Patents

Literature

54results about How to "Improve die-cutting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

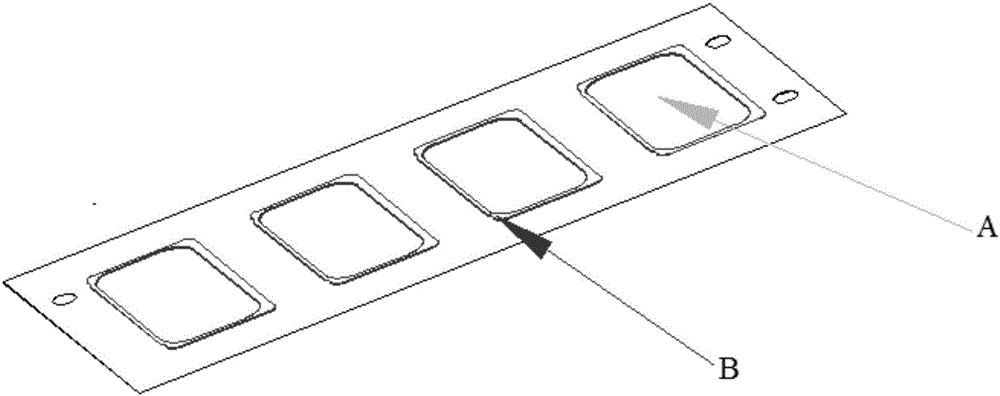

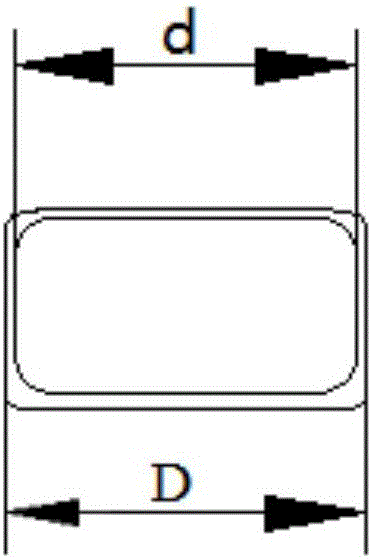

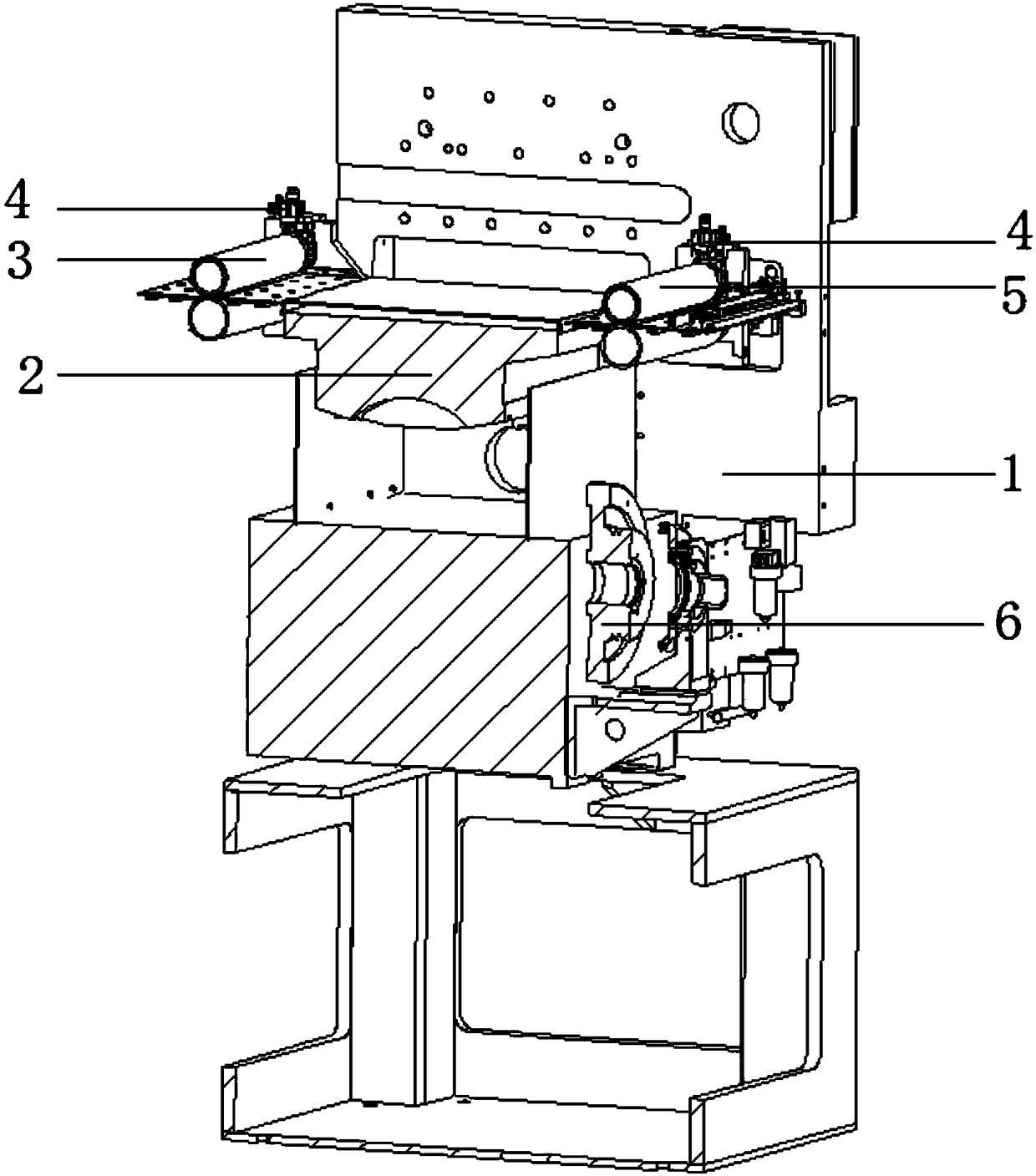

Die-cutting waste discharge device with inner frame die-cutting piece and die-cutting waste discharge method

InactiveCN106541449AGood waste discharge effectThe waste disposal process went smoothlyMetal working apparatusTectorial membranePunching

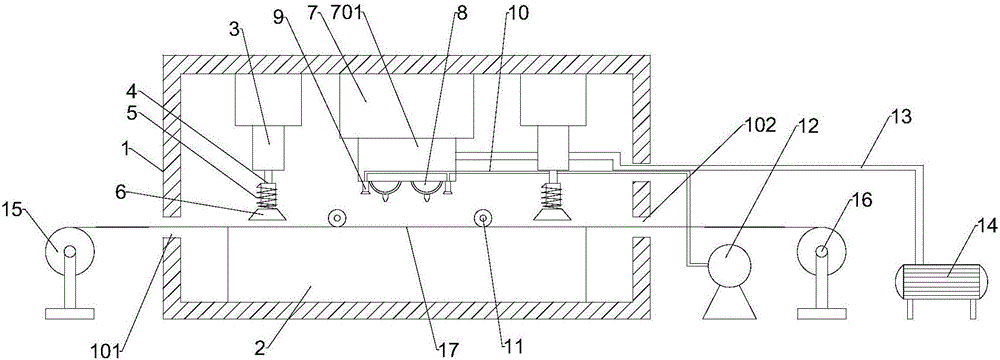

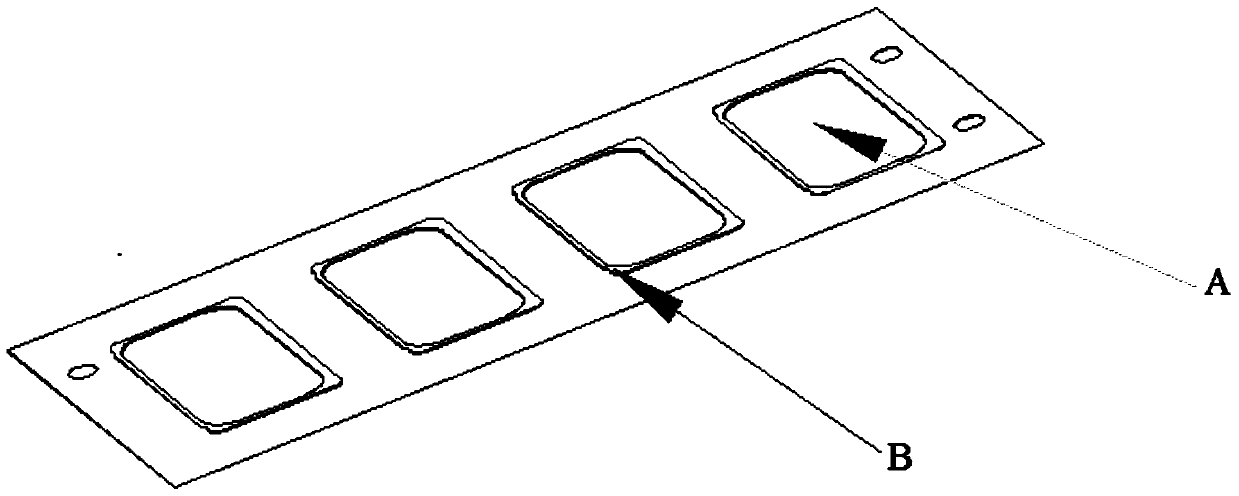

The invention relates to a die-cutting waste discharge device with an inner frame die-cutting piece and a die-cutting waste discharge method. The die-cutting waste discharge device comprises a first opposite-pressing roller, first-stamping die-cutting cutters, first waste discharge rollers, a second opposite-pressing mechanism, second-stamping die-cutting cutters and second waste discharge rollers which are arranged sequentially. The first opposite-pressing roller attaches a first single face gummed protective film to a first release film; indent inner frames are punched in first stamping by the first-stamping die-cutting cutters; the first waste discharge rollers is used to take up the first single face gummed protective films attached to wastes of the inner frames after the first-stamping punching; the second opposite-pressing mechanism attaches a second single face gummed protective film to the non-release surface of the first release film, and sequentially attaches double faced adhesive tape and a second release film to the release surface of the first release film; normal inner frames are punched in second-stamping by the second-stamping die-cutting cutters; the second waste discharge rollers are used to take up the second single face gummed protective films attached to wastes of the inner frames after the second-stamping punching; and the size of each normal inner frame is bigger than the size of each indent inner frame. Compared with the prior art, the die-cutting waste discharge device has the advantages that the effect of waste discharge is good, the product has no deformation, and efficiency is high.

Owner:YUANRANG IND SHANGHAI

Automatic facial mask die cutting and folding mechanism

InactiveCN103523300AImprove quality and efficiencyImprove die-cutting efficiencyPackagingMetal working apparatusWork in processEngineering

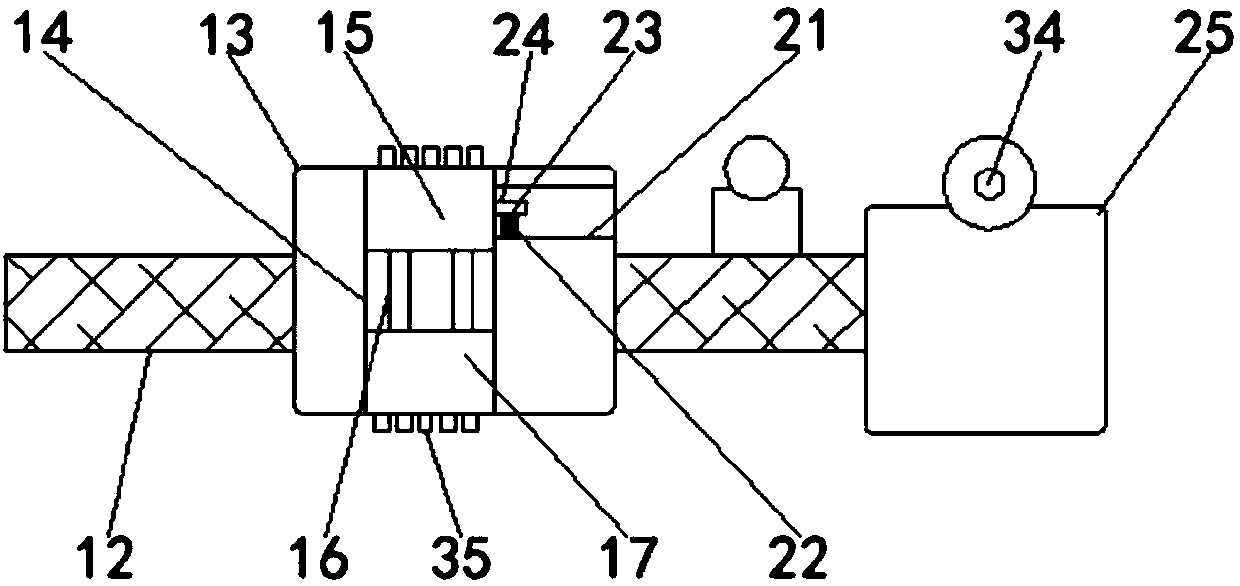

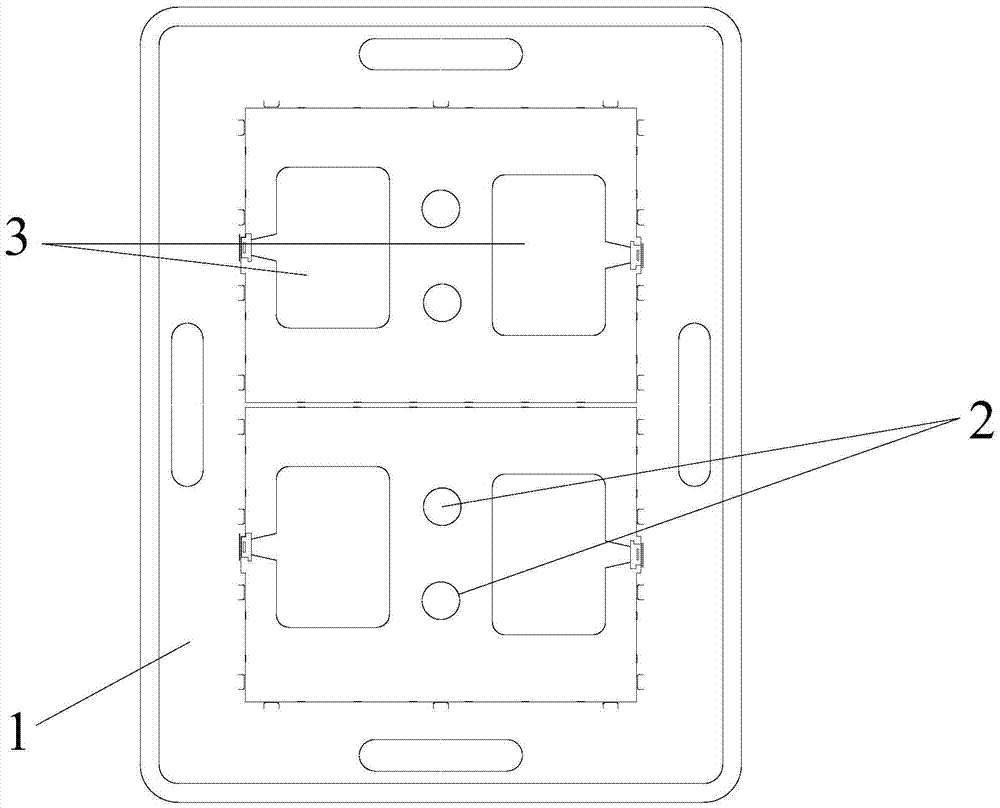

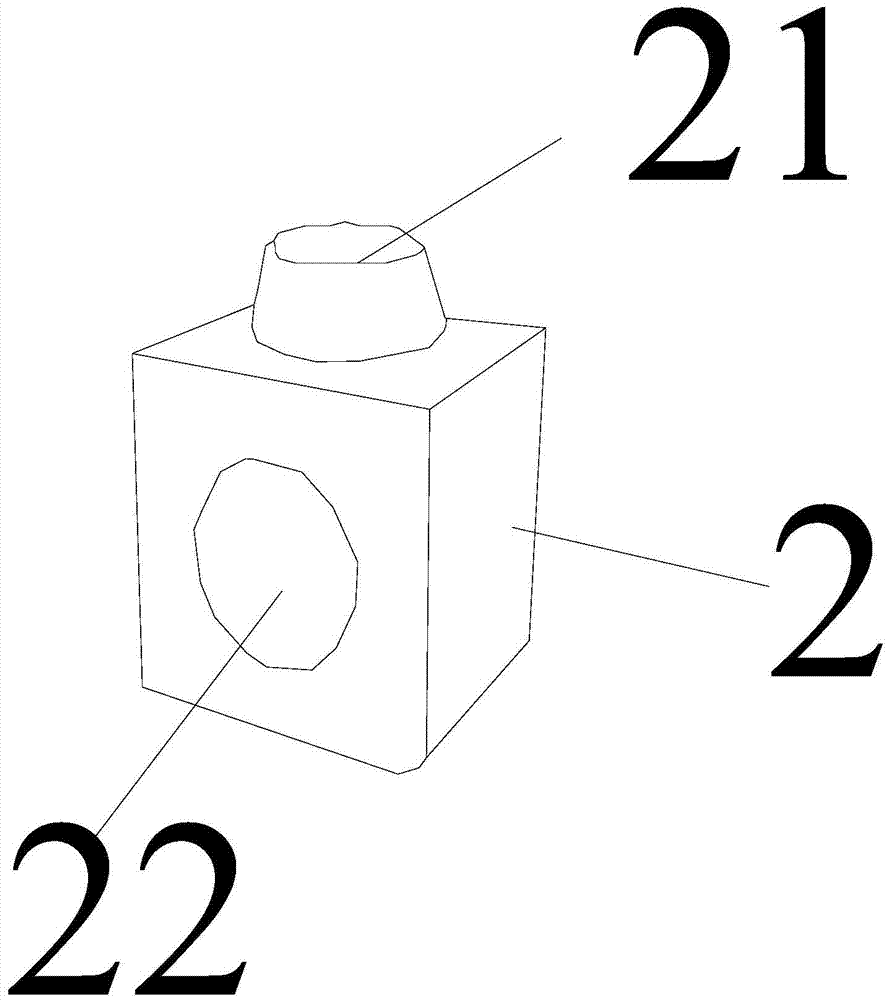

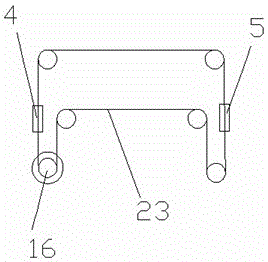

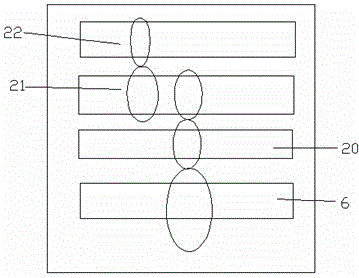

The invention discloses an automatic facial mask die cutting and folding mechanism which comprises a rack (15) and a die cutting device (5). The die cutting device comprises a die cutting frame (21), a die cutting bottom roller (23) and a die cutting cutter roller (25). Air suction discs (22) are arranged on the die cutting bottom roller and the die cutting cutter roller. A waste collecting assembly (10) is arranged on the rack and adjacent to the die cutting cutter roller. An air suction conveying assembly (11) is arranged on the rack and at the outlet of the die cutting bottom roller. A folding device (7) is arranged on the rack and above the outlet of the air suction conveying assembly. According to the automatic facial mask die cutting and folding mechanism, a facial mask undergoes die cutting through the die cutting device and waste of the facial mask is collected by the waste collecting assembly, so that die-cut waste of the positions of the eyes and the mouth will not retain on the facial mask and the semi-finished facial mask is lengthwise and automatically folded through the folding device. Thus, die cutting and folding are fast, friendly to environment and sanitary. The die cutting quality and the die cutting efficiency of the facial mask are obviously improved.

Owner:RUIAN DAWEI MACHINERY

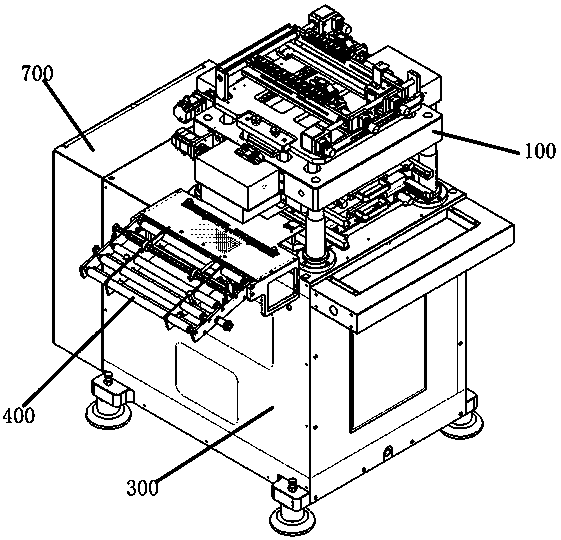

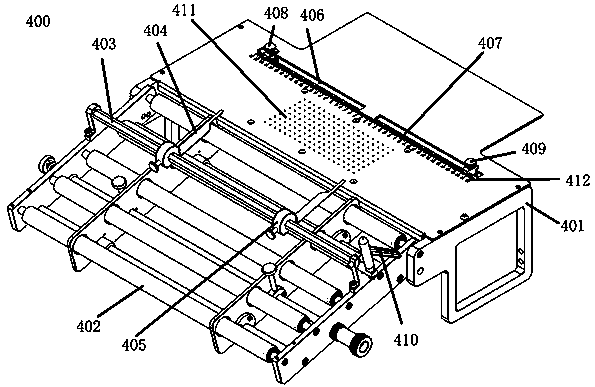

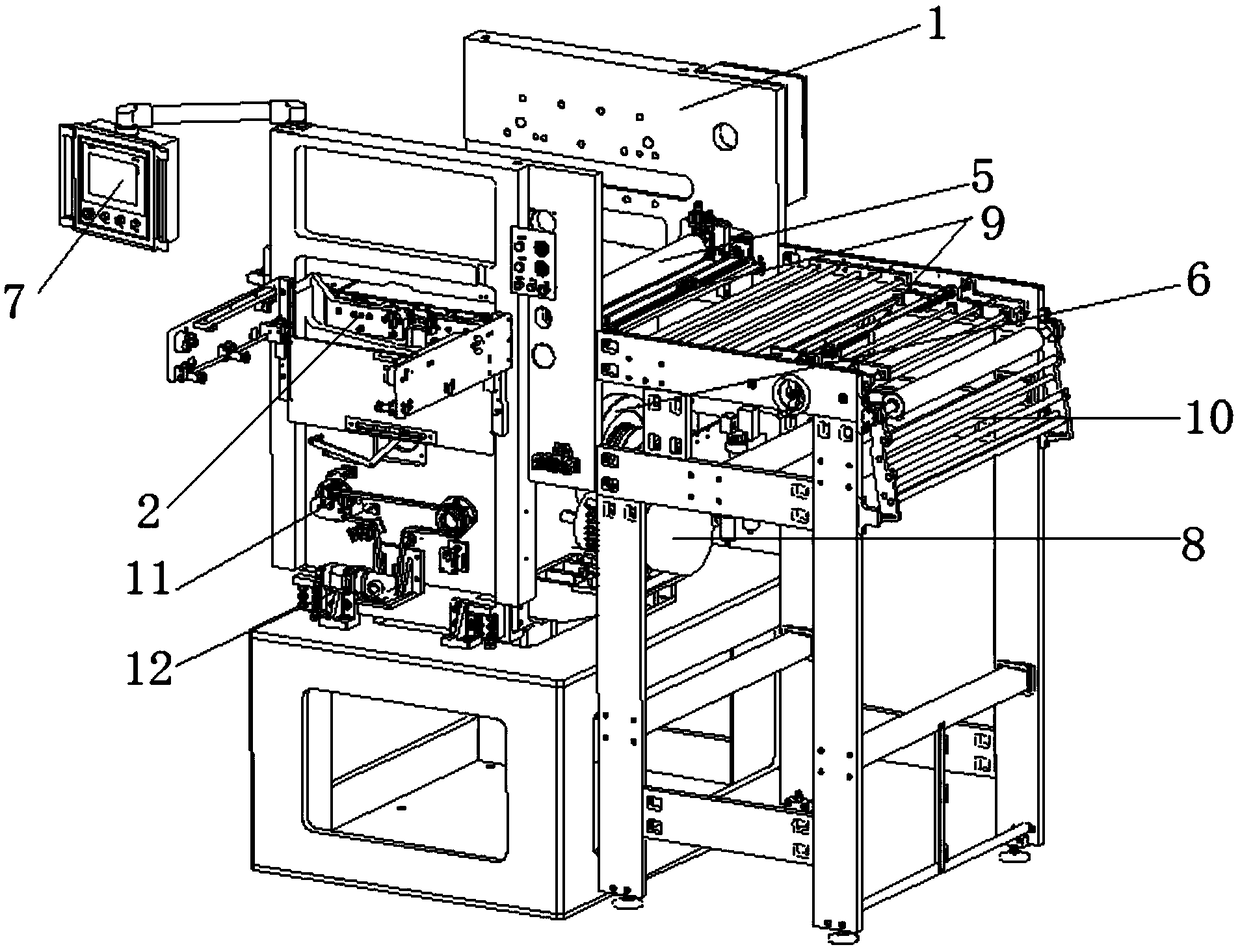

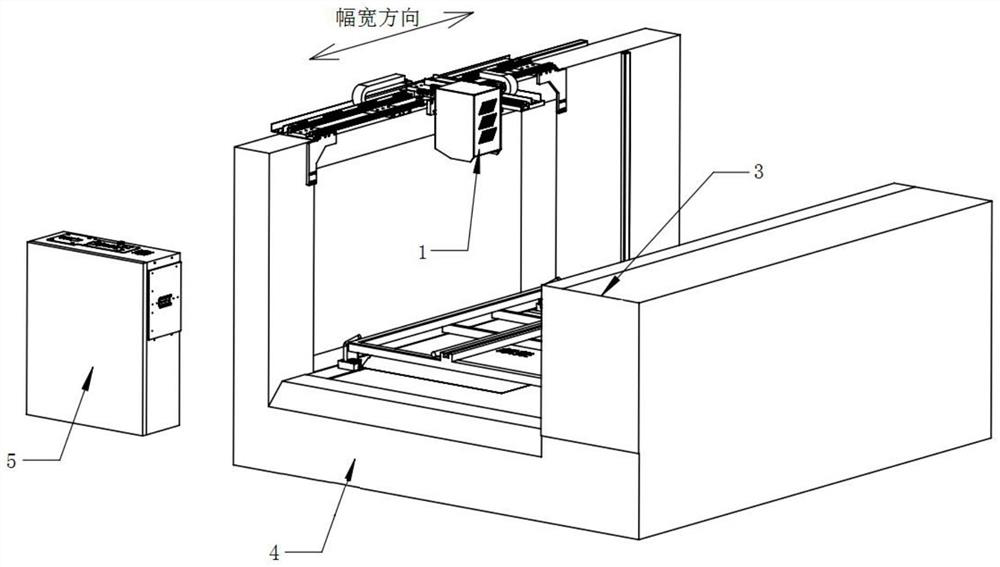

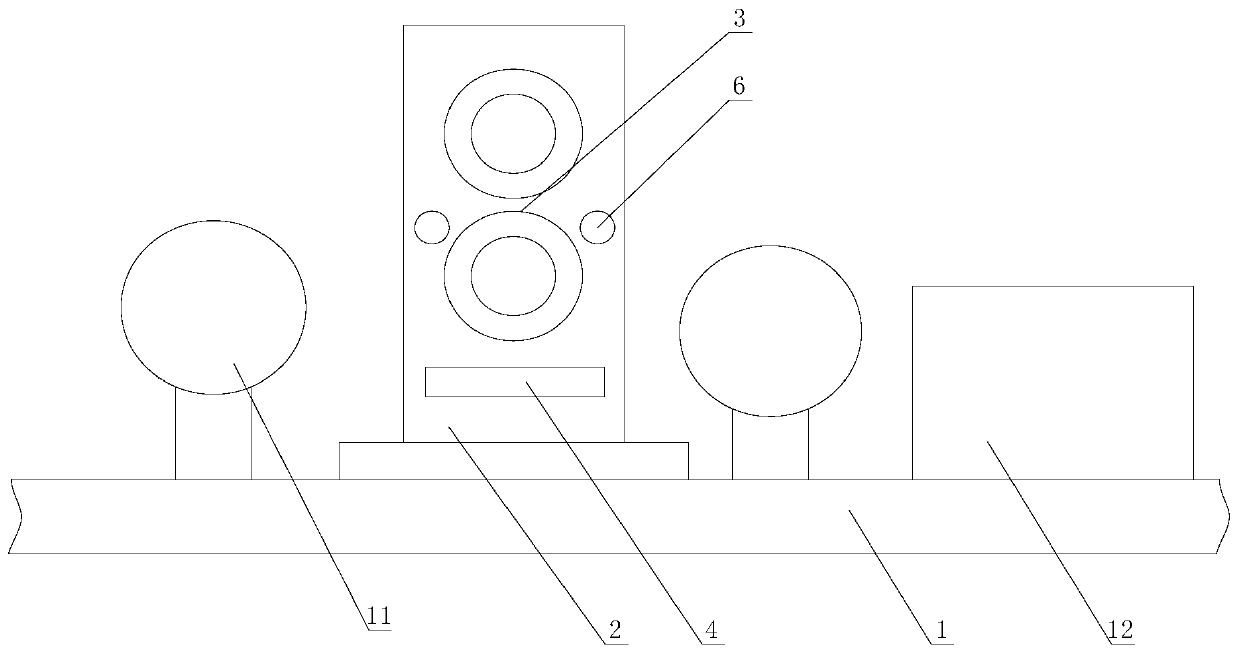

CCD automatic positioning die cutting machine

PendingCN110696093AImprove die-cutting accuracyImprove die-cutting efficiencyMetal working apparatusMachineDie cutting

