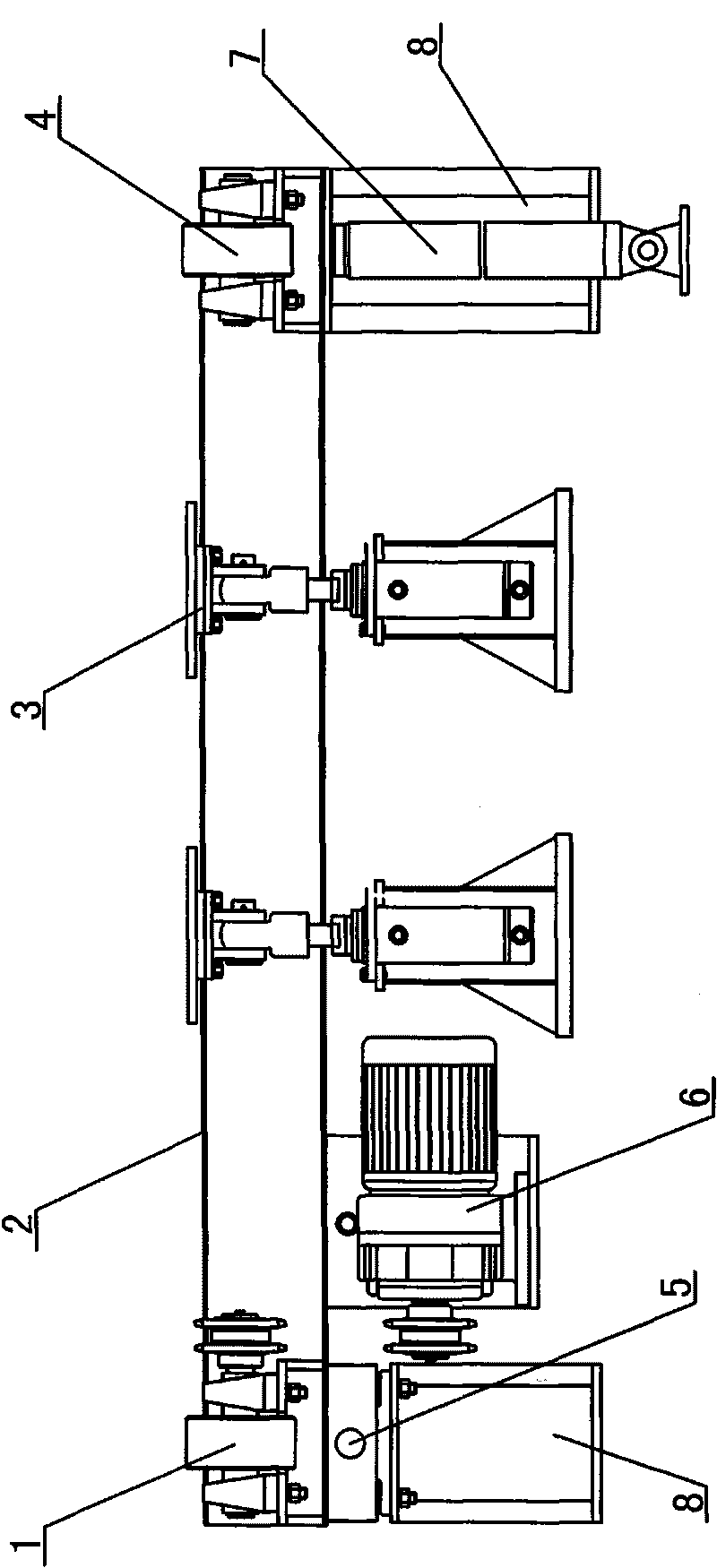

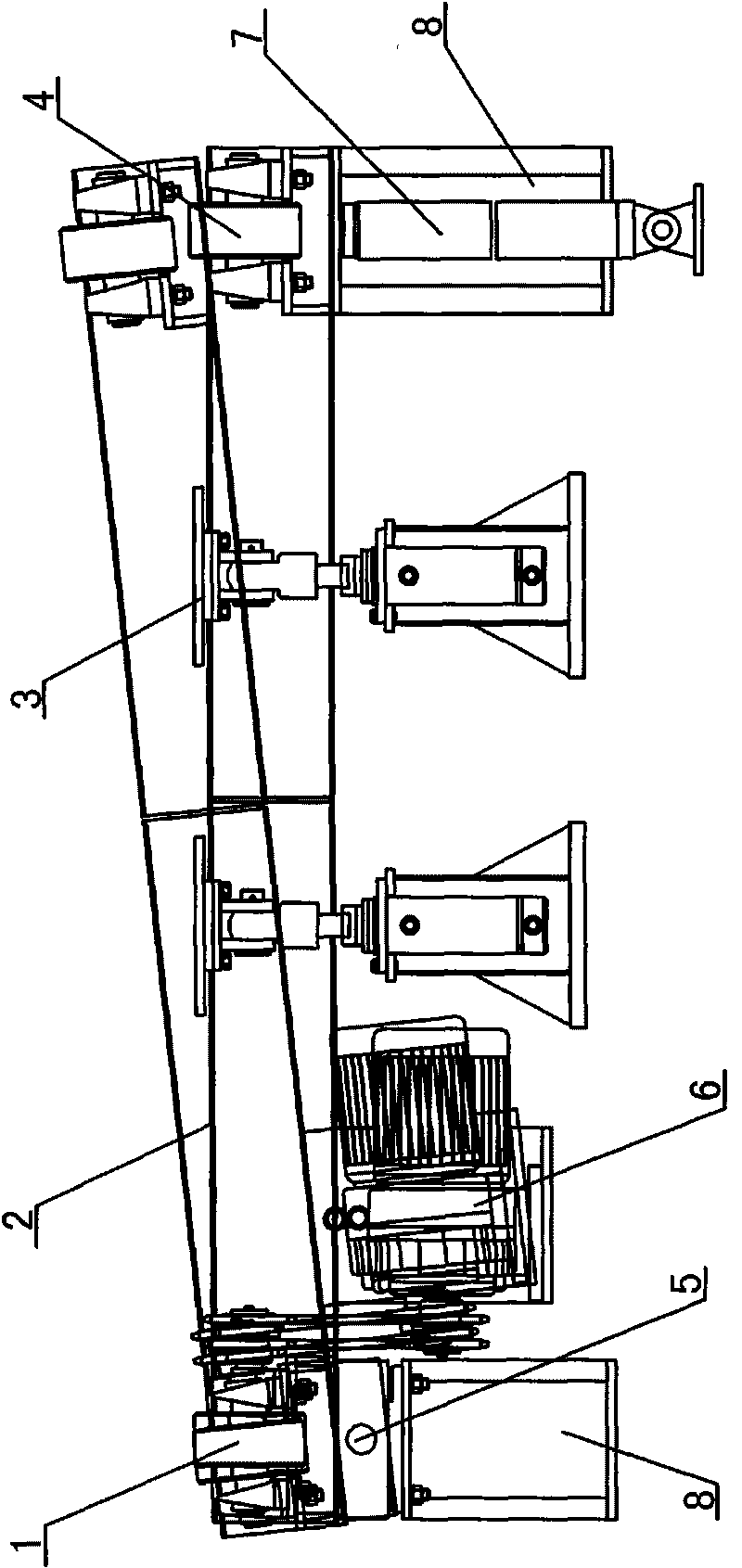

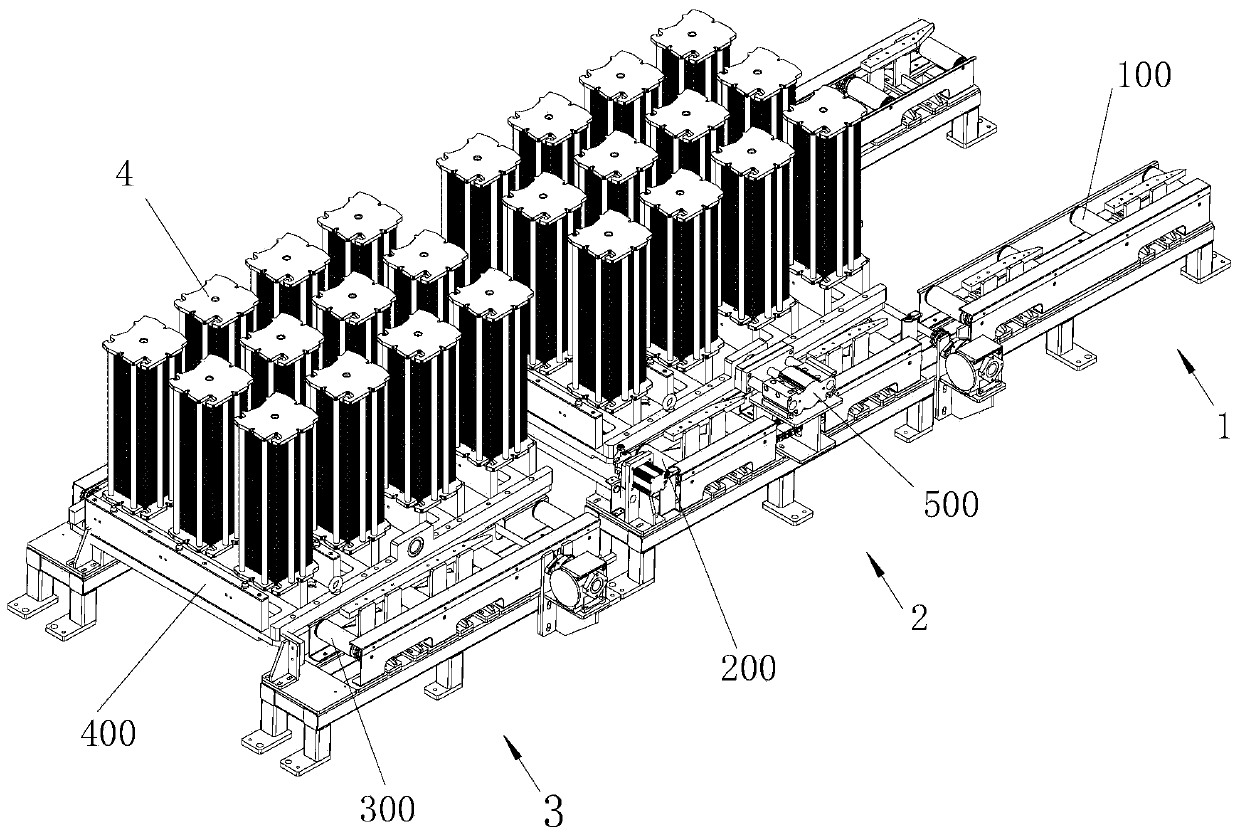

