Patents

Literature

255results about How to "Improve surface uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface processing apparatus

InactiveUS20080035608A1Uniform deposition and material removal ratePrevent thermal degradationElectric discharge tubesDecorative surface effectsEngineeringSurface processing

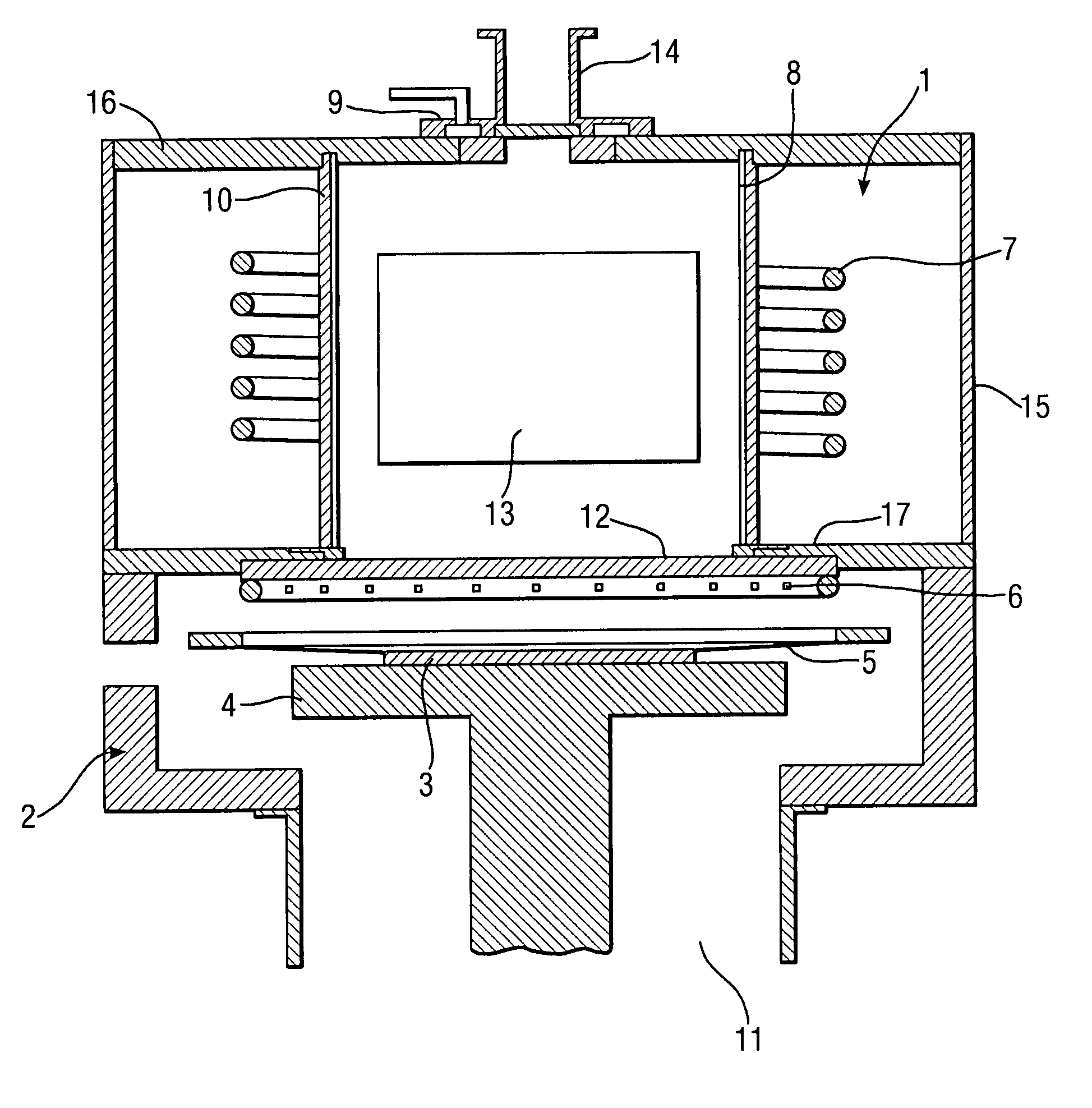

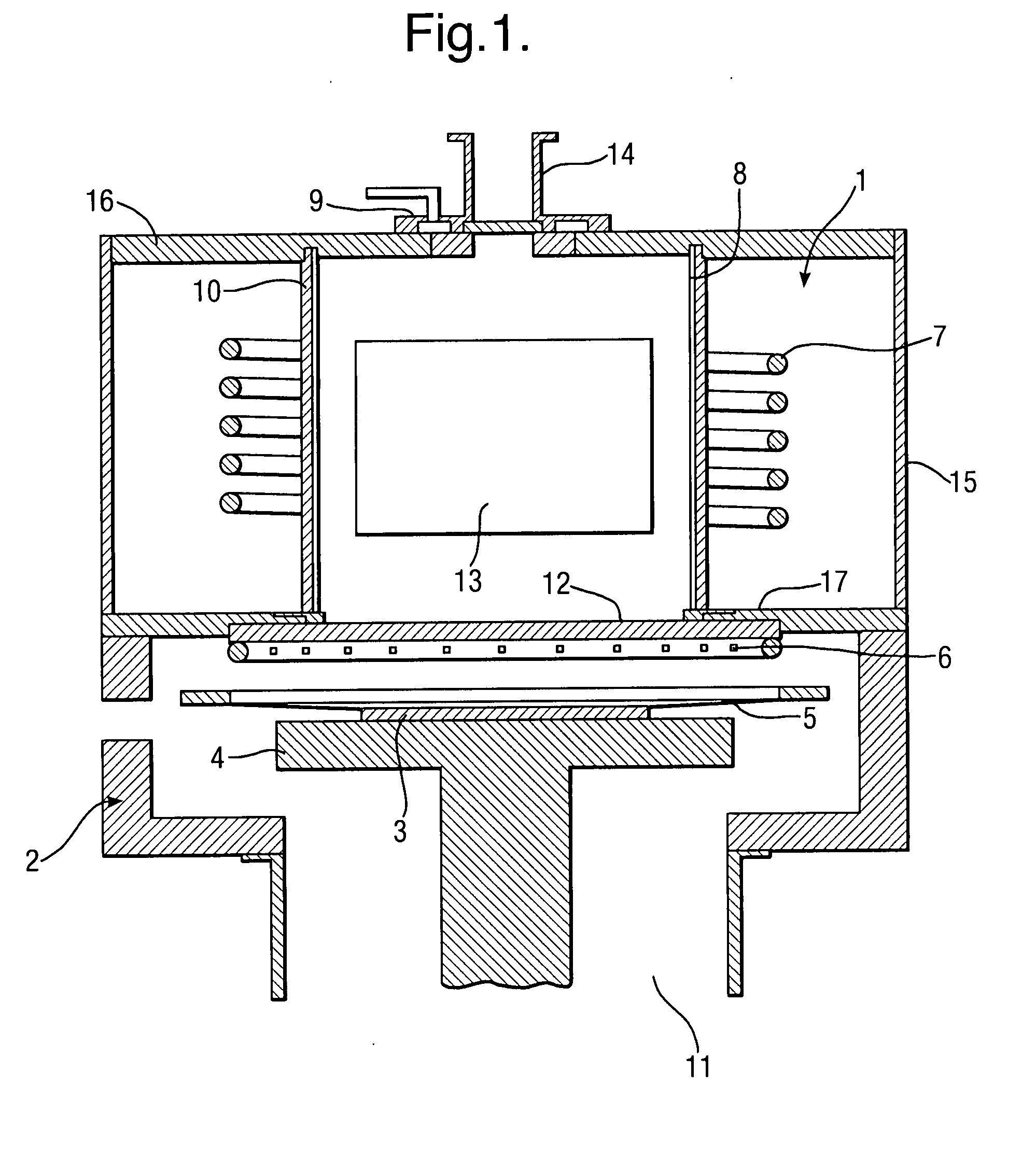

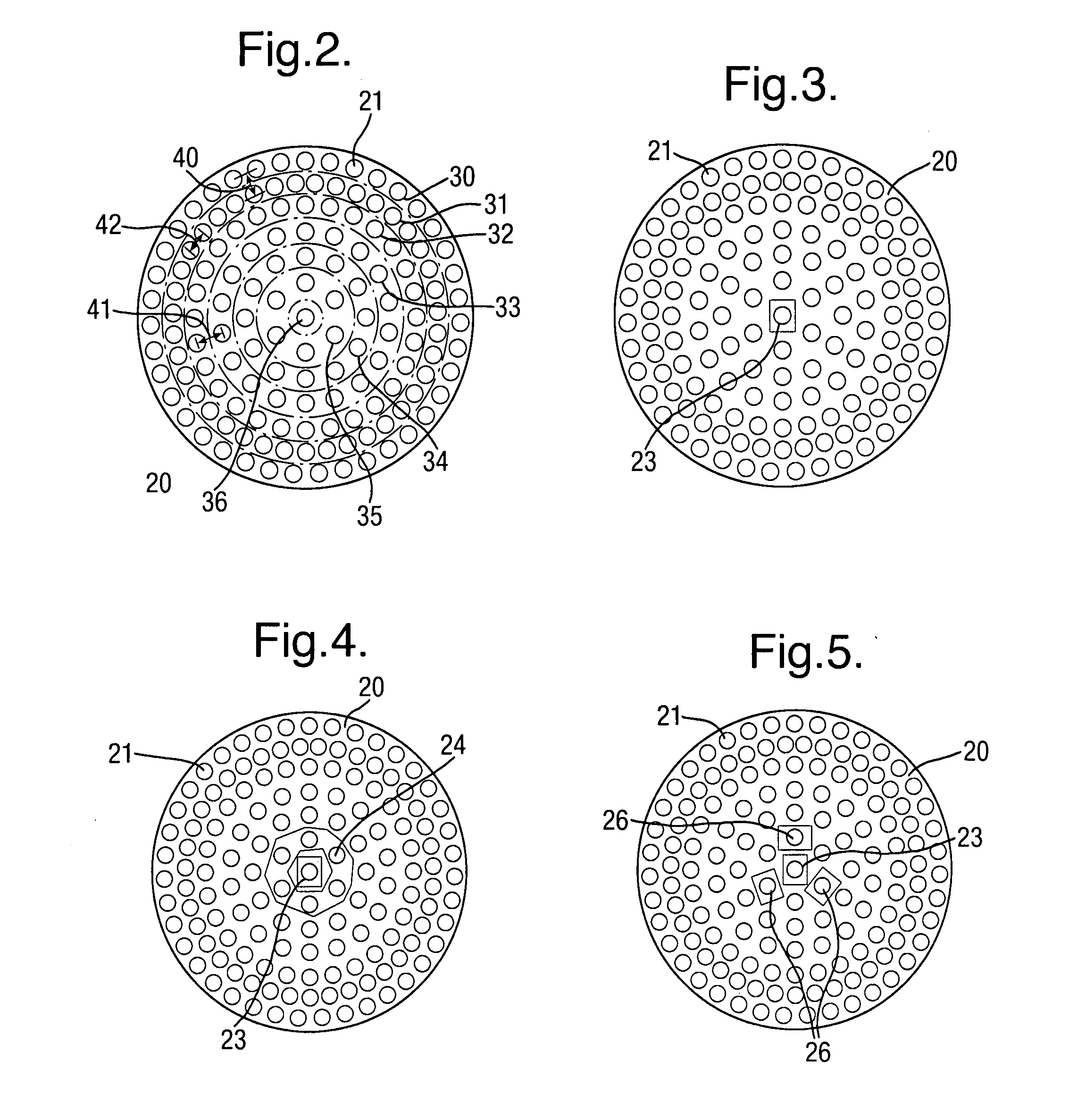

A surface processing apparatus is provided for use in the surface processing of a substrate. The surface processing apparatus comprises a plasma source and processing chamber in which a substrate is mounted in use. The processing chamber is operatively connected to the plasma source and the surface processing apparatus is characterised by a transmission plate for the transmission of plasma in use between the plasma source and processing chamber. The transmission plate comprises one or more apertures wherein the physical form of the one or more apertures and / or the distribution of the one or more apertures is adapted to provide a predetermined processing pattern upon the surface of the substrate. Typically the design of the apertures is adapted to provide a substantially uniform deposition rate across a wafer substrate.

Owner:OXFORD INSTR NANOTECH TOOLS

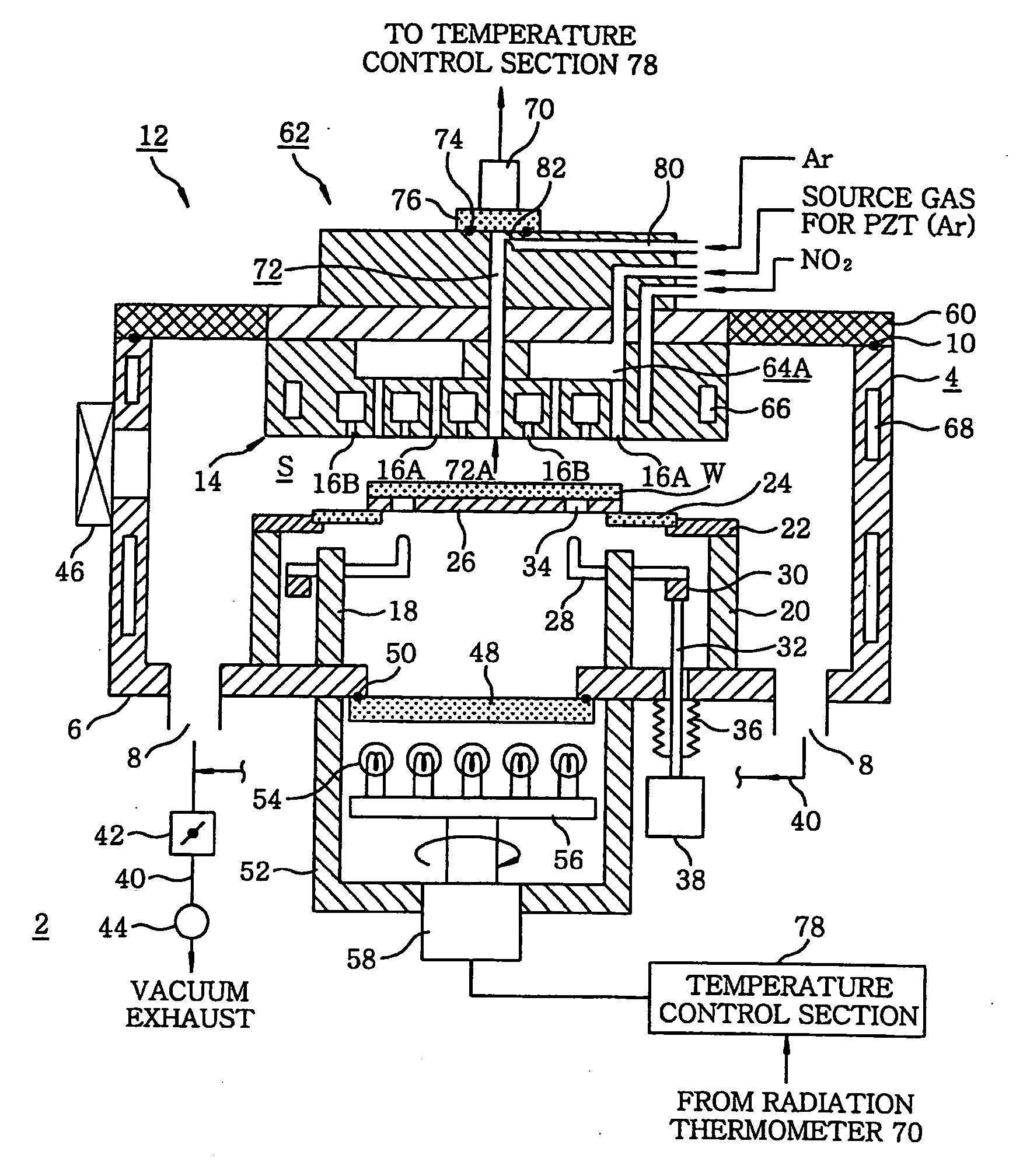

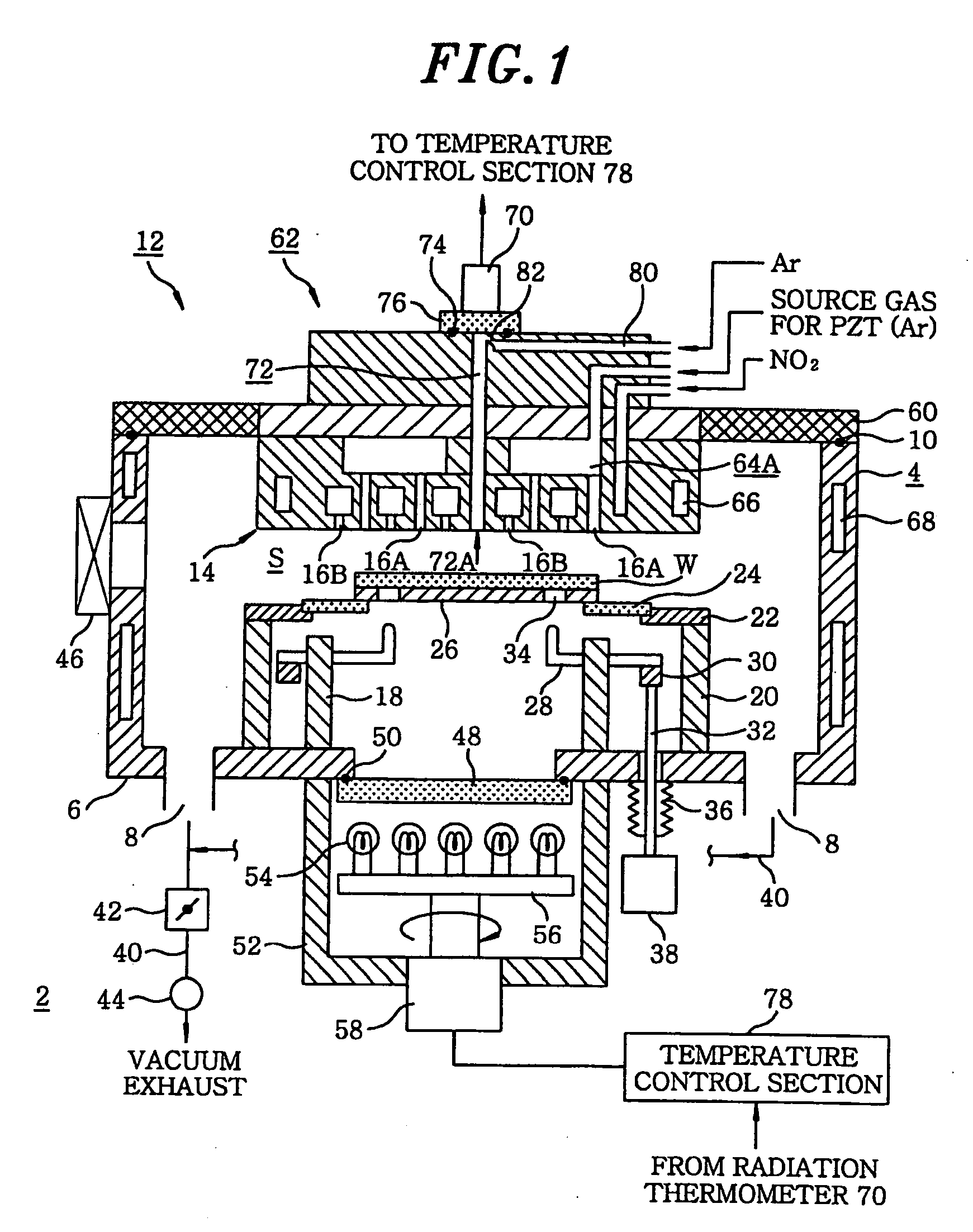

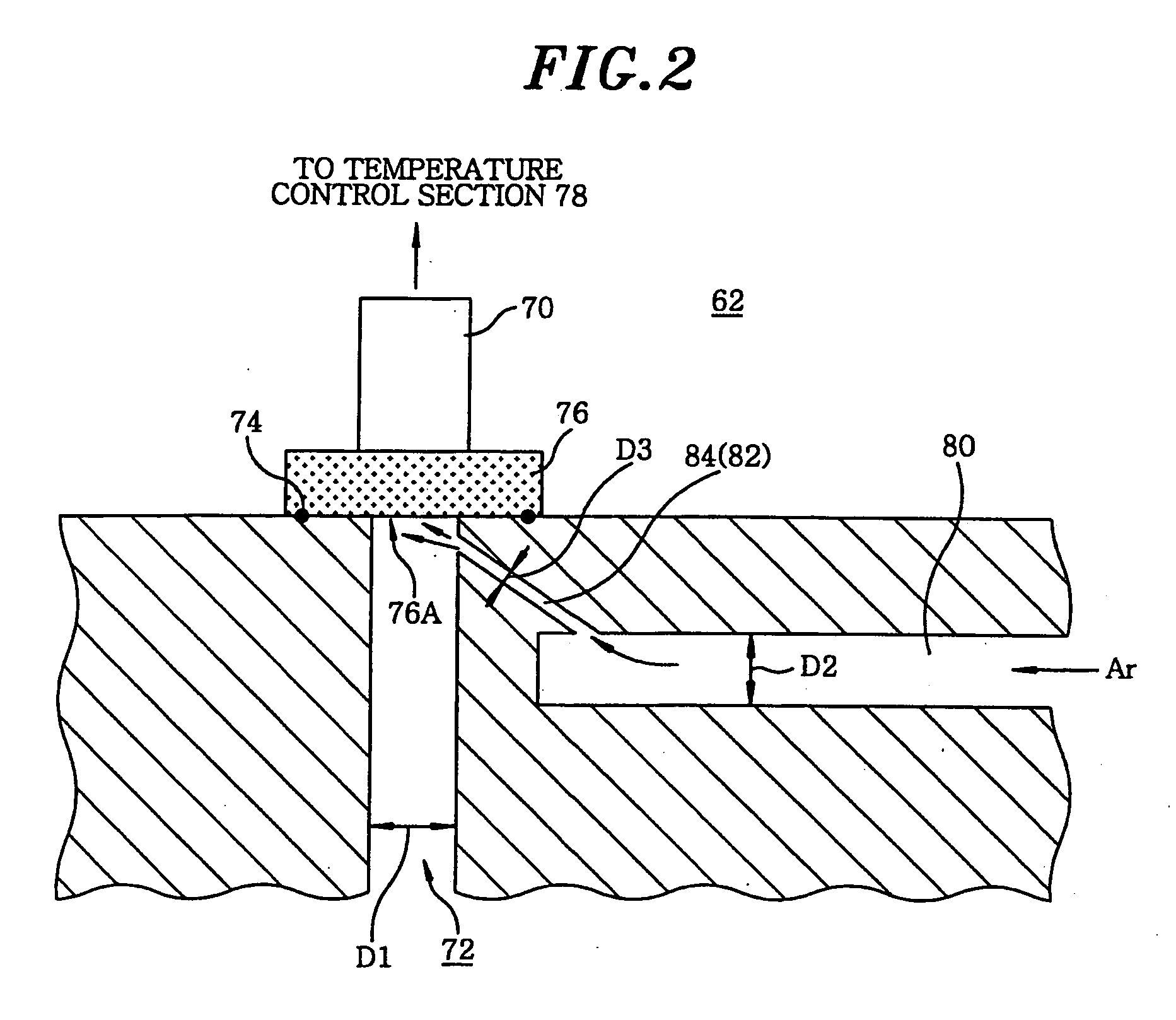

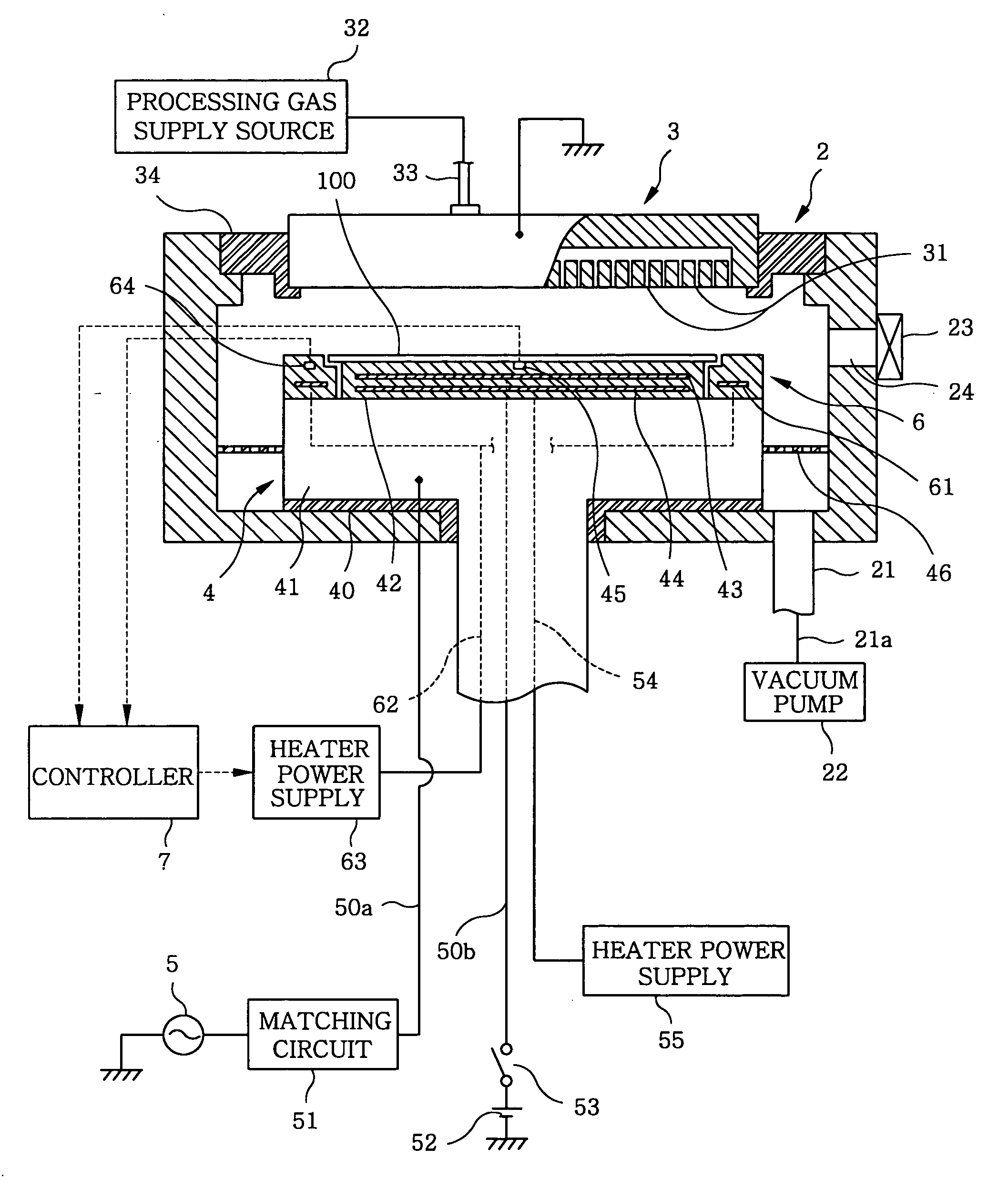

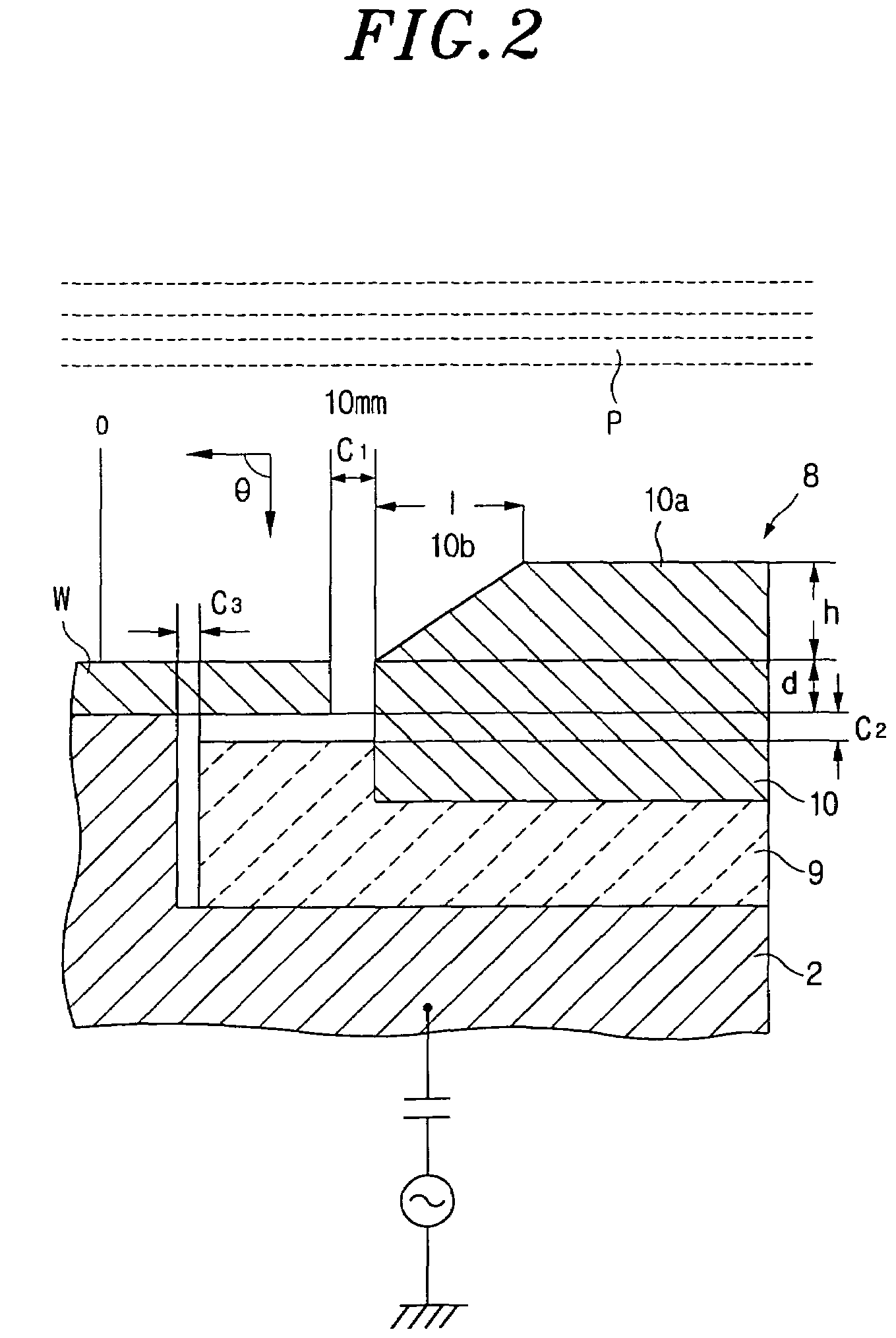

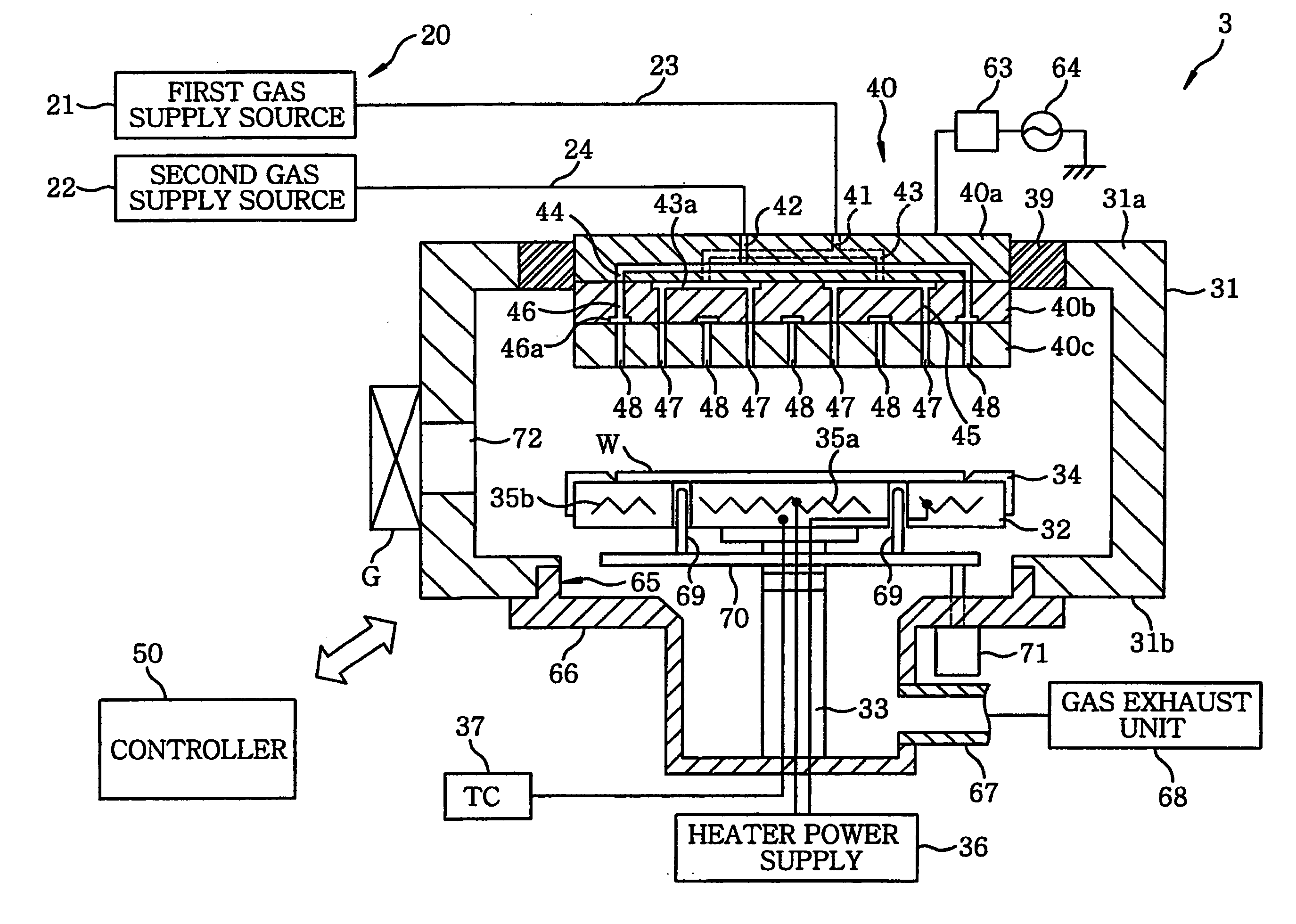

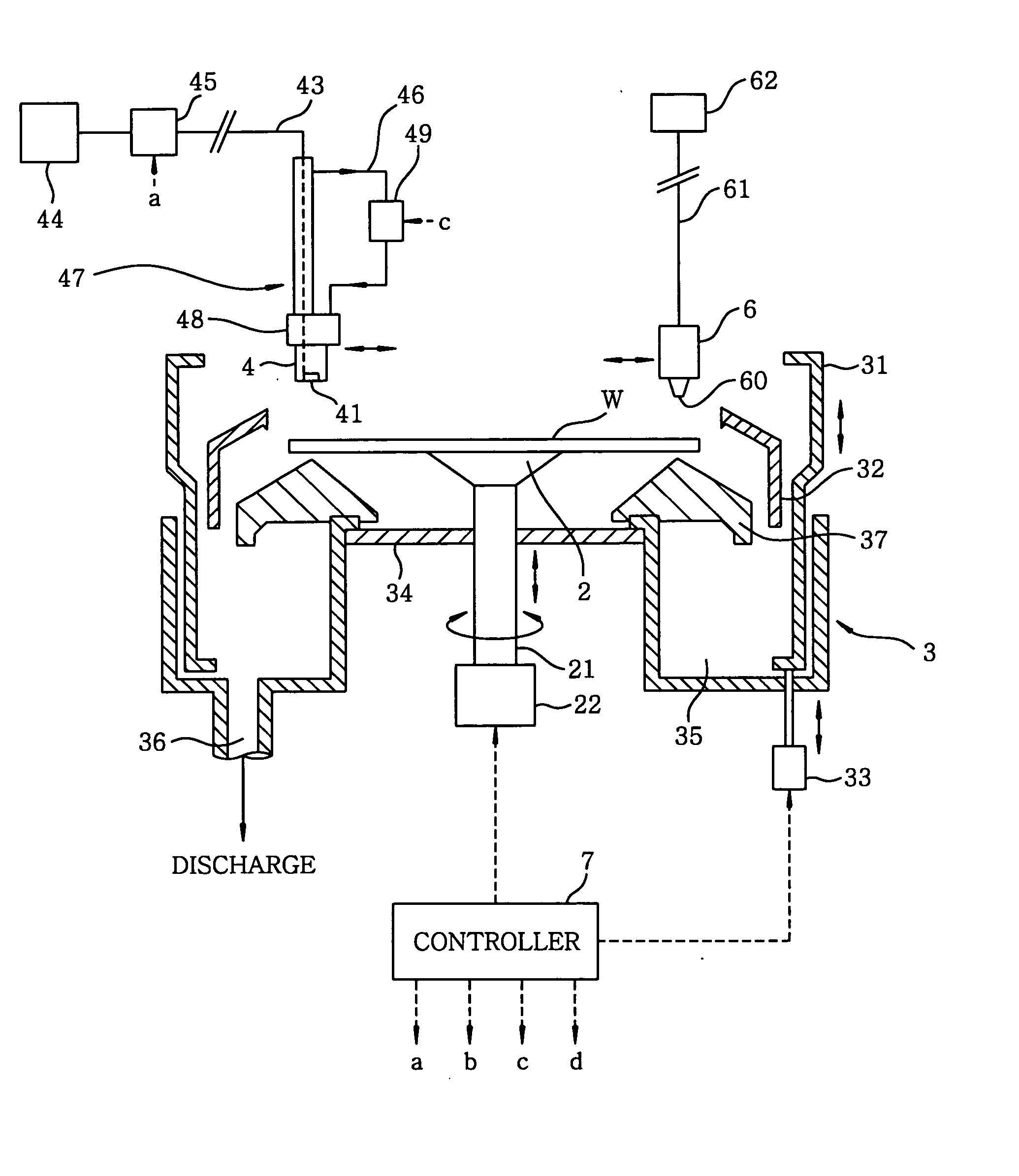

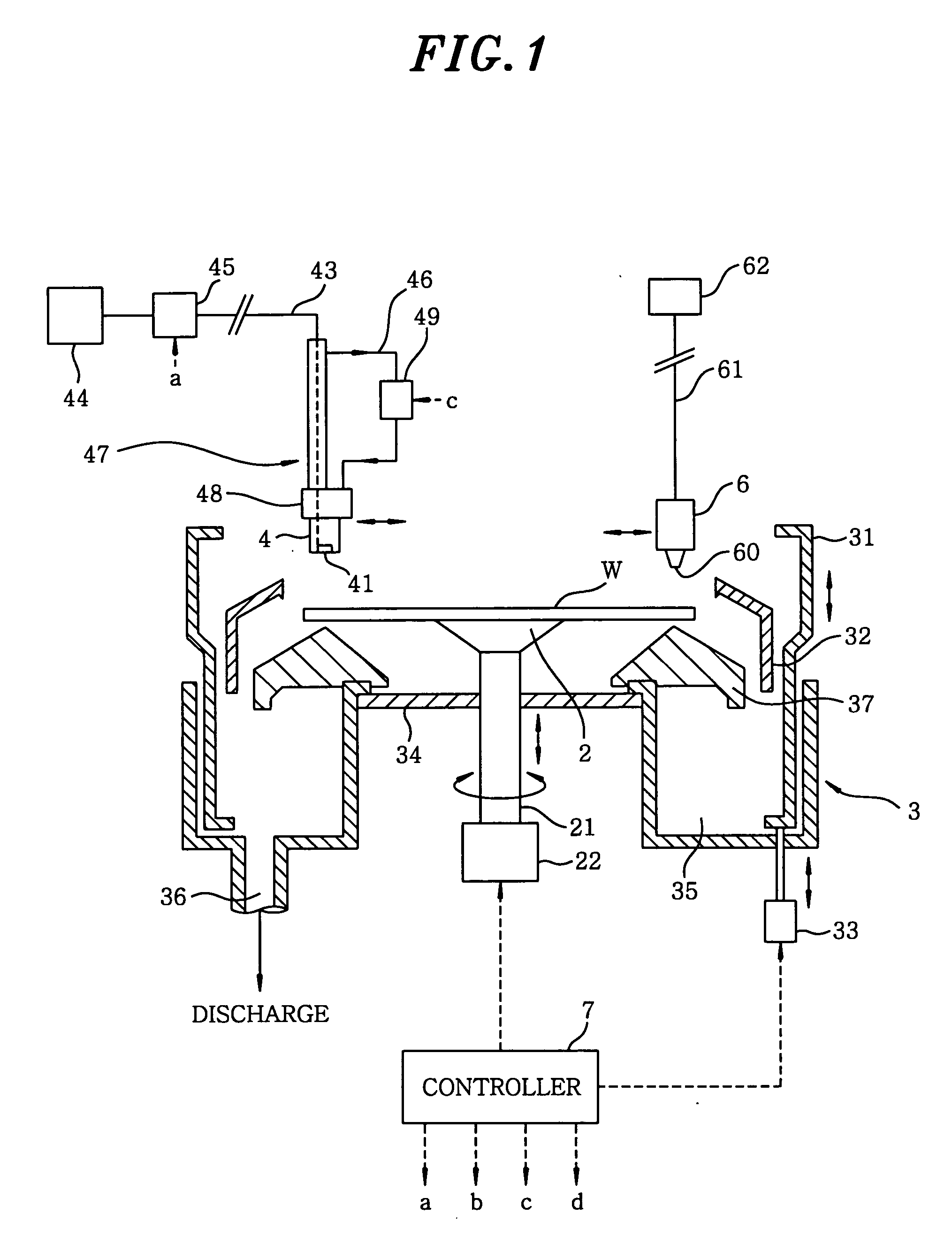

Shower head structure and treating device

InactiveUS20060021568A1Avoid depositionSuppression problemLiquid surface applicatorsSemiconductor/solid-state device manufacturingRadiation thermometerEngineering

A shower head structure characterized by comprising a shower head section, opposed to the upper surface of a mounting table in an evacuable treating vessel, for injecting a processing gas into the treating vessel; a temperature observation through-hole which opens in the lower surface of the shower head so as to be opposed to the upper surface of the mounting table, a transparent observation window which hermetically seals the upper end of the temperature observation through-hole, a radiation thermometer disposed on the upper surface of the transparent observation window, an adhesion preventive gas supply path communicating with the temperature observation through-hole to prevent a film from adhering to the transparent observation window, wherein the adhesion preventive gas supply path communicates with the temperature observation through-hole through an injection nozzle for injecting the adhesion preventive gas to the transparent observation window.

