Patents

Literature

1540results about How to "Eliminate static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

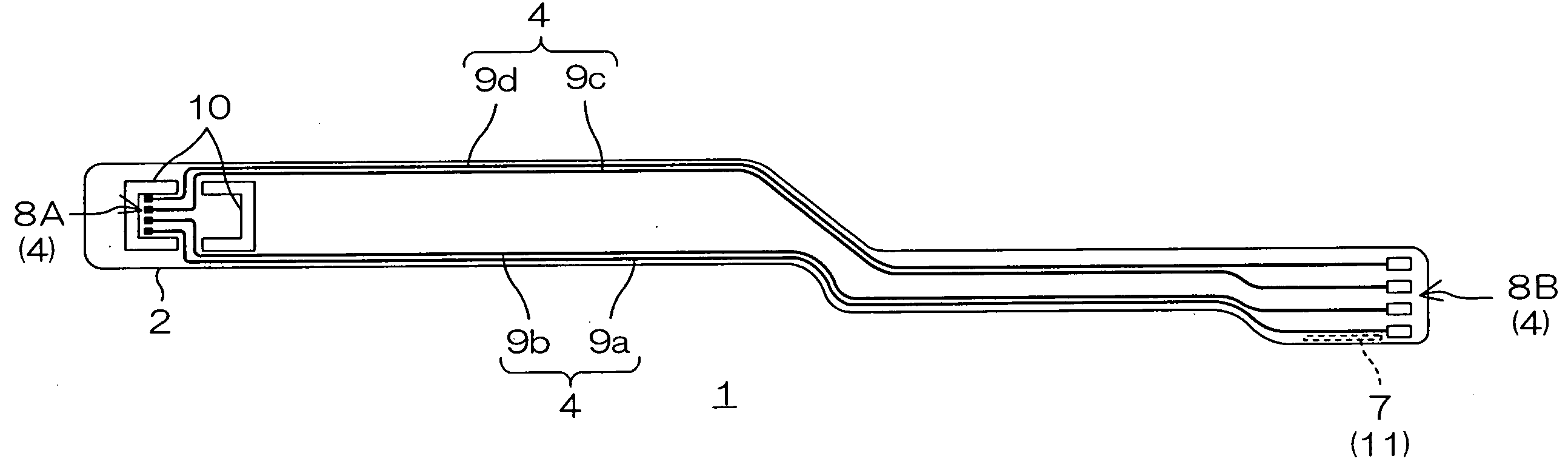

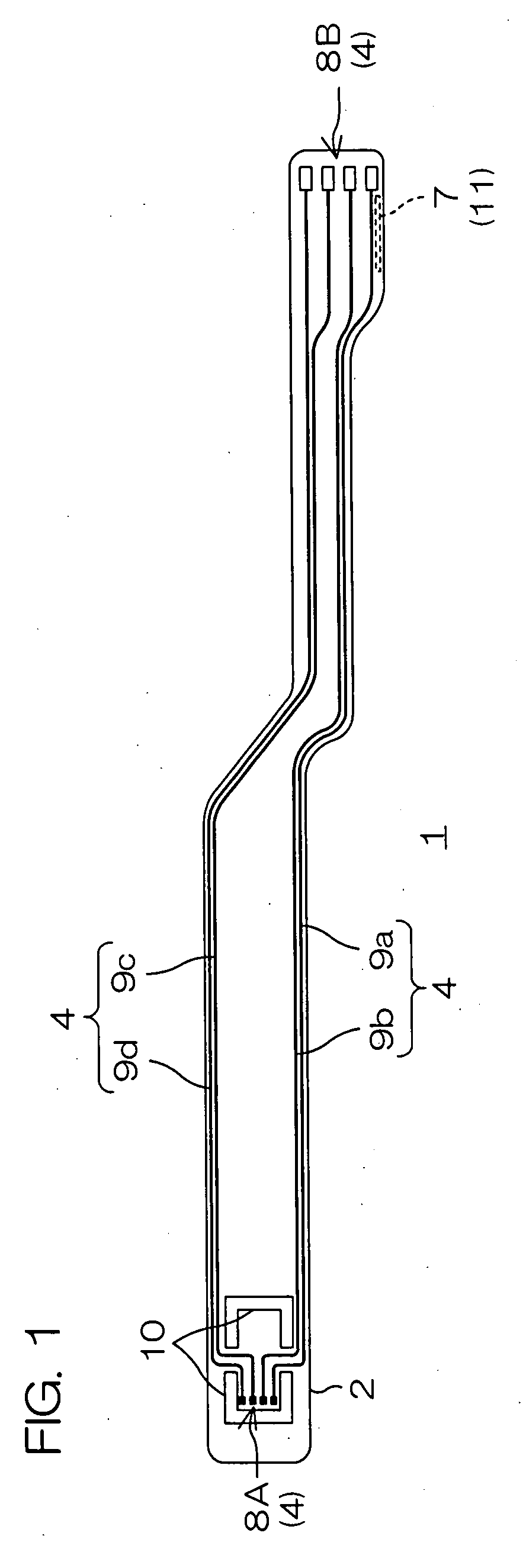

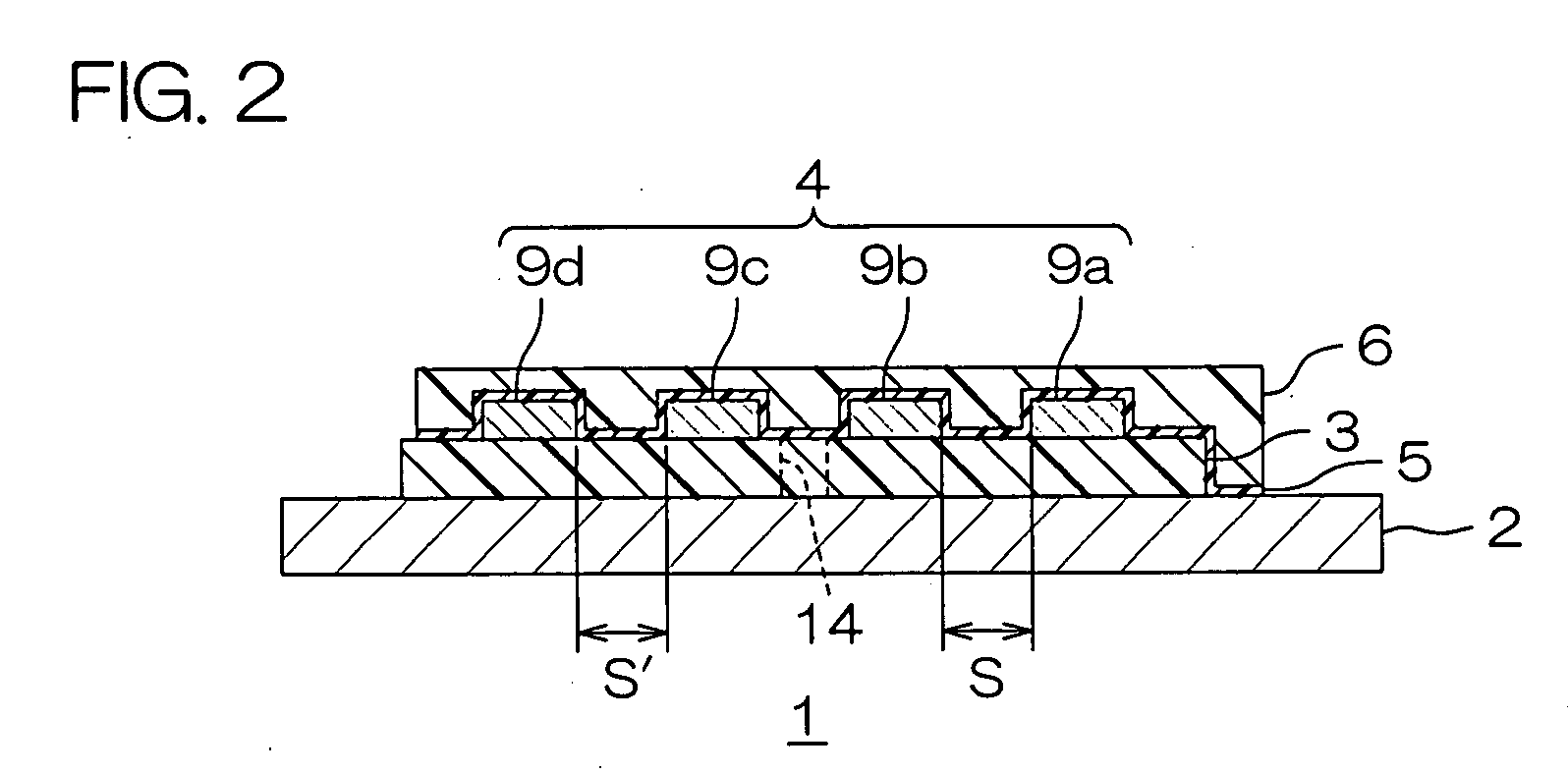

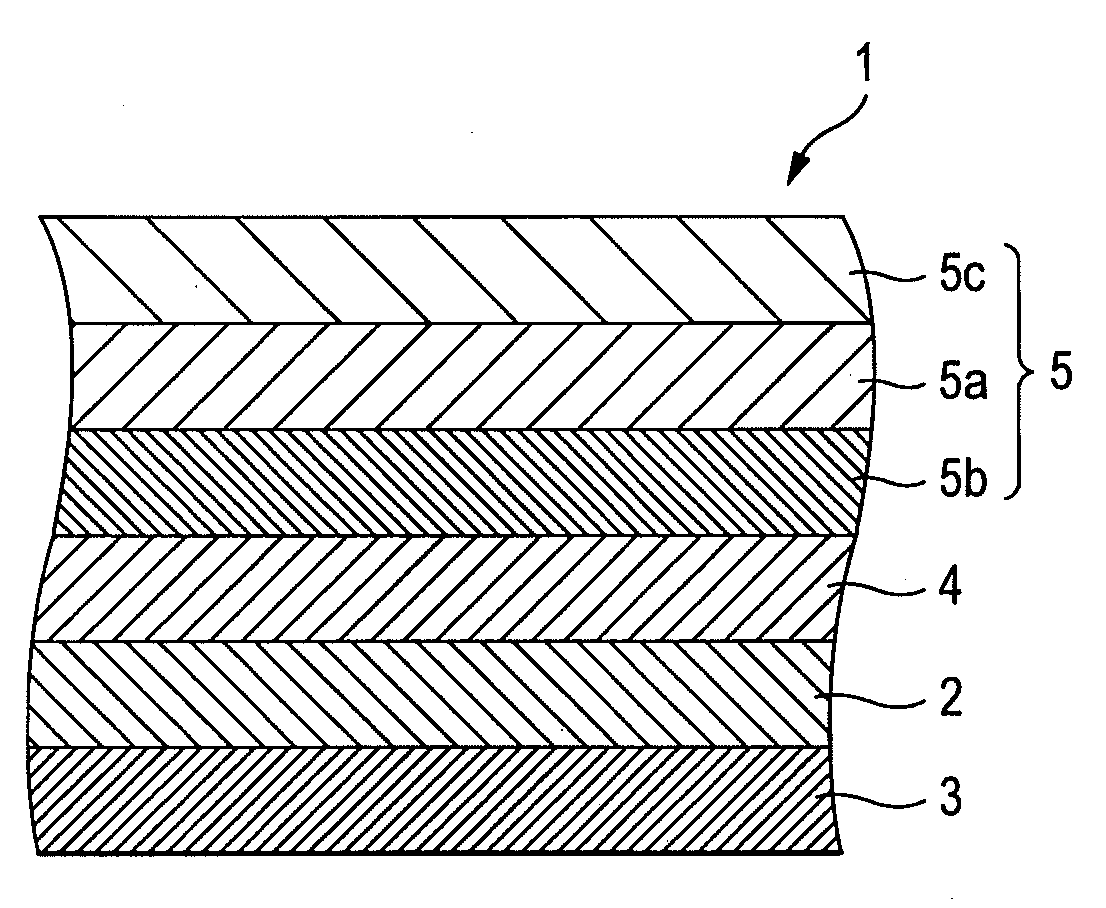

Wired circuit board

InactiveUS20070253176A1Inhibition formationAvoid componentsPrinted circuit aspectsHigh voltage circuit adaptationsPrinted circuit boardSemiconductor

A wired circuit board has a metal supporting board, an insulating base layer formed on the metal supporting board, a conductive pattern formed on the insulating base layer and including at least one pair of wires arranged in mutually spaced-apart and opposed relation having different potentials, a semiconductive layer formed on the insulating base layer to cover the conductive pattern and electrically connected to the metal supporting board on one side outside a region where the pair of wires are opposed, and an insulating cover layer formed on the semiconductive layer.

Owner:NITTO DENKO CORP

Electrostatic-resisting rubber board and its production

ActiveCN101074301AWill not polluteWon't change colorOther chemical processesEngineeringPolymer science

An anti-electrostatic rubber plate (desk pad and floor mattress) and its production are disclosed. The anti-electrostatic rubber plate consists of anti-electrostatic layer and conducting layer. It is prepared by preparing anti-electrostatic layer, preparing conducting layer film and vulcanizing to obtain final product.

Owner:浙江一远静电科技有限公司

Antistatic automobile glass cleaning agent

InactiveCN101798550AReduce resorptionGuaranteed long-termOrganic detergent compounding agentsSurface-active detergent compositionsCleansing AgentsToxicity

The invention relates to an antistatic automobile glass cleaning agent. On the basis of maintaining and enhancing the basis cleaning capability, a functional component is added, therefore, the invention enables the glass surface to have the properties of recontamination resistance, fast dryness, fog resistance, hydrophilicity, no trace after cleaning, and the like, and has the advantages of no toxicity, environment protection, corrosion resistance and the like.

Owner:HEBEI AGRICULTURAL UNIV.

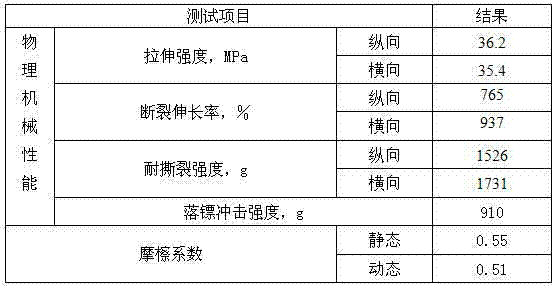

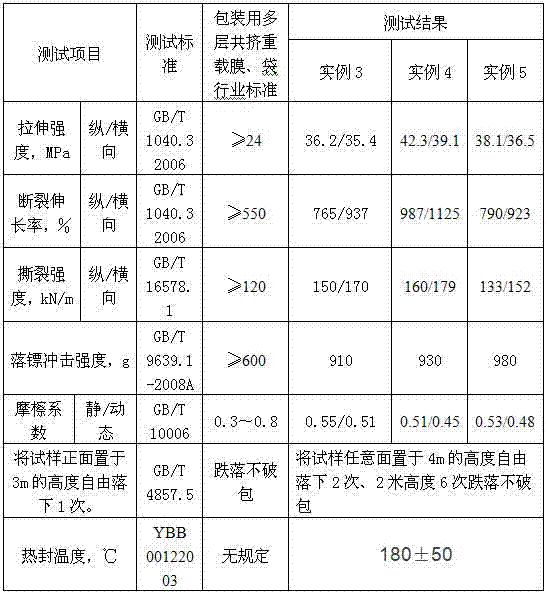

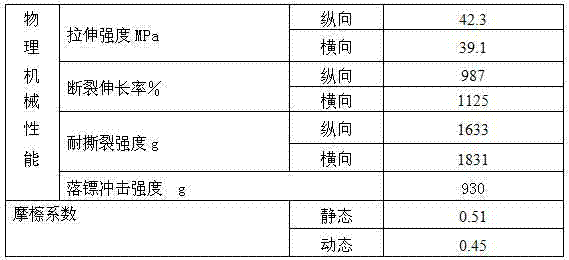

Three-layer coextrusion heavy packaging membrane and fabrication method thereof

The invention relates to the technical field of heavy packaging membranes, in particular to a three-layer coextrusion heavy packaging membrane and a fabrication method thereof. An inner layer of the three-layer coextrusion heavy packaging membrane contains LLDPE (linear low density polyethylene) and m-LLDPE (metallocene-linear low density polyethylene); a middle layer thereof contains m-LLDPE, LLDPE, MDPE (medium density polyethylene), EVA (ethylene-vinyl acetate) and a color masterbatch; and an outer layer thereof contains LLDPE, LDPE (low density polyethylene) and m-LLDPE. The fabrication method of the three-layer coextrusion heavy packaging membrane adopts the proportioning, and a product is fabricated on a certain technological condition. Compared with the prior art, the membrane has the characteristics that the membrane is excellent in mechanical property and good in deflexion; a skin-friction coefficient of the membrane is moderate; and a heat-seal window can reach 180 minus / plus 50 DEG C. The membrane can fully meet the requirement of normal use of downstream packaging, is particularly suitable for high-speed FFS (form-fill-seal) packaging, and has a good economic benefit and a social benefit.

