Patents

Literature

359results about How to "Reduce control requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

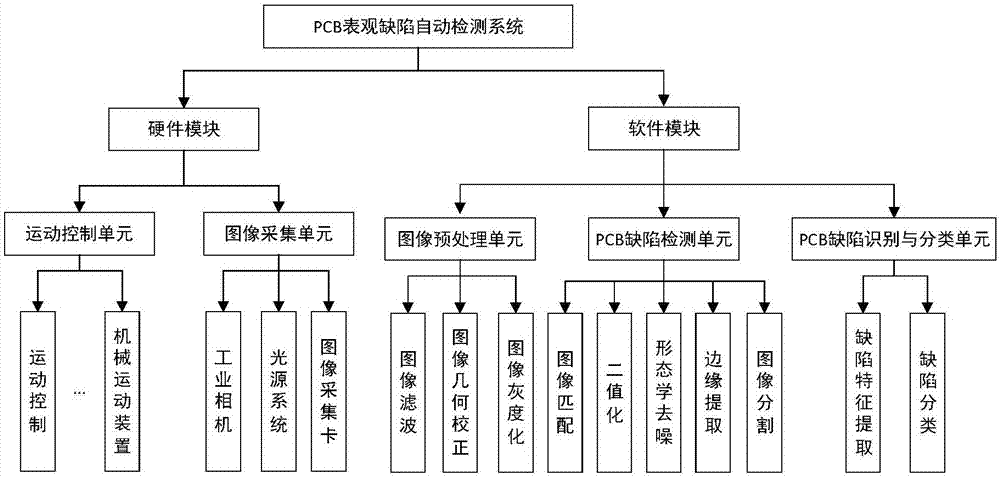

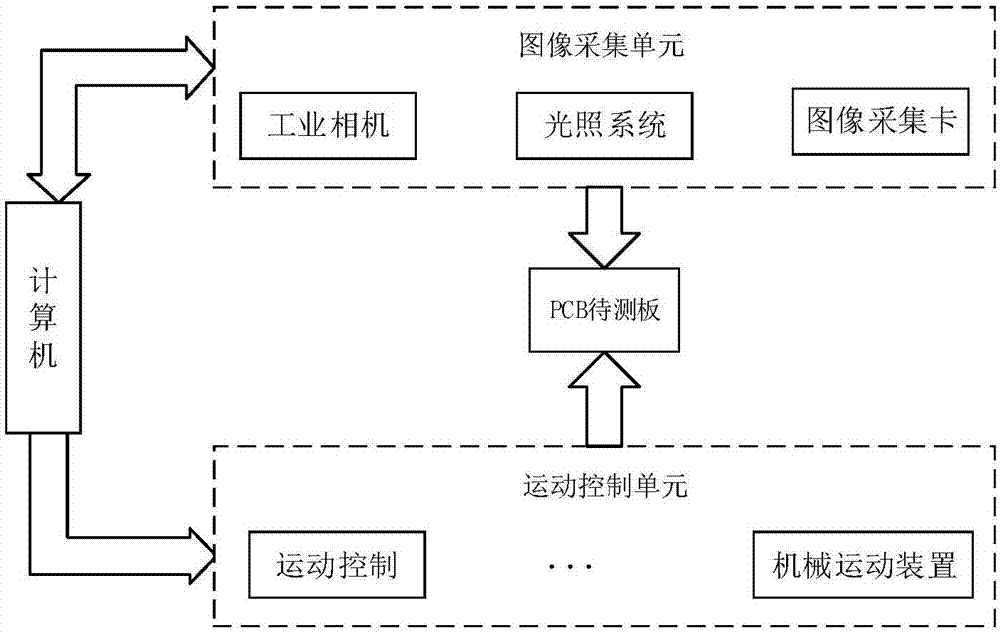

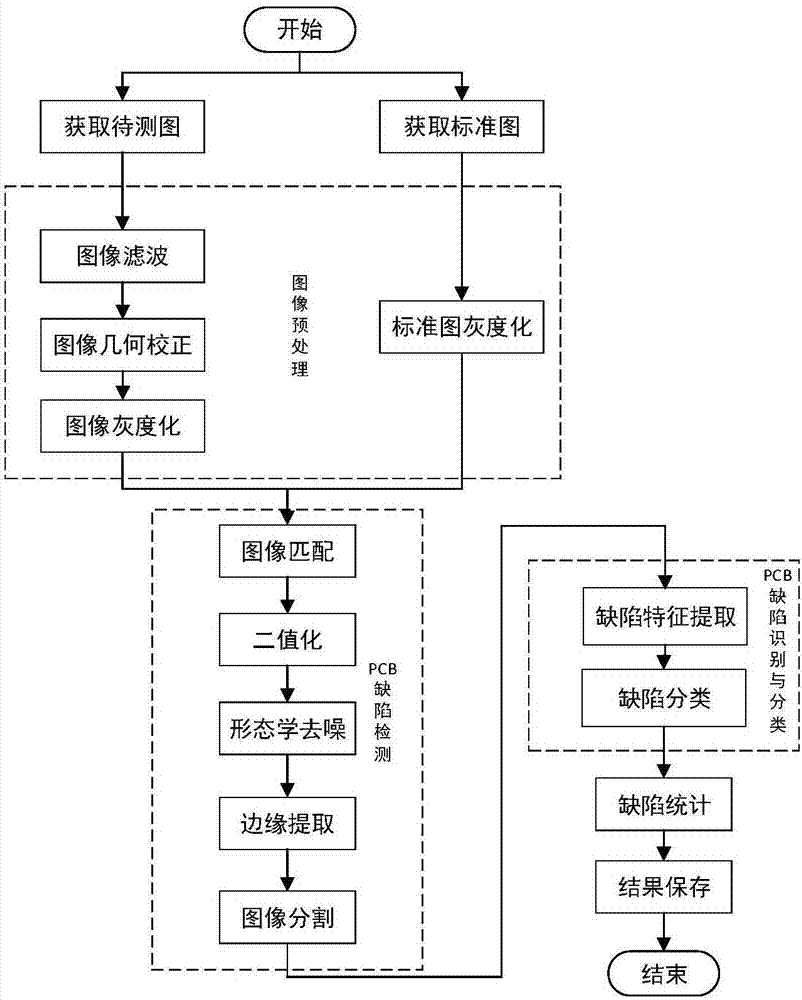

PCB apparent defect automatic detection system and method based on image

InactiveCN107389701AImprove detection efficiencyReduce false detection rateImage enhancementImage analysisMovement controlAutomatic testing

The invention provides a PCB apparent defect automatic detection system and method based on an image and aims at solving the problems that detection efficiency is low and misjudgment rate is high. The method comprises the following steps: firstly transmitting a to-be-detected PCB to a specified position by virtue of a motion control unit; acquiring an image of the to-be-detected PCB by utilizing image acquisition equipment such as an image acquisition card and an industrial camera; then sequentially carrying out a series of operation such as image preprocessing, PCB defect detection and PCB defect identification and classification on the acquired image, so that PCB defect automatic detection is completed; and finally realizing real-time automatic sorting of an unqualified PCB and timely reporting a defect position and a defect analysis result to an operator. The system and method which are provided by the invention can automatically detect the PCB defect and identify the defect type to a great extent, and false detection rate is reduced, so that enterprise cost is reduced, and the system and method which are provided by the invention have stronger practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

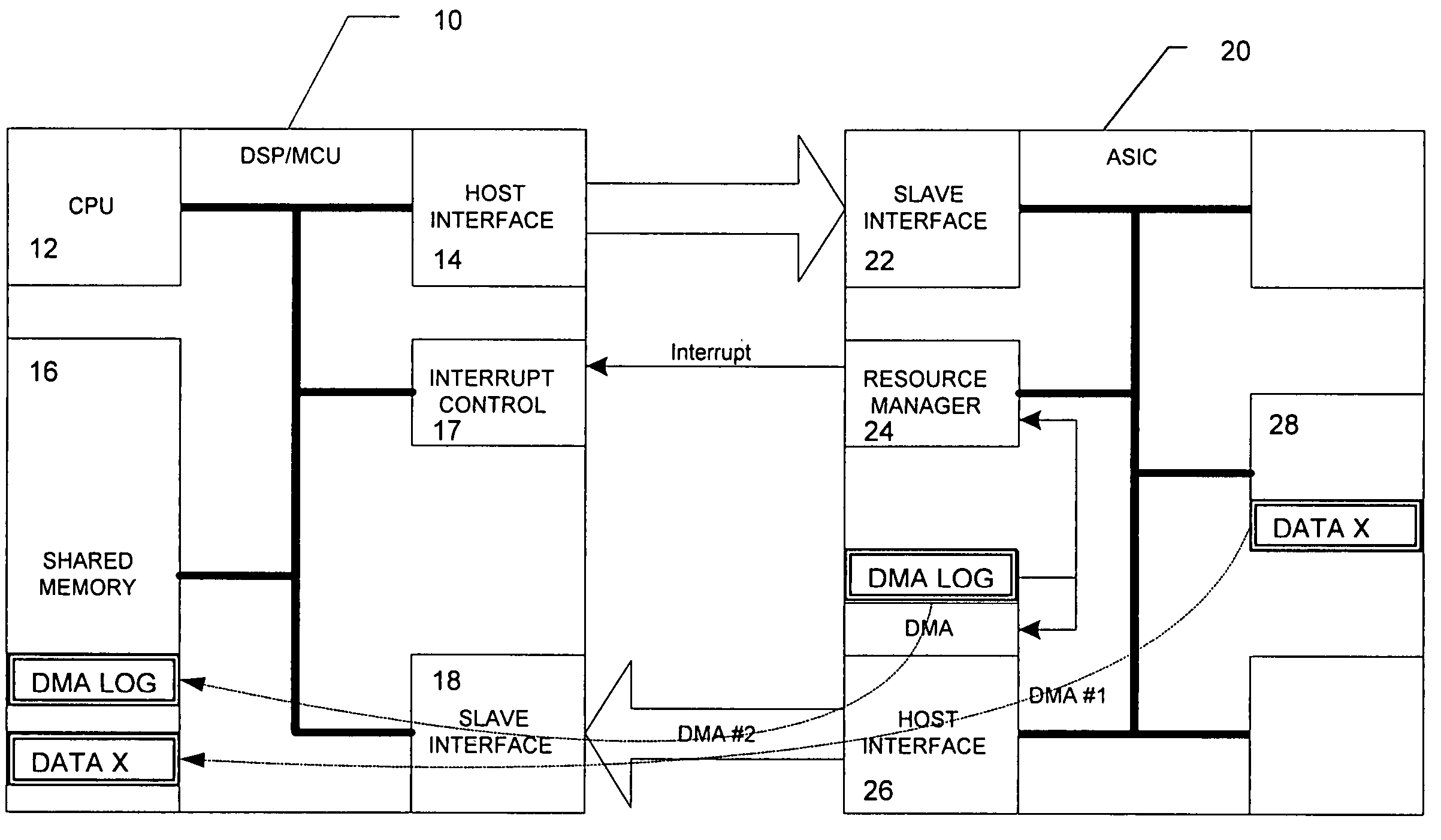

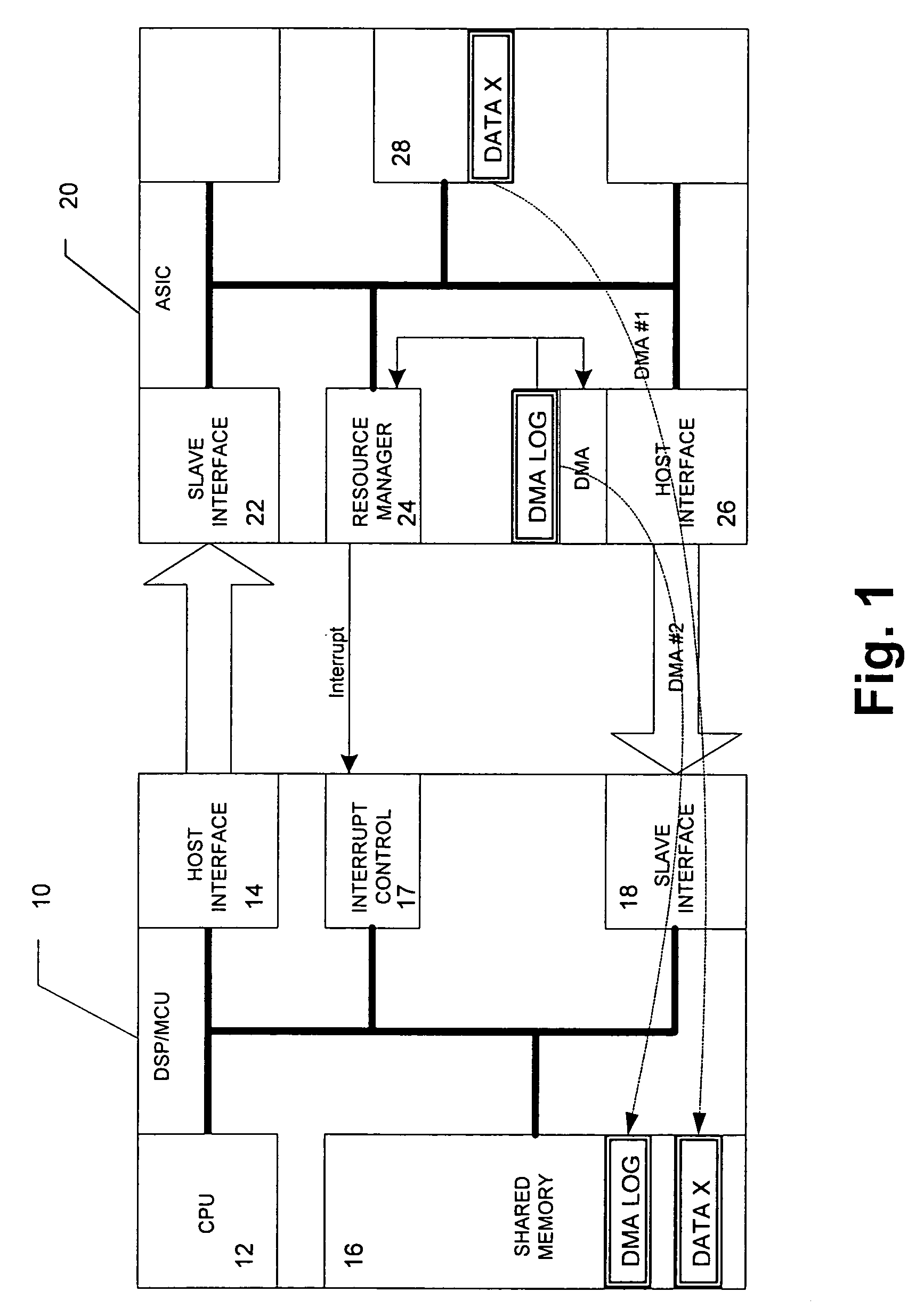

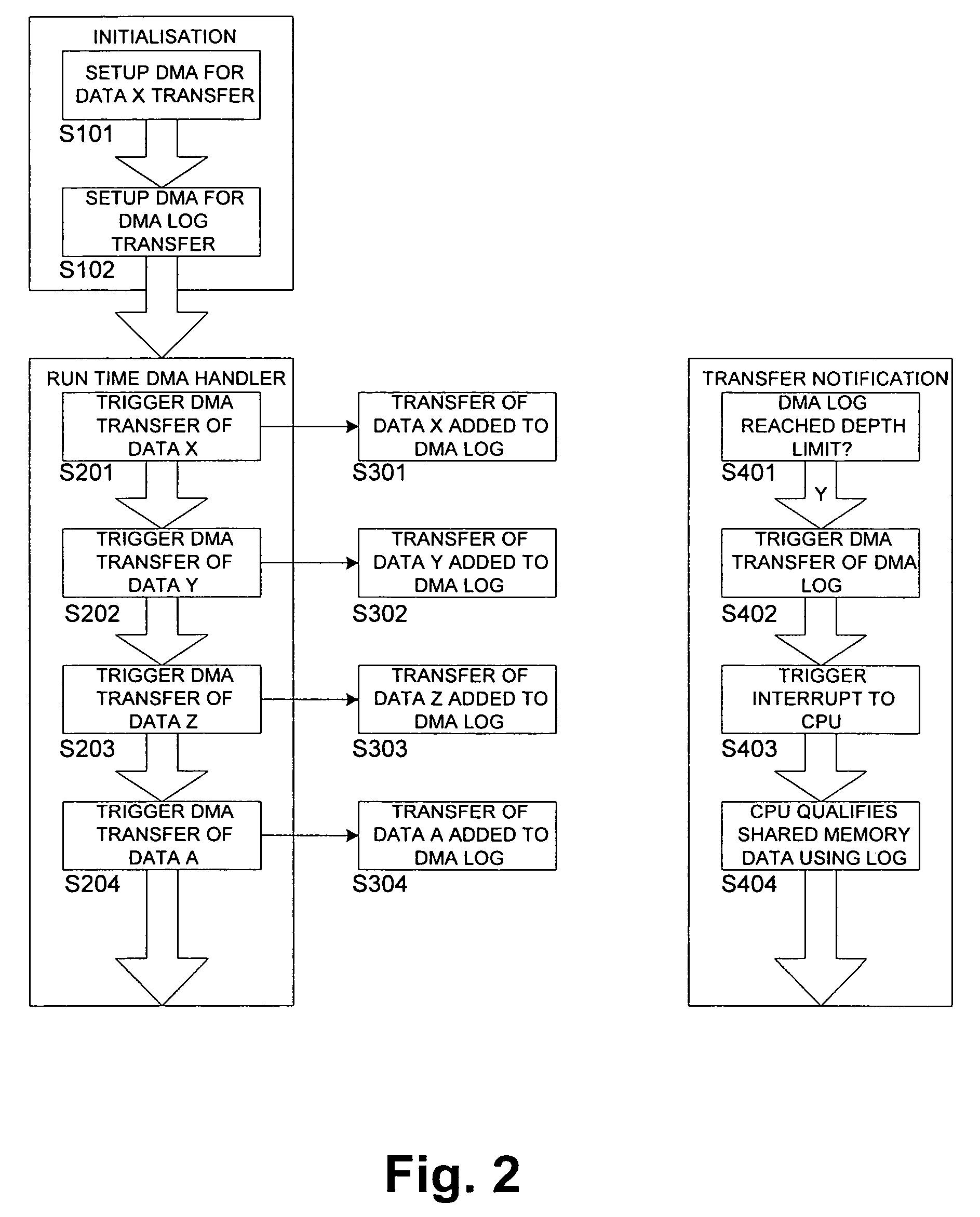

DMA data transfer between low-overhead processor and connected external circuitry using transactions log

InactiveUS7293119B2Reduce loadReduce overheadDigital computer detailsSpecific program execution arrangementsTransaction logData transmission

Owner:NOKIA SOLUTIONS & NETWORKS OY

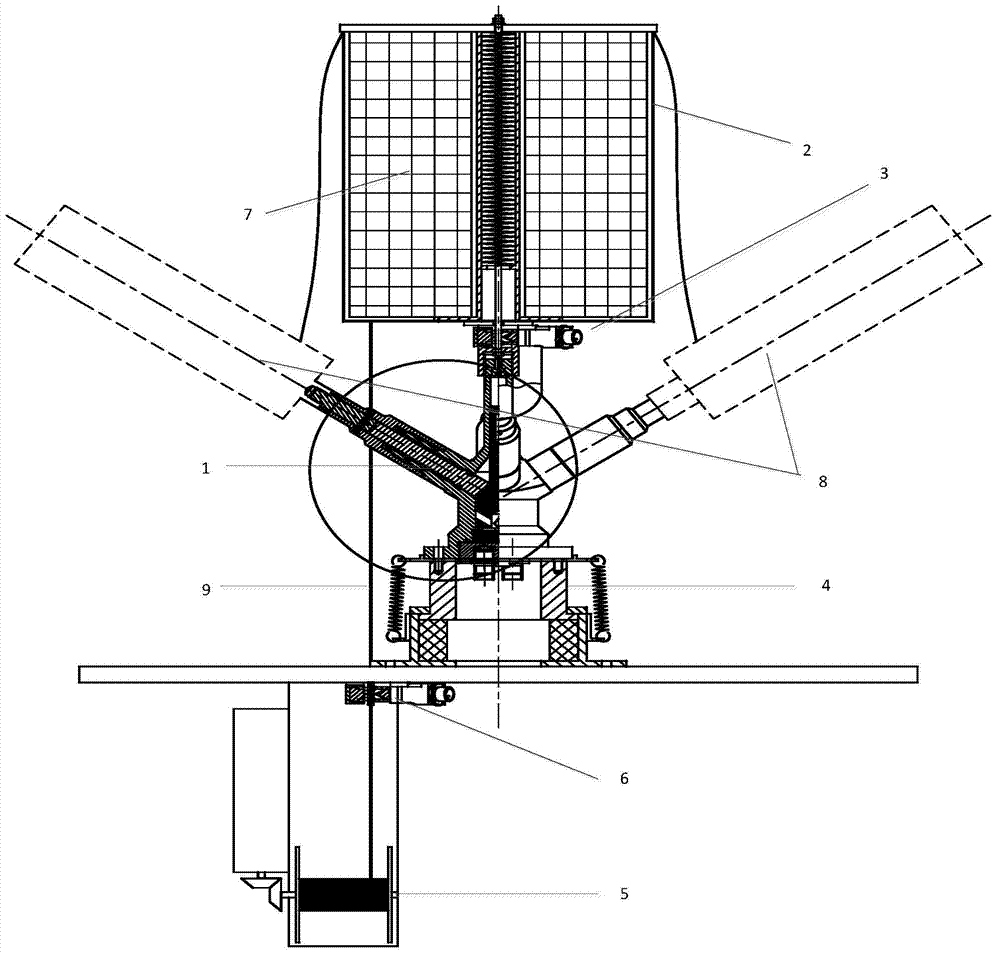

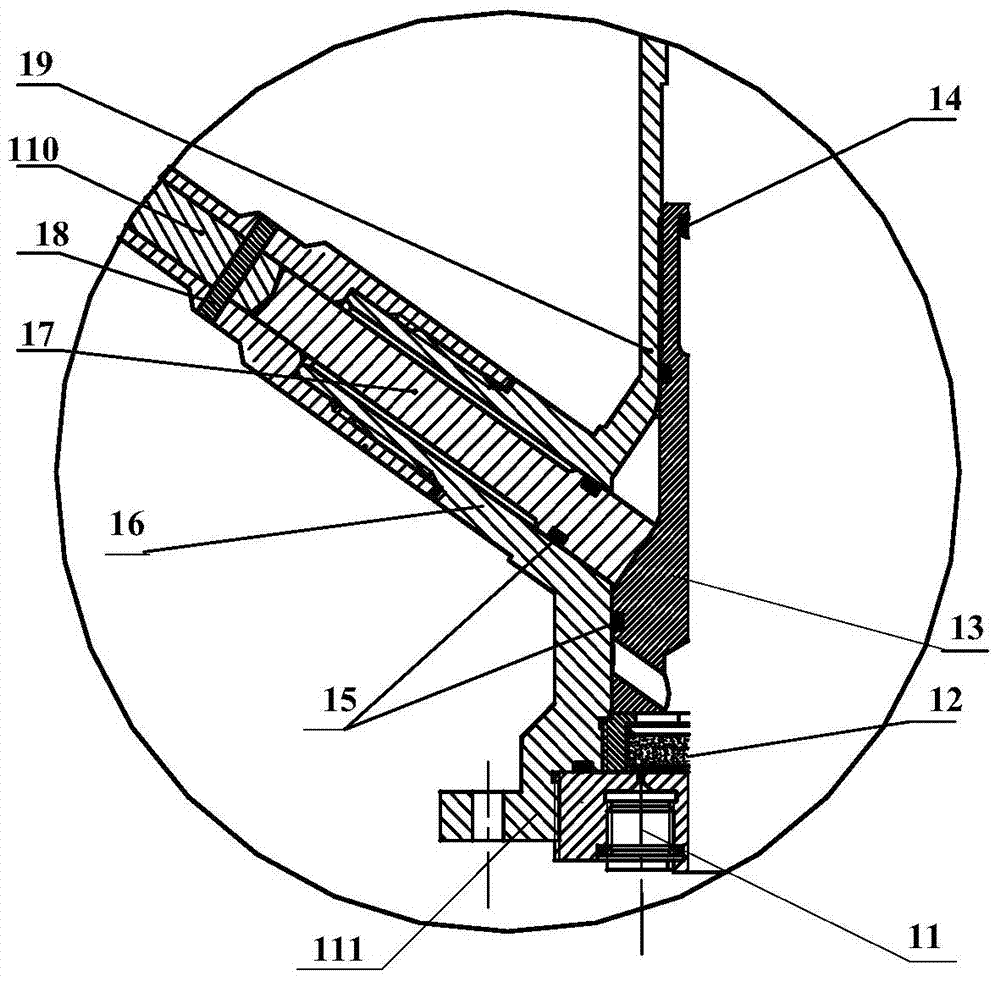

Rope net type space debris capturing and cleaning system

The invention discloses a rope net type space debris capturing and cleaning system which comprises a transmission subsystem and a fly net subsystem. The transmission subsystem comprises a transmitter, a net cabin, a net cabin cover ejecting device, a buffer device, a tying rope tension control device and a tying rope cutter, and the fly net subsystem comprises a rope net and four mass blocks; a net cabin cover can be ejected out of an outlet of the net cabin, and the rope net can be driven by the net cabin cover to be drawn out of the net cabin; the transmitter works at the moment when the fly net and a tying rope are straightened, the sides of the rope net are driven by four mass blocks according to preset transmitting opening angles, so that the rope net can fly out and is opened simultaneously until the rope net is fully opened, an object is netted after the rope net reaches the objective position, a port of the rope net is tightened under the control of the mass bocks, and the object can be completely captured; after the tying rope draws the captured object aircraft away from an orbit, the tying rope cutter cuts off the tying rope, and the object aircraft can be separated from a satellite platform. The rope net type space debris capturing and cleaning system has the advantages that a secondary transmission mode is adopted, so that twining and knotting can be prevented in rope net spreading procedures; the mass blocks are pushed to be synchronously transmitted, so that a millisecond-level synchronous transmission effect can be realized, and the shape of the rope net can be controlled advantageously.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Livestock and poultry breeding wastewater treatment technology