Owner:TOKYO ELECTRON LTD

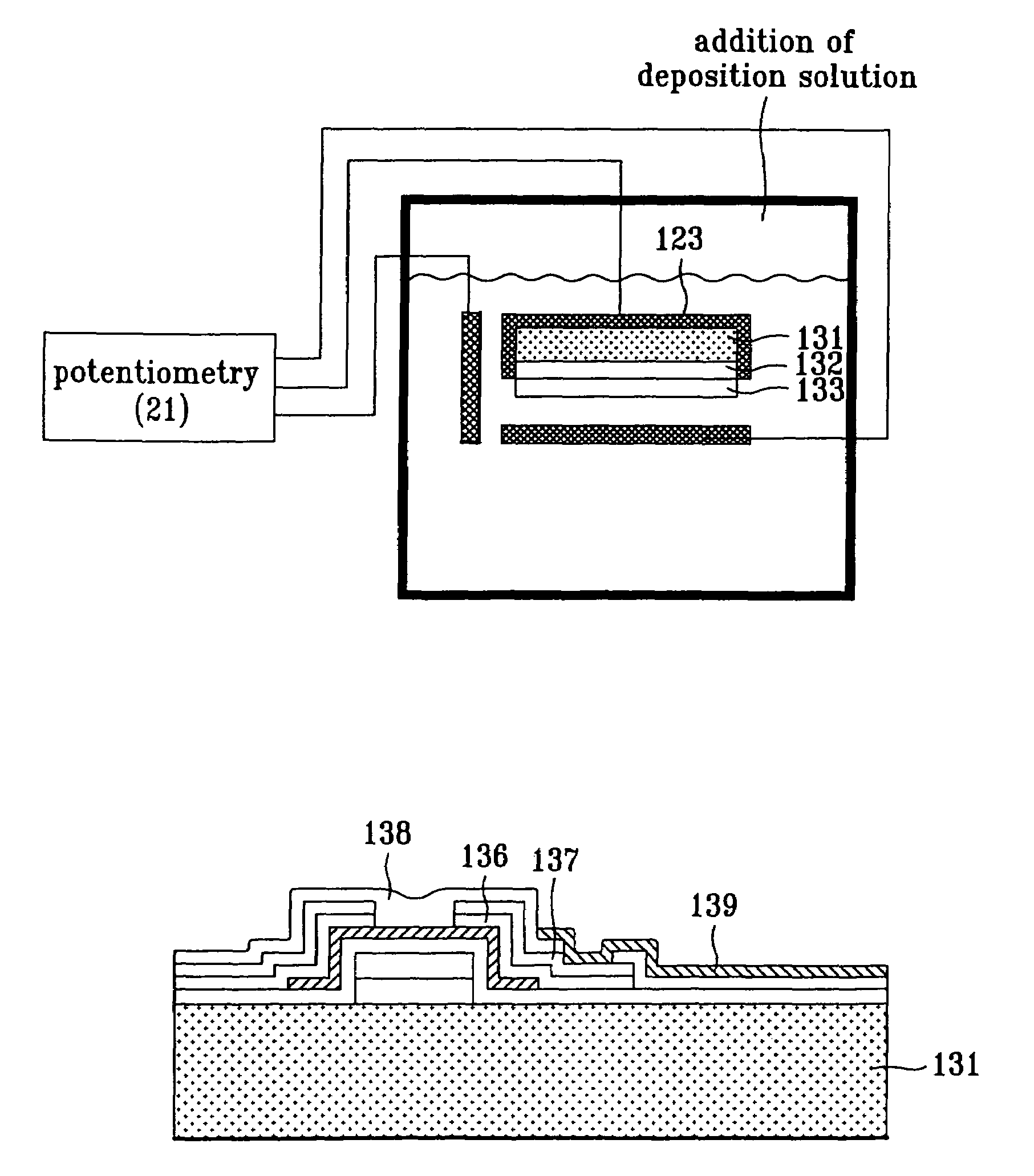

Method for forming thin film and method for fabricating liquid crystal display using the same

InactiveUS7011981B2Simple processImprove surface uniformitySemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDiffusion barrier

A method for forming a thin film and a method for fabricating a liquid crystal display device using the same are provided. The method provides a process that is simplified. Uniform thin film characteristics can be obtained. The method for forming a thin film includes the steps of forming a diffusion barrier film on a substrate, forming a metal seed layer on the diffusion barrier film, removing a metal oxide film formed on a surface of the metal seed layer using an electric plating method, and depositing metal on the metal seed layer in which the metal oxide film is removed.

Owner:LG DISPLAY CO LTD

Ink jet recording element

InactiveUS6110601AIncrease volumeResistance to image bleedingLayered productsDuplicating/marking methodsPolyvinyl alcoholPolyethylene glycol

An ink jet recording element comprising a water-impervious support having thereon the following layers: a) a water-absorbing layer; and b) an image-recording layer comprising a colloidal oxide and a pigment dispersed in a binder, the binder comprising a mixture of poly(ethylene glycol) having a molecular weight of from about 1400 to about 35,000 and poly(vinyl alcohol), the ratio of the poly(ethylene glycol) to the poly(vinyl alcohol) being from about 1:0.8 to about 1:1.5.

