Patents

Literature

570results about How to "Solve the damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

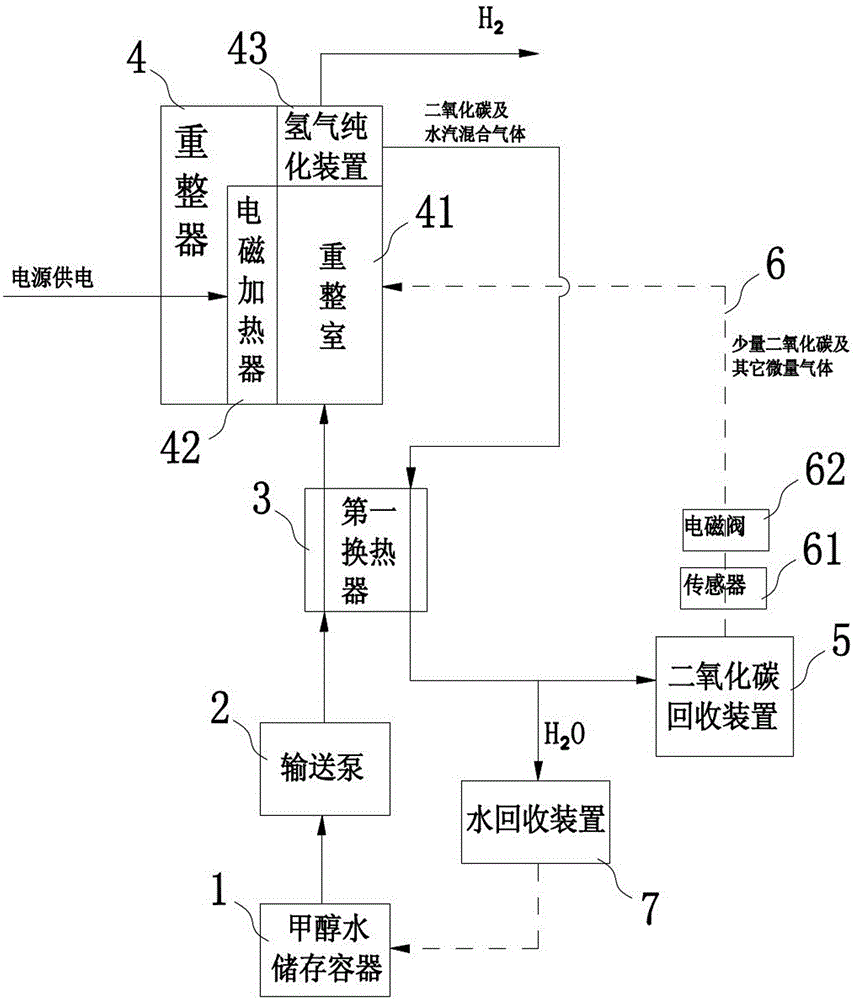

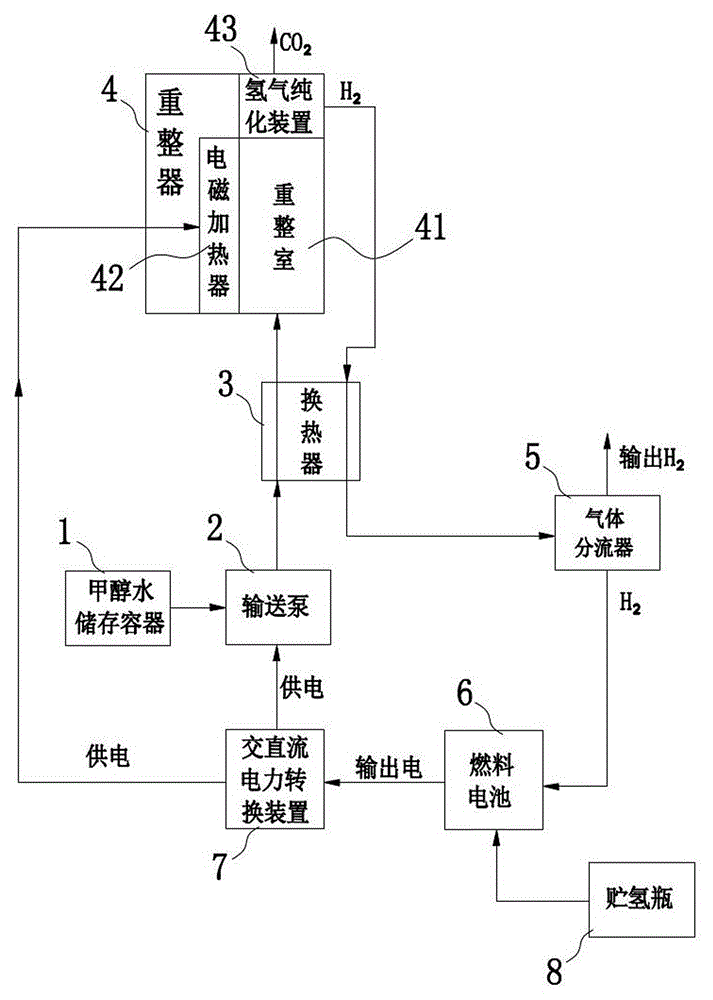

Zero-carbon-emission hydrogen production system by methanol water reforming as well as application and hydrogen production method thereof

The invention discloses a zero-carbon-emission hydrogen production system by methanol water reforming and application and a hydrogen production method thereof. The hydrogen production system comprises a methanol water storage vessel, a delivery pump, a first heat exchanger, a reformer and a carbon dioxide recovery device, wherein the reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device; the electromagnetic heater provides heat energy for the reforming chamber; the reforming chamber is used for hydrogen production reaction of methanol and water by reforming to obtain carbon dioxide and hydrogen; carbon dioxide and hydrogen are mixed with water vapor to form high-temperature mixed gas, and the high-temperature mixed gas is delivered into the hydrogen purification device; after purification and separation, hydrogen is delivered out, at the same time carbon dioxide and unreacted water vapor mixed gas are also delivered out, and then carbon dioxide and unreacted water vapor mixed gas are delivered into the carbon dioxide recovery device after passing through the first heat exchanger; the carbon dioxide recovery device is a replaceable modular carbon dioxide recovery device and used for recovering carbon dioxide and part of the water vapor. The zero-carbon-emission hydrogen production system provided by the invention can recover carbon dioxide, has no impact on the environment and causes no harm to the hydrogen production system self and is beneficial for popularization and application in the field of new energy resources such as fuel cell cars.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

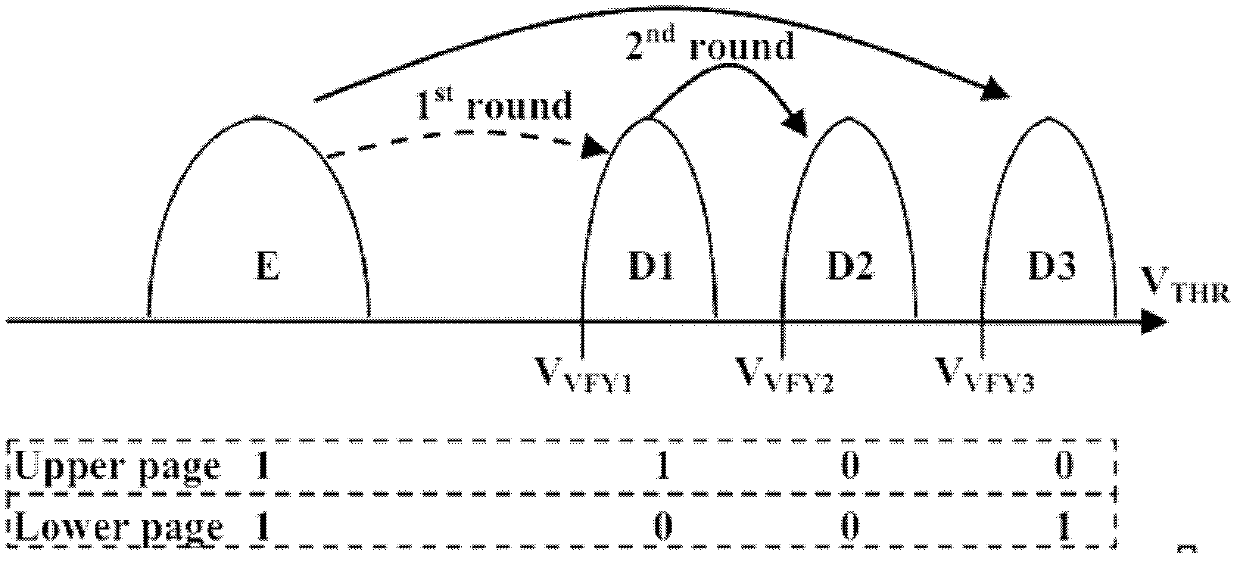

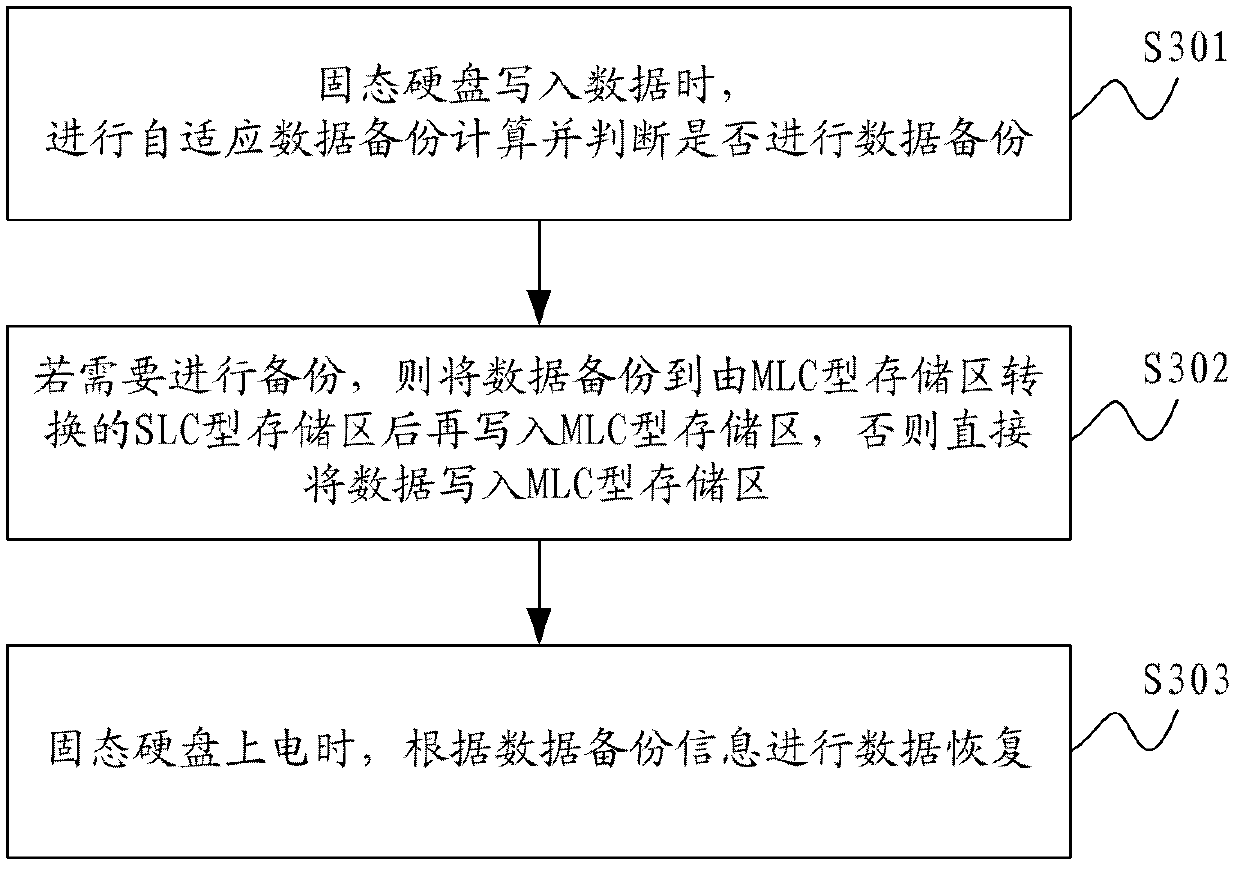

Processing method for power down and abnormal writing of solid state disc and system

ActiveCN102591807ASolve the damageReduce performance lossMemory loss protectionPower supply for data processingElectricityPhysical address

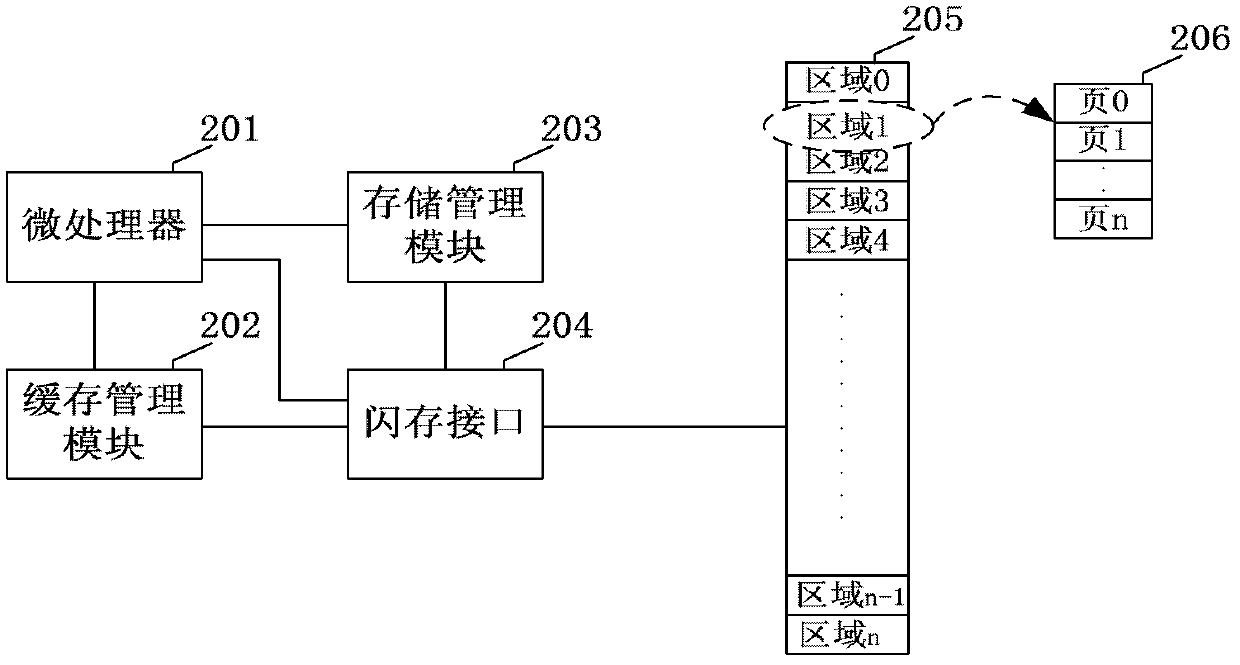

A processing method for power down and abnormal writing of a solid state disc comprises the steps of step 100, scanning a flash array, obtaining stored management information, performing initialization after extracting the management information, generating a plurality of mapping areas, dynamically adjusting the mapping areas, and managing the conversion between a multi level cell (MLC) to a single level cell (SLC); step 200, performing data reading and writing, during reading, finding a corresponding physical address through the two mapping areas, and reading the data on a flash memory; step 300, when the data is written, if finding a first mapping area already has no spare low level page, then starting waste page recovery management and abrasion balance management, after the abrasion balance management preferably recovers the waste page according to information in a mapping list of the first mapping area and then distributes the spare page, writing the data into the first mapping area; and step 400, when the conditions of power down or abnormal writing happen, enabling the plurality of mapping areas to perform corresponding operations to recover the data.

Owner:RAMAXEL TECH SHENZHEN

Solid state disc and power failure protection method and system thereof

InactiveCN102591748AAvoid destructionSolve the damageRedundant operation error correctionElectricitySingle level