InactiveCN103466882AHigh in phosphorusImprove fertilizer efficiencySludge treatment by de-watering/drying/thickeningWaste water treatment from animal husbandryCavitationSludge

The invention relates to a livestock and poultry breeding wastewater treatment technology. The livestock and poultry breeding wastewater treatment technology comprises the steps that water in a septic tank enters an artificial grid, so that impurities are removed, and then water enters an adjusting tank; wastewater in the adjusting tank is lifted by a lift pump to enter a cavitation air floatation tank, a flocculating agent is added so as to generate flocculent precipitates, the wastewater flows into an anaerobic tank, phosphorus contained in phosphorus accumulating bacteria is released, the wastewater flows into a tank A, water flowing out of the tank A flows into a contact oxidation tank, and organic matters in the wastewater are oxidized and decomposed; the wastewater flows into a secondary sedimentation tank and is subjected to solid-liquid separation, precipitated liquid supernatant enters a disinfecting tank, ClO2 is added to the disinfection tank for disinfection, and yielding water reaching the standards is discharged through a standardized exhaust port; and the sludge treatment is carried out. The livestock and poultry breeding wastewater treatment technology has the advantages that the technological process is simple, the anaerobic biochemical treatment and the aerobiotic biochemical treatment are combined, nitrogen and phosphorus are removed; sludge is rich in phosphorus and has very high fertilizer efficiency; and the comprehensive energy consumption is low, the high-efficiency energy conservation is realized, the shock resistance is strong, the control requirements are low, and the secondary pollution is avoided.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

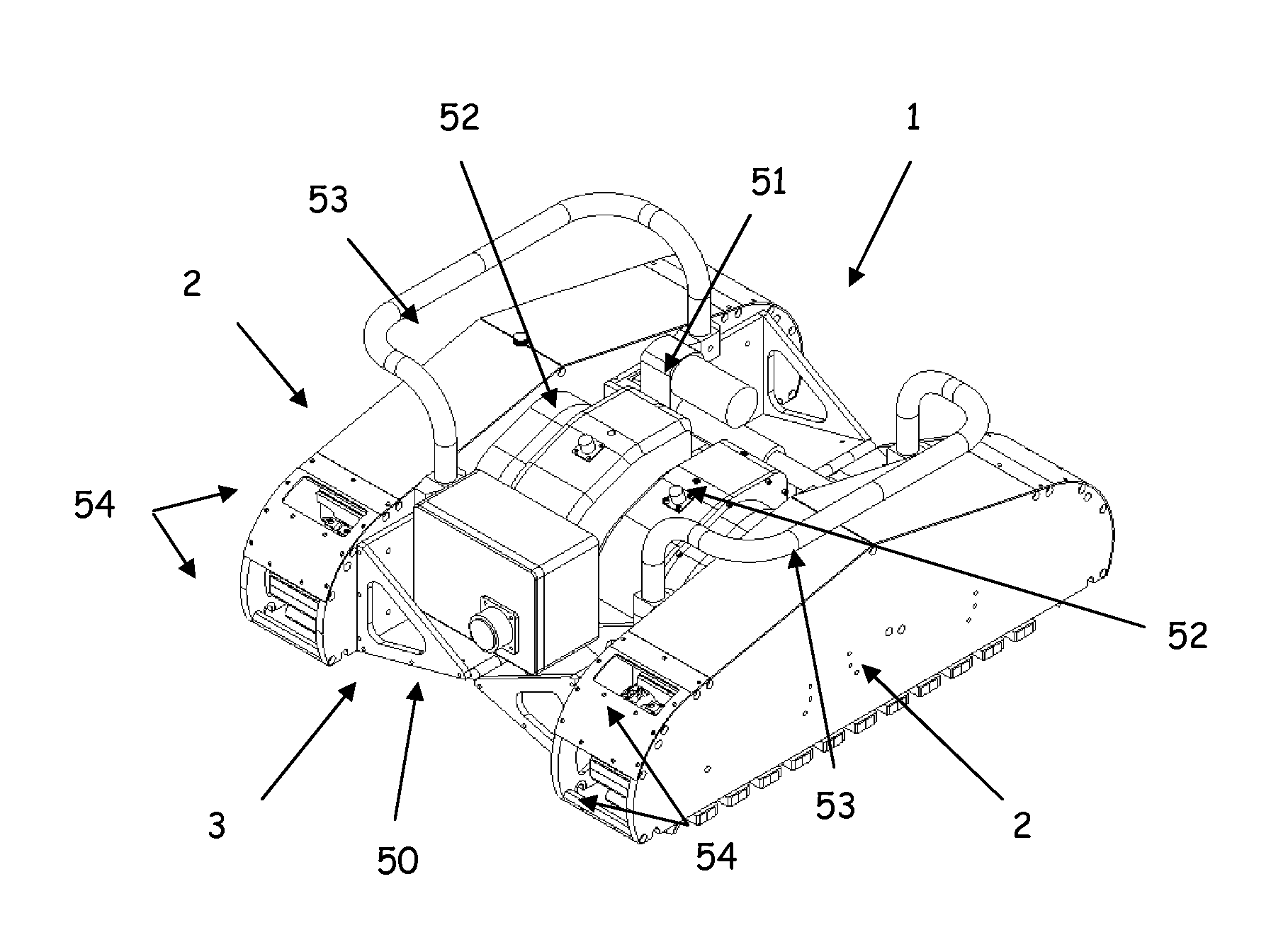

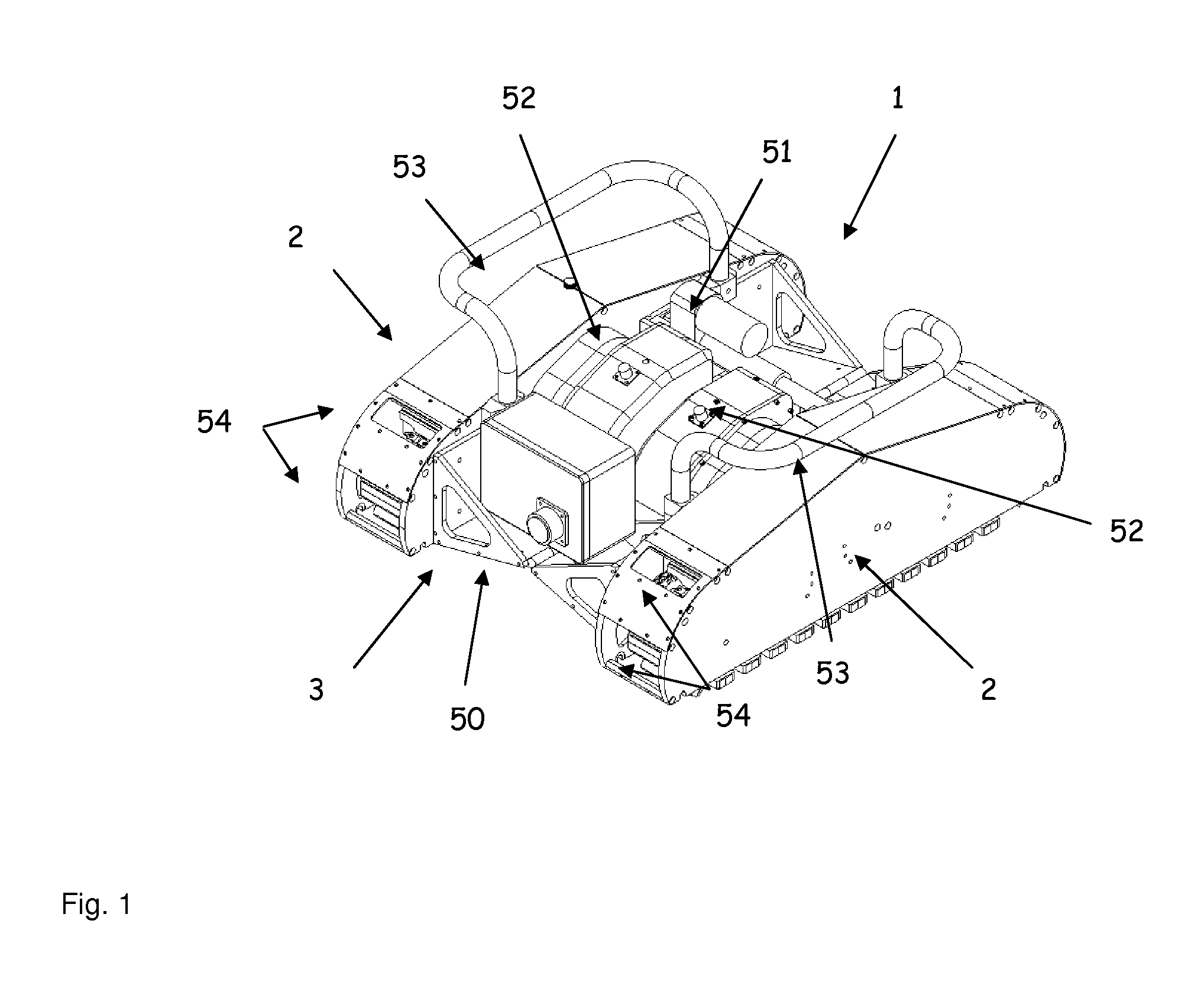

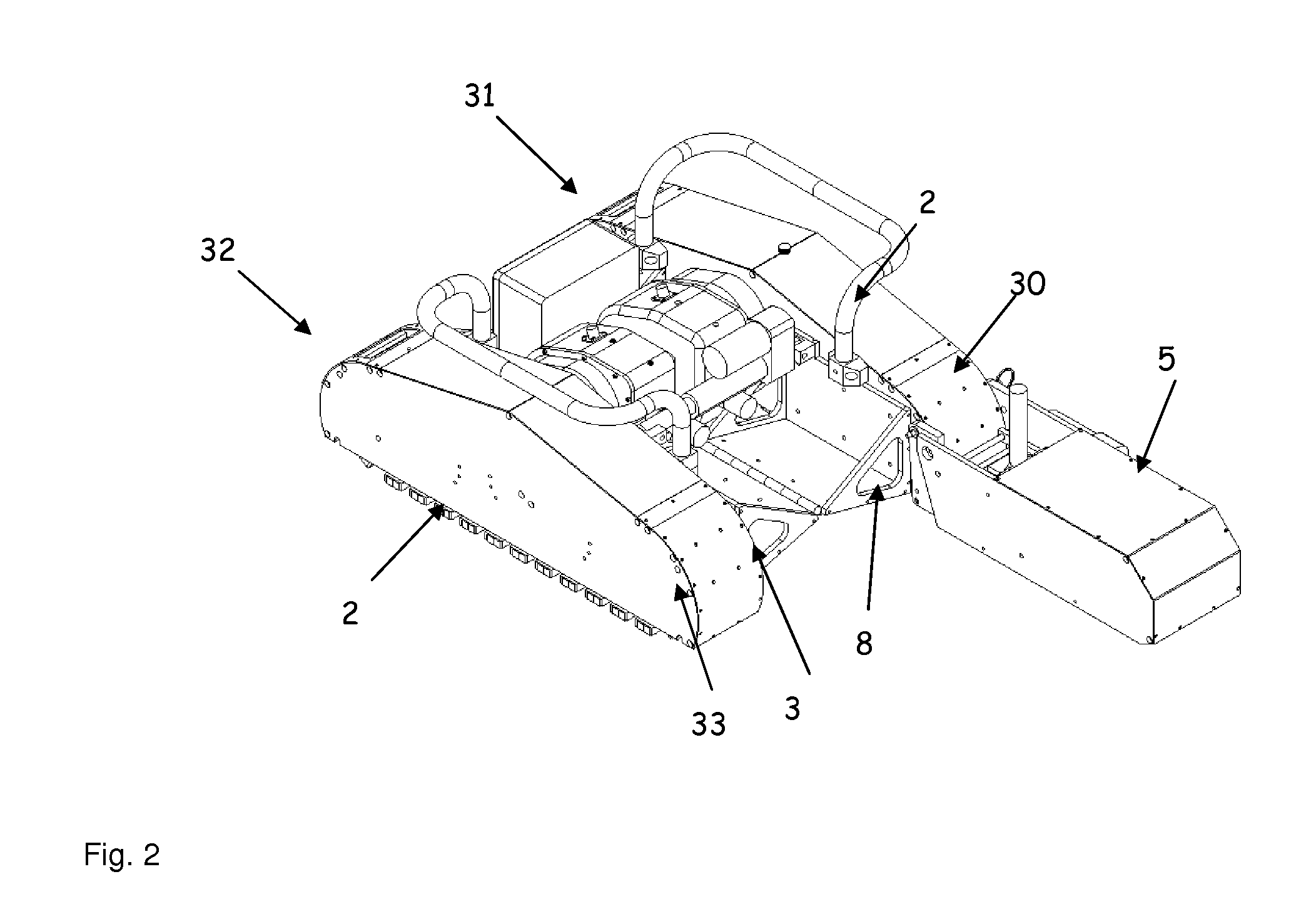

Mobile, climbing endless track robotic system to perform remote inspections on structures

ActiveUS20120116583A1Maximize the system payload to weight ratio.Reduce control requirementsProgramme-controlled manipulatorEndless track vehiclesRobotic systemsManipulator

An endless-track type mobile climbing vehicle containing a suspension apparatus, transducer manipulator and surface cleaning system to perform non-destructive examination of structures while traversing the structure in all positions. The invention is able to conform to large range of irregularities of the climbing surface while maintaining contact between the track and adhering members and uniformly distributing the climbing loads on the adhering members giving the system a high payload to weight ratio. The invention is moves the inspection transducer over the surface while maintaining correct alignment of the tool relative to the surface. The invention allows an operator to perform an inspection on structures that require cleaning or other preparation prior to inspection. The invention allows an operator to perform an inspection remotely.

Owner:BEARD JAMES +2

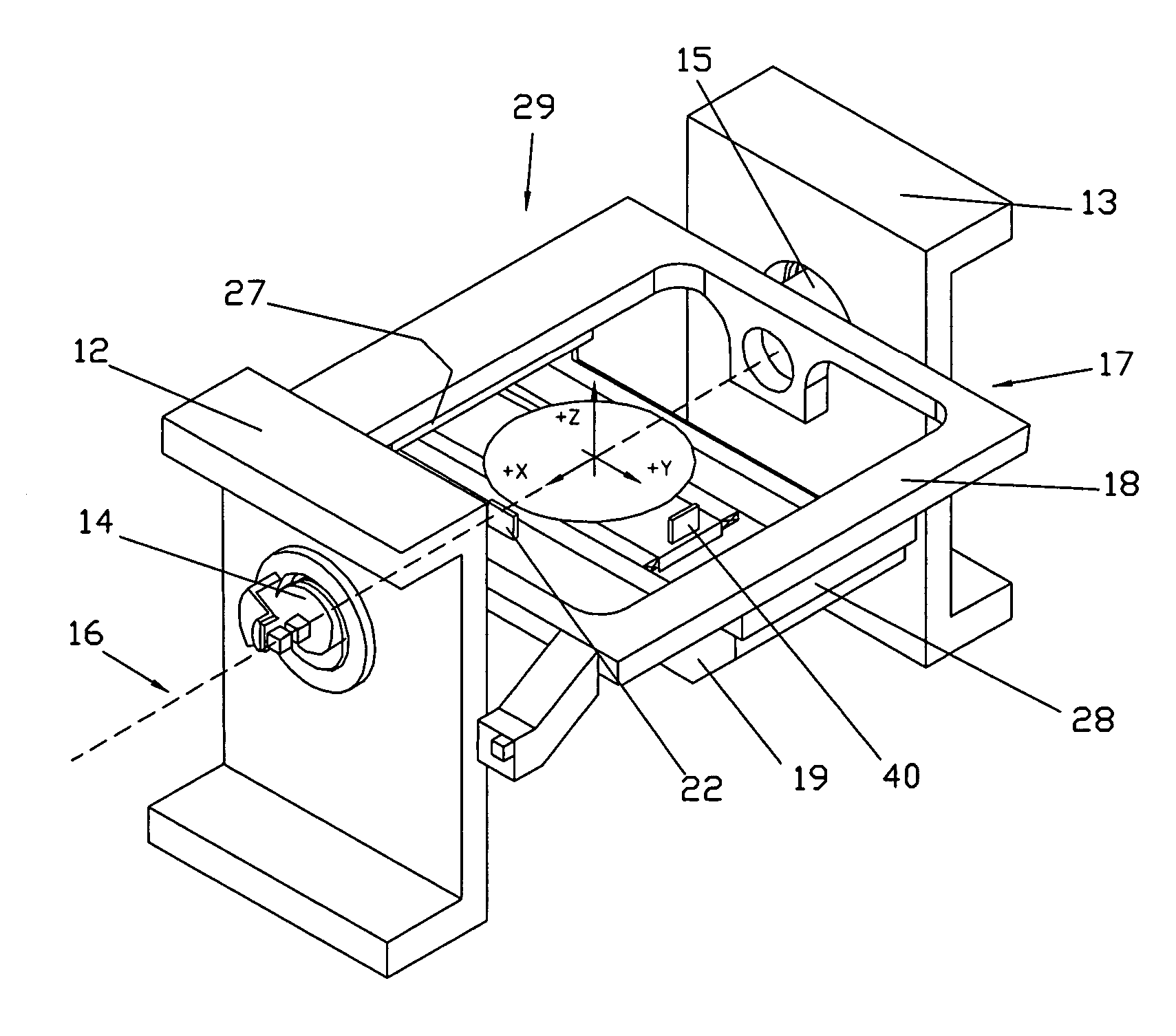

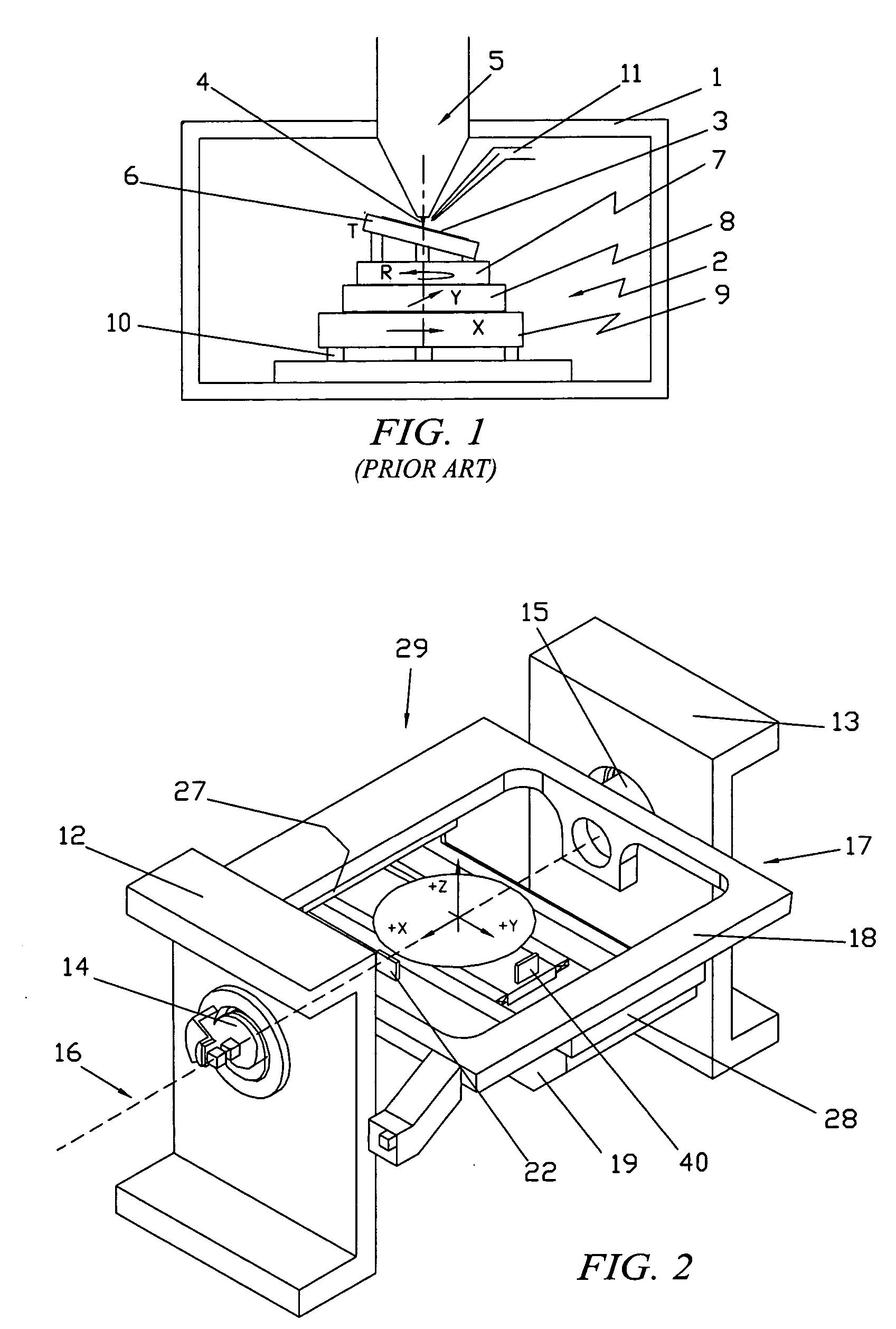

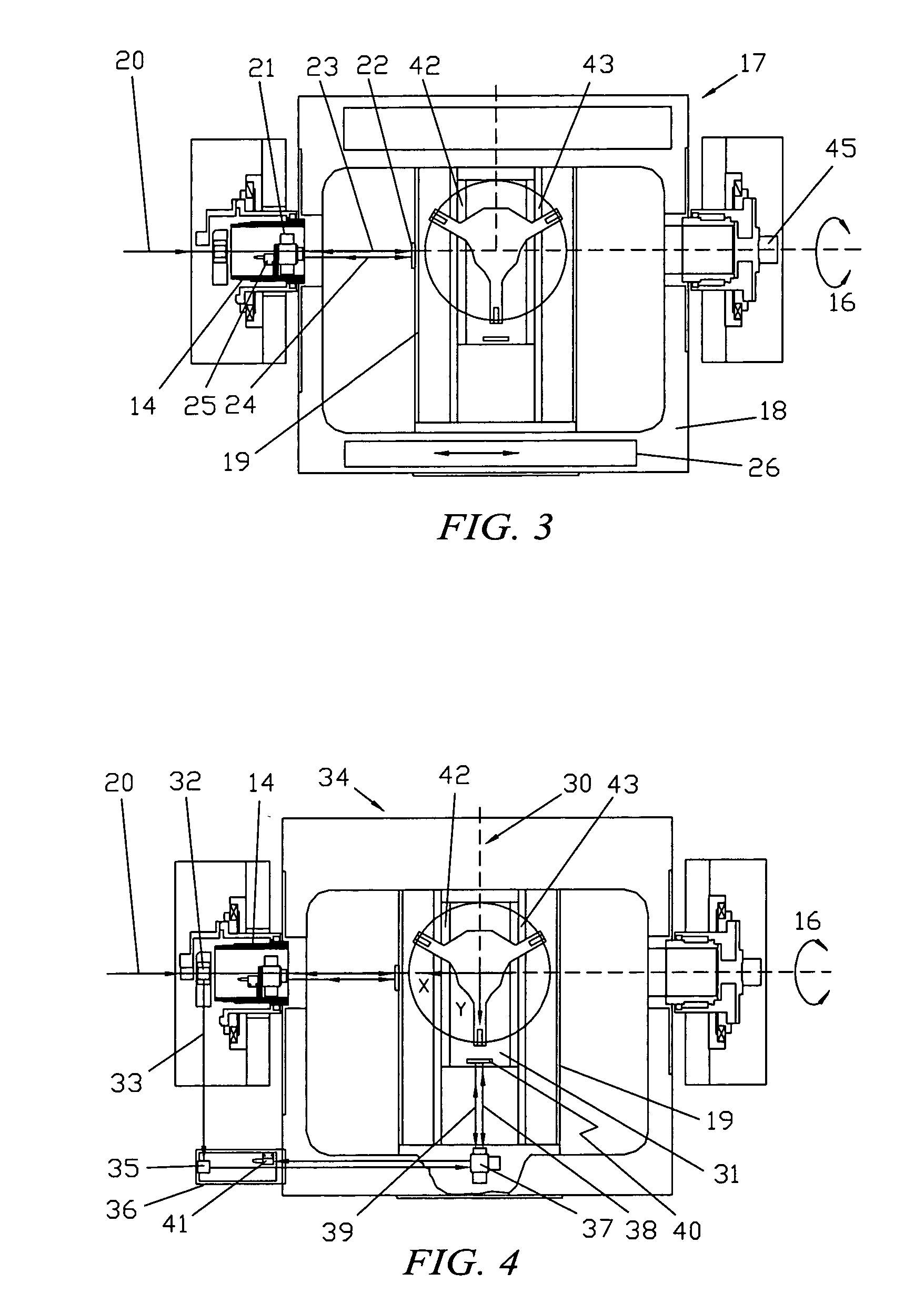

System and method for positioning an object

InactiveUS20070023684A1Accurate and Precise MeasurementsEasy to controlElectric discharge tubesUsing optical meansEngineeringMotion system

A motion system includes a first stage that is configured to rotate about a first axis and a second stage coupled to the first stage that includes an object carrier adapted to position an object in at least one other axis. The motion system has a novel arrangement of laser interferometer elements and axes of motion. The arrangement permits accurate and precise measurement of a position of the object carrier in up to three (or more) axes of motion even as the first stage of the motion system is tilted through relatively large angles. The novel arrangement of the axes of motion also enables very precise control of the position of the object carrier even at high tilt angles.