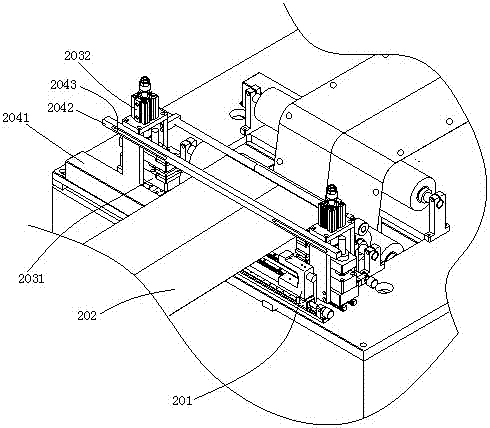

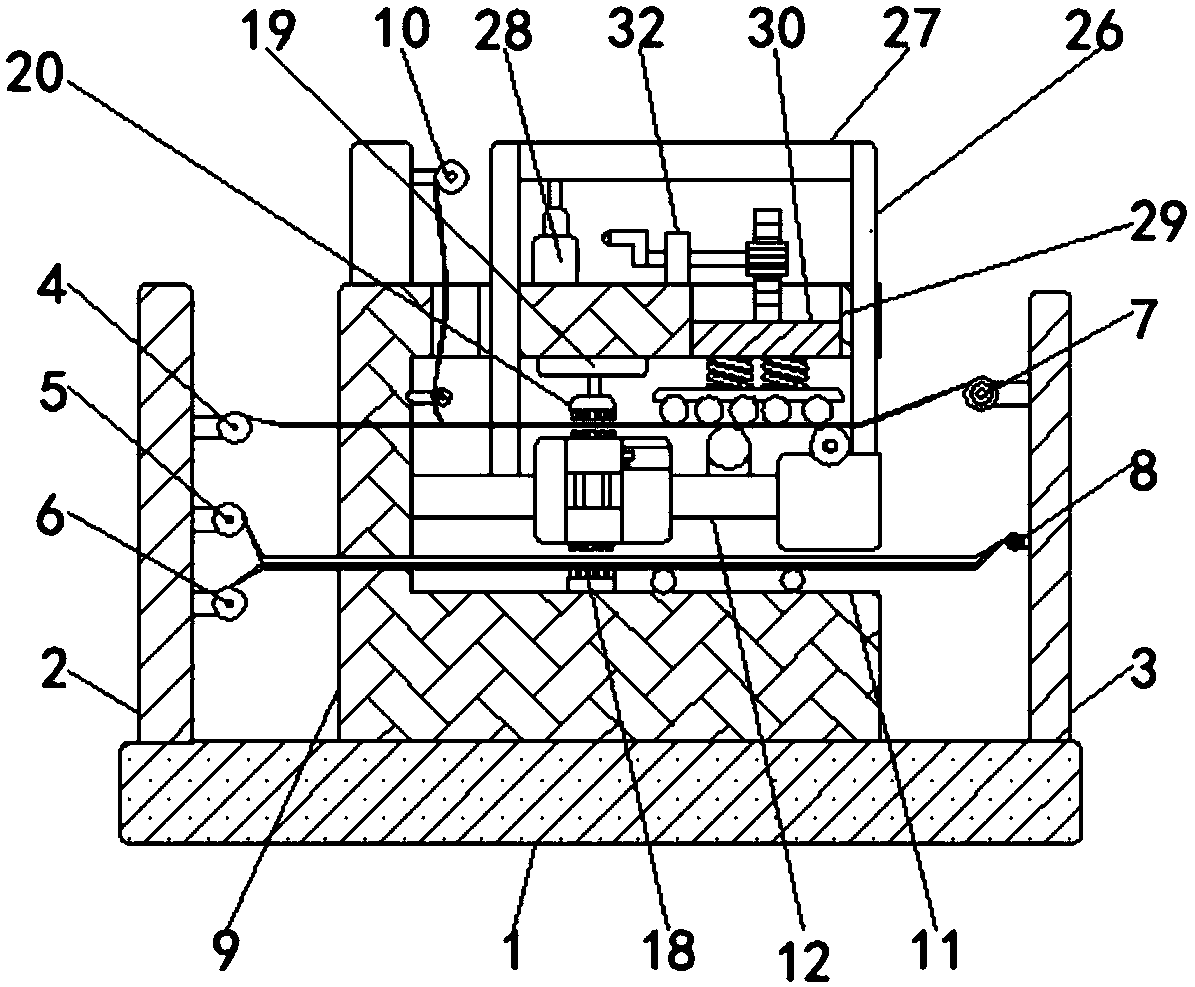

The invention provides a CCD automatic positioning die cutting machine, and belongs to the field of die cutting equipment. The CCD automatic positioning die cutting machine comprises a die cutting main machine for providing stamping power, a control box for centralized control, a feeding mechanism for feeding materials and a positioning adjusting mechanism for die cutting horizontal adjusting automatic positioning. The control box is mounted behind the die cutting main machine, the adjusting mechanism is mounted on the die cutting main machine, and the feeding mechanism is mounted on the sideportion of the die cutting main machine. Compared with the prior art, adjusting in the horizontal direction can be carried out under the condition without halts, meanwhile, the die cutting precision and the die cutting efficiency are improved, it is not needed to worry about the situation that the die cutting position is wrong due to material staggering, and the CCD automatic positioning die cutting machine has the beneficial effects that the die cutting precision and the die cutting efficiency are higher.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

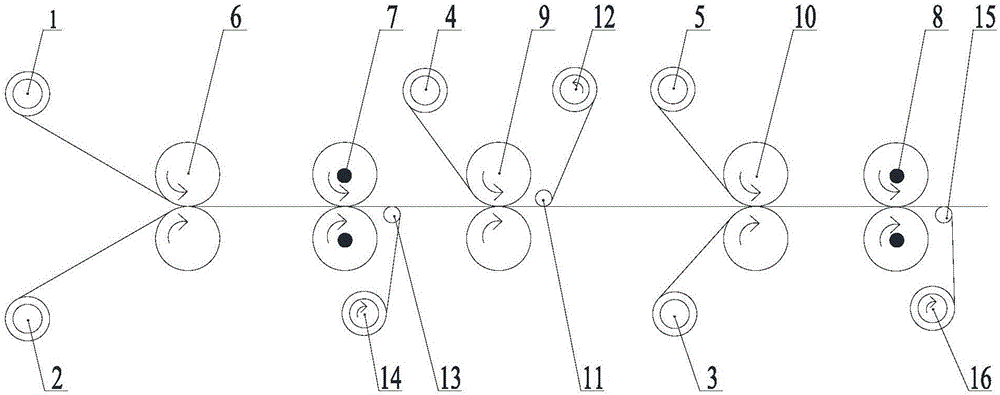

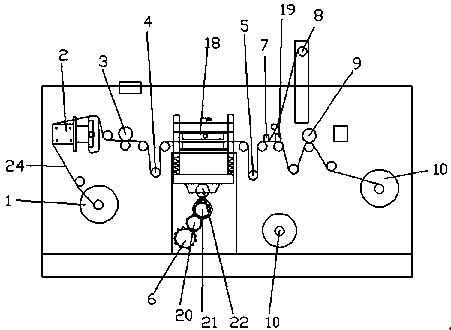

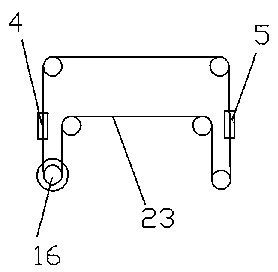

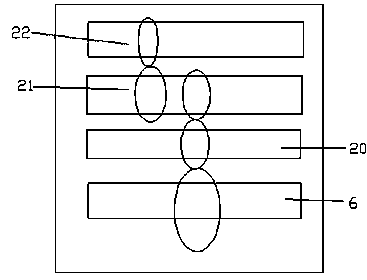

Multi-lug high-speed die cutting machine

InactiveCN106945114AImprove die-cutting efficiencyReduce processing costsElectrode manufacturing processesMetal working apparatusPunchingEngineering

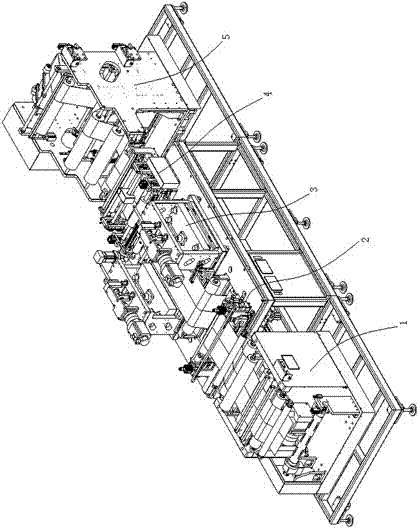

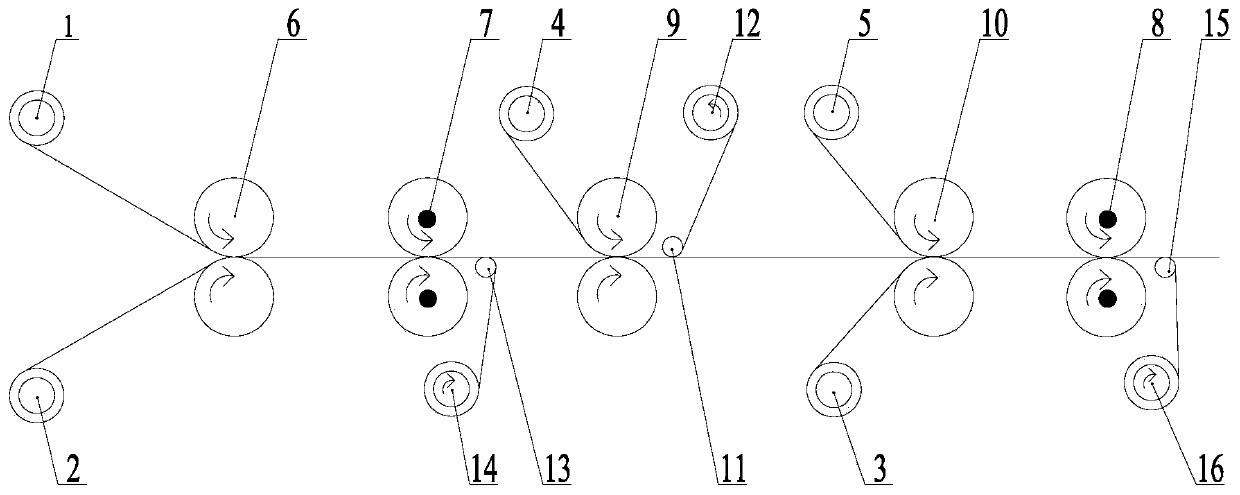

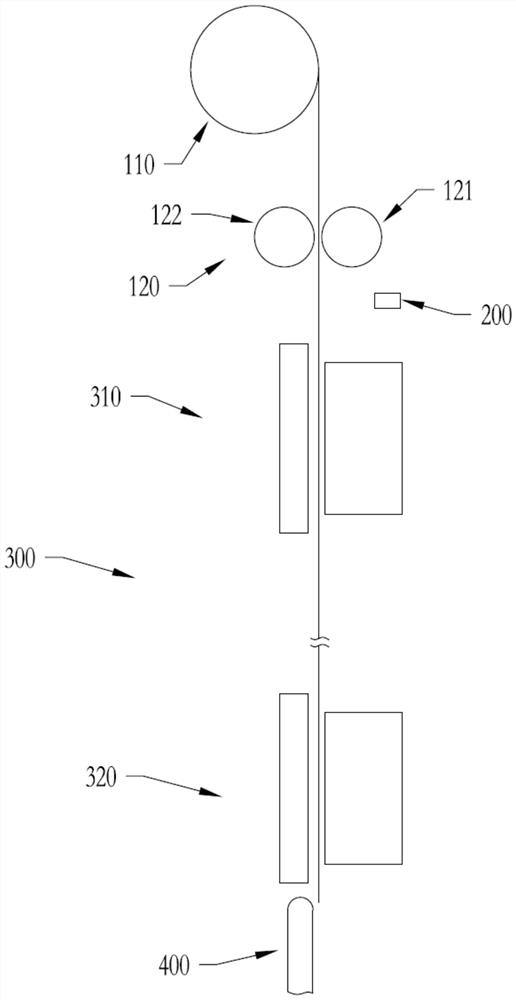

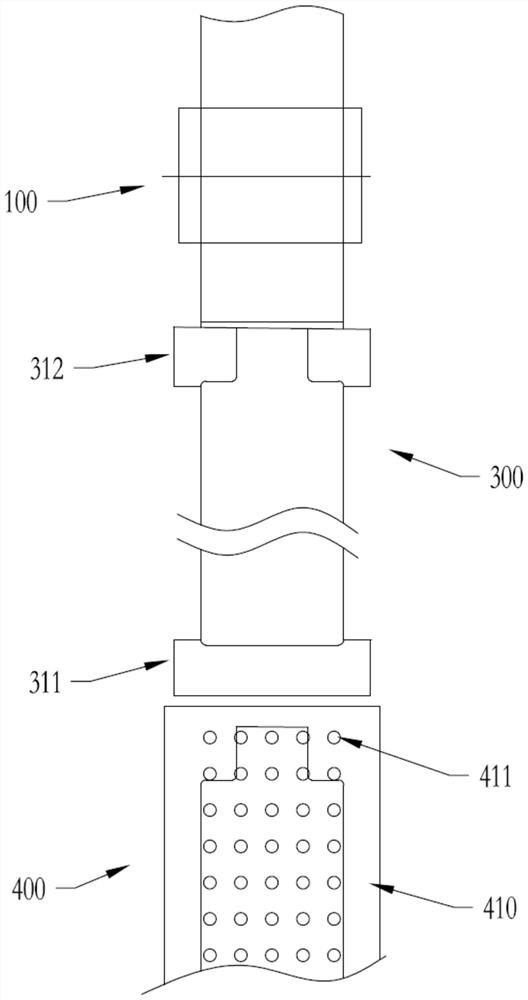

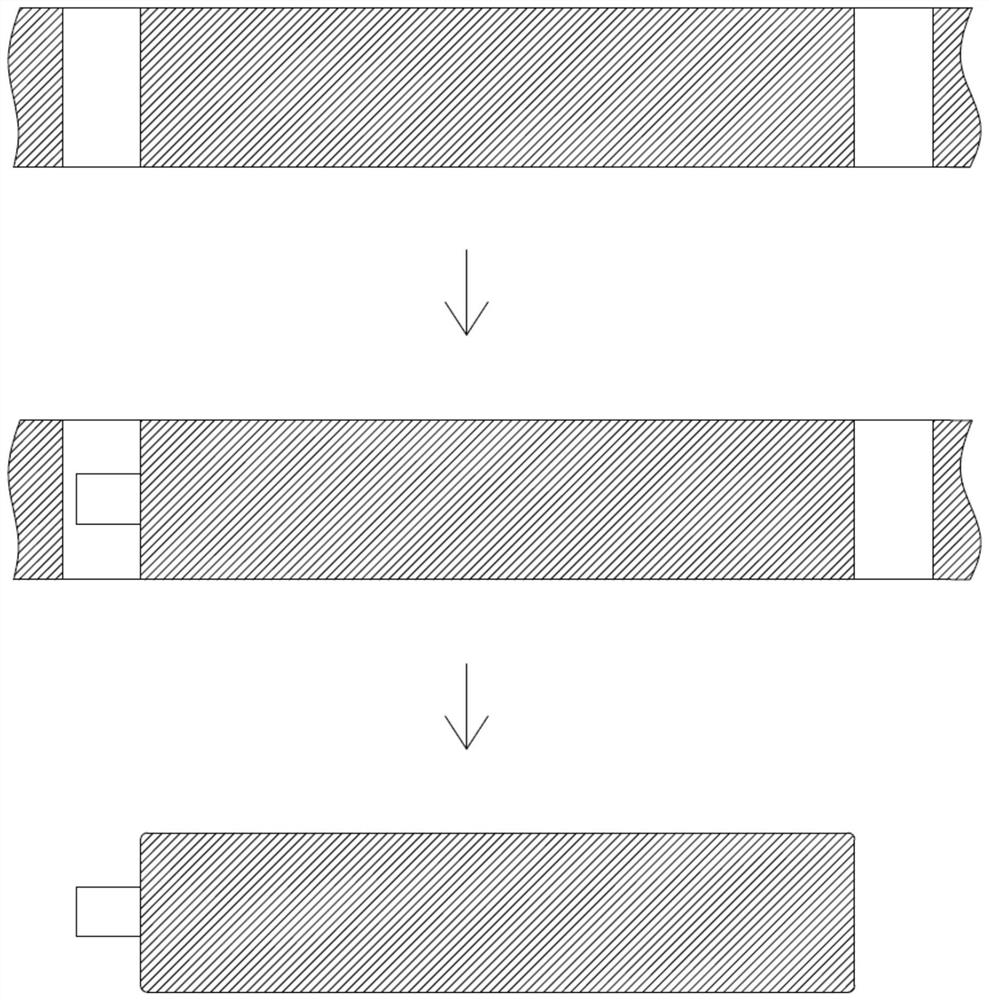

The invention embodiment provides a multi-lug high-speed die cutting machine comprising an automatic feed mechanism used for providing raw materials, a positioning and punching mechanism used for positioning, punching and marking the raw materials, a die cutting mechanism used for die cutting of the raw materials, an automatic separate cutting mechanism used for separately cutting the raw materials after die cutting to form first raw materials and second raw materials, a double rolling-up mechanism used for rolling up the first raw materials and the second raw materials separately cut, and a control mechanism used for controlling the running state of the multi-lug high-speed die cutting machine, and all mechanisms are arranged in turn. In the invention embodiment, double positioning and punching, die cutting and rolling-up can be performed simultaneously, the die cutting efficiency of the raw materials can be improved effectively, and the machining cost is reduced; at the same time, the multi-lug high-speed die cutting machine is simple in structure, and automatic in operation in the whole process; potential safety hazards caused by manual operation are avoided.

Owner:东莞市伟升机械设备科技有限公司

Die cutting machine with efficient die cutting tool

ActiveCN106272696ASimple structureSolve the adsorption problemMetal working apparatusEngineeringPiston rod

The invention provides a die cutting machine with an efficient die cutting tool. A connecting base is fixedly connected with a plurality of downward air blowing nozzles which sequentially communicate through an air inlet pipe. The other end of the air inlet pipe is connected with an air supply machine. The two sides of the part, in a machine case, of the connecting base are provided with downward pressing air cylinders correspondingly. The end portions of piston rods of the downward pressing air cylinders are fixedly connected with connecting rods sleeved with elastic pieces. One end of each elastic piece is fixedly connected with the corresponding connecting rod, and the other end of each elastic piece is connected with a pressing block. The pressing blocks face paper, and the pressing blocks can move relative to the connecting rods under the action force of the elastic pieces. The novel die cutting machine is simple in structure, transverse die cutting and longitudinal die cutting can be conducted on the paper at the same time, two tool rollers are arranged and can cut two printed products at the same time, the die cutting efficiency is improved, and the problem of paper adsorption in the die cutting process is effectively solved as well.

Owner:天津市文雅印刷标识有限公司

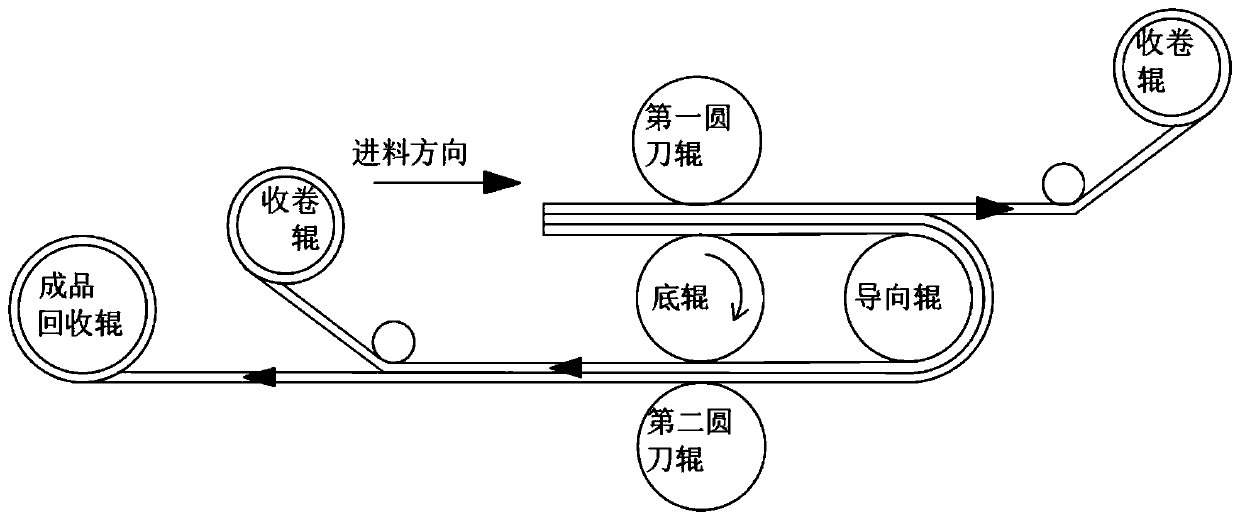

Circulating wiring die cutting process

InactiveCN109822672ACompact structureReasonable structureMetal working apparatusTectorial membraneAdhesive

The invention relates to a circulating wiring die cutting process. A product with a double-face structure and a shape is molded through die cutting at one time; an adopted die cutting knife group comprises a first circular knife roll, a bottom roll and a second circular knife roll which fit each other; raw materials are correspondingly bonded on the two faces of a double side adhesive tape in twolayers to form a main material strip; a first protective film and a second protective film are correspondingly bonded on the surfaces of the two layers of raw materials; the main material strip penetrates through a first circular knife mold and the bottom roll; the first circular knife roll and the bottom roll are matched with each other to simultaneously carry out die cutting on the first protective film and the raw materials in the upper layer; by using one group of winding rolls, the first protective film and waste materials are wound and separated from the raw materials in the lower layer;the separated raw materials in the lower layer and the second protective film penetrate through the space between a second circular knife mold and the bottom roll after turning back for 180 degrees;die cutting is carried out on the raw materials in the lower layer and the second protective film; and by using the other group of winding rolls, the second protective film and the waste materials arewound. The die cutting accuracy of the double-face product is greatly improved, and the die cutting efficiency of the double-face product is greatly enhanced.

