Patents

Literature

344results about How to "Consistent position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

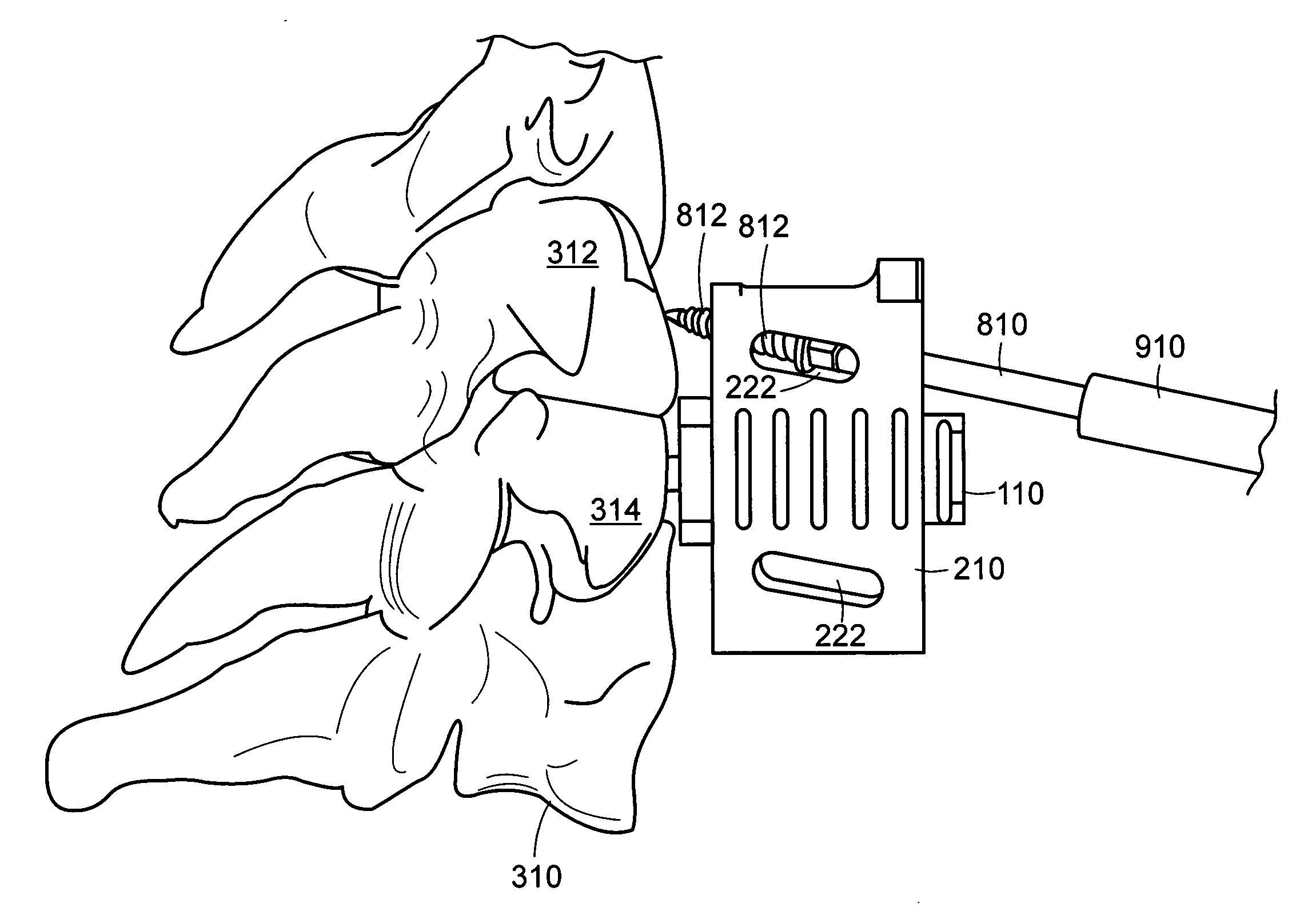

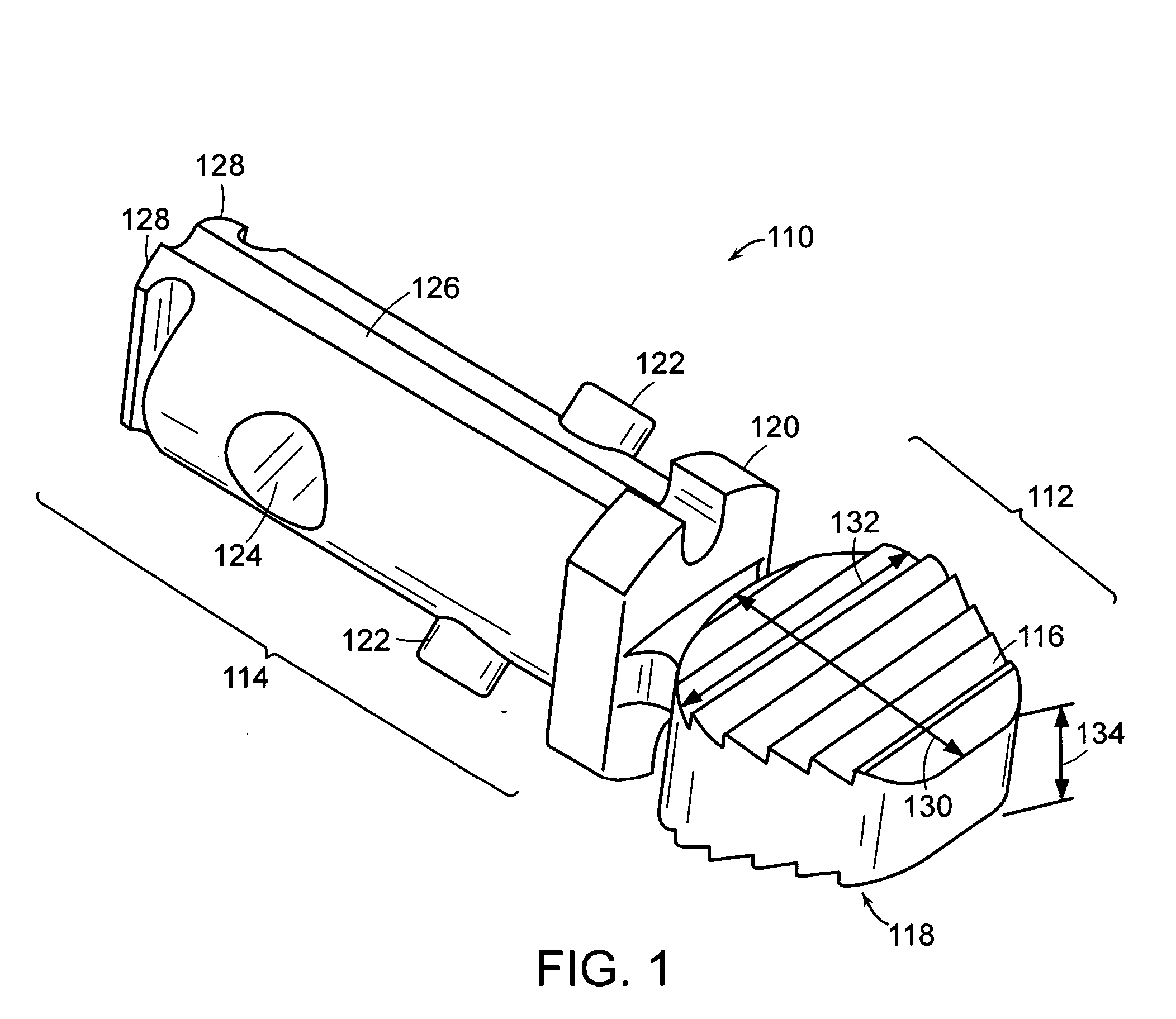

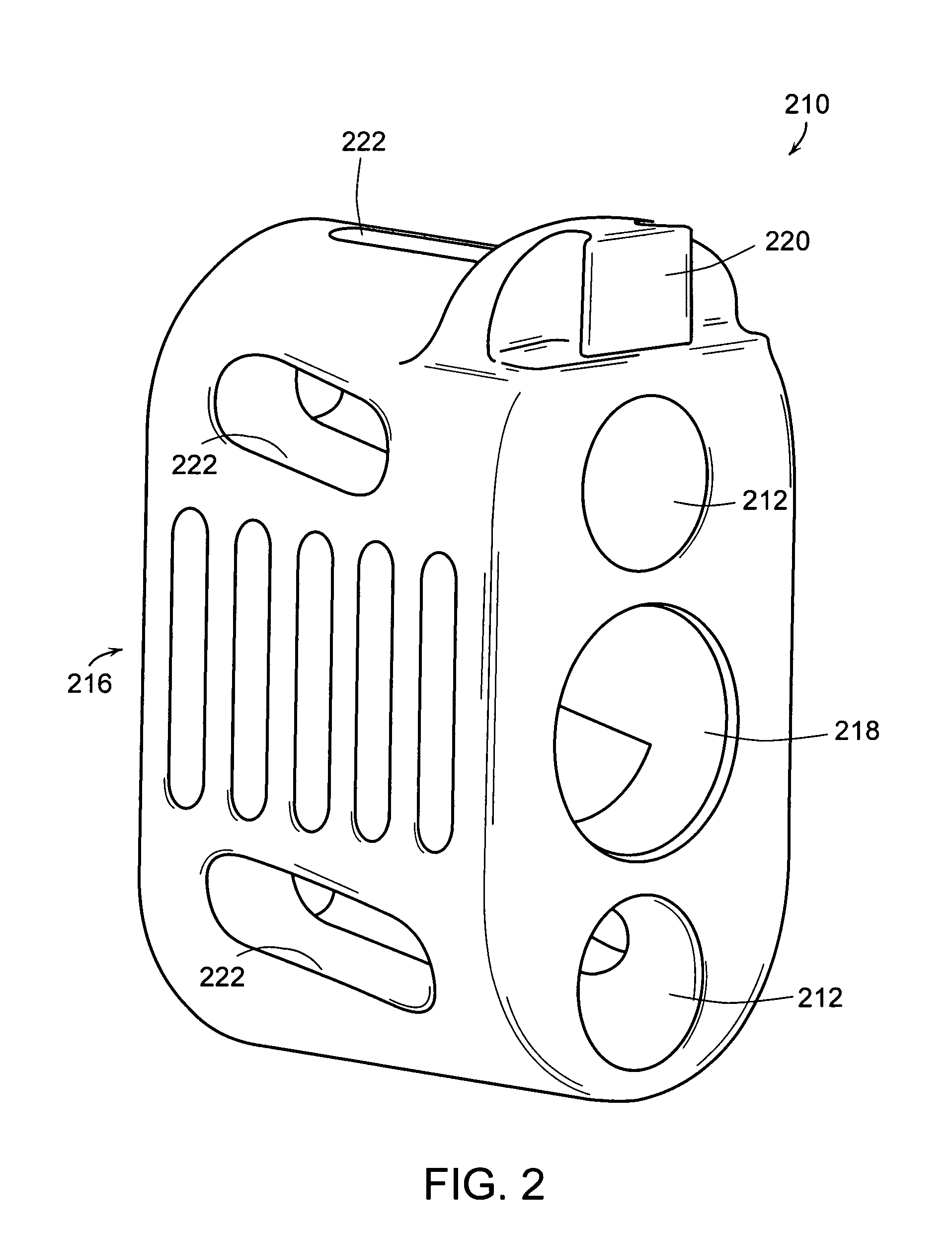

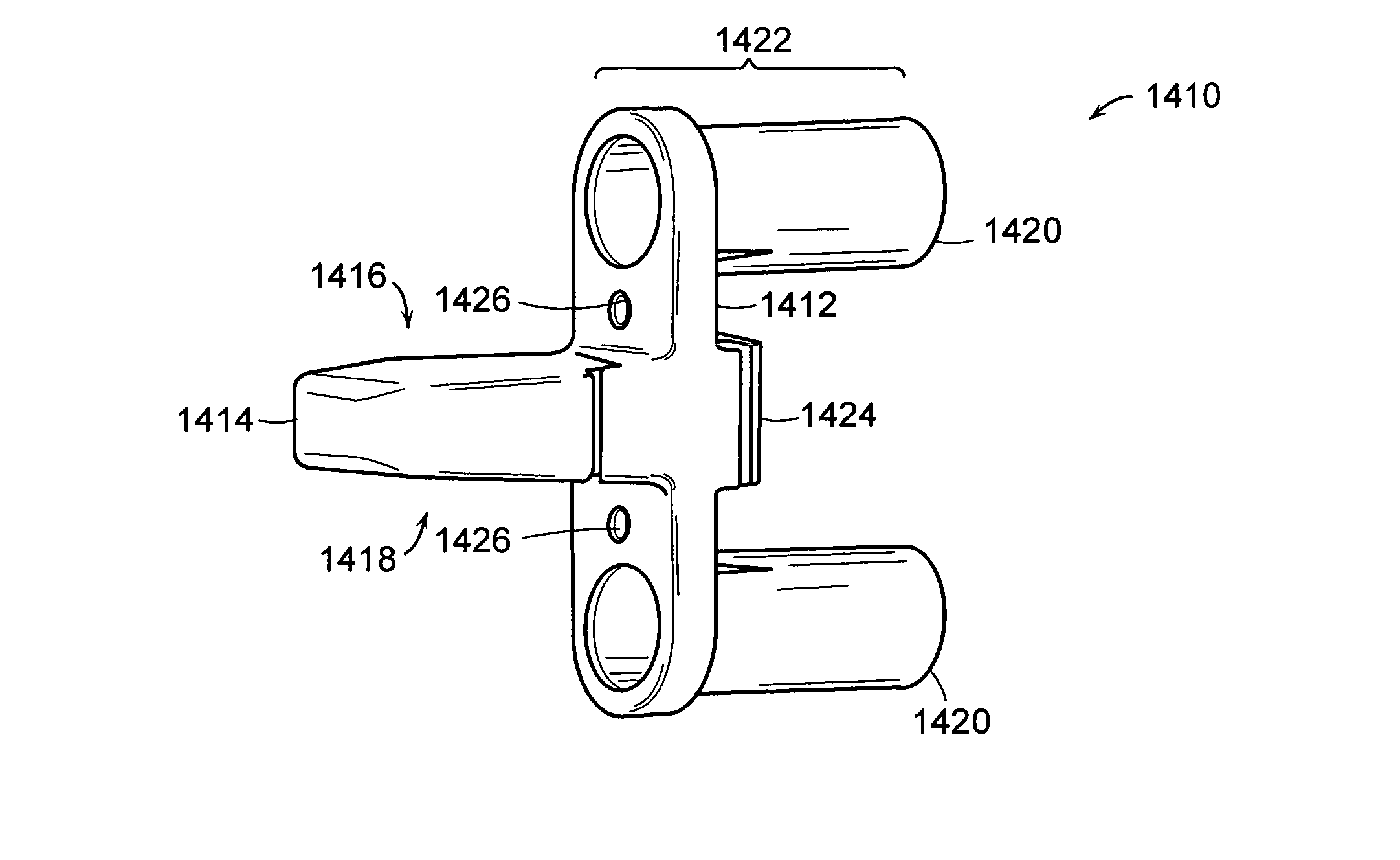

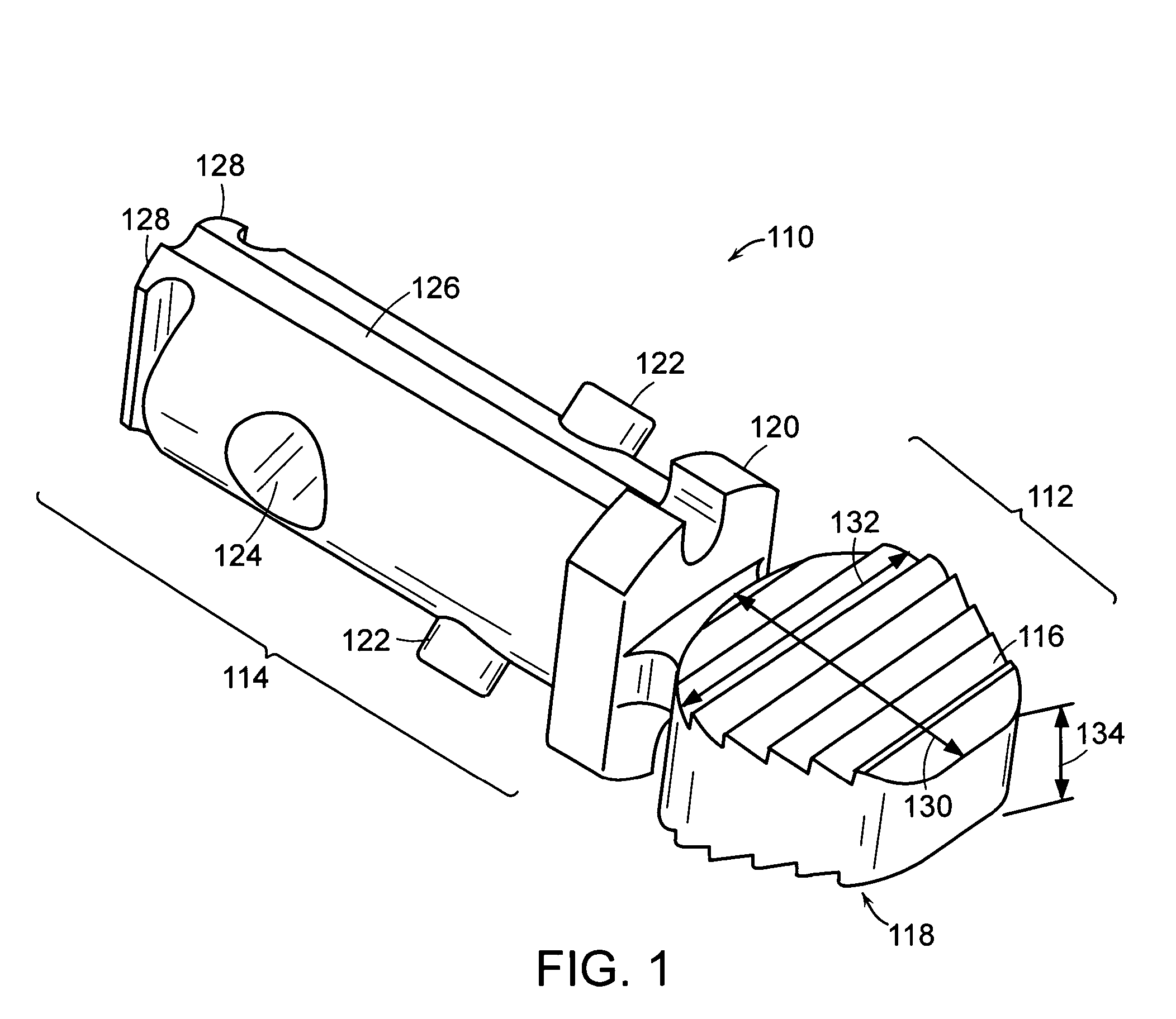

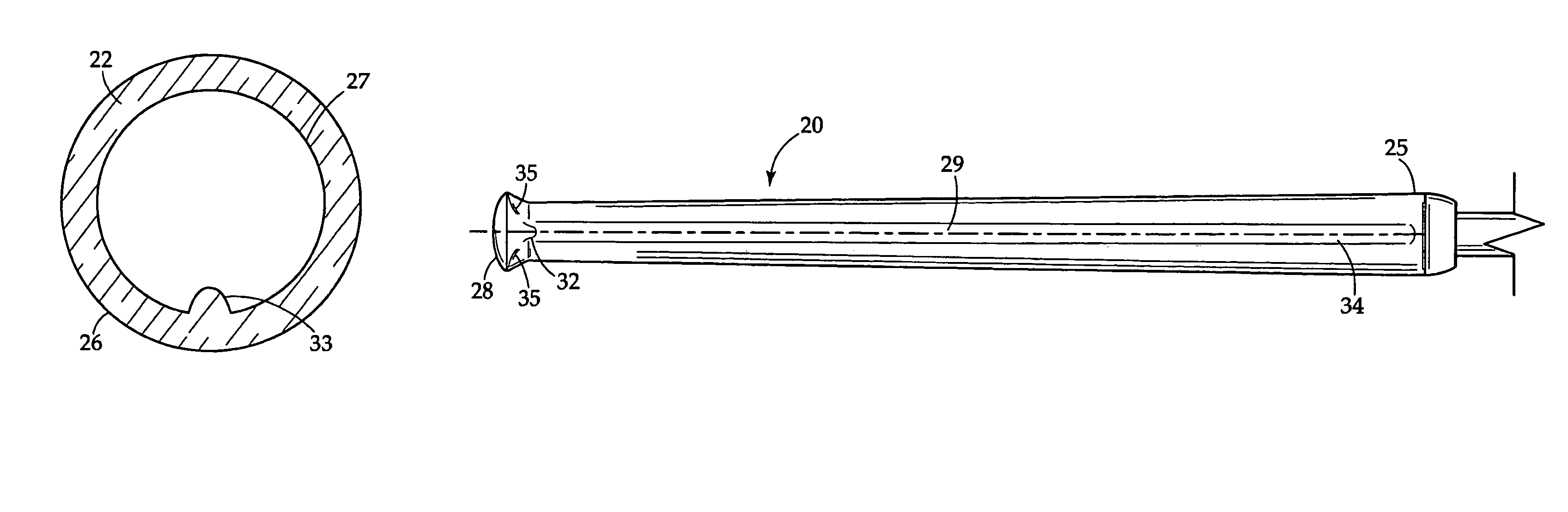

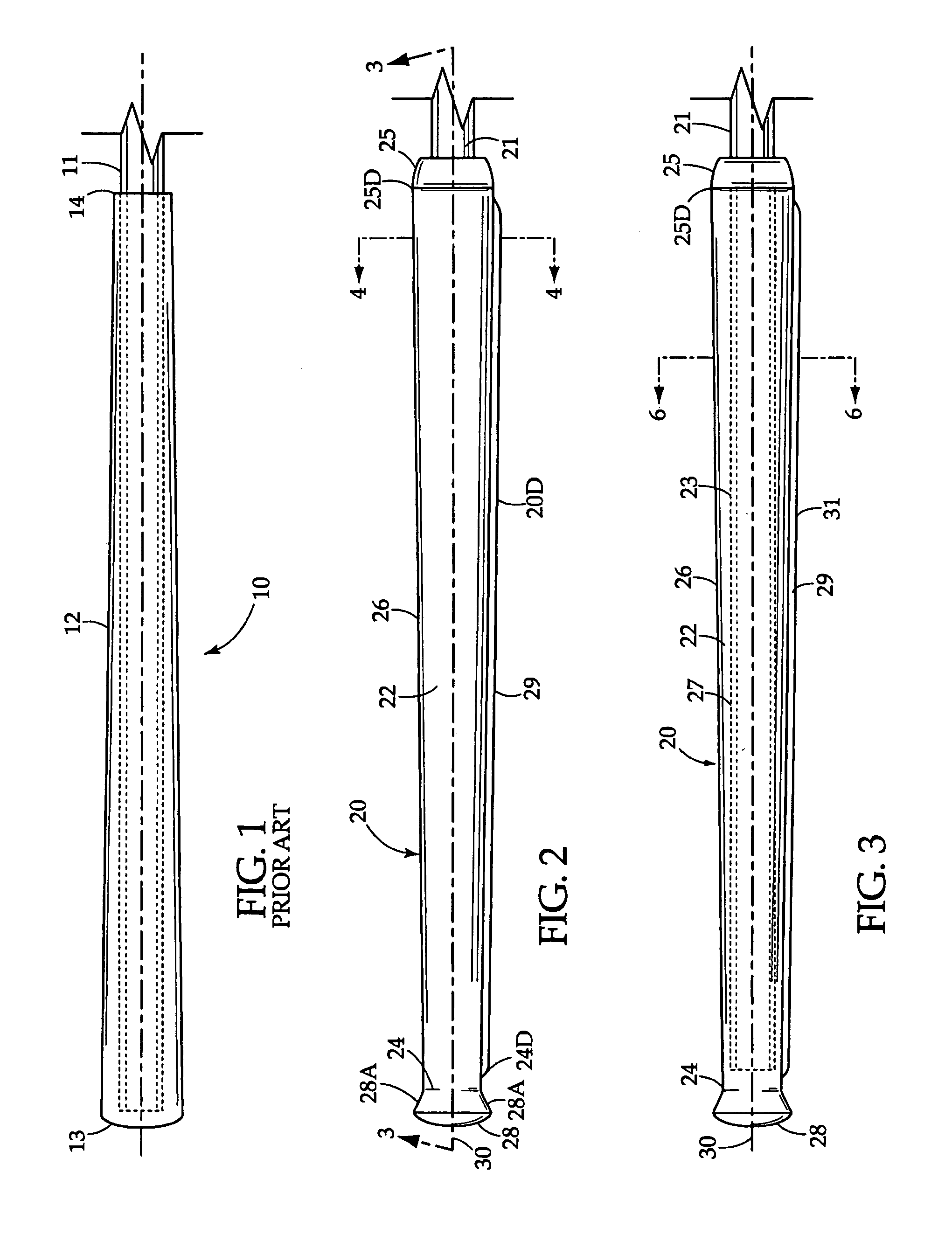

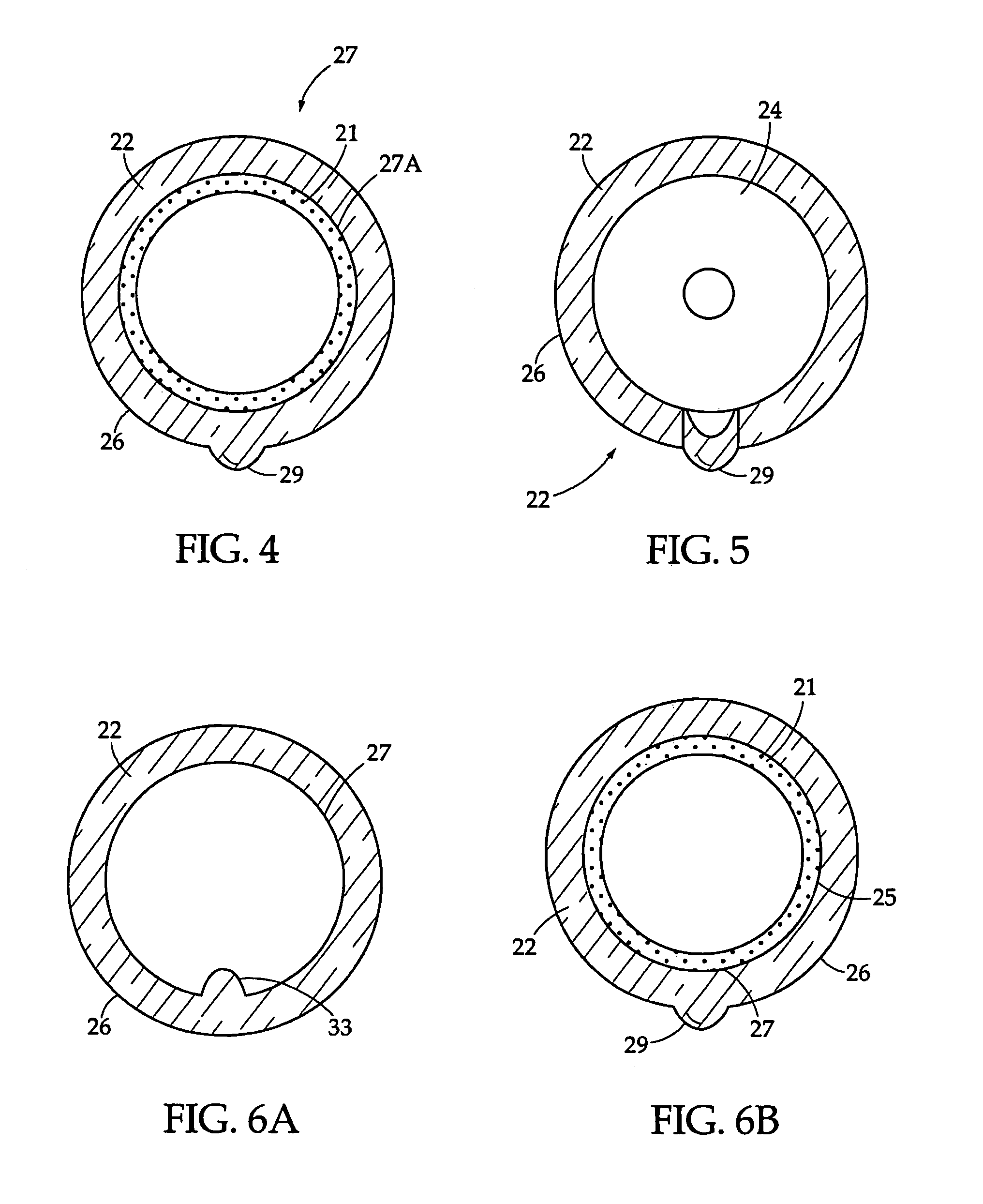

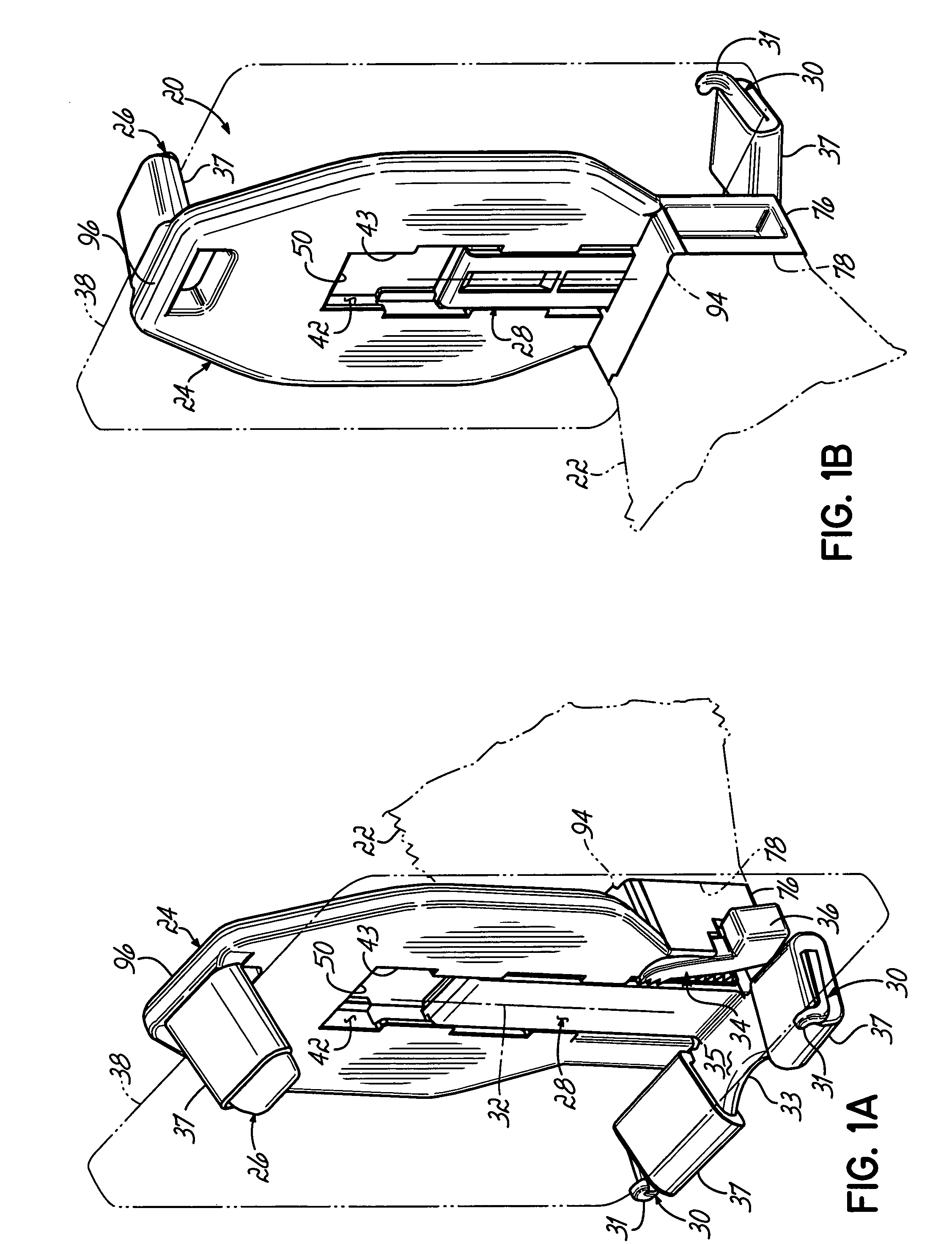

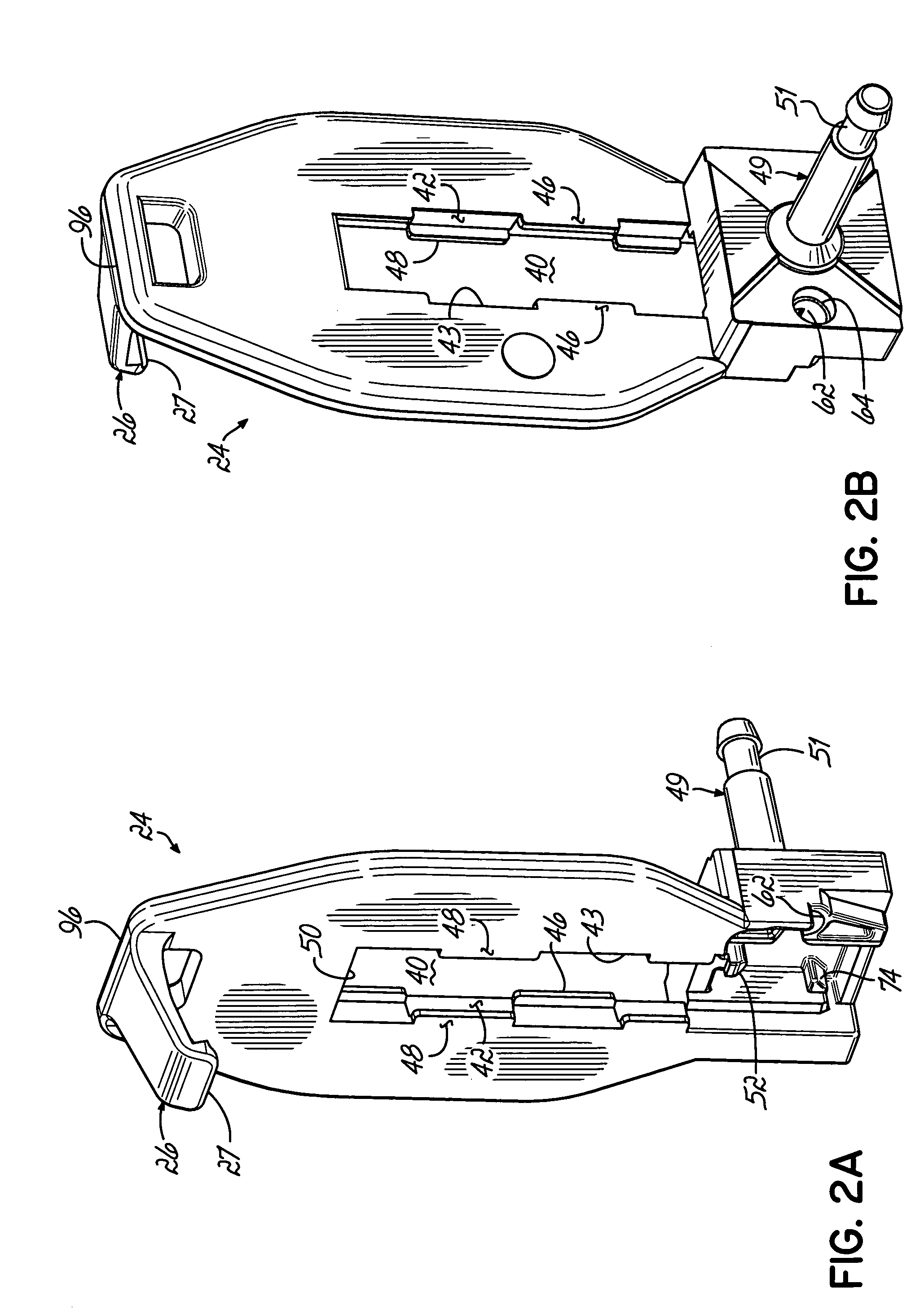

Instrument and method for the insertion and alignment of an intervertebral implant

ActiveUS20060084986A1The method is simple and reliablePrecise alignmentInternal osteosythesisJoint implantsDistractionCoronal plane

The present invention includes pin guides and methods for placing pins in adjacent vertebrae. The present invention also includes methods for placing pins in adjacent vertebrae using the pin guides described herein. The present invention also includes an intervertebral implant insertion and alignment instrument, a distraction instrument, an intervertebral implant insertion guide, and methods for inserting an implant into an intervertebral space. Despite existing tools and techniques, present positioning of implants in intervertebral spaces and pins in adjacent vertebrae often depend on a surgeon's skill, experience and technique. Practice of the present invention can aide in the placement of an implant into an intervertebral space and placement of pins in adjacent vertebrae, e.g., midline to the coronal plane spine and / or parallel to vertebral endplates that abut the intervertebral space.