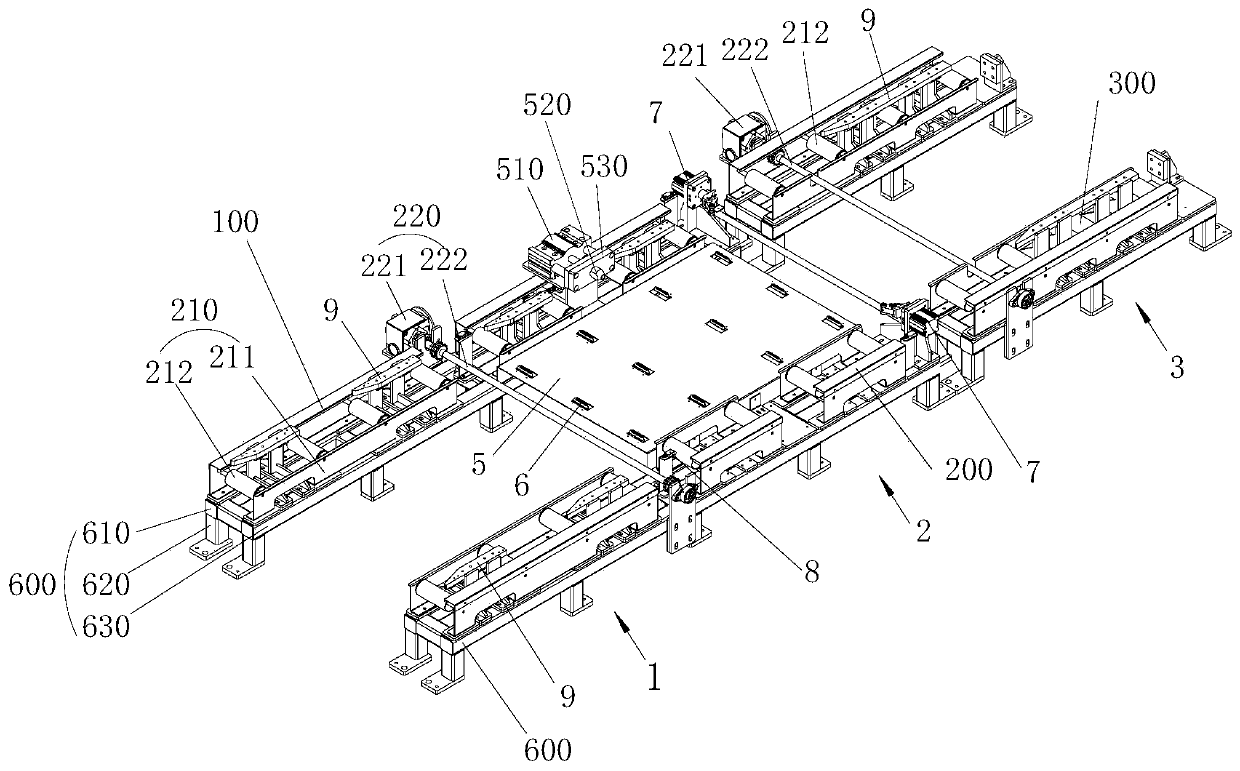

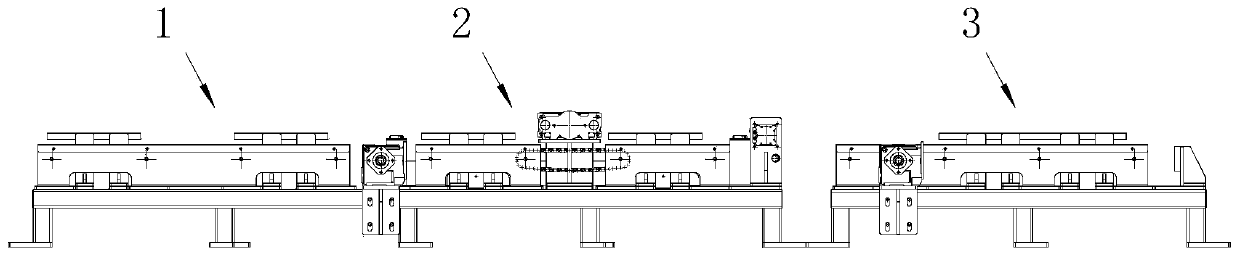

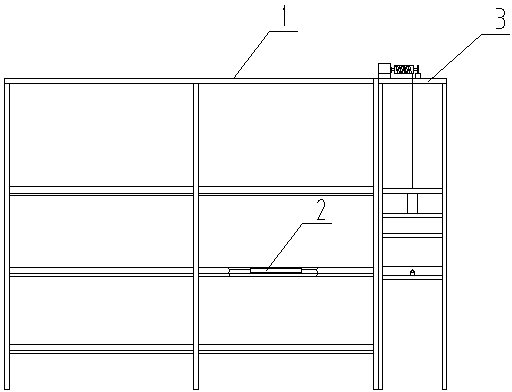

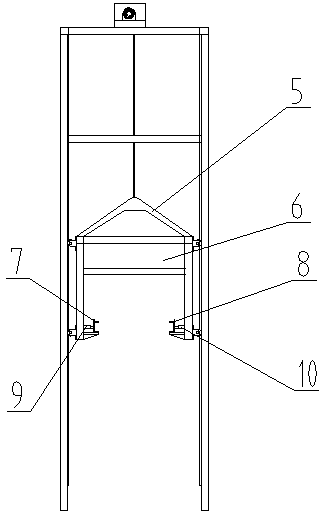

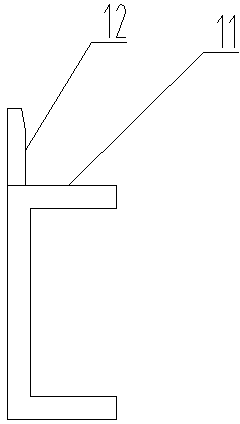

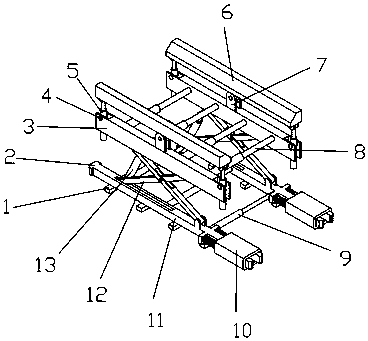

Shuttle-type stereoscopic warehouse unit

ActiveCN104925441AAccurate and reliableRealize automatic chargingStorage devicesMechanical conveyorsPush and pullLinear motion