Owner:GUANGDONG SUNION CHEM & PLASTIC

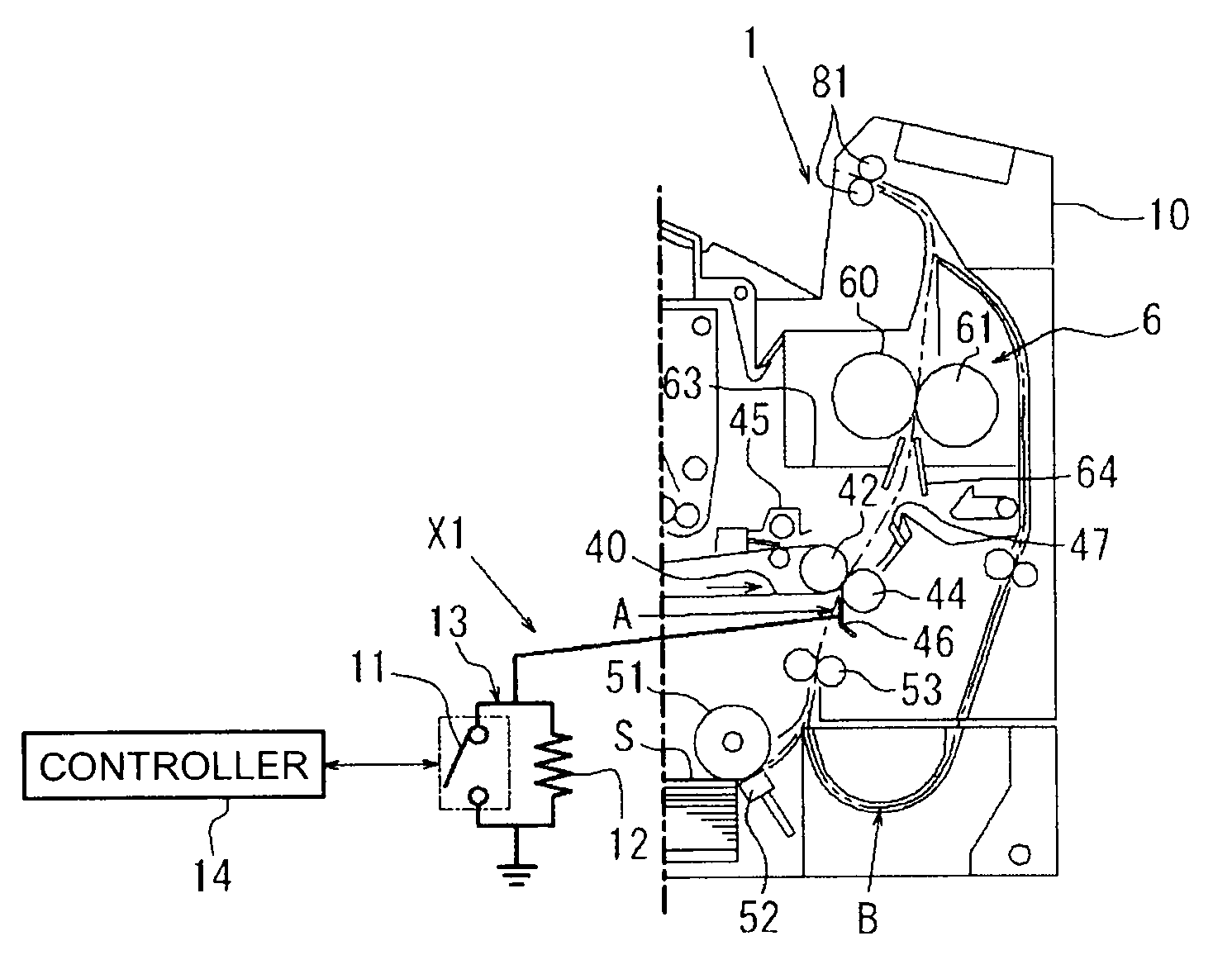

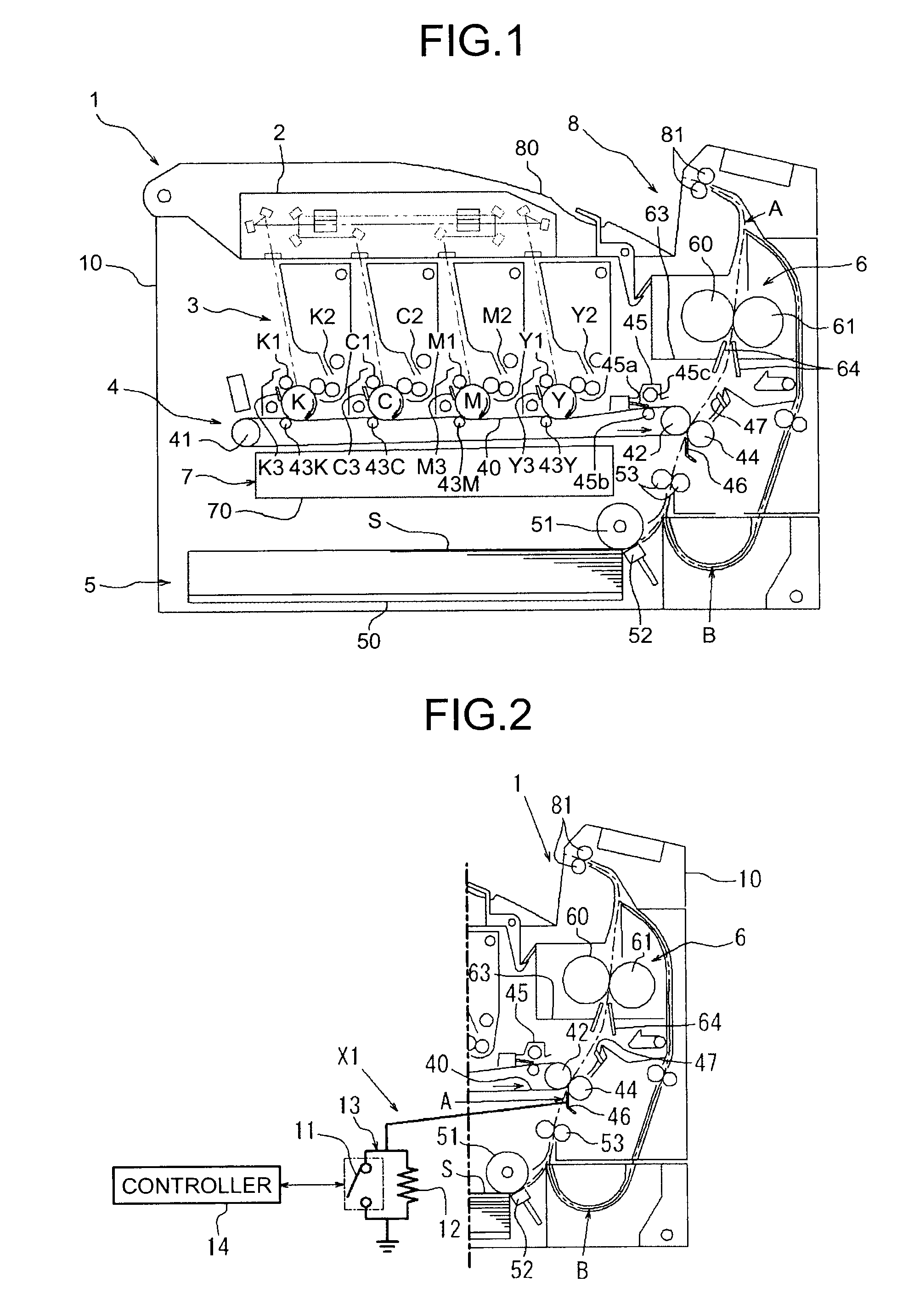

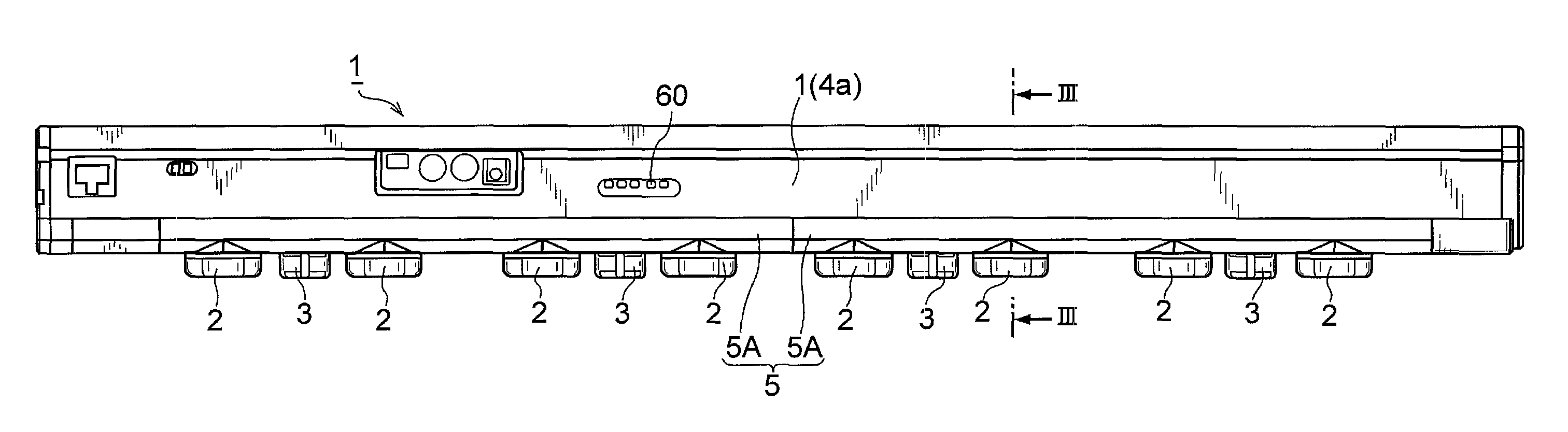

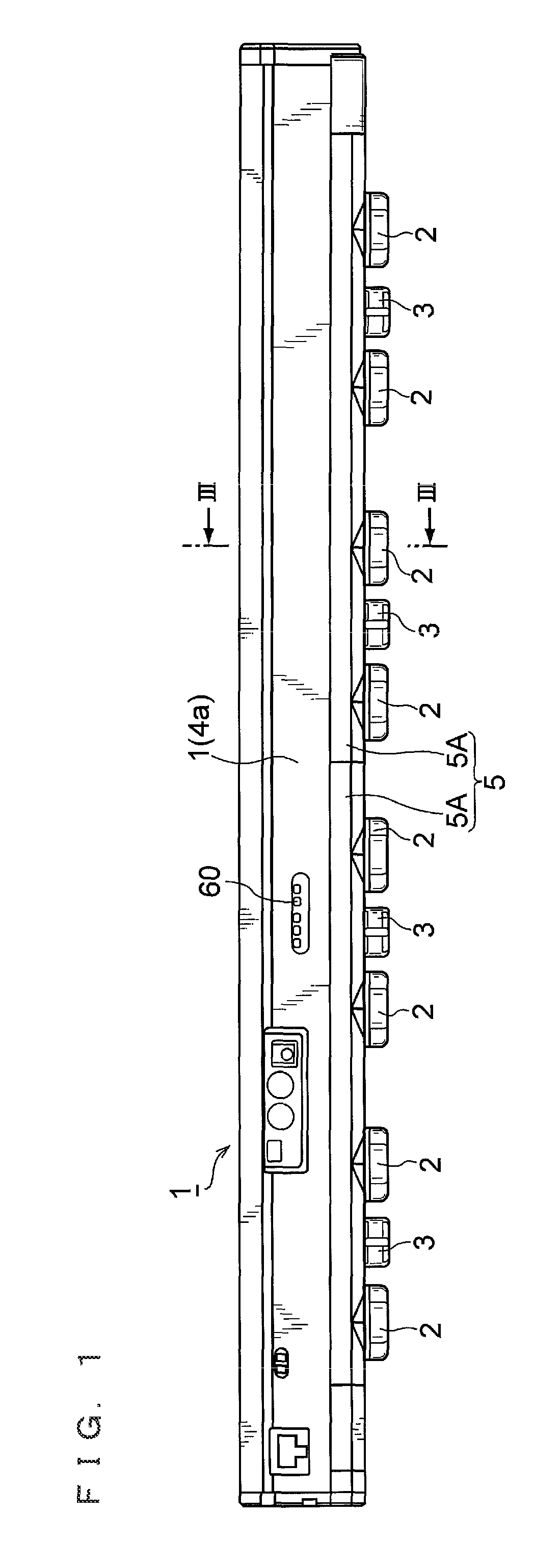

Transfer device and image forming apparatus

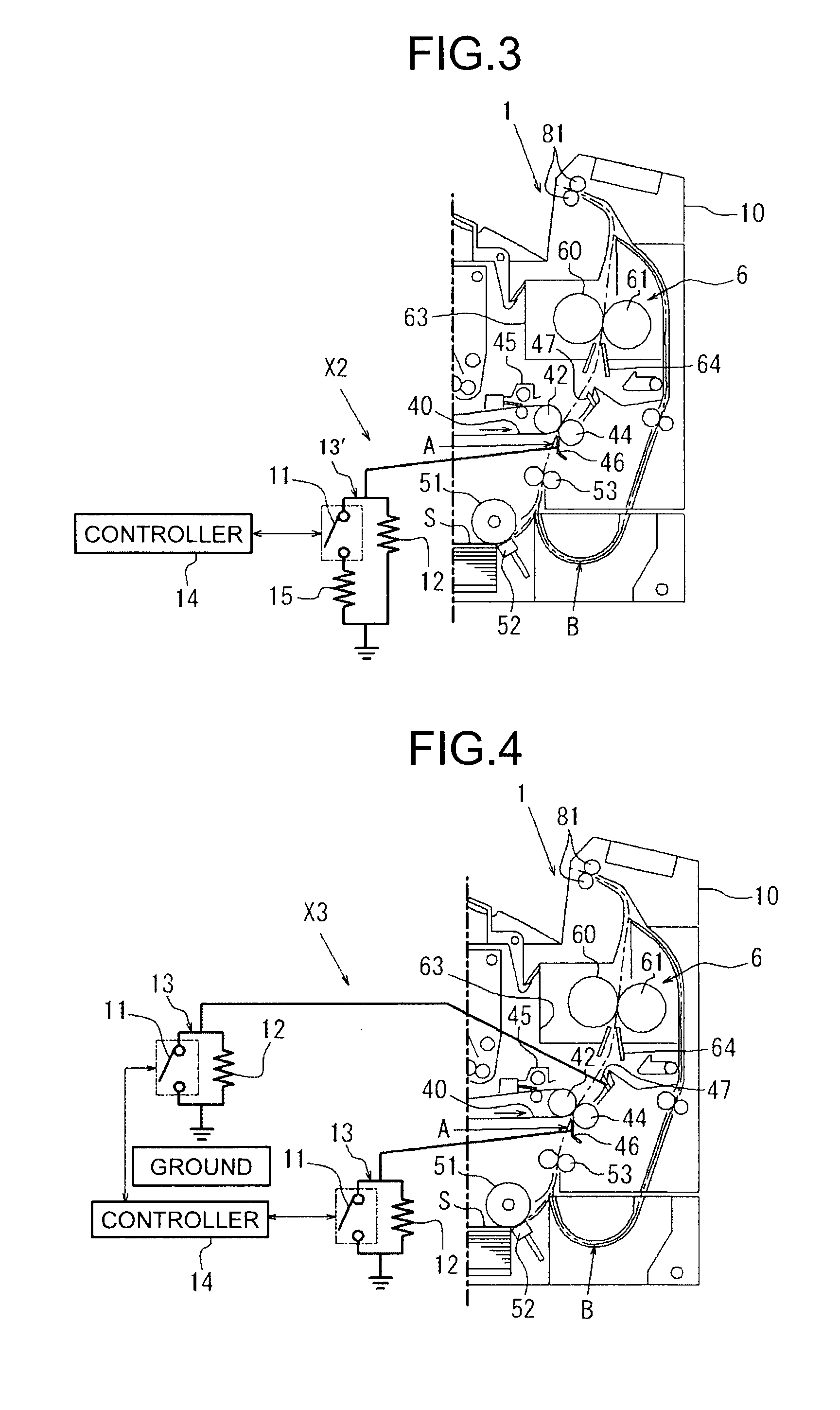

InactiveUS20090129831A1Solve problemsPrevent leakageElectrographic process apparatusElectricityConductive materials

A neutralizing mechanism is provided on at least one conveying path proximal member installed on a conveying path of a sheet material in a vicinity of a transfer position, and is grounded by using a conducting material. The neutralizing mechanism includes a neutralizing circuit that includes a resistor and a ground switch electrically connected in parallel to each other. The ground switch is turned off at least at a time of applying the transfer bias to prevent a leakage of a transfer current, and turned on for a predetermined time at a time other than the time of applying the transfer bias to earth and remove a static electricity from the conveying path proximal member.

Owner:RICOH KK

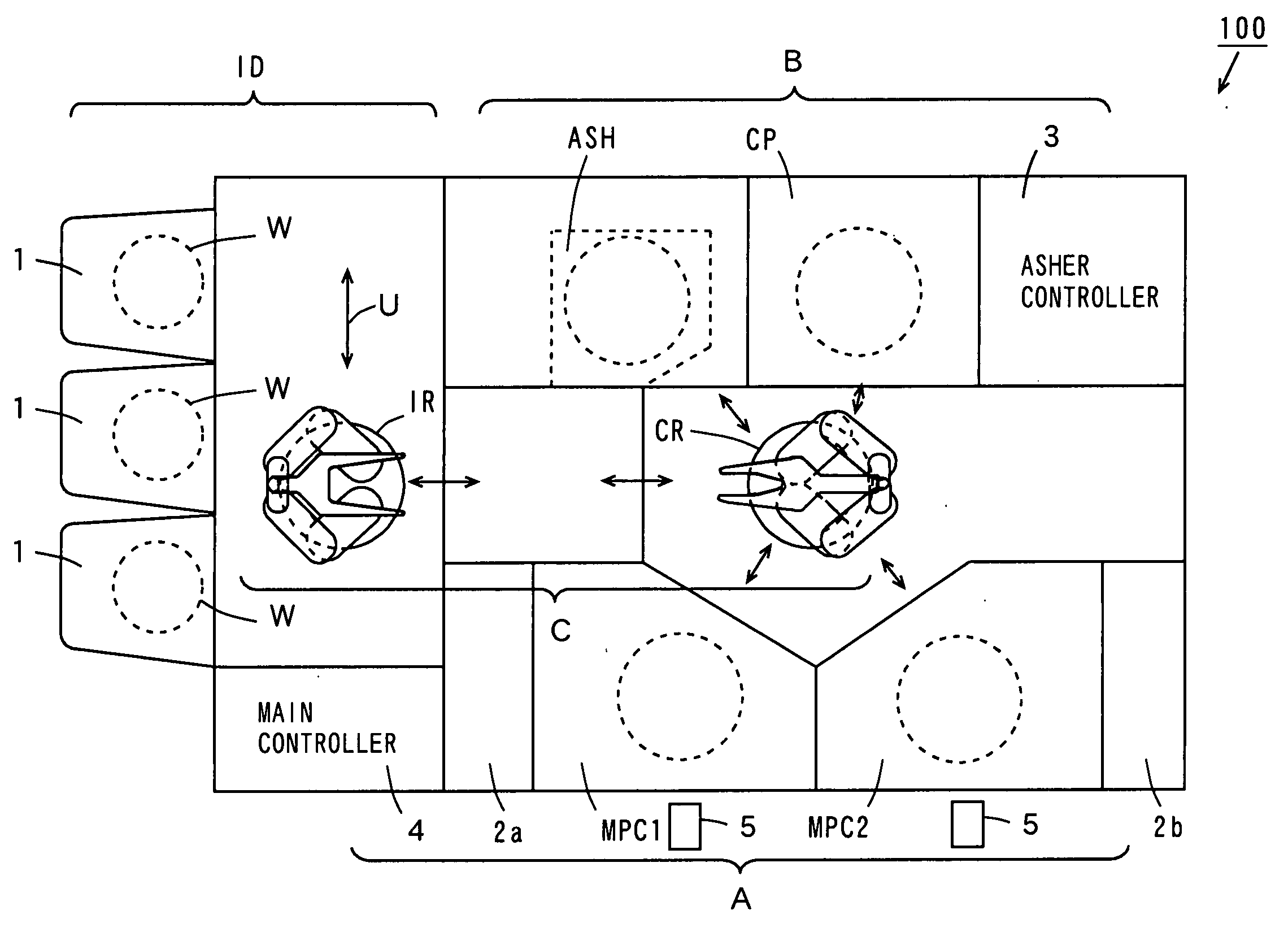

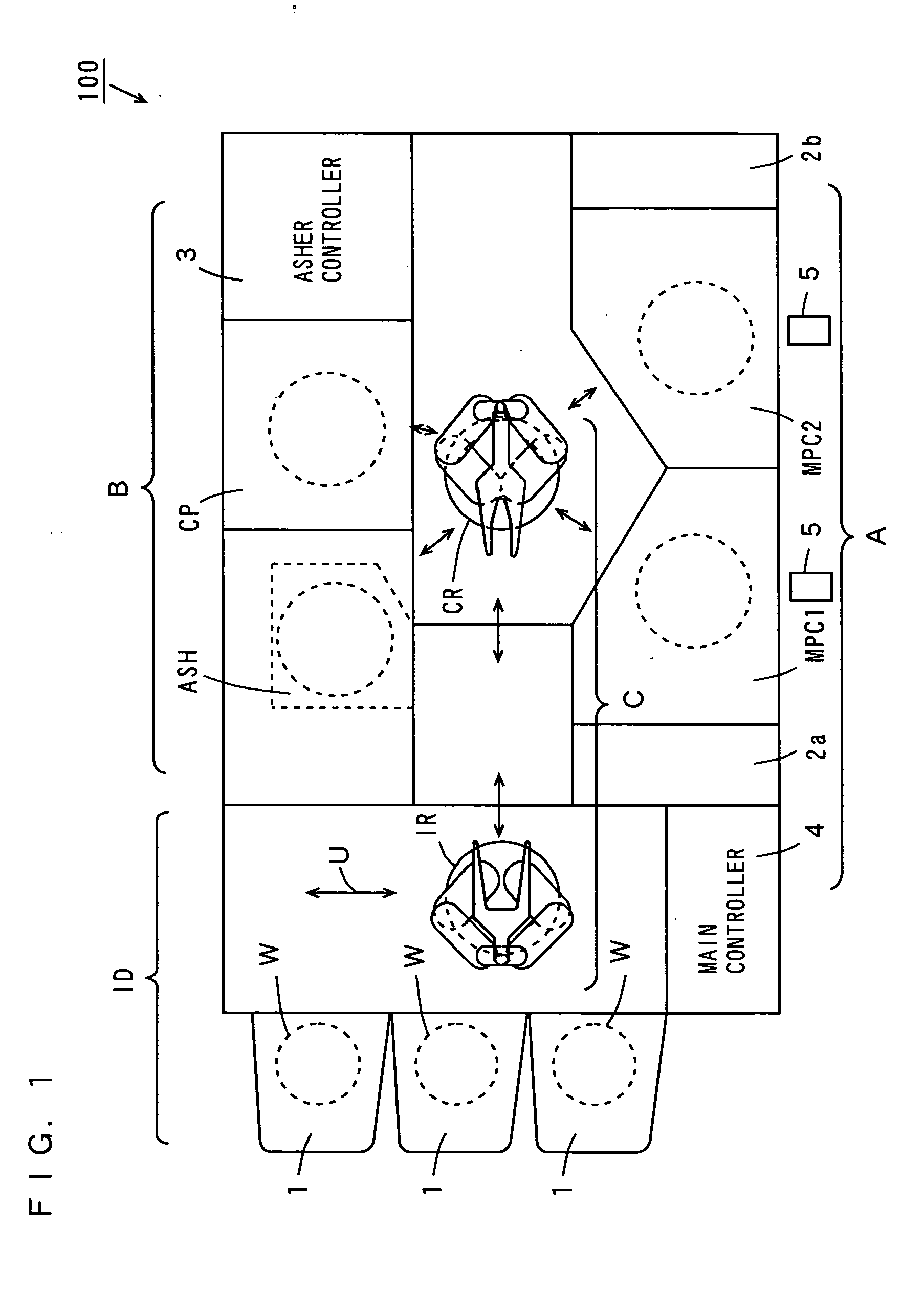

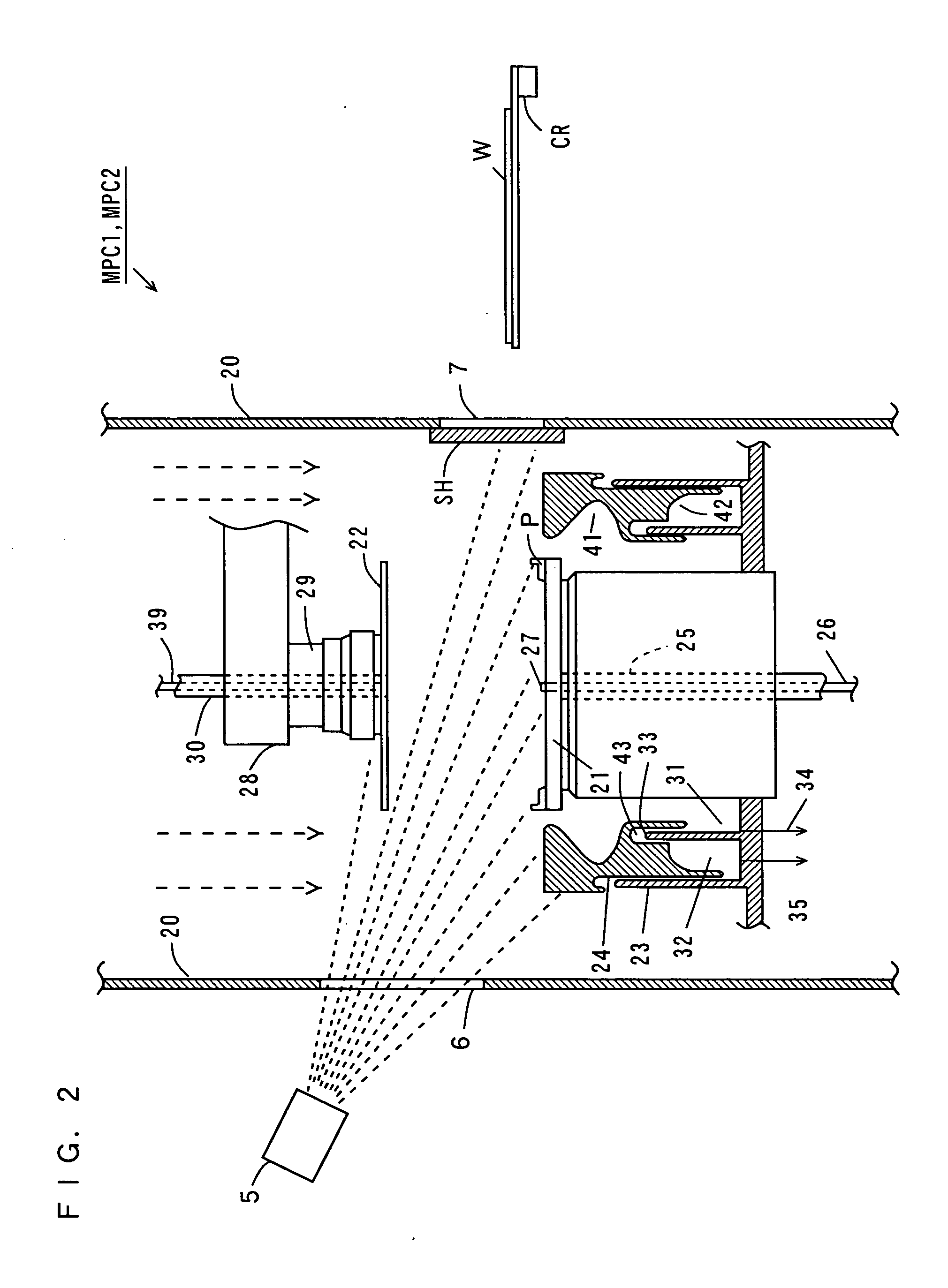

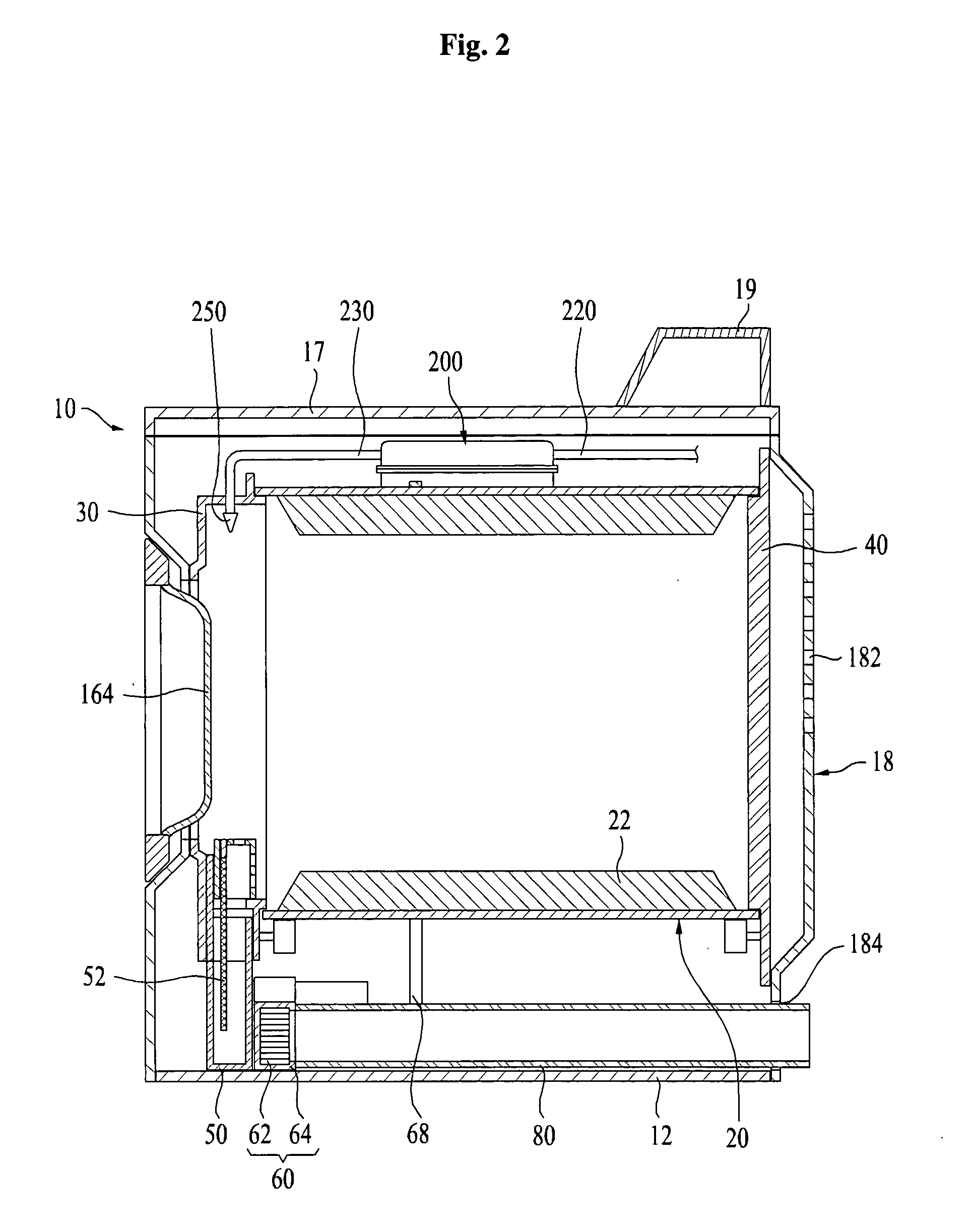

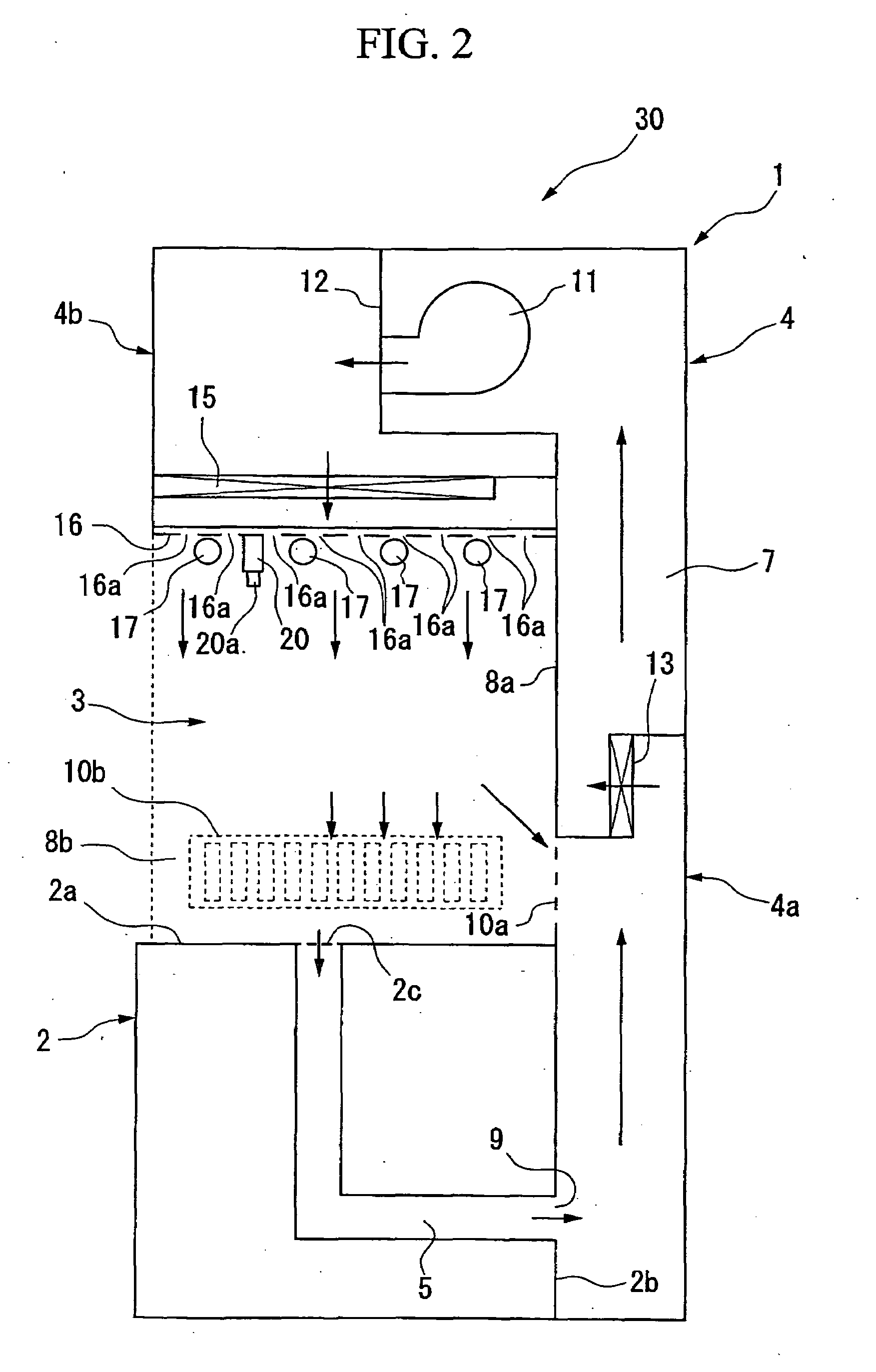

Substrate processing apparatus and substrate processing method

InactiveUS20050028928A1Eliminate static electricityRemoving static electricity from a substrate more effectivelySemiconductor/solid-state device manufacturingCleaning using liquidsPolyimideElectrical and Electronics engineering

A transmitting window is provided on one side of a casing opposite to a substrate outlet. An ionizer is provided outside the transmitting window of a cleaning unit. The transmitting window is made of a polyimide resin or an acrylic resin, for example. Weak X-rays emitted from the ionizer pass through the transmitting window to reach the substrate outlet, shutter, spin chuck, guard, and the like in the cleaning unit. The spin chuck comprises a plurality of conductive holding pins.