Owner:DEPUY SPINE INC (US)

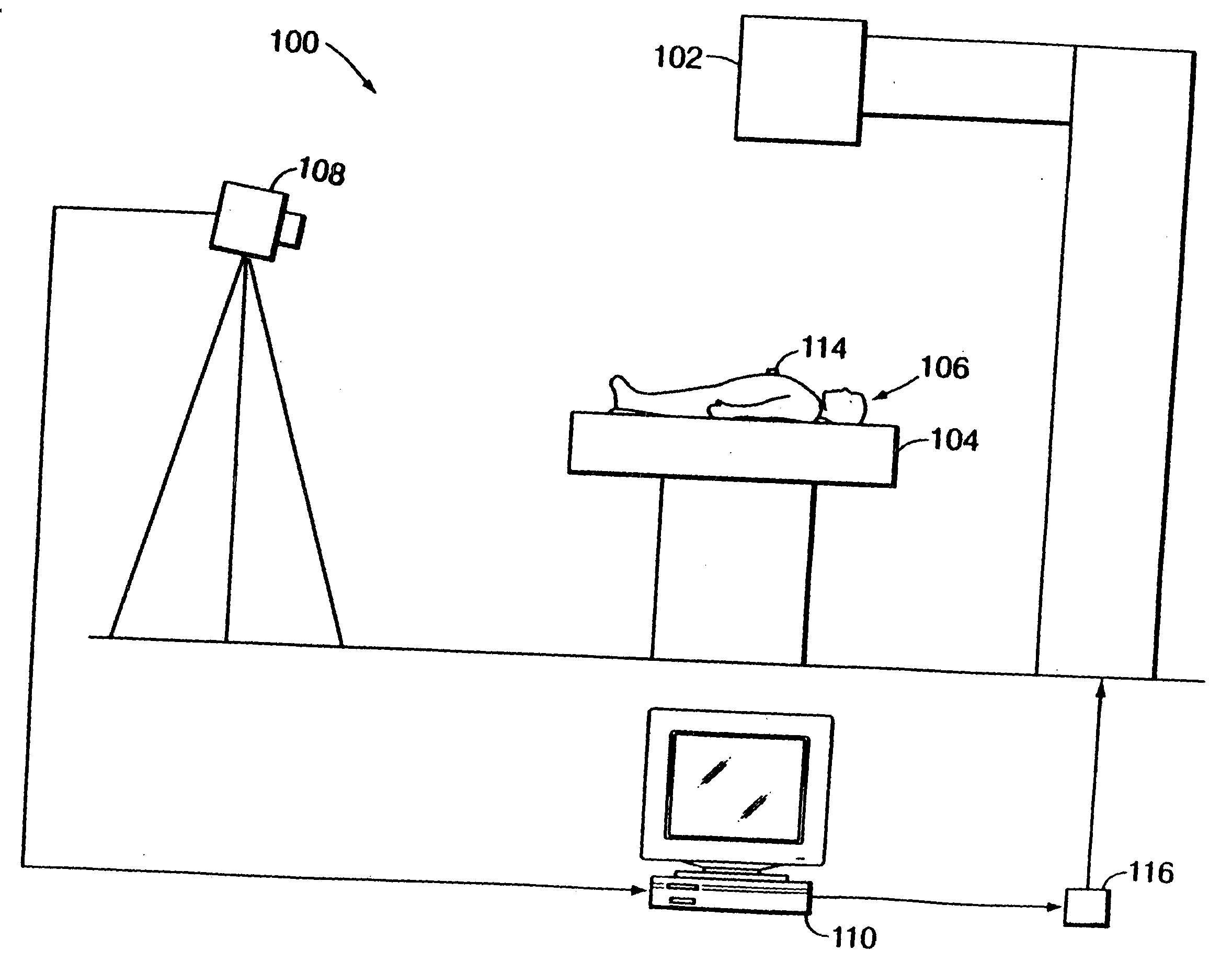

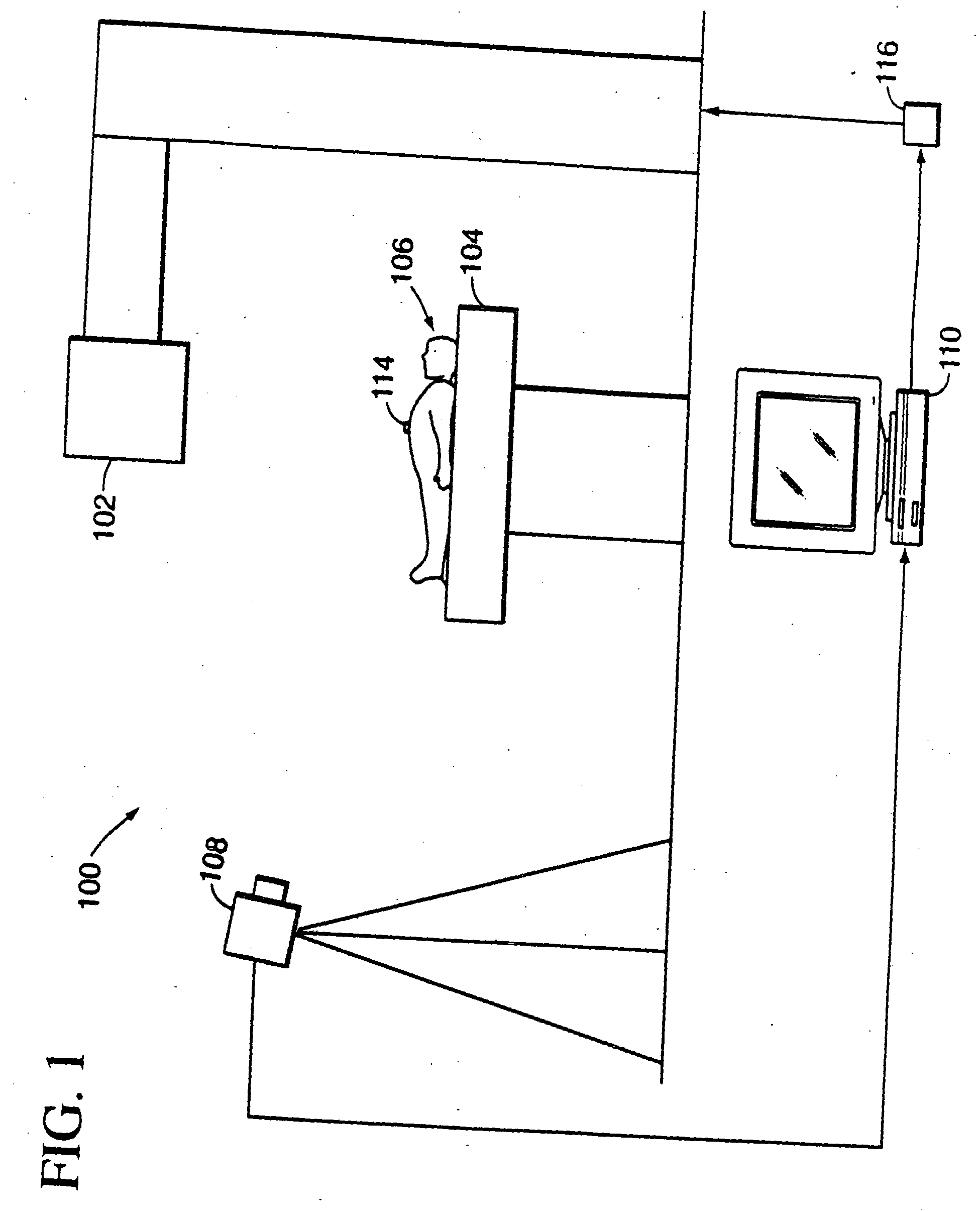

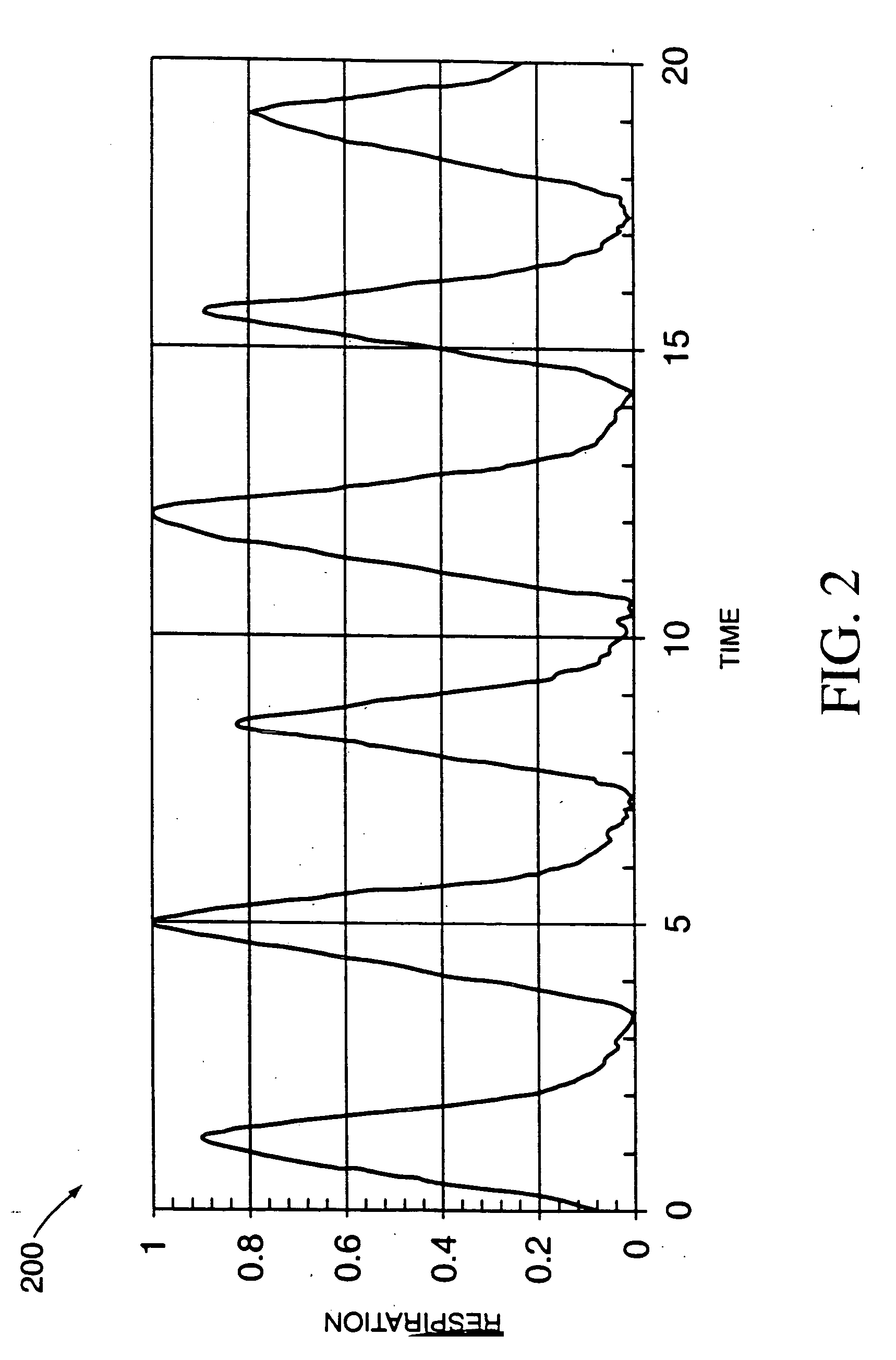

Method and system for predictive physiological gating

InactiveUS20050201510A1Consistent positionEasy to FeedbackSurgeryDiagnostic markersRetrospective gatingComputed tomography

A method and system for physiological gating is disclosed. A method and system for detecting and predictably estimating regular cycles of physiological activity or movements is disclosed. Another disclosed aspect of the invention is directed to predictive actuation of gating system components. Yet another disclosed aspect of the invention is directed to physiological gating of radiation treatment based upon the phase of the physiological activity. Gating can be performed, either prospectively or retrospectively, to any type of procedure, including radiation therapy or imaging, or other types of medical devices and procedures such as PET, MRI, SPECT, and CT scans.

Owner:VARIAN MEDICAL SYSTEMS

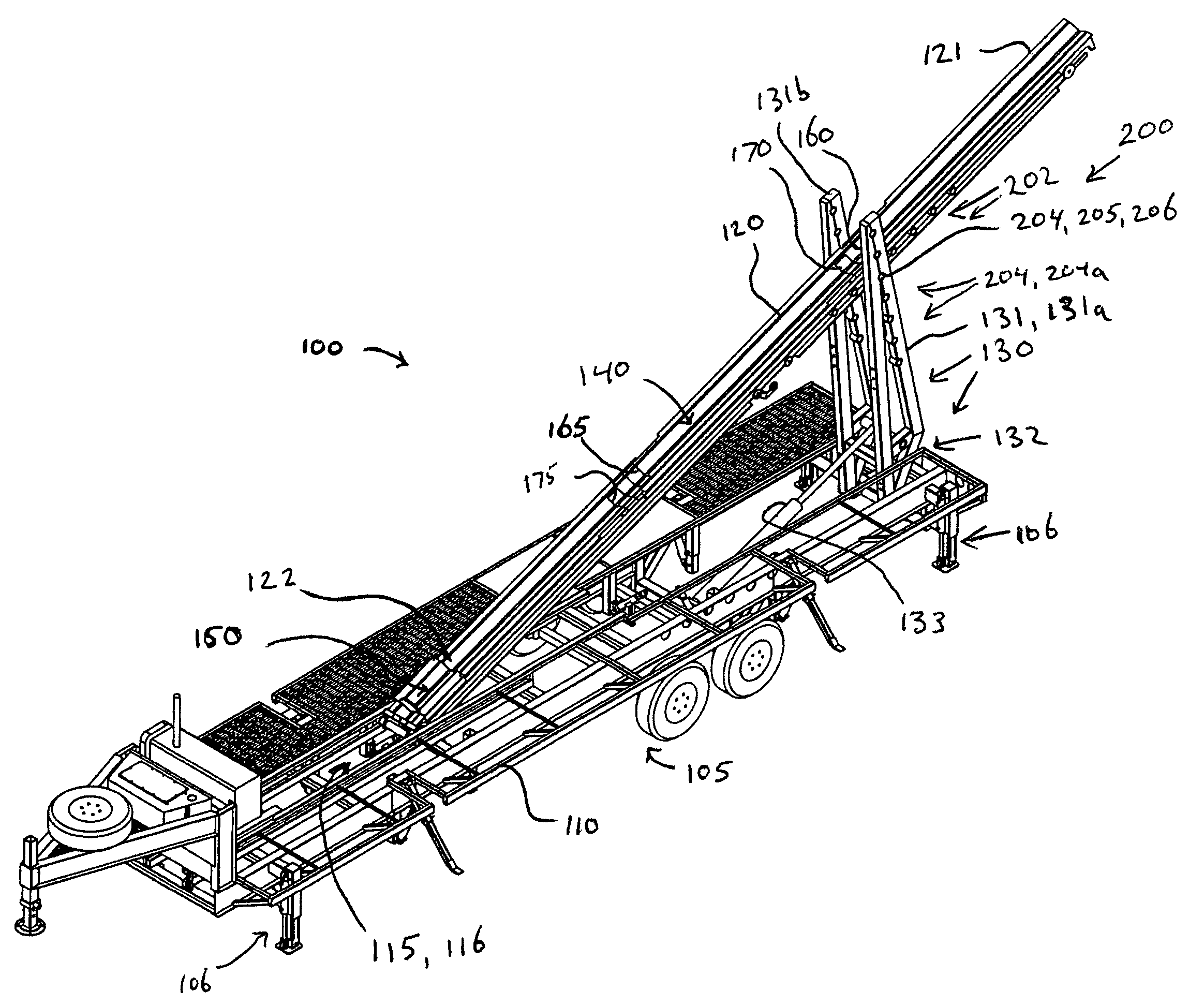

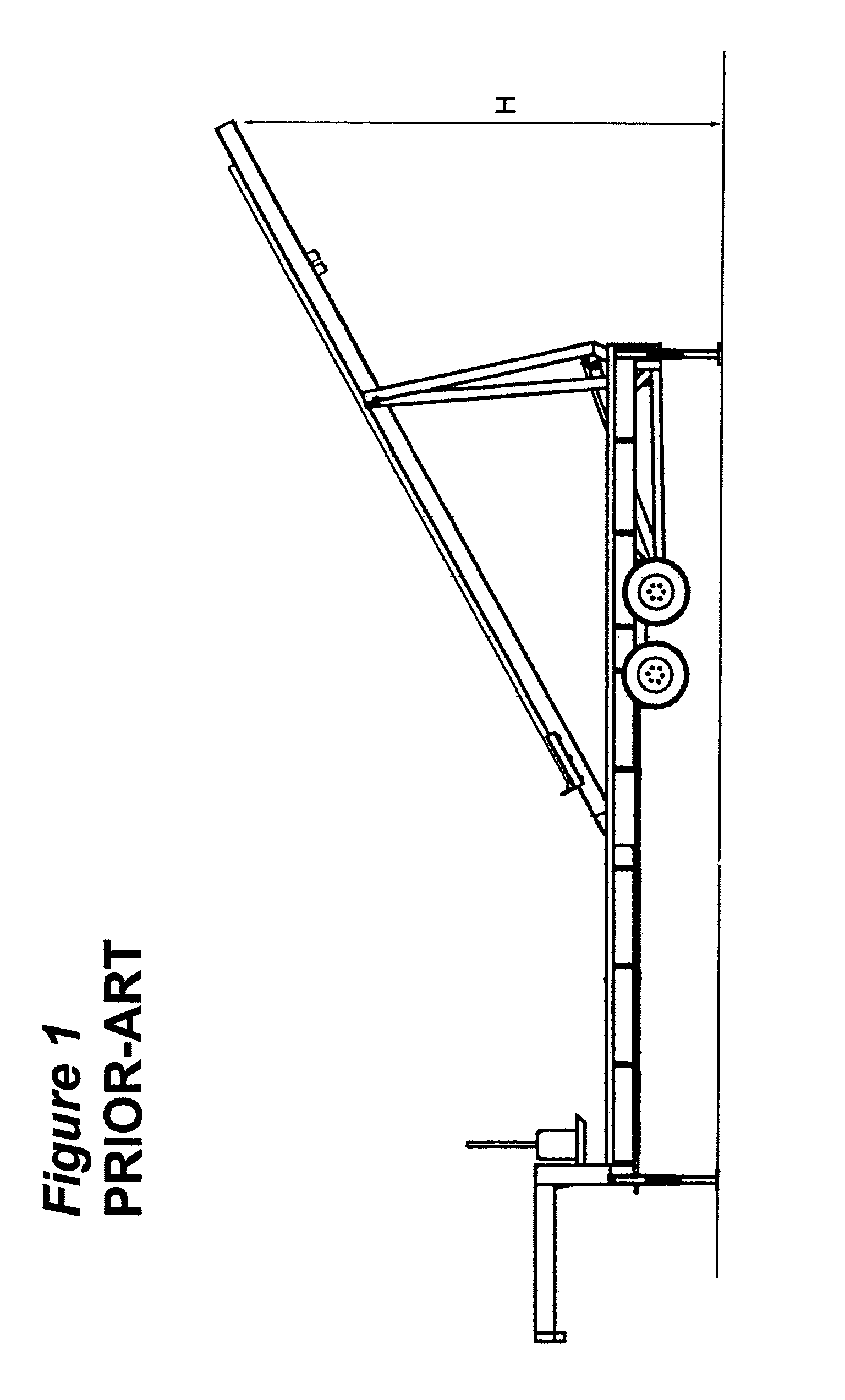

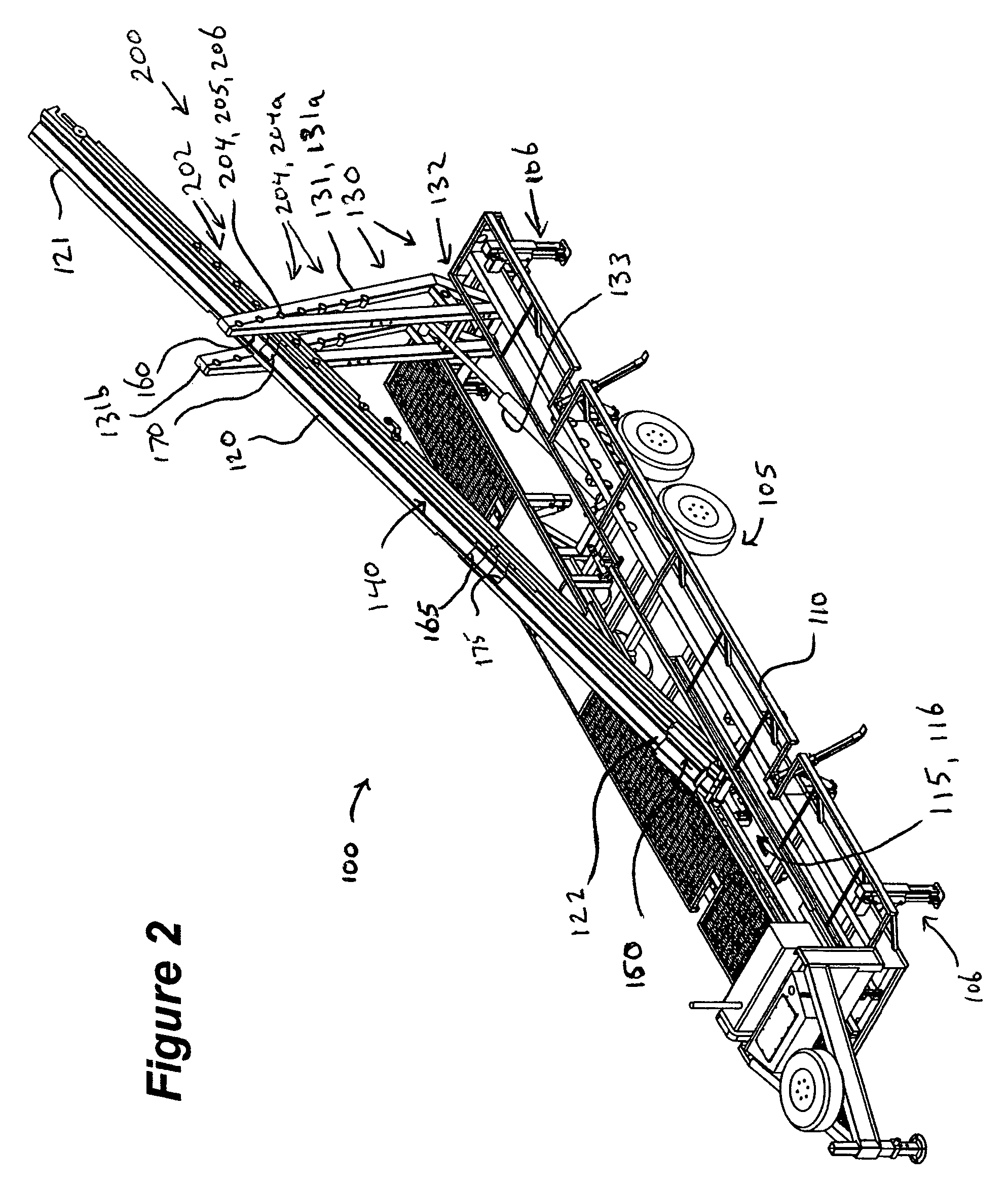

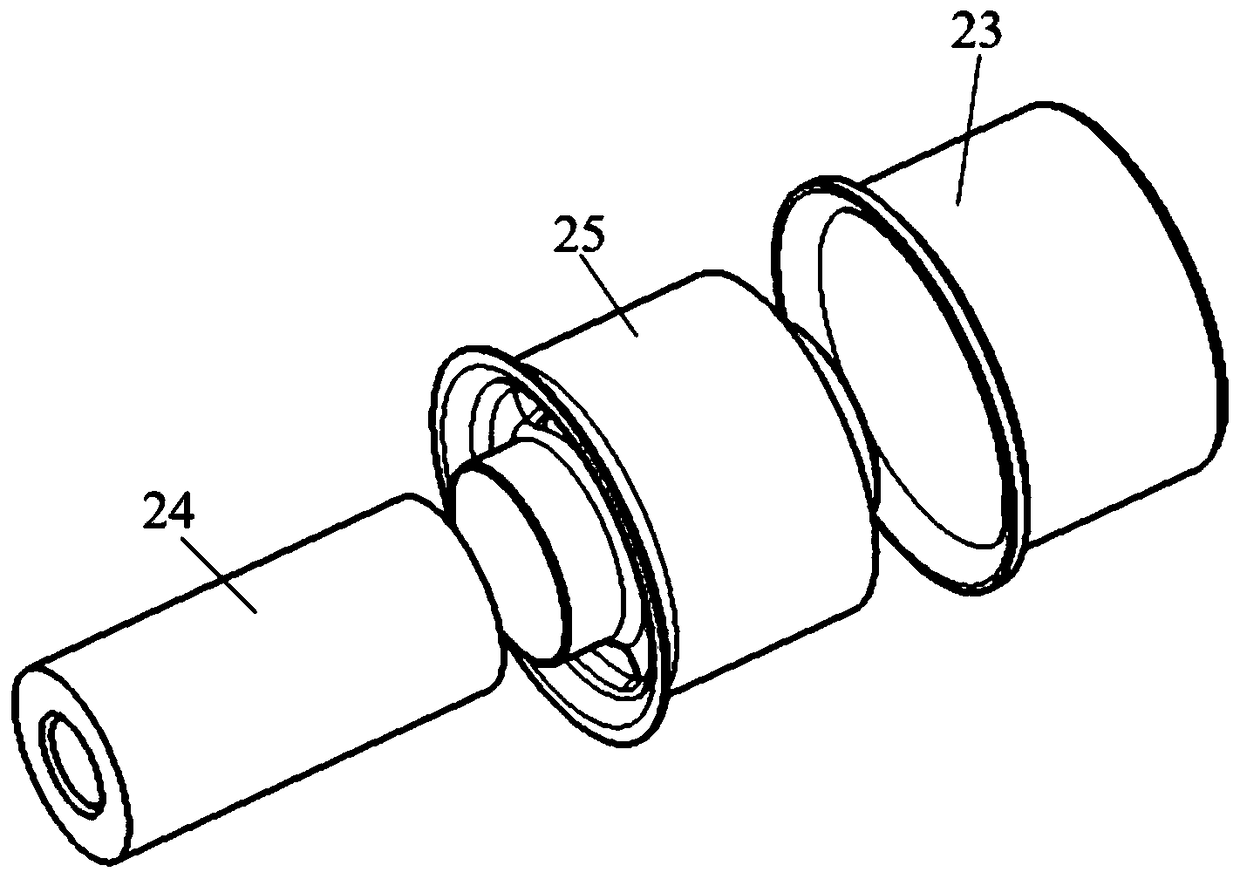

Multi-position height adjustment system for a pipe handling apparatus

ActiveUS7163367B2Easy to adjustConsistent positionPipe laying and repairDrilling rodsEngineeringCantilever

A system for adjusting the height of a boom on a pipe handling apparatus. A cavity is formed in the base between proximal and distal ends. The boom is nestable in said cavity and has a distal end guided along the base. A pivoting member is pivotally coupled to said boom for raising a proximal end for positioned adjacent a work floor for handling of pipe therebetween. A plurality of ports are arranged along the boom at a pre-determined spacing. A plurality of ports are is similarly arranged along the same predetermined spacing along the pivoting member. The spacing of the boom and arm ports is such that a hinge pin can engage any one of corresponding pairs of boom and arm port when the boom is lowered to nestle inside the cavity as each boom port corresponds with an arm port.

