Patents

Literature

81results about How to "Small flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

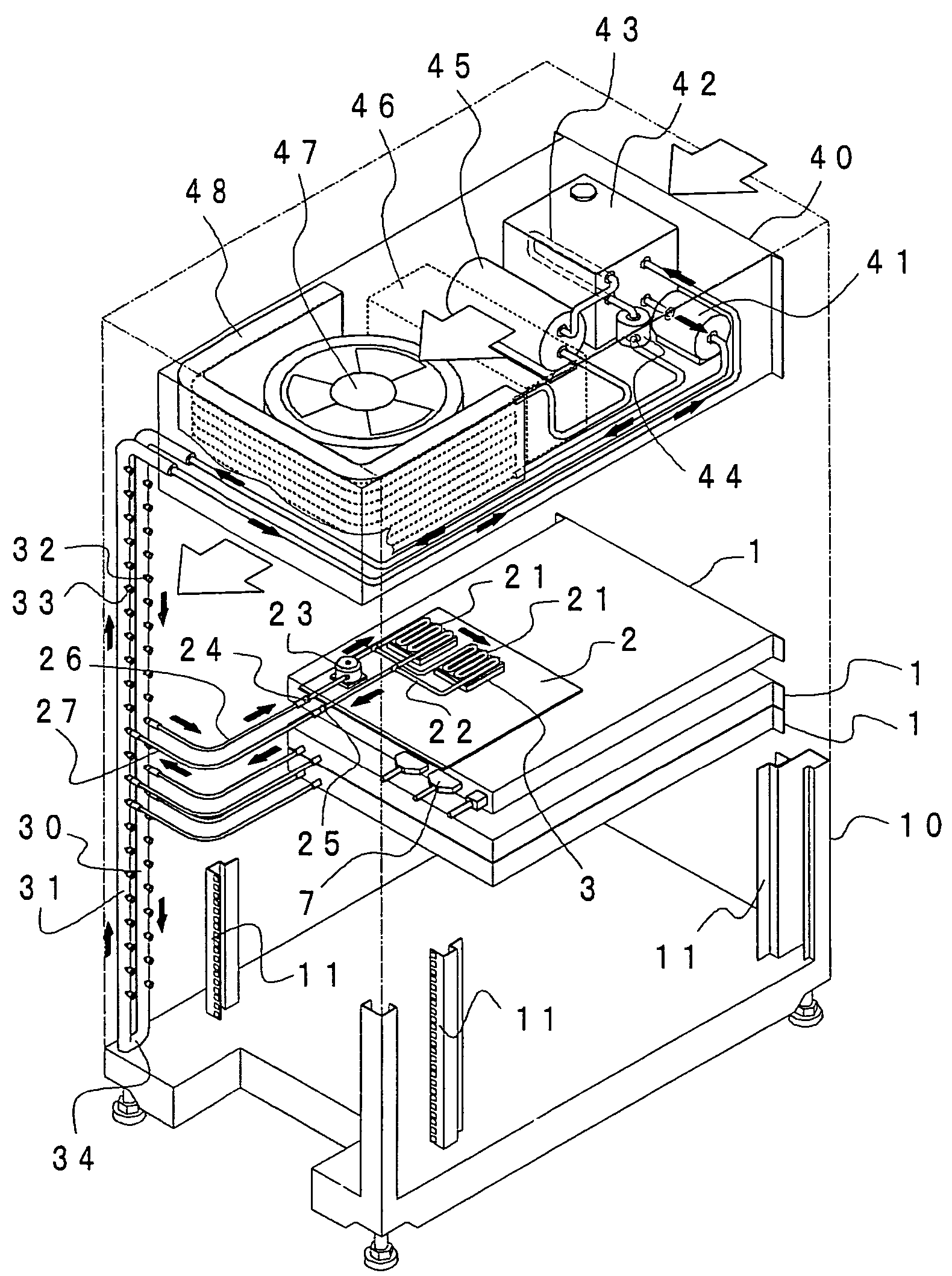

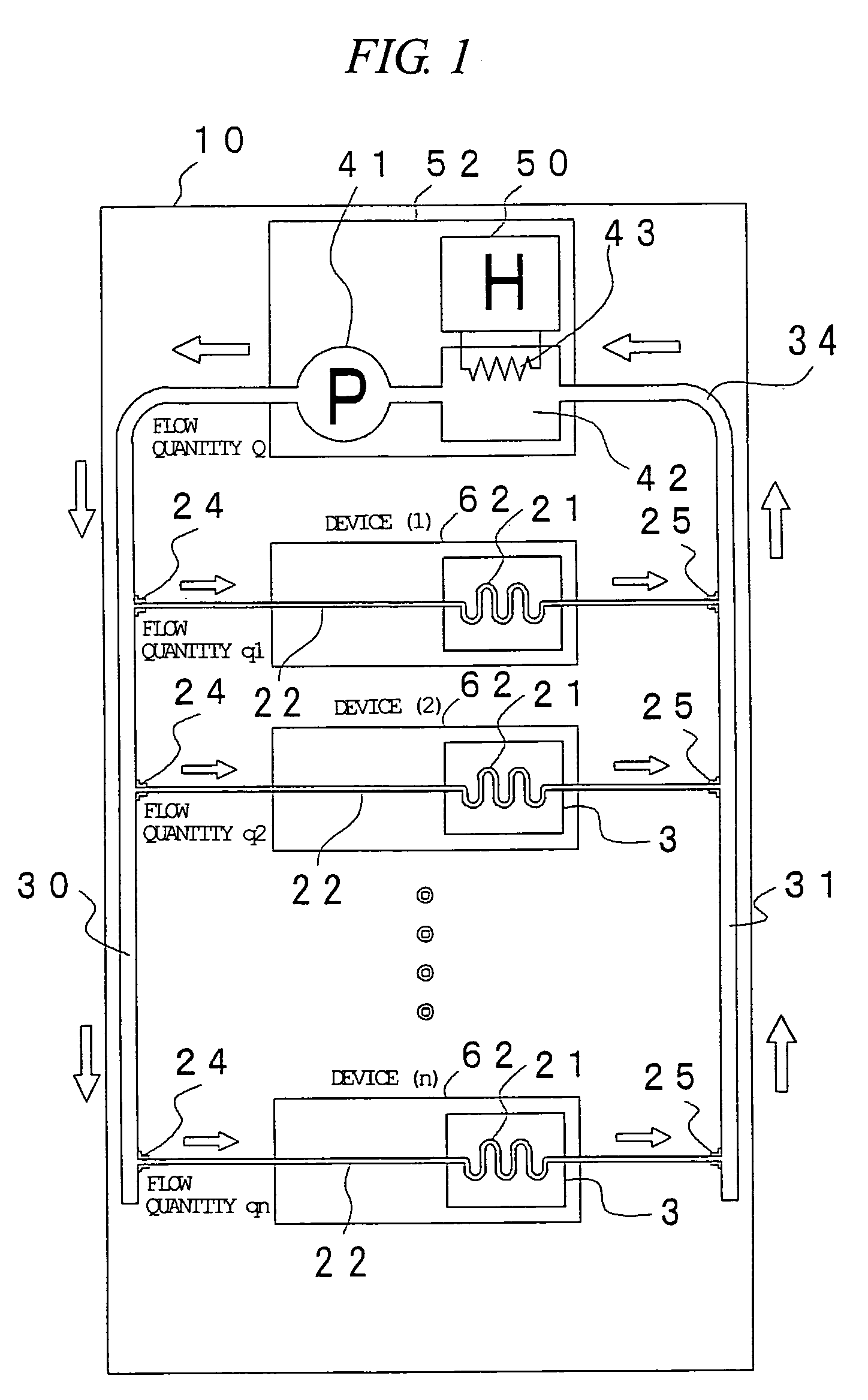

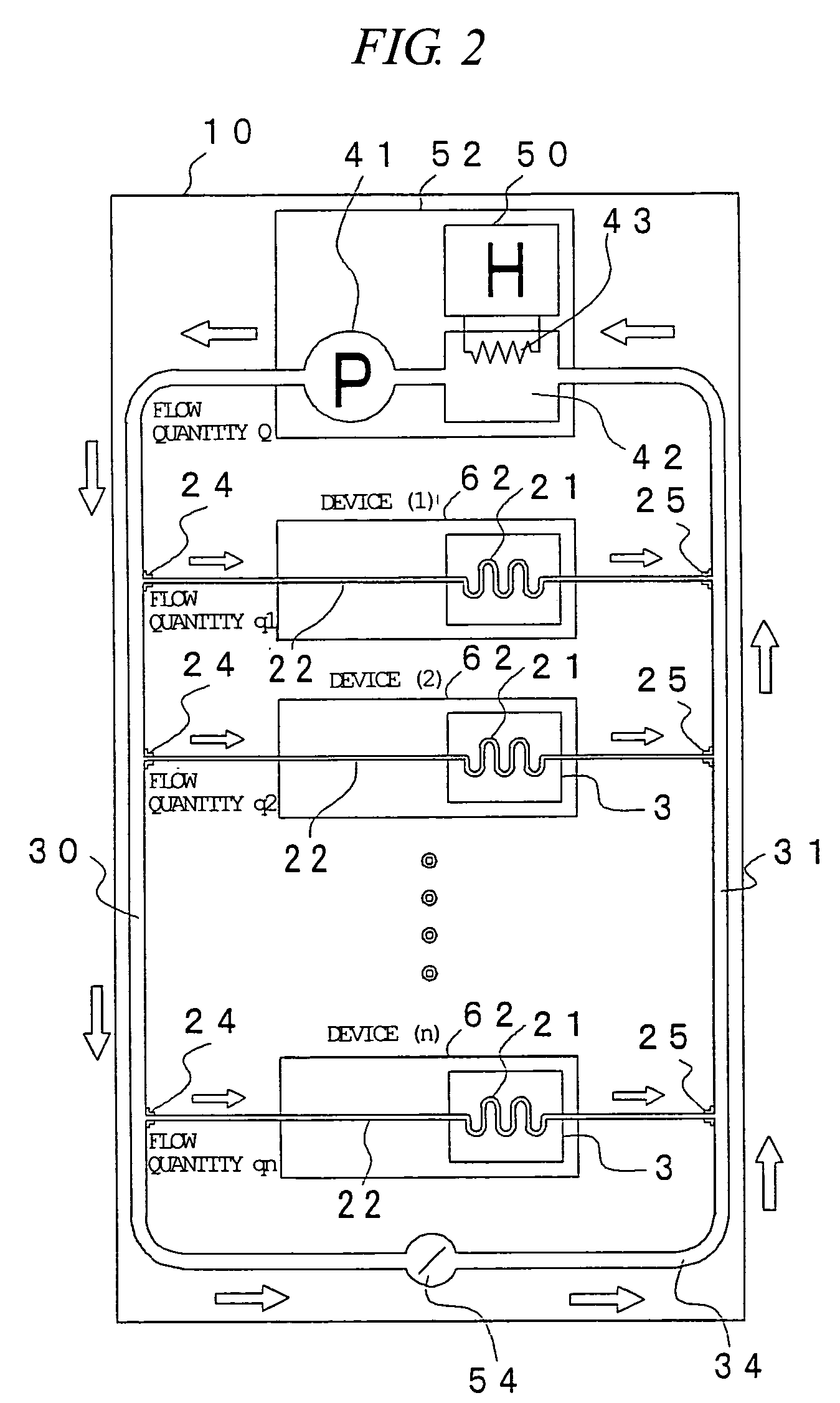

Liquid cooling system for a rack-mount server system

ActiveUS7318322B2Suppress mutationImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringComputer module

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as a CPU is cooled by a coolant has a plurality of server modules with heat-generating components which are cooled by the circulating coolant. The server modules are connected in parallel to a circulation coolant path through which the coolant to cool the server modules is circulated. In the middle of the coolant circulation path is a cooling unit that cools the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules.

Owner:MAXELL HLDG LTD

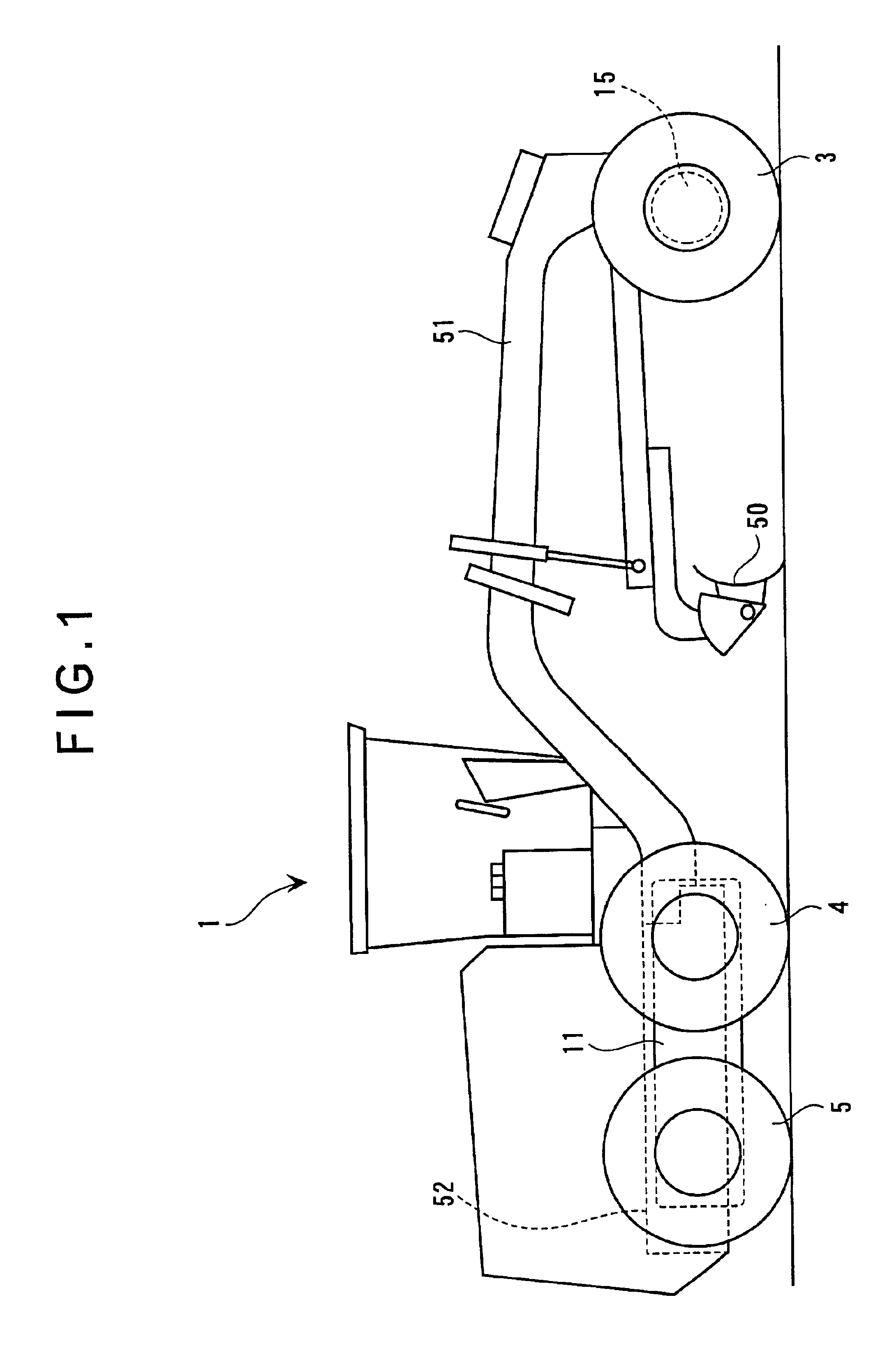

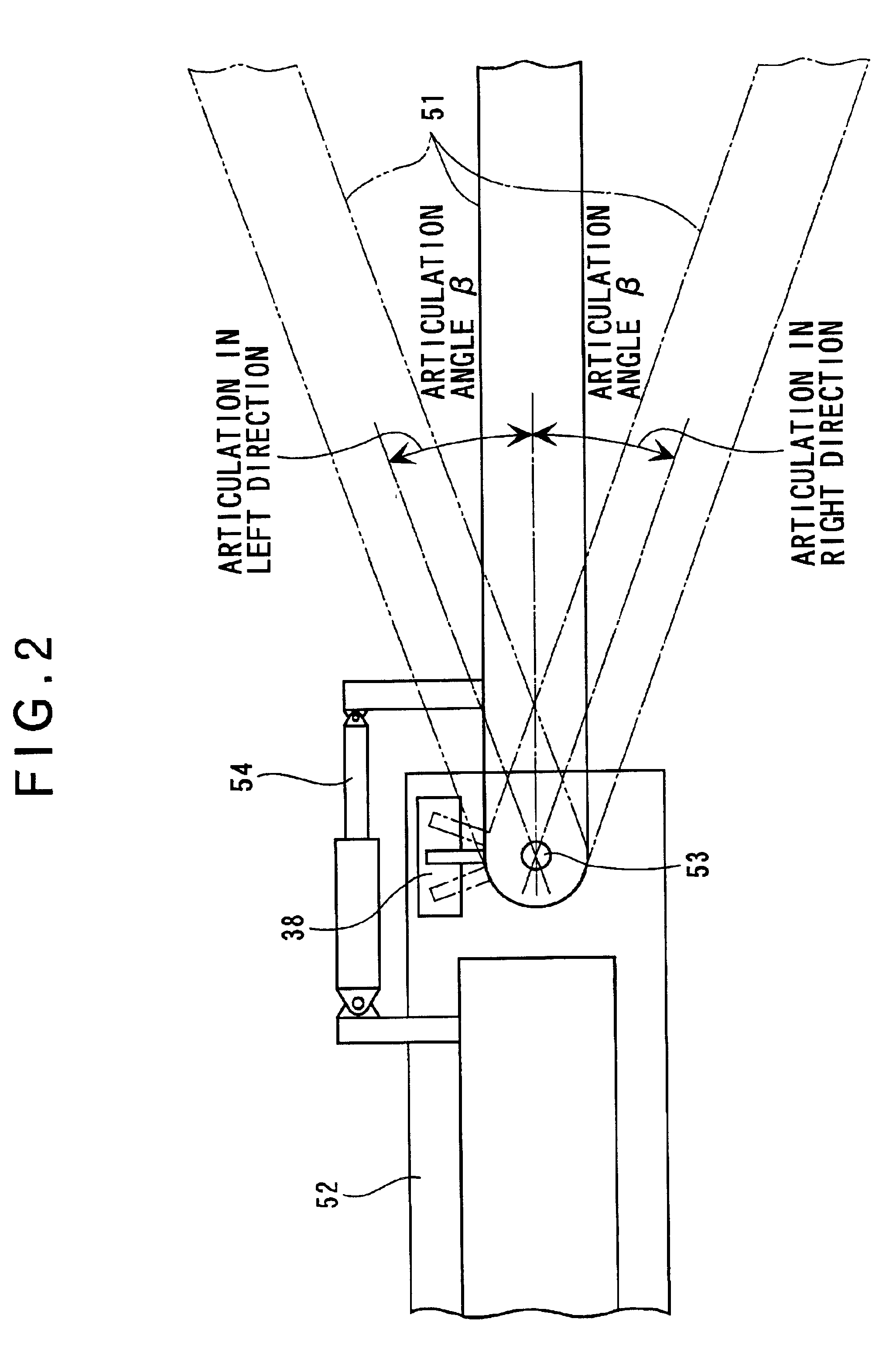

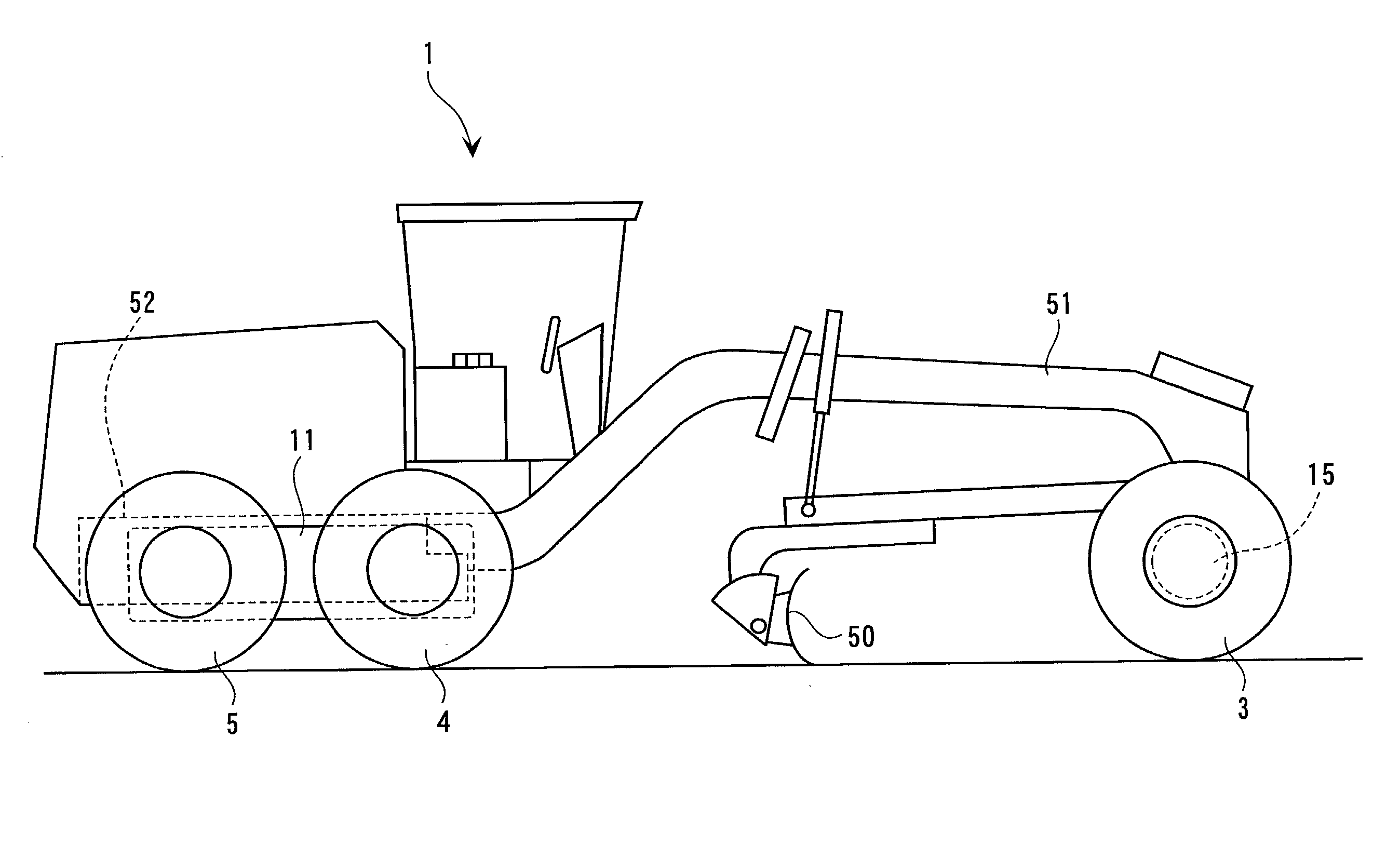

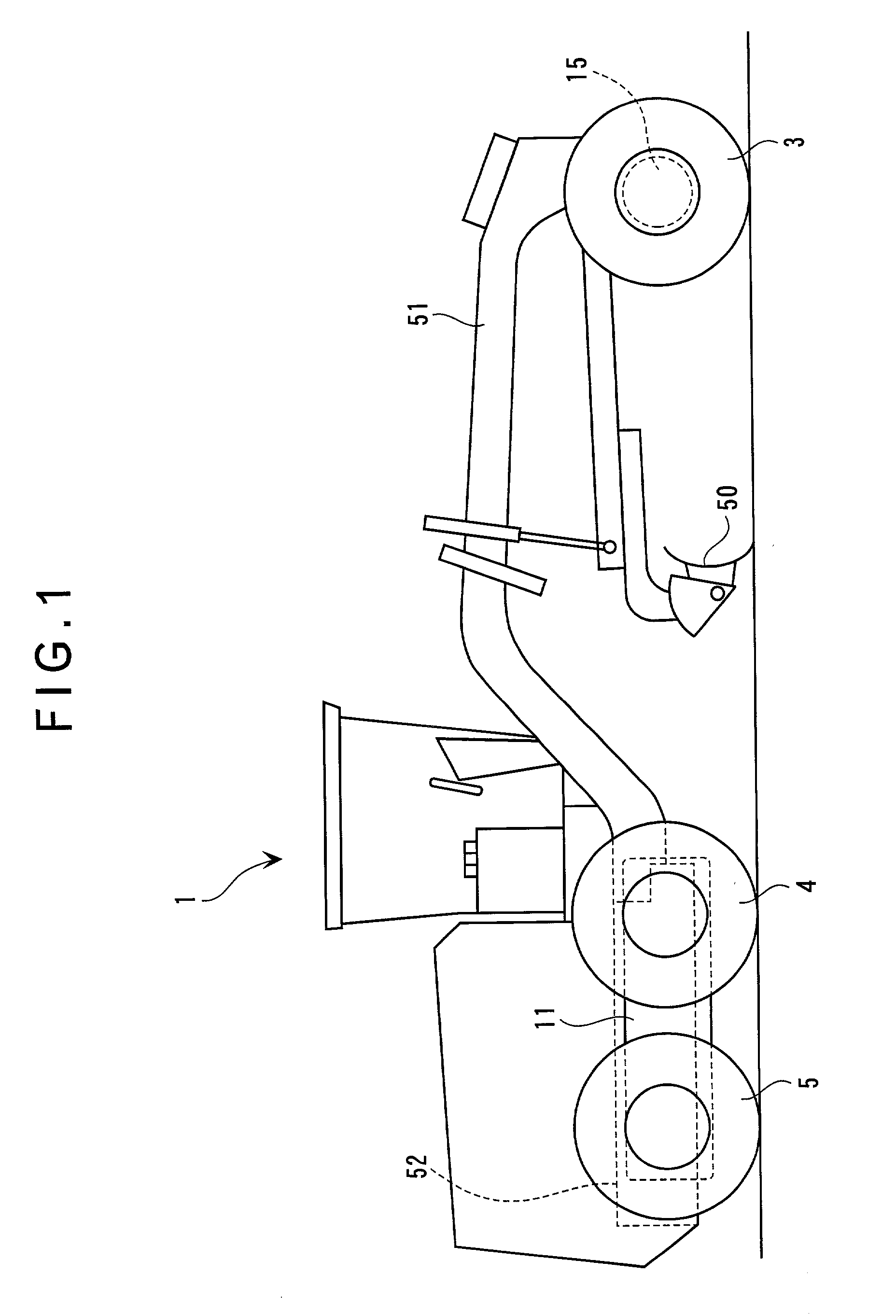

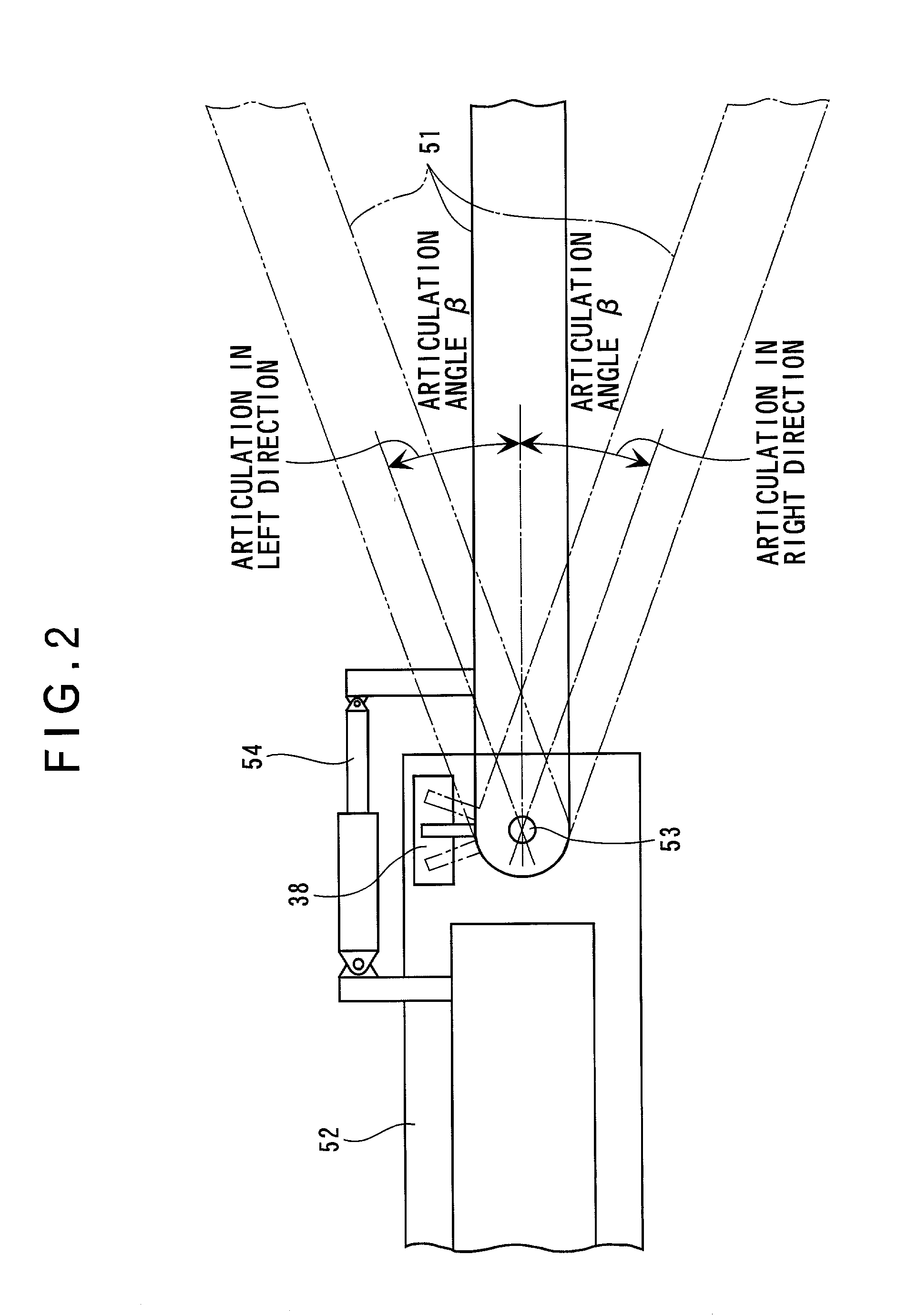

Steering-wheel revolution number correction system of all-wheel-drive vehicle

InactiveUS6857494B2Easily and accurately controllingTight-corner braking phenomenon can be restrainedAuxillary drivesSteering linkagesHydraulic motorSteering angle

