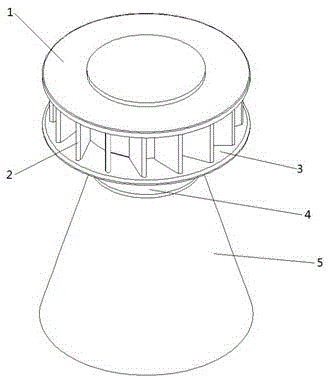

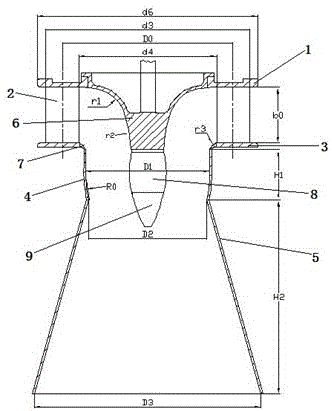

Small-hydropower axial flow turbine device

A technology of axial flow and water turbine, applied in the field of fluid machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

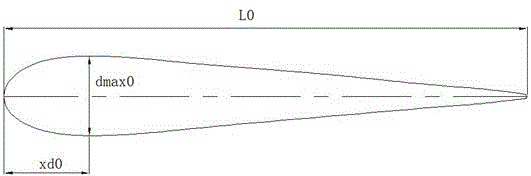

Method used

Image

Examples

example 1

[0044] Example 1, set impeller diameter D 1 is 1.2m, the working water head is 3m, the rated speed of the runner is 260r / min, and the measured flow rate of the unit is 5.464m 3 / s, shaft power 136.8kW, turbine efficiency 85.06%.

example 2

[0045] Example 2, set impeller diameter D 1 is 1.2m, the working water head is 4m, the rated speed of the runner is 300r / min, and the measured flow rate of the unit is 6.307m 3 / s, shaft power 210.4kW, turbine efficiency 85.01%.

example 3

[0046] Example 3, set impeller diameter D 1 is 1.2m, the working water head is 4m, the rated speed of the runner is 335r / min, and the measured flow rate of the unit is 7.048m 3 / s, shaft power 300.8kW, turbine efficiency 87.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com