Owner:DAINIPPON SCREEN MTG CO LTD

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

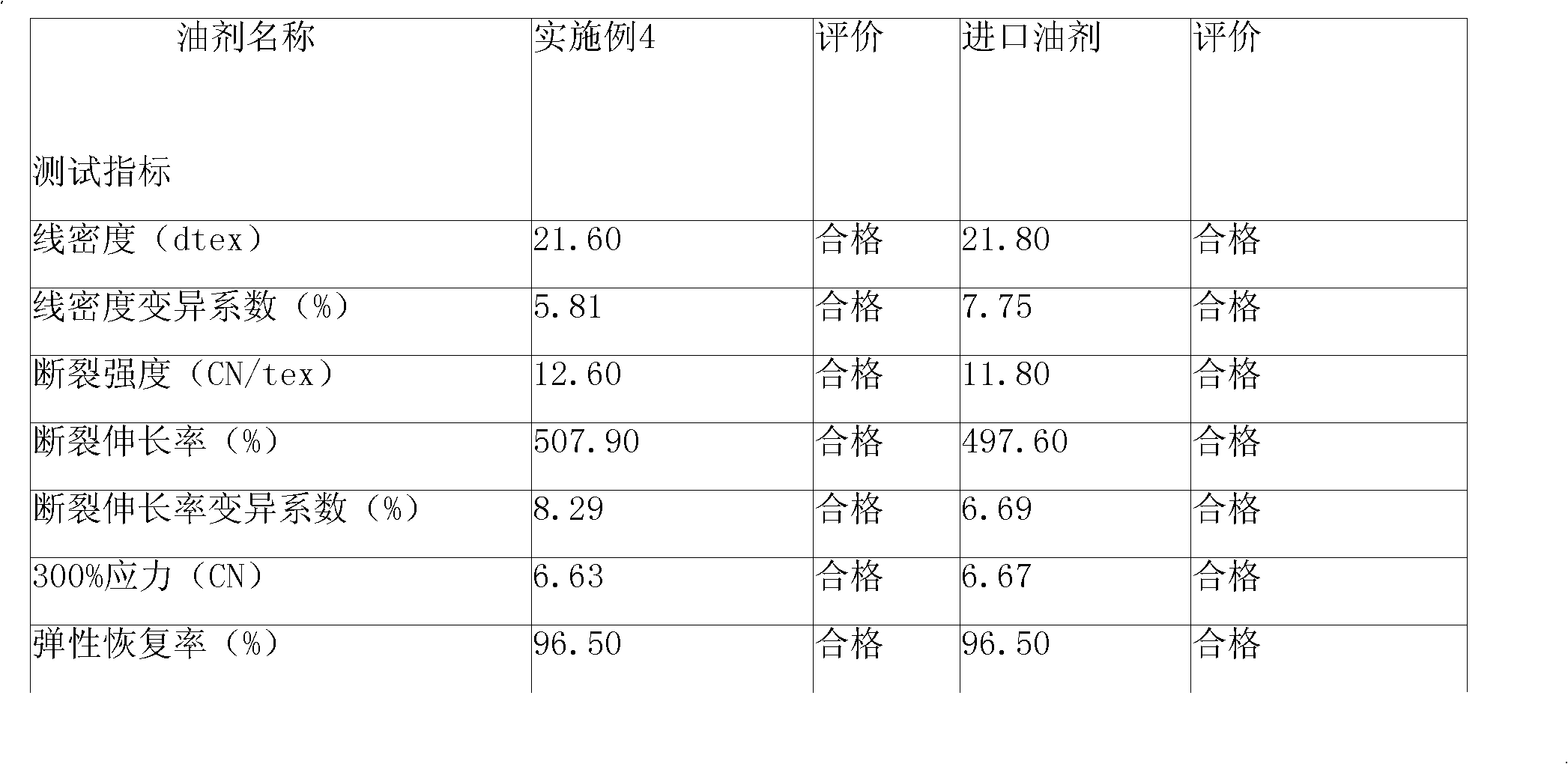

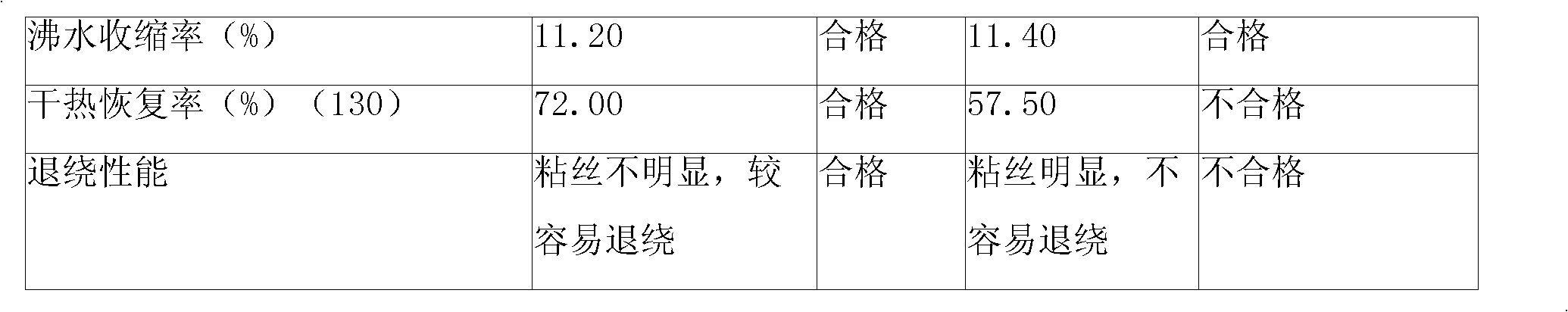

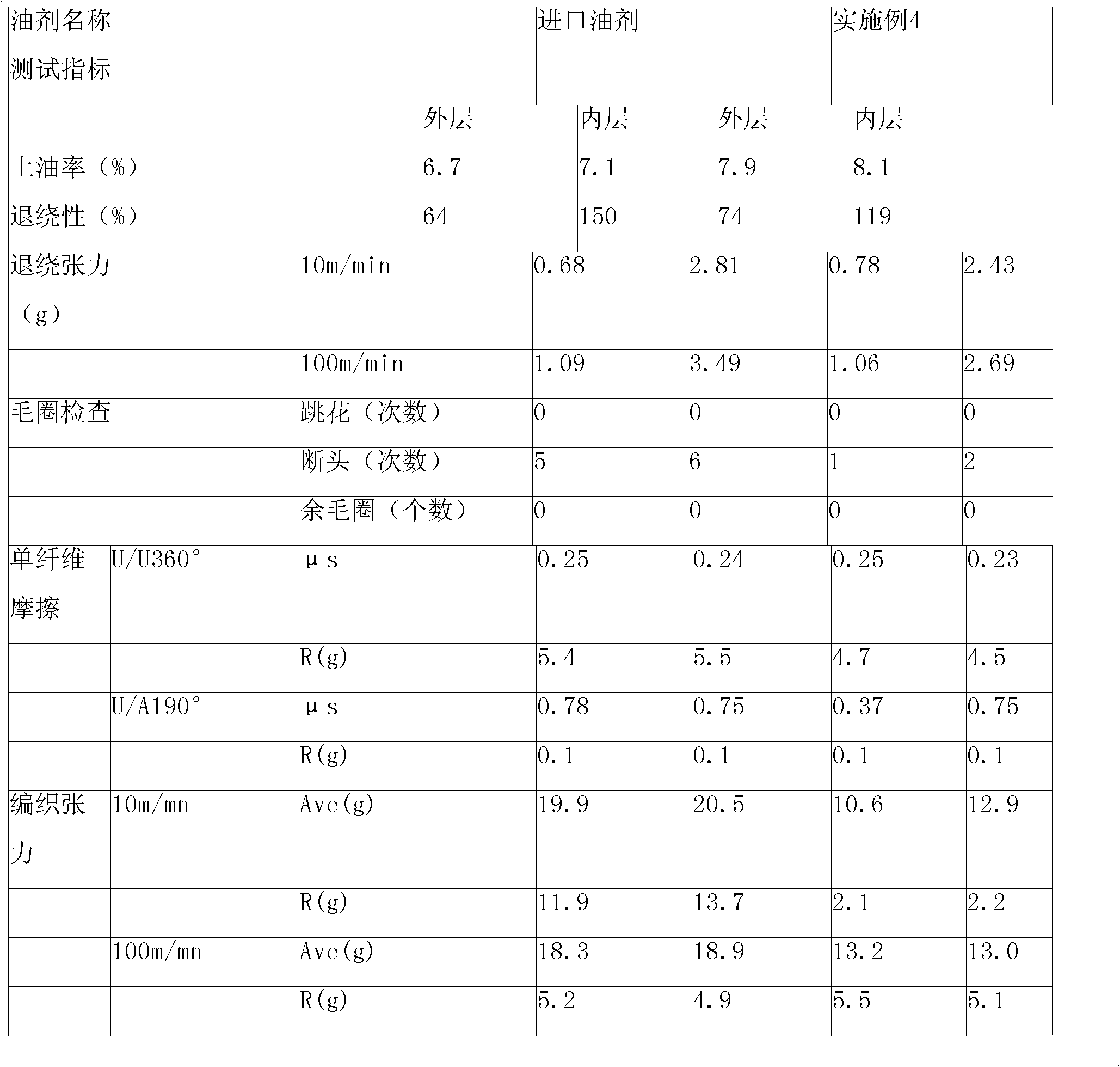

Polyurethane fiber dry spinning oil agent and preparation method thereof

The invention discloses a polyurethane fiber dry spinning oil agent, which comprises 30 to 80 weight percent of dimethyl silicon oil, 10 to 50 weight percent of mineral oil, 1 to 7.5 weight percent of high-carbon isomeric fatty alcohol or acid, 1 to 5 weight percent of dispersed component, 0.1 to 1.5 weight percent of stearate and 2 to 20 weight percent of antistatic component. The dispersed component is a mixture of an organic silicon surfactant and acrylic acid-maleic acid copolymer, and the weight ratio of the organic silicon surfactant to the crylic acid-maleic acid copolymer is 1:0.5-2; and the antistatic component is a mixture of polyether silicon oil and nonionic isomeric alcohol polyethenoxy ether, and the weight ratio of the polyether silicon oil to the nonionic isomeric alcohol polyethenoxy ether is 1:0.5-2. The polyurethane fiber dry spinning oil agent has excellent smoothness, softness, antistatic property, stable performance and excellent anti-adherent performance; polyurethane fiber treated by the oil agent has good unreeling property and forming property; and in the subsequent processing flow, polyurethane filaments are easy to unreel, not drop edge and has few broken filaments.

Owner:BEIJING GUANGHUA TEXTILE GRP +2

Electrically conductive thread

InactiveCN1671901ASmall twistNo obvious mutual interferenceNon-insulated conductorsHeating element shapesEngineeringMechanical engineering

The invention relates to electrically conductive thread. Said thread comprises at least one elastic core thread, at least one electrically conductive thread that is wound around the core thread and at least one binding thread that is wound around the core thread and is non-electrically conductive. The extensibility of the entire electrically conductive thread is restricted by the binding thread.

Owner:W ZIMMERMANN

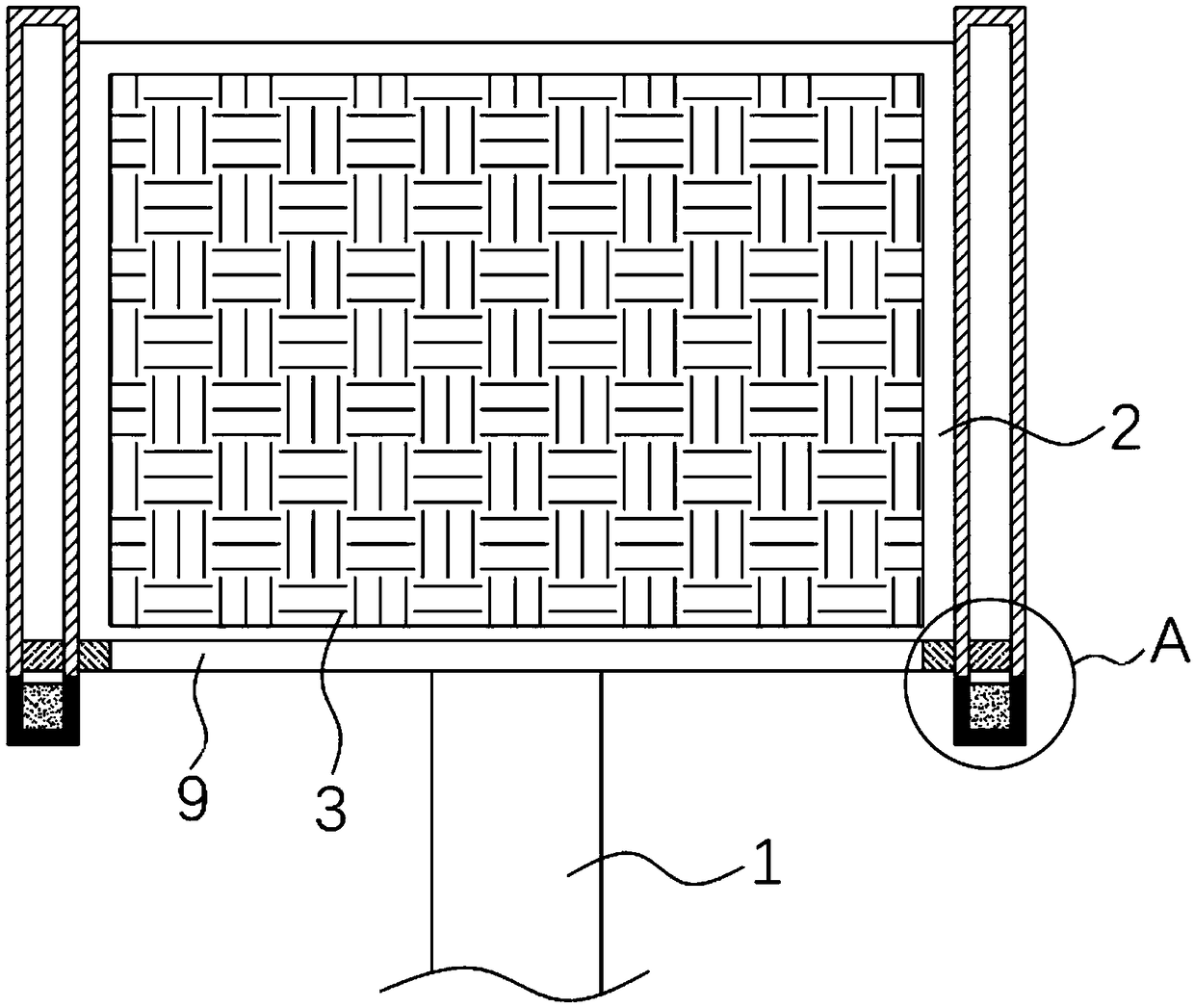

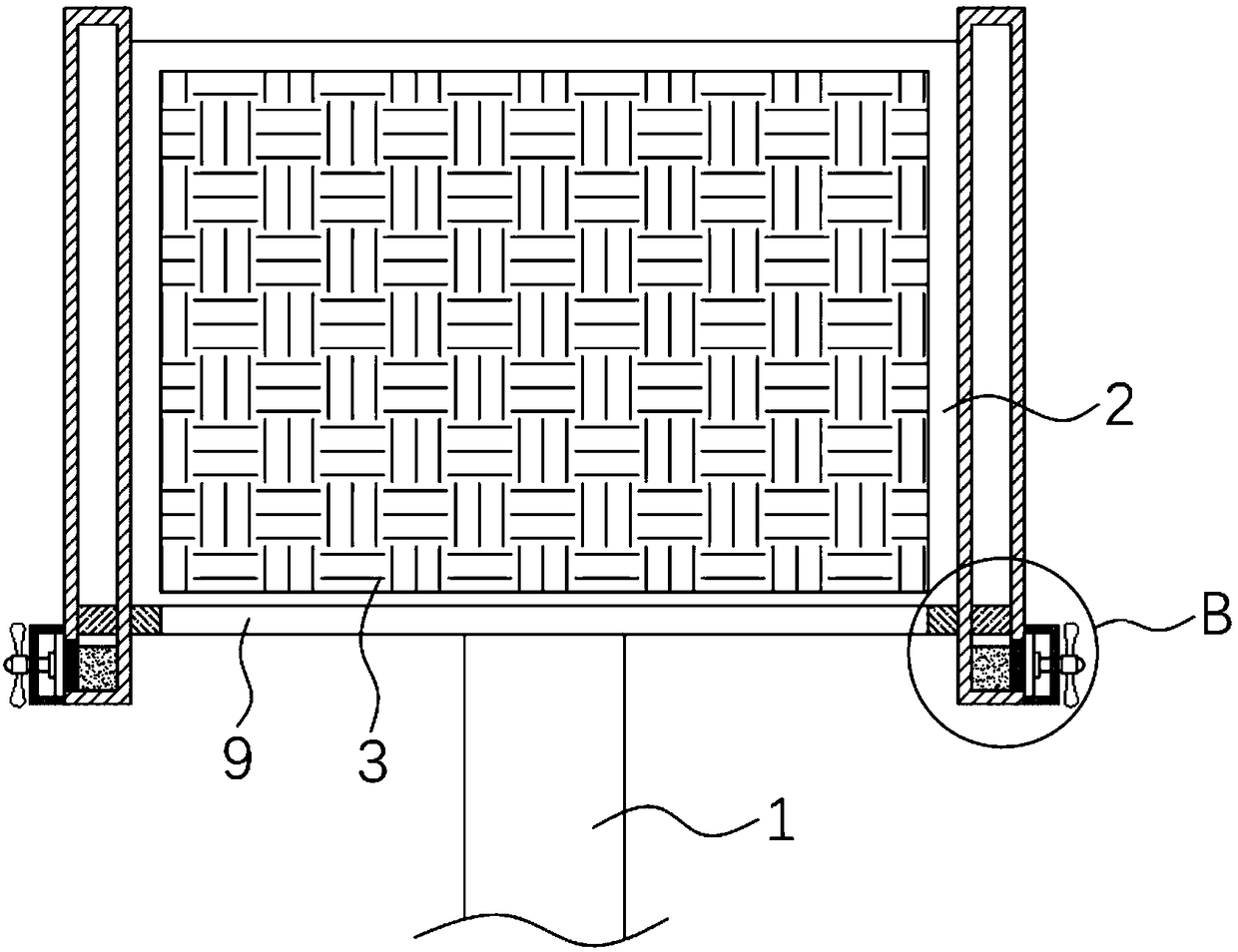

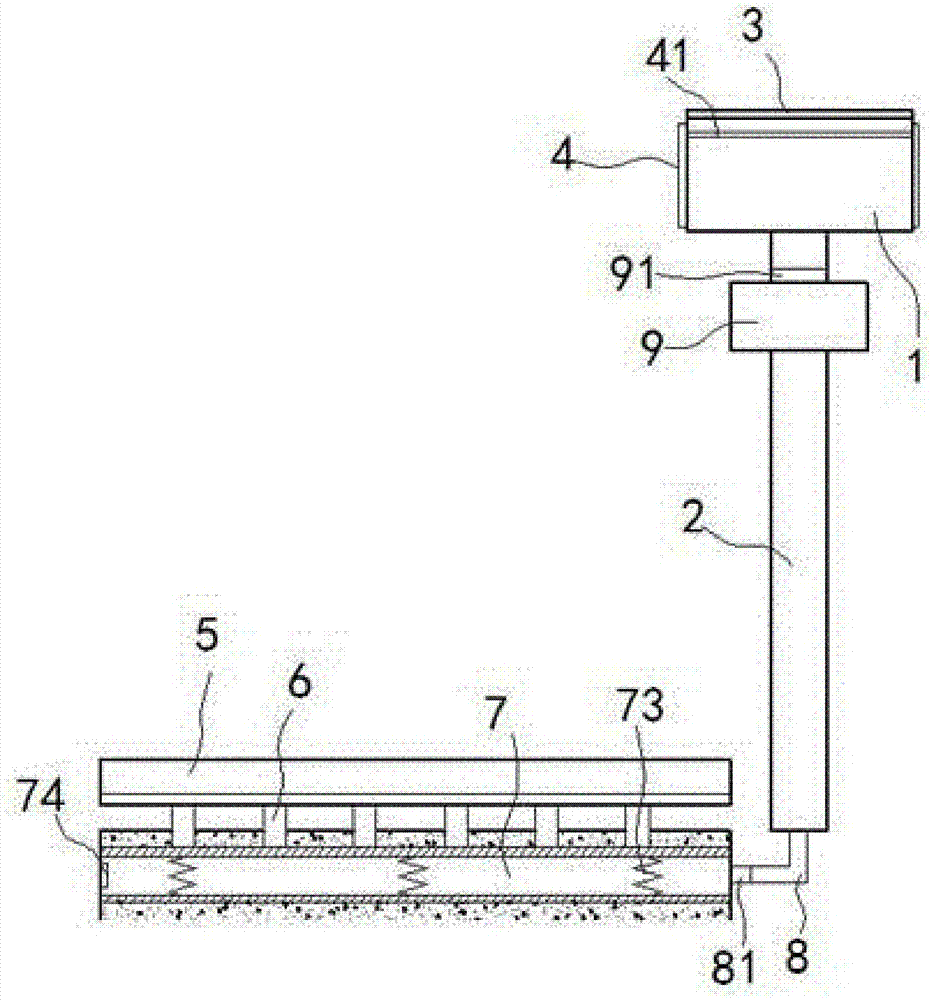

Self-cleaning photovoltaic board for street lamp

InactiveCN109506189AImprove cleanlinessHigh transparencyMechanical apparatusLighting elementsBoiling pointEngineering

The invention discloses a self-cleaning photovoltaic board for a street lamp. The self-cleaning photovoltaic board comprises a lamp pole, a mounting board and a photovoltaic board. The mounting boardis obliquely mounted at the top of the lamp pole. The photovoltaic board is fixedly mounted on the upper end face of the mounting board. Motion barrels with openings formed in the lower sides are fixedly connected to the side walls of the two sides of the mounting board. The self-cleaning photovoltaic board has the advantages that heated barrels are utilized for absorbing natural solar energy, thenatural solar energy is converted into heat to be conducted into low-boiling-point evaporated liquor, the low-boiling-point evaporated liquor evaporates to be vaporized and drives two pistons to moveupwards, and driving magnets adsorb driven magnets and drive an electric conduction brush to do sweeping motion upwards; when the temperature is reduced, the low-boiling-point evaporated liquor is liquefied and accumulated in the heated barrels, the two pistons are driven to move downwards, and the driving magnets adsorb the driven magnets and drive the electric conduction brush to do sweeping motion downwards; and destaticizing is carried out on the photovoltaic board, dust is separated from the photovoltaic board under the action of external force, the surface cleanliness of the photovoltaic board is guaranteed, transparency and irradiance are improved, and the photoelectric converting efficiency is improved.

