Landing mechanism-based legged mechanical cushioning device

A buffer and leg-type technology is applied in the field of buffer machinery to achieve the effects of improving the ability to resist large impact loads, reducing costs and increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

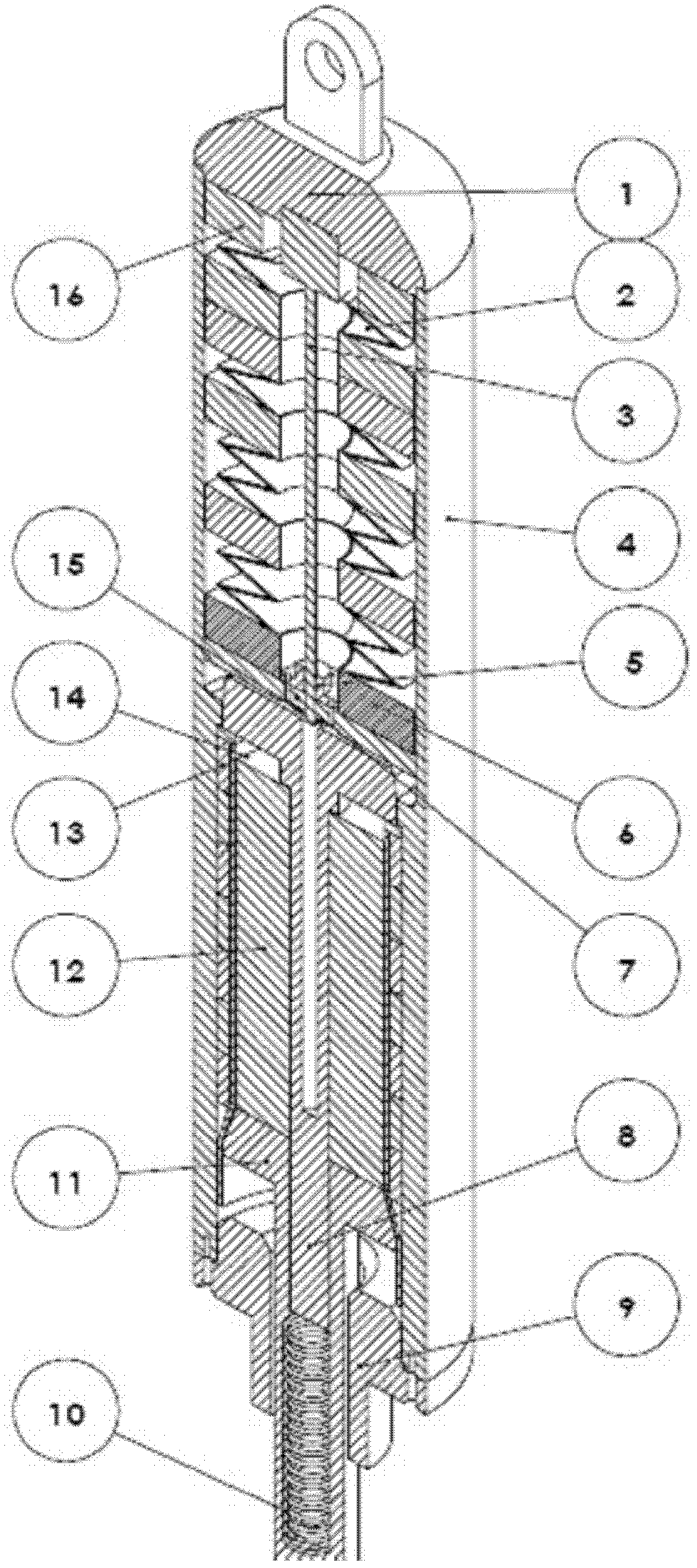

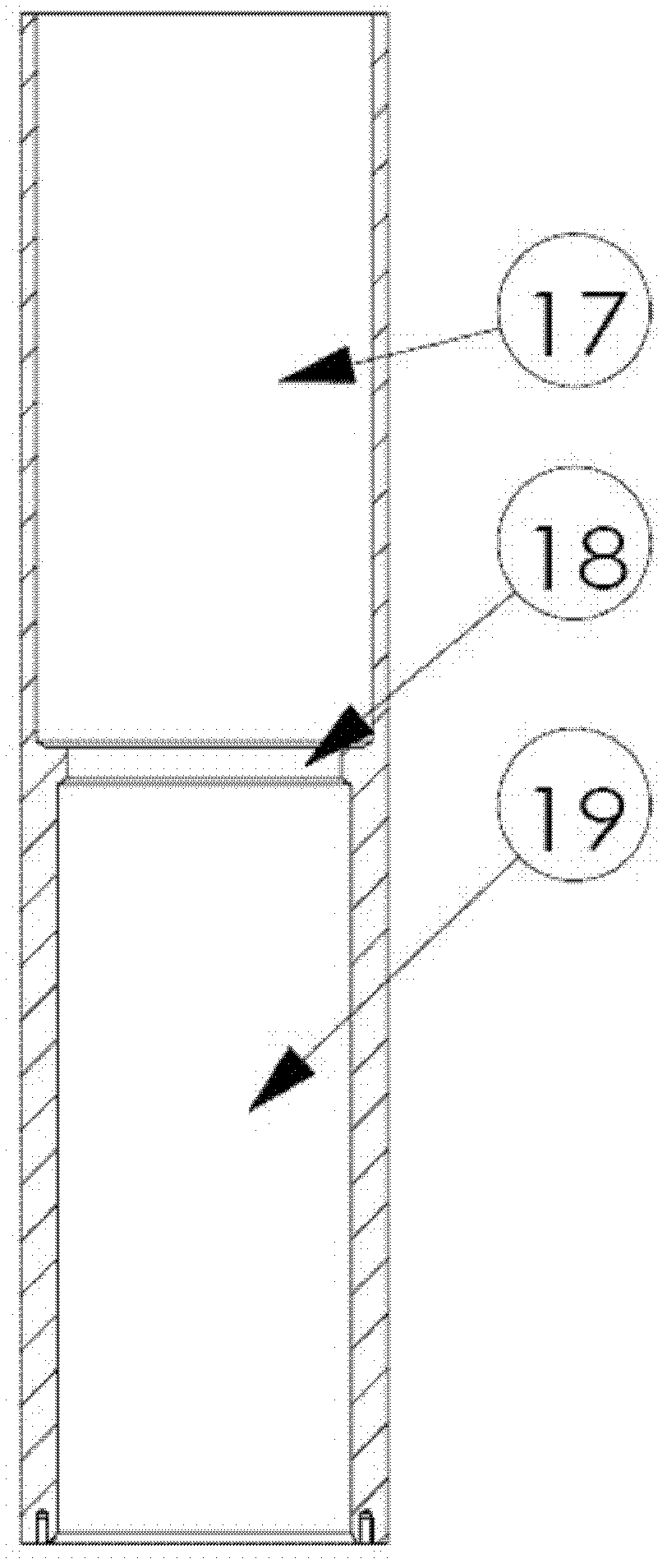

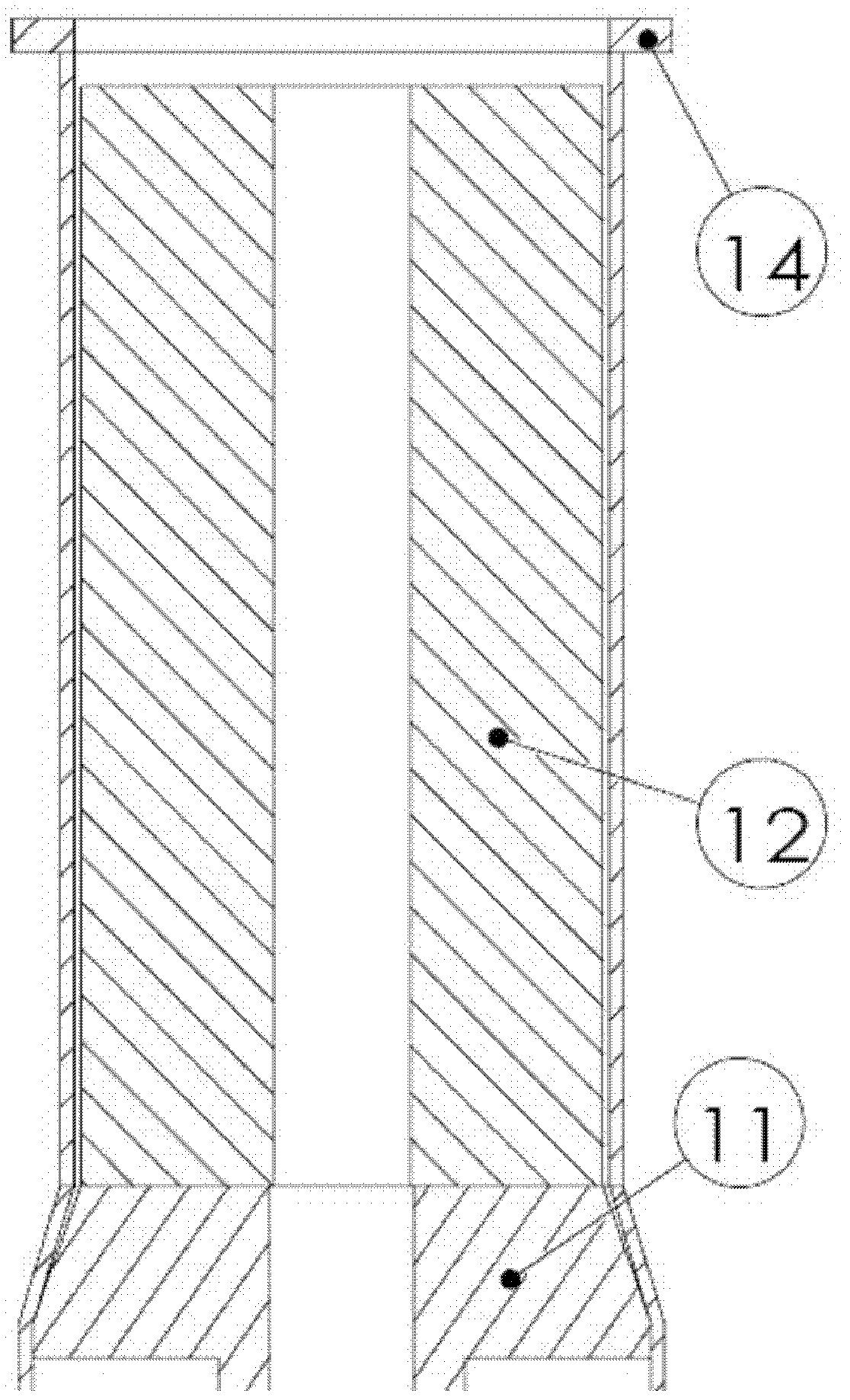

[0039] See figure 1 , The present invention is a leg-type mechanical buffer based on a landing mechanism, which is composed of an upper end cover 1, a DC screw motor 3, a disc spring 2, a damping baffle 7, a force sensor 15, an expansion ring 14, and a piston push rod 8. , Cone ring push rod 11, buffer cavity shell 4, motor screw guide ring 5, foam metal filling block A6, foam metal filling block B13, foam metal filling block C16, flexible porous material 12, bottom end cover 9, compression spring 10 Composition; the positional connection relationship between them is: the upper end cover 1 and the buffer chamber shell 4 are coaxially welded together, and the bottom end cover 9 is coaxially connected with the buffer chamber shell 4 by screws to form the buffer outer shell. An expansion ring 14 is embedded in the lower cavity of the buffer cavity shell 4. The expansion ring 14 and the buffer cavity shell 4 are filled with a foamed metal filler block B13. An upward blind hole is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com