Borehole casing pressure-proof seepage sealing grouting device and process for roadway breaking water burst surrounding rock

A grouting device and roadway technology, applied in tunnels, shaft equipment, earthwork drilling and mining, etc., can solve problems such as damage, affecting mine production, disturbing and destroying roadway surrounding rock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

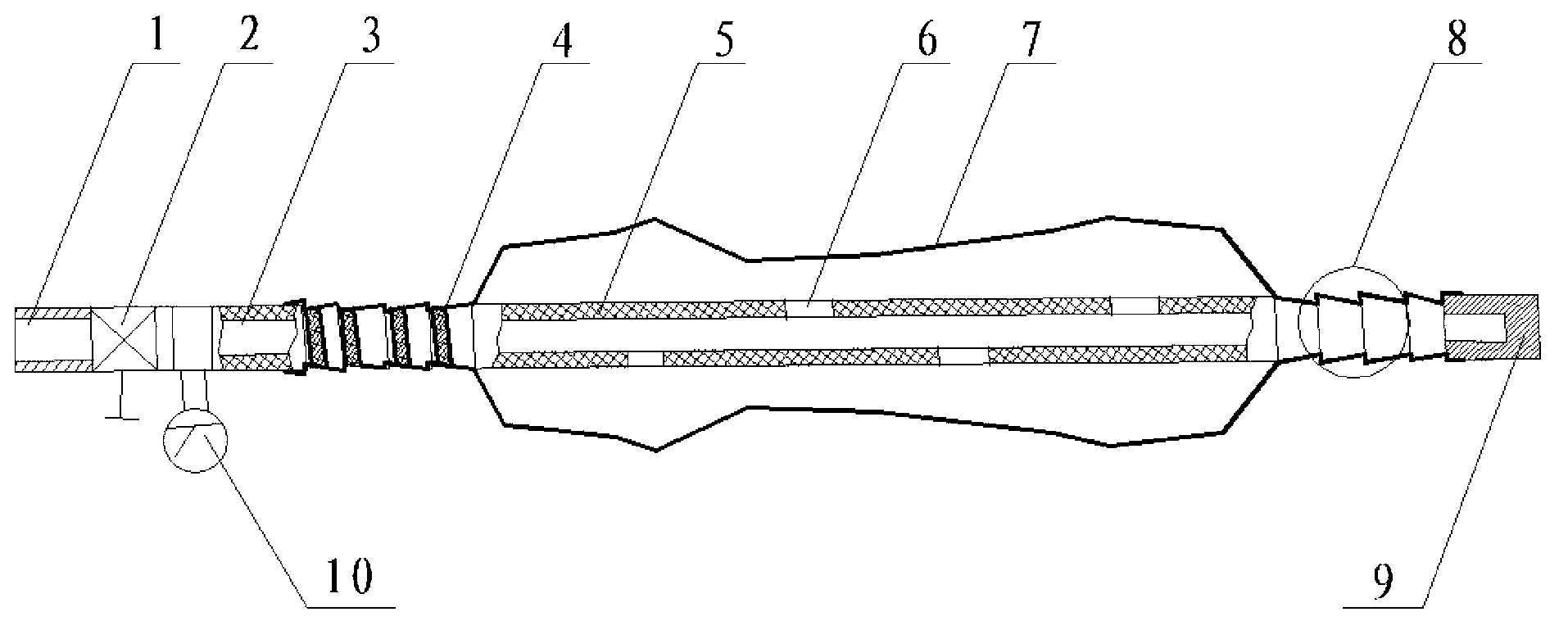

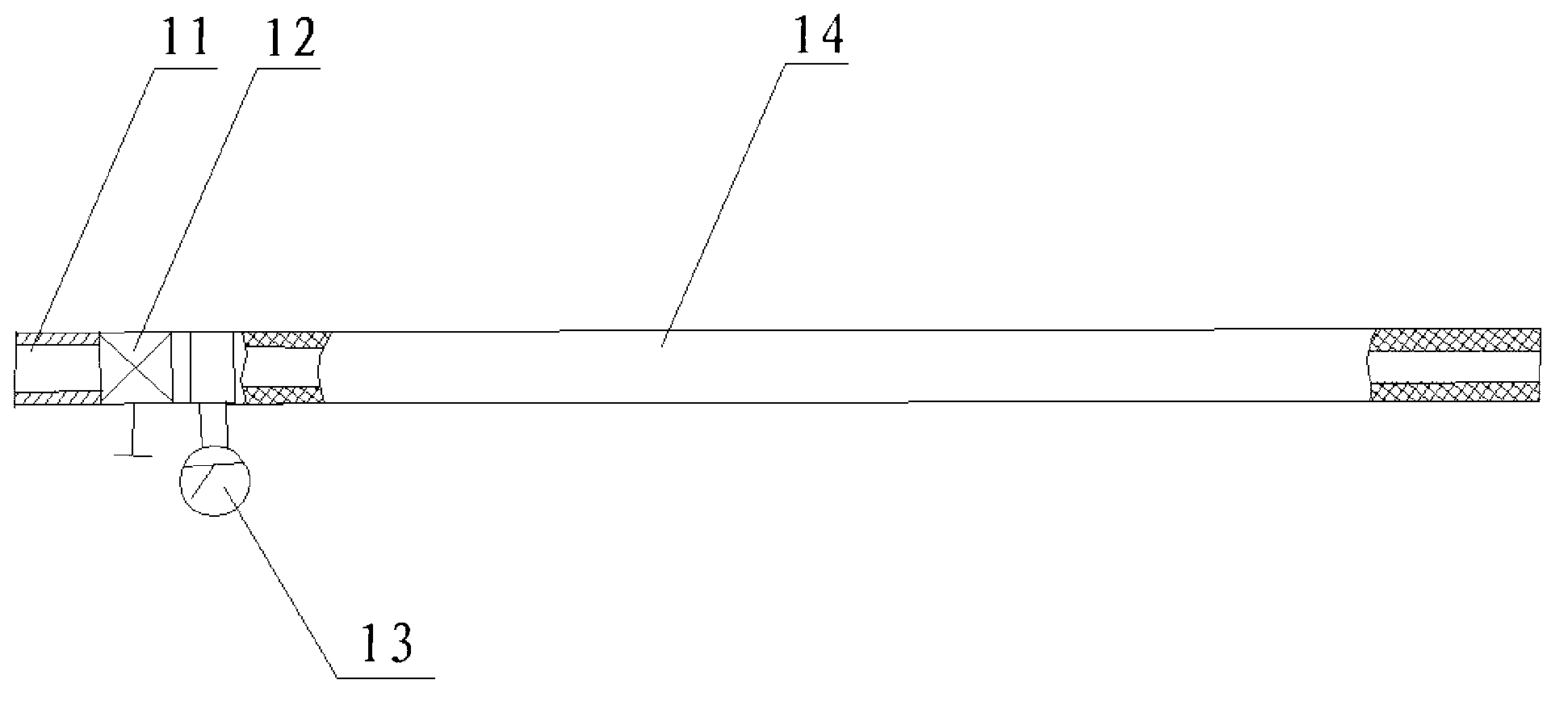

Method used

Image

Examples

Embodiment

[0098] A coal mine started construction on October 16, 2005, and started production and operation in March 2010. The designed production capacity is 2.4 million t / a, and the service life is 52.4 years. It is a mine with complex hydrogeological conditions and is seriously threatened by high temperature, high pressure pore water and rock burst. During roadway excavation or working face mining, water inrush often occurs, causing great pressure on mine drainage.