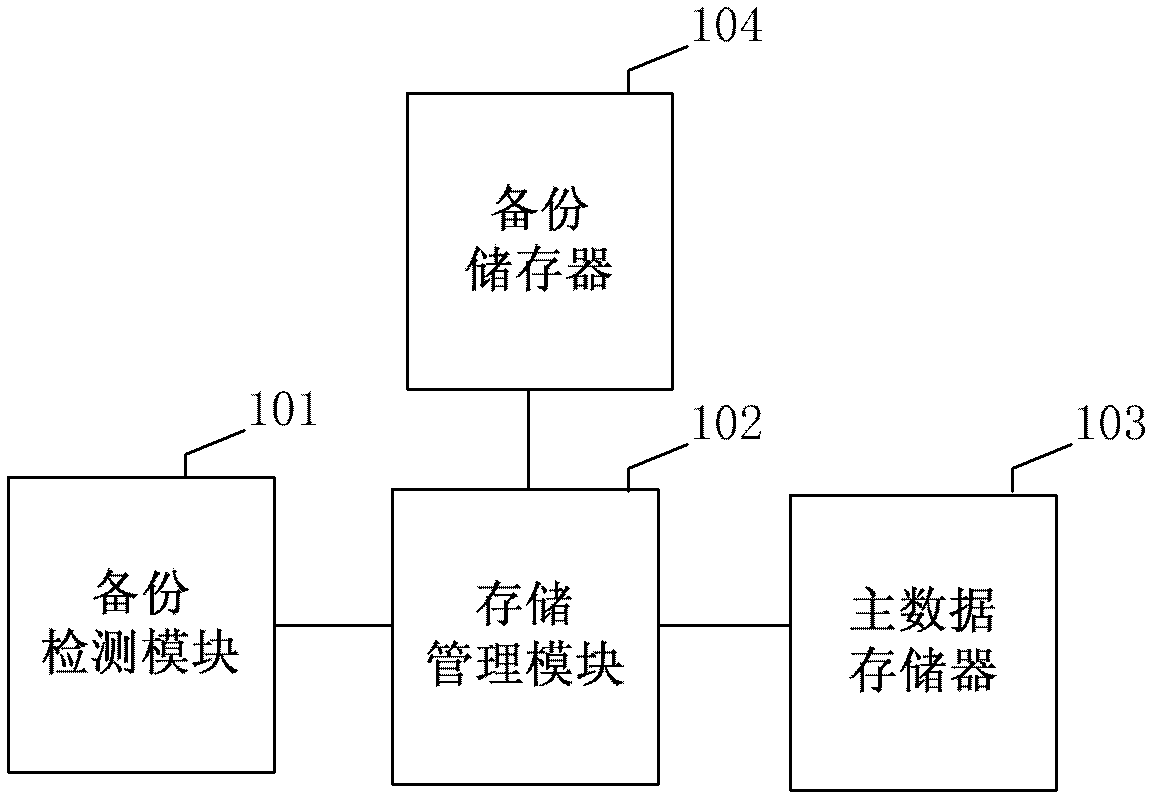

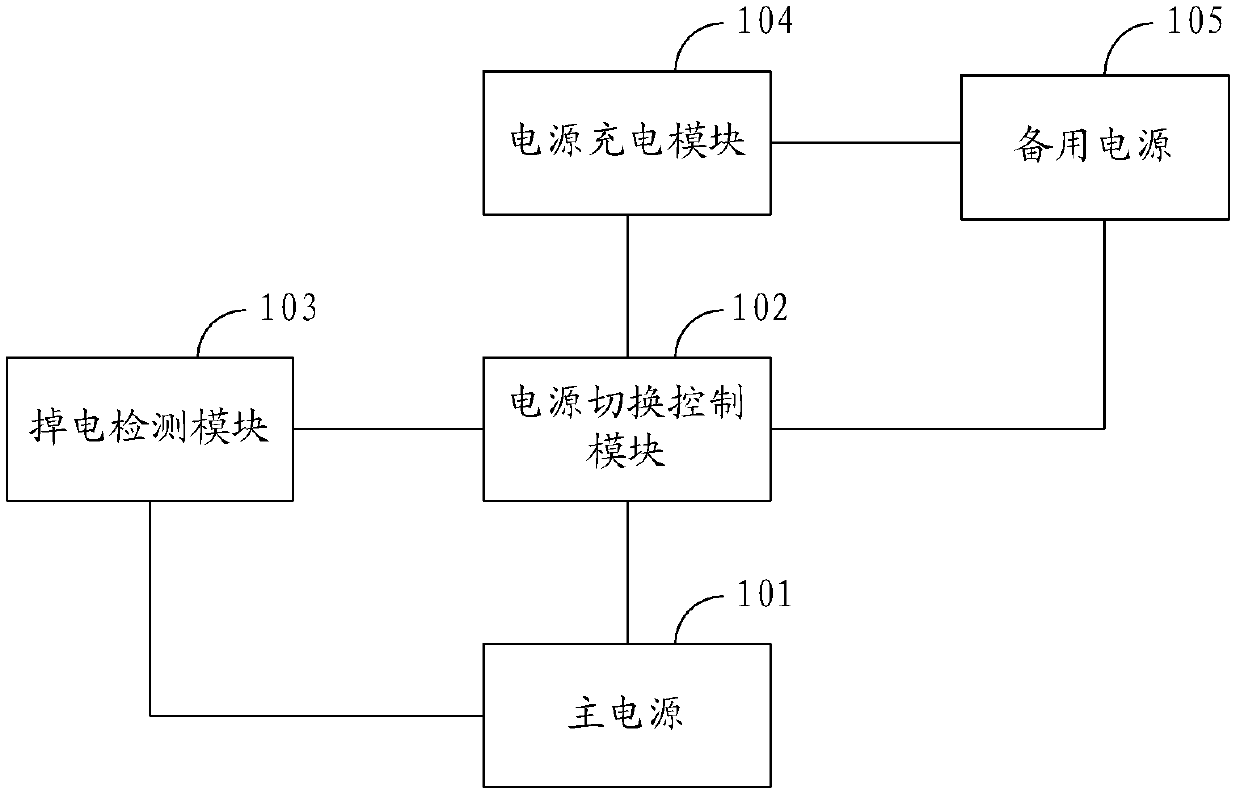

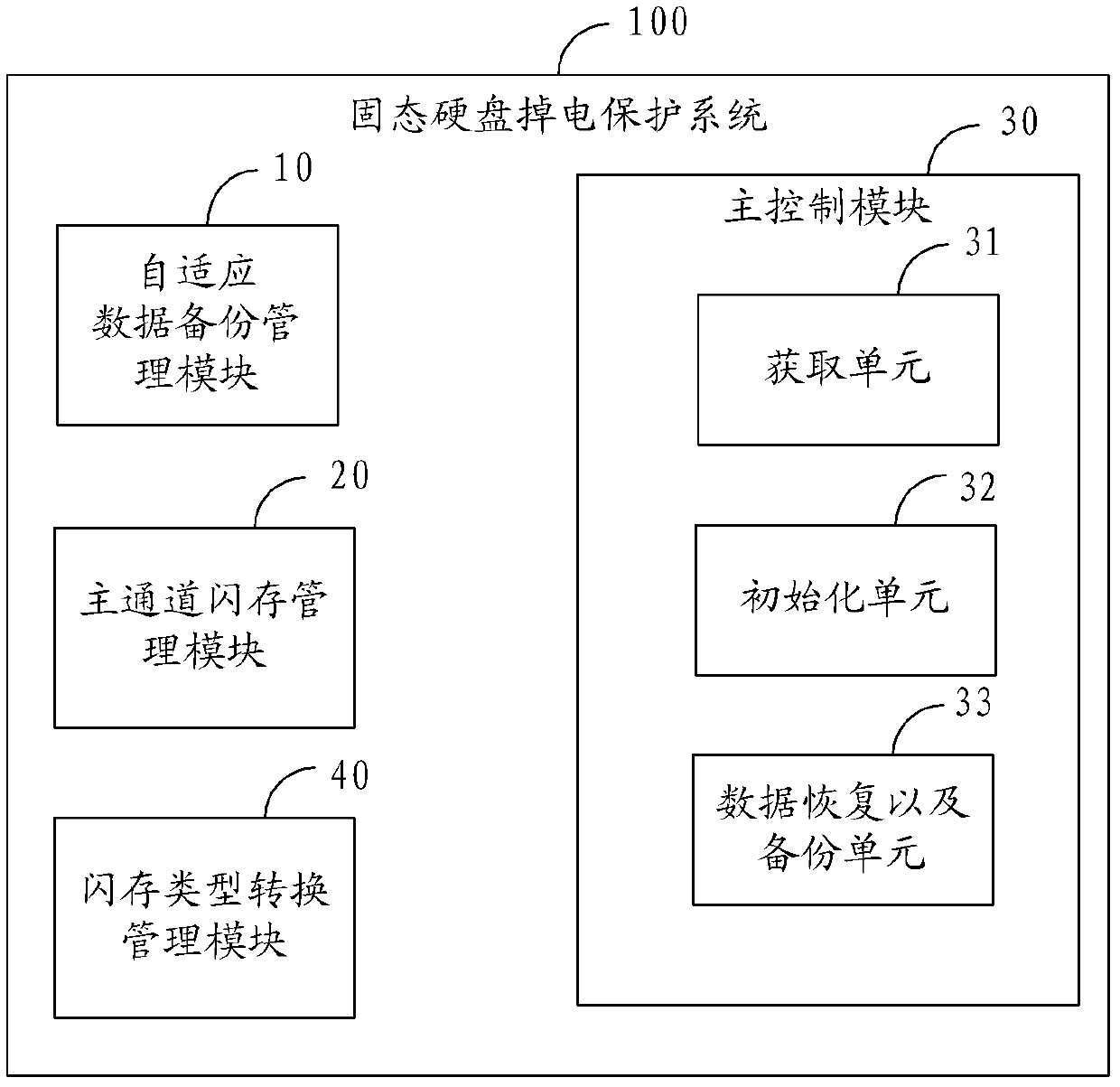

The invention is applied to the fields of solid state discs and information storage and provides a solid state disc and a power failure protection method and a system thereof. The method comprises the steps of performing self-adaption data backup computation and judging whether to proceed data backup when data is written into the solid state disc; if backup is required, backuping the data to a single level cell (SLC) type storage area converted from a multi level cell (MLC) type storage area, then writing the data into the MLC type storage area, otherwise directly writing the data into the MLC type storage area; and when the solid state disc is powered on, the data is recovered according to data backup information. Therefore, the solid state disc and the power failure protection method and the system of the solid state disc can solve the problem of data damage of coupling pages in Nand Flash caused by abnormal power failure by means of a self-adaption backup technology on the basis that hardware design cost and complexity are not increased.

