Patents

Literature

4718 results about "PTFE - Polytetrafluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. The best known brand name of PTFE-based formulas is Teflon by Chemours. Chemours is a 2015 spin-off of DuPont Co., which discovered the compound in 1938.

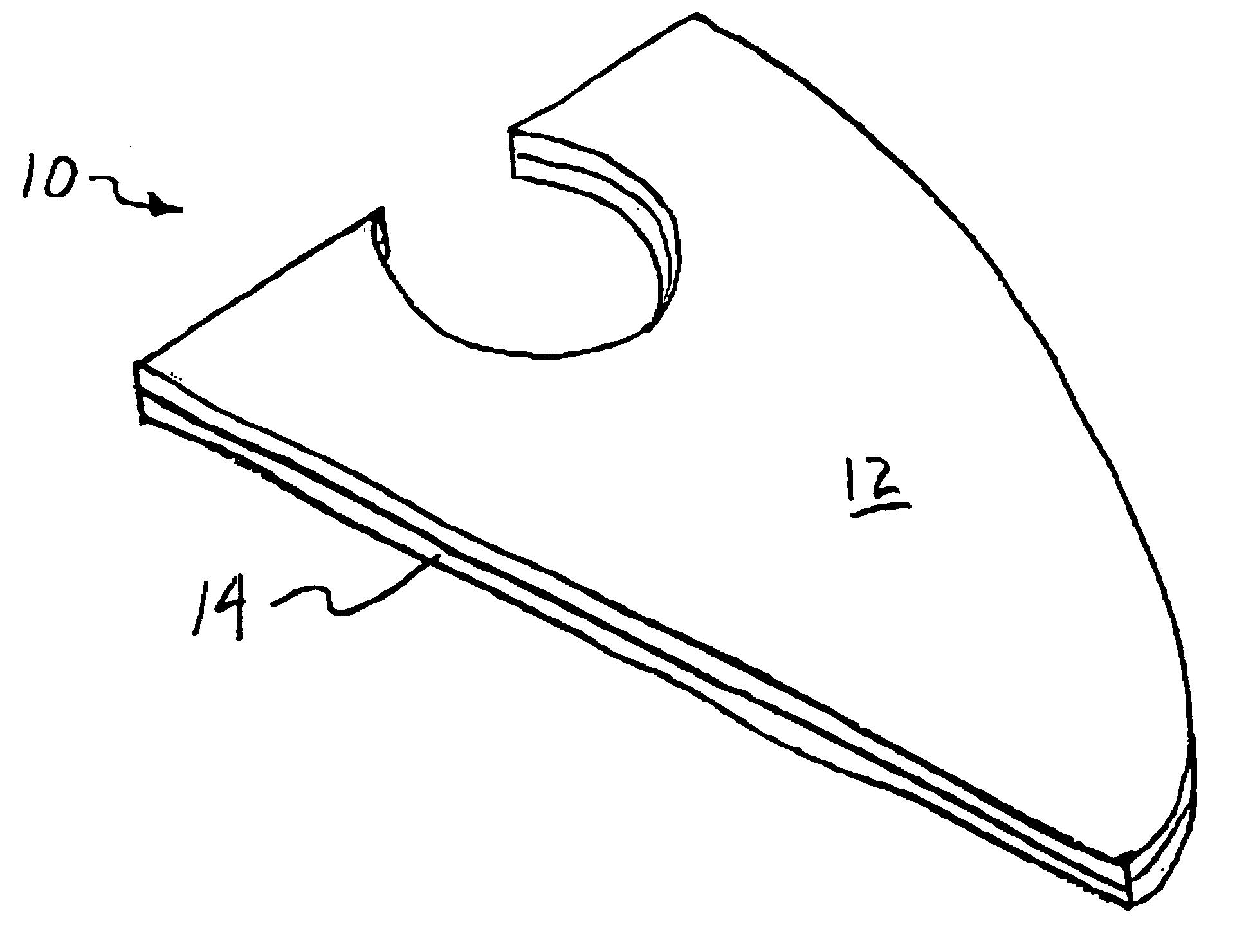

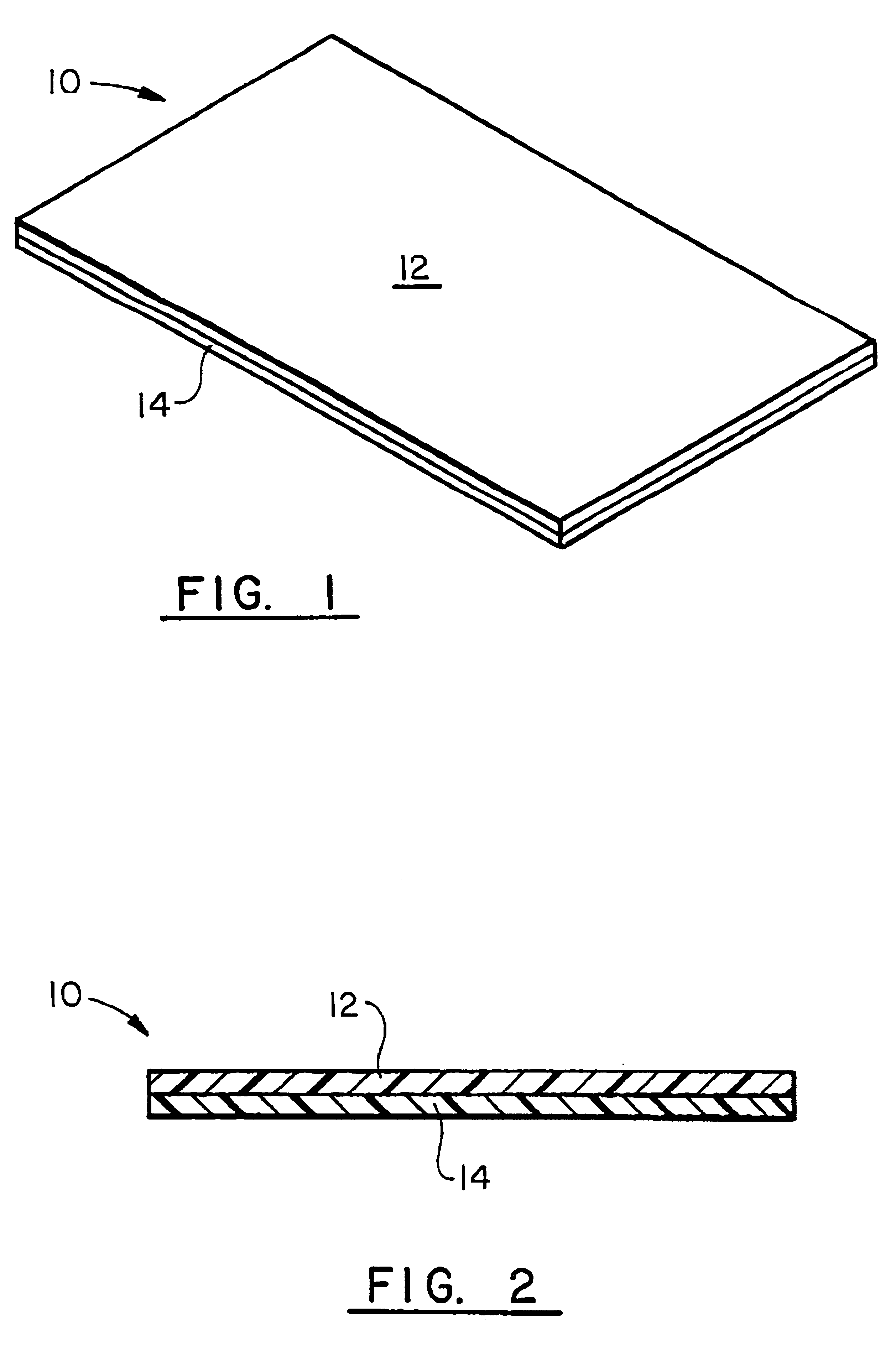

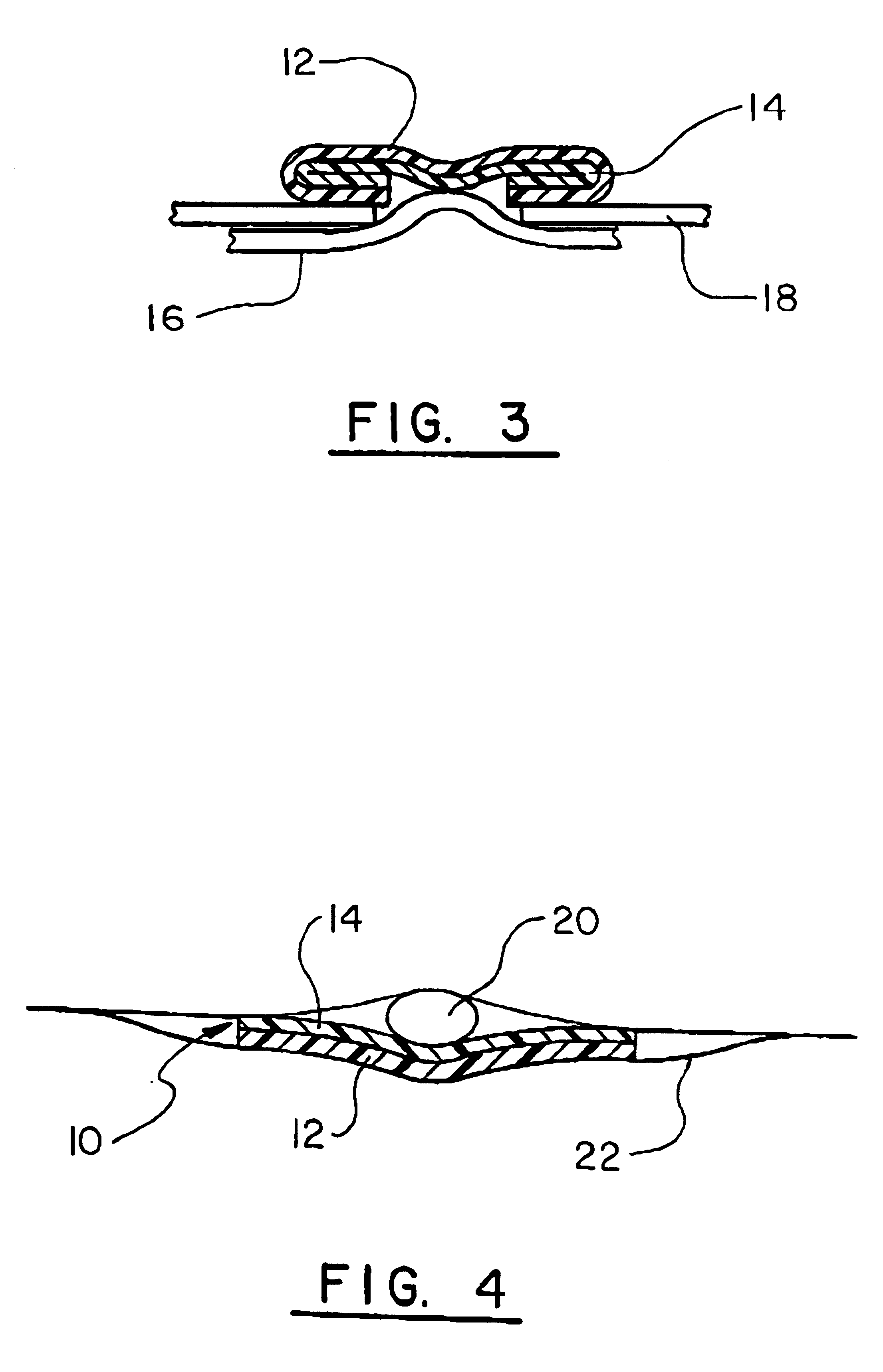

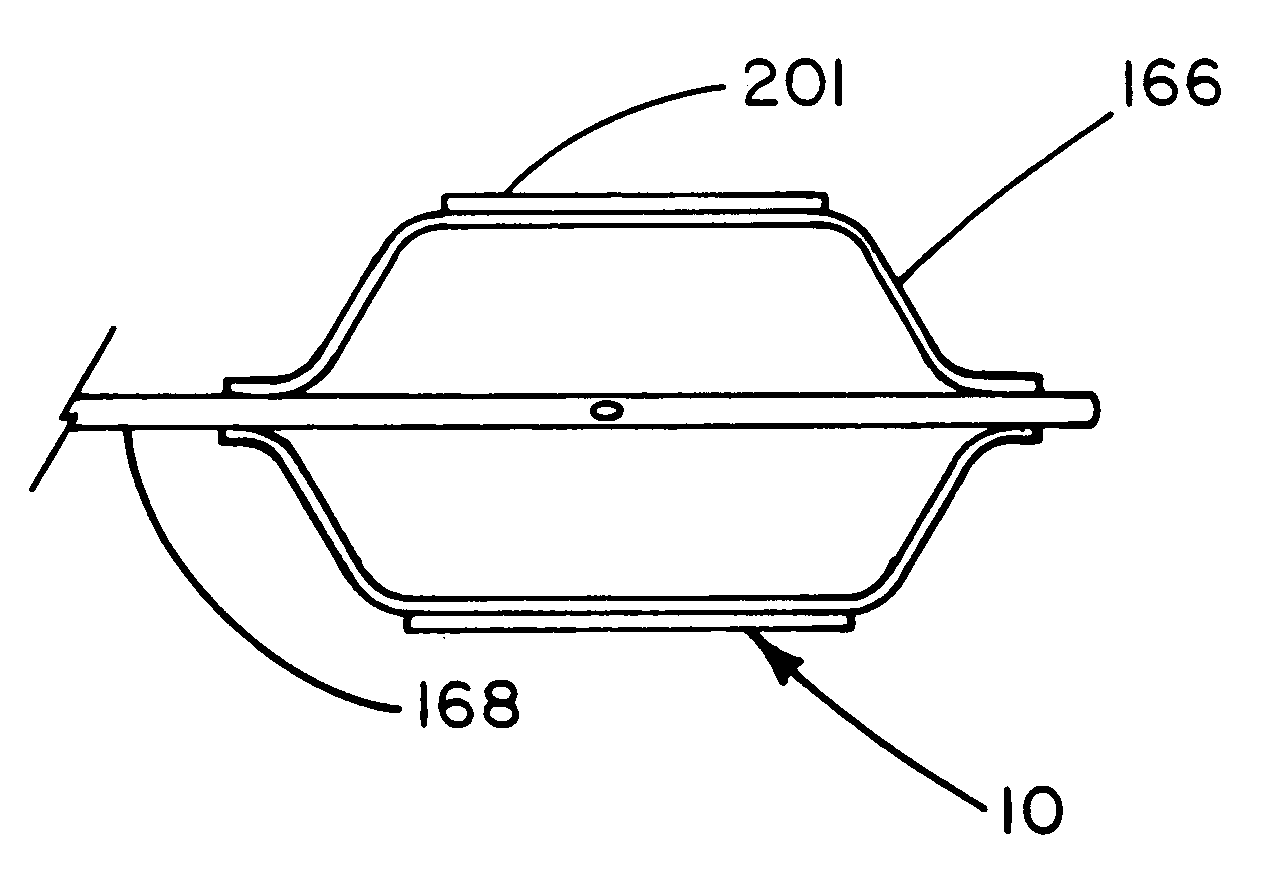

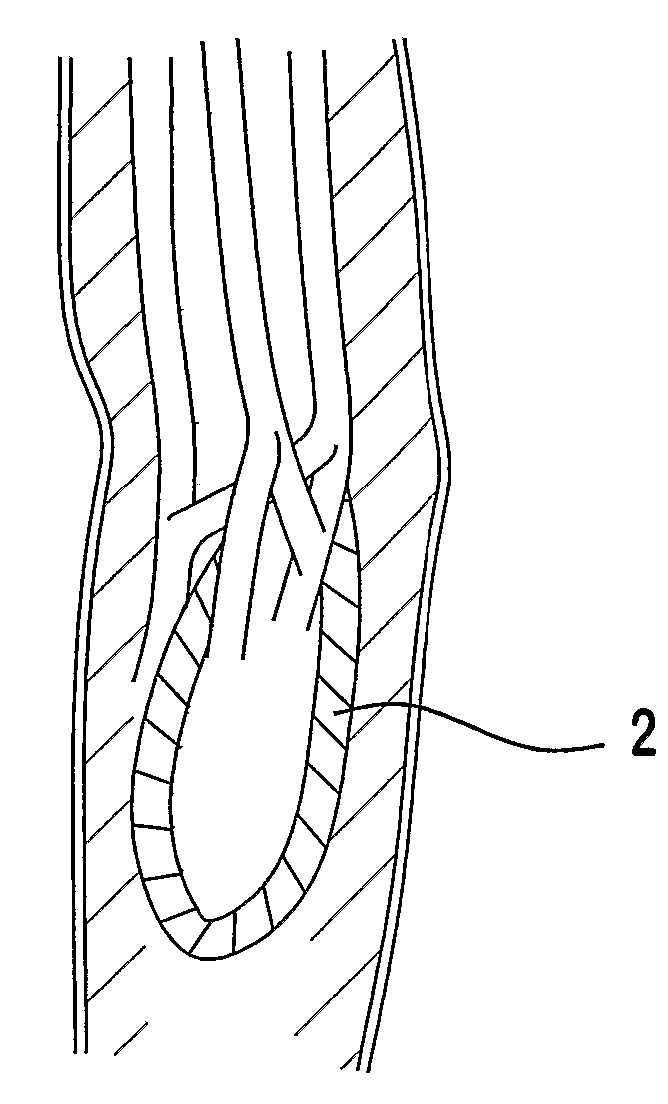

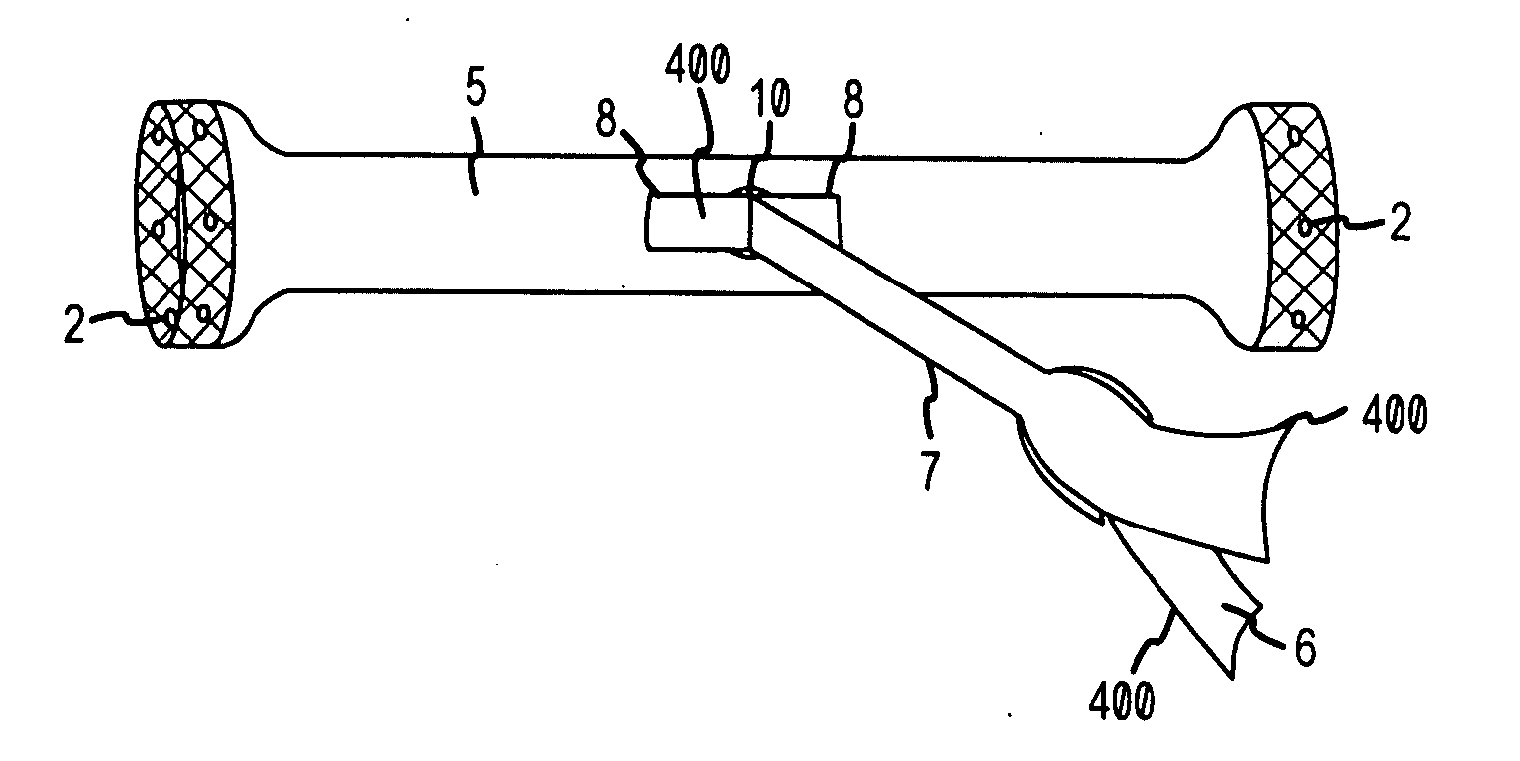

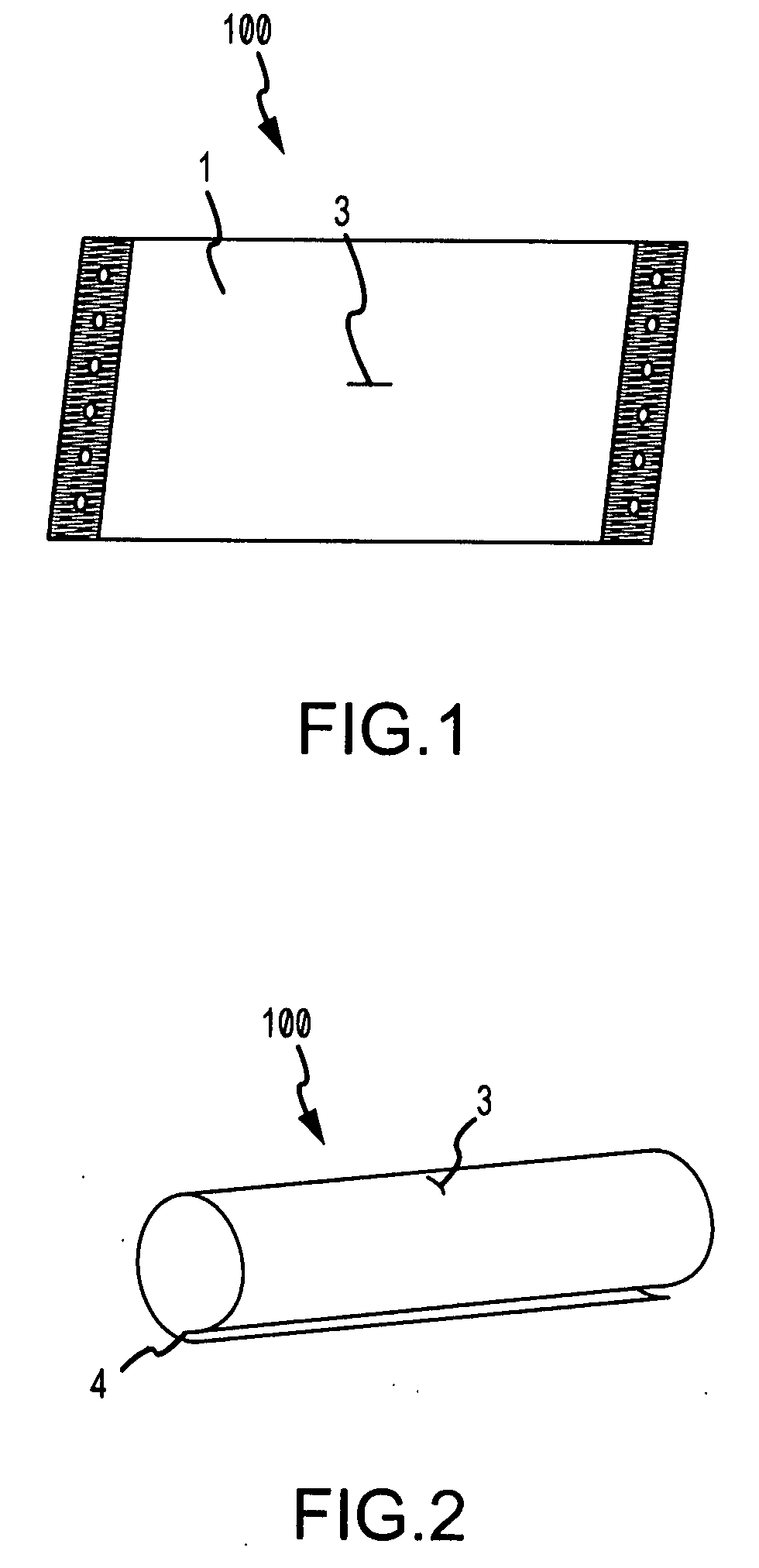

Method of repairing inguinal hernias

A universal, surgical prosthesis for hernia repair is provided in the form of a foldable sheet. The prosthesis includes a barrier layer formed of a material adapted to prevent biological adherence thereto, such as polytetrafluoroethylene, and a second surface layer formed of a material adapted to promote biological tissue adherence thereto, such as polypropylene. The second surface may be formed of a series of spaced projections. The prosthesis is adapted to be manipulated into an operative position to exhibit an appropriate exterior when in the operative position. In this manner, the universal, surgical prosthesis can be utilized for a wide range of surgical procedures.