Owner:EASTMAN KODAK CO

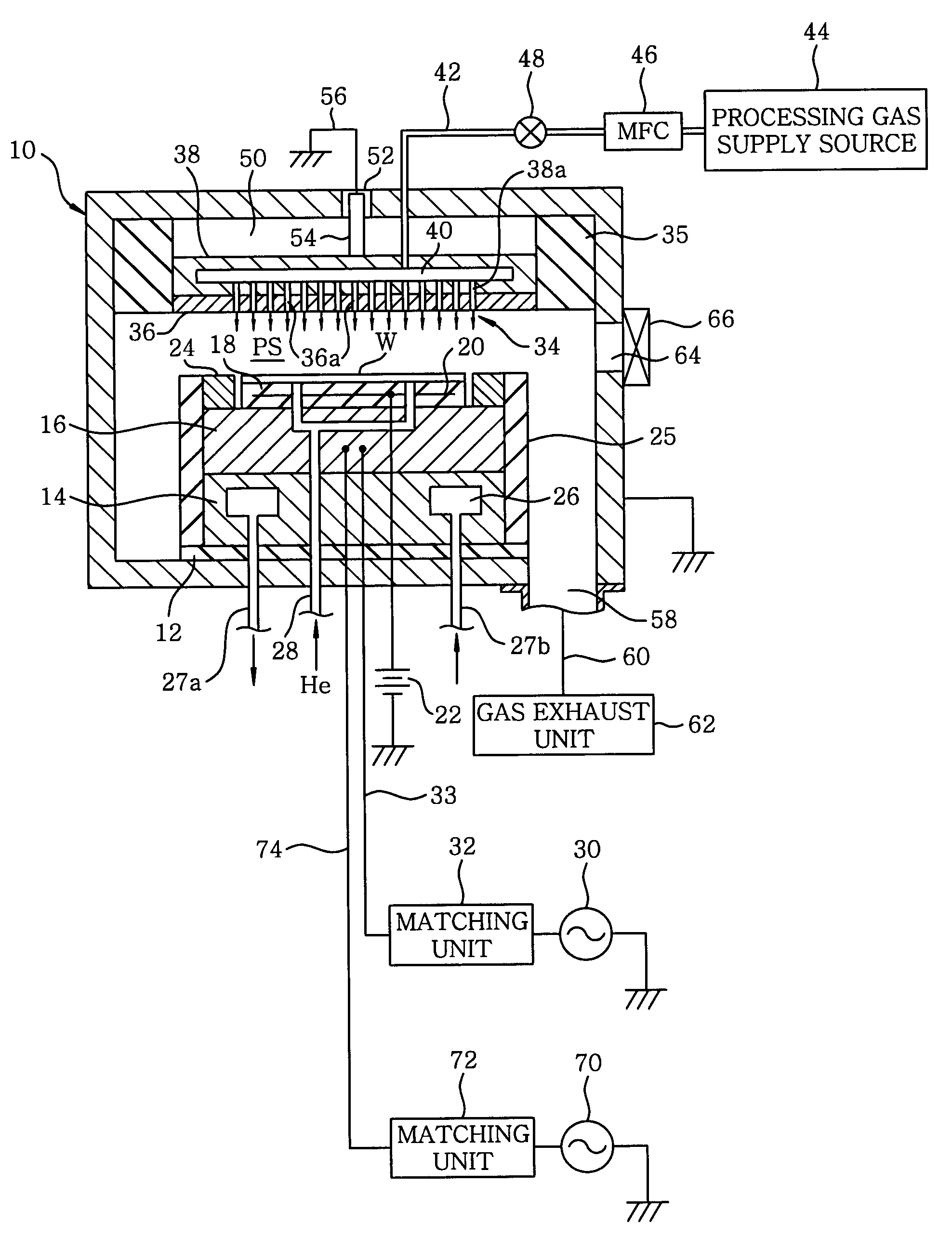

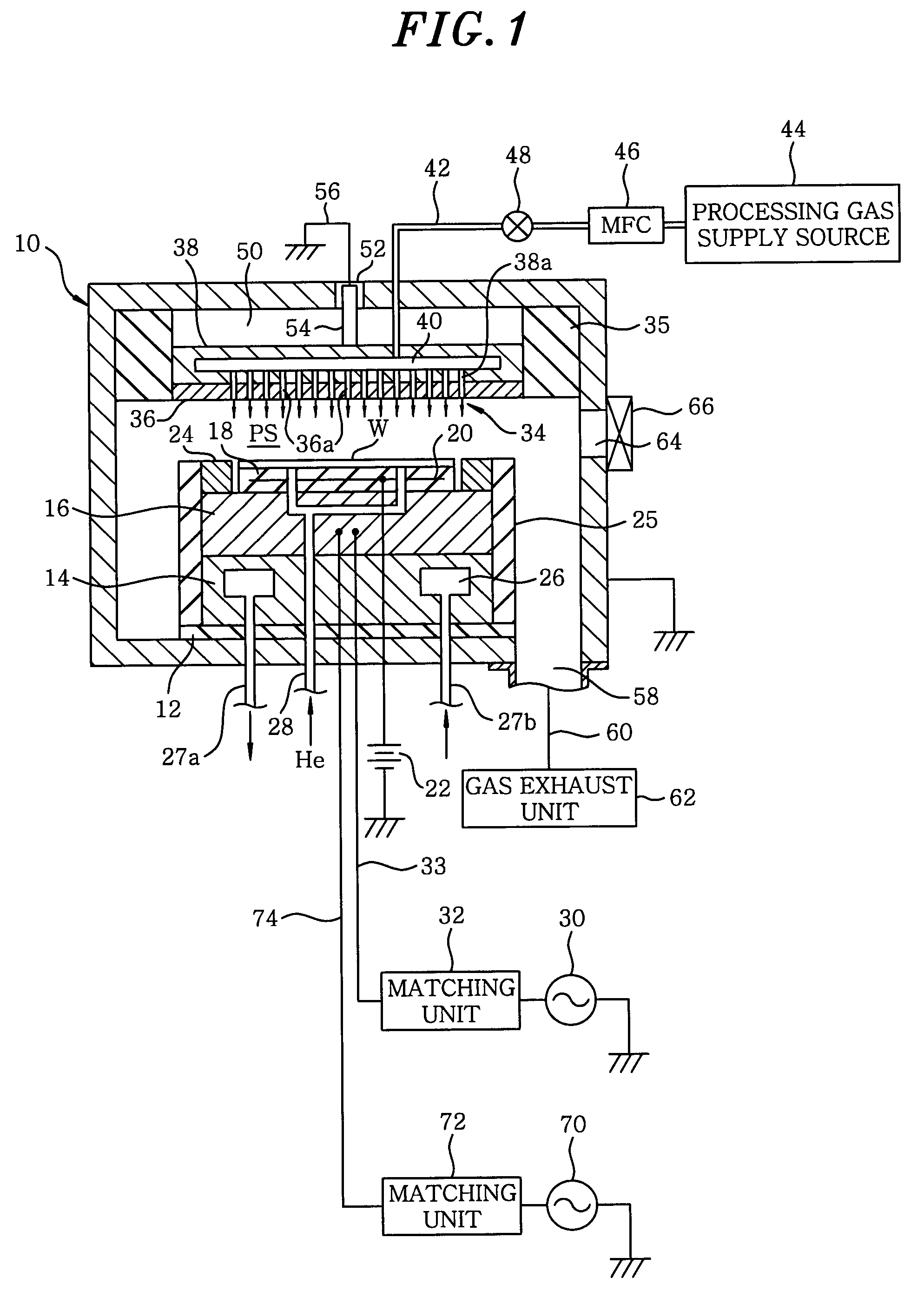

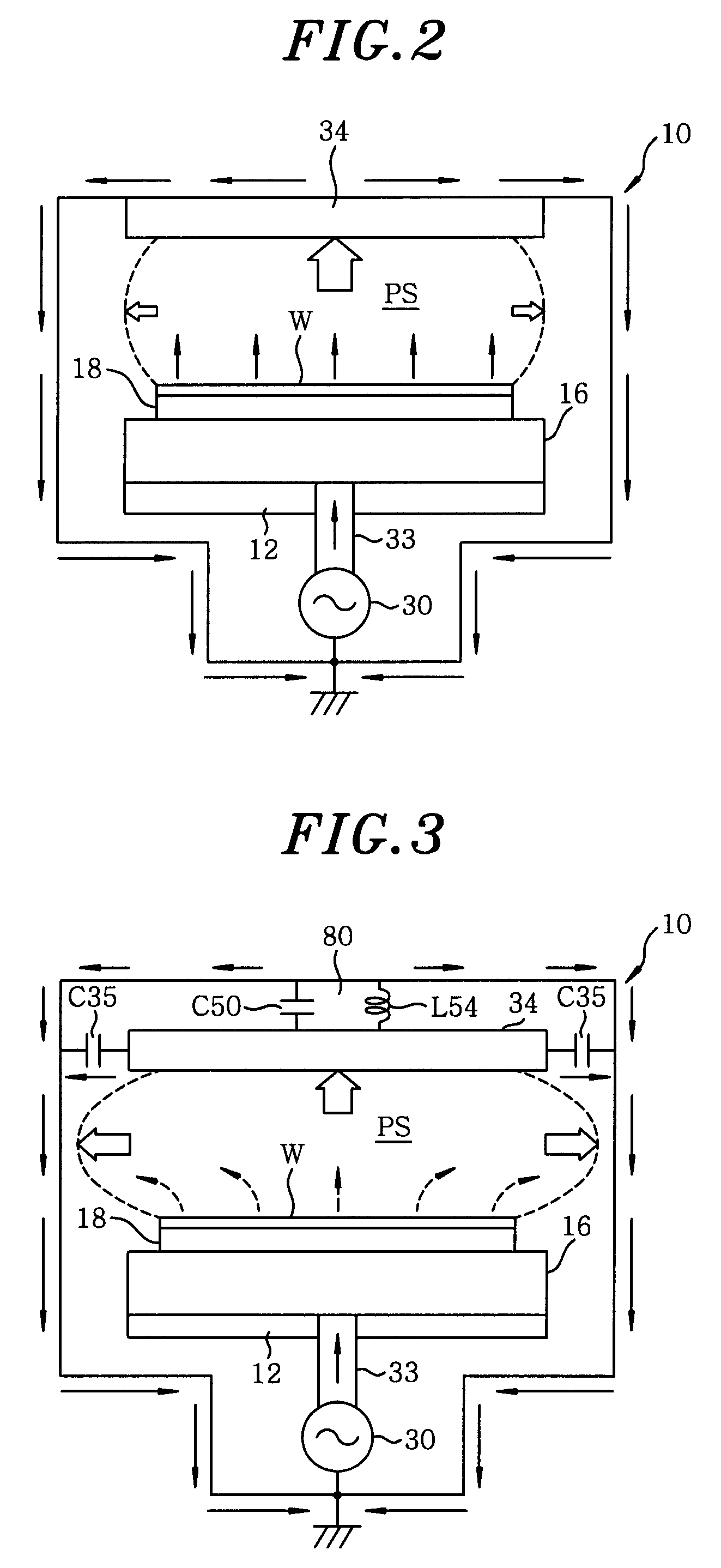

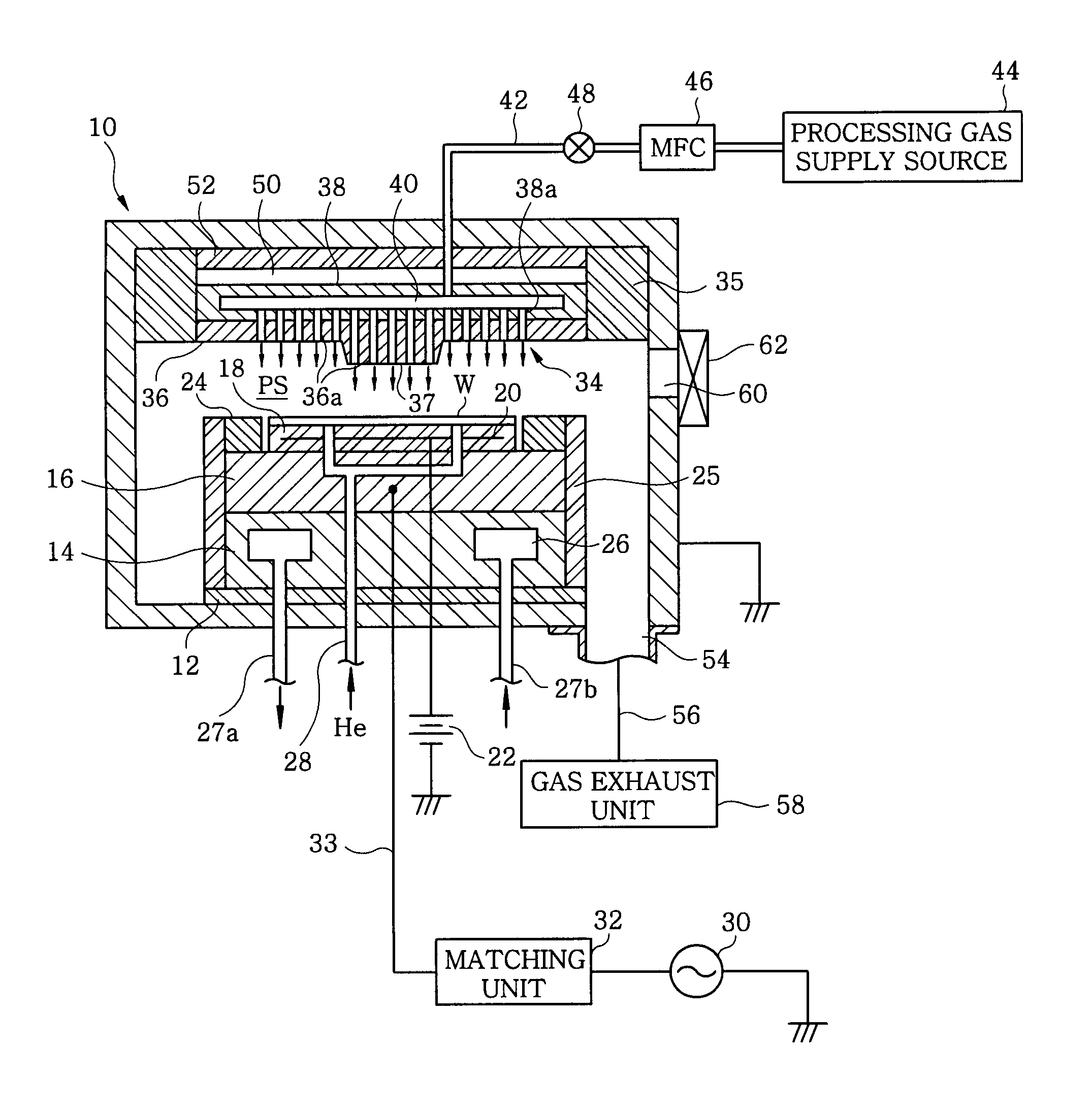

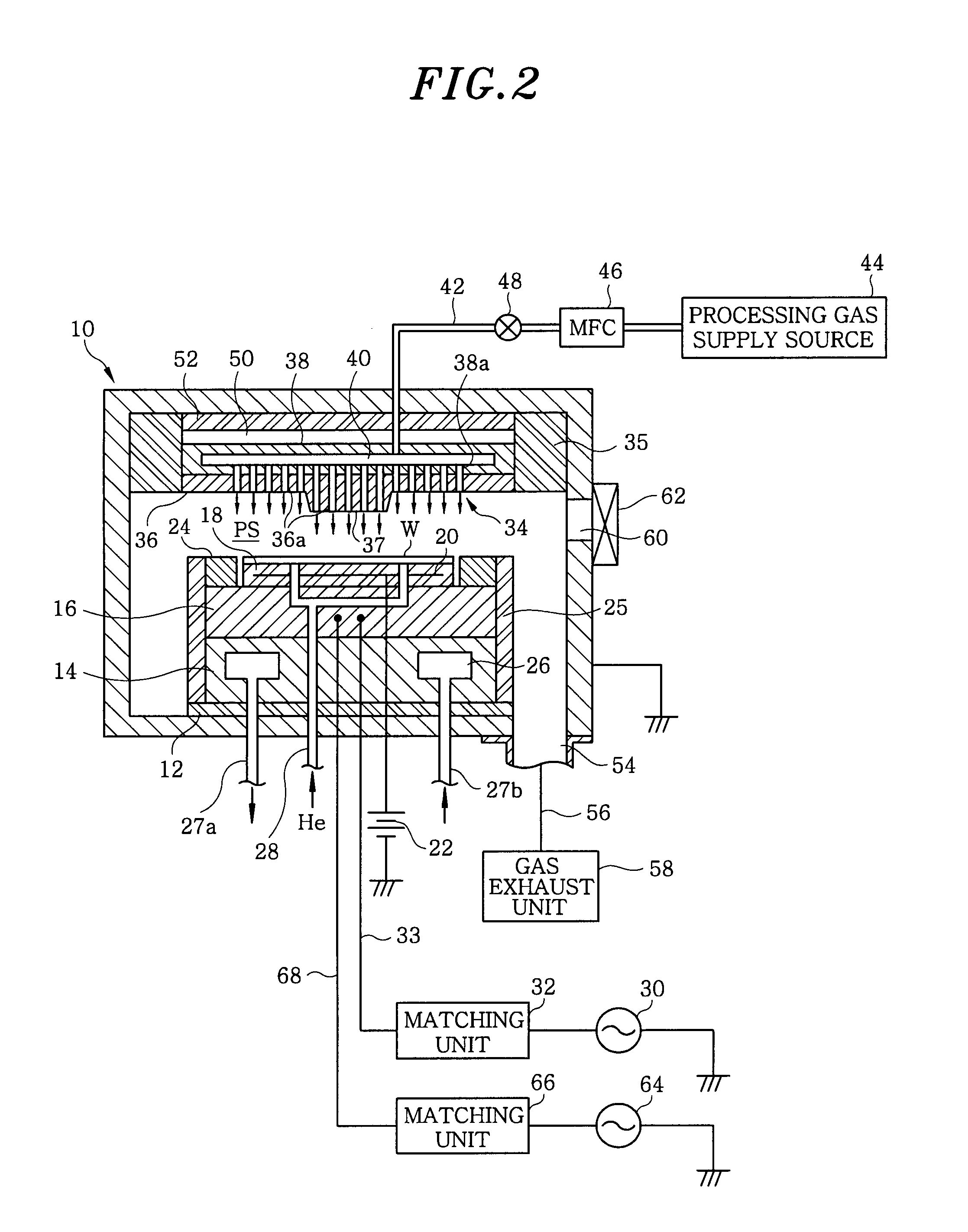

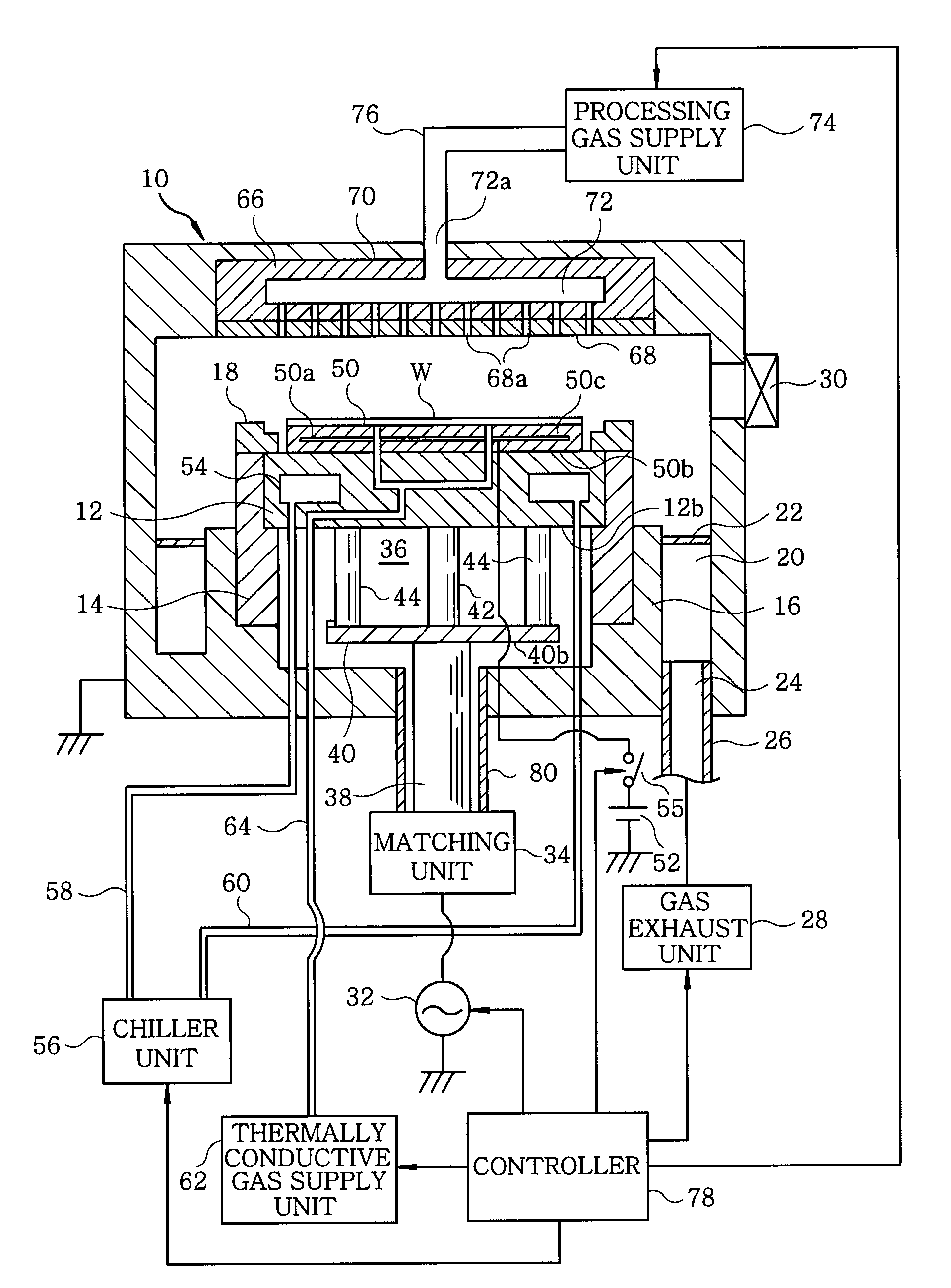

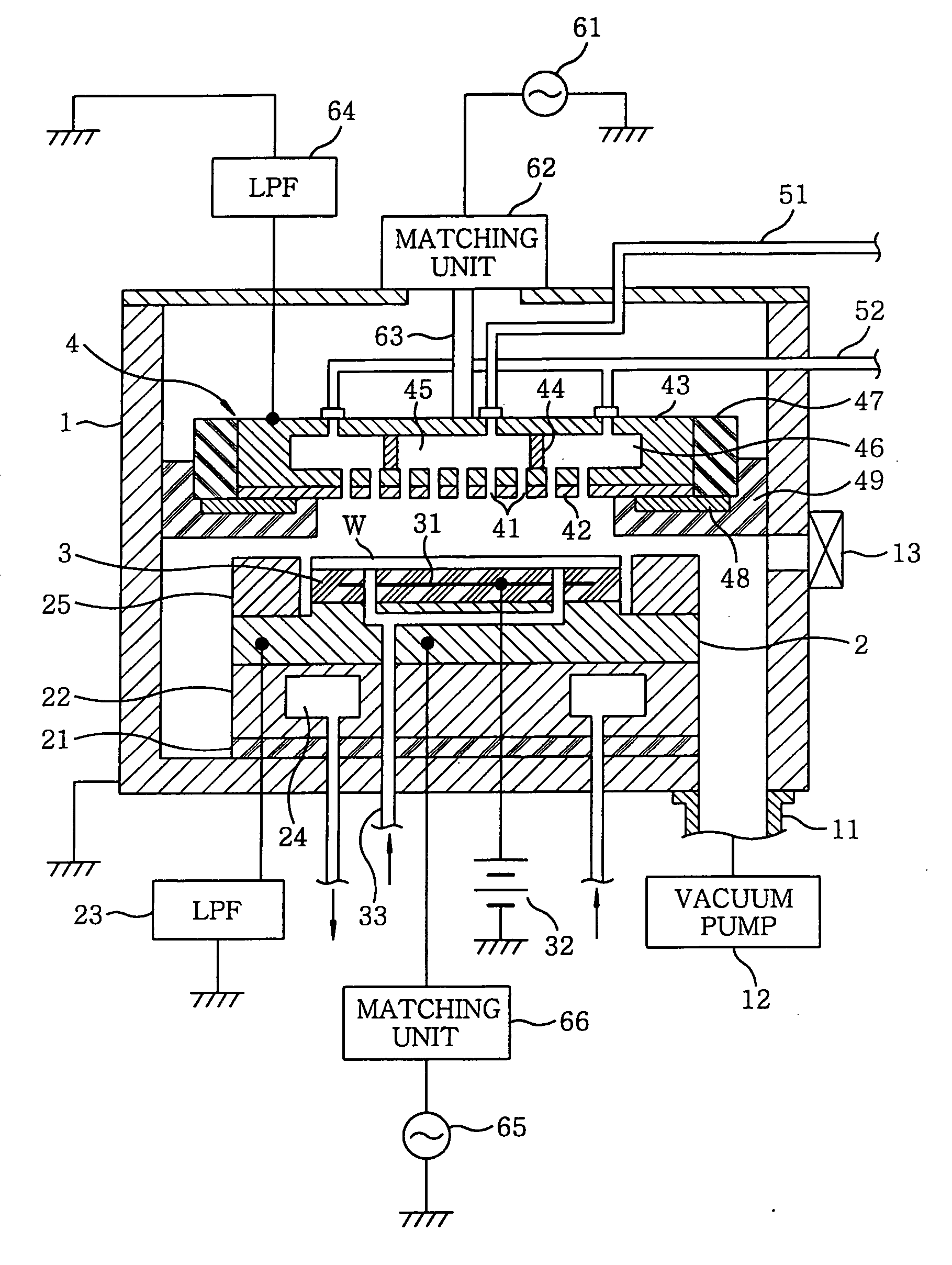

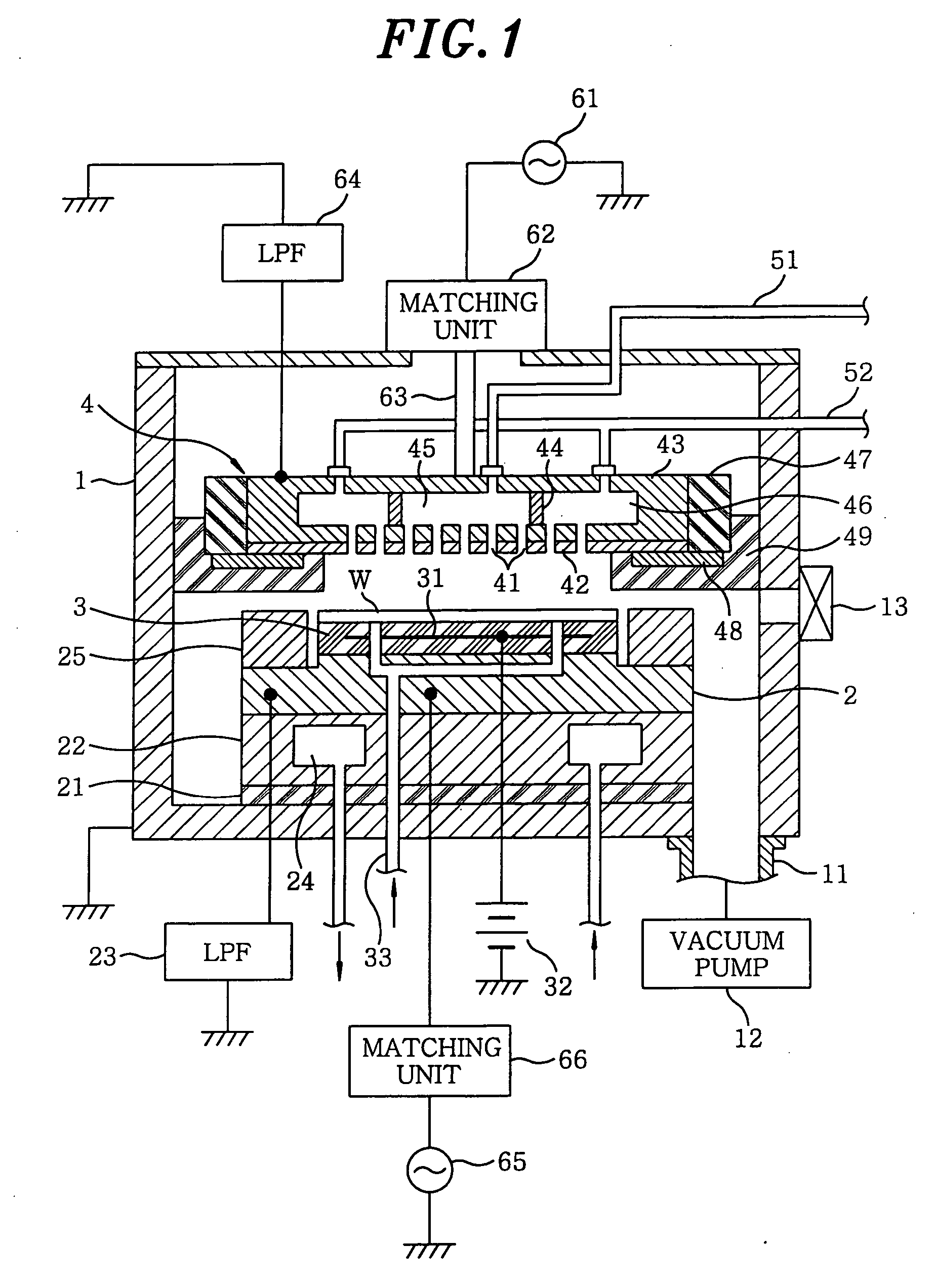

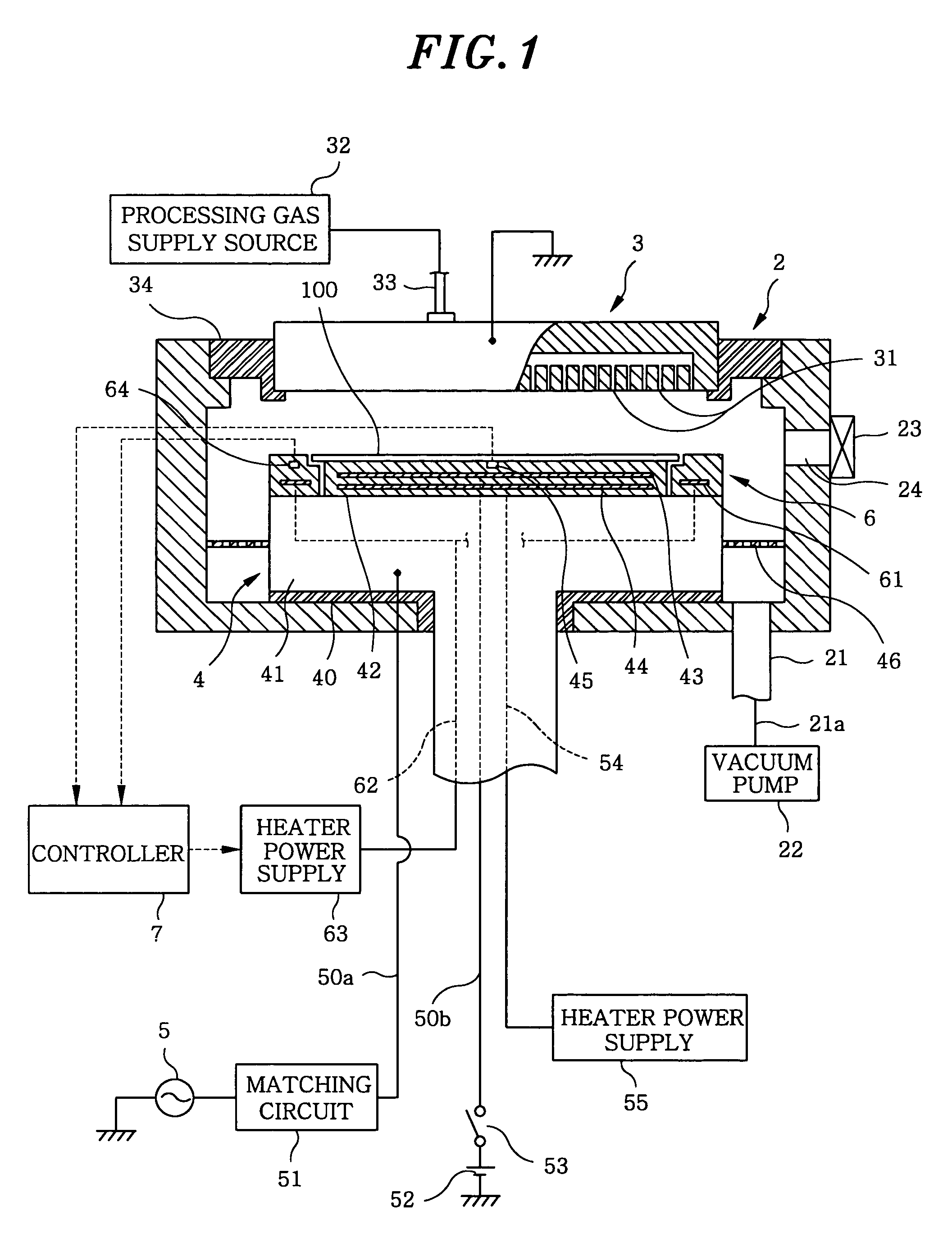

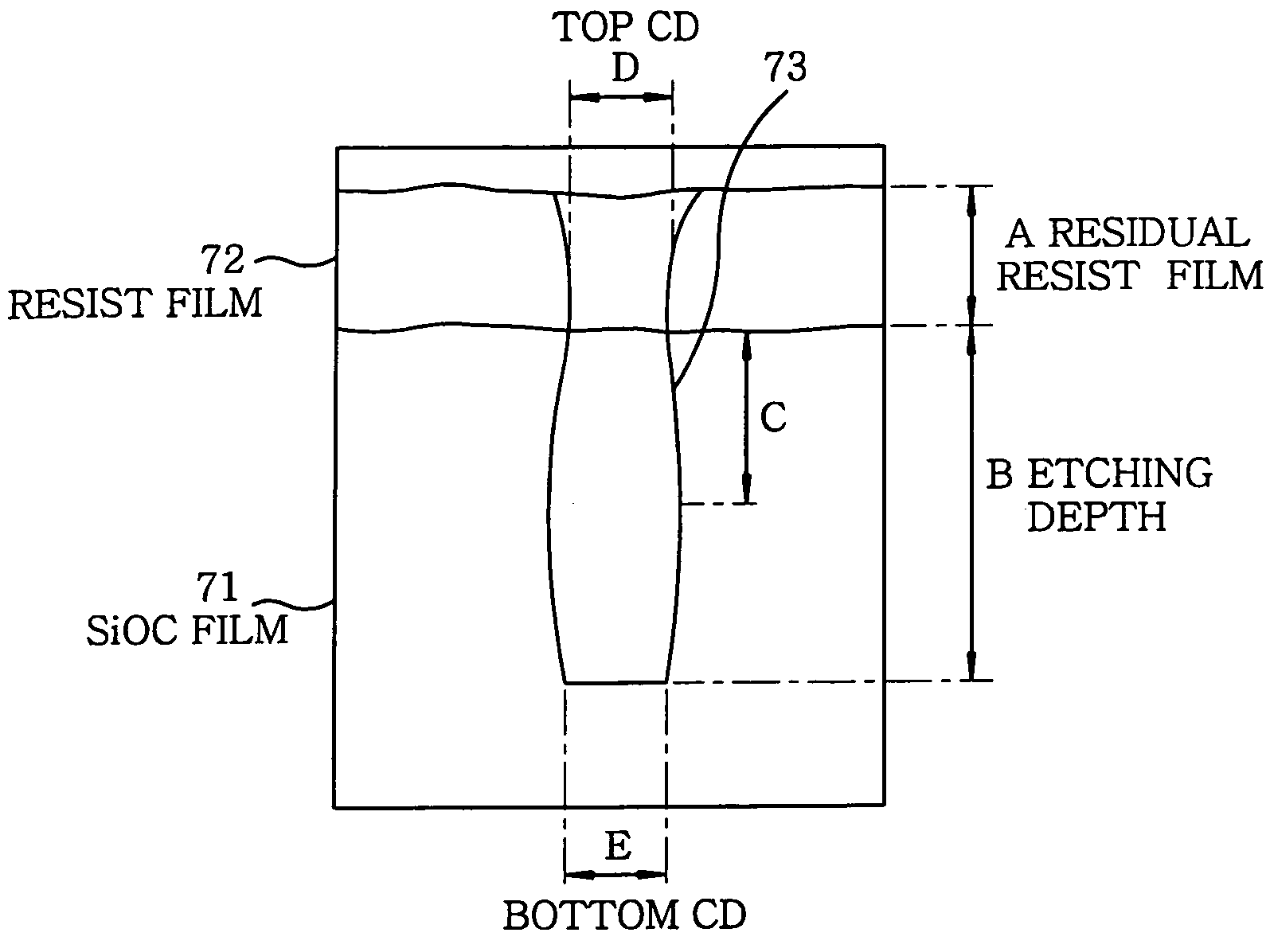

Plasma processing apparatus and plasma processing method

ActiveUS20070235426A1Improve uniformityEffectively sputteredElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityInductor

In a plasma processing apparatus, a first electrode is attached to a grounded evacuable processing chamber via an insulating material or a space and a second electrode disposed in parallel with the first electrode spaced apart therefrom in the processing chamber, the second electrode supporting a target substrate to face the first electrode. A first radio frequency power supply unit applies a first radio frequency power of a first frequency to the second electrode, and a second radio frequency power supply unit applies a second radio frequency power of a second frequency lower than the first frequency to the second electrode. Further, a processing gas supply unit supplies a processing gas to a processing space formed by the first and the second electrode and a sidewall of the processing chamber. Moreover, an inductor electrically is connected between the first electrode and a ground potential.

Owner:TOKYO ELECTRON LTD

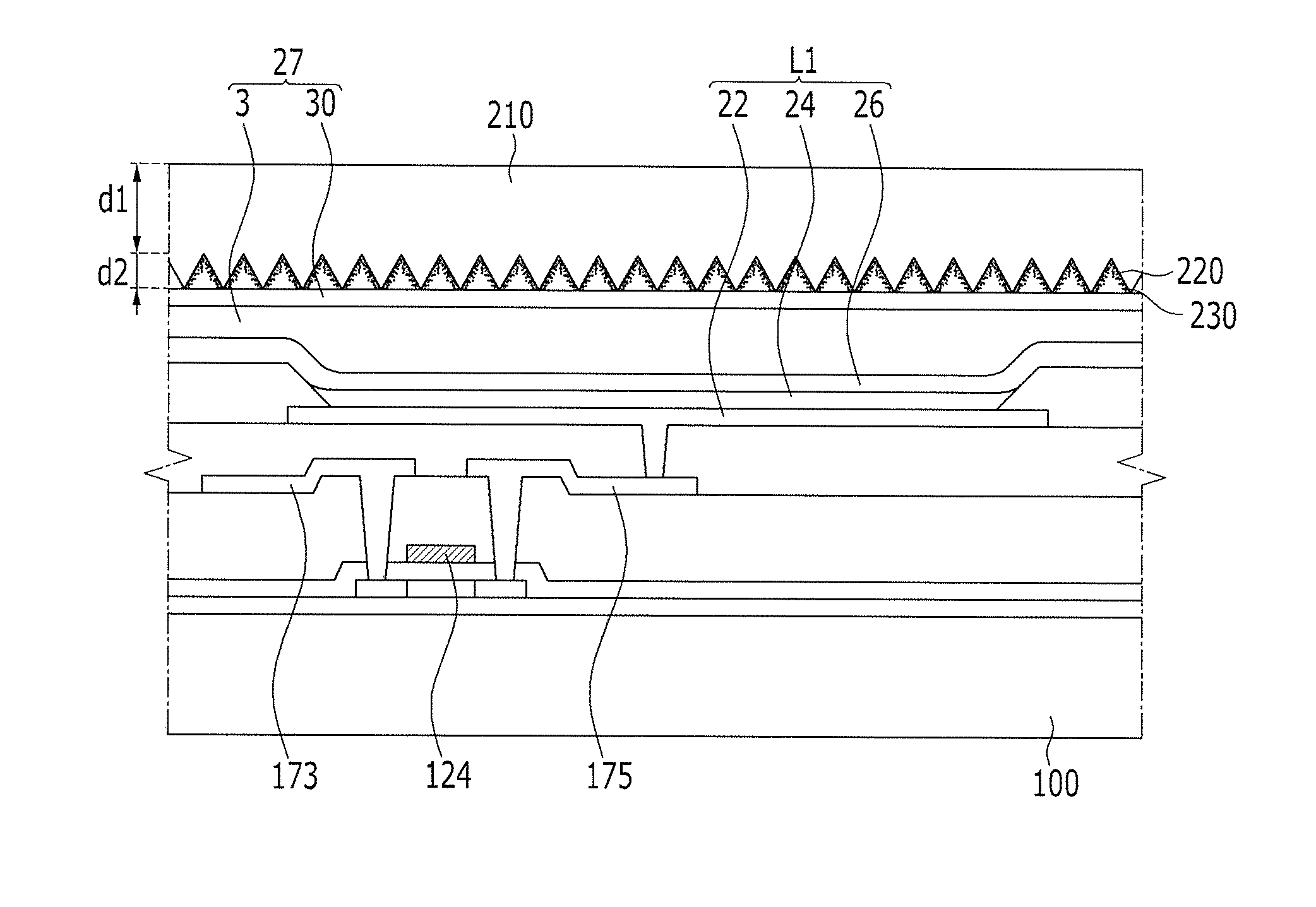

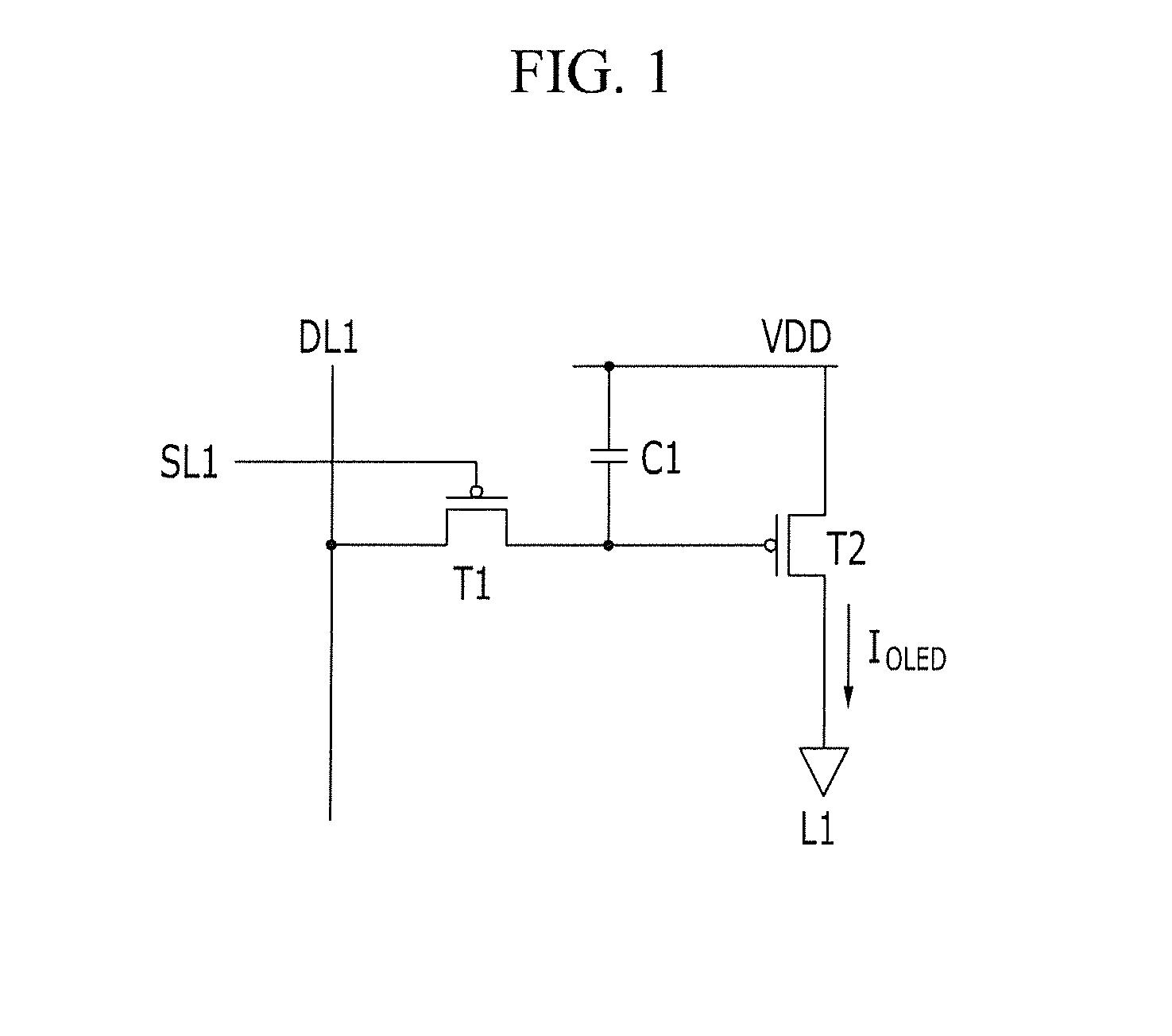

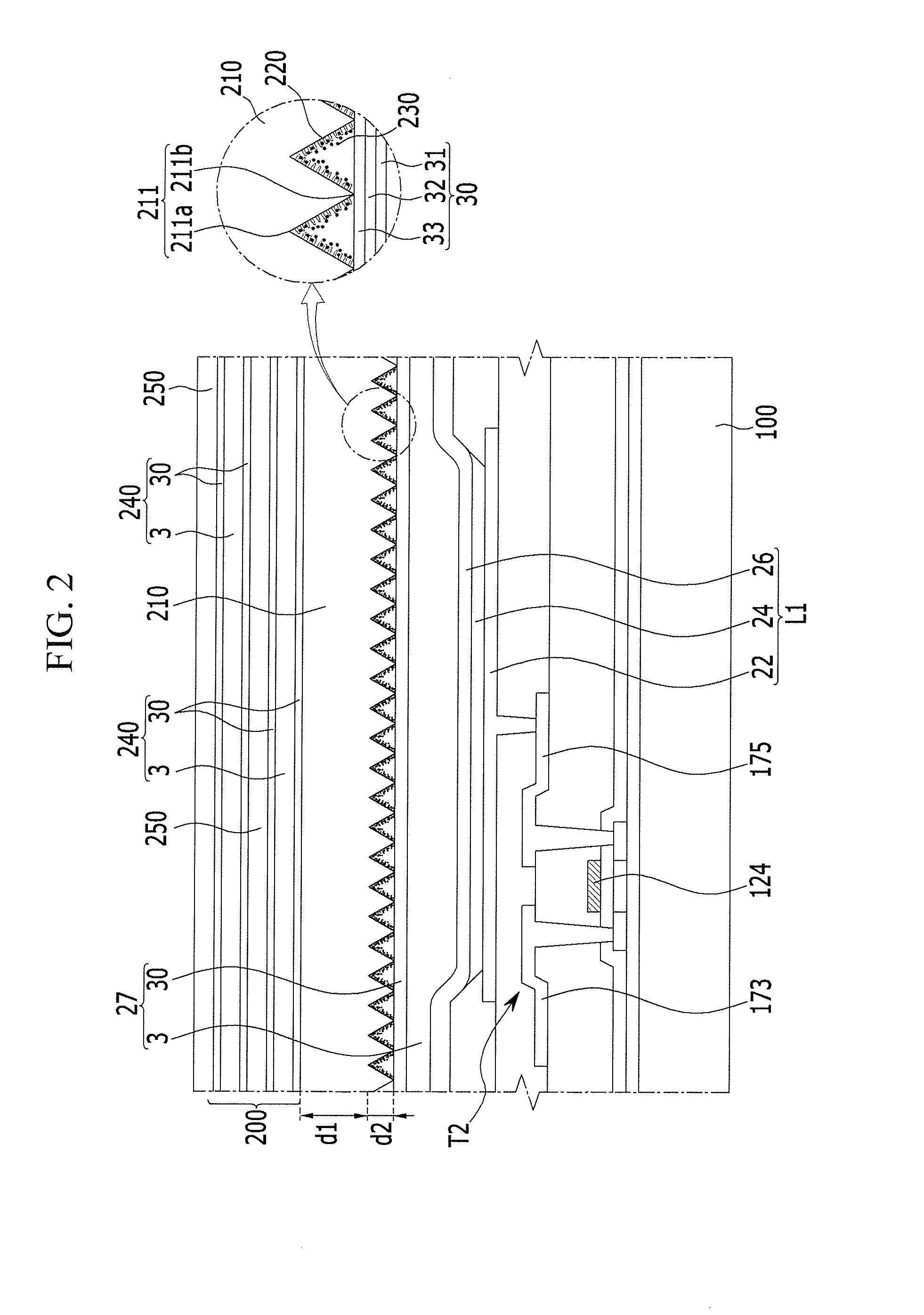

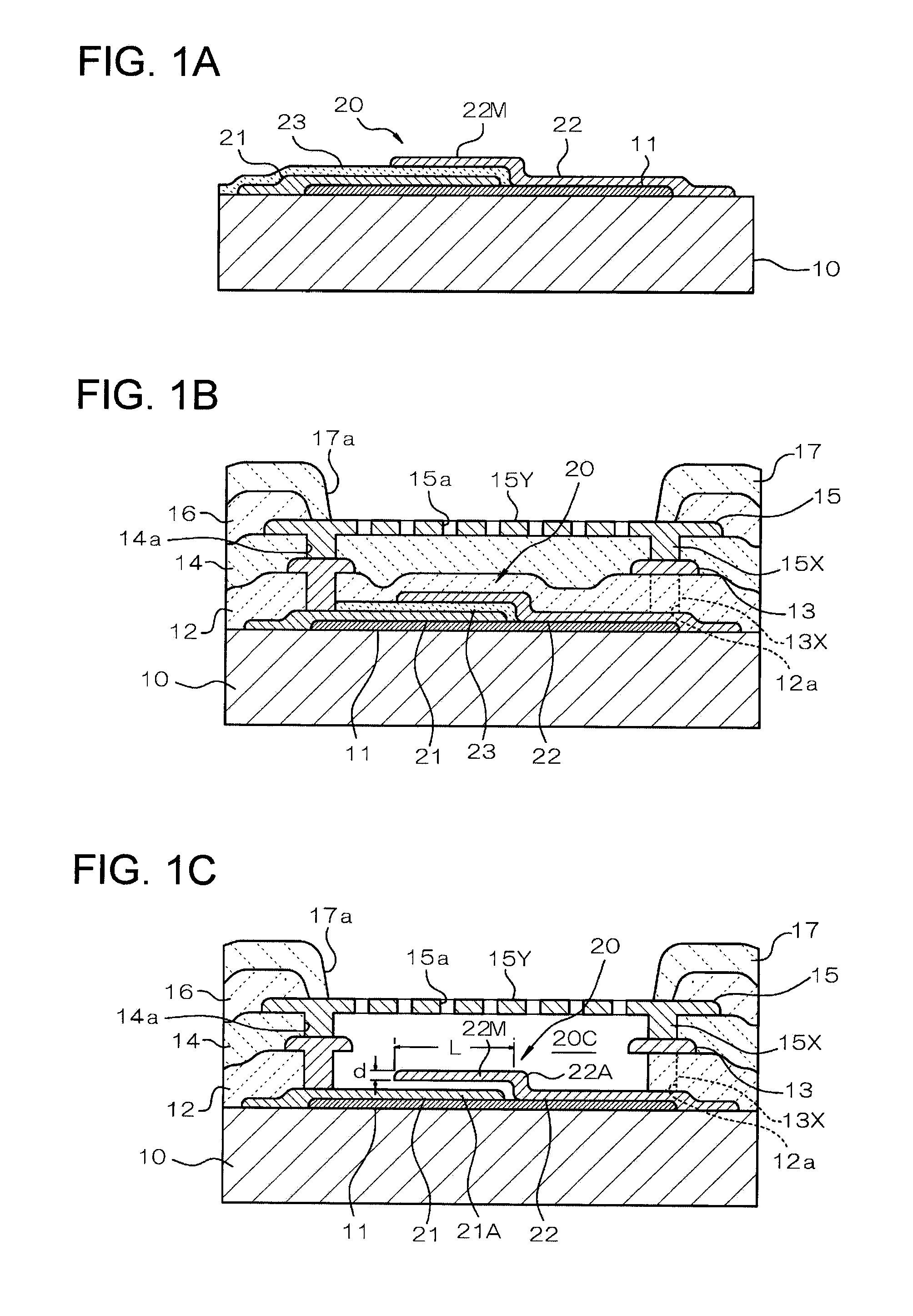

Organic light emitting diode display and manufacturing method thereof

ActiveUS20120326194A1AdhesionExtend your lifeSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

An OLED display according to an exemplary embodiment includes: a substrate; an organic light emitting diode formed on the substrate; an overcoat covering the organic light emitting diode; and a patterned metal sheet attached on the overcoat and having a plurality of protrusion and depression portions. A plurality of protrusions may be formed in a bottom surface of the patterned metal sheet where the protrusion and depression portions of the patterned metal sheet and the overcoat face each other.

