Patents

Literature

2981 results about "Tension control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

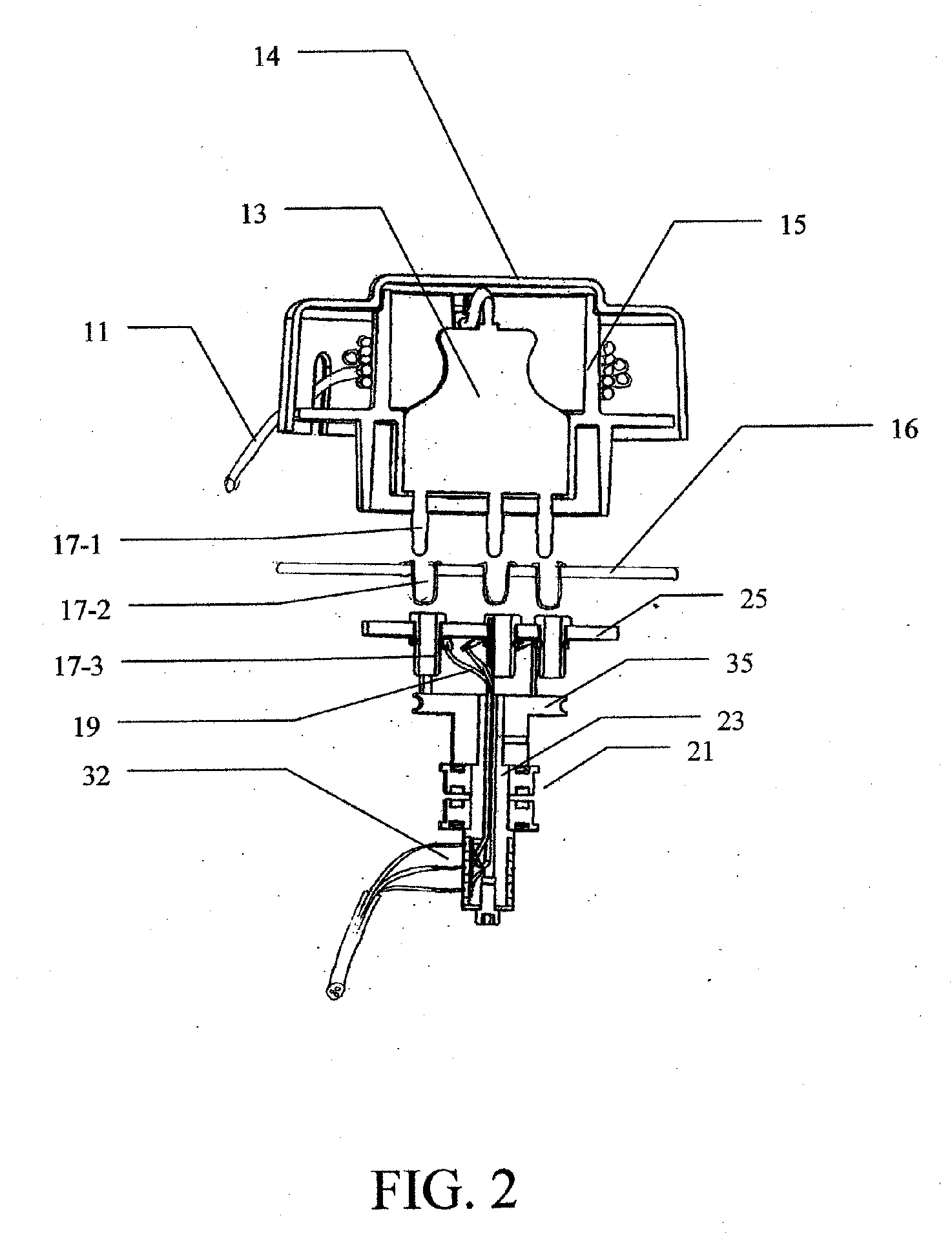

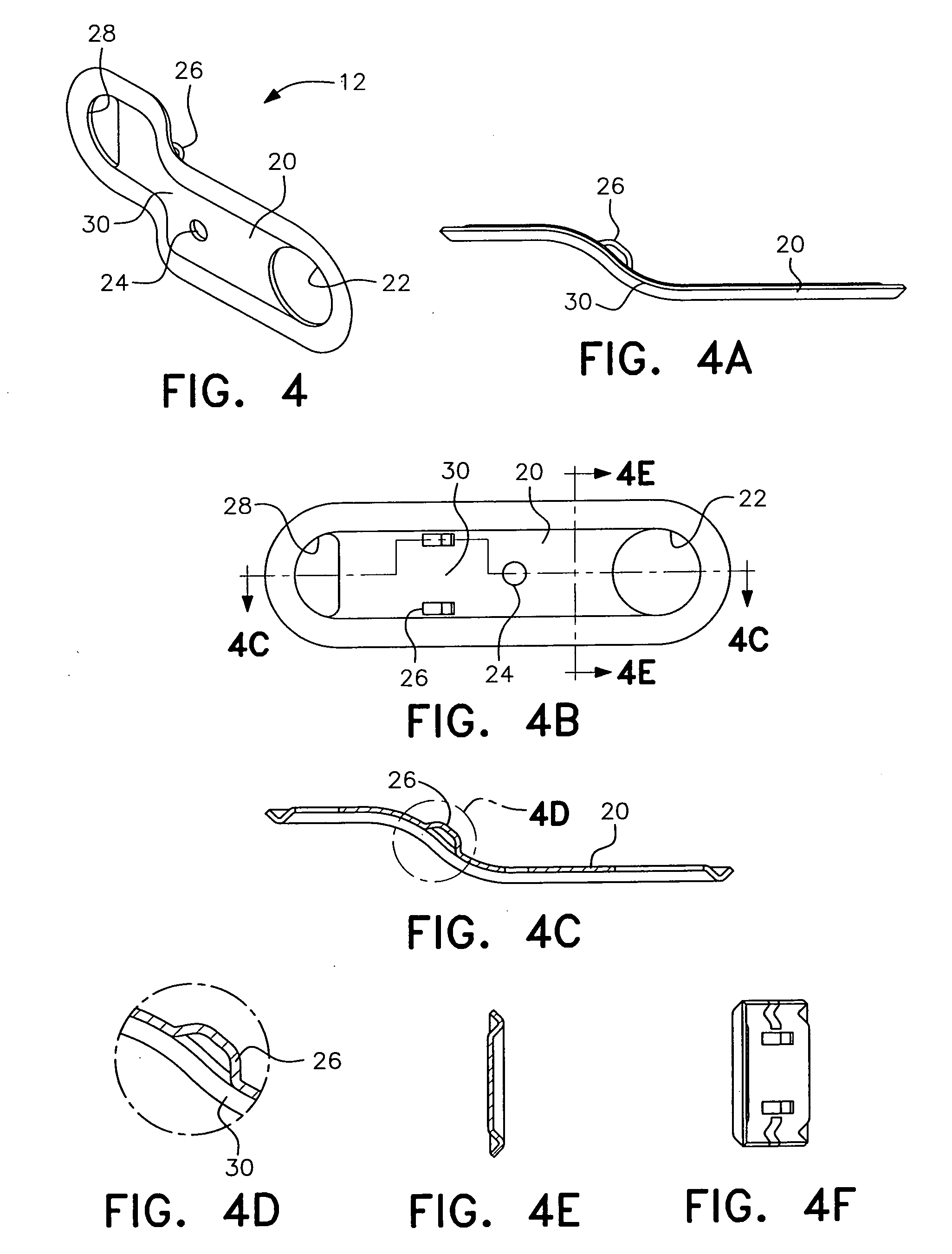

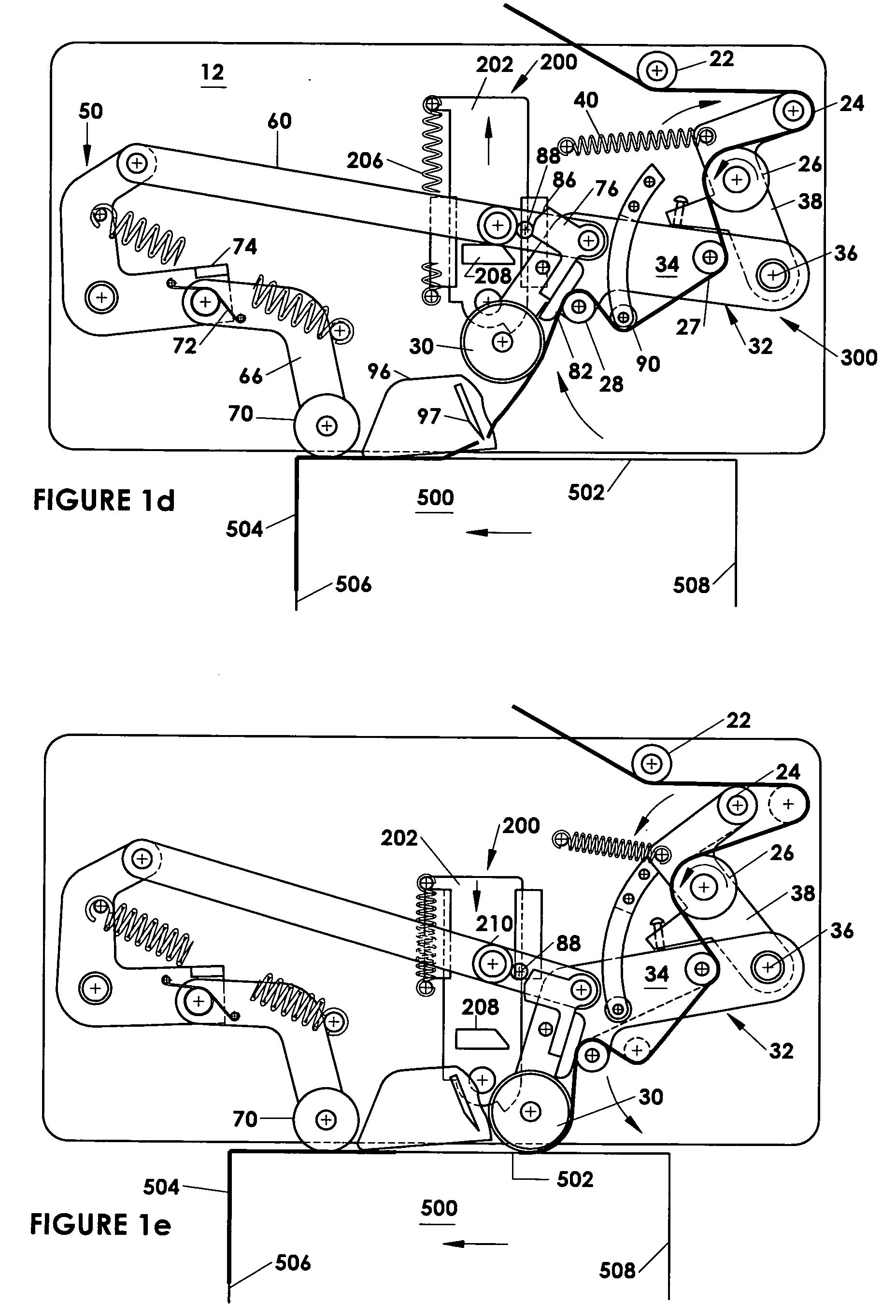

Endoscopic suturing tension controlling and indication devices

Various exemplary methods and devices are provided for tensioning sutures. The methods and devices are particularly useful in surgical suturing applications in which it is desirable to maintain tension on a suture being delivered. In various embodiments, the device is incorporated into the handle of a suture device configured to deliver a suture to a surgical site. Other embodiments comprise a device that is separate from, but may be used in connection with, a suture device configured to deliver a suture to a surgical site. A suture locking device is also provided which enables the surgeon to ascertain when a desired amount of tension has been applied to a suture prior to affixing knotting tying elements thereto.

Owner:ETHICON ENDO SURGERY INC

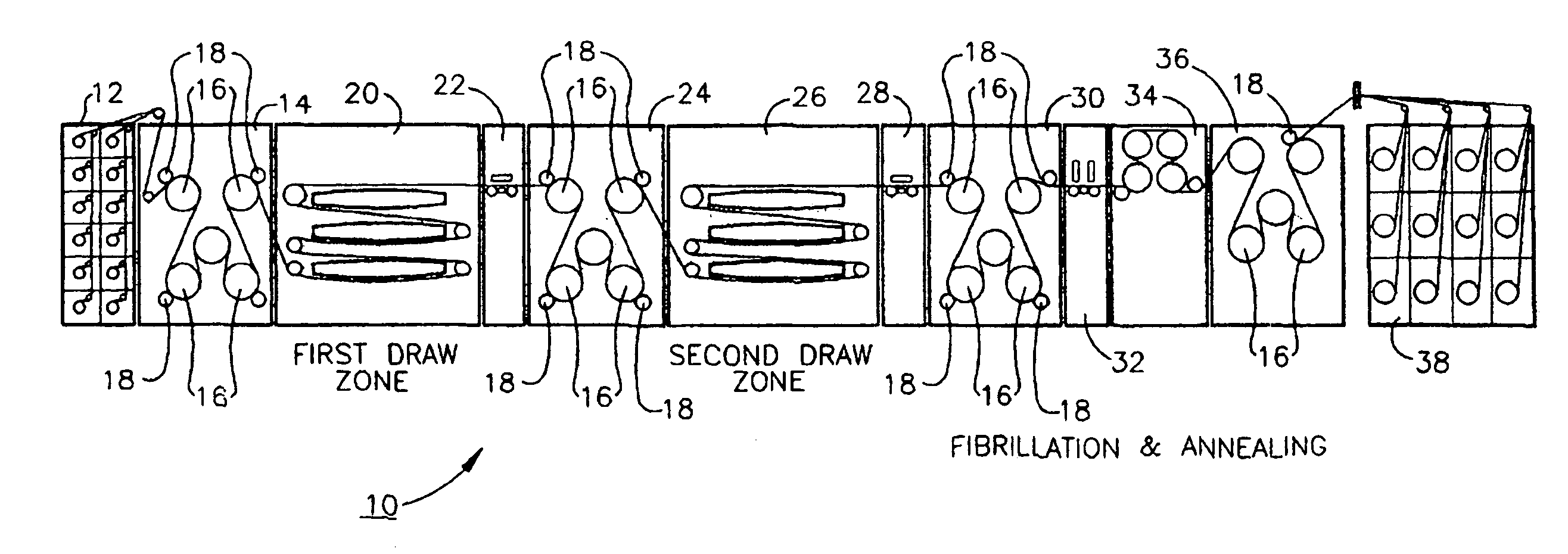

Ultra high molecular weight polyethylene fibers

InactiveUS6951685B1Easy knittingSynthetic resin layered productsDomestic articlesDental flossingFiber

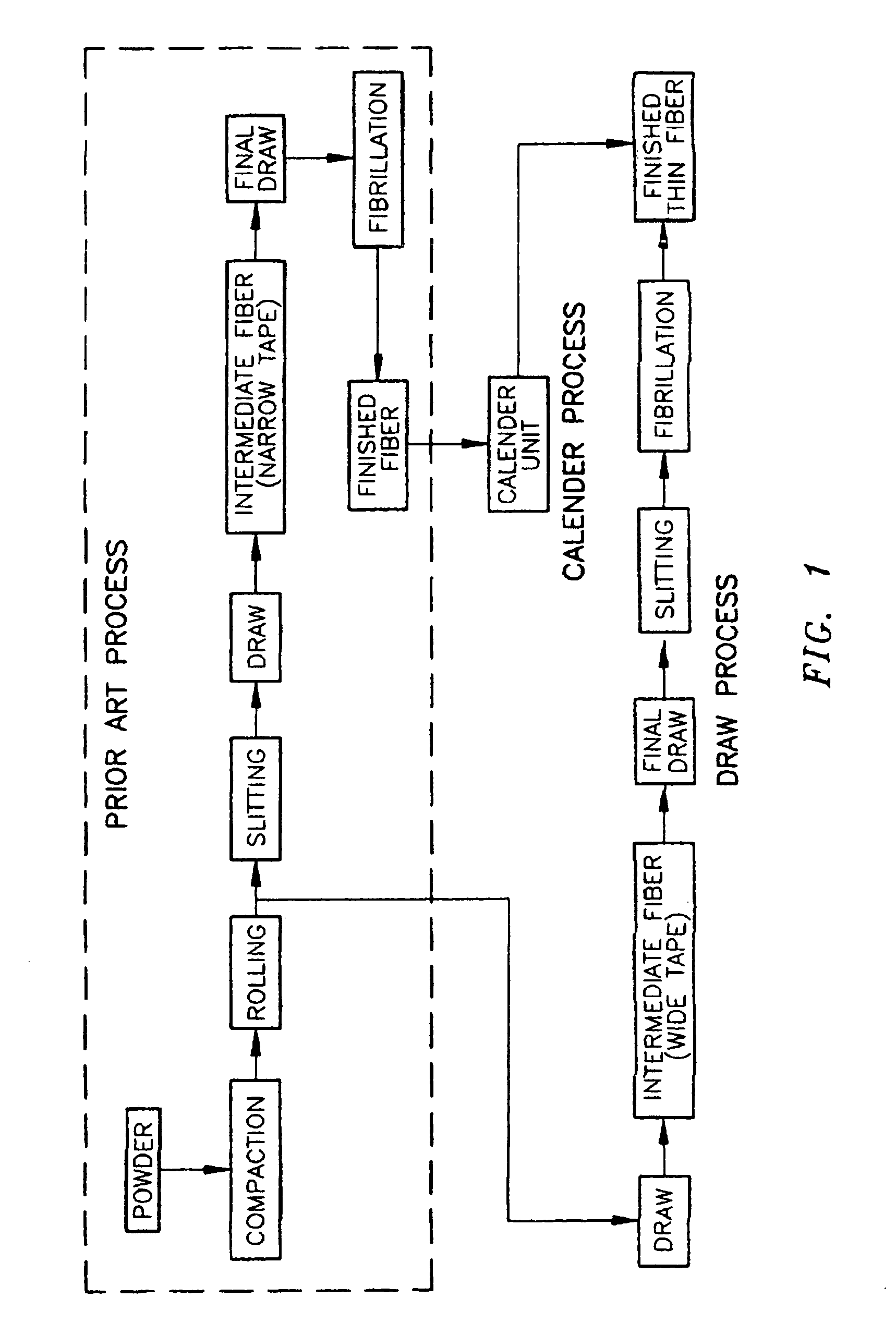

A method for the production of films / fibers of UHMWPE below 3 mils and preferably about 2 mils in thickness. The process involves calendering and / or drawing the materials of the prior art under careful tension control at a temperature above the melting point of the UHMWPE material. Before and after subsequent slitting, and / or fibrillation, UV resistance treatments, etc the thin films / fibers thus produced find use in such diverse applications as personal armor, dental floss, and sails for sail boats.

Owner:EI DU PONT DE NEMOURS & CO

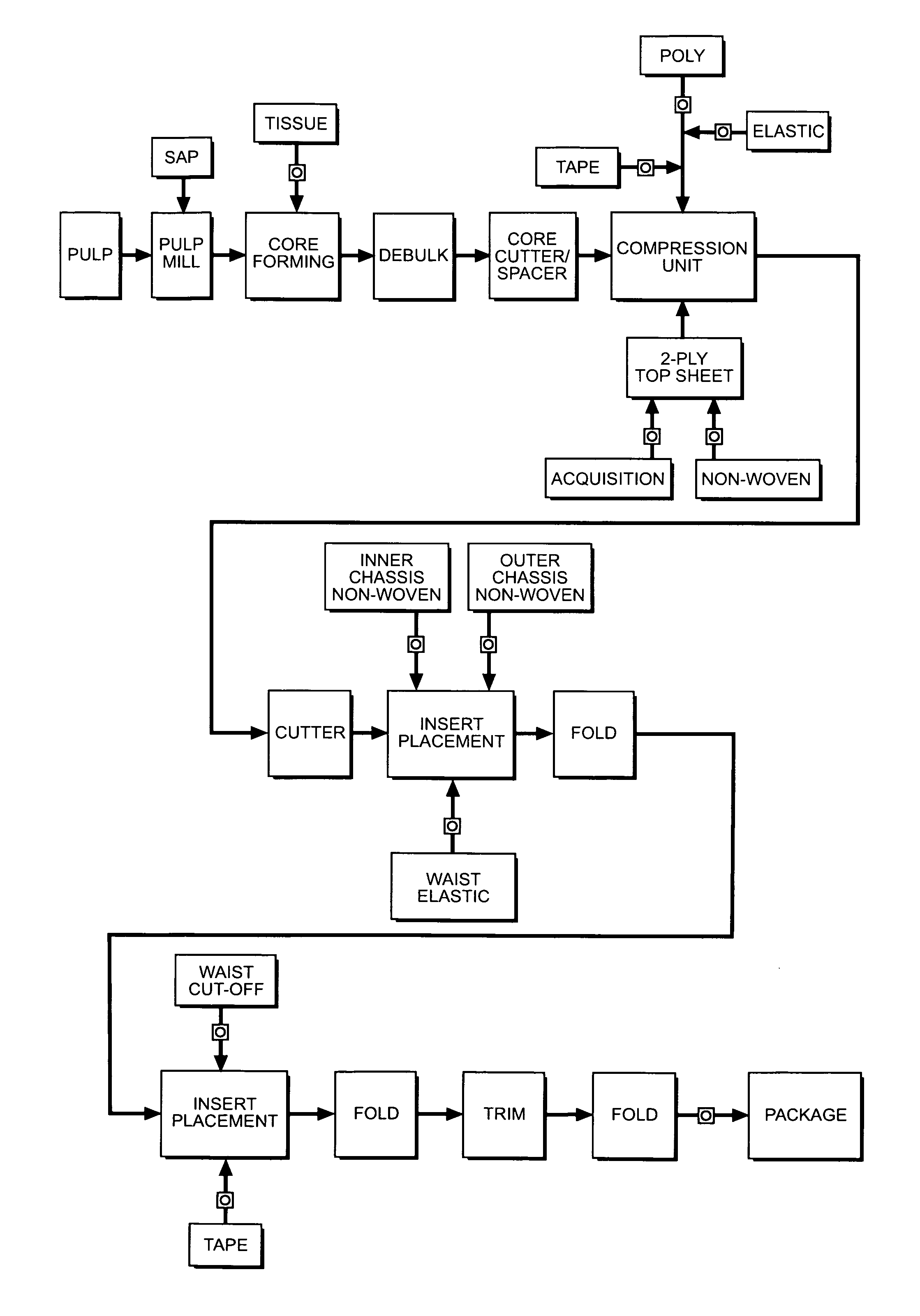

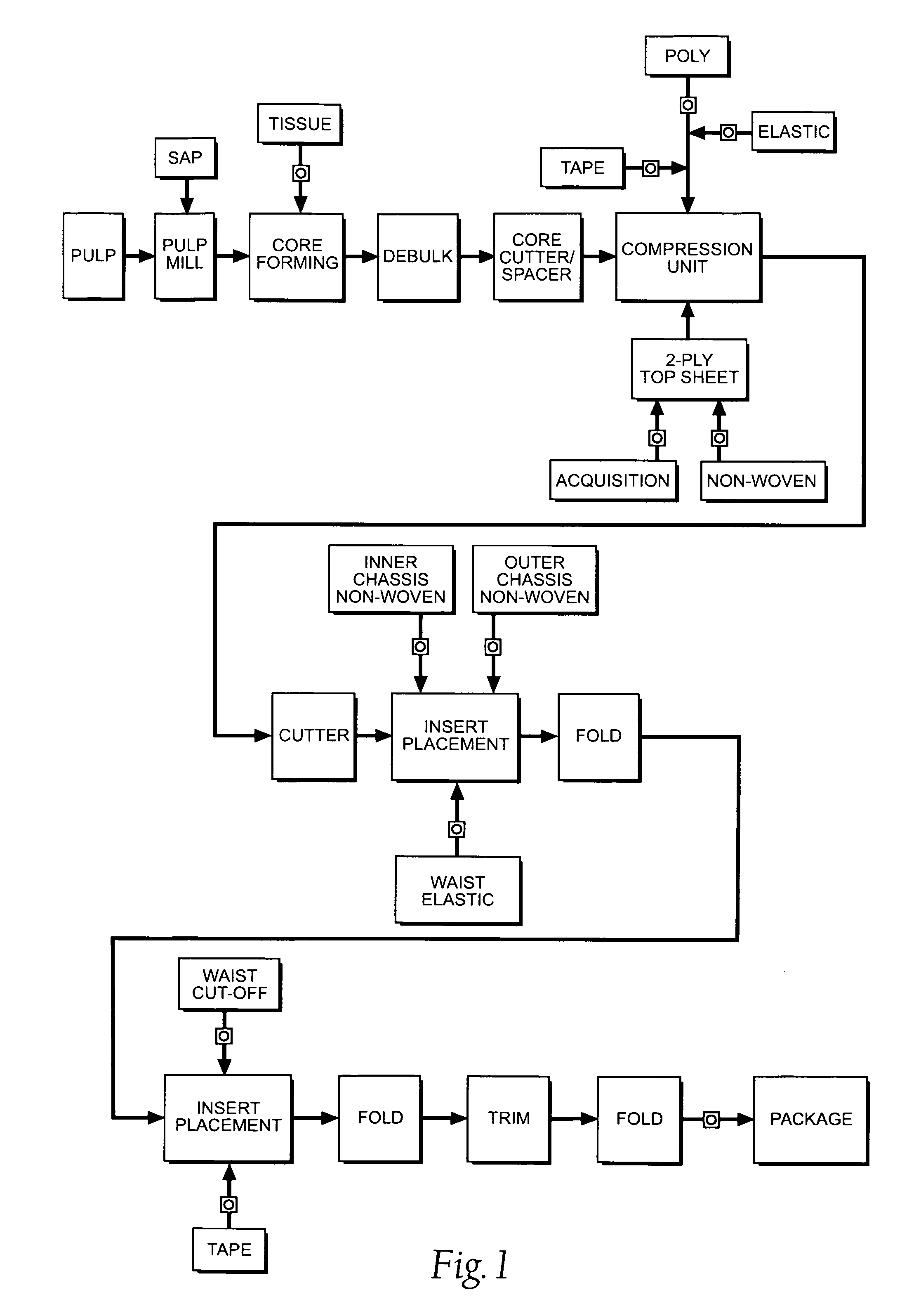

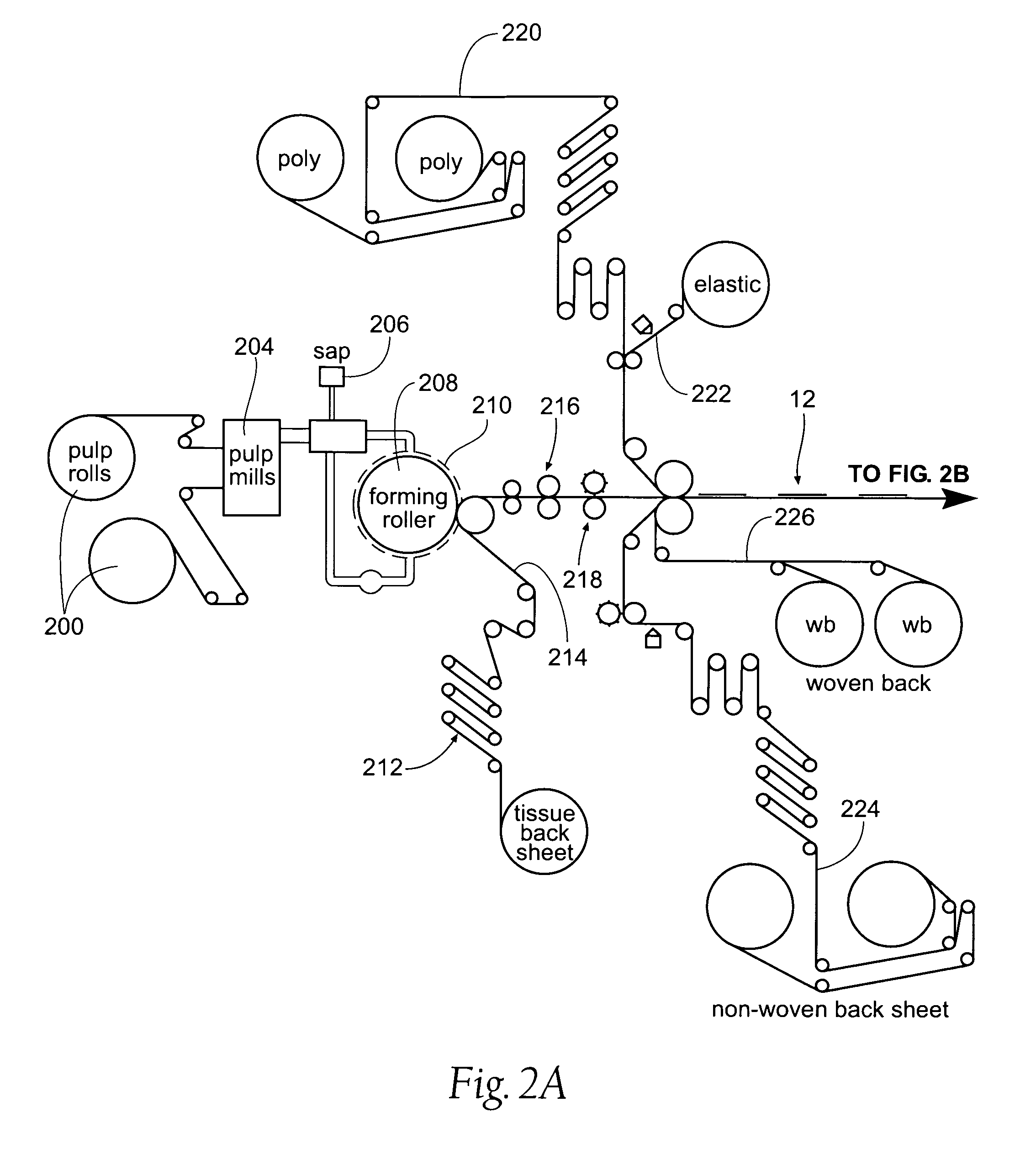

Controlling web tension, and accumulating lengths of web, by actively controlling velocity and acceleration of a festoon

InactiveUS6473669B2The result is accurateMultiple dynamo-motor startersFilament handlingControl systemActive force

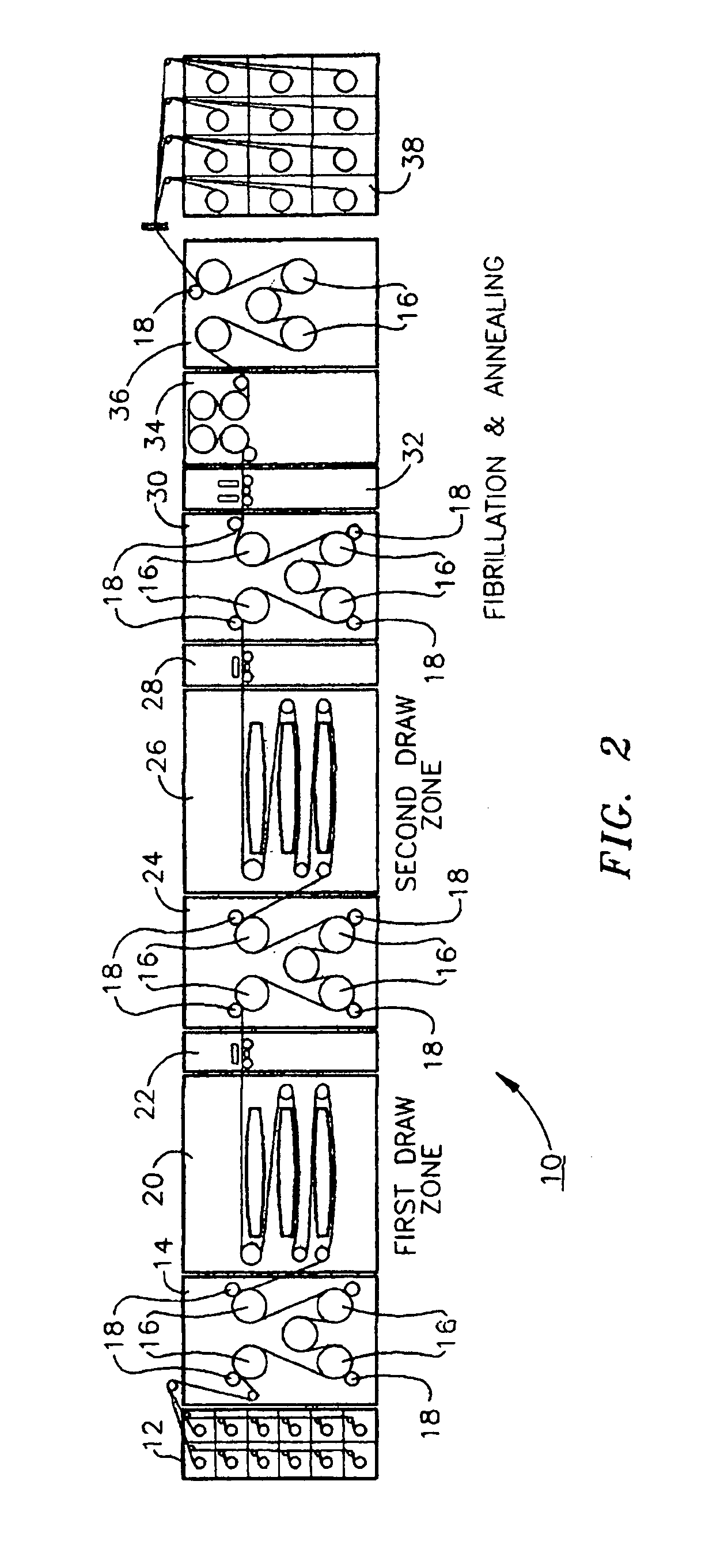

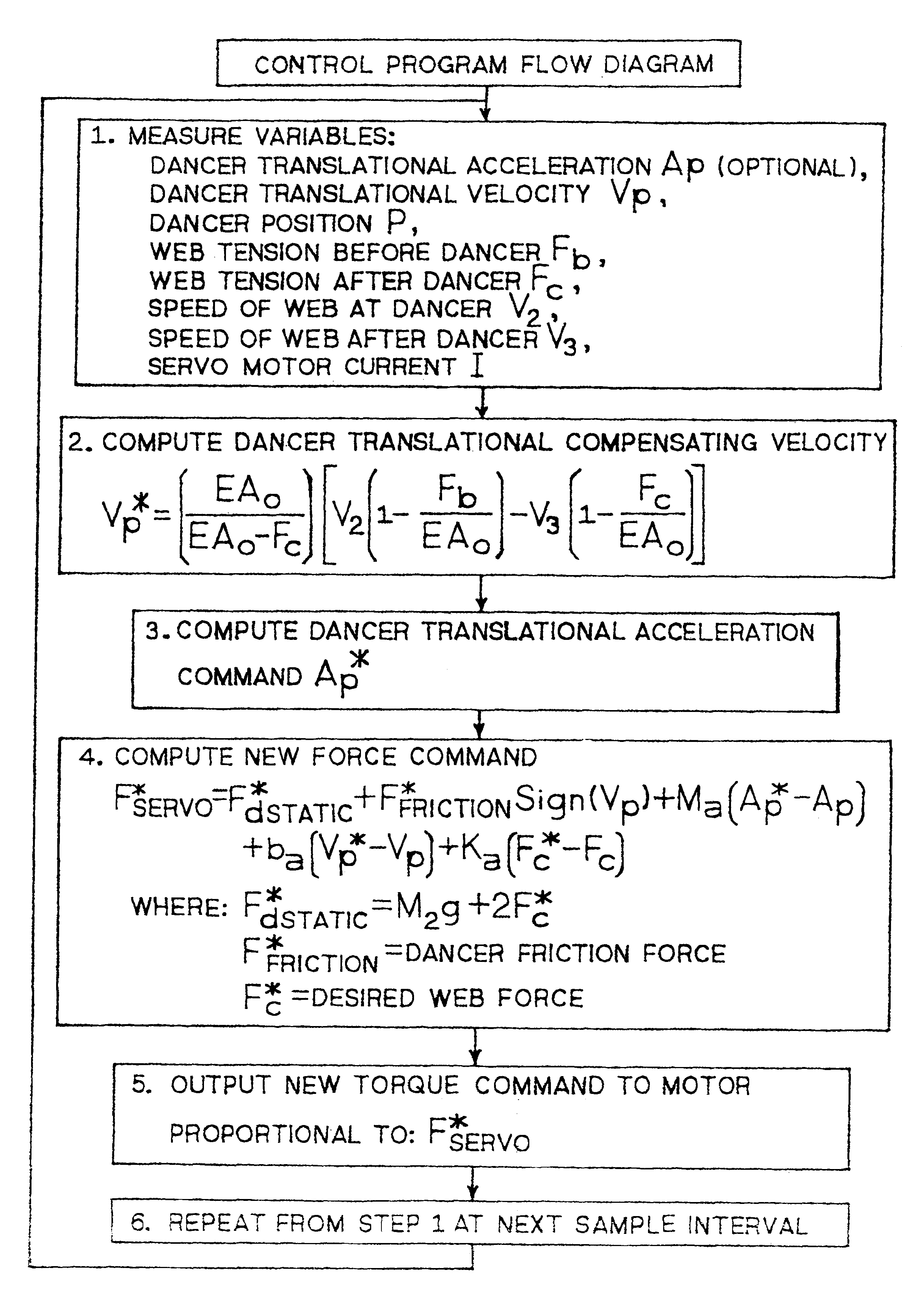

This invention pertains to processing continuous webs such as paper, film, composites, and the like, in dynamic continuous processing operations. More particularly, it relates to accumulating limited lengths of such continuous webs and to controlling tension in such continuous webs during the processing operation. Both tension control and limited accumulations are achieved in a festoon system by connecting a corresponding festoon to actuator or the like, sensing variables such as position, tension, velocity, and acceleration parameters related to the web and the festoon, and providing active force commands, in response to the sensed variables, to cause translational movement, generally including a target acceleration, in the upper festoon rolls to control tension disturbances in the web while providing limited accumulation of a length of the web. In some applications of the invention, the festoon control system is used to attenuate tension disturbances. In other applications of the invention, the festoon control system is used to create controlled tension disturbances.