Owner:KOMATSU LTD

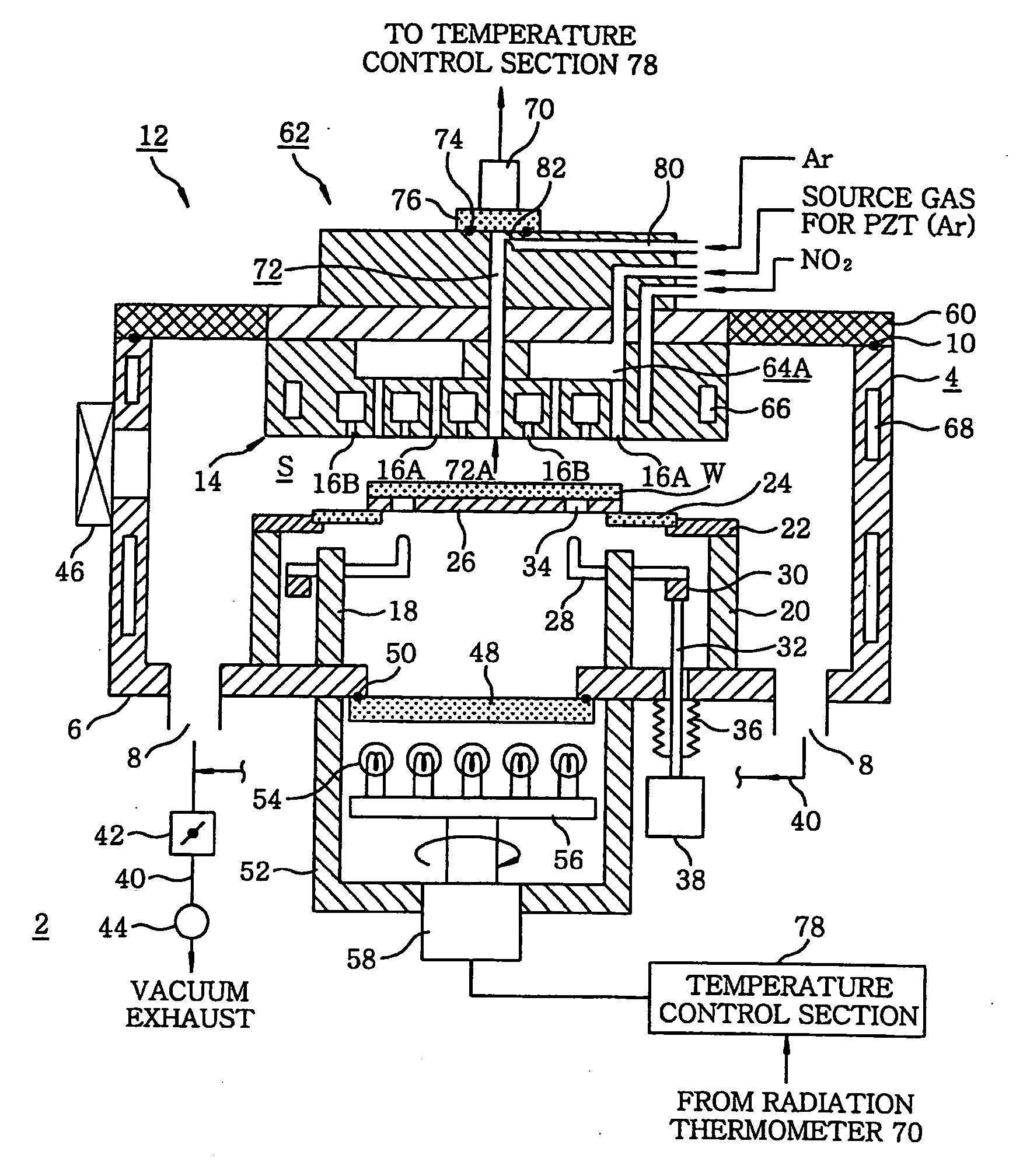

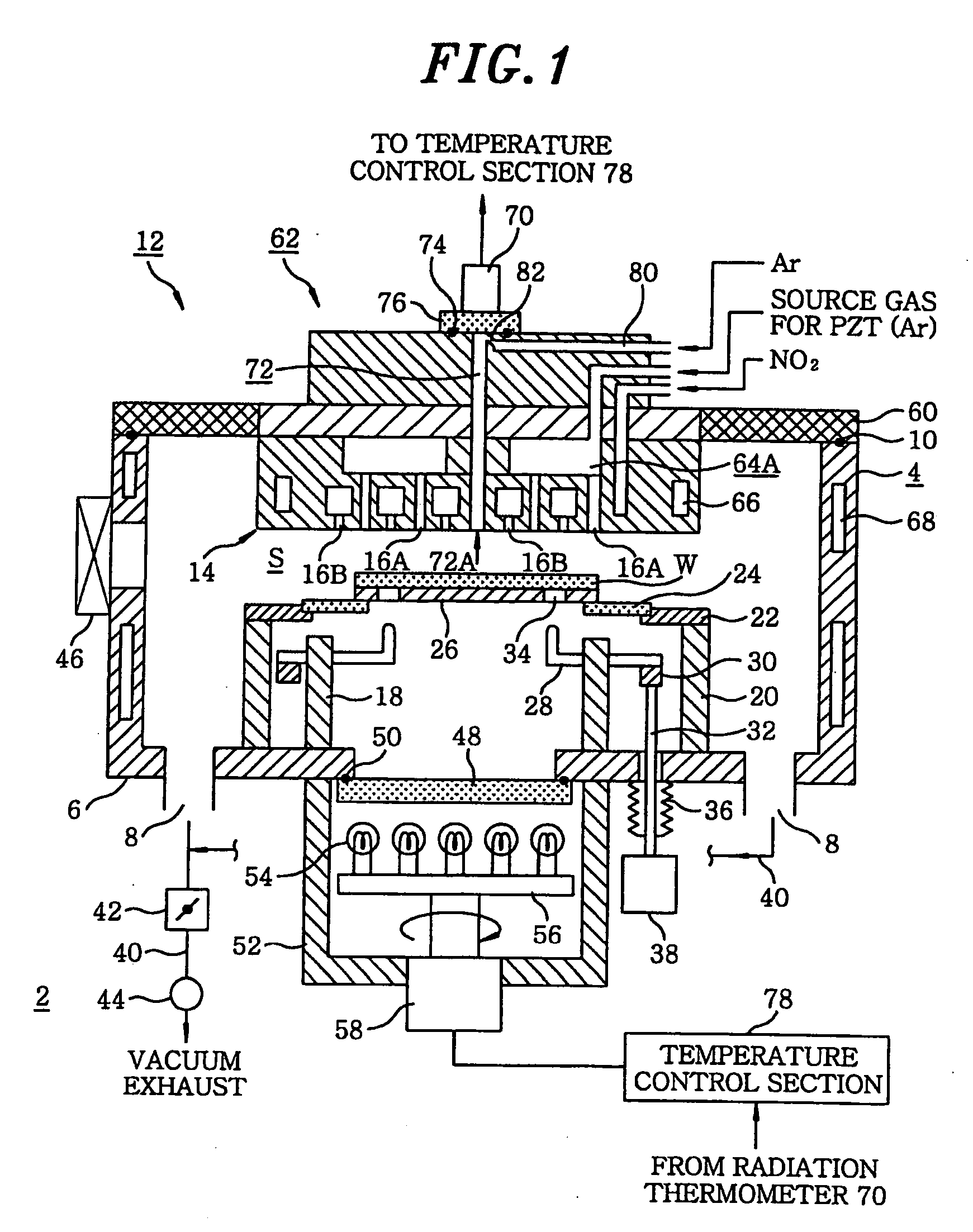

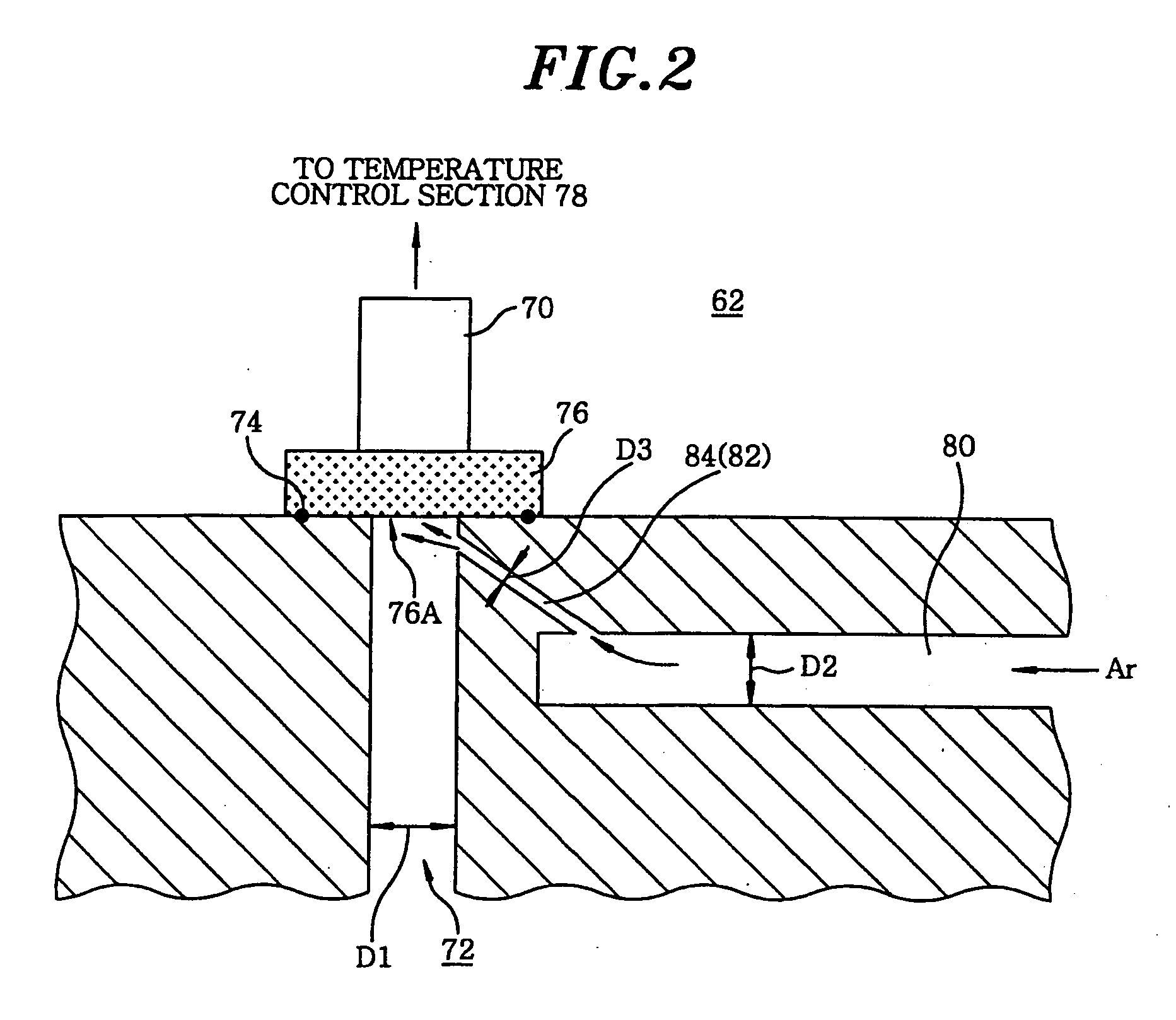

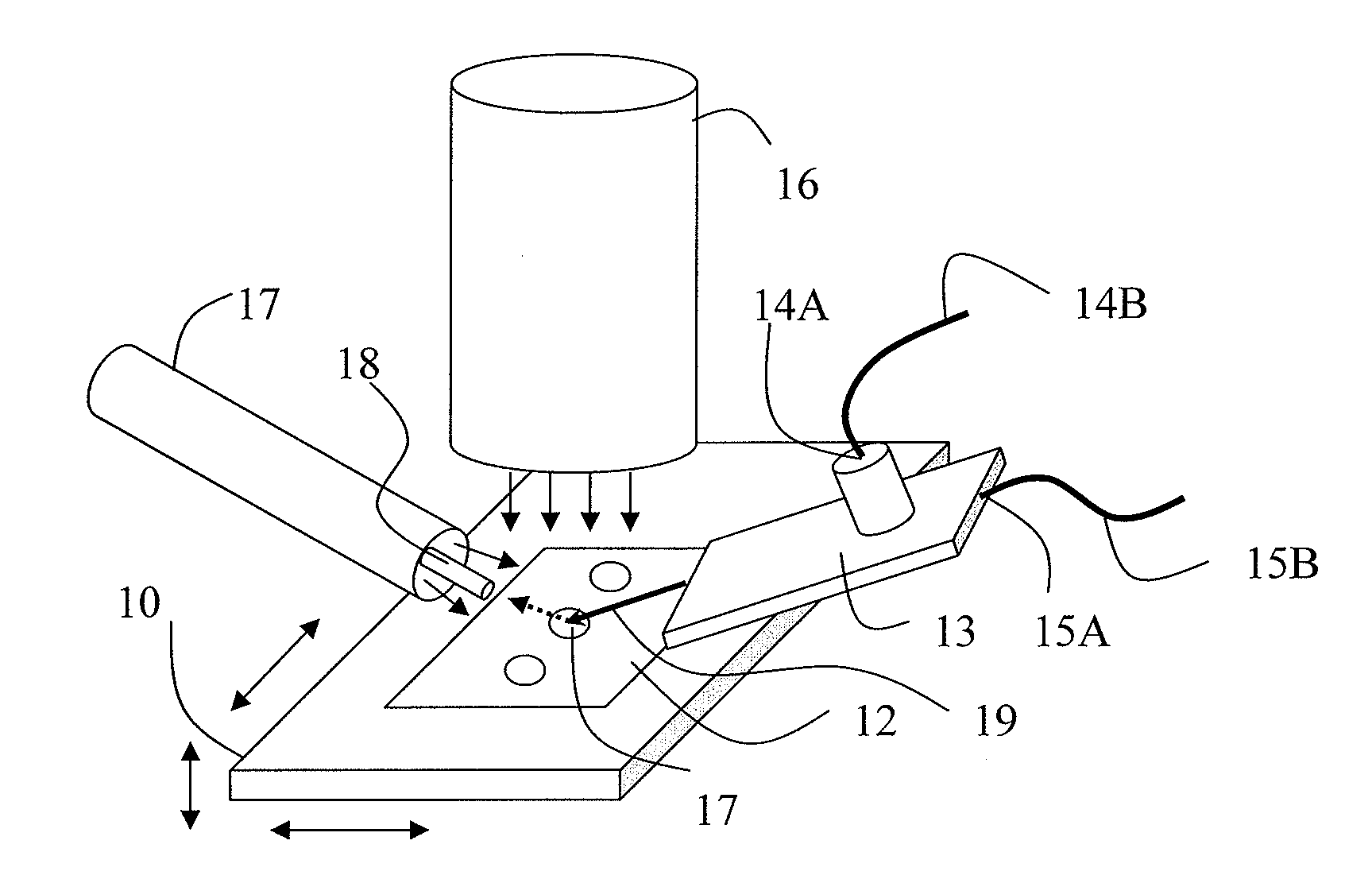

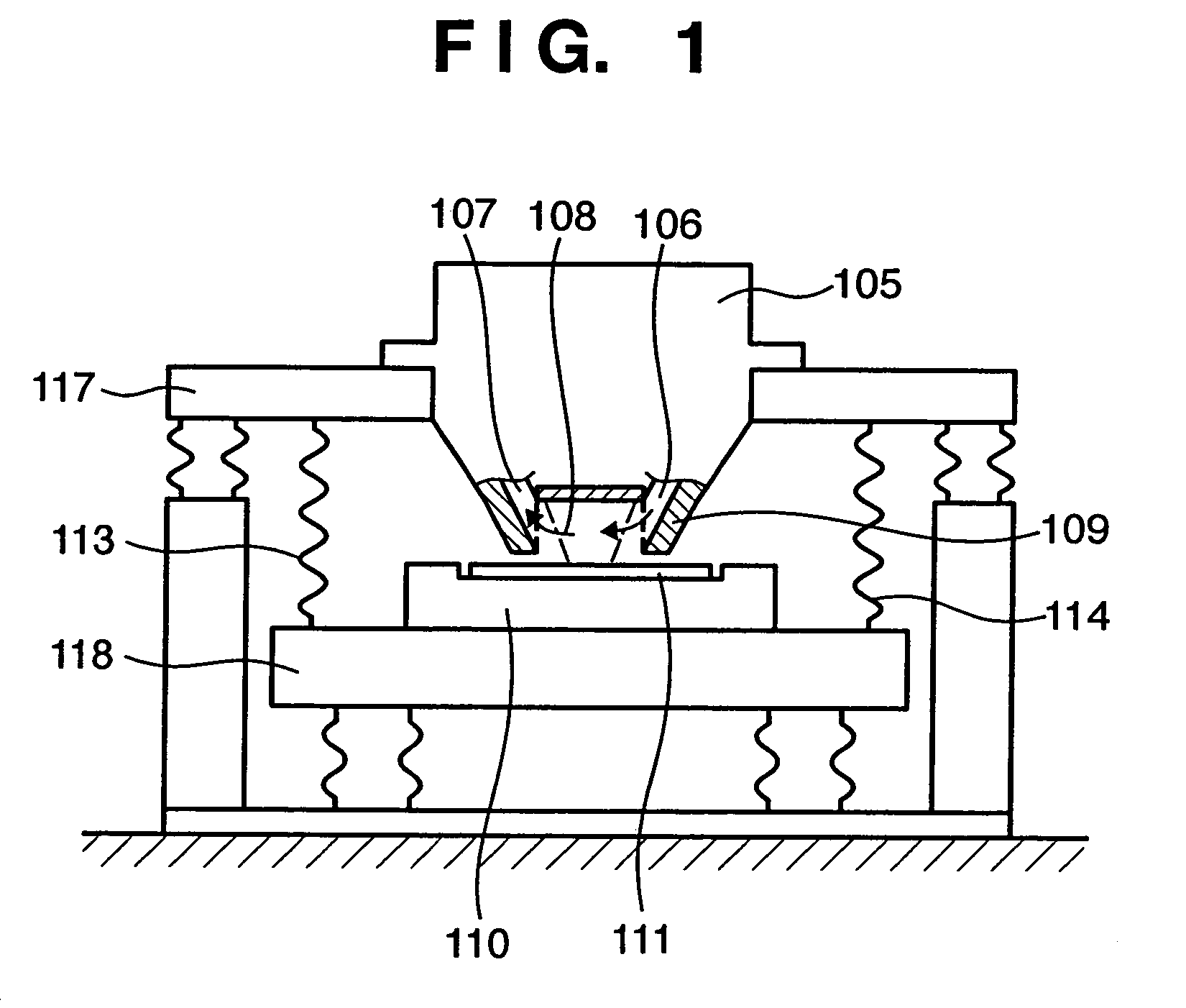

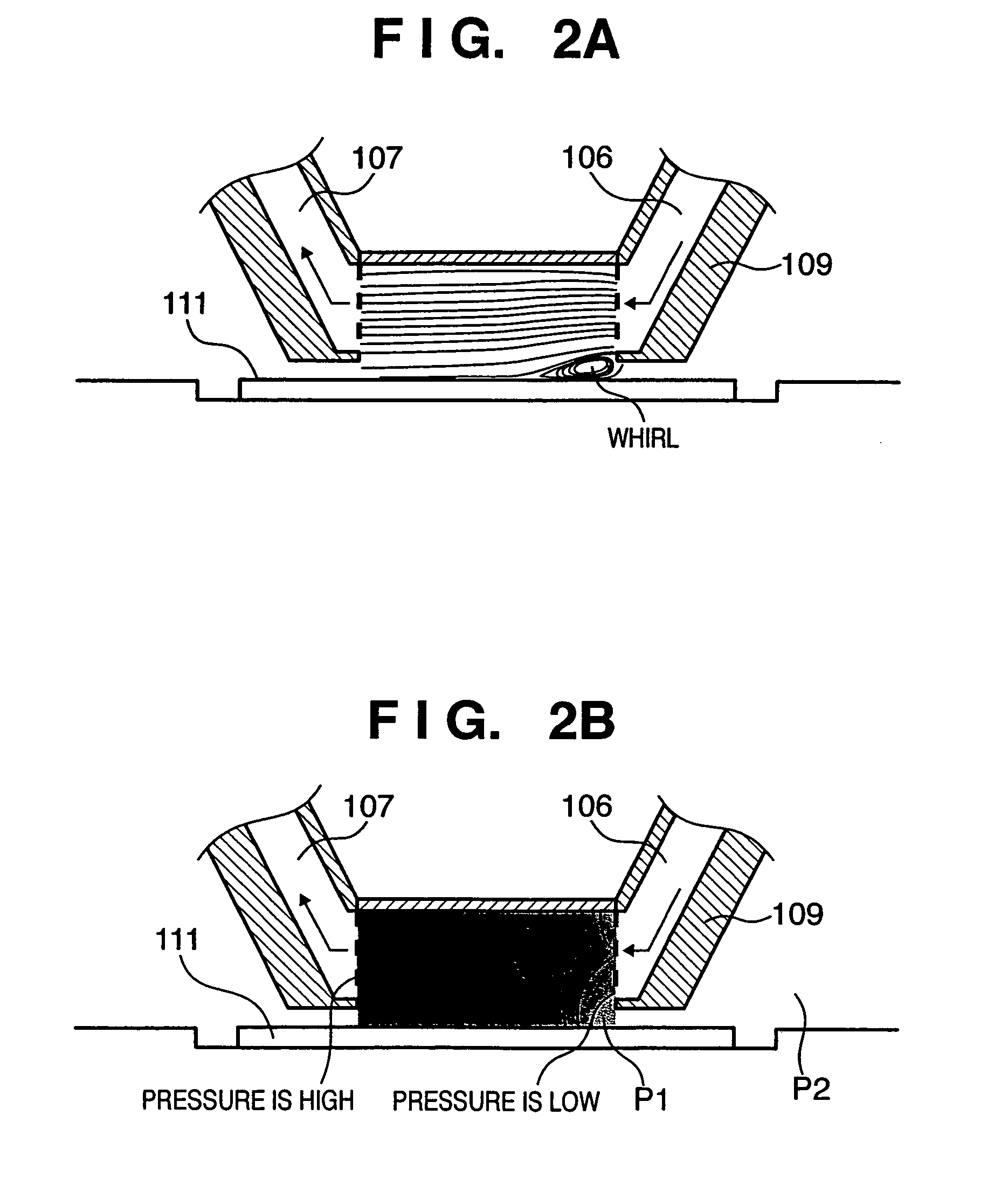

Shower head structure and treating device

InactiveUS20060021568A1Avoid depositionSuppression problemLiquid surface applicatorsSemiconductor/solid-state device manufacturingRadiation thermometerEngineering

A shower head structure characterized by comprising a shower head section, opposed to the upper surface of a mounting table in an evacuable treating vessel, for injecting a processing gas into the treating vessel; a temperature observation through-hole which opens in the lower surface of the shower head so as to be opposed to the upper surface of the mounting table, a transparent observation window which hermetically seals the upper end of the temperature observation through-hole, a radiation thermometer disposed on the upper surface of the transparent observation window, an adhesion preventive gas supply path communicating with the temperature observation through-hole to prevent a film from adhering to the transparent observation window, wherein the adhesion preventive gas supply path communicates with the temperature observation through-hole through an injection nozzle for injecting the adhesion preventive gas to the transparent observation window.

Owner:TOKYO ELECTRON LTD

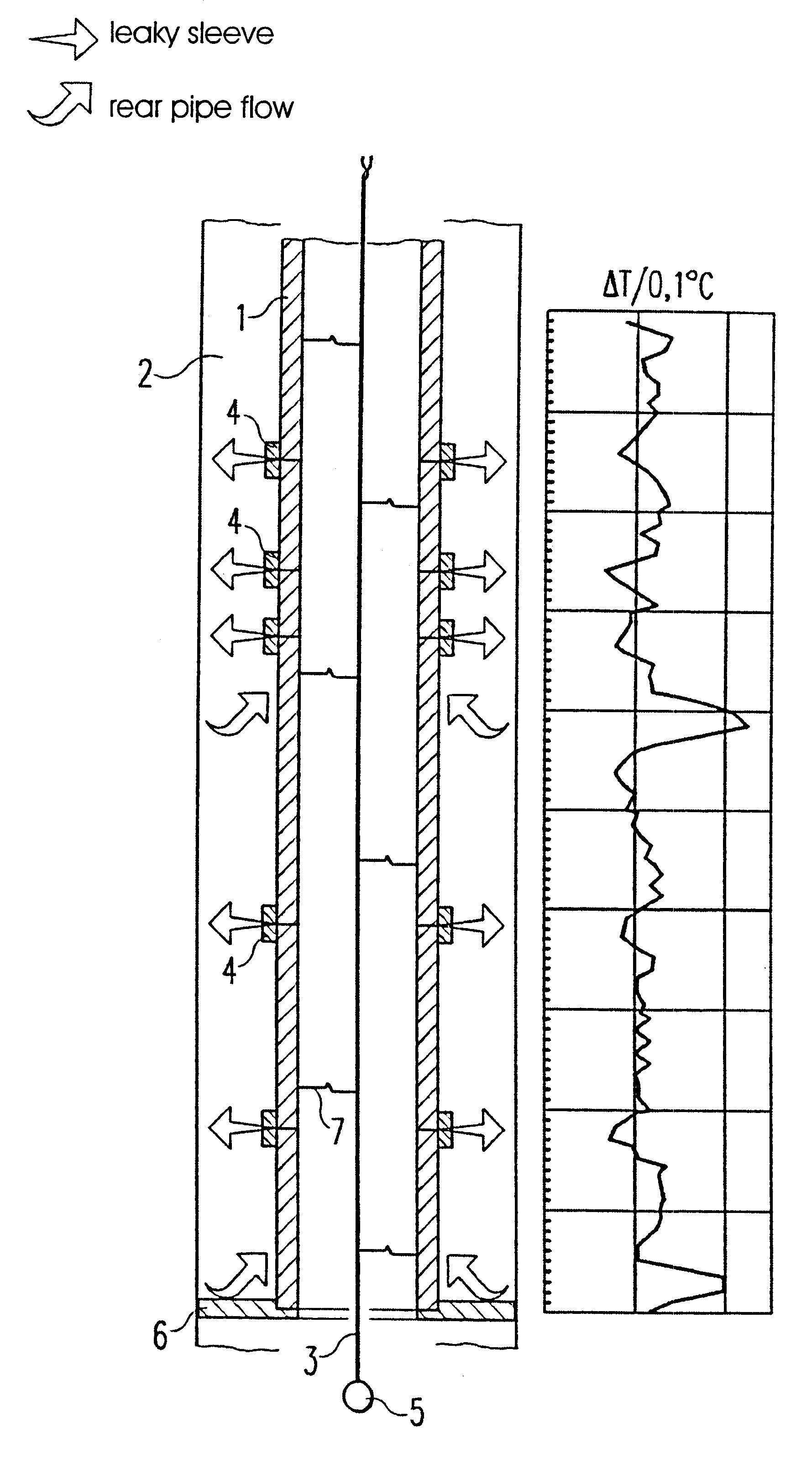

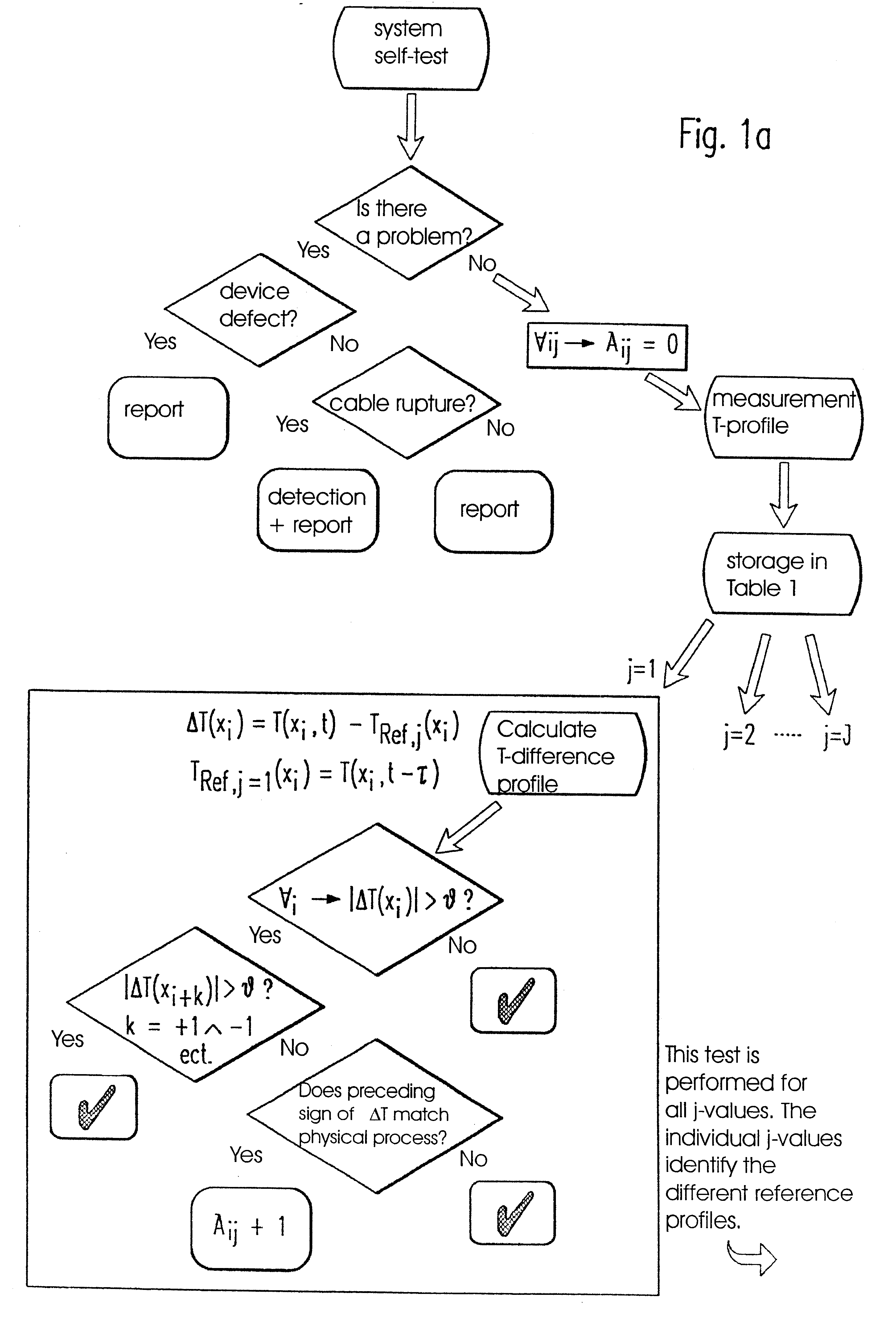

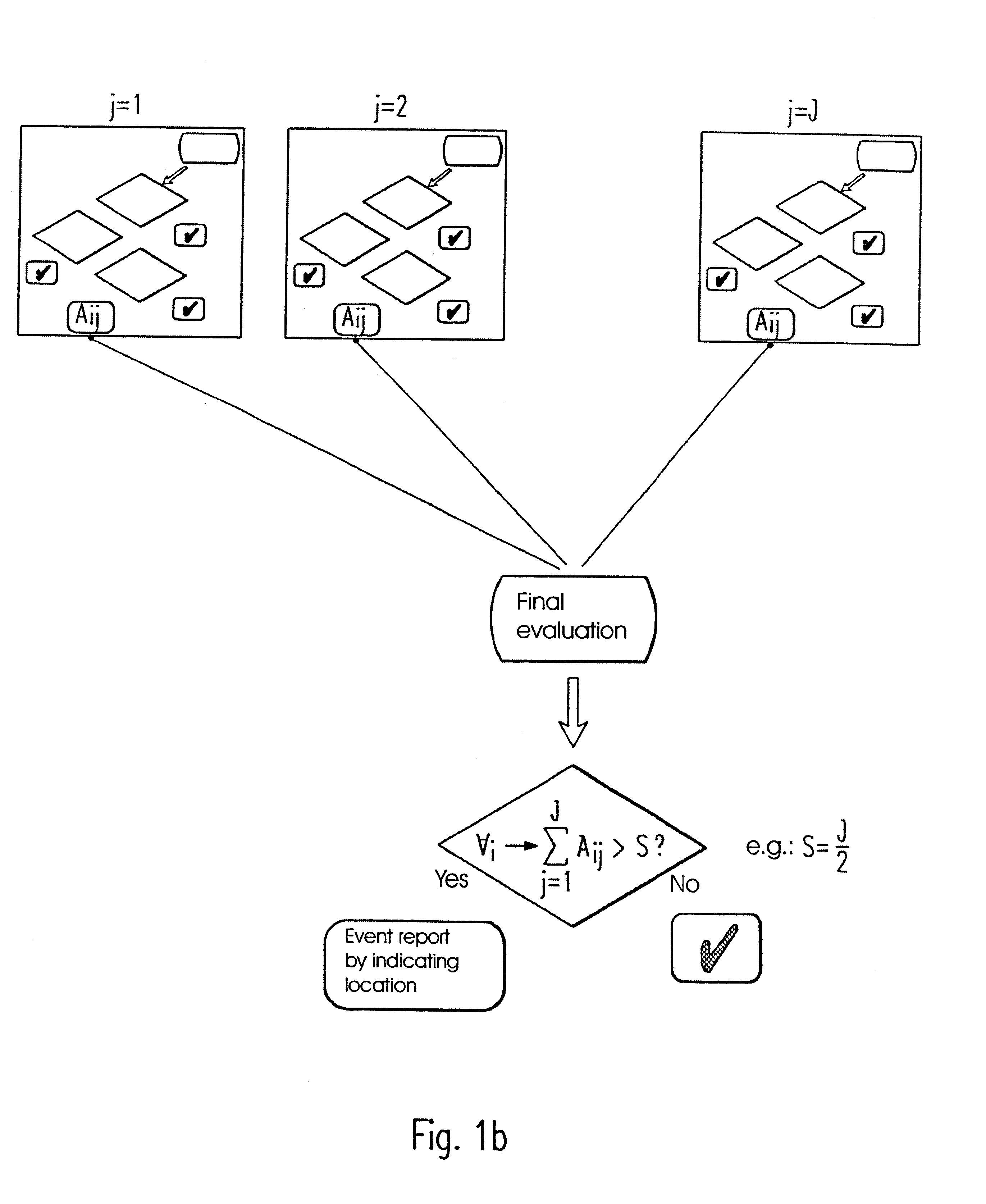

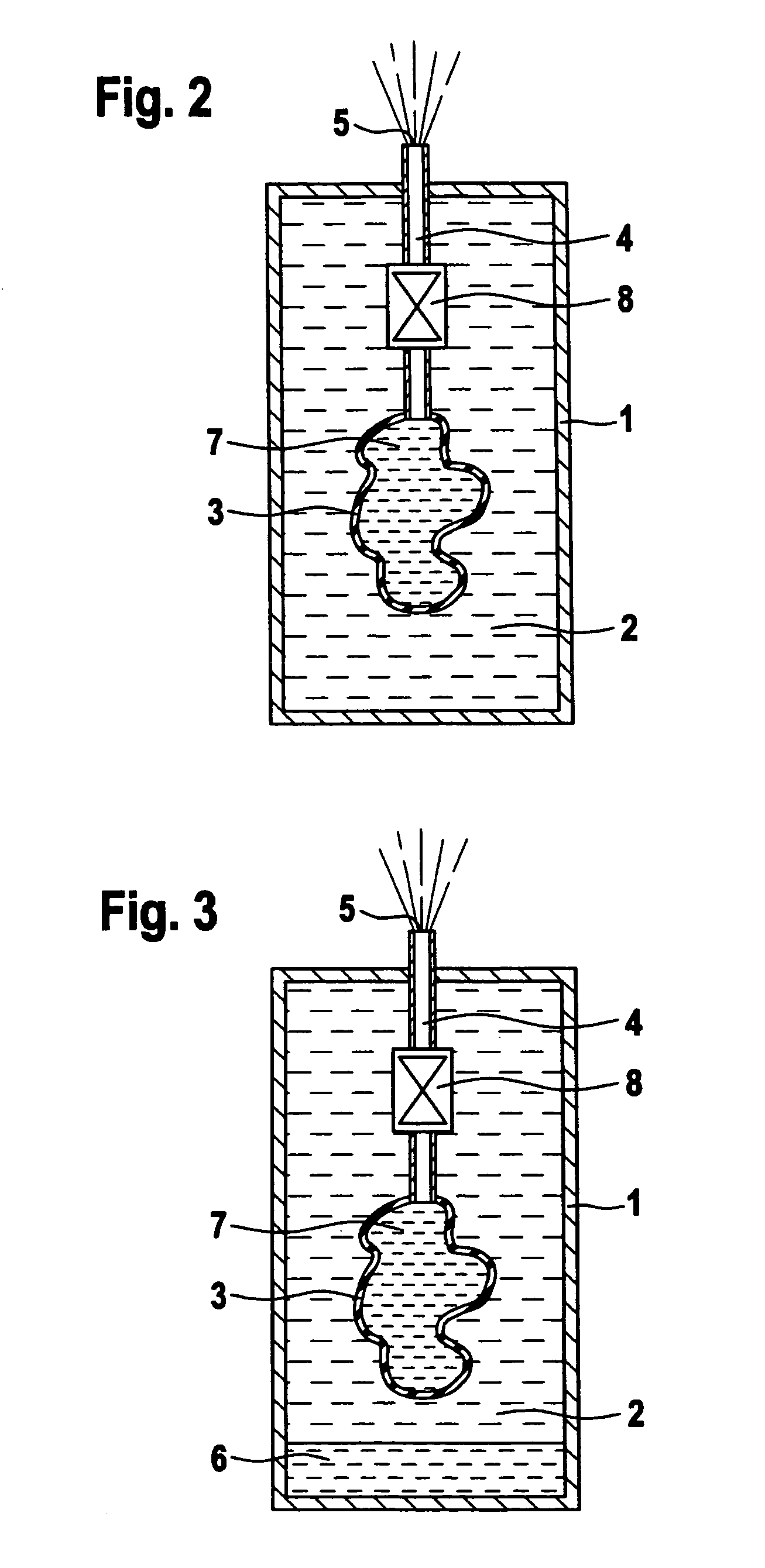

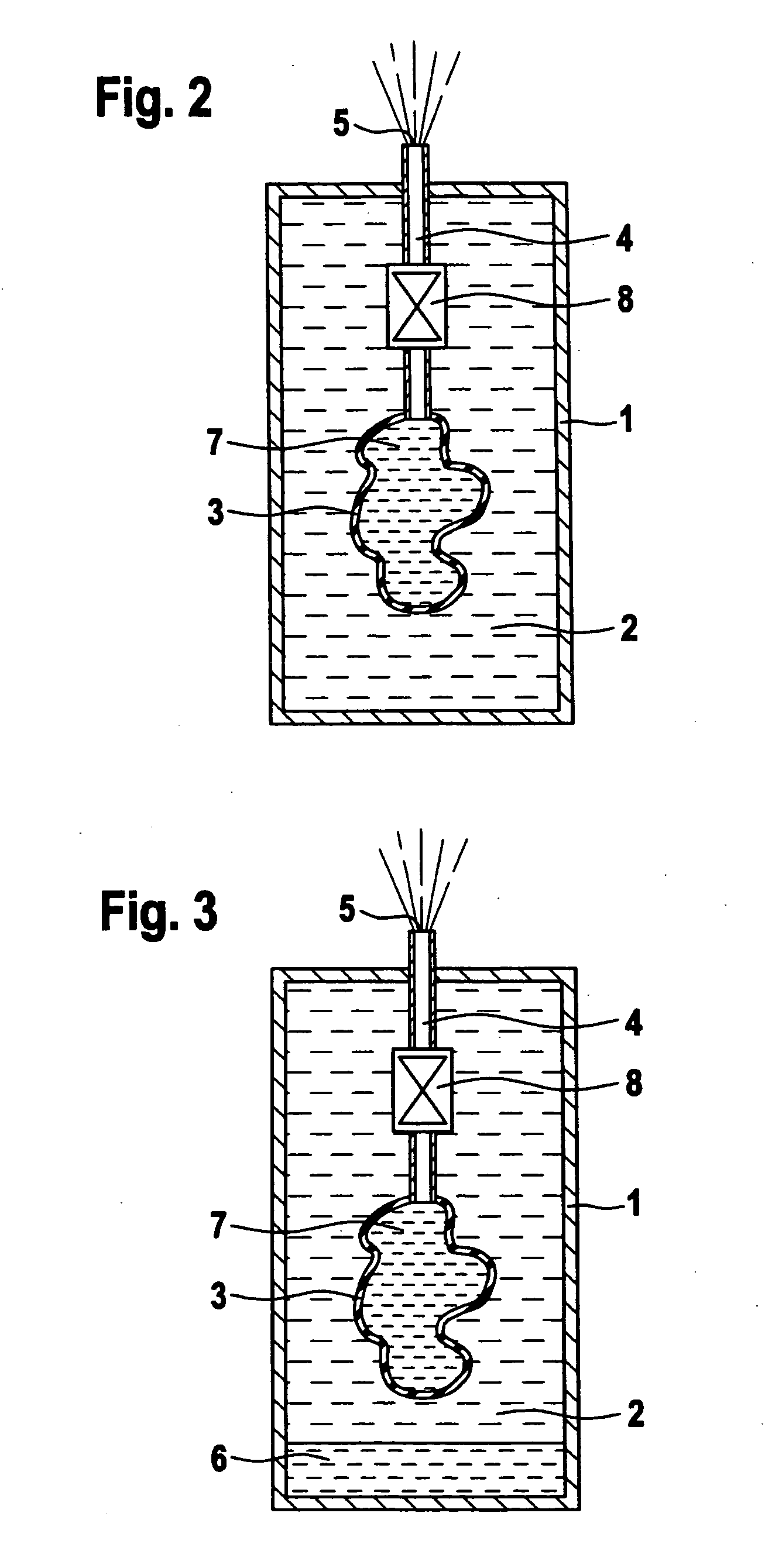

Device for monitoring temperature distribution on the basis of distributed fiber-optic sensing, and use of same

InactiveUS6547435B1Eliminate potential safety hazardsHigh resolutionThermometer detailsRadiation pyrometryFiberMonitoring temperature

The invention relates to a method and a device for monitoring, also permanently and automatically, temperature distributions and / or temperature anomalies on the basis of distributed fiber-optic temperature sensing as well as to the use of such methods. According to the invention the detection of local temperature extremes, i.e. minimums or maximums, in view of the evaluation is performed by an evaluation without numeric derivations. With the device for monitoring ascending and supply pipes surrounded by an annular space it is possible to check the safety of pressurized installations, particularly in the field of low-pressure gas storage, in a cost-efficient manner. Moreover, the position of an underground watershed or respectively the direction and flow rate of the flows in flooded drift sections can be determined on the basis of fiber-optic temperature measurements. The defined arrangement of preferably vertical sensor cables inserted into the bores also makes it possible to examine the tightness of base sole and lateral walls in building excavations. Finally, the virtually horizontal, meander-shaped arrangement of fiber-optic cables situated in several levels makes it possible to evaluate and control the efficacy and homogeneity of leaching processes in leaching dumps and fills.

Owner:O FUR SENSORIK GEOTECHNN UMWELTSCHUTZ & MATHEMATISCHE MODELLIERUNG MBH JENA

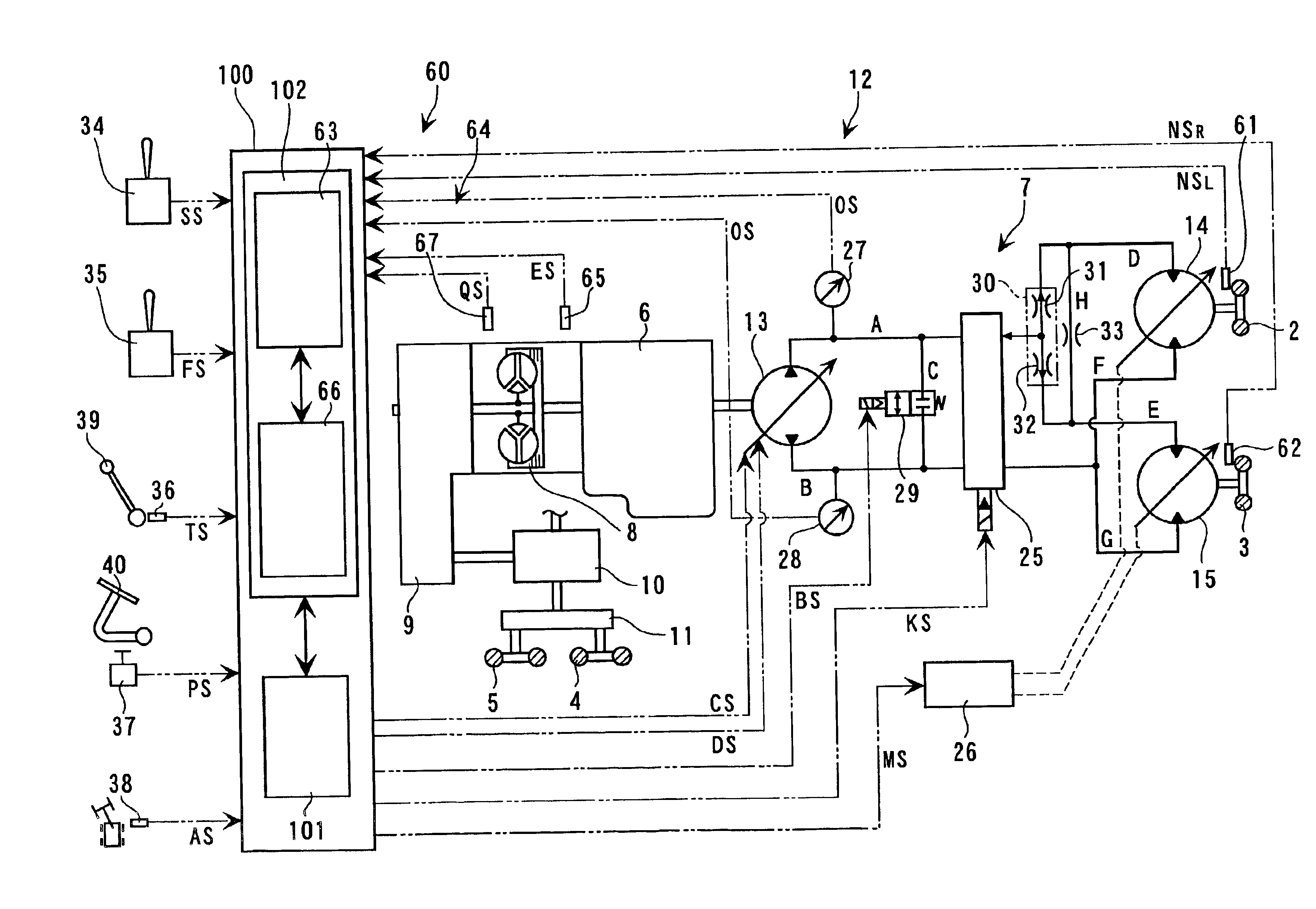

Steering-wheel revolution number correction system of all- wheel-drive vehicle

InactiveUS20020027025A1Smooth rotationFast spinSteering linkagesAutomatic steering controlHydraulic motorSteering angle

Turning radius is calculated from steering angles of steering-wheels (2, 3) and articulation angles of respective frames, and the steering-wheels (2, 3) are automatically rotated faster than rear-wheels (4, 5) based on the turning radius, the revolution number of the rear-wheels (4, 5), engine speed of an engine (6) and a speed range of hydraulic motors (14, 15), so that conventional trouble for manipulating operation lever etc. while turning a motor grader (1) and skill-requiring work for adjusting the revolution number of the steering-wheels (2, 3) in accordance with the revolution number of the rear-wheels (4, 5) can be eliminated, thereby easily and accurately controlling the revolution number of the steering-wheels (2, 3) and securely preventing tight-corner braking phenomenon.