Owner:DAVOL

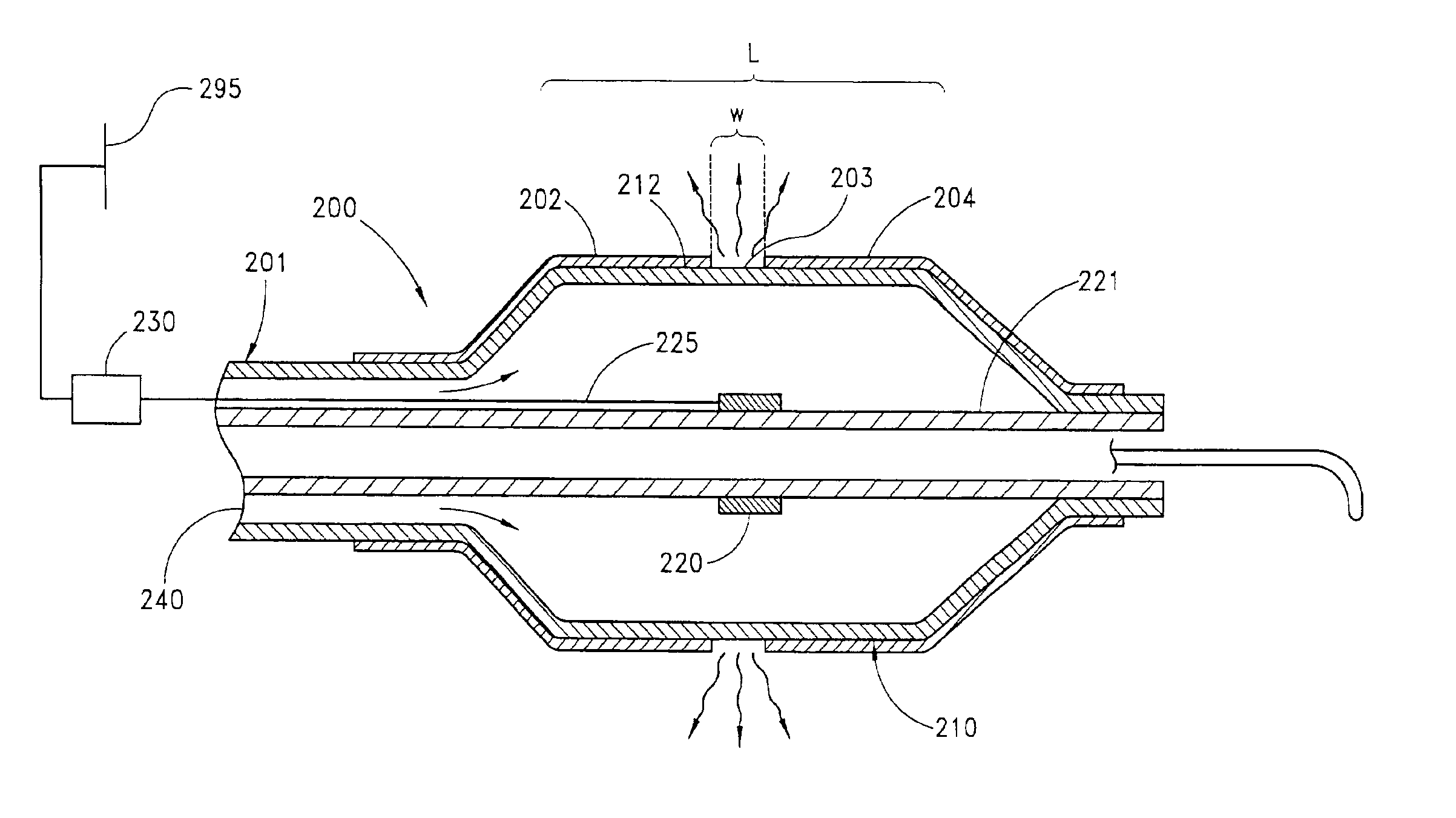

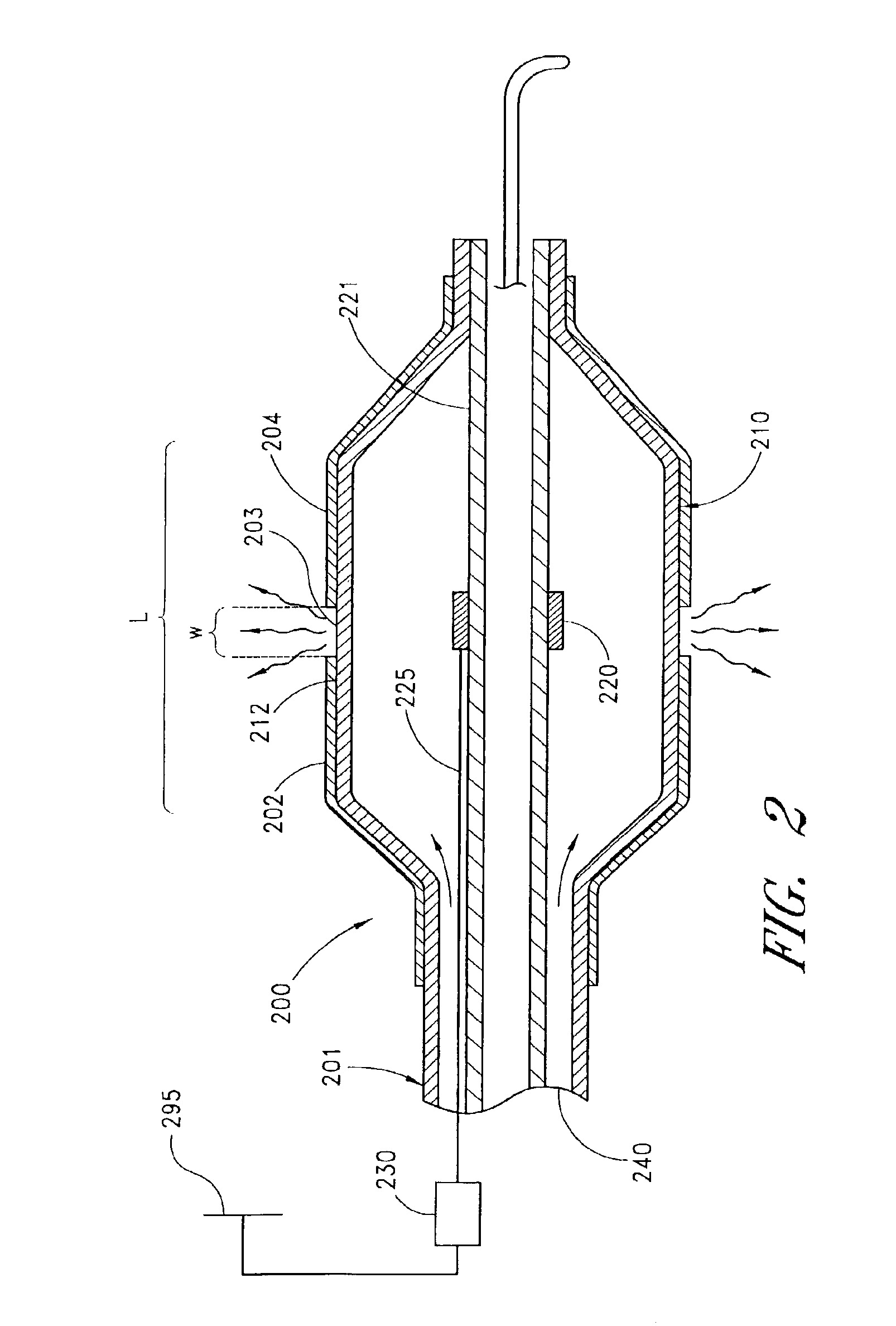

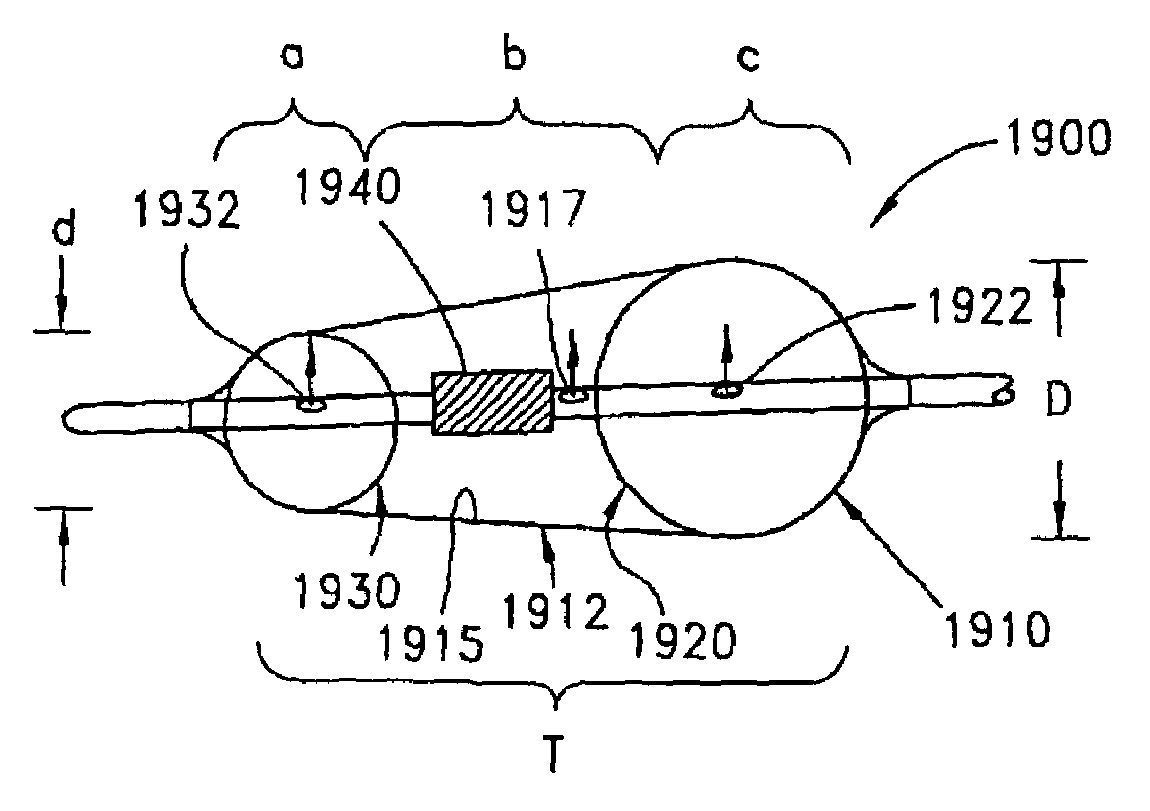

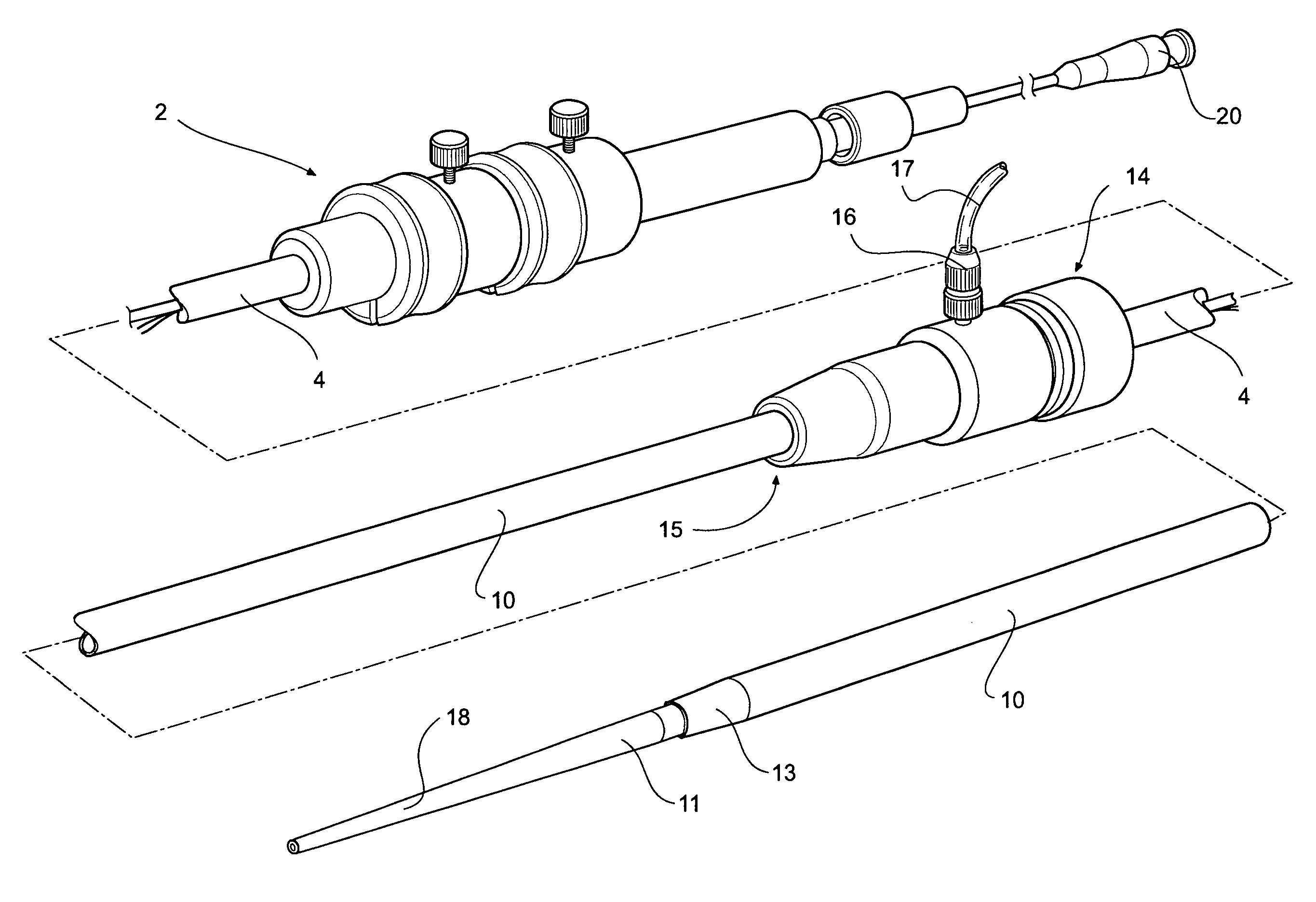

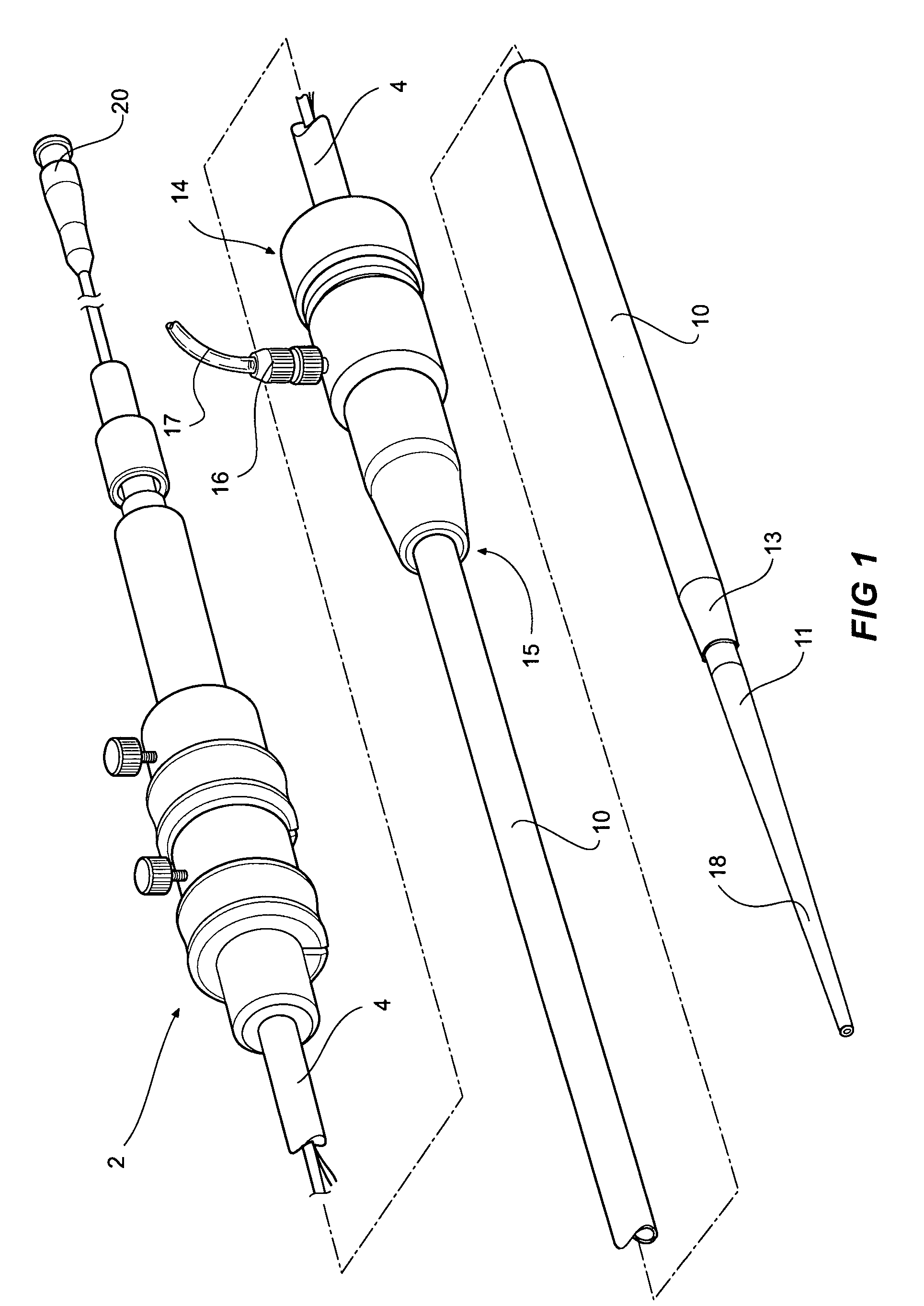

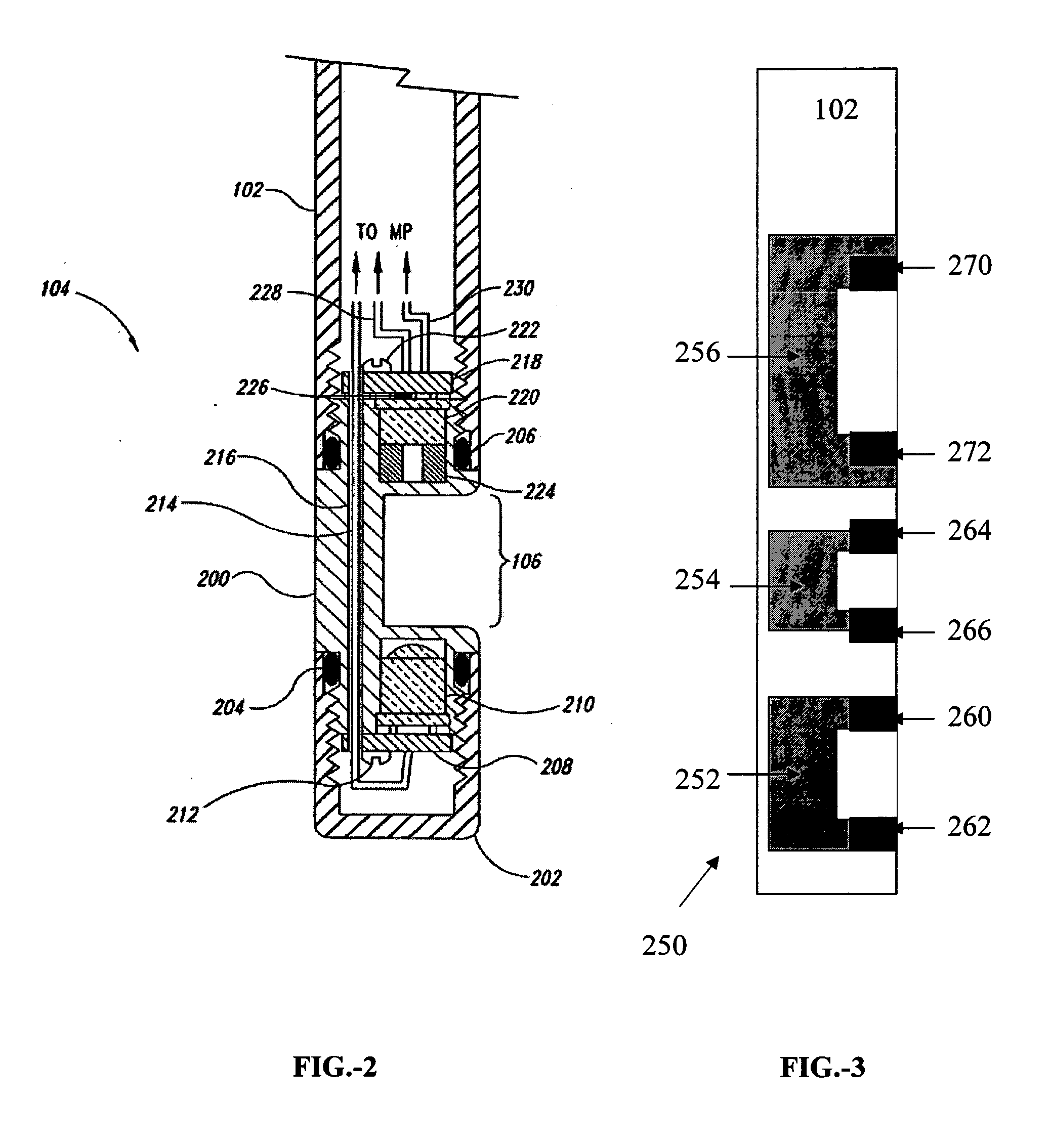

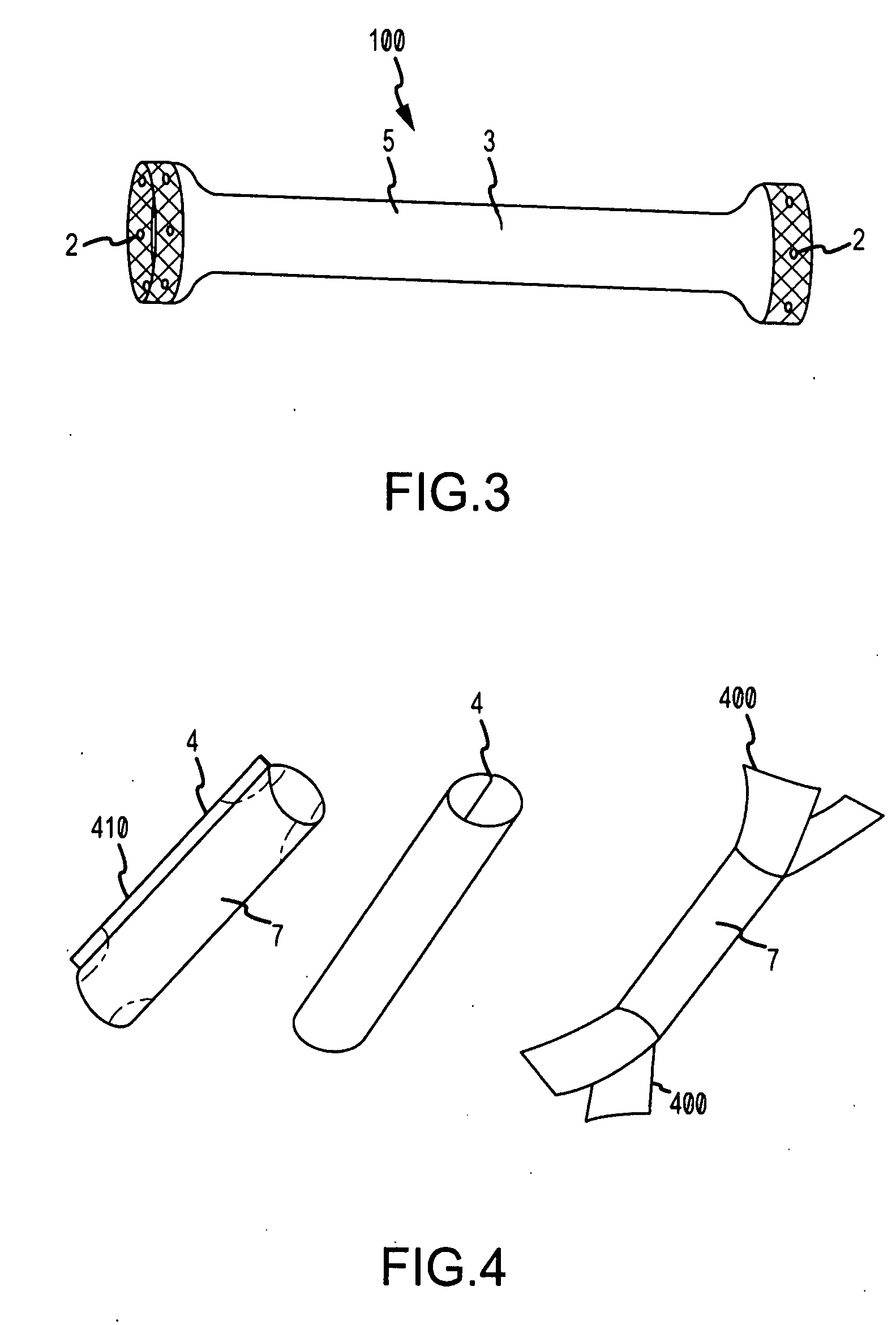

Circumferential ablation device assembly and methods of use and manufacture providing an ablative circumferential band along an expandable member

InactiveUS6954977B2Strong connectionConsistent positionElectrotherapyDiagnosticsFluoropolymerBalloon catheter

A medical balloon catheter assembly includes a balloon having a permeable region and a non-permeable region. The balloon is constructed at least in part from a fluid permeable tube such that the permeable region is formed from a porous material which allows a volume of pressurized fluid to pass from within a chamber formed by the balloon and into the permeable region sufficiently such that the fluid may be ablatively coupled to tissue engaged by the permeable region. The non-permeable region is adapted to substantially block the pressurized fluid from passing from within the chamber and outwardly from the balloon. The porous material may be a porous fluoropolymer, such as porous polytetrafluoroethylene, and the pores may be created by voids that are inherently formed between an interlocking node-fibril network that makes up the fluoropolymer. Such voids may be created according to one mode by expanding the fluoropolymer. The balloon may be formed such that the porous material extends along both the permeable and non-permeable regions. In one mode of this construction, the porous material is porous along the permeable region but is non-porous along the non-permeable region, such as for example by expanding only the permeable region in order to render sufficient voids in the node-fibril network to provide permeable pores in that section. The voids or pores in the porous material may also be provided along both permeable and non-permeable sections but are substantially blocked with an insulator material along the non-permeable section in order to prevent fluid from passing therethrough. The insulator material may be dip coated, deposited, or extruded with the porous material in order to fill the voids. The insulator material may in one mode be provided along the entire working length of the balloon and then selectively removed along the permeable section, or may be selectively exposed to only the non-permeable sections in order to fill the voids or pores there.

Owner:MAGUIRE MARK A +1

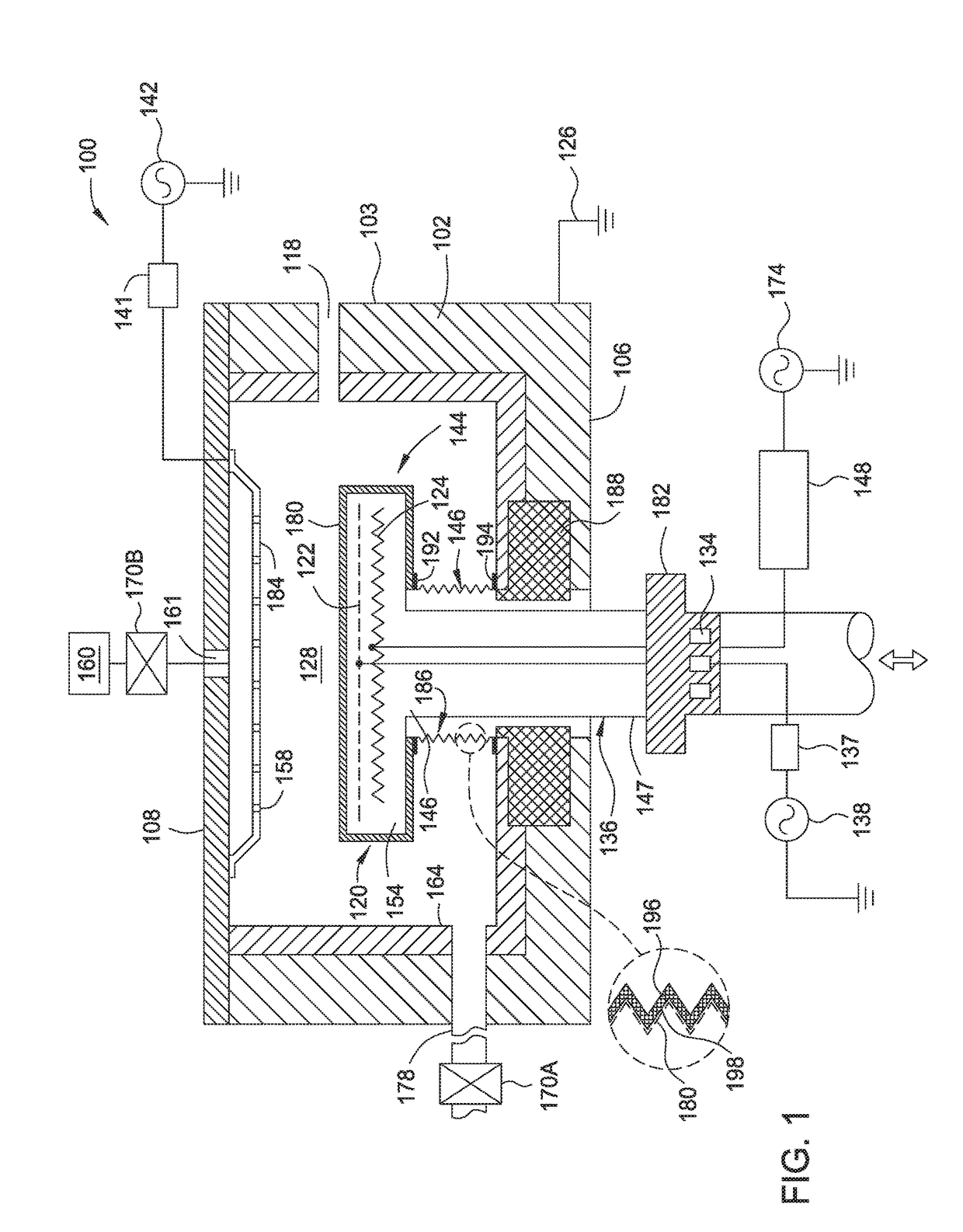

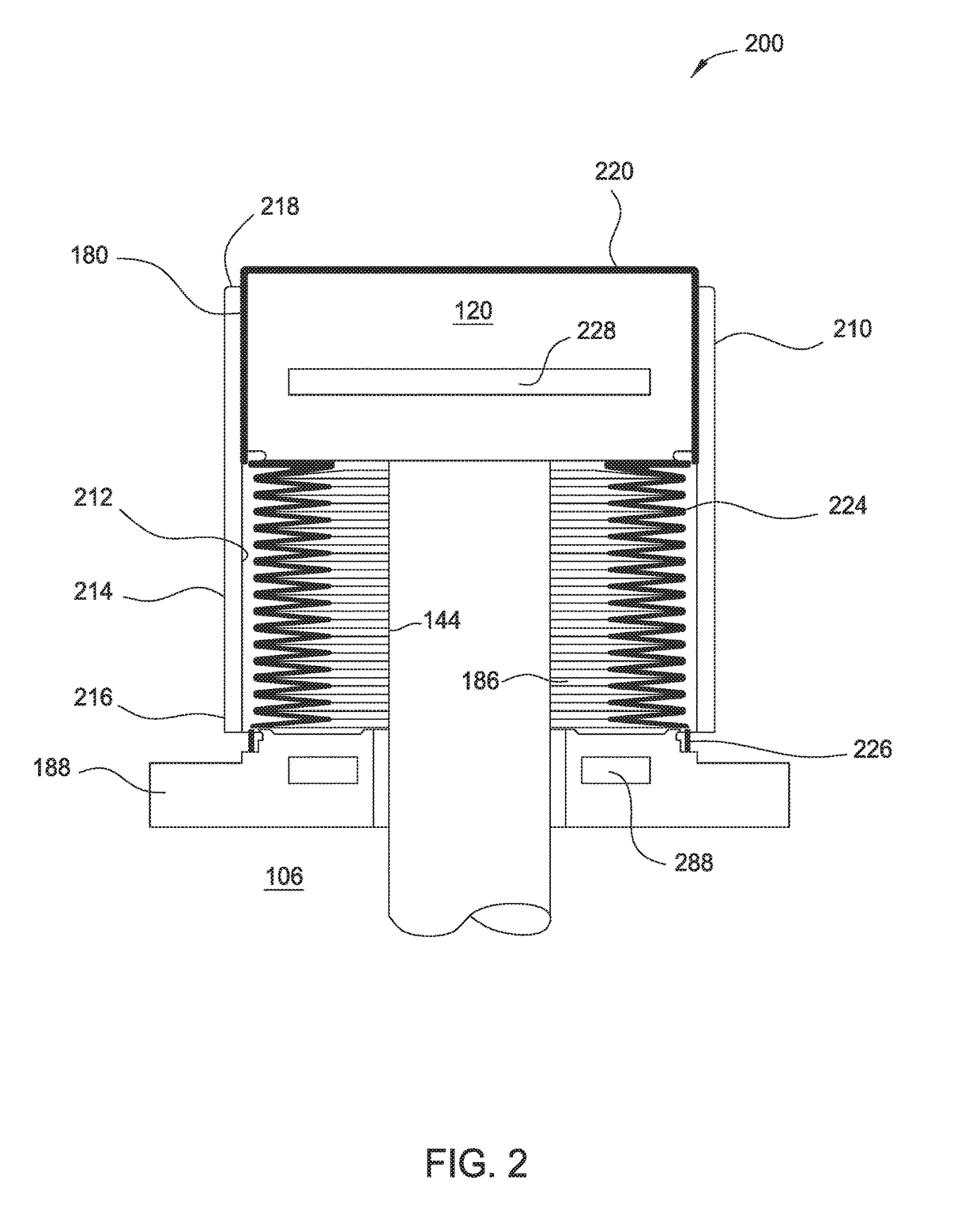

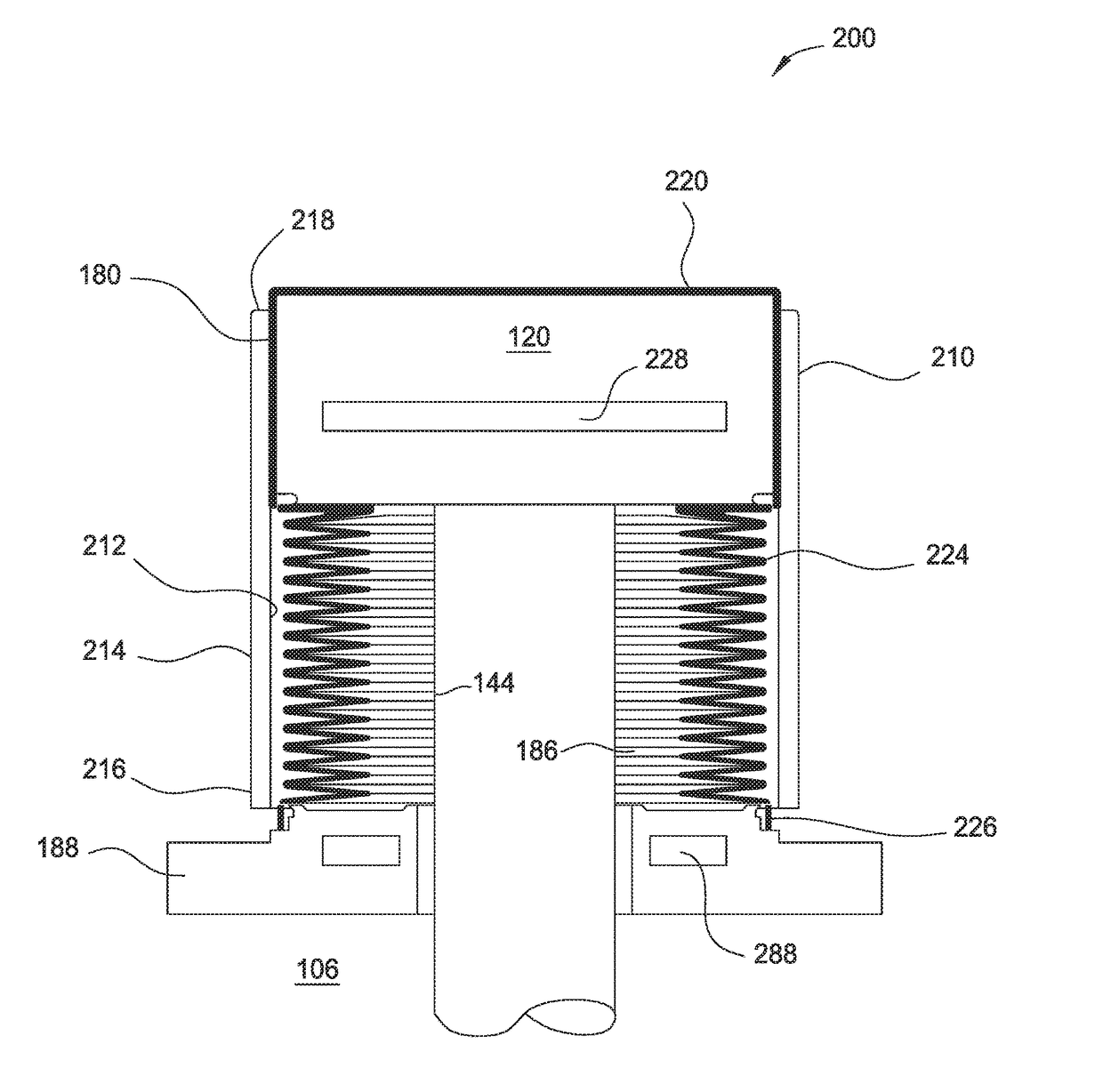

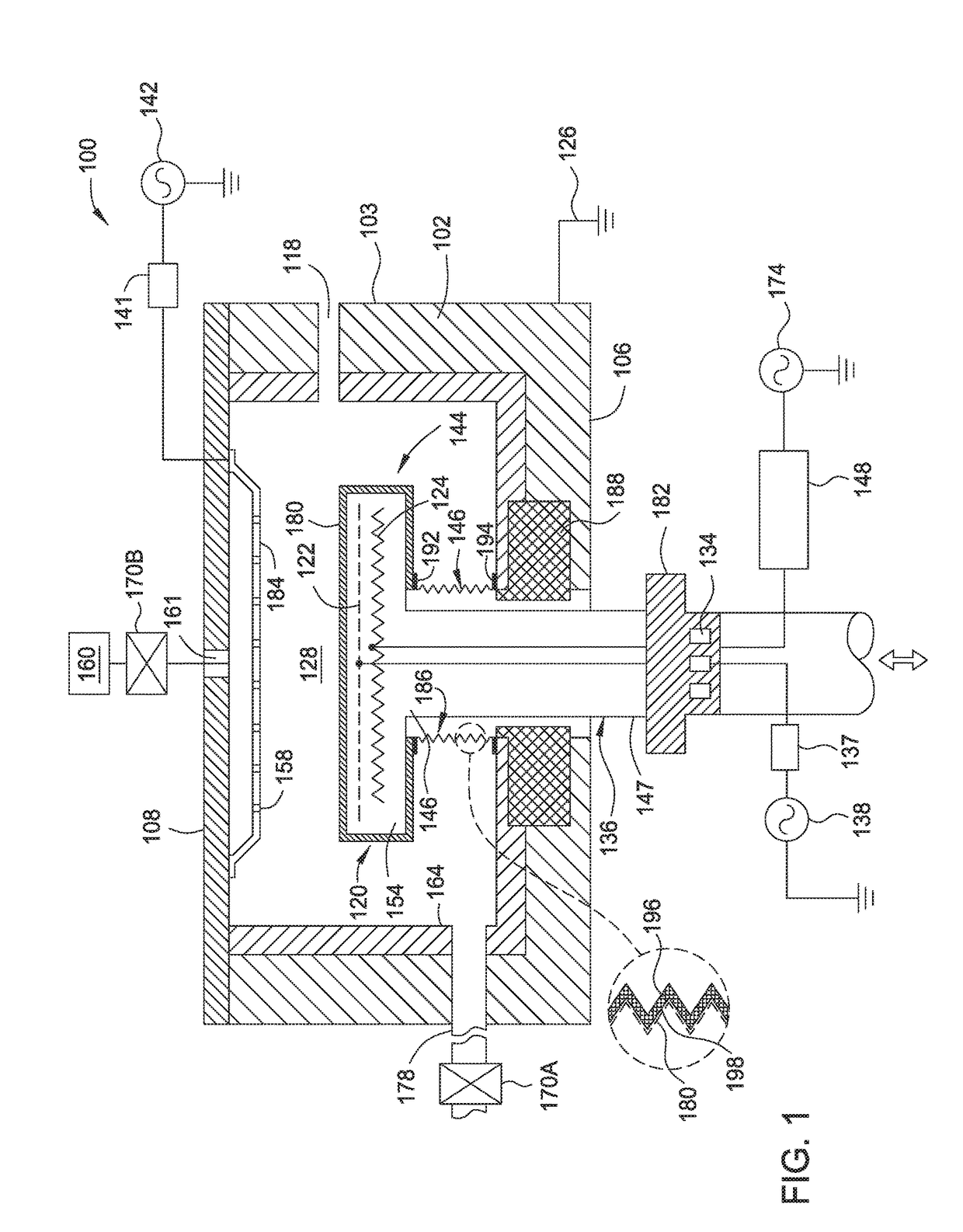

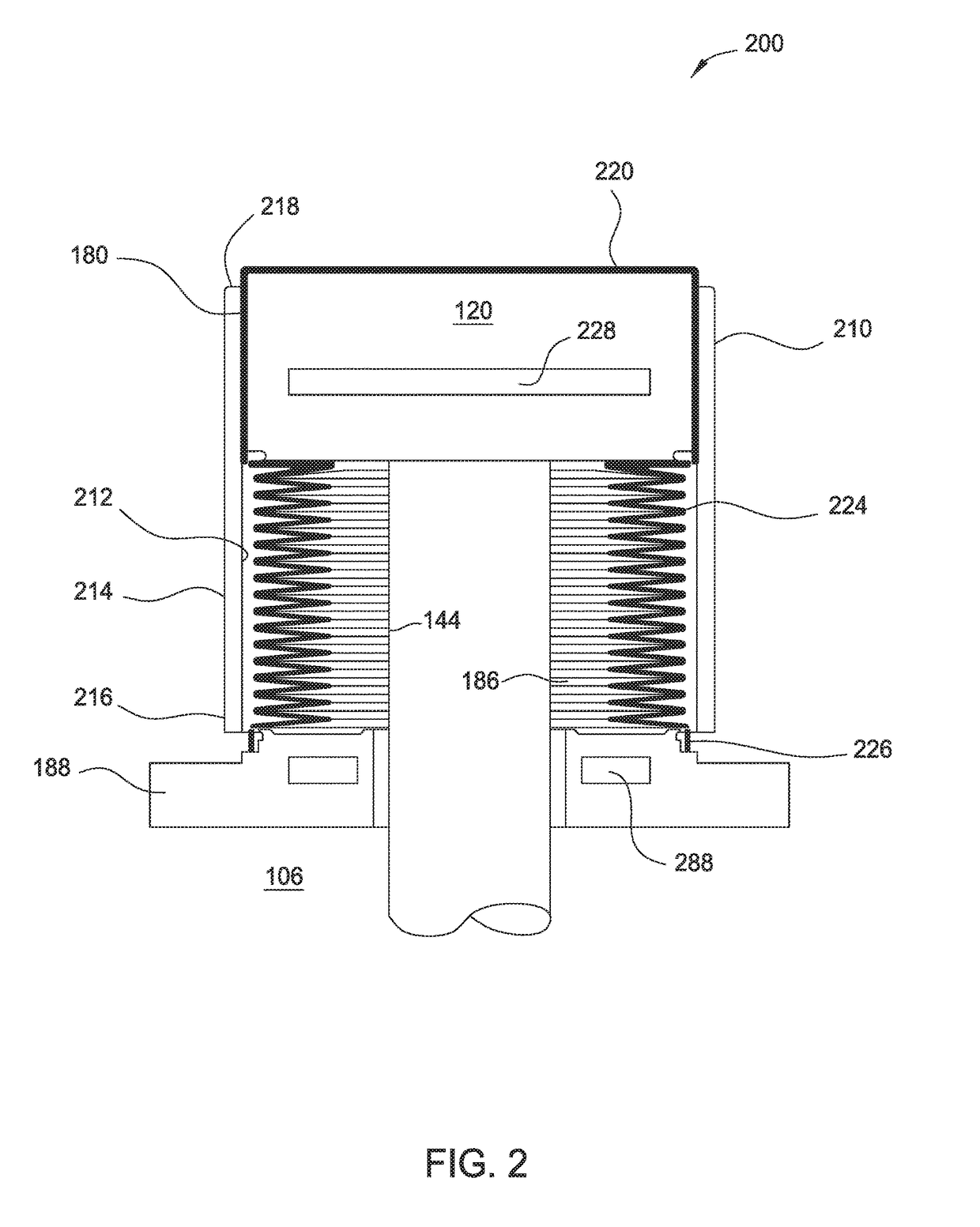

Corrosion control for chamber components

Owner:APPLIED MATERIALS INC

Circumferential ablation device assembly and methods of use and manufacture providing an ablative circumferential band along an expandable member

A medical balloon catheter assembly includes a balloon having a permeable region and a non-permeable region. The balloon is constructed at least in part from a fluid permeable tube such that the permeable region is formed from a porous material which allows a volume of pressurized fluid to pass from within a chamber formed by the balloon and into the permeable region sufficiently such that the fluid may be ablatively coupled to tissue engaged by the permeable region. The non-permeable region is adapted to substantially block the pressurized fluid from passing from within the chamber and outwardly from the balloon. The porous material may be a porous fluoropolymer, such as porous polytetrafluoroethylene, and the pores may be created by voids that are inherently formed between an interlocking node-fibril network that makes up the fluoropolymer. Such voids may be created according to one mode by expanding the fluoropolymer. The balloon may be formed such that the porous material extends along both the permeable and non-permeable regions. In one mode of this construction, the porous material is porous along the permeable region but is non-porous along the non-permeable region, such as for example by expanding only the permeable region in order to render sufficient voids in the node-fibril network to provide permeable pores in that section. The voids or pores in the porous material may also be provided along both permeable and non-permeable sections but are substantially blocked with an insulator material along the non-permeable section in order to prevent fluid from passing through. The insulator material may be dip coated, deposited, or extruded with the porous material in order to fill the voids. The insulator material may in one mode be provided along the entire working length of the balloon and then selectively removed along the permeable section, or may be selectively exposed to only the non-permeable sections in order to fill the voids or pores there.