Owner:KIMBERLY-CLARK WORLDWIDE INC

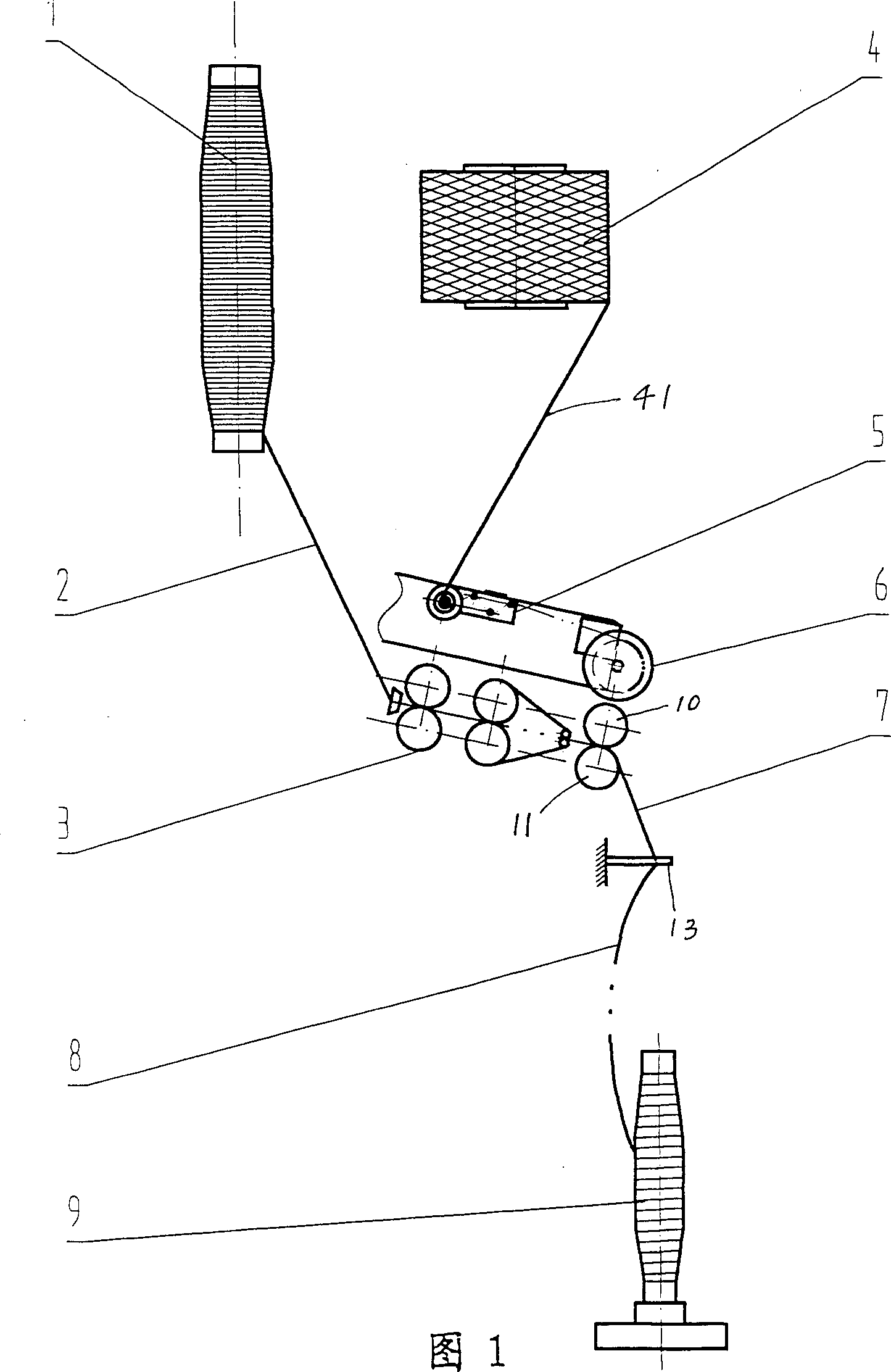

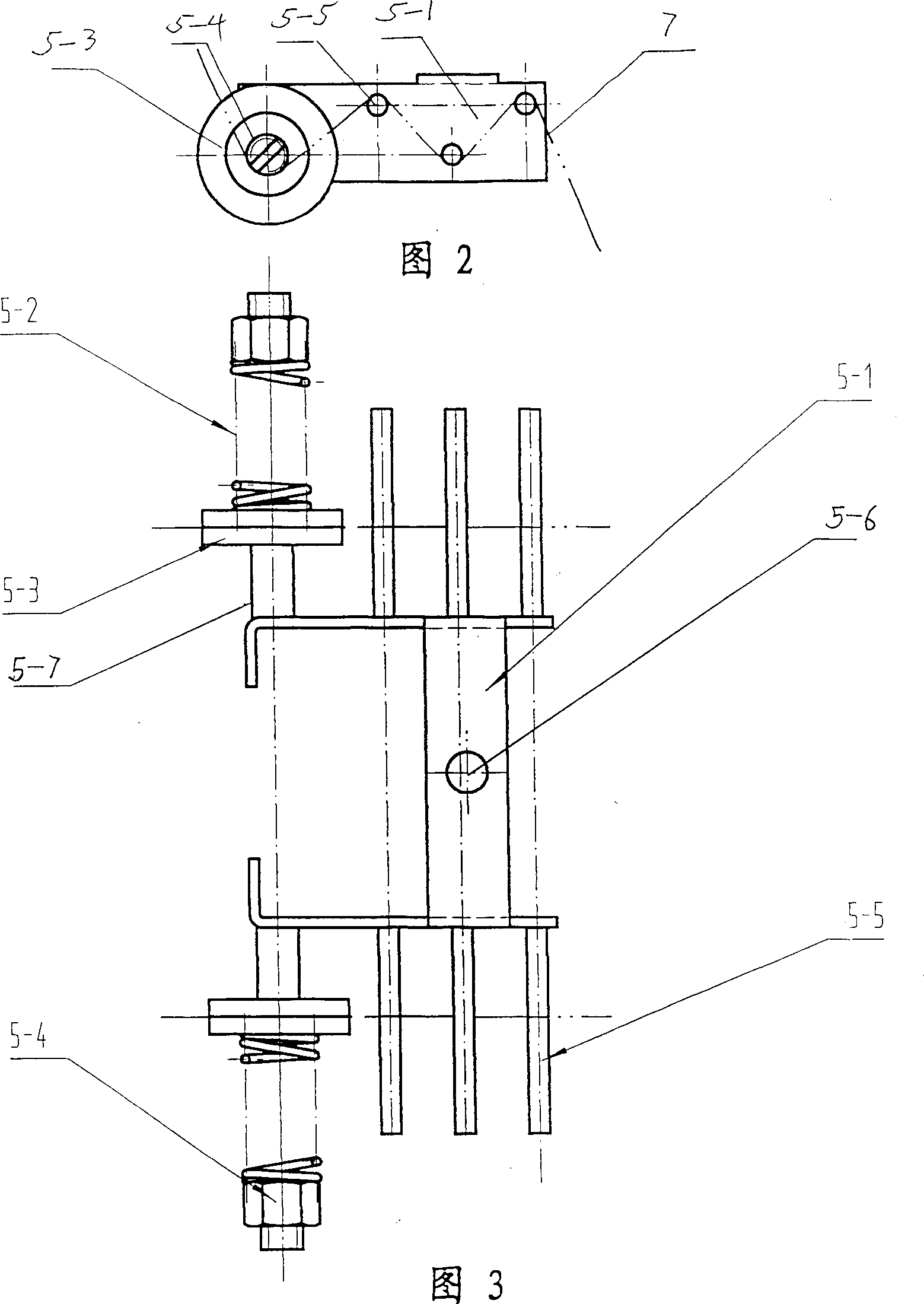

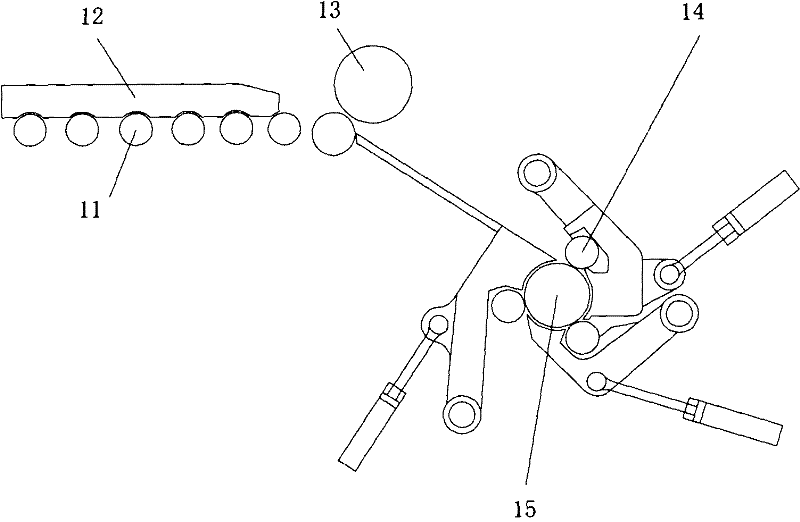

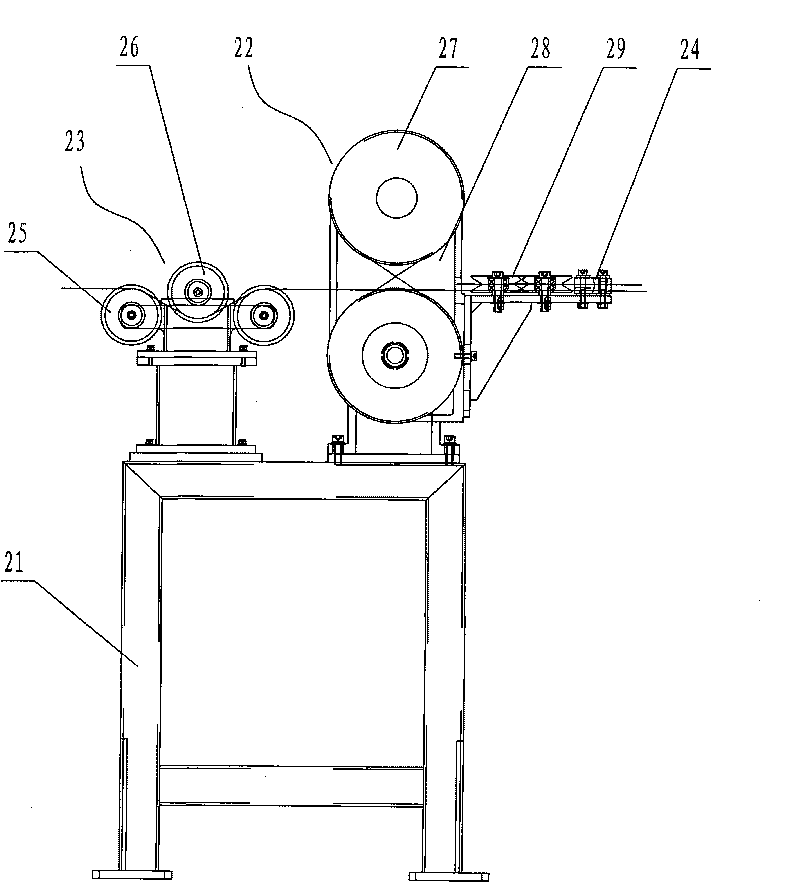

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

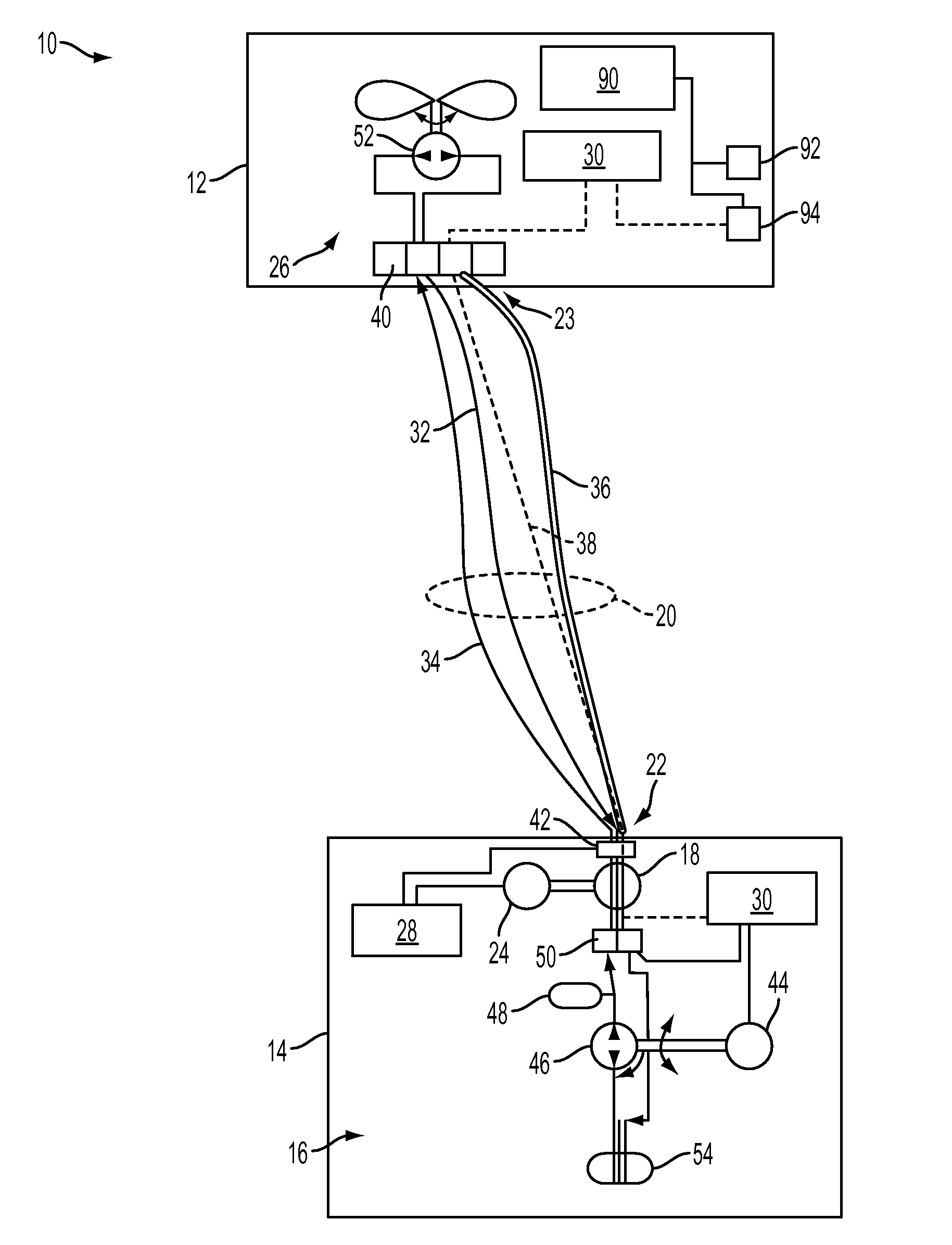

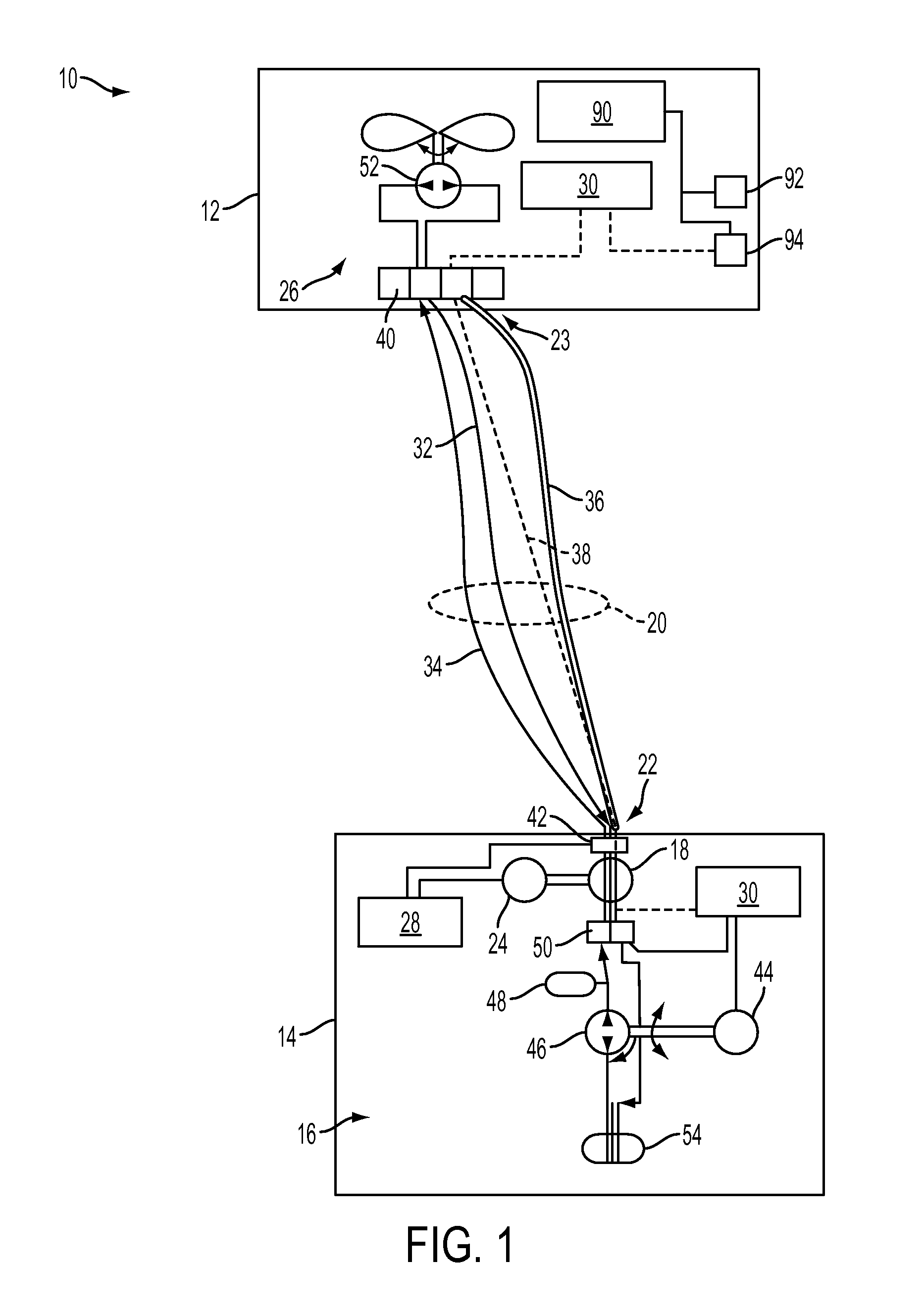

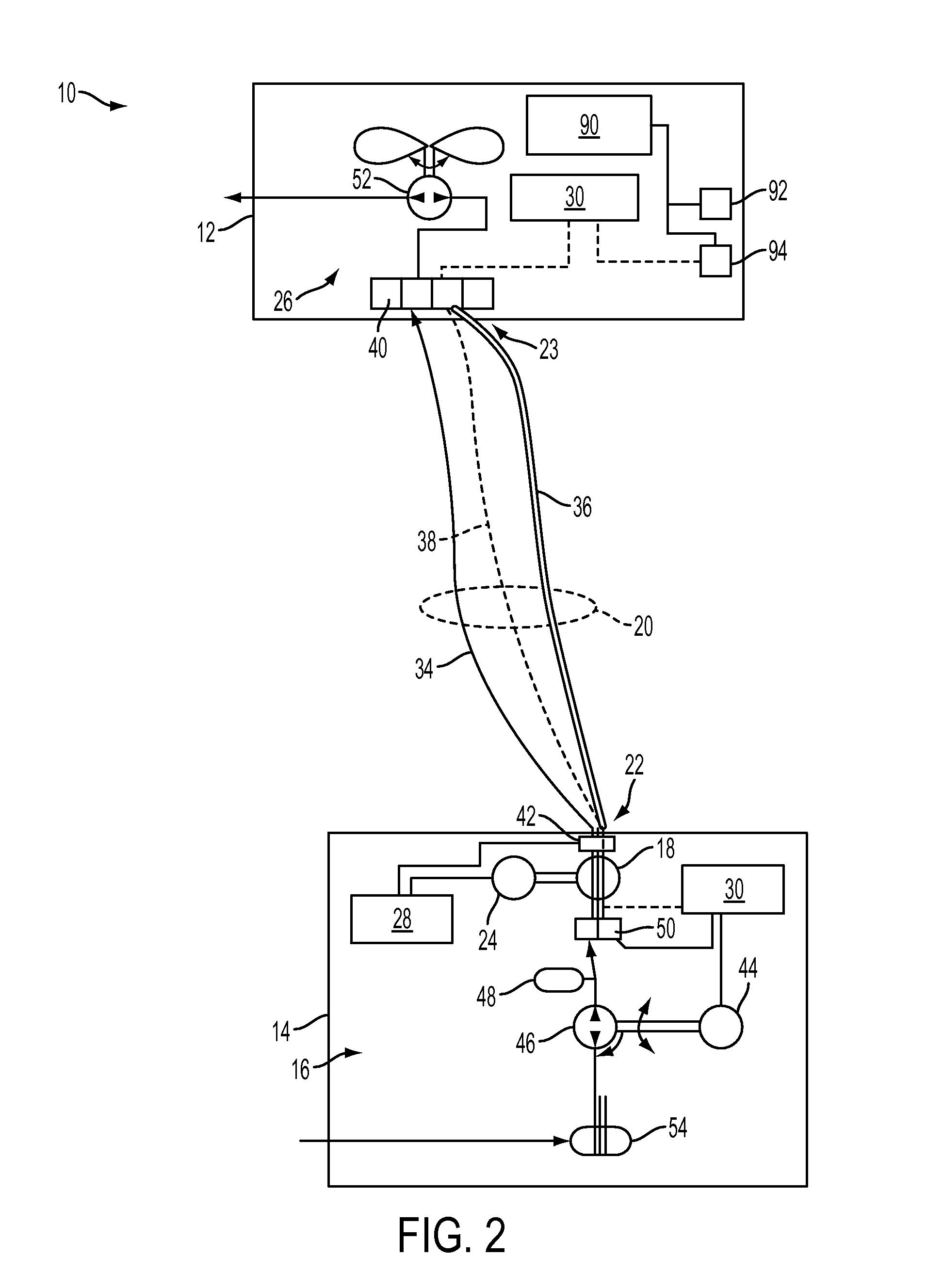

Tether energy supply system

InactiveUS20110180667A1Eliminate weightEliminate riskTethered aircraftPower plant fuel tanksDistributed control systemElectric machinery

A tether continuous energy supply system for an unmanned aerial vehicle comprising: a ground station, a ground station energy system, a spool coupled to the ground station energy system at a rotating joint, a tether that is wound about the spool, wherein a first end of the tether is coupled to the rotating joint, a tension control motor coupled to both the spool and the ground station energy system, an unmanned aerial vehicle coupled to a second end of the tether, a UAV energy system, a fluid that moves throughout the tether continuous energy supply system, a tension control system that receives and transmits signals from a plurality of sensors contained within the tether continuous energy supply system, and a distributed controls system that receives and transmits signals from the plurality of sensors contained within the tether continuous energy supply system.