Owner:张玉梅

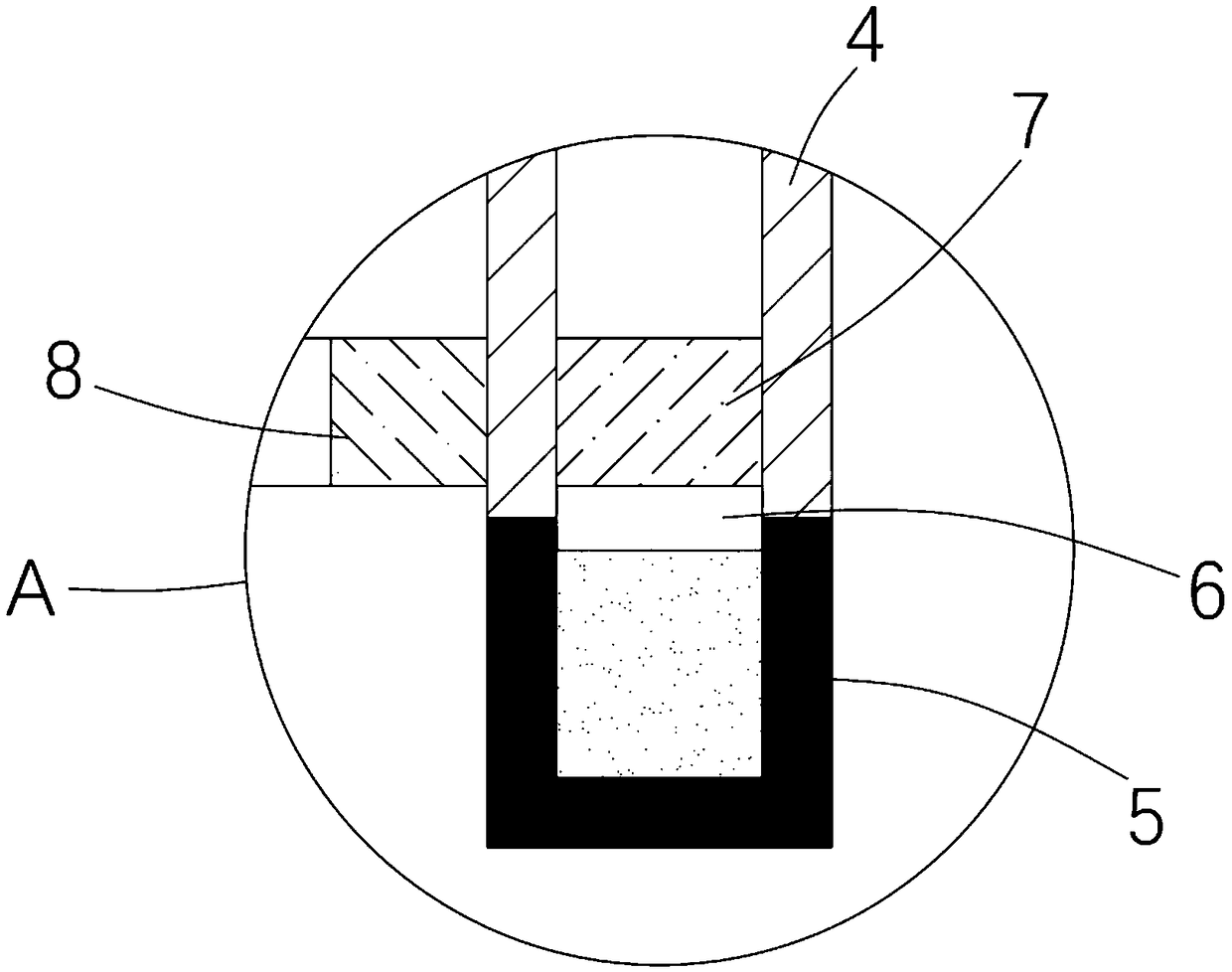

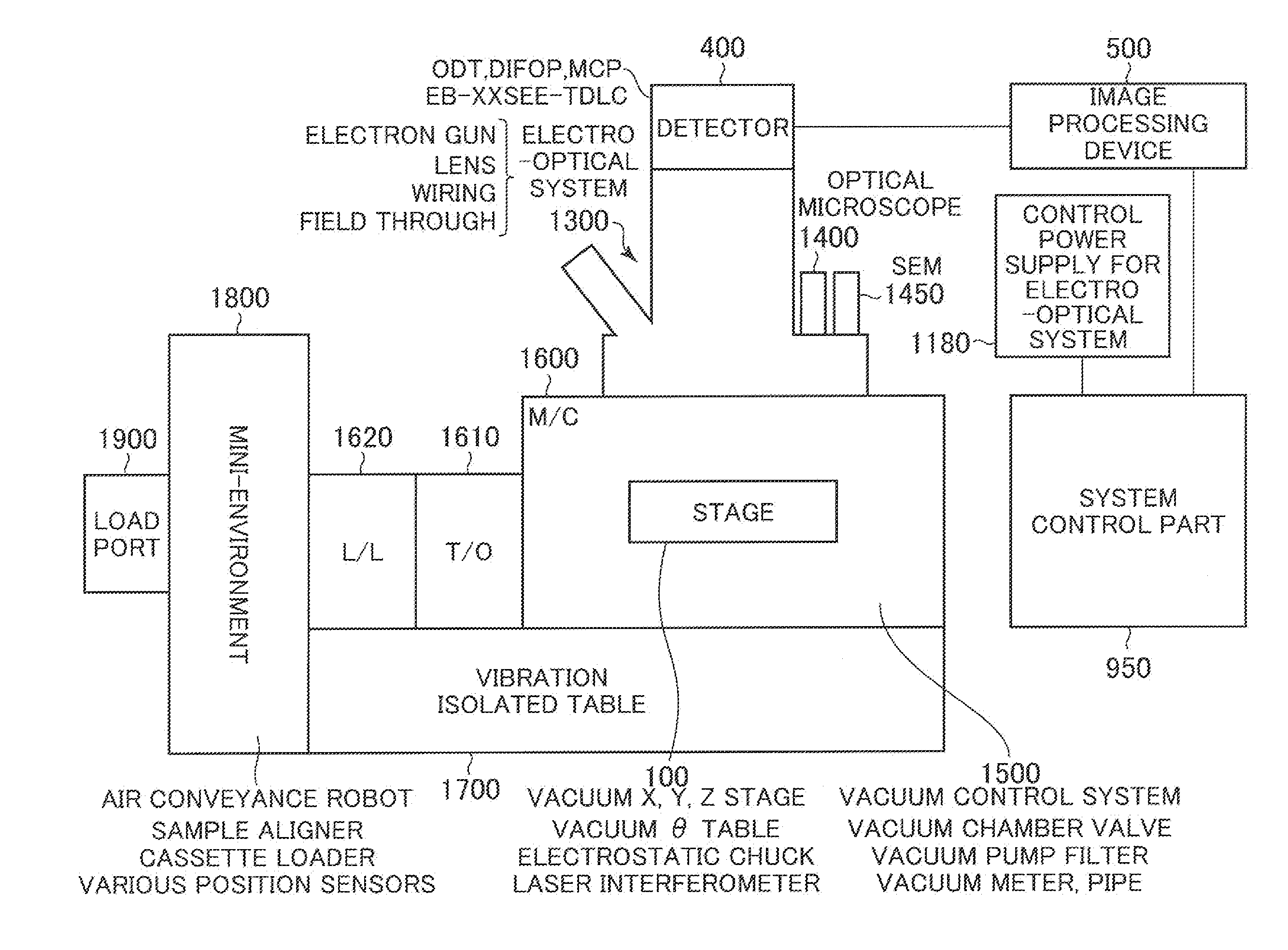

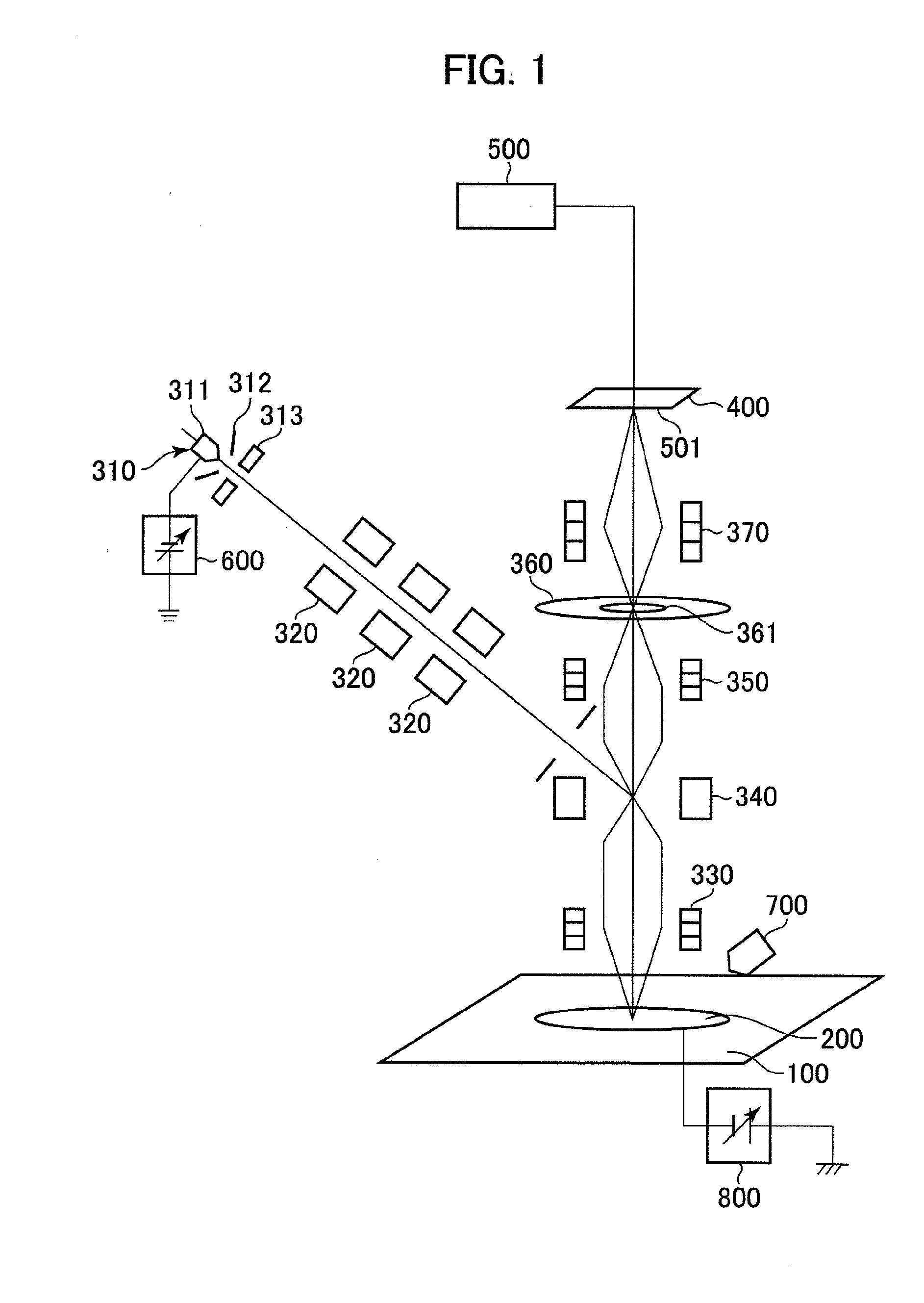

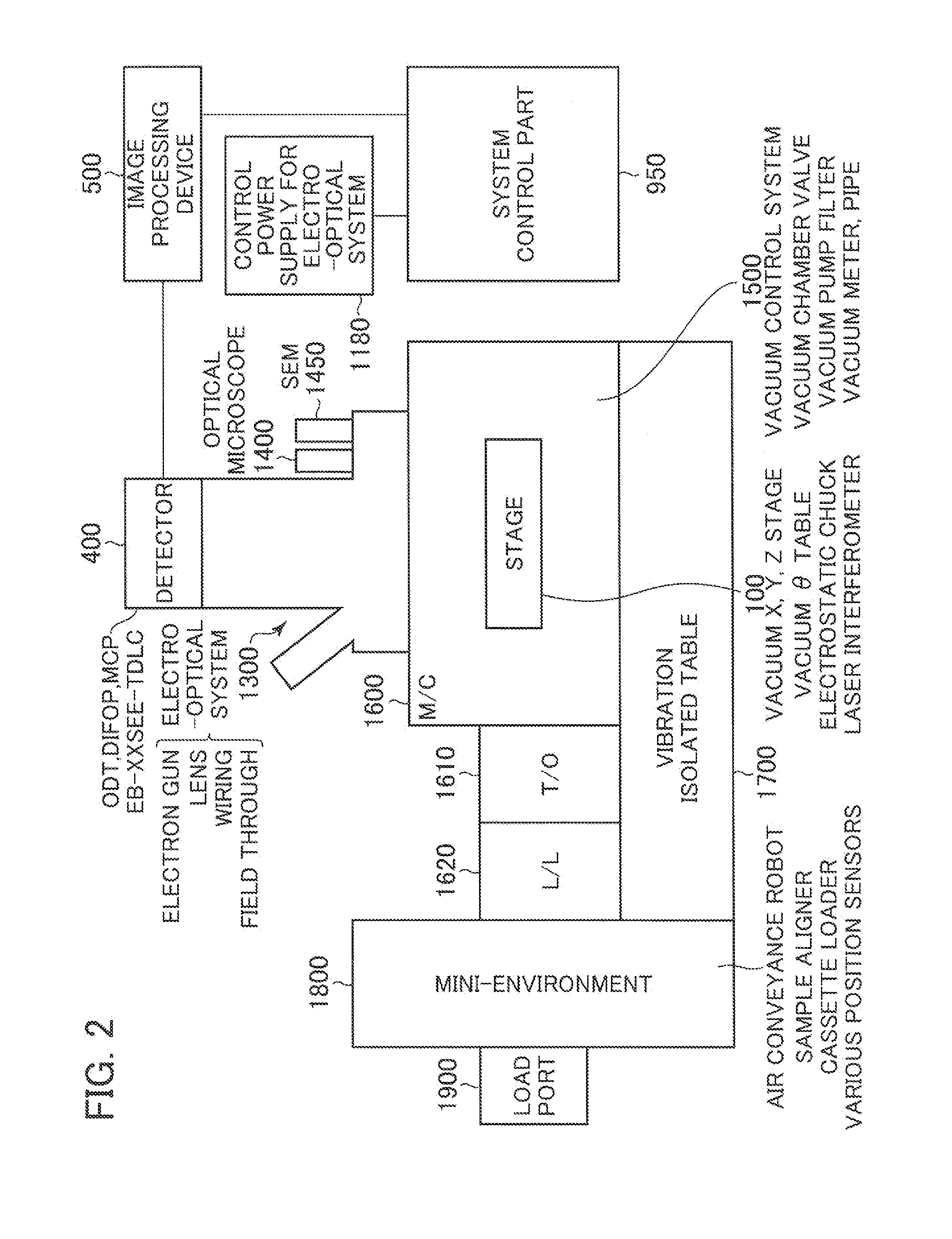

Electro-optical inspection apparatus and method with dust or particle collection function

InactiveUS20120074316A1Easy to detectGood for observationElectric discharge tubesMaterial analysis using radiation diffractionElectrical polarityVacuum chamber

An electro-optical inspection apparatus is provided that is capable of preventing adhesion of dust or particles to the sample surface as much as possible. A stage (100) on which a sample (200) is placed is disposed inside a vacuum chamber (112) that can be evacuated to vacuum, and a dust collecting electrode (122) is disposed to surround a periphery of the sample (200). The dust collecting electrode (122) is applied with a voltage having the same polarity as a voltage applied to the sample (200) and an absolute value that is the same or larger than an absolute value of the voltage. Thus, because dust or particles such as particles adhere to the dust collecting electrode (122), adhesion of the dust or particles to the sample surface can be reduced. Instead of using the dust collecting electrode, it is possible to form a recess on a wall of the vacuum chamber containing the stage, or to dispose on the wall a metal plate having a mesh structure to which a predetermined voltage is applied. In addition, adhesion of dust or particles can be further reduced by disposing a gap control plate (124) having a through hole (124a) at the center above the sample (200) and the dust collecting electrode (122).

Owner:EBARA CORP

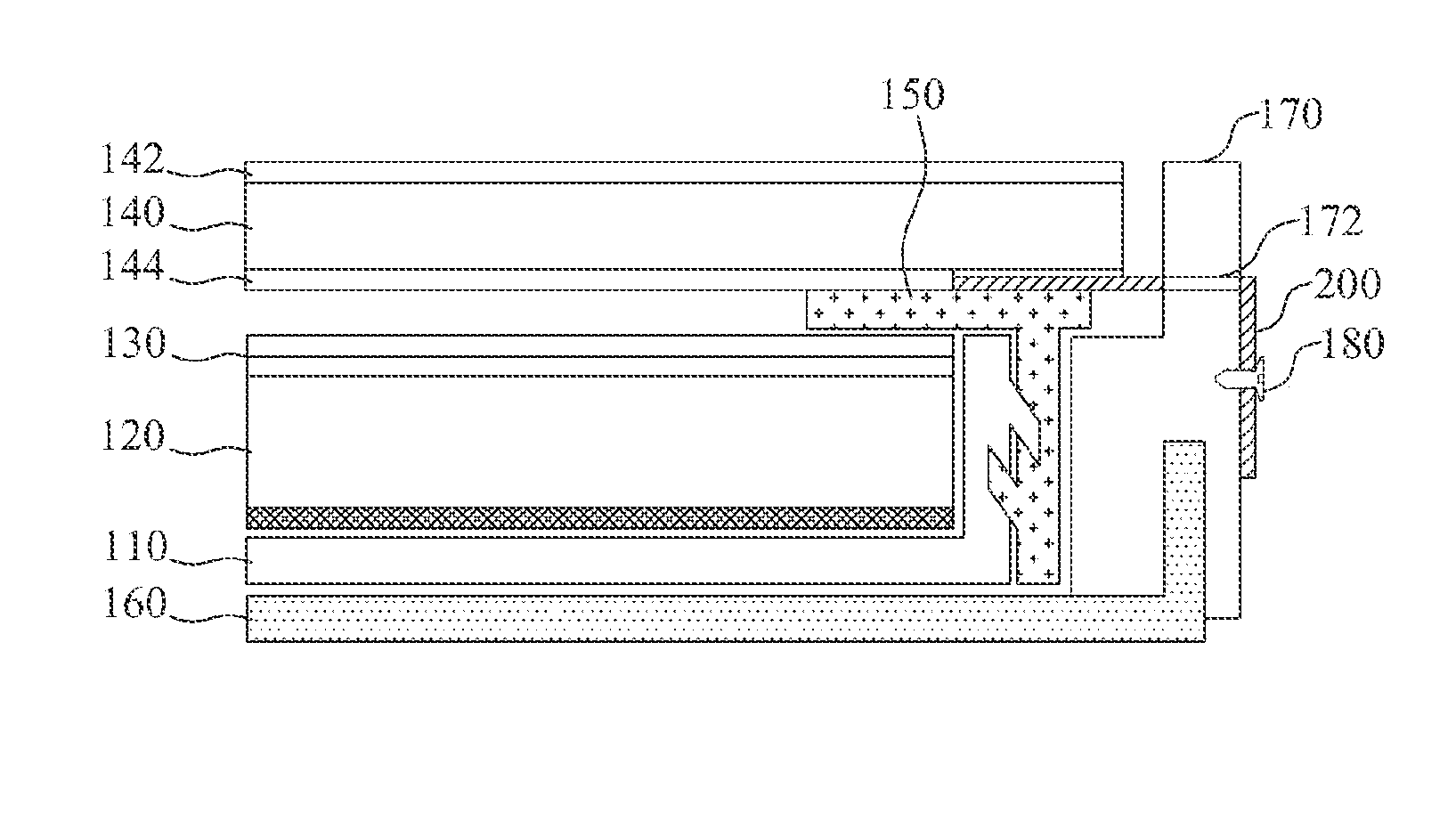

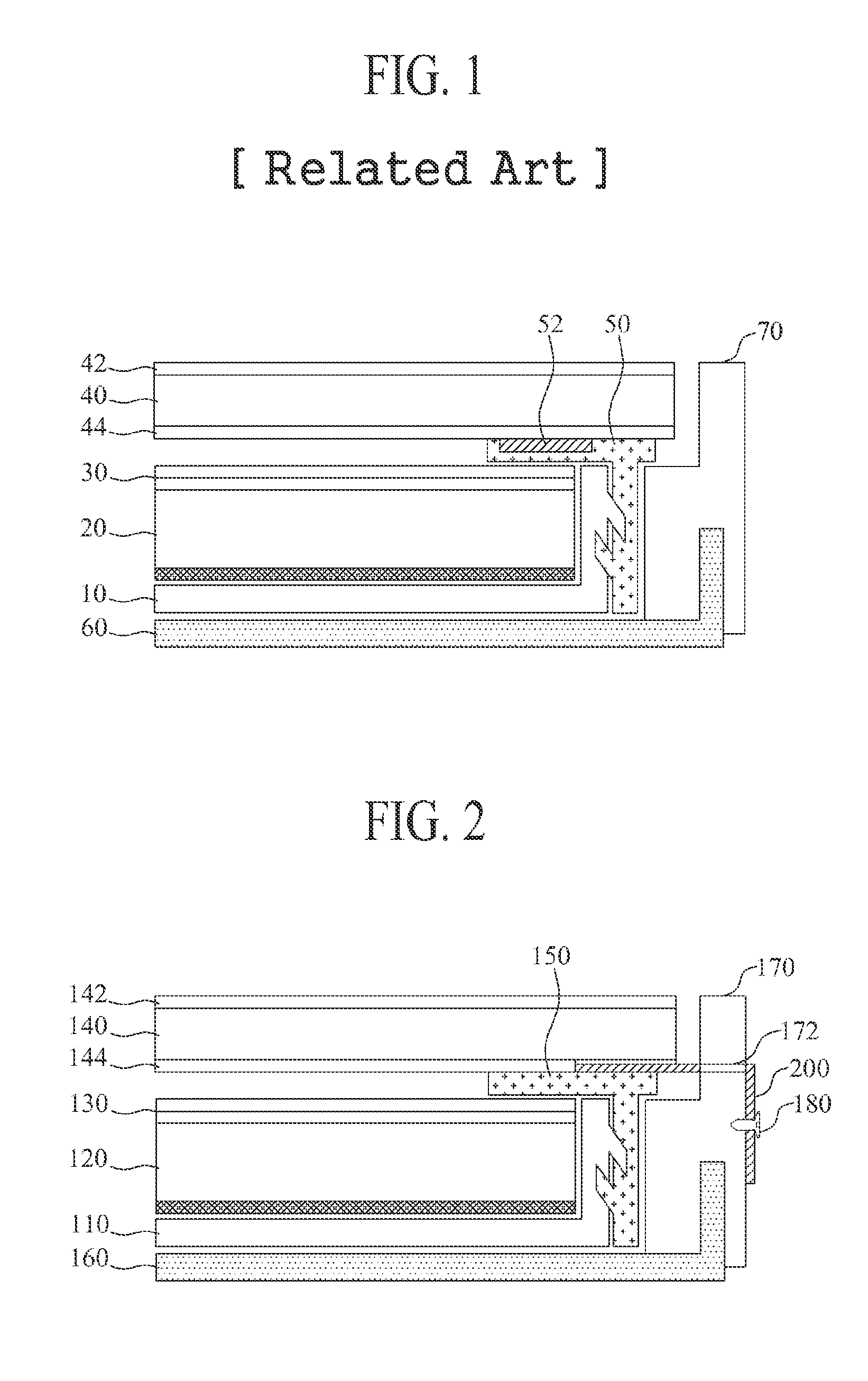

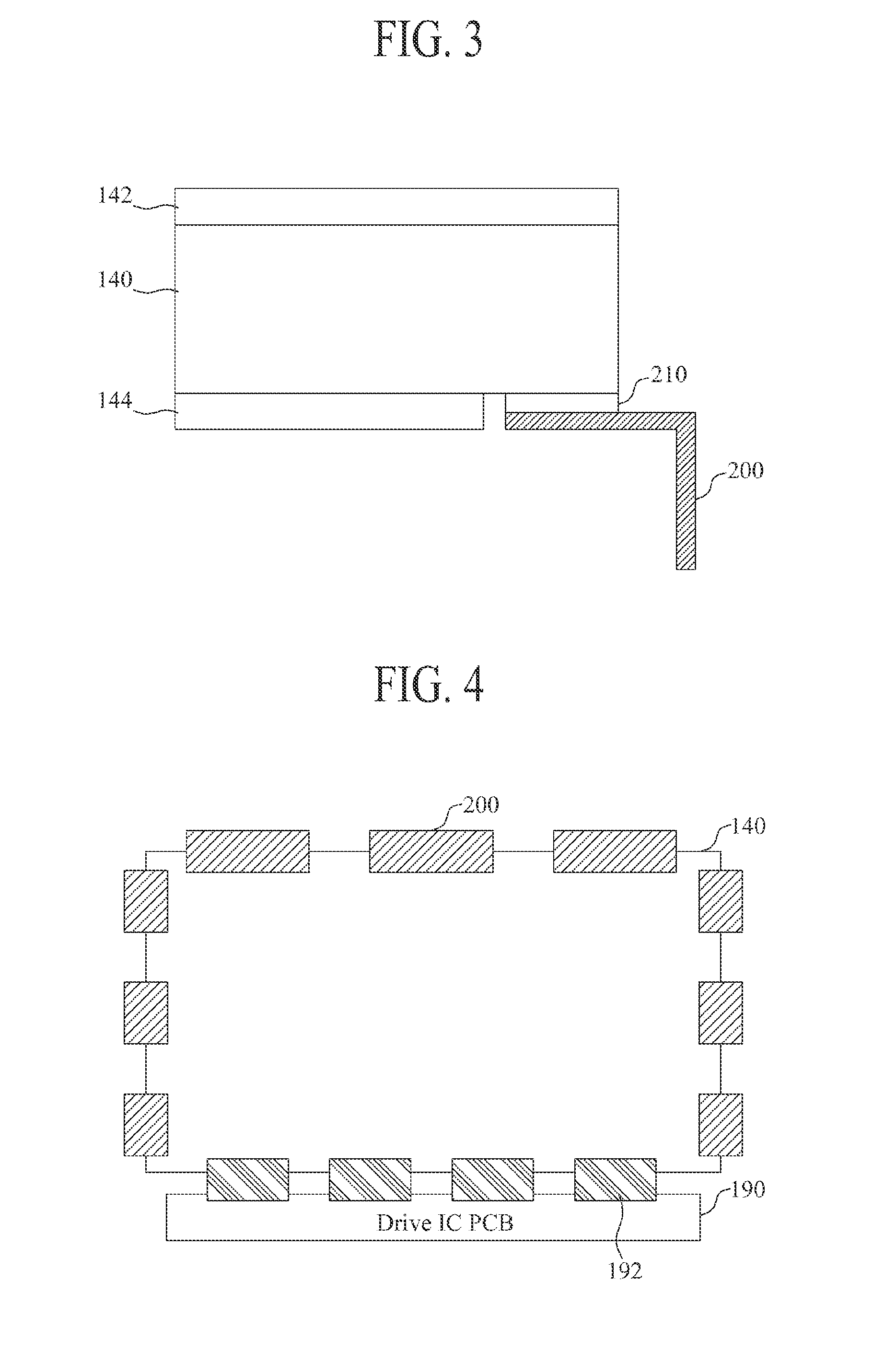

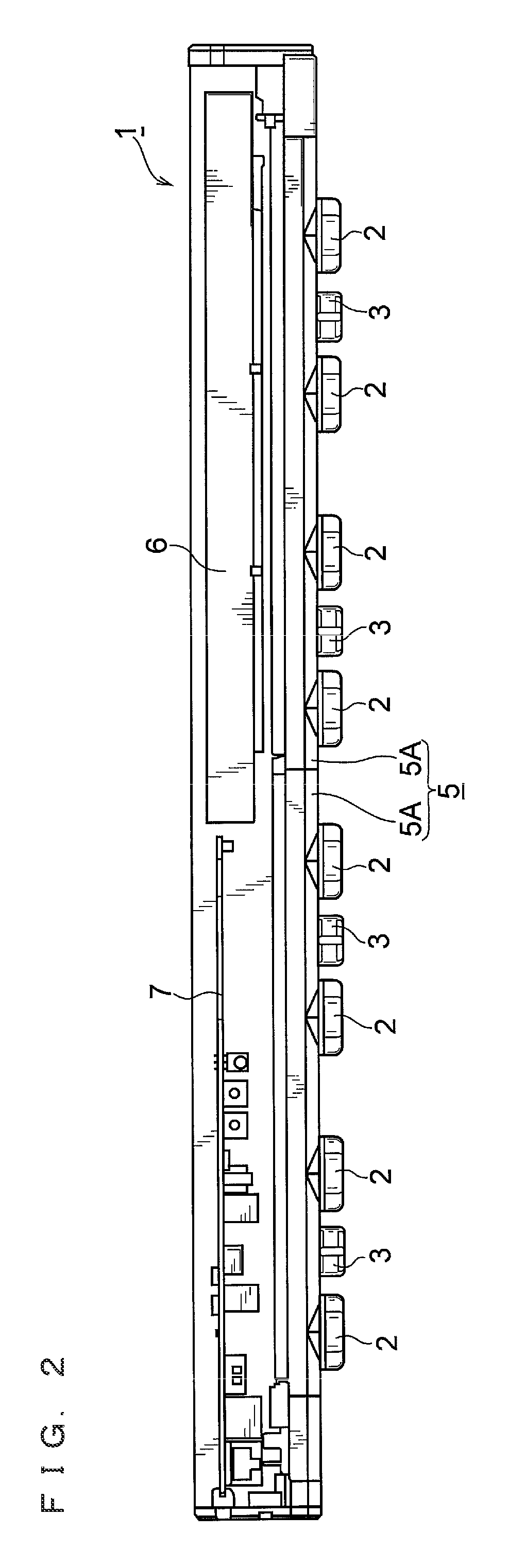

Liquid Crystal Display Device

Discussed is an LCD device. The LCD device includes a guide panel, a side cover, a flexible film, and an adhesive member. The guide panel includes a side wall and a support part formed to surround a lower edge of a liquid crystal panel, and supports the liquid crystal panel. The side cover is formed to surround a side surface of the liquid crystal panel and a side surface of the guide panel, and a hole is formed at a portion of the liquid crystal panel having a certain height. The flexible film is disposed between the support part of the guide panel and the liquid crystal panel. The adhesive member adheres a bottom of the liquid crystal panel to the flexible film.