Owner:ATRIONIX

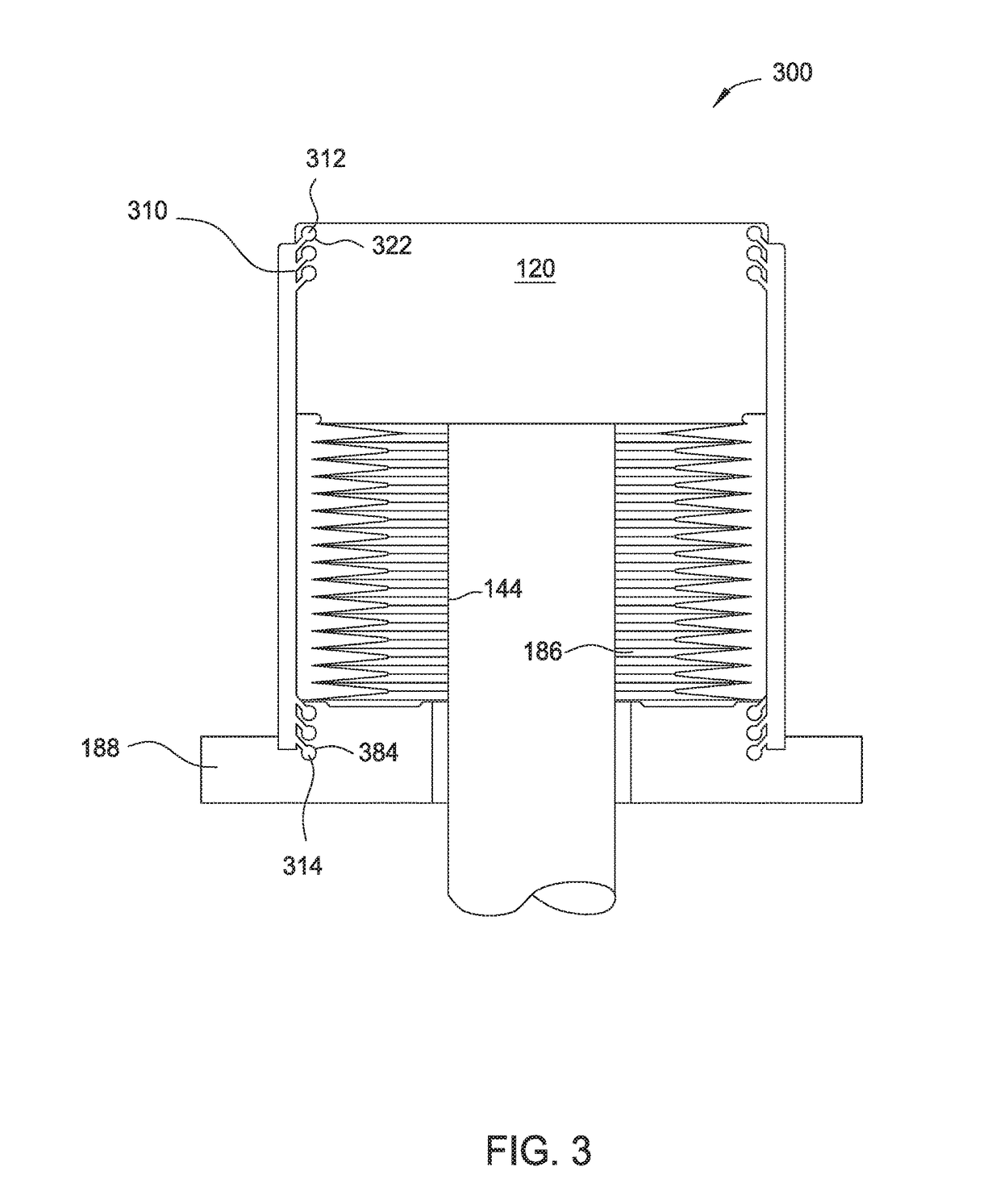

Corrosion control for chamber components

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

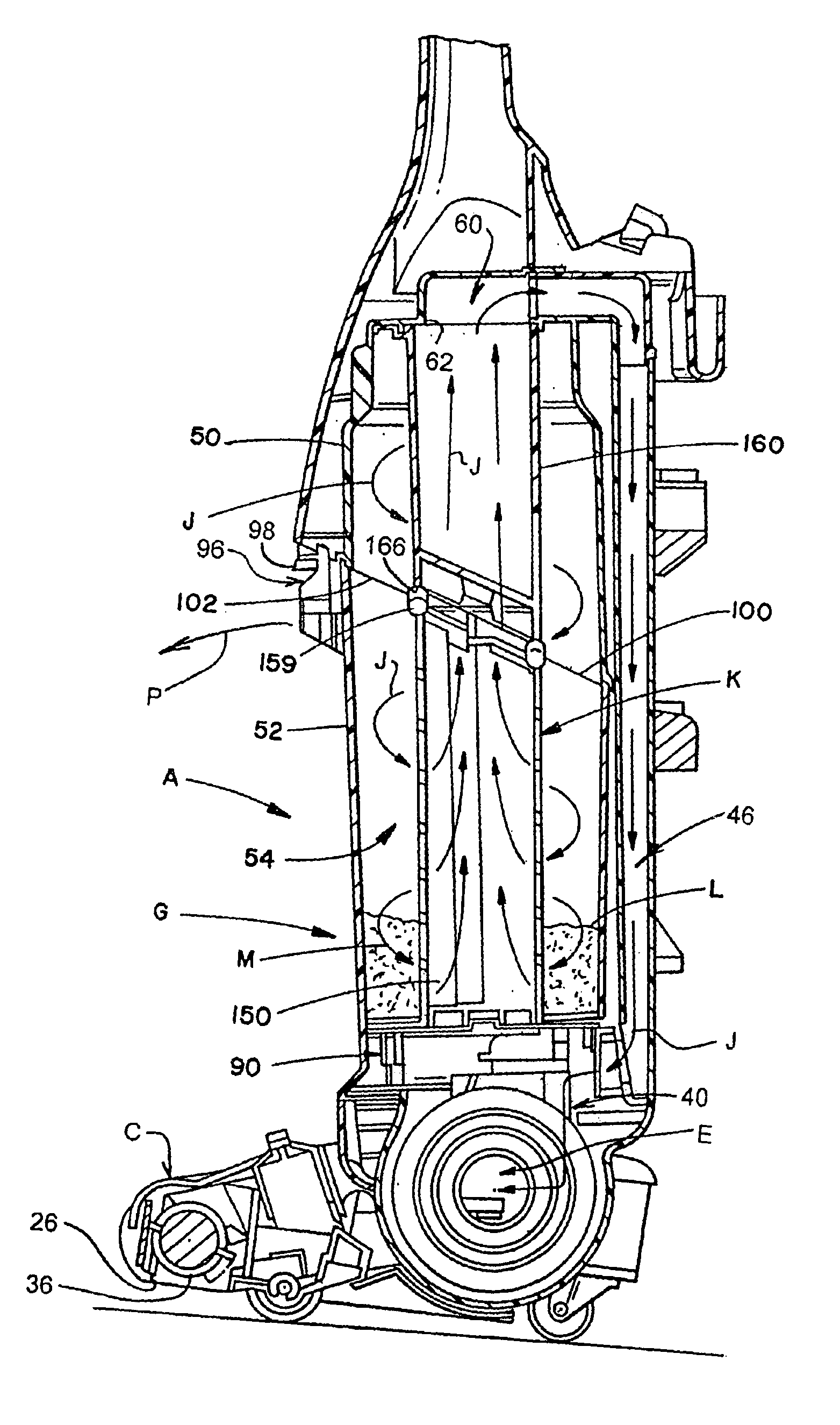

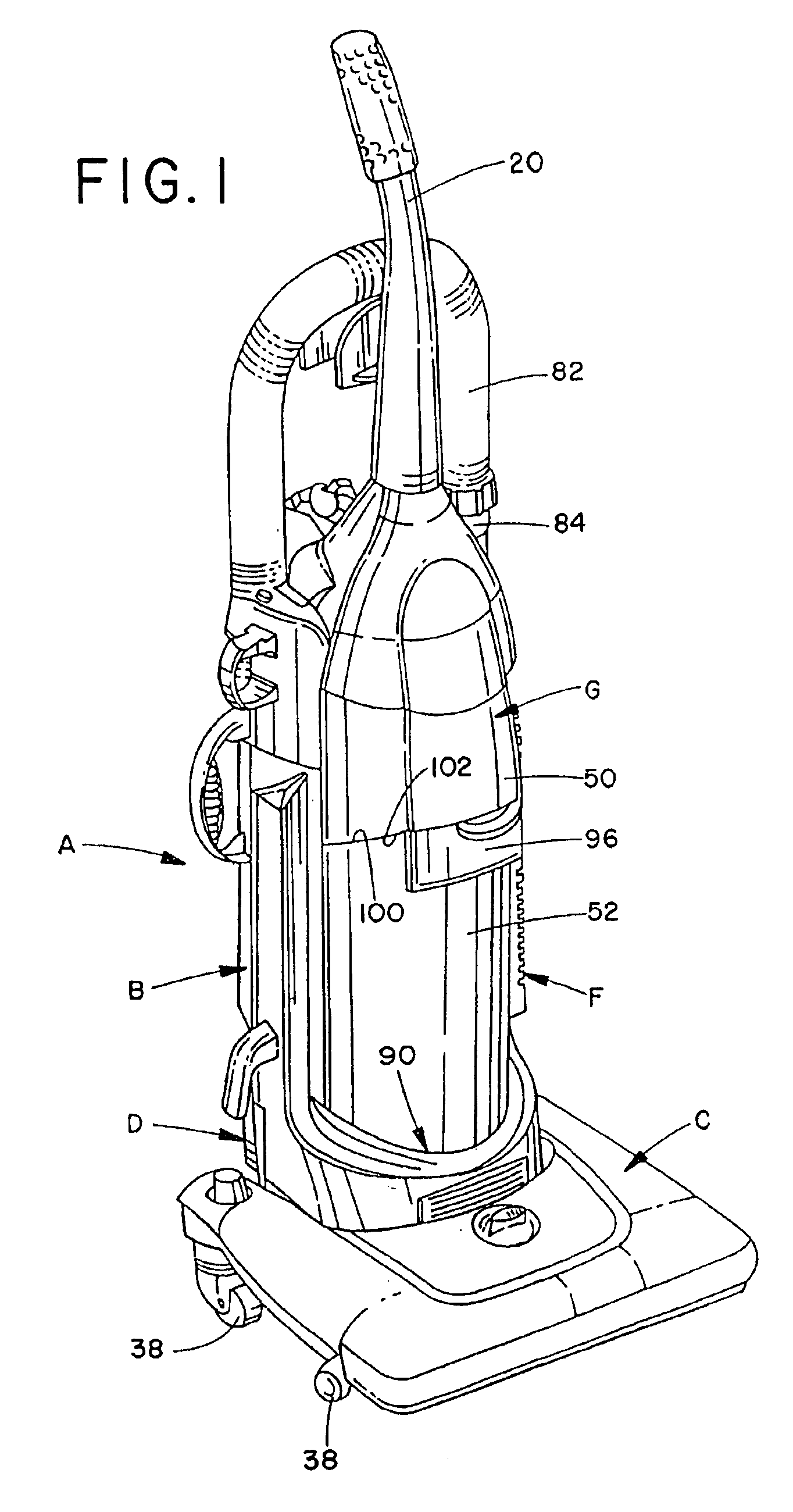

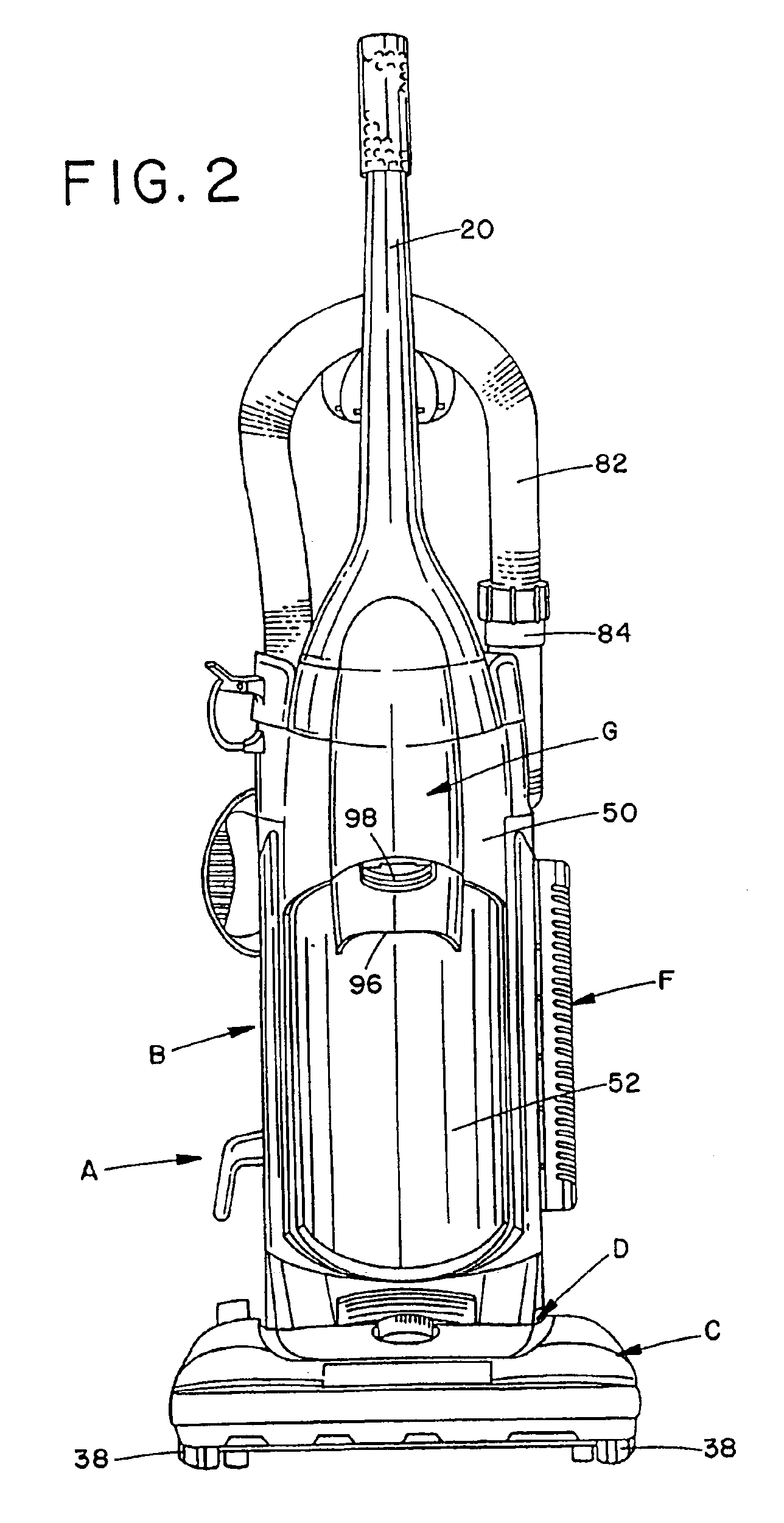

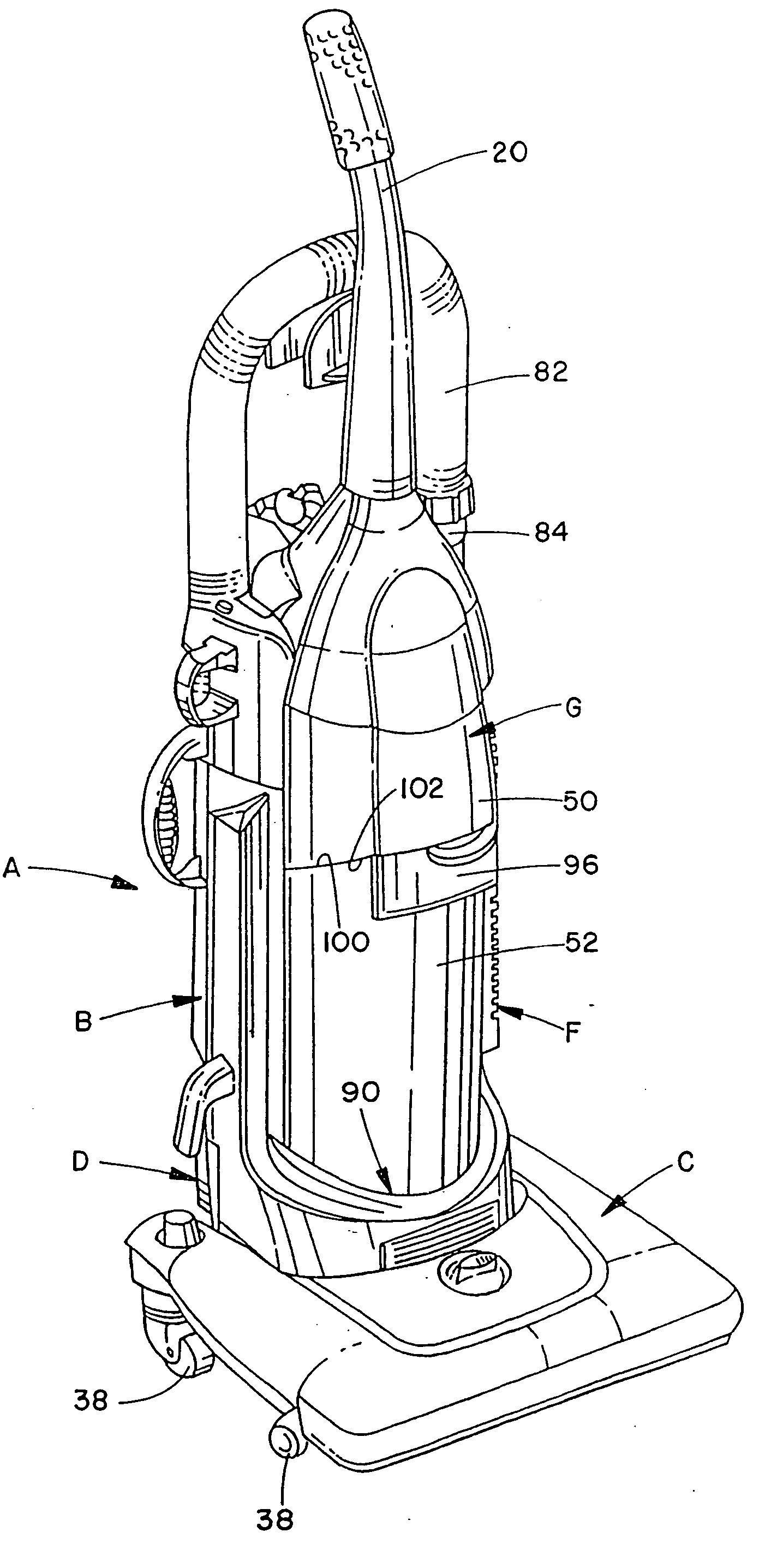

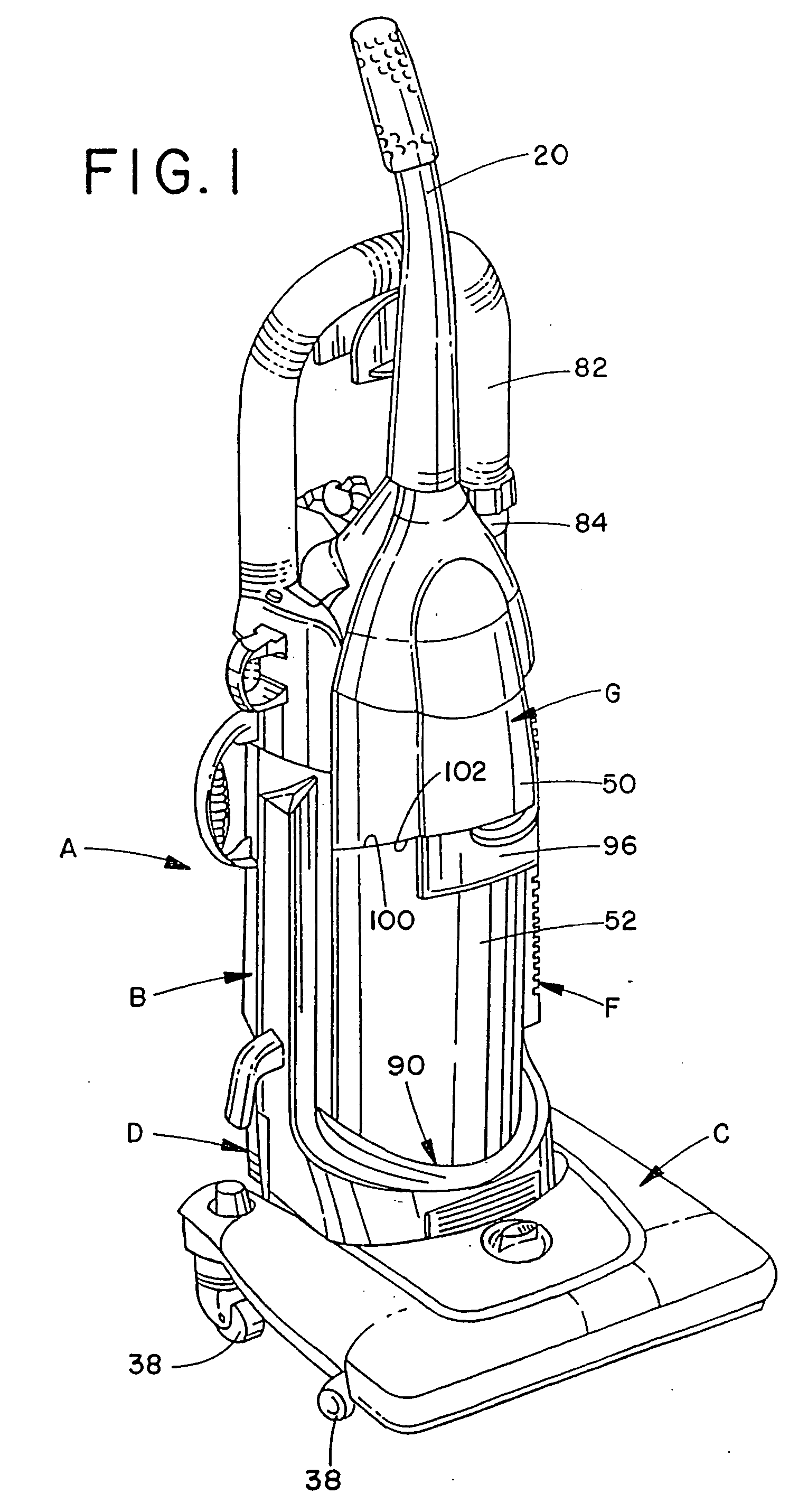

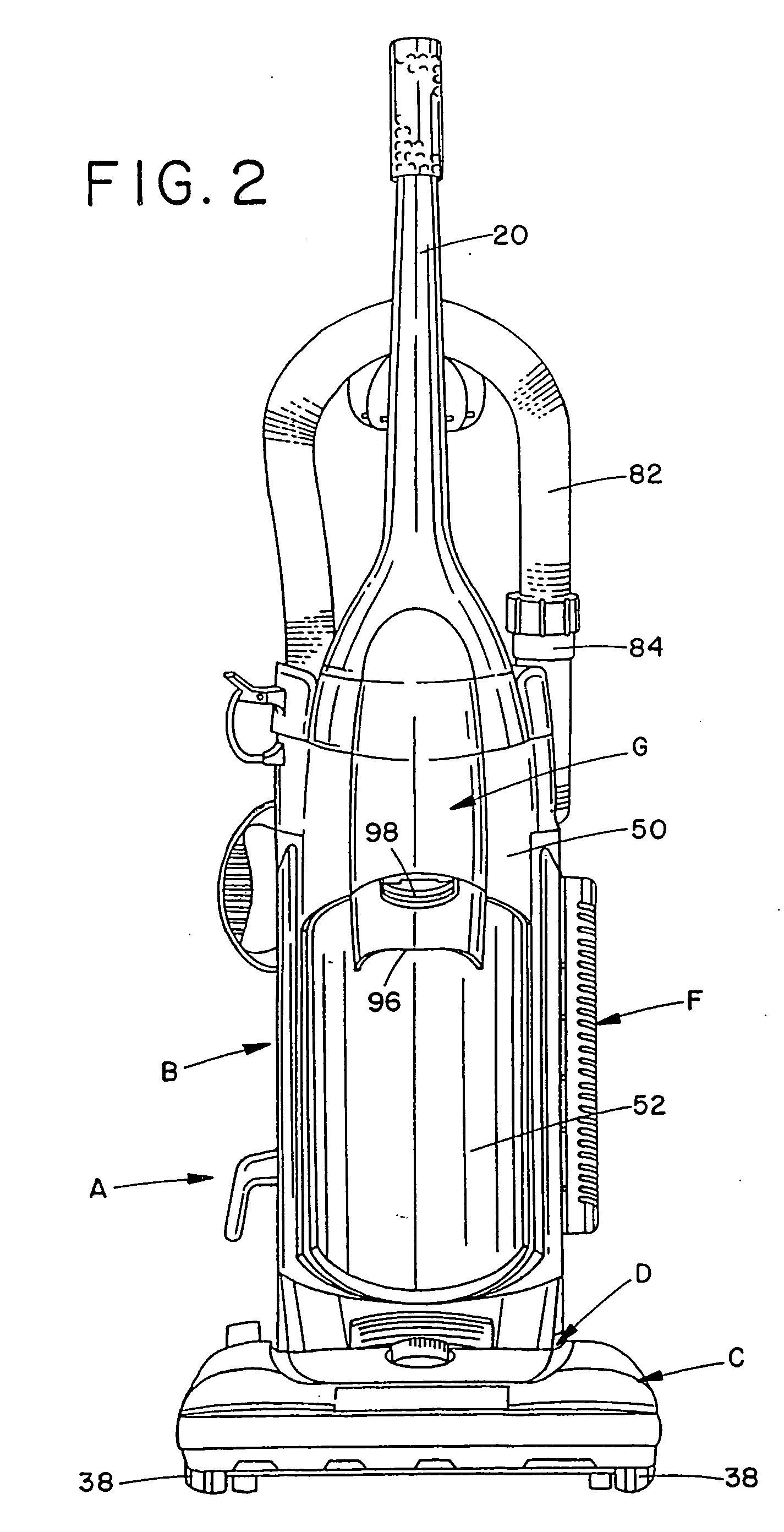

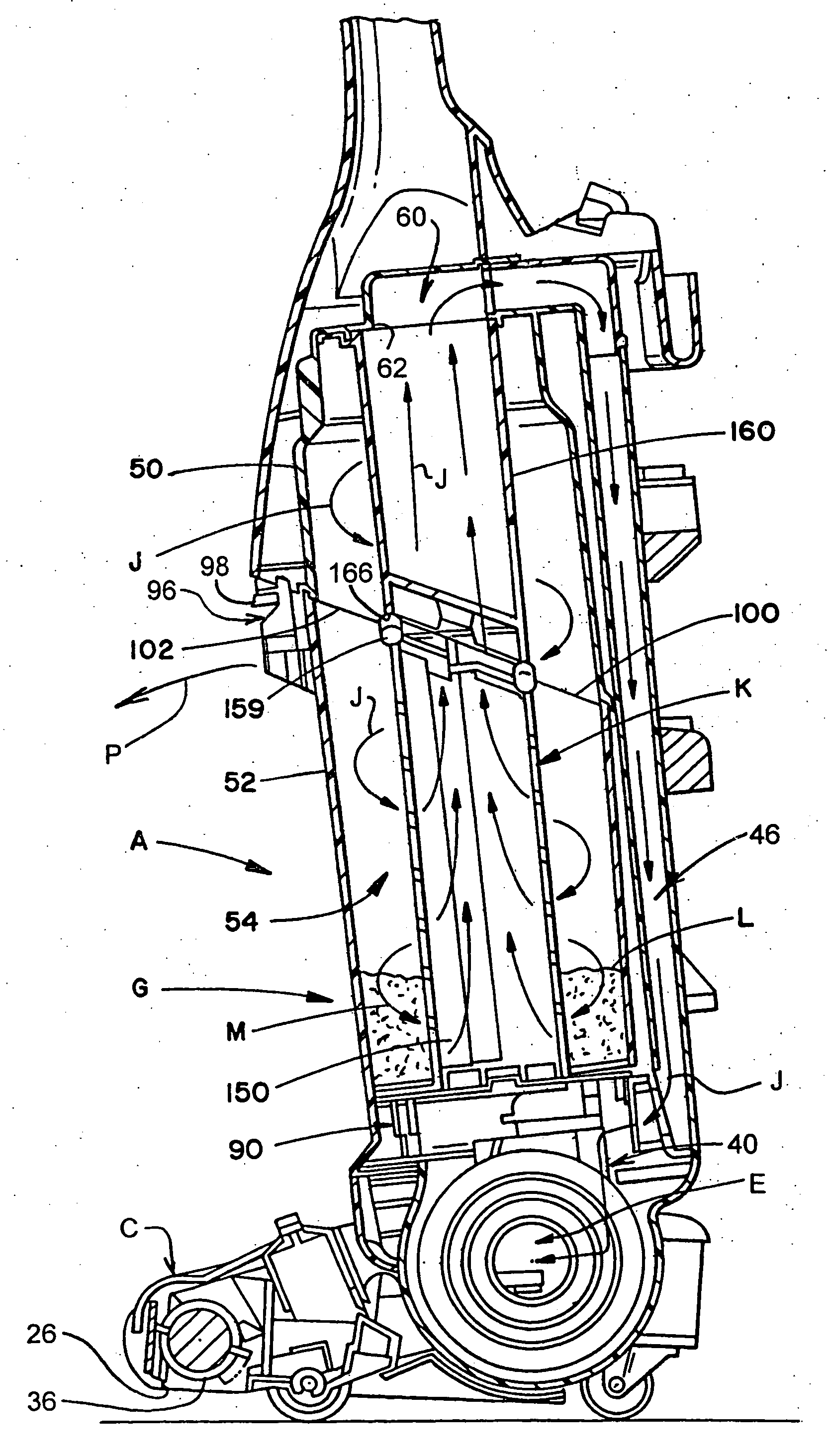

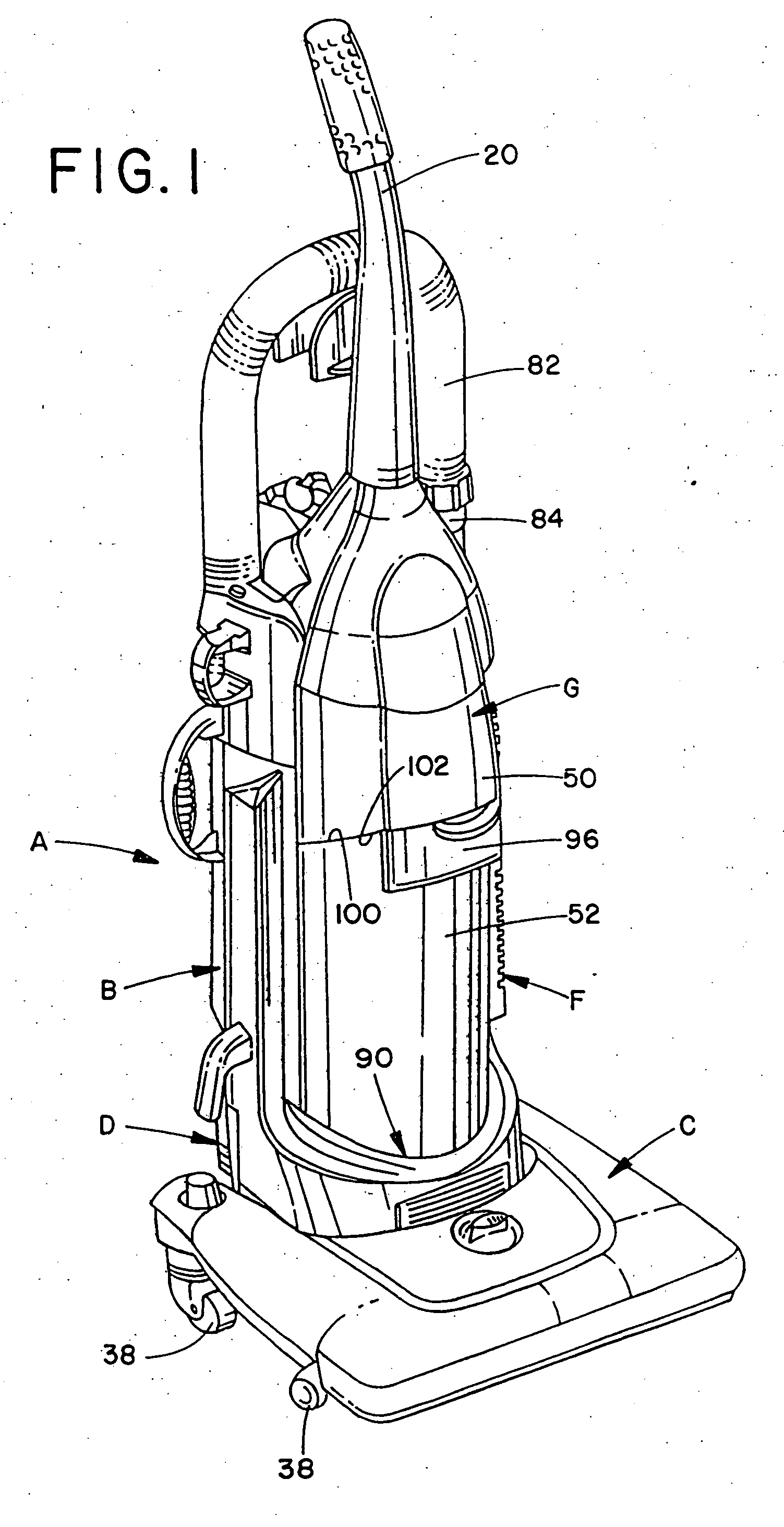

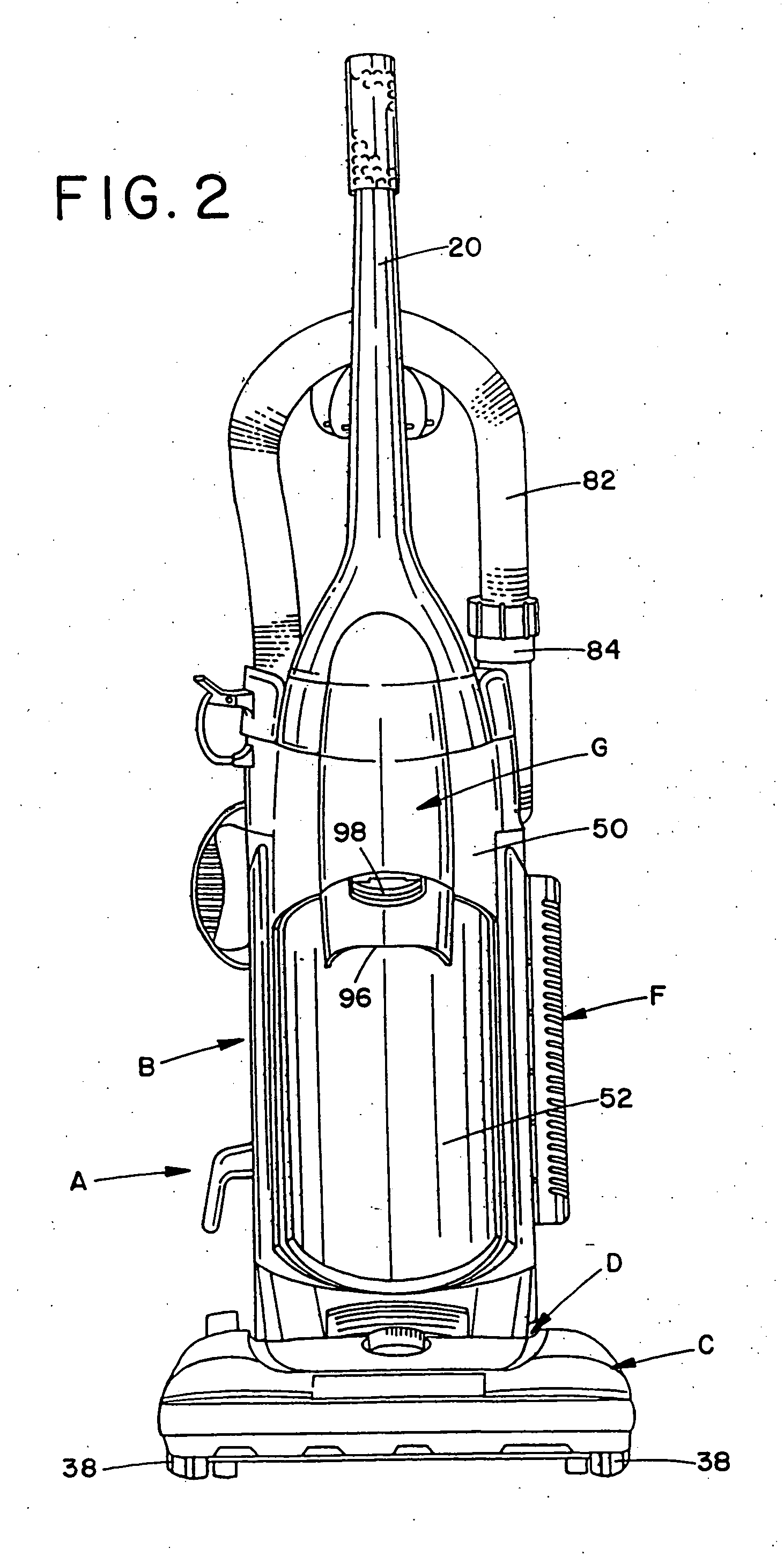

Upright vacuum cleaner with cyclonic airflow

InactiveUS6848146B2Easily and conveniently emptied dirt cupEffective filteringCleaning filter meansCombination devicesHEPACyclone

A vacuum cleaner includes a first housing defining a cyclonic airflow chamber and a second housing defining a main suction opening that is in communication with an inlet of the cyclonic chamber. A suction source has a suction airstream inlet in communication with an outlet of the cyclonic chamber, and establishes a suction airstream that enters said main suction opening, passes through said cyclonic chamber, and passes to an outlet of said suction source. A substantial portion of particulates entrained in the suction airstream are separated therefrom when said suction airstream moves in a cyclonic fashion through the cyclonic chamber. A main filter assembly, preferably including filter medium comprising polytetrafluoroethylene (PTFE), is located in the cyclonic chamber so that a suction airstream moving from the main suction opening to the inlet of said suction source by way of the cyclonic airflow chamber passes through the filter medium thereof after said airstream moves in a cyclonic fashion within the cyclonic airflow chamber to remove residual particulates from the suction airstream before it leaves the cyclonic chamber. A HEPA filter can be provided to filter the suction airstream exhausted through the outlet of the suction source prior to the airstream being discharged from the vacuum.