Owner:KOMATSU LTD

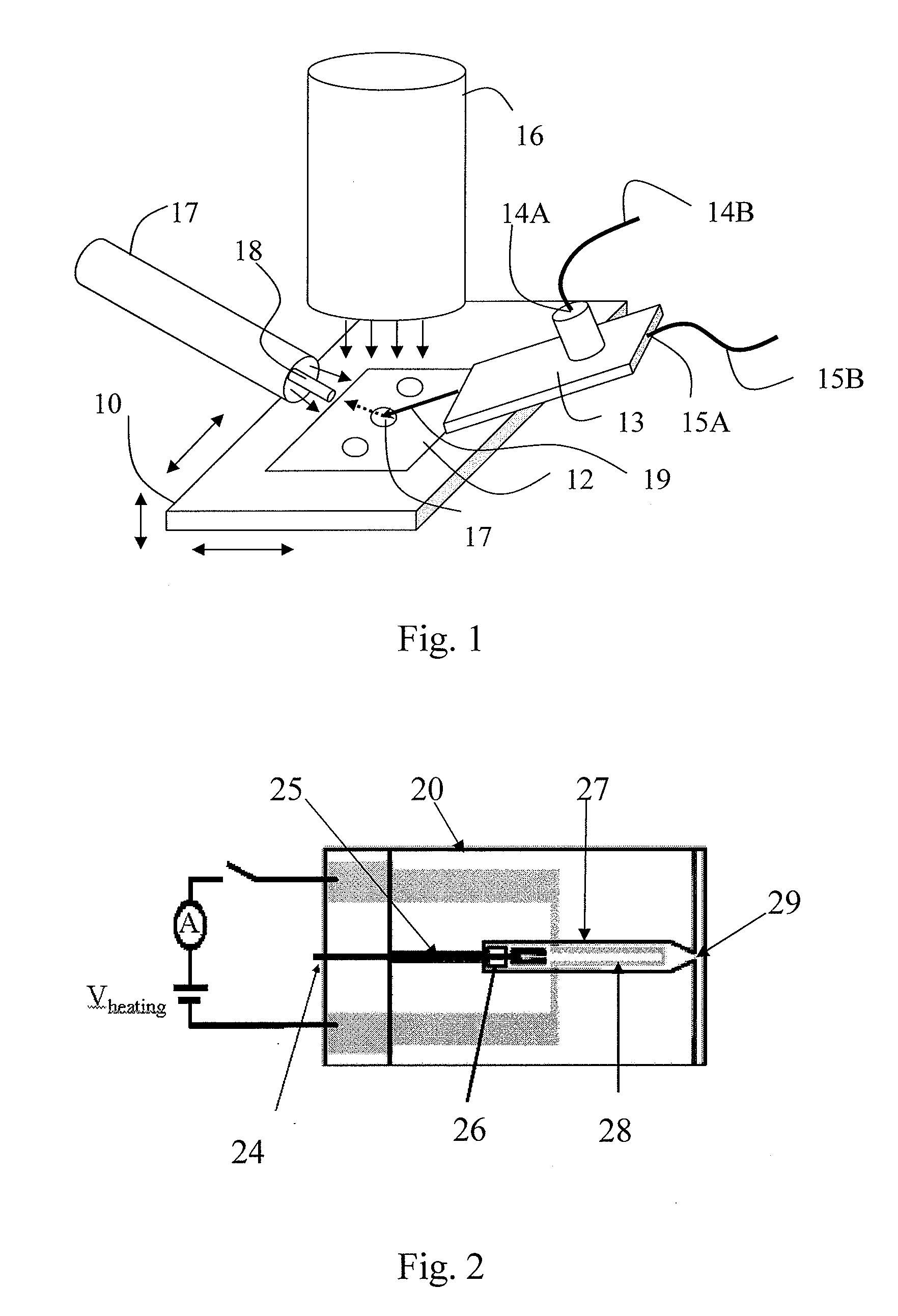

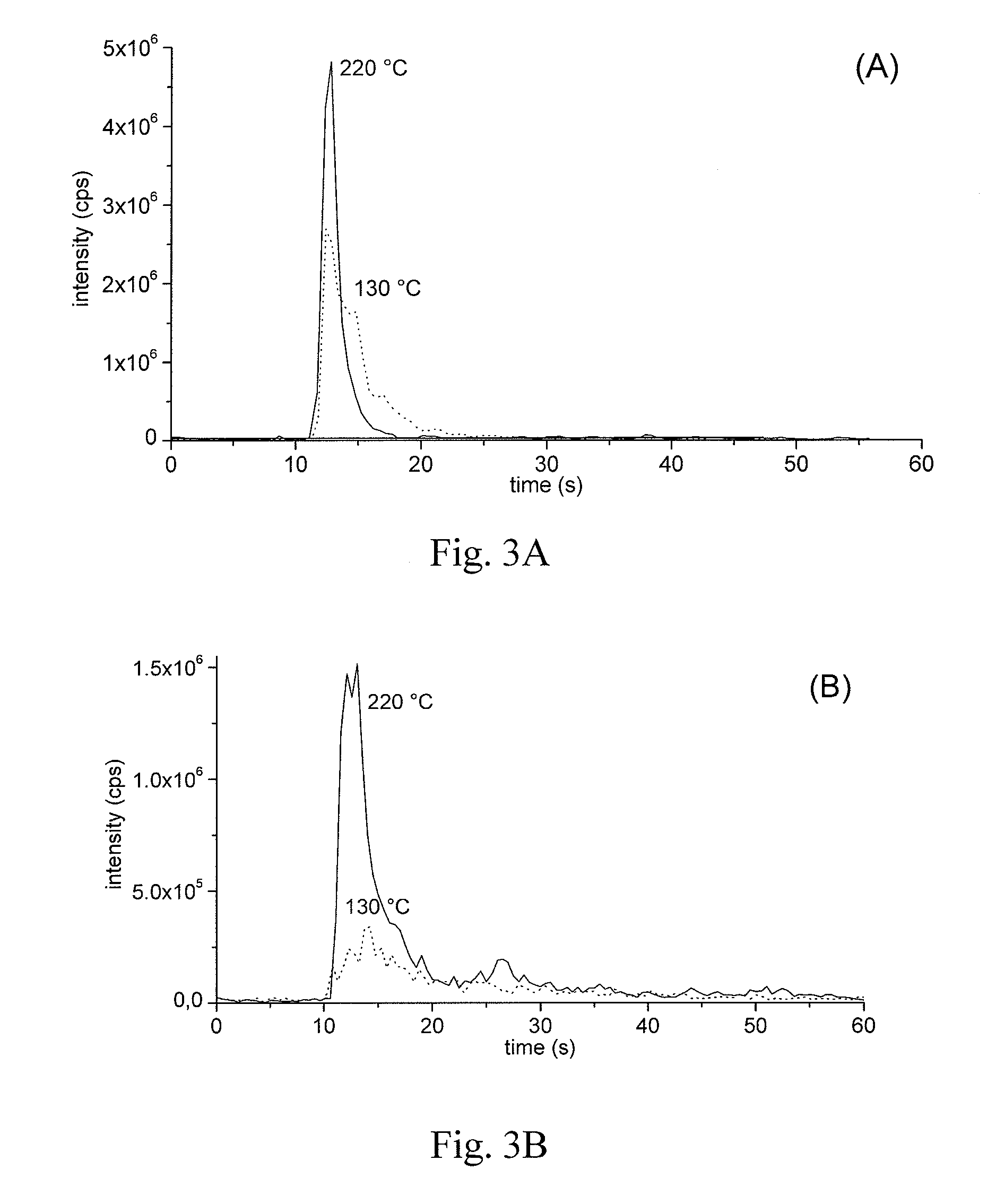

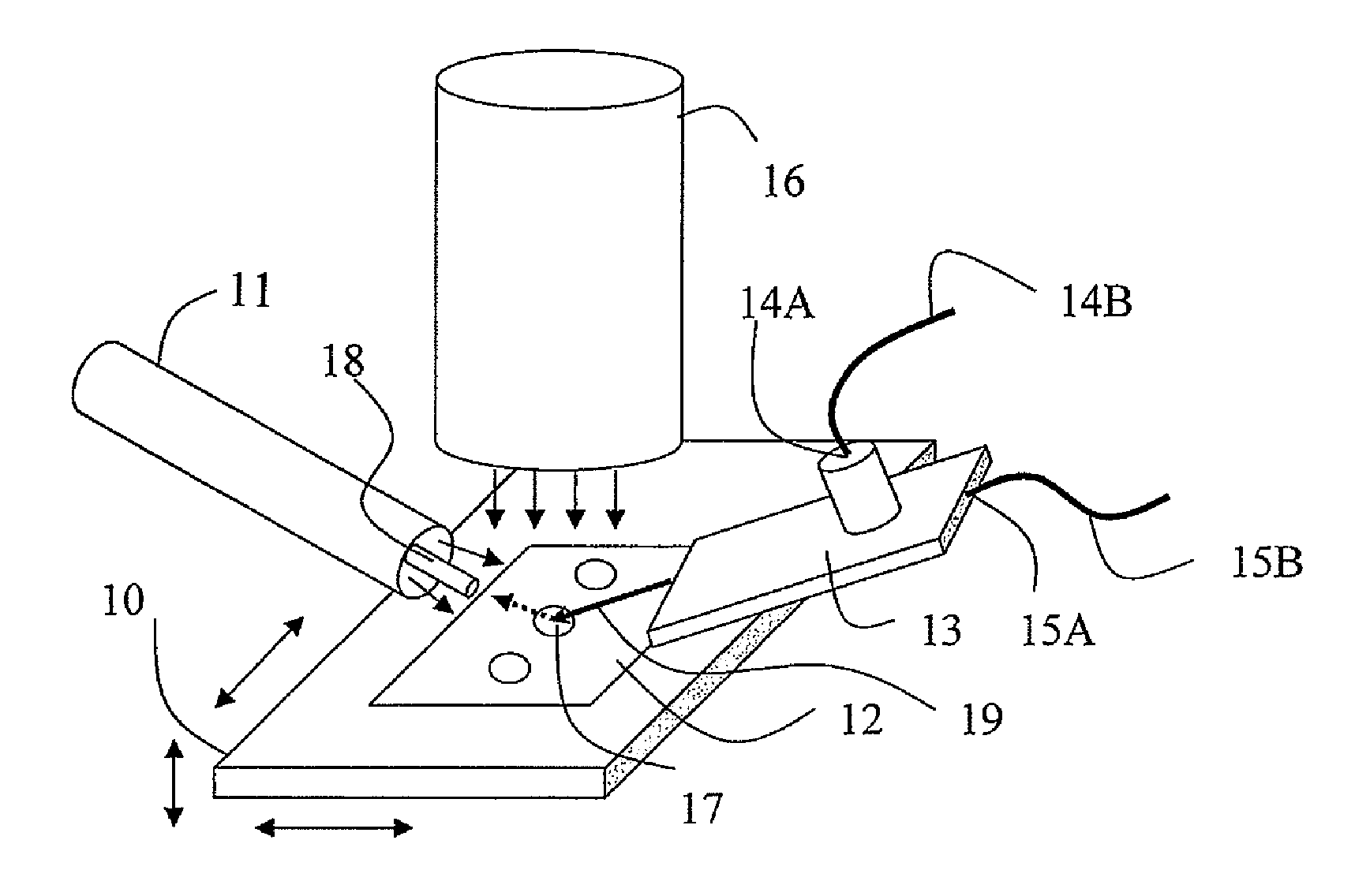

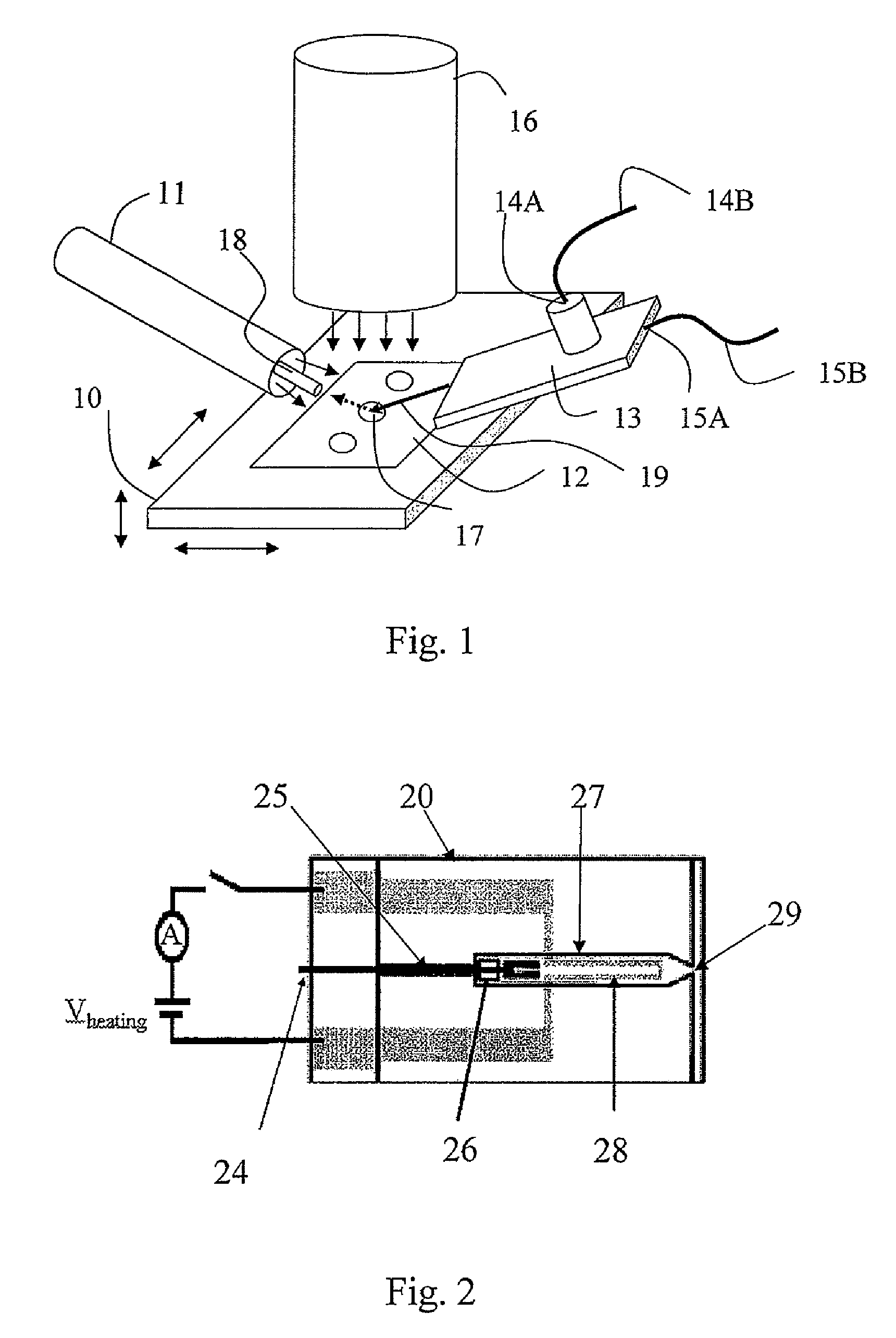

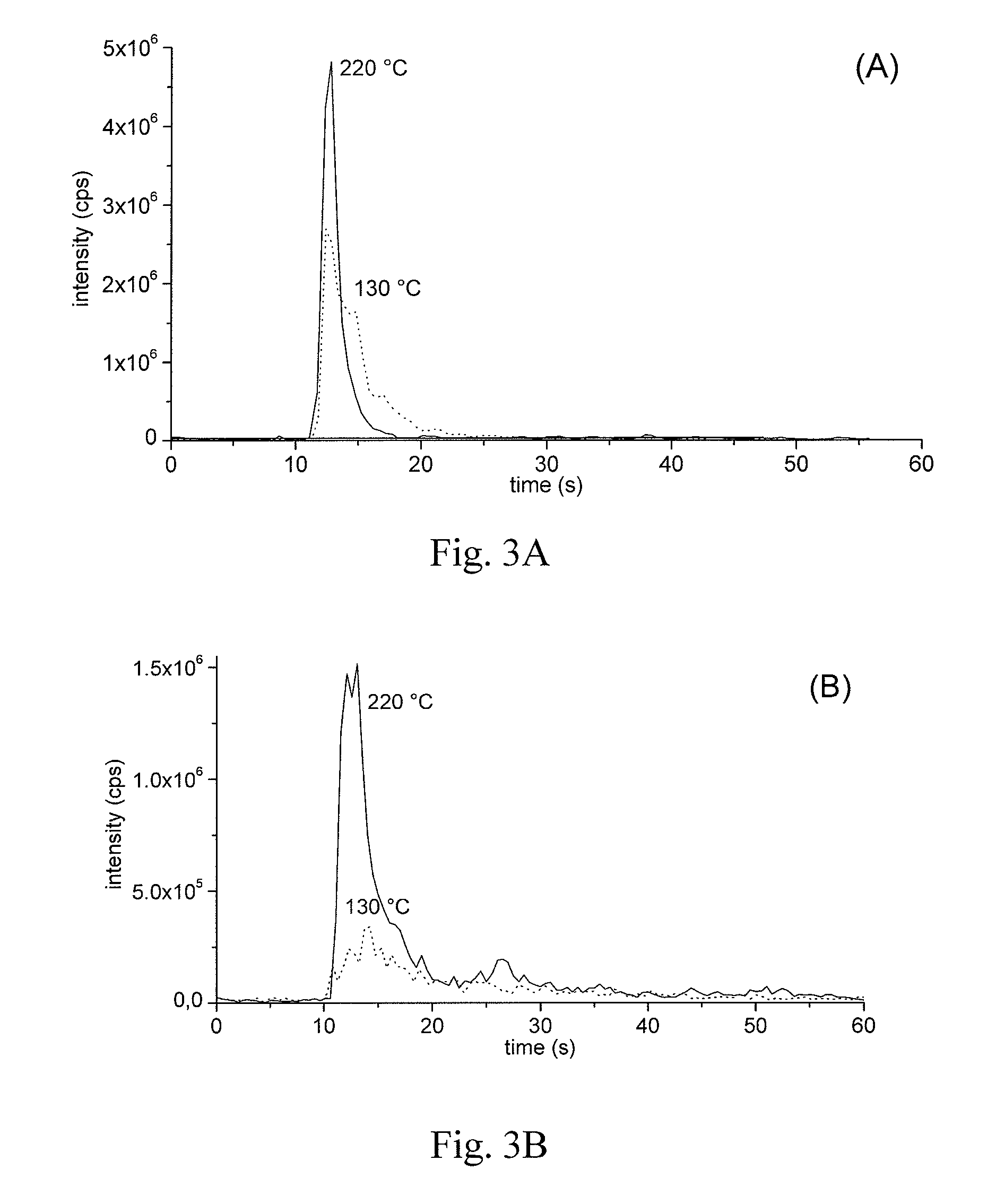

Method and system for desorbing and ionizing chemical compounds from surfaces

InactiveUS20090159790A1Efficient productionSimple technologyParticle separator tubesIsotope separationAnalyteDesorption

The invention relates to a method and system for ionizing analyte-containing sample lying on a surface of a substrate. The method comprises directing to the sample a heated flow of desorption gas in order to desorb analyte from the surface, and simultaneously directing to the sample light capable of ionizing the desorbed analyte in the presence of the desorption gas. The invention provides a method and system suitable for efficiently producing ions of neutral and nonpolar molecules on surfaces, for example for mass spectrometric purposes.