Owner:RAMAXEL TECH SHENZHEN

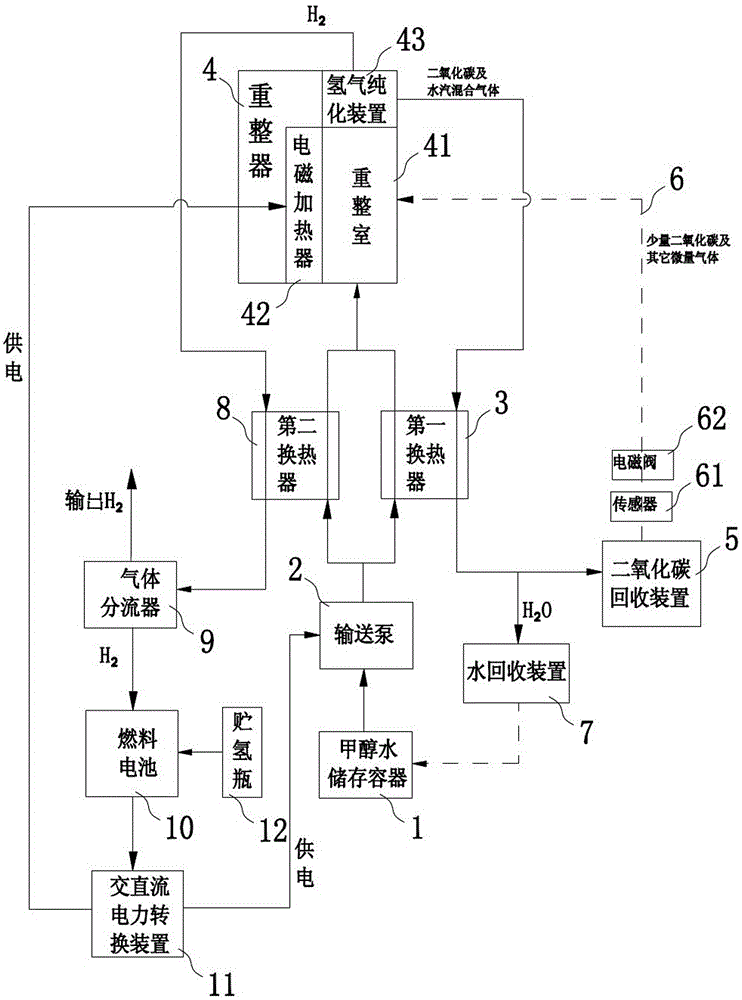

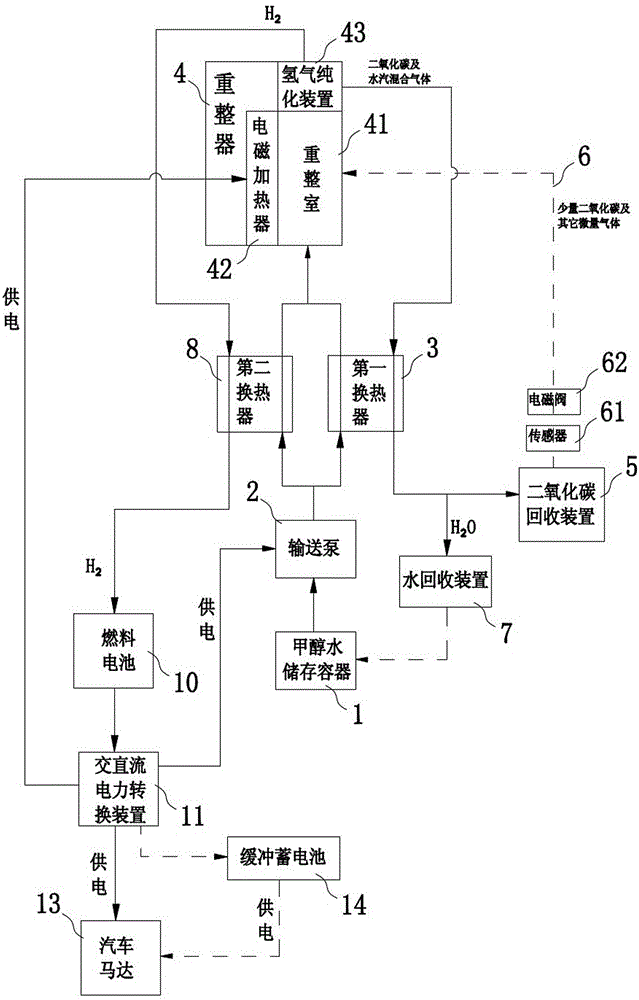

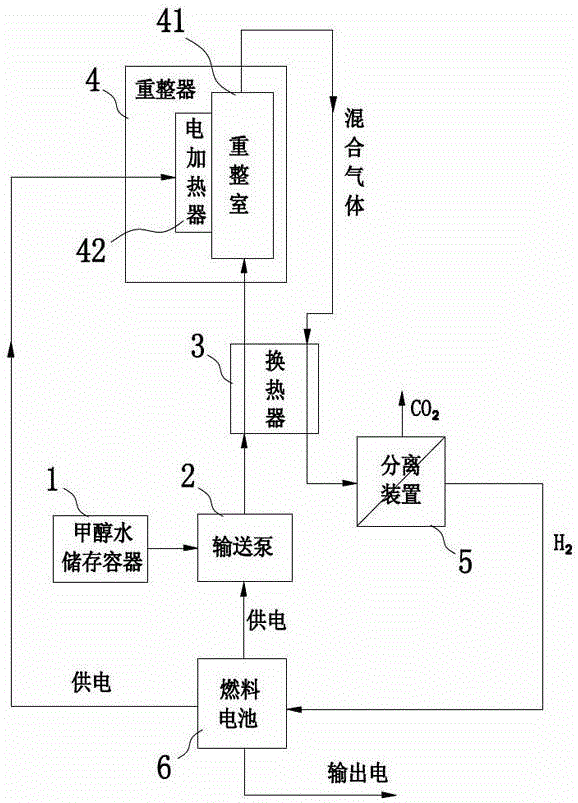

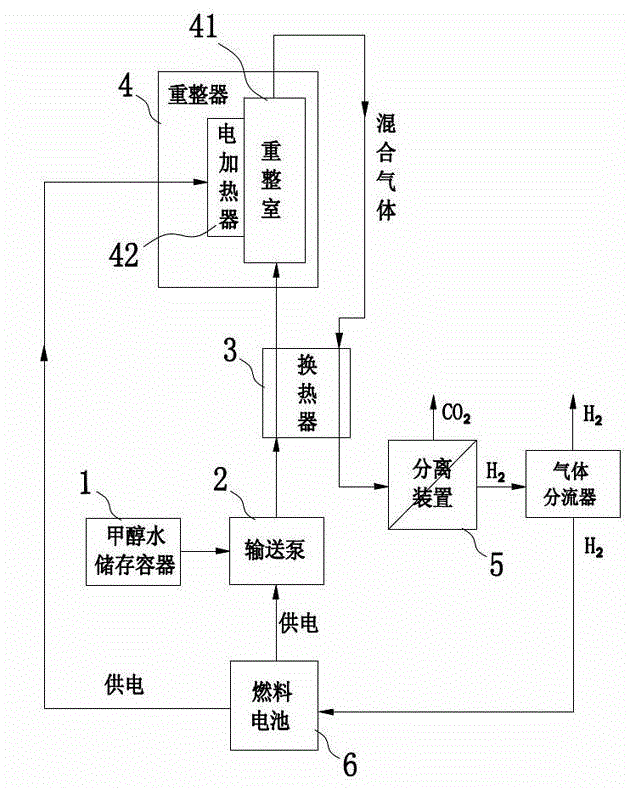

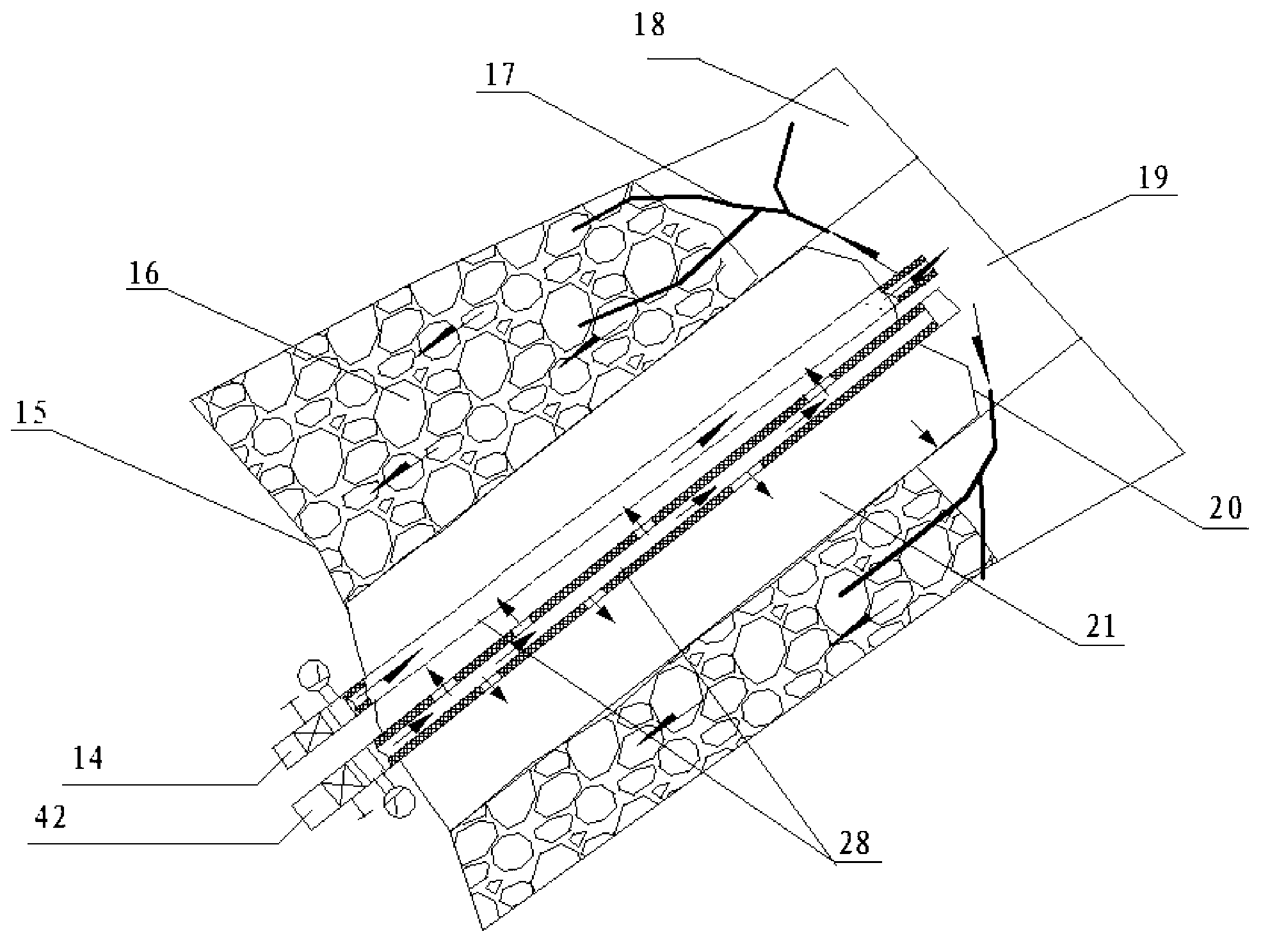

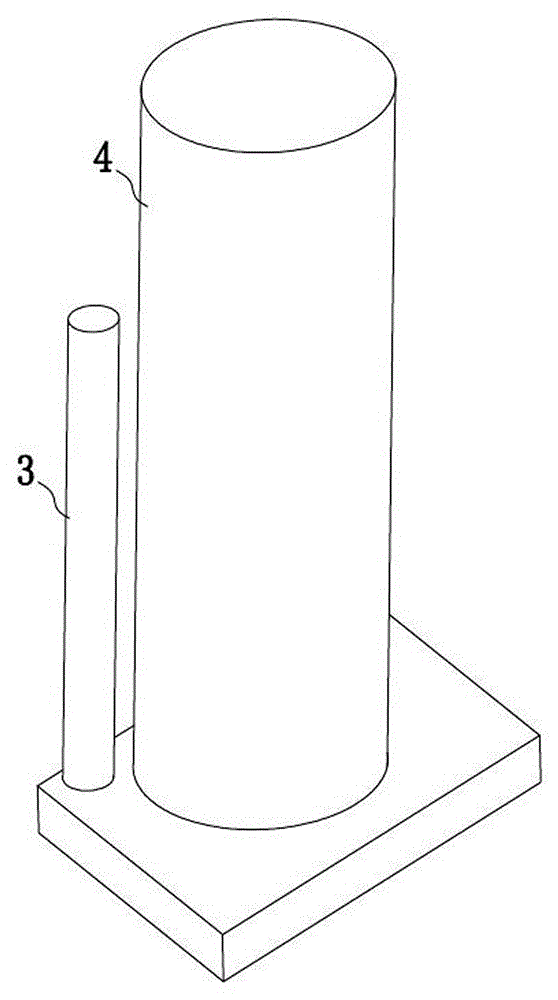

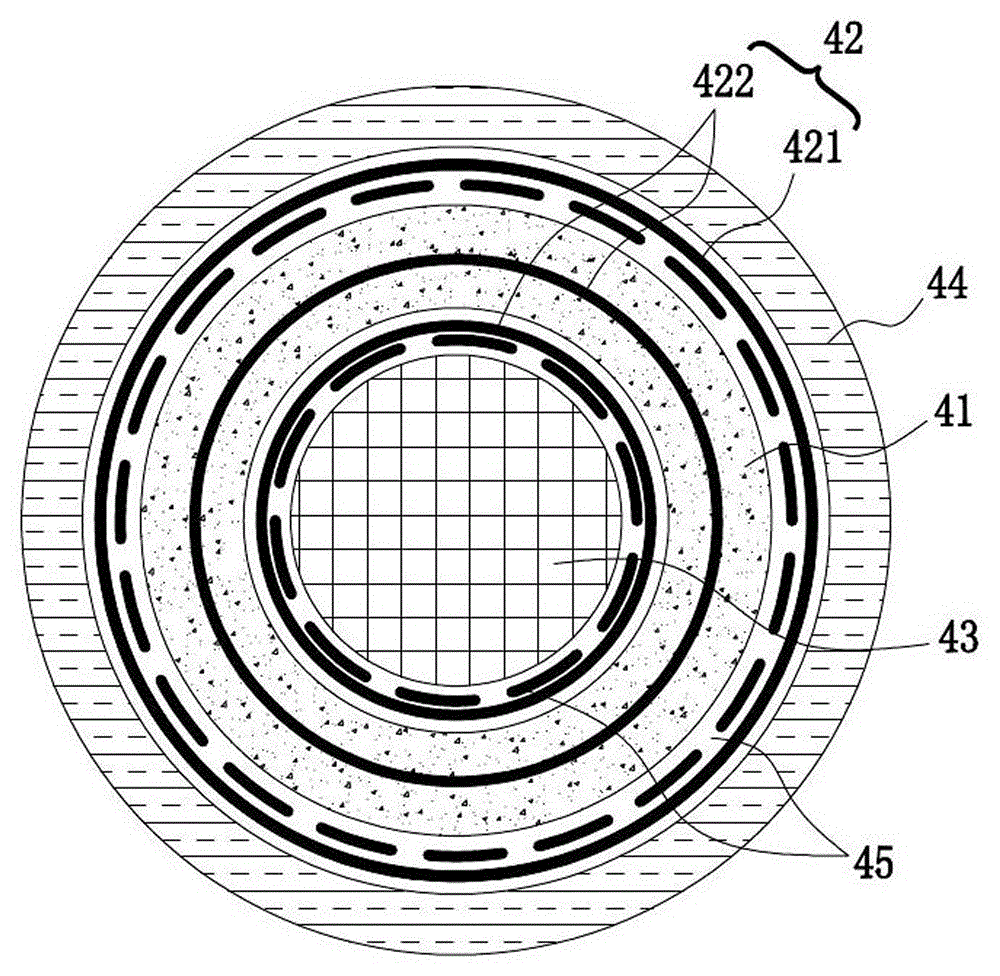

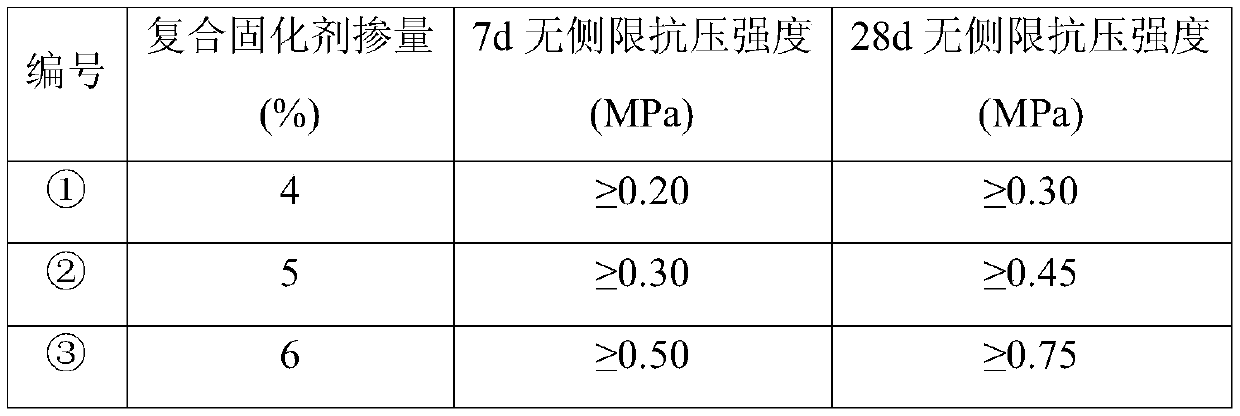

Electric generator based on methanol water hydrogen-making system and electricity generation method thereof

InactiveCN104362359ASolve the damageReduce structural complexityHydrogenFuel cell heat exchangeElectrochemical responseCombustion chamber

The invention discloses an electric generator based on a methanol water hydrogen-making system and an electricity generation method thereof. The electric generator comprises a methanol water storage container, a delivery pump, a heat exchanger, a reformer, a separation device and a fuel cell, wherein the delivery pump is used for delivering methanol and water to a reforming chamber of the reformer; the heat exchanger is used for carrying out heat exchange on the low-temperature methanol and water and a high-temperature mixed gas output from the reforming chamber; the reformer is provided with the reforming chamber and an electric heater, and the electric heater provides heat energy for the reforming chamber; and the high-temperature mixed gas which takes carbon dioxide and hydrogen as main parts is prepared in the reforming chamber, passes through the heat exchanger and then enters the separation device to be separated to obtain the hydrogen, and the hydrogen is delivered to the fuel cell and subjected to electrochemical reaction in the fuel cell to generate electric energy, a part of the electric energy provides electricity for the delivery pump and the electric heater, and the rest of the electric energy is output. According to the electric generator, the reformer has no need of being provided with a combustion chamber, an air inlet fan, an air inlet channel and a smoke window, the heating temperature inside the reformer is easily controlled and stable, and the reformer is simple in structure, stable in operation and low in overhaul difficulty.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

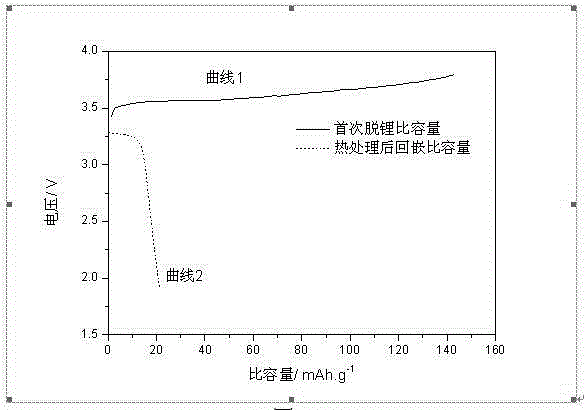

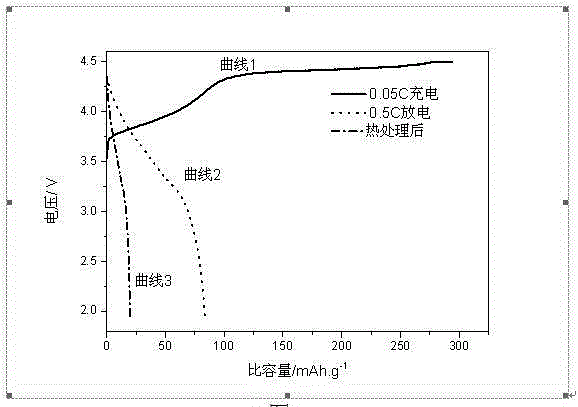

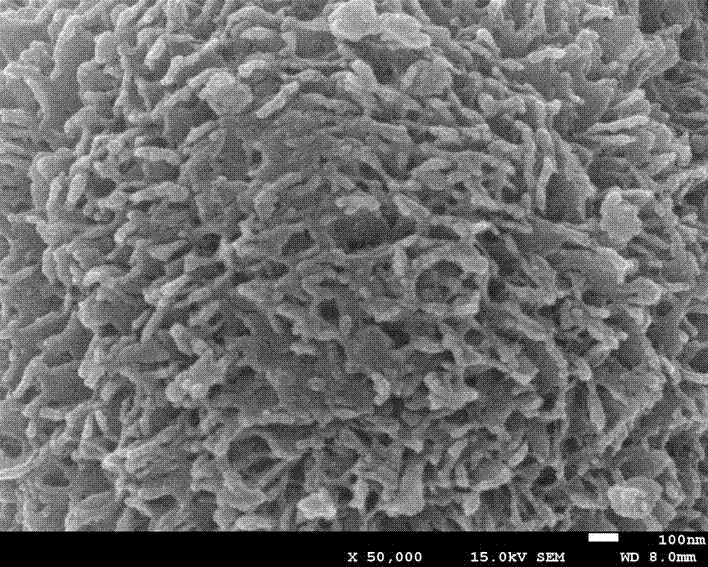

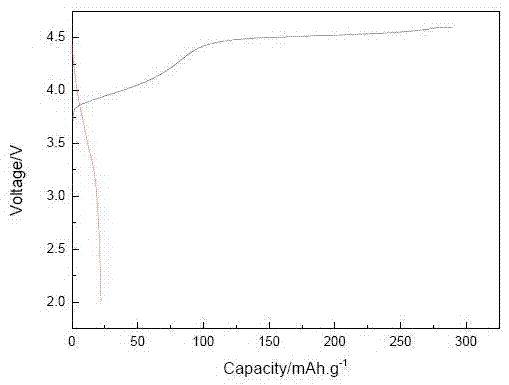

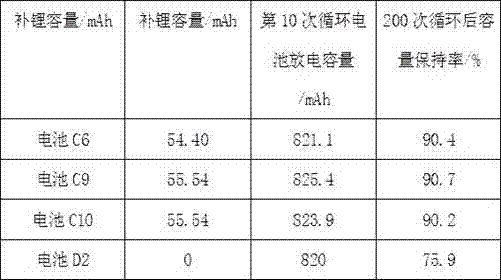

Lithium ion batteries cathode material additive, preparation method thereof, and cathode material and lithium ion battery both containing same

An additive for a positive electrode material includes an internal component and an external component. The internal component contains a silane coupling agent modified inorganic lithium salt. The external component is formed on a surface of the internal component and contains a polymer with a low melting point. The internal component and the external component form a core-shell structure together, and the shell has a porosity of 0.01%to 20%. A positive electrode material and a lithium-ion battery including the additive, and method of preparing the lithium-ion battery are also provided.

Owner:BYD CO LTD

Additive for anode material of lithium ion battery, preparation method of additive, positive electrode material containing additive and lithium ion battery

InactiveCN106898737AImprove cycle performanceHelp conductionFinal product manufactureCell electrodesPorosityLithium-ion battery

The invention provides an additive for a positive electrode material of a lithium ion battery, a preparation method of the additive, a positive electrode material containing the additive and the lithium ion battery. The additive has a core-shell structure; a core material contains silane coupling agent modified inorganic lithium salt, and a shell material contains a low-melting-point polymer and a conductive carbon material; and the porosity of a shell is 0.01%-20%. By adding the additive into the positive electrode material of the lithium ion battery, rich lithium at a cathode is realized; and compared with a routine method of supplementing lithium to the positive electrode or the cathode by directly adding active lithium, the safety is relatively high.