Owner:宝德精密材料(无锡)有限公司

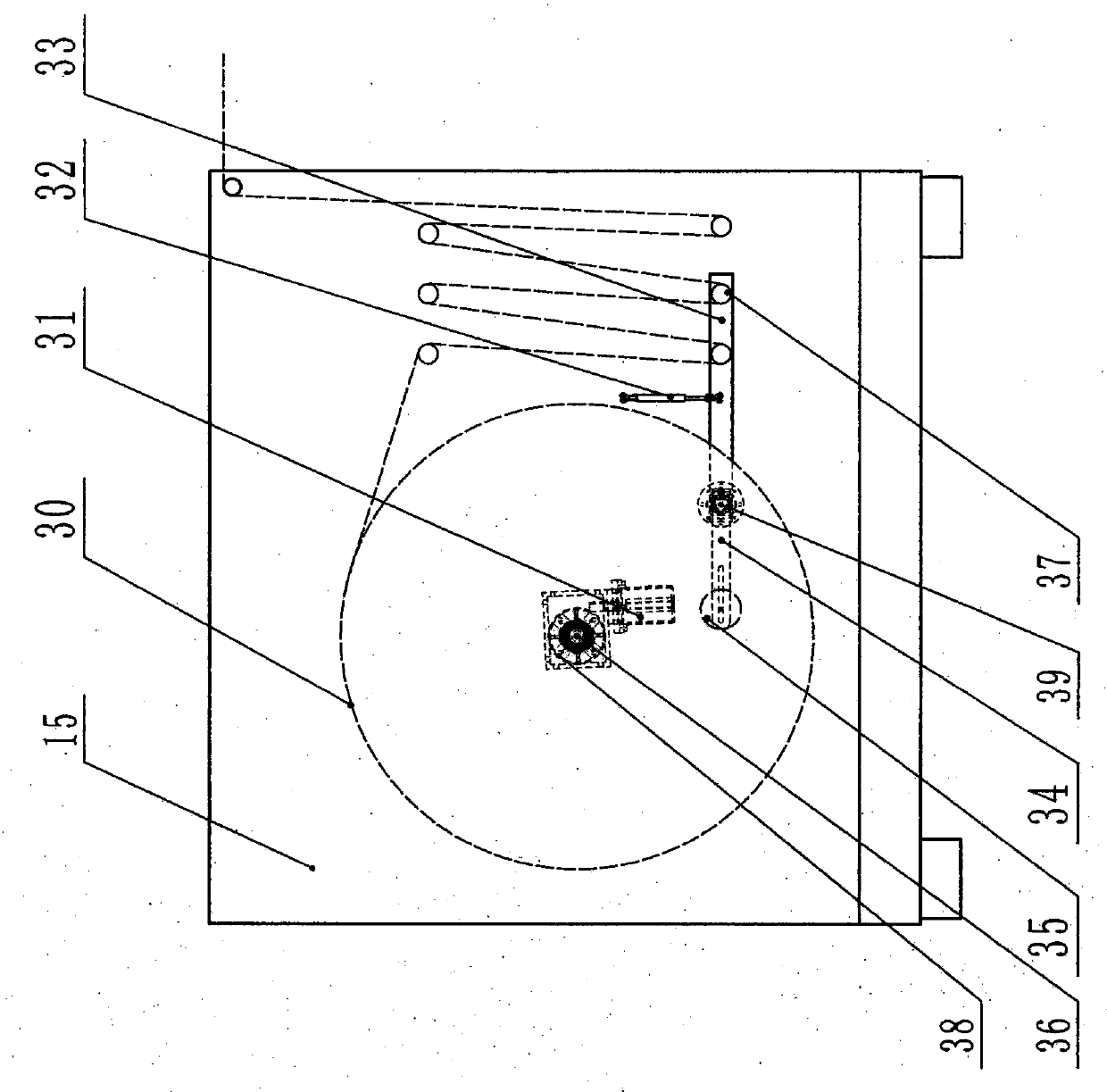

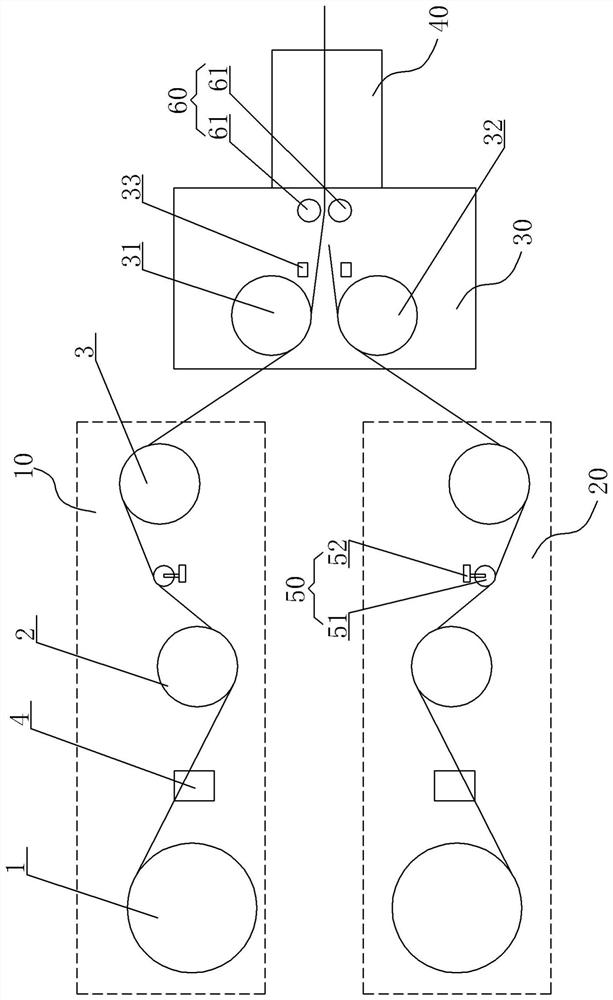

Constant-speed closed-loop photo electrically controlled mask discharging mechanism

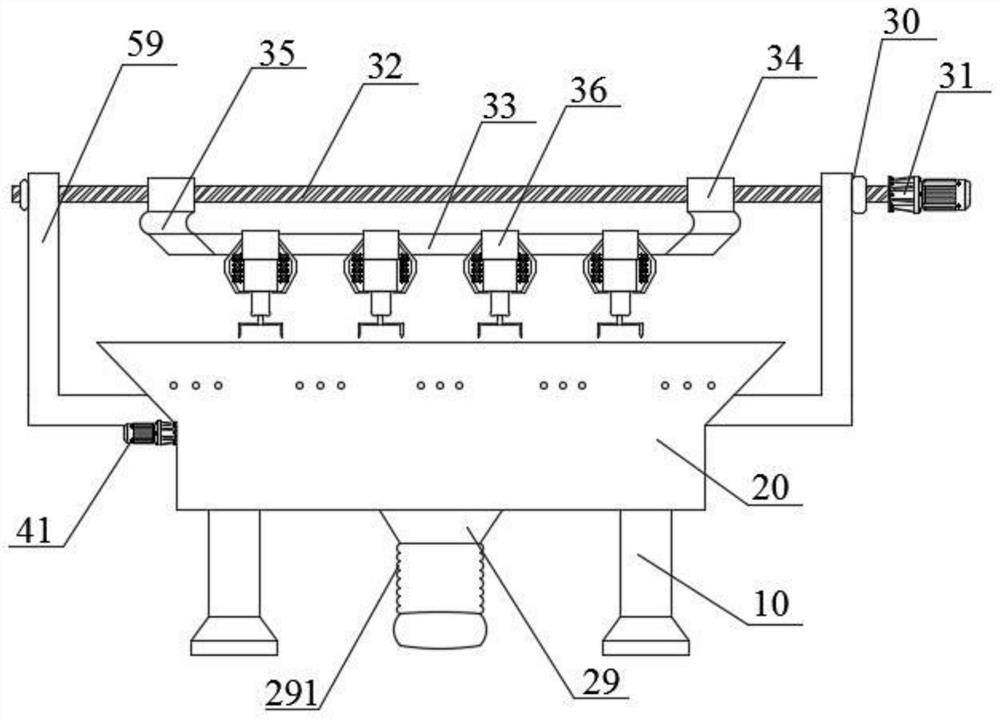

InactiveCN103738768AImprove die-cut qualityImprove die-cutting efficiencyWebs handlingClosed loopMicrocomputer control

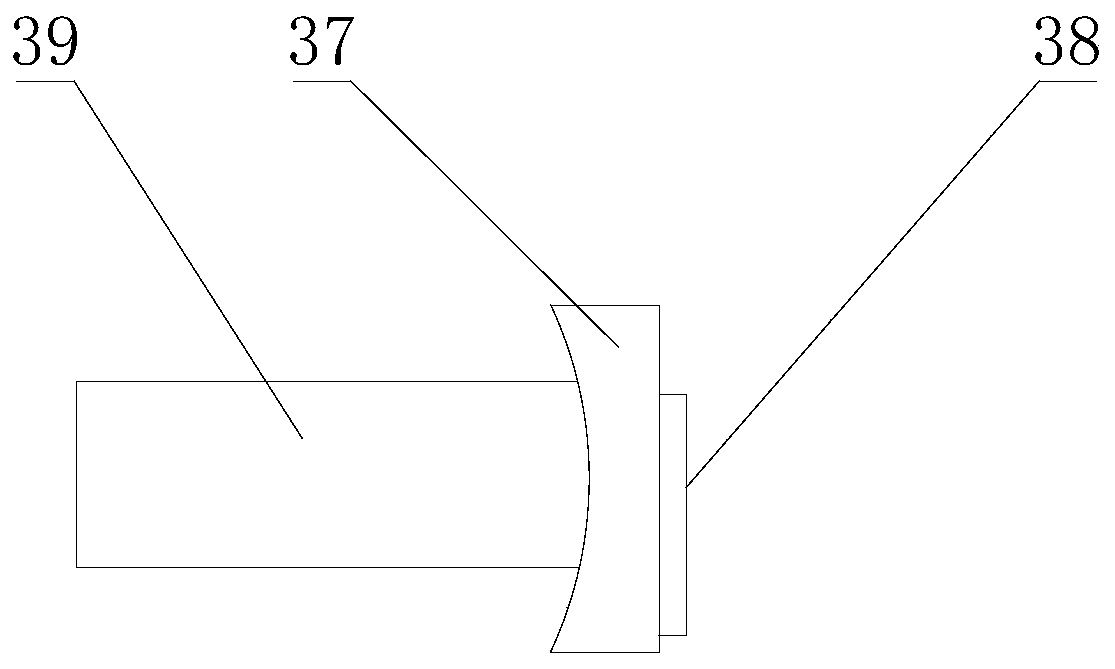

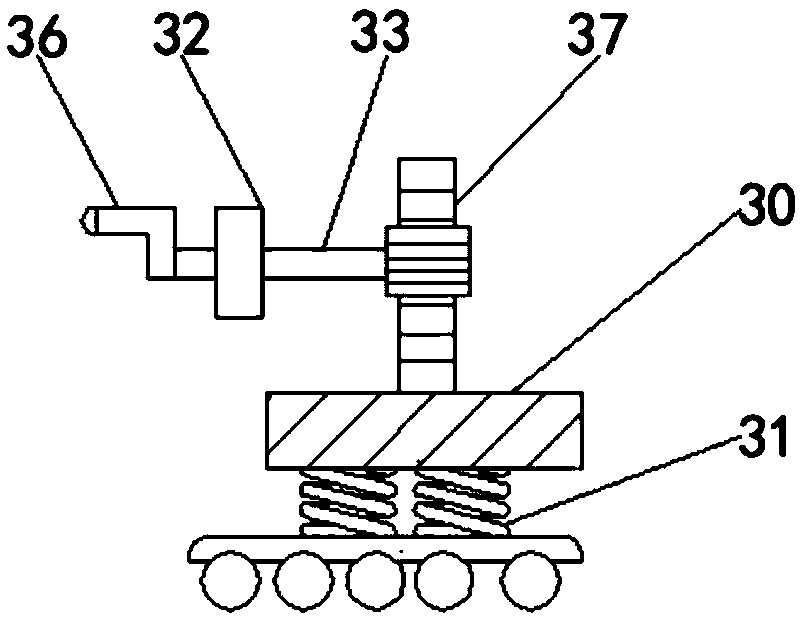

The invention discloses a constant-speed closed-loop photo electrically controlled mask discharging mechanism. The mechanism comprises a rack (15), a bearing shaft (36) and guide rollers (37). The bearing shaft is connected with a discharge motor (31) through an intermediate transmission component (38), a swing arm mandrel (39) is arranged on the rack, a floating balance component is arranged at one end of the swing arm mandrel, and a floating swing arm (33) is arranged at the other end of the swing arm mandrel. The guide rollers are arranged on the floating swing arm, and a displacement sensor (32) is arranged on the floating swing arm. According to the mechanism, by the vertical floating produced by the floating swing arm and the guide rollers, the displacement sensor produces corresponding expansion conditions to be fed back to a micro computer control mechanism, the rotation speed of the discharge motor is adjusted correspondingly, and main traction and discharge linear speeds are identical eventually to achieve synchronous discharging, delivery and die cutting, so that the accuracy is high, and the quality and the efficiency of mask die cutting are improved.

Owner:RUIAN DAWEI MACHINERY

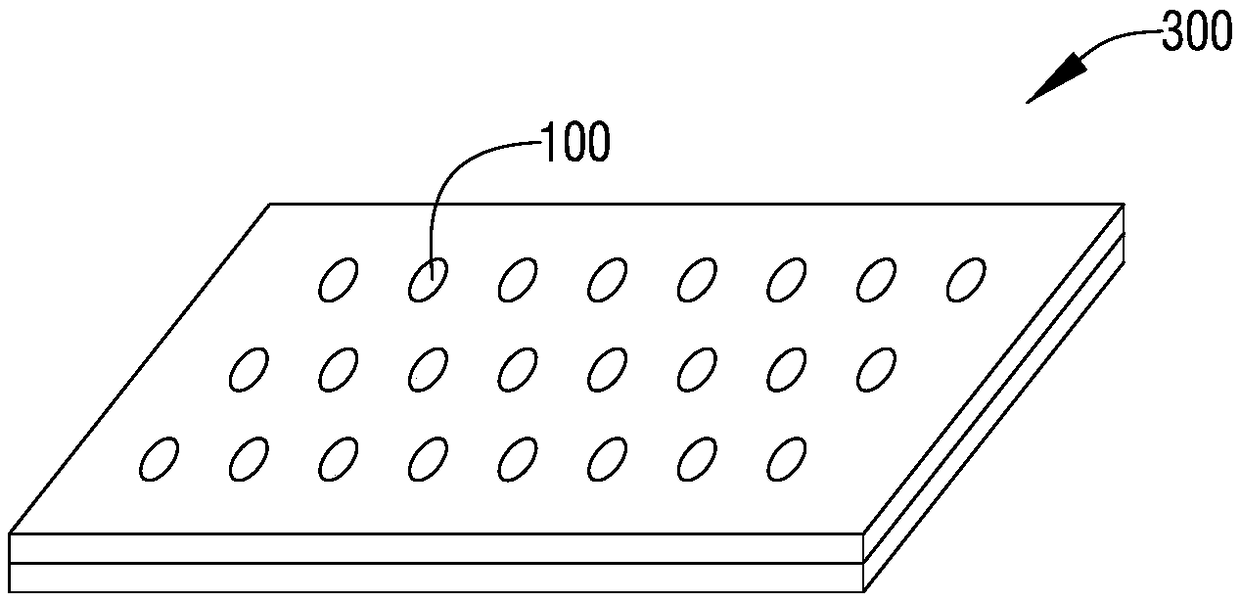

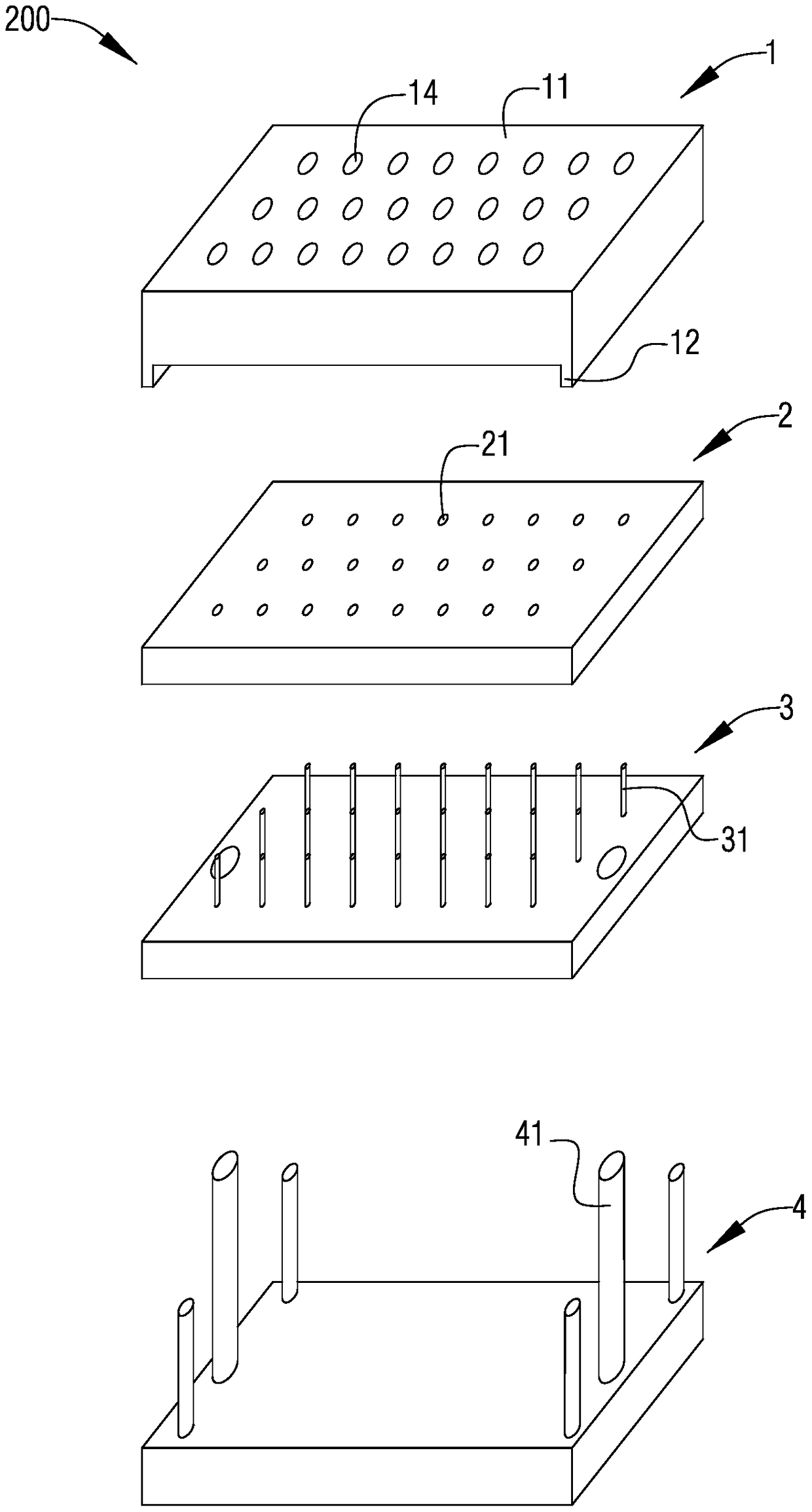

Device for small hole die cutting

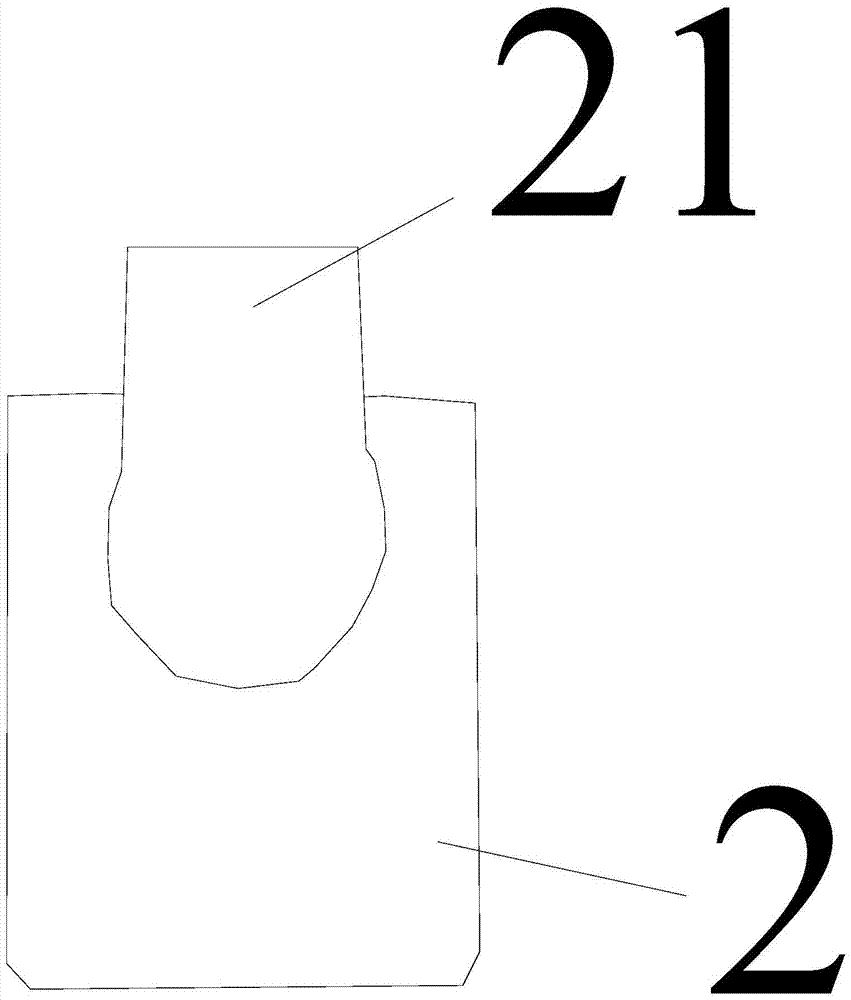

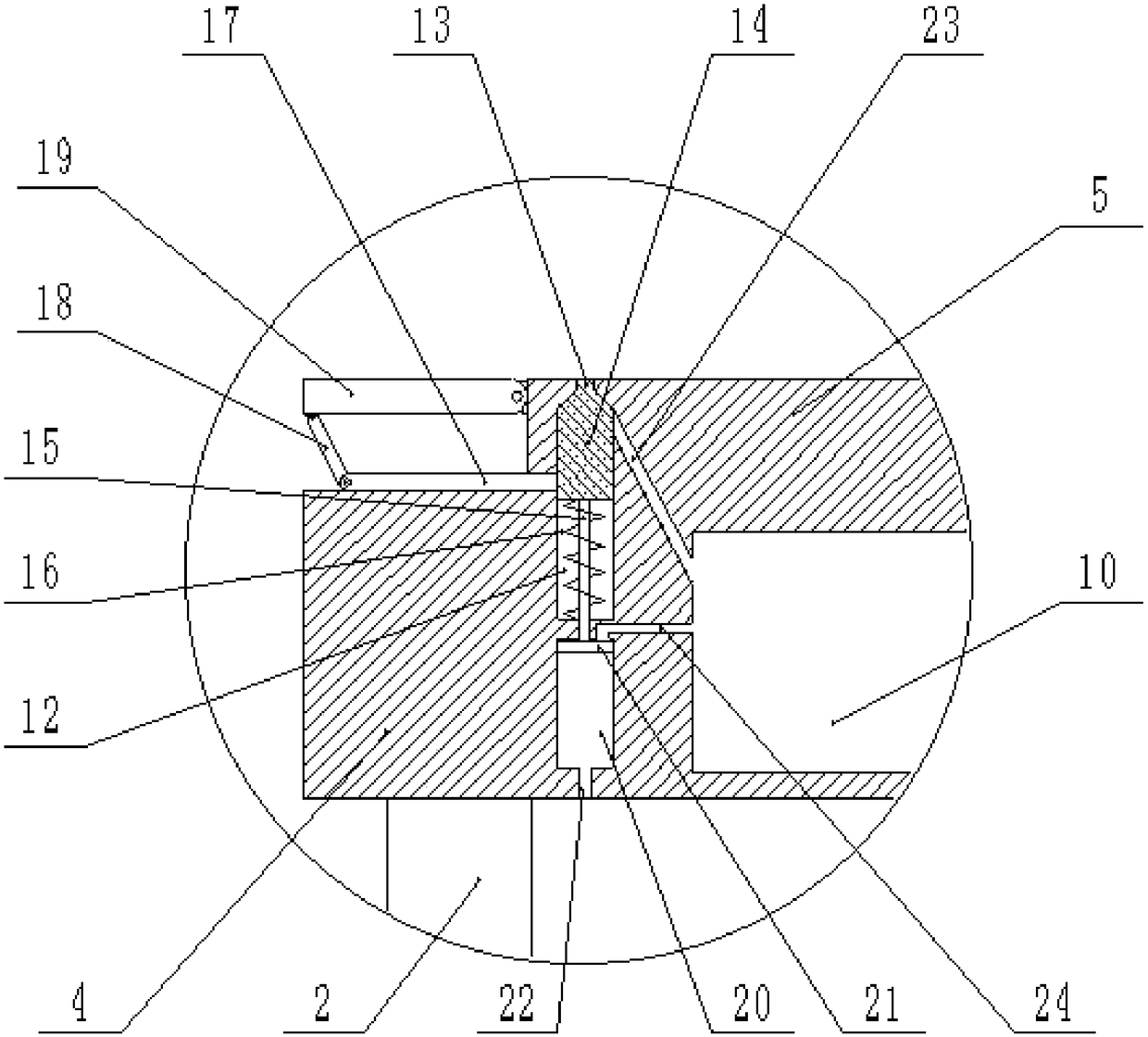

ActiveCN109454699AImprove die-cutting efficiencyEfficient separationMetal working apparatusEngineeringSmall hole

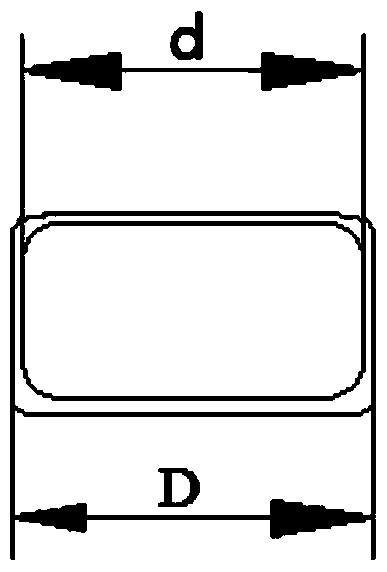

A device for small hole die cutting comprises an upper tool plate, a lower tool plate and an ejector plate. The upper tool plate comprises a body part, a limiting part and a tool bit part. The limiting part and the tool bit part 13 are equal in height. The body part and the tool bit part are provided with penetrating waste discharging holes, wherein the waste discharging holes are the same with small holes in diameter. The lower tool plate is provided with guiding holes, and the diameter of the guiding holes is smaller than the diameter of the small holes. The ejector plate is provided with ejector columns, the diameter of the ejector columns is smaller than or equal to the diameter of the guiding holes, and the height of the ejector columns is larger than the thickness of the guiding holes. The tool bit part, the guiding holes and the ejector columns are coaxially arranged, and the lower tool plate and the ejector plate can be in sliding connection. According to the provided device for small hole die cutting, through the arrangement of the movable lower tool plate and matched ejector rods, the cut waste can be effectively separated, and the small hole die cutting machining efficiency can be greatly improved.