Owner:LICENTIA OY

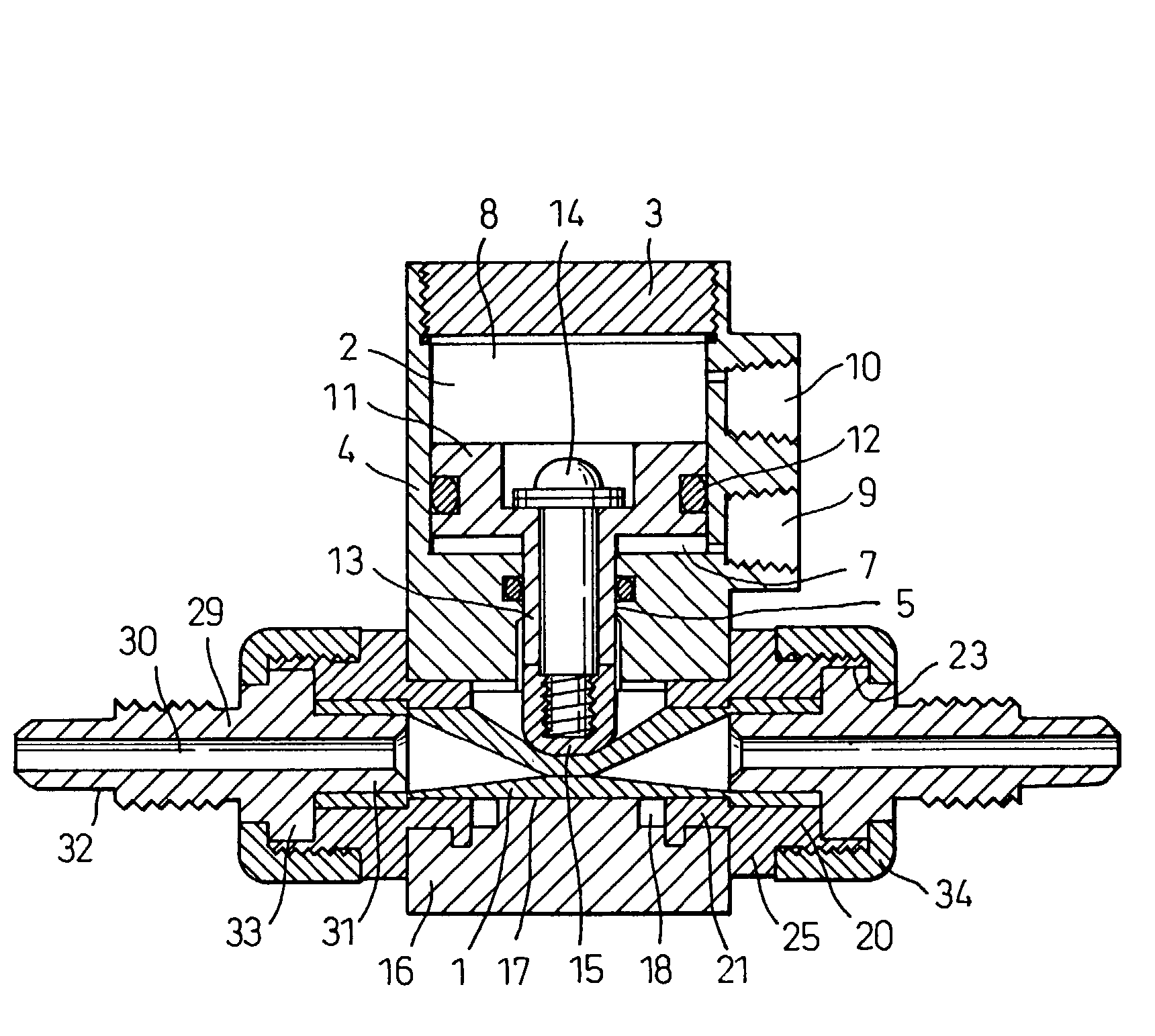

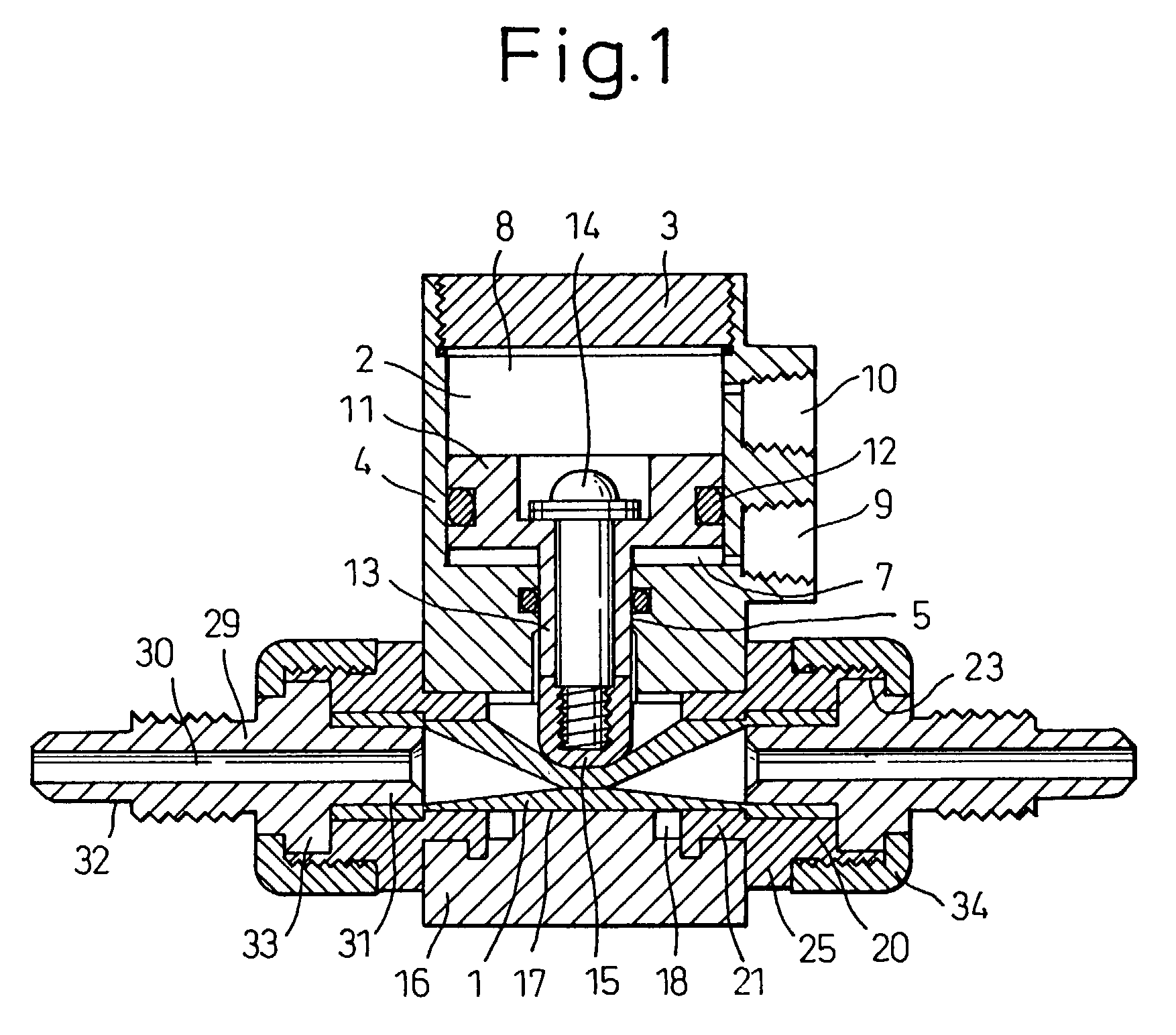

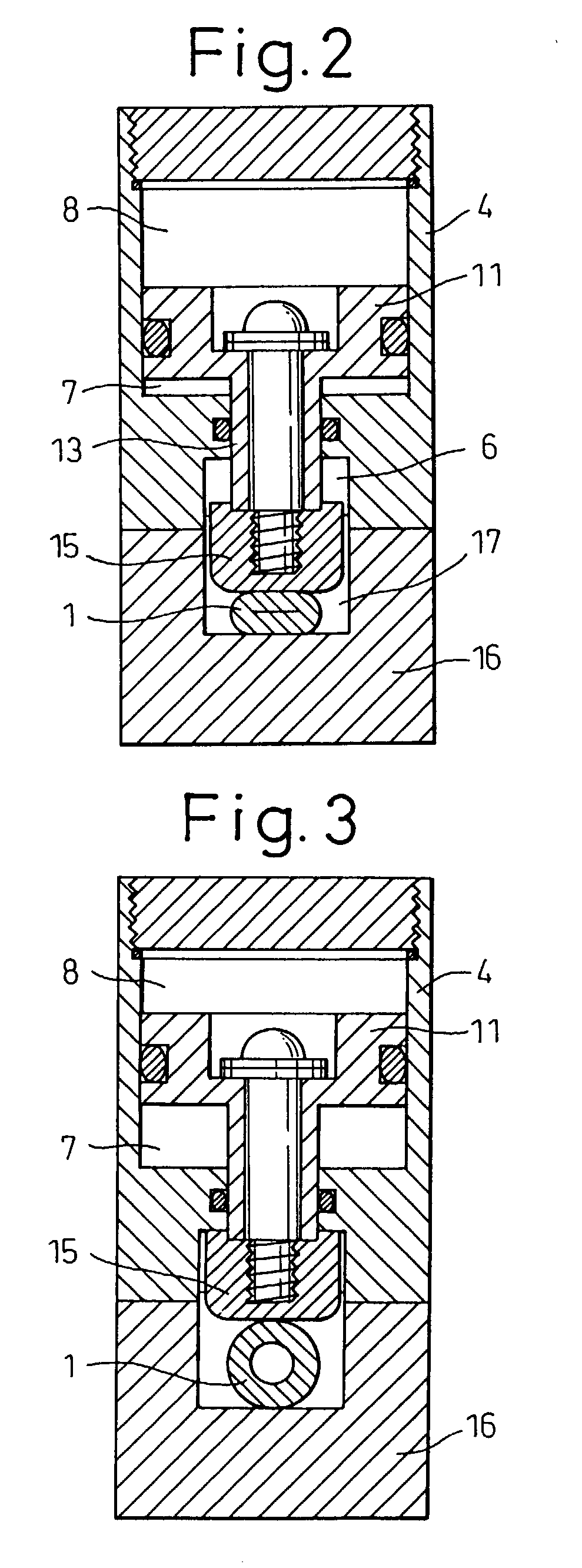

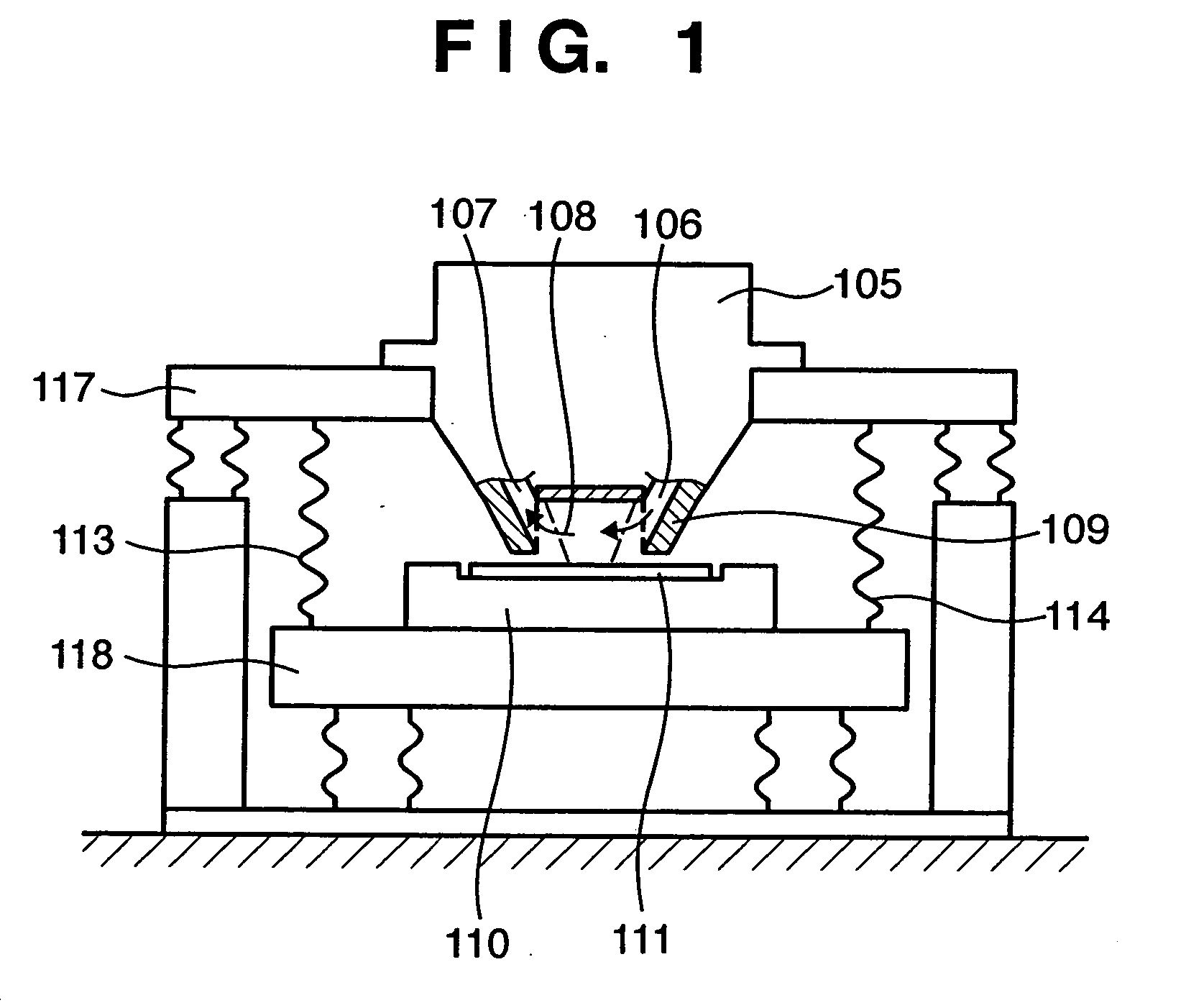

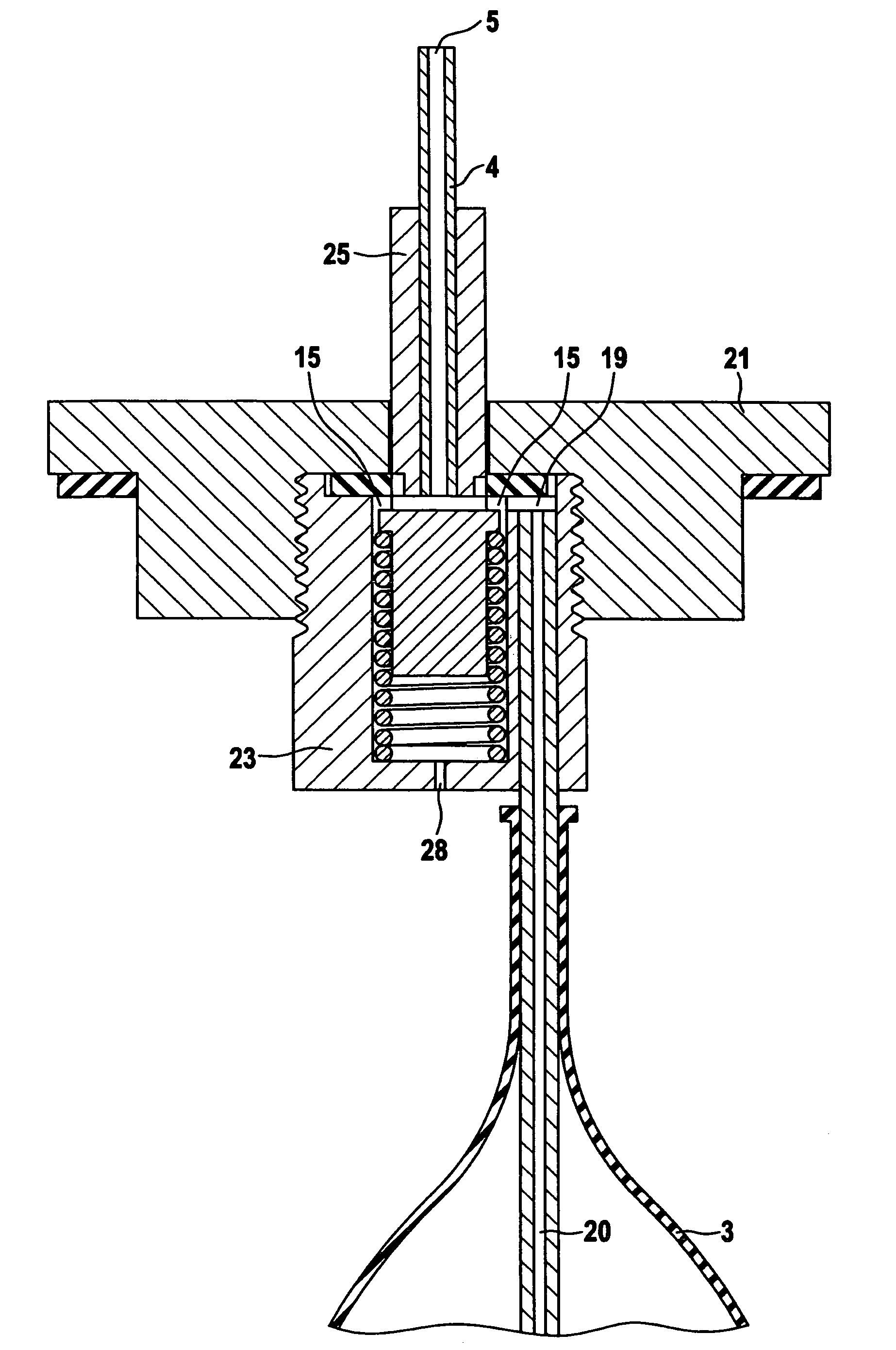

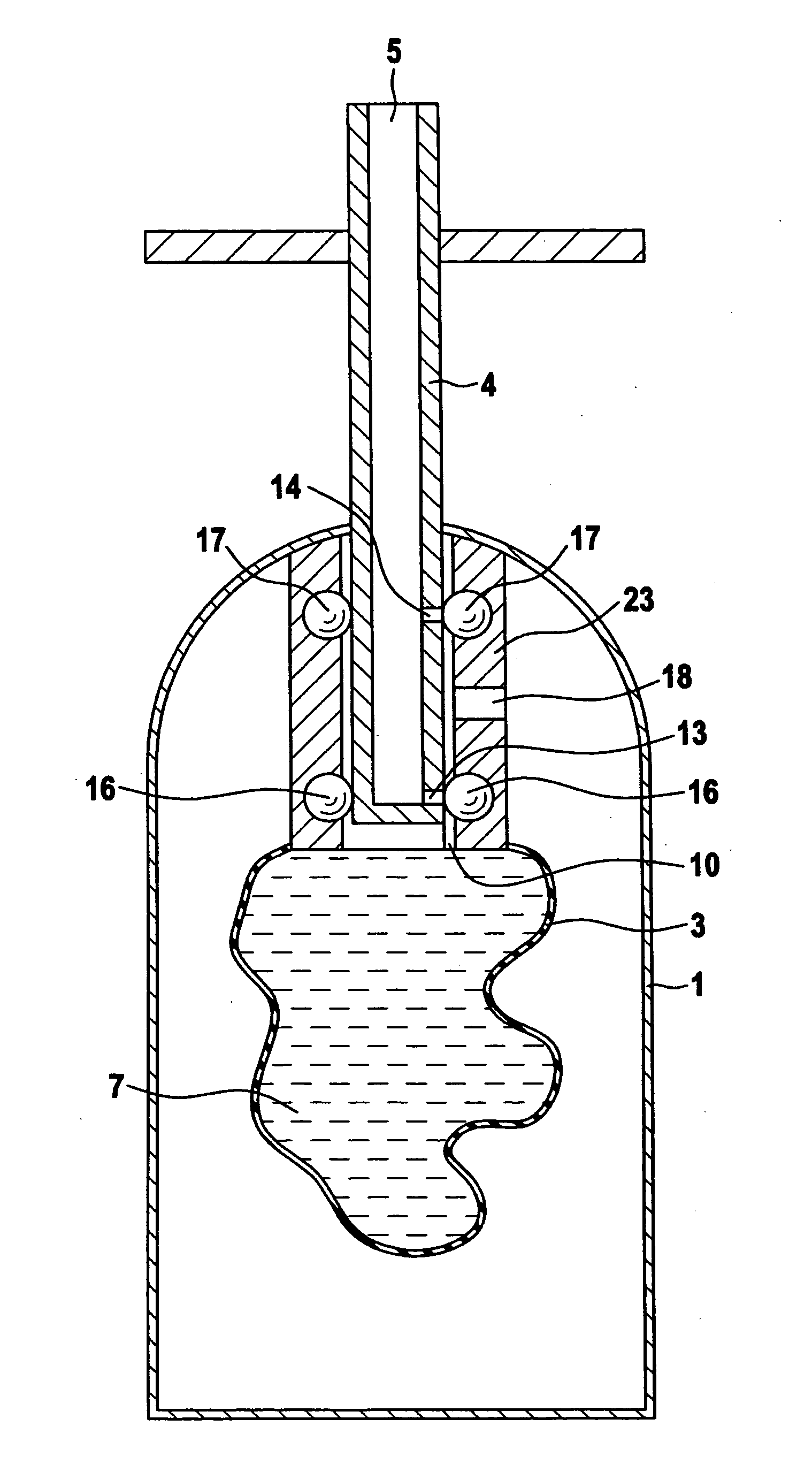

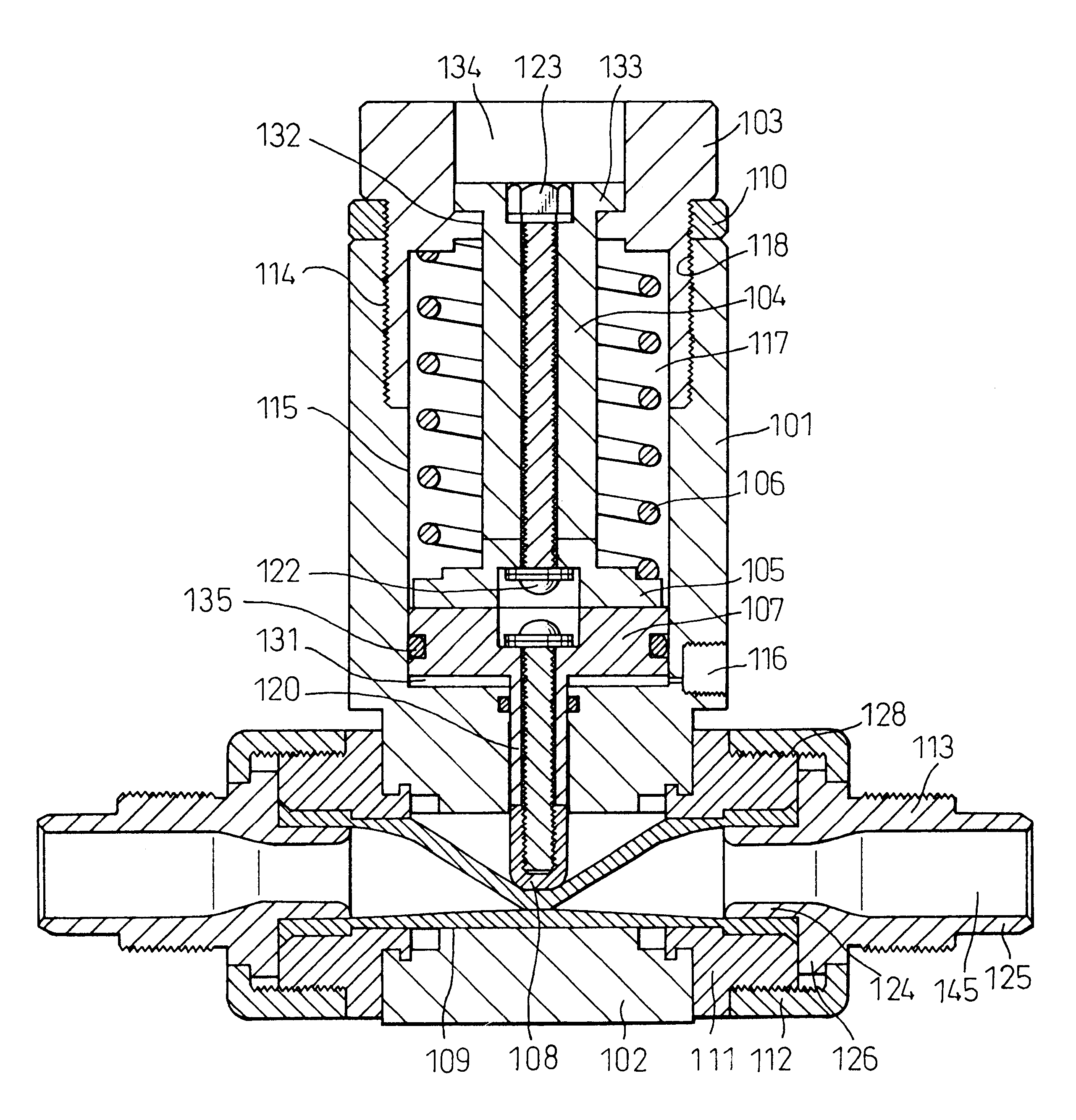

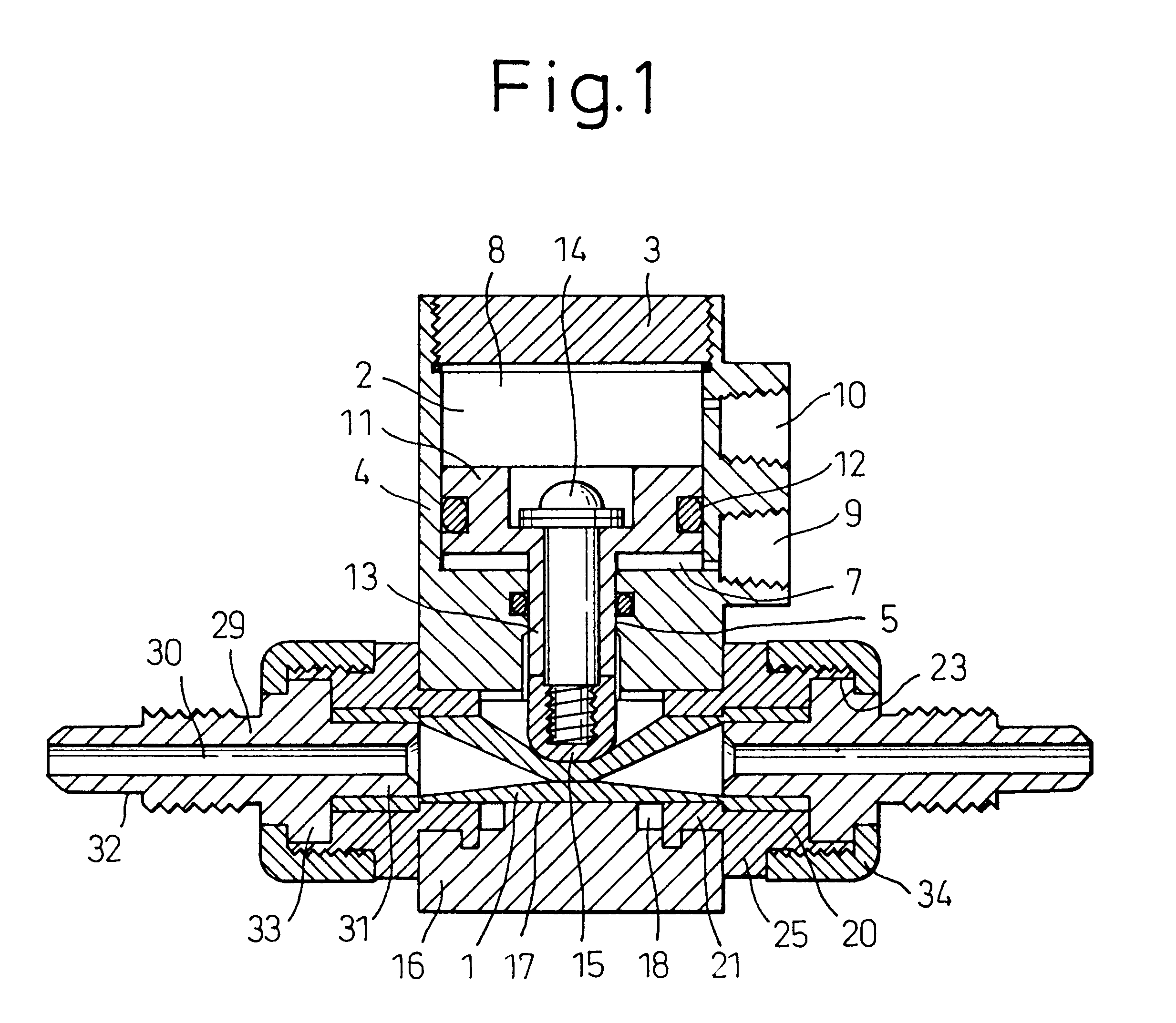

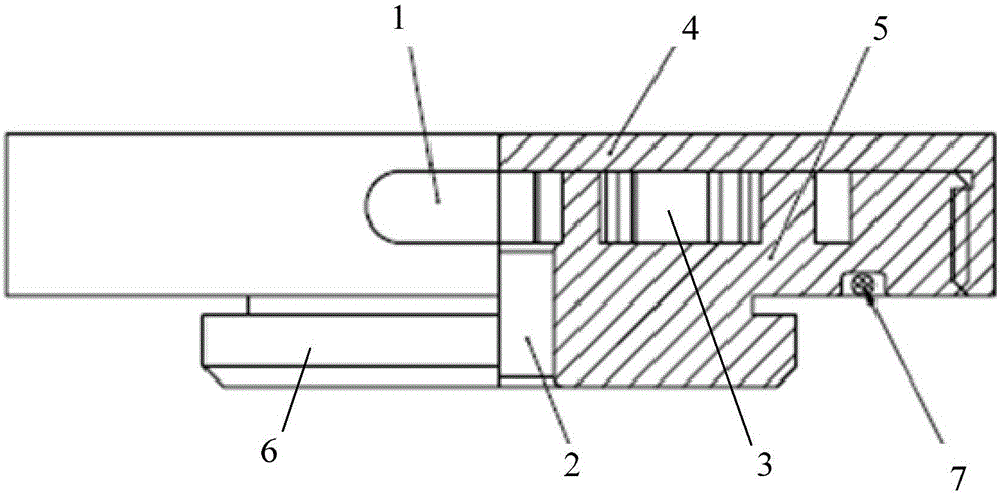

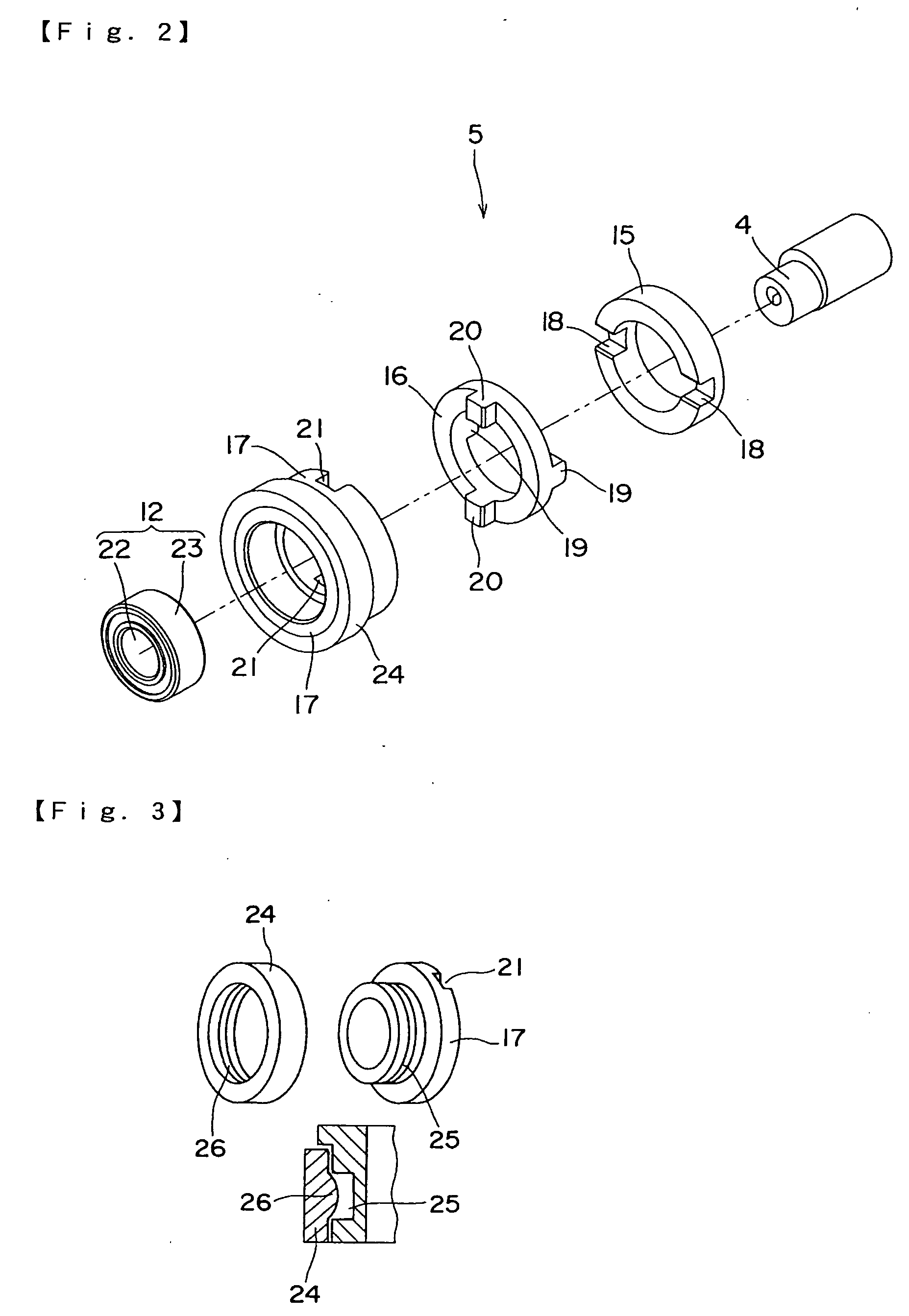

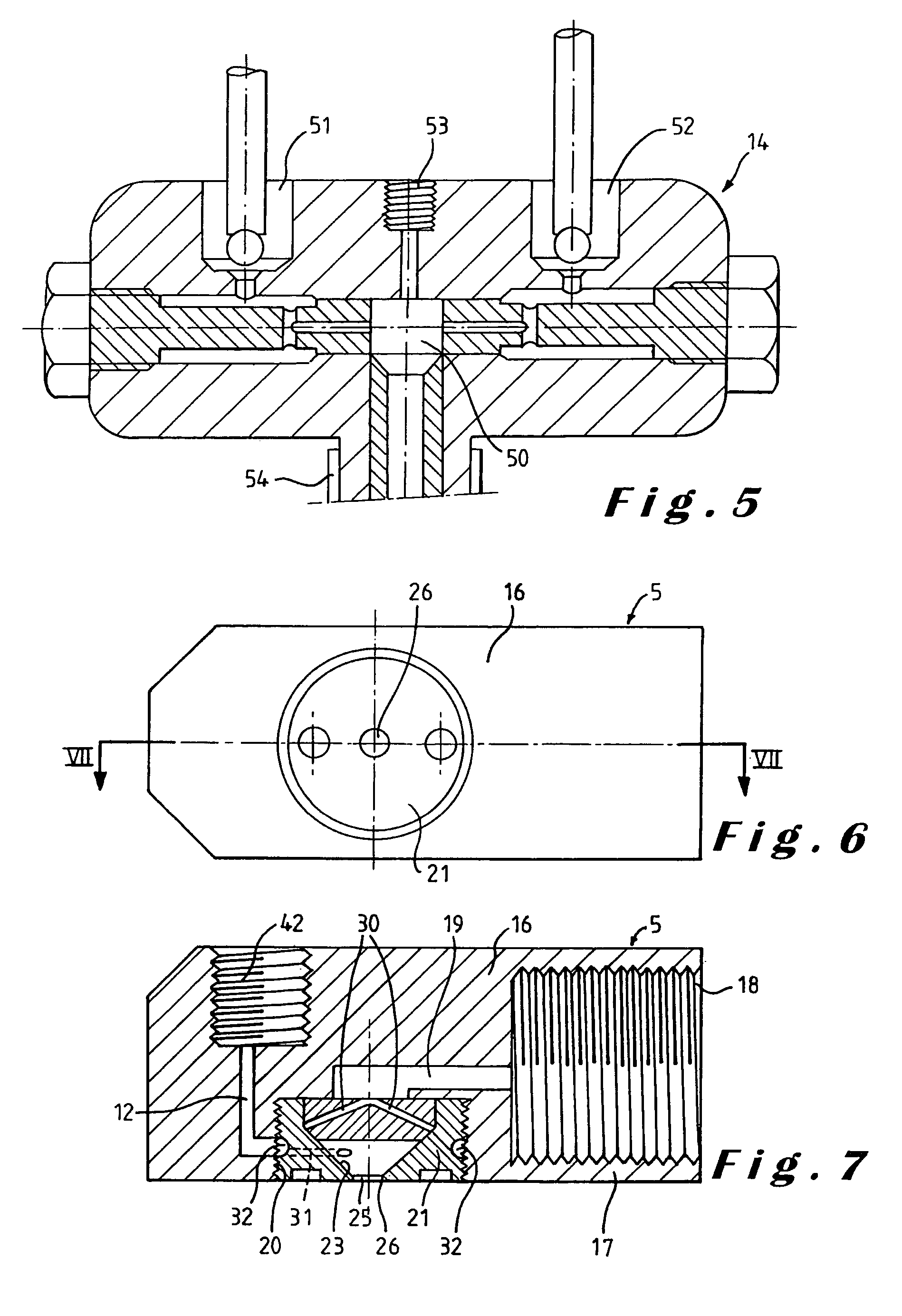

Pinch valve

InactiveUS20030010946A1Increased durabilitySmall flow rateDiaphragm valvesOperating means/releasing devices for valvesPinch valveCylinder block

A pinch valve of the invention comprising an elastic tube body 1, a cylinder body 4 having a cylinder portion 2 and a cylinder cover 3, a piston 11 sliding on the inner periphery of the cylinder body, a pressing piece 15 fixed to a connecting portion 13 suspended from the piston, a body 16 joined to the cylinder body and having a groove 17 receiving the tube body 1, a pair of connecting body carriers 20 engaged with grooves of the body and having a through-hole 26 receiving the tube body 1, a first and a second space portions 8, 7 formed above and under the piston 11, respectively, and a pair of air ports 10, 9 respectively communicating with the first and second space portions 8, 7. The whole pinch valve is made compact in construction.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Method and system for desorbing and ionizing chemical compounds from surfaces

InactiveUS8044346B2Efficient productionEasy to changeParticle separator tubesIsotope separationAnalyteChemical compound

The invention relates to a method and system for ionizing analyte-containing sample lying on a surface of a substrate. The method comprises directing to the sample a heated flow of desorption gas in order to desorb analyte from the surface, and simultaneously directing to the sample light capable of ionizing the desorbed analyte in the presence of the desorption gas. The invention provides a method and system suitable for efficiently producing ions of neutral and nonpolar molecules on surfaces, for example for mass spectrometric purposes.

Owner:LICENTIA OY

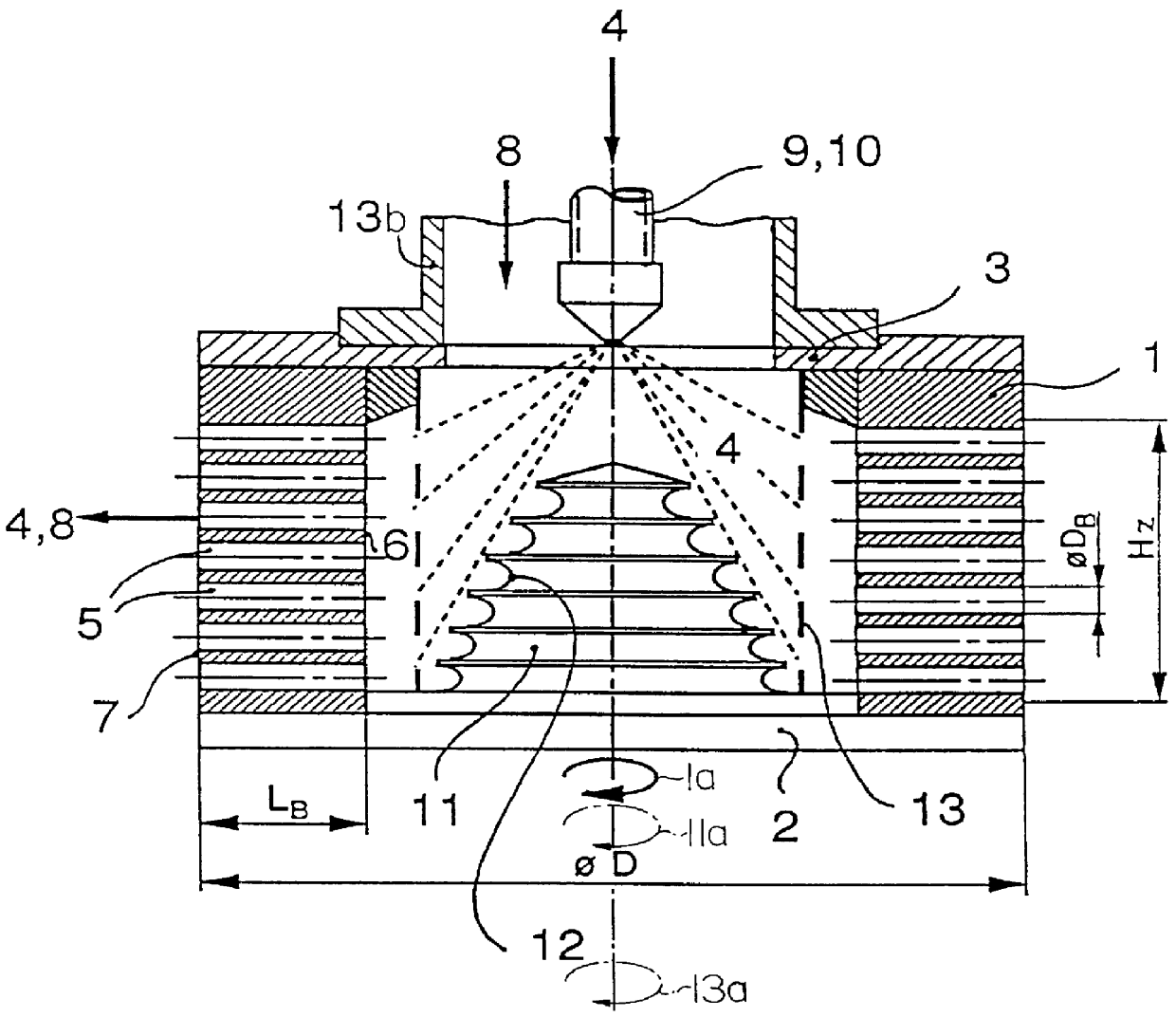

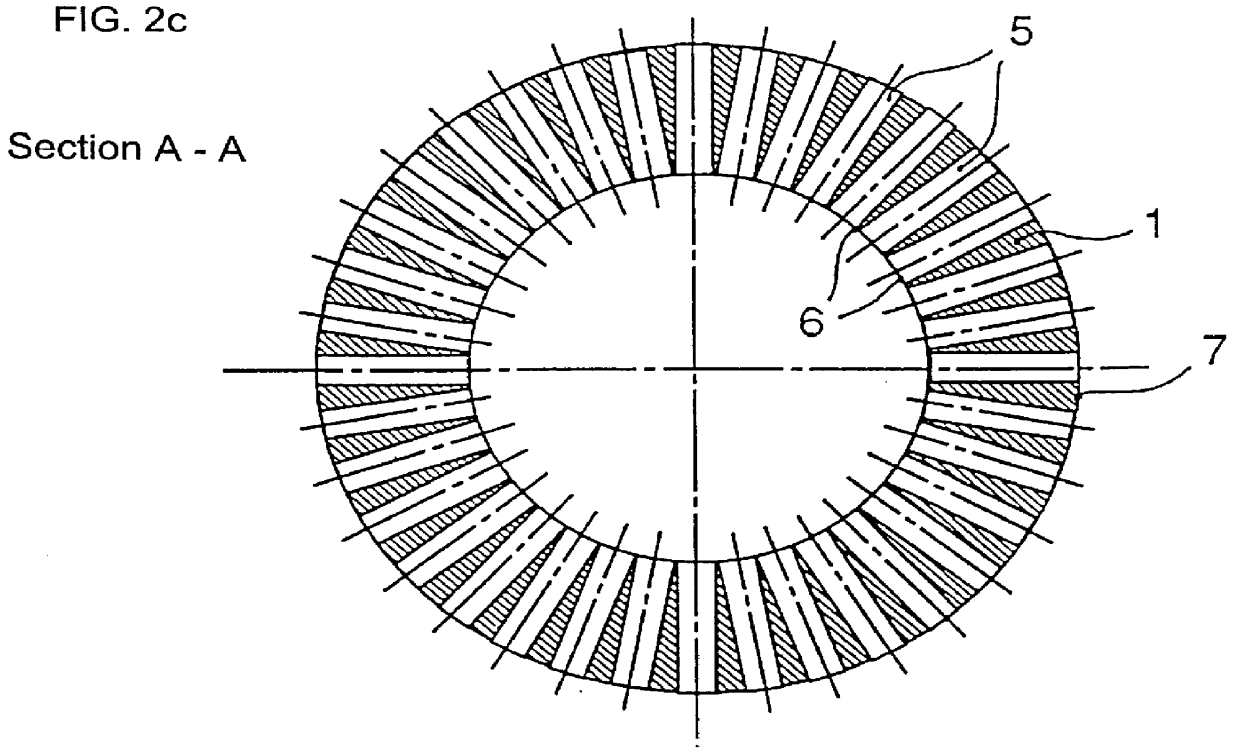

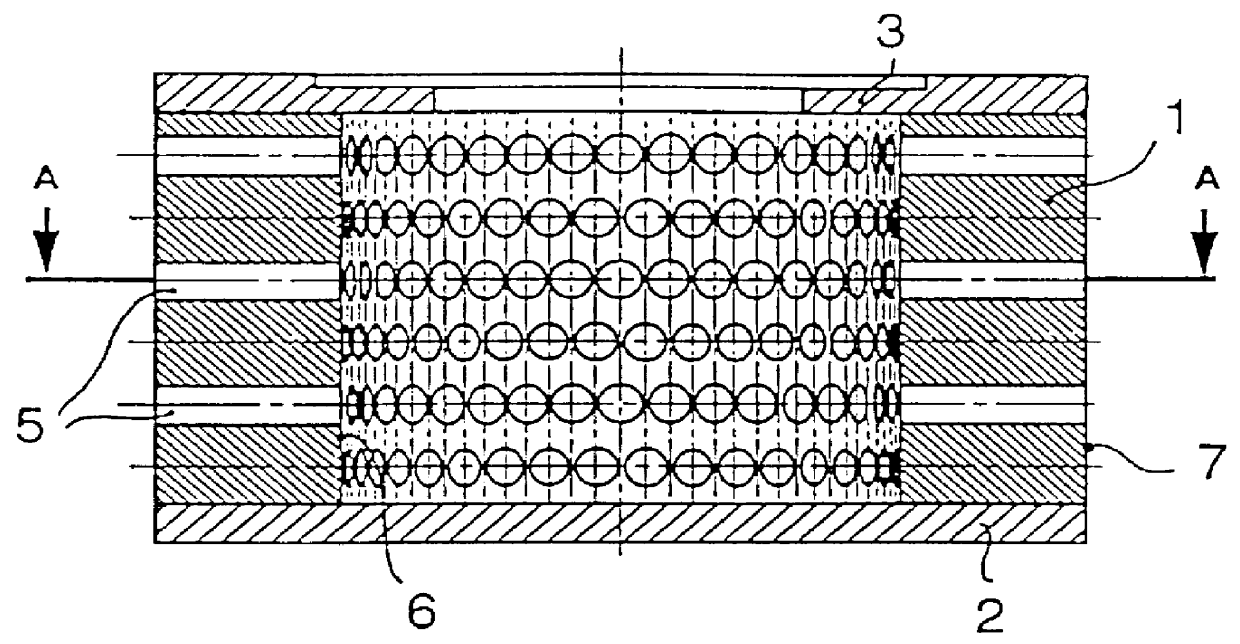

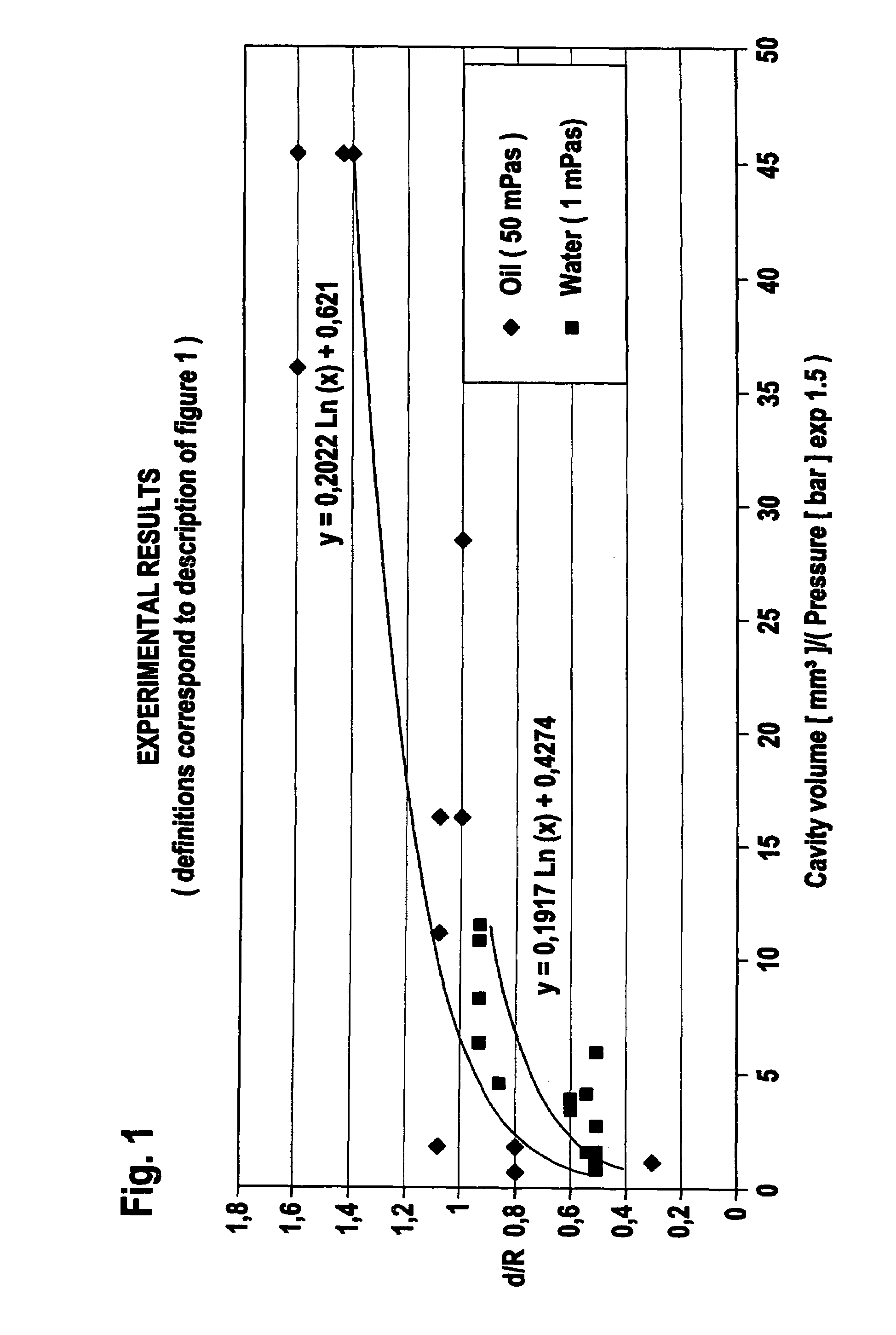

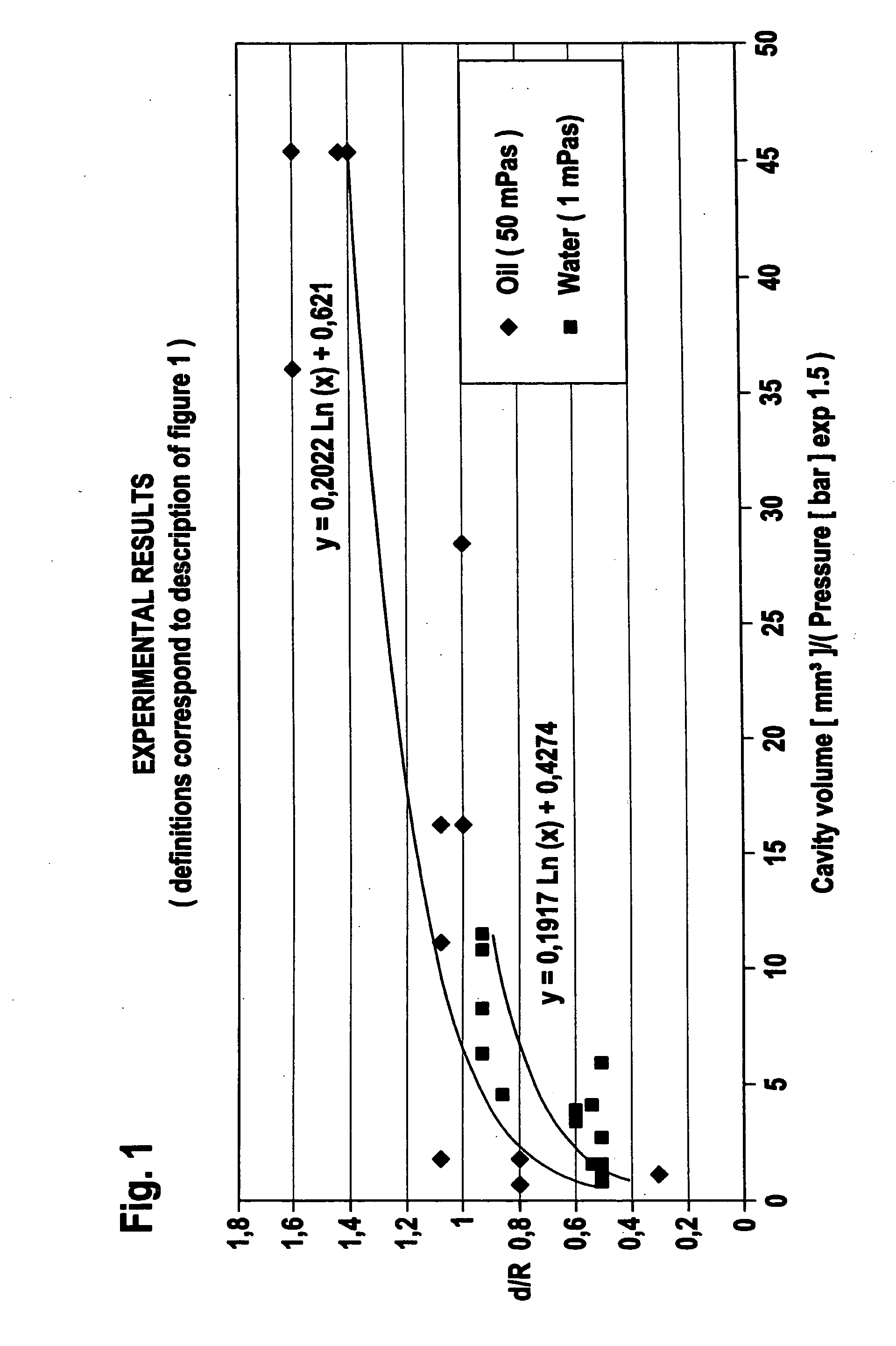

Process and a device for atomizing liquids

InactiveUS6098895ALarge caliberAvoid easy cloggingBurnersMovable spraying apparatusDecompositionEngineering

The liquid to be atomized is uniformly sprayed on the inner surface of a hollow rotating cylinder, for example by means of one- or two-fluid-nozzles and is thus distributed on bores provided in the cylinder wall. The rotation of the cylinder causes the liquid to flow outwards through the bores. Droplets are generated when the liquid flows out of the bores by laminary decomposition of the jet. The flow rate in each bore lies in the range 1.0<+E,dot V+EE B (a3 rho 5 / sigma 5)0.25<16 to prevent the droplets from becoming too large and to satisfy the condition of an adequate flow laminarity, i.e. for the value of the Reynolds number for the continuous liquid flow in the boress not to exceed Re delta 400. +E,dot V+EE B represents the flow rate of the liquid in each bore, a represents the centrifugal acceleration at the outer surface of the cylinder, rho represents the density of the liquid and delta indicates the surface tension of the liquid. The large number N>200 of bores having the diameter DB in the cylinder wall causes the flow rate of liquid through each bore to be relatively low, so that a continuous laminary flow in each bore is ensured even at low viscosities and technically useful total flow rates. Preferably cylindrical bores with a minimum length at least three times larger than the bore diameter are provided in the cylinder wall, with a narrow spacing in the range defined by 1.1<t / DB<5, so that a number of bores as large as possible may be arranged in the wall of the cylinder.

Owner:NIRO

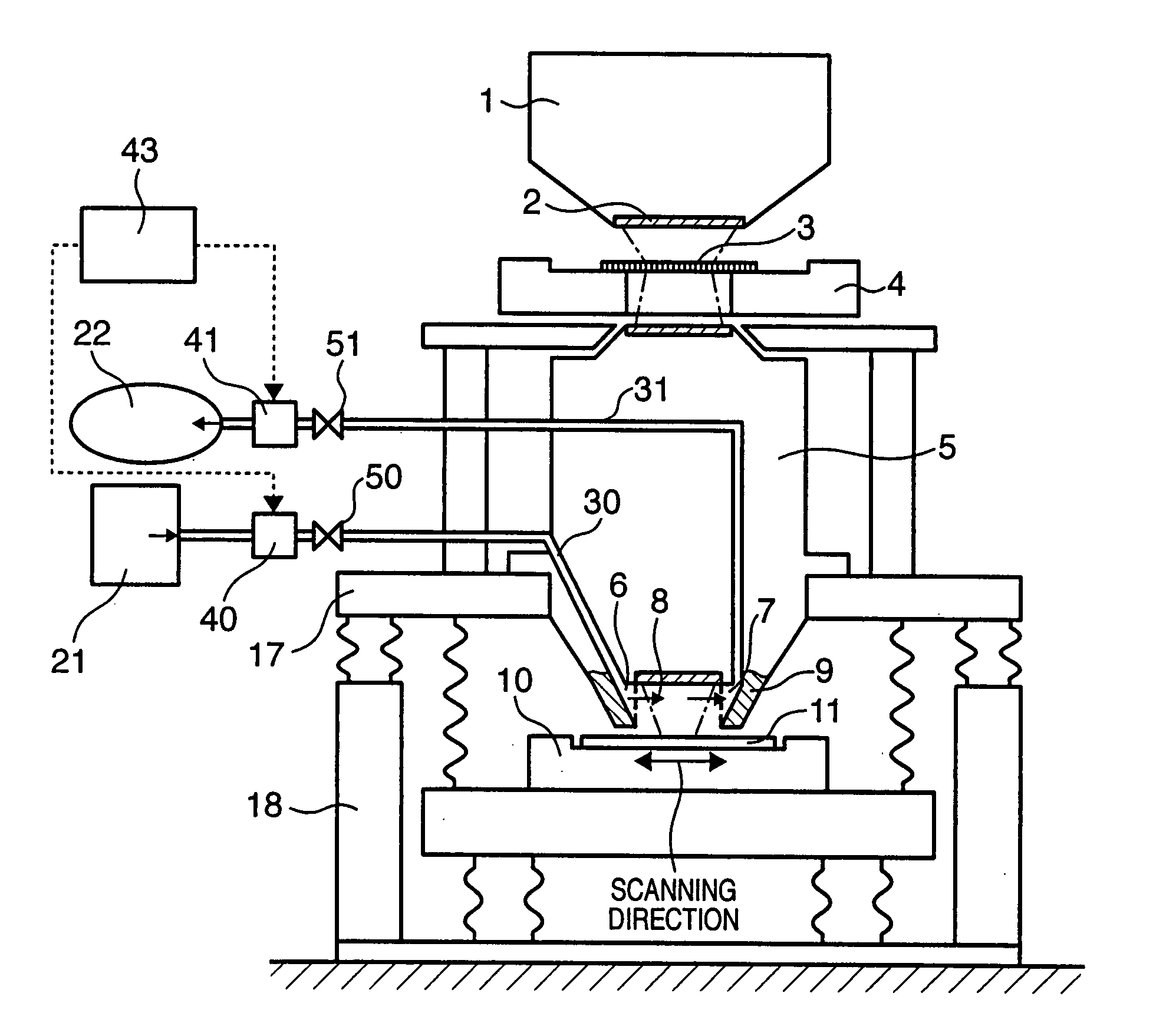

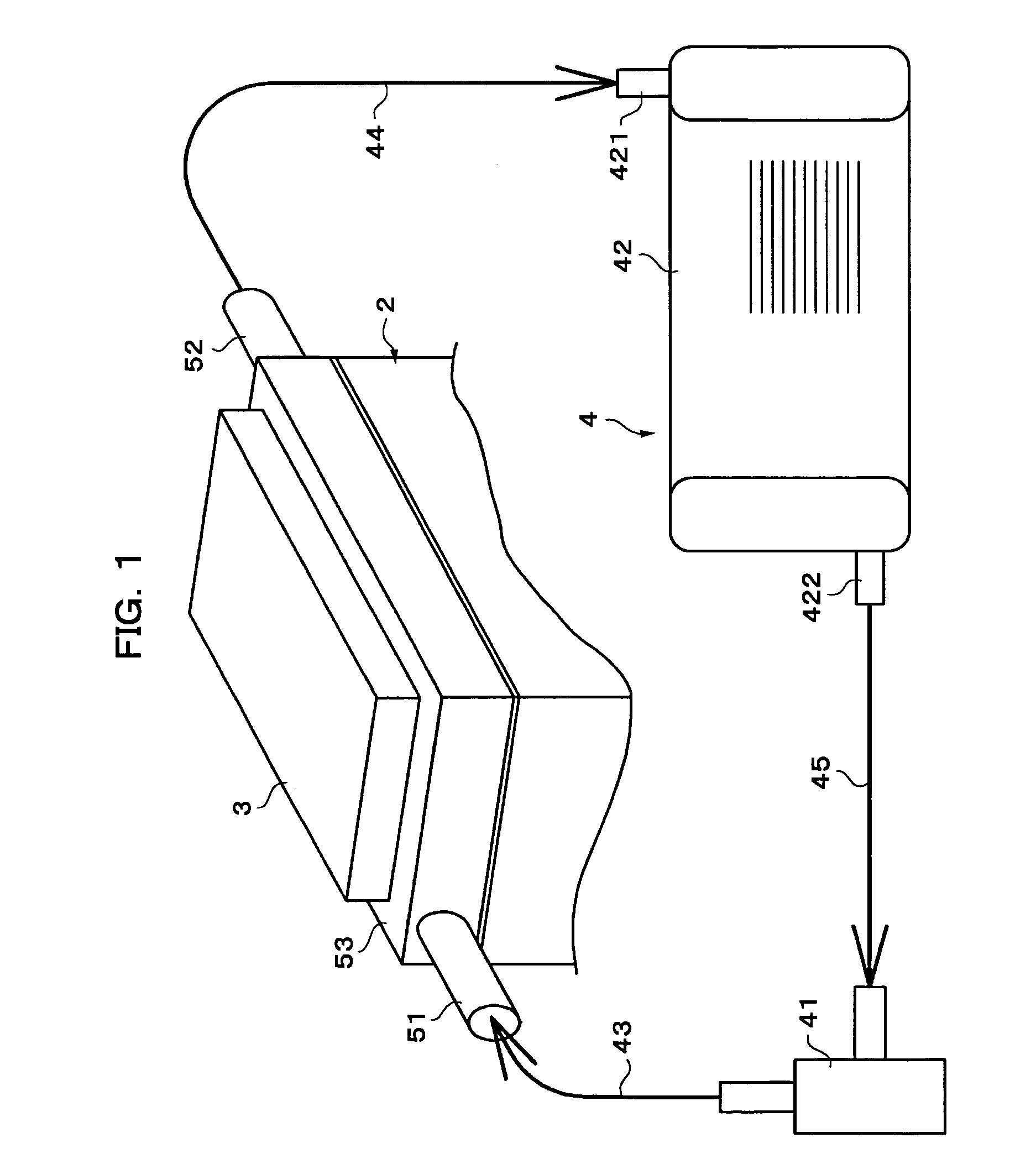

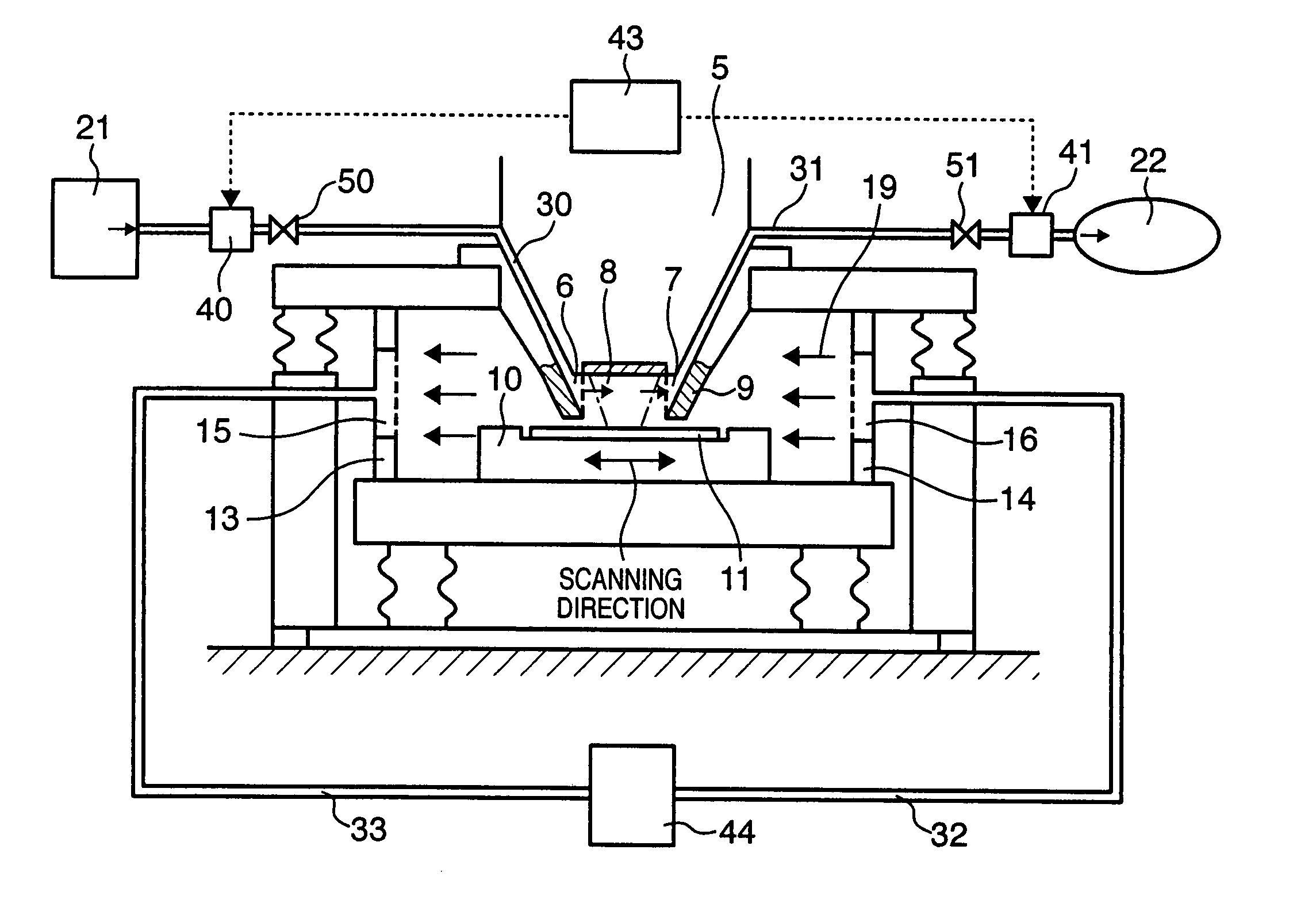

Exposure apparatus

InactiveUS20050030496A1Small flow rateSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptical pathAirflow

An exposure apparatus for irradiating a photosensitive substrate arranged on a wafer stage with exposure light through a projection optical system includes a cover which extends from a wafer-side end of the projection optical system toward a vicinity of the wafer stage to surround an exposure optical path, a supply port through which purge gas formed of inert gas blows out to inside the cover, and a recovery port through which the purge gas supplied through the supply port is drawn by suction. The purge gas blows out through the supply port and is recovered through the recovery port, to form a purge gas flow inside the cover. At this time, control operation is performed such that the flow rate of the purge gas recovered through the recovery port is smaller than the flow rate of the purge gas supplied through the supply port.