Owner:BYD CO LTD

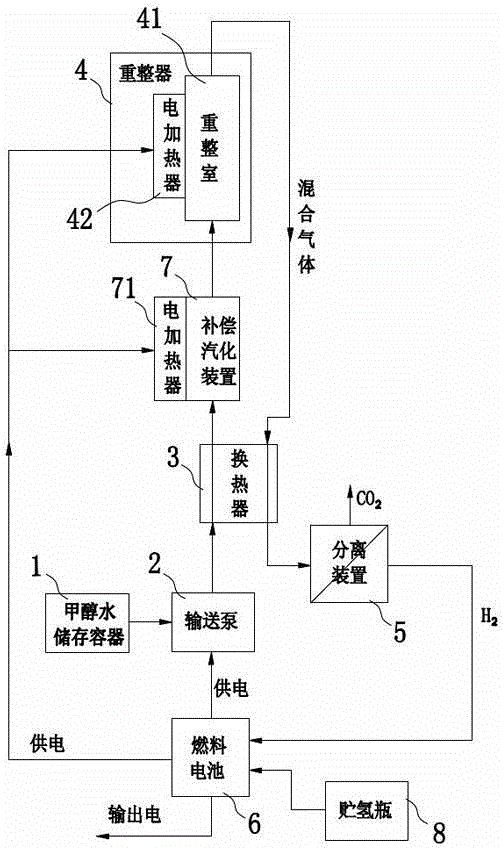

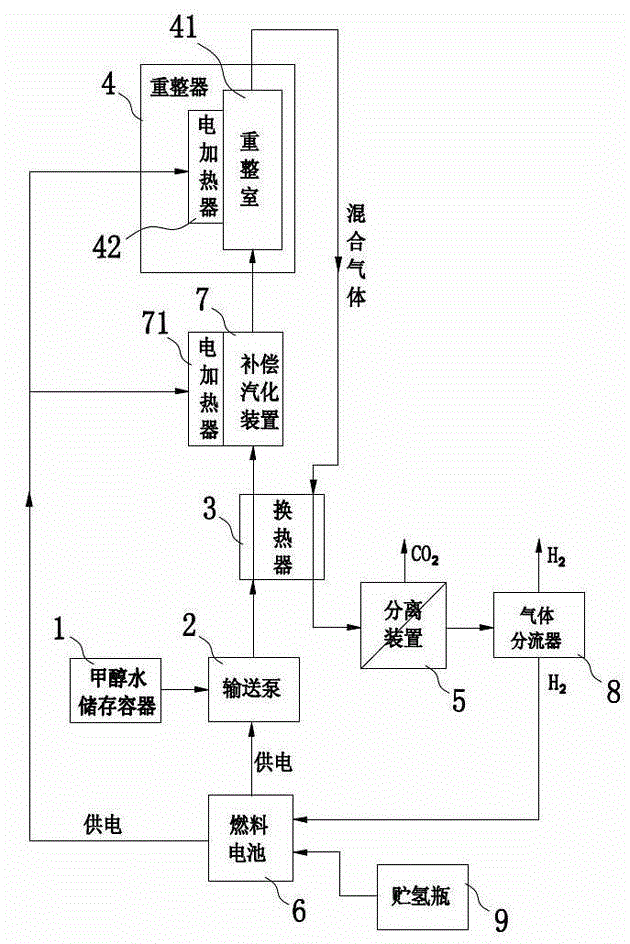

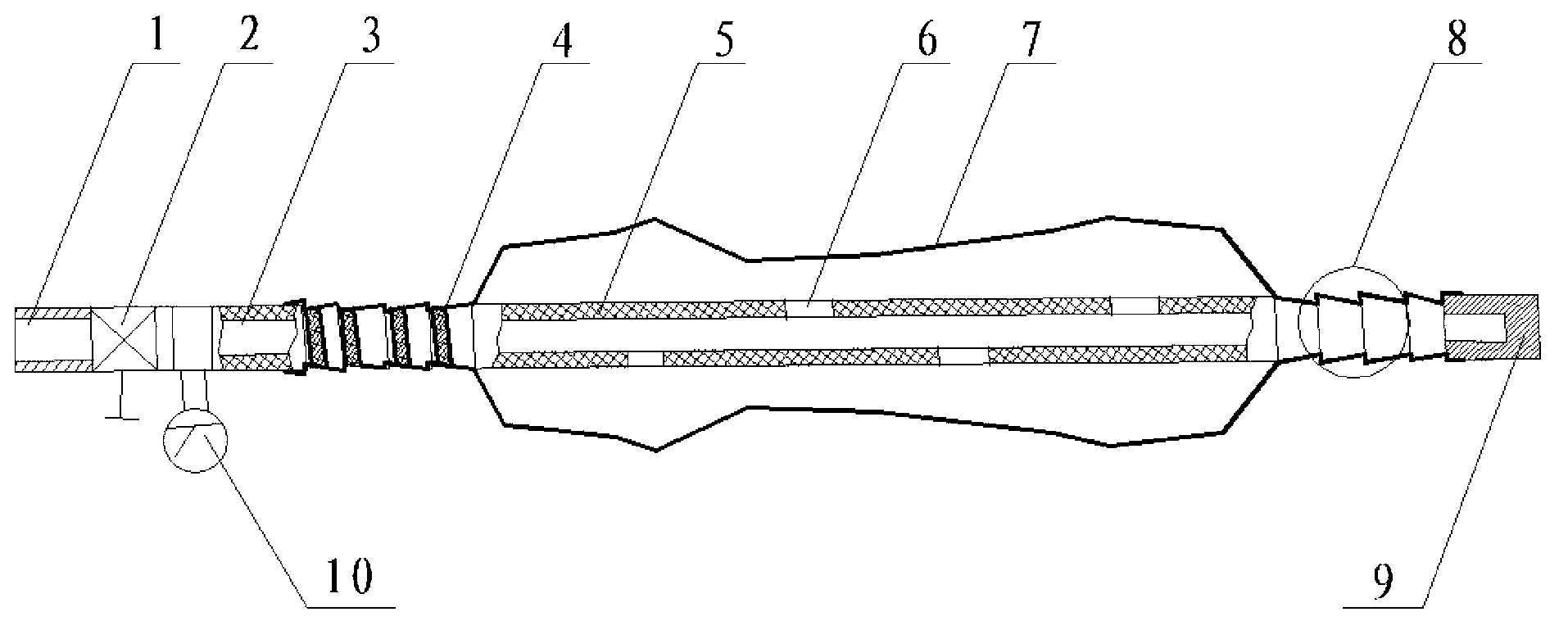

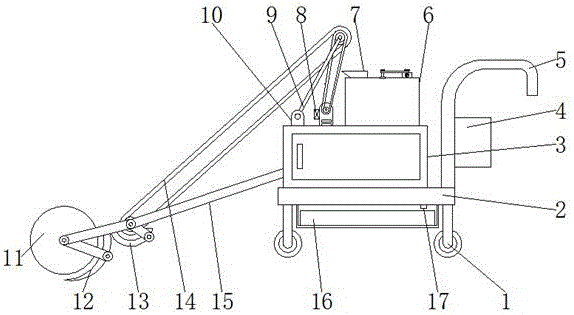

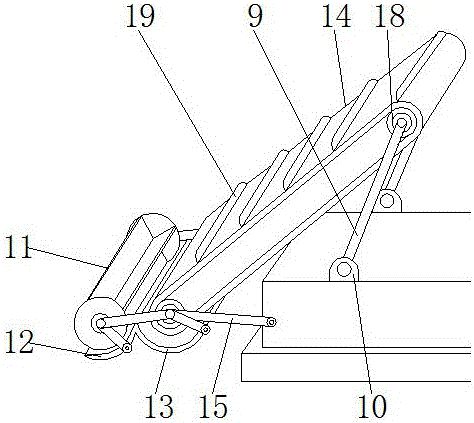

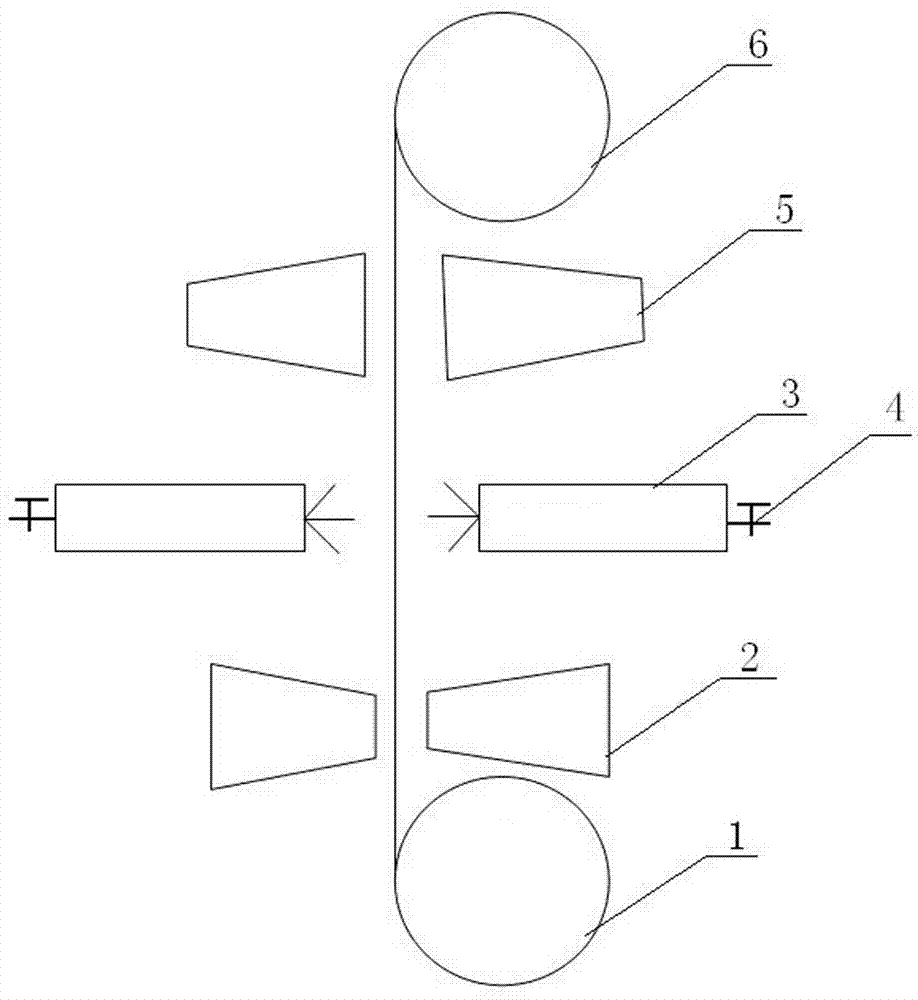

Methanol water hydrogen-making machine and hydrogen-making method thereof

InactiveCN104362355ASolve the damageReduce structural complexityHydrogenCell electrodesElectrochemical responseCombustion chamber

The invention discloses a methanol water hydrogen-making machine and a hydrogen-making method thereof. The methanol water hydrogen-making machine comprises a methanol water storage container, a delivery pump, a heat exchanger, a reformer, a separation device and a fuel cell, wherein the delivery pump is used for delivering methanol and water inside the methanol water storage container to a reforming chamber of the reformer; the heat exchanger is used for carrying out heat exchange on the low-temperature methanol and water and a high-temperature mixed gas output from the reforming chamber; the reformer is provided with the reforming chamber and an electric heater, and the electric heater provides heat energy for the reforming chamber; and the high-temperature mixed gas which takes carbon dioxide and hydrogen as main parts is prepared in the reforming chamber, passes through the heat exchanger and then enters the separation device to be separated to obtain the hydrogen, and a part of the hydrogen enters the fuel cell and generates electrochemical reaction in the fuel cell to generate electric energy to provide electricity for the delivery pump and the electric heater. According to the methanol water hydrogen-making machine, the reformer has no need of being provided with a combustion chamber, an air inlet fan, an air inlet channel and a smoke window, the heating temperature inside the reformer is easily controlled and stable, and the reformer is simple in structure, stable in work and low in overhaul difficulty.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

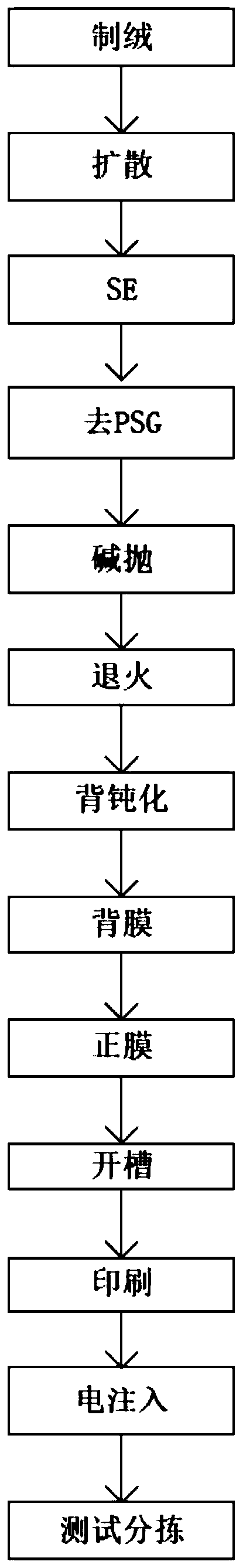

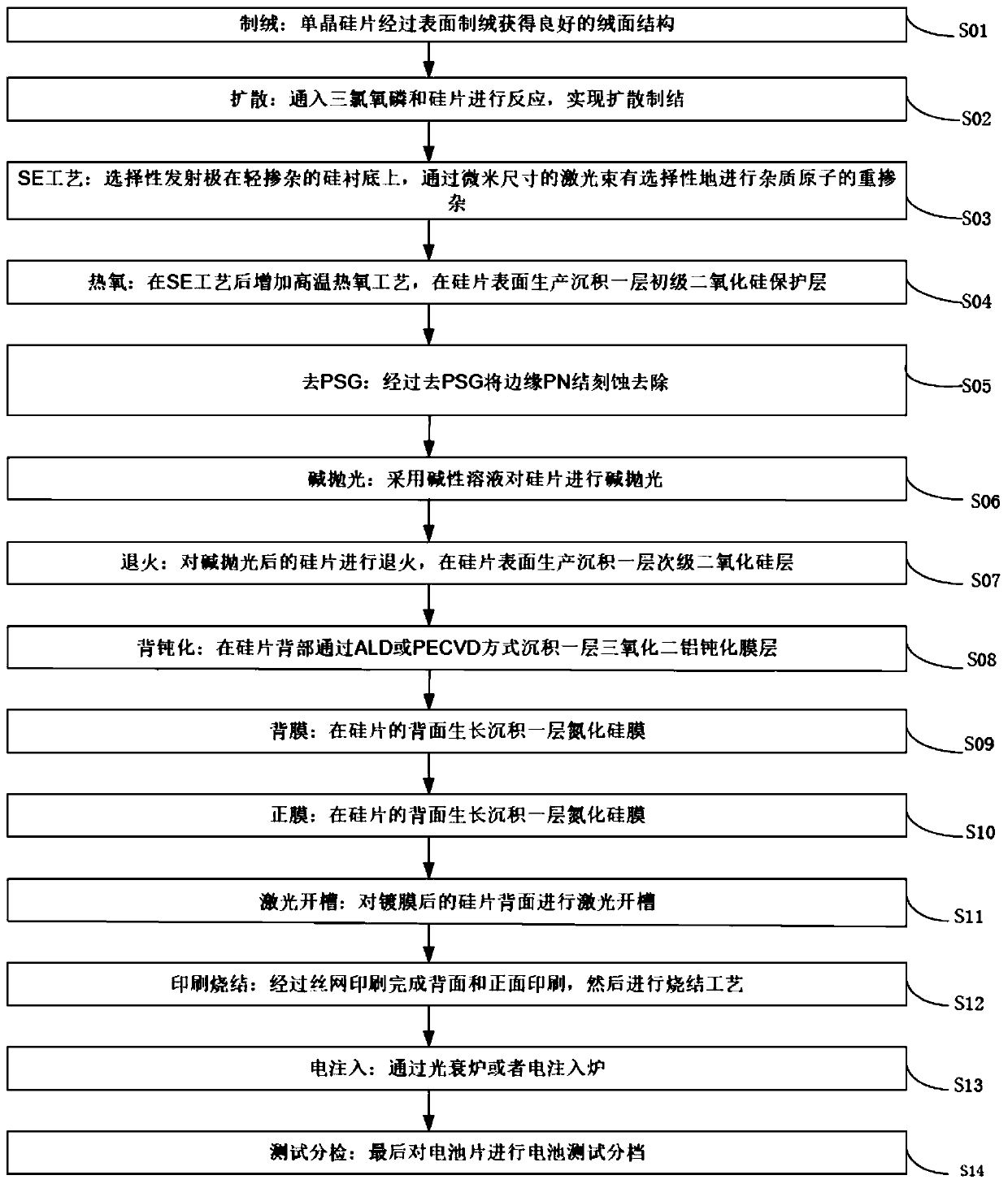

Alkali-polishing efficient PERC battery and preparation process thereof

ActiveCN109888061AReduce usageEnvironmental protectionFinal product manufacturePhotovoltaic energy generationScreen printingSilicon dioxide

The invention discloses a preparation process of an alkali-polishing efficient PERC battery. The preparation process comprises the following steps: step S01, texturing; step S02, diffusing; step S03,SE process; step S04, thermal oxidation; step S05, removing PSG; step S06, alkali-polishing; step S07, annealing; step S08, back passivating; step S09, back film; step S10, front film; step S11, laserslotting; and step S12, printing and sintering: accomplishing the back printing and the back printing through silk-screen printing, and then performing sintering process; step S13, electric injection: electric injection: through a light attenuation furnace or an electric injection furnace; and step S14, testing and sorting: performing battery testing and sorting on the cell. The invention furtherdiscloses an alkali-polishing efficient PERC battery. By adding the high-temperature thermal oxidation process flow after the SE, a layer of silicon dioxide protection layer is grown at the front SEregion at high temperature, a pyramid textured surface of the SE region is effectively protected, and the process flow can guarantee that the stable and continuous production of the SE alkali-polishedPERC battery.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

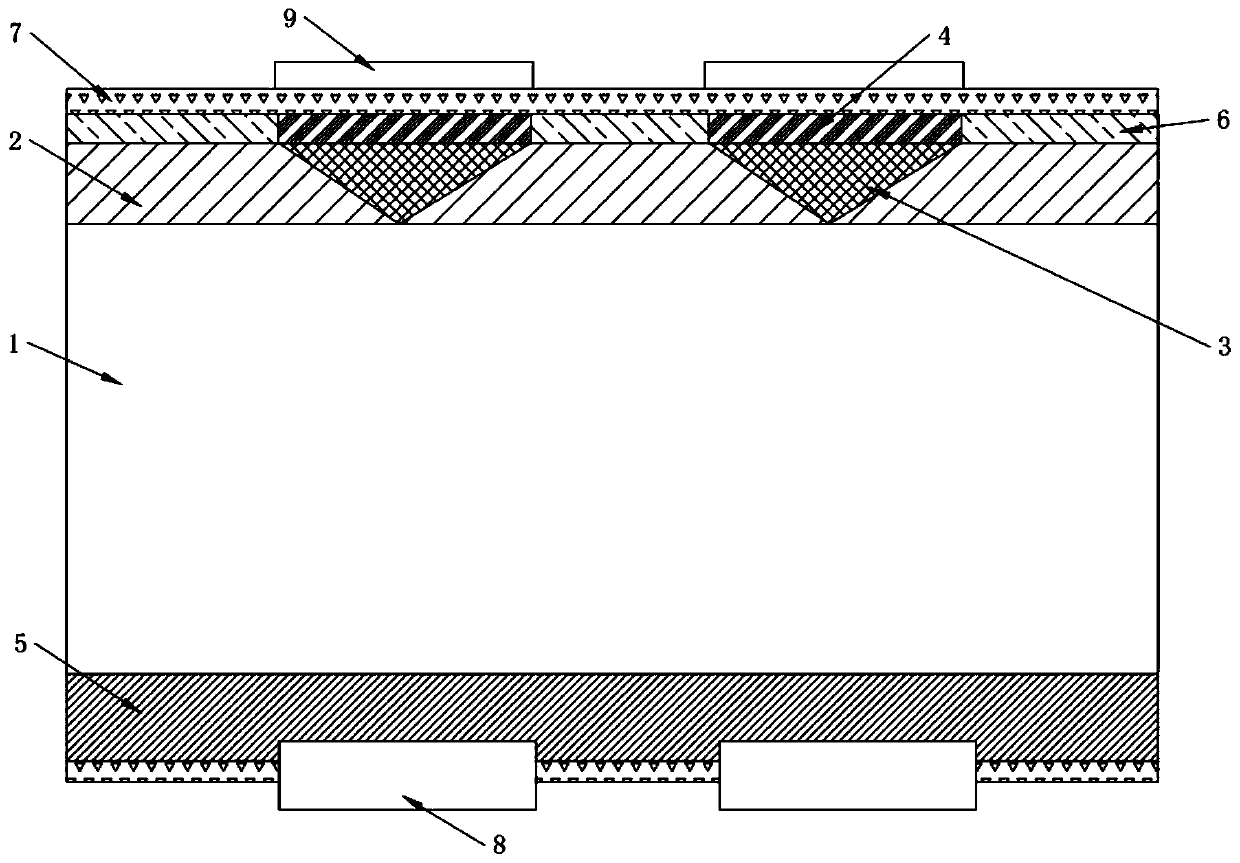

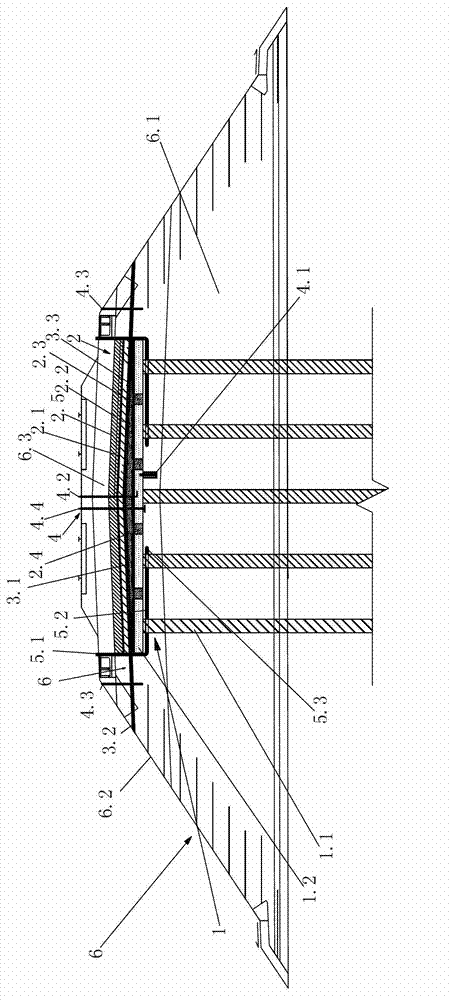

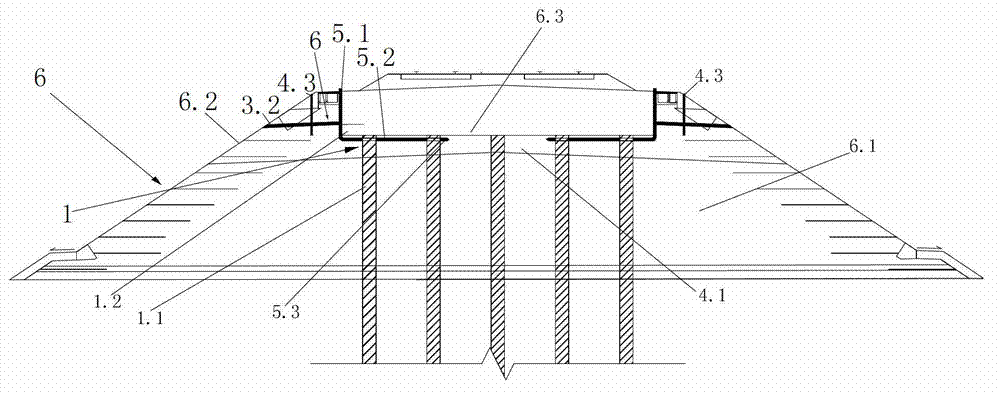

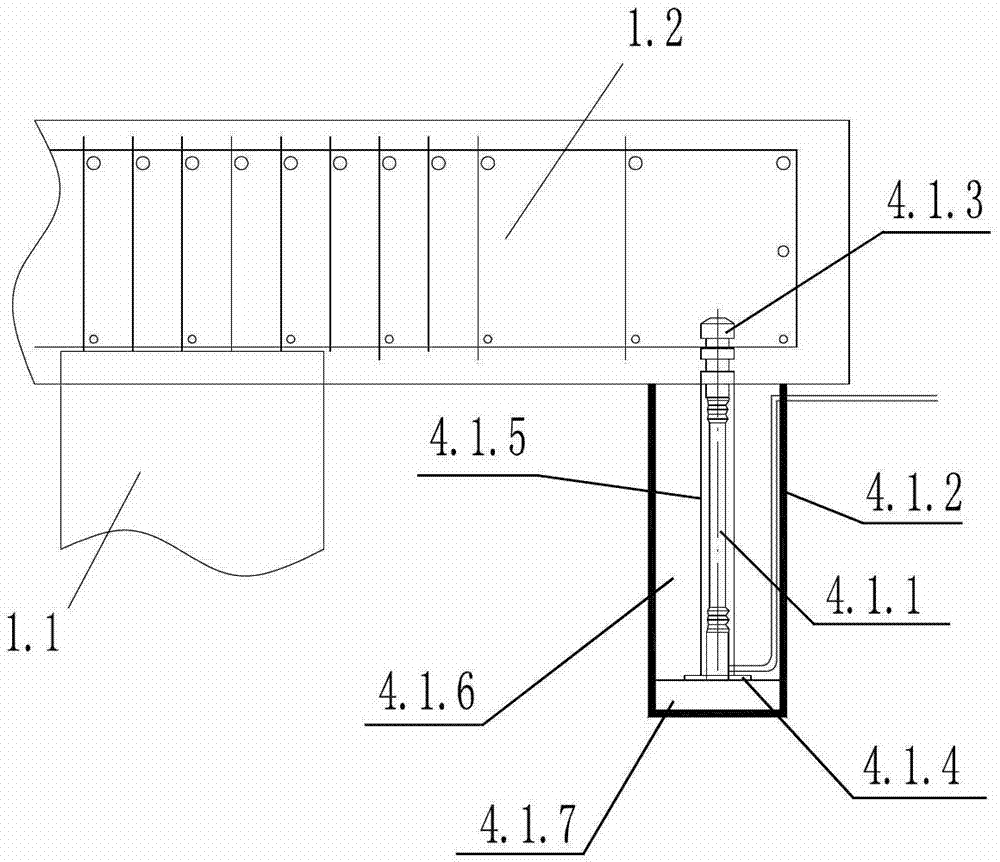

Reinforcement method and reinforcement structure for treating railway soft soil roadbed settlement overweight before operation