Owner:SAMSUNG DISPLAY CO LTD +1

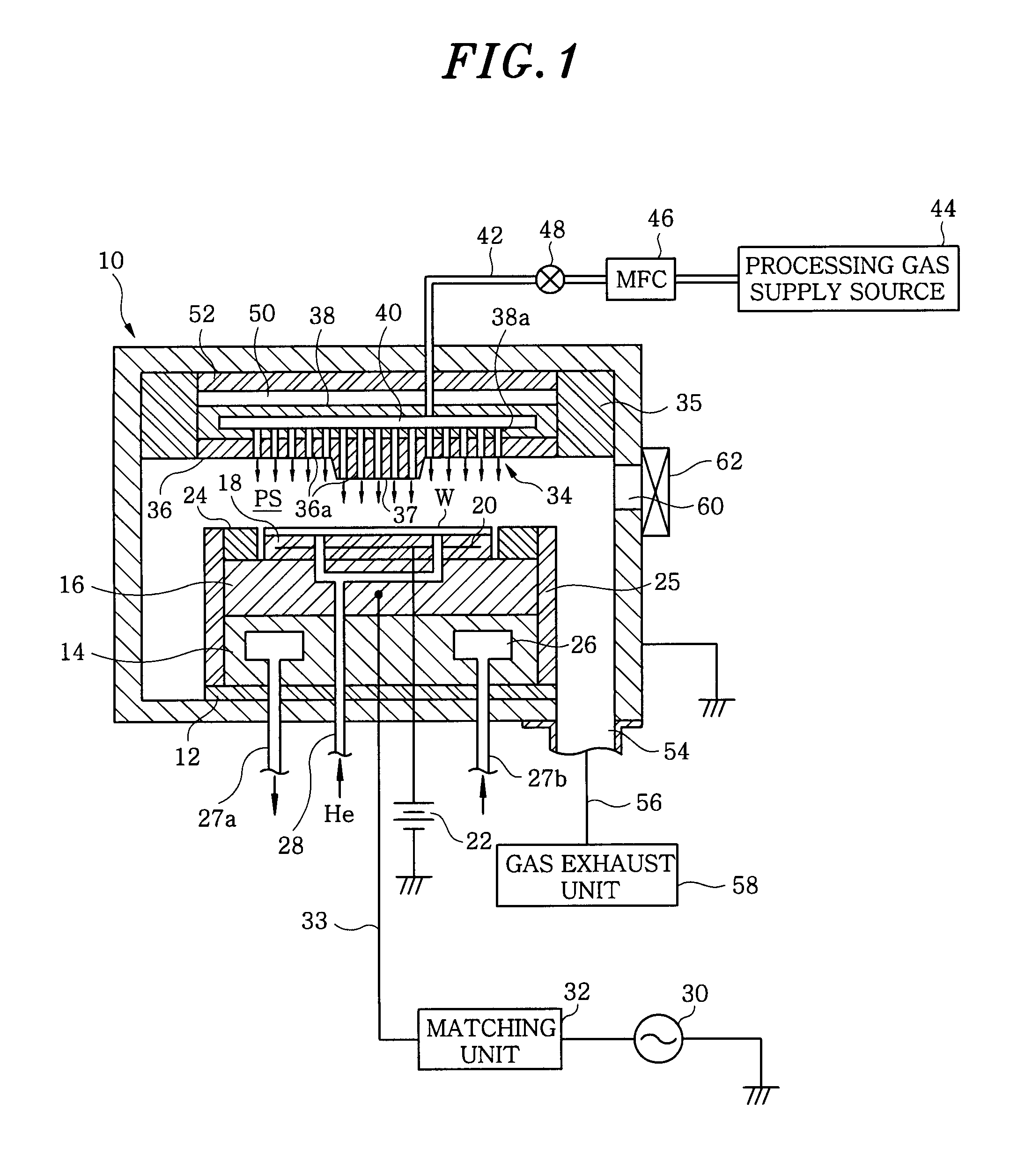

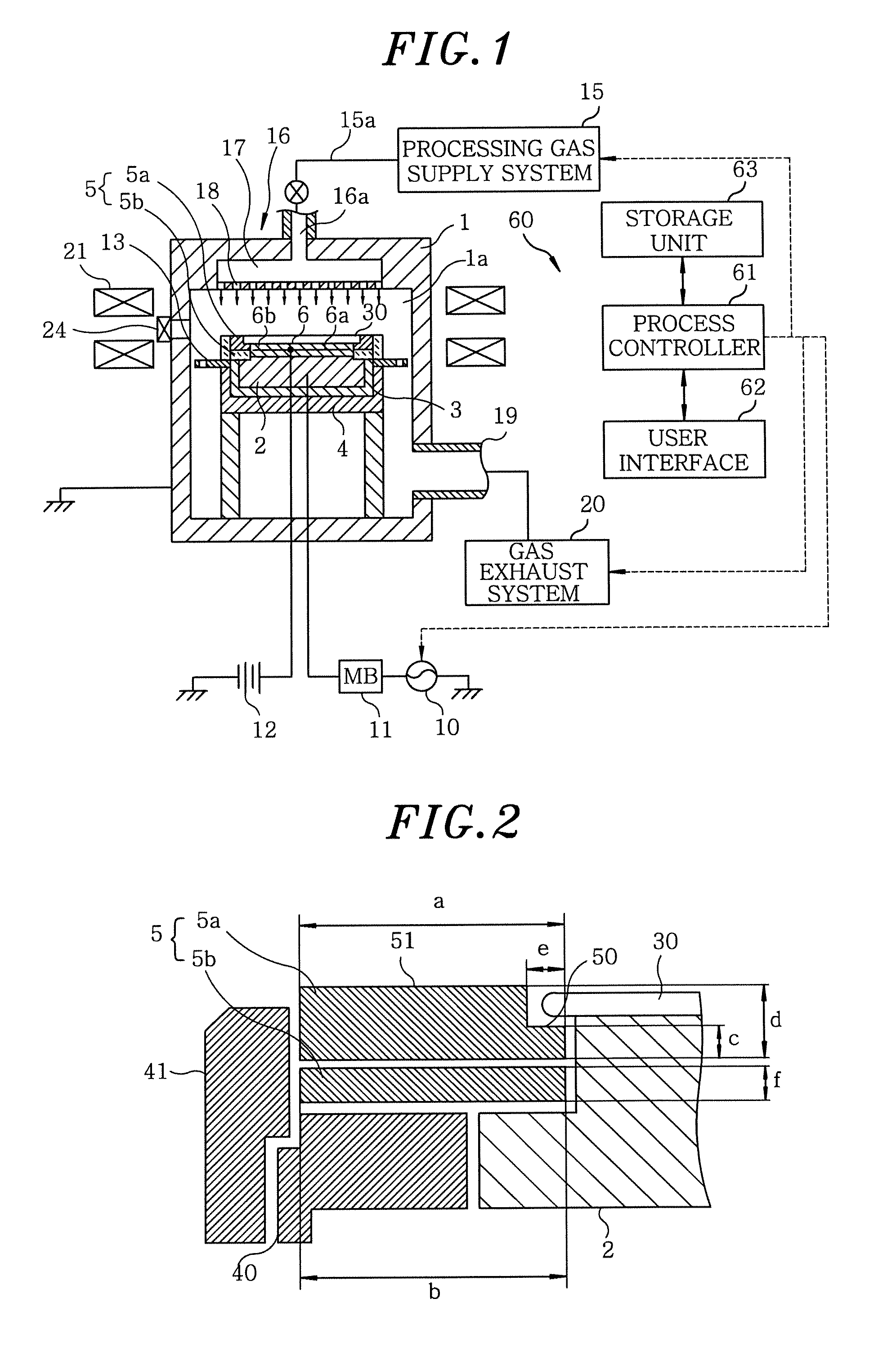

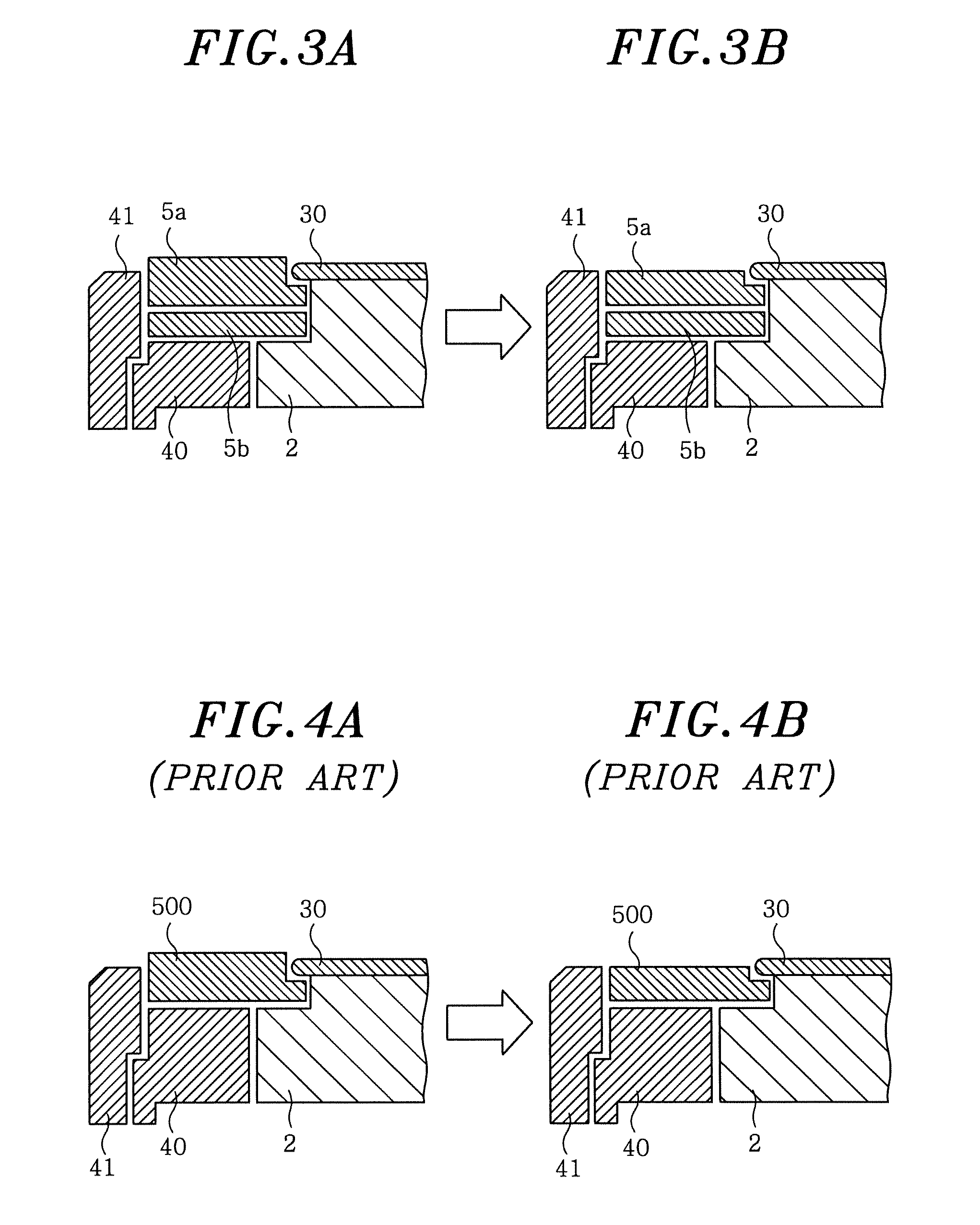

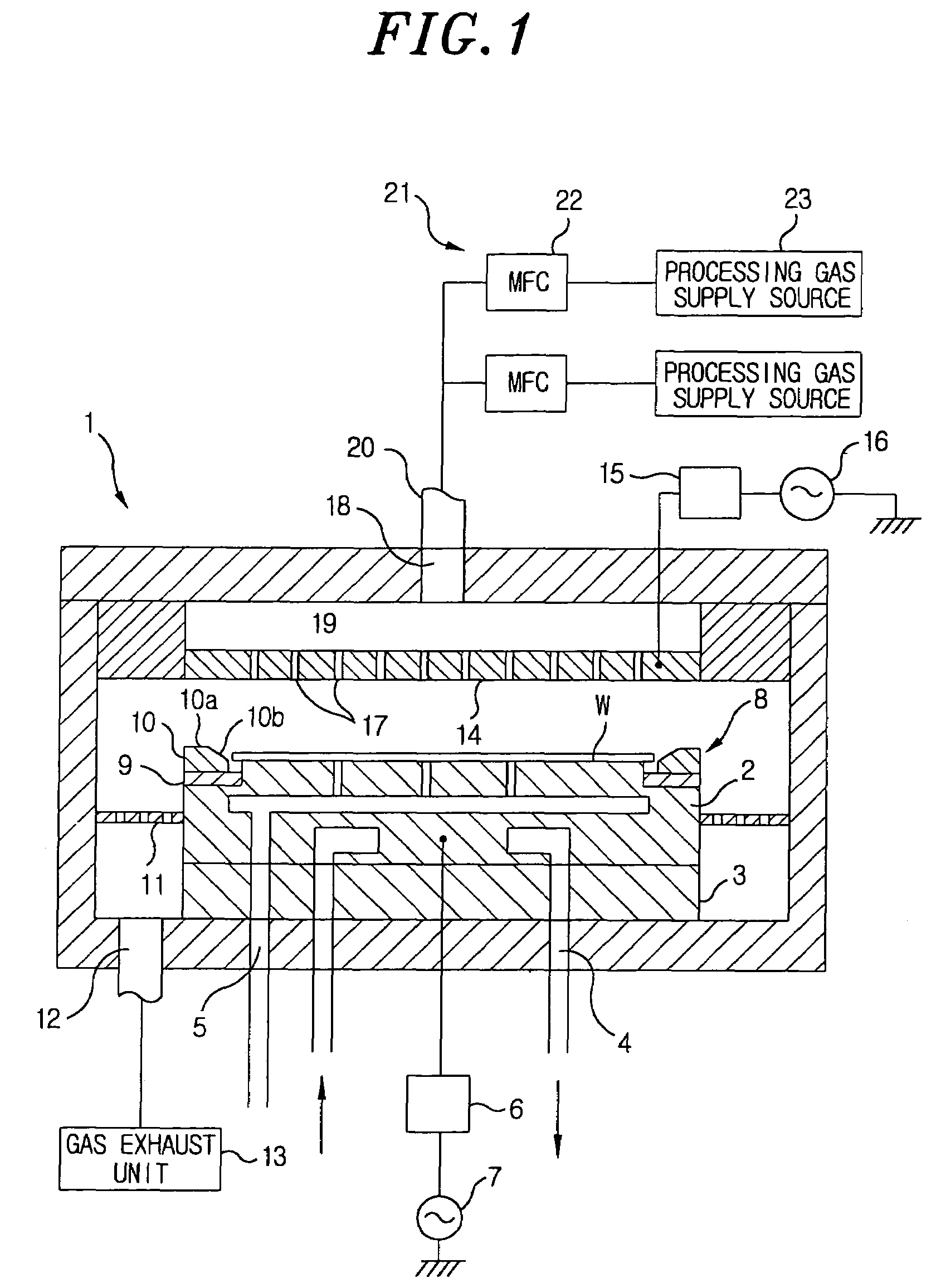

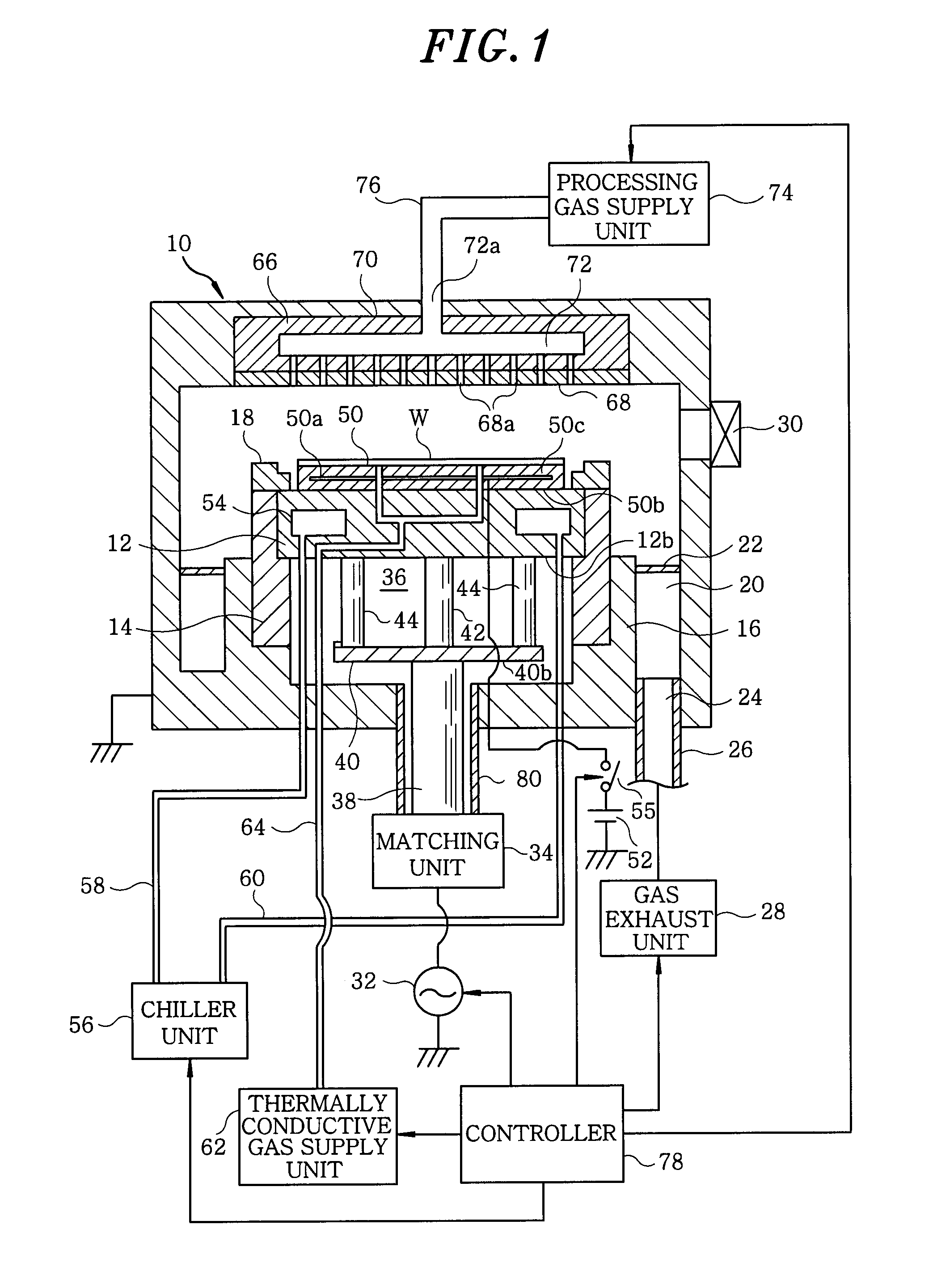

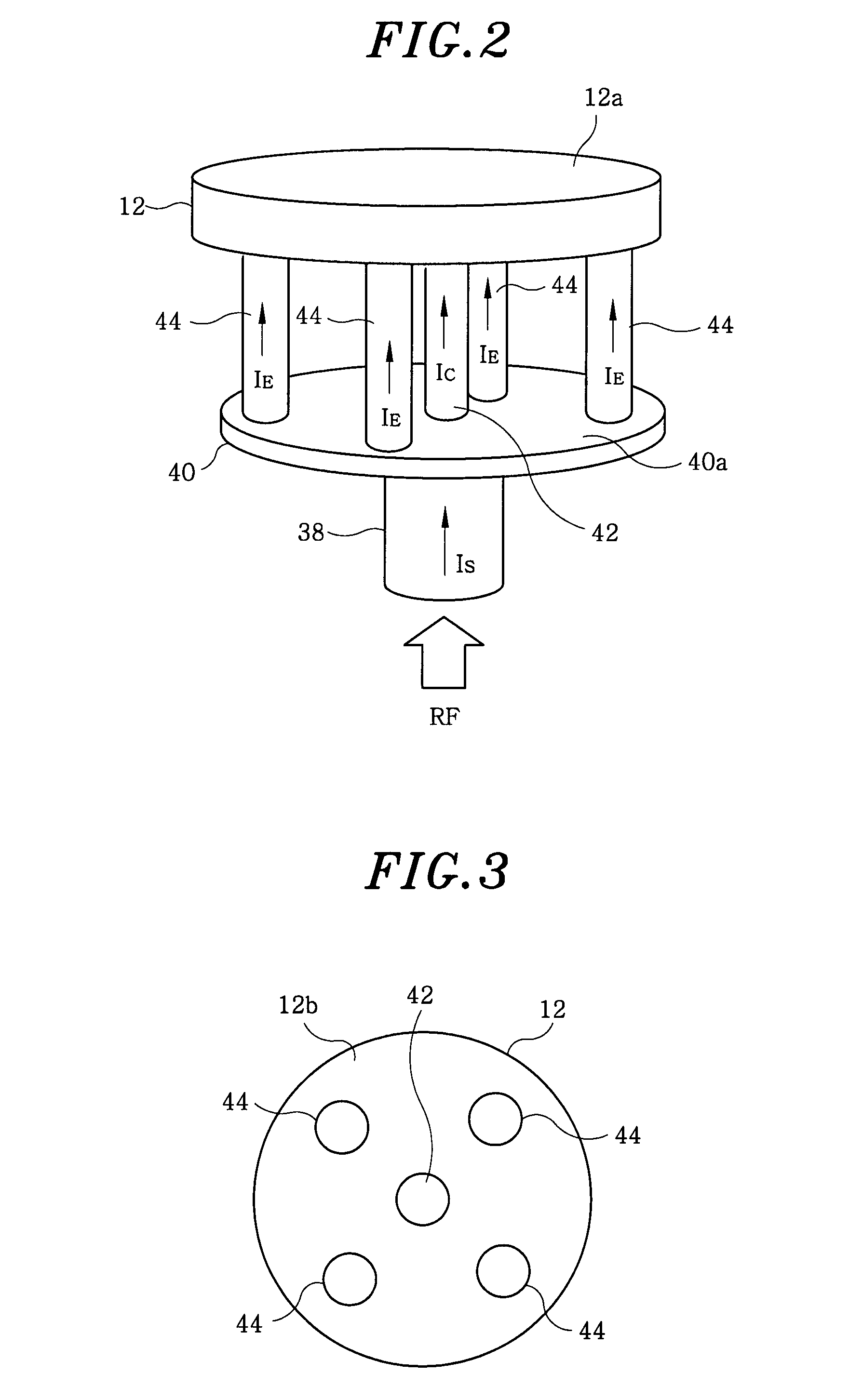

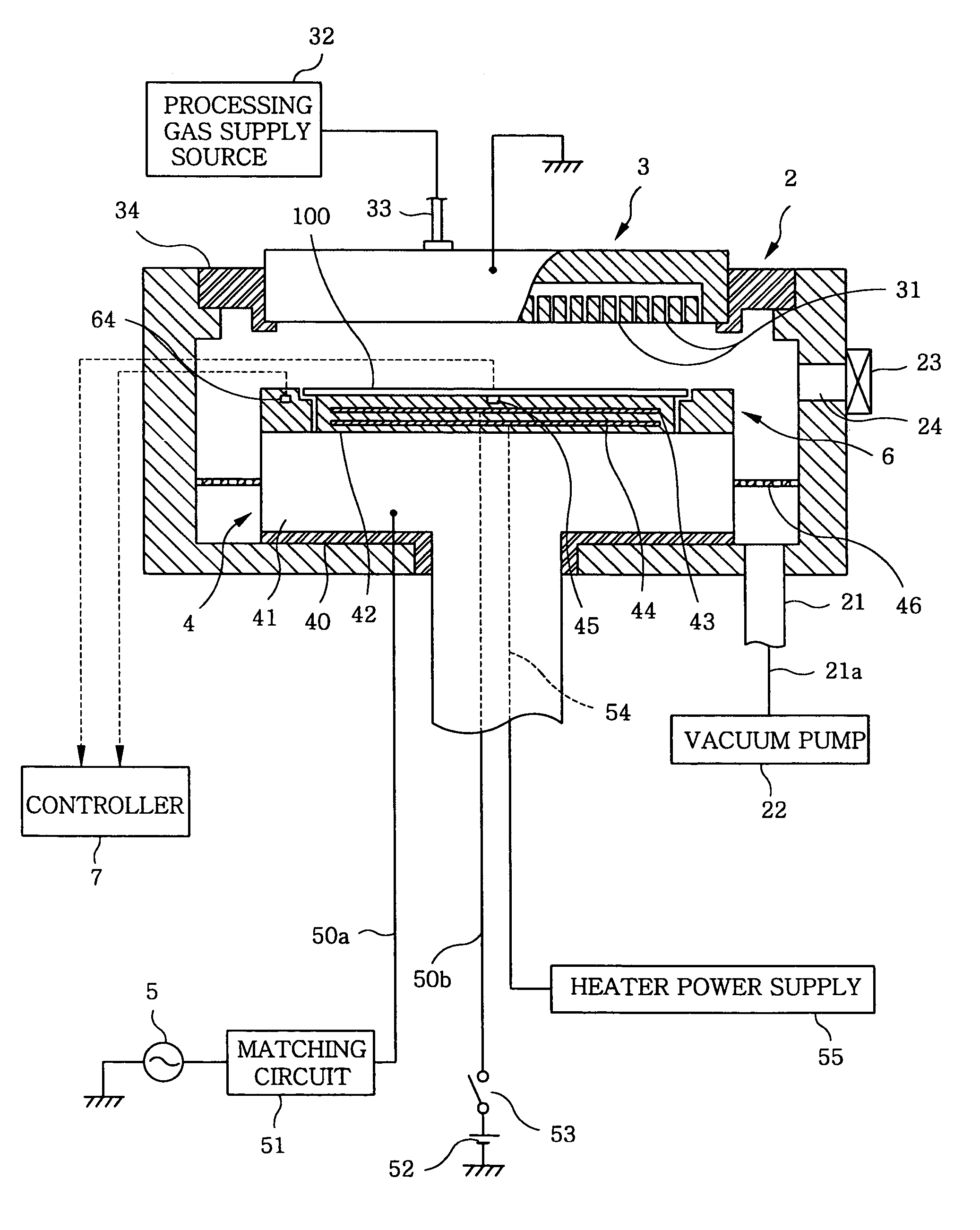

Plasma processing apparatus

InactiveUS20070227666A1Improving in-surface uniformityImprove surface uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyPlasma processing

A plasma processing apparatus includes a processing vessel capable of being vacuum evacuated; a first electrode installed in the processing vessel to be in a state electrically floating via an insulating member or a space; a second electrode disposed in the processing vessel to be in parallel to the first electrode with a specific interval, for supporting a target substrate thereon to face the first electrode; a processing gas supply unit for supplying a processing gas into a processing space between the first electrode, the second electrode and a sidewall of the processing vessel; and a first radio frequency power supply unit for applying a first radio frequency power to the second electrode to generate a plasma of the processing gas in the processing space. A protrusion projected toward the second electrode is formed at a central portion of the first electrode.

Owner:TOKYO ELECTRON LTD

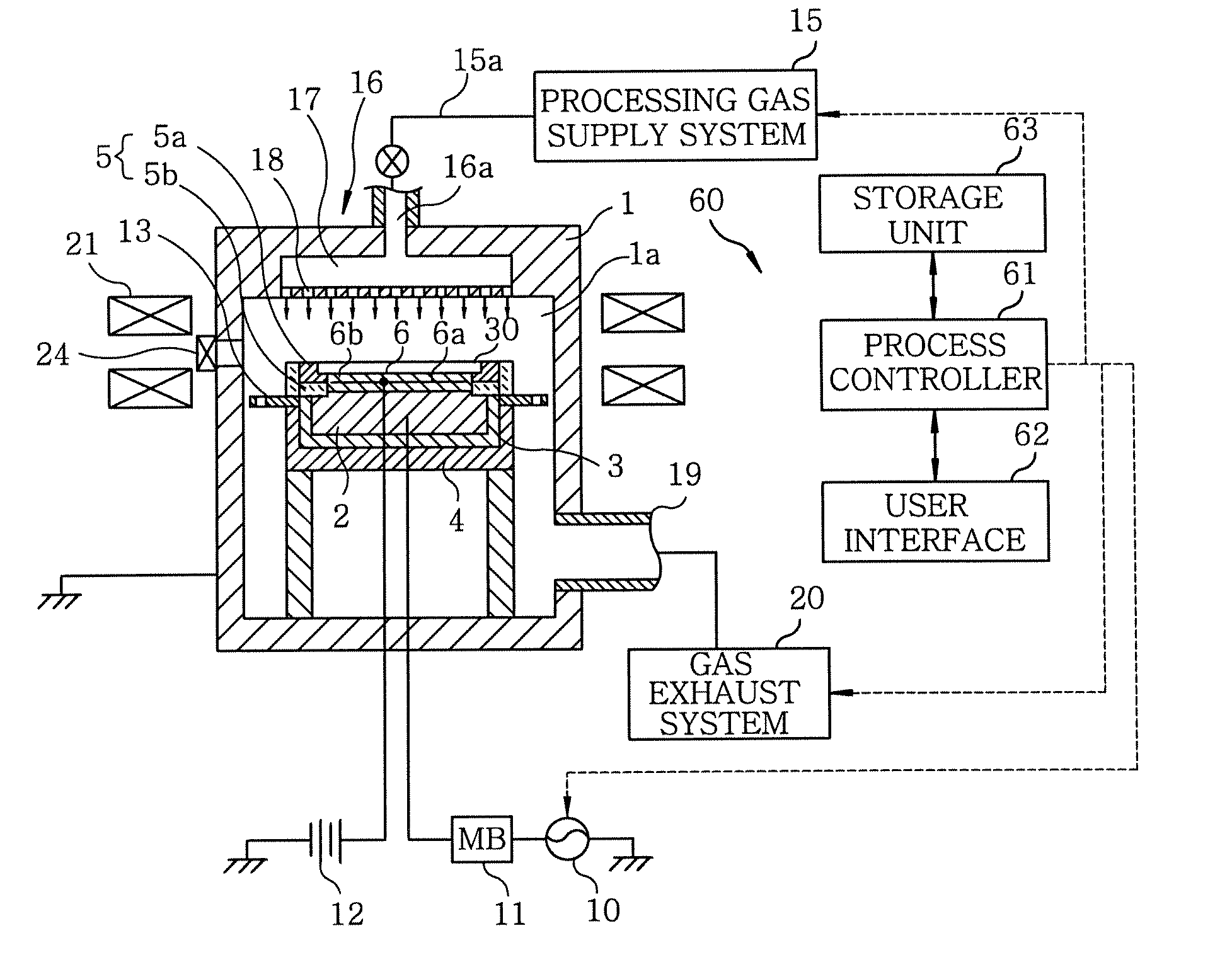

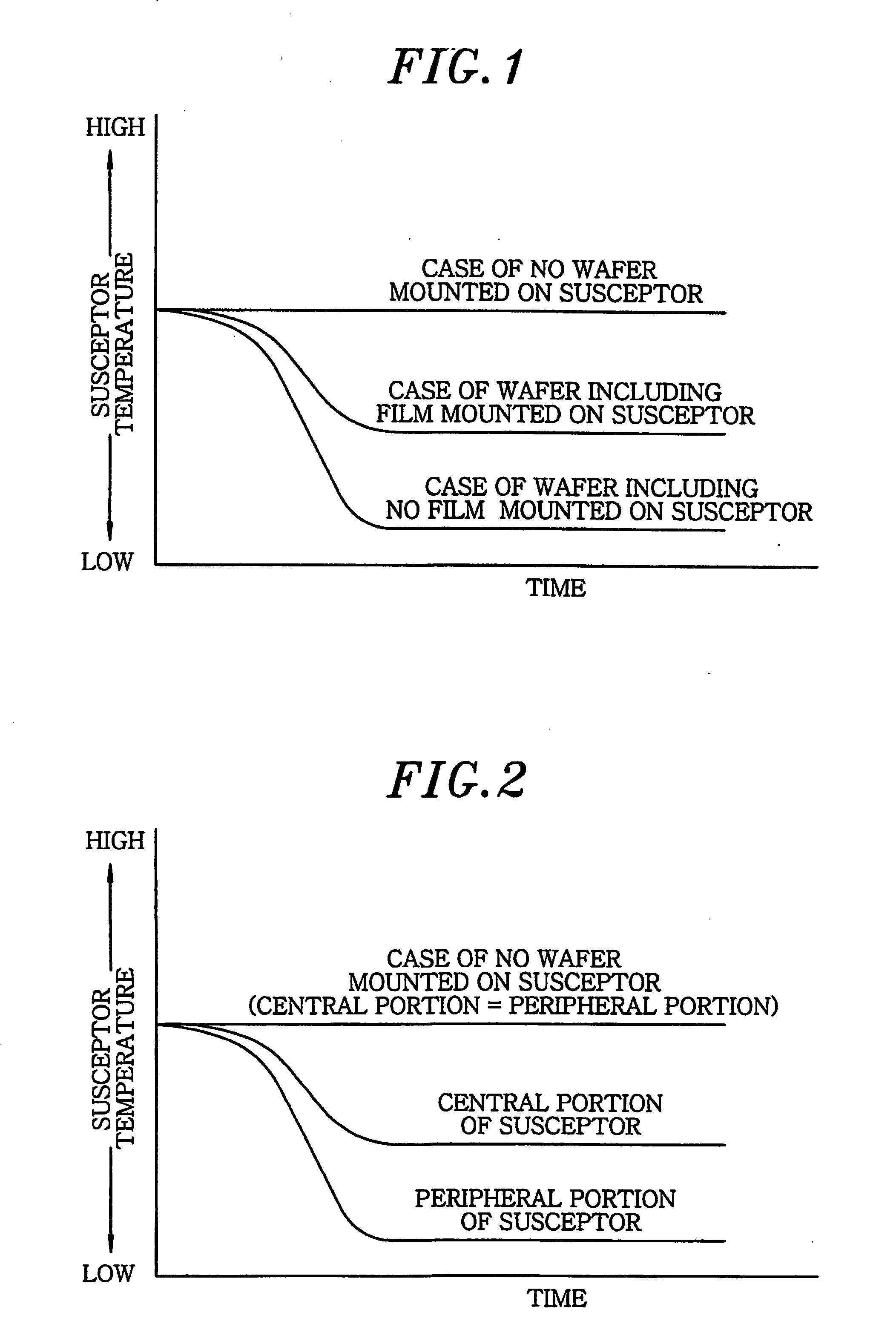

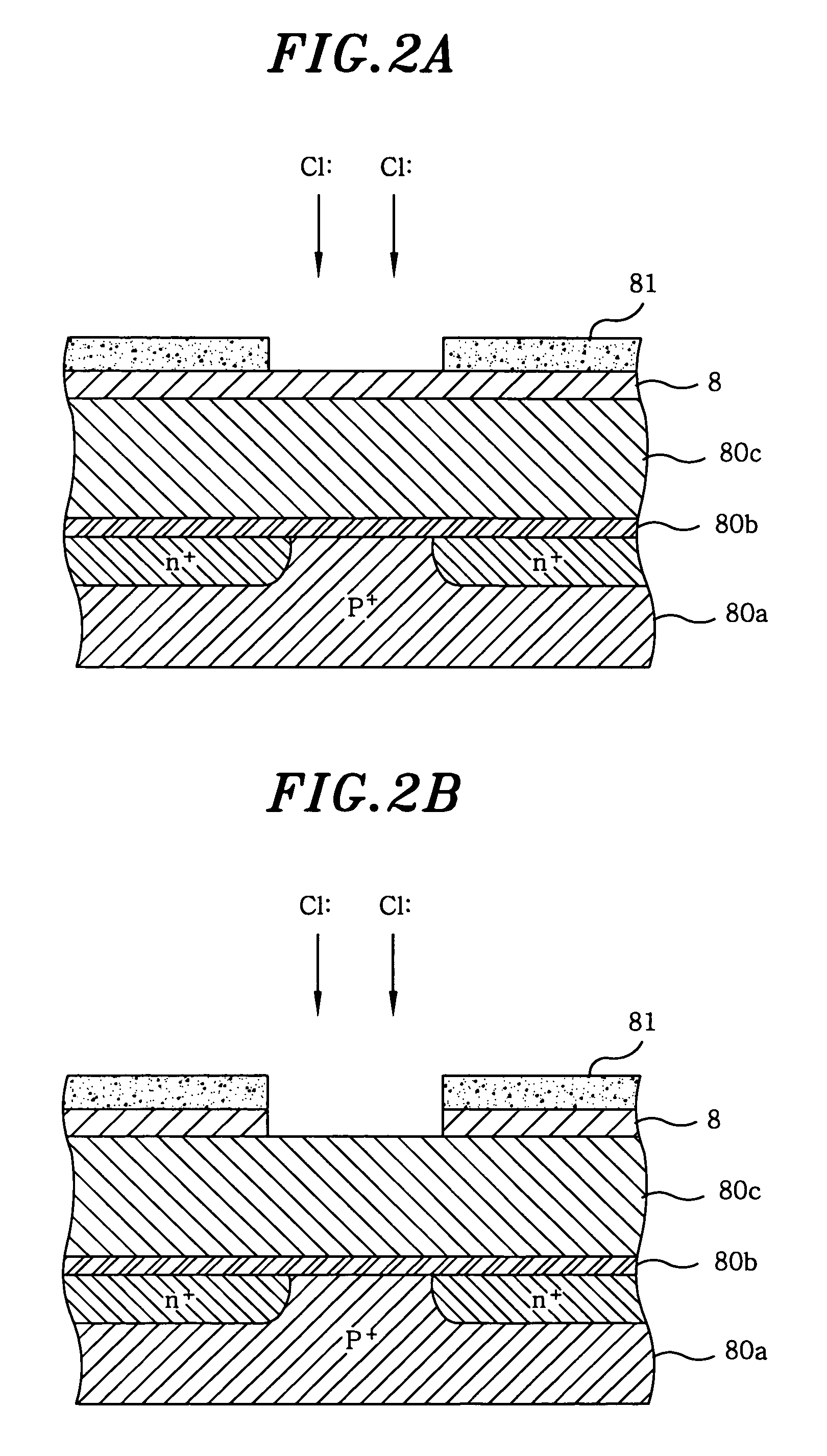

Plasma processing apparatus and method

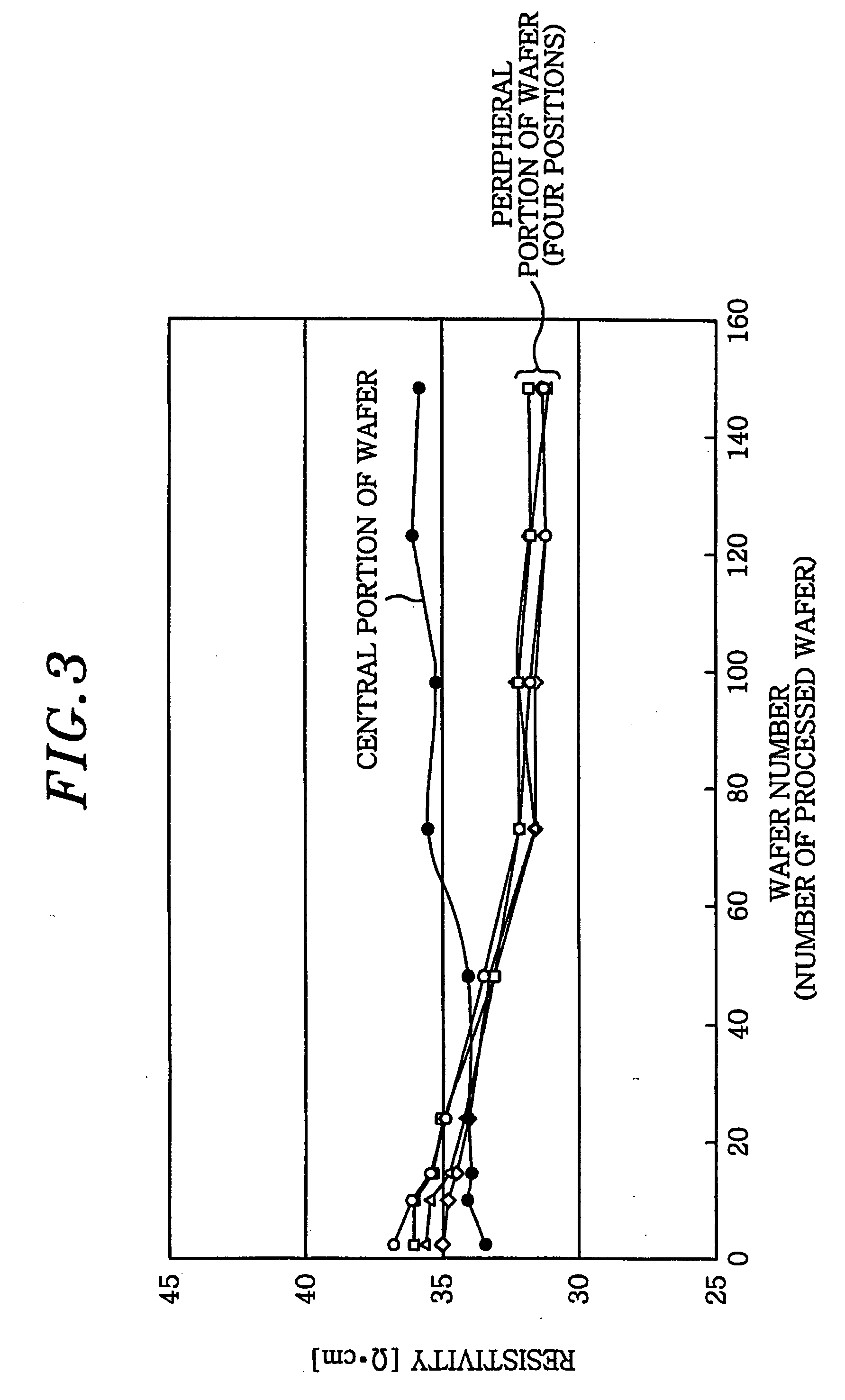

InactiveUS20050274321A1Improve surface uniformityIncrease temperatureLiquid surface applicatorsDecorative surface effectsTemperature controlHigh frequency power

A plasma processing apparatus for converting a processing gas into a plasma by a high frequency power in a processing chamber and performing a plasma processing on a substrate mounted on a mounting table includes a ring portion disposed to surround the substrate on the mounting table, and a temperature control unit for establishing a temperature difference between the ring portion and the substrate, such that the ring portion is at least 50° C. higher than the substrate. Further, the processing gas generates chlorine radicals, and the temperature control unit is at least one of a heating unit for heating the ring portion and a cooling unit for cooling the mounting table.

Owner:TOKYO ELECTRON LTD

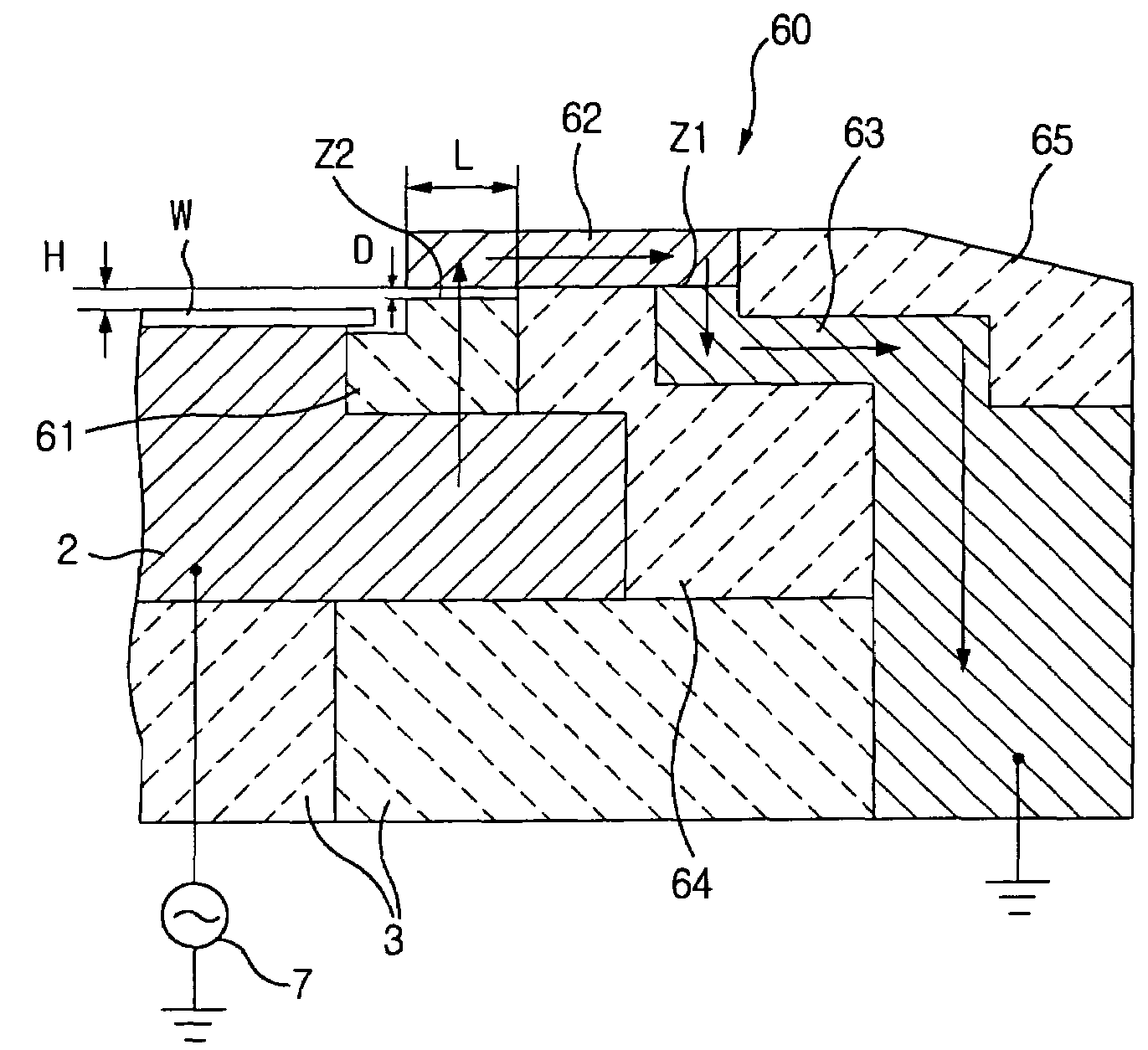

Focus ring and plasma processing apparatus

InactiveUS20080066868A1Improve surface uniformityImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringConductive materials

A focus ring of a plasma processing apparatus for performing a plasma processing on a target substrate to be processed is disposed on the mounting table to surround the target substrate. The focus ring includes a first ring-shaped member made of a conductive material and having a stepped portion at an inner peripheral portion thereof, the stepped portion being positioned lower than a bottom surface of the target substrate mounted on the mounting table and extended below a peripheral portion of the target substrate. The focus ring further includes a second ring-shaped member made of an insulating material and disposed under the first ring-shaped member to be interposed between the first ring-shaped member and the mounting table.