The present invention discloses a shuttle-type stereoscopic warehouse unit. The stereoscopic warehouse unit comprises a column of multilayer penetrating type storage shelves (1), a shuttle vehicle (2) and an elevator (3). Goods are supported through two shuttle vehicle guide rails positioned at two sides of a lifting platform, the shuttle vehicle guide rails are driven by a transverse moving mechanism to transversely move in a reverse direction, the goods can be loaded and unloaded through reverse transverse moving of the shuttle vehicle guide rails and elevating motion of the lifting platform, transverse moving distance of the guide rails is short when the goods are loaded and unloaded, and consumed time of the transverse moving process is short. An automatic electrical connection device is installed in a charging room over the lifting platform, a stirring rod rotating around a rotation center stirs a positioning seat fixedly installed on the shuttle vehicle to enable the shuttle vehicle to tightly attached to a backplate, a plug is aligned to the center of a socket, automatic plugging of the plug and the socket is achieved in a manner that a linear motion mechanism pushes and pulls the plug, operation is convenient, and the shuttle vehicle can be automatically charged.

Owner:毕玉玲

Automatic automobile exhaust pipe welding production line

InactiveCN112338396ARealize automatic lockingAchieve liftingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineAssembly line

The invention discloses an automatic automobile exhaust pipe welding production line, and relates to the field of automatic equipment. The automatic automobile exhaust pipe welding production line comprises a conveying mechanism, a position changing mechanism and a welding robot, wherein the conveying mechanism is used for conveying a welding tool to each station; the position changing mechanism is used for lifting the welding tool located on the conveying mechanism and enabling the welding tool to rotate; the welding robot is installed on a robot workbench and used for being matched with theposition changing mechanism to weld a product on the welding tool; and in the conveying direction of the conveying mechanism, the workbench is located on one side of the position changing mechanism. The automatic automobile exhaust pipe welding production line is based on the assembly line type production principle, the welding tool is arranged on the conveying mechanism so that the welding tool can reach each station to achieve different treatment processes, when the welding tool reaches the welding station, automatic locking, lifting and rotating of the welding tool can be achieved by meansof the position changing mechanism so as to be matched with the welding robot to carry out corresponding welding operation, manual feeding and discharging are omitted, and the welding efficiency is remarkably improved.

Owner:季学良

Grinding device with clamping function for bearing machining

InactiveCN109129055AFast processSanding works fastRevolution surface grinding machinesGrinding work supportsEngineeringGrinding process

The invention discloses a grinding device with a clamping function for bearing machining. The grinding device comprises a workbench. The top of the workbench is fixedly connected with a grinding mechanism, a clamp is slidingly connected to the portion, located below the grinding mechanism, of the top of the workbench, and the bottom of the workbench is fixedly connected with a dust removal mechanism. The workbench comprises a tabletop. The two sides of the bottom of the tabletop are fixedly connected with landing legs, and the top of the tabletop is fixedly connected with a protective cover. Through the cooperative use of the workbench, the grinding mechanism, the clamp and the dust removal mechanism, a bearing can be turned over and moved in the bearing grinding process, it is better guaranteed that grinding work is rapidly carried out, the grinding efficiency is greatly improved, ground chippings can be adsorbed in the grinding process, the bearing does not need to be ground regularly, it is better guaranteed that the grinding work is rapidly carried out, and great convenience is brought to the grinding work.