Owner:HONEYWELL INT INC

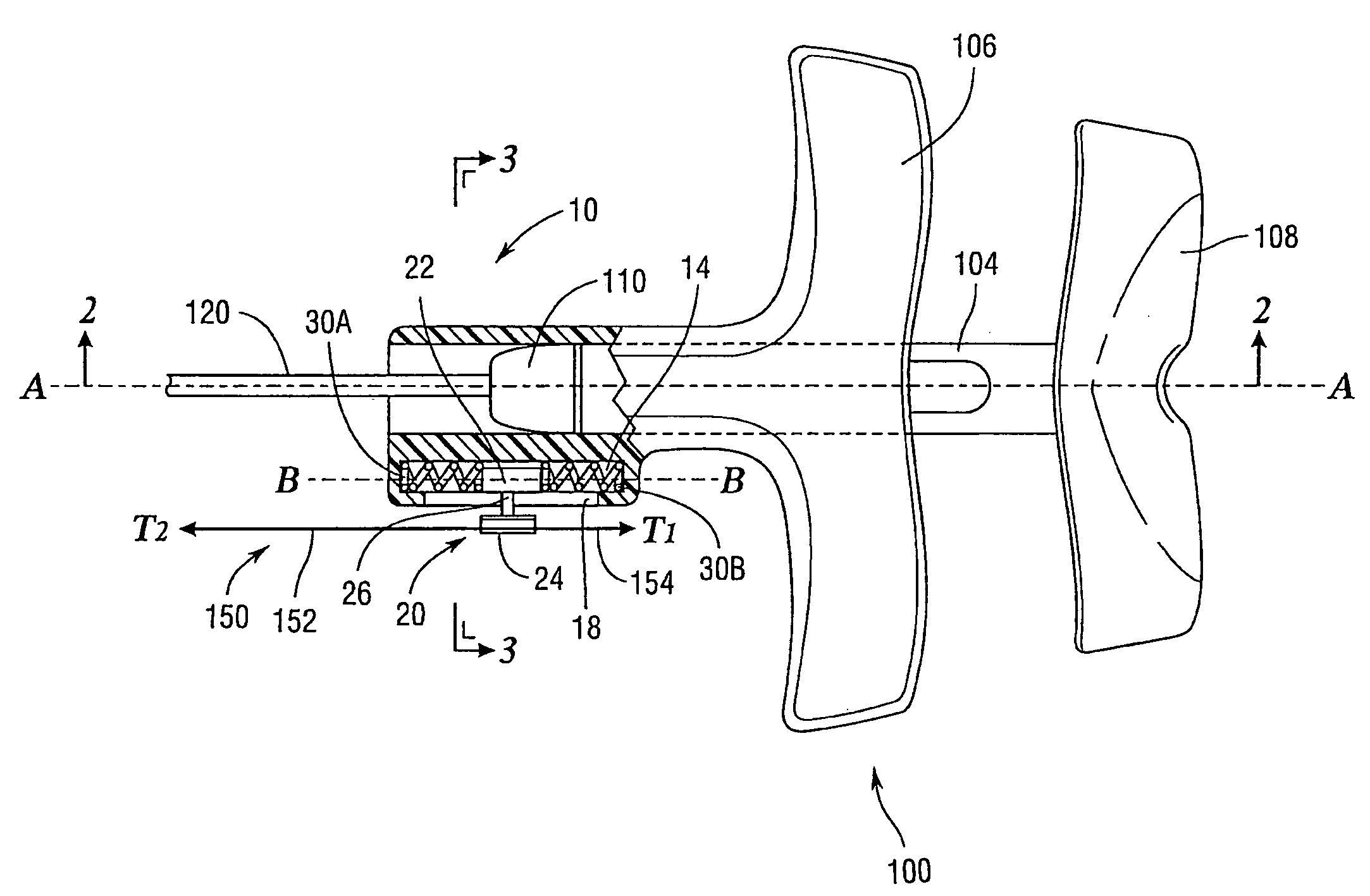

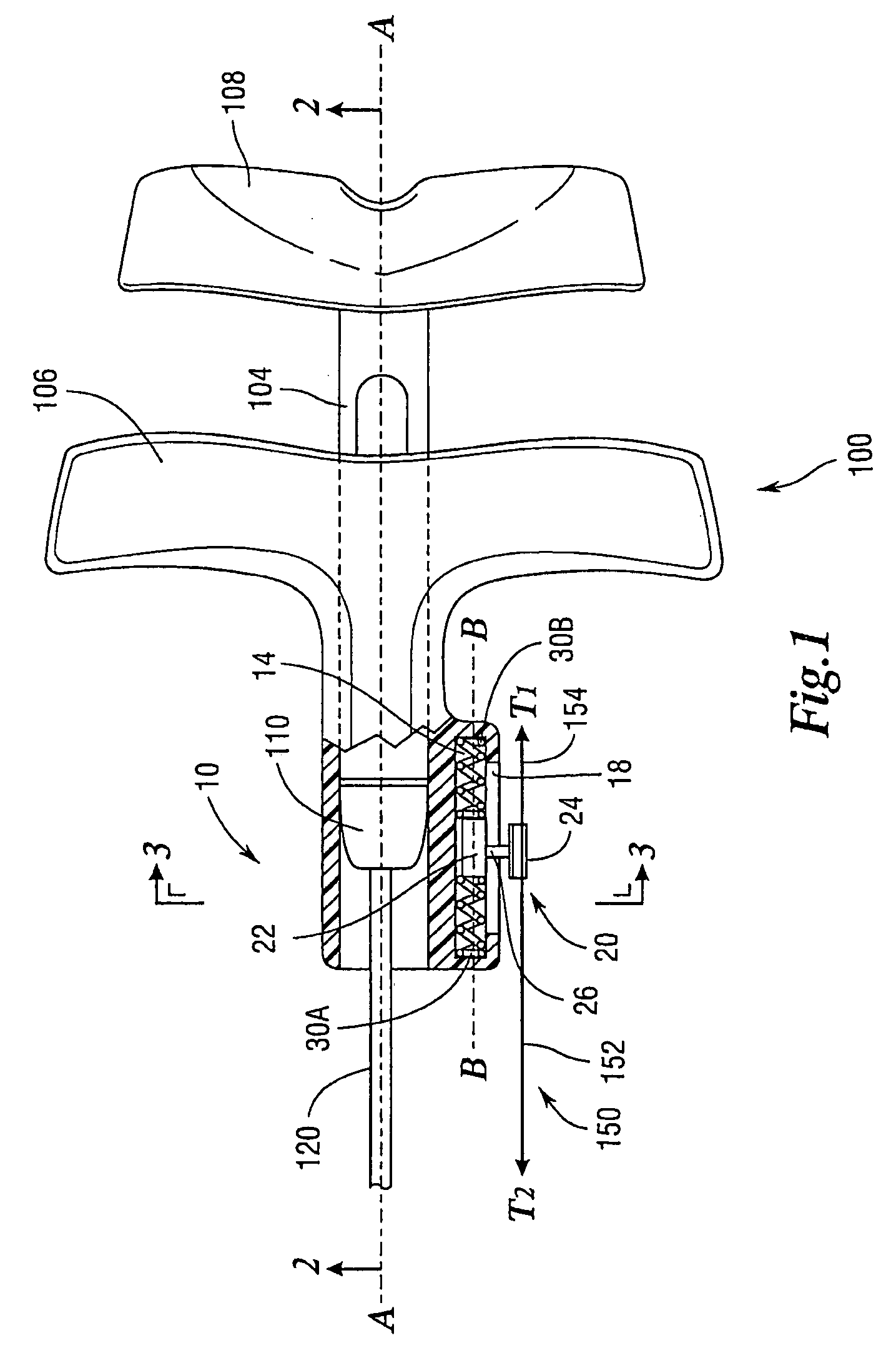

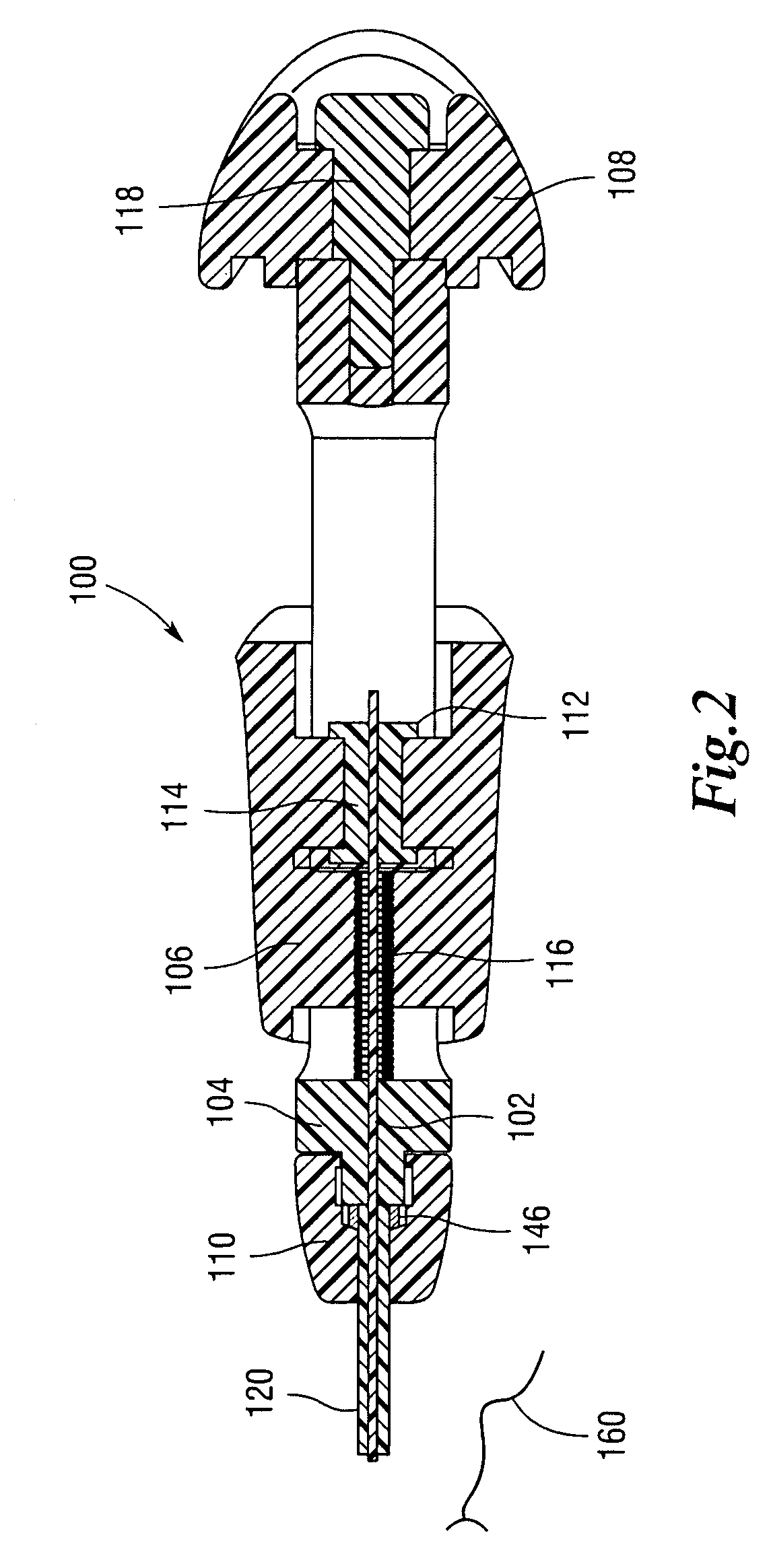

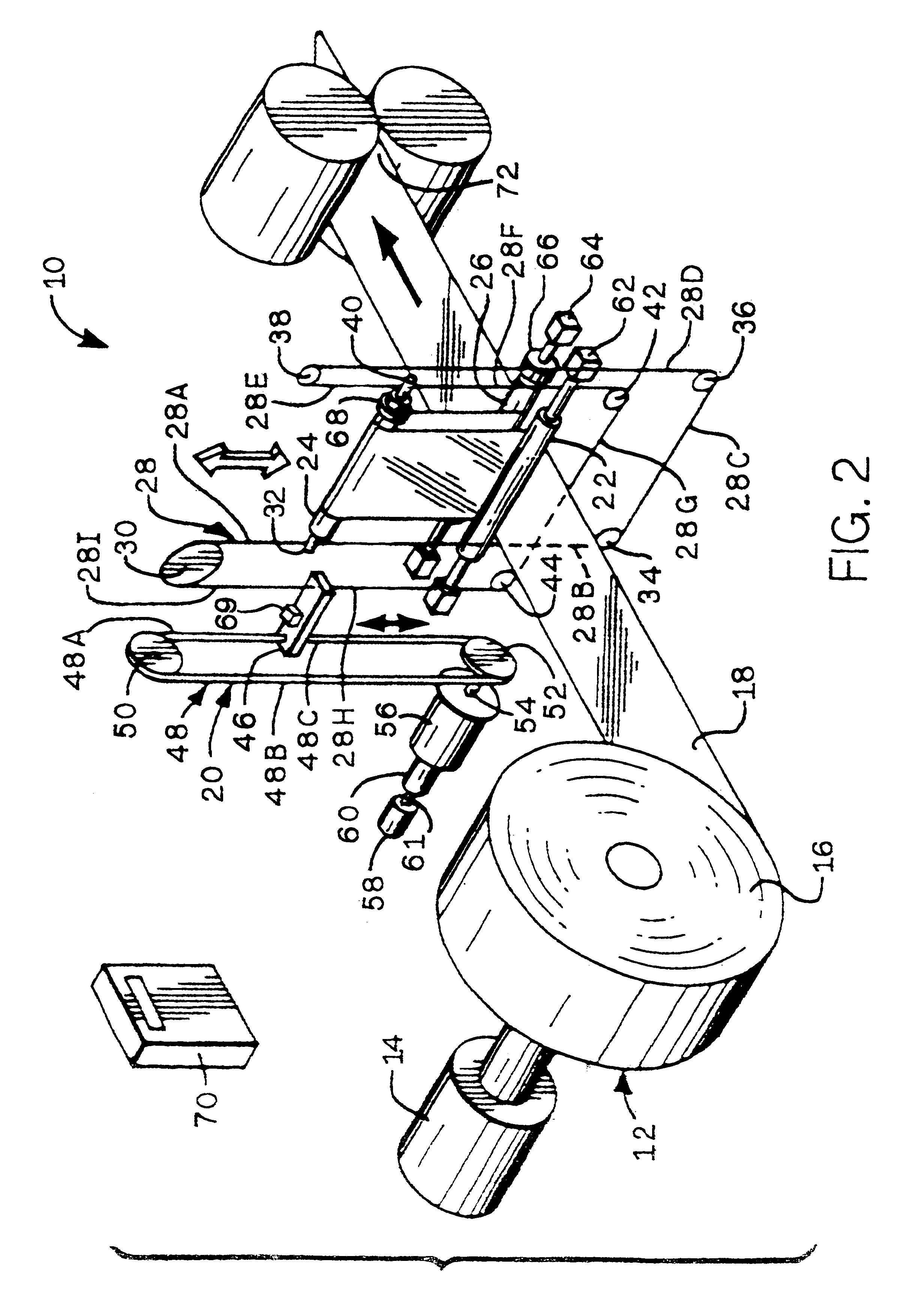

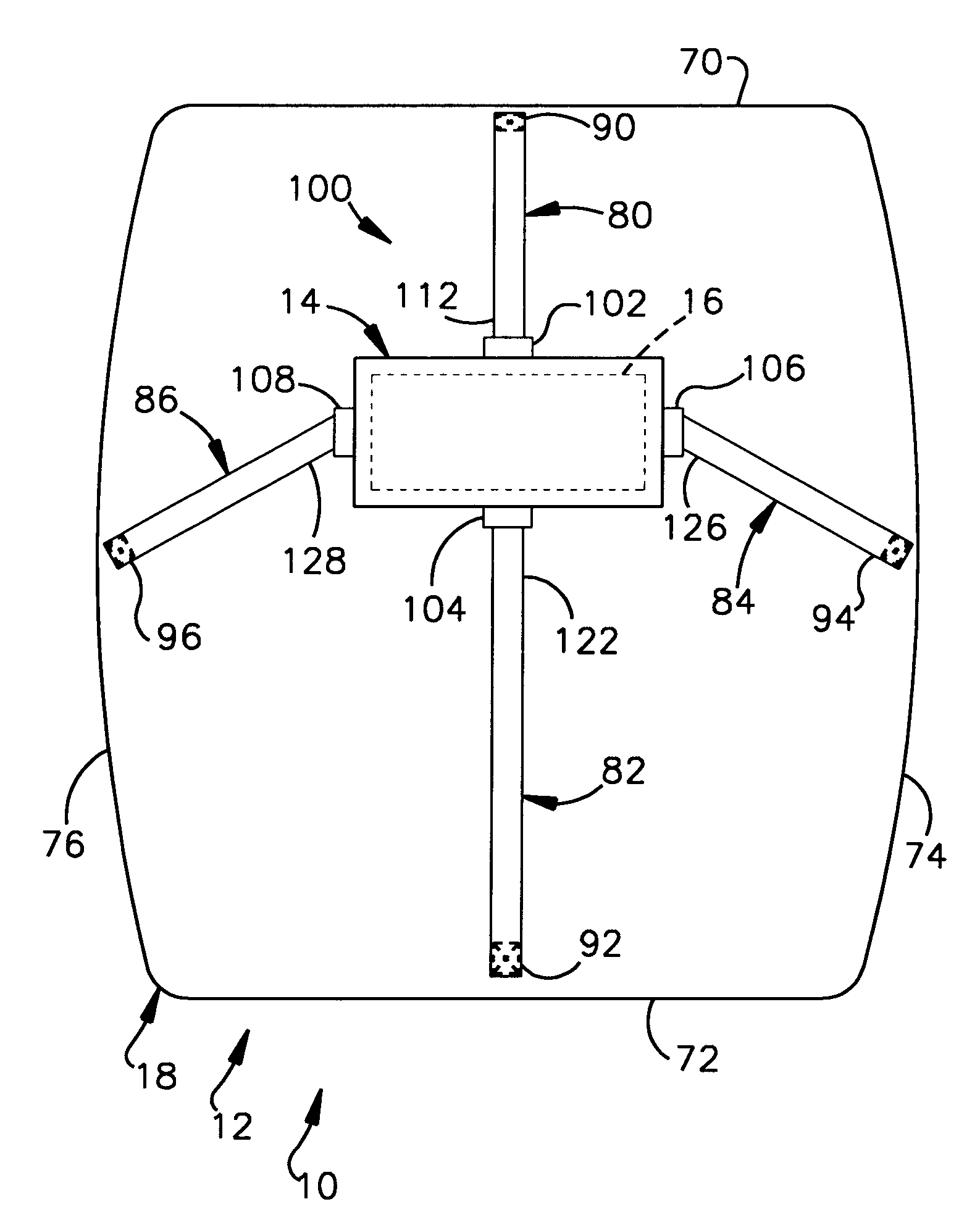

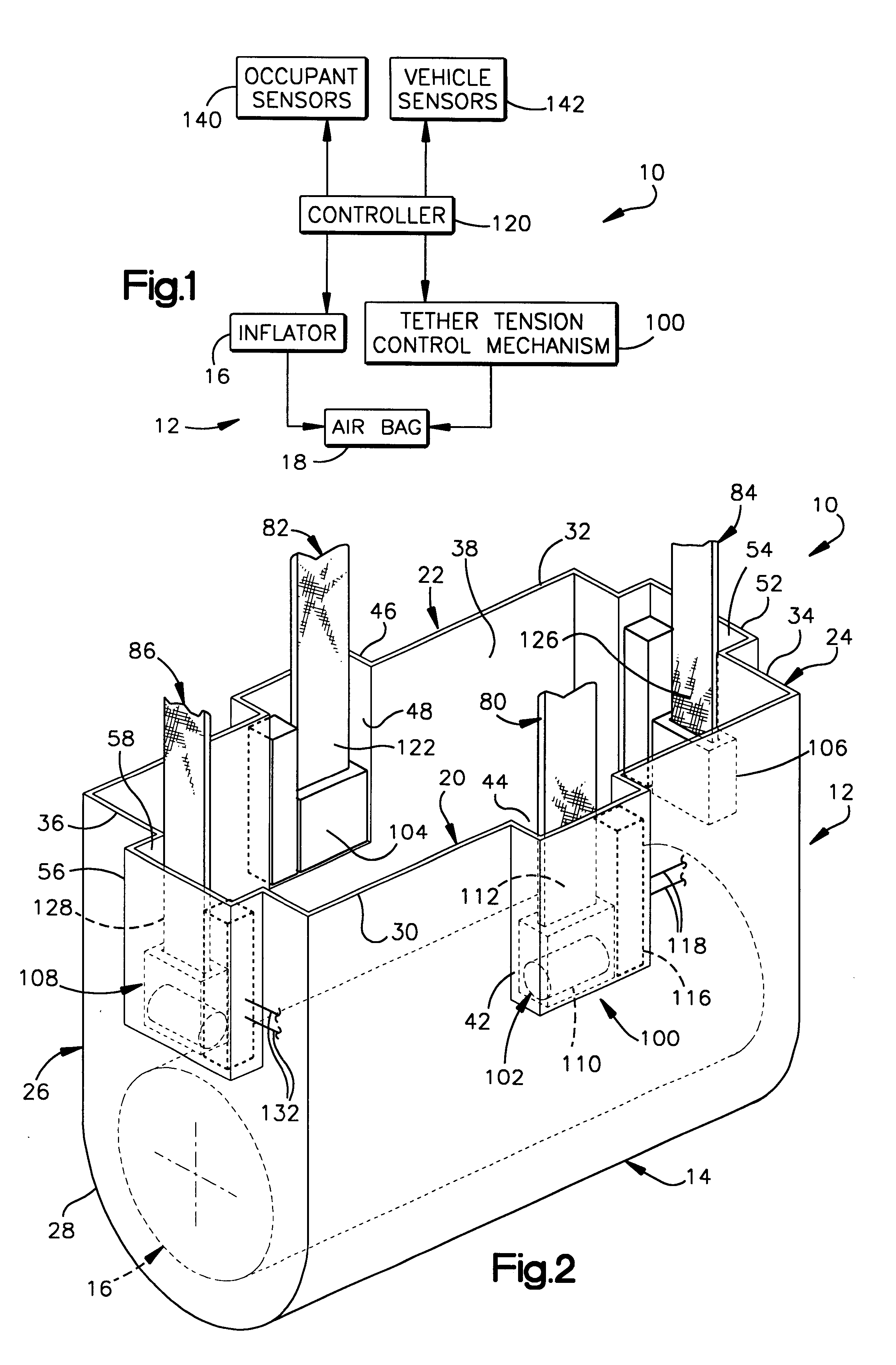

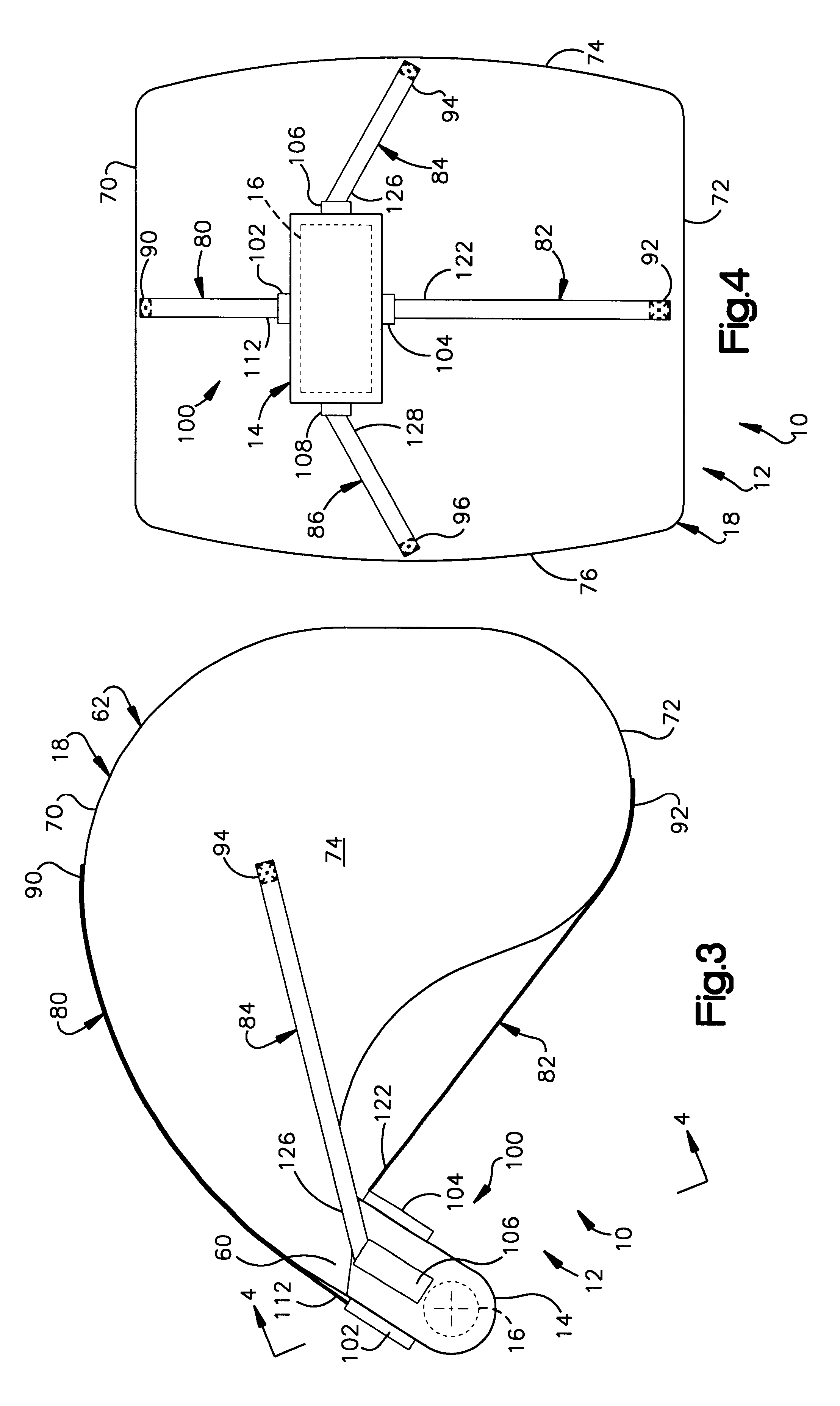

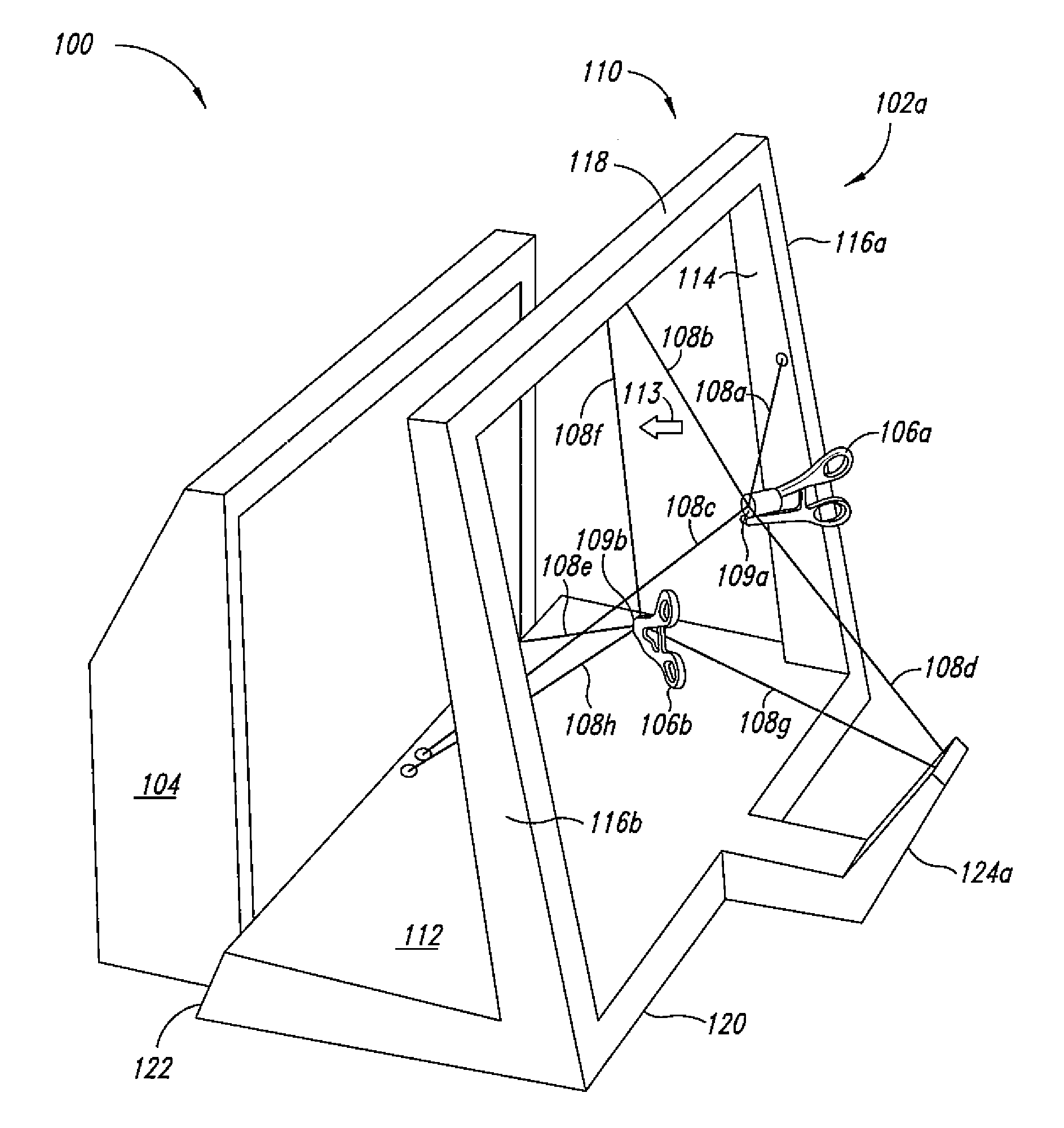

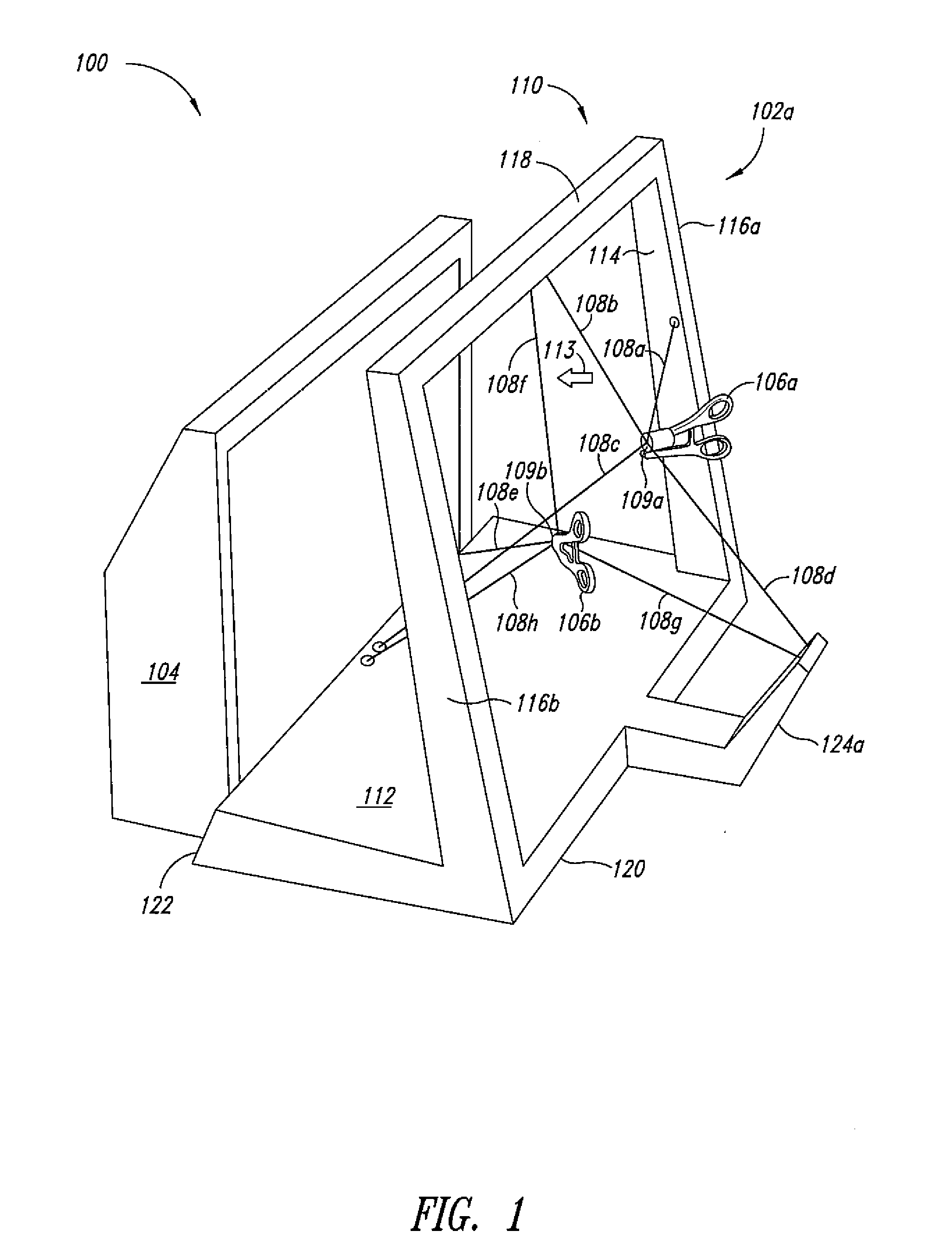

Apparatus for positioning an inflated air bag

A vehicle occupant protection apparatus (10) comprises an inflatable device (18) for helping to protect an occupant of a vehicle. At least one tether (82, 84, 86, 88) is connected with the inflatable device (18) to control the location of the inflatable device when inflated. The occupant protection apparatus (10) includes at least one sensor (140) for sensing at least one condition relevant to a determination of where to locate the inflatable device (18) when inflated. The occupant protection apparatus (10) also includes a tether tension control mechanism (102, 104, 106, 108, 120) for tensioning the at least one tether (82, 84, 86, 88) in accordance with the sensing of the at least one condition.

Owner:TRW VEHICLE SAFETY SYST

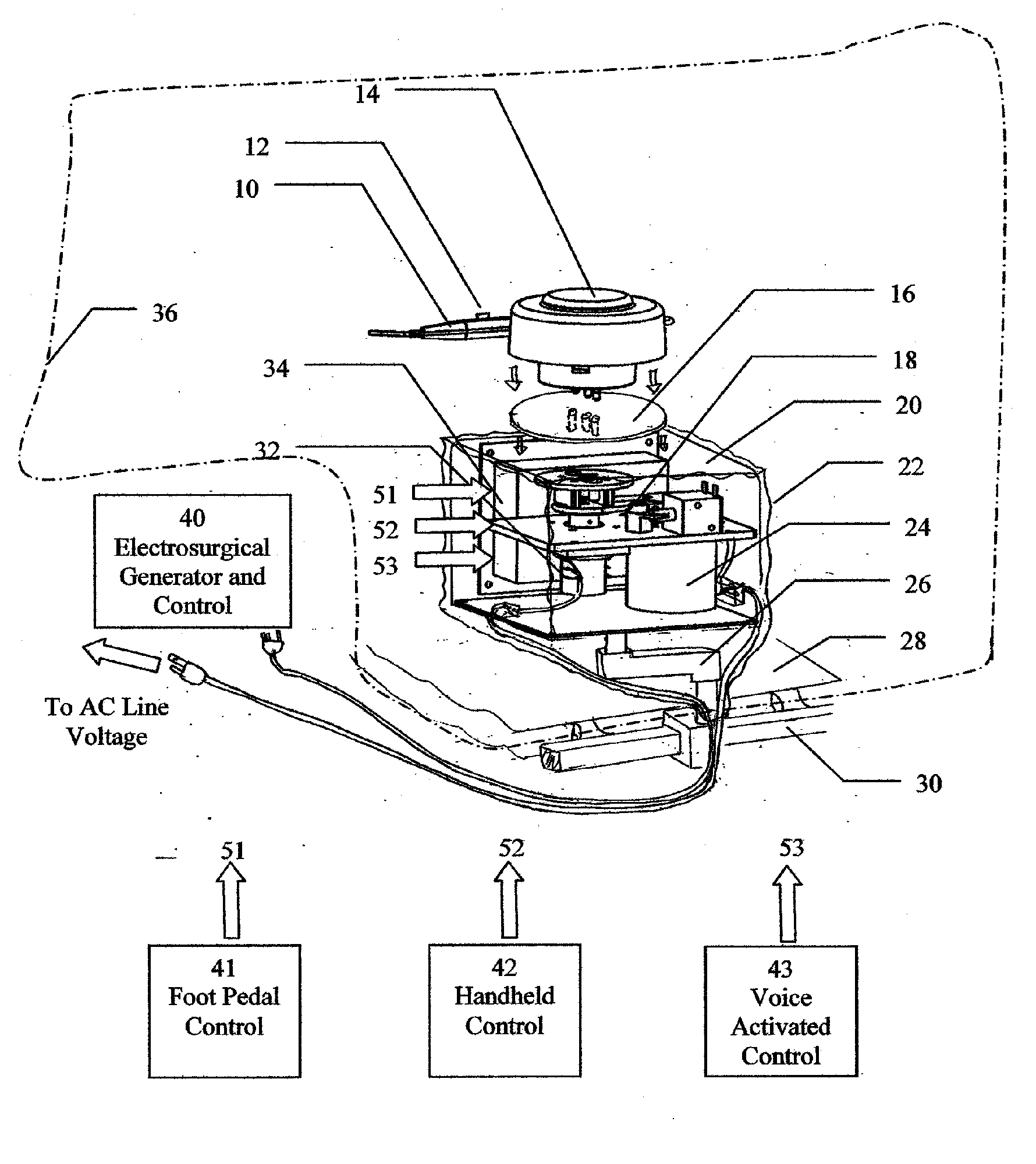

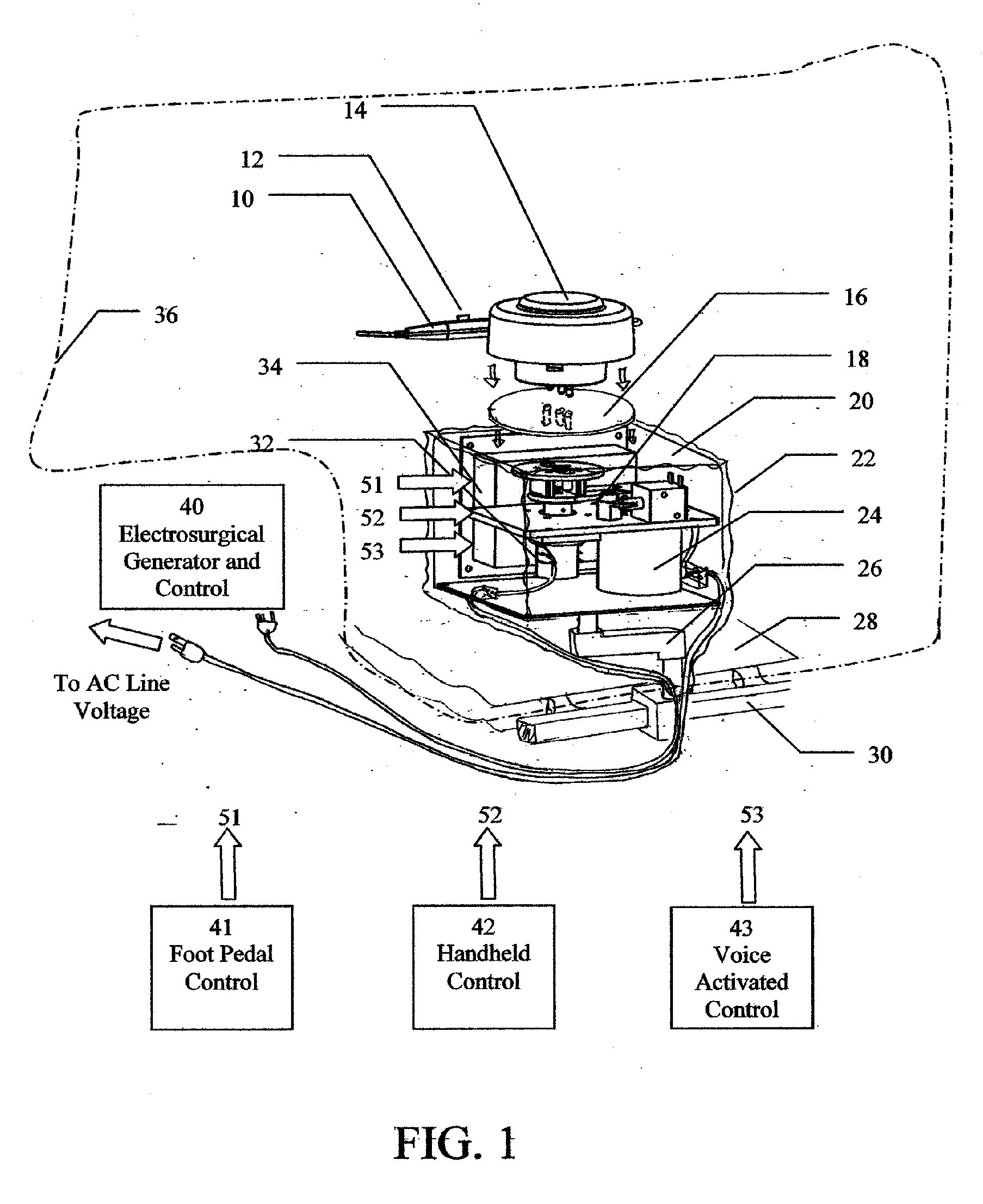

Retractable Surgical Instruments

InactiveUS20060264921A1Avoid pollutionSmoothly withdrawnSurgical instruments for heatingElectric machineryEngineering

An electrosurgical instrument system for ready deployment of the instrument at the end of a line within a sterile surgical field employs a disposable reel detachably mounted on a base unit which allows smooth manual withdrawal and provides controlled motor-driven retraction of the line and instrument. The line includes power, control and ground circuits and the circuits are completed through a reel in a detachable cassette mounted on a base unit, which includes a tension-controlled belt permitting manual payout and controlled drive return of the line and instrument.

Owner:IMFLUX INC

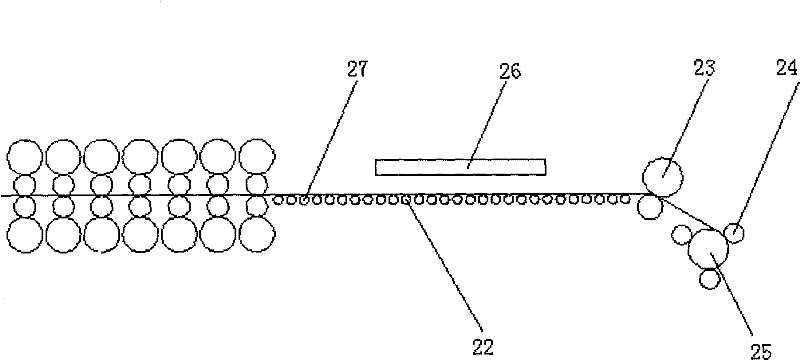

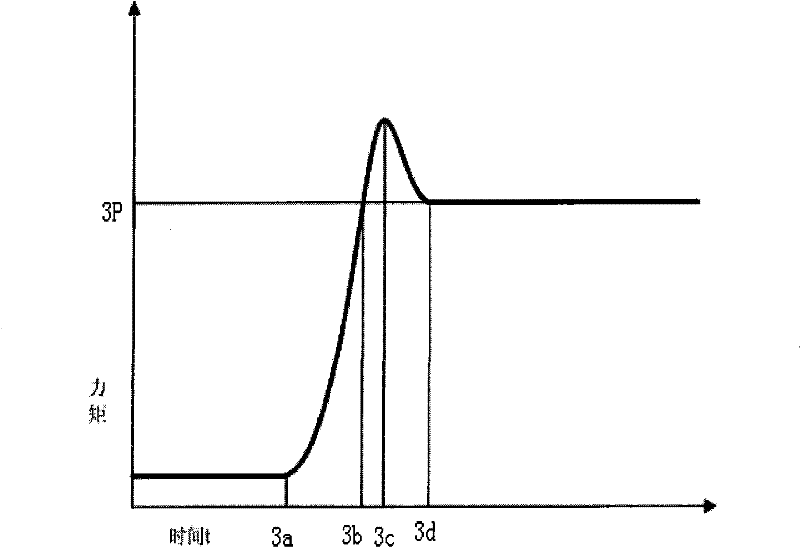

Method for controlling hot rolling coiling tension

ActiveCN102125936ASolve the problem of narrowing the widthAvoid quality problemsTension/compression control deviceEngineeringStrip steel

The invention discloses a method for controlling hot rolling coiling tension. Strip steel coiling is controlled by a two-level tension control method. The method mainly comprises the following steps of: calculating a first level set value and a second level set value; starting first level tension control according to a calculating result when the head part of strip steel enters a coiling machine;when actually measured coil moment reaches the first level moment set value, delaying some time and starting second level tension control until the strip steel is completely coiled; detecting and determining the width and the coiling quality of the strip steel, and adjusting a tension coefficient if the detected width and coiling quality of the strip steel is unqualified; and performing a self-adapting step. The control method overcomes the defects of the prior art and well solves the problem that the width quality and the coiling quality of the strip steel cannot be qualified at the same time, and the width of the strip steel is ensured as well as the coiling quality of the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

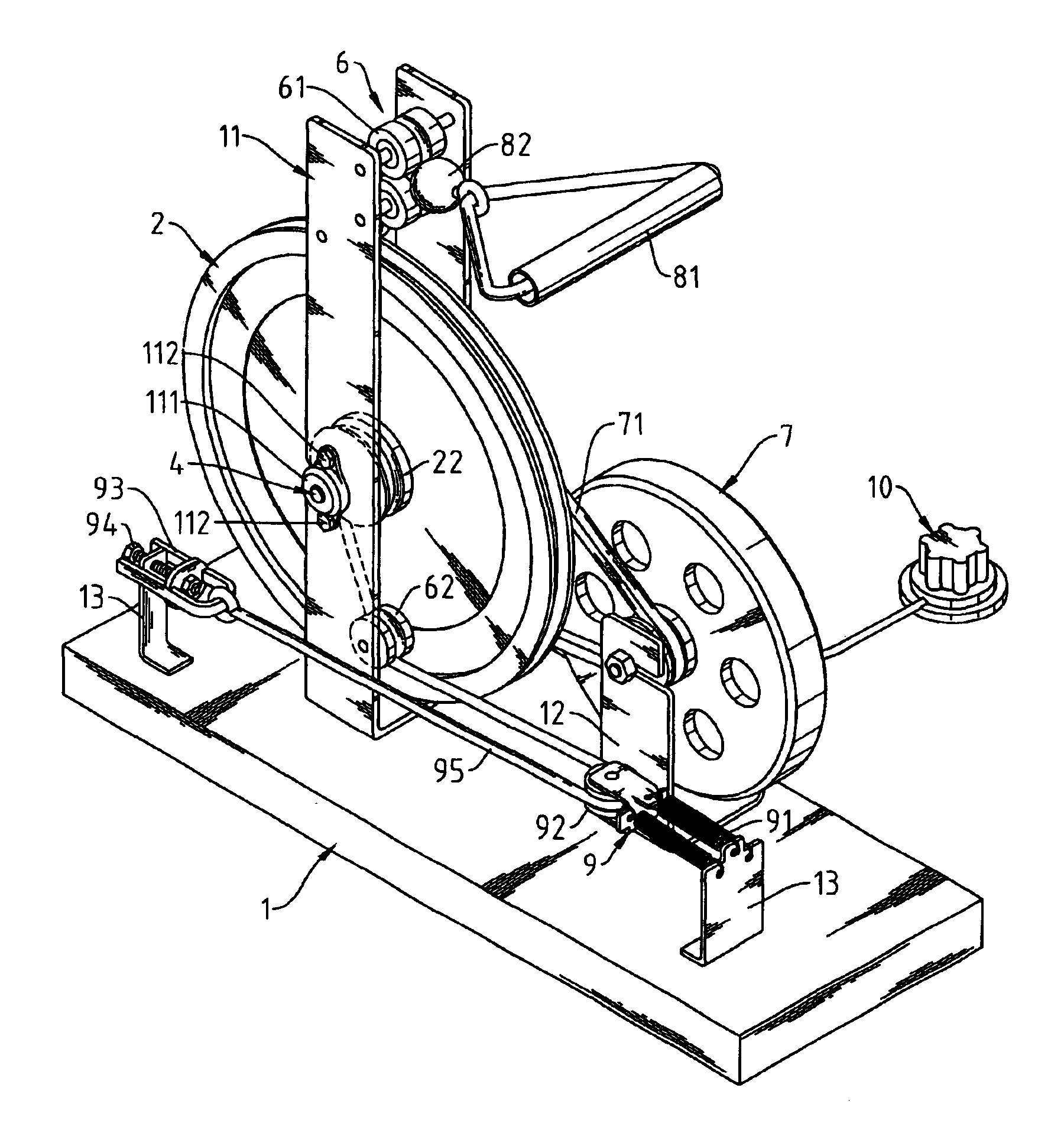

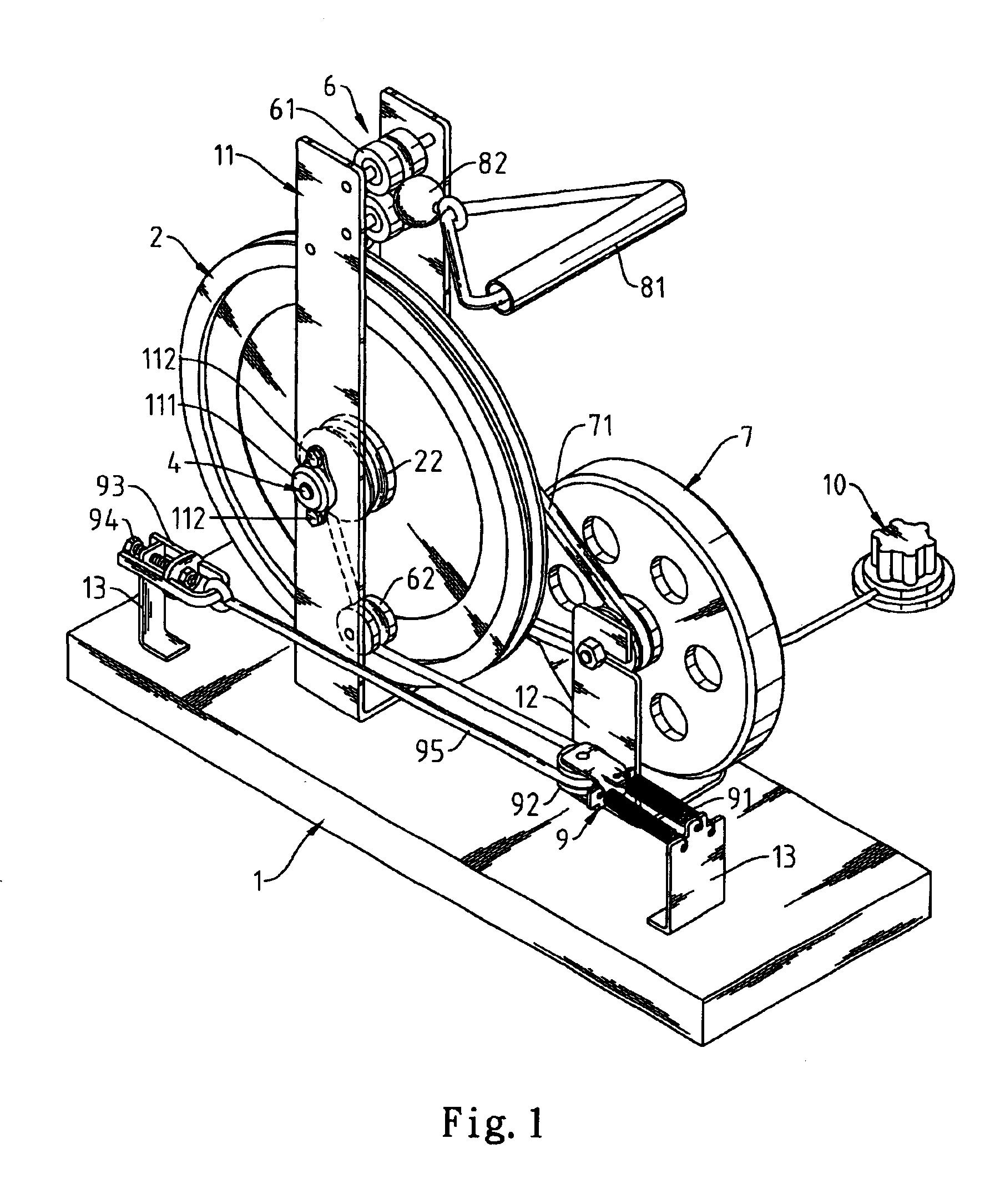

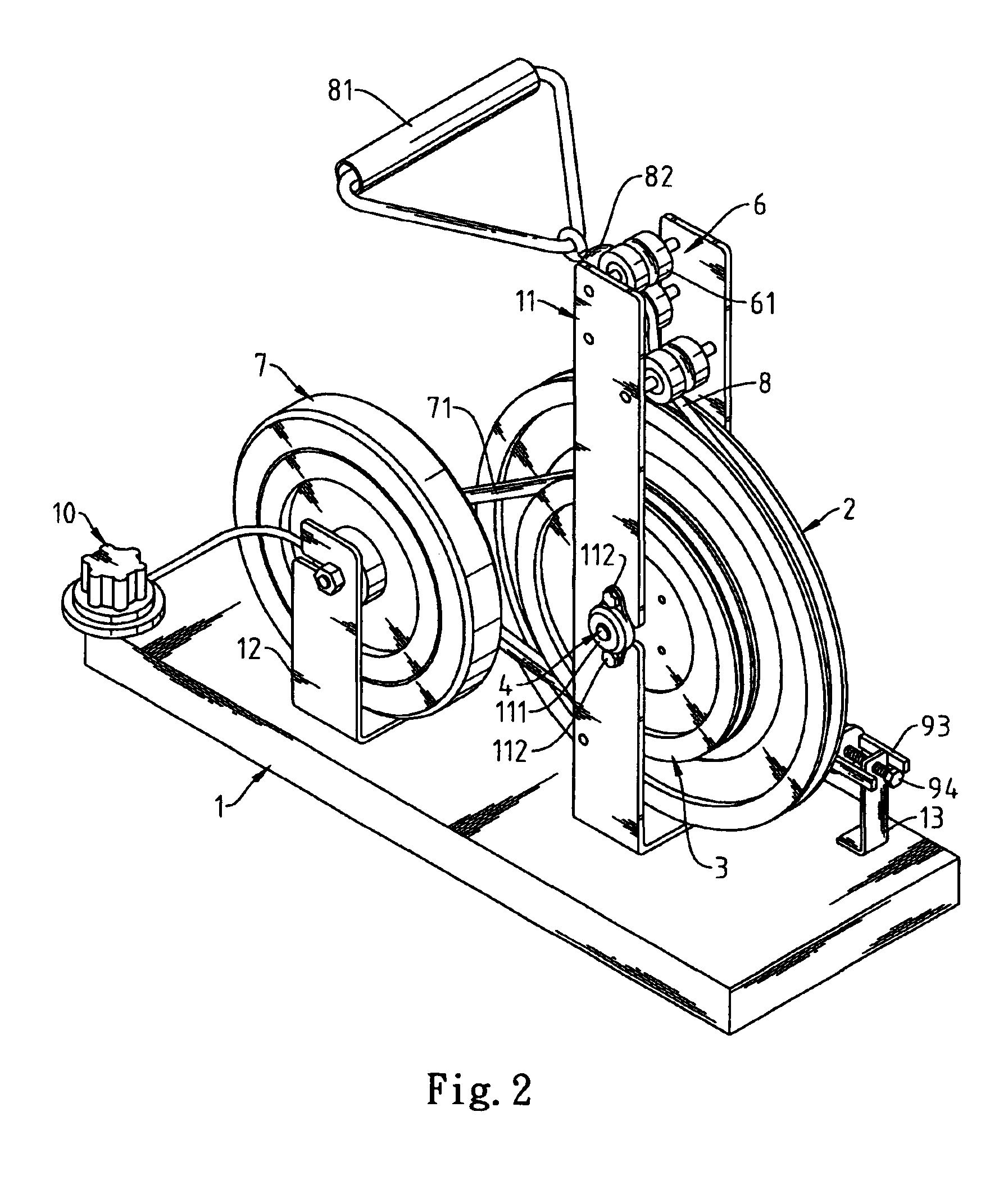

Magnetic tension control weight training machine

The present invention relates to a magnetic tension control weight training machine containing a base, large revolver wheel, belt disc, shaft set, bearing assembly, pulley assembly, magnetic resistance flywheel, pulling rope and a reposition device. A wheel spacer is welded to the center of the large revolver wheel within which there is a bearing assembly, on one side fixed with a small revolver wheel for reposition. The shaft set fits through the bearing assembly, one end welded with a shaft disc to fasten the belt disc that is connected with the magnetic resistance flywheel and the large revolver wheel by means of the belt. The size of the small revolver wheel and the active pulley makes the extension length of the flexible components quite short. The reposition device adjusts the reposition course through the active pulley and the adjustment bolt, allowing for the control of the force.