Owner:LG DISPLAY CO LTD

Electroconductive plastics and method of producing the same

ActiveCN101402776AImprove mechanical propertiesImprove shrinkageNon-conductive material with dispersed conductive materialGlass fiberPolymer substrate

The invention relates to a conductive plastic which consists of the following components by mass percentages: 30 percent to 70 percent of polymer matrix, 15 percent to 50 percent of glass fiber, 10 percent to 35 percent of conductive carbon black and 1 percent to 5 percent of modifier. The invention also provides a preparation method of the conductive plastic. The conductive plastic comprises the glass fiber and the conductive black, wherein, the glass fiber can enhance the mechanical performance of the conductive plastic, improve the shrinkage of the plastic, eliminate static electricity effectively and have good high temperature resistance simultaneously.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

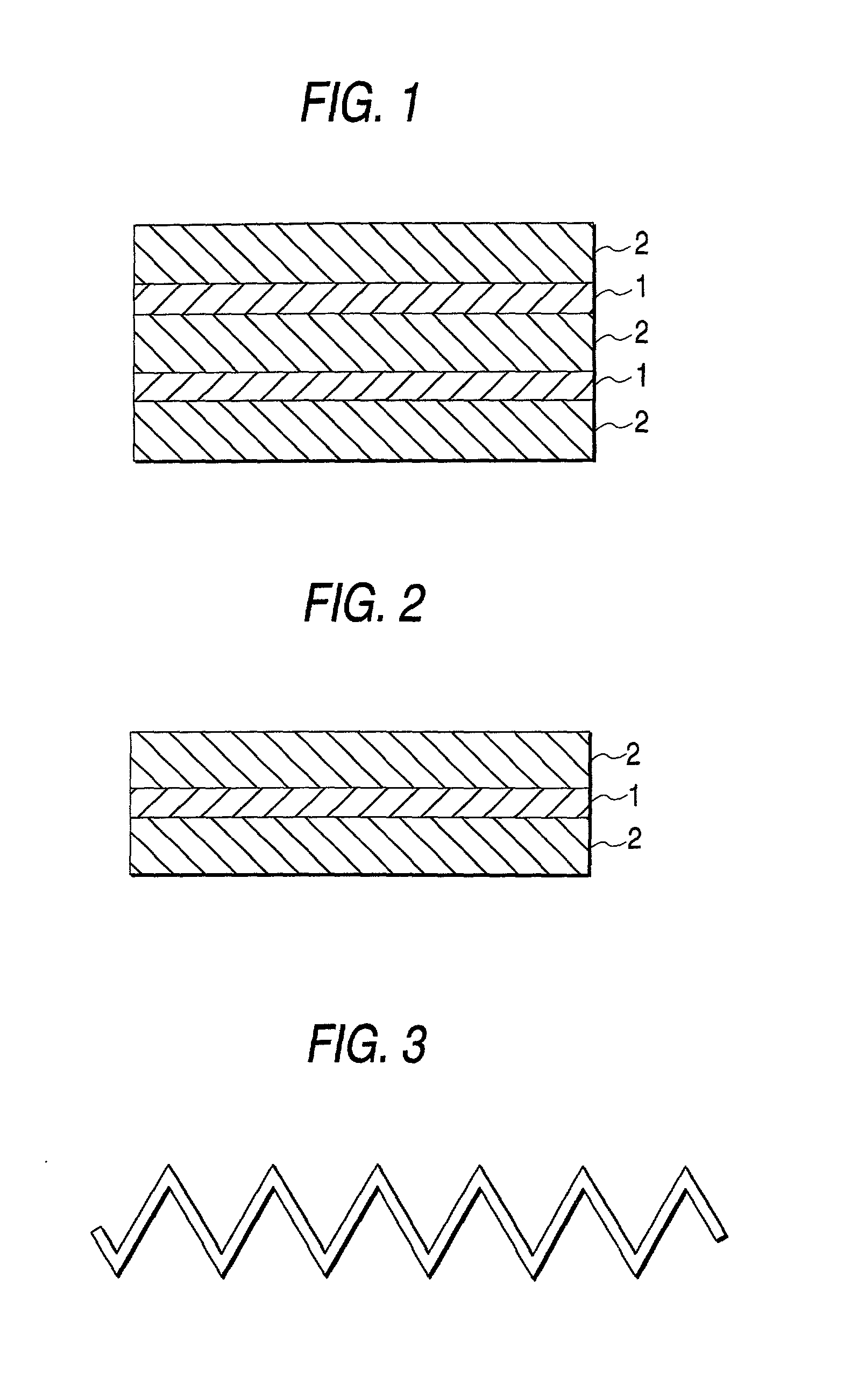

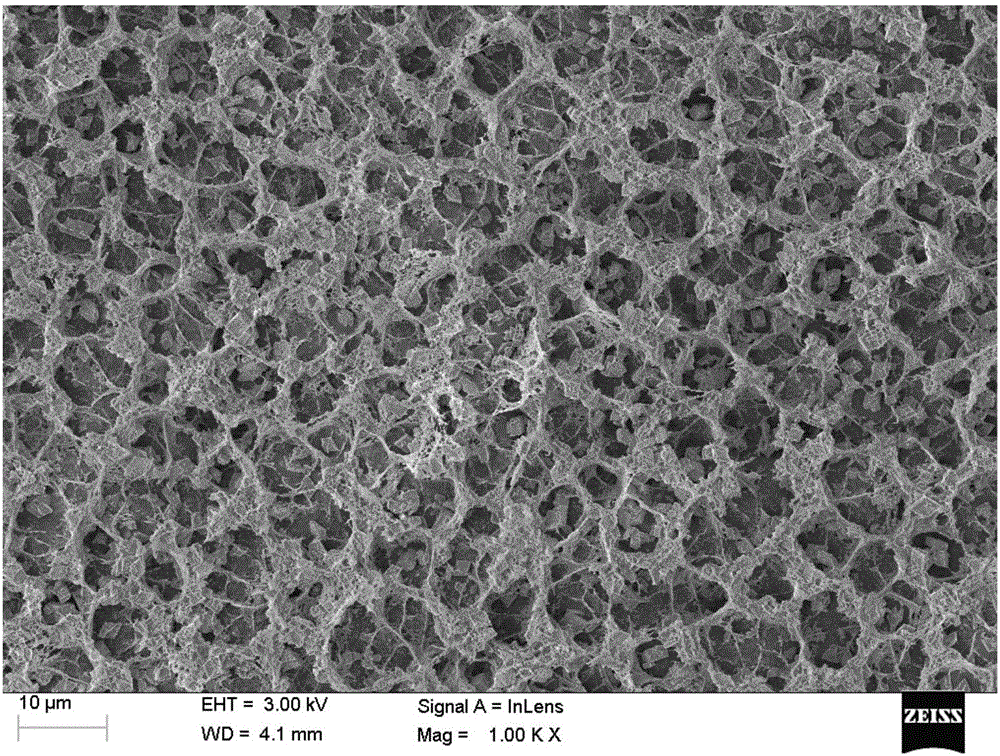

Filtering medium for air filter and process for producing the same

InactiveUS20020170434A1Easy to measureInhibition formationCombination devicesSemi-permeable membranesEngineeringPTFE - Polytetrafluoroethylene

A filtering medium for air filters, comprising a laminate including at least one porous polytetrafluoroethylene (PTFE) membrane and at least one air-permeable supporting member, the filtering medium having a surface potential of 0.3 kV or lower in terms of absolute value. By regulating the absolute value of surface potential so as to be within that range, the formation of a through-hole attributable to a discharge (spark) caused by, e.g., contact with a bare hand can be prevented. Thus, the leakage phenomenon observed in filtering media for air filter using a porous PTFE membrane can be inhibited.

Owner:NITTO DENKO CORP

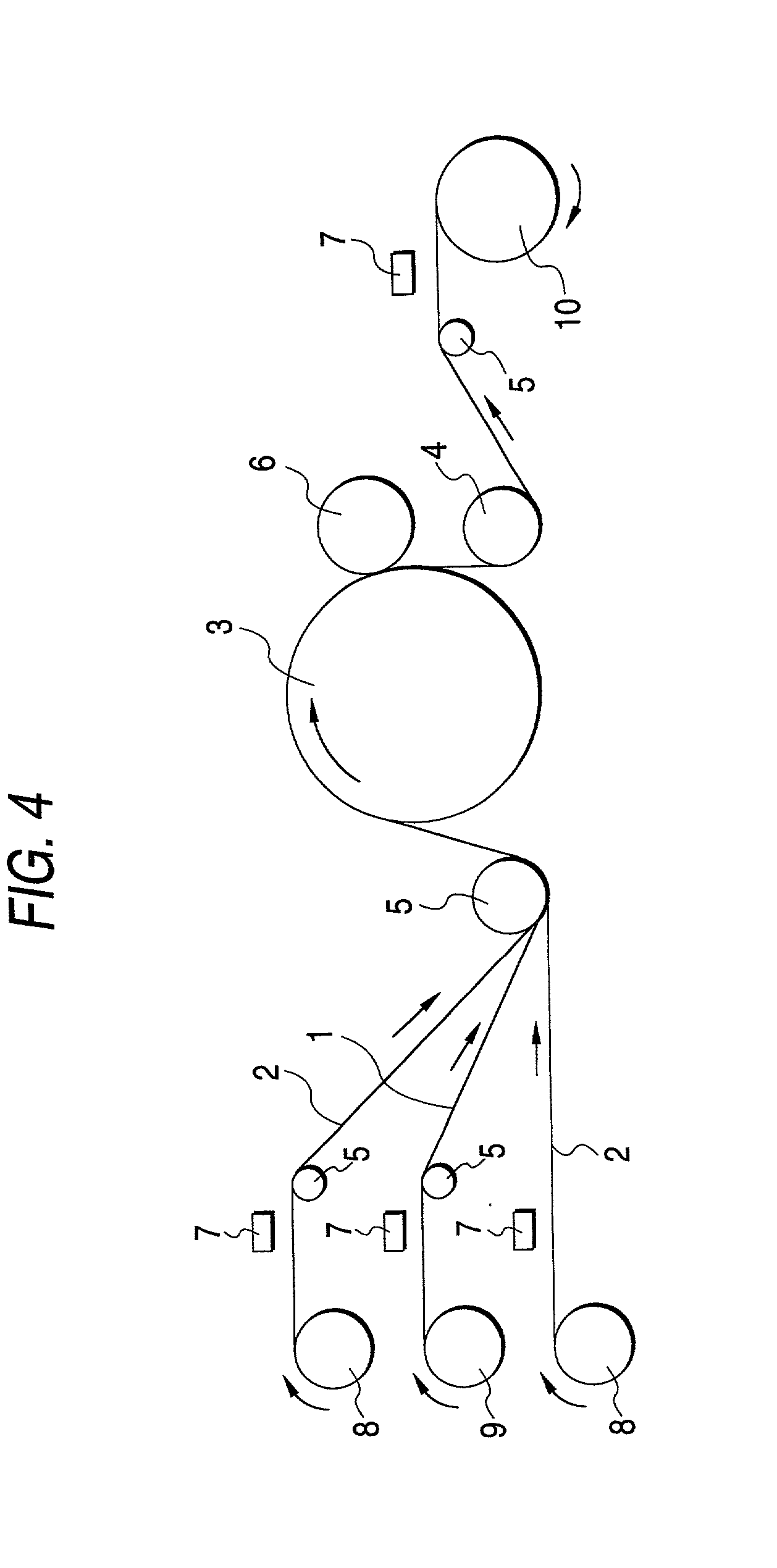

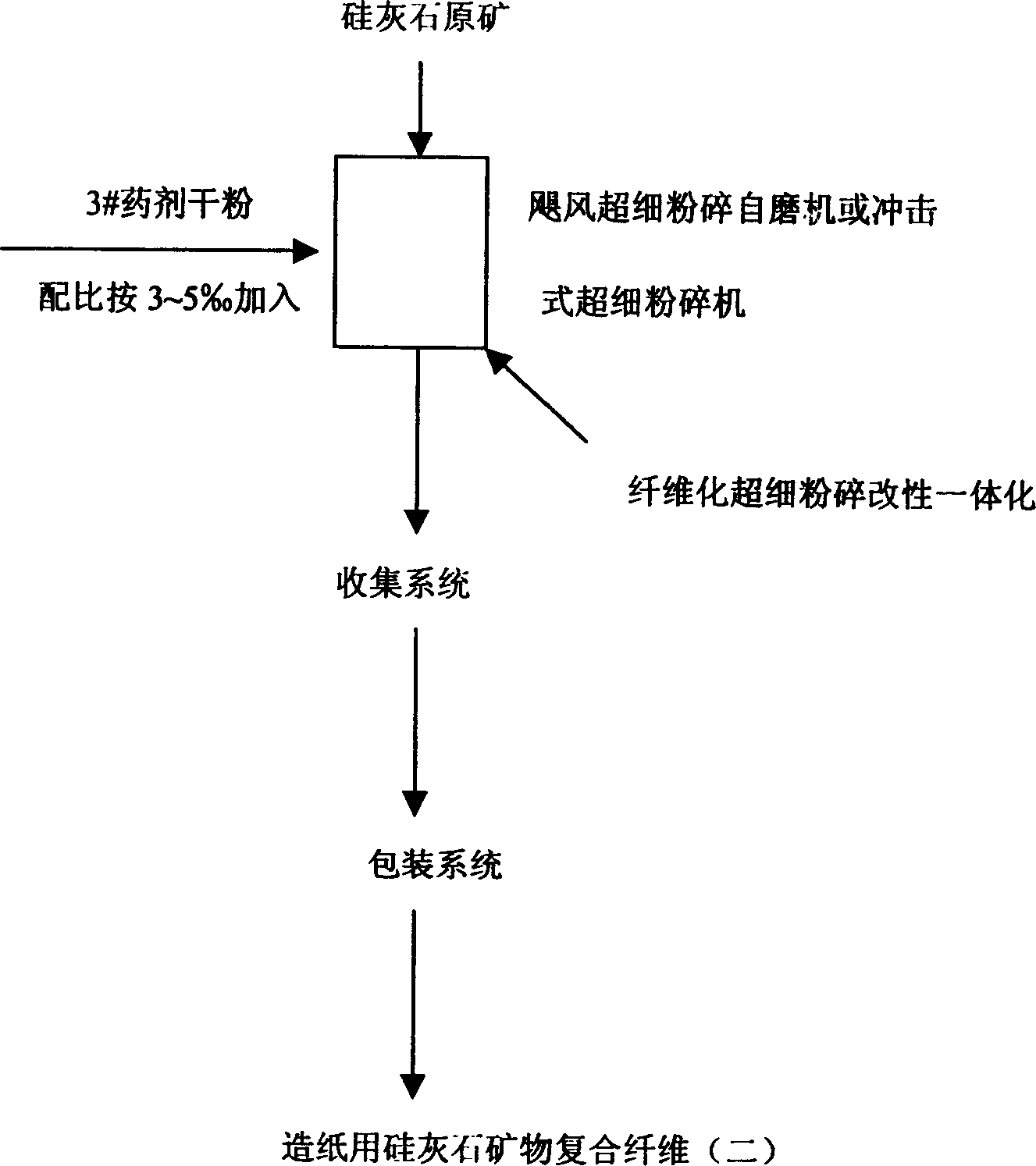

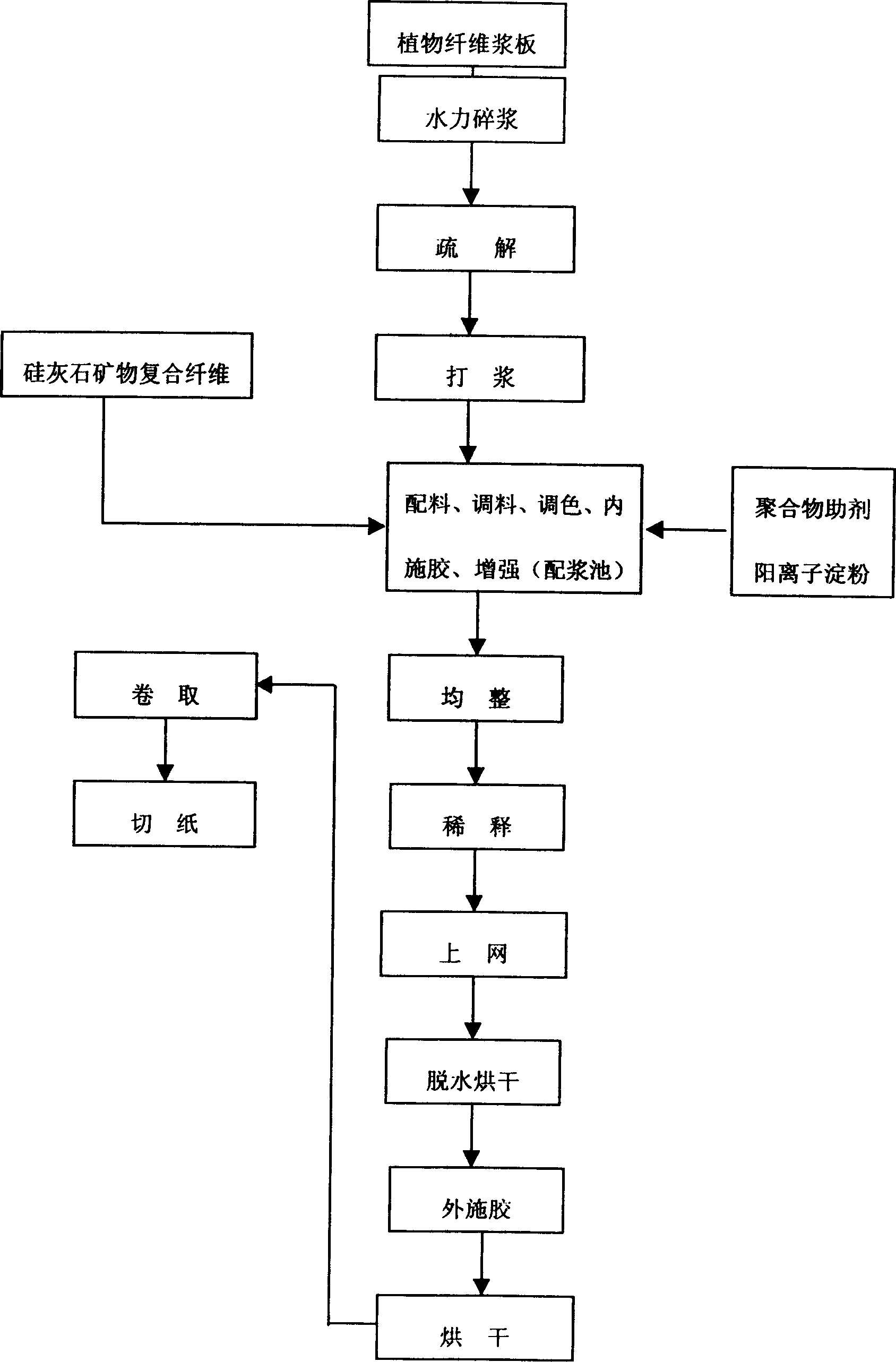

Modified wollastonite mineral composite fibre for making paper and its paper-making process

The present invention provides a modified wollastonite mineral composite fibre for making paper and its paper-making method. It includes the following steps: breaking wollastonite raw ore to obtain the thin-long fibre whose grain size is 5-20 micrometer and the ratio of mid-diameter:length=1:6-30, and according to the ratio of alkali or salt of aluminium: alkali or salt of sodium=1:1 adding modification agent whose added quantity is 3-10% of wollastonite mineral composite fibre weight so as to obtain the wollastonite mineral composite fibre covered with modification agent. In the course of preparing pulp in paper-making process 5-50% of modified wollastonite mineral composite fibre and 50-95% of plant fibre and paper-making auxiliary material are added, it can reduce production cost.

Owner:云南省非金属矿产应用研究所

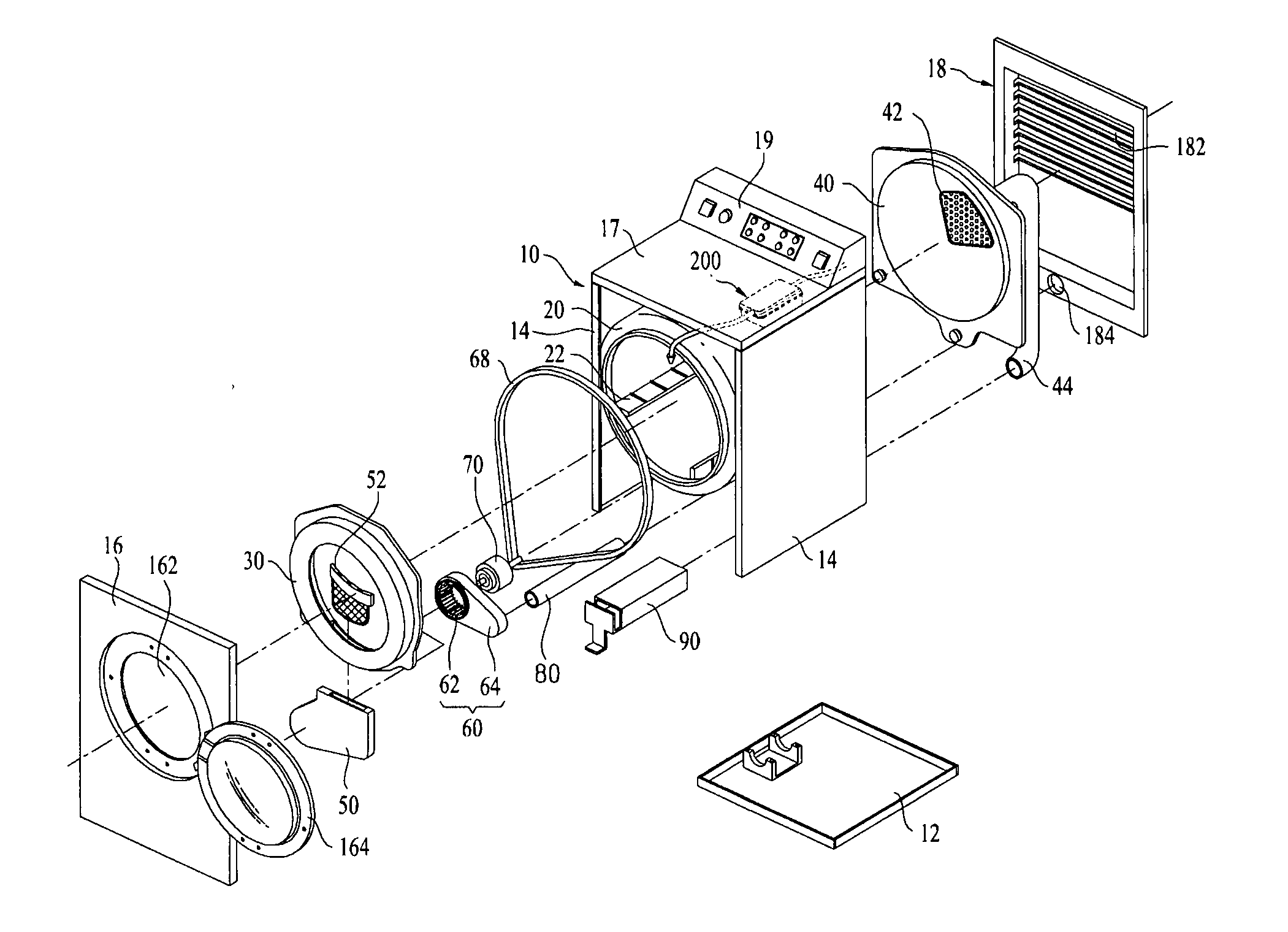

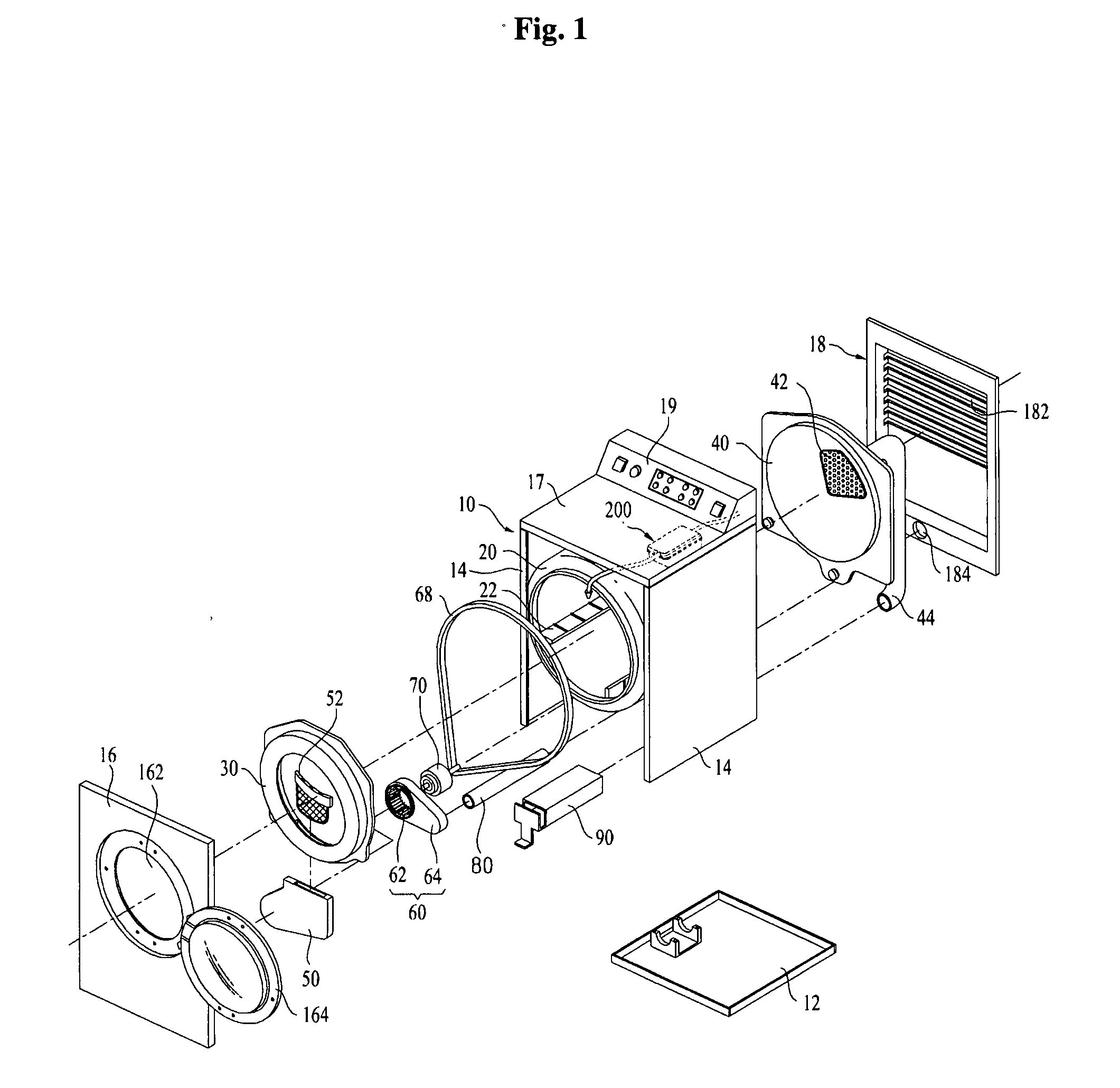

Method for controlling laundry machine

InactiveUS20080148596A1Avoid wrinklesEliminate static electricityDrying solid materials with heatDrying solid materials without heatProcess engineeringLaundry

Method for controlling a dryer having a steam generator for generating high temperature steam with heat generation of a steam heater, including a hot air supply step for supplying dried hot air to a drum for drying clothes, and a moisture supply step for supplying moisture to the drum for removing static electricity from the clothes dried in the hot air supply step.