Owner:LEIYANG XINDAWEI TECH

Pressing wheel mechanism for motor synchronous wheel assembling

ActiveCN110238627AImprove assembly qualitySolve crackingMetal working apparatusMechanical engineeringEngineering

Owner:富士通(广东)电梯集团有限公司

Flexible material feeding and discharging device

The invention relates to a flexible material feeding and discharging device. The flexible material feeding and discharging device comprises a main rack, an ionic wind rod, a feeding mechanism, a recycling mechanism, a conveying mechanism, a manipulator and a main control device; a flexible material is stored in a material box; the manipulator is a work fixture provided with an electrostatic chuck;the inner sidewalls of two side plates of the main rack are provided with the conveying mechanism; the feeding mechanism and the recycling mechanism are positioned above the front end of the conveying mechanism; the ionic wind rod and the manipulator are arranged at the tail end of the conveying mechanism; the feeding mechanism comprises a lifting mechanism, a push plate cylinder and retaining plates; the retaining plates are installed in the horizontal direction and are symmetrically arranged at the two sides of the material box; the lower parts of the two sides of the material box are eachprovided with a notch used for inserting the corresponding retaining plate; the recycling mechanism comprises a lifting mechanism and lock bolts; the lock bolts are symmetrically arranged below the two sides of the material box and are of a press-contraction type; the lower part of an extending part of each lock bolt is a smooth bevel, and the upper end face is horizontal. The flexible material feeding and discharging device can preferably satisfy the characteristics that a flexible material is light, thin, fragile, prone to being damaged and the like, and is beneficial for improving the safety and the work efficiency in feeding and discharging processes of the flexible material.

Owner:BEIJING NOWOGEN TECH CO LTD

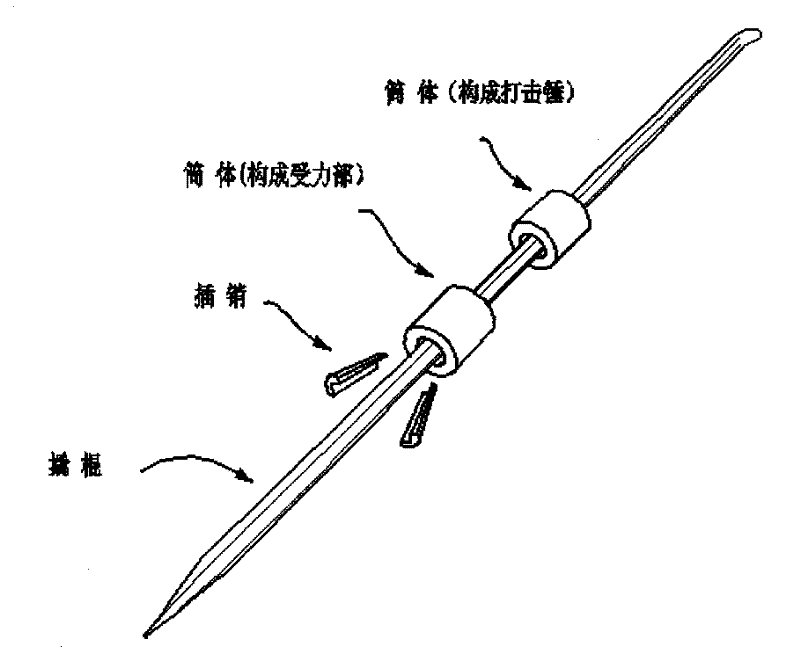

Quick assembly disengaging device

InactiveCN102343578AFast loading and unloadingSimple structureCrowbarsHand hammersSelf lockingEngineering

The invention discloses a quick assembly disengaging device. Two kinds of parts, namely a bolt and cylinders are assembled on a standard crowbar; and by a self-locking principle, one cylinder is fixed and the other cylinder is used as a peening hammer to form the disengaging device. The disengaging device has the function of the crowbar, becomes the disengaging device once assembled, and can disengage on special parts which cannot be excessively disturbed or have narrow spaces, wherein one cylinder is a metal cylinder, the middle of the cylinder is provided with a taper hole having a larger end and a smaller end, the slope of the taper is kept consistent with the slope of the bolt, a self-locking angle can be reached, and after the cylinder is sleeved in the crowbar, the bolt is inserted into a gap formed between the larger hole and the crowbar, and a stress body is formed after the bolt is tightly knocked; and the other cylinder is used as the peening hammer and moves along the crowbar vertically for peening.