Owner:YEH YONG SONG

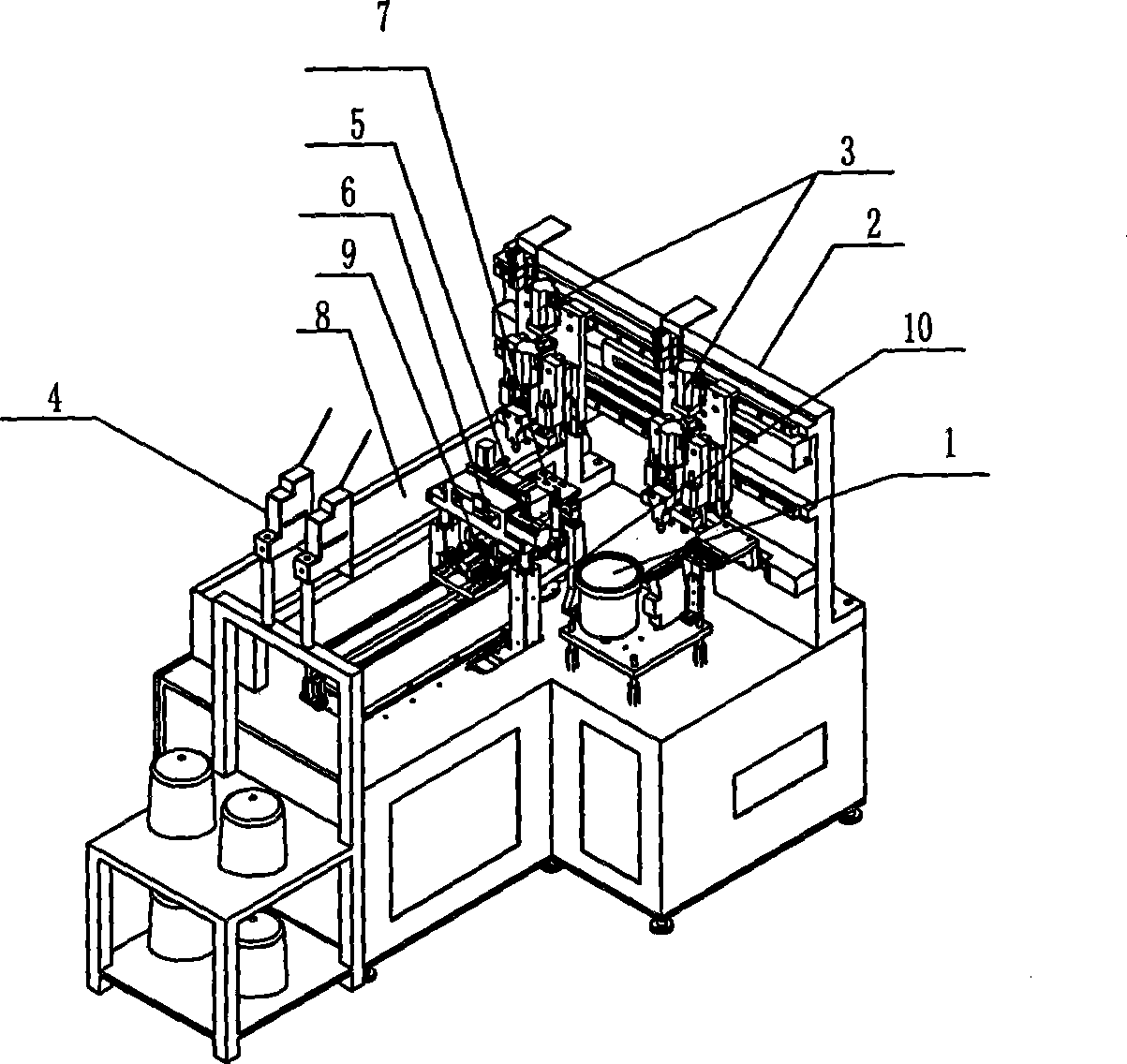

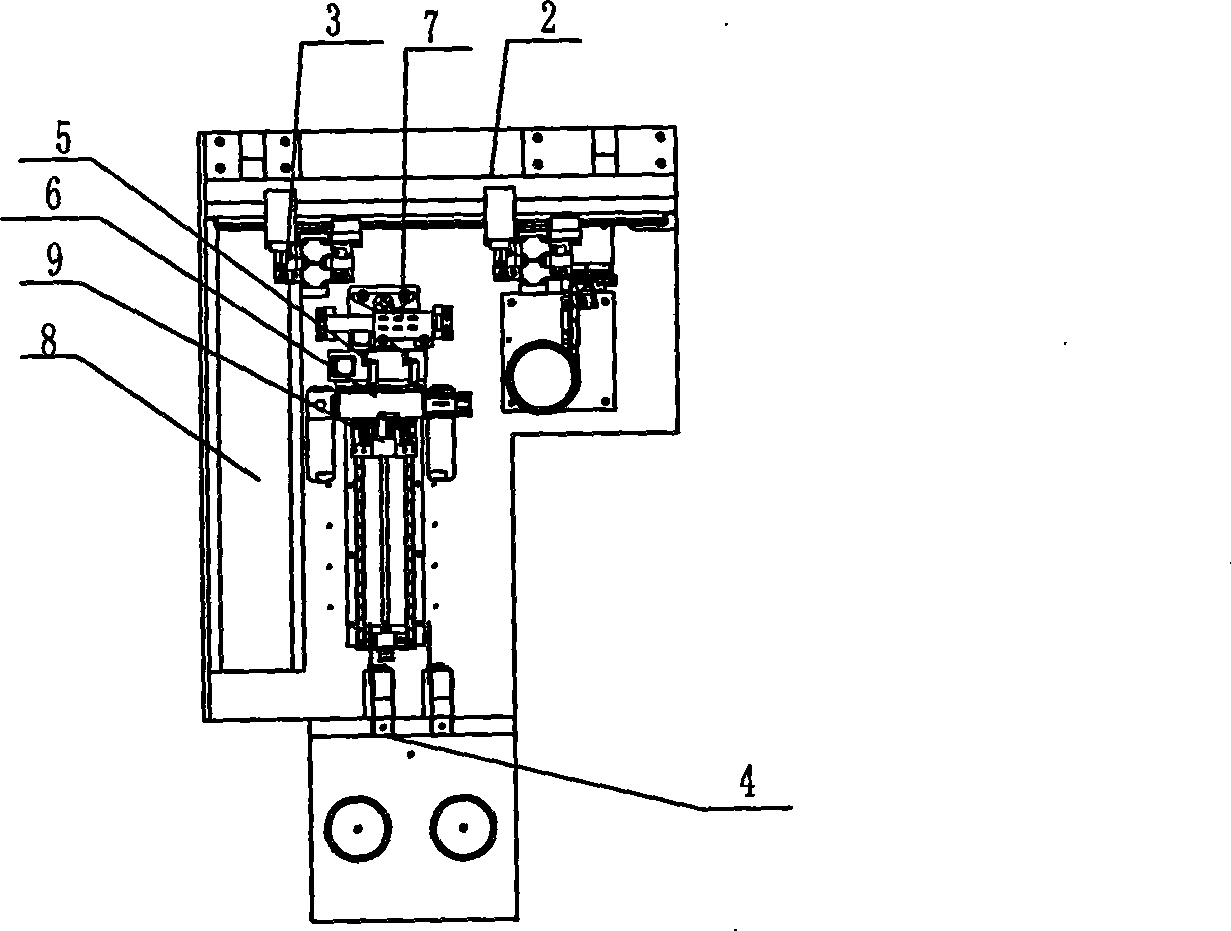

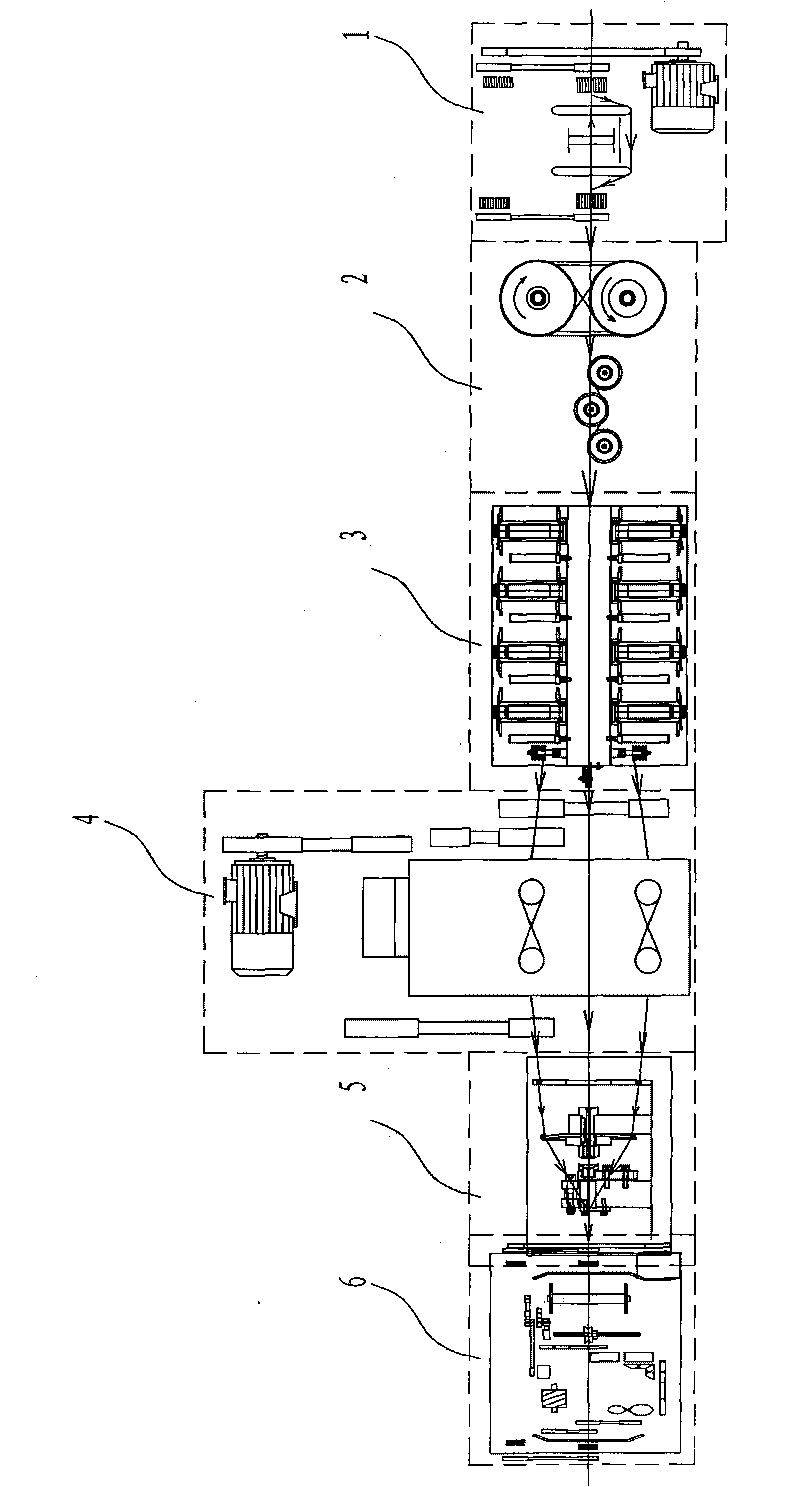

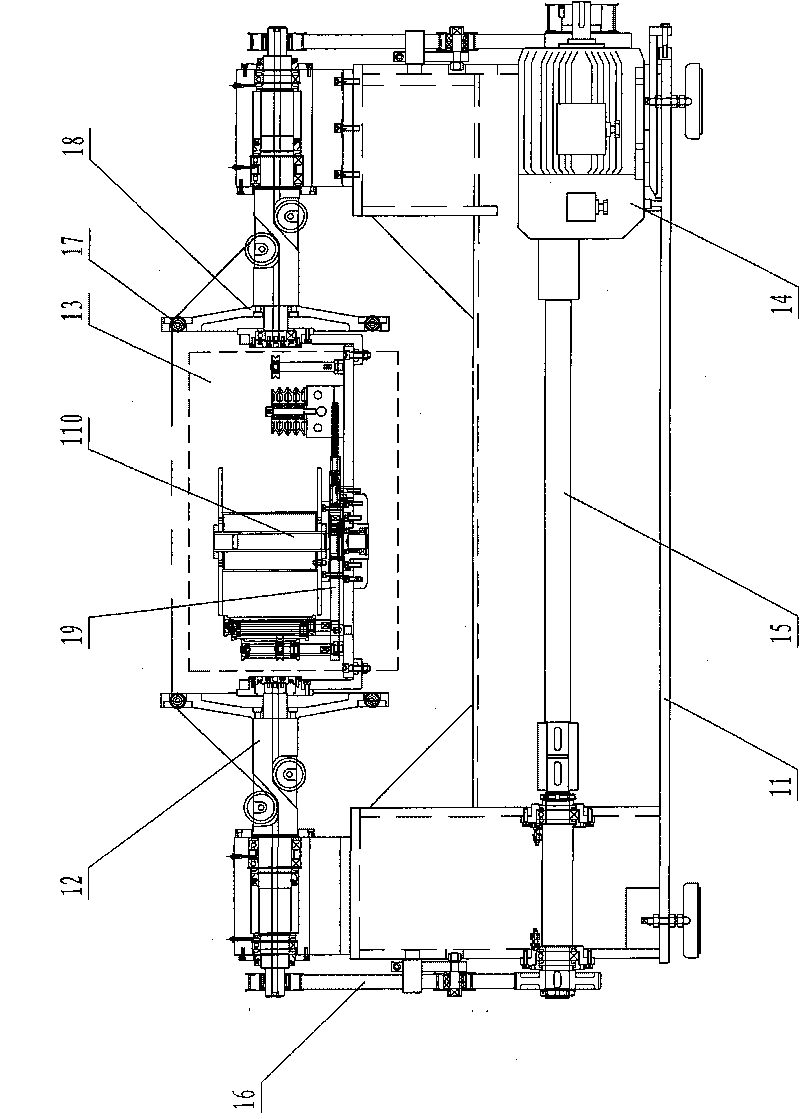

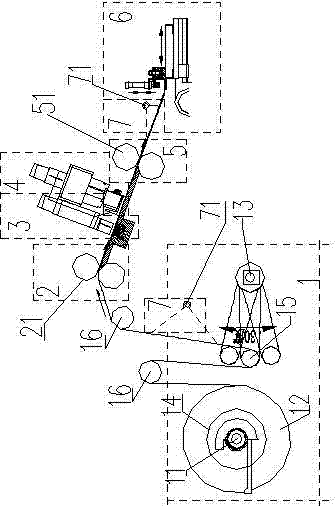

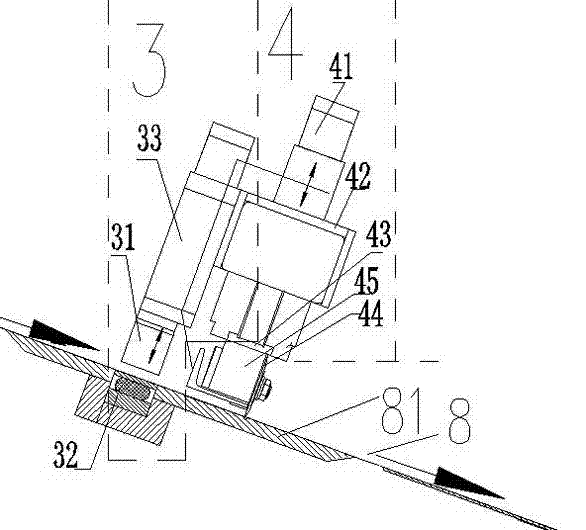

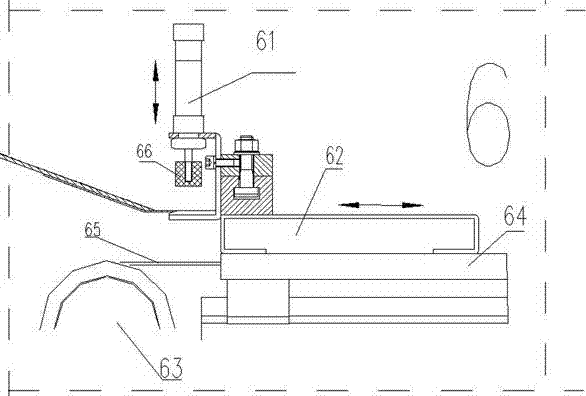

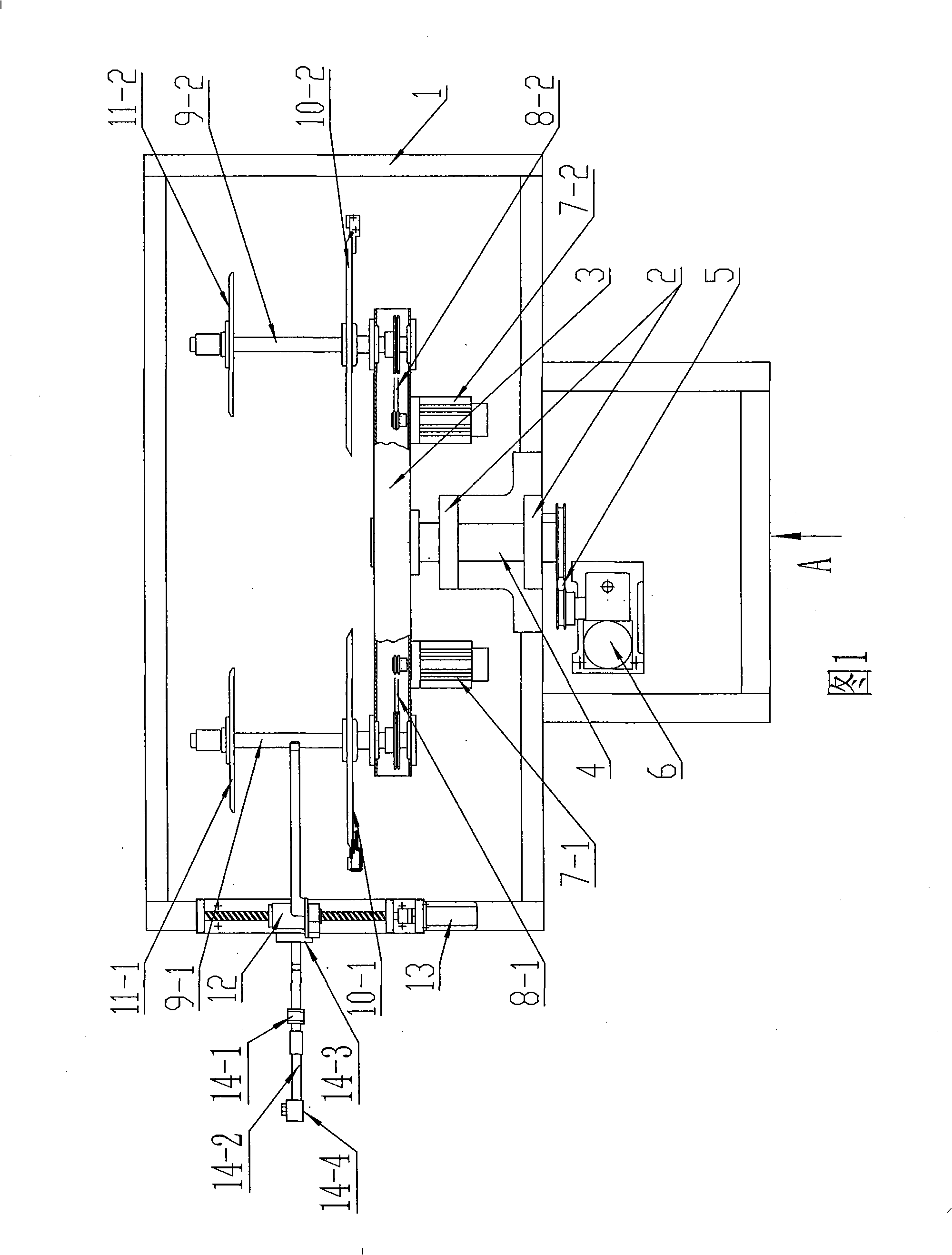

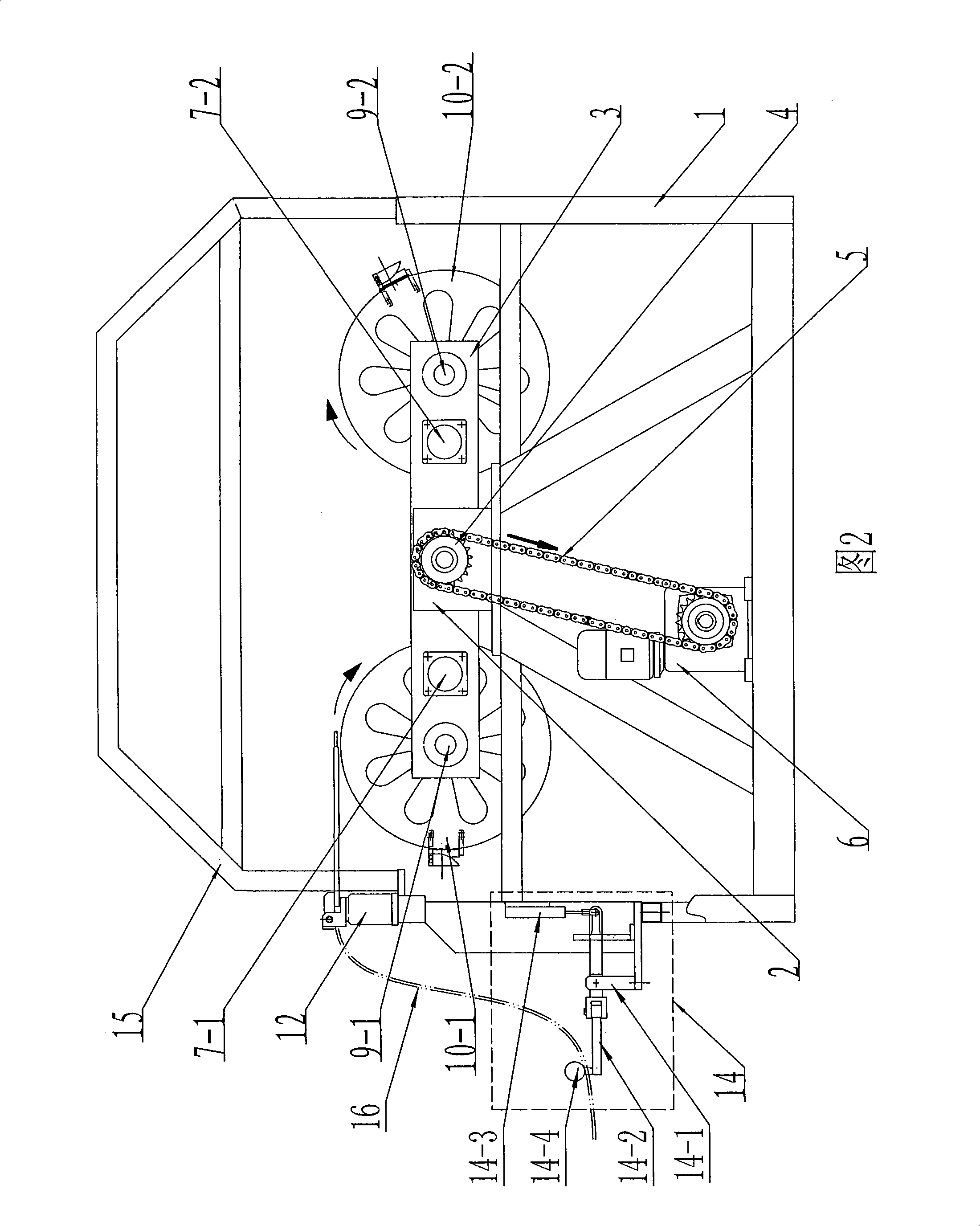

Biax full-automatic coiling machine

InactiveCN101441935AIncrease profitReduce production processCoils manufactureWinding machineEngineering

The present invention discloses a dual spindle full-automatic winding machine which is set on the base and characterized in that, it mainly comprises a feeding mechanisms, a mobile mechanism, a pick-and-place mechanism, a tension control mechanism, a thread drawing mechanism, a wire winding and arranging mechanism, a curing mechanism, and a discharging mechanism who are interactive with each other for coordination under PLC control; the above mechanisms coordinate with each other from imputing to magnetic core in the shape of 'I' to final product outputted according to requirement of winding process. The invention is full-automatic, practical, can improve production efficiency and has good promotion value.

Owner:广东昭信平洲电子有限公司

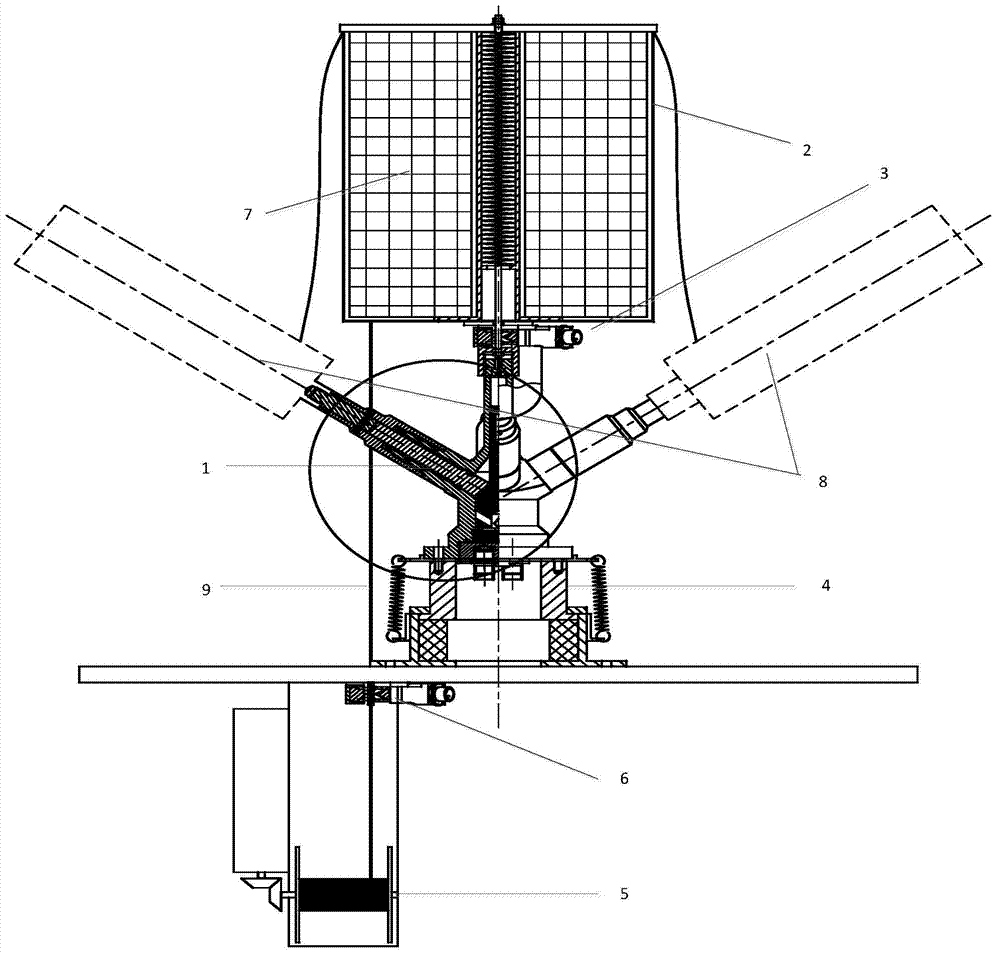

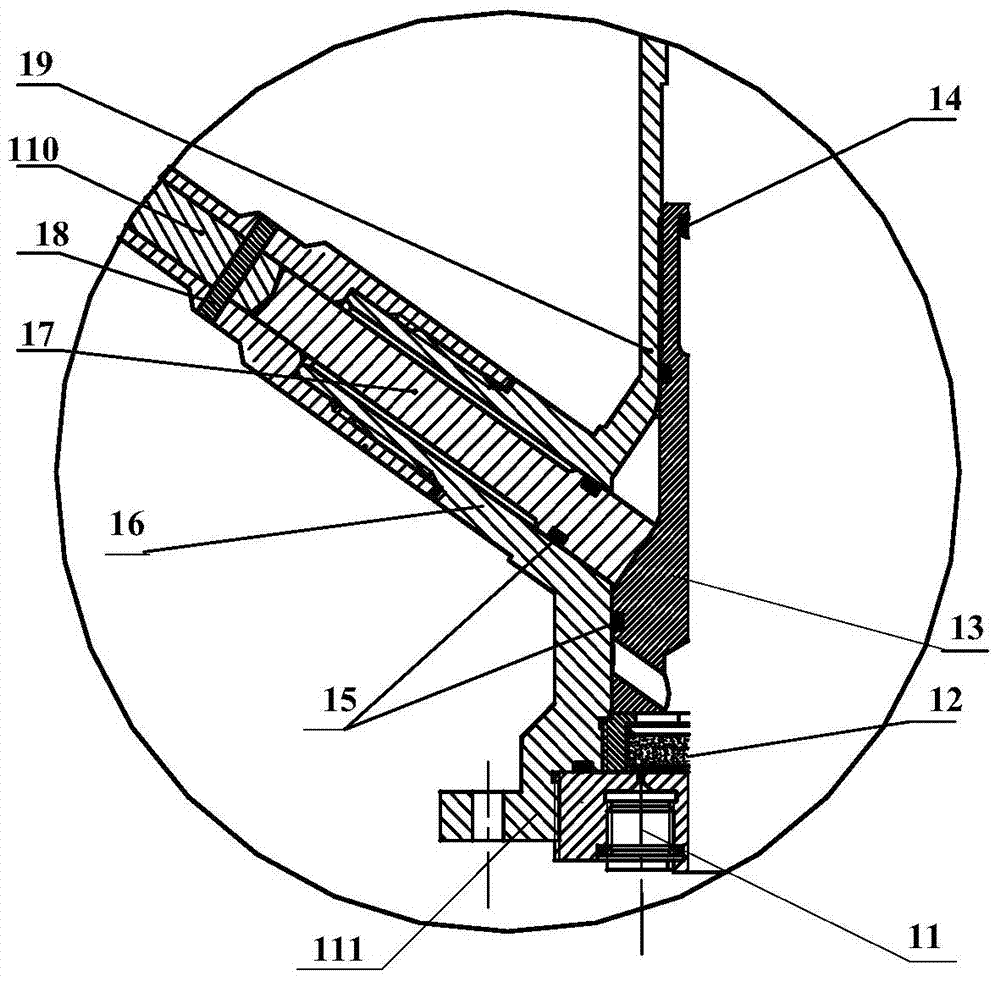

Rope net type space debris capturing and cleaning system

The invention discloses a rope net type space debris capturing and cleaning system which comprises a transmission subsystem and a fly net subsystem. The transmission subsystem comprises a transmitter, a net cabin, a net cabin cover ejecting device, a buffer device, a tying rope tension control device and a tying rope cutter, and the fly net subsystem comprises a rope net and four mass blocks; a net cabin cover can be ejected out of an outlet of the net cabin, and the rope net can be driven by the net cabin cover to be drawn out of the net cabin; the transmitter works at the moment when the fly net and a tying rope are straightened, the sides of the rope net are driven by four mass blocks according to preset transmitting opening angles, so that the rope net can fly out and is opened simultaneously until the rope net is fully opened, an object is netted after the rope net reaches the objective position, a port of the rope net is tightened under the control of the mass bocks, and the object can be completely captured; after the tying rope draws the captured object aircraft away from an orbit, the tying rope cutter cuts off the tying rope, and the object aircraft can be separated from a satellite platform. The rope net type space debris capturing and cleaning system has the advantages that a secondary transmission mode is adopted, so that twining and knotting can be prevented in rope net spreading procedures; the mass blocks are pushed to be synchronously transmitted, so that a millisecond-level synchronous transmission effect can be realized, and the shape of the rope net can be controlled advantageously.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