Owner:FORUM US

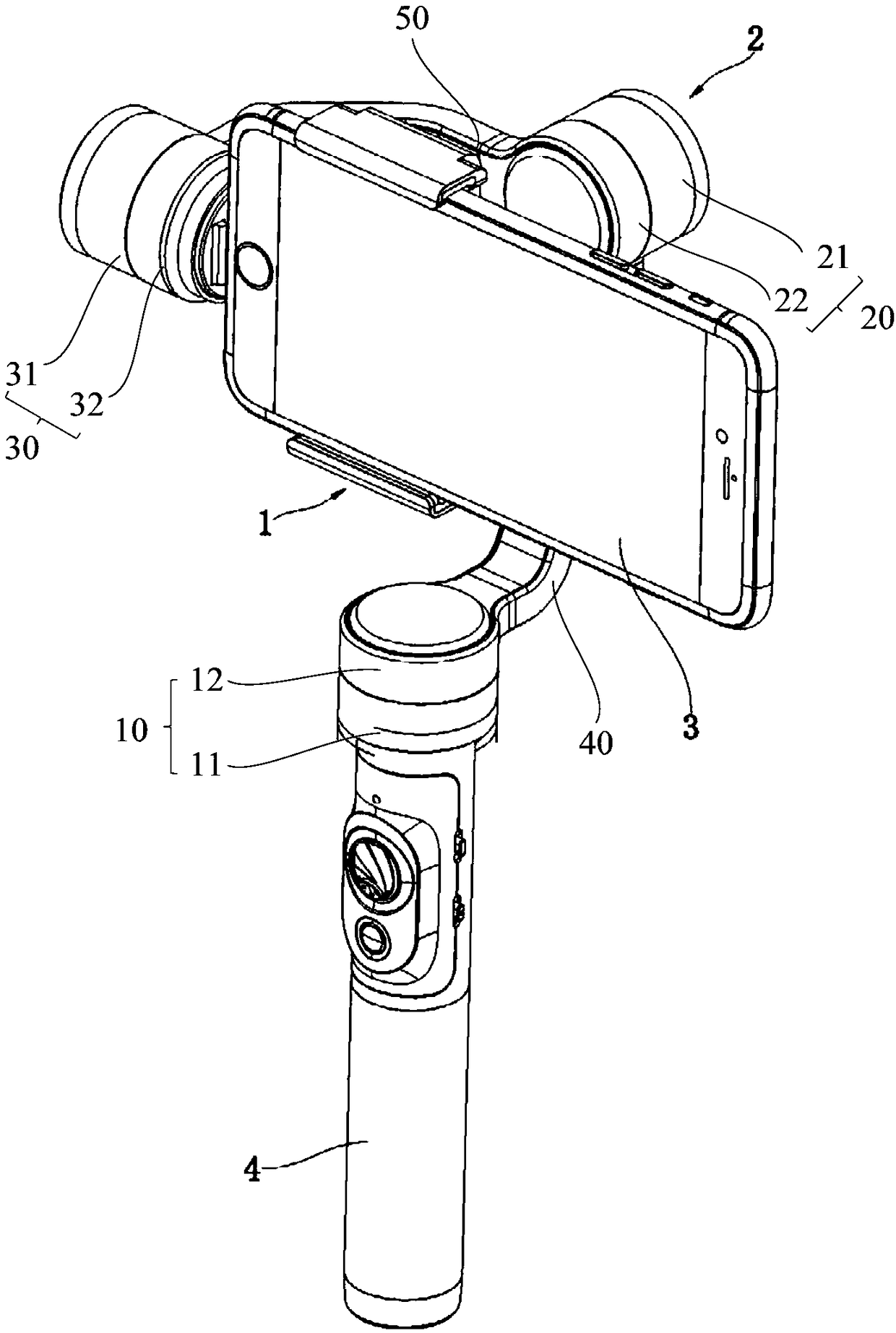

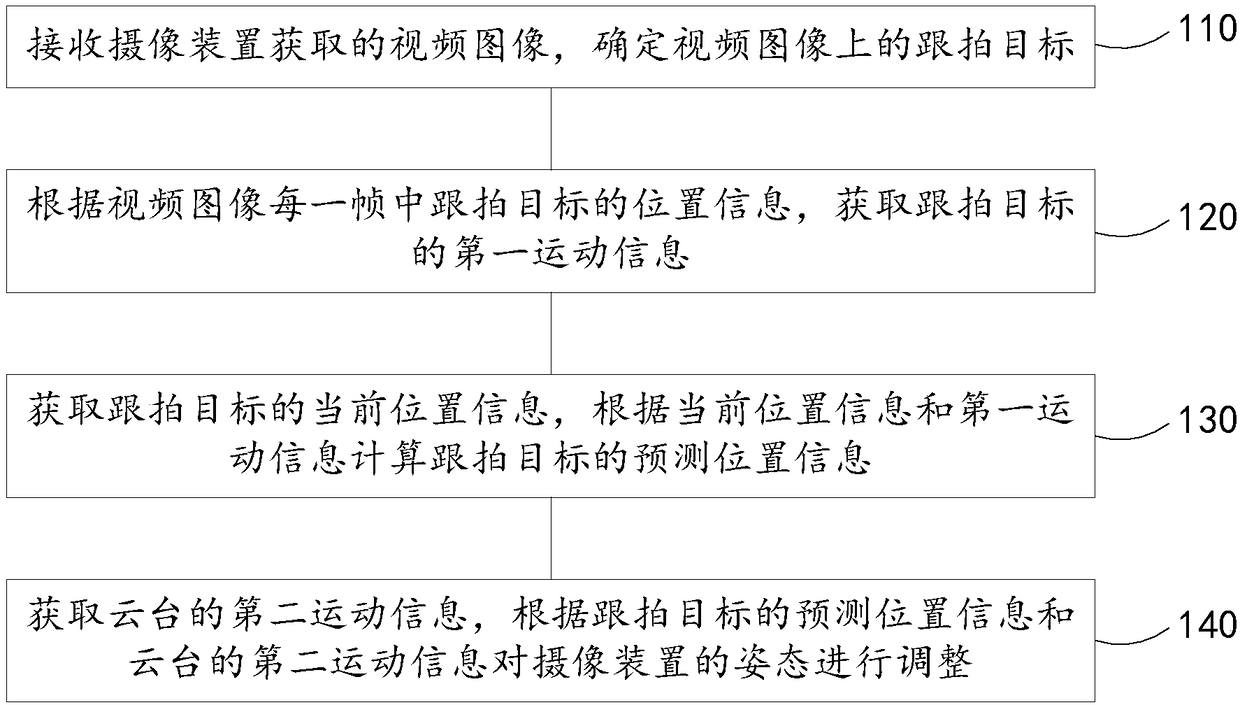

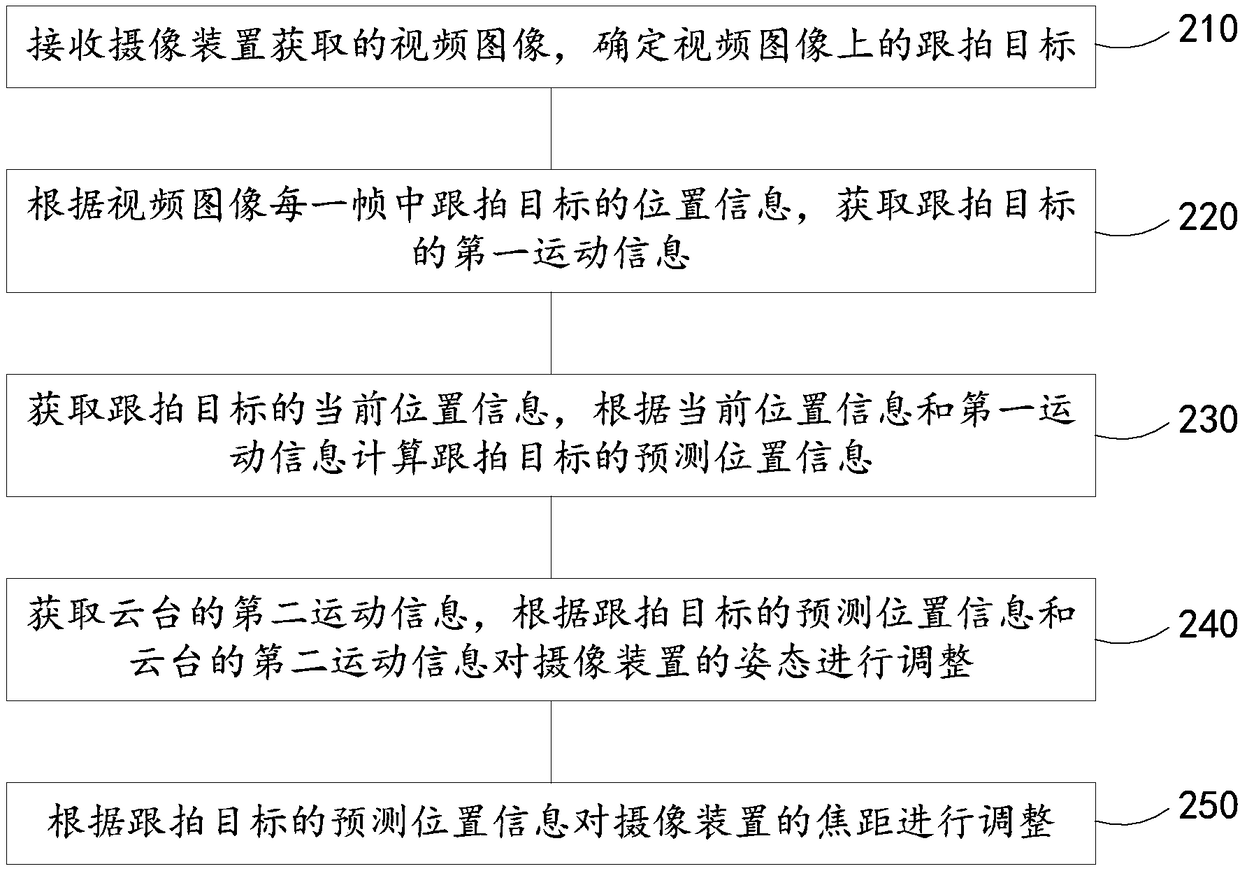

Following shot control method and device of cradle head and cradle head

ActiveCN108259703AImprove real-time performanceConsistent positionTelevision system detailsColor television detailsComputer graphics (images)Video image

The invention discloses a following shot control method and device of a cradle head and the cradle head; the cradle head is used for installing a photographic device; the method comprises the following steps of receiving a video image acquired by the photographic device and determining a following shot target of the video image; acquiring first motion information of the following shot target according to the position information of the following shot target in each frame of the video image; acquiring current position information of the following shot target; calculating predicated position information of the following shot target according to the current position information and the first motion information; and acquiring second motion information of the cradle head and adjusting the posture of the photographic device according to the predicted position information and the second motion information. According to the method, in the following shot process, the positions of the followingshot target can be kept consistent in the video image, so that the shot pictures are stable and coherent during the following shot process.

Owner:SHENZHEN YUEJIANG TECH CO LTD

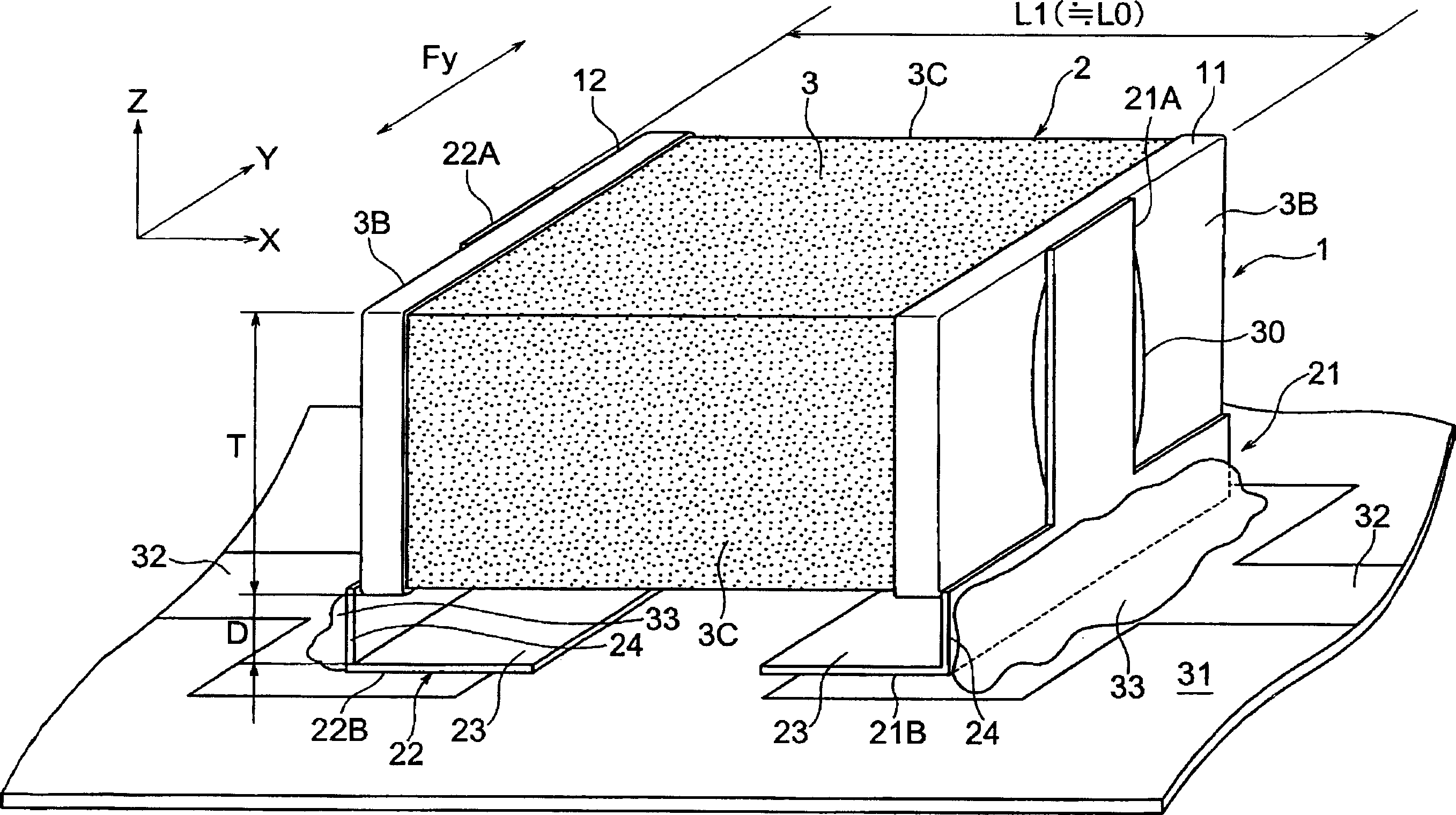

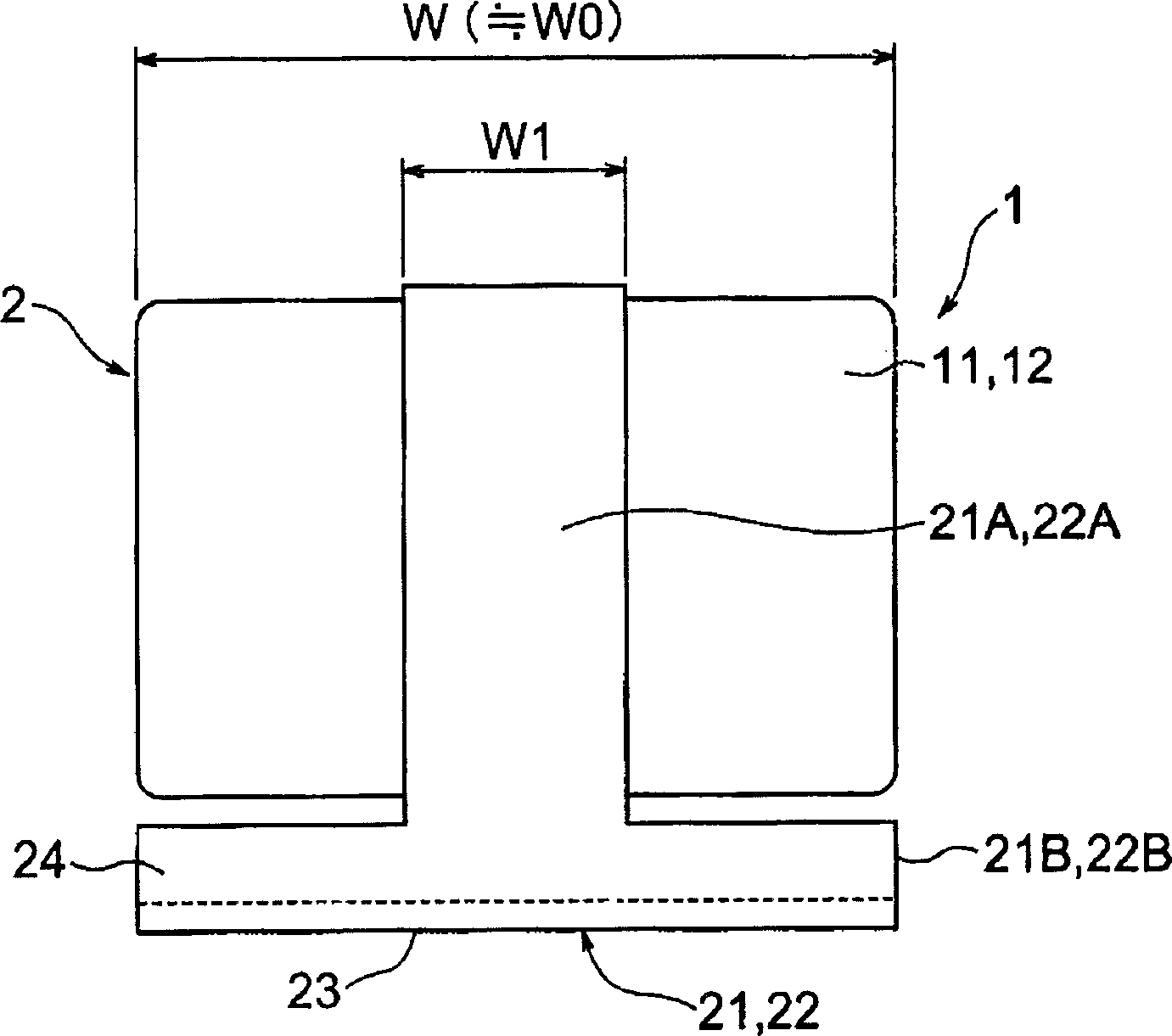

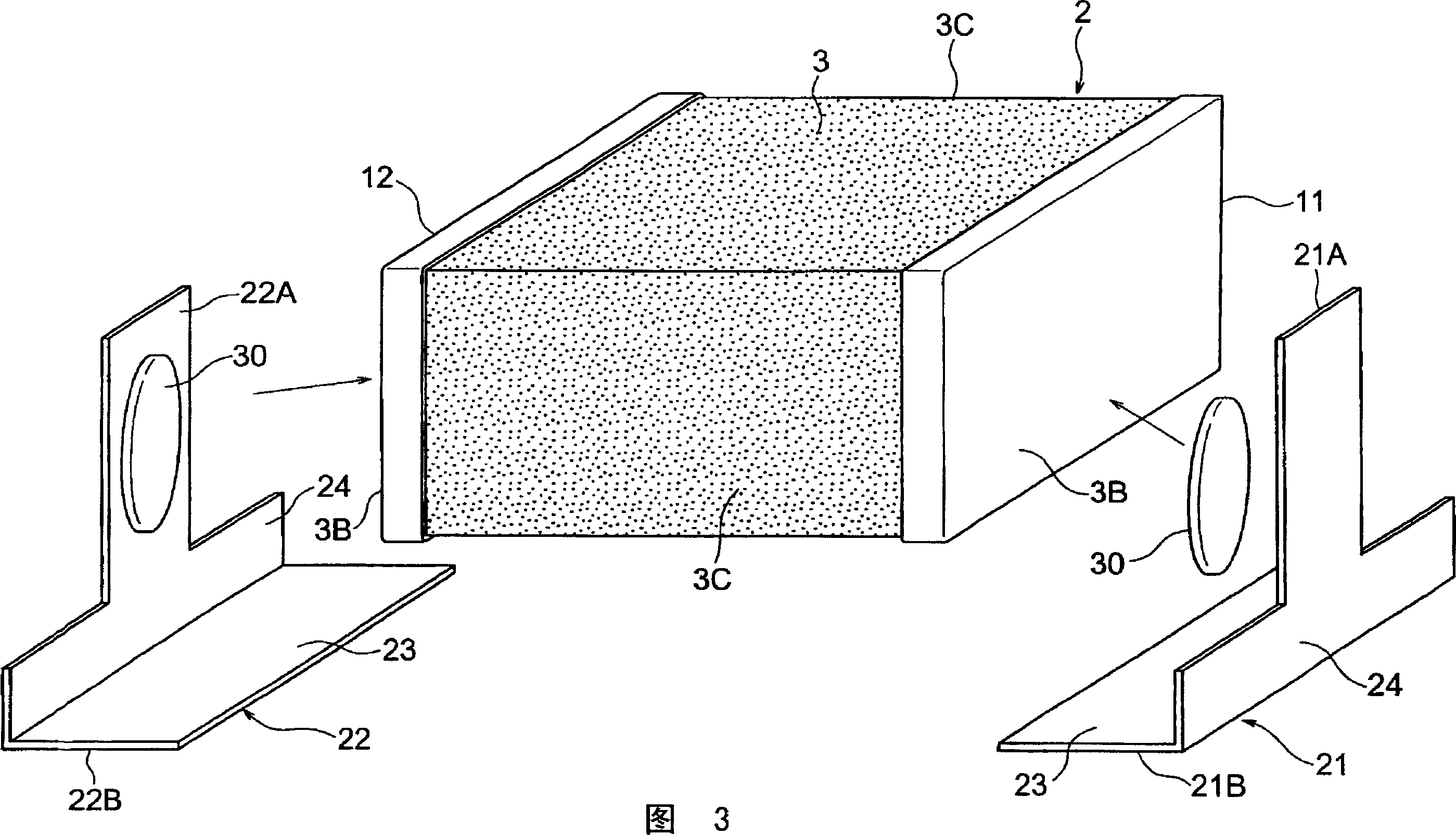

Electronic part

ActiveCN1532860AConsistent positionReduce manufacturing costPrinted circuit assemblingPiezoelectric/electrostriction/magnetostriction machinesEngineeringCapacitor

Terminal electrodes 11 and 12 of a main body 2 of a multilayer capacitor 1 are connected to electrode connection parts 21A and 22A of a pair of external terminals 21 and 22 formed by a metal material. At the bottom part of the electrode connection part 21A, an external connection part 21B connected to the electrode connection part 21A is formed. At the bottom part of the electrode connection part 22A, an external connection part 22B connected to the electrode connection part 22A is formed. The widths of the terminal electrodes 11 and 12 and the widths of the external connection parts 21B and 22B are substantially the same, but the widths of the electrode connection parts 21A and 22A are formed narrower. Due to this, propagation of vibration can be suppressed and generation of noise reduced.

Owner:TDK CORPARATION

Instrument and method for the insertion and alignment of an intervertebral implant

ActiveUS8298235B2The method is simple and reliablePrecise positioningInternal osteosythesisJoint implantsDistractionCoronal plane

The present invention includes pin guides and methods for placing pins in adjacent vertebrae. The present invention also includes methods for placing pins in adjacent vertebrae using the pin guides described herein. The present invention also includes an intervertebral implant insertion and alignment instrument, a distraction instrument, an intervertebral implant insertion guide, and methods for inserting an implant into an intervertebral space. Despite existing tools and techniques, present positioning of implants in intervertebral spaces and pins in adjacent vertebrae often depend on a surgeon's skill, experience and technique. Practice of the present invention can aide in the placement of an implant into an intervertebral space and placement of pins in adjacent vertebrae, e.g., midline to the coronal plane spine and / or parallel to vertebral endplates that abut the intervertebral space.

Owner:DEPUY SPINE INC (US)

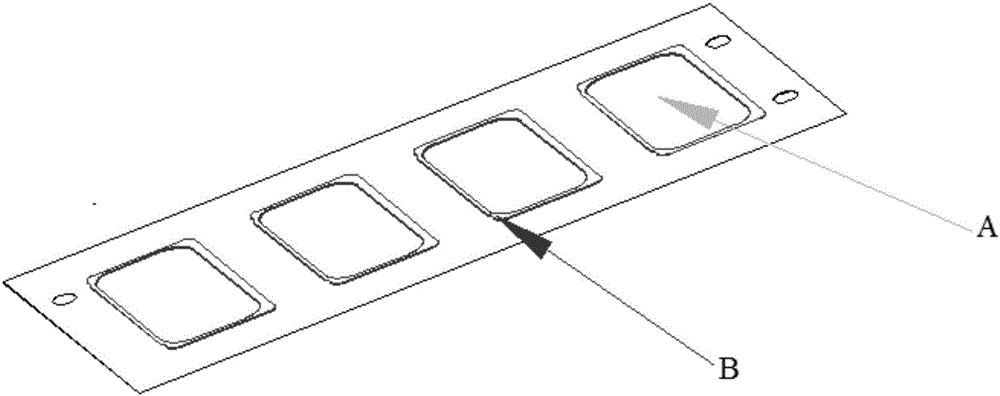

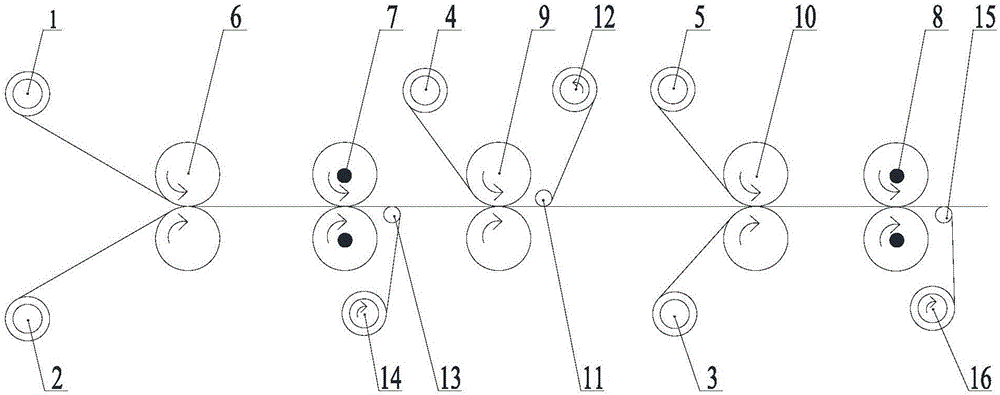

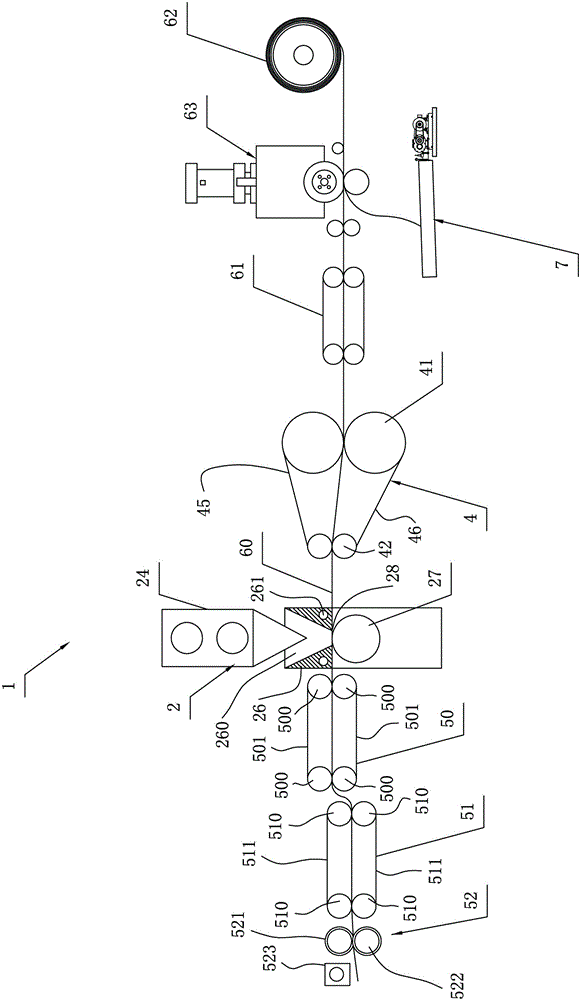

Die-cutting waste discharge device with inner frame die-cutting piece and die-cutting waste discharge method

InactiveCN106541449AGood waste discharge effectThe waste disposal process went smoothlyMetal working apparatusTectorial membranePunching

The invention relates to a die-cutting waste discharge device with an inner frame die-cutting piece and a die-cutting waste discharge method. The die-cutting waste discharge device comprises a first opposite-pressing roller, first-stamping die-cutting cutters, first waste discharge rollers, a second opposite-pressing mechanism, second-stamping die-cutting cutters and second waste discharge rollers which are arranged sequentially. The first opposite-pressing roller attaches a first single face gummed protective film to a first release film; indent inner frames are punched in first stamping by the first-stamping die-cutting cutters; the first waste discharge rollers is used to take up the first single face gummed protective films attached to wastes of the inner frames after the first-stamping punching; the second opposite-pressing mechanism attaches a second single face gummed protective film to the non-release surface of the first release film, and sequentially attaches double faced adhesive tape and a second release film to the release surface of the first release film; normal inner frames are punched in second-stamping by the second-stamping die-cutting cutters; the second waste discharge rollers are used to take up the second single face gummed protective films attached to wastes of the inner frames after the second-stamping punching; and the size of each normal inner frame is bigger than the size of each indent inner frame. Compared with the prior art, the die-cutting waste discharge device has the advantages that the effect of waste discharge is good, the product has no deformation, and efficiency is high.

Owner:YUANRANG IND SHANGHAI

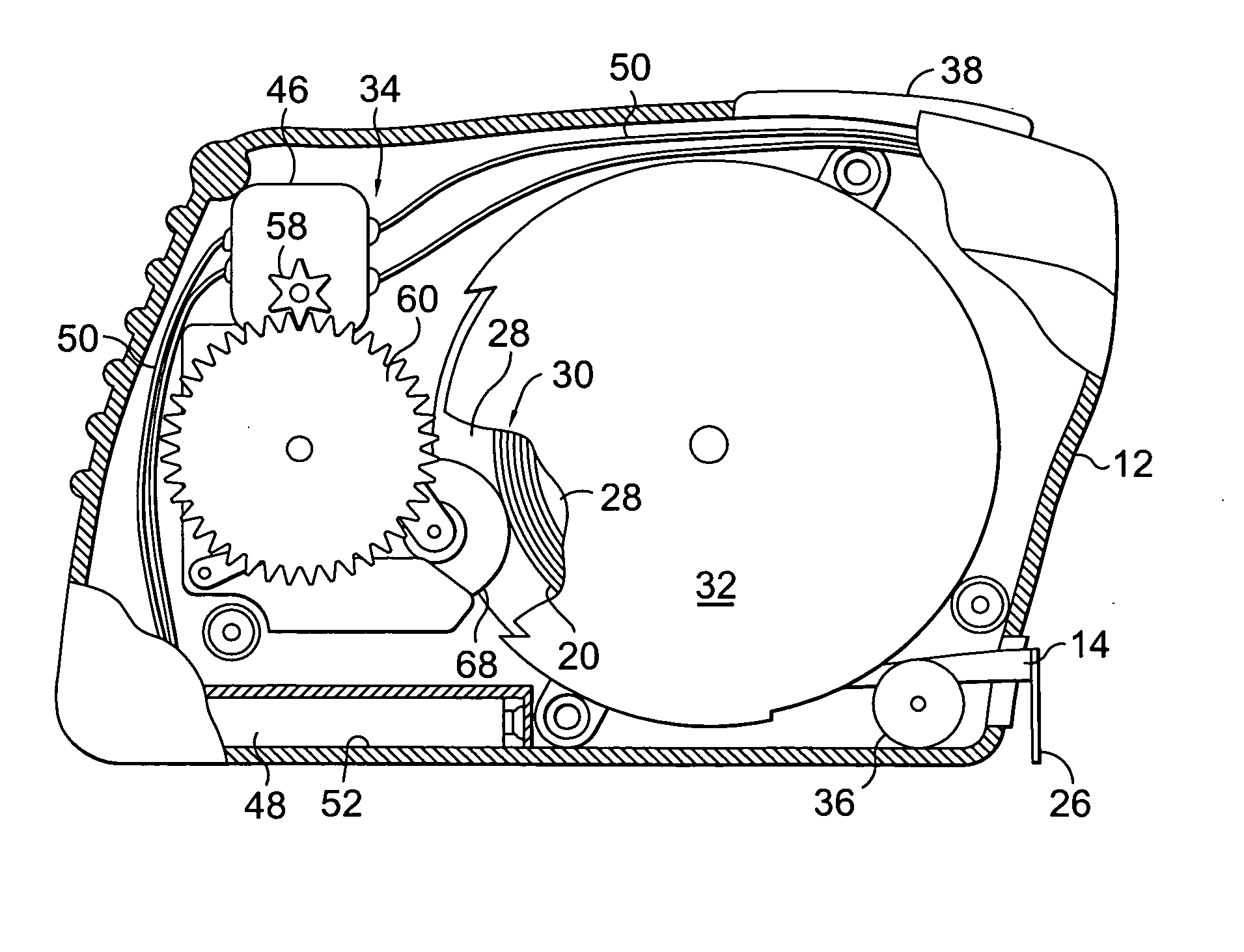

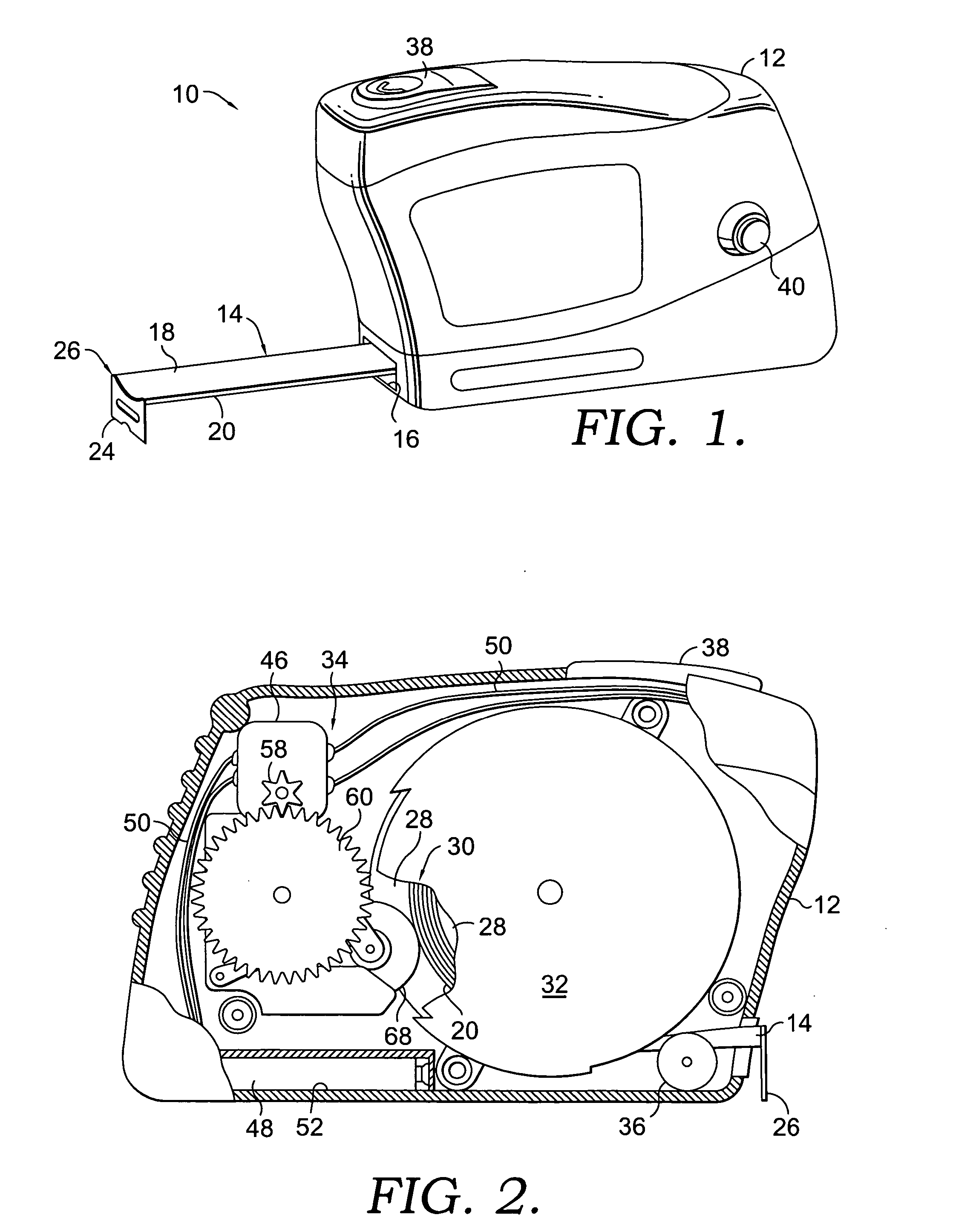

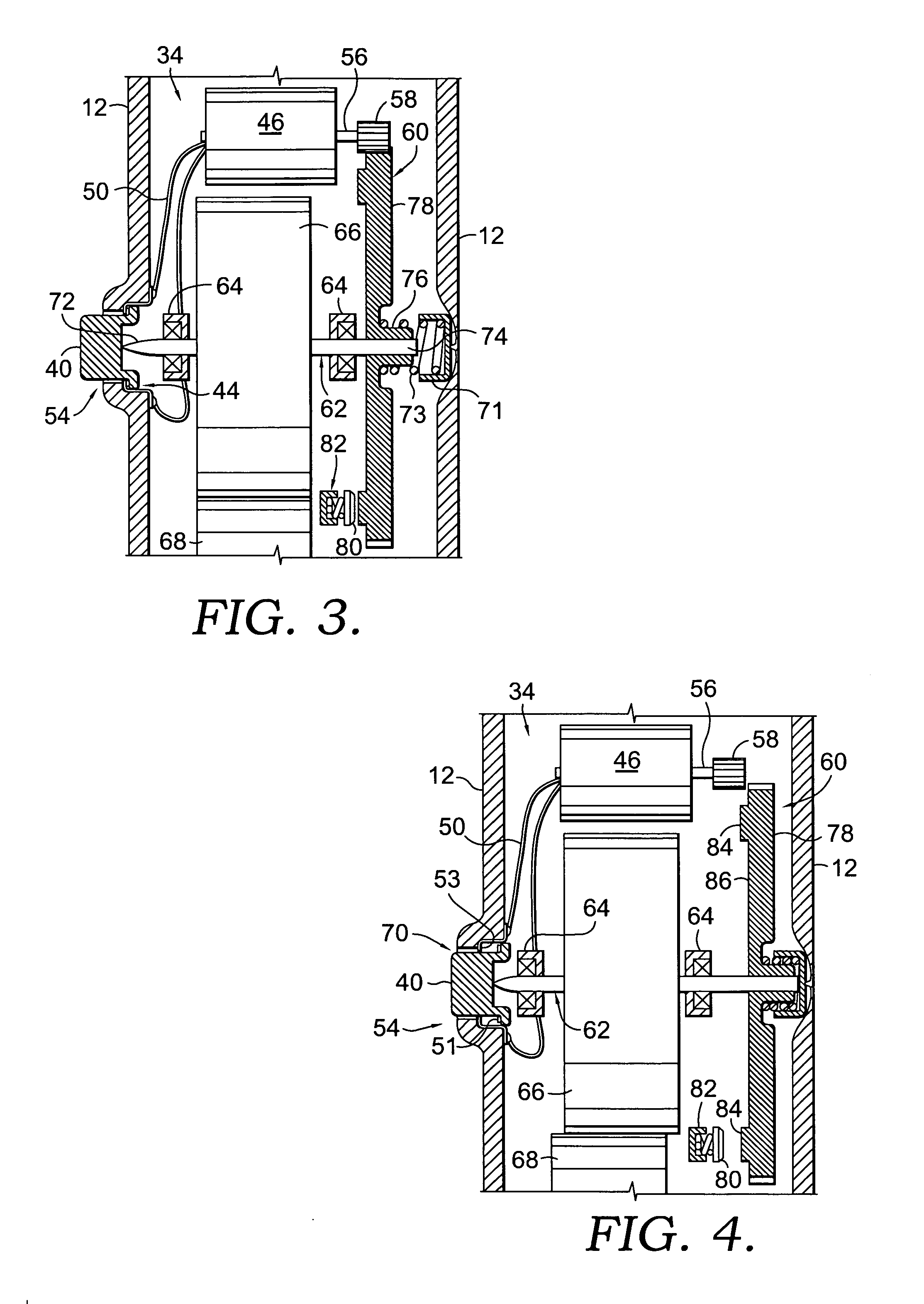

Tape measure utilizing mechanical decoupling of power tape extension feature for tape retraction