ActiveCN102926304AReduce damageThe construction period of the main structure is shortRoadwaysFoundation testingOverweightObservation system

The invention discloses a reinforcement method and a reinforcement structure for treating railway soft soil roadbed settlement overweight before operation. The reinforcement structure mainly consists of five parts, namely a main bearing structure system, a reinforced cushion layer structure system, a foundation bed drainage system, a settlement observation system and a reserved grouting system. The technical problems that the existing roadbed is greatly damaged, the construction period is long, the construction property is low, the quality is difficult to control and the problem that the soft soil roadbed settlement overweight is caused in the conventional technical scheme are effectively solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Buring free, steaming free bearing building blocks or bricks prepared from tailing sand of iron ore, and manufacturing process

InactiveCN1727301ASolve pollutionSolve the damageSolid waste managementClaywaresBrickPortland cement

A load-bearing building block or brick is prepared from iron ore tailings (20-40 Wt%), broken stone (40-60), powdered coal ash (10-30), Portland cement (9.9-20) and water-reducing agent (0.1-1). Its making technology without calcining and steaming is also disclosed.

Owner:ANYANG IRON & STEEL GRP +1

Borehole casing pressure-proof seepage sealing grouting device and process for roadway breaking water burst surrounding rock

ActiveCN103061785ASolve sealing problemsSolve the damageUnderground chambersSealing/packingSlurryOpen hole

The invention discloses a borehole casing pressure-proof seepage sealing grouting device and process for roadway breaking water burst surrounding rock. The borehole casing pressure-proof seepage sealing grouting device comprises a pressure-proof expansion grouting device and a seepage grouting pipe which are combined together. The invention further discloses a borehole casing pressure-proof seepage sealing grouting process for the roadway breaking water burst surrounding rock. By injecting a rapid hardening consolidation material into the pressure-proof expansion grouting device to enable expansion cloth to be spread and tightly pressed on a borehole wall, disturbance damage to the breaking water burst surrounding rock caused by grouting pressure in the seepage grouting process is avoided, roadway deformation and even collapse caused in the grouting process can be avoided, an open hole section is grouted through the seepage grouting pipe, grouting slurry seeps to water guiding cracks by the grouting pressure, and an annular sealing material protecting ring can be formed in a borehole after a core taking pipe is utilized to take out the pressure-proof expansion grouting device. The protecting ring has the effects of wall protection and water stopping and guarantees sealing quality of a borehole casing.

Owner:SHANDONG UNIV

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

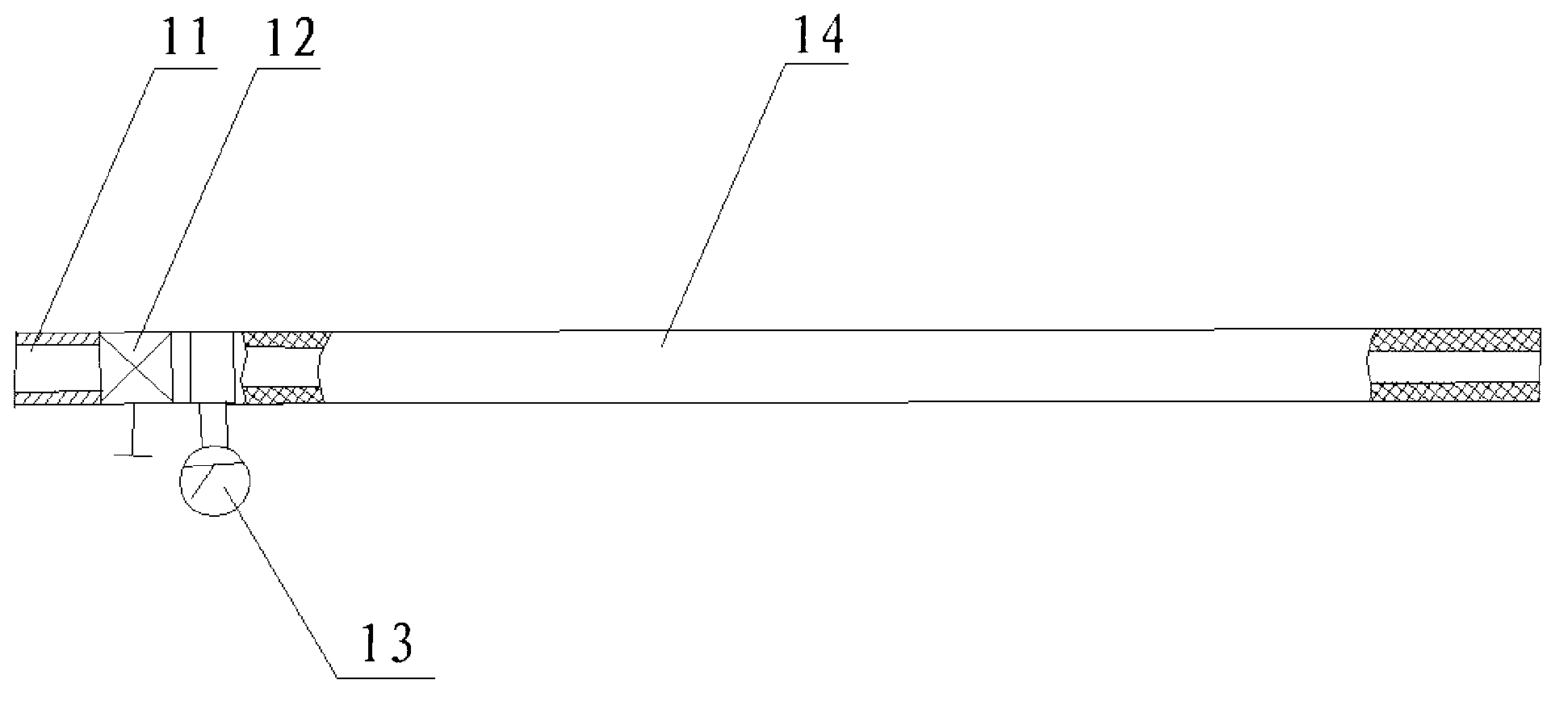

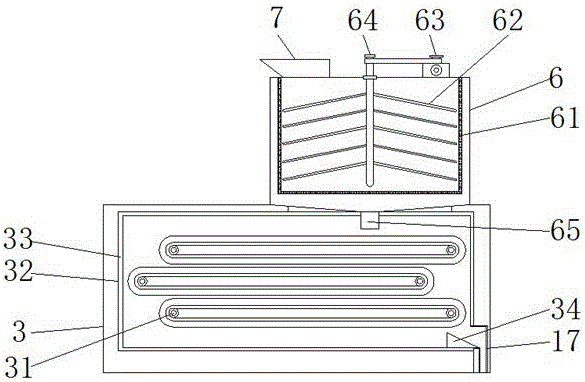

Methanol-water reforming hydrogen making machine and hydrogen making method thereof

InactiveCN104986731AAvoid heat wasteExtend your lifeHydrogenChemical industryCarbon dioxideHeating efficiency

The invention discloses a methanol-water reforming hydrogen making machine and a hydrogen making method thereof. The methanol-water reforming hydrogen making machine comprises a methanol-water storage container, a delivery pump, a heat exchanger and a reformer. The reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device. The electromagnetic heater comprises an electromagnetic coil and a metal magnet, the electromagnetic coil can generate a high frequency magnetic field after being powered up, and the metal magnet can be inducted by the magnetic field to give out heat, so that heat energy is provided for the reforming chamber. The reforming chamber is used for conducting a reforming hydrogen making reaction of methanol and water, and high temperature mixed gas mainly containing carbon dioxide and hydrogen is obtained; after heat of the high temperature mixed gas output from the reforming chamber is separated by the hydrogen purification device, hydrogen can be obtained from the hydrogen producing end of the hydrogen purification device. The methanol-water reforming hydrogen making machine is long in service life, small in amount of maintenance, small in heat lag, accurate to control, high in starting speed of the reformer, high in heat efficiency and even in heating.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

Method for preparing micro-fine and ultra-fine calcium carbonate of different crystal forms from carbide slag

InactiveCN101264920ASolve pollutionSolve the damageCalcium/strontium/barium carbonatesSlagPolyvinyl chloride

The invention discloses a preparation method of using carbide slag to produce different micro-and ultra-fine calcium carbonate of various crystal forms, belonging to the calcium carbonate. The method comprises four steps: the first step is the pretreatment of the carbide slag; the second step is the preparation of the calcium chloride solution; the third step is the metathesis reaction for the preparation of micro-and ultra-fine calcium carbonate; the fourth step is to filter and dry. The preparation method has the advantages that (1) the problem of environmental pollution brought by the emission of the carbide slag is solved; (2) since NH4C is not used for the preparation of calcium carbonate, the problem of environmental pollution caused by the NH3 is solved; (3) using HCI to react with carbide slag makes Ca(OH)2 in the carbide slag and CaCO3 generated after the carbonation of carbide slag by air both transfer into CaCl2, improving the recovery rate of the carbide slag; (4) adopting the method of mixing directly the carbide slag and water and preparing the mixture into slurry, instead of traditional drying or high-temperature calcinations pretreatment, reduces the energy consumption in the pretreatment of the carbide slag. The preparation method is suitable for the enterprises using large amount of calcium carbide, in particular to the chloral-alkali enterprises with the PVC production line.

Owner:GUIZHOU UNIV +1

Fence preservation method for prolonging shelf life of cold fresh poultry

InactiveCN101990930AAntibacterialImprove freshnessMeat/fish preservation using chemicalsBiotechnologyCold chain

The invention discloses a fence preservation method for prolonging shelf life of cold fresh poultry. The fence preservation method for prolonging the shelf life of the cold fresh poultry comprises the following steps of: placing fresh poultry which is obtained by slaughtering, washed completely and cut into a refrigeration storage at the temperature of between 2 and 5 DEG C and precooling the poultry for 1 to 2 hours, so that the surface temperature of the poultry is reduced below 5 DEG C and the internal temperature of the poultry is reduced below 10 DEG C; transferring the precooled poultry to a purification room and performing surface sterilization on the poultry through ozone or ozone solution of an ozone generator; immersing the poultry subjected to ozone sterilization into chitosan glutamate solution to retain freshness; taking out and draining the poultry; placing the poultry after corrosion prevention and freshness preservation into a food plastic packaging box; introducing carbon dioxide (CO2) and nitrogen (N2) into the food plastic packaging box and performing sealing package; and storing the packaged poultry into a cold chain at the temperature of between 2 and 5 DEG C. The fence preservation method for prolonging the shelf life of the cold fresh poultry has good effect and is suitable for retaining freshness of the fresh cut poultry.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