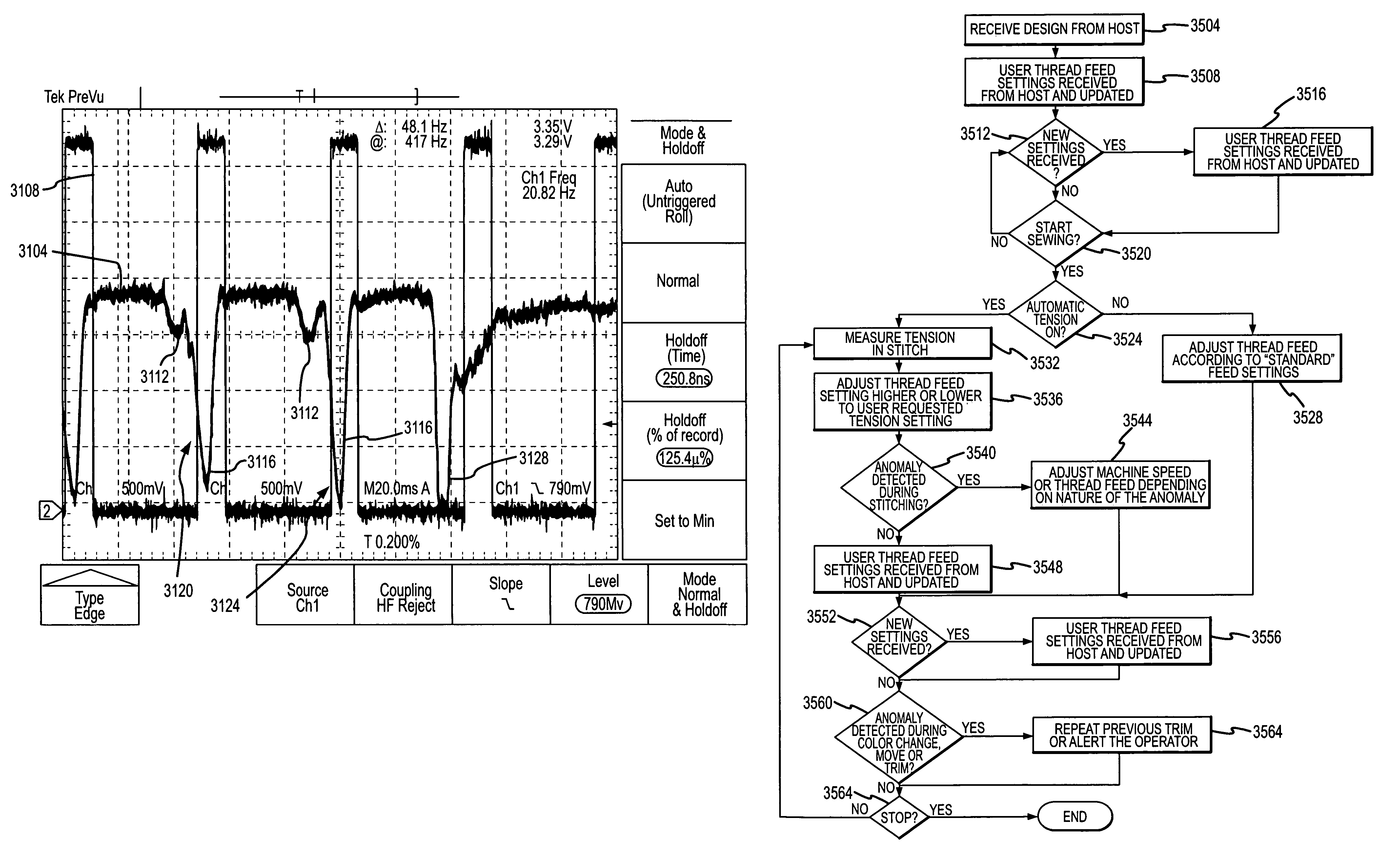

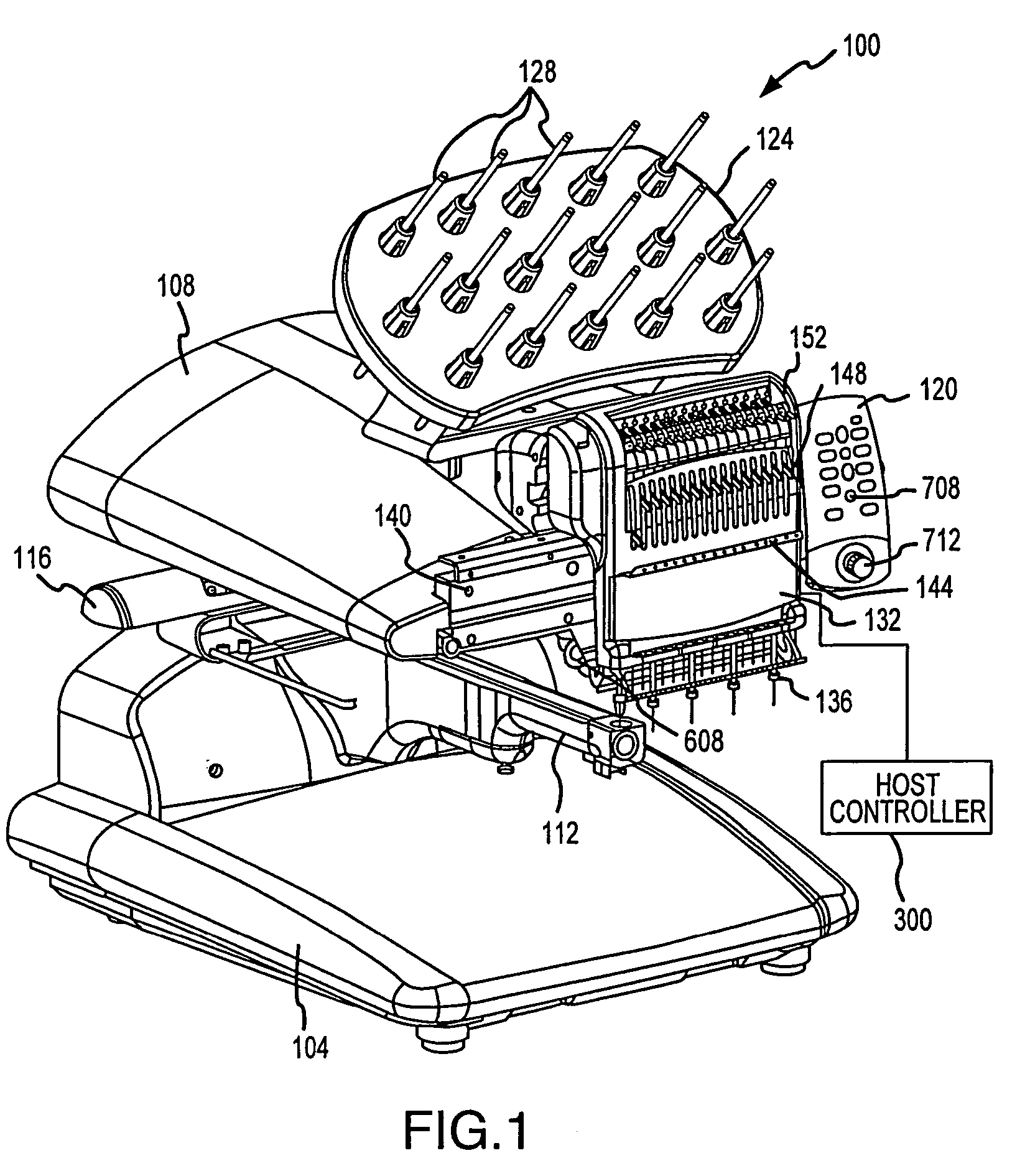

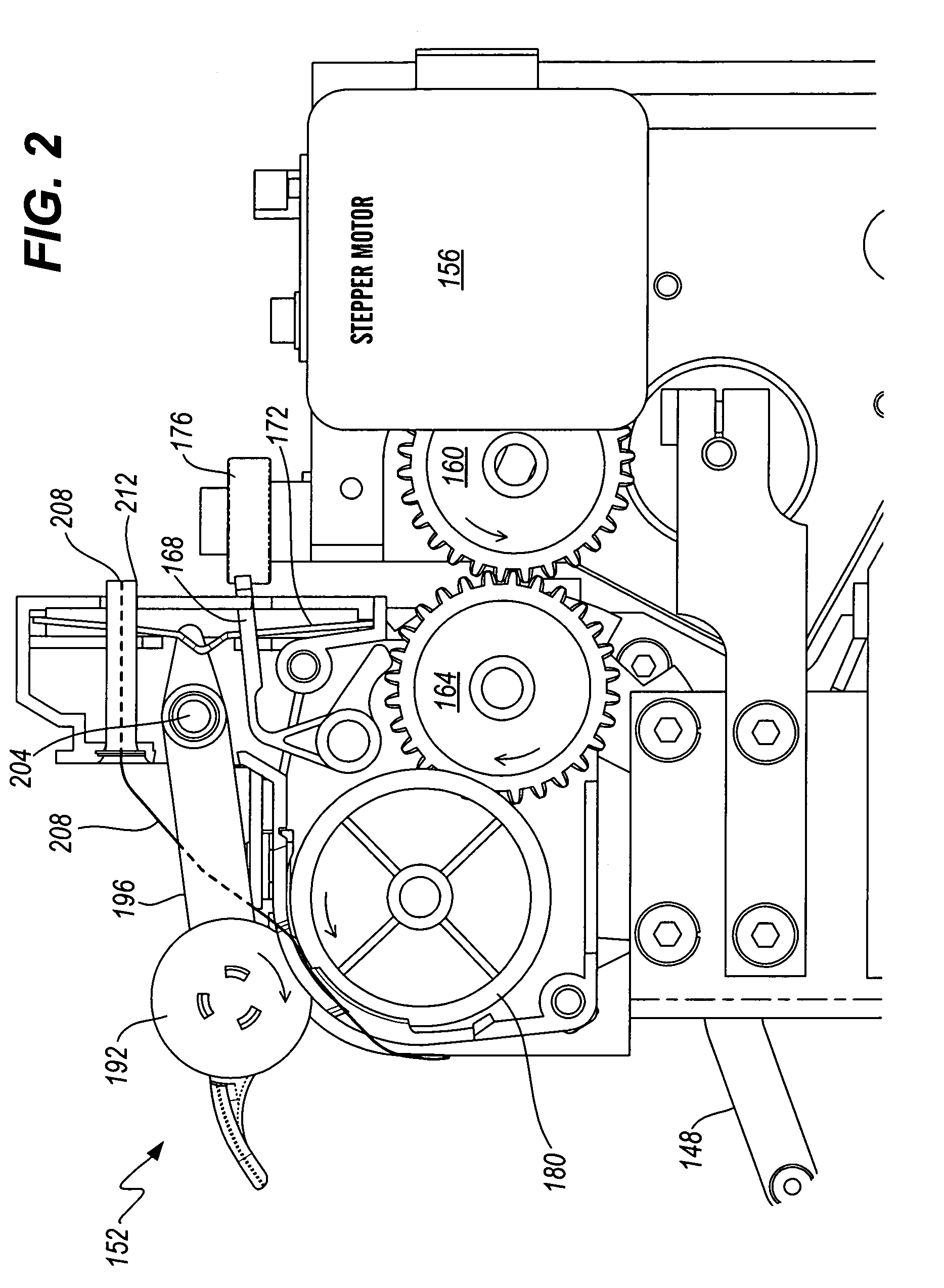

Computerized stitching including embroidering

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

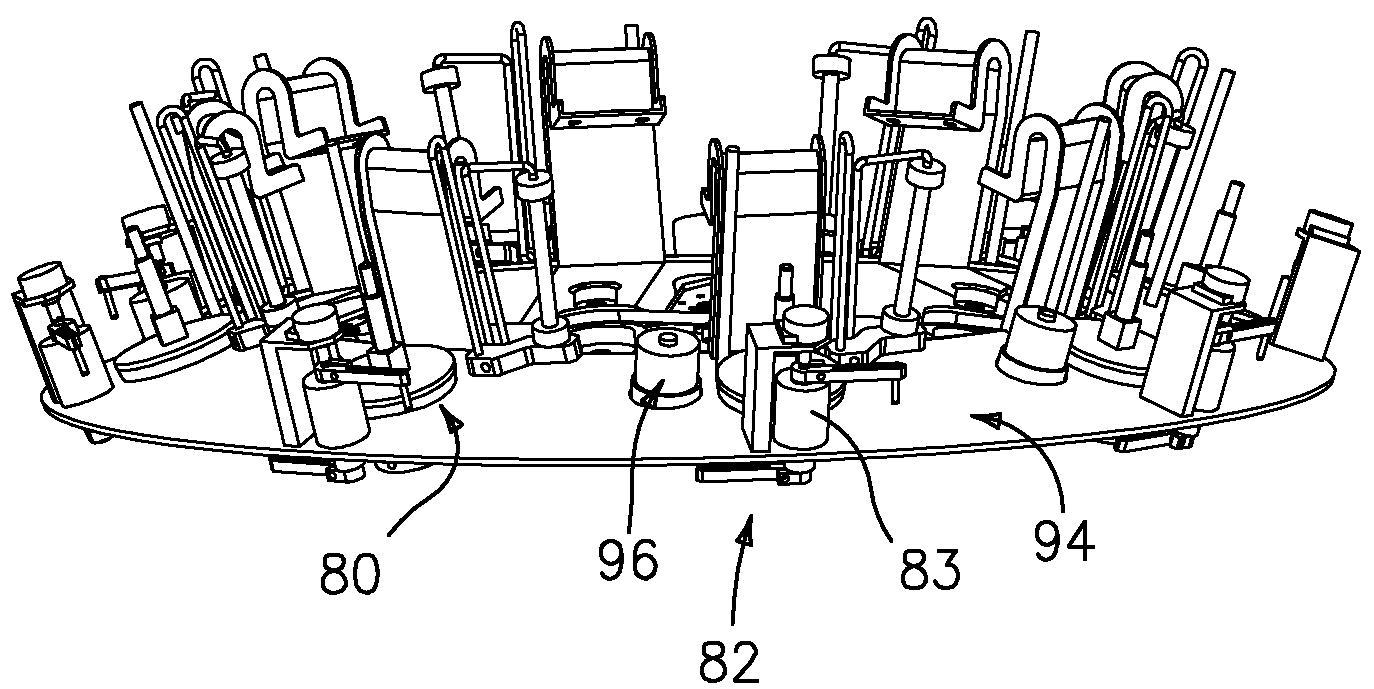

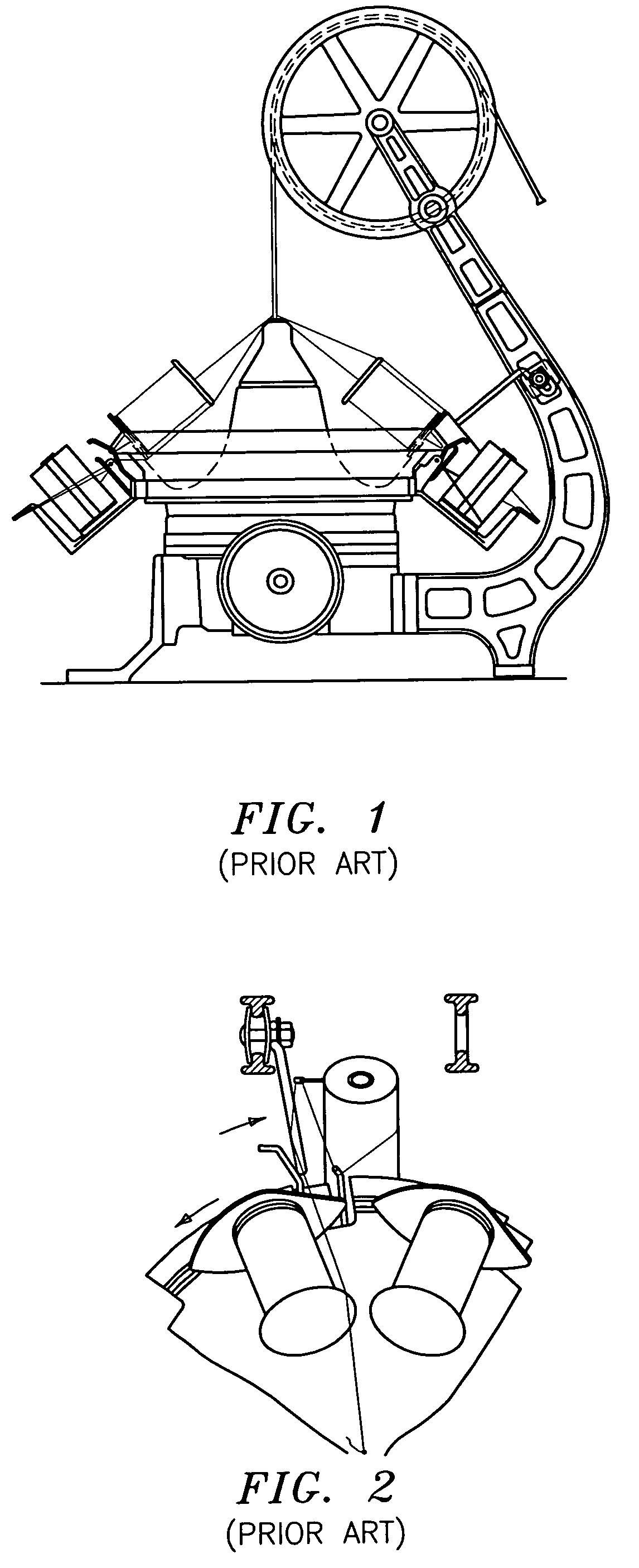

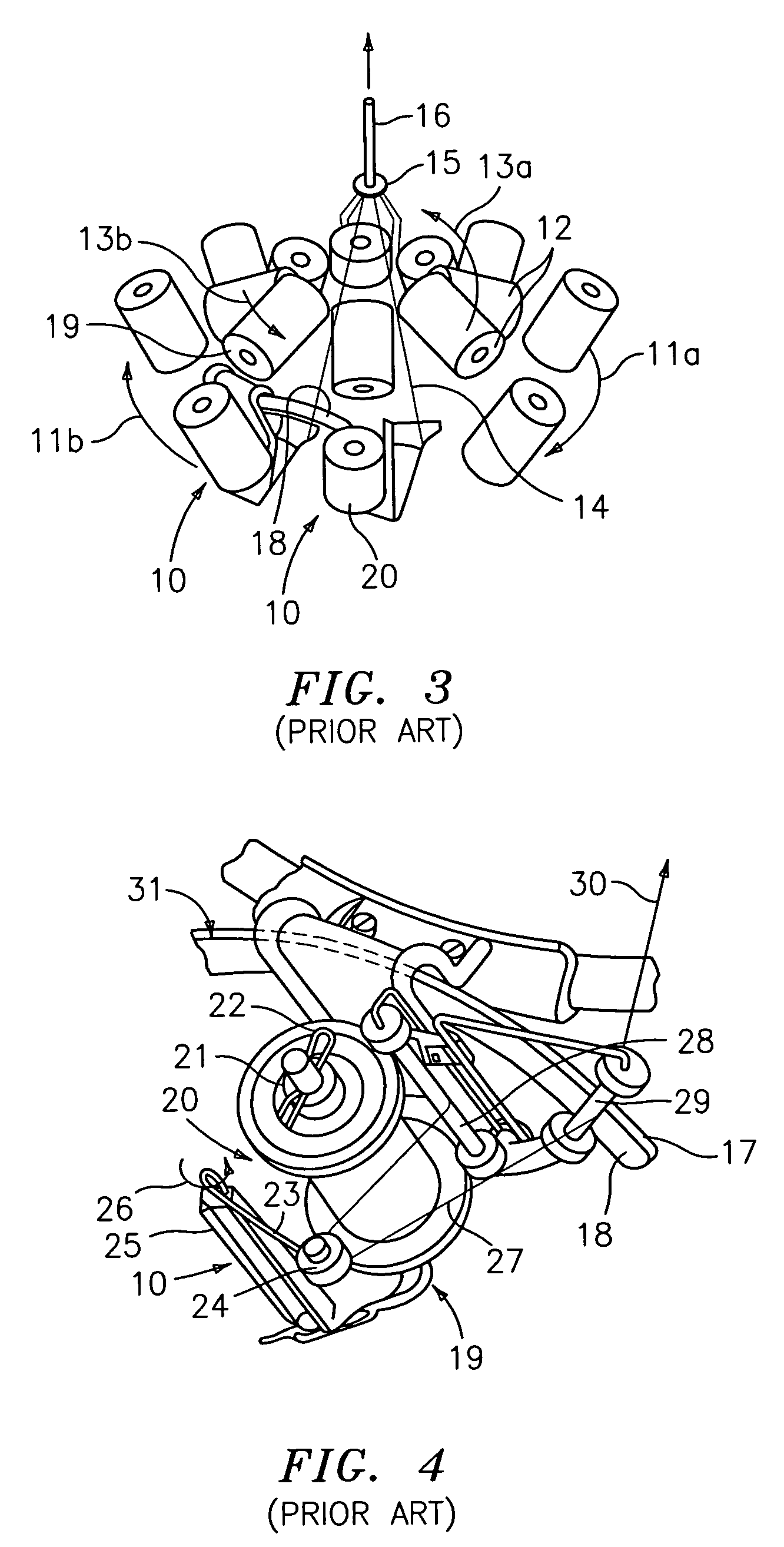

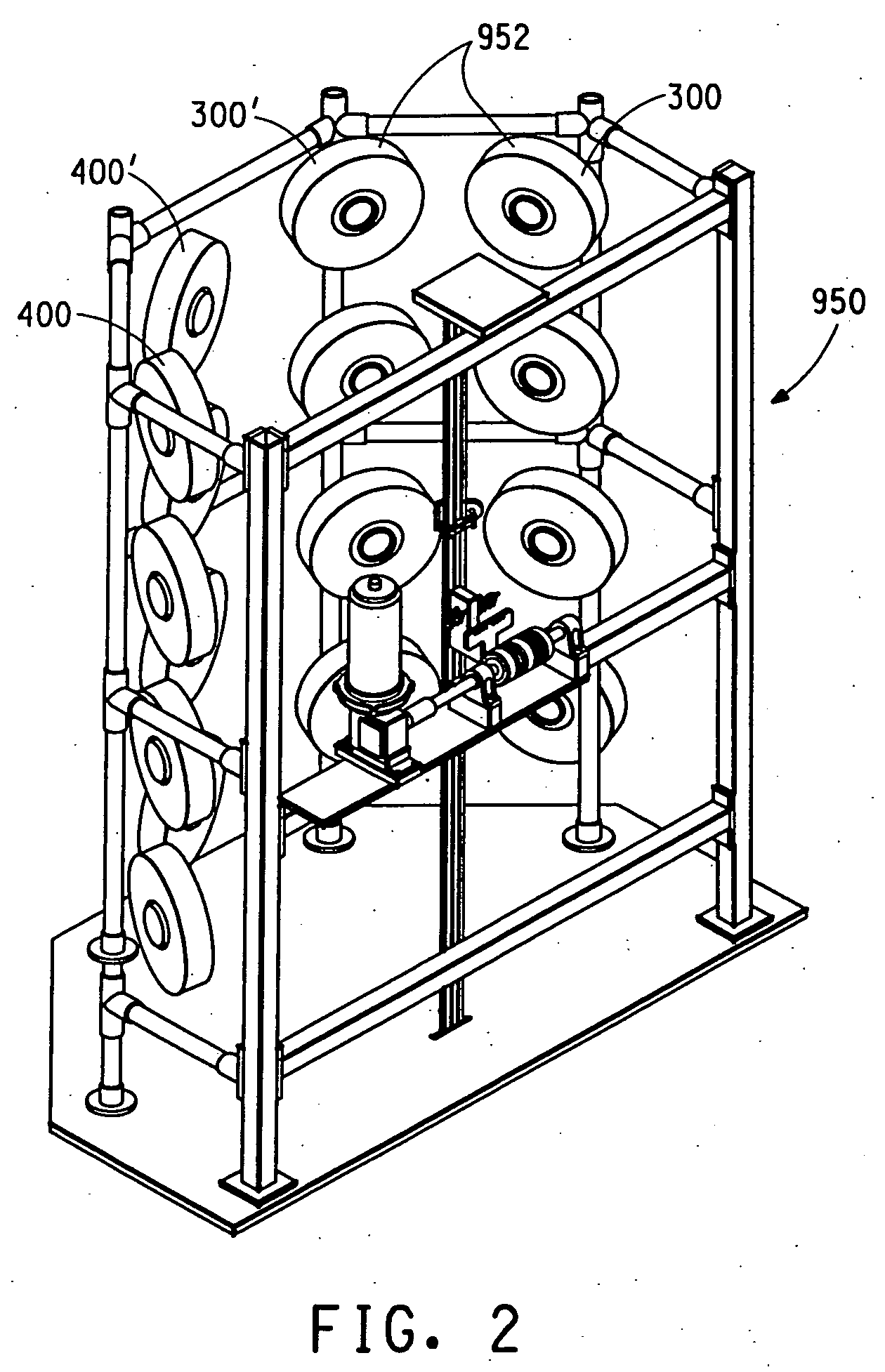

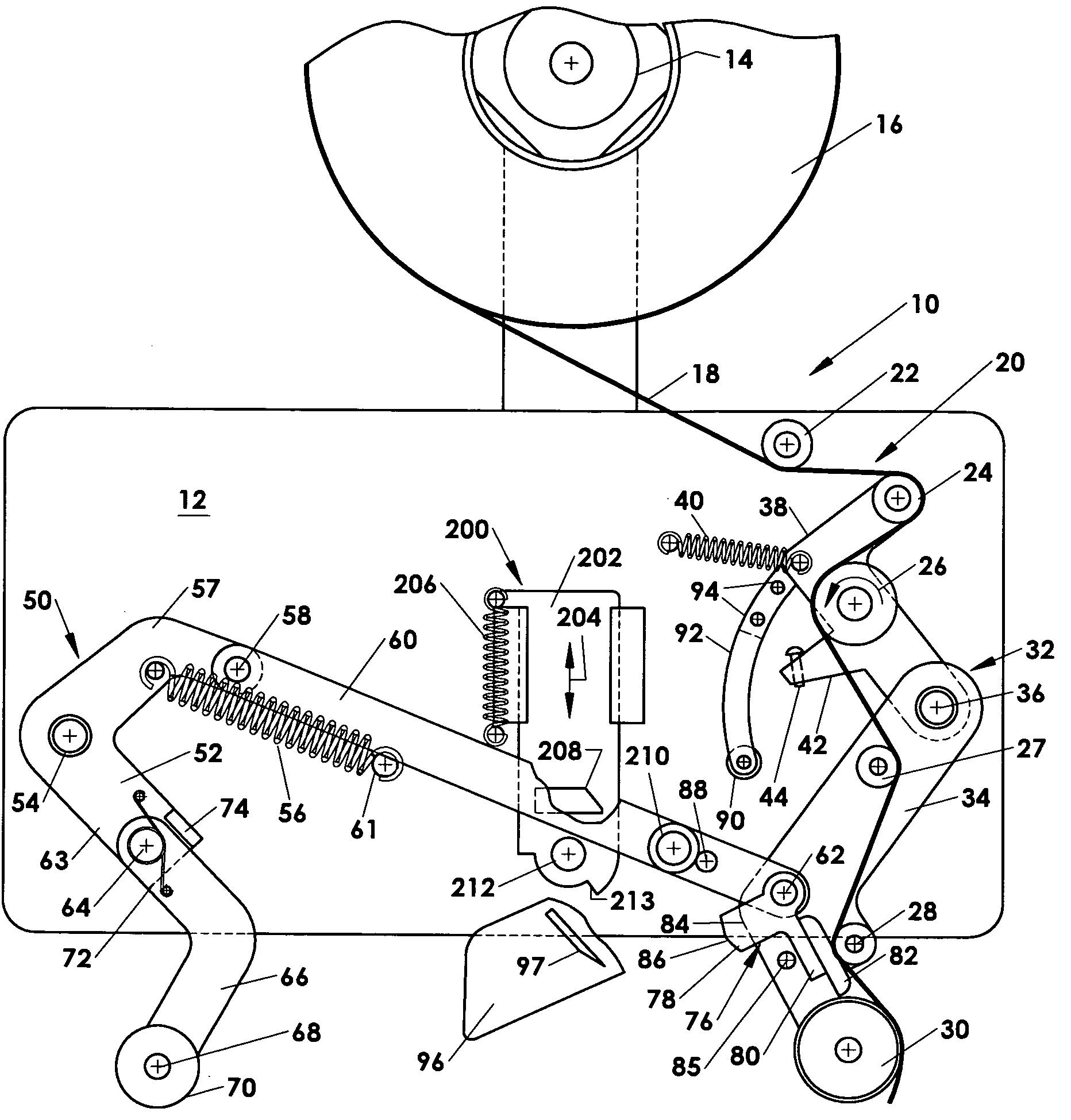

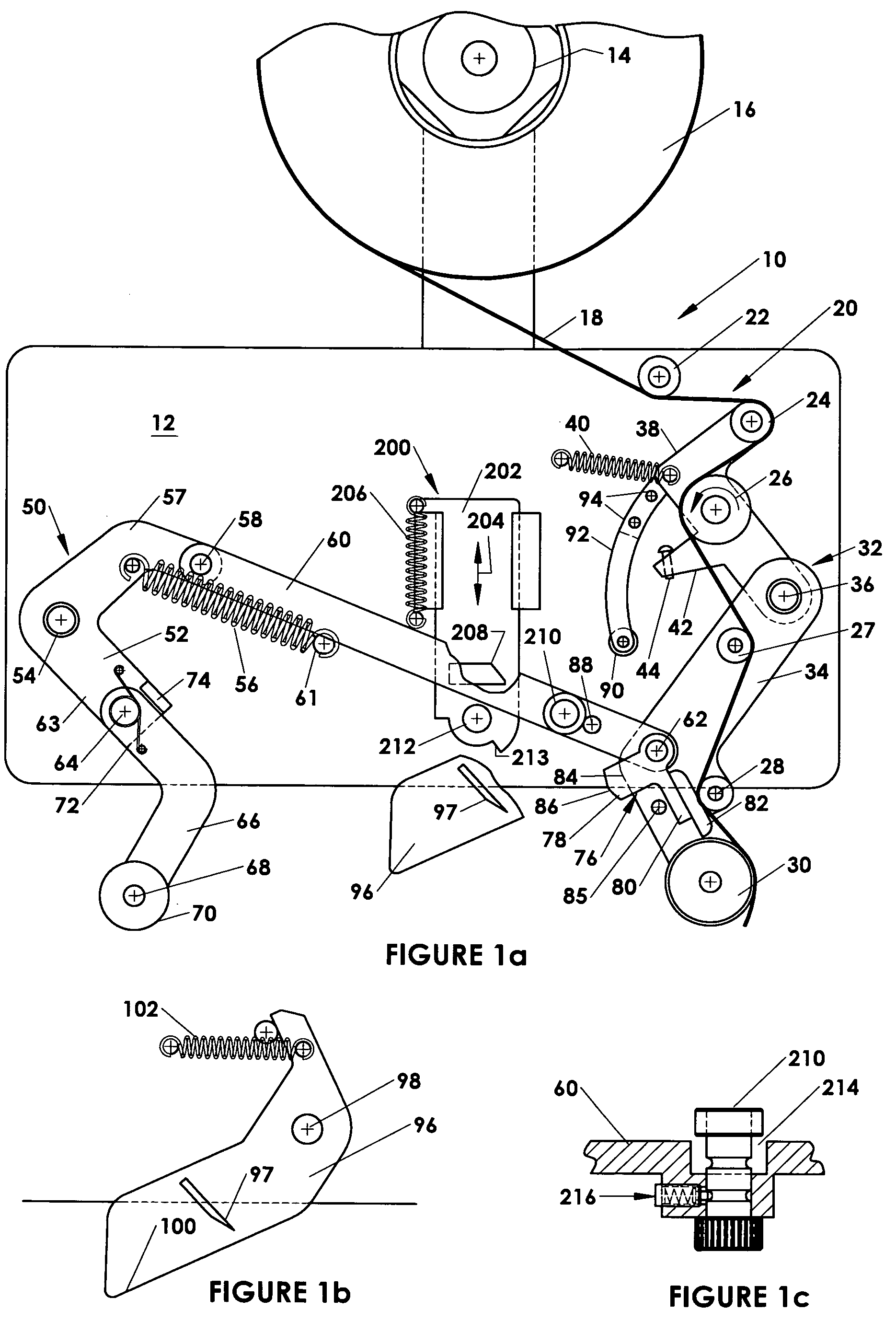

Powered lower bobbin feed system for deflector type rotary braiding machines

A Powered Lower Bobbin Feed (“PLBF”) system is disclosed for improving the operation of deflector type rotary braiding machines, such as the Wardwell Rapid Braider. The PLBF eliminates or reduces the impulsive tension spikes set up by the deflection and feed process in current rotary braiding machines by uniquely controlling the lower bobbin filament feed. These tension spikes result from: the rapid rotational acceleration and deceleration required of the lower bobbin as a result of the feed process; the lever arm tension control and bobbin ratchet mechanism; and the shape of the filament deflector surface. Such failure limits the operating speed of rotary braiding machines, the minimum size of filament that can be braided effectively, or the ability to maintain the quality of the braid produced. By eliminating or reducing these spikes, the PLBF therefore can increase the working speed of circular braiding machines and improve the uniformity of braided filaments generated by such machines at a given speed. In the preferred embodiment, the PLBF comprises: a slip ring designed to provide power to the lower bobbins; a variable speed powered lower bobbin concept; a feedback control system for the bobbins to assure bobbin feed matches braid consumption; and an improved, more contoured, deflector surface to minimize feed tension spikes. The new contour can be created: by retrofitting existing deflectors with a spline; or, by making new deflectors that incorporate the overall contour of a retrofitted deflector.

Owner:STOLBERGER

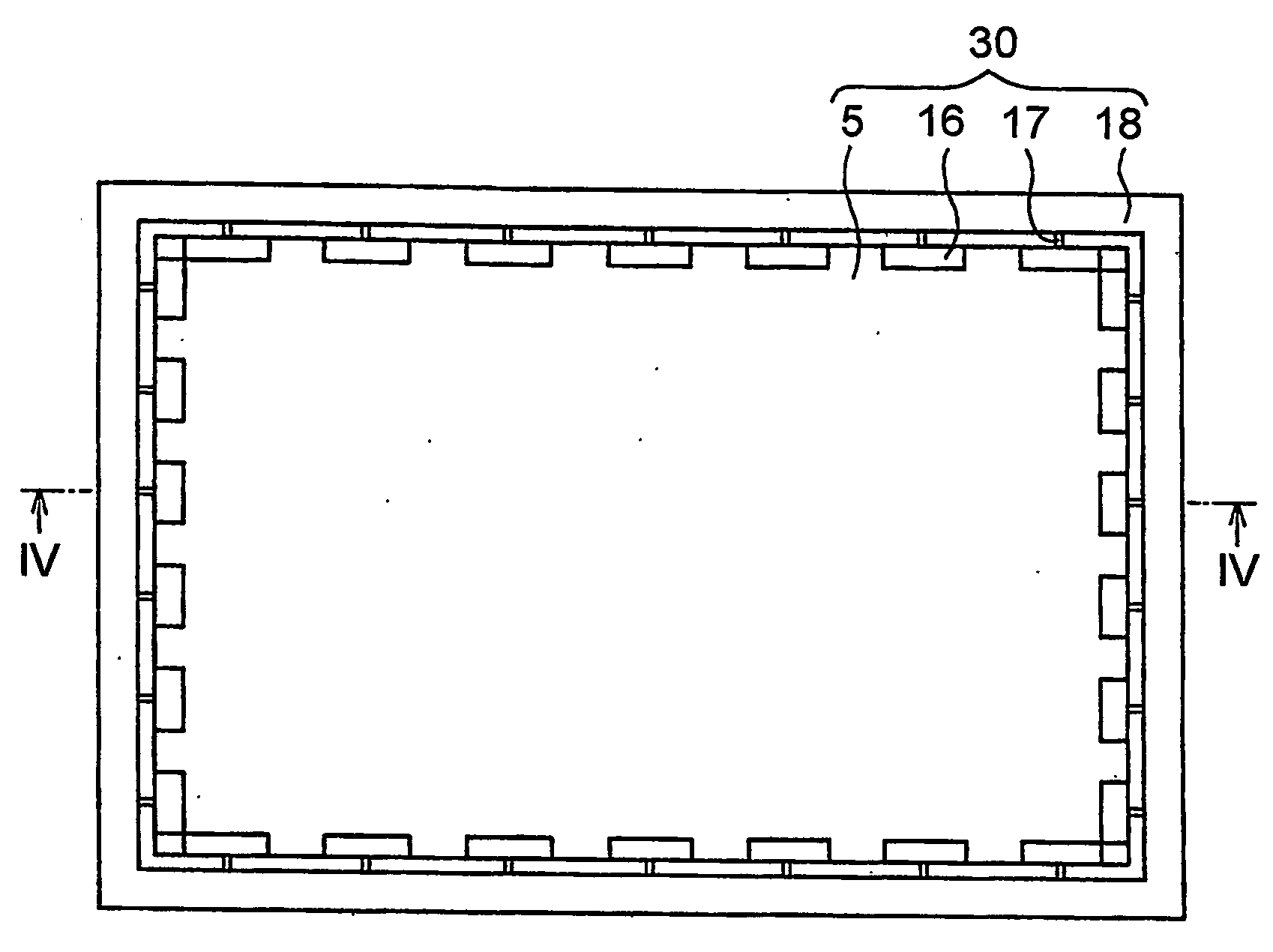

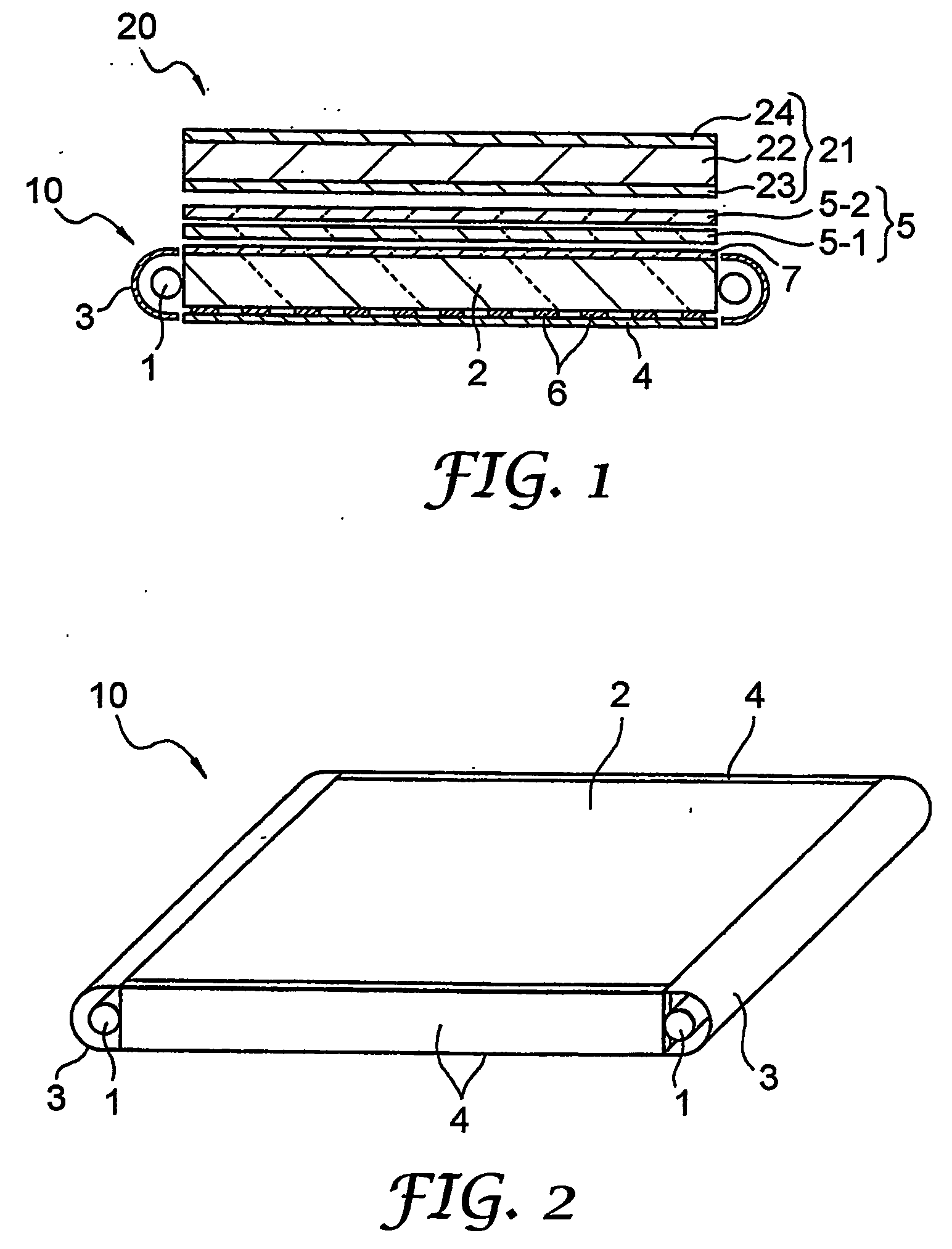

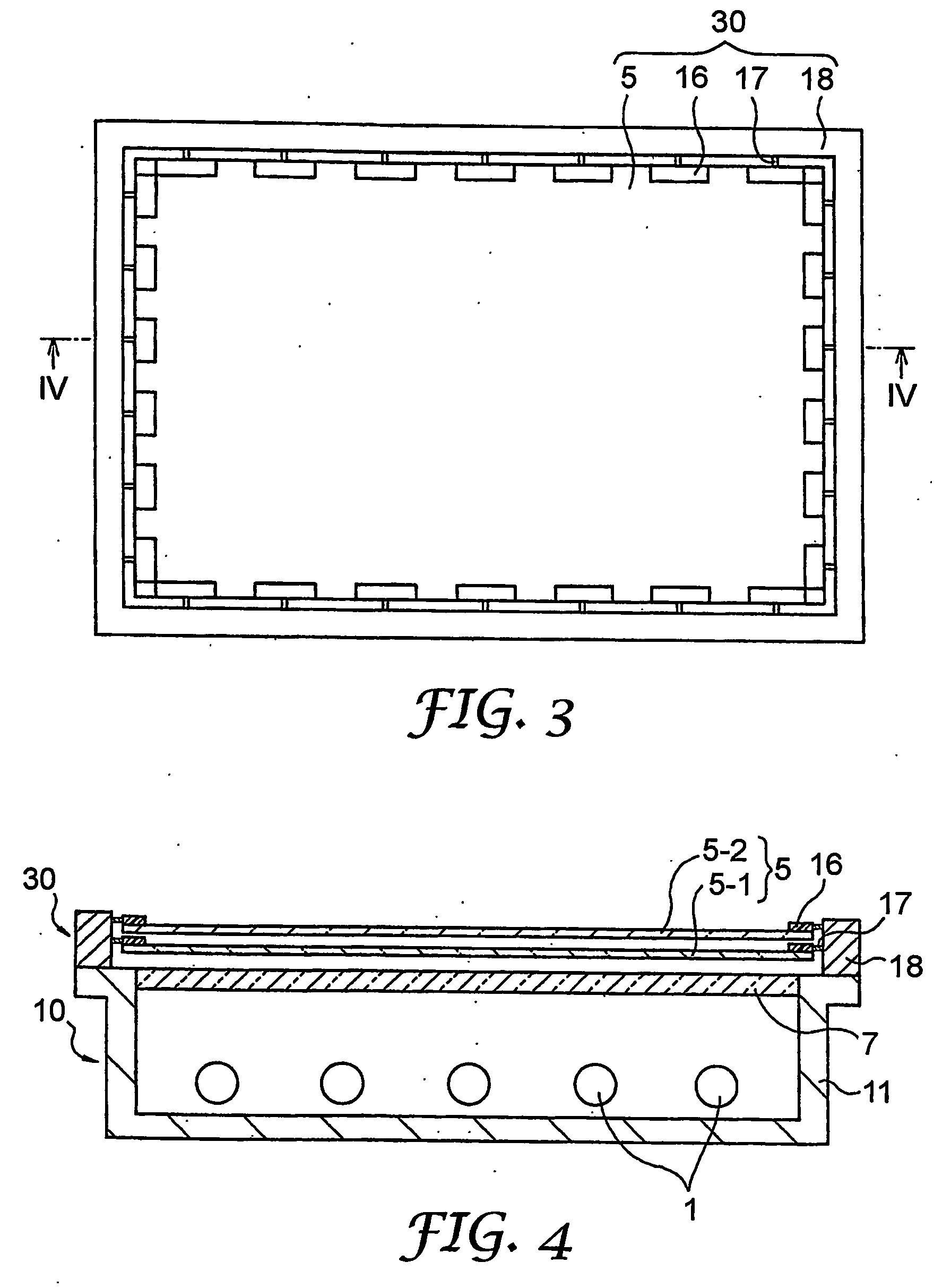

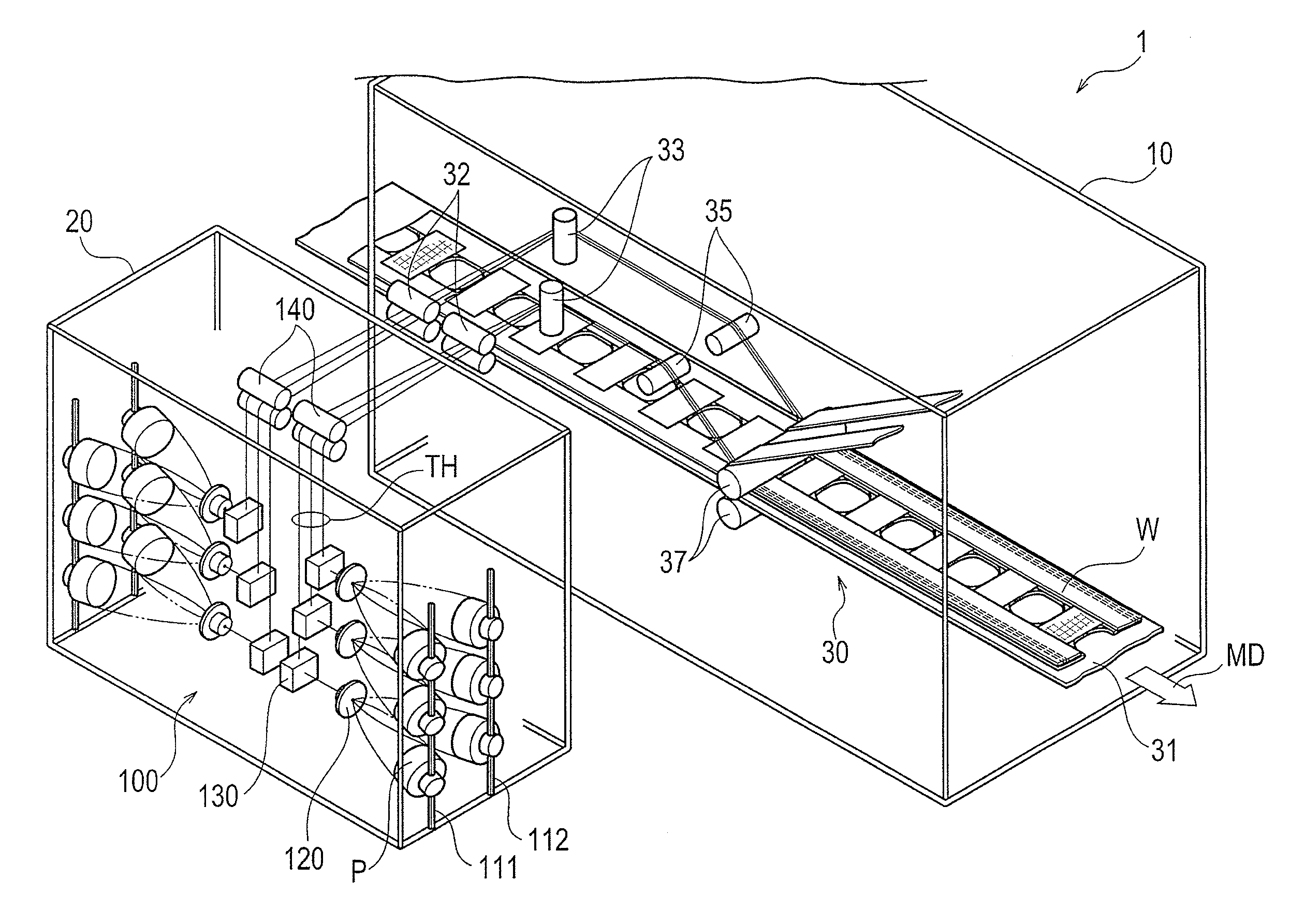

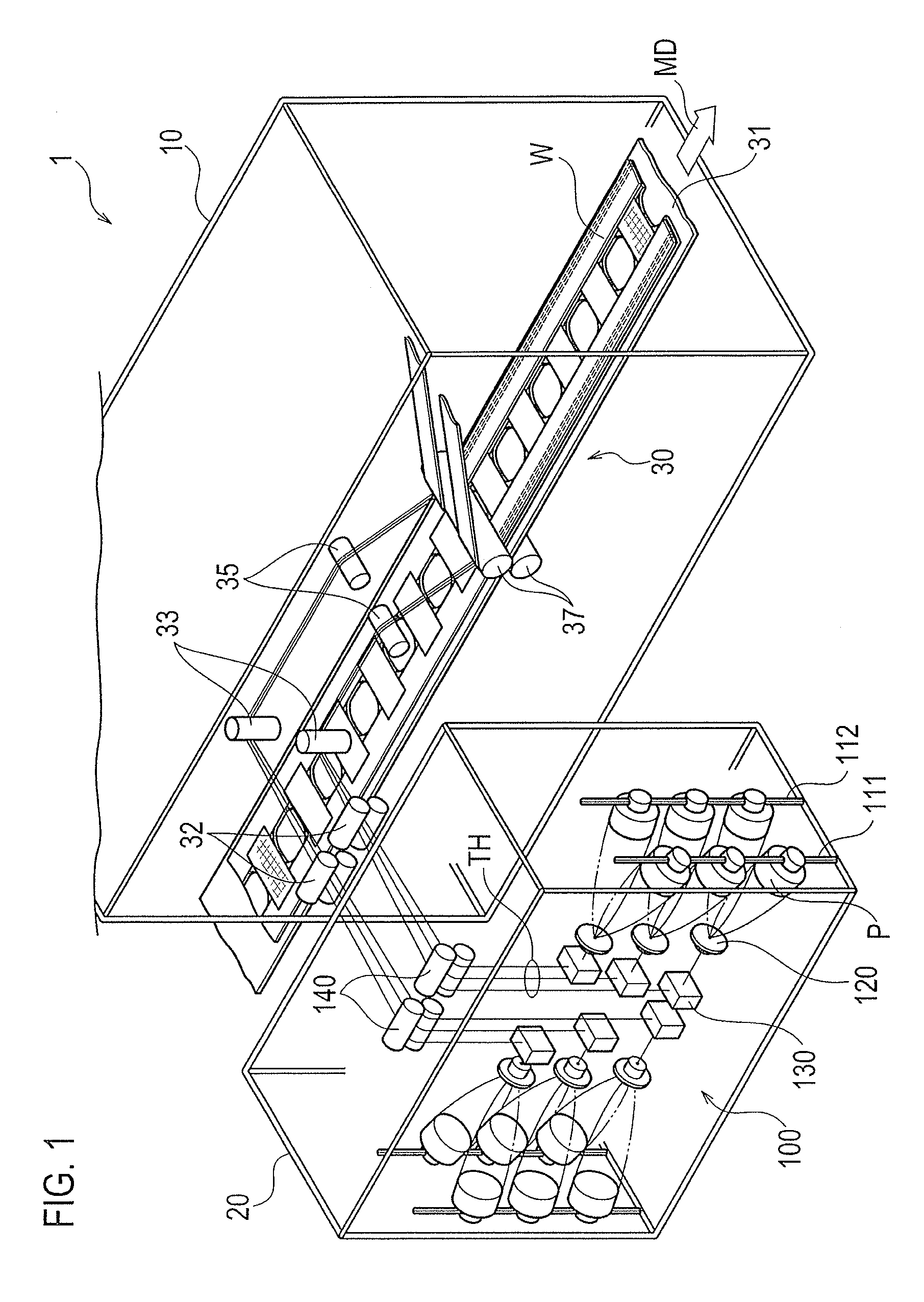

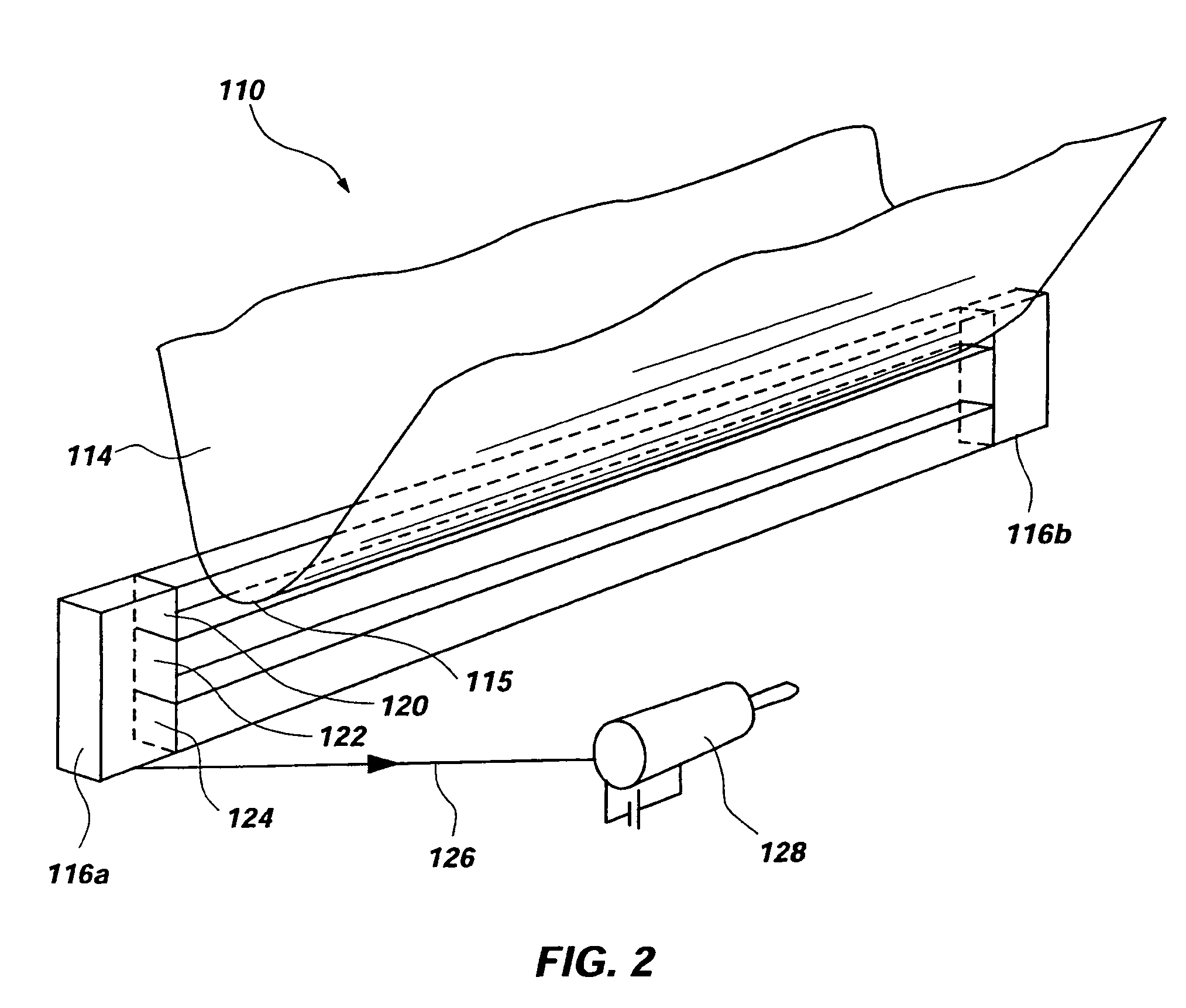

Optical film structure, illlumination apparatus and liquid crystal display device

InactiveUS20060171164A1Improve flatnessPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayFixed frame

To provide an optical film structure useful in a liquid crystal display device and capable of using thin optical films without warp and distortion. An optical film structure comprises at least one optical film, at least four film fixing parts arranged at an outer peripheral portion of the optical film, a film tension controlling member fitted at one of the ends thereof to each of the film fixing parts in such a fashion as to be capable of pulling the optical film under tension while maintaining flatness of the optical film, and a film fixing frame to which the other end of the film tension controlling member is connected and which fixes the optical film.