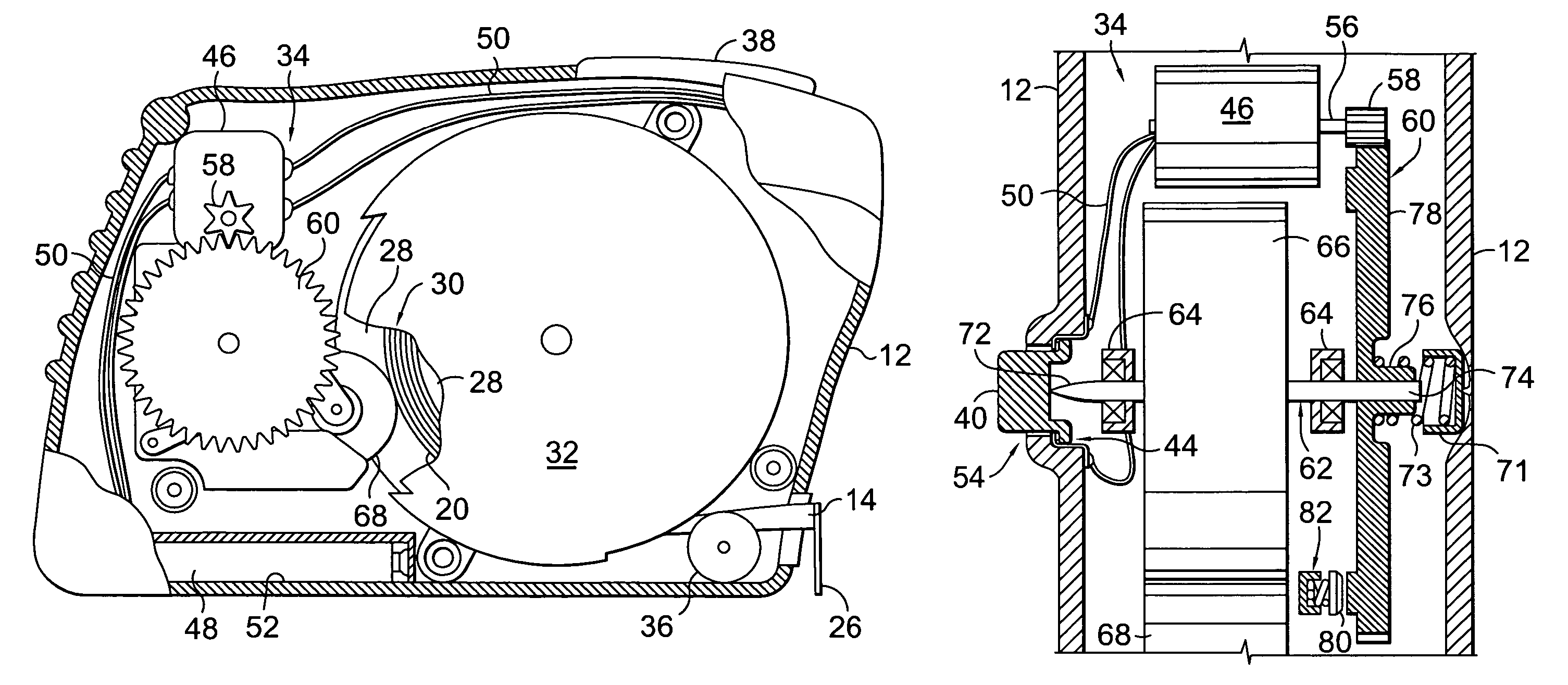

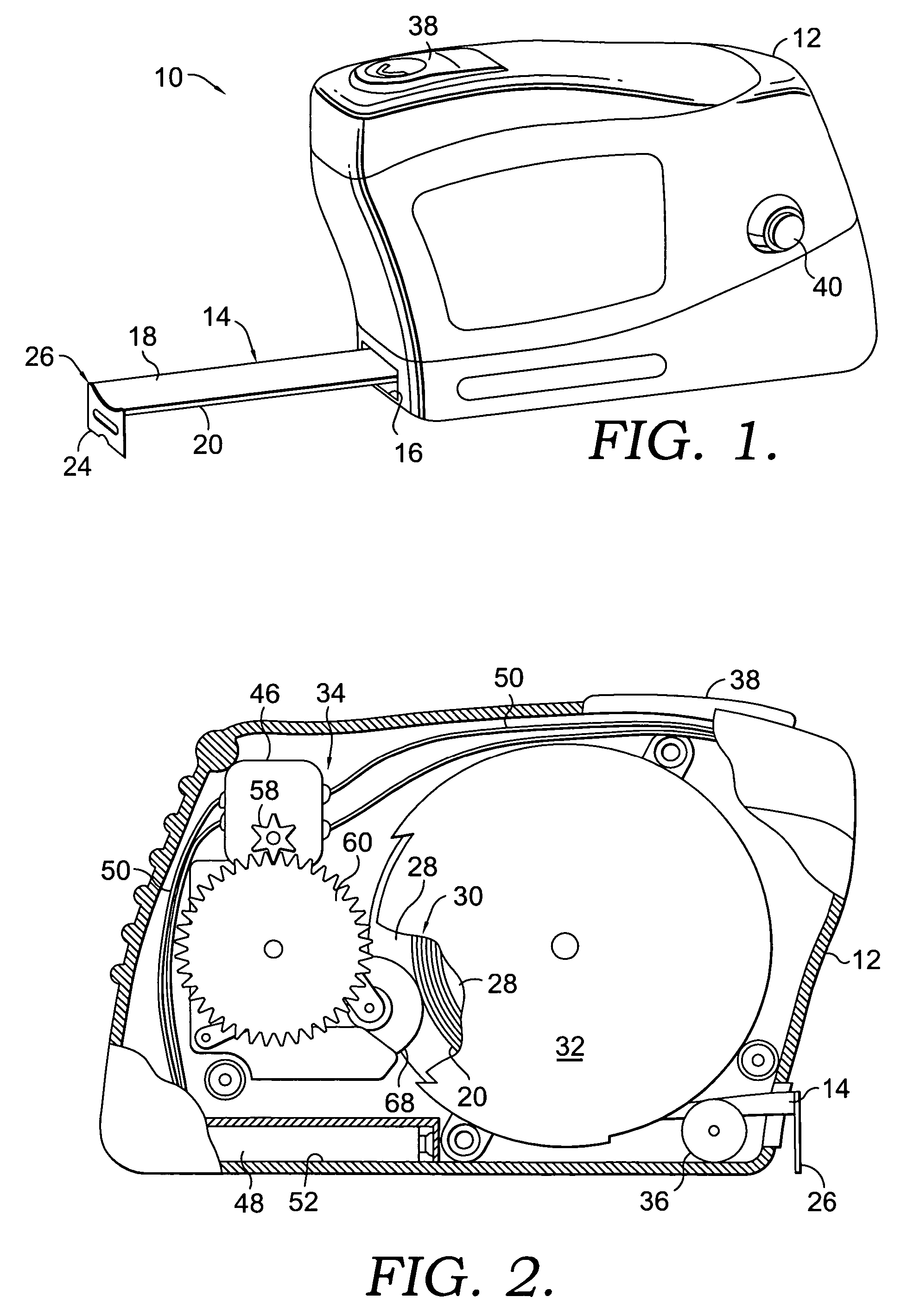

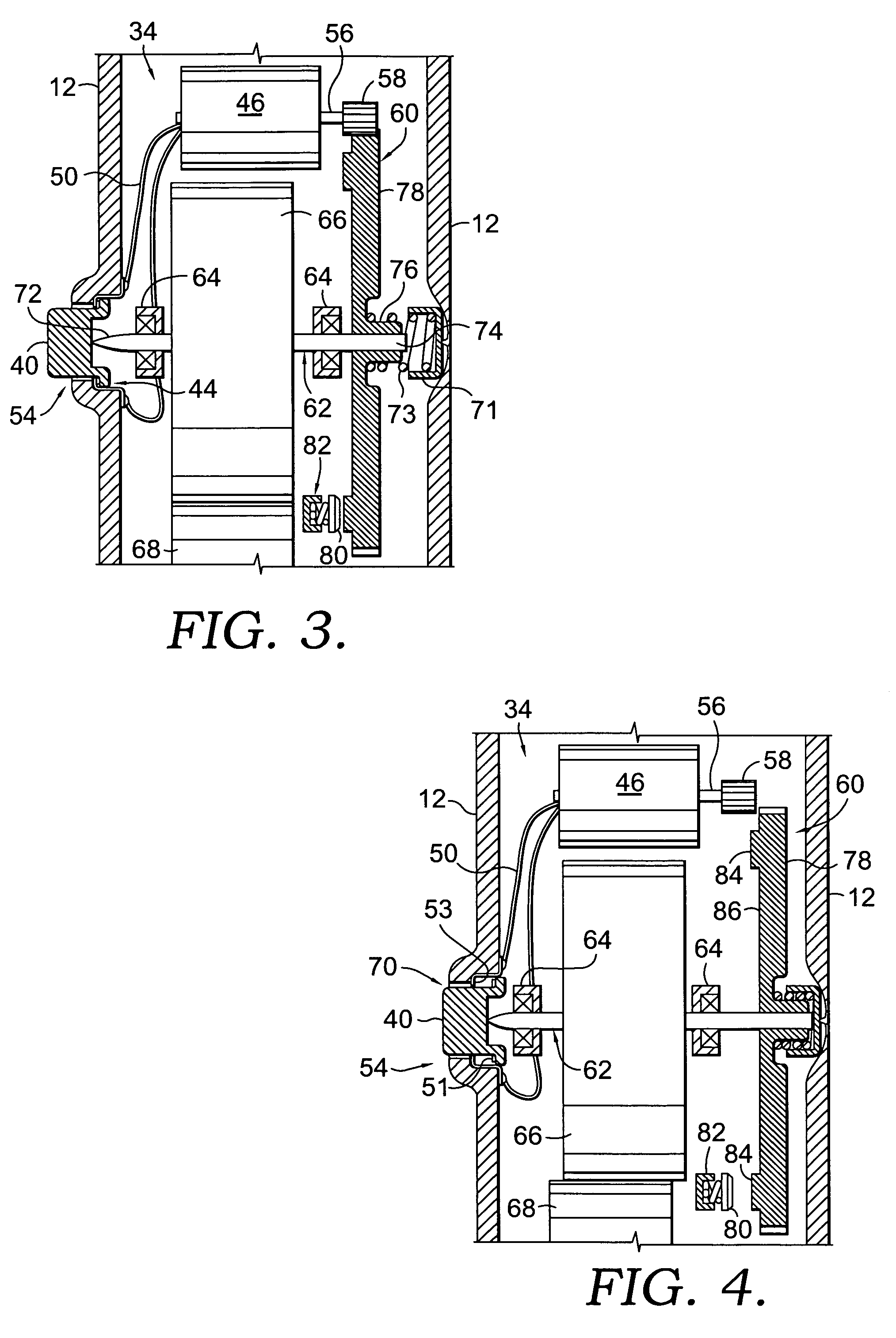

InactiveUS7475842B2Easily and consistently initiate drive mechanismConsistent positionMeasuring tapesGear wheelMagnetic tape

A power operated tape measure enables extension of a tape via a drive mechanism, as well as retraction of the tape through a mechanical decoupling within the drive mechanism. The tape measure has a housing within which is positioned a spring-biased tape assembly, the drive mechanism and a clutch. The spring-biased tape assembly includes an annular reel onto which is wound a tape having indicia for taking length measurements. The drive mechanism includes a driving gear and a driven gear, and is adapted to engage with a bottom surface of the tape to extend the tape out of the housing. The clutch is adapted to displace the driven gear out of engagement with the driving gear and thereby decouple the driving and braking force provided by the drive mechanism from acting upon the bottom surface of the tape to permit the spring-biasing of the tape assembly to retract the tape into the housing.

Owner:BLACK & DECKER INC

Golf club grip

InactiveUS7435186B1Repeatable and increased controlImprove accuracyGolf clubsRacket sportsEngineeringGolf Ball

An improved golf club grip, adaptable to a golf club shaft, which promotes a more correct grip positioning, having a grip body, having a longitudinal axis, a top end with a first diameter and a flared cap with outwardly disposed sides attached thereto, a shaft end with a second diameter, an internal surface, an external surface with a uniformly and progressively increasing diameter from the first diameter to the second diameter, and at least one reminder rib, preferably y-shaped in configuration, extending from the external surface, aligned with the longitudinal axis of the grip body and intersecting with the outwardly sides of the flared cap that allows the golfer to carry or hold the grip more loosely in the fingers because of the reverse taper feature.

Owner:MILLER R LEE

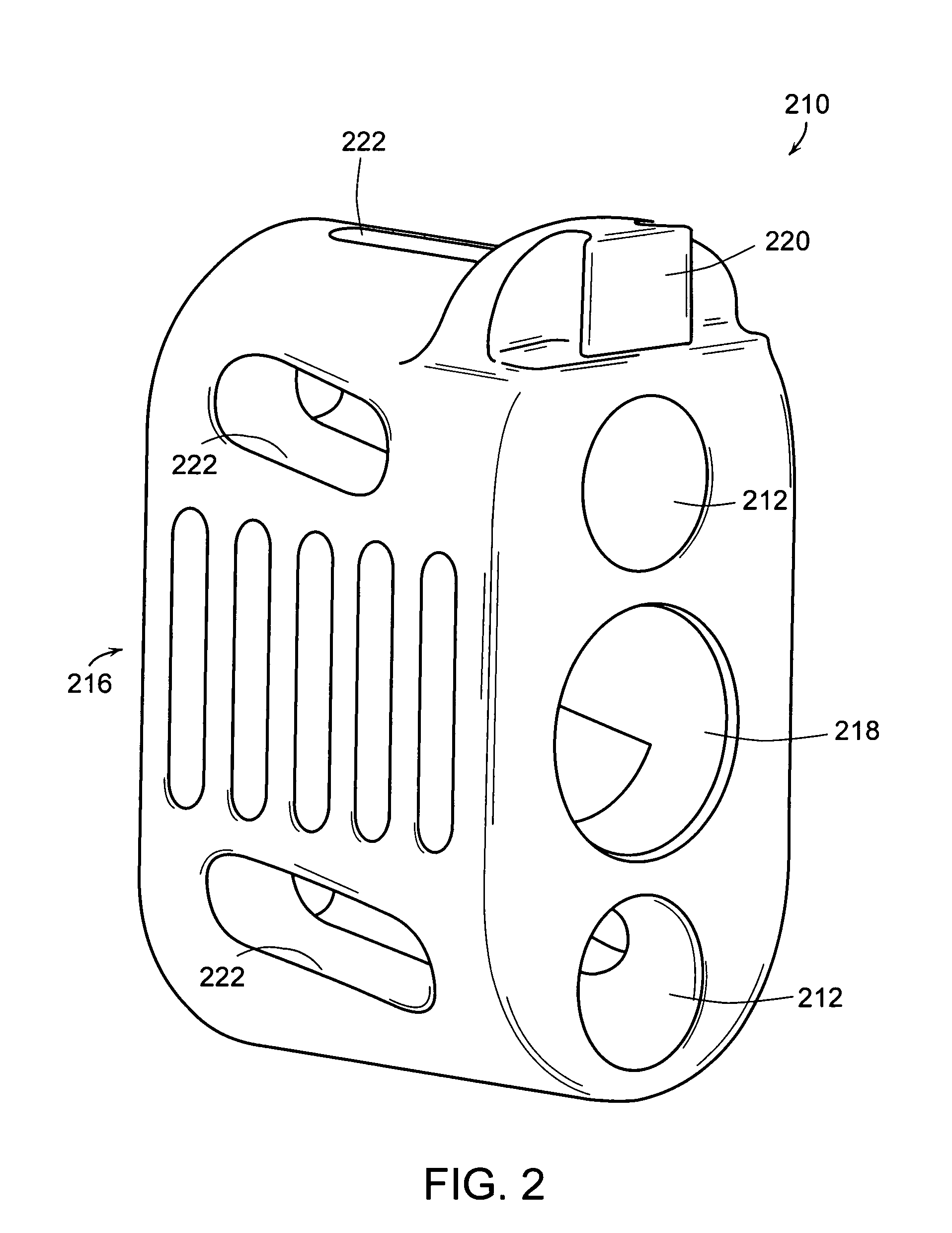

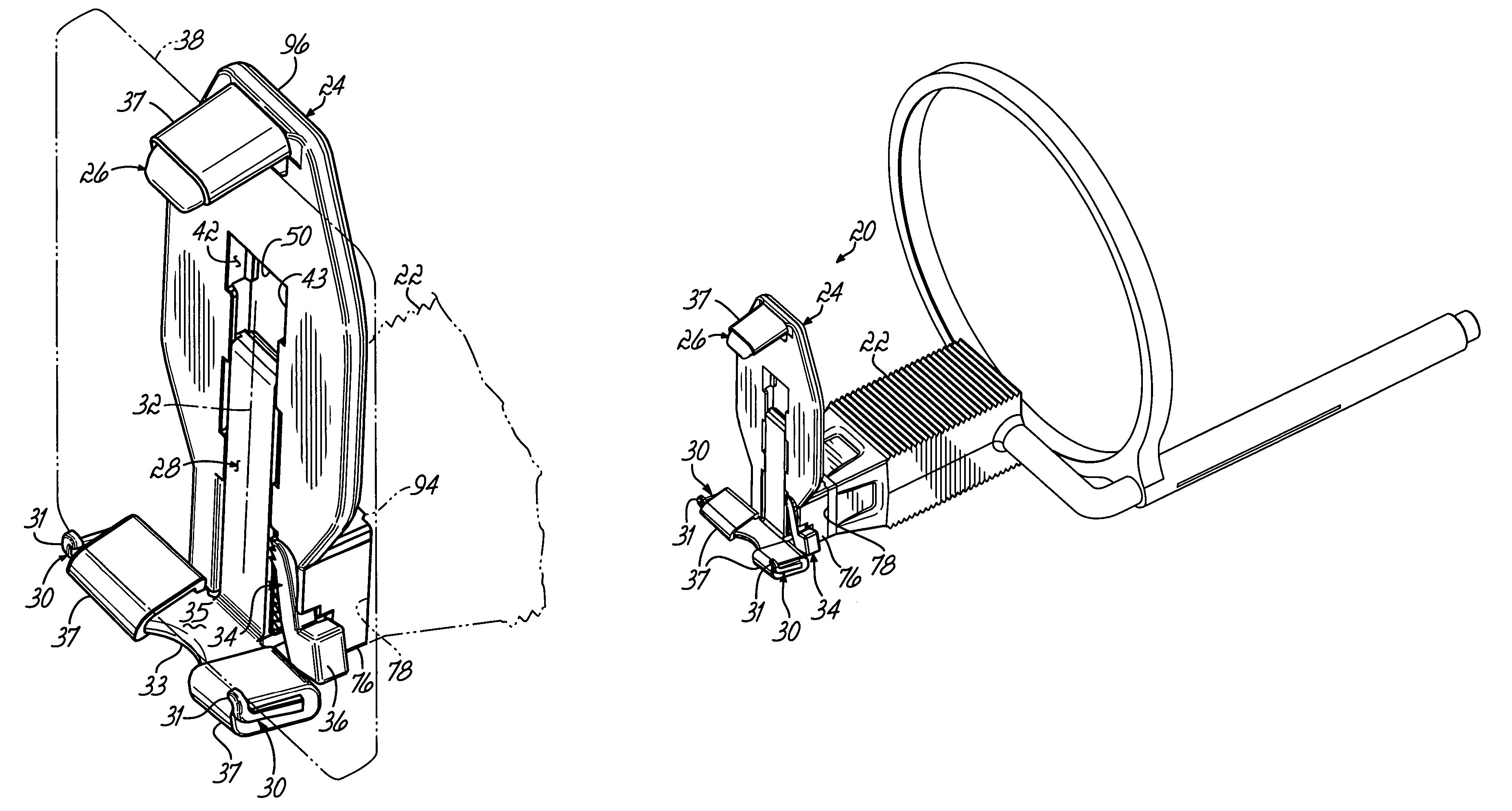

Dental sensor clamp

ActiveUS7195395B2Easy to useReliable sterilizationX-ray/infra-red processesRadiation diagnostics for dentistryBite platesBiting plates

Owner:KERRHAWE

High-yield cultivation method for sweet potatoes

InactiveCN105027883AMany buried knotsConsistent positionPlant cultivationCultivating equipmentsDiseaseCataphyll

The invention discloses a high-yield cultivation method for sweet potatoes. The high-yield cultivation method comprises the following concrete steps: I, choosing an improved variety: the improved variety is the key to produce the sweet potatoes at high yield; according to the use and the sale, the improved variety is chosen in the light of local conditions, and especially, the new variety is particularly obvious in yield-increasing effect; II, cultivating strong seedlings: the roots of the strong seedlings are numerous and developed, after being planted, the seedlings survive quickly, and hair roots bear the sweet potatoes fruitfully, which lay the foundation for full stands, strong plants, numerous potatoes and big potatoes; the standards of the strong seedlings are shown as follows: thick and strong stems, short internodes, fat blades and moderate sizes, with the features of the improved variety, no diseases, plenty latex of cuts, 50cm to 70cm of vine length and more than 0.5cm of stem thickness; III, transplanting in real time; IV, performing scientific management; V, harvesting the sweet potatoes when potato leaves start to turn yellow and the air temperature is below 20 DEG C, wherein the sweet potatoes require to be harvested before the end of October, and potato tubers should be prevented from being damaged by digging during harvesting. The high-yield cultivation method disclosed by the invention has the advantages that seeds are saved by more than 1 / 3, the buried section number of seedling vines is large, covering of soil is slight, the soil temperature is high, and after ventilation, the survival rate is high.

Owner:邵利

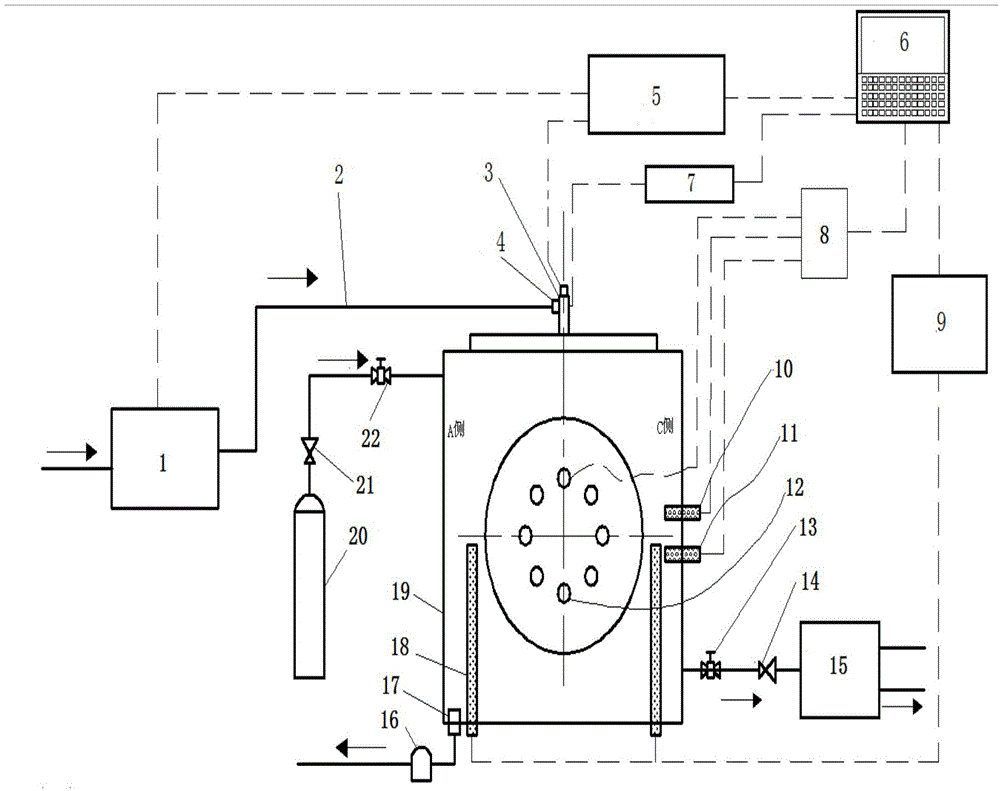

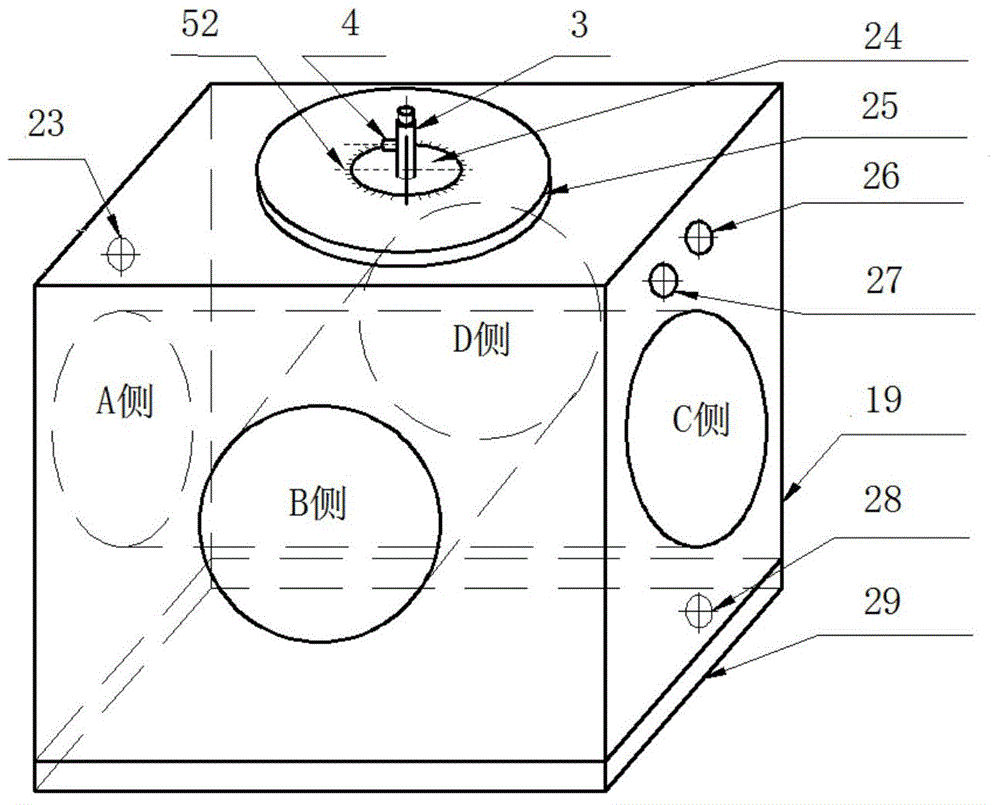

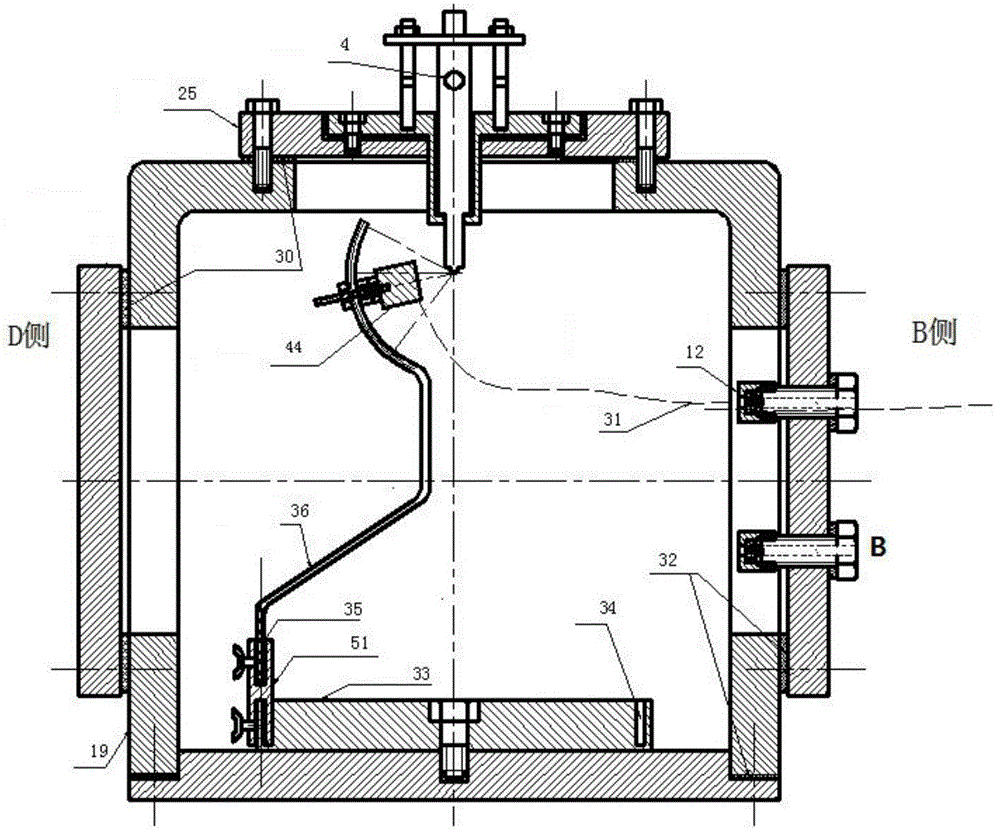

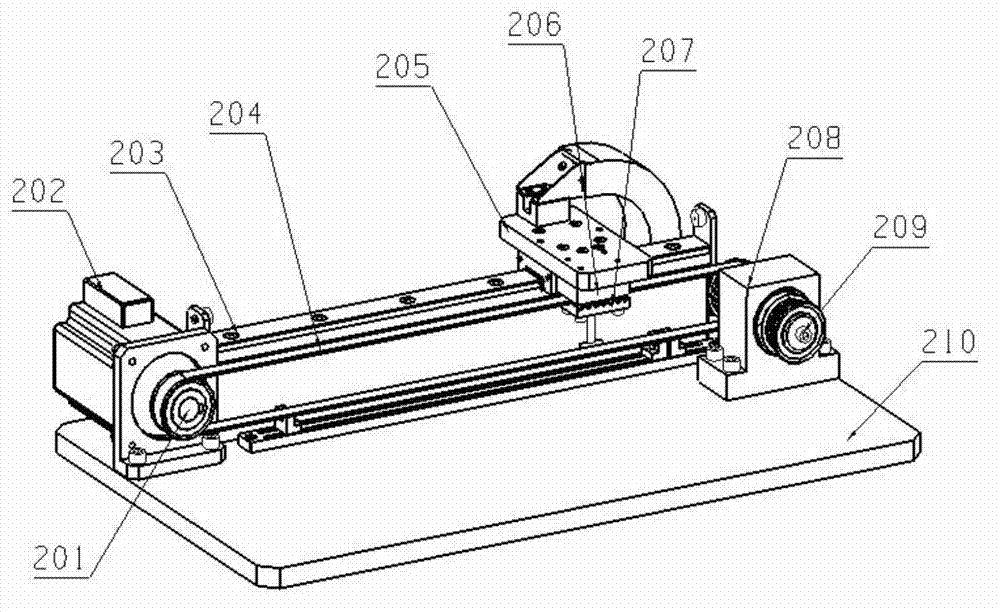

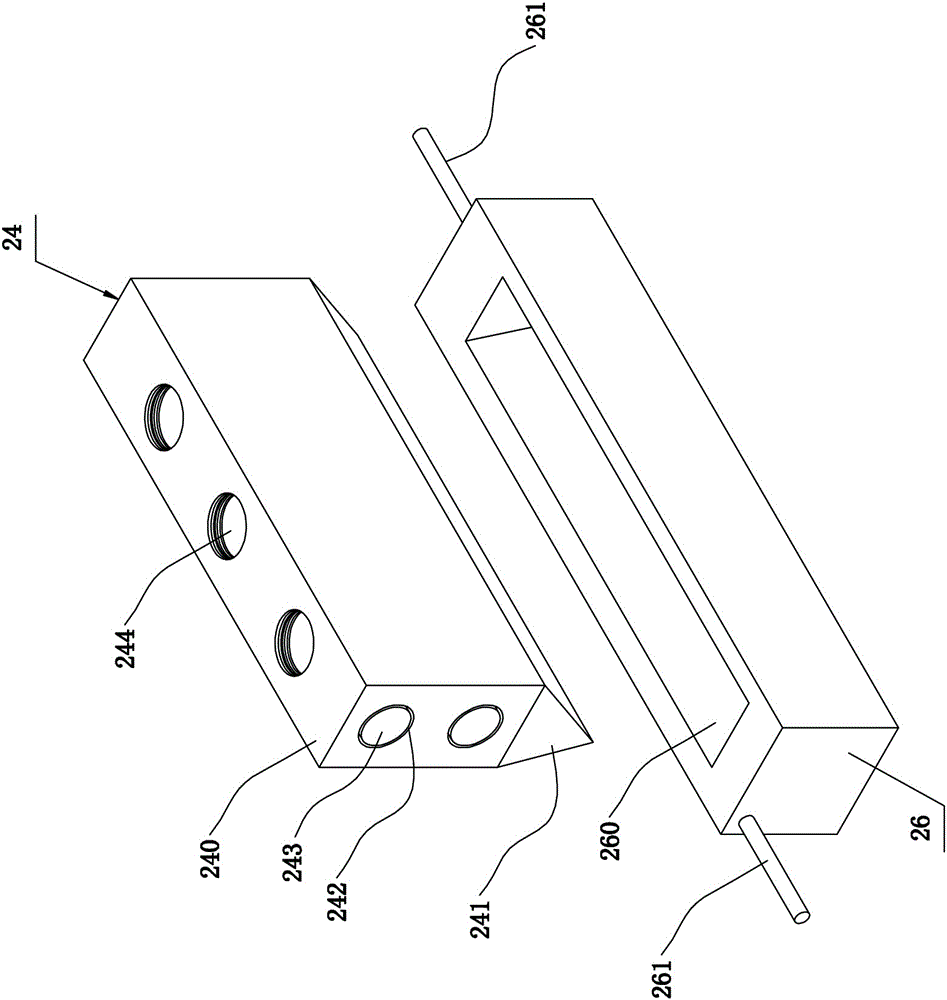

Measuring device for oil injection rule of each hole of oil injection nozzle of diesel engine

InactiveCN104405553AAccurate measurementAchieve heatingEngine testingFuel injection apparatusData acquisitionDiesel engine

The invention provides a measuring device for an oil injection rule of each hole of an oil injection nozzle of a diesel engine. The measuring device comprises a constant volume bomb matrix with holes in the upper end face, a data acquisition and analysis system and a computer, wherein at least sensor devices same as the holes of the to-be-measured oil injection nozzle in number are arranged in the constant volume bomb matrix; each sensor device comprises a force sensor, a bracket and a pedestal; each pedestal is positioned on a lower end cover of the constant volume bomb matrix; the end face, close to the to-be-measured oil injection nozzle, of each force sensor connected with the corresponding bracket is perpendicular to the axis of a to-be-measured injection hole; the data acquisition and analysis system is connected with the computer; at least one side end face of the constant volume bomb matrix is provided with at least one hole allowing a signal line to pass through; one end of the signal line is connected with the corresponding force sensor, and the other end of the signal line is connected with the data acquisition and analysis system. According to the device, accurate measurement of the oil injection rule of each hole of the porous oil injection nozzle can be realized; the signals measured by all the force sensors can be collected by the multi-channel data acquisition and analysis system; the measuring device has actual application significance.