Owner:ROYAL APPLIANCE MFG

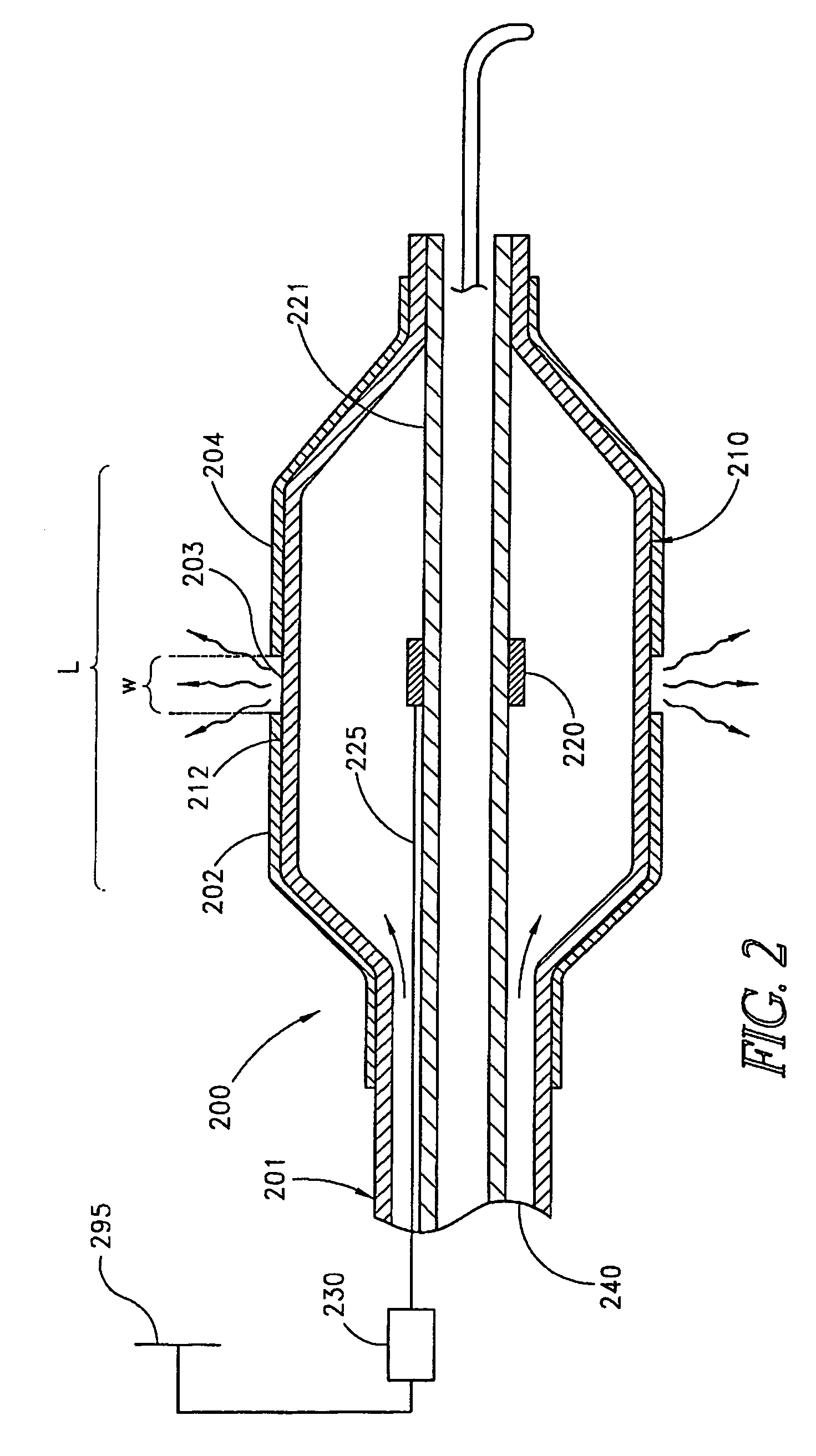

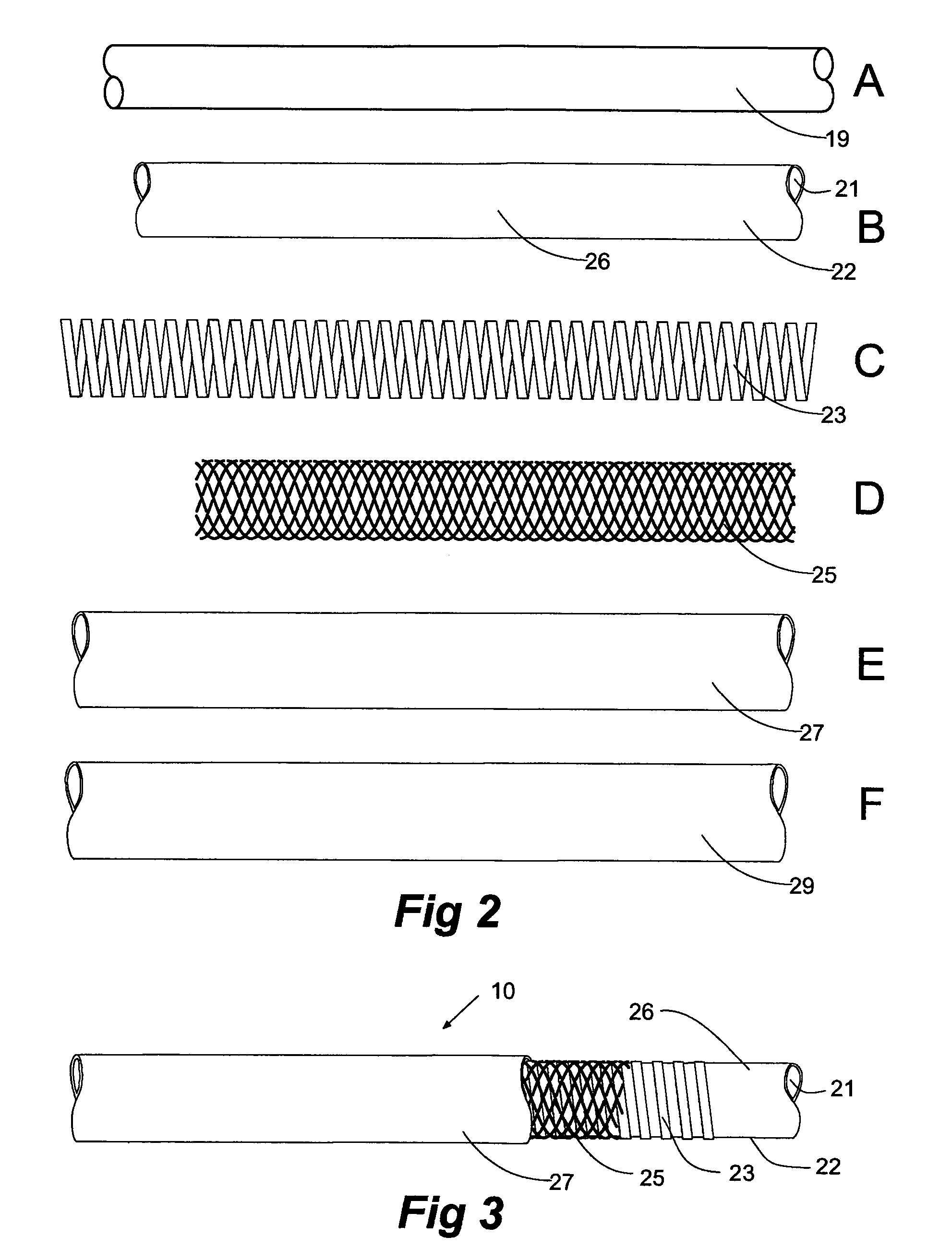

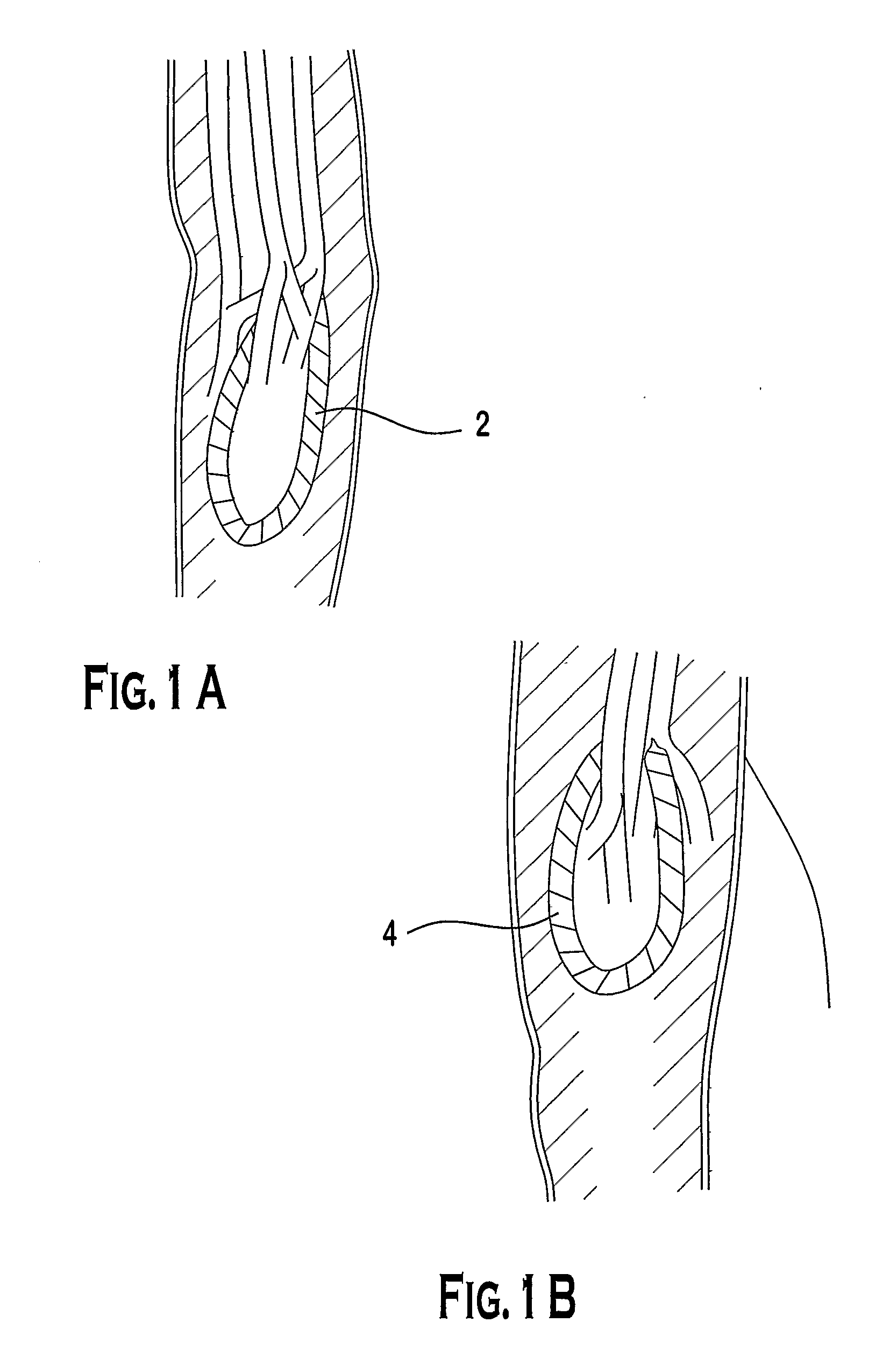

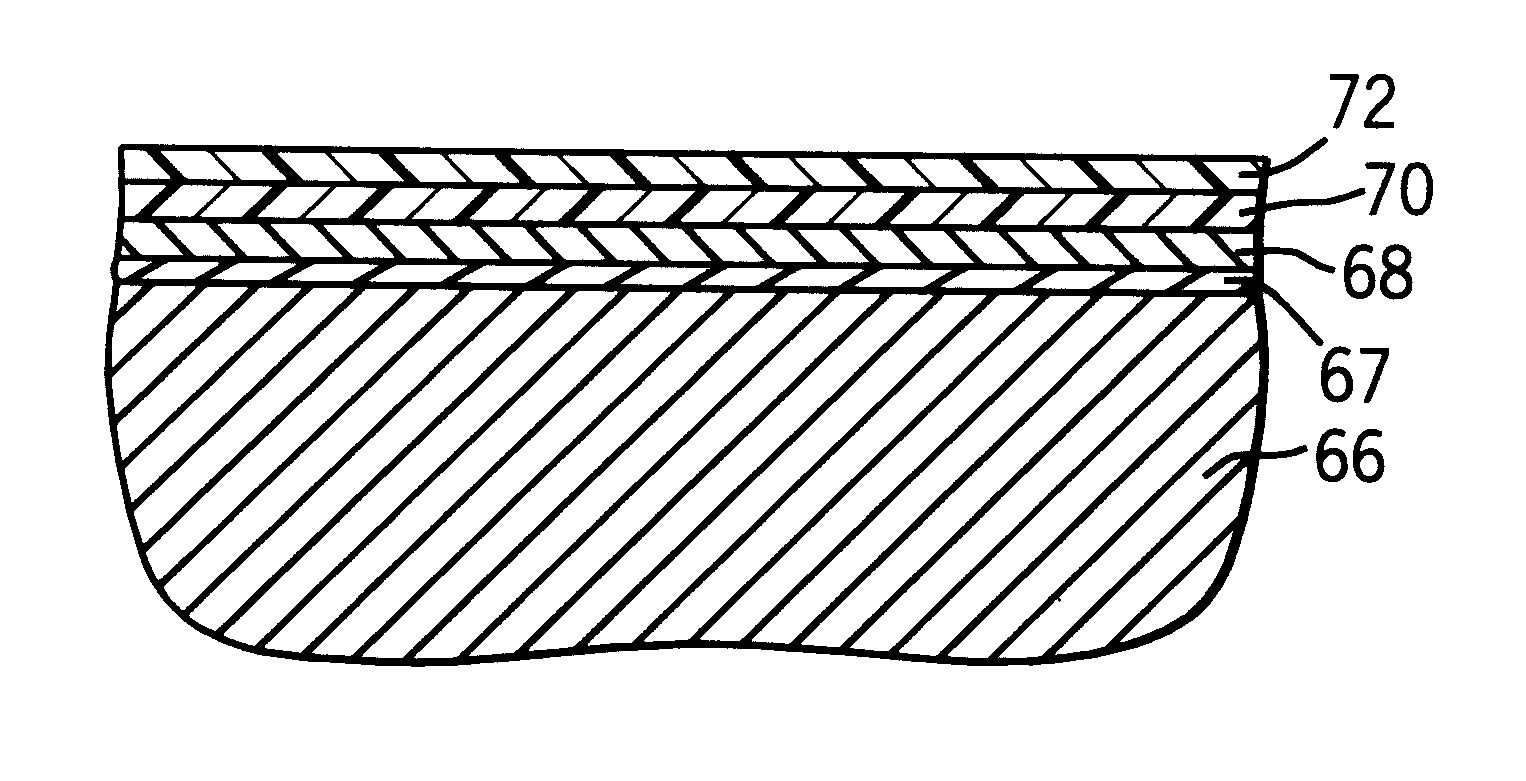

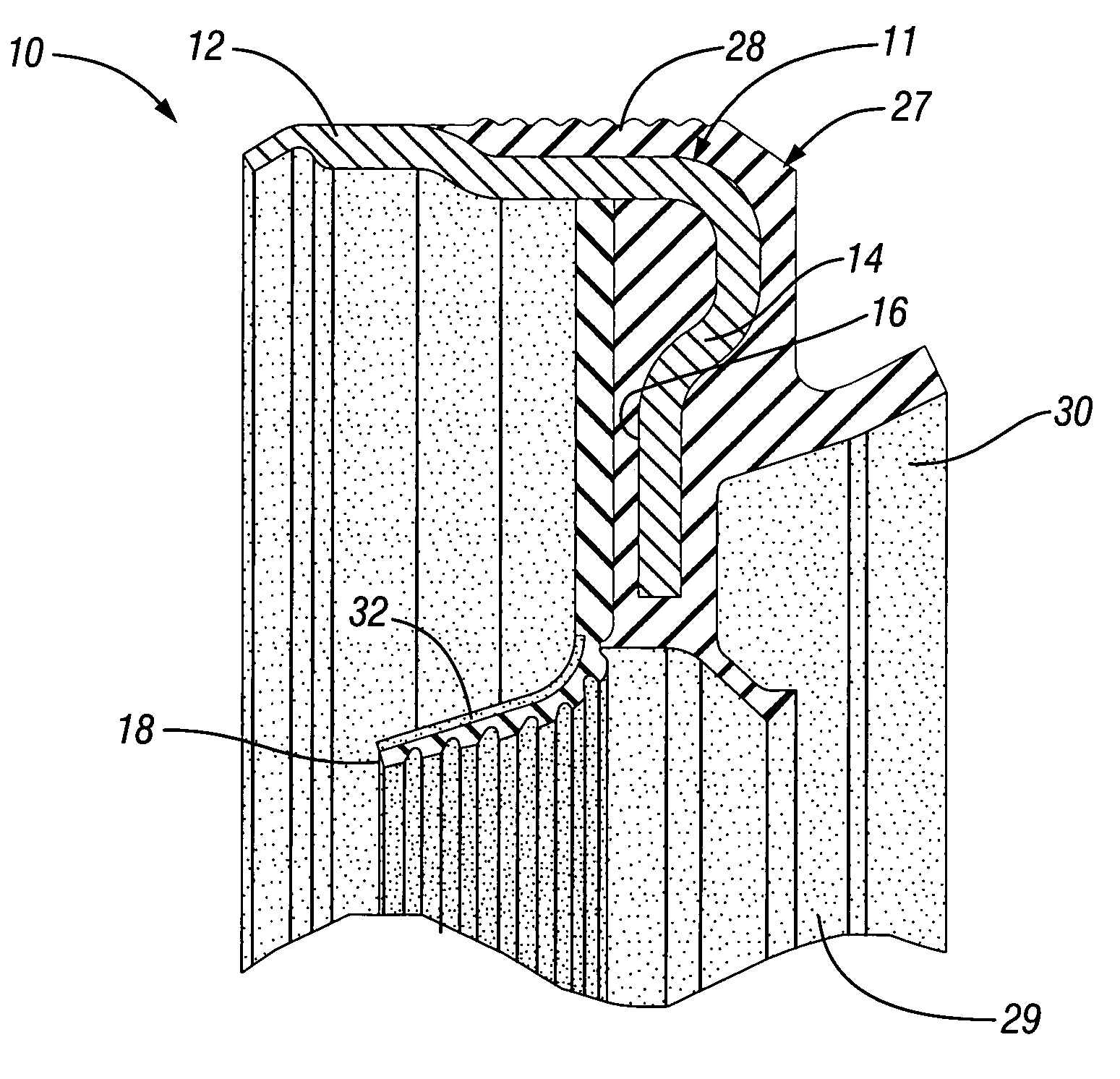

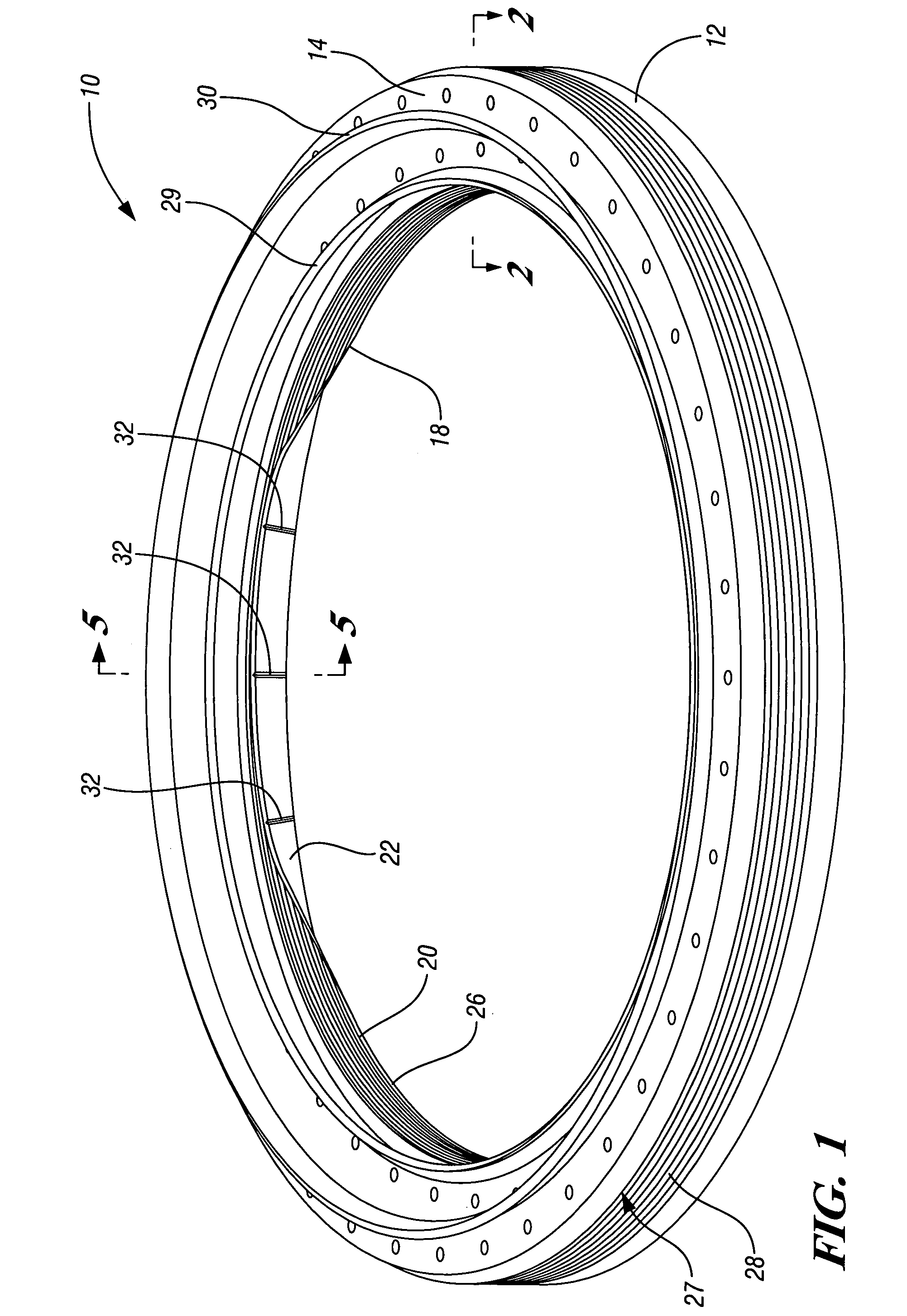

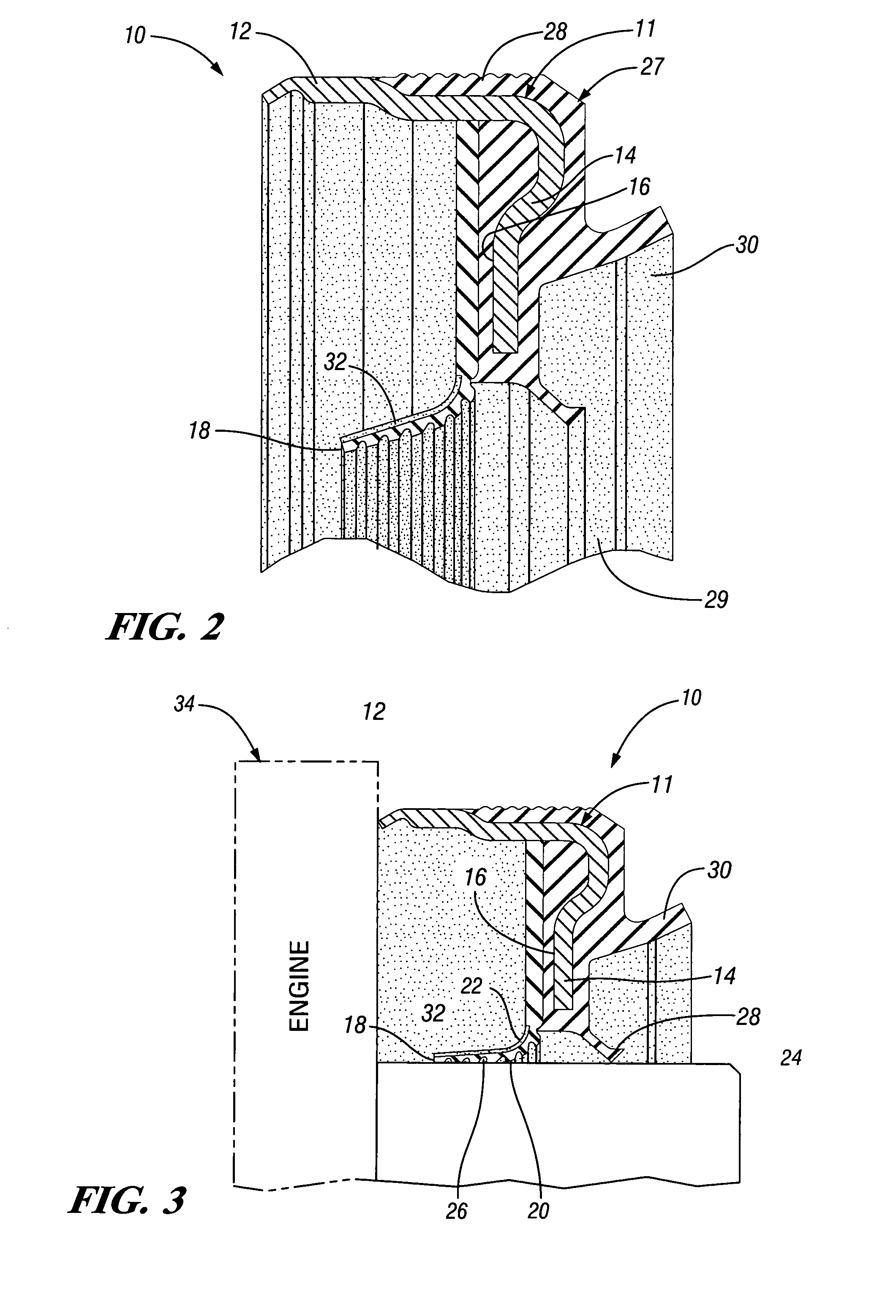

Large diameter sheath

InactiveUS20060095050A1Enhance radiographic visualizationGreat flexibility of controlStentsEar treatmentPolyamideMedical device

A large diameter, flexible, kink-resistant and rotatable introducer sheath ( 10 ) for percutaneous delivery of a contained and implantable medical device in the vasculature of a patient. The introducer sheath includes a reinforcement such as a flat wire coil ( 23 ) fitted about an inner, lubricous material such as polytetrafluoroethylene tube ( 22 ). A wire braid ( 25 ) is placed around the coil to give good transfer of rotational forces. An outer tube ( 27 ) of a heat formable polyamide material is heat formed and compressed through the spaces between the wires of the braid and turns of the wire coil to mechanically connect the outer tube to the roughened outer surface of the inner tube. The durometer of the outer tube can be varied to effect the flexibility of the sheath. A radiopaque marker ( 42 ) is positioned at the distal end of the coil and around the inner tube for radiographic visualization.

Owner:WILLIAM A COOK AUSTRALIA +1

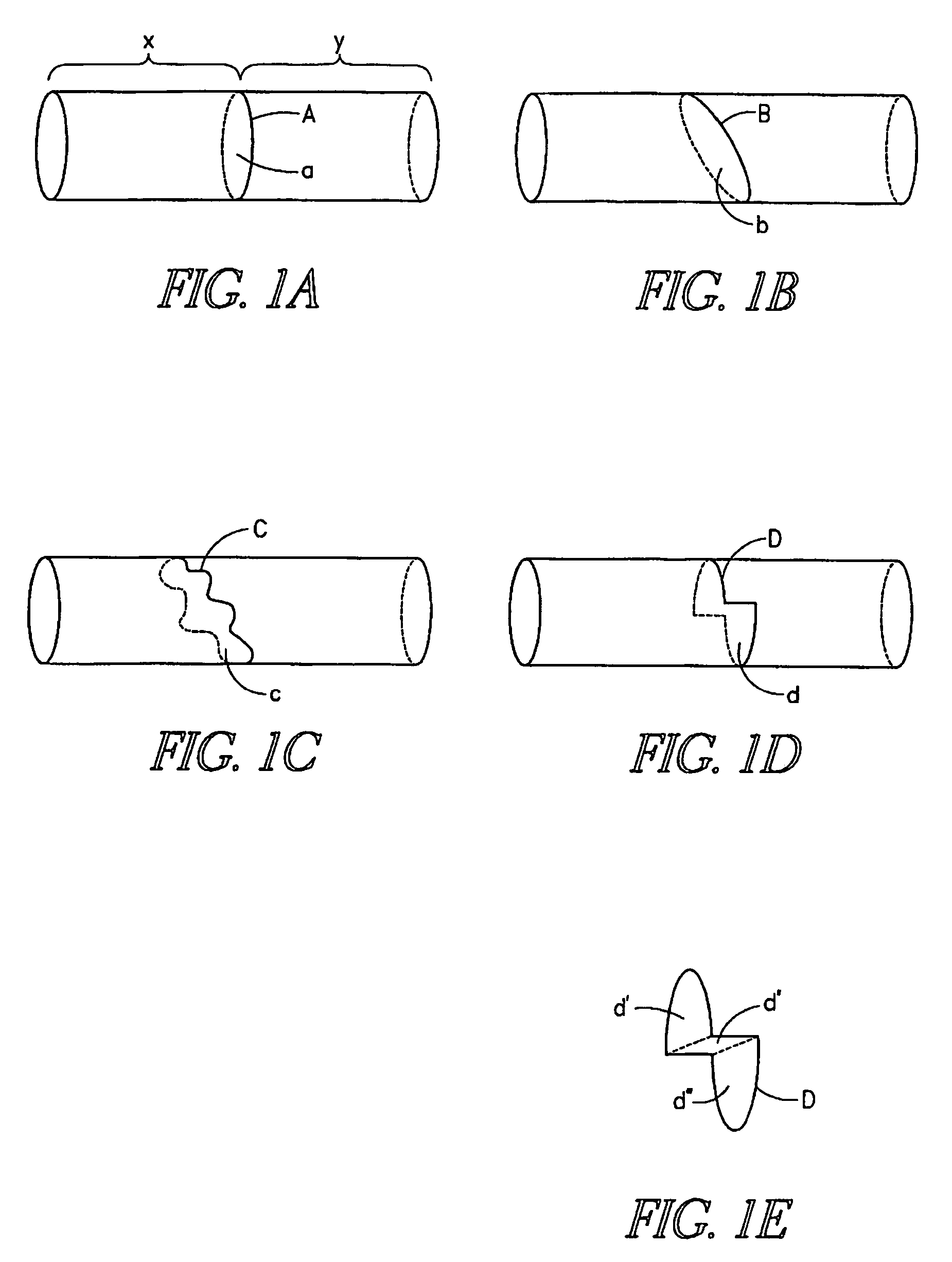

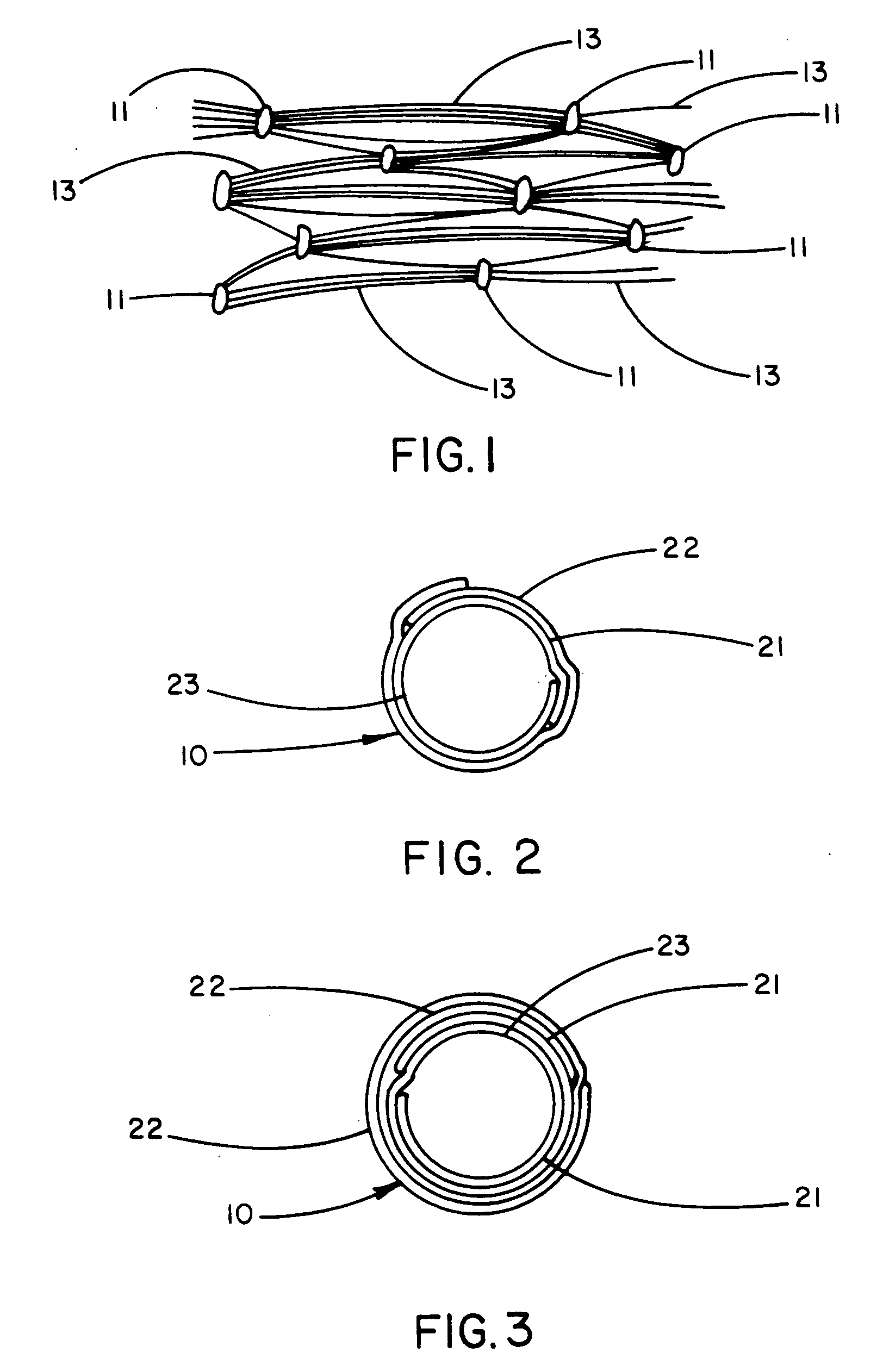

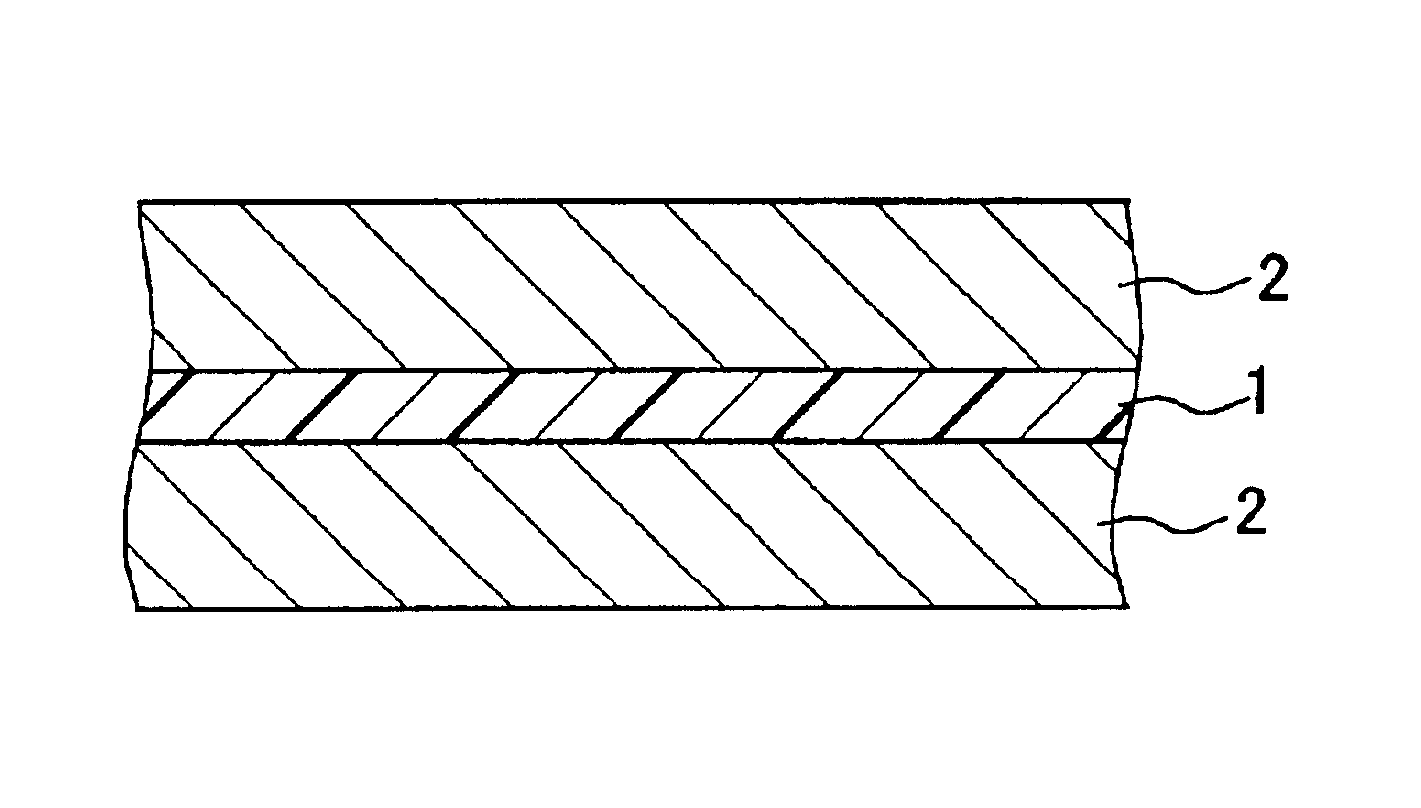

Thin-wall polytetrafluoroethylene tube

A thin-wall PTFE (polytetrafluoroethylene) tube in the form of a tube of porous expanded PTFE film wherein the porous PTFE film has a microstructure containing a multiplicity of fibrils. The thin-wall tube is used in a non-porous embodiment as the balloon portion of a balloon catheter. The thin-wall tube is not elastomeric; however, because of the thinness, strength and flexibility of the tube, it may be inserted into a body conduit in a collapsed state and then deployed from a catheter and inflated up to the maximum diameter of the thin-wall tube. The porous PTFE film is provided with a continuous layer of adhesive to provide the non-porous tube; the adhesive is preferably a thermoplastic and more preferably a thermoplastic fluoropolymer such as fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

Self-Sealing Ptfe Graft with Kink Resistance

InactiveUS20080027534A1High porosityMaintain good propertiesStentsIntravenous devicesMedicineVascular graft

A self-sealing vascular graft, including a substrate with a sealant layer and several optional additional layers, is described. The substrate can be ePTFE and the material used for the sealant and additional layers can be polyurethane. The sealant layer and additional layers may include one or more base layers, one or more foam layers, beading of different sizes and shapes, and ePTFE tape. A flared cuff may be integral to one or both ends of the substrate or may be attached to one or both ends. Various methods of making a self-sealing vascular graft are also described, including methods of disposition, methods of forming, methods of bonding and methods of attaching.