Owner:3M INNOVATIVE PROPERTIES CO

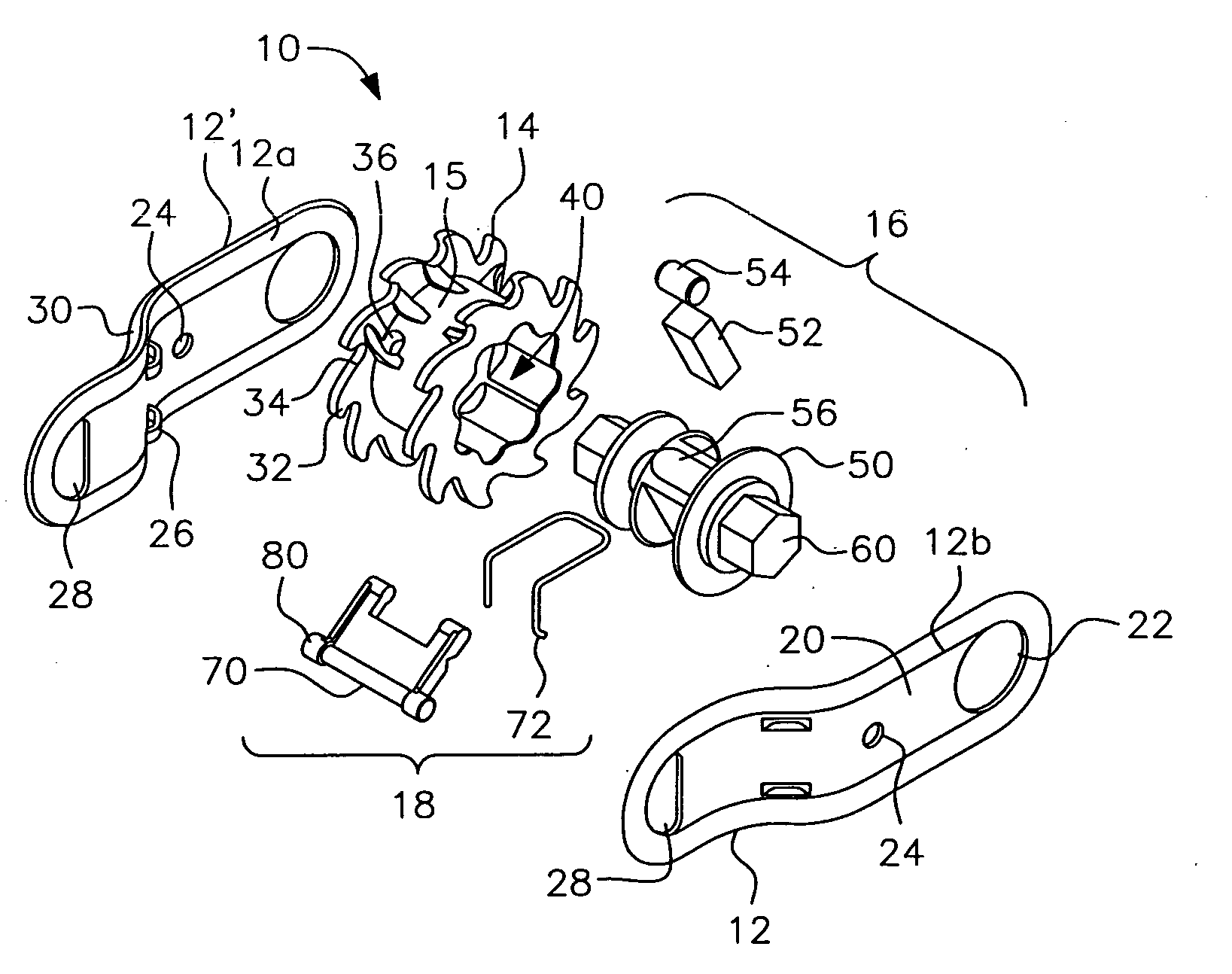

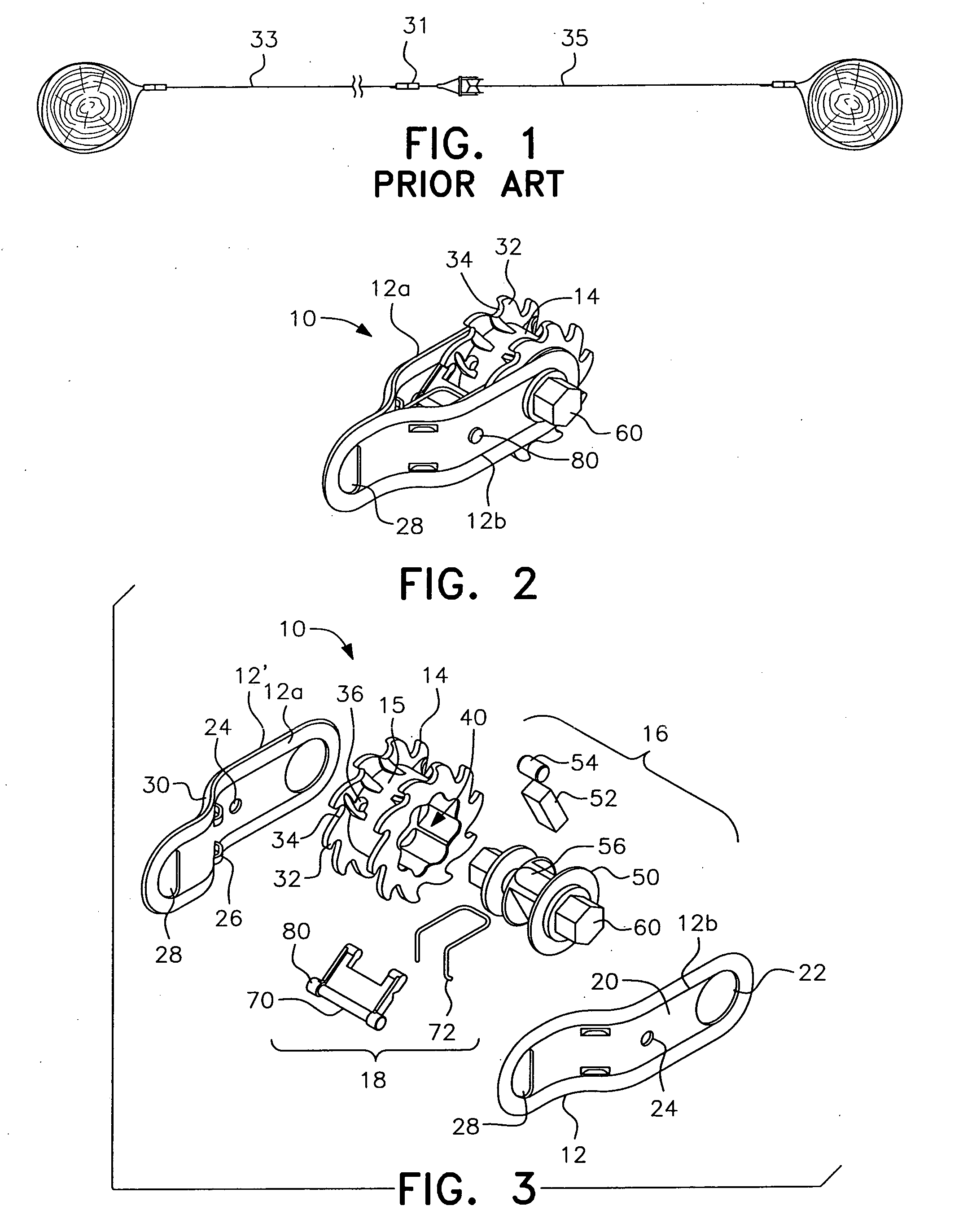

In-line strainer with tension control mechanisms for use on high tensile wire

InactiveUS20120138882A1Reduce manufacturing costLow cost manufacturingRopes and cables for vehicles/pulleyFencingHigh intensityTension control

An in-line strainer for placement within a span of wire fence to apply tension thereto is provided. The in-line strainer includes a reel having a hollow central hub for receiving a torque limiting mechanism. The torque limiting mechanism includes a central axle and a spring mechanism. As the axle is manually rotated, the reel is also rotated through its engagement with the torque limiting mechanism until a target tension on the wire is reached. Once the target tension has been reached, the torque limiting mechanism disengages, allowing the axle to “slip” relative to the reel, preventing further rotation of the reel and, consequently, further tensioning of the wire. In addition, the in-line strainer includes a failure mechanism which ensures that, when the load threshold on the fence is exceeded, the in-line strainer will automatically release tension on the wire wound thereon in a predictable and safe manner.

Owner:WOODSTREAM CORP

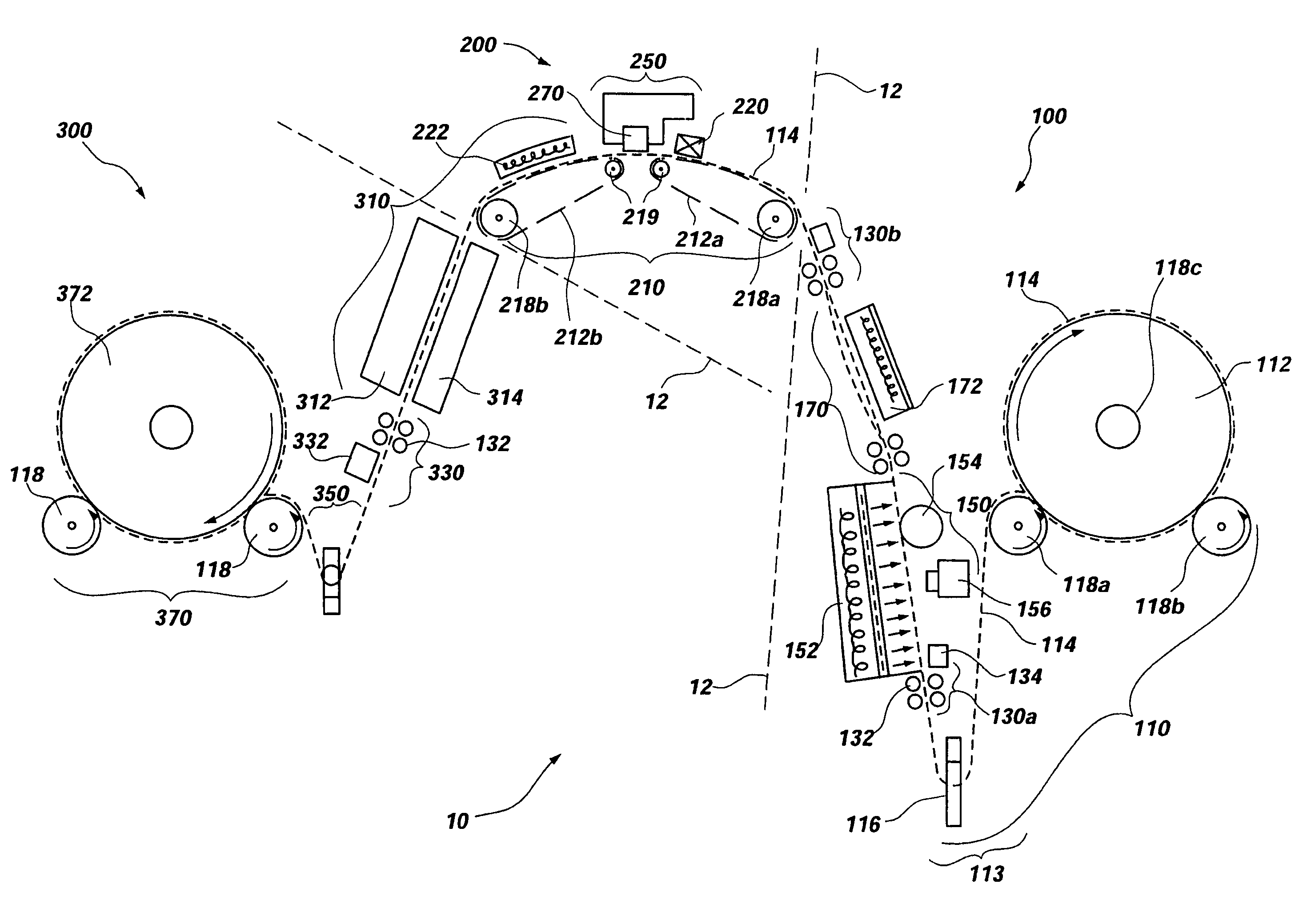

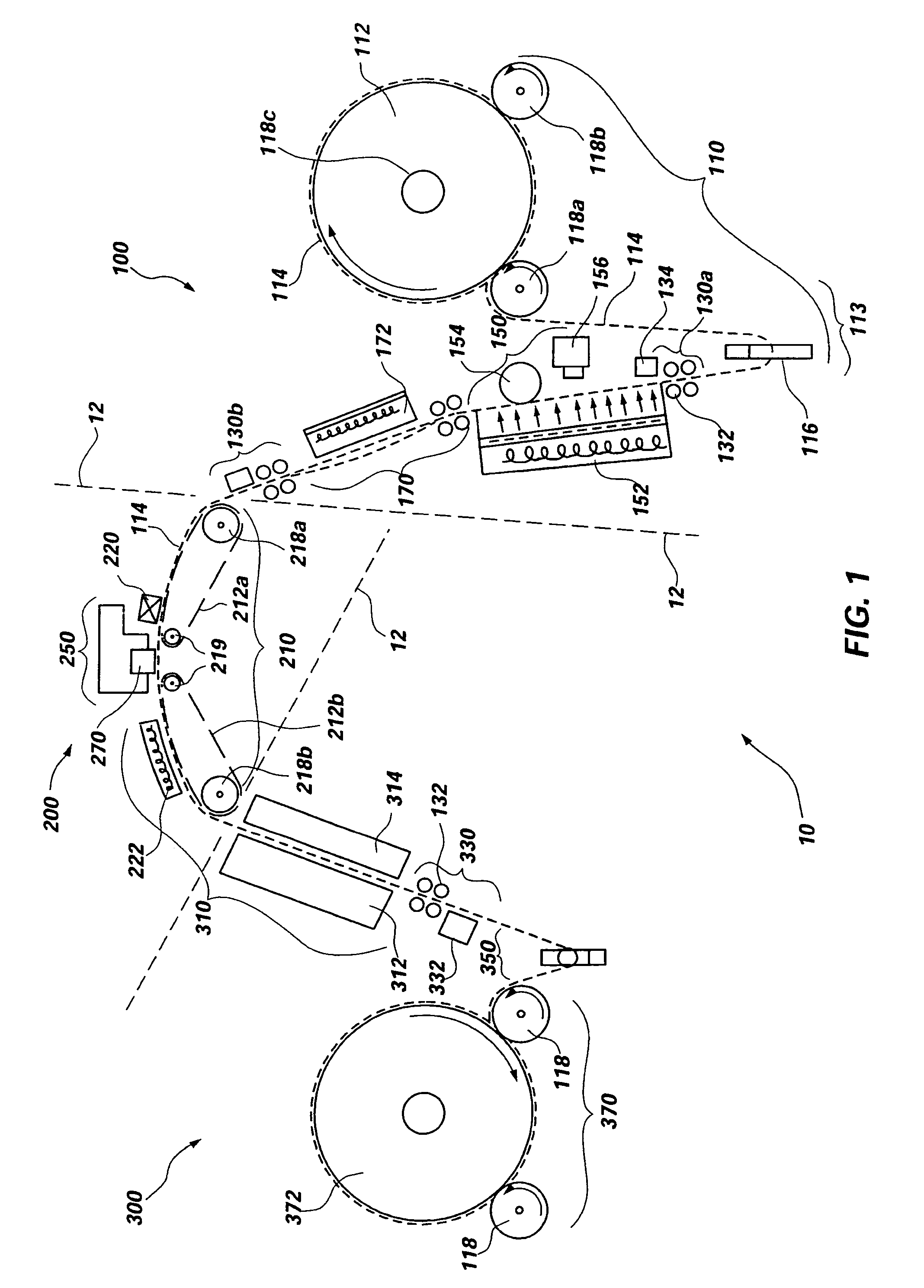

Apparatus and method for intermittent application of stretchable web to target web

ActiveUS8007623B2Mechanical working/deformationLamination ancillary operationsEngineeringTension control

Owner:CURT G JOA

Double twisting rope laying machine

The invention discloses a double twisting rope laying machine which comprises a core wire laying machine, a core wire tension mechanism, a surface wire laying mechanism, a single wire pre-twisting machine, a wire collecting mechanism and a wire-rewinding machine arranged sequentially, wherein the core wire tension mechanism comprises a broken wire detecting device, a wire roller, a tension control device and a tension detecting device; the core wire output tension is detected by the tension detecting device, and if the tension exceeds a set tension range, the core wire output tension is adjusted by the tension control device to realize accurate control of the core wire laying tension; and the single wire pre-twisting machine comprises a motor, a transmission component and a plurality of groups of rotor components which are arranged at the front surface and the back surface of a stand. Through the rotation of each group of rotor components, the single wire pre-twisting process is realized and the single wire stress is eliminated, thereby being favorable to twisting and forming, and finally, the twisted cords have good straightness, stable residual torsion and high product quality and is difficult to loose; and the specifications of the producible cords are 3+9+15*0.22, 3+9+15*0.175 and 0.25+(6+12)*0.22.

Owner:江苏泰隆机电科技有限公司

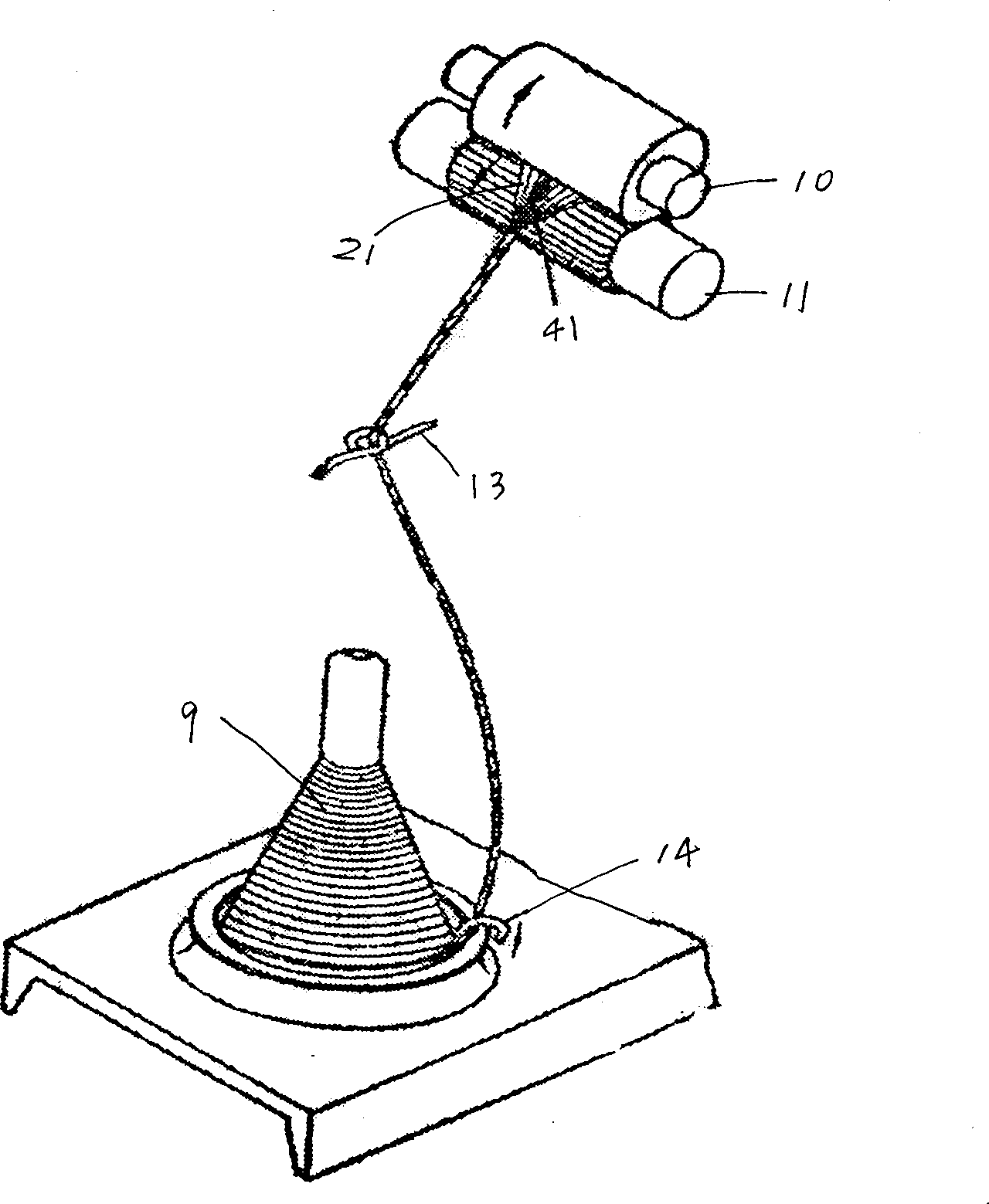

Unwind and feed system for elastomeric thread

ActiveUS20070152093A1Smoothes out tension variationInhibition of tension changesProjector film strip handlingFilament handlingFiberTension control

An overend unwind system for unwinding tacky elastomeric fiber threads such as uncoated spandex thread, capturing the ballooning affect of the thread as the thread leaves the spool, applying a first-stage tension control on the thread adjacent where the thread leaves the spool, feeding the unwound thread to a nip in a downstream process, and applying a final tension increment to the thread adjacent where the thread enters the downstream process. All thread guide surfaces encountered by the thread after leaving the spool, and while the thread is under designed operating tension, are moving surfaces, such that the tensioned thread thereby experiences a reduced level of drag as the thread traverses its path of travel from the spool to the downstream process.

Owner:HARTZHEIM ENG

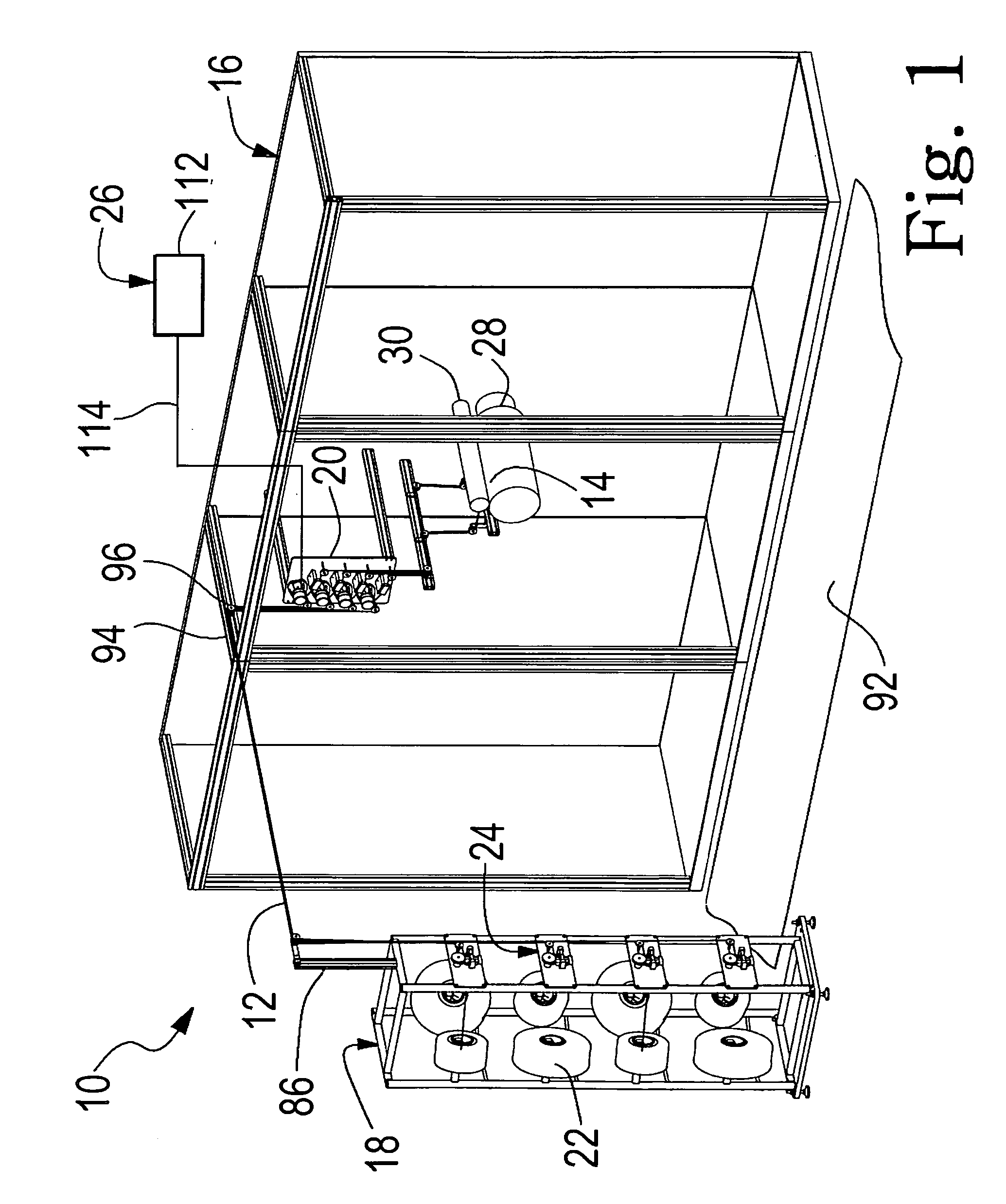

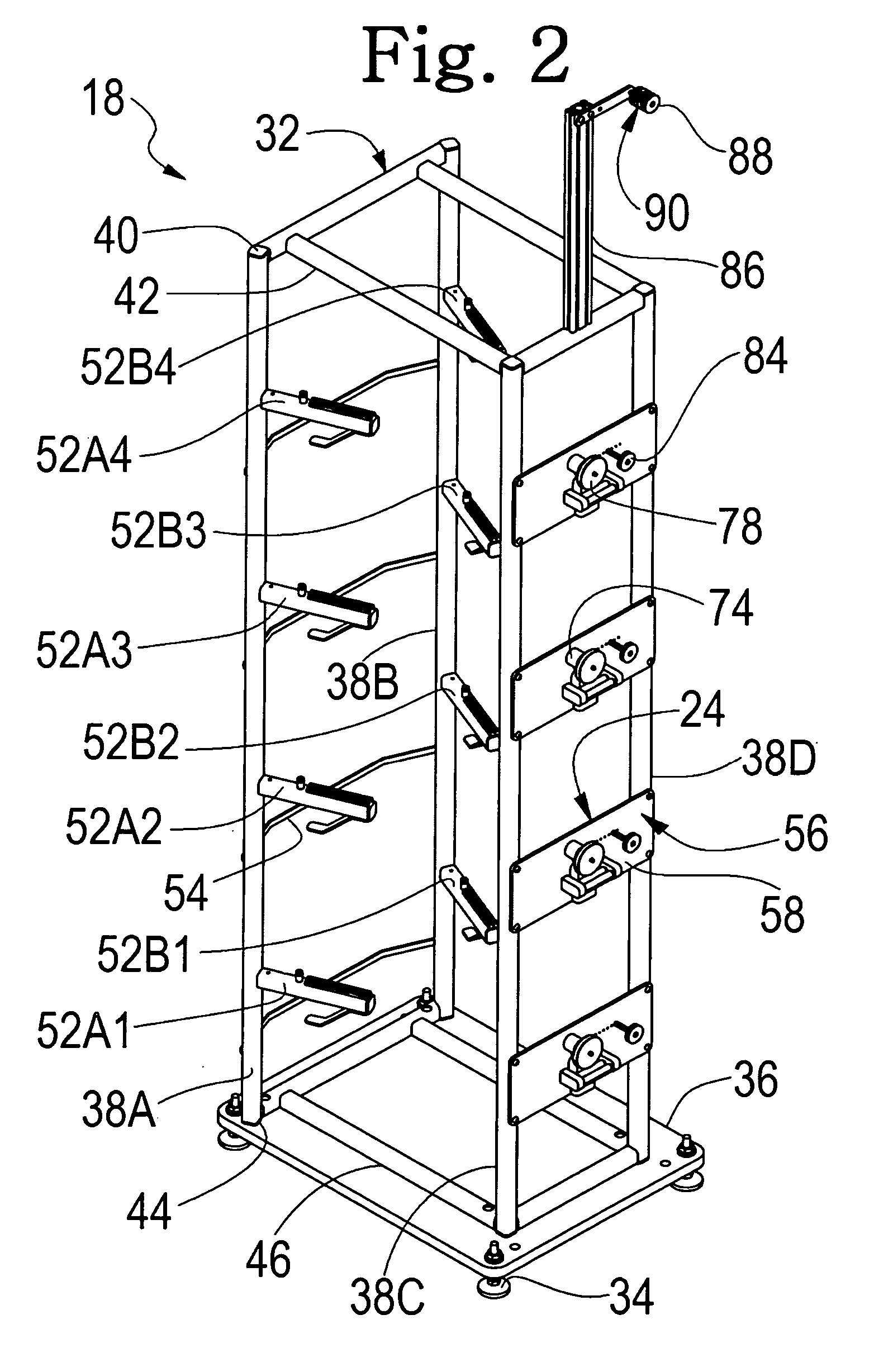

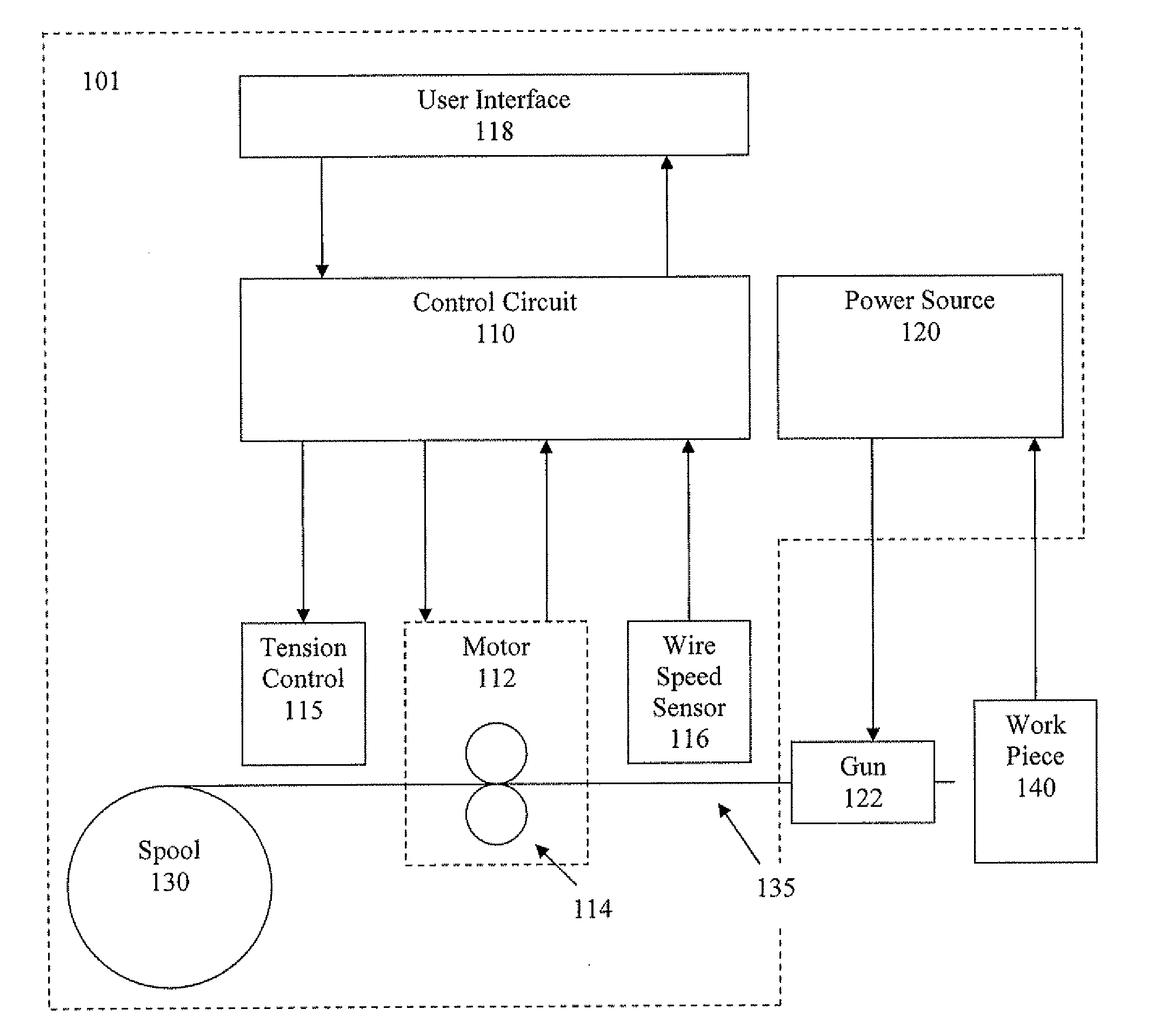

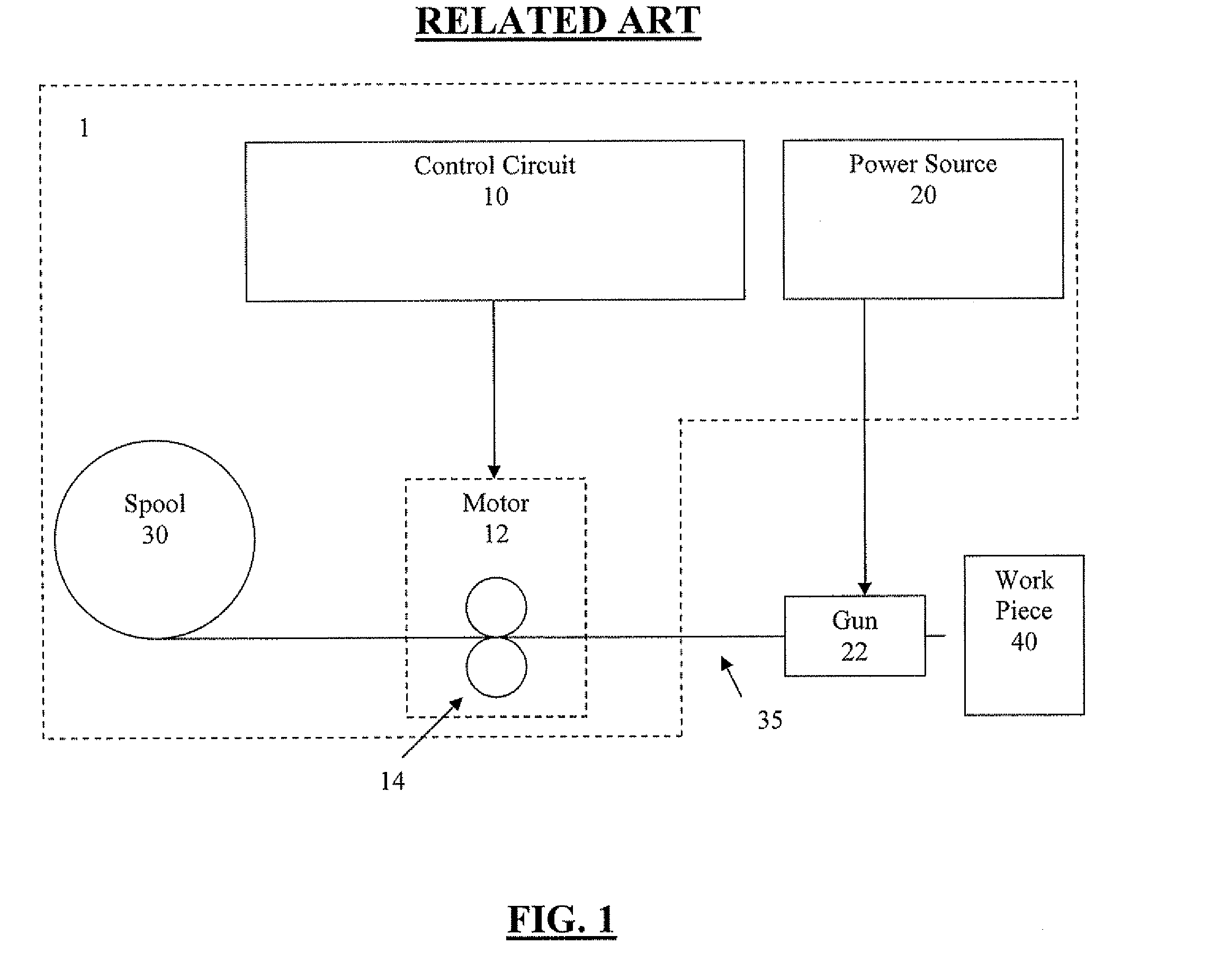

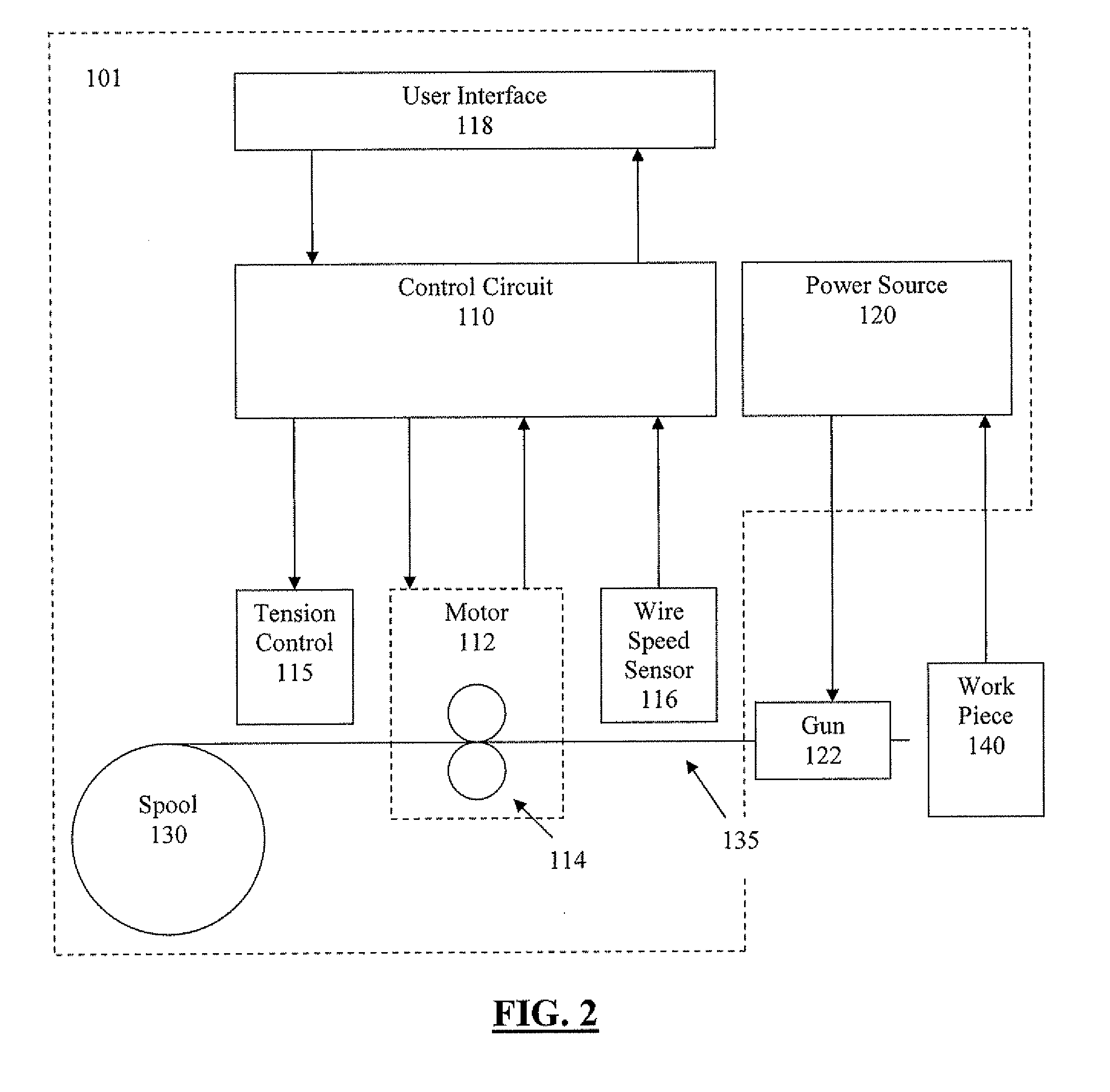

Automatic welding wire feed adjuster

An automatic wire feed adjuster, including a feeding mechanism including a pair of rollers that feeds a wire therebetween, a tension controller that adjusts a tension between the pair of rollers, a wire speed sensor that measures a fed speed of the wire after exiting the feeding mechanism, and a control circuit that compares a driven speed of the wire with the fed speed of the wire, and that decides whether to instruct the tension controller to adjust the tension between the pair of rollers.

