Technological method for realizing smooth tear opening of paper packaging box and paper packaging box

A process method and packaging box technology, which is applied to the field of paper packaging boxes to achieve smooth tearing of paper packaging boxes, can solve the problems of long processing time, high processing costs, and pollution of inner packaging products, and achieve high die-cutting efficiency, Beautiful appearance and good die-cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will describe in detail in conjunction with embodiments and accompanying drawings.

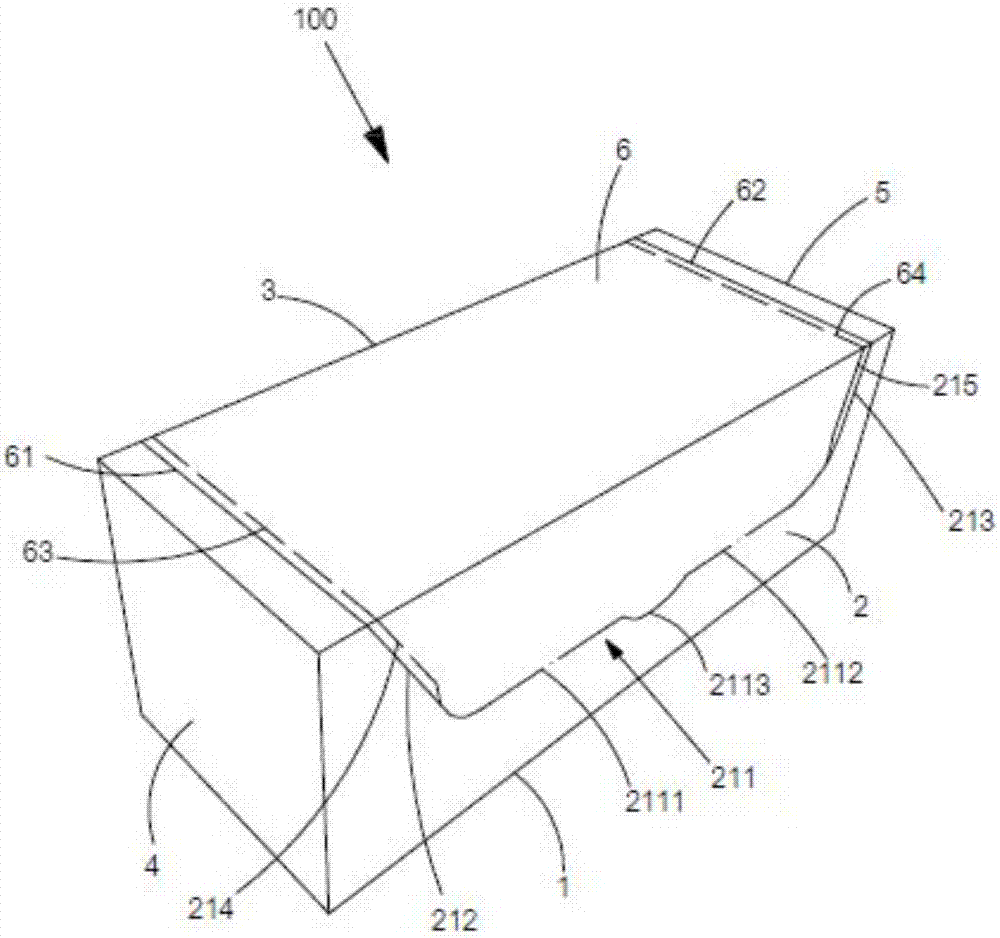

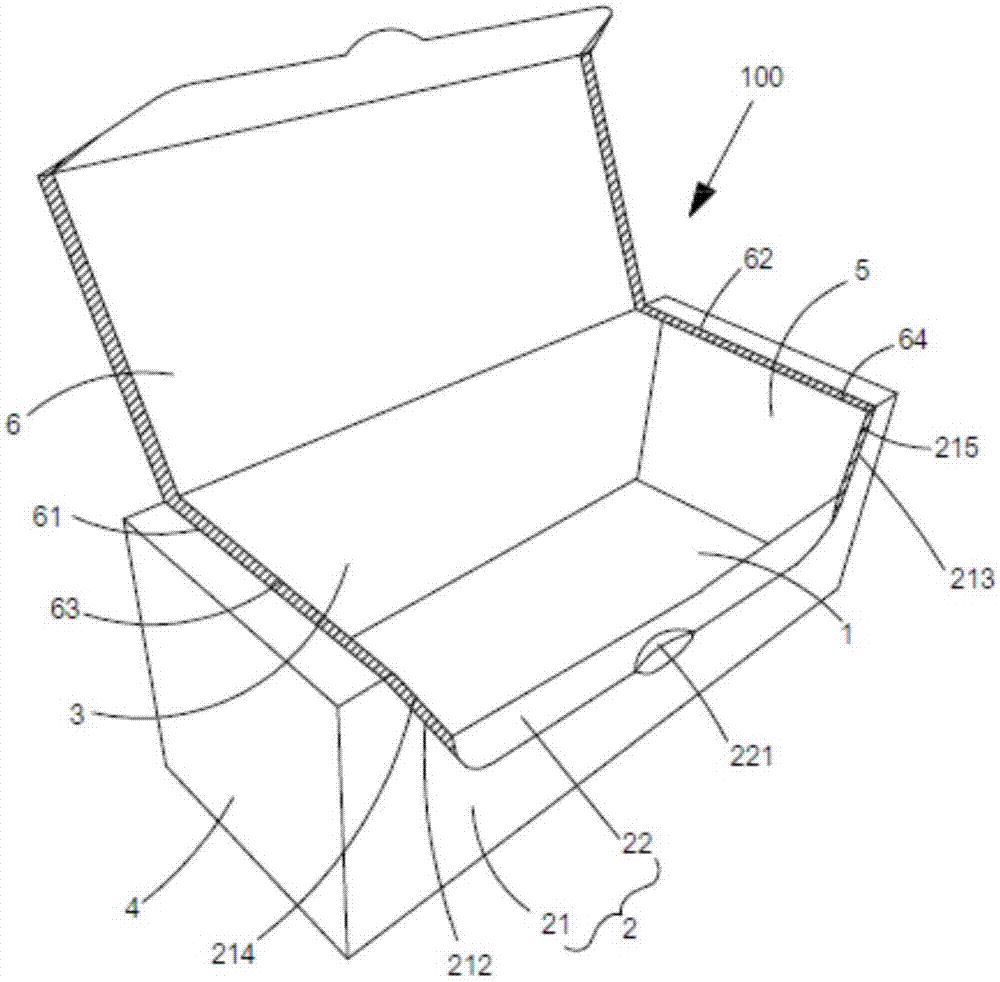

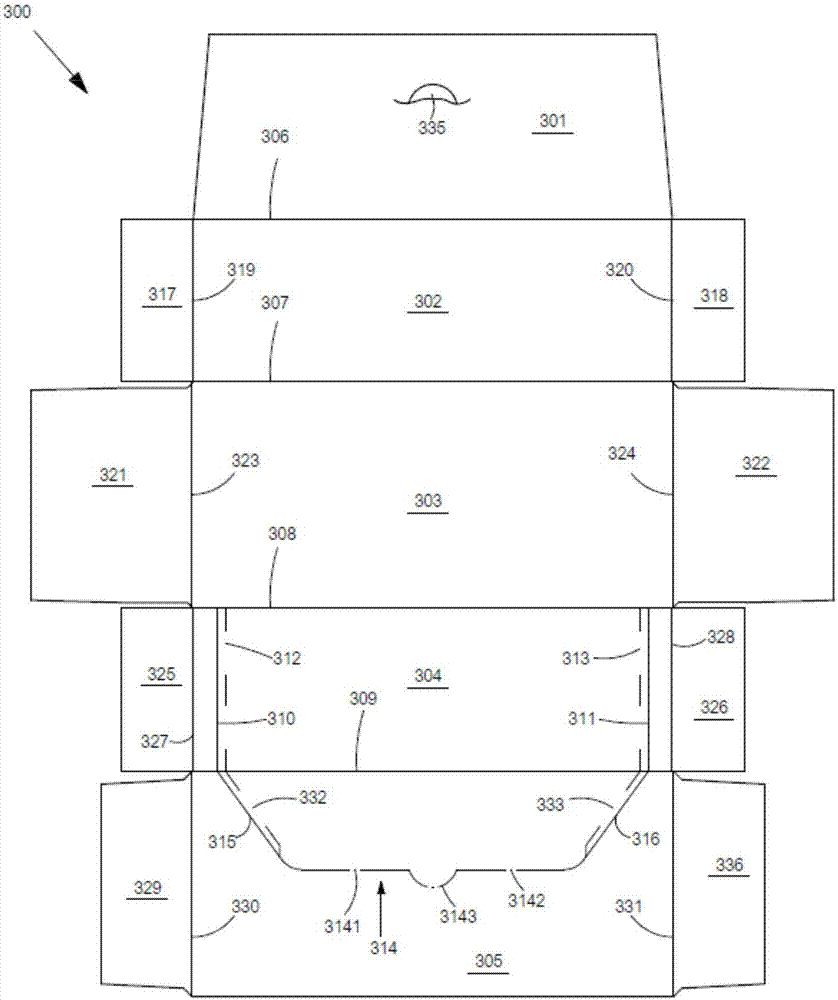

[0026] Such as figure 1 , 2 The illustrated paper packaging box with a portable opening and closing cover includes a rectangular parallelepiped and a box body 100 formed by folding and bonding a piece of white cardboard. The thickness of the white cardboard is 0.3-0.6mm. The box body 100 includes a box bottom 1, a box front side wall 2, a box rear side wall 3, a box left side wall 4, a box right side wall 5, and a box top 6. The box front side wall 2 is composed of a front outer side wall 21 and The front inner side wall 22 located on the front outer side wall 21 constitutes a double-layer structure. The lower edge of the front outer side wall 21 intersects with the front edge of the box bottom 1, and the upper edge of the front outer side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com