Owner:CR BARD INC

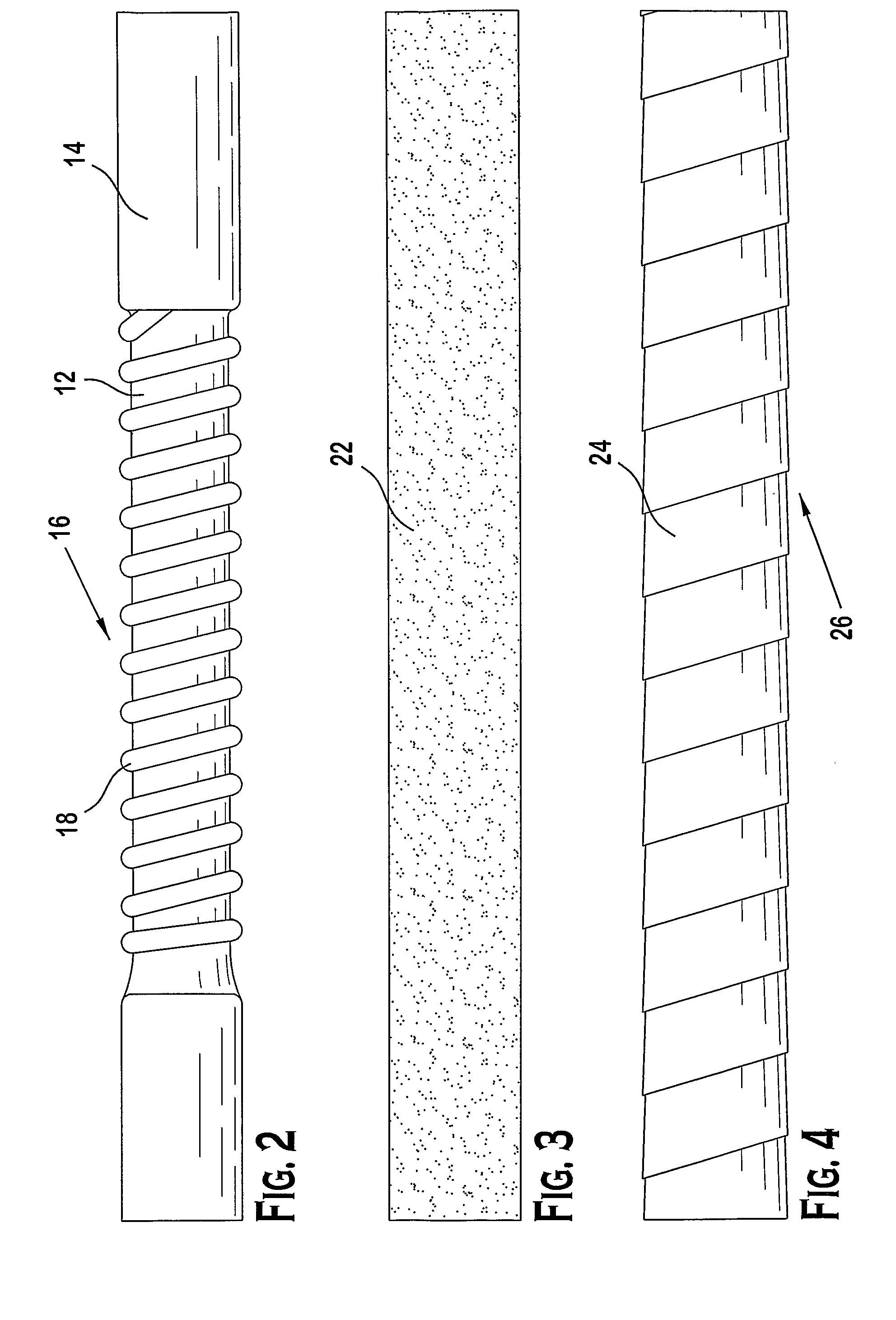

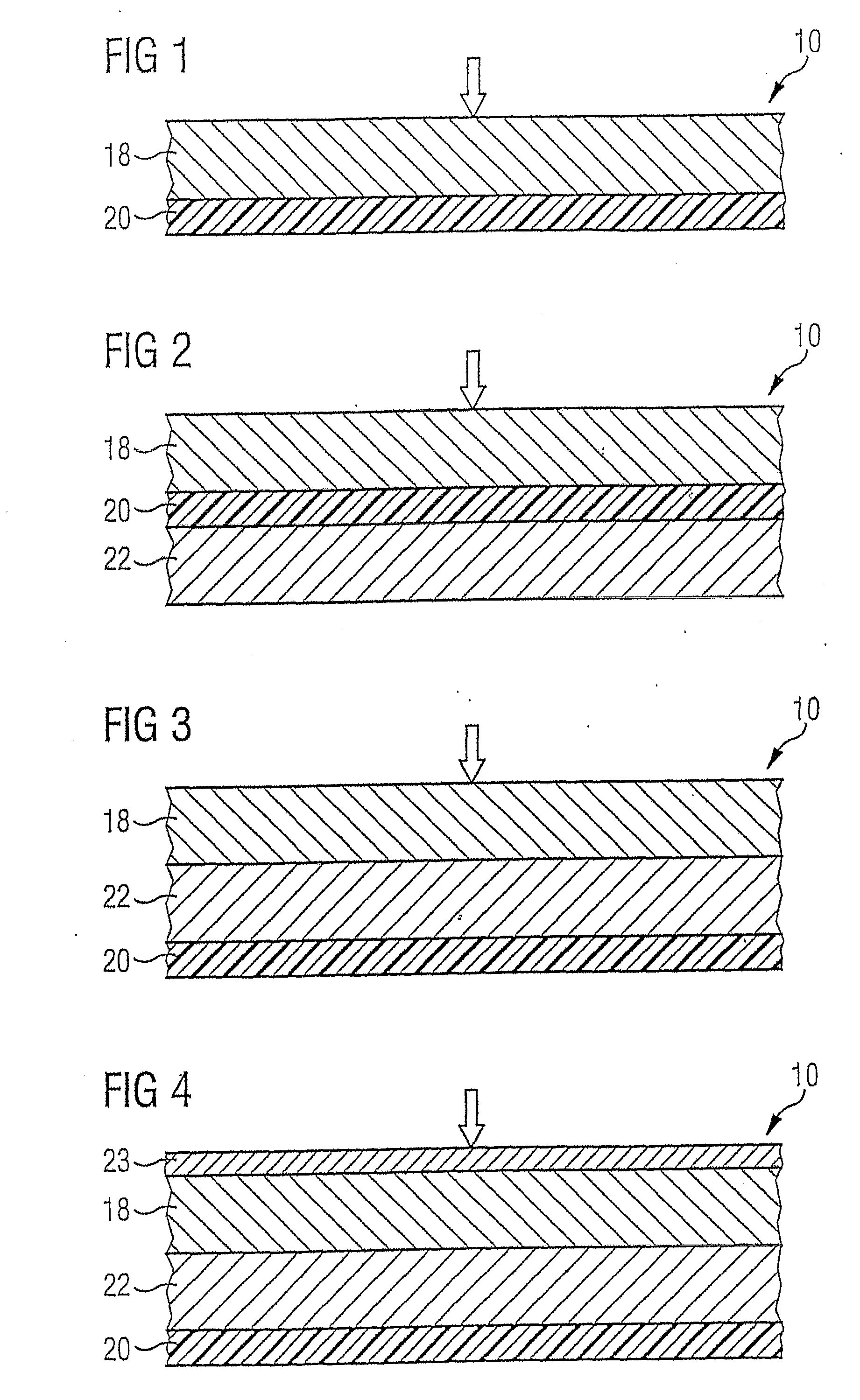

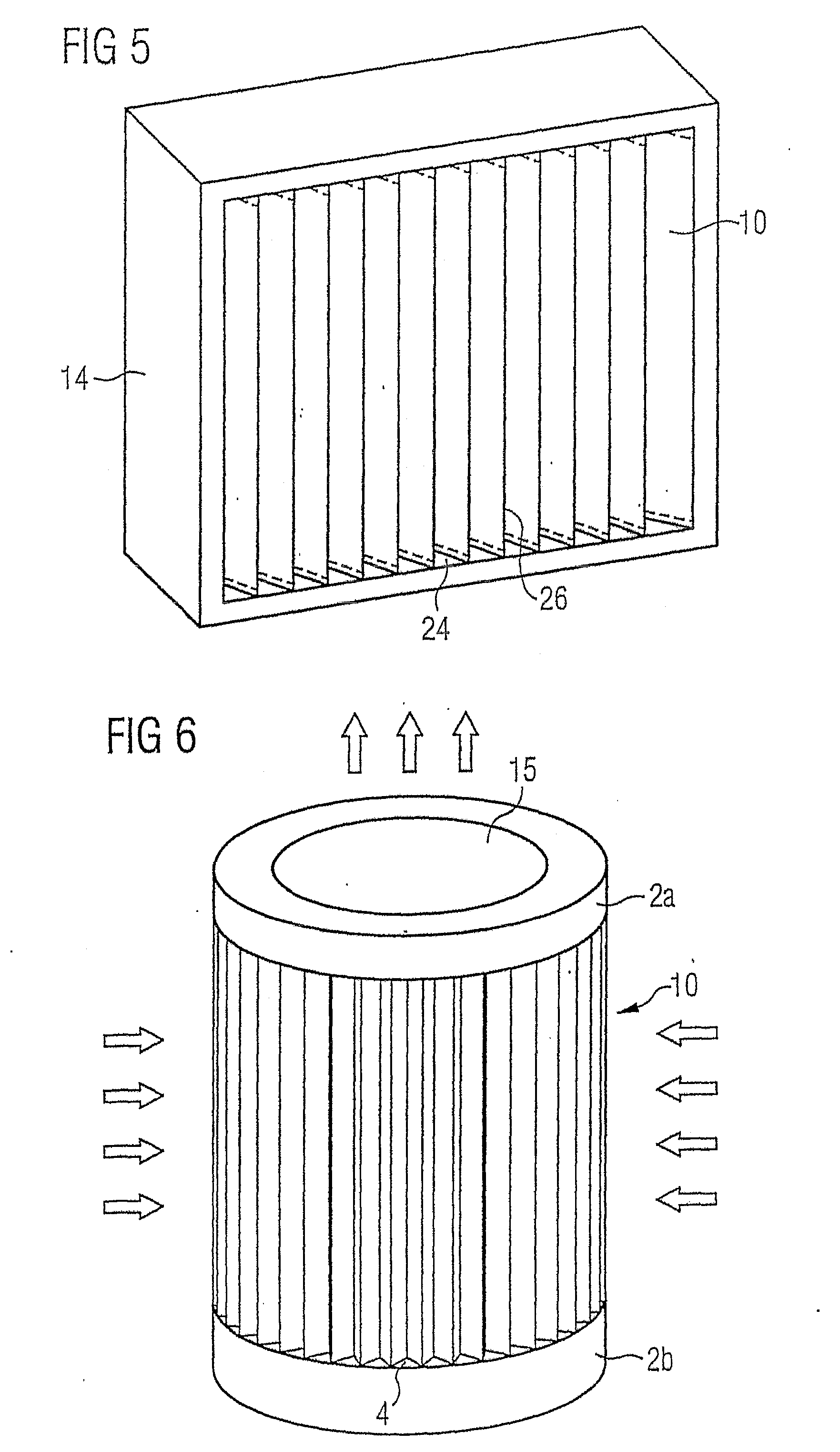

Turbine Air-Intake Filter

InactiveUS20090266048A1Improve filtering effectSimple wayGas treatmentDispersed particle filtrationFiberFiltration

A turbine air-intake filter for removal of particles from an air stream entering a gas turbine comprises a composite filter media (10) being made from a membrane filtration layer (20) comprising a porous polymeric membrane, such as porous polytetrafluoroethylene (ePTFE), and at least one depth filtration media layer (18) comprising fibers, such as a melt blown web, and being disposed on an upstream side of the membrane filtration layer (20) relative to a direction of gas flow through the filter. The fibers of the depth filtration media layer (18) have an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT

Upright vacuum cleaner with cyclonic airflow

InactiveUS20050091786A1Easily and conveniently emptiedEffectively filters residual contaminantsCleaning filter meansCombination devicesParticulatesHEPA

A vacuum cleaner includes a first housing defining a cyclonic airflow chamber and a second housing defining a main suction opening that is in communication with an inlet of the cyclonic chamber. A suction source has a suction airstream inlet in communication with an outlet of the cyclonic chamber, and establishes a suction airstream that enters said main suction opening, passes through said cyclonic chamber, and passes to an outlet of said suction source. A substantial portion of particulates entrained in the suction airstream are separated therefrom when said suction airstream moves in a cyclonic fashion through the cyclonic chamber. A main filter assembly, preferably including filter medium comprising polytetrafluoroethylene (PTFE), is located in the cyclonic chamber so that a suction airstream moving from the main suction opening to the inlet of said suction source by way of the cyclonic airflow chamber passes through the filter medium thereof after said airstream moves in a cyclonic fashion within the cyclonic airflow chamber to remove residual particulates from the suction airstream before it leaves the cyclonic chamber. A HEPA filter can be provided to filter the suction airstream exhausted through the outlet of the suction source prior to the airstream being discharged from the vacuum.

Owner:ROYAL APPLIANCE MFG

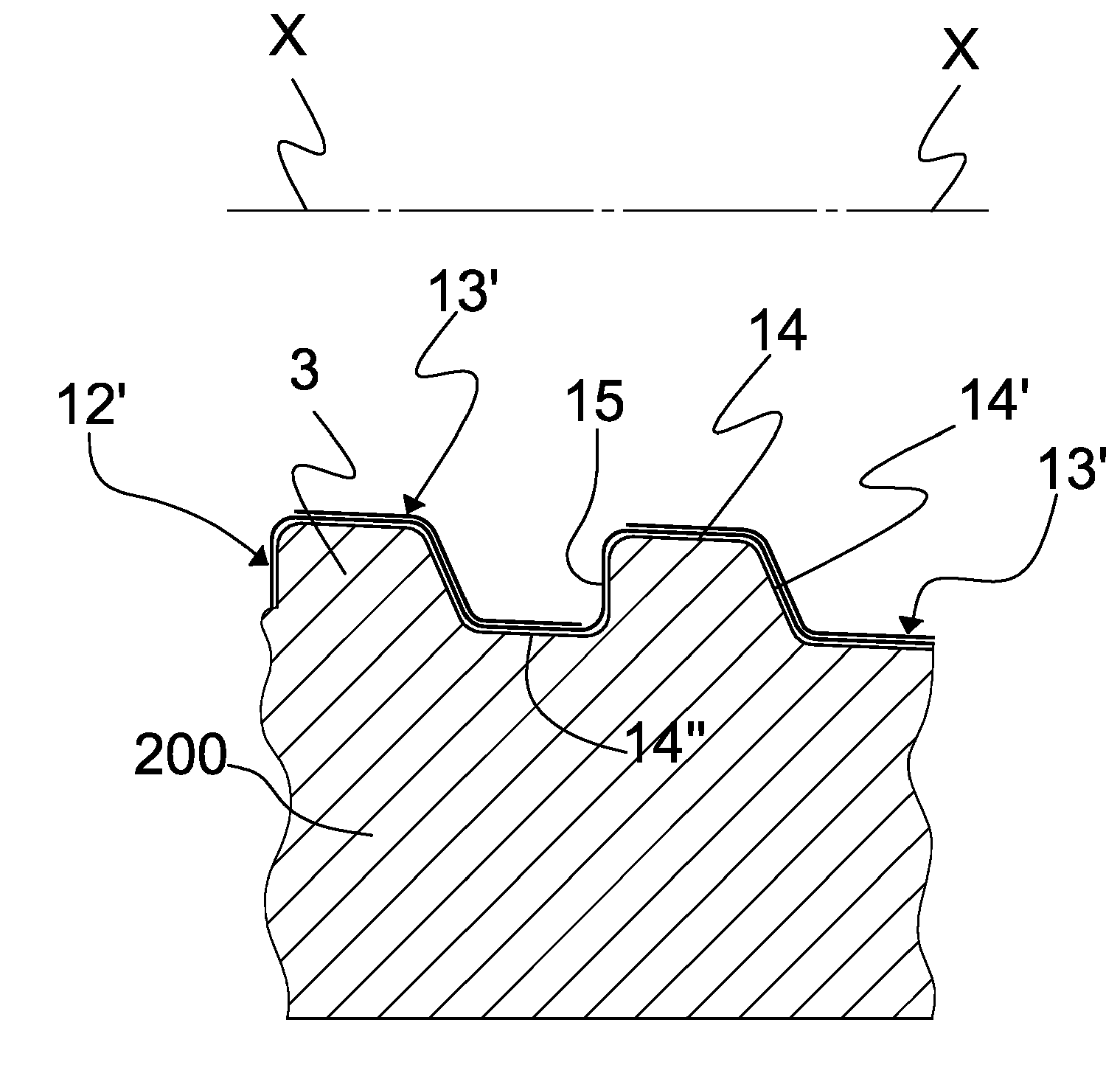

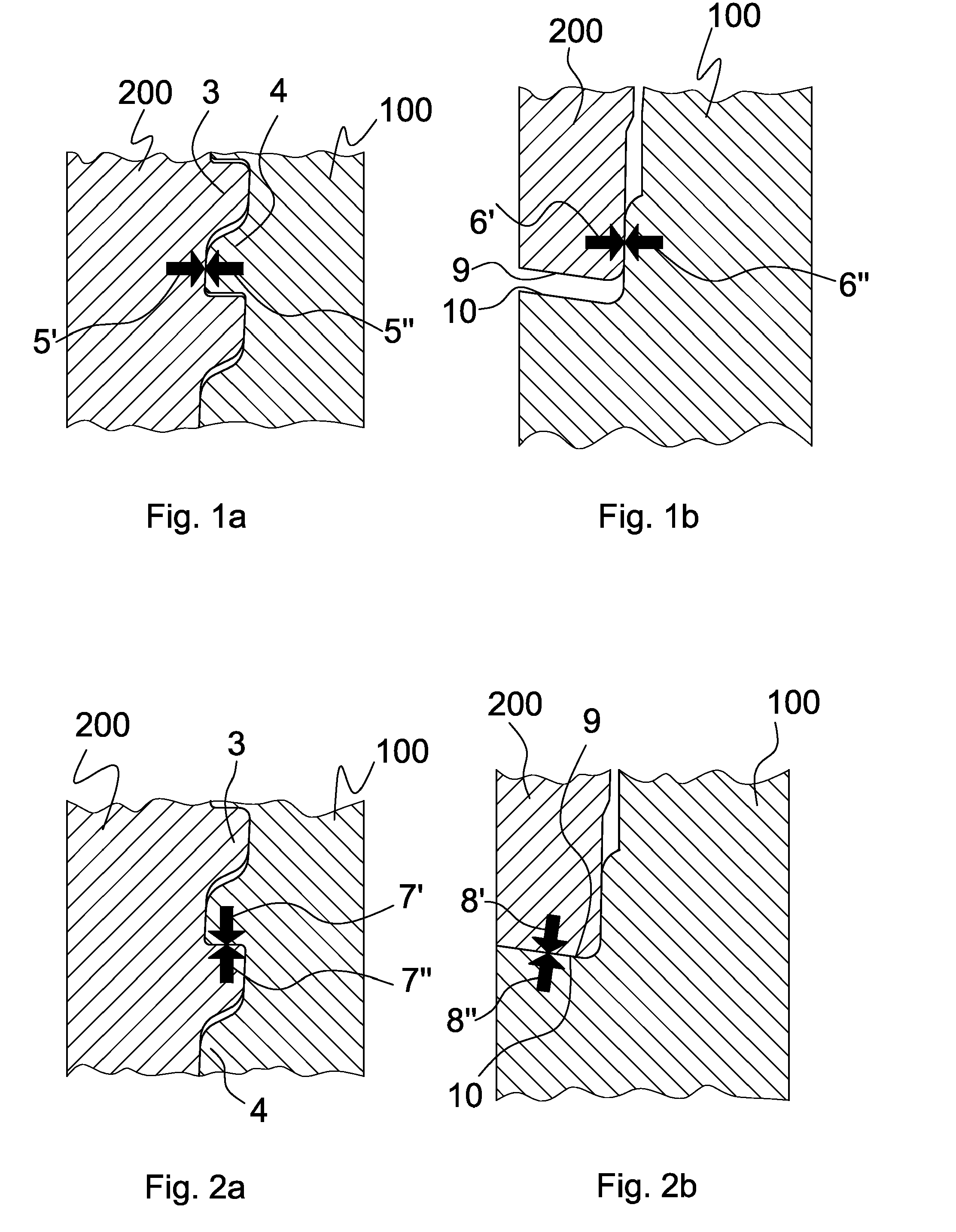

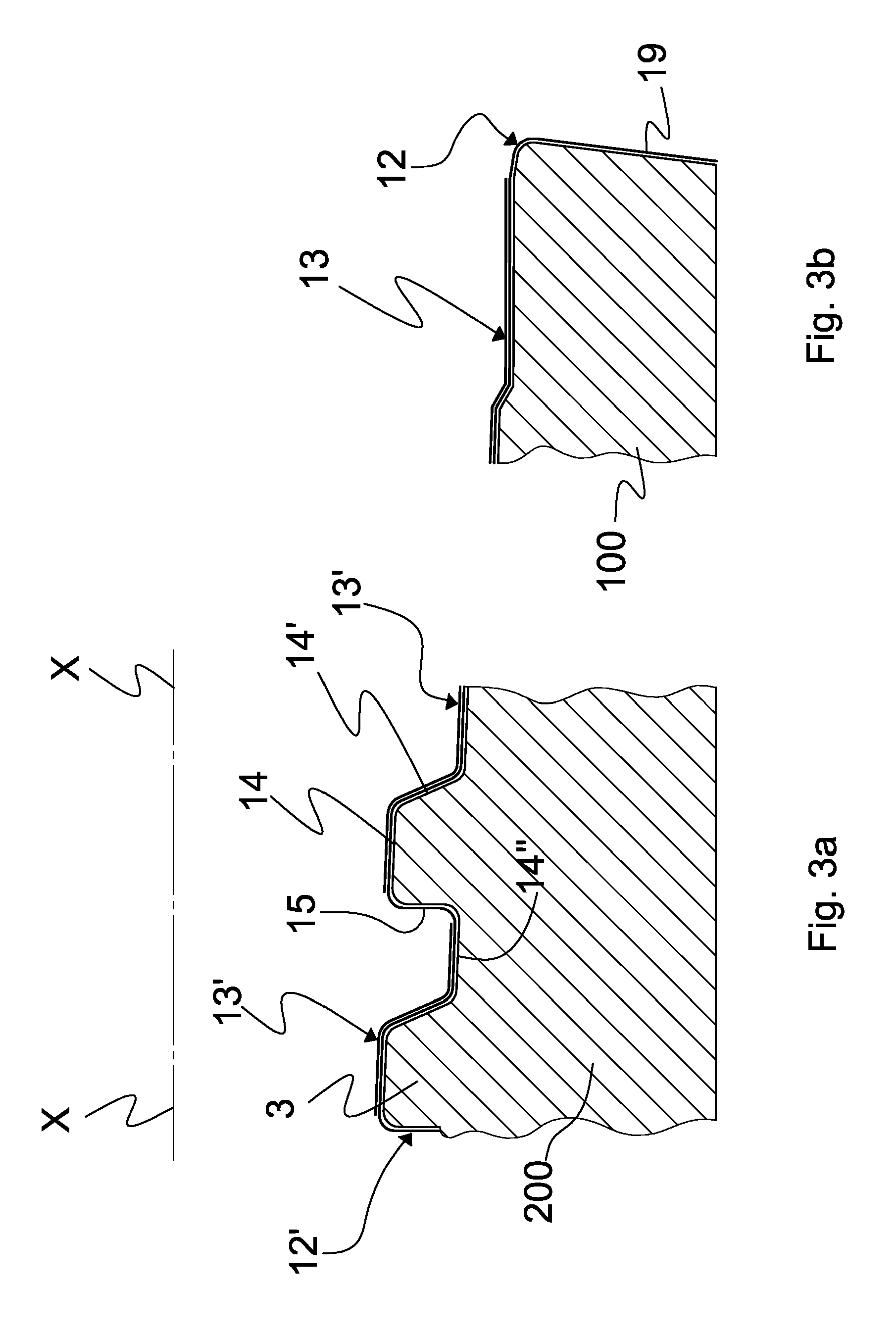

Threaded connections with high and low friction coatings

ActiveUS20090033087A1Increased torsional strengthImprove accuracyDrilling rodsPipe elementsBiomedical engineeringMetal

A threaded metallic joint has the thread surface of pin (100) and box (200) covered with a coating comprising a first layer (24) laid on the overall surface of the pin member (100), and a second layer (25) laid on part of the surfaces of either one of the pin or box members. In a first aspect, the coating comprises a first layer with high friction and anti-seize properties laid on the overall surface of the pin member (100), and a second layer (25) with low friction properties laid on specific parts of the surfaces of either one of the pin or box members. Preferably the specific surfaces are those which are in reciprocal radial contact during make-up until pin and box reach the point where shoulders (9, 10) abut. The second layer may contain polytetrafluoroethylene (PTFE). In a second aspect the first layer with a high friction and anti-seize properties laid on the overall surface of the box member (200).

Owner:TENARIS CONNECTIONS

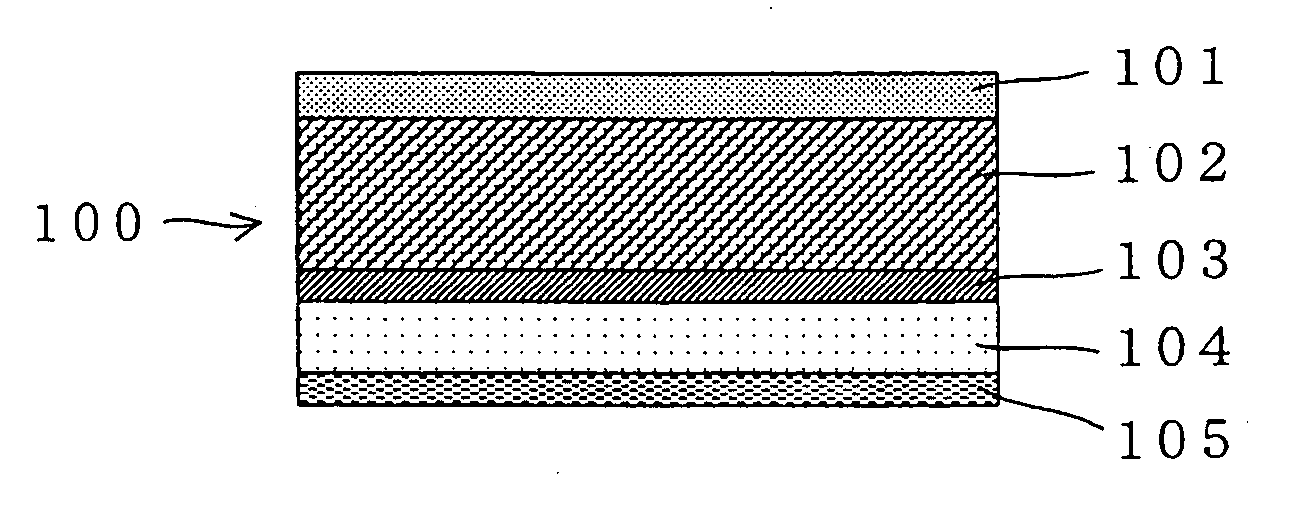

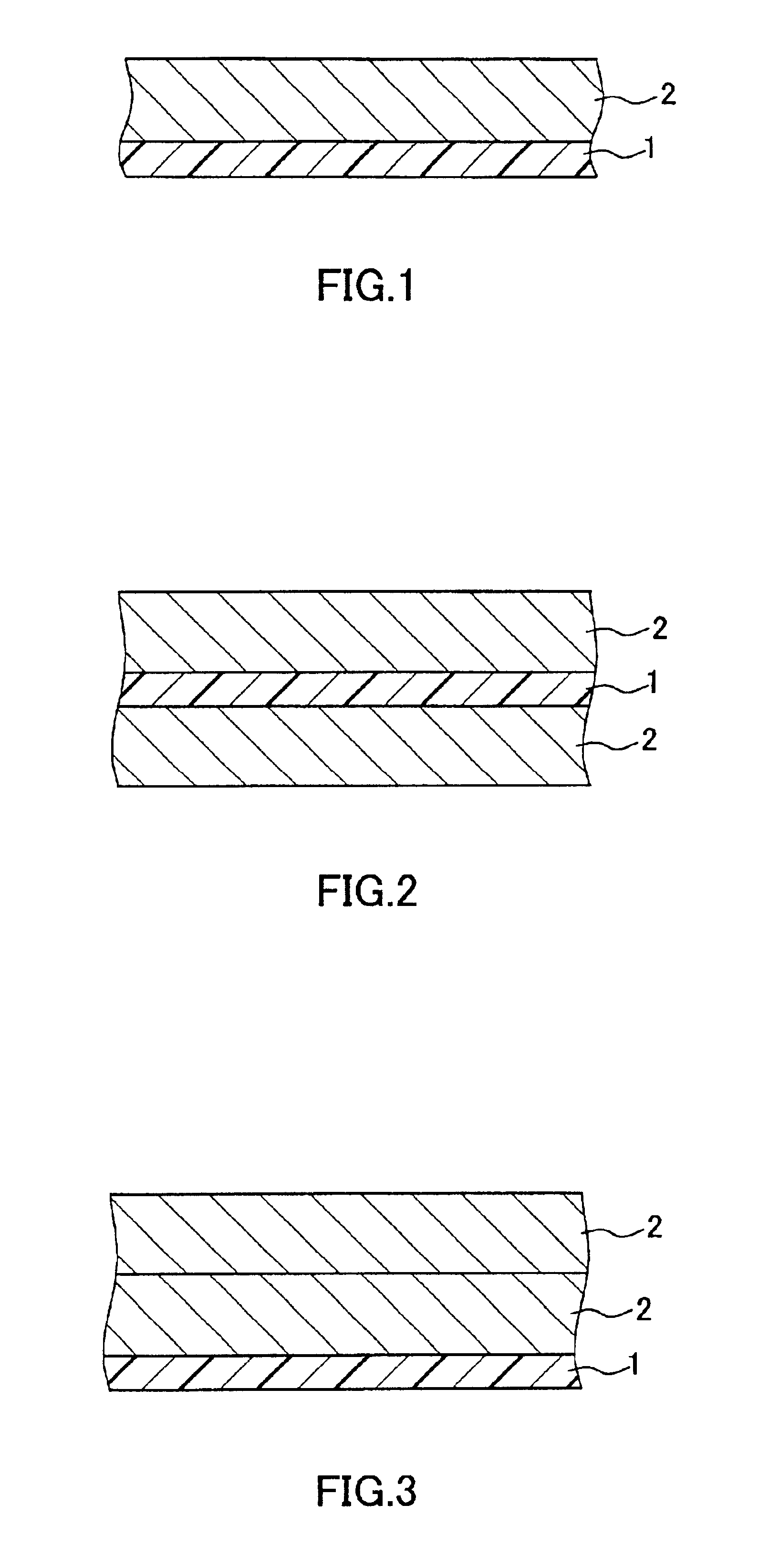

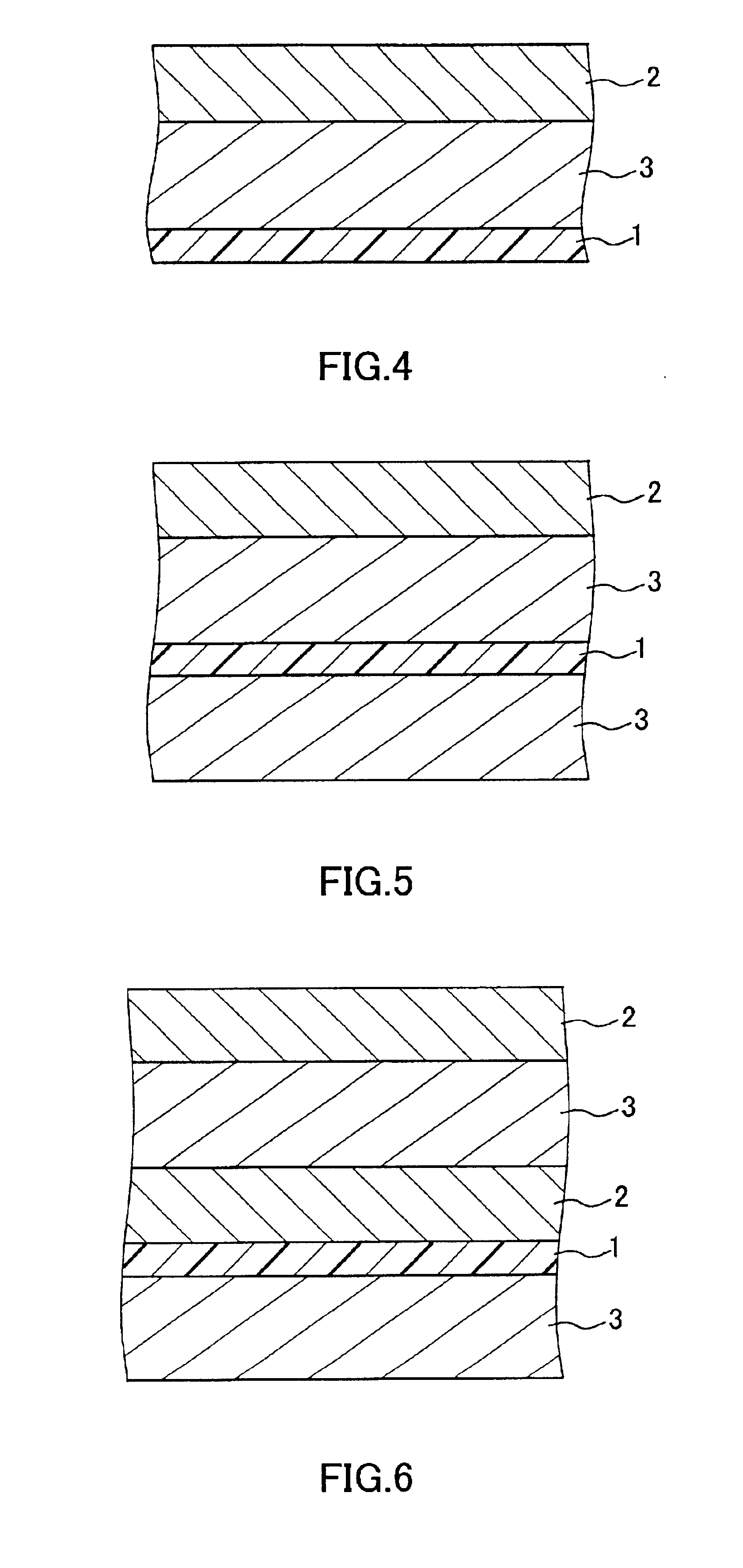

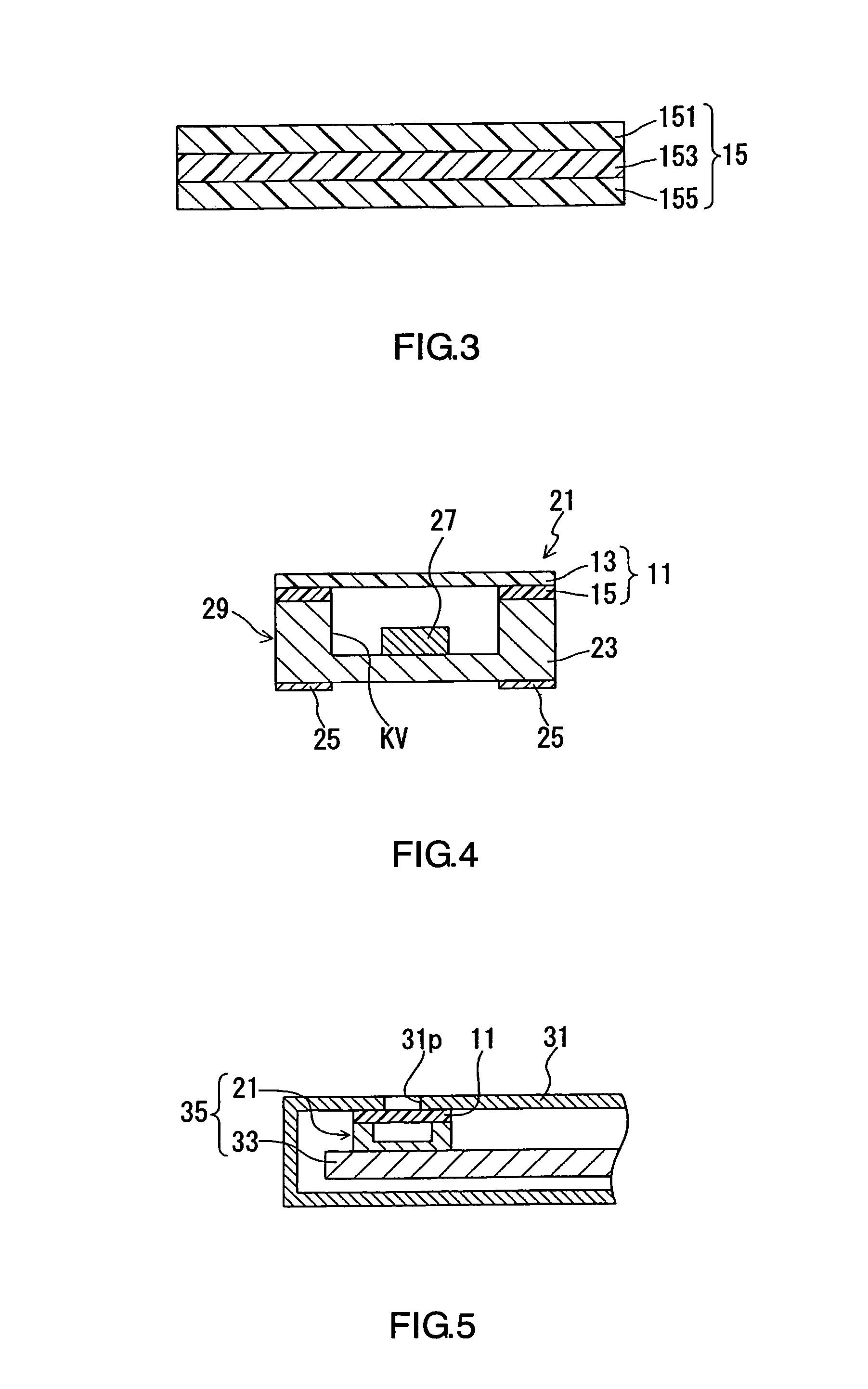

Probe cleaning sheet and cleaning method

InactiveUS20050255796A1Sufficient cushioning propertySoftly and efficiently cleaningSemiconductor/solid-state device testing/measurementElectronic circuit testingForeign matterRoom temperature

A probe cleaning sheet is provided, which can be used not only at a room temperature and high temperature but also in a low temperature environment with sufficient cushioning property and which can softly and efficiently clean a probe tip end. Specifically, the cleaning sheet has a layered structure including an elastic layer below a polishing layer, for removing, by contact with the polishing layer, foreign matter adhered on a tip end of a probe for semiconductor inspection, and the elastic layer is a polytetrafluoro-ethylene porous body layer.