Owner:CANON KK

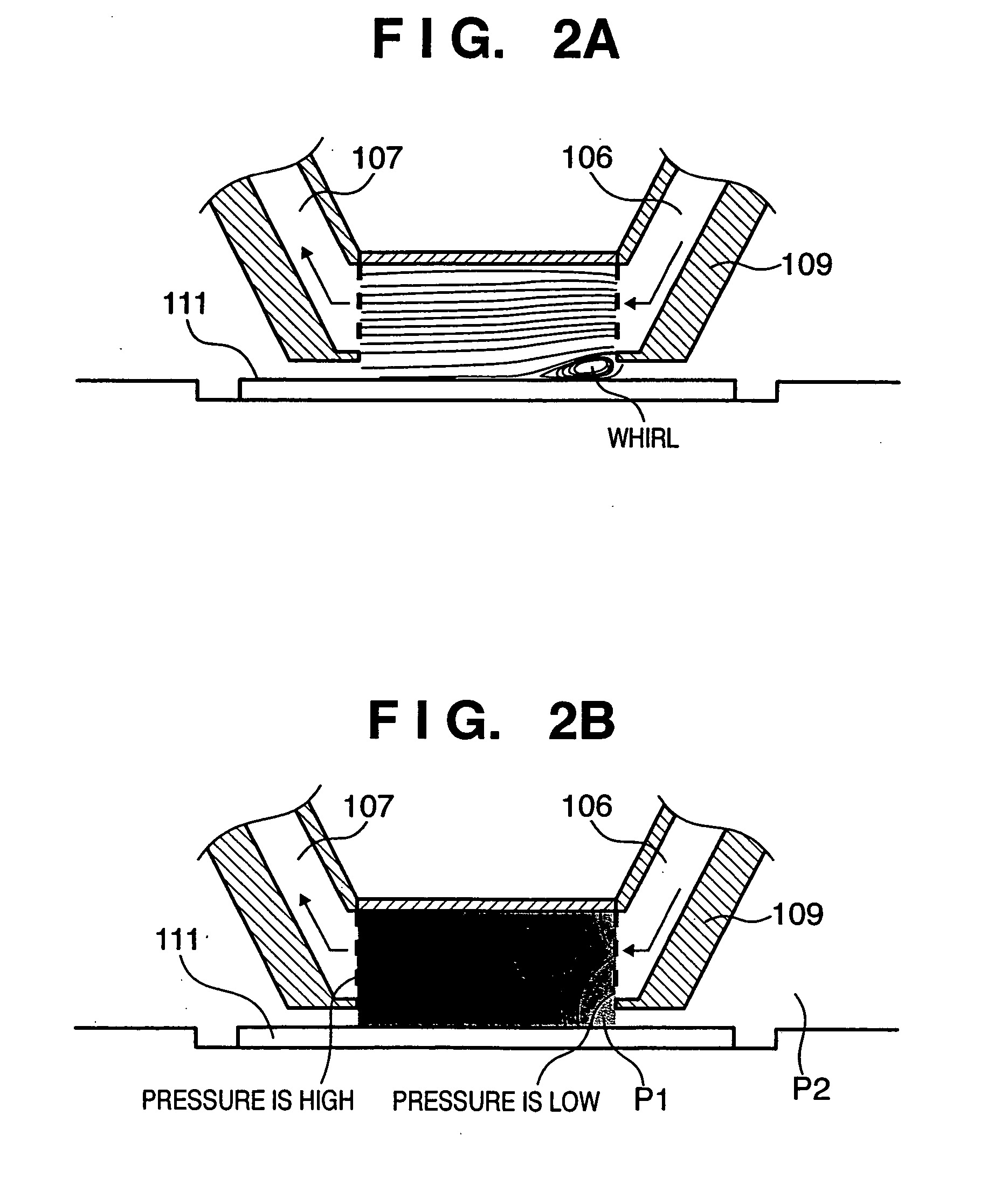

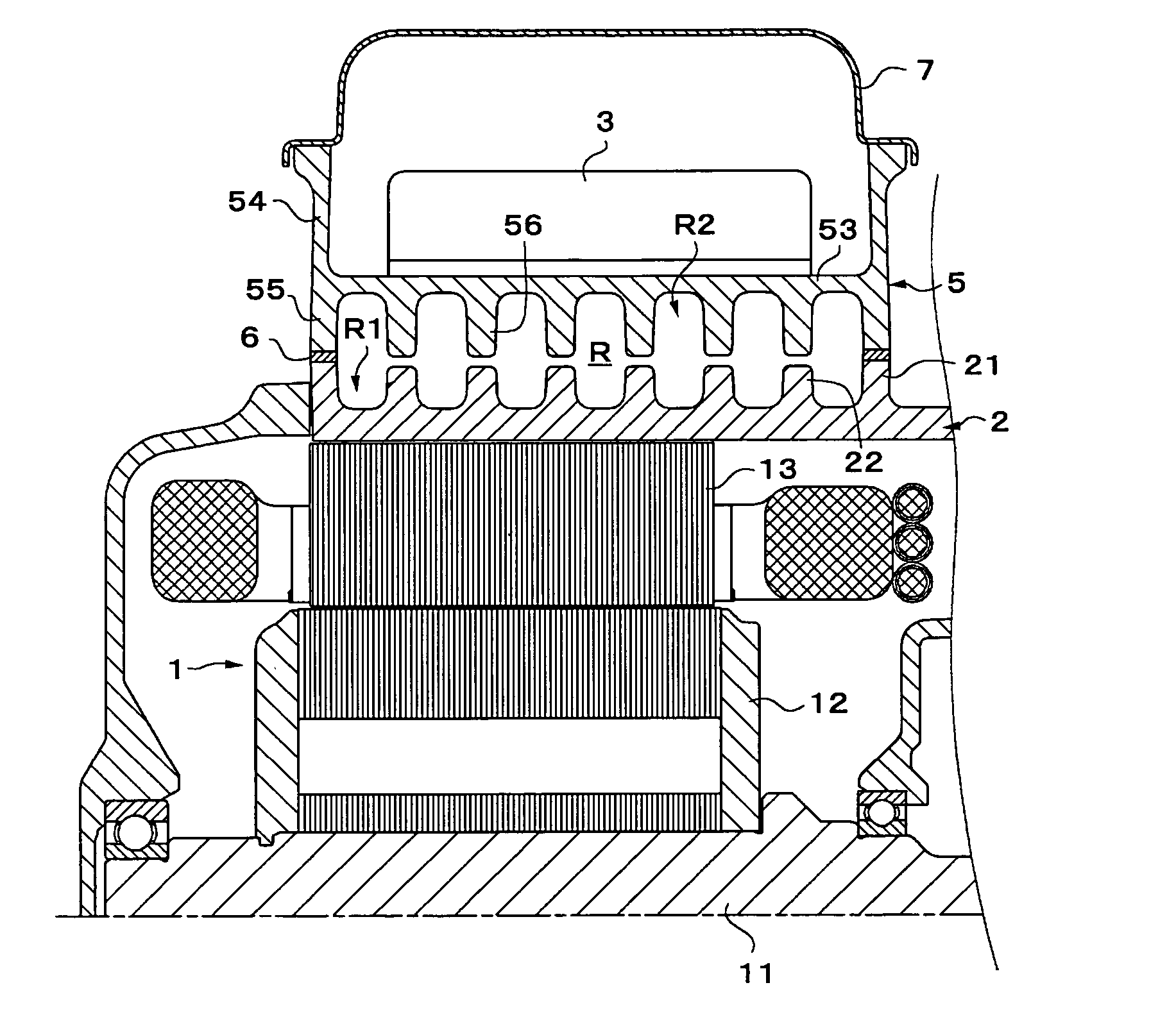

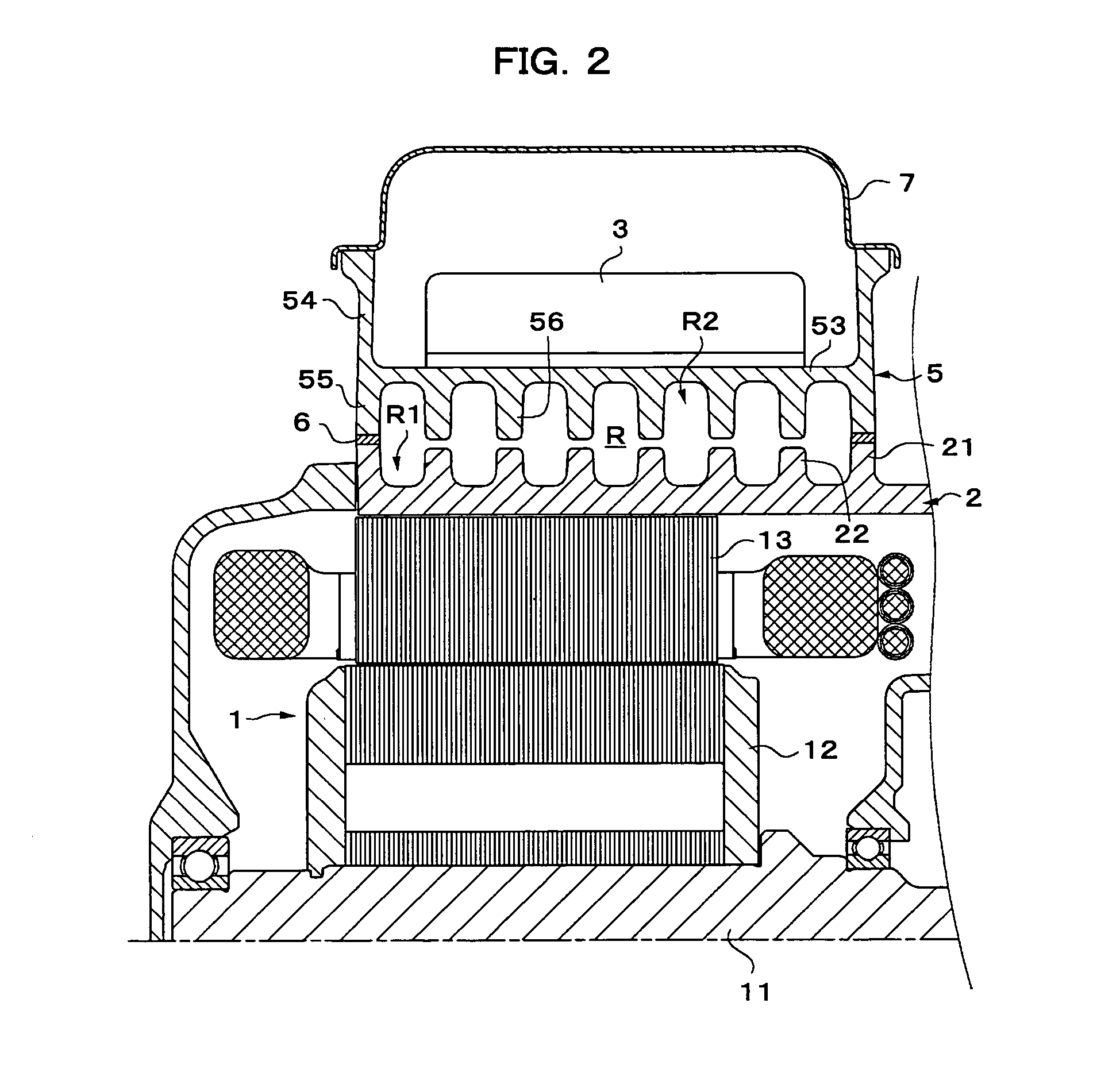

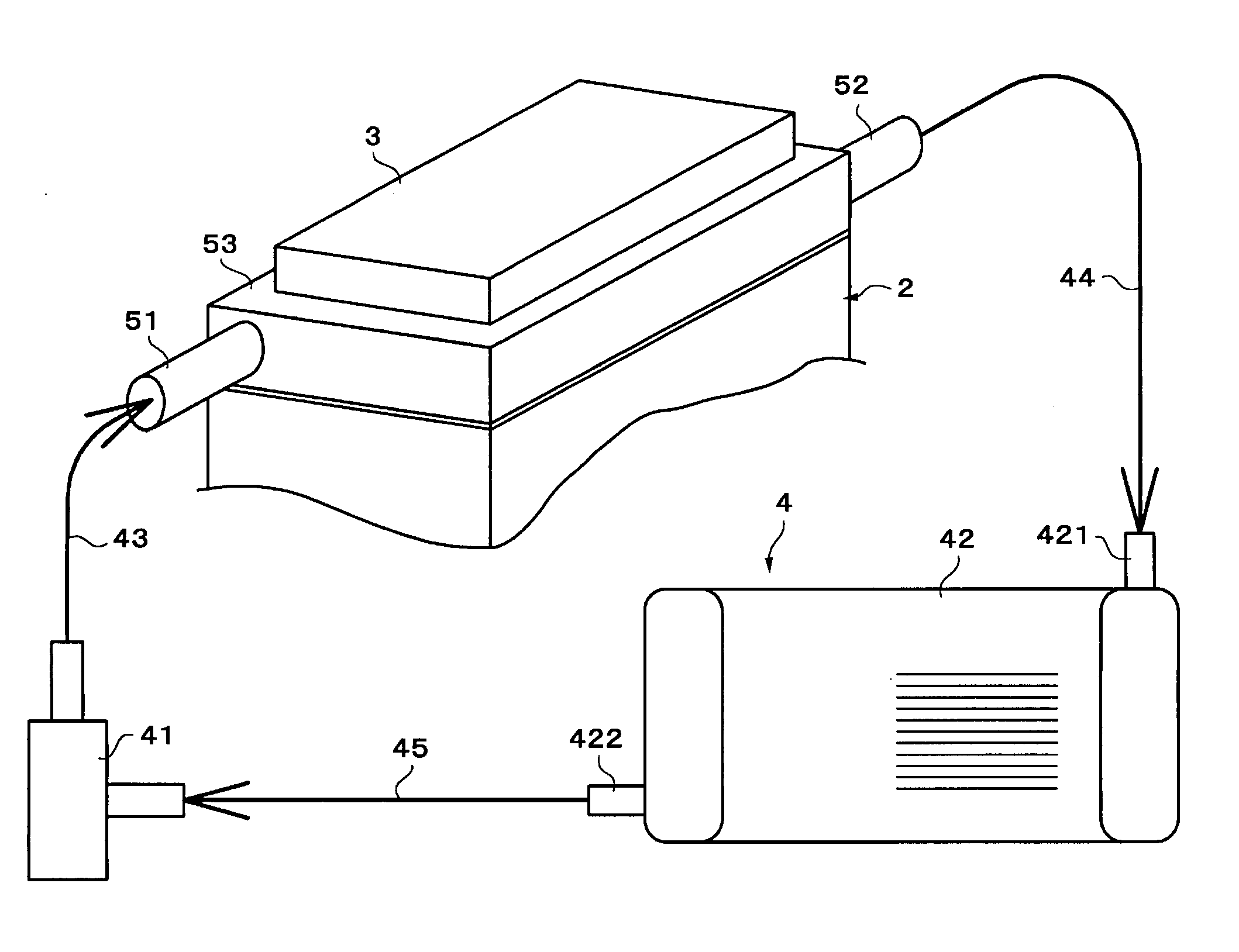

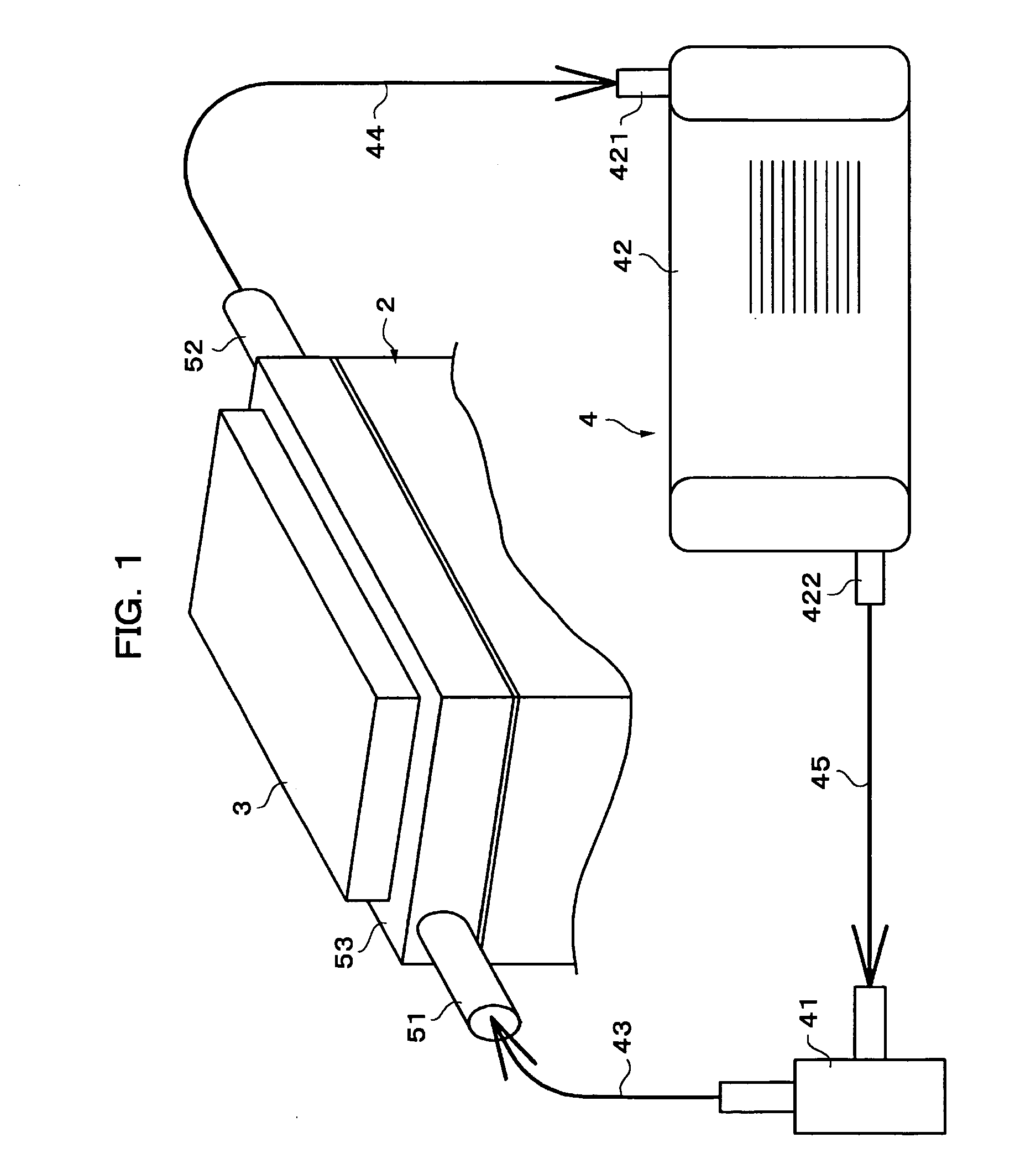

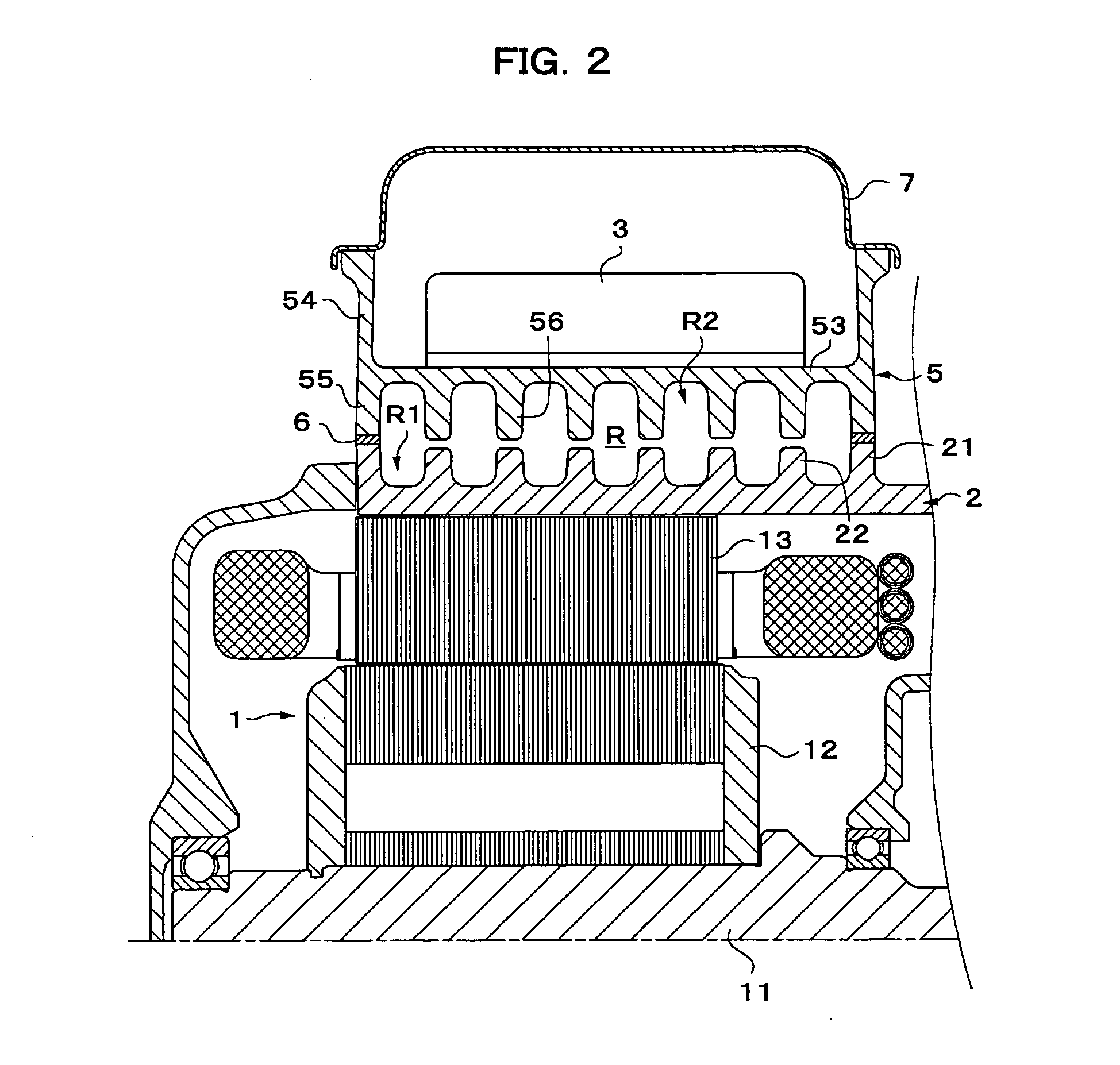

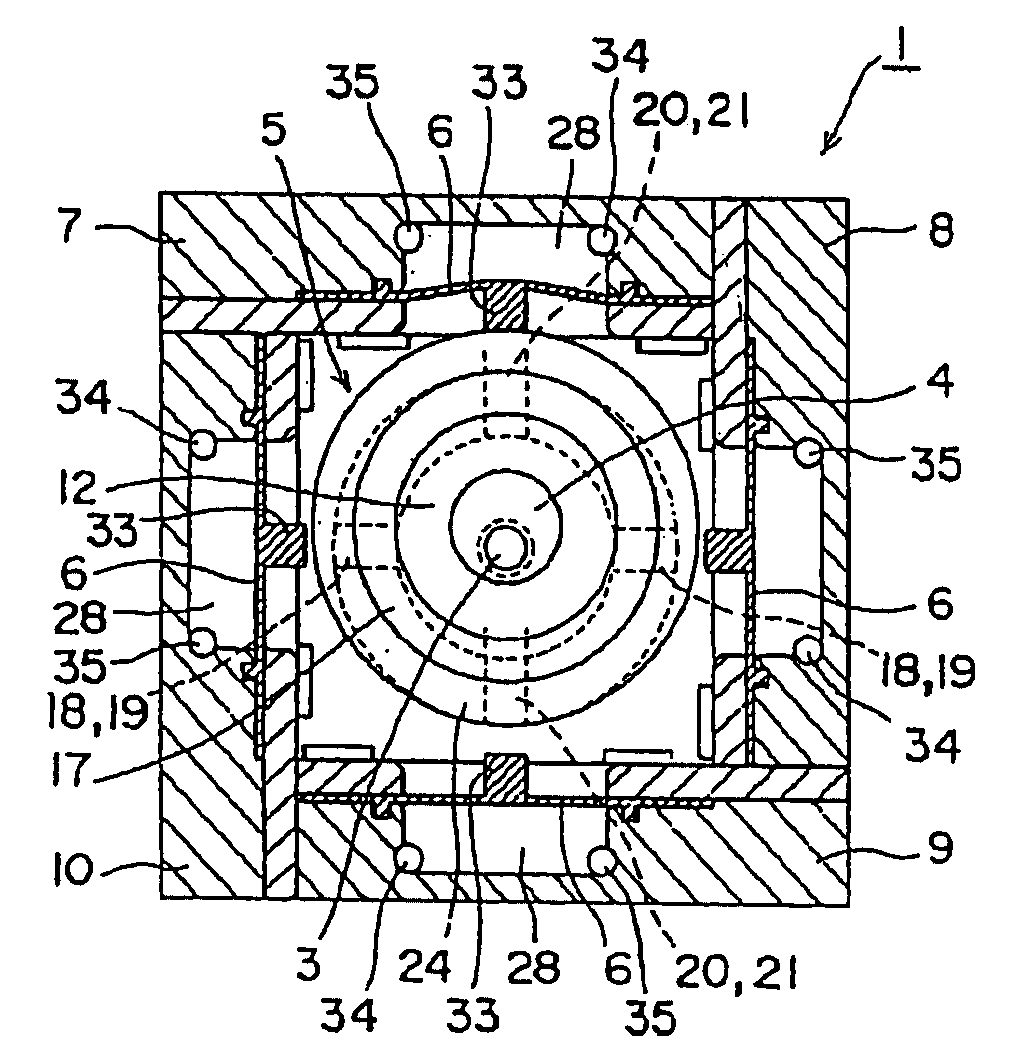

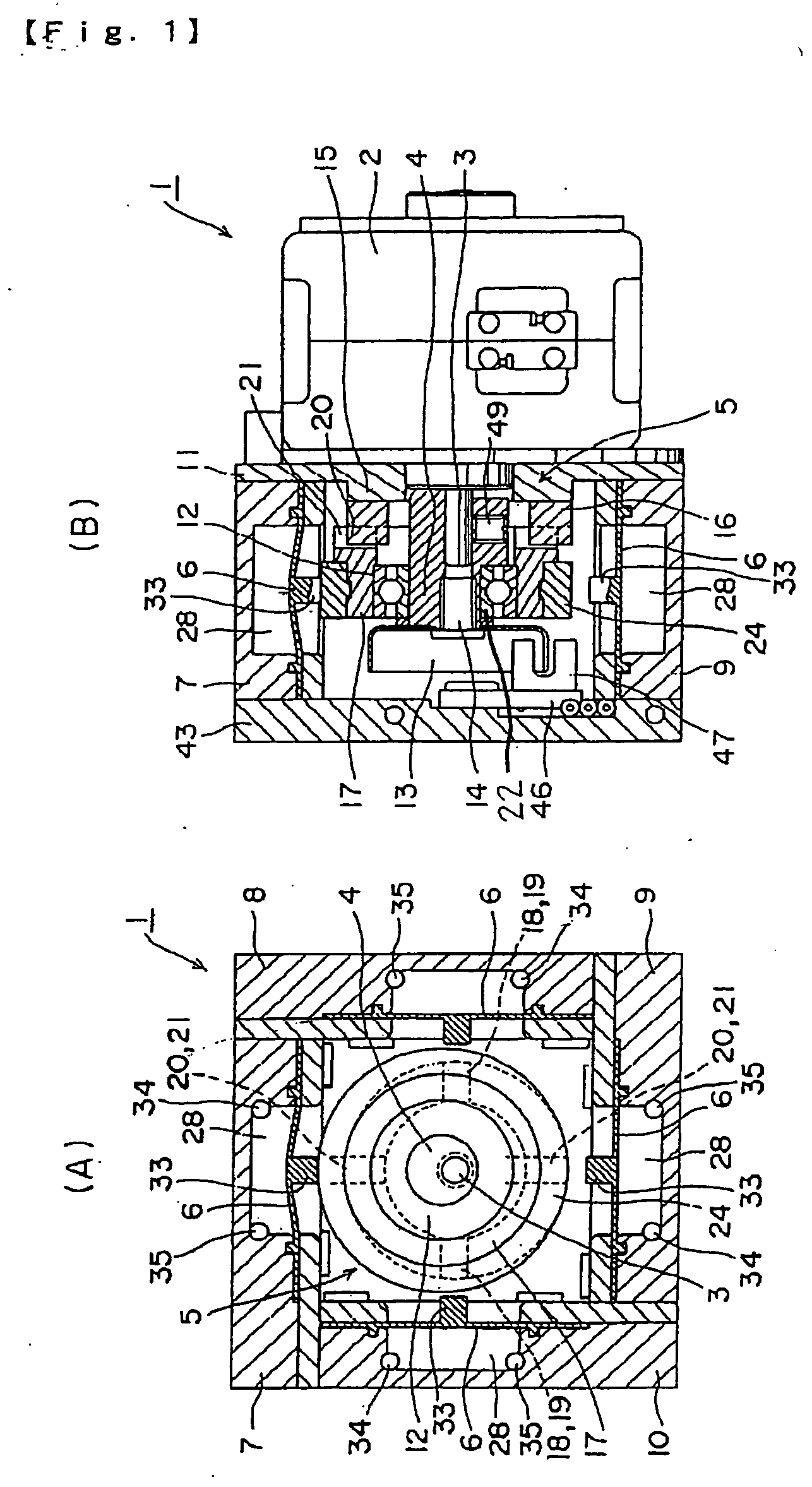

Drive device

InactiveUS7102260B2Improve cooling effectSmall flow ratePlural diverse prime-mover propulsion mountingSupport structure mountingEngineeringRefrigerant

A drive unit comprises an electric motor 1, a drive unit casing 2 accommodating therein the electric motor, an inverter 3 that controls the electric motor, and a flow passage of a refrigerant that cools the inverter. The inverter is mounted on a heat sink 53 and mounted to the drive unit casing with a space R defined, and the space is communicated to the flow passage of the refrigerant. The heat sink comprises fins 56, and the drive unit casing comprises fins 22, the both fins being apart from each other. Thereby, both a side of the drive unit casing and a side of the heat sink are effectively cooled by heat exchange with a cooling refrigerant in wide areas. Also, the fins are apart from each other whereby direct heat conduction is avoided and efficient cooling is enabled with temperature gradient conformed to heat-resistant temperatures.

Owner:AISIN AW CO LTD

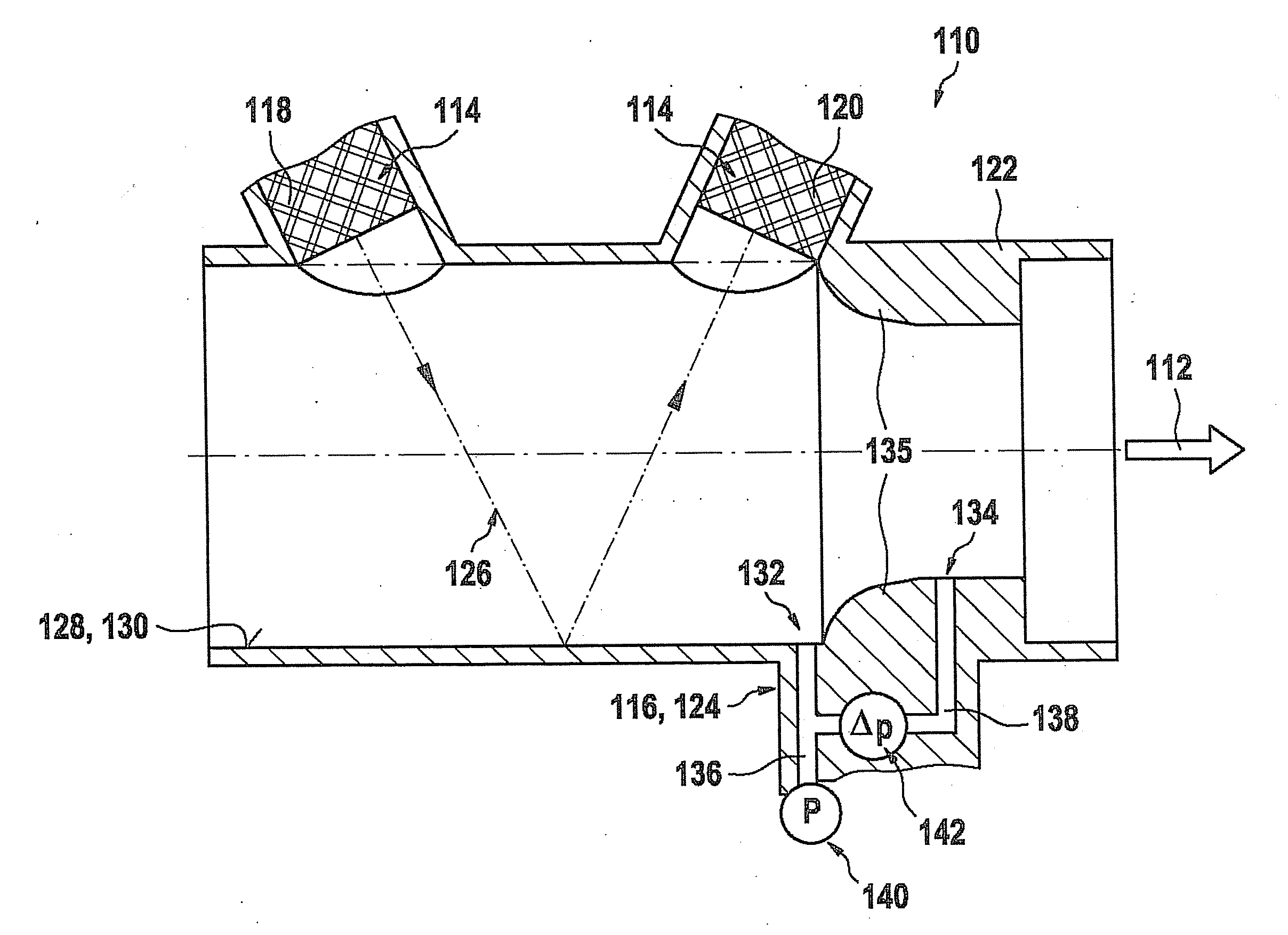

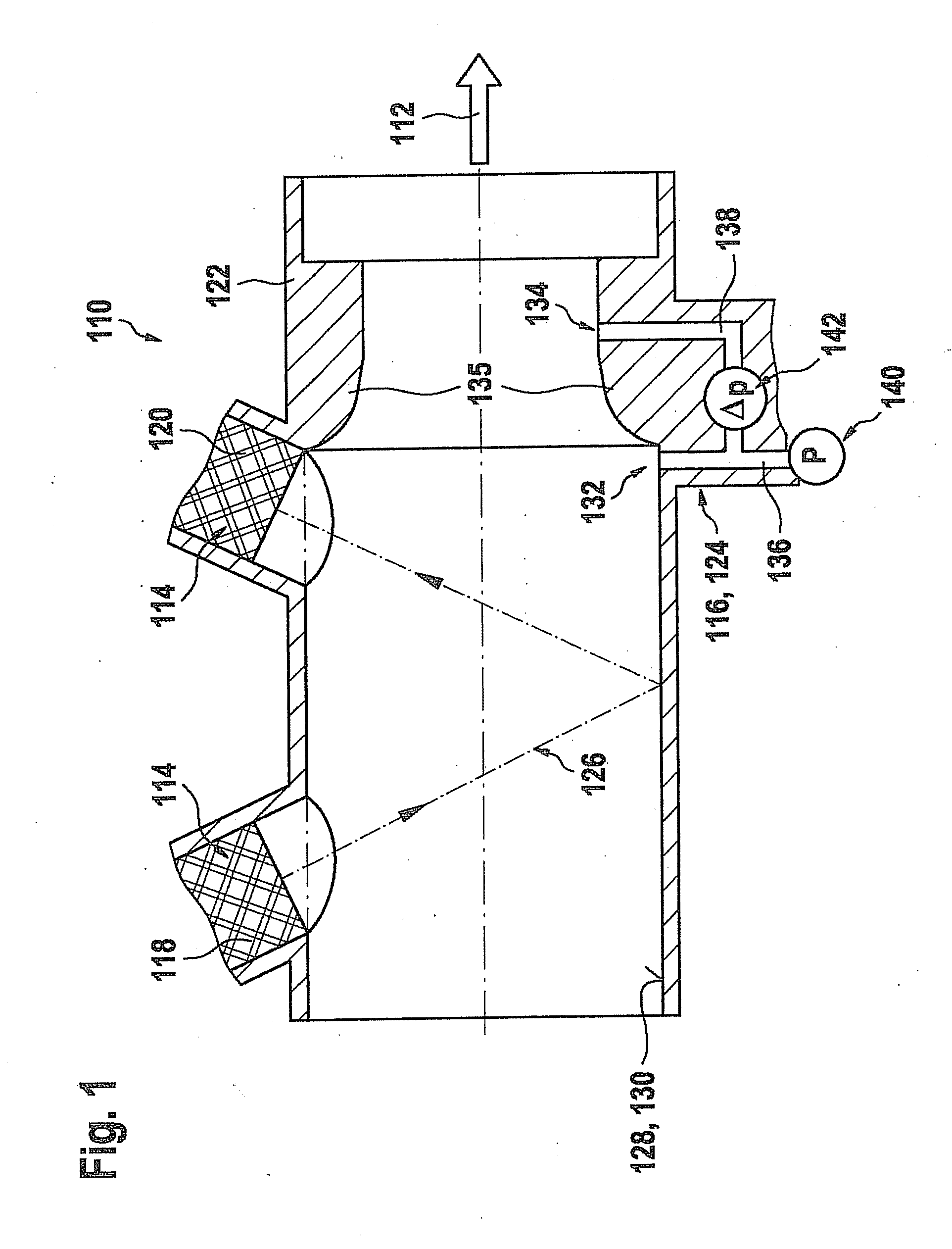

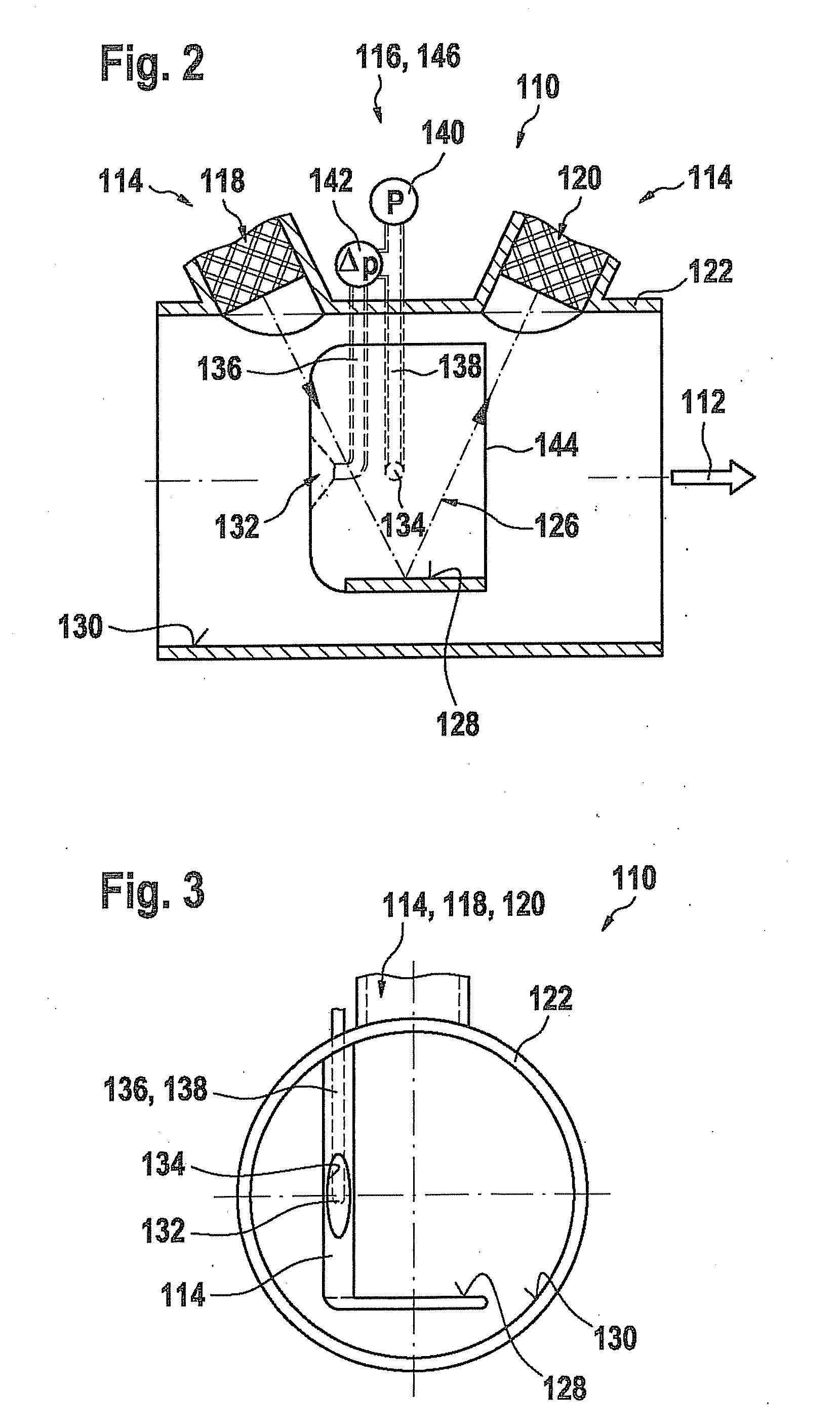

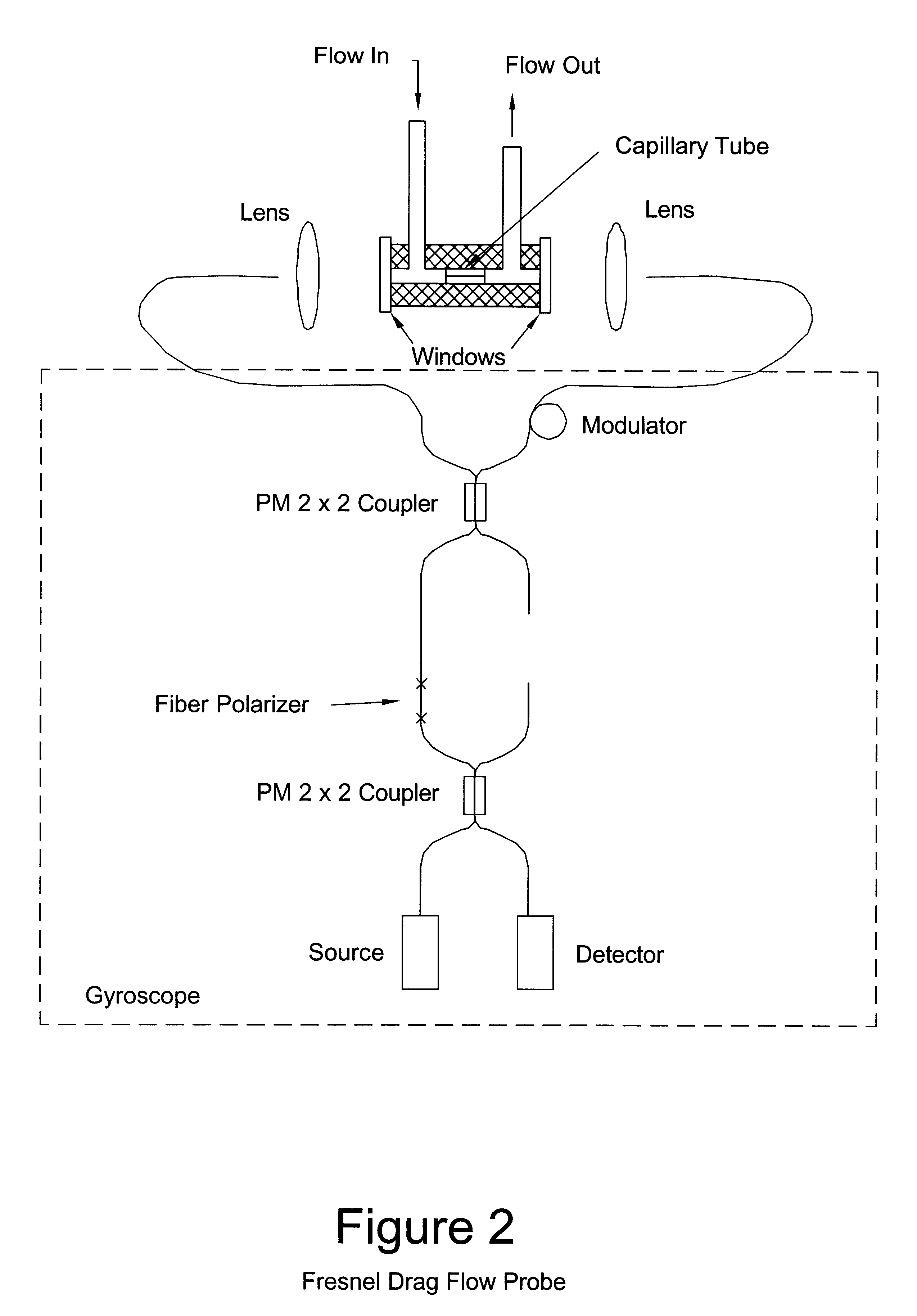

Flowmeter for detecting a property of a fluid medium

InactiveUS20120055263A1Reduce throughputSmall flow rateVolume/mass flow by dynamic fluid flow effectVolume/mass flow by differential pressureUltrasonic sensorDifferential pressure

A flowmeter for detecting at least one property of a fluid medium flowing through a flow tube, in particular a flow property, is described. The flowmeter has at least one ultrasonic sensor for detecting at least one first flow property of the fluid medium. In addition, the flowmeter has at least one differential pressure sensor for detecting at least one second flow property of the fluid medium.