Owner:TOKYO ELECTRON LTD

Focus ring and plasma processing apparatus

InactiveUS7658816B2Reduce generationUniform and good processElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricSusceptor

Owner:TOKYO ELECTRON LTD

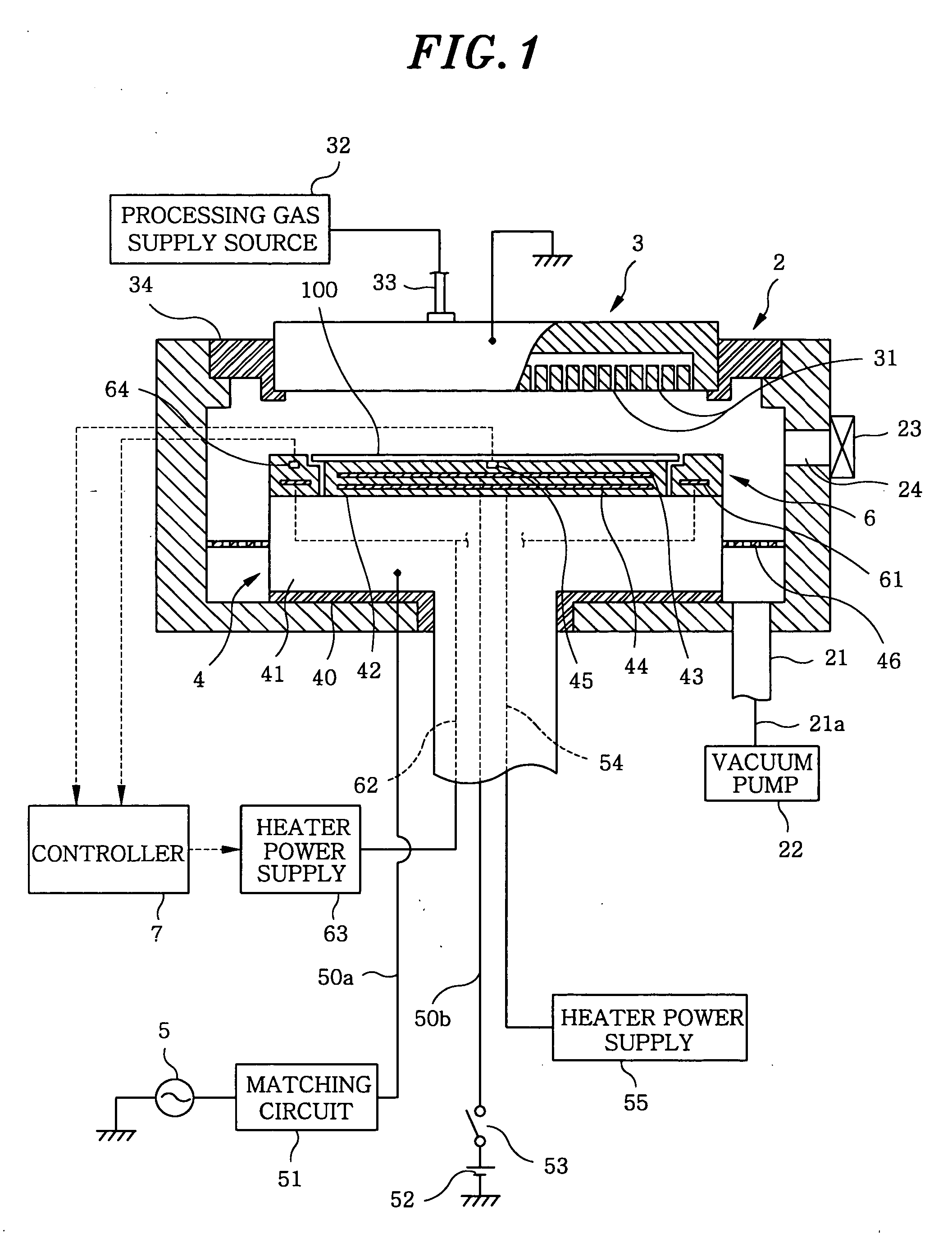

Plasma processing apparatus

InactiveUS20070235420A1Improve uniformityImprove surface uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerElectric power

A plasma processing apparatus performs a desired plasma processing on a target substrate by using a plasma generated from a processing gas by forming a high frequency electric field in an evacuable processing chamber having an electrode. The plasma processing apparatus includes a high frequency power supply for outputting a high frequency power; and a central power feeder connected with a central portion of a rear surface of the electrode to supply the high frequency power from the high frequency power supply to the electrode. The plasma processing apparatus further includes a peripheral power feeder connected with a peripheral portion of the rear surface of the electrode in parallel with the central power feeder to supply the high frequency power from the high frequency power supply to the electrode.

Owner:TOKYO ELECTRON LTD

Substrate Processing Method and Substrate Processing Apparatus

InactiveUS20070292598A1High temperature control accuracyImprove surface uniformityLiquid surface applicatorsSemiconductor/solid-state device testing/measurementTemperature controlAbsorptance

Disclosed is a substrate processing method wherein the infrared absorptance or infrared transmittance of a substrate to be processed is measured in advance, and the substrate is processed according to the measured value while independently controlling temperatures at least in a first region located in the central part of the substrate and in a second region around the first region using temperature control means which are respectively provided for the first region and the second region and can be controlled independently from each other.

Owner:TOKYO ELECTRON LTD

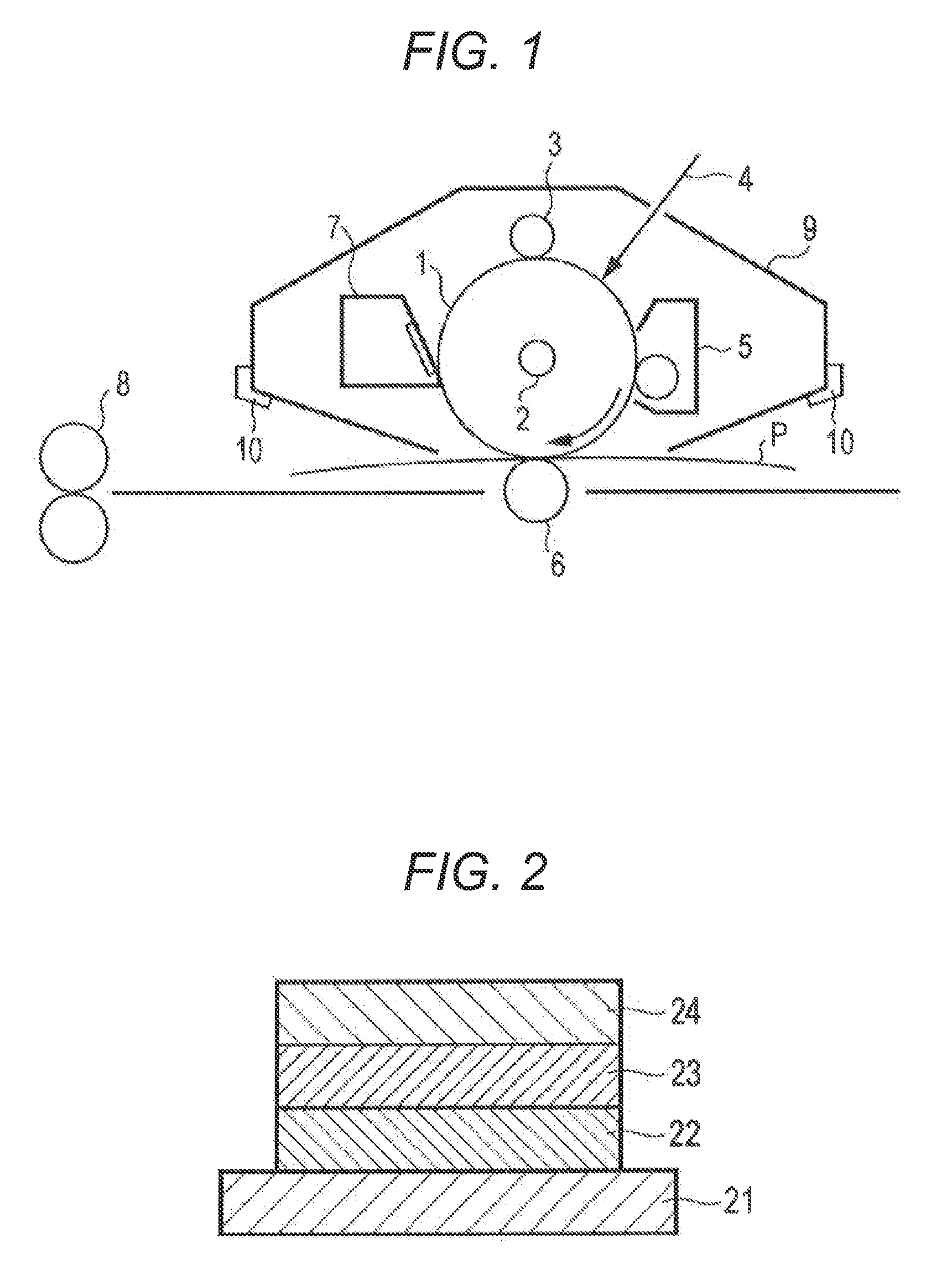

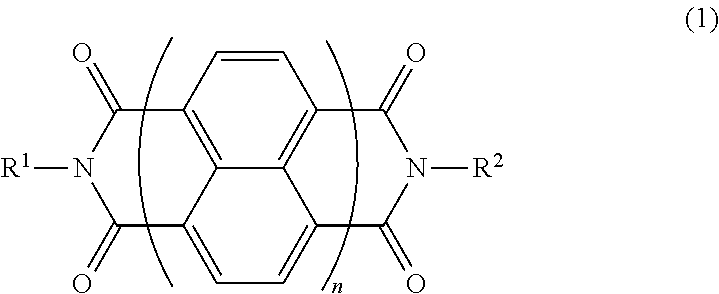

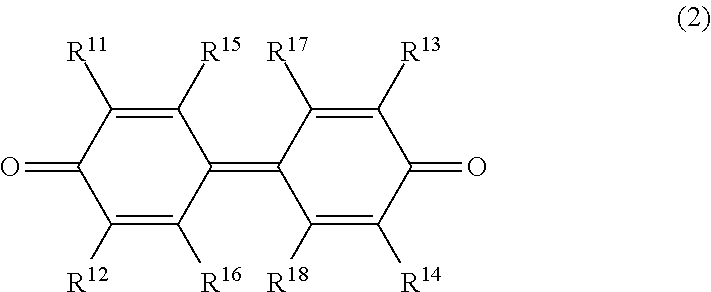

Process for producing electrophotographic photosensitive member

ActiveUS9280072B2Improve uniformityImprove surface uniformityElectrography/magnetographyCoatingsElectronPolymer chemistry

Provided is a process for producing an electrophotographic photosensitive member, the process including the steps of: preparing a dispersion liquid by dispersing particles each containing an electron transporting substance in an aqueous dispersion medium; forming the coat of the dispersion liquid on the support; and forming an undercoat layer by heating the coat at a temperature equal to or more than the melting point of the electron transporting substance.

Owner:CANON KK

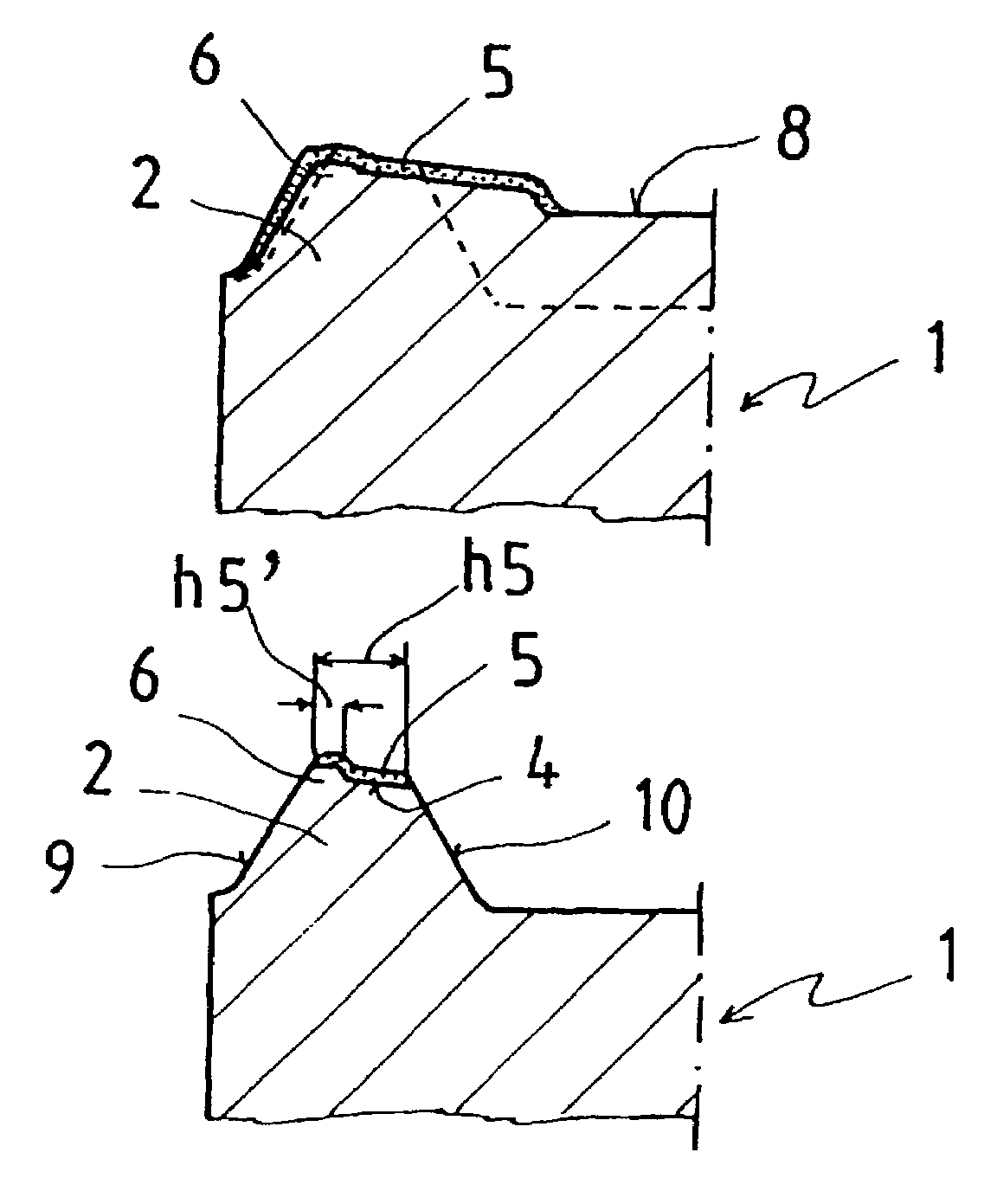

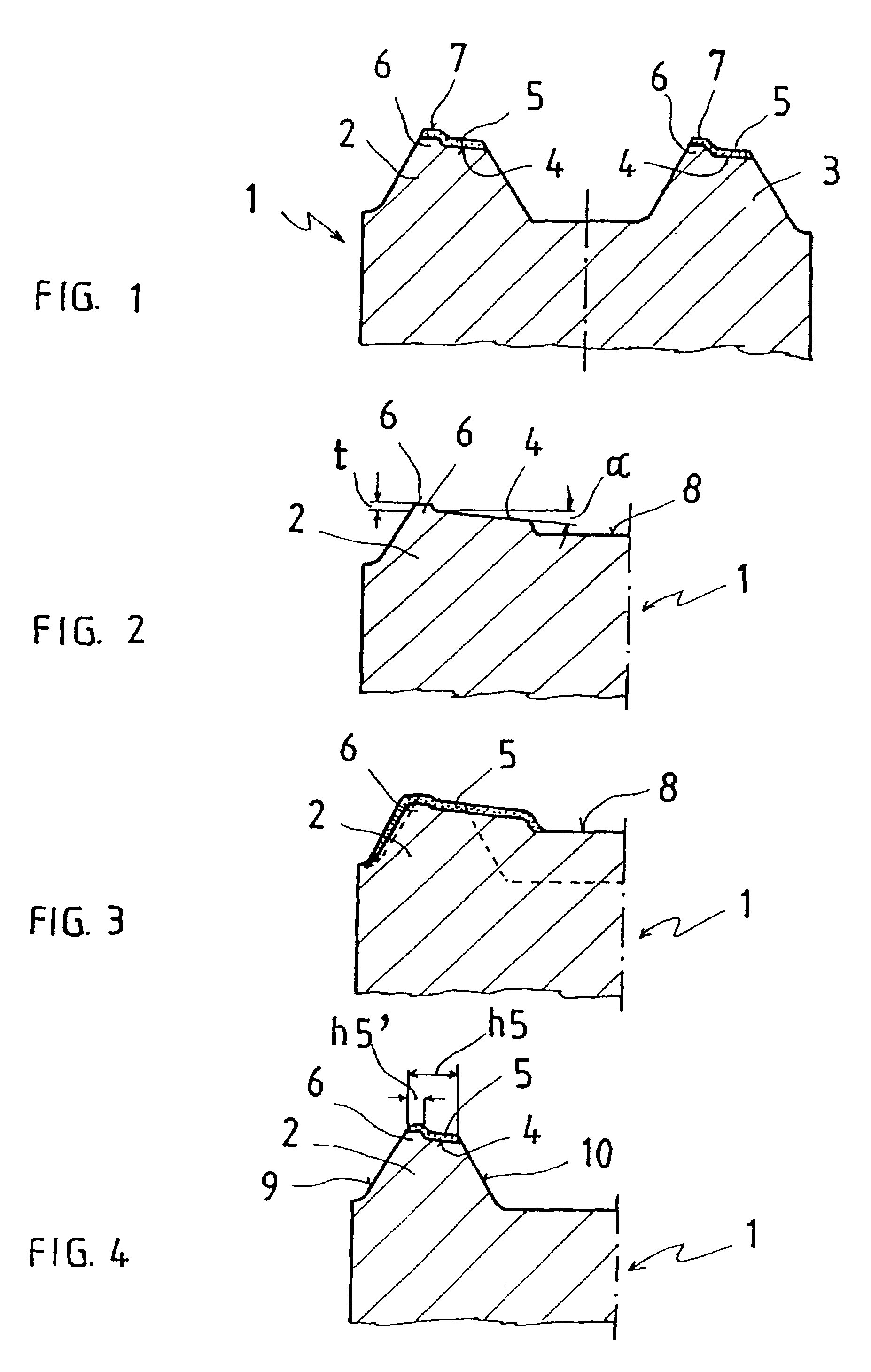

Oil-scraper piston ring and a method for producing an oil-scraper piston ring

InactiveUS7117594B2Minimize consumptionReduce fuel consumptionEngine sealsPiston ringsPiston ringWear resistant

A piston oil control ring with at least one tapered running rail, provided with a wear-resistant coating, characterized in that a radial elevation with predetermined radial height and width, which is provided with the wear-resistant coating, is provided in the region of the tapered ring plane for the running rail.

Owner:FEDERAL MOGUL BURSCHEID

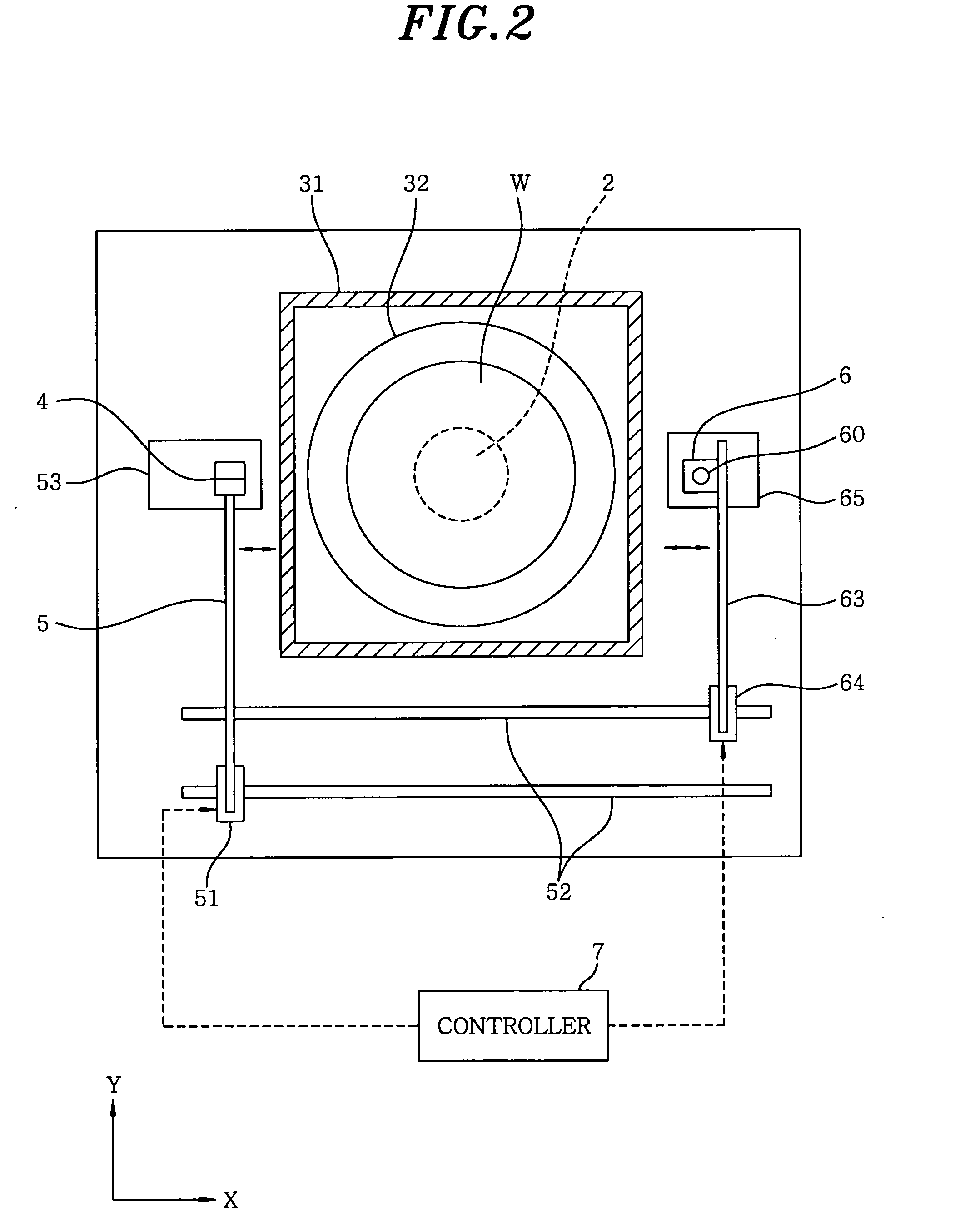

Developing apparatus and method

InactiveUS20060040051A1Improve surface uniformityHighly uniform line widthPhotomechanical apparatusPretreated surfacesSpray nozzleMechanical engineering

A developing apparatus for developing a substrate whose surface is coated with a coating solution and then exposed includes a substrate supporting unit for horizontally supporting the substrate, a rotation driving mechanism for rotating the substrate supporting unit forwardly or backwardly with respect to a vertical axis, a developer nozzle, disposed to face a surface of the substrate supported by the substrate supporting unit, having a strip-shaped injection opening extended along a direction extending from a periphery of the substrate toward a central portion thereof, a moving unit for moving the developer nozzle from an outer portion of the substrate toward the central portion thereof, and a controller for controlling operations such that while the substrate is rotated forwardly by the rotation driving mechanism, a developer is supplied through the injection opening to the surface of the substrate by moving the developer nozzle and, then, the substrate is rotated backwardly by the rotation driving mechanism.

Owner:TOKYO ELECTRON LTD

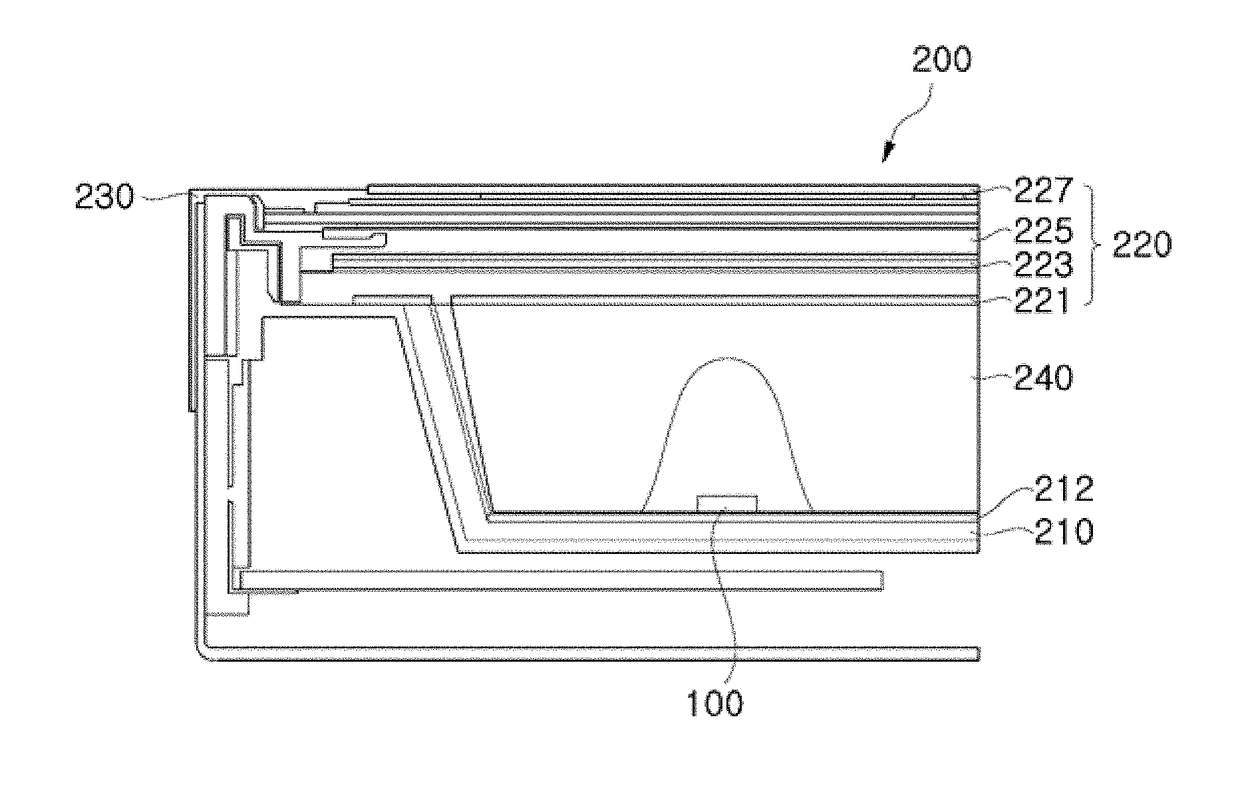

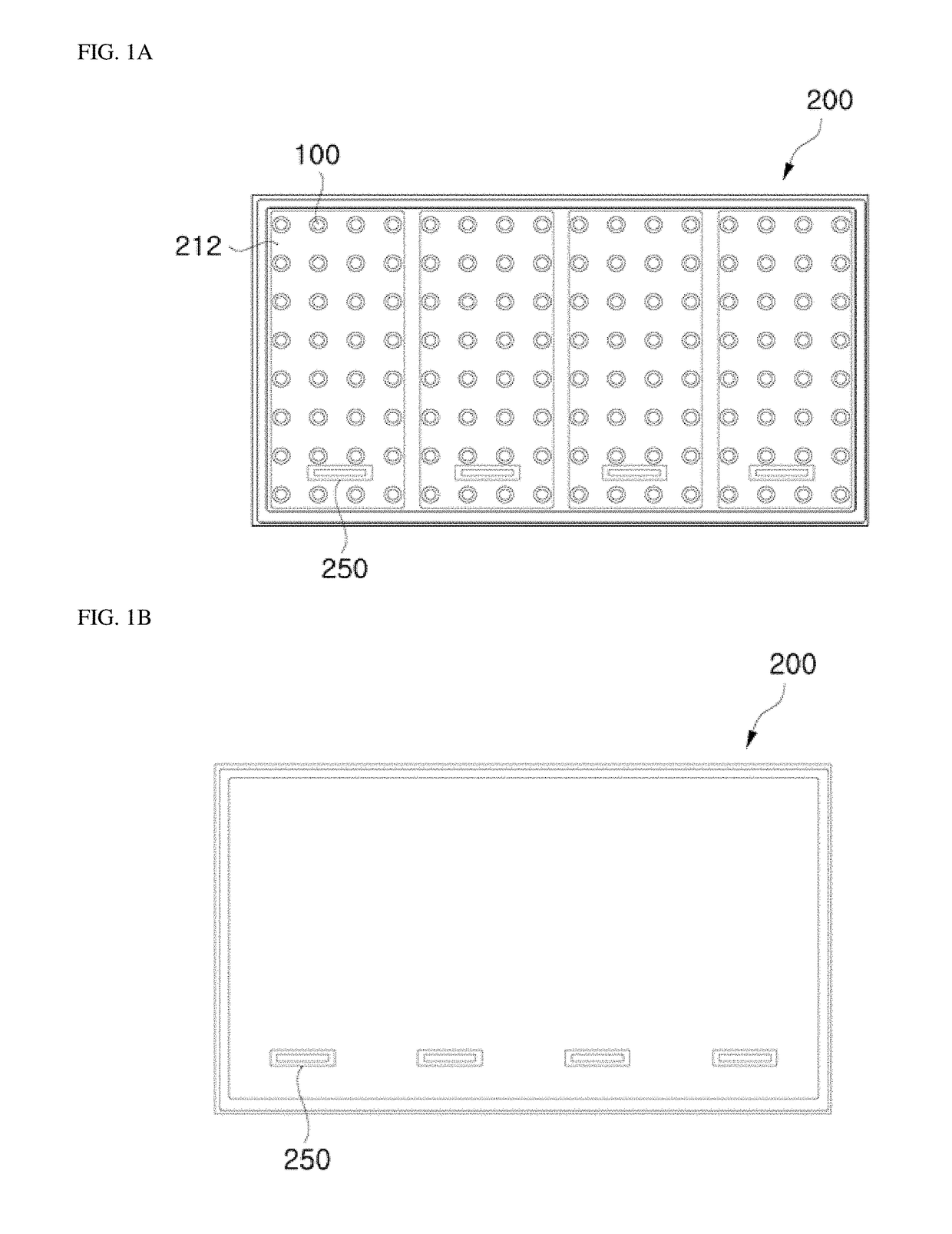

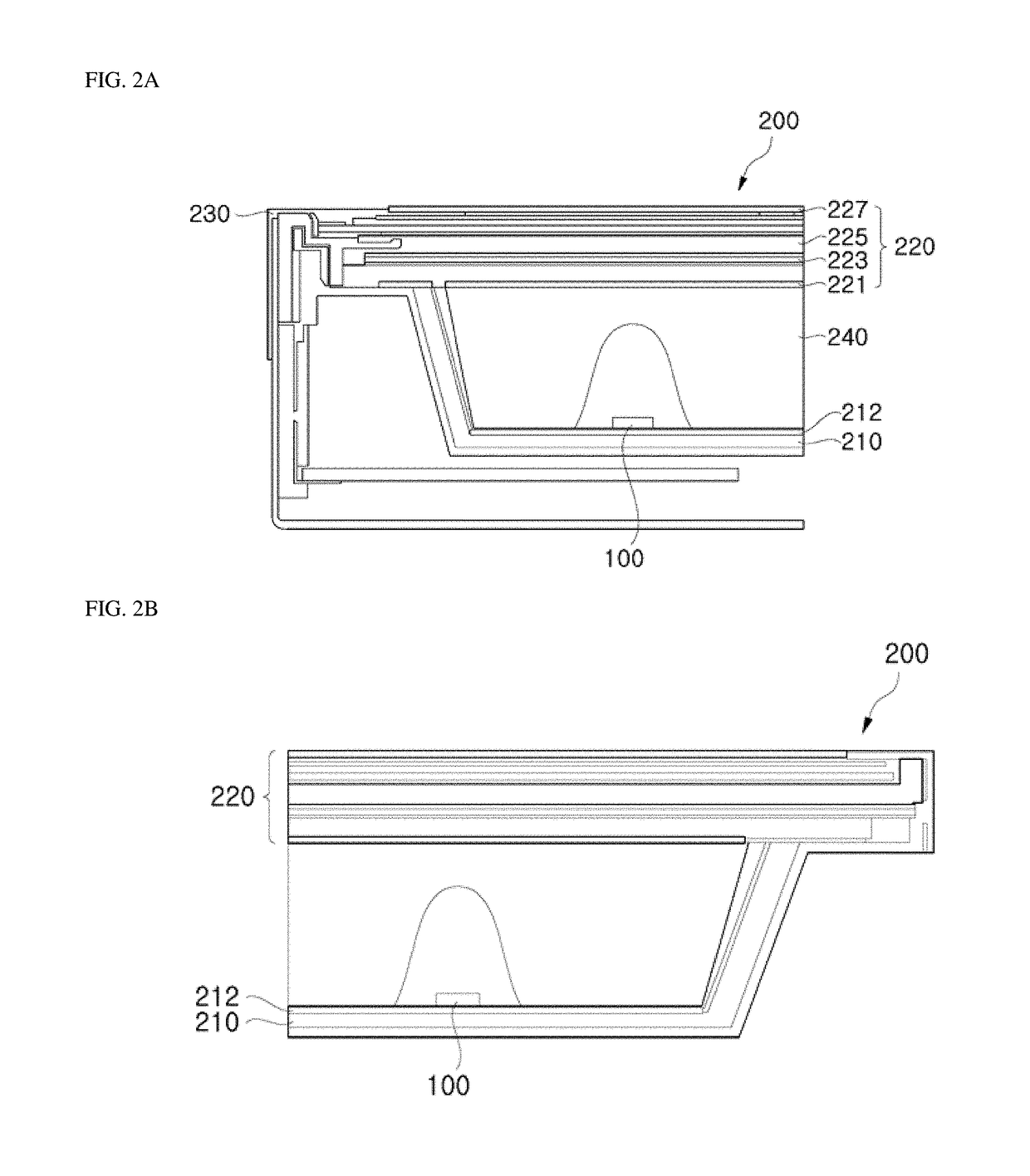

Display apparatus and backlight unit thereof

ActiveUS20180136520A1Reduce thicknessImprove surface uniformityMechanical apparatusSolid-state devicesFluorescenceLight guide

A display apparatus and a backlight unit thereof. The display apparatus includes: a frame; a plurality of light emitting diodes regularly arranged on the frame; an optical part disposed above the plurality of light emitting diodes and including a display panel and at least one of a phosphor sheet and an optical sheet; and a light guide plate disposed between the frame and the optical part to cover the plurality of light emitting diodes, wherein the light guide plate is formed with light source grooves placed corresponding to locations of the plurality of light emitting diodes, respectively, such that light emitted from each of the light emitting diodes enters the corresponding light source groove to spread light in a lateral direction when the light enters the light guide plate, thereby enabling use of a direct type backlight unit without a separate lens.