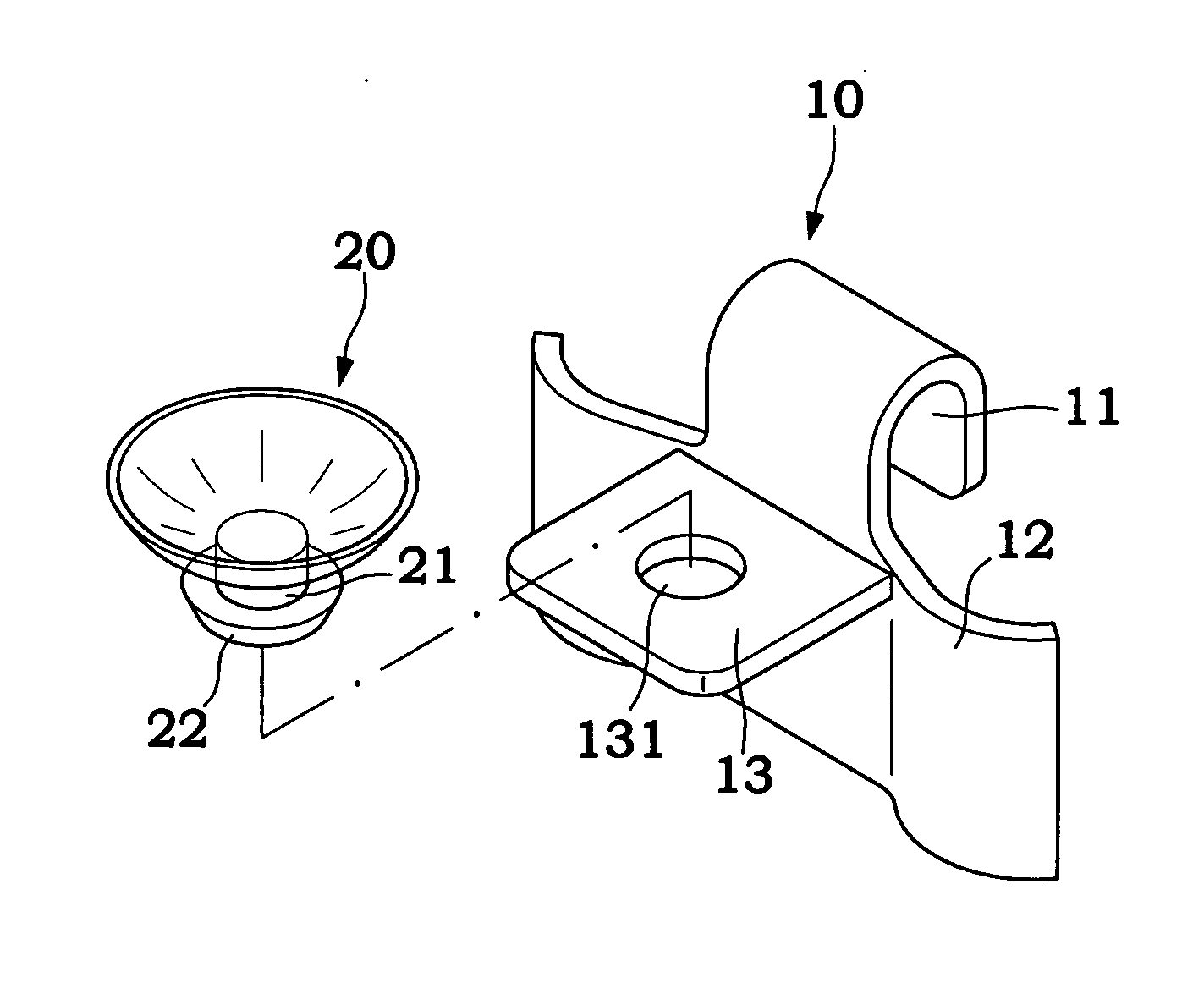

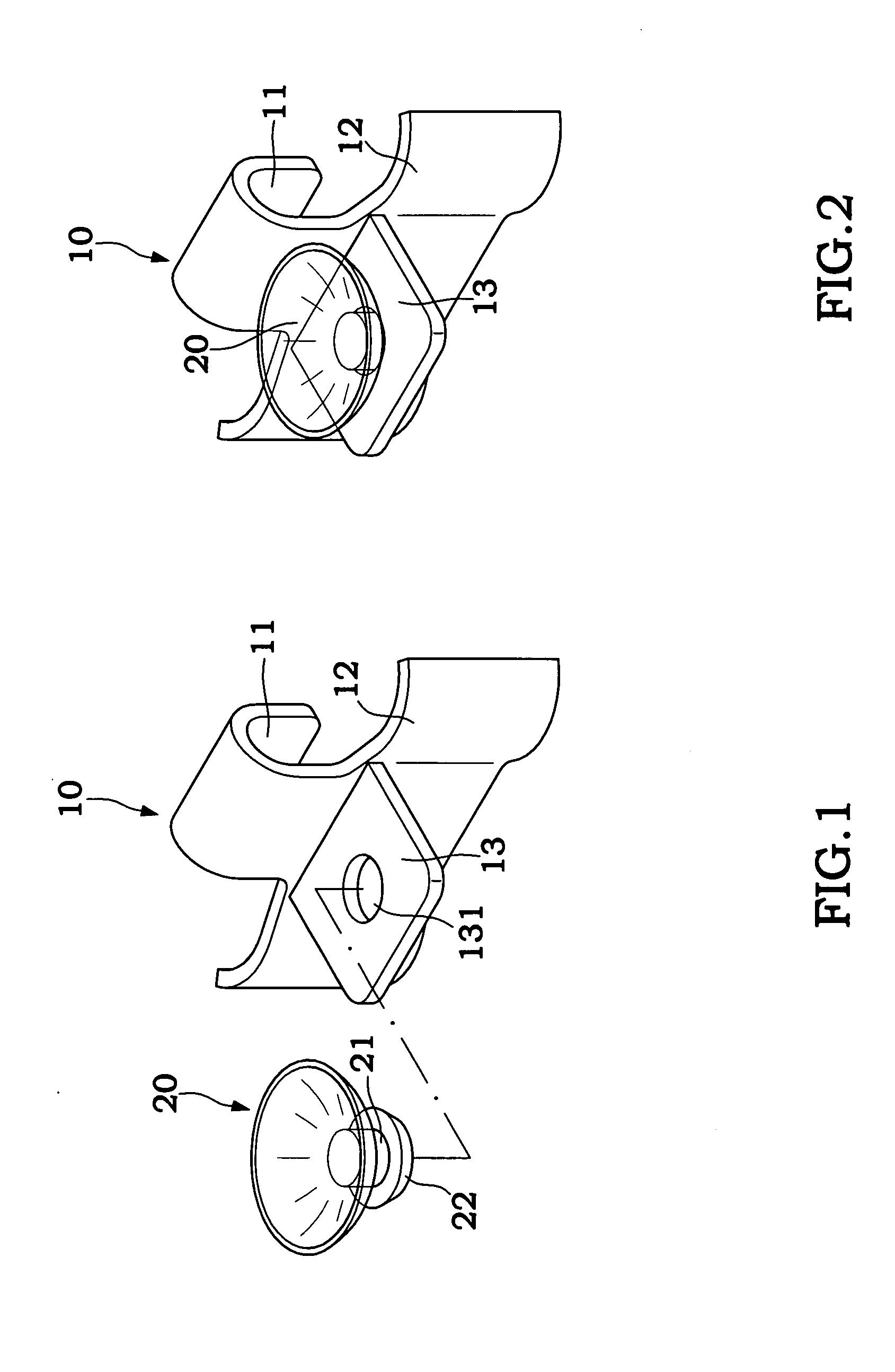

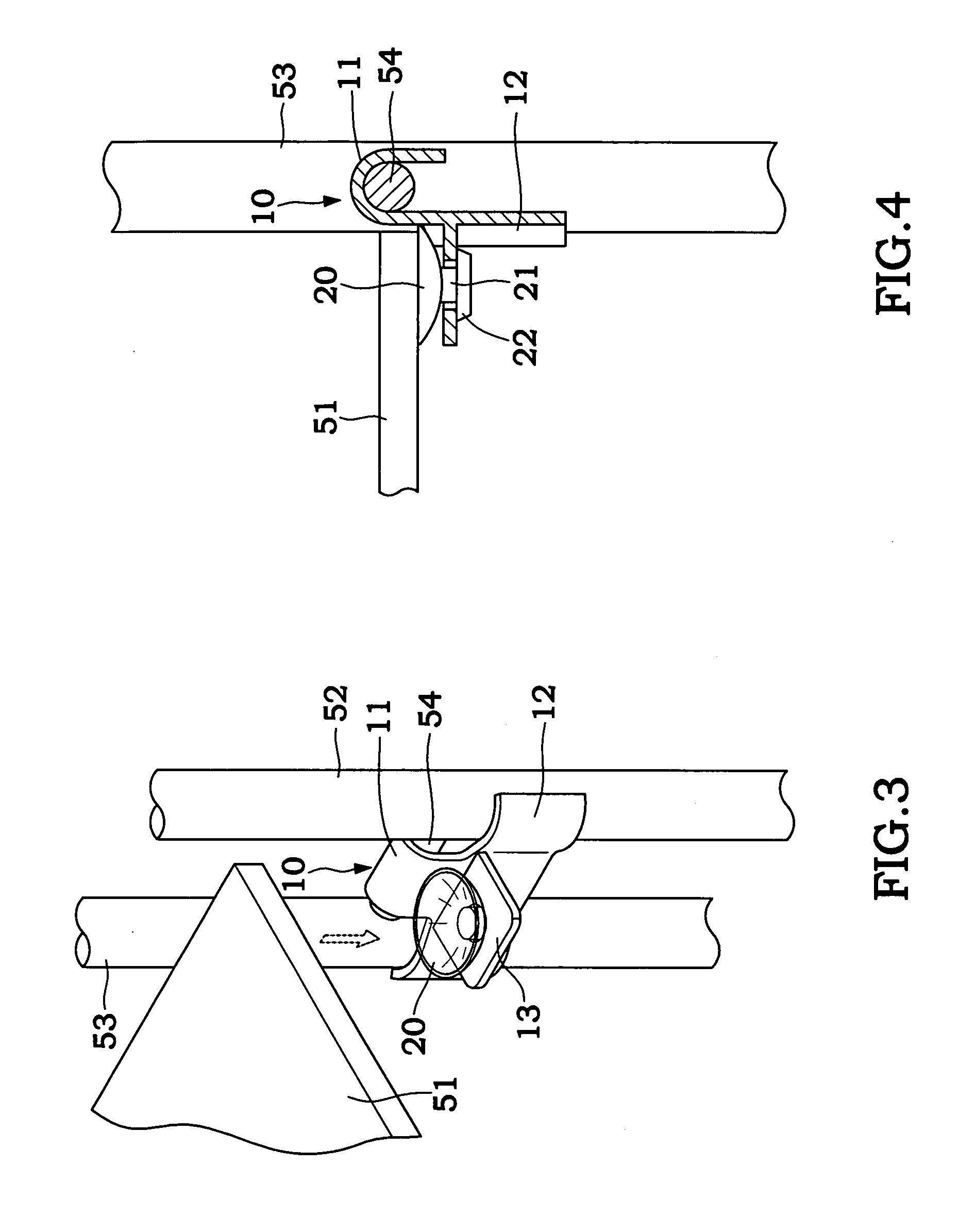

Movable positioning holder of storage rack

InactiveUS20050092706A1Solve the damageSolve strengthStands/trestlesKitchen equipmentWood plankHanging position

Owner:CHANG CHIEN KUO

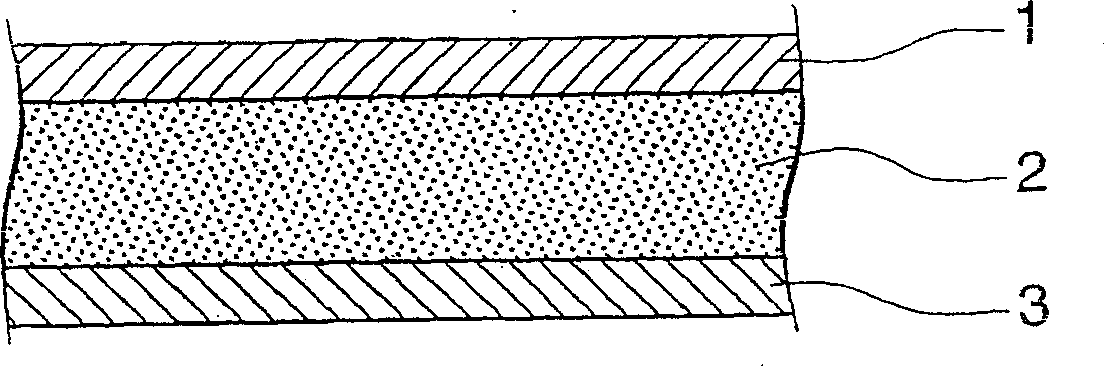

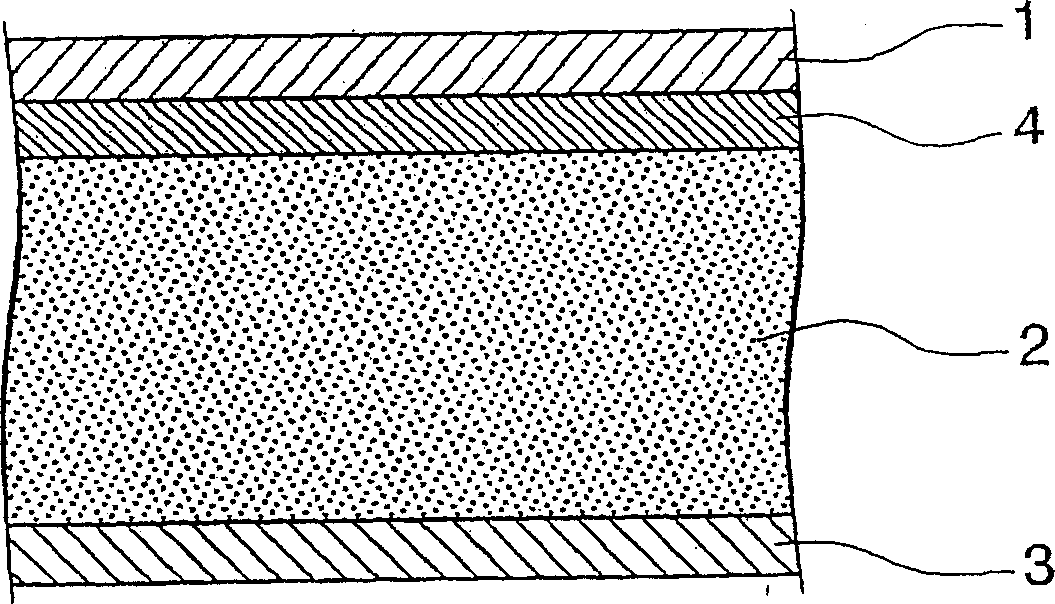

Manufacturing process of polyurethane foam sheet and layered sheet using the same

ActiveCN1732082AControllable shapeUniform shapeSynthetic resin layered productsLaminationWood veneerCushioning

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DIC CORP

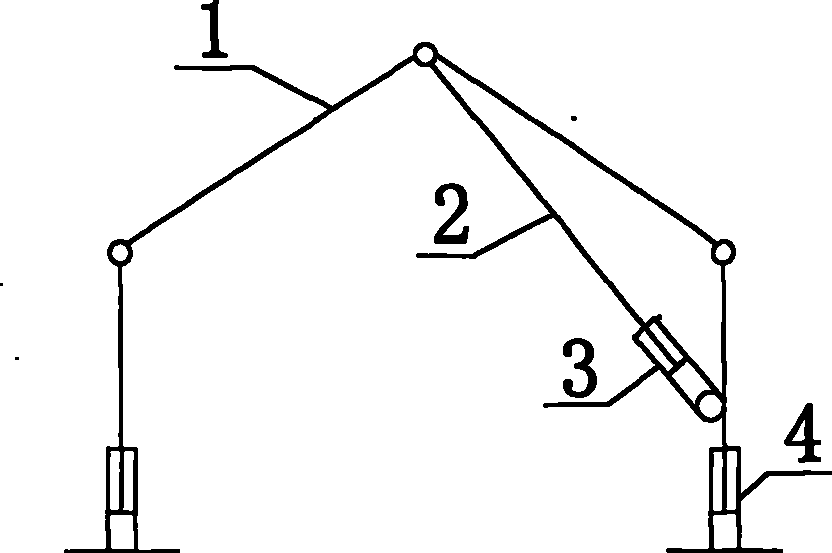

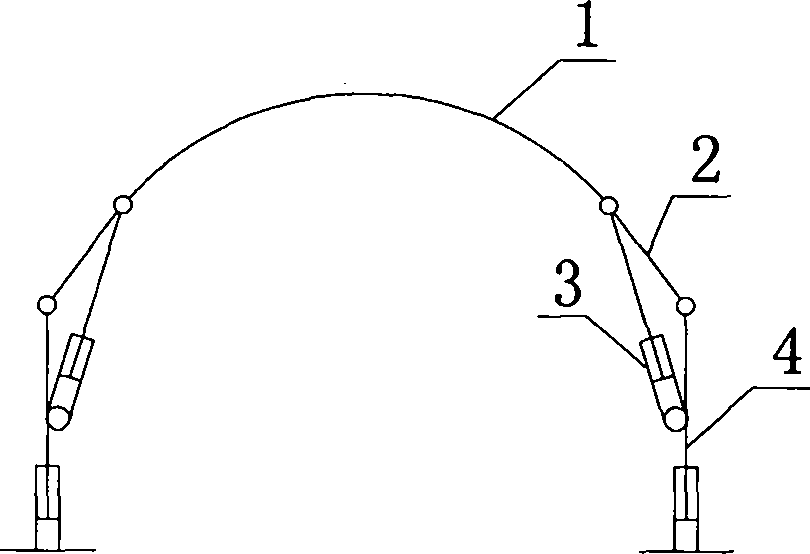

Hydraulic support used for roadway temporary support and erecting and use method of hydraulic support

ActiveCN103643979AControl deformationFacilitate installation parallel operationMine roof supportsStructural engineeringEngineering

Owner:徐州莱柯斯特矿山工程技术有限公司 +1

Underwater robot used for submarine pipeline magnetic memory detection

InactiveCN108468862AGuaranteed to rock back and forthWon't rock back and forthPipe laying and repairPipeline systemsOcean bottomLeveling mechanism

The invention provides an underwater robot used for submarine pipeline magnetic memory detection. The robot is mainly used for solving the problem that a conventional ROV cannot detect the bottom of the submarine pipeline particularly the bottom of the pipeline lying on the sea bed. The robot is characterized by comprising an ROV body, a spraying gun sand removal mechanism, a pipe attaching crawling clamping mechanism, a variable diameter sensor detection mechanism and a sediment leveling mechanism; the ROV body serves as a carrier to provide supporting and power for other devices, the spraying gun sand removal mechanism is used for cleaning sediment on a pipeline and the bottom, the pipe attaching crawling clamping mechanism is used for clamping pipelines with different diameters and achieving secondary cleaning, and it is ensured that universal rollers on a clamping jaw are tightly attached to the pipeline for crawling and cannot slip; the variable diameter sensor detection mechanismis used for achieving locking holding detection of a sensor for the pipelines of the different diameters. The robot can achieve full-cycle comprehensive non-dead-corner detection of submarine pipelines under the complex conditions of the deep water area, the sediment coverage and the like.

Owner:NORTHEAST GASOLINEEUM UNIV +1

Pig manure cleaning device for pig farm

InactiveCN106359117AImprove cleaning efficiencyReduce laborClimate change adaptationExcrement fertilisersPig farmsEngineering

The invention discloses a pig manure cleaning device for a pig farm. The pig manure cleaning device comprises a base, a shell and a mixing chamber, wherein a drying chamber is mounted in the shell; an electric heating layer is mounted on an inner wall of the drying chamber; a conveyor group is mounted in the drying chamber; the mixing chamber is mounted above the shell; a manure inlet and a mixing motor are mounted at the top of the mixing chamber; a rotating shaft is mounted in an inner barrel through a rotating bearing; mixing blades are mounted on the rotating shaft; the top end of a supporting rod is connected with a conveyor rolling shaft at one end of a conveyor belt; a fixed bracket is fixed at one side, far away from an antiskid handle, of the shell; a manure collecting groove is arranged below a connecting part of the conveyor belt and the fixed bracket; a roller manure scraper is mounted at one end, far away from the shell, of the fixed bracket; and an arc manure shovel is mounted below the roller manure scraper. The pig manure cleaning device disclosed by the invention breaks the traditional manual pig manure cleaning mode, and really realizes the efficiency, practicability, convenience, manpower economization, and environmental protection.

Owner:耒阳市丁先生农业发展有限公司

Process for making tuber of elevated gastrodia wine

InactiveCN1667113AAvoid pollutionOvercome problems such as inability to convert and utilizeAlcoholic beverage preparationSurface moistureDissolution

This invention relates to an preparation method of gastrodia tuber wine. It mainly solves existing straggling method of making gastrodia tuber wine by high temperature, steaming, boiling, shelling, dunking alum, sulfur fuming and baking drying. The pollution of alum and sulfur to gastrodia tuber wine is conquered, and the effective components running down and destruction by the existing method is also conquered. In this invention, gastrodia tuber is washed and surface moisture is thrown off, crush and jordaning technique is used. gastrodia tuber block tissue diameter is shorten, so its effective components dissolution, dunking by liquor is accelerated, the gastrodia tuber effective components in liquor is boosted, and the problem fresh gastrodia tuber block uneasy dunked by liquor, gastrodia tuber component in liquor is low, clock stem easy deterioration and pollute liquor is solved. gastrodia tuber paste dreg and gastrodia tuber starch fermented with food stuff is used in this method. Raw material is saved, cost is reduced, health component of gastrodia tuber wine is improved, and the technique is advance and novelty. It provides a new style gastrodia tuber health wine for people, so this invention has good economic extending value.

Owner:刘建华

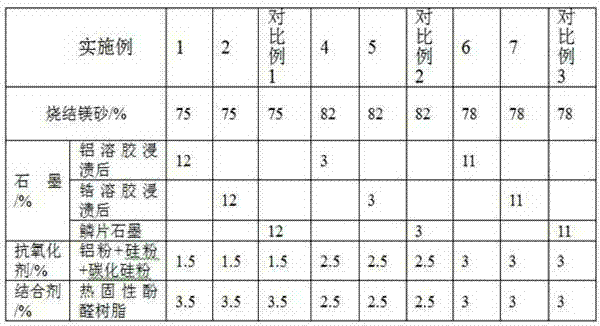

High-performance magnesia-carbon brick and production method thereof

The invention discloses a magnesia-carbon brick for a steelmaking converter and a steel ladle and a production method of the magnesia-carbon brick. The magnesia-carbon brick is prepared from the raw materials in percentage by weight: 72-83 percent of sintered magnesia, 3-15 percent of graphite grain, 1-15 percent of antioxidant and 2-5 percent of binder. The preparation method comprises the steps: (1) carrying out mechanical crushing on massive magnesia, then sending the crushed massive magnesia into a ball mill, and carrying out fine grinding on the crushed massive magnesia to prepare the magnesia in five specifications; and (2) carrying out burdening according to the required weight percentage, sending the burdened materials into a mixer to carry out mulling, adding coarse-grained magnesia, a thermosetting phenol-formaldehyde resin binder, the graphite grains and a mixed powder of fine-grained magnesia and the antioxidant into the mixer sequentially, carrying out material mixing for more than 25 minutes, and carrying out processing forming finally. According to the magnesia-carbon brick and the production method disclosed by the invention, as the graphite grains are adopted to replace crystalline flake graphite, the material yield is increased, and the spalling resistance and the structure spalling resistance of the materials are improved.