Owner:刘于颇

PVD (physical vapor deposition) coating feeding and discharging system

PendingCN109319492AFast loading and unloadingIncrease productivityConveyor partsChemical vapor depositionManipulator

The invention discloses a PVD (physical vapor deposition) coating feeding and discharging system, and relates to the technical field of automatic design. The PVD (physical vapor deposition) coating feeding and discharging system comprises a workbench and material tray parts, wherein the material tray parts are used for containing finished products or raw materials; each material tray part comprises a jig plate and a cover plate which cover each other; the multiple material tray parts are arranged on a circulating assembly and are driven by the circulating assembly to move among a plurality ofpreset positions; the movement tracks of the multiple material tray parts are closed; a dust removal assembly can grab the cover plates on the circulating assembly so as to perform dust removal and cover the cover plates subjected to dust removal on the jig plates; a discharging mechanical arm can grab the finished products from the circulating assembly and stack the finished products in a lower storage part; a feeding mechanical arm can grab the raw materials from an upper storage part and stack the raw materials on positioning platforms; and positioning mechanical arms can grab the raw materials and stack the raw materials on the jig plates on the circulating assembly. The PVD (physical vapor deposition) coating feeding and discharging system has the advantages of being reasonable in structural design, high in feeding and discharging speed and high in production efficiency.