Owner:络派科技(深圳)有限公司

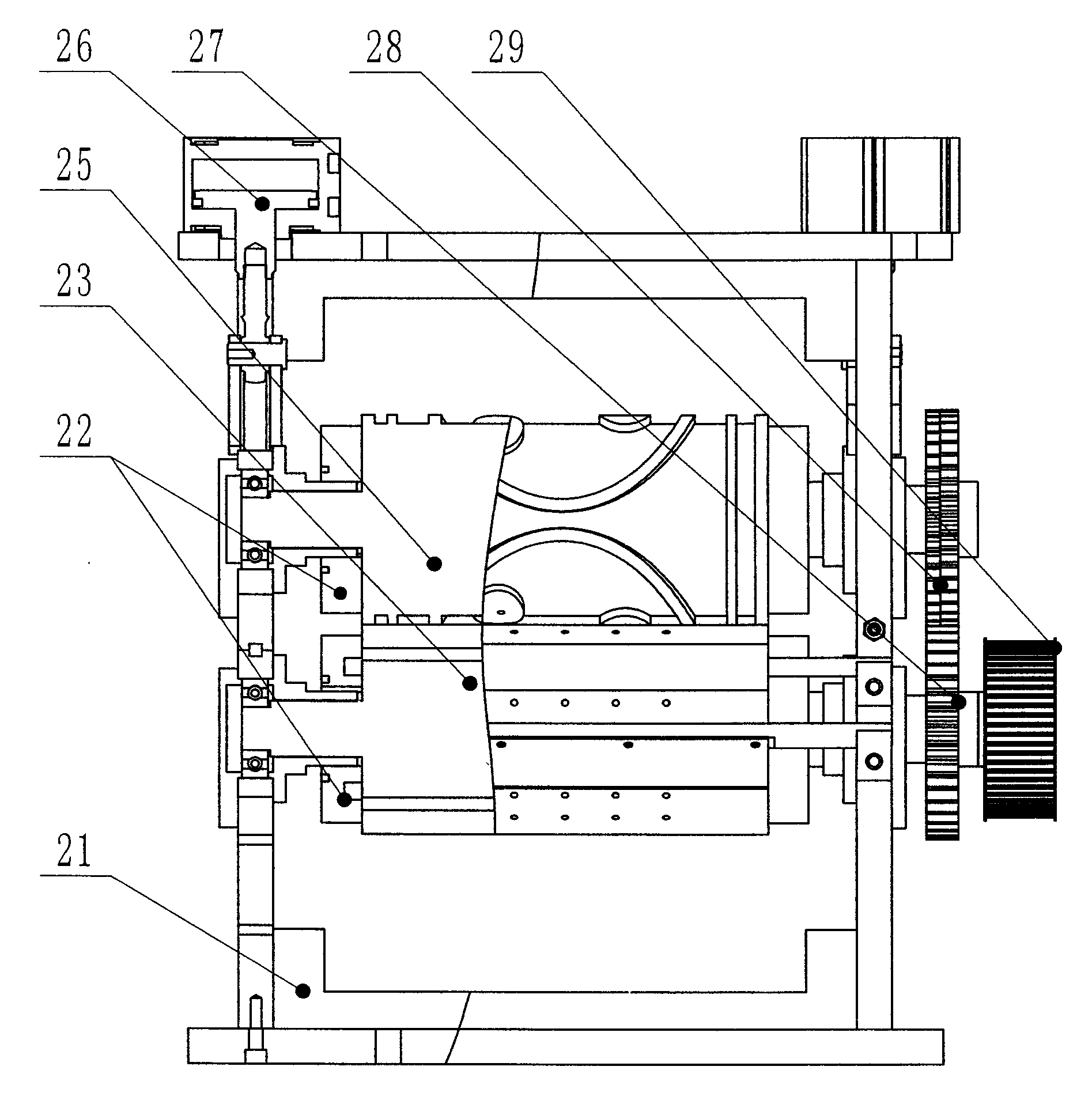

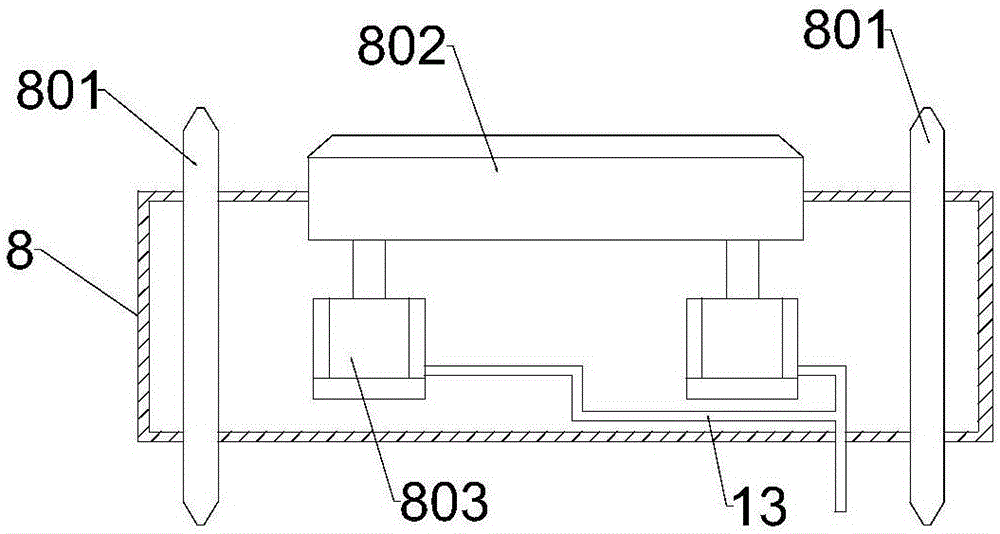

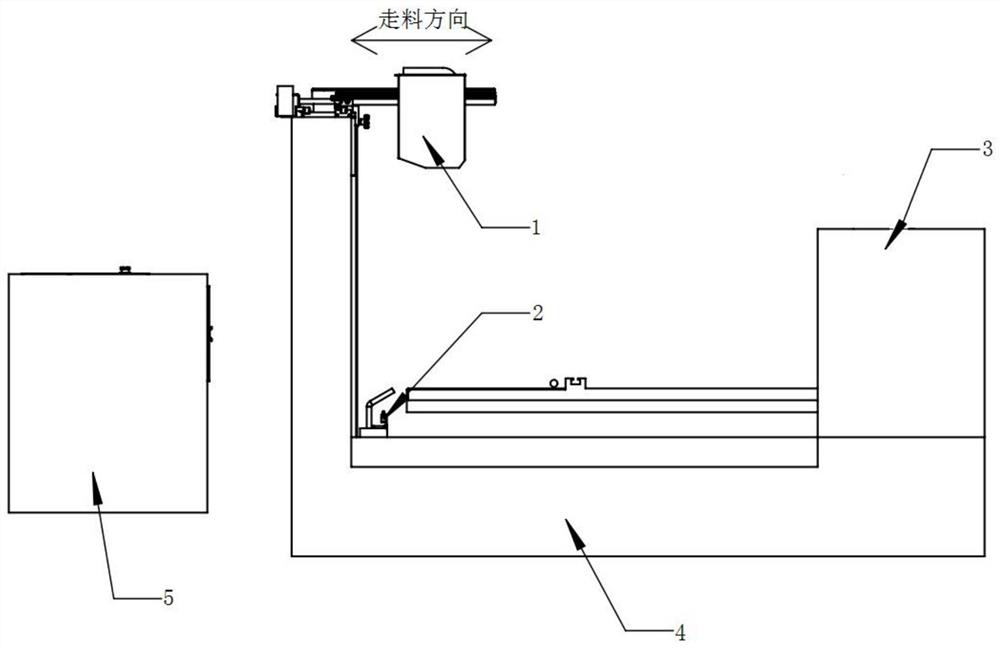

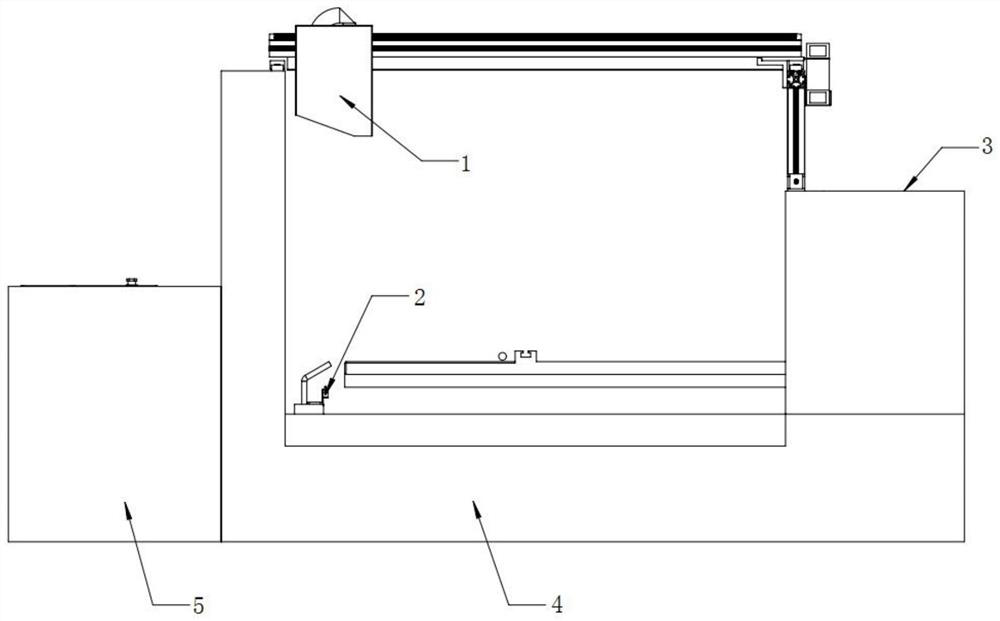

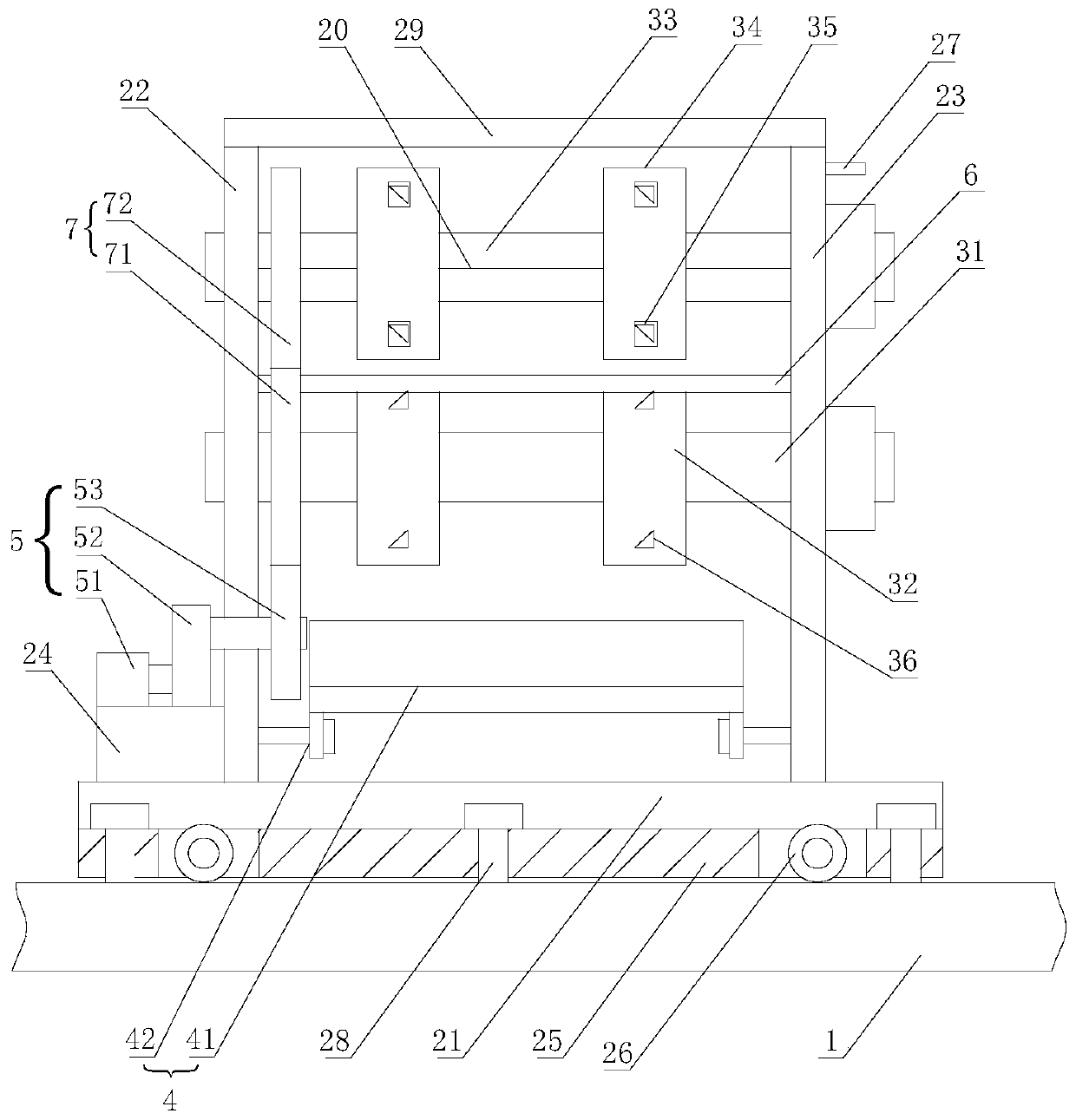

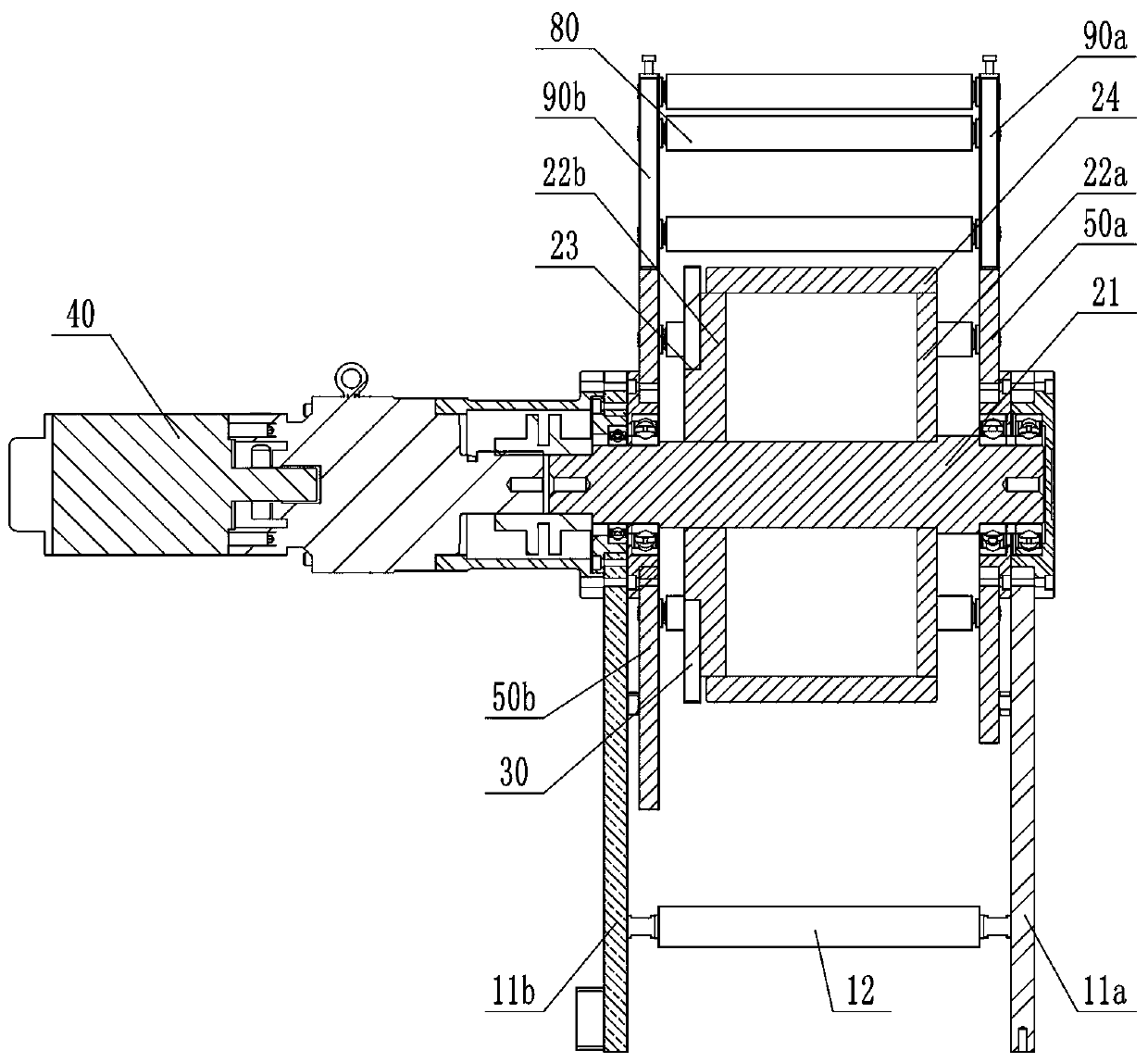

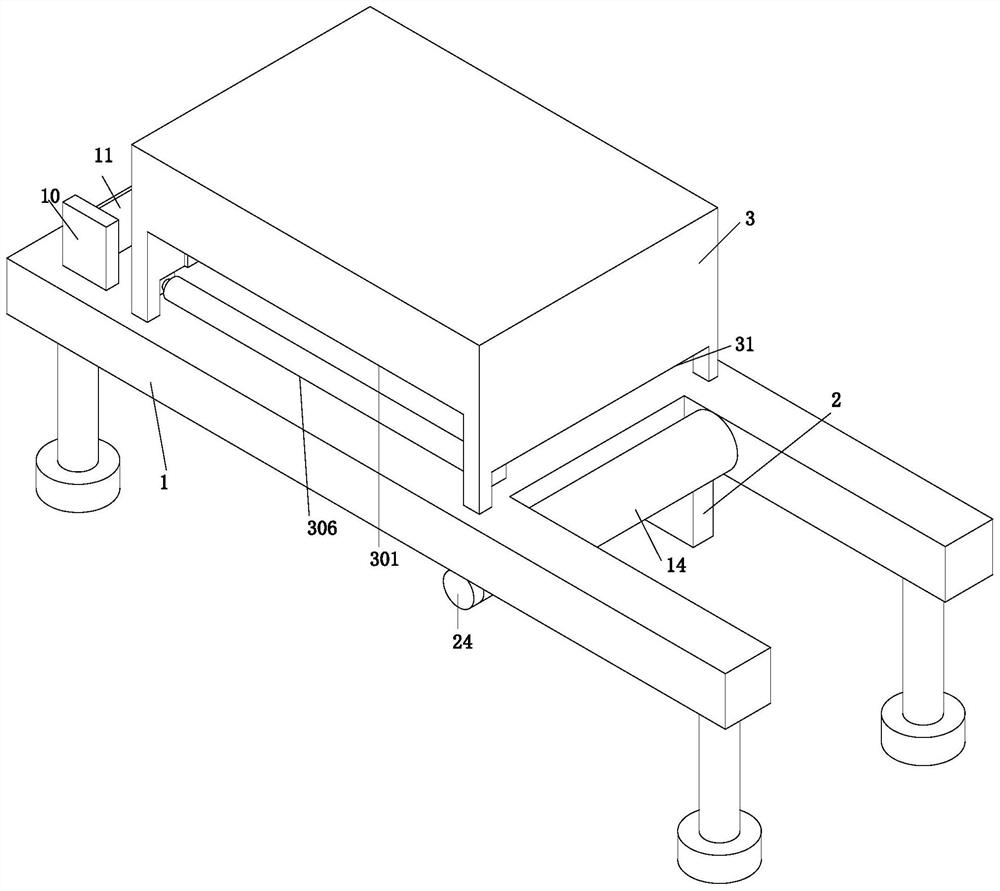

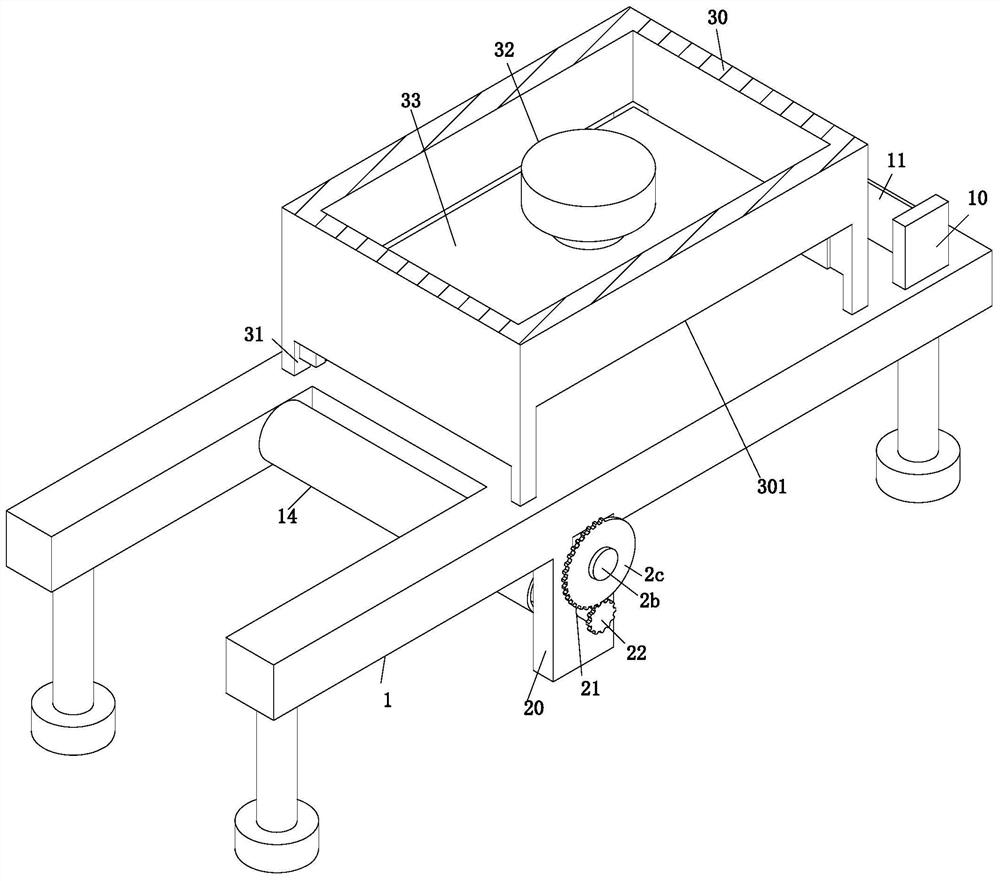

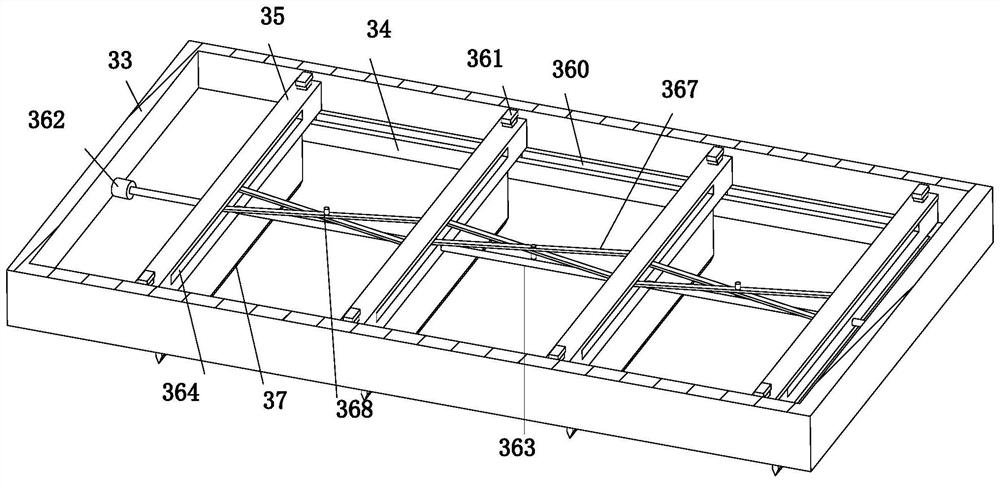

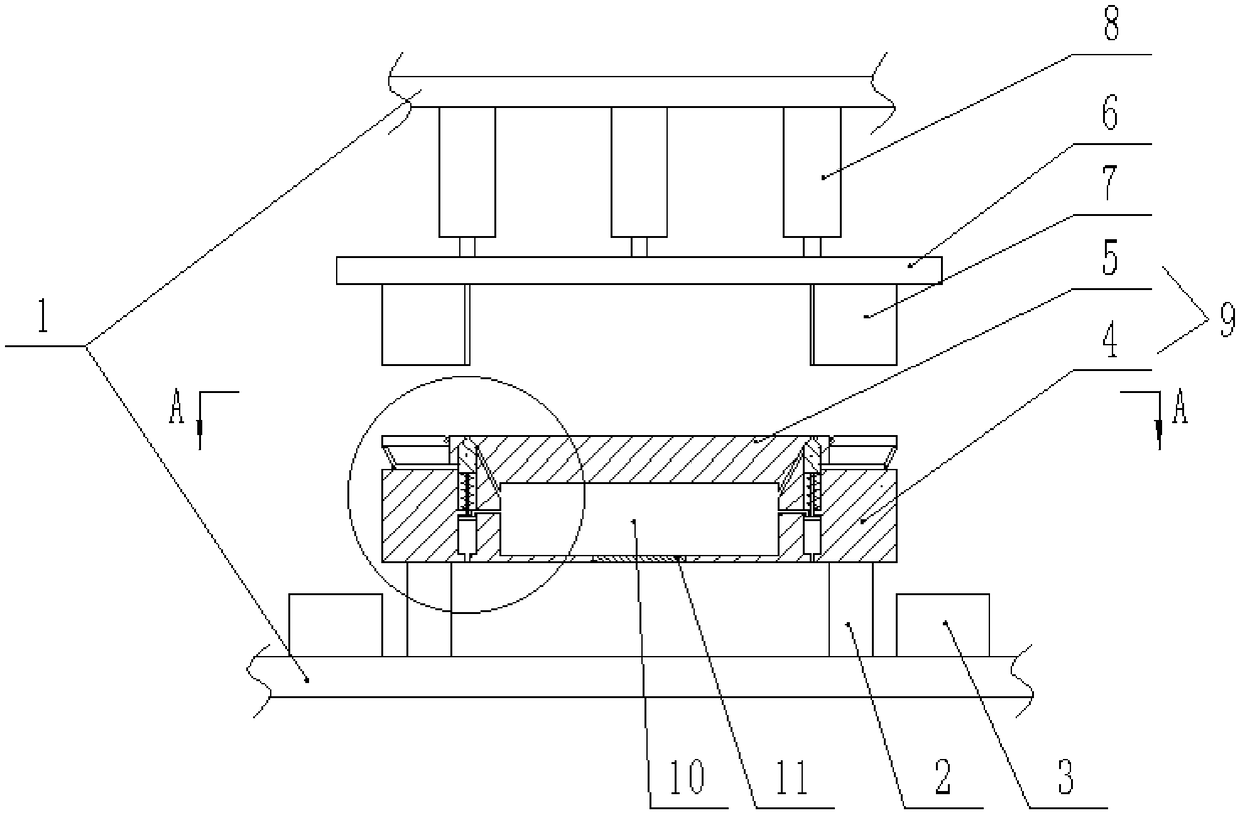

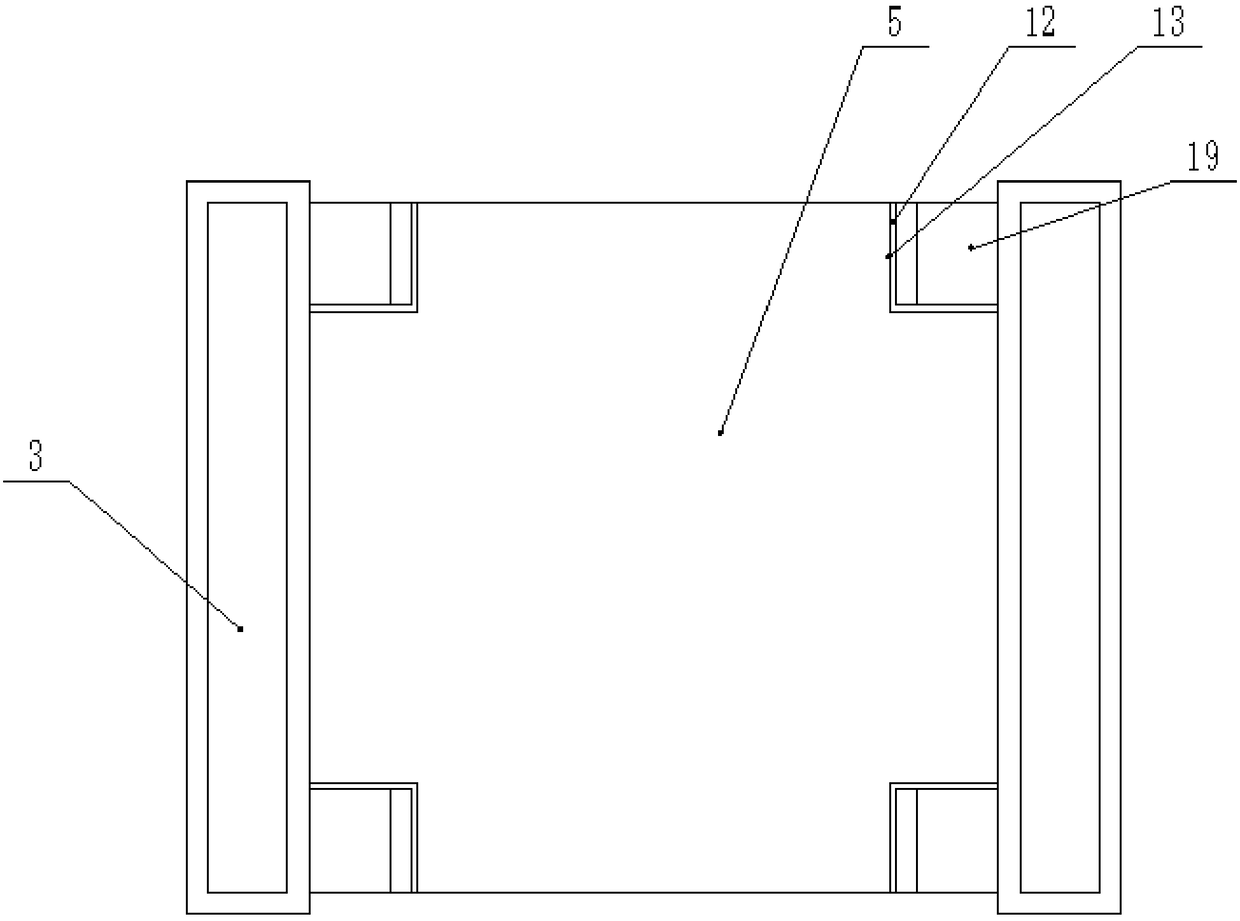

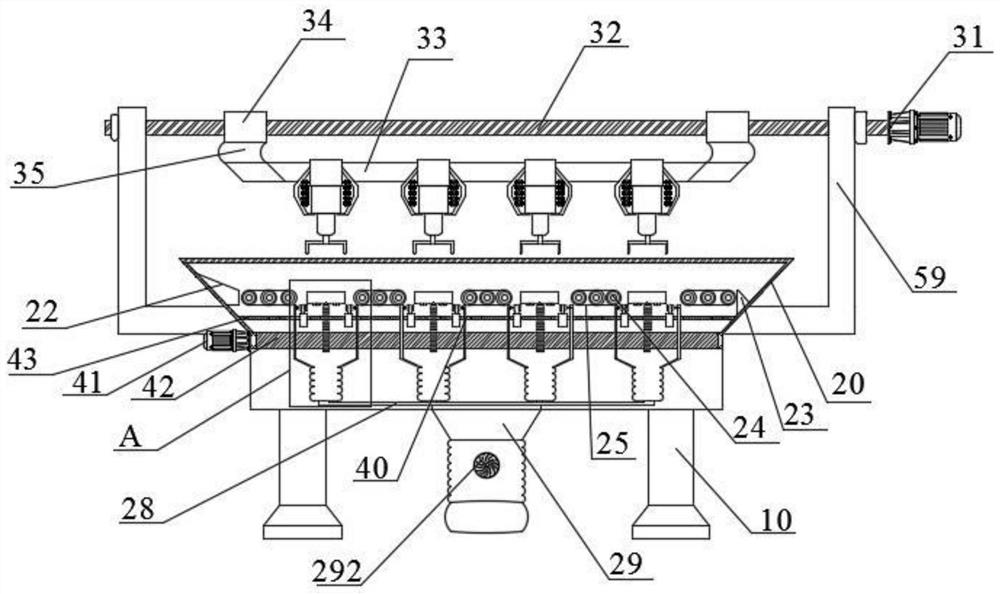

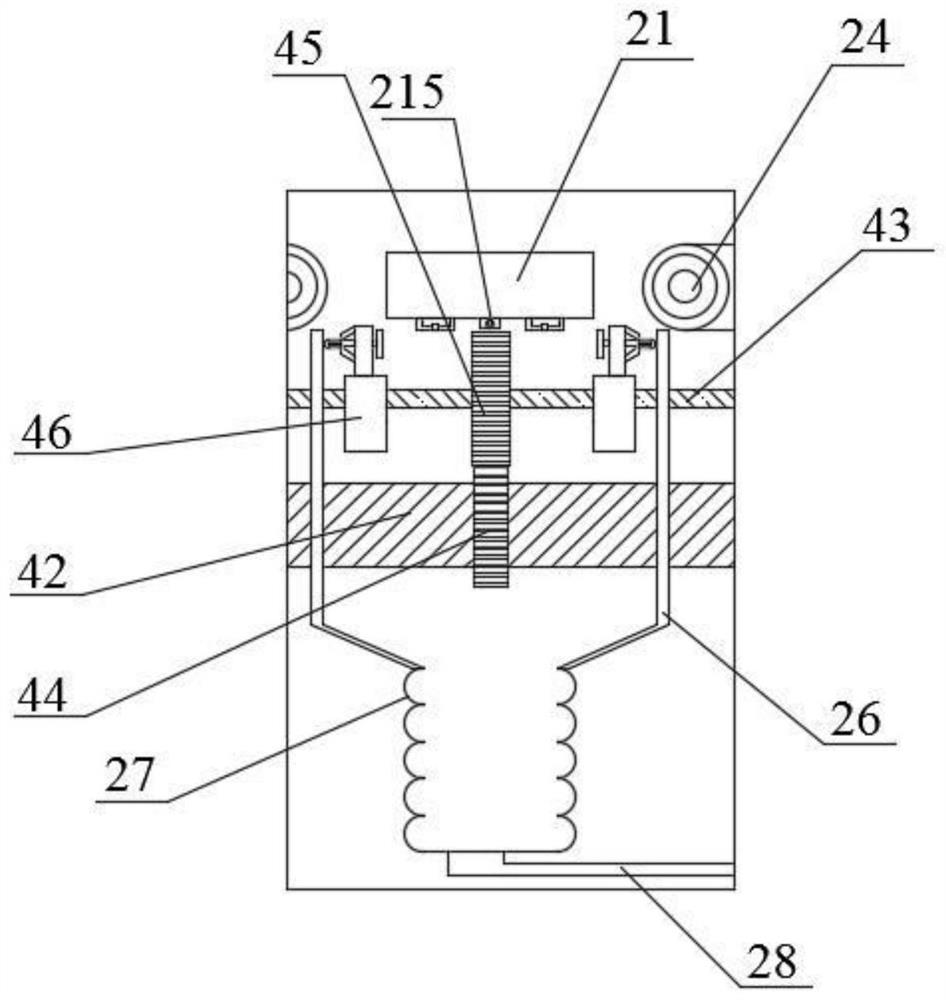

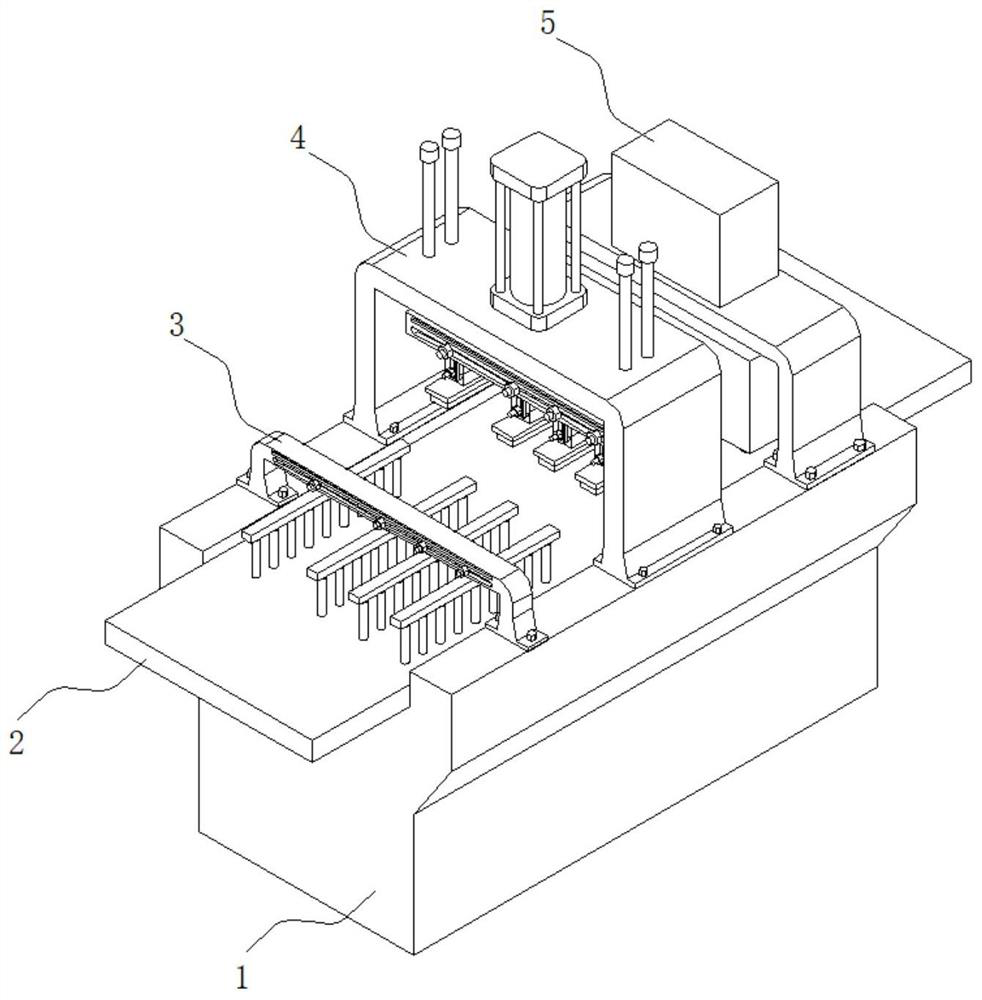

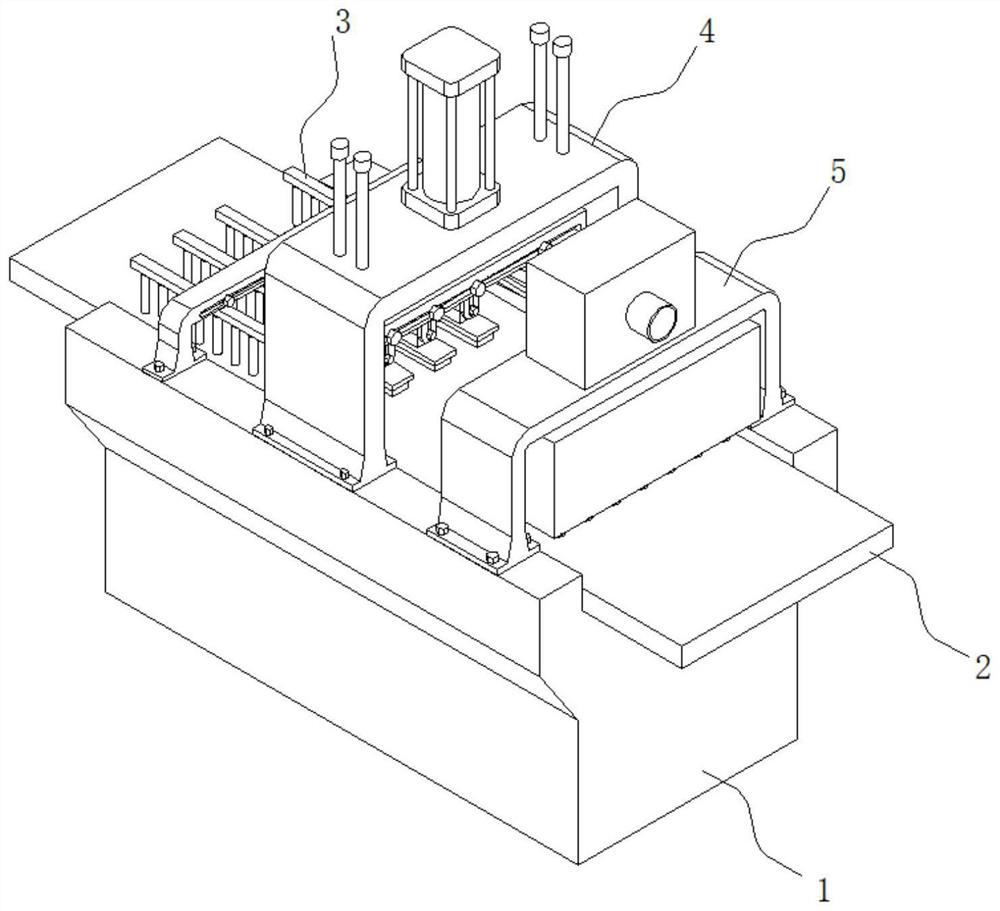

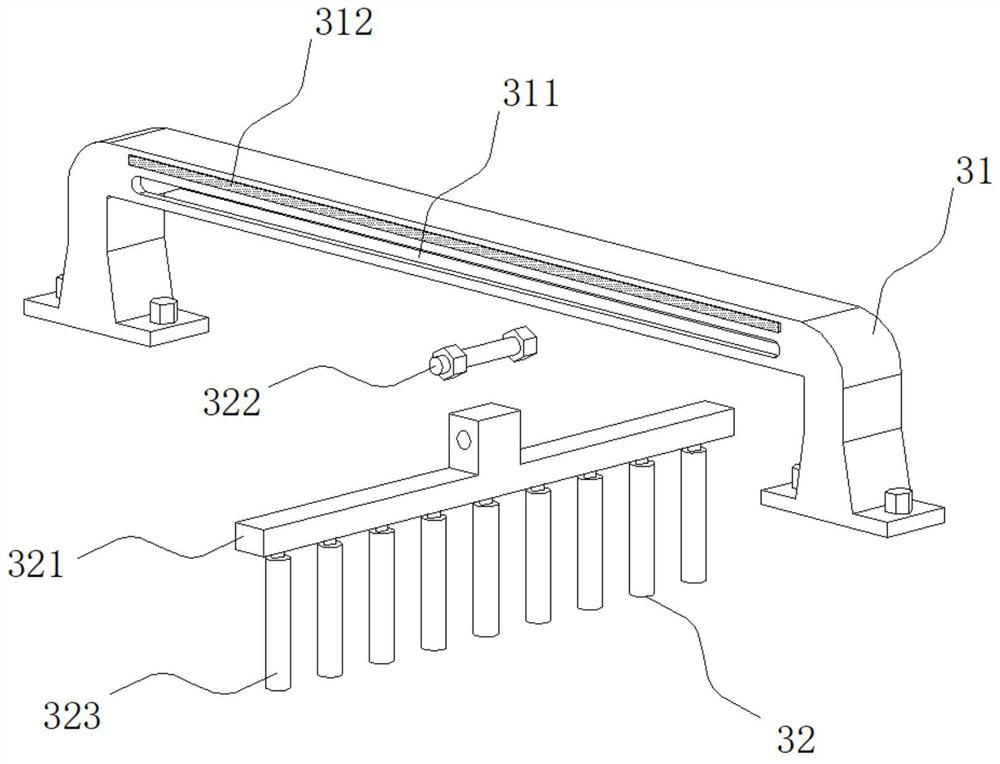

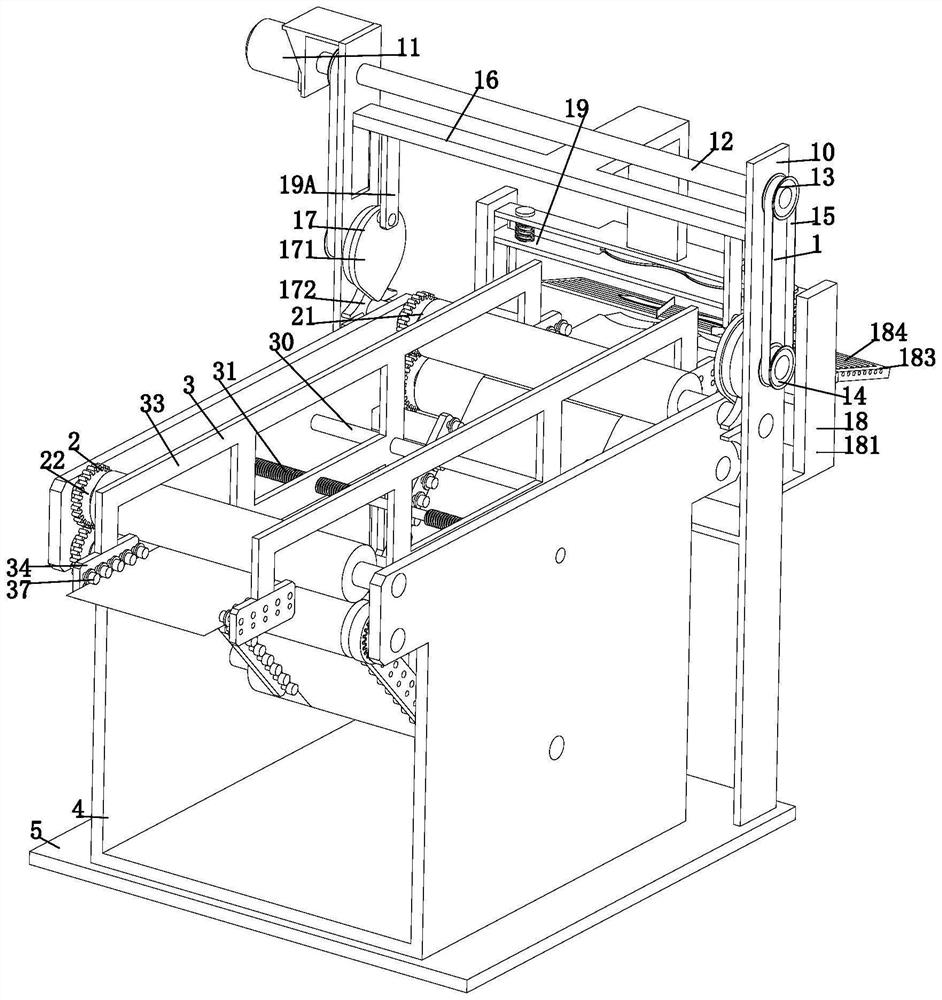

Mold table device of uncoiling die cutting machine

InactiveCN108789638AStable torque characteristicsEnsure smoothnessMetal working apparatusFeed driveEngineering

The invention relates to an all-servo mold table device of an uncoiling die cutting machine. The device comprises a mold table main body frame, an upper die cutting platform, a lower die cutting platform, a feed driving mechanism for guiding products to enter a die cutting station, and a discharge driving unit for guiding the products to shift out of the die cutting station; the feed driving mechanism and the discharge driving mechanism are both fixedly mounted on the lower die cutting platform; the lower die cutting platform is connected with a mold table driving unit; the die table driving unit controls the lower die cutting platform to move up and down; and the lower die cutting platform and the upper die cutting platform are pressed for die cutting of the products. Compared with the prior art, the device adopts an all-servo control and stick clamping mode to simplify mechanical structure and to improve the die cutting speed and the production efficiency; and through arrangement ofthe lower die cutting platform