Owner:JIANGSU UNIV

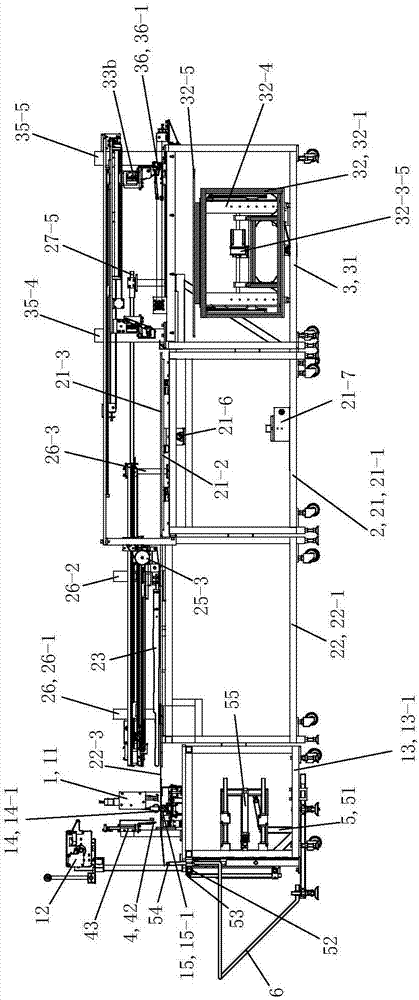

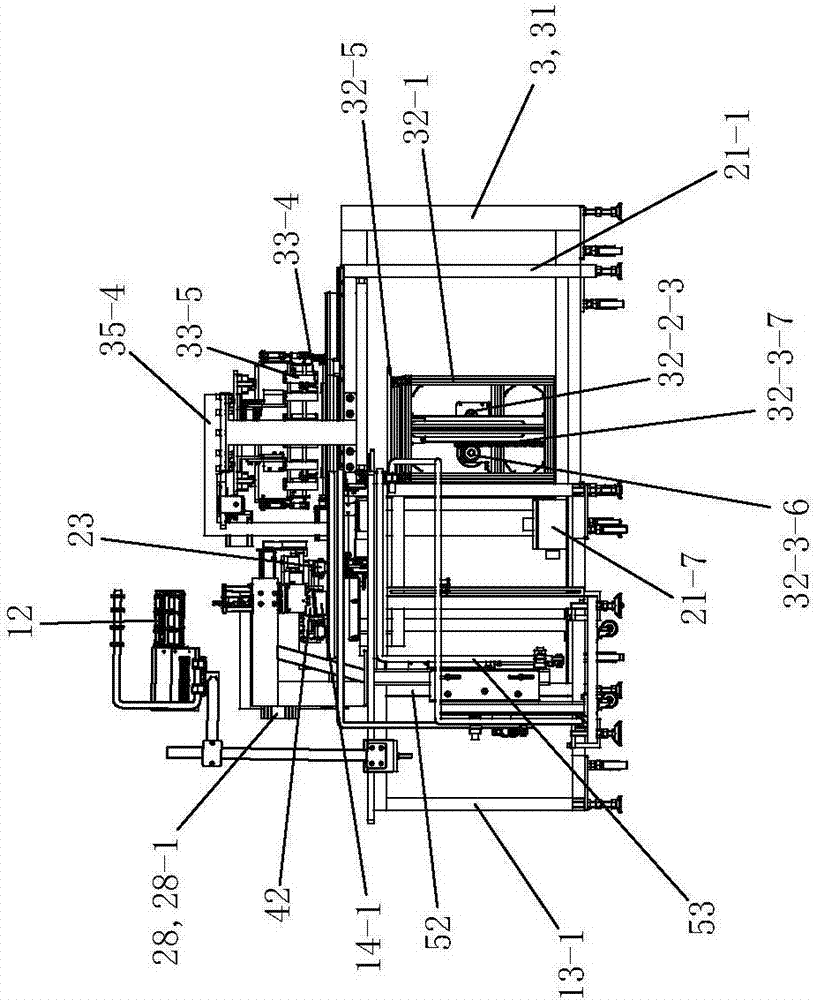

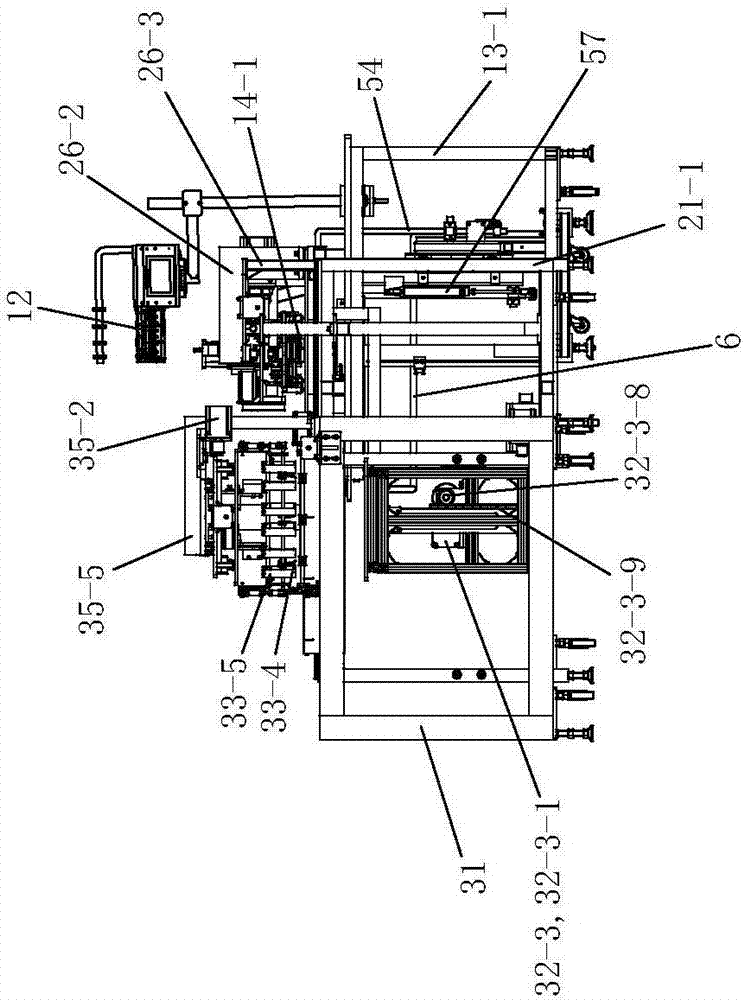

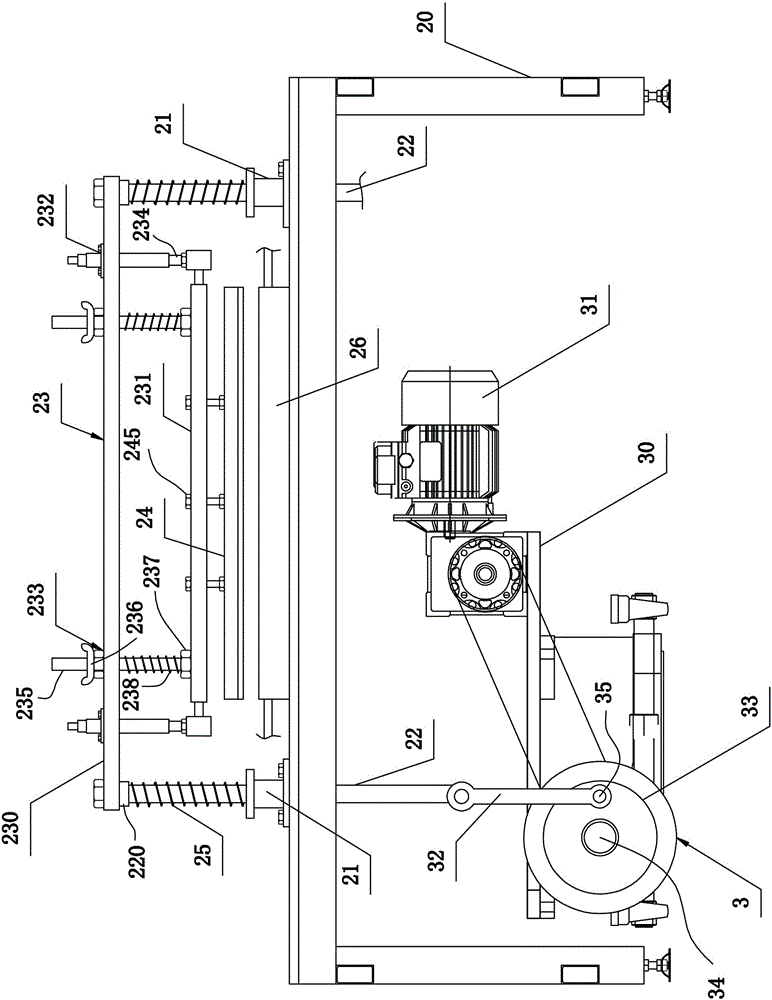

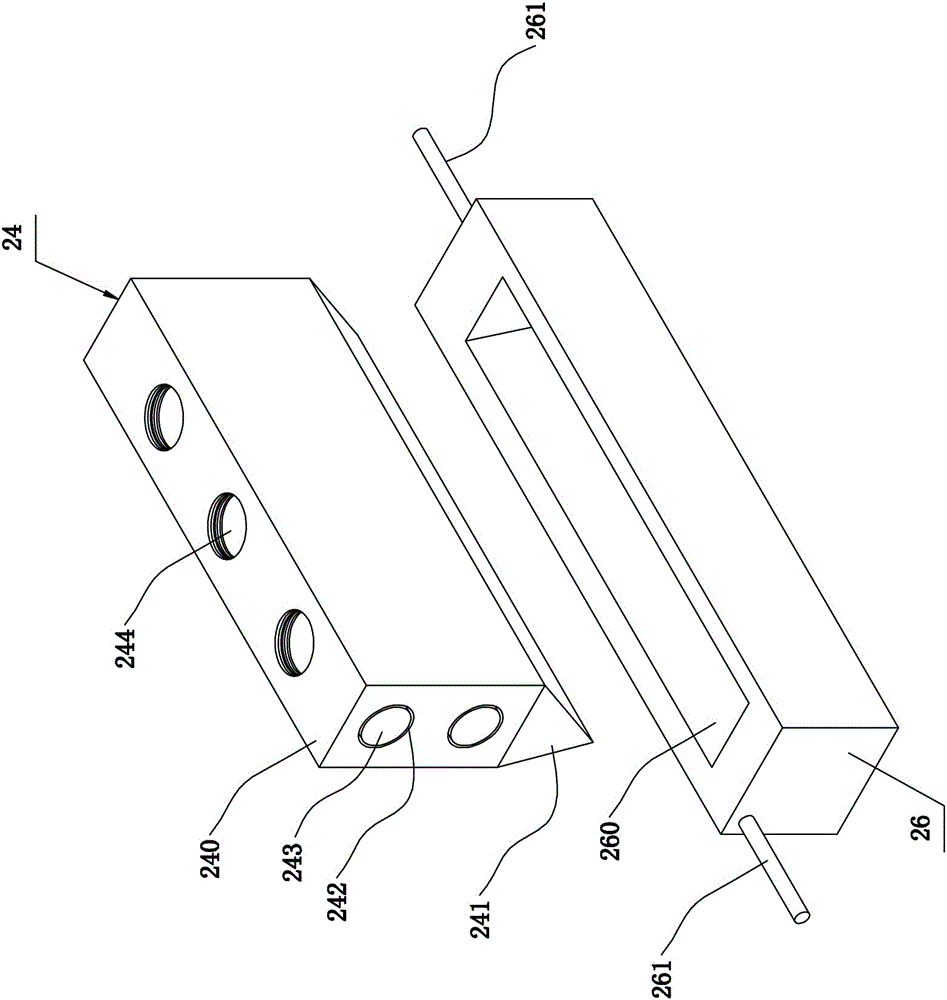

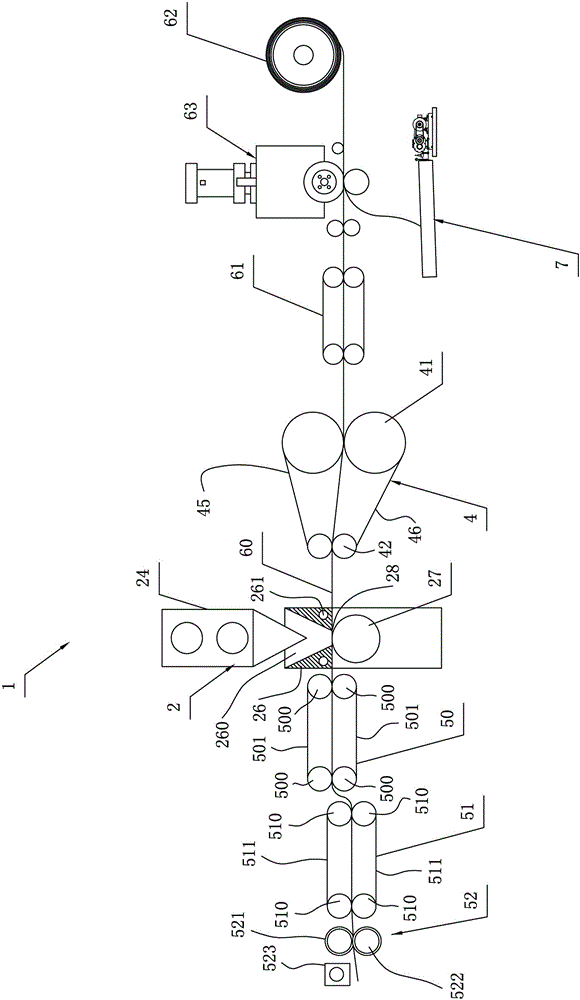

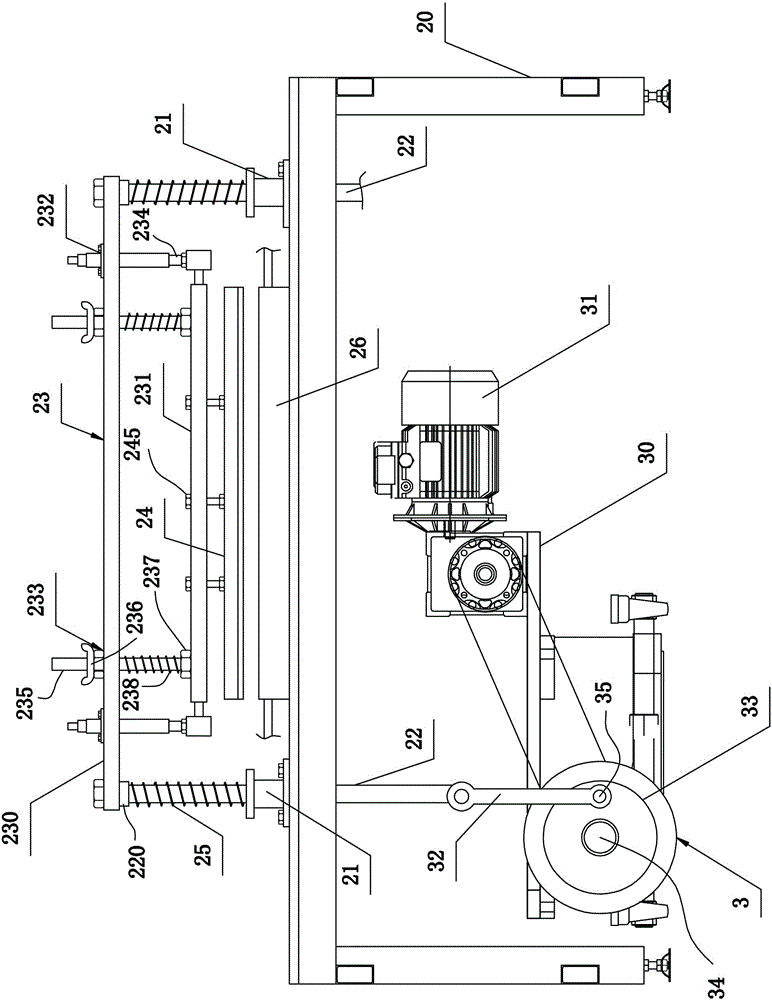

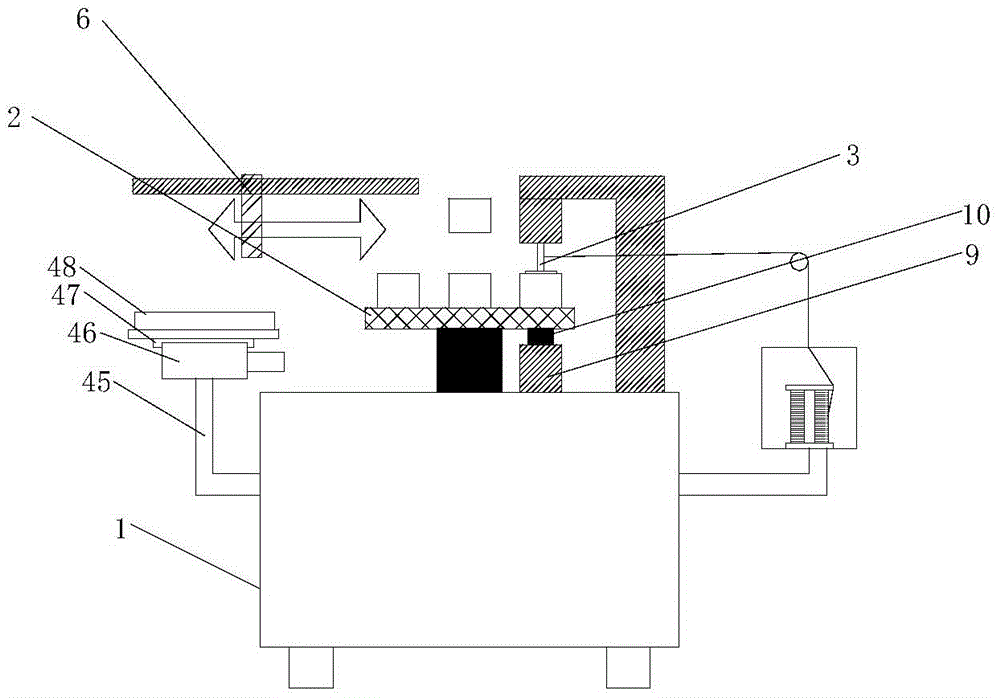

Full-automatic multi-trim-strip sewing equipment

ActiveCN107190425ASimple structureSewn flatWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention discloses full-automatic multi-trim-strip sewing equipment. The full-automatic multi-trim-strip sewing equipment comprises a sewing device, wherein the sewing device comprises a multi-needle sewing machine, a trim-strip feeding device, a first work platform, an upper tug assembly and a lower tug assembly. The full-automatic multi-trim-strip sewing equipment is characterized by further comprising a feeding device, and lower tugs of the lower tug assembly are driving wheels. The feeding device comprises a discharging table assembly, a feeding table assembly, pressing foot assemblies, and a pressing foot two-stage driving assembly. A discharging panel of the discharging table assembly is arranged on a discharging shelf in a way of moving front and back, and a feeding table panel of the feeding table assembly is fixedly arranged on a feeding table mounting shelf. The feeding table surface is communicated with a first panel and a discharging panel of the first work platform. The pressing foot assemblies comprise pressure feet. The pressure feet are arranged above the discharging panels, a feeding table panel, and the first panel in a way of moving left and right through the pressing foot two-stage driving assembly, and are used for delivering fabric of to-be-sewed trim-strips located on the discharging panel to the first panel through the feeding table panel after pressing the fabric.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Encryption and decryption method, encryption and decryption apparatus and data transmitting system

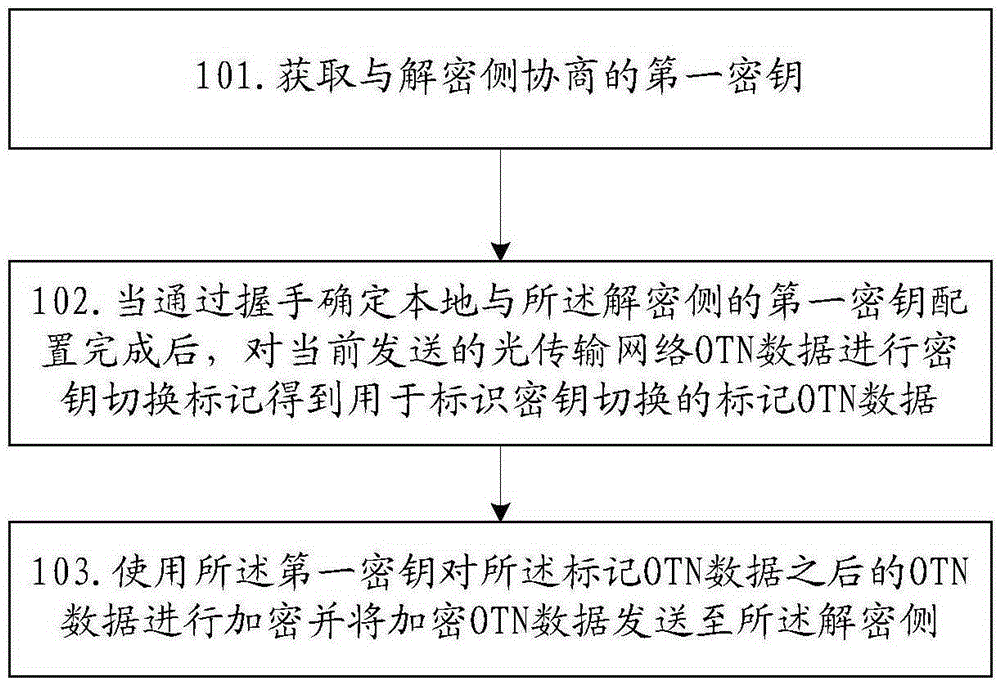

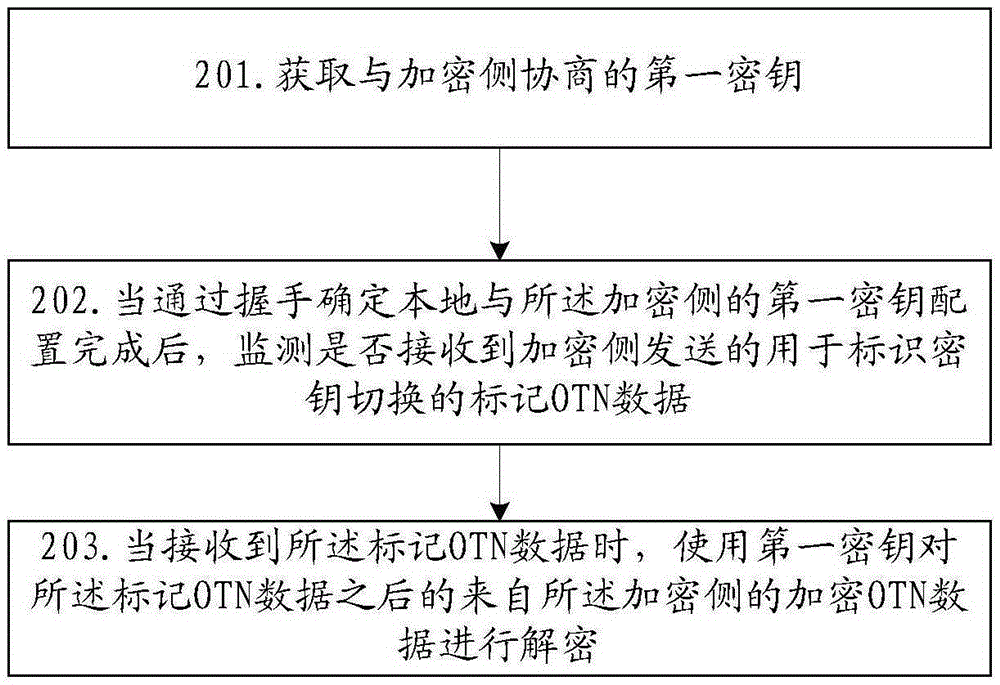

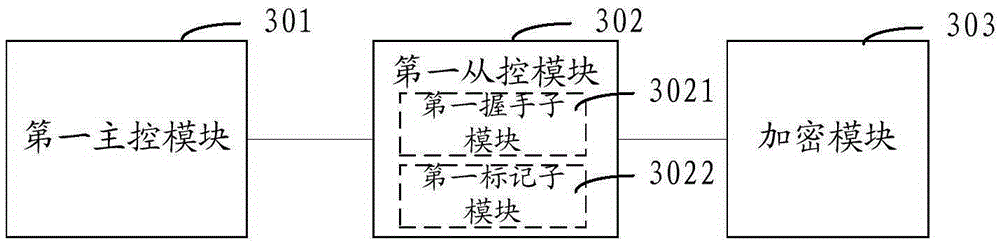

InactiveCN106803783AConsistent positionImprove data transfer performanceKey distribution for secure communicationMultiple keys/algorithms usageComputer hardwareEncryption decryption

The invention discloses an encryption and decryption method, an encryption and decryption apparatus and a data transmitting system. The method includes the following steps: an encryption side acquiring a first key which negotiates with a decryption side; if the configuration of the first key between local and the decryption side is determined to have completed through handshake, marking key changing on optical transmission network OTN data which is currently transmitted to obtain marked OTN data which is intended for marking key changing; using the first key to encrypt the marked OTN data and transmitting the encrypted OTN data to the decryption side which acquires the first key which negotiates with the encryption side; if the configuration of the first key between local and the encryption side is determined to have completed through handshake, monitoring whether the marked OTN data which is transmitted by the encryption side for marking key changing; if the marked OTN data is received, using the first key to decrypt the encrypted OTN data from the encryption side following the marked OTN data.

Owner:SANECHIPS TECH CO LTD

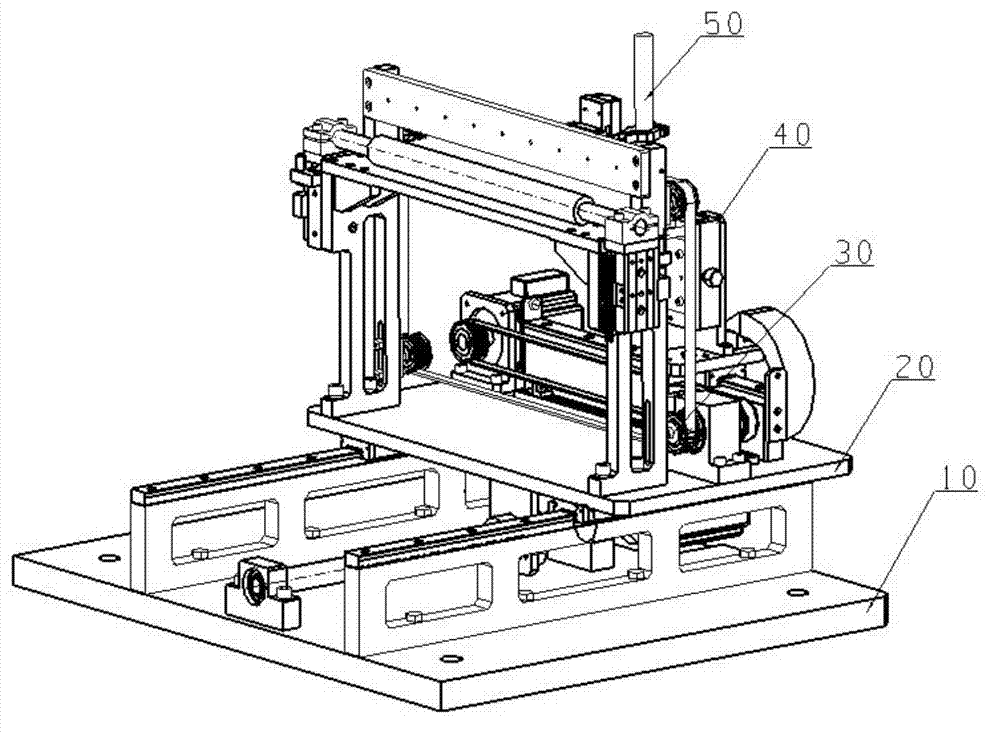

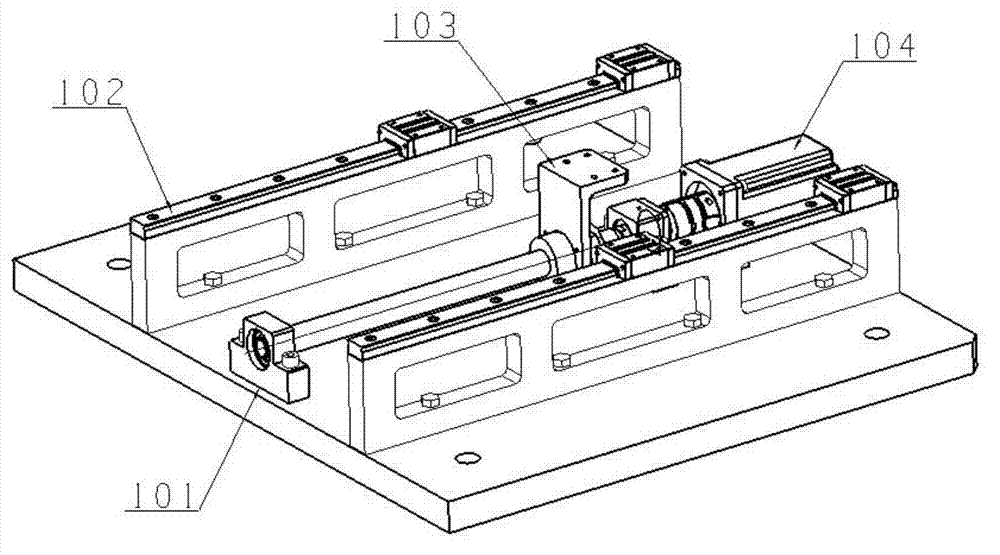

Online detection device for RFID (Radio Frequency Identification Device) label

ActiveCN103049771AAchieve integrationConsistent positionCo-operative working arrangementsEngineeringAutomation

The invention discloses an online detection device for an RFID (Radio Frequency Identification Device) label. The device comprises an X-direction feed mechanism for adjusting the position of a Y-direction feed mechanism in the X direction of the horizontal plane; the Y-direction feed mechanism located on the X-direction feed mechanism for adjusting the position of a read-write mechanism in the Y direction of the horizontal plane; the read-write mechanism located on the Y-direction feed mechanism for online reading data of the RFID label; an ink spotting moveable mechanism located on the Y-direction feed mechanism for moving the plane of an ink spotting mechanism to an unqualified RFID label; and the ink spotting mechanism located on the ink spotting moveable mechanism for spotting and marking the unqualified RFID label. The device provided by the invention can realize label reading and writing and spotting and marking functions at the same time, is suitable for online detection of multi-row and multi-line RFID labels, and has the advantages of automation, high efficiency and stability and reliability.

Owner:HUAZHONG UNIV OF SCI & TECH

Tape measure utilizing mechanical decoupling of power tape extension feature for tape retraction

InactiveUS20070152091A1Easily and consistently initiate drive mechanismConsistent positionMeasuring tapesMagnetic tapeGear wheel

A power operated tape measure enables extension of a tape via a drive mechanism, as well as retraction of the tape through a mechanical decoupling within the drive mechanism. The tape measure has a housing within which is positioned a spring-biased tape assembly, the drive mechanism and a clutch. The spring-biased tape assembly includes an annular reel onto which is wound a tape having indicia for taking length measurements. The drive mechanism includes a driving gear and a driven gear, and is adapted to engage with a bottom surface of the tape to extend the tape out of the housing. The clutch is adapted to displace the driven gear out of engagement with the driving gear and thereby decouple the driving and braking force provided by the drive mechanism from acting upon the bottom surface of the tape to permit the spring-biasing of the tape assembly to retract the tape into the housing.