Owner:ROBERT BOSCH GMBH

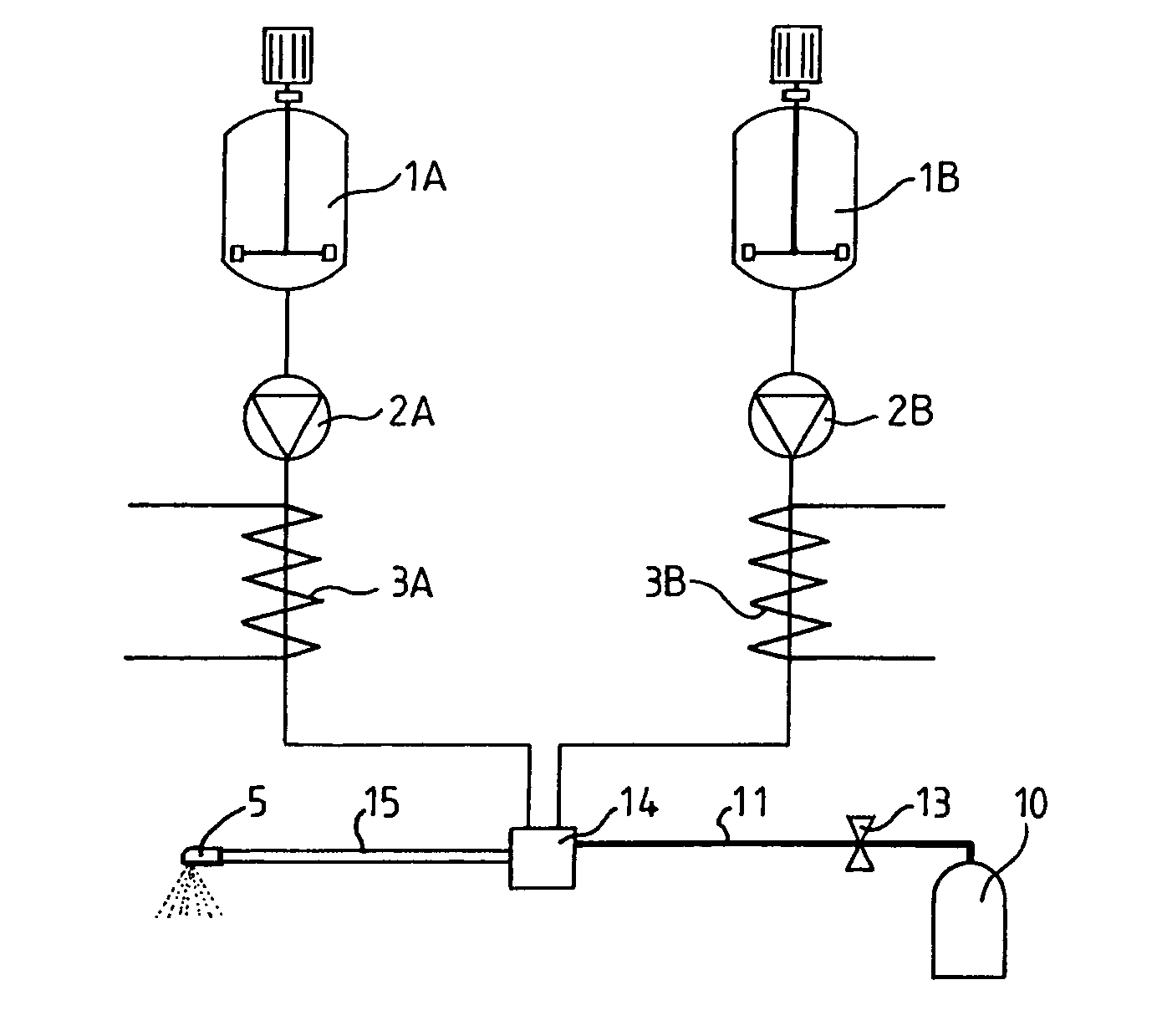

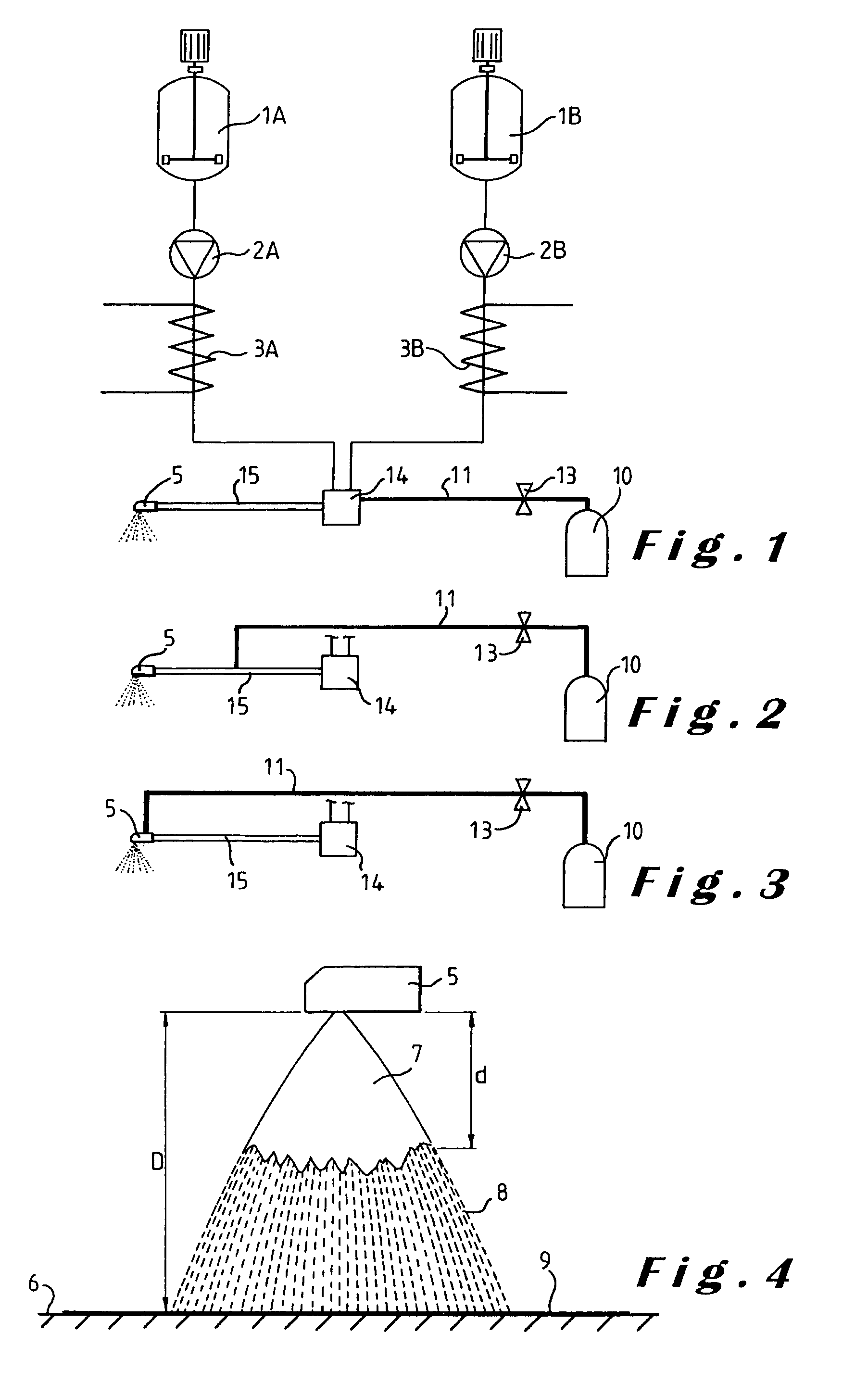

Apparatus for dispensing an atomized liquid product

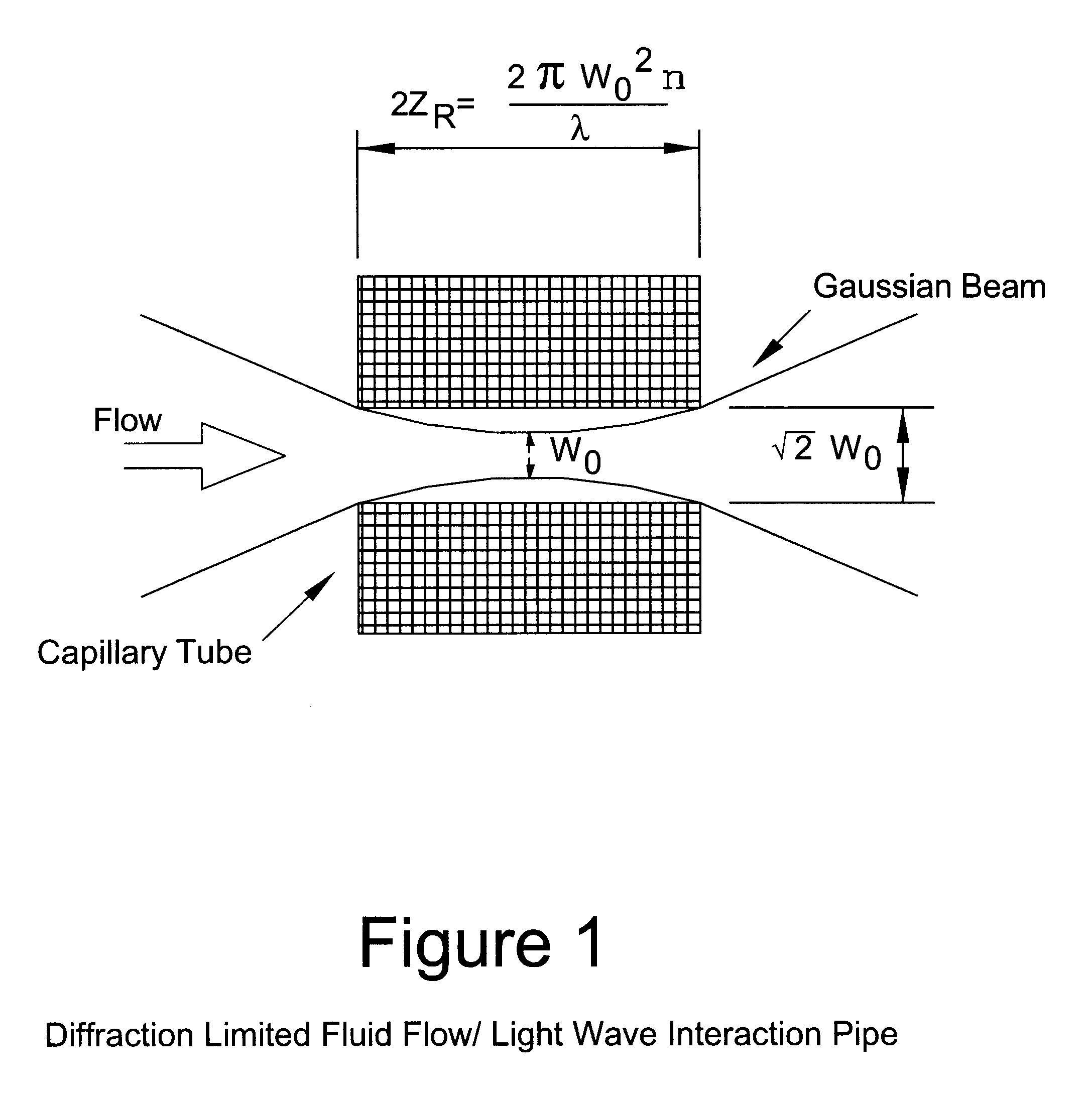

InactiveUS7237697B2Efficiently atomizedHigh viscosityLiquid spraying apparatusLiquid dispensingLiquid productGram

An apparatus for atomizing a liquid product using a propellant, which may be integrated into aerosol packs, for atomization of a liquid product. The liquid product may have a high viscosity. The total flow rate ranges from about 0.5 grams per second to about 0.01 grams per second through a single capillary tube. The liquid product is atomized within a capillary tube. The apparatus may be designed as a handheld unit or as a stationary or mobile unit using a plurality of capillary tubes.

Owner:BOEHRINGER INGELHEIM MICROPARTS

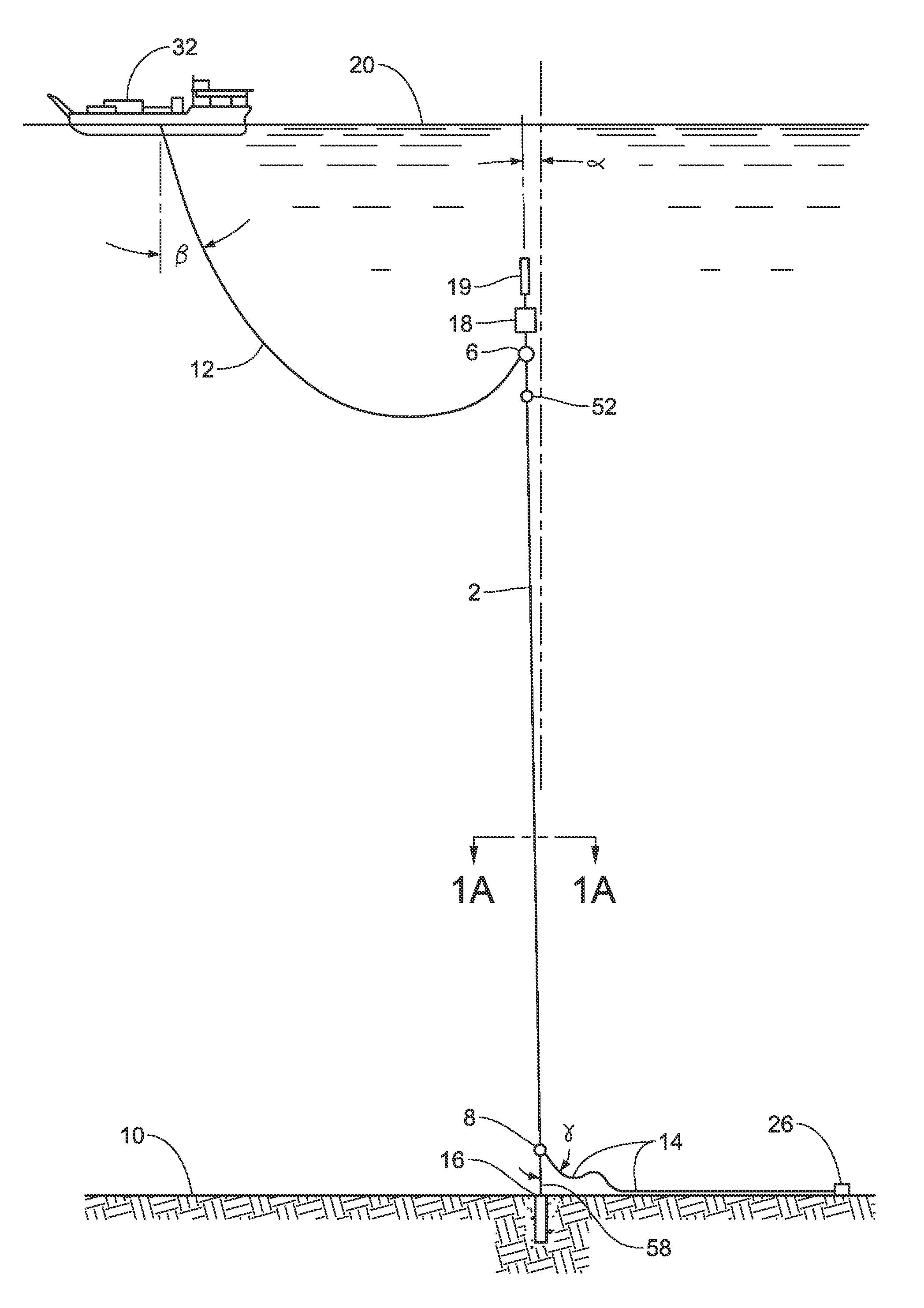

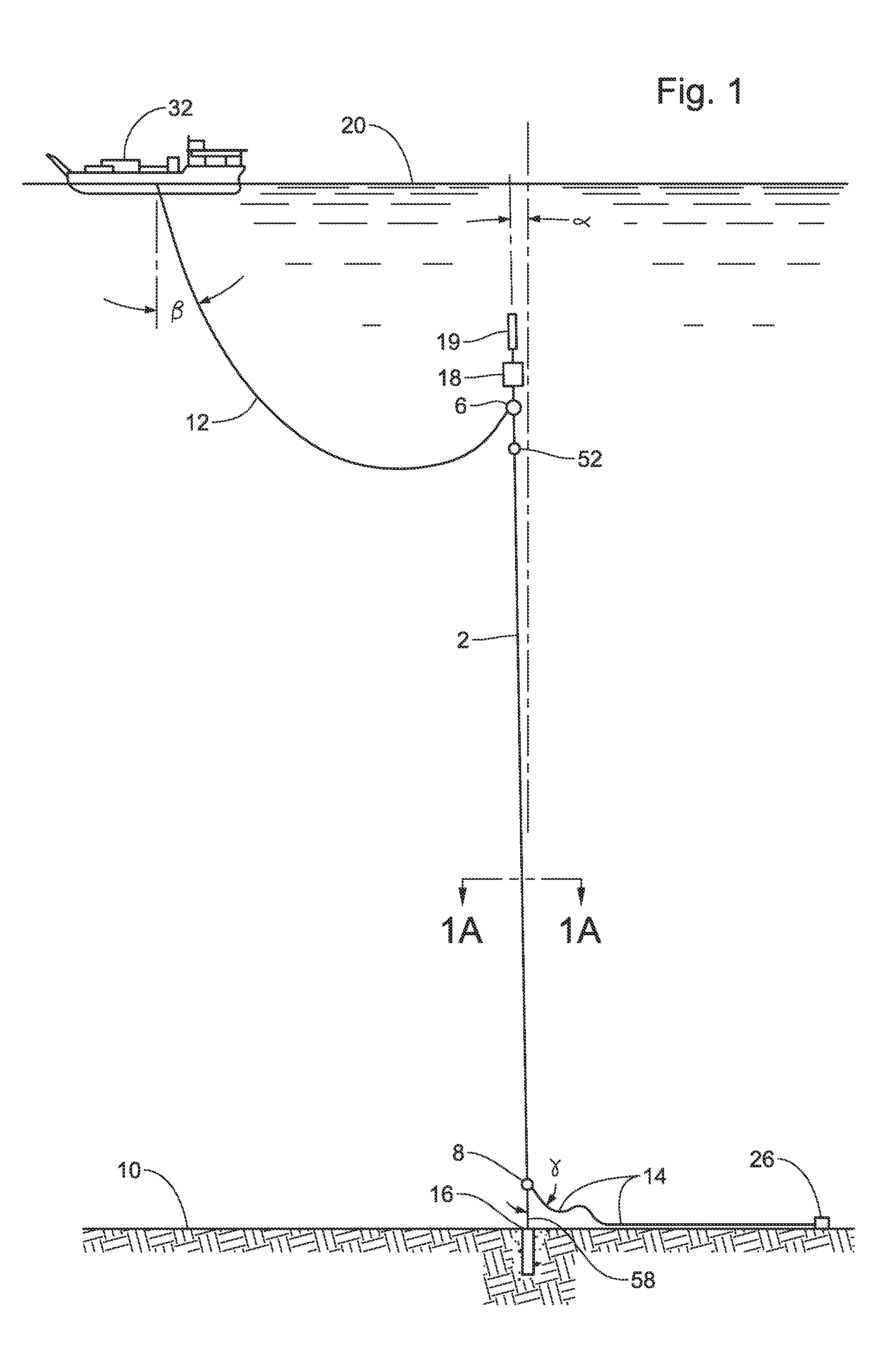

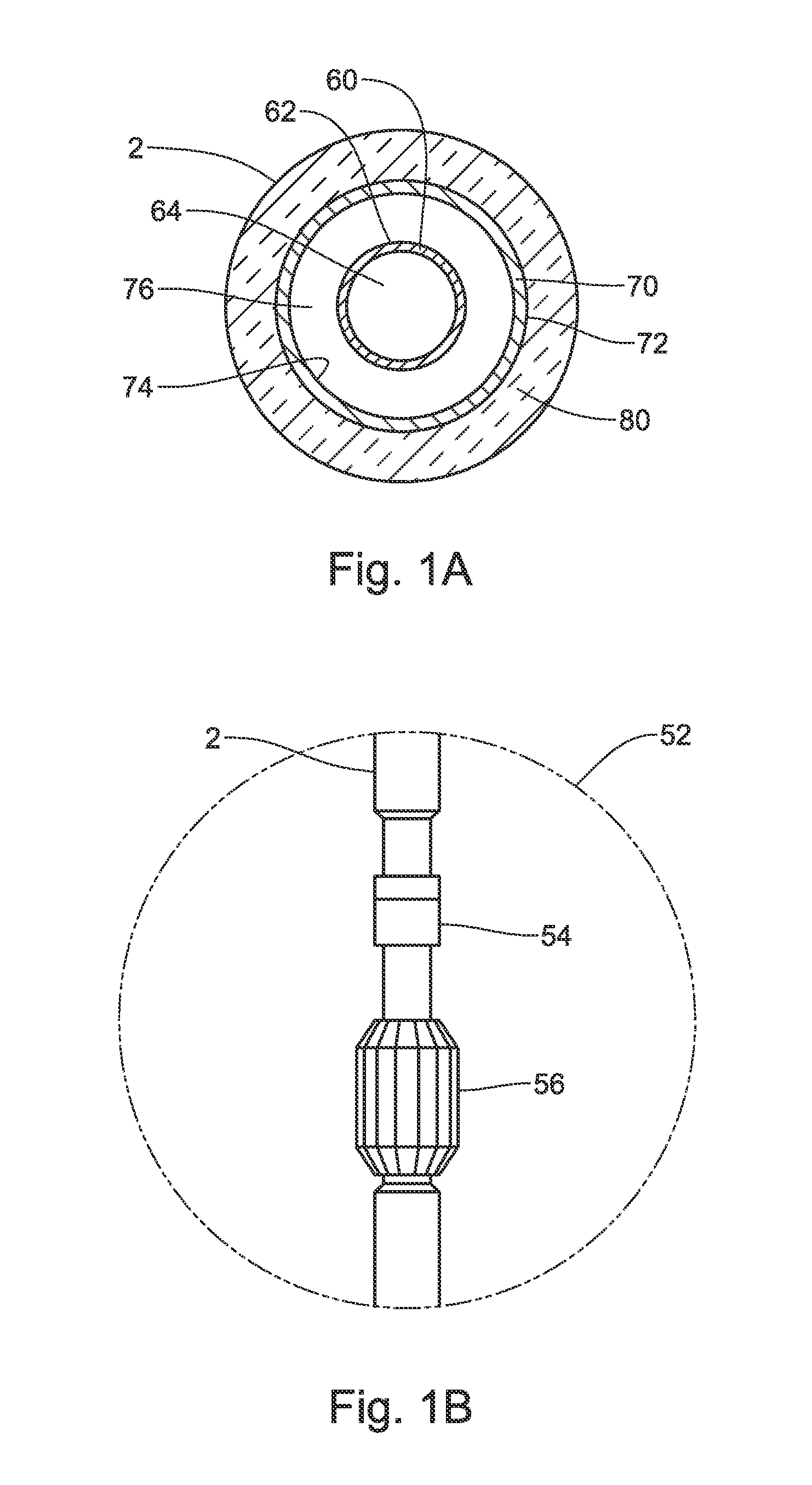

Marine Subsea Assemblies

A lower riser assembly connects a riser to a seabed mooring and to a subsea hydrocarbon fluid source. The assembly includes sufficient intake ports to accommodate flow of hydrocarbons from the hydrocarbon fluid source, as well as optional flow assurance fluid. The upper end of the member has a profile suitable for fluidly connecting to the riser. The lower end of the member includes a connector suitable for connecting to the seabed mooring. An upper riser assembly connects the riser to a near-surface subsea buoyancy device and to a surface structure. The assembly includes sufficient outtake ports to accommodate flow of hydrocarbons from the riser through a subsea flexible conduit to the surface structure. The upper end of the member includes a connector for connecting to a subsea buoyancy device. The lower end of the member comprises a profile suitable for fluidly connecting to the riser.

Owner:BP CORP NORTH AMERICA INC

Apparatus for dispensing an atomized liquid product

InactiveUS20050098588A1Reduce flow rateHigh viscosityLiquid spraying apparatusLiquid dispensingLiquid productGram

An apparatus for atomizing a liquid product using a propellant, which may be integrated into aerosol packs, for atomization of a liquid product. The liquid product may have a high viscosity. The total flow rate ranges from about 0.5 grams per second to about 0.01 grams per second through a single capillary tube. The liquid product is atomized within a capillary tube. The apparatus may be designed as a handheld unit or as a stationary or mobile unit using a plurality of capillary tubes.

Owner:BOEHRINGER INGELHEIM MICROPARTS

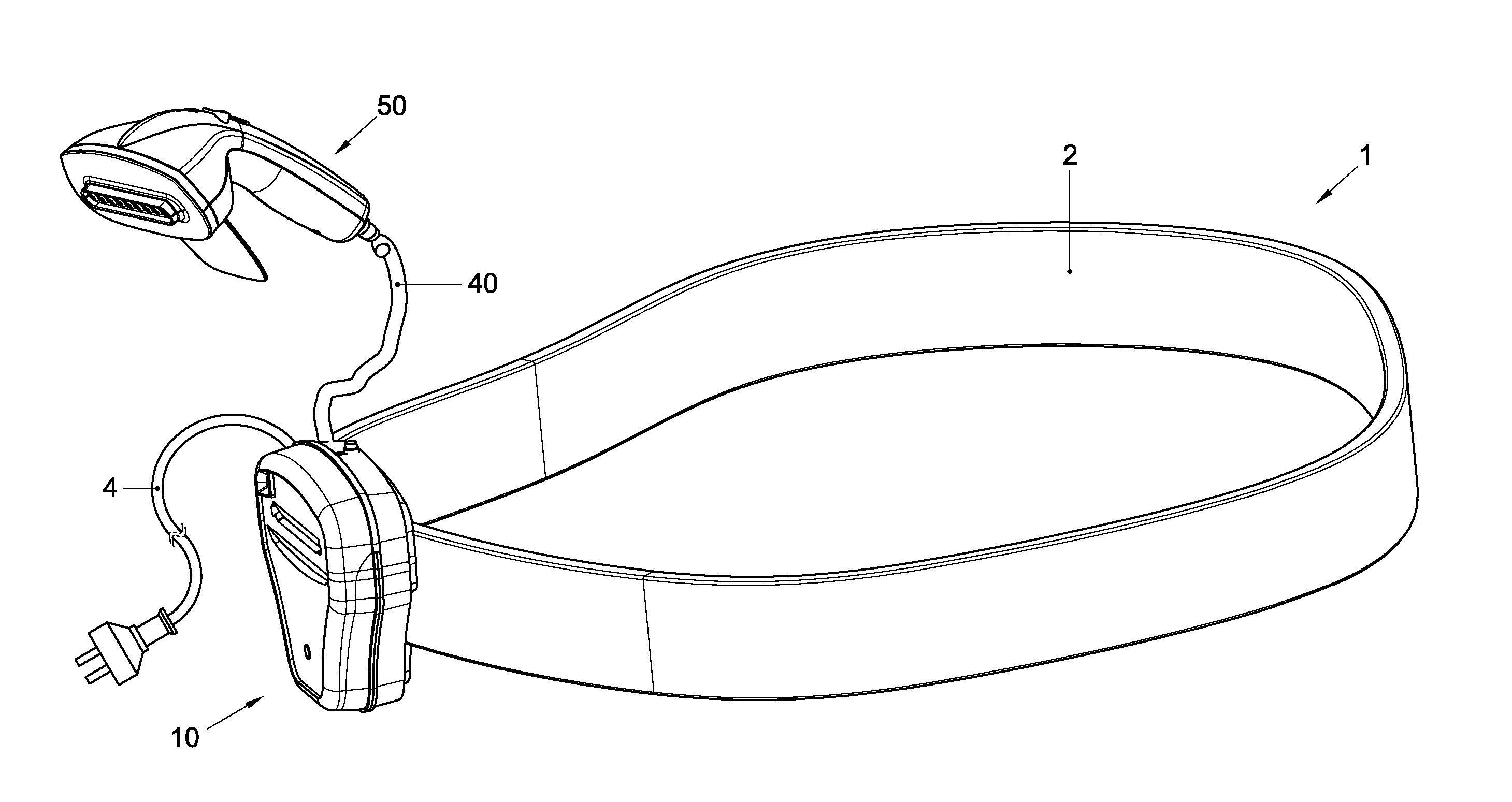

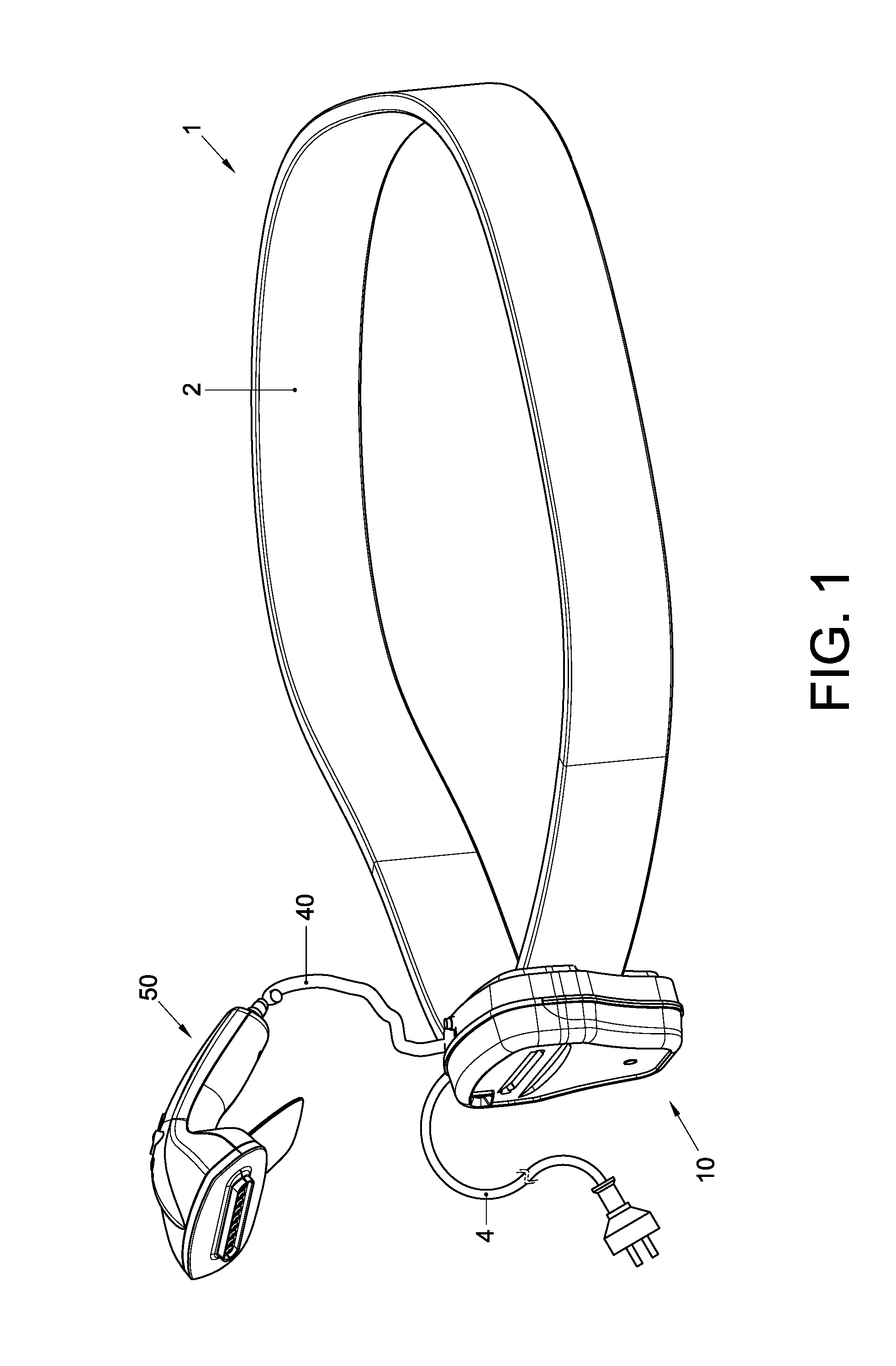

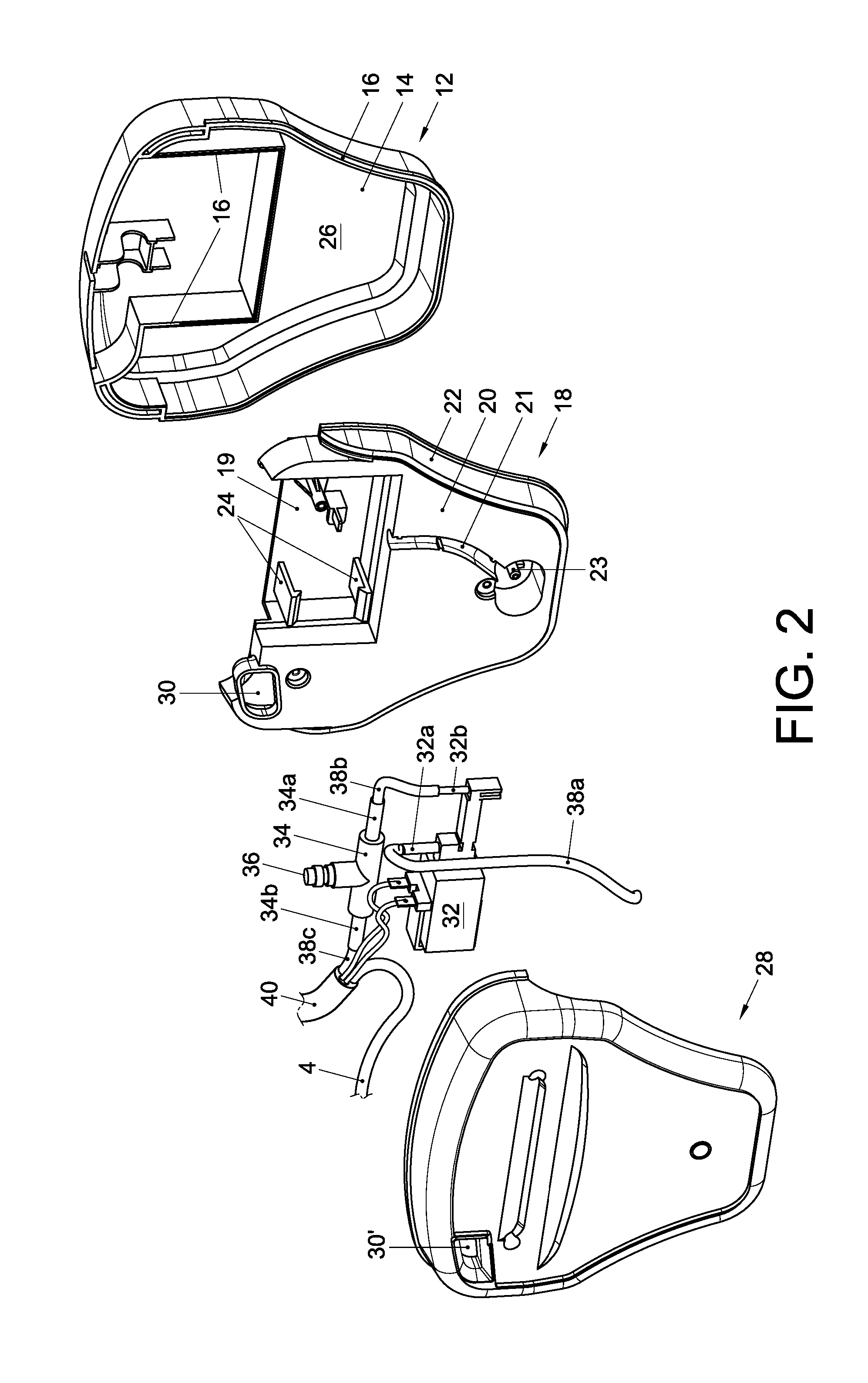

Garment steamer and method for the same

InactiveUS20150128664A1Improved manageability/maneuverabilityImprove manageabilityDrying solid materials with heatCarpet cleanersLiquid waterEngineering

A garment steamer (1) comprising a base body (10) accommodating a liquid water tank (26); a liquid water pump (32), having a water inlet (32a) and a water outlet (32b), wherein the water inlet (32a) is fluidly connected to the liquid water tank (26). The garment steamer also comprises a steam head (50) that is moveable with respect to the base body (10) and that accommodates a steam chamber (70), having a liquid water inlet and a steam outlet, wherein said steam outlet includes at least one steam nozzle (76); a heating element (72) that is provided in or adjacent said steam chamber (70), and configured to evaporate liquid water passing through said steam chamber. A liquid water tube (38b, 38c) fluidly interconnects the water outlet (32b) of the water pump (32) and the liquid water inlet of the steam chamber (70) in the steam head (50).