capable of moving, a lower mold is always bonded with the products during die cutting, and conveyed papers and the mold table are always maintained on the same plane, sothat the floating in the mold table is reduced, the up-down travel of the mold table is reduced, and the die cutting frequency can be greatly improved.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD

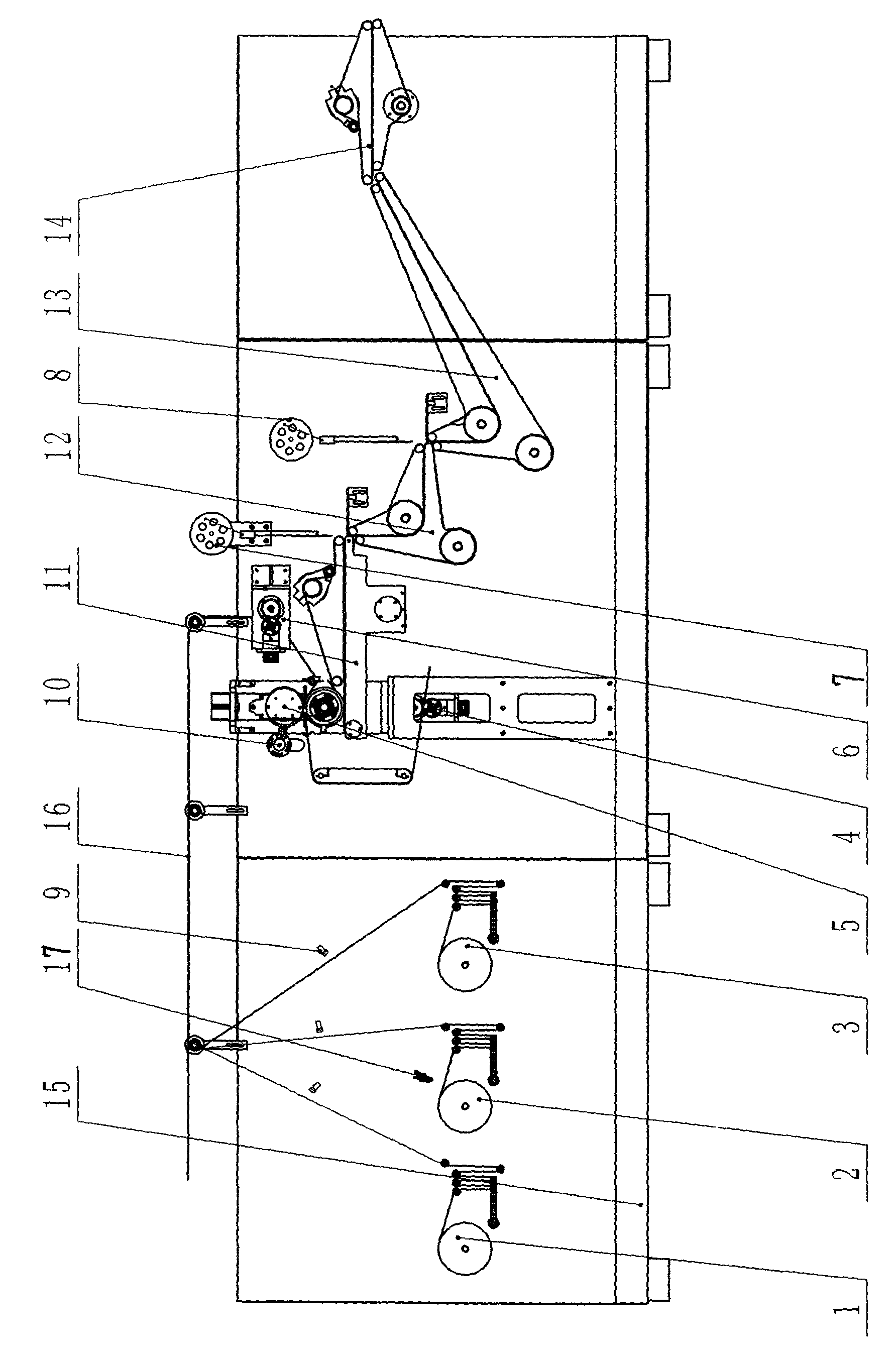

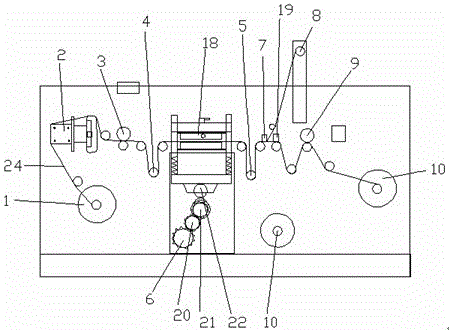

Wheel-rotating computer high-speed flat die-cutting machine

ActiveCN103770154AImprove die-cutting efficiencyMetal working apparatusWebs handlingWaste recoveryEngineering

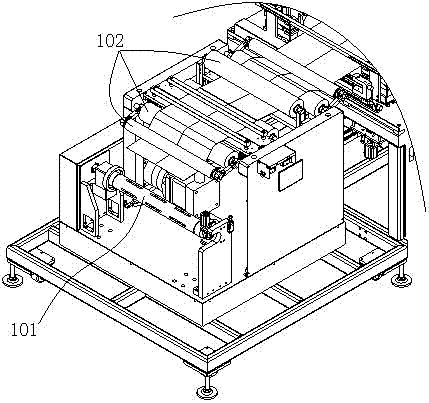

The invention discloses a wheel-rotating computer high-speed flat die-cutting machine which sequentially comprises an emptying mechanism, a deviation rectifying mechanism, a front strip conveying mechanism, a die cutting mechanism, a color mark identification detection mechanism, a striping mechanism, a rear strip conveying mechanism and at least two material receiving mechanisms, wherein a waste recovery mechanism is also arranged above the striping mechanism; a front vertical up-and-down motion mechanism is arranged in front of the die cutting mechanism; a rear vertical up-and-down motion mechanism is arranged behind the die cutting mechanism; strips sequentially pass through the deviation rectifying mechanism, the front vertical up-and-down motion mechanism, the die cutting mechanism, the rear vertical up-and-down motion mechanism, the color mark identification detection mechanism and the striping mechanism from the emptying mechanism under the action of the front strip conveying mechanism and the rear strip conveying mechanism and then enter the material receiving mechanisms. According to the invention, when the strips are subjected to die cutting, the strips do not need to stop, so that die cutting efficiency is greatly improved.