Owner:SUMITOMO ELECTRIC IND LTD

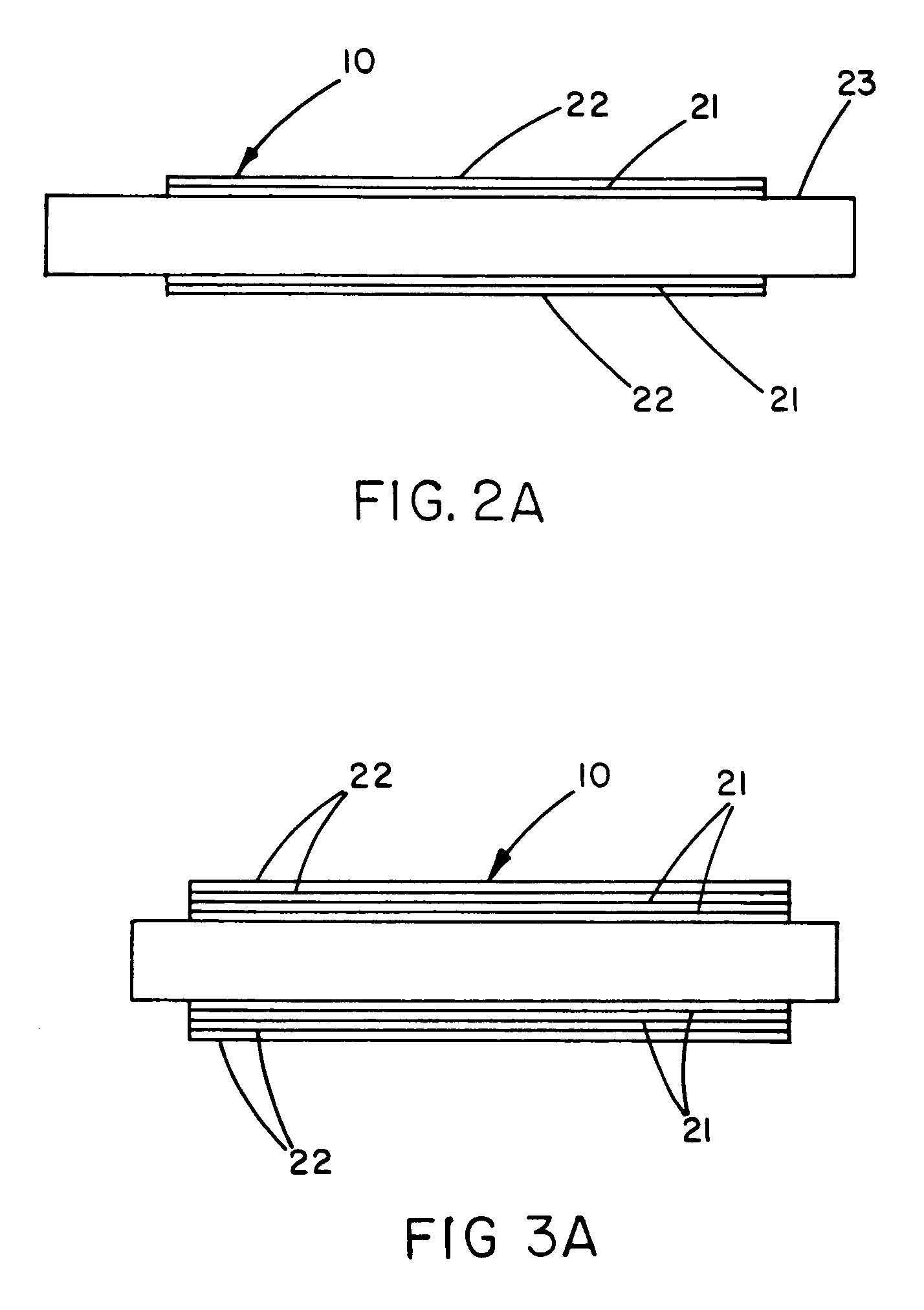

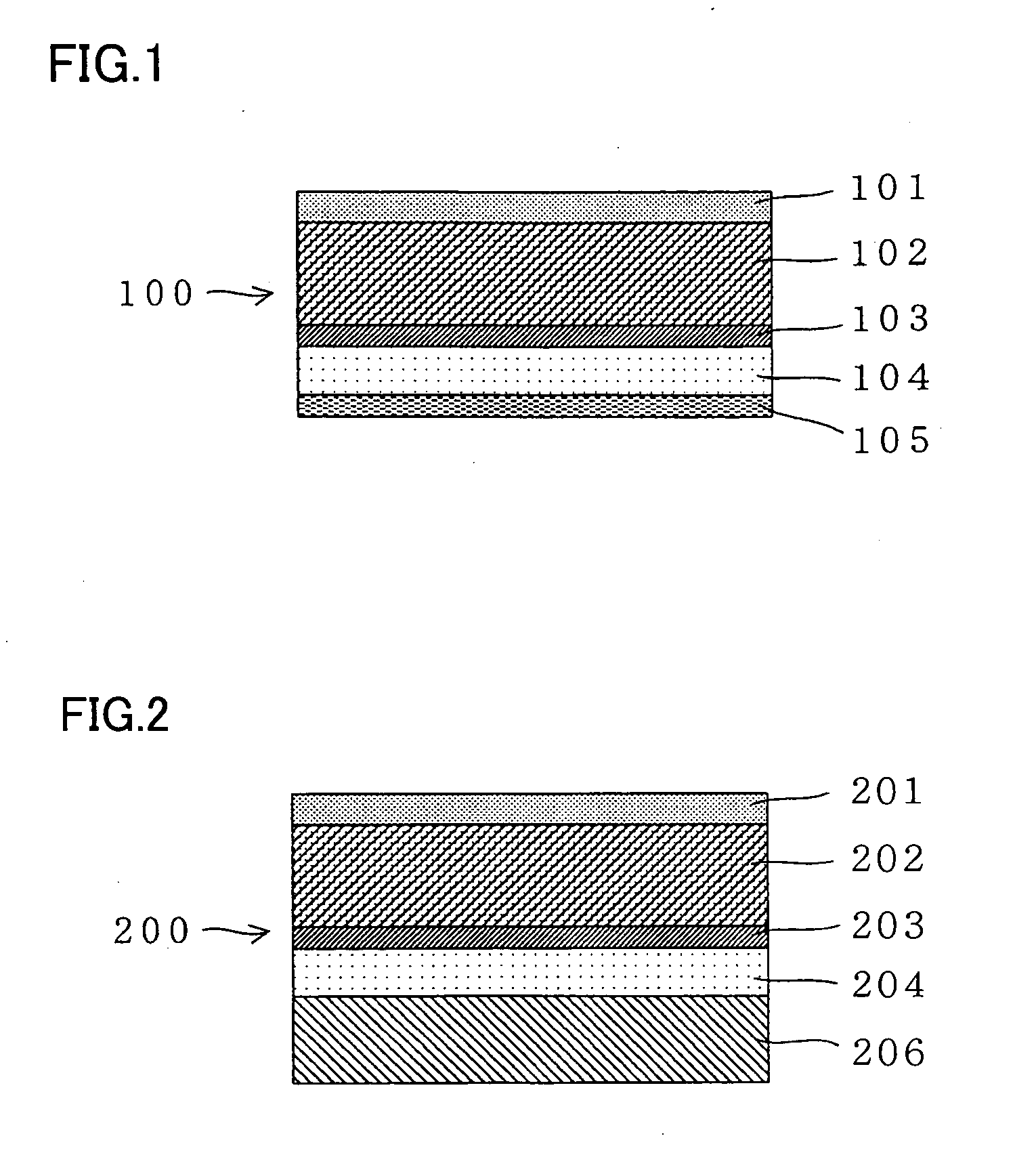

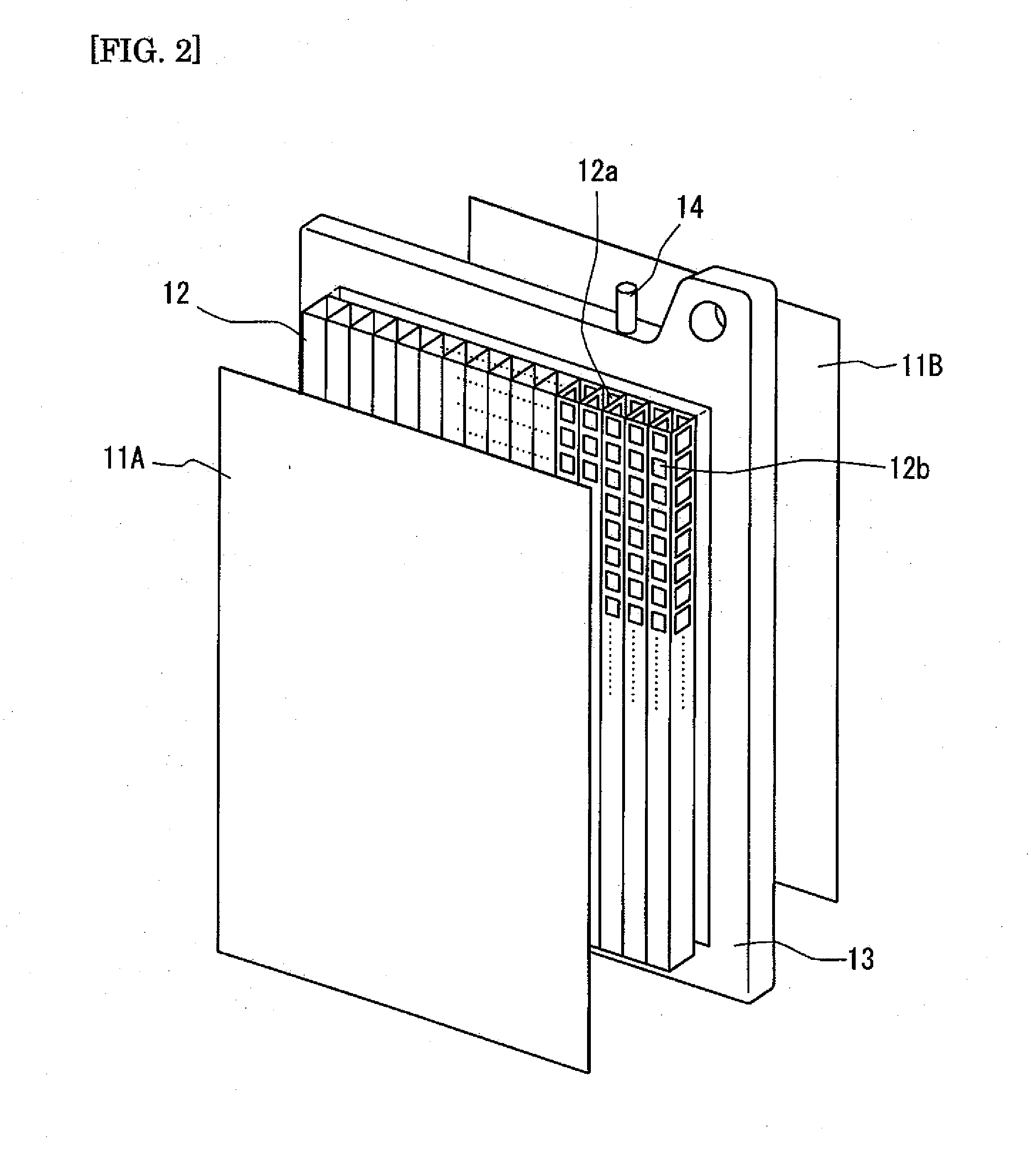

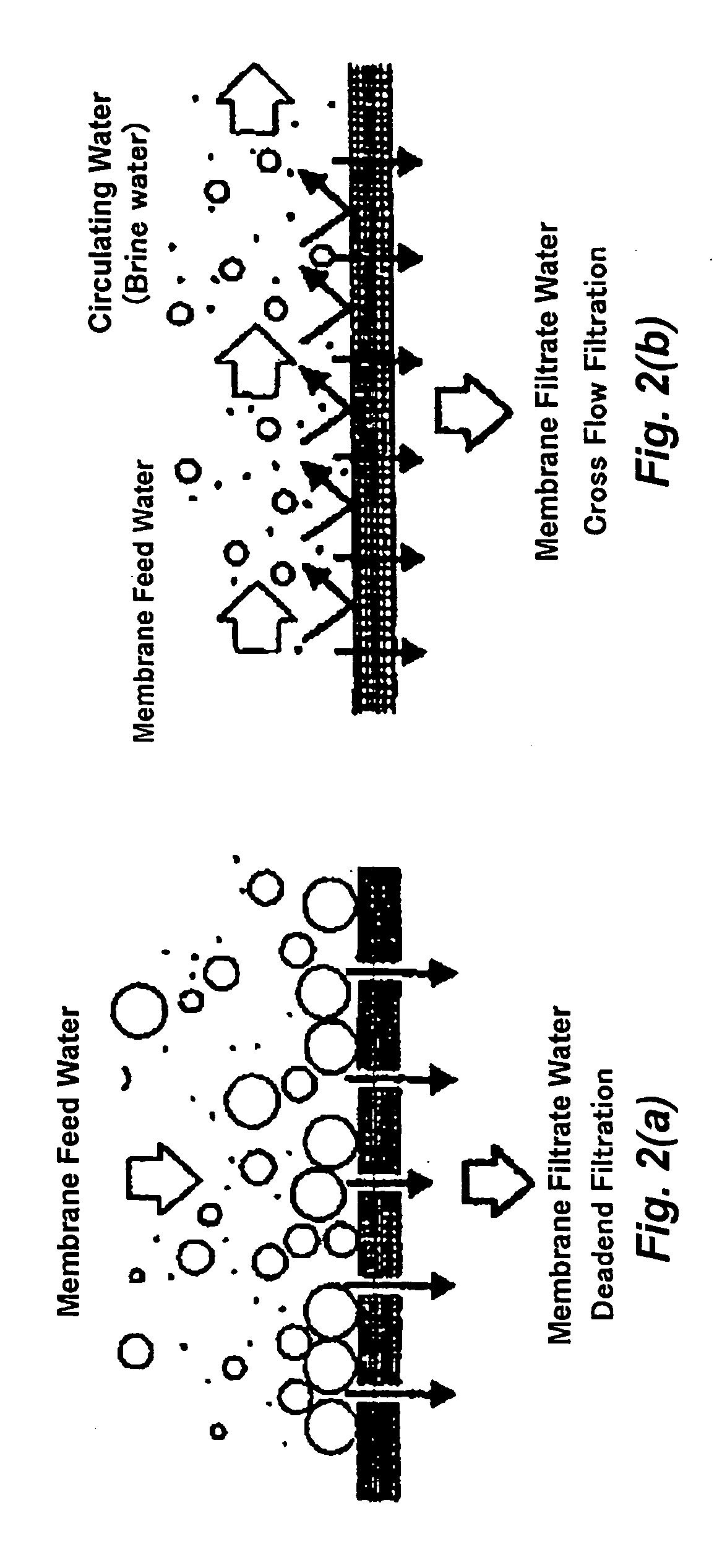

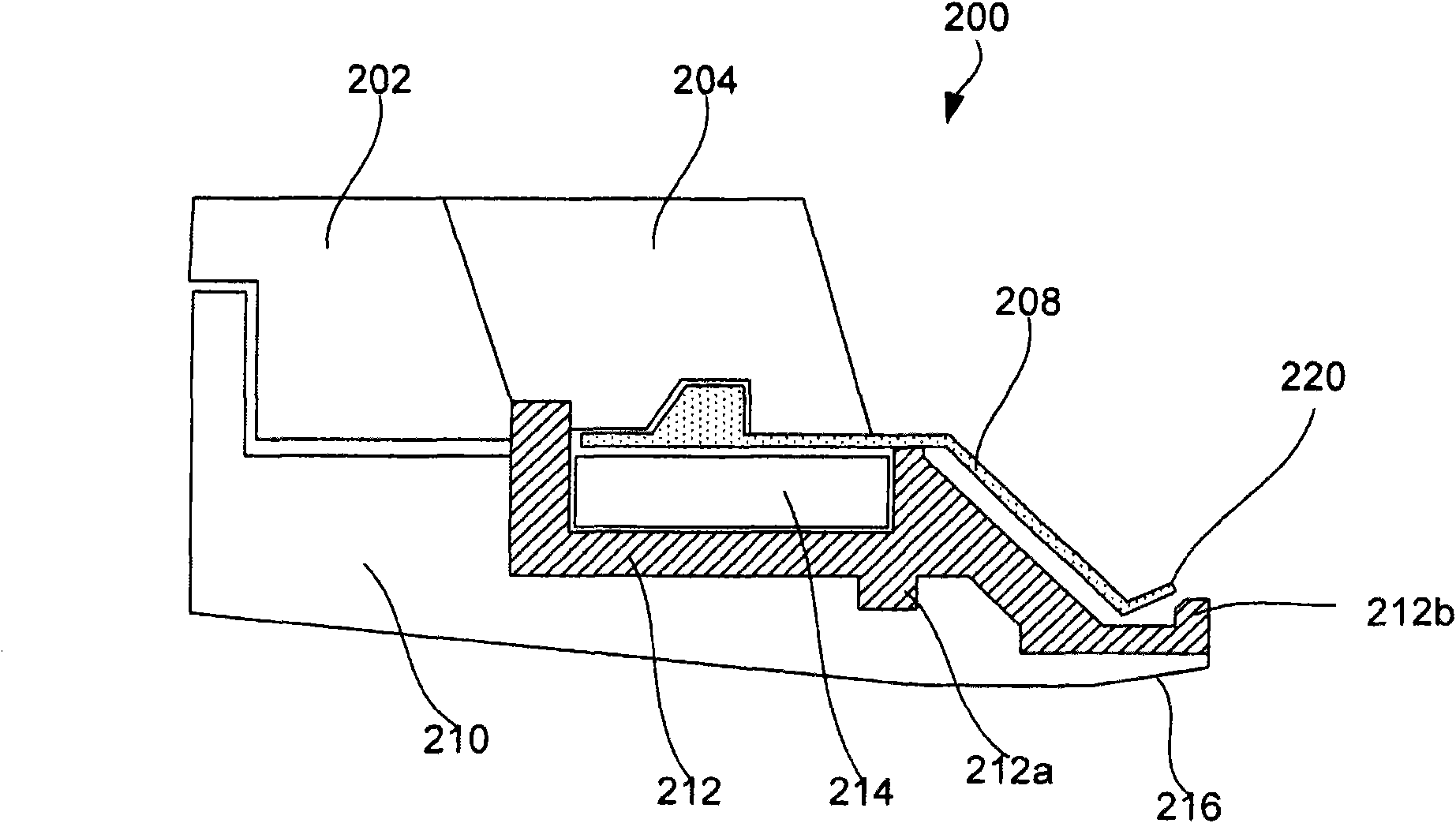

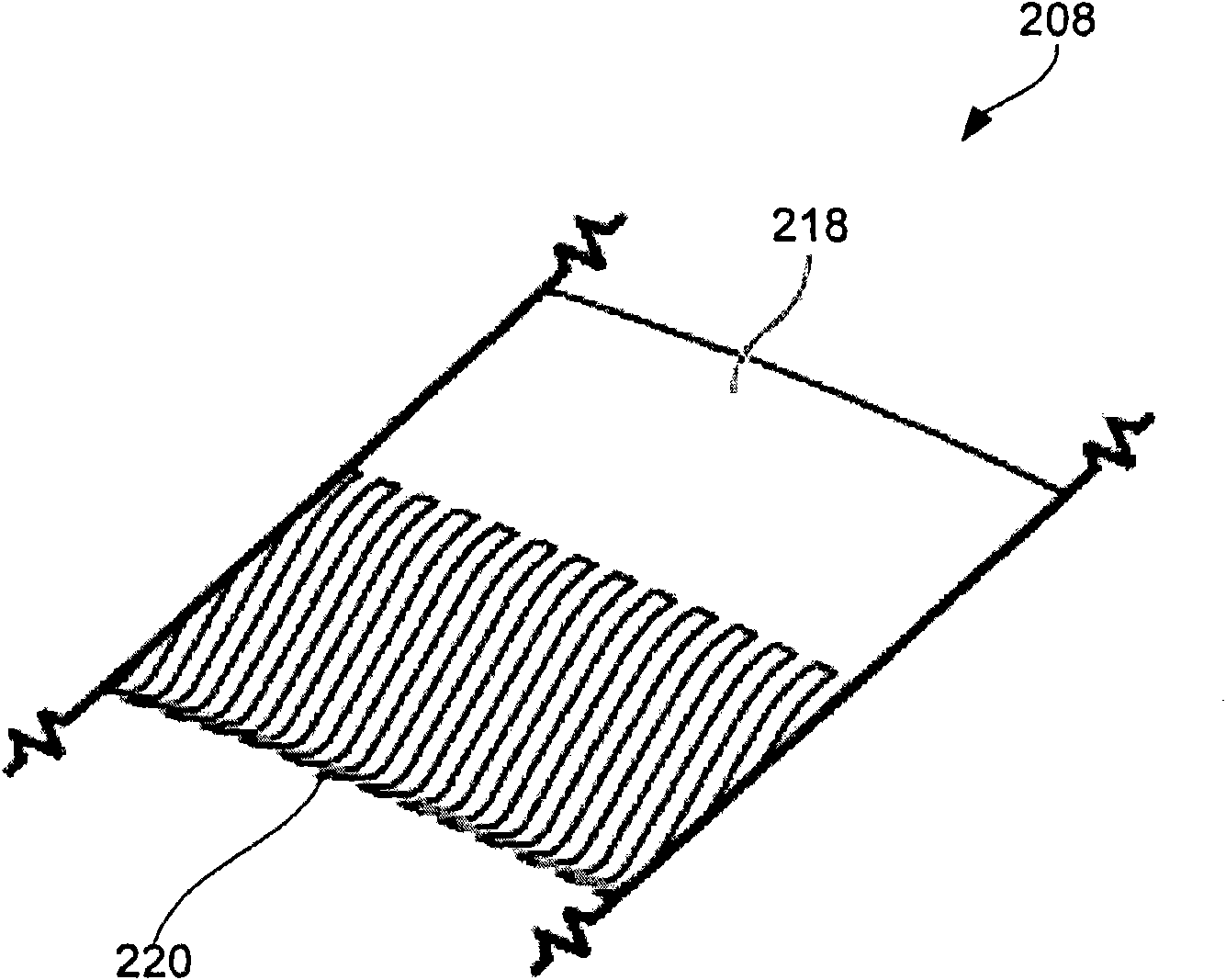

Flat sheet membrane element for filtration and flat sheet membrane filtration module

InactiveUS20100096317A1Improve performanceStable permeation flow rateMembranesUltrafiltrationFiltration membranePorous membrane

A flat sheet membrane element for performing solid-liquid separation by immersion in a liquid to be treated which contains a suspended component includes sheet-shaped filtration membranes disposed opposite to each other with a space for a treated liquid flow path, a support portion for securing the space for the treated liquid flow path, and a peripheral sealing portion for sealing the peripheral edges of the filtration membranes arranged opposite to each other so as to form at least one treated liquid outlet, the filtration membranes including at least expanded PTFE (polytetrafluoroethylene) porous membranes.

Owner:SUMITOMO ELECTRIC IND LTD

Upright vacuum cleaner with cyclonic airflow

InactiveUS20050055796A1Easily and conveniently emptiedEffectively filters residual contaminantsCleaning filter meansCombination devicesHEPACyclone

A vacuum cleaner includes a first housing defining a cyclonic airflow chamber and a second housing defining a main suction opening that is in communication with an inlet of the cyclonic chamber. A suction source has a suction airstream inlet in communication with an outlet of the cyclonic chamber, and establishes a suction airstream that enters said main suction opening, passes through said cyclonic chamber, and passes to an outlet of said suction source. A substantial portion of particulates entrained in the suction airstream are separated therefrom when said suction airstream moves in a cyclonic fashion through the cyclonic chamber. A main filter assembly, preferably including filter medium comprising polytetrafluoroethylene (PTFE), is located in the cyclonic chamber so that a suction airstream moving from the main suction opening to the inlet of said suction source by way of the cyclonic airflow chamber passes through the filter medium thereof after said airstream moves in a cyclonic fashion within the cyclonic airflow chamber to remove residual particulates from the suction airstream before it leaves the cyclonic chamber. A HEPA filter can be provided to filter the suction airstream exhausted through the outlet of the suction source prior to the airstream being discharged from the vacuum.

Owner:ROYAL APPLIANCE MFG

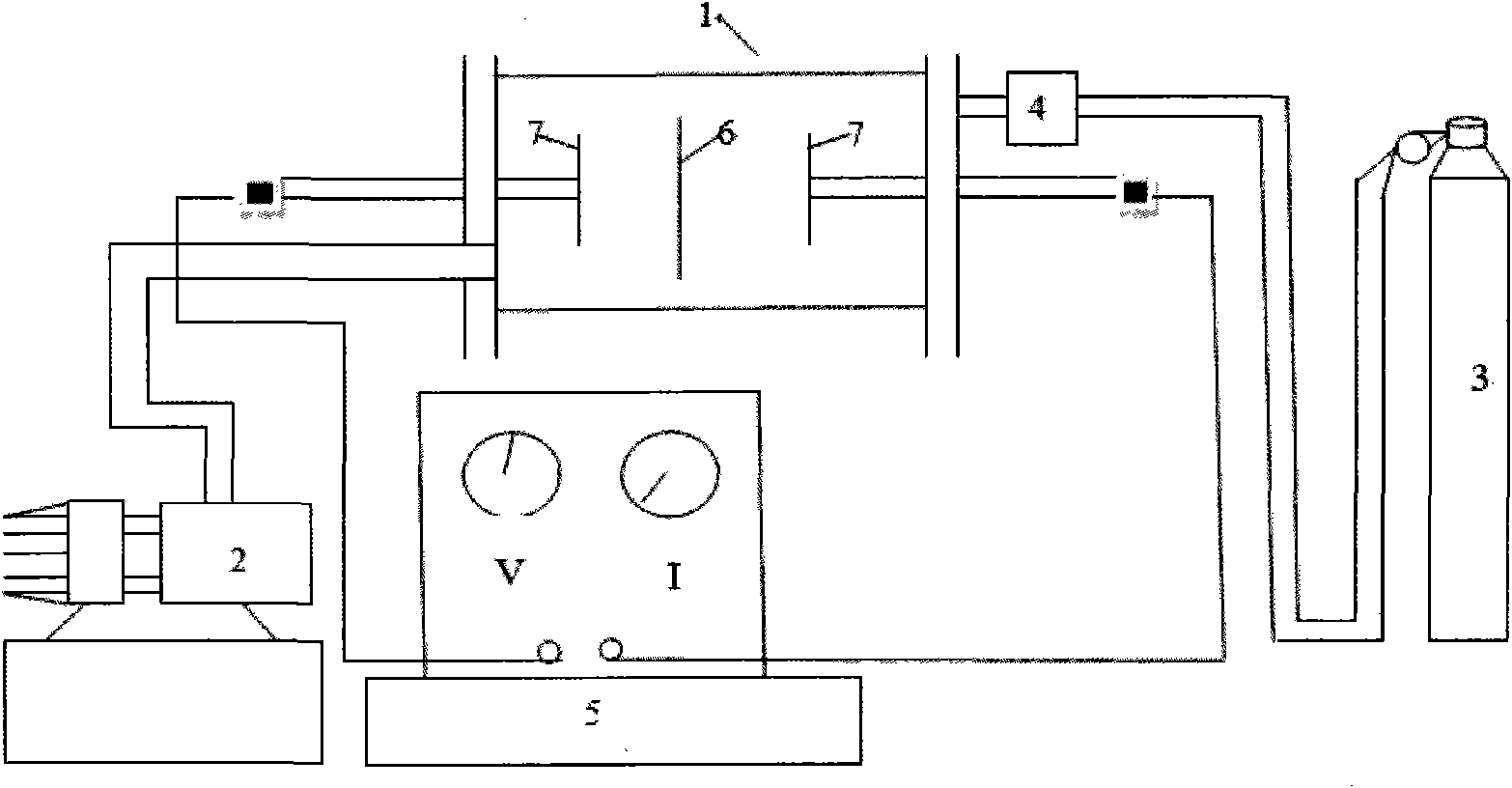

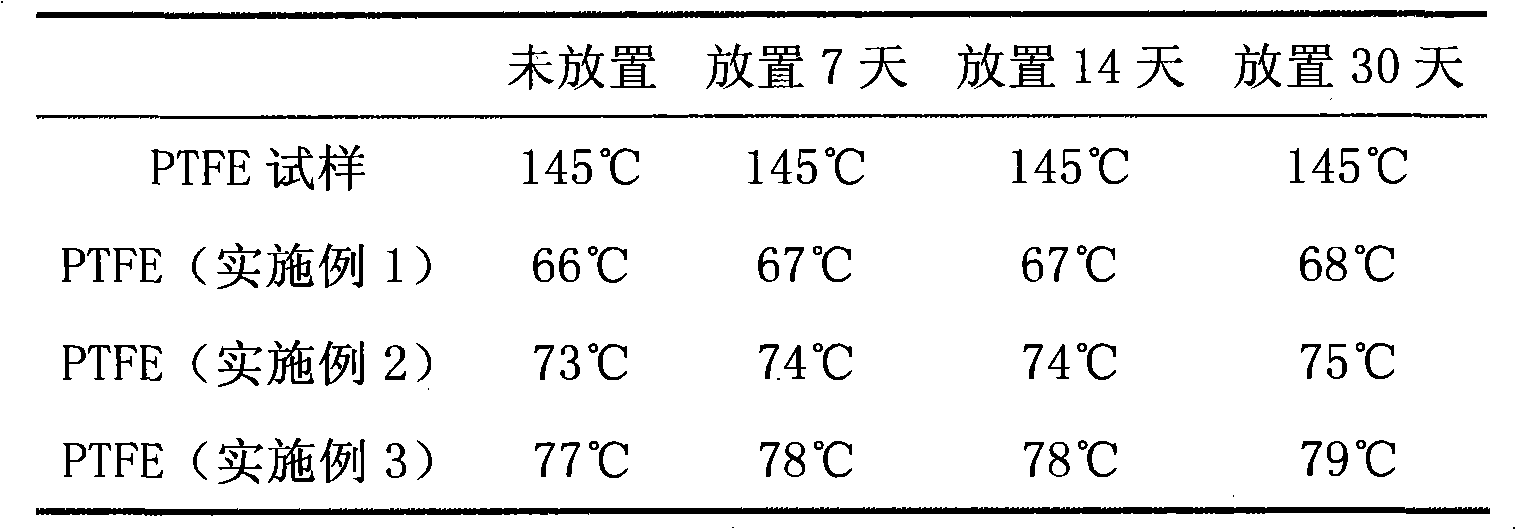

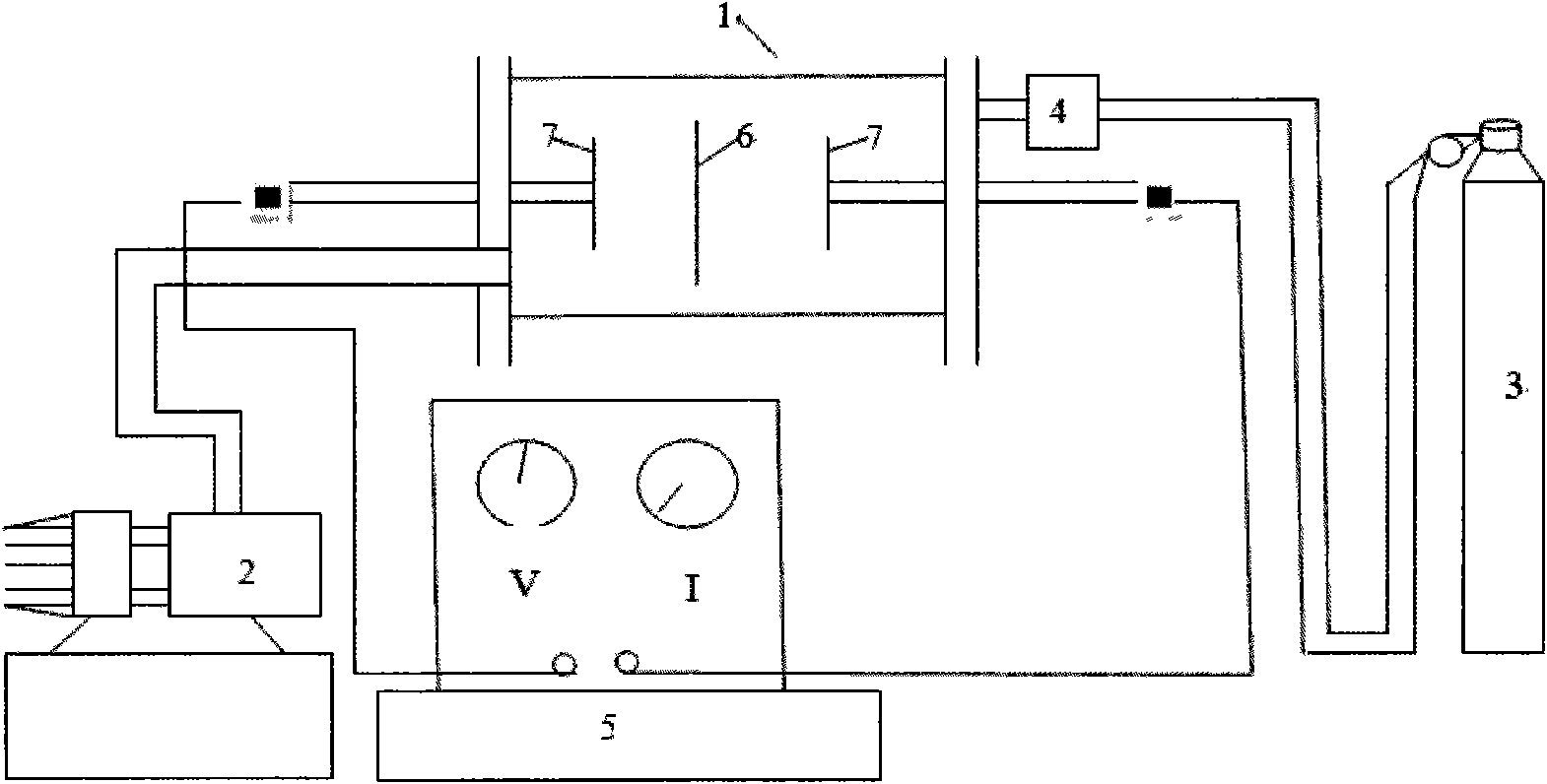

Surface hydrophilic modification method for polytetrafluoroethylene bulked membrane

InactiveCN101890314ASimple processEfficient treatment processSemi-permeable membranesWater layerLow pressure plasma

The invention relates to a surface hydrophilic modification method for a polytetrafluoroethylene bulked membrane, which is characterized by comprising the steps of: pretreating a polytetrafluoroethylene membrane by adopting low-pressure glow discharge plasma to make the surface of the polytetrafluoroethylene membrane generate active groups, and grafting acrylic acid to form a relatively stable hydrophilic layer. The method has the advantages that: the active groups are generated on the surface of the polytetrafluoroethylene membrane by low-pressure plasma treatment, and the relatively stable hydrophilic layer can be formed on the surface of the membrane by acrylic acid grafting treatment, so that the hydrophilicity of the polytetrafluoroethylene membrane is effectively improved, and the effect is lasting; and the polytetrafluoroethylene membrane is treated by the low-pressure plasma induction and acrylic acid grafting, so the treatment method is simple, high-efficiency, water and energy-saving, and suitable for industrialized production.

Owner:DONGHUA UNIV

Filter medium for turbine and methods of using and producing the same

Owner:NITTO DENKO CORP

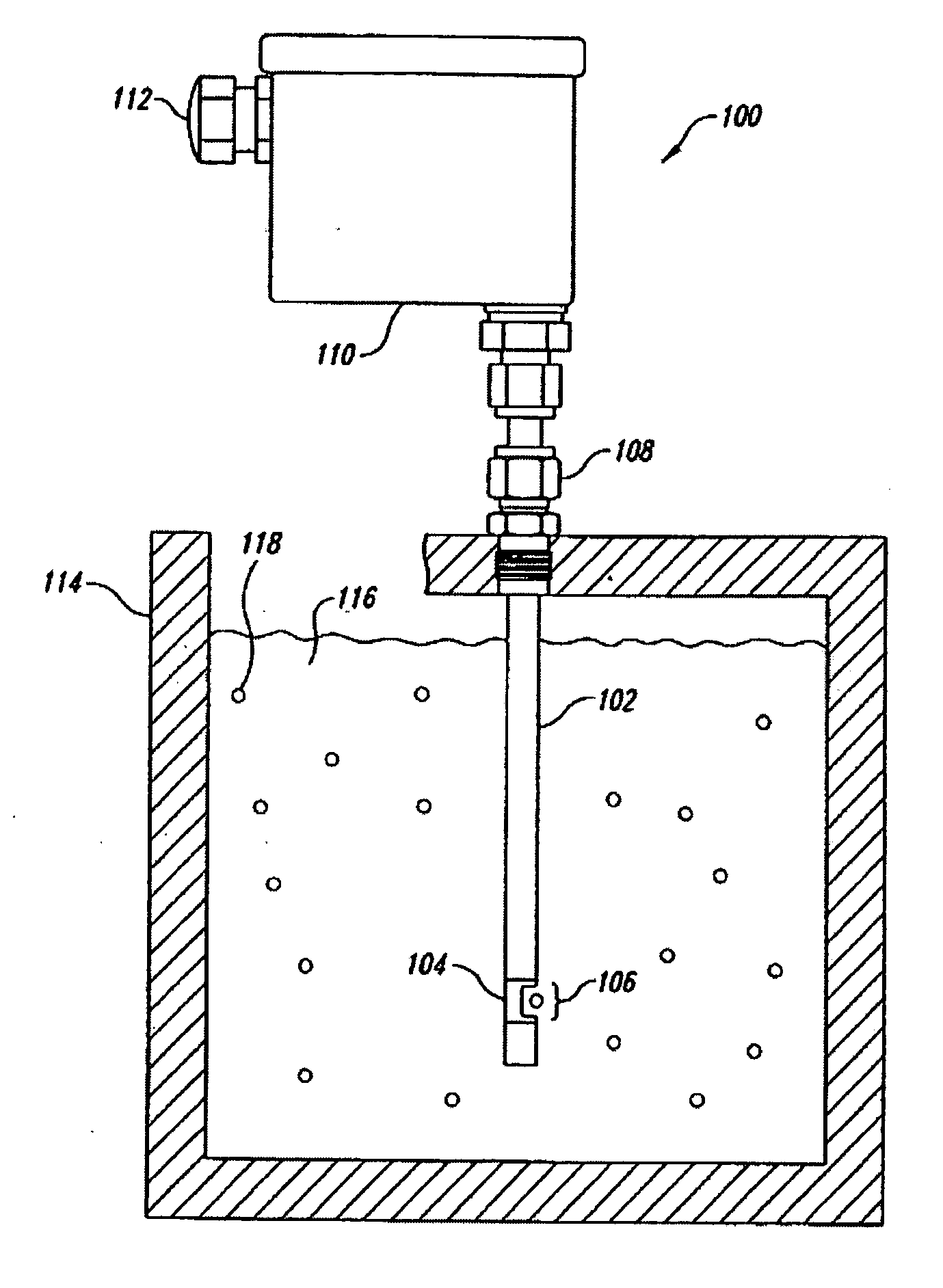

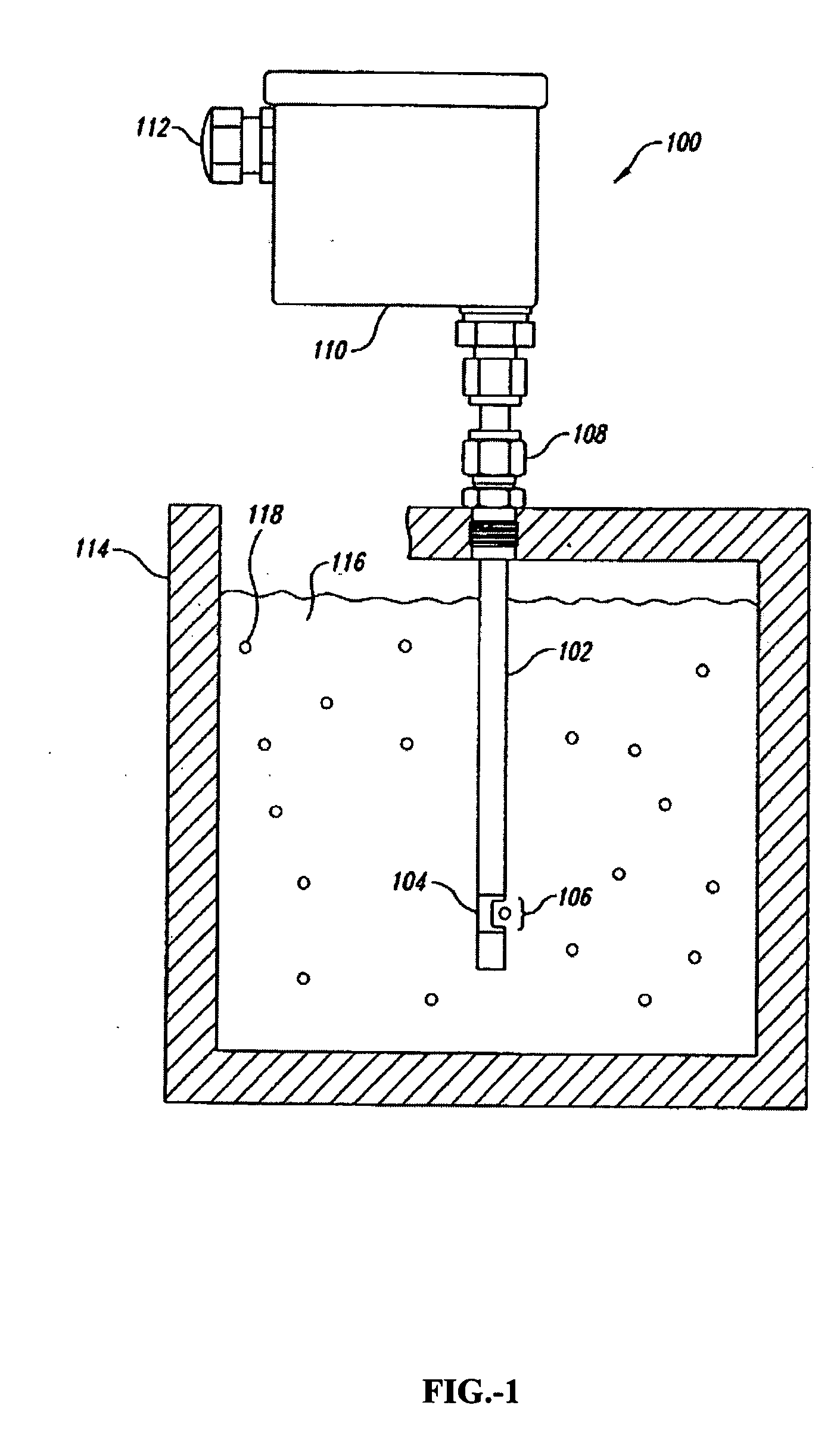

Systems and methods for in situ spectroscopic measurements

ActiveUS20050264817A1Investigating moving fluids/granular solidsScattering properties measurementsVertical-cavity surface-emitting laserBiotechnology

A circularizated semiconductor laser diode (CSLD), such as for example a vertical cavity surface emitting laser (VCSEL) may be used for optical measurements. The CSLD may be used in a cell density probe to perform cell density determination and / or turbidity determination, such as in a biotech, fermentation, or other optical absorbance application. The cell density probe may comprise a probe tip section made from a polytetrafluoroethylene material, which provides sealability, ease of manufacture, durability, cleanability, optical semi-transparency at visible and near infrared wavelengths, and other advantages. The probe tip advantageously provides an optical gap that allows for in situ measurements of optical measurements including but not limited to absorbance, scattering, and fluorescence.