Owner:LEWIS GEORGE C +1

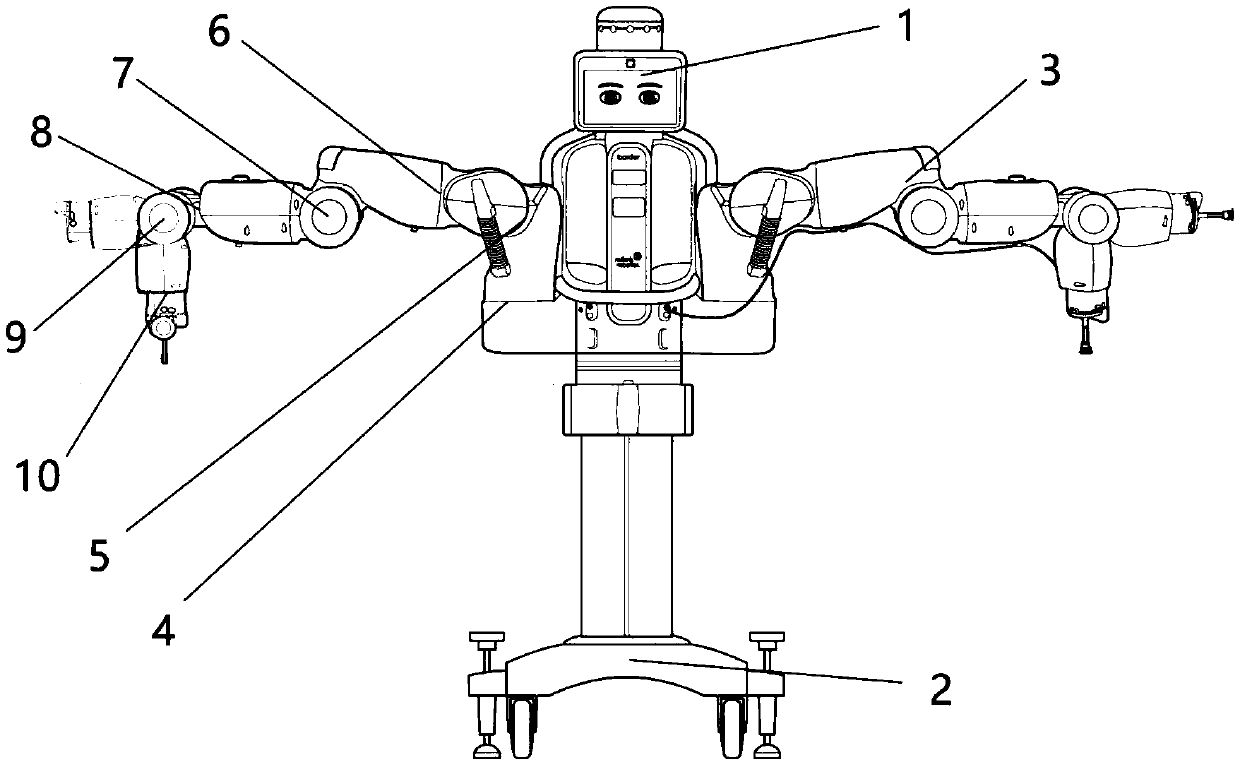

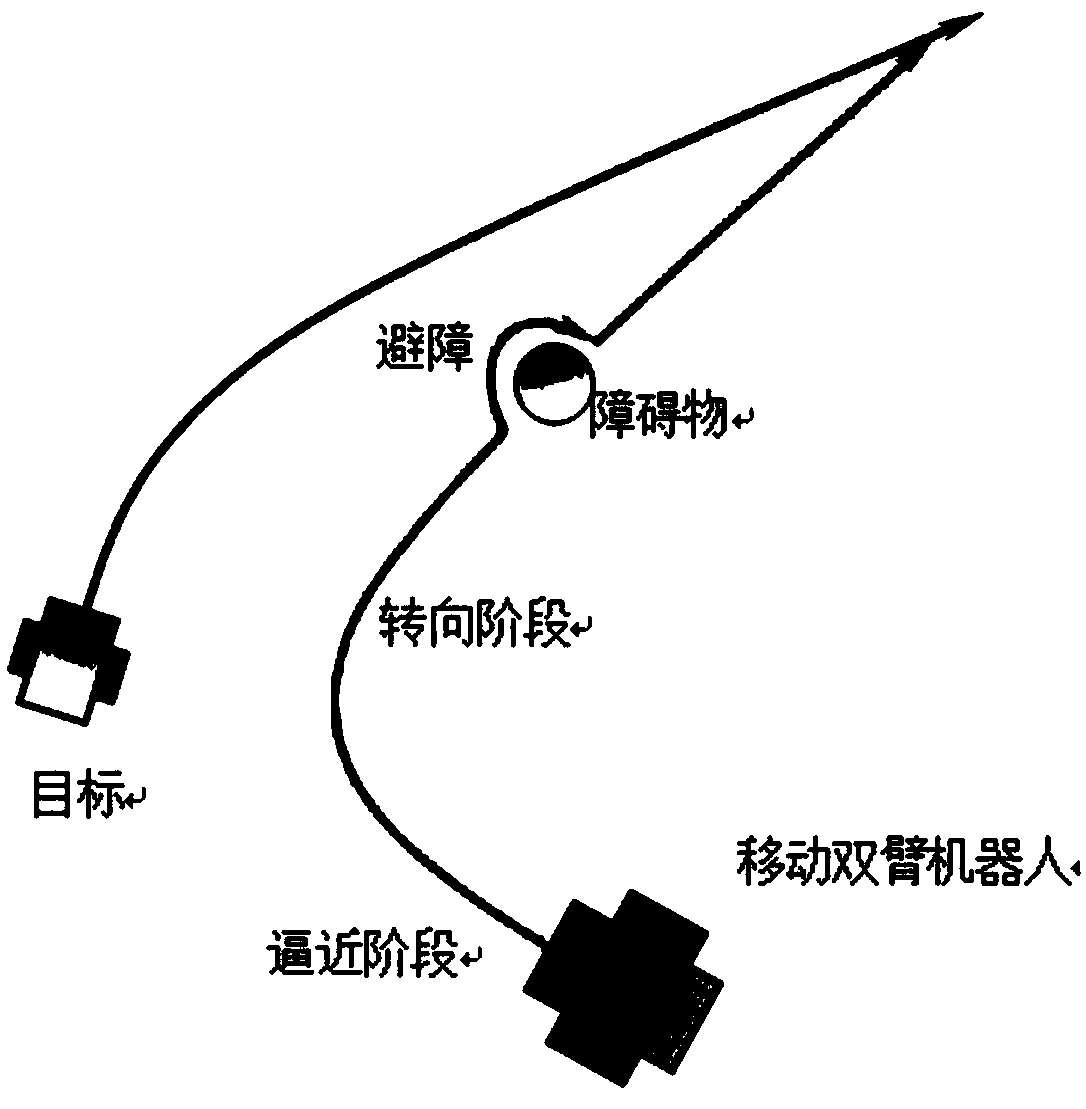

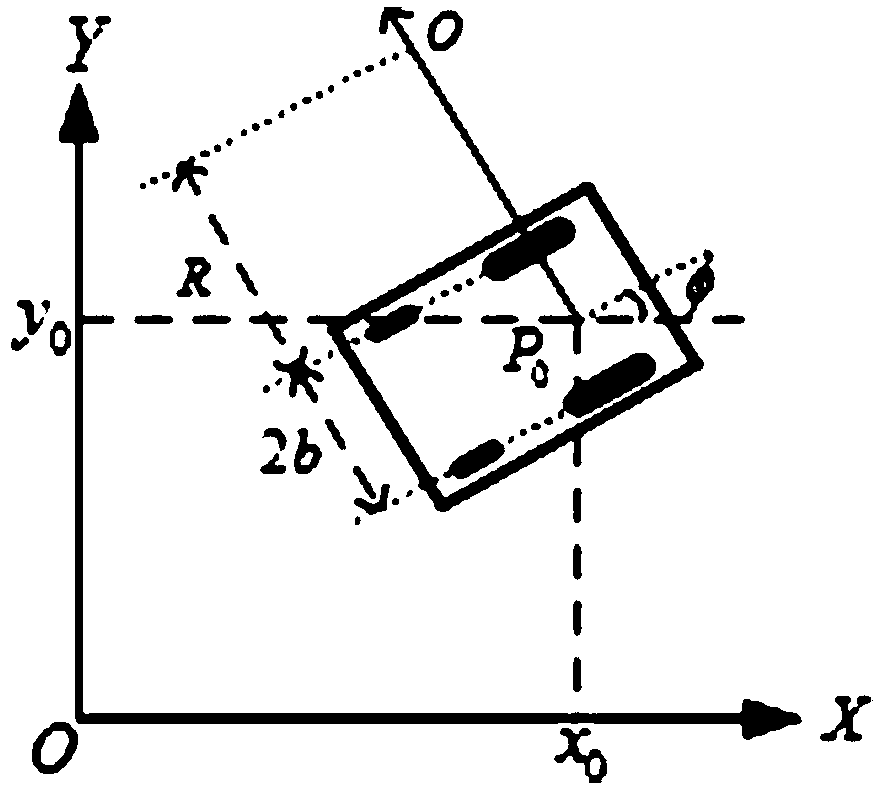

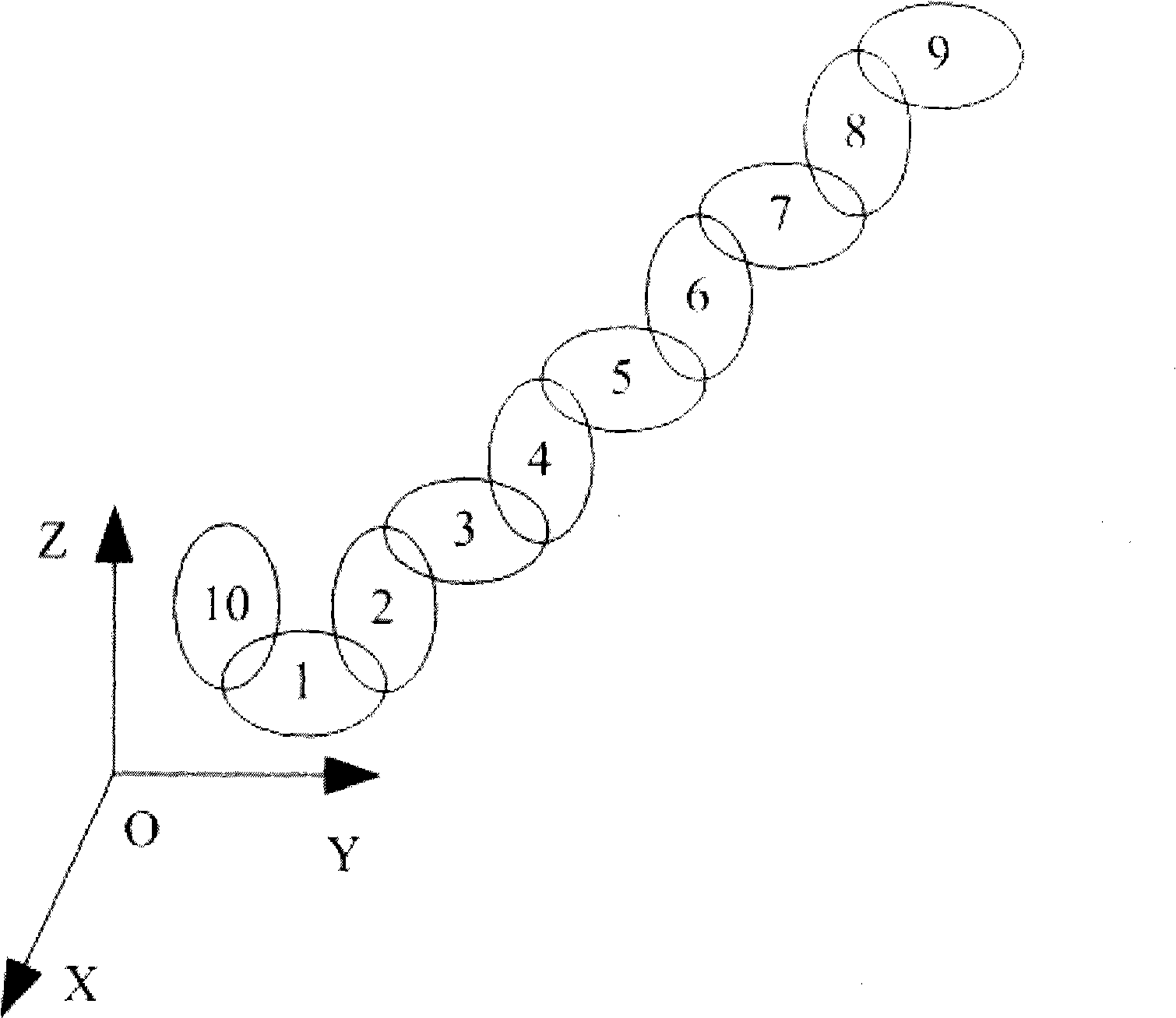

Autonomous humanoid double-arm robot and moving target tracking operating system thereof

ActiveCN108838991AGuaranteed speedWide applicabilityProgramme-controlled manipulatorPosition/course control in two dimensionsRadar systemsDecomposition

The invention discloses an autonomous humanoid double-arm robot. The autonomous humanoid double-arm robot comprises a head, a double-wheel differential driving mobile platform, two seven-degree-of-freedom humanoid arms, a moving target simulation platform and a PTZ camera system; and a speedometer, a two-dimensional laser radar system, an ultrasonic obstacle avoidance sensor system, a binocular vision measurement system and the PTZ camera system are arranged in the double-wheel differential driving mobile platform. The autonomous humanoid double-arm robot has the advantages that the double-wheel differential driving mobile platform and the high-redundancy humanoid double-arm robot are utilized to form one high-redundancy humanoid double-arm mobile service robot system based on an ROS operating system; an advanced method for performing integral motion planning on the high-redundancy humanoid double-arm mobile service robot on the basis of an integral speed decomposition control algorithm is provided; a multi-modal information fusion target acquiring and identifying and capturing system based on a PTZ vision system and a laser sensor system is established; and a path planning methodbased on a three-dimensional C space enhanced type probability map improved A* algorithm is provided.

Owner:NANCHANG INST OF TECH

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas, greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

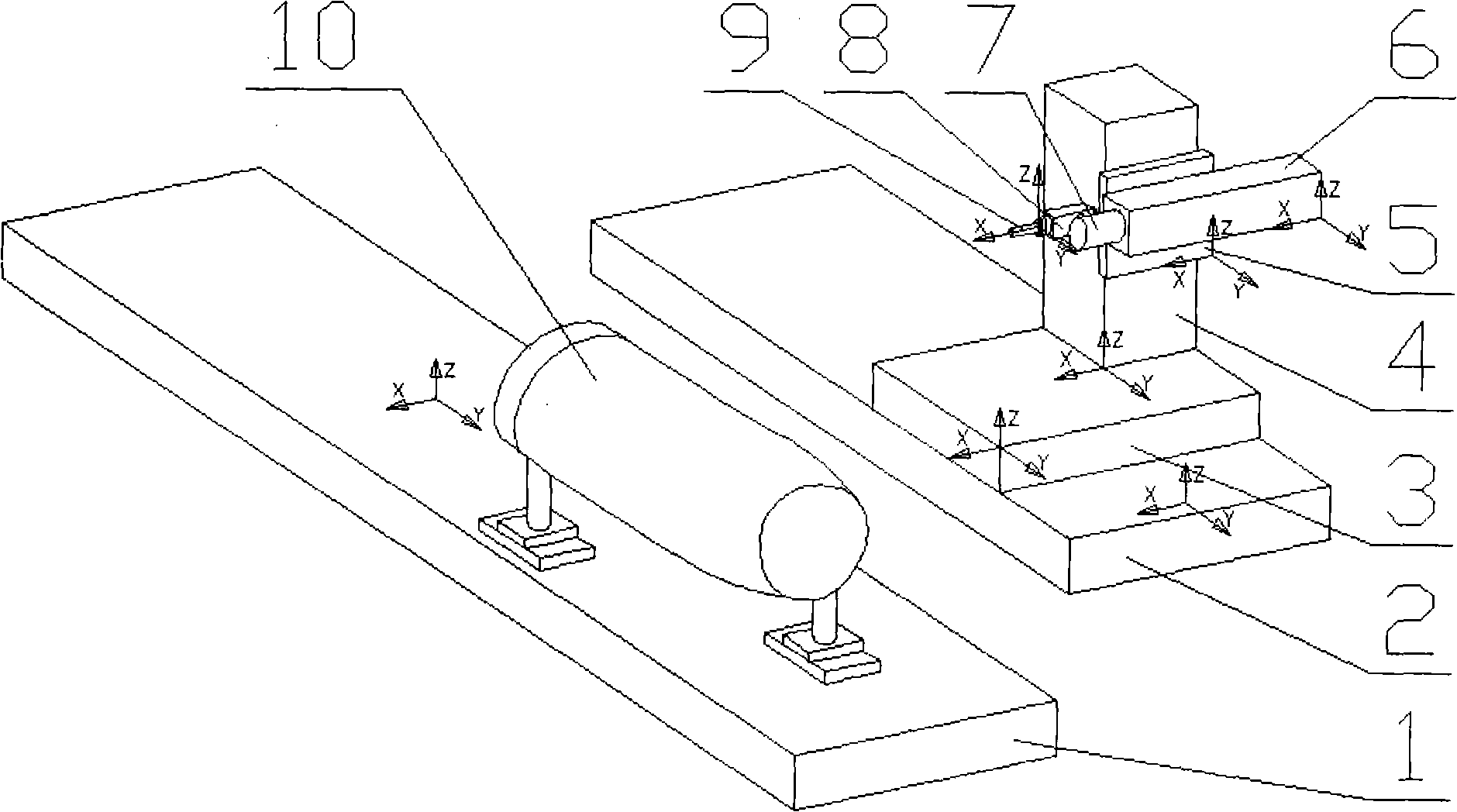

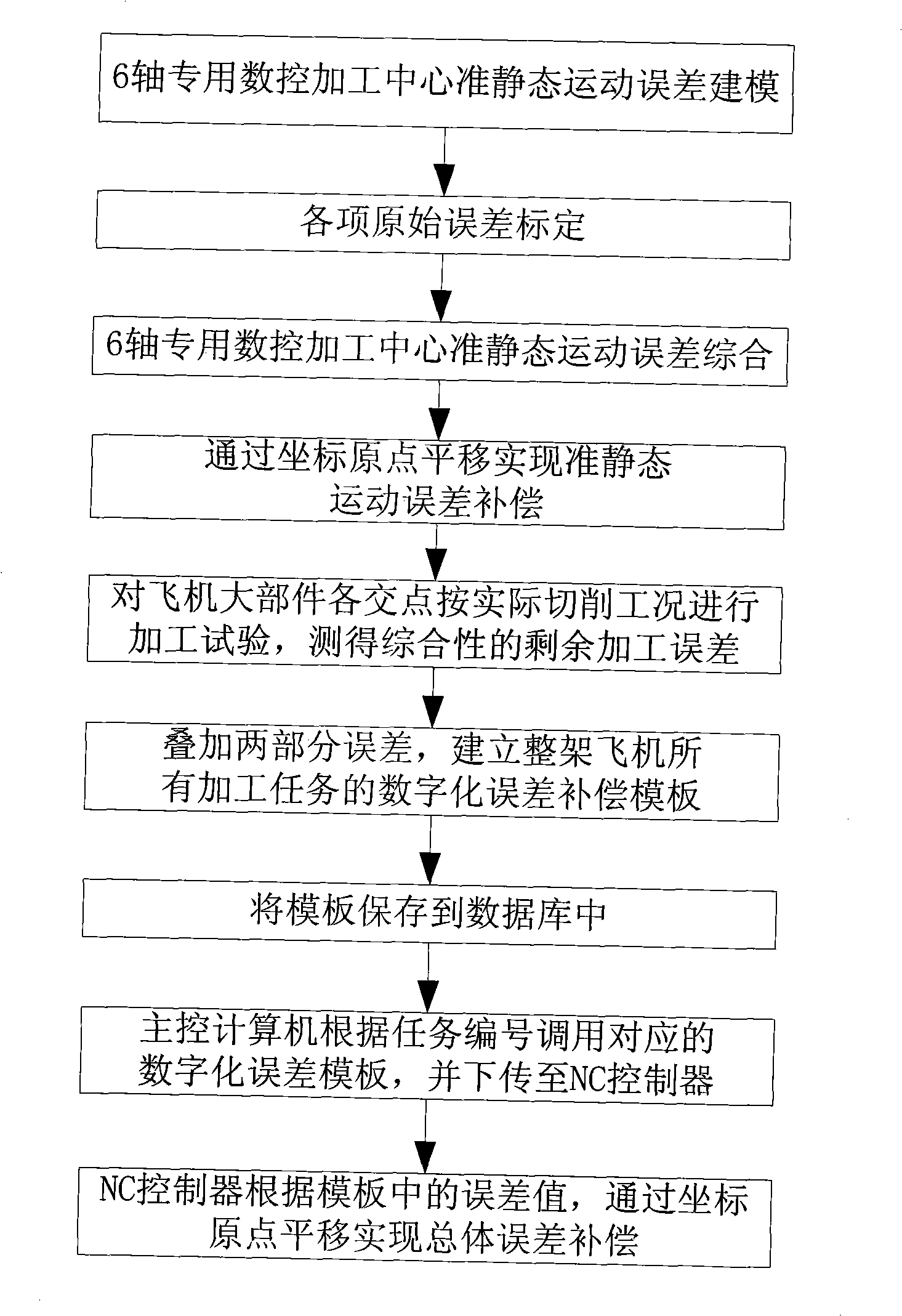

Method for implementing numerical control finish machining for large component of aeroplane based on digitalization error compensation template

InactiveCN101493683AReduced absolute motion precision requirementsReduce control requirementsProgramme controlComputer controlNumerical controlStatics

The invention discloses a method which realizes numerical control finish machining of intersection of large parts of the airplane on the basis of a digital error compensation template, comprising the steps as follows: firstly, a quasi static movement error model thereof is built, all the original errors are measured and obtained, and then a compensation of the quasi static movement error is realized; all machining tasks are carried out under a practical working condition; the comprehensive machining error residual after the first compensation is measured; and the total error compensation value is obtained comprehensively and a corresponding digital error compensation template is built. The machining precision of the intersection of a plurality of airplane wings of the same type is ensured by the repeated movement precision of a machining center. The method has the advantages that the precise numerical control machining center can be adopted to realize the precise machining of the intersection of the large parts of the airplane, the real-time performance is high, the numerical control program and the software and hardware of the machining center are not required to be changed, the advantages of the high precision of the repeated movement of the numerical control machining center is sufficiently played, and the control requirement on the workshop environmental temperature is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

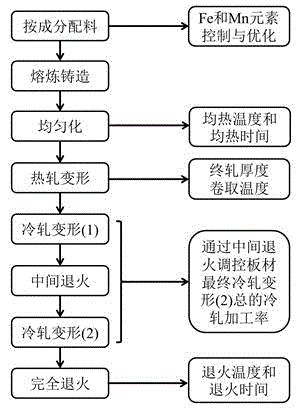

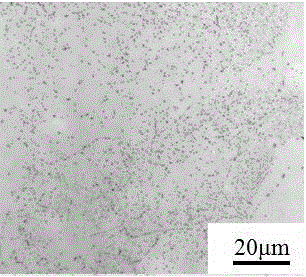

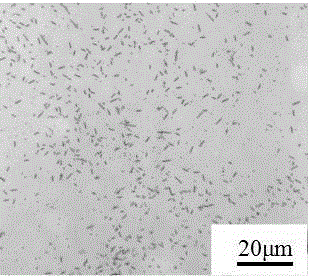

Aluminum alloy sheet material for vehicles and preparation method thereof

InactiveCN104894442AUniform recrystallized structureImprove formabilityChemical compositionAluminium alloy

The invention discloses an aluminum alloy sheet material for vehicles and a preparation method thereof. The aluminum alloy sheet material comprises 4.5-5.5wt% of Mg, 0.15-0.35wt% of Mn, 0.10-0.30wt% of Fe, less than or equal to 0.15wt% of Si, less than or equal to 0.10wt% of Ti, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of Zn, less than or equal to 0.10wt% of Cr and the balance Al and unavoidable impurities. The preparation method orderly comprises material blending, melting casting, uniformization, hot rolling deformation, primary cold rolling deformation, intermediate annealing, secondary cold rolling deformation and complete annealing. Through the design and optimization of alloy components and preparation processes, the 5XXX-series aluminum alloy sheet material with high formability and a low cost is prepared by the existing conventional plate and strip production line.