Owner:SEOUL SEMICONDUCTOR

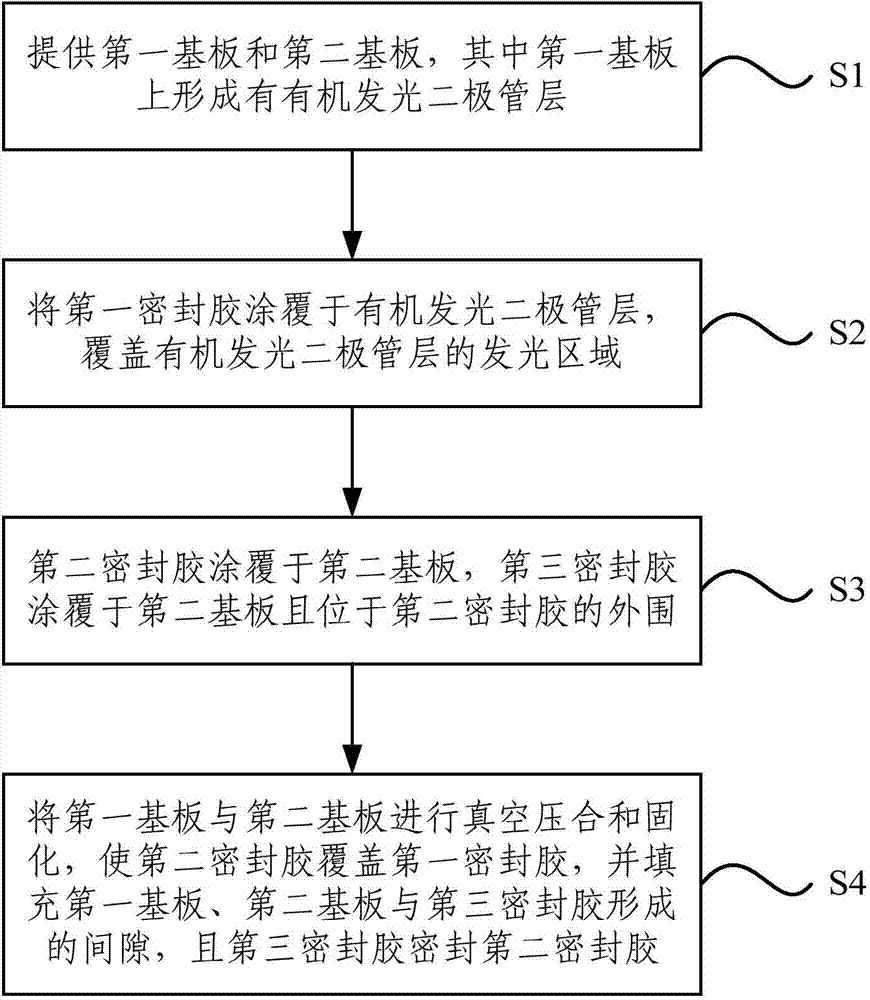

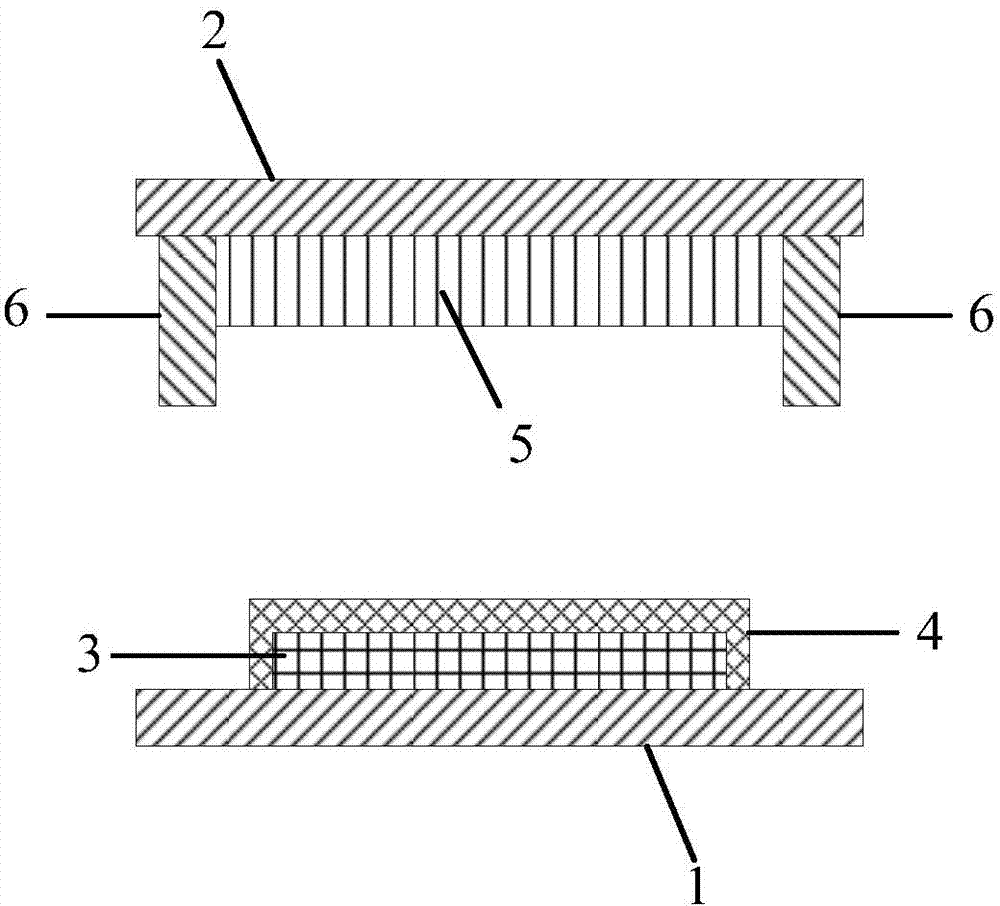

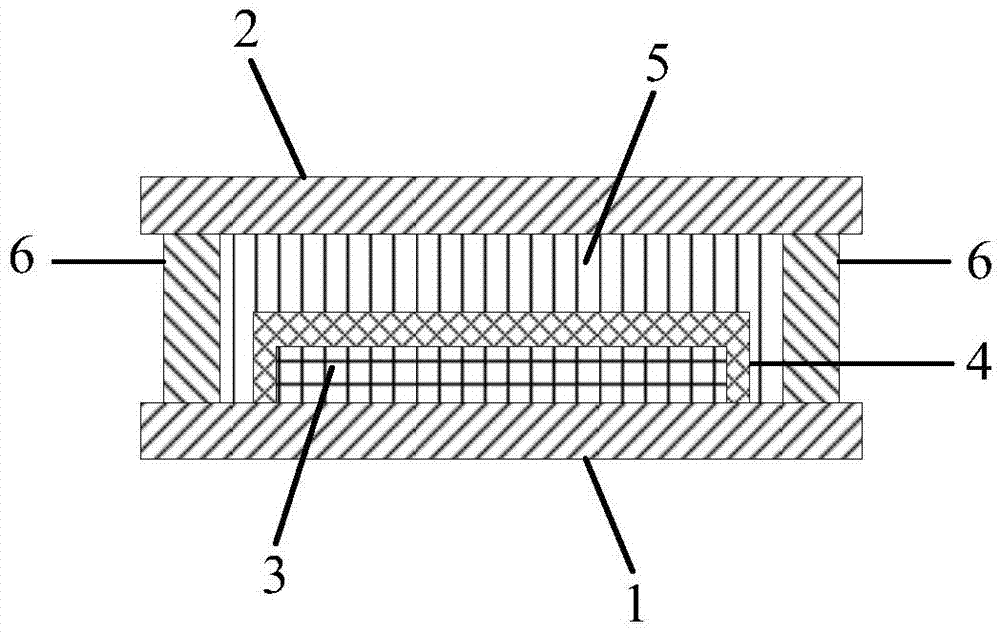

Organic light emitting diode (OLED) display panel and manufacture method thereof

InactiveCN104124268AAvoid damageImprove water resistanceSolid-state devicesSemiconductor/solid-state device manufacturingWater tightnessSealant

The invention relates to an organic light emitting diode (OLED) display panel and a manufacture method thereof. The manufacture method includes providing a first substrate and a second substrate, wherein an OLED layer is formed on the first substrate; coating a first sealant on the surface of the OLED layer located on the first substrate; coating a second sealant on the surface of the second substrate, and coating a third sealant on the periphery, located in the second sealant, of the second substrate, wherein the viscosity of the first sealant is smaller than that of the second sealant; laminating and solidifying the first substrate and the second substrate so that the second sealant covers the first sealant and fills a gap between the first and second substrates and the third sealant. By means of the OLED display panel and the manufacture method thereof, tension of contact surfaces of the sealants and an OLED during a solidifying process can be reduced, damages to the OLED are reduced, and meanwhile, good water-tightness of a sealing structure of the OLED can be guaranteed.

Owner:BOE TECH GRP CO LTD

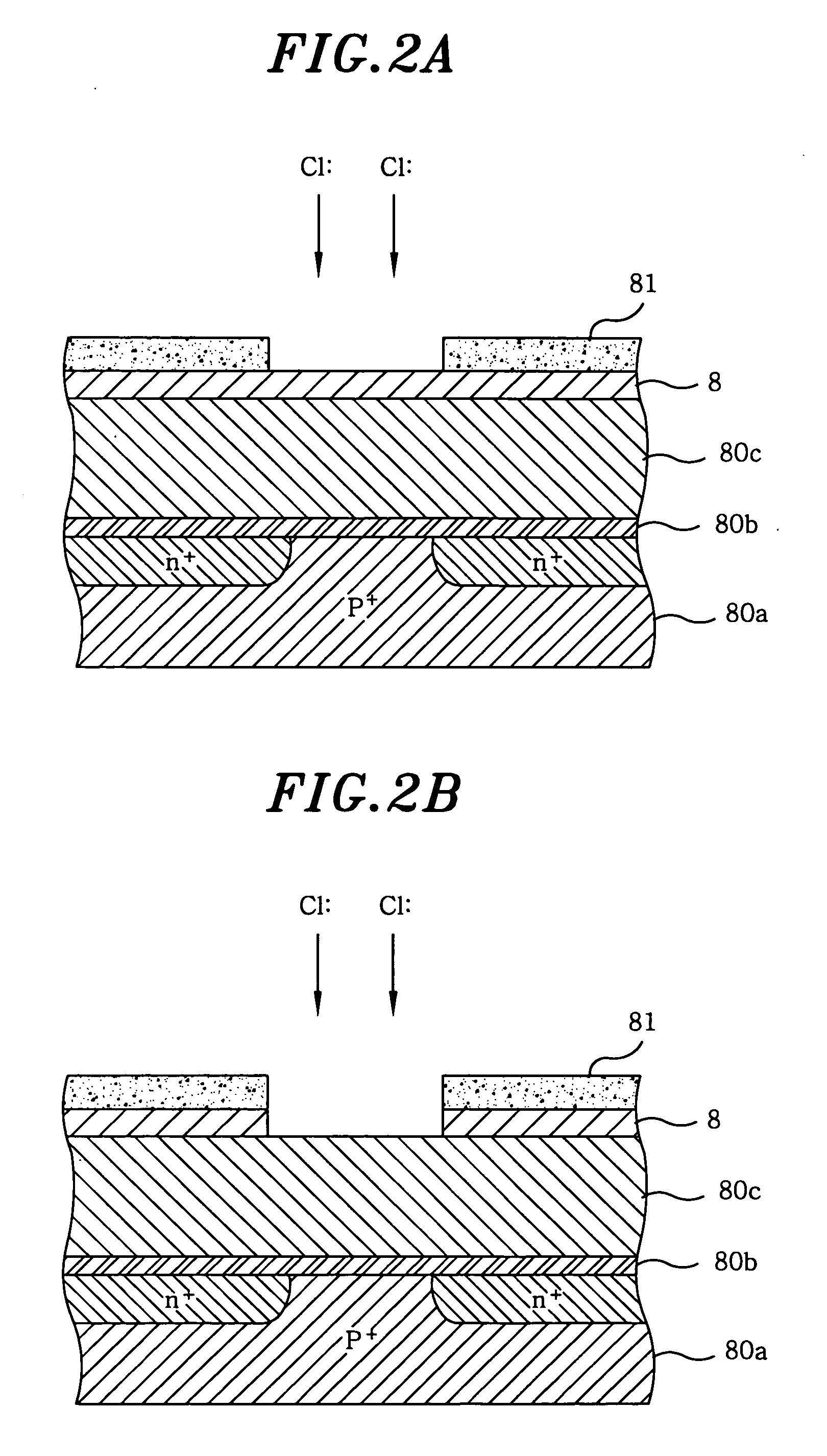

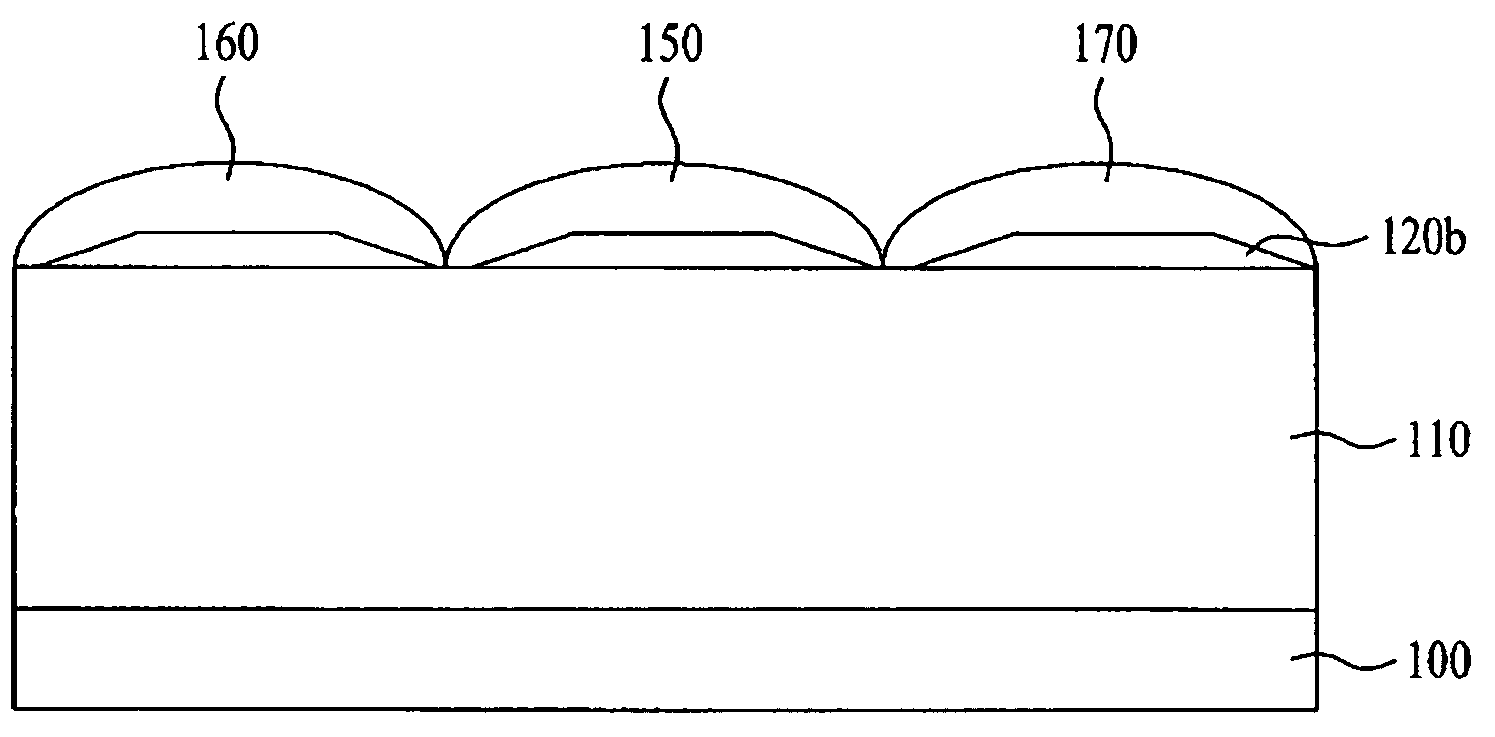

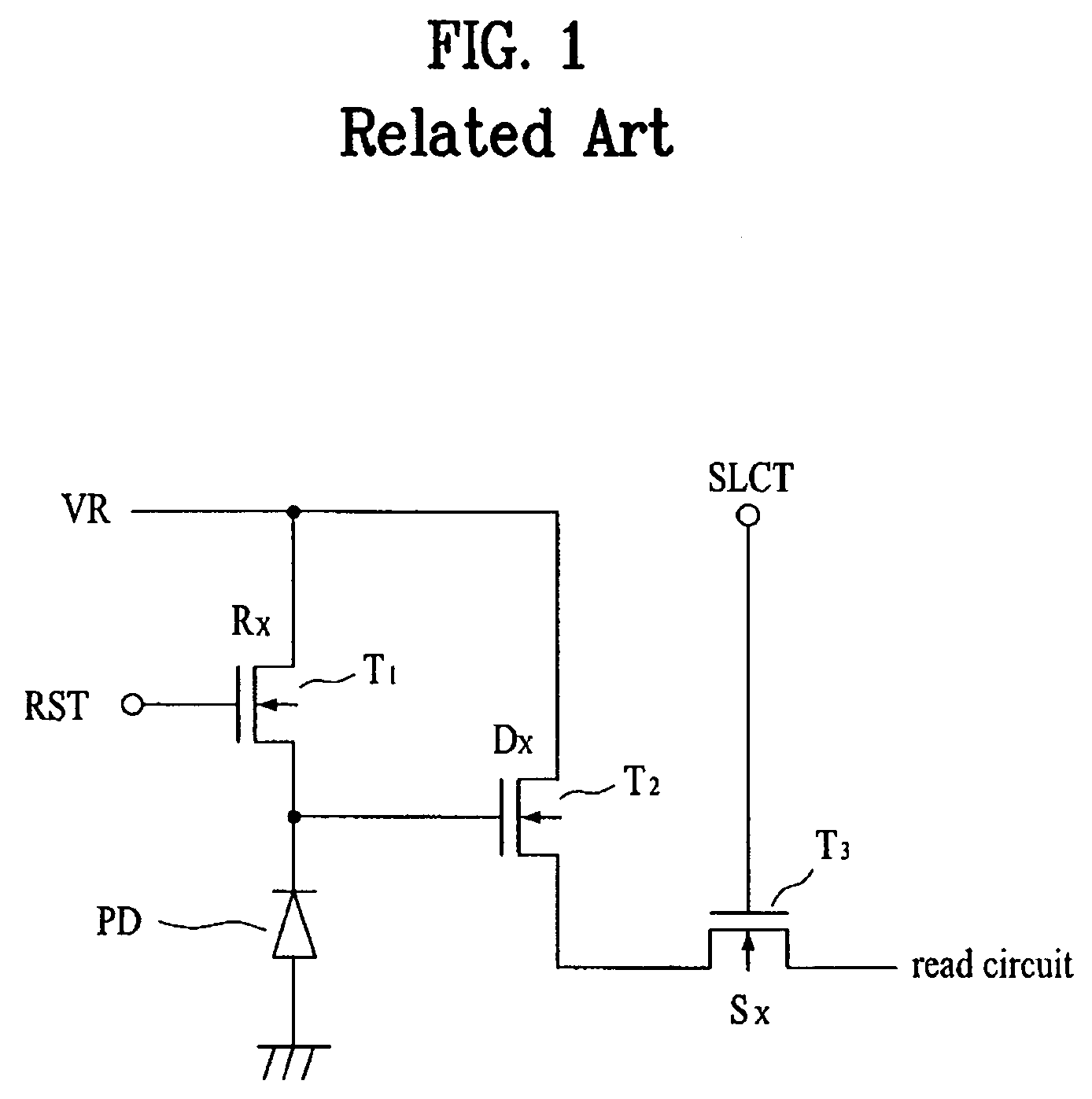

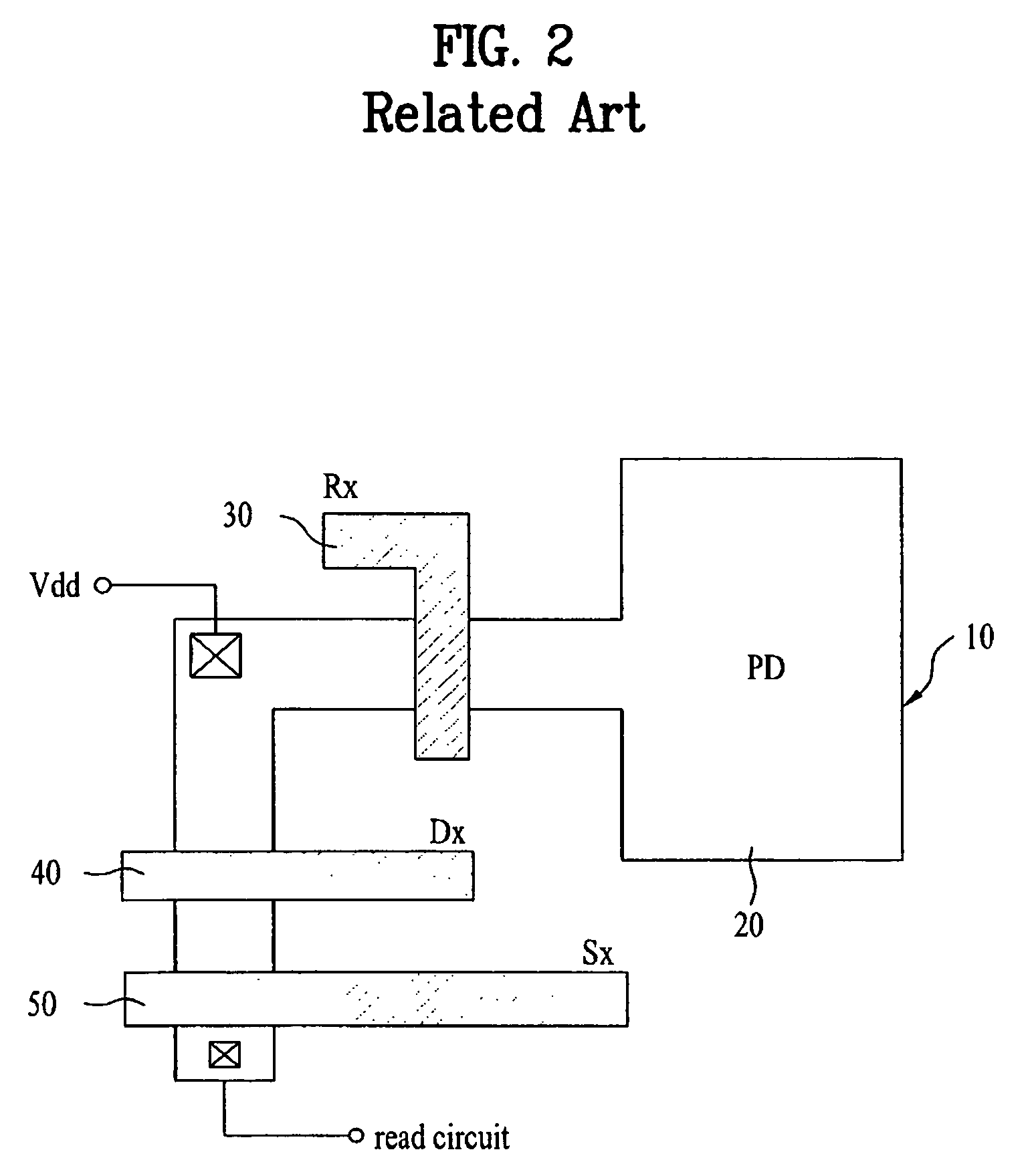

Image sensor and fabricating method thereof

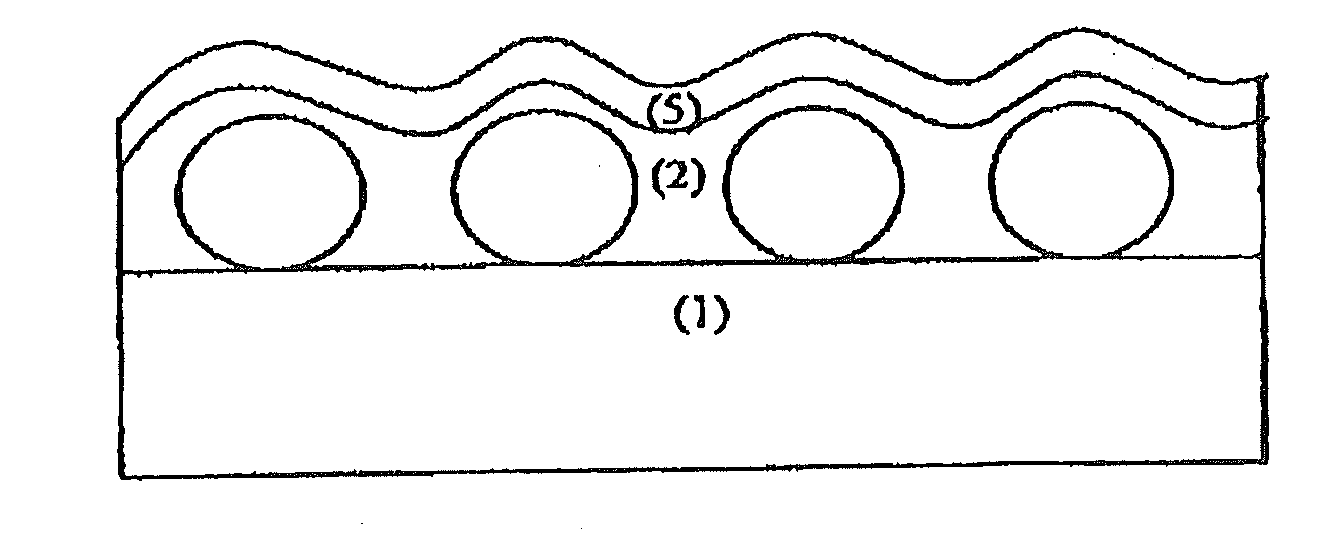

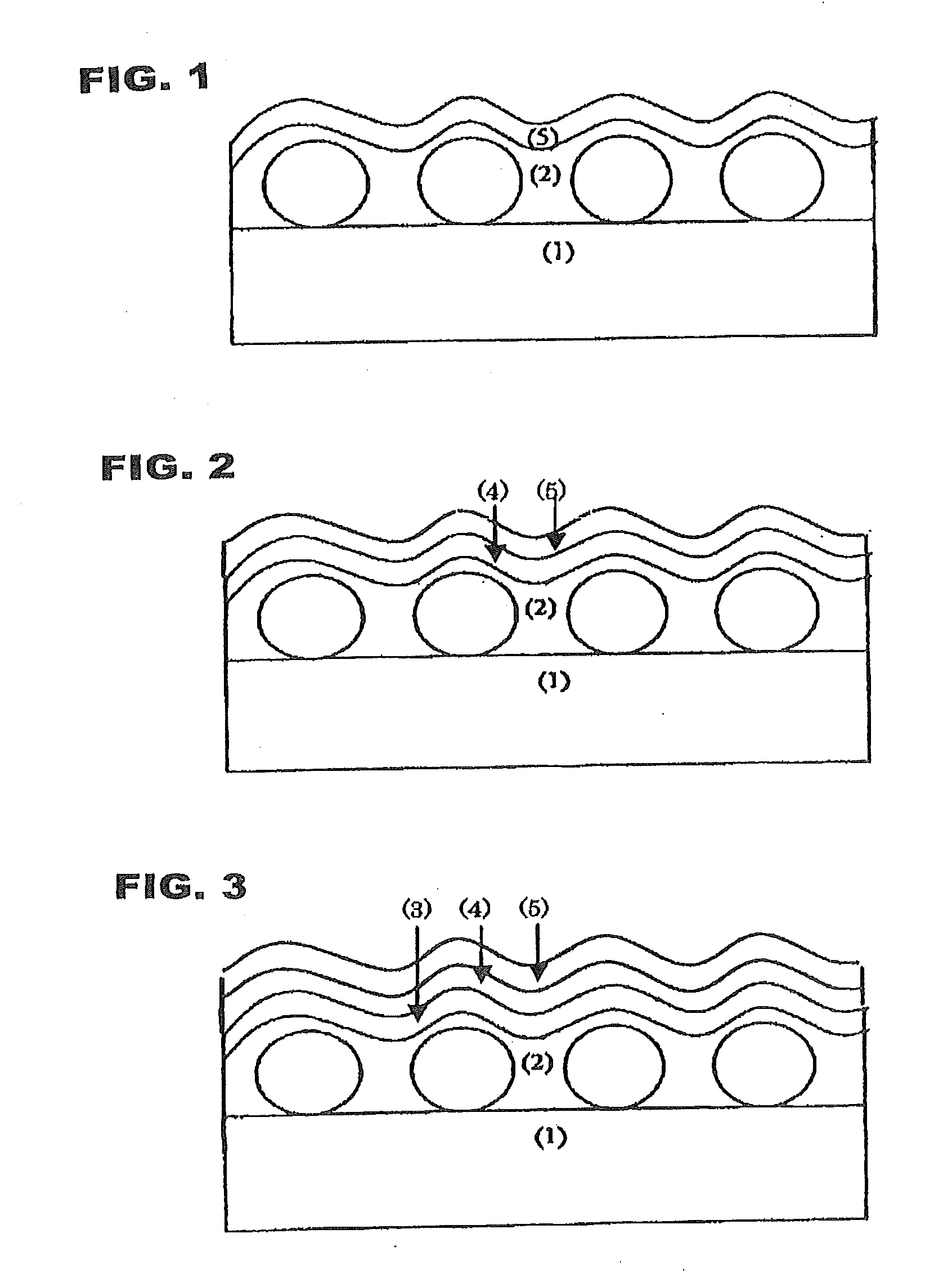

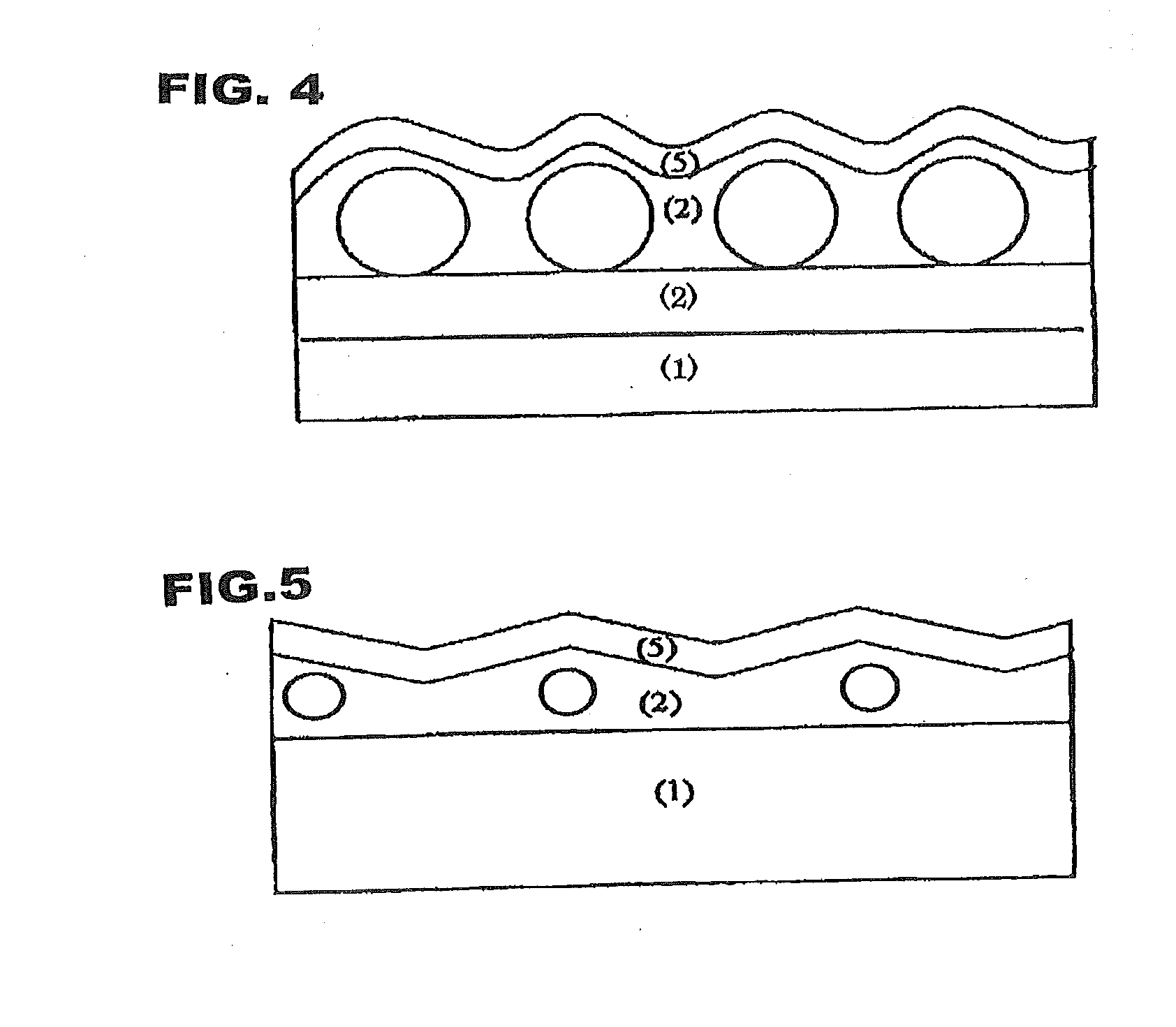

InactiveUS20070102621A1Improve surface uniformityPhotoelectric conversionSolid-state devicesSemiconductor/solid-state device manufacturingMicrolensImage sensor

An image sensor includes the steps of forming a sublayer including a photodiode, a transistor and a metal line on a substrate, forming a pattern layer on the sublayer to be overlapped with the photodiode and to having a curved surface, and forming a combined color filter and microlens on the pattern layer to have a curved surface.

Owner:DONGBU ELECTRONICS CO LTD

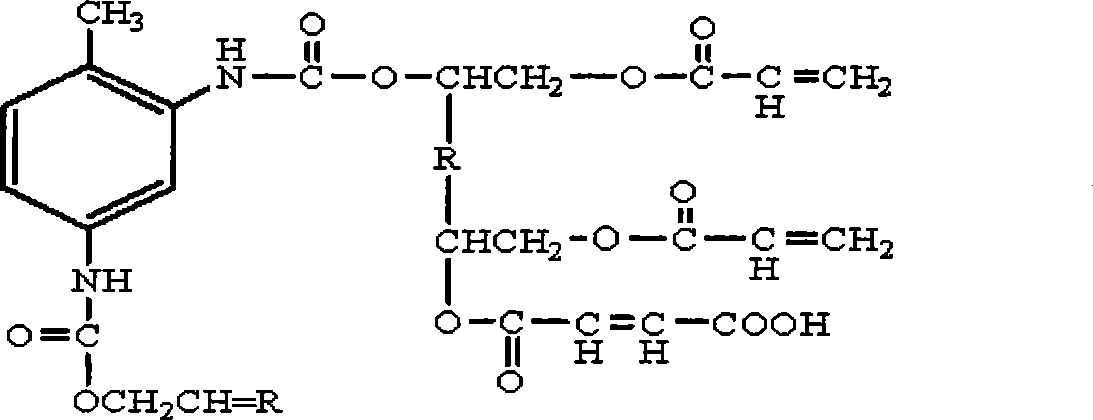

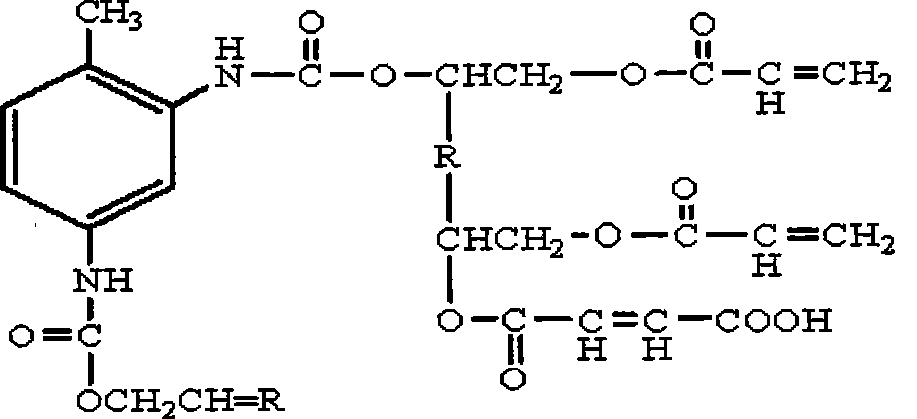

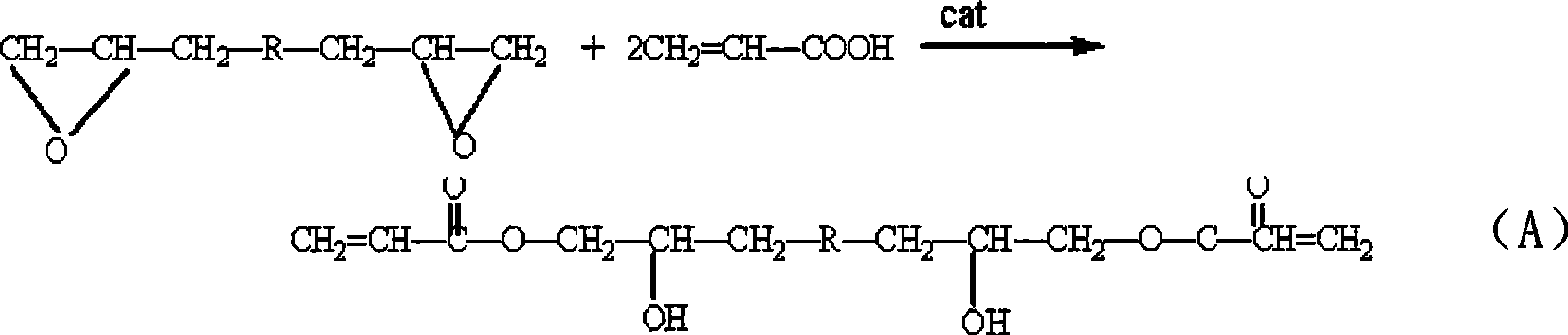

Water ultraviolet light curing epoxy acrylic ester grafted polyurethane and preparation method thereof

ActiveCN101397363AFast curingReduce energy consumptionEpoxy resin coatingsPrinting inkAddition reaction

The invention relates to the technical field of polymer materials, in particular to water based ultraviolet light-curable epoxy acrylate grafted polyurethane and a preparation method thereof; the water based ultraviolet light-curable epoxy acrylate grafted polyurethane firstly goes through the synthetic reaction of epoxy acrylate resin and the half addition reaction of alkyl aromatics isocyanate and undersaturation compounds containing primary hydroxyl group; and then self-emulsifiable transparent water based system with achromatic color to light yellow is produced by epoxy acrylate grafted polyurethane and the water based reaction thereof, namely, the polyurethane modified epoxy acrylate resin which can be cured by ultraviolet light and is applicable to water paint, printing ink. The water based ultraviolet light-curable epoxy acrylate grafted polyurethane is characterized by good chemicals resistance performance, low production cost, rapid curing speed, high paint film hardness and good water resisting property and can be applied to multiple fields.