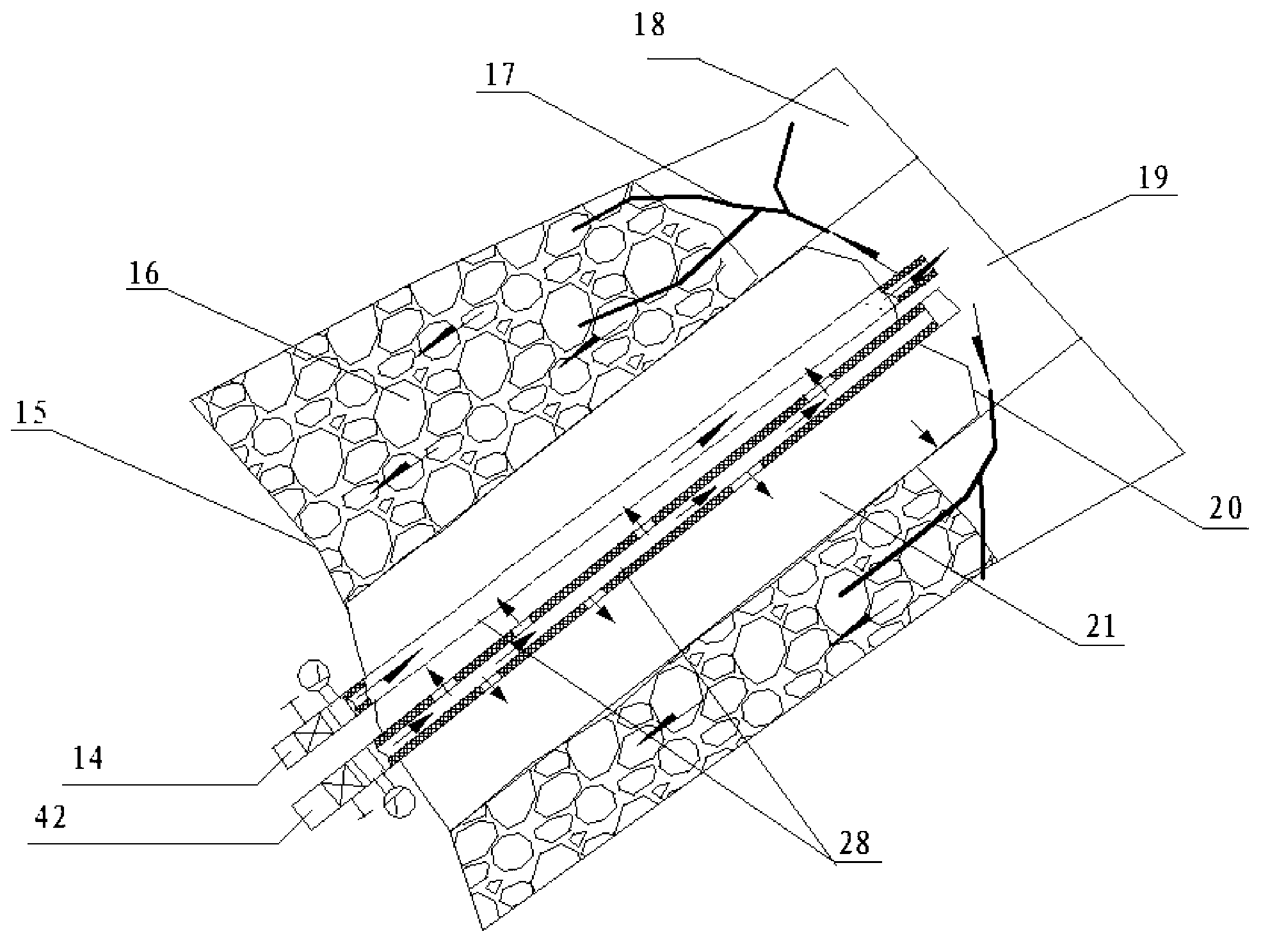

[0099] During the excavation of the roadway up the mountain with the ore belt, a normal fault with a drop of 2.2m was encountered. Since the roof of the roadway is mudstone at the fault, the roof collapsed, and then U-shaped shed was used for multi-layer support, and the roadway was supported by anchor spraying. There is an obvious water gushing point in the footwall of the fault, with a water gushing volume of 30m 3 / h. According to geological radar and borehole detection, the surrounding rock 33 of the roadway was br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com