Owner:SHANDONG NANSHAN ALUMINUM

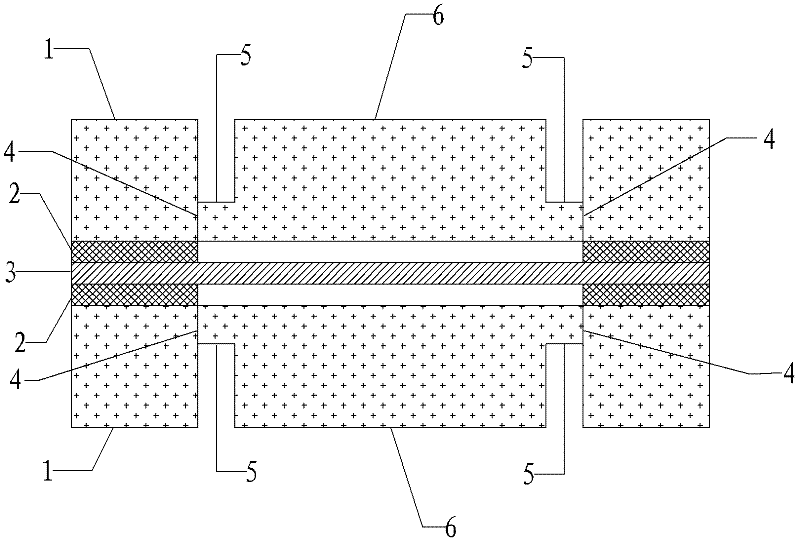

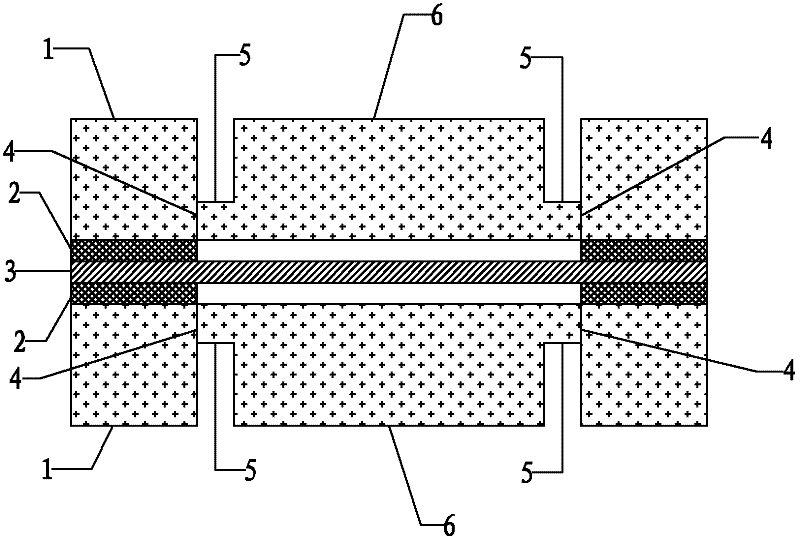

A kind of processing method of rigid-flex board

ActiveCN102271469AReduce control requirementsAvoid wastingPrinted circuit assemblingResistMilling cutter

The invention relates to a method for processing a rigid-flexible printed circuit board (PCB). The method comprises the following steps: 1. pretreatment before compression: pre-cutting the compression surface of a PCB and removing the wastes of bonding sheets, wherein the pre-cutting treatment is to cut a crevice around a waste region of the PCB with laser, wherein the PCB is not cut off; 2. compression: compressing the PCB, the bonding sheets and a flexible printed circuit (FPC) board into a whole; 3. treatment after compression and before contour processing: drilling, depositing and platingcopper, making circuit and carrying out solder resist; and 4. contour processing: using a milling cutter to mill a groove around the waste region of the PCB, controlling the depth of the milling cutter to communicate the milled groove with the crevice and then removing the wastes of the PCB. The method is convenient for the removal of the wastes of the rigid PCB, and has the beneficial effects ofpreventing the milling cutter from directly milling the flexible PCB, greatly reducing the control requirement for milling cutter depth, reducing the requirement for PCB flatness, improving the processing quality of the product and saving the production cost.

Owner:台山市精诚达电路有限公司

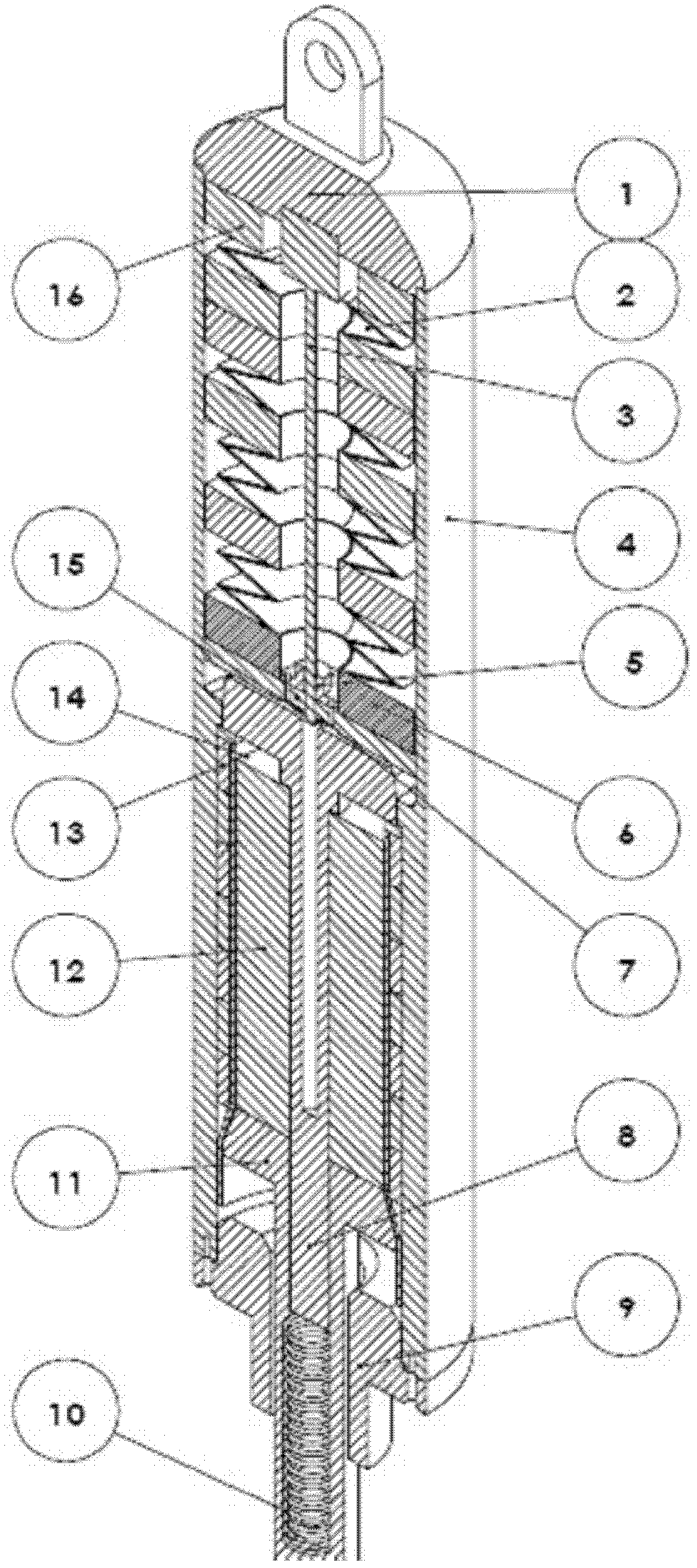

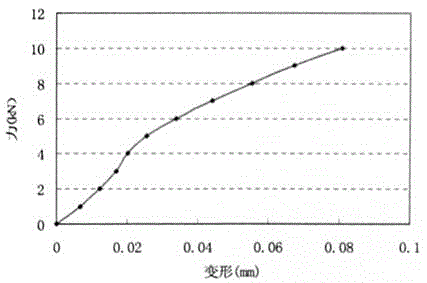

Landing mechanism-based legged mechanical cushioning device

A landing mechanism-based legged mechanical cushioning device comprises an upper end cover, a direct current lead screw motor, a disc spring, a damping baffle, a force sensor, an expansion ring, a piston push rod, a conical ring push rod, a cushioning cavity housing, a motor lead screw guide ring, a foam metal filling block filler, a flexible porous material, a bottom end cover and a pressure spring; and has two-stage cushioning energy absorption structures. The first stage is a mechanical cushioning structure designed on the basis of thin-wall metal pipe plastic deformation cushioning, and foam metal and flexible porous material plastic deformation energy absorption; and the second stage is an autonomous cushioning energy absorption structure designed on the basis of servo motor feedback control, foam metal plastic deformation energy absorption and elastic element energy storage and release. The inventive cushioning device is a composite cushioning device with simple structure, obvious energy absorption effects and stable performance.

Owner:BEIHANG UNIV

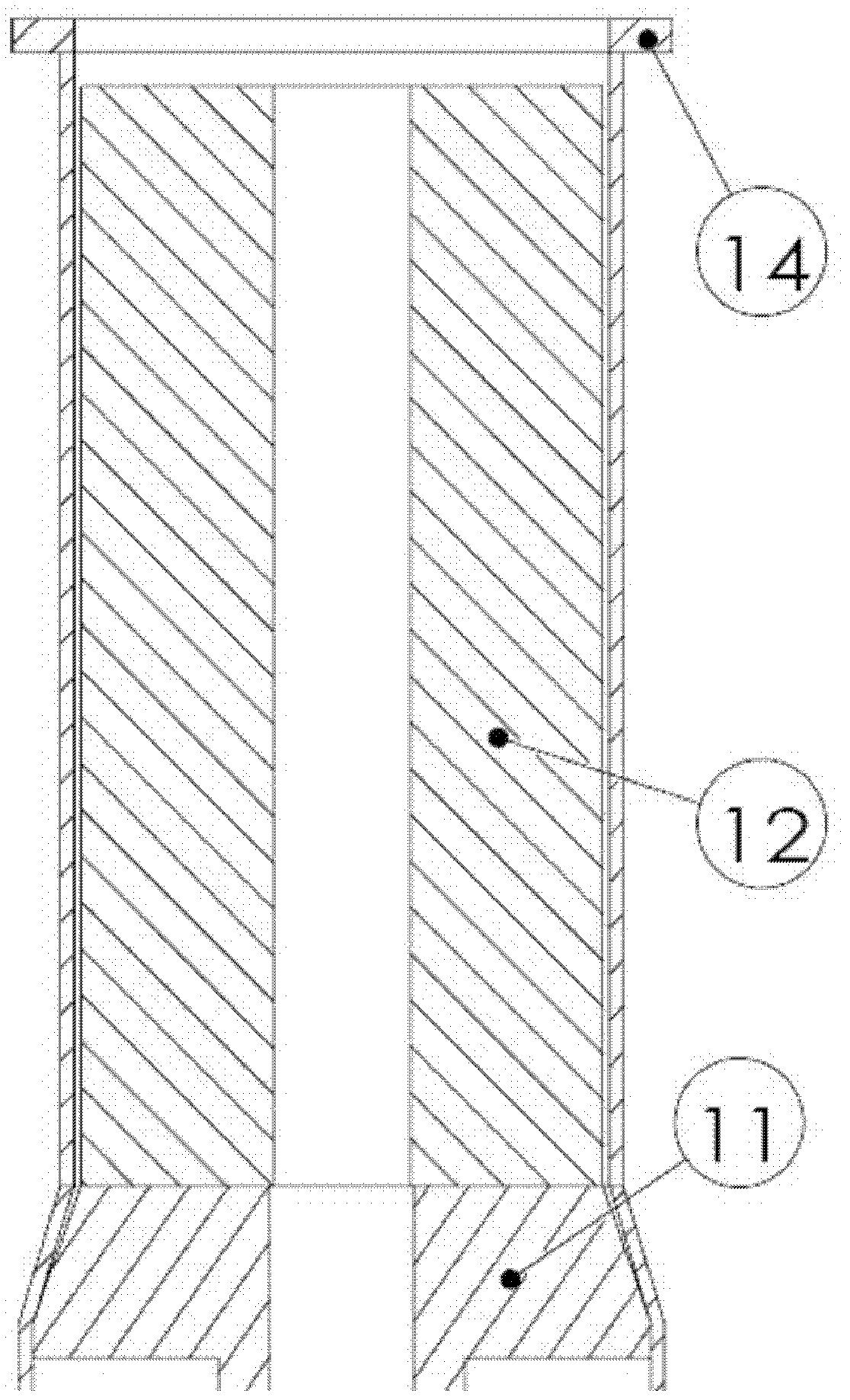

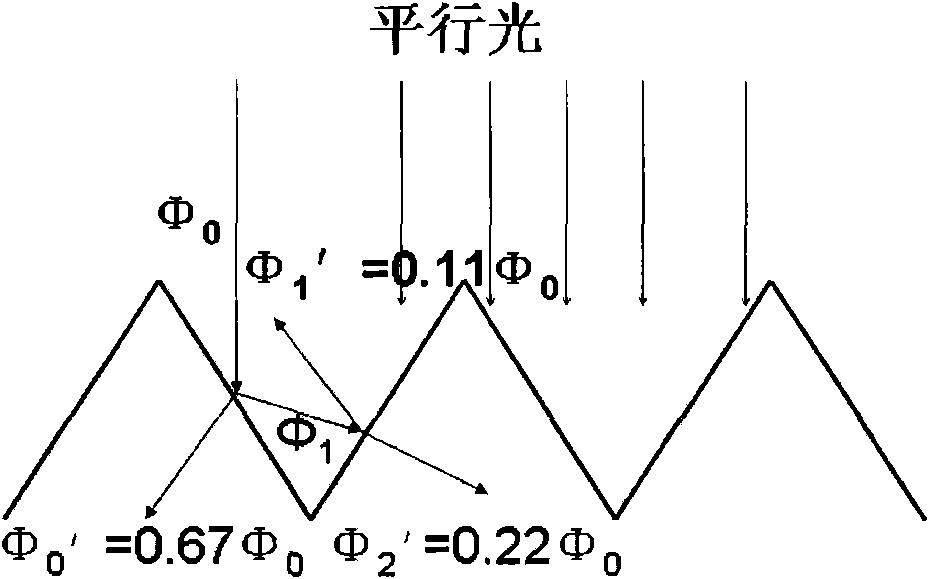

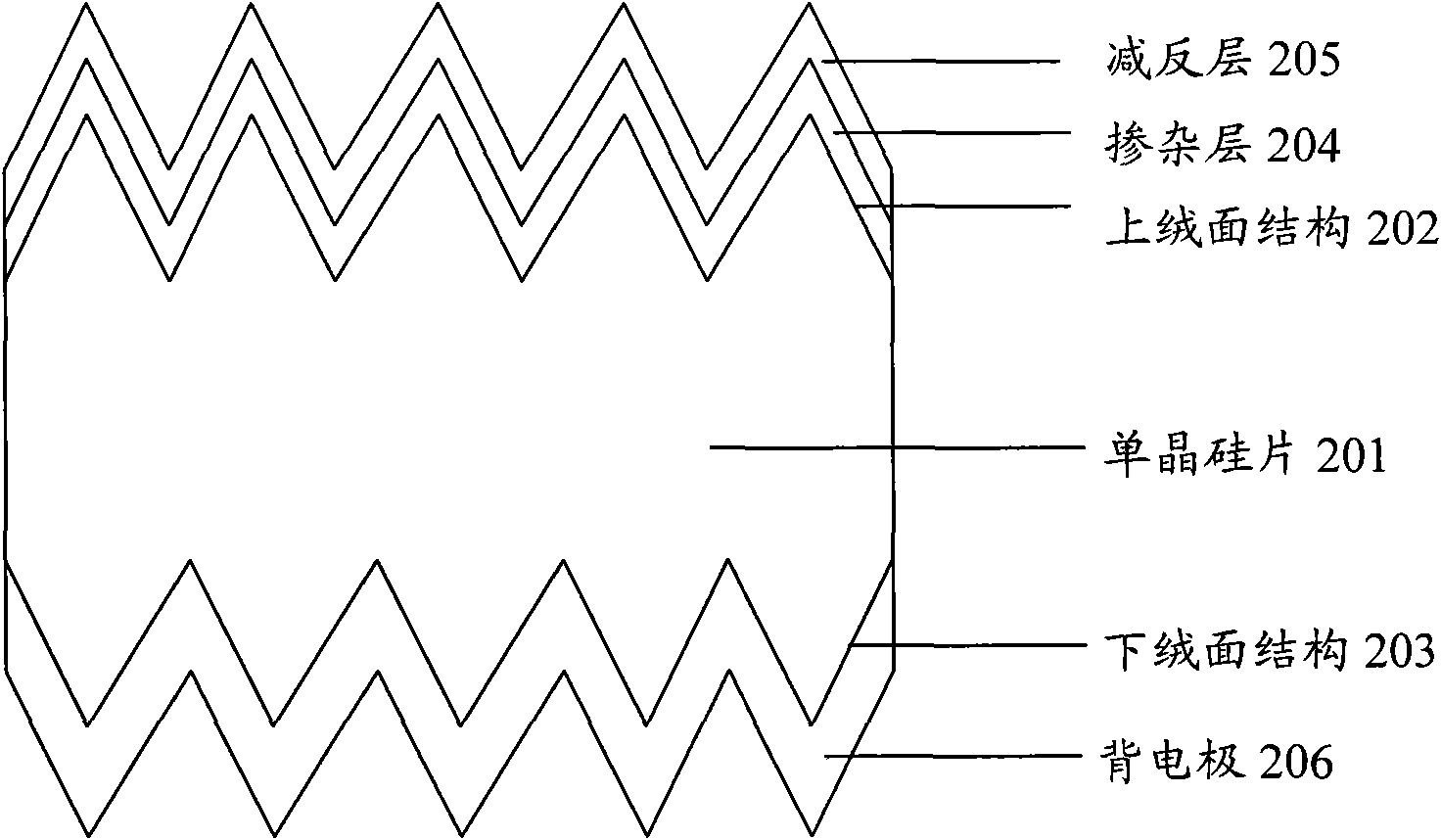

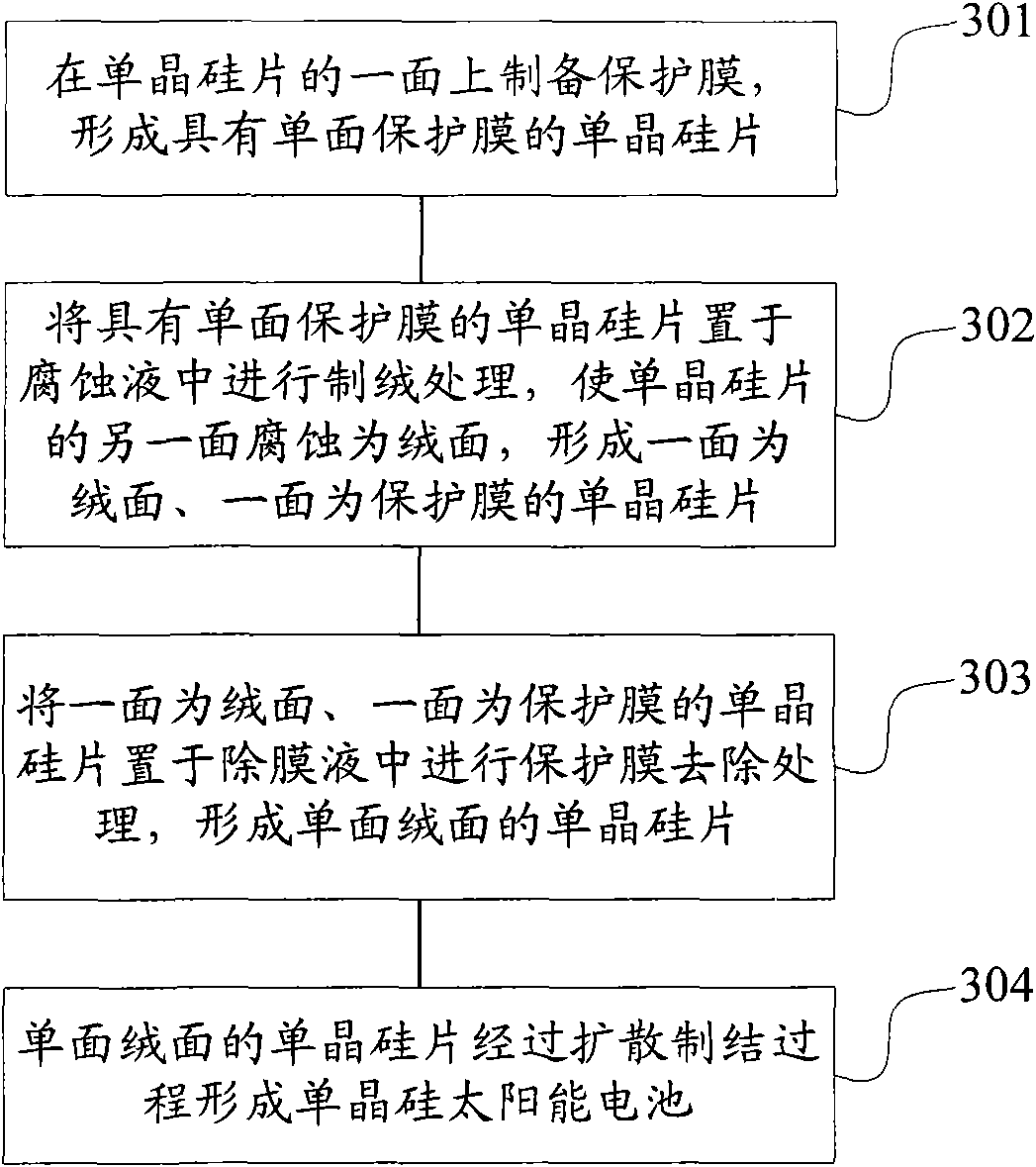

Textured mono-crystalline silicon solar battery, preparation method and preparation system thereof

InactiveCN101599514AEasy to prepareImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationProduction lineSilicon solar cell

The invention provides a method for preparing an textured mono-crystalline silicon solar battery. The method comprises the following steps: preparing a protective film on one side of a mono-crystalline silicon wafer, so as to form a mono-crystalline silicon wafer provided with a single-side protective film; placing the mono-crystalline silicon wafer provided with the single-side protective film in an etching solution to carry out the etching treatment, so that the other side of the mono-crystalline silicon wafer is etched into an textured side; placing the mono-crystalline silicon wafer with one side being the textured side and the other side being the protective layer in a film-removing solution to carry out the removal treatment of the protective film, so as to form the mono-crystalline silicon wafer with one side being the textured side; forming the mono-crystalline silicon solar battery through the processes of diffusion and junction preparation by using the mono-crystalline silicon wafer with one textured side. The invention further provides a textured mono-crystalline silicon solar battery prepared by the method and a preparation system thereof. The mono-crystalline silicon solar battery with the single-side textured structure, which is prepared by the method of the invention, improves the conversion efficiency of the battery, prevents 'aluminum bubbles' from generating, and improves the utilization rate of the devices by using the existing devices in the production line.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

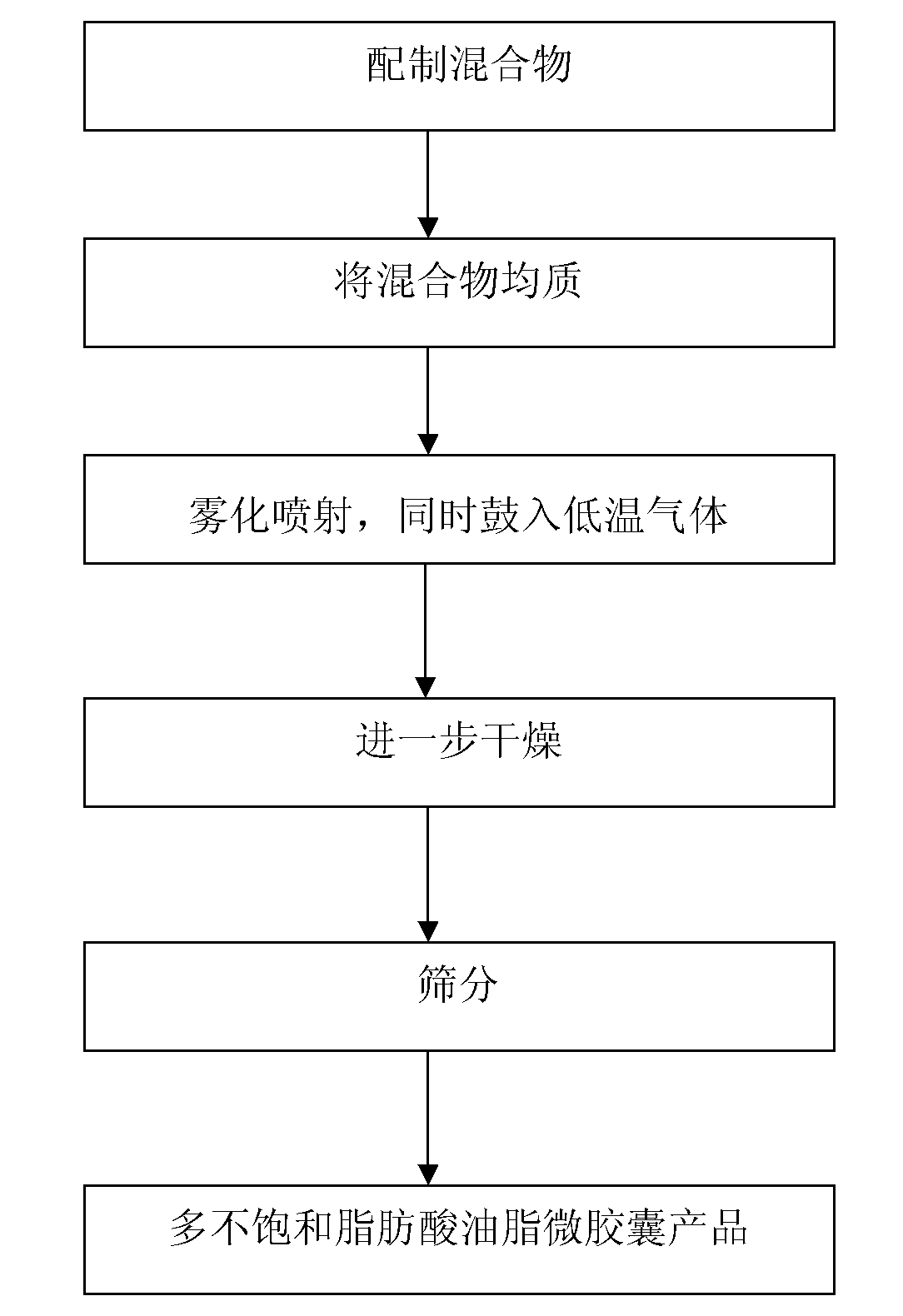

Spray freeze-drying preparation technology for polyunsaturated fatty acid oil microcapsule

The invention relates to a spray freeze-drying preparation technology for a polyunsaturated fatty acid oil microcapsule, which comprises the following technological steps: mixing oil containing polyunsaturated fatty acid with emulsifier and water to obtain mixture; homogenizing the mixture to obtain emulsion; atomizing the emulsion into liquid drops which are sprayed into a spray drying device with temperature of negative 60 DEG C to negative 10 DEG C, wherein powder embedding materials are contained at the bottom part of the spray drying device, and blasting low-temperature gas to fully mix the materials in the spray drying device and to keep the temperature in the spray drying device to be the set temperature; and further drying and screening to obtain polyunsaturated fatty acid oil microcapsule products. The invention has the advantages that the drying temperature of the preparation technology is low, the speed is fast and the nutritional ingredients are not apt to be damaged; the technology is simple and convenient and the automatic mass production can be realized; and the oil embedding rate of the obtained independent polyunsaturated fatty acid oil microcapsule particles is high, the embedding performance is good, the product shelf life is long and the stability is good.