Owner:BLACK & DECKER INC

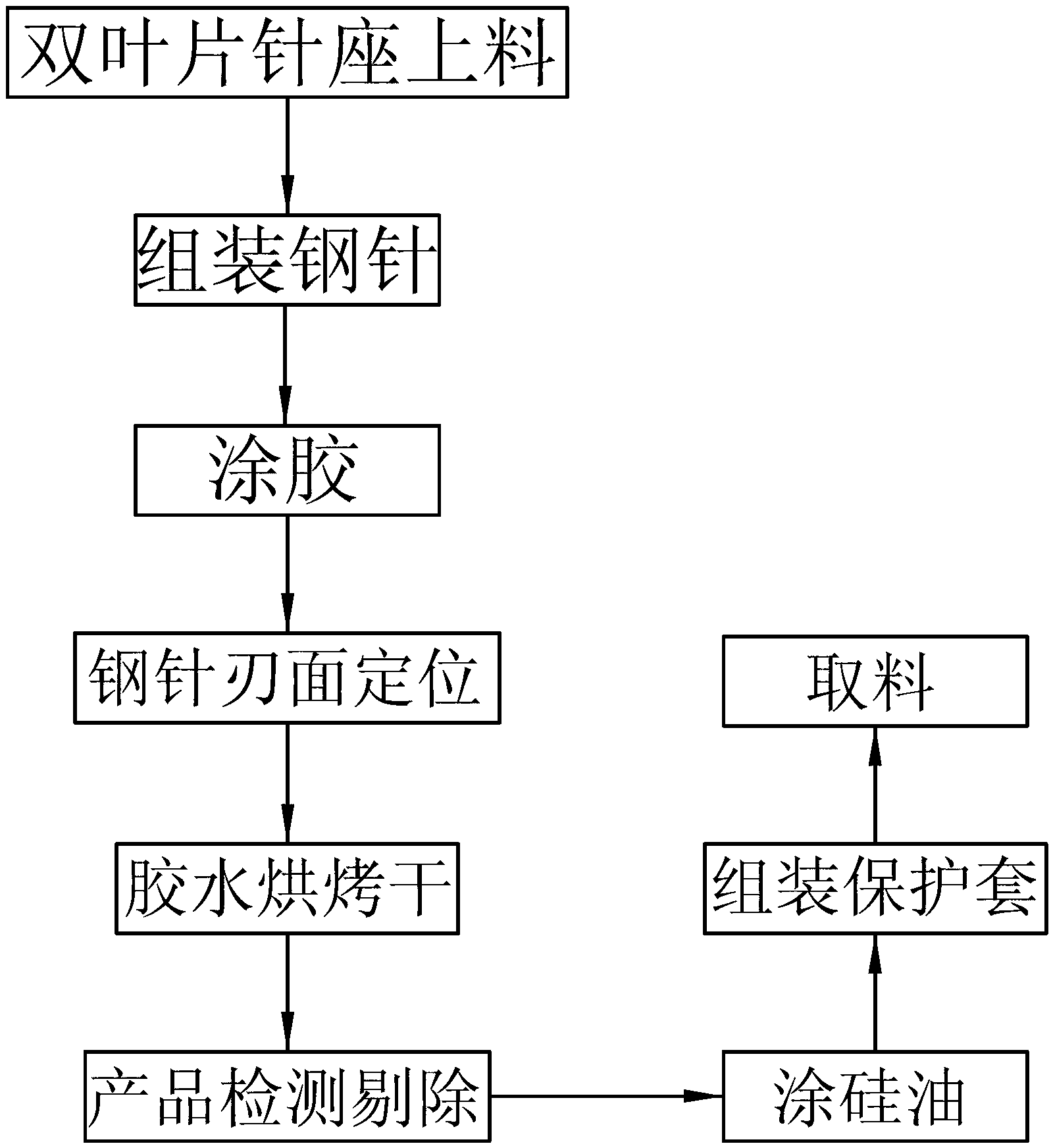

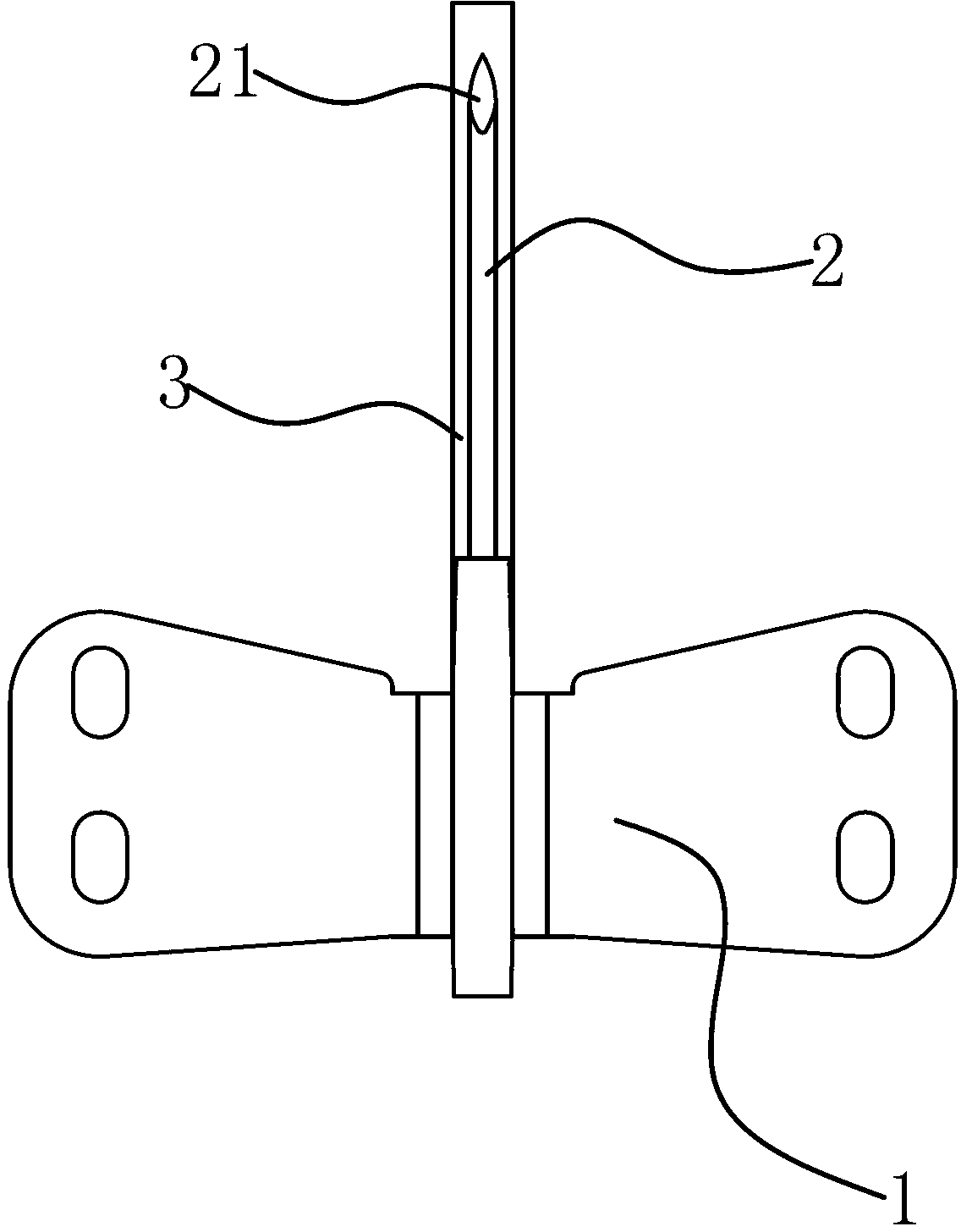

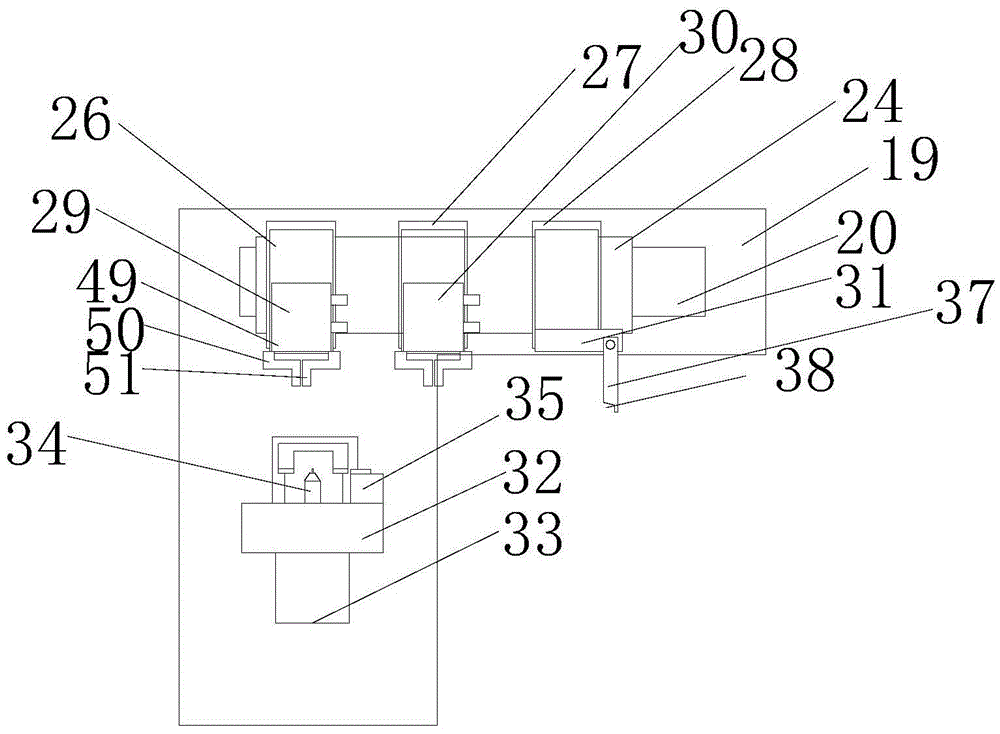

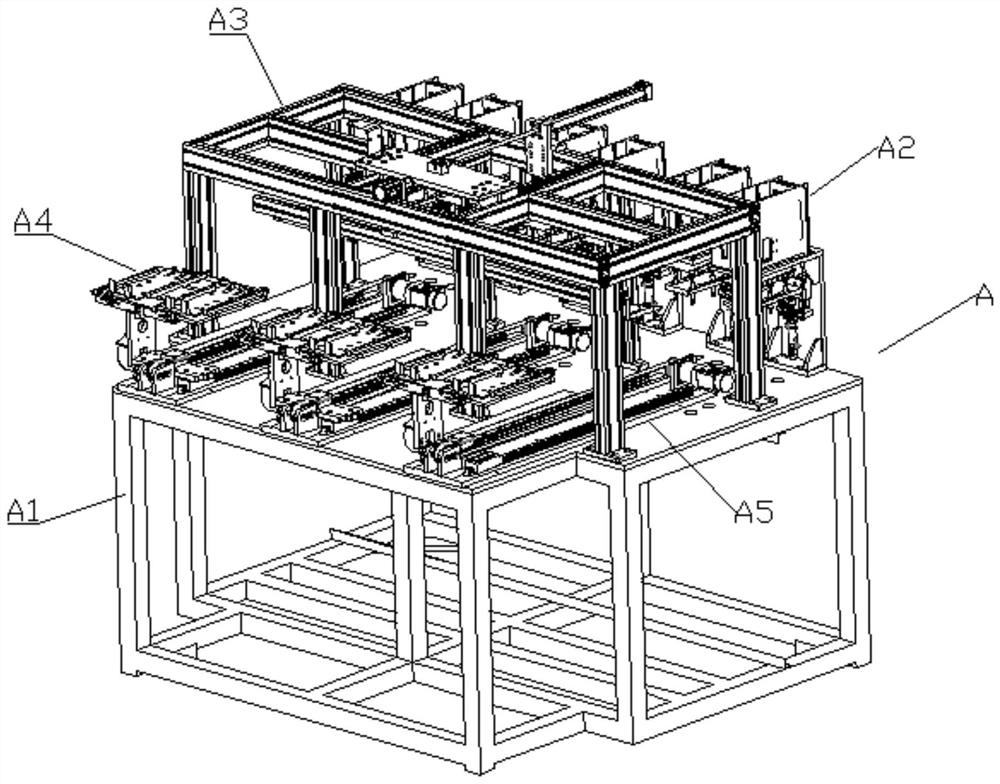

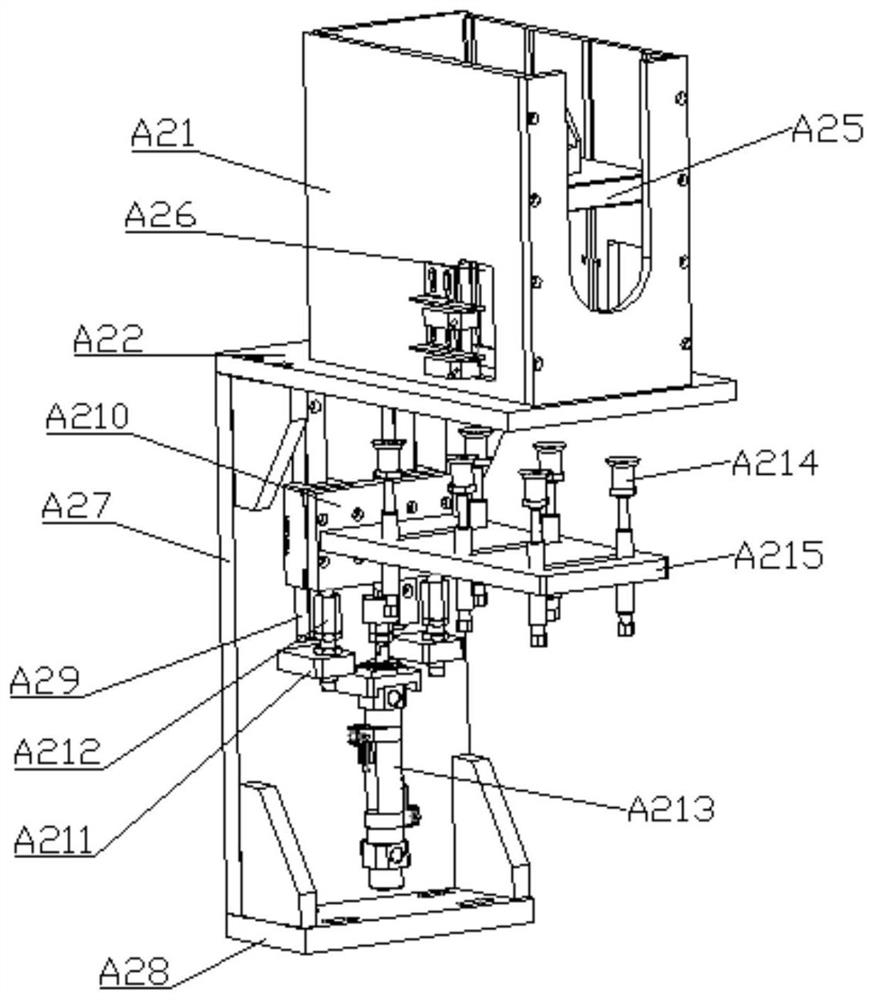

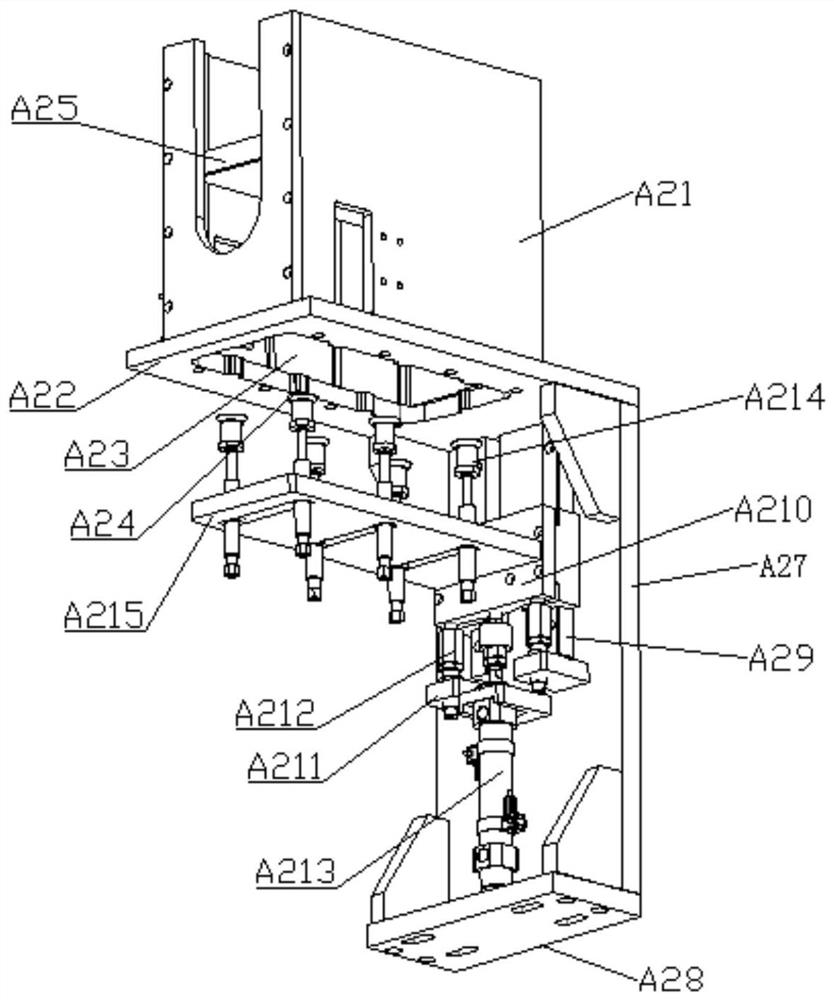

Assembly technology of medical venous needle

The invention provides an assembly technology of a medical venous needle and belongs to the technical field of medical devices. The assembly technology of the medical venous needle solves the technical problems that the assembly quality and the assembly efficiency of a product are lower in the prior art. The venous needle comprises a double-vane needle stand, a steel needle and a protective sleeve. The assembly technology comprises the following processes of: A, charging materials to the needle stand, B, assembling the steel needle, C, applying glue, D, drying the glue, E, assembling the protective sleeve, and F, taking out the venous needle. The assembly technology has the advantages of good assembly quality, high assembly efficiency and the like.

Owner:MAIDER MEDICAL IND EQUIP

Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

The invention discloses a bag making machine hot-sealing and hot-pressing mechanism capable of working stably. The mechanism comprises a fixing frame body, two guide sleeves, pull rods, a cutter fixing frame and a hot-sealing cutter. The upper ends of the pull rods are fixedly connected to the two ends of the cutter fixing frame respectively and each provided with an upper end abutting portion. The side wall of the upper portion of each pull rod is sleeved with a compression spring. The upper end and the lower end of each compression spring are connected to the corresponding upper end abutting portion and the top of the corresponding sleeve respectively in an abutting mode. At least one pull rod penetrates through the corresponding guide sleeve and then is in transmission connection with an intermittent motion mechanism. According to the bag making machine hot-sealing and hot-pressing mechanism, it can be ensured that the hot-sealing and hot-pressing positions and motion strengths of the hot-sealing cutter for air bubble films or pearl wool films under the hot-sealing and hot-pressing cutter are consistent all the time, and the hot-sealing cutter will not shift even if hot-sealing and hot-pressing are frequently and constantly carried out; accordingly, the working efficiency of the bag making machine hot-sealing and hot-pressing mechanism is greatly improved, and the service life of the bag making machine hot-sealing and hot-pressing mechanism is greatly prolonged.

Owner:洪东坡

Bag machine with improved structure

ActiveCN104985864AThere will be no offsetSimple structureBox making operationsPaper-makingEngineeringMechanical engineering

A bag machine with an improved structure comprises a convey assembly, a feed assembly, and a hot-sealing hot-pressing mechanism; the hot-sealing hot-pressing mechanism comprises a fixed rack, two guide sleeves, pull rods, a cutter fixing rack and a hot-sealing cutter; tops of each pull rod are respectively fixed on two ends of the cutter fixing rack; each pull rod is provided with a top abut portion; an upper side wall of each pull rod is sleeved by a compression spring; at least one pull rod penetrates the corresponding guide sleeve and is in transmission connection with an intermittence motion mechanism, wherein the intermittence motion mechanism is used for controlling the cutter fixing rack to complete up-down mobile motions in cycle in a fixed time. The bag machine can ensure the hot-sealing cutter to carry out hot-sealing hot-pressing for right blow bubble films or pearl cotton films with consistent positions and motion forces in each time; even under frequent continuously hot-sealing hot-pressing, no hot-sealing cutter offset condition is generated, thus greatly improving work efficiency and life of the bag machine.

Owner:洪东坡

Automatic winding device

The invention relates to the technical field of coil winding devices for metal brackets, in particular to an automatic winding device. Four stations are also arranged on a rack on the peripheral edge of a turn table; a loading device, a coil winding device, a dispensing machine and an unloading device are arranged on the four stations respectively; the loading device is used for mounting a to-be-wound metal bracket on a turn plate workpiece support device; the coil winding device is used for winding a wire on the metal bracket; the dispensing machine is used for coating the coil on the metal bracket with glue; the unloading device is used for taking out the metal bracket; the loading device comprises a loading manipulator; the coil winding device comprises a winding device and a wire cutting device; and the unloading device comprises an unloading manipulator, so that the automatic winding device saves manpower, increases the production capacity, completely eradicates manual operation and avoids pre-damage to an enamelled wire.

Owner:BESTAR HLDG

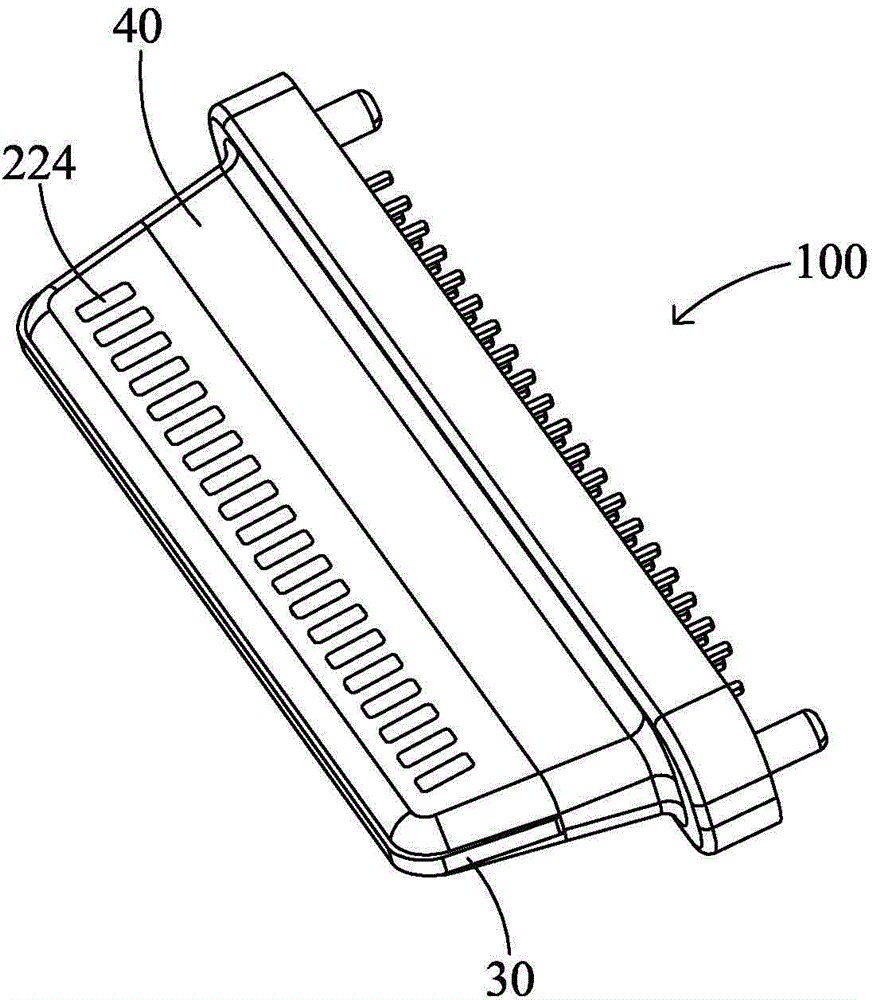

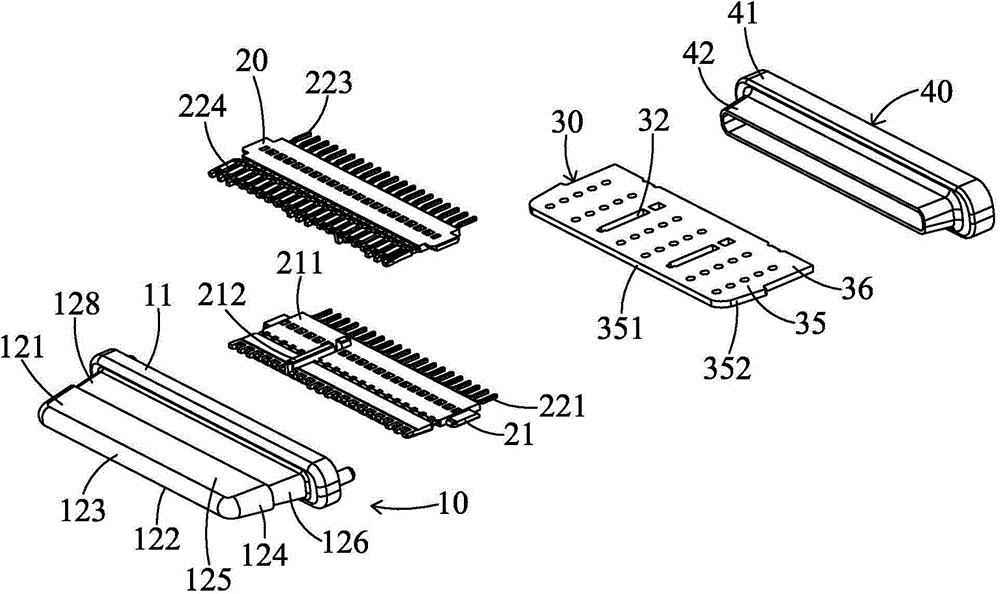

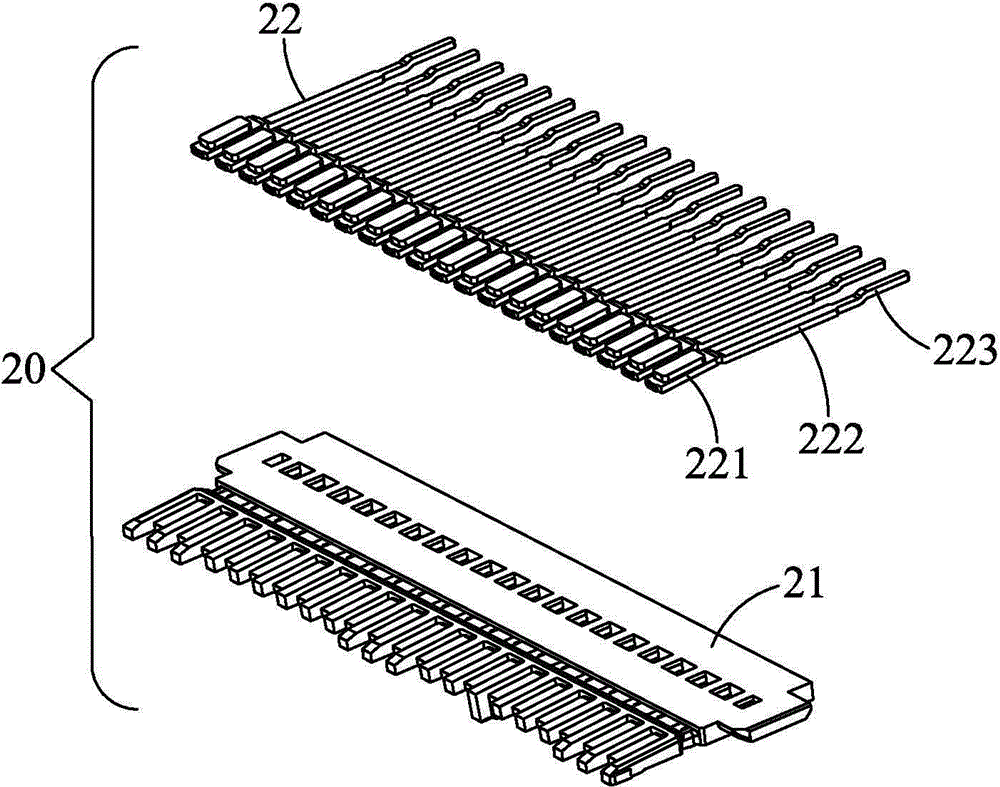

Electric connector

InactiveCN104577460AReduce manufacturing difficultyGuaranteed reliabilityCoupling protective earth/shielding arrangementsElectricityButt joint

The invention relates to an electric connector. The electric connector comprises an insulating body, two terminal modules and a metal shell. The insulting body comprises a main body and a platy butt joint portion extending forwards from the main body. The butt joint portion comprises an upper surface, a lower surface, a front end face and two side surfaces, wherein the upper surface and the lower surface are opposite, and the front end face and the two side surfaces are located between the upper surface and the lower surface. Each terminal module comprises an insulating block and a row of conductive terminals fixed to the insulating blocks, wherein each conductive terminal comprises contact portions distributed on the upper surface and the lower surface. The metal shell surrounds the outer sides of the terminal modules. The electric connector further comprises a metal shielding piece which is located between the upper surface and the lower surface of the butt joint portion. The shielding piece is exposed on the front end face. The insulating body is arranged on the terminal modules and the shielding piece through injection modeling, and the manufacturing difficulty of the electric connector is lowered.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

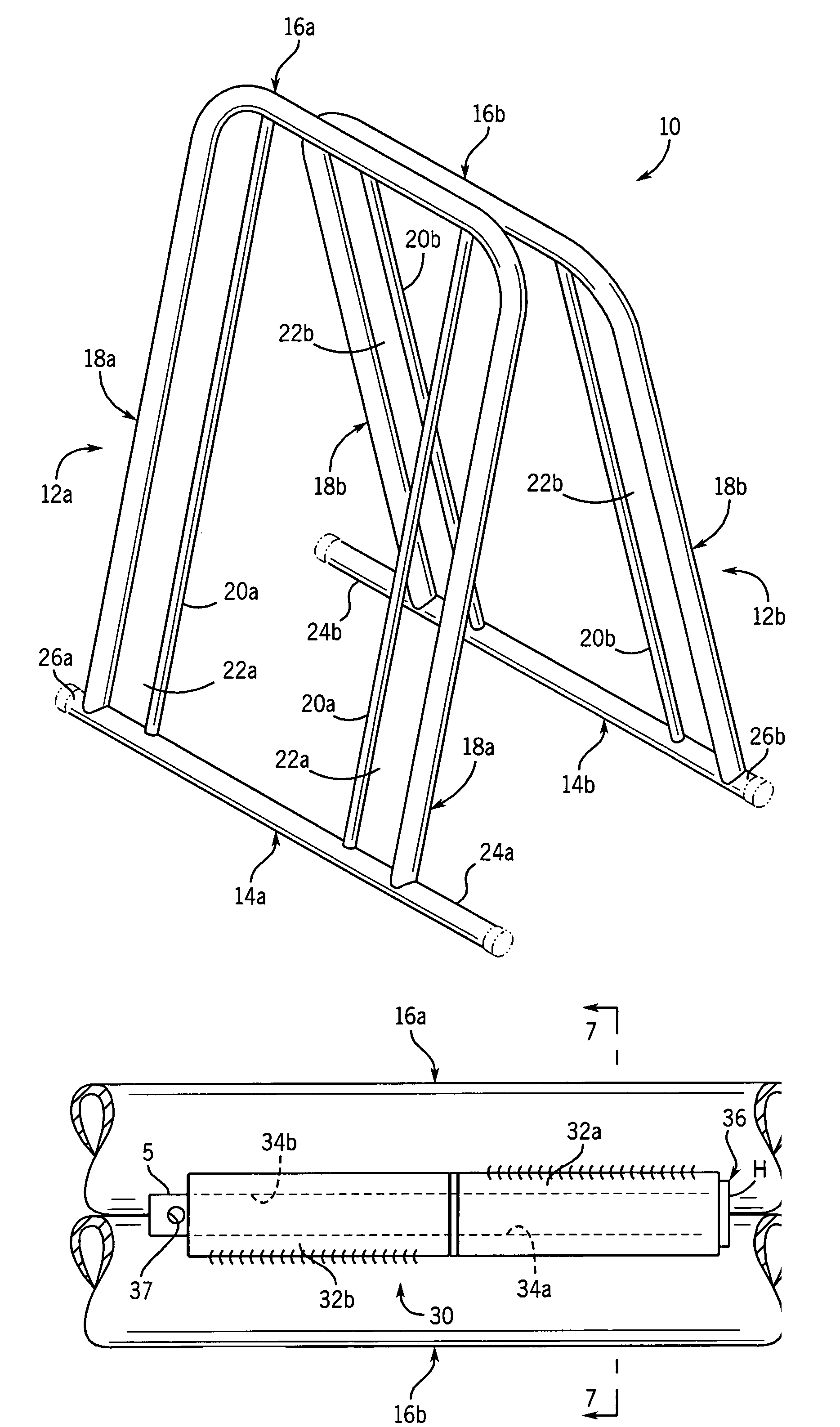

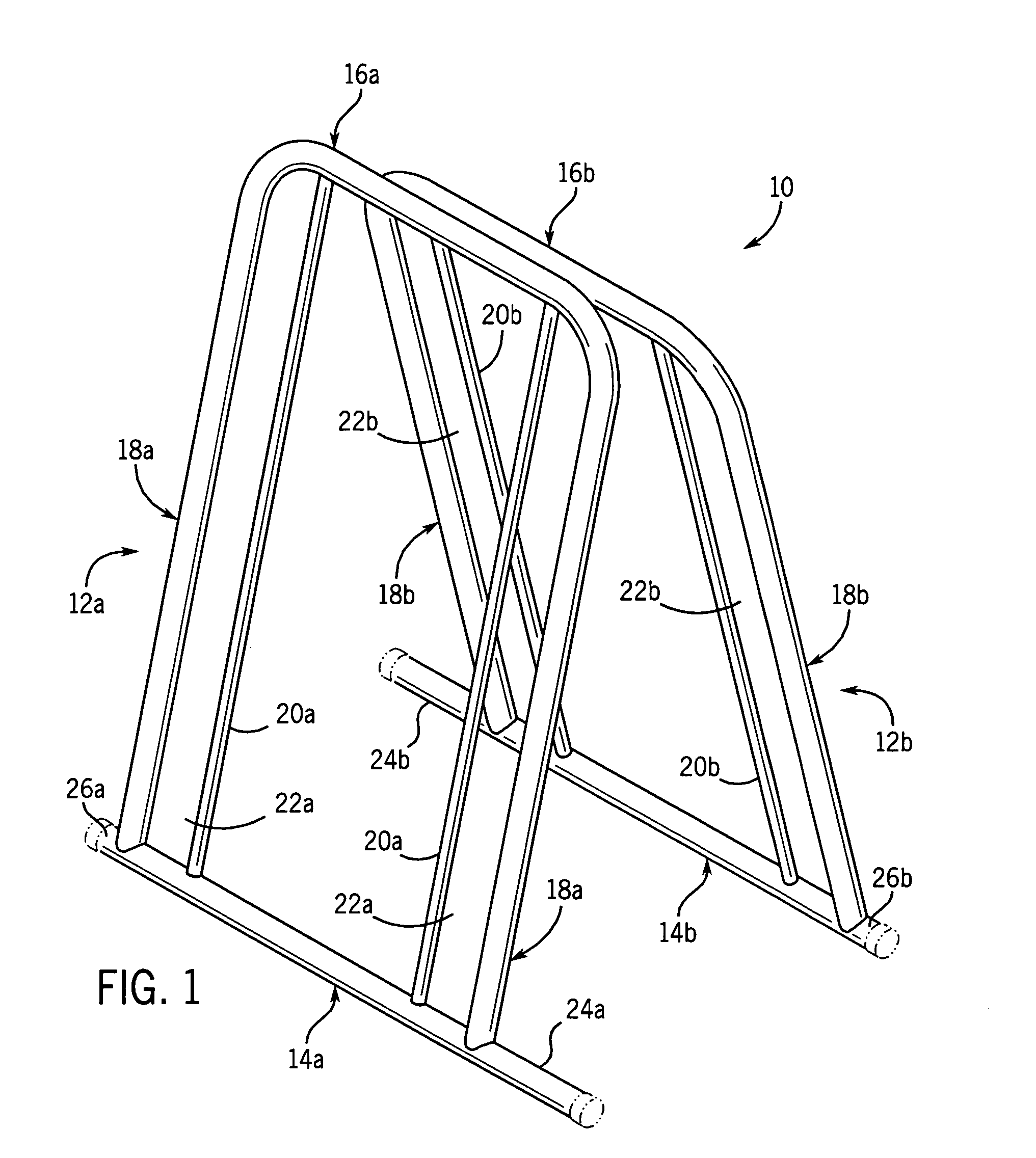

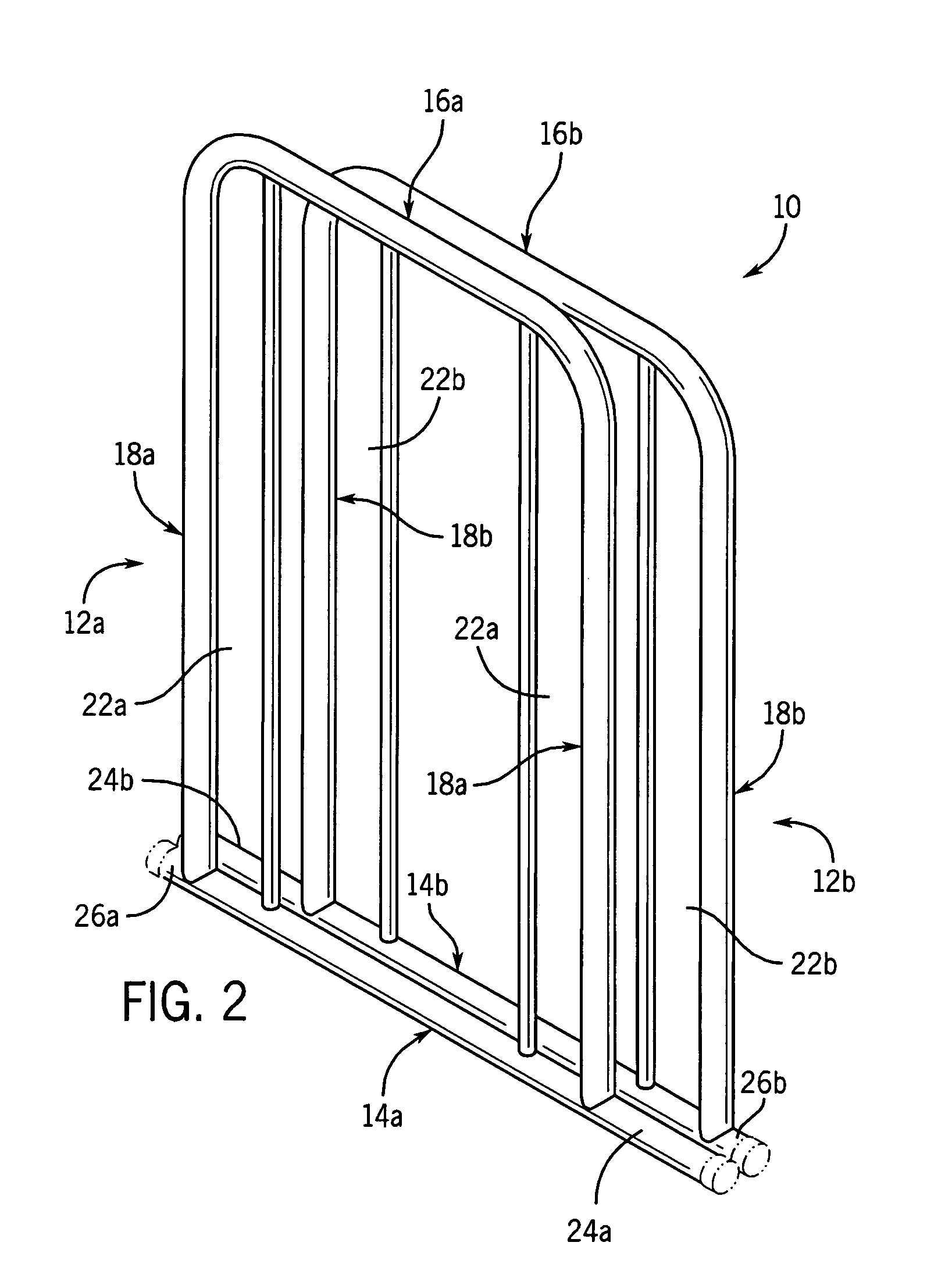

Collapsible stand for parking bicycles or the like

InactiveUS6948621B1Simple componentsEasy constructionCycle standsShow shelvesMechanical engineeringHinge angle