Owner:LG ELECTRONICS INC

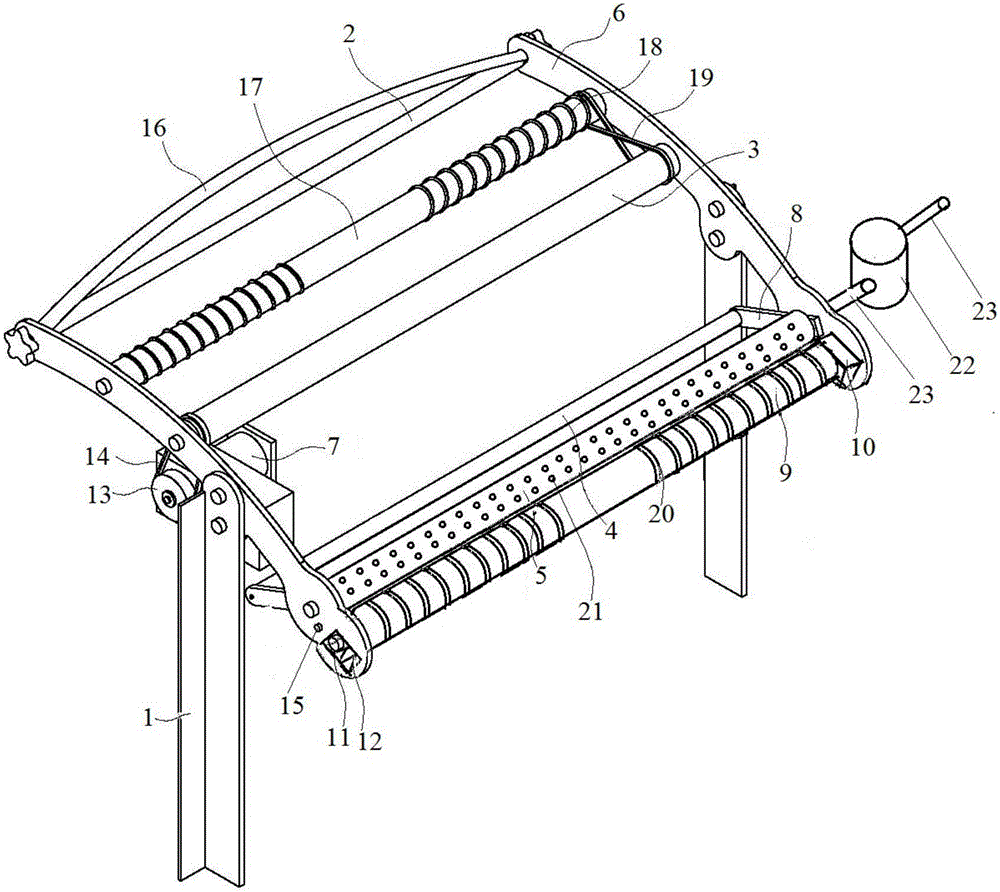

Anti-fold cloth feeding device for cloth spreading machine

InactiveCN106006163ASimple structureEasy to operateUnfolding thin materialsWebs handlingElectrostatic coatingMechanical engineering

The invention relates to an anti-wrinkle cloth feeding device of a spreading machine. The front end of the device is provided with a cloth pressing roller parallel to the cloth discharging roller. The two ends of the cloth pressing roller are embedded in the slider through bearings. The sliding block is slidingly matched with the chute arranged on the end of the cross bar of the frame, and a spring is arranged between the sliding block and the end of the chute; the cloth outlet roller and / or pressing roller are hollow rollers, and the hollow roller There are several ventilation holes evenly arranged on the wall, one end of the hollow roller is provided with a plugging head, and the other end of the hollow roller is connected to the steam source through an air pump and a pipeline; an antistatic coating is provided on the surface of the press roller, and the corresponding cloth passes through The cloth guide roller is driven by the cloth feed roller to convey to the tension roller, and is sent out from between the cloth outlet roller and the cloth pressure roller. The cloth adjusting device of the cloth spreader has the characteristics of relatively simple structure, convenient operation, smooth output cloth, can eliminate static electricity on the cloth surface, and is safe and reliable to use.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

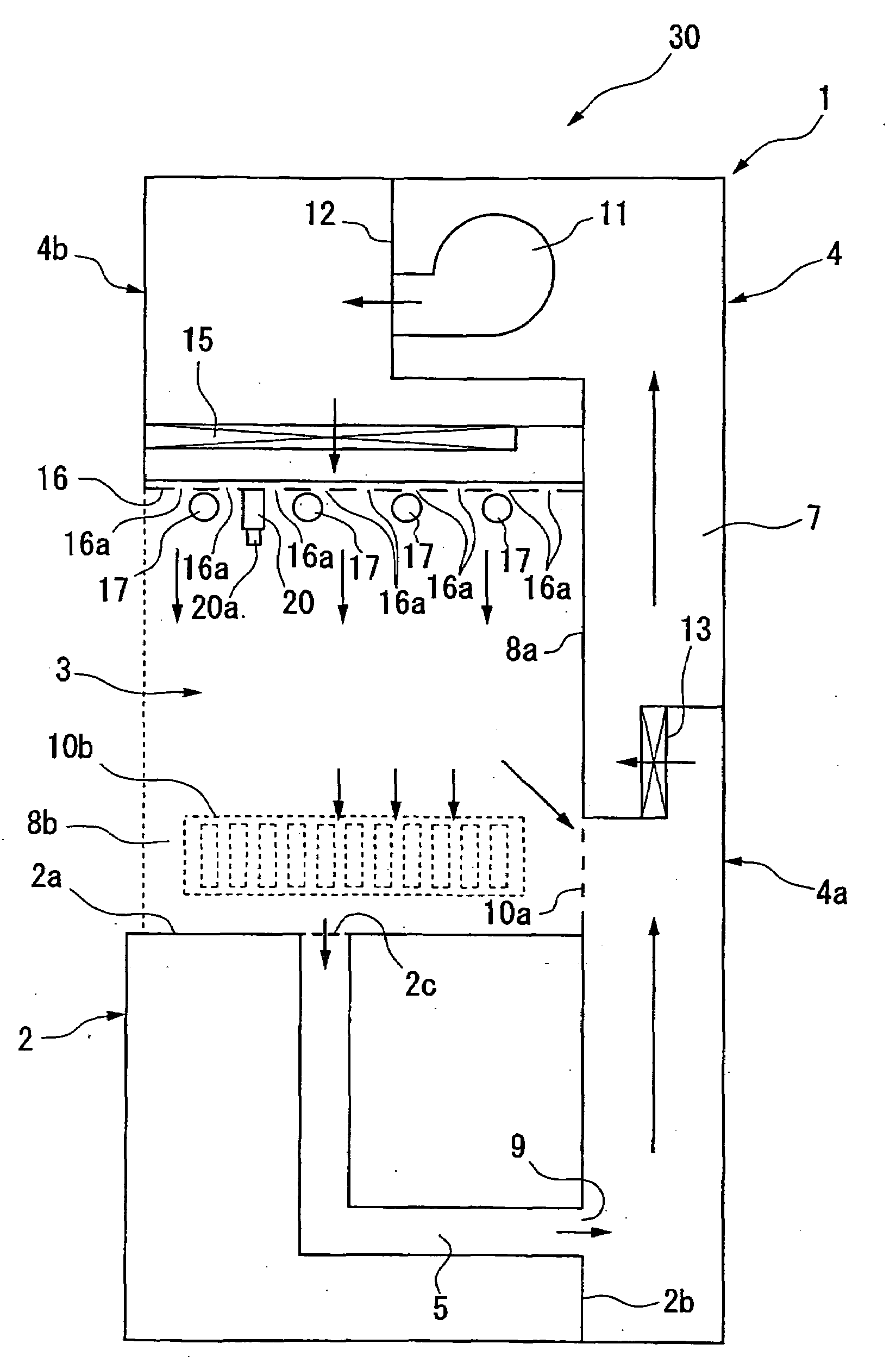

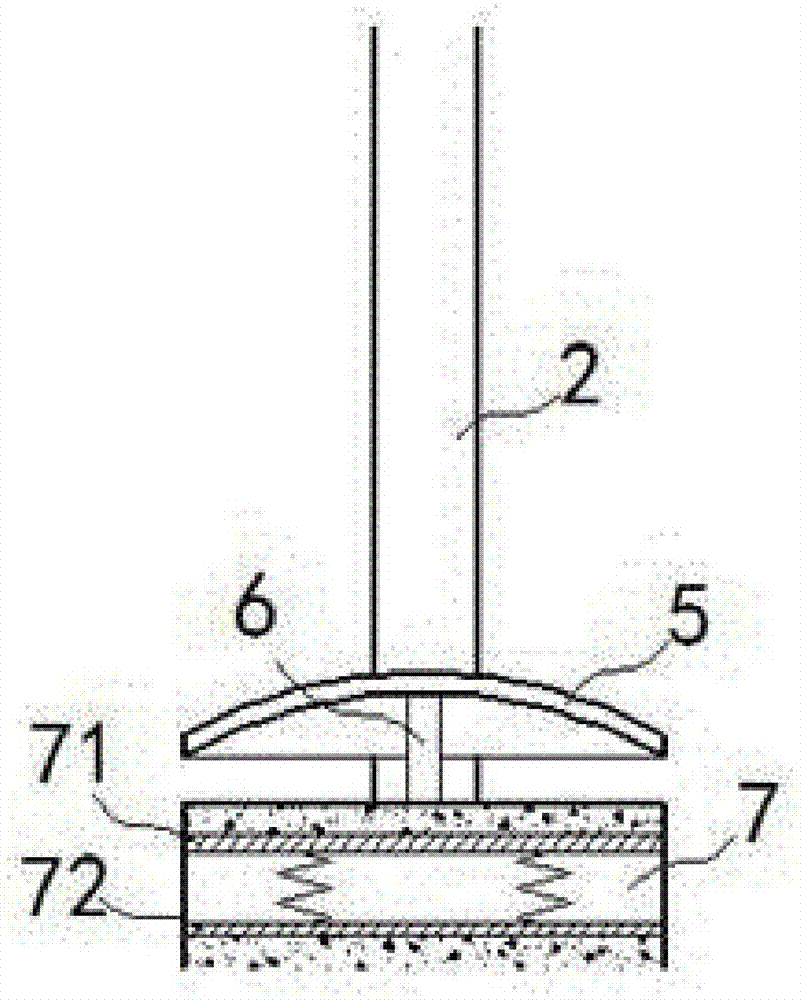

Clean bench and method of producing raw material for single crystal silicon

ActiveUS20090081108A1Improve qualityHigh purityCombination devicesSiliconPolycrystalline siliconEngineering

A clean bench comprising a worktable on which polycrystalline silicon is placed, a box part which includes side plates to surround three sides except a front face of a working space above the worktable, and a ceiling plate which covers an upper side of the working space. Supplying holes are formed in the ceiling plate of the box part, which supply clean air onto an upper surface of the worktable. An ionizer is provided, which ionizes the clean air supplied from the supplying holes to the working space and removes static electricity on the worktable. Suction holes are formed in the side plate of the box part, which suction air from the working space.

Owner:MITSUBISHI MATERIALS CORP

Cleaning method for self-cleaning photovoltaic panel of streetlamp

ActiveCN107363040AExtended service lifeReduce adsorptionPhotovoltaicsCleaning using gasesCleaning methodsTraffic flow

Owner:洪东潦

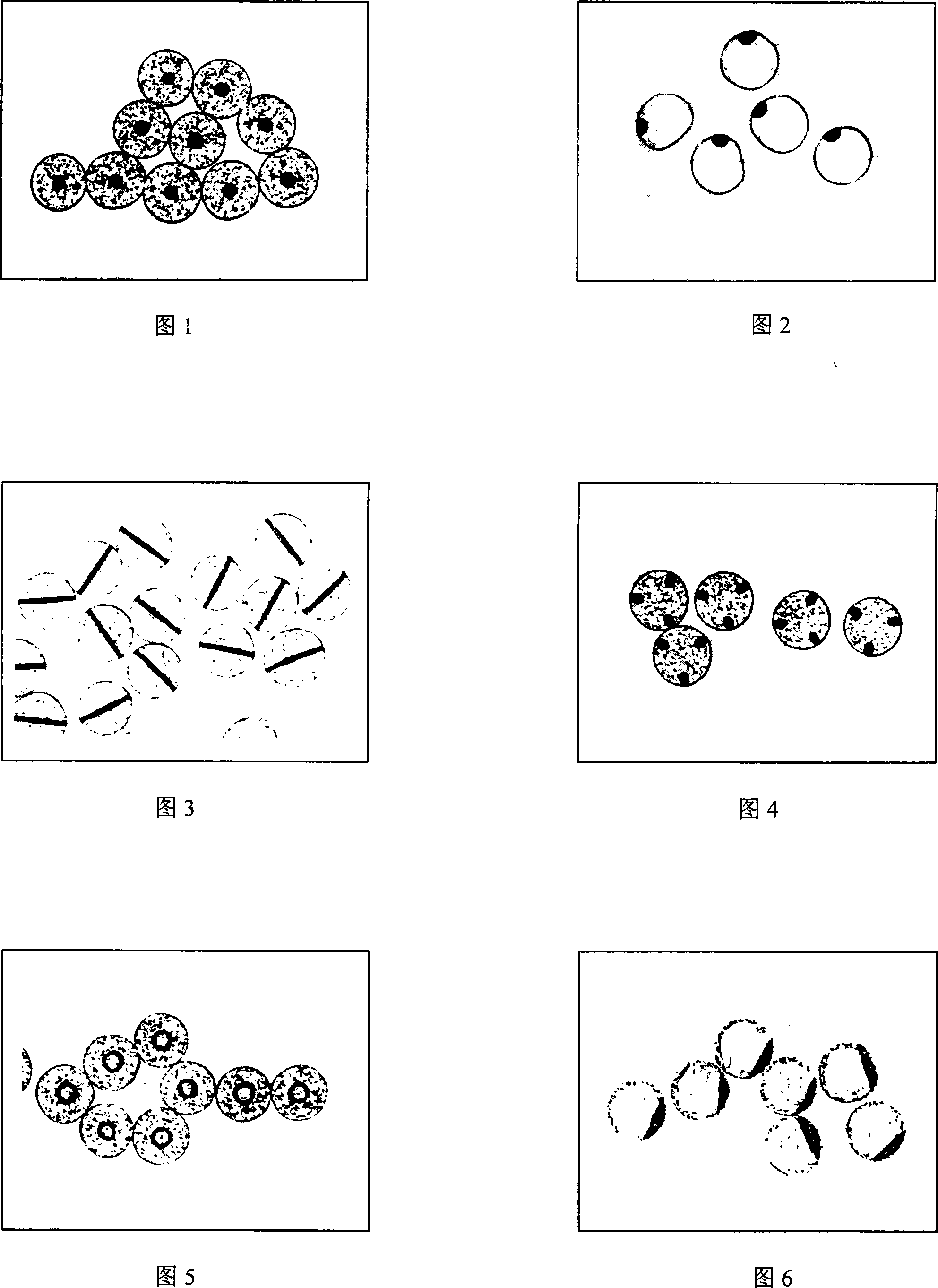

Durable high performance composite conductive fibre and manufacturing method

InactiveCN101096775AImprove conductivityIncreased durabilityElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterFiber

The invention discloses a durable high-performance composite conductive fiber and preparing method, which is characterized by the following: comprising with conductive layer and non-conducting layer; comprising the conductive layer with carrier resin as 20-30% (wt)conductive component and 80-70% (wt)non-conducting component; choosing the non-conducting as polyester or polyamide fibre-forming high polymer; choosing the conductive layer as three-flanged type and multilayer type; choosing the conductive component in the conductive layer as high conductive carbon black; utilizing mixed melting method; dispersing in the carrier resin; pelleting with double screw; forming conductive particle; choosing special three-flanged type and multilayer layer composite spinning component; utilizing composite spinning process technology. This invention possesses low conductive ratio, high conductivity and good durability, which can meet the demand of high level purification.

Owner:SINOSELEN HI TECH

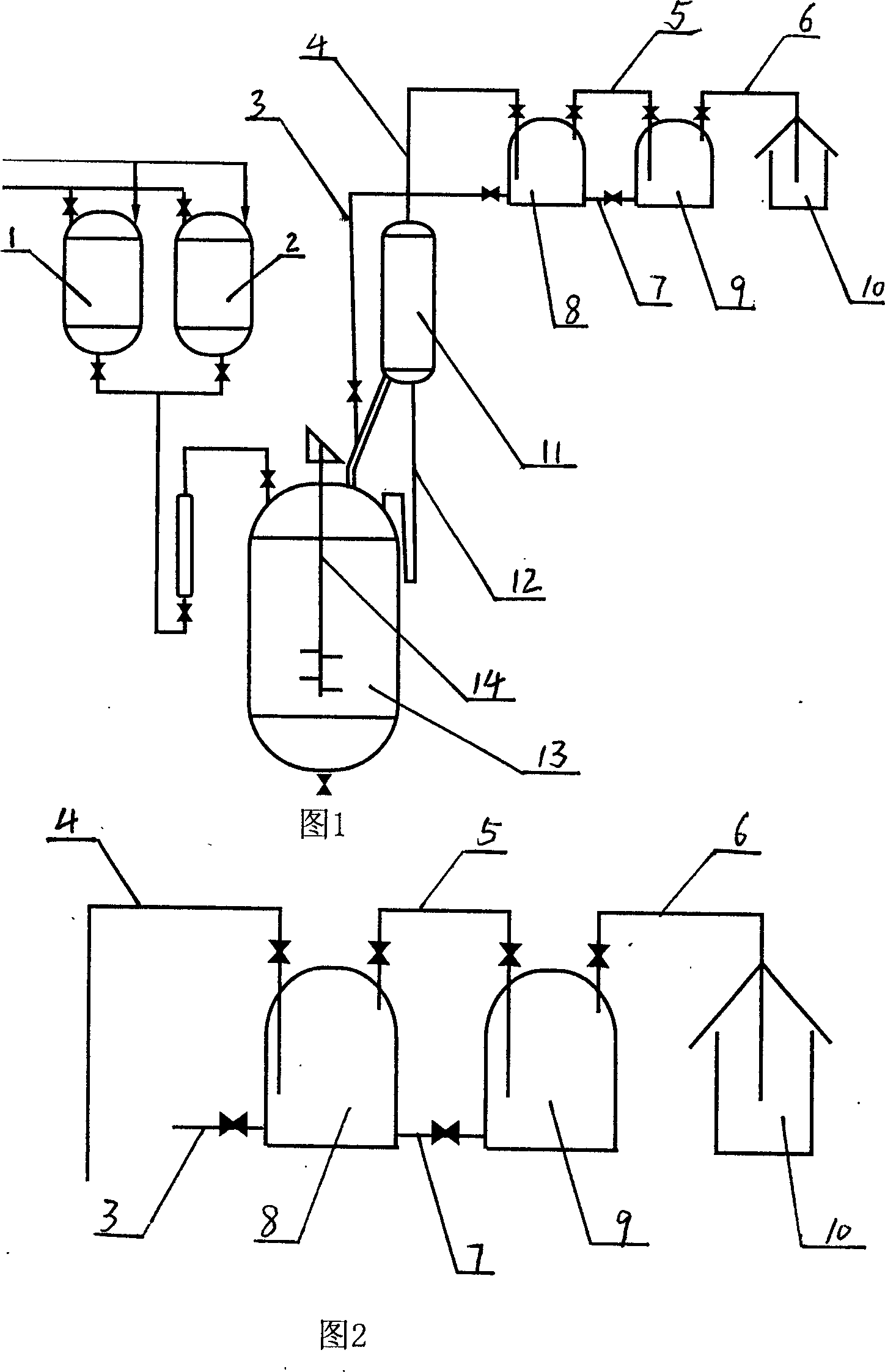

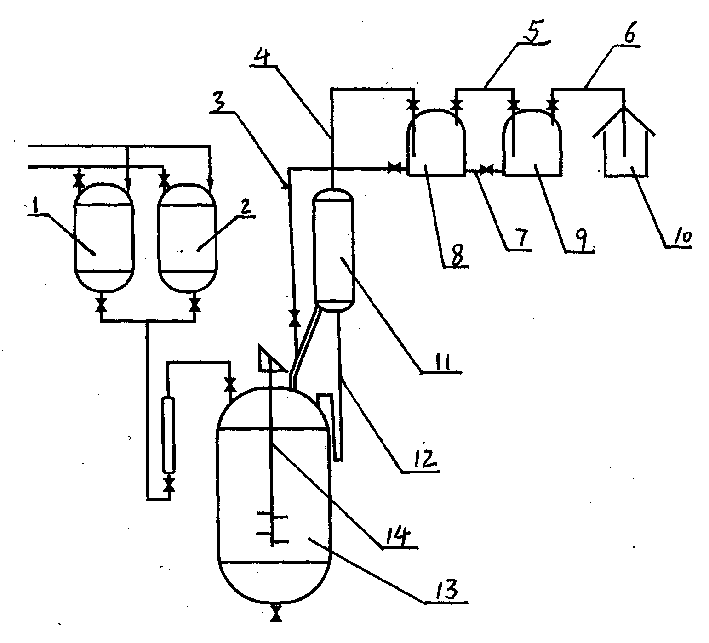

Prepn process and apparatus for alpha-acetyl-gamma-butyrolactone

InactiveCN1548427AAvoid safety hazardsEven contactOrganic chemistryAlpha-acetyl-gamma-butyrolactoneGamma-Butyrolactone

The preparation process of alpha-acetyl-gamma-butyrolactone includes reaction section, neutralization section and distillation section, and features the reaction section, which includes adding catalyst into benzene solvent, heating while stirring, fast cooling and dropping the liquid mixture of gamma-butyrolactone and acylating agent; the neutralization section before extraction; and the distillation section to prepare alpha-acetyl-gamma-butyrolactone. The present invention also relates to the reactor with one increased buffering reflux unit for preparing alpha-acetyl-gamma-butyrolactone.

Owner:LINHAI LIANSHENG CHEM

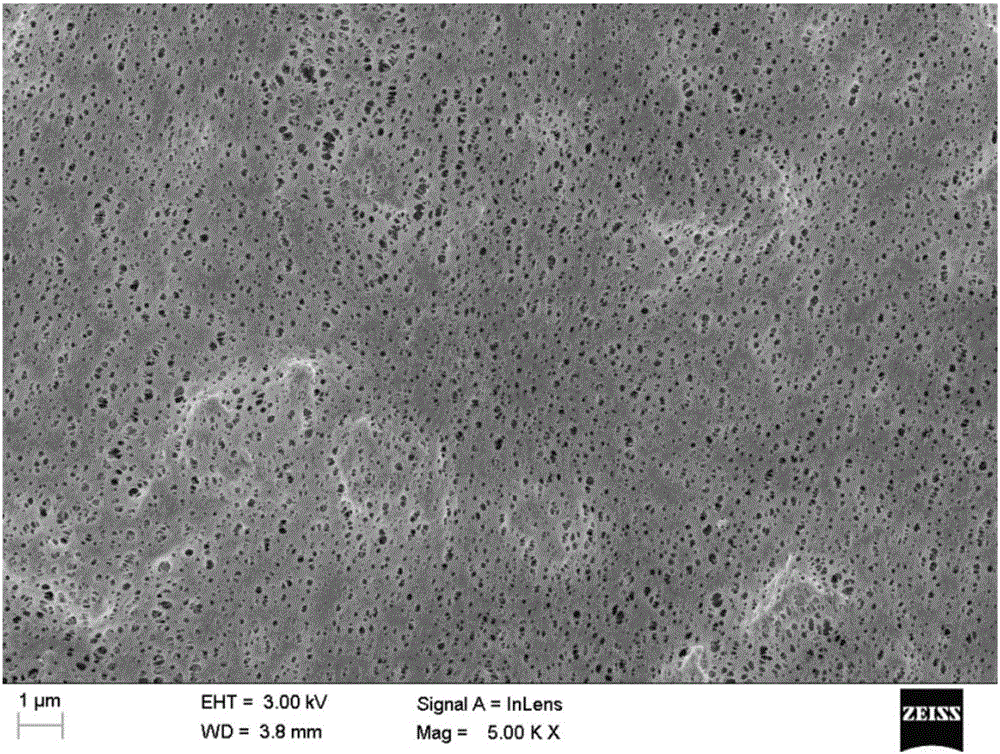

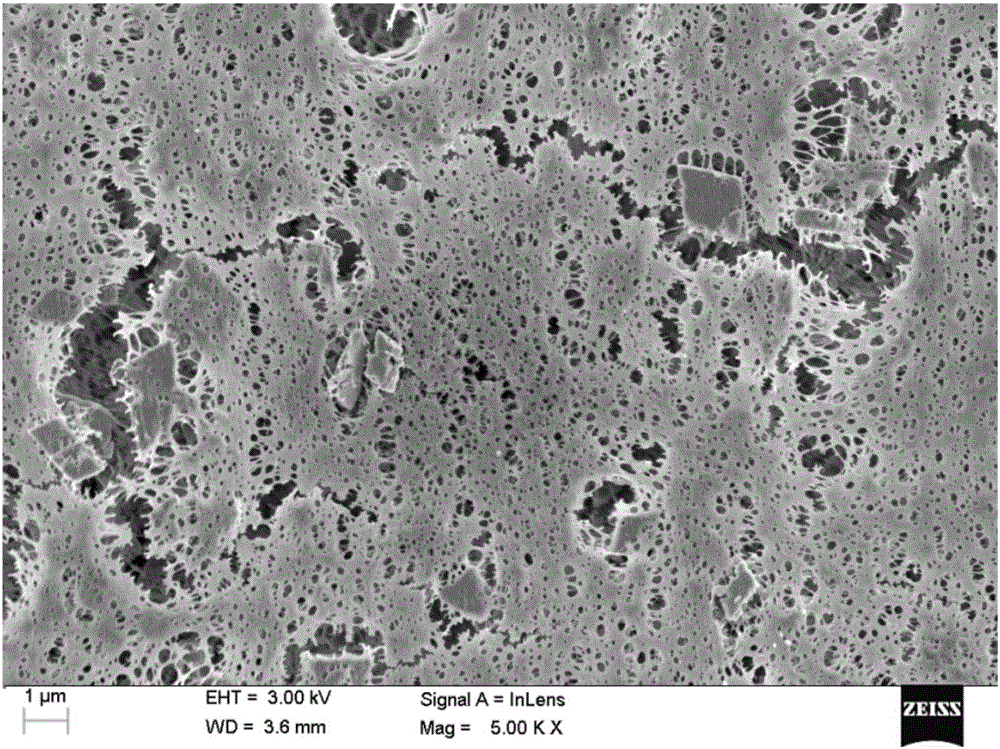

Membrane and secondary battery

ActiveCN106299222AHigh porosityImprove interfacial adhesionCell seperators/membranes/diaphragms/spacersAbsorption capacityPole piece

The application relates to the field of secondary batteries and particularly relates to a membrane and a secondary battery thereof. The membrane of the application comprises a base material and a coating adhered to the surface of the base material, wherein the coating contains an anti-static additive, a bonding agent and ceramic material particles; a carbon material is selected as the anti-static additive; the ratio of the thickness of the coating to the median particle diameter of the ceramic material particles is 1 to (0.5-1.5). The coating of the membrane has high porosity, is of a porous configuration with vertical macropores, and has good electrolyte diffusion and pole piece interface bonding force, so that the rigidity and safety performances of a battery core are improved. Since the carbon material is added as the anti-static additive, the electronic conductivity of the coating is improved, the static electricity problem of the coating is eliminated, the electrolyte absorption capacity of the coating can be further improved, and the dynamic performance of the battery core is improved.