Owner:CABIO BIOTECH WUHAN CO LTD

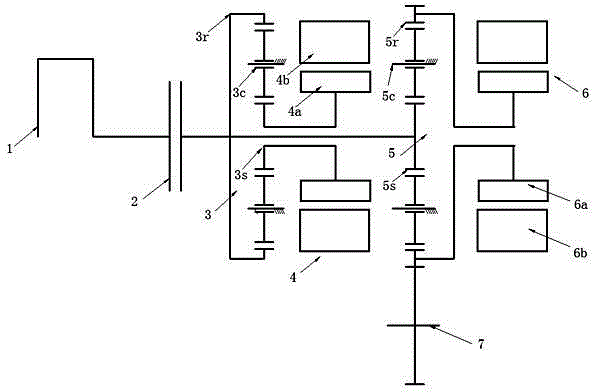

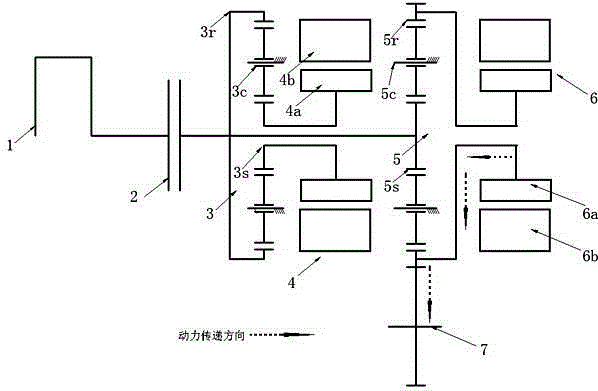

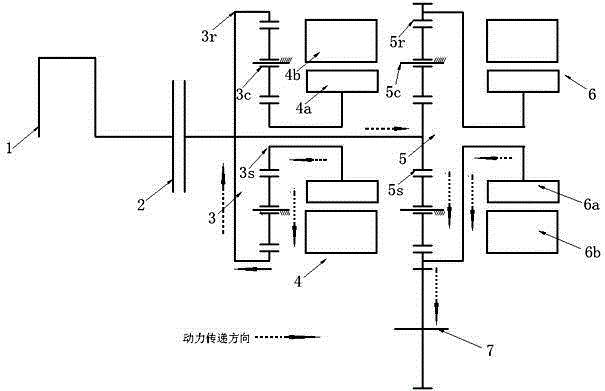

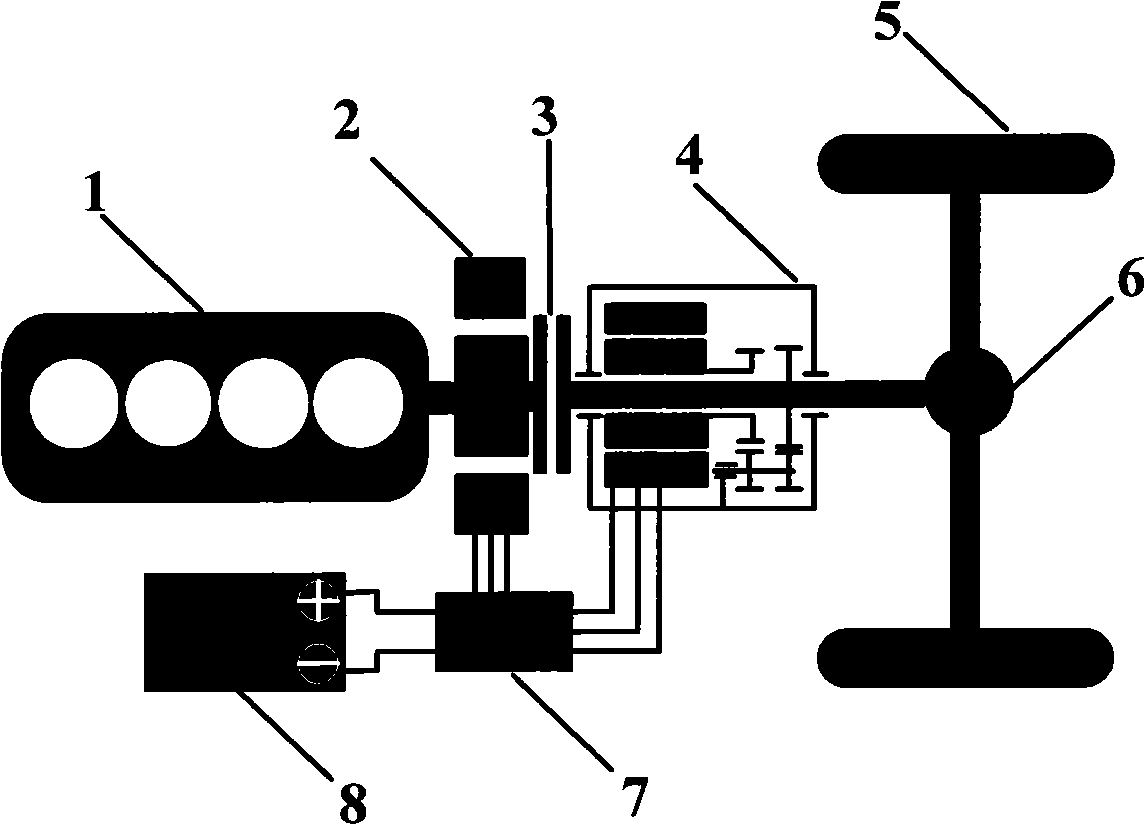

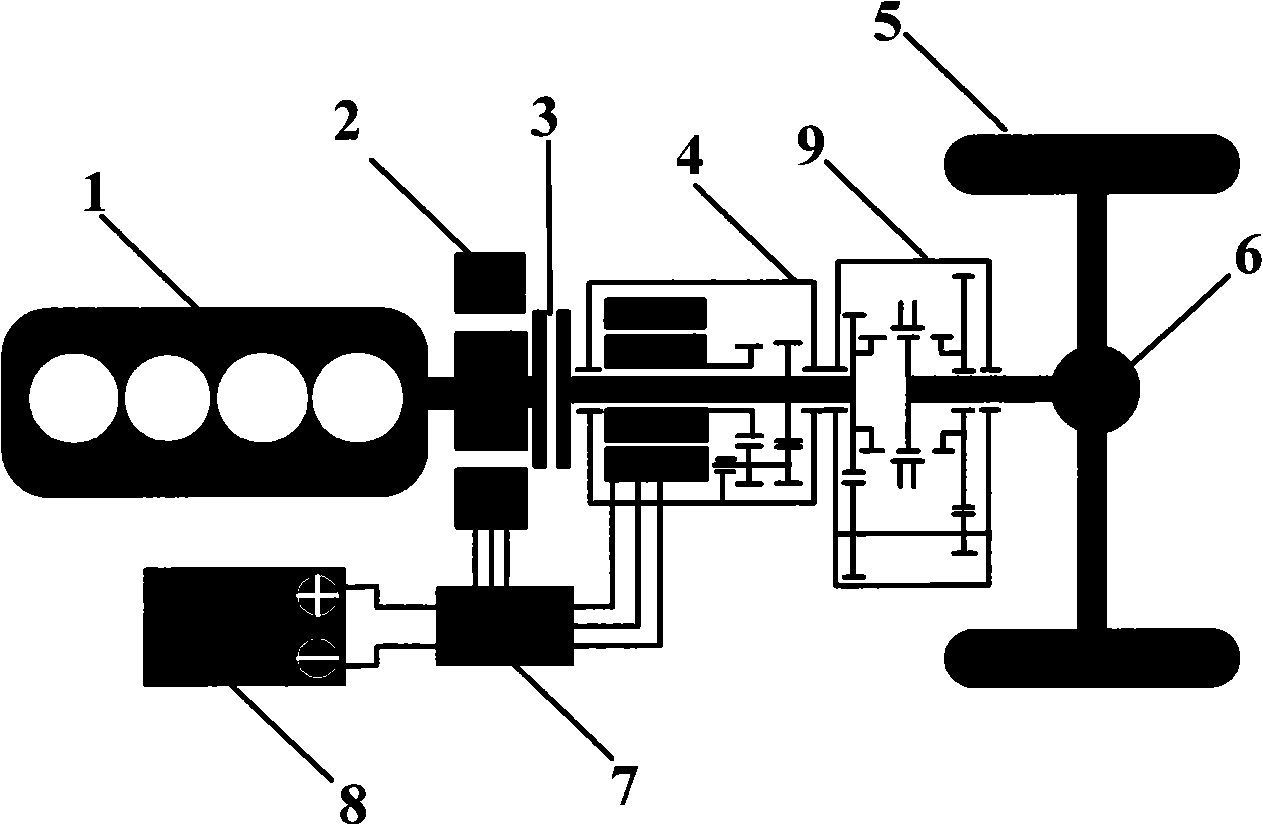

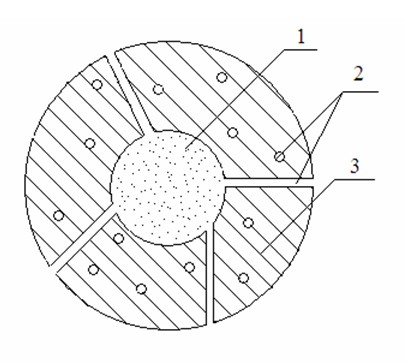

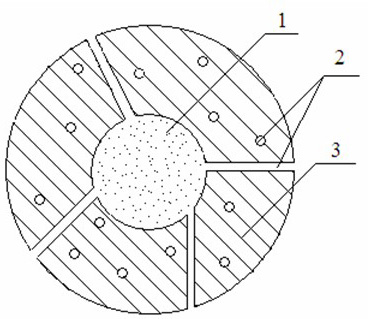

Hybrid vehicle compound planetary gear set dynamic coupling mechanism

InactiveCN105346371AAchieving the purpose of direct drive vehiclesEasy multi-mode controlGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingVehicle frameGear wheel

The invention relates to a hybrid vehicle compound planetary gear set dynamic coupling mechanism. The hybrid vehicle compound planetary gear set dynamic coupling mechanism comprises an engine, a first planetary gear set, a second planetary gear set, a first motor and a second motor; the first planetary gear set is composed of a first sun gear, a first planet carrier, a first tooth ring and a planetary gear; the second planetary gear set is composed of a second sun gear, a second planet carrier, a second tooth ring and a planetary gear; the first tooth ring of the first planetary gear set is connected with the engine through a clutch, the first planet carrier is fixed on a vehicle frame, and the first sun gear is fixedly connected with a rotor of the first motor; the second sun gear of the second planetary gear set is fixedly connected with the first tooth ring of the first planetary gear set, the second planet carrier is fixed on the vehicle frame, the second tooth ring is fixedly connected with a rotor of the second motor, and the second tooth ring is combined with a differential mechanism in order to output power. According to the invention, the function that the engine can directly drive the vehicle, multiple dynamic coupling and mode switching can be achieved, and the implementation structure of the hybrid vehicle compound planetary gear set dynamic coupling mechanism is simple in structure and low in control demand.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

Directly extrusion cast high strength aluminium alloy

The present invention relates to aluminum alloy material, and is especially one kind of directly extrusion cast high strength aluminum alloy. The aluminum alloy consists of Cu 4.0-5.0 wt%, Mg 1.0-2.0 wt%, Mn 0.4-0.8 wt%, trace alloy elements including Ti 0.05-0.25 wt%, B 0.01-0.05 wt%, V 0.05-0.20 wt% and Zr 0.05-0.20 wt%, and mixed RE 0.05-0.15 wt% except Al and inevitable impurities, including Fe less than 0.2 wt% and Si less than 0.1 wt%. The aluminum alloy is prepared through direct extrusion casting, quenching and perfect artificially ageing process, has the features of capacity of being heat treated to reinforce, high strength, low cost, etc, and is suitable for use in making heavy bearing aluminum alloy structures.

Owner:SOUTH CHINA UNIV OF TECH

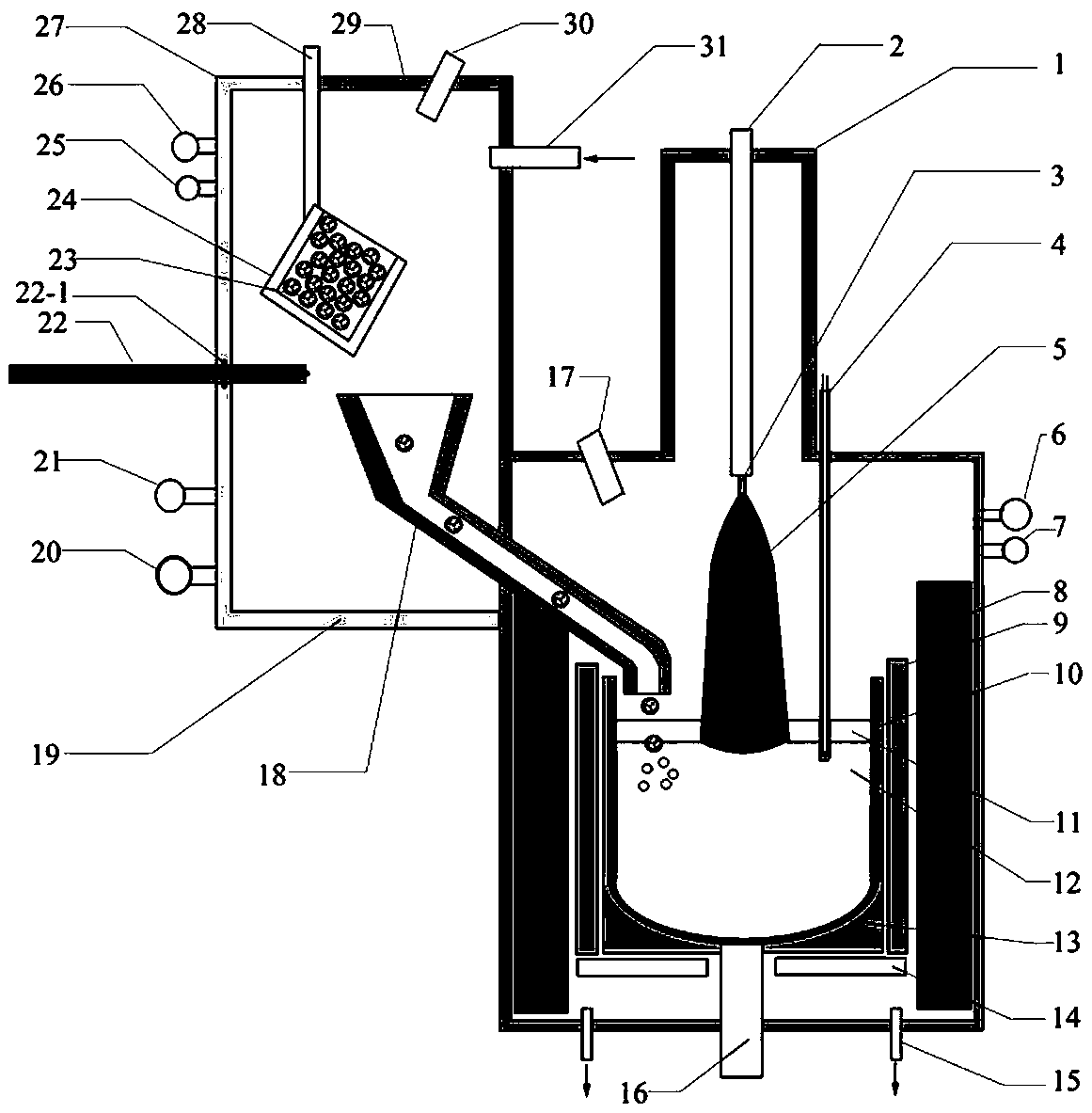

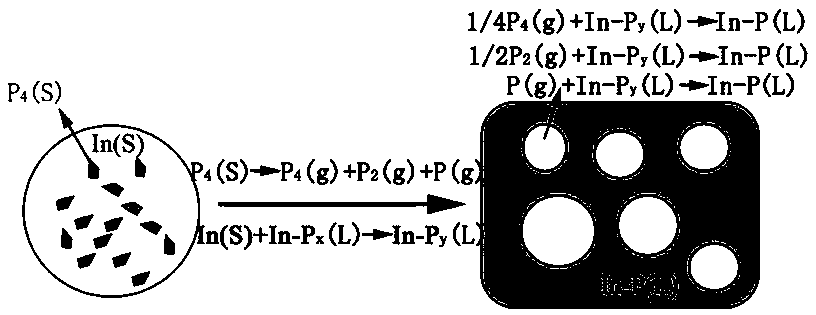

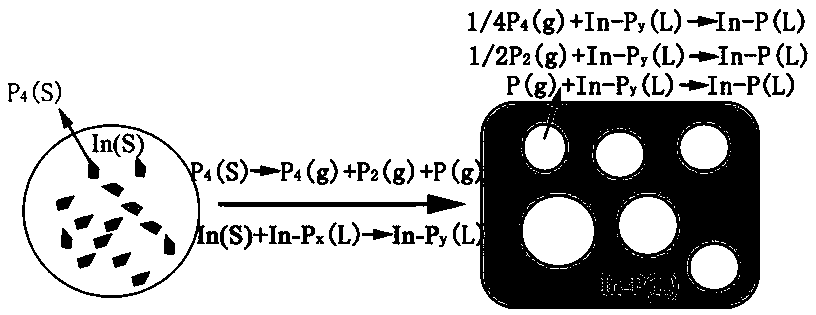

Method for preparing indium phosphide crystals by utilizing indium-phosphorus mixture

ActiveCN110760932AReduce volatilityHigh purityPolycrystalline material growthFinal product manufactureIndiumPhysical chemistry

The invention relates to a method for preparing indium phosphide crystals by using an indium-phosphorus mixture, and belongs to the technical field of semiconductors, and the method comprises the following steps of: preparing indium-phosphorus mixed balls, charging, keeping blast furnace pressure and low temperature of the indium-phosphorus mixed balls, melting a covering agent, feeding, synthesizing and growing the crystals. The proportioned indium-phosphorus mixed balls are directly melted to synthesize the indium phosphide crystals. Indium powder and phosphorus powder are uniformly mixed and pressed into spherical indium-phosphorus mixed particles, then a mixture of the indium-phosphorus mixed balls and boron oxide powder is put into a melt with a boron oxide covering agent, and crystalgrowth is carried out in situ after synthesis. The method has the advantages of being short in reaction time, high in efficiency and capable of saving raw materials, effectively reducing the risk that the materials are contaminated, saving procedures and reducing the material preparation cost.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

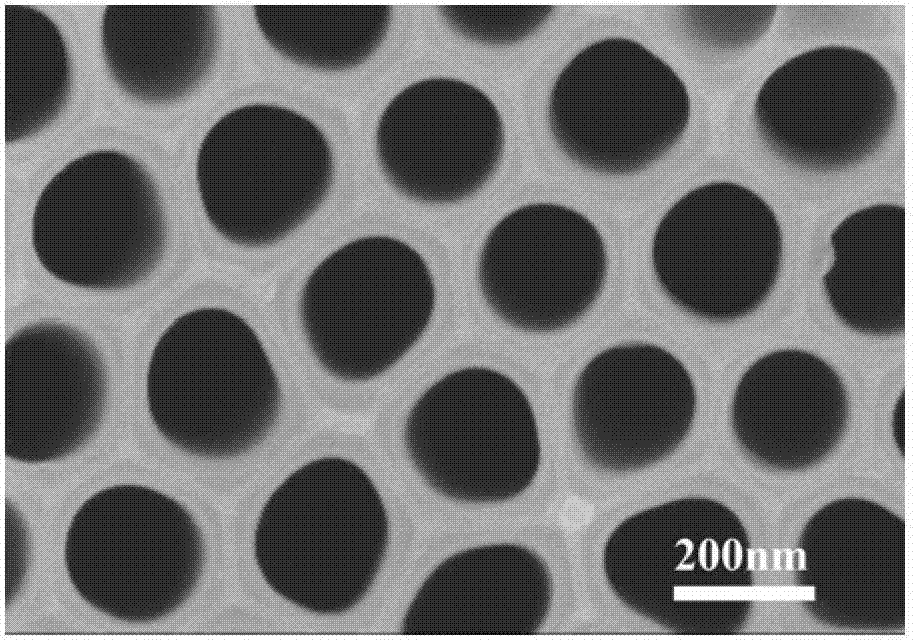

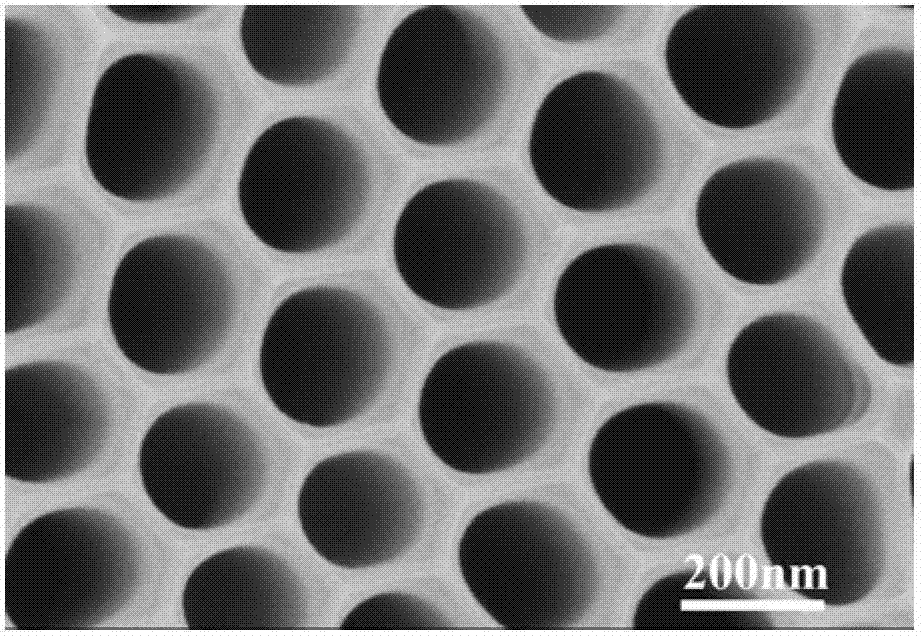

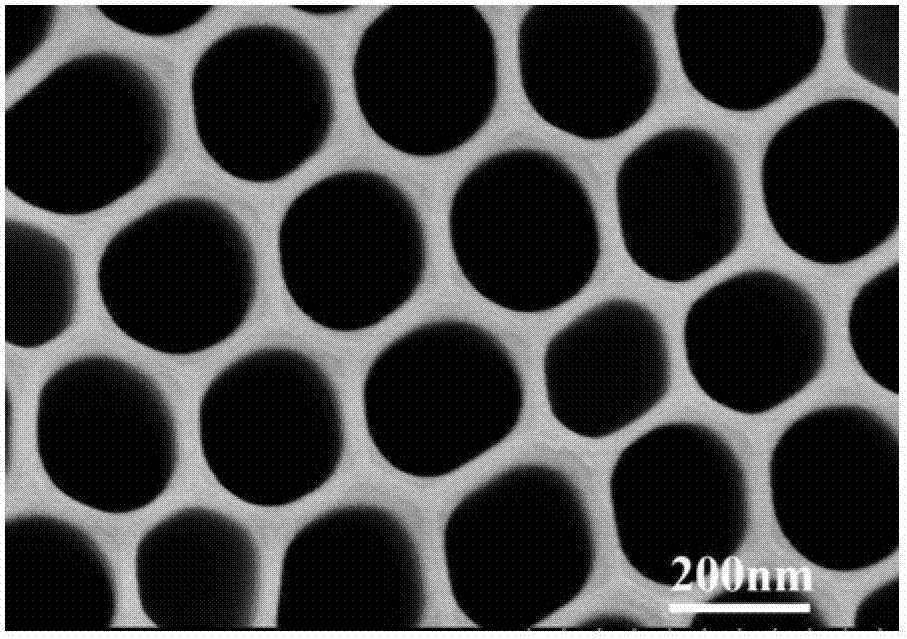

Method for preparing ordered macroporous anodic alumina film by two-step anodic oxidation

InactiveCN103243370AAperture continuously adjustableArranged in orderSurface reaction electrolytic coatingIce waterPhosphoric acid

The invention relates to a method for preparing an ordered macroporous anodic alumina film by two-step anodic oxidation. The method comprises the following steps of: carrying out hard anodizing on aluminum which is subjected to high temperature annealing, ultrasound deoiling and electrochemical polishing treatments in modified oxalic acid electrolyte, so as to obtain a porous anodic alumina film; removing an irregular porous alumina layer which is formed after first anodic oxidation by using a mixed solution of chromic acid and phosphoric acid; then carrying out second anodic oxidation, namely carrying out mild anodic oxidation on the aluminum sheet with the alumina film removed in the modified phosphate electrolyte in a constant voltage manner, wherein the voltage in the second anodic oxidation is completely the same as the voltage in the first anodic oxidation; and finally chambering the test sample subjected to anodic oxidation in a phosphoric acid solution to obtain the ordered macroporous anodic alumina film. The preparation method is carried out under an ice-water bath condition without the requirement on a very low temperature or a high voltage; the cost of used raw materials is low; and equipment is simple and is convenient to operate and easy to control, and therefore the method has a bright application prospect in the modern industry and high and new technology field.