Owner:浙江嘉盛特种印刷有限公司

Online defect detection device and method for die-cutting machine

PendingCN114486937AAvoid wastingPrevention of mixed goodsMaterial analysis by optical meansDisplay deviceComputer science

The invention provides a die-cutting machine online defect detection device and method.The device comprises an acquisition module, a sensor module, a displayer module, a die-cutting machine and a control processing module, the acquisition module and the sensor module are both installed on the die-cutting machine and both connected with the control processing module, and the displayer module is arranged on the side, away from the sensor module, of the die-cutting machine and connected with the control processing module; the control processing module is connected with the die cutting machine. And the control processing module is used for comparing the printed matter paper image with the standard printed image, judging whether the printed matter paper image has defects such as batch mixing, goods mixing, white paper, turning around or deviation and outputting a defect detection result. The printed matter paper image is shot in the static state of the printed matter paper, and the image-text information, the code information and the image-text position information in the printed matter paper image and the standard printed image are compared, so that the defects of the printed matter paper in the die cutting process can be more comprehensively detected, and the detection efficiency is higher.

Owner:BEIJING LUSTER LIGHTTECH

Film laminating machine for easy-to-tear adhesive sticker label

PendingCN110271261AAffect transmissionGuaranteed accuracyStampsLamination ancillary operationsMechanical engineeringRaw material

The invention relates to a film laminating machine for an easy-to-tear adhesive sticker label. The film laminating machine comprises a rack, wherein the rack comprises a feeding roller, a gluing device and a base, the base is arranged between the feeding roller and the gluing device, the base comprises a die cutting assembly, the die cutting assembly is rotationally connected on the base, and the base is also provided with a guide supporting rod. The film laminating machine for the easy-to-tear adhesive sticker label has the advantages that the base is arranged between the feeding roller and the gluing device, during an adhesive sticker production technology, a die cutting technology for raw materials is achieved through the die cutting assembly arranged on the base, so that the die cutting process is set before the gluing process, which cannot affect the subsequent product and changes a production technology of post-die cutting of an existing product, the base is arranged on the rack between the feeding roller and the gluing device, no additional production process is added, on the basis of the original same structure, the optimal die cutting technology is achieved, the whole die cutting method is simplified, the production cost is reduced, and the die cutting efficiency is improved.

Owner:ZHEJIANG MOZHIHUA PRINTING

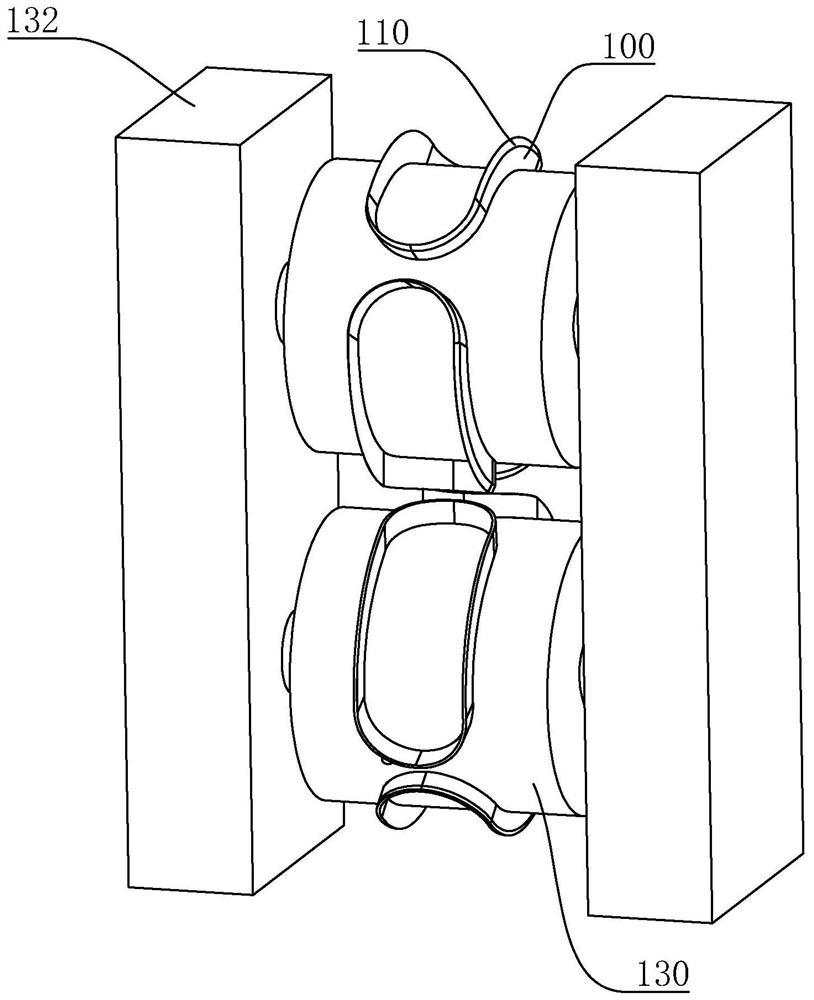

A die-cut waste discharge device and a die-cut waste discharge method for die-cut parts with an inner frame

InactiveCN106541449BGood waste discharge effectThe waste disposal process went smoothlyMetal working apparatusTectorial membranePunching

The invention relates to a die-cutting waste discharge device with an inner frame die-cutting piece and a die-cutting waste discharge method. The die-cutting waste discharge device comprises a first opposite-pressing roller, first-stamping die-cutting cutters, first waste discharge rollers, a second opposite-pressing mechanism, second-stamping die-cutting cutters and second waste discharge rollers which are arranged sequentially. The first opposite-pressing roller attaches a first single face gummed protective film to a first release film; indent inner frames are punched in first stamping by the first-stamping die-cutting cutters; the first waste discharge rollers is used to take up the first single face gummed protective films attached to wastes of the inner frames after the first-stamping punching; the second opposite-pressing mechanism attaches a second single face gummed protective film to the non-release surface of the first release film, and sequentially attaches double faced adhesive tape and a second release film to the release surface of the first release film; normal inner frames are punched in second-stamping by the second-stamping die-cutting cutters; the second waste discharge rollers are used to take up the second single face gummed protective films attached to wastes of the inner frames after the second-stamping punching; and the size of each normal inner frame is bigger than the size of each indent inner frame. Compared with the prior art, the die-cutting waste discharge device has the advantages that the effect of waste discharge is good, the product has no deformation, and efficiency is high.

Owner:YUANRANG IND SHANGHAI

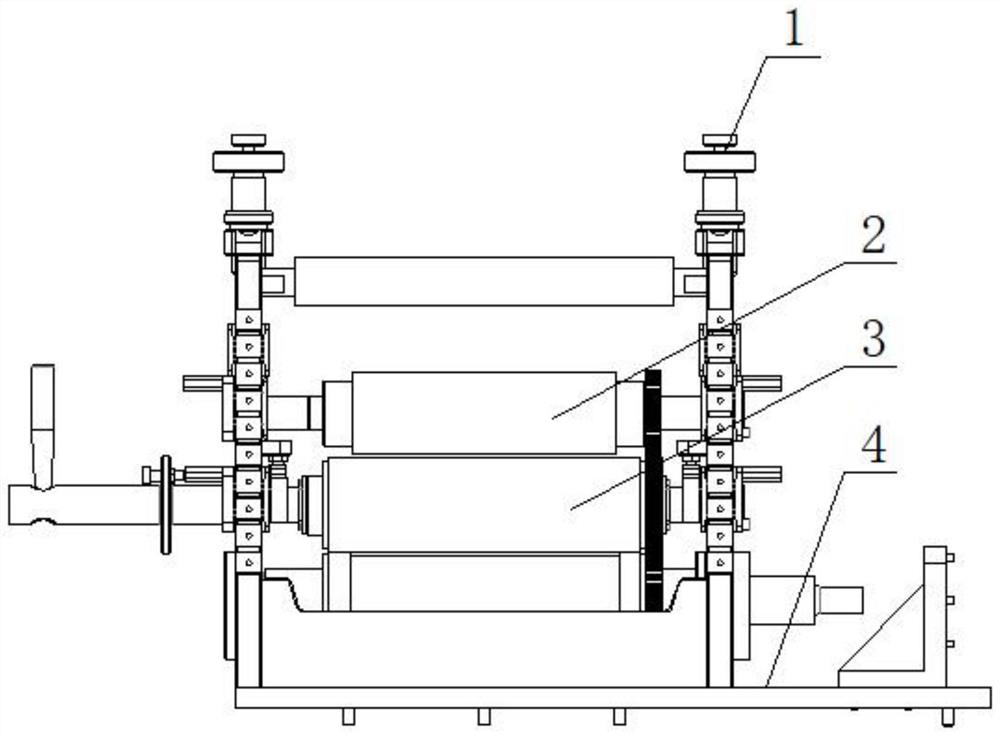

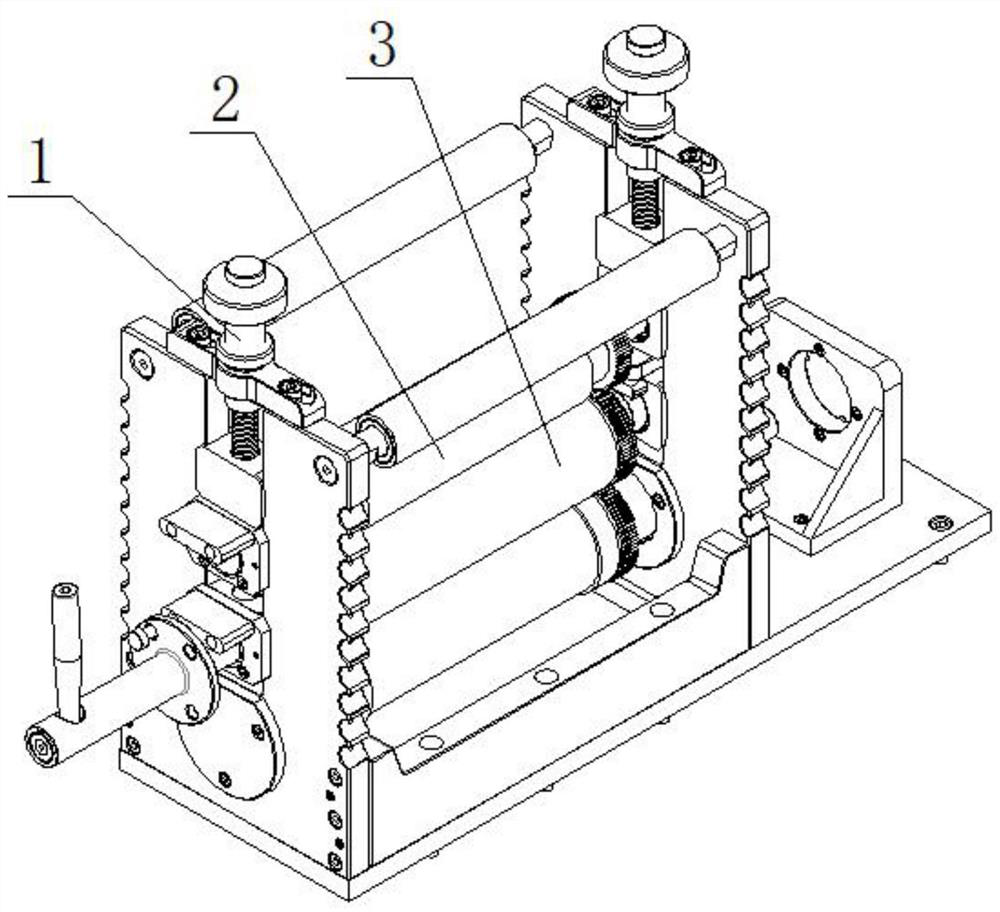

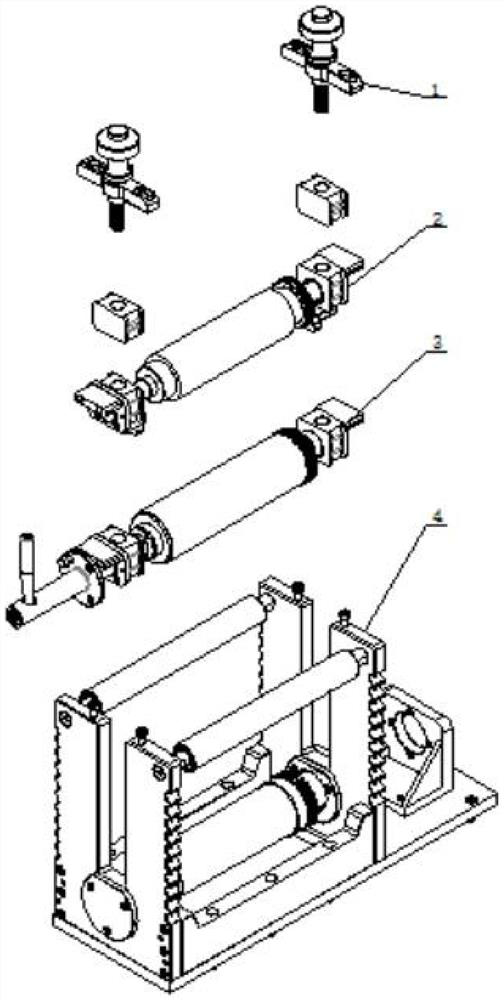

Manual cam elastic adjusting device for circular knife machine

PendingCN112720695AAchieve regulationLow experience requirementMetal working apparatusEngineeringMachine

The invention relates to a manual cam elastic adjusting device for a circular knife machine. The manual cam elastic adjusting device comprises a machine base, a bottom roller is mounted on the machine base, and a pressing roller is in pressure joint to the bottom roller. The manual cam elastic adjusting device further comprises pressure adjusting mechanisms, the pressure adjusting mechanisms acting on the two sides of the pressing roller are arranged on the machine base, and each pressure adjusting mechanism is composed of a spring supporting core, a rotating sleeve, a standby nut, a fixed block and a rectangular spring. The manual cam elastic adjusting device for the circular knife machine is scientific and reasonable in design, has the advantages of being convenient to operate, capable of saving time and labor, capable of improving the die cutting efficiency and reducing the rejection rate, high in adjusting accuracy and easy to implement, and has high innovativeness.

Owner:中融飞腾(北京)科技有限公司

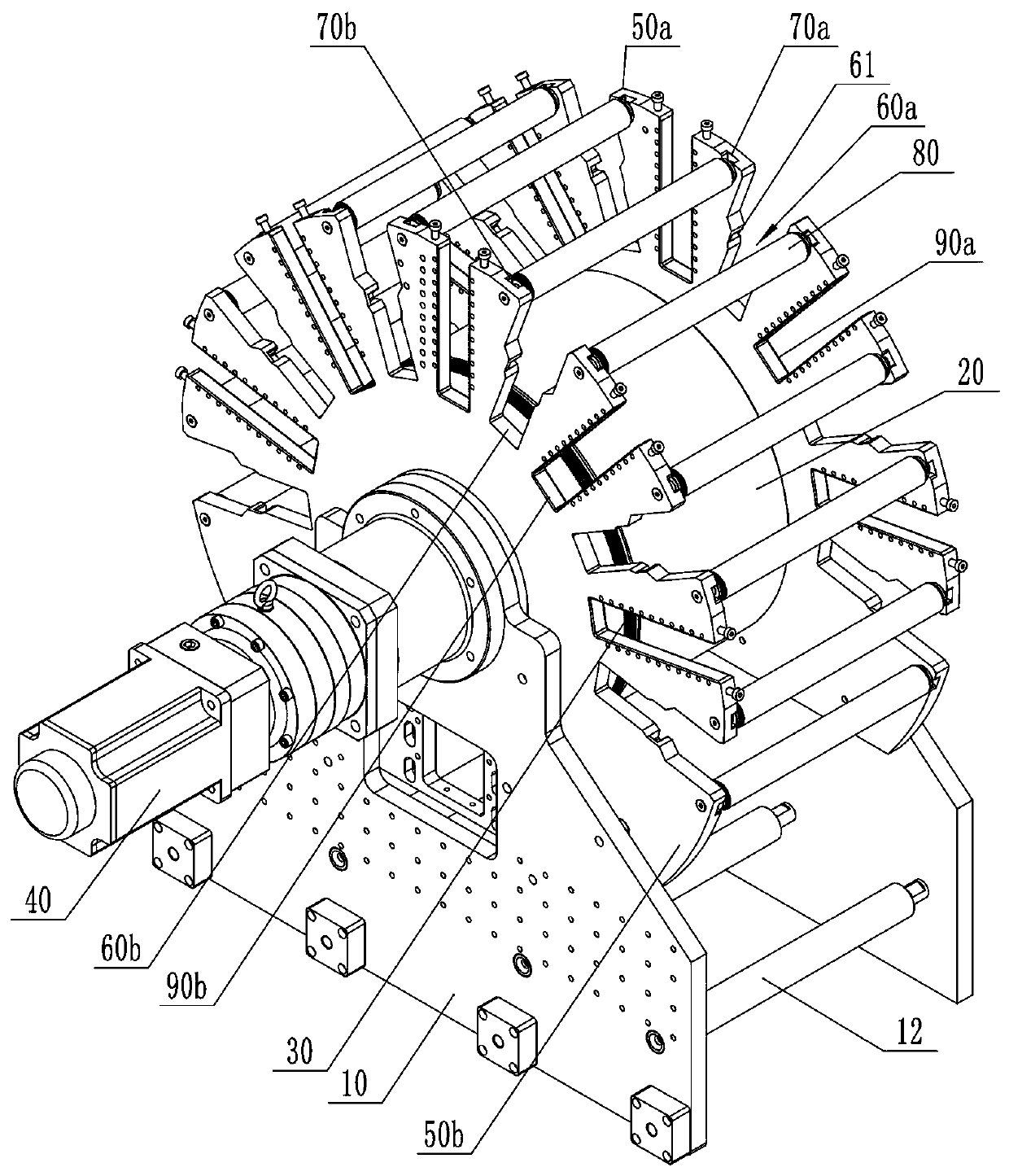

Satellite type die-cutting device

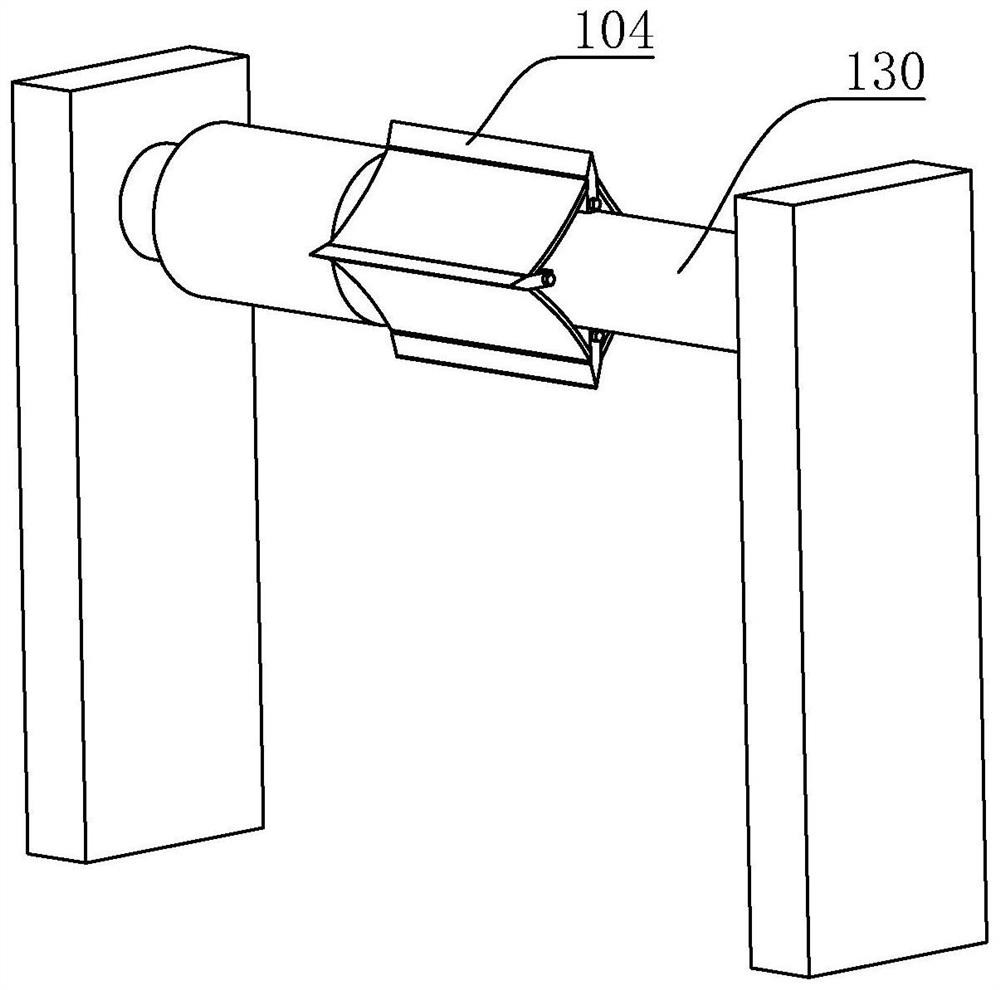

ActiveCN109895185AIncrease speedImprove die-cutting efficiencyMetal working apparatusVibration amplitudeDrive wheel

The invention belongs to the technical field of die-cutting machines and particularly relates to a satellite type die-cutting device. The satellite type die-cutting device comprises a mounting base, acore shaft rotatably mounted on the mounting base, a driving wheel fixed at the end of the core shaft and arranged coaxially with the core shaft, and a power device, wherein mounting plates fixedly connected with the mounting base are respectively arranged at two ends of the core shaft; a plurality of groups of cutter mounting structures which are arranged around the circumference of the core shaft at intervals are arranged between two mounting plates; guide shaft mounting structures are respectively arranged in positions corresponding to the cutter mounting structures between the two mounting plates; a plurality of die cutters are distributed around the circumference of the core shaft at intervals and are used for simultaneously pressing on the core shaft to carry out die cutting; the plurality of die cutters are used for simultaneously pressing on the core shaft to carry out die cutting; meanwhile, the outer diameter of the core shaft is relatively large; the core shaft can bear higher radial load; after the rotation speed of the core shaft is improved, the rotation speeds of the plurality of die cutters can be greatly improved; the die cutting efficiency can be improved; and meanwhile, the vibration amplitude during operating can be reduced.

