Die cutting hob assembly

A hob and die-cutting technology, which is applied in metal processing and other directions, can solve the problem of converging and shrinking the outer side of the final product into a pointed protrusion, and achieve the effect of improving die-cutting efficiency and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

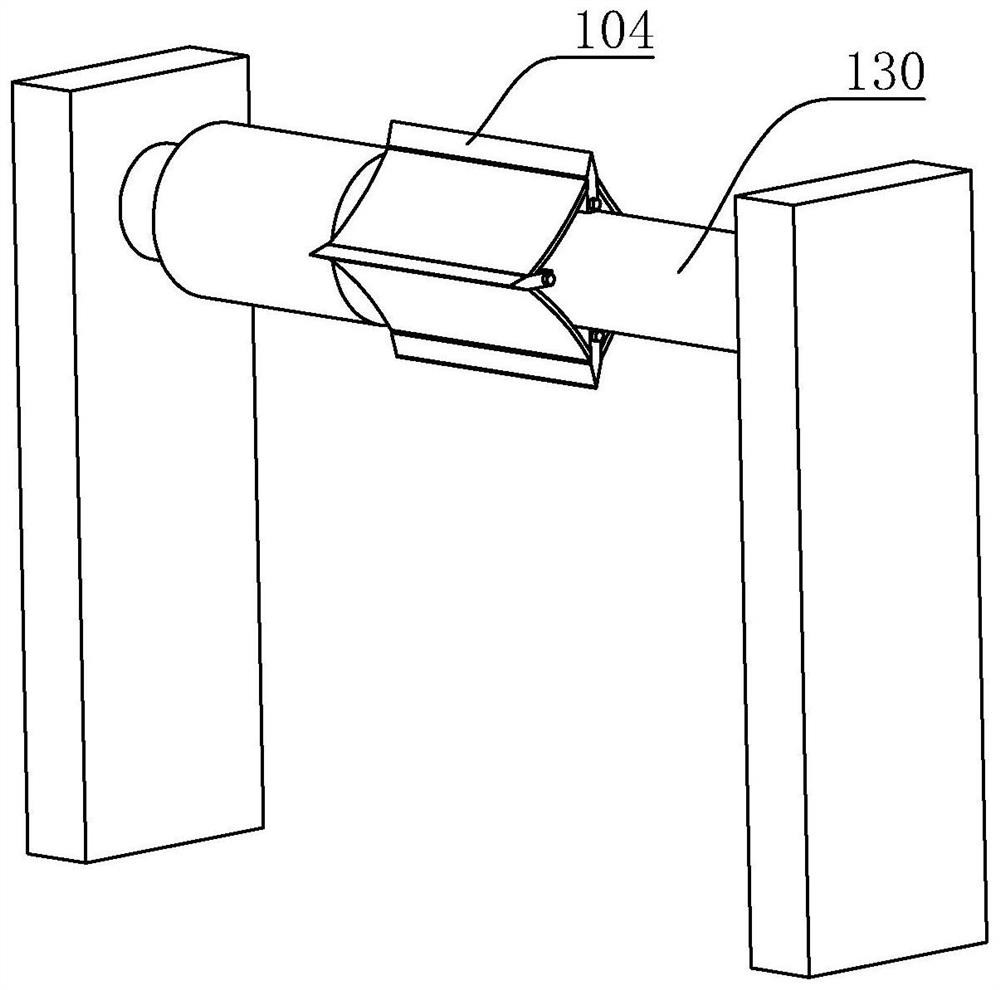

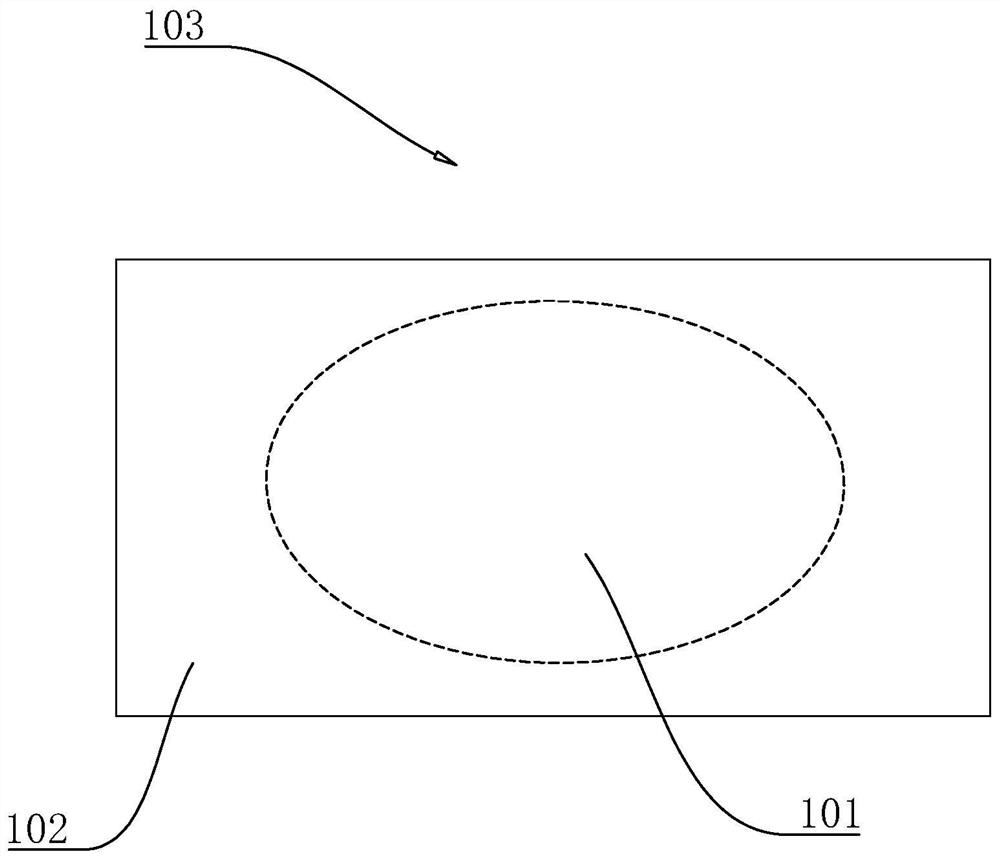

[0062] Embodiment 1 of the present application discloses a die-cutting hob assembly, referring to image 3 , Figure 4 , comprising a roller 130, at least one cutter body 100 is arranged on the roller 130, and the cutter body 100 is a closed ring shape. In this embodiment, the shape of the cutter body 100 and the object are arc-shaped segments at both ends and two segments in the middle Parallel segments, similar to the shape of a runway. The peripheral edge of the cutter body 100 is adapted to the peripheral edge of the article. In this embodiment, the two edges are equidistantly arranged. The cutter body 100 is used for die-cutting and is provided with a cutting ring edge 110, and the cutting ring edge 110 is located on the same virtual curved surface. The cutting edge 110 of the cutter body 100 has the same cross-sectional area from one side to the other side, and the thickness of the cutter body 100 along the extending direction thereof is uniform.

[0063] refer to F...

