Novel laser gyro cathode for growing graphene based on surface CVD method

A laser gyroscope, graphene technology, applied in the direction of graphene, Sagnac effect gyroscope, gyroscope/steering sensing device, etc. Accuracy requirements, sealing stability and poor air tightness, etc., to achieve the effect of reducing cathode sputtering, reducing the effect of gas scavenging, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

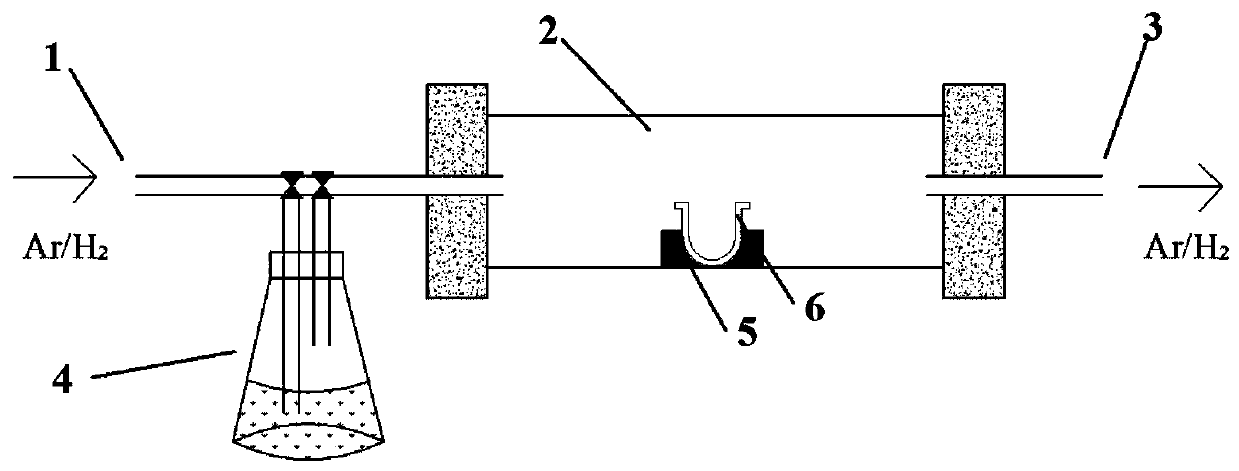

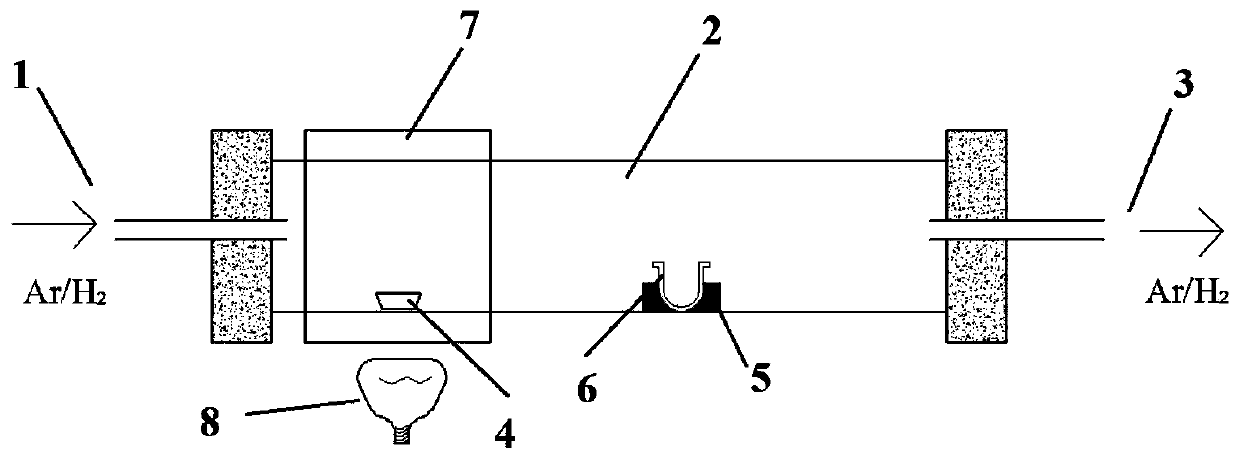

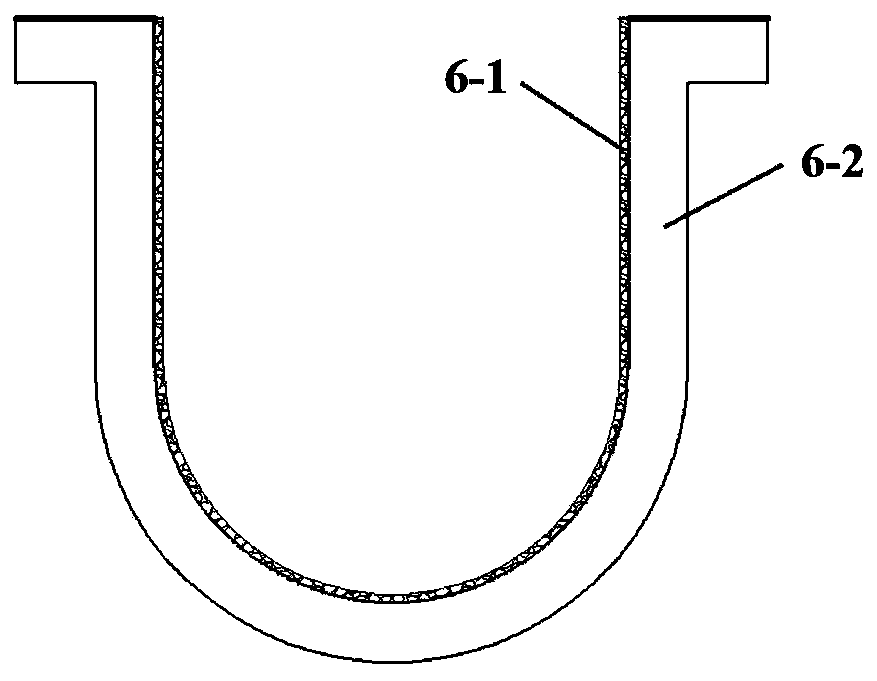

[0057] Embodiment one: a novel glass-ceramics laser gyro cathode based on surface CVD method growth graphene, comprising

[0058] 1. Glass-ceramic cathode surface polishing

[0059] Select SiO with nanoscale particle size 2 The sol is a polishing liquid, and it is polished for 5 hours in a polishing disc with a rotating speed of 20-30r / min, so that the surface roughness of the glass-ceramic is R a up to 0.3nm.

[0060] 2. Cleaning of glass-ceramics

[0061] RCA (Radio Corporation of America) wet chemical cleaning process is adopted.

[0062] (1) Submerge the glass-ceramic in acetone and heat it to 50°C for ultrasonic cleaning for 20-30 minutes;

[0063] (2) Rinse off the residual acetone on the glass-ceramic with alcohol, and then sonicate in alcohol for 10 minutes;

[0064] (3) Take out the glass substrate, rinse the substrate with deionized water, and then wash it in the mixed solution (concentrated H 2 SO 4 / H 2 o 2 =7 / 3) soaked in more than 4h;

[0065] (4) Take ...

Embodiment 2

[0073] Embodiment 2: A new type of low-expansion alloy laser gyro cathode based on surface low-temperature CVD growth of graphene, the substrate is Fe-36Ni low-expansion alloy.

[0074] 1. Metal substrate electrochemical polishing

[0075] A solution of phosphoric acid (85%) / polyethylene glycol (3 / 1, volume) is used as a polishing liquid, and stirred evenly. Blister copper is selected as the cathode, and the metal substrate to be polished is used as the anode. Polish for 30 minutes under constant voltage (1.5-1.8V) mode.

[0076] 2. Metal substrate cleaning

[0077] (1) Submerge the metal substrate in acetone and heat it to 50°C, and ultrasonically clean it for 20-30 minutes;

[0078] (2) Rinse the residual acetone on the substrate with alcohol, and then ultrasonically clean it in alcohol for 10 minutes;

[0079] (3) Take out the substrate, rinse the substrate with deionized water, and then dry it with high-purity nitrogen for later use.

[0080] 3. Graphene growth on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com