Owner:浙江金磊耐火材料有限公司

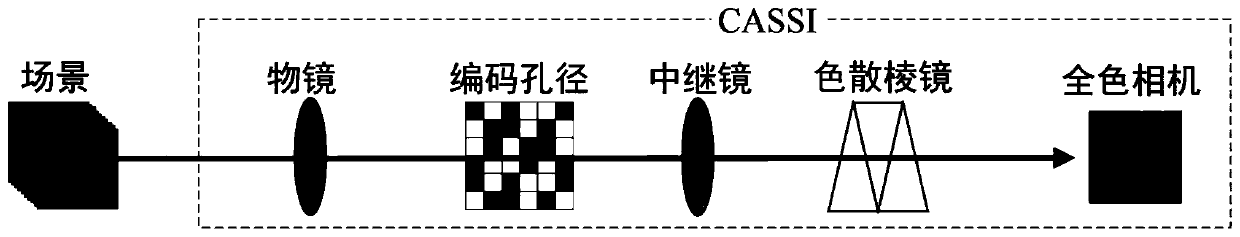

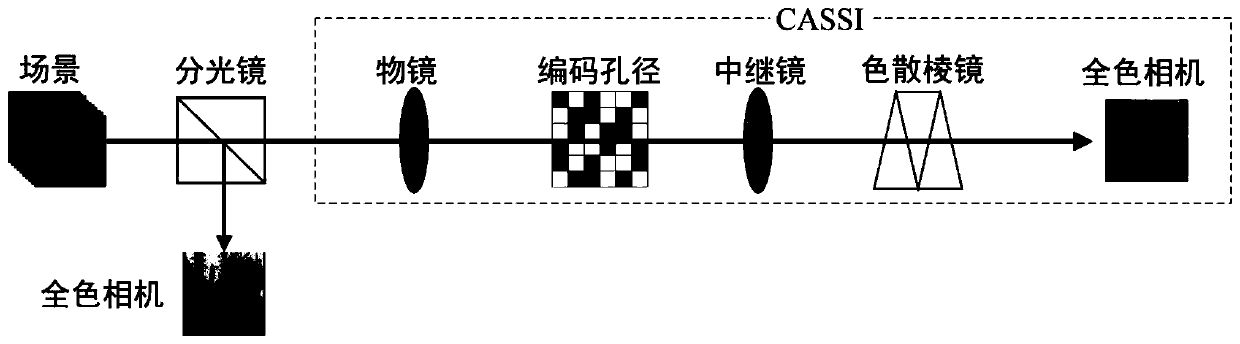

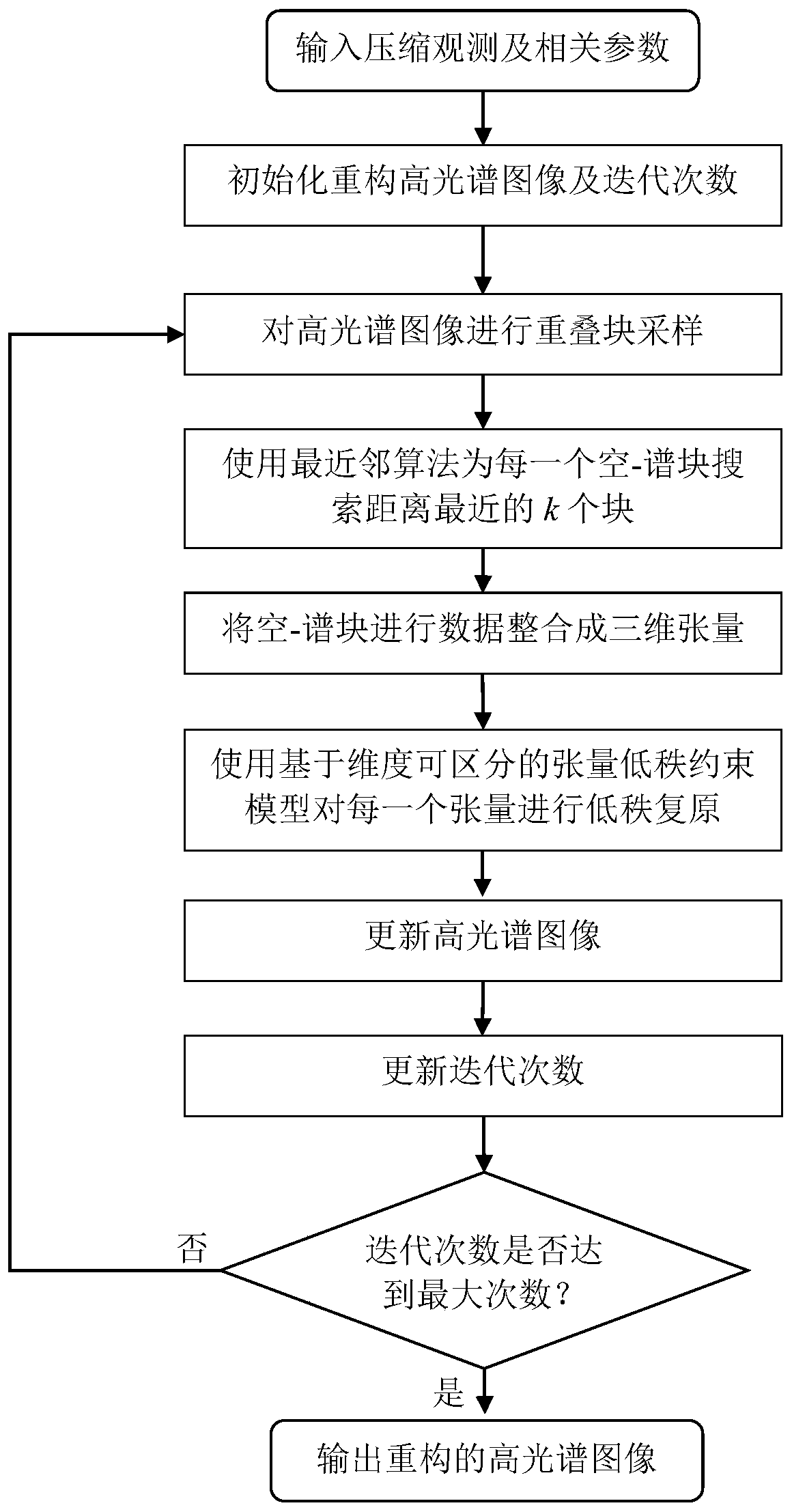

Reconstruction method of snapshot spectral imaging system based on tensor low-rank constraint

ActiveCN110501072AImprove reconstruction accuracySolve the damageImage enhancementSpectrum investigationReconstruction methodNon local

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

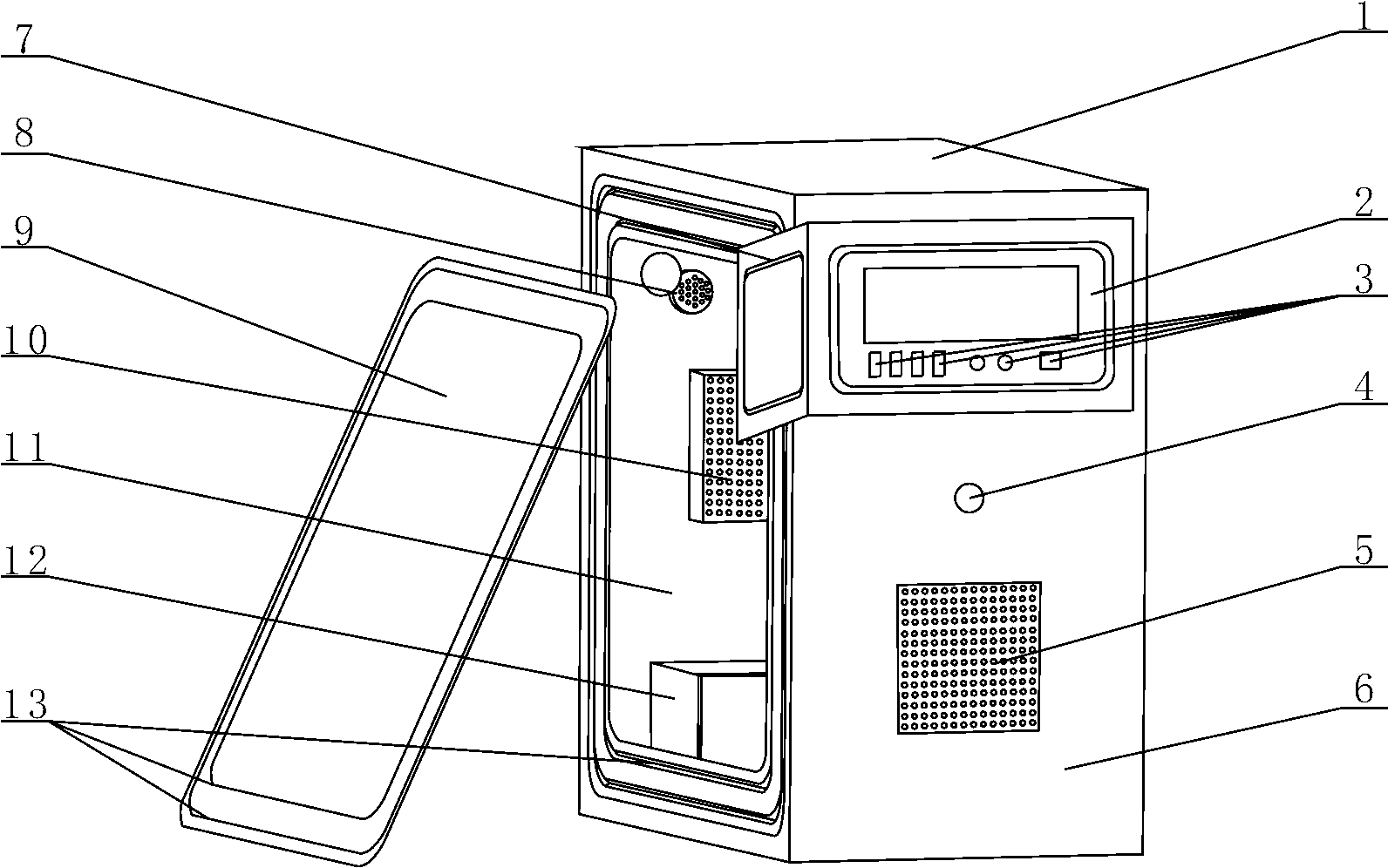

Electromagnetic shielding machine case

InactiveCN103298284ASuperiorSolve the damageMagnetic/electric field screeningElectrical apparatus casings/cabinets/drawersAviationPower filter

The invention discloses an electromagnetic shielding machine case which is composed of a machine case housing (1), side panels (9), waveguide windows, an aviation plug (8) and a power filter (12). Two side panels (9) are arranged on choke grooves (13) on two lateral sides of the machine case housing (1) respectively, the aviation plug (8) and the power filter (12) are arranged in the machine case housing (1), and a front side panel (6) and a rear side panel (11) are respectively provided with a waveguide window to achieve a purpose of efficient shielding. The electromagnetic shielding machine case is clear in structure and good in practicality, achieves the purposes of being convenient to move, high in shielding efficiency, safety and reliability, good in environment adaptation and wide in application range, solves the problems of computer damage caused by electronic pulse and electromagnetic information leaking and is suitable for military and confidential situations.

Owner:THE THIRD ENG CORPS RES INST OF THE HEADQUARTERS OF GENERAL STAFF PLA

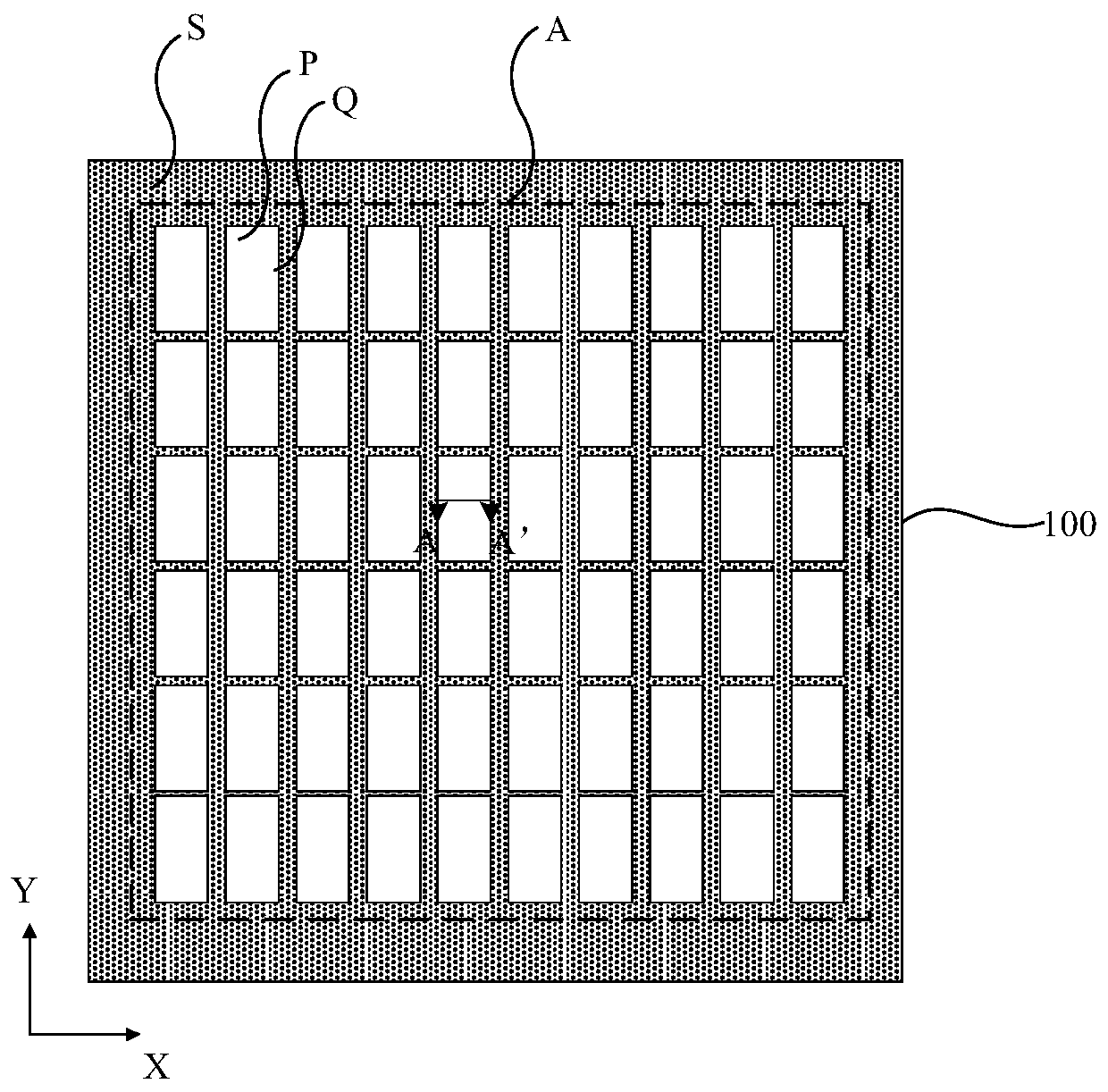

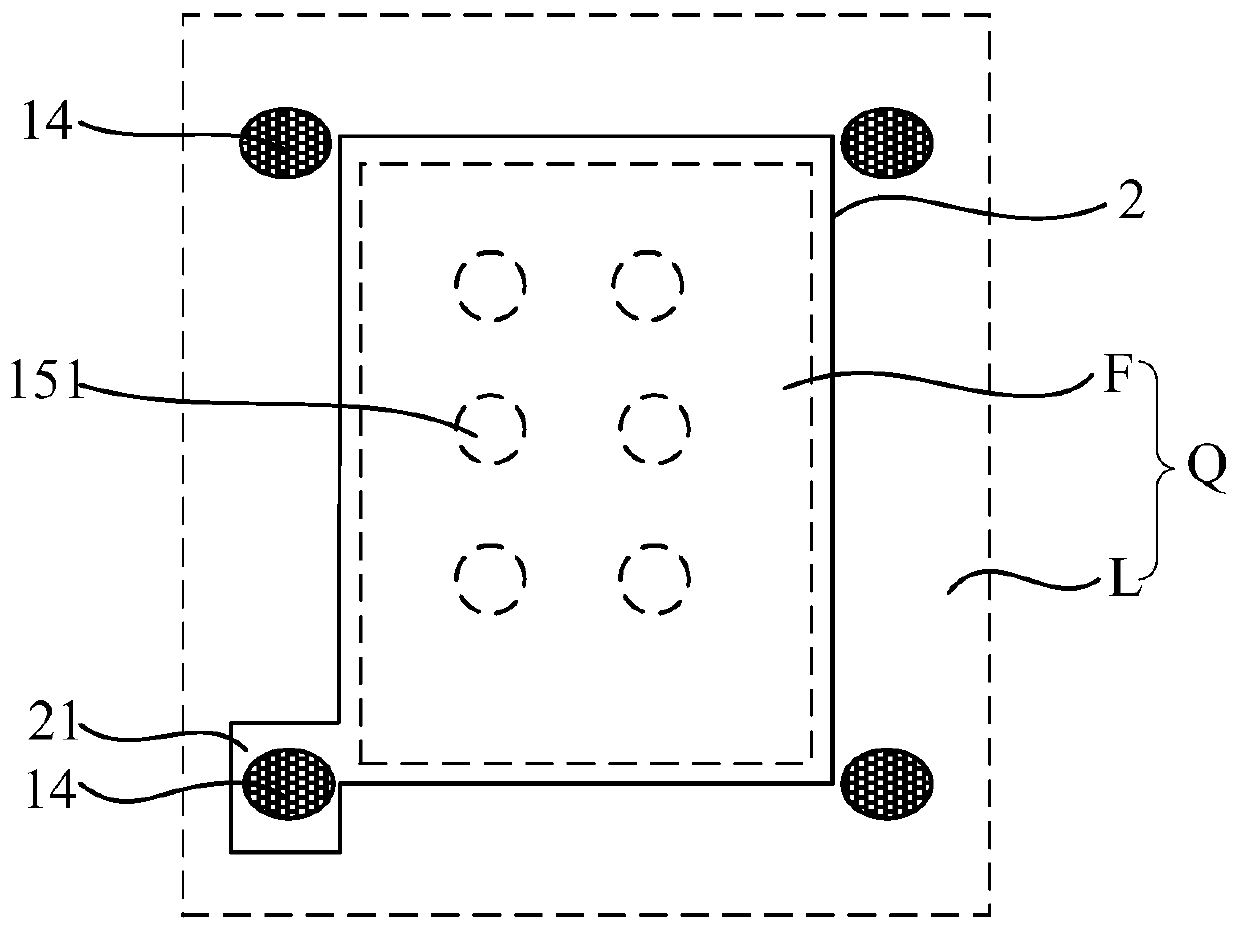

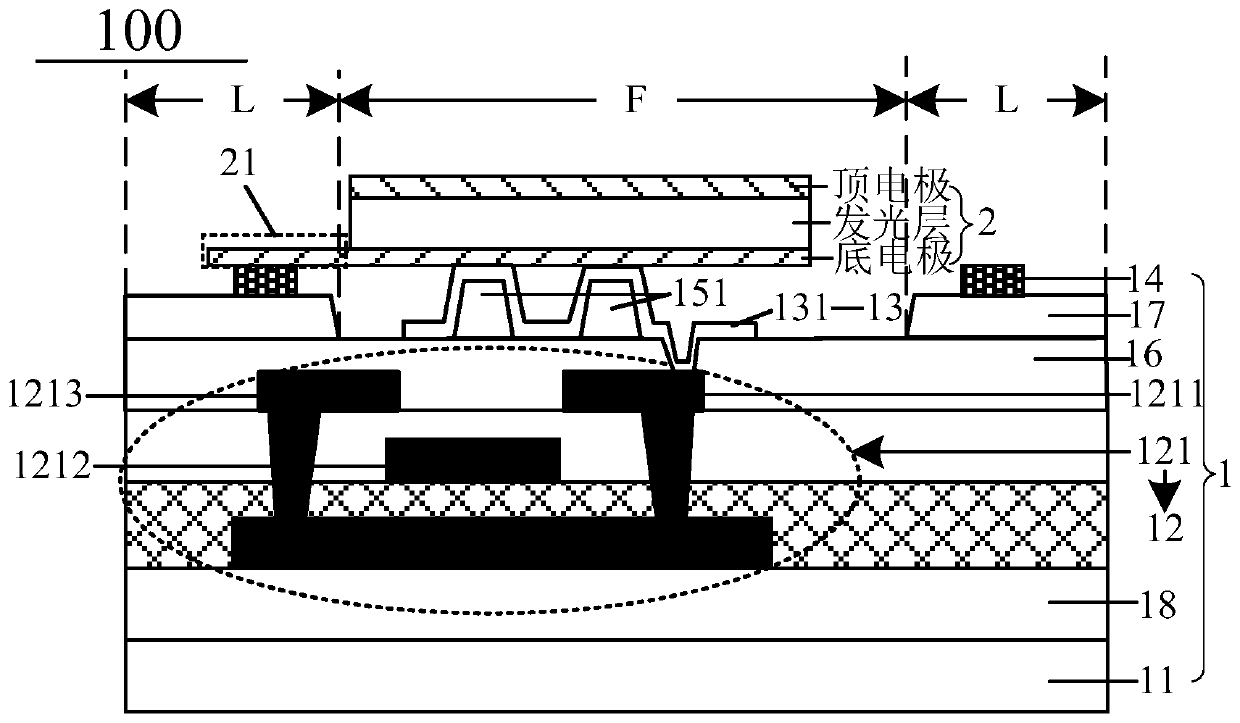

Backboard, display panel and repairing method of abnormal light emitting diode

ActiveCN110571234ASolve the damageSolid-state devicesSemiconductor devicesActive matrixLight-emitting diode

The invention relates to the display technology field and especially relates to a backboard, a display panel and a repairing method of an abnormal light emitting diode. Problems that when an abnormallight-emitting diode is repaired or replaced, a process is complex, cost is high, and damages to an active matrix of a backboard are large in a correlation technology are solved. The invention provides the backboard. The backboard comprises a plurality of sub-pixel regions. Each sub-pixel region comprises a light emitting region and a non-light-emitting region. The backboard comprises pixel driving circuits which are arranged on a substrate and located in each sub-pixel region, and driving electrodes which are arranged on one sides, far away from the substrate, of the pixel driving circuits and located in each light-emitting region. Each driving electrode comprises a first electrode, and the first electrode is electrically connected with the pixel driving circuit. The backboard further comprises at least two fixing portions arranged in each non-light-emitting region, and the at least two fixing portions are not overlapped in a thickness direction of the substrate.