Embodiment 2

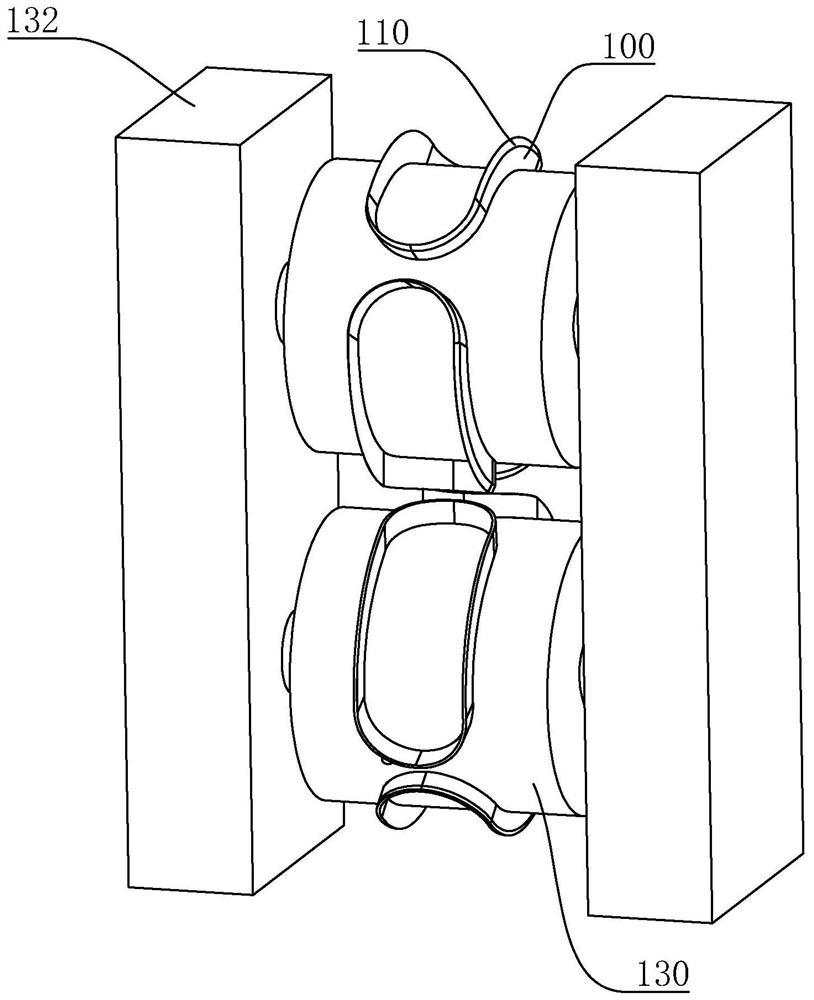

[0068] The difference from Example 1 is that, referring to Figure 6 , Figure 7 , the cutter body 100 is arranged in multiple groups along the axial direction, and a heat conduction base 140 is provided on the circumferential side wall of the roller 130. Correspondingly, the heat conduction base 140 is installed by bolts, which can be easily replaced, and can also be welded on the roller 130, and the entire roller 130 will be replaced at that time.

[0069] refer to Figure 7 , Figure 8 , the heat conduction base 140 is provided with a socket 150 for inserting and fixing the side of the cutter body 100 away from the cutting ring edge 110. The socket 150 is two clips 151 arranged side by side, and there are multiple sockets 150. The circumferential direction of the cutter body 100 is welded on the heat conduction base 140, and the side of the cutter body 100 away from the cutting ring edge 110 will be embedded between the two clips 151, and the two clips 151 are fixed and ...

Embodiment 3

[0074] The difference from Example 1 is that, referring to Figure 10 , Figure 11 , the cutter body 100 is arranged in multiple sets along the axial direction, and the heat conduction base 140 is not only in an arc shape adapted to the roller shaft 130, but also in the radial direction along the roller shaft 130, the heating element is in a ring shape adapted to the cutter body 100. In the embodiment, the heating element is a heating pipe 155 , and the heating pipe 155 coincides with the cutter body 100 on the projection along the radial direction of the roller 130 . The heat conduction base 140 has a slot 157 for inserting the heating tube 155, and the upper side of the heating tube 155 has a receiving groove 156 for inserting the cutter body 100 away from the cutting ring edge 110. When the cutter body 100 is inserted into the socket 150 When it is inside, the cutter body 100 will be inserted into the accommodating groove 156 , so that the cutter body 100 is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com