Owner:KONINKLJIJKE PHILIPS NV

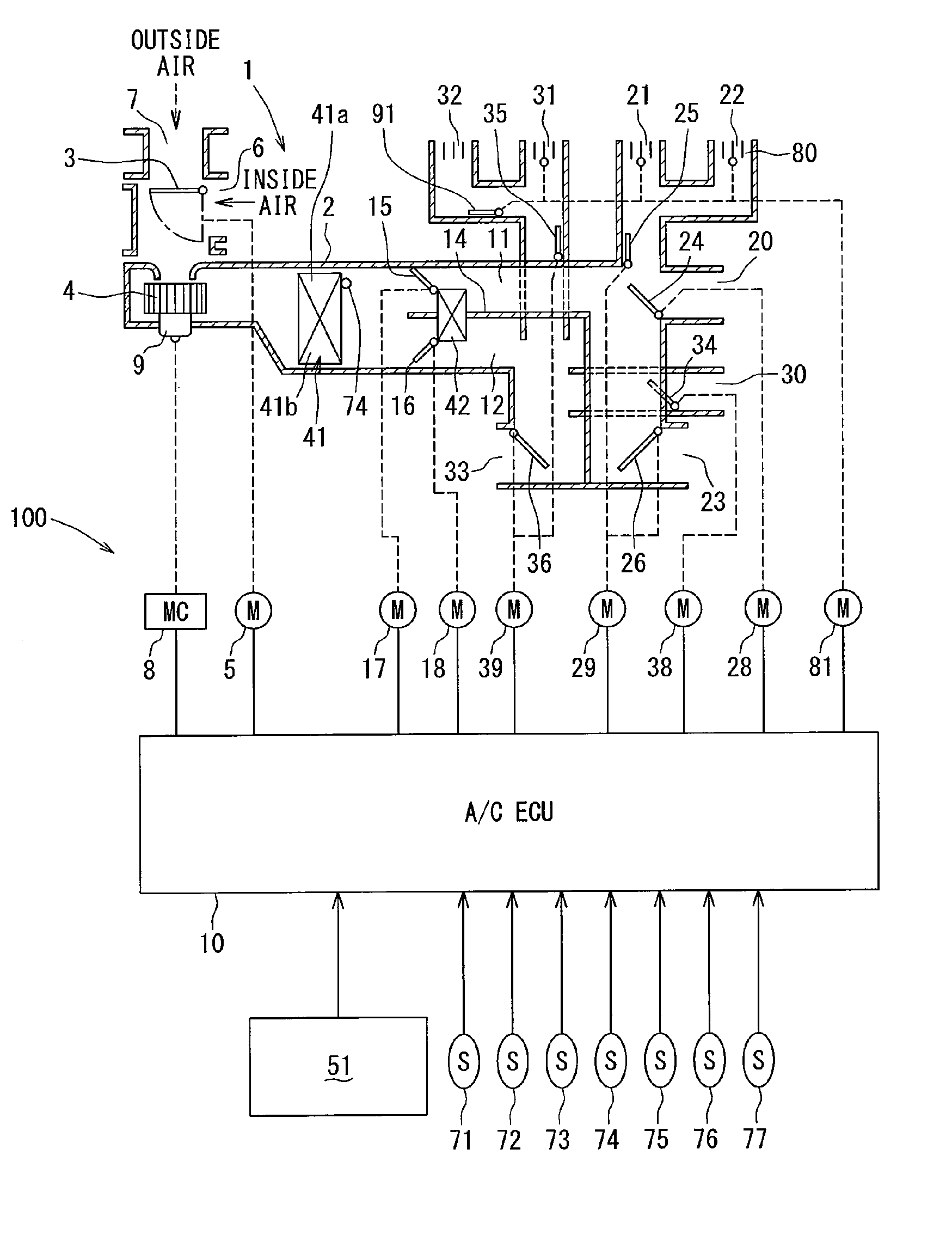

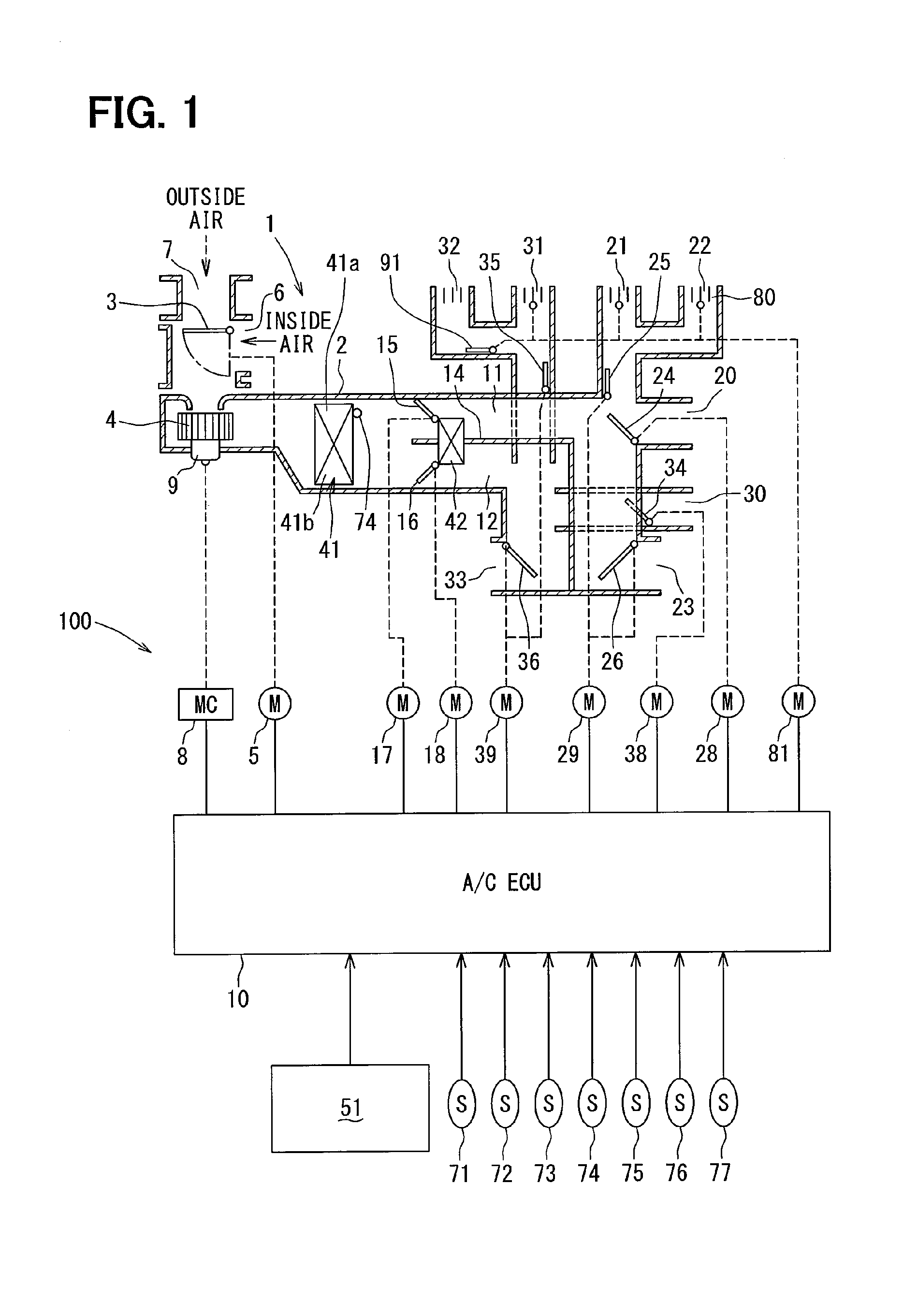

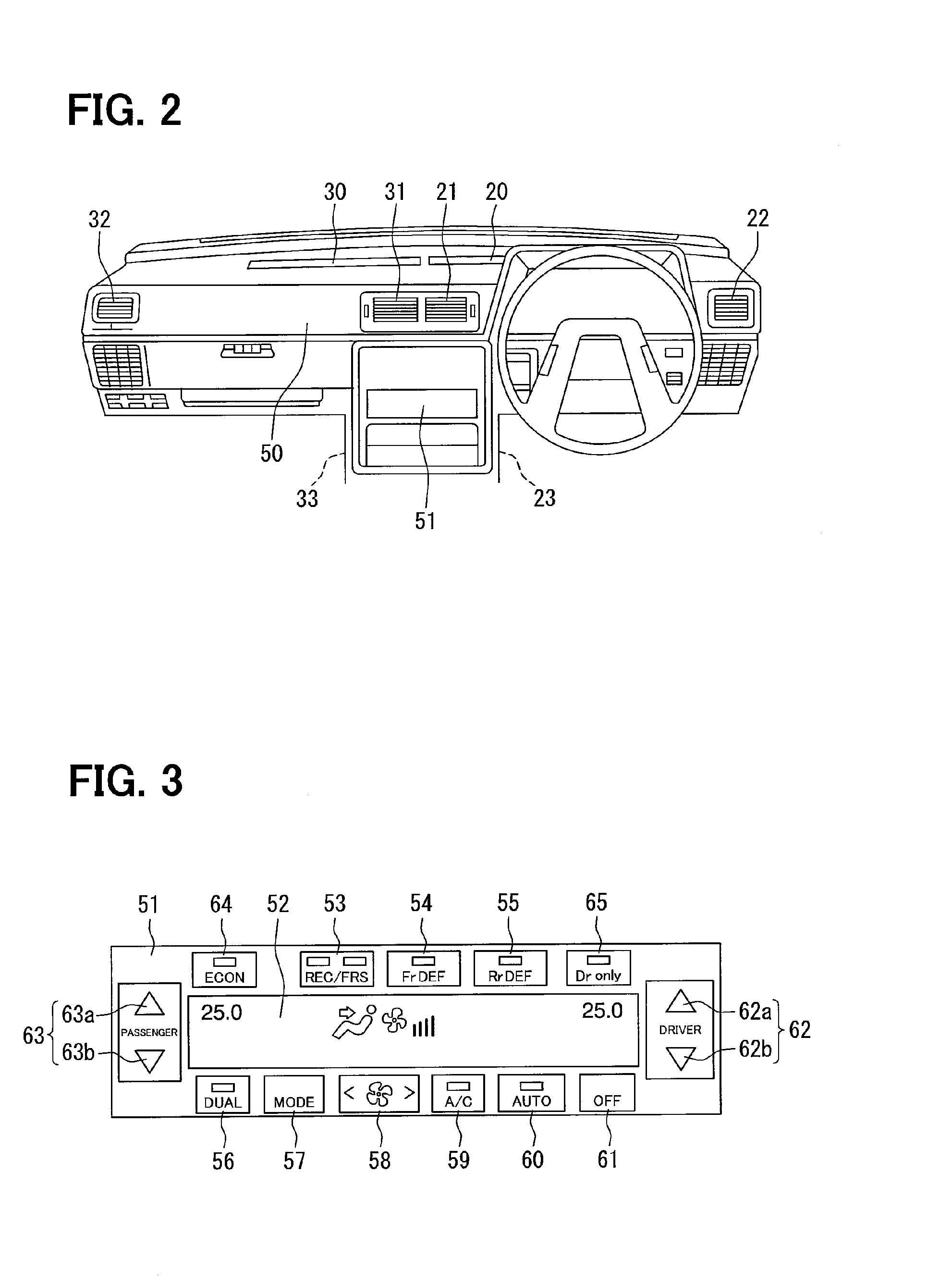

Air conditioner for vehicle

InactiveUS20140373563A1Reduce airflowReduce flow rateAir-treating devicesLighting and heating apparatusEngineeringAir conditioning

In an air conditioner for a vehicle, a flow speed of air flowing through a first ventilation part of an evaporator is faster than a flow speed of air flowing through a second ventilation part of the evaporator when an intensive air-conditioning operation for a driver seat is operated, with respect to a case where a normal air-conditioning operation is performed. In this case, a correct target evaporator temperature is calculated to be higher by a predetermined temperature than a target evaporator temperature, and a detected temperature detected by an evaporator sensor is approached to the correct target evaporator temperature. Therefore, it can restrict the second ventilation part from being frosted.

Owner:DENSO CORP

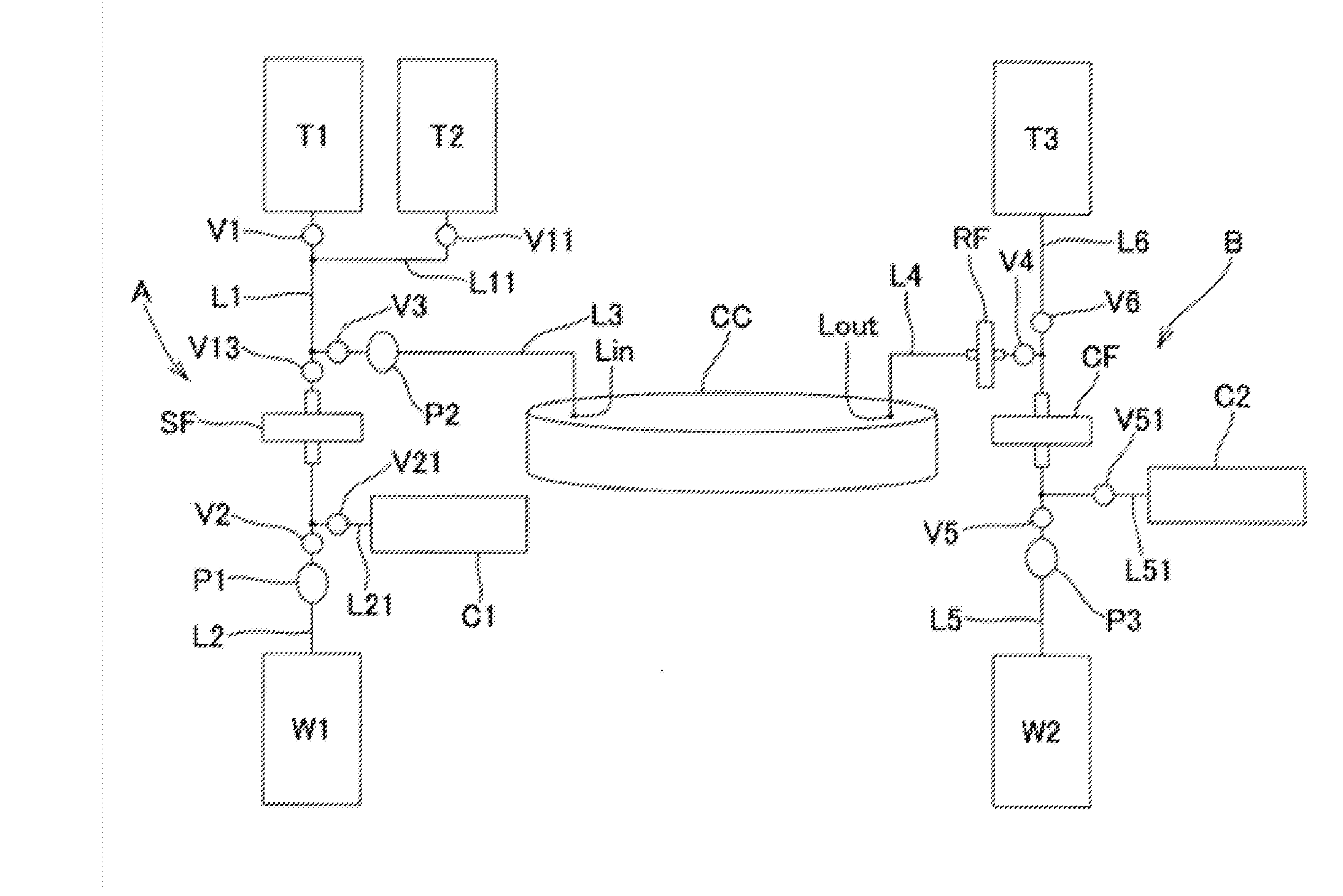

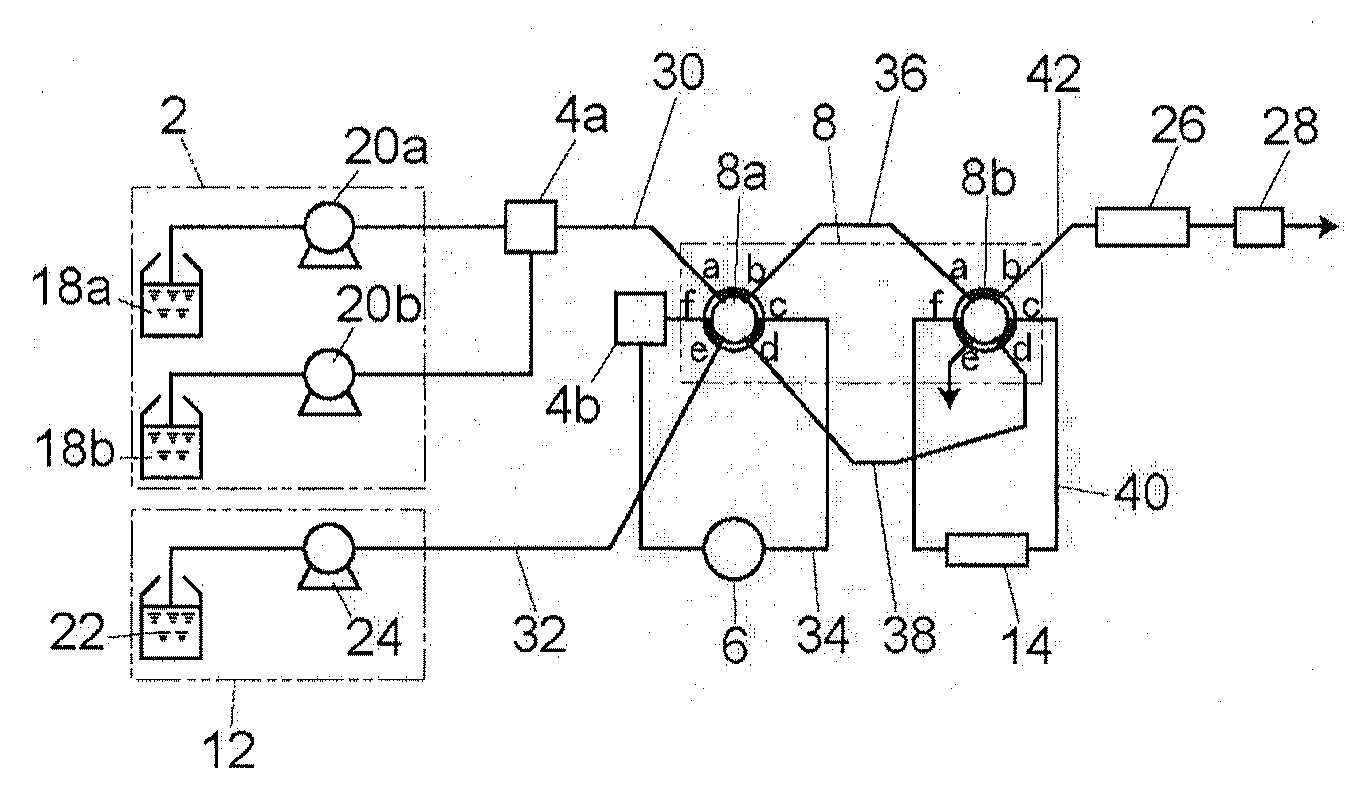

Disposable set for cell culture, cell culture device and cell preparation method

ActiveUS20130109086A1Simple structureImprove securityBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologyCell separation

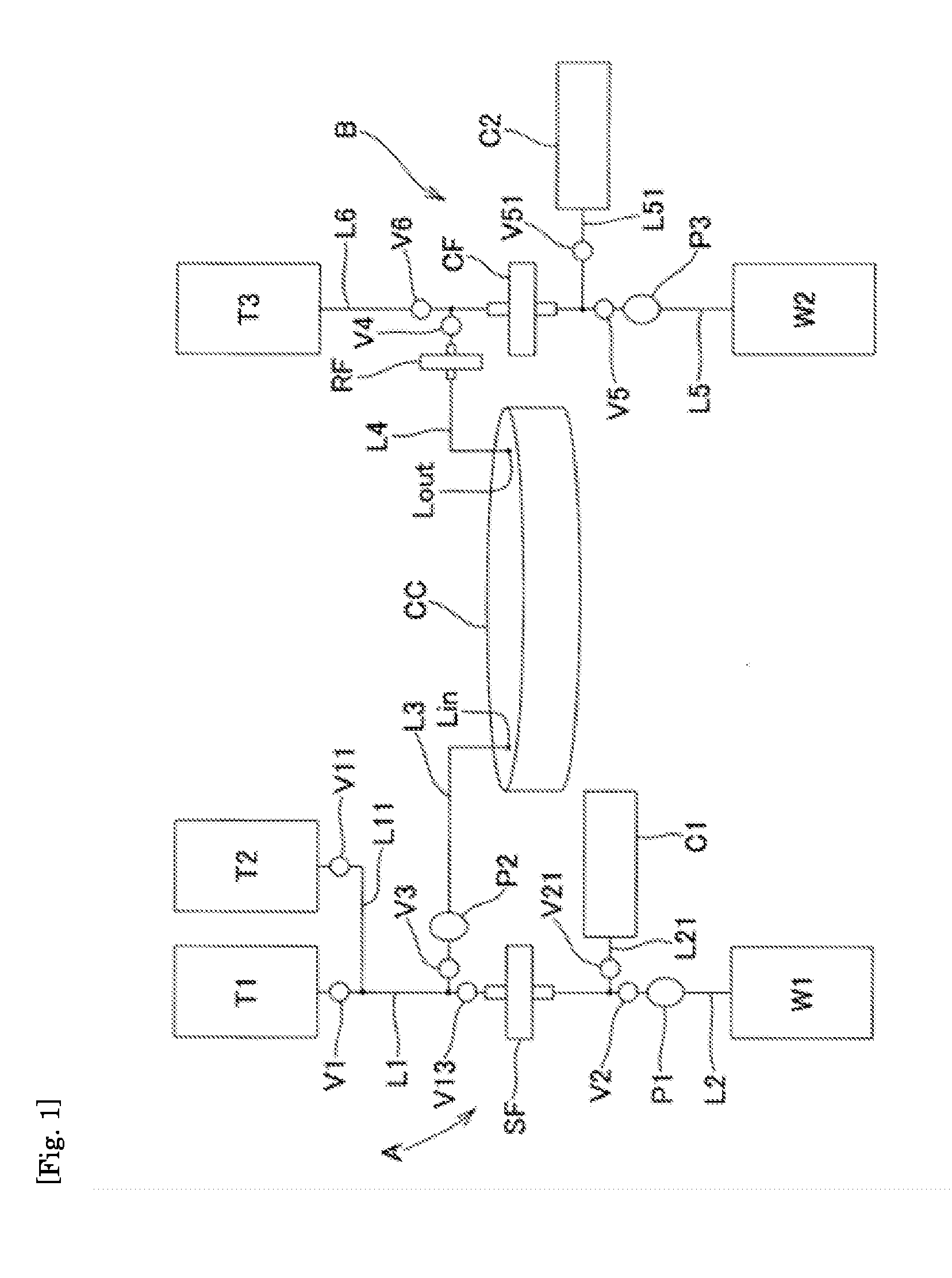

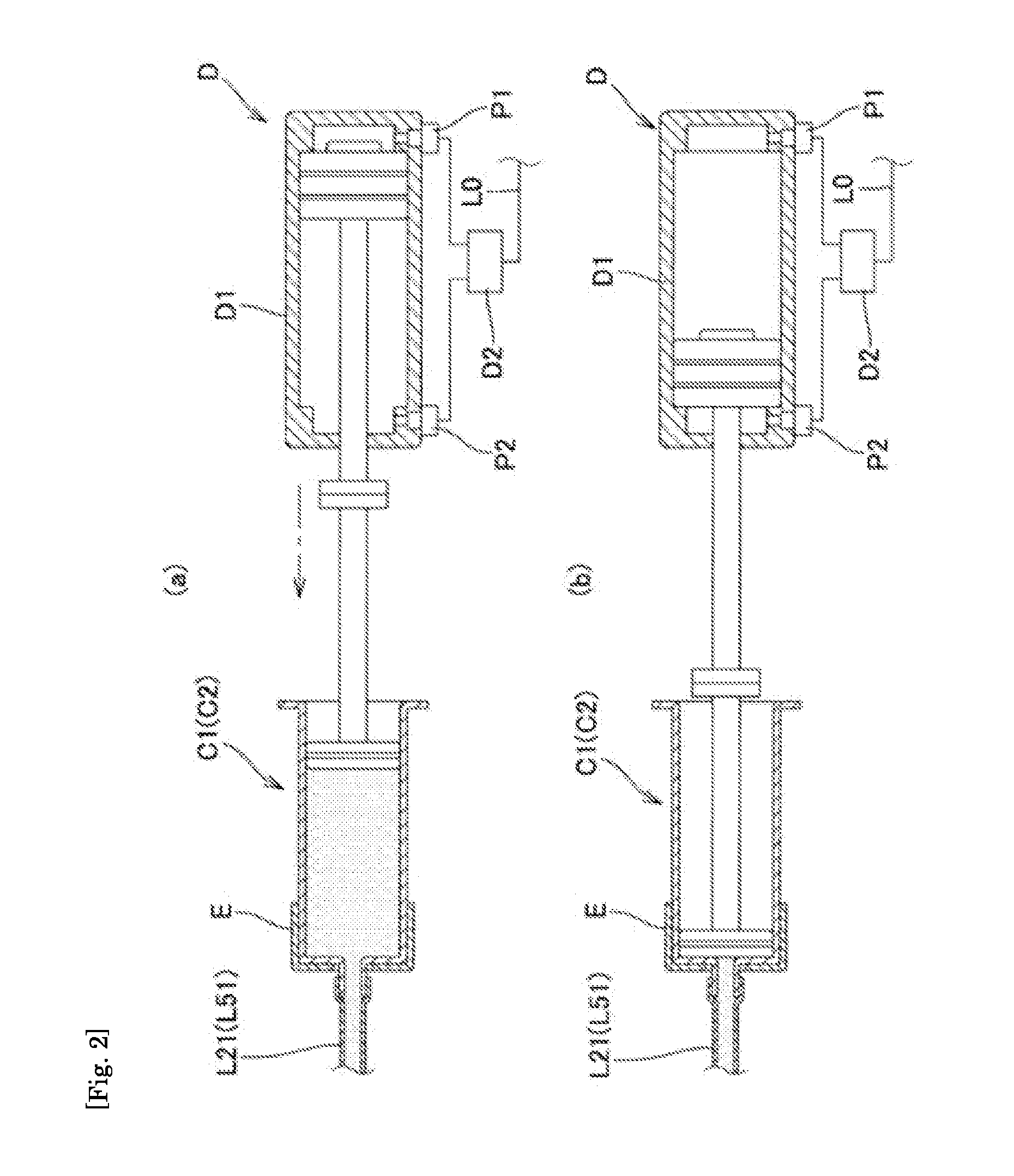

It is an object to achieve a closed system that has a simple structure without resorting to large scale equipment and that sequentially carries out all of the step of separating useful cells, the step of culturing the useful cells separated in the separation step, and the step of washing and concentrating the cells cultured in the culturing step and to enable the preparation of useful cells having high safety and quality, while improving operability. A disposable set for cell culture includes a cell culture container (CC) having a liquid inlet (Lin) and a liquid outlet (Lout), a cell separation kit (A) that is for separating cells used for cell culture and is connected to the liquid inlet (Lin), and a cell collection kit (B) that is for washing and concentrating cultured cells in the cell culture container (CC) and is connected to the liquid outlet (Lout), and a cell culture device uses the disposable set for cell culture and includes flow path on-off valves and pumps provided at appropriate positions of pipelines of the disposable set and a controller controlling them.

Owner:KANEKA CORP

Fiber optic alignment system and method

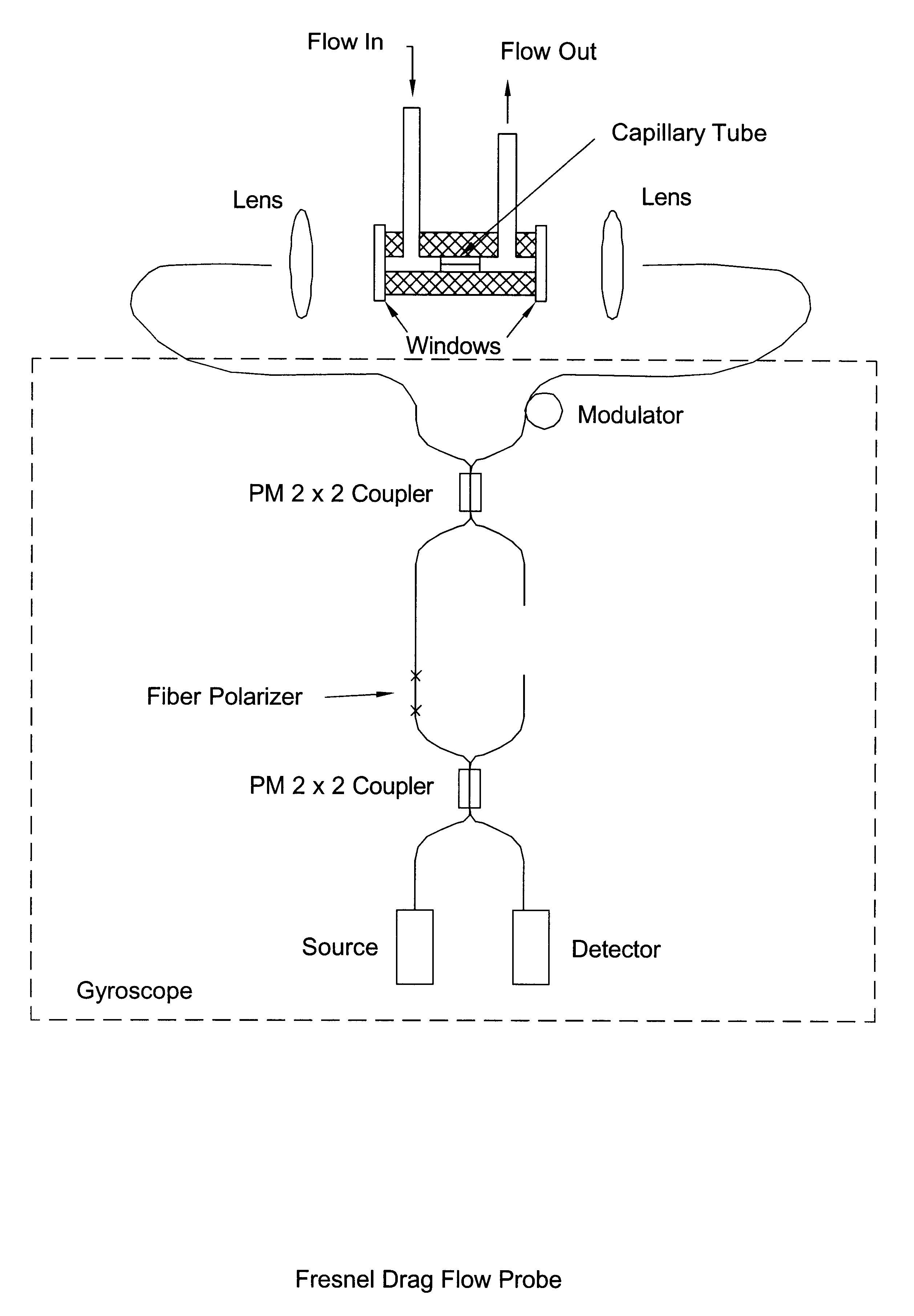

InactiveUS6545261B1High sensitivityHigh resolutionVolume/mass flow measurementInvestigating moving fluids/granular solidsFiberPhotovoltaic detectors

A method and system for aligning optical fibers includes aperturing the optical beams from the optical fibers at two points along a path. Photodetectors are placed on the apertures and the positions of the tips of the optical fibers are controlled using actuators to center the optical beams within the apertures.

Owner:BLAKE JAMES N +1

Drive device

InactiveUS20050168081A1Improve cooling effectSmall flow ratePlural diverse prime-mover propulsion mountingSupport structure mountingEngineeringRefrigerant

A drive unit comprises an electric motor 1, a drive unit casing 2 accommodating therein the electric motor, an inverter 3 that controls the electric motor, and a flow passage of a refrigerant that cools the inverter. The inverter is mounted on a heat sink 53 and mounted to the drive unit casing with a space R defined, and the space is communicated to the flow passage of the refrigerant. The heat sink comprises fins 56, and the drive unit casing comprises fins 22, the both fins being apart from each other. Thereby, both a side of the drive unit casing and a side of the heat sink are effectively cooled by heat exchange with a cooling refrigerant in wide areas. Also, the fins are apart from each other whereby direct heat conduction is avoided and efficient cooling is enabled with temperature gradient conformed to heat-resistant temperatures.

Owner:AISIN AW CO LTD

Exposure apparatus

InactiveUS7057701B2Small flow rateSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProjection opticsExposure

An exposure apparatus for exposing a substrate to light via a mask. The apparatus includes a projection optical system configured to project a pattern of the mask onto the substrate, a cover configured to surround a path of light from the projection optical system toward the substrate, a first supply port arranged inside the cover and configured to supply inert gas inside the cover, a first recovery port arranged inside the cover and configured to recover gas inside the cover, a second supply port arranged outside the cover and configured to supply gas outside the cover, and a second recovery port arranged outside the cover and configured to recover gas outside the cover. The first direction from the first supply port to the first recovery port and a second direction from the second supply port to the second recovery port oppose each other at an angle not greater than 90°.

Owner:CANON KK

Pinch valve

InactiveUS6755388B2Increased durabilitySmall flow rateDiaphragm valvesOperating means/releasing devices for valvesPinch valveEngineering

A pinch valve of the invention comprising an elastic tube body 1, a cylinder body 4 having a cylinder portion 2 and a cylinder cover 3, a piston 11 sliding on the inner periphery of the cylinder body, a pressing piece 15 fixed to a connecting portion 13 suspended from the piston, a body 16 joined to the cylinder body and having a groove 17 receiving the tube body 1, a pair of connecting body carriers 20 engaged with grooves of the body and having a through-hole 26 receiving the tube body 1, a first and a second space portions 8, 7 formed above and under the piston 11, respectively, and a pair of air ports 10, 9 respectively communicating with the first and second space portions 8, 7.The whole pinch valve is made compact in construction.

Owner:ASAHI YUKIZAI KOGYO CO LTD

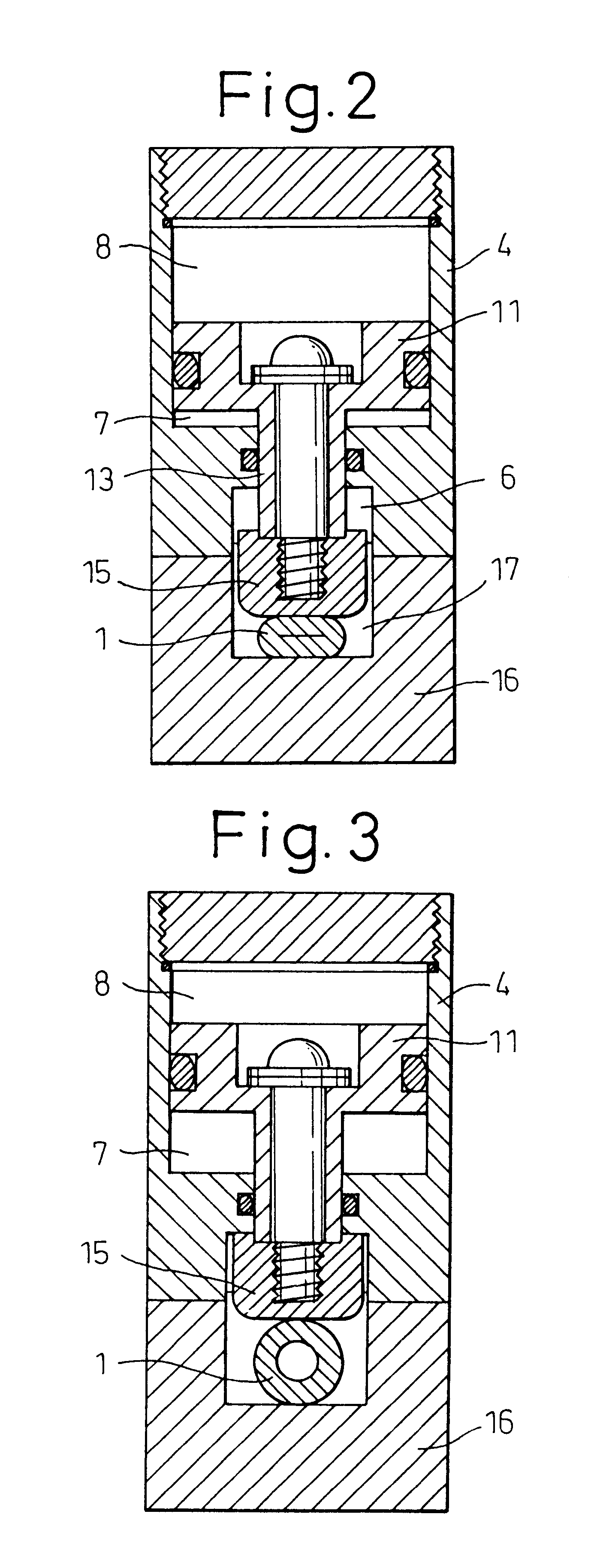

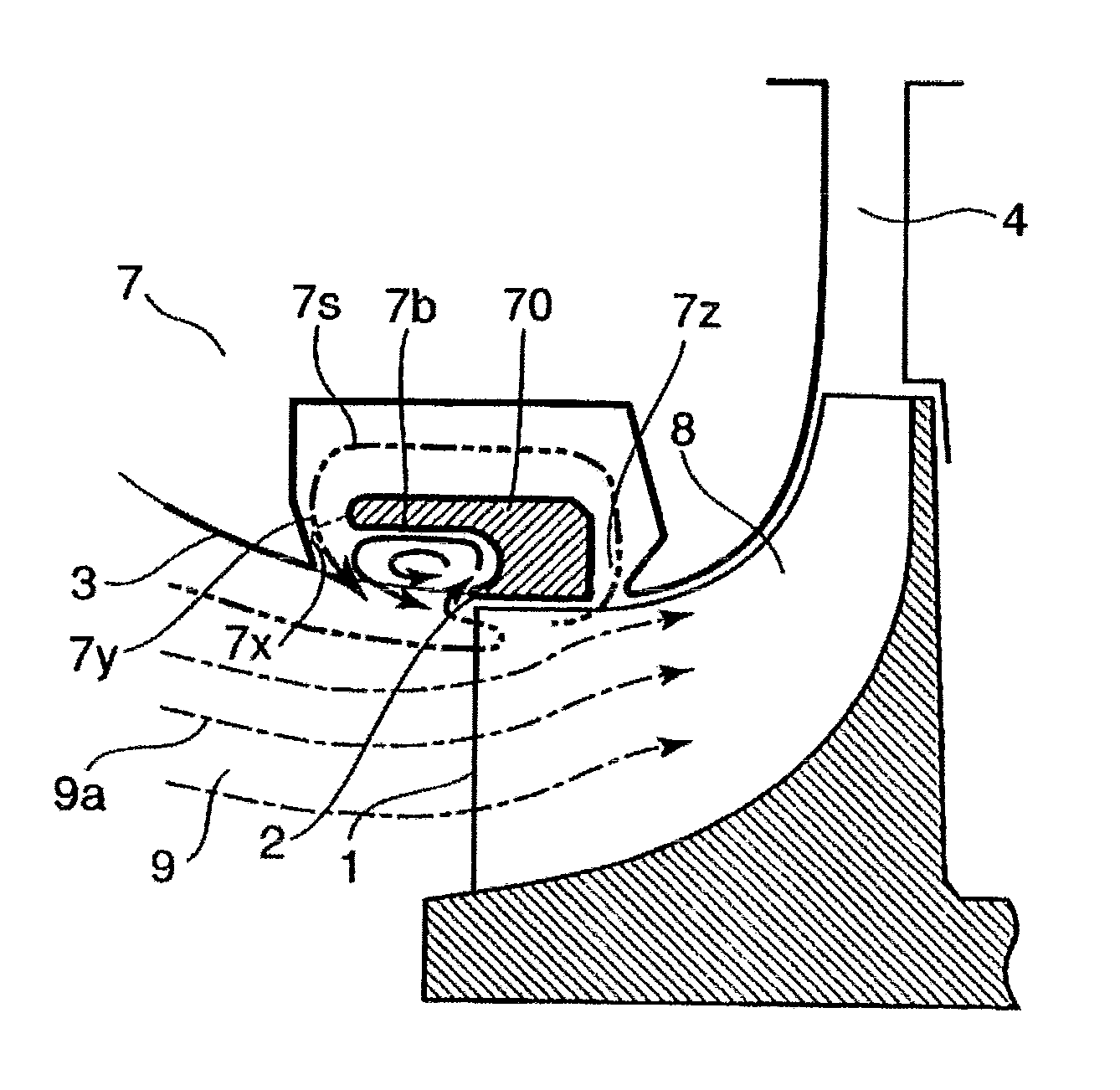

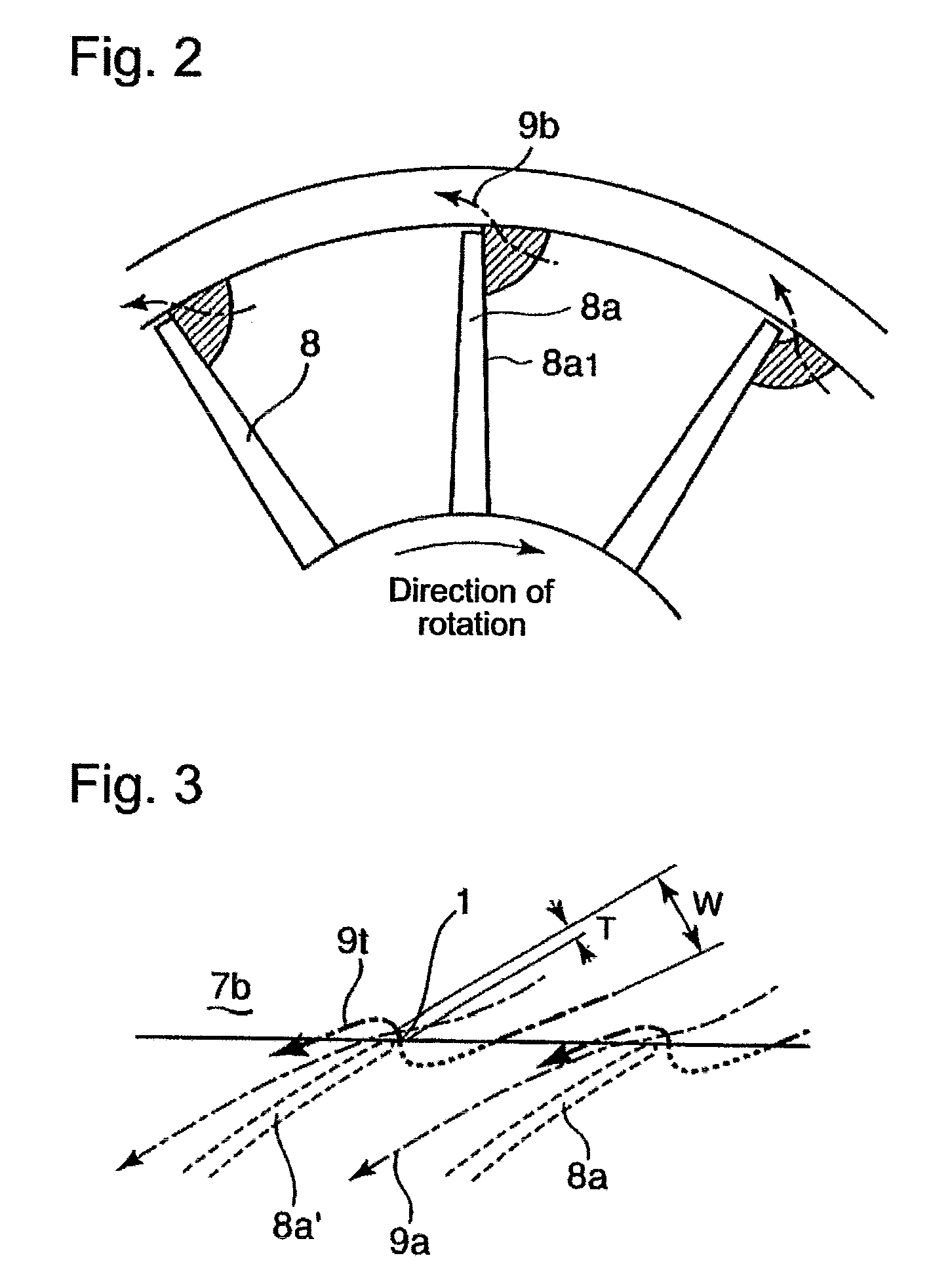

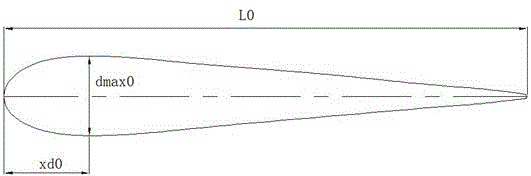

Radial compressor

ActiveUS20100143095A1Guaranteed uptimeImprove recycling efficiencyEngine manufacturePump componentsAxial compressorImpeller

A radial compressor is capable of preventing the occurrence of separation caused by a flow which goes beyond the front end of a blade and turns onto a negative pressure plane from a pressure plane, thereby reducing a surging flow rate to a smaller flow rate. The radial compressor includes an impeller which is rotatively driven, axially introduces air taken in through an air inlet passage formed in a housing, pressurizes the introduced air, and discharges the pressurized air in a radial direction, wherein an annular concave groove is formed in a peripheral wall of the air inlet passage of the housing, a rear end portion of an opening of the annular concave groove, which rear end portion meets the housing peripheral wall, is provided in the vicinity of a blade front end surface of the impeller, and the rear end portion of the opening of the annular concave groove is formed such that an axial projecting amount X thereof relative to the blade front end surface of the impeller is set to −1T≦X≦1.5T (where T denotes the thickness of the distal portion of a blade).