Owner:BOE TECH GRP CO LTD

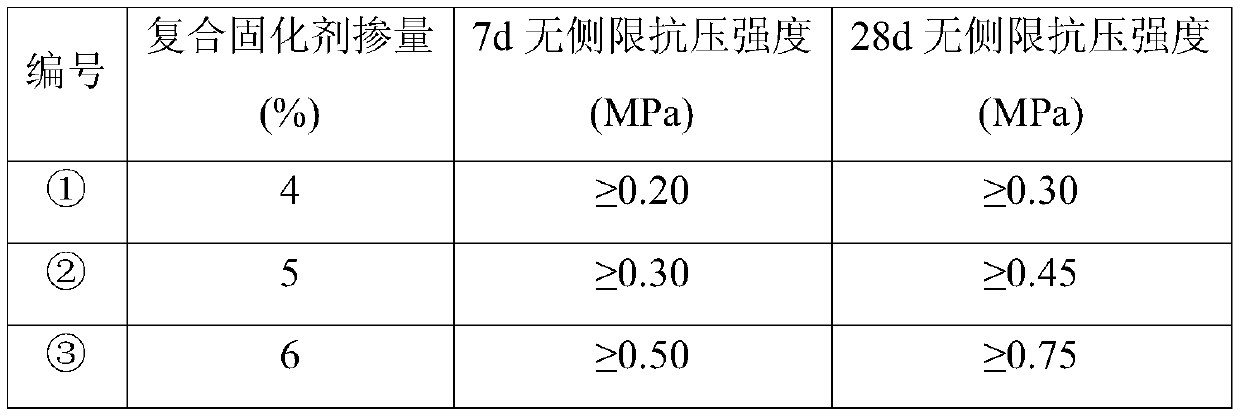

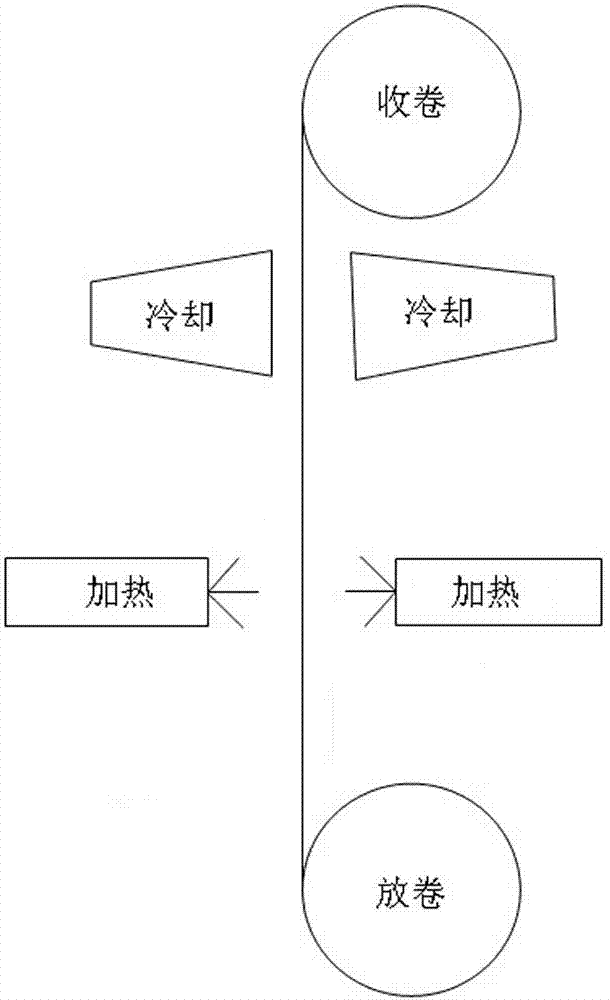

A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method using same

A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method thereof are provided; the method is characterized by comprising the following steps: (1), solidified light soil raw materials are selected, specifically, dehydrated dredged sludge, waste tire rubber powder and an industrial waste residue composite solidifying agent are selected; (2) solidified light soil mixing proportion design refers to the mass ratio of the dehydrated dredged sludge to the waste tire rubber powder to the industrial waste residue composite solidifying agent to the water, wherein the mixing ratio (volume ratio) of the dehydrated dredged sludge to the waste tire rubber powder is 80: 20-60: 40, and the mixing amount of the composite solidifying agent is 4-6%; and (3), roadbed layered filling construction: the solidified light soil roadbed construction comprises construction preparation, mixing, paving, rolling compaction, quality inspection, maintenance and slope protection. The method effectively solves the problem of recycling production and domestic solid waste, reduces the consumption of natural earthwork, and has the effects of saving resources, protecting the environment and the like.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing lithium battery current collector by plasma spraying polymer composite positive temperature coefficient (PTC) powder

InactiveCN103794801AHigh quality and reliabilityFast thermal responseElectrode carriers/collectorsManufacture by sprayingState of artReaction speed

The invention discloses a method for preparing a lithium battery current collector by plasma spraying polymer composite PTC powder. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the lithium battery current collector up to 100-300 DEG C by a heating device, and coating the lithium battery current collector with the polymer composite PTC powder obtained in the step (1) through a plasma spraying device to form a polymer composite PTC powder coating on the lithium battery current collector; (3) baking the lithium battery current collector coated with the polymer composite PTC powder coated in the step (2), and carrying out a recrystallization technology to obtain the lithium battery current collector provided with the polymer composite PTC powder coating. Compared with the prior art, the method has the advantages that the processing process is simple and convenient, the production efficiency is improved, the yield is increased, the product thickness consistency is high, the product quality reliability is high, the thermosensitive reaction speed is high, and capacity adjustment is accurate and convenient.

Owner:ZHONGYUAN ENGINEERING COLLEGE

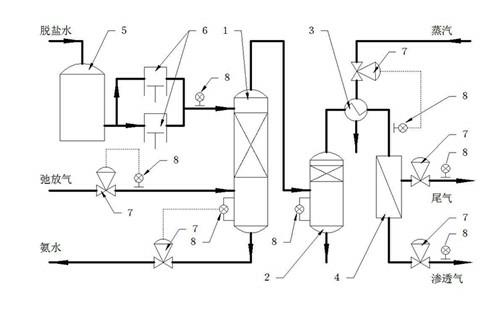

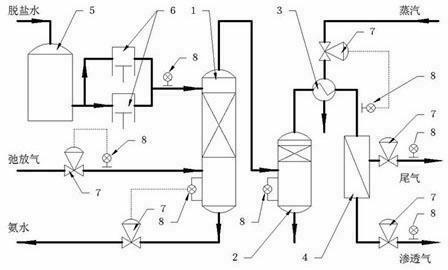

Membrane separation method and device for recycling hydrogen from purge gas of synthetic ammonia liquid ammonia storage tank

InactiveCN102515099ASo as not to damageSmall investmentHydrogen separation using solid contactAutomatic controlHigh energy

The invention relates to a membrane separation method for recycling hydrogen from purge gas of a liquid ammonia storage tank of synthetic ammonia. The method is characterized by comprising the following steps of: 1) absorbing treatment of the ammonia of the purge gas; 2) gas-liquid separation treatment; 3) membrane separation treatment; and 4) gas aftertreatment. According to the invention, the key problem that the application of the membrane separation method in the purge gas hydrogen recycling field is blocked, namely, the problems of deep ammonia removal at low pressure and low hydrogen recycling rate of membrane separation in case of low pressure difference, are solved. Meanwhile, by using a complete automatic control system, each technical parameter of the device is monitored in real time and the membrane separation device is ensured to stably operate for a long period. Compared with deep cold method and pressure swing adsorption method, the membrane separation method for recycling the hydrogen, provided by the invention, has the advantage of overcoming defects of large equipment investment, high energy consumption, low hydrogen recycling rate, poor technicality and economics and the like in the traditional hydrogen recycling method.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to the reaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

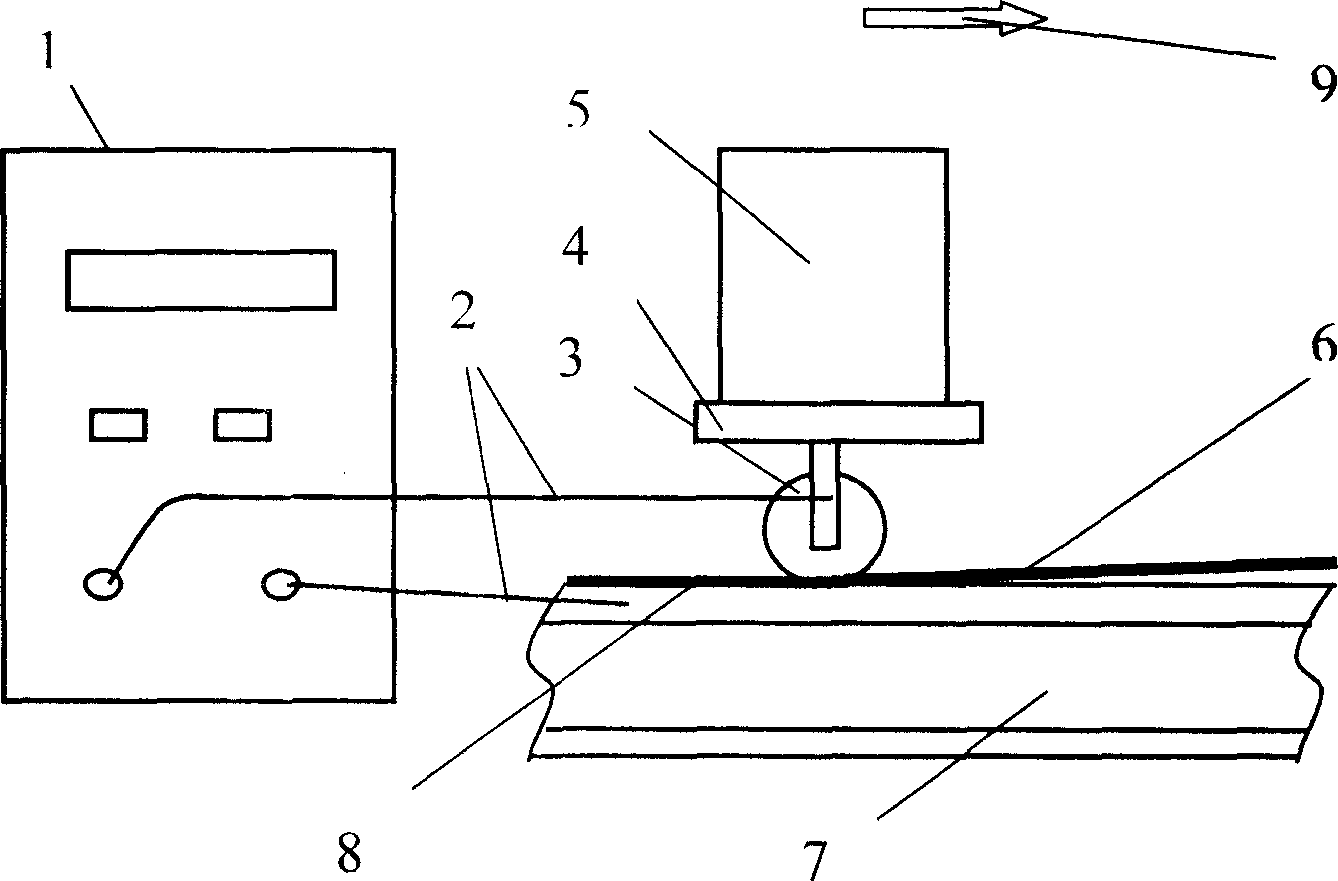

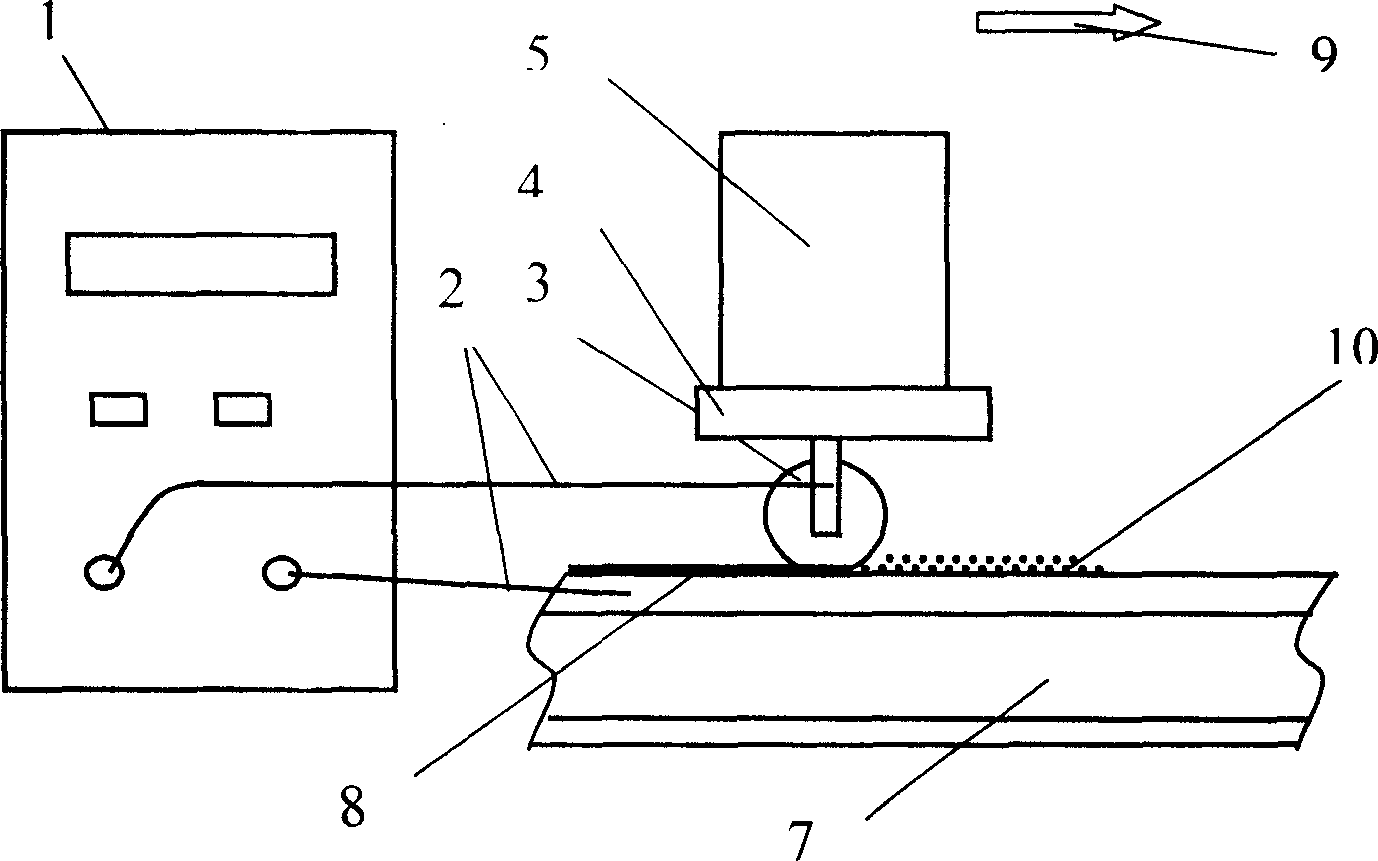

Steel rail surface alloy layer welding method and its material

InactiveCN1803370AGood welding performanceImprove corrosion resistanceWelding with roller electrodesWelding/cutting media/materialsMetallic materialsAlloy

The invention discloses a self-melting alloy powder material in the metal welding and railway signal control method, which comprises the following steps: polishing the railway surface to obtain fresh metal surface; proceeding resistance seam welding through resistance seam welding equipment; producing the needed alloy; coating alloy powder on the metal surface at 1000-1130 deg C fusing point. The powder displays NiCrBSi system self-melting alloy powder or NiCrBSiCu alloy system with HRC20-HRC45 welding layer hardness. The weight percentage of NiCrBSiCu alloy system is 0.2-0.5 percent C, 0.5-5.0 percent B, 1.0-5.0 percent Si, 3.0-15 percent Cr, 2-12 percent Fe, 3-20 percent Cu and Ni. The invention improves the bonding surface of metal and steel, which solves the problem of big rail damage and low production efficiency.

Owner:阴生毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com