Owner:FINESSE SOLUTIONS +1

High temperature resistant P.T.F.E. coated filter material

ActiveCN1768912AAvoid cloggingExcellent "surface filter" characteristicsSemi-permeable membranesSynthetic resin layered productsTetrafluoroethyleneGlass fiber

The invention relates to a high temperature-resistant polytetrafluoroethylene tectorial filter material, belonging to the improvement on present polytetrafluoroethylene composite filter material, which comprises a glass fiber base cloth and a polytetrafluoroethylene surface film. It is characterized in that: first using after-treatment agent to process the dipping process on the glass fiber base cloth, then processing the high-temperature heat compression on the polytetrafluoroethylene surface film. The invention uses film forming emulsifier, fluorine silane coupling agent and fluoroplymer emulsion to form a film on the glass fiber base cloth, which can improve the effects of anti-soil, oil-proof and preservation, and it can have fusion combination with expanded micro-pore polytetrafluoroethylene film in the condition of high-temperature heat compression, to effectively solve the problem of hard fusion combination between inorganic material of glass fiber and organic inertia material of polytetrafluoroethylene to significantly improve the fastness between them.

Owner:中材科技膜材料(山东)有限公司

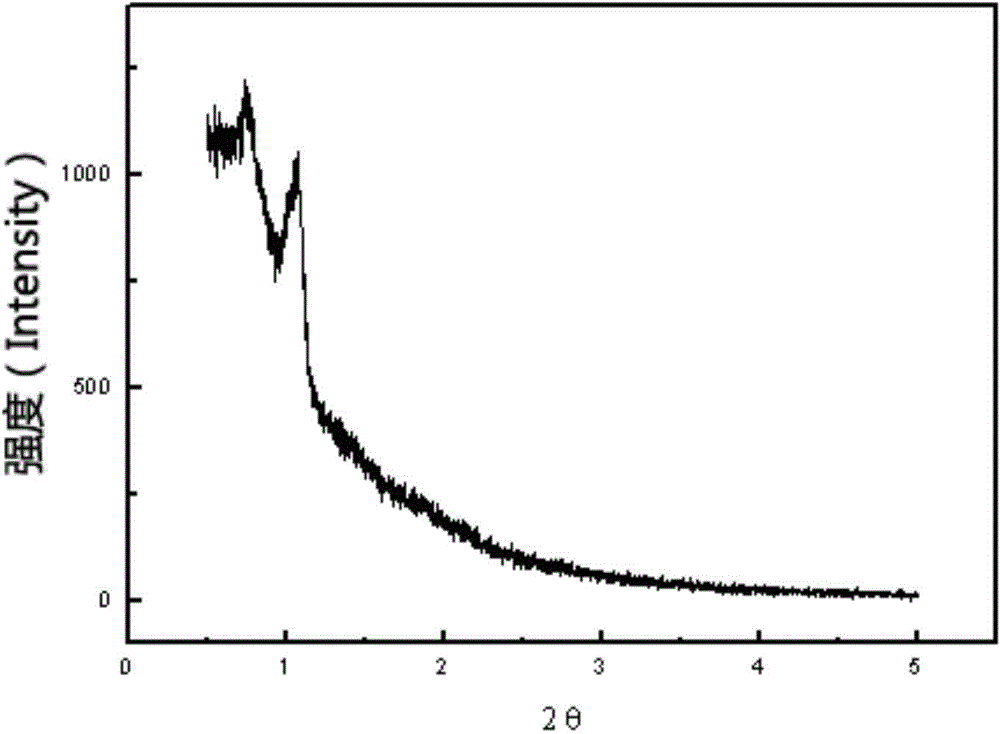

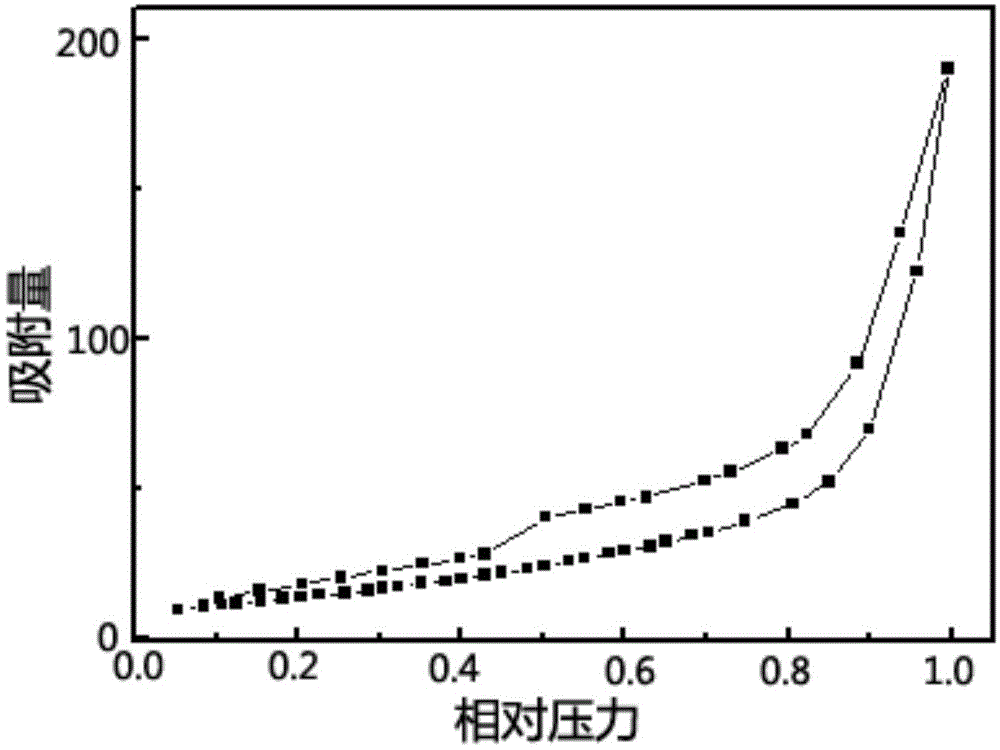

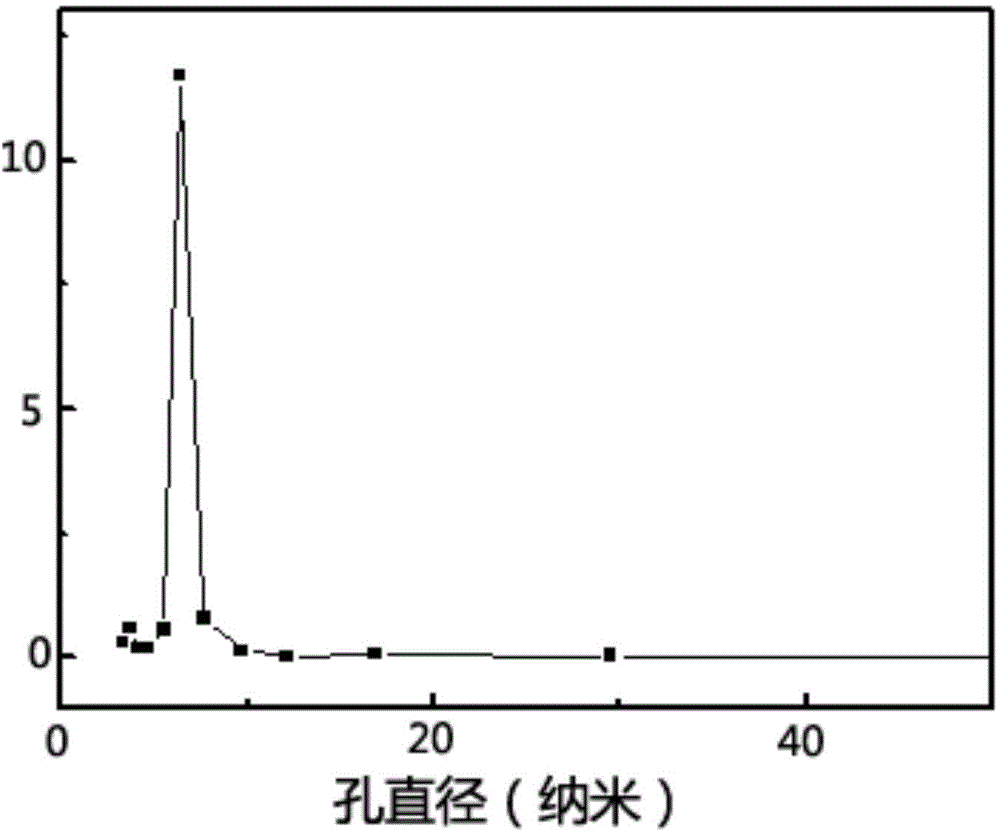

Method for preparing high-stability mesoporous molecular sieve

ActiveCN104891526APolycrystallineActs as a templating agentFaujasite aluminosilicate zeoliteMolecular sieveMicroreactor

The invention provides a method for preparing a high-hydrothermal-stability mesoporous molecular sieve. The method includes the following steps: (1) preparation of a first Y-type molecular sieve precursor; and (2) crystallization: adding a seed crystal to the first Y-type molecular sieve precursor, adjusting the pH value to 0.5-5, stirring for 10 h-24 h at the temperature of 20 DEG C-50 DEG C, then aging for 2 h-24 h at the temperature of 20 DEG C-50 DEG C, to obtain an assembled product, transferring the assembled product into a microreactor with a polytetrafluoroethylene lining, then transferring together with the reactor into a high-pressure reaction kettle, crystallizing for 10 h-48 h at the temperature of 100 DEG C-200 DEG C, filtering, washing, drying, and thus obtaining the high-stability mesoporous molecular sieve. Firstly, the microporous molecular sieve precursor is prepared, a mesoporous-microporous molecular sieve as the seed crystal is used for preparation of the mesoporous molecular sieve, the molecular sieve precursor assembly method and the seed crystal method are combined, and the high-stability mesoporous molecular sieve is obtained under the condition without use of an organic template agent. Not only is the preparation cost of the molecular sieve reduced greatly, but also the process of calcination of the template agent is omitted so as to reduce the energy consumption.

Owner:PETROCHINA CO LTD +1

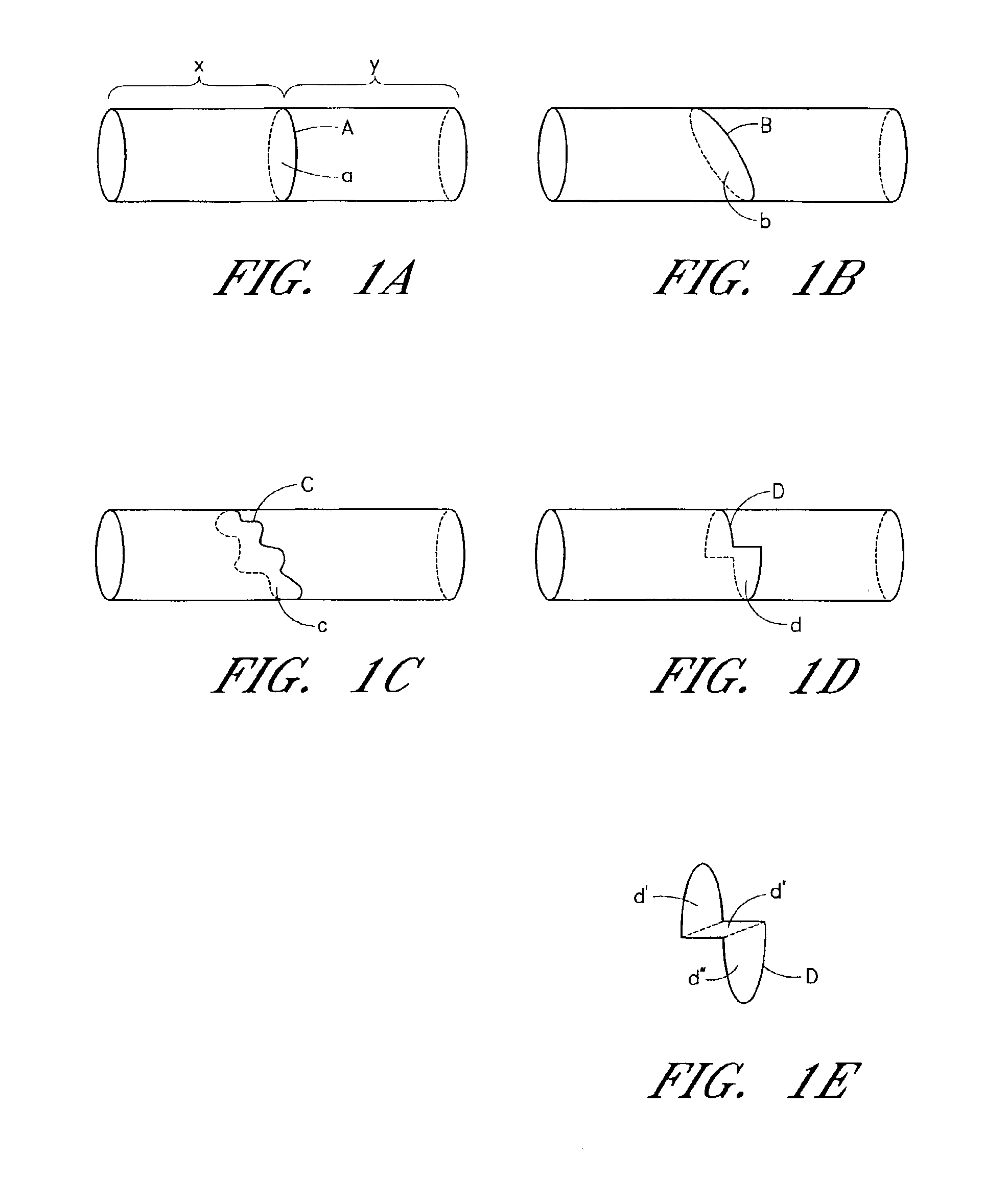

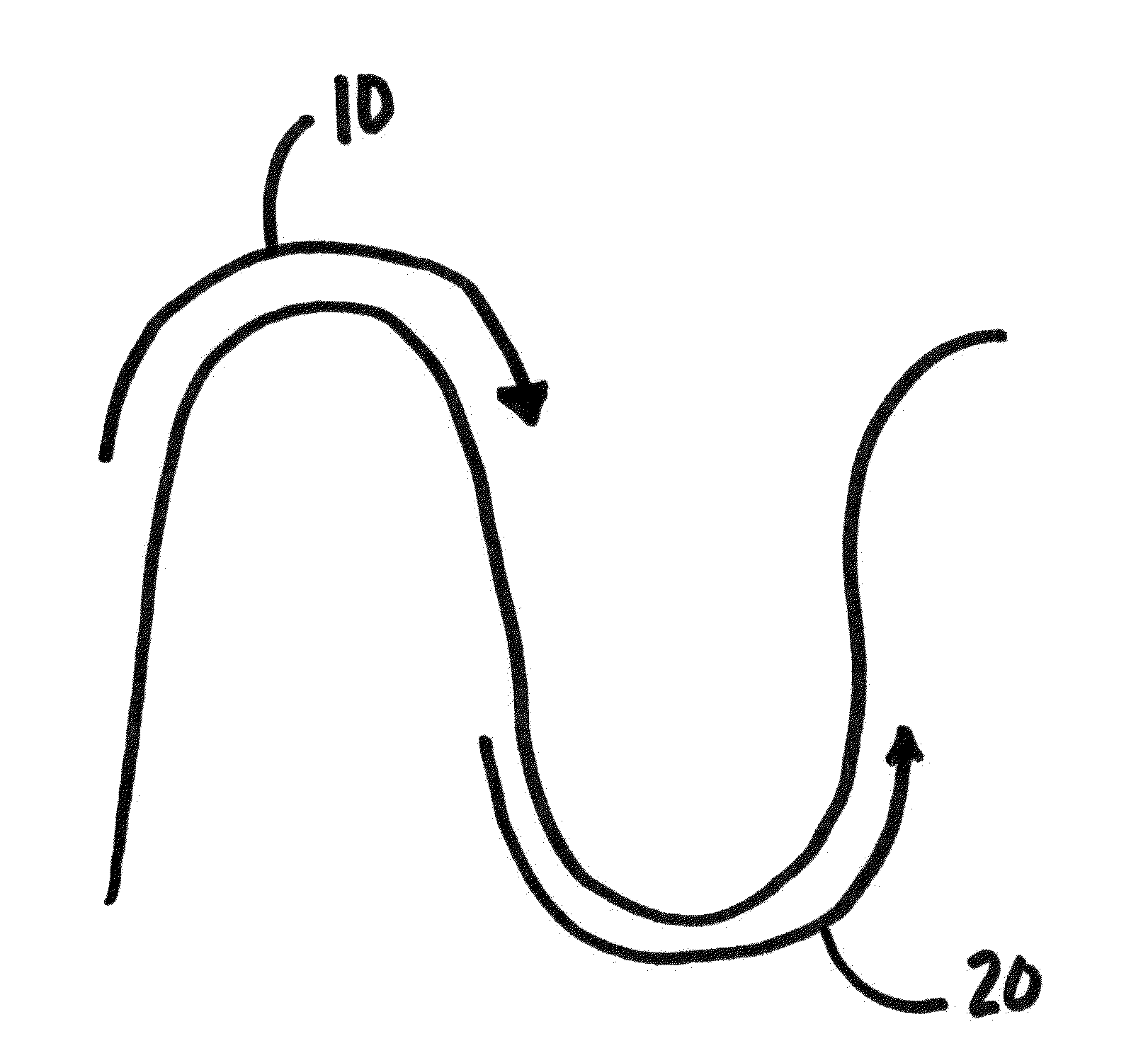

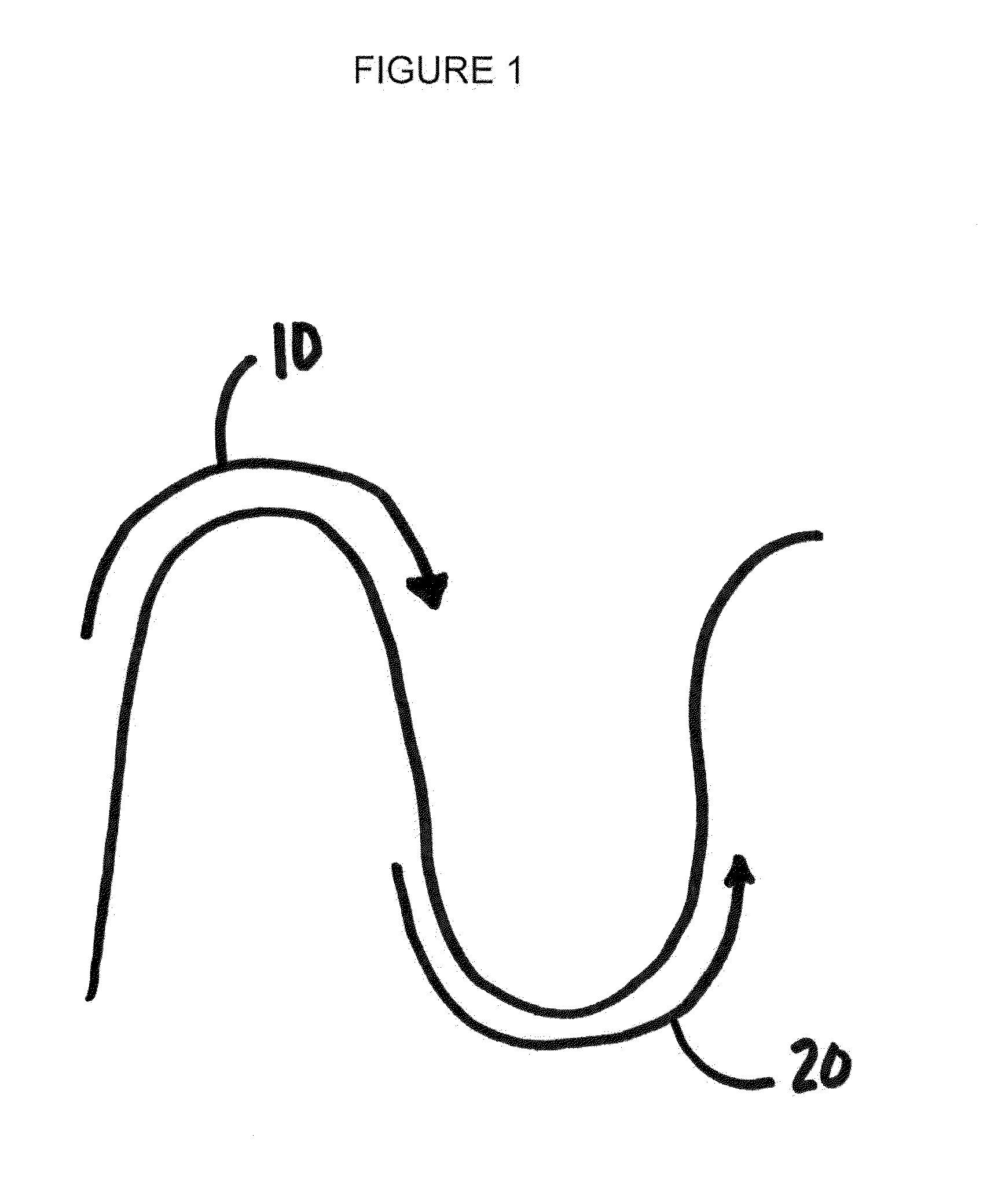

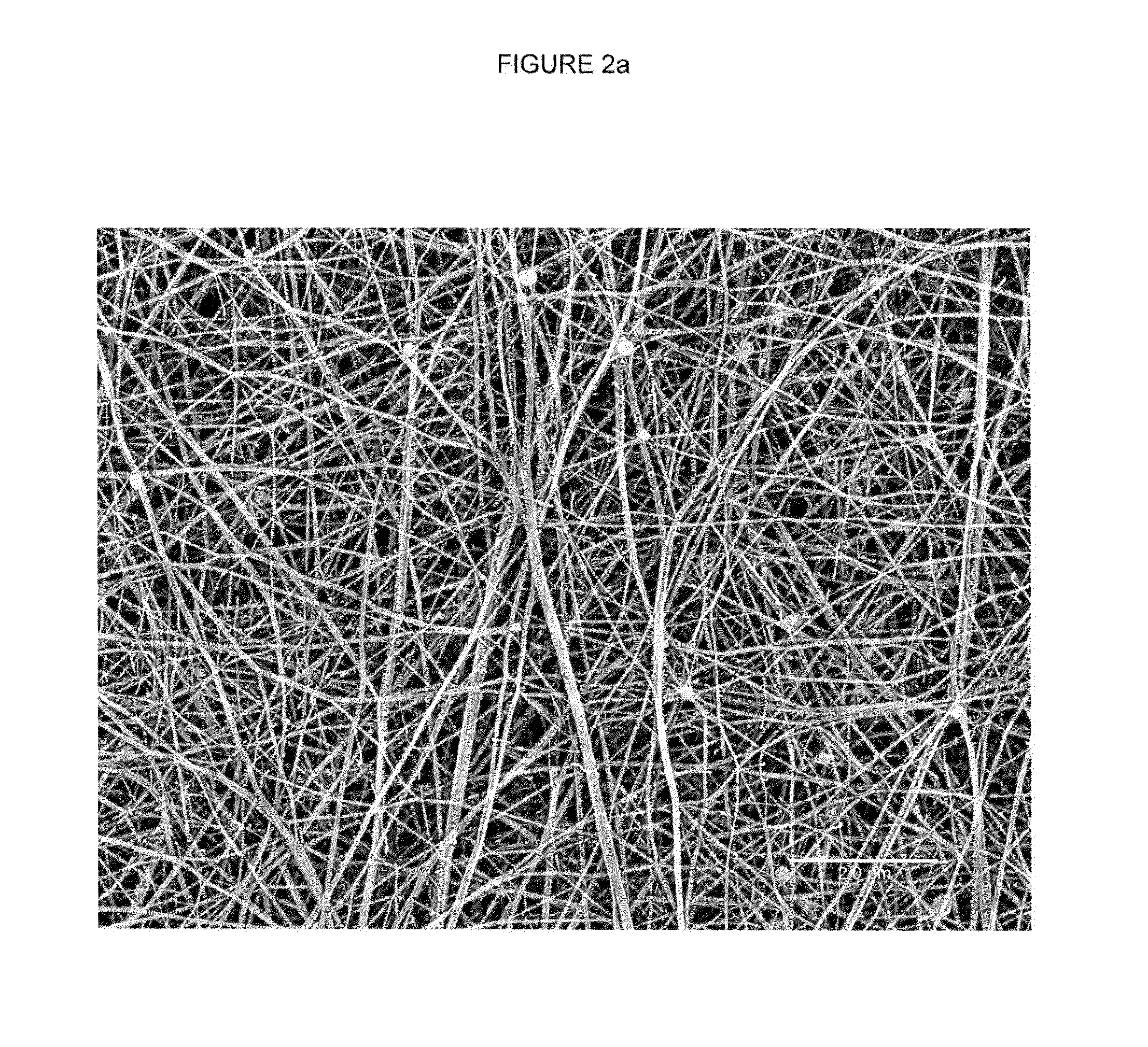

Articles including expanded polytetrafluoroethylene membranes with serpentine fibrils

InactiveUS20130183515A1High elongationSynthetic resin layered productsCeramic shaping apparatusElastomerFiber

Articles including expanded fluoropolymer membranes having serpentine fibrils are provided. The fluoropolymer membranes exhibit high elongation while substantially retaining the strength properties of the fluoropolymer membrane. The membrane may include a fluoropolymer and / or elastomer. Additionally, the article has an elongation in at least one direction of at least about 100% and a matrix tensile strength of at least about 50 MPa. The article may be formed by (1) expanding a dried, extruded fluoropolymer tape in at least one direction to produce an expanded fluoropolymer membrane and (2) retracting the expanded fluoropolymer membrane in at least one direction of expansion by applying heat or by adding a solvent. The application of a tensile force at least partially straightens the serpentine fibrils, thereby elongating the article. The expanded fluoropolymer membrane may include a microstructure of substantially only fibrils. The membranes may be imbibed with an elastomeric material to form a composite.

Owner:WL GORE & ASSOC INC

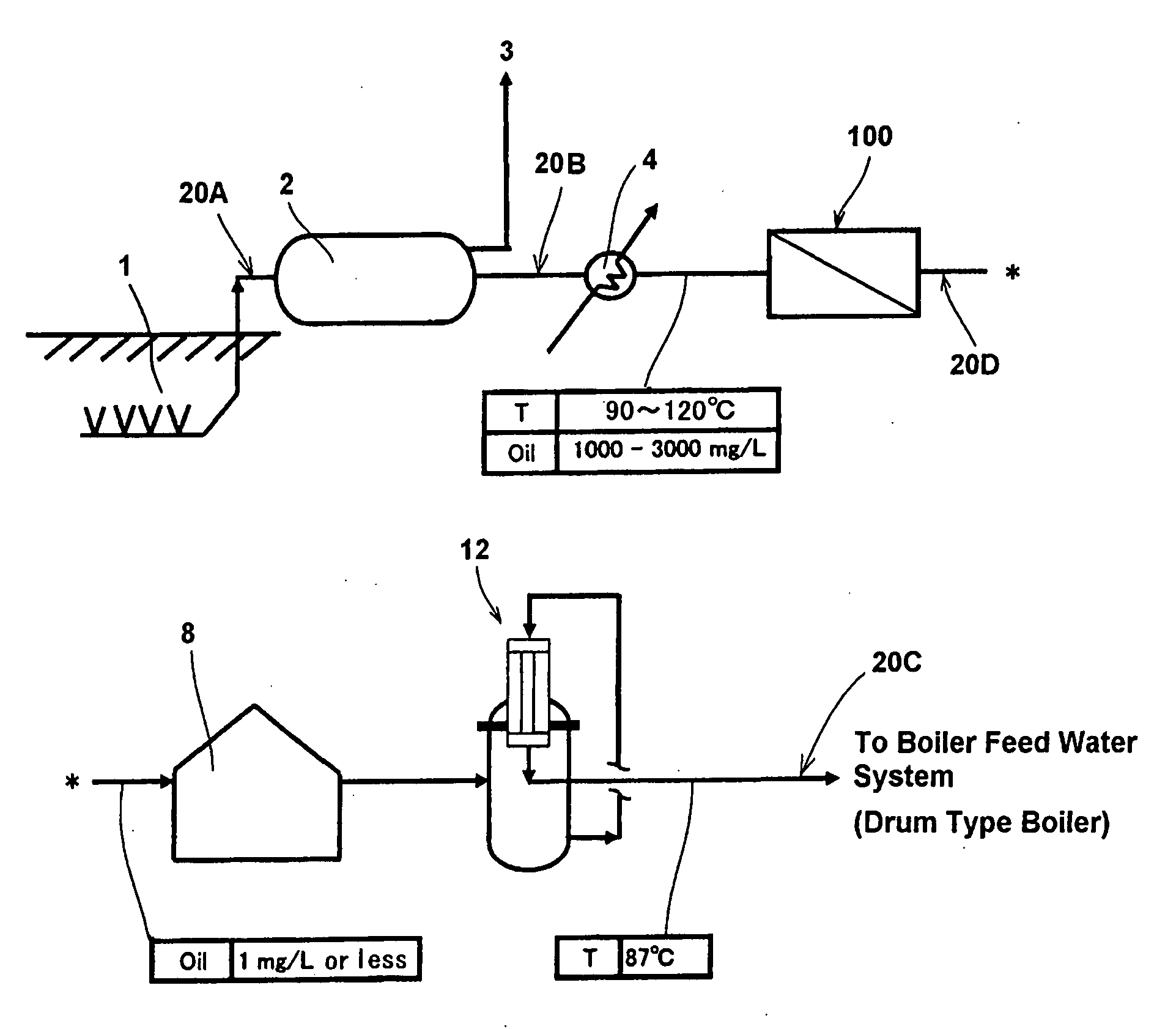

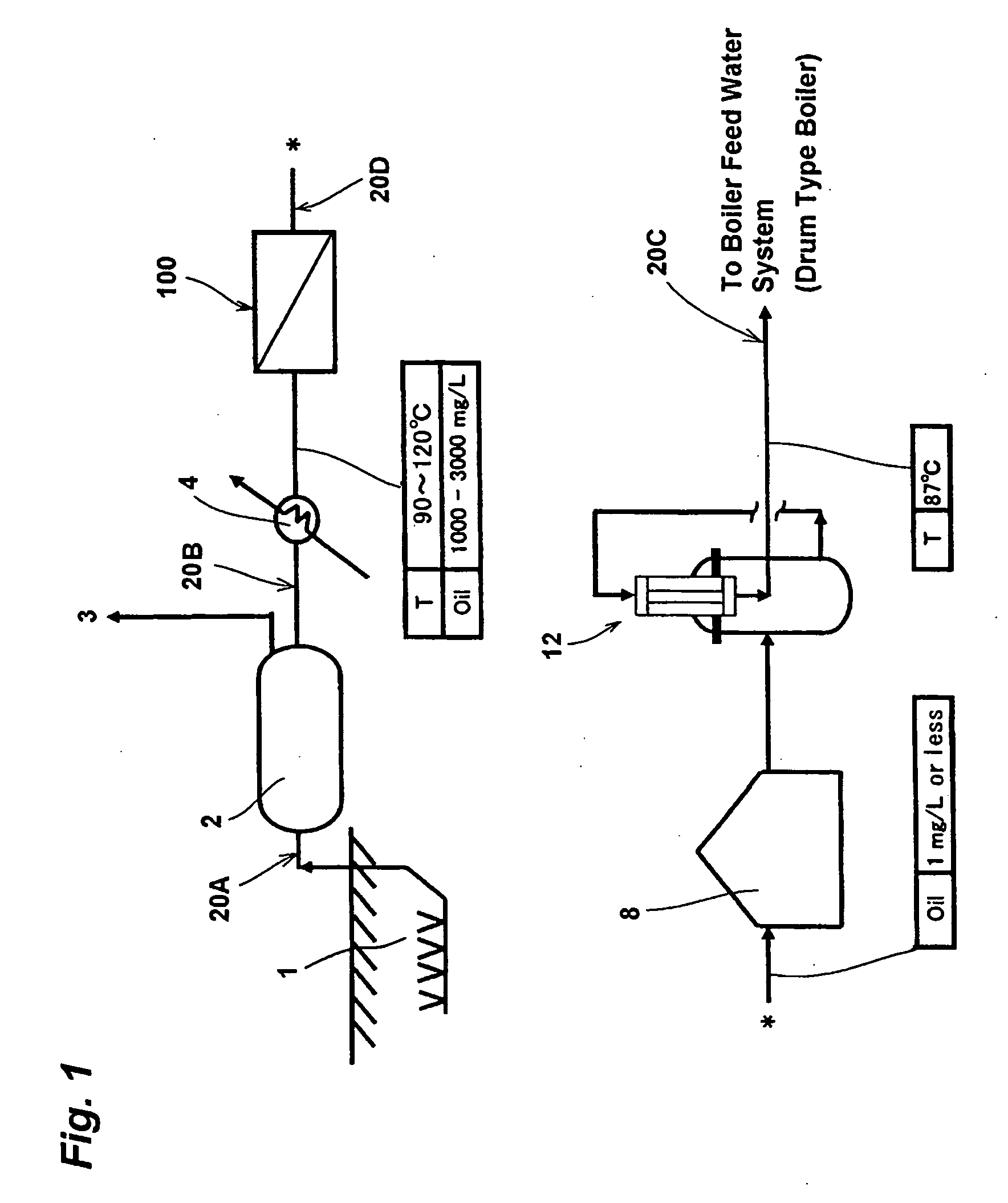

Method of produced water treatment, method of water reuse, and systems for these methods

ActiveUS20100264068A1Fatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansRecovery methodMicrofiltration membrane

A method of produced water treatment in an in-situ recovery method of producing bitumen from oil sand, the method has the steps of: separating bitumen from bitumen-mixed fluid so as to leave produced water, the bitumen-mixed fluid having been recovered from the oil sand wells; and filtering the produced water via a microfiltration membrane made of polytetrafluoroethylene.