Owner:DONGGUAN AMPEREX TECH

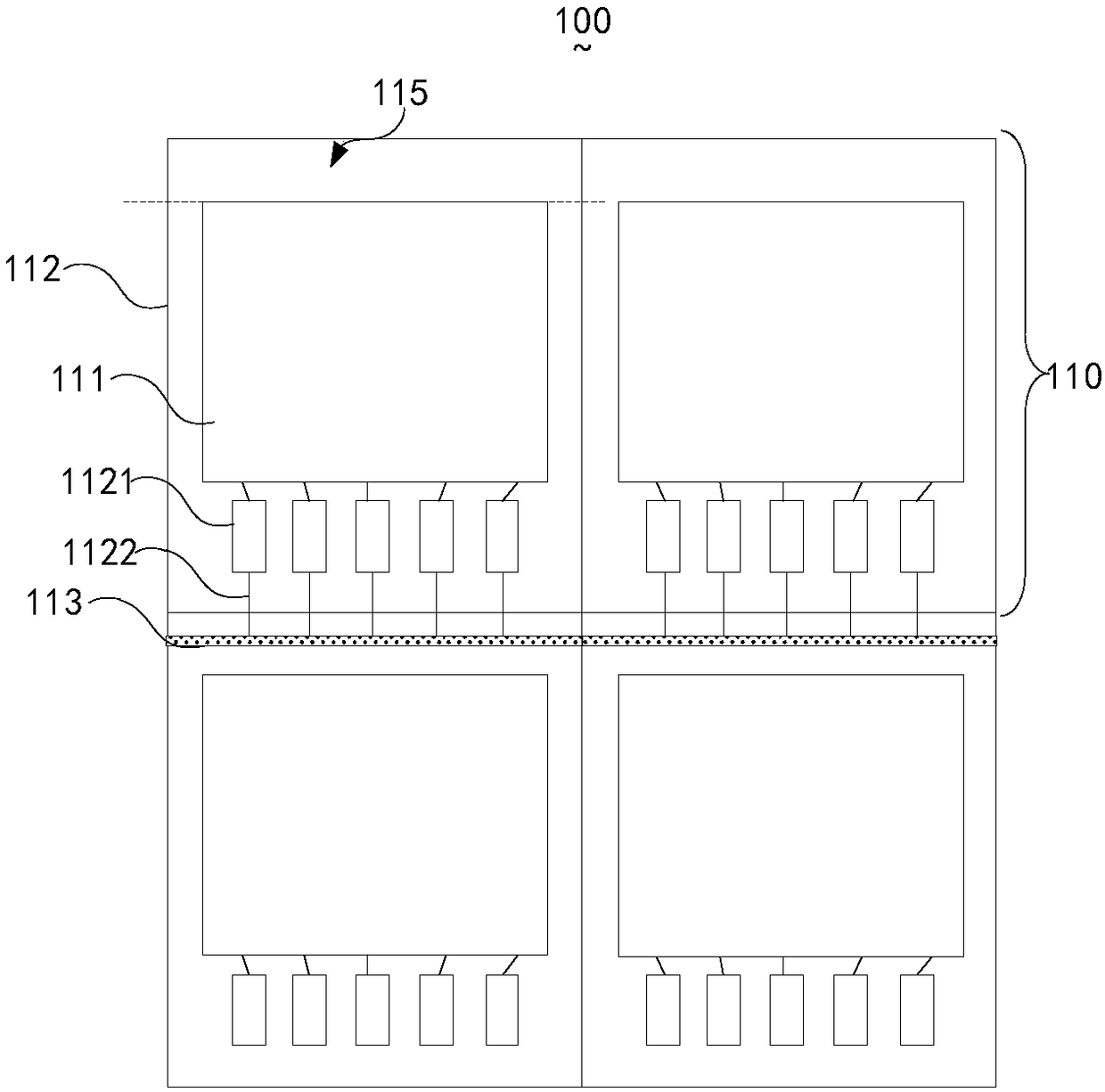

Display panel and mother board

ActiveCN109449140AEliminate static electricityImprove electrostatic protection abilitySemiconductor/solid-state device detailsSolid-state devicesStatic electricityShort circuit

The invention discloses a display panel and a mother board. The display panel mother board comprises a plurality of display panels arranged in an array mode; a display area and a non-display area on the periphery of the display area are defined on the surface of each display panel; each non-display area is provided with a plurality of conductive gaskets and a plurality of short-circuit connectinglines; an electrostatic short circuit ring is arranged on the non-display area of the display panel which is at least not in the first row; and one ends of the plurality of the short circuit connecting lines in each display panel in the same column are connected to the plurality of the conductive gaskets respectively, and the other ends of the short circuit connecting lines in each display panel are electrically connected with the electrostatic short circuit ring of the adjacent display panel in the next row. Therefore, static electricity generated for the display panels in a test or cutting process of the display panel mother board can be eliminated, and the electrostatic protection effect of the panels is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Method for preparing natural plant granular materials for filter tips

The invention relates to a method for preparing natural plant granular materials for filter tips, which comprises the steps of: taking dry plant stem pith, removing impurities and pulverizing and sieving the stem pith to obtain powdery materials with the mesh number greater than 80 meshes; uniformly mixing the powdery materials and auxiliary materials according to the proportion of the mass ratio being 10 / 10 to 0, obtaining the powdery mixed materials, stirring and uniformly mixing the powdery mixed materials by ethanol solution or water according to the proportion of the material liquid ratio being 4 to 0.5 / 1 and making the mixed materials into soft materials; or stirring and uniformly mixing the powdery mixed materials and water solution of the auxiliary materials according to the proportion of the material liquid ratio being 4 to 0.5 / 1 and making the mixed materials into soft materials; carrying out extrusion type granulation on the soft materials, and then drying granules; and sieving the dried granules by a sieve of 20 to 80 meshes, and the required natural plant granular materials for the filter tips are obtained. The natural plant granular materials for the filter tips prepared by the method has the advantages that when natural plant stem pith granules are thinner, static electricity and agglomeration properties can be eliminated, the powder granulation performance is enhanced, and the addition operability of the natural plant stem pith granular materials during the cigarette filter stick manufacture is improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

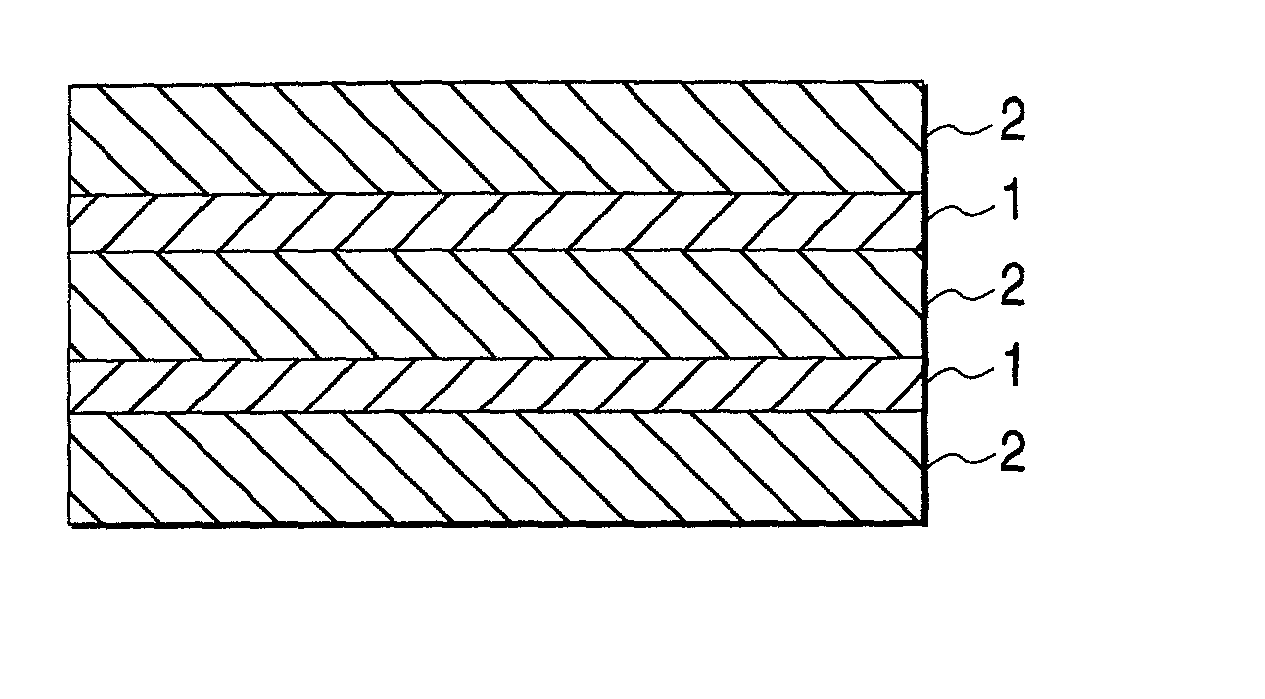

Double-sided pressure-sensitive adhesive tape or sheet for wiring circuit board and wiring circuit board

InactiveUS20090095517A1Suppress and prevent self-adhesionIncrease stickinessNon-macromolecular adhesive additivesPrinted circuit detailsEngineeringPrinted circuit board

The present invention provides a double-sided pressure-sensitive adhesive tape or sheet for wiring circuit board, which includes a pressure-sensitive adhesive layer formed by a pressure-sensitive adhesive composition, wherein the pressure-sensitive adhesive composition contains an acrylic polymer as a main component and further contains an electrically conductive filler in a proportion of 5 to 100 parts by weight with respect to 100 parts by weight of a total solid in the pressure-sensitive adhesive composition except the electrically conductive filler. The double-sided pressure-sensitive adhesive tape or sheet is excellent in adhesiveness, electrically conducting property and anti-repulsion property, and thus can be advantageously used for wiring circuit board.

Owner:NITTO DENKO CORP

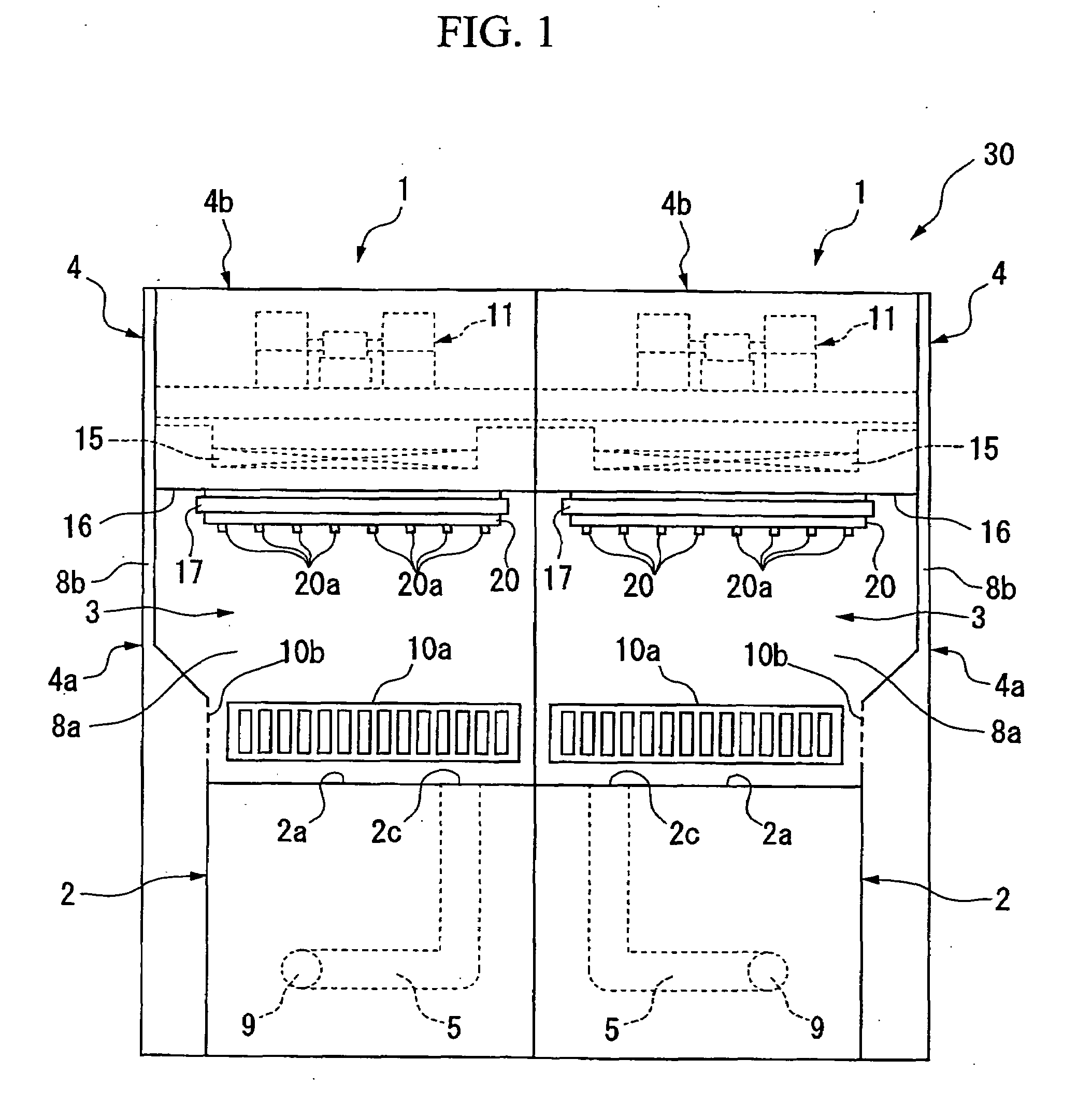

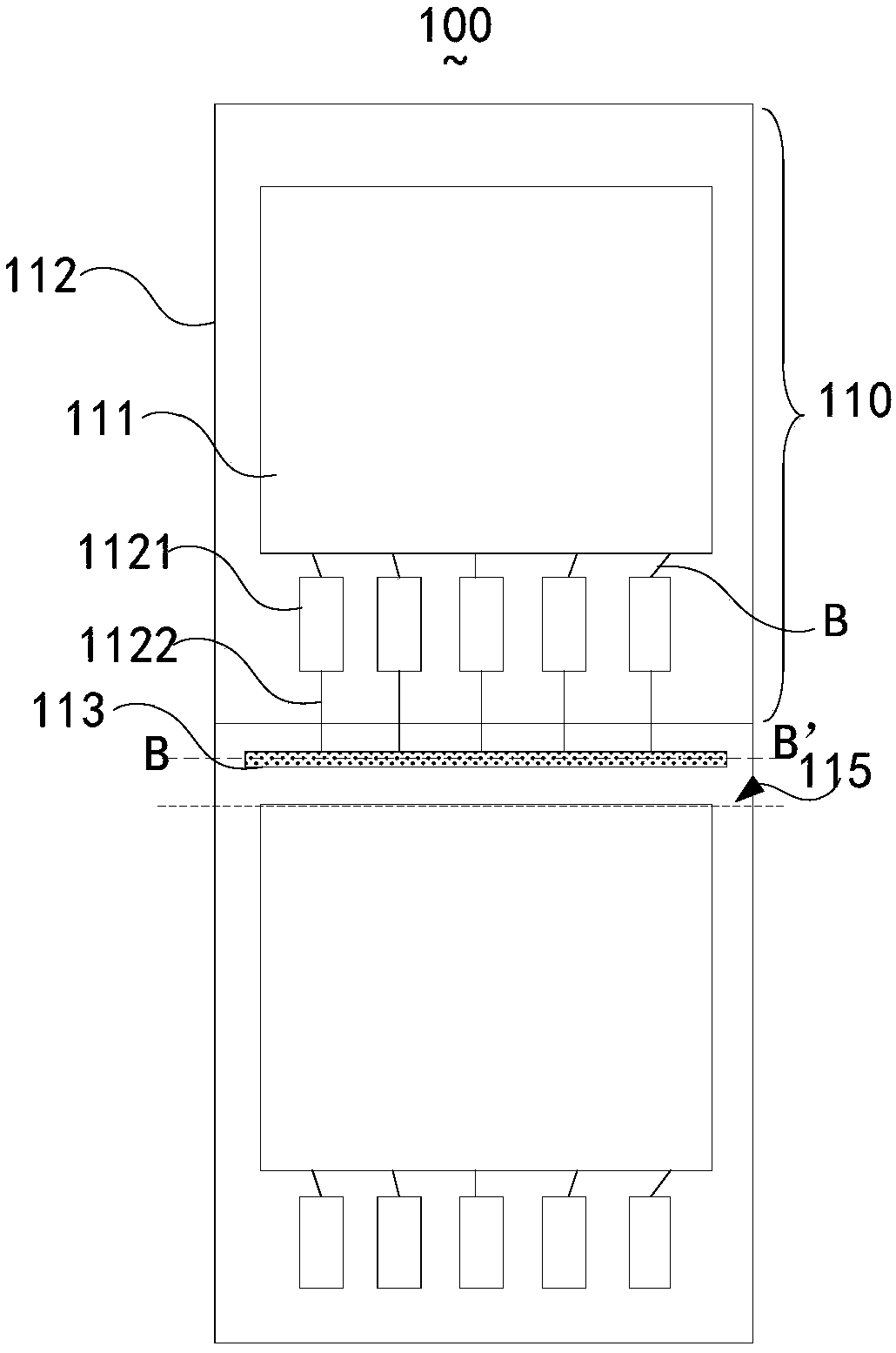

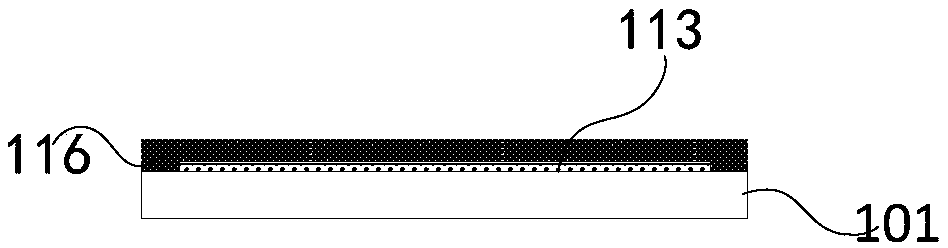

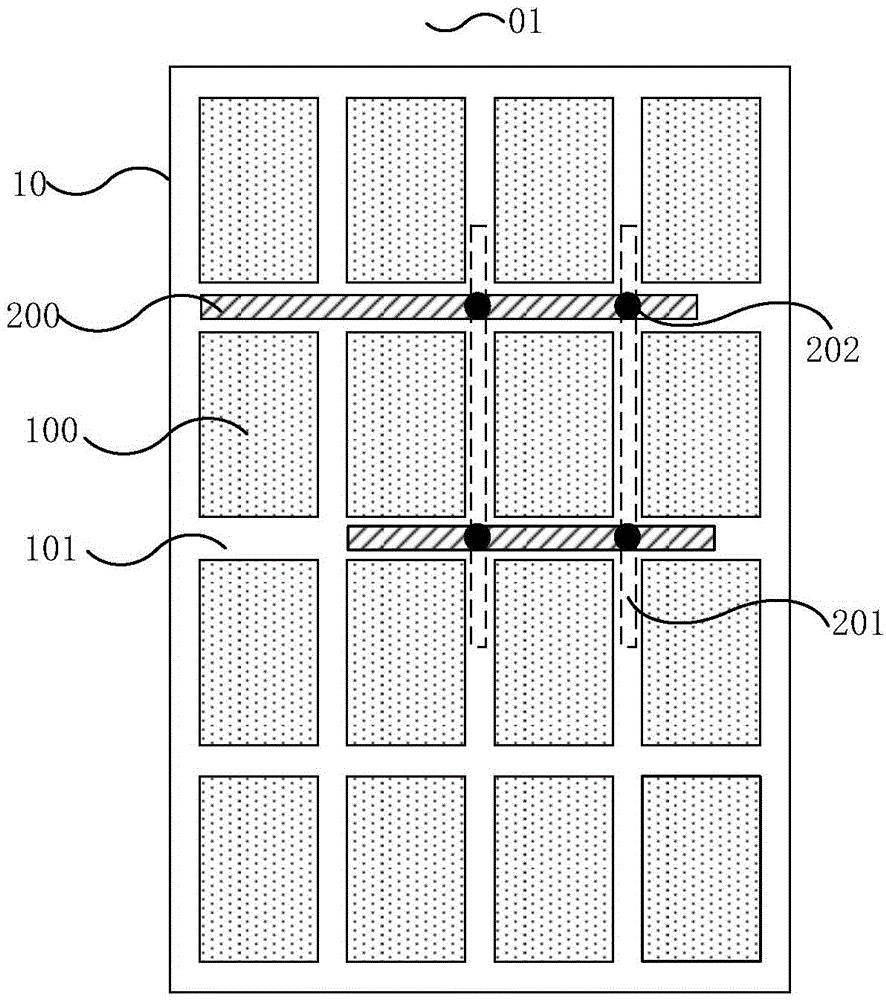

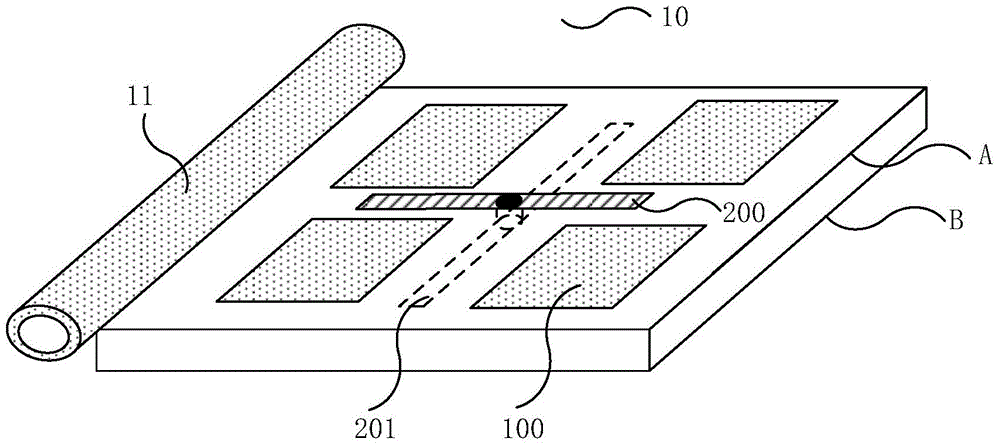

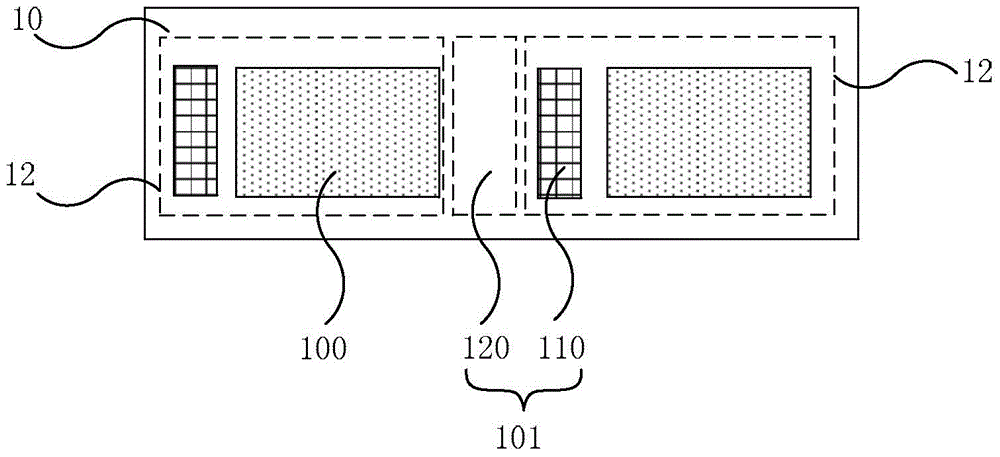

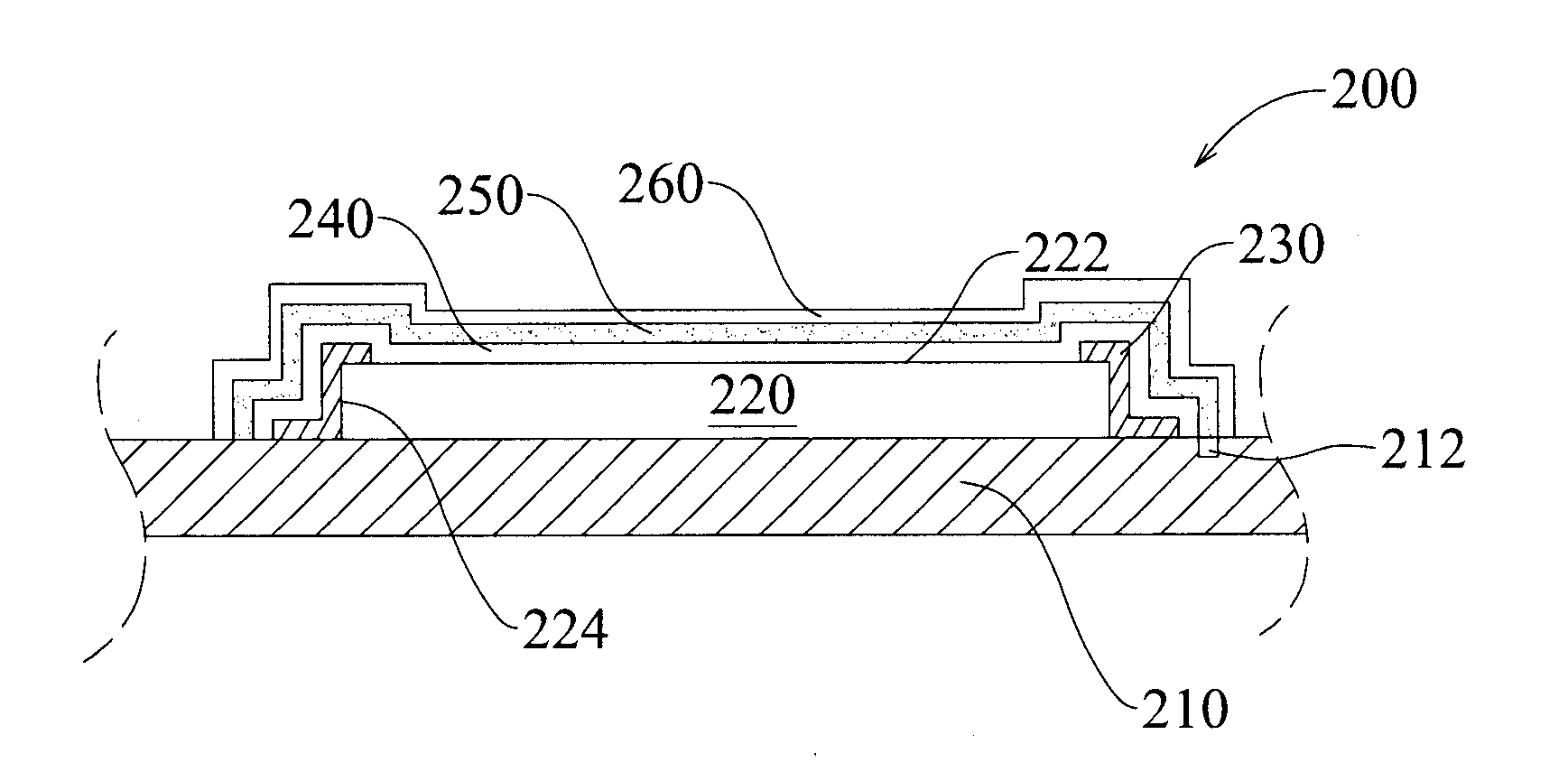

Array substrate motherboard, manufacturing method of array substrate motherboard and static electricity elimination device