Owner:广东佳景科技股份有限公司 +1

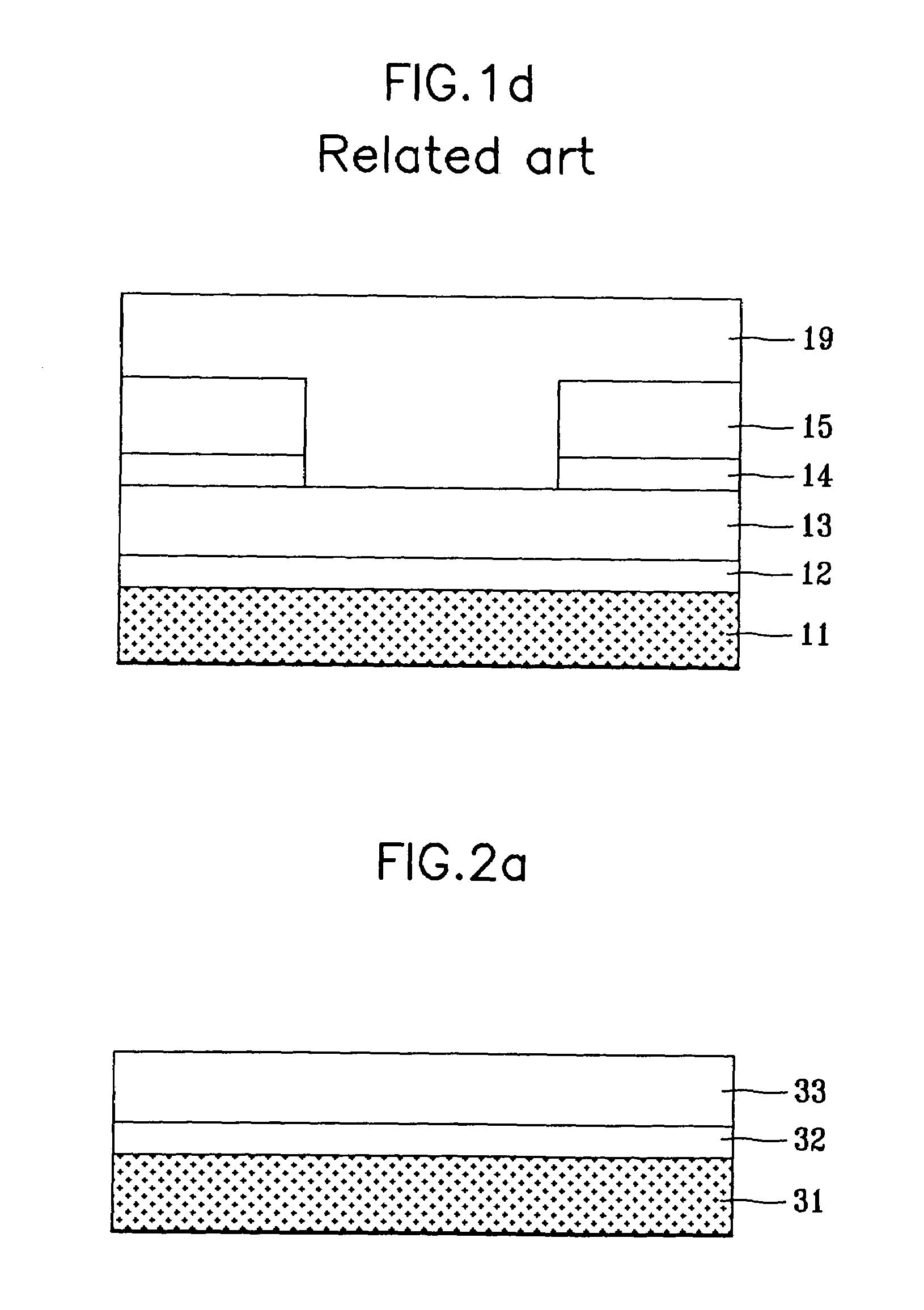

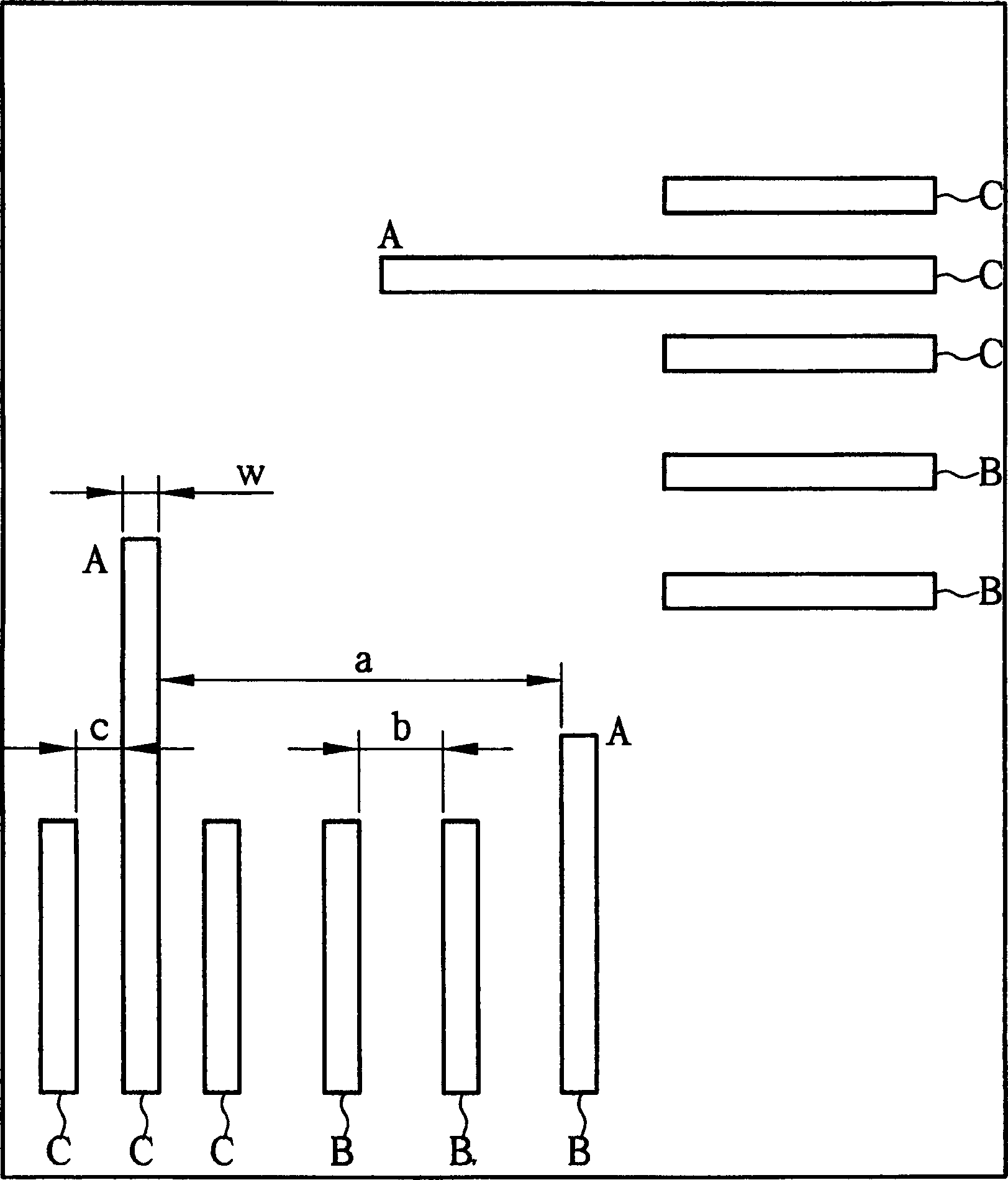

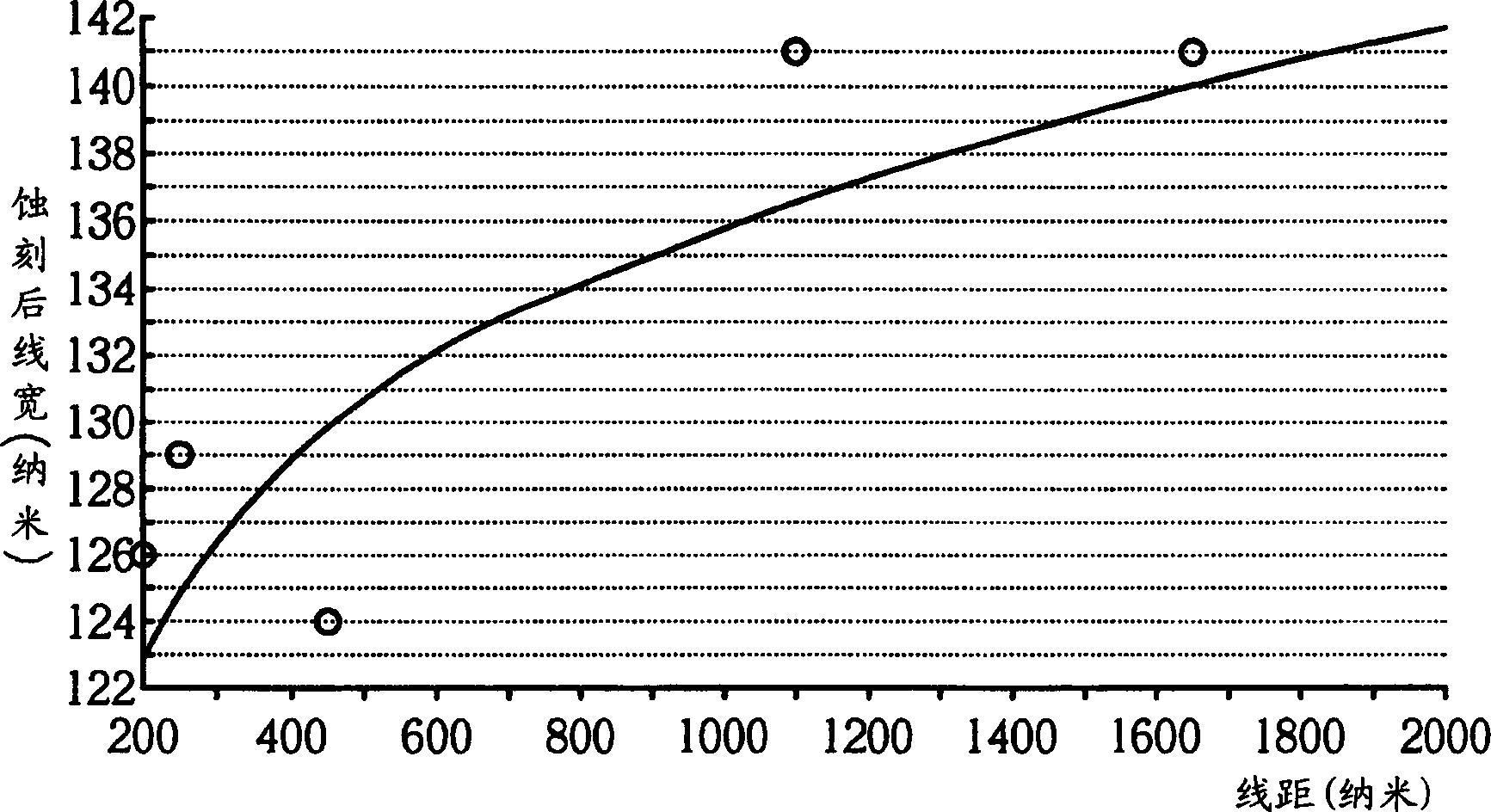

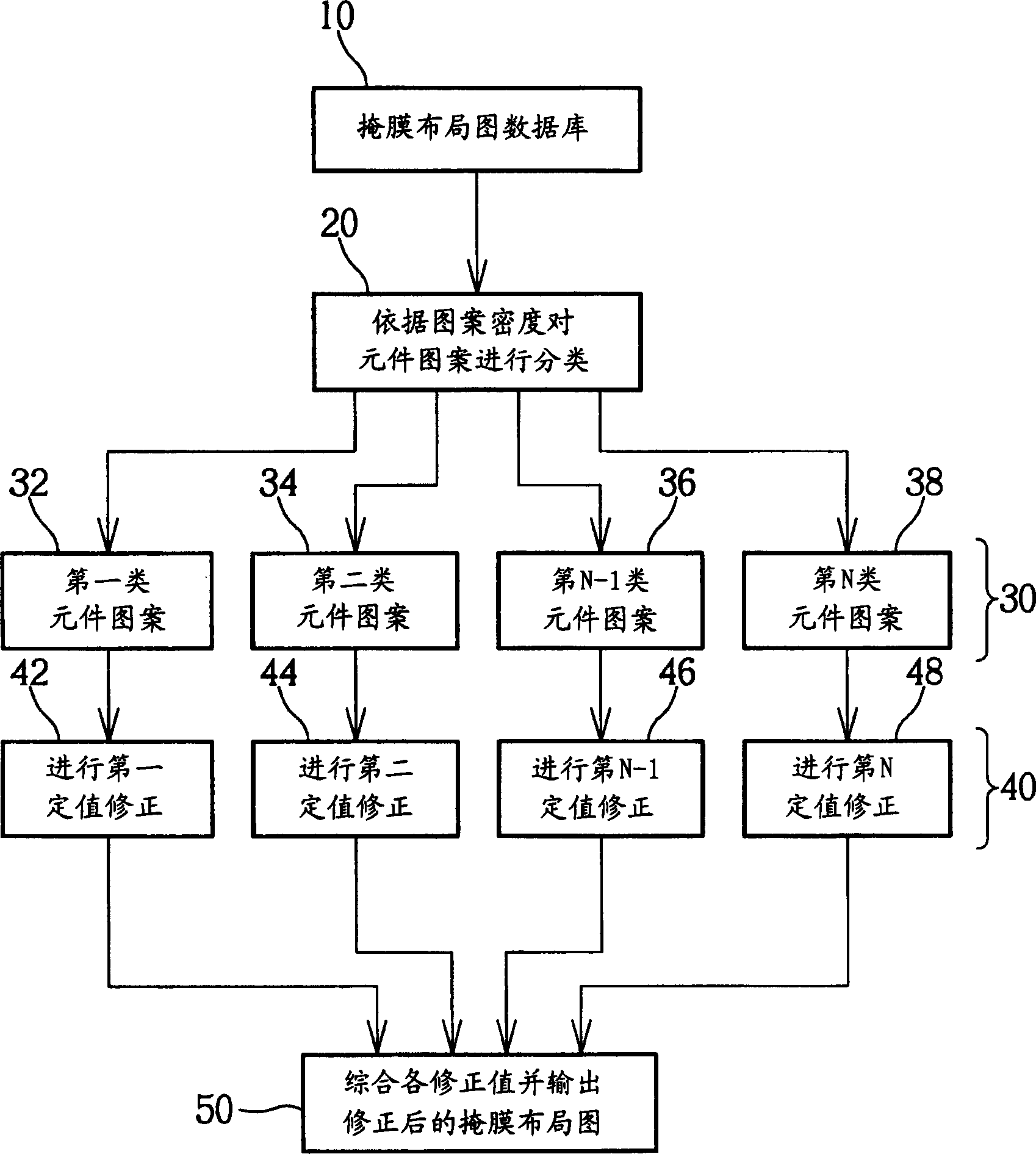

Method for correcting mask distribution pattern

InactiveCN1450407AImprove surface uniformityImprove yieldPhotomechanical apparatusOriginals for photomechanical treatmentCell patternDistribution pattern

The invention provides a method to correct the mask layout, the layout including multiple cell patterns with different densities. It firstly carries out a detecting program, and according to the densities separates various component patterns into multiple kinds of cell patterns, and finally corrects various kinds of cell patterns, respectively.

Owner:UNITED MICROELECTRONICS CORP

Optical film, Anti-reflection film, polarizing plate and image display device

InactiveUS20110256312A1Improve surface uniformityDecreasing drying unevenness and wind unevennessOptical filtersPolarising elementsDisplay deviceViscosity

Owner:FUJIFILM CORP

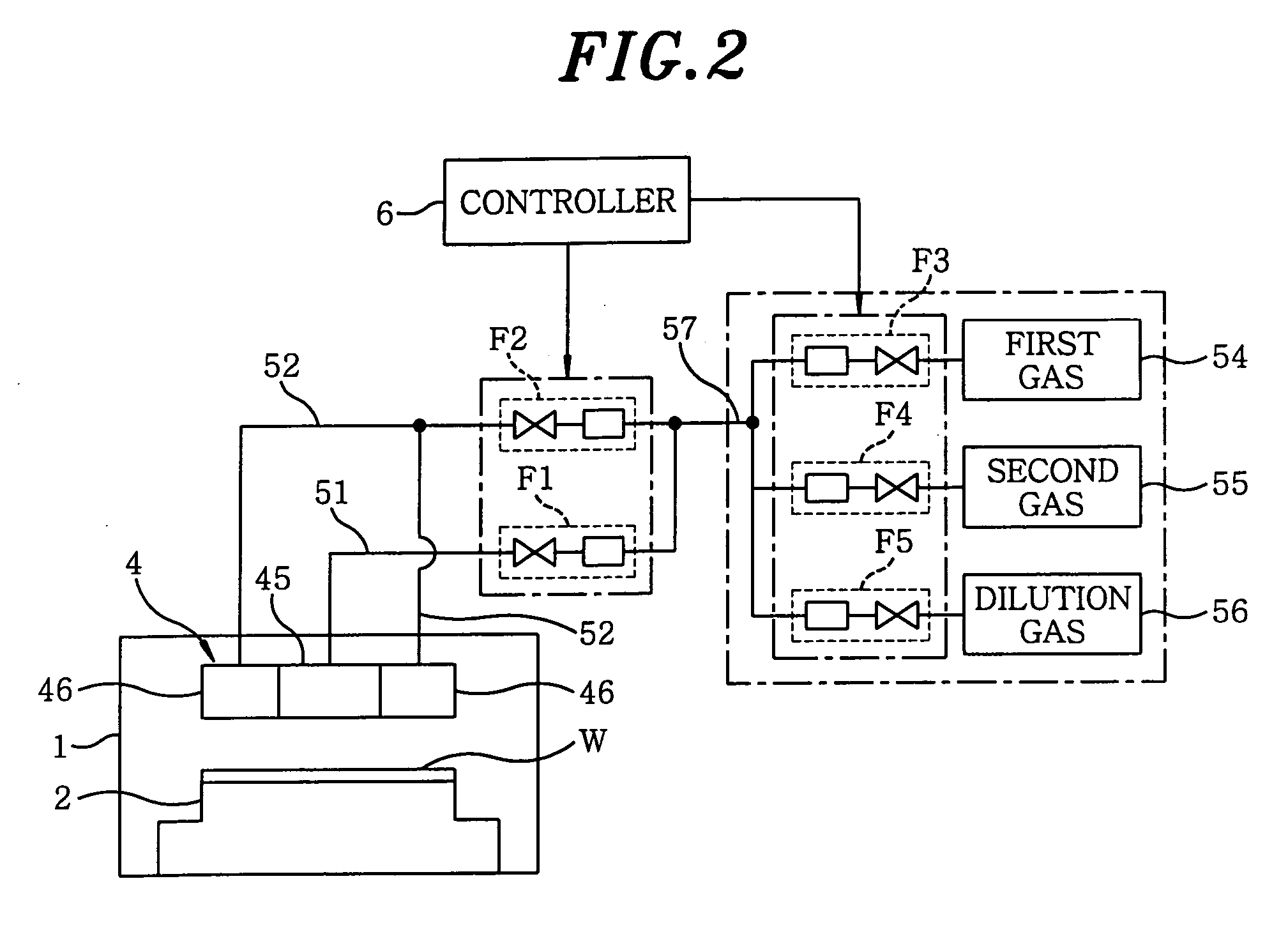

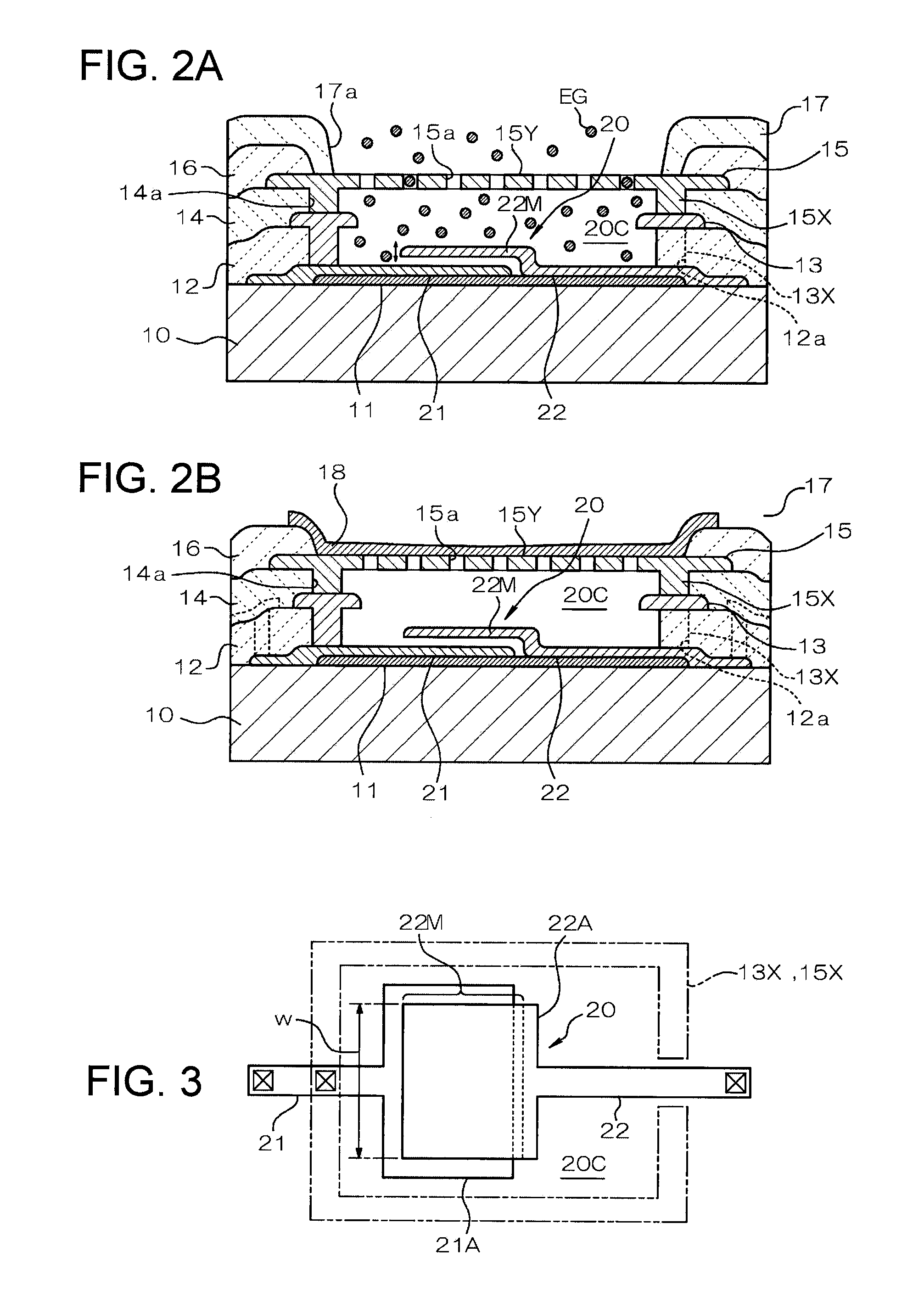

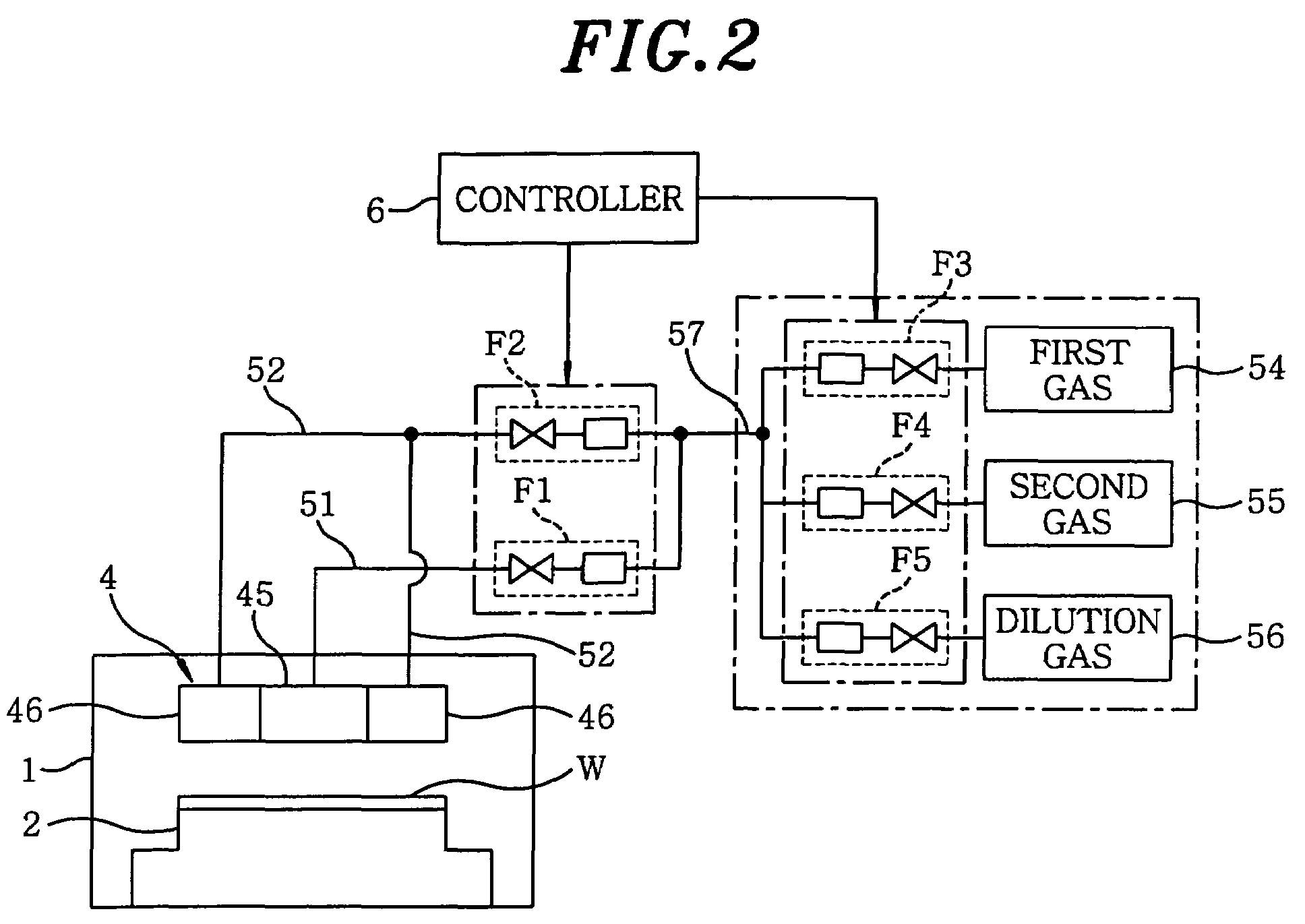

Etching method and apparatus

ActiveUS20060213864A1Improve surface uniformityHigh trafficElectric discharge tubesVacuum gauge using ionisation effectsCarbon numberHalogen

When a substrate is etched by using a processing gas including a first gas containing halogen and carbon and having a carbon number of two or less per molecule, while supplying the processing gas toward the substrate independently from a central and a peripheral portion of a gas supply unit, which face the central and the periphery part of the substrate respectively, the processing gas is supplied such that a gas flow rate is greater in the central portion than in the peripheral portion. When the substrate is etched by using a processing gas including a second gas containing halogen and carbon and having a carbon number of three or more per molecule, the processing gas is supplied such that a gas flow rate is greater in the peripheral portion than in the central portion.

Owner:TOKYO ELECTRON LTD

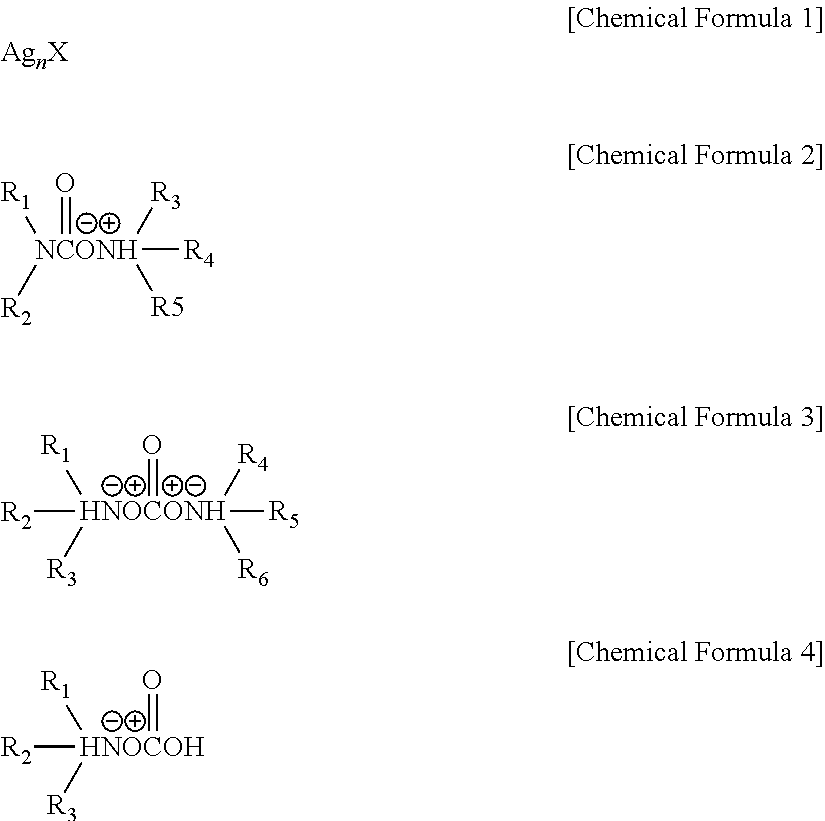

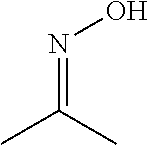

Silver ink composition

ActiveUS20140026782A1Improve stabilityImprove conductivityAntifouling/underwater paintsInksSilver inkPhysical chemistry

The present invention relates to a silver ink composition comprising: silver complexes obtained by reacting one or more silver compounds selected from chemical formula 1 with one or more ammonium carbamate-based compounds or ammonium carbonate-based compounds selected from chemical formula 2 to chemical formula 4; and oxime-based compounds.

Owner:INKTEC CO LTD

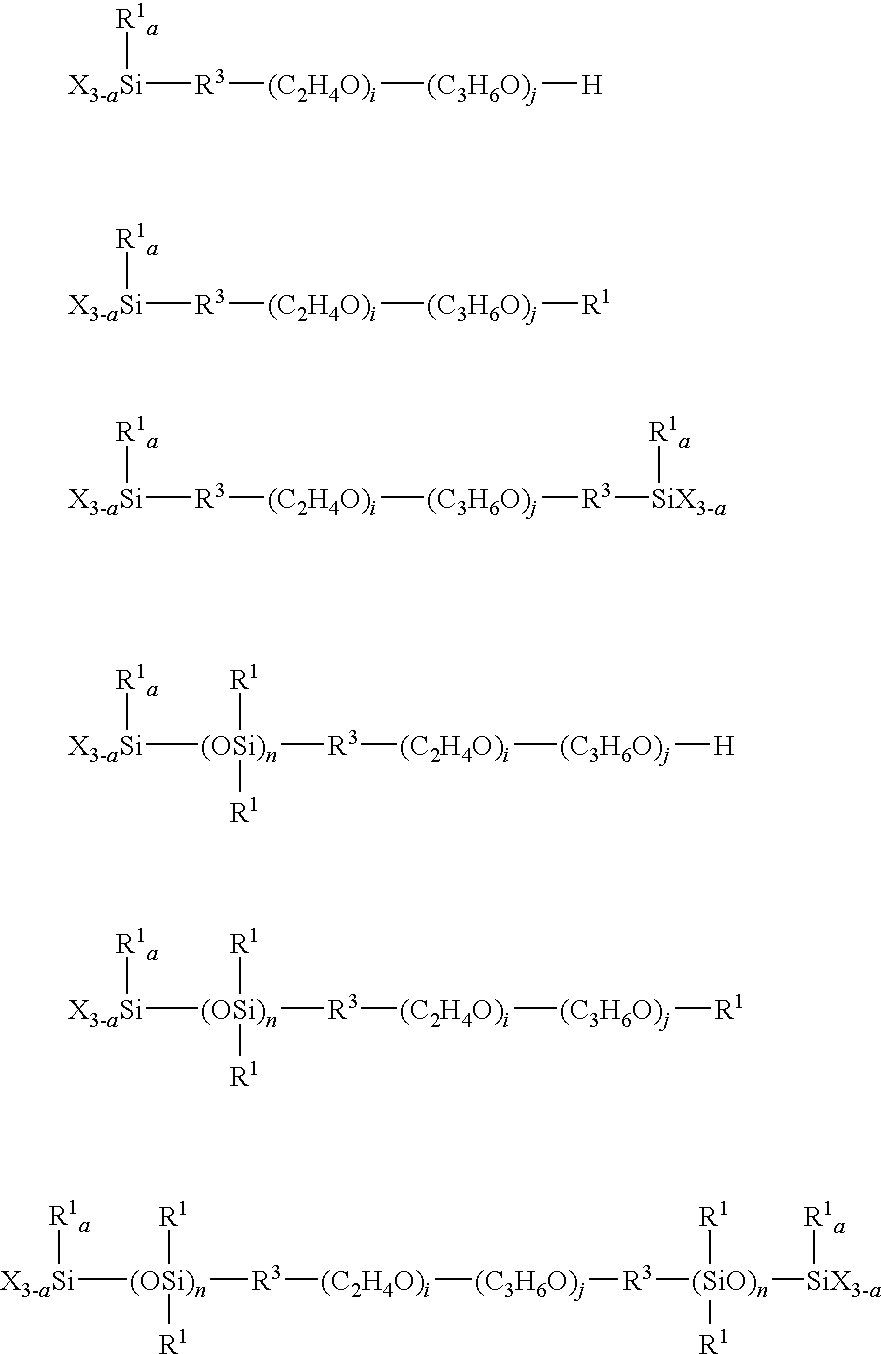

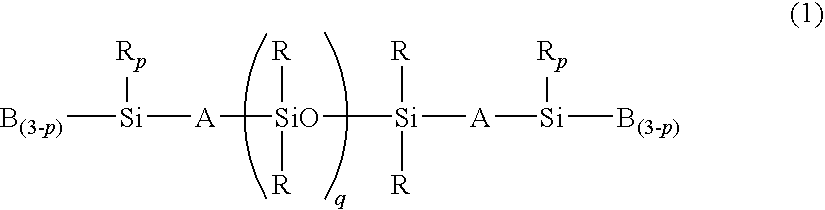

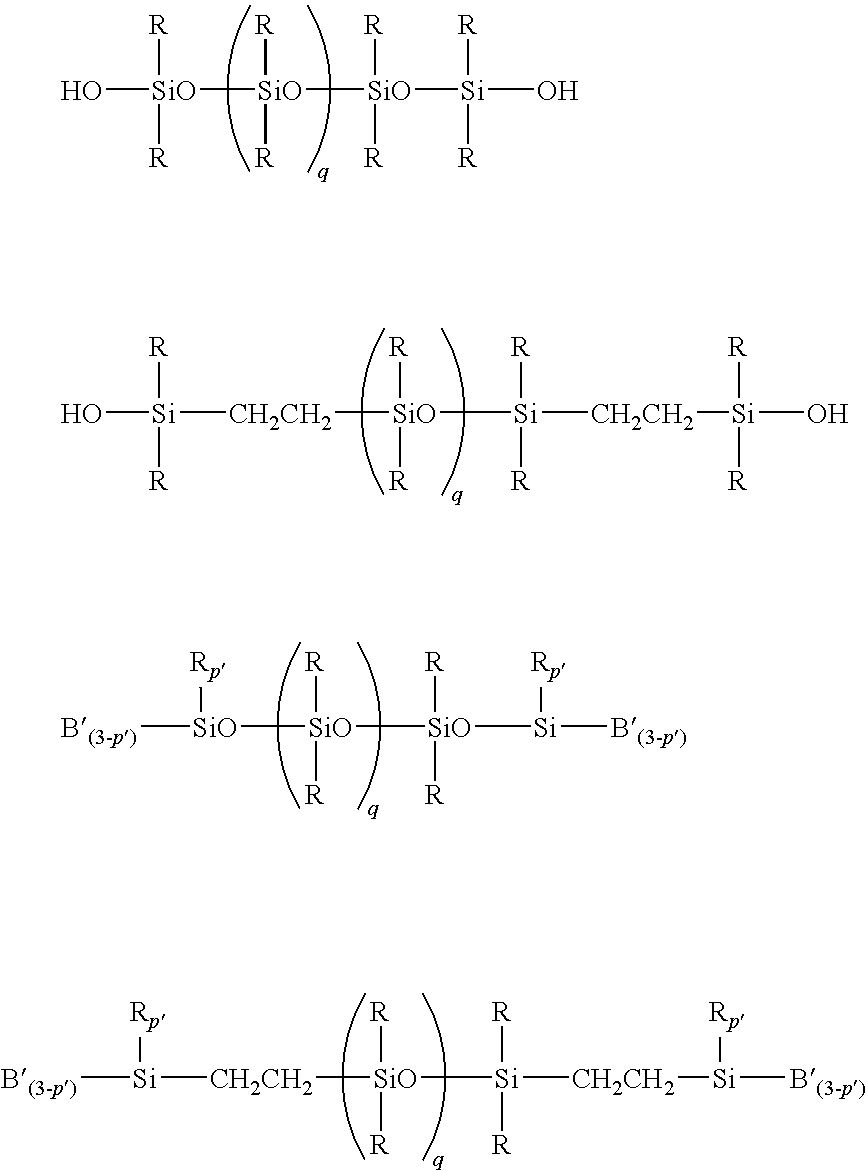

Process for producing room temperature vulcanizable organopolysiloxane composition and base material coated with composition obtained by the production process

InactiveUS20100069531A1Low viscosityImprove thixotropyLayered productsSpecial tyresPolymer sciencePartial hydrolysis

A process for producing a room temperature vulcanizable organopolysiloxane composition comprising:(A) 100 parts by weight of a diorganopolysiloxane having in one molecule at least two hydroxyl groups and / or hydrolyzable groups connecting to silicon atoms;(B) 0.2 to 10 parts by weight of an alkylene oxide compound having silicon atoms in a molecule;(C) 0.5 to 100 parts by weight of a silica; and(D) 0.5 to 30 parts by weight of a silane and / or condensate of partial hydrolyzate thereof,wherein said process comprises steps of hot-mixing component (A), component (B), and component (C) together, and subsequently mixing component (D) thereto.