Owner:DONGHUA UNIV

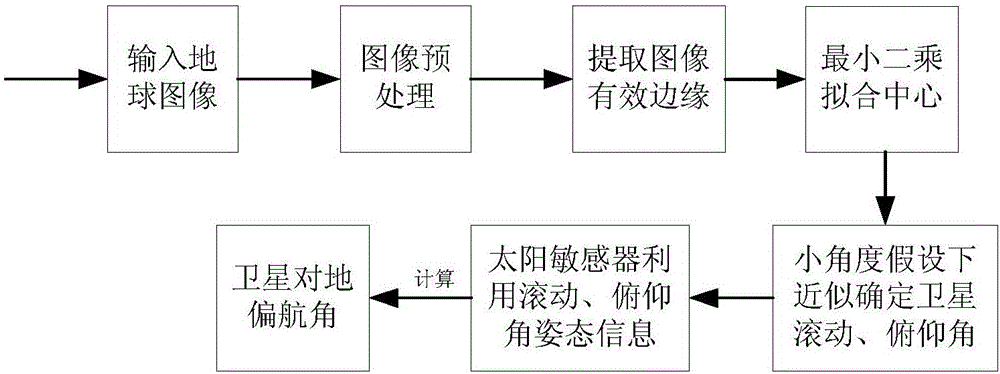

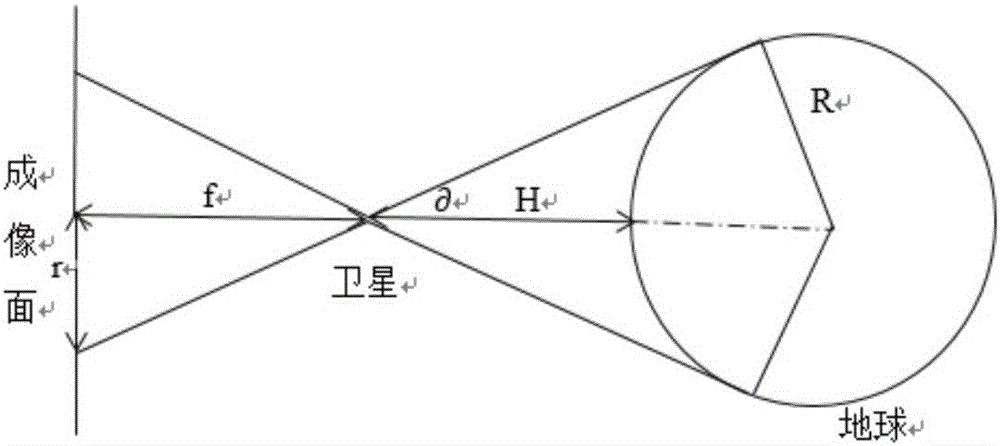

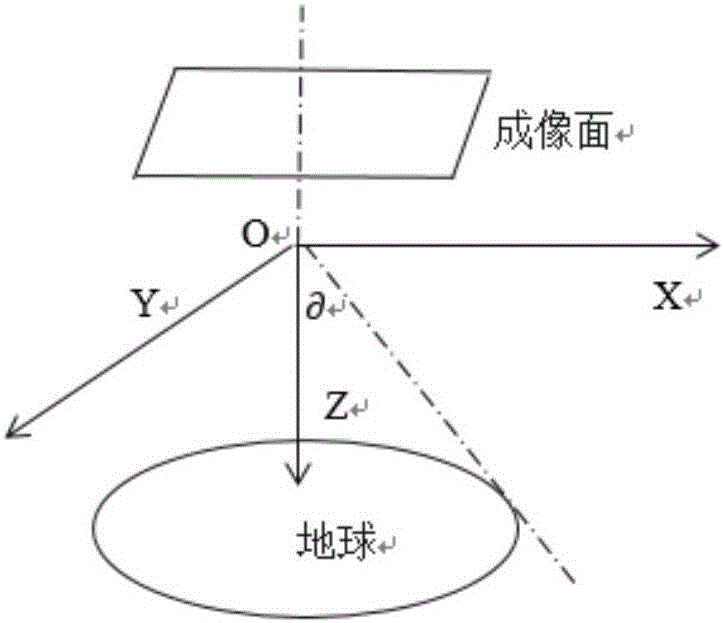

Method for determining attitude of satellite based on visible light earth sensor and sun sensor

ActiveCN105928527AHigh precisionGood precisionInstruments for comonautical navigationNatural satelliteCMOS

A method for determining the attitude of a satellite based on a visible light earth sensor and a sun sensor uses combination of the visible light earth sensor and the sun sensor to determine the earth triaxial attitude of the satellite. The method comprises the following steps: processing an earth image formed by a CMOS imaging device, extracting the effective edge of the earth image, and fitting the center of the extracted effective edge by using a least square technology; approximately calculating the earth roll angle and the pitch angle under the assumption that the earth attitude angle of the satellite is a small angle; and calculating by using the sun sensor according to the earth roll angle and pitch angle attitude information obtained after approximate calculation to obtain the earth yaw angle of the satellite. Compared with traditional methods for determining the earth triaxial attitude angle of the satellite through using earth infrared sensor and sun sensor combination, the method provided by the invention has the advantages of improvement of the measurement precision of the attitude angle of the satellite, suitableness for attitude measurement of small satellites, and conformation to the current development trend of the small satellites.

Owner:AEROSPACE DONGFANGHONG SATELLITE

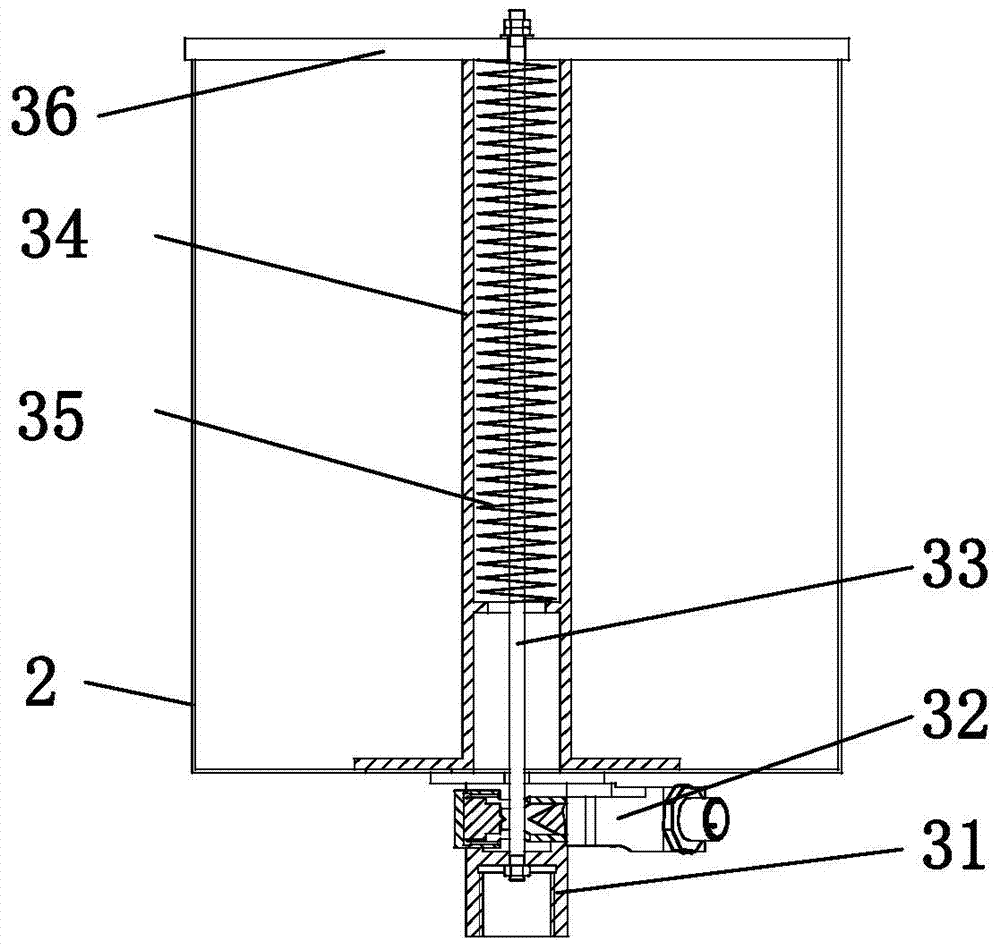

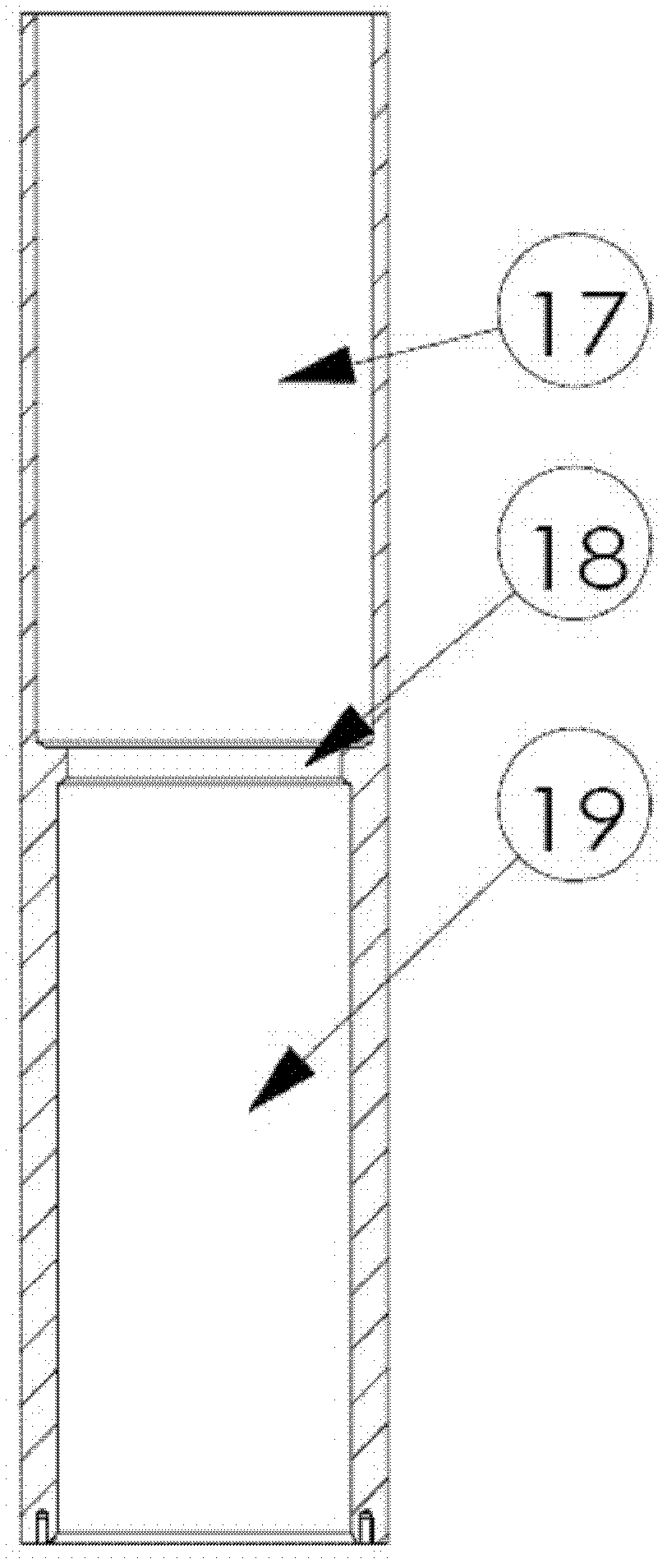

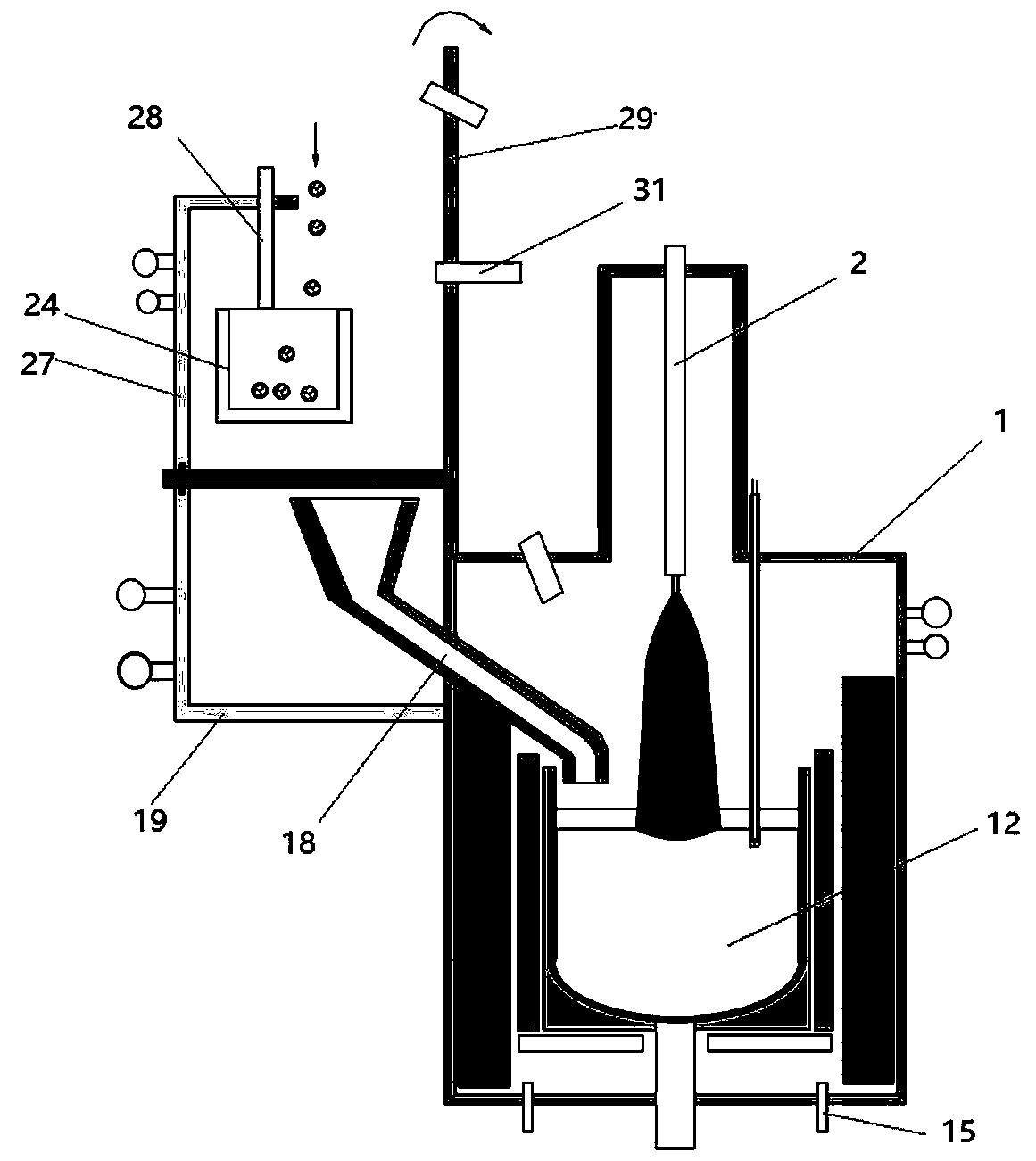

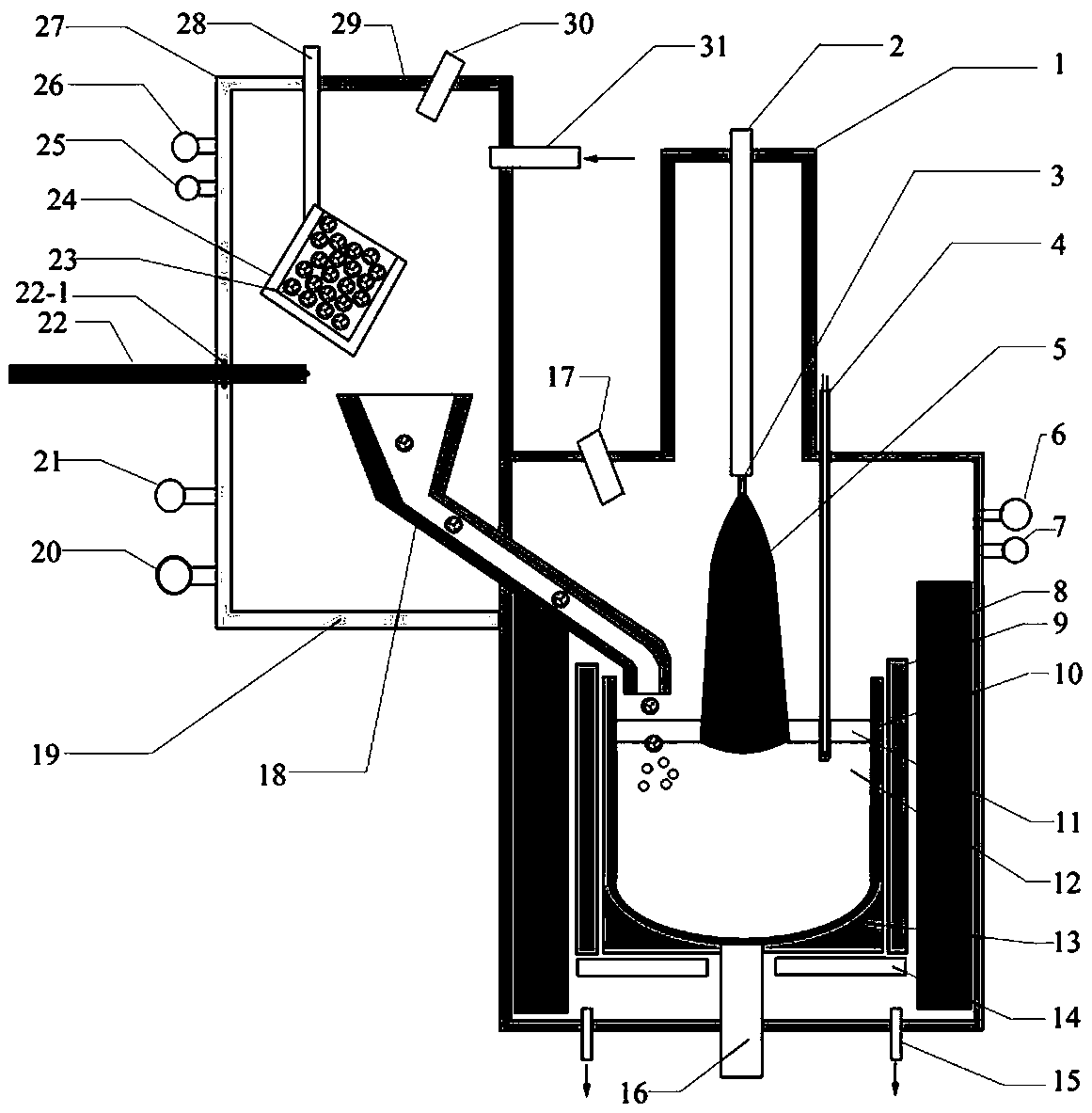

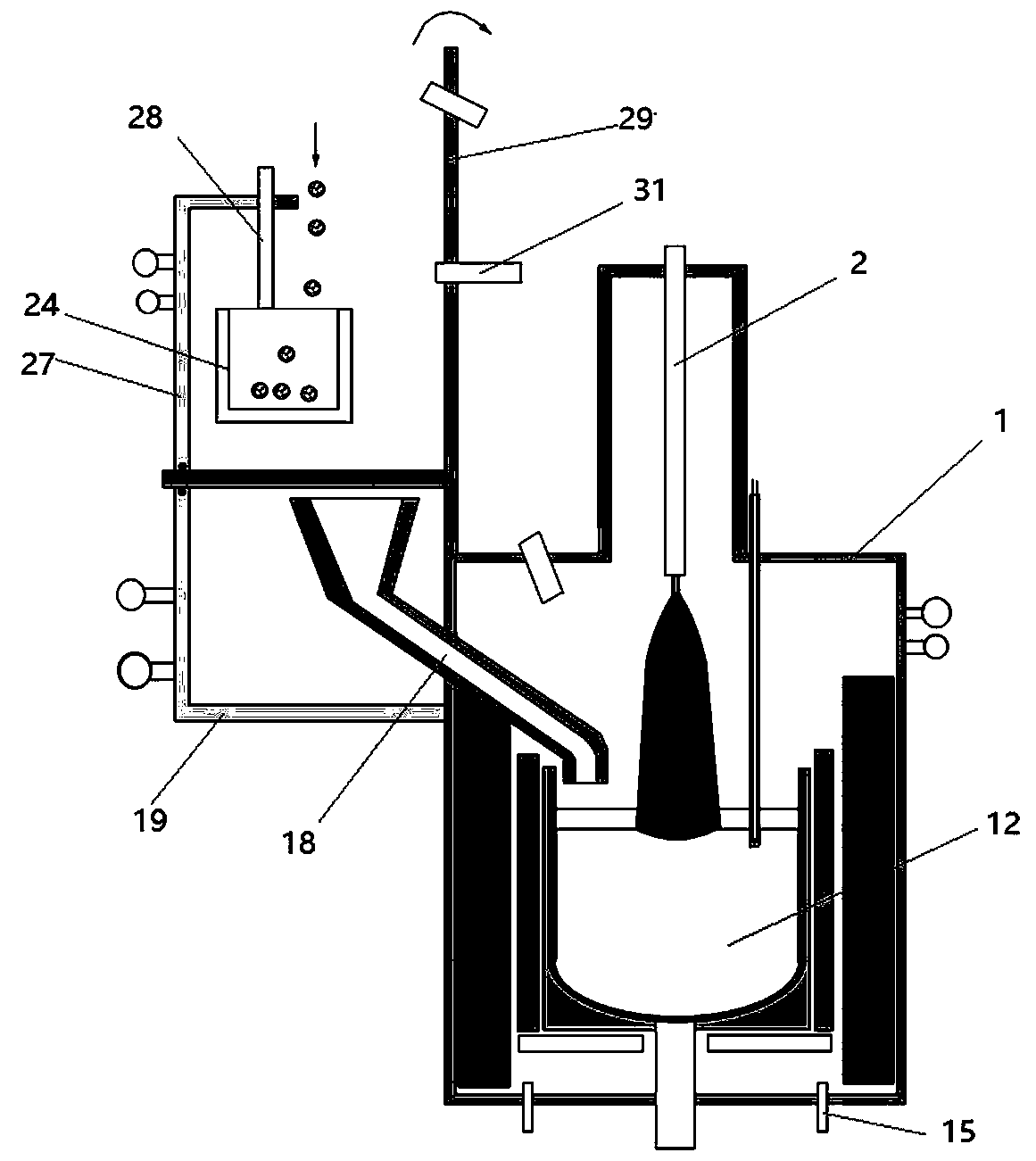

System for preparing indium phosphide crystals by utilizing indium-phosphorus mixture

PendingCN110760931ASynthesis speedReduce control requirementsPolycrystalline material growthFinal product manufactureIndiumControl system

The invention discloses a system for preparing indium phosphide crystals by using an indium-phosphorus mixture. The invention belongs to the technical field of semiconductors. The system comprises a vacuum system, an inflation and deflation system, a temperature and pressure control system, an electrical control system, a cooling circulation system, a weighing system and a furnace body, wherein acrucible rod rotary lifting mechanism and a seed crystal rod lifting mechanism are arranged on the furnace body; the system is characterized in that the furnace body is divided into a synthetic growthchamber, a feeding chamber and a charging chamber, the charging chamber and the feeding chamber are separated by an inserting plate, a turnover feeder is arranged in the charging chamber, a feeding pipe is arranged in the feeding chamber, one end of the feeding pipe is in butt joint with the turnover feeder, and the other end of the feeding pipe extends into a crucible in the synthetic growth chamber to form an indium-phosphorus mixed ball feeding structure; wherein the crucible is positioned on a crucible rod, and a seed crystal rod lifting mechanism is arranged on a top cover of the synthetic growth chamber. Indium-phosphorus mixed balls can be rapidly put into the crucible covered with liquid boron oxide, indium phosphide crystals are formed through in-situ pulling after synthesis, thesynthesis speed is higher, and industrial production is facilitated.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