ActiveCN104570493AEliminate static electricityNon-linear opticsMechanical engineeringMaterials science

The invention provides an array substrate motherboard, a manufacturing method of the array substrate motherboard and a static electricity elimination device, and relates to the technical field of display. Static electricity generated when the friction orientation process is conducted on the array substrate motherboard can be eliminated. The array substrate motherboard comprises a transparent substrate, a display area and a non-display area, wherein the display area and the non-display area are formed on the transparent substrate, and an orientation layer is arranged on the display area. In addition, the array substrate motherboard further comprises a first wire and a second wire, wherein the first wire is located on the upper surface of the transparent substrate in the non-display area, the second wire is located on the lower surface of the transparent substrate in the non-display area, the first wire and the second wire are connected through a through hole in the transparent substrate, and the upper surface and the lower surface are oppositely arranged.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

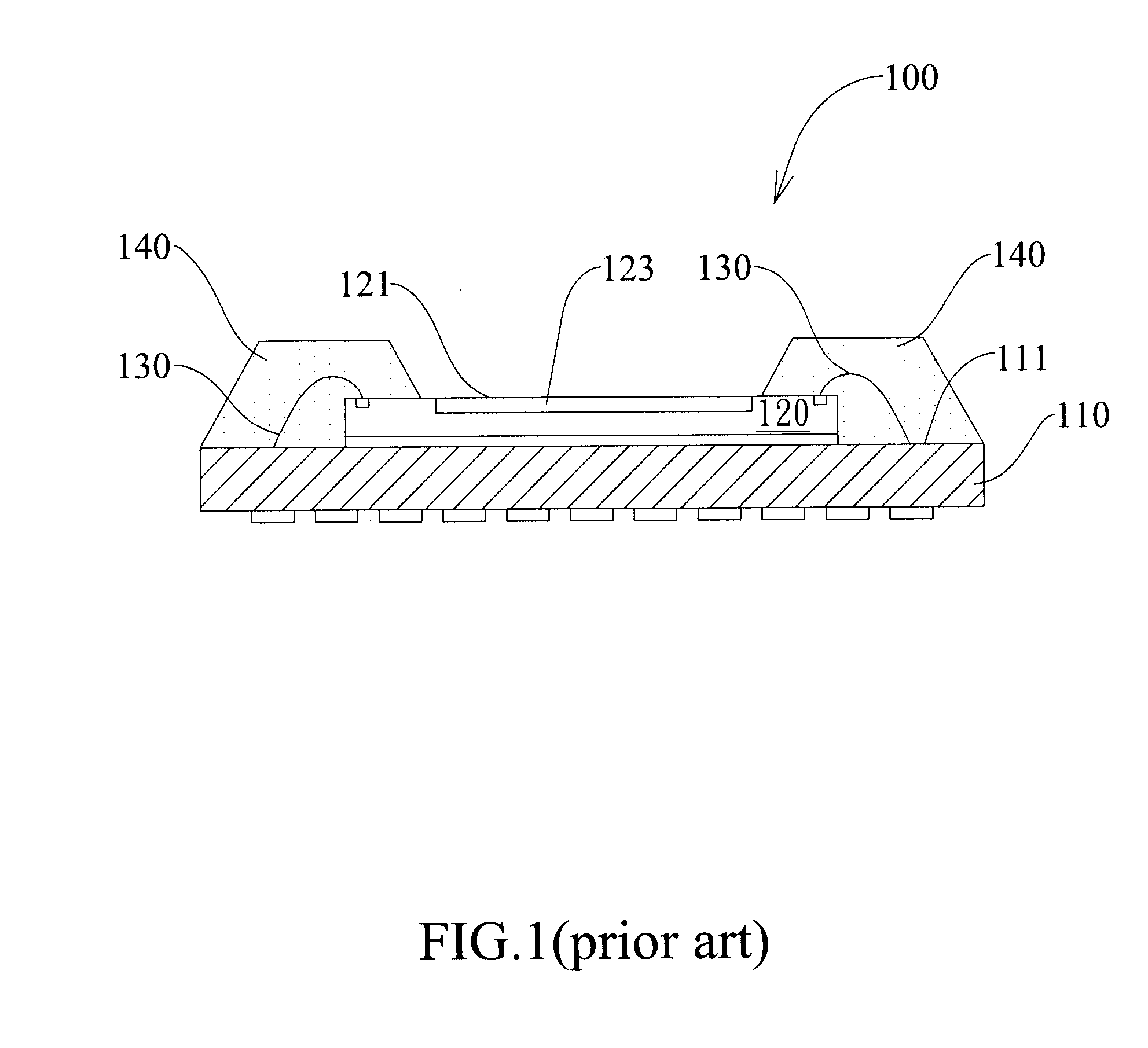

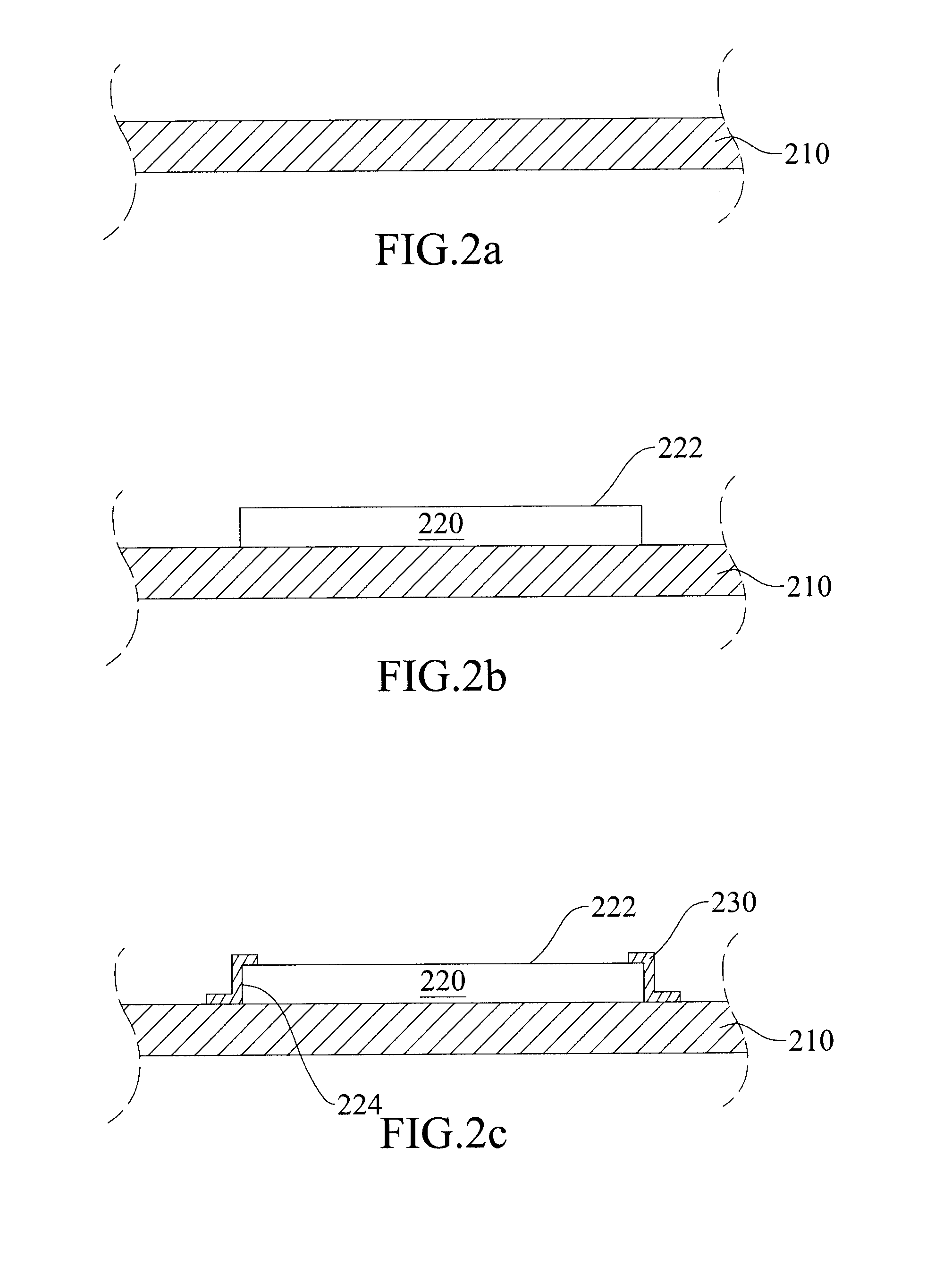

Fingerprint sensor chip package method and the package structure thereof

ActiveUS20100258891A1Improve production yieldReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEffective surfaceColloid

A fingerprint sensor chip package method and the package structure thereof are disclosed. The invention includes: providing a substrate; arranging a sensor chip on the substrate, with an active surface of the sensor chip facing upward; forming a patterned conductive colloid on the sensor chip, wherein the patterned conductive colloid extends from the periphery of the active surface of the sensor chip along the side wall of the sensor and electrically connects with the circuit layer of the substrate; forming a non-conductive film to cover the sensor chip, the patterned conductive colloid and a portion of the substrate; and forming a conductive film on the non-conductive film. The patterned conductive colloid replaces the conventional bond wires to improve the product yield and to omit the molding process. The conductive film is electrically connected with the grounding point / area on the substrate to dissipate the static charges for protecting the chip.

Owner:APTOS TECH

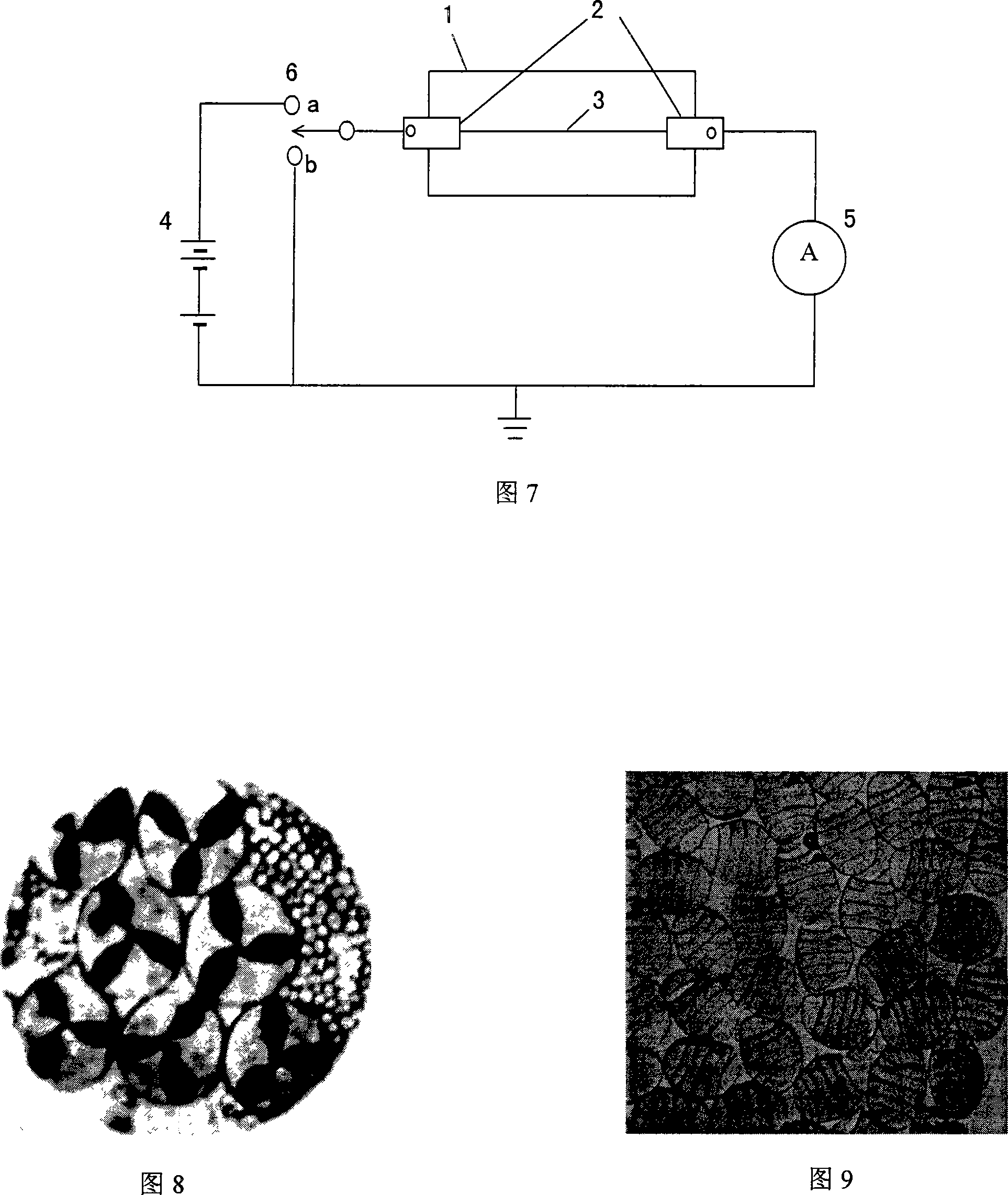

Static eliminator

InactiveUS7948733B2Accurate detectionEliminate static electricityElectrostatic chargesStatic eliminatorsContamination

There is provided a static eliminator for accurately detecting a contamination condition of a discharge electrode, in which a target value as a target frame ground current value is changed from, for example, zero as a reference alternately to the plus side and the minus side to such a degree as not to affect the ion balance of a workpiece, and the follow-up time, namely a phase delay, with respect to the change in target value differs depending on the contamination condition of the discharge electrode, and becomes longer with the progress of the contamination, and by use of this characteristic, a plurality of thresholds are prepared and compared with a detected frame ground current value, so as to detect the contamination condition of the discharge electrode.

Owner:KEYENCE

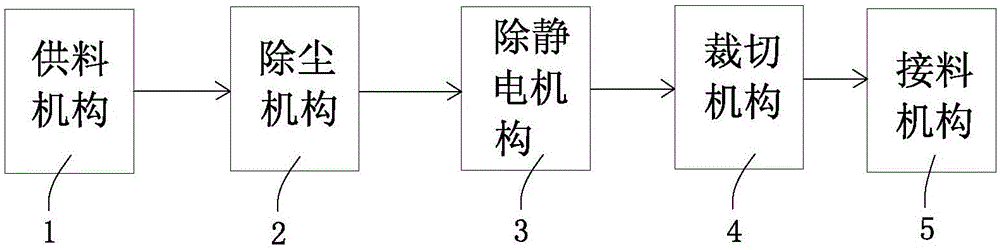

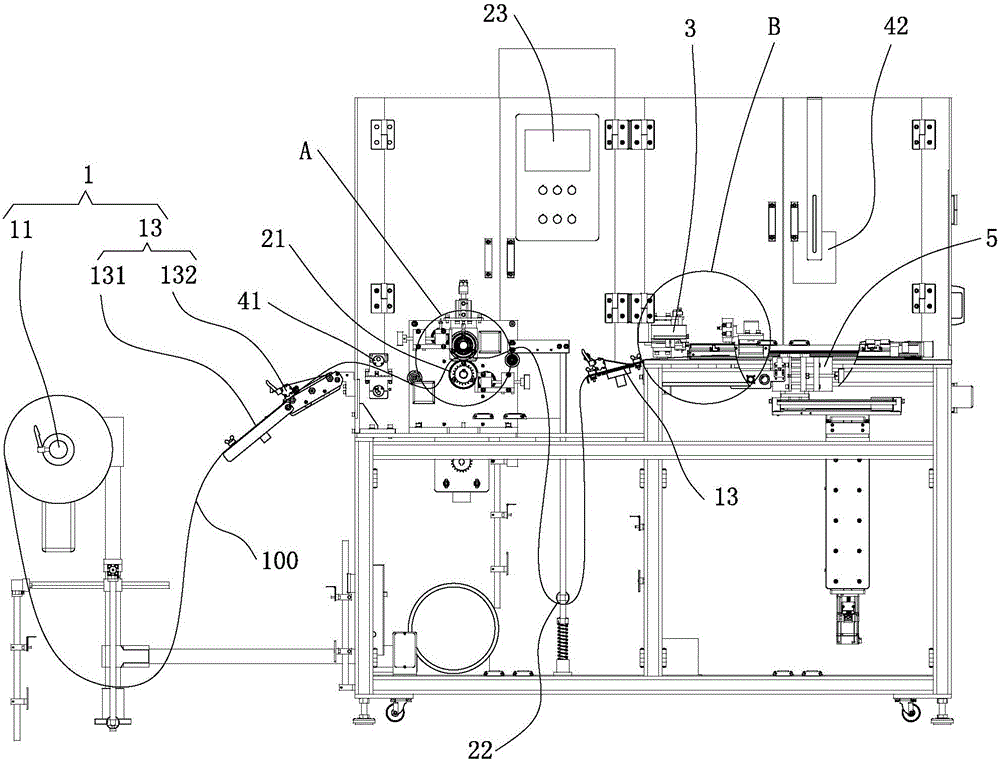

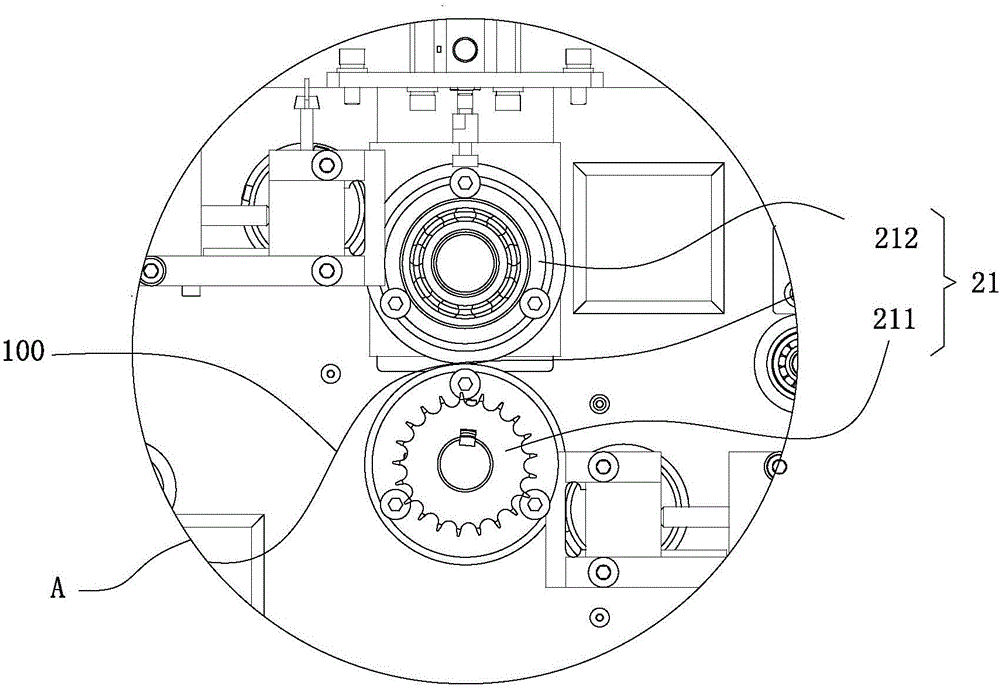

Thin film cutting device

InactiveCN106743934AEliminate static electricityAvoid the effects of stackingCleaning using toolsPile receiversEngineeringMaterial supply

The embodiment of the invention discloses a thin film cutting device. The thin film cutting device comprises a material supply mechanism, a dust removal mechanism, a cutting mechanism and an electrostatic eliminating mechanism; the cutting mechanism comprises a cutting base plate, a cutting pressing plate, a cutting knife and a driving piece; the cutting pressing plate is matched with the cutting base plate to clamp a thin film to be cut, and a cutting gap is formed in the cutting pressing plate; a cutting edge line intersects with the surface of the thin film to be cut to form a predetermined angle, and the knife point of the cutting knife penetrates through the cutting gap to cut the thin film; the driving piece drives the cutting knife to move reciprocally along the cutting gap to cut the thin film; the electrostatic eliminating mechanism comprises an electrostatic eliminating mechanism before cutting and an electrostatic eliminating mechanism after cutting. According to the embodiment of the invention, the cutting base plate and the cutting pressing plate are arranged, the cutting gap is formed in the cutting pressing plate for the cutting edge line to intersect with the surface of the thin film to be cut to form the predetermined angle, and the thin film is subjected to high-quality cutting; the surface cleanness of the cut film is effectively ensured and static electricity of the film is eliminated with the cooperation of the dust removal mechanism and the electrostatic eliminating mechanism; the thin film cutting device is beneficial to stacking films tidily.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

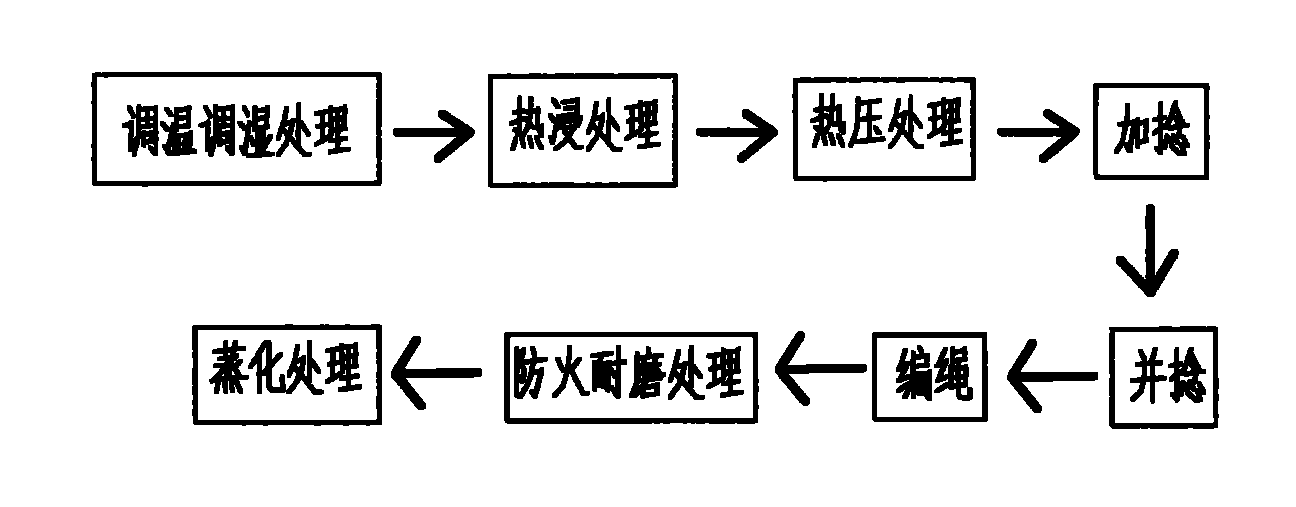

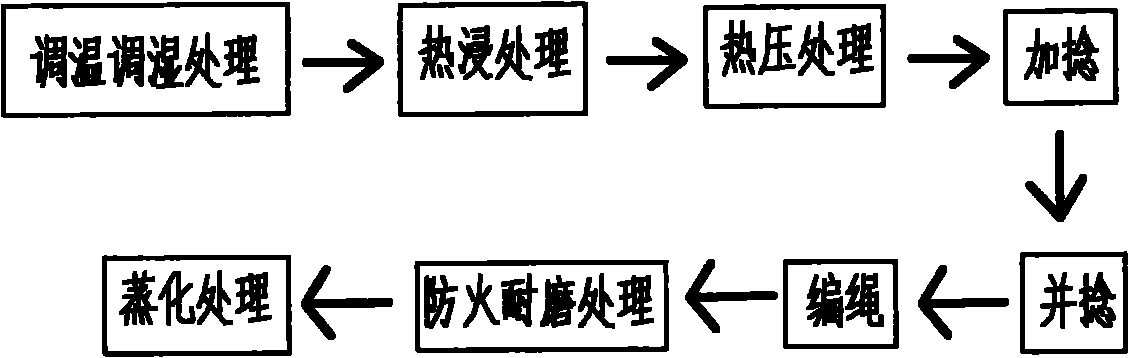

Method for producing basalt fiber rope net

ActiveCN101838885AImprove the finishHigh tensile strengthLiquid/gas/vapor removal by squeezing rollersBraidPolymer scienceActive agent

The invention discloses a method for producing basalt fiber rope nets, which comprises the following processes of: heat soaking treatment, hot-pressing treatment, weaving ropes, fireproof and wear-resistant treatment, steaming treatment, and the like. The heat soaking treatment solution contains an anionic surfactant, sodium alga acid and other aids; a tension regulation device is arranged on a high-speed braiding machine; and the fireproof and wear-resistant treatment solution contains PTFE, neutral salts, and other active agents. The method has reasonable process and advanced treatment technology and method, and the produced rope nets have the advantages of high temperature resistance, corrosion resistance, high intensity, high safety, and high cost performance.

Owner:TAIAN ROPE NET PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com