A collapsible rack or stand for supporting a bicycle or the like in an upright position includes a pair of supports that are pivotably interconnected together for movement between an open, operative position and a closed, inoperative position. Each support defines one or more vertically extending spaces, each of which is configured to receive one of the bicycle wheels for supporting the bicycle in an upright position when the supports are in the open, operative position. Each support includes a lower member and an upper member, between which the wheel-receiving spaces are located, and the upper members of the supports are pivotably interconnected via a hinge arrangement for enabling movement of the supports between the open, operative position and the closed, inoperative position. The hinge arrangement is in the form of a hinge barrel secured to the upper member of each support, and the hinge barrels define aligned passages through which a hinge pin extends. The hinge barrels are configured and arranged such that the upper members of the supports are moved into engagement with each other when the supports are moved away from the closed, inoperative position so as to place the supports in the open, operative position, thus providing a stop for consistently positioning the supports in a predetermined angular relationship when the supports are moved to the open, operative position. The supports may be identically constructed, and are preferably connected together so that the spaces of the supports are offset from each other to enable bicycle wheels to be engaged with the supports in a staggered manner from opposite sides of the stand.

Owner:SARIS CYCLING GROUP

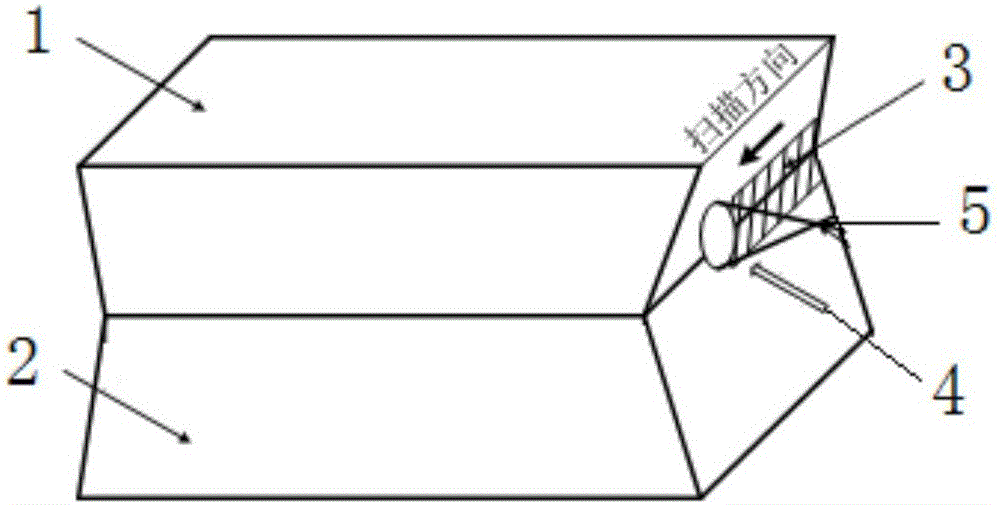

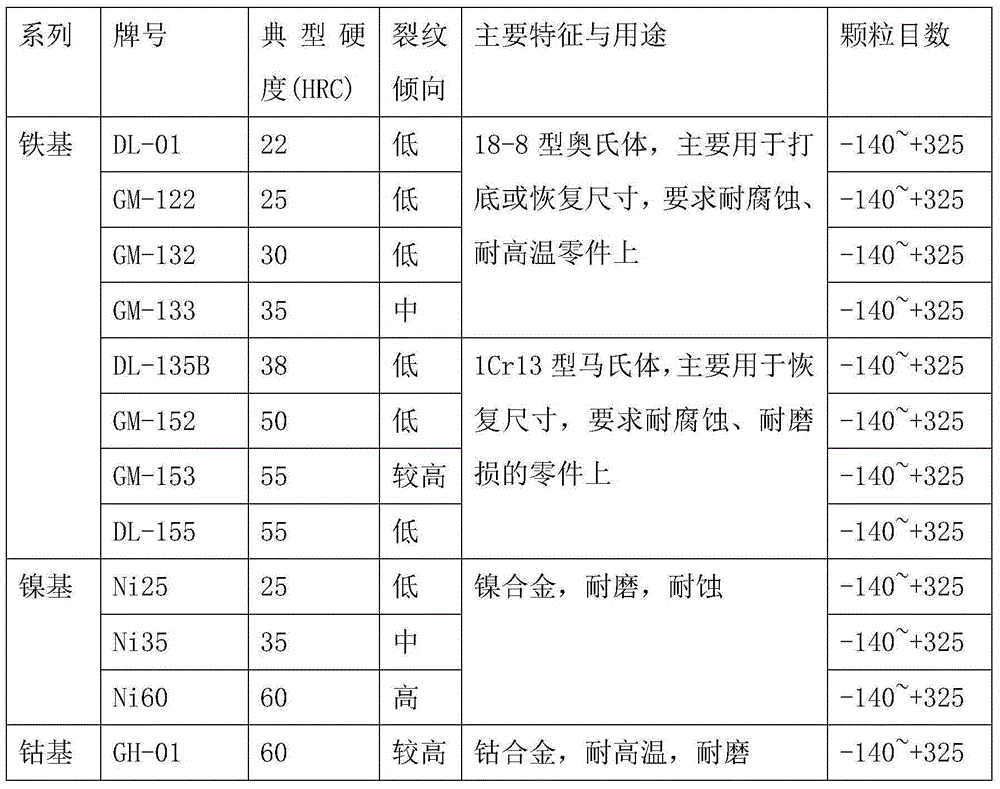

Laser cladding bonding-based cutter and workpiece diffusion couple making method

InactiveCN105067485AReduce experiment costShorten the test cycleSurface/boundary effectPreparing sample for investigationSurface oxidationEngineering

The invention relates to a laser cladding bonding-based cutter and workpiece diffusion couple making method. The method mainly comprises the following steps: 1, cutting a cutter or blade made of a known material to form a sample, and allowing the cut sample to have at least one groove or square cavity; 2, cutting a workpiece to be tested to form a sample, and laminating the cut sample to the sample obtained in step 1 to realize at least one common groove or square cavity; 3, grinding and polishing obtained two samples to make the two samples respectively have at least one polished surface; 4, laminating the polished surfaces of the two samples, clamping and fixing the two samples by using a clamp, and placing a cladding material in the groove or square cavity formed by the two samples; 5, bonding the two samples through a laser cladding technology to form a diffusion couple; 6, cleaning the produced diffusion couple, and carrying out heating and heat insulation in a heat insulation furnace; and 7, taking out the heat insulated diffusion couple, taking out a surface oxidation layer, polishing and cleaning, taking the core of the diffusion couple, and carrying out sample analysis.

Owner:SHANDONG UNIV

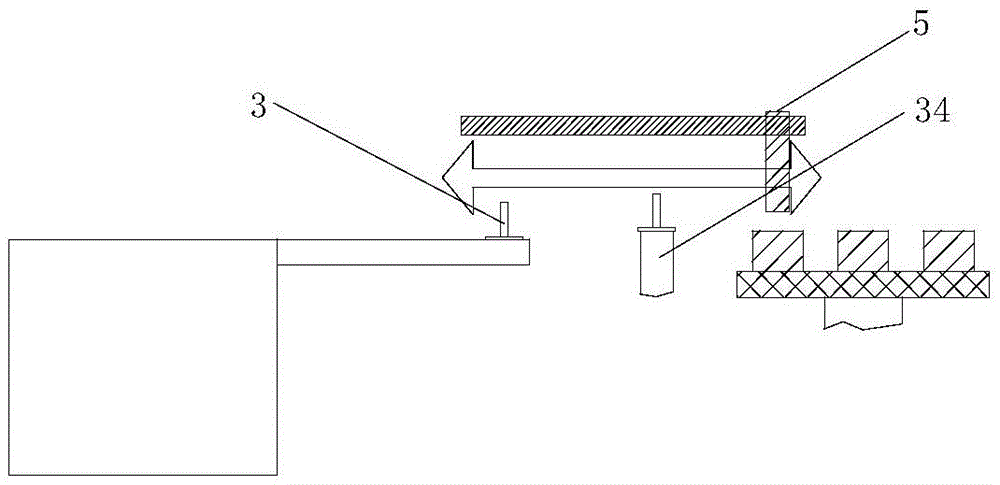

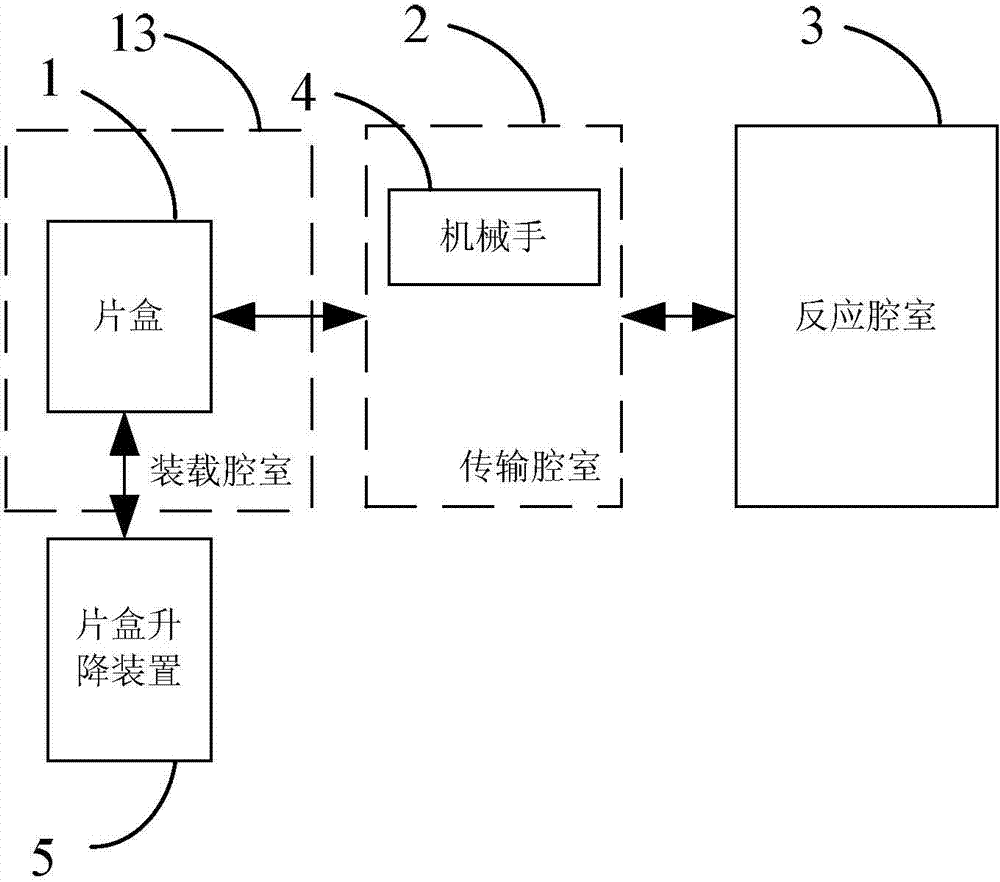

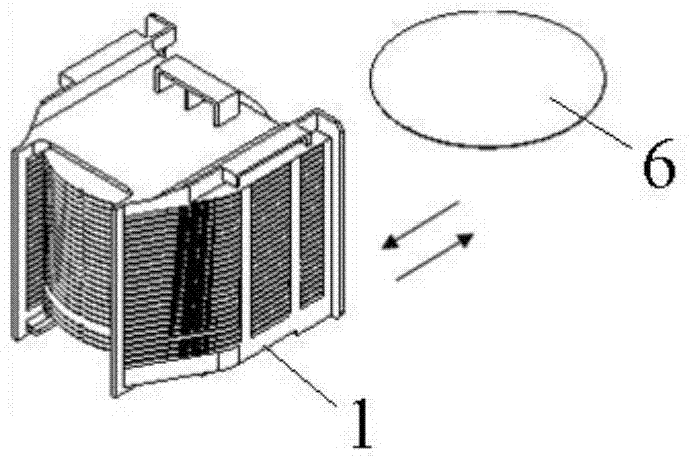

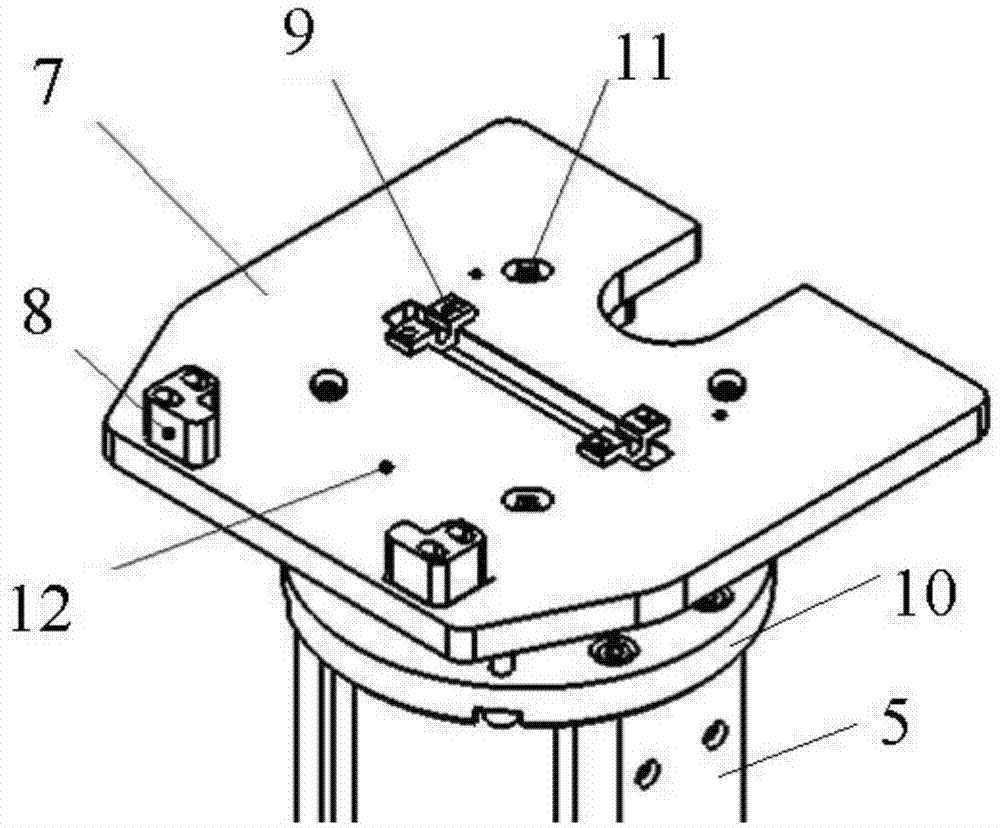

Cassette positioning device and semiconductor processing device

ActiveCN104752294AImprove transmission efficiencyImprove processing efficiencySemiconductor/solid-state device manufacturingEngineeringManipulator

Provided are a cassette positioning device and a semiconductor processing apparatus. The cassette positioning device comprises a positioning base plate (21), a rotary positioning plate (22) and a supporting post (23). The positioning base plate (21) is arranged horizontally and connected to a lifting device (31). The rotary positioning plate (22) is arranged on the positioning base plate (21) and has one end rotatably connected to one end of the positioning base plate (21). A positioning component is arranged on the rotary positioning plate (22). The supporting post (23) is arranged below the rotary positioning plate (22), and can move relative to the positioning base plate (21) in the vertical direction, so that when the supporting post (23) rises to a preset highest position relative to the positioning base plate (21), the rotary positioning plate (22) is pushed against by the supporting post (23) and rotated to a position inclined with respect to the positioning base plate (21); when the supporting post (23) is located at a preset lowest position, the rotary positioning plate (22) is stacked on and parallel to the positioning base plate (21). By means of the cassette positioning device and the semiconductor processing apparatus, all wafers in a cassette (33) can have identical positions in the horizontal direction, so that wafers fetched by a mechanical arm are all located at a unique designated position on the mechanical arm.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

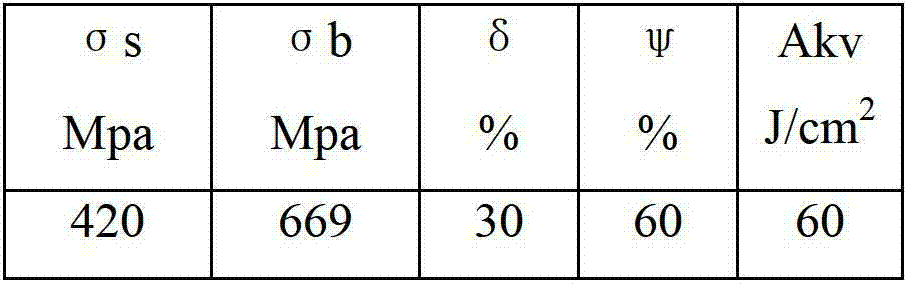

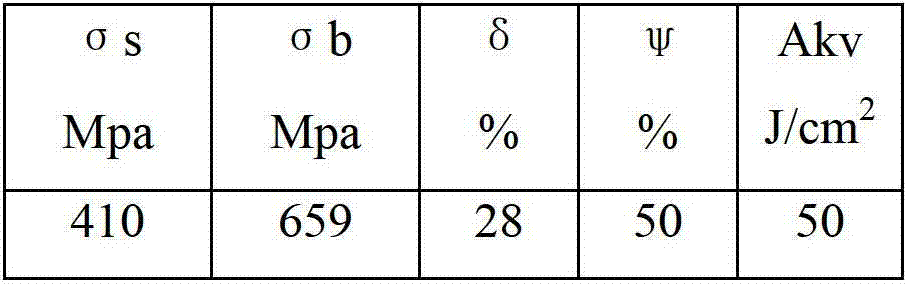

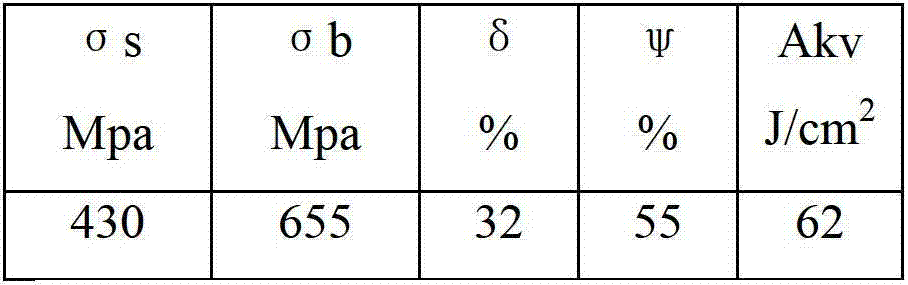

Cast steel node manufacturing process

InactiveCN102873311AReduce odorLow water solubilityMolten metal pouring equipmentsFoundry mouldsSingle injectionPhenol

The invention discloses a cast steel node manufacturing process, which comprises the following steps: S1, preparing charging and smelting molten metal; S2, carrying out a molding process by selecting an alkali phenol resin, a solidifying agent and sand by the virtue of an Alpha-set modeling method; S3, carrying out a pouring process by using a single-injection-hole and bottom-pouring-type steel ladle as well as the use of pouring in lying and cooling in lying; and S4, carrying out a heat treatment process by using a well-type heat treatment furnace. The invent has the benefits that the node manufacturing process is provided, casting for modeling at once is realized, and nodes in various shapes can be designed according to the design requirements, the spatial angle consistency of a manufactured cast steel node is excellent, the mechanical properties are excellent, and site construction and installation are facilitated; and a sand mold consisting of the alkaline phenol resin and the solidifying agent is adopted, which has excellent deformability and collapsibility as well as high regeneration efficiency, so that the cost is saved.

Owner:SICHUAN KAINENG ELECTROMECHANICAL EQUIP MFG

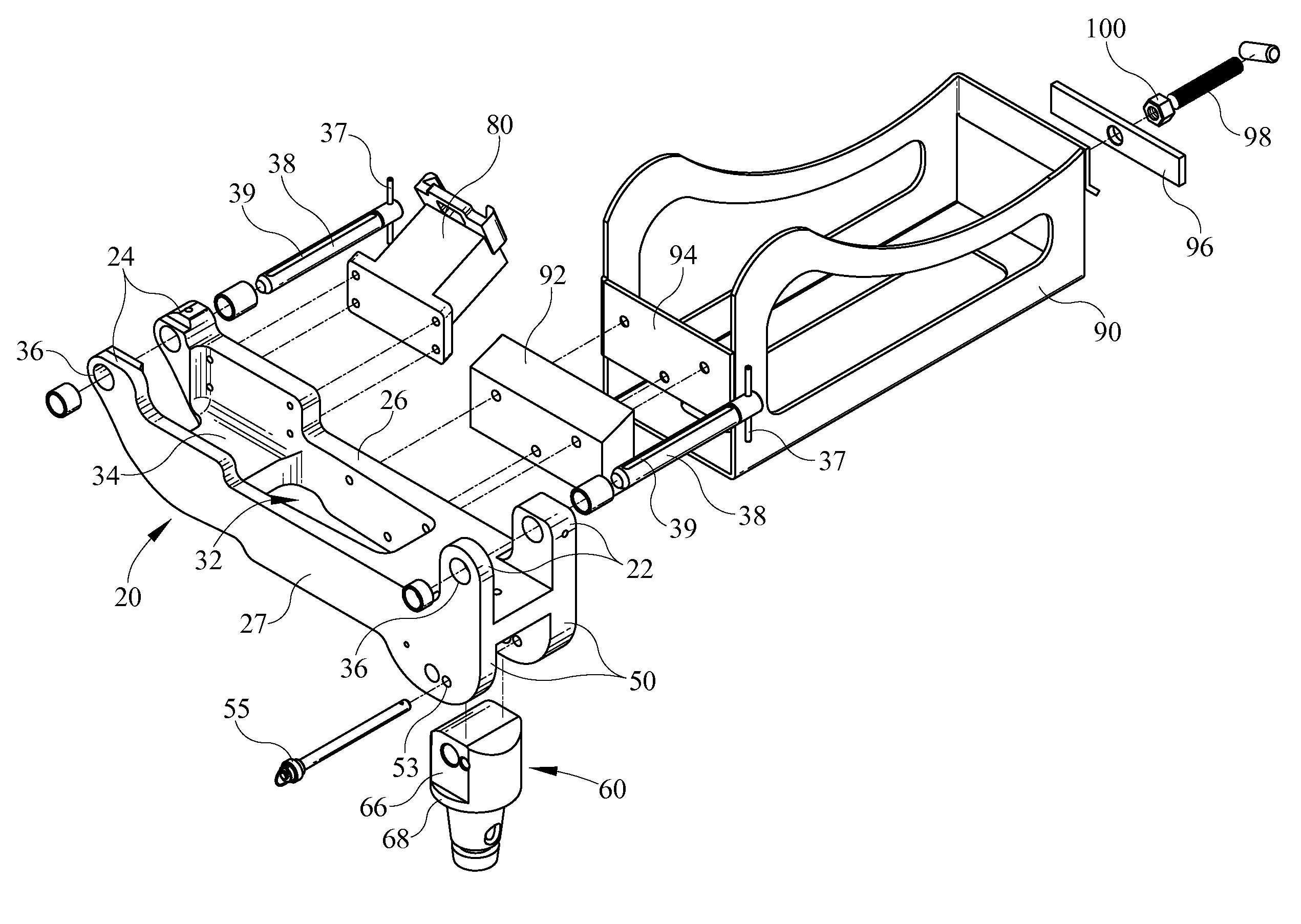

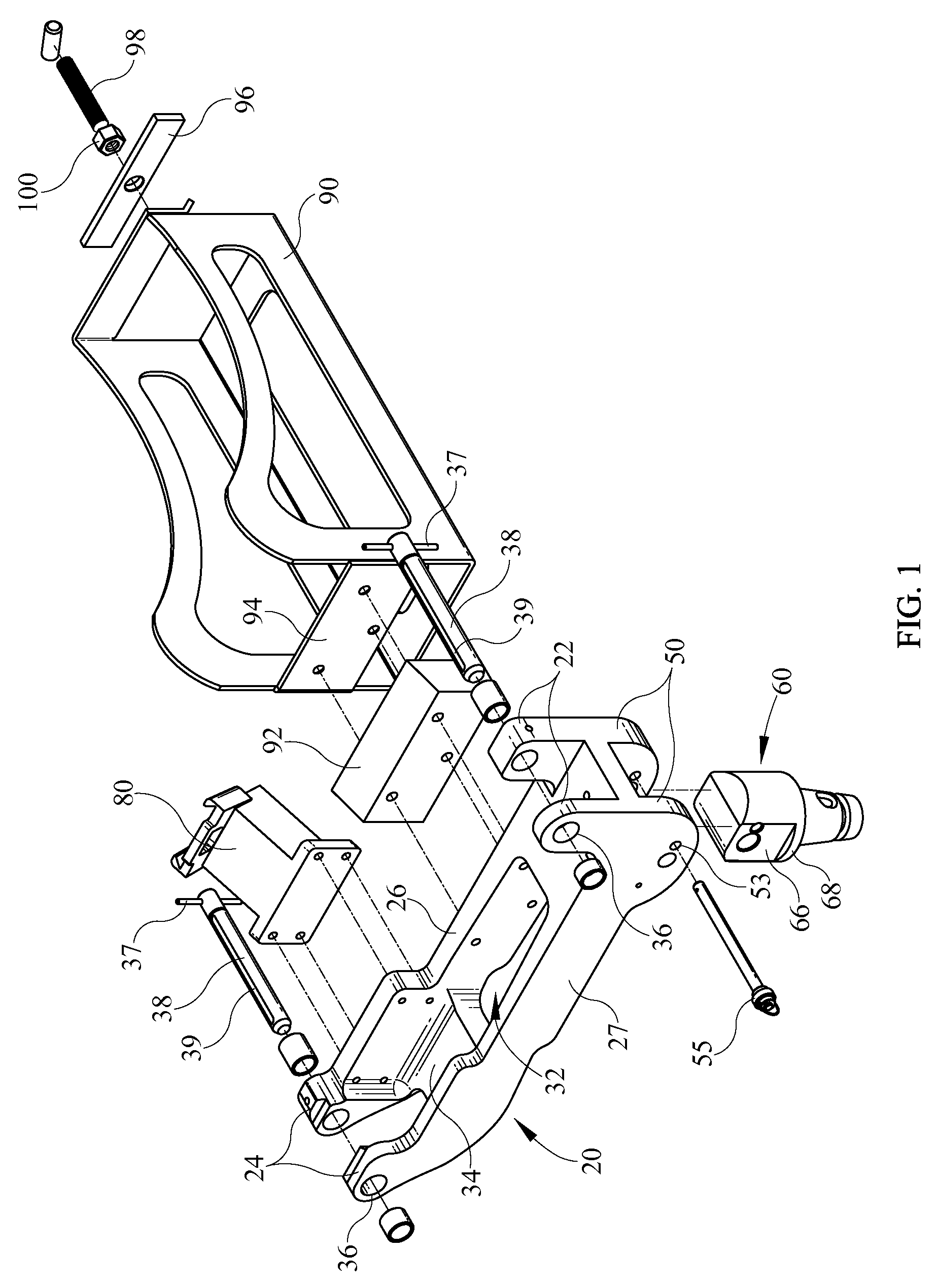

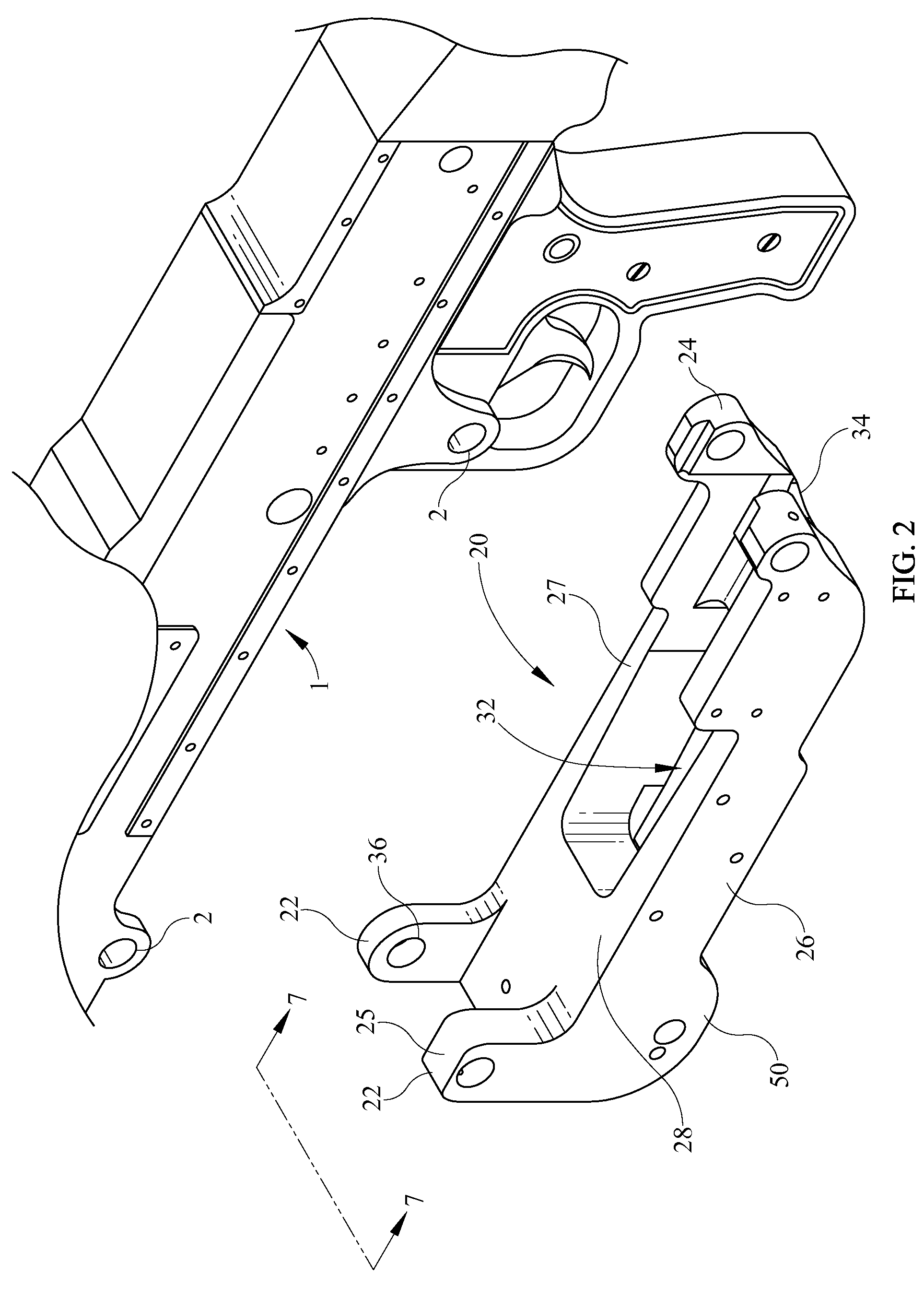

Tri-mount cradle system

A weapon mounting system for securing a weapon such as a machine gun to a platform comprises a cradle assembly including a pair of opposed front and rear flanges having apertures therein for engaging a retaining pin to secure a weapon thereto. The cradle assembly of the present invention is formed of a single piece of high strength material, for example aluminum stainless steel or titanium. The cradle assembly further includes a pair of pintle flanges to engage a pintle, thereby enabling rotation of cradle and concomitant weapon around two axes.