Owner:SHANDONG HOACO AUTOMATION TECH

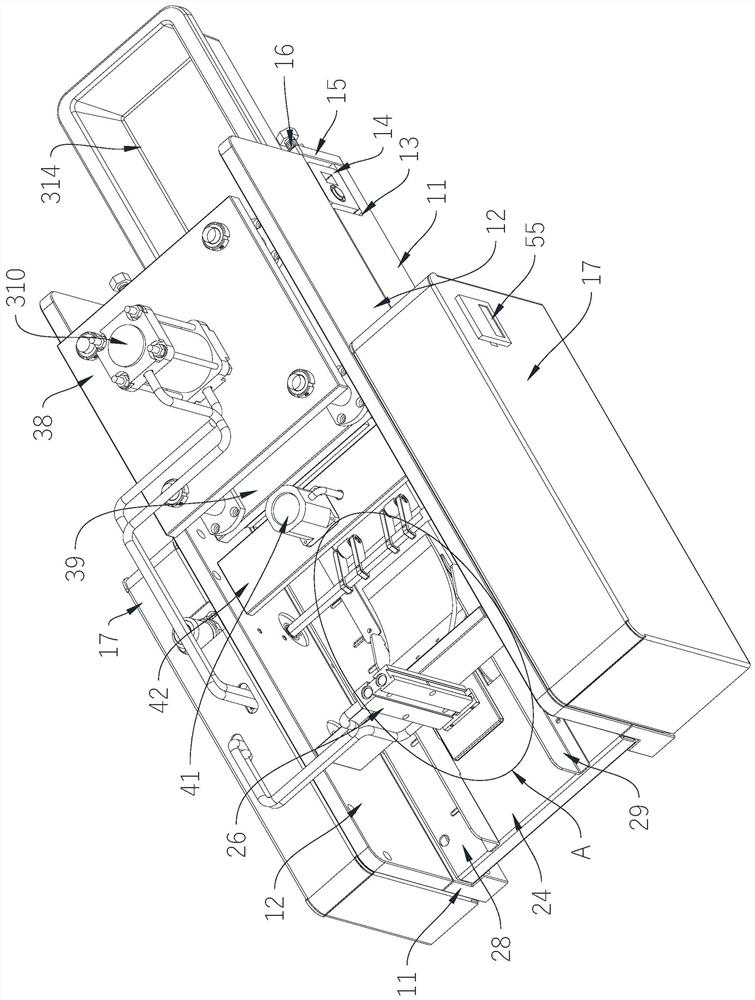

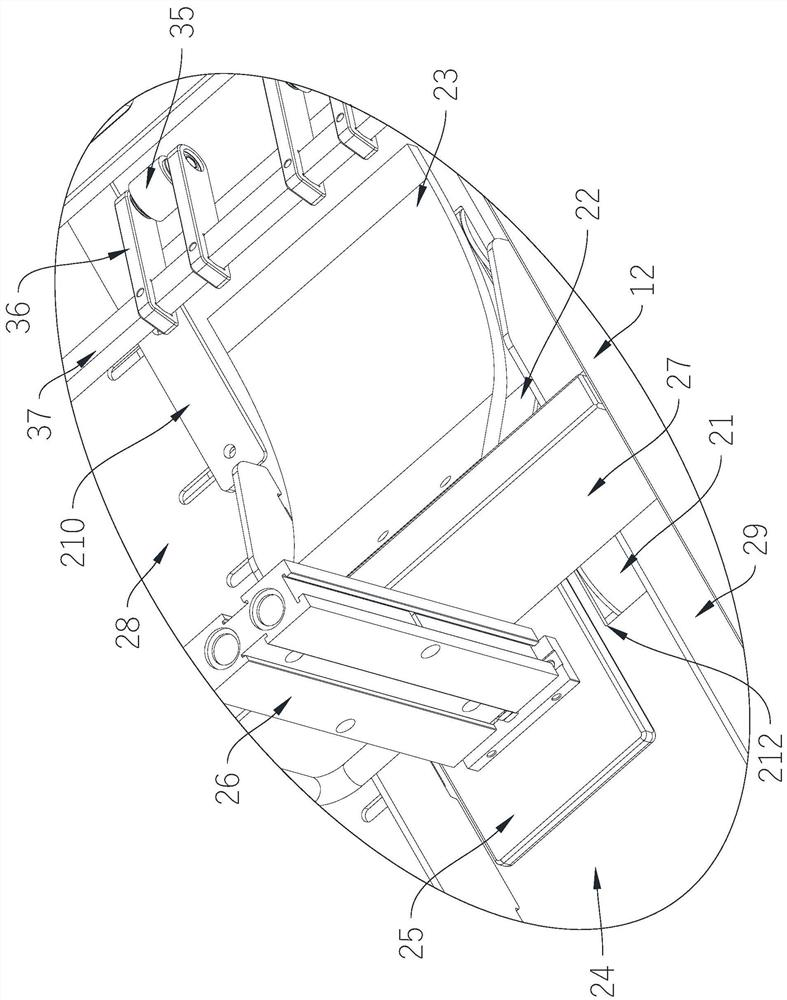

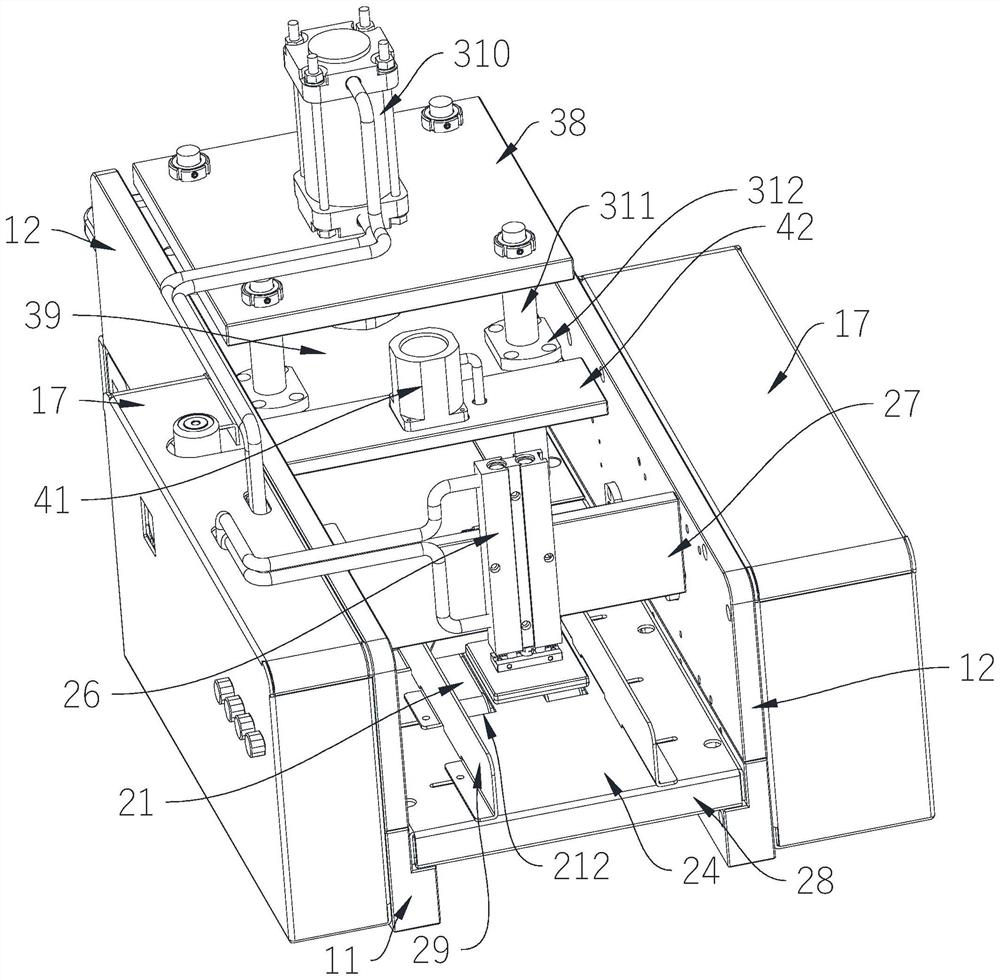

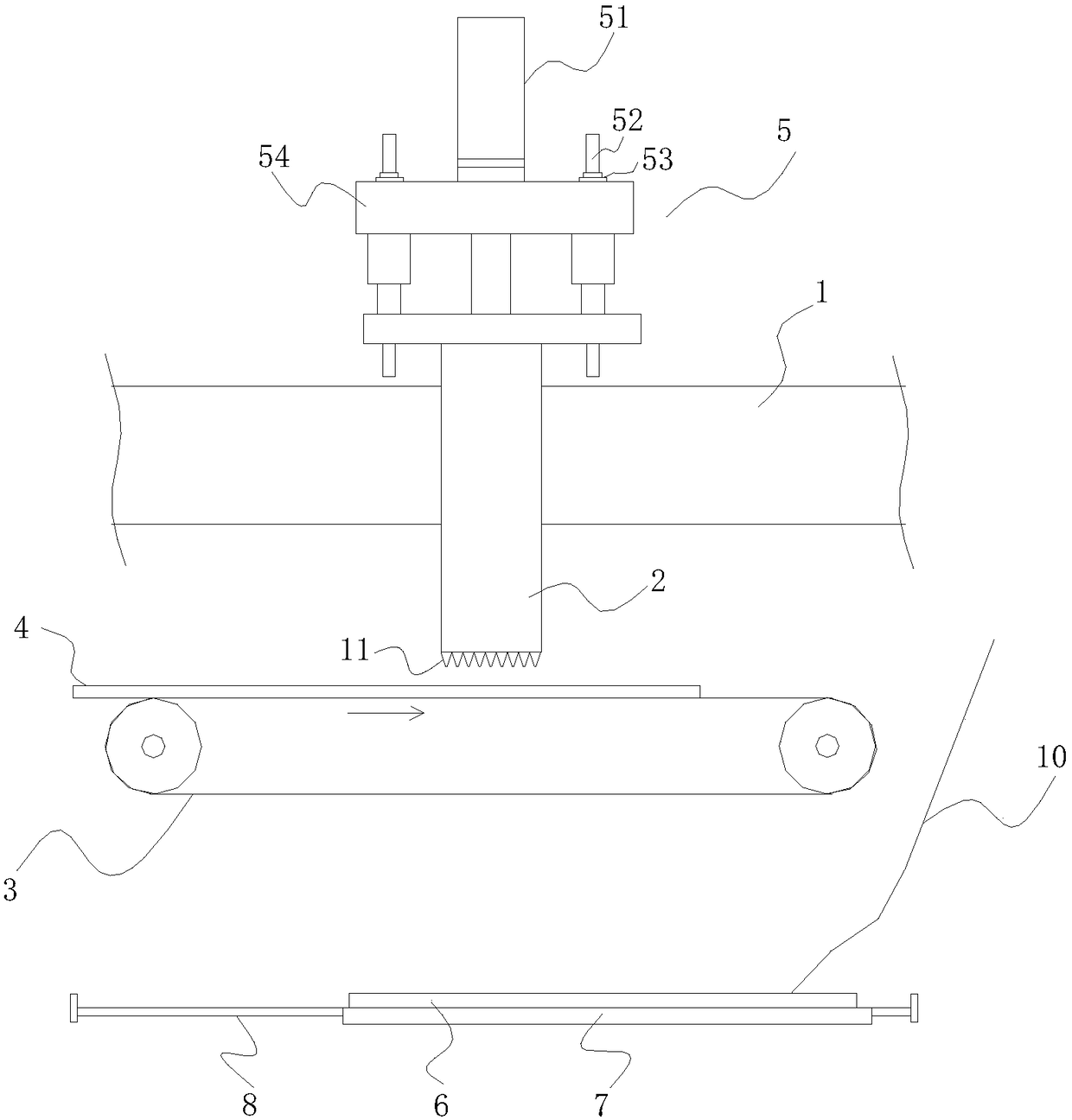

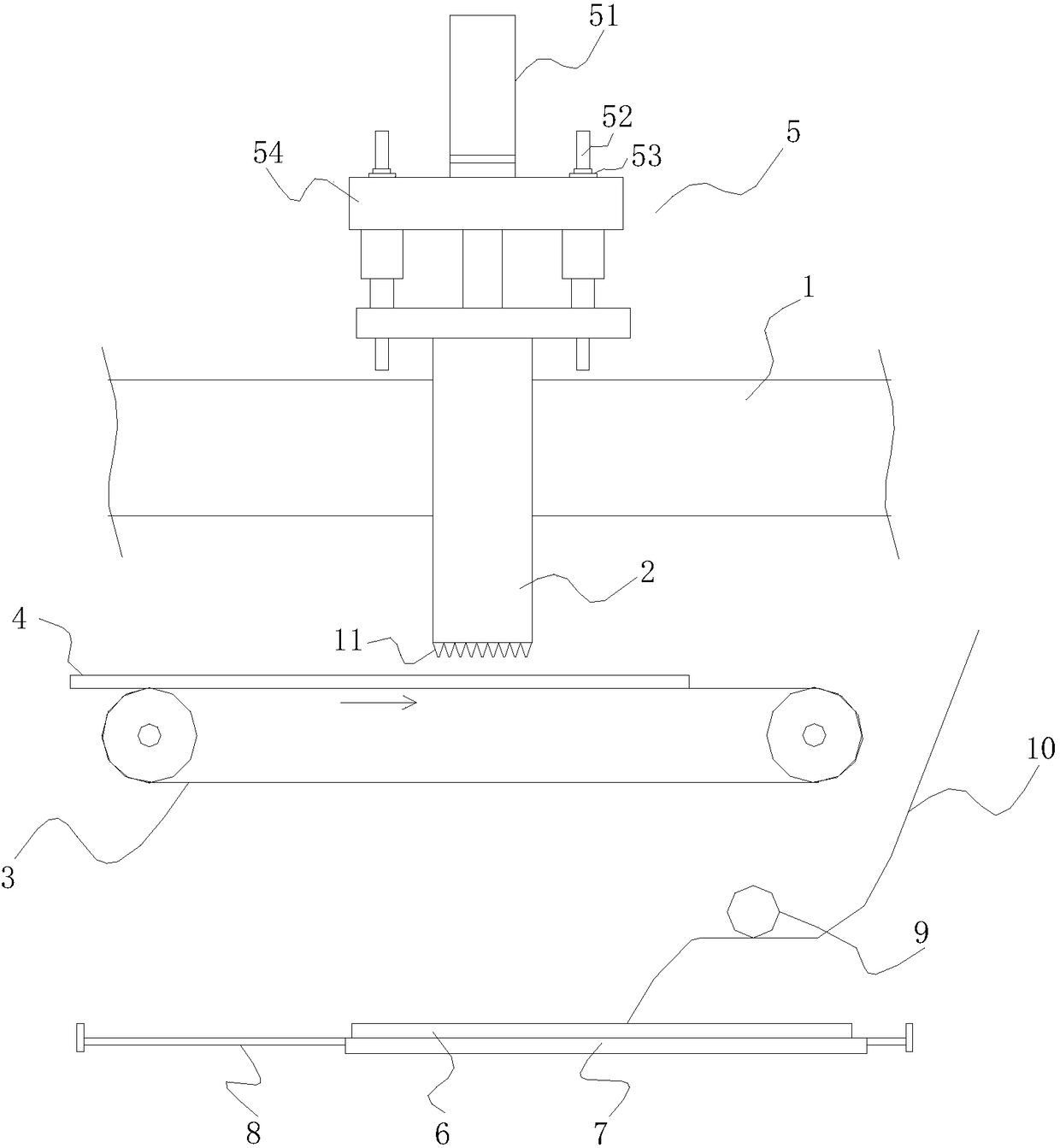

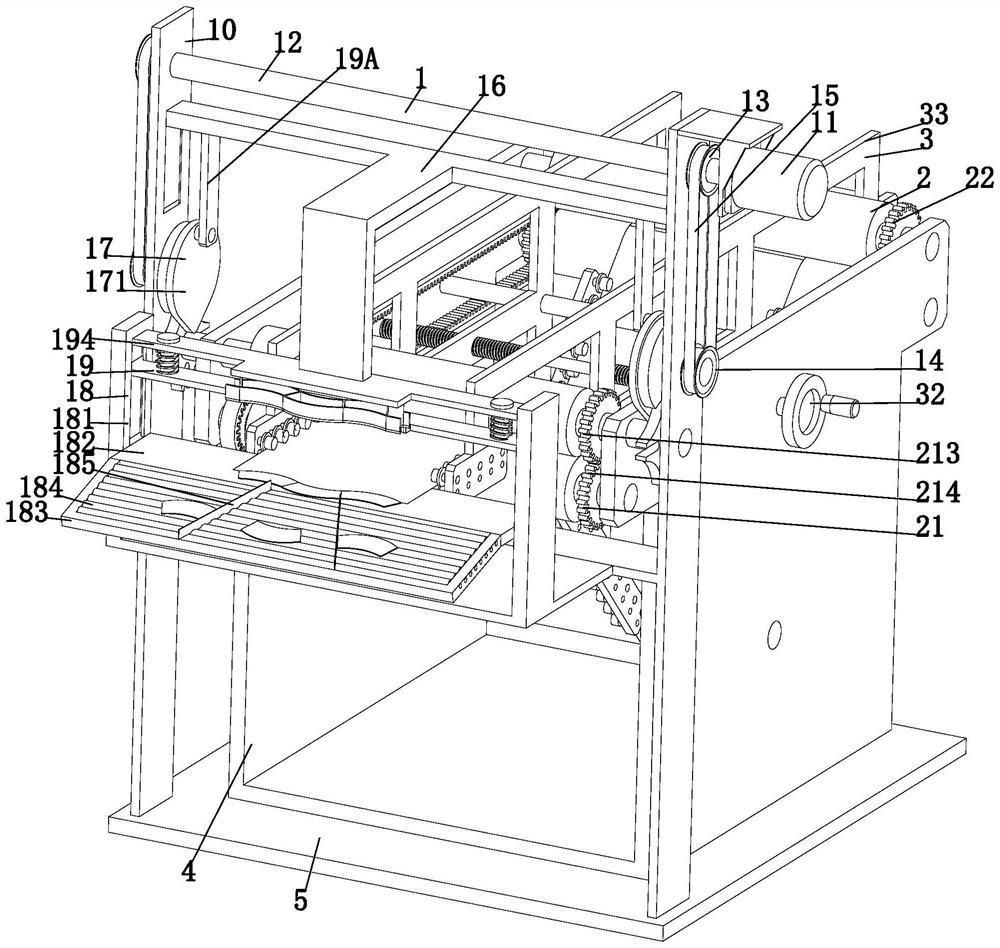

Automatic paging die cutting machine

PendingCN111762598AImplement automatic paginationImprove paging efficiencyConveyorsArticle feedersControl engineeringProcess engineering

The invention relates to an automatic paging die cutting machine. The automatic paging die cutting machine comprises a base, a paging assembly, a detection assembly and a die cutting assembly, whereinthe paging assembly, the detection assembly and the die cutting assembly are mounted on the base from front to back. The paging assembly comprises a paging belt, a baffle and a flatness limiting plate, wherein the baffle and the flatness limiting plate are mounted above the paging belt and are inclined backwards, the flatness limiting plate is a concave arc-shaped plate, the front side of the paging belt is a discharge area, and a pressing plate capable of moving up and down is arranged above the discharge area. The die cutting assembly comprises a conveying belt and a cutting die, the transmission direction of the conveying belt is the same as that of the paging belt, the cutting die is arranged above the conveying belt and can move up and down, and a lower plate fixed to the base is arranged between the upper layer and the lower layer of the conveying belt. The detecting assembly comprises a diaphragm detection element arranged above the front end of the conveying belt. According tothe automatic paging die cutting machine, continuous operation of diaphragm paging and die cutting can be realized, production steps are simplified, the degree of automation is high, the production efficiency is improved, the quality of diaphragm finished products is ensured, and the production cost is reduced.

Owner:WELL TECH ELECTRONIC TECH CHANGZHOU CO LTD

Tab die cutting method for inter-coating pole piece

ActiveCN112692152AImprove die-cutting efficiencyImprove die-cutting accuracyMetal-working feeding devicesMetal working apparatusPole pieceMechanical engineering

The invention relates to the technical field of pole piece die cutting, in particular to a tab die cutting method for an inter-coating pole piece. A material guide assembly used for pulling an inter-coating pole piece roll material, a detection assembly used for detecting the inter-coating position of the inter-coating pole piece, a die cutting assembly used for carrying out die cutting on the inter-coating pole piece introduced by the material guide assembly, and a discharging assembly used for pulling and conveying the die-cut pole piece are involved in the tab die cutting method. According to the tab die cutting method, a large-compaction-density process can be adopted, so that the capacity of a single battery cell is improved; a large-size cutter mechanism is omitted, so that dust and burrs are reduced, the quality of the pole piece is effectively improved, and the safety performance of a battery is improved; and the large-size cutter mechanism is omitted, so that the use cost of equipment is remarkably reduced, thereby greatly reducing the manufacturing cost of a battery cell.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Die cutting machine having good use effect and being convenient to adjust

The invention relates to the technical field of machining, and discloses a die cutting machine having a good use effect and being convenient to adjust. The die cutting machine comprises a base, wherein a first upright post and a second upright post are sequentially and fixedly mounted on the top of the base from left to right; and a first material receiving roller, a second material receiving roller and a second traction roller are sequentially and fixedly mounted on the right side of the first upright post from top to bottom. According to the die cutting machine having the good use effect andbeing convenient to adjust disclosed by the invention, through cooperation among the base, the first upright post, the second upright post, the first material receiving roller, the second material receiving roller, a first feeding roller, a second feeding roller, a foundation base, a groove, a cross plate, a first supporting block, a first through hole, an upper cutting block, a connecting rod, alower cutting block, a lower die cutting table, an electric push rod, an upper die cutting table, a passing hole, a spring, a limiting plate, a limiting rib, a second supporting block and a roller wheel, the upper die cutting table and the lower die cutting table can simultaneously do die cutting operations, and only in need of one electric push rod, the die cutting efficiency is improved, and electric energy is also economized.

Owner:苏州东琨科技有限公司

Automatic scrap clearing die

The invention relates to the technical field of dies, in particular to an automatic scrap clearing die. The automatic scrap clearing die comprises a die body, wherein a plurality of scrap clearing parts are arranged on the front face of the die body, a plurality of scrap clearing grooves are formed in the back face of the die body, scrap clearing inlets are formed in the top faces of the scrap clearing parts, scrap clearing outlets are formed in the side faces of the scrap clearing parts, and the longitudinal sections of the scrap clearing parts are conical. Compared with the prior art, cut scraps are discharged out through the scrap clearing parts and the scrap clearing grooves in the die cutting process, the scraps discharged out from the side faces are convenient to clear, the longitudinal sections of the scrap clearing parts are conical, the scraps easily slip out and fall down, cut boundary materials are discharged out of the scrap clearing grooves, material cracking, edge exclusion and other machining scrap phenomena caused by working time waste due to scrap clearing and manual scrap clearing in the die cutting process are avoided, and the die cutting efficiency is improved. In addition, products subjected to die cutting are more attractive in appearance, the rate of finished products is improved, and the production cost is reduced.

Owner:JIEZHUN LASER DIE CUTTING CO LTD

Manufacturing and processing equipment for anti-fake self-adhesive labels and manufacturing and processing method

PendingCN113199561AImprove efficiencyAvoid liftingMetal working apparatusWebs handlingAdhesiveManufacturing engineering

The invention relates to manufacturing and processing equipment for anti-fake self-adhesive labels and a manufacturing and processing method. The manufacturing and processing equipment comprises a workbench, a winding mechanism and a die cutting mechanism, the winding mechanism is arranged on the lower end face of the workbench, and the die cutting mechanism is arranged on the upper end face of the workbench. According to the manufacturing and processing equipment, an adjusting set in the die cutting mechanism can directly adjust the distance between cutters according to needs, the tedious phenomenon that the distance between the cutters is adjusted through disassembly and assembly is avoided, and therefore the die cutting efficiency is improved; and meanwhile, a pressing roller is adopted for rolling on the anti-fake self-adhesive labels obtained after die cutting, so that the phenomenon that die cutting openings of the anti-fake self-adhesive labels after die cutting are tilted is avoided.

Owner:刘超超

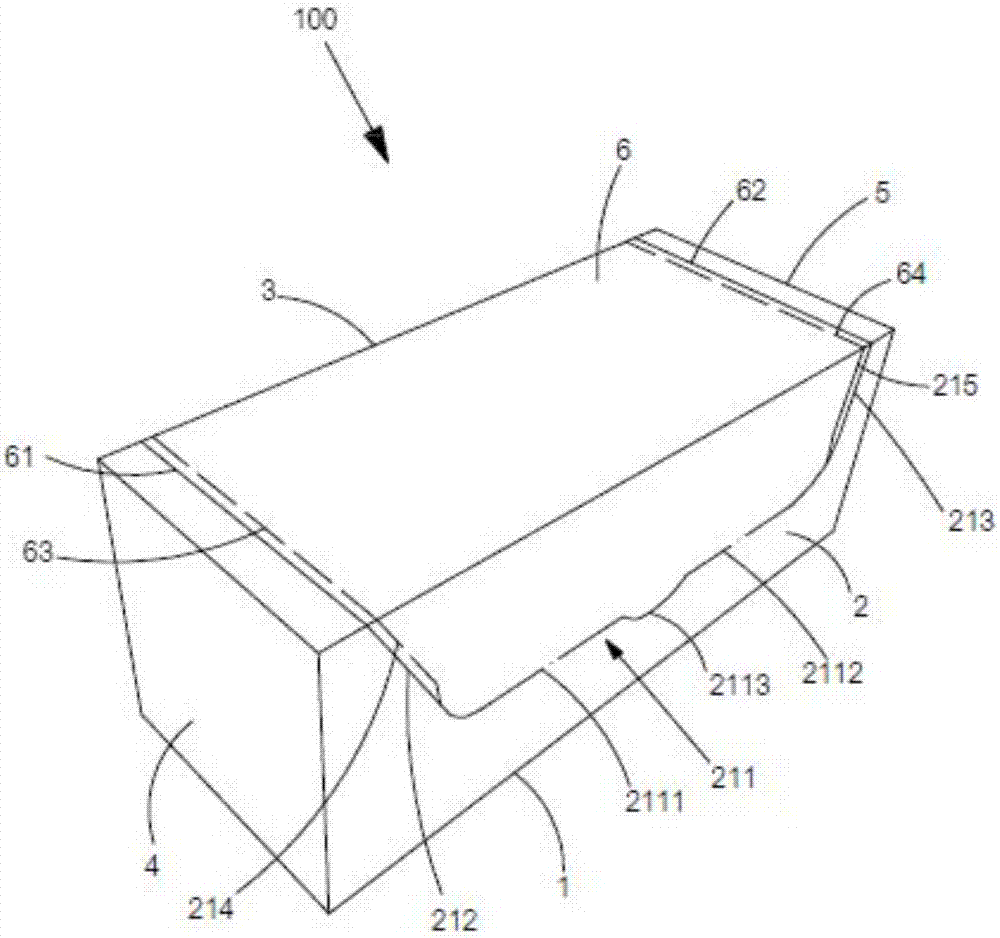

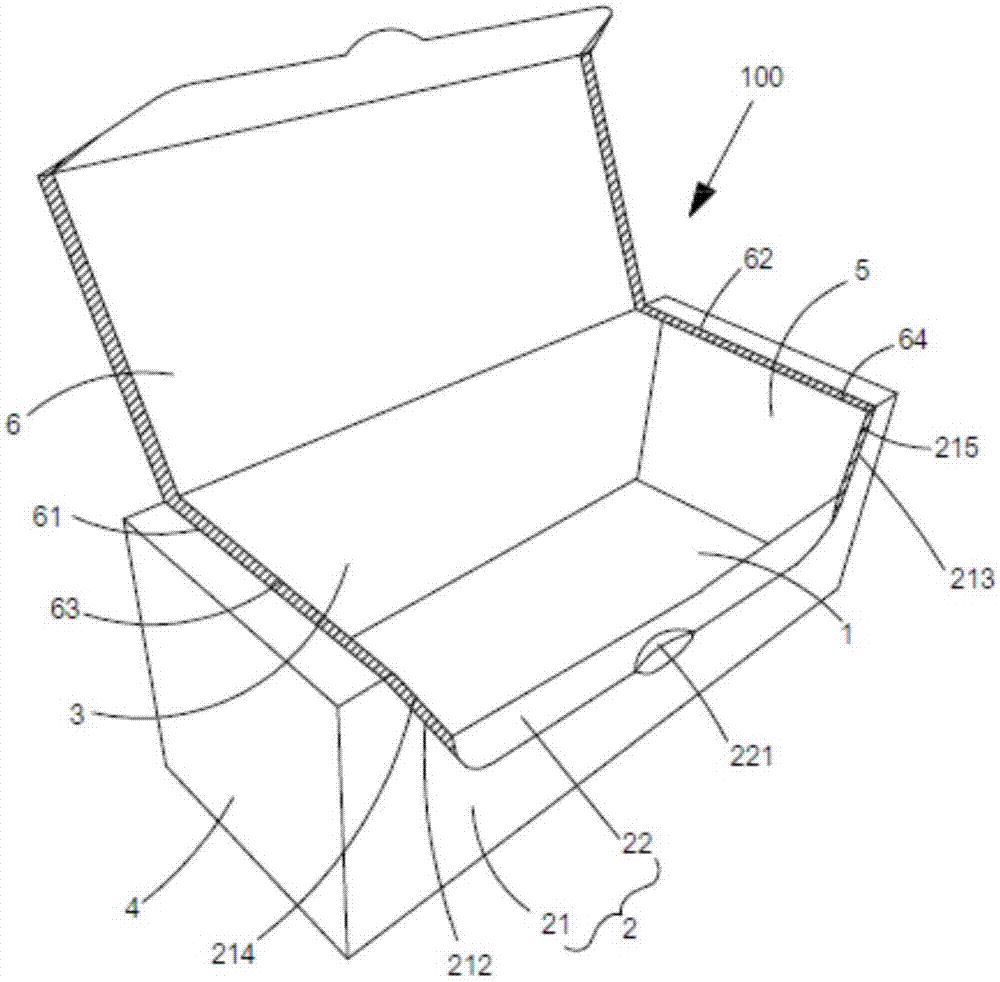

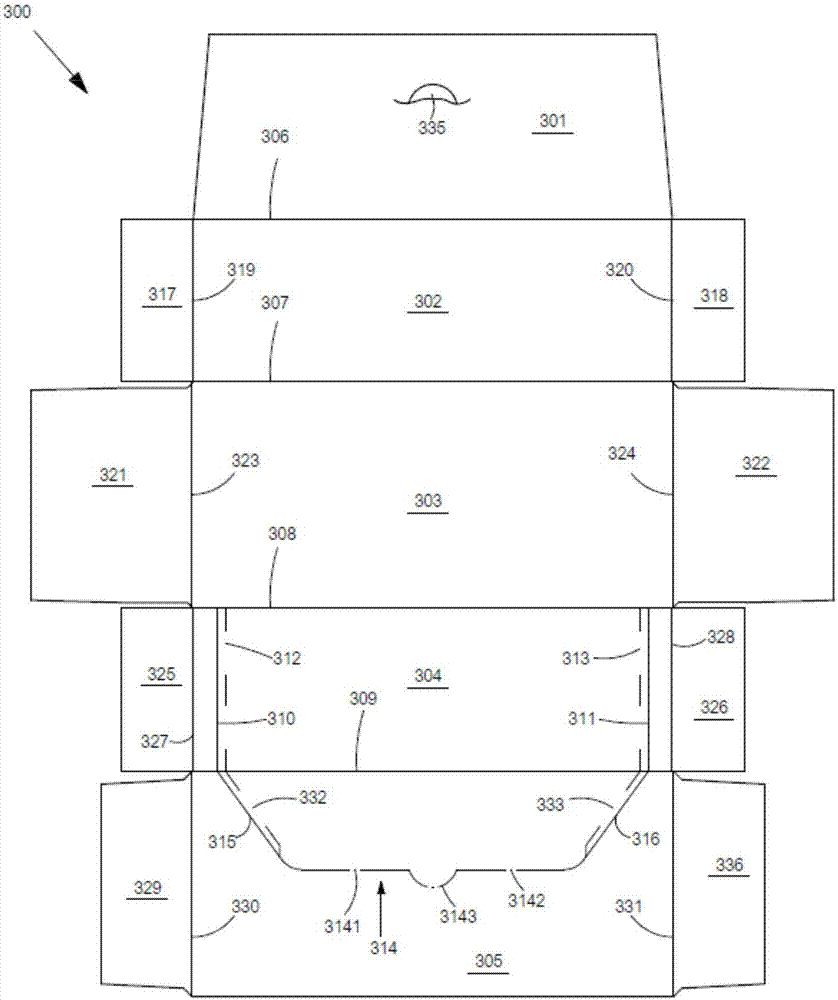

Technological method for realizing smooth tear opening of paper packaging box and paper packaging box

ActiveCN107031953AImprove die-cutting efficiencyDie-cutting quality is goodBox making operationsPaper-makingCardboardTear production

The invention relates to a technological method for realizing a smooth tear opening of a paper packaging box and the paper packaging box. The packaging box is formed by performing die cutting on a white cardboard and folding and adhering the cut white cardboards. The smooth tear opening of the paper packaging box comprises positive half knife lines and negative half knife lines which are parallel to each other and are arranged in a staggering manner; and the positive half knife lines are located on the outer surface of the packaging box, and the negative half knife lines are located on the inner surface of the packaging box. The technological method comprises the following steps: carrying out die cutting through an etching knife die arranged on a die cutting table to form the negative half knife lines, and carrying out die cutting through a decarburized steel knife die arranged on a die cutting plate to form the positive half knife lines, thus completing forming of the negative half knife lines and the positive half knife lines through one-step cutting. By the use of the etching knife die and the decarburized steel knife die, the technological method realizes one-step cutting completion of the positive and negative half knife lines, so that the die cutting efficiency is high, and the die cutting quality is high; meanwhile, the tear opening of the packaging box manufactured through the method is smooth; and compared with a conventional dentate line tear opening, the tear opening is more attractive in appearance.