Owner:GUANGDONG TOPSTAR TECH

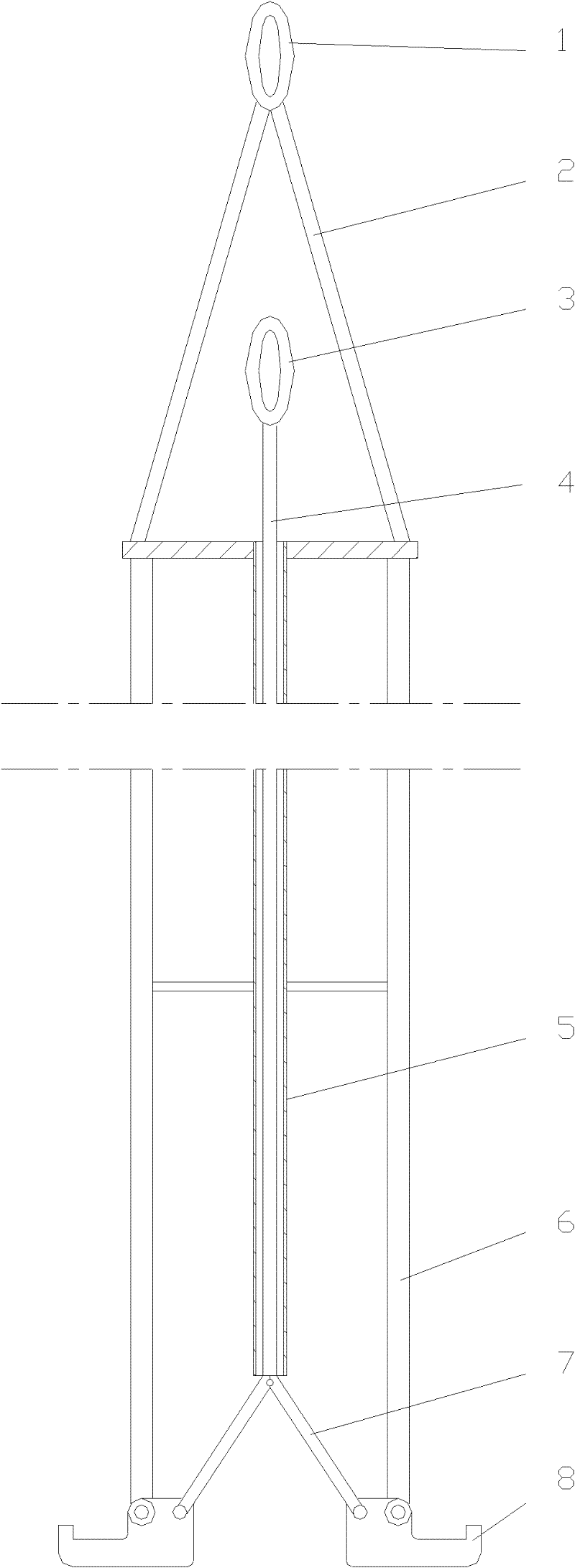

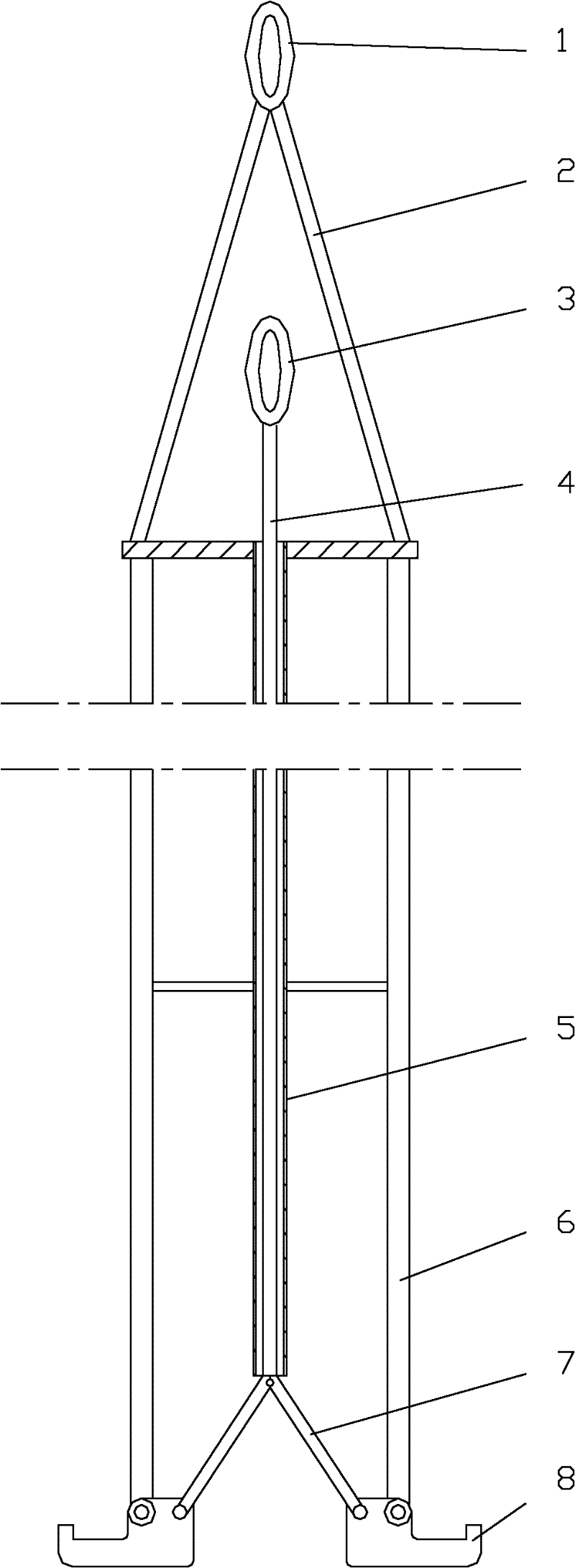

Special lifting appliance for pit type heat treatment furnace

ActiveCN102251090ASimple structureFast loading and unloadingFurnace typesHeat treatment furnacesEngineeringMechanical engineering

Owner:XINXING DUCTILE IRON PIPES CO LTD

Novel guide rail for replacing pipe jacking machine in relay well and quickly assembling head of pipe jacking machine

ActiveCN110145639AAvoid disassembly and replacementOvercome limitationsPipe laying and repairMechanical engineeringRelay

The invention discloses a novel guide rail for replacing a pipe jacking machine in a relay well and quickly assembling a head of the pipe jacking machine. A guide rail connecting joint structure is adopted to realize fast assembling and disassembling of the rail and avoid assembling and disassembling of a guide rail of a traditional pipe jacking machine head through nuts and bolts. The novel guiderail is simple and stable in structure, the assembling and disassembling speed of the rail is high, and the construction efficiency is greatly improved. Meanwhile, a telescopic adjusting rod, a supporting connecting telescopic rod and a lifting structure are adopted, the novel guide rail can be adjusted according to different pipe jacking machine head specifications, and the situation that the guide rail of the traditional pipe jacking machine head needs to be disassembled and replaced according to different pipe jacking machine head specifications is avoided. The novel guide rail does not need to be disassembled, specifications can be switched through manual control, and thus the novel guide rail greatly improves the construction efficiency. A placement guide rail adjusting hinge and ahydraulic telescopic rod are arranged, inclined drilling installation of a pipeline can be conducted, and the limitation of the guide rail of the traditional pipe jacking machine head can not realizeinclined drilling installation of the pipeline is solved.

Owner:安徽皖蜀春酒业销售有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com