Owner:KIESLER POLICE SUPPLY

Automatic infusion apparatus packaging production line

PendingCN111717469AEvenly loadedNeatly coiledWrapper twisting/gatheringIndividual articlesInfusion setProcess engineering

The invention relates to the technical field of packaging equipment, in particular to an automatic infusion apparatus packaging production line. The automatic infusion apparatus packaging production line comprises automatic packaging bag feeding and position correcting equipment, automatic packaging bag transferring and opening equipment, automatic packaging bag taking, winding and bagging equipment and automatic packaging bag sealing equipment; the automatic feeding and position correcting equipment is arranged in front of the automatic packaging bag transferring and opening equipment in theX-axis direction; the automatic packaging bag taking, winding and bagging equipment is arranged behind the automatic packaging bag transferring and opening equipment in the X-axis direction; and the automatic packaging bag sealing equipment is arranged on one side of the automatic packaging bag transferring and opening equipment in the Y-axis direction. The automatic infusion apparatus packaging production line is reasonable in overall structure arrangement, high in structural operation relation continuity, high in process continuity, high in automation degree, high in packaging efficiency andhigh in packaging success rate.

Owner:YANTAI KAIBO AUTOMATION TECH

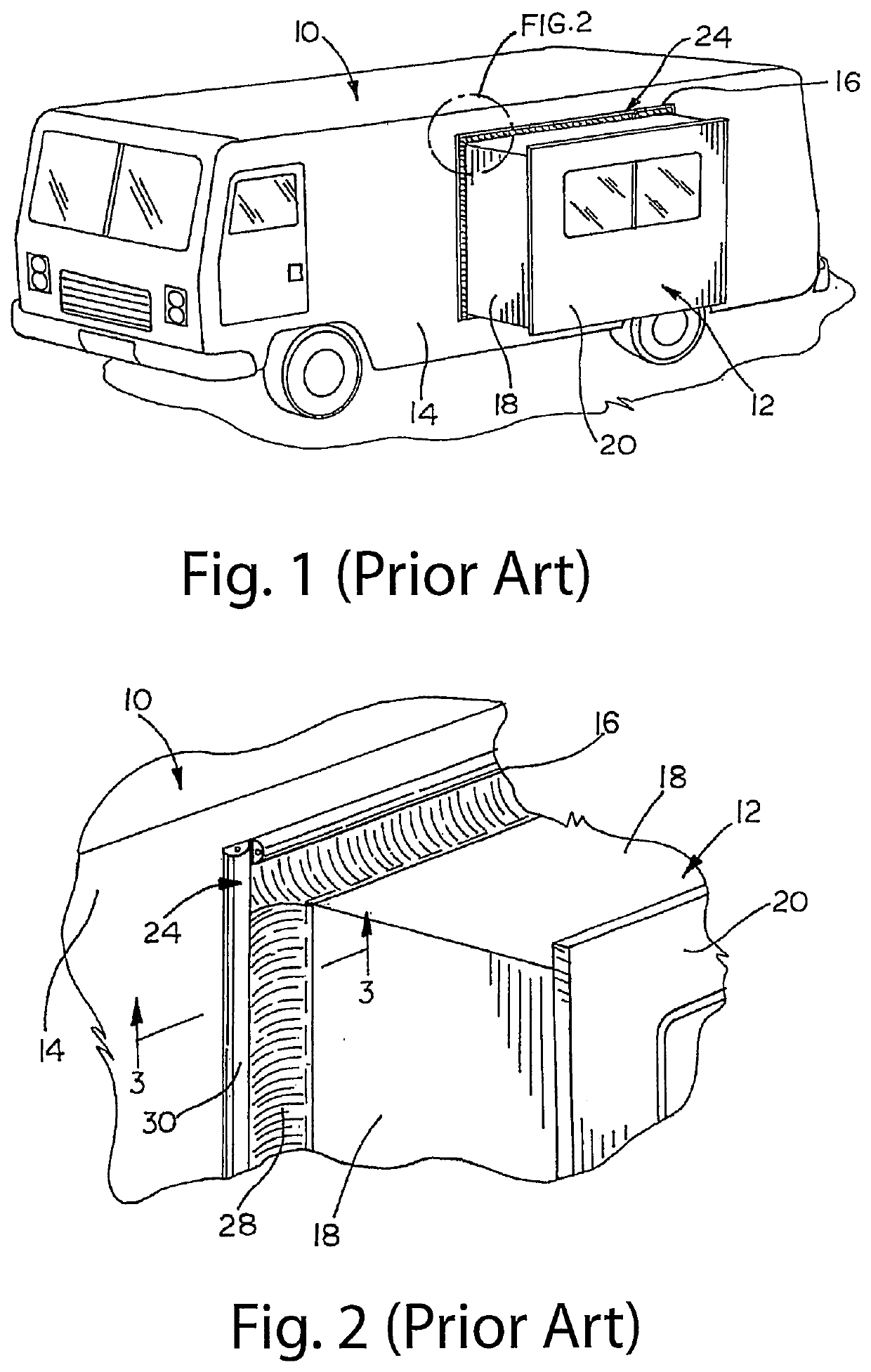

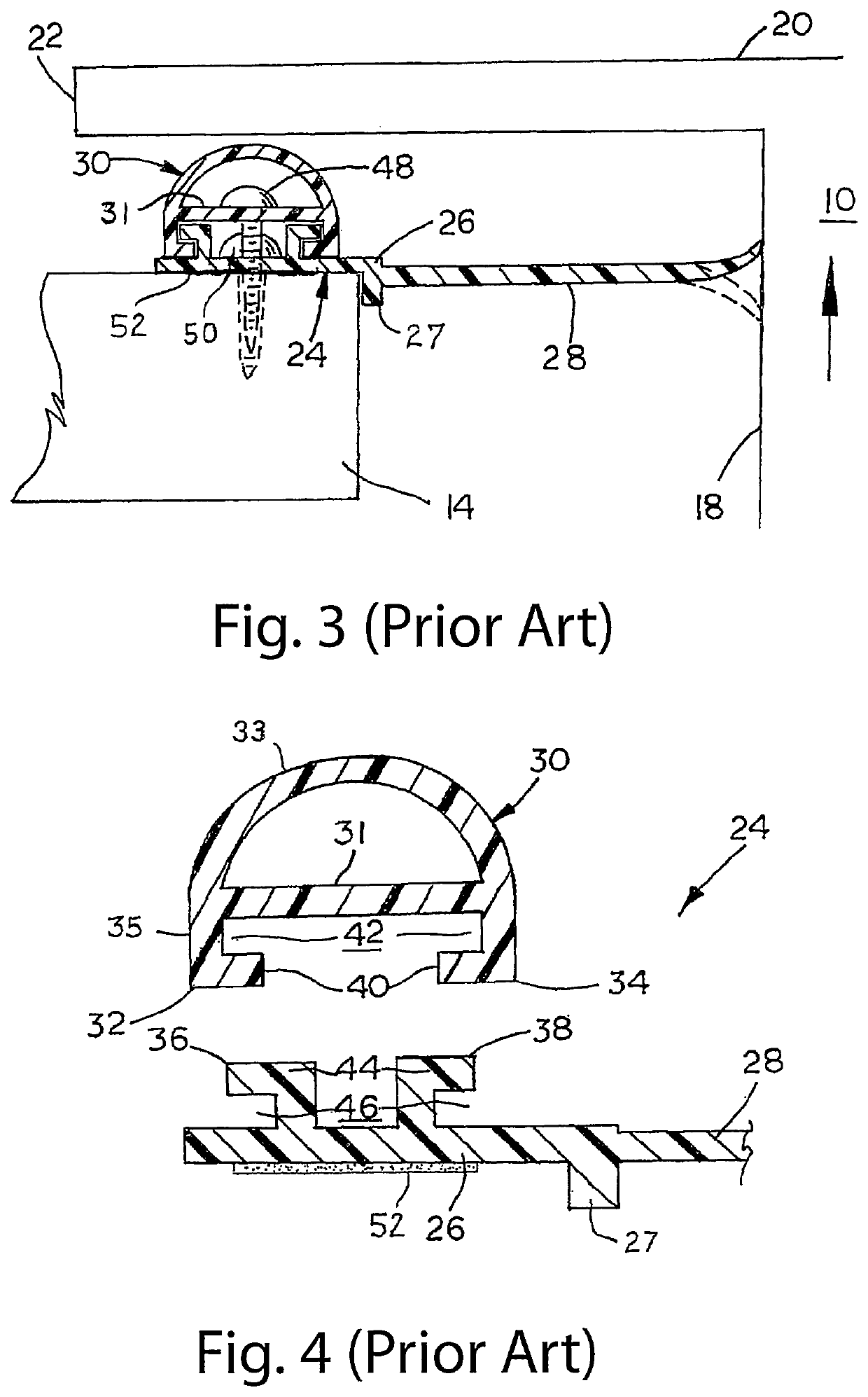

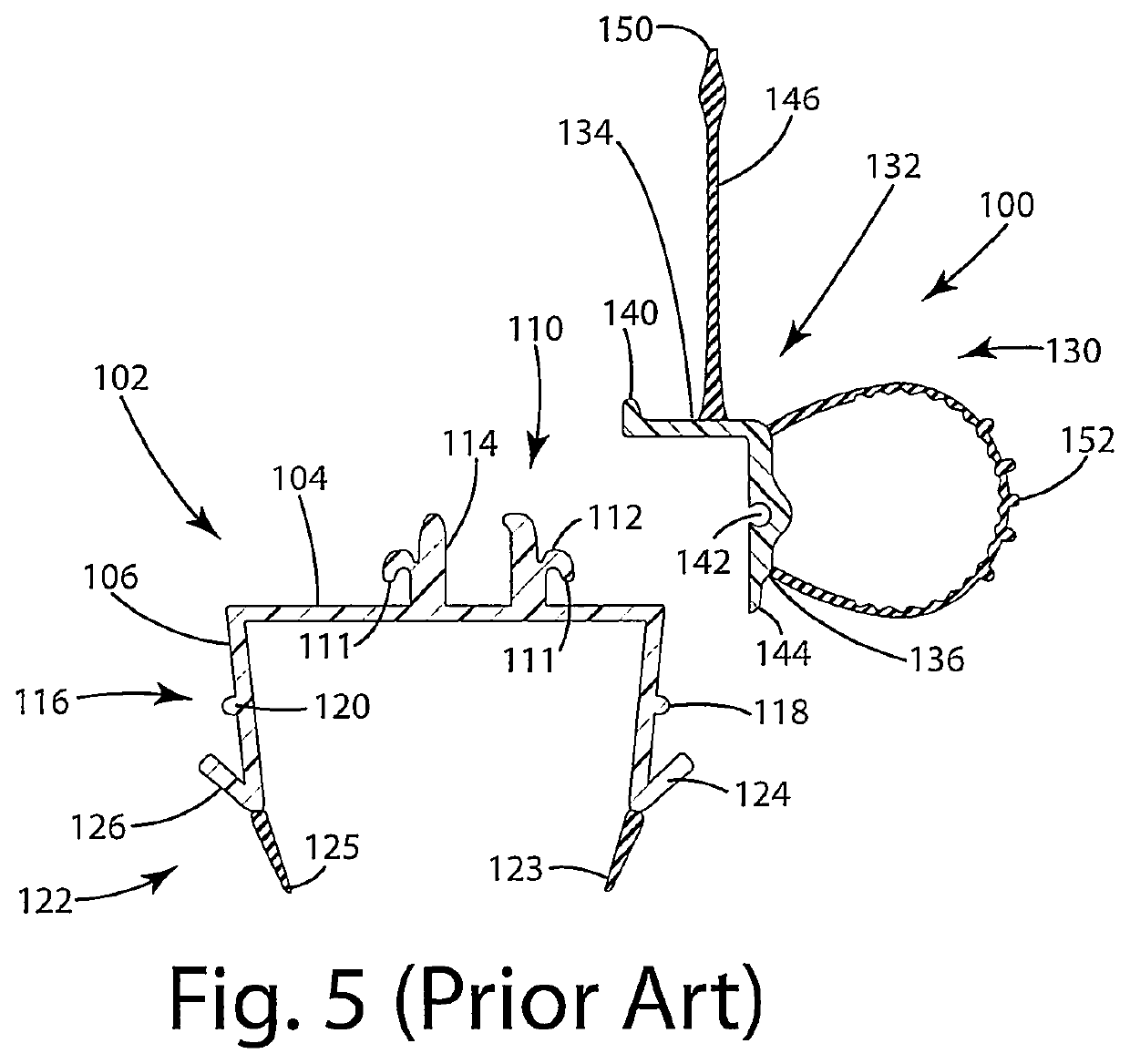

Bottom seal for use with rv slide out rooms

InactiveUS20200317143A1Easy maintenanceEasy to installEngine sealsUnderstructuresEnvironmental geologyMechanical engineering

A bottom seal assembly (500) is disclosed for use with mobile living quarters such as an RV or residential vehicle (202). The bottom seal assembly (500) can include a jacket (514) connectable to a frame of the RV (505). The jacket (514) includes a main body (520), and a pair of wipes (528, 530) extending in a parallel configuration and directed toward a slide-out room floor (503). A bight portion (529) connects together the two wipes (528, 530) so as to form a gutter (534) for carrying off water and debris. A bottom wipe (524) extends outwardly from a base (522) of the main body (520). A spacer leg (532) extends inwardly from the jacket (514) and is used to appropriately position rollers (512) or wear bars (612), which can be utilized to smoothly move the room floor (503) between a raised and lowered position.

Owner:GOODE TOBIN MICHAEL

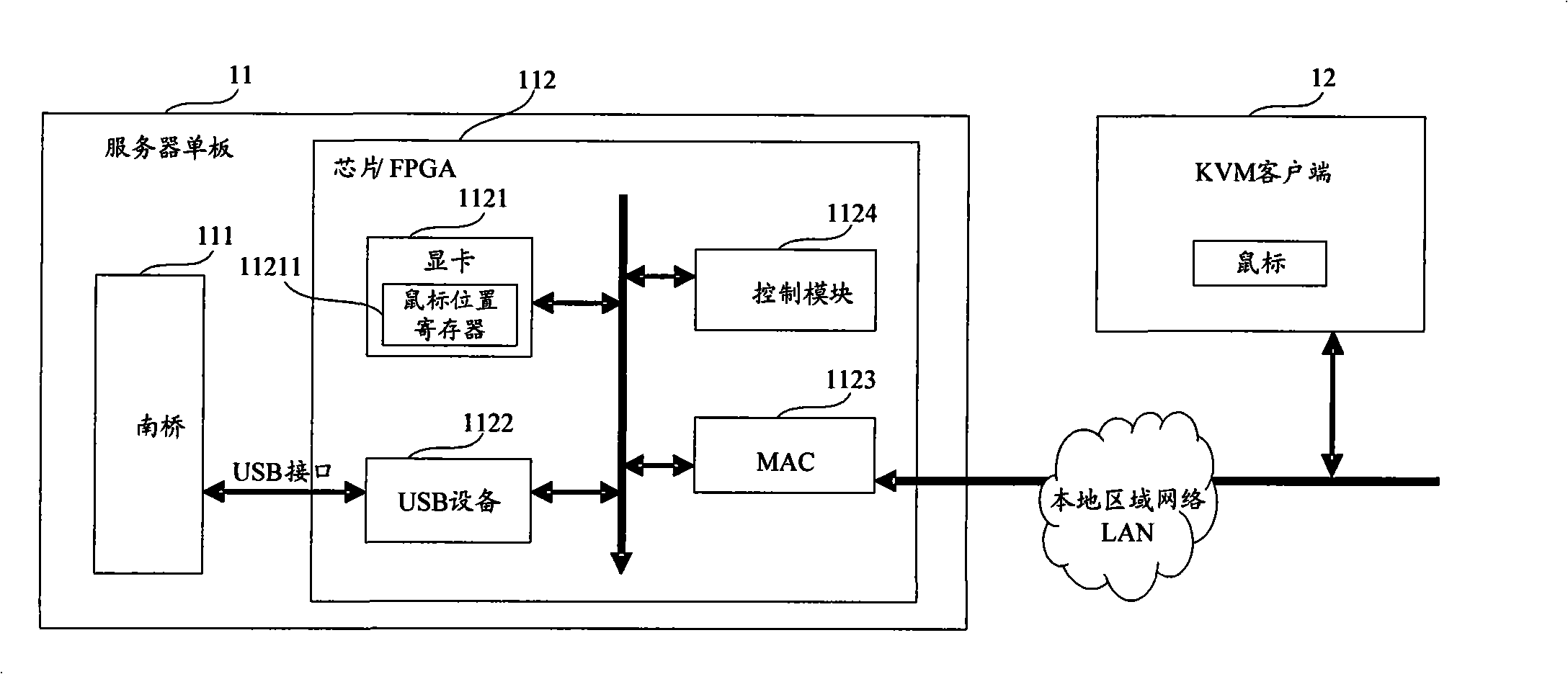

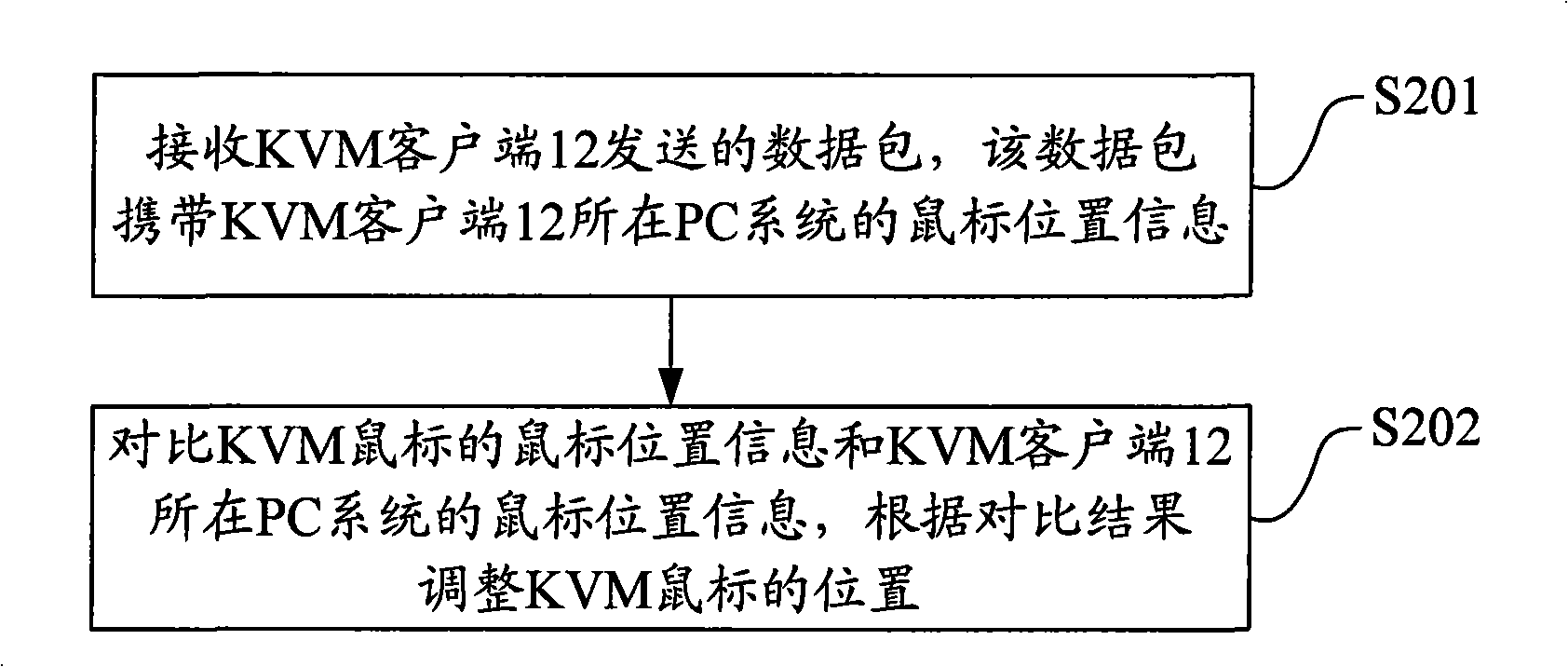

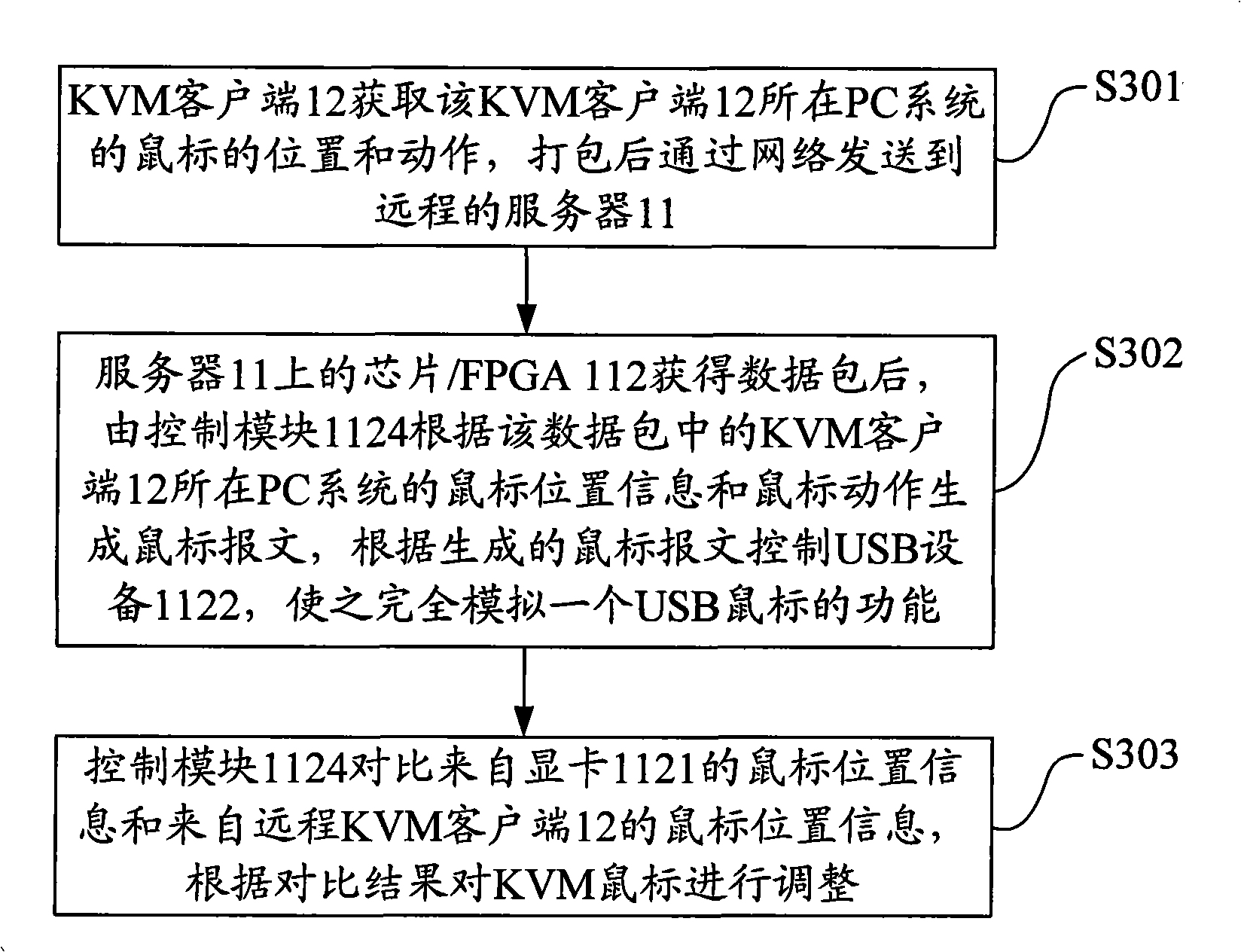

Mouse synchronization process, system and server

InactiveCN101339473AAchieve synchronizationAccurate synchronizationTransmissionInput/output processes for data processingOperational systemNetwork packet

The embodiment of the invention discloses a mouse synchronization process, system and server. The mouse synchronization process includes: receiving data packets transmitted from a Keyboard Video Mouse (KVM) client carrying mouse position information of the KVM client PC system; comparing the mouse position information of the KVM mouse with the mouse position information of the KVM client PC system, and adjusting the position of the KVM mouse according to the result. The embodiment of the invention can realize an accurate, quick and automatic mouse synchronous effect; and the embodiment of the invention can realize mouse real-time synchronization, both fore and after the server entering into the operating system, therefore operations at the KVM customer client can be convenient and simplified, and the customer client will be more friendly. Furthermore, the embodiment of the invention adopts network to transmit KVM mouse data, thereby having a good KVM mouse synchronizing effect.

Owner:HUAWEI TECH CO LTD

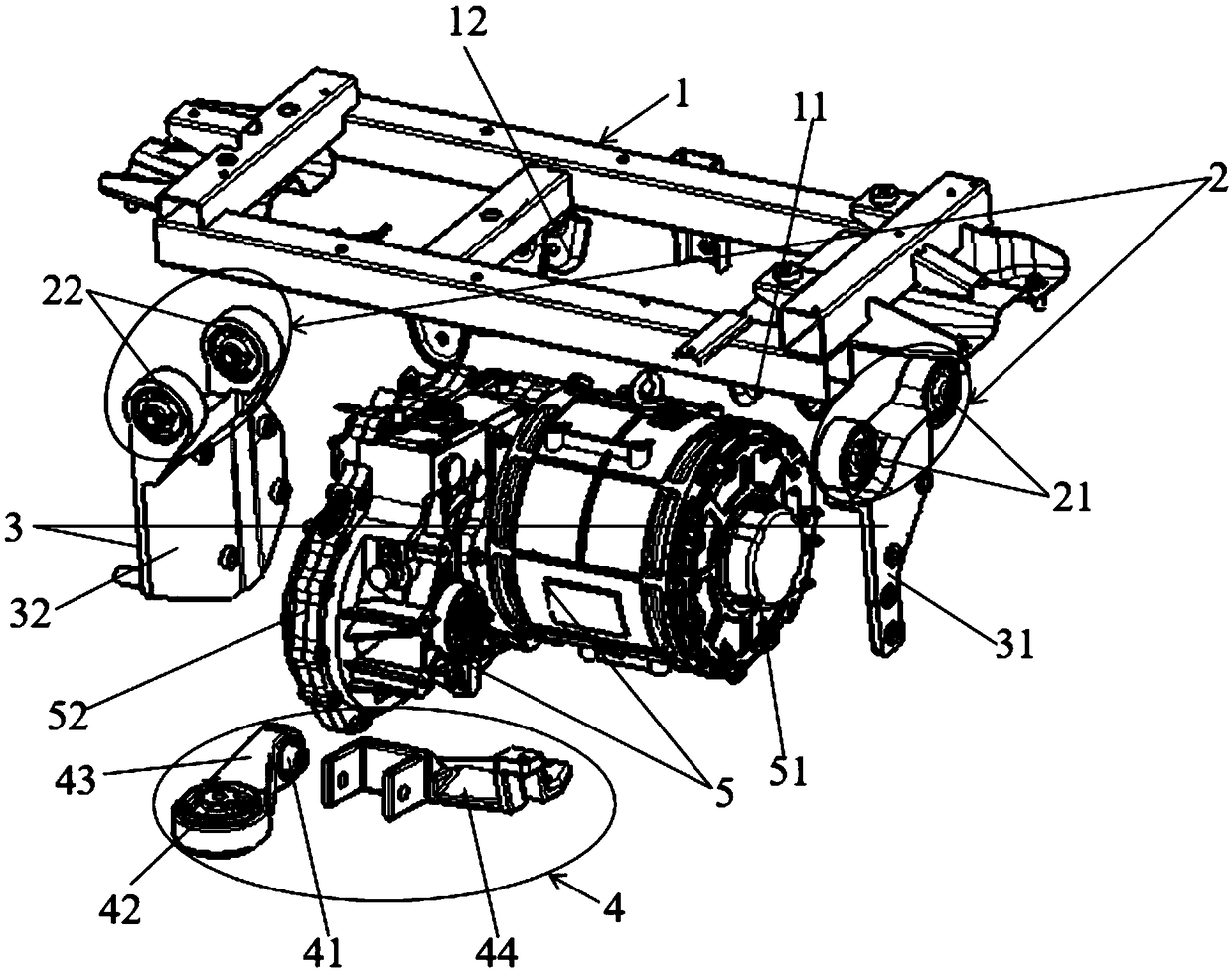

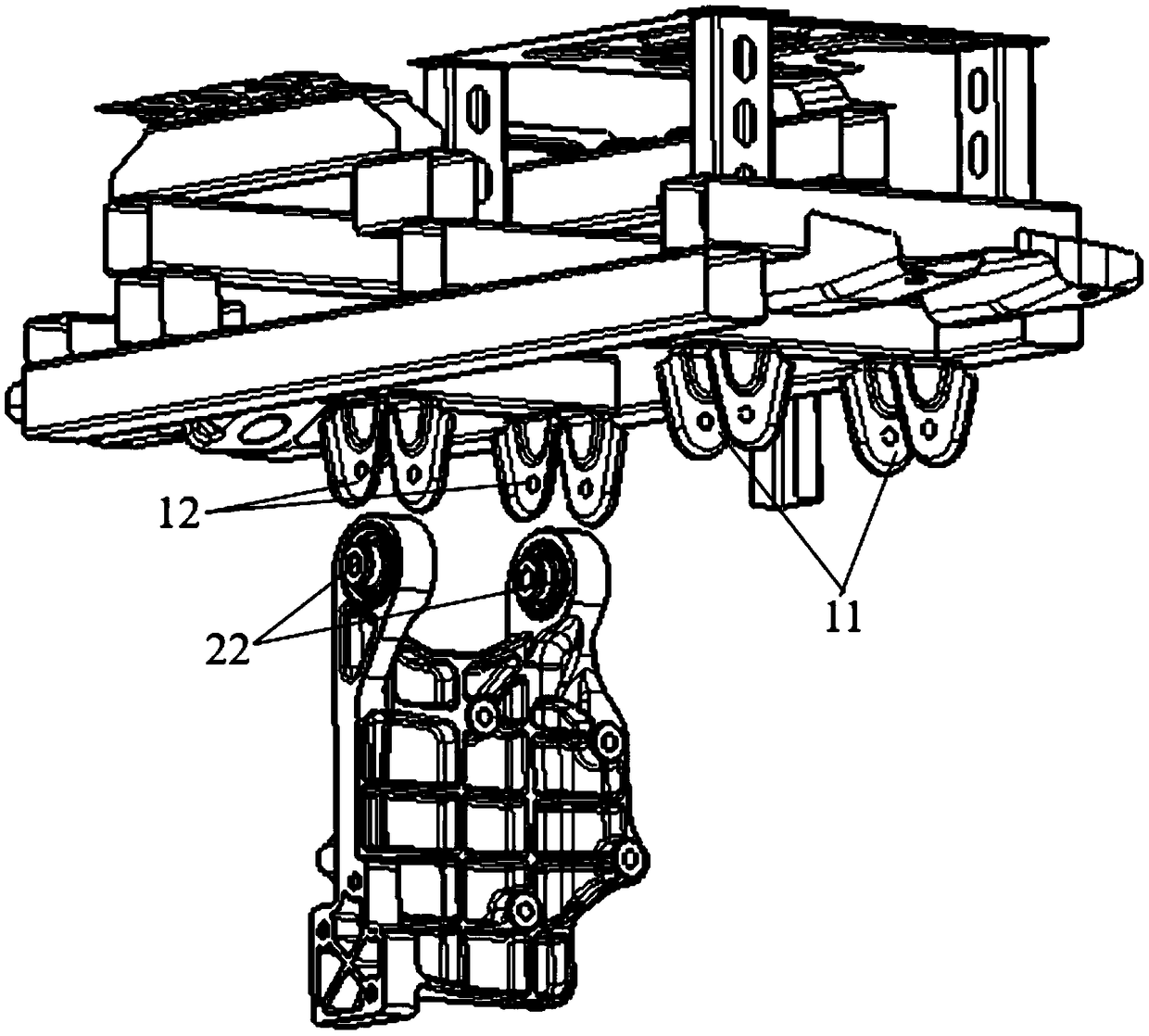

A suspension system of a suspension electric vehicle and a method for using the same

PendingCN109130818AConsistent spatial locationConsistent positionSpringsElectric propulsion mountingVehicle frameEngineering

A suspension system of a suspension electric vehicle comprises a mounting beam, a vibration damping mechanism, a load bearing mechanism and a torsion resistance mechanism, wherein the vibration damping mechanism is integrally mounted on one end of the load bearing mechanism, the other end of the load bearing mechanism is connected to the power system, the vibration damping mechanism is connected to the mounting beam, one end of the torsion resistance mechanism is connected to the power system, and the other end of the torsion resistance mechanism is connected to the subframe. The load-bearingelement skeleton I and skeleton II are arranged on both sides of the power system, the damping element I is arranged on the skeleton I, and the damping element II is arranged on the skeleton II, so that the mounting beam is more force-bearing and the structure is more stable. By adjusting the direction of the rubber bushings in the damping element I and the damping element II, the stiffness of theentire suspension system in all directions is more reasonable, the limit capacity of the suspension system to the dynamic system is improved. The vibration damping element I is arranged on the frameI and the vibration damping element II is arranged on the frame II, so that the force on the mounting beam is more reasonable and the structure is more stable. The design of the anti-torsion mechanismimproves the anti-torsion ability of the whole system. The invention also discloses a method for using the suspension system of the suspension electric vehicle.

Owner:CHERY COMML VEHICLE ANHUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com