Owner:LINCOLN GLOBAL INC

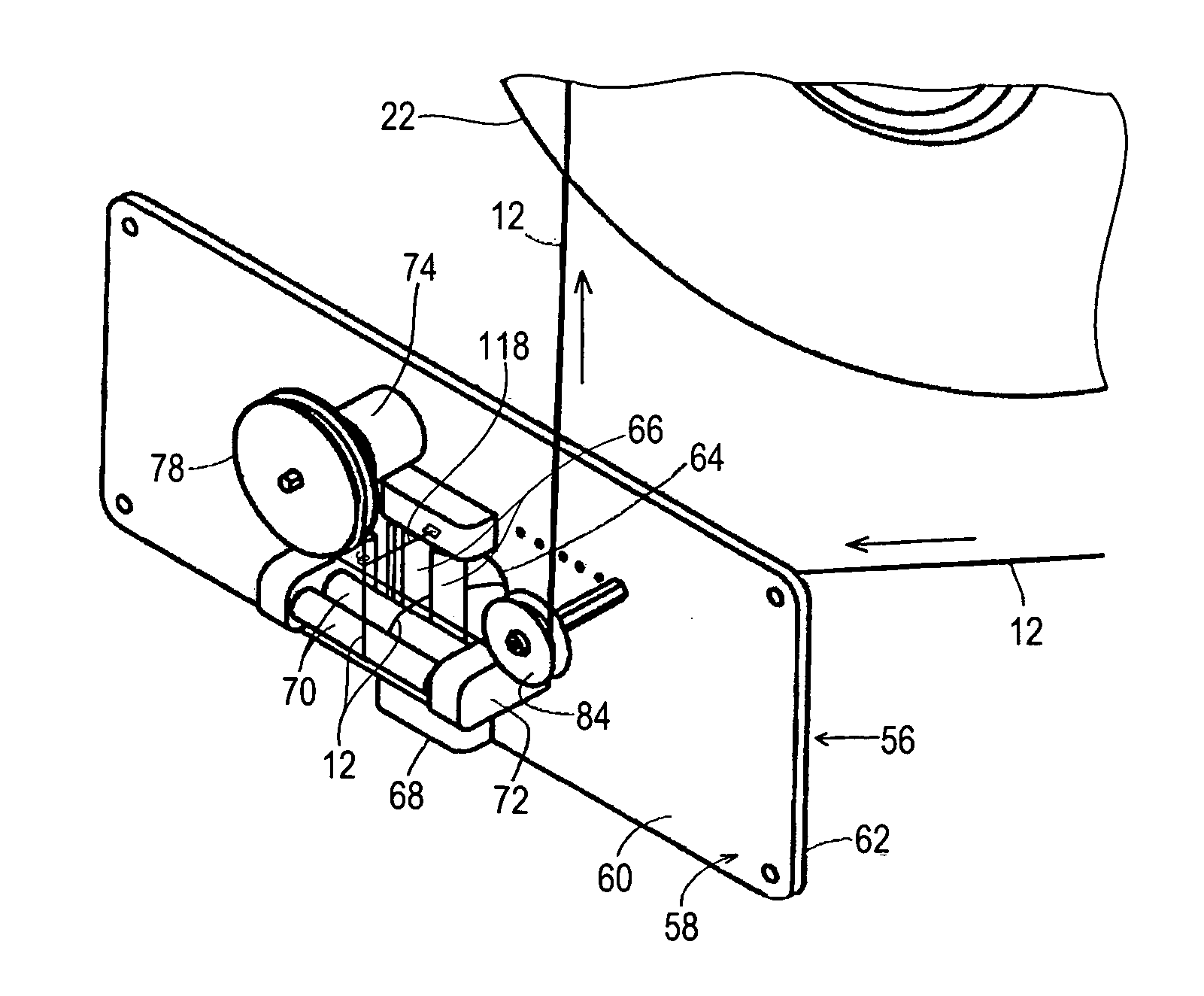

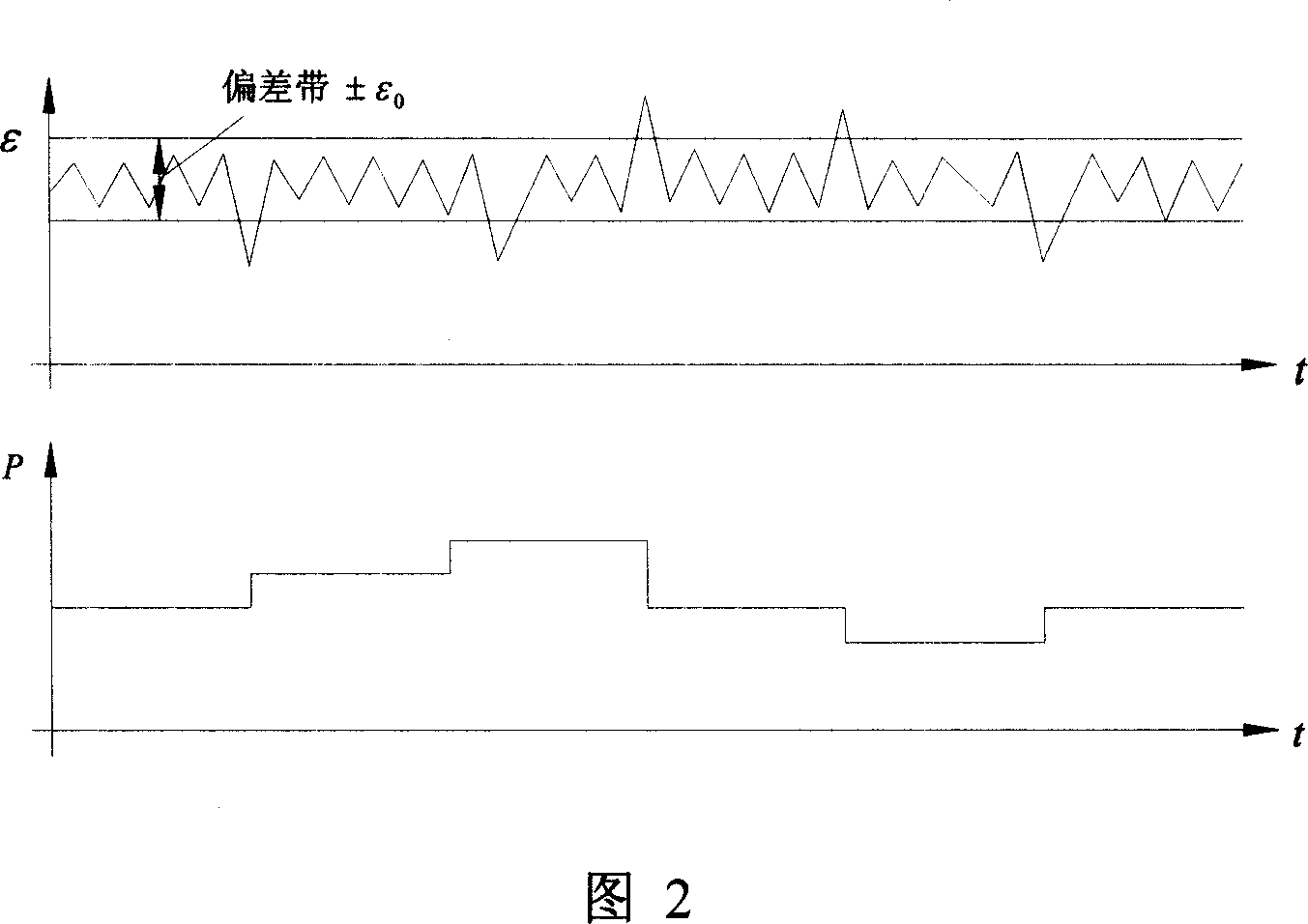

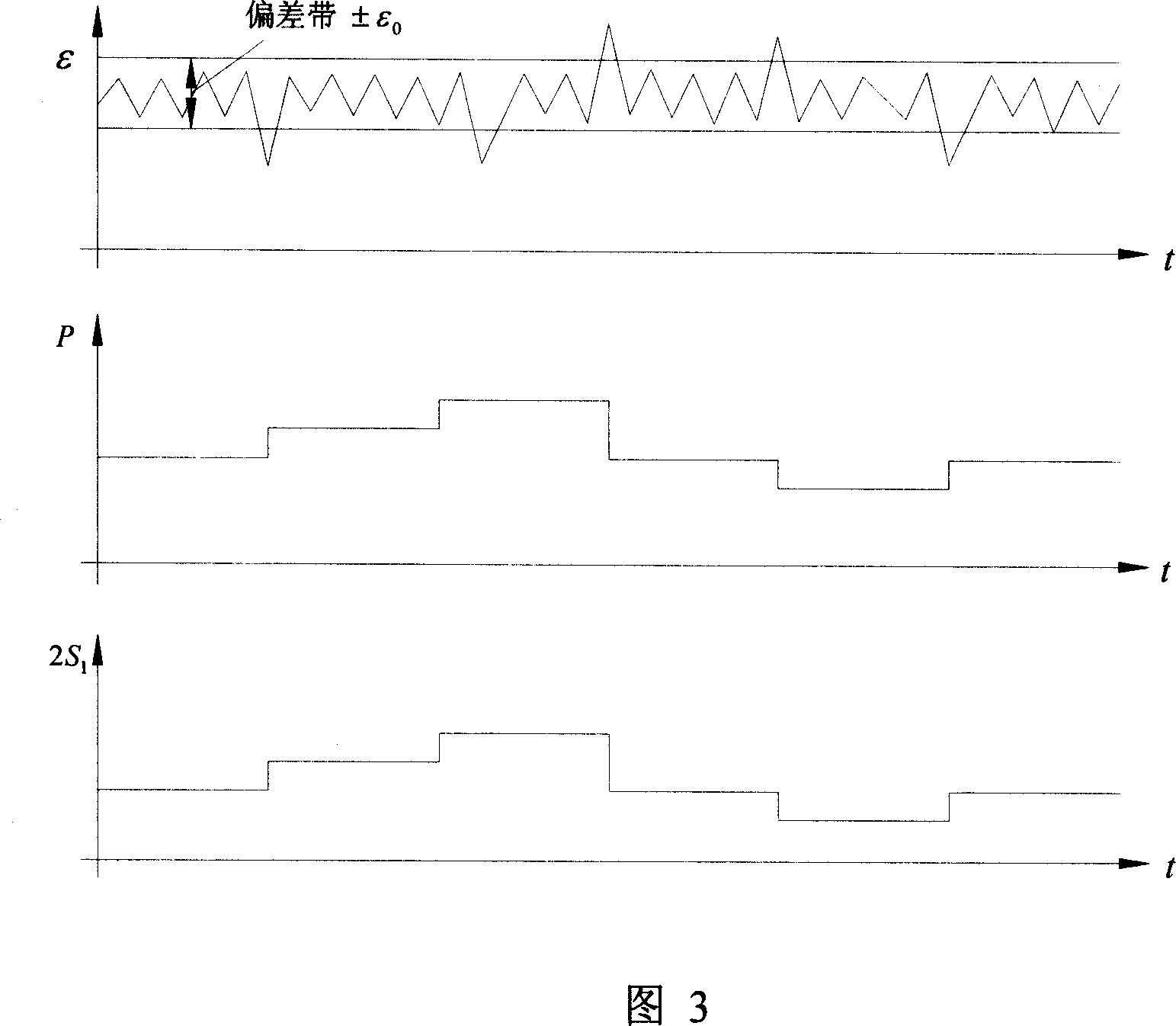

Tension controlled thread feeding system

InactiveUS20050133653A1Fast and reliable methodFast and reliableWeft knittingFilament handlingFiberHandling system

A system, apparatus and method for tension control in a thread feeding system that provides a fast and reliable method for feeding high tack elastomeric thread or fiber from a package to a thread processing system. A drive and tension control apparatus at least one of increments, maintains or decrements the speed of a driven take-off roll when the tension is out of a predetermined range of operation. A tension controller devices measures tension and determines whether the average tension for the moving threads is out-of-range relative to the predetermined tension values for the threads. Alarms and other indicators may also be used to determine the threads are at least one of broken, not moving and out-of-range for tension control.

Owner:INVISTA NORTH AMERICA R L

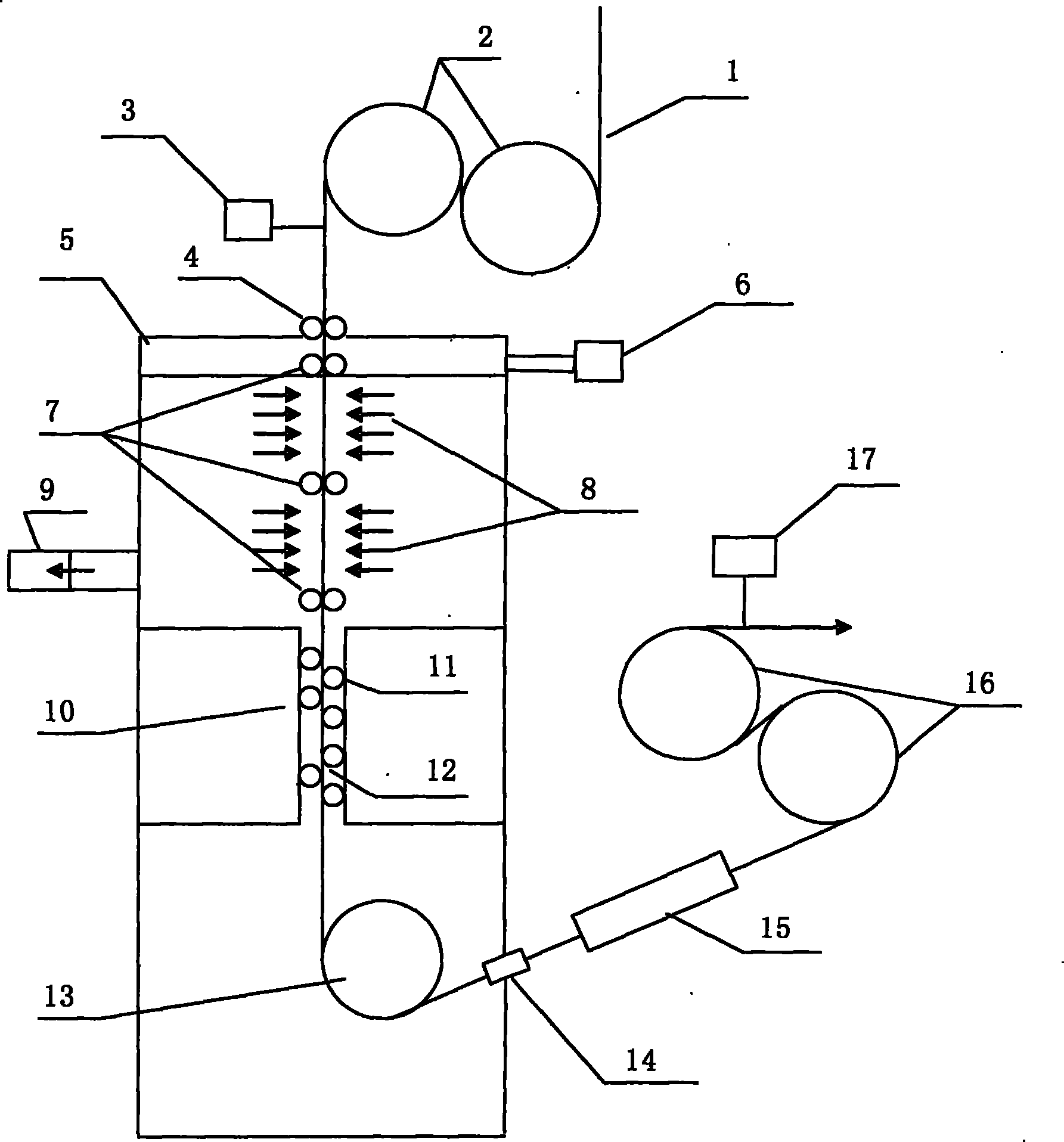

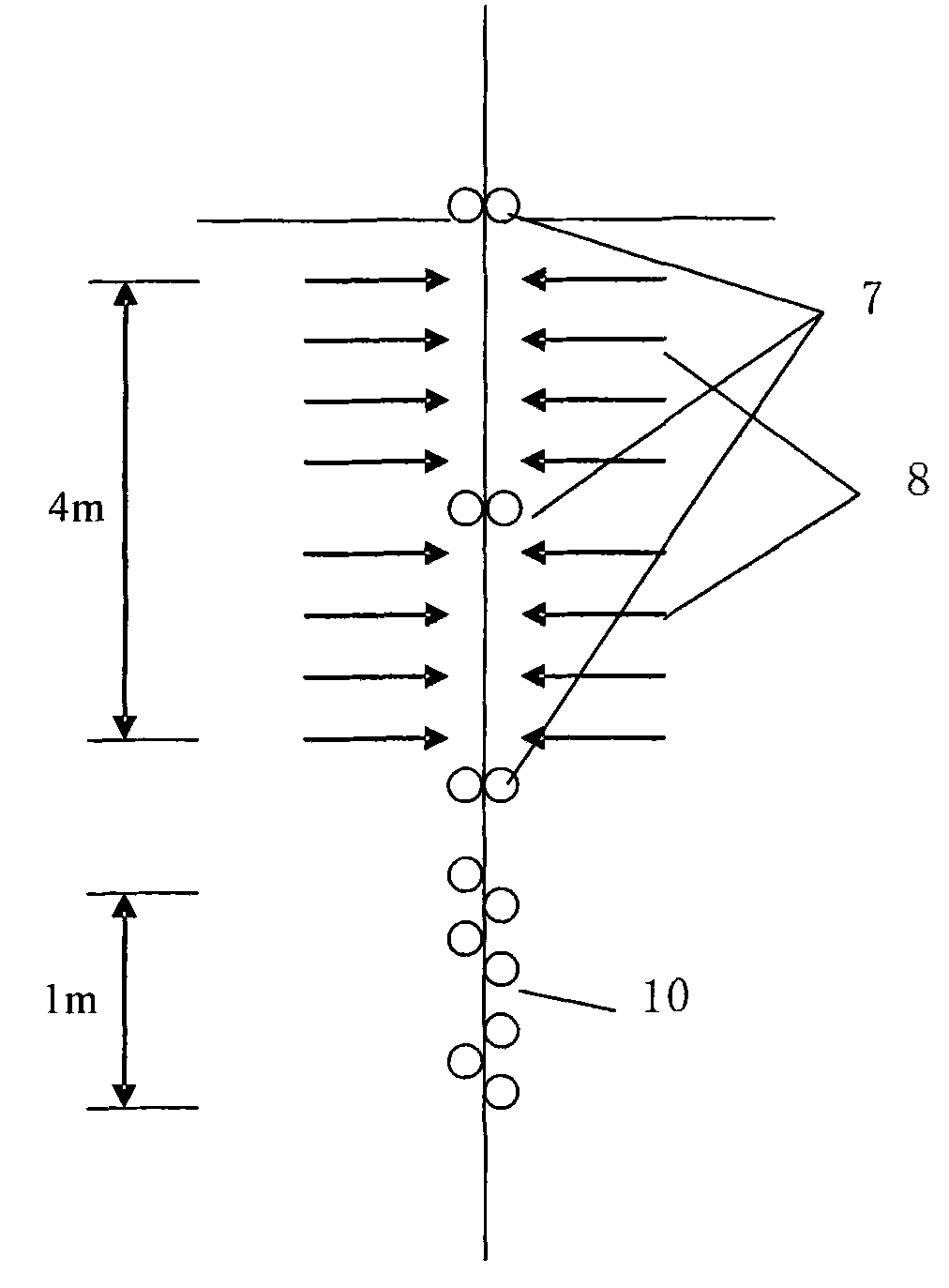

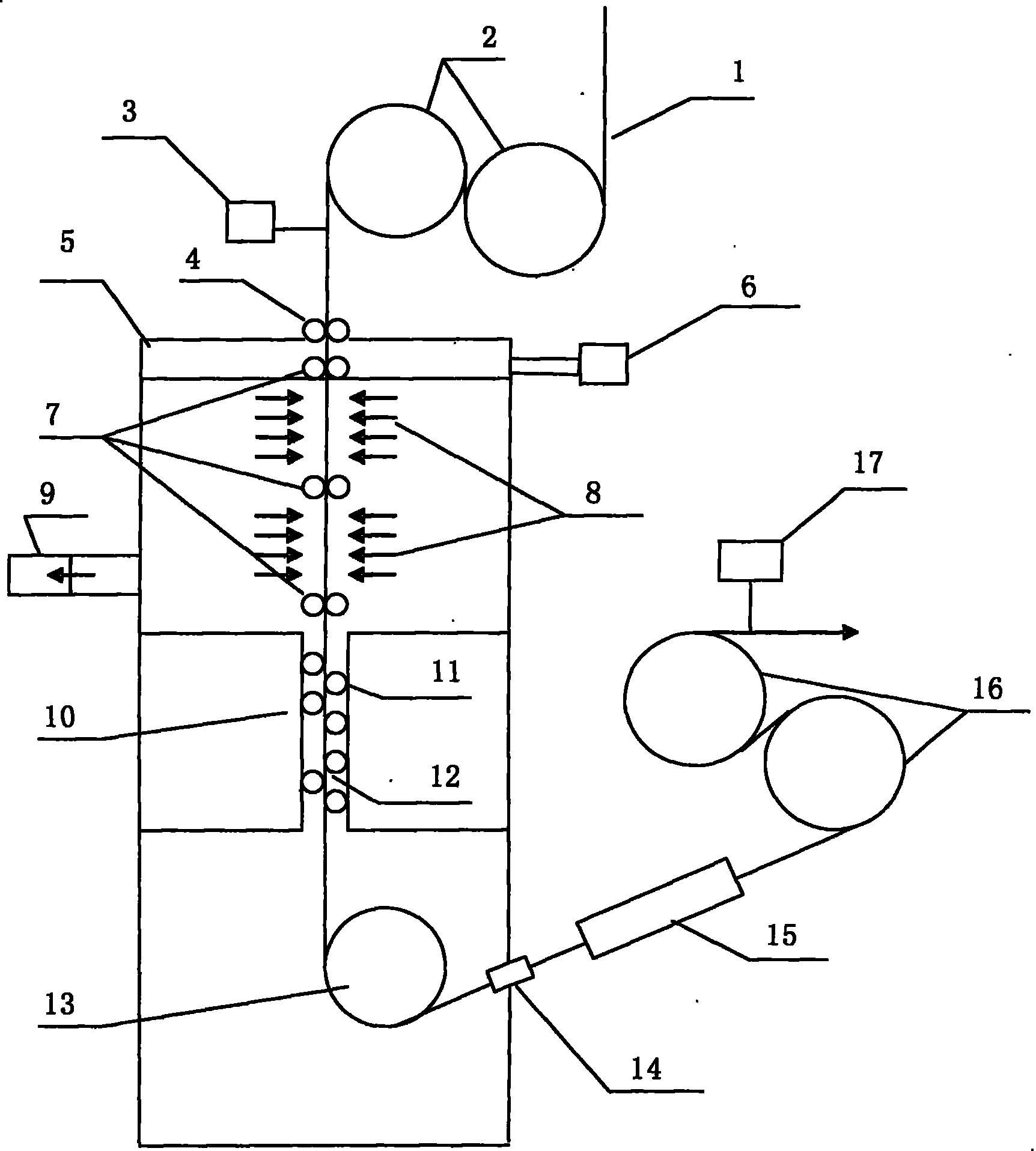

Water quenching and cooling method and device for ultrahigh-strength strip steel

ActiveCN101993995ARapid coolingGood effectFurnace typesHeat treatment furnacesSpray nozzleStrip steel

The invention has the purpose of providing a water quenching and cooling method and device for ultrahigh-strength strip steel. The device comprises an inlet tension roll (2), an outlet tension roll (16), and a water quenching and cooling tank (5), wherein water quenching nozzles (8) and a withdrawing and straightening machine (10) are arranged in the cooling tank; the cooling tank is connected with a gas sealing device (4), a gas circulating device (6), a water circulating device (9), a water sealing device (14), a drying device (15), a strip steel operating line centering device (3) and a tension control system (17); the multiple water quenching nozzles (8) in the front section of the water quenching and cooling tank eject high-pressure water to cool the strip steel when the strip steel to be cooled enters the water quenching and cooling tank (5) through the inlet tension roll (2); the steel plate passes through the withdrawing and straightening machine (10) arranged on the lower part of the water quenching and cooling tank (5) after being cooled to 250 to 350 DEG C; the shape of the strip steel plate is straightened by a mild straightening mode; the strip steel after being cooled and straightened is transferred out of the water quenching and cooling device through the outlet tension roll (16); and the rapid cooling can be realized and the ultrahigh-strength steel plate with a good shape can be obtained at the same time.

Owner:SHOUGANG CORPORATION

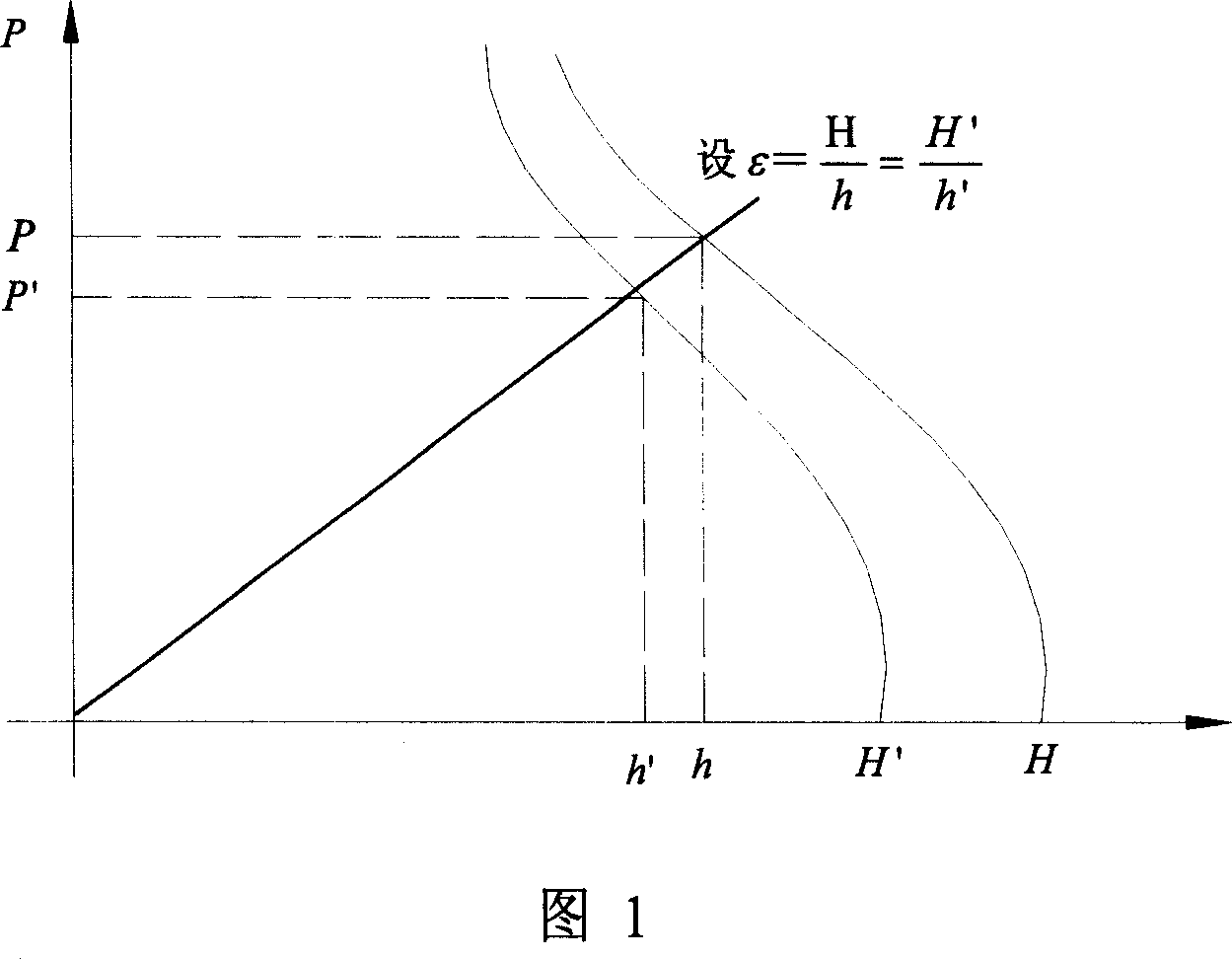

Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

ActiveCN1923391AGuaranteed accuracyGuarantee the shape qualityRoll force/gap control deviceTension/compression control deviceControl systemClosed loop

The invention relates to a method for optimizing and controlling the rolling tensioning roller of finisher. Wherein, it is in the extending rate control system; the inner ring of control closed loop is rolling pressure closed loop and tension closed loop; based on the difference of adjustment sequence of tension and rolling pressures, first adjusting tension or first adjusting rolling pressure to control the extending rate, to control extending rate and plate shape; the method that first adjusting tension is that optimizes the tension to control extending rate, when it is over limited range, keeps it constant, and adjusts the rolling force; and the method that first adjusting rolling pressure is that optimizes the rolling pressure to control extending rate, when it is over limited range, keeps it constant and adjusts the tension force. The invention can confirm the accuracy of extending rate and the quality of sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Multi-functional tape applicator

A multifunction tape applicator for applying a section or sections of pressure sensitive adhesive tape to a carton selectively in different carton sealing configurations, namely C-clip; single L-clip, front and back L-clips and sectional skip-gap taping. The multifunction tape applicator comprises a basic tape applicator unit to apply a common C-clip tape from a tape roll with built-in design apparatus for tape applying, tape cutting, tape tension control to facilitate other functions and a mechanical or powered actuation attachment unit which is to be installed onto the modified basic tape applicator unit to actuate other functions based on the requirement of the application.

Owner:LAMUS ENTERPRISES

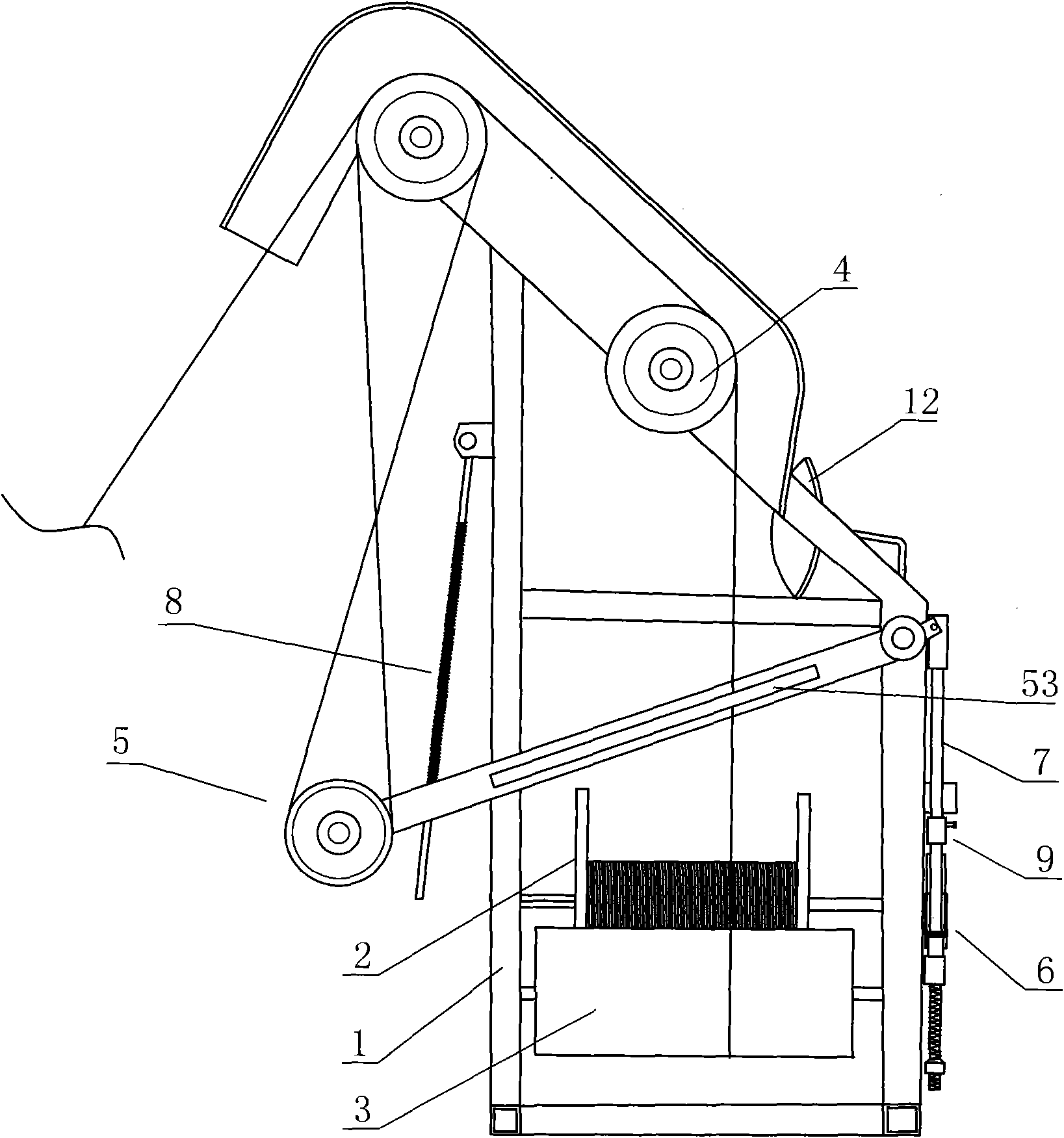

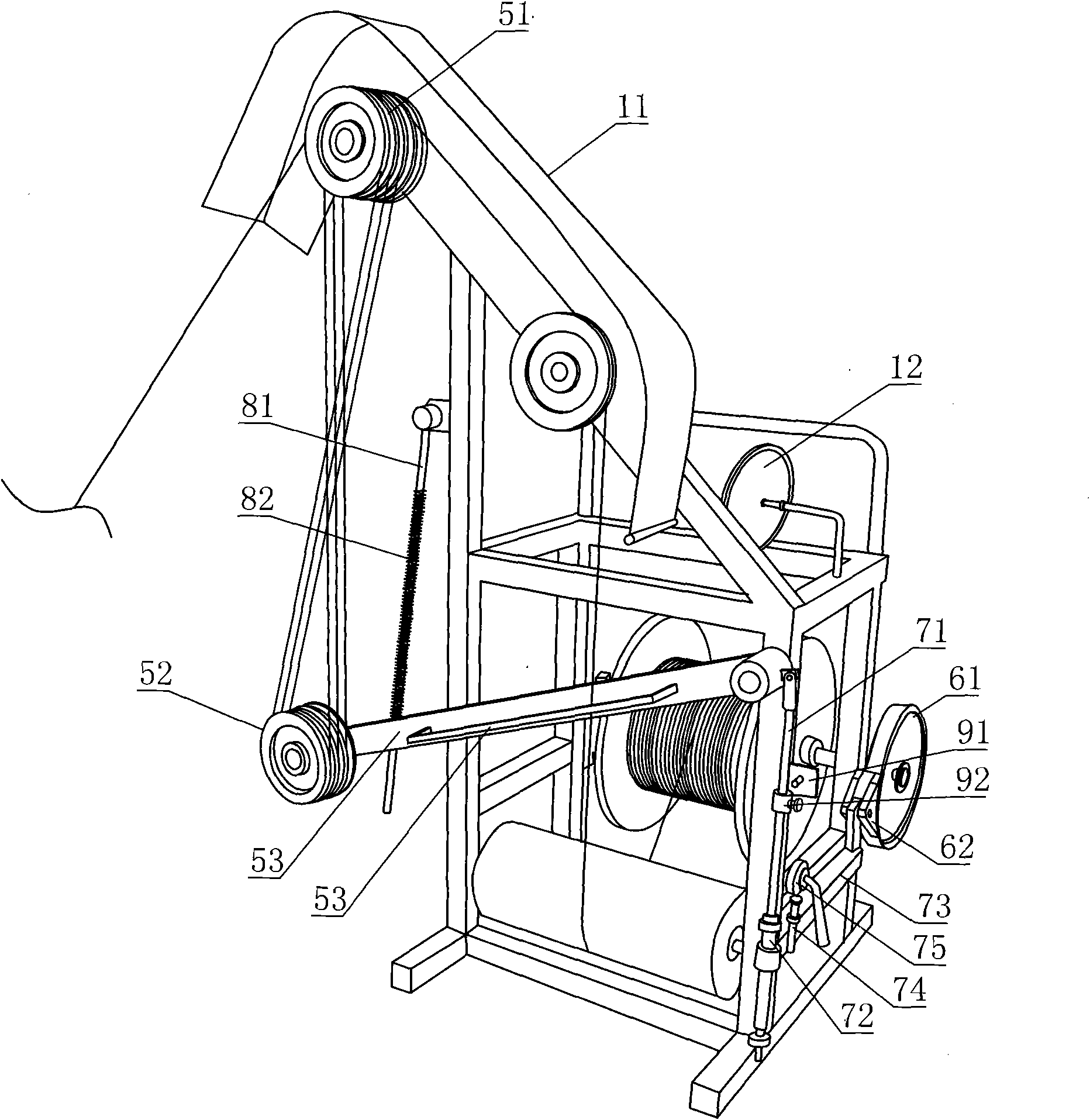

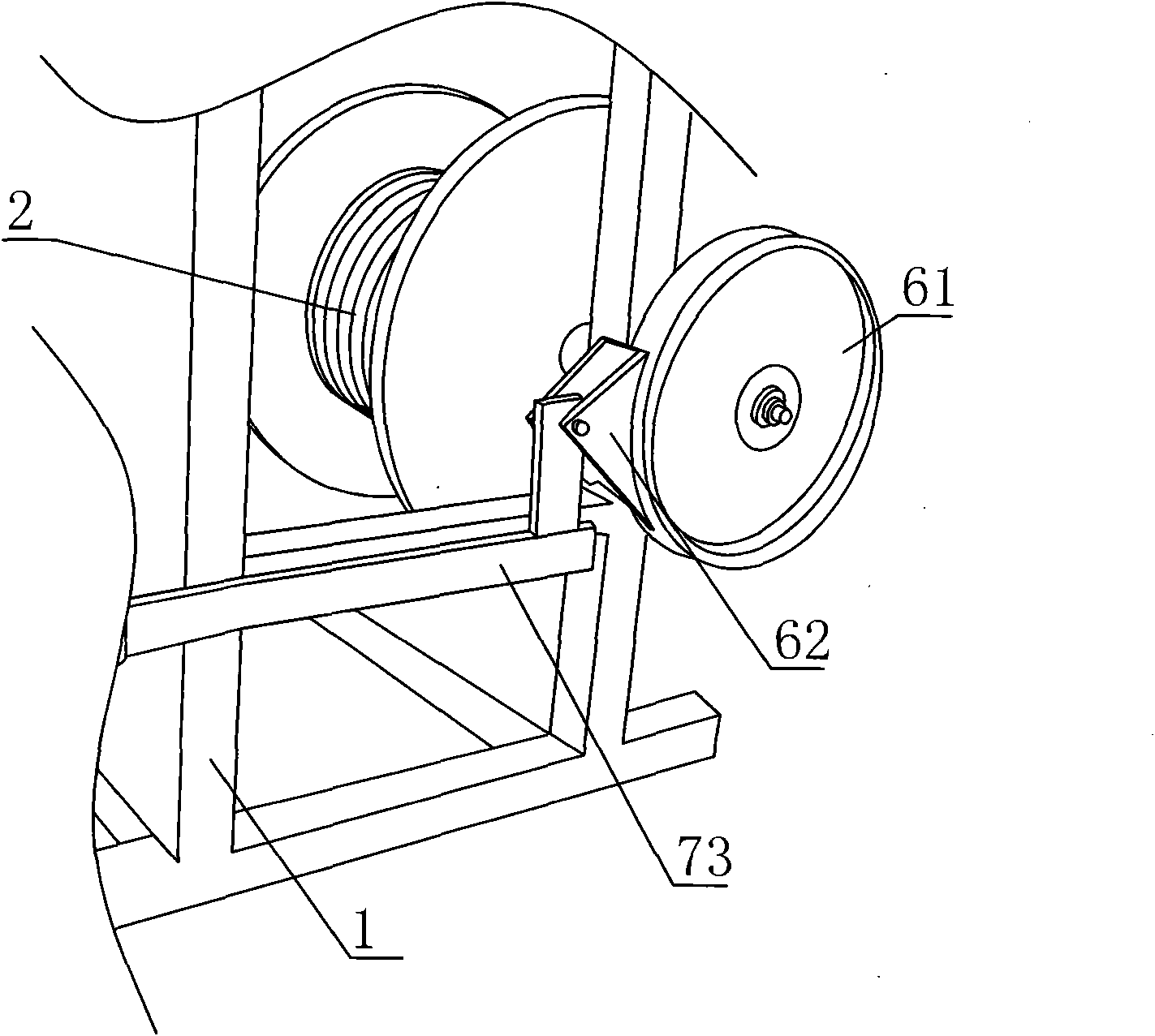

Cable conveyance tension adjustment method and device implementing same

InactiveCN101780905AEnsure personal safetyEasy to monitor working statusFilament handlingWinding machineCable transport

The invention discloses a cable conveyance tension adjustment method. In the method, a frame and a wire coil arranged on the frame are used. The method comprises the following steps: 1, preparing a cable guide roller; 2, preparing a cable guide wheel; 3, preparing a tension control device; 4, preparing a damping device; and 5, preparing an adjustment device so as to adjust the amplitude of swing of the tension control device and set corresponding damping force output by the damping device according to the amplitude of swing. The method provided by the invention has the advantages of quickly and uniformly conveying cables wound in the wire coil to a winding machine with constant tension. A device provided by the invention has a simple structure and high tension control and adjustment accuracy, automatically and continuously detects and adjusts the tension of the cables in the whole production process, keeps the tension constant all the time to actually realize cable transport with the constant tension, is convenient to operate, can automatically convey the cables wound in the wire coil to the winding machine with the constant tension only by starting the winding machine, and improves the production efficiency.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD +1

Automatic cutting equipment

InactiveCN102259774AEasy to controlGuaranteed smoothArticle deliveryWebs handlingProduction lineAutomatic control

The invention relates to full-automatic cutting equipment, comprising a main control computer arranged in a chassis and an automatic tension control discharging mechanism, a transporting and metering mechanism, an automatic punching mechanism, an automatic pressing and cutting mechanism, an automatic feeding mechanism and an automatic material receiving and folding mechanism which are arranged in turn according to a process production line. The transporting and metering mechanism, the automatic punching mechanism, the automatic pressing and cutting mechanism and the automatic feeding mechanism are installed on a transmission platform. Therefore, all functions of control discharging, metering, transporting, cutting, punching, receiving and folding materials are carried out on equipment simultaneously. Compared with the prior art, the equipment disclosed by the invention is applicable to fully-automatic cut of soft texture materials, such as an EVA (Ethylene Vinyl Acetate) film.