Owner:SUZHOU GENERAL PRINTING HOUSE

Packaging box production technology

InactiveCN108466452ALarge feedOvercoming the difficulty of cutting the bottom cardboardBox making operationsPaper-makingHydraulic cylinderPaperboard

The invention belongs to the technical field of special methods for making paper boxes, cartons, envelope or paper bags, and particularly discloses a packaging box production technology. The packagingbox production technology comprises the following steps of 1, preparing a hydraulic cylinder, a workbench and a die-cutting rule, wherein the die-cutting rule is driven by the hydraulic cylinder; 2,forming a groove which is the same as the die-cutting rule in shape and size in the workbench; 3, starting the hydraulic cylinder to drive the die-cutting rule to move so as to enable the die-cuttingrule to cut a workpiece; and 4, when the cutting edge of the die-cutting rule reaches the plane of the workbench, driving the die-cutting rule to continue feeding so as to enable the die-cutting ruleto enter the groove. The packaging box production technology aims to solve the problem that in the die cutting process of a paperboard through an existing production technology, the paperboard cannotbe completely cut off.

Owner:重庆漱心斋文化产业发展有限公司

A high-efficiency die-cutting device for release paper

ActiveCN106042063BImprove die-cutting efficiencyReduce volumeMetal working apparatusEngineeringMechanical engineering

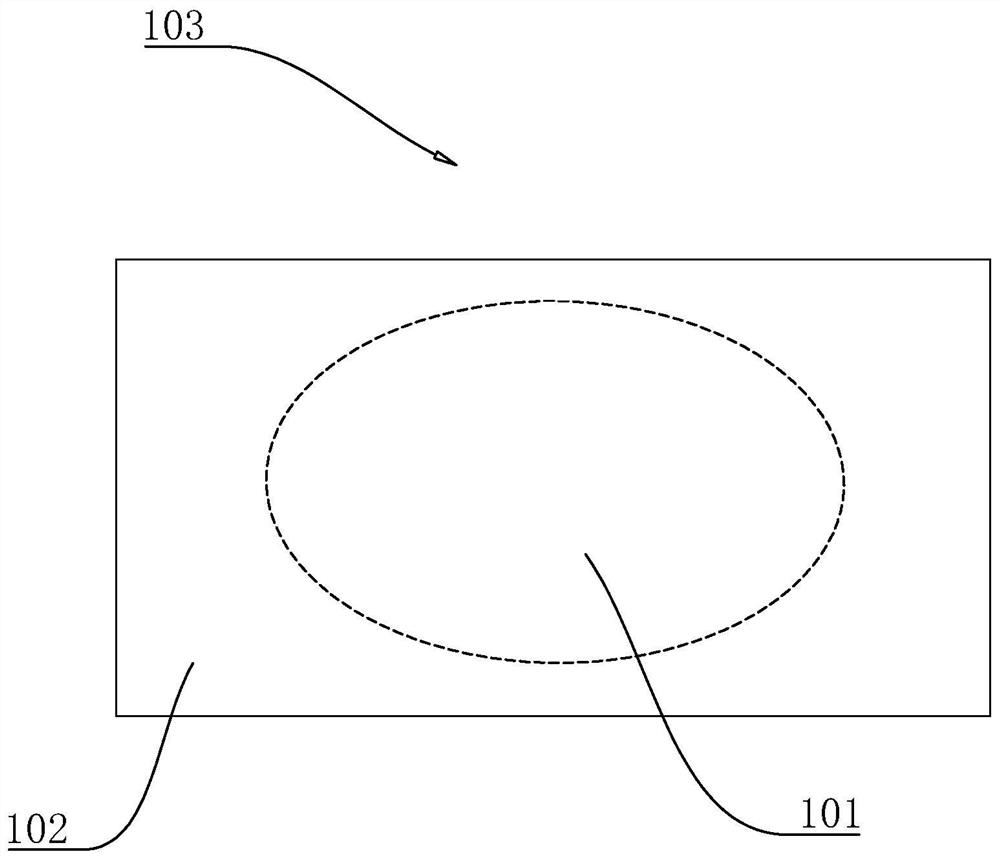

The invention relates to an efficient die cutting device for release paper. The efficient die cutting device comprises a die cutting plate and a die cutting tool cylinder. The die cutting tool cylinder penetrates the die cutting plate, and the top end and the bottom end of the die cutting tool cylinder stretch out of the upper end face and the lower end face of the die cutting plate correspondingly. A cutting edge is installed at the bottom of the die cutting tool cylinder. The die cutting device further comprises a drive cylinder, a transmission mechanism and a feeding mechanism. By means of the efficient die cutting device for the release paper, the die cutting efficiency of the die cutting device is high, the equipment is simplified, the size is reduced, cost is reduced, operation is simpler, and the efficient die cutting device is suitable for being used in small-sized or medium-sized enterprises.

Owner:北京英格条码技术发展有限公司

Die cutting process for single-sided high-hardness thick copper plate

PendingCN114535936AGuaranteed stabilityMaintain end face flatnessPrinted circuit manufactureClean environmentWaste material

The invention discloses a die cutting process for a single-sided high-hardness thick copper plate, and relates to the technical field of copper plate cutting. According to the die cutting technology, automatic feeding, limiting and fixing, adjustable die cutting and end face milling and grinding are carried out through the die cutting equipment, the stability in the single-face high-hardness thick copper plate die cutting process and the end face smoothness after die cutting are kept, the end face warping and waste material residual conditions caused by die cutting are avoided, and the die cutting efficiency is improved through multi-station automatic die cutting; waste materials generated in the die cutting process of the multiple die cutting tables fall into the branch collecting bags and fall into the main collecting bag to be collected through the first corrugated pipe and the negative pressure pipe under the negative pressure effect generated by the negative pressure draught fan, centralized recycling and reusing are facilitated, and the clean environment of the interior of the installation shell and the surface of the single-face high-hardness thick copper plate is kept. The first corrugated pipe and the second corrugated pipe are good in elasticity and shake under the negative pressure effect in the collecting process, so that the waste materials are not prone to adhering to the inner walls of the branch collecting bags and the main collecting bag.

Owner:常州海弘电子有限公司

Die-cutting machine capable of efficiently manufacturing base table paper and using method of die-cutting machine

PendingCN113500661AImprove die-cutting efficiencyAdapt to the needs of useMetal working apparatusPaper productionIndustrial engineering

The invention discloses a die-cutting machine capable of efficiently manufacturing base table paper and a using method of the die-cutting machine, and relates to the technical field of paper production. The die-cutting machine comprises a rack, a positioning mechanism, a die cutting mechanism and a waste cleaning mechanism, a workbench is arranged in a groove in the top of the rack, and the positioning mechanism, the die cutting mechanism and the waste cleaning mechanism are arranged on the top of the rack in the table paper conveying direction; the positioning mechanism comprises a positioning portal frame and a positioning assembly; and the die cutting mechanism comprises a die cutting portal frame, an air cylinder, a lifting frame and a die cutting assembly. Through the arrangement of the multiple positioning assemblies, the multiple die cutting assemblies and the multiple T-shaped air pipes, the die cutting machine can conduct die cutting on multiple pieces of table paper at the same time, so that the die cutting efficiency can be greatly improved, the positioning assemblies and the die cutting assemblies are designed in an adjustable mode, the die-cutting machine can meet the use requirements of the table paper with different widths and thicknesses, and the problems that an existing die-cutting machine for manufacturing base table paper is low in efficiency, inconvenient to adjust and difficult to adapt to paper of different specifications are solved.

Owner:宁夏金世纪包装印刷有限公司

Rotary computer high-speed flat die-cutting machine

ActiveCN103770154BImprove die-cutting efficiencyMetal working apparatusMaterial removal/additionEngineeringWaste recovery

The invention discloses a wheel-rotating computer high-speed flat die-cutting machine which sequentially comprises an emptying mechanism, a deviation rectifying mechanism, a front strip conveying mechanism, a die cutting mechanism, a color mark identification detection mechanism, a striping mechanism, a rear strip conveying mechanism and at least two material receiving mechanisms, wherein a waste recovery mechanism is also arranged above the striping mechanism; a front vertical up-and-down motion mechanism is arranged in front of the die cutting mechanism; a rear vertical up-and-down motion mechanism is arranged behind the die cutting mechanism; strips sequentially pass through the deviation rectifying mechanism, the front vertical up-and-down motion mechanism, the die cutting mechanism, the rear vertical up-and-down motion mechanism, the color mark identification detection mechanism and the striping mechanism from the emptying mechanism under the action of the front strip conveying mechanism and the rear strip conveying mechanism and then enter the material receiving mechanisms. According to the invention, when the strips are subjected to die cutting, the strips do not need to stop, so that die cutting efficiency is greatly improved.

Owner:浙江嘉盛特种印刷有限公司

Die cutting hob assembly

ActiveCN113183239AImprove die-cutting efficiencyImprove cutting effectMetal working apparatusDie cuttingPhysics

The invention relates to the technical field of packaging devices, in particular to a die cutting hob assembly which comprises a rolling shaft, at least one cutter body is arranged on the rolling shaft, the cutter body is in a closed ring shape, the perimeter edge of the cutter body is matched with the perimeter edge of an object, and cutting ring blades are arranged on the side, used for die cutting, of the cutter body. The cutting ring blades are located on the same virtual arc-shaped face, and the side, away from the cutting ring blades, of the cutter body is arranged on the side wall of the rolling shaft. The die cutting hob assembly further comprises a heating piece, and the heating piece is arranged on the rolling shaft and is used for heating the cutter body. The die cutting hob assembly has the following effects that in the subsequent thermal shrinkage process, a thermal shrinkage film needs to be shrunk to the edge of an object by the same distance, and sharp protrusions on the edge of a finished product can hardly appear.

Owner:浙江美生日化用品有限公司

Process capable of achieving GDL roll material die cutting and seamless material part switching

PendingCN113860040AQuality assuranceSave refueling timeMetal working apparatusWebs handlingTension controlTransfer line

The invention provides a process capable of achieving GDL roll material die cutting and seamless material part switching. The die cutting efficiency is improved, it is guaranteed that roll materials are stable and reliable in the conveying process, and the die cutting quality is guaranteed. A roll material conveying line is arranged to be an upper-layer conveying line and a lower-layer conveying line, automatic material cutting mechanisms are arranged at the output ends of the upper-layer conveying line and the lower-layer conveying line, slicing machines are arranged at the output ends of the automatic material cutting mechanisms, and tension control devices are arranged in the upper-layer conveying line and the lower-layer conveying line.

Owner:SUZHOU ANJIE TECH

Automatic die-cutting machine and die-cutting method for double-sided PE coated paper cup production

PendingCN114179167APrevent movementImprove product qualityMetal working apparatusKnife bladesPaper cup

The invention provides an automatic die-cutting machine and die-cutting method for double-sided PE coated paper cup production. The automatic die-cutting machine comprises a die-cutting mechanism, a conveying mechanism, a guide mechanism, a U-shaped support and a bottom plate, and solves the problems that when double-sided PE coated paper is conveyed and subjected to die-cutting, the movement track cannot be correctly guided, deflection is prone to occurring, and errors of the die-cutting size are caused; in addition, during die cutting, a blade directly falls to cut off, so that the double-sided PE coated paper moves, burrs of a notch are increased, the position of the notch is inclined, and the edge of the fan-shaped paper cup sheet is broken; paper cup pieces are connected with waste materials after die cutting forming, the waste materials need to be manually cleaned, and therefore production efficiency is reduced. The double-sided PE coated paper has buffer time during die cutting, and the double-sided PE coated paper is continuously conveyed, so that more die cutting wastes are generated, the utilization rate of die cutting forming of the double-sided PE coated paper is reduced, raw materials are wasted, the production cost is increased, and the like.

Owner:孙伟国

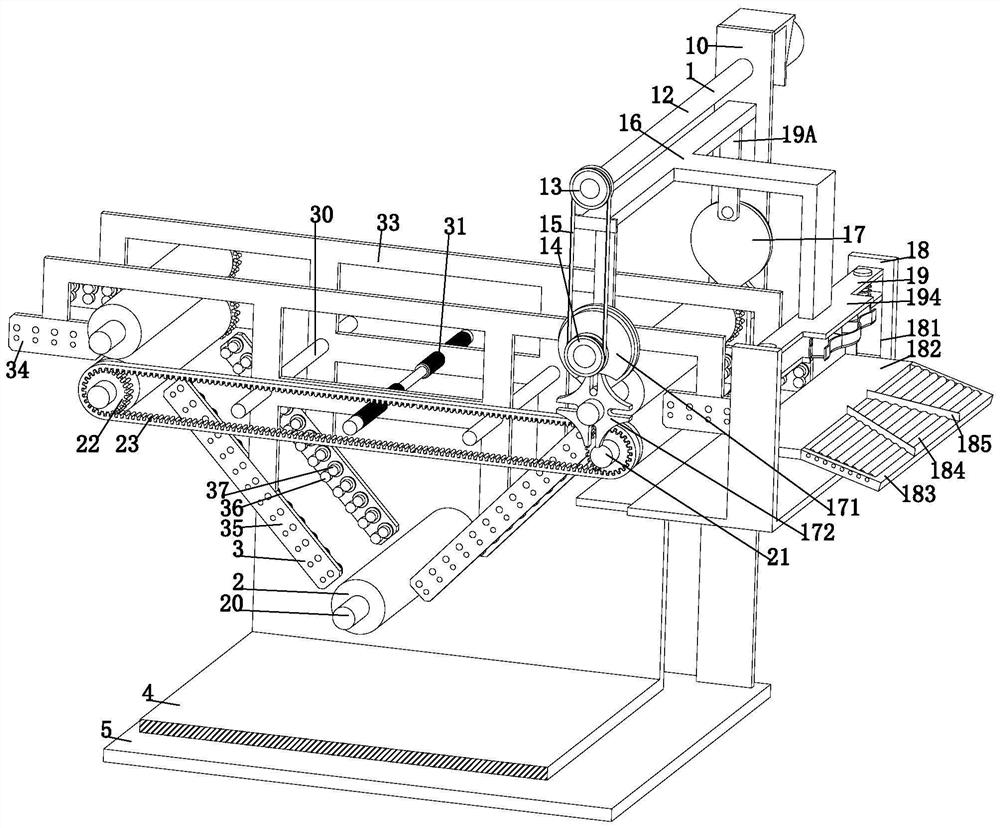

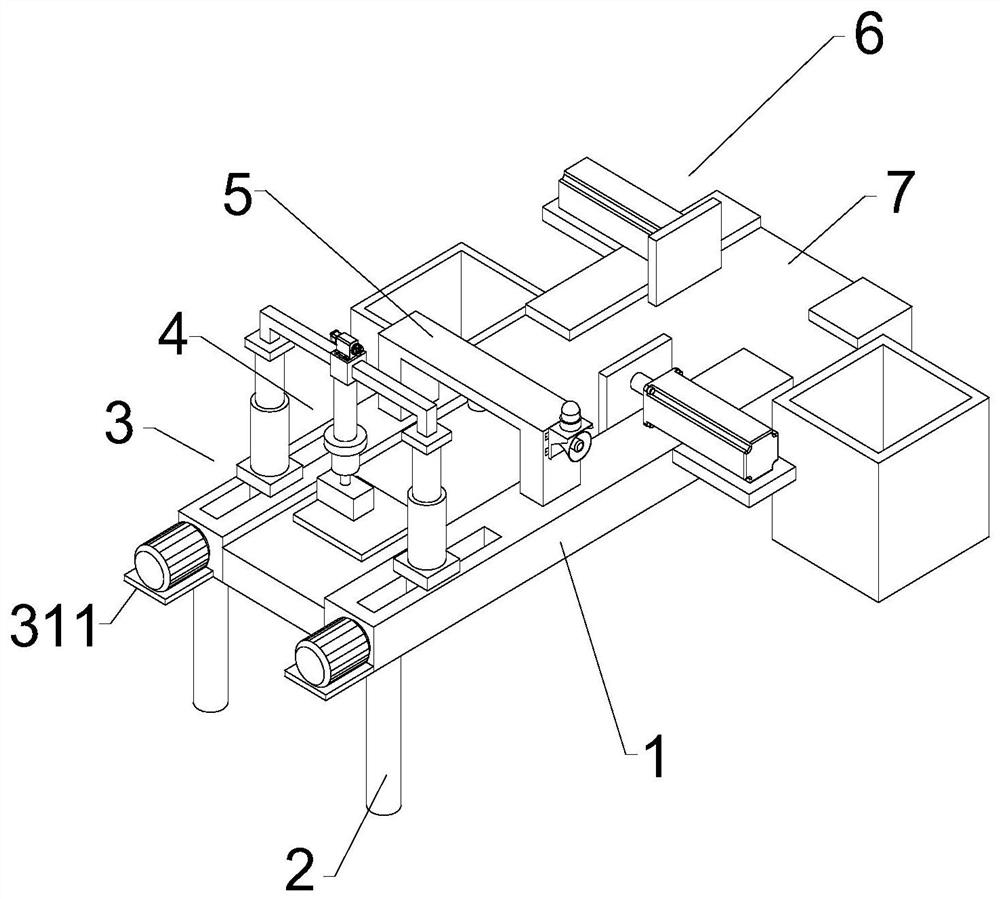

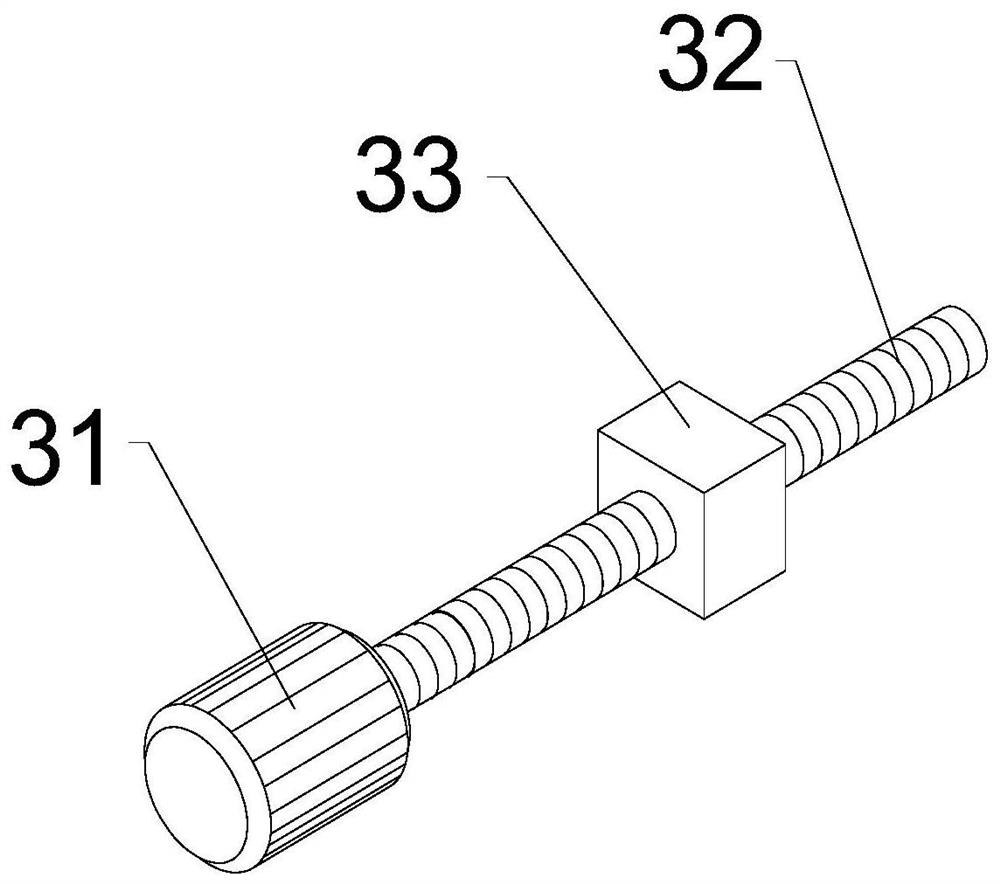

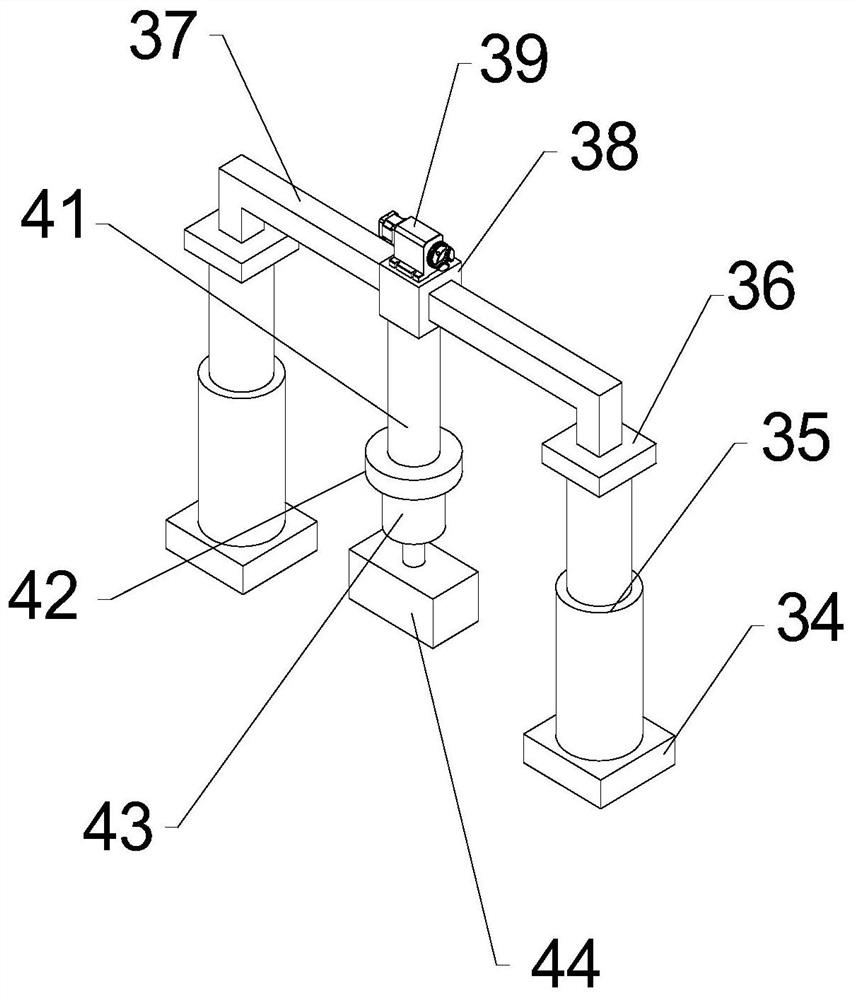

Automatic die-cutting machine

PendingCN113997331AThe structure of the die-cutting device is simpleImprove die-cutting efficiencySortingMetal working apparatusChain typeStructural engineering

The invention discloses an automatic die-cutting machine. The automatic die-cutting machine comprises a die-cutting table, wherein supporting columns are arranged at the four corners of the bottom of the die-cutting table; a chain type conveying belt is arranged at the center of the die-cutting table in the length direction of the die-cutting table; an adjusting mechanism is arranged on one side, in the length direction of the die-cutting table, of the die cutting table; a die-cutting mechanism is arranged on the adjusting mechanism; a die-cutting device is arranged on the die-cutting mechanism; a detection mechanism used for detecting materials having been subjected to die cutting is arranged on one side, in the conveying direction of the chain type conveying belt, of the die-cutting table; and one side, far away from the adjusting mechanism, of the detection mechanism is provided with a classification mechanism for judging whether a die-cut material is qualified or not. The adjusting mechanism is arranged to replace a longitudinal cutting device and a transverse cutting device in the prior art, so the die-cutting device is simpler in structure; and by arranging the detecting mechanism and the classification mechanism, whether die cutting is qualified or not can be detected, and die-cut materials can be strictly classified, so die-cutting efficiency is improved, the materials can be saved, and the die-cutting machine is very practical.

Owner:星河智源(深圳)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com