Flexible material feeding and discharging device

A material and flexible technology, applied in the field of flexible material loading and unloading devices, achieves the effects of small footprint, simple structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

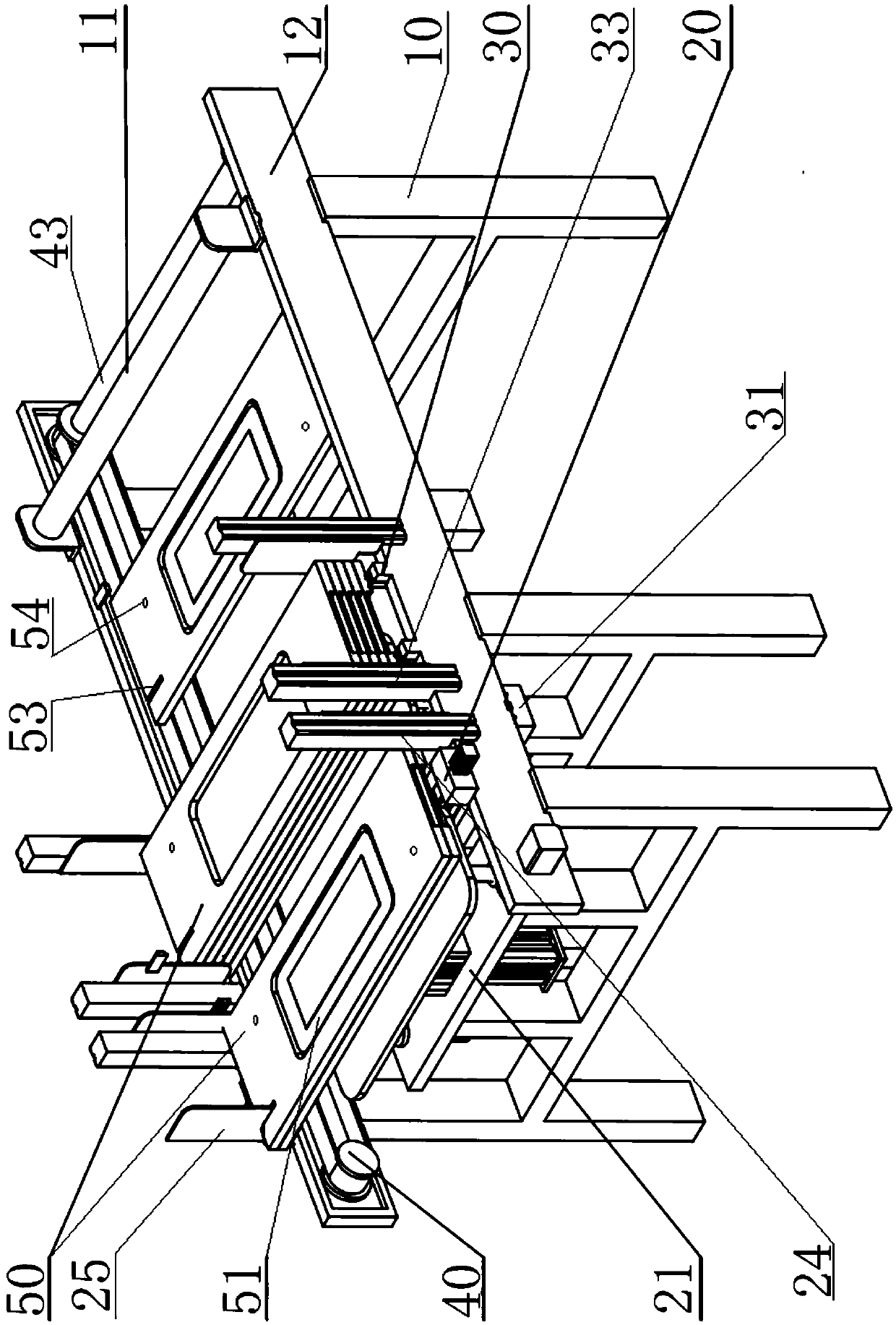

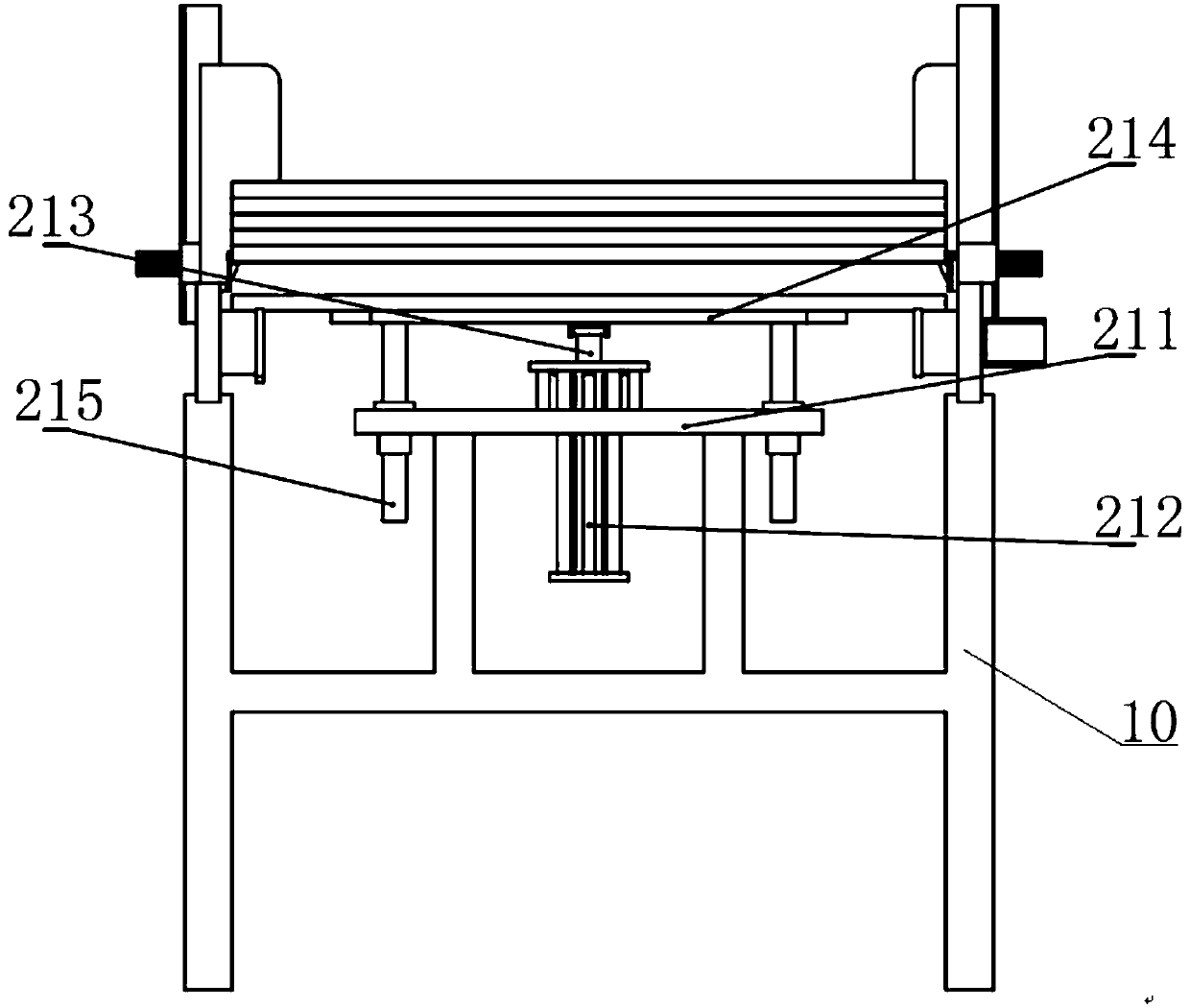

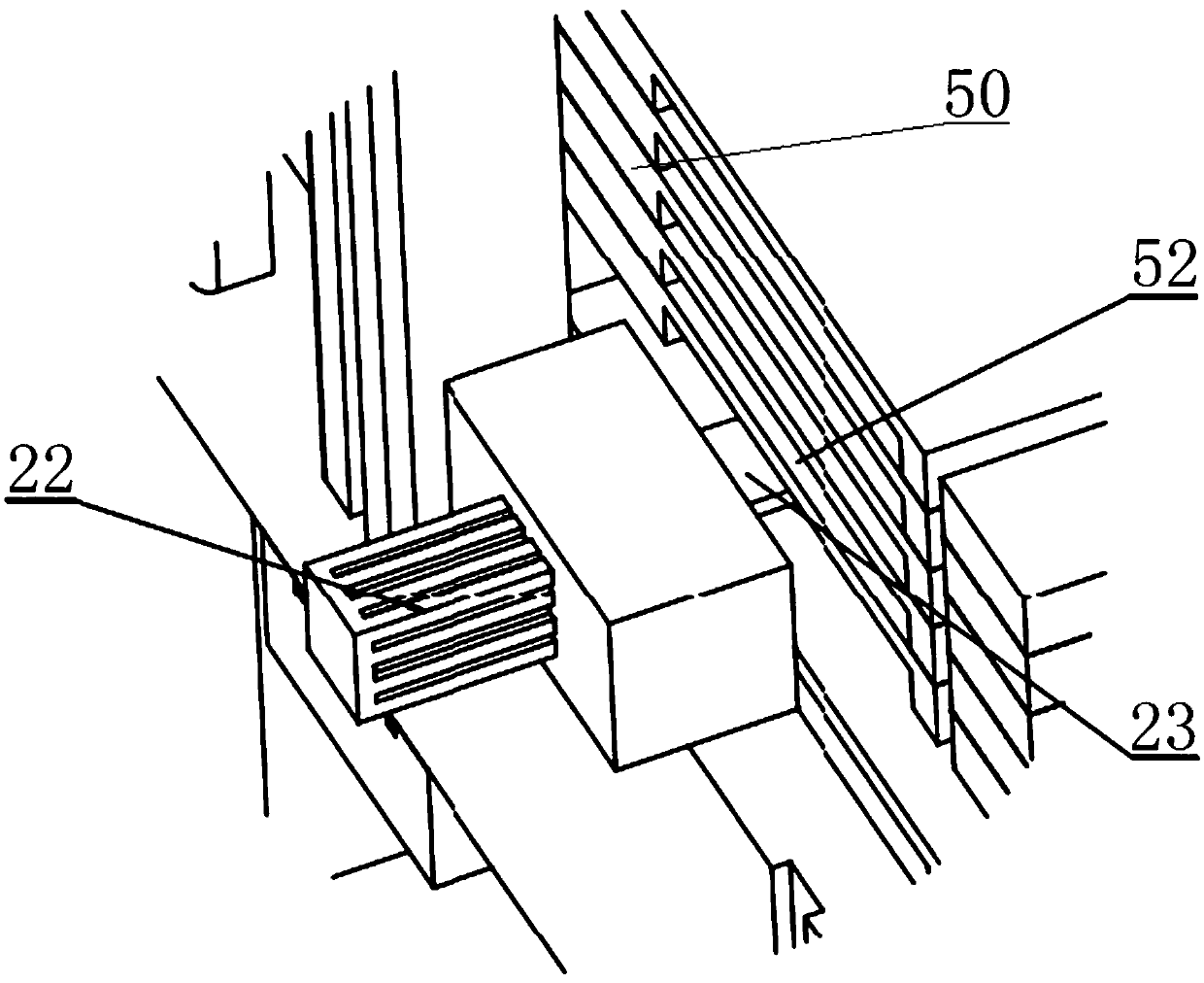

[0067] refer to figure 1 , the flexible material loading and unloading device of the present invention comprises a main frame 10, an ion wind bar 11, a feeding mechanism 20, a recovery mechanism 30, a transmission mechanism 40, a manipulator (not shown) and a main control device (not shown), and the flexible material 51 is contained in the material box 50, and is transported on the loading and unloading device along with the material box 50, and is taken and placed from the material box 50 by the manipulator. Physical properties to avoid damage to flexible materials.

[0068] A conveying mechanism 40 is provided on the inner side walls of the two side plates 12 of the main frame 10 for horizontally conveying the material box 50 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com