Owner:MITSUBISHI HEAVY IND LTD

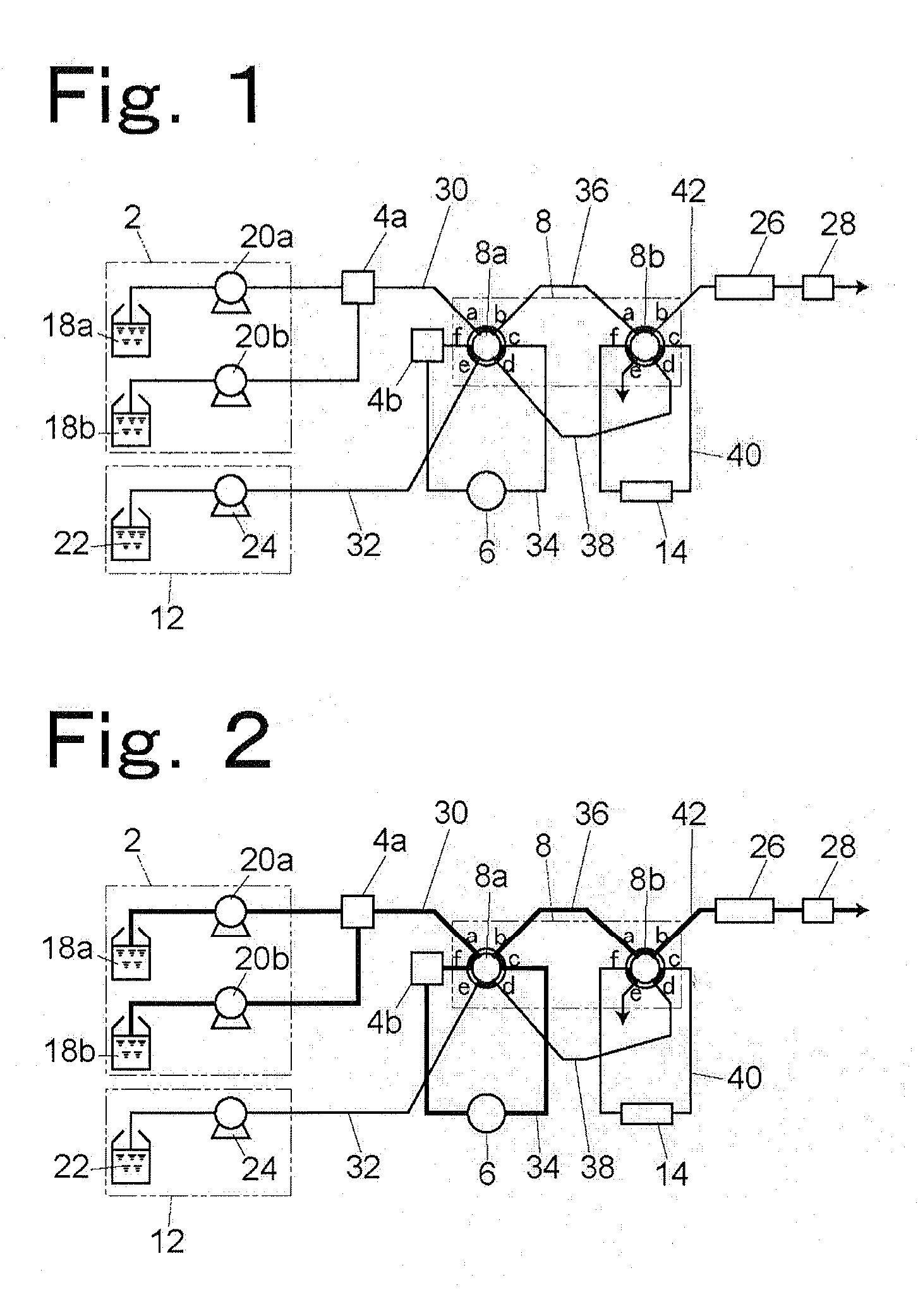

Liquid chromatograph

ActiveUS20080245715A1Well mixedGood reproducibilityIon-exchange process apparatusComponent separationEngineeringLarge capacity

A liquid chromatograph having a flow passage switching mechanism for switching among a normal analysis flow passage formed by connecting a mobile-phase-sending-unit, a second mixer having a large capacity, a sample injection portion, an analysis column and a detector in this order, a concentration flow passage formed by connecting a concentration liquid sending unit for sending a liquid for transferring a sample to be concentrated, the second mixer, the sample injection portion and a trapping column in this order, and a concentration analysis flow passage formed by connecting the mobile-phase-sending-unit, a first mixer having a smaller capacity than the second mixer, the trapping column, the analysis column and the detector in this order so that any one of the three flow passages is selectively formed, The mobile-phase-sending-unit is set so that the flow rate of a mobile phase becomes smaller when the concentration analysis flow passage is selected than when the normal analysis flow passage is selected.

Owner:SHIMADZU CORP

Oil stabilizing and water control valve

The invention discloses an oil stabilizing and water control valve. The oil stabilizing and water control valve comprises a valve body. The valve body is provided with a first liquid port and a second liquid port. A plurality of annular runners are formed in the valve body and sequentially arranged in a nested manner from interior to exterior, and the adjacent annular runners communicate. The first liquid port communicates with the annular runner on the outermost side, and the second liquid port communicates with the annular runner on the innermost side. In the using process of the provided oil stabilizing and water control valve, stratum crude oil and stratum water enter the oil stabilizing and water control valve, due to the fact that the stratum crude oil and the stratum water are different in viscosity and density, generated centrifugal force is different, the stratum crude oil flows in the circumferential direction, the stratum water flows in the radial direction, automatic distinguishing of the crude oil and the water is achieved, the excess flow of the stratum crude oil is large, and the excess flow of the stratum water is low.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Pump device

InactiveUS20050271525A1Small flow rateMiniaturizationFlexible member pumpsPiston pumpsEngineeringCam

A pump device may include an eccentric member mounted on an output shaft in an eccentric manner, a cam mechanism which is engaged with the eccentric member to convert a motion of the output shaft into a radial direction and at least one pump body which includes a diaphragm that is moved in the radial direction in relation to the output shaft by the cam mechanism for performing a pumping operation.

Owner:SANKYO SEIKI MFG CO LTD

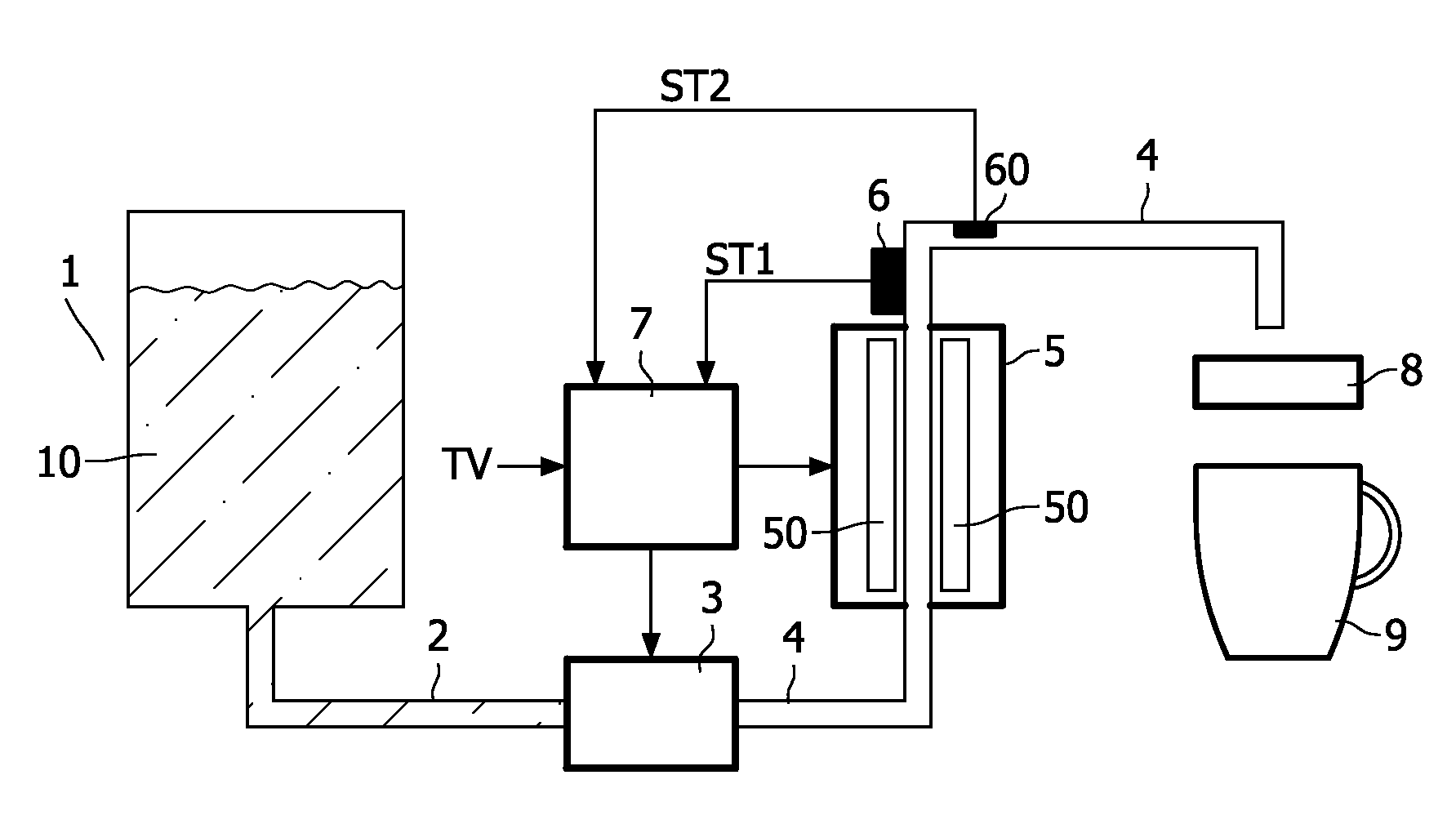

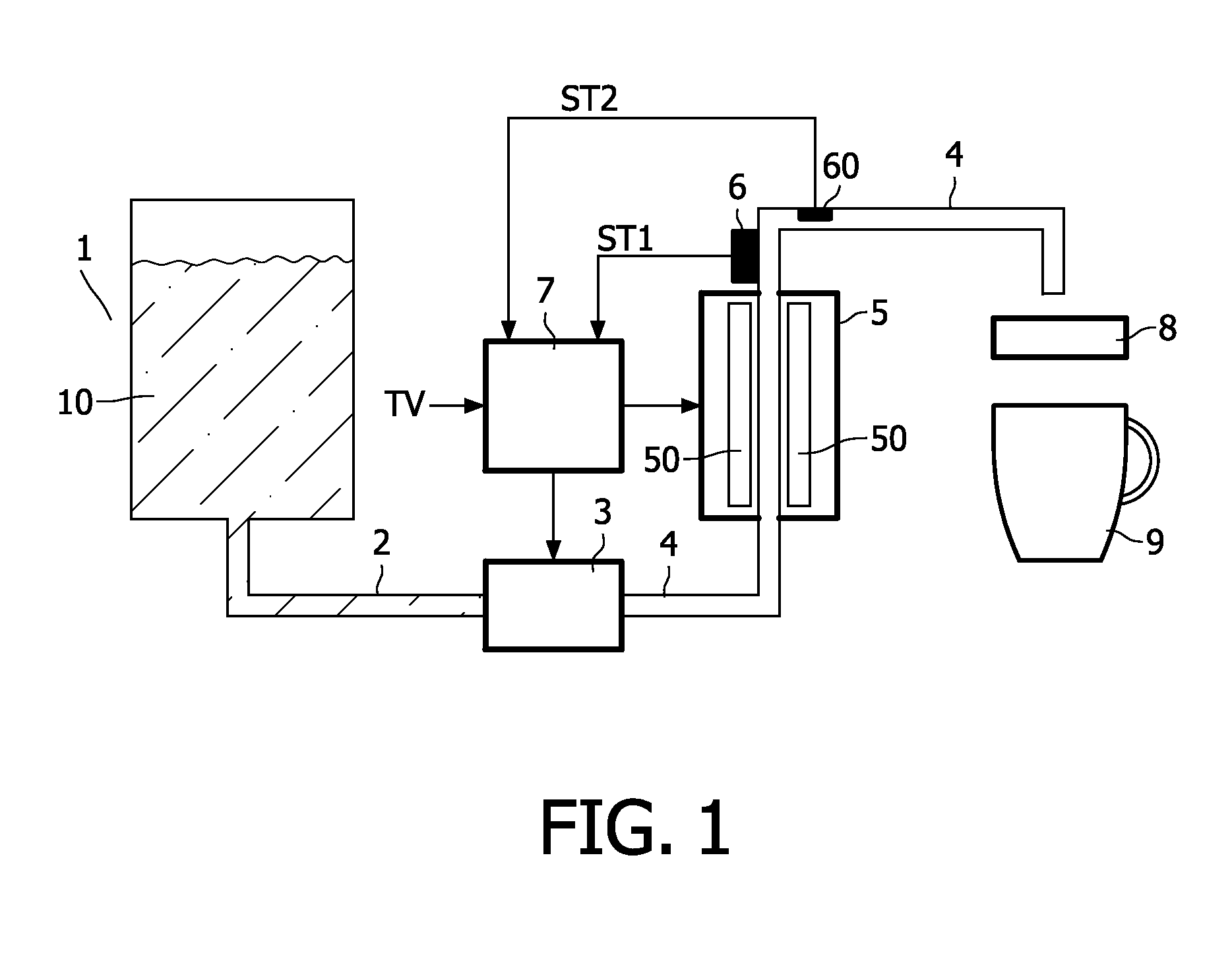

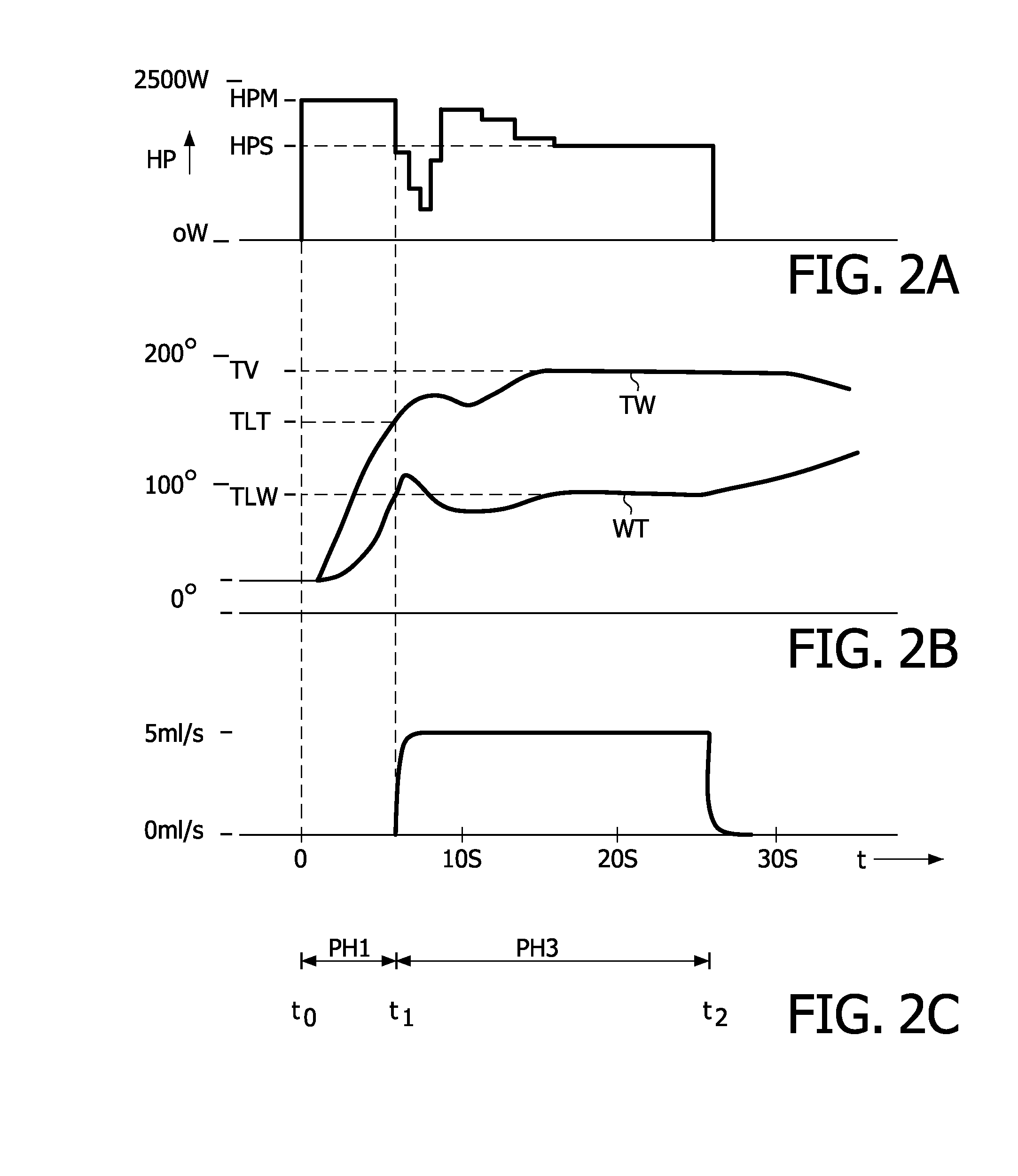

Controlling a liquid flow through heater

InactiveUS20100101427A1Improve temperature behaviorPrevent any steam generationFlow control using electric meansBeverage vesselsEngineeringHeating power

A liquid flow through heater for heating a liquid (10) comprises a channel (4) and an electric heater element (50) for heating at least a portion of the channel (4). A temperature sense unit (6, 60) senses a temperature (ST1; ST1, ST2) indicative of the temperature of the liquid. A flow control means (3) controls a flow of the liquid (10) through the channel (4). A controller (7) controls in a first phase (PH1), (i) the electric heater element (50) to pre-heat at least the portion of the channel (4), and (ii) the flow control means (3) to obtain a rate of flow of the liquid (10) through the channel (4) which is zero or relatively small with respect to a rate of flow during a second and / or third phase. The controller (7) controls in the second phase (PH2) succeeding the first phase (PH1), (i) the electric heater element (50) to supply a predetermined heating power independent on the sensed temperature (ST1; ST1, ST2), and (ii) the flow control means (3) to obtain a flow of the liquid (10) through the channel (4), and in the third phase (PH3) succeeding the second phase (PH2), (i) the electric heater element (50) to supply a heating power (HP) in dependence on the sensed temperature (ST1; ST1, ST2) to substantially stabilize the sensed temperature (ST1; ST1, ST2) on a desired target value (TV), and (ii) the flow control means (3) to obtain a flow of the liquid (10) through the channel (4).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

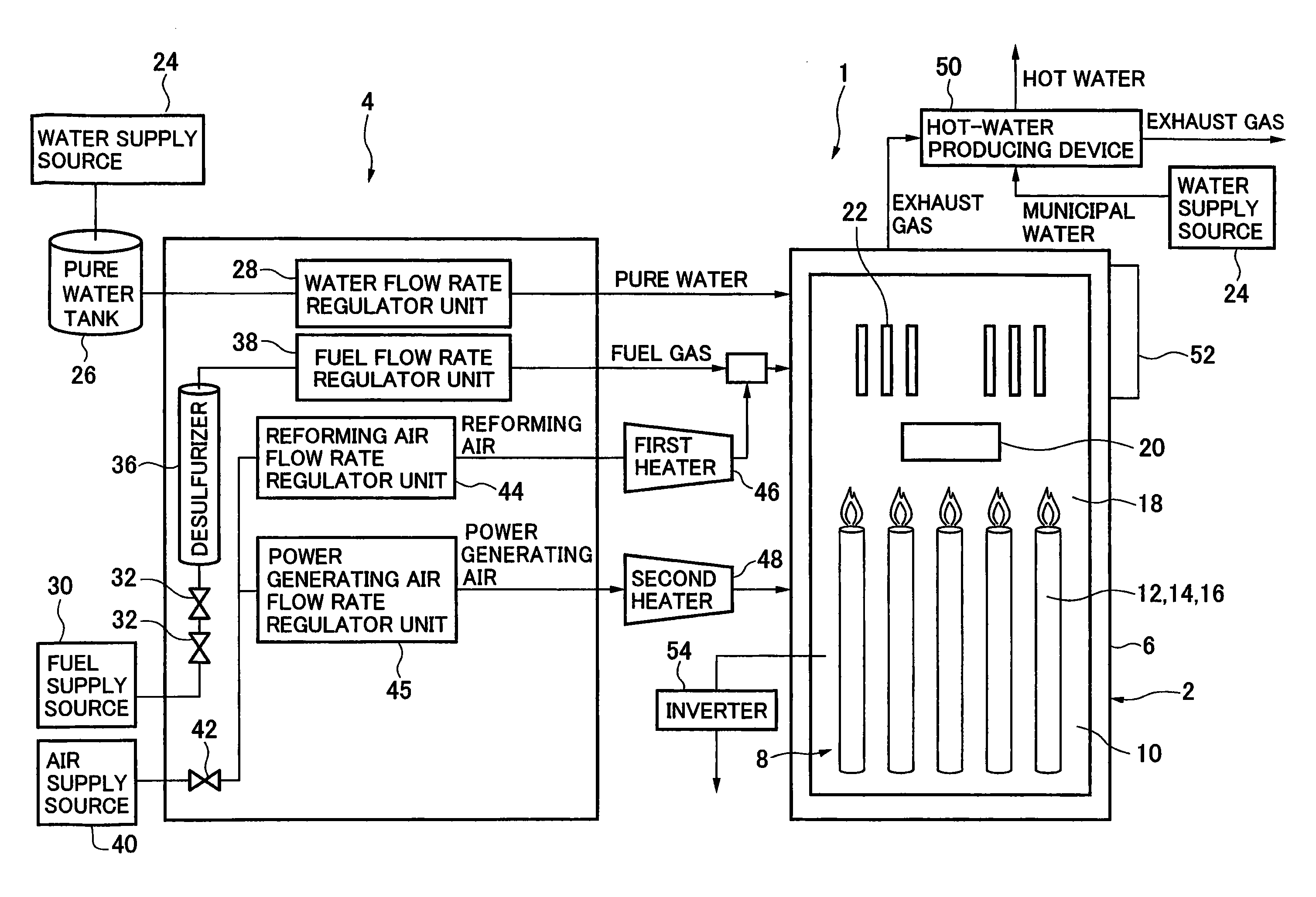

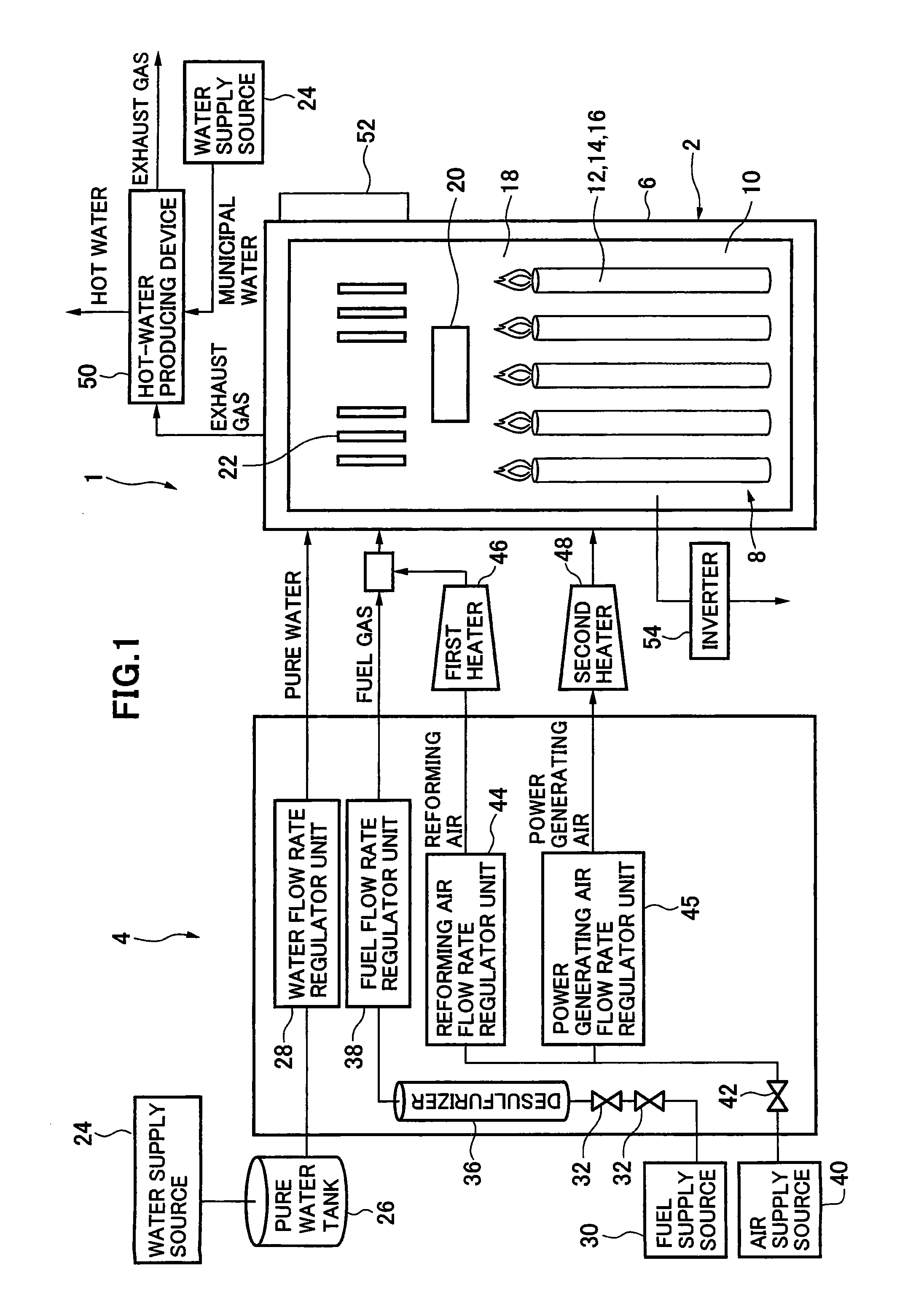

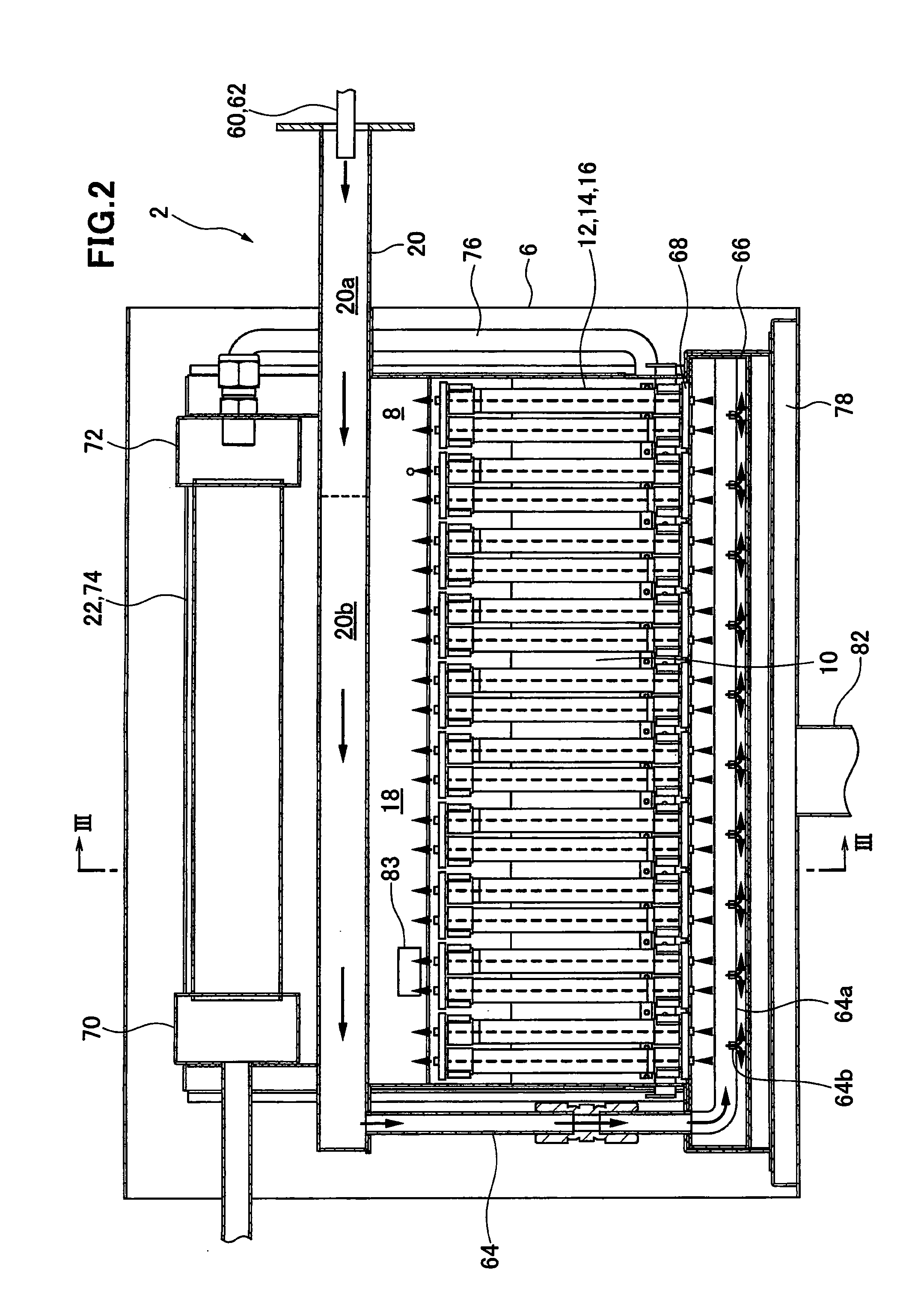

Fuel cell device

InactiveUS20100304242A1Reduce control gainAmount of control be reduceHydrogenFuel cell auxillariesFuel supplyProcess engineering

The fuel cell device has a control device for conducting, at the time of startup, a partial oxidation reforming reaction (POX) inside the reformer, then an auto-thermal reforming reaction (ATR) inside the reformer, then a steam reforming reaction (SR) inside the reformer; a water supply device is provided with a pump for intermittently supplying extremely small amounts of water to the reformer using pulsed control; the control device controls the fuel supply device, the reforming air supply device, and the water supply device to respectively supply target supply flow rates of fuel, reforming air, and water based on the outputs of various sensors; and, in the ATR region, the control device suppresses changes in the flow rate of fuel supplied by the fuel supply device during at least a predetermined interval following the supply of water by the pump.

Owner:TOTO LTD

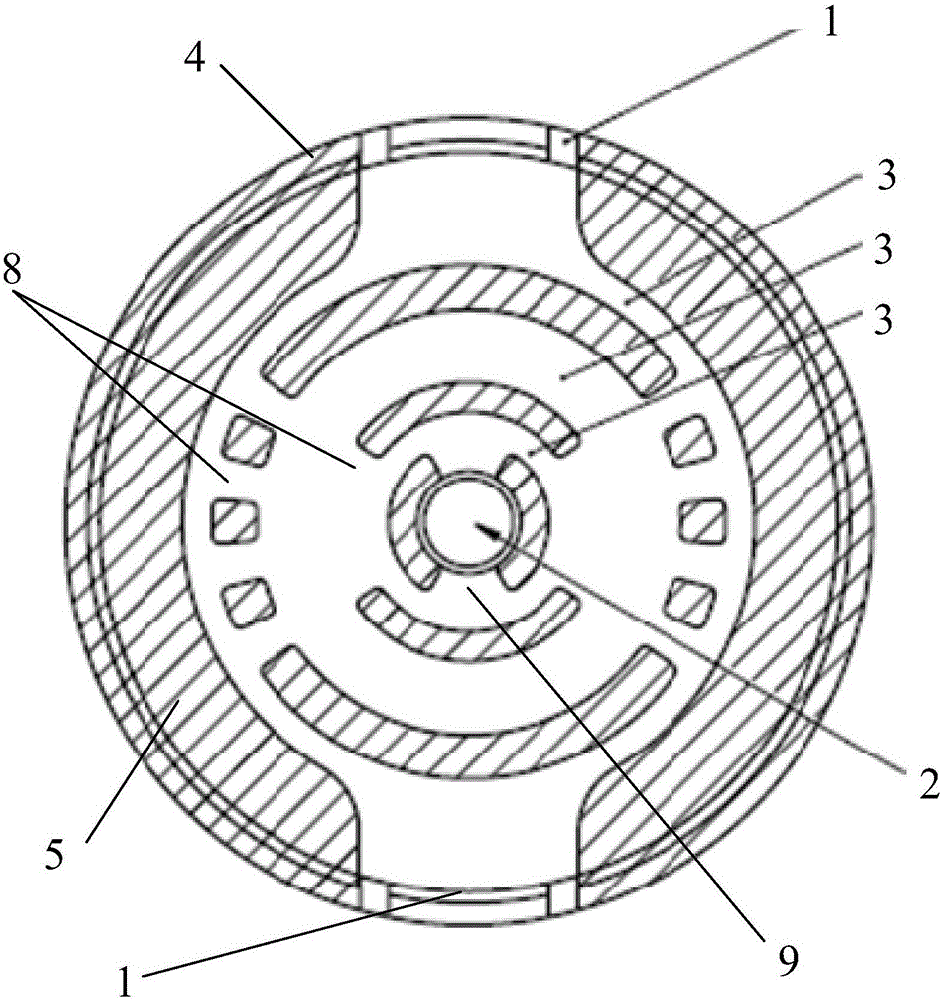

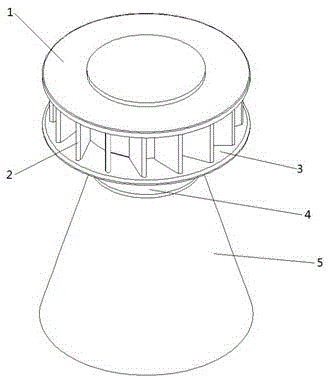

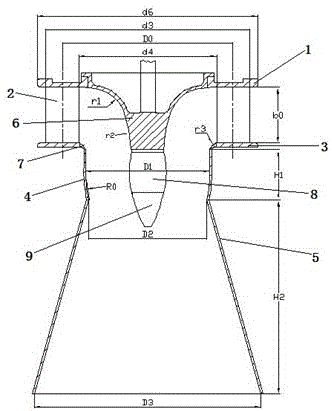

Small-hydropower axial flow turbine device

InactiveCN103912434AReduce flow lossImprove the diversion effectHydro energy generationReaction enginesPower stationWater turbine

The invention discloses a small-hydropower axial flow turbine device. The small-hydropower axial flow turbine device comprises an upper seat ring (1), a lower seat ring (3), sixteen movable guide vanes (2), a support cover (6), a bottom ring (7), a runner chamber (4), a hub (8), a runner cone (9), three blades (10) fixedly mounted on the hub and a straight-cone-shaped draft tube (5), wherein the upper seat ring (1) and the lower seat ring (3) are provided with the guide vanes. The center circle diameter of a water guide mechanism is large, the movable guide vanes and the upper and lower seat rings extend outwards by certain size from a guide vane inlet, the sixteen movable guide vanes which are large in opening are adopted, the runner is high in running speed, inlet and outlet water flow angles of the outer edges of the blades are large, the hub ratio of the runner chamber is low, excess flow is large, the shape contracts at an outlet of the runner and starts to spread again from the straight-cone-shaped draft tube, and numerical simulation shows that efficiency of a turbine can reach 85%. The small-hydropower axial flow turbine device is simple in structure, small in size, convenient to process, low in economic cost and high in efficiency, can be used for low-water-head and high-flow power stations for power generation and can also be used for small-hydropower synergistic expansion modification in the early stage.

Owner:HOHAI UNIV

Method for producing a moulded article comprising a sprayed polyurethane layer

ActiveUS8318259B2Increase kinetic energyReduce the cross-sectional areaSpray nozzlesLiquid/solution decomposition chemical coatingShell moldingKinetic energy

For producing a polyurethane layer by spraying a polyurethane reaction mixture, this mixture is supplied under pressure to a spray nozzle, within the nozzle the reaction mixture is accelerated by passing it through one or more channels having a reduced cross-sectional area, and the accelerated reaction mixture is sprayed, with a predetermined amount of kinetic energy, through a spray opening out of the spray nozzle onto a surface. The channels wherein the reaction mixture is accelerated have a total minimum cross-sectional area of S mm2, S being a value smaller than 1.0, the reaction mixture is sprayed out of the nozzle at a flow rate of between 10×S and 80×S g / sec, and, per gram reaction mixture, an amount of 0.05 to 2.5 mmol of a pressurized gas is sprayed together with the reaction mixture through said spray opening out of the nozzle to increase the kinetic energy of the reaction mixture which is sprayed out of the nozzle. By the addition of a pressurized gas to the reaction mixture, a same or even a better spray pattern can be achieved and the reaction mixture can be sprayed at a smaller flow rate.

Owner:RECTICEL AUTOMOBIL SYSTEME GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com