Pneumatic circuit for numerically controlled lathe pneumatic door opening and closing

A technology of CNC lathes and pneumatic circuits, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. Deformation of the guide rail of the pneumatic door, meeting the door opening and closing time requirements, and the effect of closing the door with small vibration and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

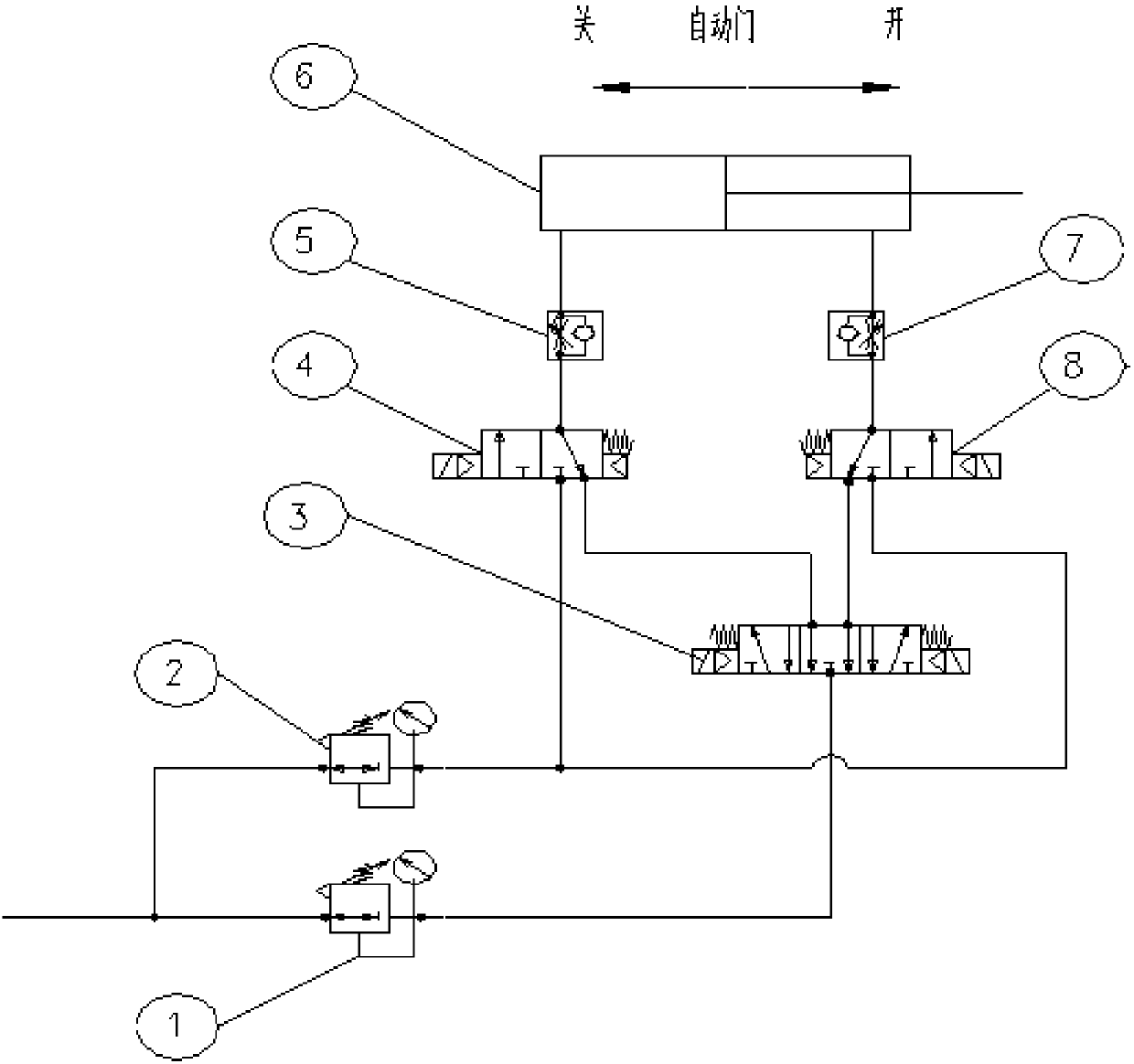

[0011] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0012] combine figure 1 , a pneumatic circuit for a pneumatic door switch of a CNC lathe, comprising an exhaust circuit, the exhaust circuit is provided with a high-speed, high-load pneumatic buffer circuit, and the high-speed, high-load pneumatic buffer circuit includes a single-rod double-acting cylinder 6, Pressure reducing valve one 1, pressure reducing valve two 2, speed regulating valve one 5, speed regulating valve two 7, solenoid valve one 4, solenoid valve two 8, solenoid valve three 3, the gas source passes through the pipeline and the pressure reducing valve on the pipeline Pressure valve 1 is connected to the air port on the air source connection side of solenoid valve 3 3, one air port on the cylinder connection side of solenoid valve 3 3 is connected to the air port on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com