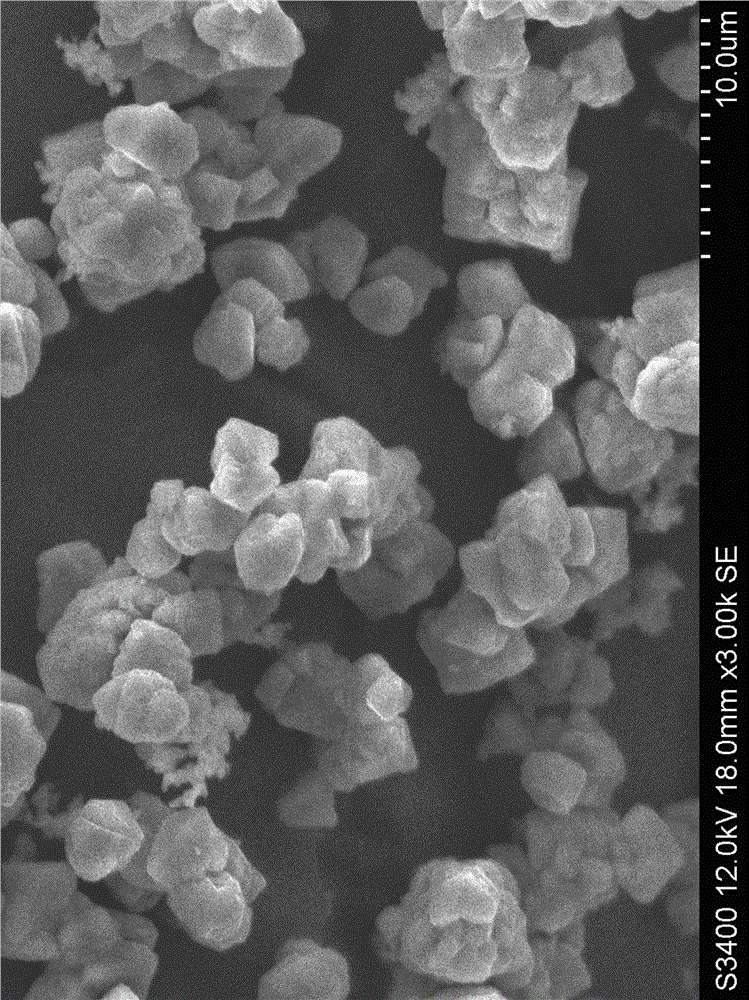

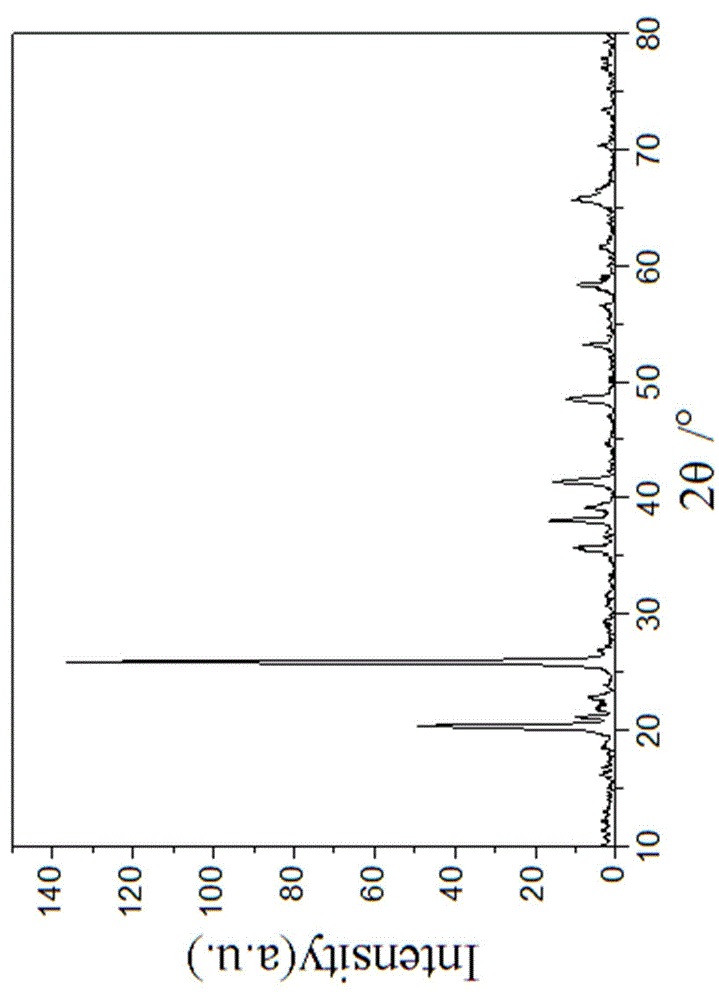

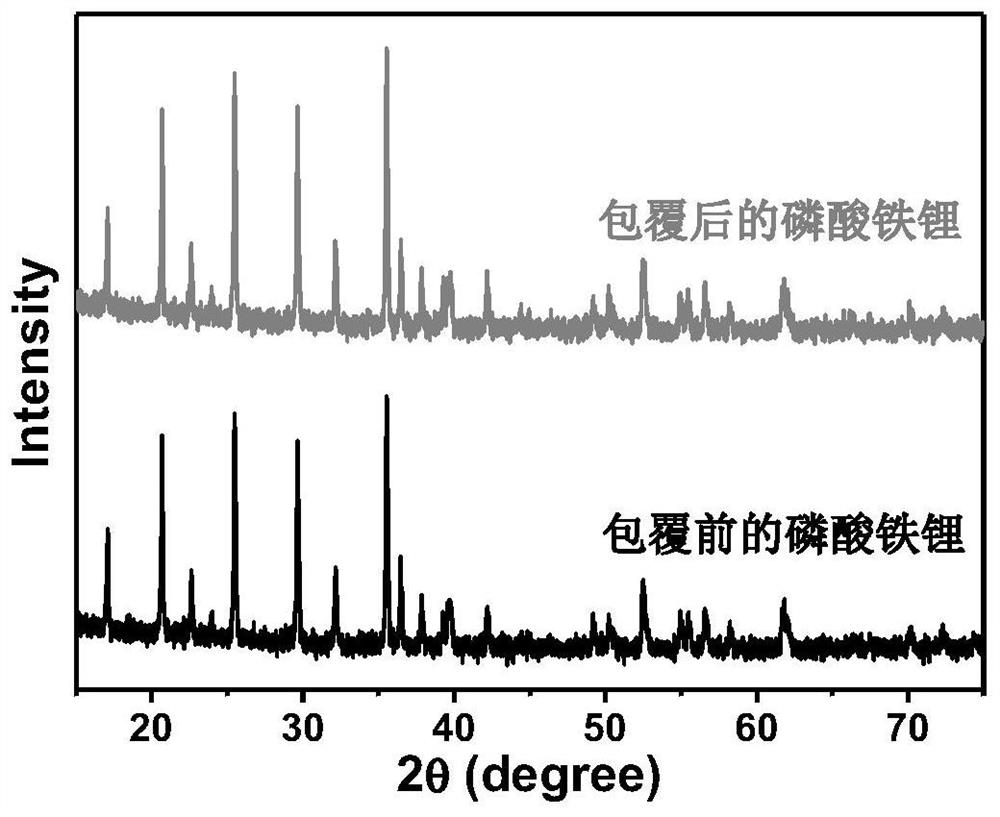

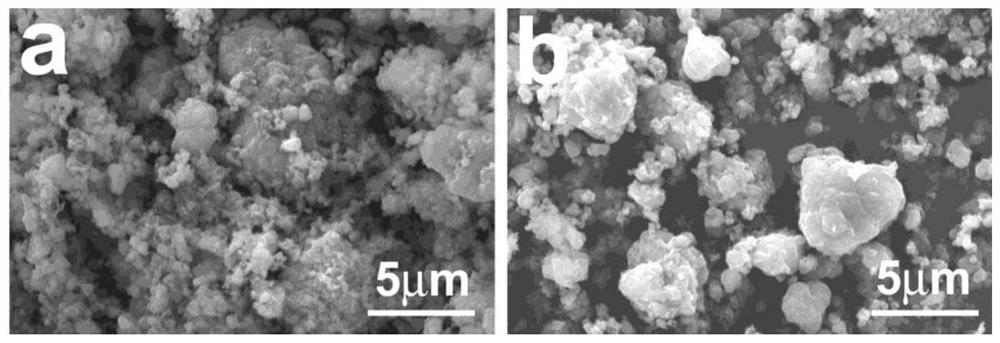

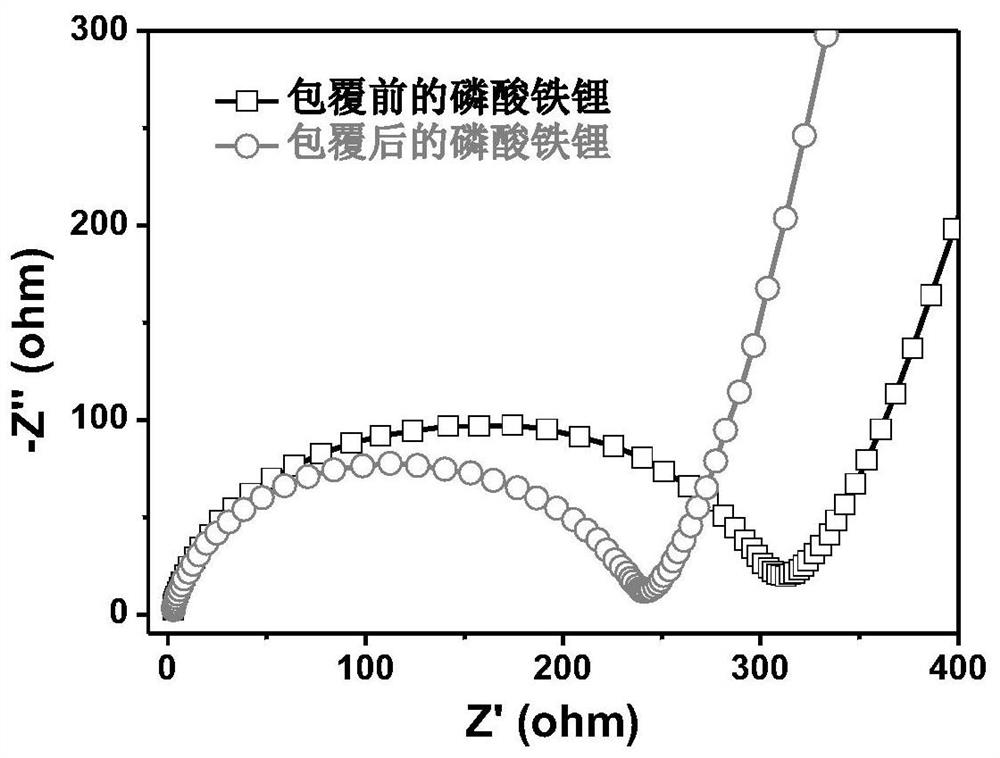

Synthetic method for high-purity iron phosphate and doped metallic element thereof

ActiveCN105185993AEasy to separateNo pollution in the processPositive electrodesLithium iron phosphatePhosphoric acid

The invention relates to a synthetic method for high-purity iron phosphate and a doped metallic element thereof. A material prepared by the synthetic method is mainly applied to the preparation of a high-quality electrode material, namely lithium iron phosphate, and the synthetic method comprises the following steps: taking a phosphor source, an iron source compound and a doped metallic oxide as raw materials, adding a surfactant, reacting by high-speed stirring under normal pressure and low temperature, finally synthesizing into the substance of which the chemical formula is Fe1-xMxPO4.nH2O through seasoning, washing, filtering and drying, wherein M is the doped metallic element, and x is greater than or equal to 0 and smaller than or equal to 3, and n is greater than or equal to 0 and smaller than or equal to 2. The pH value is not needed to control in the synthetic process, and the requirement on equipment is low, moreover, the preparation technology is simple and environment-friendly; a synthesized product is low in cost, stable in performance and high in purity.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Hard aluminum alloy for metal die casting of precision electronic product structural member

The invention discloses a hard aluminum alloy for metal die casting of a precision electronic product structural member. The hard aluminum alloy is prepared by antigravity metal die casting and natural ageing heat treatment. The hard aluminum alloy comprises, by mass, 21-30% of zinc, 5.7-7.2% of silicon, 2.0-2.4% of copper, 0.17-0.35% of manganese, 0.2-0.6% of trace alloy element and the balance aluminum and unavoidable impurities with iron content of 0.27% or less. The invention also discloses a preparation method of the hard aluminum alloy. The hard aluminum alloy can be prepared by high precision die casting, has high strength, can be subjected to high quality surface treatment, can be used for production of a high precision structural member of small, thin and light electronic products, and is suitable for large parts of spaceflight and aviation, automobiles, high-speed railway, steamships and yachts and daily hardware products.

Owner:陈灿

Motor coach hybrid power driving system

InactiveCN101327728ALow powerSeries hybrids haveGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingStarter generatorLow speed

The present invention discloses a hybrid power drive system of motor coach, and belongs to the technological field of vehicle engineering; wherein, an engine is coaxially connected with an integrated starting generator; the integrated starting generator is connected with an automatic clutch driving disc; the automatic clutch is connected with a reducing mechanism through a driving motor; the reducing mechanism is respectively connected with the driving motor and a main reducer-differential; the main reducer-differential is connected with vehicle wheels through a driving bridge; a power battery is connected with a motor controller through a cable; and the motor controller is respectively connected with the integrated starting generator and the driving motor through a cable. The hybrid power drive system maintains the traditional vehicle structure to the greatest extent, and adopts two motors to optimize the working points of the engine, so that the engine can stably operate in the high-efficiency and low-emission regions, in particular in the operating conditions of low-speed city buses.

Owner:SHANGHAI JIAO TONG UNIV

Process for preparing methyl sodiosul foaliphatate

InactiveCN101054354AReduce dosageImprove securityTransportation and packagingSulfonic acids salts preparationSulfonateAlcohol

The present invention disclosed a method for preparing sodium fatty acid methyl ester sulfonate, which takes fatty acid methyl ester sulphonic acid as raw material and reacted in pump type recycle mixing device with cooler, including re-esterification, prebleaching, neutralisation and quadric albefaction, in which disodium salt content of prepared product <=5.0%, color (5%a.m) <=50 Klett, neutralisation system MES content >=70%. The present invention rationally combines prebleaching with quadric albefaction through adding modifying agent and strictly controlling pH and using lesser methylic alcohol dosage, therefore the safety, operability and controllability of producing is capable of being greatly enhanced.

Owner:ZANYU TECH GRP CO LTD

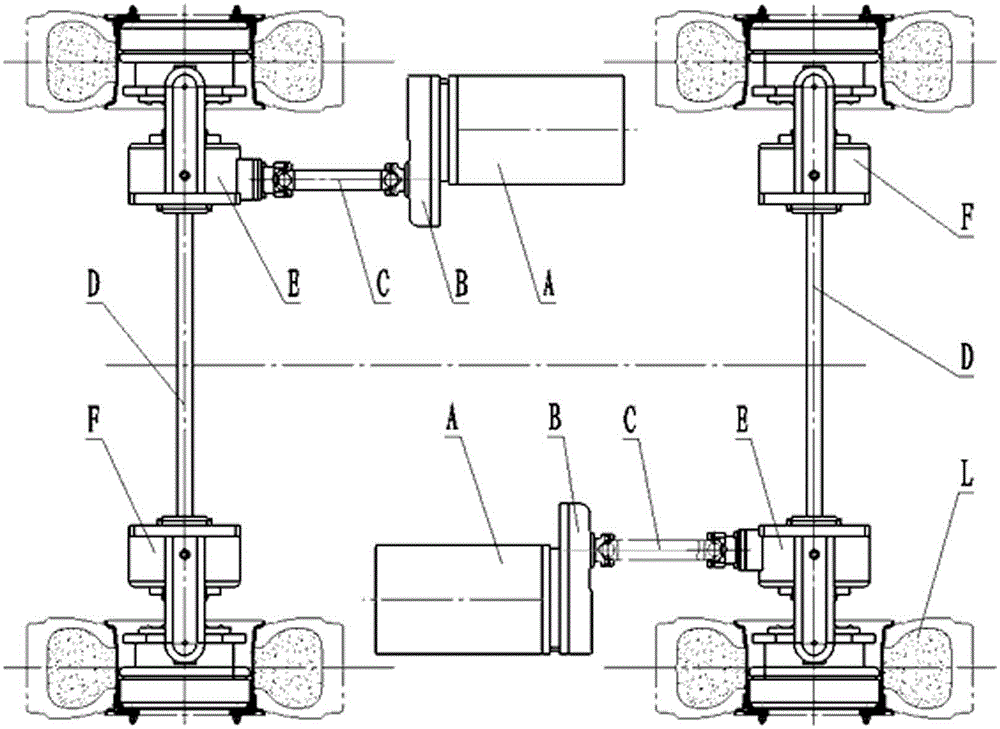

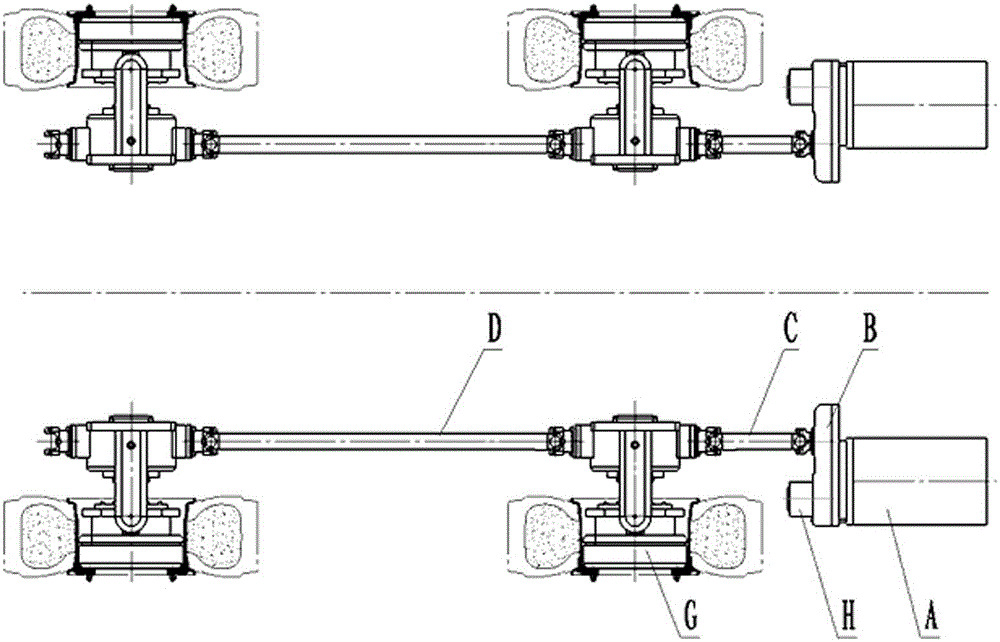

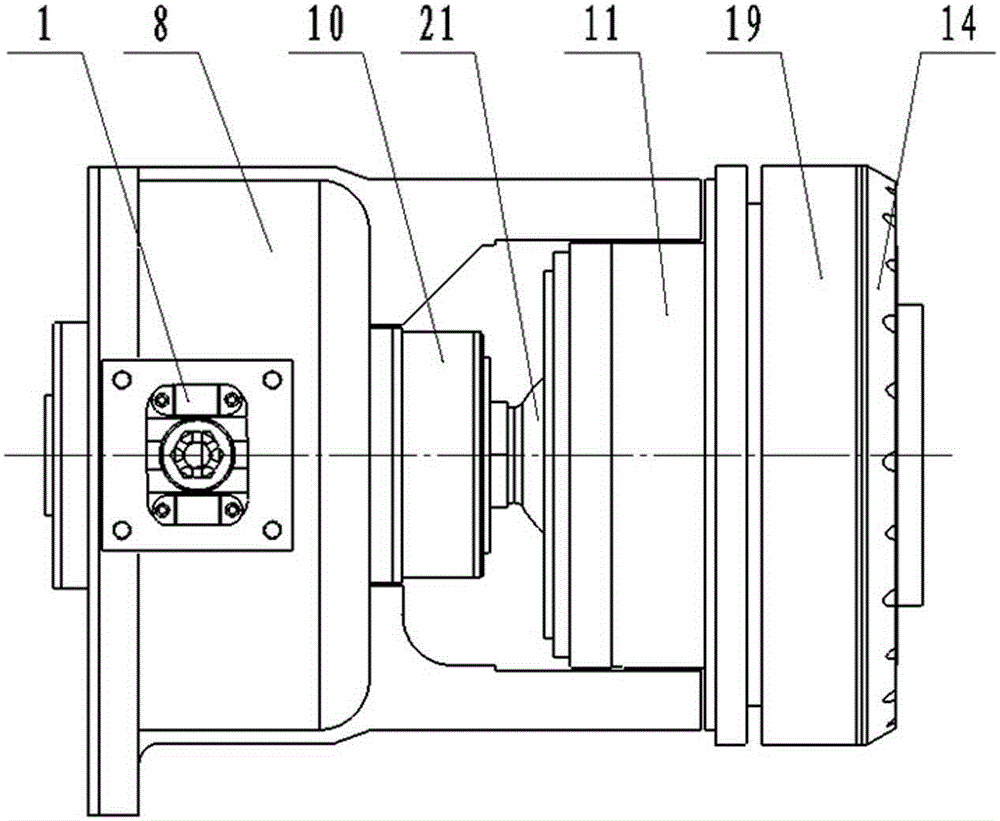

Heavy shuttle car hub driving system integrating differential respective drive and wet-type brake

ActiveCN105197020APower balance without overloadImprove power utilizationElectric motor propulsion transmissionManufacturing technologyDifferential function

The invention belongs to the technical field of design and manufacturing of underground coal mine subsidiary transport equipment parts, and provides a heavy shuttle car hub driving system integrating differential respective drive and wet-type brake. The problem that the existing shuttle car brake system is poor in steering differential function, large in brake impact and the like is solved. A drive front axle and a drive rear axle of a shuttle car are respectively controlled by two driving systems which are connected with each other in parallel; each driving system comprises a motor, a single-reduction gearbox, a hub reduction gear I and a hub reduction gear II; each hub reduction gear I and the corresponding hub reduction gear II are symmetrically mounted at two ends of a transverse transmission shaft of a corresponding shuttle car drive axle, and are positioned on the inner side of a corresponding walking rubber wheel of the shuttle car; the hub reduction gears I are connected with an outputting end of the single-reduction gearbox through transmission shafts; and the single-reduction gearbox is driven by the motors. By the two driving systems which are connected with each other in parallel, problems of abrasion of tires, eccentric load of the hub reduction gears and the like are solved, and motor power utilization rate is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

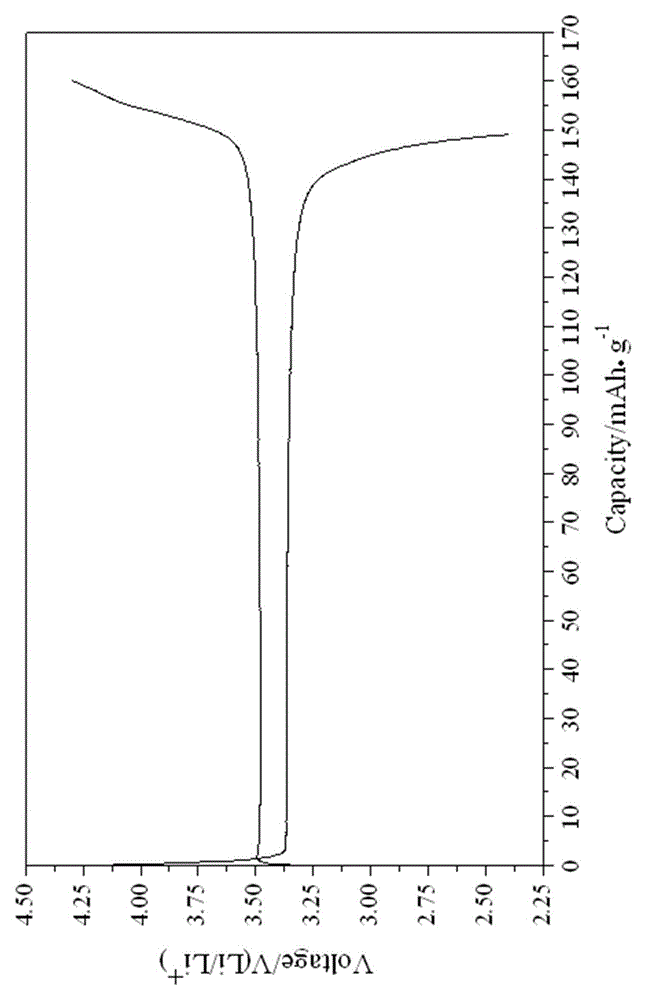

Method for compositely coating lithium battery positive electrode material with tungsten oxide and nitrogen-doped carbon

ActiveCN111900401AImprove conductivityImprove electrochemical stabilityFinal product manufactureCylindrical casing cells/batteryElectronic conductivityPolymerization

The invention belongs to the technical field of manufacturing of lithium battery cathode materials, and specifically relates to a method for compositely coating a lithium battery cathode material withtungsten oxide and nitrogen-doped carbon. A coating layer is formed on the surface of the lithium battery positive electrode material by polymerization of a carbon precursor and precipitation of a tungsten precursor. Curing and bonding of coating layer are realized through a calcining process. According to the present invention, the method has characteristics of low cost, low energy consumption and simple operation, and the lithium battery positive electrode material prepared through the method has characteristics of excellent electronic conductivity and excellent electrochemical stability.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