Owner:SHIN ETSU CHEM IND CO LTD

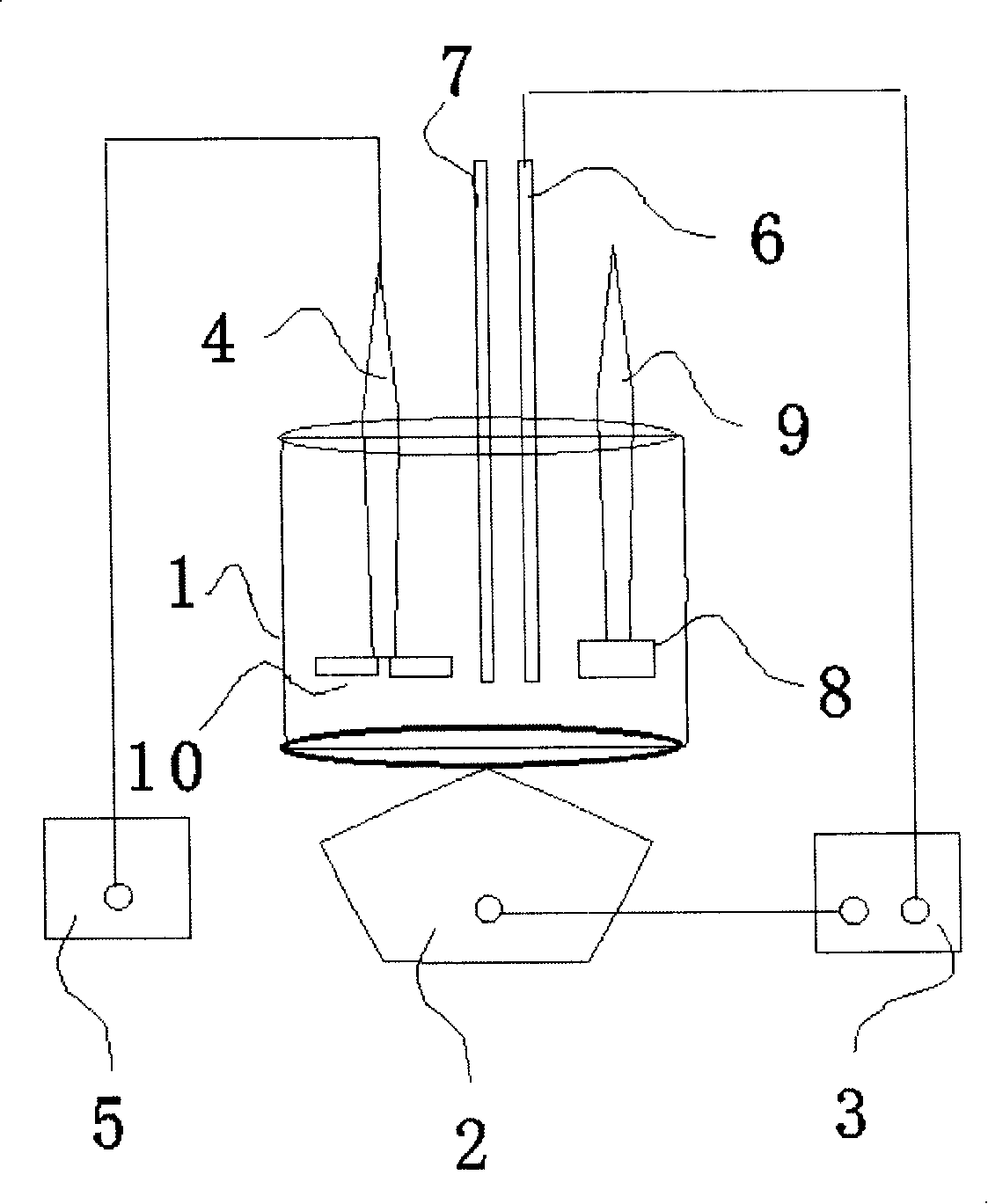

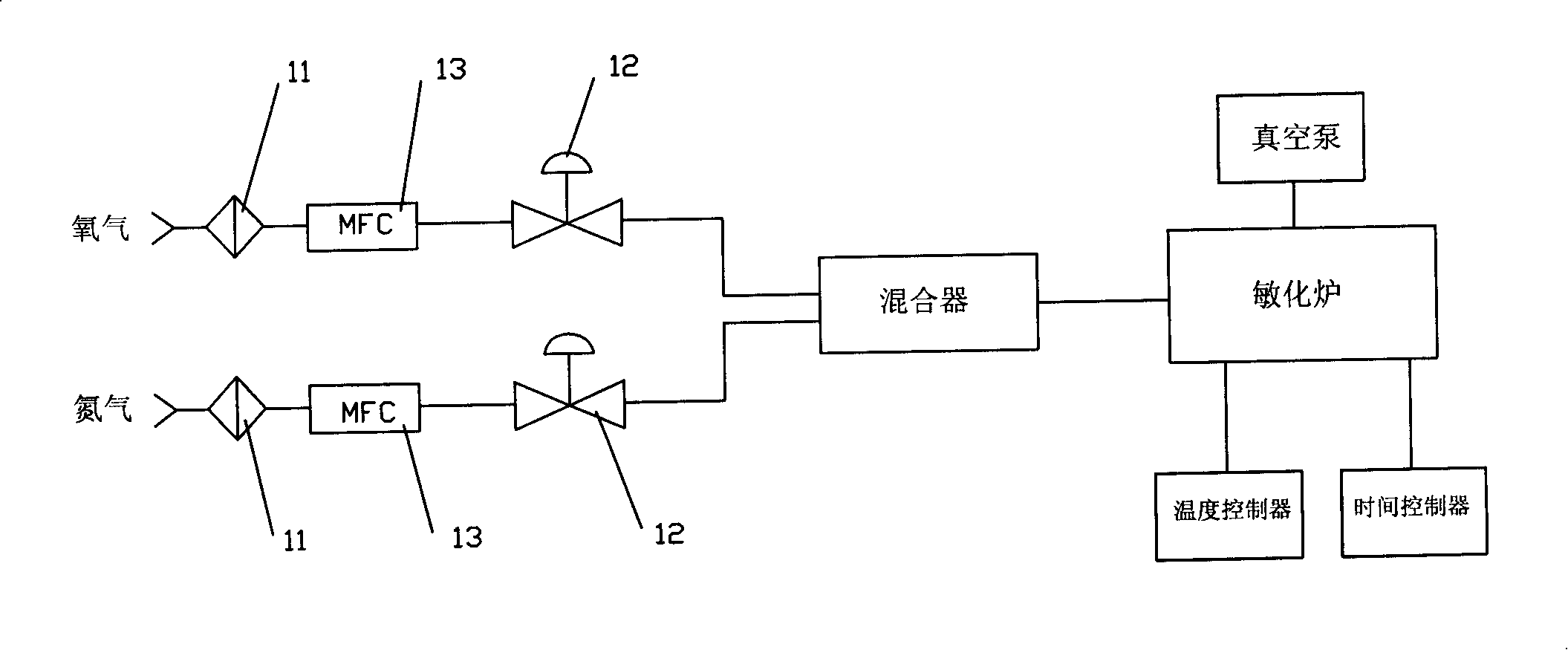

Method of making photosensitive lead salt thin film of infrared detector

InactiveCN101170149AImprove uniformityImprove surface uniformityFinal product manufactureSemiconductor devicesLead saltNitrogen

The invention relates to a method of preparing a photosensitive lead salt film of infrared detectors. Compared with the lead salt film prepared by the chemical deposition method, the invention comprises the steps of adopting a stirring method and supplements chemical mother liquid participating in reaction at right time in the preparation course and realizes the components spatial evenness of the prepared lead salt; adopting controllable large discharge gas mixture of nitrogen and oxygen to perform sensitizing treatment to the lead salt film and realizes the spatial evenness of the prepared lead salt film with photoelectrical response character. By practice test, the 25mm multiplies by 25mm PbS film prepared by the invention has the evenness of photoelectrical response more than 25 percent.

Owner:CHINA AIR TO AIR MISSILE INST

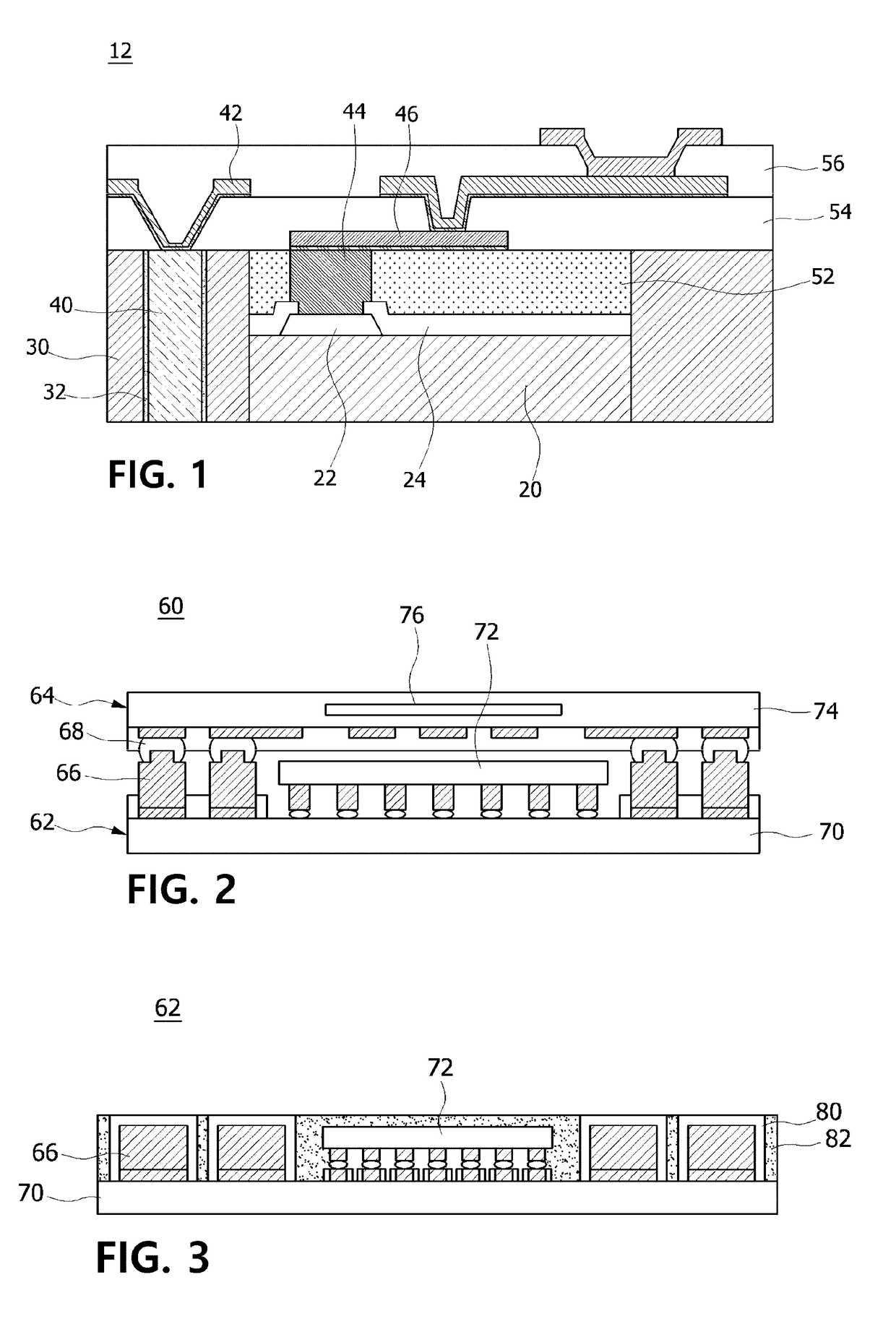

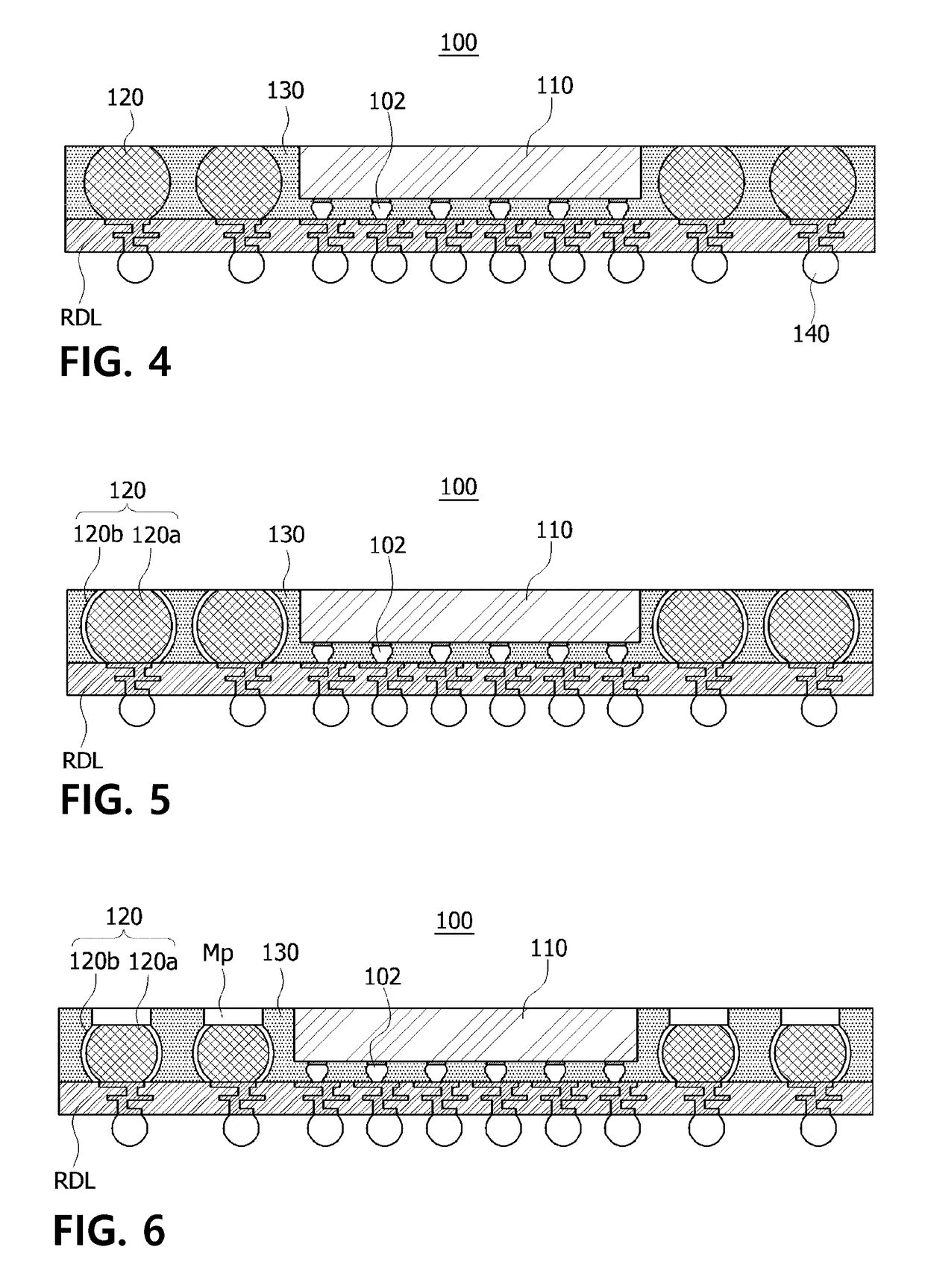

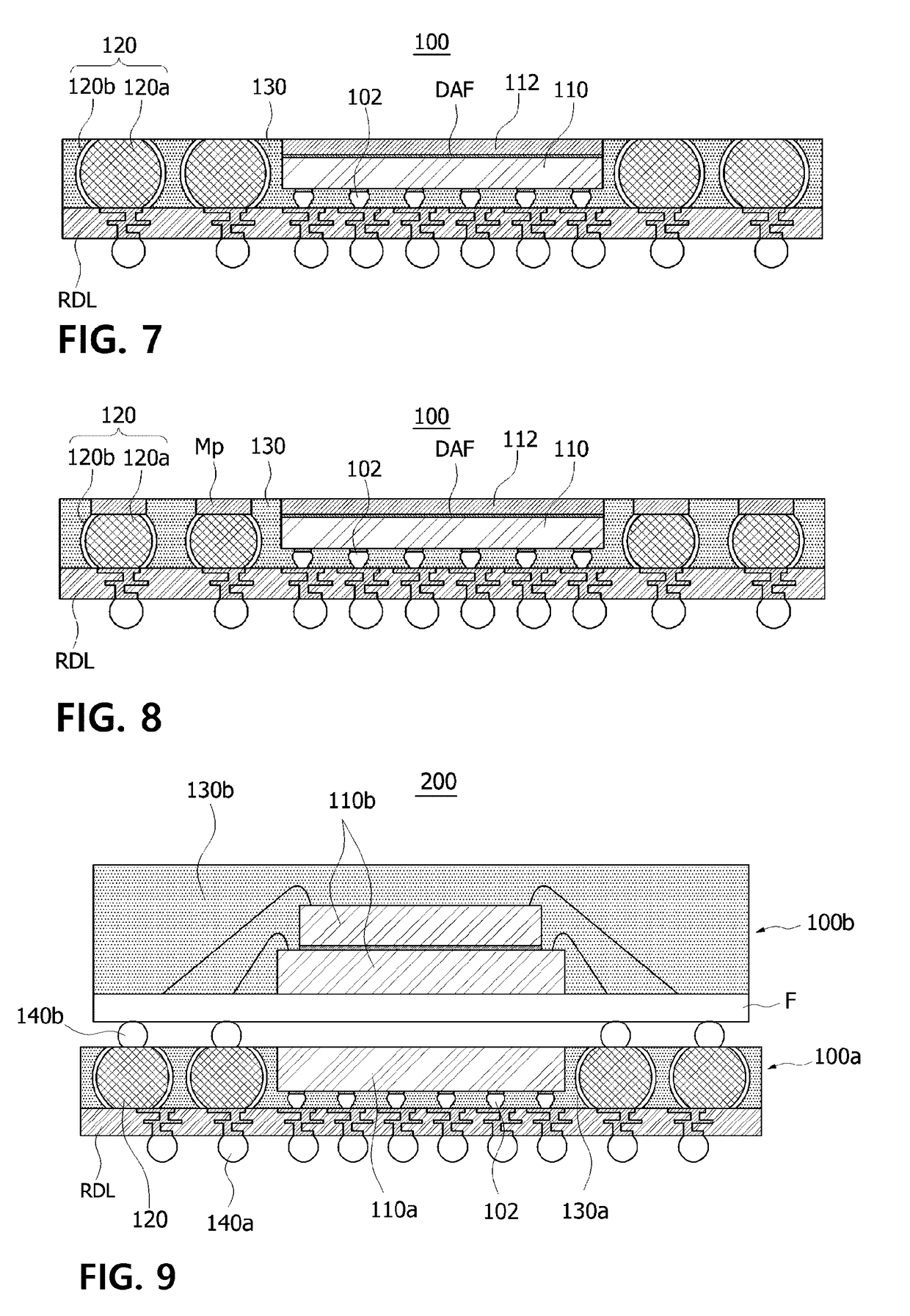

Metal core solder ball interconnector fan-out wafer level package and manufacturing method therefor

ActiveUS20180358288A1Minimize in sizeAppropriate adjustmentSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSolder ball

fan-out wafer level package is disclosed, which comprises: a redistribution layer; a semiconductor chip electrically connected with the redistribution layer through a bump; a protective member protecting the semiconductor chip, wherein a part of the protective member is removed such that the upper surface of the semiconductor chip is exposed in order to dissipate heat and prevent warpage; and an interconnector disposed outside the semiconductor chip at substantially the same level and having a lower part electrically connected with the redistribution layer and an upper part not being covered with the protective member, wherein the interconnector includes a metal core solder ball, the metal core solder ball includes a metal core and a solder buffer between the metal core and the protective member, and the metal core is formed of a combination of copper (Cu), nickel (Ni), and silver (Ag).

Owner:HANA MICRON

Plasma processing method

InactiveUS7713431B2Improve surface uniformityIncrease temperatureLiquid surface applicatorsDecorative surface effectsTemperature controlHigh frequency power

Owner:TOKYO ELECTRON LTD

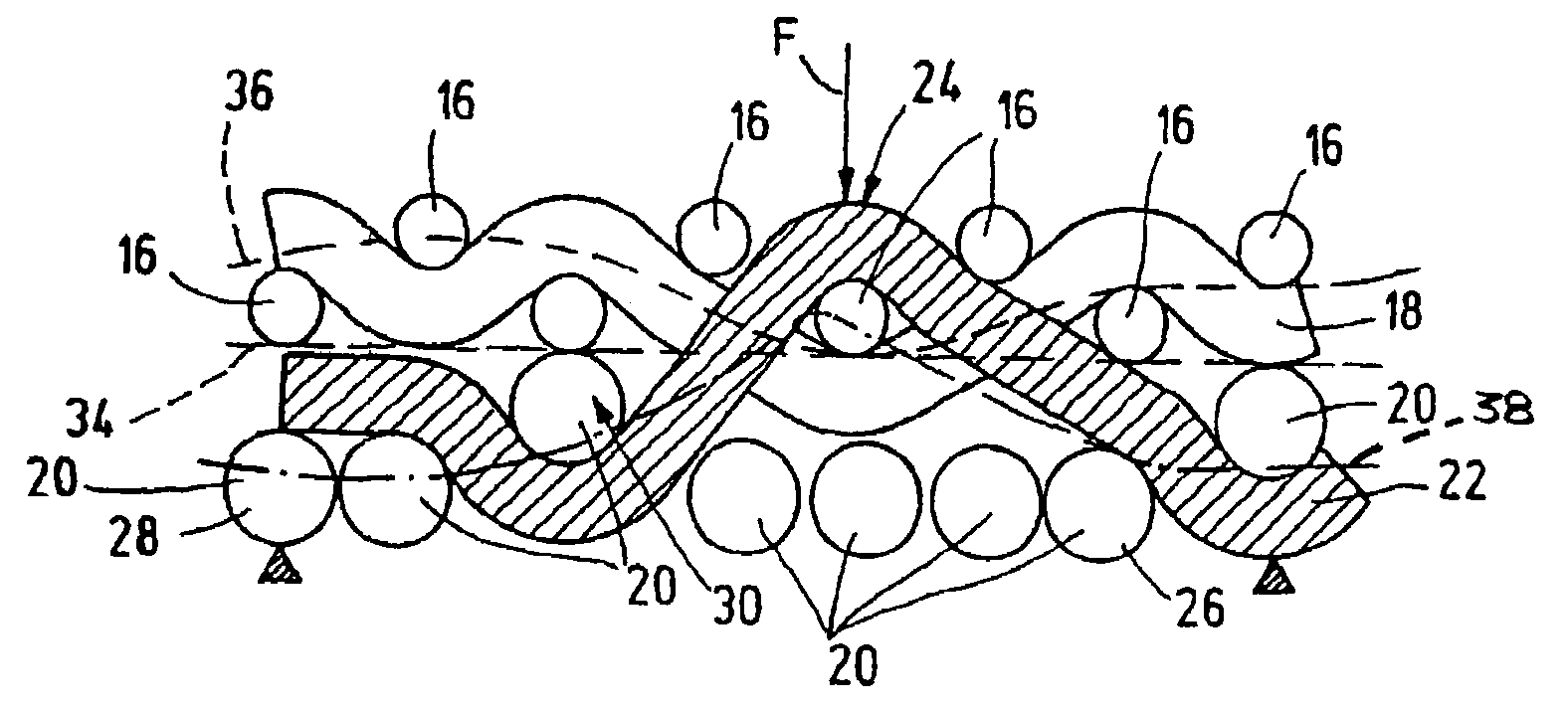

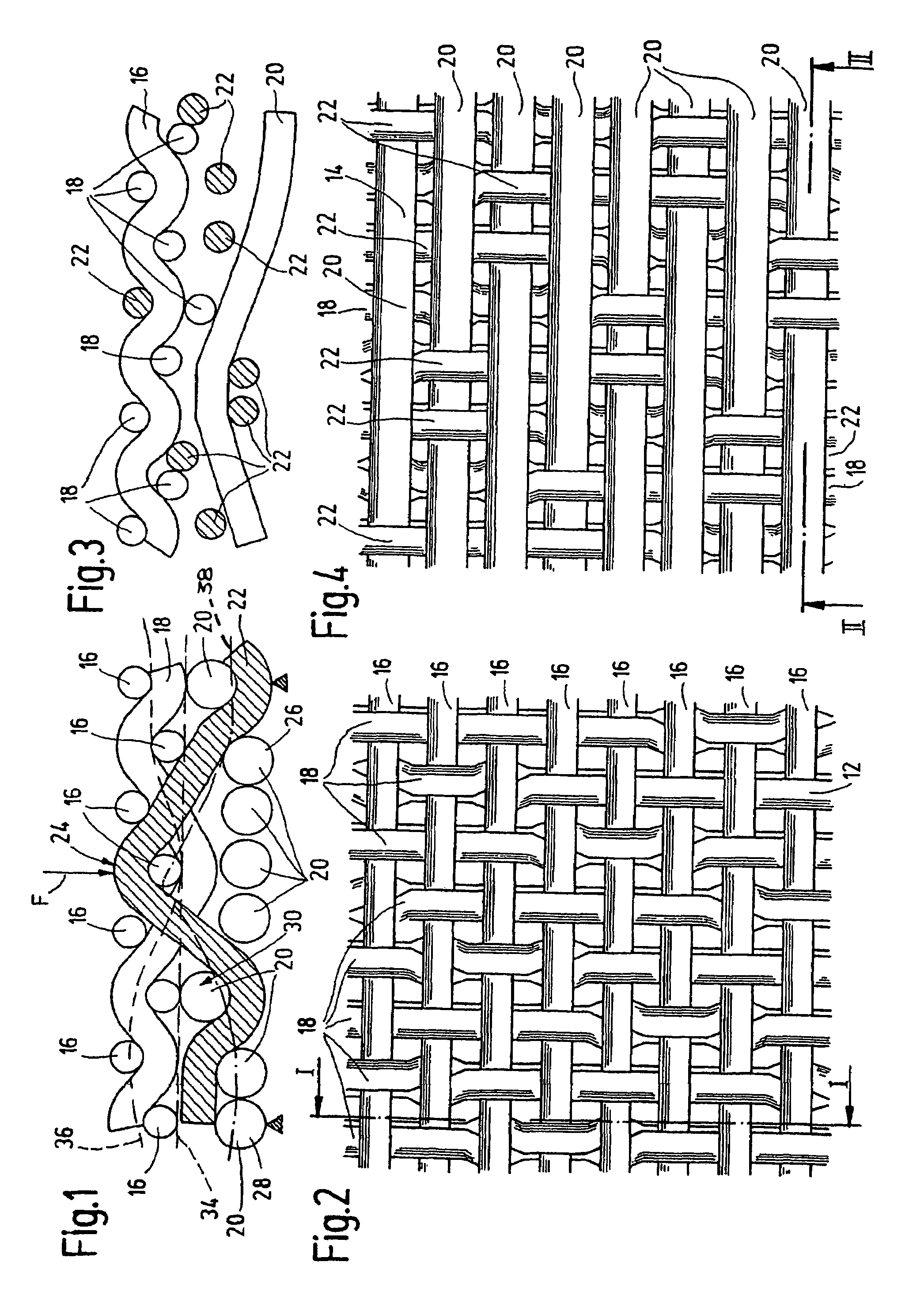

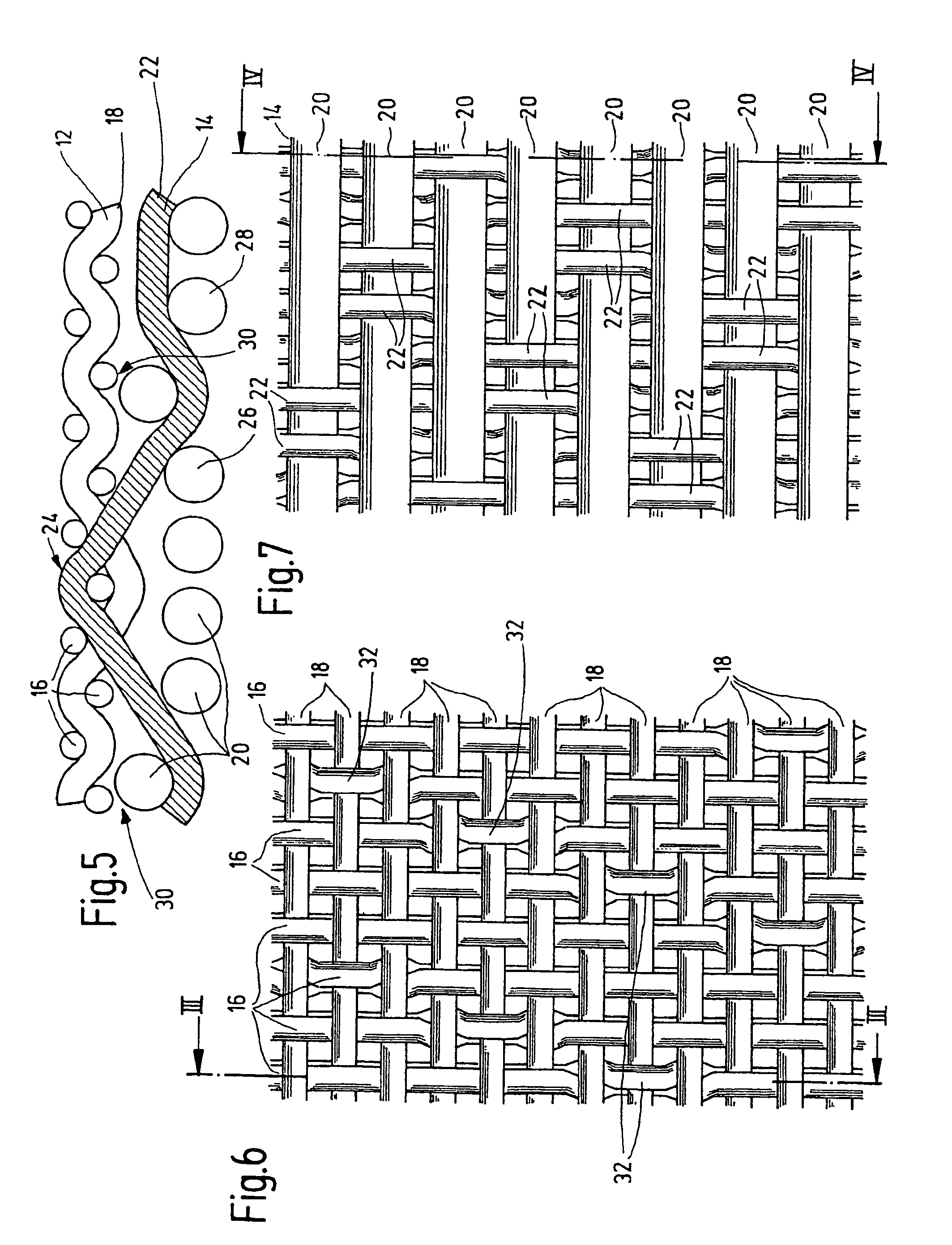

Paper-making machine wire cloth

A paper-making machine wire cloth has an individual woven cloth for the paper side (12) and an individual woven cloth for the running side (14). Each woven cloth includes a set of weft threads (16;20) and warp threads (18;22). The diameters and the number of paper side and running side warp threads (18;22) are essentially equal. The paper side warp threads (18) and weft threads (16), together, form a weave. At least a portion of the running side threads (22) passes into the paper side (12), extends over the subsequent paper side weft thread (16) and, afterwards, returns to the running side (14) each time at a location (24), at which this warp thread (22) is located above at least one assigned running side weft thread (20). A marking-free paper side is achieved in the weave, while simultaneously improving the surface uniformity. A compact binding of the individual woven cloth is effected without the use of additional binding threads, largely avoiding a layer separation of the individual woven cloth or an offset of the same with regard to one another.

Owner:ANDRITZ TECH & ASSET MANAGEMENT

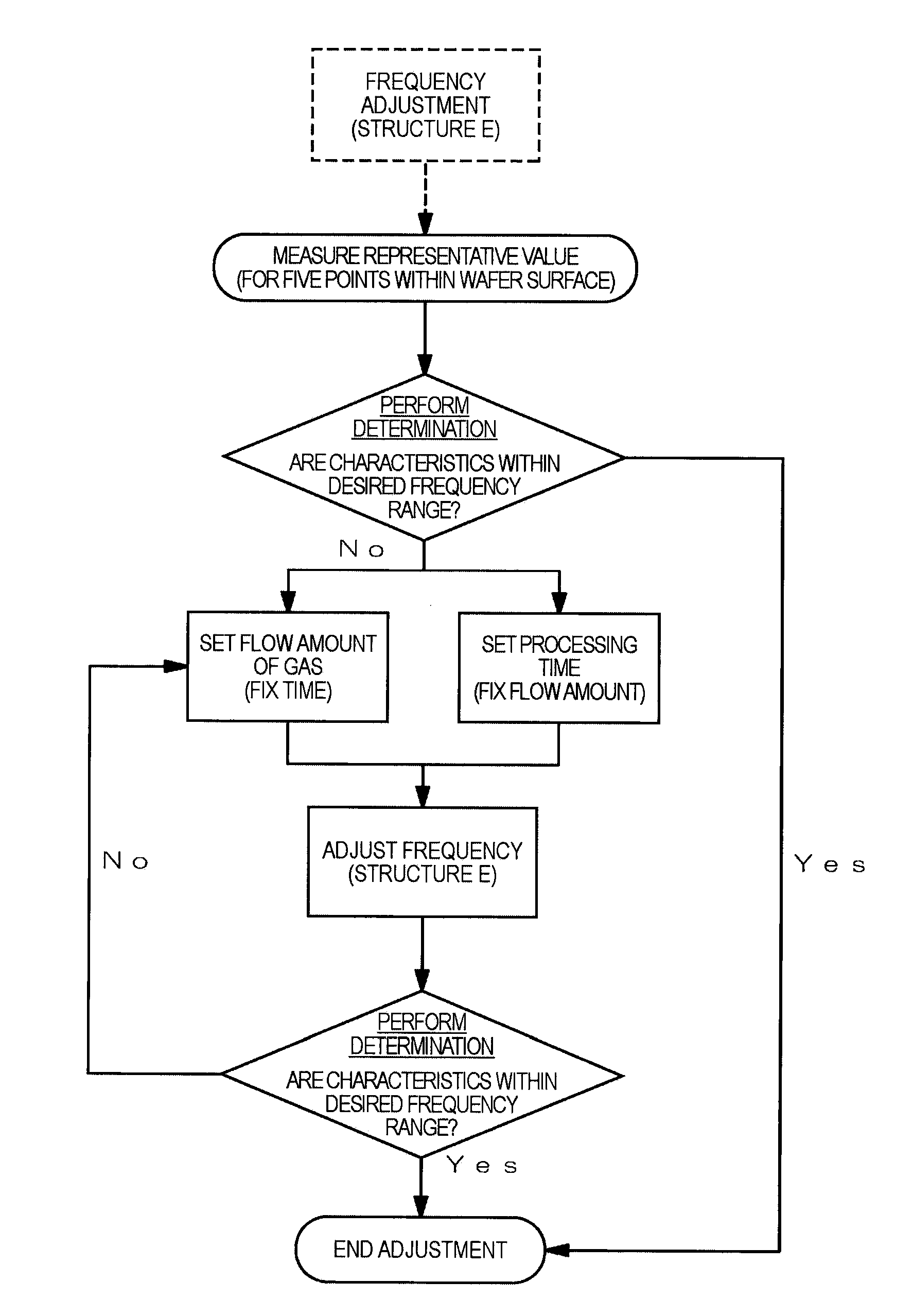

Method of manufacturing MEMS device

InactiveUS20100178717A1Easy to adjustImprove surface uniformitySemiconductor/solid-state device testing/measurementImpedence networksGas phaseEngineering

A method of manufacturing an MEMS device includes: forming a covering structure having an MEMS structure and a hollow portion, which is located on a periphery of the MEMS structure and is opened to an outside, on a substrate; and performing surface etching for the MEMS structure in a gas phase by supplying an etching gas to the periphery of the MEMS structure from the outside.

Owner:SEIKO EPSON CORP

Etching method and apparatus

ActiveUS7674393B2Improve surface uniformityHigh trafficElectric discharge tubesVacuum gauge using ionisation effectsCarbon numberHalogen

When a substrate is etched by using a processing gas including a first gas containing halogen and carbon and having a carbon number of two or less per molecule, while supplying the processing gas toward the substrate independently from a central and a peripheral portion of a gas supply unit, which face the central and the periphery part of the substrate respectively, the processing gas is supplied such that a gas flow rate is greater in the central portion than in the peripheral portion. When the substrate is etched by using a processing gas including a second gas containing halogen and carbon and having a carbon number of three or more per molecule, the processing gas is supplied such that a gas flow rate is greater in the peripheral portion than in the central portion.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com