Owner:SUMITOMO ELECTRIC IND LTD +1

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431AImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsVinyl etherGlass fiber

The invention relates to a fluororesin mixture, a copper-clad plate prepared therefrom and a manufacturing method thereof. The fluororesin mixture contains the following two substances as necessary components in 100 parts by weight of an organic solid substance: 90-99 parts of polytetrafluoroethylene (PTFE) emulsions and 1-10 parts of polytetrafluoroethylene perfluoroalkyl vinyl ether (PFA) emulsions. The copper-clad plate prepared from the fluororesin mixture comprises a plurality of superimposed varnished cloths and copper foil coating one or two surfaces of the varnished cloths, and each varnished cloth comprises a glass fiber cloth and the fluororesin mixture attached to the dipped and dried glass fiber cloth. The fluororesin mixture is prepared by using the PTFE emulsions as main resins and can dip the glass fiber cloths many times under the condition that the PTFE sintering temperature is330 DEG C to prepare the vanished cloths, and the vanished cloths prepared from the fluororesin mixture has the advantages of good gum dipping quality, level surface, flexibility and easy operation; and besides, the copper-clad plate made from the fluororesin mixture has excellent dielectric performance which meets the dielectric performance requirement of the high-frequency communication field for a base plate material, and has simple making method and process and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

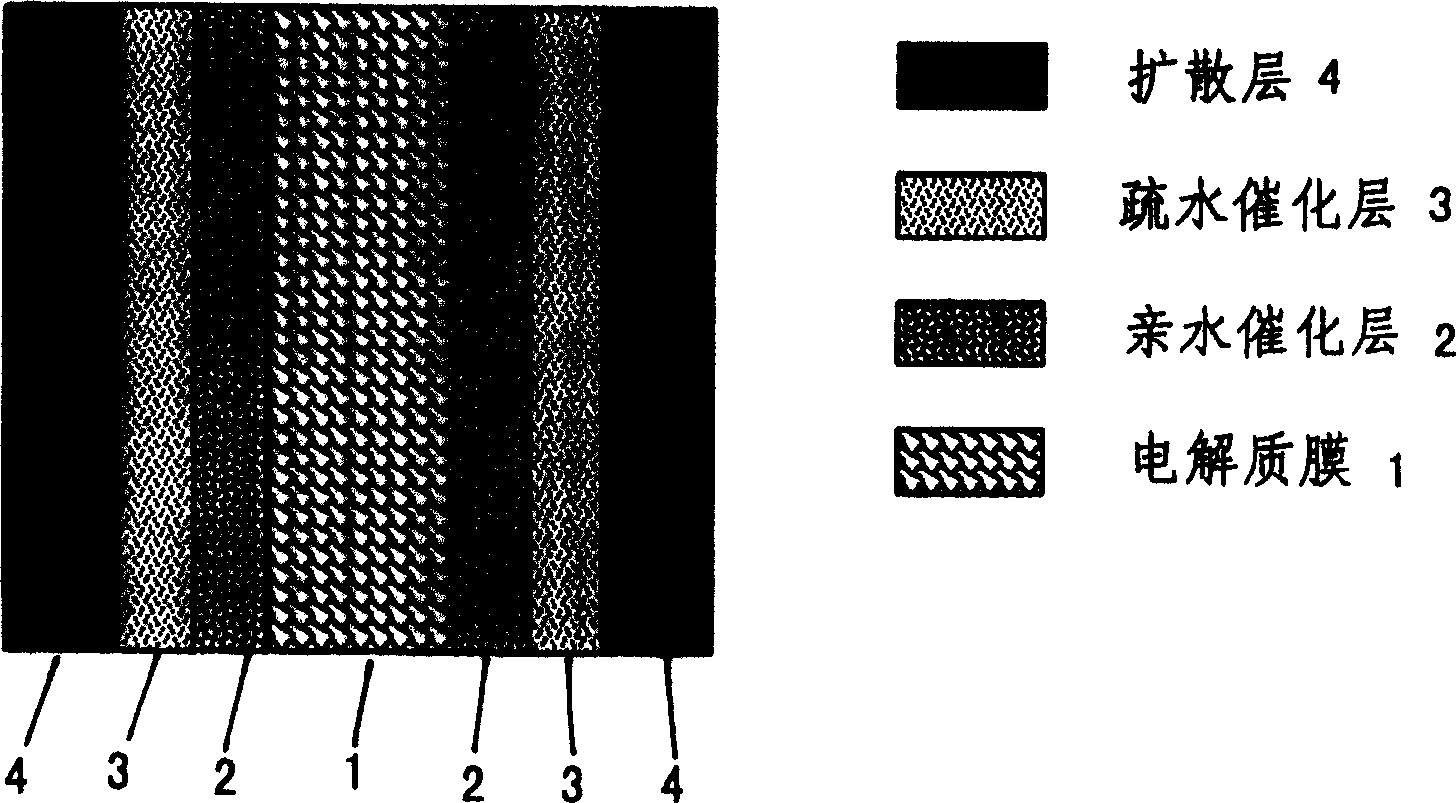

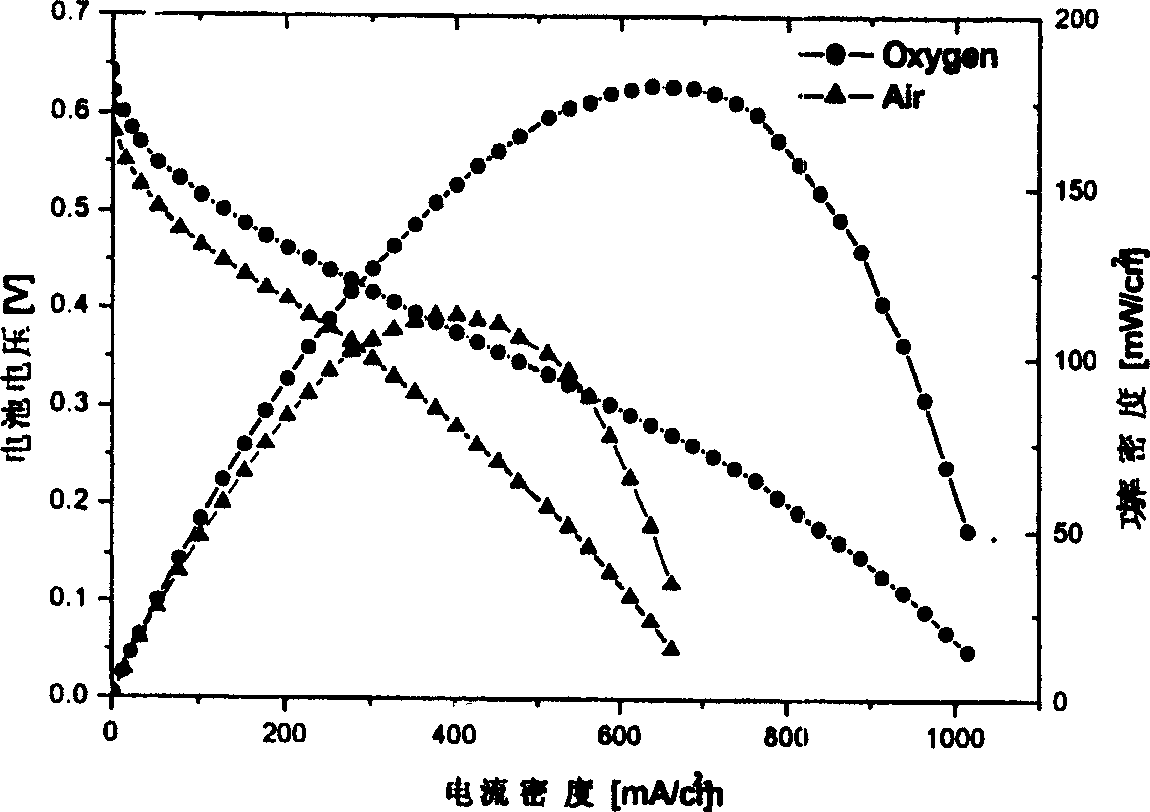

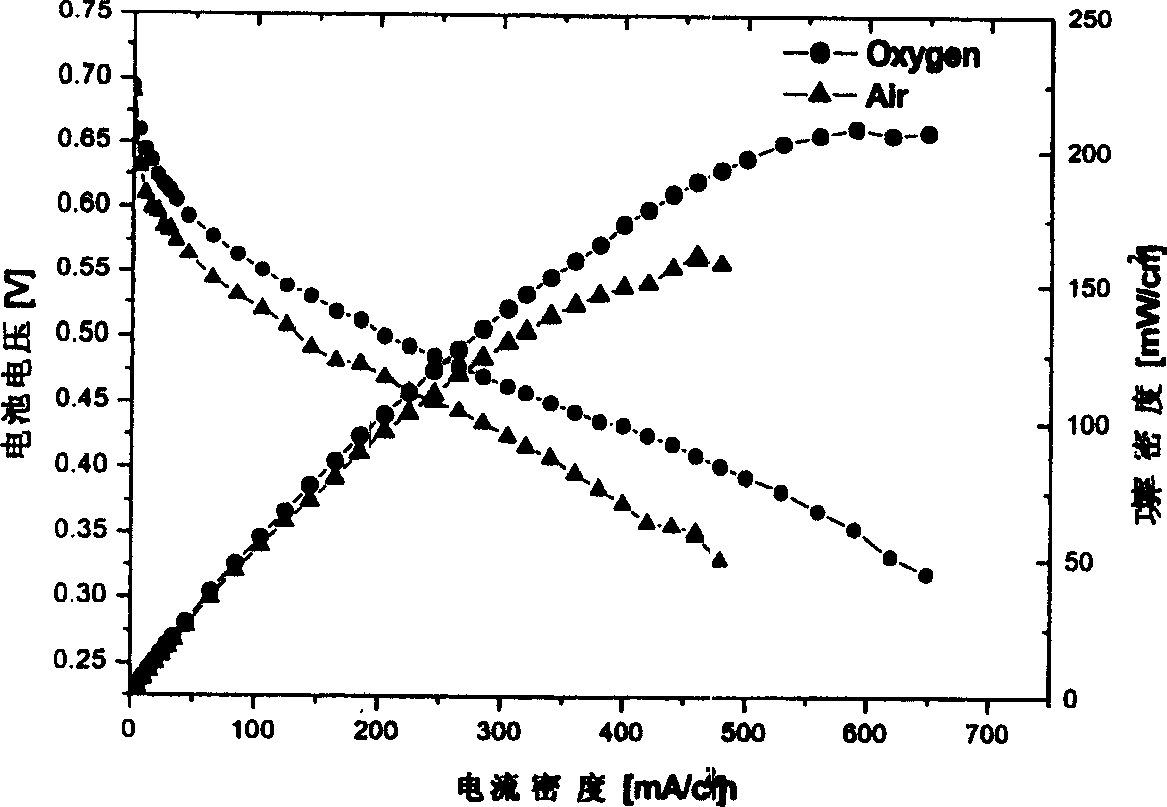

Membrane electrode structure for proton exchange membrane fuel cell and its preparing method

In structure of electrode, catalysis layer is in structure of multiple layers. The said catalysis layer composed of composite two layers including hydrophilic catalysis layer and hydrophobic catalysis layer covering on surface of membrane. Catalysis layer composed of composite two layers is fabricated through steps: catalyst and Nation are dispersed on membrane directly or dispersed on membrane through transferring press of polytetrafluoroethylene (PTFE) film indirectly. Advantages are: in favor of discharging CO2 from anode and O2 from cathode, reducing loss caused by polarization of mass transfer, increasing ultimate current density so as to raise performance of electrode and use ratio of catalyst prepared from noble metal.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

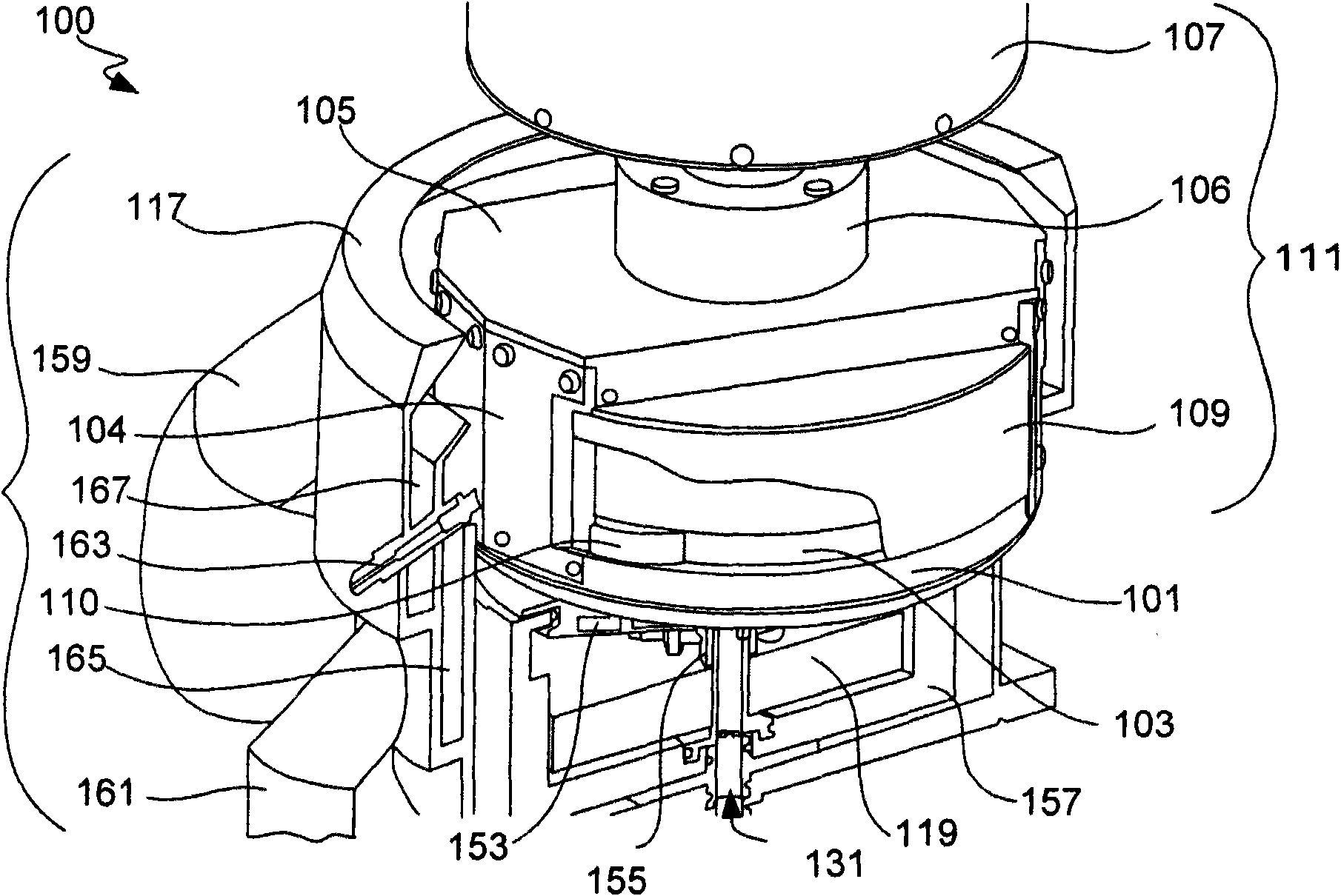

Base plate, contact ring, lipseal, electroplating device and electroplating method

Methods, apparatuses, and various apparatus components, such as base plates, lipseals, and contact ring assemblies are provided for reducing contamination of the contact area in the apparatuses. Contamination may happen during removal of semiconductor wafers from apparatuses after the electroplating process. In certain embodiments, a base plate with a hydrophobic coating, such as polyamide-imide (PAI) and sometimes polytetrafluoroethylene (PTFE), are used. Further, contact tips of the contact ring assembly may be positioned further away from the sealing lip of the lipseal. In certain embodiments, a portion of the contact ring assembly and / or the lipseal also include hydrophobic coatings.

Owner:NOVELLUS SYSTEMS

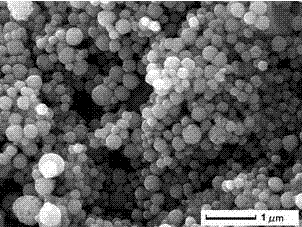

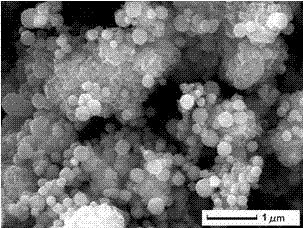

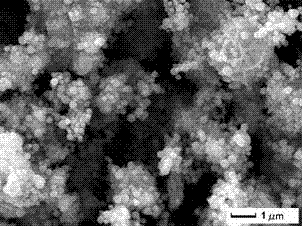

Preparation method for synthesizing MoS2/Fe3O4 nano composite material

InactiveCN103028352ASimple processHigh crystallinityInorganic material magnetismMicroballoon preparationSodium thiocyanateCrystallinity

The invention provides a preparation method of a MoS2 / Fe3O4 nano composite material, belonging to the technical field of preparation of nano inorganic functional materials. The preparation method taking Fe3O4 nano particles as the raw material comprises the following specific steps of: dispersing the Fe3O4 nano particles in de-ionized water, adding sodium molybdate, sodium chloride, sodium thiocyanate and a surface active agent CTAB (Cetyltrimethyl Ammonium Bromide), after stirring for a period of time, adjusting pH by using hydrochloric acid, then, pouring the mixture into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and naturally cooling after reacting at the pre-set temperature for a period of time; and centrifugally washing a reaction product by using the de-ionized water for several times, and drying the product to obtain the MoS2 / Fe3O4 nano composite material. The method disclosed by the invention has the advantages of being simple in process, rapid, high-efficiency and the like; MoS2 is well wrapped on the Fe3O4 nano particles; and the MoS2 / Fe3O4 nano composite material prepared by the invention is good in crystallinity, controllable in morphology and size and good in adsorption property.

Owner:JIANGSU UNIV

Venous prosthesis and vascular graft with access port

InactiveUS20070265584A1Easy and rapid and replacementEliminate needMedical devicesBlood vesselsVeinExit site

A venous polytetrafluoroethylene (PTFE) graft with integral access port system. The graft may have one, two, or more ports, which then exits the skin. The prosthesis may be made of fluoropolymer tubing fabricated in such a way as to involve several performance features. The graft may have holes for suturing, anchoring, or bio-integration to the artery. The ports have natural acting restrictions or valves at the graft juncture, throughout the implanted part body of the device and at the exit site. The ports are also naturally self-purging. A port may also incorporate a redundant hermetic hemostatic valve and closure system at the exit site.

Owner:MEMCATH TECH

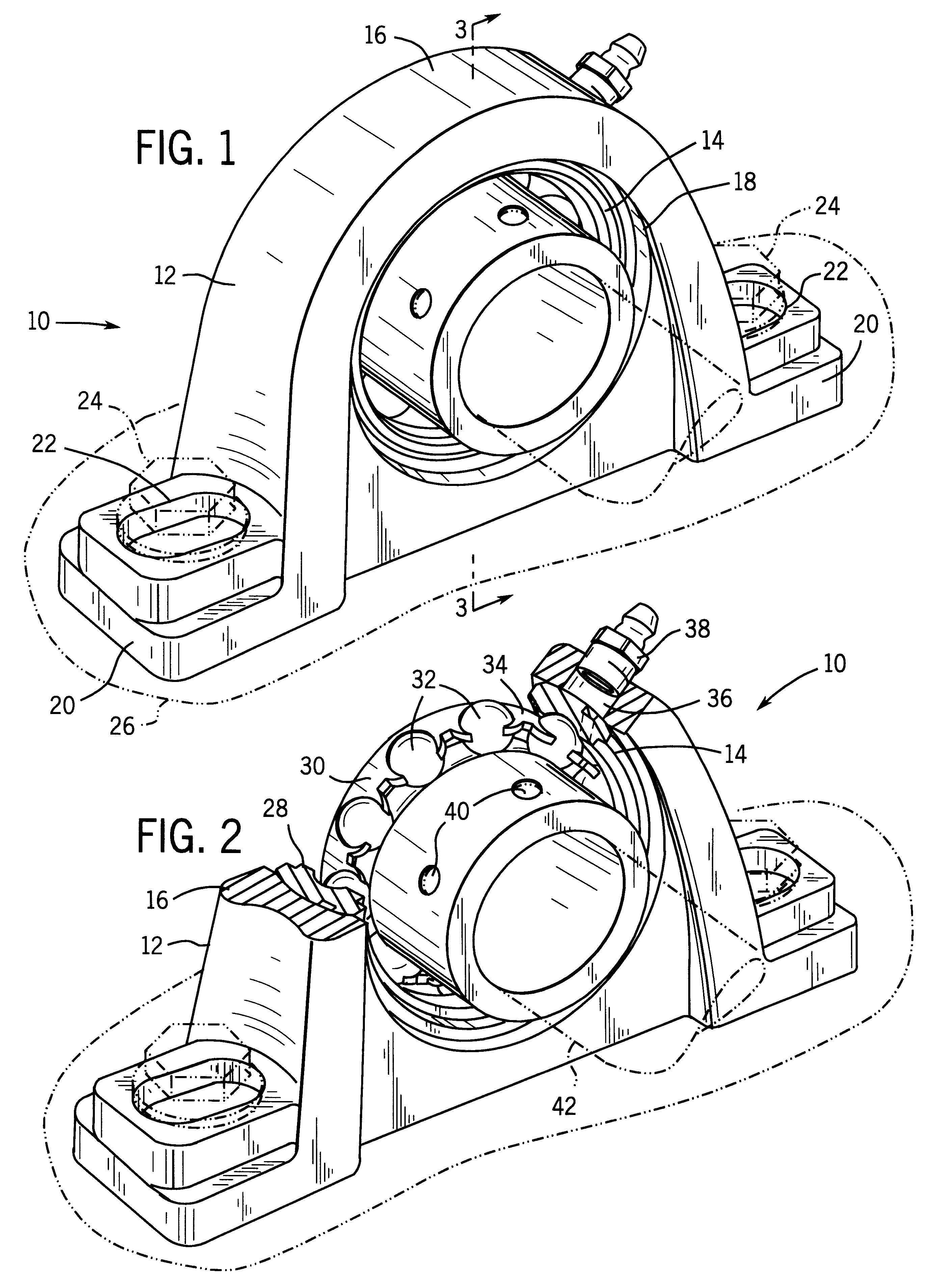

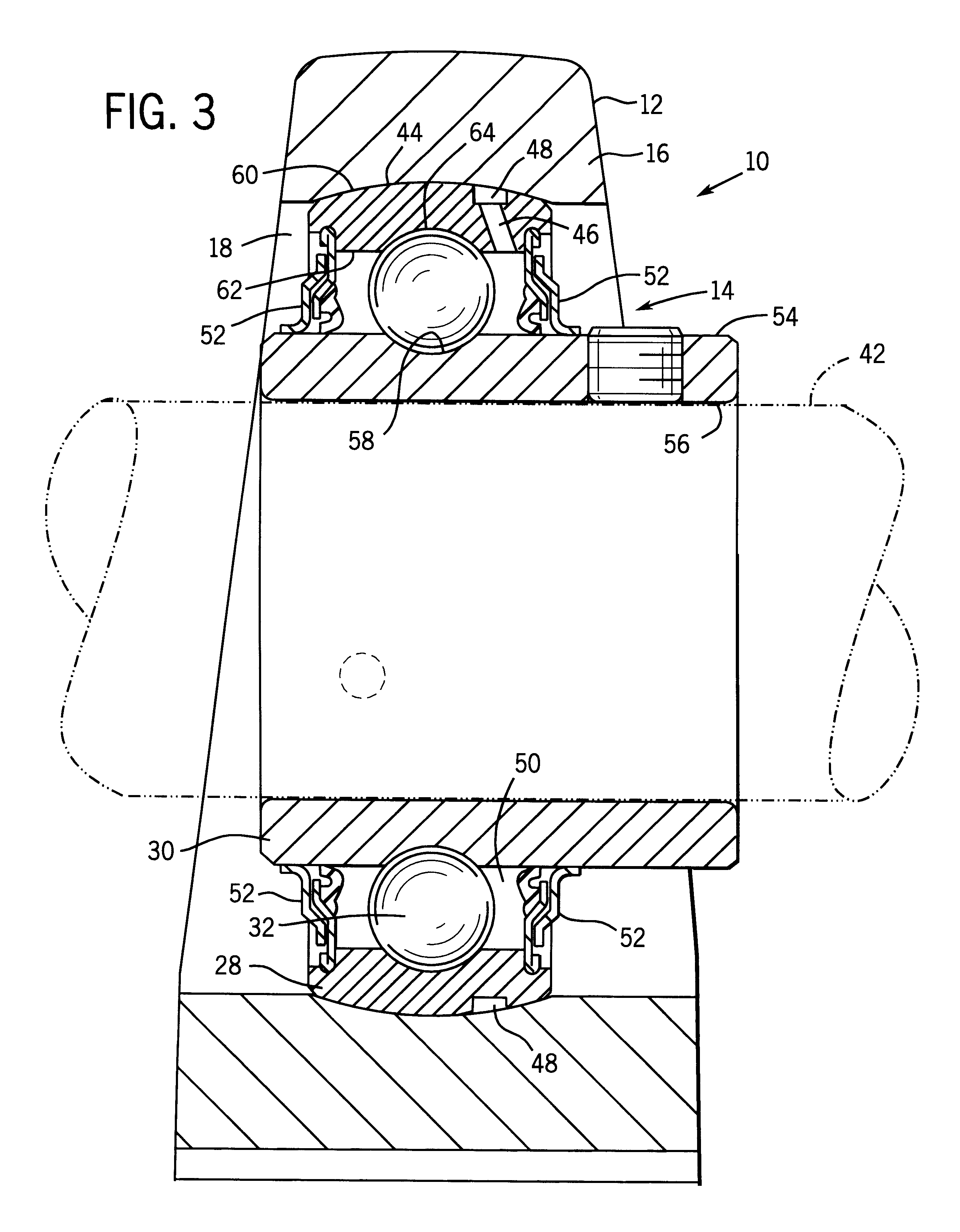

Corrosion-resistant bearing and method for making same

InactiveUS6318898B1Improve corrosion resistanceMore cost-effectiveBall bearingsBearing componentsAlloyProtection system

A corrosion-resistant antifriction bearing is disclosed that includes a multi-layer corrosion protection system over a metallic substrate. The corrosion-resistant system may be applied to a single or multiple components of the bearing, including inner and outer rings, bearing elements, collars, and so forth. The system includes a nickel-phosphorous alloy plating layer applied by an autocatalytic process after surface preparation of the protected component. The surface preparation aids in adherence of the nickel-phosphorous alloy plating layer to the substrate. The preparation may include the application of rust inhibitors, liquid vapor honing, acid neutralizing, and so forth. Additional topcoat layers may be applied to the nickel-phosphorous alloy plating layer. These may include a chromate conversion coating and a polymeric topcoat layer. The polymeric topcoat layer, such as polytetrafluoroethylene, may include a UV marker to enable identification of the bearing when placed in service and throughout its useful life.

Owner:BALDOR ELECTRIC COMPANY

Radial lip seal

A radial lip seal including an annular support with a radially extending portion having an inner periphery. An annular seal lip formed of elastomeric material such as polytetrafluoroethylene is connected to the inner periphery. The lip has an inner side adapted to seal a circumferential surface of a shaft and an outer side. The outer side of the lip has a plurality of grooves or protrusions to vary the diameter of the lip. The varied diameter creates a substantial leak between the outer side of the lip and the circumferential surface. The leak created is sufficient to be detected by a low-pressure air test.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

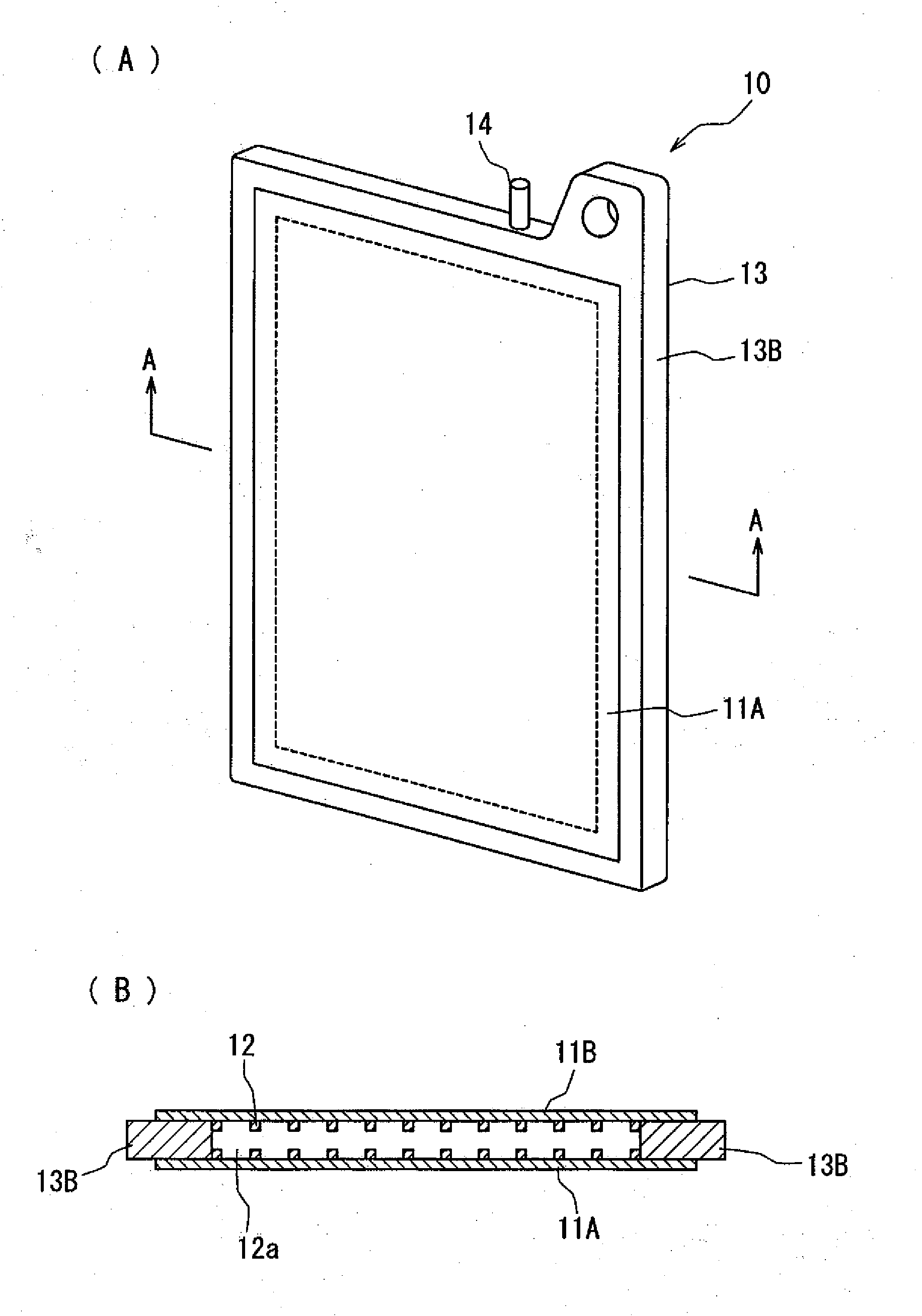

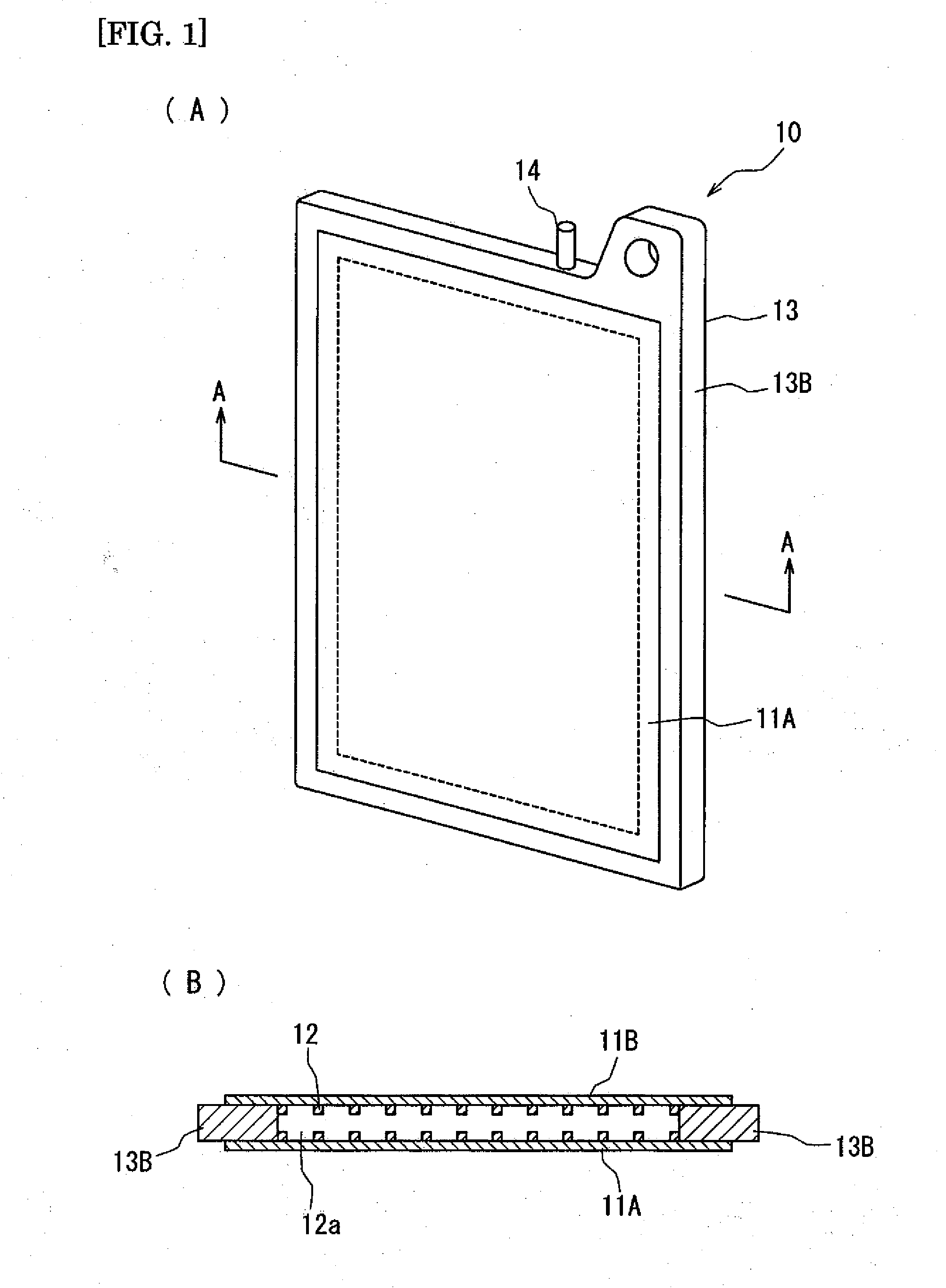

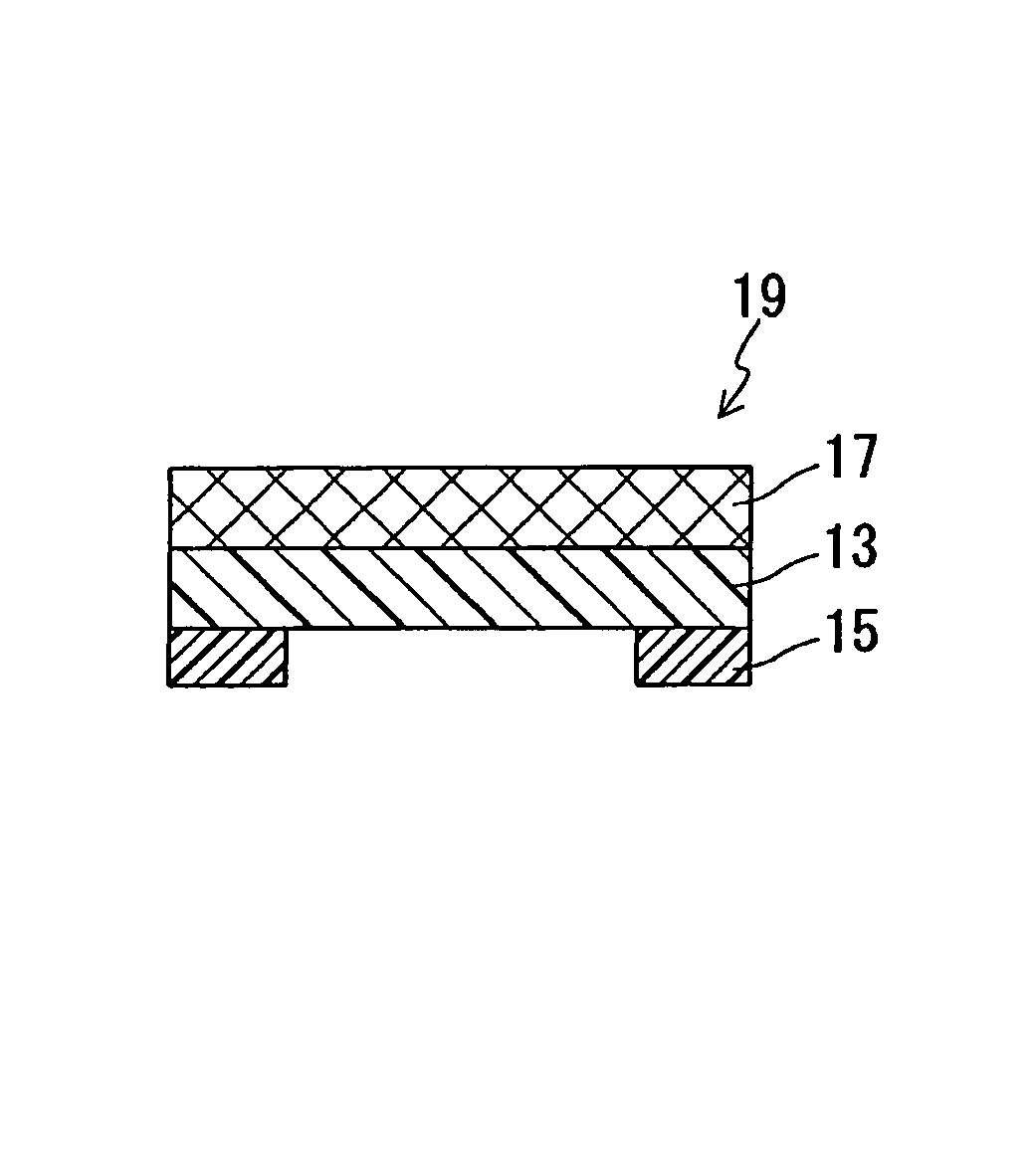

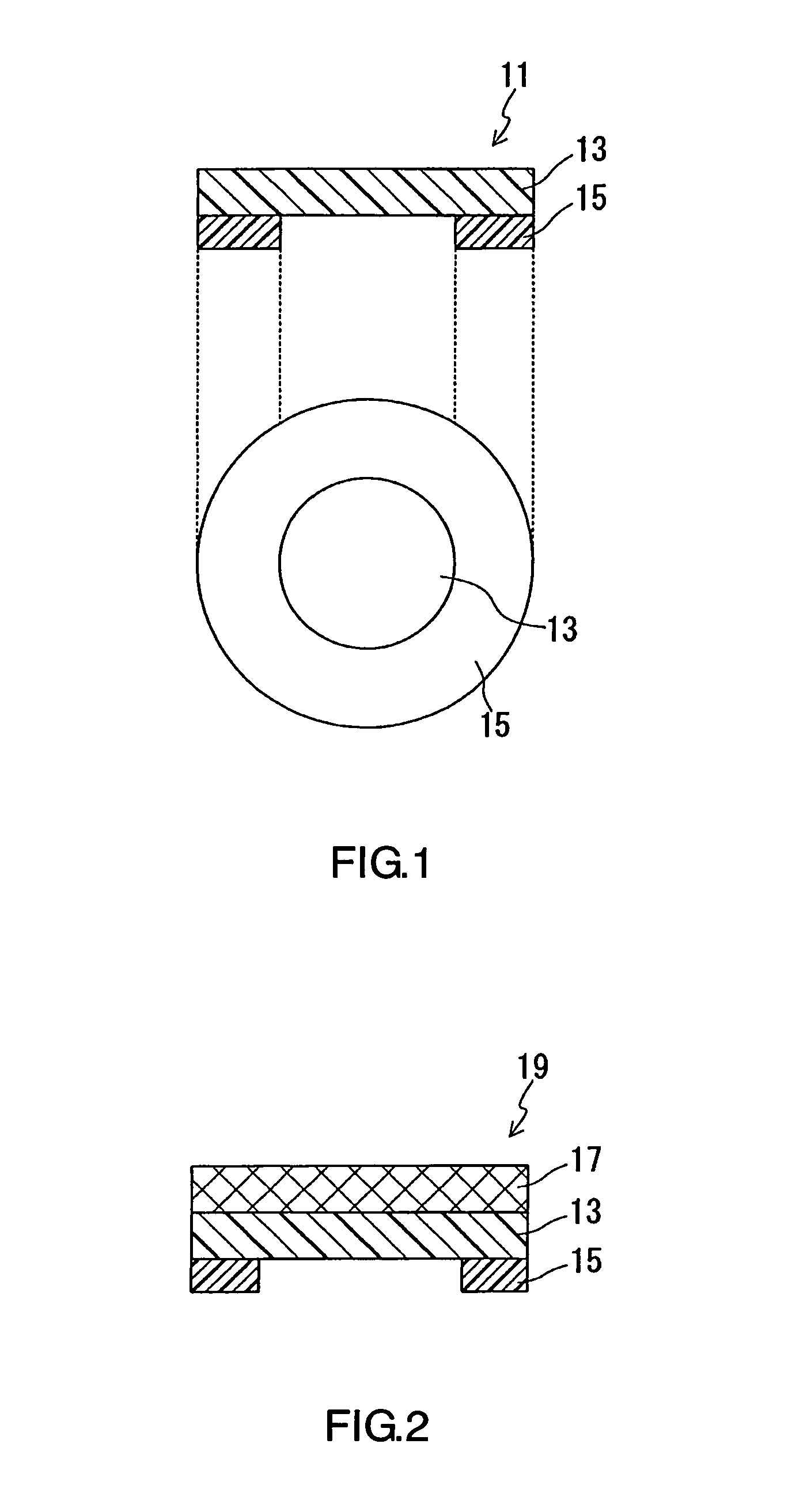

Sound-permeable film, electronic component with sound-permeable film, and method of producing circuit board having electronic component mounted thereon

ActiveUS8141678B2Improve heat resistanceHigh levelPrinted circuit assemblingLamination ancillary operationsForeign matterPorous membrane

A sound-permeable film (11) includes: a porous membrane (13) that contains polytetrafluoroethylene as its main component, allows sound to pass therethrough, and prevents an foreign object such as a water drop from passing therethrough; and a heat-resistant double-sided adhesive sheet (15) that is disposed on a part of at least one of main surfaces of the porous membrane (13).

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com