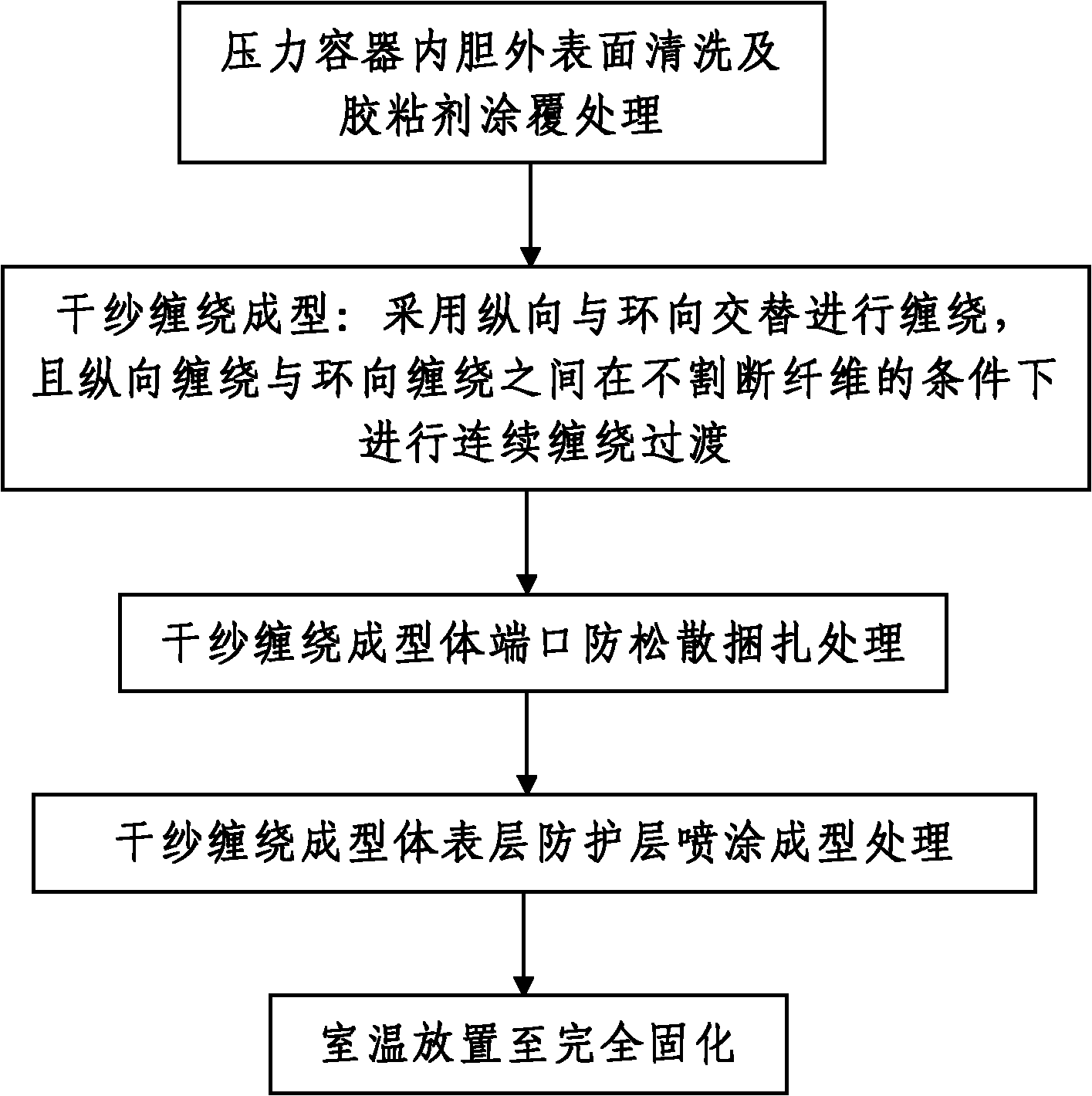

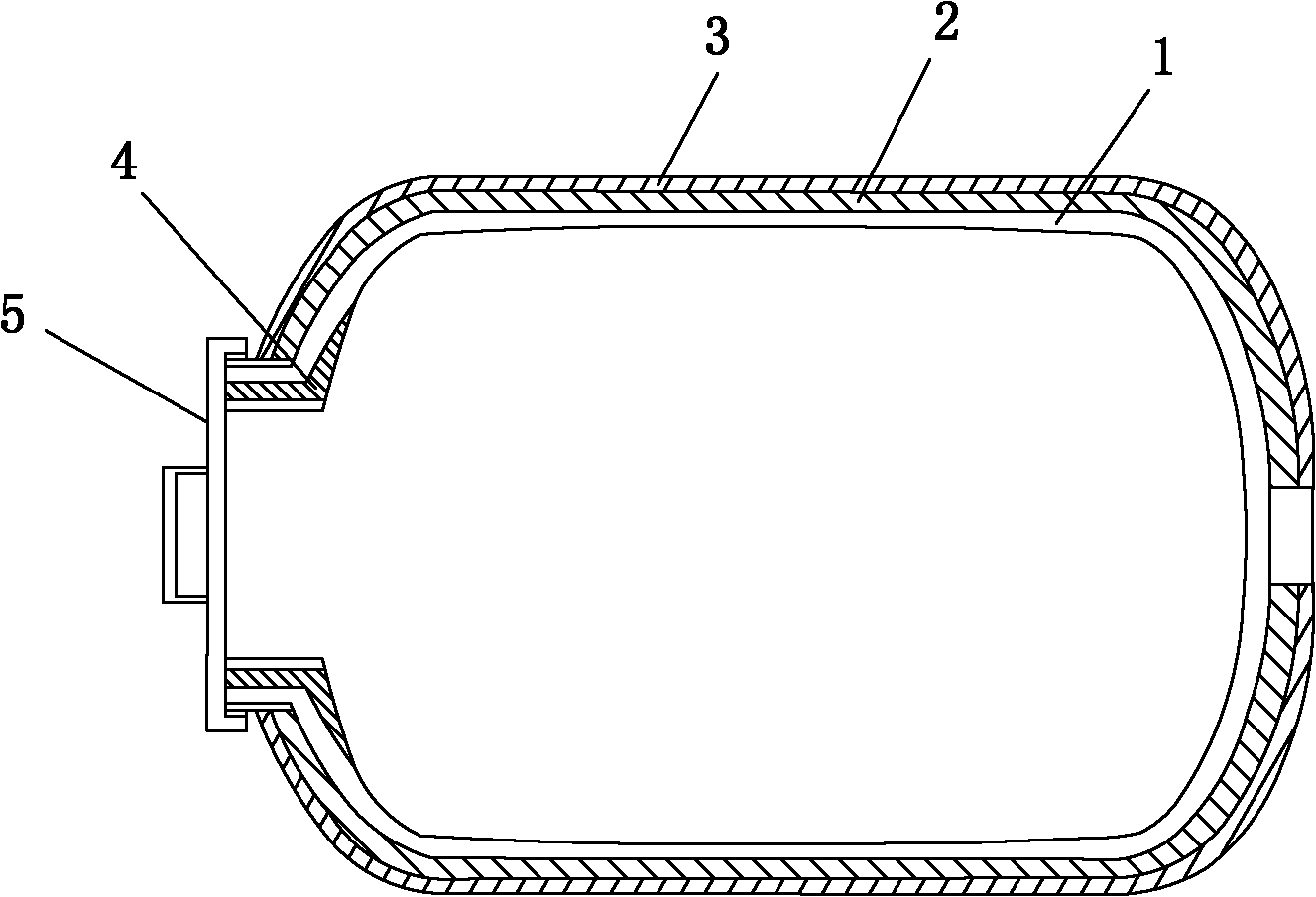

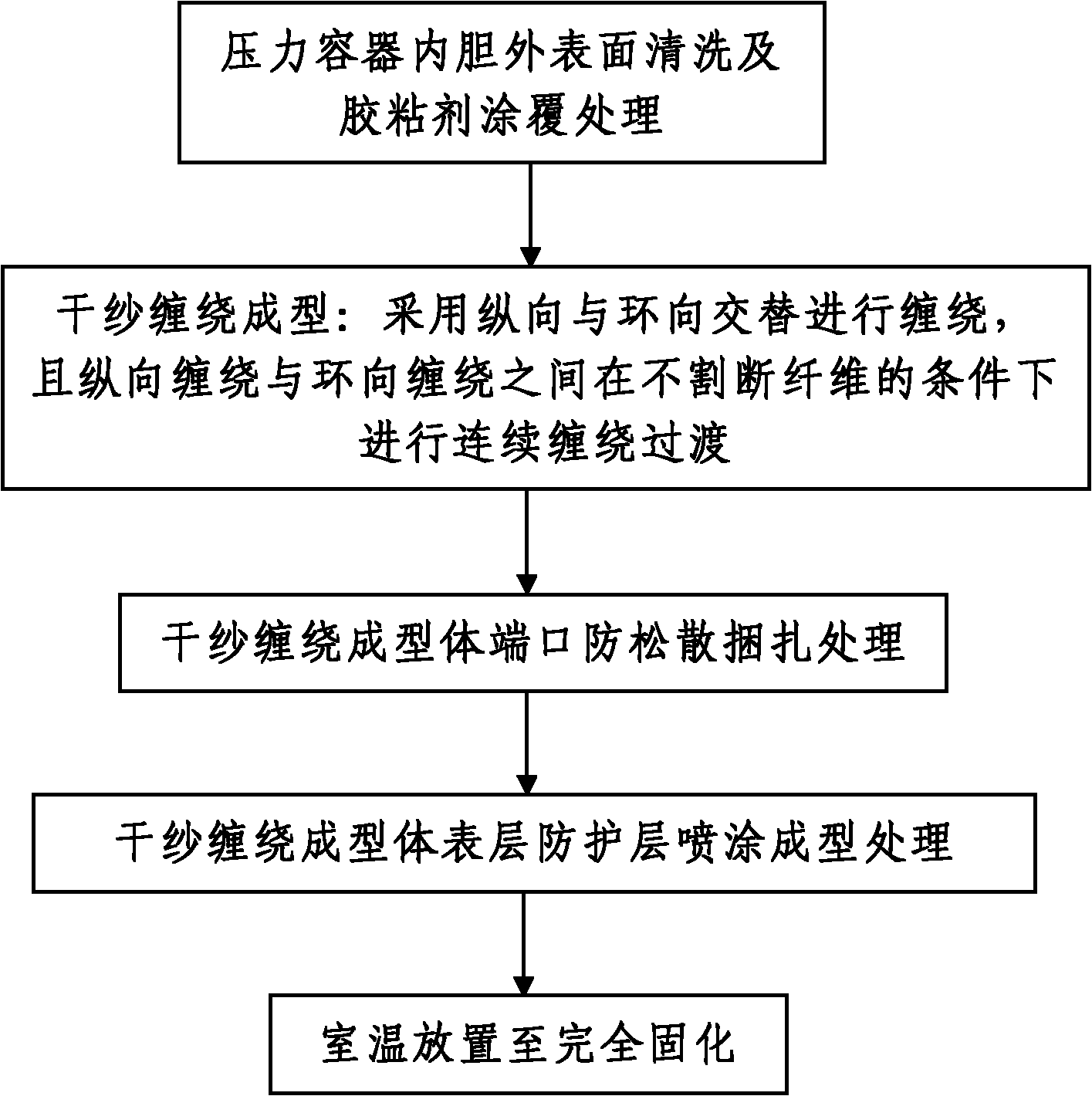

Dry yarn winding forming method for pressure container

The invention discloses a dry yarn winding forming method for a pressure container. The method comprises the following steps: 1. carrying out outer surface treatment on an inner container of the pressure container, namely coating an adhesive uniformly on the outer surface of the inner container of the cleaned pressure container; 2. carrying out dry yarn winding forming, namely winding on the outer surface of the inner container of the pressure container in a winding mode of alternative longitudinal winding and hoop winding, and carrying out continuous transition between the longitudinal winding and hoop winding under the condition that fibers are not cut off; 3. carrying out loose-proof strapping treatment on the port of a dry yarn winding forming body; 4. carrying out spraying forming treatment on a protective layer at the surface layer of the dry yarn winding forming body; and 5. placing and solidifying at room temperature. The dry yarn winding forming method for the pressure container provided by the invention has the advantages of reasonable design, simplicity and convenience in operation, convenience in control and good winding forming effect; and because an impregnation process and a solidifying process link are omitted, a plurality of practical problems, such as complex forming technology, longer production cycle, higher cost, no large scale of industrial production andthe like, of the existing winding forming process can be solved effectively.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

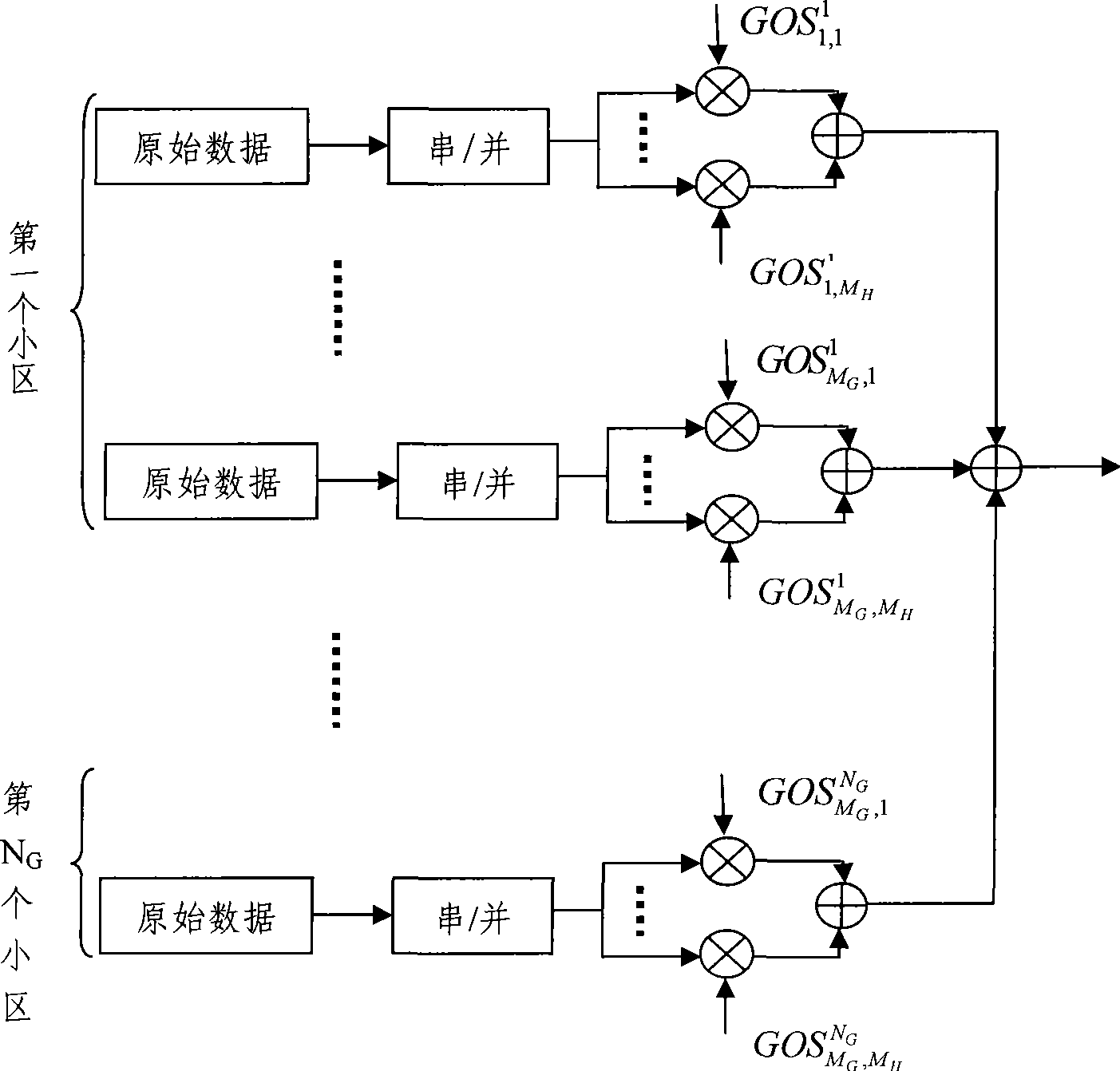

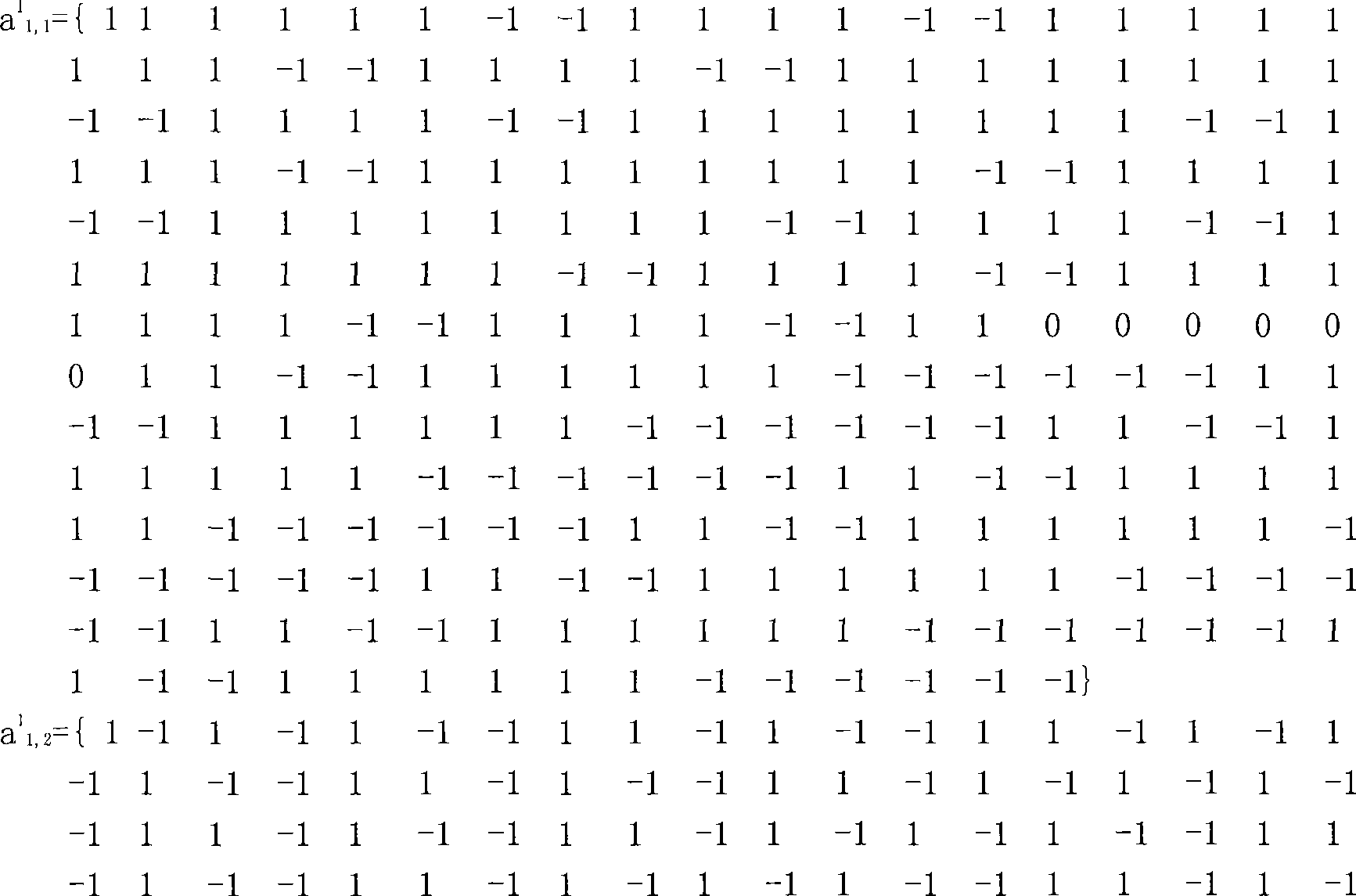

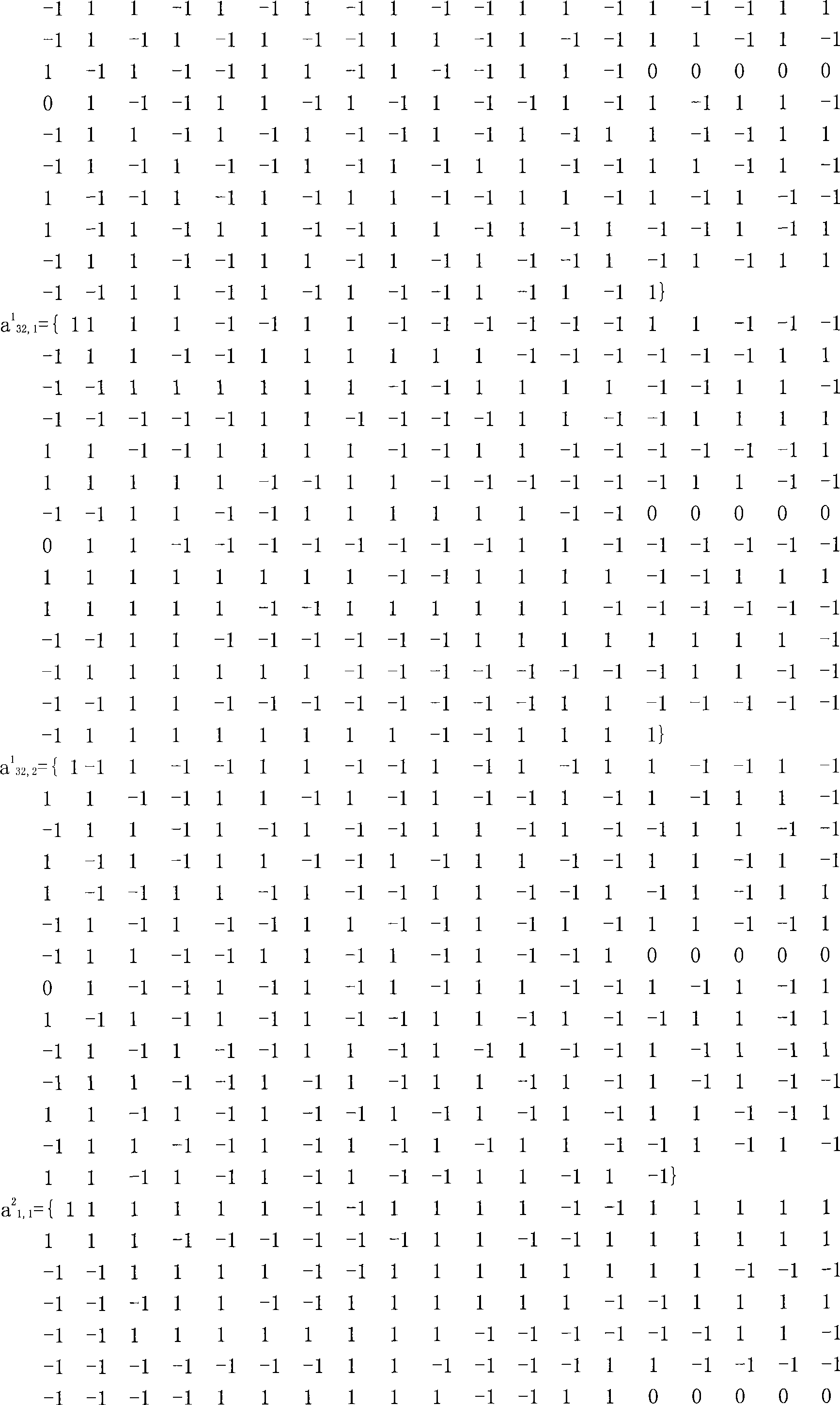

Method for generating signals of low-interference multi-velocity multi-district quasi-synchronous CDMA communication system

InactiveCN101378294AReduce distractionsChoose flexibleMultiplex code generationOrthogonal sequenceBent function

The invention discloses a signal generation method of a low-interference multispeed multi-cell quasi-synchronous code division multiple access (CDMA) communication system. The method comprises the steps: a spread spectrum sequence code group is an Hadamard matrix set with certain idealized characteristics formed by Bent functions and a Walsh-Hadamard orthogonal sequence set; a sequence set with the characteristic of a similar zero correlation zone (ZCZ) sequence is obtained by calculating with a pair of complementary sequence sets by utilizing the Hadamard matrix set; and a plurality groups of sequence sets with the similar ZCZ sequence characteristics are obtained by carrying out Cartesian convolution operation with the orthogonal sequence set by utilizing the similar ZCZ sequence set. When a system maximum synchronization error and a channel maximum multipath delay spread are in the stated range, the system interference can be reduced greatly. The parameters of the spread spectrum sequence code group and the system efficiency can be adjusted and flexibly selected according to the practical factors. Therefore, the requirements of power control and synchronization by the CDMA communication system are reduced, and the complexity of system realization is lowered.

Owner:CHONGQING WIRELESS OASIS COMM TECHCO +1

Sustained/controlled release microsphere of biological extract Genipin cross-linked chitosan coated stilbene compound and preparation method thereof

InactiveCN102240268ALow toxicityUniform qualityAntimycoticsHydroxy compound active ingredientsCross-linkMicrosphere

The invention discloses a sustained / controlled release microsphere of a chitosan coated stilbene compound using a biological extract Genipin as a cross-linking agent and a preparation method thereof. In the microsphere, a cross-linked condensation compound layer of the chitosan and the Genipin serves as a capsule shell and is used for coating a medicament 3,5-dihydroxyl-4-isopropyl stilbene, resveratrol, pterostilbene, oxidized resveratrol or piceatannol; the medicament stability of the product is improved; the sustained / controlled release of the medicament is realized; and the released Genipin after in vivo metabolism of the capsule shell has the characteristics of biocompatibility, no cytotoxicity and the like. The invention is applicable to the sustained / controlled release microspheresof Genipin cross-linked chitosan coated 3,5-dihydroxyl-4-isopropyl stilbene, resveratrol, pterostilbene, oxidized resveratrol, piceatannol and other stilbene compounds and a preparation method thereof. The preparation method is low in requirements on the control condition and easy to operate. In the microspheres, the quality is uniform; the grain size is 0.1 to 100 mu m; the surface of the microsphere has a multiporous structure; and the entrapment rate of the capsule shell to the medicament is 30 to 90 percent.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com