Owner:上海博显实业有限公司

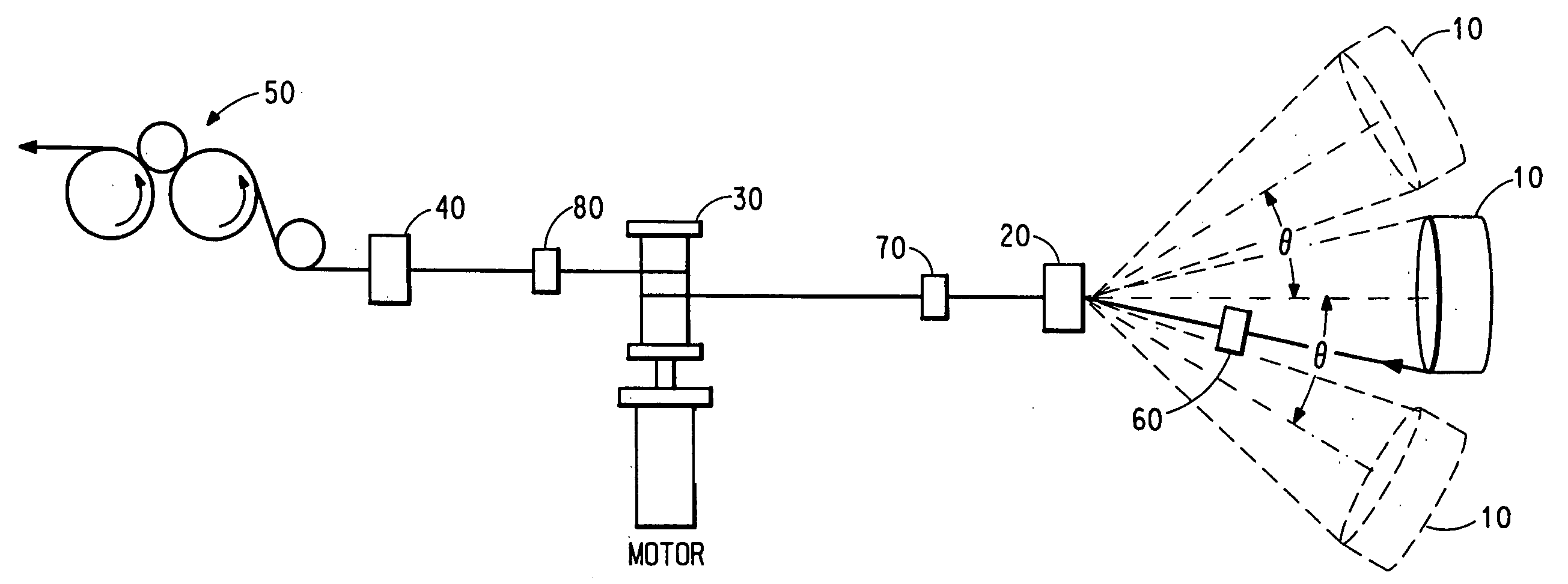

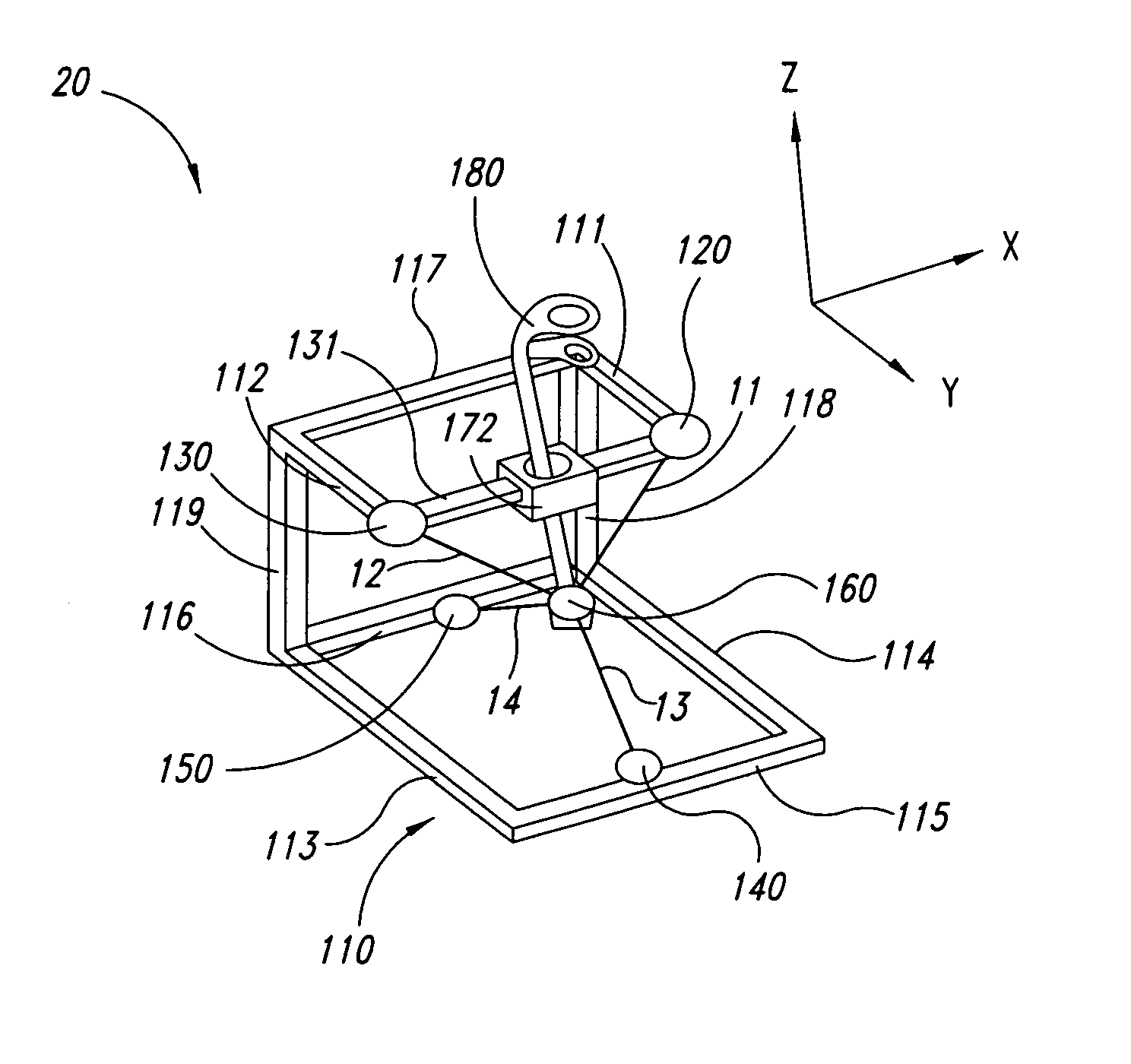

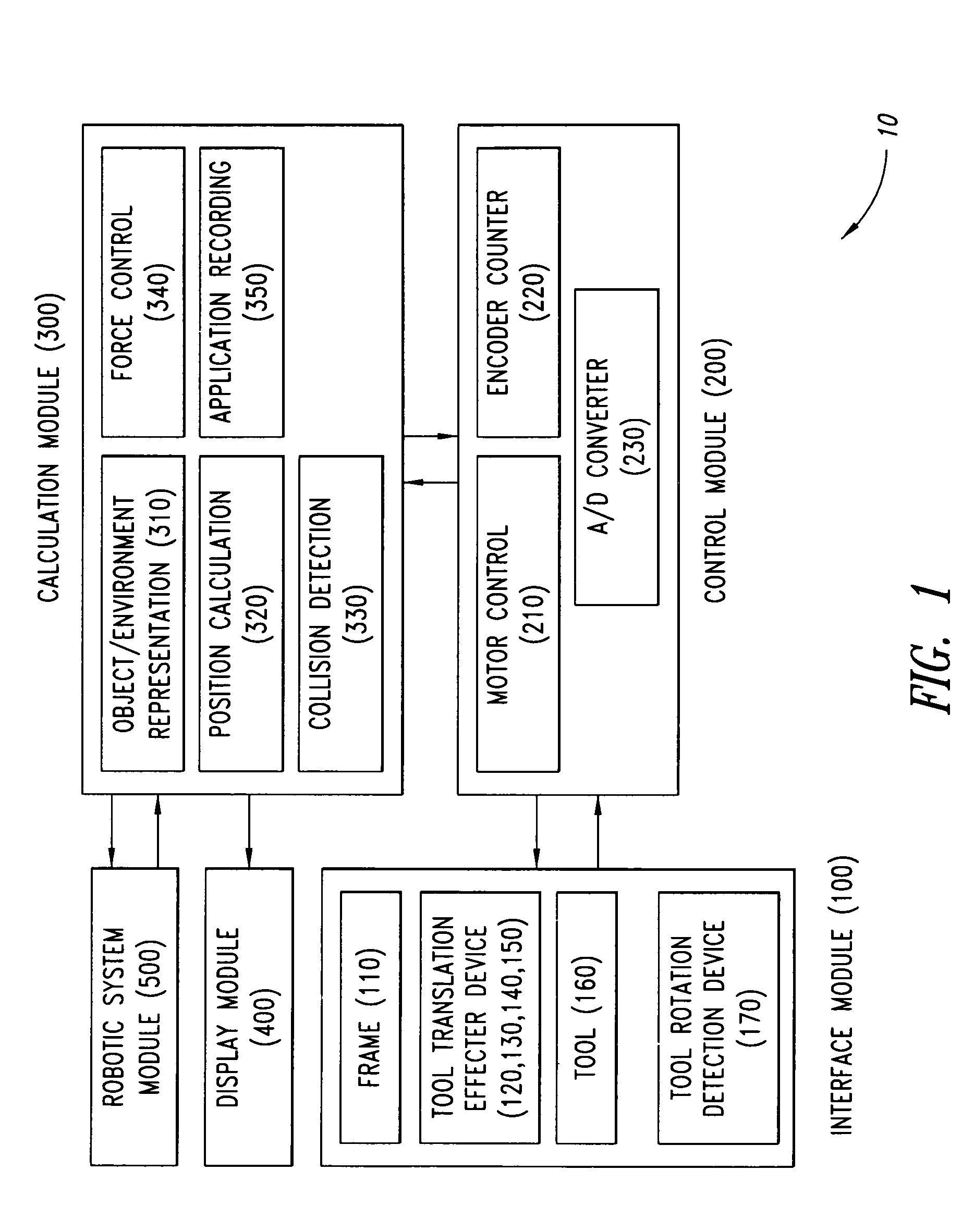

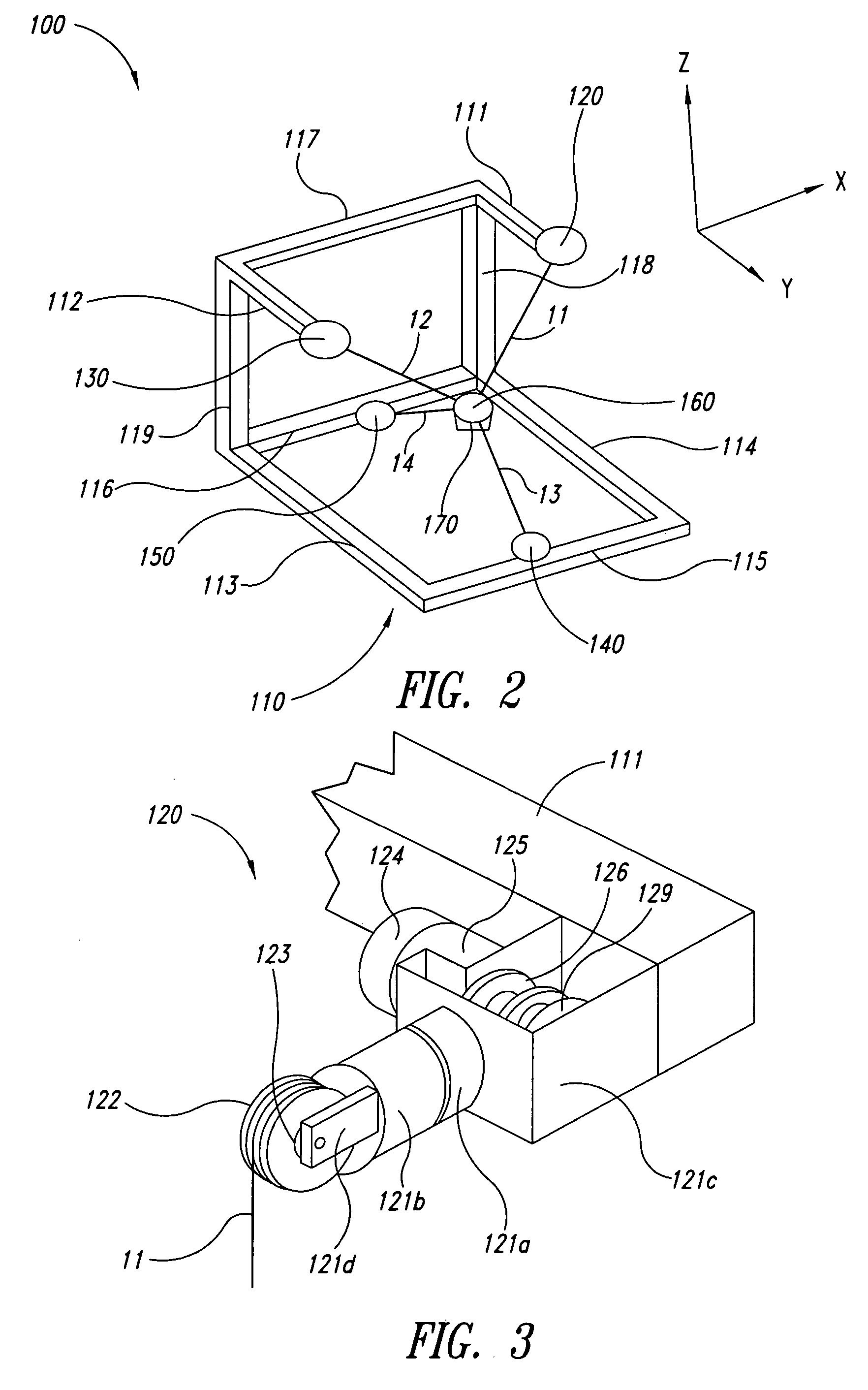

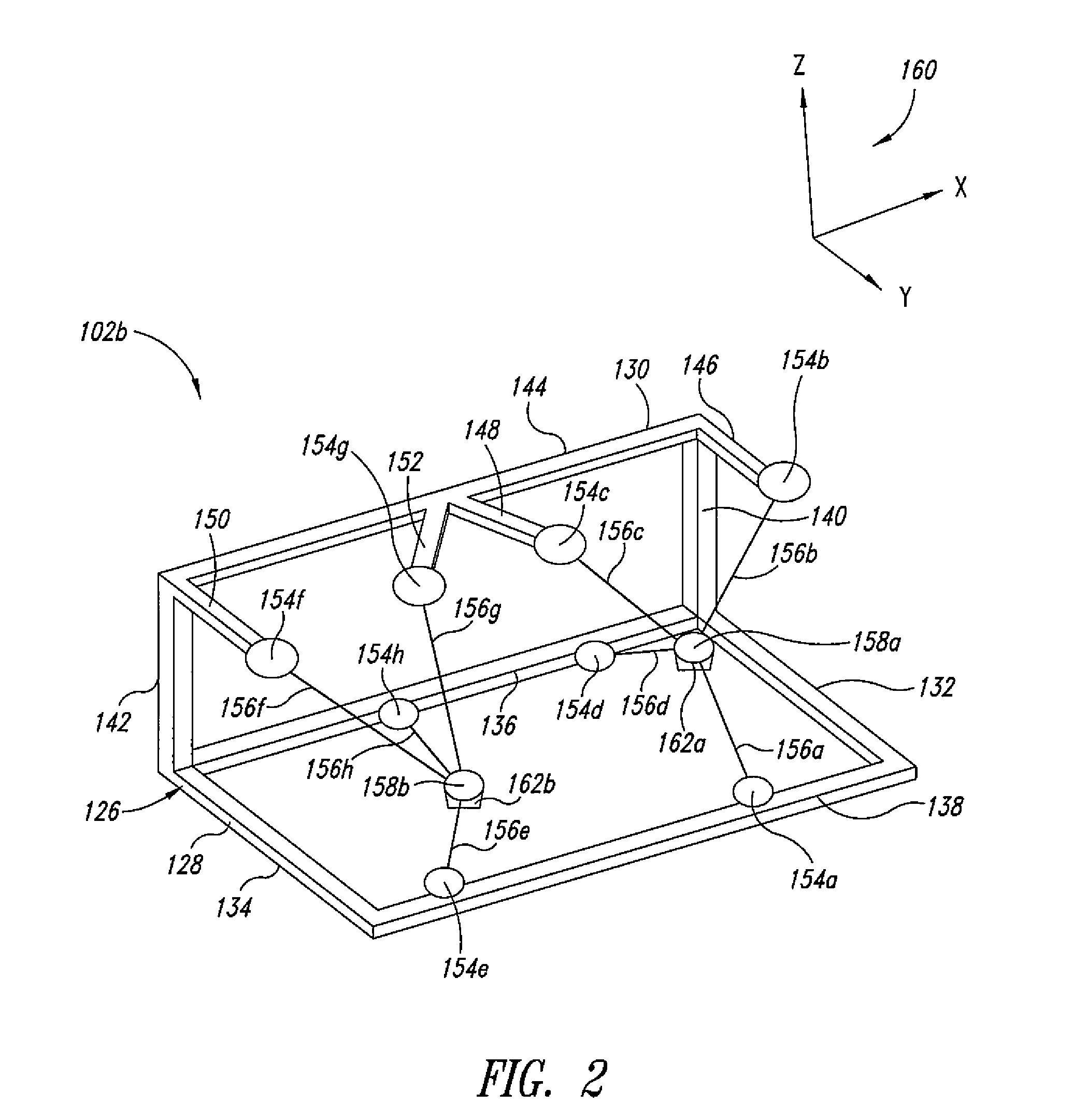

Method, apparatus, and article for force feedback based on tension control and tracking through cables

InactiveUS7880717B2Maintain positioning accuracyMinimal interventionProgramme-controlled manipulatorGripping headsSensor arrayEngineering

A haptic device for human / computer interface includes a user interface tool coupled via cables to first, second, third, and fourth cable control units, each positioned at a vertex of a tetrahedron. Each of the cable control units includes a spool and an encoder configured to provide a signal corresponding to rotation of the respective spool. The cables are wound onto the spool of a respective one of the cable control units. The encoders provide signals corresponding to rotation of the respective spools to track the length of each cable. As the cables wind onto the spools, variations in spool diameter are compensated for. The absolute length of each cable is determined during initialization by retracting each cable In turn to a zero length position. A sensor array coupled to the tool detects rotation around one or more axes.

Owner:MIMIC TECH

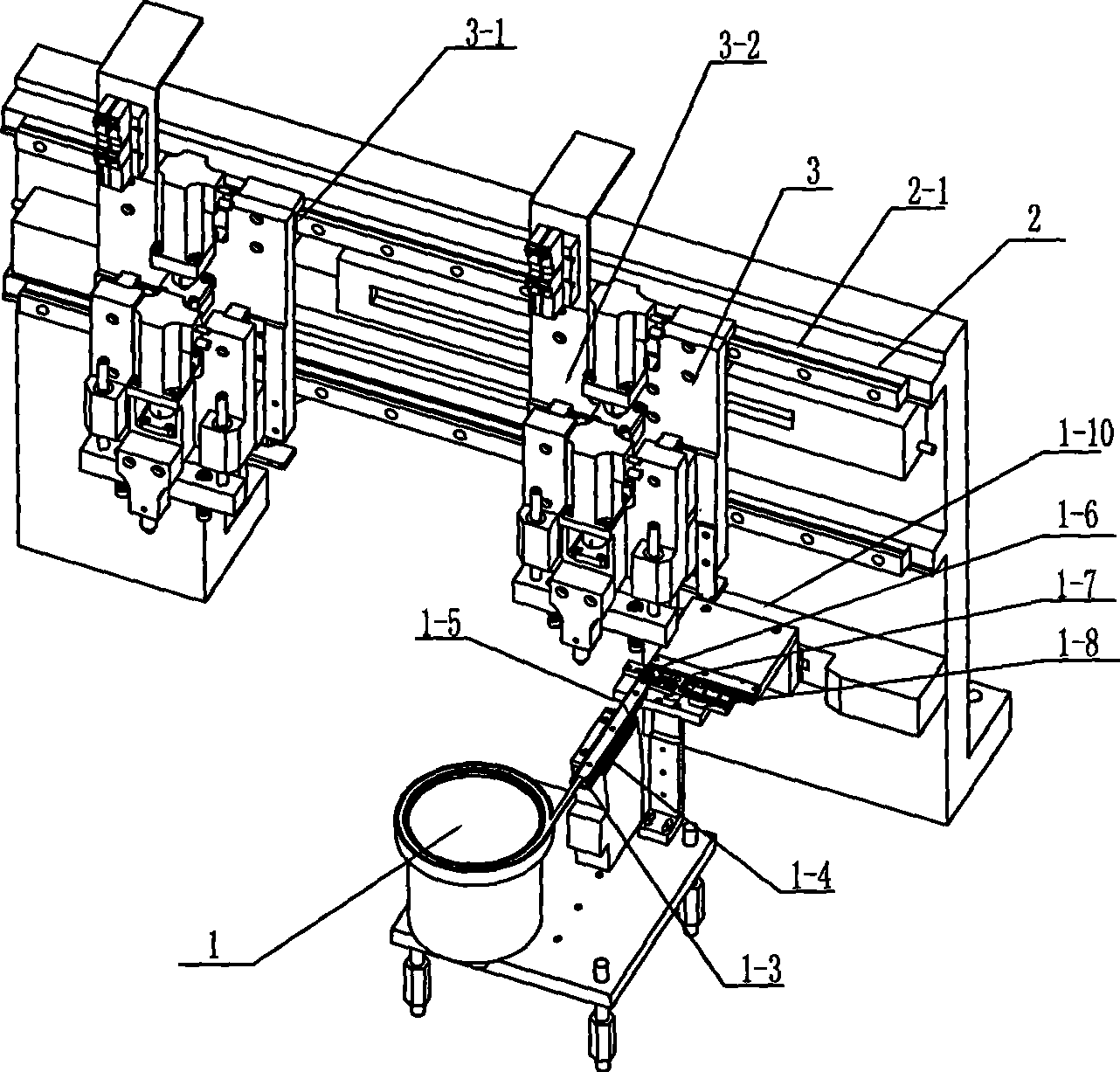

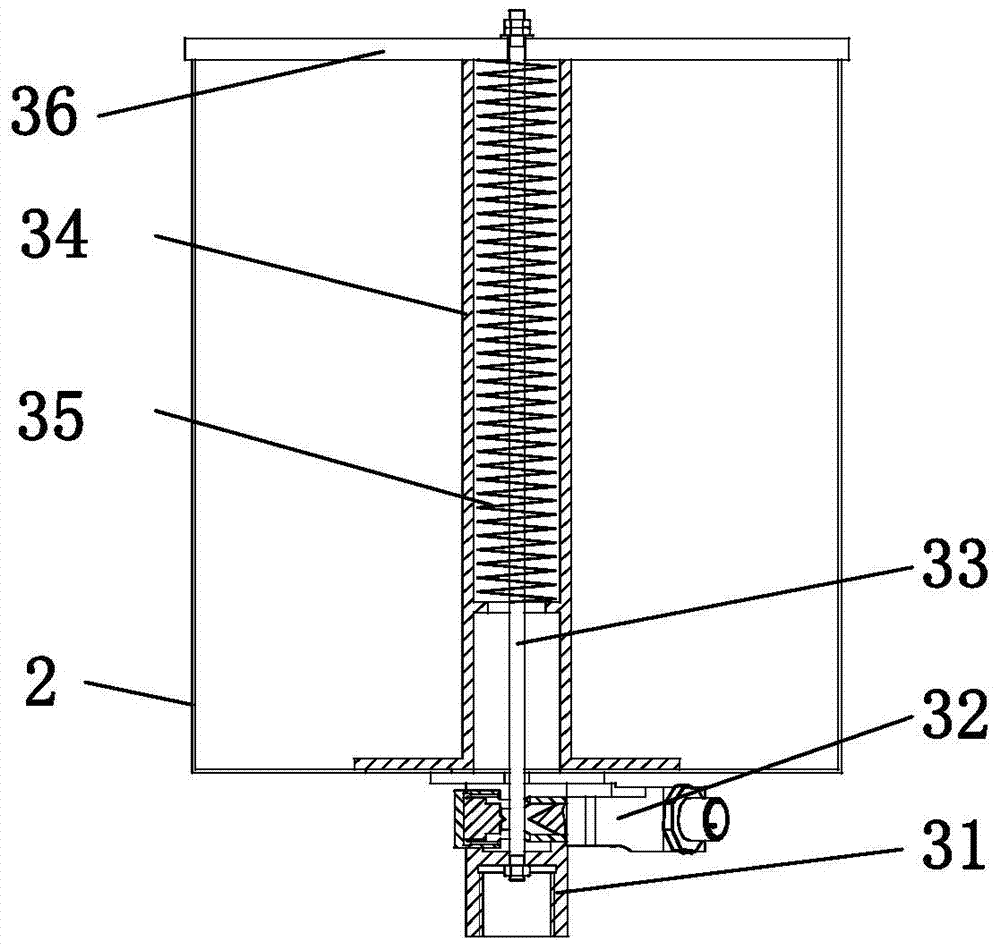

Full-automatic winding machine for winding plastic pipe

InactiveCN101301971AImprove work efficiencyGood automation effectFilament handlingWinding machineElectric machinery

The invention relates to a full-automatic winding machine used for winding plastic tubes, aiming at simplifying the complicated structure of the winding machine and comprising a main-machine base, a rotary big arm arranged on the main-machine base, a tube-distributing mechanism and a tension control mechanism, wherein, two winding disks are symmetrically arranged on the rotary big arm, and after improvement, two winding-disk driving motors are symmetrically arranged on the rotary big arm and respectively connected with the two winding disks in a transmission way. The invention adopts the design of configuring driving sources respectively for the two winding disks to overcome the defects of complicated winding disk supporting and jointing devices, etc. existing by sharing one driving source, and the improvement reduces parts and reduces the manufacturing accuracy of the parts so as to simplify action program and distinctly enhance the reliability of equipment. The full-automatic winding machine of the invention improves the automation capability of plastic hose winding, enhances winding efficiency and is suitable for the automatic manufacturing line of various plastic hoses.

Owner:武志生

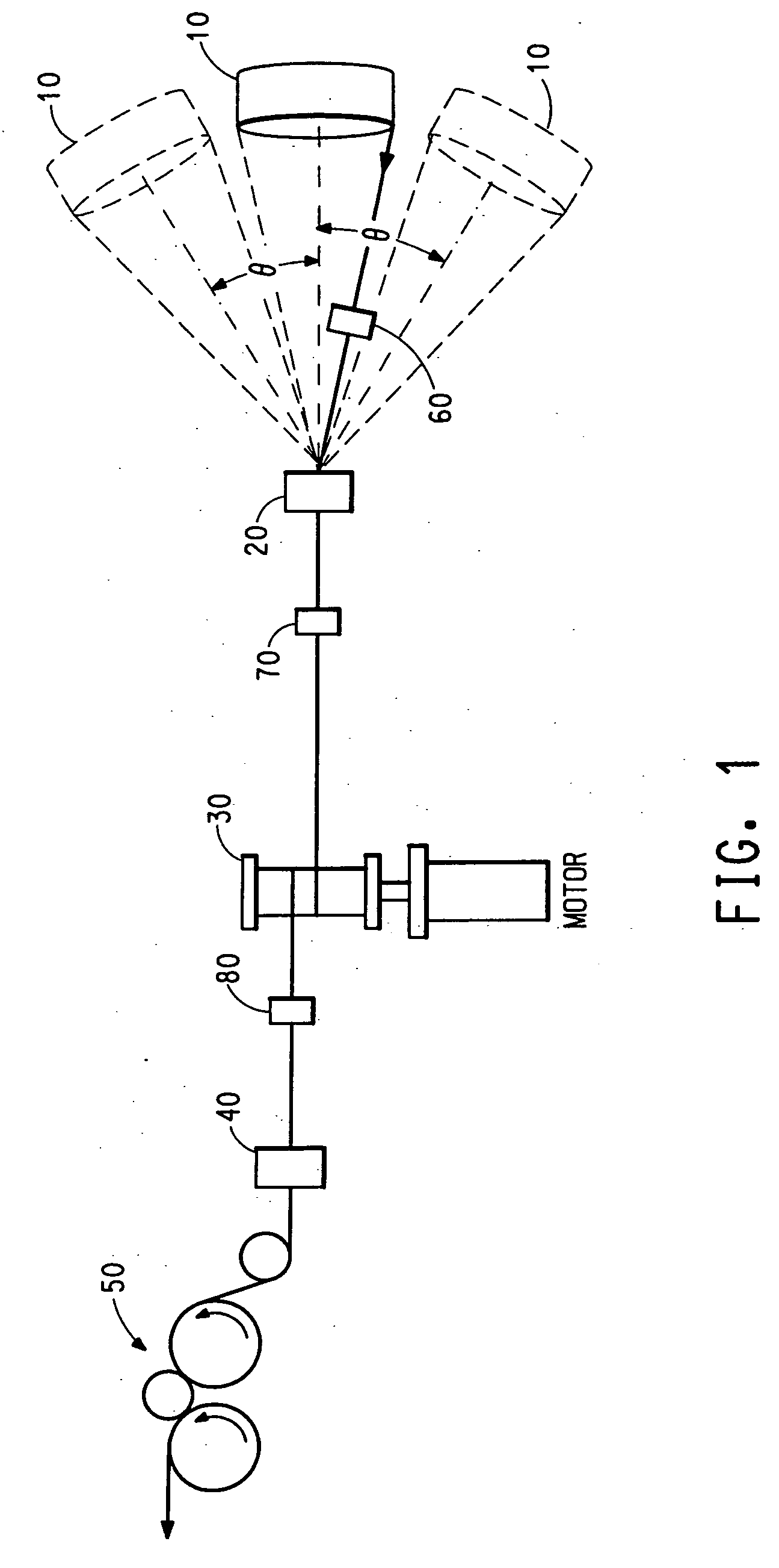

Methods, apparatus, and article for force feedback based on tension control and tracking through cables

ActiveUS20080150891A1Cathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTension control

A haptic interface system includes a cable based haptic interface device and a controller. The controller receives information related to movement of a grip in real-space and generates a stereoscopic output for a display device. The stereoscopic output includes images of a virtual reality tool whose motions mimic motions of the real-space grip.

Owner:MIMIC TECH

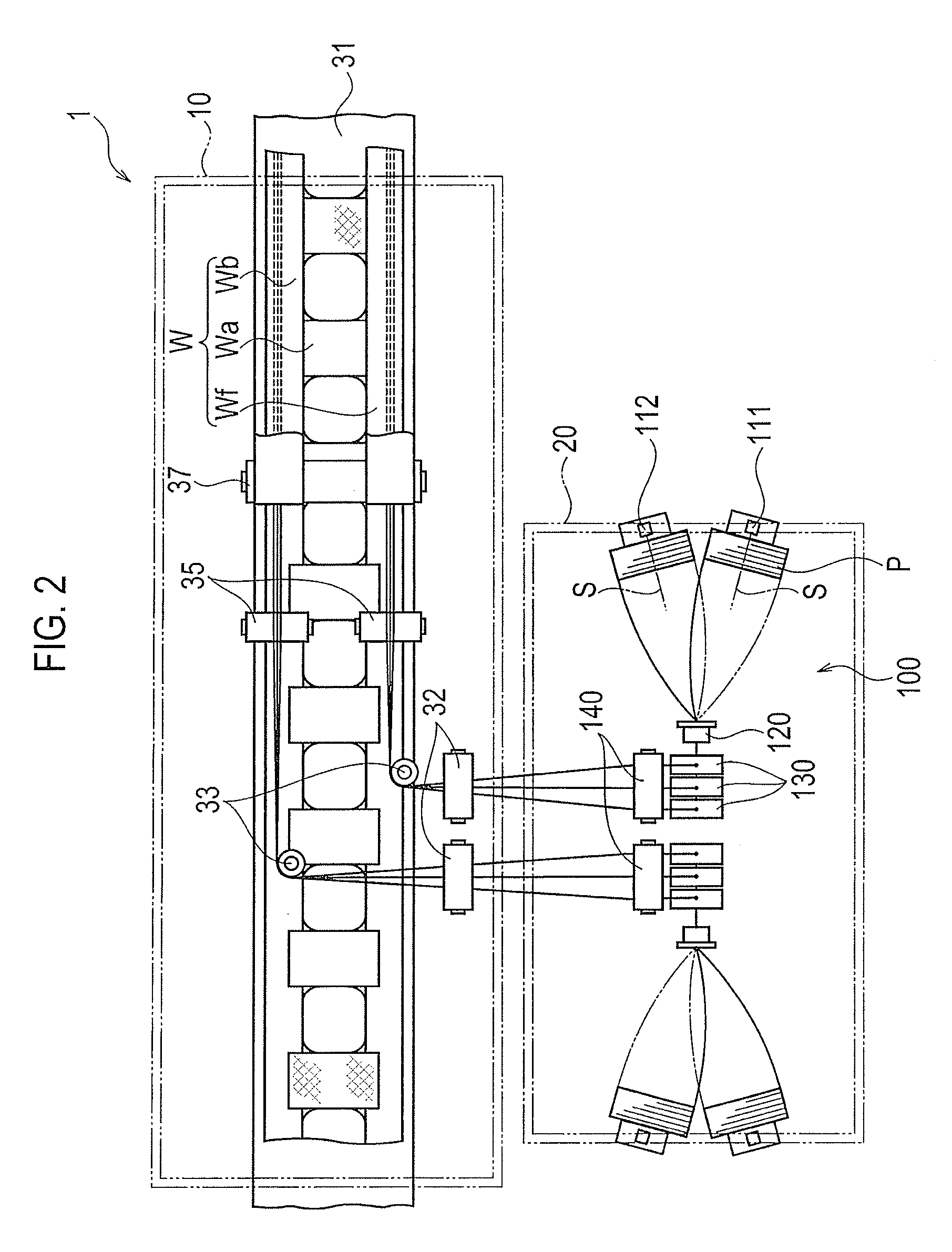

Elastic thread supply device

An elastic thread supply device including a tension controller configured to control the stress acting upon an elastic thread drawn from an elastic thread package, and a drive roll configured to supply the elastic thread dispensed from the tension controller to a processing line. The drive roll operates at a supply velocity slower than a conveyance velocity of a web, and increases or decreases the supply velocity depending on the fluctuation in the conveyance velocity.

Owner:UNI CHARM CORP

Unbacked fabric transport and condition system

An unbacked transport and conditioning printing system for printing a pattern on a fabric is disclosed. The system includes a fabric characterization and tension control subsystem for gathering information on variations in the fabric and an irregularity detection subsystem for detecting irregularities in the fabric, as well as, crease detection and removal. The fabric passes through a fabric drying and conditioning subsystem for characterization of the fabric. The system also includes a fabric control subsystem for advancing the fabric through a print zone, where a pattern is printed on an unbacked fabric. The fabric is transported through a drying and post-processing subsystem and a closed-loop color control subsystem.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com